Panasonic FP-X0 L14R, FP-X0 L40MR, FP-X0 L60R, FP-X0 L30R, FP-X0 L60MR User Manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety Precautions

Observe the following notices to ensure personal safety or to prevent acci dents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

-Battery may explode if mistreated. Do not recharge, disassemble or dispose of fire.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

-To prevent excessive exothermic he at or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured i n these

specifications.

-Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock.

-Use the external devices to function the emergency stop and interlock circuit.

-Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generation.

-Ground the protective earth (PE) terminal (Class D grounding). Failure to do so could lead to

an electric shock.

-Do not allow foreign matters such as liquid, flammable materials, metal s to go into the insid e

of the product. It could cause excessive exothermic heat or smoke generation.

-Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

Copyright / Trademarks

-This manual and its contents are copyrighted.

-You may not copy this manual, in whole or part, without written con sent of

Panasonic Electric

Works SUNX Co., Ltd.

-Windows is a registered trademark of Microsoft Co rporation in the United States an d other

countries.

-All other company names and product names are trademarks or registered trademarks of

their respective owners.

PLC_BATPE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of Contents

Difference in Specifications Between FP-X0 Models

Before You Start

Programming Tool Restrictions

1. Unit Types and Restrictions ........................................................................ 1-1

1.1 Unit T

ypes ................................................................................................ 1-2

1.2 Restrictions on Unit Combinations ........................................................... 1-4

1.3 Programming Tools .................................................................................. 1-7

2. Specifications and Functions of Control Unit ............................................ 2-1

2.1 Pa rt

s and Functions ................................................................................. 2-2

2.2 Power Supply Specifications .................................................................... 2-4

2.3 Input/Output Specifications ...................................................................... 2-5

2.4 Analog Input Specifications (For L40 and L60 types) ............................... 2-8

2.5 Terminal Layout ..................................................................................... 2-12

3. Specifications of Expansion Units and Expansion FP0 Adapter .............. 3-1

3.1 FP-X Ex

pansion Units .............................................................................. 3-2

3.2 FP-X Expansion FP0 Adapter ................................................................ 3-10

4. I/O Alloc a t ion ................................................................................................ 4-1

4.1 I/O All

ocation ........................................................................................... 4-2

4.2 I/O Allocation of FP-X0 Control Unit ......................................................... 4-3

4.3 FP-X Expansion Unit I/O Allocation .......................................................... 4-3

4.4 Allocation of FP0/FP0R Expansion Unit ................................................... 4-4

5. Installation and Wiring................................................................................. 5-1

5.1 In st

allat i on ................................................................................................ 5-2

5.2 Expansion Method ................................................................................... 5-5

5.3 Power Supply ........................................................................................... 5-6

5.4 Wirin g o f Inp ut and Output ....................................................................... 5-8

5.5 Wirin g o f Ter m i nal Bl ock ........................................................................ 5-11

5.6 Setting and Wiring of COM Port (RS485) ............................................... 5-12

5.7 Handling of Backup Battery (For L40 and L60 types) ............................. 5-13

5.8 Safety Measures .................................................................................... 5-16

6. Communication Functions .......................................................................... 6-1

6.1 Funct

ions and Types ................................................................................ 6-2

6.2 Communicaton Port Type ........................................................................ 6-4

6.3 Communication Specifications ................................................................. 6-5

6.4 Computer Link.......................................................................................... 6-7

6.5 General-purpose Serial Communication................................................. 6-17

6.6 PC(PLC) link Function (For L40MR and L60MR types) .......................... 6-31

6.7 MODBUS RTU Communication (For L40MR and L60MR types) ............ 6-46

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

7. High-speed Counter, Pulse Output and PWM Output Functions .............. 7-1

7.1 Overview of Each Functions ..................................................................... 7-2

7.2 Function Specifications and Restricted Items ........................................... 7-4

7.3 High-speed Counter Function ................................................................... 7-6

7.4 Pulse Output Function ............................................................................ 7-14

7.5 PWM Output Function ............................................................................ 7-35

8. Security Functions ....................................................................................... 8-1

8.1 Pa sswor d Protect Func tion ....................................................................... 8-2

8.2 Upload Protection ..................................................................................... 8-8

8.3 Setting Function for FP Memory Loader ................................................... 8-9

8.4 Table of Security Settings/Cancel ........................................................... 8-12

9. Other Functions ............................................................................................ 9-1

9.1 Clock/Calendar Function (For L40 and L60 types) .................................... 9-2

9.2 Sampling Trance Function (For L40 and L60 types) ................................. 9-4

9.3 Time Constant Processing ........................................................................ 9-7

9.4 P13 (PICWT) Instruction ........................................................................... 9-8

10. Self-Diagnostic and Troubleshooting ....................................................... 10-1

10.1 Sel f-Diagnostic function ........................................................................ 10-2

10.2 Troubleshooting .................................................................................... 10-3

10.3 Oper ati on Errors ................................................................................... 10-7

11. Precautions During Programming ............................................................ 11-1

11.1 Use of Duplicated Output (Double Coil) ................................................ 11-2

11.2 Instr u c ti o ns of Leading Ed ge Detection M ethod .................................... 11-4

11.3 Precautions for Pr ogramming ............................................................... 11-7

11.4 Rewrite Function During RUN ............................................................... 11-8

11.5 Processing During Forced Input and Output ....................................... 11-13

12. Specifications ............................................................................................. 12-1

12.1 Table of Specifications..........................................................................

12-2

12.2 Relays, Memory Areas and Constants .................................................. 12-9

13. Dimensions and Cable Specifications ...................................................... 13-1

13.1 Dimensions ........................................................................................... 13-2

13.2 Cable/Adapt er S p ecificati o ns ................................................................ 13-3

14. Appendix ..................................................................................................... 14-1

14.1 System Registers / Special Internal Relays / Special Data Registers .... 14-2

14.2 Table of Basic Instructions .................................................................. 14-35

14.3 Table of High-level Instructions ........................................................... 14-43

14.4 Table of Error codes ........................................................................... 14-63

14.5 MEWTOCOL-COM Communication Commands ................................ 14-76

14.6 Hexadecimal/Binary/BCD ................................................................... 14-77

14.7 ASCI I Codes ....................................................................................... 14-78

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

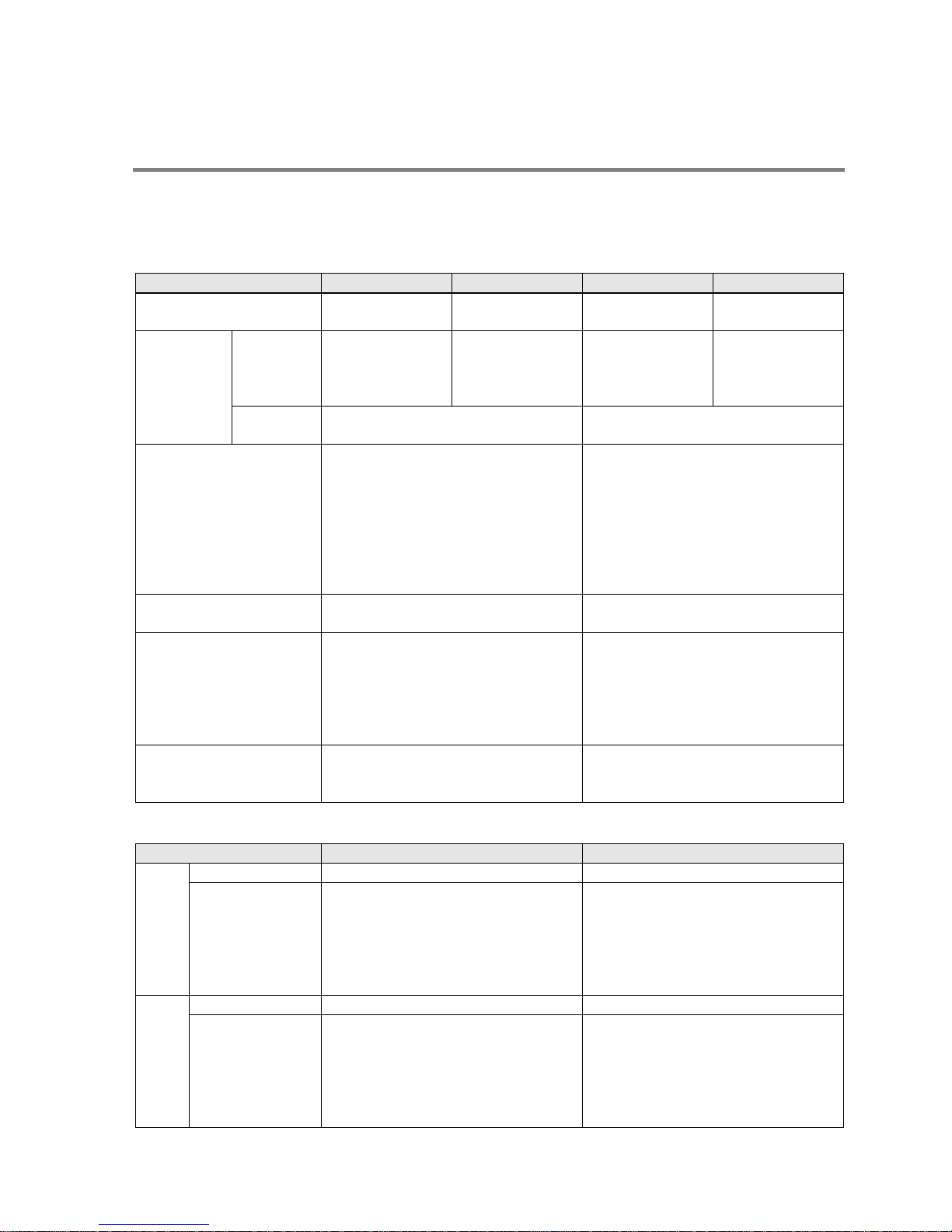

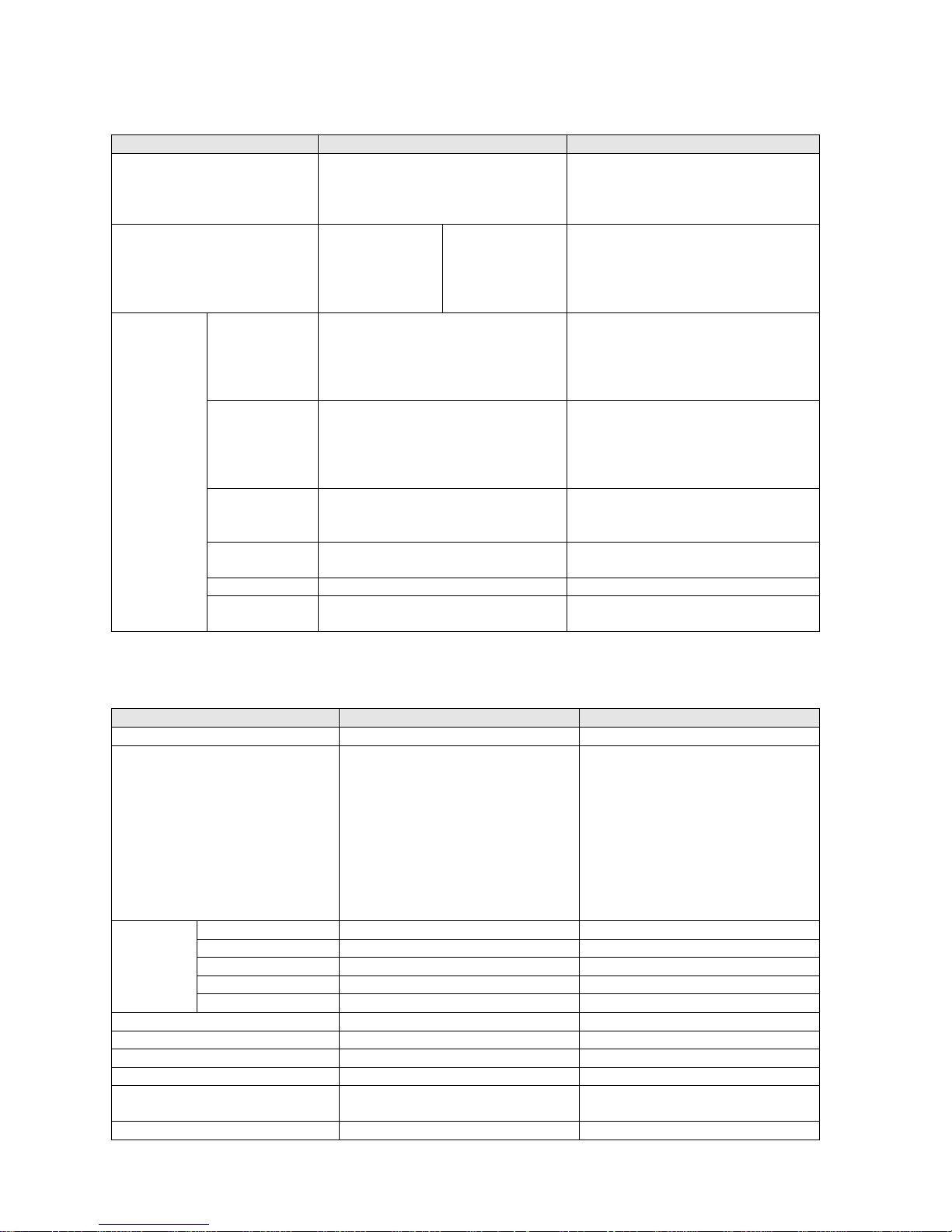

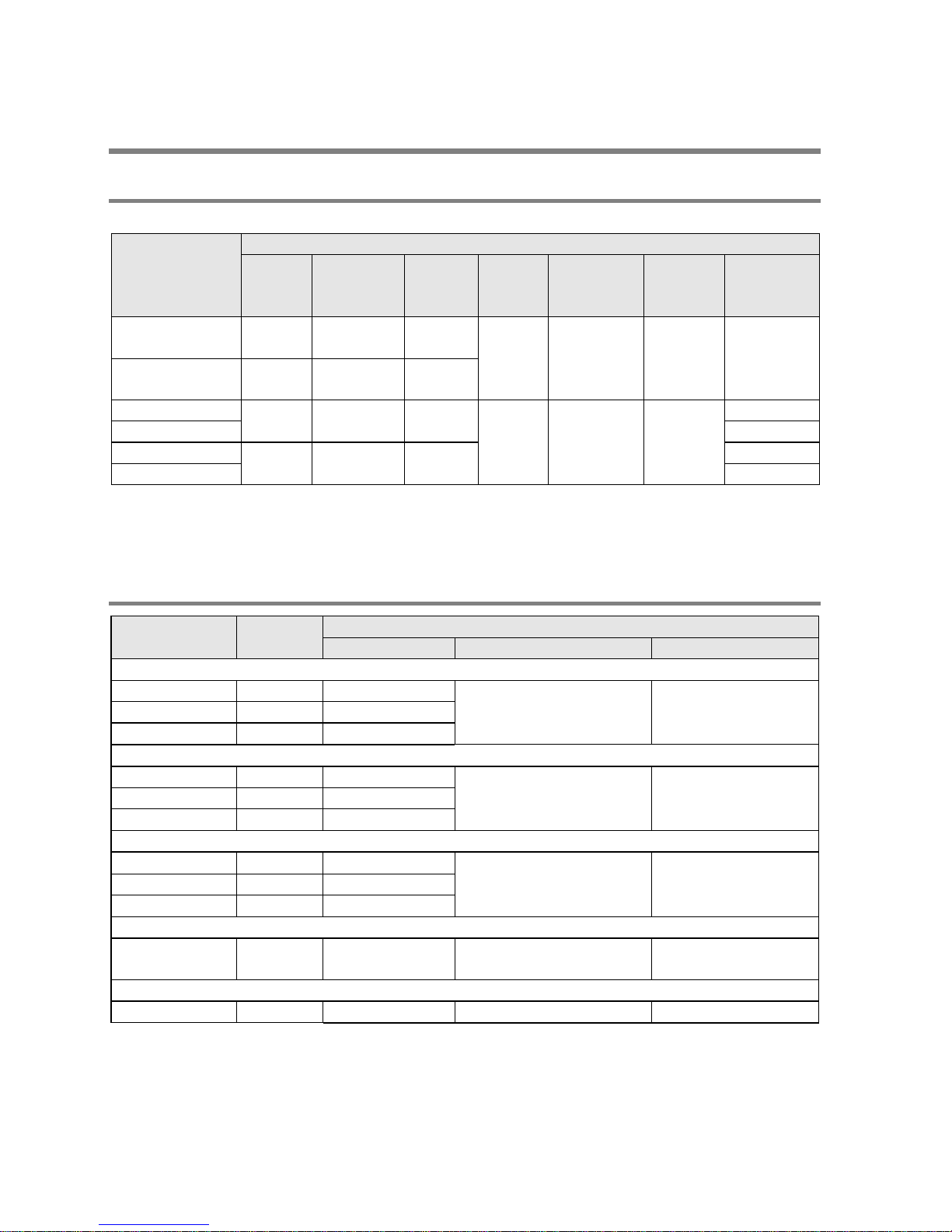

Difference in Specifications Between FP-X0 Models

The following tables show the main differences between each FP-X0 models. Ch eck those d ifferences

thoroughly before use.

Comparison of hardware specifications

Item

L14

L30

L40

L60

Service po wer supply for

input

None 24V DC 0. 3 A 24V DC 0. 3 A 24V DC 0.3 A

No. of

controllable

I/O points

Control

unit

14 points

DC input: 8

Relay o utput: 4

Tr. output: 2

30 points

DC input: 16

Relay o utput: 10

Tr. output: 4

40 points

DC input: 24

Relay o utput: 12

Tr. output: 4

60 points

DC input: 32

Relay o utput: 24

Tr. output: 4

Expansion

unit

Cannot be connected.

Max. 3 units

(Max. 90 points for expansion units)

Analog input None

Analog input x 2 points

One of the followings can be input

to the terminal block of the control

unit or they can be connected in

combination.

(1) C onn ect potenti omet er.

(2) Connect thermister.

(3) Input voltage 0 to 10V.

Clock/calendar function

(Realt im e cloc k)

None Built in

Backup battery Cannot be installed.

Can be installed.

(1) Operation memory c an be s et

whether to be held or not by system

registers.

(2) Clock/calendar (realtime clock)

function can be used.

Backup of operaiton

memory to F-ROM when

power is cut off

Counter: 6 points,

Internal relay: 80 points,

Data register: 300 words

Counter: 16 points,

Internal relay: 128 points,

Data register: 302 words

Comparison of communication interfaces

Item

L14 / L30 / L40 / L60

L40M / L60M

Tool

port

Interface

RS232C

RS232C

Usable function

- MEWTOCOL-slave

(L14/L30: 118 bytes/f rame)

- (L40/L60: 2k bytes/frame)

- General-p urpose serial

communication

-

Modem Initialization

- MEWTOCOL-slave

(2k bytes/frame)

- General-p urpose serial

communication

- Modem Initialization

COM

port

Interface

None

RS485

Usable function None

- MEWTOCOL-(master/slave)

(2k bytes/frame)

- General-p urpose commun ica t ion

- MODBUS RTU (master/sl a v e)

- PLC link

-

Modem initialization

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

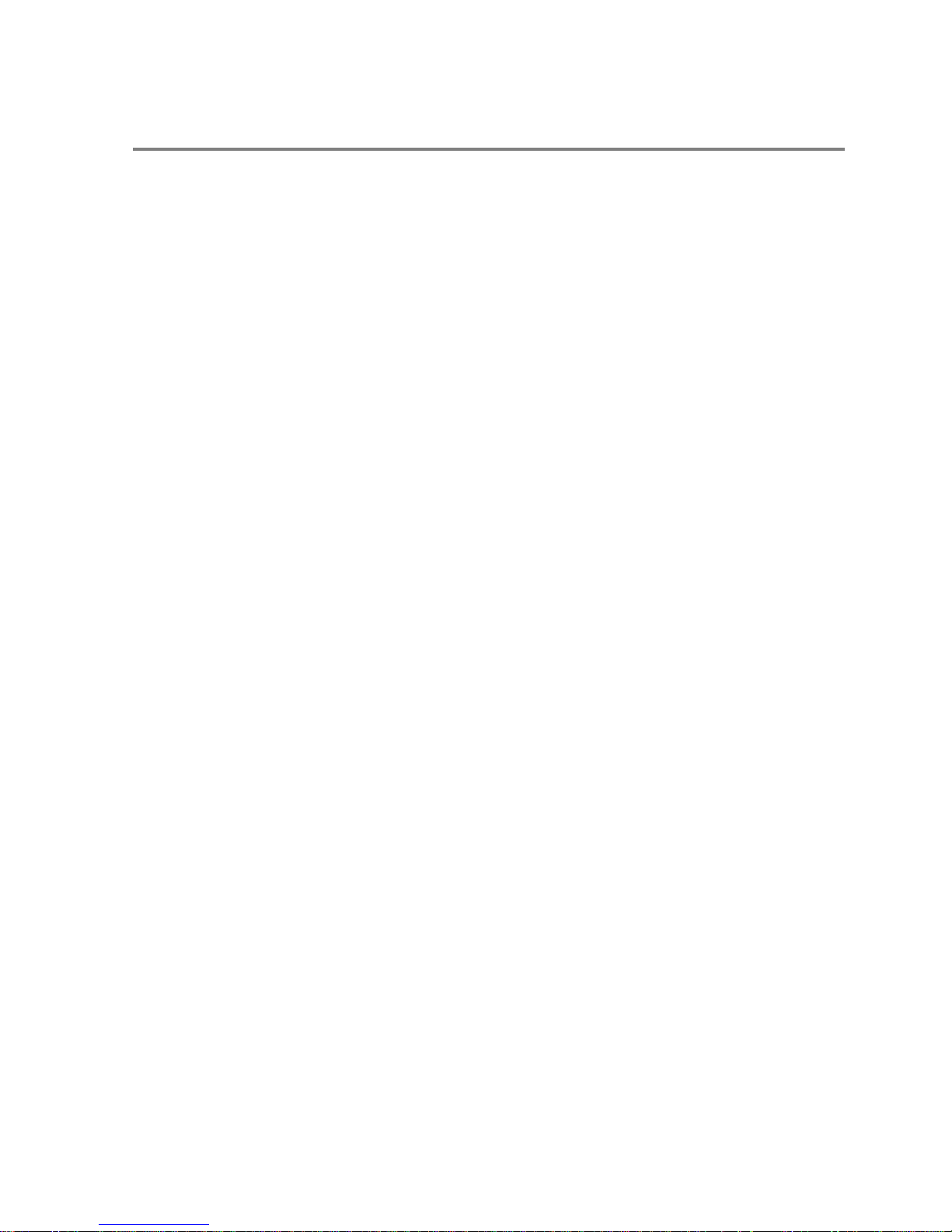

Comparison of high-speed counter and pulse output specifications

Item

L14 / L30

L40 / L60

High-speed counter

Single-phase 4 chs or

2-phase 2 c hs

Single-phase: Max. 20 kHz

2-phase: Max. 20 kHz

Single-phase 4 chs or

2-phase 2 c hs

Single-phase: Max. 50 kHz

2-phase: Max. 20 kHz

Pulse o utput / PW M output

Max. 1 ch

Pulse o utput:

Max. 20 kHz

PWM output:

Max. 1.6 kHz

Max. 2 chs

Pulse o utput:

Max. 20 kHz

PWM output:

Max. 1.6 kHz

Max. 2 chs

Pulse output: Max. 50 kHz

PWM output: M ax. 3 kHz

Related

instructions

Trapezoidal

control

F171 (SPDH)

(Acceleration ti me an d

deceleration time can be set

individually. Target speed cannot

be changed after the execution.)

Same as o n the l eft.

JOG

operation

F172 (PLSH)

(Acceleration ti me an d

deceleration time can be set

individually. Target speed cannot

be changed after the execution.)

Same as o n the l eft.

Home return

F177 (HOME)

(Deviation counter signal cannot

be used for L14 type.)

F177 (HOME)

Linear

interpolation

Not available F175 (SPSH)

PWM output

F173 (PWMH)

Same as o n the l eft.

In put pulse

measurement

Not available F178 (PLSM)

Note1) Typical specifications are described here. For t he detail s of t he restrict ions on combinations, refer

to Chapter 7.

Comparison of software specifications

Item

L14 / L30

L40 / L60、L40M / L60M

Program capacity

2.5k stpes

8k steps

Ari thmetic processing sp eed

From 0. 08µs/step

(by basic instruction)

From 0. 32µs (MV instruction)

(by high-level instruction)

Up to 3000 steps:

From 0. 08µs/step

(by basic instruction)

From 0. 32µs (MV instruction)

(by high-level instructio n)

From 3001 steps:

From 0. 58µs/step

(by basic instruction)

From 1. 62µs (MV instruction)

(by high-level instructio n)

Operation

memory

In ternal relay

1008 points

4096 points

Timer a nd co unter

256 points

1024 points

Li nk relay

None

2048 points

Note1)

Data register

32765 words

32765 words

Link register

None

256 words

Note1)

MCR points

32 points

256 points

No. of l abels (JP and LOOP)

100 points

256 points

No. of step ladders

128 stages

1000 stages

No. of subroutines

100 subroutines

500 subroutines

Simultaneous rewriting

capacity during RUN

Max. 128 steps Max. 512 steps

Sampling trace

None

Available

Note1) The PLC link function is available for L40M and L60M types.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Before You Start

Operating environment (Use the unit within the range of the general specifications when installing)

*Ambient t emperatures:0 ~ +55 ℃

*Ambient humi di ty: 10% to 95% RH (at 25°C, non-condensing)

*Keep the height below 2000m.

*For use in pollution Degree 2 environment.

*Do not use it in th e follow ing environments.

-Direct sunlight

-Sudden temperature changes causing condensation.

-Inflammable or corrosive gas.

-E-xcessive airborne dus t , met al part icles o r saline matter.

-Benzine, paint thinner, alcohol or other organic solvents or strong alkaline solutions such as

ammo nia or caustic so da.

-Direct vibration , shock or direct drop of water.

- Influence from pow er tr ansmiss ion lines, high volt age eq uipment, p ower cabl es, power equipment,

radio t ransmi t ter s, or any other equipm ent that w ould gene rate high switching surges .

(Min.100mm or less)

Static electricity

-Bef ore touching the unit, always touch a grounded piece of meta l in or der t o dis charge static el ectr icity.

-In d r y lo cati ons, exces si ve stati c electrici ty can cau se problems.

Wiring the Power Supply to the Control Unit

-Use a pow er s upply wire th at is thicker than 2 mm2 ( AWG14), and twist it.

-The unit has sufficient noise immunity against the noise generated on the power line.

How ever, it is recommen ded to take measures for reducing no is e such as using a i solating trans former

before supplying the power.

-Allocate an independent wiring for each power supplying line, input/output device and operating device.

-If usi ng a power supply witho ut a pr otective circuit, power should be s upplied throug h a protect ive

elemen t suc h as a fuse.

-Be sure to supply power to a control and an expansion units from a single power supply.

Turning on/off of the power of all the units must be conducted simultaneously.

Power supply sequence

In order to protect the power supply sequence, make sure to turn off the control unit before the

input/output power supply. If the input/output power supply is turned off before the control unit, or if the

control unit is not shut off momentarily, the controller detects change of input level, and might conduct an

unexpected operation.

Before turning on the power

When turning on the power for the first time, be sure to take the precautions given below.

- When per forming ins tal lation, ch eck t o m ake s ure t hat t here are no scraps of wir i ng, part icularly

conductive fragments, adhering to the unit.

- Verify that the power supply wiring, I/O wiring, and power supply voltage are all correct.

- Sufficiently tighten the installation screws and te rminal screws.

- Set the mode selector to PROG. Mode.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Before entering a program

Be su re t o perform a program clear operation before entering a program.

Operation procedure when using FPWIN GR Ver.2

Select “Onl in e E dit Mode” on the FPWIN GR “On line” menu.

Select “Clear Program” on the “Edit” menu.

When the confirmation dialog box is displayed, click on “Yes” to clear the program.

Request concerning program storage

To prevent the accidental loss of programs, the user should consider the following measures.

- Drafting of documents

To a voi d acciden tally l osi ng programs, destroying f iles, or overwriting the contents of a file, documents

should be printed out and then saved.

- Specifying the password carefully

The password setting is designed to avoid programs being accidentally overwritten. If the password is

fo rgotten, howev er, it will be impo ssible to overw r it e t he program even if you want t o. Al so, if a

possword is forcibly bypassed, the program is deleted. When specifying the password, note it in the

specifications manual or in another safe location in case it is forgotten at some point.

- Upload protection

When the upload protectio n sett ing i s spec ified, prog r ams will be di salbed to be r ead o ut . If the setting

is c ancell ed forci bly, all programs and system r egister s wil l be delet ed. Therefore, note that pr ograms

and system registers should be managed on your o wn responsi bi lity.

Backup battery

Do not install the battery when it is not used.

There is a possibility of leak if the battery remains discharged.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

vii

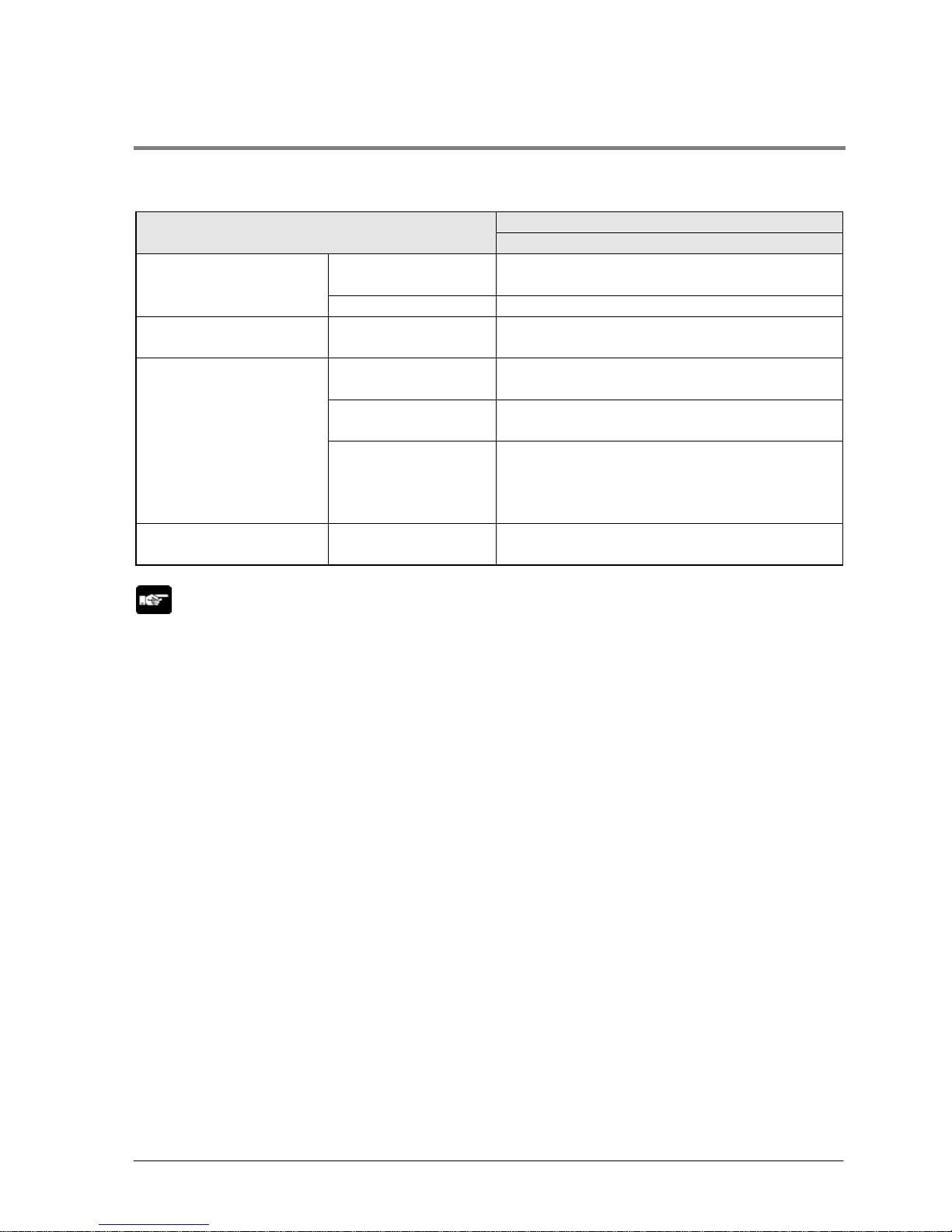

Programming Tool Restrictions

Restrictions on usable programming tools depending on the units

Type of programming tool

Type of unit

AFPX0

Windows software

FPWIN GR Ver.2

Used

(Ver. 2.91 or later)

FPWIN GR Ver.1 Not used

Windows software

Conforms to IEC61131-3

FPWIN Pro Ver.6

Used

(Ver. 6.3 or later)

Handy programming unit

AFP1113V2

AFP1114V2

Not used

AFP1113

AFP1114

Not used

AFP1111A

AFP1112A

AFP1111

AFP1112

Not used

FP memory loader

AFP8670

AFP8671

Used

(Ver.2.0 or later)

Note: Precautions concerning version upgrade

- In case of using FPWIN GR Ver.1, please purchase upgrade model FPWIN GR Ver.2.

- FPWIN GR Ver.2 can be upgraded free of charge at our web site.

- FPWIN Pro Ver.6 can be upgraded free of charge at our web site.

- The handy programming unit cannot be used.

Do not download any programs for other units such as FP1 to the FP-X0 using the handy programming

unit.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Chapter 1

Unit Types and Restrictions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.1 Unit Types

1.1.1 FP-X0 Control Units

A: Available N/A: Not available

Product No.

Specifications

DC

input

Transistor

(NPN)

output

Relay

output

Analog

input

Expansion

Clock/

calender

COM port

(RS485

port)

AFPX0L14R

8

points

2 points 4 points

N/A N/A N/A N/A

AFPX0L30R

16

points

4 points

10

points

AFPX0L40R

24

points

4 points

12

points

2

points

A A

N/A

AFPX0L40MR A

AFPX0L60R

32

points

4 points

24

points

N/A

AFPX0L60MR A

Note1) For all the units, the power supply is 100 to 240 V AC, and DC input is 24 V DC (Common

polar i t ies + & - common).

Note2) An optional backup batt ery is required to use the clock/calender functi on.

1.1.2 FP-X E xpan si on Un it (Can be ad de d to L40/ L60 on ly)

Product No.

No. of I/O

points

Specifications

Power supply

Input

Output

Relay type ( Ry typ e)

AFPX-E16R 8/8 -

24 V DC (Common

polar i t ies + & - common)

Relay

AFPX-E30R

16/14

100 to 240 V AC

AFPX-E30RD

16/14

24 V DC

Transi s tor type (NPN ) (T r type)

AFPX-E16T

8/8

-

24 V DC (Common

polar i t ies + & - common)

Transistor

(NPN)

AFPX-E30T 16/14 100 to 240 V AC

AFPX-E30TD 16/14 24 V DC

Transi s tor type (PNP ) (T r type)

AFPX-E16P

8/8

-

24 V DC (Common

polar i t ies + & - common)

Transistor

(PNP)

AFPX-E30P 16/14 100 to 240 V AC

AFPX-E30PD

16/14

24 V DC

Input-only typ e

AFPX-E16X 16/0 -

24 V DC (Common

polar i t ies + & - common)

-

Output-only type (R elay type )

AFPX-E14YR

0/14

- - -

Note) A n 8-cm expansion cable is provided with an expansion unit

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

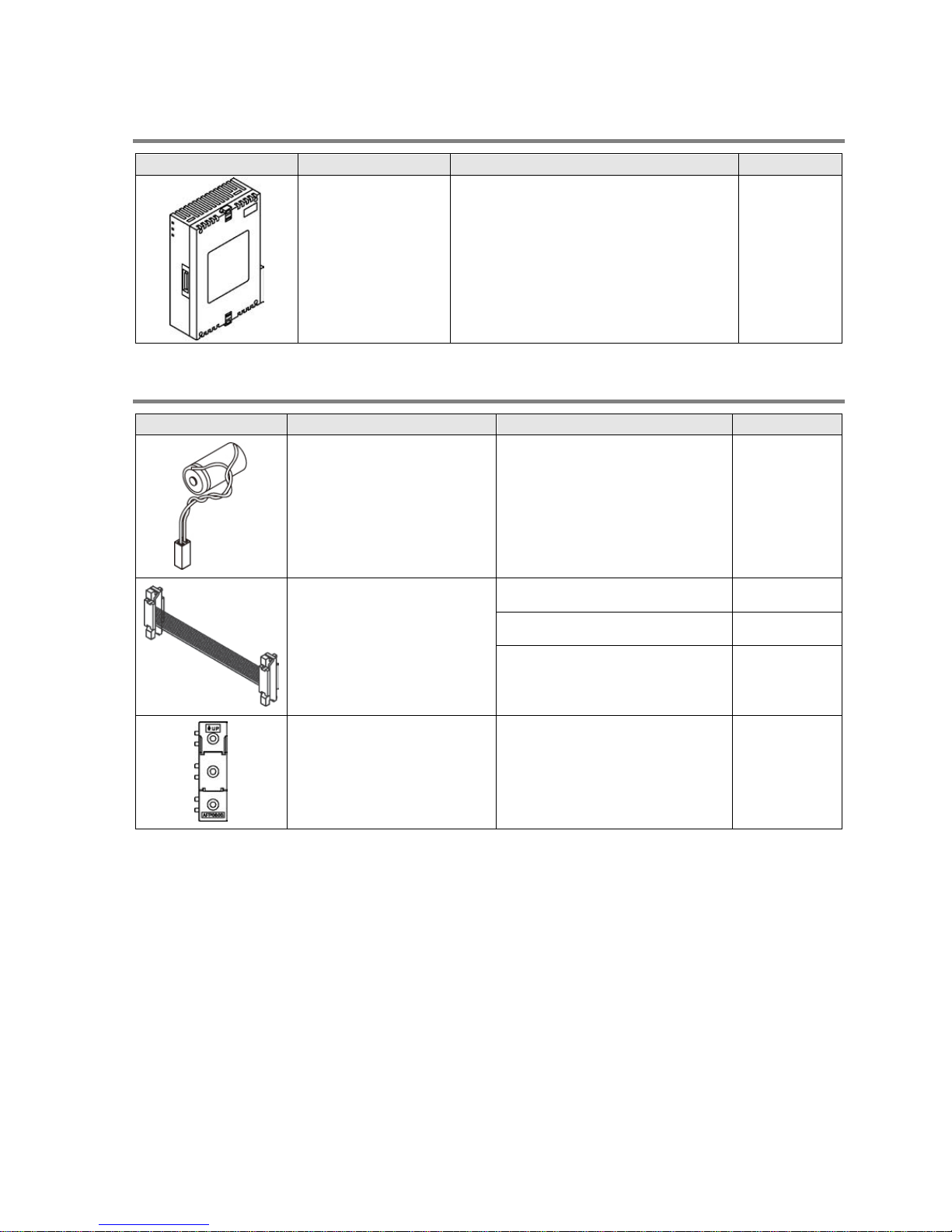

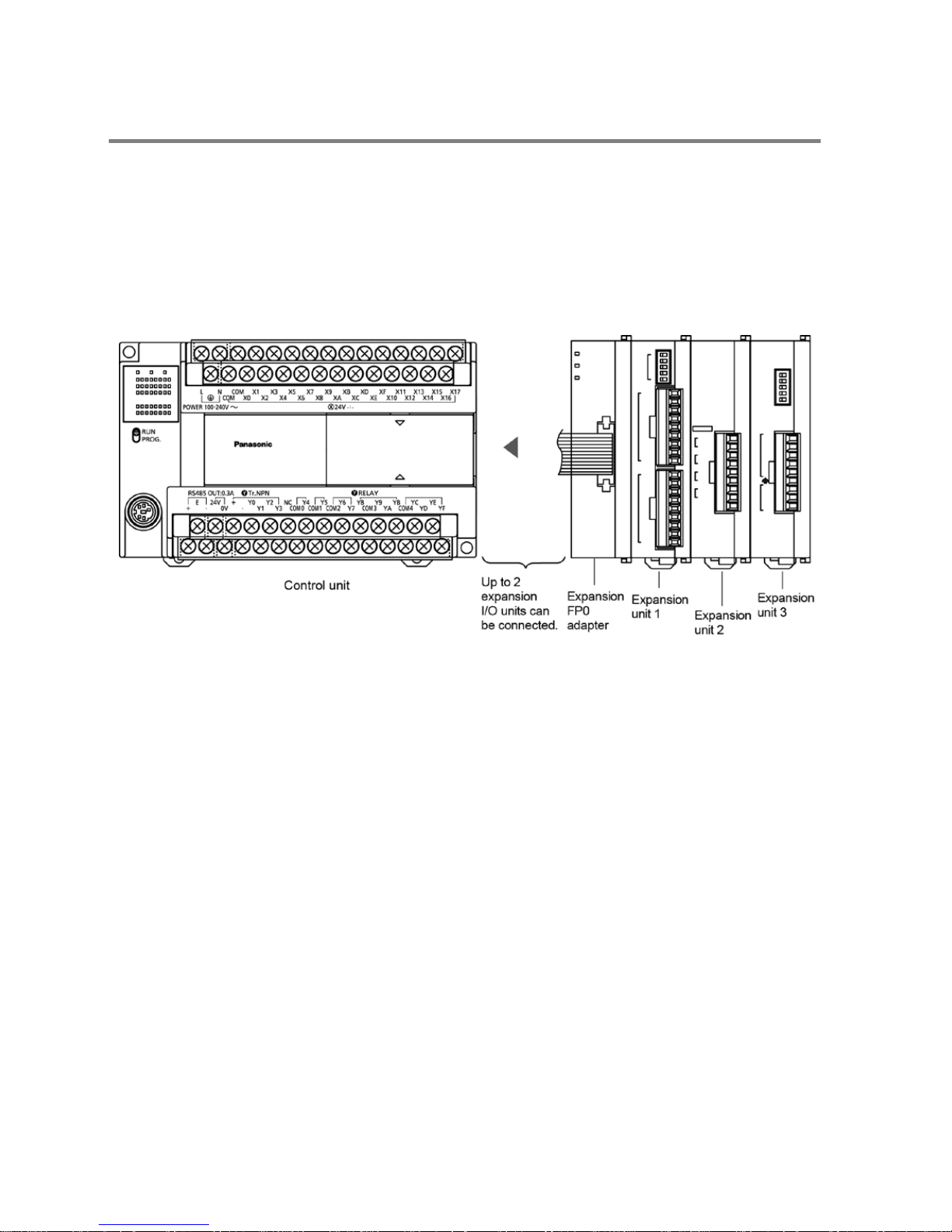

1.1.3 FP-X E xpan si on FP0 A dapt er (Can be added to L40/ L6 0 onl y)

Appearance

Name

Specifications

Product No.

FP-X Expansion

FP0 adapter (with 8

cm expansion

cable, power supply

cable)

For connecting FP0 expansion unit to

control unit

AFPX-EFP0

1.1.4 Related Parts

Appearance

Name

Description

Product No.

Backup battery

Necessary for the backup of

operation memory, real-time

cl ock data.

AFP8801

FP-X expansion cable

Note)

8 cm AFPX-EC08

30 cm AFPX-EC30

80 cm AFPX-EC80

FP0 mounting plate

(slim type)

Used for expansion FP0

adapter and FP0 Expansion

unit, 10 pcs/pack

AFP0803

Note) T he total length of the exapansion cable should be within 160 cm.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

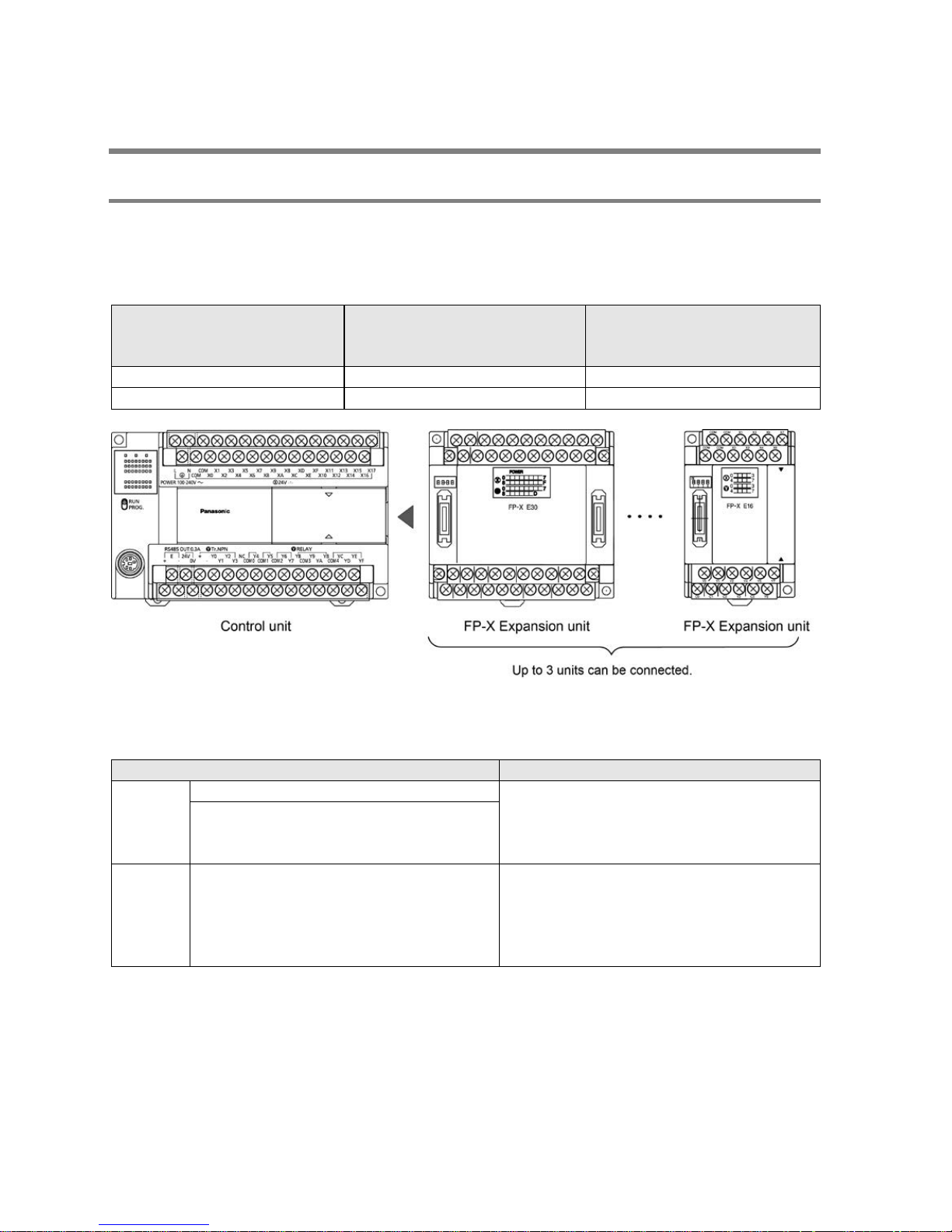

1.2 Restrictions on Uni t Combina t ions

1.2.1 Restric tions on FP-X Expansion Unit (For L40/ L60 only )

Restrictions on type of FP-X0 control unit s

- Up to three FP -X expansion units can be connected to FP-X0 L40 or L60 control unit.

- The maximum number of points when installing expansion units is as below.

Controllable I/O points

Type of control unit

Numbe r of I/O points when

using control unit

Number of I/O points when

using 3 units of E30

expansion I/O unit

FP-X0 L40R Control unit 40 points Max. 130 points

FP-X0 L60R Control unit

60 points

Max. 150 points

Restrictions on type of FP-X expansion units

- Up to three FP -X expansion units can be connected to FP-X0 L40 or L60 control unit, however, the

installable positions and the number of units differ depending on the type of expansion units as below.

Type of expansion unit

Installable position

Group A

FP-X E30 Expansion Unit

Can be installed at any position within the

limits described in t he abo ve fi gure.

FP-X E16 Expansion Unit (Ver.3)

FP-X E16T Expansion Unit (Ver.3)

FP-X E16P Expansion Unit (Ver.3)

Group B

FP-X E14YR Expansion Unit

FP-X E16R Expansion Unit

FP-X E16X Expansion Unit (Ver.2 or older)

FP-X E16T Expansion Unit (Ver .2 or older)

FP-X E16P Expansion Uni t(Ver.2 or ol der)

The expnasion units of group B do not have

a built-in ci rcuit t o supp l y bus power to t he

expansion unit installed on the right . FP-X

E16/E14 expansion units cannot be installed

on the right-hand side of those units.

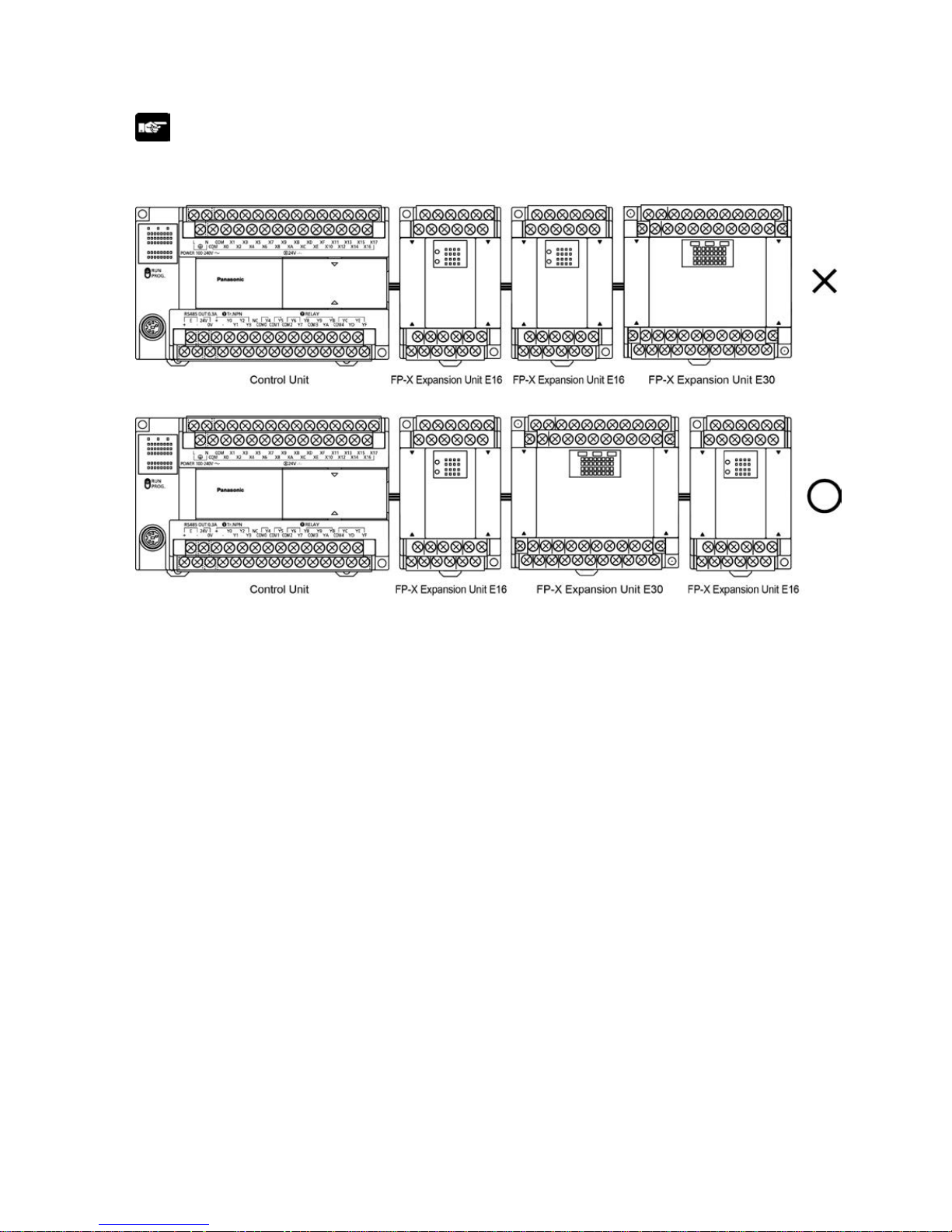

- Up t o eight units of FP-X can be connected, however, the restrictions on each expansion unit vary.

- For AFPX-E16/E14: Two units cannot be connected consecutively since the power should be supplied

from the unit with the power supply (as no power supply is built in AFPX-E16).

E16 expansion I/O unit cannot be connected on the right side of the control unit or AFPX-E30.

- For AFPX-E30: There is no rest ri ction on AFPX-E30 so that up to 8 units can be connected

consecutively.

- The total length of t he expansion cable should be within 160 cm.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Note: Restrictions on installing AFPX-E16/E14:

Target models: FP-X E14YR expansion unit, FP-X E16R expansion unit, Fp-X 16X expansion unit (Ver.2

or older), FP-X E16T expansion unit (Ver.2 or older), FP-X E16P expansion unit (Ver.2 or older)

Restriction on the length of FP-X expansion cable

- When using an expansion cable AFPX-EC30 (30 cm type) or AFPX-EC80 (80 cm type) sold separately,

the total length of the expansion cables should be within 160 cm.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.2.2 Restrictions on Usin g Ex pans ion FP0 A da pter (F or L40 /L6 0 onl y)

Restrictions on type of FP-X0 cont rol unit s

- Only one expansion FP0 adapter can be connected to FP-X0 L40 or L60 control unit .

Restrictions on installation positions of Expansion FP0 adapter

- When connecting the expansion FP0 adapter to FP-X0 L40 or L60 control unit, only one unit can be

connected at the last position of the expansion bus. Cnnect it on the righ-hand side of all other FP-X

expansion units.

- Up to two FP-X expansion I/O units can be installed between the control unit and expansion FP0

adapter.

Restrictions on installation positions of FP0/FP0R units

- Up to three FP0/FP0R expansion units and advanced units can be installed on the right-hand side of

the expansion FP0 adapter.

- Note) Install the FP0 thermocouple unit on the right side of all other expansion units. If it is installed on

th e lef t side, th e tot al pr ecis ion will deteriorate.

- Install t he FP0 CC-Link slave uni t on t he ri ght side of th e other expans ion units. There is no expansion

connector on the right side.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-7

1.3 Programming Tools

1.3.1 Software Environment and Suitable Cable

Standard ladder diagram tool software FPWIN-GR Ver.2

Type of software OS (Operating system)

Hard disk

capacity

Product No.

FPWIN GR Ver.2

Englishlanguage menu

Full type

Windows98

WindowsMe

Windows2000

WindowsXP

Windows Vista

Windows7

40MB or

more

AFPS10520

Upgrade

version

AFPS10520R

Note1) Ver.1.1 must be installed to install the upgrade version.

Note2) Ver.2.0 can be upgraded to the latest version after Ver. 2.1 free of charge at our web site

Conforms to IEC61131-3 programming tool software FPWIN-Pro Ver.6

Type of software OS (Operating system)

Hard disk

capacity

Product No.

FPWIN Pro Ver.6

English-language menu

Windows2000

WindowsXP

Windows Vista

100MB or more FPWINProFEN6

Note1) The small type and upgrade version is not available for Ver.6.

Note2) Ver.6.0 can be upgraded to the latest version after Ver. 6.1 free of charge at our web site

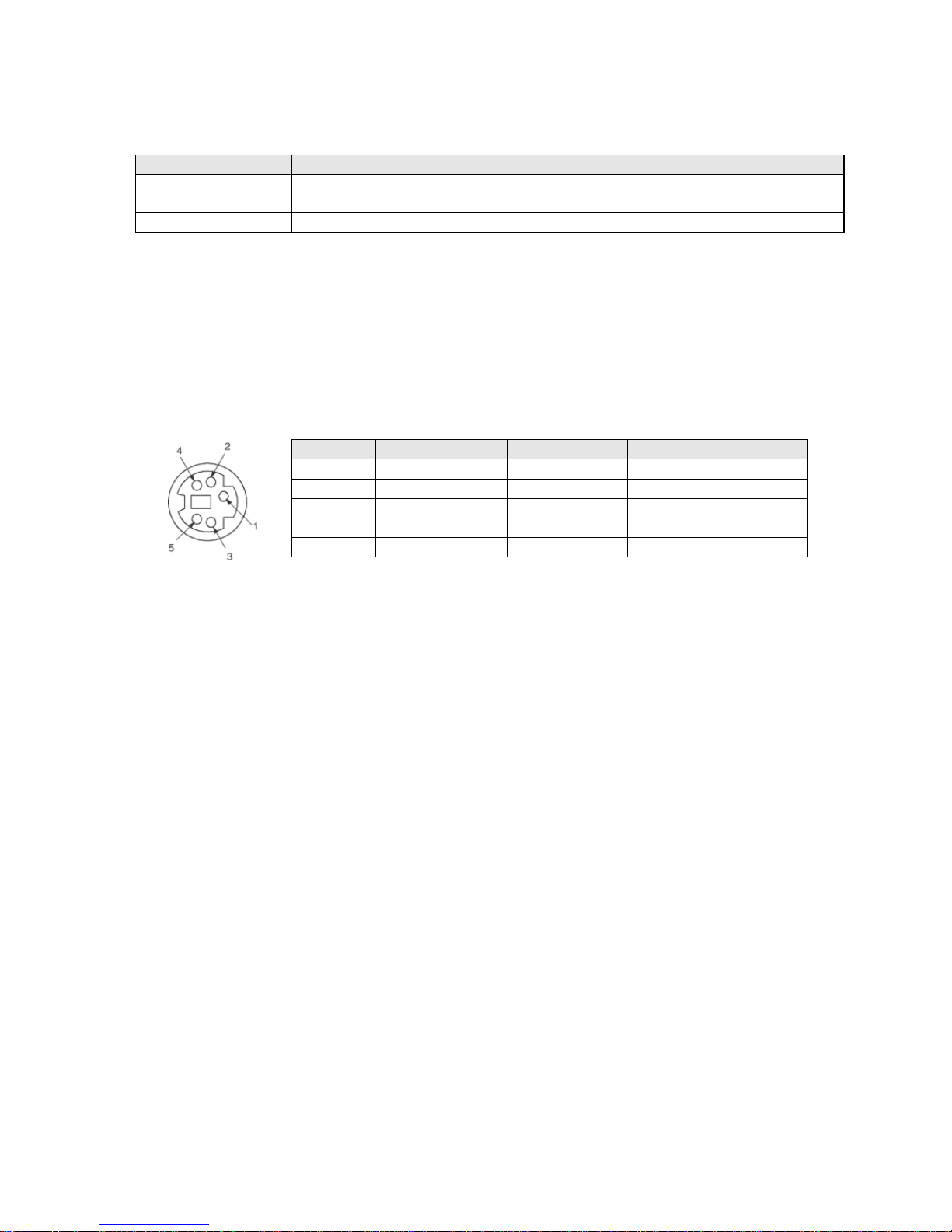

Type of computer and suitable cable

For the connection between a personal computer (RS232C) and the control unit (RS232C)

D-sub connector cable

PC side connector PLC side connector Specifications Product No.

D-sub 9-pin

female-Mini DIN round 5-pin L type (3 m) AFC8503

female-Mini DIN round 5-pin Straight type (3 m) AFC8503S

Note) A USB/RS232C conversion cable is necessary to connect with a personal computer without a

serial port using a PC connection cable.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Chapter 2

Specifica tions and Functions of Control

Unit

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

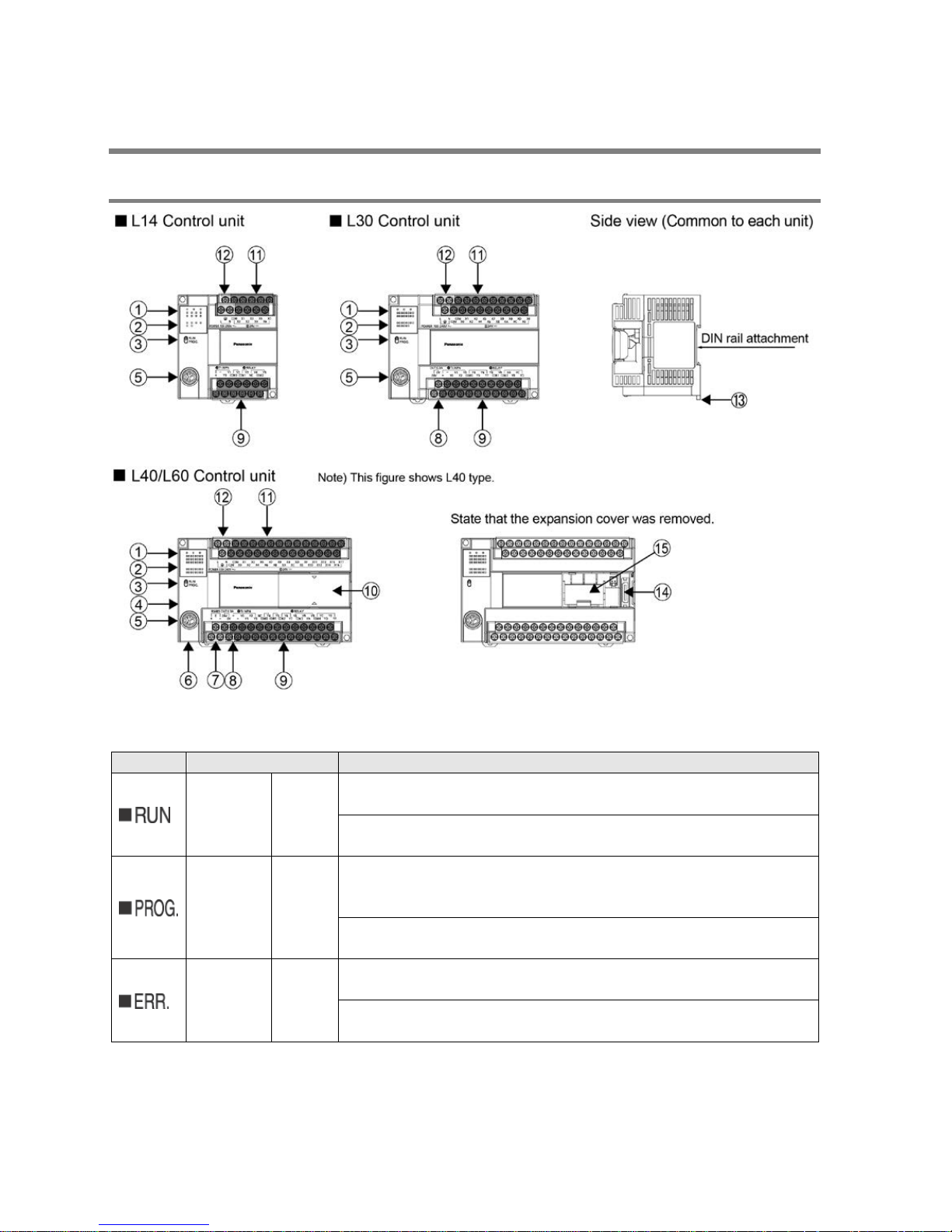

2.1 Parts and Functions

2.1.1 Parts and Functions

○

1

Status indicator LEDs

These LED s display t he current mode of operation or the occurrence of an error.

LED

LED and operation status

RUN Green

Lights when in the RUN mode and indicates that the program is

being executed.

It flashes during forced input/output. (The RUN and PROG. LEDs

flash alternately.)

PROG. Green

Lights when in the PROG. Mode and indicates that operation has

stopped.

Lights when in the PROG. Mode duri ng forced input/output.

It flashes during forced input/output. (The RUN and PROG. LEDs

flash alternately.)

ERROR/

ALARM

Red

Flashes when an error is detected during the self-diagnostic

function. (ERROR)

Lights if a hardware error occurs, or if oepration slows because of

the program, and the watchdog timer is activated . (AL ARM)

○

2

Input/output indicator LEDs

Indicates the on/off status of the input and output.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

○

3

Switch position

RUN/PROG. mode switch

This switch is used to change the operation mode of the PLC.

Operation mode

RUN (upward)

This sets the RUN mode. The program is executed is executed and operation

begins.

PROG. (downwor d)

This sets the PROG. mode. The operation stops.

• The remote switching operation from the programming tool is operable.

• When performing remote switching from the programming tool, the setting of the mode switch and the

actual mode of operation may differ. Verify the mode with the status indicator LED.

• Restart FP Σ to operate in the mode set with the RUN/PROG. mode switch.

○

4

COM port baud rate switch

This switch is used to change the baud rate of the COM port between 115200 bps and 19200 bps.

Position of switch: On the left side; 115200 bps, On the right side; 19200 bps

○

5 Tool port (RS232C)

This connector is used to connec t a pr ogr amming tool.

A commercial mini-DIN 5-pin c onn ector is used f or th e tool port on the contro l unit.

Pin No.

Signal name

Abbreviation

Signal direction

1

Signal Ground

SG −

2

Send Data

SD

Unit → E x ternal devi ce

3

Rec eive Data

RD

Unit ← Ext ernal devic e

4

(Not used) − −

5

+5V

+5V

Unit → Ext ernal devic e

- The followings are the default settings when the unit is shipped from the factory. The system register

should be used to change them.

Baud rate: 9600bps, Char. Bit: 8 bits, Parity check: Odd par ity , Sto p bit: bit

Note) The unit number of the tool port should be set by the system register.

○

6

Analog input connector (L40R, L40MR, L60R and L60MR types)

Connector for connecting an analog input cable.

○

7

COM port terminal (R S 4 8 5: L40MR and L60MR types)

It is connected for using RS485 communication. Solderless terminals for M3 are used for connection. As

fo r t he ter mi nal unit, short-circuit the ter mi nals of "E" and "-".

○

8

Service power supply for input (L30R, L40R, L40M R , L60R and L60MR types)

24 VDC power supply that can be used for the input circuit is output. Solderless terminals for M3 are

used for connection.

○

9

Output circuit terminal block

Termi nals f or output circuit. Sol derl ess t er mi nals for M 3 are used for connection .

○

10

Expansion cover

It is removed/installed when installing the expansion cable and backup battery.

○

11

Input circuit terminal block

Terminals for input circuit. Solderless ter mi nals for M 3 are used for conn ecti on.

○

12

Power supply terminal block

Power supply terminals for driving the PLC internal circuit. A solderless terminal for M3 can be used.

○

13

DIN rail attachment lever

This l ever enab les t he units t o att ach to a DIN r ail at a t ouch.

○

14

Expansion connector (L40R, L40MR, L60R and L60MR types)

Connector for connecting the expansion I/O unit and expansion FP0 adapter.

○

15

Space and connector for installing battery (L40R, L40MR, L60R and L60MR types)

It i s used for install ing an optional backup batt ery.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-4

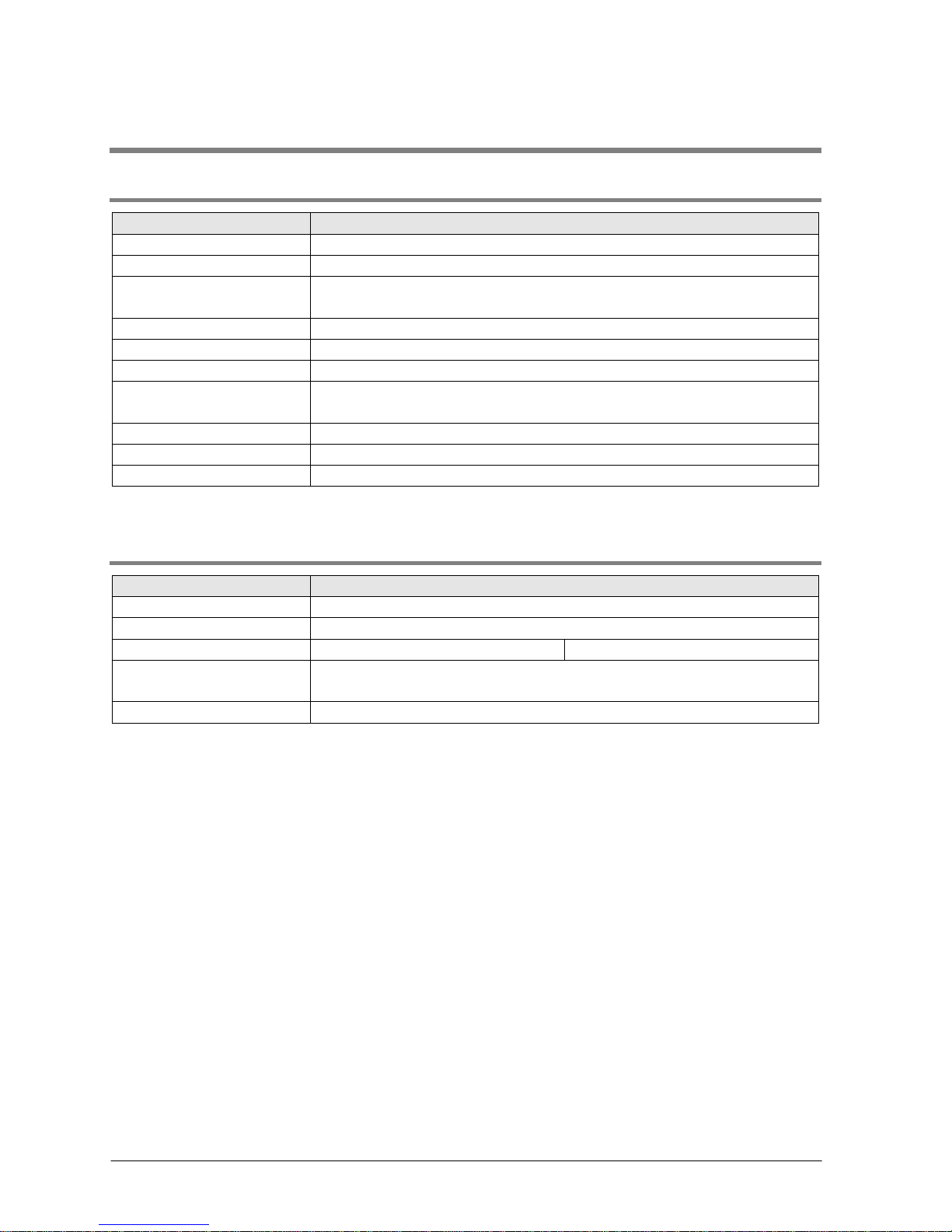

2.2 Power Supply Specifications

2.2.1 AC Power Supply

Item Specifications

Rated voltage 100 to 240 V AC

Voltage regulation range 85 to 264 V AC

Inrush current

L14: 35A or less (at 240 V AC, 25 C)

L30/L40/L60: 40A or less (at 240 V AC, 25 C)

Momentary power off time 10 ms (when using 100 V AC)

Frequency 50/60 Hz (47 to 63 Hz)

Leakage current 0.75 mA or less between input and protective earth terminals

Internal power supply part

Guaranteed life

20,000 hours (at 55 C)

Fuse Built-in (Cannot be replaced)

Insulation system Transformer insulation

Terminal screw M3

2.2.2 Service Power supply for Input (Output) (L30, L40 and L60 only)

Item Specifications

Rated output voltage 24 V DC

Voltage regulation range 21.6 to 26.4 V DC

Rated output current 0.4 A

Overcurrent protection

function

Note)

Available

Terminal screw M3

Note) This is a function to protect overcurrent temporarily, which protects the output short-circuit. If the

short-circuit is detected, all the power supply for the PLC will be turned off. If a current load that is

out of the specifications is connected and the overloaded status continues, it may lead to damages.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

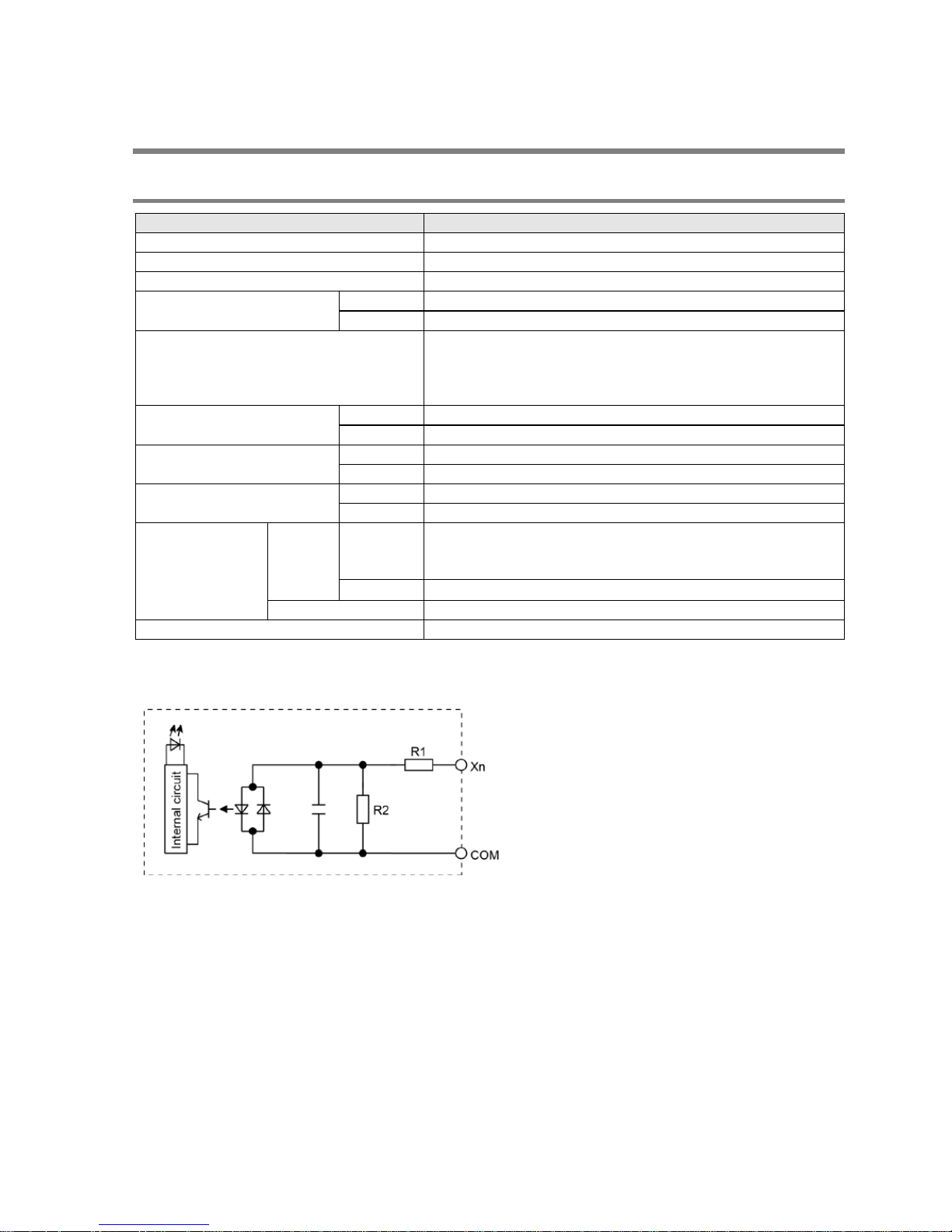

2.3 Input/Out put Spe ci fi cations

2.3.1 Input Specifications

Item

Description

Insulation method

Optical coupler

Rated input voltage

24V DC

Operating voltage range

21.6 to 26.4V DC

Rated input current

X0 to X3

Approx. 3.5 mA

From X4

Approx. 4.3 mA

In put points per common

8 points/common (L14R), 16 points/common (L30R)

24 points/common (L40R), 16 points/common x 2 (L60R)

(Ei ther th e positive or negative of the i nput power supply

can be connected to common terminal.)

Min. on voltage/

Min. on current

X0 to X3

19.2 V DC/3 mA

From X4

19.2 V DC/3 mA

Max. off voltage/

Max. off current

X0 to X3

2.4V DC/1 mA

From X4

2.4V DC/1 mA

Input impedance

X0 to X3

Approx. 6.8 kΩ

From X4

Approx. 5.6 kΩ

Response time

off→on

X0 to X3

Normal input: 1 ms or less

high-speed counter, pulse catch, interrupt nput settings:

25 µs or less (L14/L30), 10 µs or less (L40/L60)

Note)

From X4

1 ms or less

on→off

Same as above

Operating mode indicator

LED display

Note) T his s pecification i s applied when the rated input voltage is 24 V DC and the temperature is 25 °C.

Circuit diagram

For X0 to X3: R1=6.8 kΩ R2=820 Ω

From X4: R1= 5.6 kΩ R2= 1 kΩ

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

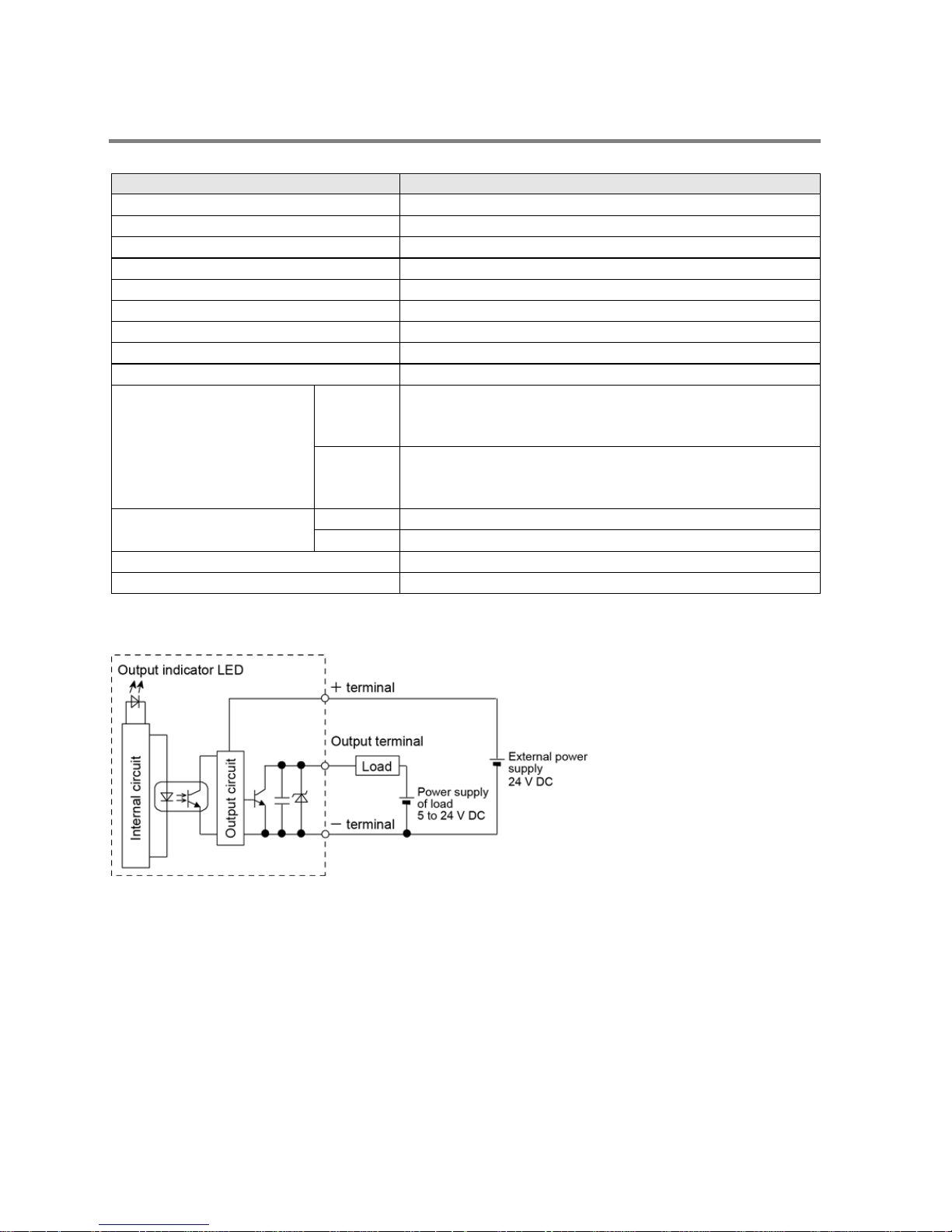

2.3.2 Output Specif ications (L14: Y0 to Y 1, L30/ L40/L60: Y 0 to Y 3)

Transistor (NPN) output

Item

Description

Insulation method

Optical coupler

Output type

Op en collector

Rated load voltage

5 to 24 V DC

Allowable load voltage range

4. 75 to 2 6.4 V D C

Max. load c urrent 0.5 A

Max. inrush curren t

1.5 A

Output points per common 2 points/common (L14), 4 points/common (L30/L40/L60)

Off state leakage current

1 µA or less

On s t ate volt age d rop 0.3 V DC or less

Response time

(at 25 °C)

OFF→ON

10 µs or less (L14/L30)

5 µs or less (L40/L60)

(Load current: at 15 mA or more)

ON→OFF

40 µs or less (L14/L30)

15 µs or less (L40/L60)

(Load current: at 15 mA or more)

External power supply

(+ and – terminals)

Voltage

21.6 to 26.4 V DC

Current

15 mA or less

Surge absorber

Zener diode

Operating mode indicator

LED display

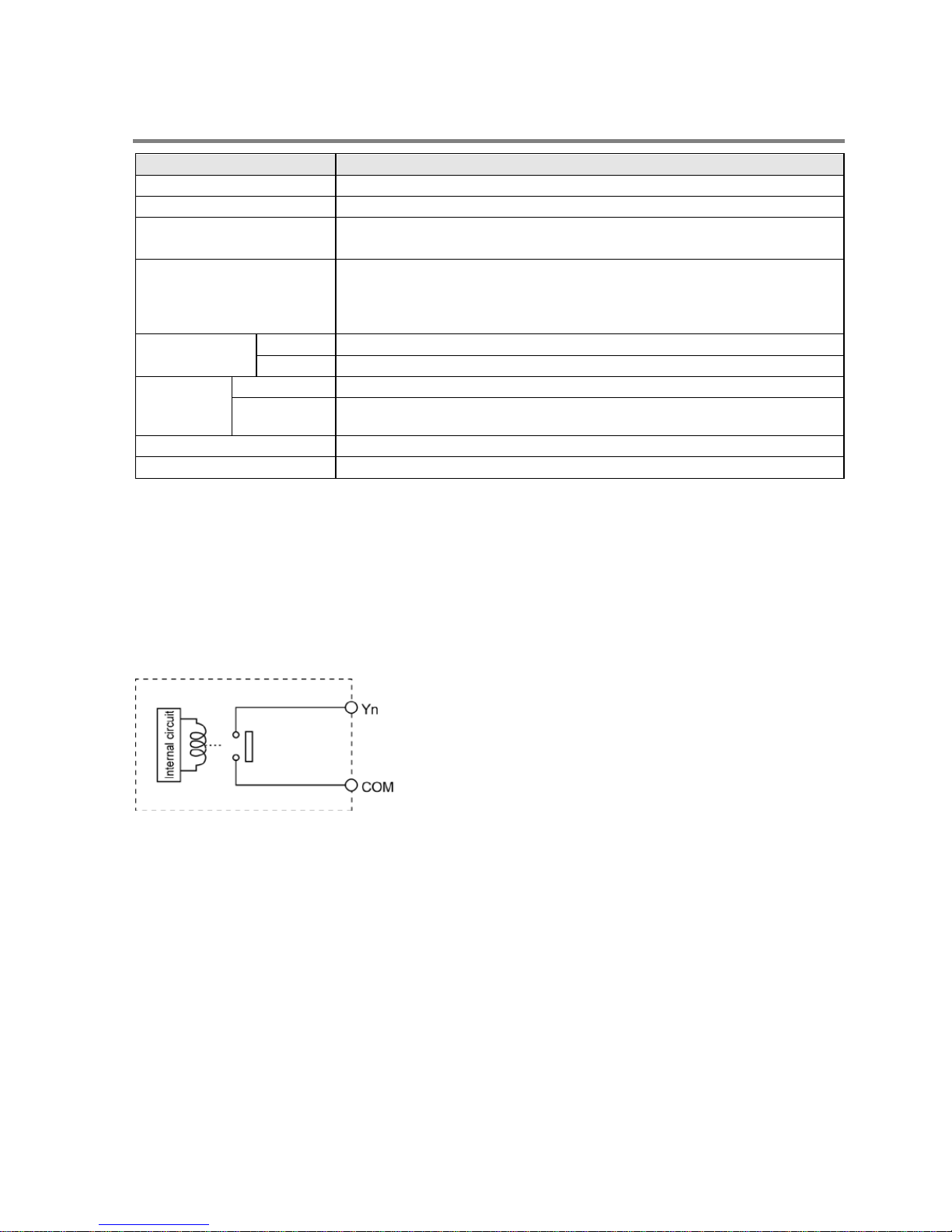

Circuit diagram

Limitations on number of simultaneous output on points

No limitatio n

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.3.3 Output Specifications (L14: From Y2, L30/L40/L60: From Y4)

Item

Description

Insulation method

Relay insulation

Output type

1a output (Relay cannot be replaced)

Rated control capacity

(Resistance load)

Note)

2 A 250 V AC, 2 A 30 V DC (per point)

Output points per common

1 point/com mon x 2, 2 point s/comm on x 1 (L14)

2 point s/comm on x 1, 4 points/ common x 2 ( L30 )

1 point /com mon x 2, 2 point s/comm on x 1, 4 points/ common x 2 (L40)

4 points/common x 6 (L60)

Response time

off→on

Approx. 10 ms

on→off Approx. 8 ms

Lifetime

Mechanical

20 million times or more (Frequency of switching: 180 times/min.)

Electrical

100 thousand times or more (Frequency of switching at the rated control

capacity: 20 times/min.)

Surge absorber

None

Operating mode indicator

LED display

Note) There are restrict ions on the rated current for each o utput bl ock. Each usable rated current is as

below.

L14: Y2 to Y5 (4 points) Max. 6A in total

L30: Y4 to YD (10 points) Max. 8A in total

L40: Y4 to YFD (12 points) Max. 8A in total

L60: Y4 to YB (8 points) Max. 8A in total, YC to Y1B ( 16 points) Ma x. 8A i n t otal

Circuit diagram

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-8

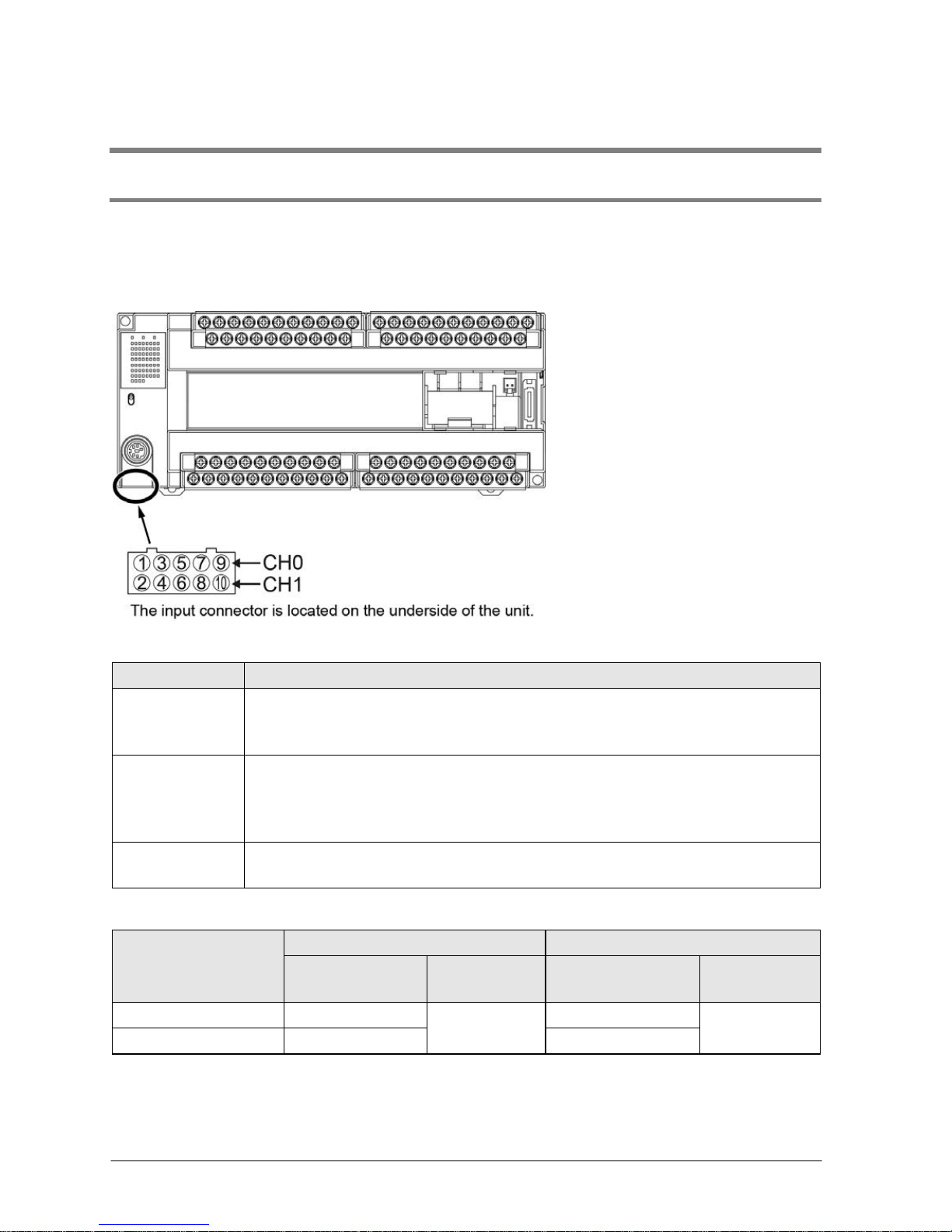

2.4 Analog Input Specifications (For L40 and L60 types)

2.4.1 Common Specifications to Analog Input

Overview

- Two-channel analog inputs are available for FP-X0.

- You can select potentiometer (volume) input, thermister input or voltage input for each channel.

- Converted digital values are stored in special data registers.

Total accuracy

Input Specifications

Potentiometer

(Volume) input

Min. potentiometer resistance 5k

Resolution 10 bits (K0 to K1000)

Accuracy ±1.0% F.S. + External resistance accuracy

Thermister input

Allowable thermister resistance (External thermister min. resistance + External

resistance > 2k)

Resolution 10 bits (K0 to K1023) :

Accuracy ±1.0% F.S. + External thermister accuracy

Voltage input

Absolute max. input voltage 10V : Resolution 10 bits (K0 to K1023) :

Accuracy ± 2.5% F.S. (F.S. = 10V)

Special data register

Analog input channel

Potentiometer (Volume) input Thermister input, voltage input

Special data

register

Range of

values

Special data

register

Range of

values

CH0 DT90040

K0 to K1000

DT90044

K0 to K1023

CH1 DT90041 DT90045

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.4.2 Connecti on of A nalog I n put Ca ble

Precautions on wiring

Note the following points, and make connection using the cable supplied with the unit.

- The wiring should be shorther t han 3 m.

- When removing the wire's insulati on, be careful not to scrat ch the core wire.

- Make sure stress is n ot appli ed to t he ca ble.

- Confirm the cable is connected properly before supplying power.

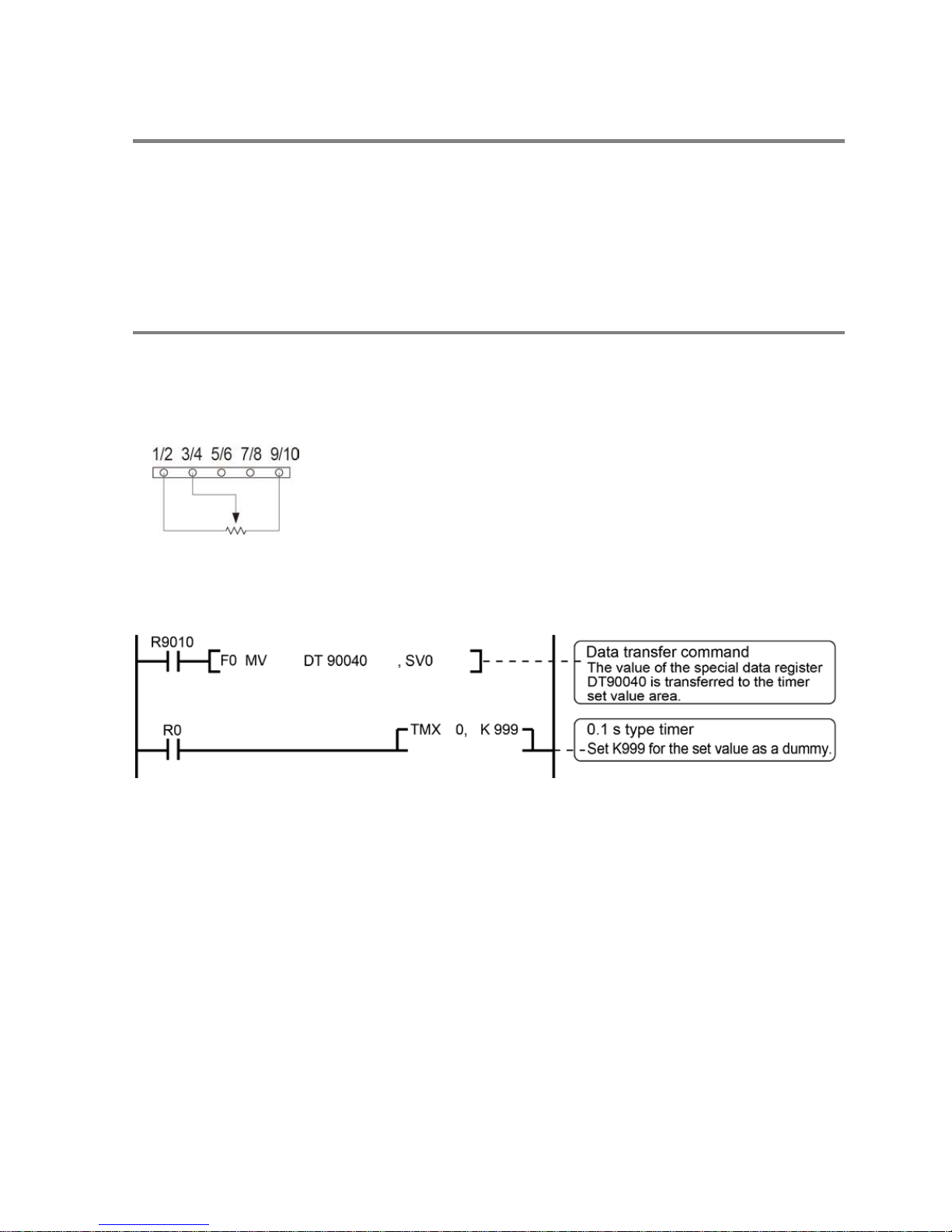

2.4.3 Potentiometer Input

Connect a potentiometer to the analog input connector externally. Values change in respo nse to the t urn

of the potentiometer.

Circuit diagram

- Do not connect anything with the 5/6 and 7/8 pins.

- Min. potentiomeneter res ist anc e s hould b e 5 kΩ.

[Example] Writing of the clock setting value

The value of the special data register (DT90040) that corre sponds to the analog inpu t CH0 is sent to the

set value area (S V0) of TMX0 to s et th e time for the clock.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

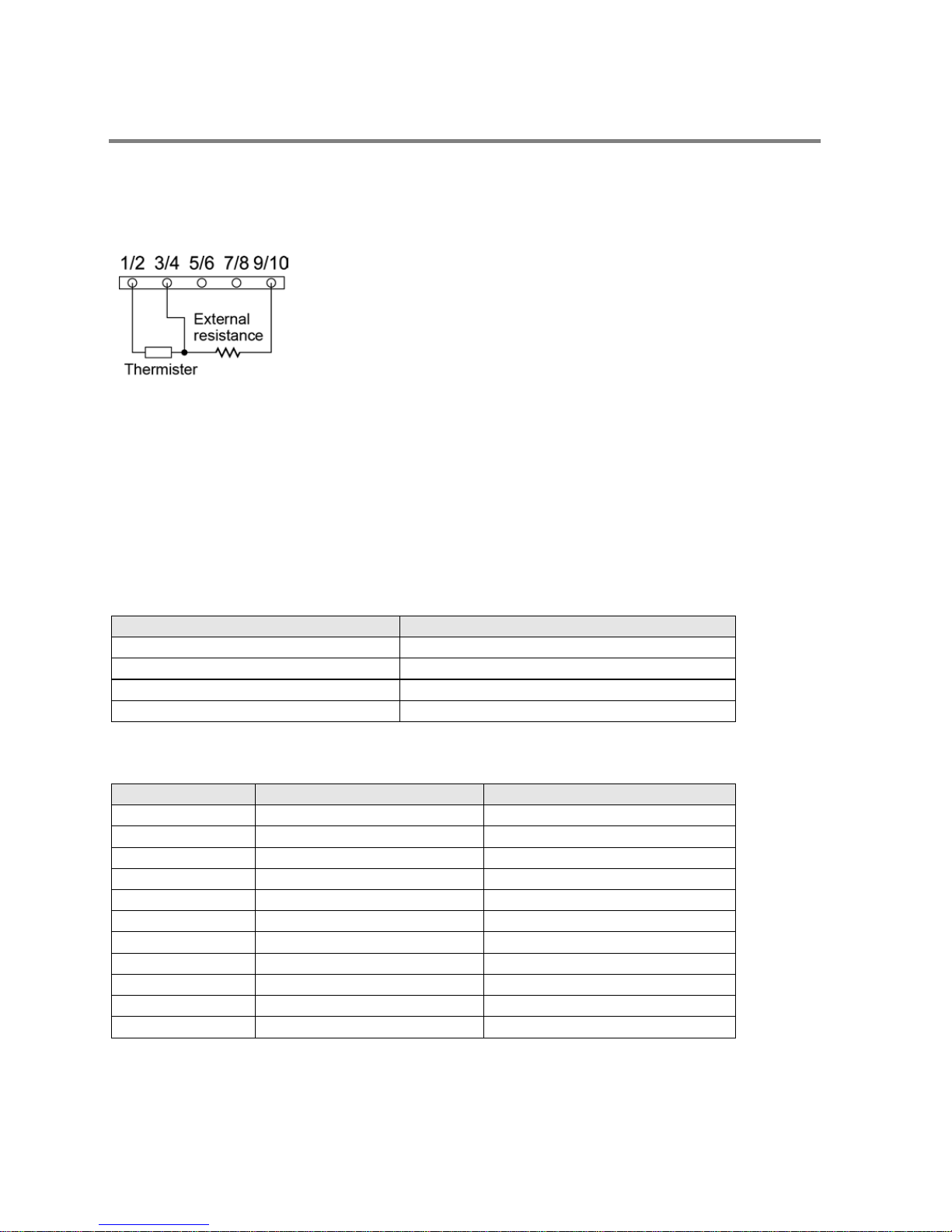

2.4.4 Thermister Input

Connect a thermister and resistor to the analog input connector externally to load the change in the

res ist anc e val ues of ther mi stor as ana log input values .

Circuit diagram

- Do not connect anything with the 5/6 and 7/8 pins.

- It i s recommend ed to use ap prox. 2 kΩ as external resistance.

Thermister resistance and digital conversion value

- Use th e fol l owing formula to convert th e t herm ister resi stance a nd digit al co nversion value.

- Digital conversion values vary between K0 and K1012.

1012 x R (kΩ)

Thermister resistanc e (kΩ) = ―――――――― − R (kΩ)

Digi tal value + 1

Connected thermister

[Examp le] R = 2 .2k

Ω

- Thermisters whose resistance is between 200 and 75kΩ can be used.

Type of thermister (B constant)

Reference of measuring range (°C)

3390K

-50 to +100 °C

3450K 50 to +150 °C

4300K

+100 to +200 °C

5133K +150 to +300 °C

Thermister measurement temperature - A/D conversion table

[Example] Thermister B constant : 3450K, external resistance: R=2.2k

Ω

Temperature (°C)

Thermister resistance (kΩ)

Digital value after conversion

50

4.3560

344

60 3.1470 421

70

2.3170

497

80 1.7340 573

90

1.3180

640

100 1.0170 690

110

0.7940

752

120 0.6277 797

130

0.5017

834

140 0.4052 865

150

0.3305

890

Note) The digital value does not include (Total accuracy of A/D converter with built-in microcomputer:

±5LSB) + (Thermister accuracy) .

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

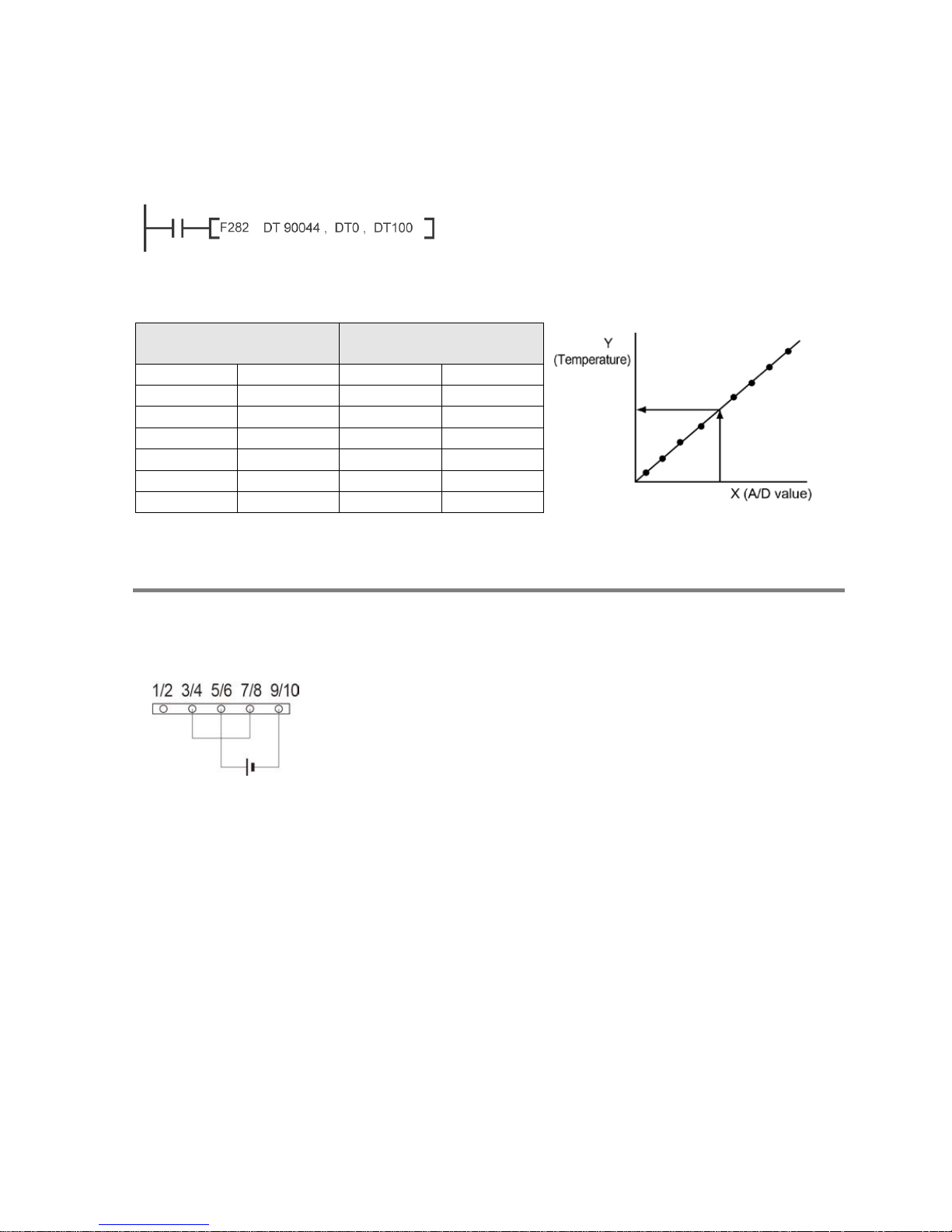

Conversion program using Scaling instruction (F282)

- Appropriately interpolated data can be obtained from nonlinear data by creating the data table of digital

values aft er conversion a nd tem perature an d execu ting t he scali ng instruction (F282).

DT90044

DT0

DT100

: Special data register

(Digital value after thermister input

conversion)

: Beginning of data ta ble

: Data after conversion (Temperature)

Example of data table

Input data (Digital value

after conversion)

Output data

(Temperature)

DT0

11

DT1 332 DT12 50

DT2

409

DT13

60

DT3 487 DT14 70

: : :

:

: : : :

DT11

878

DT22

150

Note) In DT0, specify the value of paired data.

2.4.5 Voltage in put

Connect the output line of a device to the analog input connector externally to perform voltage input.

Circuit diagram

- Do not connect anything with the 1/2 pin.

Voltage input value and digital conversion value

- Use the foll owing fo rmula to convert the volt age i nput value an d digit al conver s ion value.

(Digital conversion value + 1)

Voltage input value (V) = ―――――――――――――― x 10

1012

[Example] When digital conversion value is K900;

(K900 + 1)

Voltage input value (V)= ――――――― x 10 = 8.80V

1012

Input impedance

Approx. 1MΩ

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

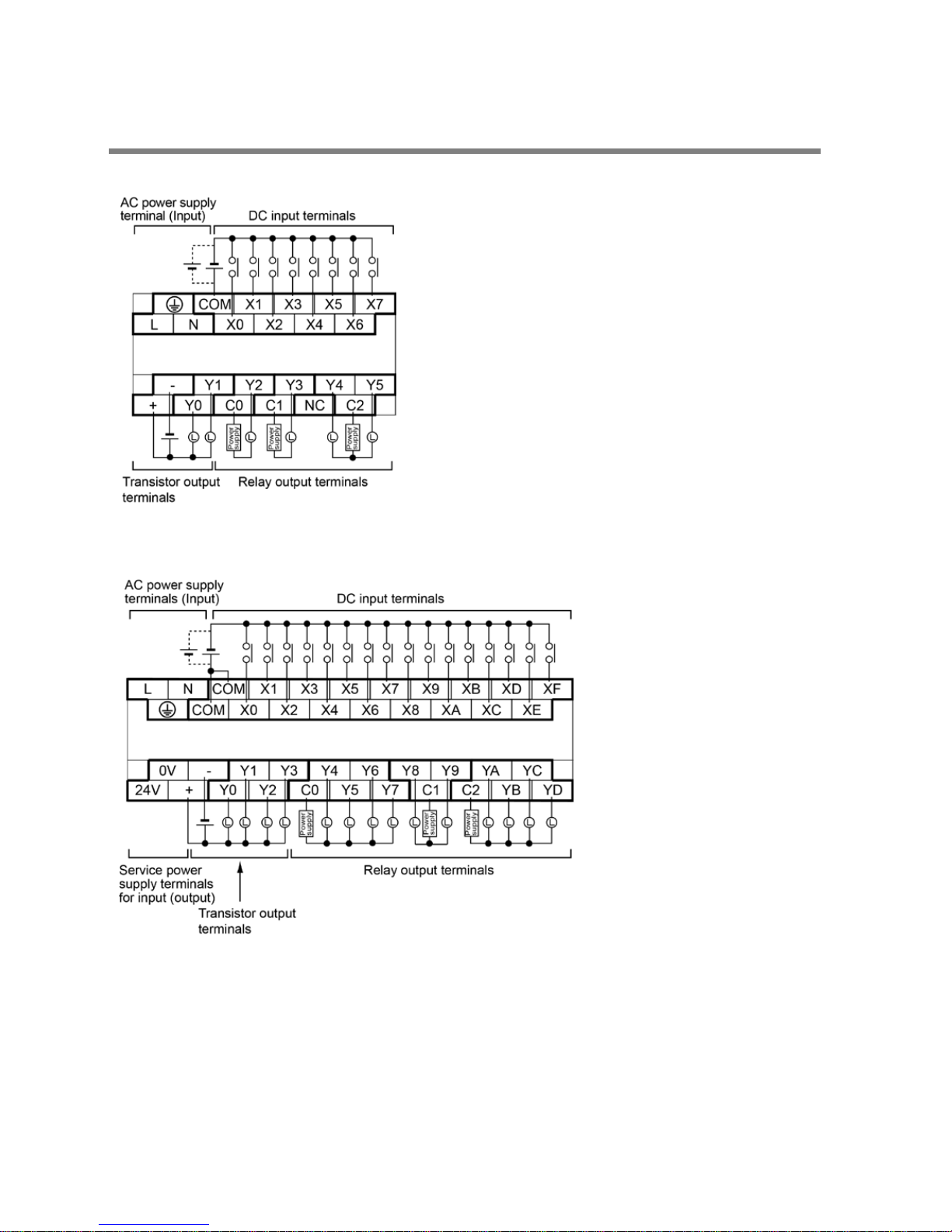

2.5 Terminal Layout

AFPX0L14R

AFPX0L30R

Note) Do not connect the service power supply terminals for input and other DC power supply in parallel.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...