Page 1

ST

IC DRIVABLE PC BOARD

RELAY FOR INDUCTIVE

LOAD SWITCHING

VDE

ST RELAYS

RoHS Directive compatibility information

http://www.mew.co.jp/ac/e/environment/

FEATURES

1. Even with small form factor,

sensitive enough for direct IC-driving

The dimensions of this high-density 4gap balanced armature are 31 mm × 14

mm × 11 mm 1.220 inch × .551 inch ×

.433 inch. Despite this small size, high

sensitivity is achieved by a mechanism

that incorporates high-efficiency

polarized magnetic circuits along with our

exclusive spring alignment method. With

an minimum operating power of about

150 mW, nominal operating power of 240

mW, this relay can be directly driven by

transistor or chip controllers.

2. High switching capability

High contact pressure, low contact

bounce, and forced separation structure

that radically improves resistance to

contact welding (1 Form A 1 Form B type

equivalent to TV-3). Strong against lamp

inductive loads, maximum switching

capacity has reached 3,040 VA (8A 380V

AC).

3. High breakdown voltage – Optimal

for control in 250 V power circuits

High breakdown voltage has been

achieved. Between contacts and coil of

3,750 Vrms; Surge breakdown voltage

between coil and contact of 6,000 V, and

between open contacts of 1,200 Vrms

mean that these relays are suitable even

for 250 V power circuit control.

4. Improved stability

Conforms to all types of safety

standards.

Insulating distance of more than 3 mm

secured. Complies with Japan Electrical

Appliance and Material Safety Law

requirements for operating 200 V power

supply circuits, and conforms with UL,

CSA and VDE standards.

5. Latching types available

In addition to single side stable types,

convenient 2 coil latching types with

memory functions are also available.

Moreover, we offer 2 Form A

specifications which, with double pole

switching for applications such as 250 V

power circuit switching, can enable safer

designs.

6. Automatic cleaning possible

The sealed design means that these

relays can undergo immersion in

automatic washing systems and are

suitable for automatic soldering. Even in

difficult environments, the contacts

remain reliable.

7. Easy to design PC board patterns

Features 4/10 dual-in-line terminals.

Because the lead spacing has a pitch

greater than 7.54 mm .297 inch,

designers can make easy adjustments

with the width of the land size. This, along

with the large insulation distance,

simplifies the drawing of PC board

patterns.

8. To improve soldering efficiency,

preapplication of solder to the

terminals is recommended.

About Cd-free contacts

We have introduced Cadmium free type

products to reduce Environmental

Hazardous Substances.

(The suffix “F” should be added to the

part number)

Please replace parts containing

Cadmium with Cadmium-free products

and evaluate them with your actual

application before use because the life of

a relay depends on the contact material

and load.

ORDERING INFORMATION

ST F

Contact arrangement

1: 1 Form A 1 Form B

2: 2 Form A

Operating function

Nil:

Single side stable

L2:

2 coil latching

Coil voltage

DC 3, 5, 6, 9, 12, 24, 48 V

Contact material

F: AgSnO2 type contact

Note: UL/CSA, VDE, SEV type is standard.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 2

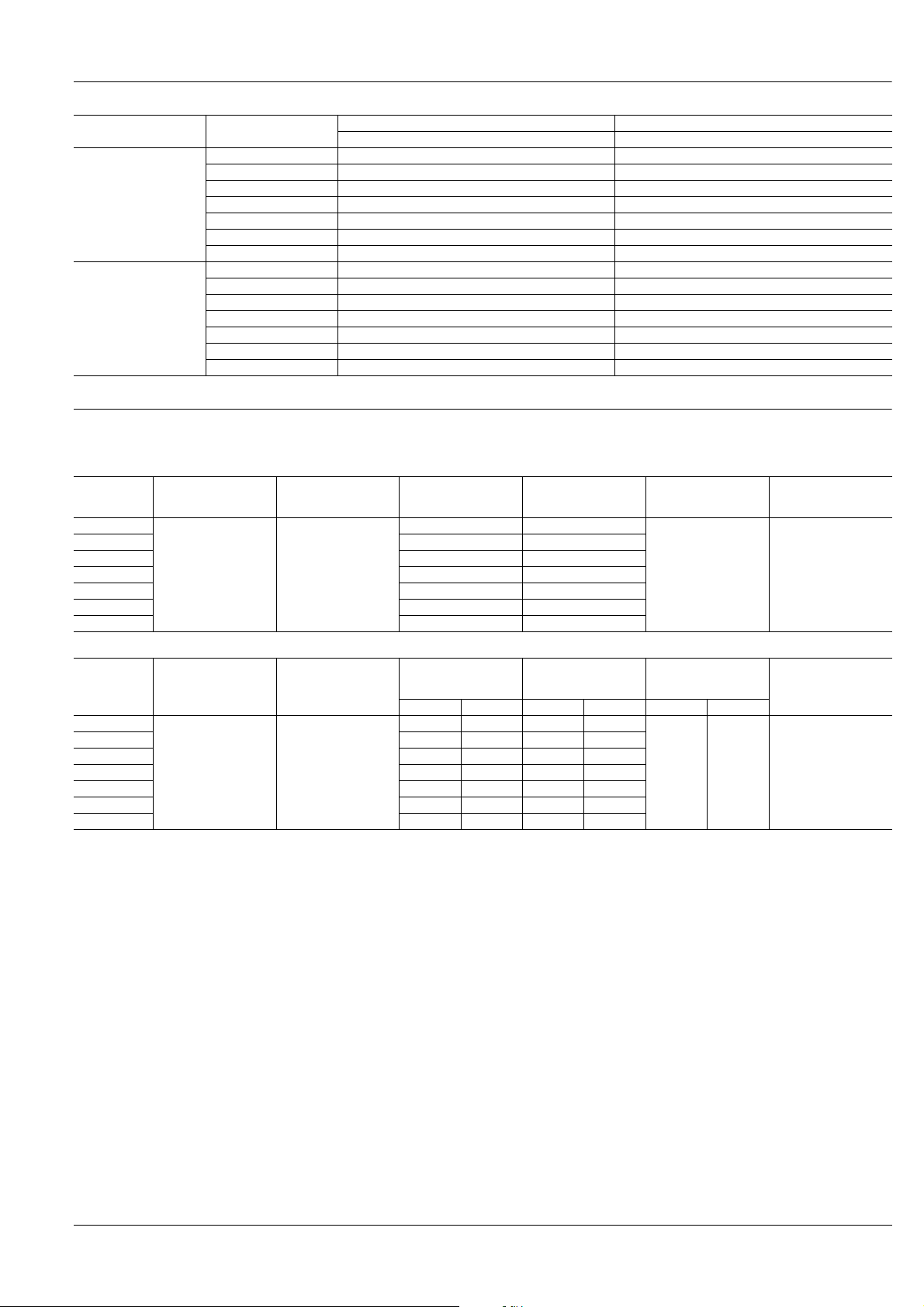

TYPES

Contact arrangement Nominal coil voltage

3V DC ST1-DC3V-F ST1-L2-DC3V-F

5V DC ST1-DC5V-F ST1-L2-DC5V-F

6V DC ST1-DC6V-F ST1-L2-DC6V-F

1 Form A 1 Form B

2 Form A

Standard packing: Tube: 50 pcs.; Case: 500 pcs.

9V DC ST1-DC9V-F ST1-L2-DC9V-F

12V DC ST1-DC12V-F ST1-L2-DC12V-F

24V DC ST1-DC24V-F ST1-L2-DC24V-F

48V DC ST1-DC48V-F ST1-L2-DC48V-F

3V DC ST2-DC3V-F ST2-L2-DC3V-F

5V DC ST2-DC5V-F ST2-L2-DC5V-F

6V DC ST2-DC6V-F ST2-L2-DC6V-F

9V DC ST2-DC9V-F ST2-L2-DC9V-F

12V DC ST2-DC12V-F ST2-L2-DC12V-F

24V DC ST2-DC24V-F ST2-L2-DC24V-F

48V DC ST2-DC48V-F ST2-L2-DC48V-F

Single side stable 2 coil latching

Part No. Part No.

RATING

1. Coil data

1) Single side stable

Nominal coil

voltage

3V DC

5V DC 47mA 105Ω

6V DC 40mA 150Ω

9V DC 25mA 360Ω

12V DC 20mA 600Ω

24V DC 10mA 2,400Ω

48V DC 4.7mA 9,000Ω

Pick-up voltage

(at 20°C 68°F)

80%V or less of

nominal voltage

(Initial)

Drop-out voltage

(at 20°C 68°F)

10%V or more of

nominal voltage

(Initial)

2) 2 coil latching

Nominal coil

voltage

3V DC

5V DC 45mA 45mA 110Ω 110Ω

6V DC 37.5mA 37.5mA 155Ω 155Ω

9V DC 25mA 25mA 360Ω 360Ω

12V DC 18.8mA 18.8mA 640Ω 640Ω

24V DC 10mA 10mA 2,400Ω 2,400Ω

48V DC 4.7mA 4.7mA 10,200Ω 10,200Ω

Set voltage

(at 20°C 68°F)

80%V or less of

nominal voltage

(Initial)

Reset voltage

(at 20°C 68°F)

80%V or less of

nominal voltage

(Initial)

Nominal operating

current

[±10%] (at 20°C 68°F)

75mA 38Ω

Nominal operating

current

[±10%] (at 20°C 68°F)

Set coil Reset coil Set coil Reset coil Set coil Reset coil

75mA 75mA 40Ω 40Ω

Coil resistance

[±10%] (at 20°C 68°F)

Coil resistance

[±10%] (at 20°C 68°F)

Nominal operating

power

240mW

Nominal operating

power

240mW 240mW

ST

Max. allowable voltage

(at 20°C 68°F)

150%V of

nominal voltage

Max. allowable voltage

(at 20°C 68°F)

150%V of

nominal voltage

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 3

ST

2. Specifications

Characteristics Item Specifications

Arrangement 1 Form A 1 Form B, 2 Form A

Contact

Rating

Electrical

characteristics

Mechanical

characteristics

Expected life

Conditions

Unit weight Approx. 10g .353 oz

Notes: *1 This value can change due to the switching frequency, environmental conditions, and desired reliability level, therefore it is recommended to check this with the

actual load.

*2 Wave is standard shock voltage of ±1.2×50µs according to JEC-212-1981

*3 Refer to 6. Conditions for operation, transport and storage mentioned in AMBIENT ENVIRONMENT

Contact material Au-flashed AgSnO2 type

Initial contact resistance, max. Max. 30 mΩ (By voltage drop 6 V DC 1A)

Max. switching power (resistive load) 3,040 VA, 150 W

Max. switching voltage 380 V AC, 250 V DC

Max. switching current 8 A

Minimum operating power 150mW (Single side stable, 2 coil latching)

Nominal operating power 240mW (Single side stable, 2 coil latching)

Min. switching capacity (Reference value)*

Insulation resistance (Initial)

(at 25°C, 50% relative humidity)

Breakdown voltage

(Initial)

Between open contacts 1,200 Vrms for 1 min. (Detection current: 10 mA)

Between contact sets 2,000 Vrms for 1 min. (Detection current: 10 mA)

Between contact and coil 3,750 Vrms for 1 min. (Detection current: 10 mA)

Surge breakdown voltage (Initial)*

Operate time [Set time] (at 20°C 68°F)

Release time [Reset time] (at 20°C 68°F)

Temperature rise (at 60°C 140°F)

Shock resistance

Vibration resistance

Functional Min. 196 m/s

Destructive Min. 980 m/s2 (Half-wave pulse of sine wave: 6 ms.)

Functional 10 to 55 Hz at double amplitude of 2 mm (Detection time: 10µs.)

Destructive 10 to 55 Hz at double amplitude of 3 mm

1

100 mA 5V DC

Min. 1,000MΩ (at 500V DC)

Measurement at same location as “Initial breakdown voltage” section.

2

6,000 V (Between contact and coil)

Max. 15 ms [Max. 15 ms]

(Nominal voltage applied to the coil, excluding contact bounce time.)

Max. 10 ms [Max. 15 ms]

(Nominal voltage applied to the coil, excluding contact bounce time.) (without diode)

Max. 55°C

(By resistive method, nominal voltage applied to the coil; contact carrying current: 8A.)

2

(Half-wave pulse of sine wave: 11 ms; detection time: 10µs.)

Mechanical Min. 107 (at 180 cpm)

Electrical Min. 105 (8 A 250 V AC resistive) (ON : OFF = 1 s : 5 s)

Ambient temperature: –40°C to +60°C –40°F to +140°F;

Conditions for operation, transport and storage*

3

Humidity: 5 to 85% R.H. (Not freezing and condensing at low temperature)

Max. operating speed 30 cps

REFERENCE DATA

1. Max. switching power 2. Coil temperature rise 3. Influence of adjacent mounting

10

5

2

1

Current, A

0.5

0.2

0.1

AC resistive load

AC

inductive load

(cosϕ =0.4)

DC resistive load

10 20 50 100 200 300

Voltage, V

100

90

80

70

60

Contact current 8A

50

40

Temperature rise, °C

30

20

10

0

0A

0.2 0.4 0.6 0.8 1.0 1.2

Coil operating power, W

Rated of change, %

-10

-20

-30

-40

40

30

20

10

0

Drop-out voltage

Pick-up voltage

5101520

Inter-relay distance, mm

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 4

DIMENSIONS (Unit: mm inch)

2 coil latching

types only.

8-DIA. 1.4

.055

2.54

.100

2.54

.100

12–+34

+–

5678

External dimensions

31.0

1.220

11.0

.433

0.3

.012

3.5 .138

7.62

.300

7

85

7.62

10.16

.300

.400

0.3 .012

1.0

.039

1.0 1.0

.039 .039

0.6 dia. .024 dia.

4321

6

General tolerance: ±0.5 ±.020

1 Form A 1 Form B 2 Form A 1 Form A 1 Form B 2 Form A

0.5

.020

Single side stable 2 coil latching

14

–+

14

.551

10.16

.400

Schematic (Bottom view)

14

–+

PC board pattern (Bottom view)

Tolerance: ±0.1 ±.004

12

–+

34

+–

ST

5678

(Deenergized condition) (Reset condition)

NOTES

1. PC board patterns for 2 coil latching

types

When applying relays in power supply

operation circuits for finished products

regulated by the Electrical Appliance and

Material Safety Law, use the pattern

shown below.

1Te rminal No. 2 3 4

2. Soldering should be done under the

following conditions:

1)

250°C 482°F within 10s

300°C 572°F within 5s

350°C 662°F within 3s

2) For automatic cleaning, the boiling

method is recommended. Avoid

ultrasonic cleaning which subjects the

relays to high frequency vibrations, which

may cause the contacts to stick.

It is recommended that a fluorinated

hydrocarbon or other alcoholic solvents

be used.

For Cautions for Use, see Relay Technical Information.

5678

5678

3. When using, please be aware that

the a contact and b contact sides of 1

Form A and 1 Form B types may go on

simultaneously at operate time and

release time.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 5

ST

VDE

ST relay socket

ST-PS

PC board terminal socket

ST-SS

Solder terminal socket

RoHS Directive compatibility information

http://www.mew.co.jp/ac/e/environment/

FEATURES

1. Possible to fit or remove the chassis

with one touch (t = 0.6 mm to 2.2 mm

.024 inch to .087 inch)

2. Easy design of PC board pattern

(2.54 mm x 4 pitch DIL terminal array)

ACCESSORIES

ST RELAYS

SOCKET

3. Complies with Japan Electrical

Appliance and Material Safety Law.

(UL and VDE certification)

SPECIFICATIONS

Item Specifications

Breakdown voltage (Initial)

Insulation resistance (Initial) Min. 1,000 MΩ between terminals (500V DC)

Heat resistance 150°C 302°F for 1 hr

Max. continuous current 10 A

Relay insertion life 15 times

DIMENSIONS

ST-PS ST-SS

1.05

.041

10.16

.400

7.62

.300

8172635

31.6

1.244

35.4

1.394

7.62

.300

4

Between contact and coil: 4,000 Vrms for 1 min. (Detection current: 10 mA)

Between contact and terminal: 2,000 Vrms for 1 min.

(Unit: mm inch)

4

.158

0.3

.012

.169

16.6

.654

4.3

10.16

0.27

.011

.400

14.6

.575

5.5

.217

4. High breakdown voltage.

16.4

.646

10.16

.400

7.62

.300

31.6

1.244

35.4

1.394

8172635

2.3

.090

7.62

.300

4

.158

16.4

5.5

.217

.646

0.3

.012

5.3

.209

10.16

.400

0.27

.011

14.6

.575

16.6

.654

4

PRECAUTIONS FOR USE (SOCKET)

1. PC board mounting method

PC board pattern

Contact

terminal

interval

Coil

terminal

interval

87 65

12 34

8-1.5 DIA.

8-.060 DIA.

2.54

.100

2.54

.100

The terminal configuration is symmetrical

on the left and right, so an arrow mark

is stamped on the socket to prevent misinsertion. We recommend printing the

same arrow mark on the component

mounting side (side opposite from

pattern) of the PC board. In this case, the

terminal configuration becomes the

terminal nos. noted near the drilling

holes.

2. Chassis cutout

Chassis cutting dimensions

A side

If the chassis hole is punched with a

press, set so the release R on the front

side (A side).

The range for chassis thickness is 0.6 to

2.2 mm .024 to .087 inch.

32.5±0.1

1.280±.004

Press

15.0±0.2

.591±.008

Claw for chassis

fastening

Chassis t = 0.6 to 2.2

.024 to .087

3. Relay mounting and removal

(1) Align the directions of the relay and

socket.

Relay

(2) Insert the relay all the way in, so it is

securely in place.

Hinge

mechanism

(3) Press the part indicated by A in the B

direction, and fasten by placing the hook

on the relay.

Relay case

cross-section

A

B

(Fastening complete)(Before fastening)

(4) When removing the relay, completely

release the hooks on both sides and pull

the relay out.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Loading...

Loading...