ORDER NO.VM1501005CE

High Definition Video Camera

Model No. HC-V270PP

HC-V270PU

HC-V270EB

HC-V270EC

HC-V270EE

HC-V270EF

B27

HC-V270EG

HC-V270EP

HC-V270GC

HC-V270GK

HC-V270GN

HC-V270GW

HC-V260EE

Colour

(K)...........Black Type

(R)...........Red Type (only HC-V270EG/EP/GC/GK)

(W)...........White Type (only HC-V270GC/V260EE)

© Panasonic Corporation 2015 Unauthorized copying and distribution is a violation of law.

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure. 1) --------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. How to Recycle the Lithium Ion Battery (U.S.

Only)-----------------------------------------------------------4

2.3. Caution for AC Cord (For EB/GC) ---------------------5

2.4. How to Replace the Lithium Battery -------------------6

3 Service Navigation------------------------------------------------7

3.1. Introduction --------------------------------------------------7

3.2. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------7

3.3. How to Define the Model Suffix (NTSC or PAL

model)---------------------------------------------------------8

3.4. Formatting----------------------------------------------------9

3.5. Baking of replacement IC and defective P.C.B.

----------------------------------------------------------------10

4 Specifications ---------------------------------------------------- 11

5 Location of Controls and Components------------------ 13

6 Service Mode ----------------------------------------------------- 16

6.1. Model/Destination Settings ---------------------------- 17

6.2. Lock Search and Error History Indication ---------- 18

6.3. Power ON Self Check Result Display--------------- 19

6.4. Adjustment function for the Service ----------------- 20

6.5. Restore the backed up adjustment data------------ 21

6.6. Touch Panel Calibration -------------------------------- 22

6.7. NFC Initialization (HC-V270 only)-------------------- 22

7 Service Fixture & Tools --------------------------------------- 23

7.1. Service Fixture and Tools ------------------------------ 23

7.2. When Replacing the Main P.C.B. -------------------- 23

7.3. Service Position ------------------------------------------ 23

8 Disassembly and Assembly Instructions --------------- 24

8.1. Disassembly Flow Chart for the Unit ---------------- 24

8.2. PCB Location---------------------------------------------- 25

8.3. Disassembly Procedure for the Unit ---------------- 26

9 Measurements and Adjustments -------------------------- 43

9.1. Electric Adjustment --------------------------------------43

10 Factory Setting--------------------------------------------------- 55

10.1. How To Turn On The Factory Settings? ------------ 55

10.2. What Is The Factory Settings? ----------------------- 56

11 Block Diagra m --------------------------------------------------- 57

11.1. Overall Block Diagram ----------------------------------57

11.2. Camera/System Control Circuit Block

Diagram----------------------------------------------------- 58

11.3. Video/Audio Signal Process(1) Circuit Block

Diagram----------------------------------------------------- 59

11.4. Video/Audio Signal Process(2) Circuit Block

Diagram----------------------------------------------------- 60

11.5. Lens Drive Circuit Block Diagram -------------------- 61

11.6. Power Supply Circuit Block Diagram---------------- 62

12 Wiring Connection Diagram --------------------------------- 63

12.1. Interconnection Diagram ------------------------------- 63

2

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essen-

tial that these critical parts should be replaced with manu-

facturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from acci-

dents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by acci-

dental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been over-

heated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

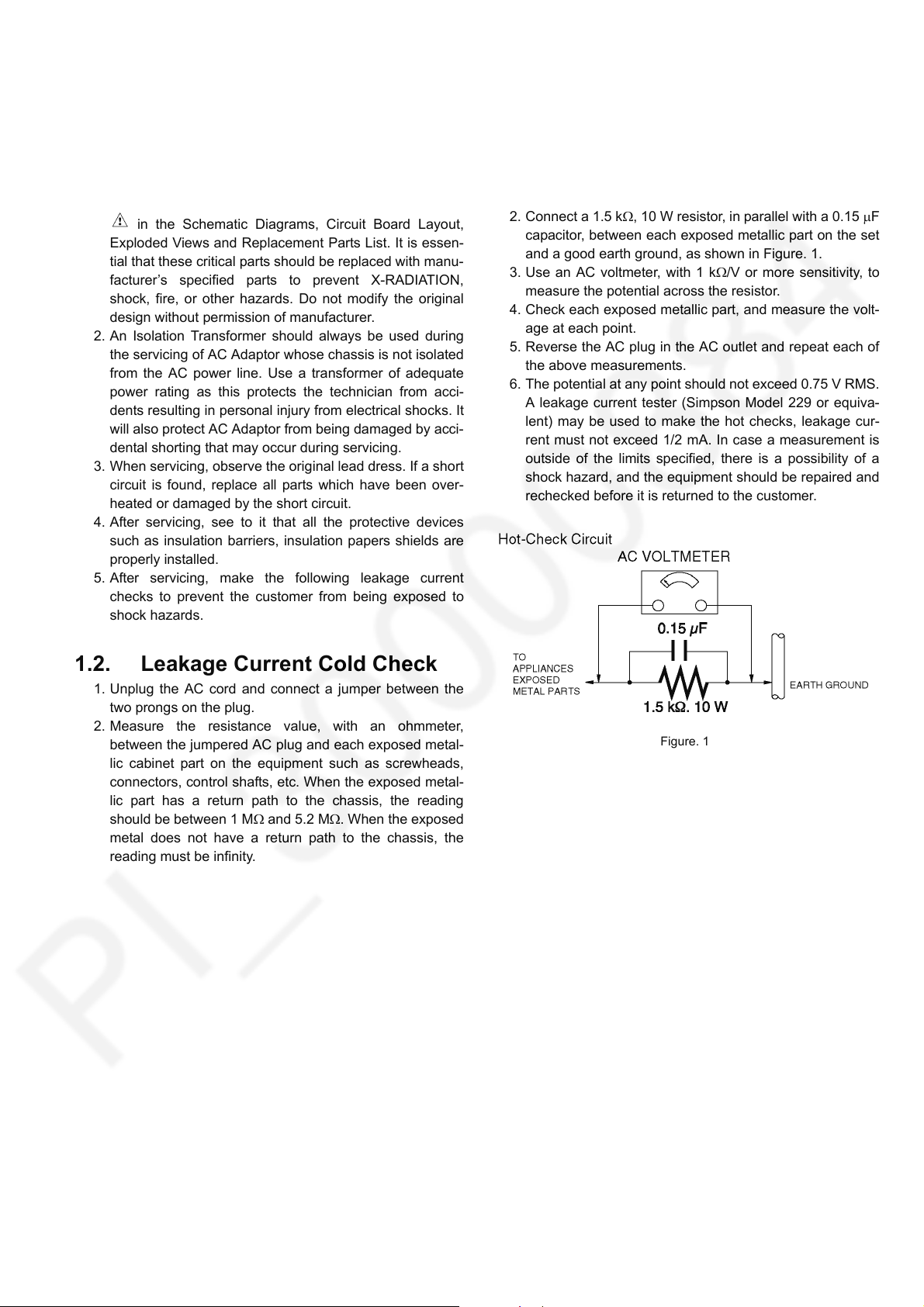

1.3. Leakage Current Hot Check (See Figure. 1)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 k, 10 W resistor, in parallel with a 0.15 F

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure. 1.

3. Use an AC voltmeter, with 1 k/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the volt-

age at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equiva-

lent) may be used to make the hot checks, leakage cur-

rent must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metal-

lic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metal-

lic part has a return path to the chassis, the reading

should be between 1 M and 5.2 M. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

Figure. 1

3

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alumi-

num foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as “antistatic (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or compara-

ble conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) suf-

ficient to damage an ES device).

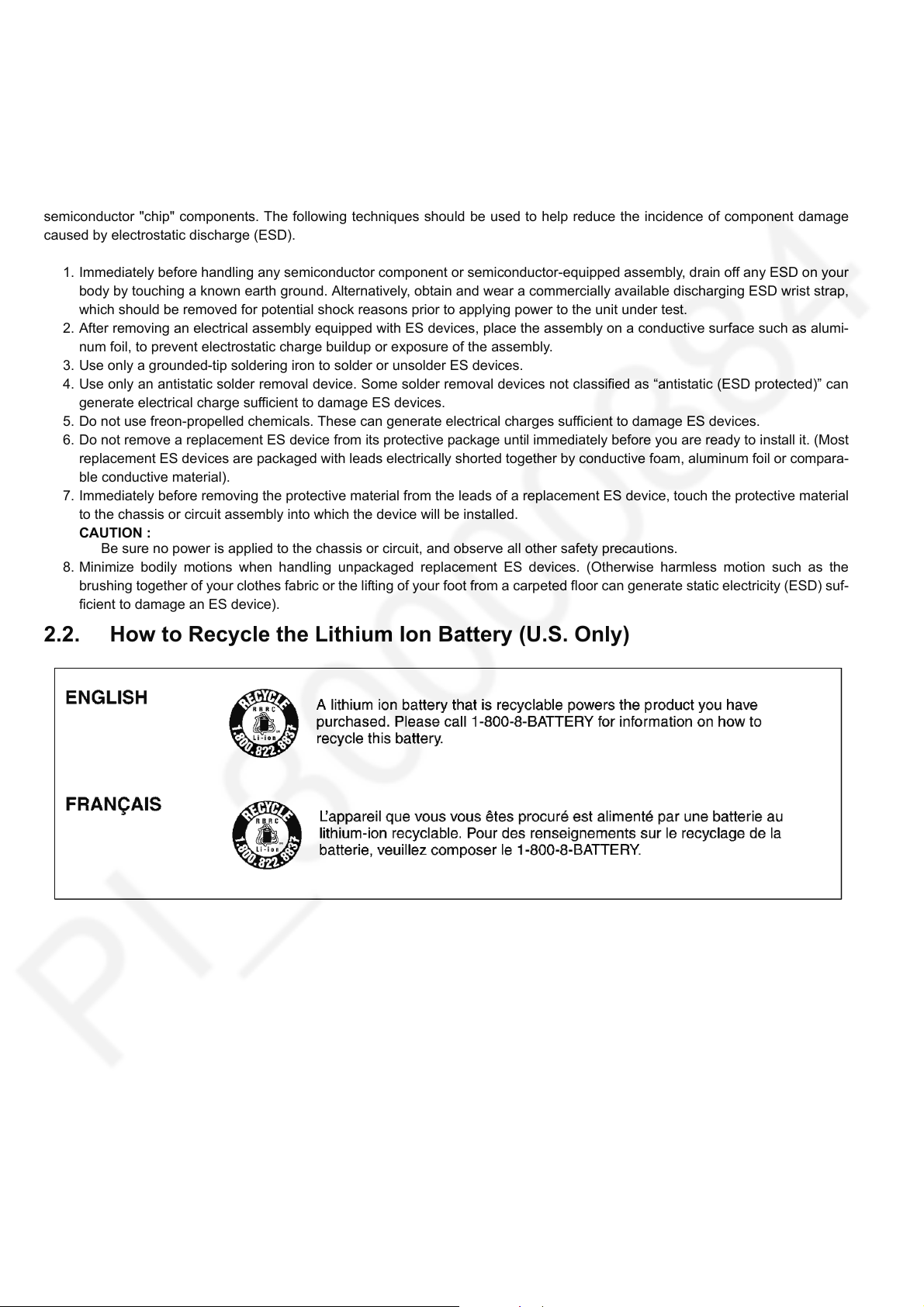

2.2. How to Recycle the Lithium Ion Battery (U.S. Only)

4

2.3. Caution for AC Cord (For EB/GC)

2.3.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

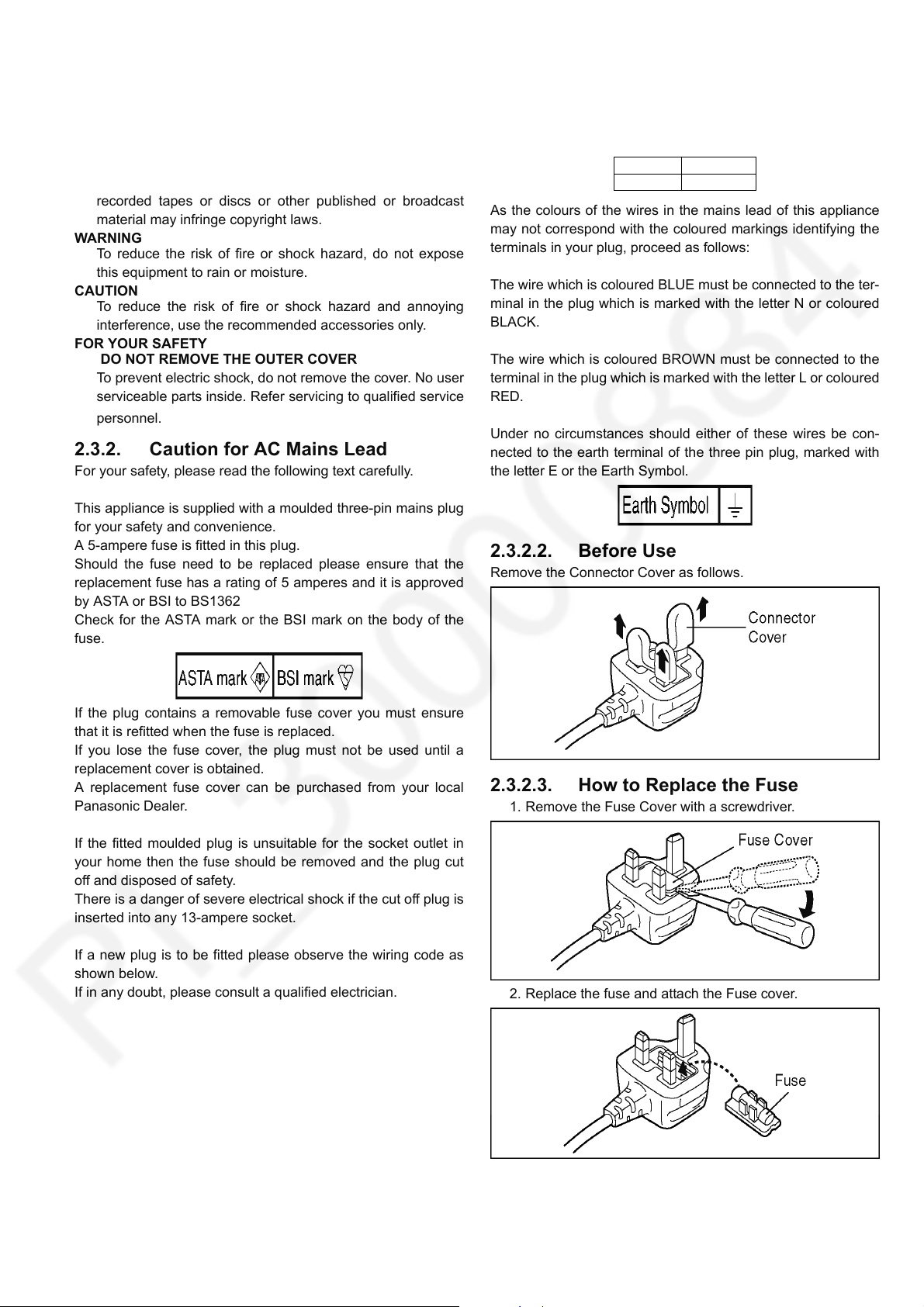

2.3.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

2.3.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

Blue Neutral

Brown Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the ter-

minal in the plug which is marked with the letter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be con-

nected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.3.2.2. Before Use

Remove the Connector Cover as follows.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.3.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

5

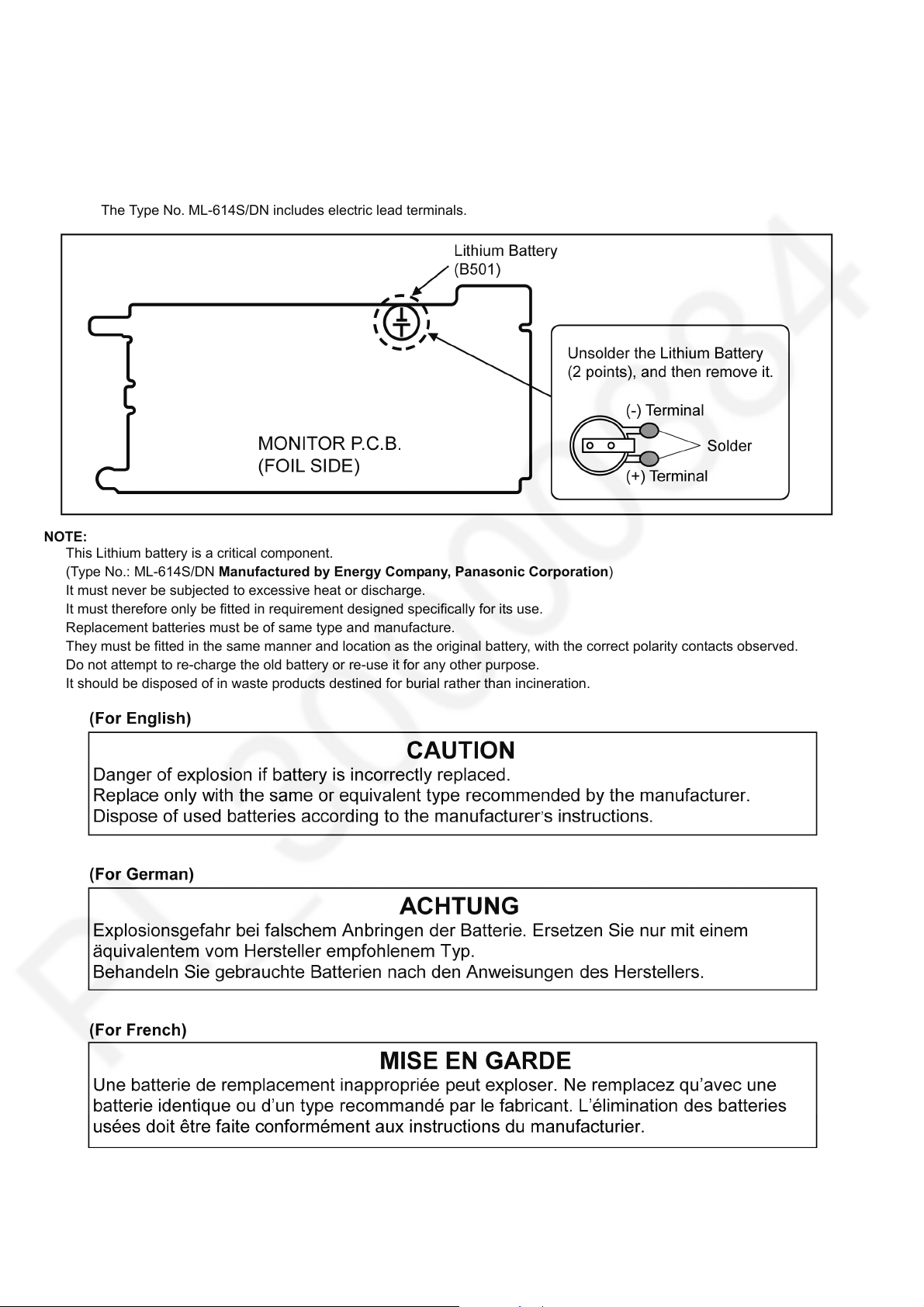

2.4. How to Replace the Lithium Battery

2.4.1. Replacement Procedure

1. Remove the MONITOR P.C.B.. (Refer to Disassembly Procedures.)

2. Unsolder the each soldering point of electric lead terminal for Lithium battery (Ref. No. “B501” at foil side of MONITOR

P.C.B.) and remove the Lithium battery together with electric lead terminal. Then replace it into new one.

NOTE:

The Type No. ML-614S/DN includes electric lead terminals.

NOTE:

This Lithium battery is a critical component.

(Type No.: ML-614S/DN Manufactured by Energy Company, Panasonic Corporation)

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in requirement designed specifically for its use.

Replacement batteries must be of same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

Above caution is applicable for a battery pack which is for HC-V270/V260 series, as well.

6

3 Service Navigation

3.1. Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

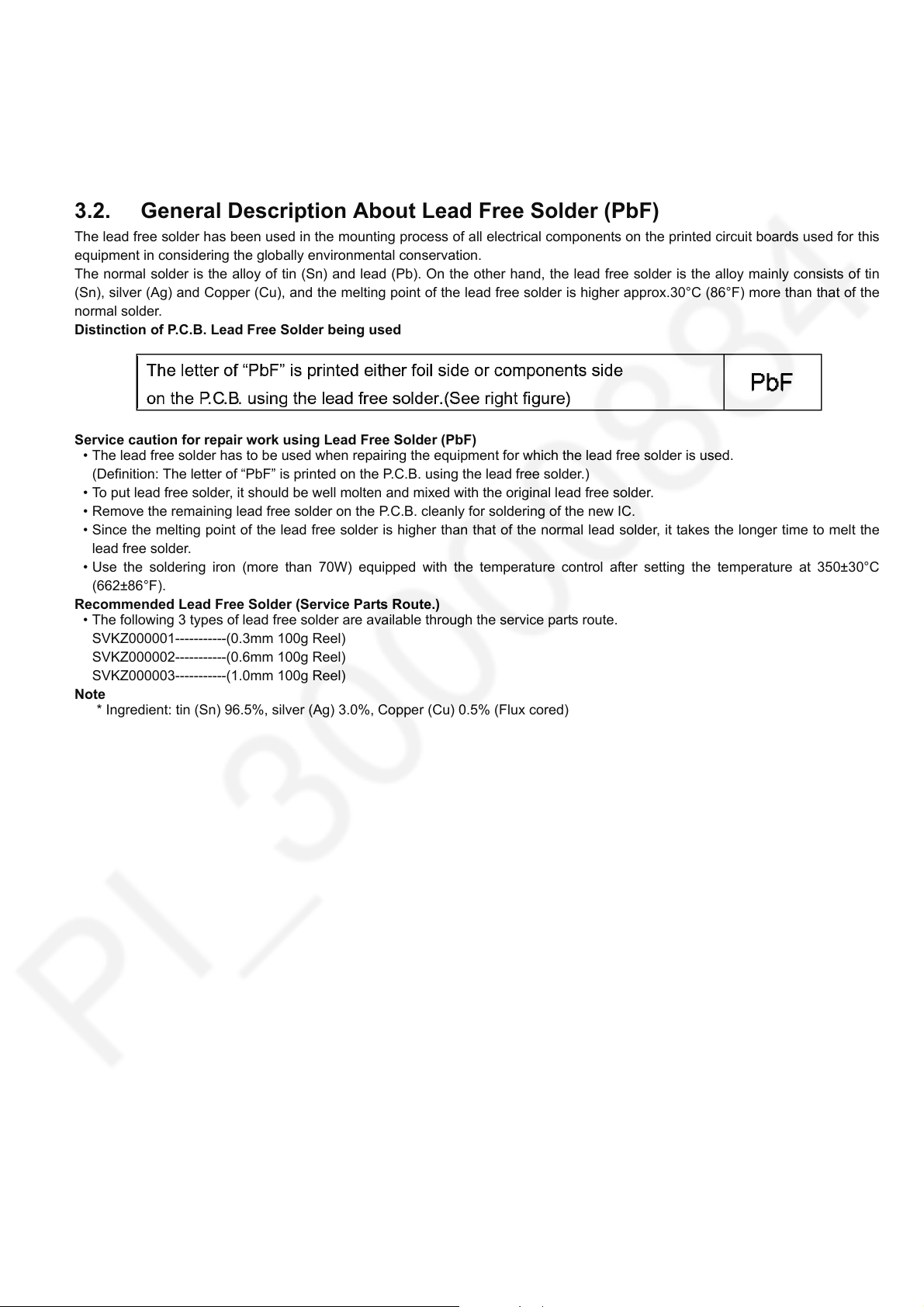

3.2. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

SVKZ000001-----------(0.3mm 100g Reel)

SVKZ000002-----------(0.6mm 100g Reel)

SVKZ000003-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5% (Flux cored)

7

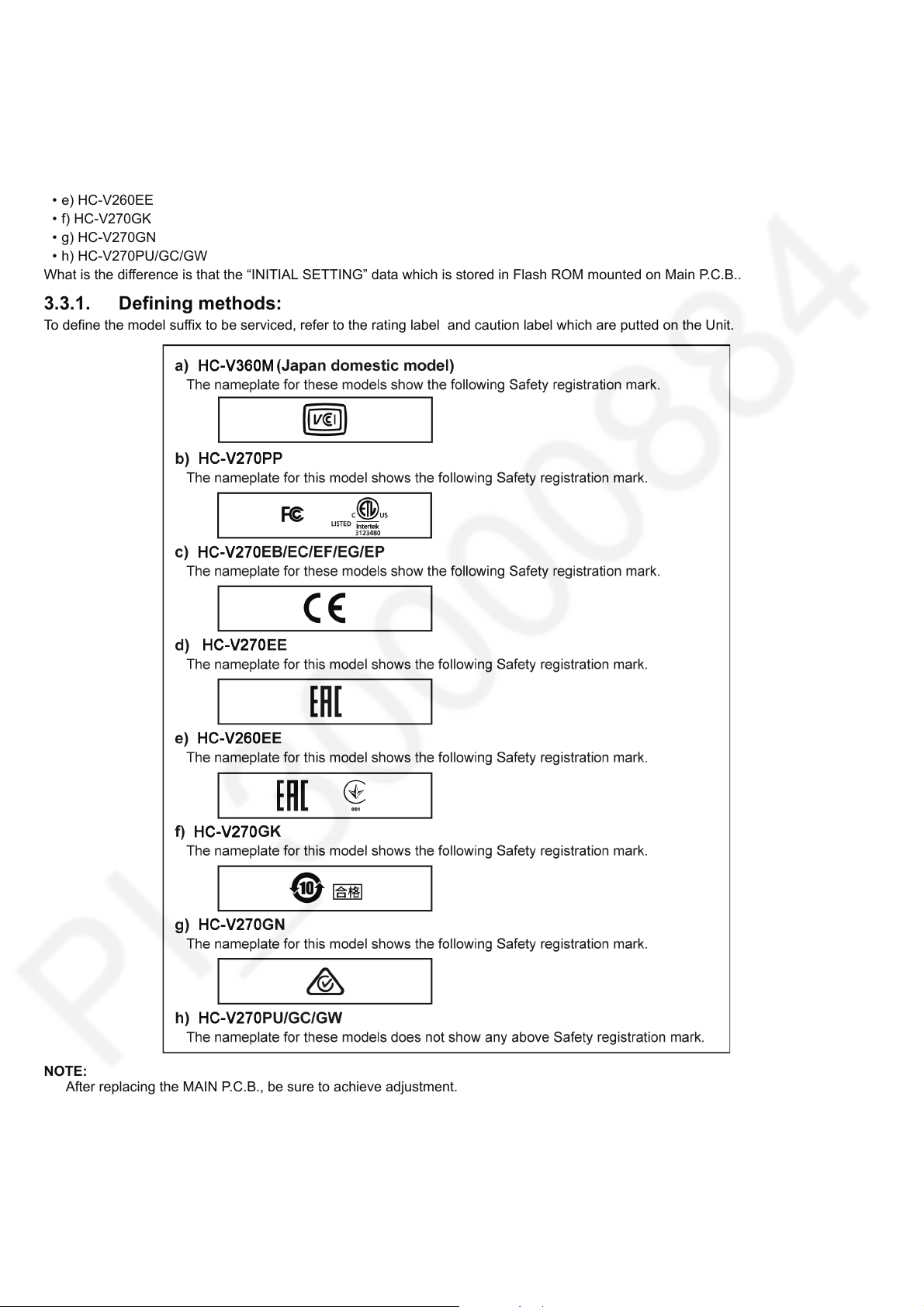

3.3. How to Define the Model Suffix (NTSC or PAL model)

There are eight kinds of HC-V270/V260.

• a) HC-V360M (Japan domestic model)

• b) HC-V270PP

• c) HC-V270EB/EC/EF/EG/EP

• d) HC-V270EE

• e) HC-V260EE

• f) HC-V270GK

• g) HC-V270GN

• h) HC-V270PU/GC/GW

What is the difference is that the “INITIAL SETTING” data which is stored in Flash ROM mounted on Main P.C.B..

3.3.1. Defining methods:

To define the model suffix to be serviced, refer to the rating label and caution label which are putted on the Unit.

NOTE:

After replacing the MAIN P.C.B., be sure to achieve adjustment.

8

3.4. Formatting

The following formatting is for HC-V270PP.

The page number in this page does not show the page number of this service manual.

9

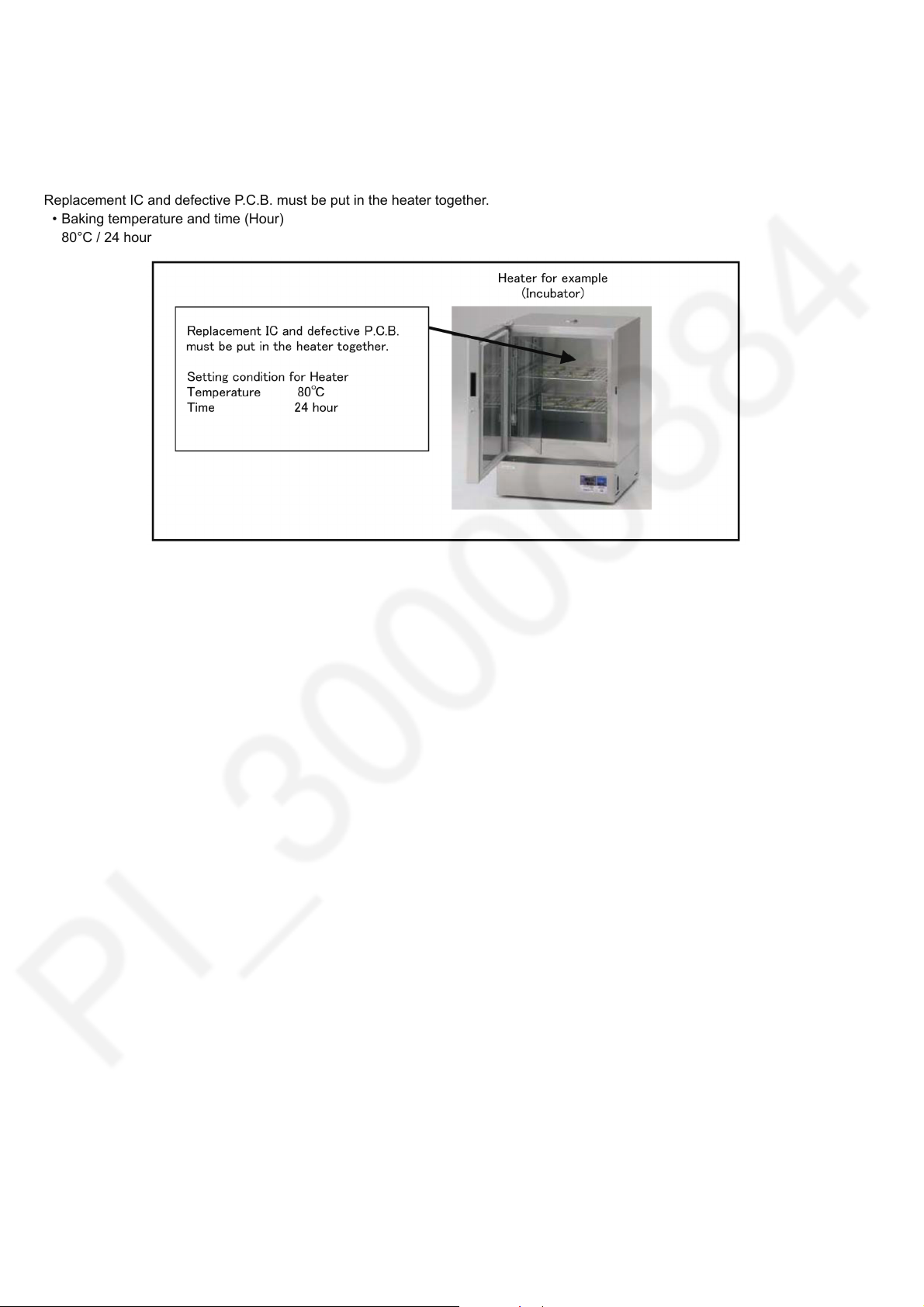

3.5. Baking of replacement IC and defective P.C.B.

When replacing the CSP/BGA/QFN type IC mounted on the P.C.B., the problem of IC crack or foil pattern breaking in the P.C.B.

might sometimes occur by rapid heating.

In order to improve the success rate of IC replacement for repair, it would be required to work out baking of replacement

IC and defective P.C.B. before replacing IC.

Please refer the way of baking as follows.

Replacement IC and defective P.C.B. must be put in the heater together.

• Baking temperature and time (Hour)

80°C / 24 hour

10

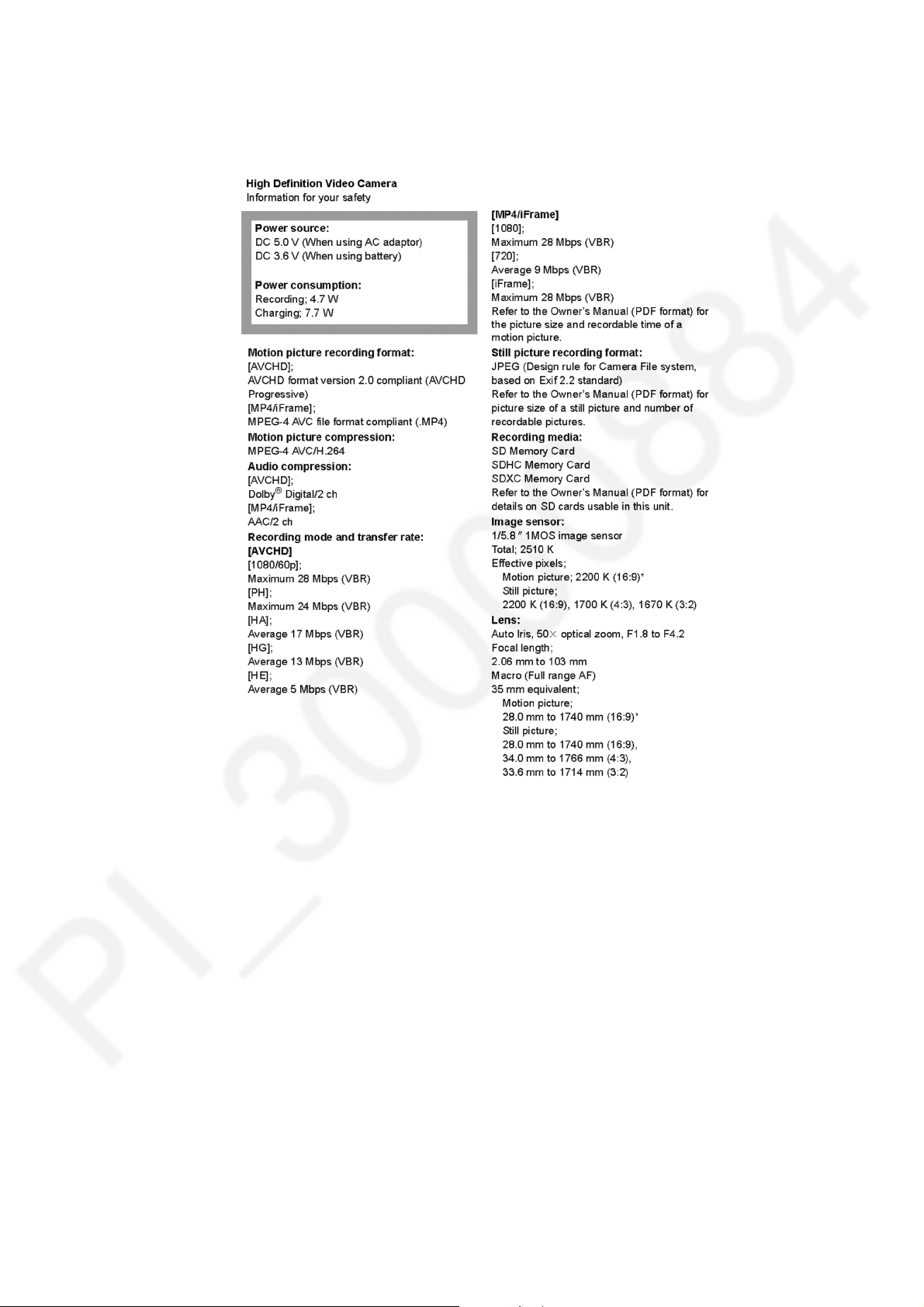

4 Specifications

The following specification is for HC-V270PP.

Some specifications may differ depending on model suffix.

The page number in this chapter does not show the page number of this service manual.

11

12

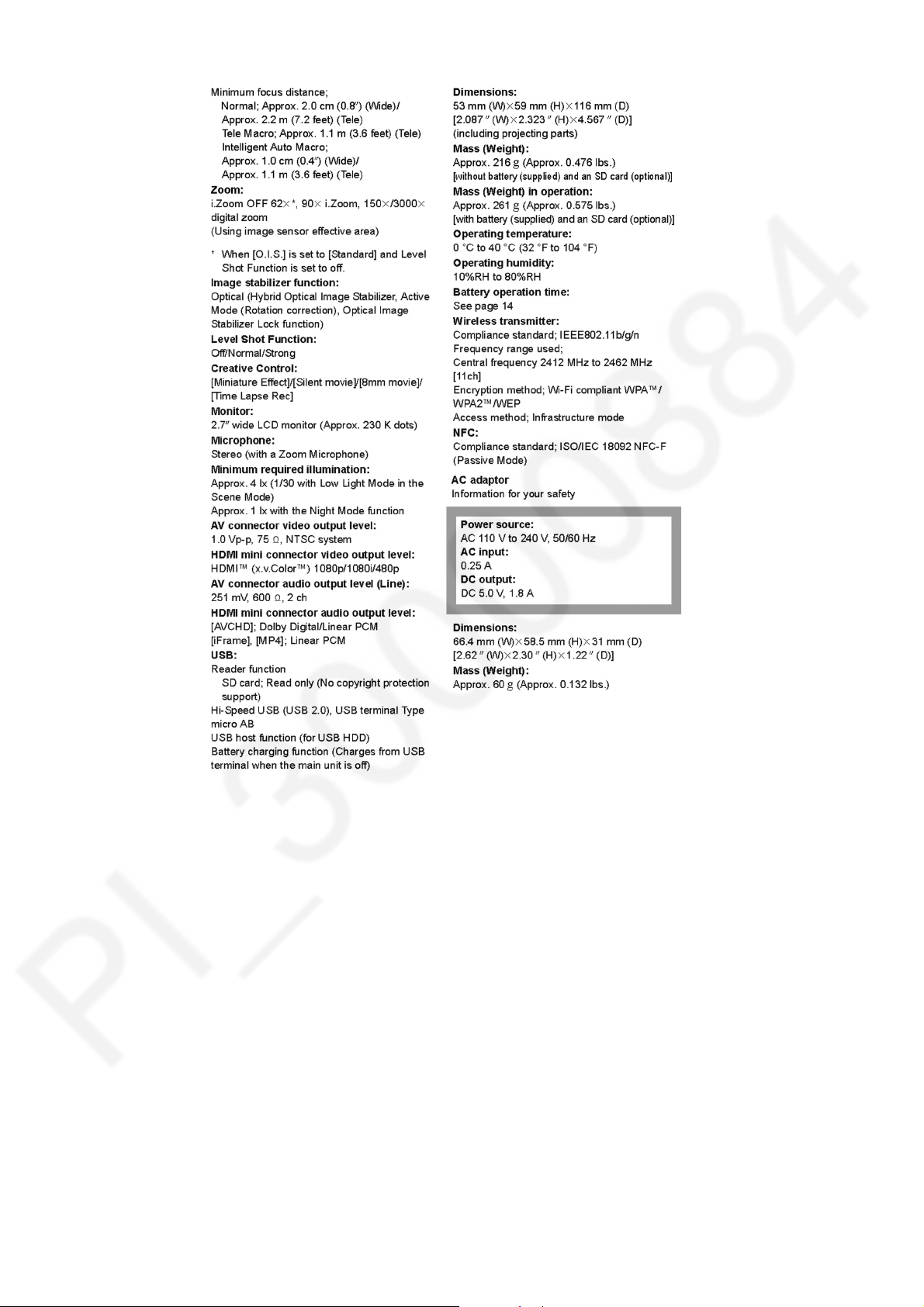

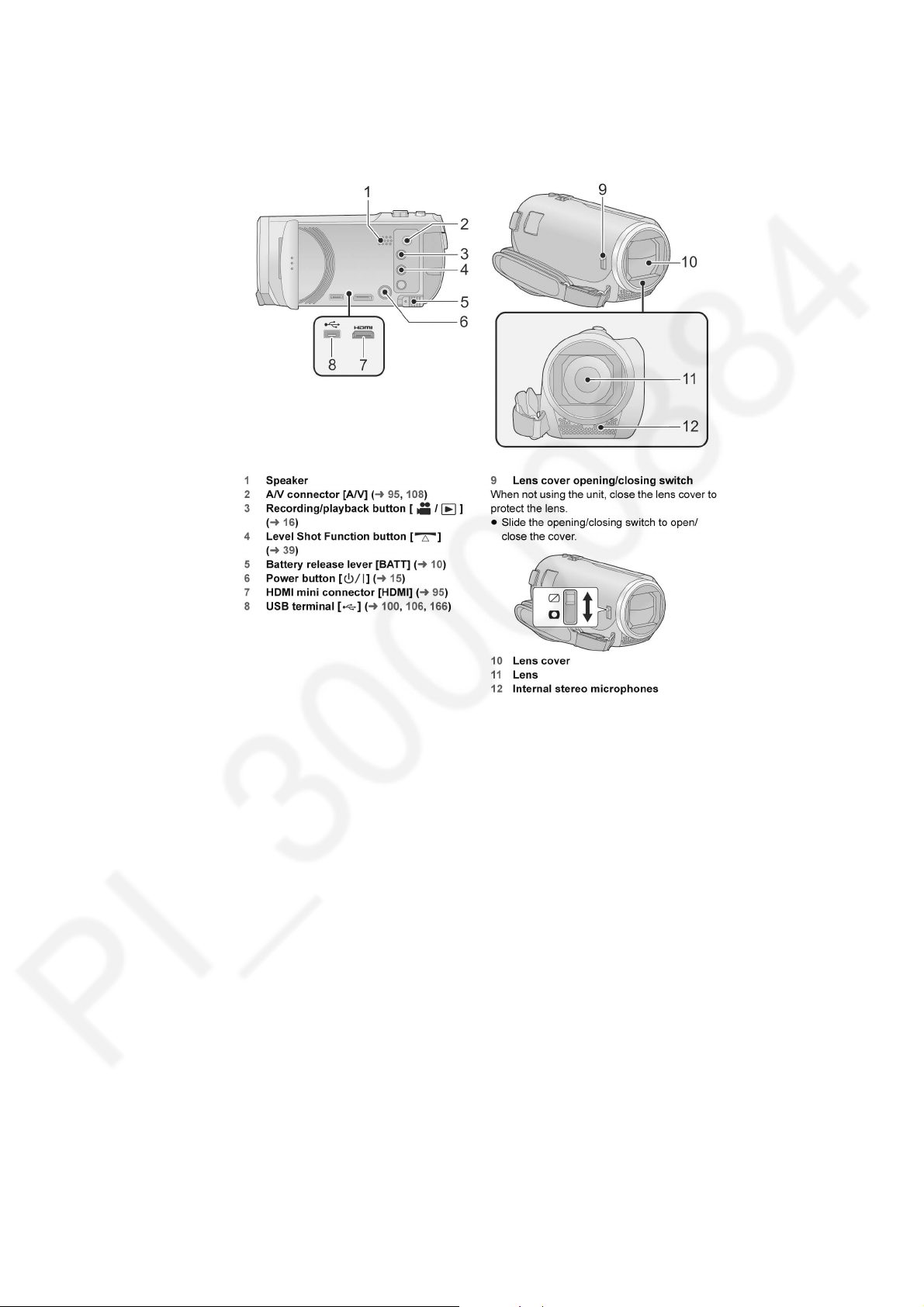

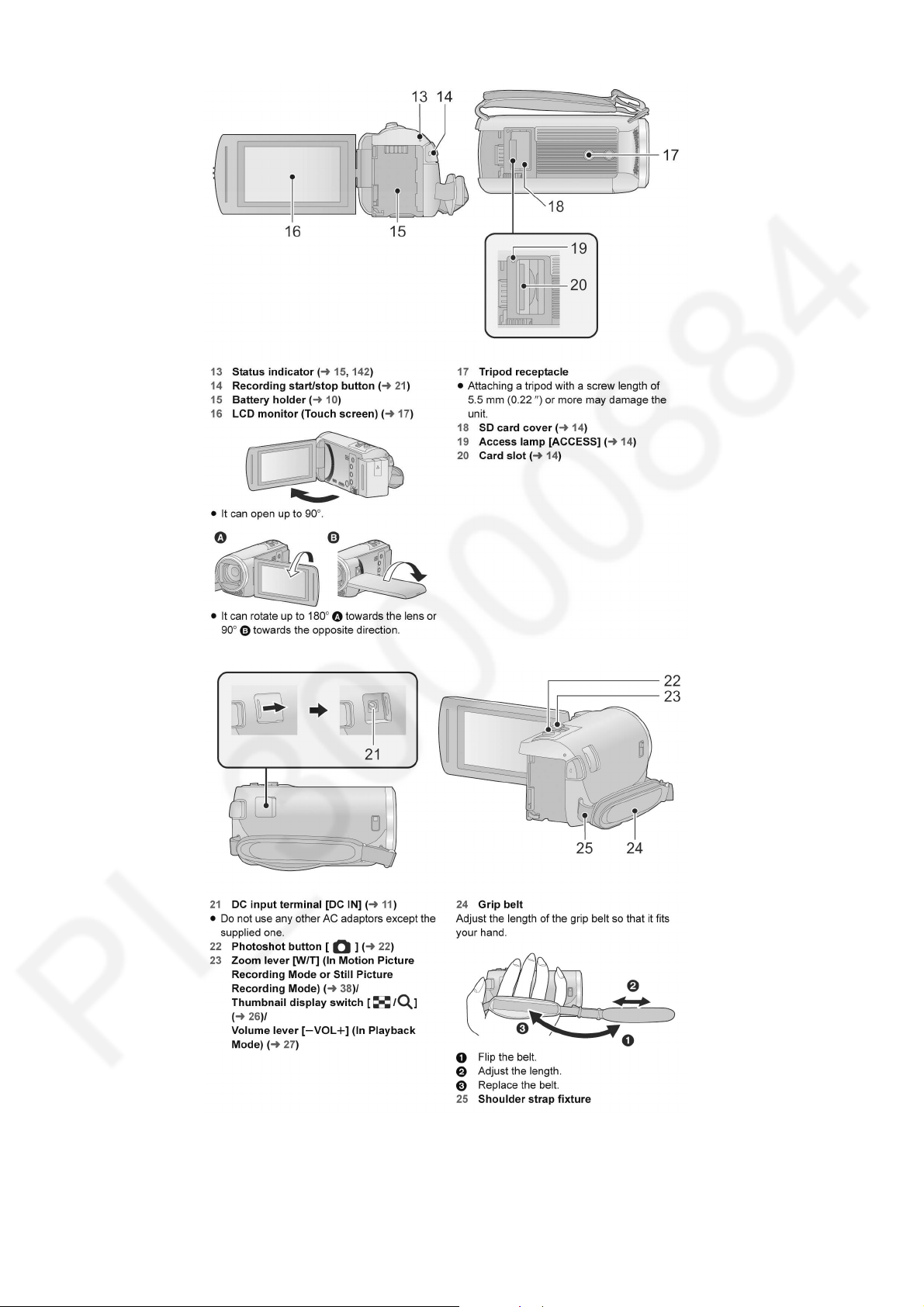

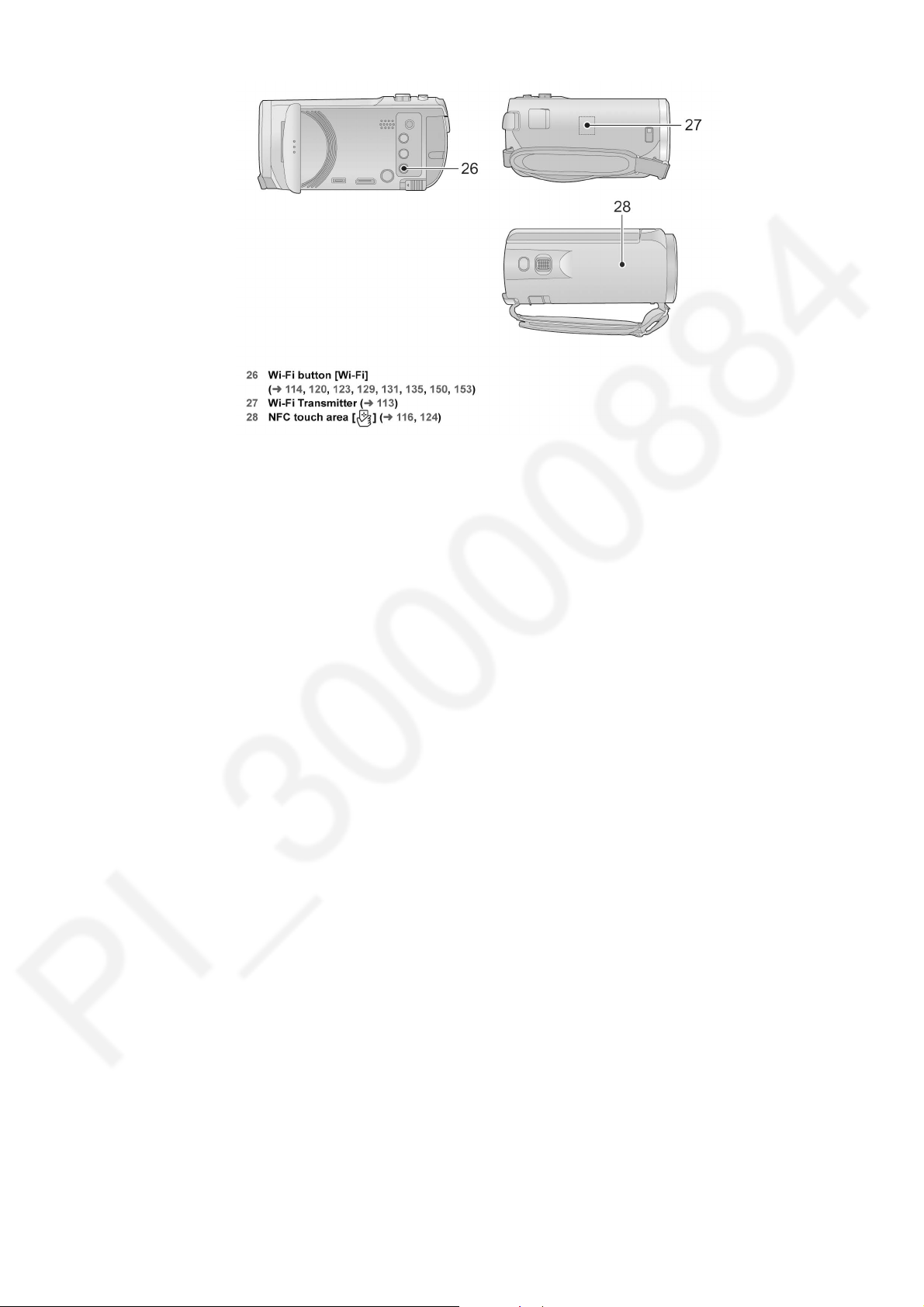

5 Location of Controls and Components

The following description is for HC-V270PP.

Some descriptions may differ depending on model suffix.

The page number in this chapter does not show the page number of this service manual.

13

141516

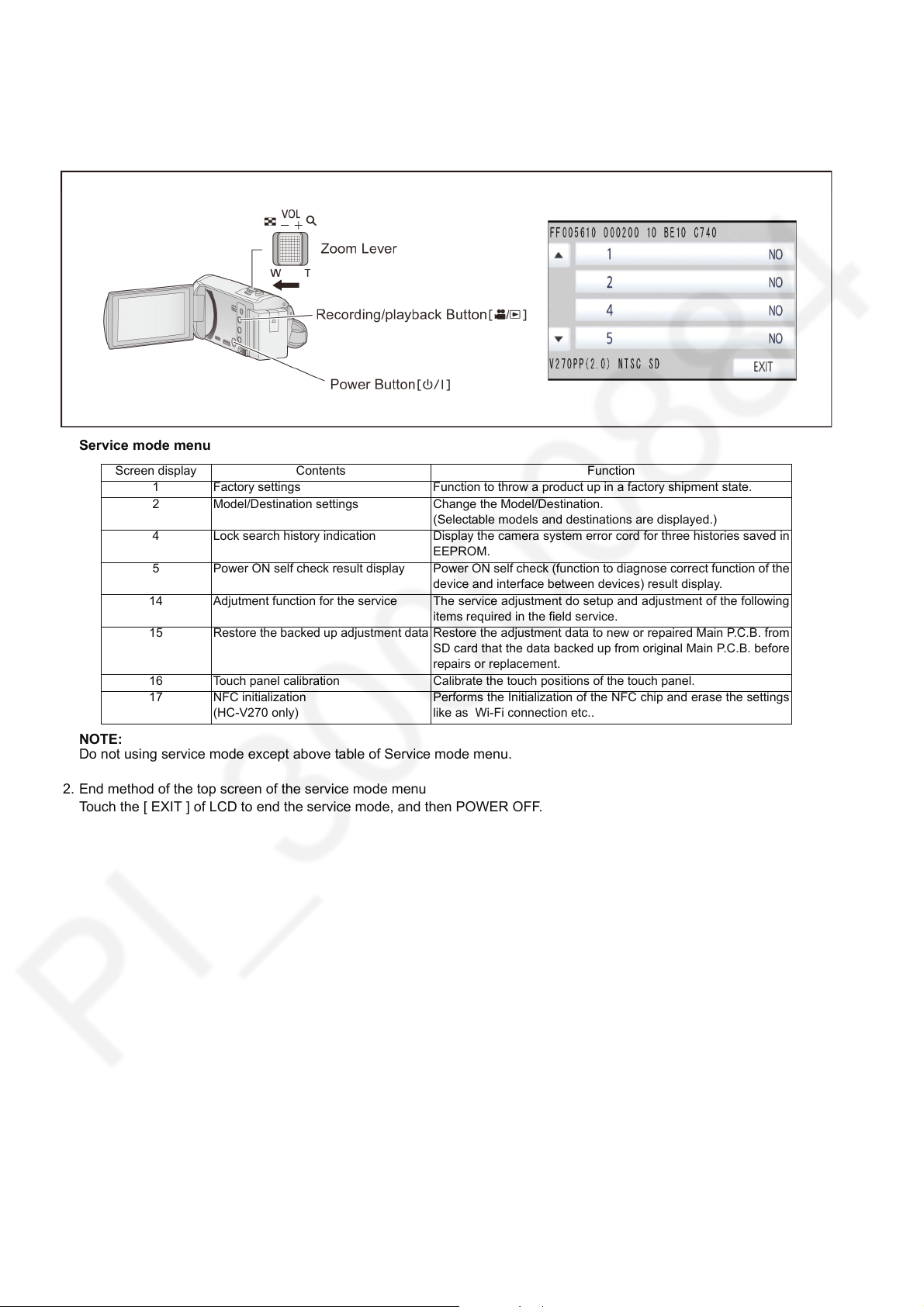

6 Service Mode

Indication method of the service menu

1. Keep pressing the “Power” button, “Zoom lever” to W side and “Recording/Playback” button for more than 3 seconds until the

top screen of the Service Mode Menu being displayed.

Service mode menu

Screen display Contents Function

1 Factory settings Function to throw a product up in a factory shipment state.

2 Model/Destination settings Change the Model/Destination.

4 Lock search history indication Display the camera system error cord for three histories saved in

5 Power ON self check result display Power ON self check (function to diagnose correct function of the

14 Adjutment function for the service The service adjustment do setup and adjustment of the following

15 Restore the backed up adjustment data Restore the adjustment data to new or repaired Main P.C.B. from

16 Touch panel calibration Calibrate the touch positions of the touch panel.

17 NFC initialization

(HC-V270 only)

(Selectable models and destinations are displayed.)

EEPROM.

device and interface between devices) result display.

items required in the field service.

SD card that the data backed up from original Main P.C.B. before

repairs or replacement.

Performs the Initialization of the NFC chip and erase the settings

like as Wi-Fi connection etc..

NOTE:

Do not using service mode except above table of Service mode menu.

2. End method of the top screen of the service mode menu

Touch the [ EXIT ] of LCD to end the service mode, and then POWER OFF.

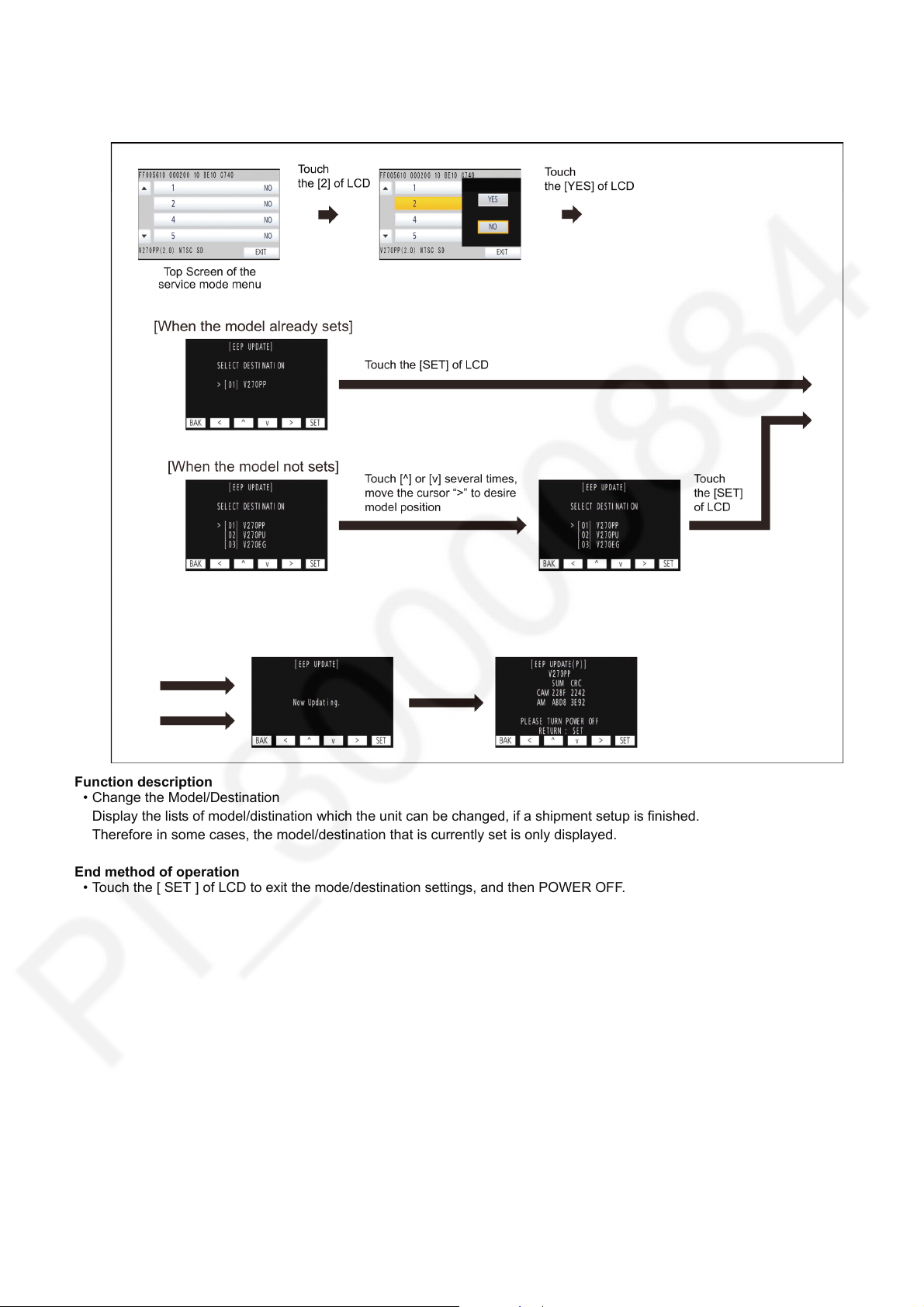

6.1. Model/Destination Settings

Touch the [ 2 ] of LCD, select model/destination settings.

Operation specifications

Function description

• Change the Model/Destination

Display the lists of model/distination which the unit can be changed, if a shipment setup is finished.

Therefore in some cases, the model/destination that is currently set is only displayed.

End method of operation

• Touch the [ SET ] of LCD to exit the mode/destination settings, and then POWER OFF.

17

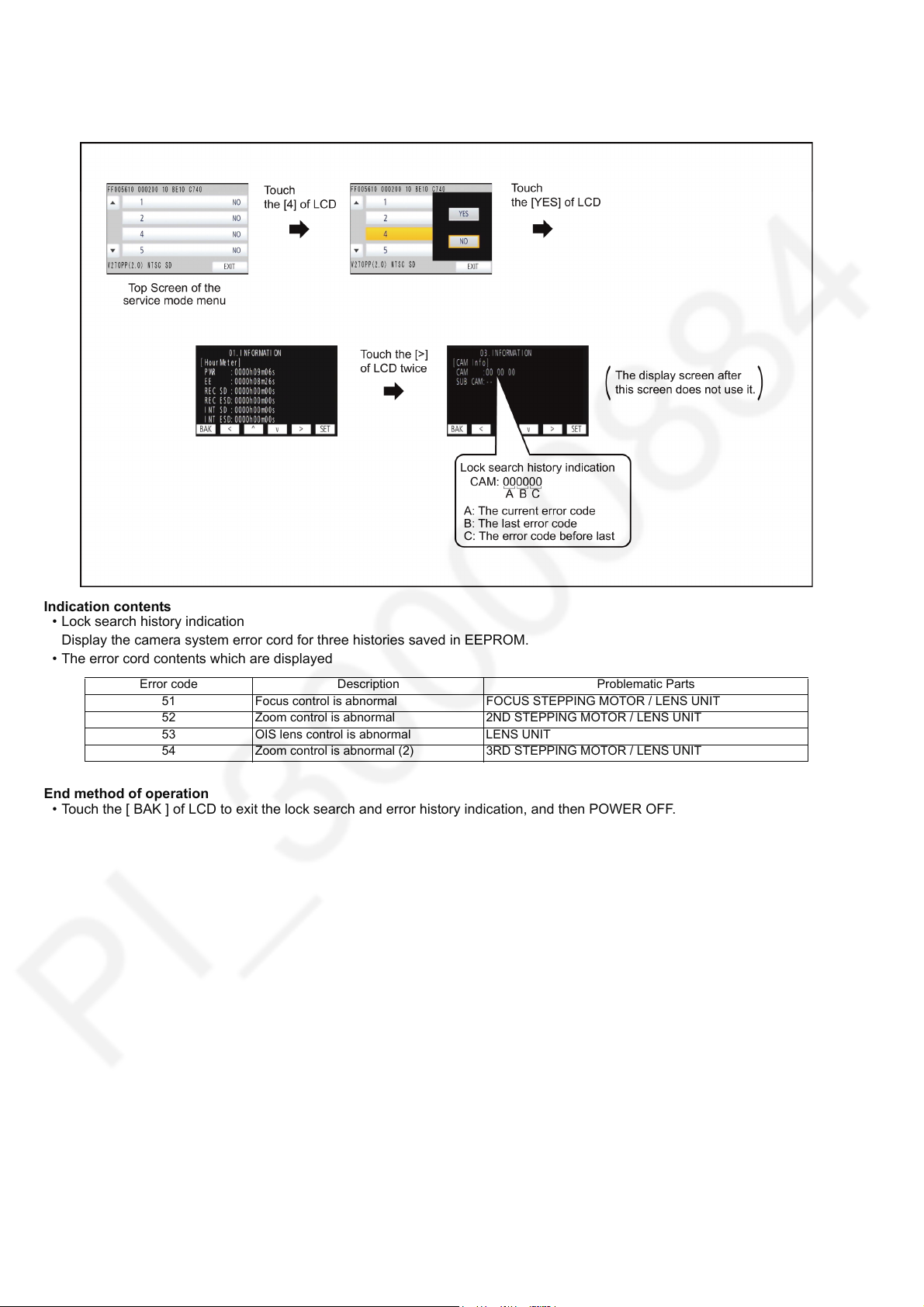

6.2. Lock Search and Error History Indication

Touch the [ 4 ] of LCD, select Lock search and error history indication.

Operation specifications

Indication contents

• Lock search history indication

Display the camera system error cord for three histories saved in EEPROM.

• The error cord contents which are displayed

Error code Description Problematic Parts

51 Focus control is abnormal FOCUS STEPPING MOTOR / LENS UNIT

52 Zoom control is abnormal 2ND STEPPING MOTOR / LENS UNIT

53 OIS lens control is abnormal LENS UNIT

54 Zoom control is abnormal (2) 3RD STEPPING MOTOR / LENS UNIT

End method of operation

• Touch the [ BAK ] of LCD to exit the lock search and error history indication, and then POWER OFF.

18

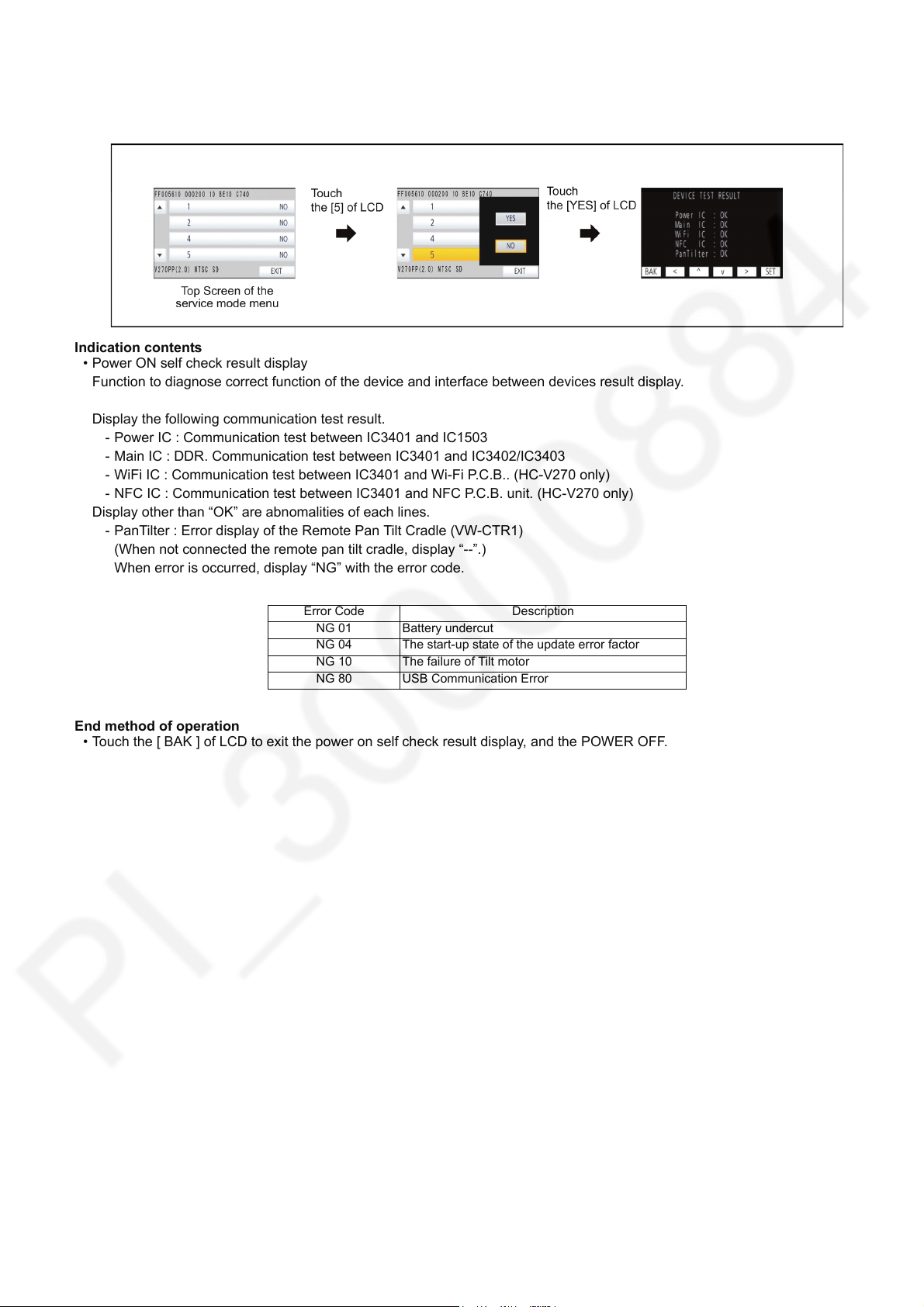

6.3. Power ON Self Check Result Display

Touch the [ 5 ] of LCD, select Power ON self check result display.

Operation specifications

Indication contents

• Power ON self check result display

Function to diagnose correct function of the device and interface between devices result display.

Display the following communication test result.

- Power IC : Communication test between IC3401 and IC1503

- Main IC : DDR. Communication test between IC3401 and IC3402/IC3403

- WiFi IC : Communication test between IC3401 and Wi-Fi P.C.B.. (HC-V270 only)

- NFC IC : Communication test between IC3401 and NFC P.C.B. unit. (HC-V270 only)

Display other than “OK” are abnomalities of each lines.

- PanTilter : Error display of the Remote Pan Tilt Cradle (VW-CTR1)

(When not connected the remote pan tilt cradle, display “--”.)

When error is occurred, display “NG” with the error code.

Error Code Description

NG 01 Battery undercut

NG 04 The start-up state of the update error factor

NG 10 The failure of Tilt motor

NG 80 USB Communication Error

End method of operation

• Touch the [ BAK ] of LCD to exit the power on self check result display, and the POWER OFF.

19

6.4. Adjustment function for the Service

Touch the [14] of LCD, select the adjustment function for the service.

Operation Specifications (until before the start of the adjustment)

Function description

The service adjustment do setup and adjustment of the following items required in the field service.

For a detailed content, such as the adjustment procedure, refer to “9 Measurements and Adjustments”.

• Model setting

• Setting of the file name for adjustment data backup to SD card.

• Execution of adjustment data backup to SD card

• Checking of Switches

• Camera adjustment

• Zoom Tracking adjustments

• Indoor White Balance Adjustment

• Outdoor White Balance Adjustment

End method of operation

• Press the power button to turn the unit off.

20

6.5. Restore the backed up adjustment data

Touch the [15] of LCD, select restoring the backed up adjustment data from SD card to the unit.

Operation Specifications

Function description

Restore the adjustment data to new or repaired Main P.C.B. from SD card that the data backed up from original Main P.C.B.

before repairs or replacement.

To backup the adjustment data, use “6.4. Adjustment function for the Service”.

Restoring procedure

End method of operation

• Press the power button to turn the unit off.

21

6.6. Touch Panel Calibration

Touch the [16] of LCD, select the calibration of touch panel.

Operation Specifications

Function description

Calibrate the touch positions of the touch panel.

End method of operation

• Press the power button to turn the unit off.

6.7. NFC Initialization (HC-V270 only)

Touch the [17] of LCD, select initialization of NFC (Near Field Communication) function.

Operation Specifications

Function description

This function performs the Initialization of the NFC chip and erase the settings like as Wi-Fi connection etc..

End method of operation

• Press the power button to turn the unit off.

22

7 Service Fixture & Tools

7.1. Service Fixture and Tools

The following Service Fixture and tools are used for checking and servicing this unit.

Parts name Parts No. Remarks

Zoom Guide Shaft VMS8231 2 use

(* When Installing the MOS Unit )

7.2. When Replacing the Main P.C.B.

After replacing the MAIN P.C.B., be sure to achieve adjustment.

7.3. Service Position

This Service Position is used for checking and replacing parts. Use the following Extension cables for servicing.

No. Parts No. Connection Form

1 RFKZ0354 FP6001(MAIN) - MONITOR FPC 37PIN 0.3 FFC

2 RFKZ0444 PP6001(MAIN) - PS6401(SD HOLDER) 50PIN 0.5 B to B

3 VFK1480 FP6003(MAIN) - ECM FPC 6PIN 0.5 FFC

4 VFK1440 FP6402(SD HOLDER) - TOP OPERATION 10PIN 0.5 FFC

7.3.1. Extention Cable Connection

23

8 Disassembly and Assembly Instructions

8.1. Disassembly Flow Chart for the Unit

This is a disassembling chart.

When assembling, perform this chart conversely.

24

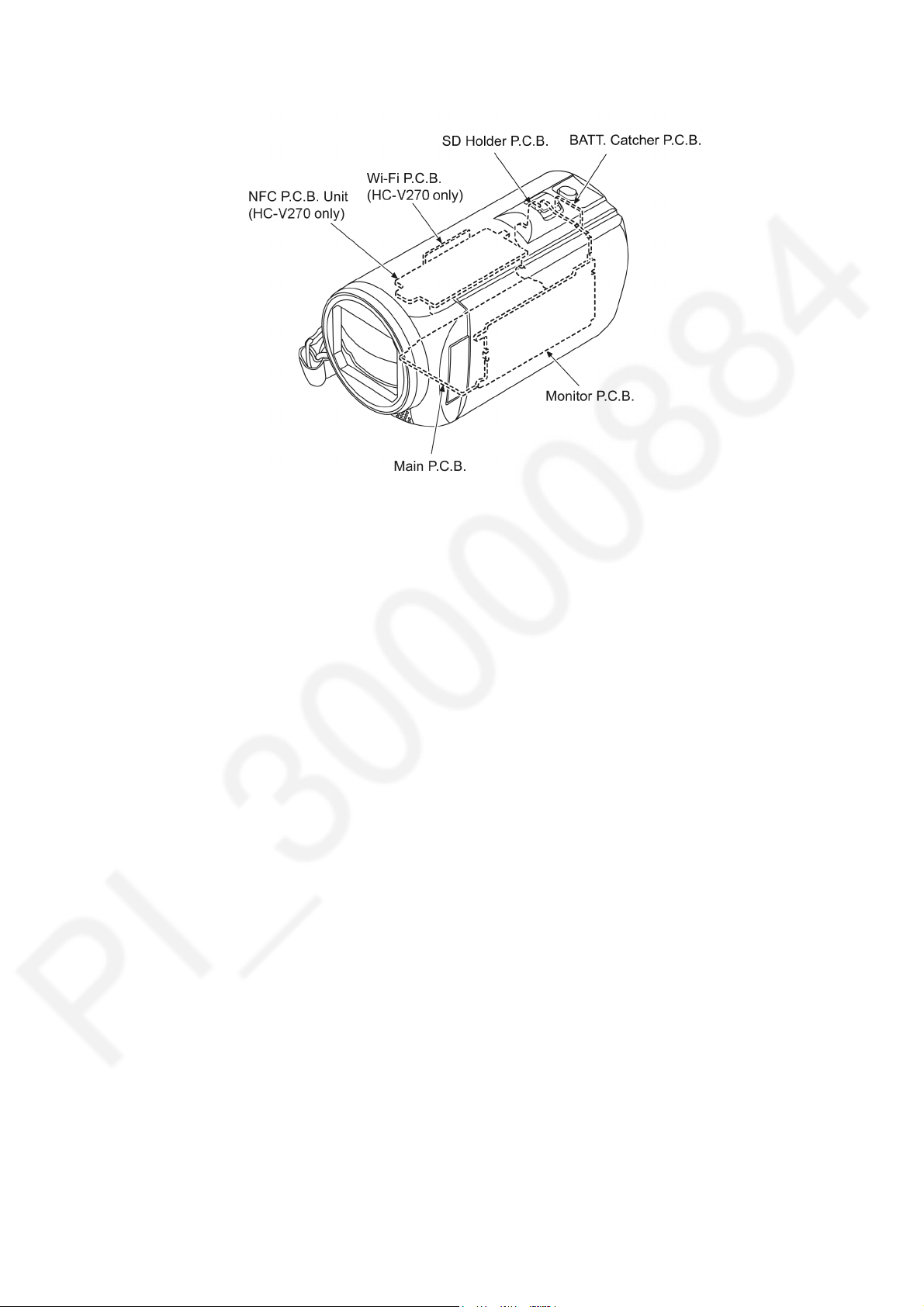

8.2. PCB Location

25

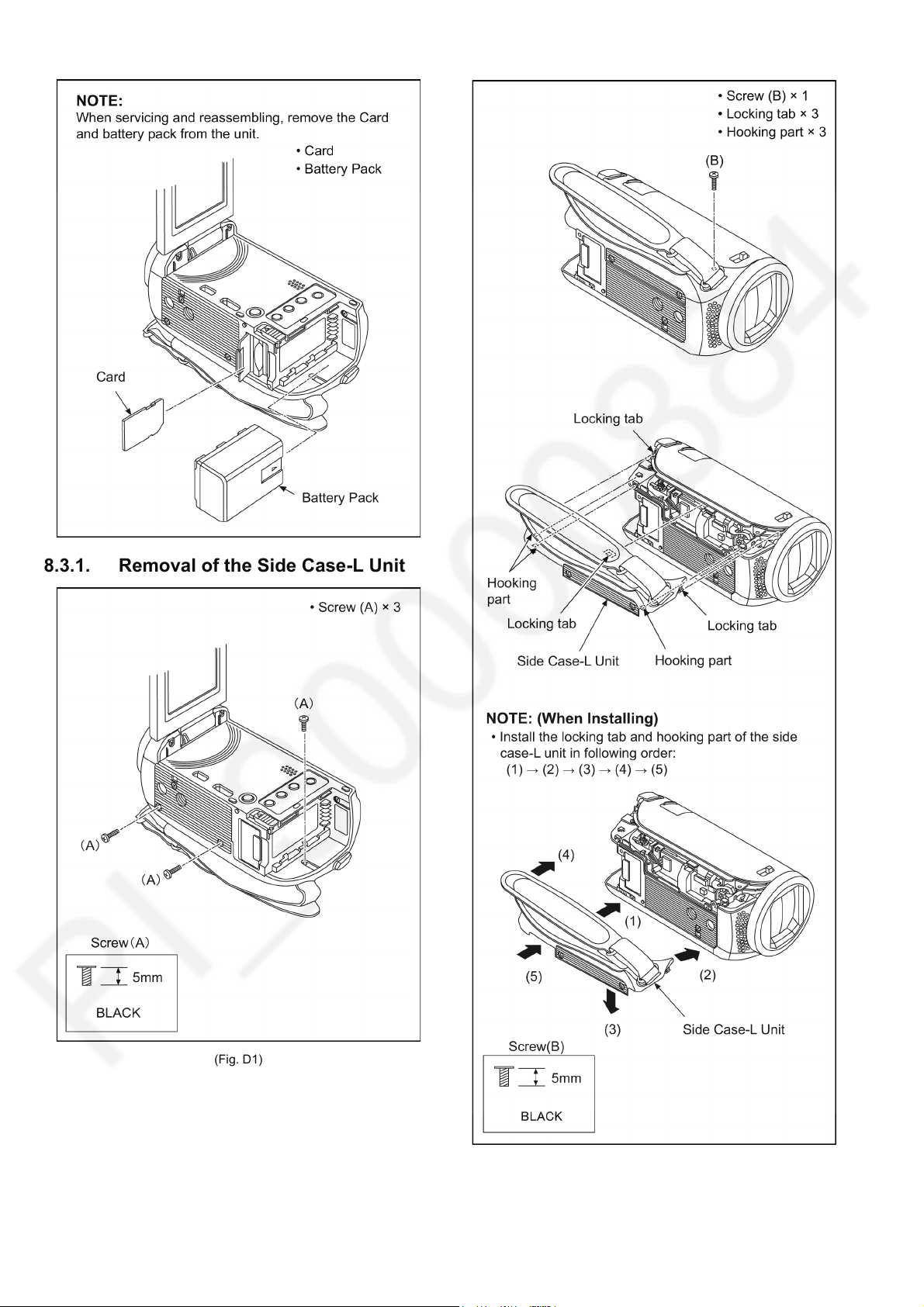

8.3. Disassembly Procedure for the Unit

No. Item Fig Removal

1 Side Case-L Unit (Fig. D1) Screw (A) x 3

(Fig. D2) Screw (B) x 1

Locking tab x 3

Hooking part x 3

Side Case-L Unit

2 Top Case Unit,

Power Panel Light,

LED Piece,

Jack Cover Piece,

Jack Cover Spring,

SS Button, SS Lever,

Jack Cover Unit

3 Front Case Unit (Fig. D4) Screw (E) x 1

4NFC P.C.B. Unit

(HC-V270 only)

5Wi-Fi P.C.B.

(HC-V270 only)

6 Lens Frame Unit (Fig. D8) Screw (J) x 1

7 Camera Lens Unit (Fig. D10) FP301 (Flex)

8Main P.C.B.,

SD Holder P.C.B.

(Fig. D3) Screw (C) x 1

Locking tab x 3

Top Case Unit

Power Panel Light

LED Piece

Screw (D) x 1

Convex x 1

Hooking part x 1

Jack Cover Piece

Jack Cover Spring

SS Button

SS Lever

Jack Cover Unit

Screw (F) x 2

FP6003 (Flex)

Screw (G) x 1

Convex x 2

(Fig. D5) Front Case Unit

(Fig. D6) Screw (H) x 1

FP6006 (Flex)

Hooking part x 1

NFC P.C.B. Unit

(Fig. D7) Flex A

Screw (I) x 1

Wi-Fi P.C.B.

Hooking part x 2

Heat Radiation Plate-L Unit

Screw (K) x 1

P6003 (Connector)

Screw (L) x 1

Convex x 2

Locking tab x 2

(Fig. D9) Lens Frame Unit

FP6008 (Flex)

Convex x 2

Camera Lens Unit

(Fig. D11) Screw (M) x 1

Screw (N) x 3

Screw (O) x 1

Convex x 2

Hooking part x 1

Heat Radiation Plate Unit

P6401 (Connector)

FP6001 (Flex)

FP6402 (Flex)

(Fig. D12) Convex x 5

Locking tab x 4

Bottom Frame Unit

Main P.C.B.

SD Holder P.C.B.

No. Item Fig Removal

9 Top Operation,

BATT. Catcher P.C.B.

10 R Frame Unit,

Speaker,

LCD Unit

11 Monitor P.C.B.,

LCD Hinge Unit,

Light Guide Plate Unit,

LCD Panel Unit

12 Spring Holder,

Barrier Lever

13 Front Base,

Barrier R,

Barrier F

14 Front Case,

Mic Cover,

Front Ornament Ring,

Flare Cut Piece,

Microphone Unit

15 MOS Unit,

IR Cut Grass

(Fig. D13) Convex x 1

Hooking part x 1

Locking tab x 1

Top Operation

Hooking part x 1

BATT. Catcher P.C.B.

(Fig. D14) Screw (P) x 2

Locking tab x 4

R Frame Unit

Convex x 1

LCD Lever

(Fig. D15) Convex x 2

Convex x 6

Speaker

Convex x 2

LCD Unit

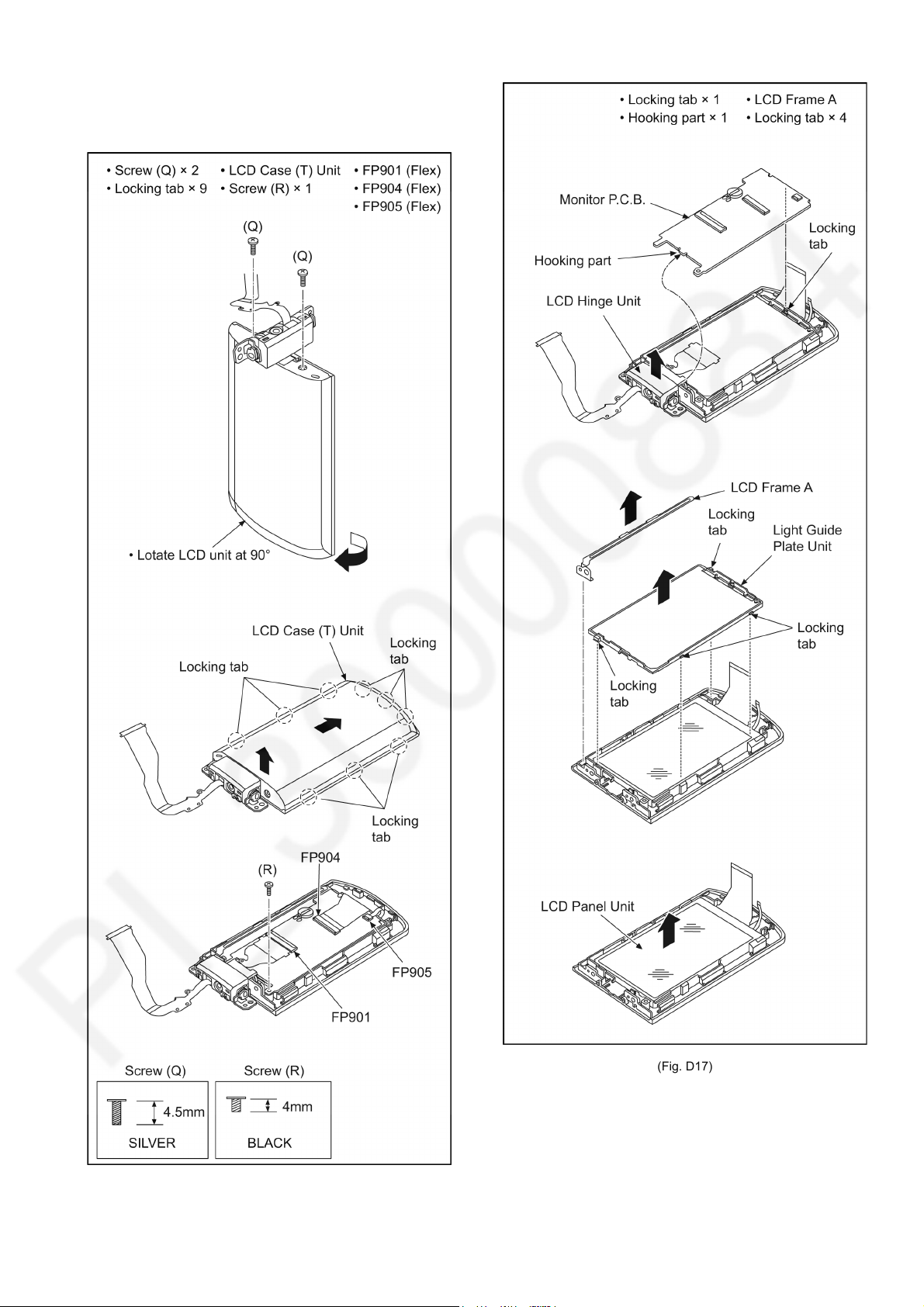

(Fig. D16) Screw (Q) x 2

Locking tab x 9

LCD Case (T) Unit

Screw (R) x 1

FP901 (Flex)

FP904 (Flex)

FP905 (Flex)

(Fig. D17) Locking tab x 1

Hooking part x 1

Monitor P.C.B.

LCD Hinge Unit

LCD Frame A

Locking tab x 4

Light Guide Plate Unit

LCD Panel Unit

(Fig. D18) Reflection Sheet

Light Guide Plate

Diffusion Sheet

Prism Sheet (B)

Prism Sheet (A)

LGP Holder

(Fig. D19) Screw (S) x 1

Spring Holder

Barrier Spring

Locking tab x 2

Barrier Lever

(Fig. D20) Projection part x 3

Lens Damper Rubber

Screw (T) x 4

Convex x 3

Front Base

Barrier R

Barrier F

(Fig. D21) Screw (U) x 2

Locking tab x 1

Front Case

Mic Cover

Front Ornament Ring

Flare Cut Piece

Mic Sponge-F

Mic Sponge-M

Microphone Unit

Mic Sponge-R

(Fig. D22) Screw (V) x 3

MOS Unit

MOS Cushion

IR Cut Grass

(Fig. D23) NOTE: (When Installing

(Fig. D24)

the MOS Unit)

26

No. Item Fig Removal

16 2nd Stepping Motor (Fig. D25) Solder x 16 points

Screw (W) x 3

Convex x 5

(Fig. D26) Screw (X) x 2

2nd Stepping Motor

17 3rd Stepping Motor (Fig. D27) Solder x 4 points

Screw (Y) x 1

Convex x 1

(Fig. D28) Screw (Z) x 2

3rd Stepping Motor

18 Focus Motor (Fig. D29) Solder x 8 points

Screw (a) x 1

Convex x 1

(Fig. D30) Screw (b) x 2

Focus Motor

27

8.3.1. Removal of the Side Case-L Unit

(Fig. D1)

(Fig. D2)

28

8.3.2. Removal of the Top Case Unit, Power Panel Light, LED Piece, Jack Cover Piece, Jack Cover Spring, SS Button, SS Lever, Jack Cover Unit

8.3.3. Removal of the Front Case Unit

(Fig. D3)

(Fig. D4)

29

(Fig. D5)

8.3.4. Removal of the NFC P.C.B. Unit (HC-V270 only)

8.3.5. Removal of the Wi-Fi P.C.B. (HCV270 only)

(Fig. D6)

(Fig. D7)

30

8.3.6. Removal of the Lens Frame Unit

(Fig. D9)

(Fig. D8)

31

8.3.7. Removal of the Camera Lens Unit

8.3.8. Removal of the Main P.C.B., SD Holder P.C.B.

(Fig. D10)

(Fig. D11)

32

8.3.9. Removal of the Top Operation, BATT. Catcher P.C.B.

(Fig. D12)

(Fig. D13)

33

8.3.10. Removal of the R Frame Unit, Speaker, LCD Unit

(Fig. D14)

(Fig. D15)

34

8.3.11. Removal of the Monitor P.C.B., LCD Hinge Unit, Light Guide Plate Unit, LCD Panel Unit

(Fig. D16)

(Fig. D17)

35

8.3.12. Removal of the Spring Holder, Barrier Lever

(Fig. D18)

(Fig. D19)

36

8.3.13. Removal of the Front Base, Barrier R, Barrier F

8.3.14. Removal of the Front Case, Mic Cover, Front Ornament Ring, Flare Cut Piece, Microphone Unit

(Fig. D20)

(Fig. D21)

37

8.3.15. Removal of the MOS Unit, IR Cut Grass

(Fig. D22)

38

(Fig. D23)

(Fig. D24)

8.3.16. Removal of the 2nd Stepping Motor

39

(Fig. D25)

8.3.17. Removal of the 3rd Stepping Motor

(Fig. D26)

(Fig. D27)

40

8.3.18. Removal of the Focus Motor

(Fig. D28)

(Fig. D29)

41

(Fig. D30)

42

9 Measurements and Adjustments

9.1. Electric Adjustment

• Adjustment method is different from a conventional High definition video camera.

• An exclusive jig are necessary for electric adjustment.

• Connection method of the main unit and an exclusive adjustment jig as follows.

Figure of connection

Figure of image when adjustment

43

Part Number of jig

1. Basic Jig

Item Contents

AC adaptor Bandled with camcorder

AC Cable Bandled with camcorder

2. Optical Jig for Camera Adjustment

Item Part number Remarks

Light box VFK1164TDVLB/RFKZ0523* Need external power supply: 12V ± 0.1V /1.8A or over

Collimator with focus chart VFK1164TCM02/VFK1164TCM03 Same as DSC

CC filter 3100K/5100K VFK1164CC10G Need 2 set. For indoor/outdoor white balance adjutment

C2 Filter 5100K VFK1164LBB2 For outdoor white balance adjustment

C8 Filter 5100K VFK1164LBB8 For outdoor white balance adjustment

ND Filter 0.1 3100K VFK1164ND01 For indoor white balance adjustment

ND Filter 0.6 3100K VFK1164ND06 For indoor white balance adjustment

* RFKZ0523 (same as DSC) is recommended.

44

9.1.1. About Light Box

When using VFK1164TDVLB Light Box

If using VFK1164TDVLB Light Box, remove the lens connection ring by loosing thumbscrew and three hexagon screws.

* RFKZ0523 Light Box has no lens connection ring.

How to remove the Front Hood

In order to utilize maximum of the diffusing surface of light box, some adjustment items need the distance between diffusing

surface of light box and camera body becomes several cent-meters.

Before the adjustments, remove the front hood of light box following steps below.

[ For VFK1164TDVLB Light Box ]

[ For RFKZ0523 Light Box ]

45

9.1.2. Adjustment Items

Adjustment item as follows.

46

9.1.3. Adjustment Procedure

All adjustments except “Touch Panel Calibration”, “Factory Setting” and “NFC Initialization” performs using “14 Adjustment function

for the service” in service mode menu.

“Touch Panel Calibration” is performed using 16 of service mode menu and “Factory Setting” is performed using 1, “NFC Initialization” is performed using 17 of service mode menu. Refer to “6 Service mode” and “10 Factory Setting”.

[Execute adjustment function for service]

1. While the power is turned OFF, keep pressing the “Power” button, “Zoom lever” to W side and “Recording/Playback” button

for more than 3 seconds until the top screen of the Service Mode Menu being displayed.

2. Touch the twice then touch the [14] of LCD.

3. Touch the [YES] of LCD.

47

[Adjustment Procedure]

Adjustments and settings are performed following order:

1. Model setting

2. Filename setting for backup to SD card

3. Backing up adjustment data to SD card

4. Checking switches

5. Camera adjustment

6. Zoom/tracking adjustment

7. Indoor white balance adjustment

8. Outdoor white balance adjustment

48

49505152535455

10 Factory Setting

10.1. How To Turn On The Factory Settings?

1. While the power is turned OFF, keep pressing the “Power” button, “Zoom lever” to W side and “Recording/Playback” button for

more than 3 seconds until the top screen of the Service Mode Menu being displayed.

2. Touch the [ 1 ] of LCD.

3. Touch the [ YES ] of LCD.

4. After few seconds “END” is displayed on LCD monitor. Cutting of battery connection or AC power supply connection as a

completion of the “FACTORY SETTINGS”.

10.2. What Is The Factory Settings?

The factory settings clean up and/or refresh the following settings.

1. Setting values of menu.

2. Clear the time and date setting.

3. Initialize the Wi-Fi data settings (HC-V270 only)

4. Initialize the NFC data settings (HC-V270 only)

The setting position of factory settings:

Name Setting position

Lens Barrier Open

56

11 Block Diagram

HC-V20/V20 OVERALL BLOCK DIAGRAM

IC705

STEPPING MOTOR

DRIVE

NOTE

: VIDEO SIGNAL

: AUDIO SIGNAL

: CLK or CONTROL LINE

IRIS

LENS(F1.8-4.2 50x)

IC701

LENS/OIS/MOTOR DRIVE

SD

CARD

SPEAKER

ECM

OPERATION

TOUCH PANEL

DC IN

BATTERY

MOS IMAGE

SENSOR

A/V

TERMINAL

HDMI mini

CONNECTOR

ZOOM/

FOCUS

MOTOR/

OIS

Analog

Analog

Analog

Analog

IC6401

GYRO

SENSOR

(PIT/YAW)

IC3404

NAND

FLASH ROM/

1Gbit

IC3402,3403

DDR3 SDRAM/

1Gbit

IC3401

VENUS ENGINE

IC1001

POWER

LED LIGHT

X3402

OSC

(60MHz)

IC302

GA

TE IC

COLOR LCD

PANEL

IC3701

AVIO

X2303

(32.768kHz)

IC1503

RTC/CHARGE/

POWER CONTROL

USB TERMINAL

IC301,703,704

REGULATOR

IC1002,1481

REGULATOR

IC1471

POWER-DISTRIBUTION

SWITCHES

Wi-Fi

MODULE

Wi-Fi ANT.

NFC

NFC ANT.

IC2301

RESET

IC1501

REGULATOR

NFC P.C.B. UNIT

HC-V20 only

HC-V20 only

Wi-Fi P.C.B.

HC-V20 only

11.1. Overall Block Diagram

57

11.2. Camera/System Control Circuit Block Diagram

HC-V20/V20 CAMERA/SYSTEM CONTROL CIRCUIT BLOCK DIAGRAM

IC3401

(VENUS ENGINE)

AF17

AE17

AD20

AC20

AF16

AE16

AF18

AE18

AF19

AE19

RL3403 RL3404

RL3401 RL3402

IC3406

(RESET)

RSTB

4

VDD

PW REG3V

2

T20

OUT

BUS240 DAP

BUS240 DAM

BUS240 DBP

BUS240 DBM

BUS240 DCP

BUS240 DCM

BUS240 DDP

BUS240 DDM

BUS240 CKP

BUS240 CKM

DOAP

DOAM

DOBP

DOBM

DOCP

DOCM

DODP

DODM

DCKP

DCKM

AE22

XVD CAM GLVD

AF22

XHD CAM

AE23

S SENS SDO

AE24

S SENS SCK

AF24

S SENS CS

VD

HD

SDI

SCK

SCS

X3402

(60MHz)

5

1

4

32

IC302

(GATE IC)

PW MOS1.8V

E NRST

(From QR2389-C)

CLK60 MOS

AF23

AF15

E MOS RST

RSTN

MCLK

MOS UNIT

X2303

(32.768kHz)

S6001

LCD OPEN

CARD LED

E KEYIN4

D6401

CARD

LED

PW REG3V

QR6402

FP905

X RIGHT

Y BOT

X LEFT

Y TOP

1

2

3

4

PW REG3V

PW REG1.8V

U25

R25

R26

P23

P24

G16

E17

E16

G15

PW REG3V

STANDBY LED B

V24

QR6401

AB13

QR3404 QR3401

QR3405

QR3402

E15

TOUCH PANEL

UNIT

IC1503

(RTC/CHARGE/POWER CONTROL)

S6002

POWER ON/OFF

D3

G5

G6

/SWIN1

E3

/SWIN2

XIN

XOUT

A5

LED

IC511

(MAGNETIC SENSOR)

4

3

1

2

VDD

OUT

GND

NC

AD TPY RIGHT

AD TPY LEFT

AD TPX TOP

SEL2 ON LOW

SEL2 ON HI

LCD RVS

SEL1 ON HI

SEL1 ON LOW

AD TPX BOT

B6

CS

B7

SCK

C6

SDI

C7

SDO

CH3408

QR3403

TOP OPERATION

FP6402

ZOOMAD

PHOTO1 HANOSHI

PHOTO2 ZENOSHI

8

7

10

6

5

4

POWER LED

2

STANDBY LED

AVREF

AVREF

PW REG3V

E KEYIN1

D15

S6404

S/S

S6401

Wi-Fi

S6403

MODE

S6402

OIS

●

ZOOM LEVER

●

PHOTO SHOT BUTTON

POWER LED

PW REG3V

QR6006

QR6008

QR6007

AA23

PW RTCVREG32

P LED ON L

S RTC DI

S RTC DO

S RTC SCK

RTC CS

ZSW

(To IC701-49)

S RTC DI

S RTC DO

S RTC SCK

AB25

AB24

AB26

RTC CS

W22

HC-V20 only

58

11.3. Video/Audio Signal Process(1) Circuit Block Diagram

HC-V20/V20 VIDEO/AUDIO PROCESS(1) CIRCUIT BLOCK DIAGRAM

MOS

UNIT

CAMERA SECTION

IC3401

(VENUS ENGINE)

BUS24 SDDAT2

BUS24 SDDA

T3

CLK24 SDCMD

CLK48 SDCARD

E CARD DET

E CARD PRO

BUS24 SDDAT1

BUS24 SDDAT0

7

8

9

1

2

5

10

12

D0

D1

D2

D3

CMD

CLK

C.DET

WP

11

ABCK1

VIDEOOUT

AODAT

AODAT0

AIDAT0

CLK B1

A7

B7

A5

B5

B6

A6

C5

C4

CLK 12M

CLK12 IN

L26

MEMORY CONTROL

MAIN CPU

HDMI

CONTROL

CAMERA

DSP

H.264

MPEG2

JPEG

AC3

PROCESSOR

AD25

AD26

AC26

AC25

AIDAT

CLK+

CLK-

S DO AVIO

S CLK AVIO

G VIDEO

E AVIO RST

Y14

E AVIO RST

HS3901

(SD CARD CONNECTOR)

ALRCK1 CLK LR1

AC24

S CS AVIO

U26

S CLK AVIO

AA24

S DO AVIO

AB23

S CS AVIO

CLK27 AUDIO

P26

CLK27 AVL3V

BUS24 SDDAT0-3

STREAM CONTROL

DATA2+

DATA2-

DATA1+

DATA1-

DATA0+

DATA0-

HPD

SCL

SDA

CEC

1 8

72

FL6001

2

3

3 6

54

5

6

1 8

72

FL6002

8

9

14

3 6

54

11

12

15

16

19

JK6003

HDMI MINI CONNECTOR

A16

TMDS2P

A8

D8

CEC

HPDTCT

C8

S DAT DDC

B8

S CLK DDC

B16

TMDS2N

A17

TMDS1P

B17

TMDS1N

A18

TMDS0P

B18

TMDS0N

A19

TMDSCLKP

B19

TMDSCLKN

HDMI DMA I/F

CAMERA SIGNAL PROCESSOR

AUDIO DSP

BUS240 DAP

BUS240 DAM

BUS240 DBP

BUS240 DBM

BUS240 DCP

BUS240 DCM

BUS240 DDP

BUS240 DDM

BUS240 CKP

BUS240 CKM

AF17

AE17

AD20

AC20

AF16

AE16

AF18

AE18

AF19

AE19

BUS20 FR D0

BUS20 FR D7

BUS 20 FR CLE

BUS20 FR ALE

BUS20 FR RB

BUS20 FR WP

BUS20 FR CS

BUS20 FR RE

BUS20 FR WE

G3

E4

W2

AB3

E3

A3

H1

D3

G1 G2H3H2 H4

BUS400 DCKP

BUS400 DCKN

BUS400 DCKE

BUS400 ZDCS

BUS400 ZRAS

BUS400 ZCAS

BUS400 ZDWE

BUS400 DBA2

AF4 AC5

AF3

AD4 AE4

AD7

AC6

DATA

IC3404

(NAND FLASH ROM/1G-bit)

41 48 5251 59

17

8 7 12 10 16 11

CTL SIG

IC3402/3403

(DDR3 SDRAM/1G-bit)

56 5857

BUS400 DQ0

BUS400 DQ15

AD8

BUS400 DBA1

AC9

BUS400 DBA0

AD9

DDR3 ZDRST

AD10

K7 K9J7J3 K3 L3

L2

M3 N8 M2 T2

BUS400 DQM0

Y3

BUS400 DQM1

AA3

Y2

BUS400 DQSN0

W1

BUS400 DQSP0

AC2

BUS400 DQSN1

AC1

E7 D3

G3 F3 B7 C7

BUS400 DQSP1

AE5

AF6

N3

N7

BUS400 DA0

BUS400 DA12

ADDRESSCTL SIG CTL SIG

DATA

L2

P4

E3

A3

BUS400 DQ16

BUS400 DQ31

BUS400 DQM2

M3

BUS400 DQM3

P3

M2

BUS400 DQSN2

L1

BUS400 DQSP2

R2

BUS400 DQSN3

R1

E7 D3

G3 F3 B7 C7

BUS400 DQSP3

CTL SIG

DATA

IC3402 ONLY IC3403 ONLY

A22

D20

A23

D22

C22

B22

E21

D21

C21

CLK36 LCD

A21

B21

S DO LCD

S CS LCD

BUS18 LCDYC0

BUS18 LCDYC1

BUS18 LCDYC2

BUS18 LCDYC3

BUS18 LCDYC4

BUS18 LCDYC5

BUS18 LCDYC6

BUS18 LCDYC7

BUS18 LCDH

BUS18 LCDV

C25

S CLK LCD

B24

C26

LCD

BUS18 LCDYC0-C7

BUS24 WIDAT0-3

E1

E2

C1

C2

D1

D2

CLK48 WIFI

CLK24 WICMD

BUS24 WIDAT0

BUS24 WIDAT1

BUS24 WIDAT2

BUS24 WIDAT3

E10

E WIFI RST

T22

W23

S DI NFC

U22

S DO NFC

IRQ NFC

R22

S SCK NFC

IRQ NFC2

(To IC1503-C4)

CH3411

3

4

2

USB TERMINAL

D-

D+

JK6001

A12

A13

Y17

USB D-

USB D+

USB IDDET L

ID

To VIDEO/AUDIO PROCESS(2

)

BLOCK DIAGRAM

Wi-Fi P.C.B.

NFC P.C.B. UNIT

(Wi-Fi MODULE)

Wi-Fi ANT.

(NFC)

NFC ANT.

HC-V20 only

59

11.4. Video/Audio Signal Process(2) Circuit Block Diagram

HC-V20/V20 VIDEO/AUDIO PROCESS(2) CIRCUIT BLOCK DIAGRAM

IC3701

(AVIO)

IC3702

(SINGLE CLOCK GENERATOR)

12

BICK

CLK B1

CLK LR1

AIDAT0

AODAT0

11

LRCK

24

VIN

CLKIN

OE

FSEL

CLKOUT

JK6402

(AV JACK)

VOUT

4

PLUGIN L

6

LOUT

5

ROUT

1

21

22

SPN

SPP

SPK-AMP

SPEAKER

V OUT

CLAMP LPF

14

SDTO

13

SDTI

E AVIO RST

18

PDN

10

CSN/SDA

8

CCLK/SCL

S CS AVIO

S CLK AVIO

S DO AVIO

9

CDTIO/CAD0

7

I2C

CLK12 IN

17

MCKI

16

MCKO

G VIDEO

CLK27 AVL3V

PLUG IN L

(To IC3401-P20)

25

6

4

5

3

PMV

PMSPK

PMPFIL

PMPLL

PMMICL

PMADL or PMADR

PMMICR

AUDIO

I/F

CONTROL

REGISTER

PMLO

PMBP

D/A

PLL

DVOL

SMUTE

+

+

++

31

32

1

ROUT

MIN

LOUT

LIN1

A/DHPF

MIC SENSE/

CORRECTION FUN.

HPF2

MONO/

STEREO

STEREO

EMPHASIS

MIC POWER

SUPPLY

LDO: 2.3V

4 BAND EQ

LPF

ALC

1 BAND EQ

HPF3

RUNNING

AVERAGE

CIRCUIT

EQ0

INPUT

BUFFER

PLL

OUTPUT

BUFFER

3

RIN1

4

LIN2

5

RIN2

MPWR

REGFIL

AVDD

ANALOG

BLOCK

MIC POWER,SPK-AMP,

LINE/VIDEO-OUT-AMP

6

2

27

TVDD

15

DVDD

20

29

PMMP

+

-

ECM[L]

+

-

ECM[R]

RL3705

RL3704

RL3708

RL3709

PW REG3V

PW REG1.8V

PW SPK3.2V

Q3701

PW 5V

PW REG3V

VDD

1

To VIDEO/AUDIO PROCESS(1

)

BLOCK DIAGRAM

60

HC-V20/V20 LENS DRIVE CIRCUIT BLOCK DIAGRAM

FILTER

MOS

M

3G ZOOM MOTOR

M

1

2

3

30

27

28

29

IC701

(LENS/OIS/MOTOR DRIVE)

3GZAP

3GZAN

3GZBN

3GZBP

4

39

37

36

38

ZAP

ZBP

IC3401

(VENUS ENGINE)

M

IRIS MOTOR

FP6008

FP6008

ZBN

ZAN

6

HALL

SENSOR

HALL

SENSOR

OIS UNIT

FP6008

PIT DRV+

PIT DRV-

PIT HO+

PIT HIN+

PIT HIN-

YAW DRV-

YAW DRV+

YAW HIN+

YAW HIN-

YAW HO-

11

12

13

16

15

14

17

18

22

21

20

19

PIT HO-

YAW HO+

IRM+

IRM-

FP6008

FP6008

IR HO+

IR HIN+

IR HO-

IR HIN-

HALL

SENSOR

PMP

IRHOP

76

IRHON

31

71

YMP

PHON

28

YMN

70

24

PHOP

57

PHINP

PMN

77

27

IRHINP

55

IRMP

5

IRMN

8

ZAP

14

ZAN

17

ZBN

10

ZBP

13

73

YHON

74

56

YHOP

YHINP

PW GYRO3V

GCSB

GSCK

GSI

GSO

29

23

32

3

12

HD

NSCS

SCK

SDI(V2L)

SDO(L2V)

DAC LD

NPORI

STORM HD225

S NSCS LEN

SCK LEN

SDO LEN

STORM VD60

22

VD

5

AE15

AB21

V23

W20

Y18

CH712

CH753

CH710

CH754

CH711

CH713

CH718

CH719

CH720

CH6401

CH6404

CH6415

CH6403

15

1

80

SDI LEN

S DACLD LENS

E LENS RST L

Y19

W24

Y25

CH721

CH722

PWMOUT1

PWMOUT2

(GYRO SENSOR:PIT/YAW)

11

MOSI

44

10

MISO

26

8

CSB

CL6406

CL6405

35

9

SCLK

1

VCC

7

VDD

2

GND1

4

GND2

6

GND3

IC6401

2G ZOOM ENC

3GZABS LEN

FP6008

8

35

7

34

10

3G ZLEDCONT

3G ZABS

ZABS

ZLEDCONT

Y24

V26

ZABS LEN

P25

LENS TEMP

C14

LEDCONT LEN

2G ZOOM MOTOR

3G ZOOM ENC

V25

FABS LEN

41

3GZOOM H

W25

CH725

CH726

(STEPPING MOTOR DRIVE)

3

MP1

5

MN1

10

MN2

11

MP2

9

E1

6

E2

1

STB

SYSCK

IC705

12

21

CK27M

15

INT

M

FOCUS MOTOR

FAP

FAN

FBN

FBP

26

24

23

25

FP6008

42

32

31

FLEDCONT

FABS

LENS TEMP

FOCUS ENC

Q775

AFAP

AFAN

AFBN

AFBP

40

37

33

36

CLK27 AUDIO

P26

5 1

4

3

2

IC3407

(GATE IC)

PW REG1.8V

11.5. Lens Drive Circuit Block Diagram

61

HC-V20/V20 POWER SUPPLY CIRCUIT BLOCK DIAGRAM

JK6701

1

3

4

2

+

T

D

-

JK6401

2

3

4

+

-

BATTERY

DC IN

PW NFCVDD2

PW RTCVREG32

FUSE RESISTOR:

QR1002

QR1001

QR1101

Q1501

1

2 3 4

5

6

8

7

Q1502

1

2 3 4

5

6

8

7

1 2 3

46

5

Q1503

IC3401

(VENUS ENGINE)

S RTC DI

S RTC DO

S RTC SCK

RTC CS

VBUS OCP

VBUS ON H

SW NOREG

S FG PWR SDA

S FG PWR SCL

AB25

AB24

AB26

W22

D9

MOSSENS ON H

AB14

E9

B14

R24

IC2301

(RESET)

1

2

4

3

VDD

GNDCDOUT

QR2389

QR2308

CH1105

Q1504

S BATT RXD

R23

S BATT TXD

IC1503

(RTC/CHARGE CONTROL)

VREG32

WKUP

F3

B2

USB

A1

OUT

C2

A3

USBSW

G2

VREG25

(R1271/R1503/R6001)

IC PROTECTOR:

(IP6401/IP6701)

Please check the Fuse Resistor and IC Protector

when an output voltage does not output.

IP6701

IP6401

NOREG

BATT +

1

USB TERMINAL

VBUS

JK6001

ADPSW

PWSW

A2

ADP

C1

VADP

SW

F2

E2

E7

BAT

E1

VUSB

D7

ISNS

F7

TDET

B6

CS

B7

SCK

E5

SWIN4

F4

WKUP RST

C6

SDI

C7

SDO

S6002

POWER ON/OFF

LI BATT

D3

/SWIN1

B501

G4

COINBAT

G3

DVIN

A6

CHG EN

F5

FULLSET

D2

BATSET

D1

USB EN

F6

USB WK CNT

B4

R6001

CH3408

QR3403

IC1501

(REGULATOR)

IC1471

(POWER-DISTRIBUTION

SWITCHES)

IC1481

(REGULATOR)

4

3

2

1

GND

CE

VIN

VOUT

IC1002

(SWITCHING

REGULATOR)

12

13

14

15

16

8

11109

1 2 3 4

PVCC

VCC

STB

RT

P

GND

PVCC

LX1

LX1

P GND

FB

INV

GND

VOUT

7

6

5

LX2

LX2

VOUT

PW WIFI3.2V

PW WIFI3V

1

2

3

4

6

5

CEVDD

VOUT GNDCS

NC

R1503

STB6

SCL

SDA

STB1234

VOSEL3

VOSEL4

VCC

VOSEL2

VREGA

GND

VO4

INV5

VO3

REGOUT

PGND45

HX5

LX5

LX6

LX4

HX4

PGND3

PGND3

LX3

LX3

HX36

LX21

HX36

PGND2

VO2E

LX22

HX2

PGND1

SWOUT

VO1E

LX1

INV6

VDD

INV7

LED

VO7

42 3941 3840 37 36 35 3433

1

2

3

4

5

6

7

8

9

10

32

31

30

29

28

27

26

25

24

23

22

14 15 16

17 18

19

LX720PGND67

21

11 12 13

IC1001

(POWER)

PW SPK3.2V

PW LENS3.2V

PW 3.2V

R1271

PW REG1.8V

PW REG3V

PW SD3.2V

PW 5V

PW HDM5V

D902-905

(LCD BACK LIGHT)

CH1241

CH1422

PW MOS1.8V

PW VDDR1.1V

CH1101

CH1001

CH1471

CH1002

CH1103

E NRST

T20

QR1004

QR1003

PW DDR1.5V

PW MOS1.2V

PW VID1.1V

6

5

4

3

1

2

EN

IN

OUT

/FAULT

ILIM

GND

4

5

6

3

2

1

QR1471

Q1471

D6

LCD ON H

E6

U24

PW MOS2.8V

5 4

1 32

IC301

(REGULATOR)

NC

IN

OUT

GNDCE

PW LENS1.5V

IC703

(REGULATOR)

4

3

2

1

GND

CE

VDD

VOUT

PW GYRO3V

IC704

(REGULATOR)

1

2

3

4

GND

STBY

VIN

VOUT

PW LCD3V

IC1422

(REGULATOR)

4

3

2

1

GND

CE

VIN

VOUT

HC-V20 only

HC-V20 only

11.6. Power Supply Circuit Block Diagram

62

12 Wiring Connection Diagram

HC-V270/V260 INTERCONNECTION DIAGRAM

MAIN P.C.B.

(FOIL SIDE)

:

(COMPONENT SIDE)

MONITOR P.C.B.

(FOIL SIDE)

SD HOLDER P.C.B.

(FOIL SIDE)

BATT. CATCHER P.C.B.

(FOIL SIDE)

:

(COMPONENT SIDE)

FP6003

65432

1

L MCE

L

MCE

DNG D

DNG D

R MCE

R MCE

MIC

)V8.2(DDVP

)V8.2(DDVP

)V2.3(TABV

)V2.3(TABV

DNG

DNG

DNG

2

TAD

3TAD

TSR

1291715131

11

97531

)V8.2(DDVP

)V8.2(DDVP

)V2.3(TABV

)V2.3(TABV

DMC

DNG

KLC

DNG

0TAD

1TAD

TS

R

0281614121

01

864

2

5006PF

8006PF

-NIHRI

+NIHRI

-MRI

SBAZ

CCVT&CCVCNEZ

+VRDTIP

+OHTIP

-OHTIP

-VRDWAY

-

OHWAY

+OHWAY

NBF

P

B

F

N

BZ

PBZ

SBAF

CCV CN

E

F

&G3

TNOCDELZG3

NAZG3

PAZG3

2

4

6

8

012141618102

22

42628203234363

83

+OHRI

-O

HRI

+

MRI

TNOCDELZ

PMET SNEL

-VRDTIP

-NIHTIP

+NIHTIP

+VRDWAY

+

N

IHWAY

-NIHWAY

NAF

PAF

PAZ

N

A

Z

TNOCDELF

SBAZG3

NBZG3

PBZG3

13579

11

31517191123252

72

92

13

335373

93

DNG

IDS

KCS

SCS

PDOD

DNG

MCOD

PKCD

DNG

MBOD

PAOD

DNG

KLCM

NTSR

V2.1

V8.1

V8.2

246

8

012141618102224262820323

DNG

DV

DH

DNG

MDOD

PCOD

DNG

MKCD

PBOD

DNG

MAOD

DNG

DNG

V2.1

V8.1

V8.2

13579

11

31517191123252729213

33

103PF

P6003

1

2

3

4

5

6

BATT +

BATT +

T

D

BATT -

BATT -

PP6001

E KEYIN4

D GND

SP OUT2

SP OUT1

D GND

NOREG

NOREG

NOREG

NOREG

NOREG

NOREG

D GND

D GND

PW REG3V

ZOOMAD

POWER LED

STANDBY LED

E KEYIN1

PLUGIN L

E CARD DET

PW SD3R2V

PW SD3R2V

PW SD3R2V

D GND

E CARD PRO

S GYRO CSB

S GYRO SCK

S GYRO SO

S GYRO SI

GYRO GND

PW GYRO3V

S ACL SCL

S ACL SDA

D GND

D GND

SD CMD

D GND

SD DATA2

SD DATA3

SD DATA0

SD DATA1

D GND

SD CLK

D GND

AV GND

G LOUT

G VOUT

G ROUT

AV GND

CARD LED B

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FP6001

THGIRYPT D

A S

TFELYPT DA S

SVR DCL

L LBDCL WP

H LBDCL WP

DNG D

DNG D

DNG D

DCL KLC

S

V3DCL WP

DNG D

DNG D

H DCL 81SUB

DNG D

6CYDCL 81SUB4CYDCL 81SUB

2CYDCL 81SUB

0CYD

C

L 81SUB

V8R1GER WP

63432303826242220281614121

01

864

2

TOB XPT DA S

POT XPT DA S

TTABIL WP

L LBDCL WP

H LBDCL WP

DNG D

DNG D

DCL OD S

DCL SC S

V3DCL WP

DCL 6

3

KLC

V DCL 81SUB

TSR DCL E

7CYDCL 81SUB

5C

YDCL 81SUB

3CYDCL 81SUB

1CYDCL 81SUB

V8R1GER WP

7353331392725232129171

51

31

11

97531

BATTERY

1076KJ

123

4

+

T

D

-

P6701

1

2

3

4

5

6

BATT +

BATT +

T

D

BATT -

BATT -

TOP OPERATION

2046PF

01

9

8765432

1

IHSONA

H 1OTOHP

DNG

DAMOOZ

F

ERVA

IHSONEZ 2OTOHP

DEL YBDNATS

DEL REWOP

DNG

FERVA

DNG

SPEAKER

P6401

2

1

SP OUT1

SP OUT2

PS6401

4NIYEK E

D

NG D

2TUO PS

1TUO PS

D

N

G D

GERON

GERON

GERON

G

ERON

GERON

GERON

DNG D

DNG D

V3GER

WP

DAMOOZ

DEL REWOP

DEL YBDNATS

1N

IYE

K

E

L NIGULP

TED DRAC E

V2R3DS WP

V2R3DS WP

V2R3DS WP

D

N

G D

O

R

P DR

A

C

E

BSC ORYG S

KCS ORYG S

O

S

ORYG S

IS OR

YG S

DNG ORYG

V3ORYG WP

LCS LCA S

ADS LCA S

DNG D

DNG D

DM

C D

S

DNG

D

2ATAD DS

3ATA

D

DS

0ATAD DS

1ATAD DS

DNG D

KL

C DS

DNG D

DNG VA

TUOL G

TUOV G

T

UO

R G

DNG VA

B DEL DRAC

5242322212029181716151

4131

211101

987

6

54321

6272829203

13233343536373839304142434

445464748494

05

FP901

PW REG1R8V

BUS9 LCDYC0

BUS9 LCDYC1

BUS9 LCDYC2

BUS9 LCDYC3

BUS9 LCDYC4

BUS9 LCDYC5

BUS9 LCDYC6

BUS9 LCDYC7

D GND

RST/GND

BUS9 LCD H

BUS9 LCD V

D GND

CLK18 LCD

D GND

PW LCD3V/REG3V

S CS LCD

S CLK LCD

S DO LCD

D GND

D GND

D GND

D GND

PW LCDBL H

PW LCDBL L

COIN BATT+

LCD RVS

SD AD TPX TOP

S AD TPYLEFT

S AD TPX BOT

S ADTPYRIGHT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Y TOP

X LEFT

Y BOT

X RIGHT

4

3

2

1

FP905

LENS UNIT

MOS UNIT

NFC P.C.B. UNIT

Wi-Fi P.C.B.

LCD

TOUCH

PANEL

6006PF

1

2

3

4

5

6

2DDVCFN WP

V3GE

R WP

2CFN ORI

CFN OD S

CFN KCS S

DNG

FP904

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

VGH

C3N

C4N

VS

C1N

C2N

VCIX2

CXP

VCIM

VCOML

VCOM

VDDIO

VSYNC

DCLK

DB0

DB2

DB4

DB6

SDA

SCS

GND

C3P

C4P

VGL

C1P

C2P

VSS2

VCI

CXN

VCOMH

VGM

VSS1

VDDL

HSYNC

NC

DB1

DB3

DB5

DB7

SCL

RESET

LCD UNIT

Wi-Fi FFC

NFC FFC

BATT.

CATCHER WIRE

MONITOR FPC

HC-V270 only

MICROPHONE UNIT

12.1. Interconnection Diagram

63

Loading...

Loading...