Panasonic LC4HR424SJ, LC4HR424J, LC4H8-R4-AC240V, LC4HR4240ACSJ, LC4H8-R4-DC24V User guide

...Page 1

48

1.890

48

1.890

64.5

2.539

LC4H

02/2003

R4/T4 systems (4-digit display)

DIN 48 SIZE

LCD ELECTRONIC COUNTER

FEATURES

1. Bright and Easy-to-Read Display

A brand new bright 2-color backlight LCD

display. The easy-to-read screen in any

location makes checking and setting procedures a cinch.

2. Simple Operation

Seesaw buttons make operating the unit

even easier than before.

mm inch

3. Short Body of only 64.5 mm 2.539

inch (screw type) or 70.1 mm 2.760

inch (pin type)

With a short body, it easily installs in

even narrow control panels.

4. Conforms to IP66’s Weather

Resistant Standards

The water-proof panel keeps out water

and dirt for reliable operation even in

poor environments.

LC4H

5. Screw terminal and Pin Type are

Both Standard Options

The two terminal types are standard

options to support either front panel

installation or embedded installation.

6. Changeable Panel Cover

Also offers a black panel cover to meet

your design considerations.

7. 4-digit or 6-digit display

Two sizes of displays are offered for you

to choose the one that suits your needs.

8. Conforms With EMC and Low

Voltage Directives

Conforms with EMC directives

(EN50081-2/EN50082-2) and low-voltage directives (VDE0435/Part 2021) for

CE certification vital for use in Europe.

R6/T6 systems (6-digit display)

Pin type Screw terminal type

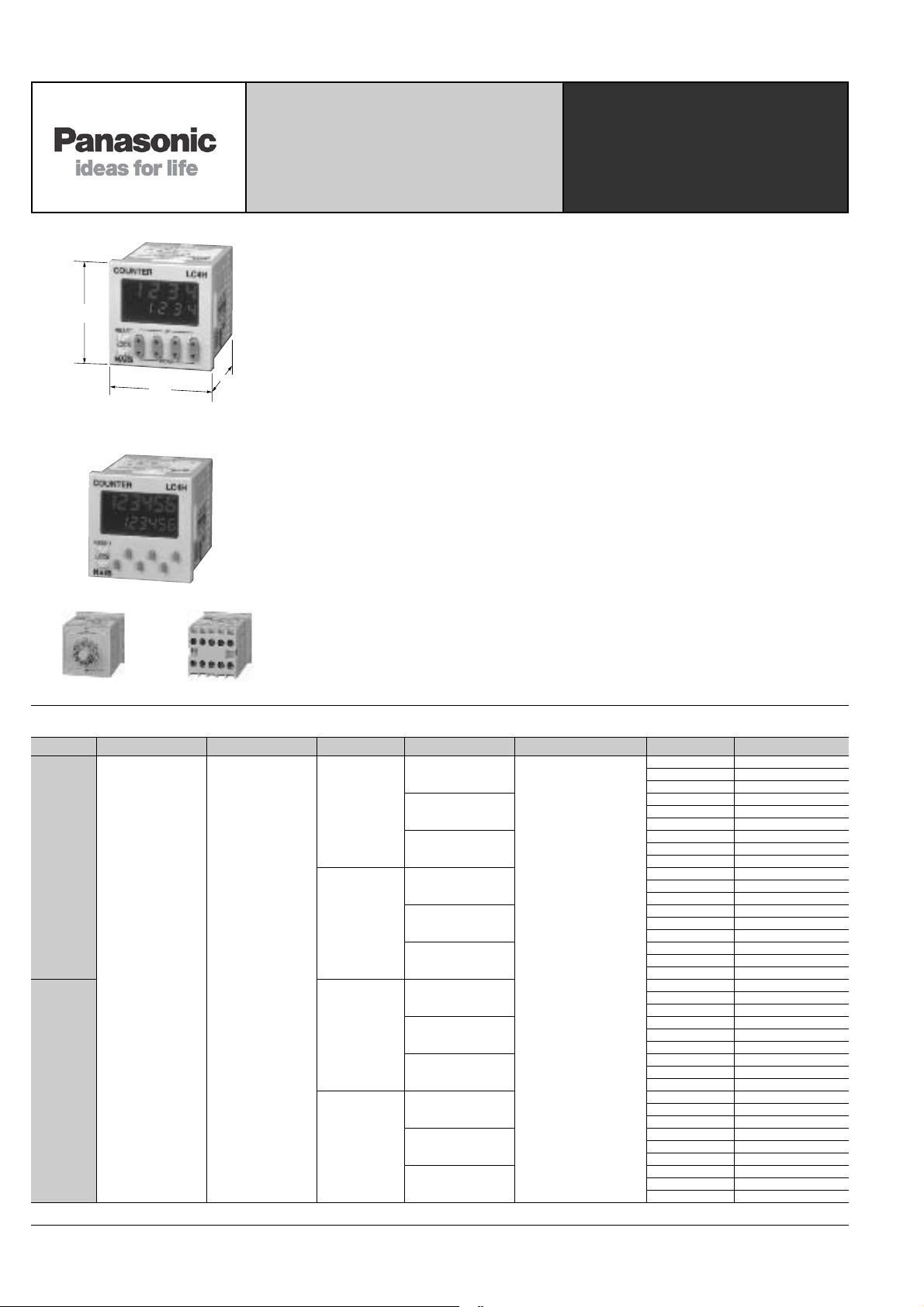

PRODUCT TYPES

Digit Count speed Output mode Output Operation voltage Power down insurance Terminal Part No.

4

• Maintain

output/hold count

• Maintain

output/over count I

30 Hz (cps)/

5 KHz (Kcps)

switchable

6

* A rubber gasket (ATC18002) and a mounting frame (AT8-DA4) are included.

76

• Maintain

output/over count II

• One shot/over

count

• One shot/recount I

• One shot/recount II

• One shot/hold

count

(7 modes)

Relay

(1c)

Transistor

(1a)

Relay

(1c)

Transistor

(1a)

100-240 V AC

24 V AC / 24 V DC

12-24 V DC

100-240 V AC

24 V AC / 24 V DC

12-24 V DC

100-240 V AC

24 V AC / 24 V DC

12-24 V DC

100-240 V AC

24 V AC / 24 V DC

12-24 V DC

Available

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

8 pin

11 pin

Screw

LC4H8-R4-AC240V

LC4H-R4-AC240V

LC4H-R4-AC240VS

LC4H8-R4-AC24V

LC4H-R4-AC24V

LC4H-R4-AC24VS

LC4H8-R4-DC24V

LC4H-R4-DC24V

LC4H-R4-DC24VS

LC4H8-T4-AC240V

LC4H-T4-AC240V

LC4H-T4-AC240VS

LC4H8-T4-AC24V

LC4H-T4-AC24V

LC4H-T4-AC24VS

LC4H8-T4-DC24V

LC4H-T4-DC24V

LC4H-T4-DC24VS

LC4H8-R6-AC240V

LC4H-R6-AC240V

LC4H-R6-AC240VS

LC4H8-R6-AC24V

LC4H-R6-AC24V

LC4H-R6-AC24VS

LC4H8-R6-DC24V

LC4H-R6-DC24V

LC4H-R6-DC24VS

LC4H8-T6-AC240V

LC4H-T6-AC240V

LC4H-T6-AC240VS

LC4H8-T6-AC24V

LC4H-T6-AC24V

LC4H-T6-AC24VS

LC4H8-T6-DC24V

LC4H-T6-DC24V

LC4H-T6-DC24VS

Page 2

PART NAMES

UP

DOWN

RESET

LOCK

COUNTER LC4H

OP.

RST

LOCK

Controlled output indicator

Reset indicator

Lock indicator

Reset switch

Lock switch

Counter display

Set value display

Up keys

Down keys

ON

12345678

DIP switches

(Same for screw-down terminal type)

RESET

LOCK

COUNTER LC4H

OP.

RST

LOCK

Controlled output indicator

Reset indicator

Lock indicator

Reset switch

Lock switch

Counter display

Set value display

Up keys

ON

12345678

DIP switches

(Same for screw-down terminal type)

02/2003

LC4H

SPECIFICATIONS

Rated operating voltage

Rated frequency

Power consumption

Control output

Input mode

Counting speed

Min. counting input time

Rating

Contact

Life

Electrical

Mechanical

Operating

conditions

Connection

Protective construction

Note: 1) the 24 V AC type can be operated also with 24 V DC.

Reset input method

Lock input

Input signal

Output mode

One shot output time

Indication

Digit

Memory

Contact arrangement

Initial contact resistance

Contact material

Mechanical

Electrical

Operating voltage range

Initial withstand voltage

Initial insulation resistance

(At 500 V DC)

Temperature rise

Vibration

resistance

Shock

resistance

Ambient temperature

Ambient humidity

Air pressure

Ripple rate

Item

Between live and dead metal parts: 2,000 Vrms for 1 min (11-pin type)

Functional

Destructive

Functional

Destructive

Ralay output type

AC type

100 to 240 V AC, 24 V AC

50/60 Hz common

Max. 10 V A

1)

DC type

12 to 24 V DC

—

Max. 3 W

1 Form C: 5 A, 250 V AC (resistive)

Addition (UP)/Subtraction (DOWN)/Direction (DIR)/Individuality (IND)/Phase (PHASE)

5 modes selectable by DIP switch

30 Hz/5 kHz (selectable by DIP switch)

16.7 ms at 30 Hz/0.1 ms at 5 kHz ON time: OFF time = 1:1

Signal reset/Push-key switch, Min. input time 1 ms, 20 ms (selected by DIP switch)

Min. input signal width: 20 ms

Contact or Open collector input/Input impedance: 1 kΩ or less, Input residual voltage: 2 V or less,

Open impedance: 100 kΩ or more, Max. energized voltage: 40 V DC

HOLD-A/HOLD-B/HOLD-C/SHOT-A/SHOT-B/SHOT-C/SHOT-D, 7 modes selectable by DIP switch

Approx. 1 s

7-segment LCD, Counter value (backlight red LED), Setting value (backlight yellow LED)

4-digit display type –999 to 9999 (–3 digits to +4 digits) (0 to 9999 for setting)

6-digit display type –99999 to 999999 (–5 digits to 6 digits) (0 to 999999 for setting)

EEP-ROM (Overwriting times: 10

1 Form C

100 mΩ (at 1 A 6 V DC)

2.0 × 10

5

ope. (At rated control voltage)

1.0 × 10

Ag alloy/Au flush

7

ope. (Except for switch operation parts)

85 to 110 % of rated operating voltage

Between input and output: 2,000 Vrms for 1 min

Between open contacts: 1,000 Vrms for 1 min

Between live and dead metal parts: Min. 100 MΩ (11-pin type)

Between input and output:

Between open contact:

Min. 100 MΩ

Min. 100 MΩ

Max. 65° C (under the flow of nominal operating current at nominal voltage)

10 to 55 Hz (1 cycle/min), single amplitude: 0.35 mm .014 inch (10 min on 3 axes)

10 to 55 Hz (1 cycle/min), single amplitude: 0.75 mm .030 inch (1 h on 3 axes)

Min. 98 m 321.522 ft./s

Min. 294 m 964.567 ft./s

–10° C to 55° C +14° F to +131° F

Max. 85 % RH

—

20 % or less — 20 % or less

860 to 1,060 h Pa

8-pin/11-pin/screw terminal

IP66 (front panel with a rubber gasket)

Transistor output type

AC type DC type

100 to 240 V AC, 24 V AC

50/60 Hz common

Max. 10 V A

1)

12 to 24 V DC

—

Max. 3 W

1 Form A: 100 mA, 30 V DC Open collector output (Max.)

5

ope. or more)

1 Form A (Open collector)

—

—

1.0 × 10

7

—

ope. (At rated control voltage)

Between live and dead metal parts: 2,000 Vrms for 1 min (11-pin type)

Between input and output: 2,000 V AC for 1 min

Between live and dead metal parts: Min. 100 MΩ (11-pin type)

Between input and output:

2

(4 times on 3 axes)

2

(5 times on 3 axes)

Min. 100 MΩ

77

Page 3

UP

DOWN

RESET

LOCK

COUNTER LC4H

OP.

RST

LOCK

48

1.890

48

1.890

48

1.890

48

1.890

50

1.969

RESET

LOCK

COUNTER LC4H

OP.

RST

LOCK

;

66

2.598

63.5

2.500

1

.039

Installation frame for

embedded installations

AT8-DA4 (supplied)

Installation frame

for embedded

installations

ATA4811 (supplied)

Installation panel

Rubber gasket

ATC18002 (supplied)

66

2.598

Installation panel

Rubber gasket

ATC18002 (supplied)

50

1.969

1

.039

(44.5

(1.752

90

3.543

(

11p cap AT8-DP11

sold separately

)

(

8p cap AD8-RC

sold separately

)

11-pin type

8-pin type

DIN rail terminal block

ATC18004 or ATC18003

(sold separately)

Device installation rail

AT8-DLA1

(sold separately)

( ) Dimensions for 8-pin type.

95.5

(90.0)

3.760

(3.543)

80 min.

3.150

80 min.

3.150

45

-0.6

0

45

-0.6

0

1.772

-.024

0

1.772

-.024

0

A

A = (48 × n – 2.5)

–0.6

0

45

-0.6

0

1.772

-.024

0

1

2

3

4

5

6

7

8

9

10

11

Reset

Input 1

Input 2

Lock

COM

NC

NO

Operation voltage

(+)(–)

1

2

3

4

5

6

7

8

9

10

11

Reset

Input 1

Input 2

Lock

Operation voltage

(+)(–)

851

7

6

2

3

4

COM

NO

Operation voltage

(+)(–)

Reset

Input 1

Input 2

851

7

6

2

3

4

Operation voltage

(+)(–)

Reset

Input 1

Input 2

12345

678910

NO NC

COM

Reset

Input 1

Input 2

Lock

Operation voltage

(–)(+)

12345

6

78910

Reset

Input 1

Input 2

Lock

Operation voltage

(–)(+)

LC4H

UP

DOWN

RESET

LOCK

COUNTER LC4H

48

1.890

48

1.890

5.5

.217

70.1

2.760

55.6

2.189

7.5

.295

(44.5

(1.752

5.5

.217

64.5

2.539

7.5

.295

(44.5

(1.752

48

1.890

RESET

LOCK

COUNTER LC4H

48

1.890

70.1

2.760

55.6

2.189

5.5

.216

64.5

2.539

7.5

.295

5.5

.217

7.5

.295

(44.5

(1.752

(44.5

(1.752

02/2003

DIMENSIONS (units: mm inch)

• LC4H electrical counter

Screw-down terminal type

(embedded installation)

Screw-down terminal type

(embedded installation)

Pin type (embedded installation/

front panel installation)

Pin type (embedded installation/

front panel installation)

• Dimensions for embedded installation (with adapter installed)

Screw-down terminal type Pin type

Dimensions for front panel installations• Installation panel cut-out dimensions

•

The standard panel cut-out dimensions are shown

below. Use the installation frame (AT8-DA4) and

rubber gasket (ATC18002).

• For connected installations

Note 1: The installation panel thickness should be between 1

and 5 mm .039 and .197 inch.

Note 2: For connected installations, the waterproofing ability

between the unit and installation panel is lost.

TERMINAL LAYOUT AND WIRING

• 8 pin type

Note: For connecting the output leads of the transistor output type, refer to 6) Transistor output on page 99.

78

• 11 pin type

Relay output type Transistor output typeRelay output type Transistor output type

• Screw-down terminal type

Relay output type Transistor output type

Page 4

ON

12345678

DIP switches See note 2

(Same for 6-digit, screw-down terminal type)

1

3

4

5

8

9

2

6

7

UP

DOWN

RESET

LOCK

COUNTER LC4H

OP.

RST

LOCK

RESET

LOCK

COUNTER LC4H

OP.

RST

LOCK

1

3

4

5

7

8

2

6

LC4H

02/2003

SETTING THE OPERATION MODE AND COUNTER

Setting procedure 1) Setting the operation mode (input mode and output mode)

Set the input and output modes with the DIP switches on the side of the unit.

DIP switches

Item

1

2

3

4

5

6

7

8

Operation mode Refer to table 1

Minimum reset input signal width 20 ms 1 ms

Maximum counter setting 30 Hz 5 kHz

Input mode Refer to table 2

Setting procedure 2) Setting the set value

Set the set value with the keys on the front of the unit.

Front display section

Q Counter display

W Set value display

E Controlled output indicator

R Reset indicator

T Lock indicator

Y UP keys

[Changes the corresponding

digit of the set value in the

addition direction (upwards)]

DIP switch

ONOFF

Table 1: Setting the output mode

DIP switch No.

1 2 3

ON ON ON SHOT-A

OFF OFF OFF SHOT-B

ON OFF OFF SHOT-C

OFF ON OFF SHOT-D

ON ON OFF HOLD-A

OFF OFF ON HOLD-B

ON OFF ON HOLD-C

OFF ON ON —

Table 2: Setting the input mode

DIP switch No.

6 7 8

ON ON ON Addition input

OFF OFF OFF Subtraction input

ON OFF OFF Directive input

OFF ON OFF Independent input

ON ON OFF Phase input

OFF OFF ON —

ON OFF ON —

OFF ON ON —

Note 1: The counter and set value displays will display DIP Err.

Note 2: Set the DIP switches before installing the unit.

The new settings

are valid after power

OFF ON

Output mode

See note 1

Input mode

See note 1

See note 1

See note 1

U DOWN keys

Changes the corresponding digit of

the set value in the subtraction

direction (downwards)

I RESET switch

Resets the set value and the output

O LOCK switch

Locks the operation of all keys on

the unit

• Changing the set value

1. It is possible to change the set

value with the up and down keys (4digit type only) even during counting.

However, be aware of the following

points.

1) If the set value is changed to less than

the count value with counting set to the

addition direction, counting will continue

until it reaches full scale (9999 with the

4-digit type and 999999 with the 6-digit

type), returns to zero, and then reaches

the new set value. If the set value is

changed to a value above the count

value, counting will continue until the

count value reaches the new set value.

Q Counter display

W Set value display

E Controlled output indicator

R Reset indicator

T Lock indicator

2) If counting is set to the subtraction

direction, counting will continue until full

scale (-999 with the 4-digit type and 99999 with the 6-digit type) regardless of

the new set value, and then the display

will change to with the 4-digit

type and with the 6-digit type.

2. If the set value is changed to “0,”

the unit will not complete count-up.

However, be aware of the following

points.

1) When counting is set to the addition

direction, counting will continue until full

scale is reached (9999 with the 4-digit

Y UP keys

Changes the corresponding digit of

the set value in the addition direction (upwards)

U RESET switch

Resets the set value and the output

I LOCK switch

Locks the operation of all keys on

the unit

type and 999999 with the 6-digit type),

return to zero, and then complete countup.

2) When counting is set to the subtraction direction, counting will continue until

full scale is reached (-999 with the 4-digit

type and -99999 with the 6-digit type),

and then the display will change to

with the 4-digit type and

with the 6-digit type.

3) For directive, independent, and phase

input, when the counter value increases

or decreases from the value "0" and then

returns back to the value "0," count-up is

completed.

79

Page 5

0 1 2 3 n-3 n-2 n-1 n

n n-1 n-2 n-3 3 2 1 0

H

L

H

L

IN1

IN2

Counting (subtraction)

Counting (addition)

Blocked

AA AA

Reset

Count-up completed

AA AA

n n-1 n-2 n-4n-3 01

012 43nn-1

H

L

H

L

IN1

IN2

Counting (subtraction)

Counting (addition)

BlockedBlocked

Reset

Count-up completed

H

L

H

L

Counting

IN1

IN2

Addition Subtraction Addition

AA AA

012 34321012 34

Reset

Counting

IN1

IN2

H

L

H

L

01 2 343 2 11223

Reset

Counting

IN1

IN2

BB

001 2 123

Reset

H

L

H

L

Phase advance Phase retard

LC4H

02/2003

OPERATION MODE

1. Input mode

For the input mode, you can choose one of the following five modes

• Addition

• Subtraction

• Directive

• Independent

• Phase

UP

DOWN

DIR

IND

PHASE

Input mode

Addition

UP

Subtraction

DOWN

Directive

DIR

Operation *Minimum input signal width 30 Hz: 16.7 ms; 5 kHz: 0.1 ms

IN1 or IN2 works as an input block

(gate) for the other input.

IN1 is the count input and IN2 is the

addition or subtraction directive input.

IN2 adds at L level and subtracts at H

level.

• Example where IN1 is the count input and IN2 is the input block (gate).

• Example where IN2 is the count input and IN1 is the input block (gate).

* “A” must be more than the minimum input signal width.

Independent

Phase

PHASE

80

IN1 is addition input and IN2 is subtraction input.

IND

Addition when the IN1 phase advances

beyond IN2, and subtraction when the

IN2 phase advances beyond IN1.

* “A” must be more than the minimum input signal width.

* IN1 and IN2 are completely independent, so there is no restriction on signal

timing.

* “B” must be more than the minimum input signal width.

Page 6

2. Output mode

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF

ON

n-3 n-2 n-1 n

321 0

Able Unable

n-2 n-1 n n+2n+1

210 -2-1

Able

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF

ON

n-2 n-1 n n+2n+1

210 -2-1

Able

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF OFF

ON

n-2 n-1 n n+2n+1

210 -2-1

Approx. 1 s

Able

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF OFF

ON

n-2 n-1 0 21

2 1 n n-2n-1

Reset (automatic)

Approx. 1 s

Able

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF OFF

ON

n-1 n n+1 10

1 0 -1 n-1n

Reset (automatic)

Approx. 1 s

Able

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF OFF

ON

n-1 n 10

1 0 n-1n

Reset (automatic)

Approx. 1 s

AbleAble Unable

Counting (addition)

Counting (subtraction)

Counting able/unable

Output control

OFF OFF

ON

02/2003

For the operation mode, you can choose one of the following seven modes

• Maintain output/hold count

• Maintain output/over count I

• Maintain output/over count II

• One shot/over count

• One shot/recount I

• One shot/recount II

• One shot/hold count

HOLD-A

HOLD-B

HOLD-C

SHOT-A

SHOT-B

SHOT-C

SHOT-D

LC4H

Output mode

Maintain output

Hold count

HOLD-A

Maintain output

Over count I

HOLD-B

Maintain output

Over count II

HOLD-C

One shot

Over count

SHOT-A

Operation (Example when input mode is either addition or subtraction)

Output control is maintained after

count-up completion and until resetting.

During that time, the count display does

not change from that at count-up completion.

* n: Set value

Output control is maintained after

count-up completion and until resetting.

However, counting is possible despite

completion of count-up.

* n: Set value

Output control is maintained after

count-up completion and until the next

signal enters. However, counting is

possible despite completion of countup.

* n: Set value

Output control is maintained after

count-up completion for a fixed time

(approx. 1 sec). Counting is possible

despite completion of count-up.

Output control is maintained after

count-up completion for a fixed time

One shot

Recount I

SHOT-B

(approx. 1 sec). Counting is possible

despite completion of count-up.

However, reset occurs simultaneous

with completion of count-up. While output is being maintained, restarting of

the count is not possible.

Output control is maintained after

count-up completion for a fixed time

One shot

Recount II

SHOT-C

(approx. 1 sec). Counting is possible

despite completion of count-up.

However, reset occurs simultaneous

with output OFF.

Output control is maintained after

count-up completion for a fixed time

One shot

Hold count

SHOT-D

(approx. 1 sec). During that time, the

count display does not change from

that at count-up completion. Reset

occurs simultaneous with output OFF.

* n: Set value

* n: Set value

* n: Set value

* n: Set value

81

Page 7

11-pin type

Screw terminal type

3 4 5 6 7

8-pin type

1 — 5 4 3

6 7 8 9 10

Reset input

Input 1

Input 2

Lock

input

11-pin type

Screw terminal type

3

4 5 6 7

8-pin type

1

— 5 4 3

6 7 8 9

10

Reset input

12 to 40V DC

Q

(The above example is for reset input)

11-pin type

Screw terminal type

3 4 5 6 7

8-pin type

1 — 5 4 3

6 7 8 9 10

Reset input

Input 1

Input 2

Lock

input

LC4H series CAUTIONS FOR USE

10

2

3

(

Fig. A

)

Input contact

point or transistor

2

3

10

Power

supply

Input

terminal

terminal

Input

10

2

3

3

2

10

(

Fig. B

)

Input contact

point or transistor

Power

supply

point or transistor

Input contact

terminal

Input

terminal

Input

(

Fig. C

)

Power

supply

3

3

Input contact

point or transistor

10

2

10

2

terminal

Input

terminal

Input

02/2003

PRECAUTIONS DURING USAGE

1. Terminal wiring

1) When wiring the terminals, refer to the

terminal layout and wiring diagrams and

be sure to perform the wiring properly

without errors.

2) For embedded installation applications, the screw-down terminal type is

recommended.

Use either the rear terminal block (AT8RR) or the 8P cap (AD8-RC) for the 8pin type, and the 11P cap (AT8-DP11)

for the 11-pin type. Avoid soldering

directly to the round pins on the unit.

For front panel installation applications,

use the 11-pin type DIN rail terminal

block (ATC18004).

3) After turning the unit off, make sure

that any resulting induced voltage or

residual voltage is not applied to power

supply terminals W through U (8-pin

type), W through P (11-pin type) or

2

and (screw-down terminal type). (If

1

the power supply wire is wired parallel to

the high voltage wire or power wire, an

induced voltage may be generated

between the power supply terminals.)

4) Have the power supply voltage pass

through a switch or relay so that it is

applied at one time. If the power supply

is applied gradually, the counting may

malfunction regardless of the settings,

the power supply reset may not function,

or other such unpredictable occurrence

may result.

2. Input connections

The power circuit has no transformer.

When an input signal is fed to two or

more counters at once, do not arrange

the power circuit in an independent way.

If the counter is powered on and off independently as shown in Fig. A, the counter's internal circuitry may get

damaged.Be careful never to allow such circuitry. (Figs. A, B and C show the circuitry for

the 11-pin type.)

one input signal can be fed to two or

more counters at once, as shown in Fig. C.

3. Input and output

1) Signal input type

(1) Contact point input

Use highly reliable metal plated contacts.

Since the contact point’s bounce time

leads directly to error in the count value,

use contacts with as short a bounce time

as possible. In general, select Input 1

and Input 2 to have a maximum counting

speed of 30 Hz and to be reset with a

minimum input signal width of 20 ms.

(2) Non-contact point input

age of less than 2 V when the transistor

is on.

* The short-circuit impedance should be

Note: The LC4H-W does not have the lock input

7

R .

less than 1 kΩ.

[When the impedance is 0 W, the current

coming from the input 1 and input 2 terminals is approximately 12 mA, and from

the reset input and lock input terminals is

approximately 1.5 mA.]

Also, the open-circuit impedance should

be more than 100 kΩ.

* As shown in the diagram below, from a

non-contact point circuit (proximity

switches, photoelectric switches, etc.)

with a power supply voltage of between

12 and 40 V, the signal can be input

without using an open collector transistor. In the case of the diagram below,

when the non-contact point transistor Q

switches from off to on (when the signal

voltage goes from high to low), the signal is input.

2) The input mode and output mode

If independent power circuitry must be used,

keep the input contacts or transistors separate from each other, as shown in Fig. B.

When power circuitry is not independent,

98

Note: The LC4H-W does not have the lock input

7

R .

Connect with an open collector. Use

transistors whose characteristics satisfy

the criteria given below.

V

CEO = 20 V min.

I

C = 20 mA min.

I

CBO = 6µA max.

Also, use transistors with a residual volt-

change depending on the DIP switch settings. Therefore, before making any connections, be sure to confirm the operation mode and operation conditions currently set.

3) For the power supply of the input

Page 8

Peak value

0

0 1.2 50

30

50

90

100

Time (µs)

Surge voltage (%)

C

C

CR

(Fig. A)

(Fig. B)

Operation power supply

Leakage current

R

C

Operation power supply

R

R

C

C

R

R

Relay Counter

Receive output

from contact

at relay R

Load’s

power supply

Inductive load

LC4H counter

Diode rating:

I

F (forward current): 1 A

V

R (reverse voltage): 600 V

device, use a single-phase or double-

Load

Load’s power supply

LC4H counter

{OI

As NPN output

Load

Load’s power supply

LC4H counter

As PNP output

{OI

LC4H counter

Input

terminals

Circuit

Rectifier circuits

Power

supply

Insulated transformer

is necessary

02/2003

phase insulated power transformer. The

second-phase side must not be grounded.

4) Since the power supply circuitry does

not contain a transformer, be aware that

it is not possible for simultaneous input

from an input contact point or transistor

to a LC4H counter with independent

power supply operation.

5) The input signal is applied by the

shorting of each input terminal with the

common terminal (terminal 1 for 8-pin

type, terminal 3 for 11-pin type and terminal 6 for screw-down terminal types).

Never connect other terminals or voltages higher than DC 40 V, because it

may destroy the internal circuitry.

6) Transistor output

(1) Since the transistor output is insulated

from the internal circuitry by a photocoupler, it can be used as an NPN output or PNP (equal value) output. (The

above example is 11-pin type)

(2) Use the diode connected to the out-

4. Output mode setting

The output mode can be set with the

switches on the side of the counter.

DIP

Make the DIP switch settings before

installing the counter on the panel.

5. Conditions of usage

1) Avoid locations subject to flammable

or corrosive gases, excessive dust, oil,

vibrations, or excessive shocks.

2) Since the cover of the unit is made of

polycarbonate resin, avoid contact with

or use in environments containing methyl

alcohol, benzene, thinners, and other

organic solvents; and ammonia, caustic

sodas, and other alkaline substances.

3) If power supply surges exceed the values given below, the internal circuits may

become damaged. Be sure to use surge

absorbing element to prevent this from

happening.

Operating voltage

AC type 6,000V

DC type

24V AC type

• Surge wave form

[± (1.2 × 50) ms uni-polar full wave voltage]

Surge voltage (peak value)

1,000V

6) Long periods of continuous operation

in the count-up completed condition (one

month or more) will result in the weakening of the internal electrical components

from the generated heat and, therefore,

should be avoided. If you do plan to use

the unit for such continuous operation,

use in conjunction with a relay as shown

in the circuit in the diagram below.

Note: With the LC4H 8-pin type and the LC4H-W,

there is no diode between points I and O.

put transistor’s collector for absorbing

the reverse voltage from induced loads.

(LC4H only)

7) When wiring, use shielded wires or

metallic wire tubes, and keep the wire

lengths as short as possible.

4) Regarding external noise, the values

below are considered the noise-resistant

voltages. If voltages rise above these

values, malfunctions or damage to the

internal circuitry may result, so take the

necessary precautions.

Power supply terminals

DC type

24V AC type

Noise

voltage

AC type

1,500V 1,000V 600V

Noise wave form (noise simulator)

Rise time: 1 ns

Pulse width: 1 µs, 50 ns

Polarity: ±

Cycle: 100 cycles/second

Input

terminals

5) When connecting the operation power

supply, make sure that no leakage current enters the counter. For example,

when performing contact protection, if

set up like that of diagram A, leaking current will pass through C and R, enter the

unit, and cause incorrect operation.

Diagram B shows the correct setup.

99

Page 9

6. Self-diagnosis function

or

02/2003

If a malfunction occurs, one of the following displays will appear.

Display Contents

Minimum value went below –999

or –99999. See note 1.

Incorrect DIP switch setting.

Malfunctioning CPU.

Malfunctioning memory. See

note 2.

Note 1: When the counter value goes below the minimum value during any of the subtraction, directive, independent, or phase input modes.

Note 2: Includes the possibility that the EEPROM’s life has expired.

Output condition Restoration procedure Preset values after restoration

Enter reset or RESET

No change

OFF

key.

Restart unit (correct DIP

switch settings)

Enter reset, RESET key,

or restart unit.

The values at start-up before the CPU

malfunction occurred.

7. CE Marking Certification

1) EMC directive (89/336/EEC)

As a counter unit, the LC4H series conforms to EMC directives. Applicable

standards are EN50081-2 and EN50082-

2.

2) Low voltage directive (73/23/EEC)

In order to satisfy VDE0435/Part 2021,

be sure to adhere to the following installation conditions and precautions.

(1) The counter uses a non-transformer

power supply and the power supply and

input signal terminals are not insulated.

• When a sensor is connected to the

input circuit, install double insulation on

the sensor side.

• With contact-point inputting, use double-insulated relays, etc.

(2) Always connect loads insulated with

basic insulation specifications to the output contact points. The counter unit is

also insulated with basic insulation specifications. The combination of the two satisfies VDE, which calls for double insulation.

(3) For the applied power supply, use

one protected by an over-current protec-

tion device that conforms with EN/IEC

standards (e.g. 250 V, 1 A fuse).

(4) During installation, always use a terminal block or the appropriate sockets.

Do not touch the terminals, or other part

of the counter unit while it is on. Before

installation or removal of the unit, first

verify that no voltage is being applied to

any of the terminals.

(5) Do not use the counter in a safety circuit. When the unit is being used in a circuit such as a heater circuit, install a protection circuit on the machine side.

No change

0

100

Loading...

Loading...