Page 1

PROGRAMMABLE CONTROLLERS

FP Web-Server

Hardware / Configurator

Page 2

Before beginning

Liability and copyright for the hardware

This manual and everything described in it are copyrighted. You may not

copy this manual, in whole or part, without written consent of Panasonic

Electric Works Europe AG (PEWEU).

PEWEU pursues a policy of continuous improvement of the design and

performance of its products. Therefore we reserve the right to change the

manual/product without notice. In no event will PEWEU be liable for direct,

special, incidental, or consequential damage resulting from any defect in

the product or its documentation, even if advised of the possibility of such

damages.

Limited warranty

We invite your comments on this manual. Please e-mail us at:

techdoc.peweu@eu.panasonic.com.

Please direct support matters and technical questions to your local

Panasonic representative.

If physical defects caused by distribution are found, PEWEU will

replace/repair the product free of charge. Exceptions include:

When physical defects are due to different usage/treatment of the

product other than described in the manual.

When physical defects are due to defective equipment other than the

distributed product.

When physical defects are due to modifications/repairs by someone

other than PEWEU.

When physical defects are due to natural disasters.

Page 3

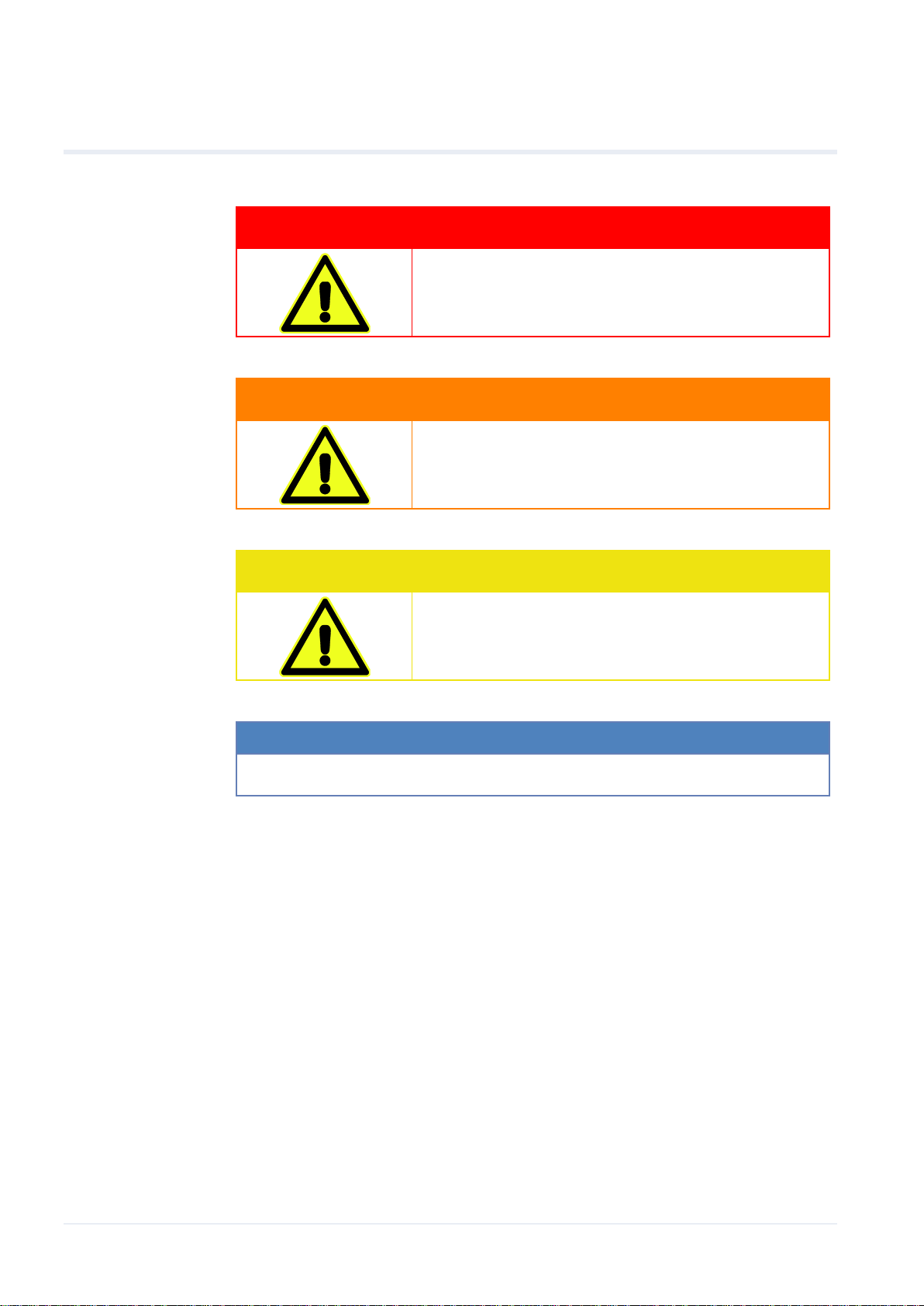

DANGER

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not

avoided, could result in serious or moderate injury.

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

Indicates a property damage message.

Warnings used in this manual

One or more of the following warnings may be used in this documentation:

2 FP Web-Server V2.810 EN

Page 4

Table of contents

Table of contents

Getting started .......................................................................................................................... 8 1.

1.1 BEFORE YOU START ........................................................................................................................ 8

1.2 Product numbers and versions ............................................................................................................ 9

1.3 System requirements........................................................................................................................... 9

1.4 Advantages and functions of the FP Web-Server ............................................................................. 10

1.5 FP Web-Server block diagram .......................................................................................................... 14

1.6 System sample network .................................................................................................................... 14

Hardware description ............................................................................................................. 15 2.

2.1 The FP Web-Server unit .................................................................................................................... 15

2.1.1 Introduction ............................................................................................................................ 15

2.1.2 Hardware version .................................................................................................................. 16

2.1.3 FP Web-Server unit package ................................................................................................ 17

2.1.4 Parts and functions................................................................................................................ 18

2.1.5 Technical data ....................................................................................................................... 19

2.1.6 Installation ............................................................................................................................. 20

2.1.7 Important notes ..................................................................................................................... 21

2.1.8 Mechanical installation .......................................................................................................... 23

2.1.9 Connecting the power supply ................................................................................................ 27

2.2 FP Web expansion unit ..................................................................................................................... 28

2.2.1 Introduction ............................................................................................................................ 28

2.2.2 FP Web expansion unit package .......................................................................................... 28

2.2.3 Parts and functions................................................................................................................ 29

2.2.4 Technical data ....................................................................................................................... 29

2.2.5 Targeted peripheral list of the USB host port ........................................................................ 30

2.2.6 Important notes ..................................................................................................................... 30

2.2.7 Mechanical installation .......................................................................................................... 31

First steps ............................................................................................................................... 32 3.

3.1 Getting started ................................................................................................................................... 32

3.2 The Ethernet network ........................................................................................................................ 32

3.3 Connection of the FP Web-Server .................................................................................................... 32

3.4 Installation of the Configurator program ............................................................................................ 33

3.5 Determination of the IP configuration ................................................................................................ 33

3.6 Generate a new Configurator project ................................................................................................ 34

3.7 Transfer a Configurator project to the FP Web-Server ..................................................................... 36

3.8 Test the FP Web-Server with an Internet browser ............................................................................ 37

3.9 Further information ............................................................................................................................ 38

FP Web-Server V2.810 EN 3

Page 5

Table of contents

Configurator Software ............................................................................................................ 39

4.

4.1 General information on the FP Web-Server Configurator ................................................................. 39

4.2 Control buttons for administering the "Configurator Project" ............................................................. 41

4.3 Control buttons for the remote FP Web-Server unit .......................................................................... 41

4.3.1 Compare ................................................................................................................................ 42

4.4 System icon menu ............................................................................................................................. 43

Base configuration ................................................................................................................. 44 5.

5.1 Main settings ("Config") ..................................................................................................................... 44

5.1.1 Ethernet IP address ............................................................................................................... 45

E-mail setup ............................................................................................................................ 47 6.

6.1 E-mail functions of the FP Web-Server ............................................................................................. 47

6.1.1 E-mail function used for communication tests....................................................................... 48

6.1.2 E-mail server for LAN or Internet .......................................................................................... 49

6.1.3 How to find out the address of the e-mail server ................................................................... 50

6.2 E-mail tab input fields ........................................................................................................................ 51

6.3 E-mail via SSL ................................................................................................................................... 51

FTP client and SD memory card control setup .................................................................... 52 7.

7.1 FTP client function of the FP Web-Server ......................................................................................... 52

7.2 Operation modes for FTP client and SD card storage ...................................................................... 53

7.3 FTP client / SD memory card settings ............................................................................................... 56

7.3.1 Enable FTP client and SD memory card control ................................................................... 56

OpenVPN client ...................................................................................................................... 58 8.

8.1 OpenVPN client function of the FP Web-Server ............................................................................... 58

8.2 OpenVPN client settings .................................................................................................................... 59

8.2.1 Enable OpenVPN client ......................................................................................................... 59

Data logger setup ................................................................................................................... 61 9.

9.1 Data logger function .......................................................................................................................... 61

9.2 Log file and CSV file structure (default) ............................................................................................. 63

9.3 Log file and CSV file structure (individual format) ............................................................................. 65

9.4 Data logger tab input fields ................................................................................................................ 66

9.5 Configure log files .............................................................................................................................. 67

9.5.1 Log file details ....................................................................................................................... 67

9.6 Logging device setup ......................................................................................................................... 68

FPWEB Script ......................................................................................................................... 69 10.

10.1 FPWEB Script settings ...................................................................................................................... 69

10.1.1 Enable FPWEB Script ........................................................................................................... 69

4 FP Web-Server V2.810 EN

Page 6

Table of contents

10.1.2 Start PPP connection ............................................................................................................ 70

10.1.3 Start FTP transmission .......................................................................................................... 70

10.1.4 Start e-mail transmission ....................................................................................................... 71

10.2 FPWEB Script function of the FP Web-Server .................................................................................. 73

HTTP client .............................................................................................................................. 75 11.

11.1 HTTP client ........................................................................................................................................ 75

11.2 Cloud client ........................................................................................................................................ 76

11.3 HTTP client setup .............................................................................................................................. 78

11.3.1 Use Dynamic Server IP/Name .............................................................................................. 78

11.4 HTTP Client SSL Connection ............................................................................................................ 79

HTTP server functions/web pages ......................................................................................... 81 12.

12.1 Details on the FP Web-Server's web page functions ........................................................................ 81

12.1.1 Testing the FP Web-Server functions ................................................................................... 81

12.1.2 Internet browser settings ....................................................................................................... 82

12.1.3 Generalities on PLC data fields in HTML pages ................................................................... 83

12.1.4 HTTP address, CGI function PLC and calling parameter ..................................................... 84

12.1.5 Configurator settings concerning the HTTP server ............................................................... 85

12.1.6 Editing HTML pages .............................................................................................................. 86

12.1.7 Compiling and transferring HTML pages .............................................................................. 88

12.1.8 Data fields for displaying PLC data on HTML pages ............................................................ 88

12.1.8.1 Examples to display PLC data in an HTML page ................................................. 91

12.1.8.2 Comments ............................................................................................................ 94

12.1.9 Using variable names instead of absolute PLC addresses .................................................. 96

12.1.10 Access protection for individual HTML pages .......................................................... 99

12.1.11 Inputs for controlling PLC internal flags on HTML pages ....................................... 101

12.1.12 Defining input fields for PLC data on HTML pages ................................................ 101

12.1.12.1 Examples on PLC data entries via HTML page ................................................. 104

12.1.12.2 Notes on strings.................................................................................................. 106

12.1.12.3 Comments on defining input fields for PLC data on HTML ................................ 107

12.1.12.4 Extended Http POST functions .......................................................................... 107

12.1.13 Example on formatting display and input fields ...................................................... 109

12.1.14 Automatic page reload upon submitting PLC data ................................................. 112

12.1.15 Notes on XML files with PLC data .......................................................................... 114

12.1.16 ASCII character codes for strings ........................................................................... 115

12.2 Configurator HTTP administration and functions ............................................................................ 116

12.2.1 PLC access rights ............................................................................................................... 118

12.2.1.1 Configuration via HTML ...................................................................................... 118

12.2.1.2 MEWTOCOL communication via HTTP server .................................................. 119

12.3 Https server ..................................................................................................................................... 120

12.4 Improve performance of HTTP visualizations with PLC data .......................................................... 120

FP Web-Server V2.810 EN 5

Page 7

Table of contents

Ethernet and serial (RS232C, RS485, USB) ports .............................................................. 123

13.

13.1 General information on the Ethernet and serial ports ..................................................................... 123

13.1.1 Server .................................................................................................................................. 123

13.1.2 Client ................................................................................................................................... 125

13.1.3 FP Web-Server and PLC timeouts ...................................................................................... 127

Dial-in setup for PPP server ................................................................................................ 130 14.

14.1 Dial-in networking setup for computer/FP Web-Server ................................................................... 130

14.1.1 TCP/IP network installation of a Windows client ................................................................. 131

14.1.2 Modem and dial-up networking installation of a Windows client ......................................... 131

14.1.3 Setup of the modem connected to the FP Web-Server for PPP-communication ............... 138

14.1.4 FP Web-Server PPP gateway functions ............................................................................. 139

14.1.5 FPWIN Pro setup to use the remote dialup network ........................................................... 141

14.1.6 PPP communication via null modem cable ......................................................................... 142

14.2 Dial-in inputs and parameters for PPP server ................................................................................. 145

Dial-out setup for PPP client ............................................................................................... 146 15.

15.1 The Internet dial-out function ........................................................................................................... 146

15.1.1 Internet e-mail settings ........................................................................................................ 146

15.1.2 Notes for advanced users ................................................................................................... 149

15.1.3 When using a cellular phone (GSM) modem ...................................................................... 152

15.1.4 GPRS Internet connections ................................................................................................. 152

15.2 Internet dial-out settings .................................................................................................................. 154

NTP server for PLC clock synchronization ........................................................................ 155 16.

16.1 (S)NTP servers ................................................................................................................................ 155

Modbus functions ................................................................................................................ 157 17.

17.1 Overview over Modbus-TCP functions of the FP Web-Server ........................................................ 157

17.2 Modbus-TCP server of the FP Web-Server in general.................................................................... 158

17.3 Modbus-TCP client of the FP Web-Servers in general ................................................................... 160

17.4 Appendix for Modbus functions ....................................................................................................... 162

IEC 60870 functions of the FP Web-Server ......................................................................... 163 18.

18.1 IEC 60870 general functions ........................................................................................................... 163

18.1.1 Details of the IEC 60870 configuration: modem and multipoint settings............................. 164

18.2 Parameters for IEC 60870 ............................................................................................................... 167

18.3 IEC 60870 library for control FPWIN Pro ........................................................................................ 167

SNMP functions .................................................................................................................... 169 19.

19.1 Overview of SNMP on the FP Web-Server ..................................................................................... 169

19.2 Parameters for SNMP ..................................................................................................................... 171

6 FP Web-Server V2.810 EN

Page 8

Table of contents

19.2.1 SNMP Version ..................................................................................................................... 171

Additional information .......................................................................................................... 173 20.

20.1 Contents of the CD and auxiliary programs .................................................................................... 173

20.2 Description of the HTML examples ................................................................................................. 173

20.3 PLC connection, cable drawings, modem ....................................................................................... 174

20.3.1 PLC connection ................................................................................................................... 174

20.3.2 Cable drawings and modem ............................................................................................... 175

20.3.3 DIP switches ........................................................................................................................ 176

20.3.4 LEDs .................................................................................................................................... 178

20.3.5 Clearing passwords ............................................................................................................. 178

20.4 IP and TCP/IP .................................................................................................................................. 179

20.5 Setup of an individual Ethernet LAN ............................................................................................... 181

20.6 Preinstalled passwords and safety instructions .............................................................................. 184

20.7 Troubleshooting ............................................................................................................................... 186

20.7.1 Network communication problems ...................................................................................... 186

20.7.2 Problems finding an FP Web-Server unit or unable to send configuration ......................... 188

FP Web-Server V2.810 EN 7

Page 9

Getting started

Chapter 1

1.1 BEFORE YOU START

Please read the following notes on HTML. It will make working with the FP

Web-Server easier for you:

Make sure that you have worked through the First Steps (see p. 32) before

you try out the HTML functions of the FP Web-Server.

In order to use HTML you do not have to be able to tag or program HTML.

Various software is at your disposal:

Getting started

Word, Frontpage (delivered with MS Office) et.al. can serve as editors

for creating HTML files.

The created HTML file will be saved on the FP Web-Server with the help

of the Configurator.

A browser (e.g. Internet Explorer) is used to display the .htm file.

These software tools provide the logical markup (i.e. text parts are

automatically adjusted to any screen format without using a lot of

memory) and easy linking that define HTML.

Please refer to the respective software company for questions on software

not provided by Panasonic mentioned in this manual (or on the software

you chose to work with HTML).

There are two ways to create HTML files:

Simple: You use editors that translate data into HTML automatically.

When using these editors, you need no special knowledge about HTML.

Advanced: You create HTML files directly. You need to have knowledge

about HTML.

For the FP Web-Server you need to have basic knowledge on how to use

HTML.

8 FP Web-Server V2.810 EN

Page 10

In case you lack knowledge about HTML, Panasonic provides you with a

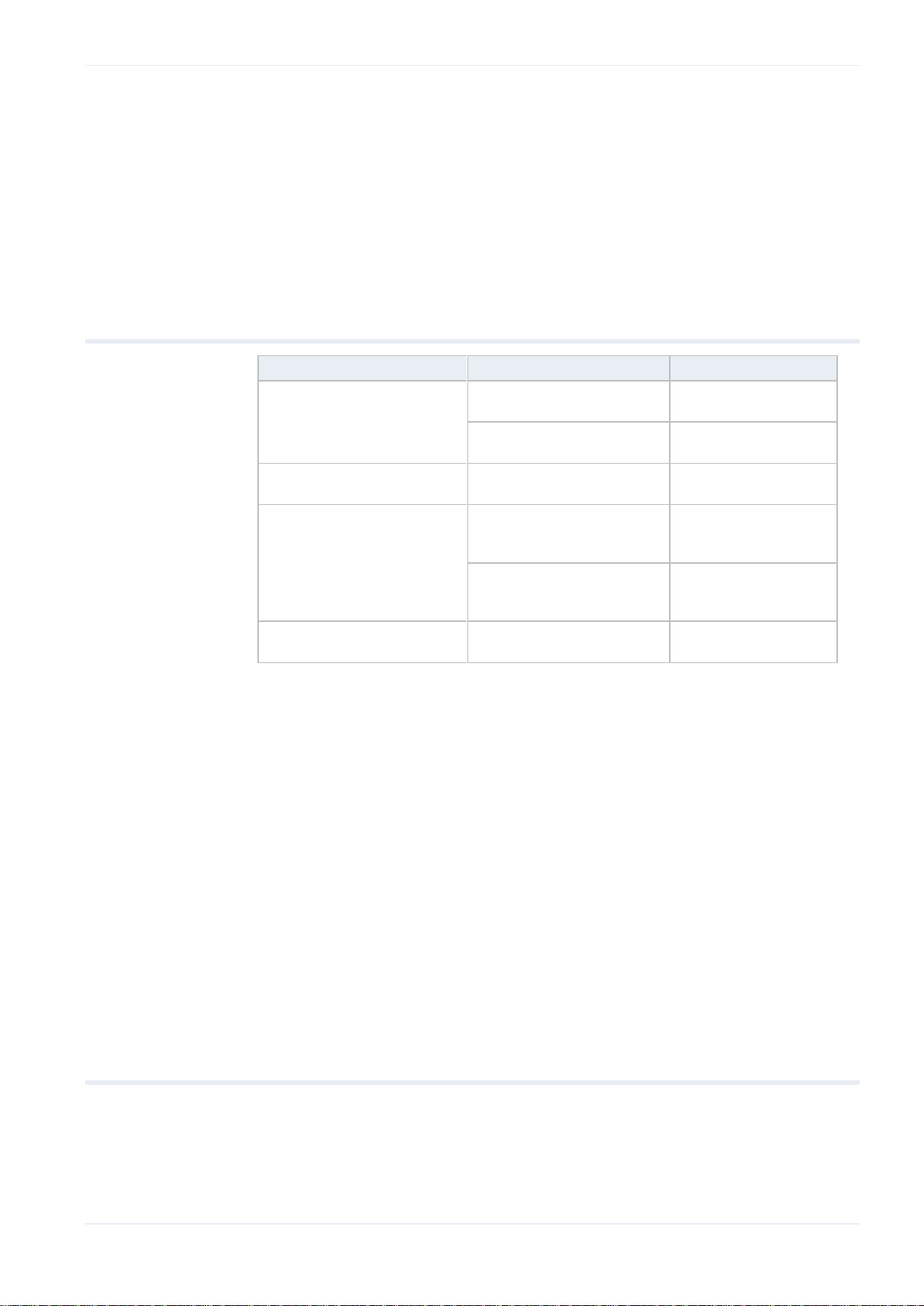

Item

Product name

Part number

FP Web-Server (Hardware)

FP WEB-SERVER UNIT

FP-WEB

(Japan: AFP0610)

FP WEB-SERVER2 UNIT

FP-WEB2

(Japan: AFP0611)

FP Web Expansion

(Hardware)

FP Web Expansion Unit

FPWEBEXP

Configurator Software

FP Web Configurator Tool

Ver.2.810

FPWEBTOOL2

(Japan:

AFPS30520-D)

FP Web Configurator Tool

Ver.2.810 Upgrade

FPWEBTOOLR2

(Japan:

AFPS35520-D)

Software for creating HTML

visualization for FP-WEB2

FP Web Designer

AFPS36510

brief introduction in the section First HTML Page Including PLC Data. In

addition, we have inserted examples on HTML (see "Description of the

HTML examples" on p. 173) on the CD (supplied with the FP Web-Server).

You can install and modify them easily without knowledge of HTML.

1.2 Product numbers and versions

Getting started

You can retrieve information on the following components by clicking on

the system icon (see p. 42) in the upper, left-hand corner and selecting

"About Configurator...":

Control FP Web Configurator Tool

Serial number

Name of owner and organization

The hardware version (see p. 16) is printed on the type plate of the FP

Web-Server.

1.3 System requirements

The FP Web Configurator Tool has the following system requirements:

FP Web-Server V2.810 EN 9

Windows® 7, Windows® 8.x or Windows® 10

Hard disk with at least 27MB free disk space

Color or monochrome monitor

Page 11

Getting started

Standard Internet browser (e.g. Microsoft Internet Explorer, Mozilla

Firefox, Google Chrome, Apple Safari, Opera) to display HTML pages

The user needs administrator rights on his computer to perform the

following actions:

Install or update the FP Web Configurator Tool

Define a default editor.

1.4 Advantages and functions of the FP Web-Server

The multifunctional FP Web-Server unit allows you to access FP Series PLCs

via Ethernet networks (Intranet and Internet) for data exchange.

Access can be carried out by a computer and a standard browser, such as

MS Internet Explorer Mozilla Firefox, Google Chrome, Apple Safari or

Opera, by specifying the target unit's IP address, which can be changed.

The HTML page can be generated with standard tools, such as Frontpage,

Dreamviewer or MS Word (not supplied with the Configurator). Panasonic

offers the FP Web Designer (Product Number: AFPS36510) for easily

designing HTML pages without any knowledge of programming languages

for HTML, PHP, Java or Javascript.

FP Web-Server advantages:

Use standard browser, save Scada software

Use existing Intranet, save wiring

Representation of PLC data in HTML pages

Value input and change of values in the PLC (set value, outputs,

internal flags) via HTML pages.

Password protection for access

E-mail send function (alternatively via Internet dialup), e.g. for the

alarm function (optionally with PLC data attachments)

Remote programming: remote access via modem (via Dial-up

Networking)

Data transfer: process control system, PLC programming, telemetry,

remote maintenance, monitored state function

Interfacing RS232C serial data via Ethernet, i.e. two FP Web-Servers

are used to send RS232C data via Ethernet

10 FP Web-Server V2.810 EN

Page 12

Getting started

Modem gateway functions to other PLCs equipped with an FP

Web-Server

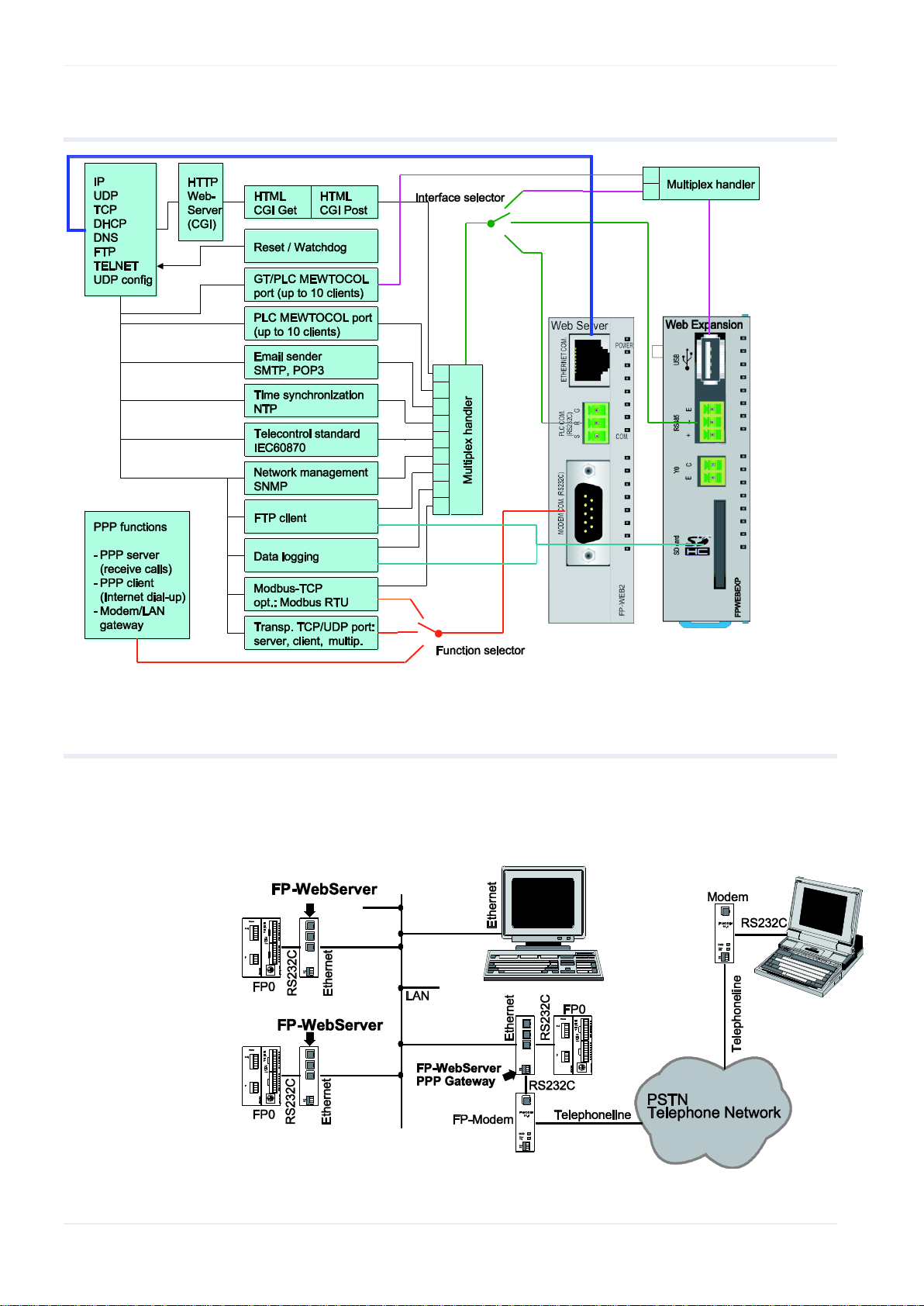

FP Web-Server functions:

The FP Web-Server works as an interface between a LAN or a WAN network

(Internet/ Intranet) and all PLCs of the FP series. The following main

features are supported:

RS232C/ Ethernet interface: (see p. 123)

RS232C to Ethernet redirection/ conversion

Programming and visualization tools access via Ethernet

Optional: password protection and IP lock security

Optional: second, full transparent port

Web-Server: (see p. 81)

PLC data presented as HTML pages

Access via standard Internet browser

HTML entry field for PLC data exchange

Optional: password protection

Optional: PLC data display using Java applets

PLC data delivery as XML files

E-mail: (see p. 47)

PLC can send out an e-mail

PLC defined or pre-stored e-mail text

FP Web-Server V2.810 EN 11

Page 13

Getting started

E-mail sending via LAN or Internet dialup

Optionally with PLC data attachments

Modem/ Ethernet gateway: (see "Dial-in networking setup for computer/FP Web-Server" on p.

130)

FP Web-Server can be dialed-up via modem for local or network access

One remote gateway for multiple FP Web-Servers provided in a local

Ethernet network

Remote password handling

IEC60870 protocol (optional): (see p. 163)

IEC60870-5-101 standard telecontrol communication protocol via serial

interfaces

IEC60870-5-104 standard telecontrol communication protocol via

Ethernet

Optionally with modem support

Network Time Server: (see p. 155)

PLC real-time clock can be synchronized via NTP server

Modbus RTU/TCP functions: (see p. 157)

Modbus RTU master/slave functionality

Modbus-TCP client/server functionality

Modbus RTU/TCP gateway

MEWTOCOL/Modbus gateway

SNMPv1 agent: (see p. 169)

The SNMP agent (see p. 169) feature allows any SNMP management

system to exchange data with FP Web-Server devices via the Ethernet

using SNMP version 1 protocol.

FTP client: (see p. 52)

The FP Web-Server unit can be configured as an FTP client (see p. 52)

for sending user-defined, current PLC data or logged data to a remote

FTP server.

12 FP Web-Server V2.810 EN

Page 14

Getting started

Data logger: (see p. 61)

The FP Web-Server unit can log PLC data (see p. 61) and store it on the

optional SD memory card or send it via FTP (see p. 52).

Secure data transmission and authentication: (see p. 58)

The FP Web-Server unit can communicate via OpenVPN (see p. 58) to

get an encrypted and secure data transmission and authentication.

The FP Web-Server comes in an FP0 housing and has the following interfaces: (see "Hardware

description" on p. 15)

RS232C interface which can be connected to the PLC (MEWTOCOL

protocol)

Ethernet 10/100BaseT interface for network connections using the TCP/

IP protocol

2nd RS232C interface for an optional modem or for full transparent

Ethernet/ RS232C communication

The optional FP Web Expansion unit has the following functions:

USB 1.1 host port

RS485 port

Digital output

SD memory card slot

Configurator software (see p. 39)

A Windows program is supplied to make the configuration and the setup of

the FP Web-Server easy. This configuration program is called "Control FP

Web Configurator Tool". It helps the user to quickly set up and change the

following items, e.g.:

Automatic integration of PLC data into HTML pages

Preparation of pre-stored mail addresses and texts

TCP/ IP address and parameter configuration (DHCP is also possible)

Password and security setup

FP Web-Server V2.810 EN 13

Page 15

Getting started

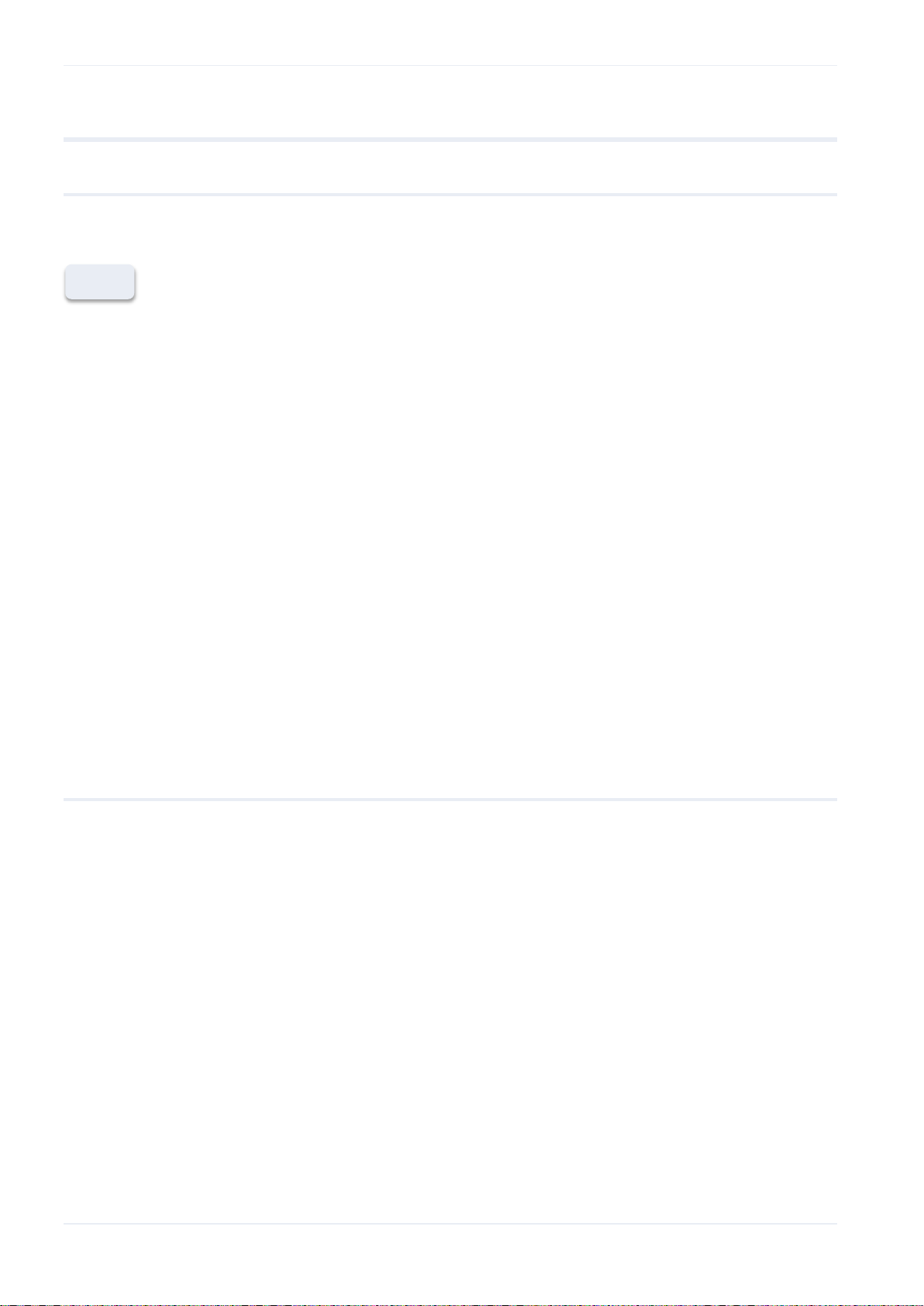

1.5 FP Web-Server block diagram

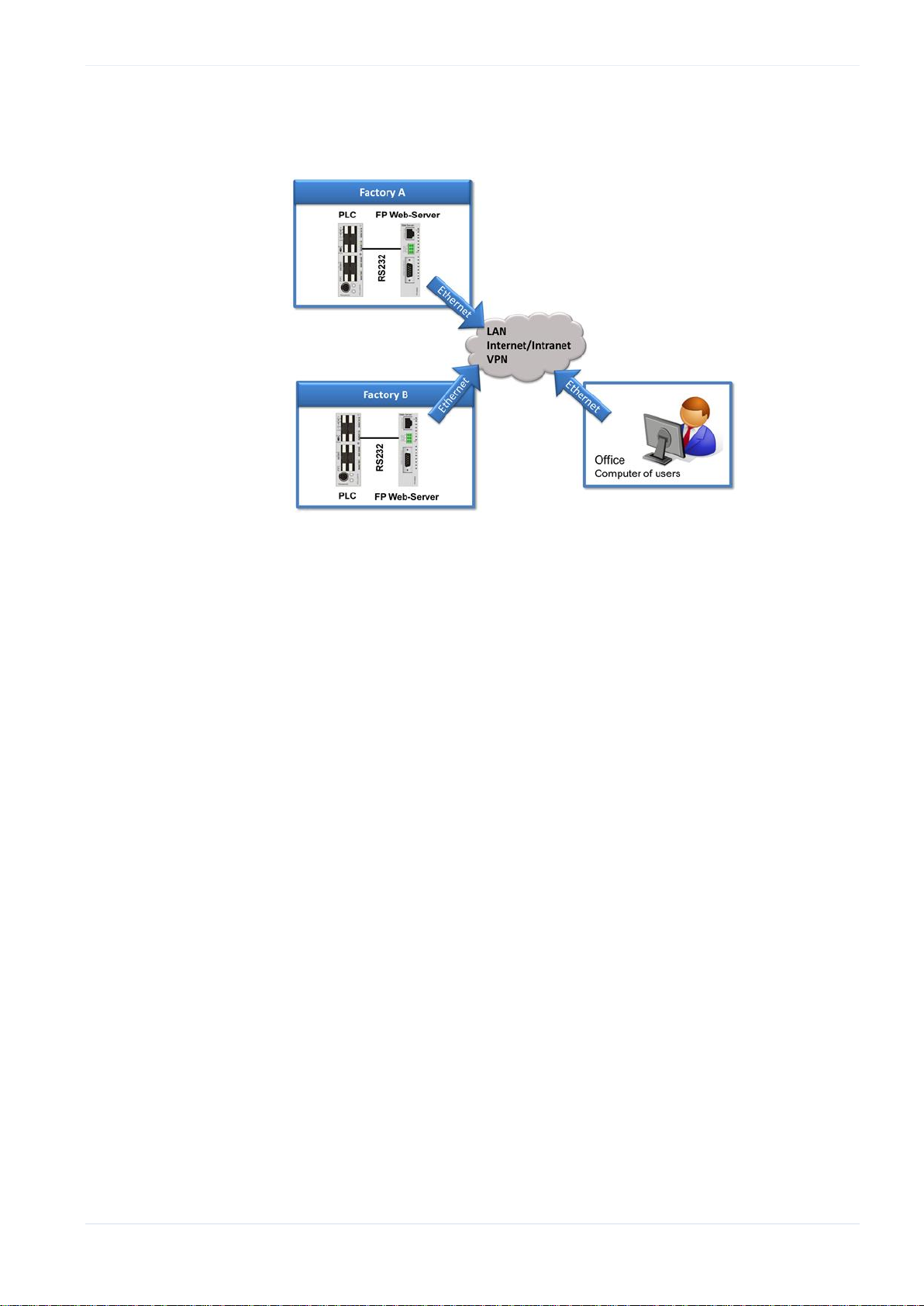

1.6 System sample network

Any combinations of the LAN and the dial-up functions are possible, e.g. an

Ethernet network connecting several FP Web-Servers with one FP

Web-Server set up as a gateway for the dial-up connections.

14 FP Web-Server V2.810 EN

Page 16

Chapter 2

Please read the safety instructions in important notes (see p. 21) and also

the section on mechanical installation (see p. 23) carefully.

Note

2.1 The FP Web-Server unit

2.1.1 Introduction

Hardware description

Hardware description

The FP Web-Server allows you to connect the Panasonic FP Series PLCs to

an Ethernet Network (LAN).

The FP Web-Server works as an Interface between a LAN or a WAN

network (Internet/ Intranet) and all PLCs of the FP Series.

The following main features are supported:

RS232C/ Ethernet Interface (remote programming monitoring and

visualization)

Web-Server (http/https server supplies HTML pages with PLC data (see

comments))

E-mail (SMTP protocol)

Modem/Ethernet gateway (PPP Server function)

Modbus-TCP/RTU functions

NTP time synchronization

Optional: IEC60870

SNMPv1 agent

FTP client, FTP server

Data logger (requires FP Web expansion unit)

A Windows program is supplied to make the configuration of the FP

Web-Server easy (see comments).

FP Web-Server V2.810 EN 15

Page 17

Hardware description

FP-WEB2

FP-WEB

Ethernet interface

100Mbps

10Mbps

Application memory

8MB Flash

0.5MB Flash

CPU speed

24 bits at 25MHz

16 bits at 20MHz

Comments:

See above for a more detailed overview (see p. 8) of the FP Web-Server

functions. There you can also find a block diagram, a list of features and a

brief description.

A data sheet can be found below which also lists the supported standards

and protocols.

A standard HTML editor (not supplied with the FP Web-Server

Configurator Tool) is needed to design HTML Web pages. HTML pages

can easily be created with the FP Web Designer (product number:

AFPS36510) without knowledge of HTML or any other programming

language.

A standard Internet browser, e.g. Microsoft Internet Explorer, Mozilla

Firefox, Google Chrome, Apple Safari, Opera, is recommended for

displaying the HTML pages.

2.1.2 Hardware version

The unit hardware model and version is printed on the type plate. Two

different hardware models are available:

Model 1: "FP Web-Server" unit (FP-WEB)

The hardware version 1.2 (available since 2003) is identical to hardware

version 1.1 except that the pin assignment of the 9-pin RS232C connector

was optimized and the UL approval sign is printed on the unit label.

Hardware version 1.3 (available since the beginning of 2006) is identical to

hardware version 1.2 but with the Panasonic logo and RoHS conformity.

Model 2: "FP Web-Server2" unit (FP-WEB2)

16 FP Web-Server V2.810 EN

Version 1.0 of this new hardware model has been available since December

2006.

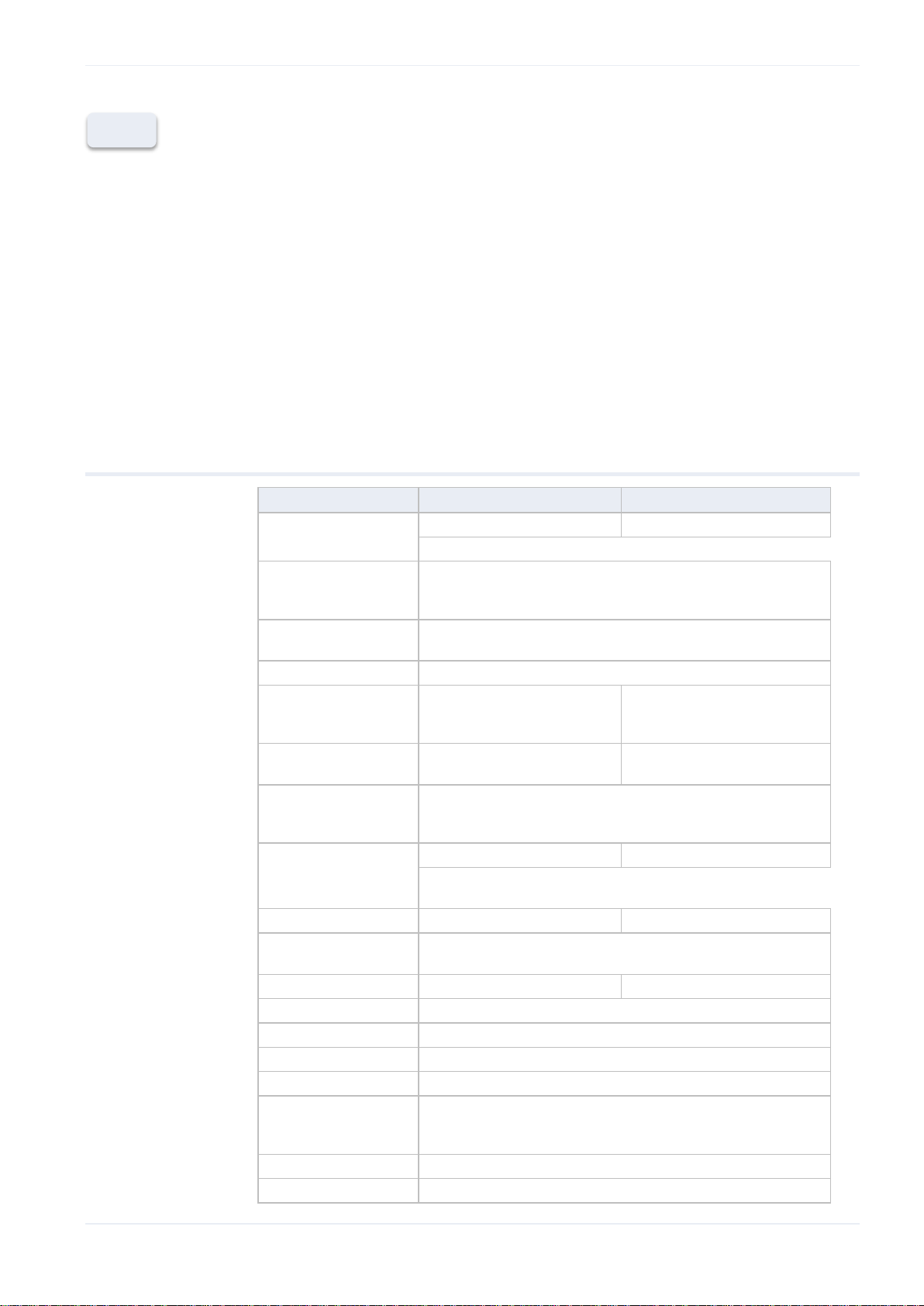

The following table presents a brief comparison of the two models.

Page 18

Hardware version 1.01 has improved PLL circuitry on the CPU for a better

start-up behavior.

Hardware version 1.1 contains an additional right-side expansion connector

to support the FP Web expansion unit .

Comment:

The FP Web Configurator Tool (Ver.2.3 and higher) can configure all

available hardware types and versions.

2.1.3 FP Web-Server unit package

The FP Web-Server unit package of Panasonic contains:

Hardware description

Comments:

one FP Web-Server unit

a 24V DC power cable

a leaflet providing installation instructions

Phoenix 3-pin screw terminal

The FP Web-Server network will be configured via the Control FP Web

Configurator Tool.

The Control FP Web Configurator Tool can be purchased separately.

For creating HTML pages a standard HTML editor (not supplied with the

Configurator) is required.

FP Web-Server V2.810 EN 17

Page 19

Hardware description

Q

Ethernet (RJ45)

(Ethernet 10-Base-T / 100-Base-Tx) use Standard Ethernet CAT.5

W

RS232C (without handshake)

Screw terminal. Connects to the PLC.

E

2nd RS232C (SUB-D 9 male)

Compatible to IBM PC serial port.

Use standard serial computer cables.

– Connects to modem (PPP), or

– Transparent communication with 2

nd

PLC, computer, panel, etc.

R

24V DC, use Panasonic power cable

brown = +24V DC

blue = GND

green = framing ground

T

Connector for FP Web expansion unit

16-pin expansion connector

2.1.4 Parts and functions

Below are two illustrations of the FP Web-Server's parts and their

functions:

18 FP Web-Server V2.810 EN

Page 20

LEDs (see p. 177).

The expansion connector is for the FP Web expansion unit only.

FP0 expansion units are not supported and may damage the FP-WEB2

unit.

Only FP-WEB2 units with hardware version greater than 1.1 are

equipped with the connector for the FP Web expansion unit.

Feature

Description: Type 1

Type 2

Product number

FP Web-Server

PN Hardware: FP-WEB

PN Hardware: FP-WEB2

PN Configurator: FPWEBTOOL2

PLC connection

PLC COM: RS232C via 3-pin screw terminal port Plug:

Phoenix product: MC1,5/3-ST-3,5 Order Number: 18 40

37 9

Modem / 2nd

RS232C

Modem COM: RS232C via 9-pin SUB-D port, with RTS,

CTS Plug: 9-pin SUB-D female

Power supply

24V DC Molex 35 plug on the bottom side of the unit

Ethernet connection

Ethernet-COM: 10BASE-T

via RJ45 female connector

10BASE-T / 100BASE-TX

autoneg via RJ45 female

connector

LEDs (see p. 177)

Power, Ethernet, PLC data

exchange

Power, Ethernet, Ethernet

data, PLC data

Protocols and

standards

TCP/IP, UDP/IP, DHCP, FTP, TELNET, http, https, SMTP,

ESMTP-Auth, POP3, PPP, IEC60870, NTP, Modbus,

DynDNS, SNMPv1

Flash memory

512KBytes

8MBytes

For further information, refer to Available Memory

Calculation in the online help.

RAM

512KBytes

8MBytes

Operating voltage

24V DC (10.8 – 26.4V DC supplied by class 2 circuit

only)

Current consumption

Approx. 75mA at 24V DC

Approx. 65mA at 24V DC

Degree of protection

IP20

Ambient temperature

0°C to +55°C

Storage temperature

-20°C to +70°C

Humidity

Max. 30% to 85% (non-condensing)

Vibration resistance

10Hz to 55Hz, 1 cycle per minute with a double

amplitude of 0.75mm; 10 minutes every X-, Y-, and

Z-axis

Shock resistance

Min. 10g; 4 times every X-, Y-, and Z-axis

Dimensions

Height 90mm, Width 25mm, Depth 64mm

Note

2.1.5 Technical data

Hardware description

FP Web-Server V2.810 EN 19

Page 21

Hardware description

Feature

Description: Type 1

Type 2

Weight

Approx. 110g

Operating conditions

Free of corroding gases and excessive influence of dust

CE conformity

EMC Standard 89/336/EEC 1989EN 55022/Class B

EN 55022/Class B; EN 61000-4-2/A1; EN 61000-4-3

EN 61000-4-4 +A1:2010; EN 61000-4-6

UL approval

UL number "2LD7" (file E232530)

Hardware version

Refer to hardware version (see p. 16)

NOTICE

Be sure to install the FP Web-Server unit in locations designed for

electrical equipment, e.g. in a closed metal cabinet such as a

switch cabinet.

Make sure you are not electrostatically charged before you touch

the FP Web-Server or one of its units: the discharge of static

electricity can damage parts and equipment.

Procedure

2.1.6 Installation

Please install the FP Web-Server in the following order:

1. Mount the unit on the DIN rail on which the FP0R PLC is mounted

For detailed information, refer to mechanical installation (see p. 23).

2. Before connecting the power supply, please read the information on

power supply (see p. 27)

3. Connect the Ethernet (10/100BaseT) with a standard cable

4. Connect the PLC via RS232C/USB/RS485

Please read the information on wiring under PLC connection, cable

drawings, modem (see p. 174) or the "FP Web-Server Installation

Instructions Leaflet".

Configuration: For the first configuration and how to get started with

the Configurator, please refer to first steps (see p. 32).

20 FP Web-Server V2.810 EN

Page 22

The USB port and the RS485 interface are only available with the FP Web

Expansion Unit.

Note

2.1.7 Important notes

Please also see the Installation Instruction leaflet "FP Web-Server2 Unit"

supplied with your FP Web-Server for important notes, cables and

installation.

Hardware description

This is a brief description on how to put an FP Web-Server into

operation.

Please read the following notes carefully before installing your FP

Web-Server.

FP Web-Server V2.810 EN 21

Page 23

Hardware description

Avoid installing the unit in the following locations:

– Ambient temperatures outside the range of 0°C to 55°C/32°F to 131°F

– Ambient humidity outside the range of 30% to 85% RH

– Sudden temperature changes causing condensation

– Inflammable or corrosive gases

– Excessive airborne dust or metal particles

– Fuel, paint thinner, alcohol or other organic solvents or strong alkaline

solutions such as ammonia or caustic soda

– Excessive vibration or shock

– Direct sunlight

– Water in any form including spray or mist

Avoid noise interference from the following items:

– Influence from power transmission lines, high voltage equipment, power

cables, power equipment, radio transmitters, or any other equipment that

would generate high switching surges.

– If noise occurs in the power supply line even after the above

countermeasures are taken, it is recommended to supply power through an

insolated transformer, noise filter, or the like.

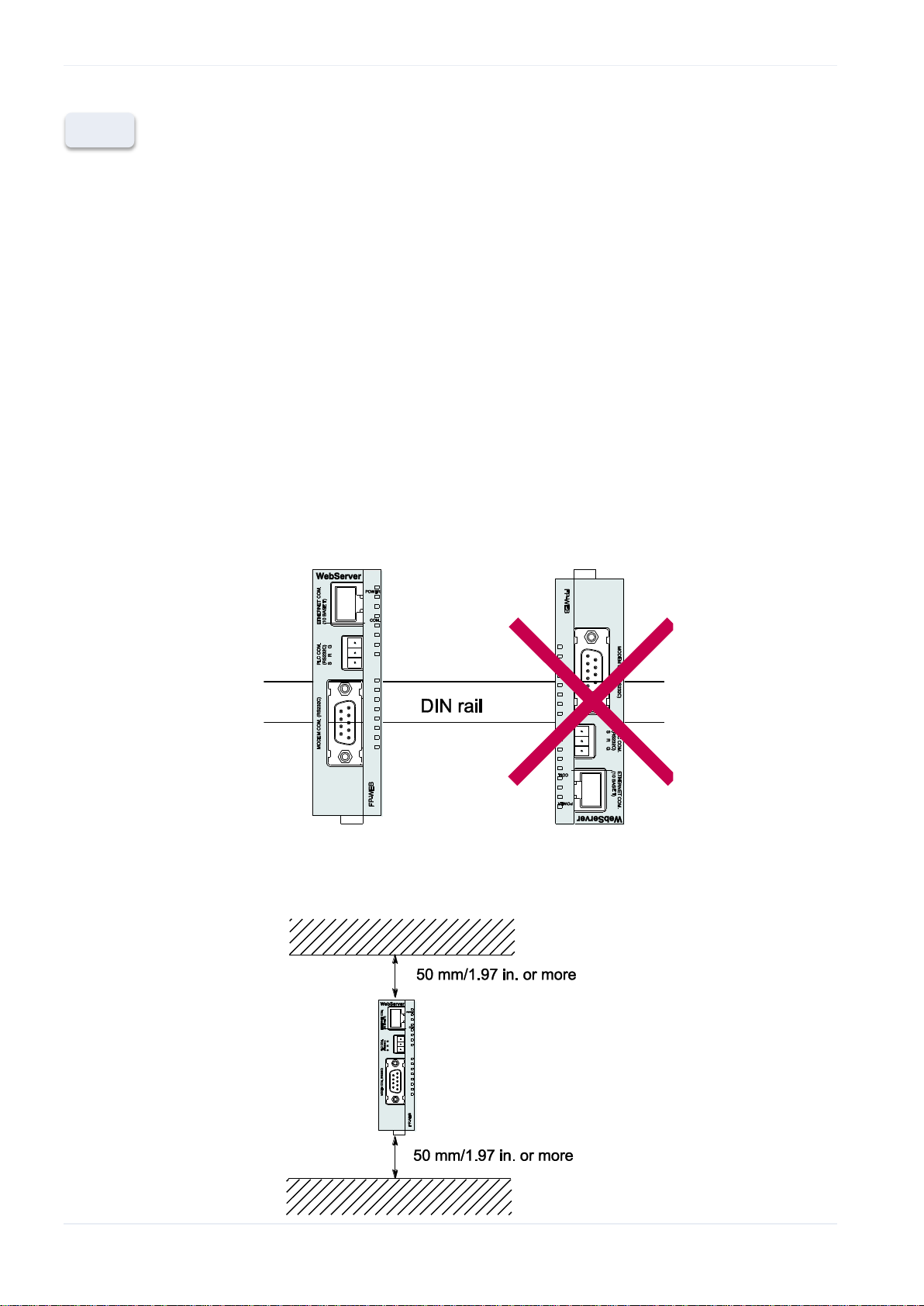

Measures regarding heat discharge:

– Always install the unit orientated with the Ethernet port facing outward on

the top in order to prevent the generation of heat.

– Do not install the unit above devices which generate heat, such as heaters,

transformers or large scale resistors.

Installation space:

– Leave at least 50mm/1.97in. of space between the wiring ducts of the unit

and other devices to allow heat radiation and unit replacement.

– Maintain a minimum of 100mm/3.937in. between devices to avoid adverse

affects from noise and heat when installing a device or panel door to the

front of the FP Web-Server unit.

Note

22 FP Web-Server V2.810 EN

Page 24

Procedure

2.1.8 Mechanical installation

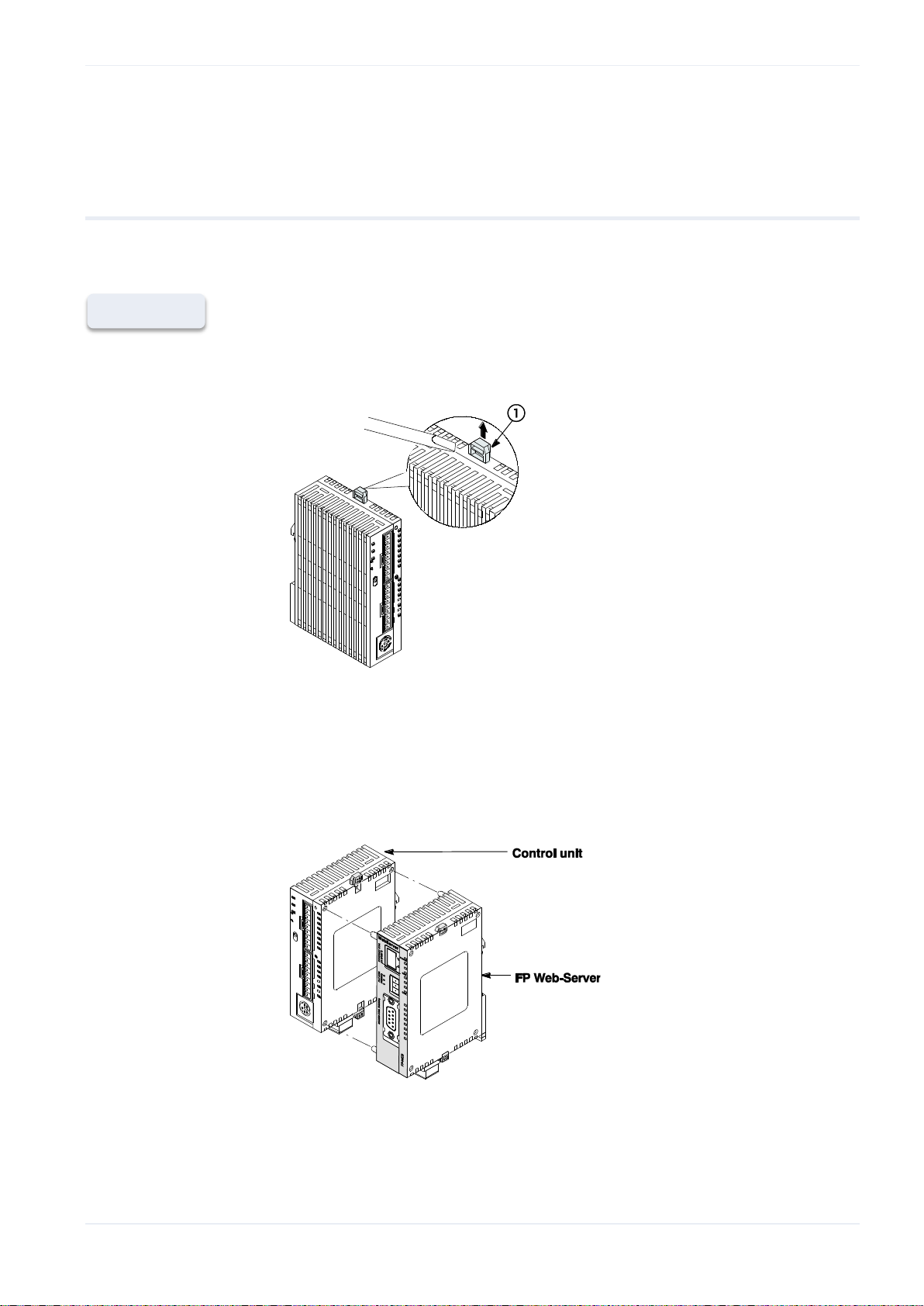

a) Adding to FP0:

1. Raise the expansion hooks on the top and bottom sides of the unit with

a screwdriver

Hardware description

2. You can align the pins and holes in the four corners of the control unit

and expansion unit, and insert the pins into the holes so that there is no

gap between the units

However you need not necessarily connect the FP Web-Server in this

way.

Note:

FP Web-Server V2.810 EN 23

Make sure that the FP Web-Server is the last unit attached. Otherwise

the CPU cannot communicate with the expansion units.

Page 25

Hardware description

Procedure

Procedure

3. Press down the expansion hooks raised in step 2 to secure the unit

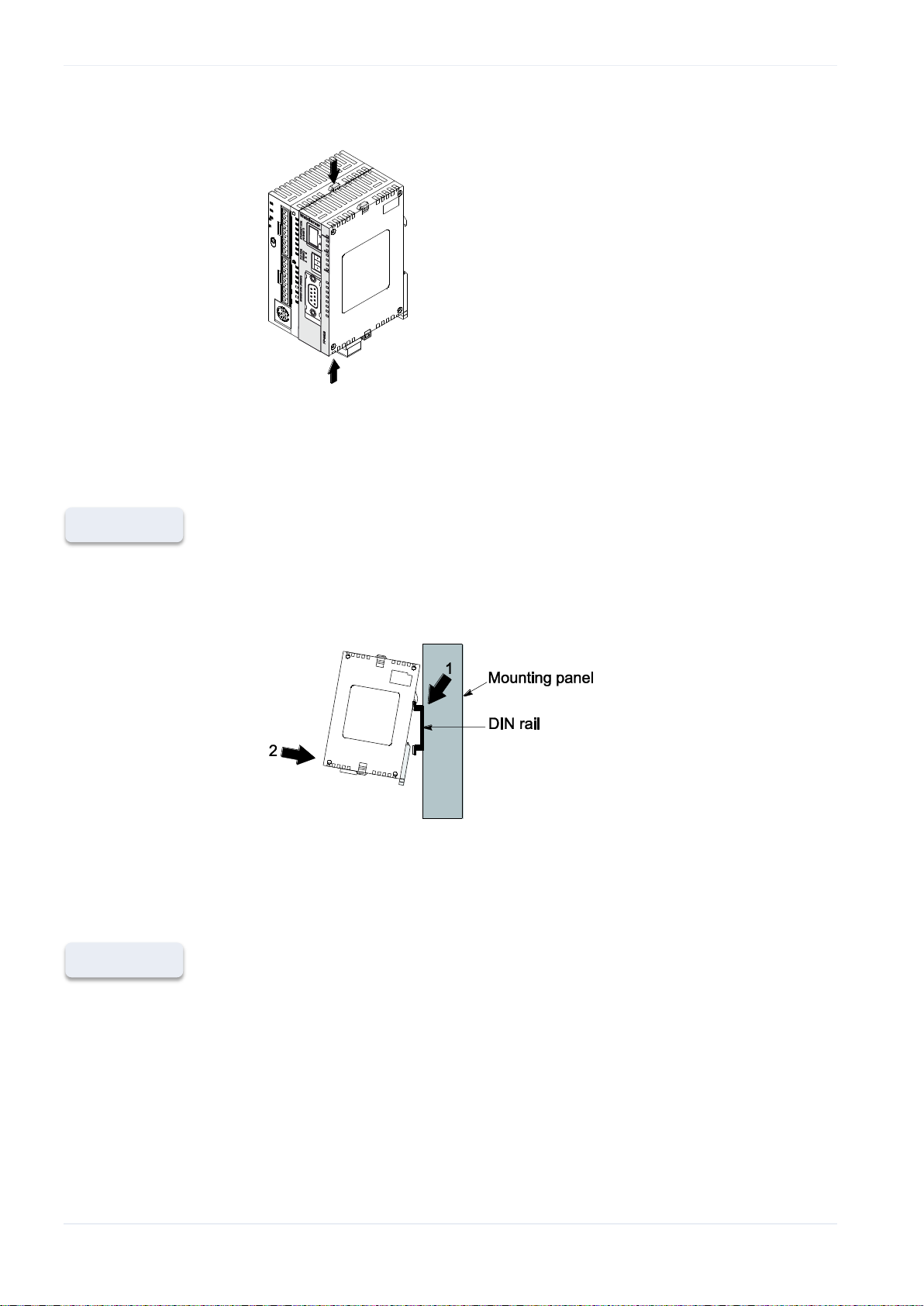

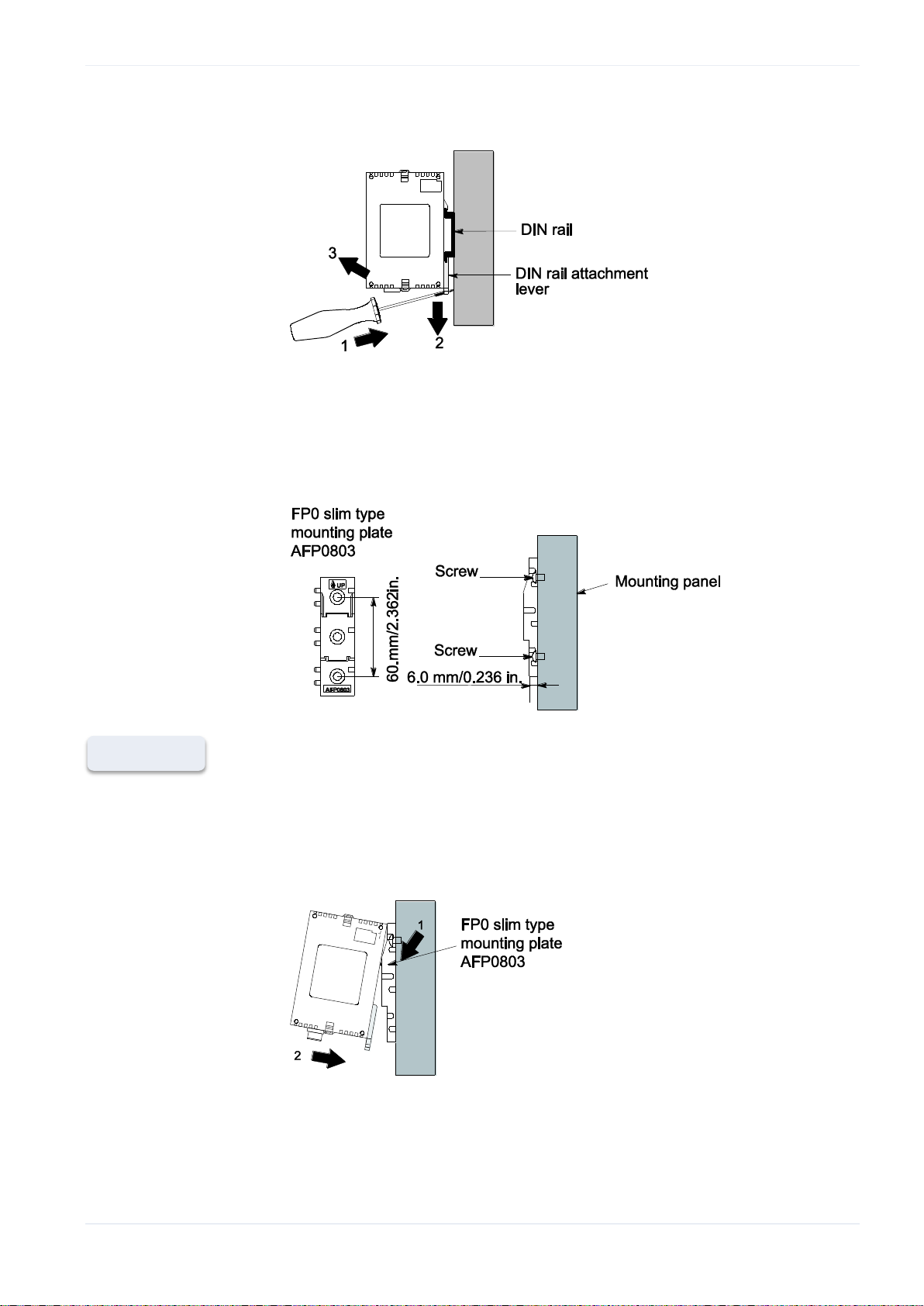

b) Attachment to DIN Rails:

The FP Web-Server unit enables a one-touch attachment to DIN rails.

1. Fit the upper hook of the FP Web-Server onto the DIN rail

2. Without moving the upper hook, press on the lower hook to fit the FP

c) Removal from DIN Rail:

You can easily remove the FP Web-Server as described below.

1. Insert a slotted screwdriver into the DIN rail attachment lever

Web-Server into position

24 FP Web-Server V2.810 EN

2. Pull the attachment lever downwards

Page 26

3. Lift up the FP Web-Server unit and remove it from the rail

Procedure

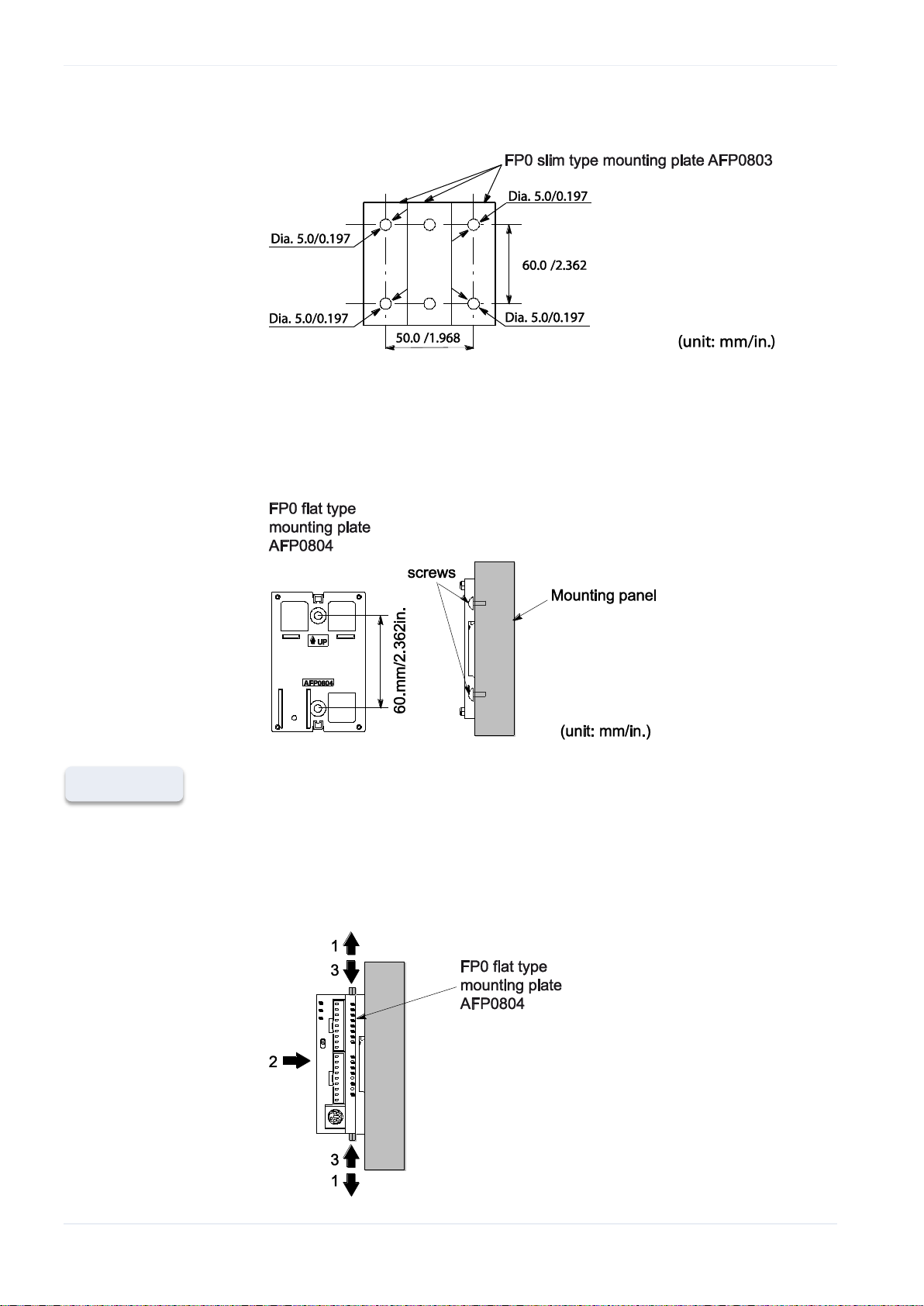

d) Installation Using FP0 Slim Type Mounting Plate

Use M4 size pan-head screws for attachment of FP0 slim type mounting

plate (AFP0803) to mounting panel.

Hardware description

1. Fit the upper hook of the FP Web-Server onto the FP0 slim type

mounting plate

2. Without moving the upper hook, press on the lower hook to fit the FP

Web-Server into position

When using an expansion unit, tighten the screws after joining all of the

FP0 slim type mounting plates to be connected. Tighten the screws at

FP Web-Server V2.810 EN 25

each of the four corners.

Page 27

Hardware description

Procedure

Example: Two Expansion Units

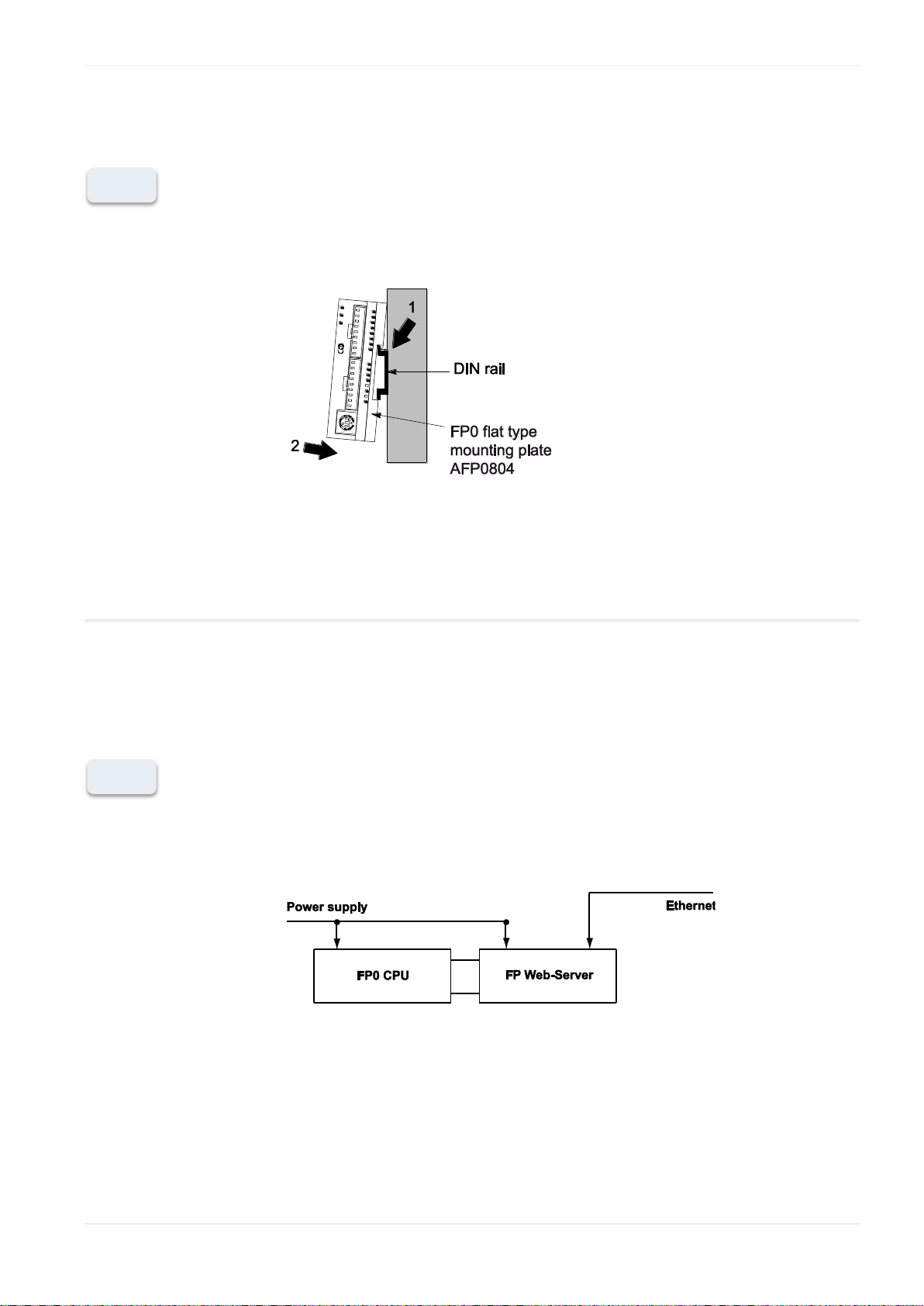

e) Installation Using FP0 Flat Type Mounting Plate

Use M4 size pan-head screws to attach FP0 flat type mounting plate

(AFP0804) and install according to the dimensions shown below.

1. Raise the expansion hooks on the top and bottom of the unit

2. Install the FP Web-Server on the FP0 flat type mounting plate

3. Align the expansion hooks with the plate and press the hooks back

down

26 FP Web-Server V2.810 EN

Page 28

Hardware description

An FP Web-Server with an attached FP0 flat type mounting plate can also

be installed sideways on a DIN rail.

When connecting the power supply (class 2 circuit) make sure

the polarity (+/-) is correct.

The FP Web-Server unit and the PLC have to be supplied by THE

SAME power supply unit.

If power is supplied, the green POWER LED will be ON.

Framing Ground (FG) must be connected.

Please read the Important Notes (see p. 21).

Please also read the "FP Web-Server Leaflet" supplied with your

FP Web-Server.

Note

Note

2.1.9 Connecting the power supply

The FP Web-Server unit will turn ON as soon as the power supply has been

connected.

FP Web-Server V2.810 EN 27

Page 29

Hardware description

Please read the safety instructions in important notes (see p. 21) and also

the section on mechanical installation (see p. 23) carefully.

Note

2.2 FP Web expansion unit

2.2.1 Introduction

The FP Web expansion unit allows you to extend the interfacing possibilities

of the Panasonic FP Web-Server unit.

The following main features are supported:

USB/ Ethernet interface (remote programming monitoring and

visualization)

RS485/ Ethernet interface (remote programming monitoring and

visualization)

High-speed digital output

SD card slot

See the technical data sheet (see p. 29) for supported standards and

protocols.

2.2.2 FP Web expansion unit package

The package for the FP Web expansion unit contains:

FP Web Expansion unit

Leaflet providing installation instructions

Phoenix 3-pin screw terminal

Phoenix 2-pin screw terminal

Comments:

The FP Web expansion unit only works when connected to an FP-WEB2

unit.

The FP-WEB2 unit is configured via the Control FP Web Configurator

Tool.

The Control FP Web Configurator Tool can be purchased separately.

28 FP Web-Server V2.810 EN

Page 30

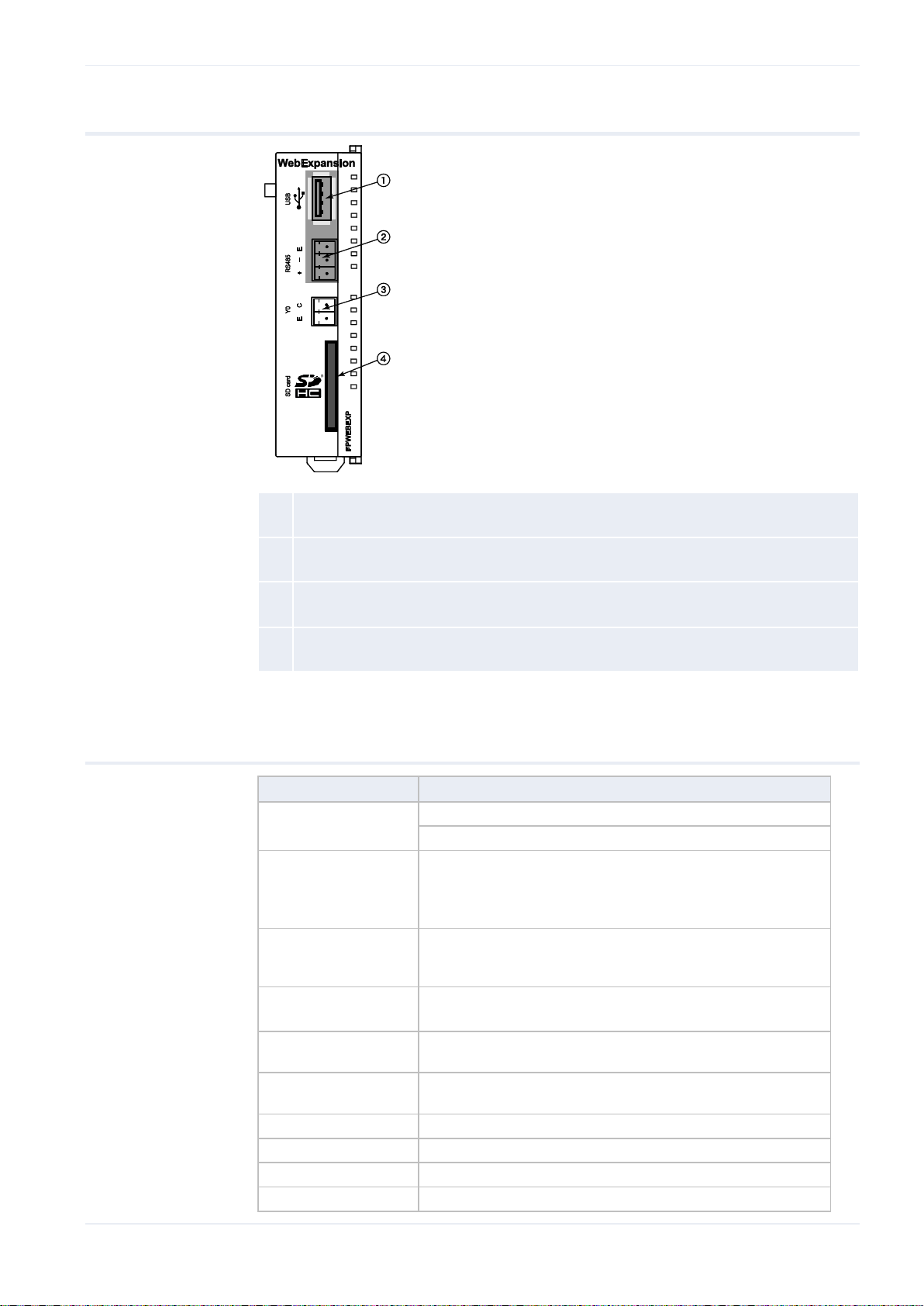

2.2.3 Parts and functions

Q

USB host port

USB 1.1 host port for Panasonic products that are supported by the FP-WEB2.

W

RS485

Screw terminal.

E

High-speed digital output

Optocoupler, phototransistor output.

R

SD card slot

SD/SDHC memory card support

Feature

FP Web Expansion Unit

Product number:

PN Hardware: FPWEBEXP

PN Configurator: FPWEBTOOL2

PLC connection

USB Port: USB 1.1 (refer to targeted peripheral list (see

p. 30))

RS485 via 3-pin screw terminal port plug: Phoenix

product: MC1.5/3-ST-3.5. Order number: 18 40 37 9

Digital output

High-speed digital optocoupler, phototransistor output

(5 to 24V DC, 50mA max., rise time:6µs or less, fall

time: 20µs or less)

SD/SDHC card slot

SD memory card supported (32M to 1GB)

SDHC memory card supported (4GB to 32 GB)

Operating voltage

3.3V DC (internal power supply via 16-pin expansion

connector from FP-WEB2)

Current consumption

Max. additional 20mA at 24V DC (depending on the SD

card used)

Degree of protection

IP20

Ambient temperature

0°C to +55°C

Storage temperature

-20°C to +70°C

Humidity:

Max. 30% to 85% (non-condensing)

Hardware description

2.2.4 Technical data

FP Web-Server V2.810 EN 29

Page 31

Hardware description

Feature

FP Web Expansion Unit

Vibration resistance:

10Hz to 55Hz, 1 cycle per minute with a double

amplitude of 0.75mm; 10 minutes every X-, Y-, and

Z-axis

Shock resistance:

Min. 10g; 4 times every X-, Y-, and Z-axis

Dimensions:

Height 90mm, Width 25mm, Depth 64mm

Weight:

Approx. 66g

Operating

conditions:

Free of corroding gases and excessive influence of dust

CE conformity:

EN 55022:2006 + A1:2007; Class B

EN 55024:1998 + A1:2001 + A2:2003; Class A

Hardware version

Refer to hardware version (see p. 16)

Manufacturer

Model

Vendor

ID

Product

ID

Description

Speed

Panasonic

Electric Works,

Ltd.

GT series

0x0986

0x0310

Panasonic GT

USB driver ver.

1.0

Full speed

Silicon

Laboratories,

Inc.

CP2101 USB

to UART

Bridge

Controller

0x10C4

0xEA60

Panasonic FP-X

series USB

driver

Full speed

2.2.5 Targeted peripheral list of the USB host port

The USB host port of the FP Web expansion unit supports FP-X PLCs and

GT series HMIs. More details can be found in the following targeted

peripheral list.

2.2.6 Important notes

Please also see the installation instruction leaflet supplied with your FP Web

expansion unit for important notes, cables and installation.

To prevent malfunction or failure, please refer to the important notes (see

p. 21) for the FP Web-Server concerning the installation environment and

space.

30 FP Web-Server V2.810 EN

Page 32

2.2.7 Mechanical installation

Refer to the installation instructions leaflet provided with the product for

instructions on:

Connecting the FP Web expansion unit to the FP Web-Server2 unit

Installing the units on a DIN rail.

Reference

For a detailed procedure about one-touch attachment to DIN rails, removal

from DIN rails, installation using FP0 Slim Type Mounting Plate or FP0 flat

type mounting plate, refer to the mechanical installation (see p. 23)

instructions of the FP Web-Server unit.

Hardware description

FP Web-Server V2.810 EN 31

Page 33

First steps

Refer to the e-mail function of the FP Web-Server (see p. 47) for an easy start.

For details on programming e-mail support on the PLC, refer to the

PEW_FPWEB library and its online help.

For further information, refer to Ethernet/serial (RS232C, RS485, USB) ports

(see p. 123).

Reference

Chapter 3

3.1 Getting started

This section describes putting the FP Web-Server into operation for the first

time. The subsequent step-by-step example depicts the general

configuration and use of the FP Web-Server for displaying HTML pages.

First steps

3.2 The Ethernet network

The FP Web-Server is supplied with a 10/100BaseT Ethernet connection.

This type of Ethernet network uses a peer-to-peer connection with twisted

pair cables. To establish a network, hubs and switches are used to connect

the participants in a star-shaped manner.

To be able to configure the FP Web-Server, a Windows computer with an

Ethernet network interface card has to be connected to the same network

as the FP Web-Server. The FP Web-Server can be connected to an existing

Ethernet network.

It is also possible to set up a separate network for the FP Web-Server. The

computer can also be directly connected to the FP Web-Server by using a

special "cross-over" Ethernet cable (see p. 181).

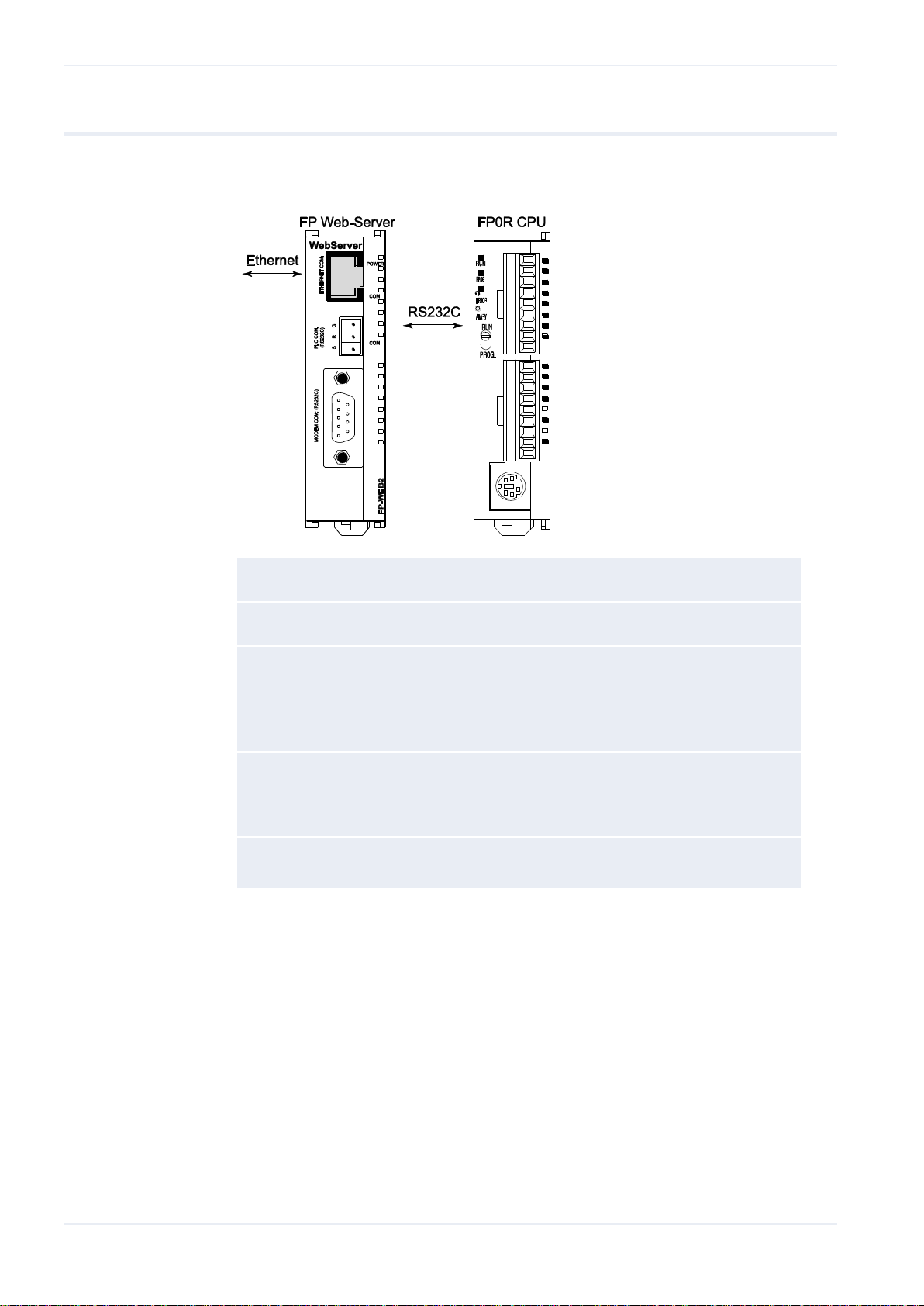

3.3 Connection of the FP Web-Server

For an initial function test (without the PLC data), the FP Web-Server has

to be connected to the Ethernet and be supplied with operating voltage

(24V DC and FG).

32 FP Web-Server V2.810 EN

Page 34

In the second step, the FP Web-Server has to be connected to the PLC (via

Please remember the ID number found on the FP Web-Server's type label.

You will need it when you configure the Web-Server.

Note

RS232C). The RS232C setting of the PLC must correspond to that of the FP

Web-Server. This setting can be defined in the PLC program (FPWIN Pro)

under the system parameter settings.

3.4 Installation of the Configurator program

First steps

Further information:

To be able to configure the FP Web-Server, a Windows computer with an

Ethernet network interface card has to be connected to the same network

as the FP Web-Server. The computer must be configured in such a way

that it supports the TCP/ IP network protocol.

To install the Configurator (administrator rights are needed), start the

setup program on the CD and follow the instructions of the installation

program "Control FP Web Configurator Tool". Various examples (see

"Description of the HTML examples" on p. 173) and HTML pages are

installed along with the Configurator. In addition, the tool DnsDisp.exe,

which locates DNS addresses of an Internet Service Provider (ISP), is

copied to the installation folder.

Contents of the CD and Auxiliary Programs (see p. 173)

The Configurator can be started in the Windows start menu under

Program files Panasonic-ID SUNX Control FP Web

Configurator 2 FP Web Configurator 2.

3.5 Determination of the IP configuration

Every Ethernet participant must have an individual IP address. This address

may not be used a second time in the same network. The IP address (see

p. 179) consists of 4 numbers (0 to 255). The first numbers define the

FP Web-Server V2.810 EN 33

Page 35

First steps

Procedure

network address, the other numbers define the participant's address. The

IP address of the FP Web-Server can be fixed or it can be allocated

dynamically by a DHCP-Server.

1. In a "self set-up" network (e.g. with only one hub) the IP addresses can

be assigned by yourself

In this case, do not use DHCP. For further information refer to Setup of

an Individual Ethernet LAN (see p. 181).

2. If the FP Web-Server is to be connected to an existing network, the

following data must be obtained from the network administrator:

Is there a DHCP-Server in the network? If NOT:

IP address: Which fixed IP address can be assigned to the FP

Web-Server?

Netmask: How is the network address set up (length of the network

address and/or the participant's address)?

Gateway: What is the gateway's IP address? (0.0.0.0 if there is no

gateway to be used).

3.6 Generate a new Configurator project

After having started the Configurator, a Configurator project can be opened

from the local hard drive with [OPEN]. A Configurator project consists of:

the configuration,

the e-mail texts, and

the HTML pages.

Upon the initial start, the "default_project" is automatically offered with

[OPEN]. With [OPEN] you can also load one of the examples (see

34 FP Web-Server V2.810 EN

"Description of the HTML examples" on p. 173). You can save it under a

new name with [SAVE AS]. On the "Config" page you can adjust the

following, most important settings. You must configure at least the

following:

The IP configuration (see "Determination of the IP configuration" on p.

33) has to be entered according to the destination network.

Page 36

First steps

The serial interface parameter used by whatever functions have been

configured. the PLC may have to be adjusted (RS232C, 19200 8O1 is

pre-adjusted).

It is also recommended to enter an individual user name and a

password of your own.

The HTTP server has to be activated for this initial test (please turn off

e-mail and PPP!):

For the initial test, no other parameters have to be altered. Save the

changed project with [SAVE].

Comments:

To receive additional help and information on the various Configurator

entries, please move the cursor to the respective input field and press

<F1>.

The "default_project" works without PLC data, i.e. it does not need to

be connected to the FP Web-Server. Nevertheless, in case "Example First web page with PLC data" is used, a PLC should be connected.

FP Web-Server V2.810 EN 35

Page 37

First steps

3.7 Transfer a Configurator project to the FP Web-Server

Use [FIND] to search the network for all FP Web-Servers. A list of all FP

Web-Servers found will be displayed. Please select the ID number of the

respective FP Web-Server (double-click or press <ENTER>).

If the FP Web-Server is put into operation for the first time (or a new

version of the Configurator has been installed), please initialize the FP

Web-Server ONCE before transferring the project, i.e. click [INITIALIZE]

and answer the safety request with [YES].

As there are HTML pages required for this initial test, the check box "Web

files" should be activated. With [SEND] you can transfer the project

(configuration plus HTML pages) to the respective FP Web-Server.

Please click [REBOOT] after transmission. Wait a little bit and then click

[FIND] again to make sure that the FP Web-Server is online again and to

find out which IP address it is using.

Comments:

Please memorize the IP address for the following tests with the browser

below.

If the FP Web-Server was configured with the wrong fixed IP address, a

query with [FIND] will result in an error message.

36 FP Web-Server V2.810 EN

Page 38

First steps

If an error message is displayed, click [YES]. This sets the FP

Web-Server to the IP address entered in the current Configurator

project. After a short waiting period, click [FIND] again.

If the current password of the FP Web-Server is not the same as the

password of the project, the user name and the password are requested

before transmission and/or restart ([SEND], [INITIALIZE], [REBOOT]).

Please refer to "Trouble Shooting (see p. 185)" if any problems occur

with the functions FIND, SELECT, INITIALIZE or SEND.

3.8 Test the FP Web-Server with an Internet browser

The HTML pages of the FP Web-Server can be displayed with a standard

Internet browser. Start the Internet browser and enter the IP address of

the FP Web-Server into the address field.

The HTML page "main.htm" of the FP Web-Server will be displayed. For

the "Default_Project" (without PLC data, FP Web-Server may not be

connected to a PLC) for example:

FP Web-Server V2.810 EN 37

Page 39

First steps

Comments:

Or for "Example - First web page with PLC data" (with PLC data):

Main.htm has the following restrictions: You cannot use PLC data items

and you cannot use password protection.

If the FP Web-Server is operated in an office network with a Proxy

gateway to the Internet, accessing the FP Web-Server HTML pages

might take a long time. In this case, shut off the Proxy function of the

browser for this specific IP address of the FP Web-Server. For the

browser setup also refer to TCP/IP Setup: Configurator/Browser

Operations Via LAN.

3.9 Further information

Details on FP Web-Server's web page functions (see p. 81)

The PLC sends e-mails (alarm e-mails with FPWIN Pro library (see p.

47))

Details on Ethernet/serial (RS232C, RS485, USB) ports (see p. 123)

Dial-up networking setup for computer and FP Web-Server (see "Dial-in

networking setup for computer/FP Web-Server" on p. 130)

IEC 60870 functions of the FP Web-Server (see p. 163)

38 FP Web-Server V2.810 EN

Page 40

Configurator Software

Chapter 4

Configurator Software

4.1 General information on the FP Web-Server Configurator

The FP Web Configurator administers "Configurator projects". These consist

of:

FP Web-Server project file (FP-Web.fpw)

FP Web-Server configuration (CHIP.INI file)

IEC 60870 configuration (mew60870.ini)

E-mail texts (MAIL_x.TXT files)

Data logger setting files (pewlog1.bin, pewlog2.bin)

Web files (MAIN.HTM; *.HTM; *.GIF; *.JPG; *.XML ...)

Certificate files for https

Every Configurator project is stored in a separate folder. A project consists

of e-mail text files, .INI text files and a sub-folder "http" in which all the

Web pages for the FP Web-Server are stored.

There are 3 ways to start the FP Web Configurator:

1. Start Program Files Panasonic-ID SUNX Control FP Web

Configurator 2 FP Web Configurator 2

2. Double-click the project file *.fpw of the project within the file explorer

3. Via a console command line that includes the configuration to be

opened

Select Start Run

FP Web-Server V2.810 EN 39

Page 41

Configurator Software

Enter e.g.: C:\Program Files (x86)\Panasonic-ID SUNX Control\FP Web

Configurator 2\FP Web Configurator 2\FPWebConfigurator.exe

Example - AJAX basics\FPWEB_AJAX\FP-Web.fpw

To administer ([OPEN], [SAVE]...) "Configurator projects", edit the

configuration (including e-mail texts and Web files) and to control the FP

Web-Server (transmission of files, initialization, reboot...), the FP Web

Configurator provides the following main components:

Control buttons (see p. 39)

Base configuration (see p. 44)

E-mail configuration and texts (see p. 47)

Web files and editor call (see p. 81)

Ethernet/Serial (RS232C, RS485, USB) ports configuration (see p. 123)

PPP server configuration (see p. 130)

IEC 60870 functions of the FP Web-Server (see p. 163)

PPP-Client Dial-Out (see p. 153)

NTP-Time (see p. 155)

Modbus functions (see p. 157)

SNMP functions (see p. 169)

FTP client functions (see p. 52)

Data logger functions (see p. 61)

and some more...

40 FP Web-Server V2.810 EN

Page 42

Configurator Software

In the following sections, the individual command buttons of the first page

("Project" page) of the Configurator are described in detail:

4.2 Control buttons for administering the "Configurator Project"

For a detailed description of the control buttons, refer to the online help

under the respective keyword of the button.

4.3 Control buttons for the remote FP Web-Server unit

FP Web-Server V2.810 EN 41

Page 43

Configurator Software

4.3.1 Compare

For a detailed description of the control buttons, refer to the online help

under the respective keyword of the button.

[Compare] will download the configuration file of the project from the

remote unit to the local disk. When the download is completed, the file will

be compared with the opened project configuration file. The number of

found differences will be shown in a little message box. Max. 8 (normally 5)

messages will be shown in the message box. An indication for more

differences is the '...' at the end of the message box. The value showed in

the message box (e.g. RS485 baud rate: 19200) is always the setting of

the remote unit.

Not all configuration parameters will be compared. Here is a list of

parameters that will NOT be compared:

Security settings (like user name, password, iplock etc.)

IEC60870 settings (only enable will be compared)

Datalogger log file settings

FPWEB Script file

E-mail texts

After the comparison is finished, the downloaded configuration file will be

deleted automatically.

42 FP Web-Server V2.810 EN

Page 44

4.4 System icon menu

Click the system icon on the title bar to open a menu, e.g. to:

change the user interface language of the FP Web Configurator

open a comment dialog

find out the software version

Configurator Software

FP Web-Server V2.810 EN 43

Page 45

Base configuration

Chapter 5

5.1 Main settings ("Config")

The main settings for the FP Web-Server are adjusted on the "Config" tab.

An Ethernet IP address (see p. 45) must be entered.

The parameters for the PLC interface may have to be adjusted (the

following figure shows the default settings).

We recommend that you specify a user name and password.

An additional static 2nd LAN IP address for the FP Web-Server unit can

be set, DNS can be enabled, the system restart function of the

Base configuration

FP-WEB2 can be activated and FTP access to the SD memory card of

the FP Web expansion unit can be restricted.

44 FP Web-Server V2.810 EN

Page 46

5.1.1 Ethernet IP address

Procedure

Every Ethernet participant must have an individual IP address. This address

may not be used a second time in the same network. The IP address

consists of 4 numbers (all numbers must be between 0 and 255, see also

IP and TCP/ IP (see p. 179)). The first numbers define the network

address, the other numbers define the participant's address.

Base configuration

The IP address of the FP Web-Server can be fixed or it can be allocated

dynamically by using a DHCP-Server.

1. In a "self set-up" network (see p. 181) (e.g. with only one switch), you

can assign the fixed IP addresses yourself

In many cases a class C network is used. The network is identified by 3

numbers. The participants (computers, units, FP Web-Server...) are

distinguished by the last number (1 to 254), e.g. 192.168.206.1 to

192.168.206.254.

If this network is connected to a second network via a gateway (e.g.

the computer for configuration might be in this network), the gateway

address also needs to be specified, e.g.:

Computer in x.y.206.z network with netmask 255.255.255.0, using the

x.y.206.1 gateway.

FP Web-Server in x.y.60.z network with the following settings:

FP Web-Server V2.810 EN 45

IP Add=x.y.60.31

Netmask=255.255.255.0

Gateway=x.y.60.1

2. If the FP Web-Server should be connected to an existing network, the

following data must be requested from the network administrator:

Is there a DHCP server in the network? If NOT:

IP address: Which fixed IP address can be assigned to the FP

Web-Server?

Page 47

Base configuration

For further information please refer to the online help under the keywords

"User name and password", "DNS parameter settings", PLC link interface"

or "Selection of the main functions".

Reference

Netmask: How is the network address set up (length of the network

address and/or the participant's address)?

Gateway: What is the gateway's IP address? (0.0.0.0 if there is no

gateway to be used).

46 FP Web-Server V2.810 EN

Page 48

Chapter 6

6.1 E-mail functions of the FP Web-Server

The FP Web-Server can send e-mails, e.g. in case of an alert. An existing

e-mail server (see p. 49) is used to distribute the e-mails triggered by the

PLC. The PLC can use predefined text messages (stored in the FP

Web-Server) as well as variably created e-mail texts (stored as ASCII

strings in the PLC). The FP Web-Server informs the PLC if the e-mail has

been sent correctly.

After a predefined interval, e.g. every 7 seconds, the FP Web-Server

E-mail setup

E-mail setup

checks an internal flag of the PLC (via MEWTOCOL) to find out if the PLC

wants to send an e-mail. The polling interval between PLC requests (and

the address of the PLC internal flag that starts the sending of the e-mail)

can be defined in the Configurator project.

Optionally, a file attachment holding PLC data can be generated.

If the HTTP/HTTPS server and/or the Ethernet<-> RS232C/RS485/USB

ports are carrying out MEWTOCOL communication with the PLC at the same

time, the polling time ís longer than specified in the configuration.

Especially when carrying out the multi-frame MEWTOCOL commands (PLC

program download) via the Ethernet<-> RS232C/RS485/USB ports, the

e-mail polling of the PLC internal flag can be delayed.

For examples on sending e-mails from the PLC, refer to the PEW_FPWEB

library or try the examples below.

A) Using an e-mail server via Ethernet LAN:

Please ask your network administrator whether the following

requirements are met:

An e-mail SMTP server in the LAN is required. Also refer to setup of an

individual Ethernet LAN (see p. 181).

The address of the e-mail server must be correct in the Configurator

project.

A defined e-mail address, which is known to the e-mail-server, should

be assigned to the PLC (or the FP Web-Server).

FP Web-Server V2.810 EN 47

Page 49

E-mail setup

See the Configurator project "Example - Web pages and e-mail" for

Ethernet LAN usage.

See the Configurator project "Example - PPP-VPN-NTP-SMS" for Internet

e-mail.

For further information, refer to the online help under the keyword "Periodic

communication tests".

For details on programming e-mail support on the PLC, refer to the

PEW_FPWEB library and its online help.

Example

Example

Reference

B) Dialing up an e-mail server in the Internet:

A modem is needed to dial up an ISP.

An e-mail account of an Internet e-mail ISP is needed.

To set up an ISP, refer to Internet e-mail settings (see p. 146).

6.1.1 E-mail function used for communication tests

Communication tests can be used with empty e-mails for a DNS request.

For continuous Internet connections (router, VPN, GPRS ...), it is

sometimes necessary to test the communication, i.e. to test the availability

of radio connections or to distribute the end unit's IP address after a restart

in case bridges or routers are used. In such cases, the DNS request

function for e-mail sending can be used. The PLC should periodically try to

send an e-mail, but the e-mail recipient address should not be set (empty

string). Then a DNS request is sent by FP Web-Server (after an optional

Internet dial-up), which tests the communication. Do not forget to set up

the FP Web-Server with a valid e-mail server name and existing DNS

server IP address.

48 FP Web-Server V2.810 EN

Page 50

6.1.2 E-mail server for LAN or Internet

A) E-mail server in the LAN

The FP Web-Server was developed to cooperate with an e-mail server in

your local network. Often, e-mail servers also allow the transmission of

SMS and FAX via e-mail. To send an e-mail to someone via the Internet,

the e-mail server needs to have access to the Internet. This poses no

problem if you are using an e-mail server in your LAN that uses the proxy

server to connect to the Internet. Contact your network administrator for

detailed information.

You only need to set the following e-mail server parameters (also refer to

the online help under the keyword "Example - Web pages and e-mail" of

the HTML examples)

E-mail setup

B) Internet e-mail

Server IP address (SMTP server) and port number

E-mail sender address

These parameters are available from your network administrator.

Optionally, you can use the server name (DNS is required) and you can log

in with a POP3 server. More detailed information can be found in the online

help under e-mail server settings.

The FP Web-Server can also use a modem connected to the 9-pin port to

establish a dial-up connection to the Internet and send e-mails via an

Internet Service Provider.

For this function, you need a modem (or GSM module) and the following

parameters:

Dial-up ISP account and DNS server address (for detailed information

refer to Internet e-mail settings (see p. 146))

Two e-mail server names (SMTP and POP3) and ports (for detailed

information refer to the online help under e-mail server settings)

E-mail account with user name and password, see also e-mail server

settings

E-mail sender address

These parameters are available at your ISP (for detailed information also

refer to the online help under e-mail server settings).

FP Web-Server V2.810 EN 49

Page 51

E-mail setup

Procedure

6.1.3 How to find out the address of the e-mail server

Normally the name of the e-mail servers can be found on the Internet

pages of the e-mail ISP. See sections on the Internet page called

"Technical details", "Experts" or "How to set up e-mail client program".

Please also make sure that no ASMTP (special encrypted login method) is

needed. The FP Web-Server only supports plain "SMTP after POP3" and

ESMTP authentication.

If possible, find out the names' IP addresses. You can request them from

the e-mail ISP or by using a Windows computer:

1. Configure and establish a remote network connection to the Internet

(via modem)

2. At the DOS command prompt, enter the command “PING xyz” which

displays the IP address

'xyz’ indicates where the SMTP (POP3) e-mail server name is.

50 FP Web-Server V2.810 EN

Page 52

6.2 E-mail tab input fields

In this section, the input fields on the "E-mail" tab are described.

E-mail setup

For context-sensitive help, highlight the button or entry field (using

<Tab>) and press <F1>.

For further information please refer to the online help under the keywords

"E-mail tab input fields".

6.3 E-mail via SSL

Since 2014 most e-mail providers have changed their server from normal

connections to SSL/TLS connections (Secure Socket Layer/Transport Layer

Security). This SSL/TLS connection should ensure that all transmitted

e-mails are encrypted so that they cannot be read by a third party. The FP

Web-Server supports SSL 3.0 / TLS 1.0 (TLS is the successor of SSL).

If your e-mail provider only works with SSL/TLS, please refer to the

information in this chapter.

For more detailed information, refer to the online help under the keyword