Programmable Controller

User's Manual

FP-Industry 4.0 Communicator

(FP-I4C)

ACGM0162V3EN

2021.01

industry.panasonic.eu

Before beginning

Before beginning

Liability and copyright

This manual and everything described in it are copyrighted. You may not copy this manual, in

whole or part, without written consent of Panasonic Electric Works Europe AG (PEWEU).

PEWEU pursues a policy of continuous improvement of the design and performance of its

products. Therefore, we reserve the right to change the manual/product without notice. In no

event will PEWEU be liable for direct, special, incidental, or consequential damage resulting

from any defect in the product or its documentation, even if advised of the possibility of such

damages.

We invite your comments on this manual. Please e-mail us at:

techdoc.peweu@eu.panasonic.com.

Limited warranty

Please direct support matters and technical questions to your local Panasonic

representative.

If physical defects caused by distribution are found, PEWEU will replace/repair the product

free of charge. Exceptions include:

• When physical defects are due to different usage/treatment of the product other than

described in the manual.

• When physical defects are due to defective equipment other than the distributed product.

• When physical defects are due to modifications/repairs by someone other than PEWEU.

• When physical defects are due to natural disasters.

2 FP-I4C

Software legal notices

This product incorporates the following software:

(1) The software developed independently by or for Panasonic Electric Works Europe AG,

(2) the software owned by third party and licensed to Panasonic Electric Works Europe AG,

(3) the software licensed under the GNU General Public License, Version 2.0 (GPL V2.0),

(4) the software licensed under the GNU LESSER General Public License, Version 2.1

(LGPL V2.1), and/or

(5) open source software other than the software licensed under the GPL V2.0 and/or LGPL

V2.1.

The software categorized as (3) - (5) are distributed in the hope that it will be useful, but

WITHOUT ANY WARRANTY, without even the implied warranty of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE.

Software legal notices

Please refer to the detailed terms and conditions thereof shown in the device settings menu.

At least three (3) years from delivery of this product, Panasonic will give to any third party

who contacts us at the contact information provided below, for a charge no more than our

cost of physically performing source code distribution, a complete machine-readable copy of

the corresponding source code covered under GPL V2.0, LGPL V2.1 or the other licenses

with the obligation to do so, as well as the respective copyright notice thereof.

Contact information: plc.peweu@eu.panasonic.com

FP-I4C 3

Important symbols

Important symbols

One or more of the following symbols may be used in this documentation.

The following symbols are used to indicate the type of hazard.

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Indicates a property damage message.

4 FP-I4C

Safety precautions

Observe the following notices to ensure personal safety or to prevent accidents. To ensure

that you use this product correctly, read this User’s Manual thoroughly before use. Make

sure that you fully understand the product and information on safety.

• Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

• Do not use this product in areas with inflammable gas. It could lead to an explosion.

• Exposing this product to excessive heat or open flames could cause damage to electronic

parts.

Safety precautions

• To prevent abnormal exothermic heat or smoke generation, do not use this product

continuously at the maximum performance values listed in the specifications.

• Do not disassemble or modify the product. It could lead to abnormal exothermic heat or

smoke generation.

• Do not touch the terminals while the electricity is turned on. It could lead to an electric

shock.

• Use external devices to ensure safety related functions such as the emergency stop and

interlock circuit.

• Connect the wires and connectors securely. A loose connection might pose an electrical

hazard, which could result in a short-circuit, exothermic heat or smoke generation.

• Do not allow foreign matter such as liquid, flammable materials, metals to enter the

product. It could cause excessive exothermic heat or smoke generation.

• Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

FP-I4C 5

Network security

Network security

Implementing measures to protect your network is crucial to keep your network and its traffic

secured.

As you will use this product connected to a network, your attention is called to the following

security risks.

• Leakage or theft of information through this product

• Use of this product for illegal operations by persons with malicious intent

• Interference with or stoppage of this unit by persons with malicious intent

It is your responsibility to take precautions such as those described below to protect yourself

against the above network security risks.

• If this product is connected to a network that includes PCs, make sure that the system

is not infected by computer viruses or other malicious entities (using a regularly updated

antivirus program, anti-spyware program, etc.).

• Use this product in an environment that has LAN, VPN (virtual private network) or leased

line network.

• Use this product in an environment where only limited people concerned can enter.

• Use this product and connected devices such as a PC and tablet securing safety.

• Do not install this product in locations where the product or the cables can be destroyed

or damaged by persons with malicious intent.

Note that incorrect setting of the connection to the existing LAN might cause malfunction in

the devices on the network. Consult your network administrator before connecting.

6 FP-I4C

Table of contents

Table of contents

Before beginning.......................................................................................................................... 2

Software legal notices................................................................................................................. 3

Important symbols....................................................................................................................... 4

Safety precautions....................................................................................................................... 5

Network security...........................................................................................................................6

1 Product overview........................................................................................................................9

1.1 Product package............................................................................................................................... 9

1.2 System requirements........................................................................................................................ 9

1.3 Features............................................................................................................................................ 9

1.4 Part names......................................................................................................................................11

1.5 Status LEDs.................................................................................................................................... 12

1.6 Reset tact switch............................................................................................................................ 13

1.7 Devices supported by USB host ports........................................................................................... 13

1.8 Specifications.................................................................................................................................. 14

1.9 Dimensions......................................................................................................................................15

2 Installation................................................................................................................................. 16

2.1 General installation procedure........................................................................................................16

2.2 Installation environment.................................................................................................................. 17

2.3 Installation space............................................................................................................................ 18

2.4 Attach the unit to a DIN rail........................................................................................................... 18

2.5 Remove the unit from a DIN rail.................................................................................................... 19

2.6 Install the unit on a slim type mounting plate................................................................................ 19

2.7 Install the unit on a flat type mounting plate.................................................................................. 20

2.8 Add FP0/FP0R expansion units to the FP-I4C unit....................................................................... 21

3 Wiring.........................................................................................................................................23

3.1 Connection to PLC TOOL port using cable AIGT8192.................................................................. 23

3.2 Connection to PLC COM port........................................................................................................ 23

3.3 RS485 connection to Eco-POWER METER.................................................................................. 24

3.4 Wire the power supply....................................................................................................................25

4 Getting started.......................................................................................................................... 26

4.1 Overview......................................................................................................................................... 26

4.2 Getting connected to the FP-I4C unit.............................................................................................27

FP-I4C 7

Table of contents

4.3 Connect the FP-I4C unit directly to a PC.......................................................................................27

4.4 Connect the FP-I4C unit to a PC via DHCP server....................................................................... 28

4.5 Change the default user names and passwords............................................................................29

4.6 User rights.......................................................................................................................................30

5 Example: Data logging from different devices......................................................................32

5.1 Functional overview........................................................................................................................ 32

5.2 Connect the devices.......................................................................................................................32

5.3 Make FP-I4C communication settings............................................................................................34

5.4 Make PLC communication settings................................................................................................ 35

5.5 Configure data logging for FP0R....................................................................................................35

5.6 Configure data logging for KW2M..................................................................................................36

5.7 Configure data logging for KW9M..................................................................................................37

5.8 Import variables from CSV files......................................................................................................39

5.9 List and download log files.............................................................................................................40

6 Example: HTTP connection to a cloud server...................................................................... 41

6.1 Functional overview........................................................................................................................ 41

6.2 Connect the devices.......................................................................................................................41

6.3 Make FP-I4C communication settings............................................................................................42

6.4 Configure the HTTP client and download the sample files............................................................ 43

6.5 Set up the programming examples................................................................................................ 44

6.6 Get weather data from a cloud server........................................................................................... 44

6.7 Forward weather data to a dashboard........................................................................................... 45

6.8 Minimize security risks....................................................................................................................46

7 Example: Web-based data visualization................................................................................ 47

7.1 Functional overview........................................................................................................................ 47

7.2 Connect the devices.......................................................................................................................47

7.3 Make FP-I4C communication settings............................................................................................48

7.4 Make PLC communication settings................................................................................................ 49

7.5 Configure the PLC connections......................................................................................................50

7.6 Create tags for PLC variables........................................................................................................51

7.7 Create a simple HTML page.......................................................................................................... 52

7.8 Import variables in HMWIN Studio.................................................................................................53

8 Record of changes...................................................................................................................54

8 FP-I4C

1 Product overview

1.1 Product package

The FP-I4C product package contains the following items.

• 1 x FP-Industry 4.0 Communicator (FP-I4C unit)

Product number: AFP4C

• 1 x 24V DC power supply cable

Product number: AFPG805

• 1 x leaflet providing installation instructions

• 1 x 16-pin spring force plug (Phoenix Contact Co. MC0.5/8-ST-2,5)

1 Product overview

1.2 System requirements

To configure your applications and to access FP series PLCs via Ethernet, you only need a

standard browser. For HMWIN Studio, your PC must meet some basic requirements.

Supported browsers:

• Microsoft Edge

• Mozilla Firefox

• Google Chrome

• Safari

• Opera

HMWIN Studio has the following system requirements:

• Microsoft Windows® 7, Windows® 8.x or Windows® 10

• Hard disk with at least 500MB free disk space, 512MB RAM, Ethernet connection

HMWIN Studio can be downloaded free of charge from the Panasonic Download Center.

1.3 Features

The FP-I4C unit works as an interface between a LAN or a WAN network (Internet/Intranet)

and all PLCs of the FP series.

The FP-I4C unit comes in a compact housing with multiple interfaces and offers various

services for data exchange.

FP-I4C 9

1 Product overview

RS232C/Ethernet interface:

• RS232C interface and a switchable RS232C/RS485 interface for PLC connections

• 2 Ethernet 10BASE-T/100BASE-T interfaces for network connections

• RS232C to Ethernet redirection

• Programming and visualization tools access via Ethernet

• Optional password protection and IP lock security

Other interfaces:

• 2 USB 2.0 host ports

• 2 digital function inputs

Web server:

• Representation of PLC data in individually created HTML5 pages

• Access via standard Internet browsers

• Password protection

Modbus RTU/TCP:

• Modbus RTU master/slave functionality

• Modbus-TCP client/server functionality

• Modbus RTU/TCP gateway

• MEWTOCOL/Modbus gateway

Data logger:

• Logging of PLC data and storage of logged data in the internal memory or transmission

via FTP

Secure data transmission and authentication:

• Communication via OpenVPN to ensure encrypted and secure data transmission and

authentication

MQTT:

• Communication in the Internet of Things (IoT)

SQL:

• Connection to databases

HTTP client:

• Communication with cloud services

REST API:

• Reading and writing PLC data using HTTP requests (GET, POST)

IEC60870 protocol:

• IEC60870-5-104 standard telecontrol communication protocol via Ethernet

10 FP-I4C

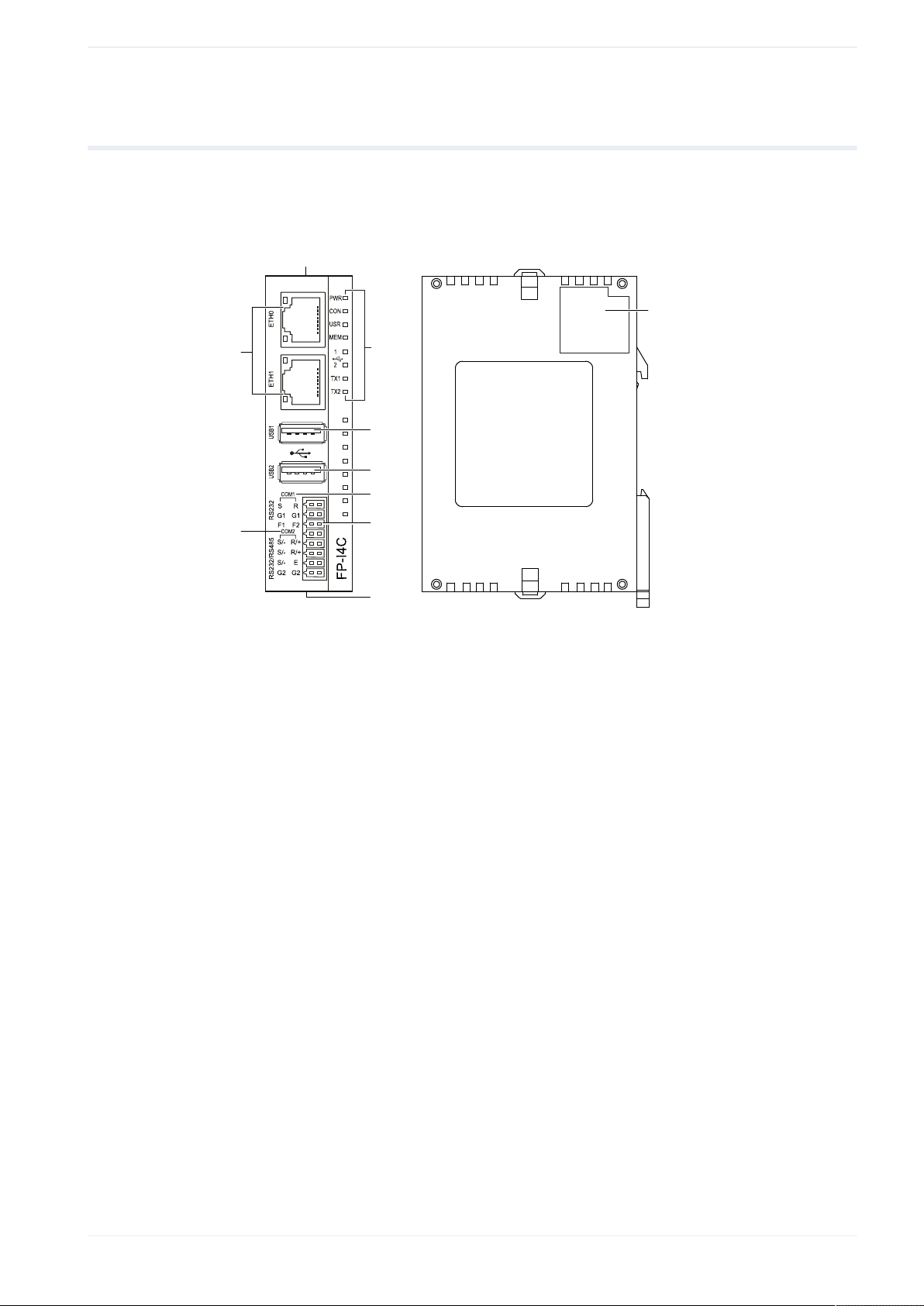

1.4 Part names

The FP-I4C unit is equipped with multiple communication interfaces, status LEDs, function

inputs, a reset tact switch, and an expansion connector.

1 Product overview

(1)

(10)

(3)

(8)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(2)

(4)

(5)

(6)

(7)

(9)

Reset tact switch

Status LEDs

ETH0, ETH1, Ethernet connectors

USB1, USB 2.0 host port (500mA)

USB2, USB 2.0 host port (100mA)

COM1 RS232 (non-insulated)

F1, F2, function inputs (pull-up design)

COM2 RS232/RS485 (insulated, switchable)

24V DC power supply connector

Expansion connector for FP0/FP0R expansion units (16 pins)

Related topics

Reset tact switch (page 13)

Wire the power supply (page 25)

Status LEDs (page 12)

FP-I4C 11

1 Product overview

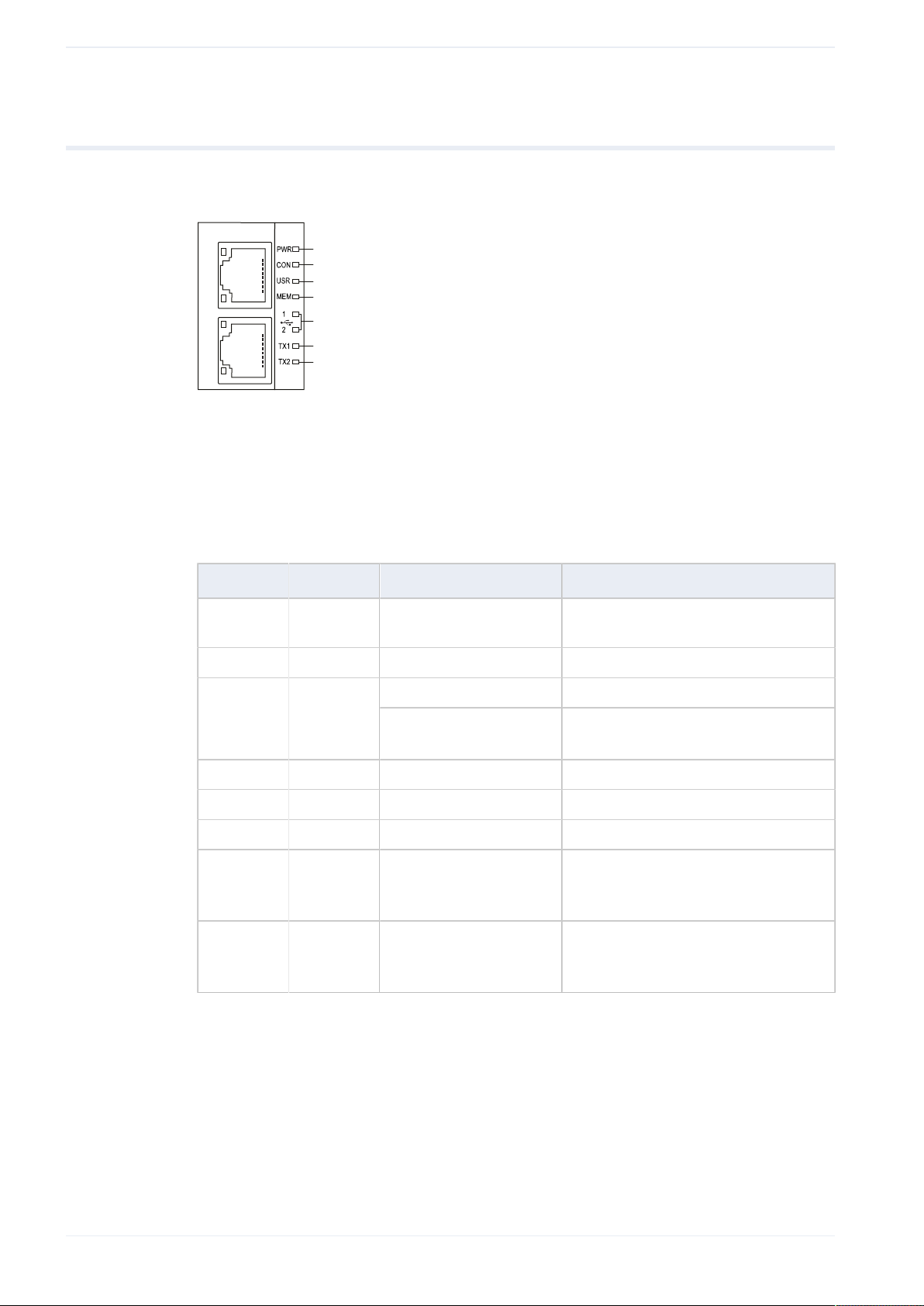

1.5 Status LEDs

The LEDs on the FP-I4C unit display the operation and communication status.

ETH0

ETH1

(1)

PWR

(2)

CON

(3)

USR

(4)

MEM

(5)

USB 1, USB 2

(6)

TX1

(7)

TX2

(1)

(2)

(3)

(4)

(5)

(6)

(7)

LED Color LED status Description

PWR Green On Power supply is on and self-test is

completed.

CON Yellow User-defined User-defined, controlled by script function

User-defined User-defined, controlled by script functionUSR Yellow

Flashes

(heartbeat 1/s)

MEM Orange On Data is written to the USB flash drive.

USB 1 Green On A device is connected to USB port 1.

USB 2 Green On A device is connected to USB port 2.

TX1 Green Flashes

(rate depending on data

traffic)

TX2 Green Flashes

(rate depending on data

traffic)

A system reset initiated by the reset tact

switch is active.

Communication via COM1 (RS232) is

active.

Communication via COM2 (RS232/

RS485) is active.

Related topics

Reset tact switch (page 13)

12 FP-I4C

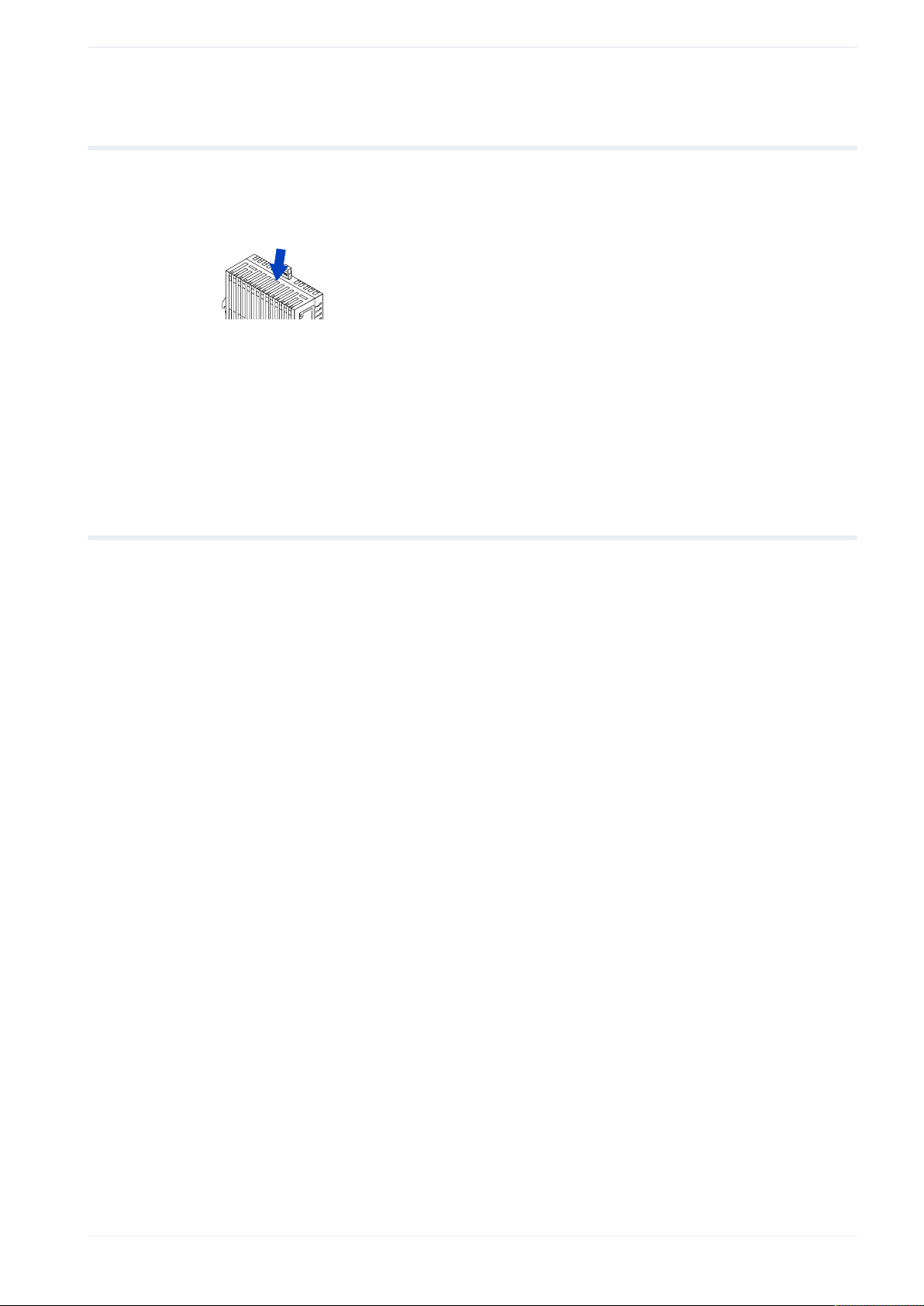

1.6 Reset tact switch

A small tact switch within the housing on the top side can be used to restart or to reset the

FP-I4C unit.

To restart or to reset the unit, use a paperclip or similar and press the tact switch 3 times

within 3s. The yellow USR LED starts flashing (heartbeat 1/s).

• To restart the unit, press the tact switch again for 3 to 6s.

• To reset the unit to the factory settings, press the tact switch again for at least 6s. The unit

will be restarted and all user data are removed.

1 Product overview

1.7 Devices supported by USB host ports

The USB host ports support the FP series PLCs and GT series HMIs listed in the following

targeted peripheral list.

Commercial USB flash drives and hard disks (max. 500mA on upper USB connector) can

also be connected.

• Panasonic GT USB driver ver. 1.0

Model: GT series, manufacturer: Panasonic Electric Works, Ltd., vendor ID: 0x0986,

product ID: 0x0310

• Panasonic FP series USB driver

Model: PLC FP0H, FP7, FP0R, manufacturer: Panasonic Electric Works, Ltd., vendor ID:

0x0986, product ID: 0x0320

• Panasonic Eco-POWER METER

Model: Eco-POWER METER, manufacturer: Panasonic Electric Works, Ltd., vendor ID:

0x04da, product ID: 0x4201

• Panasonic FP-X series USB driver

Model: CP210x UART Bridge, e.g. FP-X, manufacturer: Cygnal Integrated Products,

vendor ID: 0x10C4, product ID: 0xEA60

FP-I4C 13

1 Product overview

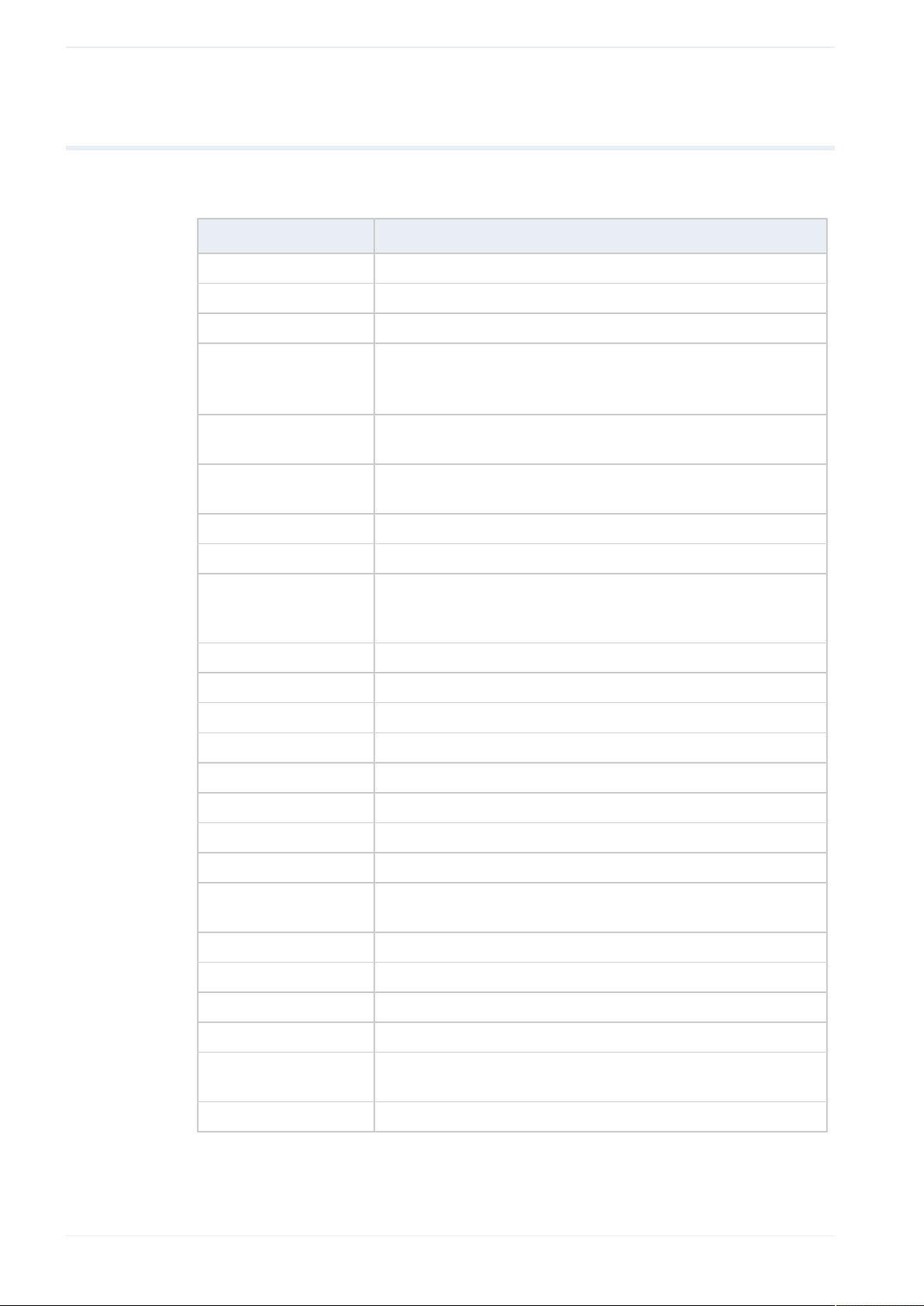

1.8 Specifications

The FP-I4C unit has the following characteristics and technical specifications.

Item Description

Product number AFP4C

Rated input voltage 24V DC, use the power supply cable (AFPG805) supplied with the unit

Operating voltage range 21.6–26.4V DC, supplied by class 2 circuit only

Serial interfaces COM1 RS232 (non-insulated), COM2 RS232/RS485 (insulated,

Ethernet 2 Ethernet connectors, 10BASE-T/100BASE-TX auto-negotiation via

USB 2 USB connectors, USB 2.0 full speed, max. 500mA (USB1), max.

switchable)

16-pin spring force plug by Phoenix Contact Co. (MC0.5/8-ST-2,5)

RJ45 female connector

100mA (USB2)

Function inputs 2 binary inputs (pull-up design) for optional functions

Operation status LEDs 7

Protocols and standards TCP/IP, UDP/IP, DHCP, FTP, FTPS, SSH, http, https, SMTP, ESMTP-

Auth, POP3, NTP, Modbus, DNS, SNMP, VPN, VNC, MQTT, SQL,

OPC UA

Flash memory 2.4GB user/configuration data

RAM 496MB

Current consumption ≈75mA at 24V DC (without expansion unit, USB flash memory, etc.)

Degree of protection IP20

Operating temperature 0°C to +55°C

Storage temperature -20°C to +70°C

Operating humidity 10%–95% RH (at 25°C, non-condensing)

Storage humidity 10%–95% RH (at 25°C, non-condensing)

Vibration resistance 10Hz to 55Hz, 1 cycle per minute with a double amplitude of 0.75mm;

10min on 3 axes

Shock resistance ≥10g, 4 times on 3 axes

Unit dimensions Height: 90mm, width: 25mm, depth: 64mm

Weight ≈110g

Operation conditions Free from corrosive gases and excessive dust

Conformity to CE

Directives

UL approval UL number "2LD7" (file E232530)

EMC Directive 89/336/EEC; EN 55022/Class B; EN 61000-4-2/A1; EN

61000-4-3; EN 61000-4-4 + A1:2010; EN 61000-4-6

14 FP-I4C

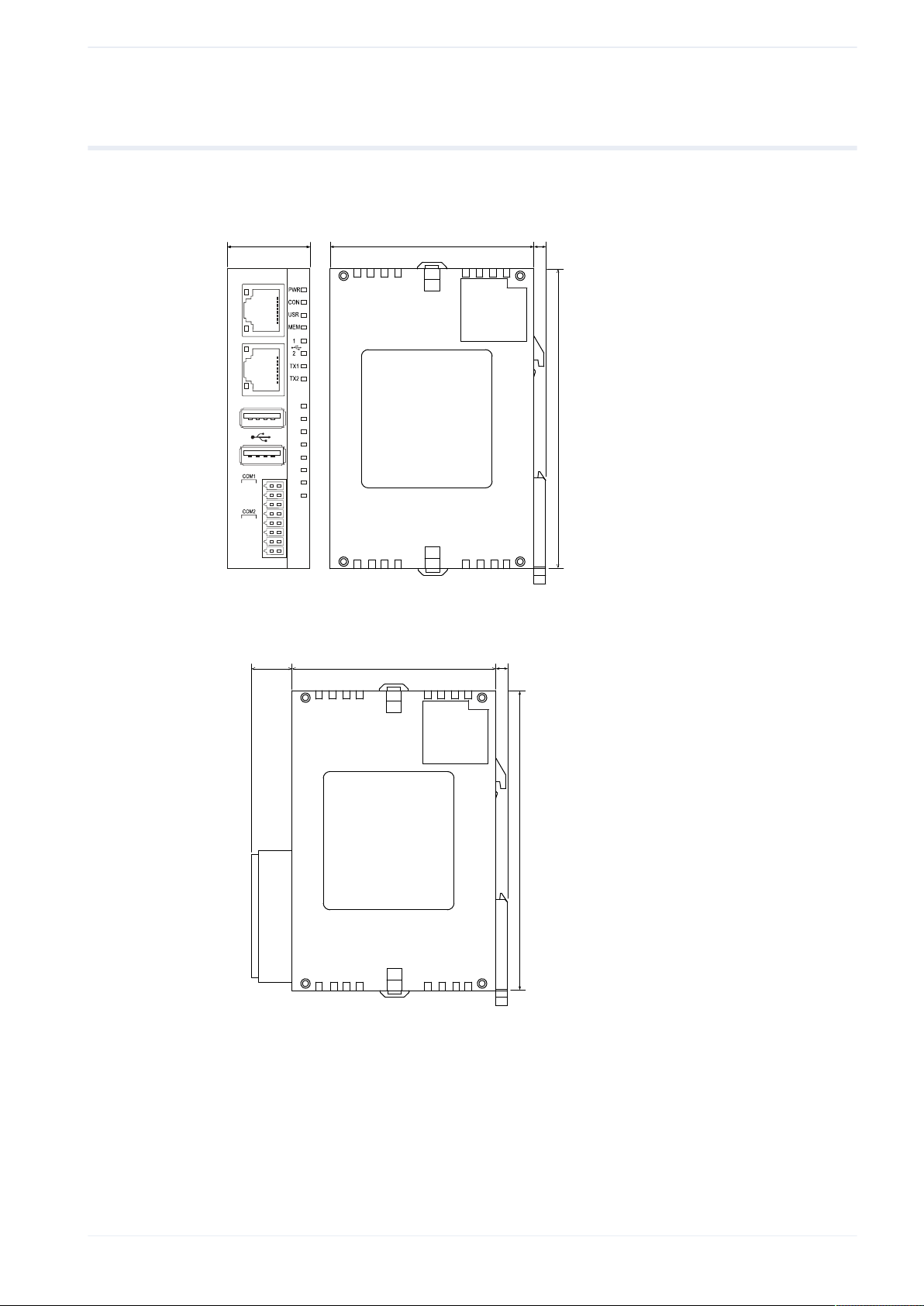

1.9 Dimensions

The dimensions of the FP-I4C unit are indicated in the technical drawing.

1 Product overview

60.0 3.5

90.0

ETH0

ETH1

USB1

USB2

S R

G1

RS232RS232/RS485

F1 F2

S/- R/+

S/S/- E

G2 G2

25.0

G1

R/+

FP-I4C

[mm]

60.011.5 3.5

90.0

[mm]

Right side view of the unit with the 16-pin spring force plug installed

FP-I4C 15

2 Installation

2 Installation

2.1 General installation procedure

Mount the unit and connect the PLC and all communication cables before you turn on the

power supply.

• Perform the installation with the power turned off.

• Before touching the unit or equipment, always touch some grounded metal to discharge

any static electricity you may have generated (especially in dry locations). The discharge

of static electricity can damage parts and equipment.

Related topics

Install the FP-I4C unit in the following order:

1. Mount the FP-I4C unit on a DIN rail or use a mounting plate.

2. Connect the FP-I4C unit to a PC with a standard Ethernet cable (at least Category 5).

Make sure you do not have an IP address conflict. The ETH0 port is configured as a

DHCP client. The ETH1 port is configured with a pre-defined fixed IP address.

Please read the instructions on how to connect the FP-I4C unit to the network.

3. Connect an FP series PLC via RS232C, USB, or RS485.

For wiring examples, refer to the section on wiring or to the “FP-I4C Installation

Instructions” leaflet.

4. Connect the power supply.

Make sure you read the information on how to connect the power supply.

Connect the FP-I4C unit directly to a PC (page 27)

Connect the FP-I4C unit to a PC via DHCP server (page 28)

Connection to PLC TOOL port using cable AIGT8192 (page 23)

Connection to PLC COM port (page 23)

Wire the power supply (page 25)

16 FP-I4C

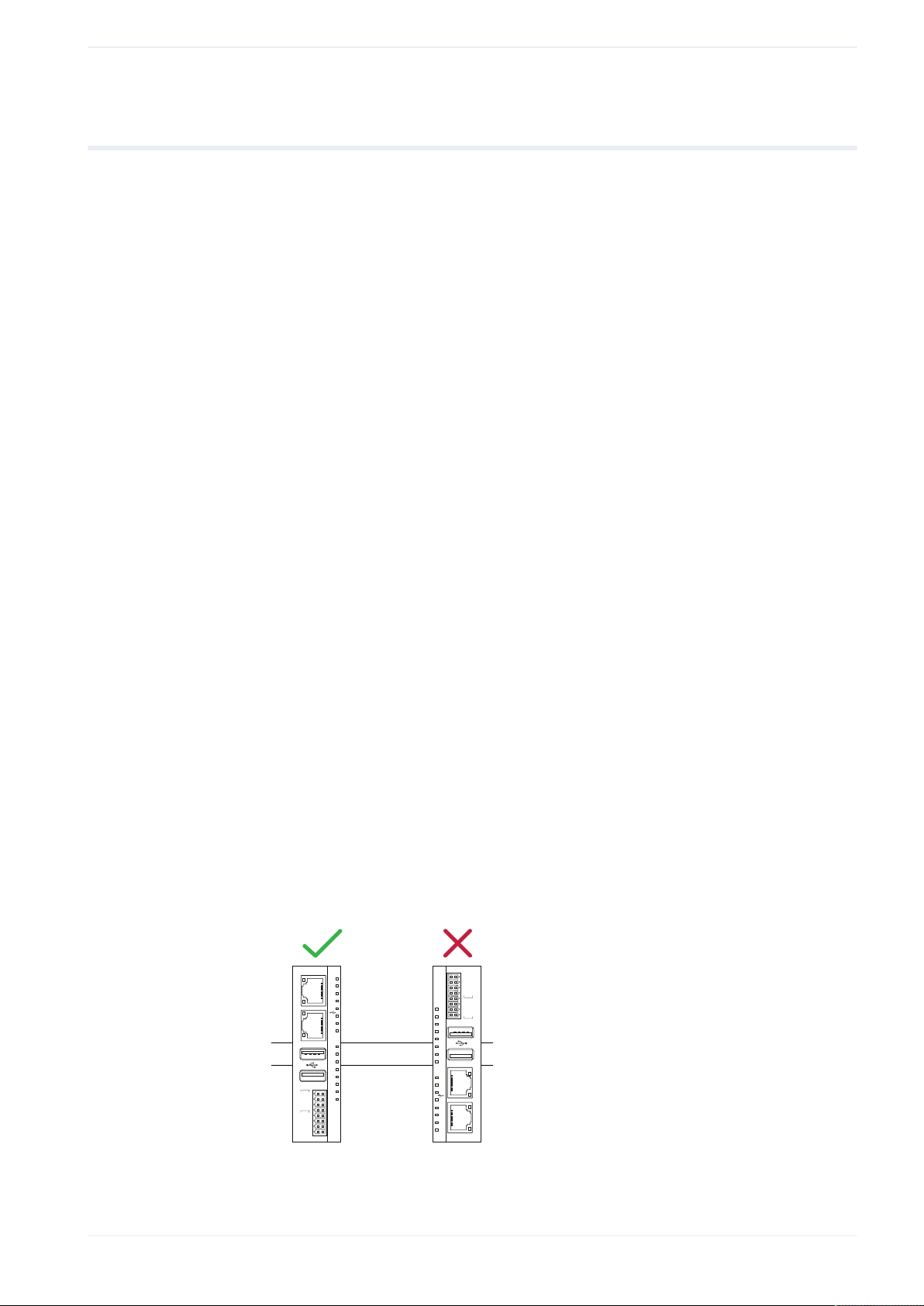

2.2 Installation environment

To prevent failure or malfunctions, the installation environment must comply with the

specifications of the FP-I4C unit.

After installing the unit, make sure to use it within the range of the general specifications:

• Operating temperature: 0°C to +55°C

• Operating humidity: 30%–85% RH (at 25°C, non-condensing)

• Pollution degree: 2

• Do not use the unit in the following environments:

‒ Direct sunlight

‒ Sudden temperature changes causing condensation

‒ Flammable or corrosive gases

2 Installation

‒ Excessive airborne dust, metal particles or salts

‒ Benzine, paint thinner, alcohol or other organic solvents, or strong alkaline solutions

such as ammonia or caustic soda

‒ Vibration, shock, or direct drop of water

• Avoid noise interference from the following items:

‒ Influence from power transmission lines, high voltage equipment, power cables,

power equipment, radio transmitters, or any other equipment that would generate

high switching surges. Maintain at least 100mm of space between these devices and

the unit.

‒ If noise occurs in the power supply line even after the above countermeasures are

taken, it is recommended to supply power through an isolated transformer, noise

filter, or the like.

• Take measures regarding heat discharge:

‒ Always install the unit orientated with the Ethernet port facing outward on the top in

order to prevent the generation of heat.

‒ Do not install the unit above devices which generate heat, such as heaters,

transformers or large-scale resistors.

FP-I4C

G2 G2

S/- E

S/-

R/+

S/- R/+

COM2

F1 F2

RS232RS232/RS485

G1

G1

S R

COM1

USB2

USB1

TX2

ETH1

TX1

2

1

MEM

ETH0

USR

CON

PWR

(1)

ETH0

ETH1

USB1

USB2

COM1

S R

G1

G1

RS232RS232/RS485

F1 F2

COM2

S/- R/+

R/+

S/S/- E

G2 G2

DIN rail

PWR

CON

USR

MEM

1

2

TX1

TX2

(1)

FP-I4C

FP-I4C 17

2 Installation

2.3 Installation space

Make sure to keep a minimum distance to other devices to avoid effects from noise or heat

and to permit unit replacement.

• Leave at least 50mm of space between the wiring ducts of the unit and other devices to

allow heat radiation and unit replacement.

(1)

(1)

(1)

50mm or more

• Maintain a minimum of 100mm between devices to avoid adverse effects from noise and

heat when installing a device or panel door to the front of the FP-I4C unit.

(1)

FP-I4C

(1)

100mm or more

(2)

Other device or panel door

(2)

• Keep the first 100mm from the front surface of the FP-I4C unit open in order to allow

room for wiring.

2.4 Attach the unit to a DIN rail

The FP-I4C unit is designed for easy installation on DIN rails.

1. Fit the upper hook of the FP-I4C unit onto the DIN rail.

18 FP-I4C

2. Without moving the upper hook, press on the lower hook to fit the FP-I4C unit into

position.

1

(1)

2

(1) Mounting panel

(2) DIN rail

(2)

2.5 Remove the unit from a DIN rail

You can easily remove the FP-I4C unit from a DIN rail with a slotted screwdriver.

2 Installation

1. Insert a slotted screwdriver into the DIN rail attachment lever.

2. Pull the attachment lever downwards.

3. Lift the FP-I4C unit and remove it from the rail.

3

1

(1) DIN rail

(2) DIN rail attachment lever

(1)

(2)

2

2.6 Install the unit on a slim type mounting plate

To attach the unit directly to the wall, you can use a slim type mounting plate, which can be

ordered separately.

Use M4 size pan-head screws to attach the FP0 slim type mounting plate (AFP0803) to the

mounting panel.

FP-I4C 19

2 Installation

(1)

60.0

(3)

(2)

6.0

(1)

FP0 slim type mounting plate AFP0803

(2)

Screw

(3) Mounting panel

[mm]

1. Fit the upper hook of the FP-I4C unit onto the FP0 slim type mounting plate.

2. Without moving the upper hook, press on the lower hook to fit the FP-I4C unit into

position.

1

2

2.7 Install the unit on a flat type mounting plate

To attach the unit sideways, you can use a flat type mounting plate, which can be ordered

separately.

Use M4 size pan-head screws to attach the FP0 flat type mounting plate (AFP0804) to the

mounting panel.

(1)

(3)

60.0

AFP0804

(1)

FP0 flat type mounting plate AFP0804

(2)

Screw

(3) Mounting panel

(2)

[mm]

1. Raise the expansion hooks on the top and bottom of the unit.

2. Install the FP-I4C unit on the FP0 flat type mounting plate.

20 FP-I4C

Note

3. Align the expansion hooks with the plate and press the hooks back down.

1

3

ETH0

ETH1

2

USB1

USB2

S R

G1

G1

RS232RS232/RS485

F1 F2

S/- R/+

S/- R/+

S/- E

G2 G2

FP-I4C

3

1

An FP-I4C unit with an attached FP0 flat type mounting plate can also be installed

sideways on a DIN rail.

2 Installation

ETH0

ETH1

USB1

USB2

2

S

R

G1

G1

RS232

F1

F2

S/-

R/+

S/-

R/+

S/-

E

G2

G2

RS232/RS485

FP-I4C

1

(1)

(2)

(1) DIN rail

(2) FP0 flat type mounting plate AFP0804

2.8 Add FP0/FP0R expansion units to the FP-I4C unit

The FP0/FP0R expansion units are connected on the right side of the FP-I4C unit.

1. Raise the expansion hooks on the top and bottom sides of the unit with a screwdriver.

FP-I4C 21

2 Installation

2. Align the pins and holes in the four corners of the control unit and expansion unit, and

insert the pins into the holes so that there is no gap between the units.

(1)

(2)

(1) FP-I4C unit

(2) FP0/FP0R expansion unit

3. Press down the expansion hooks raised in step 1 to secure the unit.

22 FP-I4C

3 Wiring

3.1 Connection to PLC TOOL port using cable AIGT8192

Use the cable AIGT8192 to connect the FP-I4C unit to the 5-pin mini DIN male TOOL port of

an FP0R, FPƩ, FP-X, or FP2SH type PLC.

Use either COM1 or COM2 depending on your setting for “Service control interface” in the

Web interface of the FP-I4C unit.

The cable AIGT8192 can be ordered as an accessory.

Using COM1:

3 Wiring

S (COM1)

G1 (COM1)

F1

2

1

AIGT8192, 5-pin mini DIN male (left) and FP-I4C 16-pin connector (right)

4

3

5

S/- (COM2)

S/- (COM2)

S/- (COM2)

R (COM1)

G1 (COM1)

F2

R/+ (COM2)

R/+ (COM2)

E

G2 (COM2)G2 (COM2)

Using COM2:

S (COM1)

G1 (COM1)

F1

S/- (COM2)

S/- (COM2)

S/- (COM2)

R (COM1)

G1 (COM1)

F2

R/+ (COM2)

R/+ (COM2)

E

G2 (COM2)G2 (COM2)

2

4

1

3

5

FP-I4C 16-pin connector (left) and AIGT8192, 5-pin mini DIN male (right)

3.2 Connection to PLC COM port

Wire the 16-pin connector of the FP-I4C unit directly to the COM port of an FP0R, FP-X,

FPƩ, FP0H, or FP7 type PLC.

Use either COM1 or COM2 depending on your setting for “Service control interface” in the

Web interface of the FP-I4C unit.

FP-I4C 23

3 Wiring

Suitable wire: AWG26-24

Using COM1:

S (COM1)

G1 (COM1)

F1

S R G

PLC COM port, 3-pin screw terminal (left) and FP-I4C 16-pin connector (right)

S/- (COM2)

S/- (COM2)

S/- (COM2)

R (COM1)

G1 (COM1)

F2

R/+ (COM2)

R/+ (COM2)

E

G2 (COM2)G2 (COM2)

Using COM2:

S (COM1)

G1 (COM1)

F1

S/- (COM2)

S R G

S/- (COM2)

S/- (COM2)

R (COM1)

G1 (COM1)

F2

R/+ (COM2)

R/+ (COM2)

E

G2 (COM2)G2 (COM2)

PLC COM port, 3-pin screw terminal (left) and FP-I4C 16-pin connector (right)

3.3 RS485 connection to Eco-POWER METER

Use COM2 RS485 to connect the FP-I4C unit to an Eco-POWER METER.

Suitable wire: AWG26-24

S (COM1)

G1 (COM1)

F1

S/- (COM2)

S/- (COM2)

S/- (COM2)

FP-I4C 16-pin connector (left) and Eco-POWER METER terminal block (right)

R (COM1)

G1 (COM1)

F2

R/+ (COM2)

R/+ (COM2)

E

G2 (COM2)G2 (COM2)

1+2+3-4

-

5

END

6

END

24 FP-I4C

3.4 Wire the power supply

Use the power supply cable (AFPG805) that comes with the unit to connect the power

supply.

3 Wiring

(1)

(2)

(3)

Related topics

(4)

(5)

(1)

Power supply connector

(2)

Power supply cable (AFPG805)

(3)

Brown: 24V DC

(4)

Blue: 0V

(5)

Green: must be connected to frame ground

The FP-I4C unit will turn on as soon as the power supply has been connected. The green

LED PWR will turn on after self-test.

When connecting the power supply (class 2 circuit), make sure the polarity (+/-) is correct.

If you connect an FP0/FP0R expansion unit, this unit and the FP-I4C unit must be supplied

by the same power supply.

General installation procedure (page 16)

FP-I4C 25

4 Getting started

4 Getting started

4.1 Overview

The FP-I4C Web interface is used to configure the interfaces and services of the FP-I4C unit.

The FP-I4C unit has multiple interfaces and connects PLCs, PCs, and other external devices

to databases, cloud servers, and other components used in automation.

HMWin runtime

via localhost

RS232

RS232/RS485

USB

INTERN

ETHERNET

127.0.0.1

PLCs

and other

devices

Services:

Data logger

FTPC

MQTT

SQL...

...

RTC updates

Device control

Logging

control

External calls

Getting data

(any interface)

Service

control

interface

Port bindings:

e.g. port 9094 → RS232

e.g. port 9095 → USB

• The services (on the left) all use the service control interface you specified in the

configuration.

• Data logging is controlled by the service control interface but can collect data from all

other interfaces.

• External clients, such as Control FPWIN Pro or SCADA systems, can use all interfaces.

• Web pages created with HMWIN Studio can collect data via all interfaces.

After you have accessed your FP-I4C unit via the Web interface, you can configure the

required services under “Application Settings”.

Go to “System Settings” to make general settings of the network addresses and services, to

change the user interface language, and to change the default user names and passwords.

Use the logout button in the title bar to log out or to switch users.

26 FP-I4C

4.2 Getting connected to the FP-I4C unit

The FP-I4C unit is configured using any standard Web browser.

To perform an initial function test and to configure the FP-I4C unit, connect a PC and an FPI4C unit in the same Ethernet network and connect the 24V DC power supply.

If you connect the FP-I4C unit and the PC directly via LAN cable, you must use the ETH1

connector, which has a fixed IP address. You must also set the proper IP address in your

PC.

In larger networks where IP addresses area usually assigned by a DHCP server, you first

need to find out the IP address of your FP-I4C unit. This can easily be done with the HMWIN

Studio software. To connect the FP-I4C unit to a network with a DHCP server, use the ETH0

connector.

When you know the IP address of your device, you can open the FP-I4C Web interface by

entering the proper URL in your browser. You can now activate and configure the services

and functions you want to use.

4 Getting started

Related topics

Connect the FP-I4C unit directly to a PC (page 27)

Connect the FP-I4C unit to a PC via DHCP server (page 28)

4.3 Connect the FP-I4C unit directly to a PC

To connect the FP-I4C unit directly to a PC use a standard LAN cable and set the IP address

in your PC.

The factory default IP address of the FP-I4C unit's ETH1 connector is 192.168.0.1. This

address is printed on a label attached to the unit's housing.

1. Connect a LAN cable between your PC and the ETH1 connector of the FP-I4C unit.

It is important that you use this bottom Ethernet connector because the ETH0 connector

above is reserved for Ethernet connections using a DHCP server.

FP-I4C

FP-I4C 27

4 Getting started

2. Set the IP address in your PC.

In Windows, go to “Network Connections” > “Change adapter options”. Select

“Ethernet” > “Properties”. On the “Network” tab, select “Internet protocol, Version

4 (TCP/IPv4)” > “Properties”. Select “Use the following IP address” and set the IP

address.

Example:

IP address: 192.168.0.10

Subnet mask: 255.255.255.0

(settings for default gateway and preferred DNS server not required)

3. Open your browser and enter the URL https://192.168.0.1/machine_config.

Depending on your browser, an insecure connection warning may be displayed. Follow

the instructions in your browser to accept the connection. You will then be forwarded to

the Web interface of the FP-I4C unit.

4. Log in with the default user name "admin" and password "admin".

You are now in the system settings area of the FP-I4C Web interface where you can

make general network and service settings or change the user interface language.

We recommend that you change the default password as soon as possible.

5. Select “Application Settings” to go to the application settings area.

You are now ready to configure the services required for your application.

Related topics

Change the default user names and passwords (page 29)

4.4 Connect the FP-I4C unit to a PC via DHCP server

If you connect the FP-I4C unit and the PC in an Ethernet network with a DHCP server, you

need to know which IP address was assigned to the unit.

You can easily find out the IP address of your unit with the HMWIN Studio software. The

software is available free of charge in our Panasonic Download Center.

1. Connect a LAN cable between the ETH0 connector of the FP-I4C unit and your Ethernet

network.

For Ethernet connections using a DHCP server it is important that you use the top

Ethernet connector ETH0.

28 FP-I4C

4 Getting started

FP-I4C

2. Start HMWIN Studio to find out the IP address of the FP-I4C unit.

3. Go to “Run” > “Manage Target” and select the “Board” tab.

In the device list of your DHCP network you can find the IP address of the FP-I4C unit. If

there are multiple devices in the list, compare the MAC address to the MAC address of

the ETH0 connector to find the right device. The MAC address is printed on a label that

can be found on the unit's housing.

4. Open your browser and enter the URL https://192.168.0.xx/machine_config.

Substitute "xx" with the last digits of the unit's IP address.

Depending on your browser, an insecure connection warning may be displayed. Follow

the instructions in your browser to accept the connection. You will then be forwarded to

the Web interface of the FP-I4C unit.

5. Log in with the default user name "admin" and password "admin".

You are now in the system settings area of the FP-I4C Web interface where you can

make general network and service settings or change the user interface language.

We recommend that you change the default password as soon as possible.

6. Select “Application Settings” to go to the application settings area.

You are now ready to configure the services required for your application.

Related topics

Change the default user names and passwords (page 29)

4.5 Change the default user names and passwords

For security reasons, we recommend that you change the default passwords in the FP-I4C

Web interface.

You can set different passwords for the administrator and standard users. There are certain

access restrictions for standard users such as deleting log files.

If you forget your password, you must reset the FP-I4C unit to the default settings with the

reset tact switch.

FP-I4C 29

4 Getting started

Related topics

The following default user names and passwords have been set:

Service User name Password

Configuration/SSH (if enabled) admin admin

SSH (if enabled) standard user user user

FTP server (if enabled) for logged data log log

1. Go to “System Settings” > “Authentication”.

2. Select “EDIT” to change the passwords.

Allowed characters for passwords: all letters, numbers and special characters (e.g. #!$).

Reset tact switch (page 13)

4.6 User rights

Access to certain functions and settings is restricted to administrators. The functions

accessible to users have a check mark.

System settings

Function Admin User

Change language ✓ ✓

View system status ✓ ✓

Save log file ✓ ✓

Change date and time ✓ ✓

Change network settings ✓ ✓

View data, settings, and main OS partitions ✓ ✓

Change, clear, and update partitions ✓ ✕

Restart system ✓ ✓

Change user password ✓ ✓

Change admin password ✓ ✕

Application settings

Function Admin User

Change COM settings ✓ ✕

Change port settings ✓ ✕

30 FP-I4C

4 Getting started

Function Admin User

PLC connection test ✓ ✓

Change data logging settings ✓ ✕

Download log files ✓ ✓

Delete log files ✓ ✕

Change MQTT settings ✓ ✕

Save or download MQTT library or example ✓ ✓

Change date and time settings ✓ ✕

Change FTP client settings ✓ ✕

Save or download FTP library or example ✓ ✓

Change script settings ✓ ✕

Change SQL client settings ✓ ✕

Related topics

Change the default user names and passwords (page 29)

FP-I4C 31

5 Example: Data logging from different devices

5 Example: Data logging from different devices

5.1 Functional overview

During data logging, the FP-I4C unit collects and saves the data from all connected devices.

The log files can then be downloaded or transmitted to a server.

In this sample application, power meters of the Panasonic Eco-POWER METER series and

an FP series PLC are connected to the FP-I4C unit. This is the basic configuration of a PLCbased monitoring and control system that uses energy consumption parameters to reduce

unwanted energy usage.

5.2 Connect the devices

In this example, two KW2M power meters are connected via Ethernet and two KW9M

power meters are connected via RS485. An FP0R PLC is connected via RS232C and

MEWTOCOL.

FP-I4C FP0R

KW2M

KW9M

Follow the instructions in this manual (see related topics) or in the device documentation to

perform the following tasks:

• Connect the TOOL port of the FP0R PLC to the COM 1 interface of the FP-I4C unit.

• Connect the FP0R unit and your PC to the FP-I4C unit and set the IP address of the PC,

e.g. 192.168.10. (must be on the same subnet as the FP-I4C unit). You can connect the

devices either directly or using a network switch.

32 FP-I4C

5 Example: Data logging from different devices

If a DHCP server is used, follow the instructions on how to connect the FP-I4C unit via

DHCP server.

Because we are using fixed IP addresses, connect the LAN cable to the ETH1 connector

of the FP-I4C unit.

• Connect the KW9M power meters in a daisy chain:

S (COM1)

G1 (COM1)

F1

S/- (COM2)

S/- (COM2)

S/- (COM2)

R (COM1)

G1 (COM1)

F2

R/+ (COM2)

R/+ (COM2)

E

G2 (COM2)G2 (COM2)

A+B

-

We recommend that you install a terminating resistor on both ends of the RS485

connection. On the FP-I4C side, place a 100Ω resistor between E and R/+. On the

second KW9M power meter, place a 120Ω resistor between A+ and B-.

• Make the communication settings for the PLC in Control FPWIN Pro.

• Make the power meter settings:

KW2M:

Set the IP address to 192.168.0.70 and 192.168.0.71 and the subnet mask to

255.255.255.0.

KW9M:

Protocol: MEWTOCOL

Baud rate: 19200

Parity: Odd (8b - o)

Station numbers: 1 and 2

A

B

+

-

Related topics

Connection to PLC TOOL port using cable AIGT8192 (page 23)

Connect the FP-I4C unit directly to a PC (page 27)

Connect the FP-I4C unit to a PC via DHCP server (page 28)

Make FP-I4C communication settings (page 34)

Make PLC communication settings (page 35)

FP-I4C 33

5 Example: Data logging from different devices

5.3 Make FP-I4C communication settings

Use a standard browser to make the communication settings for the FP-I4C unit.

1. Open your browser and enter the URL https://192.168.0.1/fp_config.

Depending on your browser, an insecure connection warning may be displayed. Follow

the instructions in your browser to accept the connection. You will then be forwarded to

the Web interface of the FP-I4C unit.

2. Log in with the default or your modified administrator credentials.

3. Select “Application Settings” to go to the application settings area.

4. Go to “COM Interface” > “COM settings - FP-I4C” and enable the COM1 RS232

interface for communication with the FP0R PLC.

Make the following settings:

“Protocol”: “MEWTOCOL”

“Autobaud”: “Enabled”

“Baud rate”: “115200”

“Parity”: “Odd”

“Timeout (ms)”: “2000”

5. Enable the COM2 RS485/RS232 interface for communication with the KW9M power

meters.

Make the following settings:

“Protocol”: “MEWTOCOL”

“Autobaud”: “Disabled” (only PLCs can respond to status requests)

“Baud rate”: “19200”

“Parity”: “Odd”

“Mode”: “RS485”

“Timeout (ms)”: “2000”

6. Enable the COM4 ETHERNET interface for communication with the KW9M power

meters.

Make the following settings:

“Protocol”: “MODBUS”

“Timeout (ms)”: “2000”

“IP address”: “192.168.0.0”

“Port”: “502”

“Address offset”: “Enabled” and set to 0

7. Select “Save” to save your configuration.

34 FP-I4C

5.4 Make PLC communication settings

Make the communication settings for the PLC in Control FPWIN Pro.

1. Create a new project and set the appropriate PLC type. When you have completed your

settings, transfer the configuration to the PLC.

2. Go to “System registers” > “Serial ports” > “TOOL”, and make the following settings:

“Communication mode”: “MEWTOCOL-COM slave”

“Station number”: “1”

“Baud rate”: “115200”

“Data length”: “8 bits”

“Parity”: “Odd”

“Stop bits”: “1 bit”

5 Example: Data logging from different devices

5.5 Configure data logging for FP0R

Configure data logging for the FP0R PLC via the RS232 interface in the application settings

area of the FP-I4C Web interface.

If you add more than one log file, you need to make the general log settings only once.

1. Go to “Data Logger” > “General log settings”, and make the following settings:

“Use data logger”: Enabled

“Delete renamed files”: Disabled

“Write midnight value to previous day”: Disabled

“Data storage location”: “Internal memory”

“CSV file header”: “3 rows”

“CSV file separator”: “,” (comma)

“CSV decimal separator”: "." (point)

“Enable PLC memory area, start address”: Disabled

“Enable PLC flags”: Disabled

2. Go to “Log file settings”, select “Add new”, and make the following settings:

“File name (max. 30 characters)”: FP0R_RS232

“File splitting”: “File per day”

“COM interface/station number”: RS232, 0

“Trigger type”: “Fixed cycle”

“Trigger cycle time (s)”: 300 (a new value is logged every 5min)

“Save cache to file flag”: Disabled

“Log records in cache”: 0

“Max. number of files before auto-delete”: 0

3. Go to “Data point settings”, select “Add new”, and make the following settings:

“Data point name (max. 30 characters)”: Temperature

“Unit (max. 7 characters)”: C

FP-I4C 35

5 Example: Data logging from different devices

“COM interface/station number”: RS232, 0

“Register type/address”: “Momentary value”, DT100

“Data format”: “INT (16 bits, signed)”, “2 decimal”, “Little Endian”

“Apply Scaling”: Disabled

With these settings, logging is performed for a single data point. If you want to configure

multiple data points, we recommend importing the variables from a CSV file.

Related topics

Import variables from CSV files (page 39)

5.6 Configure data logging for KW2M

Configure data logging for the KW2M power meter via the Ethernet interface in the

application settings area of the FP-I4C Web interface.

In this example, the two power meters log the total energy consumption. Please refer to the

power meter documentation for details on register addresses and data format.

If you add more than one log file, you need to make the general log settings only once.

1. Go to “Data Logger” > “General log settings” and make the following settings:

“Use data logger”: Enabled

“Delete renamed files”: Disabled

“Write midnight value to previous day”: Disabled

“Data storage location”: “Internal memory”

“CSV file header”: “3 rows”

“CSV file separator”: “,” (comma)

“CSV decimal separator”: "." (point)

“Enable PLC memory area, start address”: Disabled

“Enable PLC flags”: Disabled

2. Go to “Log file settings”, select “Add new”, and make the following settings:

“File name (max. 30 characters)”: KW2M_ETHERNET_70

“File splitting”: “File per day”

“COM interface/station number”: ETHERNET, 70 (station number 70 corresponds to

the last octet of the target IP address)

“Trigger type”: “Fixed cycle”

“Trigger cycle time (s)”: 300 (a new value is logged every 5min)

“Save cache to file flag”: Disabled

“Log records in cache”: 0

“Max. number of files before auto-delete”: 0

3. Go to “Data point settings”, select “Add new”, and make the following settings:

“Data point name (max. 30 characters)”: Energy

“Unit (max. 7 characters)”: kWh

“COM interface/station number”: ETHERNET, 70

36 FP-I4C

5 Example: Data logging from different devices

“Register type/address”: “Momentary value”, DT112

“Data format”: “UINT64 (64 bits, unsigned)”, “3 decimal”, “Little Endian”

“Apply Scaling”: Disabled

4. Go to “Log file settings”, select “Add new”, and make the following settings:

“File name (max. 30 characters)”: KW2M_ETHERNET_71

“File splitting”: “File per day”

“COM interface/station number”: ETHERNET, 71 (station number 71 corresponds to

the last octet of the target IP address)

“Trigger type”: “Fixed cycle”

“Trigger cycle time (s)”: 300 (a new value is logged every 5min)

“Save cache to file flag”: Disabled

“Log records in cache”: 0

“Max. number of files before auto-delete”: 0

5. Go to “Data point settings”, select “Add new”, and make the following settings:

“Data point name (max. 30 characters)”: Energy

“Unit (max. 7 characters)”: kWh

“COM interface/station number”: ETHERNET, 71

“Register type/address”: “Momentary value”, DT112

“Data format”: “UINT64 (64 bits, unsigned)”, “3 decimal”, “Little Endian”

“Apply Scaling”: Disabled

With these settings, logging is performed for a single data point. If you want to configure

multiple data points, we recommend importing the variables from a CSV file.

Related topics

Import variables from CSV files (page 39)

5.7 Configure data logging for KW9M

Configure the data logging for the KW9M via the RS485 interface in the application settings

area of the FP-I4C Web interface.

In this example, the two power meters log the total energy consumption. Please refer to the

power meter documentation for details on register addresses and data format.

If you add more than one log file, you need to make the general log settings only once.

1. Go to “Data Logger” > “General log settings” and make the following settings:

“Use data logger”: Enabled

“Delete renamed files”: Disabled

“Write midnight value to previous day”: Disabled

“Data storage location”: “Internal memory”

“CSV file header”: “3 rows”

“CSV file separator”: “,” (comma)

“CSV decimal separator”: "." (point)

FP-I4C 37

5 Example: Data logging from different devices

“Enable PLC memory area, start address”: Disabled

“Enable PLC flags”: Disabled

2. Go to “Log file settings”, select “Add new”, and make the following settings:

“File name (max. 30 characters)”: KW9M_RS485_1

“File splitting”: “File per day”

“COM interface/station number”: RS485/232, 1

“Trigger type”: “Fixed cycle”

“Trigger cycle time (s)”: 300 (a new value is logged every 5min)

“Save cache to file flag”: Disabled

“Log records in cache”: 0

“Max. number of files before auto-delete”: 0

3. Go to “Data point settings”, select “Add new”, and make the following settings:

“Data point name (max. 30 characters)”: Energy

“Unit (max. 7 characters)”: kWh

“COM interface/station number”: RS485/232, 1

“Register type/address”: “Momentary value”, DT106

“Data format”: “UDINT (32 bits, unsigned)”, “2 decimal”, “Little Endian”

“Apply Scaling”: Disabled

4. Go to “Log file settings”, select “Add new”, and make the following settings:

“File name (max. 30 characters)”: KW9M_RS485_2

“File splitting”: “File per day”

“COM interface/station number”: RS485/232, 1

“Trigger type”: “Fixed cycle”

“Trigger cycle time (s)”: 300 (a new value is logged every 5min)

“Save cache to file flag”: Disabled

“Log records in cache”: 0

“Max. number of files before auto-delete”: 0

5. Go to “Data point settings”, select “Add new”, and make the following settings:

“Data point name (max. 30 characters)”: Energy

“Unit (max. 7 characters)”: kWh

“COM interface/station number”: RS485/232, 2

“Register type/address”: “Momentary value”, DT106

“Data format”: “UDINT (32 bits, unsigned)”, “2 decimal”, “Little Endian”

“Apply Scaling”: Disabled

With these settings, logging is performed for a single data point. If you want to configure

multiple data points, we recommend importing the variables from a CSV file.

Related topics

Import variables from CSV files (page 39)

38 FP-I4C

5.8 Import variables from CSV files

Instead of adding single data points, you can import CSV files.

The following restrictions apply:

• A maximum of 700 variables can be imported. Entries beyond this number will be

ignored.

• Data point names that are longer than 30 characters will be cut during import.

• The data types DT, LD, FL, R, Y, and X can be imported. Other data types (e.g. WR, WL,

WX, WY) are skipped and an error message is displayed when the import is finished.

Use the default import settings to import variables and array elements that have been

exported in Control FPWIN Pro with the default settings.

1. Go to “Data Logger” > “Import variables from CSV”.

5 Example: Data logging from different devices

2. Select a CSV file with “Import from CSV file”.

3. Select a log file with “Import to log file”.

The variables from the CSV file are imported into this log file.

4. Select a separator from the “Separator” list box.

5. Select “Header” if your CSV file contains header lines.

Specify the number of header lines in the CSV file. By default, CSV files do not have

header lines in FPWIN Pro.

If the header settings do not match your file's header, header lines will not be imported

correctly.

6. Under “Column numbers”, specify the number of the columns containing the data point

name, the FP address, the data type, and the unit.

• “Data point name”

Specify the number of the column containing the data point name. The default

column number in FPWIN Pro is 2 (starting with column 1).

• “FP address”

Specify the number of the column containing the FP address (e.g. DT100, R10). The

default column number in FPWIN Pro is 4 (starting with column 1).

• “Data type”

Specify the number of the column containing the data type (e.g. INT, BOOL). The

default column number in FPWIN Pro is 5 (starting with column 1).

• “Unit”

Specify the number of the column containing the unit of the data point (e.g. °C, kg

etc.). The default column number in FPWIN Pro is column 7 for comments (starting

with column 1).

7. To import individual entries of the CSV file, enter any text string in the “Filter” text box.

The text is searched in all columns of the selected CSV file. Use “Set filter” to start your

search and “Reset filter” to clear the filter.

To use the filter function, you must open a CSV file.

FP-I4C 39

5 Example: Data logging from different devices

8. Select the desired entries and click “Import selection”, or click “Import all” to import all

entries from the CSV file.

5.9 List and download log files

Use this function to generate a list of all log files and to download individual or all log files.

1. Go to “Data Logger” > “List and download log files”.

2. Select the file storage area of the log files, and click “List files” to list all files available.

3. To download a single file, click on the file name. To download all files, select “Download

all files”.

This button is disabled if no log file is available.

With “Download all files”, all log files will be saved in a zipped file.

4. To delete one or more entries from the list, select the desired check boxes and click

“Delete selection”. To delete all entries, select “Delete all”.

These buttons are disabled if no files are listed.

40 FP-I4C

6 Example: HTTP connection to a cloud server

6 Example: HTTP connection to a cloud server

6.1 Functional overview

When you use the FP-I4C unit as an HTTP client, you can use the HTTP GET and HTTP

POST methods to exchange data with a cloud server. A PLC is needed to control the send

and receive operations.

In this sample application, weather data is collected from the online service OpenWeather

and forwarded to a dashboard provided by Emoncms.org (both offer free access). The FPI4C receives the commands via USB/MEWTOCOL from the PLC. The FP-I4C library for

Control FPWIN Pro offers ready-made function blocks that support the HTTP client service.

OpenWeather content and data are licensed under https://creativecommons.org/licenses/bysa/4.0/.

Emoncms.org content and data are licensed under https://www.gnu.org/licenses/

agpl-3.0.html.

6.2 Connect the devices

In this example, an FP0H PLC is connected to the USB port of the FP-I4C unit. The FP-I4C

unit and a PC are connected to the network via a DHCP server.

An Internet connection is required for the HTTP and HTTPS communication.

The HTTP client function is available from version 1.2.1.0 of the FP-I4C unit.

FP-I4CFP0H

FP-I4C 41

6 Example: HTTP connection to a cloud server

Follow the instructions in this manual (see related topics) or in the device documentation to

perform the following tasks:

• Connect the USB port of the FP0H PLC to the USB port of the FP-I4C unit.

• Connect the FP-I4C unit and your PC to the network using a DHCP server and set the IP

address of the FP-I4C unit.

Because we use a DHCP server, connect the LAN cable to the ETH0 connector of the

FP-I4C unit.

• Make the communication settings in the FP-I4C unit.

• Make the communication settings for the PLC in Control FPWIN Pro.

Related topics

Connect the FP-I4C unit to a PC via DHCP server (page 28)

Make FP-I4C communication settings (page 42)

Configure the HTTP client and download the sample files (page 43)

Set up the programming examples (page 44)

6.3 Make FP-I4C communication settings

Use a standard browser to make the communication settings for the FP-I4C unit.

1. Open your browser and enter the URL https://192.168.0.1/fp_config.

Depending on your browser, an insecure connection warning may be displayed. Follow

the instructions in your browser to accept the connection. You will then be forwarded to

the Web interface of the FP-I4C unit.

2. Log in with the default or your modified administrator credentials.

3. Select “Application Settings” to go to the application settings area.

4. Go to “COM Interface” > “COM settings - FP-I4C” and enable the COM3 USB interface

for communication with the FP0H PLC.

Make the following settings:

“Protocol”: “MEWTOCOL”

“Autobaud”: “Enabled”

“Baud rate”: “230400”

“Parity”: “Odd”

“Timeout (ms)”: “1100”

5. Go to “COM Interface” > “Service control interface” > “COM interface to control device

(PLC)” and select “USB”.

The station number 0 ("EE") is automatically set.

6. Select “Save” to save your configuration.

42 FP-I4C

6 Example: HTTP connection to a cloud server

7. Go to “Port” > “Ports” and select “Add new” to configure a redirect from the TCP port to

the COM1 RS232 interface.

Make the following settings:

“Modbus gateway”: “Disabled”

“Allow FPWIN Pro”: “Enabled”

“COM interface”: “RS232”

“Port”: “9096” (or any other port between 1025 and 65535)

“Number of clients”: “3”

“IP start address”: “255.255.255.255”

“IP end address”: “255.255.255.255”

“Timeout (s)”: “60”

All packages received on the specified port are now forwarded to the USB interface that

is used for communication with the PLC.

8. Select “Save” to save your configuration.

6.4 Configure the HTTP client and download the sample files

To set up the FP-I4C unit to function as an HTTP client, you need to enable the function and

specify a memory area in the PLC for the DUT that handles the data exchange.

1. Go to the “HTTP Client” page and enable the HTTP client function.

2. Specify free DT registers in the user area of the PLC that can be used to control data

transmission.

The same address must be set in the corresponding DUT of the programming example.

The server IP address and the login parameters are set in the PLC. Do not enter any

data in these fields in this example.

Do not enable “Use HTTPS” for now. If you want to establish a secure connection later,

specify at least a list of CA root certificates. For more information, please refer to your

HTTP server provider.

3. Download the FP-I4C library for Control FPWIN Pro and the HTTP client example by

clicking on the two “Save to PC” buttons.

4. Select “Save” to save your configuration. The settings are applied without requiring a

restart of the FP-I4C unit.

Related topics

Set up the programming examples (page 44)

FP-I4C 43

6 Example: HTTP connection to a cloud server

6.5 Set up the programming examples

The programming examples use ready-made function blocks for the HTTP client service to

collect data from a weather server and forward it to a dashboard server.

Download the FP-I4C library and the programming example for Control FPWIN Pro on the

“HTTP Client” page.

1. Unzip the downloaded library and sample files.

2. Double-click the file HTTPC_example.pce to open the sample project in Control

FPWIN Pro.

The library is automatically installed when the project is opened.

The project contains different sample POUs. These POUs contain all settings required

to establish a connection with a weather server.

3. Go to “Online” > “Communication settings” and make the following settings:

• “Network type”: “Ethernet”

Related topics

• “Title”: Enter a title for your Ethernet connection.

• “Use ET-LAN unit”: Disabled

• “Computer”:

“Automatically acquire IP address”: Disabled

“IP address”: 0.0.0.0

“Port number”: 0

• “Destination”:

“IP address”: Enter the IP address of the FP-I4C unit.

“Port number”: Enter the port number of the fP-I4C unit (in this example 9096).

• “Communications timeout (sec)”: 15s

• “Connection time out (sec)”: 60s

You can now try the sample programs available in Control FPWIN Pro.

Get weather data from a cloud server (page 44)

Forward weather data to a dashboard (page 45)

6.6 Get weather data from a cloud server

The sample program collects data from a weather server.

In this example, we will use the POU "Easy_HTTP_Client". This POU contains all settings

required to establish a connection with a weather server.

44 FP-I4C

6 Example: HTTP connection to a cloud server

Prepare and compile the PLC program:

• Make sure that the POU "Easy_HTTP_Client" is the only POU assigned to the program

task.

• Replace the value for the parameter appid in the variable sMyCommandToSend with

your API key.

You must register on the home page of the provider (api.openweathermap.org) to get

your own API key.

• Specify the start address of the g_dutFPI4C_HTTPClient DUT in the global variable list.

The default setting is DT240. (If you kept the default value DT240 on the "HTTP client"

page, you do not need to change the address.)

The project is now ready to be compiled and transmitted to the PLC.

• Select “Online” > “Online mode”, then “Compile all...” and “Download program code and

PLC configuration to PLC” to transmit the program to the PLC.

Start communication with the weather server and monitor your POU:

• Double-click on the variable bTrigger to turn the value of the Boolean variable to TRUE.

Communication with the weather server starts and weather data is received.

• Select “Monitor” > “Entry data monitor” to monitor your POU.

If the communication is working properly, you can read the weather data in the string

variable g_sHTTPC_Receive.

6.7 Forward weather data to a dashboard

The sample program collects data from a weather server and transmits the data to a

dashboard server.

In this example, we will use the POU "Weather_Power_Values_EMONCMS_GET_Method".

This POU contains all settings required to establish a connection with a weather

server. (Depending on the HTTP server you choose, you can also use the POU

"Weather_Power_Values_EMONCMS_POST_Method". Emoncms.org supports both

methods.)

Prepare and compile the PLC program:

FP-I4C 45

6 Example: HTTP connection to a cloud server

• Make sure that the POU "Weather_Power_Values_EMONCMS_GET_Method" is the only

POU assigned to the program task.

• Replace the value for the parameter appid in the variable sFileOr_URL with your API

key of the weather data server.

You must register on the home page of the provider (api.openweathermap.org) to get

your own API key.

• Replace the value of the variable sEmoncmsAPIKey of this POU with your API key of

the dashboard server.

You must register on the home page of the provider (emoncms.org) to get your own API

key.

The project is now ready to be compiled and transmitted to the PLC.

• Select “Online” > “Online mode”, then “Compile all...” and “Download program code and

PLC configuration to PLC” to transmit the program to the PLC.

Start communication with the weather server and the dashboard server:

• Double-click on the variable bTrigger to turn the value of the Boolean variable to TRUE.

First, communication with the weather server starts and weather data is received. Then

the HTTP client transmits weather information to the dashboard server.

If the communication is working properly, the weather data is displayed in your Emoncms

profile and workspace. Please refer to the tutorials on the Emoncms Web site for details

on how to configure your workspace.

6.8 Minimize security risks

To minimize security risks, you should take the following precautionary measures.

• Change the default passwords of the FP-I4C unit to new and more complex passwords.

• Be sure that only those FP-I4C services are enabled that are actually used by your

application.

• Use encrypted transmission methods for your communication. A root CA certificate list or

self-signed certificates help to ensure that you are communicating with the correct server.

Please be aware that public root CA certificate lists expire after a certain time.

46 FP-I4C

7 Example: Web-based data visualization

7 Example: Web-based data visualization

7.1 Functional overview

With the FP-I4C unit, you can visualize data from different sources on an HTML Web page.

In this sample application, two Panasonic PLCs are connected to the FP-I4C unit. You will

learn how to create a simple HTML page that displays data from these PLCs.

To create the Web pages for the FP-I4C unit, use HMWIN Studio version 4.0 or newer. The

software is available free of charge in our Panasonic Download Center.

7.2 Connect the devices

In this example, an FP0R PLC is connected via RS232C and MEWTOCOL, and an FP0H

PLC is connected via Ethernet using Modbus TCP.

Follow the instructions in this manual (see related topics) or in the device documentation to

perform the following tasks:

• Connect the TOOL port of the FP0R PLC to the COM 1 interface of the FP-I4C unit.

• Make the communication settings for the PLC in Control FPWIN Pro.

• Connect the KW2M units and your PC to the FP-I4C unit and set the IP address of the

PC, e.g. 192.168.10. (must be on the same subnet as the FP-I4C unit). You can connect

the devices either directly or using a network switch.

If a DHCP server is used, follow the instructions on how to connect the FP-I4C unit via

DHCP server.

Because we are using fixed IP addresses, connect the LAN cable to the ETH1 connector

of the FP-I4C unit.

FP-I4CFP0H FP0R

Direct connection of the devices

FP-I4C 47

7 Example: Web-based data visualization

Connection using a network switch

Related topics

Connection to PLC TOOL port using cable AIGT8192 (page 23)

Connect the FP-I4C unit directly to a PC (page 27)

Connect the FP-I4C unit to a PC via DHCP server (page 28)

Make FP-I4C communication settings (page 48)

Make PLC communication settings (page 49)

7.3 Make FP-I4C communication settings

Use a standard browser to make the communication settings for the FP-I4C unit.

1. Open your browser and enter the URL https://192.168.0.1/fp_config.

Depending on your browser, an insecure connection warning may be displayed. Follow

the instructions in your browser to accept the connection. You will then be forwarded to

the Web interface of the FP-I4C unit.

FP-I4CFP0H

FP0R

2. Log in with the default or your modified administrator credentials.

3. Select “Application Settings” to go to the application settings area.

4. Go to “COM Interface” > “COM settings - FP-I4C” and enable the COM1 RS232

interface for communication with the FP0R PLC.

Make the following settings:

“Protocol”: “MEWTOCOL”

“Autobaud”: “Enabled”

“Baud rate”: “115200”

“Parity”: “Odd”

“Timeout (ms)”: “2000”

48 FP-I4C

7 Example: Web-based data visualization

5. Select “Save” to save your configuration.

6. Go to “Port” > “Ports” and select “Add new” to configure a redirect from the TCP port to

the COM1 RS232 interface.

Make the following settings:

“Modbus gateway”: “Disabled”

“Allow FPWIN Pro”: “Enabled”

“COM interface”: “RS232”

“Port”: “9094”

“Number of clients”: “3”

“IP start address”: “255.255.255.255”

“IP end address”: “255.255.255.255”

“Timeout (s)”: “60”

7. Select “Save” to save your configuration.

7.4 Make PLC communication settings

Make the communication settings for the PLC in Control FPWIN Pro.

Create a new project for each PLC, set the appropriate PLC type, and go to the navigator.

Once you have completed your settings, transfer the configuration to the PLC.

Make settings for the FP0R PLC:

• Go to “System registers” > “Serial ports” > “TOOL”, and make the following settings:

“Communication mode”: “MEWTOCOL-COM slave”

“Station number”: “1”

“Baud rate”: “115200”

“Data length”: “8 bits”

“Parity”: “Odd”

“Stop bits”: “1 bit”

Make settings for the FP0H PLC:

• Go to “PLC” > “System registers” > “Ethernet” > “IP addresses”, and make the following

settings:

“Automatically obtain IPv4 address”: “Disable”

“IPv4 address”: “192.168.0.21” (must be on the same subnet as the FP-I4C unit)

“IPv4 subnet mask”: “255.255.255.0”

• Go to “System registers” > “Ethernet” > “User connections”:

“User connection 1”: “Enable”

“Communication mode”: “Modbus TCP master/slave”

“Communication method”: “TCP/IP”

“Open method”: “Server connection (unspecified partner)”

“Automatic opening”: “Enable”

“Source port number”: “502”

FP-I4C 49

7 Example: Web-based data visualization

7.5 Configure the PLC connections

To configure the PLC connections, you must create a new project in HMWIN Studio and then

specify the protocol for each PLC.

1. Start HMWIN Studio and select “File” > “New project” to start the project wizard.

2. Enter a project name and click “Next”.

3. Select the “FP-I4C” device and click “Next”.

4. Select “Unified” and click “Finish” to complete the creation of the new project.

5. Go to “ProjectView” > “Configuration” and double-click “Protocols”.

Make settings for the protocol used by the FP0R:

6. Click the “+” icon and select “Panasonic FP/FP7”.

Make the following settings:

“PLC network”: Deactivated

“Alias”: “FP0R”

“Node ID”: “1”