Page 1

Operating Instructions

Impact Dot Matrix Printer

KX-P3124

Panasonic

Quiet

Printing

Before operating this unit, please read these insVucticns compteiety

Page 2

FOR USERS IN UNITED STATES ONLY

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or televi

sion reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

•Consult the dealer or an experienced radio/TV technician for help.

The user may find the booklet “Something About Interference" available from FCC local

regional offices helpful.

FCC Warning: To assure continued FCC emission limit compliance, the user must use

only the recommended shield interfacing cable when connecting to a host computer. Also,

any unauthorized changes or modifications to this equipment would void the users authority

to operate this device.

All Rights Reserved. ©COPYRIGHT 1993 KYUSHU MATSUSHITA ELECTRIC CO., LTD.

Page 3

'N

WARNING

•The power source voltage of this unit is listed on the nameplate. Plug the printer only into

an outlet with the proper voltage.

•To prevent fire or shock hazard, do not expose this product to rain or any type of moisture.

•When you operate this equipment, the outlet should be near the equipment and should be

easily accessible.

The serial number of the unit may be found on the label on the rear of the unit. For your

convenience, note this number below, and retain this book, along with your proof of

purchase, to serve as a permanent record of your purchase in the event of a theft, or for

future reference.

MODEL NO.

SERIAL NO.

KX-P3124

NAME OF DEALER

DATE OF PURCHASE

IBM and IBM-PC are registered trademarks of International Business Machines

Corporation.

Proprinter is a trademark of Internationa! Business Machines Corporation.

Windows is a registered trademark of Microsoft Corporation.

Epson is a registered trademark of Seiko Epson Corporation.

Epson ESC/P2 is a trademark of Seiko Epson Corporation.

Adobe, ATM and the ATM logo are trademarks of Adobe Systems Inc., which may be

registered in certain jurisdictions..

Any details given in these Operating Instructions are subject to change without notice.

Page 4

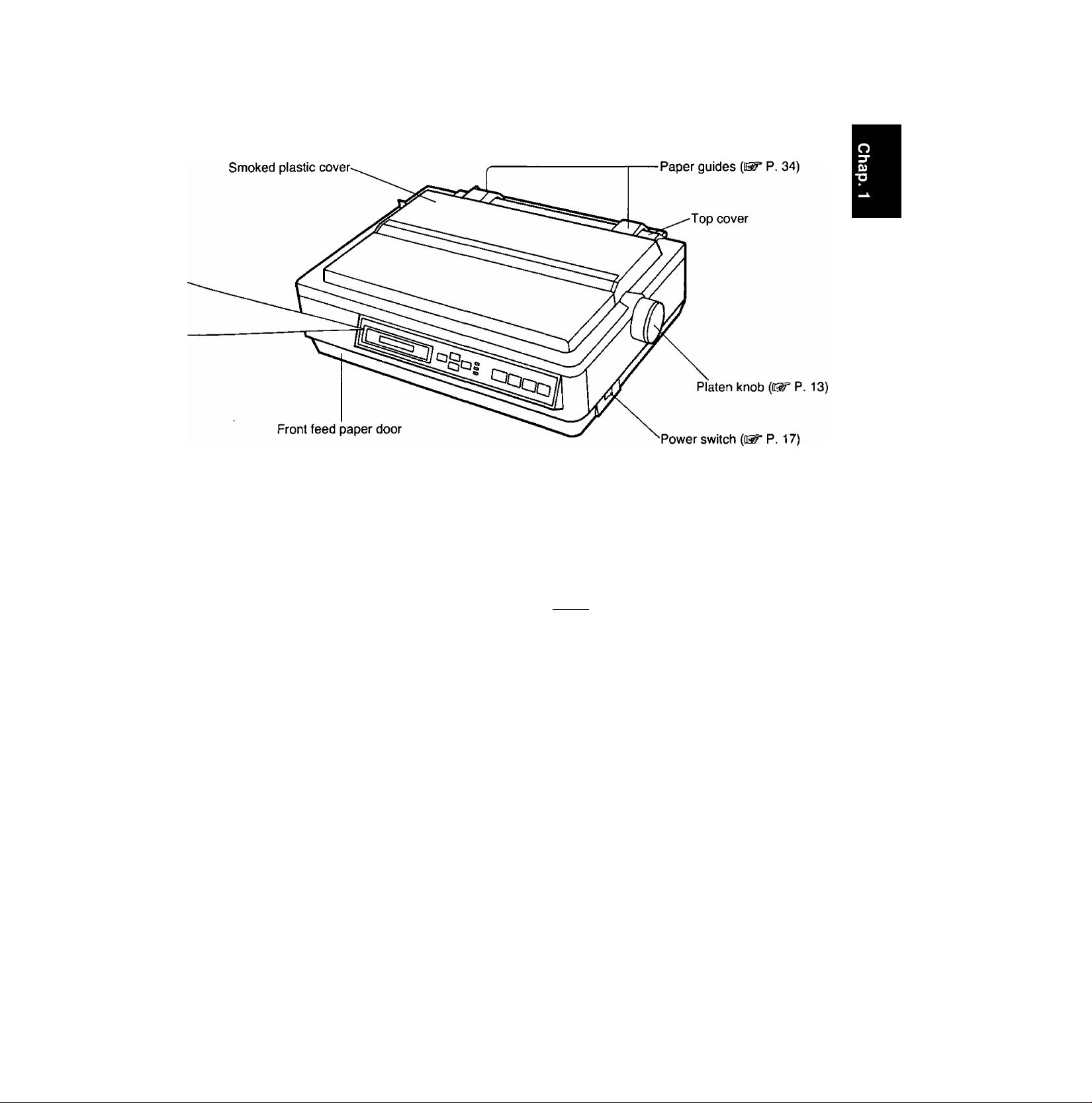

Chap. 1 Before You Start

Cautions

Operating Environment

Precautions..................

Unpacking

Assembling the parts

Parts of the Printer .

Chap. 2 Setup

Connecting to a Computer

Ribbon Cassette.................................................

Installing the Ribbon Cassette.........................................

Removing the Ribbon Cassette.......................................

Paper Feed Selection ........................................

Installing Paper

Fanfold Paper (Push Tractor Mode—Rear Feed) . .

Fanfold Paper (Pull Tractor Mode—Bottom/

Front Feed)..................................................................

Single Sheets and Envelopes (Friction Mode

—Top Feed).................................................................

Single Sheets and Envelopes (Friction Mode

—Front Feed)...............................................................

Characters Alignment

Printer-Driver Seiection.....................................

Instailing a Printer-Driver (Windows Ver. 3.1)

Self Test

....................

.................

................................

.................................................

......................................................

..............................................................

9

9

9

11

12

14

17

18

18

21

23

24

24

28

33

35

37

38

39

41

Chap. 3 Using the Printer

Super Quiet Mode............................

Feeding Paper

Form Feed/Line Feed/Micro Line Feed/

Reverse Micro Line Feed

Tear Off (Rear feeding only)

Paper Parking (Rear feeding only) . . .

Top of Form Function................................

.................................

......................

.....................

42

43

43

44

46

48

Page 5

Chap. 4 Function Mode______________________________________

Using the EZ Set Operator Panel....................................52

Operation

Setting the Function Mode Items

Direct Access to FONT and PITCH Setting

Setting POINT SIZE........................................................................ 56

........................................................................................

....................................................

....................................

52

53

55

Function Mode Menu ......................................................58

PRINT SETTING Menu.................................................................. 61

PRINT STYLE Menu

EMULATION Menu......................................................................... 63

PAGE FORMAT Menu.................................................................... 63

PRINT MODE Menu........................................................................ 64

TEXT ENHANCEMENT Menu

CHARACTER SET Menu................................................................ 66

INSTALL Menu

DISPLAY language Menu.............................................................. 69

INTERFACE Menu...........................................................................69

MACRO MODE Menu

Using the Setup Disk

Running the Setup Program............................................................ 70

Print Settings.................................................................................. 71

Setting Selections on Setup Disk

Save to Disk.................................................................................... 74

Load from Disk................................................................................ 74

Send to Printer

FACTORY Settings......................................................................... 76

Help................................................................................................. 77

......................................................................

........................................................

...............................................................................

.....

...............................................................

......................................................

....................................................

................................................................................

61

65

67

69

70

72

75

Chap. 5 Software Commands

____________

Epson ESC/P2'“ Mode (Epson LQ-570 Mode) .... 78

IBM Proprinter X24E Mode

.............................................

Command Reference Program

(Using the Setup Disk)

.........................................................

Chap. 6 Maintenance & Troubleshooting

Periodic Maintenance

Troubleshooting

...............................................................

......................................................

85

90

93

94

Page 6

Appendix_________________________

Printer Specifications......................................................97

Paper Specifications........................................................99

Fanfold Paper

‘Single Sheet.................................................................................... 99

Envelope......................................................................................... 99

Printing Area..................................................................................100

Interfacing..................................................................... 101

Parallel Interfacing.................................................................

Initialization

Hex Dump

Character Set Tables

Glossary......................................................................... 112

Index............................................................................... 119

Options and Supplies................................................... 122

.................................................................................

...

..................................................................

.....................................................................

....................................................

99

. 101

104

105

106

Page 7

Chap. 1 Before You Start

Chap.

Chap. 3 Using the Printer

Chap. 4 Function Mode

Chap. 5 Software Commands

2

Setup

Chap. 6 Maintenance & Troubleshooting

Appendix

Page 8

010

Congratulations on purchasing a Panasonic printer.

This printer is a versatile, high quality 24-pin dot matrix printer which is designed to meet the needs

of your office.

Your printer contains an EZ Set Operator Panel featuring a 16-character Liquid Crystal Display (LCD)

that lets you control a wide variety of printing conditions quickly and conveniently.

This printer has been factory set to operate with most of the popular software packages. Your

application software should control the printer functions. In most cases, there will be need to change

the initial printer settings.

0.

Features

Printer Emulation:

Setup Disk:

ATM Disk:

Super Quiet Mode:

Color Printing:

Fonts:

Printing Speed:

Paper Handling:

Epson LQ-570 and IBM Proprinter X24E

A Printer-Driver for Windows Ver. 3.1, Function mode

program and Command Reference program

Adobe Type Manager with 13 scalable Adobe fonts for

Windows 3.0 or higher

Reduces printing noise

7 colors with the optional color kit (KX-PCK11)

3 Draft ( p ica. Elite, Micron )

8 Letter Quality (Roman, Sans Serif, Courier,

Prestige, Script, OCR-B, Bold PS, ORATOR)

1 Super Letter Quality ( Roman )

6 Scalable Fonts ( Roman, Sans Serif, Courier,

Prestige, Script, Bold PS )

Draft—256 characters per second (12 cpi)

LQ—85 characters per second (12 cpi)

SLQ—42 characters per second (12 cpi)

Friction and Tractor (Pull/Push built-in)

Paper Paths:

Tear Off:

Paper Parking:

Cut Sheet Feeder Option

(KX-PT11):

Seriai Interface Option

(KX’PS13 and KX-PS14):

8

Rear, Bottom, Front, Top

Advances fanfold paper’s perforation to tear position

Allows single sheets/envelopes to be used without

removing/wasting fanfold paper

Provides fast and automatic feeding of single sheets

You may select parallel or serial when either serial

interface board is installed.

Page 9

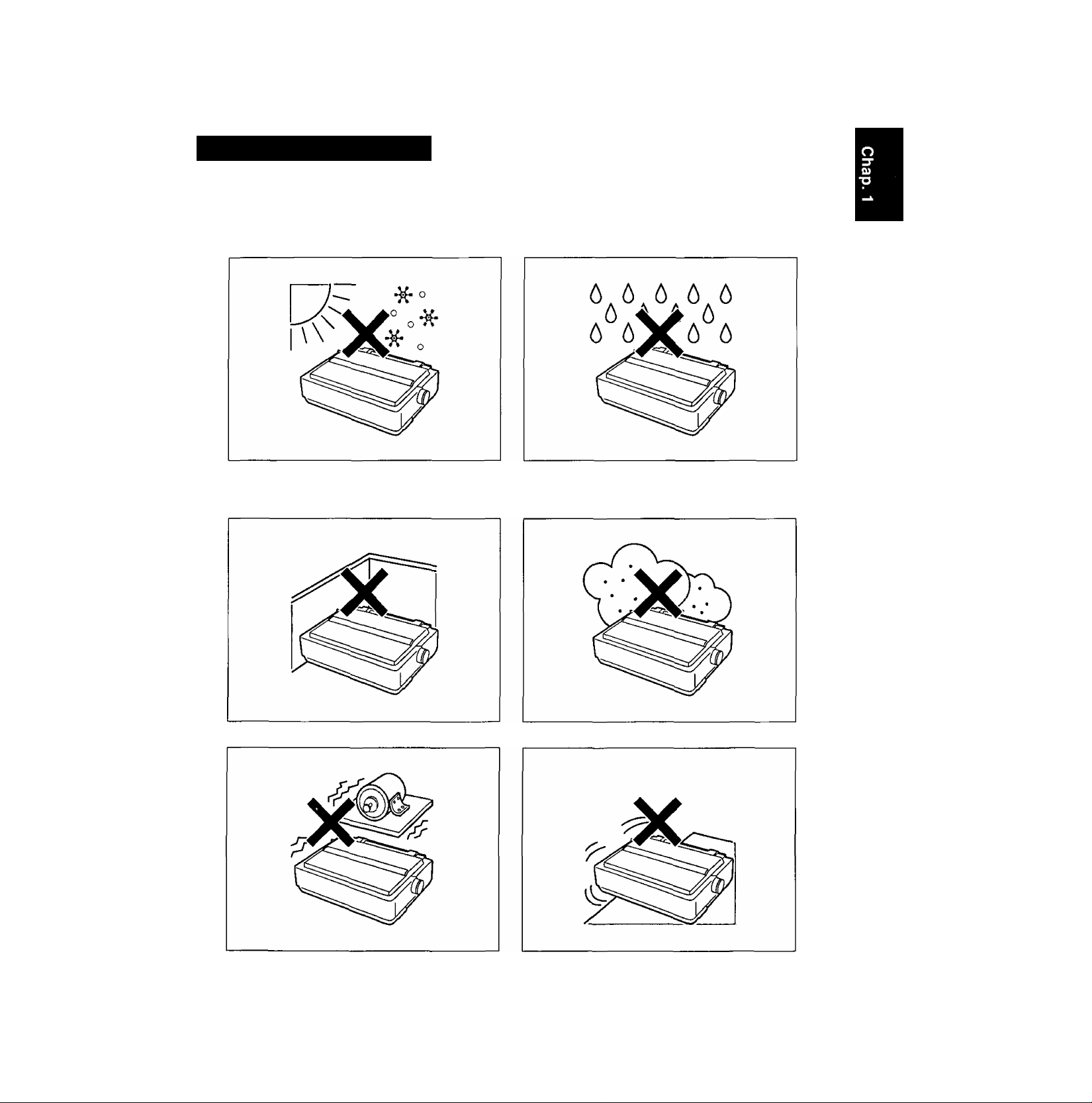

Operating Environment

• Do not use the printer under the following conditions.

Extremely high or low temperature Extremely high or low humidity

[temperature range: 10* to 35*C (50* to 95°F)] (humidity range: 30% to 80% RH)

Areas of poor ventilation

[a minimum of 4" (10 cm) clearance on all

sides is necessary to insure proper ventilation]

Areas of high dust concentration

00

(D

o

<D

<

O

c

CO

to

Areas with extreme vibration

•Power consumption:

(MAX—250 W, Stand by—12 W. Self Test—50 W)

Areas on an unstable or unlevel surface

Page 10

(^EOfflSODS

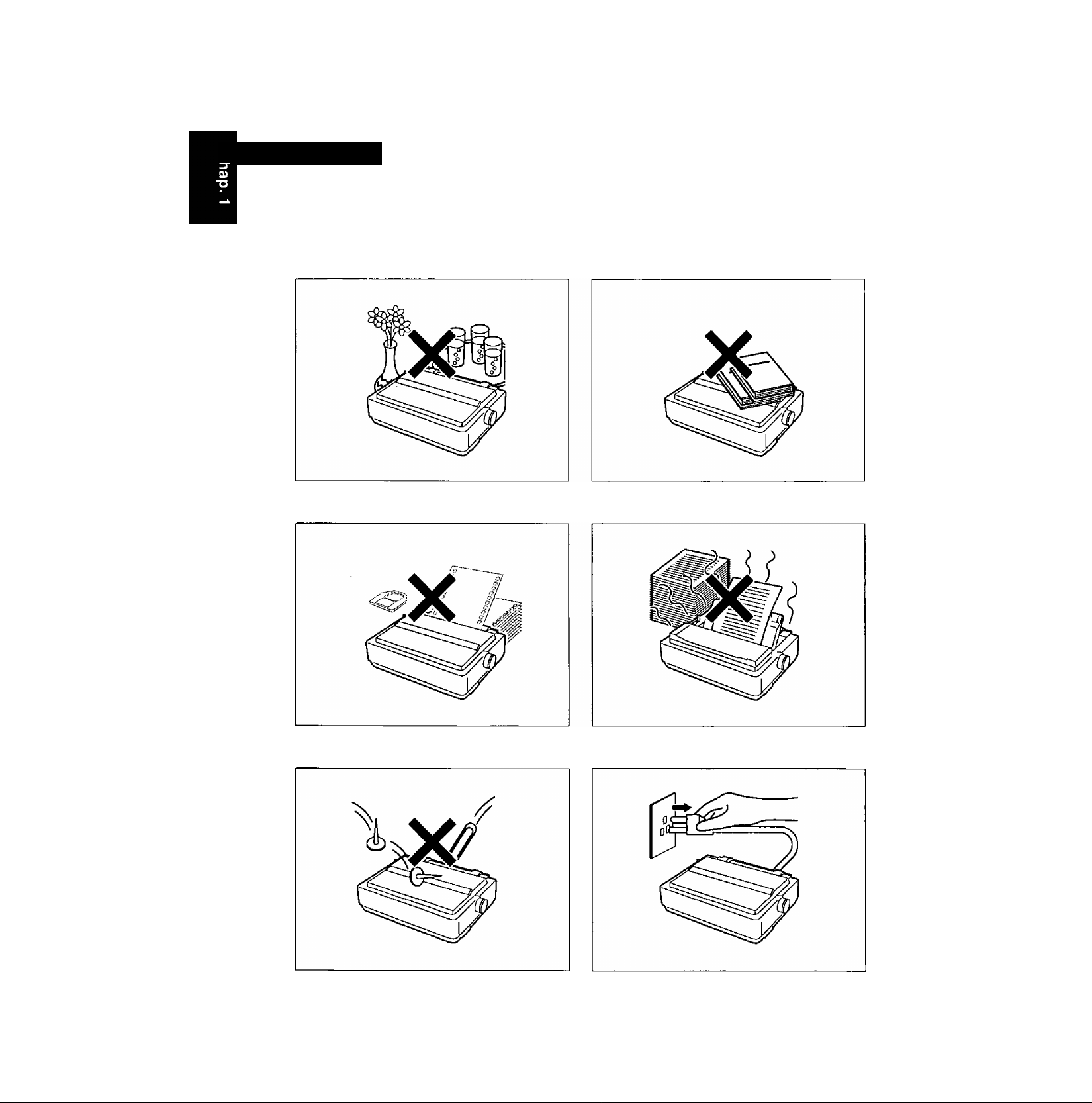

O ■ Precautions

The following precautions are recommended to extend the life of the printer.

w

(D

o

—i

o

<

o

c

CO

0)

a.

Keep all liquids away from the printer.

—Accidental spillage of a liquid into the printer Do not place books, paper, or other items

can cause severe damage. on top of the printer.

Do not operate the printer without paper

and a ribbon cassette installed.

Avoid prolonged use without allowing the

printhead time to cool.

Do not obstruct the movement of the

printhead while in operation.

10

If the printer is not going to be used for an

extended period, unplug the power cord.

Page 11

0

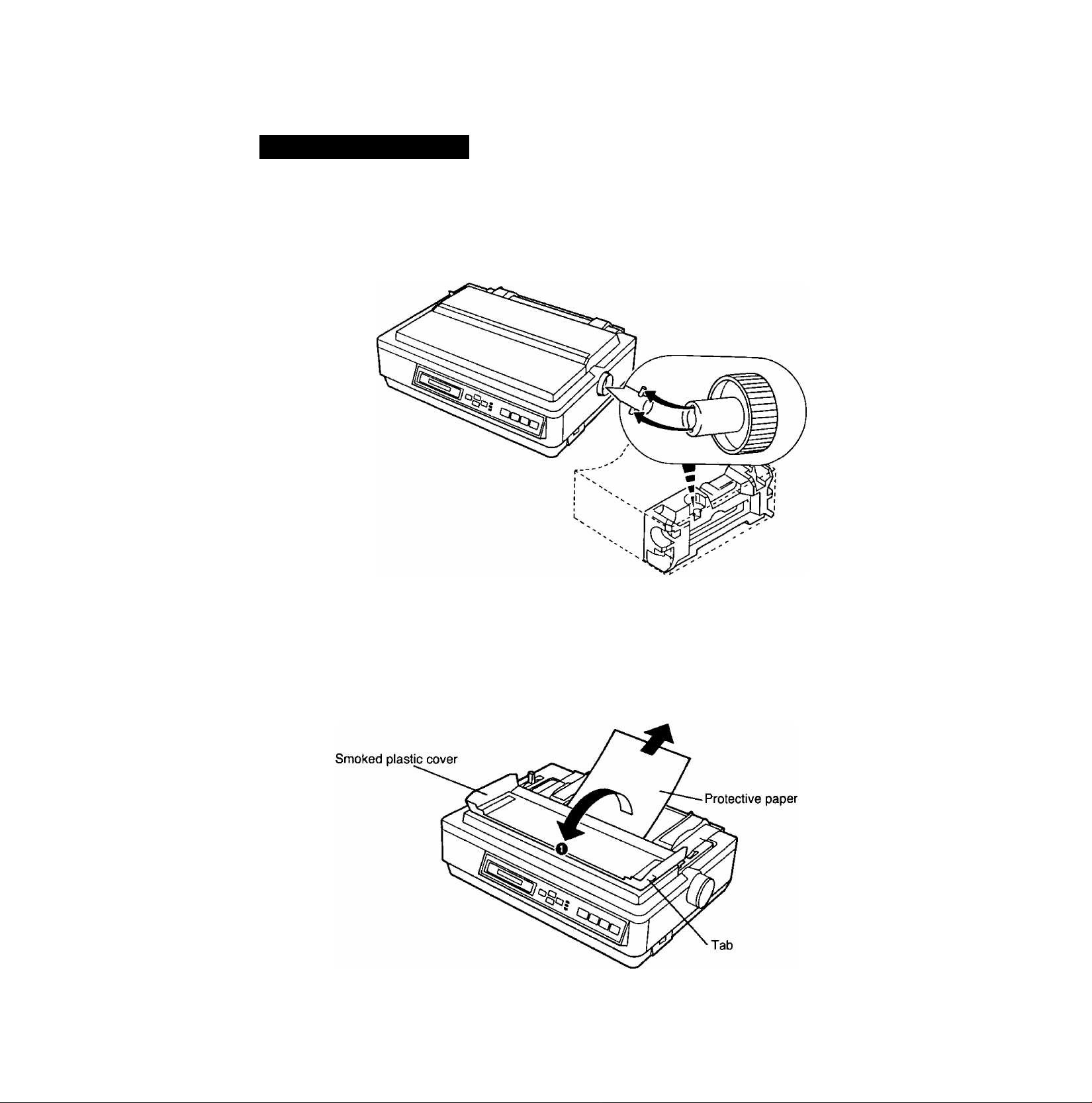

Having unpacked the printer, make sure none of the contents shown below are missing or damaged.

Report damage or shortages to the store from which the unit was purchased.

Printer (KX-P3124)

Ribbon cassette (KX-P150)

<D

C?'

CD

(D

O

(D

<

0

m

3.

)

Platen knob

Operating manual

<»

Setup Disk

• The Setup Disk contains a Printer-Driver for Windows Ver. 3.1 (t^ P. 39), a

Function Mode program {o^ P. 70) and a Command Reference program

P. 90).

• To use the Setup Disk you need to have an IBM-PC or a Compatible computer

with a 3.5" floppy disk drive.

• For detailed information on ATM Disk, refer to ATM Disk manual.

ATM Disk

Note:

• It is recommended that you save the original carton and packing materials for proper shipping

and transporting of the printer.

11

Page 12

W

(D

O

(D

-<

O

c

CO

Cl)

a.

Assembling the parts

Insert the platen knob into the hole on the right side of the printer and

1

rotate it slowly until it slips onto the shaft. Push the platen knob onto the

platen shaft to secure.

Fold the smoked plastic cover, and remove the protective paper.

12

Page 13

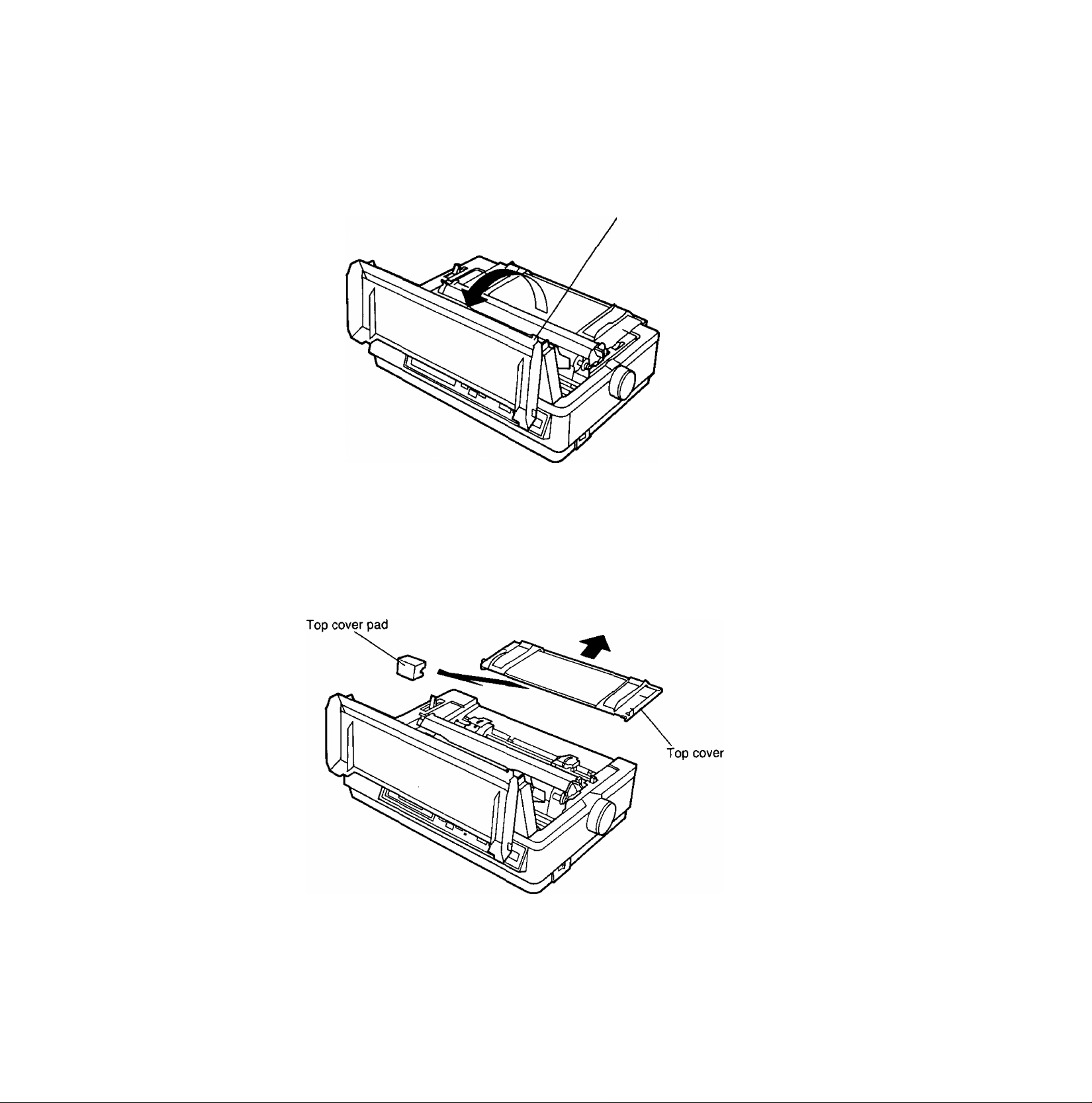

Open the smoked plastic cover.

Jab

CD

<D

O

—t

(D

<

O

c

CO

D1

3.

Remove the top cover pad.

13

Page 14

iMsfesiïtelMnfig?

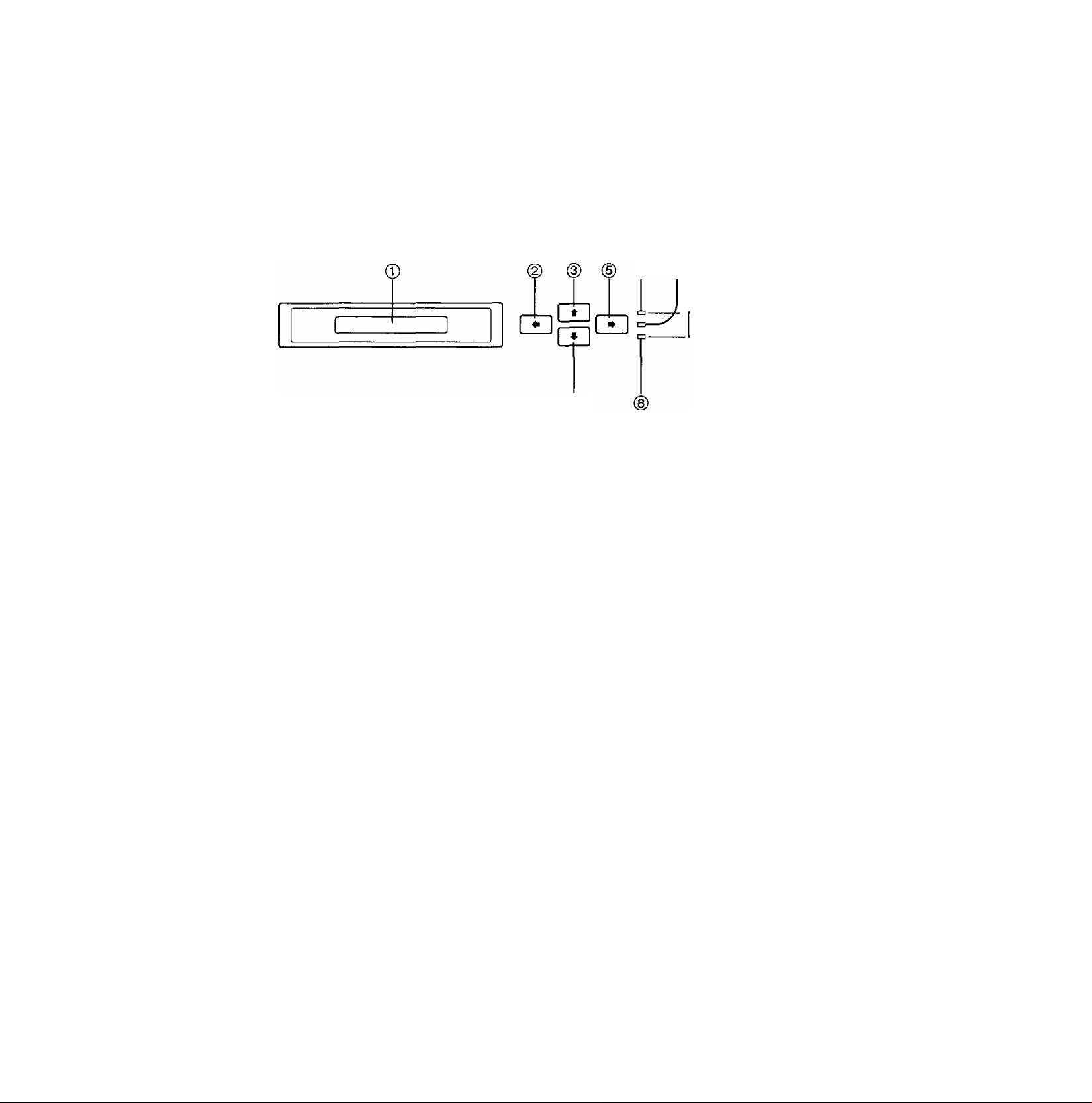

EZ set operator panel

W

O

O

(D

-<

O

c

CO

fi)

3.

© ©

® ® ® ®

16-Character Liquid Crystal Display (LCD)

A 16-character LCD prompts the user with mes

sages and step-by-step instructions.

In case of incorrect operations, the display will

immediately indicate the appropriate error mes

sages so you may take corrective action.

P. 96)

SUPER QUIET (^) Switch

Pressing this switch reduces print noise, however

it also reduces the printing speed. When it is

active, the SUPER QUIET indicator is lit and the

display briefly shows QUIET MODE=ON.

In the Function mode, this switch scrolls back

through the Main menu, the Sub-menu and the

selections or conditions of the item.

TEAR OFF (♦) Switch

Pressing this switch advances or reverses the

paper for tear off in the OFF LINE mode or when

not printing in the ON LINE mode. (Q^ P. 44)

In the Function mode, this switch returns you to

the previous menu level such as “Selection ^

Sub-menu Main menu”.

LOAD/PARK(*) Switch

This switch loads/parks the paper in the OFF

LINE mode or when not printing in the ON LINE

mode.

In the Function mode, this switch lets you scroll

down to the next menu level such as “Main menu

^ Sub-menu ^ Selection”.

TOF SET (^) Switch

This switch allows you to set the Top of Form in

the OFF LINE mode or when not printing in the

ON LINE mode, (t^ P. 50)

In the Function mode, this switch scrolls through

the Main menu, the Sub-menu and the selections

or conditions of the item.

ON LINE/FUNCTION Indicator

This indicator is lit when the printer is in the ON

LINE mode, and the indicator is not lit in the OFF

LINE mode.

In the Function mode, the indicator blinks.

@ SUPER QUIET Indicator (№■ ®)

14

POWER/PAPER OUT Indicator

®

This indicator is lit when the power switch is

turned on and paper is installed. When an out of

paper condition occurs, the POWER/PAPER

OUT indicator blinks.

Page 15

09

(D

O

<D

-<

CO

fl)

ON LINE (FONT) Switch 0

This switch opens and closes the communication

line with the computer. When the power switch is

turned on and paper is installed, the ON LINE

indicator is lit, the display shows “ON LINE", and

the printer is ready to receive data from the com

puter. In the OFF LINE mode, the indicator is out,

the display shows “OFF LINE’’ and the printer can

no longer receive data.

In the Function mode, this switch lets you di

rectly access the FONT selection with one step.

p. 55) @

FF (PITCH) Switch

S)

This switch moves the carriage to the center and

advances the paper to the top of the next page

(depending on your TOF setting) in the OFF LINE

mode or when the printer is not printing in the ON

LINE mode.

In the Function mode, this switch lets you di

rectly access the PITCH Selection with one step.

P. 55)

LF (SET) Switch

This switch advances the paper one line. Holding

the switch down performs multiple line feeds.

These functions are active in the OFF LINE mode

or when the printer is not printing in the ON LINE

mode._________________________________

In the Function mode, this switch sets selec

tions or conditions of the item shown on the dis

play and returns you to the Sub-menu.

FUNCTION Switch

This switch allows you to enter and exit the Func

tion mode.

In the Function mode, the ON LINE/FUNCTION

indicator blinks and the E2 Set Operator Panel

switches have secondary capabilities, for easily

setting your desired print conditions. ((^ P. 52)

15

Page 16

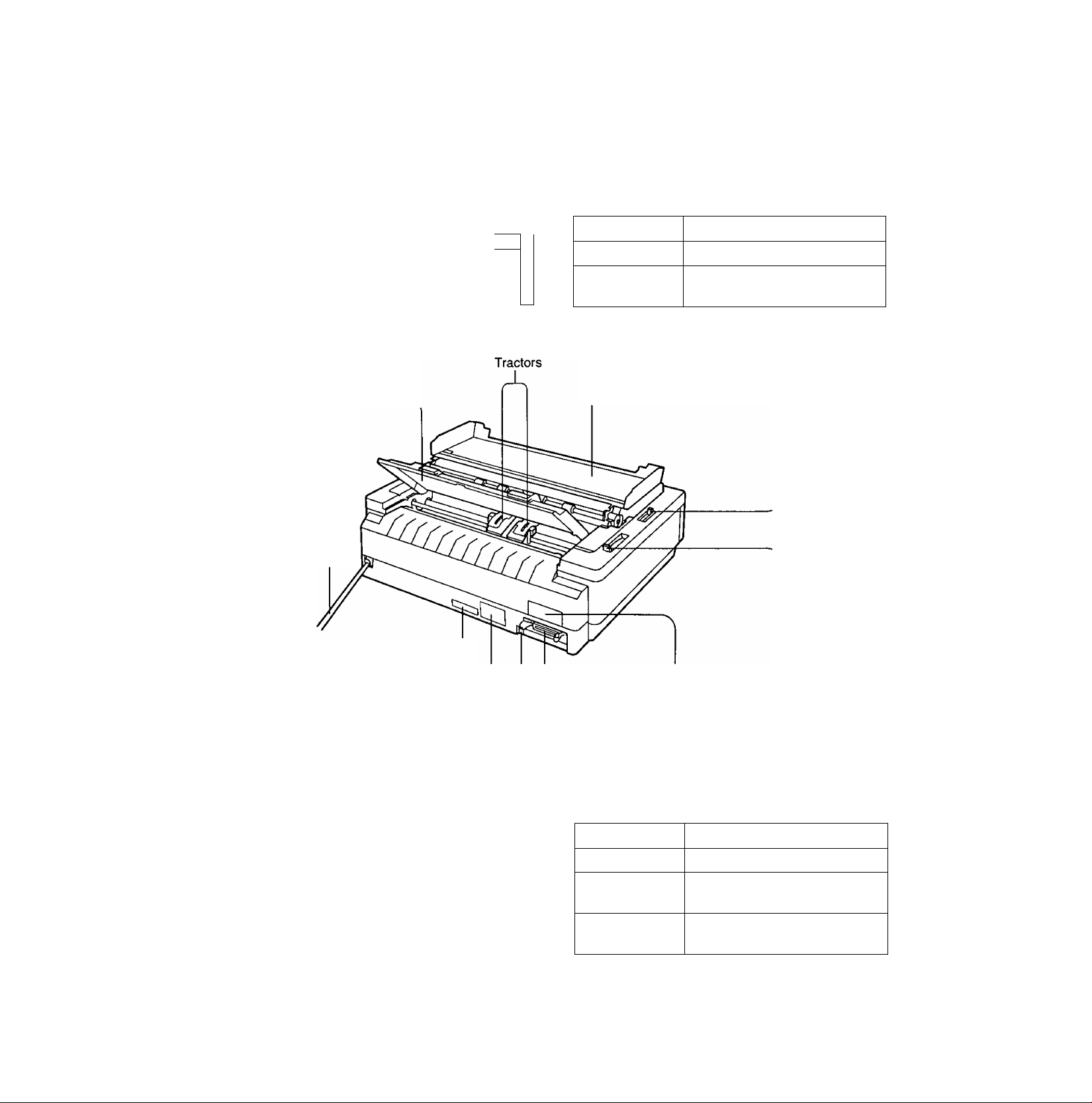

Printhead gap lever

Adjusts the gap between the platen and the printhead. The lever moves

in increments of 0.0028 inch (0.07 mm).

OD

O

o

(D

-<

O

c

0)

fii

3.

Top cover

AC power cord

p. 17)

1—-,

2-—K’

E

X‘

0

4-*-

a’

5--"

p'

6

---

+

Position

1 or 2

3, 4, 5 and 6

Smoked plastic cover

Thinner sheets

Thick or multiple sheets

Used for

Envelopes

Serial No. label

Nameplate

Frame ground terminal

Centronics parallel interface connector

Paper teed selector (o^ P. 23)

□

Serial interface cover

Position

Q (Friction)

Q (Tractor)

PULL

0 (Tractor)

PUSH

Used for

Single sheets and Envelopes

Fanfold paper with PULL

tractor mode

Fanfold paper with PUSH

tractor mode

16

Page 17

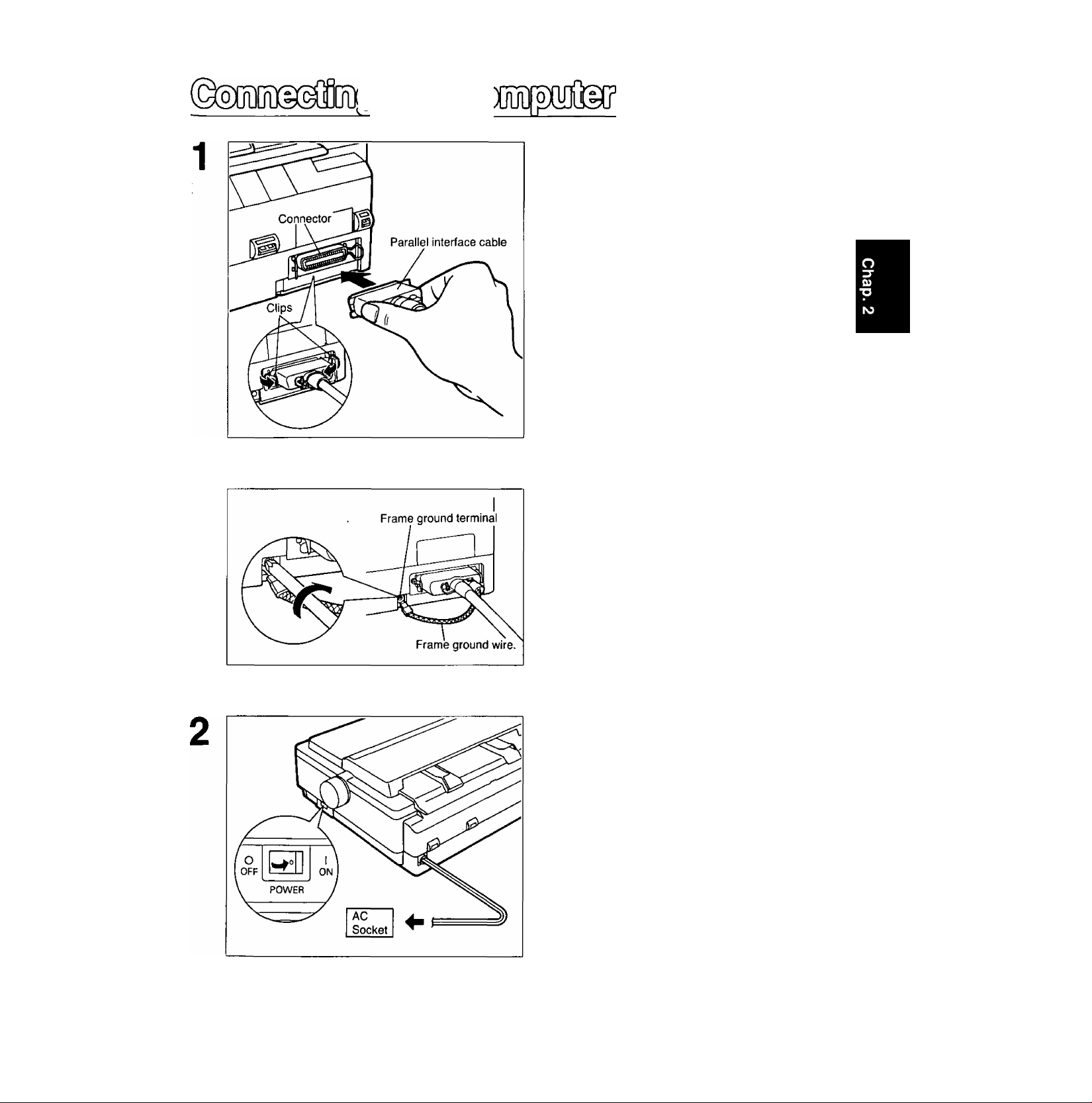

Attach one end of the parallel interface cable to your printer as shown, and the other end to your computer.

Be sure to secure the printer clips.

Note:

• If you do not have a parallel interface cable,

you will need to purchase one from your

local computer store or dealer.

If the cable has a frame ground wire, connect it to the frame ground terminal.

c/>

(D

C

■O

Plug printer into a grounded 3 prong

AC socket.

When power is supplied to the printer, the power

indicator on the EZ Set Operator Panel will light.

17

Page 18

0)

(D

C

■o

oloio

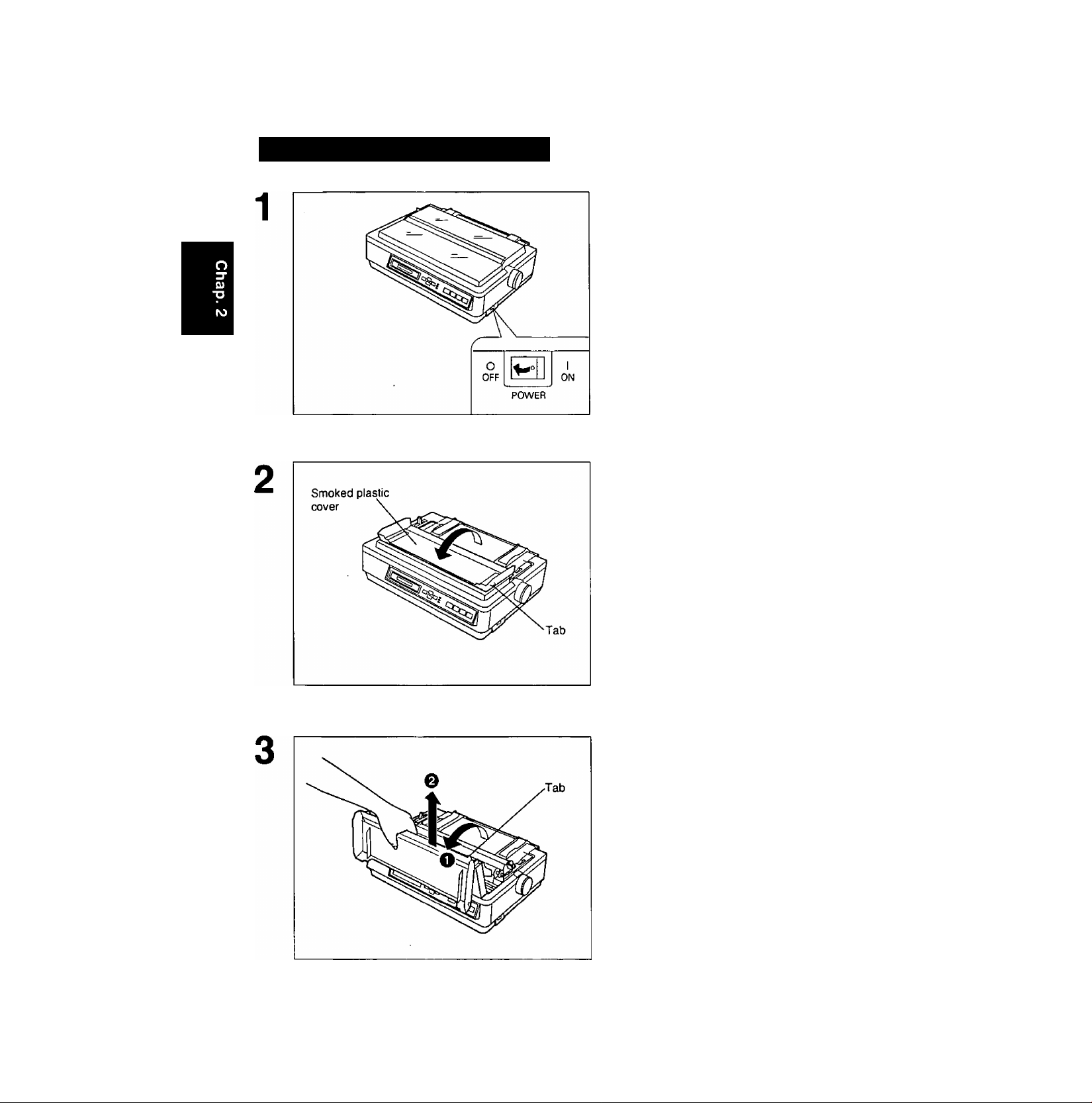

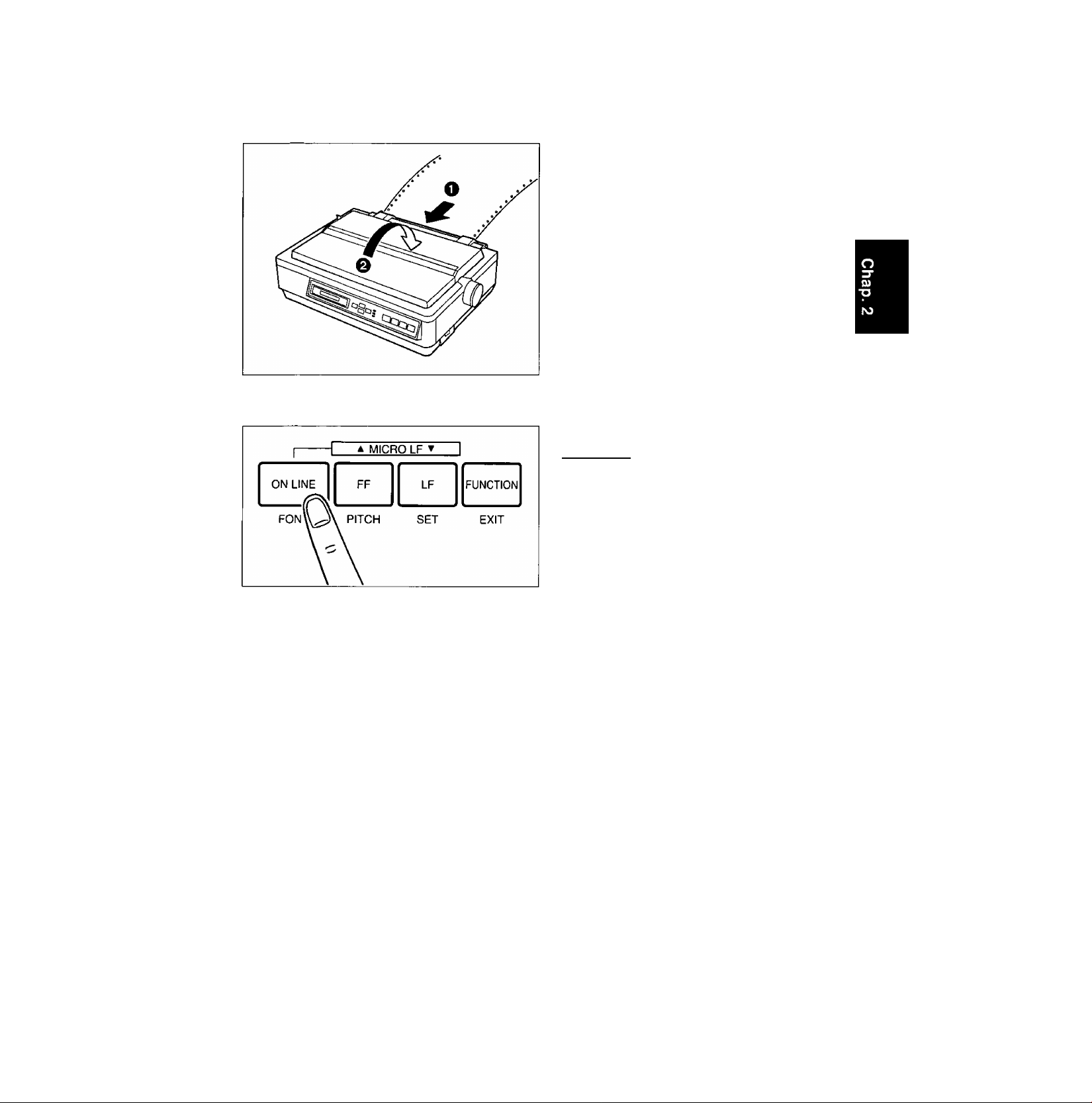

Installing the Ribbon Cassette

Turn the power switch off for safety.

Fold the smoked plastic cover forward

by lifting the tab on right side.

18

O Raise the smoked plastic cover.

0 Remove the smoked plastic cover.

Caution:

•The printhead may be hot, use caution

when cover is open.

Page 19

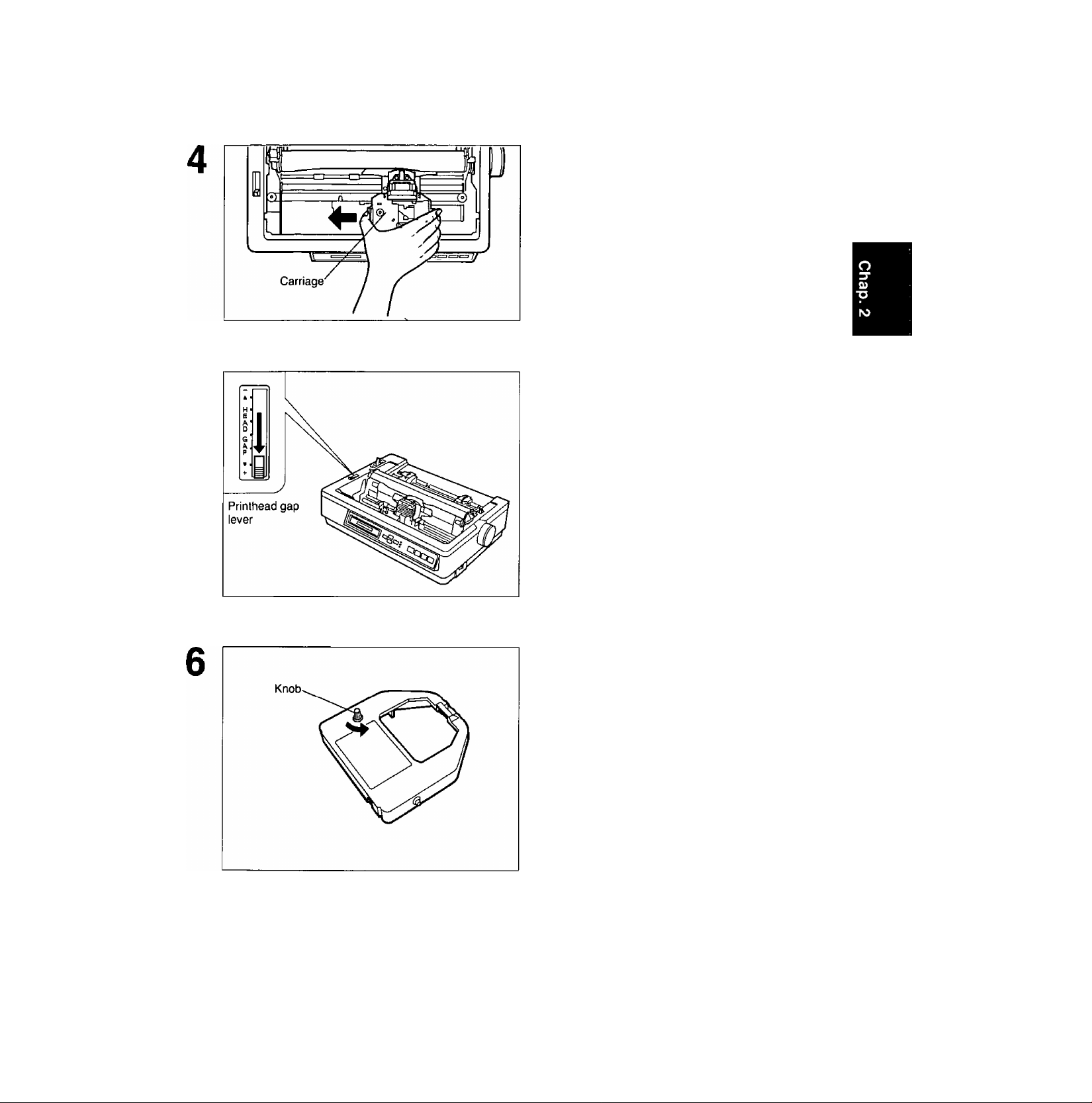

raSofeEOD

Slide the carriage gently toward the

center of the unit.

Move the printhead gap lever to the (+)

position.

CO

(D

C

■O

Rotate the knob on the ribbon cassette

to remove any slack.

19

Page 20

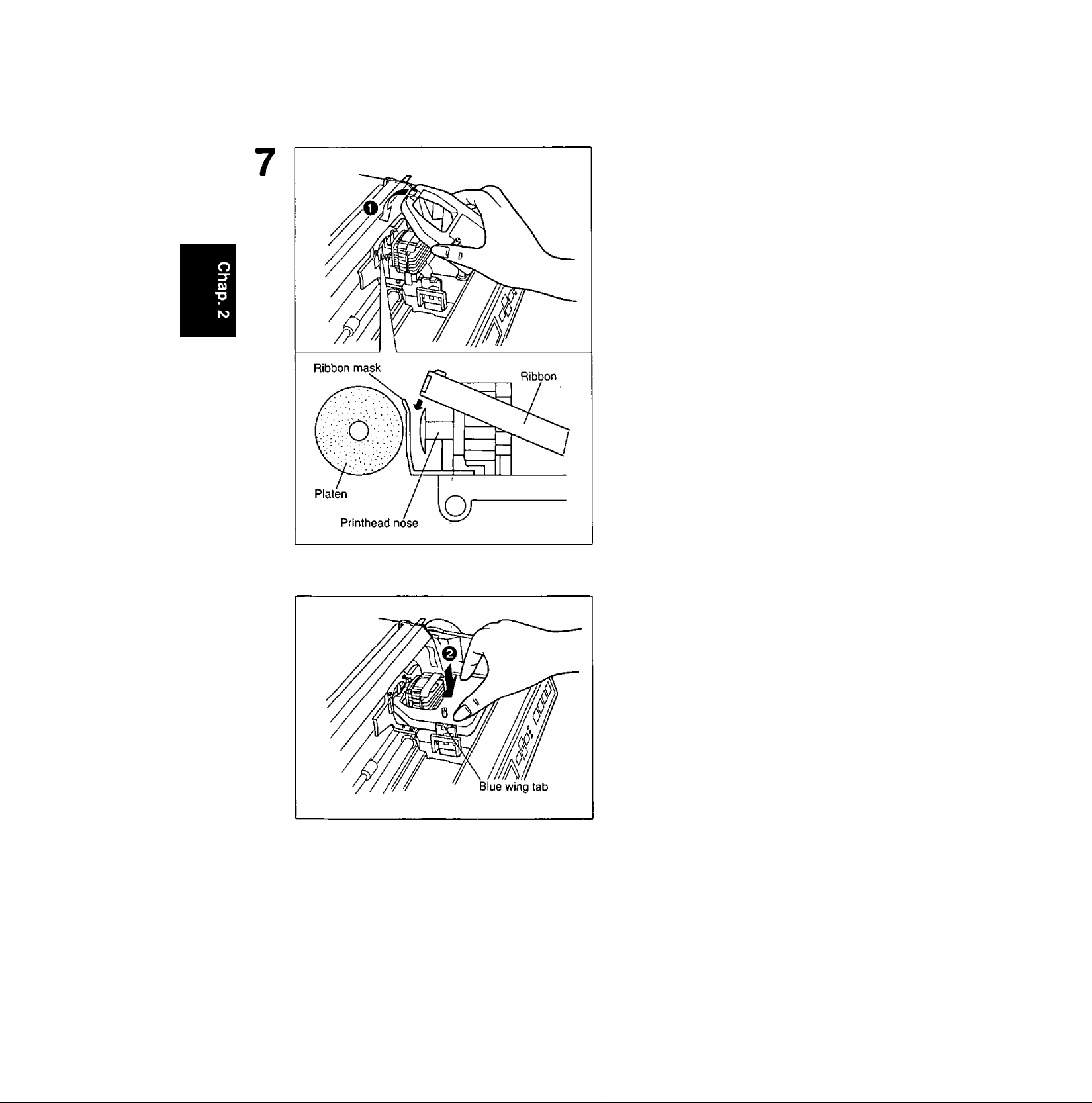

ra0tefe(sin]{^e@3Qa3

(A

(D

C

■O

O Slip the ribbon between the ribbon

mask and the printhead nose.

8

Q Press down on rear of the cassette

until the blue wing tab snaps into

place.

Replace the smoked plastic cover.

20

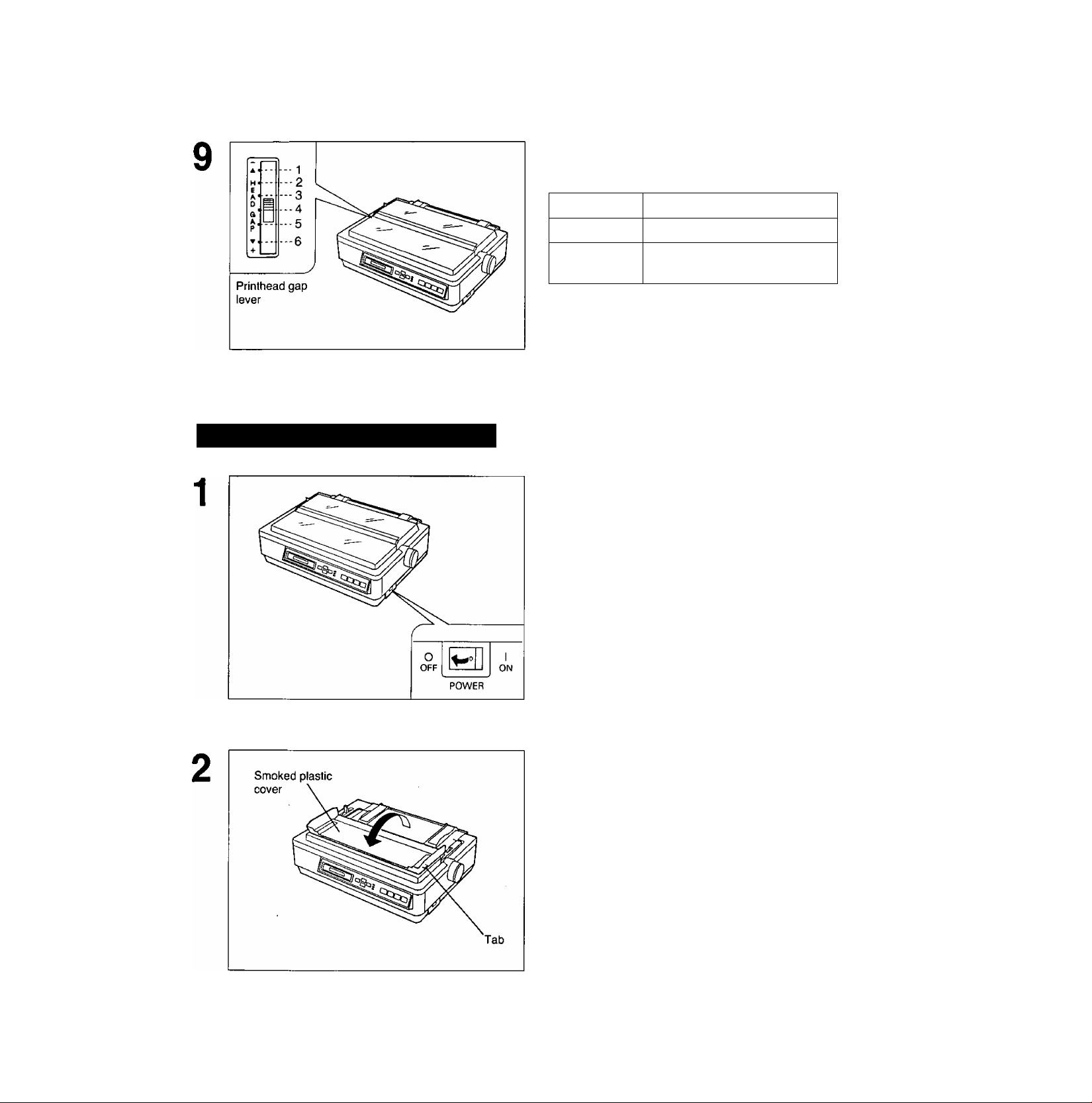

Page 21

Adjust the printhead gap lever for the

thickness of paper you are using.

Removing the Ribbon Cassette

Position

1 or 2 Thinner sheets

3, 4, 5 and 6

Turn the power switch off for safety.

Thick or multiple sheets or

envelopes

Used for

CO

(D

Fold the smoked plastic cover forward

by lifting the tab on right side.

21

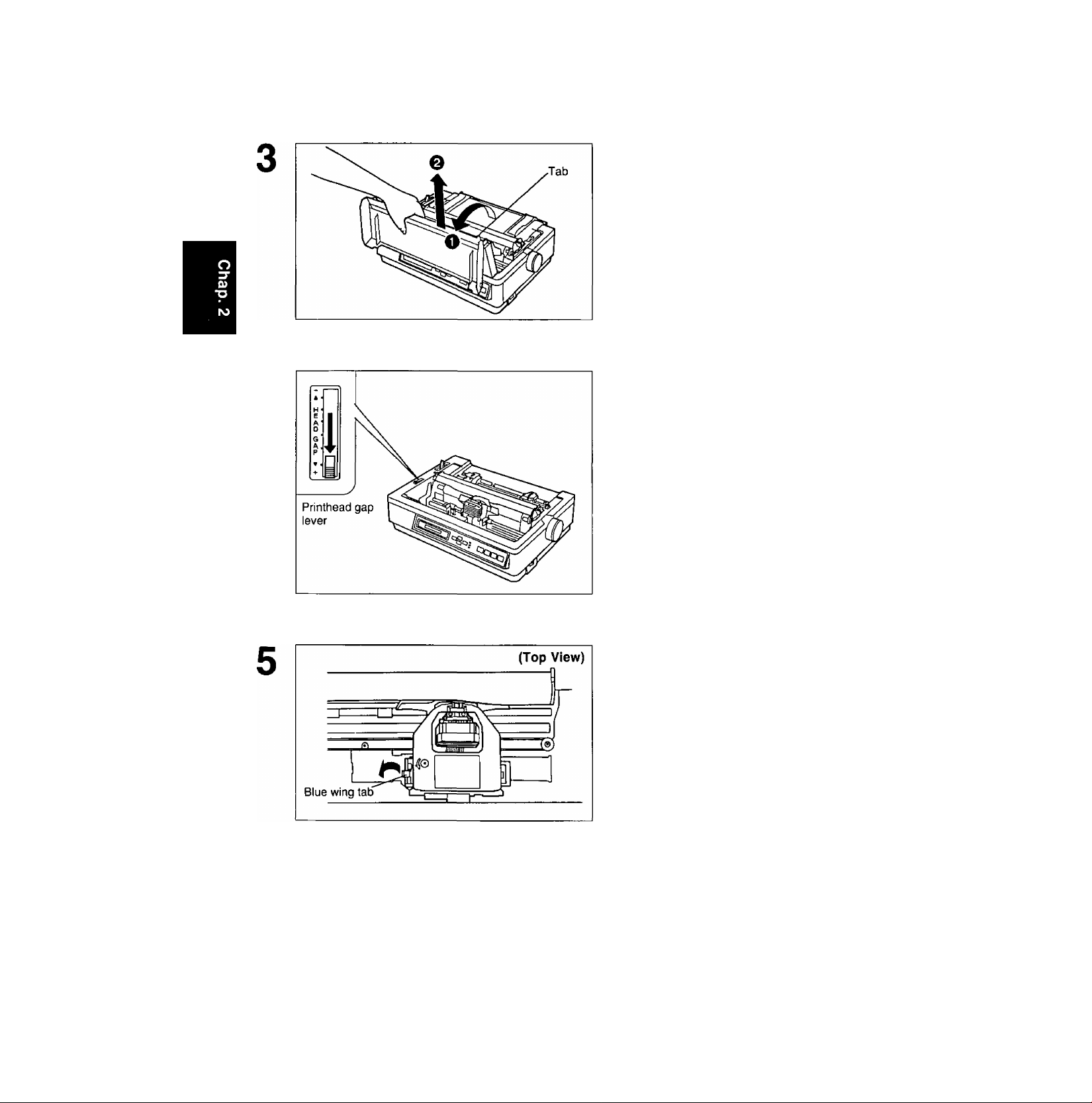

Page 22

CO

<D

C

■O

E3Qofe®0D ^3@@@03s

O Raise the smoked plastic cover.

@ Remove the smoked plastic cover.

Caution:

•The printhead may be hot, use caution

when cover is open.

Move the printhead gap lever to the (+)

position.

Spread the blue wing tab and lift up the

cassette.

22

Page 23

o o.

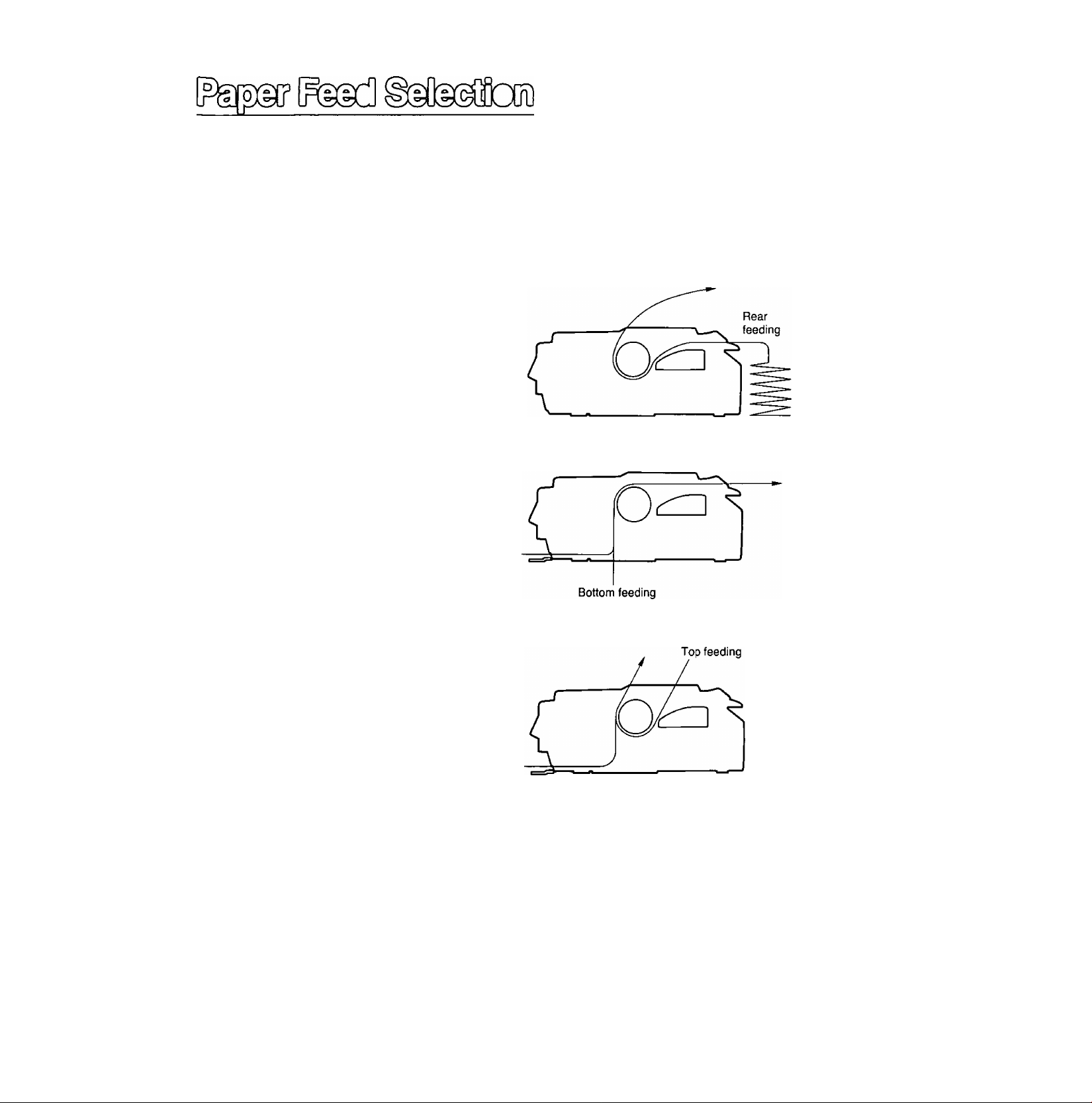

This printer has two paper feed mechanisms to support 4 paper paths. One mechanism is TRACTOR

mode for continuously fed paper. In the tractor mode you can choose between PUSH or PULL.

The other paper feed mechanism is FRICTION mode. In the friction mode you can feed single sheets

or envelopes through the front or top. The optional KX-PT11 Cut Sheet Feeder will accommodate

automatic feeding of single sheets, from the top paper path.

Push Tractor mode (Q PUSH)

—fanfold paper (1 part)

—multipart forms consisting of 2 parts

Pull Tractor mode (0 PULL)

—multipart forms consisting of 3

or 4 parts

—labels

—fanfold paper {1 part)

C/>

o

Front

feeding

Friction mode (Q)

—single sheets

(The KX-PT11 Cut Sheet Feeder

allows you to automatically feed up

to 80 sheets of 20 lb paper.)

—envelopes

Front

feeding

Note:

•For optimum print quality, do not use reverse line feeding in pull mode. If reverse feeding is

necessary in pull mode, set REV LF/PULL in the INSTALL menu to ON through the

Function mode.

•Paper Parking is not available in pull mode.

• Multipart forms consisting of 2 parts, may be used for rear feeding (PUSH mode). For 3 or

4 part forms, we recommend bottom feeding {PULL mode) for optimum print quality.

•When printing on envelopes or thick sheets, front feeding is recommended.

23

Page 24

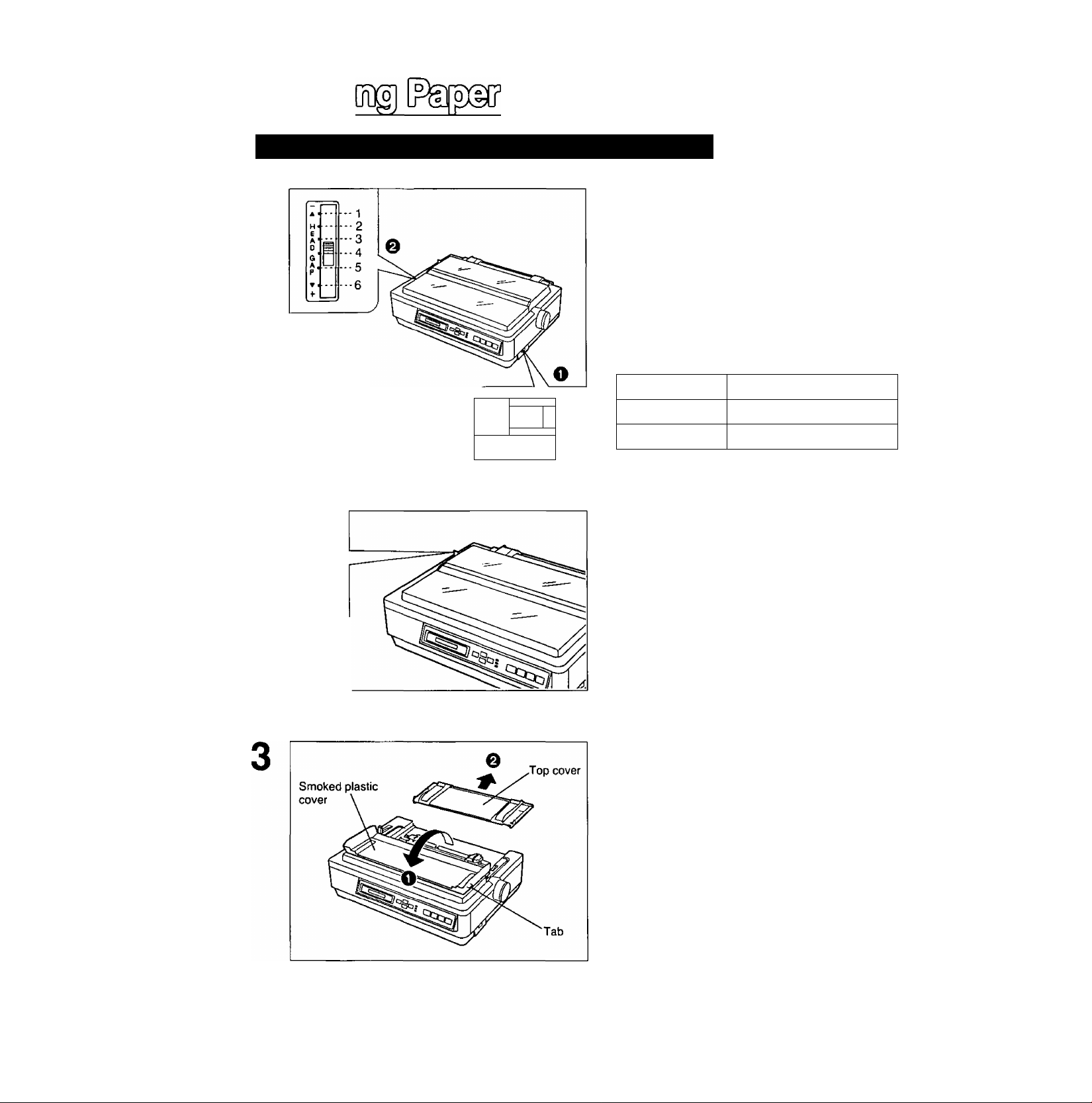

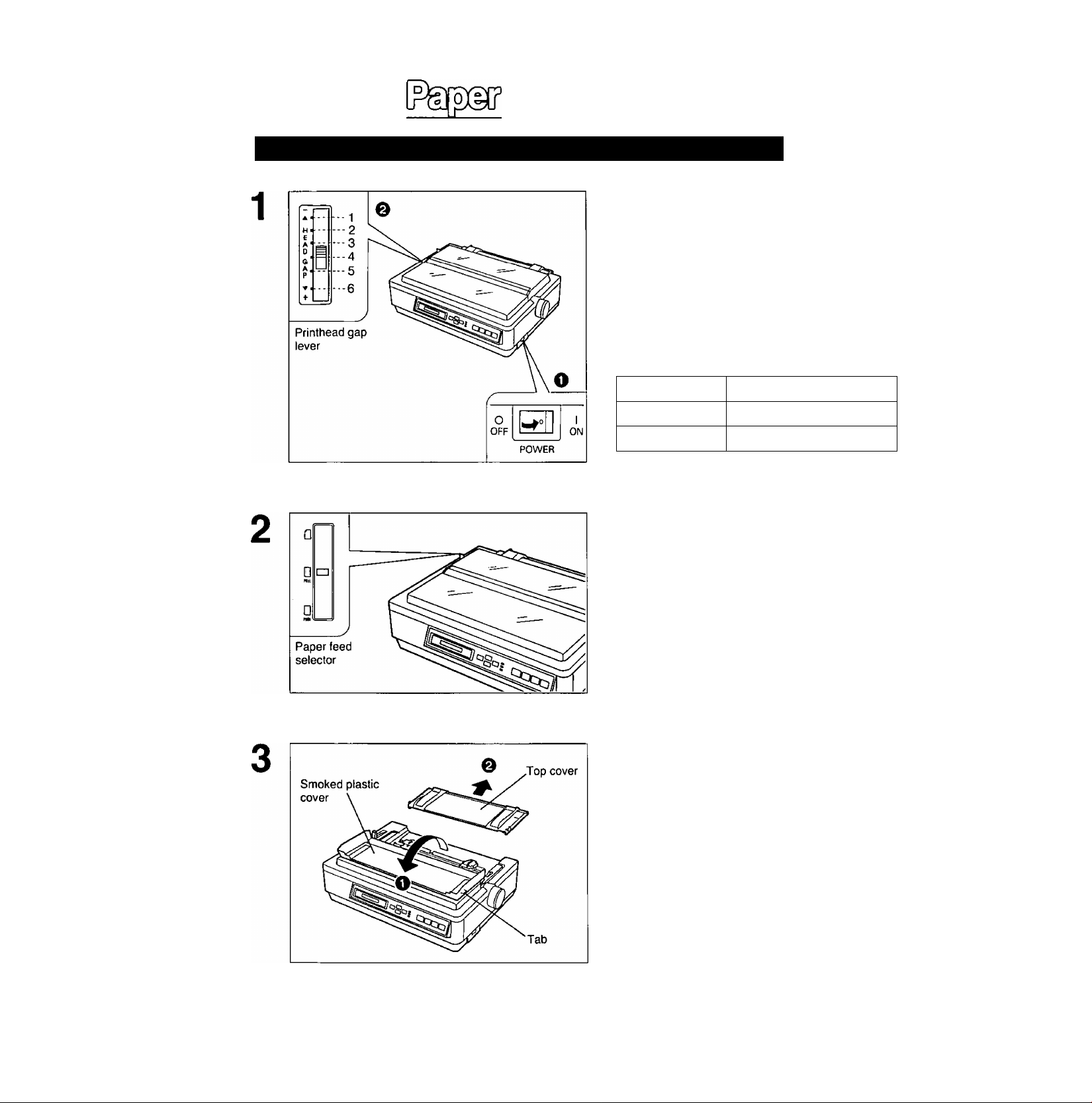

Fanfold Paper; Push Tractor Mode—Rear Feed

O Turn the power on.

1

A beep will sound once and the PAPER OUT

indicator will flash. This indicates that there is

no paper installed in the printer.

CO

<D

C

■o

Printhead gap

lever

1

Paper feed

selector

0

OFF

POWER

ON

0 Adjust the printhead gap lever for

the thickness of paper you are

using.

Position Used for

1 or 2 Thinner sheets

3, 4, 5 and 6

Set the paper feed selector to the “0 PUSH” position.

The display briefly shows “TRACTOR/PUSH".

Thick or multiple sheets

24

O Fold the smoked plastic cover for

ward by lifting tab on right side.

0 Remove the top cover.

Page 25

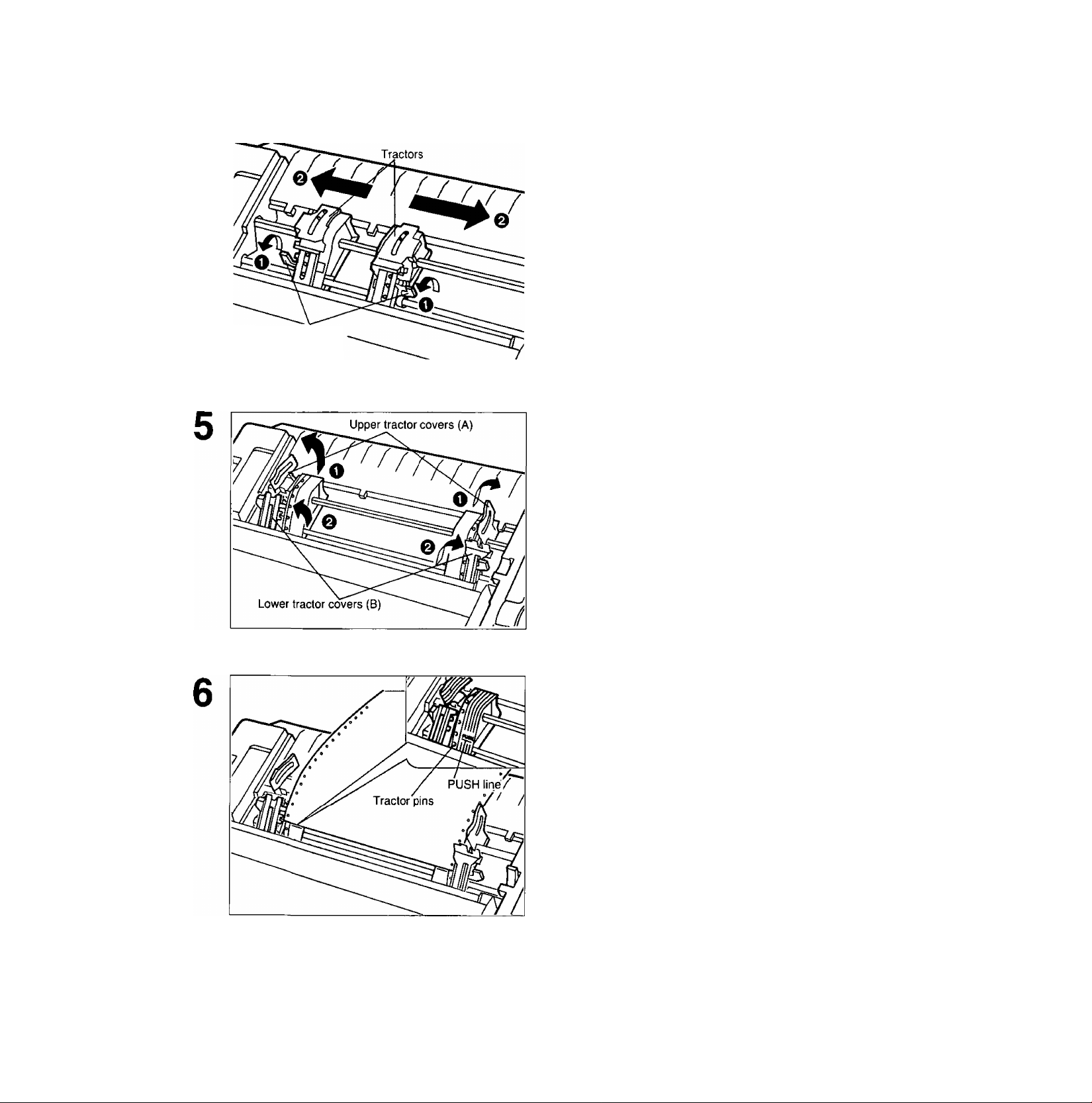

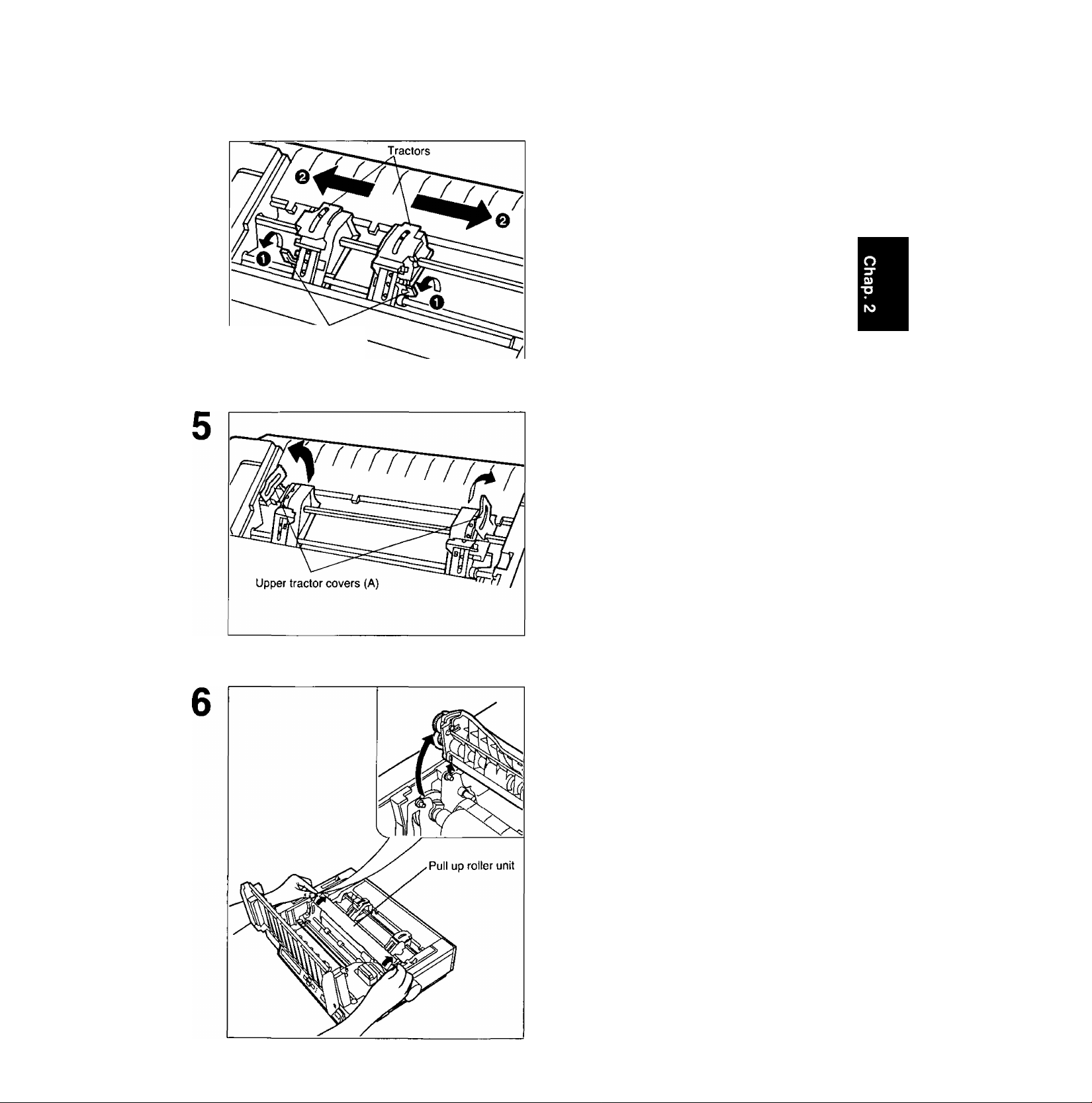

Tractor clamping

levers

ODQSíMIBiDg)

O Unlock the tractors by pulling the

tractor clamping levers forward.

0 Slide the tractors to accommodate

the approximate width of the paper

being used.

In most applications, you will find that the 0

indicator on the tear bar is a useful tool for

predetermining your left most print position.

O Raise the upper tractor covers (A).

0 Raise the lower tractor covers (B).

*o

CO

<D

C

Place paper holes onto tractor pins and

align top edge of paper with PUSH lines

on tractors.

25

Page 26

CO

(D

C

■O

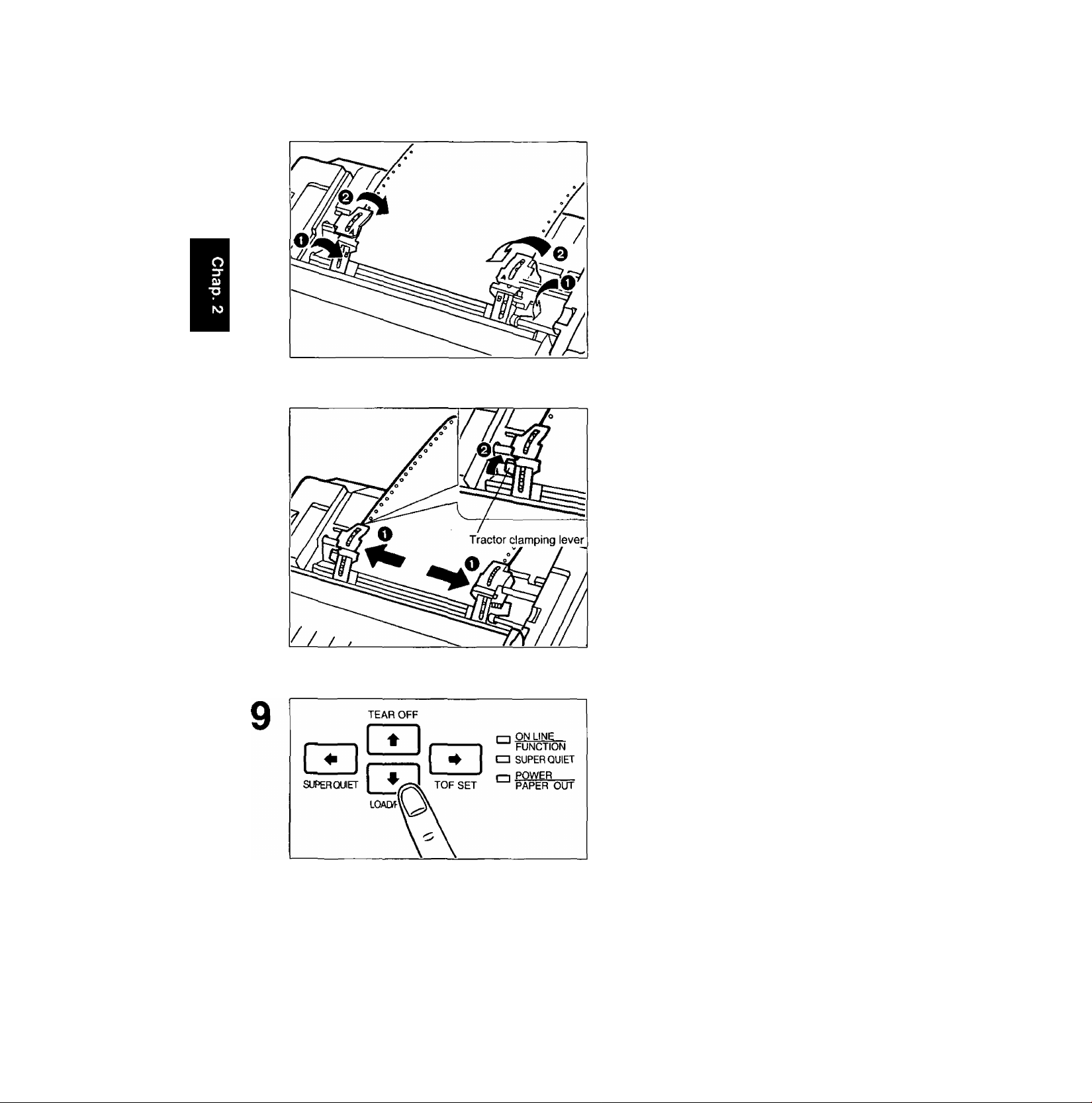

QsSMilg) [?fe(P(7

8

O Close the lower tractor covers (B).

0 Close the upper tractor covers (A).

O Adjust the tractors to remove any

slack in the paper.

0 Lock the tractor clamping levers.

26

Press [T) (LOAD/PARK).

This will load the paper to the first print line.

The display shows “PAPER LOAD” and the

PAPER OUT indicator will stop blinking.

Page 27

10

11

O Replace the top cover.

0 Close the smoked plastic cover.

If ON LINE indicator is not lit, press

[ON LINE] to get ready to print.

CO

(D

Note:

•To avoid paper cur! in PUSH mode, park

the paper after use.

27

Page 28

CO

o

c

■O

[ñlgíMlflnii^

Fanfold Paper: Pull Tractor Mode—Bottom/Front Feed

O Turn the power on.

A beep will sound once and the PAPER OUT indi

cator will flash. This indicates that there is no paper

installed in the printer.

Q Adjust the printhead gap lever for

the thickness of paper you are

using.

Position

1 or 2 Thinner sheets

Used for

3, 4, 5 and 6

Set the paper feed selector to the

“0 PULL” position.

The display briefly shows “TRACTOR/PULL”.

Thick or multiple sheets

O Fold the smoked plastic cover for

ward by lifting tab on right side.

0 Remove the top cover.

28

Page 29

Tractor clamping

levers

IMMBDïig)

O Unlock the tractors by pulling the

tractor clamping levers forward.

0 Slide the tractors to accommodate

the approximate width of the paper

being used.

In most applications, you will find that the 0

indicator on the tear bar is a useful tool for

predetermining your left most print position.

Raise the upper tractor covers (A) only.

CO

(D

C

*o

Remove the pull up roller unit as shown.

Note:

• Do not forget to remove the pull up roller

unit before using PULL mode.

29

Page 30

C/)

(D

c

*o

ODDSiMBji©

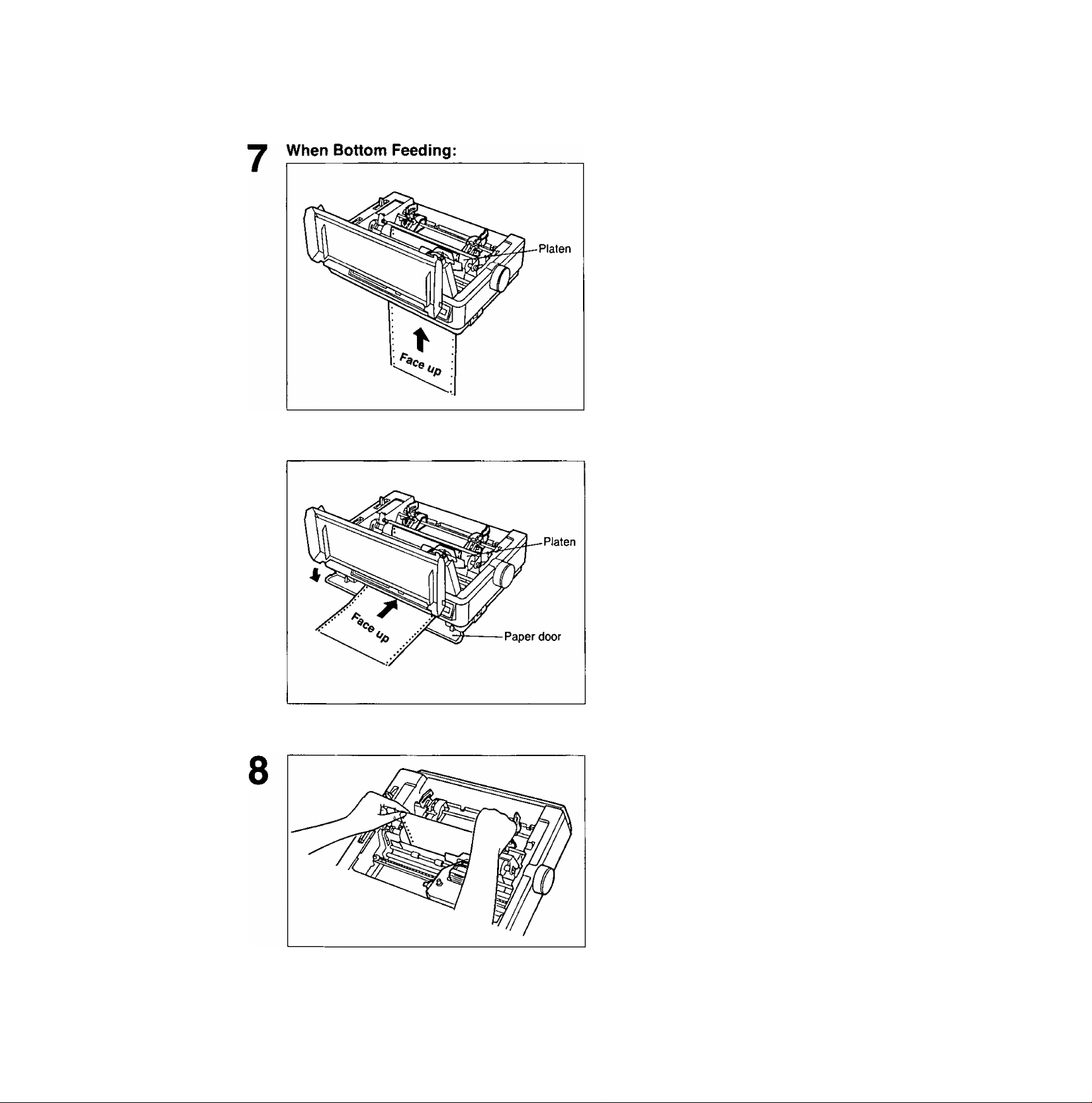

Push the paper up through the bottom

opening until it appears in front of the

platen.

When Front Feeding:

Open the paper door and insert the

paper along the paper guides until it

appears in front of the platen.

Note:

•When feeding fanfold paper through the

front paper door, paper types and condition,

as well as temperature and humidity

conditions may effect accurate line feeding

and print quality may not be optimum. For

optimum output bottom feed is

recommended.

Adjust the paper position by pulling it

up as shown.

30

Page 31

10

QseiMDDDiig

O Align the paper sprocket holes

with the tractor pins making sure

the paper is straight.

Q Close the tractor covers.

O Adjust the tractors to remove any

slack in the paper.

0 Lock the tractor clamping levers.

c/>

(D

c

■O

11

Replace the pull up roller unit.

Note:

•Be sure to press down the pull up roller unit

until it snaps into place.

31

Page 32

CO

(D

C

T3

OMMBjDg] ffepa?

12

13

O Replace the top cover to its origi

nal position.

0 Close the smoked plastic cover.

If ON LINE indicator is not lit, press [ON LINE) to get ready to print.

Note:

• In the pul! tractor mode, reverse feed functions will not feed paper correctly and the resulting

printout may not be correct.

If reverse feeding is necessary in pull mode, set REV LF/PULL in the INSTALL menu to ON

through the Function mode.

32

Page 33

ODOgteOBjilg

Single Sheets and Envelopes: Friction Mode—Top Feed

O Turn the power switch on.

A beep will sound and the PAPER OUT indica

tor will flash. This indicates that there is no

paper installed in the printer.

Q Adjust the printhead gap lever for

the thickness of paper you are

using.

CO

o

Position

1 or 2

3, 4, 5 and 6 Thick sheets or Envelopes

Set the paper feed selector to the

position.

The display briefly shows “FRICTION".

Thinner sheets

Used for

O Fold the smoked plastic cover by

lifting tab on right side.

Q Reposition the top cover into the

singie sheet position by inserting

the top cover pins into the siots in

the printer.

33

Page 34

CO

(D

C

■O

QjQ@[№l|]

Separate the paper guides to the ap

proximate width of your paper.

Note:

•To predetermine your left most print

position, move the left paper guide until it

clicks into place.

Insert one sheet of paper into the paper

guide slots.

The paper will automatically load to the first print

line.

34

Fold the smoked plastic cover until it

rests against top cover.

Page 35

If ON LINE indicator is not lit, press

(ON LINE) to get ready to print.

Note:

•If the paper does not automatically load, press (5D (LOAD/PARK).

•When the paper feed selector is in the “0” position, the buzzer will sound to inform you that

the selector is in the wrong position.

•When loading an envelope, if the envelope will not load smoothly, move the paper feed

selector to the “0 PULL” position and insert the envelope manually, then move the selector

back to the “Q” position.

•When printing on envelopes or thick sheets, front feeding is recommended.

Single Sheets and Envelopes: Friction Mode—Front Feed

O Turn the power switch on.

1

Printhead gap

lever

A Ц

H<

E

A '

0

a'

▼ 1

+

... 1

--2

...

g

...4

--5

A beep will sound and the PAPER OUT indica

tor will flash. This indicates that there is no

paper installed in the printer.

...0

0 Adjust the printhead gap lever for

the thickness of paper you are

using.

0)

(D

C

■O

0

OFF

^0

POWER

ON

Position Used for

1 or 2 Thinner sheets

3, 4, 5 and 6

Thick sheets or Envelopes

35

Page 36

CO

<0

c

■O

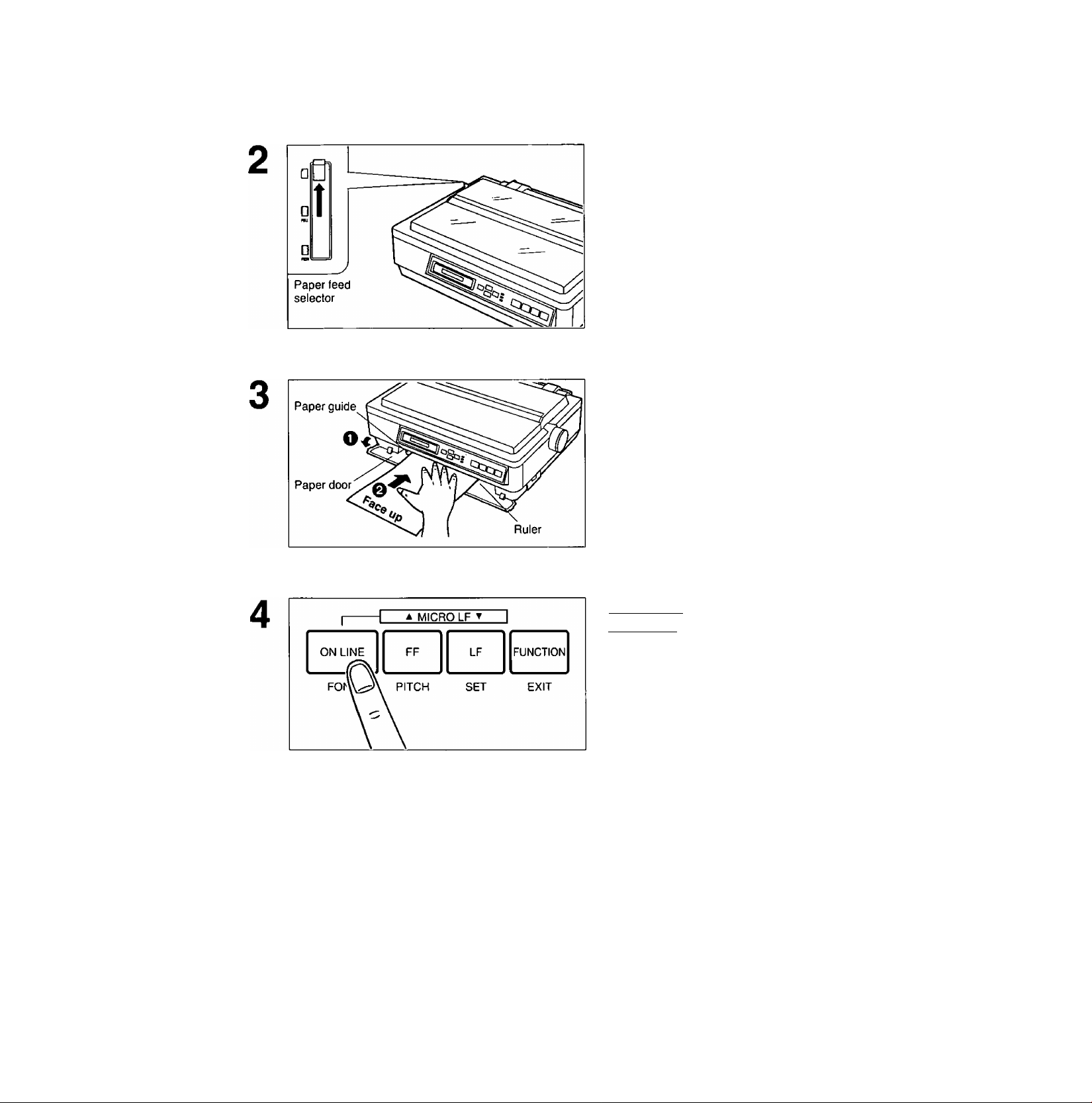

Set the paper feed selector to the

position.

The display briefly shows "FRICTION".

O Open the paper door.

0 Insert one sheet of paper along the

front paper guide until you feel re

sistance.

The paper will automatically load to the first

print line.

If ON LINE indicator is not lit, press

(ON LINE) to get ready to print.

Note:

• If the paper does not automatically load, press (5D (LOAD/PARK).

•When the paper feed selector is in the "0” position, the buzzer will sound to inform you that

the selector is in the wrong position.

•When loading an envelope, if the envelope will not load smoothly, move the paper feed

selector to the “0 PULL” position and insert the envelope manually, then move the selector

back to the “Q" position.

•When printing on envelopes or thick sheets, front feeding is recommended.

36

Page 37

OCiD@[aiB¡Dg

Characters Alignment

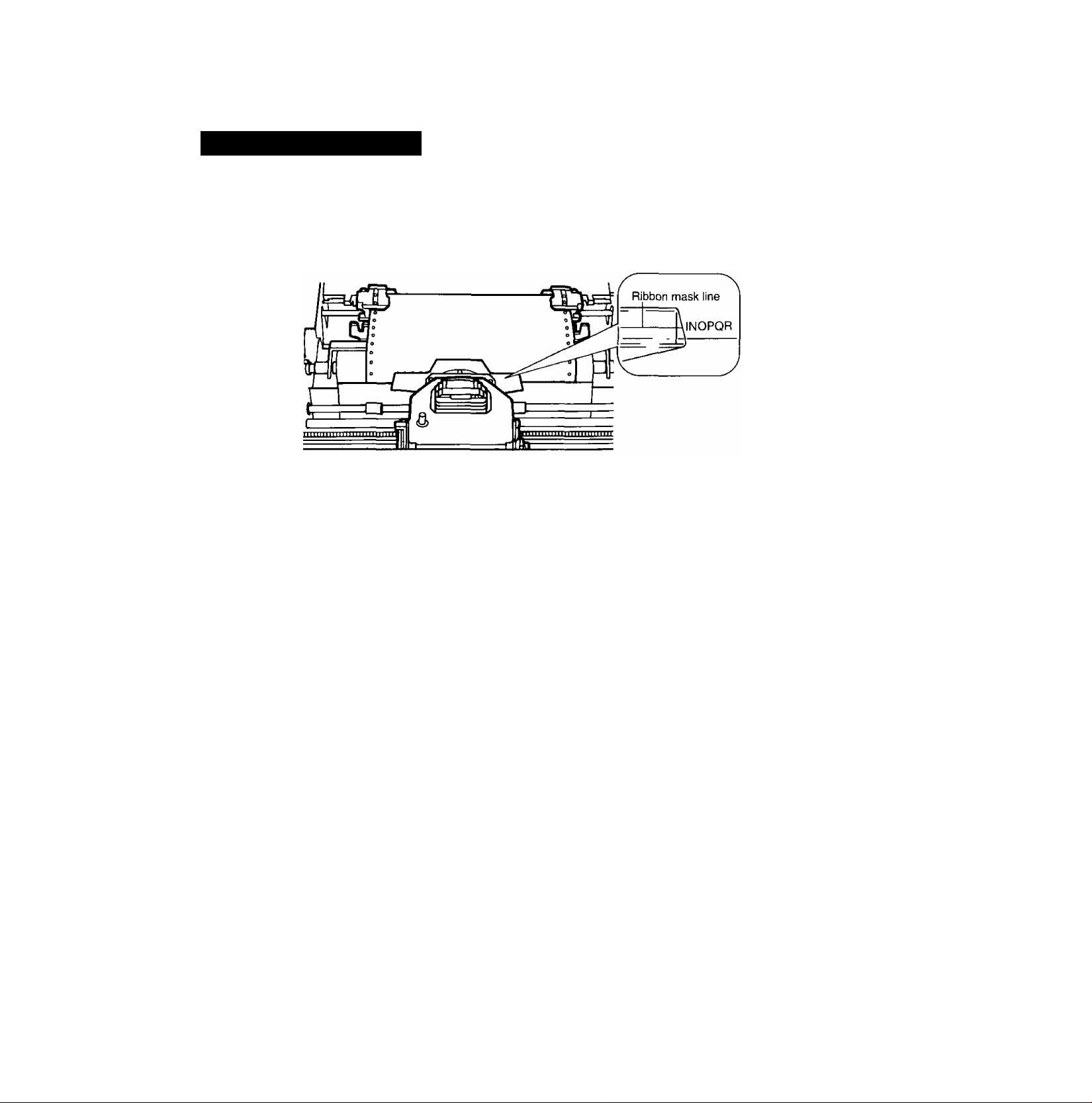

The center of all characters printed on this printer will be aligned with the ribbon mask line (RML).

The RML is a useful marker that shows you exactly where your print line is located.

CO

o

Note;

• Remember that once you rotate the platen knob, the top of form (TOP) will no longer be

recognized.

37

Page 38

The Printer-Driver Selection contains the software codes your application software program uses to

access the printer's features,

This procedure is the final step before printing and is performed in your application software program.

The steps will vary, depending on the software program. Consult your software package for proper

procedures. The Panasonic KX-P3124 will be your first choice. However, if the Panasonic KX-P3124

printer is not listed in your software, you must select an alternative from the following table.

Printer-Driver Selections (in order of priority)

Color Printer Selections'^

Printer Selection

(KX-PCK11 Color Kit must be installed

in the KX-P3124)

CO

0

C

■O

Panasonic KX-P3124

Panasonic KX-P3123 Panasonic KX-P3123

Epson LQ-570 (ESC/P2™) Panasonic KX-P2124

Panasonic KX-P2124 Panasonic KX-P2123

Panasonic KX-P2123 Epson LQ-860

Panasonic KX-P1124/

Epson LQ Series

IBM Proprinter X24E

IBM Proprinter X24

When you use IBM Proprinter X24E/X24 mode;

Change the Emulation to IBM Proprinter X24E/X24 mode in the Function mode (0^ P. 52—77) and

select the appropriate Printer-Driver in the software package.

* To obtain color and utilize the internal scalable fonts, the Panasonic KX-P3124 printer driver must

be selected in your software.

Panasonic KX-P3124

Epson LQ-2500/2550

*

38

Page 39

DoiiigiMIDCiJi]^ Q PM(sx!i!^ SdDd

If you are using Windows Ver. 3.1, please insert your Setup Disk into drive A or B and follow the

directions below.

Before you use the Setup Disk, it is recommended that you make a back-up copy and store the

original in a safe place.

Note:

• Use the DISKCOPY command of the operating system to make a back-up copy. Refer to your

DOS manual for further information.

In “Main Group”, select “Print

1

Manager”.

in “Options”, select “Printer

Setup”.

Click Add>>

In “List of Printers”, seiect

“Install Unlisted or Updated

Printer”.

Click Install...

Insert the Setup Disk into

drive A.

If you choose to insert the Setup Disk

into drive B, you must type B:\.

Default Printer —

xxxxxxxxxxxxxx

Installed Printer:

XXXXXXXXXX

Set As Default Printer

Default Printer —

XXXXXXXXXXXXXX

Installed Printer:

Set As Default Printer

List of Printers:

[insta lIlQn listedTo^Updated

Rrinters

Printers

JO

0)

(D

C

■o

Cancel

Connect..

Setup-

Remove

Add»

Help

Cancel

Connect..

Setup...

Remove

0

Add»

Help

Install...

0

39

Page 40

ODDgQaCDBdí© 0 \!5ia?o Sbí))

Click OK

InstalliDriver

co

o

Highlight your Panasonic

8

printer model.

Inserí unlisted, updated, or

vendor-provided printer driver

disk in:

A:\

List of Printers:

[gana son iclK-X;R3Y2'4

OK

Cancel

Browse...

Help

0

OK

Cancel

Help

10

11

12

40

Click OK .

Click “Set As Default Printer”.

Click Close

Exit the “Print Manager”.

Page 41

The printer has a self test feature which allows you to test the printer.

Load a sheet of paper (fanfold or single

1

sheet), then turn the power off.

((BT P. 28--36),

While pressing (lQ, turn the power on.

After starting the printing, release (TtI-

CO

<D

A sample printout will begin, which

serves as a self test.

Version

Draft

! /0123456789

! ’■#$%&’( ./0123456789:

)*+,-./0123456789: ;

):t:+./0123456789: ;<

./0123456789: ; < =

: ; < = >?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]

; < = >?@ABCDEFGHIJKLMNOPQRSTUVWXYZ [\]

< = >?@ABCDEFGHI JKLMNOPQRSTUVUJXYZ [\]

=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]

> ?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\] ab

Courier

!"#$%&'()*+,-./0123456789

!”#$%&’C)*+,-./0123456789:

"#$%&'()*+,-./0123456789:;

#$%&’()*+,-./0123456789:;<

$%&*()*+,-./0123456789: ;< =

: ;< = >?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]

; < = >?0ABCDEFGHI JKLMNOPQRSTUVWXYZ [ \ ]''.

< = >?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]"_

= >?$ABCDEFGHIJKLMNOPQRSTUVWXYZ[\2

>?0ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]"_'a!

P

If the printer is functioning properly, you

may turn the power off during the self

test, or you may run the entire test (ap

proximately 20 minutes).

.BCDE

F G HIJ KL MNO P QR S TUVWXYYJJU^

•*-*ULJtyT

----

41

Page 42

010

The Super Quiet mode is a useful feature for further reducing print noise, however, it also reduces the

printer’s speed.

Turning on the Super Quiet mode:

Press @ (SUPER QUIET).

The SUPER QUIET indicator is lit and the display

briefly shows “QUIET MODE= ON”.

Turning off the Super Quiet mode;

Press @ (SUPER QUIET) again.

(D

The SUPER QUIET indicator is off and the display

briefly shows “QUIET MODE= OFF".

Note:

•When enabled this feature will decrease your print speed.

•Your printer has the capability of saving this feature through the Function mode.

(0^ P. 52-77)

42

Page 43

You can adjust the paper position by using the front panel switches when the printer is in the OFF

LINE mode or when the printer is not printing in the ON LINE mode.

Form Feed

Pressing fFF] advances the paper to

the next top of form position.

Line Feed

Pressing (T^ once advances the paper

one line.

Micro Line Feed

Reverse Micro Line Feed

Holding the switch will advance the paper continu

ously until the switch is released.

Pressing [F0 while pressing [ON LINE] advances the paper one micro line

(Vi 80").

Holding the switches will advance the paper contin

uously until the switches are released.

Pressing [LFl while pressing [ON LINE]

reverses the paper one micro line

(Vl80").

C

w

5'

(Q

(D

"D

5'

(D

The printer cannot reverse the paper past the print

able area. Holding the switches will reverse the

paper continuously until the switches are released.

Note:

• In the pull tractor mode, Reverse Micro Line Feed will not feed paper correctly.

•When pressing (fQ or [TfI. the amount of paper which is fed is determined by the current

setting for lines per inch as specified in the Function mode or software command.

43

Page 44

o

■0

5‘

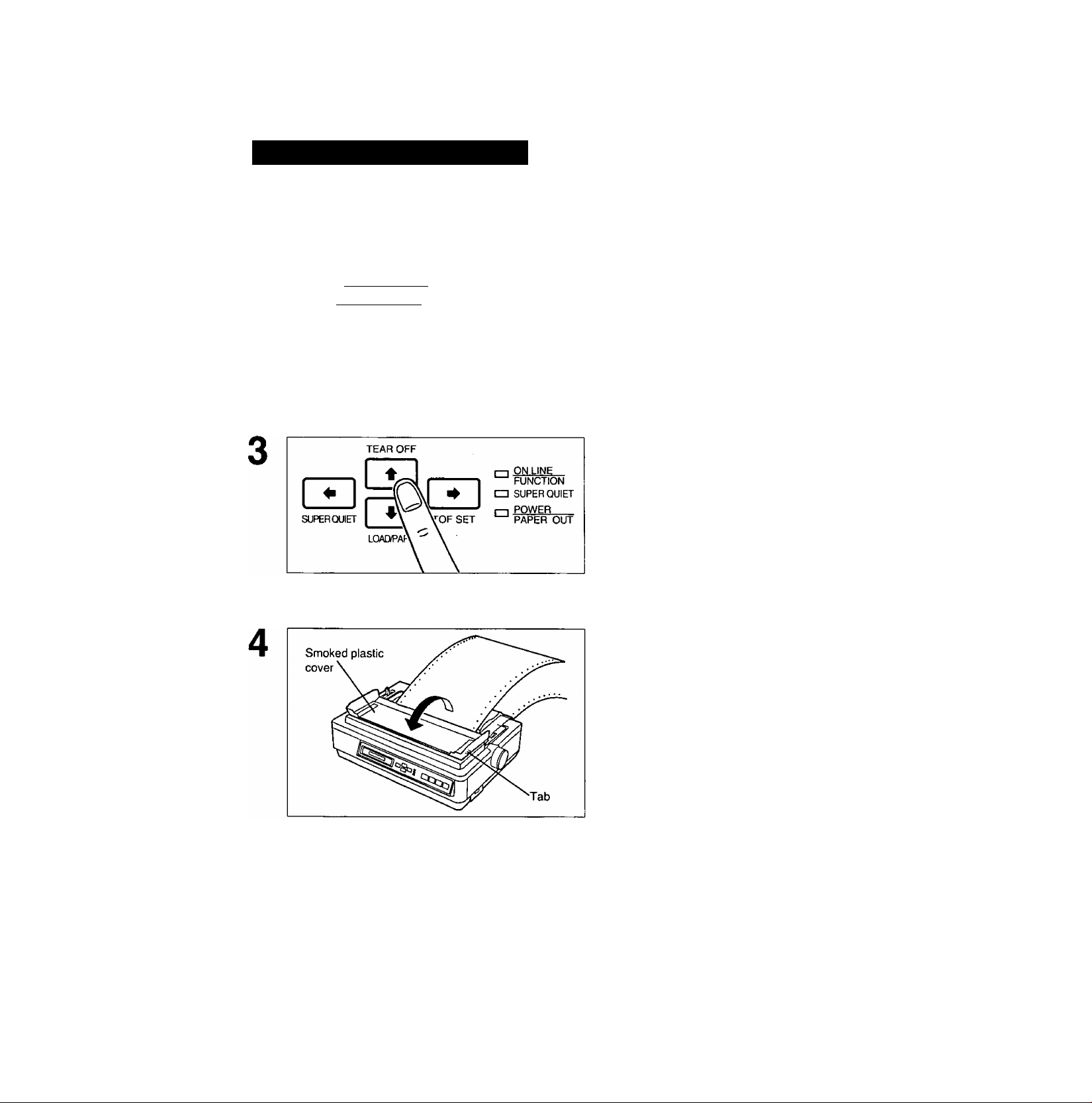

(D

Tear Off (Rear feeding only)

This function allows you to advance your fanfold paper’s perforation to the tear position. This is not

dependent on your top of form position but is dependent on your form length. After tearing off the

page you can return your paper to the top of form. This function can be automatic through the

Function mode.

If the ON LINE indicator is blinking,

1

press (FUNCTION] to exit the Function

mode.

Be sure the paper feed selector is in the

“0 PUSH” position.

Press (T] (TEAR OFF) to advance the

paper to the tear bar.

Fold the smoked plastic cover forward

by lifting the tab on right side.

44

Page 45

RaaiBDiig

Tear off the page, using the tear bar.

Press [T] (TEAR OFF) again to reverse

the paper back to the top of form.

—A Top of Form setting (0^ P. 50) past the print

able area is ignored by Tear Off. Tear Off will

use the Top of Form setting that was last saved.

—If you do not press (T] (TEAR OFF) the second

time, once data is received, the printer will auto

matically reverse the paper to the top of form

position.

Replace the smoked plastic cover.

c

S2.

5'

<Q

3*

(D

3

(D

45

Page 46

Paper Parking (Rear feeding only)

This function allows you to use single sheets or envelopes without removing or wasting your fanfold

paper.

Parking the Fanfold Paper

Be sure power is on and the paper feed

1

selector is in the “Q PUSH” position.

c

»

5'

(O

(D

"D

5'

(D If the ON LINE/FUNCTION indicator is

blinking, press [FUNCTION].

Tear off the printed page(s) of the fanfold paper being used, (et P. 44—45)

Press (X) (LOAD/PARK) to reverse the

fanfold paper to the parked position.

While the paper is going back, the display shows

"PAPER BACK”, and when the paper is parked,

the display shows “PAPER OUT”, with the PAPER

OUT indicator blinking. If the printer is in the ON

LINE mode, it automatically goes back to the OFF

LINE mode.

46

Page 47

Loading Single Sheets or Envelopes

1

Paper feed

selector

O Move the paper feed selector to the

position.

The display briefly shows “FRICTION”.

0 Fold the smoked plastic cover.

O Raise the top cover to the single

sheet position.

0 Separate the paper guide and load a

single sheet or an envelope.

(q^ P. 33-35 “Single Sheets and En

velopes”)

O Open the paper door.

0 Load a single sheet or an envelope.

([^ P. 35-36 “Single Sheets and En

velopes”)

c

<2

5'

(Q

(D

■0

5'

(D

Press (ON LINE] to enable printing.

The ON LINE indicator will be lit and the display will

show “ON LINE”.

47

Page 48

c

w

5'

(Q

(D

■D

Reloading the Fanfold Paper

When you are finished printing, remove

the sheet from the printer by rotating

the platen knob.

O Lower the top cover for fanfold

paper.

0 Replace the smoked plastic cover to

its original position.

O Close the paper door.

0 Replace the smoked plastic cover to

its original position.

48

Page 49

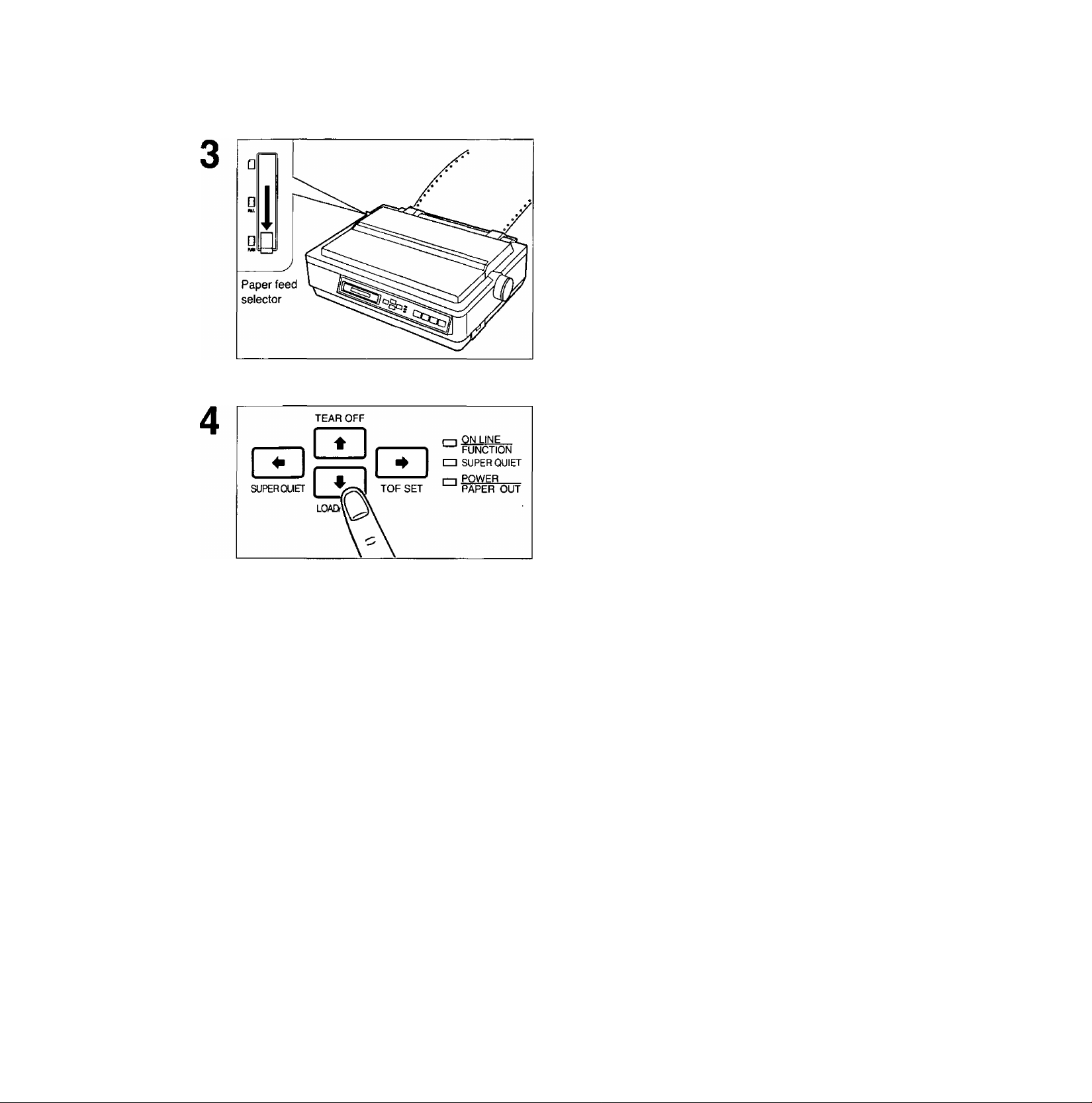

Move the paper feed selector to the

PUSH” position.

Press (2 (LOAD/PARK) to reload the

fanfold paper to the first print iine.

c

2

5*

(O

(D

“0

5'

!.

49

Page 50

Top of Form Function

This printer allows you to set and store the first print line position and automatically load the paper to

that location. The first print line position (TOF) will remain stored in memory when power is turned off.

The printer can store the 3 different top of form positions depending on the paper feed method

[fanfold paper (0 PUSH), single sheet (Q), and single sheet with the Cut Sheet Feeder option:

KX-PT11].

o

TJ

5’

<D

If necessary, redefine the page length of

1

the paper you are using through your

application software (o^ P. 82, 88) or the

printer’s Function mode (o^ P. 58, 63).

If the ON LINE/FUNCTION indicator is

blinking, press [FUNCTION].

To redefine your paper’s first print posi

tion, it is recommended that you use

your application software. If this feature

is not provided in your software, adjust

the paper position by using Line Feed,

Micro Line Feed, or Reverse Micro Line

Feed, (c^ P. 43)

A page is defined by setting the page length

through the Function Mode or the Software com

mand.

Press [T] (LOAD/PARK) to load the

paper.

50

Note:

• Do not rotate the platen knob, the printer will

not be able to count the number of lines.

Page 51

Press @ (TOP SET) to set the Top of Form for the current position.

Saved Top of Form

A Top of Form position (less than or equal to 5"

from the top of page) will be saved even after the

power is turned off. Pressing (2 (LOAD/PARK)

will advance the paper to the most recently saved

Top of Form setting.

Temporary Top of Form

A Top of Form position set in the area greater than

5 inches will not be saved after the power is turned

off, after parking the paper, after using Tear Off, or

after pressing

[fEI when using a single sheet.

Note:

•A temporary Top of Form setting is indicated by one beep. A saved Top of Form setting

is indicated by two beeps.

•When using fanfold paper, the Top of Form position must be set on the first page because the

printer does not accept a top margin which is longer than one page.

C

(0

5'

(O

<D

“O

5'

(D

51

Page 52

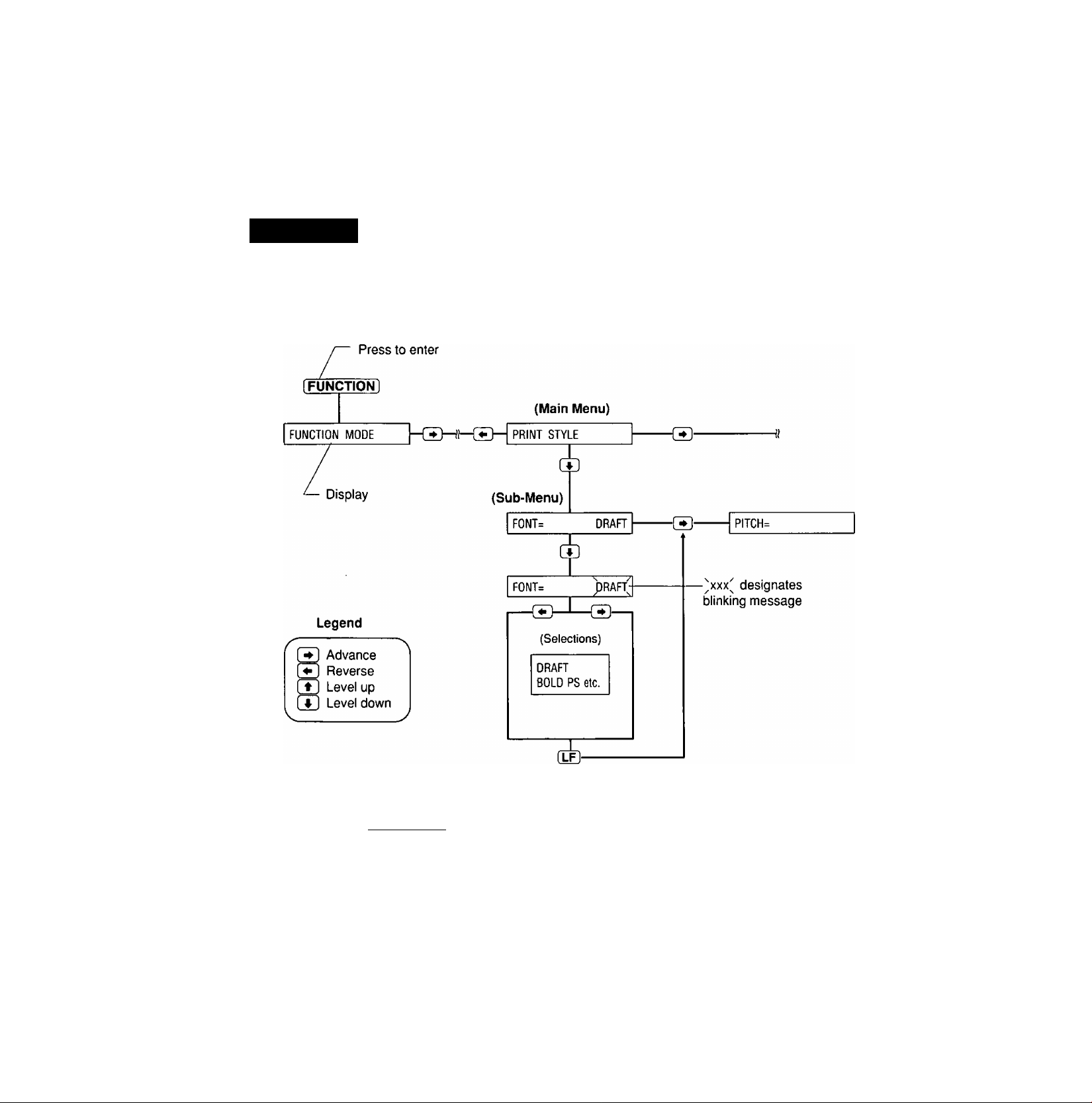

You can control a wide variety of printing conditions through the Function mode. The Function mode

is comprised of a Main menu and Sub-menus that allow you to select modes and parameters.

(D3^ P. 58-“69 “Function Mode Menu")

Operation

The following flow chart diagrams the operation using the EZ Set Operator Panel. After entering the

Function Mode, the black lettering (FONT, PITCH, SET and EXIT) and outlining (^, t, ^) will

help you navigate through the Main menus, Sub-menus and selections.

3

o

o

a

(D

SE T

Set and returns you to

the Sub-menu

Press (TUNCTioFTl to exit.

52

Page 53

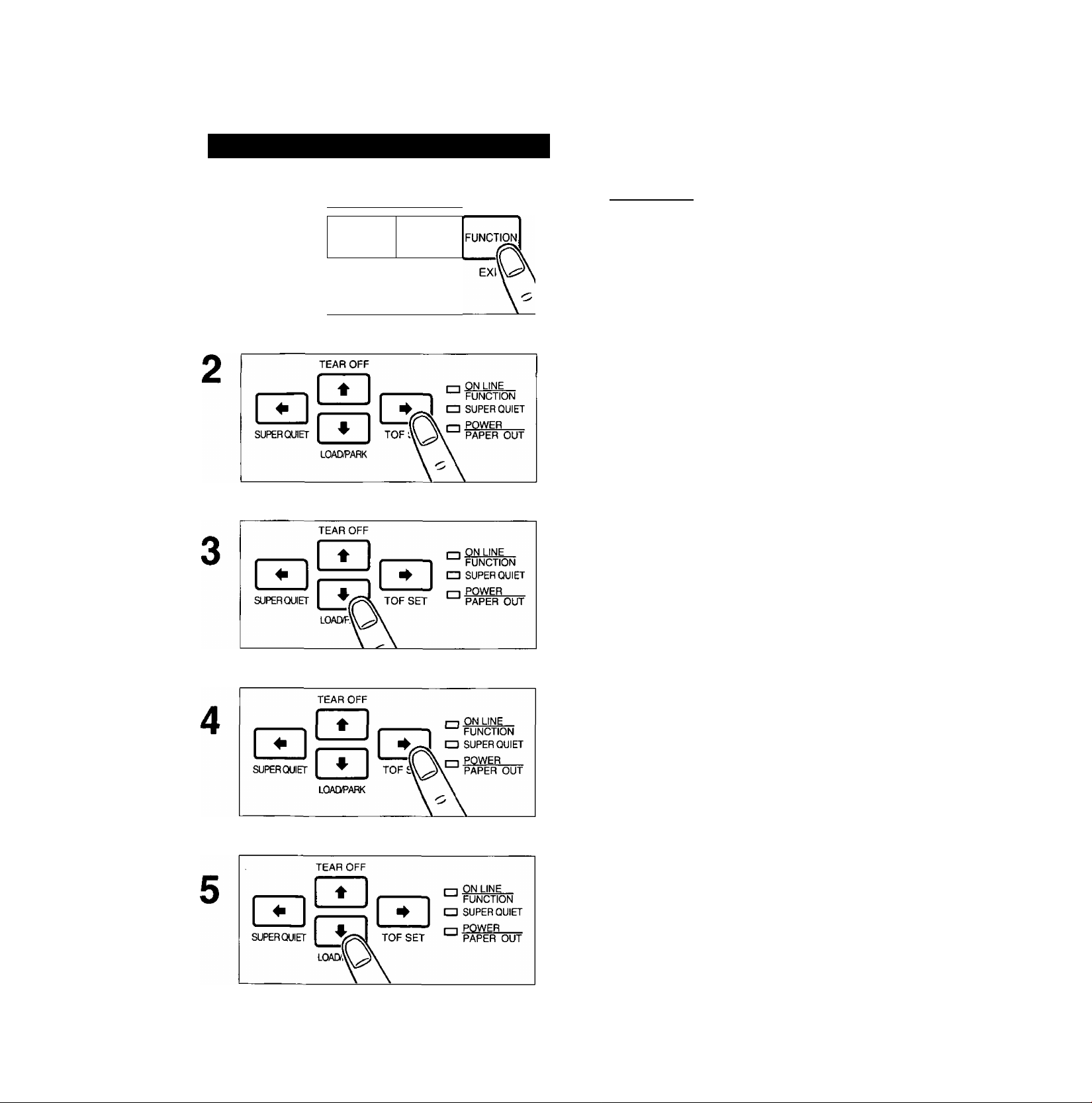

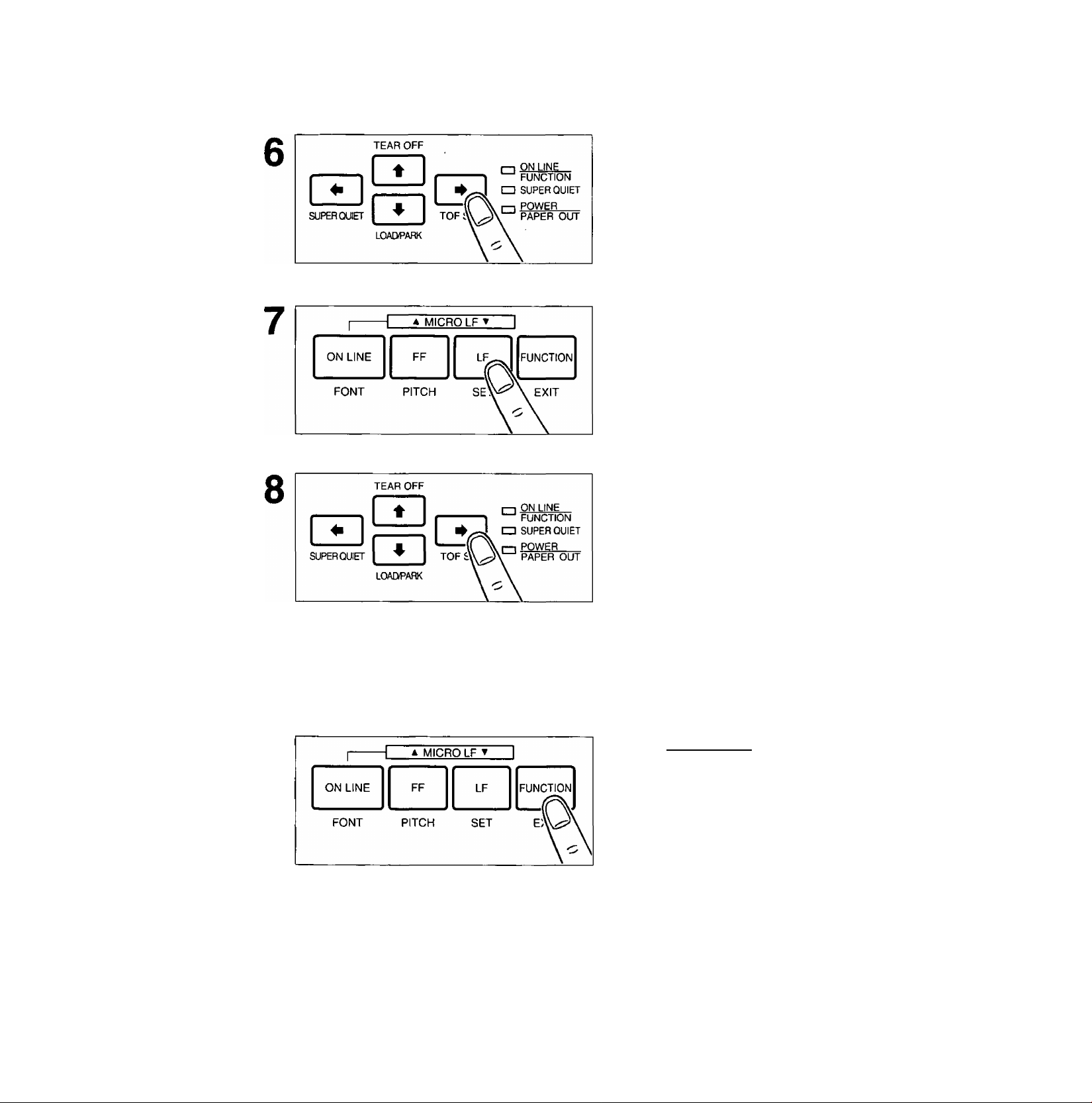

Setting the Function Mode Items

QMfflg ffi© (1§ ©SB

1

I

-------

ON LINE

FONT

1 A MICRO LF T I

■ FF LF

PITCH

Press iFUNCTION) to enter the Func

tion mode.

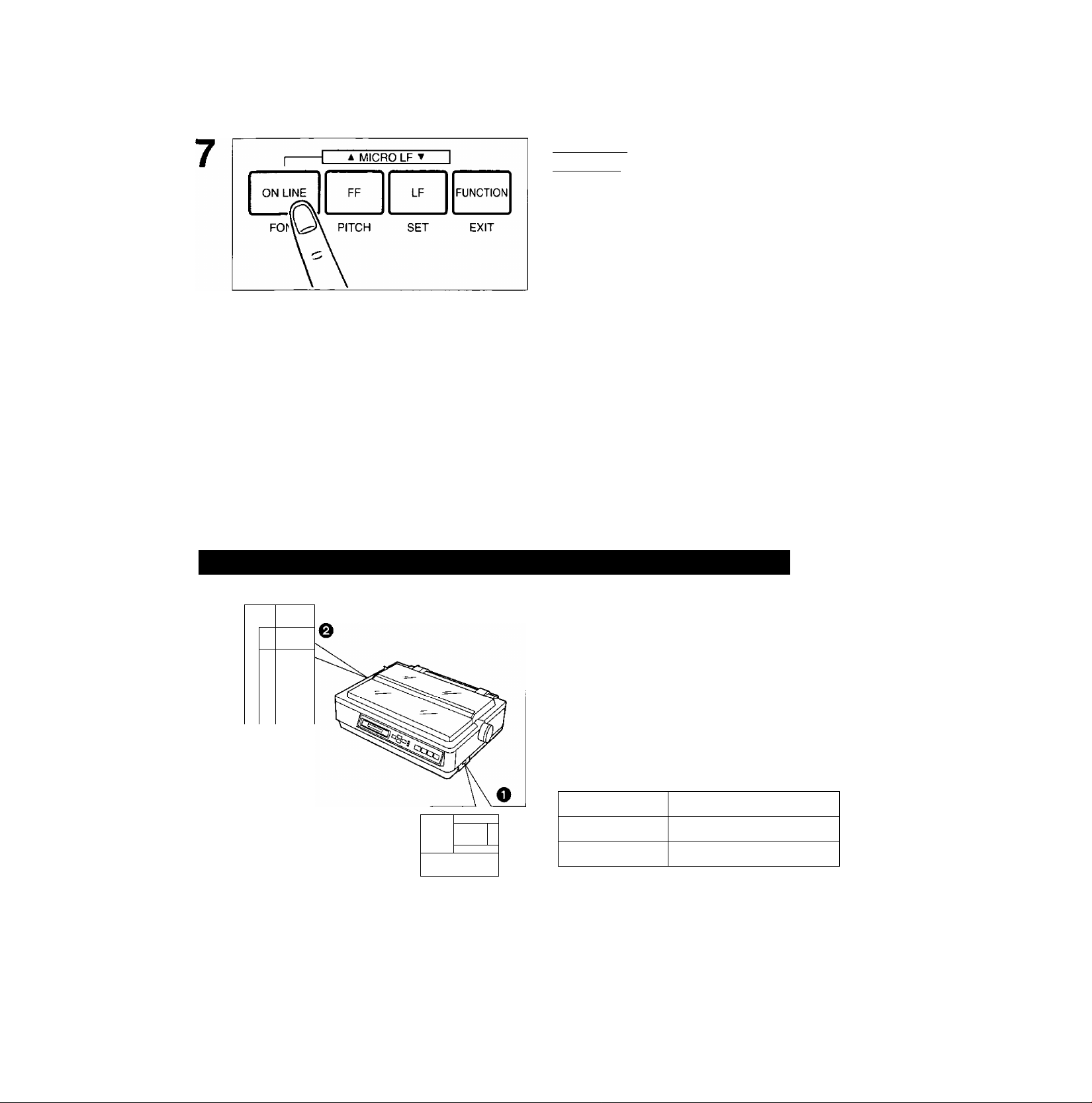

The display briefly show “FUNCTION MODE" and

the ON LINE/FUNCTION indicator blinks.

SET

Press (3 O'' E) to scroll to the appro

priate Main menu topic (ex; PRINT

STYLE).

Press to enter the Sub-menu.

A status message will appear (ex; FONT=DRAFT)

to reflect the current setting. If you do not want to

change the current setting, skip to step 8 on p. 54.

Press (3 or (3 to scroll to the appro

priate Sub-menu topic (ex; PITCH).

(3 to enter the selection menu.

A status message of your current selection will

blink. ^ ^

(ex; PITCH= NoCP()

c

3

o

o

3

o

a

o

53

Page 54

[UfeGmg ffios ®sG

Press (3 O'" (S to view the other

selections.

A blinking status message will appear as you

scroll through the selections.

Press (L0 (SET) to set the new selec

tion.

The status message will stop blinking and an

equal sign will appear to reflect your new current

selection. If other changes are required at the

Sub-menu level, repeat steps 4~7.

c

3

o

o’

3

o

a

o

10

Press (3 O'' El to make other

changes within the current Sub

menu.

If you do not want to make any other changes,

proceed to step 10.

If changes must be made to another

Main menu topic, press once and

repeat steps 2 through 7.

Press (FUNCTION] to exit the Func

tion mode.

54

•This example can be used for setting any print selection. For direct access to FONT/PITCH,

see page 55 for more details.

•All settings made are temporary unless saved in a Macro.

•Temporary settings are lost when power is turned off.

•The desired settings when power is turned on should be stored as POWER ON MACRO.

Page 55

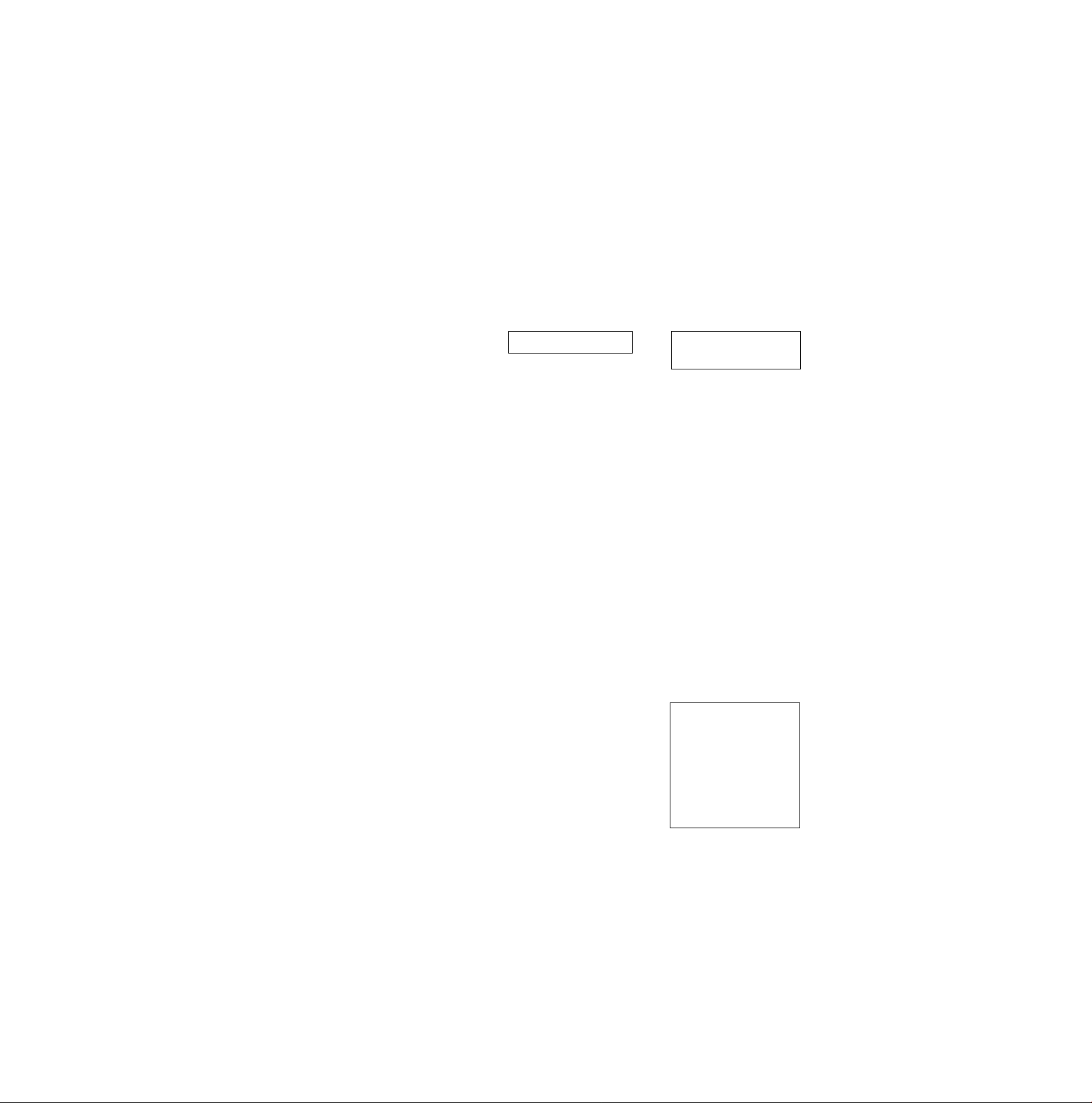

(1M]D® iii© (Ig ©SG

Direct Access to FONT and PITCH Setting

1

H AMICROLFT I

ON LINE

FONT PITCH

I

-------

ON LINE FF LF FUNCTION

FONT PITCH SET

(For FONT) (For PITCH)

TEAR OFF

SUPER C3UIET

FF LF FUNCTION

SET

1 AMICROLFT I

LOAEiPARK

EXIT

rn ON LINE

FUNCTION

□ SUPER QUIET

POWER

PAPER OUT

.a

Press [FUNCTION] to enter the Func

tion mode.

The display briefly shows “FUNCTION MODE’

and the ON LINE/FUNCTION indicator blinks.

For font, press (ON LINE! (FONT).

For pitch, press fFF| (PITCH).

A status message of your current selection will

appear. ^ ^ ^ ^

(ex; FONT=^DRAFT) (ex; PITCH=NoCPIJ

Press or El to view your desired

font or pitch.

A blinking status message will appear as you scroll

through the selections.

o

3

Press [lFI (SET) to set the new seiec-

tion.

A beep will sound, the status message will stop

blinking and an equal sign will appear to reflect

your new current setting.

Press [FUNCTiON] to exit the Function

mode.

o

a

<0

55

Page 56

ffiDS 1^ ©SG

Setting POINT SIZE

Press [FUNCTION] to enter the Func

tion mode.

The display briefly shows “FUNCTION MODE’

and the ON LINE/FUNCTION indicator blinks.

1

H A MICRO LF ▼ I

ON LINE

FONT PITCH

FF LF

SET

FUNCTION

Press (3 once to select “PRINT STYLE”.

Press (2 to enter the Sub-menu.

A status message will appear {ex; FONT=

c

3

o

DRAFT) to reflect the current setting.

o

a

<D

Press to enter the font selection menu.

A status message of your current selection will

blink.

(ex; FONT=^DRAFTJ

Press (3 or El to select the desired SC font (ex; COURIER-SC).

A blinking status message will appear as you scroll

through the selections.

“SC” is a scalable font.

56

Page 57

QJfeflDO® ffi© ig gsB

Press (lQ (SET) to set the selection.

The display will show “POINT SIZE= 10.5’’.

Press to enter the font selection menu.

A status message of your current point size will

blink.

(ex; POINT SIZE=No.5J

Press @ or ® to select the desired

point size.

A blinking status message will appear as you scroll

through the selections.

Press [L0 (SET) to set the selection.

The display will show your selected point size after

showing “UPDATING CPI" and “UPDATING LPI".

Note:

• If you set a wrong point size, pressing fTl

allows you to make a new selection.

Note:

•When a SC FONT is selected, PITCH will be changed to “PROPORTION" (Proportional

Spacing) and LINES/INCH will be changed to “SC” automatically.

c

3

o

5‘

3

o

Q.

<D

57

Page 58

010

You can control a wide variety of printing conditions through the Function mode. The Function mode

is comprised of a Main menu and Sub-menus that allow you to select modes and parameters by

using the EZ Set Operator Panel or the Setup Disk.

c

3

o

5‘

3

3

o

a

(D

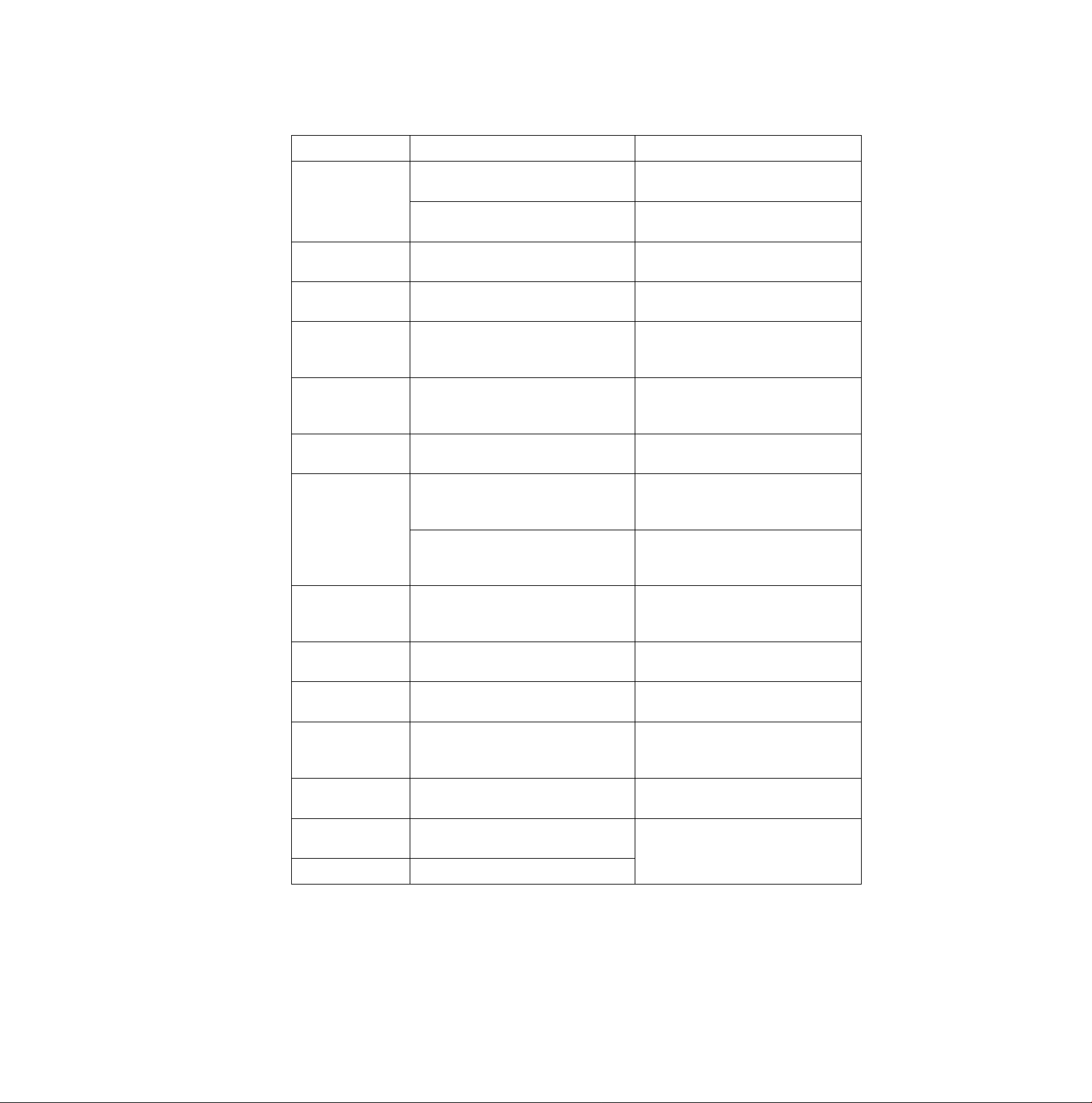

Function Mode Main menu Sub-menu

PRINT SEHING

([^P. 61)

PRINT STYLE

(D^P. 61)

H---------- EMUUTION -[T]- EMUUTION^ EPSON -(T)- EPSON

([^ P. 63)

I®

--------

PAGE FORMAT -QD“ LINES/INCH= 6 -(T>

(11^ P. 63)

-{T]- F0NT= DRAFT "(D-

POINT SIZE=

(®- PITCH= 10 CPI -[T>

Selection

■ffl (All)

-fLFl (Current)

SET

® s

DRAFT SCRIPT

BOLD PS SUPER LQ

COURIER

OCR-B COURIER-SC

ORATOR

PRESTIGE ROMAN-SC

ROMAN S.SERIF-SC

SANS SERIF

—m—j 8 to 96 with 10.5 and 21

10.5

The number increases or

decreases by 2.

10 CPI

12 CPI 5 CPI

15 CPI

17 CPI 7.5 CPI

20 CPI 8.5 CPI

1 3 6 10

4

1.5

2

4.5

2.5 5

BOLD PS-SC

PRESTIGE-SC

SCRIPT-SC

PROPORTION

6 CPi

IBM

7.5

8 SC

9

12

-m

SET

m

SET

SET

SET

SET

(Continued)

• Factory Settings are indicated in

the Sub-menus.

*’“POINT SIZE” will be displayed

only when a SC font is selected in

the FONT Sub-menu.

*2“SC” will be displayed only when a

SC font is selected in the FONT

Sub-menu.

*^The value number depends on the

CPI which has been selected.

58

¡30- P. LENGTH = 11.00" -(Ty-

(Page length)

®-|t. MRGN= 0.00" 1-(TH 0 00" to 2.50"

(Top margin)

30- B. MRGN= 0.00" -(Ty-

(Bottom margin)

L. MRGN= 0/10 CPi

(Left margin)

-CT>

(30- R. MRGN= 80/10 CPI -(T)-

(Right margin)

(®-| CTR PRINTHEAD= 40 |-(®H ^0 to 45 I—(TF)

(Centering)

O.T' to 14.9" with 11.66"

The number increases or

decreases by 0.1.

-[LF]

SET

-(LF)

The number increases or

decreases by 0.05.

0.00" to 4.90" —

0 to 88/10 CPr" I—(LF)

0 to 90/10 CPr^ 1—0

The number increases or SET

decreases by 1.

SET

SET

SET

SET

Page 59

RffilSuQsn]

Function Mode

Main menu Sub-menu Selection

PRINT MODE

((^ P. 64)

TEXT ENHANCEMENT -(T]- B0LD=

—TT1~[ G.D1RECTI0N= UNI [-[Tl— UNI (Unidirectional print)

(Graphic direction)

T,DIRECTION= 81 j Bl (Bidirectional print)

(Text direction)

- PRINT WIDTH^

PANEL LOCK= OFF

8" ~[±}-

OFF -CEh

Bl (Bidirectional print)

UNI (Unidirectional print)

8" 9"

-s>

OFF PITCH ALL

FONT F&P

OFF ON

(0^ P. 65)

DBL HIGH= OFF -[T> OFF ON

(Double high)

ra- DBL STRIKE= OFF -{JJ- OFF ON

(Double strike)

DBL WIDE= OFF -(T> OFF

(Double wide)

® s

ON

-[LF)

SET

■CkE)

SET

-dE)

SET

SET

■0

SET

-(LF)

SET

m

SET

-dE

SET

s-

CHARACTER SET “CD- COUNTRY= USA -(Th

(B^ P. 66)

(Continued)

• Factory Settings are indicated in the

Sub-menus.

^’“ITALIC” is available only in the EPSON

mode.

- ITALICS=

OFF -CD- OFF

t

OUTLINE=

SHADOW=

ZERO FONT= NORMAL -I

CDH CHR SET= ITALIC 1-CDH ITALIC

(Character set)

CODE PAGE= US^®-fuSA

OFF -[Th OFF

OFF -CDh

♦ H NORMAL POINT

ON

ON

OFF

SLASH

USA LTN AMER

DENMARK1

DENMARK2 LEGAL

FRANCE

GERMANY SPAIN1

ITALY SPAIN2

JAPAN SWEDEN

KOREA UK (England)

GRAPH1 (Graphic 1)

GRAPH2 {Graphic 2)

C.FREN (Canada French)

MULT (MuStilingual)

NORWAY

PORT (Portugal)

TURKEY

ON

(Later America)

NORWAY

-dE

SET

-dE

SET

-dE

SET

-dE

SET

-dE

SET

-dE

SET

-dE

SET

59

Page 60

Function Mode

ra

Main menu Sub-menu Selection

INSTALL “(Tl- AGM/IBM=

(0^ P. 67)

(Alternate Graphic Mode)

OFF -ffl“

OFF ON

SS

-m

SET

c

3

o

5‘

3

o

Q.

(D

I- AUTO CR/I8M= OFF “S“

J-| AUTO LF=

^2i

------------

AUTO L0ADING= ON “(T]“ ON

8UZZER=

- P.0.DETECT= ON -{T}- ON OFF

(Paper Out detector)

QUIET M0DE= OFF

SH REV LF/PULL= OFF -CT]~jO^

(Reverse Feeding

in PULL Mode)

Si TEAR 0FF= MANUAL KiDi MANUAL AUTO |—EE

)- CSF M0DE= OFF -[£}- OFF

(Cut Sheet Feeder Mode)

D0WNL0AD=

C0L0R=

OFF “S“ OFF

ON -(T]- ON

-ffl-

OFF

-53-[ot

BLACK

-CD-

OFF ON

ON

OFF

OFF

OFF ON

ON

ON

ON

BLACK ORANGE YELLOW

BLUE RED

GREEN VIOLET

-EE

-m

SET

-ClE

SET

-[LF]

SET

m

SET

-m

SET

-[lE

SET

-(lE

SET

SET

SET

-EE

SET

-EE

SET

S’

s-

s-

DISPLAY LANGUAGE “S“ LANGUAGE= ENGLISH

INTERFACE

MACRO MODE

• Factory Settings are indicated in the

Sub-menus.

^'Effective in the IBM mode only.

^^Ineffective when using the Cut Sheet

Feeder.

*^“SERIAL" is effective only when the

optional KX-PS14, RS-232C Serial in

terface board is installed.

60

(1^ P. 69)

([^ P. 69)

((^ P. 69)

ENGLISH SPANISH

FRENCH

GERMAN TURKISH

l/F=

D.LENGTH= 8 BIT “E“

(DATA Length)

H SAVE MACR0= #1 HSH #1 #2 #3 #4 |—EE

POWER ON MACR0=1 “S"

PARALLEL “S“

8 BIT 7 BIT

#1

#2 #4

1 3 F

2 4

ITALIAN

PARALLEL SERIAL"^ j—EE

-EE

#3 FCTRY

(Factory setting)

(Factory setting)

-EE

-EE

SET

SET

SET

SET

SET

-EE

SET

Page 61

H!DDD§iBa]Q

PRINT SETTING Menu

(To Print Out the Function mode Settings)

Before you change the Function mode settings, you can verify the settings by printing them.

To print...

Current settings only—Press [L0 (SET) after selecting the PRINT SETTING Main menu.

All settings (current, MACROS and Factory)—Press after selecting the PRINT SETTING Main

menu.

PRINT STYLE Menu

(To Change the Font/Pitch)

FONT

This Sub-menu in the PRINT STYLE Main menu will allow you to select and set a desired font. This

printer has draft, 8 LQ (Letter Quality), 1 Super LQ fonts and 6 scalable fonts. Draft is printed at the

fastest speed and is normally used for printing draft documents. LQ produces the high print quality

and SLQ produces much better print quality than LQ; they are used to print the final version of formal

documents. If you want to see all of the font samples, use the Self Test feature on page 39.

(Print Example)

Draft:

ABCDEFGHIJKLMN0PQRSTUVWXYZ0123456789

abcdefghijklmnopqrstuvwxyz

Bold PS:

ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789

abcdefifhi jklmnopqrstuvwxyz

Courier:

ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789

abcdefghi jklmnopqrstuvwxyz

OCR-B:

ABCOEFGHIJKLMNOPQRSTUVWXYZO123456789

abcdefghijk Lmnopqrstuvuxyz

Orator:

ABCDEFGHIJKLMN0PQRSTUVWXYZ0123il56789

ABCDEFGHIJKLMNOPQRSTUVWXYZ

Prestige:

ABCDEFGHIJKLMNOPQRSTUVWXYZ0123456789

abcdefghijklmnopqrstuvwxyz

Roman:

ABCDEFGHIJKLMNOPQRSTUVWXYZO123456789

abcdefghi jklmnopqrstuvwxyz

Sans Ser i f:

ABCDEFQHIJKLMNOPQRSTUVWXYZO123456789

abcdefgh i jkImnopqrstuvwxyz

c

3

o

5'

3

o

a

(D

A8COEFGHrJKLMNOPQRSrUVWXyZ01234567S9

at give j Ivimno z

Super Letter Quality (Roman):

ABCDEFGHIJKLMNOPQRSTUVWXYZO123456789

abcdefghi jklmnopqrstuvwxyz

61

Page 62

(SffiûSOflSïB

PITCH

The Sub-menu in the PRINT STYLE Main menu will allow you to select and set a desired pitch. This

printer has 10 pitch selections.

The height of the characters in the different pitches is the same; only the width varies. The pitches are

fixed pitch {within a pitch, all characters have the same width).

In proportional spacing, character widths vary with the character. An “I”, for example, takes up less

space than an “M” or a “W". Proportional printing gives the document a typeset appearance.

The following tables shows pitch availability for each font.

Font

Draft

Bold PS

Courier

OCR-B

Orator

Prestige

Roman

Sans Serif

Script

SUPER LQ

OCR-B micron prints using the Sans Serif font.

{Print Example)

5 6 7.5 8.5

О о о О

О о

о о

о о

о о

о о

о о

о о о

о о о

о

5 c:p± E>r-±ntinsr

О

CPicrsi elonerated.)

О о о о о

О о о о о

•

о о о

О о о о о

О о о о о о о

О о о о о о о

о о О о о о о

о о О о о о о

6 cpi printing

(Elite elongated)

7 . cp± |p]riir\%±ng

( C XT on a 1 OY>9 A ^ Ad )

8.5 cpi printing

(Compressed elongated)

10 cpi printing (Pica)

12 cpi printing (Elite)

13 cpi printing (Hlcron)

IT cpi piintiag (Coipressed)

TO cpi piloting {Elite Covrened)

Proportional Spacing

10

12

15 17 20 PS

о о о о о

о о о

о о о

•

о о о

о о о

о О

о

о

62

• For direct access to font and pitch settings, see page 55.

•To override your software with these two features (FONT and/or PITCH) activate the above

setting(s); see “PANEL LOCK”, P. 64)

POINT SIZE

You can alter the point size to make a font larger or smaller only when the scalable font (BOLD-SC,

COURIER-SC, PRESTIGE-SC, ROMAN-SC, SANS SERIF-SC and SCRIPT-SC) is selected in the

FONT Sub-menu.

When a SC font is selected, PITCH will be changed to “PROPORTION" (Proportional Spacing) and

LINES/INCH will be changed to “SC” automatically.

Page 63

RiffiDSiMiD (iil5^

EMULATION Menu

(To Change Your Printer’s Emulation)

This printer can emulate the Epson LQ-570 or the IBM Proptinter X24E.

P. 38 “Printer-Driver Selection")

PAGE FORMAT Menu

(To Change the Lines Per Inch/Page Format)

LINES/INCH This Sub-menu in the PAGE FORMAT main menu will allow you to change lines per inch.

Note:

•When a SC font is selected in the FONT Sub-menu, lines per inch will be changed to “SC”

automatically. The value of “SC” will be changed by the point size and the most suitable

space between the lines for the each point size is set up. You can change the lines per inch

within even if a SC font is selected.

Page formating is determined by:

© Page length (P.LENGTH)

(2) Top margin (T.MRGN)

@ Bottom margin (B.MRGN)

@ Left margin (L.MRGN)

© Right margin (R.MRGN)

I I

-H @ Left margin |

I

© Right margin

•The center position default is 40. If you have shortened your printable area, you may want to

reposition your printhead to a new centered position. This is accomplished through the CTR

PRINTHEAD Sub-menu in the PAGE FORMAT Main menu.

c

(5

E

Q.

O

c

p

n

E

E

o

o

CD

® ©

_l

0.

O)

c

(U

0

O)

CO

63

Page 64

ISlDDiXSiMjD (Möxa§

Note;

•When changing the left/right margins, / (3 moves the carriage right or left.

Pressing (5]! (3 when the carriage reaches the end of the platen moves it to the opposite

end.

• If the left margin is set to the right of the right margin, the right margin is reset to 80 {10 cpi)

automatically.

•The skip perforation command overrides the front panel bottom margin setting.

•When the PRINT WIDTH is changed, the left margin will default to 0" and the right margin will

default to 8" or 9" automatically depending on your selection of the print width. Please refer to

chart on page 97 for the maximum number of characters per line according to your pitch

selection. To change the print width to either 8" or 9", refer to “PRINT MODE Menu” (in this

page).

PRINT MODE Menu

(To Change Print Direction etc.)

This printer allows you to select print direction in graphics and text modes.

When you print graphics such as tables, set the G.DIRECTION Sub-menu to UNI. The printer will

print left-to-right only and provide precise vertical alignment. Setting to Bl will print in both directions

and reduces printing time, however the vertical alignment may not be as precise.

c

3

o

5’

3

o

a

(D

PRINT WIDTH

This Sub-menu in the PRINT MODE Main menu will allow you to change the print width to either 8"

or 9".

PANEL LOCK

This Sub-menu in the PRINT MODE Main menu will allow you to decide the priority between the

printer’s front, panel settings and the software commands. This PANEL LOCK Sub-menu is set to

OFF when shipped which allows the software commands to override the printer’s front panel settings.

To activate the printer’s

Font only—Set PANEL LOCK=FONT

Pitch only—Set PANEL LOCK=PITCH

Font and Pitch only—Set PANEL LOCK=F&P

All settings—Set PANEL LOCK=ALL

Note:

•When you set a SC font in the FONT Sub-menu and “FONT” in the PANEL LOCK Sub-menu,

PITCH will be changed to “PROPORTION” (Proportional Spacing) automatically.

64

Page 65

RnMBajD Gfils^

TEXT ENHANCEMENT Menu

(To Enhance Your Text)

This printer allows you to have a variety of print styles using this Sub-menus.

Any enhancements can be set to ON (enable) or OFF (disable).

Enhancements are independent and are set individually, therefore, any enhancement can be

combined with another.

Double high printing makes the height of a character twice that of a normal one.

Double wide printing makes the width of a character twice that of a normal one.

Double strike printing uses a double strike with two passes of the printhead.

Bold (Emphasized) printing is done with one pass of the printhead at half speed, which allows

horizontally adjacent dots to be printed.

Outline printing makes the outline character of a normal one.

Shadow printing makes the shadow character of a normal one.

Italic printing makes a character slope from the right downwards.

(Print Example)

Emphasized Printing

Double High

Double Strike Printing

Dovilole Wide

Italic

Shadow Printing

ZERO FONT

This mode will allow you to set one of the following zero font selections.

Numeral “0" and alphabet “0” are very similar. To easily distinguish between them in a document,

print “0” or “0" instead of normal zero. Select and set one of the following in the ZERO FONT

Sub-menu.

Selections

Printing

Zero font

c

3

o

o'

3

o

a

(D

NORMAL

POINT

SLASH

When the international character set is set to Norway, zero slash is printed as 0.

0

0

0

65

Page 66

(MïïDiXSiMjD GiaaSs

CHARACTER SET Menu

(To Change the Character Set)

COUNTRY

This Sub-menu in the CHARACTER SET Main menu will allow you to set one of the following

international character set selections.

c

3

o

5‘

3

o

a

<D

Selections

USA

DENMARK1

DENMARK2

FRANCE

GERMANY

ITALY

JAPAN

KOREA

CHR SET

This Sub-menu in the CHARACTER SET Main menu will allow you to set one of the following

character set selections.

Selections

ITALIC

GRAPH1

GRAPH2

CODE PAGE

This Sub-menu in the CHARACTER SET Main menu will allow you to set one of the following code

page selections.

Character set

USA

Denmark 1

Denmark 2

France SPAIN1

Germany

Italy

Japan

Korea

Character set

Italic

Graphic 1 Epson or IBM mode

Graphic 2

Selections Character set

LTN AMER Latin America

LEGAL

NORWAY

SPAIN2 Spain 2

SWEDEN Sweden

UK

Epson mode only

Legal

Norway

Spain 1

England

66

Selections

USA

C.FREN

MULT

Code page

USA

Canadian French PORT

Multilingual

Selections Code page

NORWAY

TURKEY

Norway

Portugal

Turkey

Page 67

(R!!InX§[M)D (Mais

INSTALL Menu

(To Control Initial Setup Conditions)

Alternate Graphics Mode

The alternate graphics mode (AGM) will allow you to selects Epson graphics while in the IBM mode.

Sub-Menu Selections Function

AGM/IBM ON

OFF

Sets Alternate Graphics Mode

Releases Alternate Graphics Mode

Automatic CR

Sub-Menu

AUTO CR/IBM

Selections Function

ON Activates Automatic CR on LF, VT, ESC+“J”

OFF Prevents Automatic CR on LF, VT, ESC+“J”

Automatic LF

Sub-Menu Selections Function

AUTO LF ON

OFF Activates CR only

Activates CR+LF

Automatic Paper Loading

When the AUTO LOADING Sub-menu is ON, the printer automatically loads a single sheet or an

envelope to the first print line.

■n

c

3

o

5’

3

o

a

(D

Buzzer Sound Controi

Select and set ON (sounds) or OFF (no sound) in the BUZZER Sub-menu.

Paper Out Detector

When the P.O.DETECT Sub-menu is ON, the printing stops once the paper is no longer under the

platen.

To avoid this and print to the end of the paper, set the P.O.DETECT Sub-menu to OFF.

67

Page 68

RiddosìM) GSteéte

INSTALL Menu

Super Quiet Printing

This feature reduces printing noise, however, it also reduces the printing speed.

Select and set ON (activate) or OFF (deactivate) in the QUIET MODE Sub-menu.

Reverse Feeding in Pull Mode

When you control reverse feeding in pull mode, select and set ON (enable) or OFF (disable) in the

REV LF/PULL Sub-menu.

Automatic Tear Off

This feature loads the fanfold paper’s perforation to the tear off position automatically.

Sub-Menu Selection Function

TEAR OFF

AUTO Automatic Tear Off

MANUAL Manual Tear Off (using TEAR OFF switch)

Cut Sheet Feeder Mode

CSF MODE

This Sub-menu will allow you to use the Cut Sheet Feeder (ON). This menu should be OFF when not

in use.

(This setting is effective only when the paper feed selector is in “Q” position and C.S.F. option

3

o

(KX-PT11) is installed. ((®° C.S.F. manual)

Download Buffer Control

o

Q.

(D

If you need to download special characters, set the DOWNLOAD Sub-menu to ON. By setting the

Sub-menu to OFF, more data can be sent to your printer’s buffer, thereby freeing up your computer.

Color Printing

Before you use this function, make sure that the color kit (KX-PCK11) is installed in the

printer. ([^ The color kit manual)

COLOR

Your desired print color may be selected through the front panel or through your application software.

68

Note:

•The appropriate driver must be selected in the application software which supports color.

Refer to page 38 for Printer-Driver Selection information.

• Only one color can be printed at a time.

Multi-color printing may be accessible through your application software.

Page 69

HaoiisuOaiD

DISPLAY LANGUAGE Menu

(To Select the Display Language)

Select and set one of the six display languages in the LANGUAGE Selection.

INTERFACE Menu

(To Select Interface)

The INTERFACE menu allows you to select the appropriate method of communication (parallel/se-

hal) with the computer.

To activate serial communication, you must first install the KX-PS13 or KX-PS14 serial interface.

With the KX-PS13 installed, the parallel interface is deactivated.

MACRO MODE Menu

(To utilize the MACROS)

A MACRO allows you to store a combination of your most frequently used print conditions {all settings

in the Function mode) into the printer’s memory which can be easily recalled and/or changed. This

will enable you to recall one of 4 combinations (MACROs #1, #2, #3, #4) at the touch of a button

eliminating the need to reset all your frequently used features.

SAVE MACRO

The SAVE MACRO is a Sub-menu in the MACRO MODE Main menu. This mode will allow you to

save your current customized printing requirements to any SAVE MACRO (#1, #2, #3 or #4)

selection. To load (recall) your customized macro select the same number in the LOAD MACRO

Sub-menu.

LOAD MACRO

The LOAD MACRO is a Sub-menu in the MACRO MODE Main menu. This mode wilt allow you to

recall your current customized printing requirements from any LOAD MACRO (#1, #2, #3 or #4)

selection.

POWER ON MACRO

The POWER ON MACRO is a Sub-menu in the MACRO MODE Main menu. This mode will allow you

to automatically recall a desired MACRO or FACTORY setting each time you turn on the printer.

FACTORY setting (Default setting): All the original settings in the Function mode can be restored

in the printer, as they were originally set when the printer was shipped. However, it does not change

any of the settings which are stored in MACRO #1, 2, 3 or 4. To do so, recall the Factory setting, and

save each Macro one at a time.

69

Page 70

Moigl §sífea[g [Ditefe

This Setup Disk can only be used in an IBM-PC or a compatible computer with a 3.5" floppy disk drive.

Before you use the Setup Disk, it is recommended that you make a back-up copy and store the

original in a safe place.

This printer has been factory set to operate with most of the popular software packages. In

most cases there will be no need to change the Function mode items. Refer to pages 58—60

to verify that the factory settings meet your requirements. If no changes are required, you

should be ready to print.

Note:

• Use the DISKCOPY command of the operating system to make a back-up copy. Refer to your

DOS manual for further information.

•You may find it convenient to install the Setup Disk programs directly onto your C Drive, rather

than reading them from the Setup Disk each time a change is necessary. Either method is

acceptable.

To perform an automatic installation of the Setup Disk files onto your C Drive, follow the steps

below:

1. Insert the Setup Disk into drive A or B.

2. Type A: {or B:) and press Enter.

3. Type INSTALL and press Enter.

C

3

o

5‘

3

S

o

Q.

(D

This procedure automatically creates a directory called 3124 and copies all of the programs

from your Setup Disk onto your C Drive.

At your C:\> prompt, type CD 3124 and press Enter.

Type SETUP and press ( Enter 1 to complete the procedure. Be sure to type this

instruction as one word.

If not, you will receive a Syntax error message.

Running the Setup Program

Insert your Setup Disk into either drive A or B.

1

<For Dos>

Type A: (or B:) and

2

press ( Enter),

Type SETUP

3

<For WINDOWS>

Select Run from the File

2

menu.

Type A:\SETUP

3

(or B:\SETUP)

70

Press ( Enter).

4

You will receive a “Please wait!I” message

until your first screen automatically appears.

Click I OK I (or Press ( Enter]).

4

Page 71

QMn® ffl© (IM^

The first screen is an introduction to the operation of the Setup Disk.

Please read it through and press any key to continue.

The <Menu> window will

be highlighted.

Note:

•You can proceed through the

Setup Disk using a computer

mouse or your arrow keys.

^ < Menu >;

GeRINTlSTyLEl

-.EMULATION

.PAGE FORMAT

.PRINT MODE

.TEXT ENHANCEMENT

.CHARACTER SET

.INSTALL

.DISPLAY UNGUAGE

.INTERFACE

.POWER ON MACRO

<< Setup Utility [XXXXXXKXXXX) »

F < Item > -

FONT

PITCH

•[ESC] exits you to DOS when

you are at the <Menu> window.

Using the keyboard:

•m / (3D to move within the

current window.

•(3) to advance to <)tem> and

<Setting> windows.

« COMMENT »

Select print style