Panasonic NA-127VB5WFR, NA-127VB5WGB, NA-127VB5WTA, NA-127VB5WPL, NA-127VB5WGN Service Manual

...

© Panasonic Corporation 2013 Unauthorized copying and distribution is a violation of law.

Order No. VES1309006CE

Drum Type Washing Machine

Model No. NA-127VB5WGB

Model No. NA-127VB5WFR

Model No. NA-127VB5WES

Model No. NA-127VB5WTA

Model No. NA-127VB5WPL

Model No. NA-127VB5WGN

Model No. NA-127VB5WNR

Model No. NA-147VB5WDE

Model No. NA-147VB5WGB

Model No. NA-147VB5WGN

Model No. NA-147VB5WNR

Product Colour

White

Destination

Germany , UK, France, Belgium, Norway ,

Italy, Spain, Hungary, Holland, Poland,

Sweden, Denmark, Finland

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

2

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

2 Specifications------------------------------------------------------4

3 Location of Controls and Components--------------------6

4 Installation Instru ctions-----------------------------------------7

5 Operating Instructions------------------------------------------9

6 Test Mode----------------------------------------------------------11

7 Service Mode-----------------------------------------------------13

8 Troubleshooting Guide----------------------------------------14

9 Critical Torque Valuess ---------------------------------------16

10 Disassembly and Assembly Instructions---------------17

11 Component Specifications-----------------------------------28

12 Wiring Connection Diagram---------------------------------37

13 Exploded View and Replacement Parts List-----------39

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

3

1 Safety Precautions

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

4

2 Specifications

2.1. Product Specifications

2.2. Name Plate

Model NA-127VB5 NA-147VB5

Product Type Front Loader Front Loader

Capacity 7 kg 7 kg

Max Spin Speed 1200 rpm 1400 rpm

Drum Volume 50 lt 50 lt

Energy Label Rating A+++ A+++

Energy Consumption 162 kWh / annum 162 kWh / annum

Water Consumption 9240 L / annum 9240 L / annum

Noise Level

Wash 58 dBA 58 dBA

Spin 74 dBA 76 dBA

Control Panel LCD Display LCD Display

Wash Programs 15 settings 15 settings

Spin Speed Setting 6 setting 7 setting

Dimensions

Height 84.5 cm 84.5 cm

Width 59.7 cm 59.7 cm

Depth 54.2 cm 54.2 cm

Door Opening Large door opening Large door opening

Delay Time Setting Yes Yes

Colour White White

Water Protection Overflow Protection

Overflow Protection

Aquastop Hose(for Germany only)

Other Features Child Lock Child Lock

Packaging Shrink package Shrink package

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

5

2.3. Dimensions

Dimension in millimetres

NA-127VB5, NA-147VB5

2.4. Twinjet Information

1. Twinjet system is designed to obtain a better washing

performance by directly injecting water with detergent

using a recirculation system and two nozzles connected

to it. With twinjet system, water consumption is

decreased by 30%, energy consumption is decreased by

10% and washing time is decreased by 15%.

2. Twinjet system is valid for all programs except spin and

drain mode. The system dos not function during Water

inlet, heating, spinning, drain phases.

3. Even with a large load of 8 kg. the washing machine will

have the minimum energy consumption by the help of

Twinjet system.

4. Washing machines with Twinjet system are very environment-friendly by having maximum washing performa nce

with minimum water consumption.

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

6

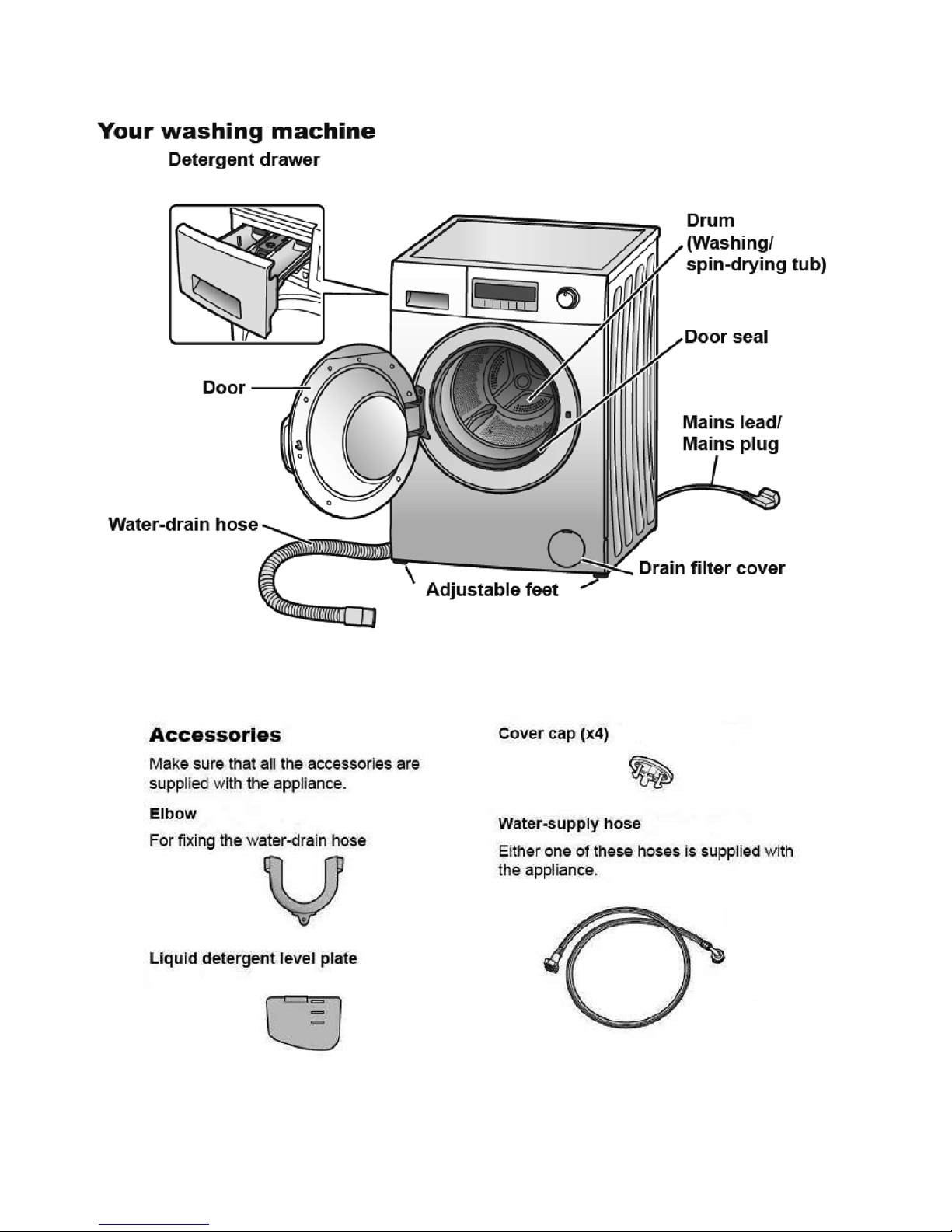

3 Location of Controls and Components

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

7

4 Installation Instructions

4.1. Moving and Installing

4.1.1. Removal of Transportation Screw

1. Transportation screws, which are located at the back side

of the machine, must be removed before running the

machine.

2. Loosen the screws by turning them anticlockwise with a

suitable spanner.

3. Pull out the screws and rubber washers.

4. The holes where the transport screws have been

removed should be covered with the plastic transport

caps found in the accessories bag.

5. The transportation screws that have been removed from

the machine must be re-used in any future transporting of

the machine.

4.1.2. Foot Adjustment

1. Do not install machine on rugs or similar surfaces.

2. For machine to work silently and without any vibration, it

should be installed on a flat, non-slippery firm surface.

Any suspended floor must be suitably strengthened.

3. You can adjust the level of machine using its feet.

4. First, loosen the plastic adjustment nut away from the

cabinet base.

5. Change the level by adjusting the feet upwards or downwards.

6. After level has been reached, tighten the plastic adjustment nut again by rotating it upwards against the base of

the cabinet.

7. Never put cartons, wooden blocks or similar materials

under the machine to balance irregularities of the floor.

4.1.3. Electrical Connection

1. Washing machine requires a 50Hz supply of 220240Volts.

2. A special earthed plug has been attached to the supply

cord of washing machine. This plug must be fitted to an

earthed socket. The fuse value fitted to this plug should

be 13 amps. If you have any doubts about electrical supply, consult a qualified electrician.

THIS APPLIANCE MUST BE EARTHED.

Insert the machine’s plug to a grounded socket which you

can easily reach.

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

8

4.1.4. Water Supply Connection

1. Washing machine is supplied with a single (cold) water

inlet.

2. To prevent leakage from the connection joints, a rubber

washer is included in the hose packing. Fit this washer at

the end of water inlet hose on the tap side.

3. Connect the hose to the water inlet valve. Tighten the

plastic connector by hand. Please call a qualified plumber

if you are unsure about this.

4. Water pressure of 0,1-1 MPa from tap will enable

machine to work more efficiently.(0,1 MPa pressure

means water flow of more than 8 litres in 1 minute from a

fully opened tap)

5. After connection is complete, check for leakage by turning

on tap completely.

6. Make sure that water inlet hoses can not become folded,

damaged, stretched or crushed when the washing

machine is in its final position.

7. Mount the water inlet hose to a 3/4” threaded water tap.

4.1.5. Drain Connection

1. Make sure that water inlet hoses are not folded, twisted,

crushed or stretched.

2. The drain hose should be mounted at a minimum height

of 60 cm, and a maximum height of 100 cm from the floor.

3. The end of the drain hose can be con nected directly to a

drainage stand-pipe or alternatively to a specific connection point designed for that purpose on the waste outlet of

a sink unit.

4. Do not extend the drain hose or guarantee will be invalidated.

4.2. Detergent Box Group

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

9

5 Operating Instructions

5.1. LCD Screen, Function Buttons & Knobs

PR Program selector 16 programs including off position

SW1 Switch 1, Start / Pause

SW2 Switch 2, Temperature Selection

SW3 Switch 3, Spin Speed Selection

SW4 Switch 4, Delay Timer Selection

SW5 Switch 5, Extra Rinse Option

SW6 Switch 6, Easy Ironing Option

SW7 Switch 7, Eco/Speed Mode Option

SS1 7 Segment LCD for Temperature Display I8 Extra Rinse Symbol

SS2 7 Segment LCD for Spin Speed Display I9 Easy Ironing Symbol

SS3 7 Segment LCD for Remaining Time I10 Eco Mode Symbol

I1 Child Lock Symbol I11 Speed Mode Symbol

I2 Door Lock Symbol I12 Cold Wash Symbol

I3 Drain Phase Symbol I13 Temperature Sign

I4 Spin Phase Symbol I14 Program Proceeding Zone

I5 Rinse Phase Symbol Slow Blink ON 0.5 sec, OFF 0.5 sec, ON 0.5 sec

I6 Wash Phase Symbol Fast Blink ON 0.10 sec, OFF 0.10 sec, ON 0.10 sec

I7 Delay Symbol

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

10

5.2. Program Details

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

11

5.3. Child Lock

Activation

Press SW7 for 5 seconds.

The Child Lock Symbol on appears on the LCD display as

Child Lock is active.

Deactivation

Press SW7 for 5 seconds.

The Child Lock Symbol will disappear on LCD displayupon

deactivation.

6 Test Mode

6.1. Autotest

Set PR to program 3 (Colours)

While pressing SW5 (Extra Rinse), change position of the PR from third program to second (Cotton-Prewash), and release the SW5

after keep more than 5 seconds.

Autotest starts.

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

12

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

13

7 Service Mode

7.1. Service Autotest

1. Set PR to program 3 (Colours) and press SW2 (TC)

2. While pressing the SW2, change PR position from third to

second, and release the SW2 after keep more than 5 seconds.

3. Bring PR to desired test step (1st ,2nd or 3rd program

position) as soon as [SAU] is displayed on LCD.

LCD Display status:

I2 Door Lock Symbol -> Fixed on

SS3 -> SAU

The test steps are as below ;

Step 1:

Selector Program 1 (Cotton) will be [HEATER ON]

Before heating it should take water till first level frequency

then start heating.

Heater will be on max. 8 minutes after this 8 minutes if the

temp. doesn’t change more than 2C then it will give N TC

failure. (E05).

Or if the NTC connection is broken then it should give again

E05 NTC failure.

At the end of heating, [SAU] visualization should make slow

blink to indicate that the step is over.

Note:

If user changes the selector position, machine will do what

is defined for the new selected position.

Step 2:

Selector Program 2 (Cotton Prewash) will be [PUMP ON]

Temperature will be measured, if it is higher than 50 C, it

should take 60 sec. cooling water, and then make [Drain + 5

sec.]

At the end of pump activation, [SAU] visualization shoul d

make slow blink to indicate that the step is over.

Step 3:

Selector position 3 (Colours) will be a 12 mins test program

where all functions of the appliance will be checked.

Machine will make exactly the same algorithm of Super

Rapid 12'. So, time for selector position 3 is 12 minutes.

At the end of test program [End] is visualized on LCD and

door is unlocked.

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

14

7.2. Failure Codes

8 Troubleshooting Guide

All repairs which must be done on the machine should be done by authorized agents only. When a repair is required for machine or

you are unable to eliminate the failure with the help of the information given below:

• Unplug the machine.

• Close the water tap.

Error Indication Error Number Indication For User Indication For Service

Yes/No Yes/No

Door is not locked E01 Yes Yes

Door is unlocked during programme E01 Yes Yes

Lack of water E02 Yes Yes

Pump failure E03 Yes Yes

Overflow E04 Yes Yes

NTC or Heater Failure E05 No Yes

Motor Failure - 1 (T achometer open-short circuit or

motor connector is disconnected)

E06 No Yes

Motor Failure - 2 (triac short circuit) E08 No Yes

Electronic Pressure Sensor E10 No Yes

FAILURE PROBABLE CAUSE METHODS OF ELIMINATION

Machine does not operate.

It is unplugged. Insert the plug into the socket.

Fuse is defective. Change fuse.

Start / Pause button has not been

pressed.

Press the start / pause button.

The program knob is in 0 (off) status. Bring the program knob on the desired status.

The door is not shut properly. Shut the door properly. You should hear the click.

Child lock is active. See section 5.3.

Machine does not receive water.

Water tap is closed. Open water tap.

The water inlet hose may be bent. Check the water inlet hose.

The ater inlet hose is obstructed. Clean the filters of water inlet hose.

The water inlet filter is obstructed. Clean the valve inlet filters.

The door is not shut properly. Shut the door properly. You should hear the click.

Machine is not draining water.

The drain hose is obstructed or bent. Check the drain hose.

The pump filter is obstructed. Clean the pump filter.

The clothes are not placed inside the

machine in a well-balanced manner.

Spread the clothes inside the machine in an orderly and

well-balanced manner.

Machine is vibrating.

The feet of machine are not adjusted. Adjust the feet.

Transportation screws are not

removed. Remove transportation screws.

There is a small amount of clothes in

the device.

It does not prevent operation of the machine.

Excessive amount of clothes are filled

in the machine or the clothes are not

placed in a well-balanced manner.

Do not exceed the recommended quantity of clothes

and spared clothes in the machine in a well-balanced

manner.

Excessive foam in the detergent

drawer

Too much detergent has been used. Press the start/pause button. In order to stop the foam,

dilute one table-spoon of softener in half liter of water

and pour it in the detergent drawer. Press the start/

pause button after 5-10 minutes. Arrange the amount of

the detergent properly in the next washing process.

Wrong detergent has been used. Use only the detergents produced for full automatic

machines.

The washing result is bad.

Laundry too dirty for the program you

have selected.

Select a suitable program.

The amount of detergent used is not

sufficient.

Use more detergent according to the detergent.

The washing result is not good.

Clothes exceeding the maximum

capacity has been filled in machine.

Put the clothes in machine in a manner not to exceed

its maximum capacity.

Water may be hard. Use the amount of detergent accord ing to the declara-

tion of the detergent producer.

Distribution of the clothes in machine is

not well-balanced.

Spread the clothes inside the machine in an orderly and

well-balanced manner.

The water is seen in the drum

during washing.

No failure. The water is at the lower

part of the drum.

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

15

There are residues of detergent

on the clothes.

The pieces of some detergents which

do not dissolve in water may stick to

clothes as white stains.

By calibrating machine for [Rinsing] program, make an

additional rinsing or eliminate the stains After drying

with the help of a brush.

There are grey stains

on the clothes.

These stains may be caused by oil,

cream or ointment.

In the next washing operation, use the maximum detergent amount declared by the detergent producer.

The spinning process is not done

or starts with delay.

No failure. The unbalanced load control

works in that way.

The unbalanced load control system will try to distribute

clothes in a homogenous manner. After clothes are distributed, passage to spinning process will be realized.

In the next washing process, place clothes into the

machine in a well-balanced manner.

FAILURE PROBABLE CAUSE METHODS OF ELIMINATION

NA-127VB5WGB / 127VB5WFR / 127VB5WES / 127VB5WTA / 127VB5WPL / 127VB5WGN / 127VB5WNR /

147VB5WDE / 147VB5WGB / 147VB5WGN / 147VB5WNR

16

9 Critical Torque Valuess

The bolts/nuts above are important for product safety purposes. Please tighten screw, bolts and nuts according to the torque values

given in table above.

Assembly Location Bolt/Nut Torque Min.

(Nm)

Torque Nom.

(Nm)

Torque Max.

(Nm)

Air Pressure

Wrench. (rpm)

* Transport Screw Assembly Transport Screws 6.50 6.50 7.00 1000

* Motor Assembly Motor Screws 6.00 6.50 7.50 800

*

Front Concrete Weight - Front

Tub Assembly

Front Counterweight Screws 14.00 14.50 14.75 600

* Upper Counter Weight Assembly Upper Counterweight Screws 25.00 27.50 30.00 440

*

Pulley - Drive Shaft - Washing

Group Assembly

Pulley - Drive Shaft Assembly

Bolt

39.50 40.00 40.50 440

* Heater Assembly Heater Assembly Nut 3.85 4.00 4.00 970

Loading...

Loading...