Page 1

Mapping fiber

FD-L46

Seating confirmation fiber

FD-L44

Alignment fiber

FD-L43

FD-L40SERIES

FIBERS FOR LIQUID CRYSTAL DISPLAY INDUSTRY

3 types of fiber for glass

substrate conveyors

Fixed-focus Reflective Type

Mapping fiber

Alignment fiber

Seating confirmation fiber

Page 2

1 2

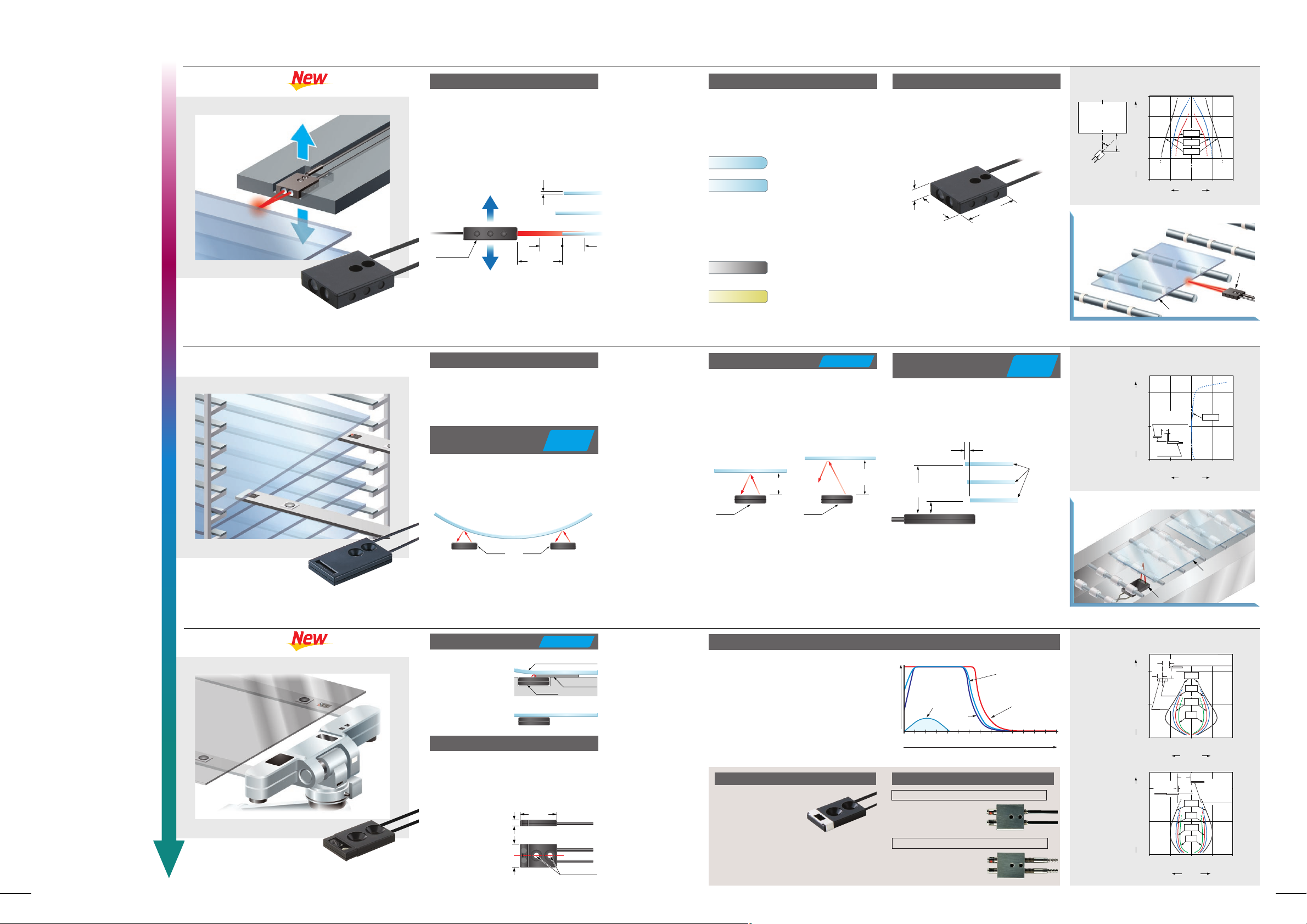

FD-L46

Glass substrate

7.3 mm

0.287 in

25 mm

0.984 in

30 mm

1.181 in

The adoption of a unique large lens allows

even thin glass substrates to be sensed

directly from the side. In addition, because

the sensing range is wide (2512.5 mm

0.9840.492 in), stable mapping is

possible even if glass substrates are in

irregular positions.

Accurate mapping even for thin glass substrates

Minor modifications allow sensing range to

be further increased so that even more

stable and high-precision alignments are

possible.

Increased sensing performance

Increases in sizes of glass substrates

mean greater amounts of flexure, but a

single fiber can sense glass even if

horizontal flexure is within 8 (previously

6).

Large light amounts can be obtained for a

variety of glass edge shapes such as R

surfaces and C surfaces, so that accurate

mapping of glass substrates inside

cassettes is possible.

Glass that has received black or yellow

masking can also be sensed in addition to

clear glass.

Can be used for a variety of glass substrates

A compact size of W25H30D7.3 mm

W0.984H1.181D0.287 in allows

installation to the ends of robotic hands. In

addition, the adoption of a resin case

means weight is light at about 39 g.

Light and compact

Stable sensing is possible over even

longer sensing ranges.

In addition, the fiber will not detect a glass

substrate 30 mm 1.181 in or more away

achieving outstanding detecting

characteristics for limited distance.

Sensing range 0 to 23 mm 0 to 0.906 in

A sensing range of 3 to 17 mm 0.118 to

0.669 in (previously 5 to 17 mm 0.197 to

0.669 in) and a positioning error of 0.2 mm

0.008 in or less makes higher precision

sensing possible.

Longest sensing range

in the industry for

seating confirmation.

Sensing is even

possible if absorption

pads are presented.

Sensing range 0 to 7 mm 0 to 0.276 in

Independent, large-scale lenses is built-in.

Large amounts of light can be received,

enabling stable sensing even of glass

substrates that have been colored (with

low reflectivity) by their treatment

conditions.

Stable sensing of colored glass substrates

Glass substrate sensing

on a roller conveyor

Sensing object (Glass substrate)

Sensing enabled from 0 mm 0 in

Ultra-thin and compact size, so takes up

less space for mounting.

Also, the center of the beam axis and the

center of the mounting hole are directly

aligned rendering system designing simple.

Ultra-thin head with thickness of 3 mm 0.118 in

Sensing object

(Glass substrate)

Fiber

head

Fiber

head

0.2 mm 0.008 in

or less

Fiber head

3 mm 0.118 in

17 mm

0.669 in

Sensing object

(Glass substrate)

Fiber

head

0 to 23 mm

0 to 0.906 in

Sensing object

(Glass substrate)

Fiber

head

30 mm 1.181 in

or more

0.5 mm 0.020 in glass

substrates can also be sensed

12.5 mm

0.492 in

12.5 mm

0.492 in

25 mm

0.984 in

(

At LONG mode

)

Fiber head

R surface

C surface

Black mask

Yellow mask

0 1

0.03920.07930.11840.15750.19760.236

Peak incident light intensity with respect to distance

Distance (mm in)

7

0.27680.31590.354100.394110.433120.472130.512140.551

Conventional seating

confirmation fiber

(Clear glass)

FD-L44

(Chrome film)

FD-L44

(ITO film)

FD-L44

(Clear glass)

SUNX fixed-focus reflective type fibers: The definitive choice for sensing glass substrates

• Horizontal

direction

Anglular deviation

(

Typical

)

Other application

Other application

Positioning characteristics

(

Typical

)

Sensing characteristics (Typical)

• Vertical

direction

FD-L46

Alignment fiber

FD-L43

Seating confirmation fiber

FD-L44

Increased performance

Increased

performance

• •Can sense small glass

substrates with narrow

pitch and wafers.

Same large amounts of

light as the FD-L44 can

be obtained.

Fiber cable length: 2 m 6.562 ft free-cut

Allowable bending radius: R25 mm

R0.984 in or more

Sensing range: 0 to 15 mm 0 to 0.591 in (LONG)

Fiber cable length: 2 m 6.562 ft fixed

Allowable bending radius: R25 mm

R0.984 in or more

Sensing range: 0 to 15 mm 0 to 0.591 in (LONG)

180 C 356 F heat-resistant type / FD-H18-L31

300 C 572 F heat-resistant type / FD-H30-L32

The short range type FD-L44S is also available

Heat-resistant fibers FD-H30-L32, FD-H18-L31 are also available

Fiber head

Absorption pad

$

Fiber head

100 50 0 50 100

0

40

1.575

30

1.181

20

0.787

10

0.394

Left Right

Operating angle $(

)

Center

FAST

1

0.039

0.5

0.020

0 0.5

0.02010.039

0

10

0.394

20

0.787

Operating point ?(mm in)

L

#

Transparent glass

substrate

2.5 mm

0.098 in

Fiber

head

3 mm

0.118 in

19 mm

0.748 in

Beam axis center

12 mm

0.472 in

Mounting holes

STD

L

Glass substrate

100100t0.7 mm

3.9373.937t0.028 in

(R edge)

LONG

STD

Mapping fiber

Setting distance L (mm in)

Does not sense

when the distance is

30 mm 1.181 in or more.

Sensing

object

Glass

substrate

Setting distance L (mm in)

Left Right

Center

2

0.07910.039

01

0.03920.079

0

5

0.197

10

0.394

L

Beamemitting

part

#

6 mm

0.236 in

LONG

FAST

STD

S-D

Transparent glass substrate (100100

t0.7 mm 3.9373.937t0.028 in

)

Left

Right

Center

Operating point ?(mm in)

Beamreceiving

part

2

0.07910.039

01

0.03920.079

0

5

0.197

10

0.394

L

2 mm

0.079 in

#

S-D

FAST

STD

LONG

Transparent glass

substrate

(100100t 0.7 mm

3.9373.937t 0.028 in)

Down

Up

Center

Operating point ?(mm in)

Setting distance L (mm in)

Setting distance L (mm in)

Incident light intensity

Glass substrate

FD-L43

Glass substrate detection

on a conveyor

Different colored glass

can also be sensed

A thickness of just

3 mm 0.118 in !

Stable and greater performance in

sensing of glass with 8 flexure

Edges with poor reflectivity

can also be sensed

Improved high-precision

sensing over wide ranges

Increased

performance

Sensing range: 0 to 4 mm 0 to 0.157 in (at STD mode)

Dimensions: W12

H19D3 mm

W0.472

H0.748D0.118 in

Senses up to 23 mm 0.906 in

(previously : 20 mm 0.787 in)

from seating position.

Longest in the industry

( )

Page 3

2431-1 Ushiyama-cho, Kasugai-shi, Aichi,

486-0901, Japan

Phone: +81-(0)568-33-7211

FAX: +81-(0)568-33-2631

SUNX Limited

Phone: +81-(0)568-33-7861

FAX: +81-(0)568-33-8591

Overseas Sales Dept.

http://www.sunx.co.jp/

All information is subject to change without prior notice.

No. PCE-FDL40 November, 2003

PRECAUTIONS FOR PROPOSER USE

FD-L46

This product is not a safety sensor. Its use is not

intended or designed to protect life and prevent body

injury or property damage from dangerous parts of

machinery. It is a normal object detection sensor.

Mounting

Cautions

Applicable amplifiers (Note 1)

Min. sensing object (Note 4)

Allowable bending radius

Fiber cable length

Ambient temperature

Ambient humidity

Weight

Accessories

FX-301(P), FX-302(P), FX-311(P)

15 to 35 mm 0.591 to 1.378 in

16 to 29 mm 0.63 to 1.142 in

0 to 23mm 0 to 0.906 in 0 to 6 mm 0 to 0.236 in 0 to 4 mm 0 to 0.157 in

12.5 to 37.5 mm 0.492 to 1.476 in 0 to 7 mm 0 to 0.276 in 0 to 4.5 mm 0 to 0.177 in

0 to 3.8 mm 0 to 0.150 in

0 to 3.5 mm 0 to 0.138 in

0 to 5.7 mm 0 to 0.224 in

0 to 5.2 mm 0 to 0.205 in

"0.3 mm "0.012 in gold wire "0.03 mm "0.001 in gold wire

R4 mm R0.157 in or more R10 mm R0.394 in or moreR25 mm R0.984 in or more

2 m 6.562 ft free cut4 m 13.123 ft free cut

40 to 60 C 40 to 140 F,

Strage:

40 to 60 C 40 to 140 F

0 to 70 C 32 to 158 F,

Strage: 0 to

70 C 32 to 158 F

40 to 60 C 40 to 140 F,

Strage:

40 to 60 C 40 to 140 F

35 to 85 %RH (No dew condensation or icing allowed), Strage: 35 to 85 %RH

Case: ABS, Lens: Norbornene resin

Case: Heat-resistant ABS, Lens: Acrylic

Case: Polycarbonate, Lens: Acrylic, Slit mask (FD-L44S only): Stainless steel (SUS304)

39 g Approx. 7.3 g Approx. 5 g Approx.

Fiber core: Acrylic, Sheath: Polyethylene

Item Model No.

Type

FD-L44SFD-L44FD-L43FD-L46

For seating confirmationFor mapping For alignment

Material

LONG

STD

FAST (Note 3)

S-D

Fiber

Fiber head

Sensing range

(Note 2)

FD-L43

FD-L44

FD-L44S

10 0.394

29

1.142

6.5 0.256

18

0.709

3.8

0.150

17 0.669

2.5 0.098

2-mounting holes for M3

countersunk head screws

("3 "0.118) Model No. tube (PVC)

Beam-emitting /

receiving part

Beam-emitting side

Beam-receiving side

"1.3 "0.0152

15

0.591

7.5

0.295

7.5

0.295

"2.2 "0.0872

20

0.787

7.3 0.287

4,000

157.48

(8 0.315)

25

0.984

6.5 0.256

19 0.748

Lens

("3.2 "0.126) Model No. tube (PVC)

2-"3.2 "0.126 mounting holes, "5.7 "0.224 countersinking, 2.6 deep

3 0.118

Beam-emitting fiber

"0.25 "0.0107

Beam-receiving fiber

"0.5 "0.020

View A View B

2.5 0.098

0.8 0.031

8 0.315

Slit mask

Lens

"1

"0.039

2-mounting holes for M3

countersunk head screws

A

B

2,000

78.740

19

0.748

2 0.079

(

"3.2 "0.126) Model No. tube (PVC)

"1.25

"0.049

("3.2 "0.126) Model No. tube (PVC)

8.5 0.335

7

0.276

12

0.472

0.6

0.024

A

2,000

78.740

8 0.315

2.9 0.114

12

0.472

19

0.748

2 0.079

8.5 0.335

7 0.276

Lens

2-mounting holes for M3

countersunk head screws

"1

"0.039

"1.25

"0.049

B

3-"3.2 "0.126 set screw mounting holes (0.5 deep, on both sides)

FD-L44

FD-L44S

SPECIFICATIONS

Notes: 1)

2)

3)

4)

Refer to the sensor general catalog 2003-2004, catalog of each amplifier (FX-301/311 series) or dedicated homepage for fiber sensor (http://www.fiber-sensor.com) for details

about the applicable amplifier.

The values for the FD-L46 are for R edge of glass substrate (100

100t0.7 mm 3.9373.937t0.028 in) for LCDs; the values for the FD-L43 and FD-L44 are for glass

substrate (100

100t0.7 mm 3.9373.937t0.028 in) for LCD, and the values for the FD-L44S are for silicon wafer (polished surfaces).

FX-311(P) does not have a FAST mode.

The minimum sensing object size is the value at maximum sensitivity. Also, note that the corresponding setting distance is different from the rated sensing distance.

20

0.787

DIMENSIONS (Unit : mm in)

( )

( )

Mount using M3 countersunk head screws (FD-L46: M3 pan head

screws. Please arrange separately). The tightening torque should be

0.3 Nm or less (FD-L46: 0.5 Nm or less).

The FD-L46 can be mounted as shown in

the figure at right using M3 set screws

(

Please arrange separately

).

The tightening torque at this time should

be 0.5 Nm or less.

•

•

•

•

•

•

•

•

•

•

•

•

FD-L43: Note that the sensing may not be stable if the sensing

object is specially processed, e.g., if light does not reflect

regularly on its surface.

Do not use the fiber at places having intense vibrations, as this

can cause malfunction.

Keep the fiber head surface intact. If it is scratched or spoiled, the

detectability will deteriorate.

If the sensing surface gets dirty, wipe dirt or stains from the

sensing faces with a soft cloth moistened with water. (Do not use

organic solvents.)

Do not expose the fiber to any organic solvents.

Do not use the fiber head surface in places where it may come in

direct contact with water. A water drop on the fiber head surface

deteriorates the sensing.

Ensure that any strong extraneous light is not incident on the

receiving face of the fiber head.

Do not apply excessive tensile force to the fiber cable.

Take care that the fiber is not directly exposed to fluorescent light

from a rapid-starter lamp or a high frequency lighting device, as it

may affect the sensing performance.

There is white dots (FD-L43) or white line (FD-L44/L44S) on the

beam-emitting fiber cable. When setting the amplifier, put the fiber

cable with white dots into the beam-emitting side.

30

1.181

FX-AT3 (Attachment for "2.2 mm fiber

"0.087 in): 1 set, FX-CT2 (Fiber cutter): 1 pc.

FX-AT5 (Attachment for "1.3 mm fiber

"0.051 in): 1 set, FX-CT2 (Fiber cutter): 1 pc.

FX-AT6 (Attachment for "1 mm "0.039 in /"1.3 mm "0.051 in mixed

fiber): 1 set, FX-CT2 (Fiber cutter): 1 pc.

mThe views A and B and

the side views are the

same for the FD-L44.

2,000 78.740

20

0.787

( )

M3 set

screw

(Cup point)

Loading...

Loading...