Page 1

Order No. VES1605003CE

Drum Type Washing Machine

Model No. NA-127VB6WSR

Product Colour : White

Destination : ISRAEL

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions----------------------------------------------- 2

2 Specifications ----------------------------------------------------- 3

3 Location of Controls and Components ------------------- 5

4 Installation Instructions---------------------------------------- 6

5 Operating Instructions------------------------------------------8

6 Test Mode ----------------------------------------------------------10

7 Service Mode -----------------------------------------------------12

8 Troubleshooting Guide----------------------------------------14

9 Critical Torque Values -----------------------------------------15

10 Disassembly and Assembly Instructions ---------------16

11 Component Specifications-----------------------------------32

12 Wiring Connection Diagram ---------------------------------40

13 Exploded View and Replacement Parts List -----------42

© Panasonic Corporation 2016 Unauthorized copying and distribution is a violation of law.

Page 2

1 Safety Precautions

2

Page 3

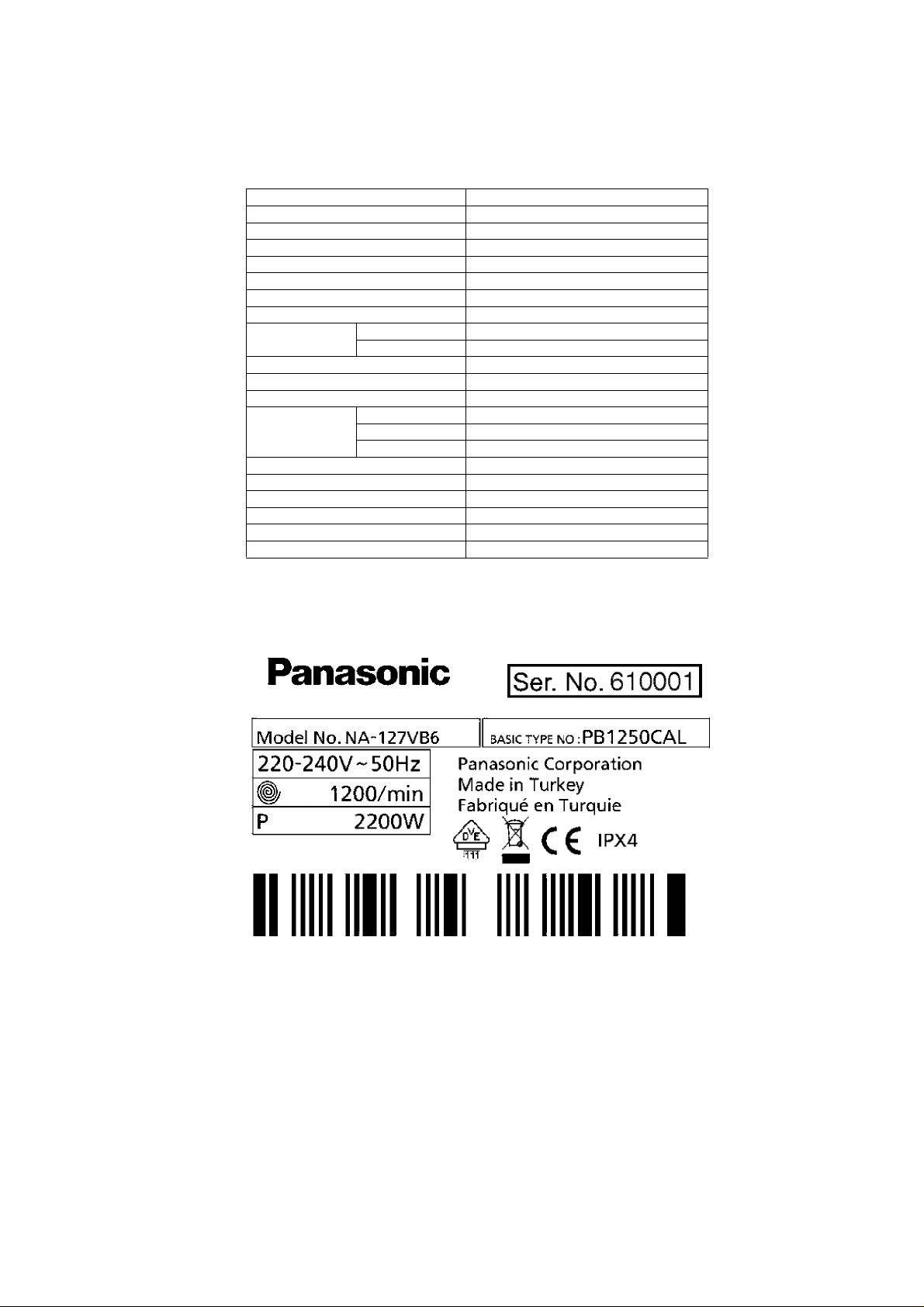

2 Specifications

2.1. Product Specifications

Model NA-127VB6

Product Type Front Loader

Capacity 7 kg

Max Spin Speed 1200 rpm

Drum Volume 50 lt

Energy Label Rating A+++

Energy Consumption 162 kWh / annum

Water Consumption 9240 L/annum

Noise Level

Control Panel LCD Display

Wash Programs 15 settings

Spin Speed Setting 7 setting

Dimensions

Door Opening Large door opening

Delay Time Setting Yes

Colour White

Water Protection Overflow Protection

Other Features Child Lock

Packaging Shrink package

Wash 58 dBA

Spin 74 dBA

Height 84.5 cm

Width 59.7 cm

Depth 52.7 cm

2.2. Name Plate (Example)

3

Page 4

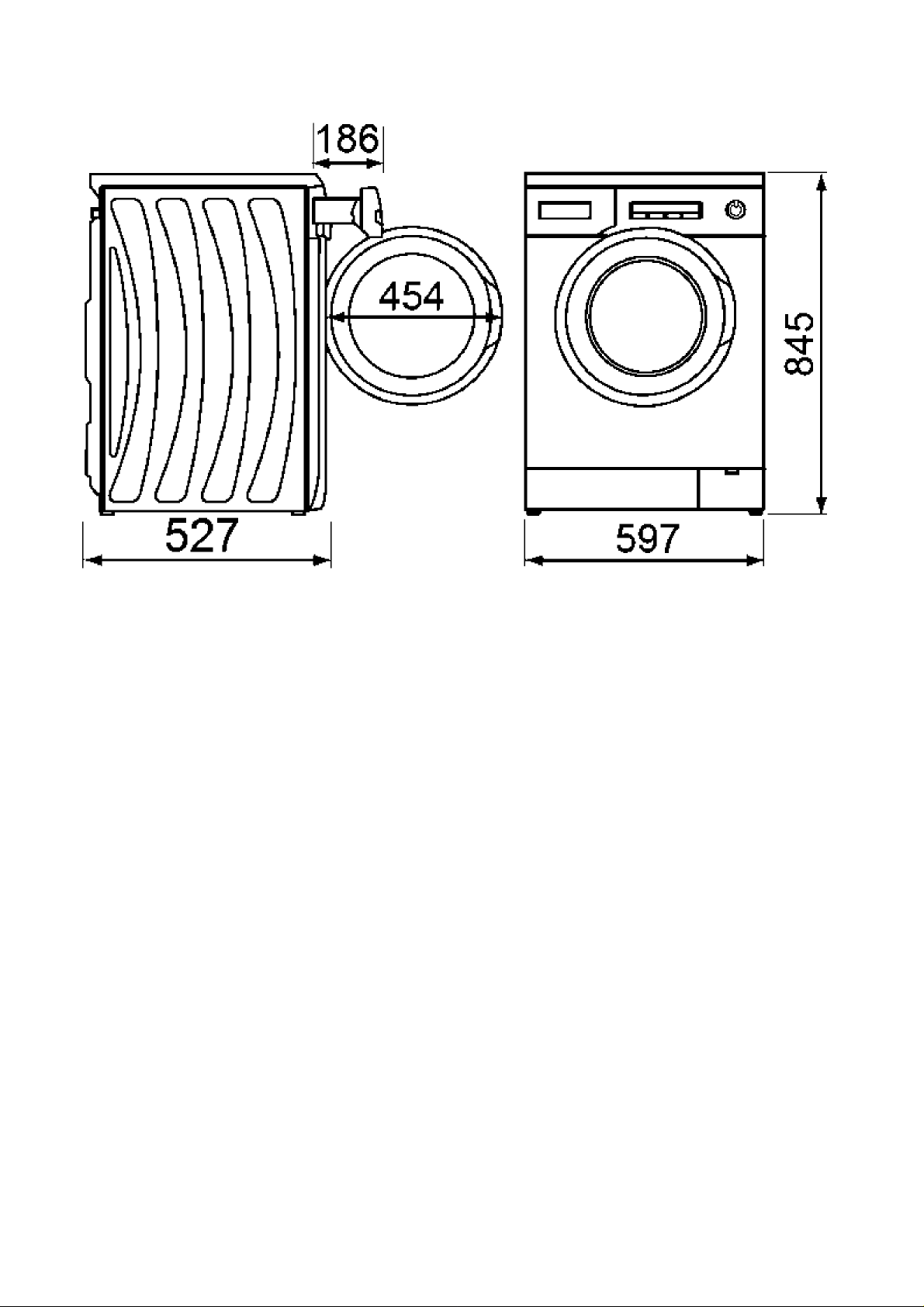

2.3. Dimension

Dimension in millimetres

NA-127VB6

4

Page 5

3 Location of Controls and Components

5

Page 6

4 Installation Instructions

4.1. Moving and Installing

4.1.1. Removal of Transportation Screw

1. Transportation screws, which are located at the back side

of the machine, must be removed before running the

machine.

2. Loosen the screws by turning them anticlockwise with a

suitable spanner.

3. Pull out the screws and rubber washers.

4.1.2. Foot Adjustment

1. Do not install machine on rugs or similar surfaces.

2. For machine to work silently and without any vibration, it

should be installed on a flat, non-slippery firm surface.

Any suspended floor must be suitably strengthened.

3. You can adjust the level of machine using its feet.

4. First, loosen the plastic adjustment nut away from the

cabinet base.

5. Change the level by adjusting the feet upwards or downwards.

6. After level has been reached, tighten the plastic adjustment nut again by rotating it upwards against the base of

the cabinet.

7. Never put cartons, wooden blocks or similar materials

under the machine to balance irregularities of the floor.

4. The holes where the transport screws have been

removed should be covered with the plastic transport

caps found in the accessories bag.

5. The transportation screws that have been removed from

the machine must be re-used in any future transporting of

the machine.

4.1.3. Electrical Connection

1. Washing machine requires a 50Hz supply of 220240Volts.

2. A special earthed plug has been attached to the supply

cord of washing machine. This plug must be fitted to an

earthed socket. The fuse value fitted to this plug should

be 13 amps. If you have any doubts about electrical supply, consult a qualified electrician.

THIS APPLIANCE MUST BE EARTHED.

Insert the machine’s plug to a grounded socket which

you can easily reach.

6

Page 7

4.1.4. Water Supply Connection

1. Washing machine is supplied with a single (cold) water

inlet.

2. To prevent leakage from the connection joints, a rubber

washer is included in the hose packing. Fit this washer at

the end of water inlet hose on the tap side.

3. Connect the hose to the water inlet valve. Tighten the

plastic connector by hand. Please call a qualified plumber

if you are unsure about this.

4. Water pressure of 0,1-1 MPa from tap will enable

machine to work more efficiently. (0,1 MPa pressure

means water flow of more than 8 litres in 1 minute from a

fully opened tap)

5. After connection is complete, check for leakage by turning

on tap completely.

6. Make sure that water inlet hoses can not become folded,

damaged, stretched or crushed when the washing

machine is in its final position.

7. Mount the water inlet hose to a

3

/4” threaded water tap.

4.1.5. Drain Connection

1. Make sure that water inlet hoses are not folded, twisted,

crushed or stretched.

2. The drain hose should be mounted at a minimum height

of 60 cm, and a maximum height of 100 cm from the floor.

3. The end of the drain hose can be connected directly to a

drainage stand-pipe or alternatively to a specific connection point designed for that purpose on the waste outlet of

a sink unit.

4. Do not extend the drain hose or guarantee will be invalidated.

4.2. Detergent Box Group

PREWASH = WATER ENTRY VALVE 1

MAIN = WATER ENTRY VALVE 2

SOFTENER = WATER ENTRY VALVE 1 + VALVE 2

7

Page 8

5 Operating Instructions

5.1. LCD Screen, Function Buttons & Knobs

PR Program selector 16 programs including off position

SW1 Switch 1, Start / Pause

SW2 Switch 2, Temperature Selection

SW3 Switch 3, Spin Speed Selection

SW4 Switch 4, Delay Timer Selection

SW5 Switch 5, Extra Rinse Option

SW6 Switch 6, Easy Ironing Option

SW7 Switch 7, Eco/Speed Mode Option

SS1 7 Segment LCD for Temperature Display I8 Extra Rinse Symbol

SS2 7 Segment LCD for Spin Speed Display I9 Easy Ironing Symbol

SS3 7 Segment LCD for Remaining Time I10 Eco Mode Symbol

I1 Child Lock Symbol I11 Speed Mode Symbol

I2 Door Lock Symbol I12 Cold Wash Symbol

I3 Drain Phase Symbol I13 Temperature Sign

I4 Spin Phase Symbol I14 Program Proceeding Zone

I5 Rinse Phase Symbol Slow Blink ON 0.5 sec, OFF 0.5 sec, ON 0.5 sec

I6 Wash Phase Symbol Fast Blink ON 0.10 sec, OFF 0.10 sec, ON 0.10 se

I7 Delay Symbol

8

Page 9

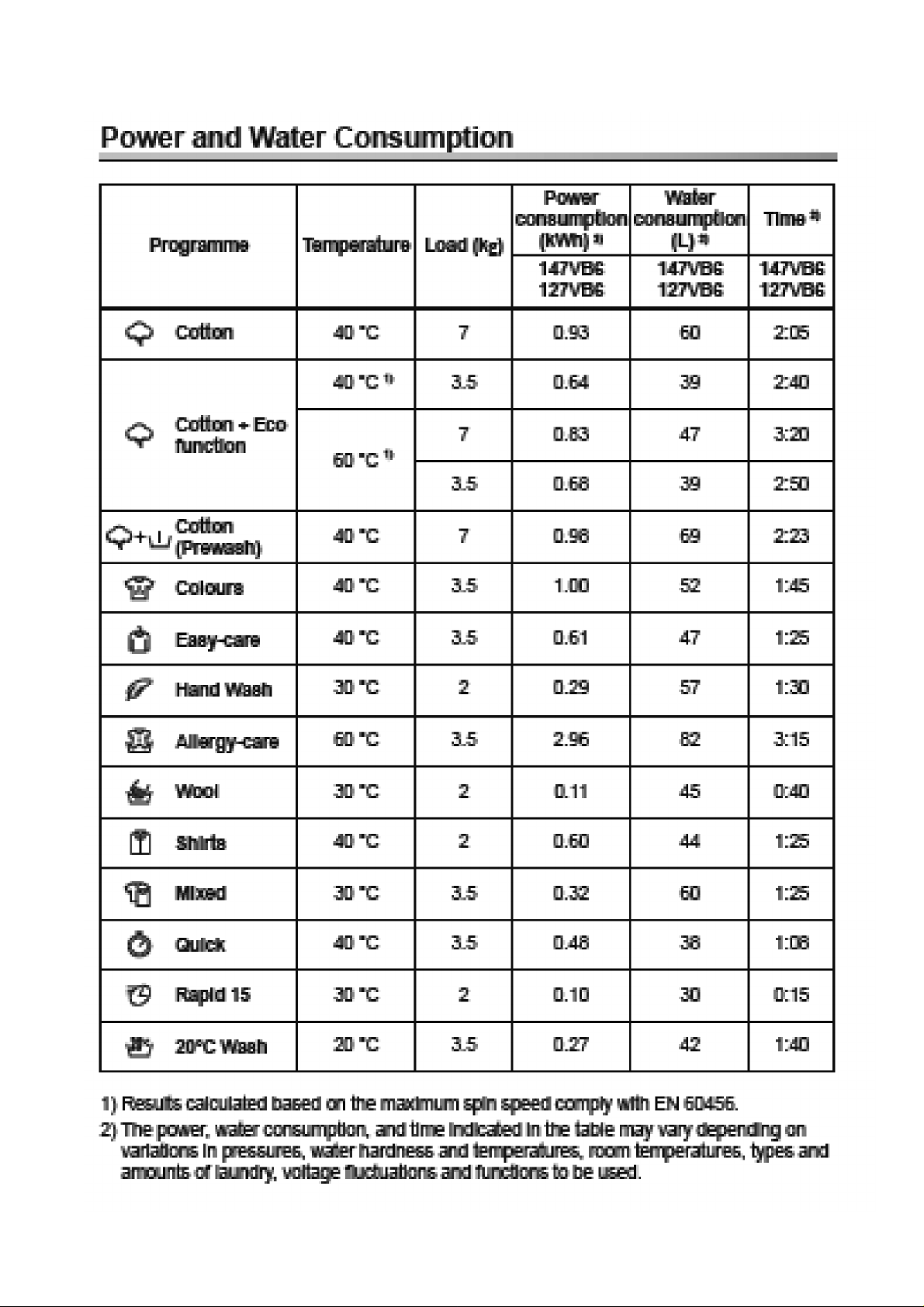

5.2. Program Details

9

Page 10

5.3. Child Lock

Activation

1. Press SW7 for 5 seconds.

2. The Child Lock Symbol on appears on the LCD display as

Child Lock is active.

6 Test Mode

Deactivation

1. Press SW7 for 5 seconds.

2. The Child Lock Symbol will disappear on LCD display

upon deactivation.

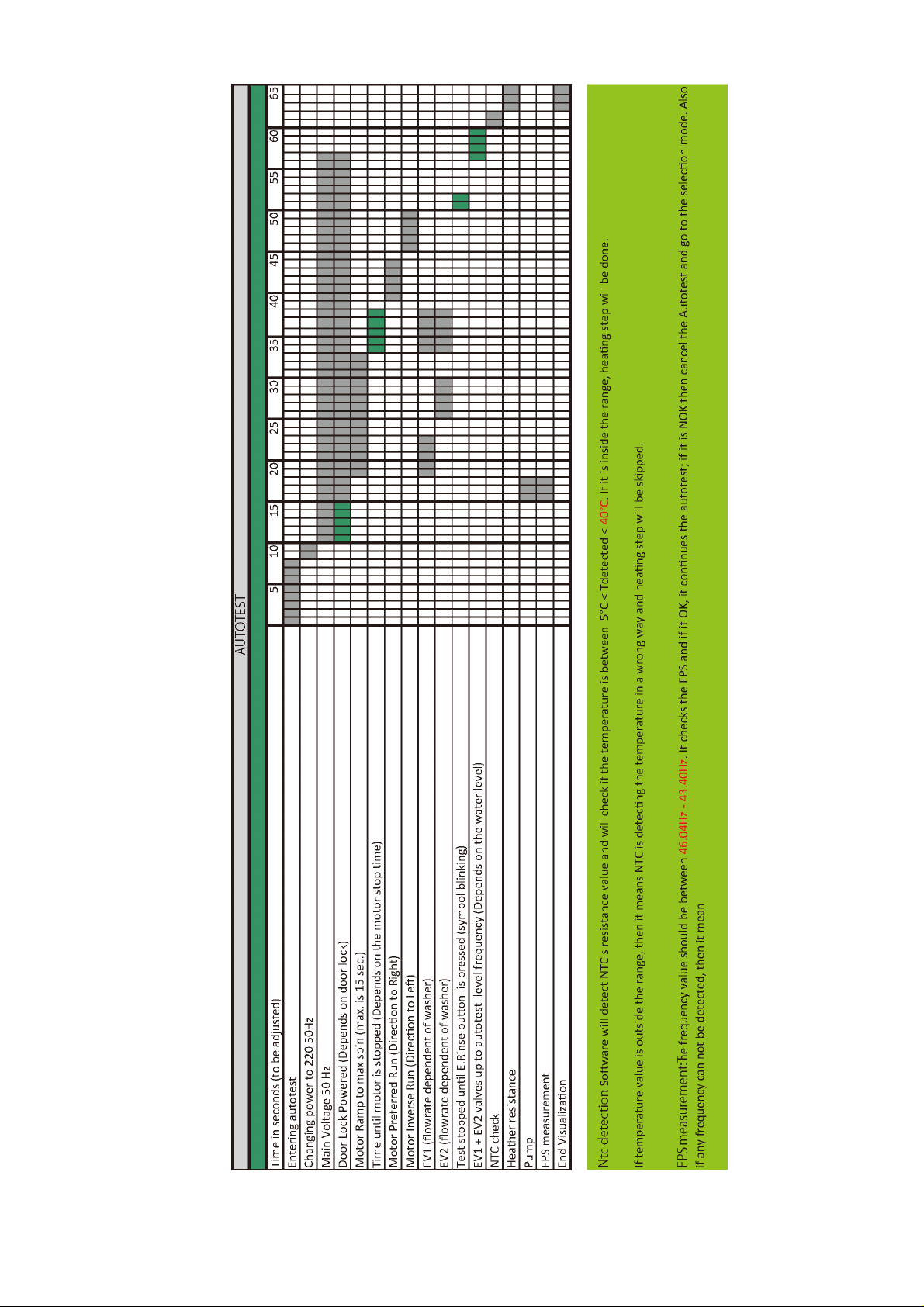

6.1. Autotest

1. Set PR to program 3 (Colours)

2. While pressing SW5 (Extra Rinse), change position of the

PR from third program to second (Cotton-Prewash), and

release SW5.

3. Autotest starts.

10

Page 11

11

Page 12

7 Service Mode

7.1. Service Autotest

1. Set PR to program 3 (Colours) and press SW2 (T°C) 2. While pressing the SW2, change PR position from third to

second, and release the SW2 button.

3. Bring PR to desired test step (1st ,2nd or 3rd program position) as soon as “SAU” is displayed on LCD.

LCD Display status:

I2 Door Lock Symbol Fixed on

SS3 SAU

Step1 Step2 Step3

PR Position:

Program 1

(Cotton)

Result Result Result

HEATER ON PUMP ON TEST PROGRAM ON

When entering in service

Comments :

test, door will be locked.

The test steps are as below ;

Step 1 :

• Selector Program 1 (Cotton) will be “HEATER ON”

• Before heating it should take water till first level frequency

then start heating.

• Heater will be on max. 8 minutes after this 8 minutes if the

temp. doesn’t change more than 2 °C then it will give NTC

failure. (E05).

• Or if the NTC connection is broken then it should give again

E05 NTC failure.

PR Position:

Program 2

(Cotton Prewash)

Door will be unlocked, machine

PR Position:

Program 3

(Colours)

(Rapid 12’)

Test is over

will go to END state.

Step 2 :

• Selector Program 2 (Cotton Prewash) will be “PUMP ON”

• Temperature will be measured, if it is higher than 5 0 °C, it

should take 60 sec. cooling water, and then make “Drain + 5

sec.”

• At the end of pump activation, “SAU” visualization should

make slow blink to indicate that the step is over.

Step 3 :

• At the end of heating, “SAU” visualization should make slow

blink to indicate that the step is over.

• Note : If user changes the selector position, machine will do

what is defined for the new selected position.

• Selector position 3 (Colours) will be a 12 mins test program

where all functions of the appliance will be checked.

• Machine will make exactly the same algorithm of Super

Rapid 12'.

So, time for selector position 3 is 12 minutes.

• At the end of test program “End” is visualized on LCD a nd

door is unlocked.

12

Page 13

7.2. Failure Codes

Error Indication Error Number

Door is not locked E01 Yes Yes

Door is unlocked during programme E01 Yes Yes

Lack of water E02 Yes Yes

Pump failure E03 Yes Yes

Overflow E04 Yes Yes

NTC or Heater Failure E05 No Yes

Motor Failure - 1 (Tachometer open-short circuit or

motor connector is disconnected)

Motor Failure - 2 (triac short circuit) E08 No Yes

Electronic Pressure Sensor E10 No Yes

E06 No Yes

Indication For User Indication For Service

Yes/No Yes/No

13

Page 14

8 Troubleshooting Guide

All repairs which must be done on the machine should be done by authorized agents only. When a repair is required for machine or

you are unable to eliminate the failure with the help of the information given below:

• Unplug the machine.

• Close the water tap.

FAILURE PROBABLE CAUSE METHODS OF ELIMINATION

Machine does not

operate.

Machine does not

receive water.

Machine is not draining water.

Machine is vibrating. The feet of machine are not adjusted. Adjust the feet.

Excessive foam in

the detergent drawer.

The washing result is

bad.

The washing result is

not good.

The water is seen in

the drum during

washing.

There are residues of

detergent on the

clothes.

There are grey stains

on the clothes.

The spinning process

is not done or starts

with delay.

It is unplugged. Insert the plug into the socket.

Fuse is defective. Change fuse.

Start / Pause button has not been pressed. Press the start / pause button.

The program knob is in 0 (off) status. Bring the program knob on the desired status.

The door is not shut properly. Shut the door properly. You should hear the click.

Child lock is active. See section 5.3.

Water tap is closed. Open water tap.

The water inlet hose may be bent. Check the water inlet hose.

The water inlet hose is obstructed. Clean the filters of water inlet hose.

The water inlet filter is obstructed. Clean the valve inlet filters.

The door is not shut properly. Shut the door properly. You should hear the click.

The drain hose is obstructed or bent. Check the drain hose.

The pump filter is obstructed. Clean the pump filter.

The clothes are not placed inside the machine in a

well-balanced manner.

Transportation screws are not removed. Remove transportation screws.

There is a small amount of clothes in the device. It does not prevent operation of the machine.

Excessive amount of clothes are filled in the machine

or the clothes are not placed in a well-balanced manner.

Too much detergent has been used. Press the start/pause button. In order to stop the

Wrong detergent has been used. Use only the detergents produced for full automatic

Laundry too dirty for the program you have selected. Select a suitable program.

The amount of detergent used is not sufficient. Use more detergent according to the detergent.

Clothes exceeding the maximum capacity has been

filled in machine.

Water may be hard. Use the amount of detergent according to the declara-

Distribution of the clothes in machine is not well-balanced.

No failure. The water is at the lower part of the drum.

The pieces of some detergents which do not dissolve

in water may stick to clothes as white stains.

These stains may be caused by oil, cream or ointment.

No failure. The unbalanced load control works in that

way.

Spread the clothes inside the machine in an orderly

and well-balanced manner.

Do not exceed the recommended quantity of clothes

and spared clothes in the machine in a well-balanced

manner.

foam, dilute one table-spoon of softener in half liter of

water and pour it in the detergent drawer. Press the

start/pause button after 5-10 minutes. Arrange the

amount of the detergent properly in the next washing

process.

machines.

Put the clothes in machine in a manner not to exceed

its maximum capacity.

tion of the detergent producer.

Spread the clothes inside the machine in an orderly

and well-balanced manner.

By calibrating machine for “Rinsing” program, make

an additional rinsing or eliminate the stains After drying with the help of a brush.

In the next washing operation, use the maximum

detergent amount declared by the detergent producer.

The unbalanced load control system will try to distribute clothes in a homogenous manner. After clothes

are distributed, passage to spinning process will be

realized. In the next washing process, place clothes

into the machine in a well-balanced manner.

14

Page 15

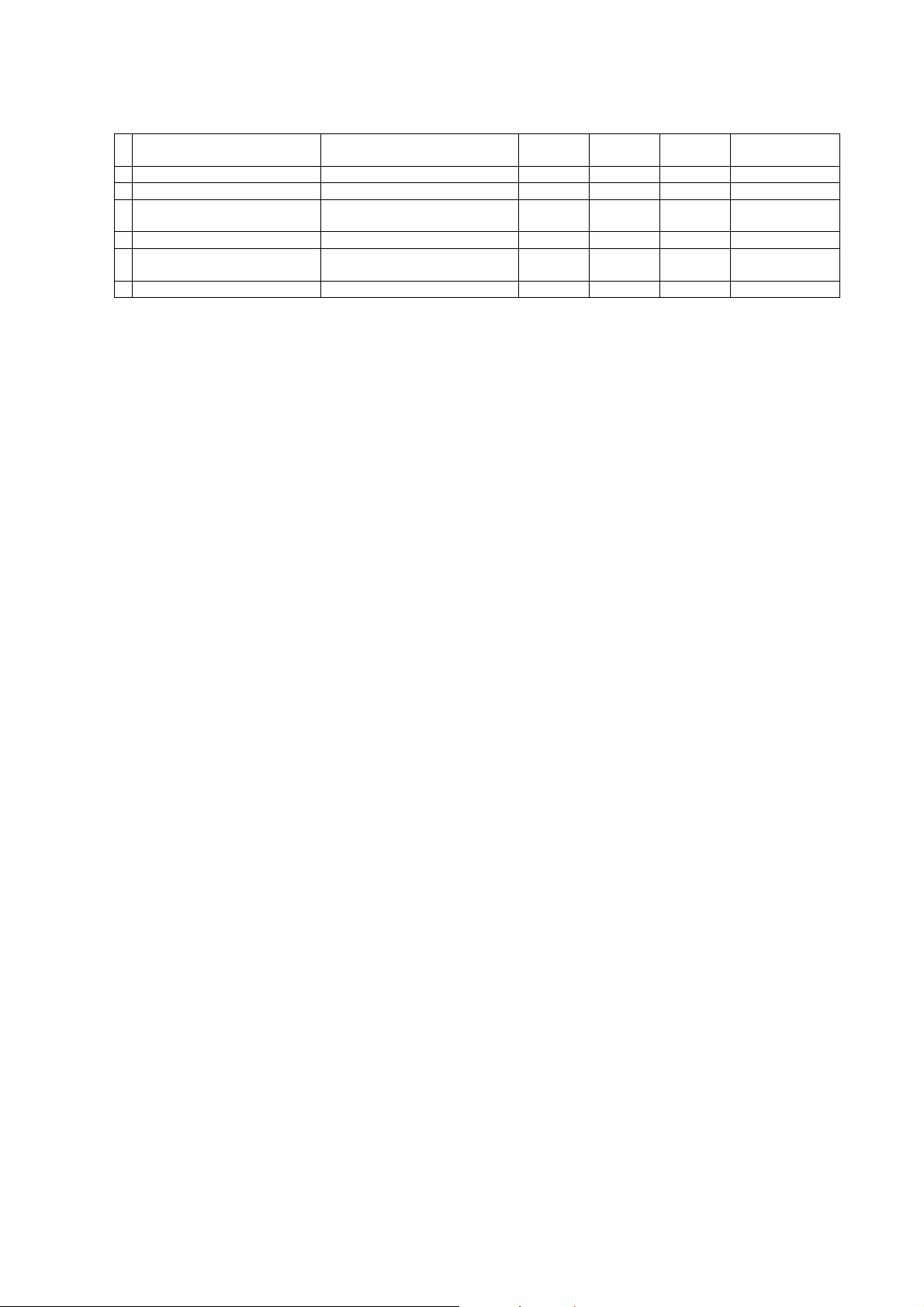

9 Critical Torque Values

ASSEMBLY LOCATION BOLT/NUT TORQUE

MIN. (Nm)

* Transport Screw Assembly Transport Screws 6.50 6.50 7.00 1000

* Motor Assembly Motor Screws 6.00 6.50 7.50 800

* Front Concrete Weight - Front

Tub Assembly

* Upper Counter Weight Assembly Upper Counter Weight Screws 25.00 27.50 30.00 440

* Pulley - Drive Shaft - Washing

Group Assembly

* Heater Assembly Heater Assembly Nut 3.85 4.00 4.00 970

Front Counterweight Screws 14.00 14.50 14.75 600

Pulley – Drive Shaft Assembly Bolt 39.50 40.00 40.50 440

TORQUE

NOM. (Nm)

TORQUE

MAX. (Nm)

Air Pressure

Wrench (rpm)

The bolts/nuts above are important for product safety purposes. Please tighten screw, bolt s and nut s according to the torque values

given in table above.

15

Page 16

10 Disassembly and Assembly Instructions

10.1. Top Plate

1. Remove two screws that fix the top-plate at the back.

2. Push the top-plate back and pull it up.

10.2. Door

1. Remove two screws that fix the door. (by using T25 tool)

2. Pull the door up.

16

Page 17

3. Remove screws that fix the door group.

6. Remove six screws that fix the door hinge.

4. Put the door outside plastic with helping screwdriver.

5. Remove the door inside plastic.

7. Remove the door handle.

8. Remove the door handle pin.

17

Page 18

10.3. Spring Wire

1. First remove the spring wire fixing the tub bellows seal by

using the small size screwdriver.

Pull the tub bellows seal.

2. Remove the tub bellows seal-body fixing sprin g .

10.4. Detergent Drawer

1. Gently pull the detergent drawer.

2. While pressing siphon cover keep pulling drawer to

remove it.

18

Page 19

10.5. Control Panel

1. Remove the screw which fixes the control panel to the

front panel.

2. Remove two screws fixing control panel.

10.6. Electronic Card

1. Depress the taps fixing the card by using a screwdriver.

2. Release the socket fixing plastic by depressing the taps

with the help of a screwdriver.

3. Pull the control panel out.

3. Remove the card out off panel.

4. Remove the sockets on the card.

19

Page 20

5. After releasing sockets, remove PCB box from its housing

around the box.

9. Remove the card from its housing and unplug its connector.

6. Disassemble the PCD box and its cover.

7. Remove the PCB card by depressing the taps that fix it.

10. Remove the LCD screen by depressing the taps by using

a screwdriver.

8. Remove the connector that fix the LCD screen.

20

Page 21

10.7. Front Panel

1. Remove the screw fixing the front panel at the bottom.

2. Remove two screws fixing the door lock.

4. Remove the tub bellows seal.

5. Remove two screws fixing front panel to body.

6. Pull front panel up.

3.

7. Remove front panel.

21

Page 22

10.8. Support Bracket

1. Remove two clips fixing detergent drawer housing to

upper support bracket..

10.9. Detergent Drawer Housing

1. Remove the tub bellow hose by releasing the holder

extensions of bellow hose.

2. Unplug connectors from feed valve.

3. Slightly turn the feed valve counter-clockwise to remove.

4. Remove the detergent drawer housing assembly.

22

Page 23

10.10. Power Cable Group and EMI Filter

1. Remove the five connectors that is connected to the EMI

filter.

2. Remove two screws fixing the EMI filter.

4. Remove EMI filter.

3. Pull the power cable group up.

23

Page 24

10.11. Electronic Pressure Switch (EPS)

1. Unplug EPS connector.

10.12. Door Lock

1. Unplug door lock connector.

2. Pull EPS up.

3. Remove clamp from EPS hose.

10.13. Drain Pump

1. Remove clamp holding drain hose by using a plier.

2. Remove clamp fixing tub outlet hose.

24

Page 25

3. Unplug drain pump connector.

4. Remove screws holding drain pump.

10.14. Front Counterweight

1. Remove three screws on the front counterweight.

(Wrench size 13 mm)

2. Gently pull counterweight out.

25

Page 26

10.15. Heater

1. Unplug heater connectors.

2. Remove nut (8 mm) fixing the heater.

10.16. Twinjet System

1. Remove twinjet hoses from tub bellow seal pulling them

up.

2. Remove screw fixing circulation pump.

3. Pull heater out gently holding both sides.

3. Lay the appliance down and press on ratchet holding circulation pump.

26

Page 27

4. Remove circulation pump.

5. Remove cable connector.

10.17. Tub Bellow Seal

1. Remove the tub gasket clip by using small screwdriver.

2. Hold the tub bellows seal and gasket-body fixing spring

together, and pull them out.

6. Remove hose connecting circulation pump to drain pump.

27

Page 28

10.18. Transport Screw

1. Remove four transport screws.

2. Hold the transport screw and pull it out.

10.19. Upper Counterweight

1. Remove two screws fixing the upper counterweight by

using box wrench size 13 mm.

2. Hold and carry upper-counterweight out.

28

Page 29

10.20. Washing Group

1. Unplug motor connectors.

4. Remove the washing group carrying it out through front

side.

2. Cut all the cable ties which fix cable group.

3. Remove the screws fixing hanger bracket.

10.21. Shock Absorber Pin

1. Remove shock absorber pins squeezing the ratchet by a

pliers.

29

Page 30

10.22. Belt

1. Remove the belt rotating the driven pulley.

10.23. Driven Pulley

1. Remove the bolt at the center of pulley by tucking a

wooden bar avoids rotation.

10.24. Motor

1. Remove two screws holding motor by using box wrench.

2. Pull motor up.

2. Remove pulley.

30

Page 31

10.25. Tub

1. Remove tub inlet bellow hose loosening the clamp

squeezing it by using a pliers.

2. Remove screw holding EPS reservoir.

4. Remove 19 screws around tub using box wrench size 8

mm.

5. Remove front tub.

3. Remove tub outlet bellowed hose loosening screwedclamp.

6. Remove drum.

31

Page 32

11 Component Specifications

11.1. Drain Pump

Drain pump is both a mechanical and electrical component

which is used to drain water inside the washing machine. It

has an synchronous motor inside. For better performance

maintenance, pump filter should be cleaned regularly.

Technical features

Nominal voltage 220-240 V

Nominal current 0.28 A(±10 %)

Nominal power 37 W

Frequency 50 Hz

Testing component

Check the resistance value on the component with multimeter as shown below.

Resistance value should be between 131 - 141

Resistor (coil) 136 (±5%)

Water flow 17 L/min (to 1 m height)

Thermal protector YES

Y ou can determine the ohm value of drain pump by measuring from the socket with two blue cables connected to the electronic

card as shown in the figure.(referring X10 on the wiring diagram)

Component test

32

Page 33

11.2. Heater

Heating element (Resistance) is a component which is

designed to regulate temperature of water inside the drum.

It has three connections: Phase, neutral and ground connections.

Heater type Tubular heating element with NTC-sensor

Nominal voltage 230 V

Technical features

Nominal power 2000 W (±5%)

Resistance 26.4 ±5%

Thermal fuse 2 sided

Testing component

Check the resistance value on the component with multimeter as shown below.

Resistance value should be between 26.4 ±5%

You can determine the ohm value of resistance by measuring from the socket with grey and brown cables

(referring to X6 on the electronic card).

Component test

33

Page 34

11.3. NTC

Component which sends signals to PCB about the water

temperature inside the tub. The Resistance (Ohm) value of

the NTC decreases as the temperature increases.

Technical features

Testing component

Check the resistance value on the component with multimeter as shown below.

You can determine the ohm value by measuring from the socket with two black cables (referring to X7 on the wiring diagram).

NTC resistance value varies depending on temperature.

Component test

34

Page 35

11.4. Valve

Valve is an electrical and mechanical component which is

designed to take water from the network system into the

washining machine. It is operated by PCB card.

Nominal voltage 220-240 V

Nominal power 8 VA

Frequency 50-60 Hz

Check the resistance value on the component with multimeter as shown below. Valve water flow rate should be between

Technical features

Rated flow 7 L/min (±15 %)

Operating water pressure 0.03 - 1 Mpa

Testing component

6 - 8 L/min. Each valve coil resistance values should be between 3.3 - 4.2 k

You can determine the resistance value of the main wash valve by measuring from the large socket which has one blue, one

black and two white cables as shown in the figure below (refers X5 on the wiring diagram). Each valve coil resistance values

should be between 3.3 - 4.2 kohm.

Component test

35

Page 36

11.5. Electronic Pressure Sensor (EPS)

Electromagnetic field occurs due to movement of pressurized membrane. The spring moves vertically by nucleus

due to electromagnetic field. The water level is regulated

according to the frequency changes of the spring by electronic card.

Testing component

Push the door lock slider with screwdriver.

Select the 1st program and start the machine.

Unplug power cable when as soon as water intake finishes

and drum begins to rotate.

Check the water level inside the drum with ruler. It should

be 10 cm ±1.

36

Page 37

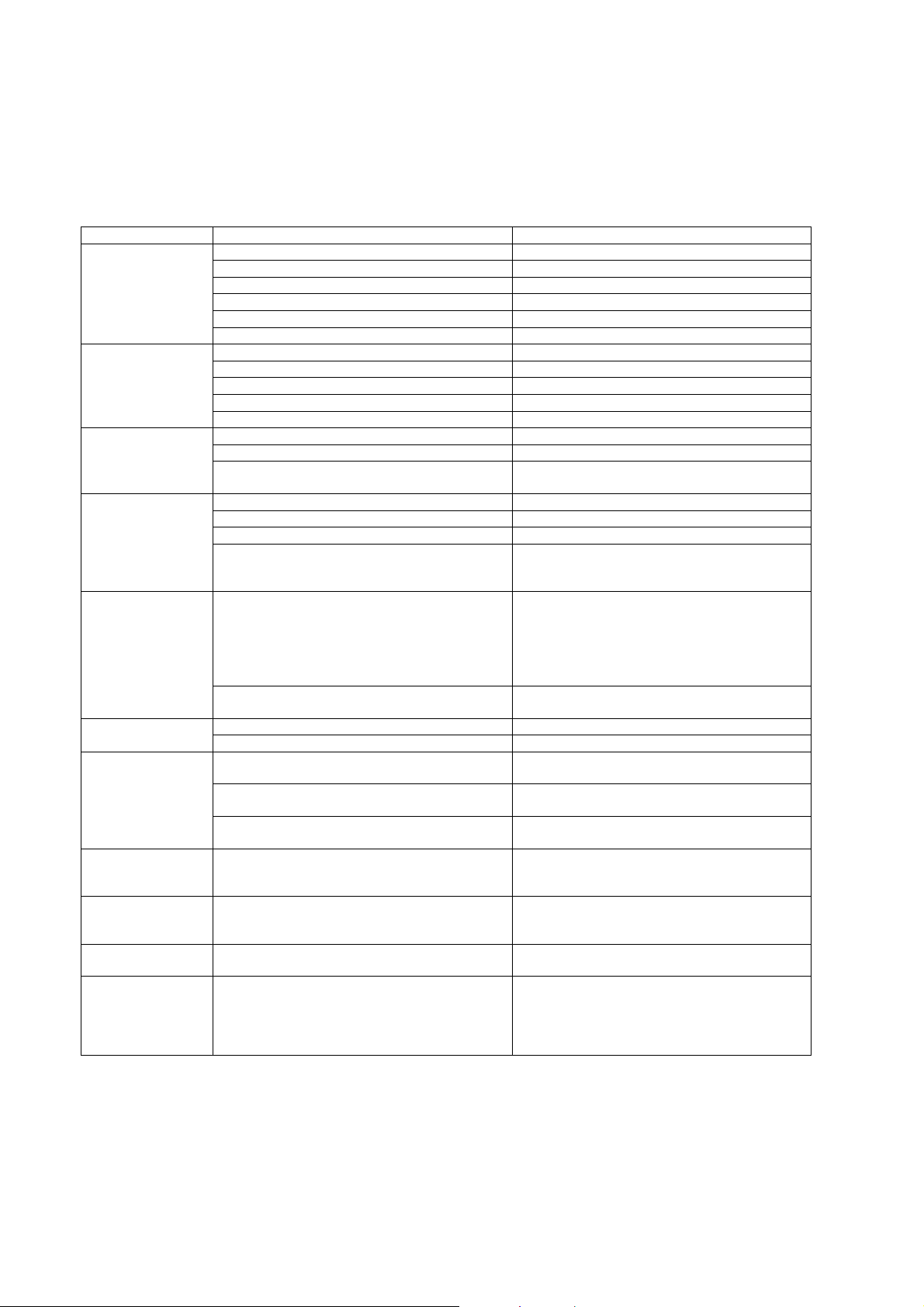

11.6. Motor

The washing machine has an asynchronous motor. It is

controlled by the PCB. It is essential to check the motor for

correct diagnosis and quick servicing. In the below picture,

socket points on the motor is shown to measure with multimeter.

Motor socket terminals

Testing components

Tacho resistance control

Check the motor tacho terminals on the motor socket with

multimeter as shown in the picture above.

You can determine the ohm value by measuring from pink

and red cables on the large socket as shown in the figure

(referring X2 on the wiring diagram)

Stator Resistance Control

Check the motor stator terminals on the motor socket with

multimeter as shown in the picture.

Y ou can determine the ohm value by measuring from black

and brown cables on the large (referring X2 on as shown in

right figure. For resistance values, refer to the table below.

Tacho and stator resistance values of motor:

37

Page 38

11.7. Door Lock

Door lock is activated at the beginning of the program in

order to prevent the door from opening. Locking is generated by supplying power to PTC-bimetal, after max 6sec

(220V), the bimetal will be warm and ready to close the

contacts. Thus the first impulse to the solenoid will allow

the contact to close and consequently the slider will be

locked by the pin of the sliderlock. The second impulse

causes no electrical and mechanical modifications. It can

be unlocked by the third impulse; the contact is opened

even if the PTC-bimetal remains energized.

Emergency Opening System (PTC-Bimetal) In

Case of Lack of Electric Energy

• In case of lack of electric energy during a washing cycle, the

PTC-bimetal assembly will cool down and after minimum 60

sec (considering previous power supply of 30 sec min and

T=20 °C) the door will be unlocked and thus can be opened.

• In case the door is closed when current comes back, the

PTC-bimetal assembly will heat again, the slider lock will

lock, the contact will close and the program will continue

from where it stopped.

Nominal voltage 250 V

Check the resistance value on the component with multi-meter as shown in below figures. Resistance value on the (PTC over-

load + solenoid) should be 240 ±20% at 25 °C. That resistance value can be measured from terminal 3-4 (refer to section12

Technical features

Testing component

Wiring Connection Diagram).

You can determine the ohm value of PTC by measuring from cables those are shown in the figure below as 3 and 4. (Referring

X3 on the wiring diagram).

Component test

38

Page 39

11.8. Circulation Pump

The component is used for circulation of water inside the

drum in order to increase washing performance.

Check the resistance value on the component with multimeter as shown below.

Technical features

Nominal voltage 220-240 V

Frequency 50 Hz

Resistor (coil) 169,5 (±5%)

Testing component

Resistance value should be between 160 - 180

You can determine the ohm value by measuring from the red cable at 5th and red cable at 12th position in the small socket

(refer wiring diagram in section 12) as shown below figure. Resistance value should be between 160 - 180

Component test

39

Page 40

12 Wiring Connection Diagram

12.1. Wiring Diagram (Board)

40

Page 41

12.2. Wiring Diagram (Socket)

41

Page 42

13 Exploded View and Replacement Parts List

13.1. Control Panel Parts

13.1.1. Exploded View Control Panel Parts

13.1.2. Control Panel Spare Parts

(U) : Indicates parts at the remarks that can be replaced by user.

: Components identified with have special characteristics important for safety. When replacing any of these components use

only manufacture’s specified parts.

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

400 DETERGENT DRAWER COVER AXWDV-151182 1

401 CONTROL PANEL AXWCV-151181 1

403 PROGRAM ADJUSTMENT SHAFT AXWSH-069325 1

411 PCB BOX AXWPB-128166 1

412 ELECTRONIC CARD GR. AXW24V-64708 1

413 PCB BOX REAR COVER AXW2CF-91225 1

415 TOUCH BUTTONS AXW146-19208 1

420 FL CARD GROUP AXW146-57870 1

424 LCD FRAME AXWLF-134899 1

429 PR. ADJ. KNOB GR AXWSH-132581 1

1108 SOCKET HOLDER AXWSH-132583 1

42

Page 43

13.2. Front Panel Spare Parts

13.2.1. Exploded View Front Panel Spare Parts

13.2.2. Front Panel Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

1 BODY GROUP PAINTED AXW1AB-13489 1

2 UPPER TRAY GROUP AXW11N-16356 1

3 FRONT PANEL GROUP AXW1BB-27924 1

5 ADJUSTABLE FEET GR. AXW31-00778 4

9 HOUSING FRAME BELLOW CLIP-PHYTON AXW1Z-023407 1

10 DOOR LOCK AXW1619-4463 1

701 PUMP COVER HOUSING AXW130-05807 1

702 PUMP COVER AXW140-67962 1

1200 HINGE SUPPORT SHEET AXWHSS-19456 1

1201 FRONT PANEL GROUP (3+1200) AXW1BB-54562 1

1602 DRAIN HOSE SPONGE AXW1DH-12749 1

43

Page 44

13.3. Washing Group Spare Parts

13.3.1. Exploded View Washing Group Spare Parts

44

Page 45

13.3.2. Washing Group Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

103 REAR TUB GROUP AXW12A-90585 1

117 FRONT TUB AXW32G-59330 1

160 DRUM GROUP AXW22B-13458 1

102 MOTOR AXW401-13066 1

113 TUB SEAL AXW212-15077 1

101 DRIVEN PULLEY AXW502-00499 1

100 BELT AXW412-25178 1

122 COUNTERSUNK HEAD BOLT 8X28 TORX AXWSS1-07899 4

206 TUB ENTERANCE WITH BELLOW HOSE AXWEBH-87110 1

118 TUB BELLOWS SEAL AXW212-25995 1

126 HEXAGON HEAD BOLT 6X30 PT AXWSS3-14521 19

900 HEXAGON HEAD BOLT 10 X 52 AXWSB1-23804 4

241 PLAIN WASHER 10.5X40X2.5 AXW420-08965 4

810 PLAIN WASHER (SAFETY) AXWSW1-06960 4

105 SHOCK ABSORBER PIN-2 AXWSAP-25094 4

119 TUB GASKET CLIP AXW212-08555 1

120 FRONT CONCRETE WEIGHT AXW1231-9244 1

121 RESISTANCE GR AXWRG1-96002 1

999 NTC AXW1EV-35970 1

899 RESISTANCE WITHOUT NTC AXWRG1-16814 1

115 RESISTANCE FIXING WIRE AXWRFW-18738 1

104 SHOCK ABSORBER AXWSA1-11586 1

213 TUB EXIT BELLOWS GR(HOSE+BALL) AXW1250-7585 1

124 COUNTERSUNK HEAD BOLT M 8X29 AXWSB2-05142 1

700 TUB HANGER SPRING PART AXWTHS-19298 2

221 HANGER SPRING SHEETIRON PLS. AXW1HS-16727 2

800 TUB SPRING AXW3441-5307 2

808 MUSHROOM HEAD SQUARE NECK BOLT M 8X65 AXWSB3-03063 2

806 PLAIN WASHER 8.4X28X3 AXWSW2-07454 2

811 UPPER CRT SUPPORT SHEETIRON PART AXWUCS-16379 2

812 HEX.NUT WITH FLANGE SERRATED M8 AXWXNF-00615 2

813 PLASTIC LIFTER AXW1PL-55352 3

112 UPPER CONCRETE WEIGHT AXW1231-3323 1

816 RESISTANCE PROTECTION FOIL-1-C AXW1PF-07557 1

817 SCREW 35X7PAN HEAD WITH COLAR CROSS RE. AXWSS4-15637 2

45

Page 46

13.4. Detergent Drawer Group Spare Parts

13.4.1. Exploded View Detergent Drawer Group Spare Parts

13.4.2. Detergent Drawer Group Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

200 DETERGENT DRAWER AXW1V-065303 1

202 SIPHON COVER AXW1PV-65308 1

214 DETERGENT DRAWER LOC. PART-BLUE AXW1DD-65309 1

203 WATER DISTRIBUTION PLATE GR AXW1WD-65322 1

205 DETERGENT DRAWER HOUSING AXW1DD-65304 1

228 PLASTIC HOSE CLAMP AXW1PH-04189 4

207 VALVE-DETERGENT BOX HOSE AXW1VD-04536 1 220mm

208 VALVE-DETERGENT BOX HOSE AXW1VD-04535 1 240mm

209 VALVE(TWO EXIT) AXW1VT-13042 1

270 DETERGENT BOX GROUP AXW21D-65326 1

275 DETERGENT BOX GROUP/HOSE AXW31D-65329 1

280 DETERGENT BOX GROUP/FULL AXW41D-10164 1

996 LIQUID DETERGENT LEVEL PLATE AXW51D-65310 1

46

Page 47

13.5. Pressure Switch Hose Group Spare Parts

13.5.1. Exploded View Pressure Switch Hose Group Spare Parts

13.5.2. Pressure Switch Hose Group Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

211 PRESSURE SWITCH HOSE (EPDM) AXW1PS-78599 1

212 PRESSURE SWITCH WATER RESERVOIR AXW1PS-88879 1

213 TUB EXIT BELLOWS GR(HOSE+BALL) AXW1250-7585 1

234

HOSE CLAMP Φ32.7

244

HOSE CLAMP Φ9.6

295 PRESSURE SWITCH HOSE GR.PYTHON

BALL SYST

AXW1HC-07366 1

AXW1HC-08991 1

AXW2PS-79698 1

47

Page 48

13.6. Body Group Spare Parts

13.6.1. Exploded View Body Group Spare Parts

48

Page 49

13.6.2. Body Group Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

20 WATER ENTRY HOSE GROUP AXW12C-14423 1

24 UPPER SUPPORT BRAKET AXW1US-96100 1

285 PUMP GROUP AXW8FT-06391 1

220 DRAIN HOSE ROUTER PLASTIC AXW1DH-19322 1

219 DRAIN HOSE AXW1DH-74837 1

225 ELECTRONIC PRESSURE SENSOR AXW1EP-06187 1

215 EMI FILTER AXW2EF-15002 1

296 CABLE GR AXW2CB-26678 1

249 CABLE HARNESS AXW14B-26679 1

250 CABLE HARNESS HOLDER PLS AXW1CH-93407 1

251 CABLE HARNESS HOLDER PLS AXW1CH-28367 1

331 LOCKING WIRE SADDLE (BLUE) AXW1CH-85086 1

895 SPRING HANGER SHEETIRON GR AXW1SH-37953 1

231 SPRING HANGER BRACKET AXW2SH-79359 1

221 HANGER SPRING SHEETIRON PLS. AXW1HS-16727 2

700 TUB HANGER SPRING PART AXWTHS-19298 2

235 DRAIN HOSE HOLDING PLS AXW1HC-14270 4

239 POWER CORD GROUP AXW4A-26588 1

222 PRESSURE SWITCH MOUNTING CLIP AXW1HC-22768 1

238 SPEED CONTROL HOLE STOPPER AXW1SC-06161 1

290 TRANSPORT SCREW GROUP-II AXW2TS-15676 4

242 TRANSPORT SCREW PLASTIC-A-II AXW1TS-18528 4

243 TRANSPORT SCREW PLASTIC-B-II AXW1TS-60789 4

240 TRANSPORT SCREW AXWSB4-08363 4

245 TRANSPORT SCREW EPDM AXW1TS-60790 4

241 PLAIN WASHER 830X29X2 AXWSW1-15272 4

132 CABLE TIE(YKB150) AXWCT-075920 7

918 DRAIN FILTER AXWDF-120197 1

919

HOSE CLAMP Φ8.6

920 FRONT PANEL DROP FIXING PLASTIC-II AXW1TP-20456 4

1404

HORT. KLPC.Φ350

1503 ST 42X95 PAN HEAD W.COL. T.UNDER. SER. EA AXWSS7-16042 2

1504 ISO 7049 ST 42X13 TORX AXWSS6-14453 4

1505 ST 42X95 TRTSB AXWSS5-14454 4

AXWHC-003440 1

AXWHC-006977 1

49

Page 50

13.7. Porthole Group Spare Parts

13.7.1. Exploded View Porthole Group Spare Parts

13.7.2. Porthole Group Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

6 OUTER DOOR PLASTIC AXW1DP-93322 1

7 DOOR GLASS AXW1GD-03771 1

8 INNER DOOR PLASTIC AXW1DP-86999 1

12 HINGE II-M5 AXW192-15559 1

13 HINGE BUSHING II AXW192-23907 4

14 DOOR HANDLE AXW1DH-04266 1

15 HOOK SPRING AXW1HS-07443 1

16 HANDLE SPRING AXW1HS-14985 1

17 DOOR HOOK II.(METAL) AXW1DH-08931 1

27 DOOR HANDLE TONGUE PIN AXW1DH-07434 3

28 SCREW 3.5X16PAN.HE.WITH COL.CR.RE.UN.HE. AXWSS7-08715 9

29 OUTER DOOR PLS INSERT PART AXW1DS-06270 1

32 OUTER DOOR PLS. INNER FRAME AXW1DS-80609 1

33 DOOR HINGE SUPPORT SHEET AXW192-08152 1

50 PORTHOLE GROUP AXW2DP-32501 1

410 SCREW 4X12 PAN HEAD WITH COLLAR UNDER HE AXWSB9-16360 6

1502 SCREW M5X8 TSB AXWSST-15092 2

50

Page 51

13.8. CIRCULATION GROUP

13.8.1. Exploded View of Circulation Pump Spare Parts

13.8.2. Circulation Pump Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

118 TUB BELLOWS SEAL AXW212-25995 1

285 PUMP GROUP(FILTER)(THER. PROTECT.) AXW8FT-06391 1

410 SCREW 4X14 PAN HEAD TYPE 2 AXWSB8-16360 1

446 ISO 7049 ST 42x13 TYPE 2 AXWSS2-08716 1

921 TWIN JET HORN/LEFT AXWTJH-25993 1

922 TWIN JET HORN/RIGHT AXWTJH-25992 1

923 TWIN JET T-ELBOW AXWTJT-25561 1

924 HANDCUFFS ?20.2 AXW2HC-08653 3

925 TWIN JET NOZZLE AXWTJN-25574 2

926 CIRCULATION PUMP AXW8CP-08568 1

927 TWIN JET CABLE HOSE HOLDER PLASTIC AXWTJC-25867 5

928

HANDCUFFS Φ26.8

929 PUMP PROTECTION FOIL-3 AXW1PF-10025 1

930 TWIN JET HOSE_N NO:1 AXWTJH-25194 1

931 TWIN JET HOSE_H NO:2 AXWTJH-31321 1

932

HANDCUFFS Φ15.88

933 PYTHON-CIRCULATION TUB GASKET GR AXWTJH-31321 1

934 TWIN _JET HOSE GROUP AXWTJH-34816 1

AXW2HC-09578 1

AXW2HC-08652 4

51

Page 52

13.9. Accessories

13.9.1. Accessories

13.9.2. Accessories Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

994 USER'S MANUEL AXW4F-157593 1

992 SERVICE LIST AXW9911-9390 1

995 ENERGY LABEL AXW90EL-8560 1

996 LIQUID DETERGENT LEVEL PLATE AXW51D-65310 1

997 DRAIN HOSE COAT RACK AXW90HC-0601 1

998 TRANSPORT SCREW STOPPER AXW1TS-16405 4

52

Page 53

13.10. Packaging Group Spare Parts

13.10.1. Exploded View of Packaging Group Spare Parts

53

Page 54

13.10.2. Package Group Spare Parts List

Safety Ref. No. Part Name & Description Parts No. Qty Remarks

900 BOTTOM STYROFOAM AXWPV-154370 1

901 TOP CARTON AXWPV-152496 1

902 REAR STYROFOAM(LEFT) AXWPV-277830 1

903 REAR STYROFOAM(RIGHT) AXWPV-277820 1

904 FRONT STYROFOAM LEFT AXWPV-277810 1

905 FRONT STYROFOAM RIGHT AXWPV-280760 1

906 CORNER CARDBOARD AXWPV-002040 1

907 TUB SUPPORT STYROFOAM AXWPV-053000 1

909 PACKAGE CARTON AXWPV-160507 1

54

Loading...

Loading...