Page 1

Programmable Controller

FP-XH Series

User’s Manual

Basic

Western version

WUME-FPXHBASG-01

2020.10

panasonic.net/id/pidsx

Page 2

(MEMO)

2 WUME-FPXHBASG-01

Page 3

Introduction

Thank you for purchasing a Panasonic product. Before you use the product, please carefully

read through the user’s manual, and understand it in detail to use the product properly.

Types of Manuals

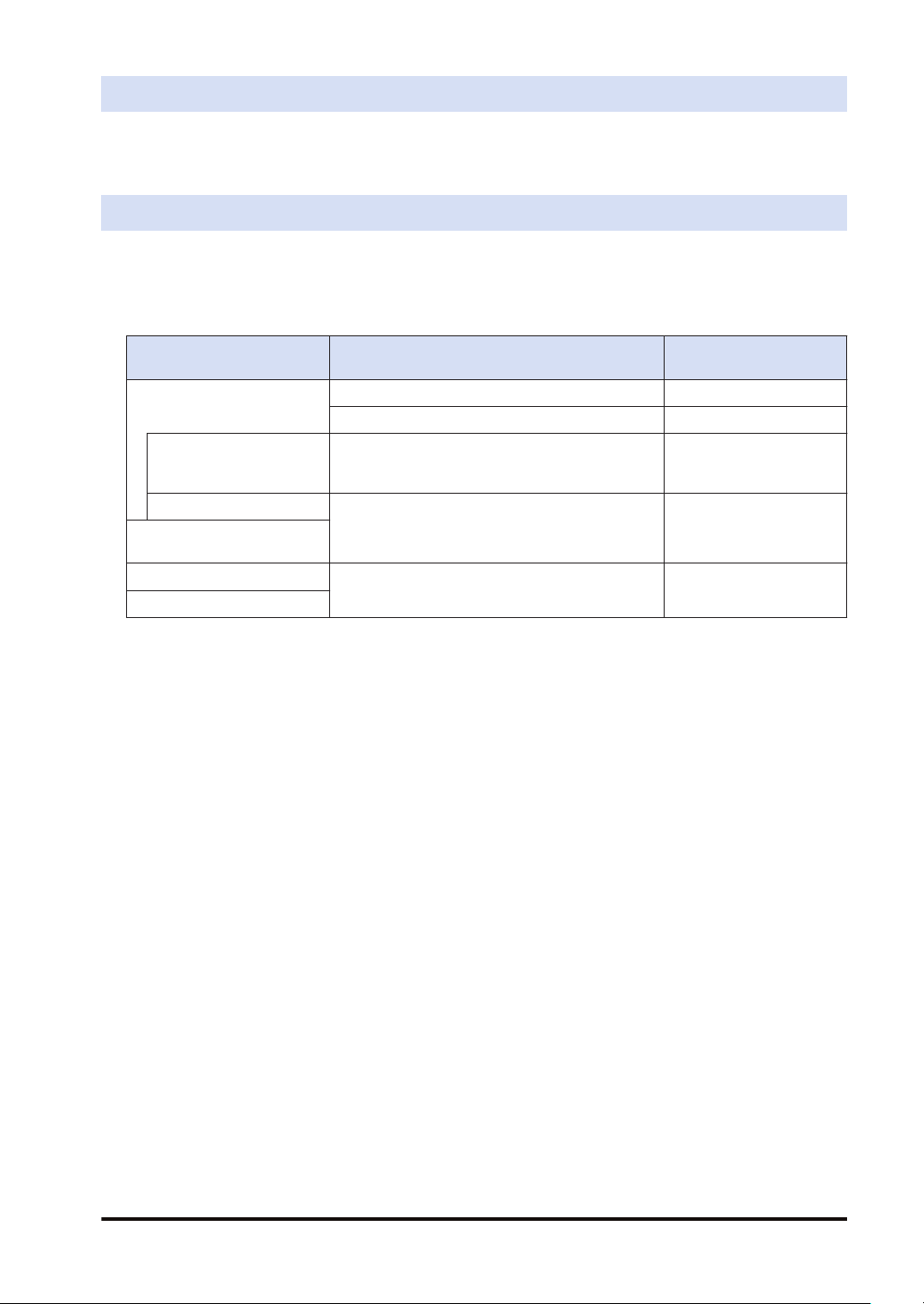

● The following user’s manuals are available for the FP-XH series. Please refer to a relevant

manual for the unit and purpose of your use.

● The manuals can be downloaded from our Download Center:https://

industrial.panasonic.com/ac/e/dl_center/.

Unit name or purpose of

use

FP-XH Control Unit

Positioning Function /

PWM Output / High-speed

Counter Function

Communication Functions

FP-X Extension

(Communication) Cassette

FP-X Expansion Unit

FP-X Function Cassettes

Manual name Manual code

FP-XH User‘s Manual (Basic) WUME-FPXHBASG

FP Series Programming Manual ARCT1F313E

FP-XH User’s Manual

(Positioning / PWM Output / High-speed Counter)

FP-XH User‘s Manual (COM Communication) WUME-FPXHCOMG

FP-X Series User’s Manual WUME-FPX

WUME-FPXHPOSG

WUME-FPXHBASG-01 iii

Page 4

SAFETY PRECAUTIONS

● To prevent accidents or personal injuries, please be sure to comply with the following items.

● Prior to installation, operation, maintenance and inspection, please read this manual carefully for proper use.

● Before using the product, please fully understand the knowledge related to the equipment, safety

precautions and all other precautions.

● Safety precautions are divided into two levels in this manual: Warning and Caution.

Incorrect operation may lead to death or serious injury.

● Take appropriate safety measures for the external circuit of the product to ensure the security of the whole

system in case of abnormalities caused by product failure or external factors.

● Do not use this product in areas with inflammable gases.

Otherwise it may lead to an explosion.

● Do not put this product into a fire.

Otherwise it may cause damage to the battery or other electronic parts.

● Do not impact, charge or heat the lithium battery, and do not put it into a fire.

Otherwise it may lead to fire or damage.

Incorrect operation may lead to injury or material loss.

● To prevent the excessive exothermic heat or smoke generation of the product, a certain margin is required

for guaranteed characteristics and performance ratings of relative products.

● Do not disassemble or modify the product.

Otherwise it may lead to the excessive exothermic heat or smoke generation of the product.

● Do not touch terminal blocks during power-on.

Otherwise it may result in an electric shock.

● Create an emergency stop and interlock circuit in the external devices.

● Connect wires and connectors reliably.

Otherwise it may lead to the excessive exothermic heat or smoke generation of the product.

● Do not carry out construction (wiring, removal, etc.) during power-on.

Otherwise it may result in an electric shock.

● If the equipment is used in a manner not specified by the Panasonic, the protection provided by the

equipment may be impaired.

● This product has been developed/produced for industrial use only.

Description on Copyright and Trademarks

● The copyright of this manual is owned by Panasonic Industrial Devices SUNX Co., Ltd

● Unauthorized reproduction of this manual is strictly prohibited.

● Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

● Ethernet is a registered trademark of Fuji Xerox Co., Ltd. and Xerox Corporation.

● Other company and product names are trademarks or registered trademarks of their respective companies.

Compatibility with the conventional FP-X series

The FP-XH series is upward compatible with a conventional FP-X Control Unit. However, be

careful with the following points.

■

Hardware compatibility

● The FP-XH series can be used in combination with FP-X Expansion Units.

iv

WUME-FPXHBASG-01

Page 5

● The FP-X Extension Cassette (Communication Cassette) and FP-X Extension Cassette

(Function Cassette) can also be used. With the FP-XH Control Unit, there are less

restrictions on the installation position.

● The wiring for the transistor type Control Unit is different. The external power supply (24 V

DC) for driving the output circuit is not necessary.

● The backup battery type is different. A special battery for the FP-XH series is required.

● The port for connecting to a personal computer is USB 2.0 (miniB type).

■

Software compatibility

● The positioning function has been largely improved. A table setting mode has been added to

facilitate simplified setting and programming. In addition, position control patterns and home

return patterns have been added.

● For using the projects (programs, comments and system registers) created for the

conventional FP-X, the projects must be converted to the projects for the FP-XH using the

“Convert PLC Type” function of the tool software.

● All the instructions for the conventional FP-X are supported.

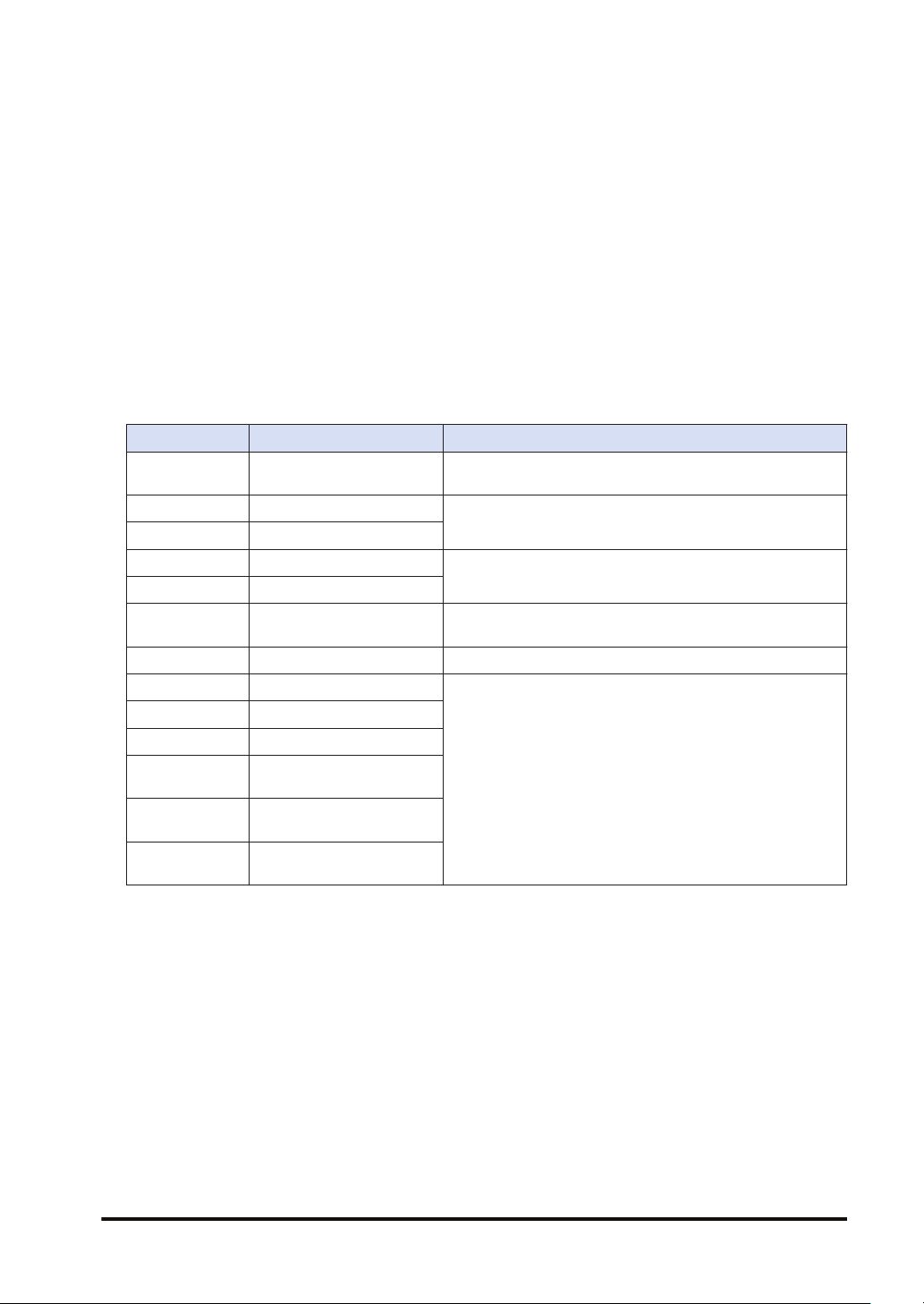

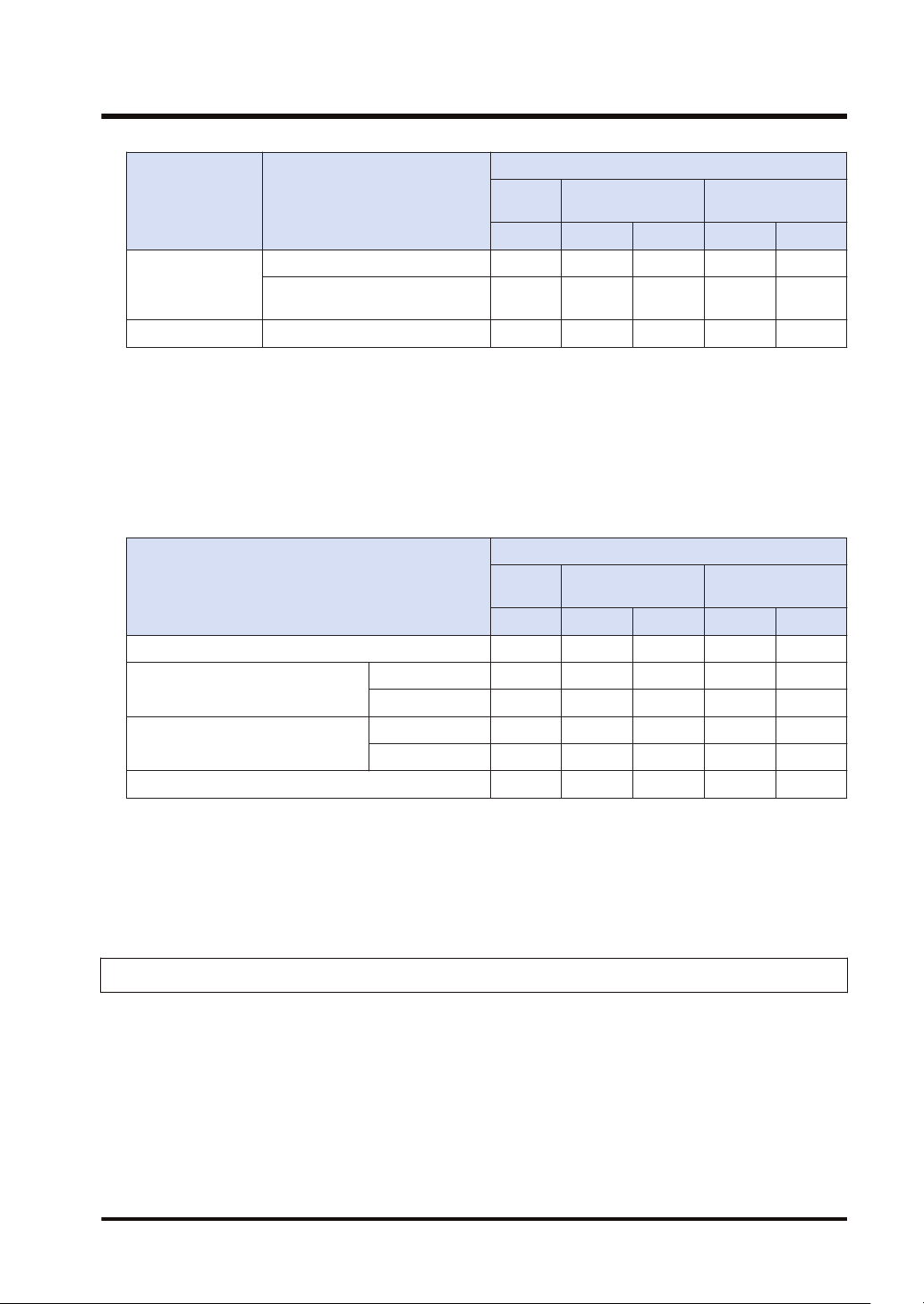

Instruction Section Main differences in specifications

SYS1

F12 (ICRD) F-ROM reading

P13 (PICWT) F-ROM writing

F145 (SEND) Data send instruction

F146 (RECV) Data receive instruction

F172 (PLSH)

F173 (PWMH) PWM output instructions Parameter settings are simplified.

F380 (POSST) Positioning table start

F381 (JOGST) JOG operation start

F382 (ORGST) Home return start

F383 (MPOST)

F384 (PTBLR)

F385 (PTBLW)

Communication condition

settings

Pulse output (JOG

operation) instruction

Positioning table

simultaneous start

Reading positioning

parameters

Writing positioning

parameters

The ranges that can be specified for the port number and

baud rate are extended.

The range for the block number to be specified when an

instruction is executed is extended.

The range for the COM port number to be specified when the

MEWTOCOL master or MODBUS master is sent is extended.

The characteristic of the acceleration / deceleration zone are

different.

Added for the positioning function (table setting mode).

WUME-FPXHBASG-01 v

Page 6

(MEMO)

vi WUME-FPXHBASG-01

Page 7

Table of Contents

1 System Configuration...........................................................................1-1

1.1 List of Units .........................................................................................1-2

1.1.1 FP-XH Control Units ........................................................................ 1-2

1.1.2 FP-X Expansion Units...................................................................... 1-2

1.1.3 FP-X Expansion FP0 Adapter.......................................................... 1-3

1.1.4 FP-X Extension Cassettes (Communication Cassettes).................. 1-3

1.1.5 FP-X Extension Cassettes (Function Cassettes)............................. 1-4

1.2 List of Unit Model Numbers.................................................................1-5

1.2.1 FP-XH Control Units ........................................................................ 1-5

1.2.2 FP-X Expansion Units...................................................................... 1-5

1.2.3 FP-X Expansion FP0 Adapter.......................................................... 1-6

1.2.4 FP-X Extension Cassettes (Communication Cassettes).................. 1-6

1.2.5 FP-X Extension Cassettes (Function Cassettes)............................. 1-6

1.2.6 Options............................................................................................. 1-7

1.2.7 Maintenance Parts ........................................................................... 1-7

1.3 Restrictions on Combinations of Units................................................1-8

1.3.1 Restrictions on Using FP-X Expansion Units................................... 1-8

1.3.2 Restrictions on Using FP-X Expansion FP0 Adapter....................... 1-9

1.3.3 Restrictions on Combinations of Extension Cassettes .................... 1-10

1.3.4 Restrictions on Communication Functions....................................... 1-12

1.3.5 Restrictions on Combined Use of Functions.................................... 1-13

1.4 Programming Tools.............................................................................1-14

1.4.1 Software Usage Environment and Applicable Cables ..................... 1-14

1.4.2 Applicable software version ............................................................. 1-14

2 Control Unit Specifications..................................................................2-1

2.1 Names and Functions of Parts............................................................2-2

2.1.1 Names and Functions of Parts......................................................... 2-2

2.1.2 Specifications of Operation Indicator LEDs ..................................... 2-3

2.1.3 Specifications of COM0 Port............................................................ 2-4

2.2 Power Supply Specifications...............................................................2-5

2.2.1 AC Power Supply Type.................................................................... 2-5

2.2.2 AC Power Supply Type: Service Power Supply for Input Circuit ..... 2-5

2.2.3 DC Power Supply Type.................................................................... 2-6

2.3 Input and Output Specifications (Relay Output Type).........................2-7

2.3.1 Input Specifications.......................................................................... 2-7

2.3.2 Output Specifications ....................................................................... 2-8

2.4 Input and Output Specifications (Transistor Output Type) ..................2-9

2.4.1 Input Specifications.......................................................................... 2-9

2.4.2 Output Specifications ....................................................................... 2-10

2.5 Terminal Layout...................................................................................2-11

2.5.1 Relay Output (AC Power Supply Type)............................................ 2-11

2.5.2 Relay Output (DC Power Supply Type) ........................................... 2-12

2.5.3 Transistor Output (AC Power Supply Type) ..................................... 2-13

2.5.4 Transistor Output (DC Power Supply Type)..................................... 2-15

WUME-FPXHBASG-01

vii

Page 8

3 Allocation of I/O Numbers....................................................................3-1

3.1 Basics of I/O Allocation.......................................................................3-2

3.1.1 How to Count I/O Numbers.............................................................. 3-2

3.1.2 Concept of I/O Number Allocation ................................................... 3-2

3.2 List of I/O Numbers for Each Unit .......................................................3-4

3.2.1 FP-XH Control Units ........................................................................ 3-4

3.2.2 FP-X Expansion Units...................................................................... 3-4

3.2.3 FP-X Function Cassettes ................................................................. 3-4

3.3 Allocation of FP0 Expansion Units......................................................3-6

3.3.1 Concept of I/O Number Allocation ................................................... 3-6

3.3.2 Types and I/O Numbers of FP0R Expansion Units.......................... 3-7

3.3.3 Types and I/O Numbers of FP0 Expansion Units ............................ 3-8

4 Installation and Wiring..........................................................................4-1

4.1 Installation...........................................................................................4-3

4.1.1 Installation Environment and Space ................................................ 4-3

4.2 Installation of Backup Battery .............................................................4-5

4.2.1 Installation of Backup Battery .......................................................... 4-5

4.3 Installation of Extension Cassette.......................................................4-6

4.3.1 Precautions When Installing the Extension Cassette ...................... 4-6

4.3.2 Installing the Communication Cassette............................................ 4-6

4.3.3 Installing the Function Cassette....................................................... 4-7

4.4 Connection of FP-X Expansion Unit ...................................................4-8

4.4.1 Setting of the Terminator Setting Switch .......................................... 4-8

4.4.2 Checking FP-X Expansion Cable..................................................... 4-8

4.4.3 Connection of FP-X Expansion Unit ................................................ 4-8

4.5 Connection of FP0 Expansion Unit.....................................................4-10

4.5.1 Connection of FP0 Expansion Unit .................................................. 4-10

4.5.2 Connection of FP-X Expansion FP0 Adapter................................... 4-10

4.6 Installation...........................................................................................4-12

4.6.1 Attachment to DIN Rail and Removal from DIN Rail........................ 4-12

4.6.2 Installation with screws .................................................................... 4-13

4.7 Wiring the Power Supply.....................................................................4-14

4.7.1 Common Precautions ...................................................................... 4-14

4.7.2 Grounding ........................................................................................ 4-14

4.7.3 Power Supply of Control Unit / Expansion Unit................................ 4-15

4.7.4 Power Supply of FP-X Expansion FP0 Adapter / FP0 Expansion

Unit.................................................................................................... 4-17

4.8 Wiring of Input and Output..................................................................4-19

4.8.1 Precautions on Wirings of Input and Output .................................... 4-19

4.8.2 Service Power Supply for Input and Output (Control Unit and

Expansion Unit: E30) ........................................................................ 4-19

4.8.3 Input Wiring...................................................................................... 4-19

4.8.4 Output Wiring ................................................................................... 4-21

4.9 Wiring the Terminal Block ...................................................................4-22

4.9.1 Suitable wires................................................................................... 4-22

4.9.2 Terminal block covers ...................................................................... 4-22

4.9.3 Installing / Removing the Terminal Block (C30 / C60)...................... 4-23

viii

WUME-FPXHBASG-01

Page 9

4.10 Safety Measures...............................................................................4-25

4.10.1 Safety Measures ............................................................................ 4-25

4.10.2 Instantaneous Power Failure ......................................................... 4-25

4.10.3 Watchdog Timer ............................................................................. 4-26

5 Procedures Before Starting Operation ...............................................5-1

5.1 Before Turning On the Power .............................................................5-2

5.1.1 Check Items ..................................................................................... 5-2

5.1.2 Procedures Before Starting Operation............................................. 5-2

5.2 Offline Edit of Program........................................................................5-4

5.2.1 Elements of Program ....................................................................... 5-4

5.2.2 System Register Settings................................................................. 5-4

5.2.3 Setting of Positioning Parameters.................................................... 5-5

5.3 Program Download and Operation .....................................................5-6

5.3.1 Before Turning ON the Power.......................................................... 5-6

5.3.2 Program Download and Mode Switching......................................... 5-6

5.3.3 Totally Checking Project................................................................... 5-9

5.3.4 Verifying Project............................................................................... 5-9

5.4 Online Edit ..........................................................................................5-13

5.4.1 Overview of Online Edit ................................................................... 5-13

5.4.2 Online Edit of Program..................................................................... 5-13

5.4.3 Online Edit of System Register ........................................................ 5-14

5.5 Program Block ....................................................................................5-16

5.5.1 Overview of Program Block ............................................................. 5-16

5.5.2 Changing the Execution Order of Program Blocks .......................... 5-16

6 Memory / Master Memory Cassette.....................................................6-1

6.1 Memory Backup..................................................................................6-2

6.1.1 Backup of Program Memory ............................................................ 6-2

6.1.2 Backup of Operation Memory .......................................................... 6-2

6.1.3 Backup of Operation Memory (With Battery) ................................... 6-3

6.1.4 Settings of Battery Error Alarm and Hold Area ................................ 6-4

6.2 RAM / ROM Transfer Function ...........................................................6-6

6.2.1 Overview of Functions ..................................................................... 6-6

6.2.2 Operation Using Tool Software ........................................................ 6-6

6.3 Function of Master Memory Cassette.................................................6-7

6.3.1 Overview of Functions ..................................................................... 6-7

6.3.2 Settings of Master Memory Unit....................................................... 6-7

6.4 Master Memory Function ....................................................................6-8

6.4.1 Overview of Functions ..................................................................... 6-8

6.4.2 Before Turning ON the Power.......................................................... 6-8

6.4.3 Data Transfer to Master Memory Cassette...................................... 6-9

6.4.4 Data Transfer from Master Memory Cassette to Control Unit.......... 6-11

6.4.5 Using Master Memory Cassette with Other Models......................... 6-13

6.5 Clock / calendar ..................................................................................6-14

6.5.1 Overview of Functions ..................................................................... 6-14

6.5.2 Clock / calendar Setting ................................................................... 6-14

6.5.3 Application Example of Clock / calendar.......................................... 6-15

WUME-FPXHBASG-01

ix

Page 10

7 Security Function..................................................................................7-1

7.1 Password Protect Function.................................................................7-2

7.1.1 Overview of Functions ..................................................................... 7-2

7.1.2 Setting with tool software ................................................................. 7-2

7.2 Program Upload Protection Function..................................................7-9

7.2.1 Overview of Functions ..................................................................... 7-9

7.2.2 Configuration.................................................................................... 7-9

7.3 Availability of Security Function ..........................................................7-11

7.3.1 Control Unit ...................................................................................... 7-11

8 Other Functions ....................................................................................8-1

8.1 Analog Potentiometer .........................................................................8-2

8.1.1 Overview of Functions ..................................................................... 8-2

8.1.2 Example Showing How to Use Analog Potentiometer ..................... 8-2

8.2 Input Time Constant Setting Function.................................................8-3

8.2.1 Overview of functions....................................................................... 8-3

9 Troubleshooting....................................................................................9-1

9.1 Self-diagnosis function........................................................................9-2

9.1.1 Operation Monitor LEDs of Control Unit .......................................... 9-2

9.1.2 Operation Monitor LEDs of FP-X Expansion FP0 Adapter .............. 9-2

9.1.3 Operation Mode When an Error Occurs .......................................... 9-3

9.2 What to Do If an Error Occurs.............................................................9-5

9.2.1 ERR. LED Flashes........................................................................... 9-5

9.2.2 Mode does Not Change to RUN Mode ............................................ 9-6

9.2.3 ERR. LED Lights.............................................................................. 9-6

9.2.4 ALL LEDs are OFF .......................................................................... 9-7

9.2.5 A Protect Error Message Appears ................................................... 9-7

9.2.6 Diagnosing Output Malfunction........................................................ 9-8

9.2.7 Expansion Unit does not Operate .................................................... 9-9

9.2.8 Communication Error Occurs (RS-232C) ........................................ 9-9

9.2.9 Communication Error Occurs (RS-422) ........................................... 9-10

9.2.10 Communication Error Occurs (RS-485) ......................................... 9-11

9.2.11 Communication Error Occurs (Ethernet) ........................................ 9-11

10 Maintenance and Inspection..............................................................10-1

10.1 Handling of Backup Battery ..............................................................10-2

10.1.1 Replacement of Backup Battery .................................................... 10-2

10.1.2 Lifetime and Time for Replacement of Backup Battery.................. 10-3

10.2 Inspection..........................................................................................10-4

11 Specifications......................................................................................11-1

11.1 Control Unit Specifications ................................................................11-2

11.1.1 General Specifications ................................................................... 11-2

11.1.2 Performance Specifications............................................................ 11-3

11.2 Communication Function Specifications ...........................................11-7

11.2.1 Communication Specifications of Control Unit ............................... 11-7

11.2.2 Communication Cassette Specifications ........................................ 11-7

x

WUME-FPXHBASG-01

Page 11

11.3 Operation Memory Area....................................................................11-10

11.4 List of System Registers ...................................................................11-12

11.4.1 List of System Registers................................................................. 11-12

11.5 List of Special Relays........................................................................11-24

11.6 List of Special Data Registers ...........................................................11-38

11.7 List of Error Codes ............................................................................11-55

11.7.1 List of Syntax Check Errors............................................................ 11-55

11.7.2 Self-diagnostic Errors ..................................................................... 11-56

11.7.3 List of MEWTOCOL-COM Communication Error Codes................ 11-57

11.8 Dimensions .......................................................................................11-59

11.8.1 External Dimensions ...................................................................... 11-59

11.8.2 Mounting Dimensions..................................................................... 11-60

WUME-FPXHBASG-01 xi

Page 12

(MEMO)

xii WUME-FPXHBASG-01

Page 13

1 System Configuration

1.1 List of Units .........................................................................................1-2

1.1.1 FP-XH Control Units ........................................................................ 1-2

1.1.2 FP-X Expansion Units...................................................................... 1-2

1.1.3 FP-X Expansion FP0 Adapter.......................................................... 1-3

1.1.4 FP-X Extension Cassettes (Communication Cassettes).................. 1-3

1.1.5 FP-X Extension Cassettes (Function Cassettes)............................. 1-4

1.2 List of Unit Model Numbers.................................................................1-5

1.2.1 FP-XH Control Units ........................................................................ 1-5

1.2.2 FP-X Expansion Units...................................................................... 1-5

1.2.3 FP-X Expansion FP0 Adapter.......................................................... 1-6

1.2.4 FP-X Extension Cassettes (Communication Cassettes).................. 1-6

1.2.5 FP-X Extension Cassettes (Function Cassettes)............................. 1-6

1.2.6 Options............................................................................................. 1-7

1.2.7 Maintenance Parts ........................................................................... 1-7

1.3 Restrictions on Combinations of Units................................................1-8

1.3.1 Restrictions on Using FP-X Expansion Units................................... 1-8

1.3.2 Restrictions on Using FP-X Expansion FP0 Adapter....................... 1-9

1.3.3 Restrictions on Combinations of Extension Cassettes .................... 1-10

1.3.4 Restrictions on Communication Functions....................................... 1-12

1.3.5 Restrictions on Combined Use of Functions.................................... 1-13

1.4 Programming Tools.............................................................................1-14

1.4.1 Software Usage Environment and Applicable Cables ..................... 1-14

1.4.2 Applicable software version ............................................................. 1-14

WUME-FPXHBASG-01

1-1

Page 14

1.1 List of Units

1.1 List of Units

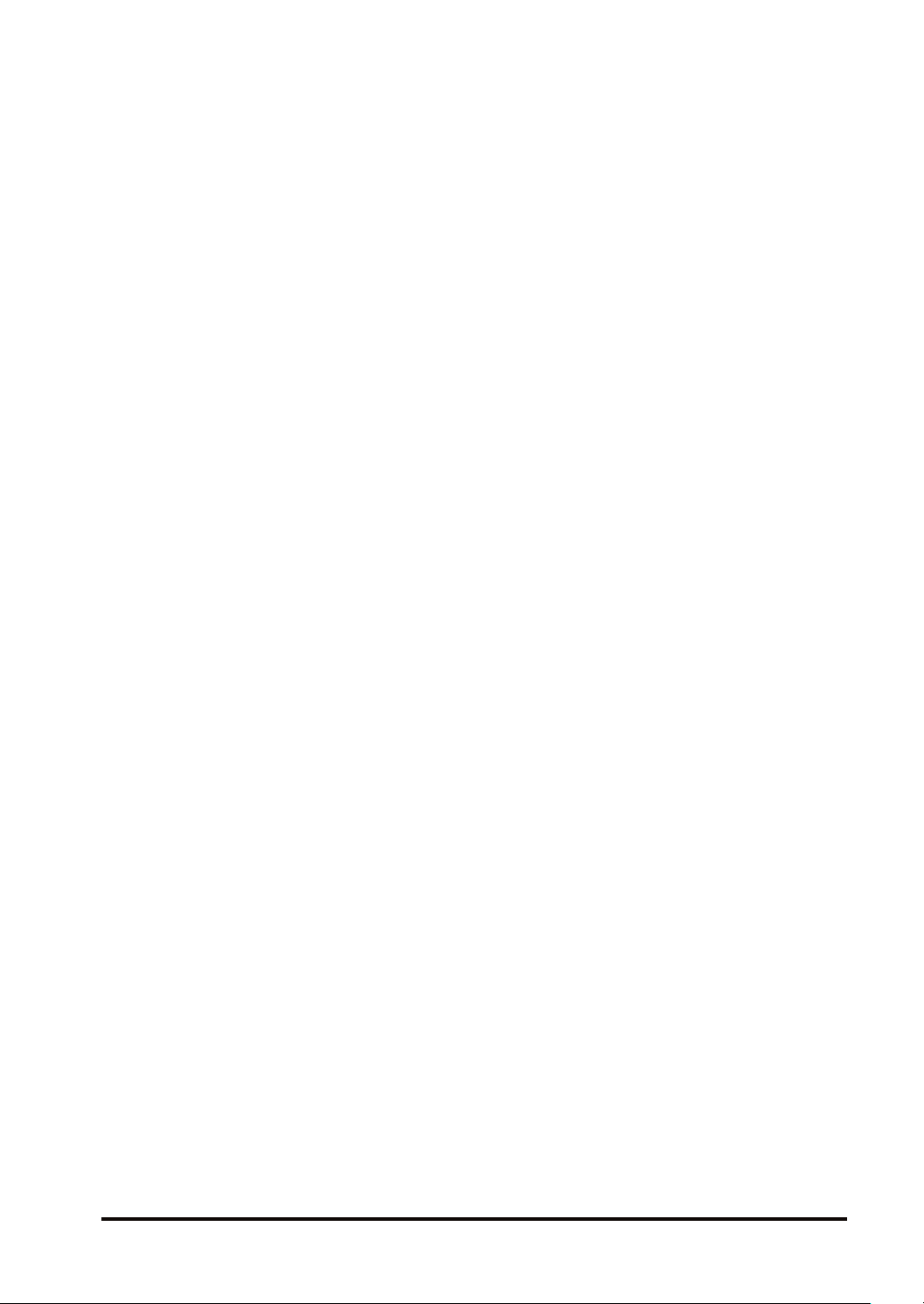

1.1.1 FP-XH Control Units

The following types are available depending on the number of points, power supply, and output

type.

Number of points 14 points / 30 points / 60 points

Power supply 100 to 240 V AC or 24 V DC

Output Relay or transistor (NPN output)

1.1.2 FP-X Expansion Units

The following types are available depending on the number of points, power supply, and output

type.

■

FP-X Expansion Units

Number of

points

Power supply No power supply 100 to 240 V AC or 24 V DC

Output Relay or transistor (NPN output or PNP output)

14 points (for output only) / 16 points (for input

only) / 16 (8/8) points

30 (16/14) points

1-2 WUME-FPXHBASG-01

Page 15

1.1 List of Units

1.1.3 FP-X Expansion FP0 Adapter

The FP-X Expansion FP0 Adapter is an interface adapter that can be connected to the FP0

Series Expansion Unit / Intelligent Unit.

1.1.4 FP-X Extension Cassettes (Communication Cassettes)

The following types are available depending on the type of communication interface or the

number of channels.

RS-232C (5-wire type) x 1 channel

RS-232C (3-wire type) x 2 channels

Communication method

WUME-FPXHBASG-01 1-3

RS-485 / RS-422 x 1 channel

RS-485 x 1 channel + RS-232C (3-wire type) x 1 channel

RS-485 x 2 channels

Ethernet x 1 channel + RS-232C (3-wire type) x 1 channel

Page 16

1.1 List of Units

1.1.5 FP-X Extension Cassettes (Function Cassettes)

The following types are available depending on the output type and function.

Analog input x 2 channels

Analog I/O

Digital I/O

Pulse I/O High-speed counter × 2 channels + pulse output × 1 channel

Master memory Master memory + real-time clock

Analog output x 2 channels

Analog input x 2 channels + analog output x 1 channel

8-point input, 8-point transistor output

4-point input + 3-point transistor output

1-4 WUME-FPXHBASG-01

Page 17

1.2 List of Unit Model Numbers

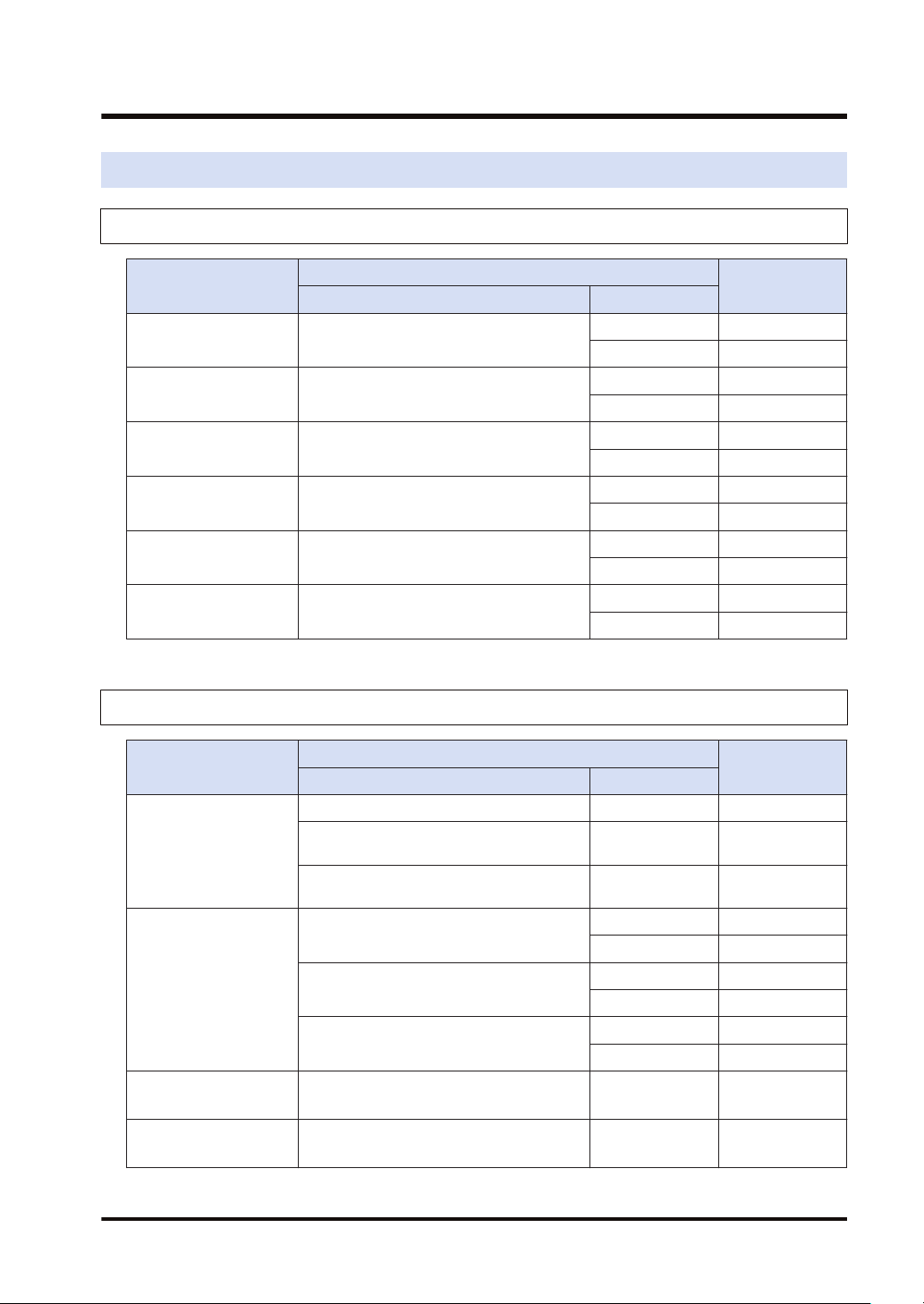

1.2.1 FP-XH Control Units

1.2 List of Unit Model Numbers

Item name

FP-XH C14R

Control Unit

FP-XH C14T

Control Unit

FP-XH C30R

Control Unit

FP-XH C30T

Control Unit

FP-XH C60R

Control Unit

FP-XH C60T

Control Unit

Input and output specifications Power supply

8-point DC input, 6-point relay output

8-point DC input, 6-point transistor output

(NPN)

16-point DC input, 14-point relay output

16-point DC input, transistor output (NPN)

32-point DC input, 28-point relay output

32-point DC input, 28-point transistor output

(NPN)

Specifications

1.2.2 FP-X Expansion Units

Item name

Input and output specifications Power supply

8-point DC input, 8-point relay output - AFPX-E16R

FP-X E16

Expansion I/O Unit

8-point DC input, 8-point transistor output

(NPN)

8-point DC input, 8-point transistor output

(PNP)

16-point DC input, 14-point relay output

FP-X E30

Expansion I/O Unit

16-point DC input, 14-point transistor output

(NPN)

16-point DC input, 14-point transistor output

(PNP)

FP-X E16

Expansion Input Unit

FP-X E14R

Expansion Output Unit

(Note 1) An 8 cm expansion cable is provided with the Expansion Unit.

16-point DC input - AFPX-E16X

14-Point relay output - AFPX-E14YR

Specifications

Product no.

100 to 240 V AC AFPXHC14R

24 V DC AFPXHC14RD

100 to 240 V AC AFPXHC14T

24 V DC AFPXHC14TD

100 to 240 V AC AFPXHC30R

24 V DC AFPXHC30RD

100 to 240 V AC AFPXHC30T

24 V DC AFPXHC30TD

100 to 240 V AC AFPXHC60R

24 V DC AFPXHC60RD

100 to 240 V AC AFPXHC60T

24 V DC AFPXHC60TD

Product no.

- AFPX-E16T

- AFPX-E16P

100 to 240 V AC AFPX-E30R

24 V DC AFPX-E30RD

100 to 240 V AC AFPX-E30T

24 V DC AFPX-E30TD

100 to 240 V AC AFPX-E30P

24 V DC AFPX-E30PD

WUME-FPXHBASG-01 1-5

Page 18

1.2 List of Unit Model Numbers

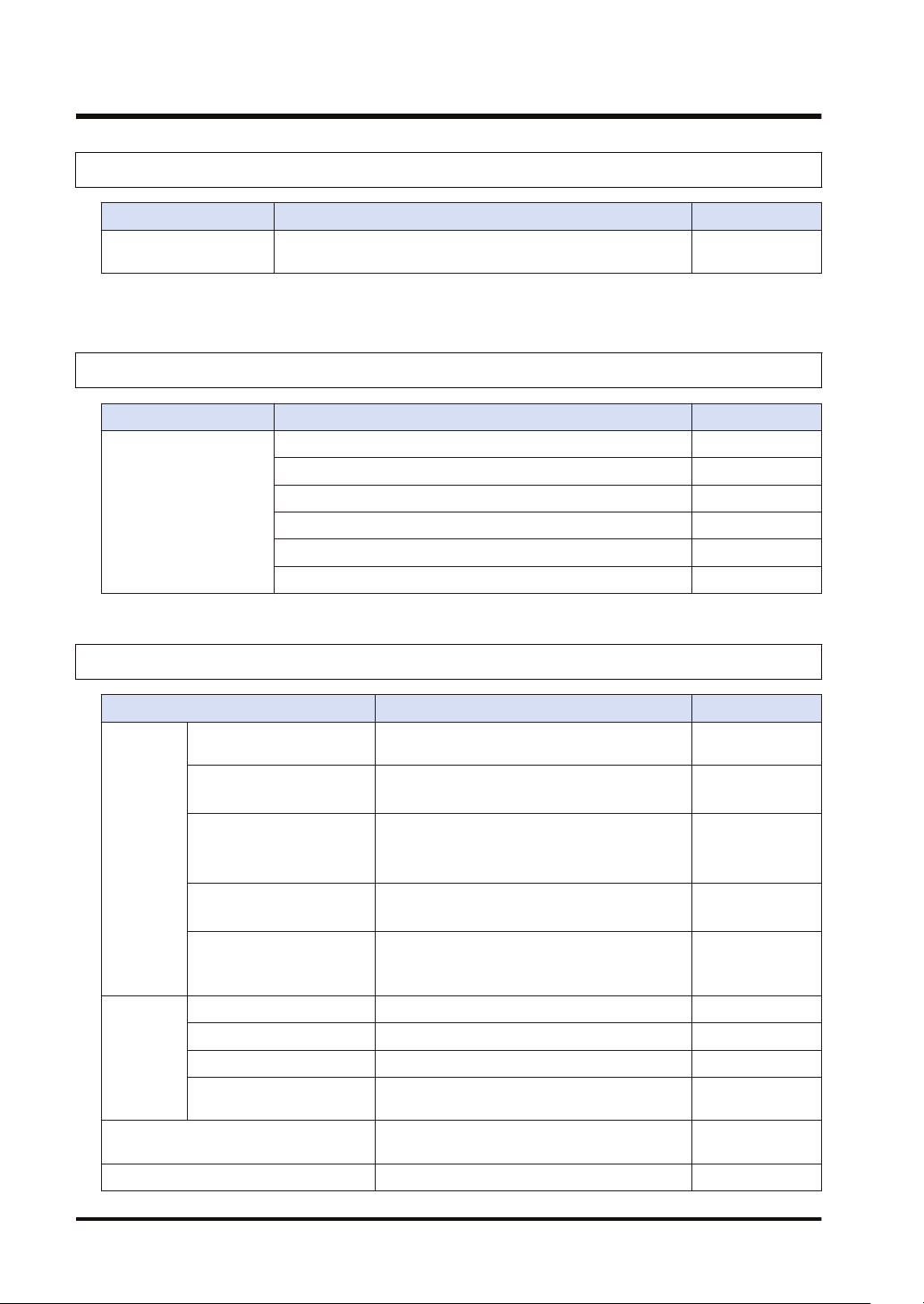

1.2.3 FP-X Expansion FP0 Adapter

Name Specifications Product no.

FP-X Expansion FP0

Adapter

(Note 1) An 8 cm expansion cable is provided with the Expansion Unit.

1.2.4 FP-X Extension Cassettes (Communication Cassettes)

Name Specifications Product no.

FP-X Communication

Cassette

For connecting the FP0 Expansion Unit AFPX-EFP0

5-wire RS-232C x 1 channel AFPX-COM1

3-wire RS-232C x 2 channels AFPX-COM2

RS-485 / RS-422 (isolated) x 1 channel AFPX-COM3

RS-485 (isolated) x 1 channel + 3-wire RS-232C x 1 channel AFPX-COM4

RS-485 (isolated) x 2 channels (non-isolated between channels) AFPX-COM6

Ethernet port + 3-wire RS-232C x 1 channel AFPX-COM5

1.2.5 FP-X Extension Cassettes (Function Cassettes)

Name Specifications Product no.

FP-X Analog Input

Cassette

FP-X Analog Output

Cassette

Analog

FP-X Analog I/O Cassette

I/O

FP-X Thermocouple

Cassette

FP-X Resistance

Thermometer Cassette

FP-X Input Cassette 8-point DC input AFPX-IN8

Digital

I/O

FP-X Output Cassette 8-point transistor output (NPN) AFPX-TR8

FP-X Output Cassette 6-point transistor output (PNP) AFPX-TR6P

FP-X I/O Cassette

FP-X Pulse I/O Cassette

FP-X Master Memory Cassette Master memory + real-time clock AFPX-MRTC

Analog input (non-isolated) x 2 channels AFPX-AD2

Analog output (isolated) x 2 channels

(isolated between channels)

AFPX-DA2

Analog input (isolated) x 2 channels

(non-isolated between channels)

AFPX-A21

+ Analog output (isolated) x 1 channel

Thermocouple input (isolated) x 2 channels

(isolated between channels)

AFPX-TC2

Resistance thermometer input (isolated) x 2

channels

AFPX-RTD2

(isolated between channels)

4-point DC input + 3-point transistor output

(NPN)

High-speed counter × 2 channels + pulse

output × 1 channel

AFPX-IN4T3

AFPX-PLS

1-6 WUME-FPXHBASG-01

Page 19

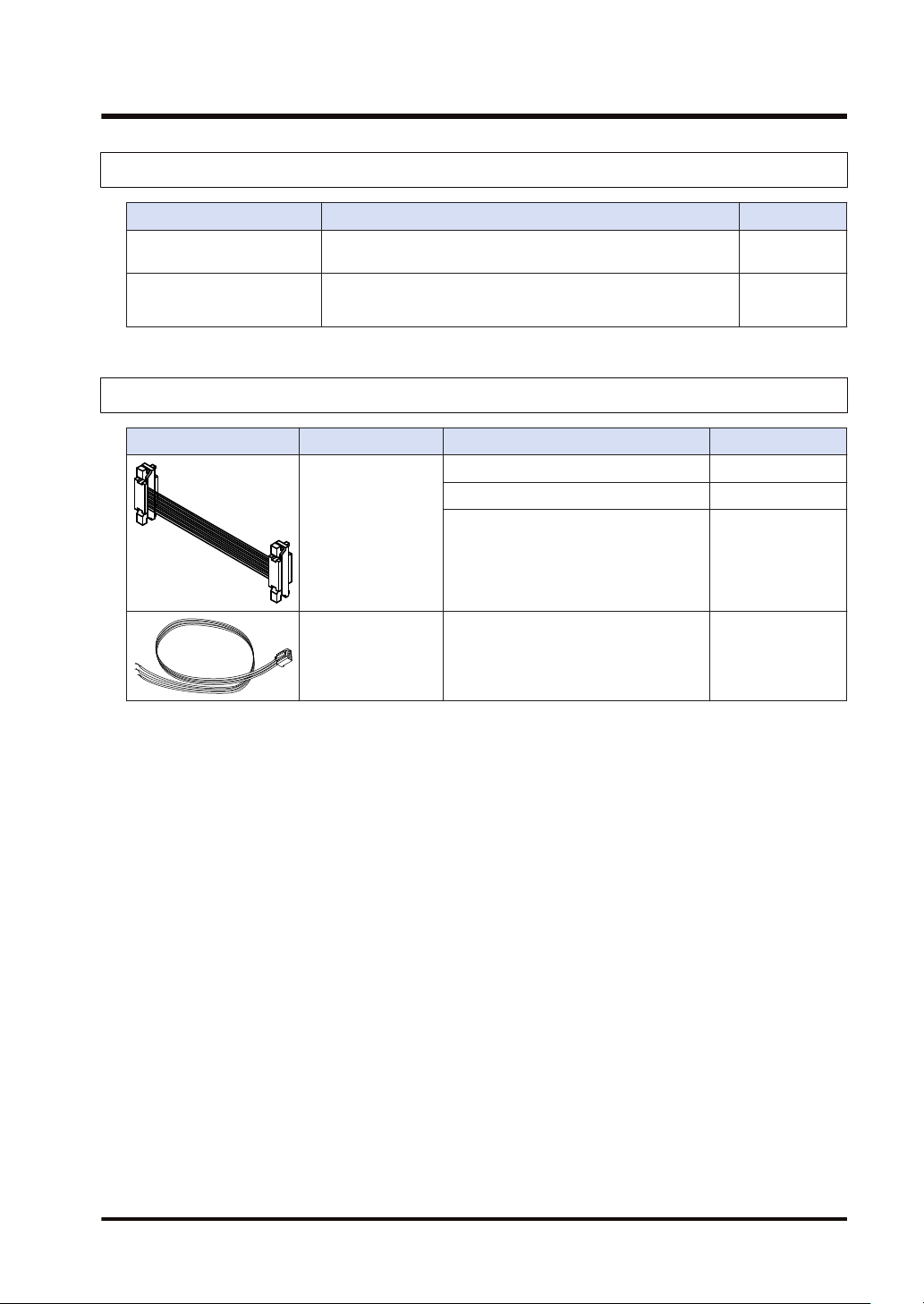

1.2.6 Options

Name Specifications Product no.

FP-XH Backup Battery

FP-X terminal block (C30/

C60)

1.2.7 Maintenance Parts

FP-X Expansion

Cable

1.2 List of Unit Model Numbers

Required when expanding the hold area of the operation

memory or when using the clock / calendar function.

For C30/C60 control unit for E30 expansion I/O unit with 21-pin

cover (no printing) 4 pcs/pack

Name Specifications Product no.

8 cm AFPX-EC08

30 cm AFPX-EC30

(Note 1)(Note 2)

80 cm AFPX-EC80

AFPABAT001

AFPX-TAN1

FP0

Power supply cable

(Note 1) An 8 cm expansion cable (AFPX-EC08) is provided with the FP-X Expansion Unit or with the FP-X

For the Expansion FP0 Adapter, length:

1 m

AFP0581

Expansion FP0 Adapter. The total length of the expansion cable should be within 160 cm.

(Note 2) If a longer expansion cable is used, an I/O check error may occur due to noise, etc. In such a case, it

is recommended that measures such as installing a ferrite core be taken.

WUME-FPXHBASG-01 1-7

Page 20

1.3 Restrictions on Combinations of Units

1.3 Restrictions on Combinations of Units

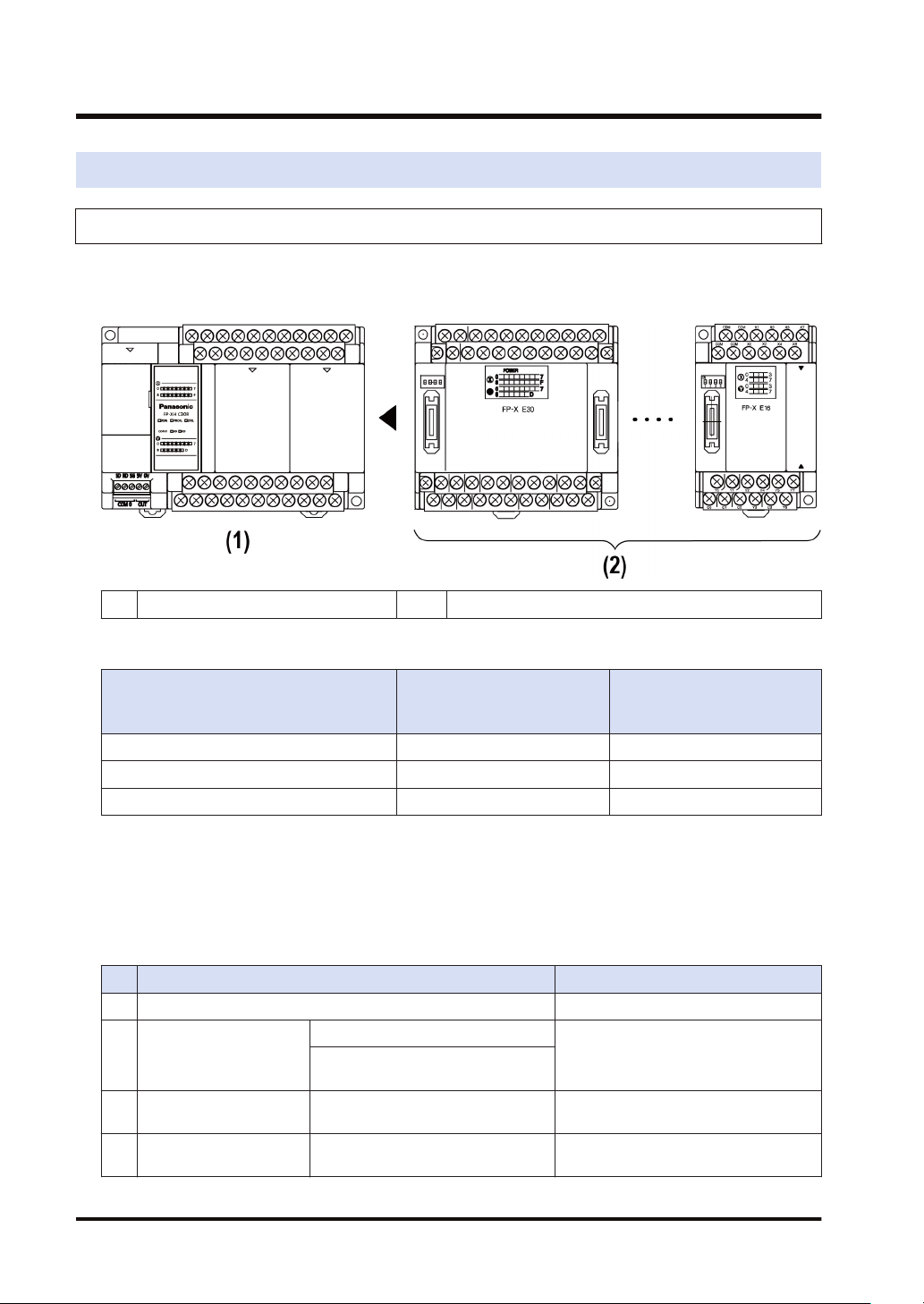

1.3.1 Restrictions on Using FP-X Expansion Units

■

Restrictions on the number of Expansion Units and mounting order (1)

● Up to 8 Expansion Units can be connected.

(1) FP-XH Control Units (2) FP-X Expansion Units

■

Maximum number of control inputs / outputs

Control unit

Type of Control Unit

FP-XH C14 Control Unit 14 points Max. 254 points

FP-XH C30 Control Unit 30 points Max. 270 points

FP-XH C60 Control Unit 60 points Max. 300 points

■

Restrictions on combinations of Expansion Cables

No. of inputs / outputs of a

single control unit

FP-X-E30

No. of inputs / outputs when

using Expansion Units

● The total length of the expansion cables should be within 160 cm.

■

Restrictions on combinations of Expansion Units (2)

● The number of units which can be expanded depends on the Expansion Unit type.

Unit type Remarks

(1) FP-XH Control Unit

E14YR, E16R

(2) FP-X Expansion I/O Unit

(3) FP-X Expansion I/O Unit E16X, E16T, E16P (Ver. 3.0 or later)

(4) FP-X Expansion I/O Unit E30

E16X, E16T, E16P (earlier than Ver.

3.0)

Expansion I/O Unit that does not have a

built-in power supply

Expansion I/O Unit that does not have a

built-in power supply

Expansion I/O Unit that has a built-in

power supply

1-8 WUME-FPXHBASG-01

Page 21

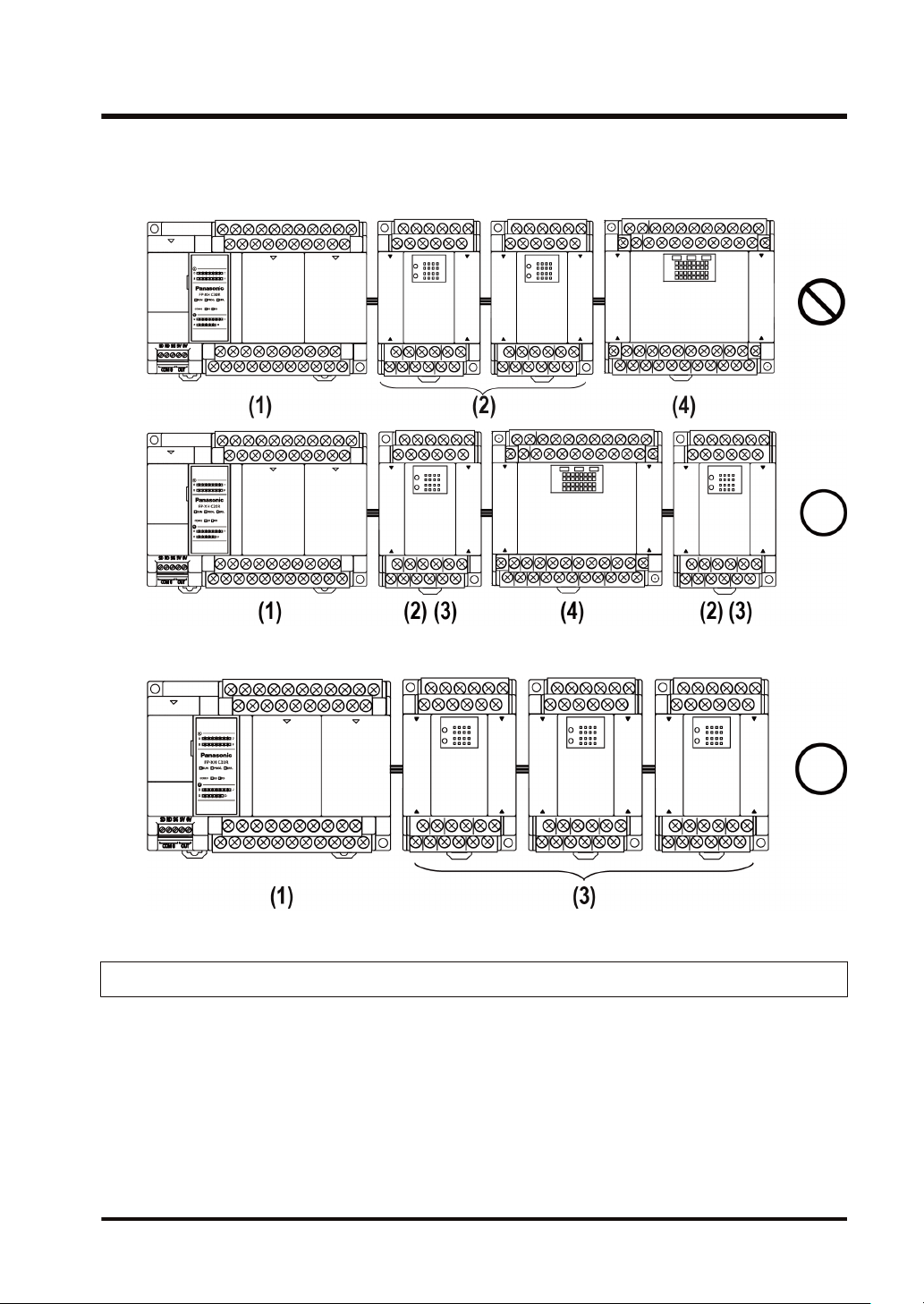

1.3 Restrictions on Combinations of Units

● Among the FP-X Expansion I/O Units, those in the group (2) in the above table cannot be

connected next to each other. However, they can be connected to the right of the Expansion

I/O Unit that has a built-in power supply.

● Among the FP-X Expansion I/O Units that do not have a built-in power supply, those in the

group (3) in the above table can be connected together up to three units.

1.3.2 Restrictions on Using FP-X Expansion FP0 Adapter

■

FP-X Expansion FP0 Adapter installation position

● Up to three FP0 Expansion Units can be connected via the FP-X Expansion FP0 Adapter.

● Up to seven FP-X Expansion Units can be connected when using the FP-X Expansion FP0

Adapter.

● Only one FP-X Expansion FP0 Adapter can be connected at the last position of the FP-X

Expansion Bus. Install it on the right of the FP-X Expansion Unit / FP-X0 Expansion Unit.

WUME-FPXHBASG-01 1-9

Page 22

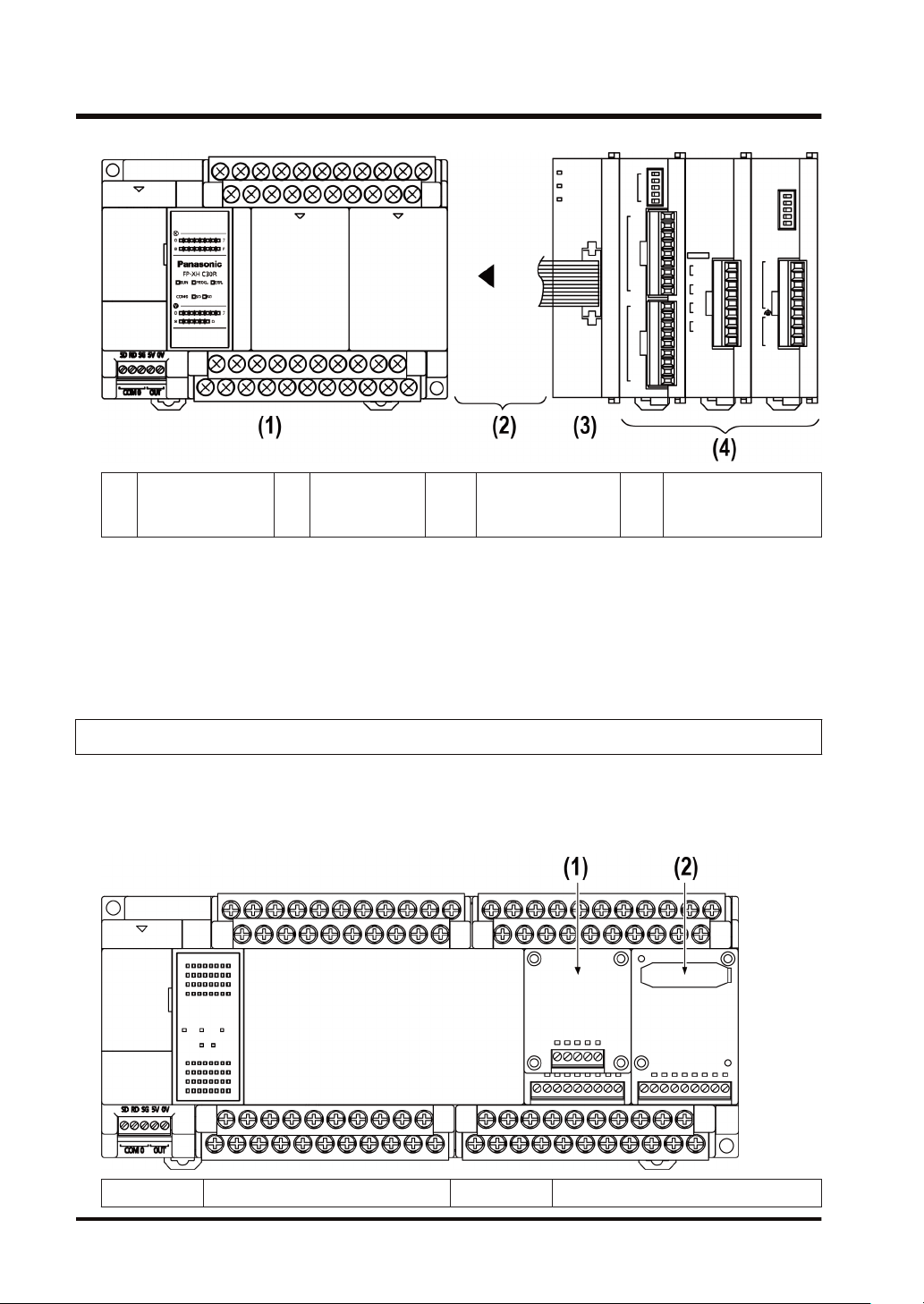

1.3 Restrictions on Combinations of Units

FP-XH

(1)

Control Unit

■

FP0 Expansion Unit / FP0 Intelligent Unit installation sequence

FP-X

(2)

Expansion Unit

FP-X

(3)

Expansion FP0

adapter

FP0 Expansion Unit

(4)

Intelligent Unit

● Install the FP0 Thermocouple Input Unit on the right side of all other FP0 Units. If it is

installed on the left side, the total precision will deteriorate.

● Install the FP0 CC-Link Unit on the right side of all other FP0 Units. There is no expansion

connector on the right side.

1.3.3 Restrictions on Combinations of Extension Cassettes

■

Extension Cassette mounting position (1)

● The FP-XH Control Unit is provided with two cassette mounting parts. In case of the C14

model, only the cassette mounting part 1 can be used.

(1) Cassette mounting part 1 (2) Cassette mounting part 2

1-10 WUME-FPXHBASG-01

Page 23

1.3 Restrictions on Combinations of Units

■

Extension Cassette mounting position (2)

● The Function Cassette can be put together with the Communication Cassette and mounted

on the same cassette mounting part. When doing so, be sure to put the Communication

Cassette on top of the Function Cassette.

(3) Communication Cassette (4) Function Cassette

■

Number of of Extension Cassettes to be mounted

● Up to two Function Cassettes and up to two Communication Cassettes can be mounted.

■

Types of Extension Cassettes and mounting position (●: Available, ○:

Conditionally available, Blank: Not available)

Mounting parts on the Control Unit

Cassette type

Type Item name Product number

AFPX-COM1

AFPX-COM2 ● ●

Communicatio

n Cassette

(Note 1)

Function

Cassette

(Note 3)

Communication

Cassette

Analog Input Cassette AFPX-AD2 ● ●

Analog Output

Cassette

Analog I/O Cassette AFPX-A21 ● ●

Thermocouple

Cassette

RTD Cassette AFPX-RTD2 ● ●

Input Cassette AFPX-IN8 ● ●

AFPX-COM3 ● ●

AFPX-COM4 ● ●

AFPX-COM5 ● ●

AFPX-COM6 ● ●

AFPX-DA2 ● ●

AFPX-TC2 ● ●

Cassette mounting

part 1

FP-XH Control

Unit

(Note 2)

●

Cassette mounting

part 2

FP-XH Control Unit

(excluding C14)

(Note 2)

●

WUME-FPXHBASG-01 1-11

Page 24

1.3 Restrictions on Combinations of Units

Mounting parts on the Control Unit

Cassette type

Type Item name Product number

Output Cassette AFPX-TR8 ● ●

Output Cassette AFPX-TR6P ● ●

I/O Cassette AFPX-IN4T3 ● ●

Pulse I/O Cassette AFPX-PLS

Master Memory

Cassette

(Note 1) When mounting it together with the Function Cassette, mount it on top of the Function Cassette.

AFPX-MRTC

(Note 2) With the AFPX-COM1, RS/CS control is possible.

(Note 3) When mounting the Function Cassette on C30, or C60 model, the Cassette can be mounted either on

the cassette mounting part 1 or cassette mounting part 2.

(Note 4) The Pulse I/O Cassette cannot be mounted on the Transistor Output Type Control Unit. If it is

mounted, the self-diagnostic error (27: Unit installed limit) will occur.

(Note 5) Only one FP-X Master Memory Cassette can be mounted. If two FP-X Master Memory Cassettes are

mounted, the self-diagnostic error (27: Unit installed limit) will occur.

Cassette mounting

part 1

FP-XH Control

Unit

(Note 4)

○

(Note 5)

○

Cassette mounting

part 2

FP-XH Control Unit

(excluding C14)

(Note 4)

○

(Note 5)

○

1.3.4 Restrictions on Communication Functions

● There are the following restrictions on functions to be used when using the communication

ports equipped with the Control Unit and Communication Cassettes.

● Allocated communication port numbers vary according to the mounting positions of

cassettes.

■

Types of communication ports / Communication Cassettes (●: Available, Blank:

Not available)

Allocated communication port no.

Product no.

Communication interface

Control

Unit

COM0 COM1 COM2 COM3 COM4

Control

Unit standard

equipment

AFPX-COM1

AFPX-COM2

RS-232C (3-wire type) x 1

channel

RS-232C (5-wire type) x 1

channel

RS-232C (3-wire type) x 2

channels

AFPX-COM3 RS-485 / RS-422 x 1 channel ● ●

RS-485 x 1 channel ● ●

AFPX-COM4

RS-232C (3-wire type) x 1

channel

Cassette mounting

●

part 1

part 2

● ●

● ● ● ●

● ●

Cassette mounting

1-12 WUME-FPXHBASG-01

Page 25

1.3 Restrictions on Combinations of Units

Allocated communication port no.

Product no. Communication interface

Control

Unit

COM0 COM1 COM2 COM3 COM4

Ethernet port x 1 channel ● ●

AFPX-COM5

RS-232C (3-wire type) x 1

channel

AFPX-COM6 RS-485 x 2 channels ● ● ● ●

(Note 1) The RS-232C port of the AFPX-COM1 is a 5-wire type, and the RS/CS control can be performed.

(Note 2) For the AFPX-COM1, select either RS-485 or RS-422. Use the switch on the Communication Cassette

to select the port.

(Note 3) For the AFPX-COM4, both 1-channel RS-485 and 1-channel RS-232C (3-wire type) can be used.

(Note 4) For the AFPX-COM5, both 1-channel Ethernet and 1-channel RS-232C (3-wire type) can be used.

■

Available functions for each communication port (●: Available, ○: Conditionally

available, Blank: Not available)

Communication functions to be used

PLC Link ○ ○

MEWTOCOL-COM

MODBUS-RTU

Master ● ● ● ● ●

Slave ● ● ● ● ●

Master ● ● ● ●

Slave ● ● ● ●

General-purpose communication ● ● ● ●

(Note 1) For the PLC link, either one of the standard COM0 port mounted in the Control Unit and the COM 1

port of a Cassette can be used.

(Note 2) The COM4 port only supports MEWTOCOL-COM communication. In addition, the communication

parameters (unit number, communication format, baud rate) when the power is ON are same as the

setting of the COM3 port. After RUN, you can also change the conditions by SYS1 instruction.

Control

Unit

COM0 COM1 COM2 COM3 COM4

Cassette mounting

part 1

Cassette mounting

part 2

● ●

Allocated communication port no.

Cassette mounting

part 1

Cassette mounting

part 2

1.3.5 Restrictions on Combined Use of Functions

● For the FP-XH series, communication with external devices can be performed via up to a

maximum of five communication interfaces in combination of the standard COM0 port

mounted in the Control Unit and the COM1 to COM4 ports of the Communication Cassette.

● When using all five ports (COM0 to COM4), the usable baud rate is up to 115.2 kbps and

usable pulse output function is up to 2 axes. When using four or less ports, the usable baud

rate is up to 230.4 kbps and usable pulse output function is up to 6 axes.

WUME-FPXHBASG-01 1-13

Page 26

1.4 Programming Tools

1.4 Programming Tools

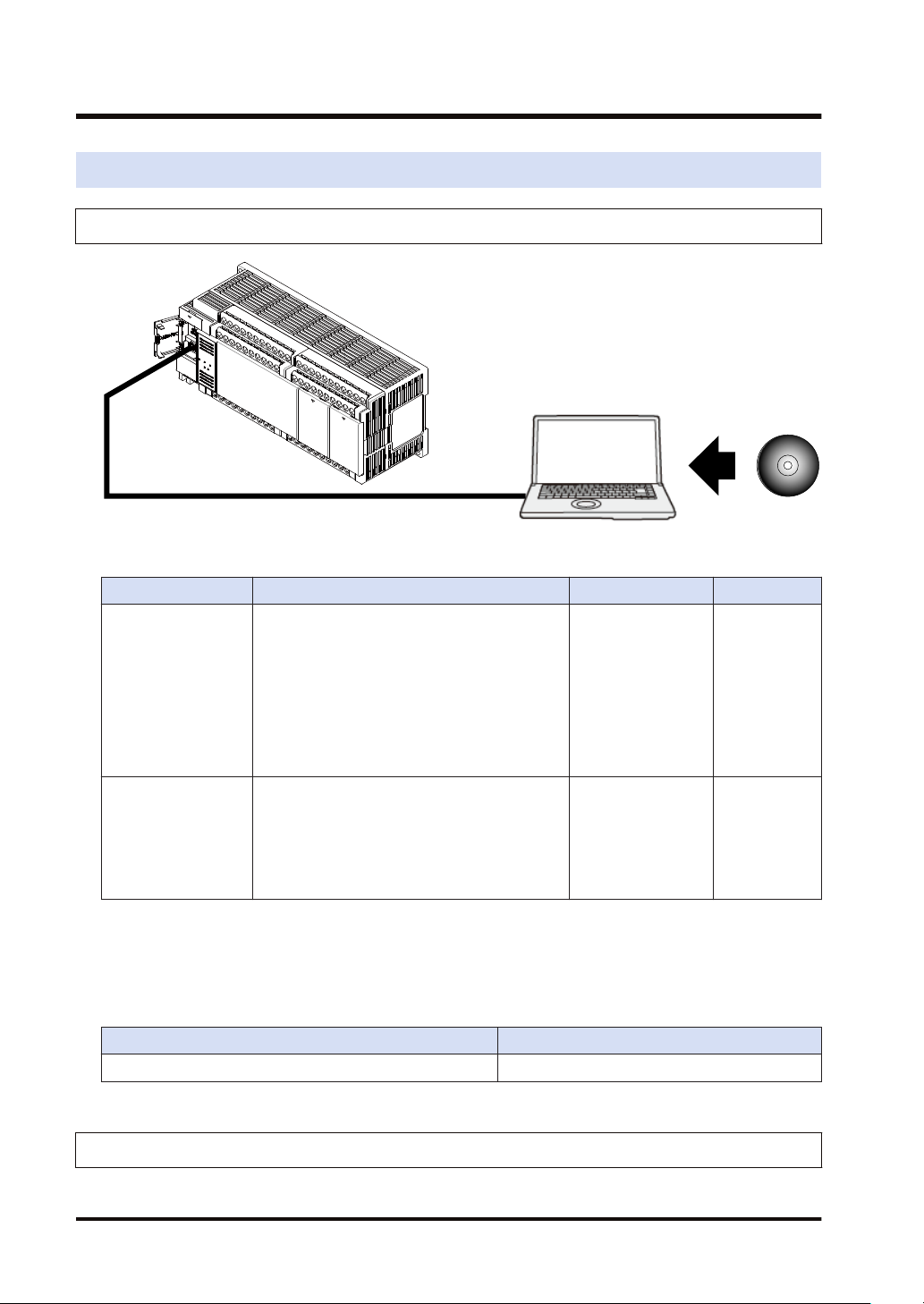

1.4.1 Software Usage Environment and Applicable Cables

■

Tool software

Software type Operating system Hard disk capacity Product no.

Windows

Windows

Windows

Control FPWIN GR7

Windows

bit version)

Windows

Windows

Windows

Windows

Control FPWIN Pro7

Windows

Windows

bit version)

(Note 1) The latest version is provided free of charge via our website (https://industrial.panasonic.com/ac/e/

dl_center/software/). Use the latest version.

(R)

10 (32-bit version / 64-bit version)

(R)

8.1 (32-bit version / 64-bit version)

(R)

8 (32-bit version / 64-bit version)

(R)

7 SP1 or later (32-bit version / 64-

(R)

Vista SP2

(R)

XP SP3

(R)

10 (32-bit version / 64-bit version)

(R)

8.1 (32-bit version / 64-bit version)

(R)

8 (32-bit version / 64-bit version)

(R)

7 SP1 or later (32-bit version / 64-

120 MB or more AFPSGR7EN

400 MB or more AFPSPR7A

■

PC connection cable

● Use a commercial USB cable.

Cable type Length

USB 2.0 cable (A:Mini B) Max. 5 m

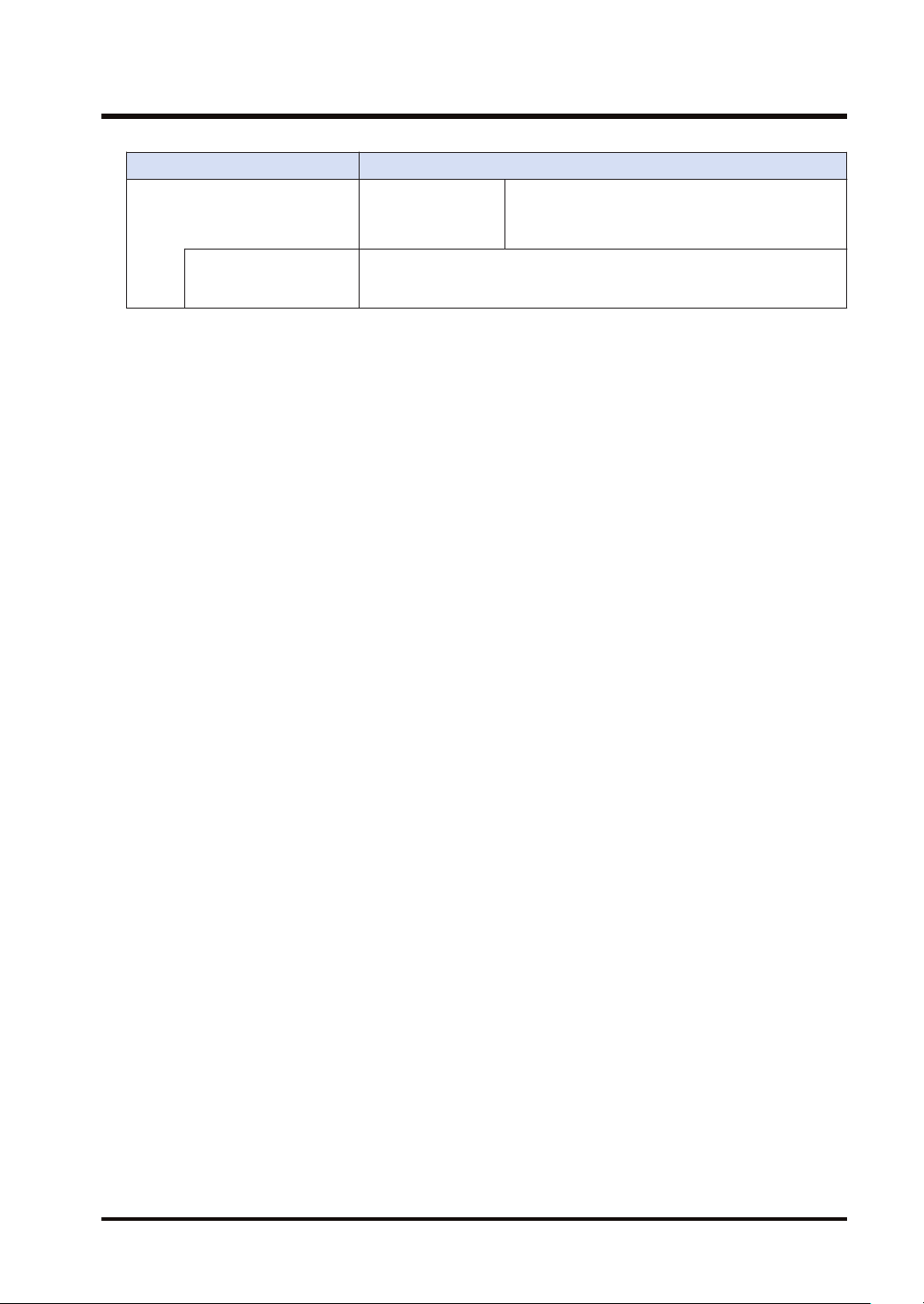

1.4.2 Applicable software version

For using the FP-XH, the following software versions are required.

1-14 WUME-FPXHBASG-01

Page 27

Item Applicable version

Programming tool

software Control FPWIN

GR / GR7 / Pro7

Configurator PMX

C14/C30/C60

It is used for using the pulse output function in the table setting mode. It is

incorporated in the FPWIN GR / GR7 / Pro7 and can be started from the

option menu.

1.4 Programming Tools

FPWIN GR Ver. 2.93 or later

FPWIN GR7 Ver. 2.5 or later

FPWIN Pro7 Ver. 7.03 or later

WUME-FPXHBASG-01 1-15

Page 28

(MEMO)

1-16 WUME-FPXHBASG-01

Page 29

2 Control Unit Specifications

2.1 Names and Functions of Parts............................................................2-2

2.1.1 Names and Functions of Parts......................................................... 2-2

2.1.2 Specifications of Operation Indicator LEDs ..................................... 2-3

2.1.3 Specifications of COM0 Port............................................................ 2-4

2.2 Power Supply Specifications...............................................................2-5

2.2.1 AC Power Supply Type.................................................................... 2-5

2.2.2 AC Power Supply Type: Service Power Supply for Input Circuit ..... 2-5

2.2.3 DC Power Supply Type.................................................................... 2-6

2.3 Input and Output Specifications (Relay Output Type).........................2-7

2.3.1 Input Specifications.......................................................................... 2-7

2.3.2 Output Specifications ....................................................................... 2-8

2.4 Input and Output Specifications (Transistor Output Type) ..................2-9

2.4.1 Input Specifications.......................................................................... 2-9

2.4.2 Output Specifications ....................................................................... 2-10

2.5 Terminal Layout...................................................................................2-11

2.5.1 Relay Output (AC Power Supply Type)............................................ 2-11

2.5.2 Relay Output (DC Power Supply Type) ........................................... 2-12

2.5.3 Transistor Output (AC Power Supply Type) ..................................... 2-13

2.5.4 Transistor Output (DC Power Supply Type)..................................... 2-15

WUME-FPXHBASG-01

2-1

Page 30

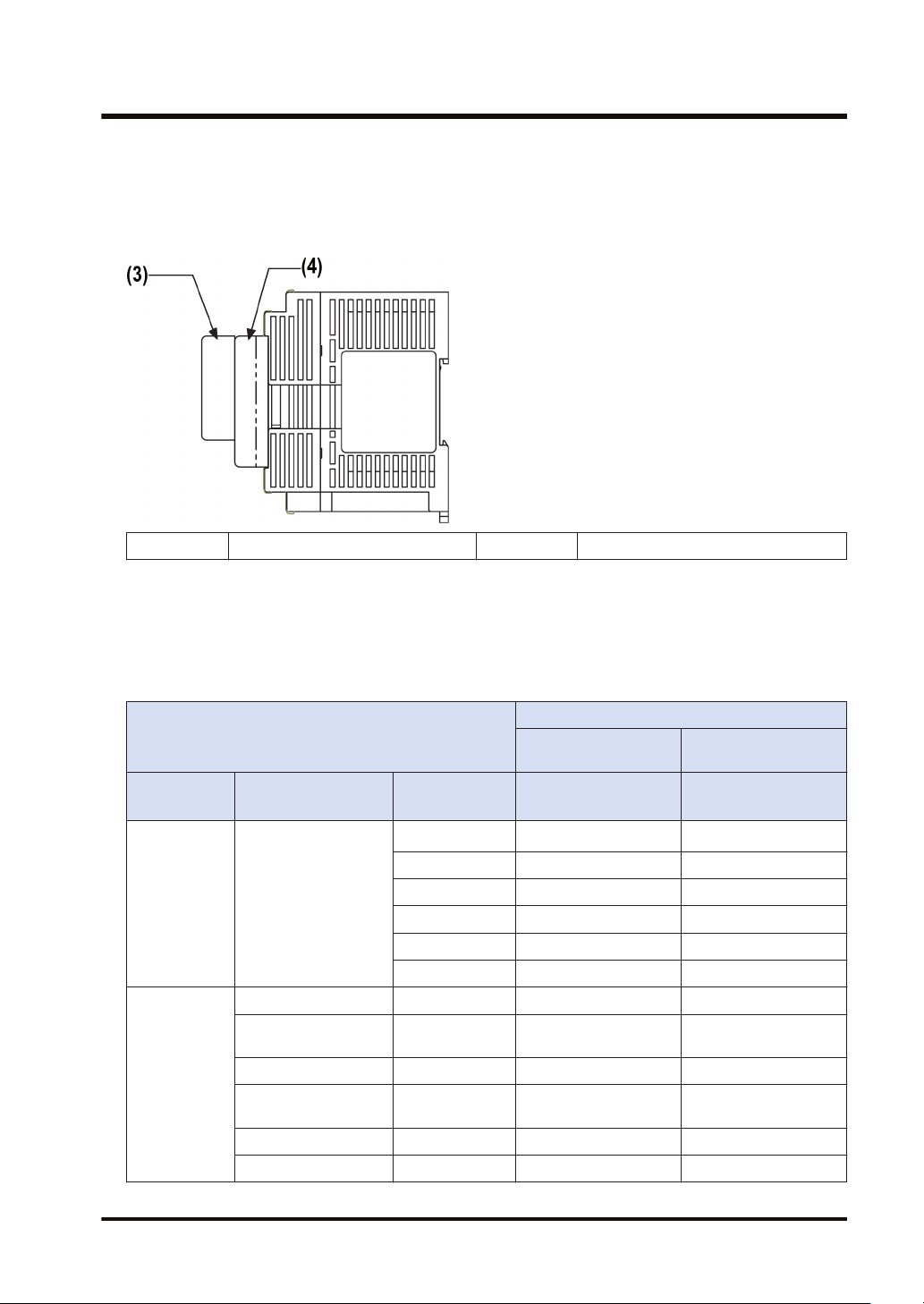

2.1 Names and Functions of Parts

2.1 Names and Functions of Parts

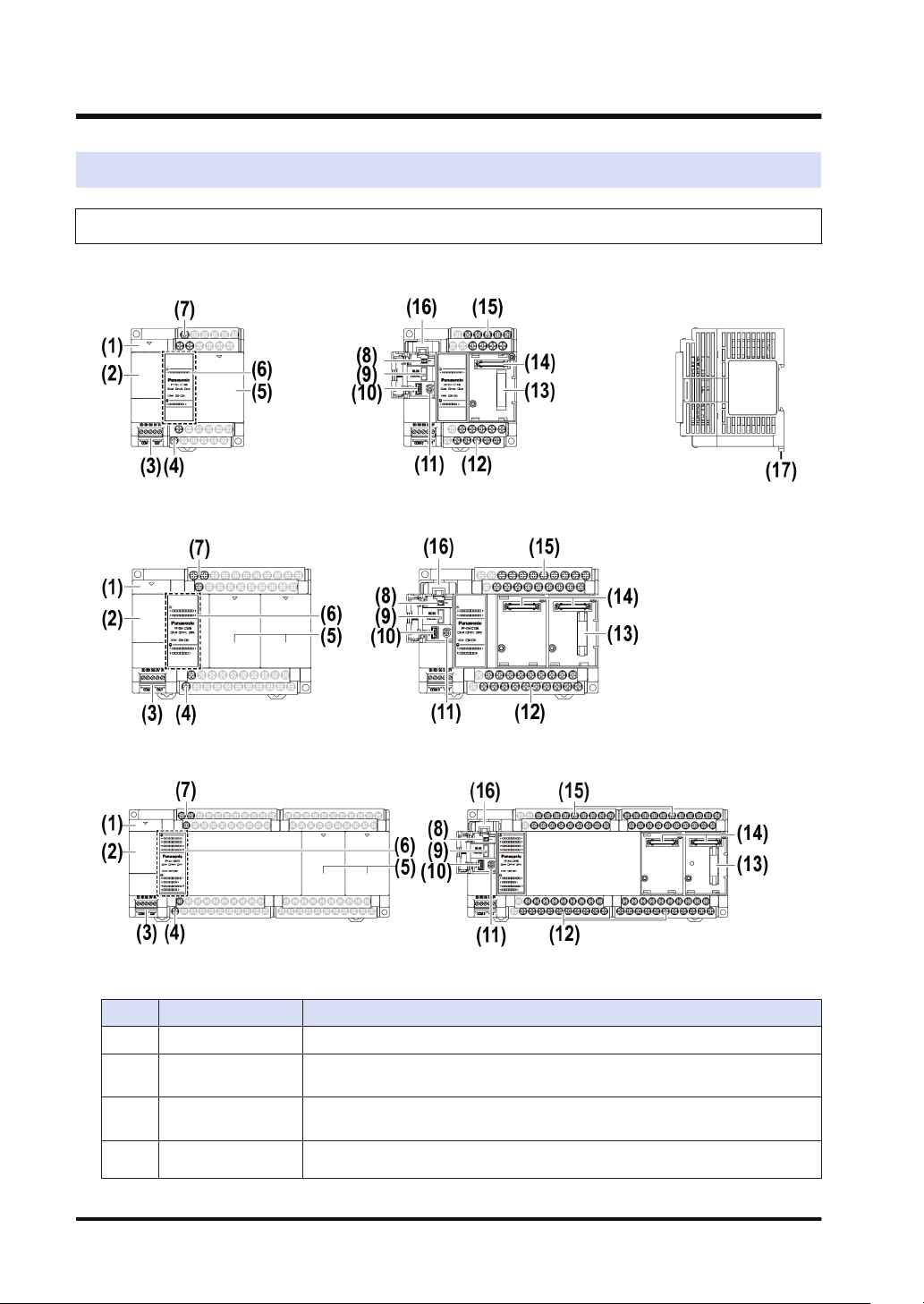

2.1.1 Names and Functions of Parts

■

FP-XH C14 Control Unit

■

FP-XH C30 Control Unit

■

FP-XH C60 Control Unit

■

Names and functions of parts

No. Name Function

(1) Battery cover This is a space for installing an optional backup battery.

(2) Operating unit cover

(3) COM0 port

Service power

(4)

supply

2-2 WUME-FPXHBASG-01

There are a built-in battery connector, RUN / PROG. mode selection switch,

USB port connector, and analog potentiometer.

Three-wire RS-232C port. A power supply terminal (5 V) is also provided for

connecting our Programmable Display GT Series.

It can be used as service power supply for the input circuit.

Page 31

2.1 Names and Functions of Parts

No. Name Function

terminal block for

input circuit

Cassette mounting

(5)

part cover

Operation monitor

LEDs /

(6)

Input and output

indicator LEDs

Power supply

(7)

terminal

(8) Battery connector This is used to insert the connector of a dedicated battery (AFPABAT001).

RUN / PROG. mode

(9)

selection switch

(10) USB port connector This is used to connect with a PC on which tool software is used.

Analog

(11)

potentiometer

(12) Output terminal This is used to connect an output device.

Expansion unit

(13)

connector

Extension cassette

(14)

connector

(15) Input terminal This is used to connect an input device.

(16) Battery holder

(17) DIN hook This is used to install the unit on a DIN rail.

(Note 1) Whether the switch is set to RUN or PROG., the mode can be switched through remote operation from

the tool software. When power is turned ON again, it operates in the mode set on the switch.

This is a space for installing an optional communication cassette and Function

Cassette.

Indicate the operation mode, error occurrence state, communication state of

COM0 port and input and output states.

This is used to connect the power supply to drive the Control Unit.

RUN (Up):

PROG.

(Down)

Sets to the RUN mode. The program is executed and operation

begins.

Sets to the PROG. mode.

Turning the potentiometer changes the values of special DT. It can be used for

the functions such as analog timer.

This is used to connect the expansion cable for mounting the Expansion Unit.

This is used to mount an optional Extension Cassette (Communication Cassette

or Function Cassette).

This is used to hold a dedicated battery for using the clock / calendar function

and extending the backup area of the operation memory. The dedicated battery

(AFPABAT001) is sold separately.

2.1.2 Specifications of Operation Indicator LEDs

WUME-FPXHBASG-01 2-3

Page 32

2.1 Names and Functions of Parts

No. LED name Color Data to display

(a) X

(b) Y

(c) RUN

(d) PROG.

(f)

COM0

(g) RD

(e) ERR. Red

SD

Gree

Indicates the input state.

n

Gree

Indicates the output state.

n

ON Turns ON when a program is being executed in RUN mode.

Gree

n

Flashes

ON Turns ON when the unit operation stops in PROG. mode.

Gree

n

Flashes

Gree

Flashes when data is sent via the COM0 port.

n

Gree

Flashes when data is received via the COM0 port.

n

Flashes Lit when an error is detected by self-diagnosis.

ON

RUN and PROG. LEDs flash alternately when the forced I/O

function is executed.

RUN and PROG. LEDs flash alternately when the forced I/O

function is executed.

This lights if a hardware error occurs, or operation slows

because of the program, and the watchdog timer is activated.

2.1.3 Specifications of COM0 Port

● This is a general-purpose three-wire RS-232C port.

● A 5 V power supply terminal is provided for connecting our Programmable Display GT02 /

GT02L Series.

■

Terminal layout

LED name Description

Send data (Unit to external

devices)

Receive data (External devices to

Unit)

5 V DC is output as the power supply for the Programmable Display GT Series.

This is a general-purpose three-wire RS-232C port.

COM 0

OUT

SD

RD

SG Signal grounding

5V

0V

2-4 WUME-FPXHBASG-01

Page 33

2.2 Power Supply Specifications

2.2.1 AC Power Supply Type

■

AC power supply type

2.2 Power Supply Specifications

Item

Rated voltage 100 to 240 V AC

Operating voltage range 85 to 264 V AC

Inrush current (240 V AC at ambient

temperature of 25℃)

Momentary power off time 10 ms (when using 200 V AC)

Frequency 50 / 60 Hz (47 to 63 Hz)

Leakage current 0.75 mA or less between input and protective earth terminals

Guaranteed life of internal power supply

part

Fuse Built-in (Cannot be replaced)

Isolation method Transformer insulation

Terminal screw M3

100 V AC

Consumption current

200 V AC

40 A or less 45 A or less

30,000 hours (at ambient temperature of 55℃)

C14R: 185 mA or less

C14T: 175 mA or less

C14R: 115 mA or less

C14T: 110 mA or less

C14 C30/C60

Specifications

C30R: 330 mA or less

C30T: 310 mA or less

C60R: 380 mA or less

C60T: 335 mA or less

C30R: 200 mA or less

C30T: 190 mA or less

C60R: 235 mA or less

C60T: 205 mA or less

2.2.2 AC Power Supply Type: Service Power Supply for Input Circuit

■

AC power supply type: Specifications of service power supply for input circuit

Item

Rated voltage 24 V DC

Operating voltage range 21.6 to 26.4 V DC

Rated output current 0.15 A 0.4 A

Overcurrent protection function Available

Terminal screw M3

WUME-FPXHBASG-01 2-5

C14 C30/C60

Specifications

Page 34

2.2 Power Supply Specifications

2.2.3 DC Power Supply Type

■

DC power supply type

Item

Rated voltage 24 V DC

Operating voltage range 21.6 to 26.4 V DC

Inrush current 12 A or less (240 V AC at ambient temperature of 25℃)

Momentary power off time 10 ms

Guaranteed life of internal power supply

part

Fuse Built-in (Cannot be replaced)

Isolation method Non-isolated

Terminal screw M3

Consumption current

30,000 hours (at ambient temperature of 55℃)

C14RD: 95 mA or less

C14TD: 90 mA or less

C30RD: 160 mA or less

C30TD: 115 mA or less

C60RD: 275 mA or less

C60TD: 170 mA or less

Specifications

C14/C30/C60

2-6 WUME-FPXHBASG-01

Page 35

2.3 Input and Output Specifications (Relay Output Type)

2.3 Input and Output Specifications (Relay Output Type)

2.3.1 Input Specifications

■

Specifications

Item

Isolation method Optical coupler

Rated input voltage 24 V DC

Operating voltage range 21.6 to 26.4 V DC

Rated input current Approx. 4.7 mA (X0 to X7) / Approx. 4.3 mA (X8 or later)

Input points per common

Min. ON voltage / Min. ON current 19.2 V DC/3 mA

Max. OFF voltage / Max. OFF current 2.4 V DC/1 mA

Input impedance 5.1 kΩ (X0 to X7) / 5.6 kΩ (X8 or later)

Response time

Operating mode indicator LED

EN61131-2 applicable type Type3 (However, the above specifications must be met.)

(Note 1) These specifications apply when the rating is 24 V DC and the ambient temperature is 25 °C.

(Note 1)

OFF→ON

ON→OFF Same as above.

C14R C30R C60R

8 points/common 16 points/common

(Either the positive or negative of input power supply can be

connected to common terminal.)

0.6 ms or less (For normal input)

X0 to X7

X8 or later 0.6 ms or less

50 μs or less (For high-speed counter, pulse catch

and interrupt input settings)

Specifications

16 points/common x

2

■

Internal circuit diagram

X0 to Xn

X0 to X7: R1 = 5.1 kΩ, R2 = 3 kΩ

X8 to Xn: R1 = 5.6 kΩ, R2 = 1 kΩ

WUME-FPXHBASG-01 2-7

Page 36

2.3 Input and Output Specifications (Relay Output Type)

2.3.2 Output Specifications

■

Specifications

Item

Isolation method Relay insulation

Output type 1a relay output

Rated control capacity

Per common 6A or less 8A or less

Input points per common

Response time

Life

Operating mode indicator LED

EN61131-2 Applicable type Type3 (However, the above specifications must be met.)

■

Internal circuit diagram

OFF→ON Approx. 10 ms

ON→OFF Approx. 8 ms

Mechanical

Electrical

C14R C30R C60R

2 A at 250 V AC, 2 A at 30 V DC (resistive load)

1-point common x 3

3-point common x 1

20 million times or more (Frequency of switching: 180 times/

min.)

100 thousand times or more (Frequency of switching at the

rated control capacity: 20 times/min.)

Specifications

1-point common x 2

4-point common x 3

1-point common x 6

2-point common x 1

4-point common x 5

2-8 WUME-FPXHBASG-01

Page 37

2.4 Input and Output Specifications (Transistor Output Type)

2.4 Input and Output Specifications (Transistor Output Type)

2.4.1 Input Specifications

■

Specifications

Item

Isolation method Optical coupler

Rated input voltage 24 V DC

Operating voltage range 21.6 to 26.4 V DC

Rated input current

Input points per common

Min. ON voltage / Min. ON current 19.2 V DC/3 mA

Max. OFF voltage / Max. OFF current 2.4 V DC/1 mA

Input impedance

Response

(Note 1)

time

Operating mode indicator LED

EN61131-2 applicable type Type3 (However, the above specifications must be met.)

(Note 1) These specifications apply when the rating is 24 V DC and the ambient temperature is 25 °C.

OFF→ON

ON→OFF Same as above.

Specifications

C14T C30T C60T

Approx. 12 mA (X0 to X3) / Approx. 4.7 mA (X4 to X7) / Approx. 4.3

mA (X8 or later)

8 points/common 16 points/common 16 points/common x 2

(Either the positive or negative of input power supply can be connected

to common terminal.)

Approx. 2 kΩ (X0 to X3) / Approx. 5.1 kΩ (X4 to X7) / Approx. 5.6 kΩ

(X8 or later)

135 μs or less (For normal input)

X0 to X3

X4 to X7

X8 or later 0.6 ms or less

5 μs or less (For high-speed counter, pulse catch and

interrupt input settings)

135 μs or less (For normal input)

50 μs or less (For high-speed counter, pulse catch and

interrupt input settings)

■

Internal circuit diagram

X0 to X3 X4 to Xn

R1 = 2 kΩ, R2 = 680 kΩ

X4 to X7: R1 = 5.1 kΩ, R2 = 3 kΩ

X8 to Xn: R1 = 5.6 kΩ, R2 = 1 kΩ

WUME-FPXHBASG-01 2-9

Page 38

2.4 Input and Output Specifications (Transistor Output Type)

2.4.2 Output Specifications

■

Specifications

Item

Isolation method Optical coupler

Output type NPN open collector

Rated load voltage 5 to 24 V DC

Allowable load voltage range 4.75 to 26.4 V DC

Rated load current 0.5 A

Max. inrush current 1.5 A

Off state leakage current 1 μA or less

ON-state max. voltage drop 0.3 V DC or less

Overcurrent protection

function

Input points per common 6-point common

Response

time

(Note 1)

Surge absorber Zener diode

Operating mode indicator LED

EN61131-2 applicable type Type3 (However, the above specifications must be met.)

(Note 1) These specifications apply when the ambient temperature is 25 °C.

OFF→ON

ON→OFF

None

1 ms or less (Y4 or later)

1 ms or less (Y4 or later)

C14T C30T C60T

2 μs or less (Y0 to Y3)

8 μs or less (Y0 to Y3)

Specifications

6-point common x 1

8-point common x 1

2 μs or less (Y0 to Y7)

1 ms or less (Y8 or later)

8 μs or less (Y0 to Y7)

1 ms or less (Y8 or later)

6-point common x 2

8-point common x 2

2 μs or less (Y0 to YB)

1 ms or less (YC or later)

8 μs or less (Y0 to YB)

1 ms or less (YC or later)

■

Internal circuit diagram

2-10 WUME-FPXHBASG-01

Page 39

2.5 Terminal Layout

2.5 Terminal Layout

2.5.1 Relay Output (AC Power Supply Type)

Input terminal

COM terminals in the same terminal block are connected within the unit. However, input

terminal 1 and input terminal 2 of the C60 are independent from other terminals. (These

terminals are not connected internally.)

Output terminal

Each COM terminal (C0, C1 …) is independent. Use them in the range surrounded by the bold

black lines.

■

AFPXHC14R

■

AFPXHC30R

WUME-FPXHBASG-01 2-11

Page 40

2.5 Terminal Layout

■

AFPX-C60R

2.5.2 Relay Output (DC Power Supply Type)

Input terminal

COM terminals in the same terminal block are connected within the unit. However, input

terminal 1 and input terminal 2 of the C60 are independent from other terminals. (These

terminals are not connected internally.)

Output terminal

Each COM terminal (C0, C1 …) is independent. Use them in the range surrounded by the bold

black lines.

■

AFPXHC14RD

2-12 WUME-FPXHBASG-01

Page 41

■

AFPXHC30RD

■

AFPX-C60RD

2.5 Terminal Layout

2.5.3 Transistor Output (AC Power Supply Type)

Input terminal

COM terminals in the same terminal block are connected within the unit. However, input

terminal 1 and input terminal 2 of the C60 are independent from other terminals. (These

terminals are not connected internally.)

Output terminal

The negative terminals are connected within the unit.

WUME-FPXHBASG-01 2-13

Page 42

2.5 Terminal Layout

■

AFPXHC14T

■

AFPXHC30T

■

AFPXHC60T

2-14 WUME-FPXHBASG-01

Page 43

2.5 Terminal Layout

2.5.4 Transistor Output (DC Power Supply Type)

Input terminal

COM terminals in the same terminal block are connected within the unit. However, input

terminal 1 and input terminal 2 of the C60 are independent from other terminals. (These

terminals are not connected internally.)

Output terminal

The negative terminals are connected within the unit.

■

AFPXHC14TD

■

AFPXHC30TD

WUME-FPXHBASG-01 2-15

Page 44

2.5 Terminal Layout

■

AFPXC60TD

2-16 WUME-FPXHBASG-01

Page 45

3 Allocation of I/O Numbers

3.1 Basics of I/O Allocation.......................................................................3-2

3.1.1 How to Count I/O Numbers.............................................................. 3-2

3.1.2 Concept of I/O Number Allocation ................................................... 3-2

3.2 List of I/O Numbers for Each Unit .......................................................3-4

3.2.1 FP-XH Control Units ........................................................................ 3-4

3.2.2 FP-X Expansion Units...................................................................... 3-4

3.2.3 FP-X Function Cassettes ................................................................. 3-4

3.3 Allocation of FP0 Expansion Units......................................................3-6

3.3.1 Concept of I/O Number Allocation ................................................... 3-6

3.3.2 Types and I/O Numbers of FP0R Expansion Units.......................... 3-7

3.3.3 Types and I/O Numbers of FP0 Expansion Units ............................ 3-8

WUME-FPXHBASG-01

3-1

Page 46

3.1 Basics of I/O Allocation

3.1 Basics of I/O Allocation

3.1.1 How to Count I/O Numbers

■

How to count and express I/O numbers

● Since I/O number are handled in units of 16 points, they are expressed as a combination of a

device type code and the lowest-digit of a decimal or hexadecimal number.

● In the case of external inputs, they are expressed as X0 to X9 and XA to XF. In the case of

external outputs, they are expressed as Y0 to Y9 and YA to YF.

3.1.2 Concept of I/O Number Allocation

■

I/O numbers of Control Unit

Fixed areas are allocated to I/O numbers.

■

I/O numbers of Expansion Unit

The starting number allocated to each Expansion Unit varies according to the installation

position.

■

I/O numbers allocated to Function Cassette

Fixed areas are allocated to I/O numbers according to the installation position.

■

List of I/O numbers

Unit type and installation position

(1) Control unit X0 to X9F WX0 to WX9 Y0 to Y9F WY0 to WY9

Input Output

I/O number I/O number

3-2 WUME-FPXHBASG-01

Page 47

3.1 Basics of I/O Allocation

Unit type and installation position

(2) Cassette mounting part 1

(Slot 0)

(3) Cassette mounting part 2

(Slot 1)

Input Output

I/O number I/O number

X100 to X19F WX10 to WX19 Y100 to Y19F WY10 to WY19

X200 to X29F WX20 to WX29 Y200 to Y29F WY20 to WY29

(4) 1st Expansion Unit X300 to X39F WX30 to WX39 Y300 to Y39F WY30 to WY39

(5) 2nd Expansion Unit X400 to X49F WX40 to WX49 Y400 to Y49F WY40 to WY49

(6) 3rd Expansion Unit X500 to X59F WX50 to WX59 Y500 to Y59F WY50 to WY59

(7) 4th Expansion Unit X600 to X69F WX60 to WX69 Y600 to Y69F WY60 to WY69

(8) 5th Expansion Unit X700 to X79F WX70 to WX79 Y700 to Y79F WY70 to WY79

(9) 6th Expansion Unit X800 to X89F WX80 to WX89 Y800 to Y89F WY80 to WY89

(10) 7th Expansion Unit X900 to X99F WX90 to WX99 Y900 to Y99F WY90 to WY99

(11)

8th Expansion Unit

(Note 1) The ranges of the I/O numbers which are actually used vary according to the types of cassettes and

Expansion Units.

X1000 to

X109F

WX100 to

WX109

Y1000 to

Y109F

WY100 to WY109

WUME-FPXHBASG-01 3-3

Page 48

3.2 List of I/O Numbers for Each Unit

3.2 List of I/O Numbers for Each Unit

3.2.1 FP-XH Control Units

■

List of I/O numbers

Input Output

Unit type

C14 8 points X0 to X7 6 points Y0 to Y5

C30 16 points X0 to X9, XA to XF 14 points Y0 to Y9, YA to YD

C60 32 points

No. of

input

points

I/O number

X0 to X9, XA to XF

X10 to X19, X1A to X1F

3.2.2 FP-X Expansion Units

■

List of I/O numbers

No. of

output

points

28 points

I/O number

Y0 to Y9, YA to YD

Y10 to Y19, Y1A to Y1D

Input Output

Unit type

E16 8 points X300 to X307 8 points Y300 to Y305

E30 16 points

E16X 16 points

E14YR - - 14 points

(Note 1) Each I/O number shown in the above table indicates the I/O number of the Expansion Unit connected

first. The I/O numbers vary according to the order of installation.

No. of

input

points

I/O number

X300 to X309, X30A to

X30F

X300 to X309, X30A to

X30F

No. of

output

points

14 points

- -

I/O number

Y300 to Y309, Y30A to

Y30D

Y300 to Y309, Y30A to

Y30D

3.2.3 FP-X Function Cassettes

■

List of I/O numbers (Analog I/O cassettes)

Installati

on

position

Cassette

mounting

part 1

Type

Analog Input Cassette: AD2 2ch WX10, WX11 - -

Analog Output Cassette: DA2 - - 2ch WY10, WY11

Input Output

No. of

input

points

I/O number

No. of

output

points

I/O number

3-4 WUME-FPXHBASG-01

Page 49

3.2 List of I/O Numbers for Each Unit

Installati

on

position

Cassette

mounting

part 2

■

Installati

on

position

Cassette

mounting

part 1

Cassette

mounting

part 2

Type

Analog I/O Cassette: A21 2ch WX10, WX11 1ch WY10

Thermocouple Input Cassette:

TC2

Resistance Thermometer Input

Cassette: RTD2

Analog Input Cassette: AD2 2ch WX20, WX21 - -

Analog Output Cassette: DA2 - - 2ch WY20, WY21

Analog I/O Cassette: A21 2ch WX20, WX21 1ch WY20

Thermocouple Input Cassette:

TC2

Resistance Thermometer Input

Cassette: RTD2

List of I/O numbers (Digital I/O cassettes)

Type

Input Cassette: IN8 8 points X100 to X107 - -

Output Cassette: TR8 - - 8 points Y100 to Y107

Output Cassette: TR6P - - 6 points Y100 to Y105

I/O Cassette: IN4T3 4 points X100 to X103 3 points Y100 to Y102

Input Cassette: IN8 8 points X200 to X207 - -

Output Cassette: TR8 - - 8 points Y200 to Y207

Output Cassette: TR6P - - 6 points Y200 to Y205

I/O Cassette: IN4T3 4 points X200 to X203 3 points Y200 to Y202

Input Output

No. of

input

points

2ch WX10, WX11 - -

2ch WX10, WX11 - -

2ch WX20, WX21 - -

2ch WX20, WX21 - -

Input Output

No. of

input

points

I/O number

I/O number

No. of

output

points

No. of

output

points

I/O number

I/O number

■

List of I/O numbers (Pulse I/O cassettes)

Installati

on

position

Cassette

mounting

part 1

Cassette

mounting

part 2

Type

High-speed Counter Cassette 3 points X100 to X102 - -

Pulse Output Cassette - - 3 points Y100 to Y102

High-speed Counter Input

Cassette

Pulse Output Cassette - - 3 points Y200 to Y202

Input Output

No. of

input

points

3 points X200 to X202 - -

I/O number

No. of

output

points

I/O number

WUME-FPXHBASG-01 3-5

Page 50

3.3 Allocation of FP0 Expansion Units

3.3 Allocation of FP0 Expansion Units

3.3.1 Concept of I/O Number Allocation

■

I/O numbers of FP0 Expansion Units and FP0 Intelligent Units

● The starting number allocated to each FP0 expansion block varies according to the

installation position of the FP-X Expansion FP0 Adapter.

● The starting number allocated to each unit varies according to the installation order of the

FP0 Expansion Units and FP0 Intelligent Units.

FP-X

(1)

Expansion FP0

Adapter

■

List of I/O numbers

FP-X

Expansion

FP0

Adapter

installation

position

1st Expansion

Unit

2nd

Expansion

Unit

3rd Expansion

Unit

4th Expansion

Unit

5th Expansion

Unit

6th Expansion

Unit

7th Expansion

Unit

X300 to X31F Y300 to Y31F X320 to X33F Y320 to Y33F X340 to X35F Y340 to Y35F

X400 to X41F Y400 to Y41F X420 to X43F Y420 to Y43F X440 to X45F Y440 to Y45F

X500 to X51F Y500 to Y51F X520 to X53F Y520 to Y53F X540 to X55F Y540 to Y55F

X600 to X61F Y600 to Y61F X620 to X63F Y620 to Y63F X640 to X65F Y640 to Y65F

X700 to X71F Y700 to Y71F X720 to X73F Y720 to Y73F X740 to X75F Y740 to Y75F

X800 to X81F Y800 to Y81F X820 to X83F Y820 to Y83F X840 to X85F Y840 to Y85F

X900 to X91F Y900 to Y91F X920 to X93F Y920 to Y93F X940 to X95F Y940 to Y95F

FP0

(2)

Expansion unit

1

FP0 Expansion Unit installation order

Expansion unit 1 Expansion unit 2 Expansion unit 3

Input Output Input Output Input Output

FP0

(3)

Expansion unit 2

FP0

(4)

Expansion unit 3

3-6 WUME-FPXHBASG-01

Page 51

3.3 Allocation of FP0 Expansion Units

FP-X

Expansion

FP0

Expansion unit 1 Expansion unit 2 Expansion unit 3

FP0 Expansion Unit installation order

Adapter

installation

Input Output Input Output Input Output

position

8th Expansion

Unit

(Note 1) The ranges of the I/O numbers which are actually used vary according to the types of cassettes and

X1000

to X101F

Expansion Units.

Y1000

to Y101F

X1020

to X103F

Y1020

to Y103F

X1040

to X105F

Y1040

to Y105F

3.3.2 Types and I/O Numbers of FP0R Expansion Units

The following table shows the I/O numbers when FP-X Expansion FP0 Adapter is connected to

the Control Unit as the first Expansion Unit.

■

List of I/O numbers (1st Expansion Unit)

FP0R

Expansion Unit

FP0R

Analog Input

Unit

Unit type Number of

allocation

AFP0RE8X Input (8 points) X300 to X307 X320 to X327 X340 to X347

Input (4 points) X300 to X303 X320 to X323 X340 to X343

AFP0RE8R

Output (4

points)

AFP0E8YT/P

AFP0RE8YR

Output (8

points)

AFP0RE16X Input (16 points) X300 to X30F X320 to X32F X340 to X34F

AFP0RE16R

AFP0RE16T/P

AFP0RE16YT/P

Input (8 points) X300 to X307 X320 to X327 X340 to X347

Output (8

points)

Output (16

points)

Input (16 points) X300 to X30F X320 to X32F X340 to X34F

AFP0RE32T/P

Output (16

points)

Input (16 points)

CH0, 2, 4, 6

Input (16 points)

CH1, 3, 5, 7

AFP0RAD4

1)

AFP0RAD8

(Note

Output (16

points)

Range setting

Output (16

points)

Averaging

setting

Expansion unit1Expansion unit2Expansion unit

3

Y300 to Y303 Y320 to Y323 Y340 to Y343

Y300 to Y307 Y320 to Y327 Y340 to Y347

Y300 to Y307 Y320 to Y327 Y340 to Y347

Y300 to Y30F Y320 to Y32F Y340 to Y34F

Y300 to Y30F Y320 to Y32F Y340 to Y34F

WX30

(X300 to X30F)

WX31

(X310 to X31F)

WY30

(Y300 to Y30F)

WY31

(Y310 to Y31F)

WX32

(X320 to X32F)

WX33

(X330 to X33F)

WY32

(Y320 to Y32F)

WY33

(Y330 to Y33F)

WX34

(X340 to X34F)

WX35

(X350 to X35F)

WY34

(Y340 to Y34F)

WY35

(Y350 to Y35F)

WUME-FPXHBASG-01 3-7

Page 52

3.3 Allocation of FP0 Expansion Units

FP0R

Analog Output

Unit

Unit type Number of

allocation

Input (32 points)

Status

Output (16

AFP0RDA4

points)

CH0, 2

(Note 2)

Expansion unit1Expansion unit2Expansion unit

3

WX30

(X300 to X30F)

WX31

(X310 to X31F)

WY30

(Y300 to Y30F)

WX32

(X320 to X32F)

WX33

(X330 to X33F)

WY32

(Y320 to Y32F)

WX34

(X340 to X34F)

WX35

(X350 to X35F)

WY34

(Y340 to Y34F)

Output (16

FP0R

Analog I/O Unit

AFP0RA21

3)

AFP0RA42

(Note

points)

CH1, 3

(Note 2)

Input (16 points)

CH0, 2

Input (16 points)

CH1, 3

Output (16

points)

CH0

(Note 4)

WY31

(Y310 to Y31F)

WX30

(X300 to X30F)

WX31

(X310 to X31F)

WY30

(Y300 to Y30F)

WY33

(Y330 to Y33F)