Page 1

Panasonic

Operating Instructions

Impuct Dtx Matrix Printer

KX-P3626

Page 2

FOR USE IN THE UNITED ST A TES ONL Y

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of FCC Rules, These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

The user may find the booklet “Something About Interference” available from FCC local

regional offices helpful.

FCC Warning: To assure continued FCC emission limit compliance, the user must use

only the recommended shield interfacing cable when connecting to a host computer. Also,

any unauthorized changes or modifications to this equipments would void the users

authority to operate this device.

WARNING

• The power source voltage of this unit is listed on the nameplate. Plug the printer only

into an outlet with the proper voltage.

• To prevent fire or shock hazard, do not expose this product to rain or any type of

moisture.

• When you operate this equipment, the outlet should be near the equipment and should

be easily accessible.

The serial number of the unit may be found on the label on the rear of the unit. For your

convenience, note this number below, and retain this book, along with your proof of

purchase, to serve as a permanent record of your purchase in the event of a theft, or for

future reference.

MODEL NO. KX-P3626

SERIAL NO.

IBM and IBM-PC are trademarks of International Business Machines Corporation.

Proprinter is a trademark of International Business Machines Corporation.

Microsoft and Windows are trademarks of Microsoft Corporation.

Epson is a trademark of Seiko Epson Corporation.

Epson ESC/P2 is a trademark of Seiko Epson Corporation.

NAME OF DEALER

DATE OF PURCHASE

Any details given in these Operating Instructions are subject to change without notice.

All Rights Reserved. © COPYRIGHT 1994 KYUSHU MATSUSHITA ELECTRIC CO., LTD.

Page 3

Table of Contents

4 Introduction 4 Features

Chap. 1

Chap. 2

Chap. 3

Before You Start

Cautions 6

5

5

5

Operating Environment

Precautions 9

Unpacking

7 Preparation

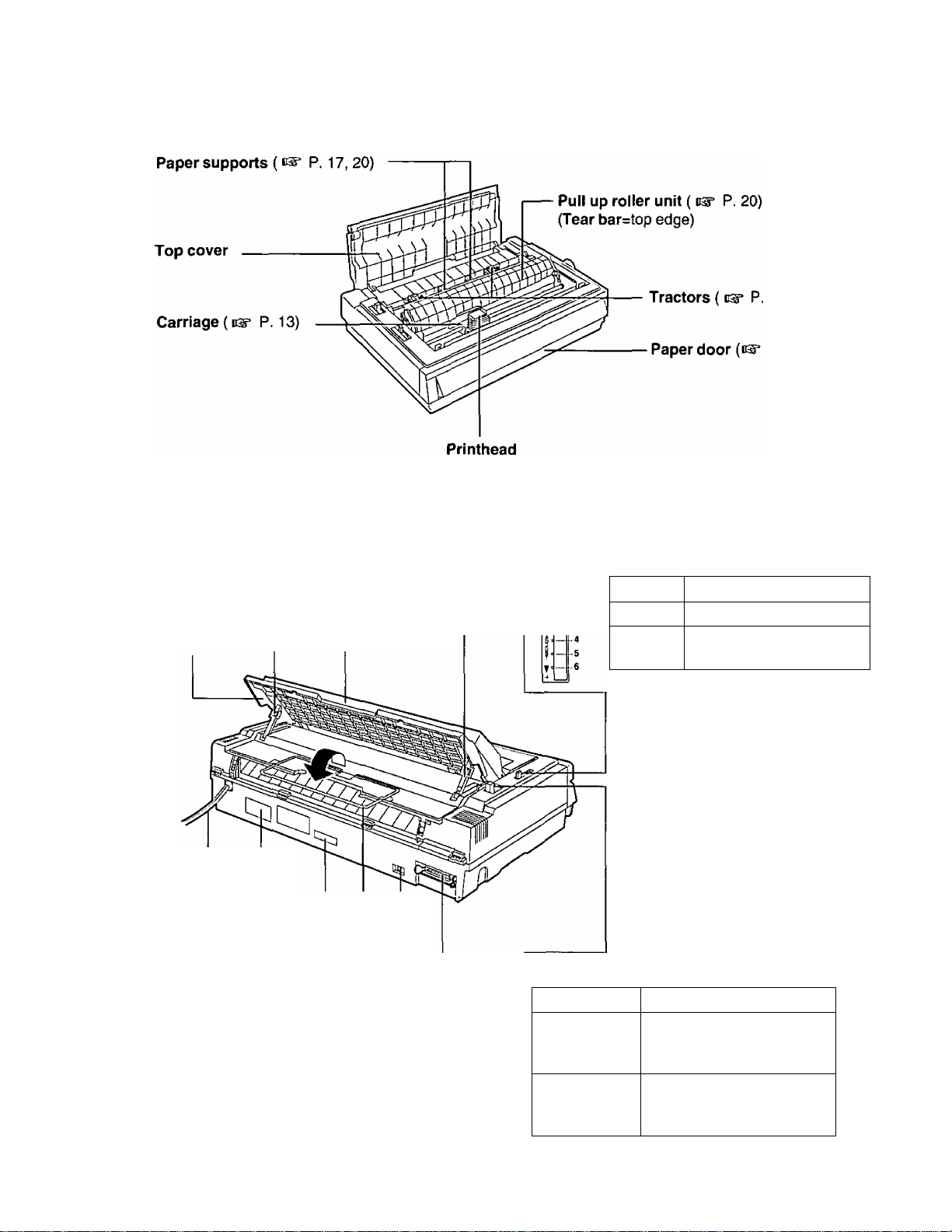

Parts of the Printer

Setup

Connecting to a Computer 19 Fanfold Paper

11

12 Ribbon Cassette

12

14

15

16 installing Paper 26

16

Installing the Ribbon Cassette

Removing the Ribbon Cassette

Paper Feed Selection

Fanfold Paper

{Rear Feed/Push Tractor Mode)

23

25 Self Test

Printer Driver Selection

27 Installing a Printer Driver (Windows Ver. 3.1)

Using the Setup Disk

28 Initial Setup Mode 36

32 Running the Initial Setup Program

33

34 Print Settings 38

34

35

Exiting the Initial Setup Program 38

Display Setting List

Setting Selections on Setup Disk

37 Load from Disk (Recall Settings)

39

(Bottom,Front Feed/Pull Tractor Mode)

Single Sheets and Envelopes

(Top Feed/Friction Mode)

Save to Disk

Send to Printer

Resetting to Factory Setting

Help

Chap. 4

Using the Control Panel

Using the Control Panel

40

40

40

41 Super Quiet Mode 46

42

Selecting a Character Font 44

Selecting a Character Pitch 45

Line Feed/Form Feed [LF/FF] 47 Initial Setup Mode

Chap. 5 Software Commands

Command Reference Program (Using the Setup Disk)

52

Chap. 6

Maintenance & Troubleshooting

Periodic Maintenance/ 55

55

Troubleshooting 55

Appendix

57 Initialization/Hex Dump

57 Initialization/Hex Dump

Printer Specifications

58

60 Paper Specifications 70

60

61 Printing Area

Fanfold Paper/Single Sheet/ 73

Envelope 75

43

62 Interfacing

62 Parallel Interfacing

64 Character Set Tables

Top of Form Function (TOF SET)

Tear Off [TEAR OFF]

Paper Parking [ LOAD/PARK ]

Paper Out Detector

Periodic Maintenance

Troubleshooting

Glossary

Index

Options and Supplies

Page 4

Introduction

Congratulations on purchasing a Panasonic printer.

This printer is a versatile, high quality 24-pin dot matrix printer which is designed to meet the needs

of your office.

This printer has been factory set to operate with most of the popular software packages. Your

application software should control the printer functions. In most cases, there will be no need to change

the initial printer settings.

Features

Printer Emulation:

Setup Disk:

Super Quiet Mode:

Fonts:

Printing Speed:

Paper Handling:

Paper Paths:

Epson LQ-1170 and IBM Proprinter XL24E

Setup program, Command Reference program and a

Printer Driver for Windows Ver, 3.1

Reduces printing noise

3 Draft (Pica, Elite, Micron)

7 Letter Quality (Courier, Bold PS, Prestige, Script,

Sans Serif, Roman, OCR-B)

1 Super Letter Quality (Roman)

6 Scalable Fonts (Courier, Bold PS, Prestige, Script,

Sans Serif, Roman)

Draft — 300 characters per second (15 cpi)

LQ — 100 characters per second (15 cpi)

SLQ — 40 characters per second (12 cpi)

Friction and Tractor (Push/Pull built-in)

Rear, Bottom, Front, Top

Tear Off:

Paper Parking:

Cut Sheet Feeder Option

(KX-P38):

Serial Interface Option

(KX-PS13 and KX-PS14):

Copies: Original plus four non-carbon copies

Advances fanfold paper’s perforation to tear position

Allows single sheets/envelopes to be used without

removing/wasting fanfold paper

Provides fast and automatic feeding of single sheets

You may select parallel or serial when the KX-PS14

serial interface board is installed

Page 5

©gKufiO®®

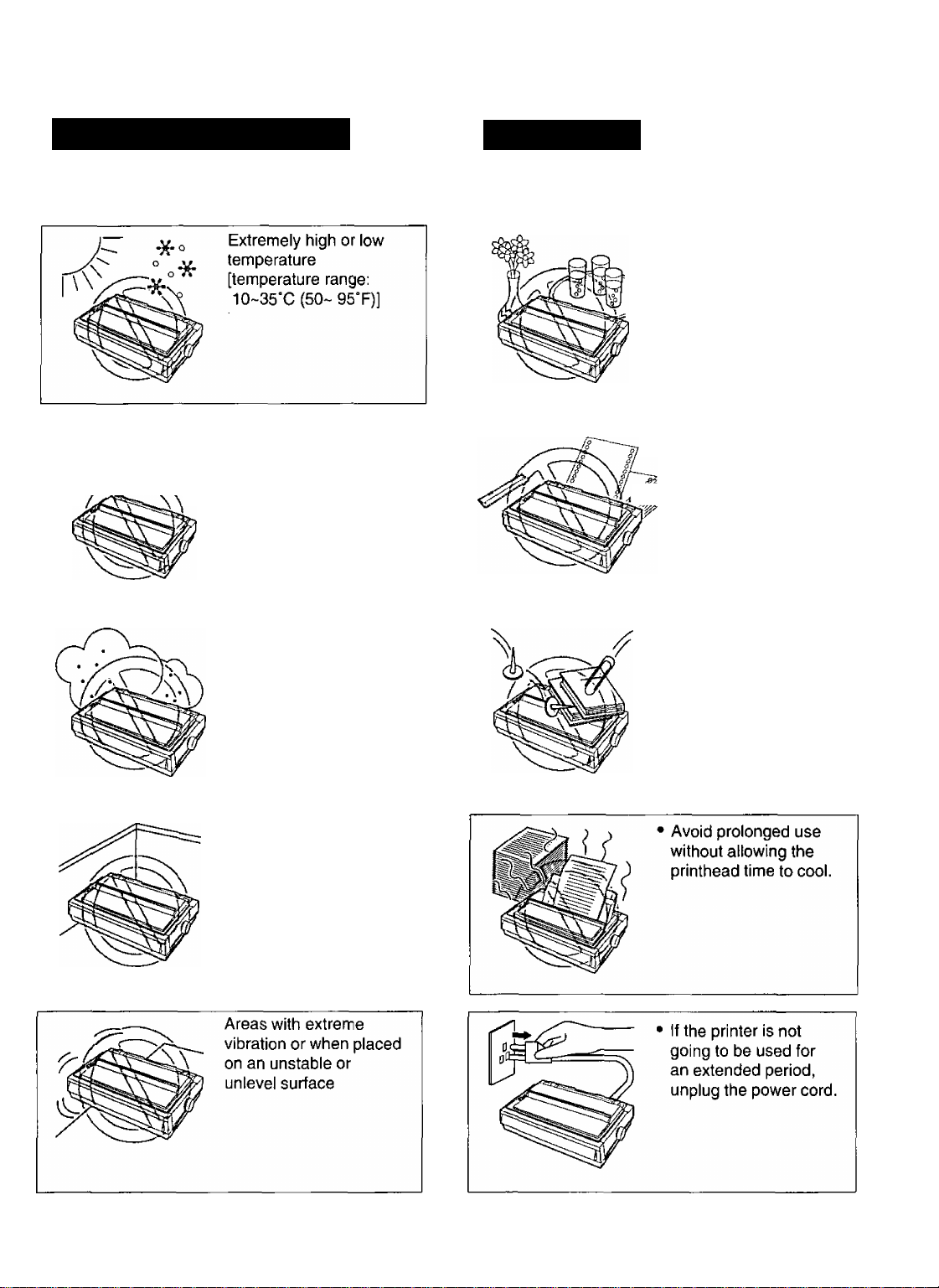

Operating Environment

Do not use the printer in the following conditions.

A A A A A Extremely high or low

6^0 6^ humidity

A A^A'^A A (humidity range:

^ ^ On_ QAO/ DU\

20-80% RH)

Precautions

Thefollowing precautions are recommended to extend

the life of the printer.

Keep all liquids away

from the printer

— Accidental spillage

of a liquid into the

printer can cause

severe damage.

• Do not operate the

printer without paper

and a ribbon cassette

W installed.

Areas of high dust

concentration

Areas of poor ventilation

[a minimum of

4" (10 cm) clearance on

all sides is necessary to

insure proper ventilation]

Do not place books,

paper, or other items

on top of the printer.

Do not obstruct the

movement of the

printhead while in

operation.

Page 6

CO

Q>

0

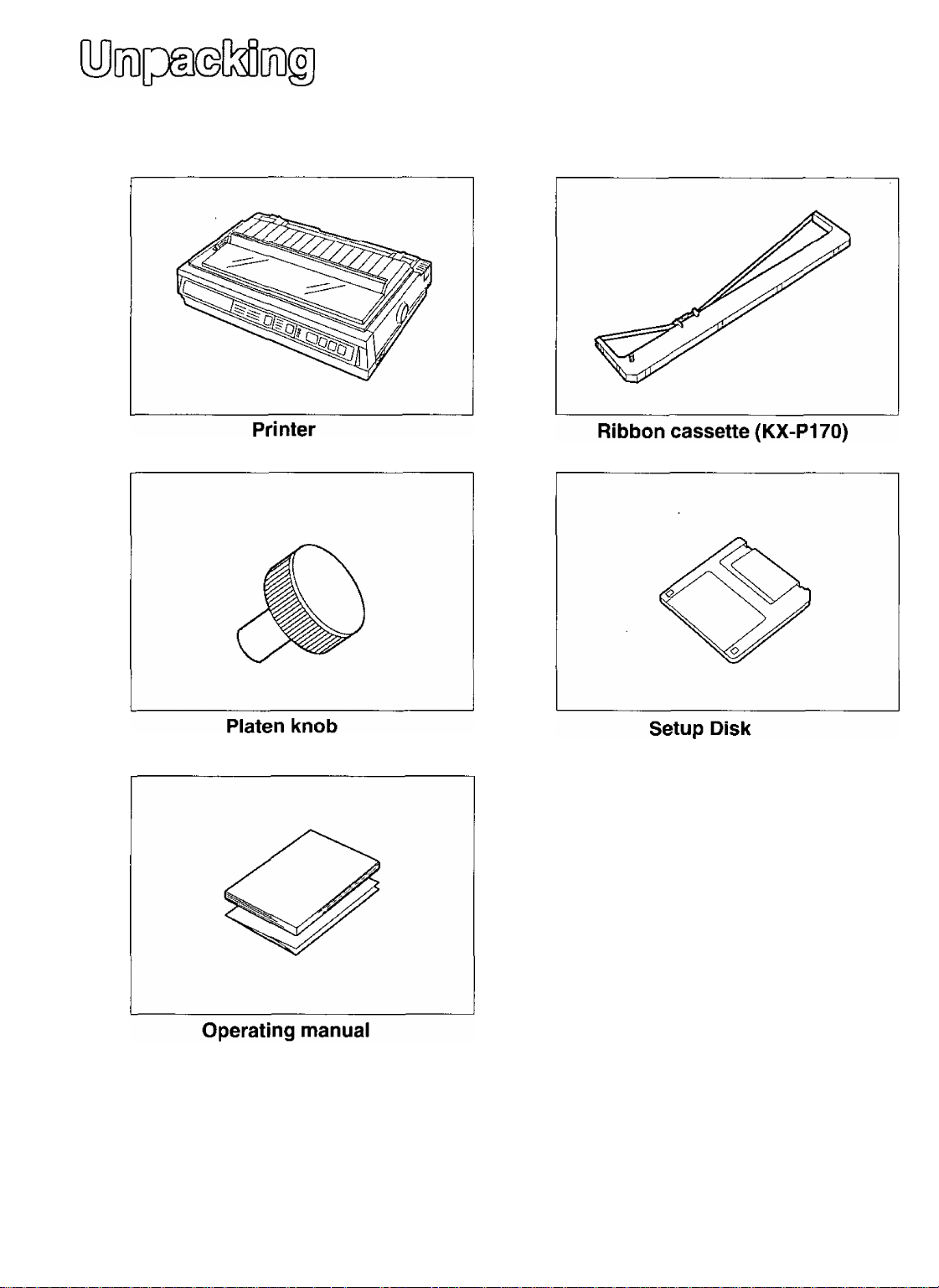

Having unpacked the printer, make sure none of the contents shown below are missing or damaged.

Report damages or shortages to the store from which the unit was purchased.

f

------------------------------------------------------------

• The Setup Disk contains a Printer

Driver for Windows Ver. 3.1 (P.

27), a Setup program ( P. 28)

and a Command Reference

program ( P. 52).

• To use this Setup Disk, you need to

have an IBM-PC or a compatible

computer with a 3.5'' floppy disk

drive.

Quick start guide

Note:

• It is recommended that you save the original carton and packing materials for proper shipping and

transporting of the printer.

N

Page 7

Preparation

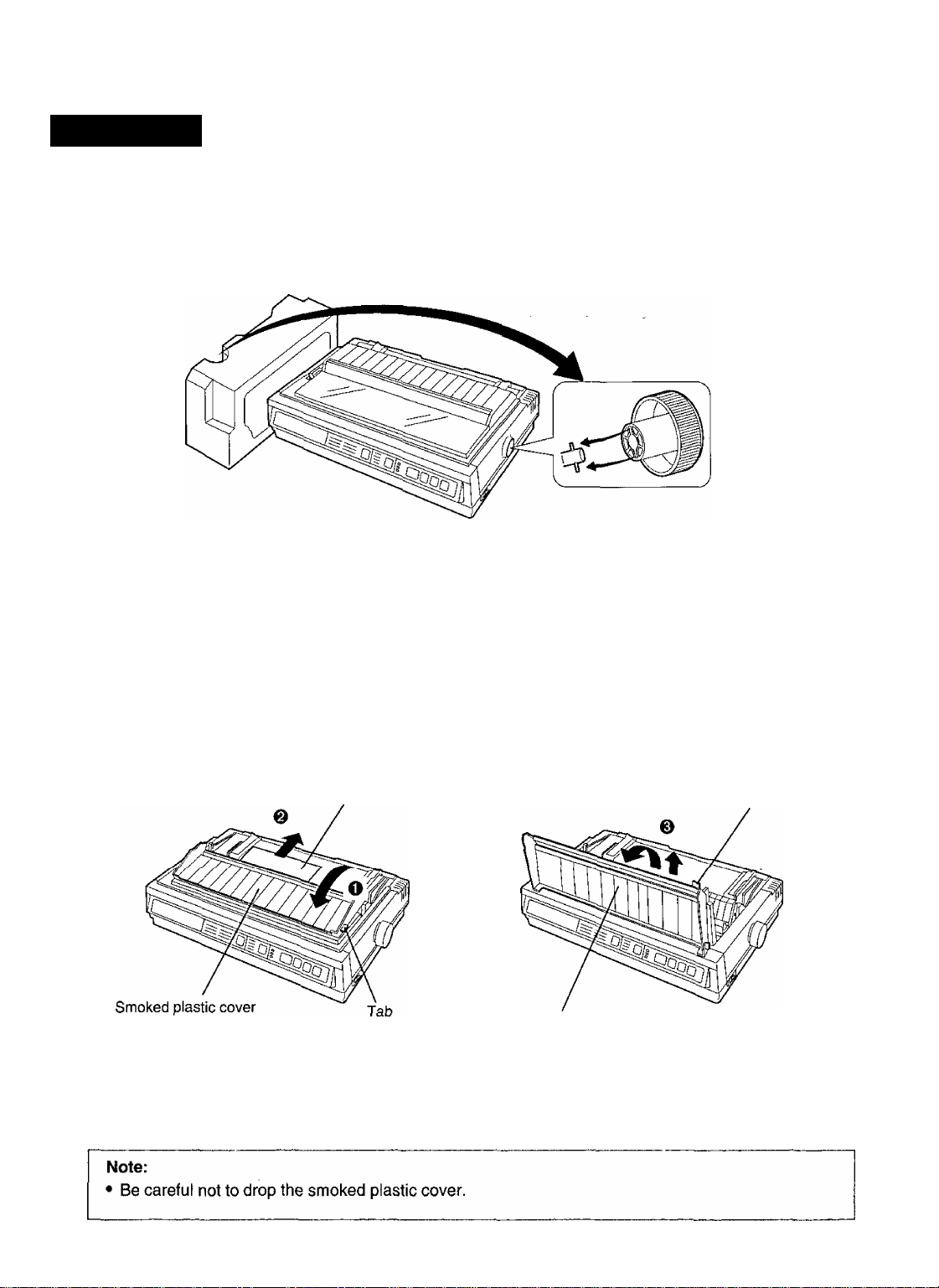

(a) Insert the platen knob into the hole on the right side of the printer and rotate it slowly until it slips onto

the shaft. Push the platen knob onto the platen shaft to secure.

m

(D

o

<D.

-<

O

c

CO

fia

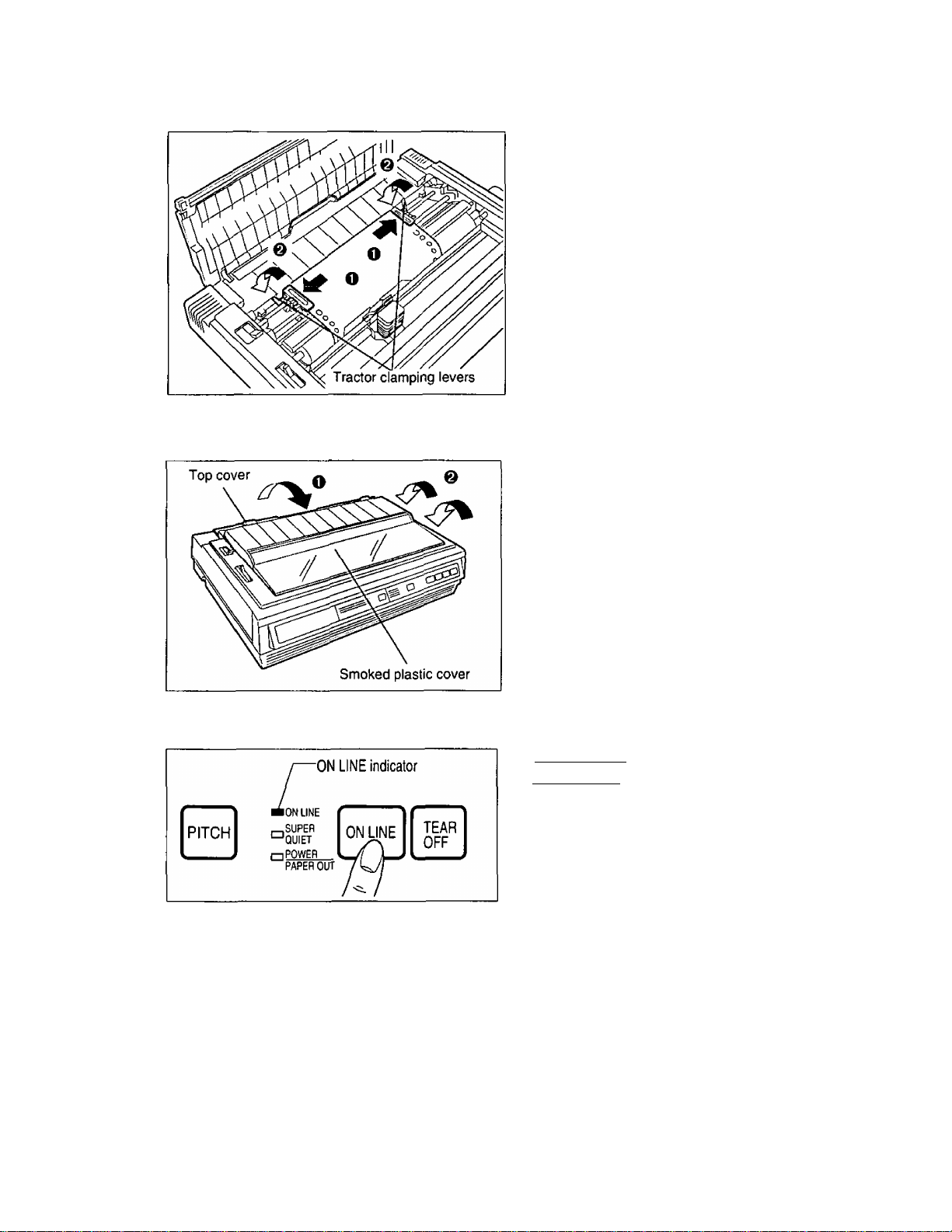

(b) O Fold forward the smoked plastic cover.

© Remove the protective paper which includes unpacking instructions.

© Raise the smoked plastic cover and remove it.

Protective paper

Smoked plastic cover

Tab

Page 8

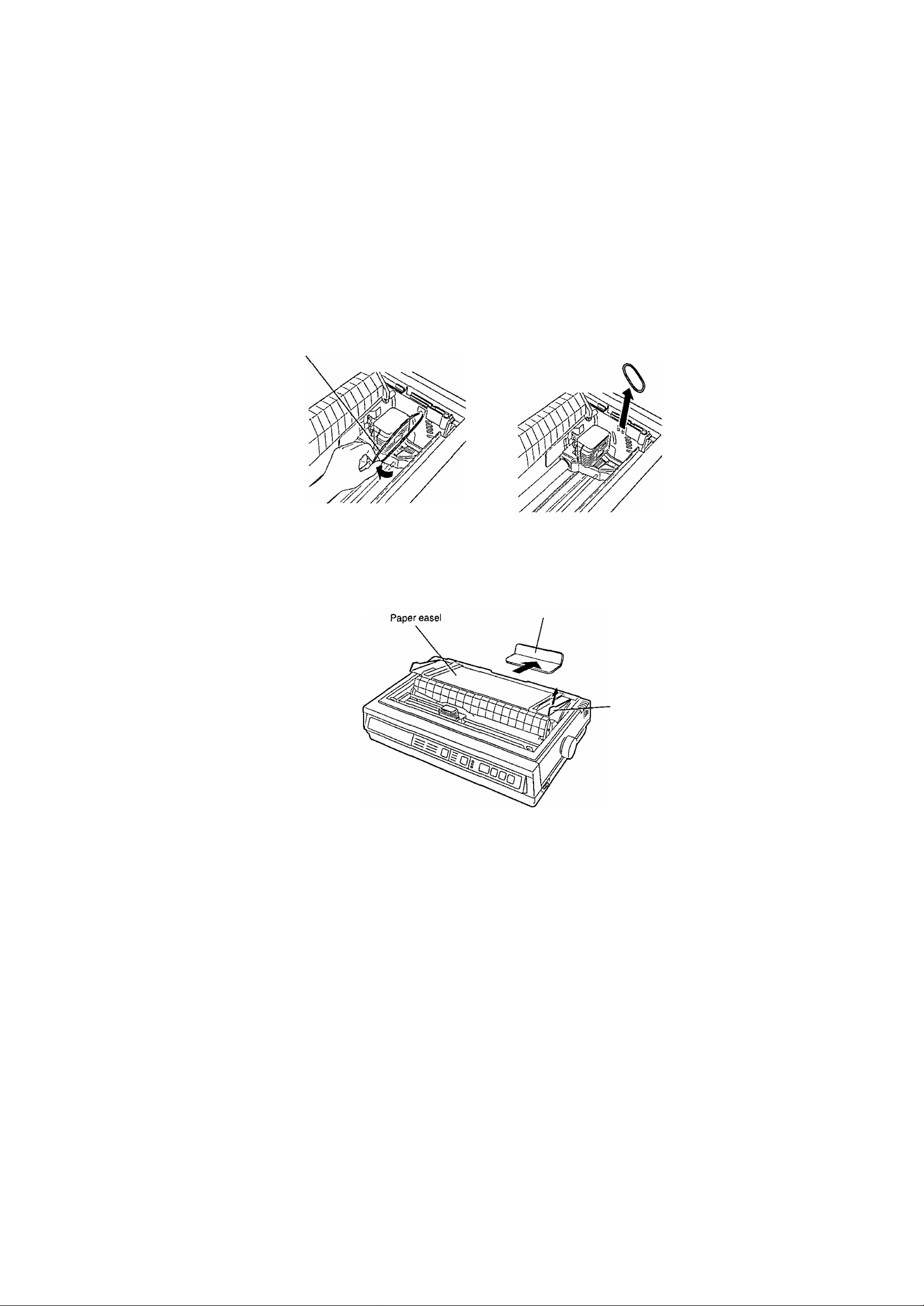

(c) Remove the carriage stopper band, as shown,

Carnage stopper band

(d) Remove the separator pad lifting the paper easel by holding the tab of it

Separator pad

Tab

r Note:

•

I

• Be sure to replace the carriage stopper band and the separator pad before transporting the printer

8

Page 9

1®= p. 40)

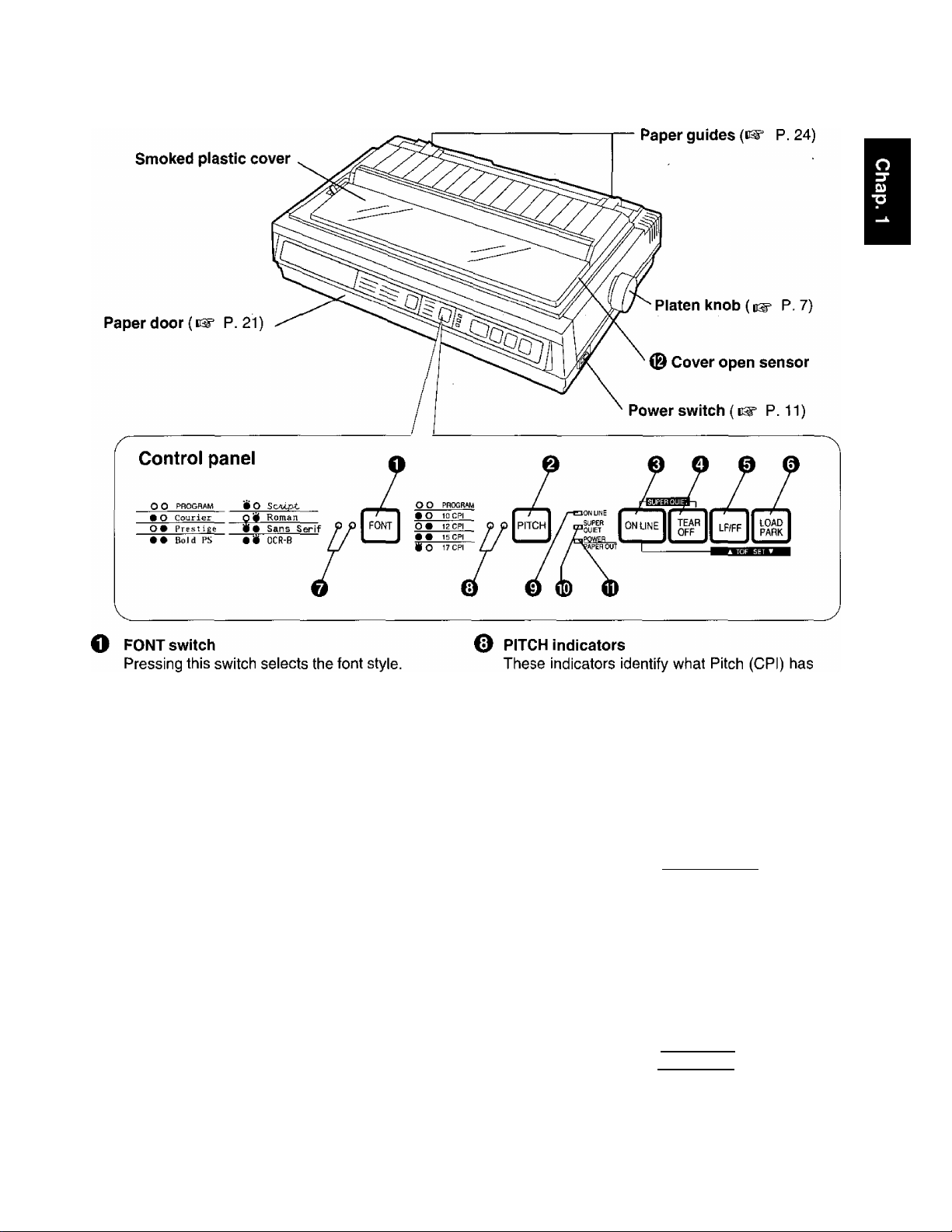

e PITCH switch

Pressing this switch selects the characters per

inch (cpi). (P. 40)

0

ON LINE switch

This switch opens and closes the

communication line with the computer.

O TEAR OFF switch

Pressing this switch advances or reverses the

paper for tearing off. { P. 44)

© LF/FF switch

Pressing this switch advances the paper one

line at a time. Holding this switch advances the

paper to the first print line of the next page.

{P. 42)

0

LOAD/PARK switch

Pressing this switch loads or parks the paper.

(P. 45)

O FONT indicators

These indicators identify which Font has been

selected. (P. 40)

been selected. {eg* P. 40)

0

ON LINE indicator

This indicator is lit when the printer is in the ON

LINE mode, and is not lit when in the OFF LINE

mode.

® SUPER QUIET indicator

This indicator is lit when the printer is in the

SUPER QUIET mode. (While pressing the ON

LINE switch, press the [ TEAFVOFF] switch.)

{ ^ P. 41)

0 POWER/PAPER OUT indicator

This indicator is lit when the power is on and

paper is installed. It blinks when paper is not

installed. (P. 46)

0

Cover open sensor

When the cover is opened, the machine will

beep and printing will stop. To resume printing

close cover and press [ ON LINE].

Page 10

CD

(D

O

(D

-<

O

c

c/>

D)

Paper easel

{i^ P. 18,23)

Rear supports (cs" P. 18)

________\__________

Paper easel hand

guide (eg* P. 18, 23)

Head gap lever

Adjusts the gap between the platen and the

printhead. The lever moves in increments of

0.0028 inch (0.07 mm).

■Q-

Position

1 or 2

3, 4,5

or 6

Thinner sheets

Thick sheets, multi-part

forms or envelopes

Used for

AC power cord

(C3= P. 11)

Nameplate

Serial No. label *

Paper separator ( eg* P.18)

Frame ground terminal

(P. 11)

Centronics parallel interface

connector {P. 11)

* For units sold in Canada, Serial No. is located

on the Nameplate.

10

Paper feed selector

Position Used for

Q (Friction)

[H] (Tractor)

Single sheets and

envelopes

Fanfold paper (Front,

bottom and rear feeding)

Page 11

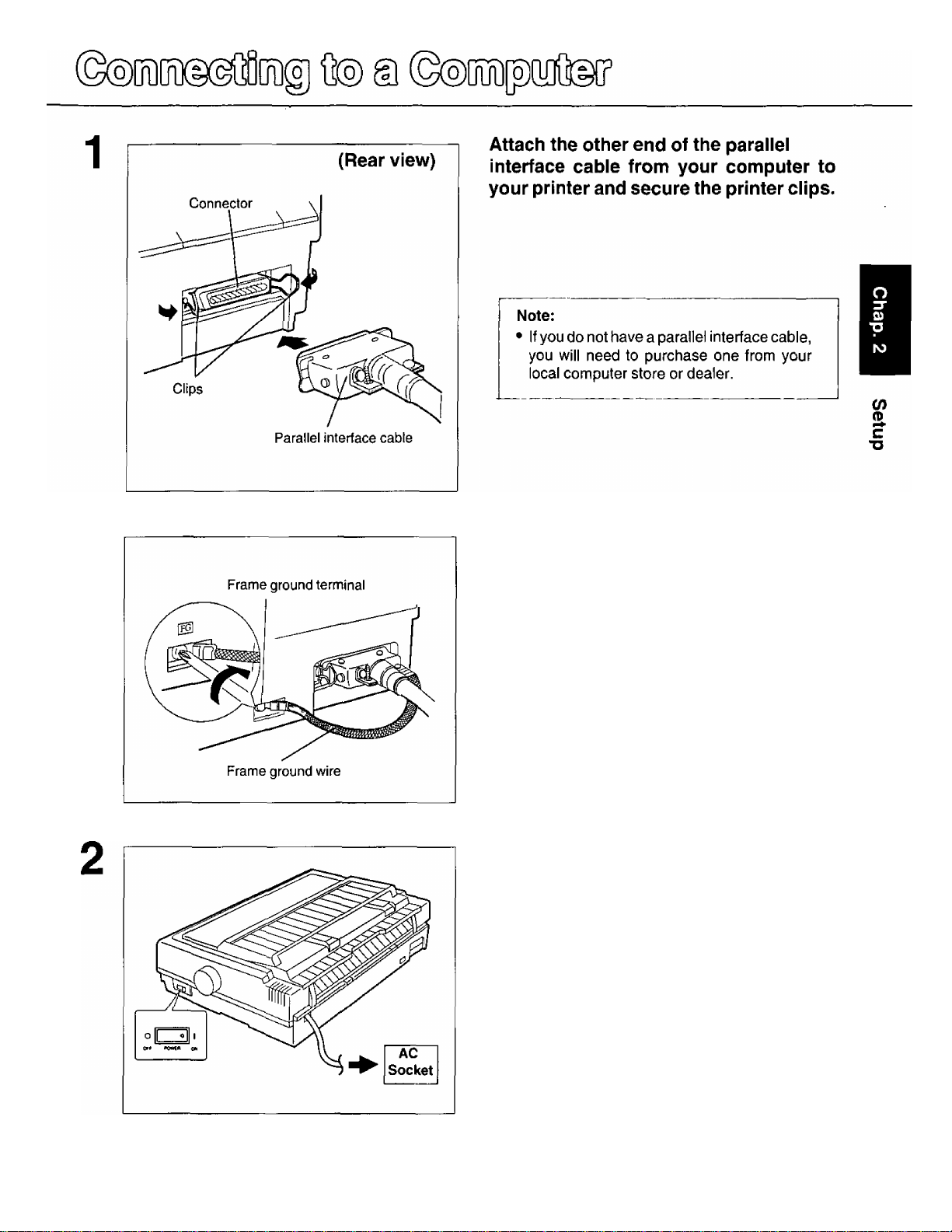

If the cable has a frame ground wire,

connect it to the frame ground terminal.

Plug printer into a grounded 3 prong AC

socket.

When the power is supplied to the printer, the power

indicator on the control panel will light.

11

Page 12

O)

(D

c

■O

!^0№)®(iì) ©agsMìife

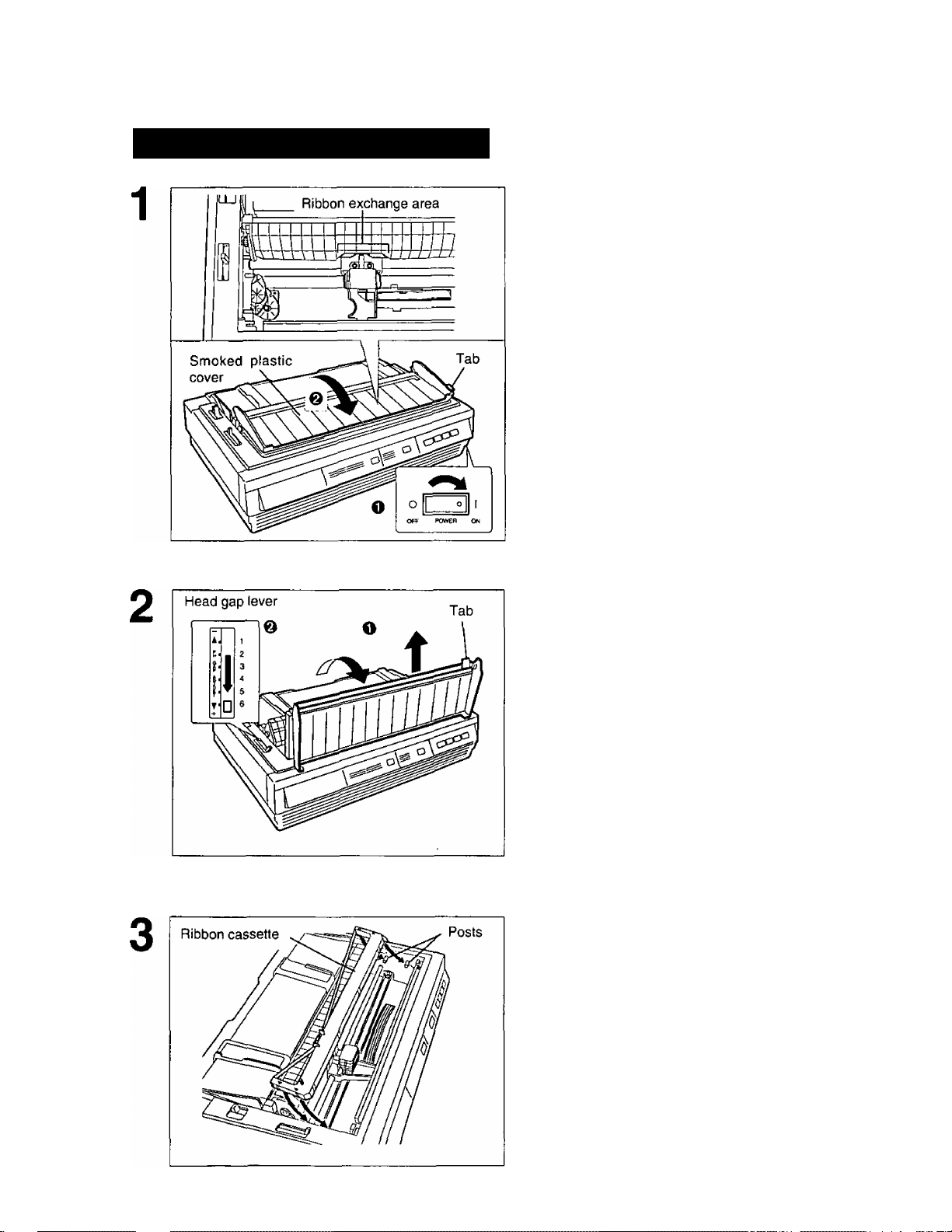

Installing the Ribbon Cassette

O Turn the power on.

The carriage will automatically move to the ribbon

exchange area.

I Note:

! • The ribbon cassette can only be installed in

! this area.

O Fold forward the smoked plastic

cover.

O Raise the smoked plastic cover and

remove it.

0 Move the head gap lever to the (+)

position.

Note:

• Be careful not to drop the smoked plastic

cover.

• The printhead may be hot, use caution when

cover is open.

1

__

Lower the ribbon cassette onto the four

ribbon posts (gold in color), insert the

back portion of the ribbon into the printer

first.

12

Page 13

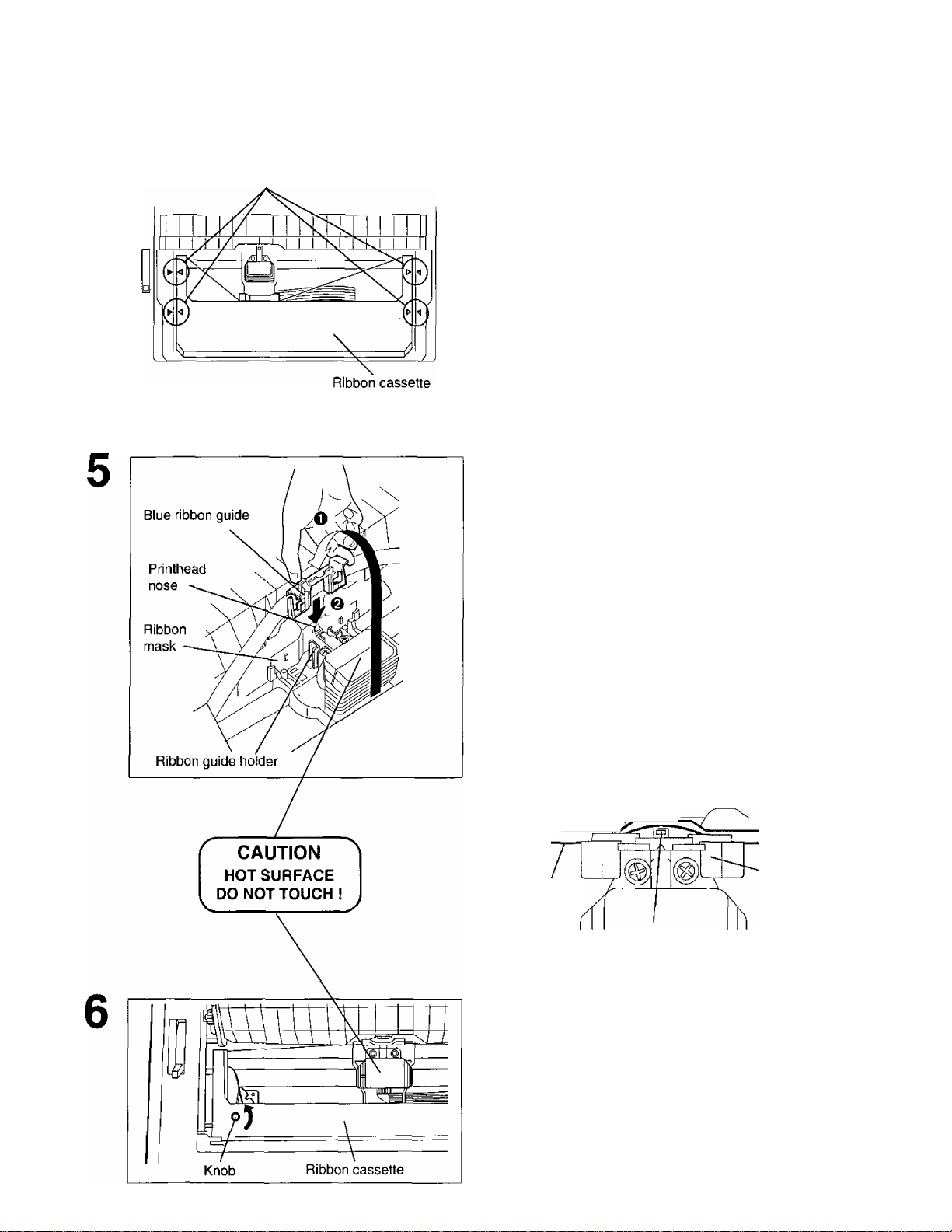

Arrows

Line up the 4 arrows on the ribbon

cassette with the arrows on the left and

right sides of the frame. Push 4 arrows

down until they click into place.

Note;

• Make sure that the ribbon cassette is

perfectly placed in position.

O Grasp the top of the blue ribbon guide

with your thumb and forefinger,

remove the blue ribbon guide by lifting

from the ribbon cassette.

@ Slide the blue ribbon guide onto the

ribbon guide holder of the carriage

and push the blue ribbon guide down.

C/)

(D

Note:

• If the ribbon does not insert easily between

the printhead nose and the ribbon mask

rotate the knob to reduce slack.

Top view

Ribbon

Ribbon mask

Blue ribbon

guide

Printhead nose

Rotate the knob on the ribbon cassette

counterclockwise to remove any slack.

13

Page 14

CO

(D

C

■O

SïïÈÈxaîo ©a@g3GS§

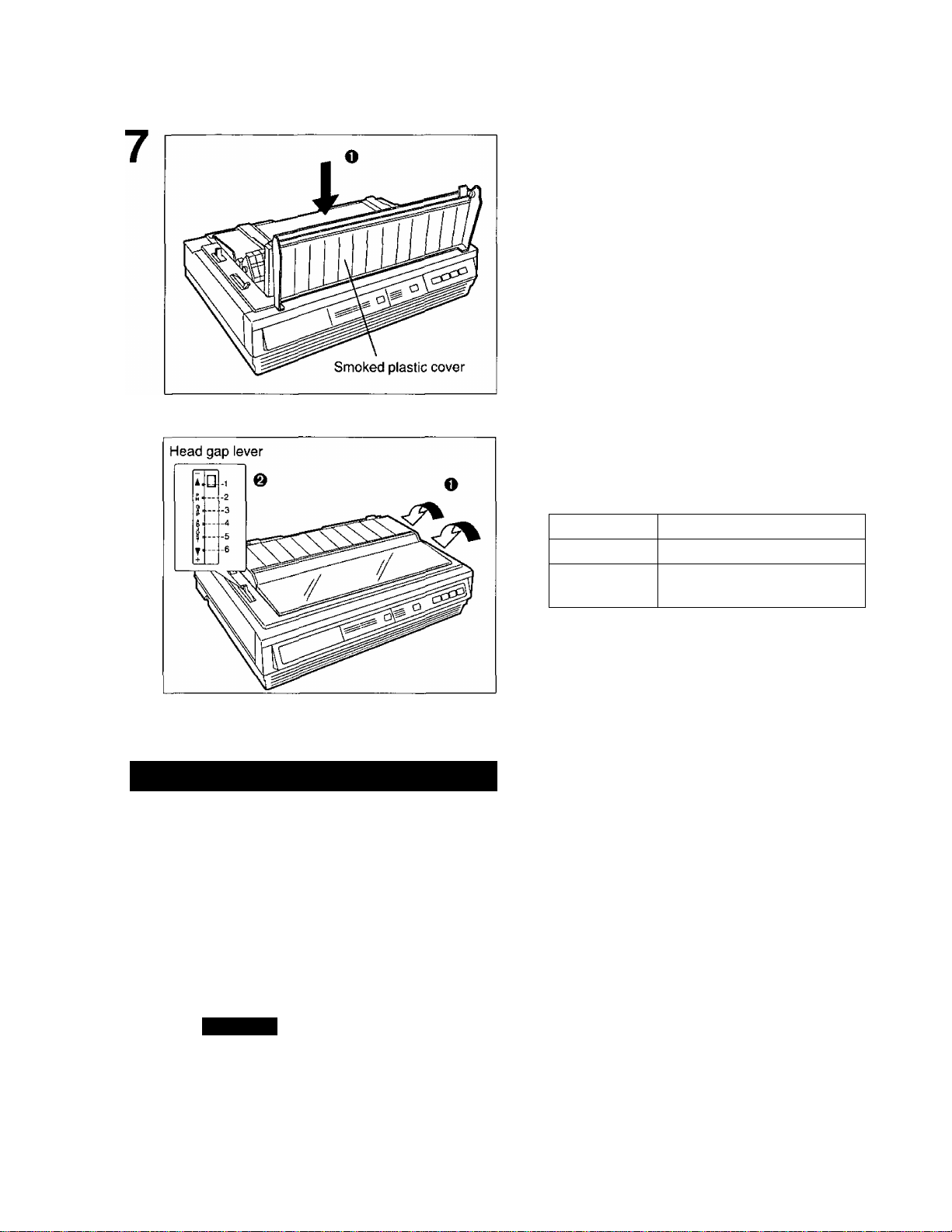

0 Replace the smoked plastic cover

O Adjust the head gap lever for the

thickness of paper you are using.

Position

1 or 2 Thinner sheets

3, 4, 5 or 6

Thick sheets, multi-part

forms or envelopes

Used for

Removing the Ribbon Cassette

To remove the ribbon cassette, perform step 1-2 of “Installing the Ribbon

1

Cassette” at first. ( P.12)

Then reverse the installation procedure, (step 5 step 4 step 3 of “Installing

the Ribbon Cassette”. (P. 12~13)

14

Caution:

• The printhead may be hot, use caution when cover is open.

• Do not lift up the flat cable located under the carriage when removing the ribbon cassette. It may

break off.

Page 15

0

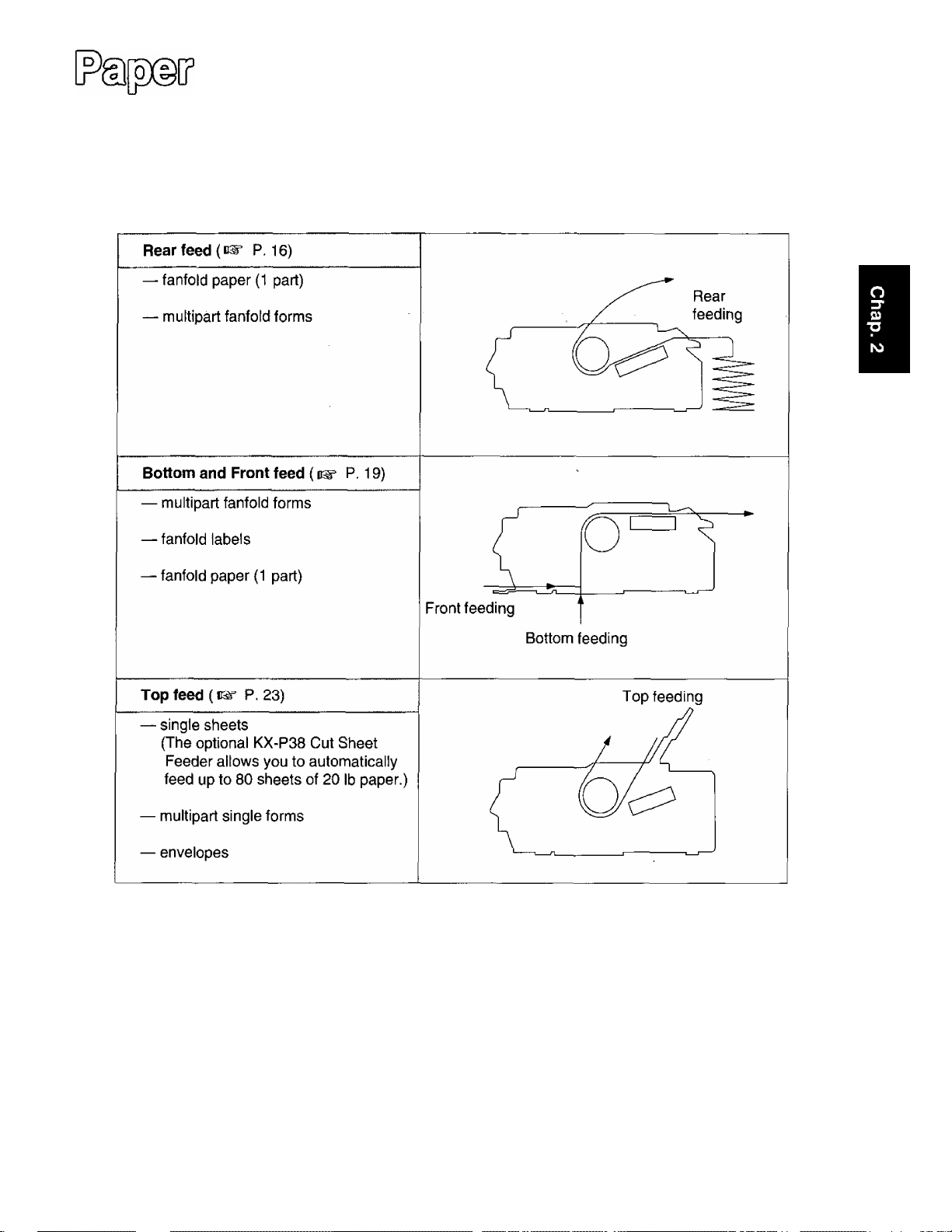

This printer supports 4 paper paths (rear, bottom, front and top feeding). Rear, bottom and front

feedings are for continuously fed" paper. Top feeding is for single sheets or envelopes.

The optional KX-P38 Cut Sheet Feeder will accommodate automatic feeding of up to 80 single sheets

from the top paper path.

©©20®[ji]

0)

(D

Note:

• For optimum print quality, do not use reverse line feeding in bottom and front feeding. If reverse

feeding is necessary in bottom and front feeding, set REVERSE LF/PULL in the INSTALL menu

to ON by using the Setup Disk.

• Paper Parking is not available in bottom and front feeding.

• When using multipart fanfold paper especially in environments that have very high or low

temperature and/or humidity, we recommend the use of the bottom feed pull mode to optimize

paper handling and print quality.

15

Page 16

o

Fanfold Paper: (Rear Feed/Push Tractor Mode)

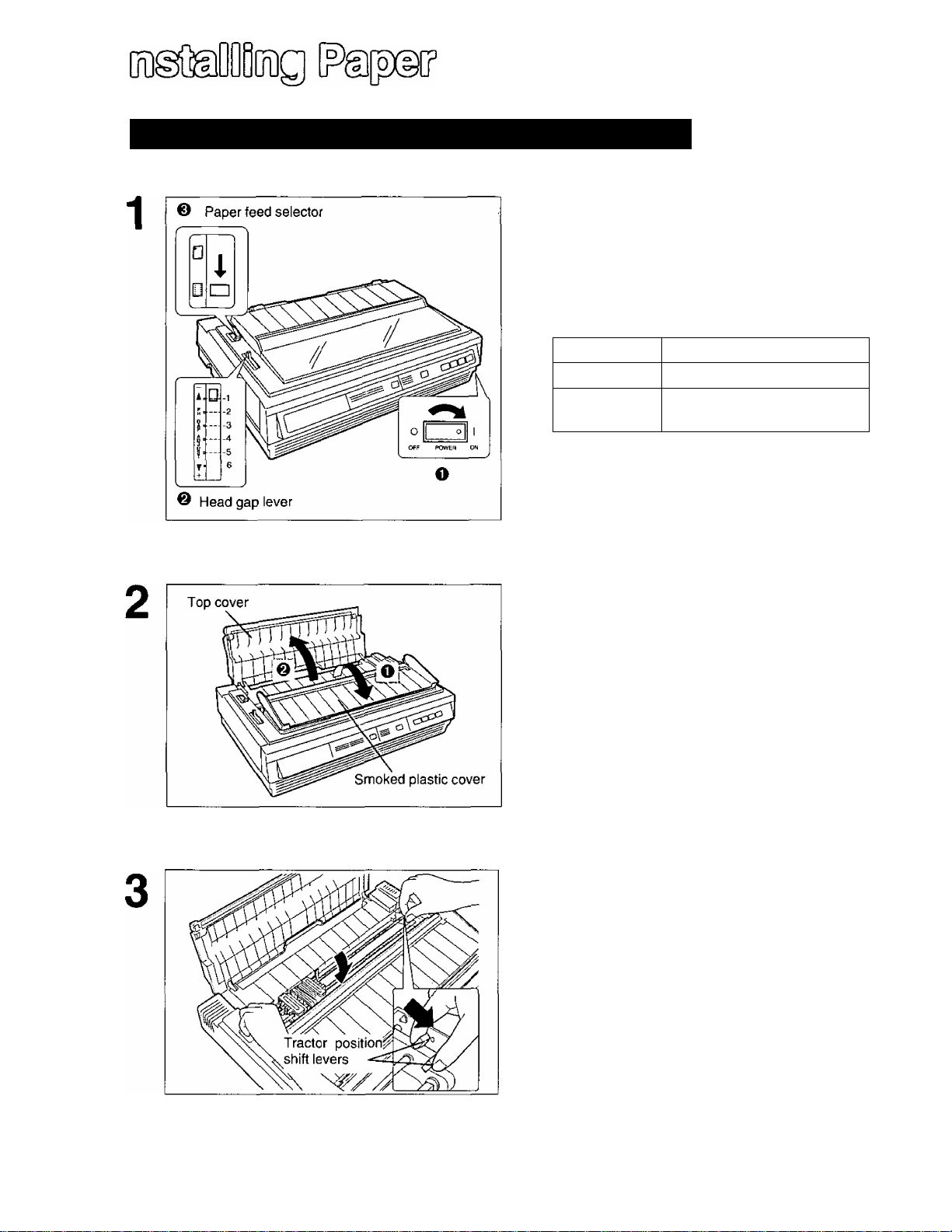

O Turn the power on.

The PAPER OUT indicator will flash indicating

that paper is not installed in the printer.

O Adjust the head gap lever for the

thickness of paper you are using.

Ü)

(D

C

■o

Position

1 or 2

3, 4, 5 or 6

Thinner sheets

Thick sheets or multi-part

forms sheets

Used for

© Set the paper feed selector to

“ p ” (Tractor Mode).

O Fold forward the smoked plastic

cover.

© Open the top cover.

16

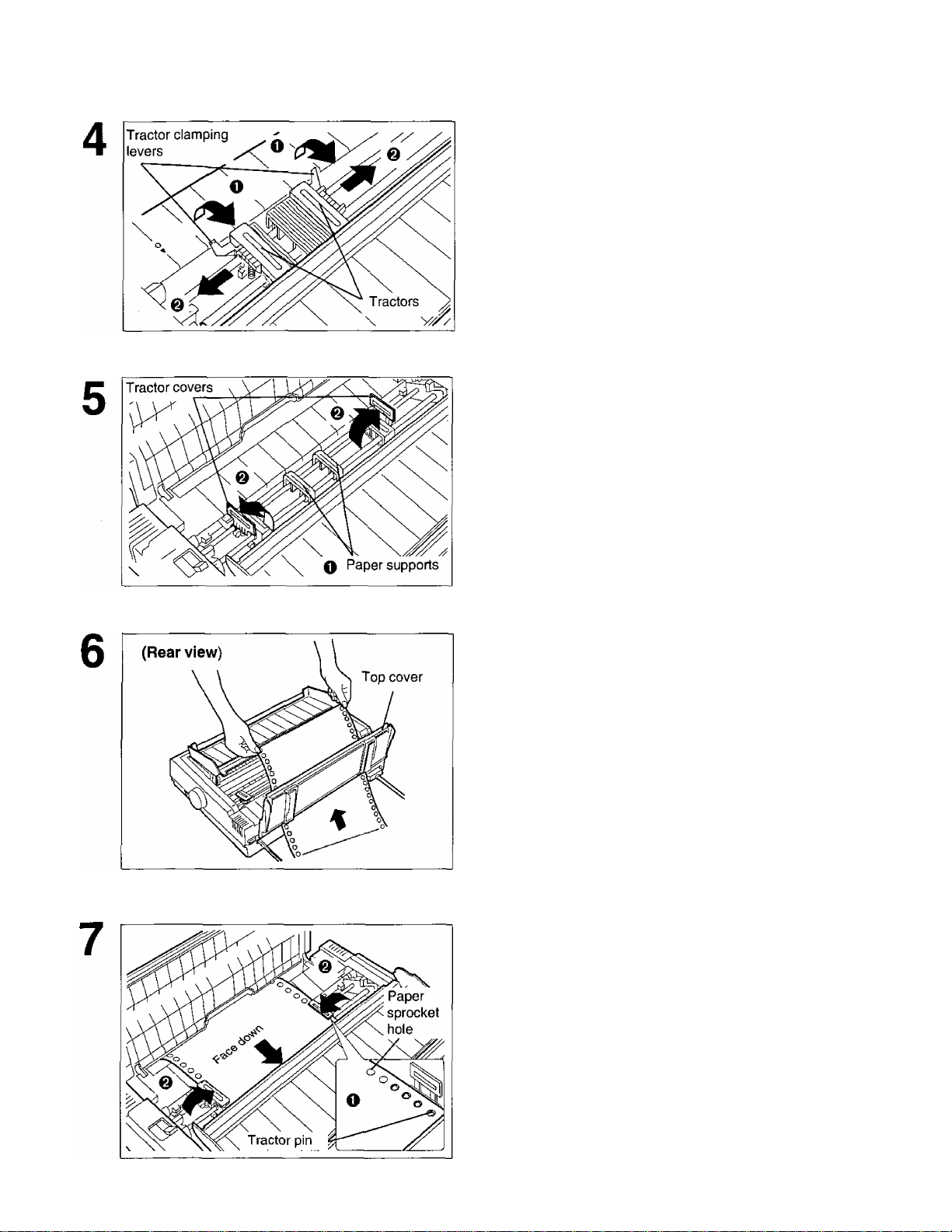

Pinch both left and right tractor position

shift levers and lower the tractor

mechanism downward until the tractors

fall into place, then release.

Page 17

ODDSíMBji©

0 Unlock the tractors by pulling the

tractor clamping ievers forward.

@ Siide the tractors to accommodate the

approximate width of the paper being

used.

In most applications, you will find that the “0”

indicator on the tear bar is a useful tool for

predeterrnining your left most print position.

O Slide the two paper supports between

the tractors at equal spaces.

© Open the tractor covers.

Feed paper through opening between

printer and the top cover.

CO

(D

C

■O

O Align the paper sprocket holes with

the tractor pins, making sure the

paper is straight.

© Ciose the tractor covers.

17

Page 18

ttMMBDDg]

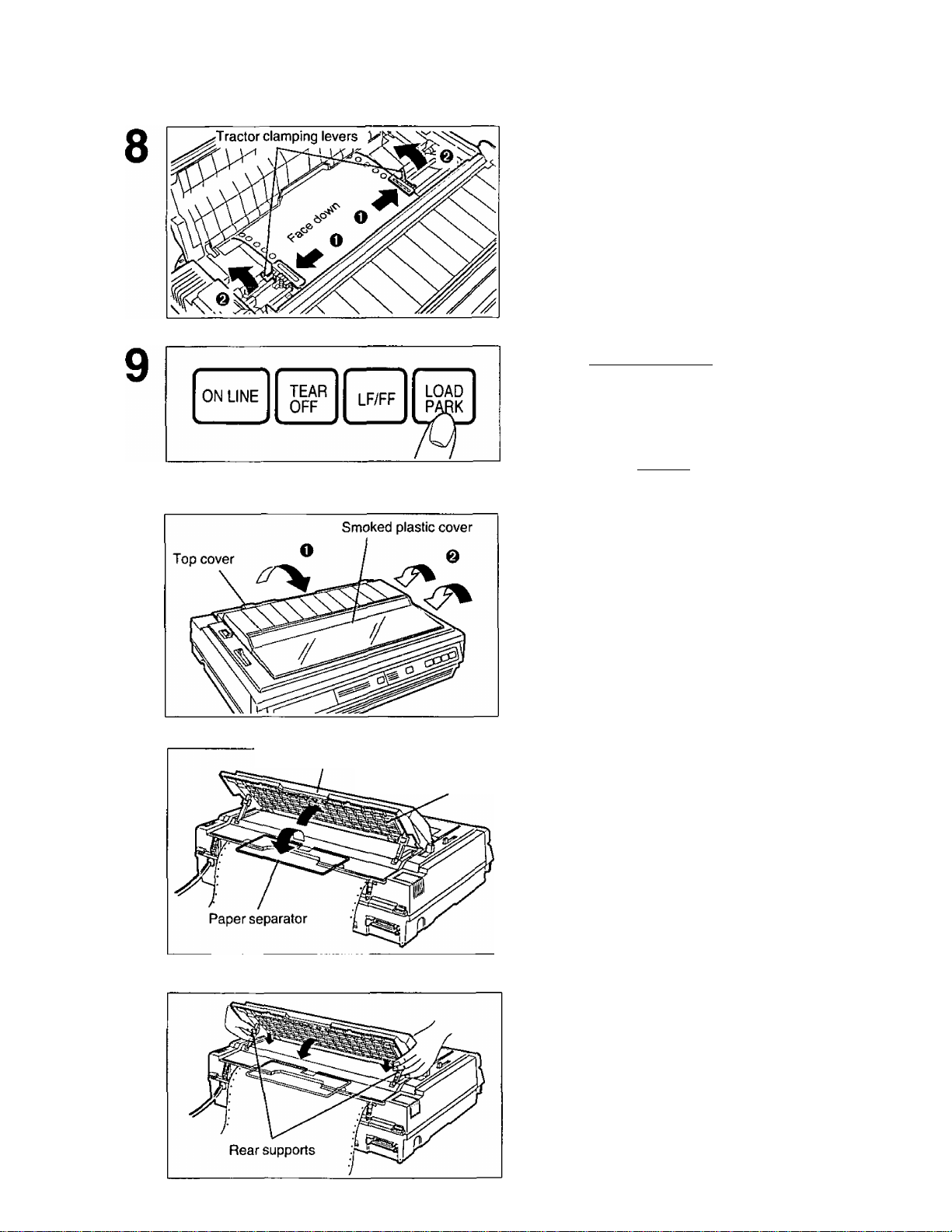

O Adjust the tractors to remove any

slack in the paper.

@ Lock the tractors by pushing the

tractor clamping levers back.

r Note:

Put the tractor pins in the center of the paper

sprocket holes when locking.

Press (LOAD/PARK).

CO

(D

10

11

Paper easel hand guide

Paper easel

This will load the paper to the first print line.

Note:

• Do not use (LF/FF) to load paper.

O Close the top cover.

0 Fold back the smoked plastic cover.

Extend the paper separator by first

raising the paper easel by lifting the

paper easel hand guide and then

unfolding it.

12

18

Lower the paper easel by simultaneously

depressing the rear supports.

Note:

• Be careful not to pinch your fingers.

• When in tractor mode please do not use

paper guides to guide the paper path. In

tractor mode the paper is guided by the

tractor units themselves.

Page 19

ODOgL^DOoog) [?fe(?e(F

13

press (ON LINE] to get ready to print.

r'

Note:

• If setting up the printer for the first time,

proceed to Printer Driver Selection.

(B^ P.26)

Fanfold Paper: (Bottom, Front Feed/Pull Tractor Mode)

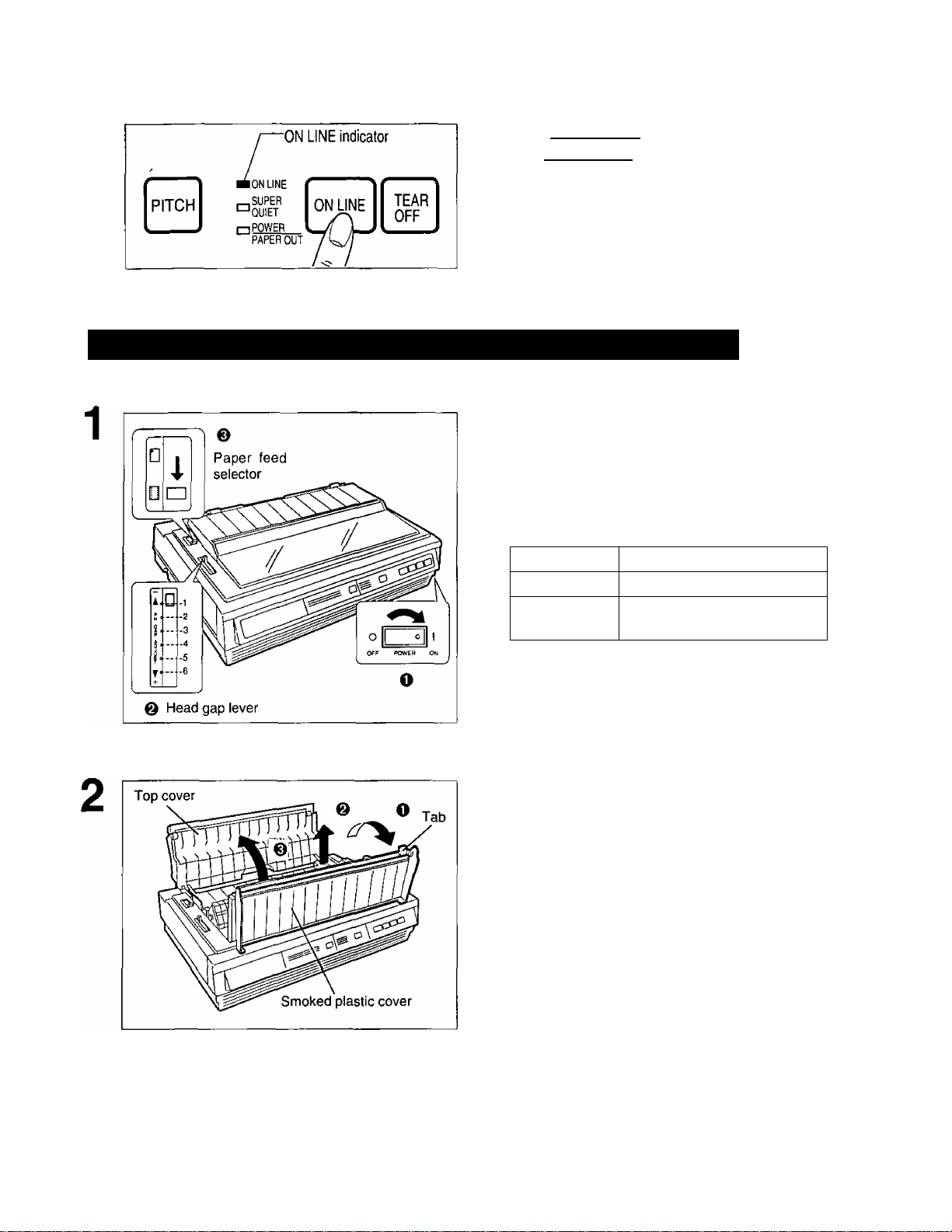

O Turn the power on.

The PAPER OUT indicator will flash indicating

that paper is not installed in the printer.

@ Adjust the head gap lever for the

thickness of paper you are using.

Position

1 or 2 Thinner sheets

3, 4, 5 or 6

If ON LINE indicator is not lit,

Used for

Thick sheets or multi-part

forms sheets

CO

(D

C

■O

0 Set the paper feed selector to

“ [Til ” (Tractor Mode).

O Fold forward the smoked plastic cover

and raise it.

0 Remove the smoked plastic cover.

© Open the top cover.

19

Page 20

(/)

(D

ODDSiMBODg] [?^][^

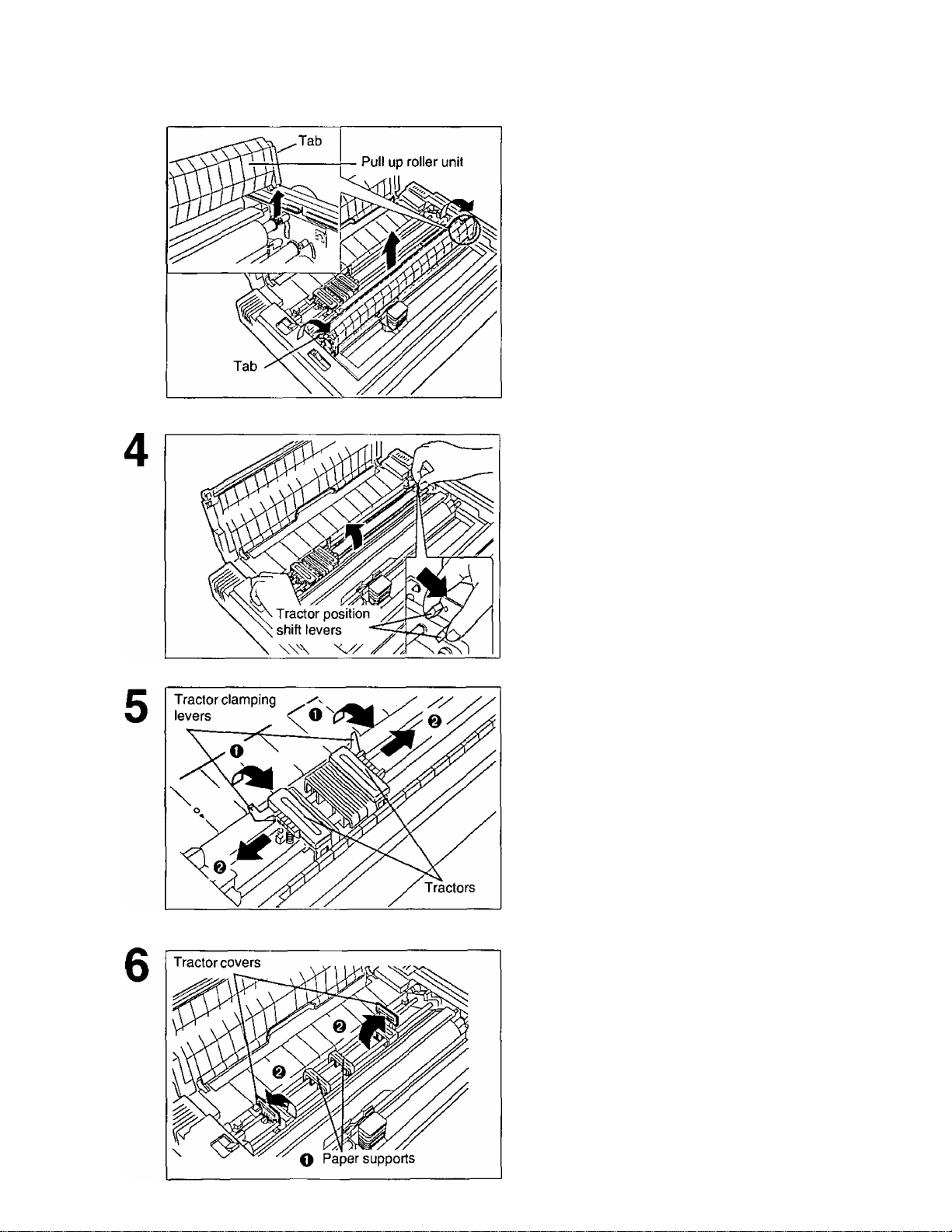

Remove the pull up roller unit by gently

rotating forward using the tab until you

feel it release, then lift up.

Note:

• Do not misplace the pull up roller unit.

Pinch both left and right tractor position

shift levers, and lift the tractor

mechanism up then release the levers.

O Unlock the tractors by pulling the

tractor clamping levers forward.

O Slide the tractors to accommodate the

approximate width of the paper being

used.

In most applications, you will find that the “0”

indicator on the back of the cover is a useful tool

for predetermining your left most print position.

O Slide the two paper supports between

the tractors at equal spaces.

O Open the tractor covers.

20

Page 21

0DD@[yD0OD® (?fe(óXiCP

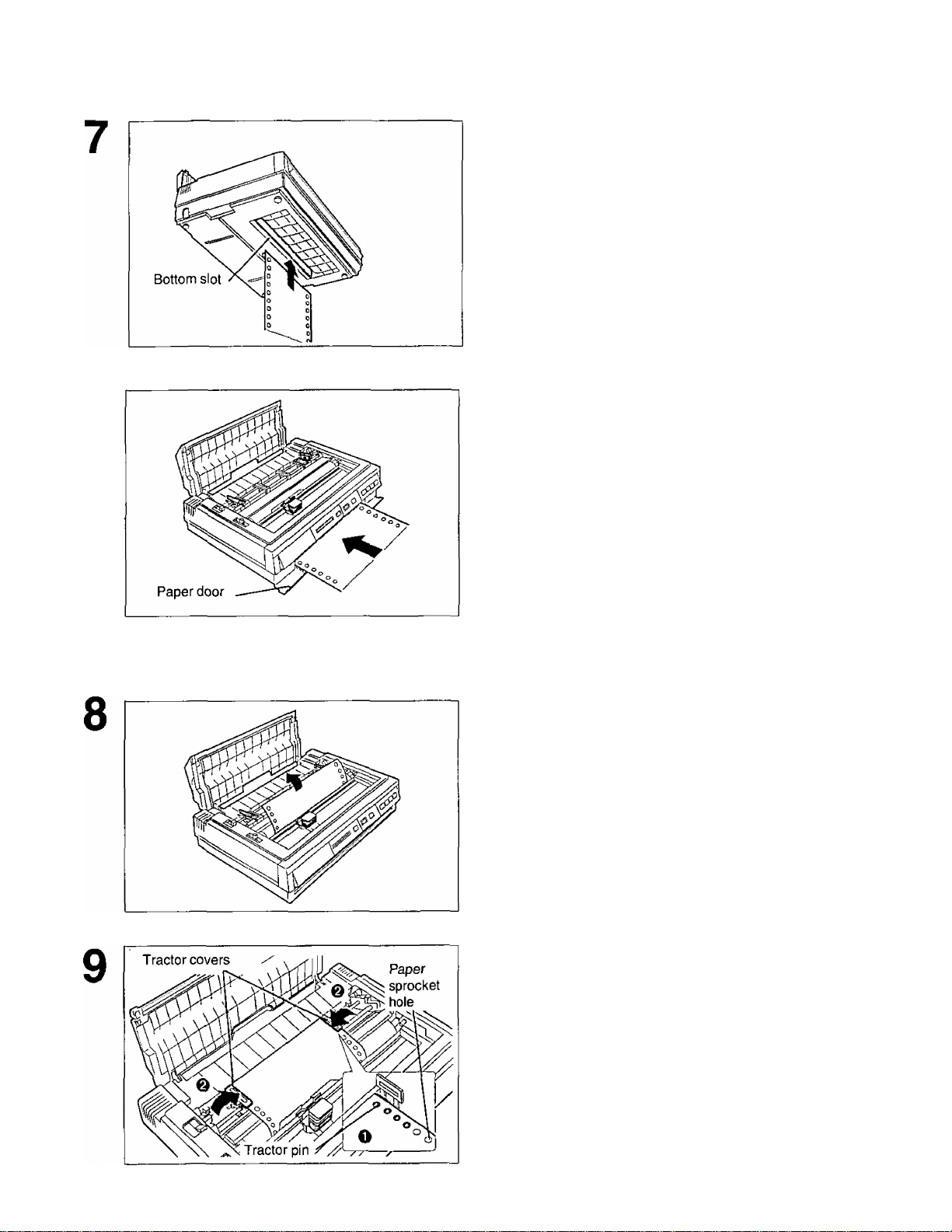

When Bottom Feeding:

With the printer being supported by a

printer stand, or on a table that allows for

bottom feed, push the paper up through

the bottom opening until it appears in

front of the platen.

When Front Feeding:

Open the paper door and insert the paper

until it appears in front of the platen.

Note;

• When feeding fanfold paper or lables

through the front paper door, paper types

and condition, as well as temperature and

humidity conditions may effect accurate line

feeding and print quality may not be

optimum. For optimum output bottom feed is

recommended.

Adjust the paper position by pulling it up

as shown.

cn

(D

c

T3

O Align the paper sprocket holes with

the tractor pins, making sure the

paper Is straight.

@ Close the tractor covers.

21

Page 22

O)

(D

C

■O

10

11

O Adjust the tractors to remove any

slack in the paper.

O Lock the tractors by pushing the

tractor clamping levers back.

Note:

• Put the tractor pins in the center of the paper

sprocket holes when locking.

O Close the top cover.

& Replace the smoked plastic cover.

* •

12

22

If ON LINE indicator is not lit, press

[ON LINE) to get ready to print.

Note:

• If setting up the printer for the first time

proceed to Printer Driver Selection.

( P. 26)

Note:

• In bottom and front feed, reverse feed functions will not feed paper correctly and the resulting printout

may not be correct.

If reverse feeding is necessary in bottom or front feed, set REVERSE LF/PULL in the INSTALL

menu to ON by using the Setup Disk.

• When in tractor mode please do not use paper guides on the top cover to guide the paper. In tractor

mode the paper is guided by the tractor units themselves.

Page 23

Single Sheets and Envelopes: (Top Feed/Friction Mode)

O Turn the power on.

The PAPER OUT indicator will flash indicating

that no paper is installed in the printer.

& Adjust the head gap lever for the

thickness of paper you are using.

Position Used for

1 or 2 Thinner sheets

3, 4, 5 or 6

€) Set the paper feed selector to

“ Q ” (Friction Mode).

Thick sheets or envelopes

ODOSiMBDQg]

CO

(D

C

■Q

O Fold forward the smoked plastic

cover.

Q Raise the paper easel by lifting the

paper easel hand guide.

23

Page 24

ODDSifeflBODg)

O Separate the paper guides to the

approximate width of your paper or

envelope.

0)

(D

C

■O

Note:

• To predetermine your left most print

position, move the left paper guide until it

clicks into place. |

@ Insert a sheet of paper through the

paper guides.

The paper will automatically be loaded to the first

print position.

Note:

• To disable Auto Loading, turn it OFF in the

Install Menu on your Setup Disk.

{ ^ P. 30)

• If Auto Loading is disabled, you must

press [ LOAD/PARK1 to load paper.

• If you need to align the paper horizontally or

vertically, set the paper feed selector to

“ i".

This releases the paper and allows the

paper to be positioned manually as

required. Set the-selector back to “ Q ”

before printing.

1

Fold back the smoked plastic cover.

If ON LINE indicator is not lit, press

[ ON LINE ] to get ready to print.

Note:

• If setting up the printer for the first time,

proceed to Printer Driver Selection.

{ 1®= P. 26)

Note: ^

• When the paper feed selector is in “ o ”, the buzzer will sound to inform you that the selector is in

the wrong position. ^ j

• When loading an envelope, if the envelope will not load smoothly, move the paper feed selector to '

“ jyj ” and insert the envelope manually, then move the selector back to “ Q ”. ;

* •

I

24

Page 25

The printer has a self test feature which allows you to test the printer. When activated, this feature will

print 5 lines of each resident font. When complete, it will return to the draft font and continue

approximately 20 minutes.

Load fanfold paper or a single sheet

of paper, then turn the power off

I

p. 16-24).

While pressing [ LF/FF ) , turn the power

on, then release.

0)

(D

C

“O

Version

Draft

! ’( ./0123456789

! "#$%&’( )*+,”./0123456789:

’( ./0123456789: ;

./0123456789: ; <

$%&’( )*+ ./0123456789: ;

Courier

!"#$%&’()*+,-./0123456789

!”#$%&’()*+.-./0123456789:

"#$%&'()*+,-./0123456789:;

#$%&'()*+,-./0123456789: ;<

$%&*()*+,-./0123456789: ;< =

Prestige

/0123456789

! '()*+,- ./0123456789 :

’()*+,-./0123456789 ; :

: ; < = >?@ABCDEFGHIJKLMNOPQRSTL

; < = >?@ABCDEFGHIJKLMNOPQRSTUV

<=>?@ABCDEFGHIJKLMNOPQRSTUVU

^>?@ABCDEFGHIJKLMNOPQRSTUVW>

> ?@ABCDEFGHI JKLMNOPQRSTUVWX'f

: ;< = >?@ABCDEFGHIJKLMNOPQRSTt

;<=>?@ABCDEFGHIJKLMNOPQRSTUX

< = >?@ABCDEFGHIJKLMNOPQRSTUVV

= >?@ABCDEFGHIJKLMNOPQRSTUVW)

>?@ABCDEFGHIJKLMNOPQRSTUVWX^

::<=>?@ABCDEFGHIJKLMNOPQRSTl

:<=>?@ABCDEFGHIJKLMNOPQRSTU\

<=>?@ABCDEFGHIJKLMNOPQRSTUVV

=>?@ABCDEFGHIJKLMNOPQRSTUVW)

Once you see that the printer is

functioning properly, you may turn

the power ofif during the self test, or

you may run the entire test.

(Approximately 20 minutes)

ABODEFGHIJKLMNOPQRSTUVWX

25

Page 26

0)

<D

C

T3

The printer driver allows your application software to properly control your printer’s features. The printer

driver is contained in your application software.

Selecting a printer driver is the final step before printing and is performed in your application software

program. The steps will vary, depending on the software program. Consult your software package for

proper procedures. The Panasonic KX-P3626 will be your first choice. However, if the Panasonic

KX-P3626 printer is not listed in your software, you must select an alternative from the following table.

Note: If using Microsoft Windows Version 3.1, you will need to install a Windows printer driver. This

driver is located on the Setup Disk supplied with your printer. Proceed to Installing a Printer

Driver section on page 27 for the installation procedure.

Printer Driver Seiections (in order of priority)

Printer Seiections

Panasonic KX-P3626

Panasonic KX-P3624

Epson LQ-1170 (ESC/P2TM)

Panasonic KX-P3123/3124

Panasonic KX-P2624

Epson LQ series

IBM Proprinter XL24E*

If selecting the IBM Proprinter XL24E in your software, printer emulation must also be changed in

the Initial Setup items, (c^ P. 28-39, 47-49)

26

Page 27

P/0lM)SS55© W@(?o ®bU))

The following steps are only necessary if using Microsoft Windows Version 3.1. The Setup Disk

packaged with your printer contains a Panasonic KX-P3626 Printer Driver for Windows Version 3.1.

To install this printer driver, you must begin at the Program Manager screen in your Windows program.

Follow the steps below for the proper installation procedure.

Note;

• Use the DISKCOPY command of the operating system to make a back-up copy. Refer to your DOS

manual for further information.

In “Main Group”, select “Control

1

Panel”.

In “Control Panel”, select

“Printers”.

If you have installed a printer driver, the

dialog box expands to display a list of

printers available in the Windows Ver. 3.1

package, and I Add>:T| is unavailable. In

“Installed Printers”, select the printer you

want. Go to step 9.

Click Add»

Printers

Default Printer —

xxxxxxxxxxxxxx

Installed Printers:

xxxxxxxxxxx

Set As Default Printer

I Cancel I

j Connect... [

[ Setup... 1

Remove

Add »

Help

Click OK .

Install-Driver

Insert unlisted, updated, or

vendor-provided printer driver disk in:

A:\

[ Cancel I

I Browse... 1

I Help I

The printer driver KX-P3626 is shown in

the dialog box.

Click OK

8

Add Unlisted or Updated Printer

List of Printers:

Panasonic KX-P3626

OK

OK

Cancel

^ * <D

---

1

In “List of Printers”, select

“Install Unlisted or Updated

Printer”.

Click Install...

5

Insert the Setup Disk into drive

6

A.

If reading the printer driver disk from drive

B, type B:\

Help

Click Set As Default Printer

9

10 Click I Close

11 Exit the “Control Panel”.

27

Page 28

roMaO

This printer allows you to select 48 initial setup items shown in the table below. You can select all

these items by using the Setup Disk.

C

S2.

5'

(O

(D

0)

o

c

T3

D

w'

7T

Menu

PRINT STYLE

EMULATION

PAGE

FORMAT

Item

FONT Draft*

Bold PS

Courier

OCR-B

Prestige

Roman

Sans Serif

Script

PITCH 10 CPI*

12 CPI 5 CPI

15 CPI

17 CPI

20 CPI

POINT SIZE

[displayed only

when -SC

sequences are

selected in Font.

EMULATION

LINE/INCH

PAGE LENGTH

TOP MARGIN

BOTTOM

MARGIN

LEFT MARGIN

RIGHT MARGIN

CTR PRINTHEAD

(Centering

printhead)

10.5* (8 to 96) Point

EPSON*

IBM

1 LPI 4 LPI 8 LPI

1.5 LPI 4.5 LPI 9 LPI

2 LPI 5 LPI 10 LPI

2.5 LPI 6 LPI* 12 LPI

3LPI 7.5 LPI Scalable

14 inch

12 inch

11^ inch

11 inch*

0.00"* to 2.50"

(0.00 cm to 6.35 cm)

0.00"* to 5.00"

(0.00 cm to 12.70 cm)

0* to 134 column (10 CPI)

2 to 136* column (10 CPI)

42* (10 to 80) column (10 CPI)

Setting

Super LQ

Bold PS-SC

Courier-SC

Prestige-SC

Roman-SC

Sans Serif-SC

Script'SC

PROPORTIONAL

6 CPI

7.5 CPI

8.5 CPI

8.5 inch

8 inch

5.5 inch

FREE

Description

Selects Draft, LQ (Letter

Quality), SLQ (Super Letter

Quality) or SC (Scalable).

Selects the desired

characters per inch (cpi) or

Proportional Spacing.

The number increases or

decreases by 2 (plus 10.5

and 21).

Sets the emulation mode to

Epson LQ-1170 or IBM

Proprinter XL24E.

Selects the desired lines per

inch (cpi).

“Scalable” can be set only

when a SC FONT is selected

in the FONT Setting.

When you select “FREE”, the

number increases or

decreases by W' from 0.5"

to 15.0".

The number increases or

decreases by W' (about

0.35 mm).

The number increases or

decreases by i/72" (about

0.35 mm).

The value number depends

on the PITCH and PRINT

WIDTH selected.

The value number depends

on the PITCH and PRINT

WIDTH selected.

The number increases or

decreases by 1.

28

* denotes setting when shipped from factory.

Page 29

lifiSI

§@QDq^ (l®c33

Menu

PRINT MODE GRAPHIC

DIRECTION

TEXT DIRECTION Bl DIRECTION*

PRINT WIDTH

TEXT

ENHANCEMENT

CHARACTER

SET

BOLD (determines

weight or thickness of

a character)

DOUBLE HIGH

(height of a character

is twice that of a

normal one)

DOUBLE STRIKE

(two passes of the

printhead)

DOUBLE WIDE

(width of a character

is twice that of a

normal one)

ITALICS

OUTLINE OFF*

SHADOW

ZERO FONT

COUNTRY U.S.A.*

CHARACTER

SET

CODE PAGE

Item Setting Description

B1 DIRECTION

UNI DIRECTION*

UNI DIRECTION

13.6 inch*

8.0 inch

OFF*

ON

OFF*

ON

OFF*

ON

OFF*

ON

OFF*

ON

ON

OFF*

ON

NORMAL*

POINT

SLASH

JAPAN

FRANCE

GERMANY

U.K. (England)

DENMARK 1

SWEDEN

ITALY

SPAIN 1

ITALIC*

GRAPHIC 1

GRAPHIC 2

U.S.A.*

MULTILINGUAL

PORTUGAL

CANADA FRENCH

NORWAY

DENMARK 2

SPAIN 2

L.AMERICA

(Latin America)

KOREA

LEGAL

NORWAY

TURKEY

Graphics are printed left-to-right

only (UNI DIRECTION) or in both

directions (Bl DIRECTION).

Text is printed left-to-right only

(UNI DIRECTION) or in both

directions (Bl DIRECTION).

Selects the desired print width.

Activates bold printing (ON),

deactivates bold printing (OFF).

Activates double high printing

(ON), deactivates double high

printing (OFF).

Activates double strike printing

(ON), deactivates double strike

printing (OFF).

Activates double wide printing

(ON), deactivates double wide

printing (OFF).

Activates italic printing (ON),

deactivates italic printing (OFF).

Activates outline printing (ON),

deactivates outline printing

(OFF).

Activates shadow printing (ON),

deactivates shadow printing

(OFF).

Selects zero character

NORMAL (0), POINT (G) or

SLASH (0).

Selects one of 14 language or

legal character sets.

Selects the italics or

graphics/character sets 1 or 2.

(“ITALIC” is available only in

the Epson mode.)

Selects one of 6 code pages.

o

CO

<D

C

■a

V)

3T

* denotes setting when shipped from factory.

29

Page 30

Irntial

©san?) 0ÌÌM5

c

M

5'

(O

(D

CO

(D

C

TJ

(A

3T

Menu Item

INSTALL

AGM/IBM

AUTO CR/IBM OFF*

AUTO LF

BUZZER

AUTO LOADING OFF

PAPER OUT OFF

DETECT

SUPER QUIET

LF/PULL

TEAR OFF

CSF MODE

DOWNLOAD OFF*

AUTO ON LINE

(Alternate

Graphics Mode)

MODE

REVERSE

Setting

OFF*

ON

ON

OFF*

ON

OFF

ON*

ON*

ON*

OFF*

ON

OFF*

ON

MANUAL*

AUTO

OFF*

ON

ON

OFF

ON*

Description

Sets Alternate Graphics mode (selects

Epson graphics) to on or off in the IBM

mode. (This setting is effective only in the

IBM mode.)

Activates (ON) or deactivates (OFF)

Automatic CR on LF, VT, ESC+“J”.

(This setting is effective only in the IBM

mode.)

Activates (ON) or deactivates (OFF)

Automatic LF after CR.

Buzzer sounds (ON) or doesn’t sound (OFF).

Setting to ON automatically loads a single

sheet or envelope to the first print line.

[This setting is inoperative when using the

optional Cut Sheet Feeder (KX-P38)].

Paper Out Detector is active (ON) or ignored

(OFF).

Reduces (ON) or doesn’t reduce (OFF) the

printing noise.

Setting to ON enables the reverse feeding in

bottom and front feed.

When set to MANUAL, the paper’s

perforation doesn’t advance to the tear off

position unless you press the (TEAR OFFl.

Setting to AUTO advances the paper’s

perforation to the tear off position

automatically.

[This setting is operational when using the

optional Cut Sheet Feeder (KX-P38)].

Setting to ON allows you to download (userdefined) special characters and setting to

OFF allows you to send more data to your

printer’s buffer, thereby freeing up your

computer.

Setting to ON enables the printer to

automatically enter ON LINE mode after

installing paper.

30

denotes setting when shipped from factory.

Page 31

Initial

®gíц^WlsSs

Menu

INTERFACE

[The setting is

effective only

when the

optional

KX-PS14,

RS-232C

serial interface

board is

installed.]

T.O.F.

SETTING

(Top of Form

Setting)

Item ^

INTERFACE

DATA LENGTH

BAUD RATE +1

PARITY *1

PROTOCOL *1

SDT *1

RDT+1

SIGNAL

POLARITY *1

TRACTOR 0.00" to 5.00" (60/180"*)

FRICTION 0.00" to 5.00" (60/180"*)

CUT SHEET

FEEDER

PARALLEL*

SERIAL

8 BITS*

7 BITS

150 BPS 2400 BPS

300 BPS 4800 BPS

600 BPS 9600 BPS*

1200 BPS

NONE* ODD

IGNORE EVEN

DTR*

XON/OFF

RBC 128*

RBC 512

SDT+128*

SDT+256

MARK*

SPACE

(0.00 cm to 12.70 cm)

(0.00 cm to 12.70 cm)

0.00" to 5.00" (60/180"*)

(0.00 cm to 12.70 cm)

Setting

Description

Selects parallel interface or

serial interface.

Selects data length 8 bits or 7

bits.

Selects the desired baud rate.

Selects the desired parity.

Selects the desired protocol

DTR or XON/OFF.

Selects the remaining buffer

capacity (R.B.C.) 128 byte or

512 byte to suspend data

transfer (S.D.T.) (X/OFF).

Selects the remaining buffer

capacity (R.B.C.) 128 byte or

256 byte to resume data

transfer (R.D.T.) (X/ON).

Selects the signal polarity mark

or space.

The number increases or

decreases by Vi so"

(about 0.14 mm).

The number increases or

decreases by Vi so"

(about 0.14 mm).

The number increases or

decreases by Vi so"

(about 0.14 mm).

[This setting is operational

when using the optional Cut

Sheet Feeder (KX-P38)].

C

S2.

5'

(D

<D

CO

o

c

■a

GO

3T

* denotes setting when shipped from factory.

*1 displayed only when SERIAL is selected in INTERFACE.

31

Page 32

Imil'ial

This Setup Disk can only be used in an IBM-PC or a compatible computer with a 3.5" fioppy disk drive.

Before using the Setup Disk, it is recommended that you make a back-up copy and store the original

in a safe place.

This printer has been factory set to operate with most of the popuiar software packages. In

most cases there will be no need to change the initial setup items. Refer to pages 28-31 to

verify that the factory settings meet your requirements. If no changes are required, you should

be ready to print.

Note:

• Use the DISKCOPY command of the operating system to make a back-up copy. Refer to your

DOS manual for further information.

• You may find it convenient to install the Setup Disk programs directly onto your C Drive, rather

than reading them from the Setup Disk each time a change is necessary. Either method is

acceptable.

To perform an automatic installation of the Setup Disk files onto your C Drive, follow the steps

below:

1. Insert the Setup Disk into drive A or B.

C

S£.

5‘

zr

(D

(/)

(D

C

■O

a

w'

ytr

2. Type A: (or B:) and press [ Enter).

3. Type INSTALL and press ( Enter ].

This procedure automatically creates a directory called 3626 and copies all of the programs from

your Setup Disk onto your C Drive. If you want to run the Initial Setup Program, press [2 • If you

want to exit, press (W].

To recall the programs from your C Drive.

<For DOS>

At your C; \ > prompt, type CD 3626 and press [ Enter ].

Type SETUP and press [Enter] .

<ForWINDOWS>

Select Run from the File menu.

Type C:\3626\SETUP and click OK| (or press [ Enter] ).

Be sure to type SETUP as one word. If not, you will receive a Syntax error message.

Running the Initial Setup Program

32

Insert your Setup Disk into either drive A or B.

<For DOS> <For WINDOWS>

Type A: (or B:) and press [Enter].

2

Type SETUP

3

Press [Enter].

4

Select

Run from the File menu.

2

Type A:\SETUP (or B:\SETUP)

3

Click

OK (or Press [Enter]).

4

Page 33

Initial

©SQM!») (i!0®33

C The first screen is an introduction to the operation of the Setup Disk.

^ Please read it through and press any key to continue. (If your display is

monochrome, press “M” key.)

C The <Menu> window will be ^ highlighted.

Menu

lI*;PFllNfT STYLE

* EMULATION

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SEHING

« COMMENT ;

Select print style.

< KEY OPERATION » ---------------- ,

[Ft =HELP] (F3.SAVE TO DISK] [F5-PRINT SEHING] [F6.LIST]

[F2=FACT0RYSETTING] [F4.L0AD FROM DISK] [F10=SENDTOPRINTER] [ESC=EXIT]

Note:

• You can proceed through the Setup Disk using a computer mouse or your arrow keys.

Using the keyboard:

• QQ / (t) to move within the current window.

• @ to advance to <ltem> and <Setting> windows.

• [Enter] to make selection in <Setting> window.

• @ to return to the previous window.

Using the mouse:

• Highlight the selection and click the left mouse button.

Setup Utility (XXXXXXXXXX)

t^< Item >

__________

FONT

PITCH

...........

..............

C

to

5'

to

(D

CO

(D

c

■O

(0

7T

Exiting the Initial Setup Program

Press fESCl until the “Exit’

1

screen appears.

“E”; Exit to DOS.

“C”: Return to <MENU> window.

Exit to DOS ?

{ CANCEL

33

Page 34

iKfitial

©SQOfl[p (Mséfe

Print Settings

Before you change any selections on the Setup Disk, you can verify the settings by getting a printout.

C

W

S'

(O

(D

CO

(D

C

■o

Hi

7T

^ Press

A Print Setting window will be displayed.

O Press [y] or [n] , or highlight

^ the appropriate command and

press fEnter).

“Y”: Current print settings will

be printed.

“N”: The print settings won’t be

printed and the display will

■;=< Manu >

IT PRINT STYLE

* EMULATION

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SETTING

« COMMENT »

Selea prim style.

« KEY OPERATION >> ■

[Ft.HELP] [F3.SAVETODISK] (F5=PRINT SETTING] [F6-LIST1

¡F2.FACTORY SETTING] ¡F4=LOAD FROM DISK] (F10=SEND TO PRINTER] [ESC-EXIT]

« Setup Utility (XXXXXXXXXX) »

r^< Item >

FONT

PITCH

— Option -

INTERFACE

PORT

RYl'YeTi lN]No

-----------------

PRINT SETTING

: PARALLEL

: LPT1:

Are you sure ?

return to the Main screen.

Note:

• When sending the data by serial interface, change the option items on the display to the required

setting, (ex; INTERFACE)

1. After pressing (F51 . press (J) to highlight PARALLEL.

2. Press [Enter].

3. Press (J) until SERIAL is highlighted.

4. Press [Enter] .

Three items {BAUD RATE, PARITY and DATA LENGTH) will be added to the PRINT SETTING

window.

You may need to change the settings of additional options, without pressing again repeat

steps 1-4.

Display Setting List

Before you change any selections on the Setup Disk, you can view the current setting list on the display.

Press

1

The setting list will be displayed.

p Press any key to return to the ^ Main screen.

34

FONT

PITCH

EMULATION

LINE/INCH

PAGE LENGTH

TOP MARGIN 0.0 inch

BOnOM MARGIN

LEH MARGIN

RIGHT MARGIN

CTR PRINTHEAD

GRAPHIC DIRECTION

TEXT DIRECTION

PRINT WIDTH

Bao

DOUBLE HIGH

DOUBLE STRIKE

DOUBLE WIDE

Draft

10 CPI AUTO CRftBM

EPSON

6 LPI BUZZER

11 inch AUTO LOADING

0.0 inch SUPER QUIET MODE

0 column

136 column

40 column CSF MODE OFF

UNI DIRECTION

Bl DIRECTION

13.6 inch INTERFACE

OFF DATA LENGTH

OFF

OFF

OFF PROTOCa

AGNIIBM

AUTO LF OFF

PAPER OLfT DETECT

REVERSE LFlPULL

TEAR OFF

DOWNLOAD

AUTO ON LINE

BAUD RATE

PARRY

Exit: Press any key.

OFF

OFF

ON

ON

ON

OFF

OFF

MANUAL

OFF

ON

PARALLEL

8 BITS

960CBPS

NONE

OTR

Page 35

Setting Selections on Setup Disk

H In the <Menu> window,

' press g] or [T].

Select the desired menu

{ex; PRINT STYLE).

2 Press g.

<ltem> window will be highlighted.

iFîtai

©3ÎÏ!Q[p GasXife

0 Press (t] or IT] -

Highlight the desired item

(ex; FONT).

^ Press @ .

<Setting> window will be highlighted.

e Press (tj or g].

Highlight the desired setting

(ex; Bold PS).

0 Press [Enter].

The desired item has been set.

A V will appear next to the new setting.

Press @.

<ltem> window will be highlighted.

To make additional changes in the

<ltem> window, repeat steps 3 to 6.

f;—< Menu >

[4"PRint style

* EMULATION

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SEHING

« COMMENT »

Select tont style.

Style of typeface.

SC is SCALABLE FONT.

« KEY OPERATION »

[FI .HELP]

[F2=FACT0RYSEniNG] [F4.LOAD FROM DISK] [F10.SENDTOPRlfiTER] [ESC=EXrT]

Menu >

r^-PRlNT STYLE"

* EMULATION

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SETTING

« COMMENT »

Select font style.

Style of typeface.

SC is SCALABLE FONT.

« KEY OPERATION »

[FI-HELP]

[F2=FACT0RYSEniNG] [F4iOAD FROM DISK] [FlO-SENDTOPRIMTER] [ESC-EXIT]

« Setup Utility (XXXXXXXXXX) »

------

---------

■p< Item >

cfomt:

PITCH

[F3=SAVE TO DISK] [F5=PRINT SEHING] [F5.LIST]

Setup Utility (XXXXXXXXXX)

r=< Item > .

lFONT:

PITCH

[F3.SAVE TO DISK] [F5=PR1NT SEHING] [F6=LIST]

>> -----

=<: Setting >

V Draft

Setting > =

Draft

Bold-PS

Courier

OCR-B

Prestige

Roman

Sans Serif

Script

Super LO

Bold PS-SC

Courier-SC

Prestige-SC

Roman-SC

Sans Serif-SC

Script-SC

—

rSold-PS-----------

Courier

OCR-B

Prestige

Roman

Sans Serif

Script

Super LO

Bold PS-SC

Courier-SC

Prestige-SC

Roman-SC

Sans Seril-SC

Script-SC

35

Page 36

g Press g.

<Menu> window will be highlighted.

To make additional changes in the

<Menu> window, repeat steps 1 to 6.

When all changes have been

made, you may perform any

one of the following

operations:

Save to Disk — (US’ P. 36)

Print Settings—icg* P.34)

Display Settings --T^ (c®* P. 34)

Send to Printer—[F10] (i®* P.38)

,=< Menu >

* PRIMT STYLE'

* EMULATION

* PAGE FORMAT

» PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SETTING

« COMMENT >:

Select pmt style.

< KEYOPERATTON »

[F1=HELP] [F3=SAVETODISK] [FfcPRlMT SETTING] [F5-LIST]

[F2=FACTORySEniNG] [F4J.OAD FROM DISK) [FIO=SENDTOPRINTEH] ESC-EXfT)

Setup Utility (XXXXXXXXXX) »

,;=< Item > —

FONT

PITCH

C

to

5'

(Q

S’

(D

Oi

o

c

T3

(0

3T

10

After performing one of the

previous operations, and with

the <Menu> window

highlighted, press [ESC].

Press or [C

11

“E": You have exited the Setup

program.

"C": The display will return to

the <Menu> window.

Save to Disk

^ Press [F3] .

A Save to Disk window will be displayed.

To change Drive, press [TAB]

four times and type the letter

for the drive you want to use.

To change Directory, press

[tab] a fifth time and select the

new directory by using [fl or

If you do not change the Drive or Directory

proceed to Step 3.

___

, then press f^ter

Menu >

* PRINT STYLE'

* EMULATION

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SETTING

« COMMENT >

Select print style.

« KEY OPERATION

[Ft .HELP]

[F2.FACT0RYSETTING] ¡F44.0ADFROM DISK] [FlO-SENDTOPRlNTER] ¡ESC-EXIT]

[=< Menu >

* PRINT STYLEJ

* EMULATION

Filename

*.OAT

Path

C:\

« KEY OPERATION

[Ft .HELP]

[F2.FACT0RY SETTING] [F4.L0AD FROM DISK] [FlO-SENDTOPRlNTER] [ESC-EXIT]

Setup Utility (XXXXXXXXXX) »

ri=< Item > —

FONT

PITCH

Exit to DOS ?

il-EXir-]

[F3-SAVE TO DISK] [F5-PRINT SETTING] [F6-LIST]

« Setup Utility (XXXXXXXXXX) »

-----

rx=< ttem > I

OK

EXFT

[F3.SAVE TO DISK] [F5=PRINT SEHING] [F6-LIST]

FONT

PITCH

SAVE TO DISK

Rtes

CANCEL

OrNe ; [C: ] i

Directory :

□

36

Page 37

Press [TAB] repeatedly to

move the cursor to the

Filename position. (^.DAT)

Delete ^ and enter a file name

(up to 8 characters) and press

[Enter].

All the settings will be saved on the disk

and the display will return to the Main screen.

Note:

[shift] + [tab] performs a

reverse tab function and moves the

cursor to the previous selection.

If you want to save the setting(s) as a file

name previously saved, after entering the

same file name, press f EnteT] then press (Y)

_ j

The current settings will be written

over the old settings.

The display will return to a

n

<Save to Dtsk> window.

Load from Disk (Recall Settings)

Press

1

A Load from Disk window will be

displayed.

To change Drive, press [TAB]

four times and type the letter

for the driver you want to use.

To change Directory, press

[t/^] a fifth time and select

the new directory by using

(t] or [J] , then press [Enter].

___

Setup Utility (XXXXXXXXXX) »

—g Menu > =_

PRINT STYLE“

* EMULATION

Filename

.DAT

Path ;

CA

OK

SelË

« KEY OPERATION »

[F1=HELP]

[F2=FACT0RY SEHING] [F44.0AD FROM DISK) [F10=SEND TO PRINTER) [ESC=EXn)

[^< Item > —

FONT

PITCH

LOAD FROM DISK

Fies

EXIT

[F3=SAVE TO DISK] [F5-PR1NT SETTING] [F6=LIST]

Drive (C: ]l

Direawy ;

C

«

5’

(O

o

</)

o

c

*o

o

CÔ*

3T

If you do not change the Drive or

Directory, proceed to Step 3.

Press [tab] repeatedly to

move the cursor to the Files position.

37

Page 38

®3ai(pGi)®(a3

A Use (t] or 5] to highlight

^ your desired file name.

g Press (Enter] .

All the settings in the file will

be recalled. To view them on

your screen, press

To transfer these settings to your

printer, you must perform the Send

to Printer operation below.

Send to Printer

C

«

5’

(O

=r

(D

CO

(D

c

*D

(A

Press ( FIO 1.

A Send to Printer window will be

displayed.

2 Press [y] or [n]

Y”: All the settings will be

sent to the printer.

N”: The display will return to

the Main screen.

Note:

• When sending the data by serial interface, change the option items on the display to the

settings you desire. ( P. 34 “Print Settings”)

Resetting to Factory Setting

f^< Menu >

nrPRIMTSTYlE

* EMUlATiON

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

» INSTALL

* INTERFACE

* T.O.F. SETTING

« COMMENT »

Select print style.

« KEY OPERATION »

[Fl-HELP]

[F2.FACT0RYSEniNG] [F4.L0AD FROM DISK] [FlO-SENDTOPRINTER] ¡ESC-EXIT]

« Setup Utility (XXXXXXXXXX) »

r=< Item > -iJi'

FONT

PITCH

SEND TO PRINTER

— Option --------------------------

IMTERFACE

PORT

[F3.SAVE TO DISK] [F5.PRINT SEHING] [F6=LIST]

: PARALLEL

: LPT1:

Are you sure ?

ny]'VeT [N]No

38

■I Press (F2].

O Press [y] Of O.

“Y”: All the screen settings will be

reset to thè FACTORY settings.

“N": The display will return to the

Main screen.

,^< Menu > =

[3*PR|MT STYLE"

* EMULATION

* PAGE FORMAT

* PRINT MODE

* TEXT ENHANCEMENT

* CHARACTER SET

* INSTALL

* INTERFACE

* T.O.F. SETTING

Setup Utility (XXXXXXXXXX) »

n=< Item > =

FONT

PITCH

Factory Setting

Are you sure ?

CtXM [N)No

« COMMENT »

Select print style.

« KEY OPERATION »:

[Fl-HELP]

[F2.FACT0RY SETTING] [F4=LOAD FROM DISK] [FlCUSENDTOPRlNTER] [ESC=EXIT]

[F3.SAVE TO DISK] [F5=PR1NT SEHING] [F6=LIST]

Page 39

(MMl ®3aoa[p (№x^

If [Y] was selected, you may

then perform one of the

following operations:

Save to Disk — [Ml P. 36)

Print Settings — [fS) ( ds* P. 34)

Display Settings —(T§ ( P. 34)

Send to Printer —fFiOl {P. 38)

Help

If you cannot remember what a particular function does, a HELP program will display to you the

explanations of the functions.

-| Press [FU .

A Help Item screen will be displayed.

2 Press [t]/(J]/@ / ©•

Highlight your desired item.

(ex; AGM/IBM)

0 Press [Enter] .

A definition will be displayed.

A Press (T| / [T).

To move to the previous or next Help

item without leaving the display.

. i-iPI P ITFM

'^AGM/IBMi]

<AUTOCR/IMB>

<AUTOLF>

<AUTOLOADING>

<AUTOONLINE> <INSTALL> <RIGHT MARGIN?

<B0n0MMAR6IN>

<BOLD> <1TALIC> <SHAD0W?

<CHARACTERSET>

<COOE PAGE> <LEFT MARGIN? <TEXT DIRECTION?

<COUNTRY> <LINE/INCH?

<CSFMOOE>

«KFYOPERATIONHFI Pii

r<AGMnBM>n

^UTOCRnMB>

<AUTOLF>

<AUTOLOADING>

<AUTOONLINE>

[f]

1^1 , [^]

[i]

<AGM/IBM>

The alternate graphics mode (AGM) will allow you to select

Epson graphics while in the IBM mode. If what you printed is

not exactiy what is on the screen, but there is a symboi that

is replacing the symboi you expect, change the character set.

<EMULATION> <P01NTSIZE>

<FACTORYSEniNG>

<FONT> <PRINT STYLE?

<GRAPH1C DIRECTION?

<1NTERFACE> <SER1AL>

<ITALICS> <SUPER QUIET MODE?

<OUTLINE?

[ENTER KEY]

« HELP ITEM

<EMULATION> <POINTSIZE>

<FACTORY SETTING> <PRINT MODE>

<FOMT> <PRINTSmE>

<GRAPHIC DIRECTION> <PRINT W1DTH>

<INSTALL> <RIGHT MARG1N>

<PRINTMODE?

<PRINT WIDTH?

<T.O,F, SETTING?

<TOP MARGIN?

»

[ESCnEXIT]

(D

ay

(D

C

■o

CA

7T

C Press (ESC) .

The Help Item screen will be displayed.

0 Press .

The display wilt return to the Main

screen.

:KEYOP£RATiON HELP:

m

1^1 , (^I

[i]

[ENTER KEY]

[ESC-EXIT]

39

Page 40

(y]©Döig) ©®ooiMI lF>gi(iii®

Selecting a Character Font

• Press and release [ FONT ]

This printer contains resident fonts which are accessible through the Control Panel.

You can select any one of the character fonts by pressing the FONT switch on the Control Panel.

The combination of FONT indicators indicates the current character font selected, as shown below.

EXAMPLES

■0

fi)

3

o

FONT

FONT =Courier

FONT = Pres t i ge

=PR0GRAM

• =light is lit

• •

FONT =Bold PS

• o

FONT

o Ü

FONT

o=light is out

=Roman

• =light is blinking

• • FONT

• •

FONT

=Sans Serif

=0CR-B

Note: '

• When the power is turned off, font will reset to default setting. If you want to save a font selection as 1

your default, you may do so by using the Setup Disk. (cs* p. 28)

• You must be in PROGRAM {both FONT indicators are off) to allow your software to control your font

selection.

Selecting a Character Pitch

40

Press and release ( PITCH ]

This printer contains resident pitches which are accessible through the Control Panel.

You can select any one of the character pitches by pressing the PITCH switch on the Control Panel.

The combination of PITCH indicators indicates the current character pitch selected, as shown on the

next page.

Page 41

EXAMPLES

OflgflDDgGCi©©«^^

o o PITCH

• o PITCH

o • PITCH

=!ight is lit

•

Note:

• When the power is turned off, pitch will reset to default setting. If you want to save a pitch selection

as your default, you may do so by using the Setup Disk. (P. 28)

• You must be in PROGRAM (both PITCH indicators are off) to allow your software to control your

pitch selection.

=PROGRAM

=10 CPI

=12 CPI

Super Quiet Mode

o=light is out

• •

PITCH

• 0

PITCH

• =

• =light is blinking

=15 CPI

=17 CPI

The Super Quiet mode is a useful feature for further reducing print noise. Your printer has the capability

of saving this feature by using the Setup Disk. (P. 28-39)

Note:

• When enabled, this feature will decrease your print speed.

Turning on the Super Quiet mode:

While pressing [ ON LINE ],

press [tear off) .

The SUPER QUIET indicator is on.

Turning off the Super Quiet mode:

While pressing [ ON LINE ],

press [tear off] .

C

£2.

5‘

(O

D"

(D

o

o

3

"D

0)

3

o

The SUPER QUIET indicator is off.

41

Page 42

№Qoiigi]Dos©2)K^

Line Feed/Form Feed

You can adjust the paper position by using the front panel switches when the printer is in the OFF

LINE mode or when the printer is not printing in the ON LINE mode.

Line Feed

With paper installed, pressing (LF/FF] once

advances the paper one line.

Form Feed

With paper installed, holding [ LF/FF) moves the

printhead to the center and advances the paper to

the top of the next page.

Micro Line Feed

c

CO

5'

(Q

CD

O

o

3

■0

D>

3

(D

- Reverse Micro Line Feed

Note:

When pressing [LF/FF], the amount of paper which is fed is determined by the current setting for

lines per inch as specified by the Setup Disk, control panel (Initial Setup Mode) or your application

software.

Reverse Micro Line Feed is not recommended when the paper is fed through the bottom or front in

Puli Tractor Mode. Paper may not feed properly and print quality may not be optimum.

With paper installed, while pressing [ ON LINE~],

press (LFffF] once to advance the paper one micro

line (Vi8o"). Holding the switches will advance the

paper continuously until you release the switches.

Using the Micro Line Feed within 5" from the top of

your paper automatically stores the position as the

Top of Form.

With paper installed while pressing ( ON LINE ) ,

press ( LOAD/PARK] once to reverse the paper one

micro line (Vieo'O- Holding the switches will reverse

the paper continuously until you release the

switches. Using the Reverse Micro Line Feed within

5" from the top of your paper automatically stores the

position as the Top of Form.

42

Page 43

OMiD® GCds ©sXJM

Top of Form Function (TOF SET)

This printer has a Top of Form (TOF) function which stores the first print line position and loads the

paper to the designated position automatically. The first print line position will be stored even after the

power is turned off. Additionally, the printer can store 3 different Top of Form positions depending on

the paper feed method [fanfold paper-rear feed { [[| ), fanfold paper-bottom/front feed ( [[T| ) and

single sheets and envelopes-top feed ( Q ) including the optional Cut Sheet Feeder (KX-P38)].

You can adjust the Top of Form position by using the Setup Disk (cs* P. 28-39), or using Micro Line

Feed or Reverse Micro Line Feed within 5" from the top of your paper.

Note:

• Do not rotate the platen knob, otherwise the printer will not be able to count the number of lines.

• When setting TOF for fanfold paper, all adjustments must be made on the first sheet. If you wish

to change the setting after advancing additional sheets you must first park then reload the paper.

lf necessary, redefine the page length

of the paper you are using through the

I

Setup Disk (d? p. 28-39), control panel

{I®* p. 47-49) or your application

software { P. 52-54).

Micro Line Feed

Reverse Micro Line Feed

A page is defined by setting the page length through

the Initial Setup mode (via the Setup Disk or through

the control panel) or the Software command.

While pressing [ ON LINE ), press ( LF/FF ].

This advances the paper one micro line (Viso")-

Holding the switches will advance the paper

continuously until you release the switches.

While pressing [ON LINE I. press I LOAD/PARK I.

This reverses the paper one micro line (Viso").

Holding the switches will reverse the paper

continuously until you release the switches.

The printer cannot reverse the paper past the

printable area.

c

2.

5*

(a

<D

o

o

3

■D

3

(D

At your desired position, release the switches.

The paper position will be stored automatically as the

new Top of Form position.

43

Page 44

Q!te0ro®(l]DS©C2Xj^

Tear Off

With fanfold paper installed through the rear paper path (available for Push Tractor Mode only), this

function allows you to advance your paper to the tear position. After tearing off the page you can return

your paper to the first print line by pressing (TEAR OFF] again. If [TE^AR OFI^ is not pressed a

second time, the printer will automatically reverse to the first print line upon receiving data from the

computer.

Uiildiliii

Press [tear off) to advance the paper

1

LF/FF

LOAD

PARK

to the tear bar.

Fold forward the smoked plastic cover.

c

i2.

5‘

(Q

(0

o

o

3

~a

0)

3

(D

Tear off the page.

Press (TEAR OFF] to reverse the paper back to the first print line.

0 Fold back the smoked plastic cover.

44

Page 45

QMjD®®©©oXn^

Paper Parking f LOAD/PARK

This function moves the fanfold paper fed through the rear paper path (Push Tractor Mode) to the park

position, enabling you to use single sheets or envelopes without removing or wasting your fanfold

paper.

Tear off the printed page(s) of the

1

fanfold paper being used.

Press fLOAD/PARI^ to reverse the

2

ON LINE

fanfold paper to the park position.

O Move the paper feed selector to

“ Q ” (Friction Mode).

0 Load single sheets or envelopes.

( c®’ P. 23 “Single Sheets and Envelopes”)

When you are finished printing, remove the sheet (or

envelope) from the printer.

O Lower the paper easel.

0 Fold back the smoked plastic cover.

0 Move the paper feed selector to

“ 0 ” (Tractor Mode).

Press fLOAD/PARK] to reload the

fanfold paper to the first print line.

o

O

o

3

■D

fi)

3

(D

45

Page 46

(!M5D®ffi©(§©ia[^

Paper Out Detector

Your printer has a paper out detector. When an out of paper condition occurs, printing stops, the printer

goes to the OFF LINE mode, and the PAPER OUT indicator starts blinking. To continue printing to the

end of the current page, follow the steps below.

Press [ON LINE) repeatedly until the page is completed.

Install the new paper. (^ p. ^e~24)

If the ON LINE indicator is not lit, press [ON LINE] .

■D

fi)

3

o

Note:

• When the PAPER OUT DETECT is set to ON, printing stops at 0.5" from the bottom of the paper.

• The paper out detector can be disabled through the Setup Disk. (<^ P. 30)

46

Page 47

(lMA©®i©©®0^

Initial Setup Mode

The following features (items) can be set in the Initial Setup mode through the Control Panel;

Emulation, Auto Line Feed, Graphic Direction, Page Length and the optional Cut Sheet Feeder Mode,

if optional KX-P38 is installed. These features can also be set using the Setup Disk.

(US’ P. 28)

Setting the Printer Setup Mode

Load a sheet of paper (p 16-24), and

1

turn the power off.

^ To enter the Initial Setup mode

While pressing [ LOAD/PARK ] , turn the power on.

Both FONT indicators and the Super Quiet indicator

will be blinking.

The current settings will be printed automatically.

^ Selecting the Item

Press and release [ FONT ].

Each time you press [ FONT) , you will advance to

the next item. Select the desired item according to

the status of the FONT indicators (on, off, blinking).

(cs= P.48)

^ Setting the Item’s status

Press and release [ PITCH 1.

The item’s status will change each time you

press [PITCH] . (I®' P. 48)

To change additional settings, repeat steps 3 and 4.

C

5*

(Q

(D

o

O

3

o

■0

fi)

3

(D

47

Page 48

IlMiD® ffi©

Emulation; Press f FONT] once.

Epson mode

---------- Press [ PITCH )

IBM mode

o • FONT O O PITCH

O • FONT

O • PITCH

Auto Line Feed: Press [ FÖNT] twice.

Oft

------------------------

• O FOriT O O PITCH

Press [ PITCH 1

On

• O FONT

O • PITCH

Cut Sheet Feeder Mode; Press [ FONT 1 3 times.

Off

----------------------

► Press [ PITCH 1

--------- On

[This setting is only necessary when the optional Cut Sheet Feeder {KX-P38) is

installed.]

• • FONT

O O PITCH

• • FONT

O • PITCH

Graphic Direction: Press [ FONT] 4 times.

Unidirectional

O • FONT

-------

' Press [PITCH ]

O • PITCH

Bi directional

O • FONT

O O PITCH

Page Length: Press [ FONT] 5 times.

11"

c

----------------------

► Press [ PITCH ]

-------

► 12"

5’

(Q

S'

(D

o

o

■D

0)

s

(D

«i O FONT

O O PITCH

Press [ PITCH 1

Press [ PITCH ]

Press [ PITCH ]

Press ( PITCH ]

FONT/PITCH indicators condition:

• O FONT

------- 11 (11.67")

'4 O FONT

O • PITCH

O PITCH

• • PITCH

O iii PITCH

O PITCH

48

• =light is lit o flight is out

• =light is blinking

Page 49

QMJOg ffios

^ To exit the Initial Setup mode

Press [ LOAD/PARK ).

FONT indicators will go off and the current conditions

will print.

Setting the Serial Setup Mode (Only when the KX-PS14 is installed)

Only when the KX-PSI4 {Serial Interface Board) is installed, the following items can be set in the Serial

Setup mode through the Control Panel.

You can select and change the desired item according to the status of the FONT/PITCH indicators.

Load a sheet of paper (p. 16-24), and

1

turn the power off.

^ To enter the Serial Setup mode

While pressing [ PITCH] , turn the power on.

Both FONT indicators and the Super Quiet indicator

will be blinking.

The current settings will be printed automatically.

^ Selecting the Item

Press and release ( FONT] .

Each time you press f FONT] , you will advance to

the next item. Select the desired item according to

the status of the FONT indicators (on, off, blinking).

(P. 50)

(D

o

O

3

■O

0)

3

(D

49

Page 50

QMiDg ffl©

^ Setting the Item’s status

Press and release [ PITCH ].

The item’s status will change each time you

press [pitch! . See the table below to verify desired

status.

To change additional settings, repeat steps 3 and 4.

(fi

C

5‘

3"

(D

o

o

■D

3

(D

ITEM

Print Current

Setup Condition

Interface

Data Length

Baud Rate

Parity

Protocol

S.D.T.

R.D.T.

Signal Polarity

Setting

— —

Parallel

Serial

8 bit

7 bit

9600

300

600

1200

2400

4800

None

Ignore

Odd

Even • •

DTR

X/ON-X/OFF

128 byte

512 byte

S.D.T.+128 byte

S.D.T.+256 byte

MARK

SPACE

Press

FONT key

once o

twice

3 times

4 times

5 times

6 times

7 times

8 times o o

FONT indicators

S 1 i-

•

•

• •

o

• o

•

*

o

•

V 1 ^

•

A

Press

PITCH key

*1

t

1

1

t

I

1

*1

J

I

!_J

*1 I"*”

i

ij

*1

t

J

*1

t

J

1

*1

f

J

1

*1

i

1

PITCH indicators

0 o

0 o

0

0 o

0

0 o

0 •

•

• •

0

> 1 #

•

0 o

0

•

0 o

o

o 0

0

0 0

o •

o o

o •

•

•

o

0

•

o

•

•

50

FONT/PITCH indicators condition:

• =light is lit o =light is out =light is blinking

The item’s status will change each time you press [ PITCH ].

^ To exit the Serial Setup mode

Press I LOAD/PARK I .

FONT indicators will go off and the current

conditions will print.

Page 51

(yteflDO®®©(§®llCO^

Returning All Current Settings to the Factory Settings

This procedure will reset ALL settings to the original factory settings. This includes those settings made

through the Setup Disk.

Follow the instructions below:

If paper is loaded, you will automatically get a printout of the current settings.

^ To enter the Initial Setup mode

Whiie pressing ( LOAD/PARK ], turn the

power on, then reiease.

Make sure that FONT indicators and the Super Quiet

indicator are blinking.

Press i TEAR OFF ] .

All current settings will be reset to the Factory

settings, and a beep will sound.

^ To exit the initiai Setup mode

Press [ LOAD/PARK] .

If paper is installed, a printout will

verify the current setting.

■D

Q}

3

(D

51

Page 52

©@[MlDuD©[ii^ [RR^D^DDD (pMa@ffii©@@Q3D[^ii^^

The Command Reference program allows you to access a detailed explanation of each software

command on the screen. Each displayed explanation can be printed out if required.

Before using the Setup Disk, it is recommended that you make a back-up copy and store the original

in a safe place.

Note:

• Use the DISKCOPY command of the operating system to make a back-up copy. Refer to your DOS

manual for further information.

• You may find it convenient to install the Setup Disk programs directly onto your C Drive, rather than

reading them from the Setup Disk each time a change is necessary. Either method is acceptable.

To perform an automatic installation of the Setup Disk files onto your C Drive, refer to page 32.

Insert your Setup Disk into either drive A or B.

1

<For DOS>

2 Type A: (or B:) and Press [ Enter].

0 Type CMDREF

Press [Enter].

The first screen is an introduction

to the operation of the Setup Disk.

5

Please read through it and

press any key to continue.

(If your display is monochrome,

press “M” key.)

Screen 1 will be displayed.

0 Press (D or (T) .

Select an emulation.

<For WINDOWS>

Select Run from the File menu.

2

2 Type A:\CMDREF (or B:\CMDREF)

^ Click |0K| (or Press [ Enter]).

Screen 1

«Panasonic KX-P3626 command reference utility (xxxxxxxxxxx)»

------

SELECT EMULATION

rEPSON"

IBM

lT]/|il

(Enter]

(E]

-------

Select emulation

Set emulation

Exit to DOS

52

Note:

• You can proceed through the Command Reference program using a computer mouse or your

keyboard. Highlight the desired item and click the left mouse button, or follow the directions on your

screen for keyboard operation.

• There is a list of proportional spacing tables after the software commands list. If you want to see a

proportional spacing table, select your desired table and press [ EnteT] .

Page 53

Screen 2

©camssM^

Press [ Enter) .

The emulation will be set and

screen 2 will be displayed.

« Panasonic KX-P3626 command relerence utility (xxxxxxxxxxx) »

------

SELECT COMMAND — — (EPSON)

FONT SELECTION

i ESC+,y+n,.„^ _ _ __ _

ESC+’k’+n

ESC+’S’+O

ESC+’S’+1 Selects subscript printing

ESC+T

ESC+'X'+m+ni+nz

CHARACTER PITCH SELECTION

ESC+'P’

ESC+’M’ Sets elite pitch (12 cpi) printing

ESC+'g'

SI or ESC+SI Sets compressed pitch (17 cpi) printing

DC2

ESC+’p'+n

[T]/[i]

[Pg.Up]/[Pg,Down]

[Enterl View command description

[Esc] SELECT EMULATION mode

[E] :

[ T ]/[ 4. 1

[Pg.Up]/

[Pg.Down]

Moves the cursor one line up/down

Moves the cursor to the first command of

the previous/next item

Selects print quality 1

Selects print font style

Selects superscript printing

Releases sub/superscript printing

Selects font by pitch and point

Sets pica pitch (10 cpi) printing

Sets micron pitch (15 cpi) printing

Releases compressed pitch (17 cpi) printing

Sets/Releases proportional spacing

Select command

Go to previous/next category

Exit to DOS [P] : Print Command List

[Enter] Displays the explanation of the command

[Esc] Returns to screen 1

[E]

[P]

Exits to DOS

Prints Command List

If you want to print the command list with

parameters, press [p] and press (Y).

The command list with parameters

will be printed.

The display will return to screen 2.

N”

Q Press (Pg.Up] / [ Pg.Dri)

Of ® / ffl •

Screen 3

« Panasonic KX-P3626 command reference utility (xxxxxxxxxxx) »

-------SELECT COMMAND

FONT SELECTION

X+n ^ ___________

ESC+'k'+n

ESC+’S’+O

ESC+'S’+I

ESC+T’

ESC+’X’+m+ni+na

CHARACTER PITCH SELECTION

ESC+’P'

ESC+’M' Sets elite pitch (12 cpi) printing

ESC+’g’ Sets micron pitch (15 cpi) printing

SI or ESC+SI

DC2 Releases compressed pitch (17 cpi) printing

ESC+’p’+n