Page 1

FP0 Series

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Programmable Controller

Panasonic ... the new name for

Page 2

FP0 – Super Compact PLC

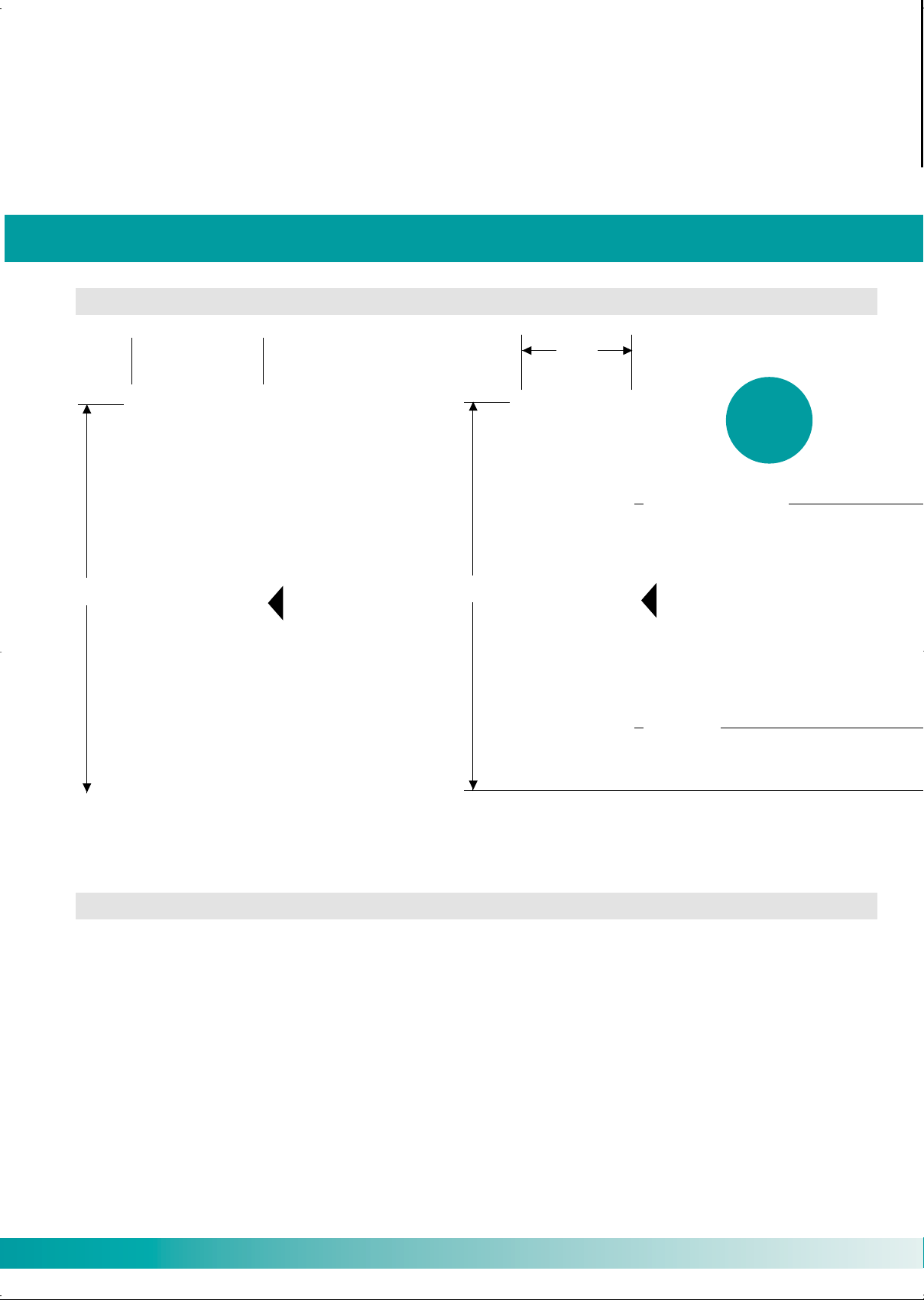

Input/output terminal

TOOL-Port

Hooks up by using the programming

software

or FPWIN GR and a single cable.

25mm

90mm

The photo shows an I/O

14-point control unit.

This size is uniform for

all except the I/O 32-point

control unit.

Supply voltage: 24VDC

NAiS Control FPWIN Pro

90mm

AC Power Supply:

• Supply voltage

85 to 265VAC

• Output 24VDC/

0.7A for FP0 PLC

(DC type)

NOTE:

A seperation between

the power supply and

the FP0 is needed to

allow for heat

dissipation.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Incredibly small, alone or even as multiple combined units

From I/O 10-points…

➝

30.4mm

➝

Actual

size

COM-Port: 2nd RS232C Interface

(optional for all CPU units for serial communication)

Super Compact Size

A control unit a mere 25mm in width. Even expanded to I/O 128 points, the width is still only 105mm.

The attachment area is the smallest in its class.

The control unit's dimensions are: W25* x H90 x D60mm.

Also, the I/O unit can be expanded to a maximum of

128-points. Even so, the size is still only W105 x H90 x

D60mm, a super compact design that breaks all previous

common sense rules on small-scale PLCs. With the

smallest-ever attachment area, the FP0 is perfect for

installation in machines, facilities, and control boards

where miniaturization is progressing even further.

*30mm width limited to I/O 32-points control unit.

2

Choose among 3 types of attachment

DIN rail

Slim attachment

plate model

Flat attachment plate

model (cannot be used

with expansions)

Page 3

Either 10 Points or the Maximum of 128 Points

Because of its super compact size and high capabilities,

the units are useful in a wide variety of applications.

Relay sequence

replacement

In-house detectors

Conveyer control

Parts feeders

Food processing and

packaging machines

Parking meters

Auto-stockers

Driving range

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

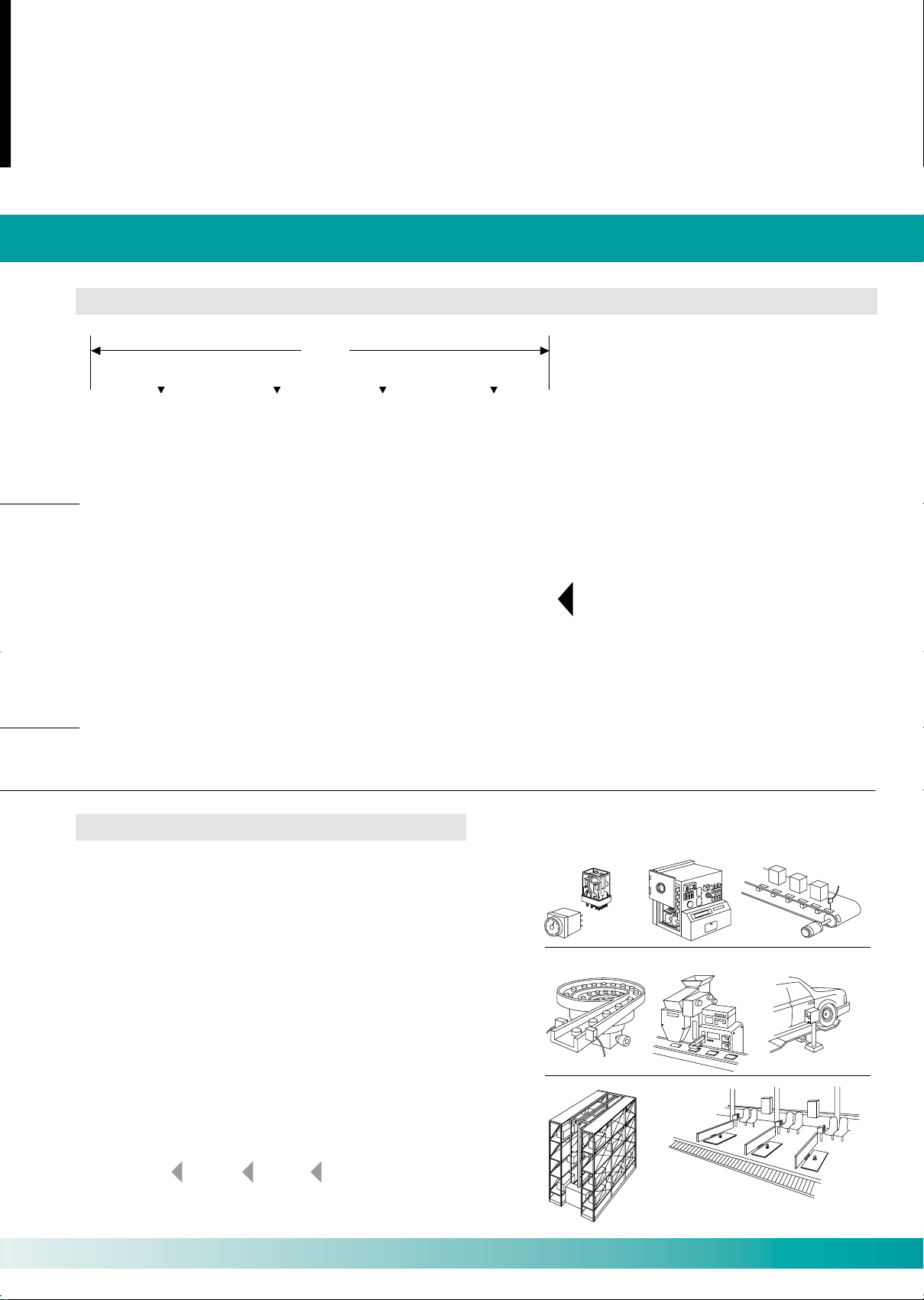

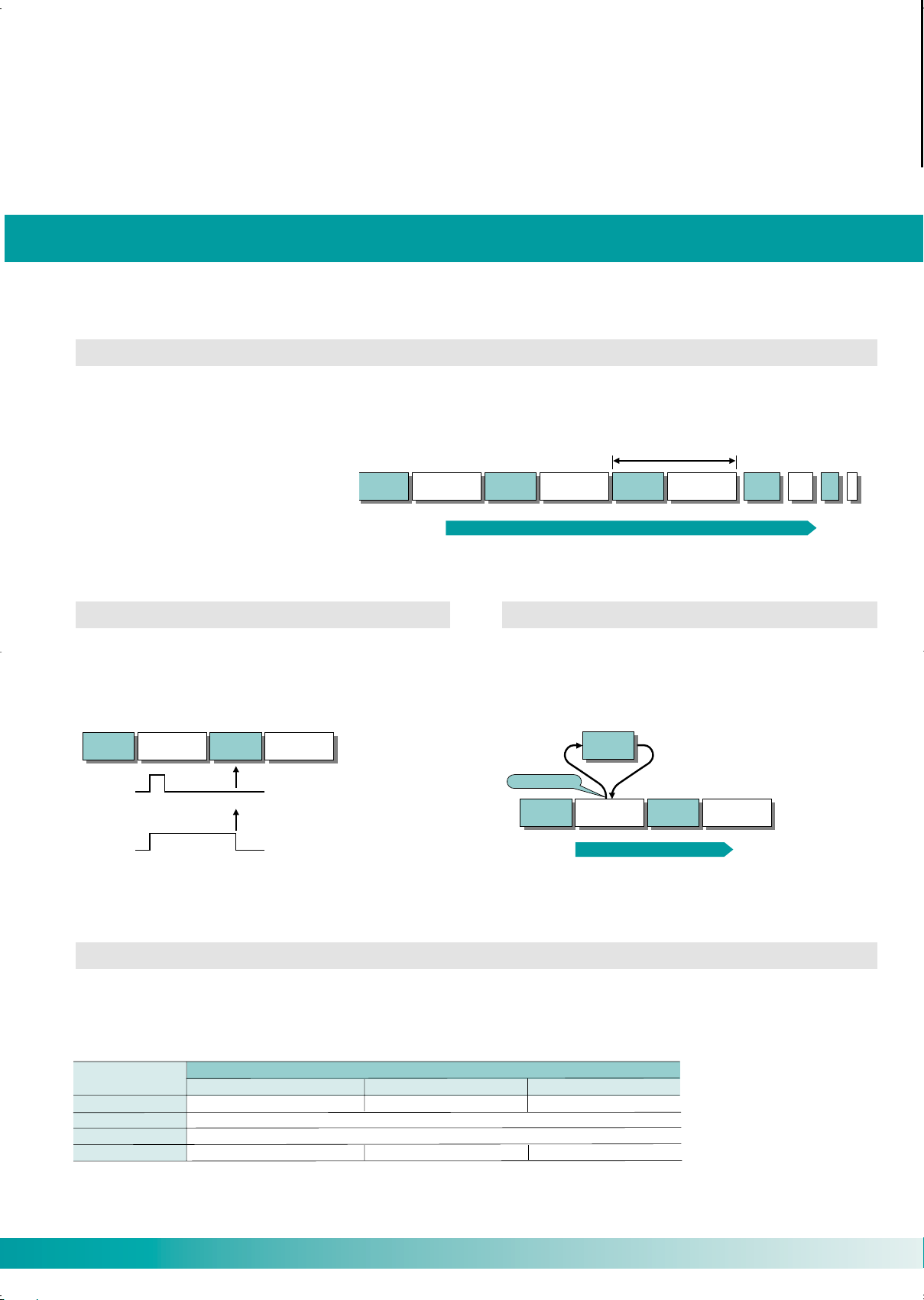

You save this much space!

…up to 128 I/Os

105mm

Control unit Expansion unit Expansion unit Expansion unit

■ Networking:

- ETHERNET

- PROFIBUS

- S-LINK

- MEWNET-F

■ Analogue modules featuring

different numbers of input and

output channels

■ Programming software:

- Control FPWIN Pro according

to IEC 61131-3

- Control FPWIN GR easy,

conventional programming

The photo illustrates adding

three I/O 32-point expansion

units to an I/O 32-point control

unit, yielding 128 points.

Supply voltage 24VDC.

Easy Expansion

The expansion unit can be attached easily

without any cables.

The expansion unit can easily be attached directly to the

control unit. Special expansion cables, backplanes, and

so forth, are unnecessary as the expansion unit employs

a stacking system that uses expansion connectors and

locking levers on the surface of the unit itself.

(Maximum possible expansion is three units)

Control

unit

Expansion

unit

Expansion

unit

Expansion

unit

3

Page 4

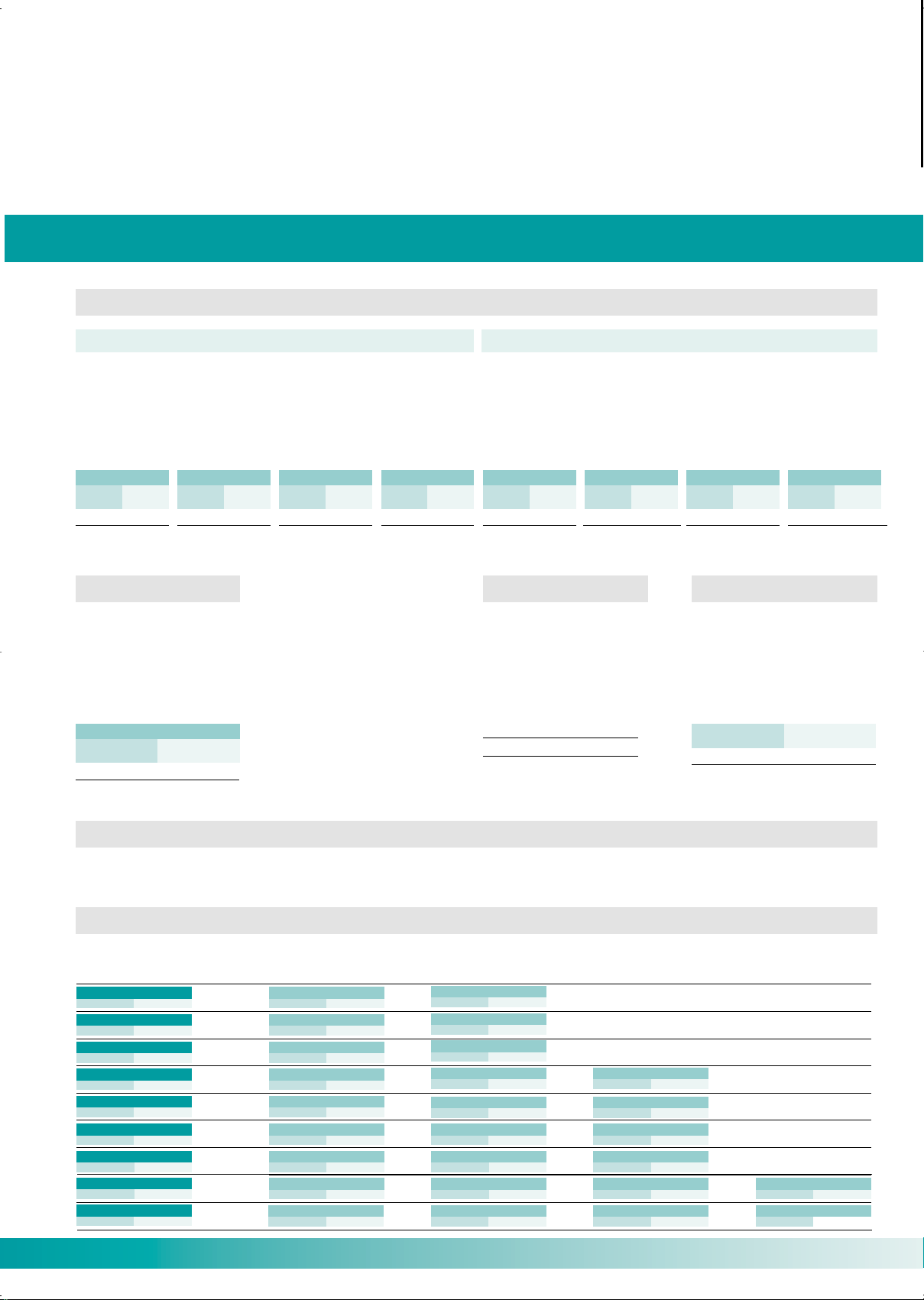

FP0 CPU Units

=

+

=+

=+

=+

=+

+

+

=++

=++

= +++

= +++

22

Input 12 Output 10

14

Input 8 Output 6

8

Input 4 Output 4

26

Input 14 Output 12

10

Input 6 Output 4

16

Input 8 Output 8

30

Input 16 Output 14

14

Input 8 Output 6

16

Input 8 Output 8

34

Input 18 Output 16

10

Input 6 Output 4

16

Input 8 Output 8

8

Input 4 Output 4

38

Input 20 Output 18

14

Input 8 Output 6

16

Input 8 Output 8

8

Input 4 Output 4

42

Input 22 Output 20

10

Input 6 Output 4

16

Input 8 Output 8

16

Input 8 Output 8

46

Input 24 Output 22

14

Input 8 Output 6

16

Input 8 Output 8

16

Input 8 Output 8

54

Input 28 Output 26

14

Input 8 Output 6

16

Input 8 Output 8

16

Input 8 Output 8

8

Input 4 Output 4

()

Total number

of I/O points

()

Control unit

()

Expansion unit 1

X20~/Y20~

()

Expansion unit 2

X40~/Y40~

()

Expansion unit 3

X60~/Y60~

=+++

62

Input 32 Output 30

14

Input 8 Output 6

16

Input 8 Output 8

16

Input 8 Output 8

16

Input 8 Output 8

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

A rich line-up of both single and combined units

Control Units

Relay output type Transistor output type

10 points

Input

6 points

Output

4 points

FP0-C10RSA FP0-C10CRSA

Control Unit 10k

FP0-T32C

10 points

Input

6 points

with 2nd RS232C

Output

4 points

14 points

Input

8 points

FP0-C14RSA

Output

6 points

14 points

Input

8 points

FP0-C14CRSA

with 2nd RS232C

This advanced FP0 CPU

offers additional features:

■ 10,000 steps

Output

6 points

16 points

Input

8 points

FP0-C16PA (PNP)

FP0-C16TA (NPN)

Output

8 points

S-LINK CPU

FP0-SL1

16 points

Input

8 points

FP0-C16CPA (PNP)

FP0-C16CTA (NPN)

with 2nd RS232C

Output

8 points

32 points

Input

16 points

FP0-C32PA (PNP)

FP0-C32TA (NPN)

Output

16 points

32 points

Input

16 points

FP0-C32CPA (PNP)

FP0-C32CTA (NPN)

with 2nd RS232C

AC Power Supply

FP0-PSA2

program memory

■ Battery backed RAM

■ Real-time clock

■ 16383 words

32 points

Input

16 points

FP0-T32CPA (PNP)

FP0-T32CTA (NPN)

with 2nd RS232C

Output

16 points

data register

S-LINK master

for up to 128 I/Os

Input

85 to 265VAC

Terminal type

Output

24VDC/0.7A

Expansion combinations

A maximum of 3 expansion units can be added to the control unit. (

is also possible. In this event, the maximum number of I/O points when using a relay output type control panel is 110.)

Combining relay output types

and transistor output types

Output

16 points

Combinations with relay output type – Examples

4

Page 5

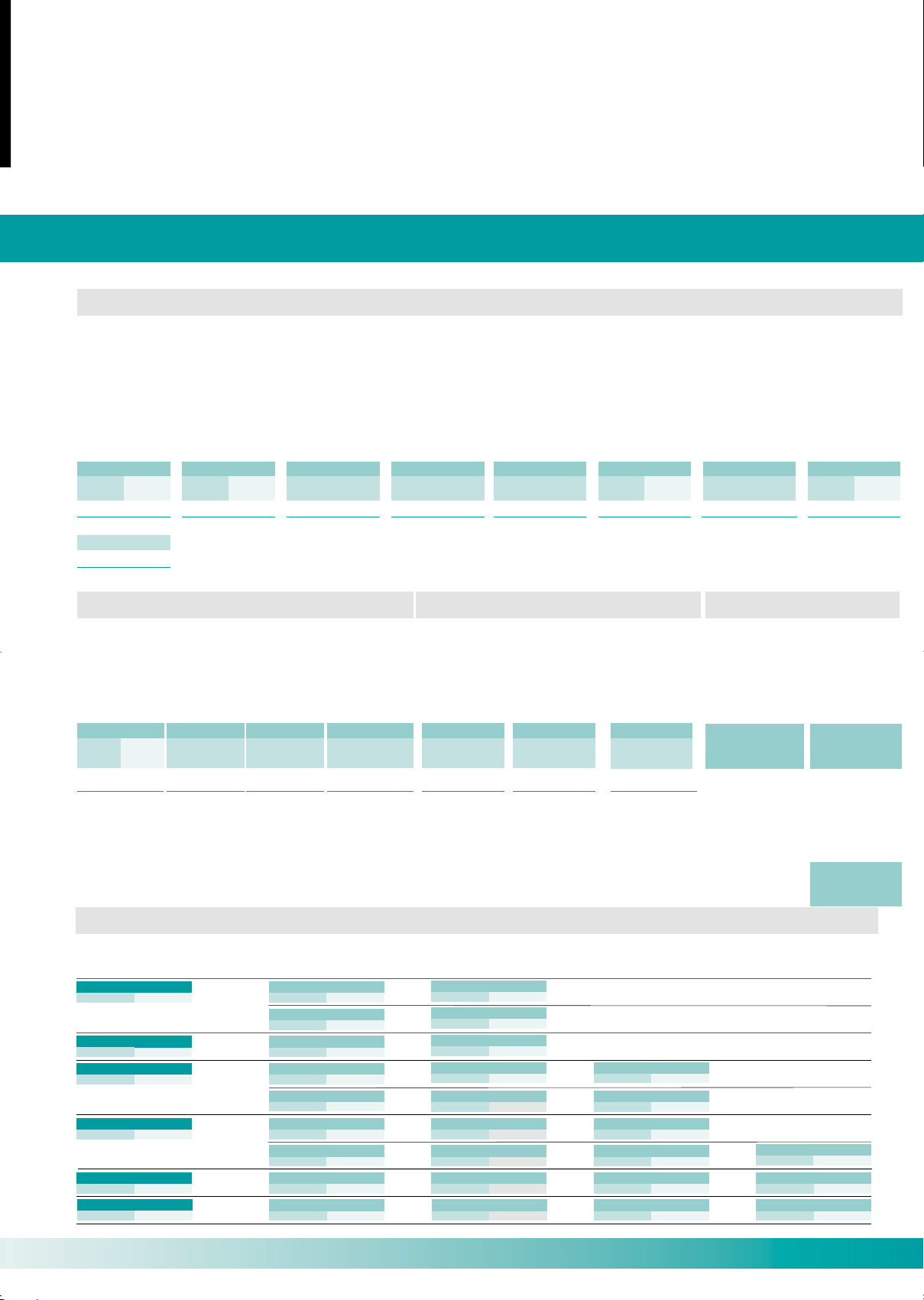

FP0 Expansion Units

=

+

=+

=+

=+

=+

+

+

=++

=++

= +++

+

= +++

48

Input 24 Output 24

32

Input 16 Output 16

16

Input 8 Output 8

16

Input 8 Output 8

32

Input 16 Output 16

64

Input 32 Output 32

32

Input 16 Output 16

32

Input 16 Output 16

80

Input 40 Output 40

32

Input 16 Output 16

32

Input 16 Output 16

16

Input 8 Output 8

16

Input 8 Output 8

32

Input 16 Output 16

32

Input 16 Output 16

96

Input 48 Output 48

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

16

Input 8 Output 8

32

Input 16 Output 16

32

Input 16 Output 16

112

Input 56 Output 56

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

16

Input 8 Output 8

()

Total number

of I/O points

()

Control unit

()

Expansion unit 1

X20~/Y20~

()

Expansion unit 2

X40~/Y40~

()

Expansion unit 3

X60~/Y60~

=+++

16

Input 8 Output 8

128

Input 64 Output 64

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

32

Input 16 Output 16

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Choose the number of I/O points to suit the application

Digital I/O Units

Relay output type Input only type

8 points

Input

4 points

Output

4 points

Option:

Output 8 points

FP0-E8YRSA

16 points

Input

8 points

FP0-E16RSA FP0-E8XA FP0-E16XAFP0-E8RSA

Output

8 points

8 points

Input

8 points

16 points

Input

16 points

Transistor output type

8 points

Output

8 points

FP0-E8YPA (PNP)

FP0-E8YTA (NPN)

16 points

Input

8 points

FP0-E16PA (PNP)

FP0-E16TA (NPN)

Output

8 points

16 points

Output

16 points

FP0-E16YPA (PNP)

FP0-E16YTA (NPN)

32 points

Input

16 points

FP0-E32PA (PNP)

FP0-E32TA (NPN)

Output

16 points

Analogue I/O Units Thermocouple and RTD Units Networking Units

Input

2 points

• Input (12 bit):

• Output (12 bit):

Output

1 points

FP0-A21A FP0-A04I FP0-A04V

10V, 0 – 5V,

0 – 20mA

10V, 0 – 20mA

Output

4 points

–

–

4 – 20mA

Output

4 points

–

–

10V

8 points3 points 4 points 4 points

Input

8 points

FP0-A80A

10V, 100mV

0 – 5V, 0 – 20mA

–

4 points

Input

4 points

FP0-TC4 FP0-TC8

• K, J, T, R type thermocouples can

be used

• Resolution: 0,1°C

• Accuracy: 0,8°C (R type: 3°C)

• Temperature range:

-100 to 1500°C

8 points

Input

8 points

6 points

Input

6 points

FP0-RTD6

• Pt100, Pt1000,

NI1000

• Temperature

range -200

to 500ºC

MEWNET-F

FP0-IOL

(MEWNET-F Slave)

S-Link CPU

FP0-SL1

(S-LINK Master)

PROFIBUS

FP0-DPS2

(DP Slave)

Combinations with transistor output type – Examples

5

Page 6

FP0 – Impressive Capabilities

I/O

refresh

Program

execution

I/O

refresh

Program

execution

1 scan

I/O

refresh

Program

execution

Internal processing in the FP0

I/O

refresh

Program

execution

I/O

refresh

Program

execution

Sensor input

signal

Cannot

read.

Lengthening

of sensor

input signal

Can

read!

With pulse catch function

Internal processing in the FP0

I/O

refresh

Program

execution

I/O

refresh

Program

execution

Interrupt

program

Interrupt input

Interrupt program executed when

interrupt input enters.

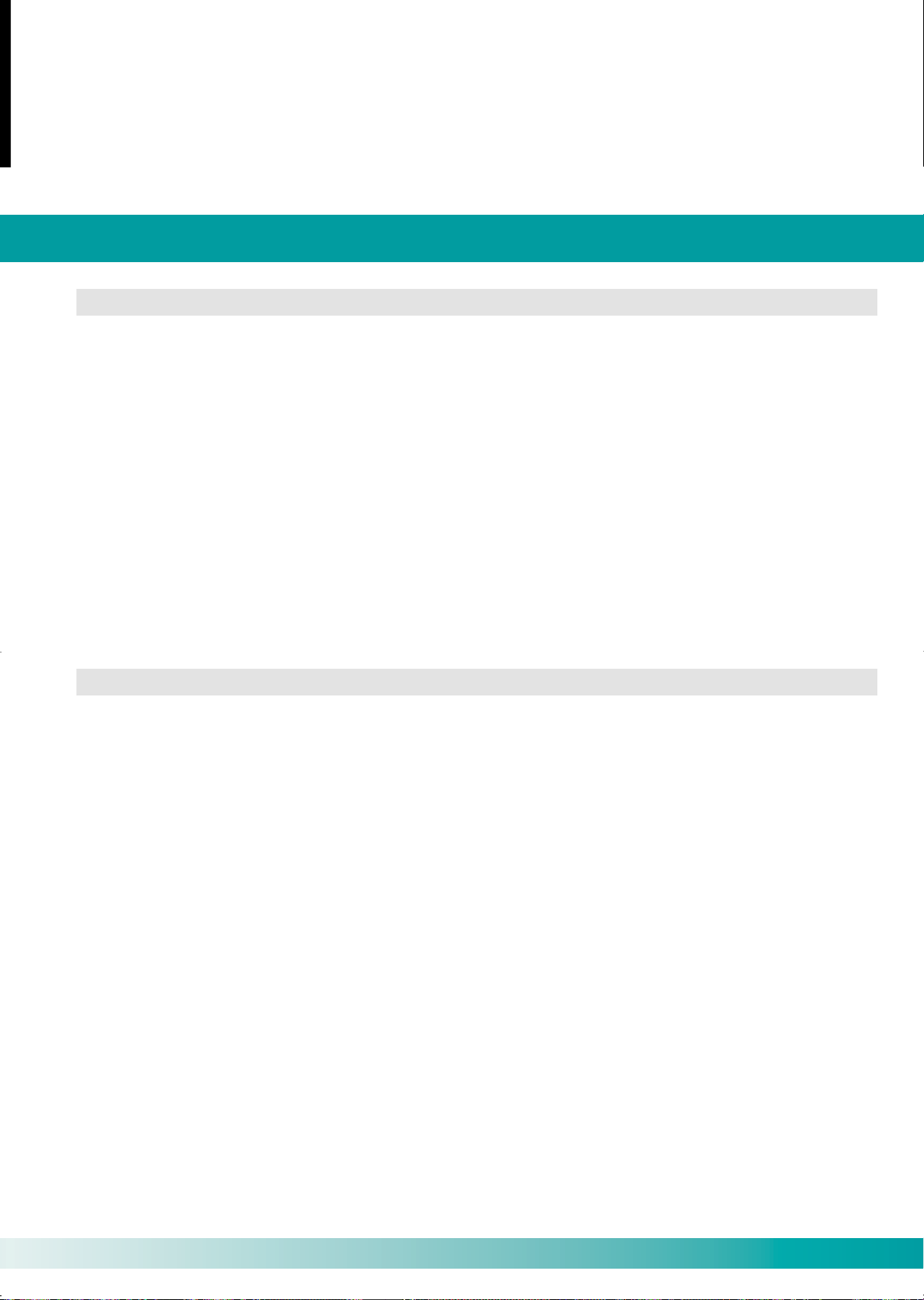

I/O 10-point, 14-point, 16-point type

Control unit type

I/O 32-point type

2 720 steps

1 660 words

5 000 steps

6 144 words

1 008 points

144 points

FP0-T32 CP/T

10 000 steps

16 383 words

Program size

Internal relays

Timers/Counters

Data registers

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

High specifications for both speed and capacity

0.9µs per basic instruction. Pulse catch and interrupt input functions meet the need for high-speed response.

High-speed execution

Execution speed of 0.9µs per basic instruction. 500 steps program yields a scanning time of 1ms, which means the FP0

boosts the fastest processing time among the products of this class.

• Internal processing in the FP0

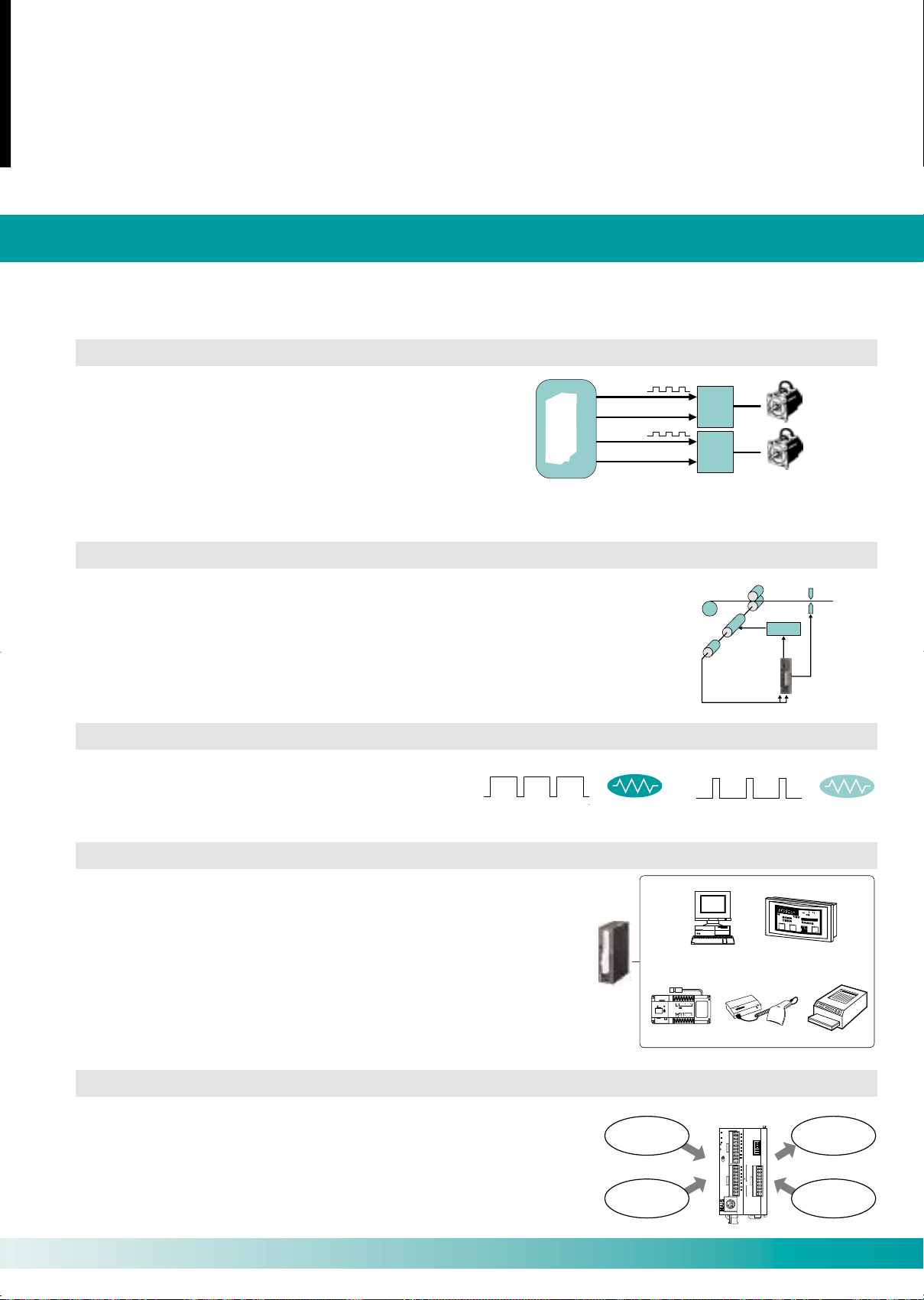

Pulse catch function

Can read pulses as short as 50µs, which greatly facilitates

sensor input.

Interrupt input function

Accurate processing, unaffected by scan time

• Interrupt input function

• Pulse catch function

Large capacity

A top-class large 5k and 10k steps program capacity housed within a compact body. Furthermore, data capacity for internal

devices like the data register is also ample. The unit's high performance is even suited to complicated controls

and controls with multiple amounts of data.

6

Page 7

FP0 – Impressive Capabilities

Y0

Y2

Motor

driver 1

Pulse output

Clockwise output/

counter-clockwise output

Y1

Y3

Motor

driver 2

Pulse output

Clockwise output/

counter-clockwise output

Feeder roller

Lead wiring,

tape

Cutter

Encoder

Motor

START/STOP

signal

Inverter

Cutter blade

control signal

Encoder output

inputted into

high-speed counter

Host computer

(Personal computer)

Operation

display panel

FP0

●

For connecting to computers and operation display panels

●

For data communication with RS232C devices

Imagechecker Bar code reader Serial printer

RS-232C

POWER READY

MODE

A

B

C

KEY PAD

CAMERA

MONITOR

COM COM D2 D4 D6 D8 D9

FLASH

D1 D3 D5 D7

READY

MICRO-IMAGECHECKER

M100

Matsuhita Electronic Works, Ltd.

24VDC

START

ACK IN1 IN3 IN5

COM COM IN2 IN4 COM

Heater

power up

● When pulse width values are increased...

● When reduced...

PROG.

RUN

ALARM

ERROR

PROG

RUN

Pressure sensor

Laser analogue

sensor

Inverter

Potentiometer

MODE

OFF ON

V 0

IN

I 0

COM

FP0 - A21

OUT

I 1

V

I

1

2

3

4

5

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

FP0 functions

Equipped with 2-axis independent positioning and high-speed counter for support of PWM output.

Pulse output function

(For transistor output type only) The unit comes equipped with

2 channels for the output of up to 10kHz pulses (5kHz during

2-channel output). Since these two channels can be separately

controlled, the PLC is also suitable for independent 2-axis

positioning. Setting automatic trapezoid control, automatic return

to home position and JOG operation are made very easy by using

instructions specially designed for such operations.

Positioning control is a breeze with

the auto trapezoid control command!

High-speed counter function

The high-speed counter is prepared for 4 channels in single phase, and 2 channels in

2-phase. In single phase, the 4-channel total is 10kHz, and in 2-phase the 2-channel total is

2kHz total speed, making the unit suitable for conveyer control, inverter control, and so

forth using an encoder.

PWM output function

Its PWM (Pulse Width Modulation) output function makes

it possible to provide temperature control with a single

compact FP0 unit. (For transistor output type only)

● When reduced...

Stepping

motor

Servo motor

Stepping

motor

Servo motor

power up

Heater

power down

Serial communication function

• The FP0’s second RS232C port (types C10CRS, C14CRS, C16C, C32C,

and T32C) allows direct connection to computers and operation display

panels. Also, bi-directional data communication with barcode readers

and other RS232C devices is made easy.

• Both the relay type and transistor output type control units are optionally

equipped with a 2nd RS232C port.

Analogue control function

Analogue control is made simple with four types of analoque modules

featuring different numbers of input and output channels.

Also, despite the small size, the I/O resolution is a high 1/4000 (12 bits).

Support various I/O ranges by setting the DIP switches on the analogue

I/O unit for simple operation.

7

Page 8

FP0 Communication

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Serial interfaces and modem compatible

Communication – Simple and efficient via two serial interfaces: TOOL-Port and COM-Port (RS232C interface).

Programming interface TOOL-Port (also for communication)

In Computer Link mode, this port offers access to the entire FP0 memory area. For example during data exchange between

a host PC running SCADA software and an FP0 PLC, the Windows

the communications protocol (MEWTOCOL.COM). Therefore the user can disregard the allocation of data ranges and

transfer parameters, because there is no additional programming required. The programmer is thus free to concentrate

exclusively on the project application requirements.

®

based MEWNET-DDE Server assumes total control of

Communication Interface COM-Port

(flexible with two modes of operation, Computer Link and General Purpose)

In addition to the Computer Link communication possibilities described above, the optional integrated RS232C COM-Port

in the FP0 CPU module (types FP0-C10CRS, FP0-C14CRS, FP0-C16C, FP0-C32C and FP0-T32C) offers flexible programming

i.e. General Purpose. In this configuration it is possible to realise communication connections with different RS232C

peripheral devices, e.g. Bar Code Readers, slave devices, printers, measurement sensors or telecommunication

transmitters, etc.

Communication Interface COM-Port

Freely programmable RS232C interface for CPU modules type FP0-C10CRS,

FP0-C14CRS, FP0-C16C, FP0-C32C and FP0-T32C

Programming Interface TOOL-Port

For programming, and additionally Master/Slave communication, using

MEWTOCOL COM (Matsushita protocol)

Modem compatible

Even modem communication function is built into this compact body. Using a single telephone line,

programming maintenance can be carried out in remote facilities. With C-NET, multiple FPO units can be

connected.

■ 1:1 communication ■ 1:N communication ■ Multidrop communication

8

Page 9

FP0 Communication

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Easier maintenance than ever before

Maintenance saving

Program memory uses EEPROM. In addition, programs can be changed even in RUN mode!

■ Overwrite function in RUN mode

It is possible to overwrite a program while the FP0 is running, such as during program debugging and startup

adjustments.

■ Backup battery unnecessary

The program memory uses EEPROM. The program and device contents can be stored without a backup battery, and

even programming for a machine builder is safe.

■ Password function

A password function can be set in order to change a program. Limited to people authorized to make program changes,

protection can be guaranteed better than ever.

■ Input/output verification LED

Every unit is equipped with LED I/O indicators, housed within a compact body. Input/output status can be verified

at a glance.

Simple installation

Comes with either terminal block or connector. Either type is easy to connect to wiring by simply

removing the terminal section.

Terminal block

Terminal type can be

plugged straight in without

resorting to crimping (made

by Phoenix Contact Co.).

Can handle wires from

0.3 to 1.25mm

Compatible models

FP0-C10RS, C10CRS, C14CRS, E8RS, E16RS

2

.

MIL connector

Unit connectors can be used

with 16-points and 32-points

units. Due to the loose-wiring,

pressure contact type design,

wiring is easy without the

need for insulation.

(MIL-C-83503)

Compatible models

FP0-C16T/C16P/C16CT/C16CP, C32T/C32P/C32CT/C32CP,

E16T/E16P, E32T/E32P,

FP0-T32CP/T32CT

9

Page 10

FP0 PROFIBUS DP Slave or Remote I/O Unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

For cost effective control of distributed field device

The FP0 DPS2 can operate either as a DP slave module or as a remote I/O

system to which different decentralised inputs and outputs can be

connected. A DIP switch can be used to switch between the two modes:

Mode 1:

DP-Slave module. Connect the FP0 or FP∑ (Sigma) CPU + expansion

modules to the PROFIBUS network.

Mode 2:

Remote I/O. Connect up to three expansion modules without CPU to the

PROFIBUS network.

In Remote I/O mode the unit can be connected to any PLC which offers a

PROFIBUS communication interface, making it totally independent of

NAiS PLCs.

FP0-DPS Specifications

Item Description

Type designation

PROFIBUS standards complied with

Baud rates

Range of adresses that can be set 0..125

PROFIBUS connection

Configuration

FP0 communication

Power supply 24VDC (21.6VDC … 26.4VDC)

Max. power consumption 100mA

DP-Slave

Remote I/O

FP0 DP Slave unit, Ord. No. FP0DPS2

EN 50170, DIN 19245 Part 1 and Part 3

9.6 / 19.2 / 93.75 / 187.5 / 500 / 1,500 / 3,000 / 6,000 / 12,000 Kbaud

automatic baud rate detection

9-pin D-sub connector

2 words input / 2 words output, up to 6 words input / 6 words output if no other expansion is connected

Remote I/O, max. 3 FP0 expansion units

Via FP0 system bus

Special developed software tools ensure

easy configuration and start-up of

PROFIBUS products.

AFP86910

FP2 DP or FMS Master

FP0 DP Slave FP∑ (Sigma) DP Slave

DP Slave Remote I/O

Configuration with digital I/O

up to 96 transistor I/O or up to

48 relay I/O are possible

DP Slave Remote I/O Configuration

with analogue I/O up to 12 outputs or

24 analogue inputs or up to 24

thermocouple inputs are possible

PLC

(Master)

PLC

(Slave)

Remote I/O

(Slave)

10

Page 11

FP0 S-LINK Unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Connects directly to the S-LINK for reduced wiring

S-Link is a system which simplifies connection of rapidly increasing control devices accompanying

progressing automation and is useful in reducing your costs and construction time.

Features

1. Small size of only W30 x H90 x D60 mm.

Makes use of the T-shaped connectability of the S-LINK for reduced wiring and reduced size

of the control panel.

2. Controls 64 input points and 64 output points.

Able to control up to 128 points for S-LINK-related devices.

3. Allows simultaneous use of expansion units.

Similar to other FP0 units, up to three expansion units can be used for efficient I/O wiring.

FP0-SL1

4. A wide range of I/O modules allow manifold customer-oriented network layouts.

Power Supply Specification

Item Description

Power supply 24VDC

Performance Specifications

Item Description

Number of I/O points

Expansion

Operation speed 0.9µs/step

Internal memory

Memory capacity 5k steps

Memory Internal relay

of

execution

Timer/Counter

Data register

S-LINK block: 64 input points,

64 output points (fixed)

Max. 3 units

Expansion section:

Max. 96 points

EEPROM

1,008 points

144 points in total

6,144 words

Applicable Functions

Item Description

Pulse catch/Interrupt input

Analogue I/O

Volume input

High-speed Counter

Pulse output None

RS232C port

None

Available by adding analogue I/O unit

None

None

1 ch is equipped.

3P terminal blocks (made by

Phoenix Contact Co.)

Applicable Network

Item Description

Control unit functions as S-LINK

Remote I/O

Inter-PLC link

Computer link

Modem connection

master station.

Available as a slave station of

MEWNET-F by adding I/O link unit

Not available

Linkable with tool port or

RS232C port

Available, Type with RS232C

port can also send data

Other Built-in Functions

Item Description

Program block-edit

during RUN

Constant scan

Adjustable input time

filtering

Clock/Calendar function

Available

Available

Not available

None

Direct connection for reduced wiring

FP0

S-LINK Control unit

W30 × H90 × D60

T-branch multi

drop wiring

The layout of devices becomes flexible

and the design is easier due to the

‘T’-branch multi-drop wiring.

Maximum length: 200m

Max. 128 points

2 signal wires

2 power

supply wires

Wire-saving

The use of wires is greatly reduced and the number of connecting

terminal blocks is minimized, resulting in large reduction in cost, as

well as, the waste generated during wiring.

Space effective

S-Link devices are compact. The control box can be mounted in a

tight space.

Quick construction

Sensors cab be easily connected with plug-in connection.

11

Page 12

FP0 MEWNET-F Unit

FP2 (Master station)

FP0 (Slave station) FP0 (Slave station) FP0 (Slave station)

Twisted pair cable or VCTF

C-NET

adapter

AC 100 to 200V

24V DC

: AFP8536

: AFP8532

C-NET

adapter

S2 type

(AFP15402)

Max. 32 units

Max. 1,200 m

FP0

( )

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Networking units

MEWNET-F

The FP0 can be used as a slave station for MEWNET-F (remote I/O system) by adding I/O link unit.

MEWNET-F is a reduced-wiring remote I/O system that connects PLCs

located separately and I/O slave stations with 2-core cabling. By adding an

I/O link unit to the FP0, you can link master station PLC and FP0 inputs and

outputs via the network.

FP0-IOL FP0-IOL FP0-IOL

FP0-IOL Link Unit Specifications

Item Description

Communication method

Synchronous system

Transmission line 2-wire cable (Twisted-pair cable or equivalent to VCTF 0.75 mm2x 2C)

Transmission distance

(Total distance)

Transmission speed (Baud rate) 0,5Mbit/s

Number of control I/O points

per an I/O link unit

Remote I/O map allocation

Interface

Transmission error check

Two-wire, half duplex transmission

Start stop synchronous system

Max. 700m per port (using twisted pair cable)

Max. 400m per port (using VCTF cable)

64 points

(Input: 32 points and Output: 32 points)

32X/32Y

Conforms to RS485

CRC (Cyclic Redundancy Check) method

C-NET

By using C-NET, you can use multiple FP0s as data collection terminals.

By using the C-NET network and exclusive

adapters, you can connect multiple FP0s by

multi-drop connection with 2-wire cables.

You can use computers for separate control

or have network terminals for a centralized

management system.

MEWNET-F Slave

FP0-IOL

12

Page 13

FP0 Thermocouple Input Expansion Units

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Enable high precision temperature control at low cost

The FP0-TC4 and FP0-TC8 thermocouple units are suitable for user

friendly temperature acquisition using standard thermocouples with

high precision.

■ Up to three units can be added to each control unit, enabling

temperature control of up to 24 channels.

■ The temperature data obtained using the thermocouple is converted to

the digital value to be read into the FP0 control unit.

■ Standard types of thermocouples can be used: K, J, T and R

■ 3 temperature measurement ranges are available:

-100°C to +500°C (Thermocouple types: K and J)

-100°C to +400°C (Thermocouple type : T)

- 0°C to +1500°C (Thermocouple type : R)

■ The temperature data measured using the sensor is converted to

degrees Celsius or degrees Fahrenheit inside the Thermocouple Unit.

■ The converted data (°C or °F) is averaged, so that even unstable input

signals can be properly read.

■ Broken thermocouples can be detected.

FP0-TC4 and FP0-TC8 specifications

Temperature control

FP0 TC8

8 channels

FP0 TC4

4 channels

Item Specification

Input points

Input range

Resolution 0.1°C

Sampling cycle

Accuracy

Input Impedance

Insulation method

Up to 8 channels per unit (The number of input points can be changed 2, 4, 6 and 8 channels are available)

Thermocouple types K, J -100°C to 500°C

Thermocouple types T -100°C to 400°C

Thermocouple types R 0°C to 1500°C

300ms: when using 2 channels for an input points

500ms: when using 4 channels for an input points

700ms: when using 6 channels for an input points

900ms: when using 8 channels for an input points

Range for K and J (-100°C to 500°C): 0.8°C

Range for T (-100°C to 400°C): 0.8°C

Range for R (0°C to 99.9°C): 3°C

more than 1MΩ

- between thermocouple input terminals and control unit internal circuits Photo-coupler insulation/DC-DC insulation

- between thermocouple input terminal channels PhotoMOS relay insulation

(100°C to 299.9°C): 2.5°C

(300°C to 1500°C): 2°C

13

Page 14

Analogue Signal Processing

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

FP0 Analogue Units

Features

FP0-A21

2 Inputs/1 Output

■ Multimode A/D, D/A conversion ■ High resolution: 12-bit

Voltage, current and temperature selectable

■ 2 analogue inputs (FP0-A21): ■ High conversion speed

-10 to + 10V, 0 to 5V, 0 to 20mA, FP0-A04V, FP0-A04I: 500µs

8 analogue inputs (FP0-A80):

-10 to + 10V, 0 to 5V, -100 to + 100mV, 0 to 20mA ■ PID instruction with auto tuning

■ 1 analogue output (FP0-A21): -10 to + 10V, 0 to 20mA

4 analogue outputs (FP0-A04V): -10 to + 10V ■ Screw terminal connection

4 analogue outputs (FP0-A04I): 4 to 20mA

The analogue units can be used with the FP0 and FP∑ (Sigma) so wide range applications are possible from smallscale machines to factory production systems.

Each CPU supports up to 3 FP0 analogue units. Combination with digital and analogue expansion units is freely allowed.

Highest performance is offered with 12-bit resolution. With a current and voltage output conversion time of up to

500µs, the units are capable of high-speed processing.

FP0-A80

8 Inputs

FP0-A04V

4 Outputs

FP0-A04I

4 Outputs

The multimode FP0 analogue unit can be configured via the DIP switches on the front side into the required analogue

ranges. Communication with the FP0 CPU unit is achieved via the expansion bus. The expansion bus is automatically

connected after the FP0 analogue unit is connected to the FP0 CPU unit.

Note: Function Blocks for FPWIN Pro Programming System can be downloaded free of charge from our WEB-page.

14

Page 15

Analogue Signal Processing

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

FP0 Analogue Units

General specifications

Item Description

Rated operating voltage

Operating voltage range

Rated current consumption FP0-A80: 60mA or less, FP0-A21/A04V: 100mA or less, FP0-A04I: 130mA or less

Ambient temperature 0°C to +55°C

Storage temperature -20°C to +70°C

Size 90 x 25 x 60mm

Weight appoximately 100g

Analogue input specification

24VDC

21.6 to 26.4VDC

Item

Product

Number of channels

Input range selectable

( 2 CH)

Digital output

Resolution

Conversion speed

Overall accuracy

Input impedance

Maximum input

Insulation

FP0 input address

(*1) K means decimal constants.

(*2) Reference temperature → Reference points is start points.

(*3) Reference temperature → Reference points is end points.

(*4) The address varies depending on the position of the analogue unit. (WX2/3, WX4/5 or WX6/7)

Voltage mode 0 to 5V/-10V to +10V

Current mode 0 to 20mA

Thermocouple mode K, J, T type thermocouple

0 to 5V/0 to 20mA: K 0 to K 4000 (H 0000 to H 0FA0) (*1)

-10 to +10V (-100 to +100mV): K -2000 to K +2000 (HF830 to H07D0)

Thermocouple: The value of broken wire detection is K 20000.

Voltage/current mode: 1ms/channel

Thermocouple mode: 560ms/channel

Thermocouple mode: Offset error (0 to 55°C), 2% for full-scale (K-type)

DC/DC converter insulation between analogue input terminal and analogue output terminal

32 input contact points: First 16 points analogue input CH0 data (WX2) (*4)

K up to 1000°C or -100°C to terminal temperature (selectable)

J up to 750°C or -100°C to terminal temperature (selectable)

T up to 350°C or -100°C to terminal temperature (selectable)

For plus: K temperature of terminal (*2) to K 1000 (Unit is Celsius)

For minus: K-100 to K temperature of terminal (*3) (Unit is Celsius)

linearity error (0 to 55%): 1% for full scale

Last 16 points analogue input CH1 data (WX3) (*4)

FP0-A21 FP0-A80

2 channels/unit 8 channels/unit

Voltage/current mode: 1% for full-scale (0 to 55°C), 0.6% for full-scale (at 25°C)

2.7% for full-scale (J-type)

5.8% for full-scale (T-type)

Optical coupler insulation between analogue input terminal and FP0 internal circuit

DC/DC converter insulation between analogue input terminal and analogue I/O unit external power supply

(No insulation between analogue inputs)

Description

12 bits (1/4000)

Voltage mode: 1M ohm or more

Current mode: 250ohm

Voltage mode: +/- 15V

Current mode: +30mA

-100 to +100mV/0 to 5V / -10V to +10V

–

–

2ms/channel

–

–

0 to 20mA

32 input contact points:

First 16 points analogue input

CH0, 2,4,6 data (WX2) (*4)

Last 16 points analogue input

CH1,3,5,7 data (WX3) (*4)

Analogue output specification (FP0-A21)

Item Description

Product

Number of channels

Output signal selectable

Digital input (*1)

Resolution

Conversion speed

Overall accuracy

Output impedance

Maximum output current

Allowable output load

resistance

Insulation

Reserved CPU addresses (*4)

Voltage mode -10V to +10V

Current mode 0 to 20mA

0 to 20mA: 0 to 20mA: K 0 to K 4000

-10V to +10V: -10V to +10V: K -2000 to K+2000

FP0-A21 FP0-A04V FP0-A04I

1 4 4

-10V to +10V

K -2000 to K+2000 K 0 to K 4000

500ms 500µs 500µs

less than 300Ω 1000Ω or more less than 500Ω

DC/DC converter insulation between analogue output terminal and analogue I/O unit external power supply

16 output points 32 output points 32 output points

1% for full-scale (0 to 55°C), 0.6% for full-scale (at 25°C)

Optical coupler insulation between analogue output terminal and FP0 internal circuit

DC/DC converter insulation between analogue output terminal and analogue input terminal

12 bits (1/4000)

Voltage mode: less than 0.50Ω -

Voltage mode: +/- 10mA -

4 to 20mA

15

Page 16

FP0 RTD Input Expansion Unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

User friendly acquisition of temperatures with high precision

Features

■ The module can be easily installed in an existing system: Special

connection cables, backplanes, and so forth are unnecessary as the

expansion unit employs a stacking system that uses expansion

connectors and lock levers on the surface of the unit itself.

■ Multiple RTD types are allowed in one module, creating a cost-effective

solution.

■ About the Application areas:

- Measurement and control equipments

- Process and Machine controls

- Greenhouse and Agro industries

FP0-RTD6

6 channels

Take advantage of the various FPWIN Pro libraries with many functions and function blocks. These ready-made programs can be saved and reused time and again and will help you to shorten the time needed to develop applications

drastically, and consequently to save valuable human resource costs.

Controller Library: NCL-MR-LIB

The programmable logic arrays of the controller library simplify

the programming of closed loop controlled electrical installations.

The library includes linear and non linear controller types such as

the P/I/PI/PID controller and two points-/three-points controller with

and without hysteresis. Programmable logic arrays for dead band,

interpolation, lamp limiting, dead time and averaging are also included.

FP0-RTD6 specifications

Item Specification

Input points

Input type

Sampling cycle

Temperature resolution

Accuracy

at ambient temperature: 0-55°C

Accuracy

at ambient temperature: 25°C

Size

Up to 6 channels per unit

- 3 inputs per one Phoenix screw terminal

- for every sensor 3 screws

Pt 100 -200°C to 500°C (3 wire)

Pt 1000 -100°C to 200°C (2 wire)

Ni 1000 -30°C to 150°C (2 wire)

Resistor measurement

0.1sec / 1sec for 6 channels

- depending on the switch setting

(slower cycle timer = higher accuracy)

0.1 K

cycle time 0.1 sec: Pt 100: 0.5%/3.5K, Pt 1000: 05%/2.5K, Ni 1000: 2K, Resistor:2Ω

cycle time 1 sec: Pt 100: 0.35%/2.5K, Pt 1000: 035%/1.7K, Ni 1000: 1K, Resistor:1Ω

cycle time 1 sec:

W 25 x H 90 x B 60 mm

Pt 100: 0.3K from -10 to +30°C, 0.2%/1.4K from -200 to +500°C

Pt 1000: 0.3K from -10 to +30°C, 0.2%/1.0K from -200 to +300°C

16

Page 17

Item Description

Rated operating voltage 24 VDC

Operating voltage range 21.6 to 26.4 VDC

Allowable no voltage time

10 points, 14 points type

5ms (at 21.6 V), 10ms (at 24 V)

16 points, 32 points, S-LINK type

10ms (at 21.6 V / 24 V)

Ambient temperature 0°C to +55°C

Storage temperature -20°C to +70°C

Ambient humidity 30 to 85% RH (Non-condensing)

Storage humidity 30 to 85% RH (Non-condensing)

Breakdown voltage

Between input/output terminals and power/ground terminals: 500VAC for 1 minute (for the relay output type, 1500VAC for 1 minute)

Between input terminals and output terminals: 500VAC for 1 minute (for the relay output type, 1500VAC for 1 minute)

Insulation resistance

Between input/output terminals and power/ground terminals: Over 100 MΩ (using a 500VDC megger)

Between input terminals and output terminals: Over 100MΩ (using a 500VDC megger)

Vibration resistance 10 to 55Hz, 1 sweep/min., double amplitude of 0.75mm, 10min. on 3 axes

Shock resistance

98m/s

2

or more, 4 times on 3 axes

Noise immunity 1,000 V(p-p) with pulse widths 50ns and 1ms (using a noise simulator)

Operating condition Free from corrosive gasses and excessive dust

Type of control unit

C10 series C14 series C16 series C32 series

S-LINK type

T32 series

Programming method / Control method Relay symbol/Cyclic operation

Number of

I/O points

No expansion

(control unit only)

Total: 10

Total: 14

Total: 16

Total: 32

Total: 32

W/expansion 1

*Same type of control and expansion units

Max. 58 Max. 62 Max. 112 Max. 128

Expansion section:

max.96 points

Max. 128

W/expansion 2

*Mix type of relay and transistor units

Max. 106 Max. 110 Max. 112 Max. 128 Max. 128

Program memory EEPROM (No back-up battery required)

Program capacity 2.7K steps 5K steps 10K steps

Kinds of

instruction

Basic 83

High-level 115

Operation speed (central value/step) 0.9µs (Basic instruction)

Memory for

execution

Relay

Intermal relay (R)

1,008 points

Timer/Counter (T/C)

144 points

Memory

area

Data register (DT)

1,660 words 6,144 words 16,384 words

Index register(IX,IY)

2 words

Master control relay (MCR) 32 points

Number of labels (JMP and LOOP) 64 labels 255 labels

Differential points Unlimited number of points

Number of step ladder 128 stages 704 stages

Number of subroutines 16 subroutines 100 subroutines

Special

functions

High speed counter

1 phase/4 points (10kHz in total) or 2 phases / 2 points (2kHz in total)*

Not available

Pulse output Not available

2 points (10 kHz* in total),enable to control 2

channels individually*

Not available

PWM output Not available 0.15Hz to 1kHz Not available

Pulse catch input/interrupt input

6 points(with high speed counter) Not available

Interrupt program 7 programs (external 6 points, internal 1 point)

Periodical interrupt 0.5ms to 30s

Constant scan Available

RS232C port

One RS232C port is mounted on each of the models FP0- C10CR, C14CR,C16CT, C16CP, C32CT, C32CP, T32CT, T32CP and SL1 type (3P terminal block)

Transmission speed (Baud rate): 300 to 19200bits/s , 3m Communication method: half duplex

Transmission distance: 3m

Maintenance

Memory

back up

Stored program and system register in EEPROM

Operation

memory

Stored fixed area in EEPROM

Counter: 4 points

Internal relay: 32 points

Data register: 8 words

Counter: 16 points

Internal relay: 128 points

Date register: 32 words

Backup is provided by

secondary battery. The

holding range for the

timers, counters, internal

relays, and data registers are specified with

the programming tool.

Self-diagnosis functions Watchdog timer, program syntax checking, etc.

Clock/calender function Not available Available

Other functions Runtime editing, password setting

* For the limitations while operating units, see the manual.

Stored fixed area in EEPROM

Total:128

(Input: 6, Output: 4) (Input: 8, Output: 6) (Input: 8, Output: 8) (Input: 16, Output: 16) (Input: 64, Output: 64) (Input: 16, Output: 16)

Program and system register

(Relay output type only) (Relay output type only)

(Transistor output type only) (Transistor output type only) (Transistor output type only)

Available (same as

32 points series)

1 program (internal 1 point)

Available (same as

32 points series)

FP0 Series

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Specification tables

FP0 Specifications

General Specifications

17

Page 18

FP0 Series

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Specification tables

Interfaces

Item Description

Programming TOOL-Port

Communication COM-Port

RS232, mini DIN socket (5 pin), 9600 or 19200 BAUD, (8 data bits, odd parity, 1 stop bit), Computer link for

programming and communication with MEWTOCOL.COM, user configurable modem connection

RS232 (SD, RD, GND) 3 way screw terminal, 300 to 19200 BAUD, (7 or 8 data bits, none/even/odd parity,

1 or 2 stop bits, start code: none/STX, end code: CR/CR+LF/ETX/none, CCU mode for programming and

communication with MEWTOCOL.COM, user configurable modem connection, GENERAL PURPOSE MODE

controlled by program for general purpose RS232 communication.

Input specifications

Item

Insulation method Optical coupler

Rated input voltage 24VDC

Operating voltage range 21.6 to 26.4VDC

Rated input current 4.3mA or less (at 24VDC)

Input points per common

ON voltage/ON current 19.2V or less/ 3mA or less

OFF voltage/OFF current 2.4V or more/ 1mA or more

Input impedance Approx. 5.6kΩ

OFF➔ ON

Response time

ON➔ OFF

Operating indicator LED display

Note: (*): Since the response time of X0 to X5 is very fast (for high-speed counter input), the FP0 happens to catch chattering noise as an input signal.

To prevent this, it is recommended that timer instruction should be included in the program.

6 points/common (C10RS) 8 points/common (C14RS,C16T/C16P,E16T/E16P) 16 points/common (C32T/C32P,E32T/E32P)

50µs or less (at X0,X1)(*)

100µs or less (at X2 to X5)

2ms or less (at X6 to XF)

same as above

Description

Output specifications

1) Relay output type

Item

Output type Normally open(1 Form A)

Rated control capacity

Response time

Life

Surge absorber None

Operation indicator LED display

The FP0 series conforms to the following standards under the EMC Directive

and the Low Voltage Directive.

EMC Directive (89/336/EEC) Low Voltage Directive (73/23/EEC)

EN 50081-2: 1993 VDE 0160: 1988 (EN 50178: 1995)

EN 50082-2: 1995 (Overvoltage Category II,

OFF➔ ON

ON➔ OFF

Mechanical

Electrical

2A 250VAC, 2A 30VDC(4.5A/common)

10ms or less

8ms or less

20million operations or more

100k operations or more

Description

non-mains-circuit, pollution degree 2)

EN 61131-2: 1995

2) Transistor output type

Item

Insulation method Optical coupler

Output type Open collector

Rated load voltage 24VDC 5 to 24VDC

Load voltage allowable range 4.75 to 26.4VDC

Max. load current

Max. inrush current 0.3A

Leakage current at OFF time 100µA or less

Max. voltage down at ON time

External power

supply

(For internal circuit)

Response time

Surge absorber Zener diode

Operating indicator

Notes:

(*1): 8points/common(C16T/C16P,E16T/E16P), 16points/common(C32T/C32P,

T32CP, E32T/E32P)

(*2): 50µs or less at Y0, Y1 only

Voltage 21.6 to 26.4VDC

Current 240mA or less

OFF➔ ON

ON➔ OFF

0.1A/points(at DC26.4V) (1A/common)(*1)

1.5V or less

1ms or less

1ms or less(*2)

LED display

Description

18

Page 19

Control FPWIN Pro

FP Programmer II Ver. 2

Programming cable

AFC8513D

Programming cable

AFC8523

Programming

software

Connect with RS232C cable

FP0

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

PLC programming software conforming to IEC 61131-3

Control FPWIN Pro is the Matsushita programming software according to the international standard IEC 61131-3.

Control FPWIN Pro works with the FP0 as well as any FP series programmable controller. Also, since the tool port is an

RS232C, connection to a PC is easy – it only requires a single cable. No converter or adapter is required.

Control FPWIN Pro – Programming

The most important highlights at a glance:

■

Reuse of ready made functions and function blocks saves time for programming and debugging

■

5 programming languages (Instruction List, Ladder Diagram, Function Block Diagram,

Sequential Function Chart, Structured Text)

■

Convenient comment application in 6 languages (English, German, French, Italian, Spanish, Japanese)

■

4 standard libraries (IEC Standard library, Matsushita library (M Lib), Pulsed library (P Lib), NC Tool library (NC Tool Lib))

■

Fewer errors through defined data types and encapsulation

■

Well-structured through programme organisation units, task-

and project management

■

Online monitoring and diagnostic

■

Ethernet and Modem communication for remote-programming,

-service, and -diagnostic

■

Password protection with different levels

■

Many additional application libraries available

■

IEC 61131-3 protects your investments for the future

19

Page 20

Control FPWIN GR

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

PLC programming software for easy operation

Features

FP Series programming software for Windows.

1. To facilitate operation on site, a mouse is not required for input, search, write, monitor and timer edit operations.

Everything can be accomplished with a keyboard alone.

2. Standard Windows operations, such as copy and paste, are included.

3. Supports all FP series machines. Software created with NPST-GR Ver. 3 or 4 can also be used.

4. Inherits convenient functions developed for NPST-GR.

Usage environment

OS

Required hard disc capacity

Recommended CPU

Recommended installed memory

Recommended screen resolution

Recommended display colors

Menu

Program status display

Program display

Windows 95/98/NT (Ver. 4.0 or later)/XP

At least 30MB

Pentium 100MHz or higher

32MB or more

800 x 600 or higher

High Color (16-bit or higher)

Applicable PLC types

*All products on the market are supported.

All FP series types are supported:

FP∑ Sigma, FP0, FP-e, FP1, FP2, FP2SH, FP3, FP10SH, FP-M

Note: FPWIN GR Vers. 2.2 or later is needed to program the FP-e

Tool bar

Access often-used

functions using icons.

Function bar

Provides information

regarding command

input and confirmation,

on-line/off-line

selection and PLC

mode selection.

Function instruction list

Classified by type, function

commands can be selected

from the displayed list.

(Simple help included.)

I/O comment edit function

Successive I/O comments can

be input for each device type.

Data from Excel and other

applications can be copied and

pasted via the clipboard.

Status display

Displays information

concerning PLC usage

environment and settings,

and detailed information

when an error occurs.

20

Page 21

Control CommX, PCWAY, OPC Server

Plant

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Visualisation software for ready made or customised solutions

Control CommX

The connection in ActiveX technology.

■

Connects your Visual Basic application to Matsushita PLCs.

■

Gives you the possibility to easily develop highly customised control solutions.

■

Create your own application very quickly by simply adding the functionality of ActiveX control to your code written with

Visual Basic.

■

No knowledge of MEWTOCOL (Matsushita's PLC communication protocol) needed.

Setup Process

Initial Setup in Visual Basic Configuration of Communication Register of Various Programming

▲

▲

Communication Types

▲

PCWAY

Add-on software for Excel to monitor and change PLC data.

■

The Excel add-in software PCWAY is available for data collection of the networked

PLCs. The contents of the PLC bits and data registers can be simply shown and

managed on Excel worksheets.

■

Settings in PCWAY can be used to switch display contents and character colour

corresponding to contact on/off status and register values, and perform calculations

based on register values. Excel macros are not necessary.

MEWTOCOL OPC Server

The connection between PLC and SCADA software.

■

Provides a standard interface between our FP Series PLCs and various

SCADA/HMI software* used to build a monitoring system compliant

with commercially available OPC clients. It is also possible to use OPC

automation interface to link our FP series PLCs with Visual Basic.

■

OPC (OLE for Process Control) is an interface standard for linking

software with various companies’ control devices. This standard

allows connections between OPC-compliant products.

Remote

supervisory

control

▲

Completion

* We have confirmed linking with iFIX Ver.2.6 (Intellution),

InTouch Ver.7.0 (Wonderware), and RSView32 Ver.6.3 (Rockwell Software).

Plant

Plant

21

Page 22

FP0 Control and Expansion Units

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Products and order numbers

Control units

Relay output type

Order number: FP0-C10RSA

Transistor output type

Order number: FP0-C16PA (PNP)

Expansion units

10 points

Input 6 points

Output 4 points

Terminal type

16 points

Input 8 points Output 8 points

PNP/NPN output type

FP0-C16TA (NPN)

Relay output type Input only type

10 points

Input 6 points Output 4 points

Terminal type

Order number: FP0-C10CRSA

with 2nd RS232C interface

16 points

Input 8 points Output 8 points

PNP/NPN output type

Order number: FP0-C16CPA (PNP)

FP0 -C16CTA (NPN)

with 2nd RS232C

interface

14 points

Input 8 points Output 6 points

Terminal type

Order number: FP0-C14RSA

32 points

Input 16 points

PNP/NPN output type

Order number: FP0-C32PA (PNP)

Output 16 points

FP0-C32TA (NPN)

14 points

Input 8 points Output 6 points

Terminal type

Order number: FP0-C14CRSA

with 2nd RS232C interface

32 points

Input 16 points

PNP/NPN output type

Order number: FP0-C32CPA (PNP)

Output 16 points

FP0-T32CPA (PNP, 10K)

FP0-C32CTA (NPN)

FP0-T32CTA (NPN, 10K)

with 2nd RS232C

interface

Input 4 points

Terminal relay type

Order number: FP0-E8RSA

Output 4 points

8 points

Order number: FP0-E16RSA

16 points

Input 8 points Output 8 points

Terminal relay type

8 points

Input 8 points

Order number: FP0-E8XA

16 points

Input 16 points

Order number: FP0-E16XA

Transistor output type

8 points

Output 8 points

PNP/NPN output type

Order number: FP0-E8YPA (PNP)

Order number: FP0-E16YPA (PNP)

FP0-E8YTA (NPN)

Notes:

■ A power cable (order number AFP0581) is enclosed with the control unit and the relay output type upgrade units (Transistor output type upgrade units do

not require a power cable).

■ Two Phoenix terminals (9-pin) are needed with the relay output type terminal type. A 2.5mm width screwdriver is needed for the wiring.

Have ready a dedicated terminal screwdriver (order number AFP0806: Phoenix order number SZS0, 4 X 2.5 compatible), or equivalent.

■ A loose-wiring pressure socket and contact (2 pins with order numbers FP0-C16T/P, E16T/P, and 4 pins with order numbers FP0-C32T/P, E32T/P) are needed

with the transistor output type. A loose-wiring connector pressure contact tool (order number AXY52000) is needed for the wiring.

16 points

Output 16 points

PNP/NPN output type

FP0-E16YTA (NPN)

16 points

Input 8 points Output 8 points

PNP/NPN output type

Order number: FP0-E16PA (PNP)

FP0-E16TA (NPN)

32 points

Input 16 points

PNP/NPN output type

Order number: FP0-E32PA (PNP)

Output 16 points

FP0-E32TA (NPN)

22

Page 23

FP0 Analogue and Networking Units

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Products and order numbers

Analogue units

Input 2 points

Order number: FP0-A21A

3 points

Output 1 points

Terminal type

Temperature control units

4 points

Input 4 points

Terminal type

Order number: FP0-TC4

Networking units

8 points

Input 8 points

Terminal type

Order number: FP0-A80A

8 points

Input 8 points

Terminal type

Order number: FP0-TC8

4 points

Output 4 points

Terminal type

Order number: FP0-A04V

6 points

Input 6 points

Terminal type

Order number: FP0-RTD6

4 points

Output 4 points

Terminal type

Order number: FP0-A04I

Handy Programmer

PROFIBUS

PROFIBUS

DP-Slave or Remote I/O

Order number: FP0-DPS2

AC power supply

Input

85 to 265VAC

Terminal type

Order number: FP0-PSA2

Output

24V DC/ 0.7A

MEWNET-F

MEWNET-F

Slave

Order number: FP0-IOL

Input

85 to 265VAC

Terminal type

Order number: FP-PS24-050E

Output

24VDC/ 2.1A

S-LINK CPU

S-LINK

Master

Order number: FP0-SL1

FP Memory Loader

Read or write programs from

or to a PLC

Order number: AFP8670

FP Programmer Ver. 2

Order number: AFP1114V2

23

Page 24

Terminal screwdriver

Necessary when wiring relay output type & terminals (Phoenix).

Attachment example

Wiring tools Parts for attachment I/O cables & networks

Order number

: AFP0806

Slim attachment plate model

Screw-stop attachment plate. Slim model.

Order number

: AFP0803 (set of 10)

Attachment example

DIN rail attachment

example

Flat attachment plate model

Screw-stop attachment plate. Flat model.

<Length 1m > 2 cable set

<Length 3m > 2 cable set

Transistor output type I/O cable

Loose-wiring cable (10 leads) AWG24 with connectors

attached at one end, 1 set: 2 cables

Order number

: AFP0804 (set of 10)

Input simulator

for FP0 relay output type, 6 switches

Order number

: SWITCH-FP0

Loose-wiring connector pressure contact tool

Necessary when wiring transistor output type connectors.

Order number

: AXY52000

Order number

:

AT8DLA1

C-NET adapter S2 type

Adapter for linking to a higher-placed computer.

With 30cm dedicated cable. Power source unnecessary.

Order number

: AFP15402

DIN rail

Standard DIN rail of width 35mm 1.378inch

and length 1m.

Order

number:

Stopper fitting

DIN rail stopper fitting.

ATA4806

Order

number:

AFP0521

Order

number:

AFP0523

Accessories

Terminal socket

Attaches to relay output terminal type.

Additional part.

Order number

: AFP0802

2 sockets

per pack

()

Loose-wiring pressure socket

Transistor output type connectors.

Additional part.

Order number

: AFP0807

2 sockets

per pack

()

Power cable

Attaches to control units and relay output

type expansion units. Length: 1m.

Order number

: AFP0581

1 cable

per pack

()

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Products and order numbers

Options

Notes:

(1) One I/O cable set (2 cables) is necessary with the following models: FP0-C10RS, C14RS, E8RS, E16RS.

(2) One I/O cable set (2 cables) is necessary with the following models: FP0-C16T/C16P, E16T/E16P.

(3) Two I/O cable sets (total 4 cables) are necessary with the following models: FP0-C32T/C32P, E32T/E32P.

Additional parts

24

Page 25

Programming Tools and Current Consumption List

Control

Control

Made in Germany

Made in Germany

Matsushita Electric Works, Ltd.

1995-2000

1995-2000

Matsushita Electric Works, Ltd.

FPWIN GR

FPWIN GR

Ver.2

Ver.2

Control

Control

Made in Germany

Made in Germany

Matsushita Electric Works(Europe)AG

1995-2000

1995-2000

Matsushita Electric Works(Europe)AG

FPWIN Pro

FPWIN Pro

Ver.5

Ver.5

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Products and order numbers

Programming software and cables

Control FPWIN Pro

English, German, French, Italian,

Spanish, Japanese menu selectable.

According to IEC 61131-3 Standard

Order number:

■ small version for MINI-PLC only

(FP0, FP-e, FPM, FP1, FP∑ (Sigma)

• FPWINPROSEN (English manual)

• FPWINPROSDE (German manual)

• FPWINPROSFR (French manual)

■ full version for all FP-Series PLCs

• FPWINPROFEN (English manual)

• FPWINPROFDE (German manual)

• FPWINPROFFR (French manual)

Control FPWIN GR

English, Italian, Spanish,

menu selectable

Order number:

■ full version for all FP-Series PLCs:

• FPWINGR F2 (English manual)

Programming cable

PC (D-SUB 9-pin) to the PLC

(mini-DIN 5-pin)

Order number: AFC8513

Programming cable

for use with FP Programmers

D-SUB15-pin, mini-DIN 5-pin

Order number: AFC8523

Other Software Tools

PCWAY

Order number:

AFW10011 (Software

+ Printer port dongle)

AFW10031 (Software

+ USB port dongle)

Control CommX

Order number:

AFW20011 (Software

+ Printer port dongle)

AFW20031 (Software

+ USB port dongle)

MEWTOCOL

OPC Server

Order number:

AFPS01510 (1 license)

AFPS01515 (5 licenses)

AFPS01516 (10 licenses)

Current consumption list

Type of unit Part number

Supply to the power supply connector of the control unit *1

C10 series, C14 series 100mA or less —

Control unit

C16 series 40mA or less —

C32 series, T32 series 60mA or less —

SL1 150mA or less —

E8X 10mA or less —

E8YRS 10mA or less 100mA or less

E8YT, E8YP 15mA or less —

Expansion unit

E8R 20mA or less 50mA or less

E16R 20mA or less 100mA or less

E16X 20mA or less —

E16T, E16P, E16YT, E16YP 25mA or less —

E32T, E32P 40mA or less —

A21 20mA or less 100mA or less

A80 20mA or less 60mA or less

Intelligent unit

A04V 20mA or less 100mA or less

A04I 20mA or less 130mA or less

IOL 30mA or less 40mA or less

TC4,

TC8, RTD6

25mA —

PROFIBUS unit FP0-DPS2 10mA or less 100mA or less

FP programmer AFP1114V2 50mA or less —

C-NET adapter AFP15402 50mA or less —

Notes)

*1 The current consumption from the power supply connector block of the control unit. Calculate the total current consumption based on the combination of the units.

*2 The current consumption from the power supply connector block of the expansion unit and intelligent unit.

Current Consumption

Supply to the power supply connector of the expansion and intelligent units *2

25

Page 26

FP0 Series

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Power Supplies

Features

■ Incredibly small size:

- FP0 power supply: 90 x 60 x 30.4mm

- FP power supply: 115 x 75 x 42mm

■ Maximum output current:

- FP0 power supply: 0.7A (24VDC)

- FP power supply: 2.1A (24VDC)

■ Multiple voltage input:

85 to 265VAC

■ Optimal protection:

overvoltage, overcurrent,

overheating, etc.

■ Global approvals

(UL/cUL, EN, CE-marking)

■ DIN-rail mounting

(FP0 power supply also side

mounting)

➝

30.4mm

➝

90mm

➝

FP0 Power supply

FP0-PSA2

➝

42mm

➝

115mm

➝

FP Power supply

FP-PS24-050 E

➝

➝

Performance specifications

Order number:

Primary side:

Rated operating voltage

Operating voltage range

Rated operating frequency

Operating frequency range

Inrush current

Current consumption

Over voltage protection

Secondary side:

Rated output voltage

Output voltage range

Nominal output current

Output current range

Output ripple

Short circuit protected

Over voltage protected

Over load protected

Holding time

Power OK signal – Yes

145mA (at 230VAC and 0.7Aoutput current)

electronic, automatic restart mode

Yes (switch off at approx. 0.8A and more)

FP0-PSA2

115/ 230VAC

85 to 265VAC

50/ 60Hz

40 to 70Hz

< 50A at 55°C < 50A at 25°C /< 70A at 55°C

400mA (at 230VAC and 2.1A output current)

PROTECTED

24VDC

23.5V to 24.5VDC

0.7A

0 to 0.7A

< 60mV

pp

Yes

Yes (switch off at approx. 3.5A and more)

min. 20ms at 230VAC

FP-PS24-050E

2.1A

0 to 2.1A

< 240mV

continuous

min. 110ms at 230VAC

General specifications

Ambient temperature

Storage temperature

Ambient humidity

Storage humidity

Vibration resistance

Shock resistance

Life time min.

Mounting

Size

Input connection AC side

Output connection DC side

Status display

10 to 55Hz, 1 cycle/min.: double amplitude of 0.75mm, 10 min. on 3 axes

7 years at nom. load, 25°C ambient temperature,

20000 h at 55°C with full load/continuous operation

DIN rail or FP0 flat attachement plate

90 x 60 x 30.4mm

MC connector, 2 pin

MC connector, 6 pin, 3 pin for „+“ and 3 pin for „-“

LED (green) at the front side for the secondary voltage indication

0°C to +55°C

-20°C to +70 °C

5 to 95% non-condensing

5 to 95% non-condensing

10g min., 4 times on 3 axes

DIN rail

115 x 75 x 42mm

2 pin

5 pin, 2 pin for „+” and 2 pin for „-”; 1 pin Power OK

pp

NOTE:

1) Mounting distance between the FP0 power supply and the FP0 CPU is needed to

permit heat radiation for the FP0-CPU

2) For side mounting, 2 additional

blue clips are needed: order part-no.

677-021-17101 (1pce.) for FP0-PSA2

3) Mounting distance between the power

supply FP-PS24-050E and other devices is

needed for cooling/ heat radiation.

Standards

EMC

LVD

Others

Protection

EN 50082-2, EN50082-1,

EN 50081-2, EN 50081-1

EN 60950, EN 50178

(overvoltage category 3)

UL Recognized according to UL 508, UL 1950,

cUL Recognized according to CAN/CSA-C22.2 No. 950.95

IP30 IP20 outside/IP67 inside

EN 55011/B, EN 55022/B,

EN 61000-4-2, -4-3, -4-4, -4-5, -4-6, -4-11

EN 60950, EN 50178

(overvoltage category 2)

26

Page 27

FP0 Product Overview

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10/2004

Order numbers

1. Control Units

Product Name Part Number

FP0-C10RS, 6 Inputs / 4 Outputs (p+n / Relay) FP0-C10RSA

FP0-C10CRS, 6 Inputs / 4 Outputs (p+n / Relay), RS232 COM-Port Interface FP0-C10CRSA

FP0-C14RS, 8 Inputs / 6 Outputs (p+n / Relay) FP0-C14RSA

FP0-C14CRS, 8 Inputs / 6 Outputs (p+n / Relay), RS232 COM-Port Interface FP0-C14CRSA

FP0-C16P, 8 Inputs / 8 Outputs (p+n / Transistor PNP) FP0-C16PA

FP0-C16CP, 8 Inputs / 8 Outputs (p+n / Transistor PNP), RS232 COM-Port Interface FP0-C16CPA

FP0-C32P, 16 Inputs / 16 Outputs (p+n / Transistor PNP) FP0-C32PA

FP0-C32CP, 16 Inputs / 16 Outputs (p+n / Transistor PNP), RS232 COM-Port Interface FP0-C32CPA

FP0-C16T, 8 Inputs / 8 Outputs (p+n / Transistor NPN) FP0-C16TA

FP0-C16CT, 8 Inputs / 8 Outputs (p+n / Transistor NPN), RS232 COM-Por t Interface FP0-C16CTA

FP0-C32T, 16 Inputs / 16 Outputs (p+n / Transistor NPN) FP0-C32TA

FP0-C32CT, 16 Inputs / 16 Outputs (p+n / Transistor NPN), RS232 COM-Por t Interface FP0-C32CTA

FP0-T32CP, 16 Inputs / 16 Outputs (p+n / Transistor PNP), RS232 COM-Port Interface, 10 000 steps Program memory FP0-T32CPA

FP0-T32CT, 16 Inputs / 16 Outputs (p+n / Transistor NPN), RS232 COM-Port Interface, 10 000 steps Program memory FP0-T32CTA

FP0-SL1, S-LINK CPU, Master FP0-SL1

2. Expansion Units

Product Name Part Number

FP0-E8RS, 4 Inputs / 4 Outputs (p+n / Relay) FP0-E8RSA

FP0-E8X, 8 Inputs (p+n) FP0-E8XA

FP0-E8YP, 8 Outputs (Transistor PNP) FP0-E8YPA

FP0-E8YT, 8 Outputs (Transistor NPN) FP0-E8YTA

FP0-E16RS, 8 Inputs / 8 Outputs (p+n / Relay) FP0-E16RSA

FP0-E16P, 8 Inputs / 8 Outputs (p+n / Transistor PNP) FP0-E16PA

FP0-E16T, 8 Inputs / 8 Outputs (p+n / Transistor NPN) FP0-E16TA

FP0-E16X, 16 Inputs (p+n) FP0-E16XA

FP0-E16YP, 16 Outputs (Transistor PNP) FP0-E16YPA

FP0-E16YT, 16 Outputs (Transistor NPN) FP0-E16YTA

FP0-E32P, 16 Inputs / 16 Outputs (p+n / Transistor PNP) FP0-E32PA

FP0-E32T, 16 Inputs / 16 Outputs (p+n / Transistor NPN) FP0-E32TA

FP0-A21, 2 analogue inputs / 1 analogue output FP0-A21A

FP0-A80, 8 analogue inputs FP0-A80A

FP0-TC4, 4 thermocouple inputs FP0-TC4

FP0-TC8, 8 thermocouple inputs FP0-TC8

FP0-RTD6, 6 RTD Inputs, Pt 100, Pt 1000, Ni 1000 FP0-RTD6

3. AC Power Supply

Product Name Part Number

FP0-AC Power Supply 24VDC / 0.7A FP0-PSA2

4. Network

Product Name Part Number

FP0-DPS2, PROFIBUS DP Slave or Remote I/O unit FP0-DPS2

FP0-IOL, MEWNET-F Slave unit, I/O link FP0-IOL

FP0-SL1, S-LINK CPU, Master FP0-SL1

C-NET S2 Adapter (Multi drop network slave adapter) AFP15402

C-NET Adapter (RS232/422 PORS485 Interface adapter), 230VAC AFP8536

5. Programming Tools

Product Name Part Number

NAiS Control FPWIN Pro Programming software FP0/FP-e/FP1/FP M including English manual FPWINPROS EN

NAiS Control

NAiS Control

Handheld programmer for FP0 and all other FP programmable controllers AFP1114V2

FP0-Programming cable PC <-> TOOL-Port (SUB-D/MiniDIN5), 3m AFC8513

FP0-Programming cable Handheld programmer <-> TOOL-Port (SUB-D15/MiniDIN5), 1m AFC8521

FP0-Programming cable Handheld programmer <-> TOOL-Port (SUB-D15/MiniDIN5), 3m AFC8523

6. Additional Parts

Product Name Part Number

Transistor output type I/O cable, Loose-wiring cable (10 leads), 1 set: 2 cables, 1m AFP0521

Transistor output type I/O cable, Loose-wiring cable (10 leads), 1 set: 2 cables, 3m AFP0523

Power cable, 1m, 1 cable per pack AFP0581

Slim attachment plate model (set of 10) AFP0803

Flat attachment plate model (set of 10) AFP0804

Terminal socket (2 sockets per pack) AFP0802

Loose-wiring pressure socket (2 sockets per pack) AFP0807

Loose-wiring connector pressure contact tool AXY52000

Input simulator for FP0 relay output type, 6 switches SWITCH-FP0

DIN rail 35 mm (DIN EN 50 022), 1m AT8DLA1

DIN rail stopper fitting ATA4806

FPWIN Pro Programming software for all FP-series PLC (FP0, FP1, FP-M, FP2/2SH, FP3, FP10SH) including English manual

FPWIN GR Programming software for all FP-series PLC (FP0, FP1, FP-M, FP2/2SH, FP3, FP10SH) including English manual

FPWINPROF EN

FPWINGR F EN

27

Loading...

Loading...