Panasonic mva18fbas6hbcp, mva24fbas6hbcp, mva30fbas6hbcp, mva36fbas6hbcp, mva42fbas6hbcp Operation Manual

...Page 1

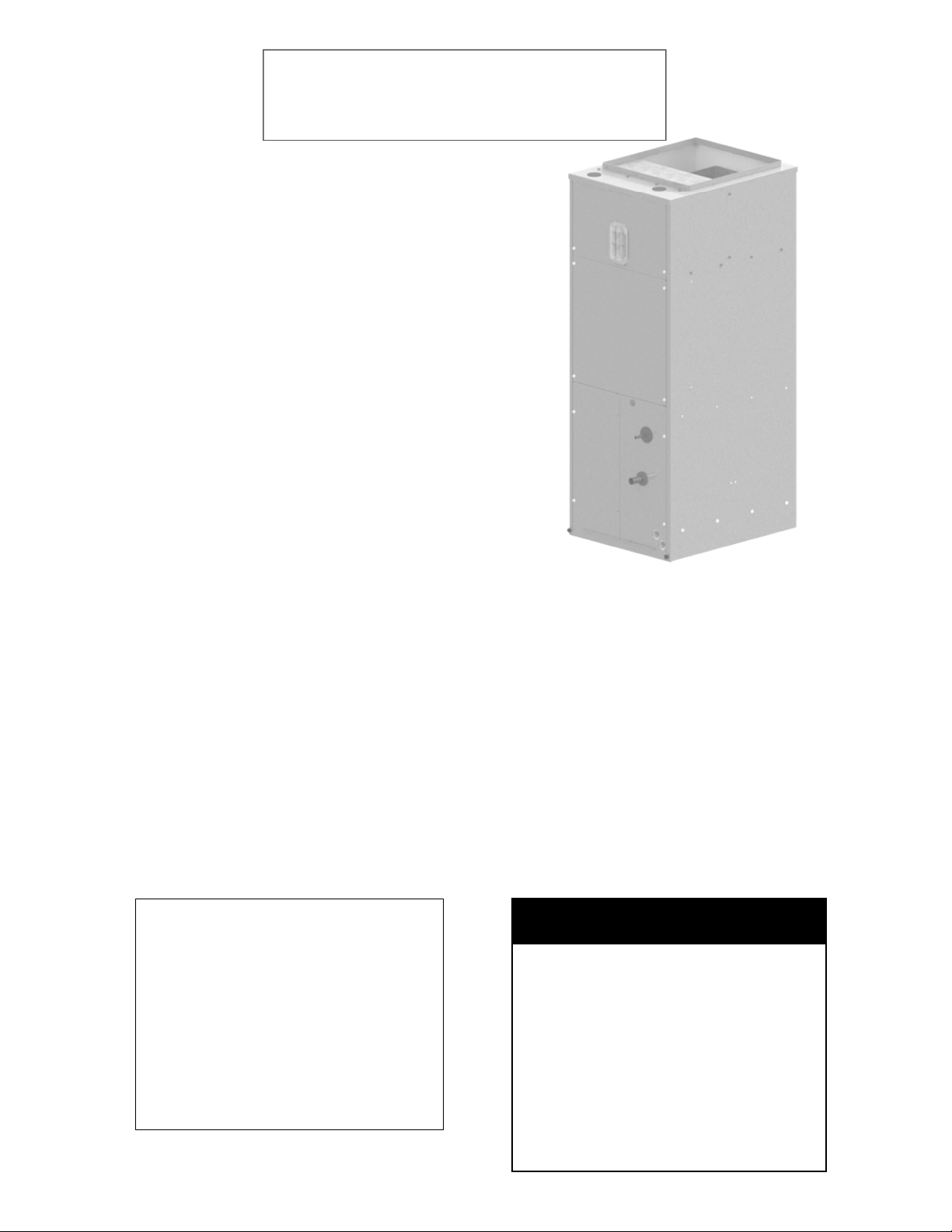

MVA Series Air Handling Unit

Installation, Operation and Maintenance

Manual

MVA Series units are direct drive vertical and

multi-position Air Handlers delivering nominal cooling capacities of 1.5 to 5 tons. Units

may be specified with hot water or electric heating coils to meet space cooling loads or heating

loads or both. Two styles of unit orientation are

available for maximum flexibility.

How to Use this Manual:

This manual gives instructions regarding installation, operation and maintenance for the

MVA Series air handling units.

Use these instructions in conjunction with

other appropriate instructions, including but

not limited to those instructions supplied with

the outdoor unit. Installation must comply

with all applicable local codes.

SAFETY WARNING:

Installer should pay particular attention to

the following words:

NOTE–intended to clarify or make installation easier.

CAUTION–given to prevent equipment

damage.

WARNING–to alert installer that personal

injury and/or equipment damage may

result if installation procedure is not

properly followed.

GENERAL

Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes and regulations and are

experienced with HVAC equipment of this type.

WARNING: Sharp edges, coil surfaces

and rotating fans are a potential injury

hazard – avoid contact.

WARNING: Hazardous voltage – Disconnect and Lock Out all incoming power

sources before servicing or installing unit.

ELECTRIC SHOCK CAN CAUSE DEATH.

WARNING: This equipment may be installed well above finished floor—Use extreme caution when working at heights.

UNPACKING-CHECK FOR DAMAGE!

Immediately inspect each unit for damage upon receipt.

Inspect units for external and concealed

damage immediately.

File any damage claims in accordance

with the Freight Damage Policy and

Terms and Conditions.

Do not repair damaged units without

written authorization.

Protect stored units from damage.

035-000039-001 Page 1 of 32 MVA IOM 1.3 9-10-2014

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

035-000039-001 Page 2 of 32 MVA IOM 1.3 9-10-2014

Page 3

MVA Series Air Handling Unit

Installation, Operation and Maintenance

Manual

/ŶƐƚĂůůĂƟŽŶ ^ƚĂƌƚ-Up

and Service

/ŶƐƚƌƵĐƟŽŶƐ

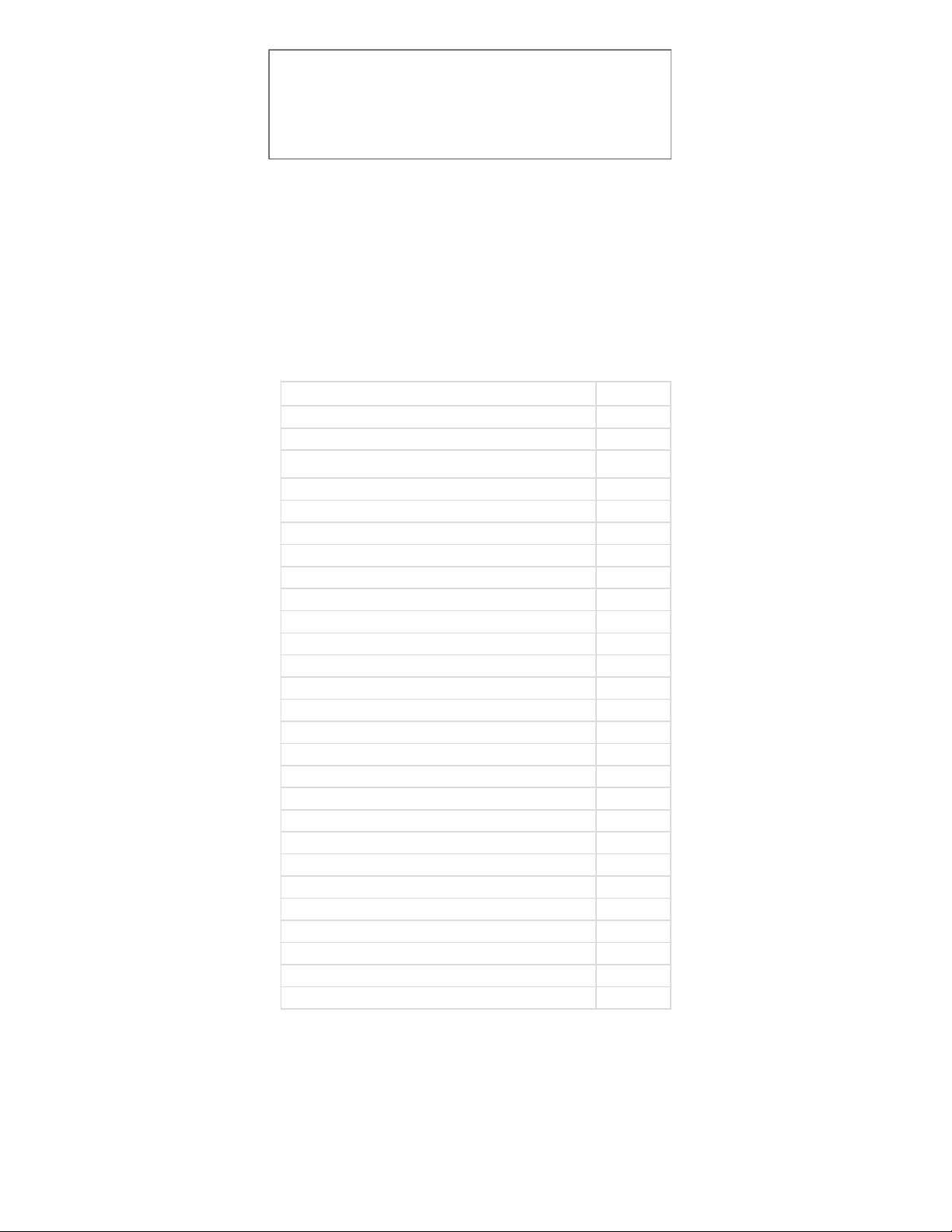

Topic Page

SAFETYCONSIDERATIONS

PRODUCT NOMENCLATURE

UNPACKING

INSTALLATION

Pre-installation

Rigging

Unpackaging

Service Clearances

Return Air & Unit Orientation

Vertical to Horizontal Conversion (EEV)

Unit Suspension or Floor Mount

Condensate Drain

Ductwork

Refrigerant Piping

Electric Heater Accessory

Electrical

START-UP

Fan Airflow Step-Up

Airflow Data

SERVICE

Fan & Fan Motor

Filters

Access Panels

Coil & Drain Pan Service

ELECTRICAL RATINGS

DIMENSIONS

Startup Report

1, 5

6-7

8

8

8

8

8

8,11

9

10

8,12,13

12

12

14

14-15

16-21

22-23

23-24

23-24

25-28

25-26

27

27

28

29

30

31

035-000039-001 Page 3 of 32 MVA IOM 1.3 9-10-2014

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

035-000039-001 Page 4 of 32 MVA IOM 1.3 9-10-2014

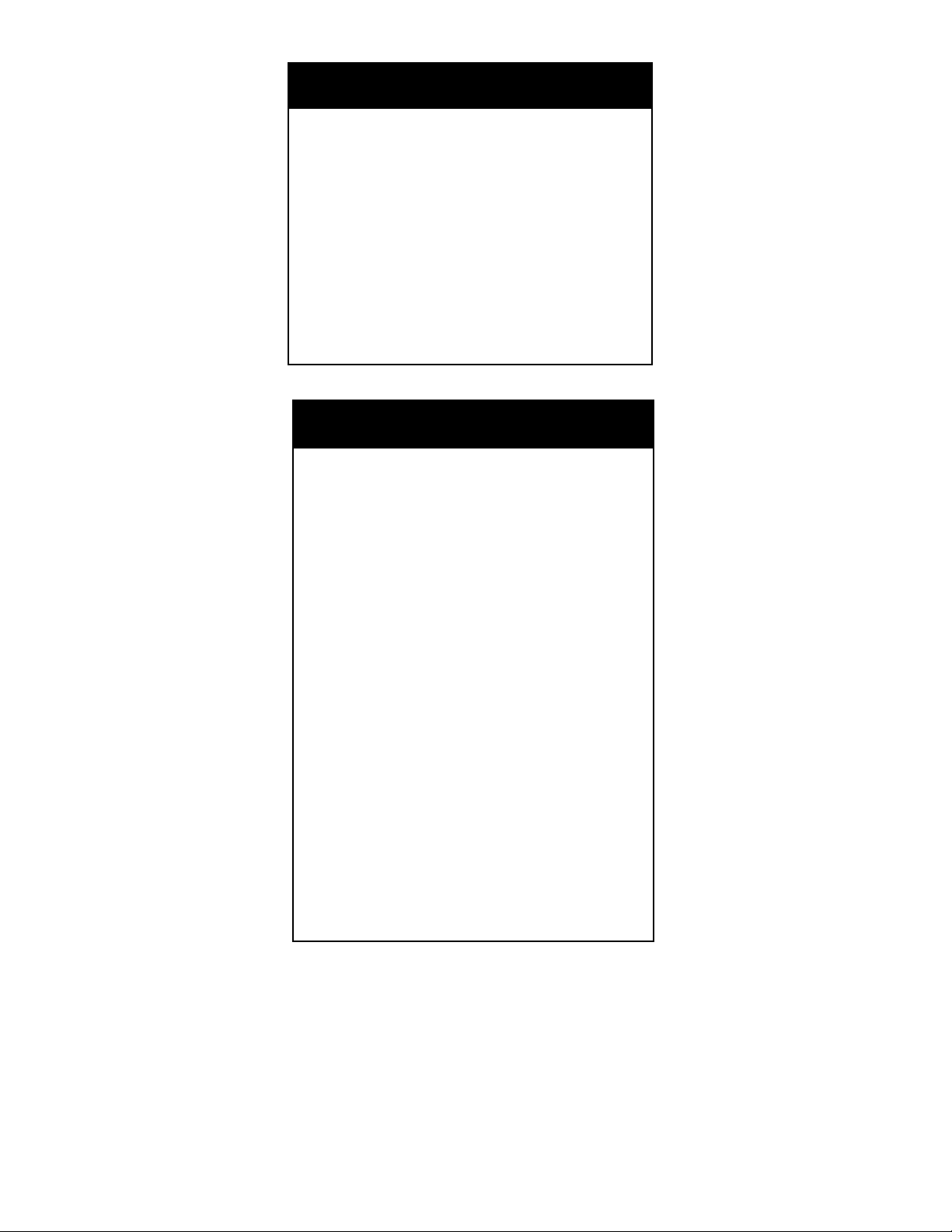

Page 5

DANGER

NEVER enter an enclosed fan cabinet or reach into

a unit while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect switch before working on a fan. Take fuses

with you and note removal on tag. Electric shock

can cause personal injury or death.

LOCK OPEN AND TAG the electric heat coil power

disconnect switch before working on or near heaters.

Failure to follow these warnings could lead to personal injury or death.

WARNING

CHECK the assembly and component weights to

be sure that the rigging equipment can handle

them safely.

Note also, the centers of gravity and any specific

rigging instructions.

CHECK for adequate ventilation so that fumes will

not migrate through ductwork to occupied spaces

when welding or cutting inside air-handling unit

cabinet or plenum.

WHEN STEAM CLEANING COILS be sure that

the area is clear of personnel.

DO NOT attempt to handle access covers and removable panels on outdoor units when winds are

strong or gusting until you have sufficient help to

control them. Make sure panels are properly secured while repairs are being made to a unit.

DO NOT remove access panel fasteners or open

access doors until fan is completely stopped. Pressure developed by a moving fan can cause excessive force against the panel which can injure personnel.

DO NOT work on dampers until their operators are

disconnected.

BE SURE that fans are properly grounded before

working on them.

Failure to follow these warnings could result in personal injury or equipment damage.

035-000039-001 Page 5 of 32 MVA IOM 1.3 9-10-2014

Page 6

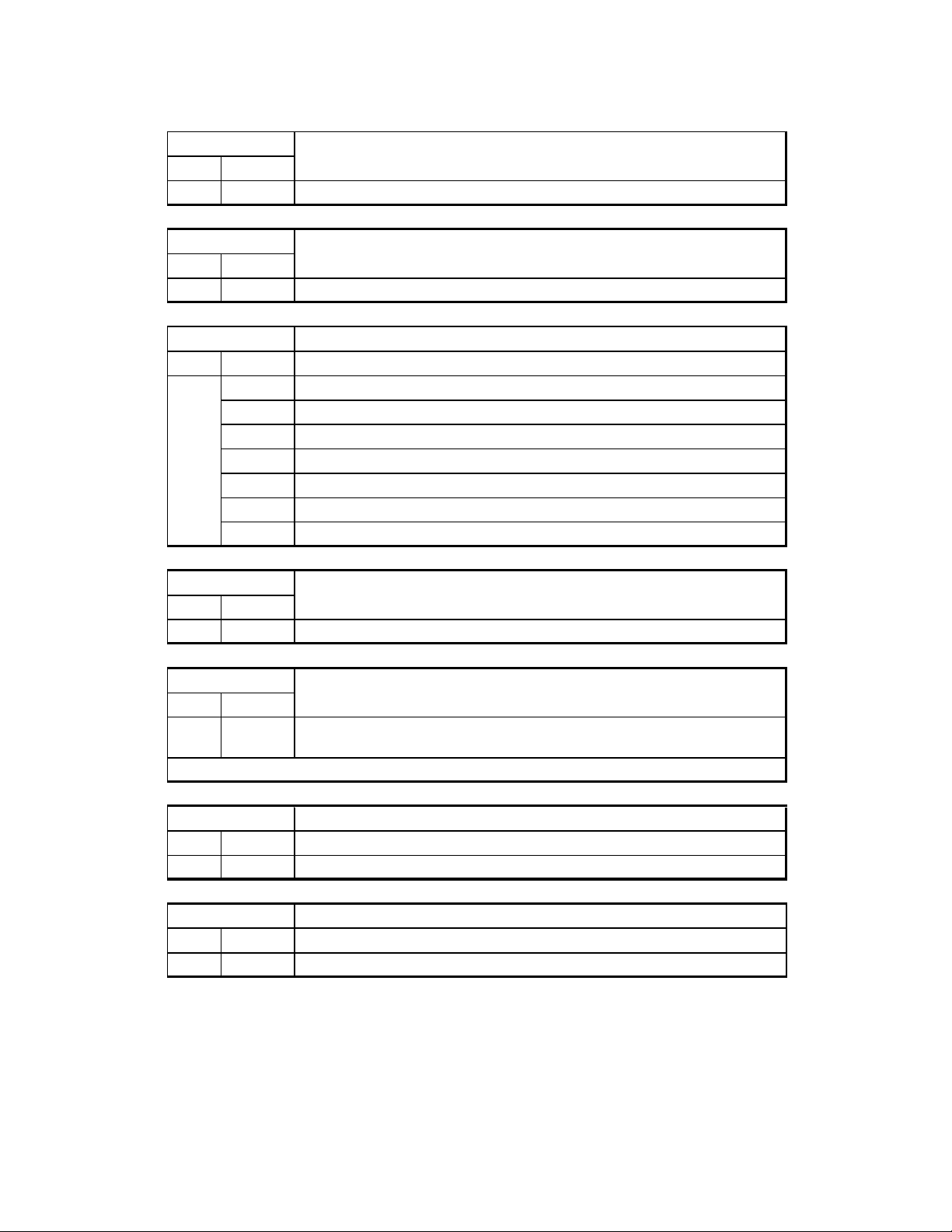

PRODUCT NOMENCLATURE

Unit Type/Size

Code Selection

01, 02 MV

Generation/Series

Code Selection

03 A

Unit Type/Size

Code Selection NOM Capacity

18

24

30

04, 05

Primary Coil Type

Code Selection

06

36

42

48

60

F

Description

Direct Drive Multiposition air handling unit

Description

Revision Level

Description

18,000 Btu/hr

24,000 Btu/hr

30,000 Btu/hr

36,000 Btu/hr

42,000 Btu/hr

48,000 Btu/hr

60,000 Btu/hr

Description

4 ROWDX with electronic expansion valve,R-410a

HeatingCoil

Code Selection

07

Future Use Description

Code Selection

08

Unit Grade Description

Code Selection

09

Description

Electric Heat Ready (readyto accept field installed EH Accessory kit, ordered

B

Future Use

A

Standard

S

separately)

035-000039-001 Page 6 of 32 MVA IOM 1.3 9-10-2014

Page 7

Selection

Selection

OrderingNumber

Selection

Selection

Selection

PRODUCT NOMENCLATURE—CONT’D

Unit Voltage

Code

10

Controls

Code

11 H

ReturnAir Cabinet Options

Code

12

DrainPan

Code

13

Tracking Description

Code

14

Description

208/230/1/60 ECM-VE(customer change transformer tapfor 208V)

6

Description

Internal Use

Description

Unit Orientation

Vertical (Front RH Cond

Drain Cnx)or Horizontal

B

C

P

Right

Description

drain panandcabinet insulationtype

Fiberglass, Universal Drainpan - Galvanized

Internal Use

ReturnLocation

Bottom Return

Accessory Electric Heater Kits

P/N Description Unit Size Power kW*

012-000458-001 FC EH-HEATER MVA-3-1-240 3KW MVA18-60 240/1/60 3

012-000458-002 FC EH-HEATER MVA-5-1-240 5KW MVA18-60 240/1/60 5

012-000458-003 FC EH-HEATER MVA-6-1-240 6KW MVA18-60 240/1/60 6

012-000458-004 FC EH-HEATER MVA-8-1-240 8KW MVA18-60 240/1/60 8

012-000458-005 FC EH-HEATER MVA-9.5-1-240 9.5KW MVA18-60 240/1/60 9.5

*Note: If unit power is 208V/1ph/60Hz, then the kW is reduced to 75% of the table value.

Accessory Filter Kits

P/N Description

473-550115-001 2" FILTER RACK MERV 8 - MVA18/24

473-550115-002 2" FILTER RACK MERV 8 - MVA30/36

473-550115-003 2" FILTER RACK MERV 8 - MVA42/48

473-550115-004 2" FILTER RACK MERV 8 - MVA60

473-550116-001 4" FILTER RACK MERV 13 - MVA18/24

473-550116-002 4" FILTER RACK MERV 13 - MVA30/36

473-550116-003 4" FILTER RACK MERV 13 - MVA42/48

473-550116-004 4" FILTER RACK MERV 13 - MVA60

035-000039-001 Page 7 of 32 MVA IOM 1.3 9-10-2014

Page 8

INSTALLATION

Pre-installation

1. Check items received against packing list.

2. Do not stack unit components or accessories during storage. Stacking can cause

damage or deformation.

3. If unit is to be stored for more than 2 weeks

prior to installation, observe the following

precautions:

a. Choose a dry storage site that is rea-

sonably level and sturdy to prevent undue stress or permanent damage to the

unit structure or components. Do not

store unit on vibrating surface. Damage

to stationary bearings can occur. Set

unit off ground if in heavy rain area.

b. Remove all fasteners and other small

parts from jobsite to minimize theft. Tag

and store parts in a safe place until

needed.

c. Cover entire unit with a tarp or plastic

coverall. Extend cover under unit if

stored on ground. Secure cover with

adequate tie-downs or store indoors.

Be sure all coil connections have protective shipping caps.

d. Monthly — Remove tarp from unit, en-

ter fan section through access door or

through fan inlet, and rotate fan and

motor slowly by hand to redistribute the

bearing grease and to prevent bearing

corrosion.

Rigging — Do not remove shipping skids or

protective covering until unit is ready for final

placement. Use slings and spreader bars as applicable to lift unit. Do not lift unit by coil connec-

tions or headers.

Do not remove protective caps from coil

piping connections until ready to connect

piping.

WARNING-AUXILIARY DRAIN PAN

RECOMMMENDED:

This product has an auxiliary condensate drain

which should be piped to a condensate overflow

sensor or safe drain location or both to protect

the equipment and property from damage in the

case of condensate overflow.

In addition, the International Mechanical Code

(IMC) section 307.2.3 requires the use of auxiliary drain pans. Many municipalities have

adopted this code.

This practice represents the standard for professional installation whether or not this code has

been adopted in a specific municipality or territory. As such, water damages that would have

been prevented had an auxiliary pan been deployed will not be considered for compensation.

This position is taken regardless of whether the

source of the moisture was specified as a potential failure mode in the applicable building

code or not. A freeze burst, cracked drain pan,

failed weld, or corrosion induced leak are some

of the potential failure modes that are mitigated

when an auxiliary pan is properly installed. Professional installers recognize the value of protecting customer assets against foreseeable

events. Customers who choose to avoid the

cost of common protective measures waive their

right to seek damages when those foreseeable

events occur. If the product is located above a

living space or where damage may result from

condensate overflow, install a watertight pan of

corrosion-resistant metal beneath the unit to

catch over-flow which may result from clogged

drains or from other reasons. Provide proper

drain piping for this auxiliary pan. Consult local

codes for additional precautions before installation.

Unpackaging

1. Remove all packaging and any foreign material from unit.

2. Check blower wheel for free rotation.

3. Check copper lines, coil etc. for internal or

hidden damage.

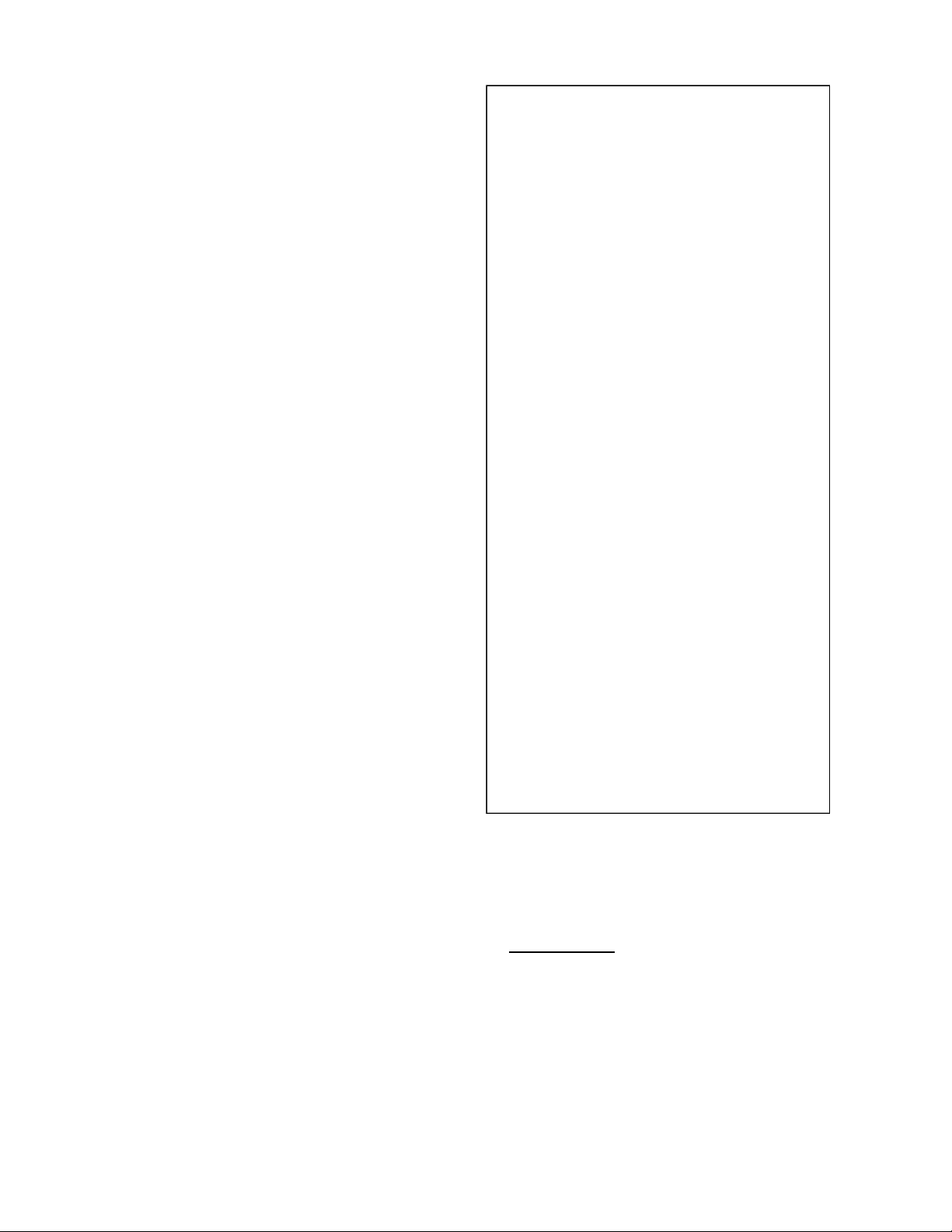

Return Air and Unit Orientation

Units may be positioned in several configura-

tions depending on the return air configuration selected—see Figure 1.

NOTE: Right and left return units are not

recommended for horizontal installation.

Service Clearance

inches) of clearance. This allows substantial freedom in the positioning of the unit to

best serve the requirements of the structure.

Unit Support

Floor mounting: Unit may be mounted on a

housekeeping pad, floor, platform or plenum.

Provide a suitable isolation pad to minimize

sound transmission to the structure. CAU-

TION! Make sure to allow enough elevation to permit construction of the condensate trap. Also allow enough elevation

and clearance for opening the filter door

(removes to the front). See Service Clear-

ances.

The fan coil is completely serviceable from

the front. Units are approved for 0” (zero

035-000039-001 Page 8 of 32 MVA IOM 1.3 9-10-2014

Page 9

INSTALLATION

NOTE:

Electronic Expansion Valve (EEV)

must be oriented vertically, and is

shipped for vertical cabinet orientation.

For horizontal cabinet orientation,

follow procedure to rotate the EEV

assembly. Refer to Figure 2.

Return Configurations and

Unit Orientations

WARNING

FOR HORIZONTAL CABINET ORIENTATION, EEV MUST BE ROTATED TO

VERTICAL POSITION! Failure to reorient the EEV can result in improper

unit operation or equipment damage

or dangerous condition.

Figure 1

035-000039-001 Page 9 of 32 MVA IOM 1.3 9-10-2014

Page 10

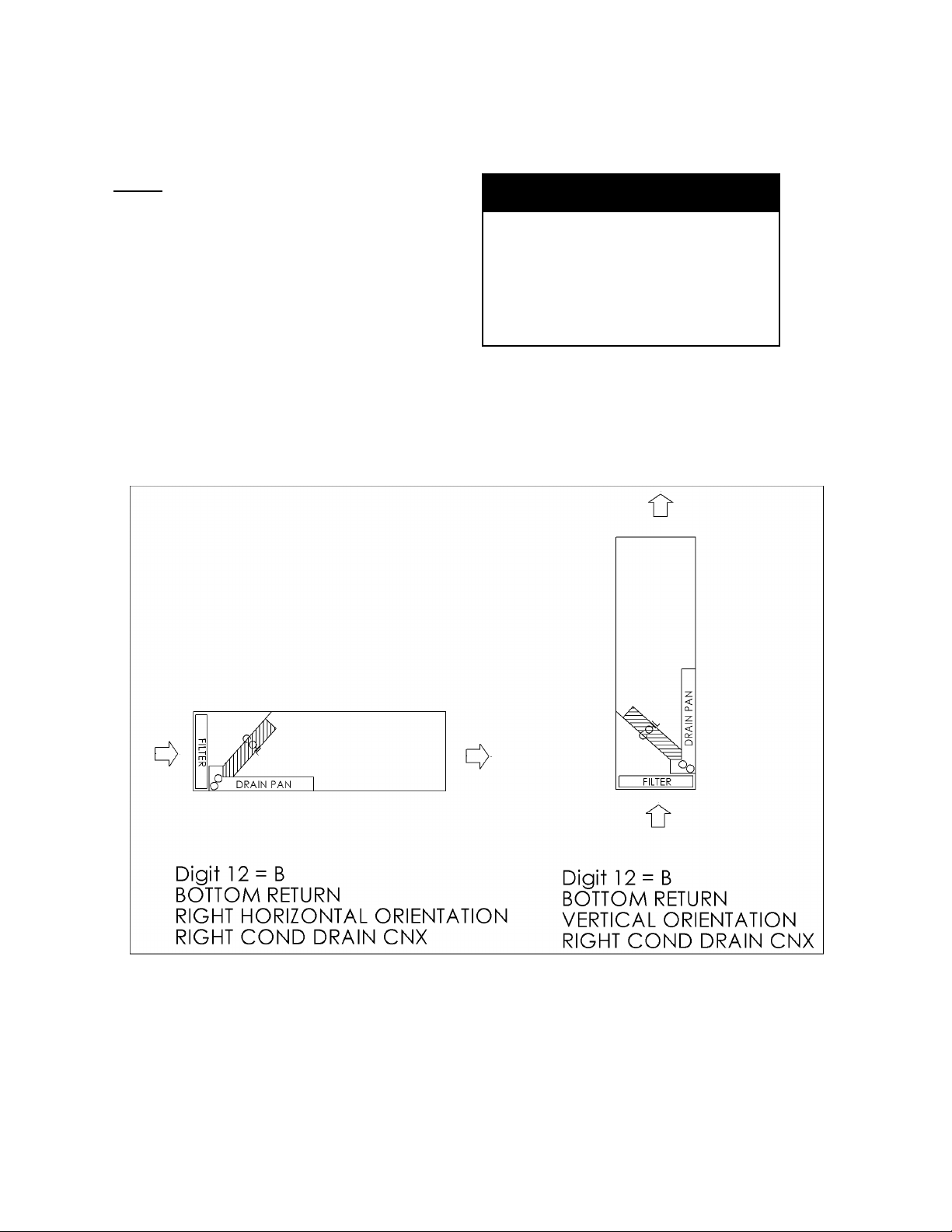

INSTALLATION—VERTICAL TO HORIZONTAL CONVERSION—EEV ROTATION

WARNING

FOR HORIZONTAL CABINET

ORIENTATION, EEV MUST

BE ROTATED TO VERTICAL

POSITION! Failure to reorient the EEV in VERTICAL

position can result in improper unit operation or equipment damage or dangerous

condition.

CONVERSION PROCEDURE:

1. UNIT IS SHIPPED WITH NITROGEN

CHARGE. IF UNIT HAS ALREADY BEEN

CHARGED WITH REFRIGERANT, REMOVE REFRIGERANT CHARGE PER LOCAL CODES BEFORE PERFORMING CONVERSION PROCEDURE.

2. REMOVE PIPING PLUGS AND SAVE FOR LATER USE. NITROGEN WILL DISCHARGE FROM

COIL.

3. REMOVE PIPING GROMMETS; REMOVE LIQUID INLET CAP FOR HORIZONTAL POSITION.

4. REMOVE BLOWER PANEL, LEFT AND RIGHT

COIL PANELS

5. SECURE EEV BRACKET WITH WRENCH AND

TURN COUPLING FLANGE NUT COUNTER

CLOCKWISE WITH 3/4" WRENCH TO LOOSEN

AND DISCONNECT COUPLING. THE COUPLING TAIL NUT SHOULD BE ALLOWED TO

TURN FREELY.

6. REPOSITION EXPANSION VALVE ASSEMBLY

AS SHOWN IN FIGURE 2d. ENSURE EXPANSION VALVE IS VERTICAL WITHIN +/- 15 DEG

WITH UNIT INSTALLED IN HORIZONTAL POSITION

7. REATTACH COUPLING AND

TIGHTEN TO 10-12 FT LBS

WHILE SECURING EEV BRACKET WITH WRENCH.

8. AS AN ALTERNATIVE TO

STEP 5 COUPLING MAY BE

TIGHTENED UNTIL NO

THREADS ARE SHOWING

AND COUPLING IS BOTTOMED OUT. THEN TURN

AN ADDITIONAL 60 DEG

(OR ONE HEX FLAT) TO

TIGHTEN.

9. REINSTALL FRONT

PANELS, GROMMETS,

AND PIPING PLUGS.

Figure 2a-

Vertical

Orientation

Figure 2b-

Vertical

Orientation

Figure 2d-Horizontal

Orientation

EEV BRACKET

Detail A-

EEV Detail

EEV INVERTICAL

ORIENTATION

Figure 2c-Vertical

Orientation, Panels

Removed

035-000039-001 Page 10 of 32 MVA IOM 1.3 9-10-2014

Page 11

INSTALLATION—SERVICE CLEARANCES

035-000039-001 Page 11 of 32 MVA IOM 1.3 9-10-2014

Page 12

INSTALLATION

Install the unit so that it is level or pitches

slightly –(1/8 inch) – toward the condensate

drain connection.

Anchor the unit to the plenum or platform

through the bottom flange using 2ea #10 sheet

metal screws on each side (4 screws total).

Ceiling Suspension: Mount the unit in ceilingsuspended horizontal orientation per suspension details (Figure 4). Unit is NOT intended

to be wall mounted. Consult a qualified structural engineer for special mounting considerations.

WARNING

INSURE THAT THE UNIT IS ADEQUATELY SUPPORTED FROM

STRUCTURE TO PREVENT DAMAGE

OR INJURY CAUSED BY FALLING

EQUIPMENT! If uncertain about how

to connect to the structure, consult a

qualified structural engineer.

Install the unit so that it pitches slightly –(1/8

inch) – toward the condensate drain connection.

NOT TO SCALE

MAINTAIN THESE DIMENSIONS FOR ADEQUATE TRAP

SEAL:

A = 3.5” MINIMUM

B = 2.0” MINIMUM

NOTES:

1. CONDENSATE DRAIN PIPING RECOMMENDATIONS:

A. MINIMUM 3/4” Φ PIPE SIZE

B. COPPER OR PVC PIPE MATERIAL

C. USE DIELECTRIC UNION FOR DISSIMILAR METALS.

D. INSULATE PER PROJECT SPECIFICATIONS.

2. PAD OR PLENUM HEIGHT AS REQUIRED TO INSTALL

TRAP AND CONDENSATE DRAIN PIPING.

3. AVOID BLOCKING FILTER SERVICE ACCESS WHEN

INSTALLING CONDENSATE DRAIN PIPING.

Fig. 3 — Condensate Drain

Condensate Drain

Install a trapped condensate drain line at unit drain

connection. All MVA units have 3/4 in. FPT condensate main and auxiliary drain connections.

Provide adequate trap clearance (trap depth) beneath the unit as indicated in Fig. 3. Provide

freeze-up protection as required to insure reliable

condensate drainage. Freeze protection

measures are customer-supplied and installed.

Pipe to condensate drain using PVC or copper or

other suitable material. Pitch drain piping downward at a minimum slope of 1/8 inch per foot.

Pipe auxiliary drain to “tell tale” drain location or

floor drain to clearly indicate when condensate

drain service is required. Alternately, use a fieldprovided condensate overflow detection device in

the auxiliary drain connection to provide alarm or

other controls action when the drain pan fills to the

level of the auxiliary drain.

Placing Unit In Ductwork

1. Utilize flexible transitions on supply and return

connections to reduce noise and vibration transmission to the structure.

2. When the connecting return air duct is

smaller than the coil inlet opening, construct

the transition piece so that the vertical and

horizontal dimensions of the transition piece

do not increase more then one inch for every seven inches of length of the transition

piece.

2. Provide at least three feet of straight

duct work preceding the unit inlet.

Duct Insulation and Vapor Proofing:

Properly select and install duct insulation as

required by the application.

All externally insulated duct work must have

an adequate vapor seal for summer operation. This is particularly important where the

duct is exposed to highly humid conditions

in such places as attics, vented crawl spaces, unconditioned basements, and utility

rooms. The vapor seal prevents condensation of moisture in the insulating material

and subsequent loss of its insulating value.

035-000039-001 Page 12 of 32 MVA IOM 1.3 9-10-2014

Page 13

Figure 4

CEILING SUSPENSION DETAILS

035-000039-001 Page 13 of 32 MVA IOM 1.3 9-10-2014

Page 14

INSTALLATION

CAUTION

Direct-expansion coils are shipped pressurized

with dry nitrogen. Release pressure from the coil

through valves in protective caps before removing caps.

Do not leave piping open to the atmosphere unnecessarily. Water and water vapor are detrimental to the refrigerant system. Until the piping

is complete, recap the system and charge with

nitrogen at the end of each workday. Clean all

piping connections before soldering joints.

Failure to follow these procedures could result in

personal injury or equipment damage.

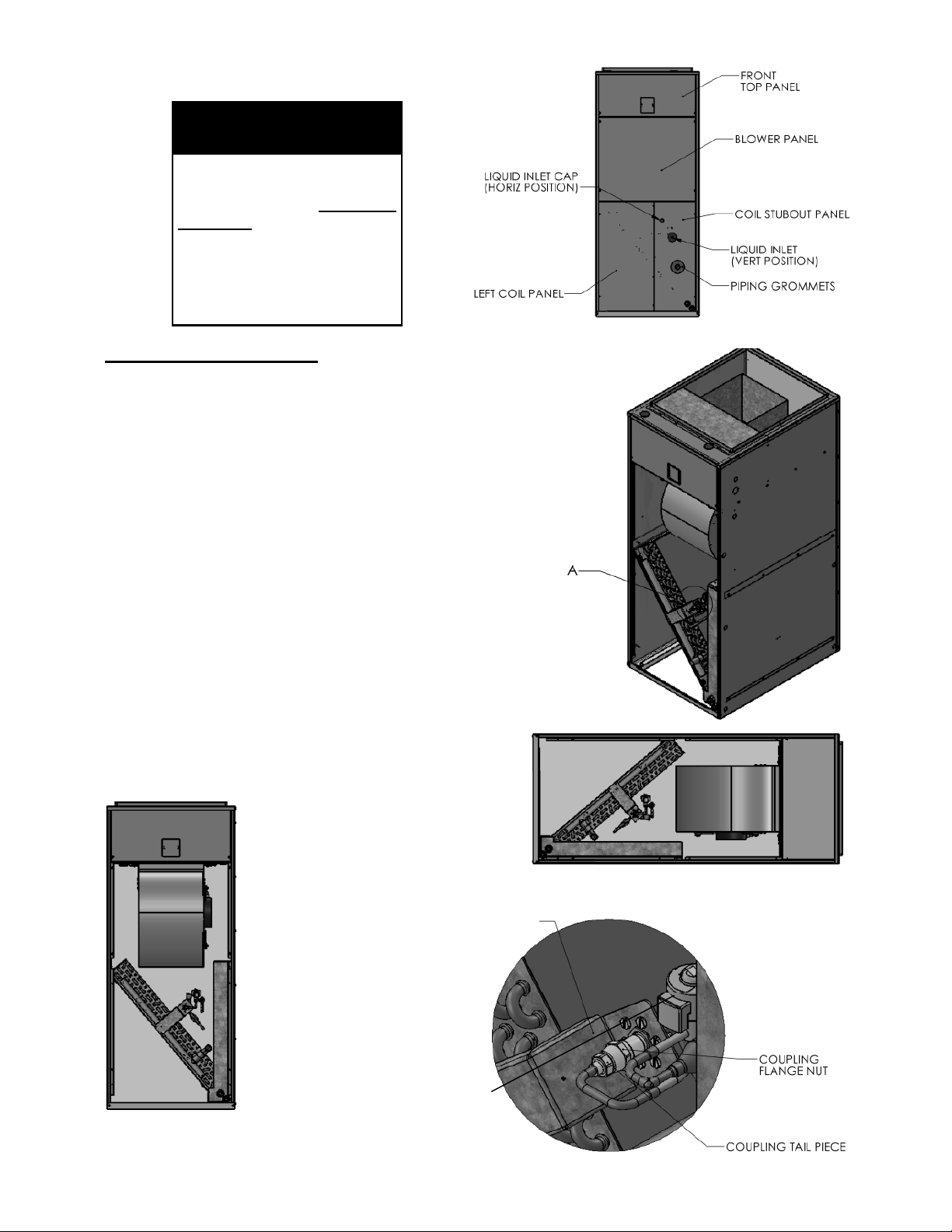

Refrigerant Piping

Refrigerant Coils: Direct-expansion coils

have liquid and suction line connections

through the front of the cabinet. CAUTION:

Use proper care when brazing including use

of heat sink (wet cloth or other method) to prevent damage to liquid line and suction line

components.

Fig. 5 — Heater Accessory Installed

(right side panel not shown)

Size and install refrigerant lines in accordance

with the condensing unit manufacturer’s instructions. Provide insulation on the suction

line, to prevent condensation. Provide insulation on the liquid line if unit to be used for heat

pump service or if otherwise required.

System Design Regulation

When connecting MVA units in the VRF system (mix or all), keep indoor/outdoor unit

capacity ratio with the range of 50% to

130%. For other conditions, refer to the VRF

System standard piping design regulations.

Electric Heater Accessory

The electric heater may be factory-installed or

field-installed. See Figures 5 through 8.

Removal Procedure:

To remove the electric heater,

1. Disconnect and lock out electrical power

from the unit. Remove heater access panel.

Disconnect power wires from the power

switch—DANGER! - MAKE SURE there is no

voltage on these wires before disconnecting!

2. Disconnect 2 harness connectors at the

blower deck.

3. Remove 2 screws holding heater support

feet to the blower deck.

4. Remove 4 screws that mount the heater to

the heater bulkhead. Handle heater carefully

to avoid damaging the wire heating elements.

Remove heater from the unit.

Fig. 6 — Heater Accessory Installed

(right side and heater access panels

not shown)

DANGER

WARNING: Hazardous voltage. Only qualified

personnel must install the electrical service. Disconnect and Lock Out all incoming power sources

before connecting to electrical service.

WARNING: This appliance must be permanently

grounded in accordance with the National Electrical

Code and local code requirements.

WARNING: For use with copper conductors only.

035-000039-001 Page 14 of 32 MVA IOM 1.3 9-10-2014

Page 15

INSTALLATION

Install Procedure:

To install the electric heater,

1. Disconnect and lock out electrical power from

the unit. Remove heater access panel. Disconnect field power wires from the unit power wires.

DANGER! - MAKE SURE there is no voltage

supply to the unit before proceeding!

2. Disconnect and discard 1 harness connector at

the blower deck.

3. Remove blank plate from heater access panel

(covers square hole for breaker style power

switches).

4. Remove SAT sensor and sensor holder from

heater bulkhead and reposition on unit discharge

ductwork routing through auxiliary SAT sensor

hole on top panel.

5. Install SAT 3 feet after the first 90 degree turn

in the discharge ductwork.

6. Remove plate on the heater bulkhead (4

screws).

7. Install heater by carefully supporting the heater

and inserting it into the opening in the heater bulkhead. NOTE: Make sure to guide the pin into the

hole at the back of the heater shroud. Secure the

heater to the bulkhead with 4 screws.

8. Connect 2 wiring harnesses (male) to the

DANGER

WARNING: Hazardous voltage. Only qualified

personnel must install the electrical service. Disconnect and Lock Out all incoming power sources

before connecting to electrical service.

matching female receptacles in the blower deck.

9. Connect field wiring to the breaker-style power

switches on the front of the heater. WARNING! Be

sure to provide the appropriate wire size and

branch circuit protection as required by the unit

nameplate!

10. Install the heater access panel.

11. Install the silicone cover “boot” over the top of

the power switches. This protects them from dust

buildup. The switches may be activated through the

flexible boot material.

12. Mark the nameplate label with the matching

heater kW rating. Label is located on the exterior of

the front top panel.

13. Update EEPROM settings to values shown in

the table. Refer to test run manual for detailed in-

Item Code New Settings

07 0001

38 0002

3C -001

COVER

BOOT

HEATER

ACCESS

PANEL

H

G

I

R

HEATER

ASSEMBLY

POWER

SWITCH(ES)

HEATER

SHROUD

PIN

E

D

I

S

T

Fig. 8 — Heater

Accessory

Installed

HEATER

SHROUD

HEATER

BULKHEAD

Fig. 7 — Heater Accessory Removal

(right side and heater access panels

not shown for clarity)

035-000039-001 Page 15 of 32 MVA IOM 1.3 9-10-2014

Page 16

INSTALLATION-ELECTRICAL

DANGER

DANGER

WARNING: Hazardous voltage. Only qualified

personnel must install the electrical service. Disconnect and Lock Out all incoming power sources

before connecting to electrical service.

WARNING: This appliance must be permanently

grounded in accordance with the National Electrical

Code and local code requirements.

WARNING: For use with copper conductors only.

Typical wiring diagrams are shown on the following

pages FOR REFERENCE. Always refer to the wiring diagram on the air handling unit for actual wiring.

NOTE: CHECK MOTOR RATING PLATE FOR

CORRECT LINE VOLTAGE.

Connect electrical service to unit. Refer to unit wiring diagram.

NEVER enter an enclosed fan cabinet or reach into

a unit while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect switch before working on a fan. Take fuses

with you and note removal on tag. Electric shock

can cause personal injury or death.

LOCK OPEN AND TAG the electric heat coil power

disconnect switch before working on or near heaters.

Failure to follow these warnings could lead to personal injury or death.

CAUTION

Use only copper conductors for field-installed electrical wiring. Unit terminals are not designed to

accept other types of conductors.

Do not allow wiring to touch the refrigerant tubing,

compressor, or any moving parts of the fan.

Make wiring connections in accordance with the

system wiring system diagram and these instructions. Wrong wiring may cause improper operation

or unit damage!

Power Wiring

For power supply connection, route field power wiring L1 and L2 and connect either:

1. Unit Without EH: to field-provided and installed

disconnect switch and from switch to power

entry (unit side) and to unit power leads inside

the unit electrical section; or

2. Unit With EH: into the unit through power entry

(unit side) and then to the factory installed power switch inside the electrical section (see Figure 9). Note: power switch looks like a circuit

breaker but does not provide overload pro-

tection. Power switch provided only with electric heater (field kit or factory installed). NOTE:

When electric heat greater than 10kW is provided, two power supply circuits are required,

as shown on the wiring diagram.

Refer to nameplate or Electrical Ratings (page 30)

for FLA, maximum overcurrent protection device

(MOPD) and minimum circuit ampacity (MCA). Also

refer to wiring diagram affixed to unit to make control and power wiring connections. For new heater

installation, mark the nameplate label with the

matching heater kW rating. Label is located on the

exterior of the front top panel.

Unauthorized changes in the internal wiring can be

very dangerous. The manufacturer will accept no

responsibility for any damage or malfunction that

occurs as a result of such unauthorized changes.

other convenient location. Control voltage wiring

leads exit the bottom of the control box and are

ready for field-connection.

CAUTION! To prevent malfunction of the air conditioner caused by electrical noise, route control wiring

and inter-unit control wiring SEPARATELY FROM

THE POWER WIRING!

POWER

SWITCH

NOTE: Installer is responsible for power wiring and

branch circuit over current protection.

Control Voltage Wiring

Control voltage wiring may enter the unit at the control box located behind the blower access door, or

035-000039-001 Page 16 of 32 MVA IOM 1.3 9-10-2014

Unit with Electric Heat

Figure 9

Page 17

INSTALLATION-ELECTRICAL

control wiring

DANGER

General

Provide strain relief where field wiring passes

through cabinet. Wiring within the cabinet has

been positively located and supported so that it

does not pass over sharp metal edges or come in

contact with moving parts. After servicing, position

wiring properly in the original supports.

All field-installed wiring, including the electrical

ground, MUST comply with the National Electrical

Code (NEC) as well as applicable local codes. In

addition, all field wiring must conform to the Class

II temperature limitations described in the NEC.

Refer to factory wiring diagrams installed in the

unit. Use the MCA and MOPD from the nameplate

or electric heat nameplate or Electrical Ratings

(page 30) to size power supply wiring and overcurrent protection device. Installation must comply

with NEC and local codes.

For communicating controls, refer to Figures 10

through 13 for max lengths, sizing and intercon-

Building System Wiring Diagram

(multiple indoor & outdoor units)

WARNING: Hazardous voltage. Only qualified

personnel must install the electrical service. Disconnect and Lock Out all incoming power sources

before connecting to electrical service.

WARNING: This appliance must be permanently

grounded in accordance with the National Electrical

Code and local code requirements.

WARNING: For use with copper conductors only.

CAUTION

Loose wiring may cause the terminal to overheat

or result in unit malfunction or cause a fire hazard.

Insure that all wiring is tightly connected!

nections. Refer to the condensing unit operation manual for more details.

Figure 10

NOTE: See table below for wire requirements

for lines above marked “A”, “B”, “C” and “D”.

Control wiring

(A) Inter- unit (be tween

outdoor a nd indoor units)

AWG #18(0.75 mm2) AWG#18 (0.75 mm2)

Max. 3,280 ft. Max. 1,640 ft.

(C) Control wiring for group

control

AWG #18(0.75 mm2) AWG#18 (0.75 mm2)

Max. 650 ft. (Total) Max. 980 ft.

035-000039-001 Page 17 of 32 MVA IOM 1.3 9-10-2014

(B) Remote control wiring

(D) Inter- outdoor unit

control wiring

Page 18

INSTALLATION-ELECTRICAL

Figure 11

Inter-Unit Control Wiring

Do not install the inter-unit control wiring

in a way that forms a loop.

Figure 12

Inter-Unit Control Wiring

Do not install inter-unit control wiring with splices or “star branch” pattern. Star branch wiring

causes misaddress setting errors.

Figure 13

Branched Inter-Unit Control Wiring

If branching the inter-unit control wiring,

the number of branch points should be

16 or fewer. (Branches less than 3.3 ft.

are not included in the total branch number.)

035-000039-001 Page 18 of 32 MVA IOM 1.3 9-10-2014

Page 19

INSTALLATION-ELECTRICAL (cont’d)

TYPICAL WIRING DIAGRAM—

Unit sizes 18 & 24

TYPICAL WIRING—MVA18, MVA24

035-000039-001 Page 19 of 32 MVA IOM 1.3 9-10-2014

Page 20

INSTALLATION-ELECTRICAL (cont’d)

TYPICAL WIRING DIAGRAM—

Unit sizes 30, 36, 42, 48 & 60

TYPICAL WIRING—MVA30, MVA36,

MVA42, MVA48, MVA60

035-000039-001 Page 20 of 32 MVA IOM 1.3 9-10-2014

Page 21

INSTALLATION-ELECTRICAL (cont’d)

TYPICAL WIRING DIAGRAMS—

Electric Heat: 3-6kW and 8-9.5kW

3

TYPICAL WIRING—ELECTRIC HEAT

TYPICAL WIRING—ELECTRIC HEAT

035-000039-001 Page 21 of 32 MVA IOM 1.3 9-10-2014

Page 22

START-UP

Pre-Startup

Building Envelope—All building windows and doors should

be installed and closed before starting unit. During summer

construction, avoid unit sweating by allowing for gradual pull

down: use reduced capacity and use maximum available

airflow.

Temperature Controls-Check that unit is connected to the

controls system and communicating properly.

Outside Air and Freeze Protection

WARNING: Insure that the property is protected against

freezing conditions Failure to provide freeze protection

may result in property damage. Freeze protection

measures are customer-provided and installed and include

but are not limited to low-limit thermostats, automatic temperature controls, and outside air dampers.

Startup

1. Insure electrical installation agrees with the unit nameplate (voltage, branch circuit protection, wire size).

2. Close all panels and access doors. Make sure filter media is clean before starting unit. Replace filter if necessary.

3. Verify that discharge ductwork and input plenum are in

place and secure.

4. Apply power to unit. If unit is equipped with on-board

power switch(es), turn switch(es) to the “On” position.

5. Insure that controls system has power and is operational.

6. Force control system to send fan on signal and speed

signal. Refer to unit wiring diagram and electrical section

for fan speed control arrangement.

7. Fan should start and run. Make sure fan operates without significant noise or vibration.

8. Allow control system to start condensing unit, or as required for the installation.

9. Complete the checklist on the Start-Up Report.

10. Follow additional startup procedures for the system as

required by the condensing unit.

Fig. 14 — Fan Wheel Rotation—

FORWARD CURVED FAN

Fan Airflow Step-Up

If the duct system ESP is higher than planned and increased

Air Handler ESP is needed, shift the terminals as shown in

Figure 15.

Refer to Airflow tables and curves for airflow performance.

035-000039-001 Page 22 of 32 MVA IOM 1.3 9-10-2014

Page 23

Stay

Shift all

three

down

Figure 15

Increasing ESP setting

MVA18

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 969 833 188 1022 804 197 1067 780 206 1132 743 215 1173 711 222 1201 666 224

High 902 774 156 955 749 163 1016 717 173 1067 690 181 1102 656 193 1144 611 201

Medium 898 772 152 960 737 160 1012 711 169 1091 669 176 1132 633 182 1158 569 187

Low 827 711 116 897 670 123 956 641 131 1050 596 137 1090 555 142 1115 473 149

MVA24

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 1236 1052 394 1265 1034 396 1301 996 383 1327 953 345 1351 897 340 1430 838 261

High 1109 959 284 1155 929 296 1198 908 302 1233 882 311 1284 849 319 1304 780 302

Medium 969 833 188 1022 804 197 1067 780 206 1132 743 215 1173 711 222 1201 666 224

Low 902 774 156 955 749 163 1016 717 173 1067 690 181 1102 656 193 1144 611 201

MVA30

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 828 1263 275 851 1221 287 865 1186 286 898 1142 301 922 1105 306 915 1082 309

High 764 1160 219 795 1114 224 819 1076 239 843 1037 241 825 1014 243 874 975 251

Medium 708 1064 171 737 1017 175 758 973 178 794 932 190 785 886 194 856 844 204

Low 630 940 121 663 892 125 693 835 130 730 797 138 750 743 143 806 696 152

MVA36

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 934 1425 406 943 1396 414 966 1358 417 988 1319 426 1005 1279 432 1032 1246 440

High 881 1342 393 900 1311 347 920 1271 356 939 1229 356 967 1195 365 986 1160 370

Medium 764 1160 219 795 1114 224 819 1076 239 843 1037 241 825 1014 243 874 975 251

Low 708 1064 171 737 1017 175 758 973 178 794 932 190 785 886 194 856 844 204

MVA42

Airflow Performance

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 967 1722 525 985 1679 529 1009 1642 541 1029 1597 546 1050 1557 558 1071 1510 567

High 835 1475 332 862 1425 343 890 1388 353 918 1335 365 940 1287 372 970 1238 370

Medium 760 1311 248 784 1271 258 803 1229 263 834 1195 274 870 1151 286 900 1114 290

Low 717 1228 211 742 1184 218 767 1140 225 803 1099 236 840 1046 246 878 994 254

MVA48

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 1057 1894 1040 1080 1872 1031 1093 1816 1020 1104 1764 1010 1109 1685 990 1122 1629 975

High 967 1722 525 985 1679 529 1009 1642 541 1029 1597 546 1050 1557 558 1071 1510 567

Medium 835 1475 332 862 1425 343 890 1388 353 918 1335 365 940 1287 372 970 1238 370

Low 760 1311 248 784 1271 258 803 1229 263 834 1195 274 870 1151 286 900 1114 290

MVA60

Fan Setting RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS RPM SCFM WATTS

High Top 982 2323 1010 1010 2269 1040 1037 2222 1050 1064 2180 1070 1093 2132 1090 1115 2092 1110

High 878 2082 699 909 2027 711 946 1959 733 979 1932 754 1007 1889 771 1038 1844 791

Medium 760 1793 427 807 1716 450 825 1667 466 873 1623 488 913 1577 506 956 1517 520

Low 689 1603 314 724 1544 326 761 1489 342 805 1425 362 846 1373 380 890 1335 400

NOTES:

1. Data at sea level w/ 1" throw-away filter and dry coil.

As Shipped

0.000 0.100 0.200 0.300 0.400 0.500

0.000 0.100 0.200 0.300 0.400 0.500

0.000 0.100 0.200 0.300 0.400 0.500

0.000 0.100 0.200 0.300 0.400 0.500

0.000 0.100 0.200 0.300 0.400 0.500

0.000 0.100 0.200 0.300 0.400 0.500

0.000 0.100 0.200 0.300 0.400 0.500

Higher Fan Setting

ESP

ESP

ESP

ESP

ESP

ESP

ESP

Areas not recommend for operation due to excess velocity

035-000039-001 Page 23 of 32 MVA IOM 1.3 9-10-2014

Page 24

Airflow Performance Curves

MVA18

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

External Static Pressure ( inch W.G.)

0.00

400 500 600 700 800 900

M

L

Airflow (SCFM)

HTH

exessive airflow

Area not re commen ded for use for

MVA30

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

External Static Pressu re ( inch W.G.)

0.00

600 70 0 800 90 0 1000 1100 12 00 1 30 0

Airflow (SCFM)

MVA24

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

External Static Pressure ( inch W.G.)

0.00

600 700 8 00 9 00 100 0 1100

Airflow (SCFM)

HTHML

exessive airflow

Area not rec ommen ded for use for

MVA36

0.50

0.45

0.40

0.35

0.30

0.25

HTHML

0.20

0.15

0.10

0.05

External Static Pressu re ( inch W.G.)

0.00

800 90 0 1000 1 100 1200 1300 14 00 1 500

Airflow (SCFM)

HTHML

MVA42

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

External Static Pressu re ( inch W.G.)

0.00

800 10 00 1200 14 00 1600 1800

Airflow (SCFM)

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

External Static Pressu re ( inch W.G.)

0.00

120 0 1400 160 0 180 0 20 00 220 0 2400

MVA48

0.50

0.45

0.40

0.35

0.30

0.25

HTHML

0.20

0.15

0.10

0.05

External Static Pressu re ( inch W.G.)

0.00

100 0 1200 1400 1600 1800 2000

Airflow (SCFM)

HTHML

MVA60

HTHML

Airflow (SCFM)

035-000039-001 Page 24 of 32 MVA IOM 1.3 9-10-2014

Page 25

DANGER

NEVER enter an enclosed fan cabinet or reach

into a unit while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect switch before working on a fan. Take fuses with you and note removal on tag. Electric

shock can cause personal injury or death.

LOCK OPEN AND TAG the electric heat coil power disconnect switch before working on or near

heaters.

Failure to follow these warnings could lead to personal injury or death.

SERVICE

General

1. Review Safety Considerations at beginning of

these instructions. Good safety habits are important tools when performing service procedures.

2. To make speed measurements, use a laser-style

tachometer.

Fan Motor Replacement

WARNING: Shut off motor power and lock out power

supply.

MOTOR

HARNESS &

CONNECTORS

Figure 16

MOTOR

HARNESS &

CONNECTORS

Remove Blower/Motor Assembly

Procedure:

1. Disconnect wiring harness plugs from motor (Fig.

16 and 17).

2. Remove blower mounting bolts, which secure the

blower rails upward against the blower deck

(2ea).

3. Remove motor/wheel assembly from the MVA

unit by sliding out (Figure 18).

4. See Figure 19. Loosen shaft set screw (opposite

motor side) and motor mount tightening screw

until motor can be removed.

5. Remove motor. Install new motor (Fig. 20), tighten motor mount bolt, then locate fan wheel and

tighten shaft set screw.

6. Reverse steps 1-4 to reinstall fan. Make sure

that the two clips at the back hold the blower rails

up against the blower deck.

7. Spin fan by hand to make sure there is no rubbing or interference.

8. Close unit access doors, remove lockout/tag out

and restore the unit to operation.

Figure 17

035-000039-001 Page 25 of 32 MVA IOM 1.3 9-10-2014

Page 26

DANGER

NEVER enter an enclosed fan cabinet or reach

into a unit while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect switch before working on a fan. Take fuses with you and note removal on tag. Electric

shock can cause personal injury or death.

LOCK OPEN AND TAG the electric heat coil power disconnect switch before working on or near

heaters.

Failure to follow these warnings could lead to personal injury or death.

Fan System Periodic Maintenance

1. Use of a Preventive Maintenance program is

strongly recommended to insure that the unit operates safely and efficiently.

2. Motor bearings are permanently sealed and do not

require lubrication.

3. Clean the fan’s flow area - maintenance interval in

accordance with the degree of contamination.

4. The fan wheel can be cleaned with a moist cloth.

5. Do not use any aggressive, paint solvent cleaning

agents when cleaning.

6. Never use a high-pressure cleaner or water-spray

for cleaning - particularly when the fan is running.

MOTOR/

BLOWER

SLIDES OUT

Figure 18

Coil Cleaning

DETERGENT — Spray mild detergent solution on

coils with garden-type sprayer. Rinse with fresh water.

Check to ensure condensate line is free. Excess water

from cleaning may flood unit if condensate line is

plugged.

Figure 19

Figure 20

035-000039-001 Page 26 of 32 MVA IOM 1.3 9-10-2014

Page 27

SERVICE—Filters

Filters

FILTER SECTIONS — Open or remove

filter panel to replace old filter with a new

filter. See physical data tables for filter

data. See Figure 21.

Figure 21

Figure 22

Access Panels

The 3 sections of the unit can be reached

using the front access panels, removable

using 5/16” socket or driver or flat head

screwdriver. See Figure 22.

035-000039-001 Page 27 of 32 MVA IOM 1.3 9-10-2014

Page 28

SERVICE-Coil Removal and Reinstallation Procedure

1. Perform procedure on the ground for safety. If

working at heights USE EXTREME CAUTION observe all FALL SAFETY considerations. Under all

conditions, LOCK OUT all power supplies before

performing this procedure. WARNING! Coil section can be heavy—use proper lifting equipment.

2. Isolate coil and reclaim refrigerant. Disconnect

unit from piping. Remove supply piping to allow

access into the coil section from the front.

3. Remove blower access door and coil access

doors.

4. Carefully remove temperature sensors from the

coil and set them aside, clear of the coil & drain

pan assembly. Disconnect electronic expansion

valve (EEV) wiring from the EEV.

5. Remove 4 screws on the drain pan side of the

cabinet (right side shown in Fig. 23). Remove 4

screws from coil support side of the cabinet (left

side shown in Fig. 23).

6. Slide coil & drain pan assembly out of the unit (Fig

19).

7. Coil can be detached from drain pan using 5/16”

driver, 2 screws. Coil can be detached from coil

support using 5/16” driver, 4 screws.

8. Follow instructions in reverse to install new coil.

9. Re-install sensors back in original positions. CAUTION! Be sure to place sensors in correct locations for proper unit

operation.

10. Re-install wiring to EEV.

11. Re-install unit access panels.

12. Return unit to service.

COIL SUPPORT

DRAIN PAN

Figure 23

035-000039-001 Page 28 of 32 MVA IOM 1.3 9-10-2014

Page 29

UNIT ELECTRICAL RATINGS

035-000039-001 Page 29 of 32 MVA IOM 1.3 9-10-2014

Page 30

UNIT DIMENSIONS

MVA18-60 Elec Heat Ready

RH Drain Connections—Configuration B

035-000039-001 Page 30 of 32 MVA IOM 1.3 9-10-2014

Page 31

MVA Series Air Handling Unit

Start-up Report

Job Name City

Sales Order # Unit Tag

Model Number Serial Number

Installer Quantity of Units

STARTUP REPORT

Group Checklist Item Yes No

Does electrical service correspond to unit nameplate?

Operational

Electrical/

Structural

Piping Check

-Nameplate Supply Voltage/Phase: Rated_________ Measured___________

-Nameplate Rated FLA motor current: Rated_______ Measured__________

Does all field wiring conform to unit wiring diagram?

Is field-provided freeze protection present? (if required)

Is fan wheel turning the correct direction?

Is the filter clean?

Is unit properly supported?

Is unit installed level (necessary for proper condensate drainage)?

Is properly sized condensate trap present?

Is the condensate disposal system operating correctly?

Is auxiliary external condensate drain pan installed or auxiliary drain connection

utilized as recommended by IOM? (not required for valid warranty)

CRITICAL! For Horizontal Unit Orientation: Is the EEV in vertical orientation?

Is the DX system charged per the condensing unit instructions?

Is unit piping correct and insulated to prevent condensation?

Are the refrigerant pipe lines properly insulated?

Are there any leaks detected: interior to unit or at connections?

035-000039-001 Page 31 of 32 MVA IOM 1.3 9-10-2014

Page 32

MVA Series Air Handling Unit

Installation, Operation and Maintenance Manual

035-000039-001 Page 32 of 32 MVA IOM 1.3 9-10-2014

Loading...

Loading...