Page 1

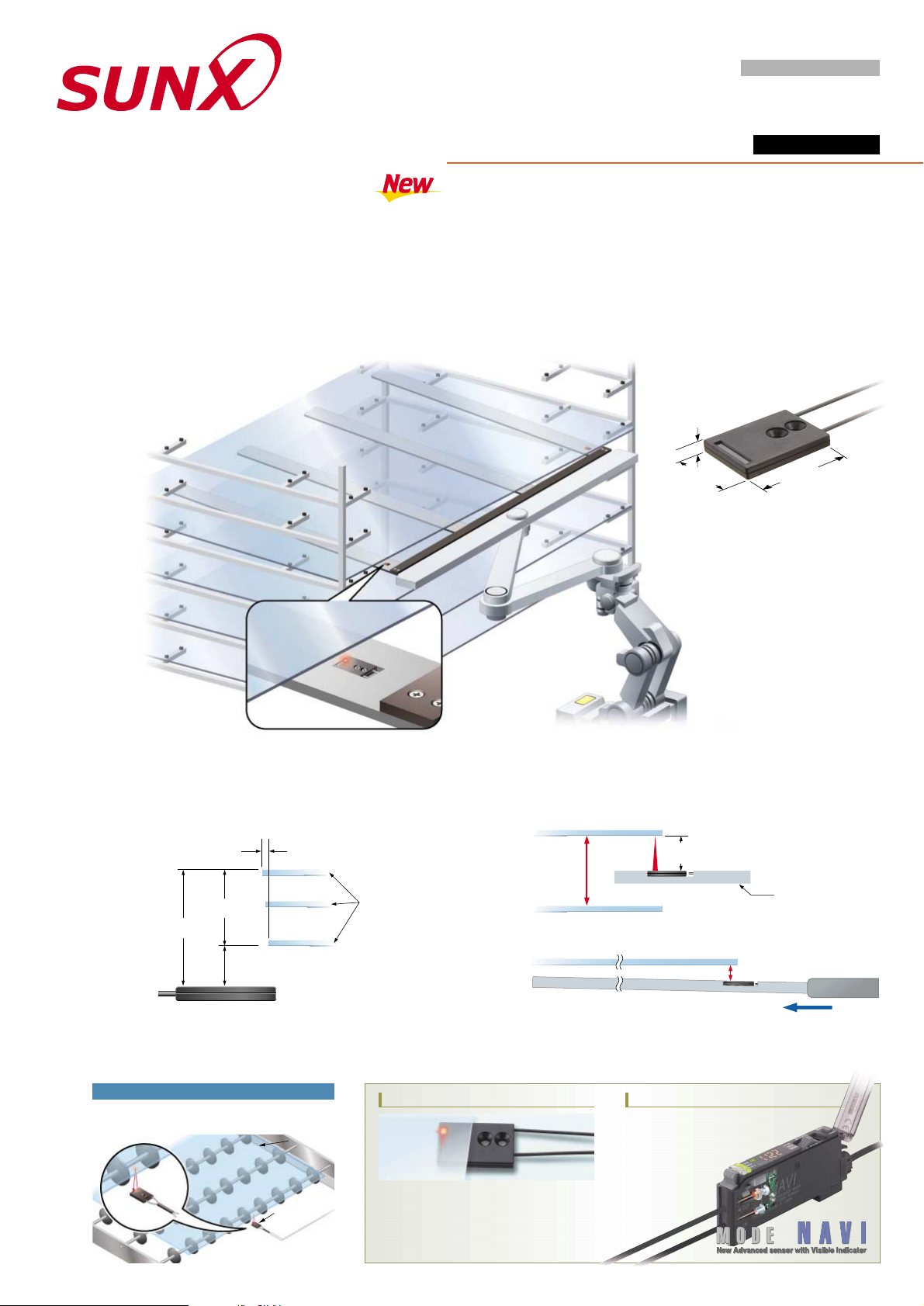

FD-L45

Glass

substrate

3.8 mm

0.150 in

29 mm

1.142 in

20 mm

0.787 in

Arm

Positioning precision

0.2 mm 0.008 in or less

Sensing object

(glass substrate)

Fiber head

25 mm

0.984 in

10 mm

0.394 in

Alignment

range

Maximum sensing range

30 mm 1.181 in (FAST mode)

Glass substrate

pitch

50 to 60 mm

1.969 to 2.362 in

This fiber is perfect for enlarged processing lines constructed to

handle the recent increase in the scale of glass substrates.

Alignment at an even longer range made possible

Ideal for the increasing size of glass substrates

• Fiber cable length 3 m 9.843 ft (Free-cut)

Designed for mounting on large-scale robots

• Alignment possible in FAST mode (150 ¨s)

Throughput is improved thanks to its quick startup.

This fiber has a sensing range of 0 to 30 mm 0 to 1.181 in and an

alignment range of 10 to 25 mm 0.394 to 0.984 in. This wide range of

alignment makes it perfect for large glass substrates. (FAST mode)

Ideal for 6th and beyond

generation large glass substrates

Easy operation

FD-L43 short-range type also available

Sensing range:

0 to 23 mm 0 to 0.906 in (STD mode)

Alignment range: 3 to 17 mm 0.118 to 0.669 in

(Positioning precision 0.2 mm 0.008 in or less)

Angular deviation:

Right and left side inclination

of the sensing object 8

Accurate sensing can also be performed at a long

range for checking objects on a conveyor.

Other application

FX-300 SERIES

A long sensing range =more leeway in the alignment range

• Sensing possible even if the pitch between glass substrates is wide.

• Extended sensing range handy for when large-scale robot arms

bend increasing the distance of the object from the fiber.

New Advanced sensor with Visible Indicator

FD-L45

GLASS SUBSTRATE ALIGNMENT FIBER

OPTICAL FIBER HEAD

Fixed-focus Reflective Type

Page 2

2431-1 Ushiyama-cho, Kasugai-shi, Aichi,

486-0901, Japan

Phone: +81-(0)568-33-7211

FAX: +81-(0)568-33-2631

SUNX Limited

Phone: +81-(0)568-33-7861

FAX: +81-(0)568-33-8591

Overseas Sales Dept.

http://www.sunx.co.jp/

All information is subject to change without prior notice.

No. PCE-FDL45 May, 2004

Beam-emitting

side

Beam-receiving

side

"1.3 "0.0512

3.8

0.150

2-mounting holes for M3

countersunk head screws

6.5

0.256

10

0.394

2.5

0.098

"3.2 "0.126 Model No. tube (PVC)

Beam-emitting /

receiving part

Sensing direction

A

A

Beam-emitting / receiving

fiber core "0.25 "0.0109

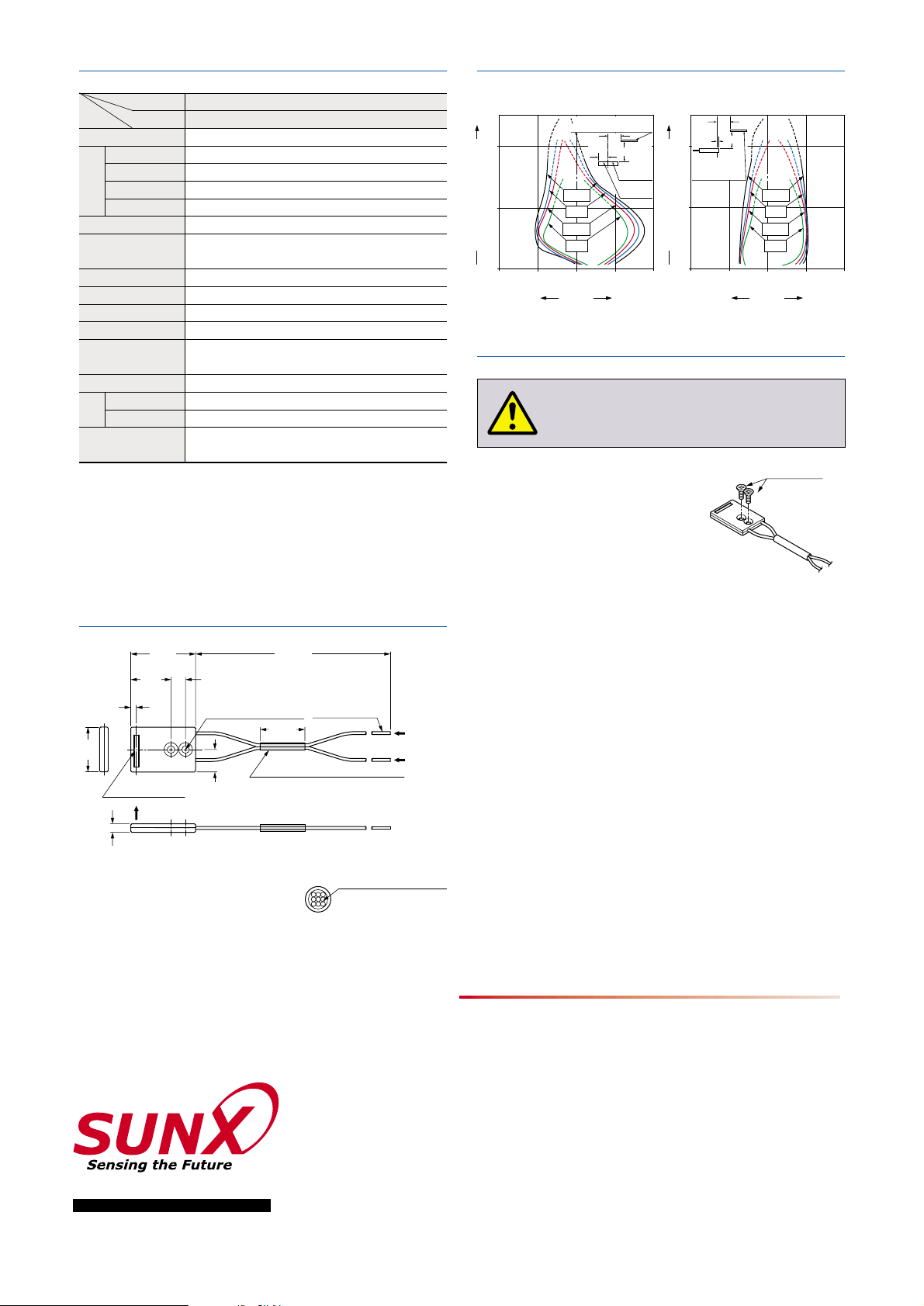

View A

4

0.15720.079

02

0.07940.157

0

20

0.787

40

1.575

LONG

FAST

STD

S-D

Beamemitting part

Beamreceiving part

• Horizontal direction

0

20

0.787

40

1.575

LONG

FAST

STD

S-D

L

2.5 mm

0.098 in

#

• Vertical direction

20

0.787

29

1.142

18

0.709

3,000

118.110

Setting distance L (mm in)

Setting distance L (mm in)

Transparent glass plate (100 100

t 0.7 mm 3.9373.937t 0.028 in)

L

#

10 mm

0.394 in

Left

Right

Center

Operating point ?(mm in)

Transparent glass plate

100

100t 0.7 mm

3.937

3.937t 0.028 in

2

0.07910.039

01

0.03920.079

Down

Up

Center

Operating point ?(mm in)

M3 countersunk

head screws

Please arrange

separately.

)

)

( )

20

0.787

( )

SPECIFICATIONS

SENSING FIELDS (TYPICAL)

Applicable amplifiers (Note 1)

Sensing object

Angular deviation (Note 2)

Position sensing accuracy (Note 2)

Allowable bending radius

Fiber cable length

Bending durability

Ambient temperature

Ambient humidity

LONG

STD

FAST (Note 3)

S-D

Fiber cable

Fiber head

Accessories

Sensing range (Note 2)

Material

Fixed-focus reflective

FD-L45

FX-301(P), FX-311(P)

0 to 36 mm 0 to 1.417 in

0 to 30 mm 0 to 1.181 in

0 to 30 mm 0 to 1.181 in

0 to 21 mm 0 to 0.827 in

LCD glass

0.2 mm 0.008 in or less (at sensing range 10 to 25 mm 0.394 to 0.984 in)

R4 mm R0.157 in or more

3 m 9.843 ft free cut

100,000 times or more (at R4 mm R0.157 in)

35 to 85 % RH, Strage: 35 to 85 % RH

Fiber core: Acrylic, Sheath: Polyethylene

Case: Heat-resistant ABS, Lens: Acrylic

PRECAUTIONS FOR PROPOSER USE

Type

Model No.

Item

0 to70 C 32 to158 F (No dew condensation or

icing allowed), Strage: 0 to

70 C 32 to158 F

Right and left side inclination of the sensing object:

6

(at sensing range 10 to 25 mm 0.394 to 0.984 in)

FX-AT5 (Attachment for "1.3 mm "0.051 in fiber): 1 set

FX-CT2 (Fiber cutter): 1 pc.

Notes: 1)

2)

3)

Refer to the sensor general catalog 2003-2004, catalog of each

amplifier (FX-301/311 series) or SUNX website (http://www.sunx.

co.jp/) for details about the applicable amplifier.

The sensing range, the angular deviation and the position sensing

accuracy are specified for glass substrate (100

100t 0.7 mm

3.937

3.937t 0.028 in) as the object. Furthermore, the

angular deviation and position sensing accuracy are the values for

FAST mode.

FX-311(P) does not have a FAST mode.

DIMENSIONS (Unit : mm in

)

The CAD data in the dimensions can be downloaded

from the SUNX website: http://www.sunx.co.jp/

This product is not a safety sensor. Its use is not

intended or designed to protect life and prev ent body

injury or property damage from dangerous par ts of

machinery. It is a normal object detection sensor.

Mount using M3 countersunk head

screws. The tightening torque should

be 0.3 N m or less.

•

•

•

•

•

•

•

•

•

•

•

Note that the sensing may not be stable if the sensing object is

specially processed, e.g., if light does not reflect regularly on its

surface.

Do not use the fiber at places having intense vibrations, as this

can cause malfunction.

Keep the fiber head surface intact. If it is scratched or spoiled, the

detectability will deteriorate.

If the sensing surface gets dirty, wipe dirt or stains from the

sensing faces with a soft cloth moistened with water. (Do not use

organic solvents.)

Do not expose the fiber to any organic solvents.

Do not use the fiber head surface in places where it may come in

direct contact with water. A water drop on the fiber head surface

deteriorates the sensing. No dew or liquid drop is present on

surface of fiber head or sensing object.

Ensure that any strong extraneous light is not incident on the

receiving face of the fiber head.

Do not apply excessive tensile force to the fiber cable.

Take care that the fiber is not directly exposed to fluorescent light

from a rapid-starter lamp or a high frequency lighting device, as it

may affect the sensing performance.

There is white dots on the beam-emitting fiber cable. When

setting the amplifier, put the fiber cable with white dots into the

beam-emitting side.

Mounting

Cautions

Loading...

Loading...