Page 1

Programmable Controller

FP0H Control Unit

User's Manual

Logging/Trace Function

WUME-FP0HLOG-03

2020.3 panasonic.net/id/pidsx/global

Page 2

(MEMO)

2 WUME-FP0HLOG-03

Page 3

Introduction

Thank you for purchasing a Panasonic product. Before you use the product, please carefully

read through the user’s manual, and understand it in detail to use the product properly.

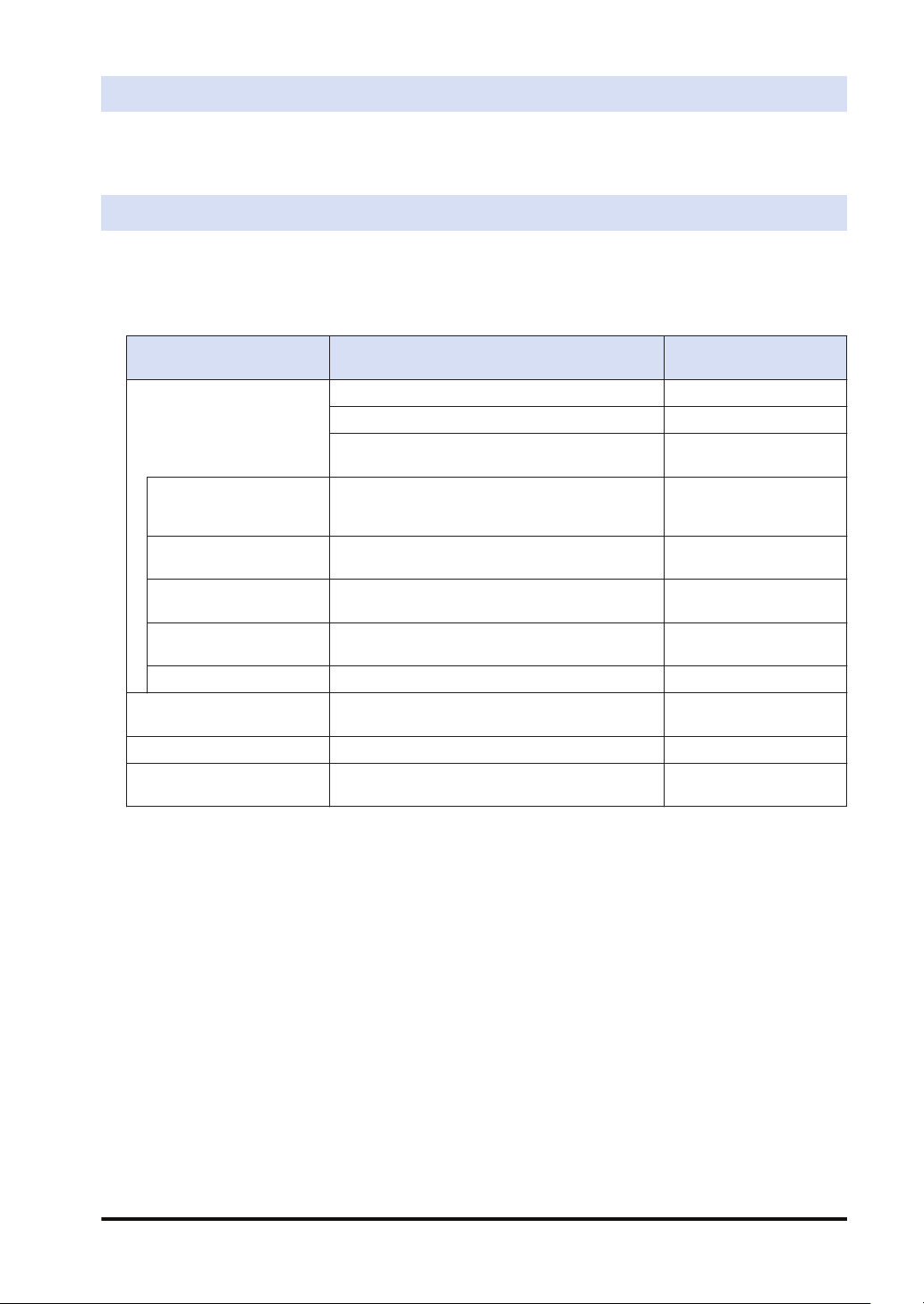

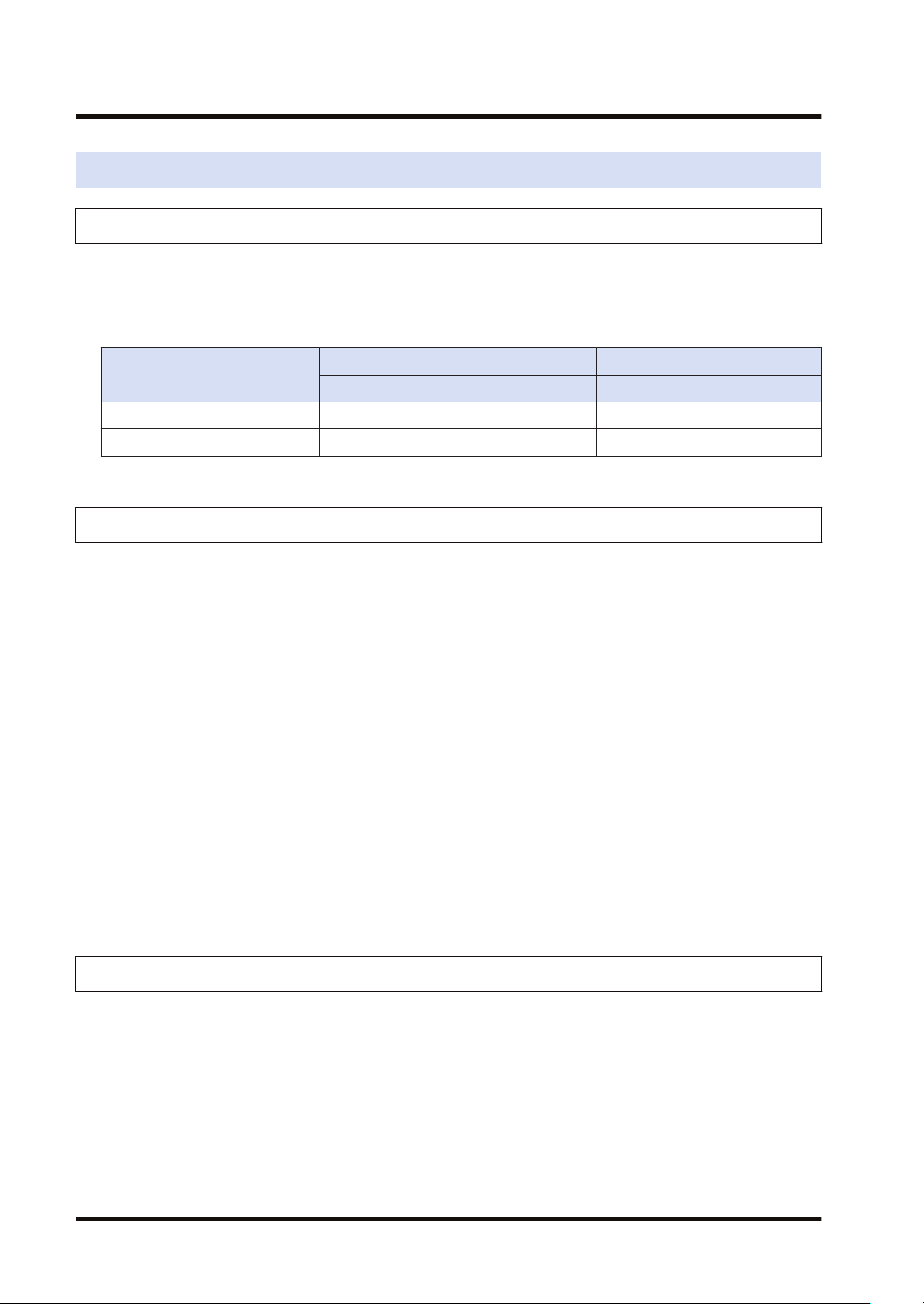

Types of Manual

● There are different types of user’s manual for the FP0H series. Please refer to a relevant

manual for the unit and purpose of your use.

● The manuals can be downloaded on our download center: https://

industrial.panasonic.com/ac/j/dl_center/.

Unit name or purpose of

use

FP0H Control Unit

Positioning Function/PWM

Output/High-speed

Counter Function

Serial Communication

Function

Ethernet Communication

Function

EtherNet/IP

Communication Function

Logging trace function FP0H User‘s Manual (Logging/Trace Function) WUME-FP0HLOG

FP0H Extension

(Communication) Cassette

FP0H Positioning Unit FPsigma Positioning Unit User’s Manual ARCT1F365E

FP0H Positioning Unit RTEX

Manual name Manual code

FP0H User‘s Manual (Basic) WUME-FP0HBAS

FP series Programming Manual ARCT1F313E

FP0H Programming Manual (SD Card Access

Instructions)

FP0H User‘s Manual

(Positioning/PWM Output/High-speed Counter)

FP0H User‘s Manual (COM Communication) WUME-FP0HCOM

FP0H User‘s Manual (Ethernet Communication) WUME-FP0HET

FP0H User‘s Manual (EtherNet/IP) WUME-FP0HEIP

FP0H User‘s Manual (COM Communication) WUME-FP0HCOM

FP0H Positioning Unit RTEX User’s Manual

(FPWIN GR7)

WUME-FP0HSD

WUME-FP0HPOS

WUME-FP0HRTEXGR7

WUME-FP0HLOG-03 iii

Page 4

SAFETY PRECAUTIONS

● To prevent accidents or personal injuries, please be sure to comply with the following items.

● Prior to installation, operation, maintenance and check, please read this manual carefully for proper use.

● Before using, please fully understand the knowledge related to the equipment, safety precautions and all

other precautions.

● Safety precautions are divided into two levels in this manual: Warning and Caution.

Incorrect operation may lead to death or serious injury.

● Take appropriate safety measures to the external circuit of the product to ensure the security of the whole

system in case of abnormalities caused by product failure or external.

● Do not use this product in areas with inflammable gases.

Otherwise it may lead to an explosion.

● Do not put this product into a fire.

Otherwise it could cause damage to the battery or other electronic parts.

Incorrect operation may lead to injury or material loss.

● To prevent the excessive exothermic heat or smoke generation of the product, a certain margin is required

for guaranteed characteristics and performance ratings of relative products.

● Do not decompose or transform it.

Otherwise it will lead to the excessive exothermic heat or smoke generation of the product.

● Do not touch terminal blocks during power-on.

Otherwise it may result in an electric shock.

● Set an emergency stop and interlock circuit in the external devices.

● Connect wires and connectors reliably.

Otherwise it may lead to the excessive exothermic heat or smoke generation of the product.

● Do not undertake construction (such as connection and disconnection) while the power supply is on.

It could lead to an electric shock.

● If the equipment is used in a manner not specified by the Panasonic, the protection provided by the

equipment may be impaired.

● This product has been developed/produced for industrial use only.

Description on Copyright and Trademarks

● The copyright of this manual is owned by Panasonic Industrial Devices SUNX Co., Ltd

● Unauthorized reproduction of this manual is strictly prohibited.

● Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

● Ethernet is a registered trademark of Fuji Xerox Co., Ltd. and Xerox Corporation.

● EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vendor Association).

● SDHC and SD logos are trademarks of LLC.

● Other company and product names are trademarks or registered trademarks of their respective companies.

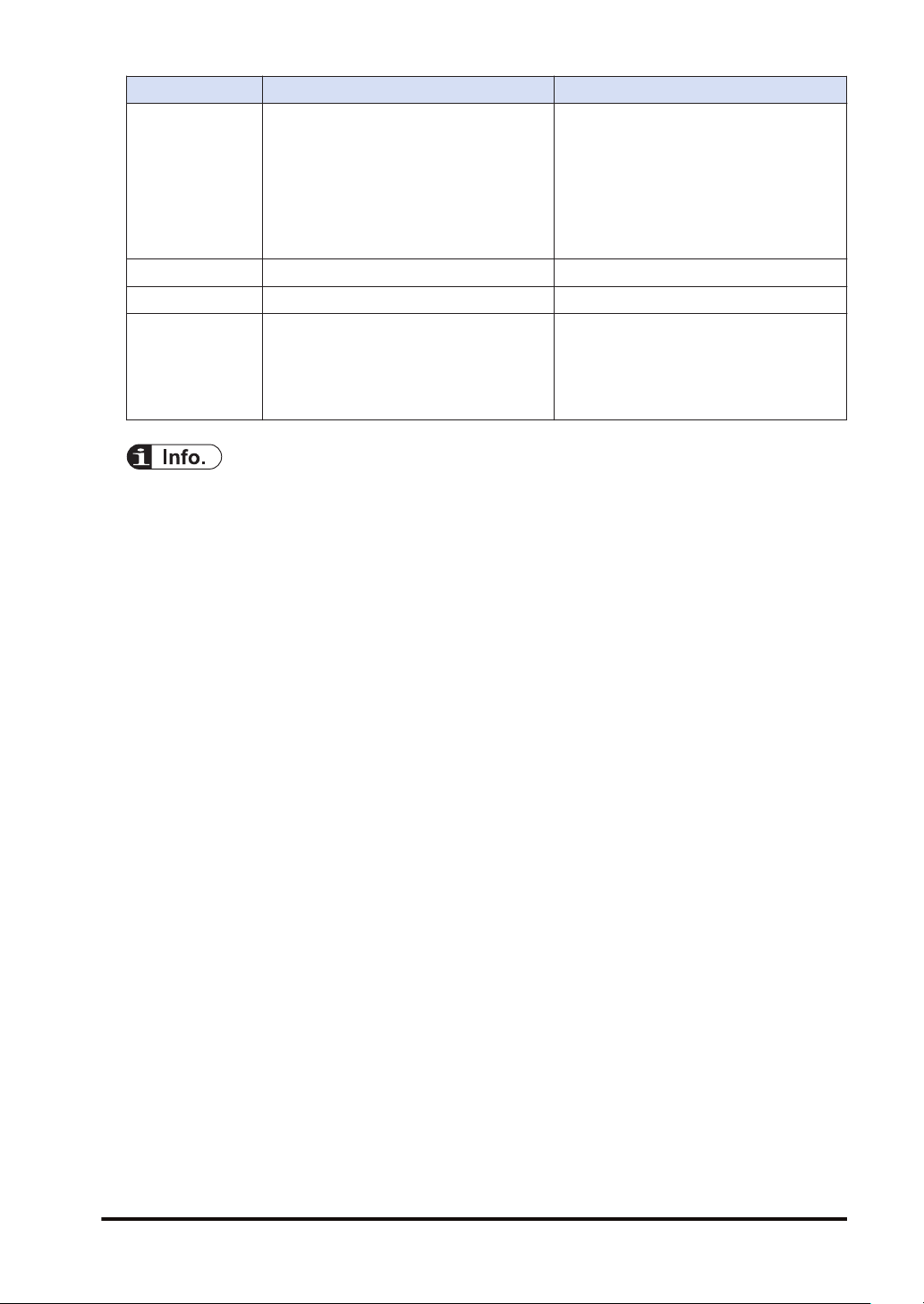

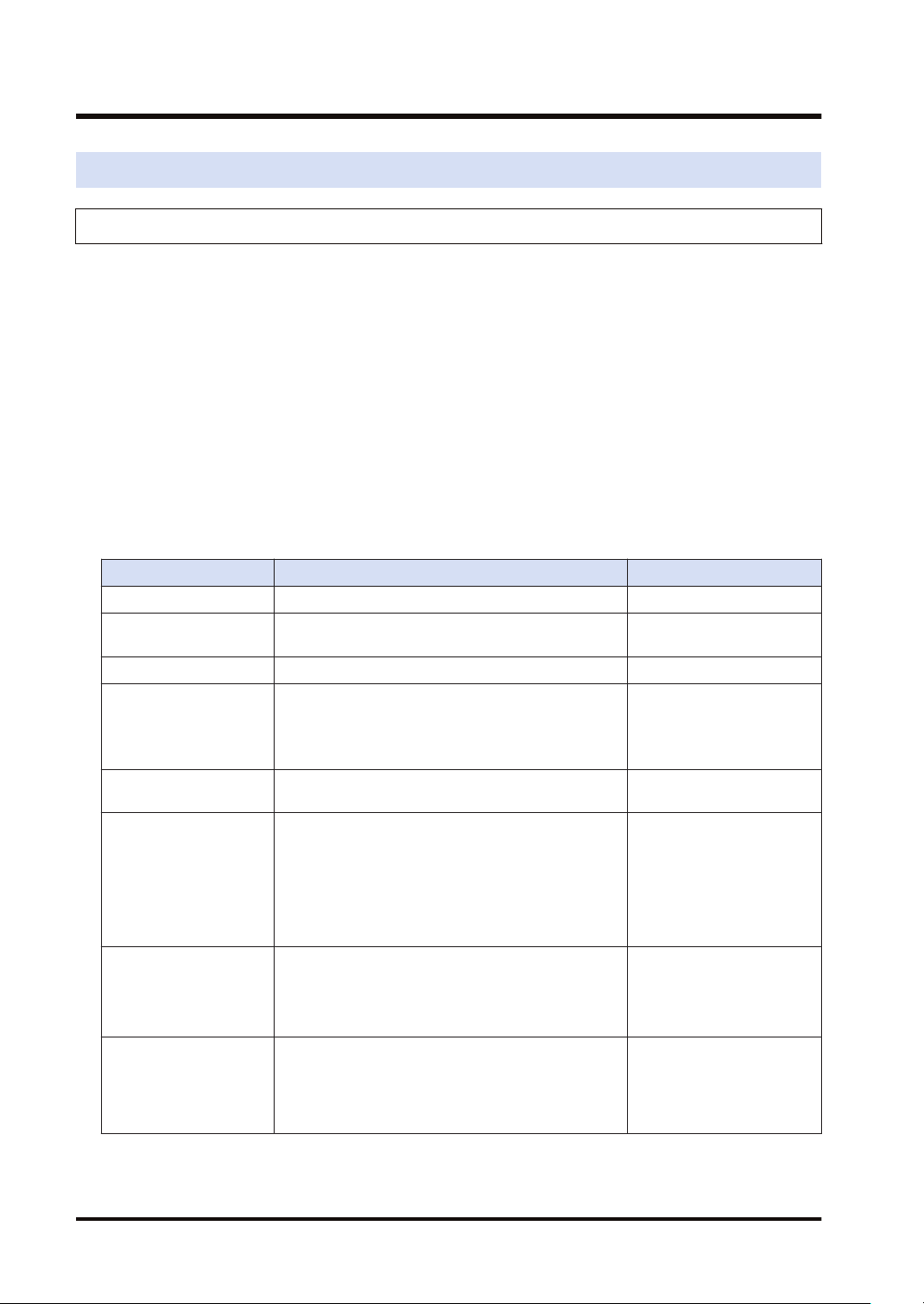

Contents of This Manual

This manual describes the "logging/trace function" and "sampling trace function" implemented

in FP0H Control Unit.

■

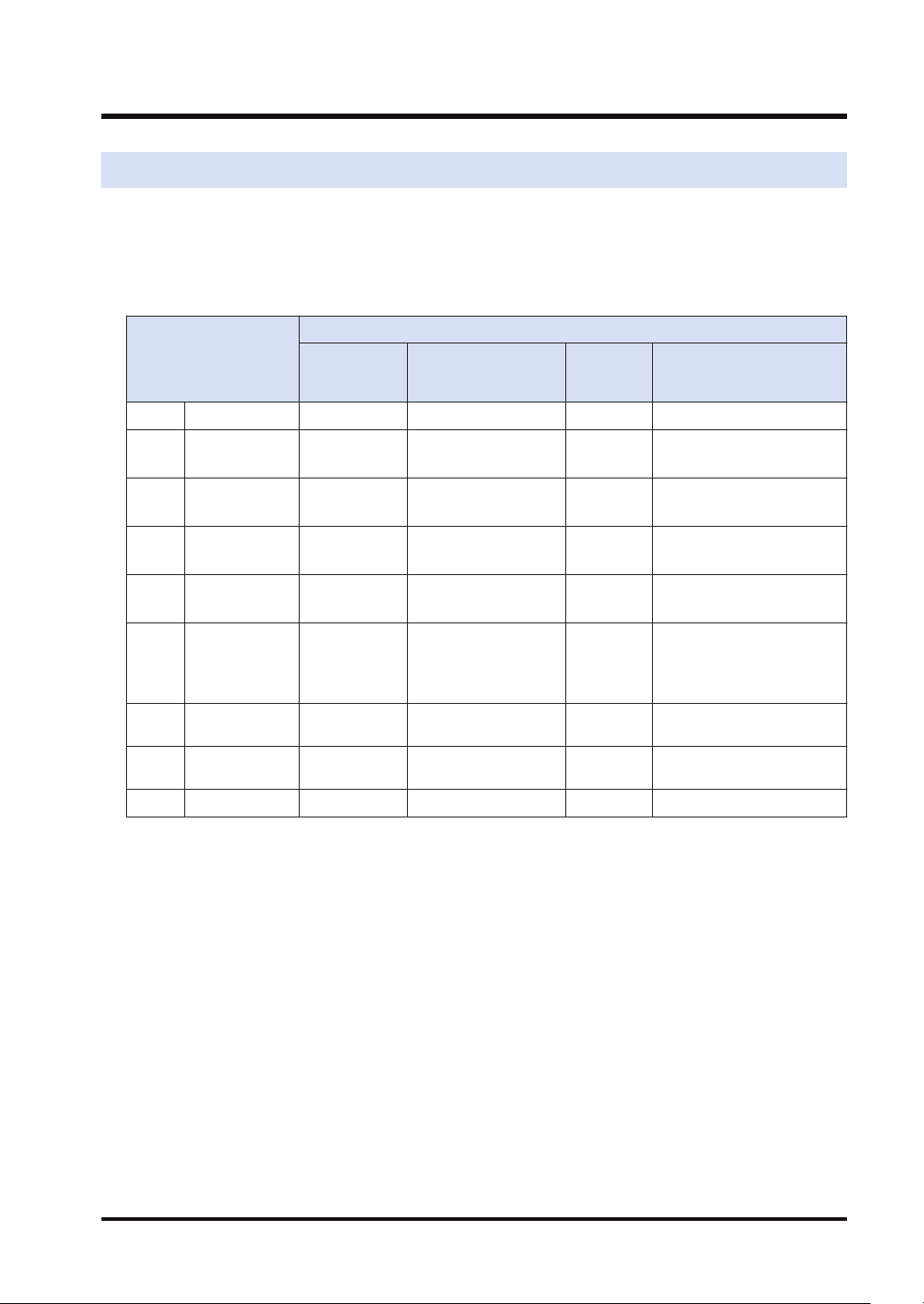

Functional comparison

Item Logging/trace function Sampling trace function

Applicable model

iv WUME-FP0HLOG-03

Type with Ethernet function only

AFP0HC32ET/AFP0HC32EP

All FP0H models

Page 5

Item Logging/trace function Sampling trace function

Operation information of arbitrary contacts

and data is saved in the buffer memory in

the control unit together with time stamp

Description

No. of devices Max. 128 devices (Max. 256 words) 16 contacts (for 1 word) + 3 words

Memory capacity Max. 64 K words For 1000 samples

Trigger condition

information. With the logging function, they

can also be recorded in an SD memory

card. In comparison with the sampling trace

function, the number of devices that can be

registered and trigger condition has been

extended.

Bit device ON

Cycle: Hour, minute, second

Time: Per minute, Per hour, Every day,

Every week, Every month, Every year

Instruction: F420 (LOGST) instruction

This function can be used by similar

operations to those of the sampling trance

function of existing models FP0R/

FPsigma/FP-X.

Cycle (10 ms to 30 s)

Instruction: F155 (SMPL) instruction

● For details of the logging/trace function, refer to "1 Overview of Logging/Trace Function" to

"6 Logging/Trace Troubleshooting".

● For details of the sampling trace function, refer to "7 Sampling Trace Function".

WUME-FP0HLOG-03 v

Page 6

(MEMO)

vi WUME-FP0HLOG-03

Page 7

Table of Contents

1 Overview of Logging/Trace Function.................................................. 1-1

1.1 For Using Logging/Trace Function......................................................1-2

1.1.1 Applicable model.............................................................................. 1-2

1.1.2 Precautions on Using This Function ................................................ 1-2

1.1.3 Selection of SD Memory Cards........................................................ 1-2

1.2 Overview of Functions ........................................................................1-4

1.2.1 Overview of Logging Function ......................................................... 1-4

1.2.2 Overview of Trace Function ............................................................. 1-5

1.3 Format of Saved Files.........................................................................1-7

1.3.1 File Format (For Logging Function) ................................................. 1-7

1.3.2 File Name (For Logging Function) ................................................... 1-7

1.3.3 File Format (For Trace Function) ..................................................... 1-8

1.3.4 File Name (For Trace Function)....................................................... 1-8

1.4 Data Format........................................................................................1-9

2 Configuration of Logging/Trace Function ..........................................2-1

2.1 Definition of Buffer Memory ................................................................2-2

2.1.1 Setting Method................................................................................. 2-2

2.2 Logging Information Setting................................................................2-3

2.2.1 Confirmation and Settings of File Information.................................. 2-3

2.2.2 LOG File Setting Items (For Logging) .............................................. 2-4

2.3 Trace Information Setting....................................................................2-7

2.3.1 Confirmation and Settings of File Information.................................. 2-7

2.3.2 LOG File Setting Items (For Trace).................................................. 2-8

2.4 Registration of Device Information......................................................2-11

2.5 Operation When Setting Cycle for Logging Trigger ............................2-13

2.6 Downloading Setting Data to Control Unit ..........................................2-15

2.6.1 Downloading to Non-volatile Memory .............................................. 2-15

3 Logging/Trace Start, Stop and Monitor...............................................3-1

3.1 Start and Stop of Logging/Trace Operation ........................................3-2

3.1.1 Start and Stop by Tool Software ...................................................... 3-2

3.1.2 Start and Stop by Instructions.......................................................... 3-3

3.1.3 Automatic Start by Setting ............................................................... 3-3

3.2 Operation Check Using Logging/Trace Monitor..................................3-4

3.2.1 Logging/Trace Monitor ..................................................................... 3-4

3.2.2 Special Internal Relays Relating to Logging/Trace Operation ......... 3-5

3.2.3 Special Data Registers Relating to Logging/Trace Operation.......... 3-6

3.2.4 Checking Logging Speed (When Selecting Logging For

Application) ....................................................................................... 3-6

4 Logging Operation................................................................................4-1

4.1 Flow of Logging Operation..................................................................4-2

4.1.1 Operation Flow................................................................................. 4-2

WUME-FP0HLOG-03

vii

Page 8

4.2 Operation When Logging is Selected for Application .........................4-4

4.2.1 Operation When Logging Operation is Started ................................ 4-4

4.2.2 Operation When Logging Operation Stops ...................................... 4-4

4.2.3 Operation When Power Supply Turns Off........................................ 4-4

4.2.4 Operation When the Battery Cover of Control Unit is Open ............ 4-4

4.2.5 Operation When the Number of Determination Files Reaches the

Maximum Number of Generations.................................................... 4-5

4.3 System Management Information Relating to Logging Function ........4-7

4.3.1 System Management Information and Operation ............................ 4-7

4.3.2 Clearing Management Information................................................... 4-7

5 Trace Operation and Time Chart..........................................................5-1

5.1 Flow of Trace Operation .....................................................................5-2

5.1.1 Flow of Trace Operation................................................................... 5-2

5.2 Operation When Trace is Selected for Application .............................5-4

5.2.1 Operation When Trace Operation is Started.................................... 5-4

5.2.2 Operation When Logging Operation Stops ...................................... 5-4

5.2.3 Operation When Power Supply Turns Off........................................ 5-4

5.2.4 Operation When the Battery Cover of Control Unit is Open ............ 5-4

5.3 Trace Monitor (Time Chart).................................................................5-6

5.3.1 Display Method of Time Chart.......................................................... 5-6

5.3.2 Explanation of Time Chart Monitor................................................... 5-7

5.3.3 Settings for Time Chart Display Area............................................... 5-9

5.3.4 Register Device................................................................................ 5-12

5.3.5 Sampling Condition Setting.............................................................. 5-13

6 Logging/Trace Troubleshooting ..........................................................6-1

6.1 Operations When Errors Occur...........................................................6-2

6.1.1 Operation When Power Supply Turns Off........................................ 6-2

6.1.2 Operation When Errors Occur (Only When Selecting Logging for

Application) ....................................................................................... 6-2

6.1.3 Operations When Inserting/Removing SD Memory Card During

Logging/Trace................................................................................... 6-3

6.2 Troubleshooting ..................................................................................6-4

6.2.1 Errors When Start/Stop Operation was Executed Using FPWIN

GR7................................................................................................... 6-4

6.2.2 Errors When Operation was Executed Using LOGST, LOGED or

LOGSMPL Instruction....................................................................... 6-4

6.2.3 Error of Logging/Trace ..................................................................... 6-5

6.2.4 Error When Copying Data in SD Memory Card ............................... 6-5

7 Sampling Trace Function .....................................................................7-1

7.1 Operation of Sampling Trace Function ...............................................7-2

7.2 Details of Sampling Trace Function....................................................7-3

7.3 How to Use Sampling Trace ...............................................................7-4

7.3.1 Sampling by free run........................................................................ 7-4

7.3.2 Sampling at regular time intervals.................................................... 7-4

7.3.3 Sampling by instruction.................................................................... 7-5

viii

WUME-FP0HLOG-03

Page 9

1 Overview of Logging/Trace

Function

1.1 For Using Logging/Trace Function......................................................1-2

1.1.1 Applicable model.............................................................................. 1-2

1.1.2 Precautions on Using This Function ................................................ 1-2

1.1.3 Selection of SD Memory Cards........................................................ 1-2

1.2 Overview of Functions ........................................................................1-4

1.2.1 Overview of Logging Function ......................................................... 1-4

1.2.2 Overview of Trace Function ............................................................. 1-5

1.3 Format of Saved Files.........................................................................1-7

1.3.1 File Format (For Logging Function) ................................................. 1-7

1.3.2 File Name (For Logging Function) ................................................... 1-7

1.3.3 File Format (For Trace Function) ..................................................... 1-8

1.3.4 File Name (For Trace Function)....................................................... 1-8

1.4 Data Format........................................................................................1-9

WUME-FP0HLOG-03

1-1

Page 10

1.1 For Using Logging/Trace Function

1.1 For Using Logging/Trace Function

1.1.1 Applicable model

The logging/trace function is available for the models of Ethernet type (SD card). However, this

function and the sampling trace function cannot be used concurrently.

■

Applicable models (●: Available, Blank: Not available)

Item

Logging/trace function ●

Sampling trace function ● ●

Ethernet type Non-Ethernet type

C32ET/C32EP C32T/C32P

1.1.2 Precautions on Using This Function

As an SD memory card is used for the logging function, there are risks of loss of data or data

damage depending on usage conditions. Consider possible risks, design a system and make

an evaluation of the system before using the function.

■

Precautions when powering off the PLC

If the PLC is powered off during logging or accessing an SD memory card, the following

problems may occur.

● Data accumulated in the buffer memory are lost.

● Files may be damaged.

● The SD memory card may be damaged.

Take necessary measures such as the use of an uninterruptible power system (UPS) as

necessary.

■

Logging speed and writing speed into an SD memory card

When the speed accumulating data is faster than the writing speed into an SD memory card,

data cannot be saved. Make an evaluation thoroughly before use.

1.1.3 Selection of SD Memory Cards

For the Control Units with the Ethernet function (AFP0HC32ET/AFP0HC32EP), SD memory

cards can be used for copying projects and logging/trace applications. Note the following points

when selecting and using SD memory cards

■

Usable SD memory cards

Please use Panasonic SD memory cards for industrial use.

https://panasonic.net/cns/sdcard/industrial_sd/index.html

(Note): An operation check has not been conducted for SD memory cards made by other

manufacturers.

1-2 WUME-FP0HLOG-03

Page 11

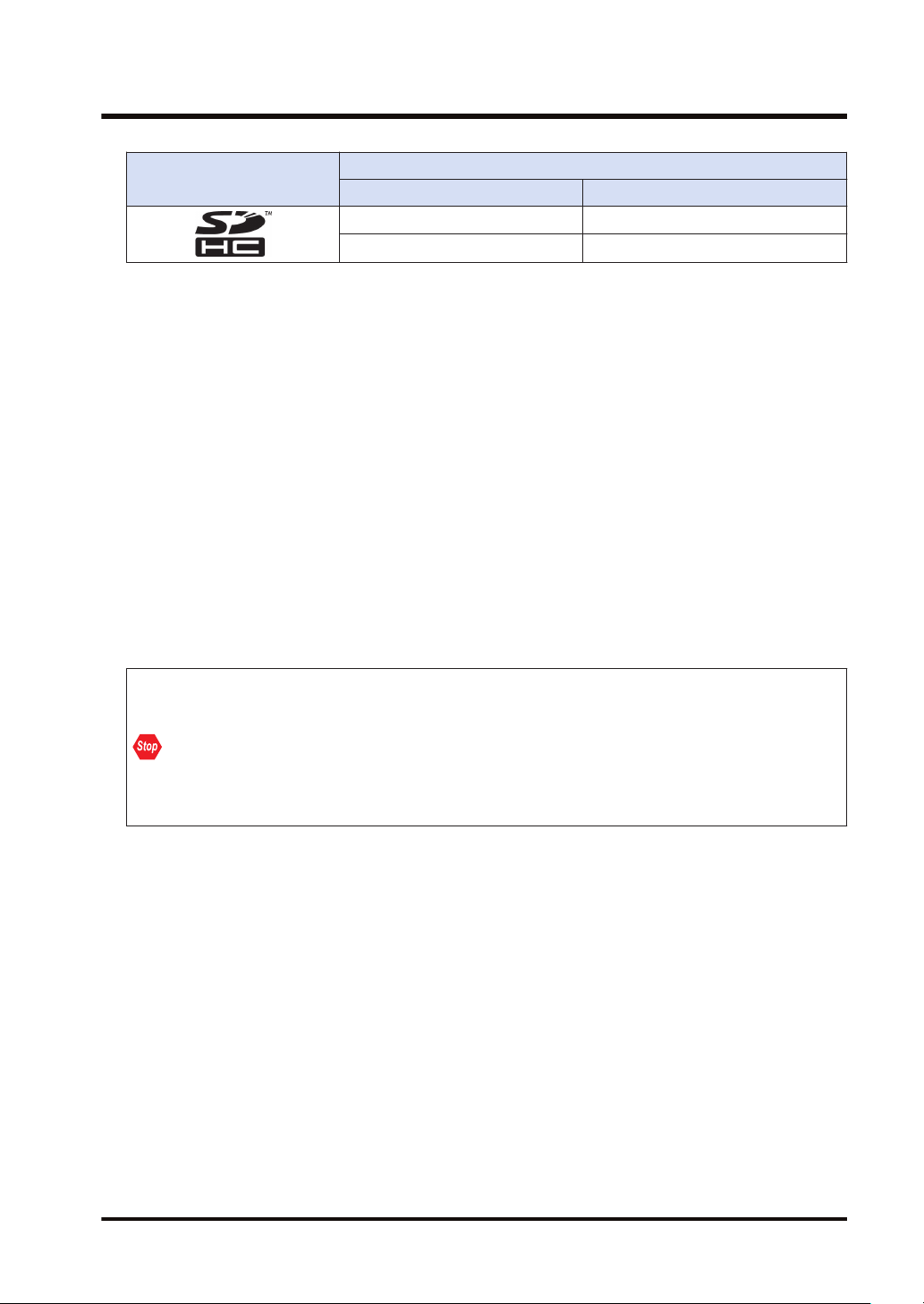

1.1 For Using Logging/Trace Function

Control Unit

printed logo

■

Cautions on handling an SD memory card

Usable SD memory cards

Card type Capacity

SD memory card 2GB

SDHC memory card 4GB to 32GB

The data saved in the SD memory card may be lost in the following cases. We assume no

responsibility whatsoever for the loss of saved data.

● The user or a third party has misused the SD memory card.

● When the SD memory card was affected by any static electricity or electrical noise.

● The SD memory card was taken out, or the PLC body was powered off, while the card was

being accessed.

■

Formatting an SD memory card

In principle, SD memory cards have been formatted by the time of purchase, and no formatting

by the user is required. If formatting becomes necessary, download formatting software for SD

memory cards on the following website.

"Our website (Japanese only)"

https://panasonic.jp/support/sd_w/download/index.html

"SD Association’s website"

https://www.sdcard.org/

● A file system formatted by PC's standard formatting software does not satisfy the SD

memory card specifications. Please use the dedicated formatting software.

● It is recommended to save important data in another media for backup.

● Never remove the card or power off the PLC while accessing the card. Data may be

damaged.

● Do not use an SD memory card the memory capacity of which is more than the usable

capacity. Data in the card may be damaged.

WUME-FP0HLOG-03 1-3

Page 12

1.2 Overview of Functions

1.2 Overview of Functions

1.2.1 Overview of Logging Function

■

Overview

● The logging function is used to record arbitrary contacts and data information together with

time stamp information at any time, and save them in an SD memory card inserted in the

control unit.

● Log data is saved as CSV format files.

● Use the Logging/Trace Settings menu of tool software to set the conditions.

● The settings are downloaded to the PLC as a part of project data, and stored in the nonvolatile memory.

● The logging operation is executed by any of those operations; (1) tool software, (2) dedicated

instructions or (3) Autostart by the setting.

● To perform data logging at high speed, the buffer memory in the control unit is used.

■

Specifications

Item Specifications Remarks

Max. number of records 60000 records -

Number of file

generations

Number of logs Max. 128 devices (Max. 256 words) per record -

Buffer memory

Logging start-stop

Logging trigger condition

File determination

condition

(Logging stop trigger

condition)

File format Data is saved in CSV format.

(Note 1) Logging is executed when the condition is met at the end of scan.

(Note 2) Use it together with the (DF) instruction to turn ON only for one scan.

Max. 2,000 generations per log -

Max. 64 K words

Can be divided into max. 4 (LOG0 to LOG3) areas for

use.

Capacity per division: 4K words to 64K words

Selectable from the tool software, instructions or

autostart.

Bit device ON

Cycle: Hour, minute, second

Time: Per minute, Per hour, Every day, Every week,

Every month, Every year

Instruction: Executes F420 (LOGST) instruction with

an arbitrary condition and starts logging.

Bit device ON

Time: Per minute, Per hour, Every day, Every week,

Every month, Every year

Max. number of records

(Note 1)

(Note 1)

(Note 1)

(Note 2)

Shared with the trace

function.

-

-

-

Arbitrary comments can be

given.

The upper limit of the

capacity on the file system is

4 GB.

1-4 WUME-FP0HLOG-03

Page 13

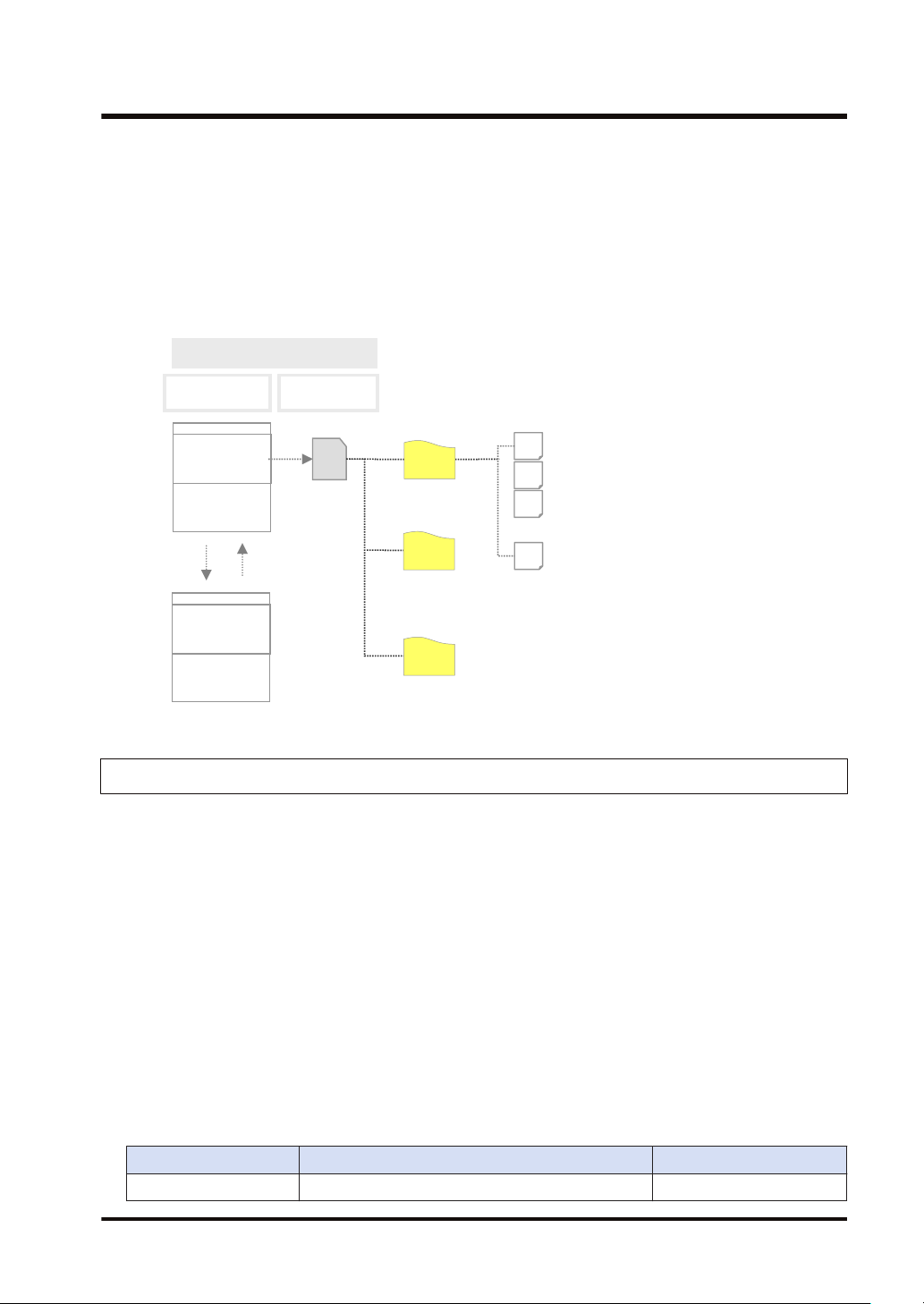

PLC

Internal memory

(RAM)

SD

Logging buffer

memory

Log 0

SD memory

card

Log1

Log 3

2

Sample (200724_120100).csv

3

1

X

Sample (200724_120200).csv

Sample (200724_120300).csv

Sample (20xxxxx_xxxxxx).csv

Operation

device

1.2 Overview of Functions

(Note 3) Data stored in the buffer memory will be cleared when the power turns off.

■

Image of logging function

When the set conditions (bit device ON, cycle, time, and instruction) are met, the values of

operation devices will be saved in the logging buffer memory (RAM). The logging operation

continues until the file determination condition is met. Writing data to an SD memory card from

the logging buffer memory is automatically performed by PLC. It is not possible to perform this

operation by users.

1.2.2 Overview of Trace Function

■

● The trace function is used to record arbitrary contacts and data information together with

● Logging data can be uploaded from the buffer memory to the tool software after the trace

● When the trace stop condition is set to bit device, the operation can be stopped after logging

● Use the Logging/Trace Settings menu of tool software to set the conditions.

● The settings are downloaded to the PLC as part of project data, and stored in the non-

● The trace operation is executed by any of those operations; (1) tool software, (2) dedicated

■

WUME-FP0HLOG-03 1-5

Overview

time stamp information in the buffer memory in the control unit at any time.

operation, and can be displayed as a time chart. Traced data can be saved in SD memory

cards as CSV format files.

data of the specified number of samplings after the stop condition has been met.

volatile memory.

instructions or (3) Autostart by the setting.

Specifications

Item Specifications Remarks

Number of logs Max. 128 devices (Max. 256 words) per record -

Page 14

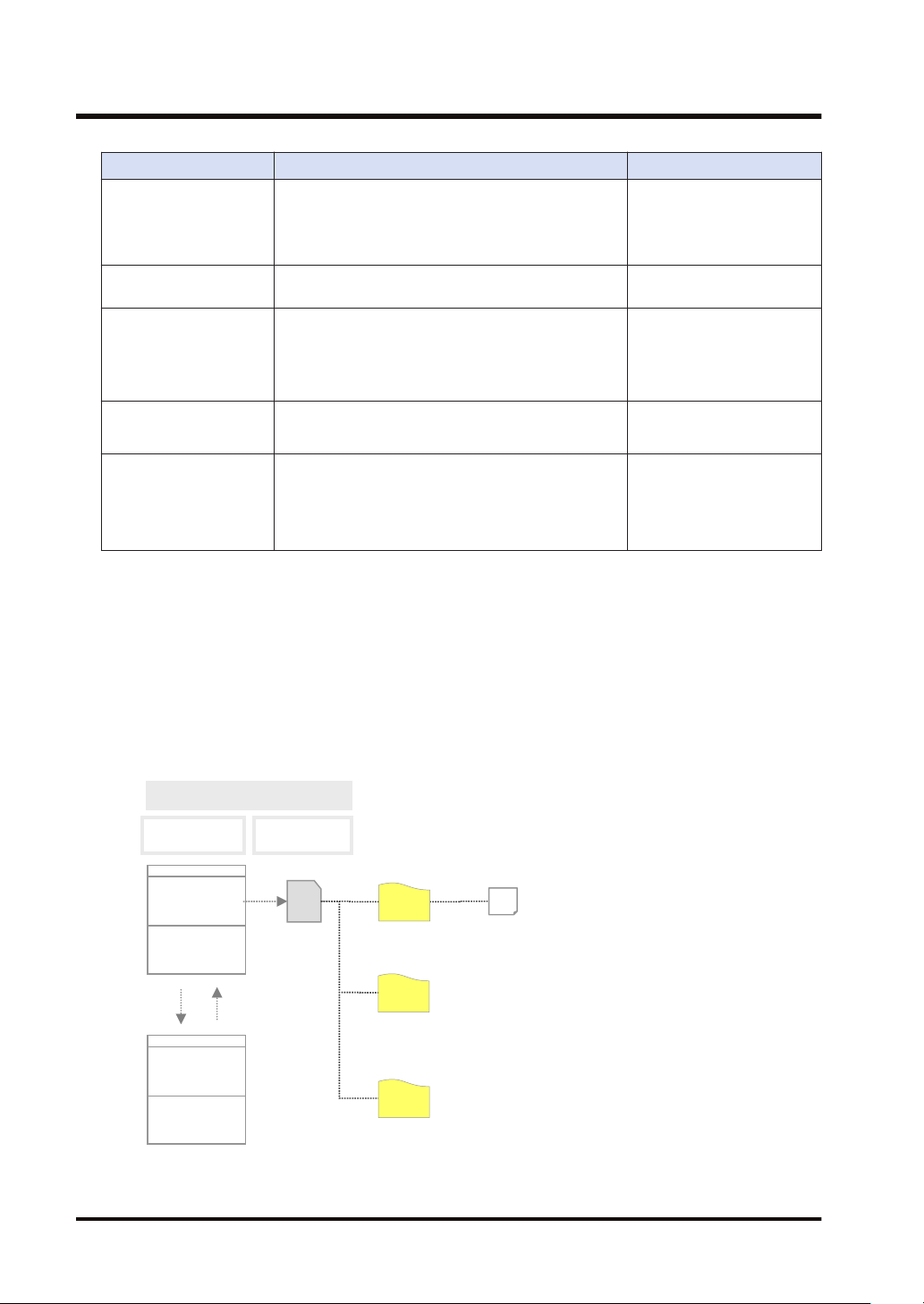

PLC

Internal memory

(RAM)

SD

Logging buffer

memory

Log 0

SD memory

card

Log1

Log 3

Sample (200724_120100_TRACE).csv

1

Operation

device

1.2 Overview of Functions

Item Specifications Remarks

Max. 64 K words

Buffer memory

Can be divided into max. 4 (LOG0 to LOG3) areas for

use.

Capacity per division: 4K words to 64K words

Trace start

Trace trigger condition

Selectable from the tool software, instructions or

autostart.

Bit device ON

Cycle: In msec.

(Note 1)

(Note 1)

Instruction: Executes F420 (LOGST) instruction with

an arbitrary condition and starts tracing.

Trace stop condition

Bit device ON

Buffer full

(Note 2), (Note 3)

File format Data is saved in CSV format.

(Note 1) The trace operation is executed when the condition is met at the end of scan.

(Note 2) When selecting "Bit" for the trace stop condition, logging data of the specified number of samples is

possible after the condition is met.

(Note 3) Unlike the file determination condition of the logging function, logging of data for the specified number

of samples starts when the bit device changes from OFF to ON.

Shared with the logging

function.

-

-

-

Arbitrary comments can be

given.

The upper limit of the

capacity on the file system is

4 GB.

■

● The trace function can also be activated only with the internal memory of the control unit.

● SD memory cards are used only for recording trace data in recording media.

Image of trace function

1-6 WUME-FP0HLOG-03

Page 15

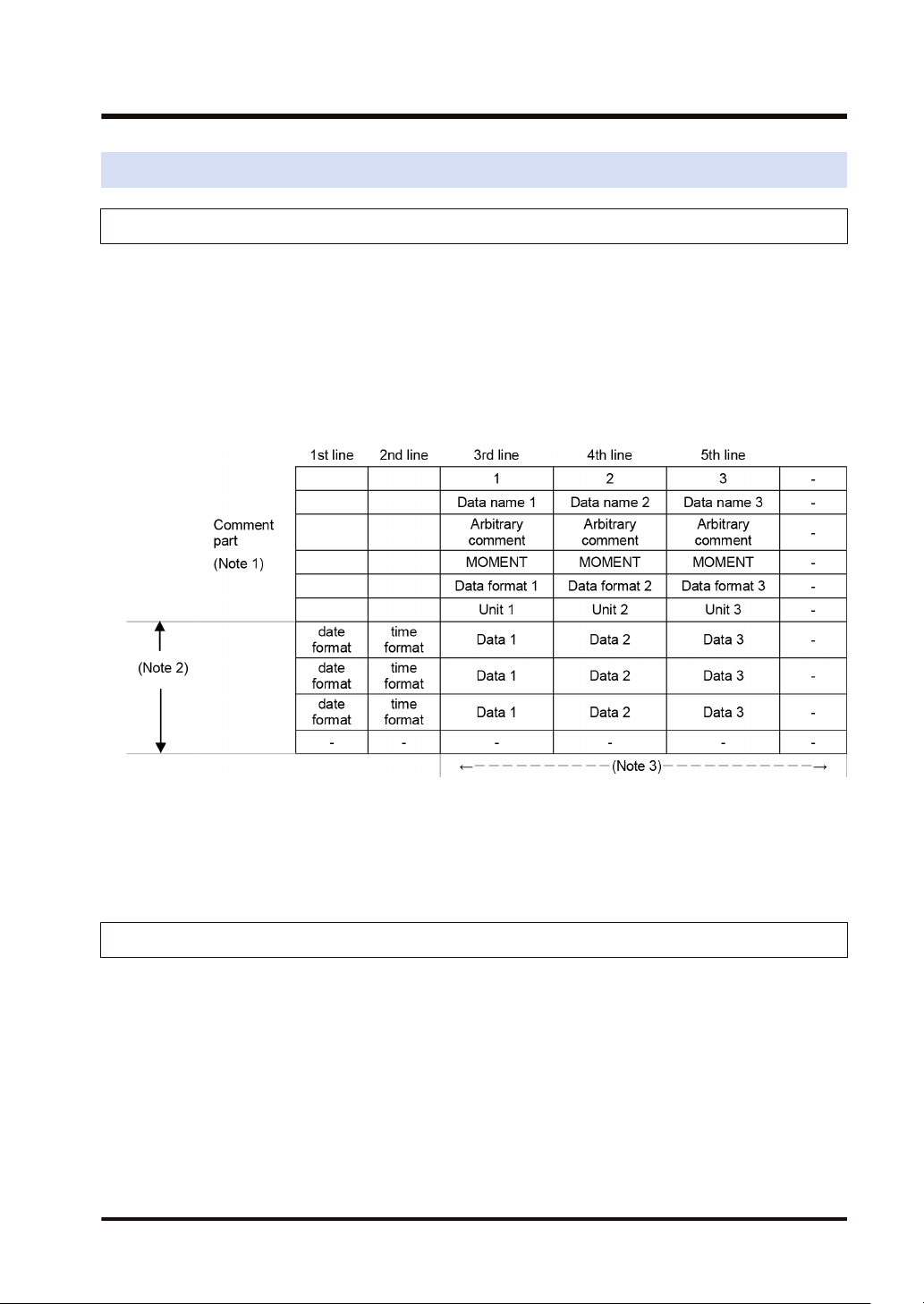

1.3 Format of Saved Files

1.3 Format of Saved Files

1.3.1 File Format (For Logging Function)

● Files are saved in CSV format.

● For the details of setting methods, refer to "2.2 Logging Information Setting".

■

CSV format

● Time stamp information (year/month/day/hour/minute/second) and information of registered

devices are saved.

● The data length varies depending on the types of specified devices.

● Comments can be given at the beginning of data.

(Note 1) The contents of comment part vary depending on the settings of configuration data.

(Note 2) The number of records varies depending on the settings of file determination condition. Max. 60000

records.

(Note 3) The number of data varies depending on the setting of the number of devices. Max. 128 devices

1.3.2 File Name (For Logging Function)

● A file name to be saved is an arbitrary file name (date_hour-minute-second data of the first

record).

● Enter a desired file name in the “Logging/Trace Settings” dialog box for each LOG number.

Example) When the file name is "Sample", and the time stamp of the first record is 12:00:00 on

July 24, 2020;

Sample(200724_120000).csv

WUME-FP0HLOG-03 1-7

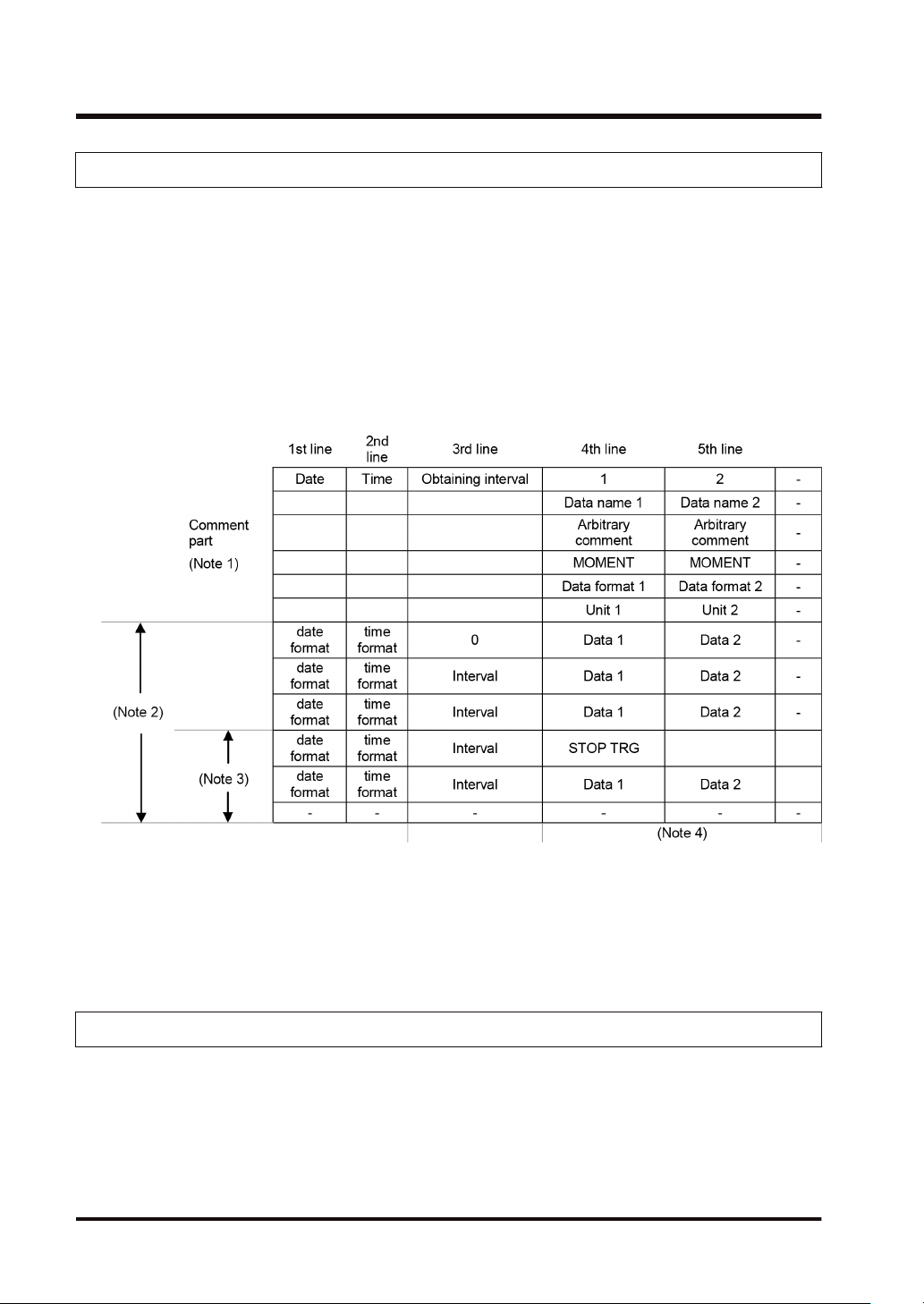

Page 16

1.3 Format of Saved Files

1.3.3 File Format (For Trace Function)

● Files are saved in CSV format.

● For the details of setting methods, refer to "2.3 Trace Information Setting".

■

CSV format

● Time stamp information (year/month/day/hour/minute/second), obtaining interval and

information of registered devices are saved.

● Comments can be given at the beginning of data.

● The unit for the obtaining interval is 10µs. The intervals of obtaining data are saved. The time

from the previous obtainment of data is saved in the line of stop trigger (STOP TRG).

● The data length varies depending on the types of specified devices.

(Note 1) The contents of comment part vary depending on the settings of configuration data.

(Note 2) The number of records varies depending on the settings of file determination condition. Max. 60000

records.

(Note 3) The number of records after the stop trigger varies depending on the settings of configuration data.

(Note 4) The number of data varies depending on the setting of the number of devices. Max. 128 devices

1.3.4 File Name (For Trace Function)

● A file name to be saved is an arbitrary file name (date_hour-minute-second data of the stop

trigger).

● Enter a desired file name in the “Logging/Trace Settings” dialog box for each LOG number.

Example) When the file name is "Sample", and the time stamp of the stop trigger is 12:00:00 on

Friday, July 24, 2020;

Sample(200724_120000_TRACE).csv

1-8 WUME-FP0HLOG-03

Page 17

1.4 Data Format

1.4 Data Format

● The format of the data to be output as logging data and saved in a file varies according to the

type of devices.

● For the details of setting methods, refer to "2.4 Registration of Device Information".

■

Device type and data format

Output type to files

Data type

BIT Bit data 1 words 0 or 1 1 0 or 1

US

SS

UL

SL

SF

Hex 1 words 1 words

Hex 2 words 2 words

STR String data 1 to 20 bytes Character data 1 to 20 + 2 "ABCD"

(Note 1) Decimal integers (US, SS, UL, SL) and hexadecimal integers (Hex) are output in zero suppression

(Note 2) Decimal integers (US) are output in 5 digits when a specified decimal point output position value is 0,

(Note 3) Decimal integers (SS) are output in 6 digits when a specified decimal point output position value is 0,

(Note 4) Decimal integers (UL) are output in 10 digits when a specified decimal point output position value is 0,

(Note 5) Decimal integers (SL) are output in 11 digits when a specified decimal point output position value is 0,

(Note 6) For a signed integer (SS, SL), a sign is output at the beginning and “+” is replaced with a space.

(Note 7) Zero is added before and after decimal point by the settings of data value and decimal point output

Unsigned

16-bit integer

Signed

16-bit integer

Unsigned

32-bit integer

Signed

32-bit integer

Single-precision

floating

point real

number

format.

in 6 digits when it is 1-4, and in 7 digits when it is 5.

in 7 digits when it is 1-4, and in 8 digits when it is 5.

in 11 digits when it is 1-9, and in 12 digits when it is 10.

in 12 digits when it is 1-9, and in 13 digits when it is 10.

position, and the data is output.

When "Data type" is US and data value is "12345", the output value is "0.12345" when setting

"Decimal point" to 5.

When "Data type" is US and data value is "123", the output value is "0.00123" when setting "Decimal

point" to 5.

No. of

occupied

words

1 words

1 words

2 words

2 words

2 words

Data type

Decimal integer

(unsigned)

Decimal integer

(signed)

Decimal integer

(unsigned)

Decimal integer

(signed)

Decimal or exponential

form

(auto)

Hexadecimal integer

(unsigned)

Hexadecimal integer

(unsigned)

No. of

characters

5 0 to 65536

6 -32768 to 32767

10 0 to 4294967295

11

13 -1.175494E-38

4 0 to FFFF

8 0 to FFFF FFFF

Range or sample

-2147483648

to 2147483647

WUME-FP0HLOG-03 1-9

Page 18

1.4 Data Format

(Note 8) Double quotation marks “ “ are added before and after character string data.

1-10 WUME-FP0HLOG-03

Page 19

2 Configuration of Logging/

Trace Function

2.1 Definition of Buffer Memory ................................................................2-2

2.1.1 Setting Method................................................................................. 2-2

2.2 Logging Information Setting................................................................2-3

2.2.1 Confirmation and Settings of File Information.................................. 2-3

2.2.2 LOG File Setting Items (For Logging) .............................................. 2-4

2.3 Trace Information Setting....................................................................2-7

2.3.1 Confirmation and Settings of File Information.................................. 2-7

2.3.2 LOG File Setting Items (For Trace).................................................. 2-8

2.4 Registration of Device Information......................................................2-11

2.5 Operation When Setting Cycle for Logging Trigger ............................2-13

2.6 Downloading Setting Data to Control Unit ..........................................2-15

2.6.1 Downloading to Non-volatile Memory .............................................. 2-15

WUME-FP0HLOG-03

2-1

Page 20

2.1 Definition of Buffer Memory

2.1 Definition of Buffer Memory

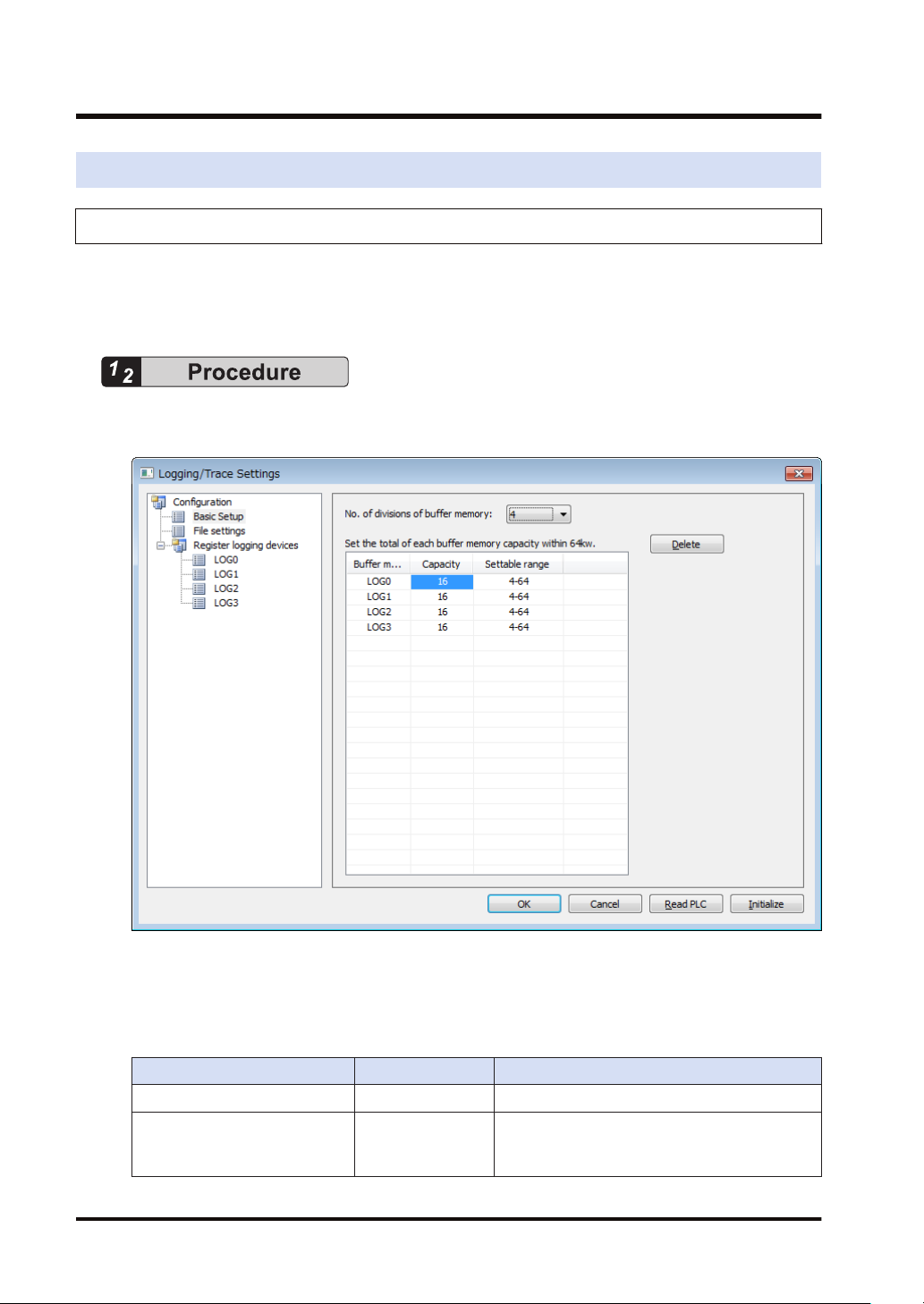

2.1.1 Setting Method

Setting method

● Define the buffer memory of the control unit used for the logging/trace function.

● The buffer memory is set with the tool software FPWIN GR7.

1. Select "Tool">"Logging/Trace Settings" in the menu bar.

The “Logging/Trace Settings” dialog box appears.

2. Select "No. of divisions of buffer memory" from the range of 1 to 4.

3. Double-click on the field of Capacity, and input a desired capacity.

Capacity is allocated to each buffer memory.

Setting range

Item Default Setting range

No. of divisions of buffer memory 4 1-4

LOG0-LOG3

Buffer memory capacity (unit: k

word)

2-2 WUME-FP0HLOG-03

16 4-64

Page 21

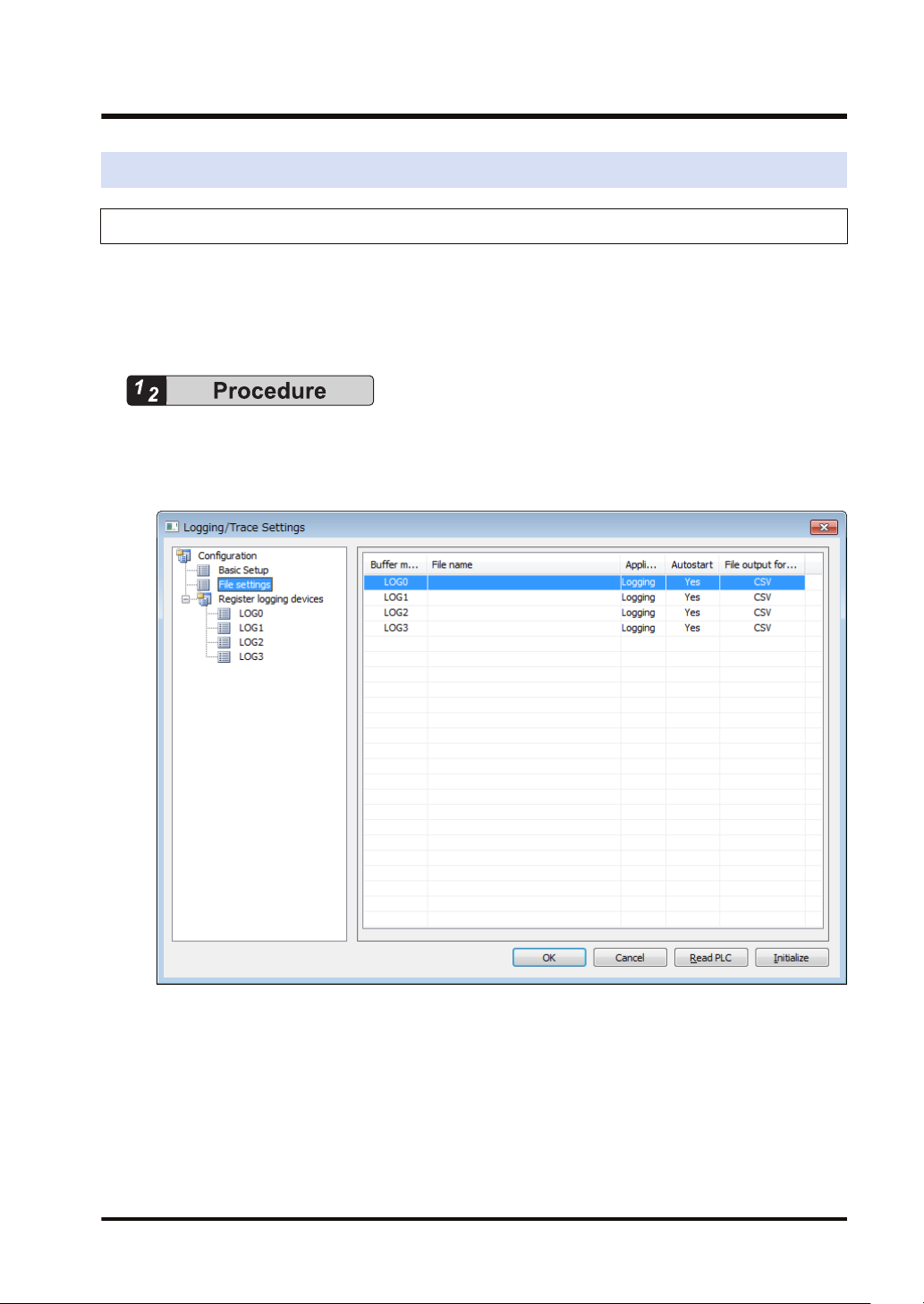

2.2 Logging Information Setting

2.2 Logging Information Setting

2.2.1 Confirmation and Settings of File Information

Overview

● After completing the definition of buffer memory, set the data to be logged and the format of

saved files.

● File formats and logged device data are set for each buffer memory (LOG0 to LOG3).

1. Select "Tool">"Logging/Trace Settings" in the menu bar.

The “Logging/Trace Settings” dialog box appears.

2. Select "File settings" from the list on the left.

3. Double-click a desired buffer memory from the list on the right.

The LOG0 to LOG3 file settings dialog box appears.

WUME-FP0HLOG-03 2-3

Page 22

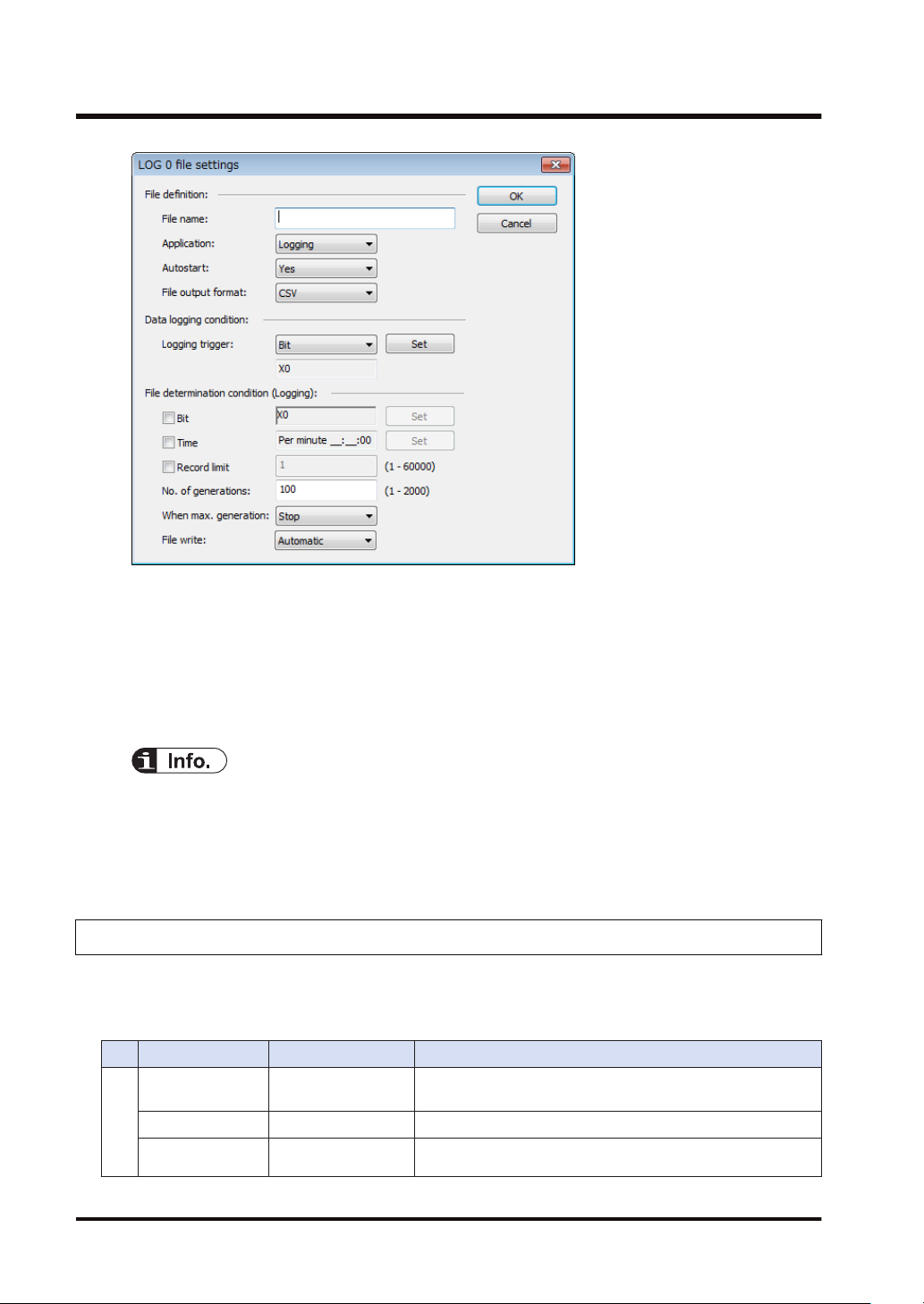

2.2 Logging Information Setting

LOG file settings dialog box

4. Set information in each field of File definition, Data logging condition and File determination

condition.

For the details of setting methods, refer to "2.2.2 LOG File Setting Items (For Logging)".

5. Press the [OK] button.

This returns to the Logging/Trace Settings dialog box.

● More than one file determination condition can be set for logging application.

● Even when active logging stops, a file is determined.

● For the bit device of file determination condition, select a bit which turns on for only one

scan at the end of scan.

2.2.2 LOG File Setting Items (For Logging)

The following items are set in the LOG file settings dialog box.

■

Setting item

Item Setting range Settings

File name

Application Logging Select Logging.

Autostart Yes / No

File definition

Within 32 one-byte

characters

Enter a file name to be saved in a selected LOG number.

Yes: Logging operation starts when changing to the RUN

mode.

2-4 WUME-FP0HLOG-03

Page 23

2.2 Logging Information Setting

Item Setting range Settings

No: Logging operation is started or stopped by the operation

of programming tool or the F420(LOGST) instruction/

F421(LOGED) instruction in user programs.

File output format CSV Select CSV.

Logging trigger Select a condition to start logging data.

Select this for setting bit conditions as logging trigger. Press

the [Set] button, and select a device type and a number.

1)

Bit

Specify an arbitrary

bit device.

(Note

Select this for setting time as logging trigger. Input a cycle for

executing logging.

(Note 2)

1 second, 2 seconds, 3 seconds, 4 seconds, 5 seconds, 6

Cycle Time data

seconds, 10 seconds, 15 seconds, 30 seconds,

1 minute, 2 minutes, 3 minutes, 4 minutes 5 minutes, 6

minutes, 10 minutes, 15 minutes, 30 minutes,

1 hour, 2 hours, 3 hours, 4 hours, 6 hours, 12 hours, 24 hours

Data logging condition

Time Clock data

Select this for setting clock time as logging trigger. Specify the

time for starting logging.

Per minute, Per hour, Every day, Every week, Every month,

Every year

Instruction -

Bit

Specify an arbitrary

bit device.

Trigger conditions occur by executing the F422(LOGSMPL)

instruction under arbitrary conditions in user programs.

Select this for setting bit conditions as file determination

condition. Press the [Set] button, and select a device type and

a number.

Per minute, Per

Time

hour, Every day,

Every week, Every

month, Every year

Select this for setting a fixed time as file determination

condition. Specify a time for determining files.

Clock data

Record limit 1 to 60000

Select this for setting the number of records as file

determination condition. Specify the upper limit.

No. of generations 1 to 2000 Set the number of files (generations) to be saved in folder.

When max.

File determination condition

generation

Stop, Continue

Stop: Stops logging.

Continue: Determines a file, and deletes the oldest file in the

PLC. After that, creates a new file.

Automatic: Once a file is determined, executes writing it into

File write

Automatic, 1 record

unit

an SD memory card.

1 record unit: Writes data to a file every time one record is

written.

(Note 1) For the bit device of file determination condition, select a bit which turns on for only one scan at the

end of scan.

(Note 2) When the logging trigger is cycle and setting per second or per minute, adjust to occur a trigger at 0

min. 0 sec. of every hour. When the unit of cycle is time, adjust to occur a trigger at 00:00:00 of every

day. For details, refer to "2.5 Operation When Setting Cycle for Logging Trigger".

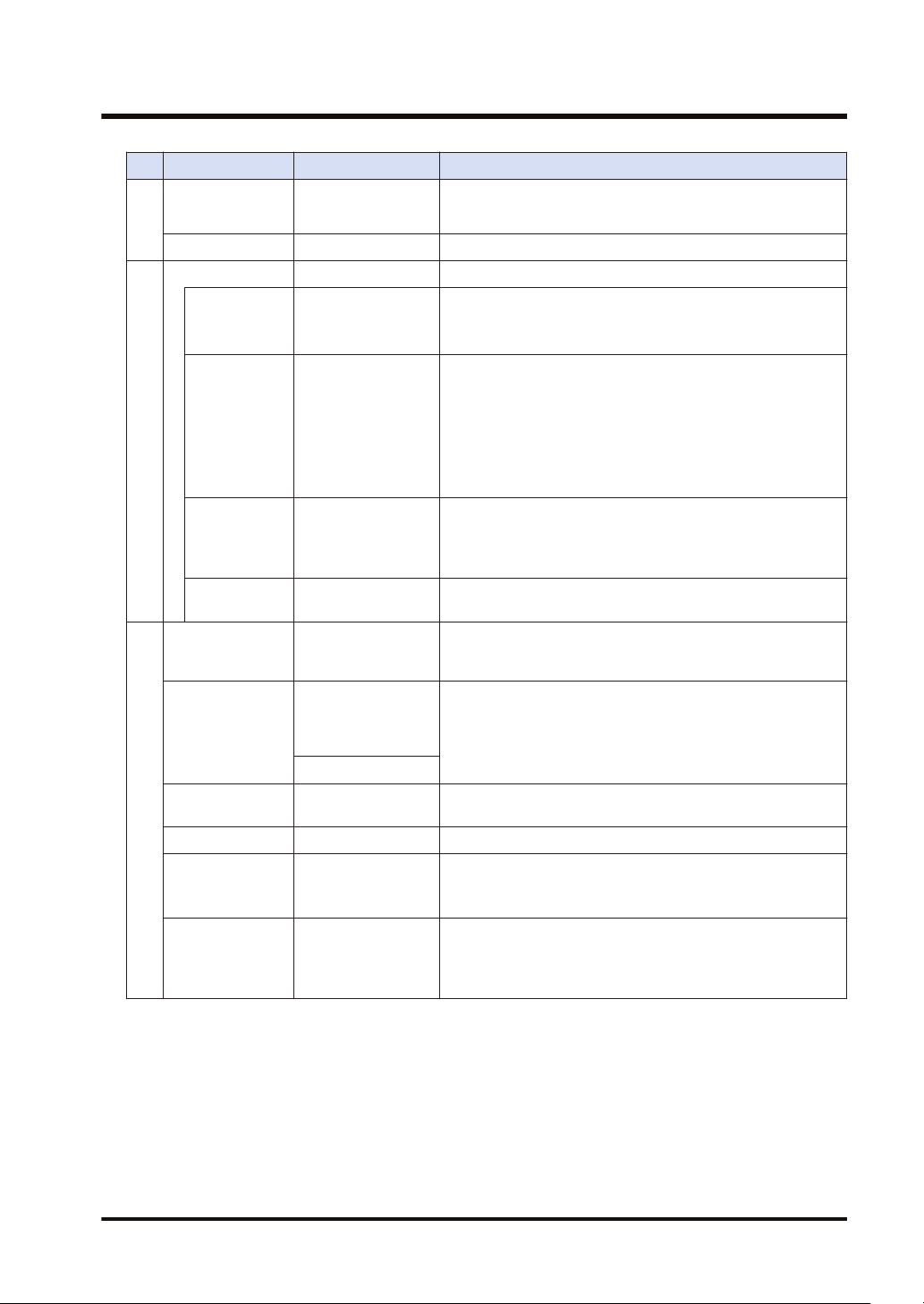

■

"Logging trigger" - "Trigger device" setting dialog box

● Set this for using bit device for the condition to start logging.

WUME-FP0HLOG-03 2-5

Page 24

2.2 Logging Information Setting

■

"Logging trigger" - "Periodic Trigger" setting dialog box

● Set this for performing logging periodically.

■

"Logging trigger" - "Time Trigger" setting dialog box

● Set this for performing logging at fixed intervals.

■

"Logging trigger" - Trigger condition setting with F422 (LOGSMPL) instruction

● Specify a logging number with the dedicated instruction, and execute with an arbitrary

condition.

2-6 WUME-FP0HLOG-03

Page 25

2.3 Trace Information Setting

2.3 Trace Information Setting

2.3.1 Confirmation and Settings of File Information

● The following items are set in the LOG file settings dialog box.

Overview

● After completing the definition of buffer memory, set the data to be traced and the format of

saved files.

● File formats and traced device data are set for each buffer memory (LOG0 to LOG3).

1. Select Tool>Logging/Trace Settings in the menu bar.

The “Logging/Trace Settings” dialog box appears.

2. Select "File settings" from the list on the left.

3. Double-click a desired buffer memory from the list on the right.

The LOG0 to LOG3 file settings dialog box appears.

WUME-FP0HLOG-03 2-7

Page 26

2.3 Trace Information Setting

4. Set information in each field of File definition, Data logging condition and Trace stop.

For the details of setting methods, refer to "2.3.2 LOG File Setting Items (For Trace)".

5. Press the [OK] button.

This returns to the Logging/Trace Settings dialog box.

● ”No. of samplings after stop trigger” is available only when the stop trigger is set to Bit.

● Check the box of [Write file after completion of trace] to create a file in a SD memory card

after the completion of trace.

2.3.2 LOG File Setting Items (For Trace)

● The following items are set in the LOG file settings dialog box.

■

Setting item

Item Setting range Settings

File name Within 32 characters Enter a file name to be saved in a selected LOG number.

Application Trace Select Trace.

Yes: Trace operation starts when changing to the RUN mode.

Autostart Yes / No

File definition

File output format CSV Select CSV.

No: Trace operation is started by the operation of

programming tool or the LOGST instruction in user programs.

2-8 WUME-FP0HLOG-03

Page 27

2.3 Trace Information Setting

Item Setting range Settings

Logging trigger Select a condition to start logging data.

Bit

Cycle Time data

Data logging condition

Instruction -

Stop trigger

No. of samplings

after stop trigger

detection

Trace stop condition

File write Auto

Specify an arbitrary

bit device.

Bit

Buffer full Trace operation stops once the buffer is full.

0 to 65536

Select this for setting bit conditions as logging trigger. Press

the [Set] button, and select a device type and a number.

Select this for setting time as logging trigger. Input a cycle for

executing trace.

1 second, 2 seconds, 3 seconds, 4 seconds, 5 seconds, 6

seconds, 10 seconds, 15 seconds, 30 seconds,

1 minute, 2 minutes, 3 minutes, 4 minutes 5 minutes, 6

minutes, 10 minutes, 15 minutes, 30 minutes,

1 hour, 2 hours, 3 hours, 4 hours, 6 hours, 12 hours, 24 hours

Specify in msec: 1 to 1000

Trigger conditions occur by executing the F422(LOGSMPL)

instruction under arbitrary conditions in user programs.

Stops Trace.

Press the [Set] button to specify a device type, a number and

the number of samplings after the detection of stop trigger.

Specify the number of samplings after the detection of stop

trigger.

On completion of trace operation, executes writing data into

an SD memory card.

■

"Logging trigger" - "Trigger device" setting dialog box

Set this for using bit device for the condition to start tracing.

■

"Logging trigger" - "Periodic Trigger" setting dialog box

Set this for performing tracing periodically. When selecting Trace for Application, it can be

specified in msec.

WUME-FP0HLOG-03 2-9

Page 28

2.3 Trace Information Setting

■

"Logging trigger" - Trigger condition setting with F422(LOGSMPL) instruction

Specify a logging number with the dedicated instruction, and execute with an arbitrary

condition.

2-10 WUME-FP0HLOG-03

Page 29

2.4 Registration of Device Information

2.4 Registration of Device Information

Overview

● Devices on which logging/trace is performed are registered in "Register logging devices".

1. Select a desired LOG number of Register logging devices from the list on the left side.

2. Double-click a desired buffer memory from the list on the right.

The “Register devices” dialog box appears.

3. Enter a desired device number and comments, and press the [OK] button.

The device on which logging is performed is registered in the LOG number.

WUME-FP0HLOG-03 2-11

Page 30

2.4 Registration of Device Information

4. Repeat the registration of devices for each LOG number.

● The number of devices that can be registered in one LOG number is up to 128 devices.

● Press the <INS> key to insert items in the device list, and press the <DEL> key to delete

them.

Setting items (”Register devices” dialog box)

Item Setting range Settings

X, Y, R, L, T, C

Device type

No. Device no. Specify a device number to be logged.

Data type

Decimal point 0 to 11

No. of continuous

registrations

Data name Within 16 characters

Arbitrary

application

Unit Within 8 characters

Register comment

WX, WY, WR, WL, DT, LD, I,

SV, EV

Bit data

Unsigned 16-bit integer

Signed 16-bit integer

Unsigned 32-bit integer

Signed 32-bit integer

Single-precision real

HEX (1 word)

HEX (2 words)

String

1 to max. 128

Within 8 characters

Specify a device type to be logged.

Specify a data format to be output. The settable

range varies according to the number of selected

devices.

The position of decimal point can be set when an

integer type is selected for Data type. The settable

range varies according to the selected data type.

Input a number for specifying the same type of

devices all at once. The settable range varies

according to the number of selected devices.

Output to the comment area when saving data in

CSV format.

2-12 WUME-FP0HLOG-03

Page 31

2.5 Operation When Setting Cycle for Logging Trigger

2.5 Operation When Setting Cycle for Logging Trigger

When setting Cycle for logging triggers, the time of the first trigger is adjusted to perform

subsequent logging at good timing.

● When the unit of cycle is second or minute, adjust to occur a trigger at 0 min. 0 sec. of every

hour.

● When the unit of cycle is time, adjust to occur a trigger at 00:00:00 of every day.

■

Example of timing of trigger occurrence (when the unit of cycle is second)

Time at which

logging

trigger condition is

met

12:01:05 1

12:01:05 2

12:01:05 3

12:01:05 4

12:01:05 5

12:01:05 10

12:01:05 15

12:01:05 30

Set

cycle

seconds

seconds

seconds

seconds

seconds

seconds

seconds

seconds

Time at which the 1st trigger

occurs after adjustment

12:01:06 12:01:07, 12:01:08

12:01:06 12:01:08, 12:01:10

12:01:06 12:01:09, 12:01:12

12:01:08 12:01:12, 12:01:16

12:01:10 12:01:15, 12:01:20

12:01:10 12:01:20, 12:01:30

12:01:15 12:01:30, 12:01:45

12:01:30 12:02:00, 12:02:30

Time at which subsequent triggers

occur

■

Example of timing of trigger occurrence (when the unit of cycle is minute)

Time at which

logging

trigger condition is

met

12:01:00 1

12:03:00 2

12:05:00 3

12:05:00 4

12:05:00 5

12:01:00 10

Set

cycle

minutes

minutes

minutes

minutes

minutes

minutes

Time at which the 1st trigger

occurs after adjustment

12:02:00 12:03, 12:04, 12:05

12:04:00 12:04, 12:06, 12:08

12:06:00 12:09, 12:12, 12:15

12:08:00 12:12, 12:16, 12:20

12:10:00 12:15, 12:20, 12:25

12:10:00 12:20, 12:30, 12:40

Time at which subsequent triggers

occur

WUME-FP0HLOG-03 2-13

Page 32

2.5 Operation When Setting Cycle for Logging Trigger

Time at which

logging

trigger condition is

met

12:59:00 15

12:10:00 30

■

Example of timing of trigger occurrence (when the unit of cycle is hour)

Time at which

logging

trigger condition is

met

12:59:00 1 hours 13:00:00 14, 15, 16 o’clock ...

12:59:00 2 hours 14:00:00 16, 18, 20 o’clock ...

12:30:00 3 hours 15:00:00 18, 21, 24 o’clock ...

12:30:00 4 hours 16:00:00 20, 24, 28 o’clock ...

12:30:00 6 hours 18:00:00 24, 30, 36 o’clock ...

12:30:00 12 hours 24:00:00 36, 48, 60 o’clock ...

12:30:00 24 hours 24:00:00 48, 72, 96 o’clock ...

Set

cycle

minutes

minutes

Set

cycle

Time at which the 1st trigger

occurs after adjustment

13:00:00 13:15, 13:30, 13:45

12:30:00 13:00, 13:30, 14:00

Time at which the 1st trigger

occurs after adjustment

Time at which subsequent triggers

occur

Time at which subsequent triggers

occur

2-14 WUME-FP0HLOG-03

Page 33

2.6 Downloading Setting Data to Control Unit

2.6 Downloading Setting Data to Control Unit

2.6.1 Downloading to Non-volatile Memory

■

Overview

Parameters set in the logging/trace settings menu are downloaded together with programs and

configuration data as project data.

WUME-FP0HLOG-03 2-15

Page 34

(MEMO)

2-16 WUME-FP0HLOG-03

Page 35

3 Logging/Trace Start, Stop

and Monitor

3.1 Start and Stop of Logging/Trace Operation ........................................3-2

3.1.1 Start and Stop by Tool Software ...................................................... 3-2

3.1.2 Start and Stop by Instructions.......................................................... 3-3

3.1.3 Automatic Start by Setting ............................................................... 3-3

3.2 Operation Check Using Logging/Trace Monitor..................................3-4

3.2.1 Logging/Trace Monitor ..................................................................... 3-4

3.2.2 Special Internal Relays Relating to Logging/Trace Operation ......... 3-5

3.2.3 Special Data Registers Relating to Logging/Trace Operation.......... 3-6

3.2.4 Checking Logging Speed (When Selecting Logging For

Application) ....................................................................................... 3-6

WUME-FP0HLOG-03 3-1

Page 36

3.1 Start and Stop of Logging/Trace Operation

3.1 Start and Stop of Logging/Trace Operation

3.1.1 Start and Stop by Tool Software

Overview

The logging/trace operation can be started and stopped by the tool software.

1.

Select "Tool">"Logging/Trace Monitor" in the menu bar.

The "Logging/Trace Monitor" dialog box appears.

2. Check the box of a desired LOG number, and press the [Start] button.

A confirmation message appears.

3. Press the [Yes] button.

Starting the logging operation is requested by the operation specified in the “Logging/Trace

Settings” dialog box. System relays relating to the execution of logging/trace can be

monitored in the above dialog box. Once the operation is started normally, the "Logging/

Trace is being executed" and "SD logging is being executed" flags turn on.

4. For stopping the logging/trace operation, check the box of a desired LOG number and

press the [Stop] button.

Stopping the logging/trace operation is requested. Once the logging/trace operation ends

normally, the "Logging/trace is complete" flag turns on.

3-2 WUME-FP0HLOG-03

Page 37

3.1 Start and Stop of Logging/Trace Operation

3.1.2 Start and Stop by Instructions

■

Overview

● The logging/trace operation can be started and stopped by user programs for each logging/

trace number.

● Specify a logging/trace number (0 to 3) using the dedicated instruction, and execute with

arbitrary conditions.

● It takes a few milliseconds to a few seconds to start or stop the logging/trace operation.

● For stopping the logging/trace operation with instructions, request the stop after confirming

that the execution active flag (R9180/R9190/R9200/R9210) turns on. If requesting to stop

LOG n during the start operation, the operation error flag (R9007/R9008) or the logging/trace

error flag (R9185/R91915/R9205/R9215) turns on.

● For starting the logging/trace operation with instructions, request the start after confirming

that the logging/trace completed flag (R9182/R9192/R9202/R9212) turns on. If requesting to

stop LOG n during the start operation, the operation error flag (R9007/R9008) or the logging/

trace error flag (R9185/R9195/R9205/R9215) turns on.

● There is no problem if a start request is made for LOG n that is activated or during the

startup operation.

● There is no problem if a stop request is made for LOG n that is stopped or during the stop

operation.

3.1.3 Automatic Start by Setting

● When "Autostart" has been selected in the "LOG file settings" dialog box, the start request of

the logging/trace operation is made immediately after the mode is switched to RUN mode.

● The trace operation stops when the trace stop condition (bit device ON or buffer full) is

met. If the operation is forcibly stopped with the tool software or instruction while the trace

stop condition has not been satisfied, the trace operation is canceled and the data is not

saved.

WUME-FP0HLOG-03 3-3

Page 38

3.2 Operation Check Using Logging/Trace Monitor

3.2 Operation Check Using Logging/Trace Monitor

3.2.1 Logging/Trace Monitor

The progress situation can be confirmed with the logging/trace monitor.

■

Example of monitoring in logging operation

■

Example of monitoring on the completion of trace operation

3-4 WUME-FP0HLOG-03

Page 39

3.2 Operation Check Using Logging/Trace Monitor

3.2.2 Special Internal Relays Relating to Logging/Trace Operation

■

Special Internal Relay

Device

no.

Name Operation

Turns on while the logging/trace function is activated. Another system relay

allocated to the same LOG number is reset during the start operation.

The logging/trace function is activated by any of the following methods; 1:

Autostart, 2: Start by instruction, 3: Start by tool software. Storing data in the

R9180

Logging/trace is

being executed.

buffer memory is executed while this relay is on.

R9181

R9182

Logging/trace

buffer storage/File

being written

Logging/trace

completed

Turns on when writing files into an SD memory card becomes enabled after

turning on the logging/trace active relay and enabling the logging in the

buffer. This relay is always off when selecting Trace for the application.

Turns on after the completion of file writing when requesting to stop the

logging trace operation or performing the automatic stop.

Turns on when the buffer logging speed exceeds the writing speed to an SD

memory card in the logging processing. Turns on when the number of data

previously stored and the number of data stored this time increase.

Turns on at the timing of buffer logging, and turns off at the timing of buffer

R9183

Logging overspeed relay

logging or the end of scan.

Turns on when the buffer memory has been exhausted. The buffer overflow

counter (DT90620) is incremented by one. At that time, new data cannot be

stored. Also, writing data into the SD memory card does not stop.

The buffer overflow relay turns off at the end of scan when a vacancy occurs

R9184 Buffer overflow

in the buffer as writing data into an SD memory card progresses, and the

buffer overflow counter is cleared to 0. Also, after the occurrence of vacancy

in the buffer, data logging is executed once the logging trigger condition is

met.

This relay is always on when buffer full occurs as the stop condition when

selecting Trace for the application.

R9185 Logging/trace error

Turns on when an error is detected during the logging/trace operation and

stops the operation.

Turns on when one of the following conditions is met during the logging/trace

R9186

No SD card free

space

operation and stops the logging/trace operation.

When an SD memory card is running out of free space

When an error in accessing an SD memory card occurs.

Turns on when an error is detected in setting values during the startup

R9187

Device/trigger

setting error

operation. The logging/trace error relay R9185 also turns on. At that time,

the active relay does not turn on because the logging/trace function cannot

be activated.

R9188

Trace stop trigger

monitor

Trace data

R9189

acquisition

completed

(Note 1) The above device numbers are those for LOG0. Special internal relay numbers vary depending on

LOG numbers as shown in the table below.

Monitors a registered trace stop trigger when executing tracing. Turns on

when the condition is met. This relay is always off when selecting Logging

for the application.

Turns on after logging data for a specified number of times after detecting

the trace stop trigger during the execution of trace. This relay is always off

when selecting Logging for the application.

LOG no. 0 1 2 3

Relay no. R9180 to R9189 R9190 to R9199 R9200 to R9209 R9210 to R9219

WUME-FP0HLOG-03 3-5

Page 40

3.2 Operation Check Using Logging/Trace Monitor

3.2.3 Special Data Registers Relating to Logging/Trace Operation

■

Special data registers

Device

no.

DT90600 Buffer free space

DT90620

DT90640

DT90660

DT90680

-DT90681

(Note 1) The above device numbers are those for LOG0. Special data register numbers vary depending on

LOG no. 0 1 2 3

Buffer free space DT90600 DT90601 DT90602 DT90603

Buffer overflow counter DT90620 DT90621 DT90622 DT90623

No. of written records of current file DT90640 DT90641 DT90642 DT90643

No of files (generations) stored in folder DT90660 DT90661 DT90662 DT90663

Oldest clock data of file stored in folder DT90680

Name Operation

Stores free space of buffer memory during logging. This is always

zero when selecting Trace for the application.

Buffer overflow

counter

No. of written records of

current file

No of files (generations)

stored in folder

Oldest clock data of file

stored in folder

LOG numbers as shown in the table below.

Increments the value by one when the buffer overflow occurs. This is

always zero when selecting Trace for the application.

Stores the number of written records in a current file as 16-bit data.

Increments the number by one every time data is written in the

current file. It is reset to zero when a new file is created.

Stores the number of files stored in a folder (number of generations)

as 16-bit data.

Stores the oldest clock data of a file stored in a folder as 32-bit data

in seconds. The clock data is the number of seconds accumulated

from 00:00:00 on January 1, 2001.

-DT90681

DT90682

-DT90683

DT90684

-DT90685

DT90686

-DT90687

3.2.4 Checking Logging Speed (When Selecting Logging For Application)

● When the logging speed to the buffer memory of the control unit is faster than the writing

speed into an SD memory card, the logging over-speed relay turns on. The logging overspeed relay turns on at the timing of logging trigger, and turns off if the speed does not

exceed at the end of scan.

● If overspeed occurs frequently, the buffer memory will be full and data cannot be

accumulated.

● Once the buffer memory is full, the buffer overflow flag turns on, and the buffer overflow

counter is incremented by one.

● If the buffer overflow occurs continuously, revise the logging conditions to decrease the

logging speed.

● To know how much logging data was lost at the time of buffer overflow, register the buffer

overflow counter as logging data.

● Even if the buffer overflow occurs, recording data into an SD memory card goes on, and

logging continues when free space becomes available in the buffer.

3-6 WUME-FP0HLOG-03

Page 41

3.2 Operation Check Using Logging/Trace Monitor

● The free space of buffer memory can be checked with the system data registers DT90600 to

DT90603.

● The system relays (R9184/R9194/R9204/R9214) give a warning when the buffer memory of

each LOG number is full.

WUME-FP0HLOG-03 3-7

Page 42

(MEMO)

3-8 WUME-FP0HLOG-03

Page 43

4 Logging Operation

4.1 Flow of Logging Operation..................................................................4-2

4.1.1 Operation Flow................................................................................. 4-2

4.2 Operation When Logging is Selected for Application .........................4-4

4.2.1 Operation When Logging Operation is Started ................................ 4-4

4.2.2 Operation When Logging Operation Stops ...................................... 4-4

4.2.3 Operation When Power Supply Turns Off........................................ 4-4

4.2.4 Operation When the Battery Cover of Control Unit is Open ............ 4-4

4.2.5 Operation When the Number of Determination Files Reaches the

Maximum Number of Generations.................................................... 4-5

4.3 System Management Information Relating to Logging Function ........4-7

4.3.1 System Management Information and Operation ............................ 4-7

4.3.2 Clearing Management Information................................................... 4-7

WUME-FP0HLOG-03

4-1

Page 44

4.1 Flow of Logging Operation

4.1 Flow of Logging Operation

4.1.1 Operation Flow

■

Triggers of logging operation and file contents

Step OperationTrigger of operation File in LOG folder File contents

● Tool software

(1) Start

(2) Logging

File

(3)

determin

ation

(2) Logging

File

(3)

determin

ation

Logging, file determination, and logging operation continues until the stop condition is met.

(4) Stop

(Note 1) "Logging in the logging buffer (RAM)" and "writing to an SD memory card from the logging buffer" are

controlled on the system side. They cannot be controlled by user programs.

operation

● Instruction

● Auto start by setting

● Bit device ON

● Cycle

● Instruction

Sample(------current------).csv”

Comment file part

First record

● Time

● Bit device ON

● Cycle

● Instruction

● Time

Sample(------current------).csv”

Comment file part

First record

Second record

Logging operation continues until the file determination condition is met.

● Bit device ON

● Time

● Record limit

● Bit device ON

● Cycle

● Instruction

● Time

Sample(130401_120000).csv”

Sample(------current------).csv” Comment file part

Sample(130401_120000).csv”

Sample(------current------).csv”

Comment file part

Records up to file

determination

Comment file part

Records up to file

determination

Comment file part

First record

Logging operation continues until the file determination condition is met.

● Bit device ON

● Time

● Record limit

● Tool software

operation

● Instruction

● Max. generation

Sample(130401_120000).csv”

Sample(130401_130000).csv”

Sample(------current------).csv” Comment file part

Sample(130401_120000).csv”

Sample(130401_130000).csv”

Sample(130401_140000).csv”

Comment file part

Records up to file

determination

(Note 1)

Comment file part

Records up to file

determination

Comment file part

Records up to stop

(Note 1)

(Note 1)

4-2 WUME-FP0HLOG-03

Page 45

4.1 Flow of Logging Operation

■

Flow of Logging Operation

Step (1) Startup of logging operation

● The logging operation is started by any of the following methods; Tool software operation,

Instruction in a user program, and Autostart setting.

Step (2)-a: Data logging into logging buffer memory (RAM)

● After the startup of logging operation, logging data is executed with a specified condition

once the specified trigger condition (bit device ON, cycle, or time) is met.

● Logged data is stored once in the logging buffer memory (RAM) of the control unit.

Step (2)-b: Data transfer to SD memory card from logging buffer memory (RAM)

● Data is stored in the logging buffer memory (RAM) sequentially, and automatically written to

a file in an SD memory card by the control unit. It cannot be controlled by user programs.

● A LOG folder is created in an SD memory card for the LOG number that a file name is set.

● A file "specified file name (------current------).csv" for saving logging data is created in the

LOG folder.

● After that, the control unit continues saving data into the same file until the file determination

condition is met.

Step (3): Determination of file

● The file is determined when the specified file determination condition (bit device ON, time,

record limit) is met.

● The file determination is to rename the file "specified file name (------current------).csv"

created in step (2) after writing all the data stored in the buffer into the SD memory card.

● The time data of the oldest record is added to the specified file name.

Example) When the file name is Sample, and the oldest record was recorded in 12 o'clock on

April 1, 2013, it is saved as "specified file name (130401_120000).csv".

● Once the file is determined, a new file "specified file name (------current------).csv" for saving

the next logged data is created. The logging operation restarts when the logging trigger

condition is met.

Step (4): Stop of logging operation

● The logging operation is stopped by either of instruction in user programs or tool software

operation.

● Once the logging operation stop is requested, all the data in the buffer memory in the control

unit is written into the file in the SD memory card and determined. While the logging

operation is continuing, the records logged so far are saved and the file is determined even if

the specified file determination condition has not been satisfied.

● The time data of the oldest record is added to the specified file name.

● When the logging trigger setting is "Bit", "Cycle" or "Time", data is stored in the buffer memory

at the end of the scan time. In the case of Instruction, it is stored when the F422 LOGSMPL

instruction is executed.

WUME-FP0HLOG-03 4-3

Page 46

4.2 Operation When Logging is Selected for Application

4.2 Operation When Logging is Selected for Application

4.2.1 Operation When Logging Operation is Started

The following operations are executed when the start operation is requested.

● Registered data is confirmed.

● Once the logging/trace becomes executable, the logging/trace execution active flag (R9180/

R9190/R9200/R9210) turns on. When the logging trigger condition is met under this

condition, the logging/trace operation starts.

● All logging/trace control relays other than the logging/trace execution active flags for LOG n

(R9180/R9190/R9200/R9210) are cleared once during the start request operation.

● Once writing data into an SD memory card becomes enabled after the logging/trace

execution active flag (R9180/R9190/R9200/R9210) turned on, the SD card buffer logging/file

writing active flag (R9181/R9191/R9201/R9211) turns on.

● When an SD memory card that can be normally read and written is not inserted, or the

battery cover is open, an operation error occurs.

4.2.2 Operation When Logging Operation Stops

■

Operation when switching from RUN mode to PROG. mode

● All logging operations stop.

● All information saved in the buffer memory of the control unit is written into a file, and the file

is determined.

4.2.3 Operation When Power Supply Turns Off

■

Operation When Power Supply Turns Off

● When activating the logging/trace function, the power off flag during SD memory card access

(R917F) turns on.

● The data stored in the logging buffer of the control unit will be discarded.

● In case of the middle of file writing, written data or files may be damaged, or the SD

memory itself may not be read.

4.2.4 Operation When the Battery Cover of Control Unit is Open

The following operations are performed when the battery cover is open during the logging

operation.

4-4 WUME-FP0HLOG-03

Page 47

4.2 Operation When Logging is Selected for Application

■

Operation of system relays

● The logging/trace execution active flag and the SD card logging execution active flag

(R9180/R9190/R9200/R9210) stays on while the battery cover is open.

● The logging/trace execution active flag (R9180/R9190/R9200/R9210) turns off when the

condition to stop the logging operation is met. The SD card buffer logging/file writing active

flag (R9181/R91919/R9201/R9211) is kept in the on state.

● The logging operation into the logging buffer (RAM) continues even when no SD memory

card is inserted. Once the logging buffer (RAM) becomes full, the buffer overflow flag turns

on.

● When the battery cover is closed, the SD card buffer logging/file writing active flag (R9181/

R91919/R9201/R9211) also turns off.

■

File status in SD memory card

● The file "specified file name (------current------).csv" in which logging data was saved before

opening the cover is held in the SD memory card.

● Once the battery cover is closed, saving data into files starts again.

4.2.5 Operation When the Number of Determination Files Reaches the Maximum Number of Generations

■

Operation when the number of determination files reaches the maximum number

of generations

● The operation when the number of determination files reaches the maximum number of

generations varies depending on the log file settings.

File determination

condition

Setting of "When

max. generation"

Stop

Continue

Operation

1. Determines a current file "specified file name (------current------).csv", gives the

time data of the oldest record, and renames it.

2. Creates a new current file "specified file name (------current------).csv".

1. Determines a current file "specified file name (------current------).csv", gives the

time data of the oldest record, and renames it.

2. Deletes the oldest file.

After deleting it, updates the data of the oldest file displayed in the system

monitor area (SM).

3. Creates a new current file "specified file name (------current------).csv".

WUME-FP0HLOG-03 4-5

Page 48

4.2 Operation When Logging is Selected for Application

”Logging File Settings” dialog box

4-6 WUME-FP0HLOG-03

Page 49

4.3 System Management Information Relating to Logging Function

4.3 System Management Information Relating to Logging Function

4.3.1 System Management Information and Operation

● Files are managed in the PLC as follows. The PLC performs operations based on the stored

management information even if an SD memory card is removed during logging, and another

SD memory card in different conditions from the conditions managed in the PLC is inserted.

● Writing data into an undetermined file "specified file name (------current------).csv" is executed

every time specified records are stored. The number of written records can be confirmed in

the special data registers (DT90640 to DT90643).

● The number of determined files (generations) of determined files is managed during the

logging operation. The number of determined files can be confirmed in the special data

registers (DT90660 to DT90663).

● When the file is determined, the determined date is managed in the internal memory. The

time data of the oldest file is stored in the special data registers (DT90680 to DT90687). The

clock data is the number of seconds accumulated from 00:00:00 on January 1, 2001.

4.3.2 Clearing Management Information

■

Clearing management information

Log file management information of the PLC is cleared in the following cases.

● When LOG n settings are deleted or all log settings are initialized from the tool software

FPWIN GR7

● When a buffer allocation different from stored data is downloaded, all log settings are

initialized.

● When a LOG n definition different from stored data is downloaded, only the different LOG n

is cleared.

● If the above clearing operation is performed, log file management information is initialized, and

files remained in the SD memory card are regarded as non-existent. Delete files beforehand,

and use it.

● When restarting logging with the same condition without changing the settings, the operation

continues with the previous system information, the number of generations and the oldest time

data of the file. After restarting logging, the number of generations is added to the data before

the restart, and the existing value is held for the oldest time data.

WUME-FP0HLOG-03 4-7

Page 50

(MEMO)

4-8 WUME-FP0HLOG-03

Page 51

5 Trace Operation and Time

Chart

5.1 Flow of Trace Operation .....................................................................5-2

5.1.1 Flow of Trace Operation................................................................... 5-2

5.2 Operation When Trace is Selected for Application .............................5-4

5.2.1 Operation When Trace Operation is Started.................................... 5-4

5.2.2 Operation When Logging Operation Stops ...................................... 5-4

5.2.3 Operation When Power Supply Turns Off........................................ 5-4

5.2.4 Operation When the Battery Cover of Control Unit is Open ............ 5-4

5.3 Trace Monitor (Time Chart).................................................................5-6

5.3.1 Display Method of Time Chart.......................................................... 5-6

5.3.2 Explanation of Time Chart Monitor................................................... 5-7

5.3.3 Settings for Time Chart Display Area............................................... 5-9

5.3.4 Register Device................................................................................ 5-12

5.3.5 Sampling Condition Setting.............................................................. 5-13

WUME-FP0HLOG-03

5-1

Page 52

5.1 Flow of Trace Operation

5.1 Flow of Trace Operation

5.1.1 Flow of Trace Operation

■

Triggers of trace operation and file contents

Step OperationTrigger of operation File in LOG folder File contents

Tool software operation

(1) Start

(2) Logging

Trace

stop

(3)

Trace

stop

Instruction

Auto start by setting

Bit device ON

Cycle

Instruction

Bit device ON

Cycle

Instruction

Logging operation continues until the trace stop condition is met.

When buffer full is set

for stop trigger

When bit device ON is

set for stop trigger

Logging operation continues for the number of samplings after the detection of stop

trigger.

Completion of logging

for the number of

samplings

- -

- -

- -

Sample

(130401_120000_TRACE).csv”

Sample(------current------).csv”

Sample

(130401_120030_TRACE).csv”

Comment file part

First record

Second record

・・・・・・・・・・・

・・・・・・

STOP TRG

Comment file part

First record

Second record

・・・・・・・・・・・

・・・・・・

STOP TRG

Comment file part

First record

Second record

・・・・・・・・・・・

・・・・・・

STOP TRG

・・・・・・・・・・・

・・・・・・

XXX records

■

Flow of Trace Operation

Step (1) Startup of trace operation

● The trace operation is started by any of the following methods; Tool software operation,

Instruction in a user program, and Autostart setting.

Step (2): Data logging

5-2 WUME-FP0HLOG-03

Page 53

5.1 Flow of Trace Operation

● After the startup of the trace operation,tracing data is executed with a specified condition

when the specified trigger condition (bit device ON, cycle, or instruction) is met.

● Traced data is stored in the logging buffer memory (RAM) in the control unit.

● After that, the trace operation continues until the trace stop condition is met.

Step (3): Stop of trace operation

● The trace operation stops when either condition is met, bit or buffer full.

● When the trace stop condition is bit, the trace operation stops after the logging performed for

the specified number of samplings after the condition was met.

● When the trace stop condition is buffer full, the trace operation stops immediately.

● When the trace operation is complete successfully, the trace data acquisition done flag

(R9189/R9199/R9209/R9219) turns on. At that time, a time chart can be displayed on the