Panasonic FP-7818, FP-7830, FP-7845, FP-7850, FA-S620 Service Manual

...

ORDER NO. OED9909380B8

© 1999 Matsushita Graphic Communication

Systems, Inc. All rights reserved. Unauthorized

copying and distribution is a violation of law.

FP-7818/7824/7830/7835/7845/7850 Service Manual

Service Manual

Parts Manual

Plain Paper Copier

FP-7818/7824/7830

FP-7835/7845/7850

Staple Sorter

FA-S620/660

System Console

FA-DS72/82

WARNING

This service information is designed for experienced repair technicians only and

is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of

potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced

professional technicians. Any attempt to service or repair the product or products

dealt with in this service information by anyone else could result serious injury or

death.

For U.S.A

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment on a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his/her own expense.

Any unauthorized changes or modifications to this equipment would void the users

authority to operate this device.

For U.S.A

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Document Imaging Co. for the sole purpose of providing information

necessary for the equipment’s proper support. It is intended that this information

be confidential and may not reproduced without prior written consent from

Panasonic Document imaging Co. Panasonic Document imaging Co. reserves

the right to change any information enclosed herein without prior notification.

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Co. for the sole purpose of providing information necessary for the

equipment’s proper support. It is intended that this information be confidential

and may not be reproduced without prior written consent from Panasonic Co.

Panasonic Co. reserves the right to change any information enclosed herein without

prior notification.

This manual dose not contain descriptions of PCB Connector and Signal

Information and Sub Assemblies Operation which are discribed and unchanged

in the FP-7718/7722/7728/7735/7742/7750 service manual. For those items not

covered in this manual, please refer to the FP-7718/7722/7728/7735/7742/7750

service manual or PCB repaire manual.

Contents / Index

I. Introduction

1.1 Specification ..................................................................................... 1-1

1.2 Features............................................................................................ 1-3

1.3 System Configuration ....................................................................... 1-4

1.4 Operation .......................................................................................... 1-6

(1) Special Effects Panel (FP-7818/7824/7830/7835) ...................... 1-7

(2) Communications Monitor (FP-7818/7824/7830/7835) ................ 1-8

1.5 Component Location......................................................................... 1-9

(1) Inner view.................................................................................. 1-10

(2) Fan/Motor Location ................................................................... 1-11

(3) Sensor Location ........................................................................ 1-12

(4) Solenoid/Clutch/Discharge lamp Location ................................ 1-13

(5) PCB Location ............................................................................ 1-13

1.6 Copy Process ................................................................................. 1-14

1.7 Precautions on Set Up.................................................................... 1-15

1.8 Precautions with Consumables ...................................................... 1-16

II. New Function

2.1 Image Control

Qualitative Reasoning Based Adaptive Controller .........

2-1

2.2 Toner Density Control....................................................................... 2-3

2.3 Trouble Avoidance Mechanism ........................................................ 2-5

2.4 Toner Recycling System................................................................... 2-7

2.5 Re-try Control for Paper Misfeed ...................................................... 2-8

III. Sub Assemblies

3.1 Main Drive......................................................................................... 3-1

(1) Detecting sheet bypass paper size ............................................. 3-2

(2) Developing .................................................................................. 3-3

(3) Supplying toner ........................................................................... 3-4

(4) Toner level detection................................................................... 3-5

(5) Temperature control.................................................................... 3-6

(6) Automatic detection of original paper size .................................. 3-7

(7) Adjusting quantity of light of AE sensor ...................................... 3-7

i

Introduction

Control

Functions

Sub Assemblies

Preventive

Maintenance

Troubleshooting

Unpacking/

Installation

IV. Preventive Maintenance

4.1 Precautions for Periodic Maintenance Service ................................. 4-1

4.2 Maintenance chart ............................................................................ 4-2

4.3 Cleaning Method............................................................................... 4-4

4.4 Disassembly and Re-assembly ........................................................ 4-7

(1) Multi-feed bypass ........................................................................ 4-8

(2) Paper feed unit.......................................................................... 4-11

(3) Developer unit ........................................................................... 4-14

(4) Fuser unit .................................................................................. 4-19

(5) Optics unit ................................................................................. 4-24

(6) Automatic duplex unit (ADU ).................................................... 4-32

(7) Main Body ................................................................................. 4-35

V. Troubleshooting

5.1 Service Mode.................................................................................... 5-1

(1) Service mode functions............................................................... 5-1

(2) Service mode procedure ............................................................. 5-2

(3) F4 mode ...................................................................................... 5-4

(4) F5 mode Copier function programming..................................... 5-16

(5) F6 mode Adjustment and programming.................................... 5-23

(6) F7 mode electronic counter....................................................... 5-29

(7) F8 mode copier operation adjustment ...................................... 5-31

(8) F9 Telephone# input ................................................................. 5-33

5.2 Self-diagnostics/Machine Malfunctions........................................... 5-34

(1) User error .................................................................................. 5-34

(2) Paper Jam................................................................................. 5-40

(3) Machine error ............................................................................ 5-43

5.3 User Preset Mode........................................................................... 5-58

VI. Unpacking/Installation

6. 1 Installation Requirements ............................................................... 6-1

6.2 Contents Check ............................................................................... 6-1

6.3 Unpacking........................................................................................ 6-1

6.4 Installation Procedure ...................................................................... 6-2

6.5 Adjustment....................................................................................... 6-7

6.6 White Density Adjustment.............................................................. 6-10

Caution:

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacture's instructions.

For Sweden, and Denmark

SPECIALSÄKRING: ENDAST AV APPARATFABRINKANTEN LEVERERAD

SÄKRING FåR ANVÄNDAS.

VARNING!

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller ekvivalent typ som rekommenderas av

apparattillverkaren. Kassera använt batteri enligt fabrikantens instruktion.

ADVARSEL!

Lithiumbatteri—Eksplosionsfare ved

fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Lever det brugte batteri tilbage til

leverrandoren.

CAUTION!

Danger of explosion if battery is incorrectly replaced. Replace only with the

same or equivalent recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions.

For Holland

Batterij niet

weggooien, maar

inleveren als KCA.

NL

ii

For U.K.

FOR YOUR SAFETY PLEASE READ THE FOLLOWING TEXT CAREFULLY.

This appliance is supplied with a moulded three pin mains plug for your safety and

convenience. A 13 amp fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the replacement fuse has a rating

of 13 amps and that it is approved by ASTA or BSI to BS1362.

Check for the ASTA mark or the BSI mark on the body of the fuse.

If the plug contains a removable fuse cover you must ensure that it is refitted when the fuse

is replaced.

If you lose the fuse cover the plug must not be used until a replacement cover is obtained.

A replacement fuse cover can be purchased from your local Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE FOR THE SOCKET OUTLET IN YOUR

OFFICE THEN THE FUSE SHOULD BE REMOVED AND THE PLUG CUT OFF AND

DISPOSED OF SAFELY.

THERE IS A DANGER OF SEVERE ELECTRICAL SHOCK IF THE CUT OFF PLUG IS

INSERTED INTO ANY 13 AMP SOCKET.

If a new plug is to be fitted please observe the wiring code as shown below.

If in any doubt please consult a qualified electrician.

WARNING: THIS APPLIANCE MUST BE EARTHED.

IMPORTANT: The wires in this mains lead are coloured in accordance with the following

code:

Green and Yellow :Earth

Blue :Neutral

Brown :Live

As the colours of the wires in the main lead of this appliance may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured GREEN-AND-YELLOW must be connected to the terminal in the

plug which is marked by letter E or by the safety EARTH symbol “ ” or coloured GREEN or

GREEN-AND-YELLOW.

The wire which is coloured BLUE must be connected to the terminal in the plug which is

marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be connected to the terminal in the plug which is

marked with the letter L or coloured RED.

How to replace the fuse.

Open the fuse compartment with a screwdriver and replace the fuse.

Fuse

Fuse

iii

1-1

Introduction

Section I

Introduction

1. 1 Specifications

1.Type Desk Top

2.Copy process Electrostatic photographic method

3.Development process Two component magnetic brush

4.Maximum original size Ledger(11"x17") / A3(297 x 420mm)

5.Copy speed

FP-7818 FP-7824 FP-7830 FP-7835 FP-7845 FP-7850

(cpm)

<PU> <PG> <PU> <PG> <PU> <PG> <PU> <PG>

Ledger/A3 :

12.5 15.5/16.0 18.50/19.00 20/20.5

Legal/B4,FLS

:

14 17.5/17.0 21.00/20.50 23.5/23

Letter-R/A4R

:

15.5 19.5/19.0 24.00/23.50 28.5/27.5 43/41.5

Letter/A4 :

18 24.0 30.00 35 45 50

Invoice/A5 :

18 24.0 30.00 35 45 50

6.First copy time

FP-7818 FP-7824 FP-7830 FP-7835 FP-7845 FP-7850

(sec) letter/A4 size

4.8 4.0 4.0 4.0 2.9 2.9

without Auto mode

letter/A4 size

6.2 5.1 5.1 5.1 3.6 3.6

with Auto mode

7.Copy ratio Enlargement(fixed) : 2.00, 1.73, 1.41, 1.22, 1.15

Reduction (fixed) : 0.87, 0.82, 0.71, 0.58, 0.50

Zoom : 50%-200% (1%step)

8.Copy size Ledger/A3–Invoice/A5

9.Paper capacity Cassette :

550 sheets x 2 (550 sheets:FP-7818)

Multi-feed bypass : 50 sheets

10.Paper feed Front loading universal paper cassette

Multi-feed bypass tray

11.

Paper exit tray capacity

250 sheets

12.Paper weight Cassette : 16–24 lbs ( 60–90g/m

2

)

Bypass : 15–30 lbs (55–130g/m

2

)

13.Special paper OHP,Label paper, Tracing paper

(Through multi-feed bypass)

14.Continuous copying 1-999 reset to 1 (1-99 reset to 1 : FP-7818)

1-2

15.Fusing system Heat and Pressure

16.Photoreceptor Organic Photo Conductor(OPC)

17.Exposure control 7 step digital+Photo/Auto button

18.Warm up time FP-7818 approx. 40 sec.

FP-7824 approx. 50 sec.

FP-7830 approx. 75 sec.

FP-7835 approx. 75 sec.

FP-7845 approx. 180 sec.

FP-7850 approx. 270 sec.

19.Power consumption Less than 1.45 kW/1.5 kW

20.Power source AC120V 60Hz / AC220 - 240V 50Hz

21.Dimensions (W x D x H) 23.9" x 26.0" x 22.9" / 606 x 661 x 582 mm

(23.9" x 26.0" x 18.1" / 606 x 661 x 479 mm : FP-7818)

22.Weight (PU) (PG)

FP-7818 138.6 lbs / 64 kg

FP-7824 149.6 lbs / 70 kg

FP-7830 149.6 lbs / 70 kg

FP-7835 149.6 lbs / 70 kg

FP-7845 161 lbs / 73.5 kg

FP-7850 161.5 lbs / 73.7 kg

23.Ambient conditions Temperature : 50–86F/10–30 °C

Relative humidity : 30–80%

24.Optional accessories i-ADF FA-A888

ADF FA-A505

Sorter FA-S280

(10bin sorter: FP-7818/7824/7830)

FA-S575/S660/S680

(20bin sorter: except FP-7818)

System console FA-DS72: FP-7818/7824/7830/7835

FA-DS82: FP-7845/7850

LCC FA-MA301

* Specifications are subject to change without notice.

1-3

Introduction

1. 2 Features

• Introducing Qualitative Reasoning Based Adaptive Controller copy density

control

With Qualitative Reasoning Based Adaptive Controller used for copy density control,

optimum copies are maintained for a long time in variable environmental conditions.

• User friendly operation

The touch panel enables simple operation. (FP-7845/7850)

• Enhancements in serviceability

If a problem should occur the self diagnosis system will indicate which area is

responsible.

• Standard Automatic Duplexing (FP-7850)

An Automatic Duplex Unit is provided as standard, in addition to front paper loading

(550 sheets) + Multiple sheet bypass (50 sheets).

• Functional expansion through optional accessories

Equipping with the system stand and LCC allows a high copy volume

Maximum feed paper capacity

FP-7818 2,250 sheets : four drawers + multiple sheert bypass

FP-7824 2,800 sheets : five drawers + multipler sheet bypass

FP-7830/7835/7845

5,800 sheets : five drawers + LCC + multiple sheet bypass

FP-7850 5,250 sheets : four drawers + LCC + multiple sheet bypass

ADF and sorter can be connected with the main system easily by using exterior

connectors.

• Environmental considerations

Quieter operation, lower power consumption, a higher content of recyleable plastic

and our new Qualitative Reasoning Based Adaptive Controller. (FP-7830/7835/

7845/7850)

1-4

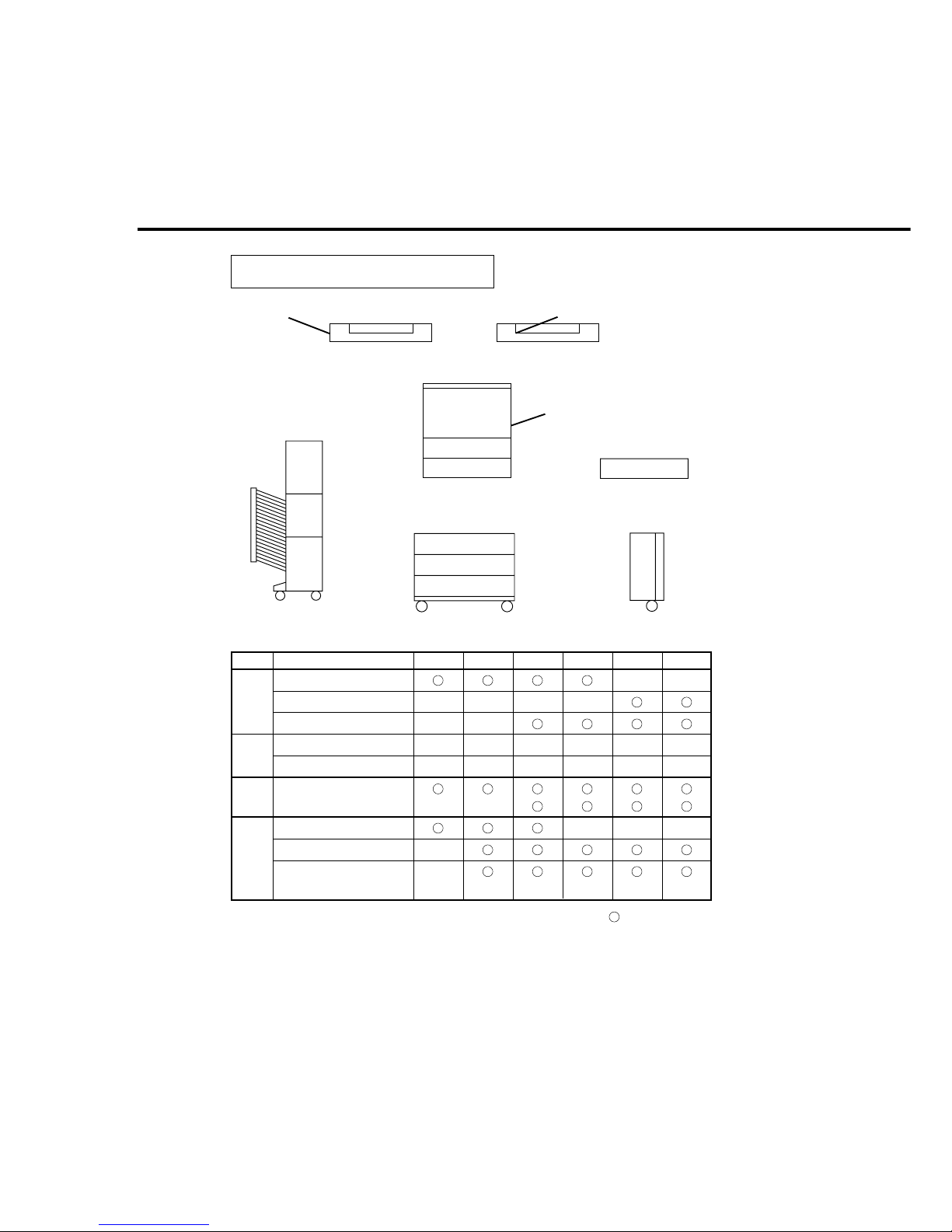

<Commonality of accessories>

1. 3 System Configuration

i-ADFADF

Main Unit

50

ADU

550

Sorter

Paper drawer

550

System console

550

Cover

Storage

LCC

3000

Accessories FP-7818 FP-7824 FP-7830 FP-7835 FP-7845 FP-7850

FA-DS72

xx

FA-DS82

xxxx

LCC ( FA-MA301 )

xx

Number of drawer 1 2 2 2

1 + ADU 1 + ADU

Auto Duplex unit (FA-MADM6)

x

Option Option Option

Standard Standard

ADF FA-A505

i-ADF FA-A888

xx

10bin sorter FA-S280

xxx

20bin sorter FA-S575

x

20bin staple sorter

x

FA-S660/S680

ADF

Copier

paper feed

System

console

Sorter

Key: = OKx = N/A

System Console FA-DS72: Storage tray,Cover x 1

( 2 drawers drive mechanism )

FA-DS82: 550 sheets paper drawer, Storage tray, Cover

( 3 drawers drive mechanism )

1-5

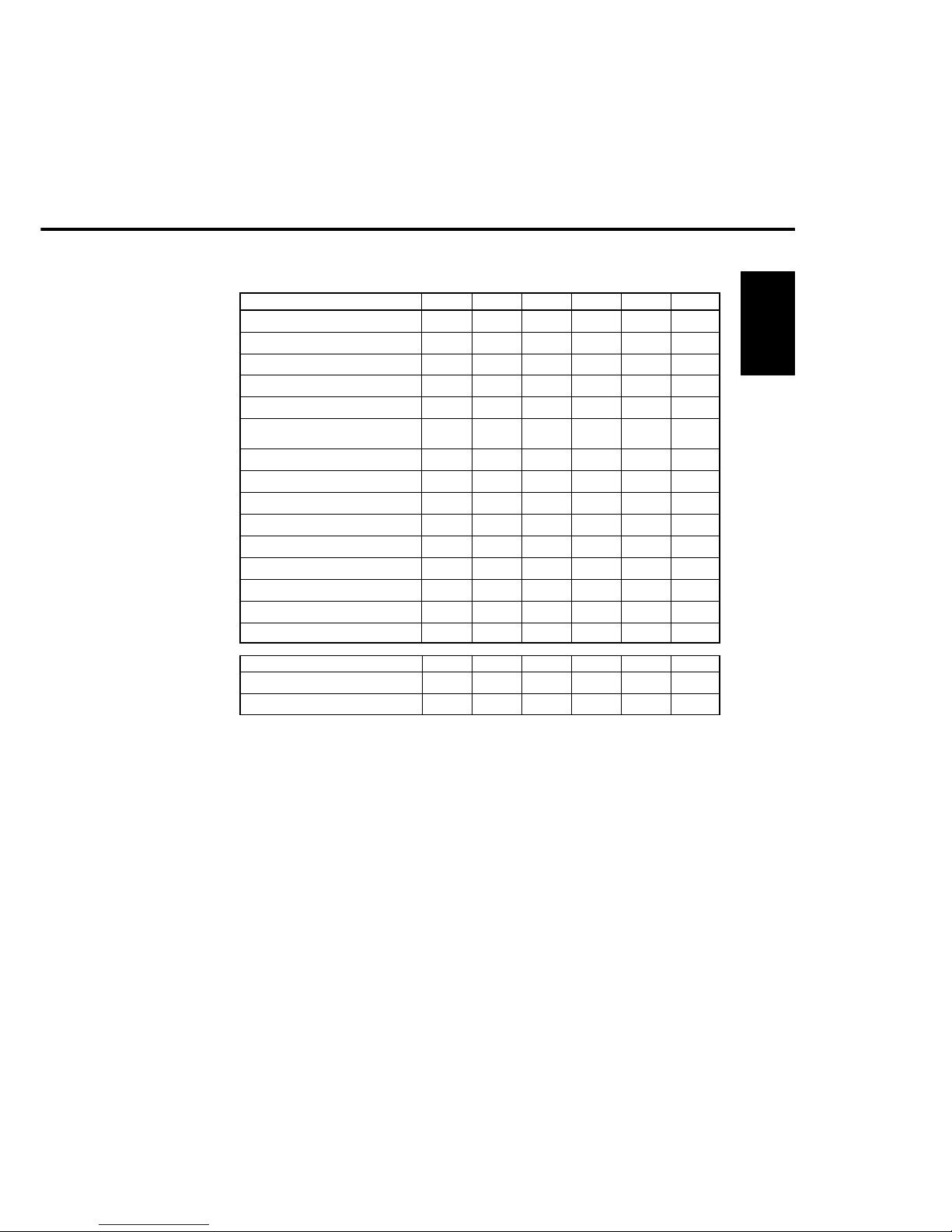

Introduction

Department counter 50 50 100 100 300 300

Cover, Interleaving, Presentation No * No * No * No * Yes Yes

Job memory 2 2 2 2 5 5

This Service Manual is based on the FP-7850.

To identify areas where the other models differ, please refer to this chart and the

Field Service Manual for each model.

FP-7818 FP-7824 FP-7830 FP-7835 FP-7845 FP-7850

Warm up time ( sec.) 40 50 70 70 180 210

First copy time ( sec.) 4.8 4.0 4.0 4.0 2.9 2.9

Paper feed cassette 1 2 2 2

1+ADU 1+ADU

System stand DS72 DS72 DS72 DS72 DS82 DS82

Copy speed 18 22 28 35 42 50

Control panel design LED LED

LCD display LCD display LCD touch panel LCD touch panel

Transfer corona cleaner No No No No Yes Yes

Drum separation finger No No No No Yes Yes

Fuser lamp 1 1 1 1 2 2

Process speed ( mm/sec. ) 170 210 210 210 340 340

Developer suction No No No No Yes Yes

Fresh toner recycling No No Yes Yes Yes Yes

Toner bottle life 10K 10K 20K 20K 20K 20K

Waste toner bottle capacity 10K 10K 120K 120K 120K 120K

PM cycle 80K 80K 120K 120K 120K 120K

[ Comparison of specifications ]

* Except OHP Interleaving

1-6

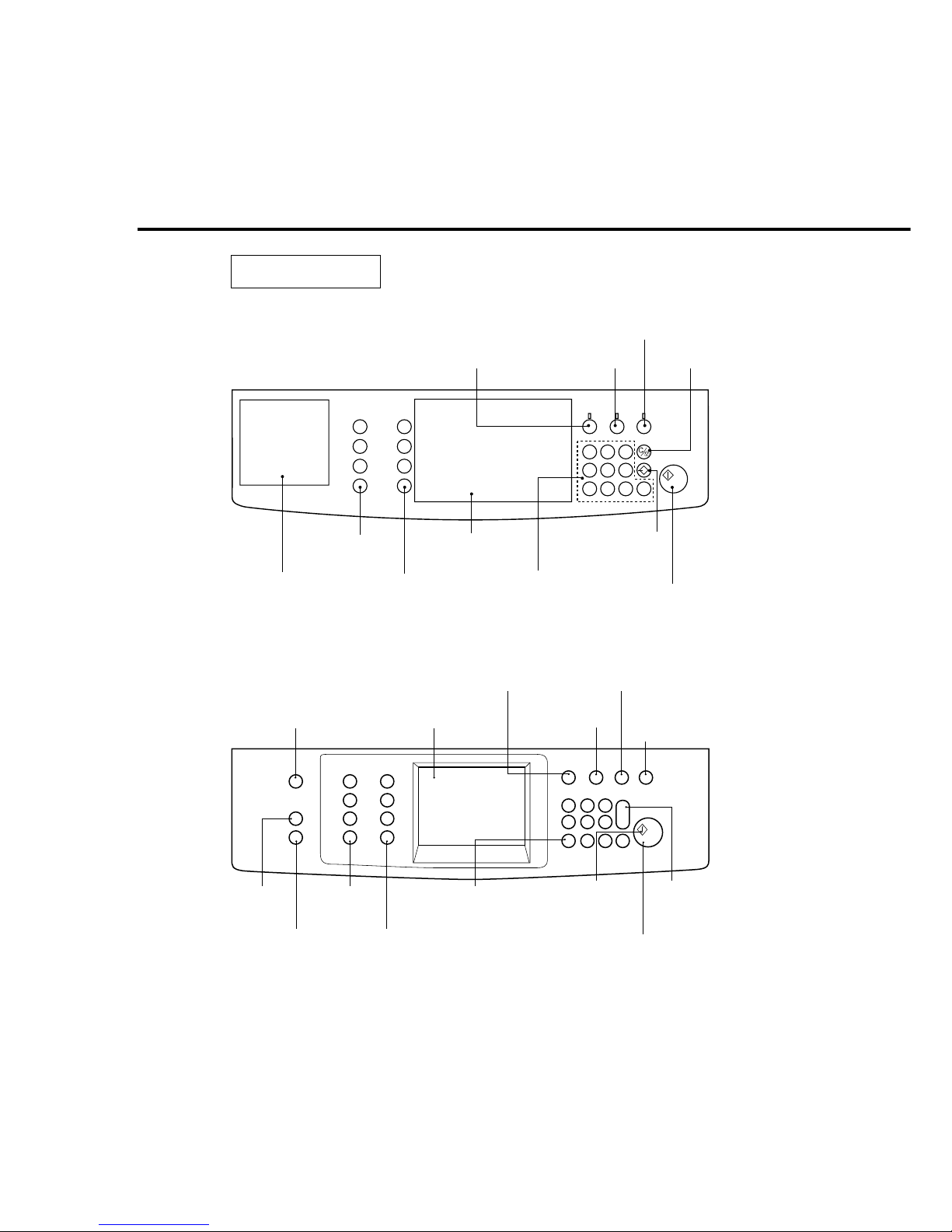

21

5

8

3

6

90

4

7

1. 4 Operation

Energy Saver

Interrupt Key

User Preset Key

Touch Panel Display Manual Key

Clear/Stop Key

Press to stop copy run

or clear copy count in

display.

Print Key

Reset Key

Press to reset all

features to initial

power-on state.

Original Size

Keys

Multi Size

Key

Job Memory Key Copy Size Keys

Quantity Keys

Ready Indicator

Ready: Green LED

Not ready: Red LED

Copy Reservation: Flashing

• FP-7845/7850

LEDGER

LEGAL

LETTER

INVOICE

1 2 3

4 5 6

7 8 9 0

Print Key

Recall Key

To recall the number

of copies selected

during a copy run.

Quantity Keys

Communications

Monitor

Copy Size Keys

Original Size

Keys

Special Effects Panel

• FP-7818/7824/7830/7835

Energy

Saverkey

Interrupt

Key

Reset Key

Clear/Stop

Key

1-7

Introduction

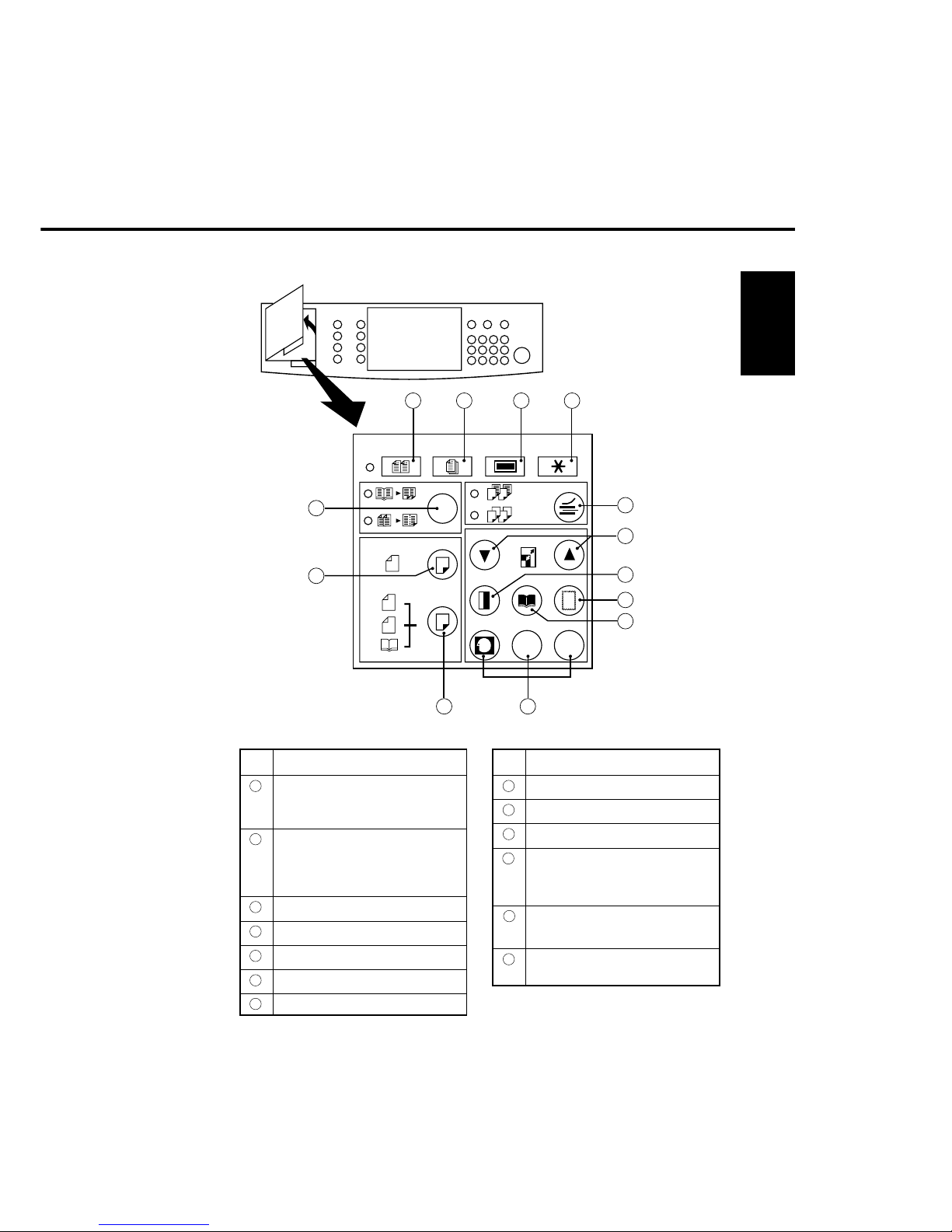

No. Keys

8 Edge Mode

9 Book Mode

10

Memory In/Job programs

11

Duplexing mode selection

(Except FP-7818/7824)

• Using ADU

12

2:1 Copy (Except FP-7818/7824)

• Using i-ADF

13

2-Page copy/2 in 1 mode selection

(2 in 1 : Except FP-7818/7824)

No. Keys

1 Multi-Size Feeding

(Except FP-7818/7824)

• Using i-ADF

2 Original Count

(Except FP-7818/7824)

• Using i-ADF and ADU 2 in 1

mode

3 Access

4 User Preset

5 OHP interleaving mode

6 Zoom

7 Margin Shift Mode

(1) Special Effects Panel (FP-7818/7824/7830/7835)

2

2

1

1

2

M

M1 M2

OHPOHP

OHPOHP

1 2 3

4

5

6

7

8

9

1011

12

13

321

1-8

%

mm

FP-7818/7824

FP-7830/7835

LEDGER

LEGAL

LETTER

LETTER

INVOICE

FP-7718

STAPLE

SORT

STACK

STAPLE

SORT

STACK

1 12 3 4 5 6 7

13

14

15

16

9 81710111812

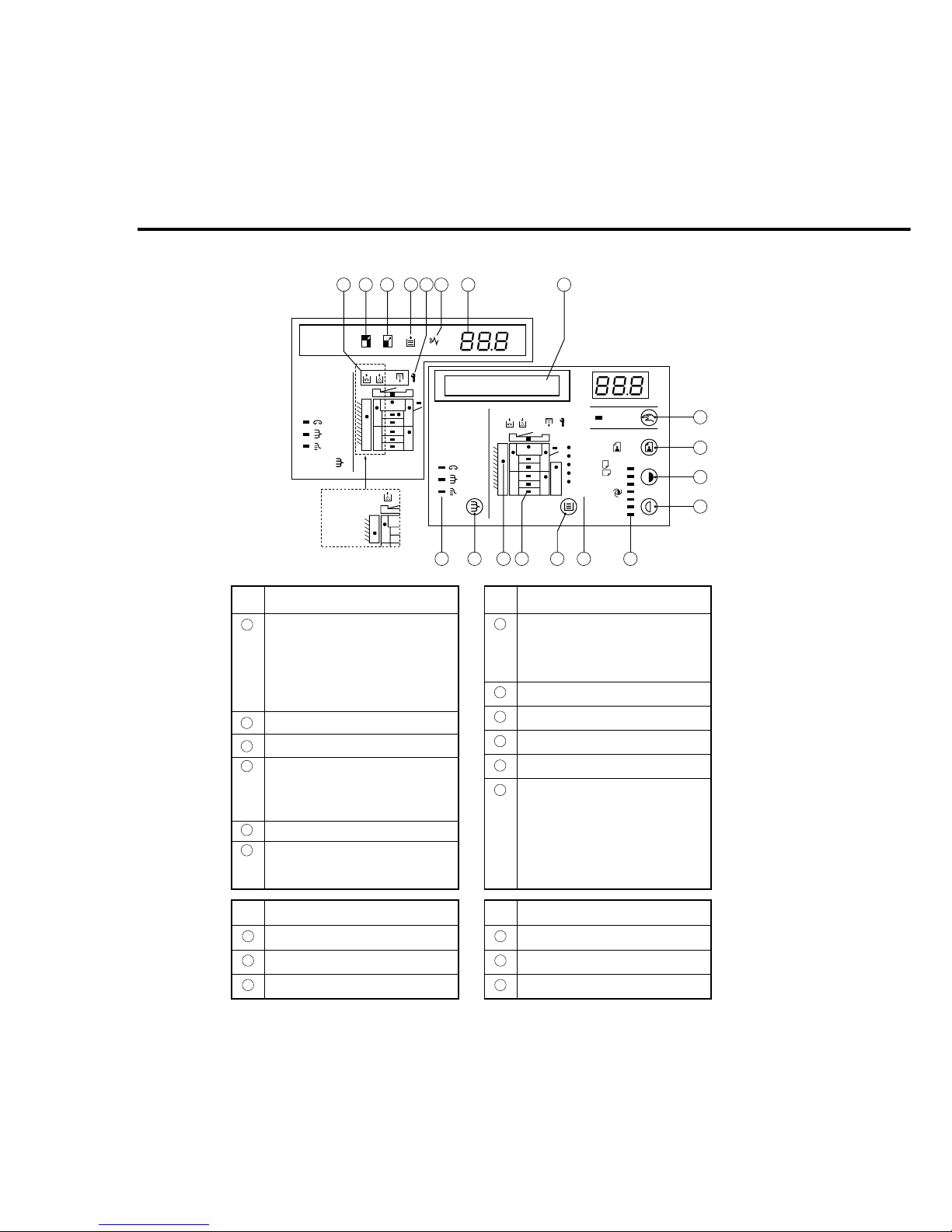

(2) Communications Monitor (FP-7818/7824/7830/7835)

No. Indicator

1 Adding

Paper

Toner

Staple (Except FP-7818)

Replacing

Waste Toner Bottle

2 Reduction

3 Enlargement

4 Service Call

• Flashes for routine maintenance.

• Lights steadily for duplex

maintenance

5 Paper Misfeed

6 Copy Count Display

Indicates number of copies, zoom

ratio and error code.

No. Indicator

7 Message Display

(FP-7830/7835)

Indicates procedures, functions

maintenance, etc.,

8 Exposure Indicator

9 Paper Size Indicator

10

Paper Drawer/Tray Indicator (–)

11

Paper misfeed location (•)

12

Mode Select Indicator

Staple Sort (Except FP-7818)

Sort

Group

No. Keys

13

Manual Key

14

PHOTO/AUTO

15

Exposure Control (DARK)

No. Keys

16

Exposure Control (LIGHT)

17

Paper Drawer/Tray

18

Mode Select Key

1-9

Introduction

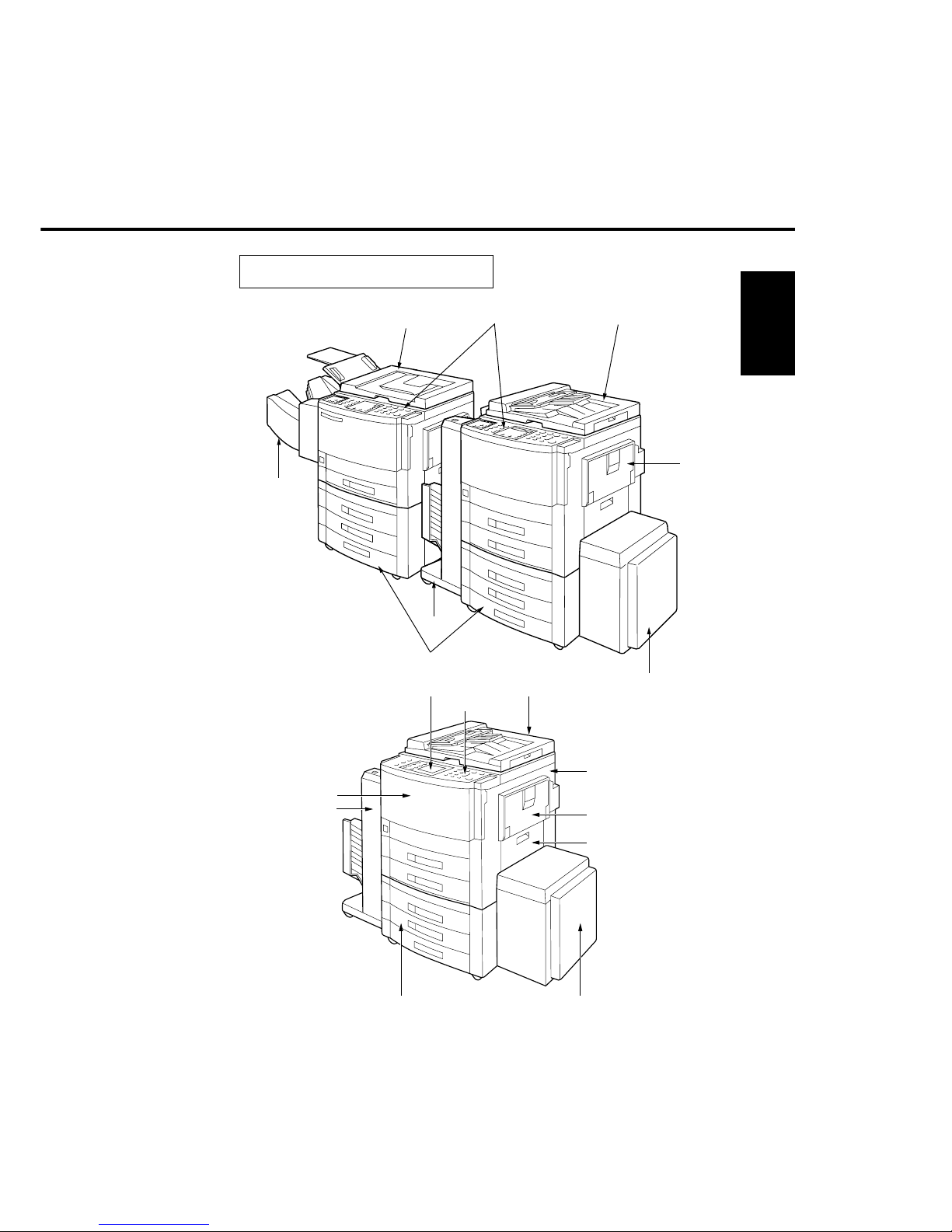

1. 5 Component Location

( Outer view )

Control Panel

i-ADF

ADF

FP-7818

System console

Sorter

LCC

(Except FP-7824)

Bypass

Sorter

FP-7824/7830/7835

LCD touch panel

Control panel

i-ADF

Right cover

Bypass

Paper feed cover

LCC

FP-7845/7850

System console

Front panel

Sorter

1-10

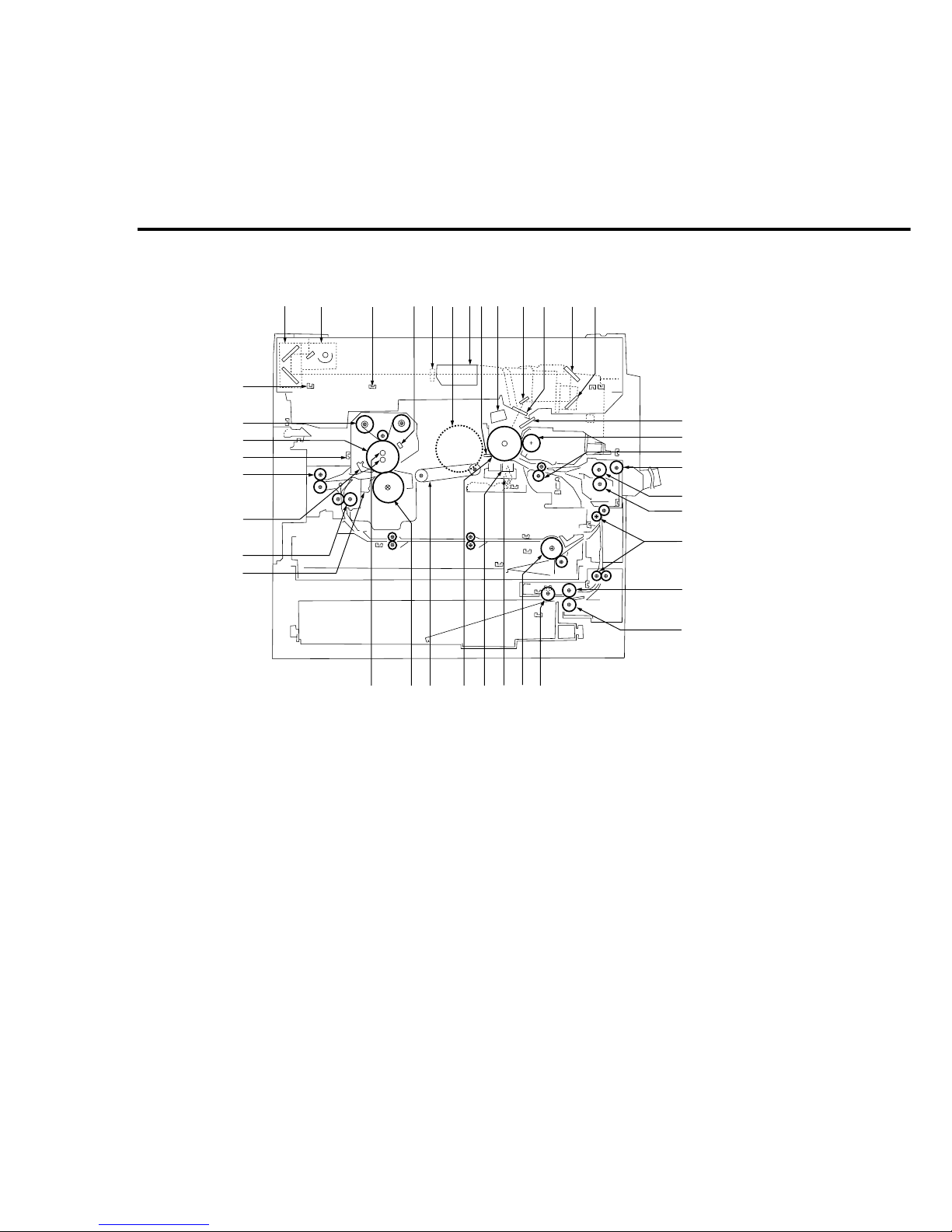

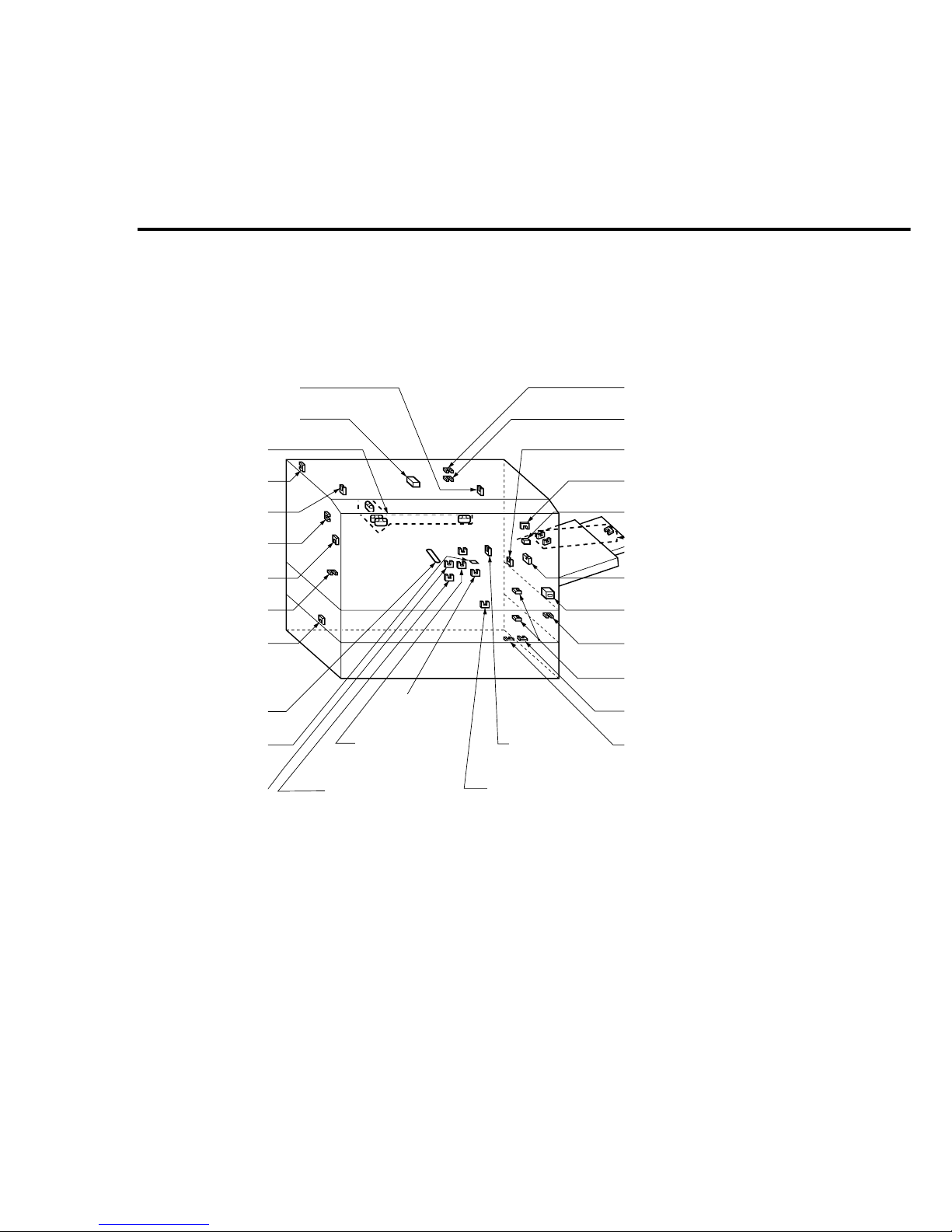

(1) Inner view

1 Half-speed unit

2 Full-speed unit

3 Lens Position sensor

4 Thermistor

5 AE Sensor

6 Main motor

7 Lens unit

8 Charge corona

9 No.6 mirror

10 Slit glass

11 No.4 mirror

12 No.5 mirror

13 LED array

14 Magnetic roller

15 Registration roller

16 Bypass pick-up roller

17 Bypass paper feed roller

18 Bypass DFP roller

19 Middle roller

20 Paper feed roller

21 DFP roller

22 Pick-up roller

23 ADU Paper feed roller

24 Corona cleaner

25 Transfer/Separation corona

26 Drum

27 Transfer belt

28 Pressure roller

29 Fuser lamps

30 Fuser separation finger (lower)

31 Reverse roller

32 Fuser separation finger (upper)

33 Paper exit roller

34 Paper exit sensor

35 Heat roller

36 Cleaning Web roller

37 Full-speed unit home postion sensor

38 Drum separation finger

234567388 9 10 11 12

13

14

15

16

17

18

19

20

21

222324252627

28

29

30

31

32

33

34

35

36

37

1

1-11

Introduction

Mirror stepping

motor

Optics drive

motor

Lens stepping

motor

Developer

cooling fan

Toner bottle

motor

Dust collecting

fan

ADU paper length guide

motor (FP-7850)

ADU paper width

guide motor

(FP-7850)

ADU drive motor

(FP-7850)

Optics fan

Optics fan

Main motor

Optics fan

Exhaust fan

Lifting motor

(lower stage)

Suction/Ozone

fan

(2) Fan/Motor Location

1-12

(3)Sensor Location

Mirror home position

Exposure lamp

home position

Platen cover

open/close

Platen cover

angle

AE (Automatic original

density sensor)

Original size

ADU

detection

(FP-7850)

Toner density

Copy density

ADU paper

length

(FP-7850)

ADU paper

pass 1 (FP-7850)

Paper exit

Lens home

position

Front cover

open/close

ADU paper width

(FP-7850)

Paper level

(lower stage)

ADU paper

detection

(FP-7850)

ADU paper

pass 2

(FP-7850)

Registration

roller paper pass

Paper detection

(lower stage)

Bottom plate upper limit

sensor (lower stage)

Middle roller paper pass

(upper/lower stage)

Waste toner

bottle

Total counter

Bypass paper

detection

Bypass paper size

Toner level

Toner bottle

home position

Paper feed cover

open/close

1-13

Introduction

(4) Solenoid/Clutch/Discharge lamp Location

Paper feed clutch

Registration roller clutch

Discharge lamp

Middle roller clutch

Bypass pick-up solenoid

Paper feed clutch (lower stage)

Separation

solenoid

Paper exit

solenoid

(FP-7850)

Power switch

Door switch

ADU clutch (FP-7850)

Pick-up solenoid (lower stage)

Recycle solenoid

(5) PCB Location

HVPS (High voltage

power supply)

LED array

Control panel 4

Control panel CPU

Control panel 3

Paper feed driver

LVPS (Low voltage

power supply)

AC driver

Main CPU

Automatic duplex

unit driver

(FP-7850)

1-14

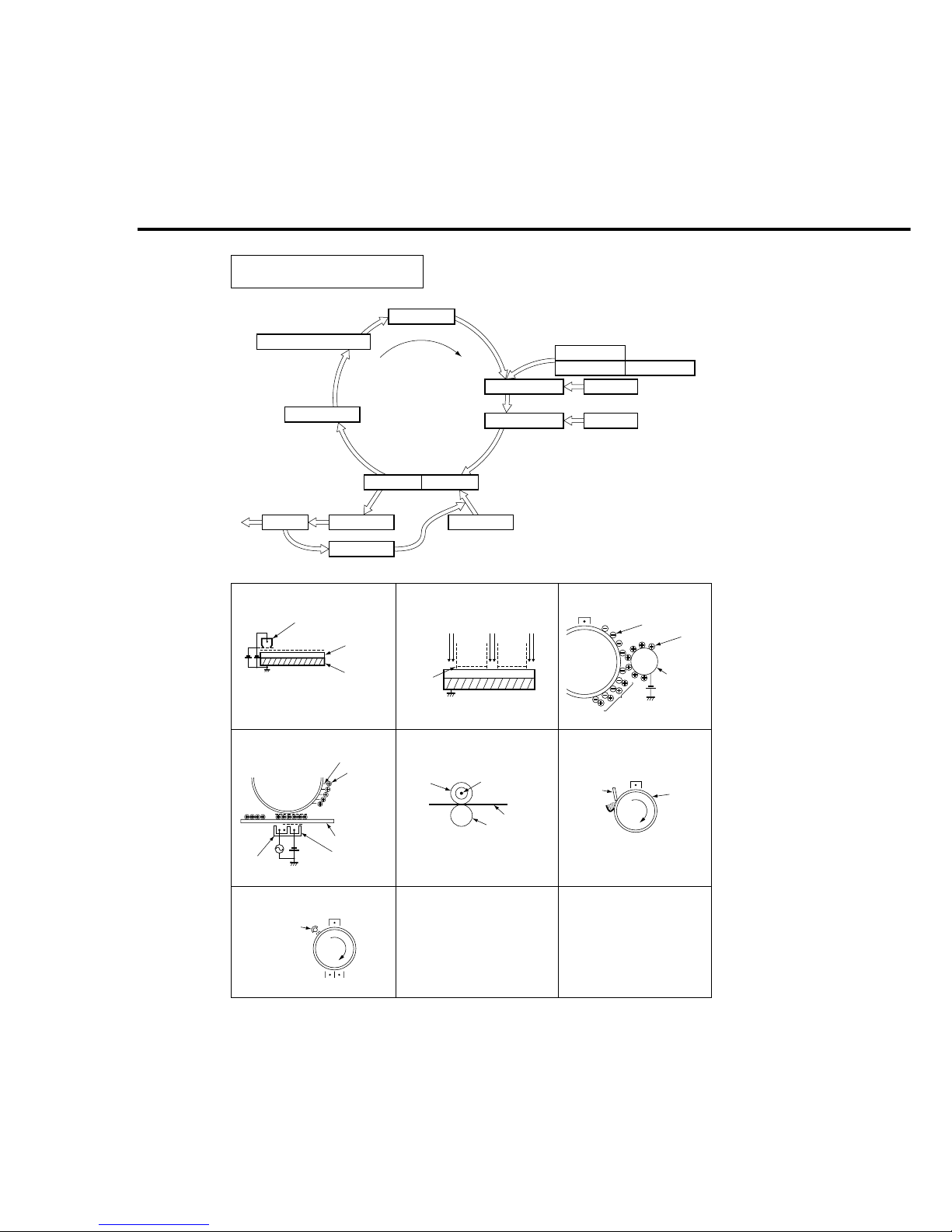

1. 6 Copy Process

Charger

Discharge lamp

Cleaning

Fusing

Exit

ADU

Paper feed

Separation

Transfer

Developer

Toner

Exposure

Original

Reduction Discharge

Trimming

–DC

Discharge lamp:

Transfer/Separation Fusing: Cleaning:

Primary Charge: Image Exposure: Developing:

Drum surface

approximately-800V DC

Charge corona

Drum

Latent

charge

image

Illumination

Magnetic

roller

Latent charge

image(–)

Discharge

lamp

Heat roller

Fuser lamp

Paper

Pressure

roller

Latent image

Transfer

corona

Cleaning

blade

Drum

Blacking prevention

Toner (+)

Toner

Paper

Separation

corona

1-15

Introduction

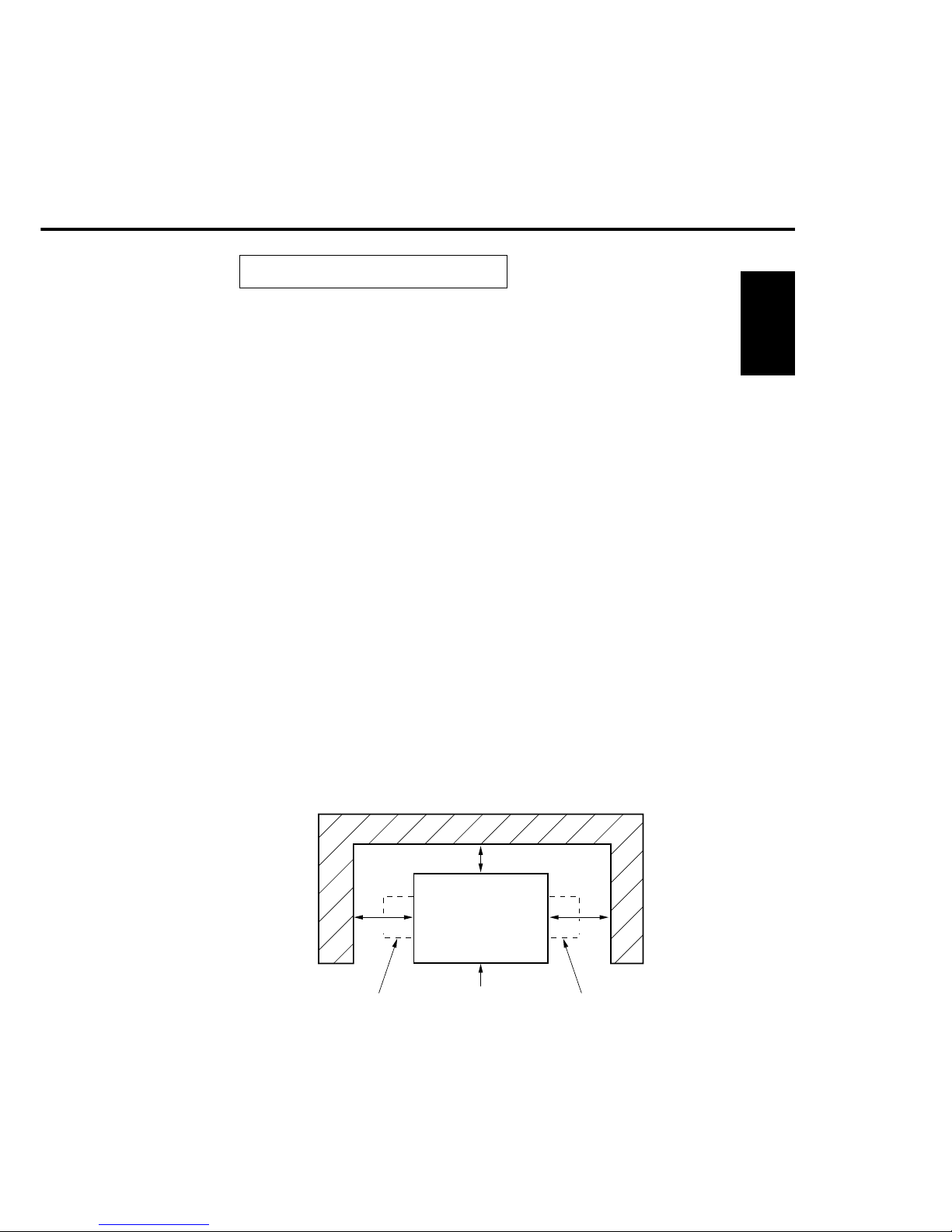

1. 7 Precautions on Set Up

Copy machine performance and the copy quality is subject to and dependant

on environmental conditions. To maintain good performance, quality, and safe

operation, observe the following precautions:

1) For safe operation and to avoid trouble do not install the system under the

following conditions:

• High temperature, high humidity, low temperature or low humidity

• The temperature or humidity varies suddenly

• Being exposed to direct sunlight

• Dusty space

• Badly ventilated location

• Exposed to chemical gases (such as ammonia gas)

• Exposed to strong vibration

• Directly exposed to direct wind (ex. outlet of air conditioner)

2) The weight of machine is 220lb(100 kg) or more with options. It must be placed

on a firm platform which is level.

3) The maximum power consumption is 1.45 kW. Use an independent power

supply of 120 V and 15 A (220-240V and 7A)or higher. (Do not use a extension

cord.)

4) Make sure the machine is properly grounded. (Do not ground to gas or water

pipe.)

• A ground terminal is provided on the back of the copier main body.

5) Install the machine with enough space around it.

4"/100 mm

14"/350mm

28"/700mm

Copier

Multi sheet bypassExit tray

1-16

1. 8 Precautions with Consumables

(1) Photoreceptor drum

• Do not touch the surface (with the hand or anything else).

• Stand the drum with the drum gear up for storage.

• Be careful not to smear with saliva, water, oil and so on.

• Do not place a where the temperature is high.

• Do not place it in strong light (such as direct sunshine or at window).

• Do not expose it to chemical gas or vapor.

• Do not store the developer unit with the photo receptor drum installed without

covering it with clean paper.

(2) Toner Developer

1) Do not mix different types of toner and developer.

• The machines are designed to use exclusive toner and developer for specific

models. Do not mix with toner and developer for other models.

2) Do not mix foreign materials.

Be careful not to include foreign materials in the toner and developer. If you

spilled toner or developer on a table or floor when adding toner or developer in

the developer unit, discard what was dropped. Such supplies may damage

the drum as well as cause other trouble with the image.

3) Do not place into other containers.

Toner and developer must not be placed into other containers, because some

containers may change the characteristics of the supply. Vinyl chloride

potentially changes the characteristics of supplies because of migrating

plasticizers.

4) Precautions on storage and transport

• Toner and developer additives are sensitive to temperature (high temperature

in particular) and humidity (high humidity in particular). Pay attention to the

following items for storage and transport.

• Store them in a dark and cool location (lower than 95 F/35 C) and out of direct

sunshine.

• Be careful not to expose them to rain or direct sunshine during transportation.

When delivered by truck the temperature inside must be not higher than 104

F/40 C.(Under the sun in summer, the inside temperature can typically be

140 F/60 deg.C or higher in a closed vehicle compartment.)

1-17

Introduction

• There are normally no special problems with storage and transport in a cold

climate but, store in a low humidity condition. Do not put supplies near heaters.

5) Safety and hygiene

Toner has the property of easily being wind blown. Toner on skin does not

cause any damage to health but, inhaling it is undesirable even if a powder is

simply dust. Therefore, be careful not to inhale toner .

• Handle the toner gently when changing cartridges, and developer when pouring

in the developer unit. If you have breathed in a lot of toner by mistake, rinse

out your mouth with water completely. Any toner on the skin should be washed

off with soapy water.

• Toner stuck on clothing must be removed in a dry condition (by a vacuum

cleaner, brush, or beating,) and then washed with soapy water. Wiping off with

benzine, alcohol, or thinner is not recommended because it may partially melt

the components of toner even more, resulting in a harder stain and spot.

• Toner spilled must be cleaned with a vacuum cleaner, and then wiped with a

cloth dampened with a neutral detergent and wrung out.

• If exposed to flames toner and developer will burn. Keep these supplies away

from open flames.

• Any wasted consumables (photo receptor, developer and toner) should be

recycled.

• Wear rubber gloves, eye protection and so on before handling any solvents

such as IPA.

Control

Functions

2-1

Section II

Control Functions

2. 1 Image Control

Qualitative Reasoning Based Adaptive Controller

• Even if the toner density is at it's standard level, the copy image may vary with time

depending on the characteristics of drum and the environmental variations.

To prevent this change, the copy density sensor which is installed under the

developer unit controls the image to stablize the copy image.

• Controlling the image

During initialization after turning on the power, the copy density sensor reads the

white density, medium density (line pattern density patch) and black density

developed on the drum surface.These three values are compared with the ideal

gamma curve stored in the copiers memory.

The copier detects the amount offset from the standard gamma curve (such as "a

little background" or "light image") and calculates the variables for copy density

control in accordance with Qualitative Reasoning Based Adaptive Controller. In

this way it finds the optimum compensation values to tighten the gamma curve for

maintaining peak copy quality.

By means of this process, copy quality is stabilized by the various compensations

enabled by Qualitative Reasoning Based Adaptive Controller adjustment in image

production.

• The control of the gamma curve stabilizes copy quality by monitoring three points

of copy quality (white density, medium density and black density) and has a direct

effect on background, solid area density and good reproduction of fine lines

regardless of environmental changes and variation with time and copy volume.

2-2

• Qualitative Reasoning Based Adaptive Controller

Qualitative Reasoning Based Adaptive Controller is adaptive control on the basis

of quantative reasoning theory. While successively reasoning and learning the

change of process characteristics regardless of environmental changes and the

variations with time and the number of copies on the copier, the system reads the

patch marks and determines the best values of exposure and surface potential to

establish the best gamma curve for optimum copy quality.

• Qualitative Reasoning Based Adaptive Controller is applied at the following intervals.

a) During initialization after turning on the power.

b) After every 1,000 sheets following execution of Qualitative Reasoning Based

Adaptive Controller

(But, every 200 sheets following the execution of F8-09 for the next

500 sheets)

c) After turning on the power (up to 200 copies)

d) After replacing the toner bottle (up to 200 copies)

• Copy density detecting sensor

Two sensors for detection of copy density are used, one for white density, and line

pattern density and one for detection of black density. (Temperature and humidity

sensors are not used.)

• To correct for toner build up on the sensor, clean the sensor at the same time as

the replacement of the drum. The system provides a measured amount of light

and detects the reflected light. The resultant value is used for sensor compensation.

This becomes the reference value.

• As the reference value of the white density changes, various components are

adjusted according to characteristics of the gamma curve.

Reference F5-25: Qualitative Reasoning Based Adaptive Controller

Operation ON/OFF

F mode F6-80: Automatic compensation value (read only)

F6-81: Automatic compensation value (read only)

F6-82: Automatic compensation value (read only)

F6-28: White density reference value

(set by Qualitative Reasoning Based Adaptive

Controller)

F6-29: Black density reference value

(set by Qualitative Reasoning Based Adaptive

Controller)

Control

Functions

2-3

Amount of carrier passing TDC sensor Toner density condition Sensor output voltage

Less High Lower than normal

Much Low Higher than normal

<Control>

The following controls are necessary for normal control of toner density

1) Automatic adjustment of TDC sensor gain (during execution of F8-C09)

(to attain the standard reference level).

2) Maintain the standard level by control of toner density during use.

<Explanation of the control system>

1) Automatic adjustment of TDC sensor gain

Automatically adjust the reference through the TDC sensor by executing service

mode F8-09.

The operation flow is as shown below.

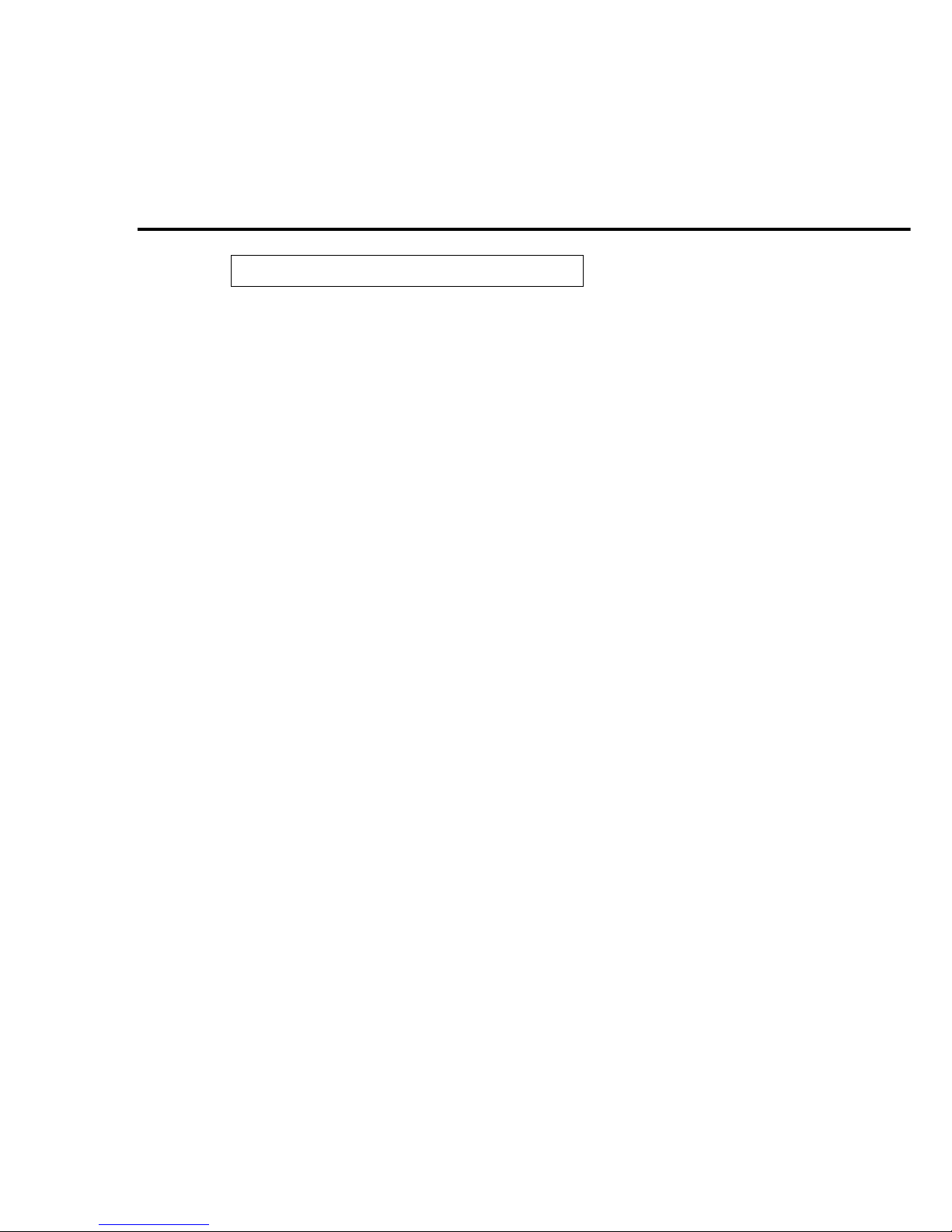

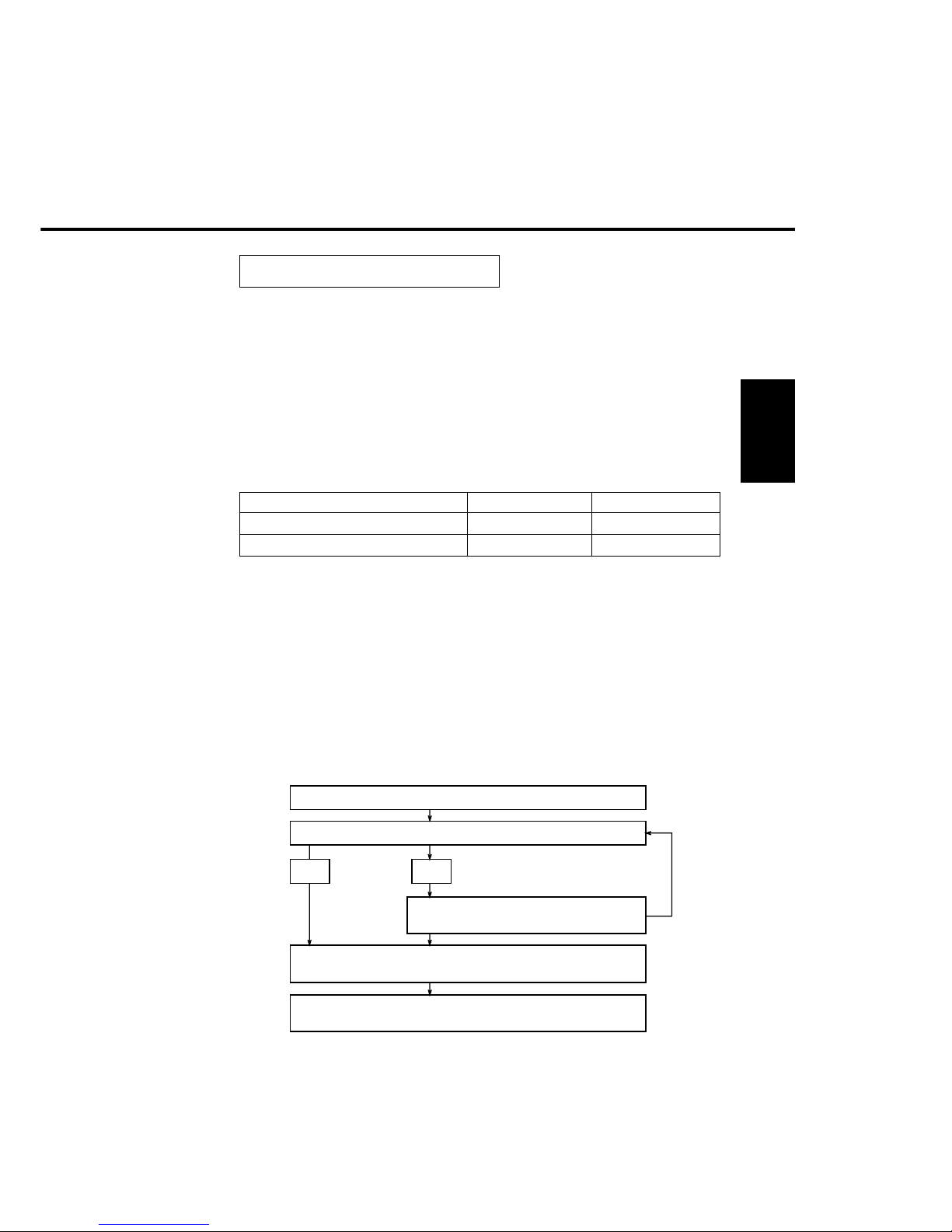

2. 2 Toner Density Control

To keep toner density(toner carrier ratio) in the developer unit constant, the TDC

sensor (toner density sensor) which is installed under the developer unit detects the

amount of carrier in the developer unit to control the toner density.

<Fundamentals>

The change in magnetic flux density in accordance with the amount of carrier

(magnetic power) in the developer (mixture of toner and carrier) is detected by the

TDC sensor and is converted to a voltage to control the toner density.

<Change of toner density and change of TDC sensor output voltage>

F8-09 start

CPU will check toner density sensor output. (2.5 V)

CPU will adjust sensor gain

control signal

Memory number will be changed to new number in memory.

(F6-21 or F6-26)

Toner density sensor output voltage will be adjusted to 2.5 V

Yes

No

2-4

2) Maintain standard toner density

While checking the output voltage of the TDC sensor for every copy, control the

timing of toner supply to the developer unit so that the output voltage is 2.5V at

all times to keep the toner density constant.

Supply toner: supply from reserve tank for 6 seconds

(amount of toner supply: approx. 1.4 g)

Rotate bottle for 7 seconds: supply toner to reserve

tank. (Toner is not supplied to developer unit.)

Check TDC sensor output voltage at copying (or mixing).

Is the measured output voltage over 2.5V?

Do not supply toner.

Note) During bottle rotating, toner is not supplied.

YES

NO

(Reference 1) Toner supply route

(Reference 2) Forced toner supply

Note: Bottle rotation means toner is being added to the reserve tank, not the

developer unit. This is not a final confirmation for proper TDC adjustment.

Reserve tank (hopper)

Developer unit

Bottle

Supply toner: supply for 4 seconds from reserve tank.

(amount of toner supply: approx. 1.1 g)

Rotate bottle for 7 seconds: supply toner to reserve tank.

(Toner is not supplied to developer unit.)

Perform twice.

Control

Functions

2-5

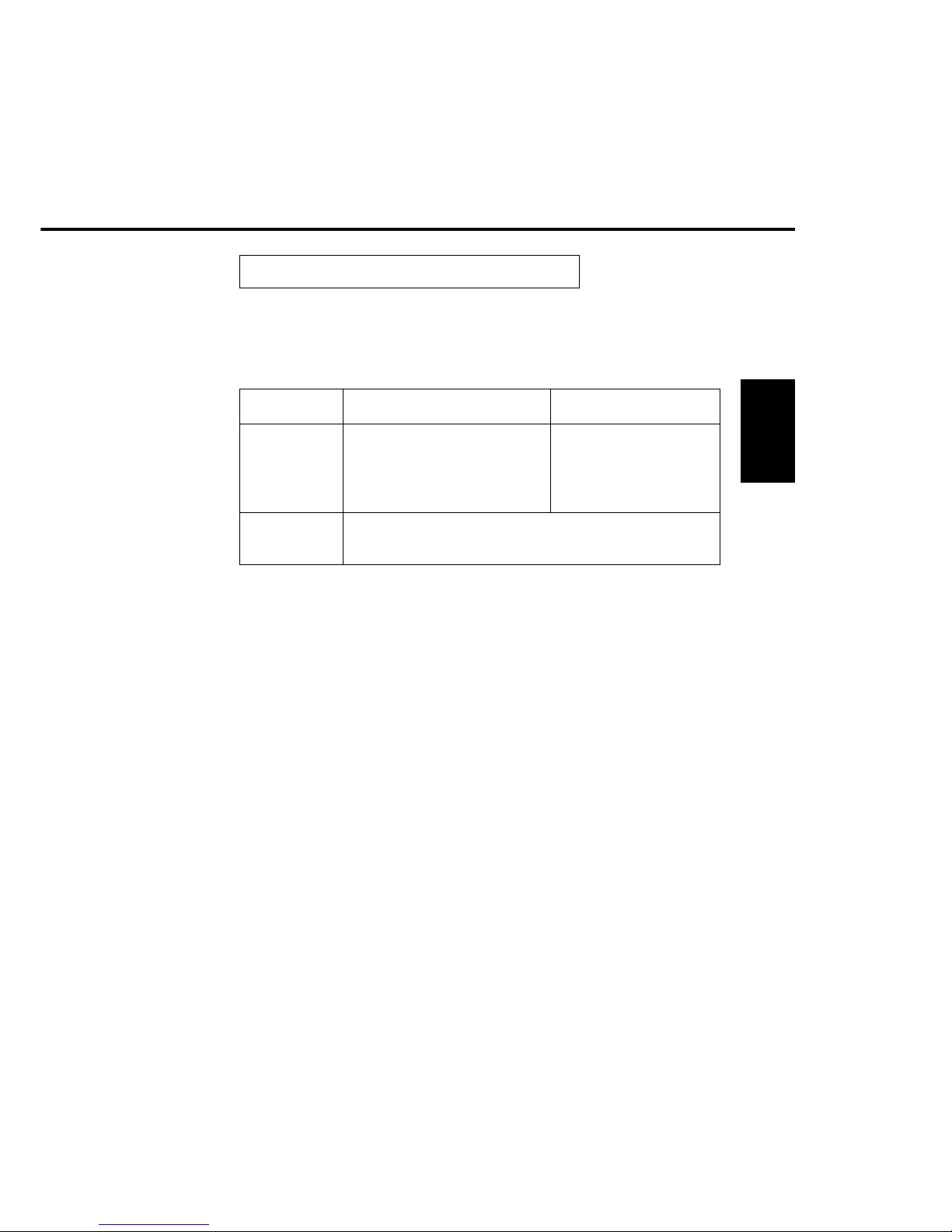

2. 3 Trouble Avoidance Mechanism

When some malfunction happens, this mechanism allows regular copy operation

without error conditions (service man call) (providing the malfunction does not affect

the basic copying operation and the appropriate function is not selected).

<Indication>

Appropriate function selected

Appropriate function not selected

The selected function is unavailable, Normal indication of copying

repair is necessary,

select others.

"(EX-XX)"

EX-XX XXXXXX

(Error code) (Electronic counter value at malfunction)

User mode

Service mode

Note: Only 30 records can be stored. Earliest records are

replaced by new ones as space is required.

Loading...

Loading...