Page 1

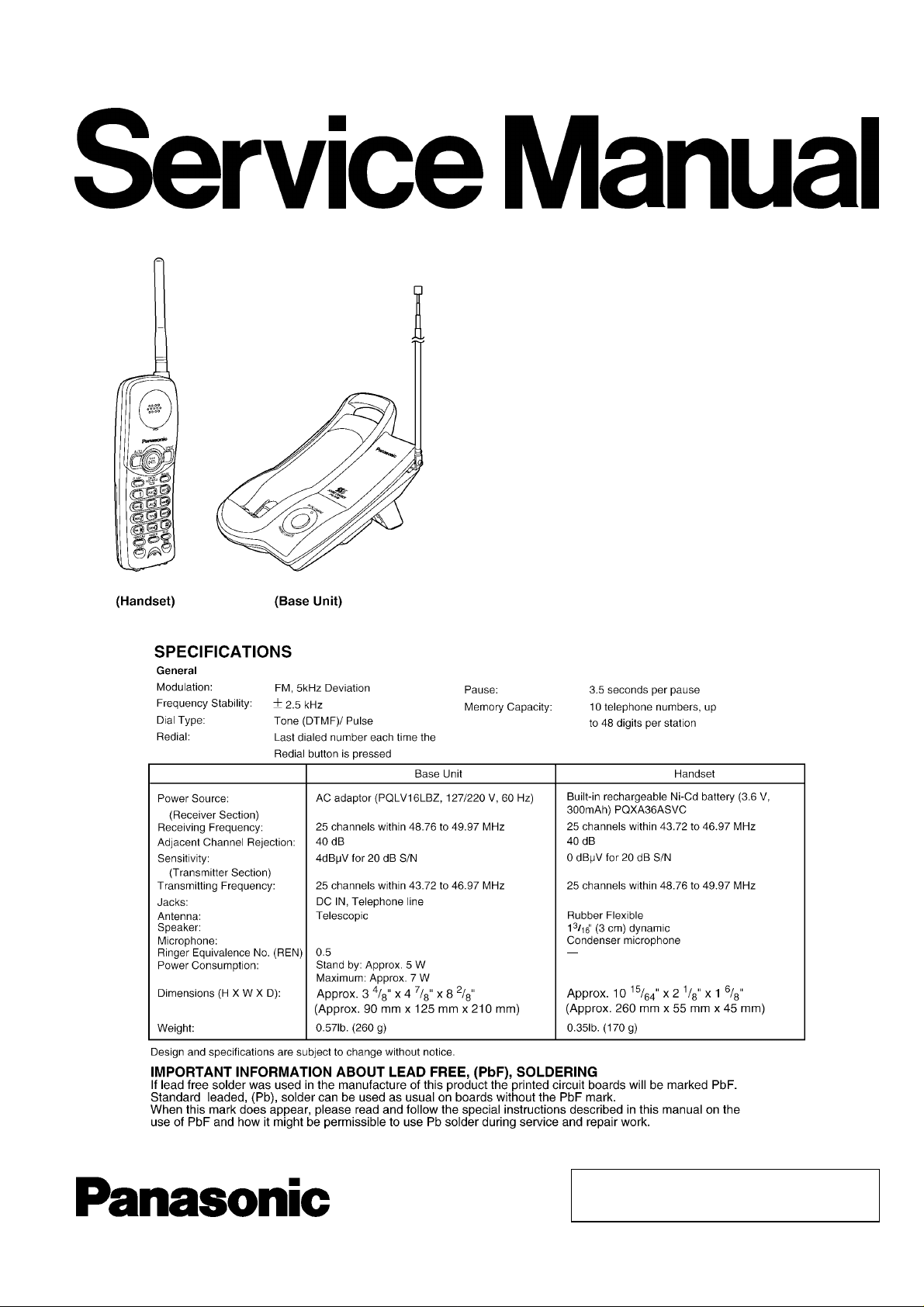

ORDER NO. KM40510896CE

Telephone Equipment

KX-TC2105LBB

Cordless Phone

Black Version

(for Brazil)

© 2005 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

KX-TC2105LBB

Note:

Because CONTENTS 4 is the extract from the Operating Instructions of this model, it is subject to change without notice. You can

download and refer to the original Operating Instructions on TSN Server for further information.

CONTENTS

Page Page

1 ABOUT LEAD FREE SOLDER (PbF: Pb free) 4

1.1. Suggested PbF Solder

1.2. How to recognize that Pb Free Solder is Used

2 FOR SERVICE TECHNICIANS

3 CAUTION

4 OPERATING INSTRUCTIONS

4.1. Battery

4.2. Location of Controls

4.3. Connection

4.4. Troubleshooting

5 DISASSEMBLY INSTRUCTIONS

6 TROUBLESHOOTING GUIDE

6.1. Check Power

6.2. Bell Reception

6.3. Check Battery Charge

6.4. Check Link

6.5. Check Handset Transmission

6.6. Check Handset Reception

7 ADJUSTMENTS (BASE UNIT)

7.1. Test Mode Flow Chart (Base Unit)

7.2. How to change the channel

7.3. Adjustment

7.4. Adjustment Standard (Base Unit)

8 ADJUSTMENTS (HANDSET)

8.1. Test Mode Flow Chart (Handset)

8.2. How to change the channel

8.3. Adjustment

8.4. Adjustment Standard (Handset)

9 RF SPECIFICATION

9.1. Base Unit

9.2. Handset

10 HOW TO CHECK THE HANDSET SPEAKER

11 FREQUENCY TABLE (MHz)

12 EXPLANATION OF CPU DATA COMMUNICATION

12.1. STAND-BY -> TALK, TALK -> STAND-BY

12.2. Ringing

10

12

13

14

15

16

17

18

19

19

20

20

21

22

22

23

23

24

25

25

25

25

26

27

27

28

4

5

5

5

6

6

7

8

9

12.3. Changing the Channel

12.4. Ports for transmitting and receiving of data

12.5. Waveform of DATA used for cordless transmission and

reception

13 B LOCK DIAGRAM (BASE UNIT)

14 CIRCUIT OPERATION (BASE UNIT)

14.1. Outline

14.2. Power Supply Circuit

14.3. Reset Circuit

14.4. Charge Circuit

14.5. Telephone Line Interface

14.6. Transmitter/Receiver

15 B LOCK DIAGRAM (HANDSET)

16 CIRCUIT OPERATION (HANDSET)

16.1. Outline

16.2. Reset Circuit

16.3. Battery Low / Power Down Detector

17 SIGNAL ROUTE

18 CPU DATA (Base Unit)

18.1. IC201

19 CPU DATA (Handset)

19.1. IC701

20 RF IC (Base Unit and Handset)

20.1. Base Unit: IC401, Handset: IC801

21 HOW TO REPLACE THE FLAT PACKAGE IC

21.1. PREPARATION

21.2. FLAT PACKAGE IC REMOVAL PROCEDURE

21.3. FLAT PACKAGE IC INSTALLATION PROCEDURE

21.4. BRIDGE MODIFICATION PROCEDURE

22 CABINET AND ELECTRICAL PARTS (BASE UNIT)

23 CABINET AND ELECTRICAL PARTS (HANDSET)

24 ACCESSORIES AND PACKING MATERIALS

25 TER MINAL GU IDE OF THE ICs, TR ANSISTO RS AND DIODES

25.1. Base Unit

25.2. Handset

29

30

30

31

32

32

33

34

35

35

36

38

39

39

39

40

41

42

42

43

43

44

44

45

45

45

46

46

47

48

49

50

50

50

2

Page 3

KX-TC2105LBB

26 REPLACEMENT PARTS LIST 51

26.1. Base Unit

26.2. Handset

26.3. Accessories and Packing Materials

27 FOR SCHEMATIC DIAGRAM

27.1. Base Unit (SCHEMATIC DIAGRAM (BASE UNIT))

27.2. Handset (SCHEMATIC DIAGRAM (HANDSET))

28 SCHEMATIC DIAGRAM (BASE UNIT)

51

53

54

55

55

55

56

29 SCHEMATIC DIAGRAM (HANDSET)

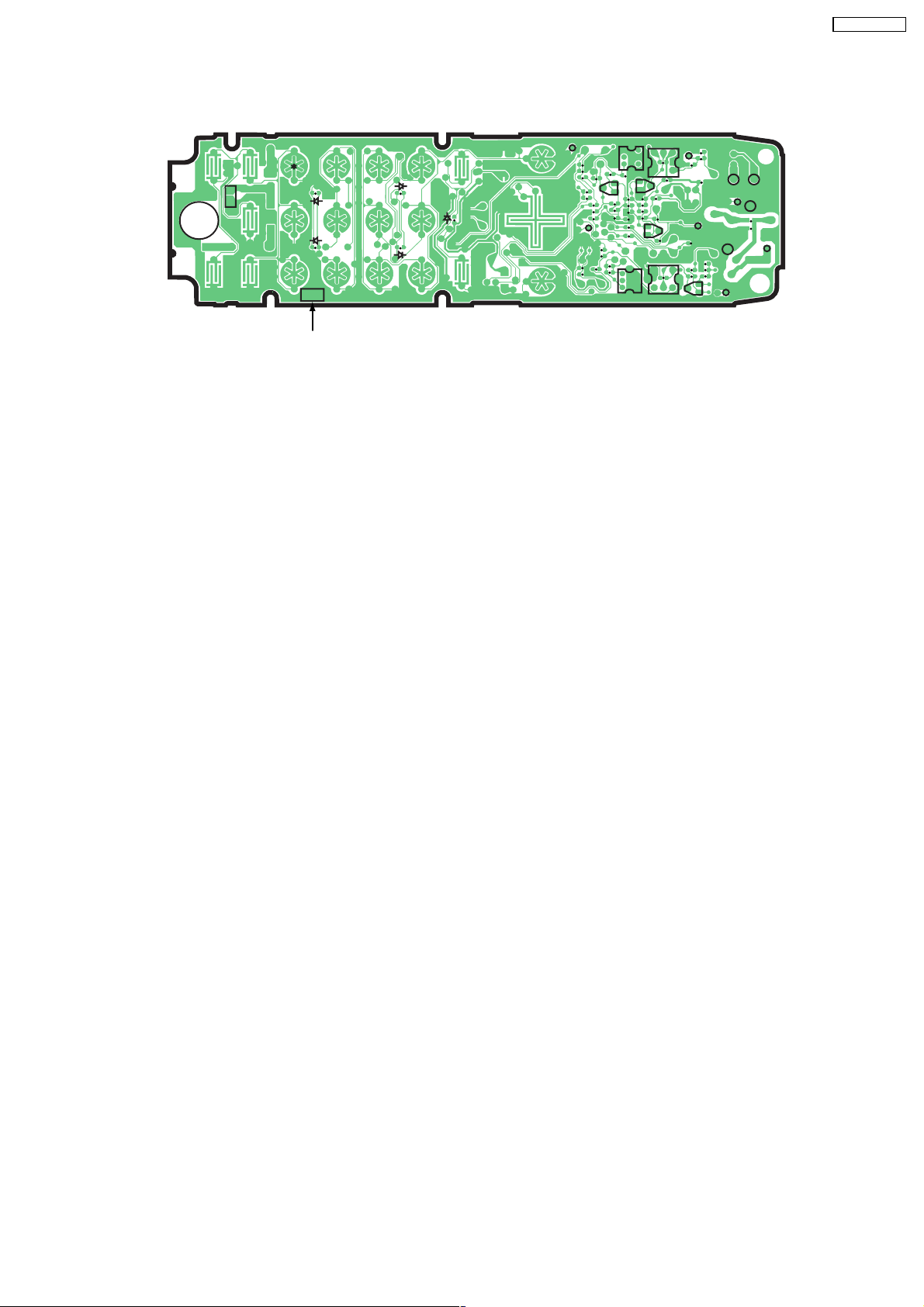

30 CIRCUIT BOARD (BASE UNIT)

30.1. Component View

30.2. Flow Solder Side View

31 CIRCUIT BOARD (HANDSET)

31.1. Component View

31.2. Flow Solder Side View

57

59

59

60

61

61

62

3

Page 4

KX-TC2105LBB

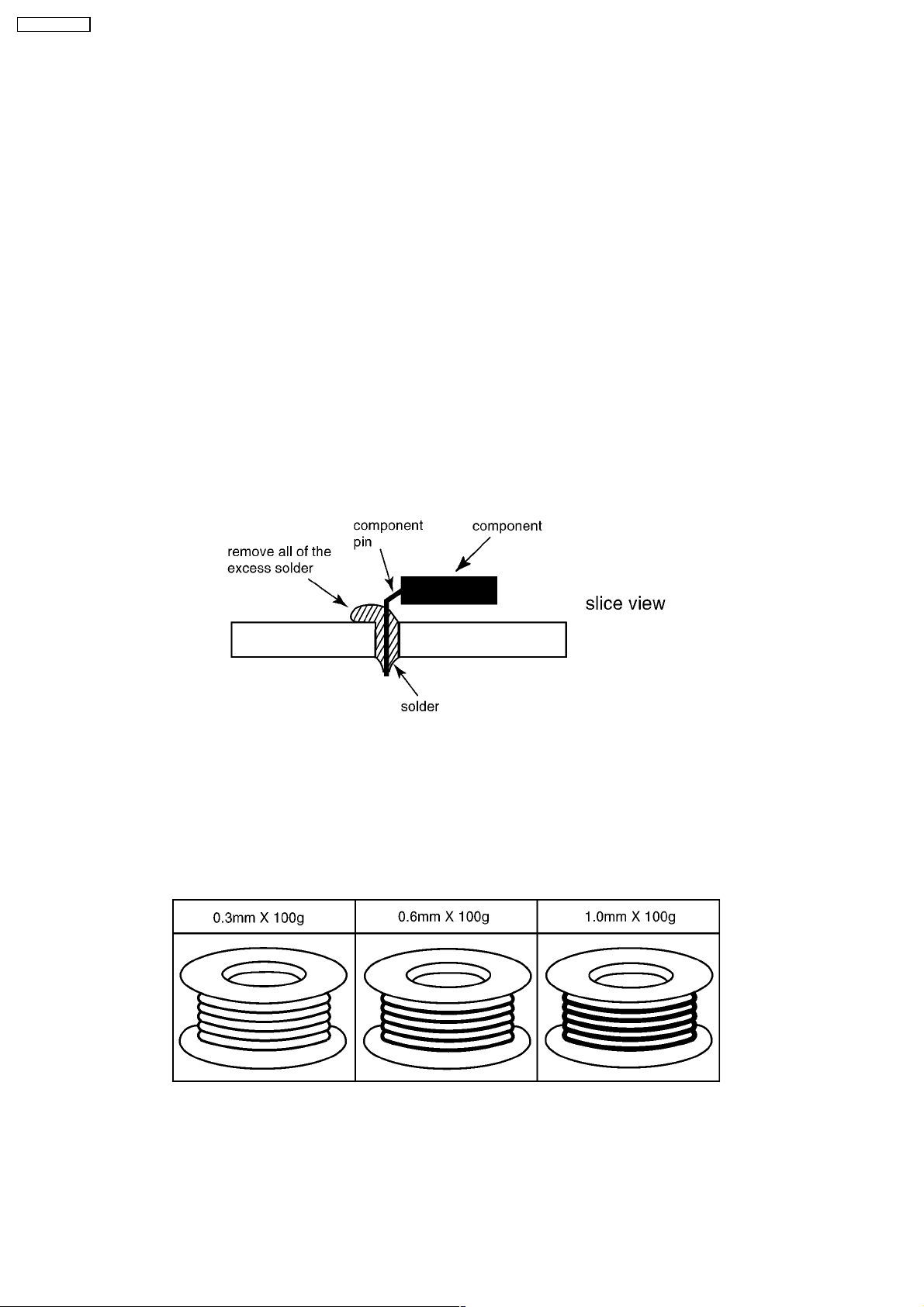

1 ABOUT LEAD FREE SOLDER (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

• PbF solder has a melting point that is 50°F ~ 70° F (30°C ~ 40°C) higher than Pb solder. Please use a soldering iron with

temperature control and adjust it to 700°F ± 20° F (370°C ± 10°C). In case of using high temperature soldering iron, please

be careful not to heat too long.

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F (600°C).

• If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible

and be sure that any remaining is melted prior to applying the Pb solder.

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See the figure below).

1.1. Suggested PbF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper

(Sn+Ag+Cu), you can also use Tin and Copper (Sn+Cu), or Tin, Zinc, and Bismuth (Sn+Zn+Bi). Please check the manufac

turer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

4

Page 5

1.2. How to recognize that Pb Free Solder is Used

(Example: Handset P.C.B.)

PROGRAM

LOUD

12

GND OUTPUT

MIC

RINGER

PAUSE

CH

7

4

LED703

8

0

LED704

9

#

LED702

5

LED705

6

FLASH LED701

1

2

3

TALK

REDIAL

PbF

AUTO

DIRECT

DTCOUT

R843

C866

C864

PSAVE

C839

C838

R848

C848

TXVCO

C861

R837

Q804

R838

R841

C862

C860

R839

C858

C836

C804

C832

R802

C831

Marked

Note:

The location of the "PbF" mark is subject to change without notice.

2 FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on worktable.

4. Do not grasp IC or LSI pins with bare fingers.

KX-TC2105LBB

TXPOWER

1

C852

6431

6

C865

Q802

C854

C870

C857

R830

R835

C855

R836

C863

R804

Q803

C808

R834

433

C805

1

C873

3

C872

C851

4

R831

R833

C856

664

R801

1

SP+ SP-

C853

NDTC

GND

IFOUT

R803

C803

Q801

C802

C801

ANT_TP

IFGND

R851

C871

R850

RXVCO

3 CAUTION

1. Danger of explosion if battery is incorrectly replaced.

2. Replace only with the same or equivalent type recommended by the manufacturer.

3. Dispose of used batteries according to the manufacturer´s Instructions.

5

Page 6

KX-TC2105LBB

4 OPERATING INSTRUCTIONS

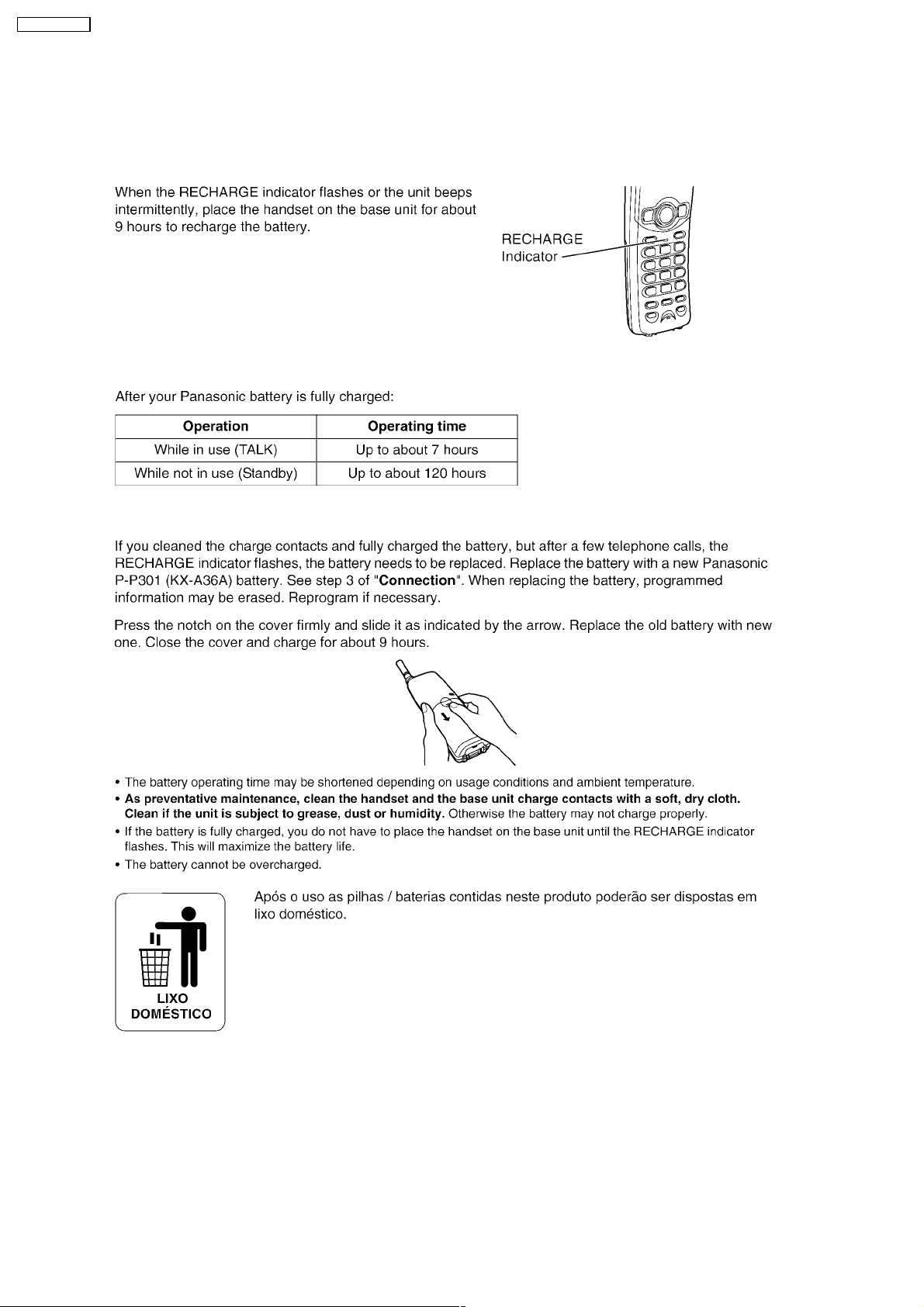

4.1. Battery

4.1.1. Recharge

4.1.2. Battery information

4.1.3. Battery Replacement

6

Page 7

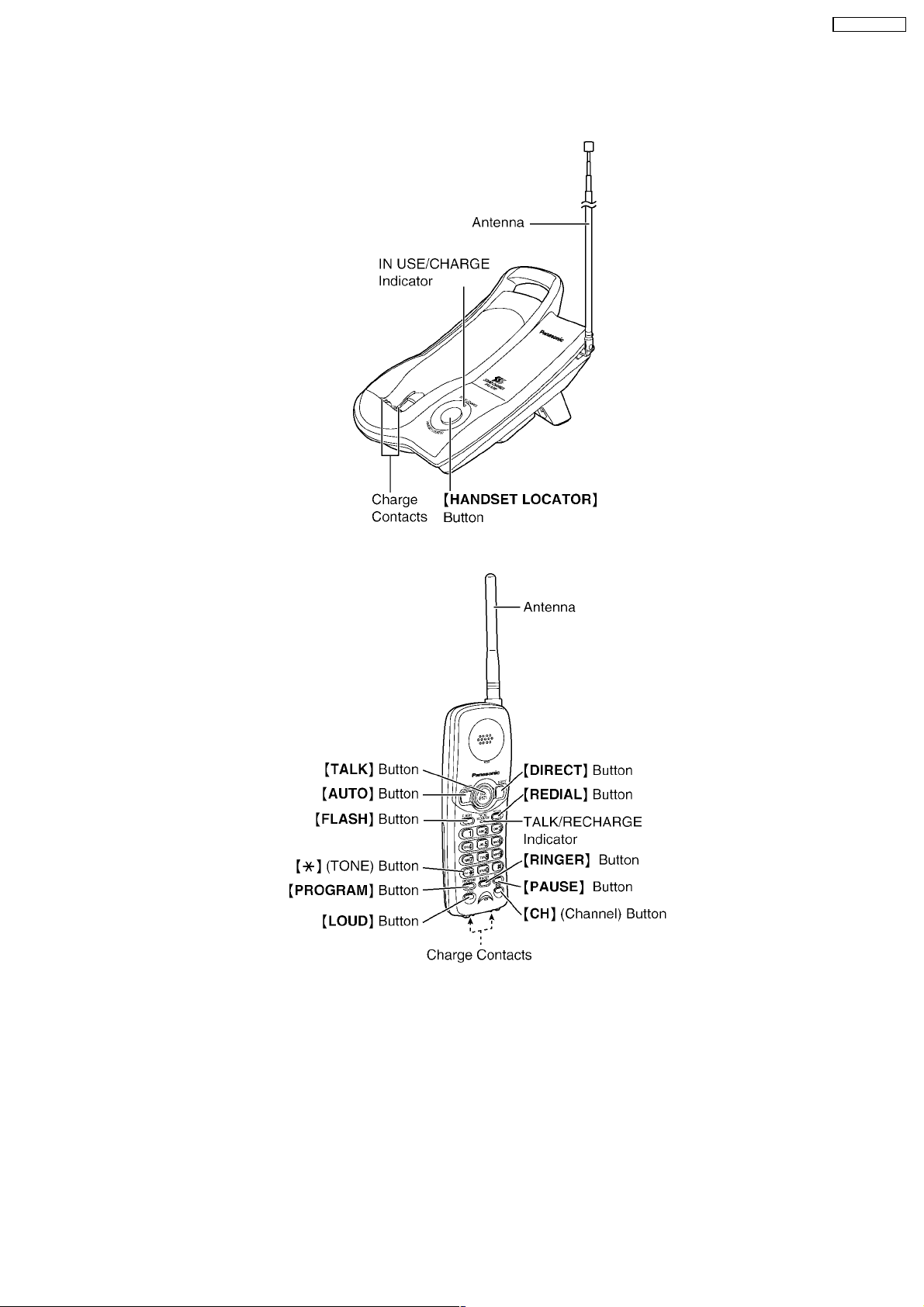

4.2. Location of Controls

4.2.1. Base Unit

KX-TC2105LBB

4.2.2. Handset

7

Page 8

KX-TC2105LBB

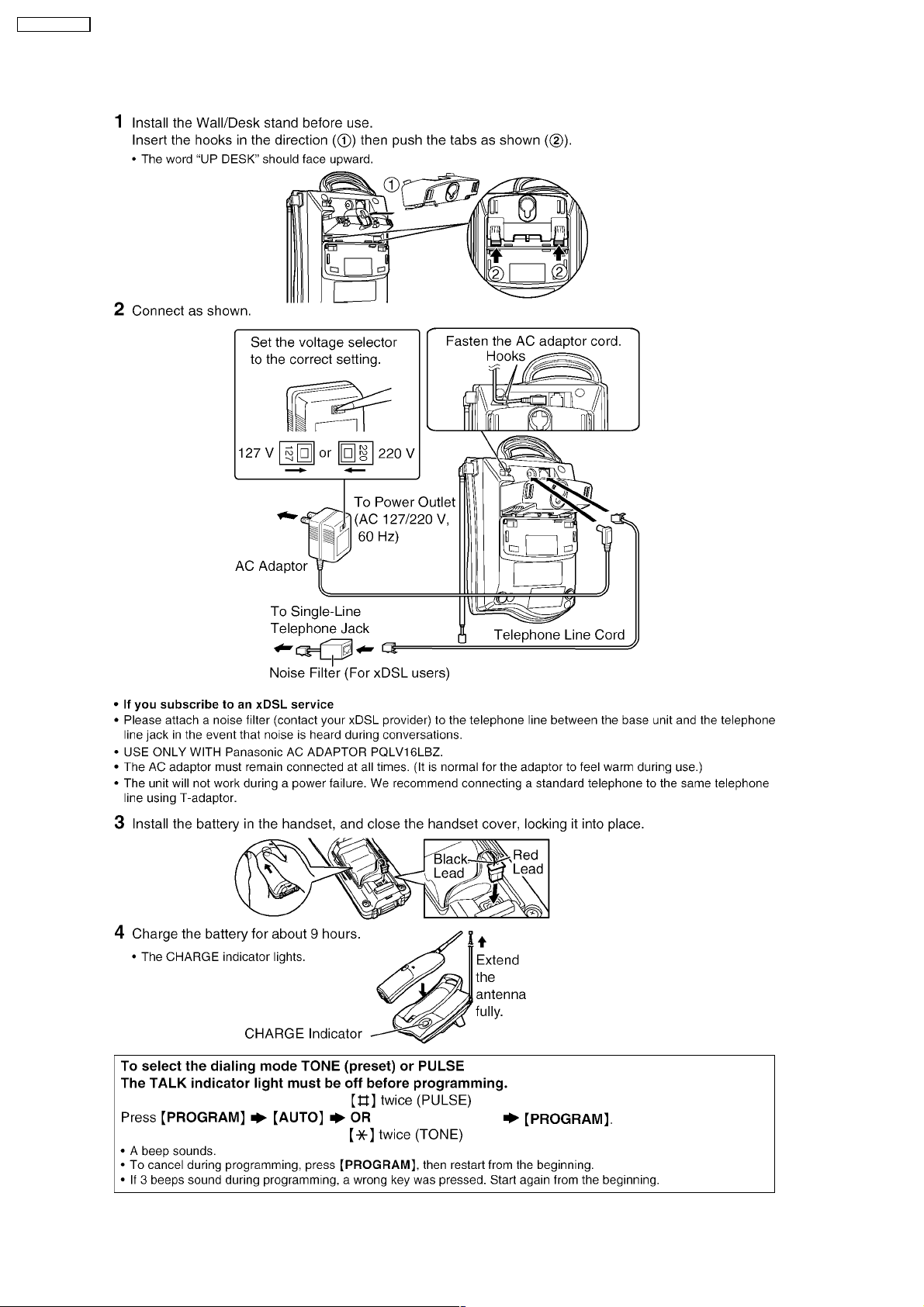

4.3. Connection

8

Page 9

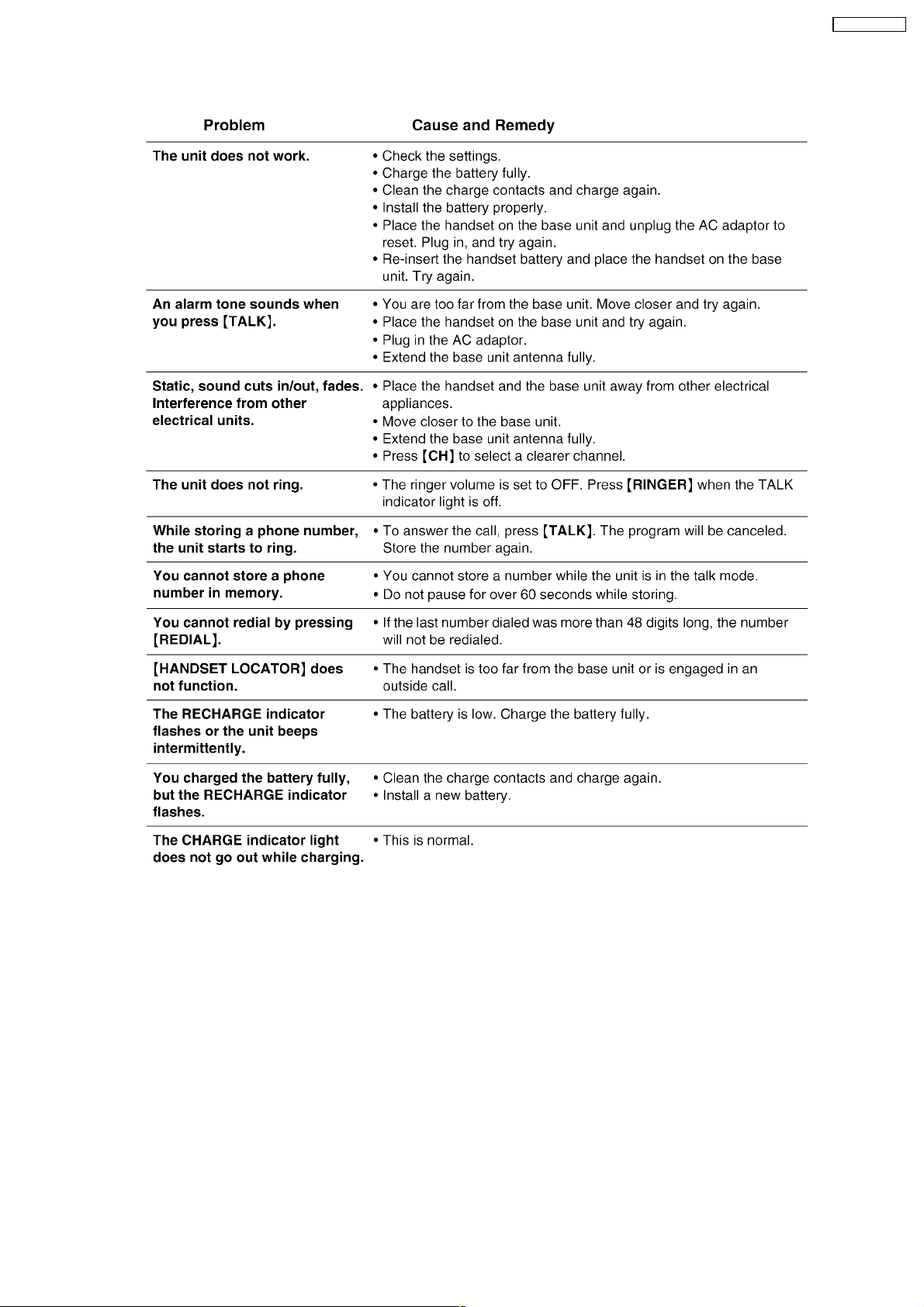

4.4. Troubleshooting

KX-TC2105LBB

9

Page 10

KX-TC2105LBB

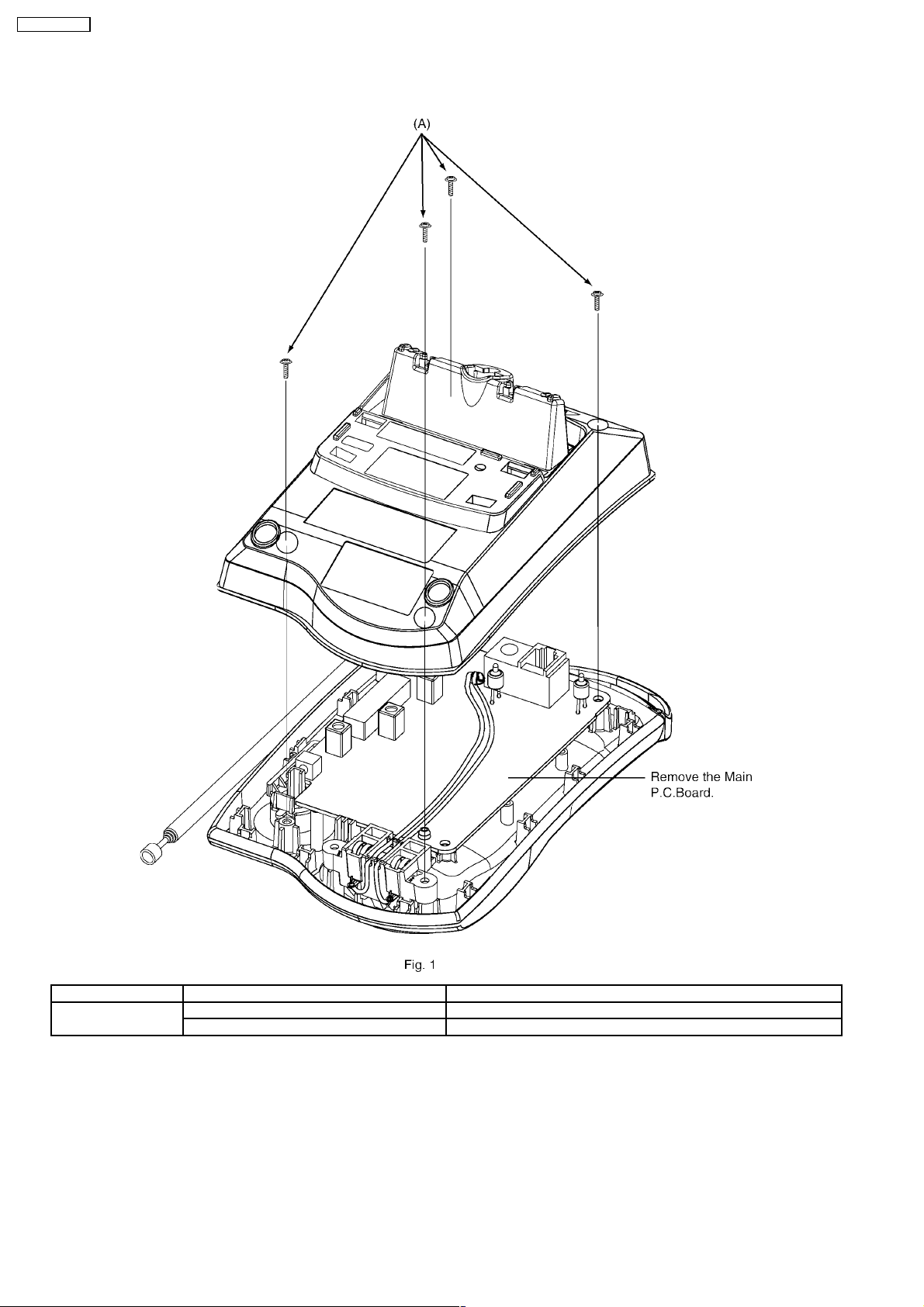

5 DISASSEMBLY INSTRUCTIONS

Shown in Fig.- To Remove Remove

1 Cabinet Cover Screws (2.6 × 12)....................... (A) × 4

Main P.C. Board Main P.C. Board

10

Page 11

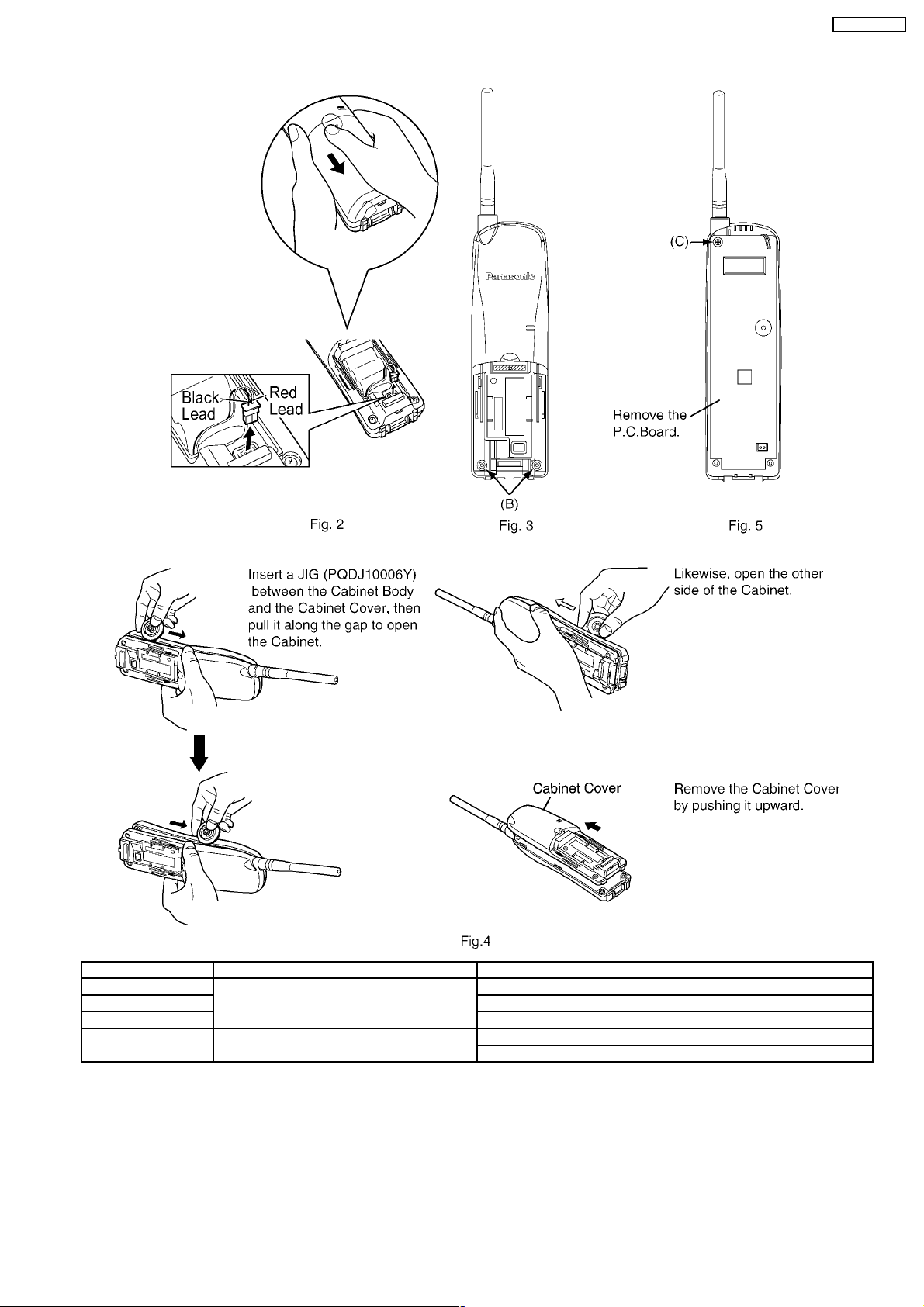

KX-TC2105LBB

Shown in Fig.- To Remove Remove

2 Cabinet Cover Battery compartment cover.

3 Screws (2.6 × 12)......................(B) × 2

4 Follow the procedure.

5 Main P. C. Board Screw (2.6 × 12)........................(C) × 1

Main P. C. Board

11

Page 12

KX-TC2105LBB

6 TROUBLESHOOTING GUIDE

Cross Reference:

Check Power (P.13)

Bell Reception (P.14)

Check Battery Charge (P.15)

Check Link (P.16)

Check Handset Transmission (P.17)

Check Handset Reception (P.18)

12

Page 13

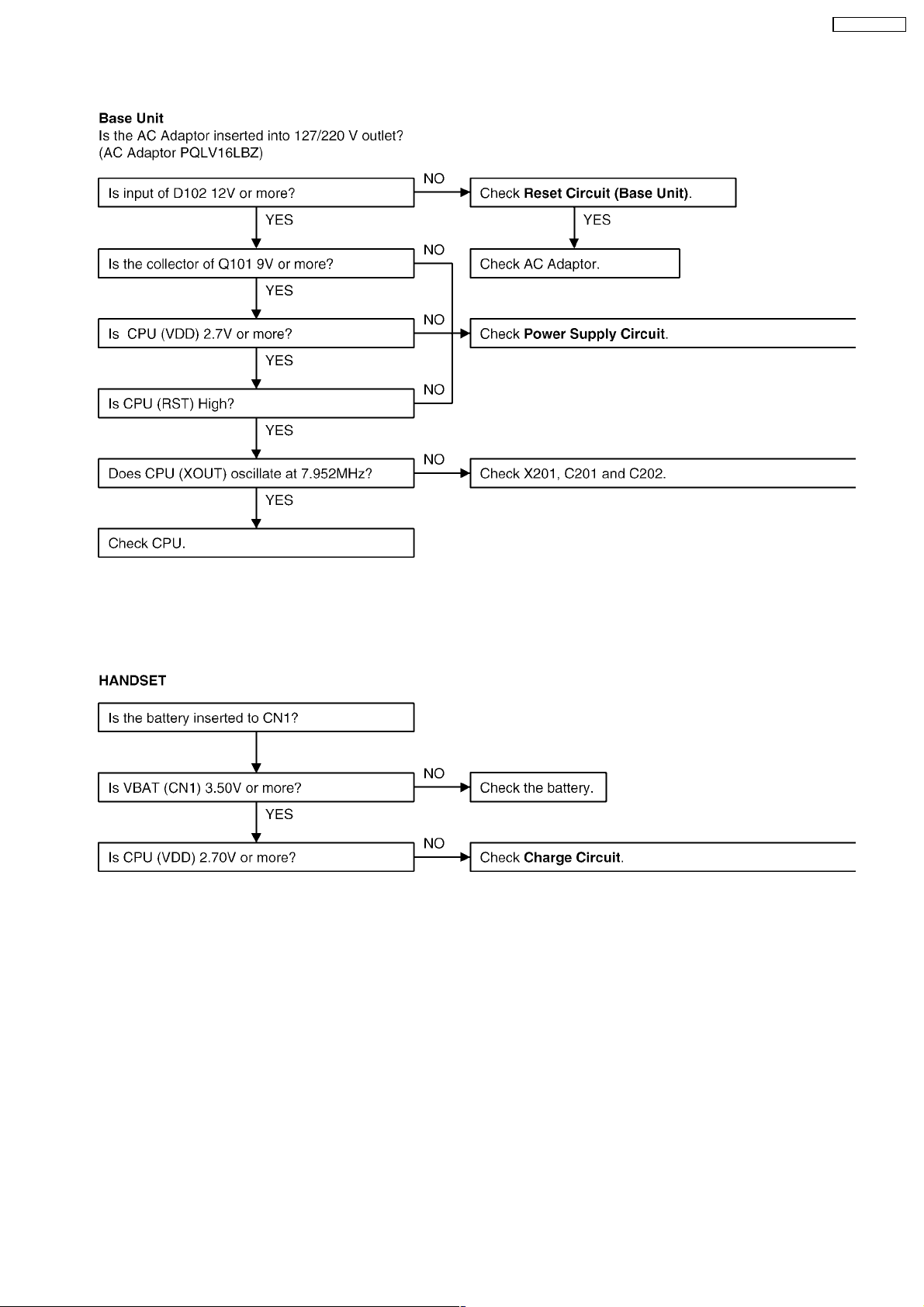

6.1. Check Power

KX-TC2105LBB

Cross Reference:

Reset Circuit (P.34)

Power Supply Circuit (P.33)

Cross Reference:

Charge Circuit (P.35)

*: Each measurement points are shown in CIRCUIT BOARD (BASE UNIT) (P.59) or CIRCUIT BOARD (HANDSET) (P.61)

Note:

*CPU: IC201

Note:

*CPU: IC701

13

Page 14

KX-TC2105LBB

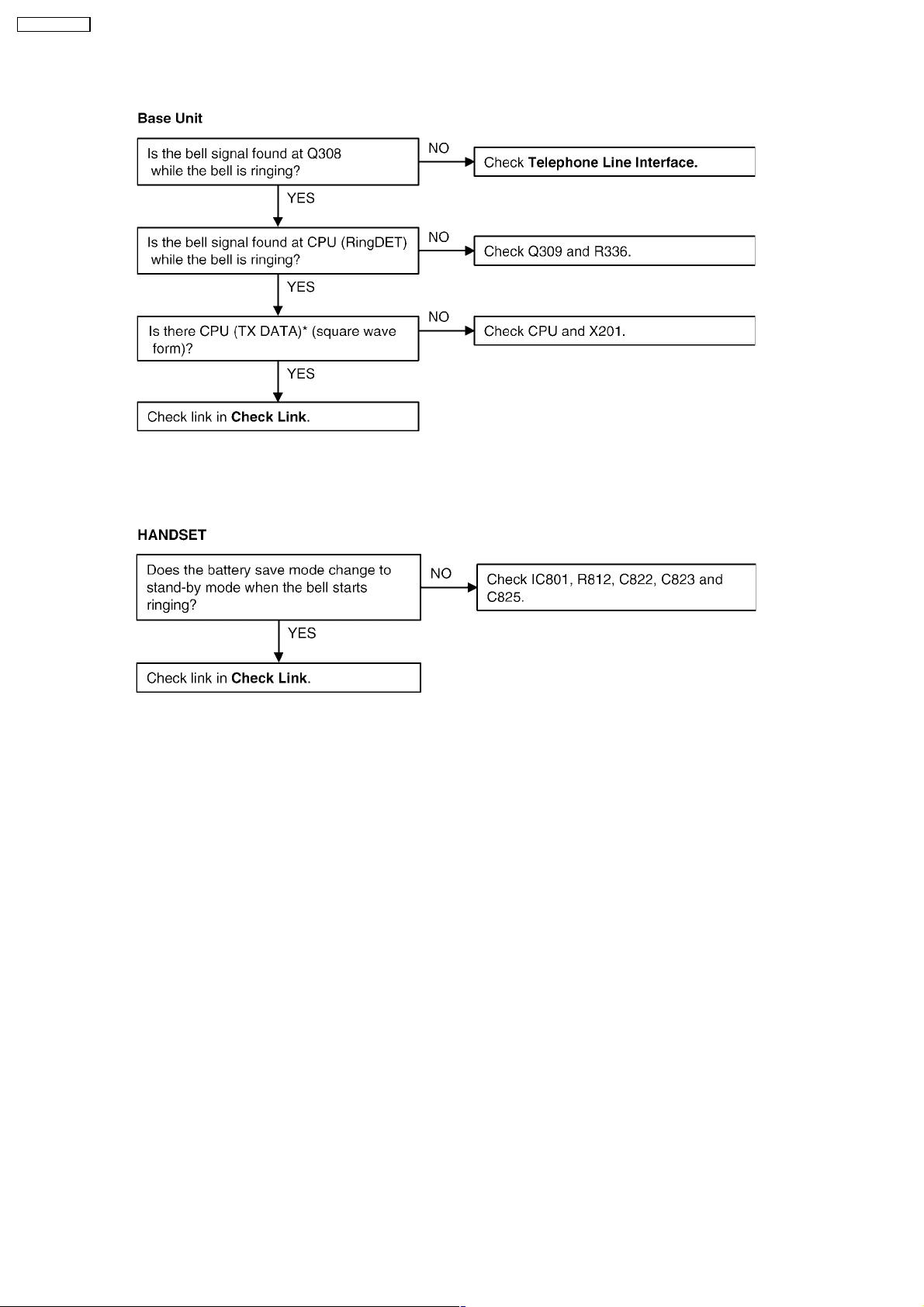

6.2. Bell Reception

Cross Reference:

Check Link (P.16)

Telephone Line Interface (P.35)

Cross Reference:

Check Link (P.16)

*: Each measurement points are shown in CIRCUIT BOARD (BASE UNIT) (P.59) or CIRCUIT BOARD (HANDSET) (P.61)

Note:

*CPU: IC201

Note:

*CPU: IC701

14

Page 15

6.3. Check Battery Charge

KX-TC2105LBB

Cross Reference:

Charge Circuit (P.35)

Cross Reference:

Reset Circuit (P.39)

*: Each measurement points are shown in CIRCUIT BOARD (BASE UNIT) (P.59) or CIRCUIT BOARD (HANDSET) (P.61)

Note:

*CPU: IC201

Note:

*CPU: IC701

15

Page 16

KX-TC2105LBB

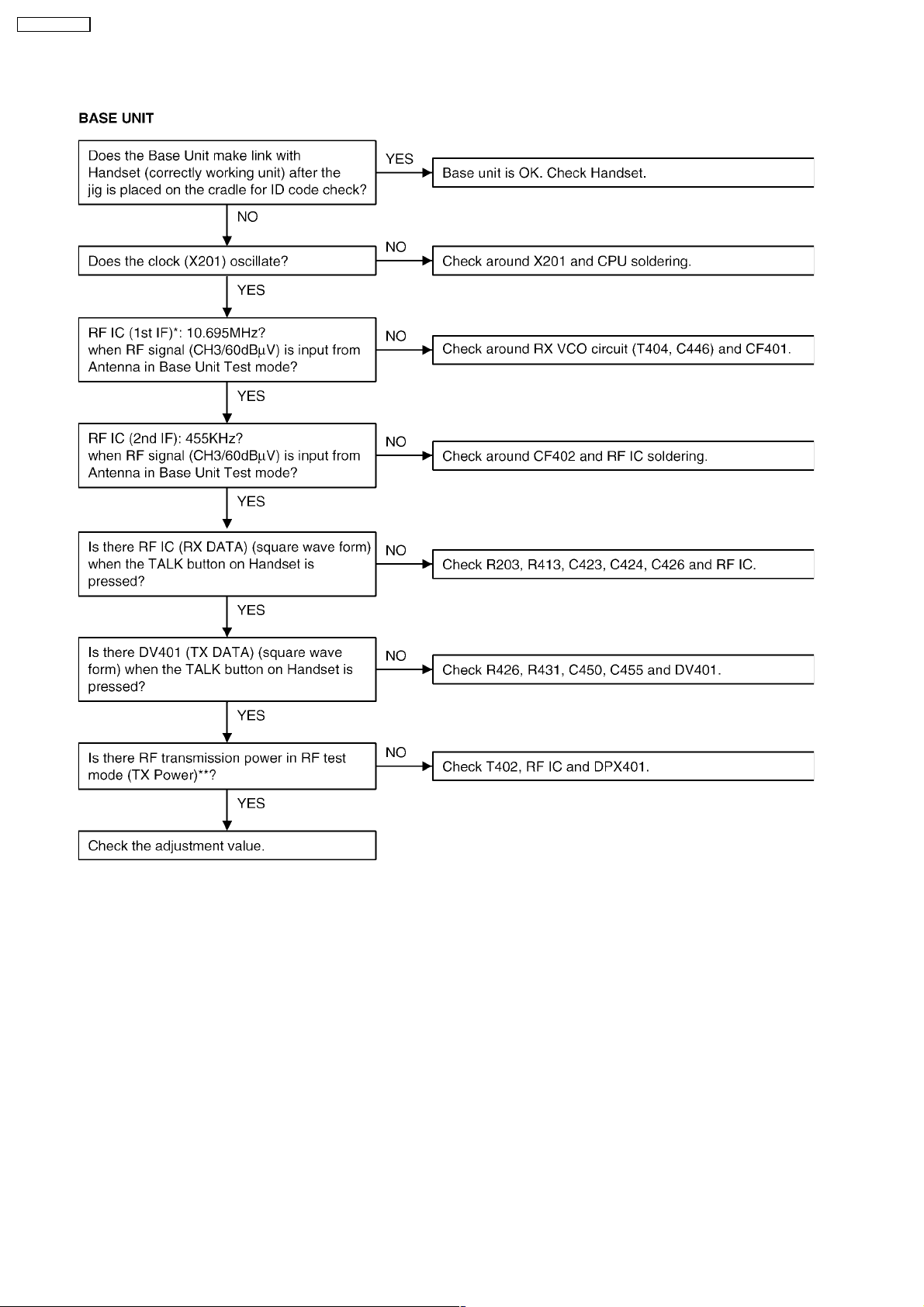

6.4. Check Link

**: Refer to Adjustment (P.20) Note:

*CPU: IC201

*RF IC: IC401

*: Each measurement points are shown in CIRCUIT BOARD (BASE UNIT) (P.59) or CIRCUIT BOARD (HANDSET) (P.61)

16

Page 17

KX-TC2105LBB

**: Refer to Adjustment (P.23). Note:

*CPU: IC701

*RF IC: IC801

*: Each measurement points are shown in CIRCUIT BOARD (BASE UNIT) (P.59) or CIRCUIT BOARD (HANDSET) (P.61)

6.5. Check Handset Transmission

Cross Reference:

SIGNAL ROUTE (P.41)

17

Page 18

KX-TC2105LBB

6.6. Check Handset Reception

Cross Reference:

SIGNAL ROUTE (P.41)

18

Page 19

7 ADJUSTMENTS (BASE UNIT)

If your unit has below symptoms, adjust or confirm each item using remedy column from the table.

Symptom Remedy*

The base unit does not respond to a call from handset. Make adjustments in item (A)

The base unit does not transmit or the transmit frequency is off. Make adjustments in item (B)

The transmit frequency is off. Make confirmation in item (C)

The transmit power output is low, and the operating distance between the base unit and

the handset is less than normal.

The reception sensitivity of base unit is low with noise. Make confirmation in item (E)

The transmit level is high or low. Make confirmation in item (F)

The reception level is high or low. Make confirmation in item (G)

The unit does not link. Make confirmation in item (H)

*: Refer to Adjustment (P.20).

7.1. Test Mode Flow Chart (Base Unit)

The operation-flow of Test mode and main check items are shown below.

Make adjustments in item (D)

KX-TC2105LBB

Note:

**: Refer to the above table.

19

Page 20

KX-TC2105LBB

7.2. How to change the channel

Note:

Refer to Adjustment Standard (Base Unit) (P.21) for connection.

7.3. Adjustment

Adjustment Items Test Mode Adjustment

(A) RX VCO

Adjustment

(B) TX VCO

Adjustment

(C) TX Frequency

Confirmation

(D) TX Power

Adjustment

(E) RX Sensitivity

Confirmation (2nd

IF output)

(F) Line Output Level

Confirmation

(G) Line Input

Modulation

Confirmation

(H) Noise Squelch

Confirmation

3ch Talk T404

3ch Talk T402

3ch Talk -

3ch Talk T403

3ch Talk T401 1. Apply -60dBm output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Apply -60dBm output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Input via loop simulator 1.0KHz, 55mV (measured at T-R) signal.

3ch Talk - 1. Measure the S.S.G. output level when the noise squelch changes from

Point

*Procedure Check or

• Adjust T404 so that the reading of the Digital Voltmeter is 1.5 ± 0.3 V.

• Adjust T402 so that the reading of the Digital Voltmeter is 0.8 ± 0.3 V.

• Confirm so that the reading of the frequency counter is 43.820MHz ±

700Hz.

• Adjust T403 so that the reading of the RF VTVM is more than -8dBm.

0KHz).

2. Confirm that the reading of AF VTVM is the maximum value (more than

20mV).

3KHz).

2. Confirm that the reading of AF VTVM is more than 250mV (600Ω load).

2. Apply -60dBm output from S.S.G. (modulation frequency 1KHz, dev.

0KHz).

3. Confirm so that the reading of FM Deviation Meter is 2.0 ± 0.5KHz.

Low to High.

2. Confirm that the S.S.G. output level is -95dBm ~ -100dBm.

Replace

Parts

IC401, T404,

C446

IC401,

DV401,

T402

IC401, X401,

DV401,

C440,

C441

IC401, Q403,

Q405, T403,

DPX401

DPX401,

T401,

CF401,

CF402

IC401, Q304

IC401,

DV401

IC401,

DPX401

* : The connections of adjustment equipment are as shown in Adjustment Standard (Base Unit) (P.21).

S.S.G. Frequency: 48.86 MHz

20

Page 21

KX-TC2105LBB

CH-UP

GND2

C306

R221

R222

R320

R224

GND3

R308

R318

R319

C314

Q305

CH_UP

R223

C203

R226

R323

33

34

R305

C315

R225

R227

C313

R321

R236

C321

R317

R322

R228

R304

C310

23

R333

22

44

R229

R303

R310

C309

C205

R230

RING

TIP

C307

R313

R207

IC201

1

R231

R302

C206

RING

C305

R311

TP7

R435

C204

R209

Loop

Simulator

600ohm

PbF

R337

R312

Q402

R208

R215

R216

R217

11 12

R205

R232

R210

TIP

R427

R206

R233

C201

R234

C452

R428

SQL

C208

C450

R426

R235

PWR_GND

SA303

Q309

C455

C451

C449

C202

R203

R202

Q202

PWR_GND

C101

R425

C445

R334

C323

R336

R431

C463

C439

5VREG

PDown

DC 12V

DC12V

C322

R102

R103

R335

R110

C461

R433

TXVCO

R421

R422

C448

C475

C441

R420

C437

C436

DC12V

CH+

C453

R429

3

R424

1

R423

C440

C433

Q201

R105

R436

C434

1

C438

R106

Q104

R439

R430

4

6

RXVCO

C442

R419

R417

RXDT

R109

Q403

C457

C446

C432

R441

C447

C430

R418

R108

C454

C474

Q404

435642

14

R416

R315

C468

C458

R432

IC401

R316

CH-

R107 R443

Q405

R442

C456

C408

15

R434

R405

C429

C428

C467

R437

C465

C409

C311

3

1

3

1

C466

C464

C426

C424

C427

R211

C103

C412

C425

C470

R438

C410

C459

29

28

R411

R412

C471

R440

4

6

C411

C423

C420

C207

4

6

9.1VREG

R402

R447

C416

C415

DET

C419

R410

R413

R444

R415

TP2

C472

RXGND

RXANT

C405

C406

C414

R408

GND1

C105

R403

1

6

R446

R407

C418

C421

LOCATOR

TXGND

C473

Q401

R404

R409

R406

C404

IFOUT

C417

C422

R204

TP6

TP1

C402

R401

R445

3

4

LED201

C403

TXANT

C407

IFGND

GND

TXANT

(A)

RXVCO

(C)

Frequency Counter

RXGND

DC Volt Meter

IFGND

IFOUT

(D)

Spectrum Analyzer

RF Signal Generator

Audio Analyzer

TXGND

RXANT

DC Volt Meter

(B)

TXVCO

RF Volt Meter

7.4. Adjustment Standard (Base Unit)

When connecting the Simulator and Equipments for checking, please refer to the illustration below.

(G)

Oscilloscope

Note: (A) - (G) is referred to ADJUSTMENTS (BASE UNIT) (P.19)

21

Page 22

KX-TC2105LBB

8 ADJUSTMENTS (HANDSET)

If your unit has below symptoms, adjust or confirm each item using remedy column from the table.

Symptom Remedy*

The movement of Battery Low Indicator is wrong. Make confirmation in item (A)

The base unit does not respond to a call from the handset. Make adjustments in item (B)

The base unit does not transmit or the transmit frequency is of f. Make adjustments in item (C)

The transmit frequency is off. Make confirmation in item (D)

The transmit power output is low, and the operating distance between the base unit and

the handset is less than normal.

The reception sensitivity of the handset is low with noise. Make confirmation in item (F)

Does not link between the base unit and the handset. Make confirmation in item (G)

The reception level is high or low. Make confirmation in item (H)

The transmit level is high or low. Make confirmation in item (I)

*: Refer to Adjustment (P.23).

Unit condition:

1. Remove the antenna lead wire from P.C. Board of the handset.

2. Power Supply: DC 3.9V (DC power supply)

3. Volume: HIGH (When P.C. Board of handset is in test mode, volume condition is medium. Press “LOCATOR” key once.)

4. Speaker Load: 150Ω

CH TX Frequency RX Frequency

CH3 48.860MHz 43.820MHz

Make adjustments in item (E)

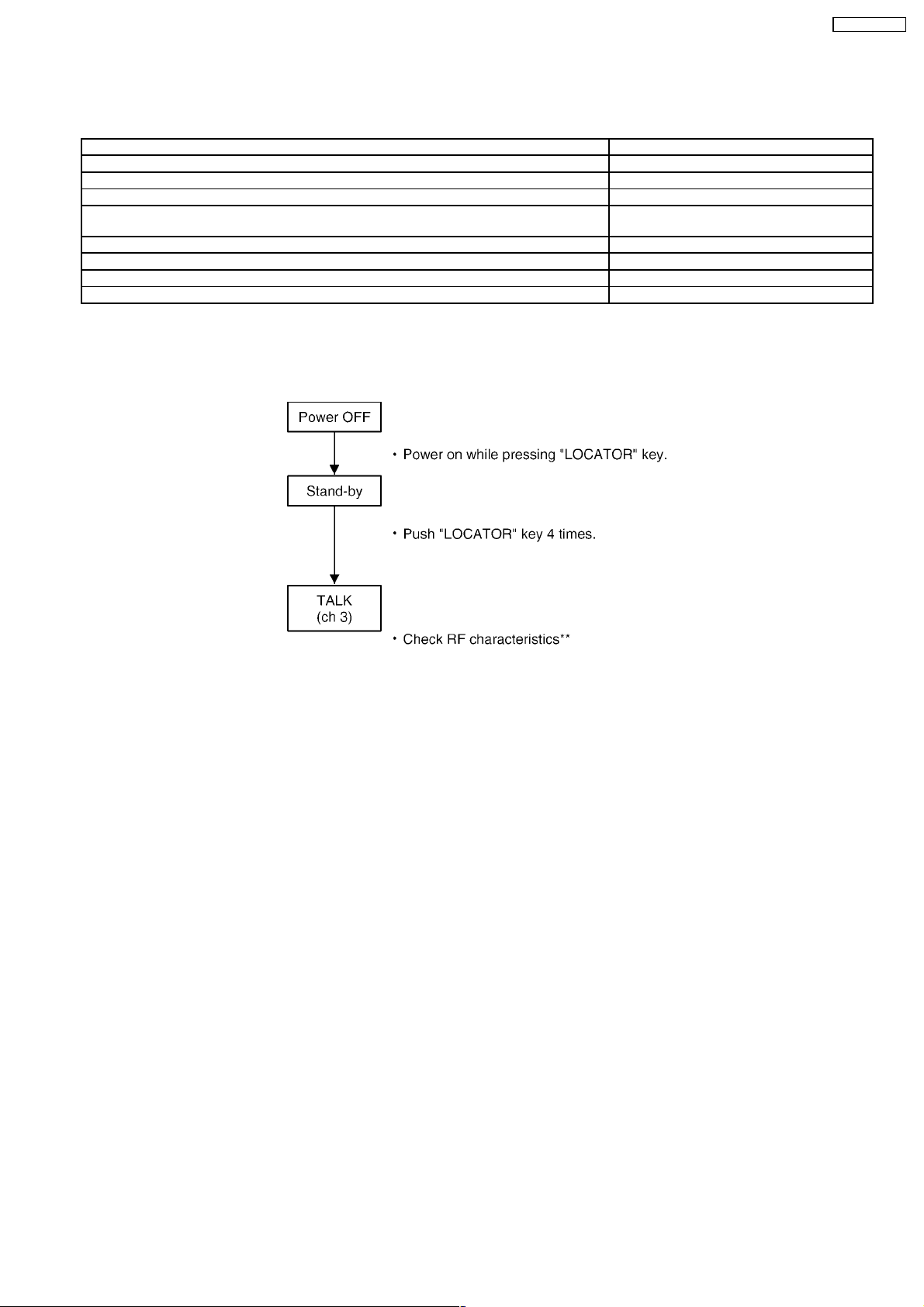

8.1. Test Mode Flow Chart (Handset)

Note:

Refer to CIRCUIT BOARD (HANDSET) (P.61)

SIGNAL ROUTE (P.41)

22

Page 23

8.2. How to change the channel

8.3. Adjustment

KX-TC2105LBB

Adjustment Items Test Mode Adjustment

(A) Battery Low

Confirmation

(B) TX VCO

Adjustment

(C) RX VCO

Adjustment

(D) TX Frequency

Confirmation

(E) TX Power

Adjustment

(F) RX Sensitivity

Confirmation

(2nd IF output)

(G) Noise Squelch

Confirmation

(H) Speaker

Output Level

Confirmation

(I) Mic Modulation

Factor

Confirmation

(J) Data

Modulation

Confirmation

3ch Talk - 1. Adjust the power supply voltage to DC 3.60V and confirm so that the

3ch Talk T803

3ch Talk T804

3ch Talk -

3ch Talk T802

3ch Talk T801 1. Apply -60dBm output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Measure the S.S.G. output level when the noise squelch changes from

3ch Talk - 1. Apply -60dBm output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Apply a MIC signal (1KHz, 4mV at 600Ω load).

3ch Talk -

Point

*Procedure Check or

reading of oscilloscope is High.

2. Adjust that power supply voltage to DC 3.40V and confirm so that the

reading of oscilloscope is Low.

• Adjust T803 so that the reading of the Digital Voltmeter is 0.8 ± 0.3 V.

• Adjust T804 so that the reading of the Digital Voltmeter is 1.0 ± 0.3 V.

• Confirm so that the reading of the frequency counter is 48.860MHz ±

700Hz.

• Adjust T802 so that the reading of the RF VTVM is more than -5dBm.

0KHz).

2. Confirm 2nd IF output so that the reading of AF VTVM is the maximum

value(more than 20mV).

Low to High. (modulation frequency 1KHz, dev.3KHz)

2. Confirm that the S.S.G. output level is -100dBm.

3KHz).

2. Confirm that the reading of AF VTVM is more than 30mV

(Distortion:less than 7%) (volume High)

2. Confirmation so that the reading FM Deviation Meter is 2.2 ± 0.5KHz.

• Confirm for 4KHz ~ 7KHz FM Deviation Meter reading.

Replace

Parts

IC801

IC801, X801,

T803, DV1

IC801, X801,

T804,C831

IC801,

DPX1,

T802

IC801, Q802,

Q804, T802,

DPX1

DPX1, T801,

CF801,

CF802

IC801, DPX1

IC801

IC801, DV1

Q802, Q804,

T802, DV1,

DPX1

*: The connections of adjustment equipment are as shown in Adjustment Standard (Handset) (P.24).

S.S.G. Frequency: 43.82 MHz

23

Page 24

KX-TC2105LBB

(H)

(A), (G)

Modulation Meter

RF Signal Generator

(I), (J)

Spectrum Analyzer

(E)

GND

Audio Analyzer

SP-

SP+

NDTC

C872

C873

TXPOWER

(D)

C853

C851

4

3

R831

C852

1

6

C854

Q802

6

43

C865

C870

1

C861

Q804

R837

Frequency Counter

R848

C864

C866

R843

DTCOUT

AUTO

GND

R833

R830

C857

R838

C848

R841

C855

R835

C862

C860

C802

IFOUT

C856

R836

C863

R839

C858

Oscilloscope

ANT_TP

C801

IFGND

R803

R834

Q803

R804

C808

C832

C836

C804

PSAVE

R851

C803

R802

C871

6

C839

R850

R801

311

C831

C838

Q801

C805

3

644

DIRECT

RXVCO

TXVCO

(C)

IFGND

DC Volt Meter

RXVCO

(B)

IFGND

DC Volt Meter

TXVCO

(F)

TALK

IFGND

DC Power Supply

FLASH LED701

REDIAL

RF Volt Meter

IFOUT

1

4

7

PROGRAM

+

LOUD

-

2

LED702

5

8

LED703

0

RINGER

12

GND OUTPUT

MIC

LED705

LED704

3

6

9

PbF

#

PAUSE

CH

8.4. Adjustment Standard (Handset)

When connecting the Simulator and Equipments for checking, please refer to the illustration below.

Note: (A)-(J) is referred to ADJUSTMENTS (HANDSET) (P.22)

24

Page 25

9 RF SPECIFICATION

9.1. Base Unit

Item Value Refer to -.* Remarks

TX Frequency 43.820 MHz ± 700 Hz ADJUSTMENTS (BASE UNIT) (C) at CH3

TX Power more than -8dBm ADJUSTMENTS (BASE UNIT) (D) at CH3

Line Modulation factor 2.0 KHz ± 0.5 KHz ADJUSTMENTS (BASE UNIT) (G)

Data Modulation factor 5.5 KHz ± 1.5 KHz —

Line Output level more than 250 mV —

*: Refer to Adjustment (P.20).

9.2. Handset

Item Value Refer to -.** Remarks

TX Frequency 48.860 MHz ± 700 Hz ADJUSTMENTS (HANDSET) (D) at CH3

TX Power more than -5dBm ADJUSTMENTS (HANDSET) (E) at CH3 (Antenna

soldering point 50Ω

Load)

Data Modulation factor 5.5 KHz ± 1.5 KHz ADJUSTMENTS (HANDSET) (J) at CH3

MIC Modulation factor 2.2 KHz ± 0.5 KHz ADJUSTMENTS (HANDSET) (I) at CH3 (MIC terminal

4mV Input)

SP Output level more than 30 mV —

KX-TC2105LBB

**: Refer to Adjustment (P.23).

10 HOW TO CHECK THE HANDSET SPEAKER

1. Prepare the digital voltmeter, and set the selector knob to ohm meter.

2. Put the probes at the speaker terminals as shown below.

25

Page 26

KX-TC2105LBB

11 FREQUENCY TABLE (MHz)

BASE UNIT HANDSET

Channel Transmit Frequency Receive Frequency Transmit Frequency Receive Frequency

1 43.720 48.760 48.760 43.720

2 43.740 48.840 48.840 43.740

3 43.820 48.860 48.860 43.820

4 43.840 48.920 48.920 43.840

5 43.920 49.020 49.020 43.920

6 43.960 49.080 49.080 43.960

7 44.120 49.100 49.100 44.120

8 44.160 49.160 49.160 44.160

9 44.180 49.200 49.200 44.180

10 44.200 49.240 49.240 44.200

11 44.320 49.280 49.280 44.320

12 44.360 49.360 49.360 44.360

13 44.400 49.400 49.400 44.400

14 44.460 49.460 49.460 44.460

15 44.480 49.500 49.500 44.480

16 46.610 49.670 49.670 46.610

17 46.630 49.845 49.845 46.630

18 46.670 49.860 49.860 46.670

19 46.710 49.770 49.770 46.710

20 46.730 49.875 49.875 46.730

21 46.770 49.830 49.830 46.770

22 46.830 49.890 49.890 46.830

23 46.870 49.930 49.930 46.870

24 46.930 49.990 49.990 46.930

25 46.970 49.970 49.970 46.970

26

Page 27

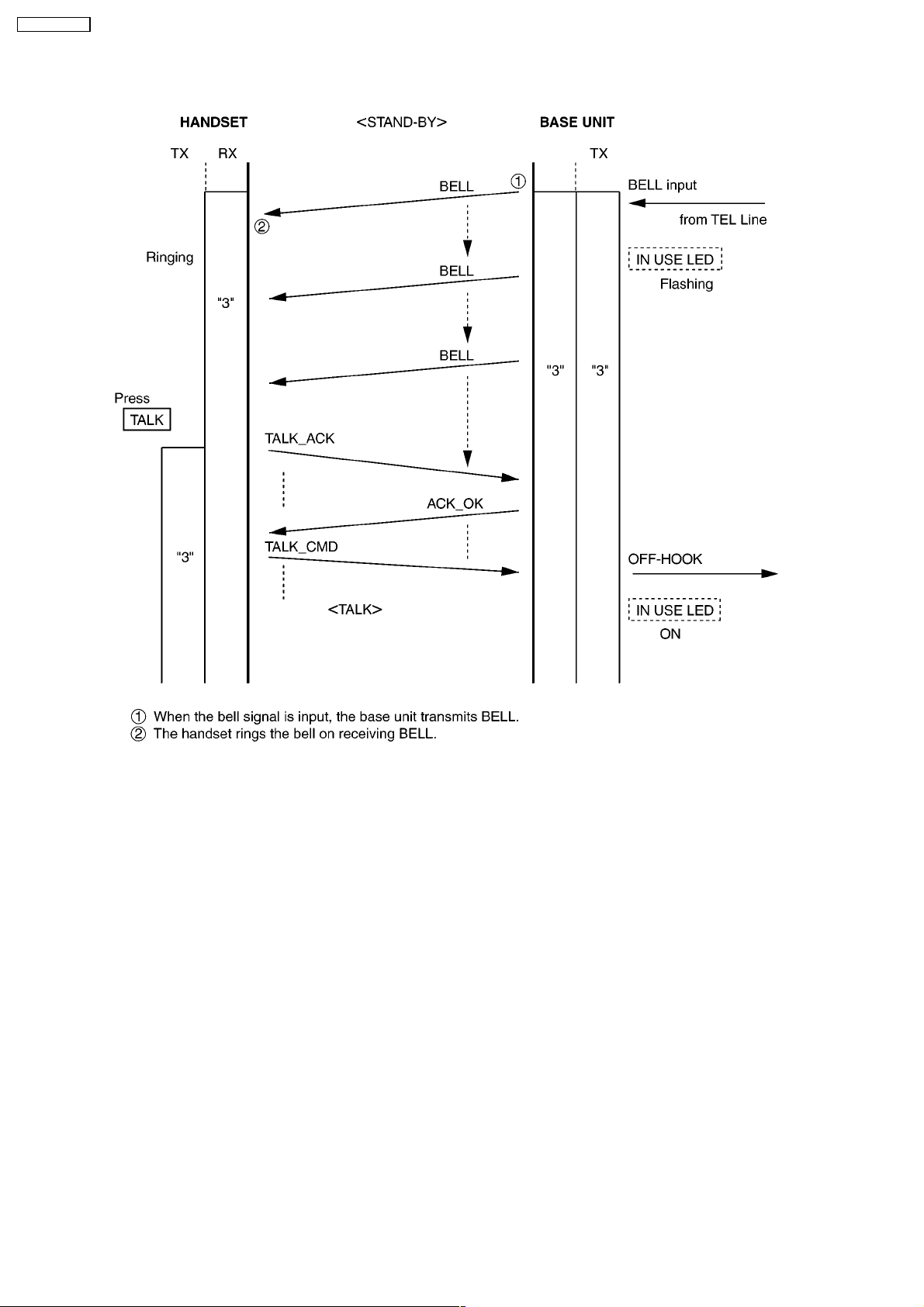

12 EXPLANATION OF CPU DATA COMMUNICATION

12.1. STAND-BY -> TALK, TALK -> STAND-BY

KX-TC2105LBB

*: The channel is changed if the noise interferes with the conversation.

27

Page 28

KX-TC2105LBB

12.2. Ringing

28

Page 29

12.3. Changing the Channel

KX-TC2105LBB

29

Page 30

KX-TC2105LBB

12.4. Ports for transmitting and receiving of data

Handset:

transmitting (TX) ... 25 Pin

receiving (RX) ... 12 Pin

Base Unit:

transmitting (TX) ... 23 Pin

receiving (RX) ... 10 Pin

12.5. Waveform of DATA used for cordless transmission and reception

The DATA which is transmitted from the Handset to the Base Unit is combination of DATA 0, DATA 1, DATA Delimit.

The DATA which is transmitted from the Base Unit to the Handset is combination of DATA 0, DATA 1, DATA Delimit.

12.5.1. Handset

12.5.2. Base Unit

• For example (one of part of data)

30

Page 31

TEL LINE

BELL DTC

D303-D306

Diode Bridge

Q309

DC 12V

Transistor

Q101,D103

KX-TC2105LBB

-

+

Q102,Q103

Charge Control

DATA Filter

Filter

PRE AMP

EXPANDER

AMP Q305

Q301,Q302

TEL LINE SW

TEL LINE

AMP Q304

LINE AMP

DATA AMP

DC9.1V

RESET

DOWN

POWER

MCU

RX DATA

RESET

RF EN

RF DATA

POWER DOWN

RF CLOCK

DC5V

CPU

LED201Q201

IC201

Q104

Charge Control

Charge Detection

KX-TC2105 BLOCK DIAGRAM (BASE UNIT)

2nd IF

Filter

Filter

1st IF

DPX401

DUPLEXER

13 BLOCK DIAGRAM (BASE UNIT)

IF Filter DET

1st Mixer 2nd Mixer

RF AMP

Q401,T401

RF IC

1st Local

RX VCO

T404,C446

IC401

Osc

Crystal

PLL

MIC AMP

LIMITER

COMPRESSOR

RX PD

TX PD

MODULATION

DV401

TX VCO

Q403,T402,

TX AMP

Q405,T403

31

Crystal

TX DATA

Page 32

KX-TC2105LBB

14 CIRCUIT OPERATION (BASE UNIT)

14.1. Outline

Base unit consists of the following ICs as shown in BLOCK DIAGRAM (BASE UNIT) (P.31).

• CPU: IC201

− Controlling the whole system

− Forming/analyzing all data signals (ACK, CMD signal etc.)

− All interfaces (ex: LED, Detector Circuit (Charge/ Power Down))

• RF IC: IC401

− PLL Oscillator

− Detection

− Compress/ Expander

− 1st/2nd mixer

− Amplifier for transmission and reception

− DC 5.5V regulator

− Reset Circuit

• Additionally,

− Power Supply Circuit

− Charge Circuit

− Telephone Line Interface Circuit

32

Page 33

14.2. Power Supply Circuit

The power supply to the CPU and RF IC from AC Adaptor (+12V) is shown in the diagram below.

The base unit power supply is DC12V. The handset power is supplied from DC 3.6V battery (Nickel-Cadmium battery) which

is installed in the handset.

Power supply for transmitter is turned on by pressing "TALK" key on the handset. During the stand-by mode, the unit stops

transmitting but receives the signal.

During on-hook condition (the handset is placed on the base unit), backup power for memory of the last dialed number is

supplied through the battery (DC 3.6V Nickel-Cadmium in the handset). The memory of this unit is not backed up by the current

from the telephone line.

The base unit DC power supply is regulated by Q101, D103. The CPU power is supplied from IC401. IC401 detects AC Adaptor

power failure and maintains the unit security code.

KX-TC2105LBB

<Fig. 1>

33

Page 34

KX-TC2105LBB

14.3. Reset Circuit

After power supply from AC adaptor, the reset signal for CPU is making in IC401. Refer to the below waveform.

<Fig. 2>

<Fig. 3>

34

Page 35

14.4. Charge Circuit

Circuit Operation:

When charging the handset on the base unit, the charge current is as follows;

DC12V → L101 → D102 → L103 → CH+(Base) → +CONTACT J601(Handset) → L602 → D602 → CN1-1 → Battery →

CN1-2 → -CONTACT J602(Handset) → CH-(Base) → L104 → Q102 → R104

In this way, the CPU on both units detects the fact that the battery is charged.

The charge current is controlled by switching Q103 of Base Unit. The battery is charged in normal mode for 9 hours and then

in trickle mode.

14.5. Telephone Line Interface

Function:

• Bell signal detection

• ON/OFF hook and pulse dial circuit

• Side tone circuit

Bell signal detection and OFF HOOK circuit:

In the idle mode, Q301 is open to cut the DC loop current and decrease the ring load. When ring voltage appears at the Tip (T)

and Ring (R) leads (When the telephone rings), the AC ring voltage is transferred as follows:

• JK1 TIP → P0301 → L301 → R334 → C322 → Q309 → IC201 Pin30

• JK1 RING → L302 → R333 → C321 → C323 → Q309 → IC201 Pin30

When the CPU detects a ring signal and press the “TALK” key on the handset, Q302 turns on and then Q301 turns on,

thus providing an off-hook condition (active DC current flow through the circuit) and the following signal flow is for the loop

current.

• Tip → P0301 → L301 → D303 → Q301 → R303 → Q302 → D306 → L302 → Ring

ON HOOK Circuit:

Q302 is open, Q301 is disconnected as to cut the DC loop current and to cut the voice signal. The unit is consequently in an

on-hook condition.

Pulse Dial Circuit:

CPU (Hook) turns Q302 ON/OFF to make the pulse dialing via Q301.

Make/Break ratio when dialing with the Handset 32% : 68%

Side Tone Circuit:

Basically this circuit prevents the TX signal from feeding back to RX signal.

As for this unit, TX signal feed back from Q304 is canceled by the side tone circuit C312, C313, R317, R318 and R319.

KX-TC2105LBB

35

Page 36

KX-TC2105LBB

14.6. Transmitter/Receiver

Base Unit and Handset mainly consist of RF (Radio Frequency) IC and CPU.

Base Unit and Handset transmit/receive voice signal and data signal through the antenna on carrier frequency.

Signal Path:

*Refer to CDL TX/RX in SIGNAL ROUTE (P.41).

14.6.1. Base to Handset

Circuit Operation:

The voice signal input from the TEL LINE interface goes to RF IC as shown in BLOCK DIAGRAM (BASE UNIT) (P.31).

In the talk mode (off-hook) condition, the telephone line voice signal passes through D303, Q301, C313, R320 and C315.

The signal goes through the compressor of RF IC, and it is output to transmitter circuit.

The signal of the data sent to the handset is applied in the anode of the variable capacitor diode (VARICAP : DV401).

The capacitor of VARICAP is changing in accordance with the voice signal from telephone line interface or TX DATA signal from

CPU. Therefore, the carrier frequency which is generated by TX VCO will be changed, and Frequency modulated RF

signal is generated and amplified by RF AMP (Q405, T403). It passes through the Duplexer DPX401 and is radiated from

Antenna.

The signal is transmitted from the base unit and received by the handset antenna and amplified by RF amplifier (Q801) through

DPX1 as shown in BLOCK DIAGRAM (HANDSET) (P.38). And then it is converted to 10.695 MHz and 455 KHz Intermediate

frequency by RF IC and related components.

The demodulated audio signal is output from RF IC (DET OUT) and passed through "Expander" process to reduce noise, then

voice signal amplified by "Receiver amplifier" is output to receiver (REC1).

The receiver loudness is adjustable by using "LOUD" key on the handset.

TX data (to Handset):

CPU (VTX) becomes low to turn on the transmission power transistor Q805, and CPU (TX-data) sends data signal. It is

FM-modulated by TX VCO and driven by RF AMP, then transmitted to the handset.

14.6.2. Handset to Base

Circuit Operation:

The voice signal from the handset user is picked up by the microphone (MIC), then it passes through "Compressor"

process to reduce noise as shown in BLOCK DIAGRAM (HANDSET) (P.38). And the voice is FM-modulated by

VARICAP (DV1).

The carrier frequency is generated by TX VCO. The transmitter power transistor Q805 is turned on/off by CPU (VTX).

The carrier signal is amplified by RF AMP and sent to the handset duplexer and antenna.

The signal of 49 MHz band (48.760~49.990) which is input from ANT is filtered at DPX401 as shown in

BLOCK DIAGRAM (BASE UNIT) (P.31), then it is input to RF IC.

The signal input to RF IC is converted through Mixer inside of RF IC, RF filter (CF1, CF2) and Expander.

The signal is transmitted from the handset and received by the base unit antenna and amplified by RF amplifier Q401, then

it is converted to10.695 MHz and 455 KHz Intermediate by RF IC. The demodulated audio signal is output from RF IC

(DET OUT) and passed through "Expander" process to reduce noise, then voice signal is led to LINE AMP. The signal passes

through TELEPHONE INTERFACE and Tel-line.

RX data (from Handset):

The data signal from handset (ex: Talk, ACK, COM) is also included in 49 MHz band same as the voice data. After second if

filter, the data signal is made square shape by data limiting AMP of the RF IC. RX data is output to CPU (RX Data).

36

Page 37

14.6.3. RF signal operation/control and PLL operation (RF UNIT)

Base unit radio frequency signal received by antenna passes through duplexer (DPX401).

RF signal is amplified by RF AMP. RF signal received from RF IC is mixed with RX local frequency at Mixer to generate

10.695 MHz wide band IF. The reference frequency is generated by X801 10.240 MHz crystal.

The 10.695 MHz is mixed with reference and 455 KHz narrow band IF is generated.

RF IC is controlled by CPU (RF EN, RF DATA, RF CLOCK). The RX local frequency is generated by RX VCO.

KX-TC2105LBB

37

Page 38

KX-TC2105LBB

DC3.9V

Battery

+

-

Filter

2nd IF

DATA Filter

Filter

PRE AMP

EXPANDER

IF Filter DET

SPEAKER

DATA AMP

SPEAKER AMP

RF IC

IC801

LIMITER

MIC

DOWN

POWER

MCU

MIC AMP

RX DATA

RF EN

RF CLOCK

RF DATA

POWER DOWN

Crystal

TX DATA

Reset

CPU

IC701

Key Matrix

Q704

Q705

Charge Detection

KX-TC2105 BLOCK DIAGRAM (HANDSET)

Buzzer

Q701,Q702

Filter

1st IF

RF AMP

DPX1

DUPLEXER

15 BLOCK DIAGRAM (HANDSET)

1st Mixer 2nd Mixer

1st Local

RX VCO

Q801,T801

Osc

Crystal

T804,C831

PLL

COMPRESSOR

TX PD

RX PD

MODULATION

DV1

TX VCO

Q804,T803,

TX AMP

Q802,T802

38

Page 39

16 CIRCUIT OPERATION (HANDSET)

16.1. Outline

Handset consists of the following ICs as shown in BLOCK DIAGRAM (HANDSET) (P.38).

• CPU: IC701

− Forming/analyzing all data signals (ACK or CMD signal)

− All interfaces (ex; LED, Key, Buzzer, Detector Circuit, Charge/Battery Low)

− RAM for keeping the data (CH Number, ID Code, etc.)

• RF IC: IC801

− PLL Oscillator

− Detection

− Compress/Expander

− 1st/2nd mixer

− Amplifier for transmission and reception

16.2. Reset Circuit

The power of handset is supplied by battery.

Whenever the battery is recharged or inserted, the impulse at CHG+ becomes Reset signal through Q704, and it is sent to CPU.

KX-TC2105LBB

<Fig. 4>

<Fig. 5>

39

Page 40

KX-TC2105LBB

16.3. Battery Low / Power Down Detector

Circuit Operation:

“Battery Low” and “Power Down” are detected by RF IC which check the voltage from battery. Shortly, every detected blocks

are inside of RF IC. The detected voltage is as follows;

• Battery Low

Battery voltage : V(Batt) < 3.457V

The CPU detects the level and “Recharge battery” LED starts flashing.

• Power Down

Battery voltage : V(Batt) < 3.0V

The output of RF IC (Power Down) becomes low level, then CPU stops working to keep the data (CH number, ID Code, etc.)

<Fig. 6>

40

Page 41

17 SIGNAL ROUTE

Each signal route is as follows.

KX-TC2105LBB

41

Page 42

KX-TC2105LBB

18 CPU DATA (Base Unit)

18.1. IC201

42

Page 43

19 CPU DATA (Handset)

19.1. IC701

KX-TC2105LBB

43

Page 44

KX-TC2105LBB

20 RF IC (Base Unit and Handset)

20.1. Base Unit: IC401, Handset: IC801

44

Page 45

21 HOW TO REPLACE THE FLAT PACKAGE IC

Even if you do not have the special tools (for example, a spot heater) to remove the Flat IC, with some solder (large amount),

a soldering iron and a cutter knife, you can easily remove the ICs that have more than 100 pins.

21.1. PREPARATION

• PbF (: Pb free) Solder

• Soldering Iron

Tip Temperature of 700°F ± 20°F (370°C ± 10°C)

Note: We recommend a 30 to 40 Watt soldering iron. An expert may be able to use a 60 to 80 Watt iron where someone with

less experience could overheat and damage the PCB foil.

• Flux

Recommended Flux: Specific Gravity → 0.82.

Type → RMA (lower residue, non-cleaning type)

Note: See ABOUT LEAD FREE SOLDER (PbF: Pb free) (P.4)

21.2. FLAT PACKAGE IC REMOVAL PROCEDURE

1. Put plenty of solder on the IC pins so that the pins can be completely covered.

Note:

If the IC pins are not soldered enough, you may give pressure to the P.C. board when cutting the pins with a cutter.

KX-TC2105LBB

2. Make a few cuts into the joint (between the IC and its pins) first and then cut off the pins thoroughly.

3. While the solder melts, remove it together with the IC pins.

When you attach a new IC to the board, remove all solder left on the land with some tools like a soldering wire. If some solder is

left at the joint on the board, the new IC will not be attached properly.

45

Page 46

KX-TC2105LBB

21.3. FLAT PACKAGE IC INSTALLATION PROCEDURE

1. Temporarily fix the FLAT PACKAGE IC, soldering the two marked pins.

*Check the accuracy of the IC setting with the corresponding soldering

foil.

2. Apply flux to all pins of the FLAT PACKAGE IC.

3. Solder the pins, sliding the soldering iron in the direction of the arrow.

21.4. BRIDGE MODIFICATION PROCEDURE

1. Lightly resolder the bridged portion.

2. Remove the remaining solder along the pins using a soldering iron as shown in the figure below.

46

Page 47

22 CABINET AND ELECTRICAL PARTS (BASE UNIT)

KX-TC2105LBB

47

Page 48

KX-TC2105LBB

23 CABINET AND ELECTRICAL PARTS (HANDSET)

48

Page 49

24 ACCESSORIES AND PACKING MATERIALS

KX-TC2105LBB

49

Page 50

KX-TC2105LBB

25 TERMINAL GUIDE OF THE ICs, TRANSISTORS AND

DIODES

25.1. Base Unit

25.2. Handset

50

Page 51

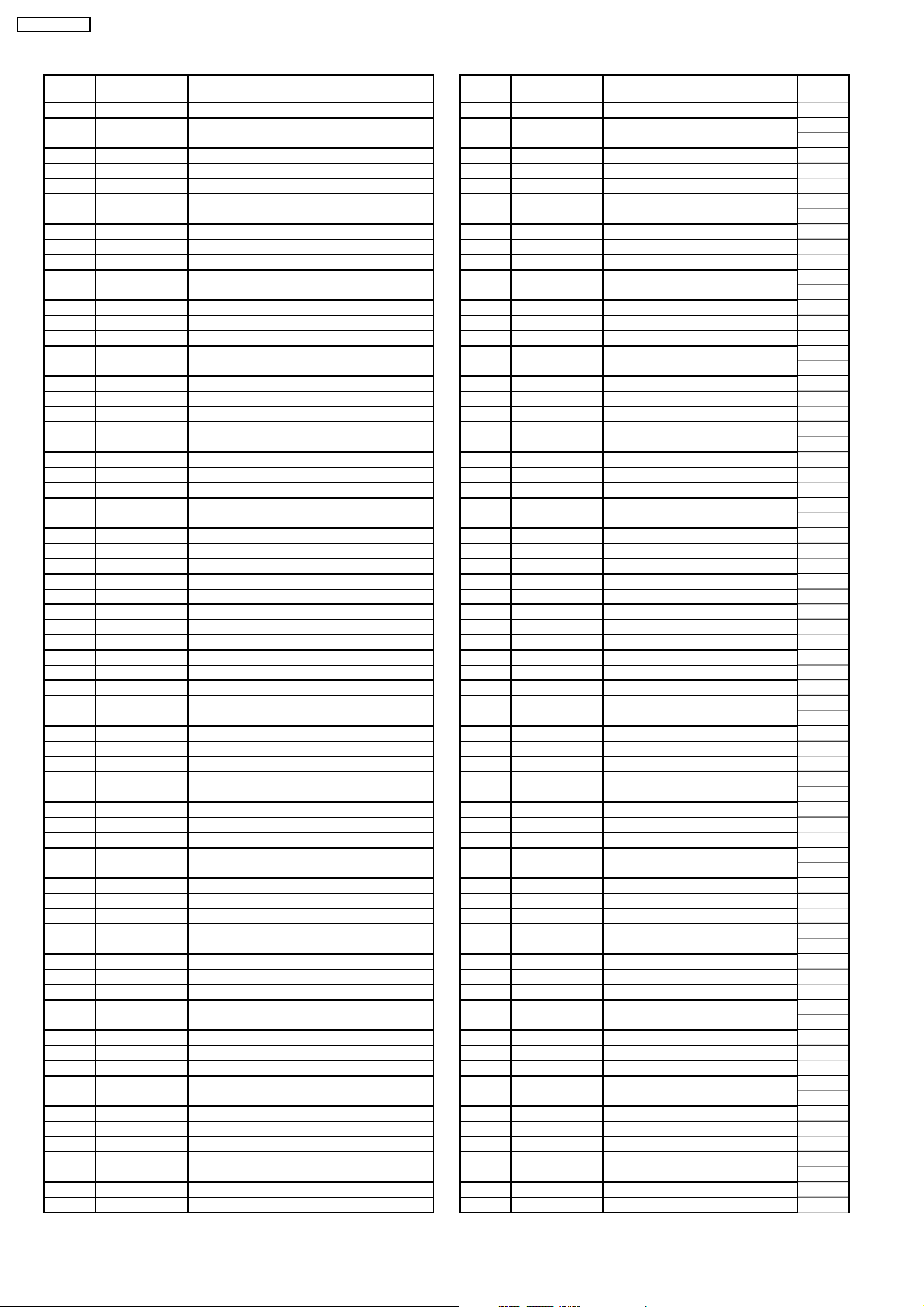

26 REPLACEMENT PARTS LIST

KX-TC2105LBB

1. RTL (Retention Time Limited)

Note:

The marking (RTL) indicates that the Retention Time is

limited for this item.

After the discontinuation of this assembly in production,

the item will continue to be available for a specific period

of time. The retention period of availability is dependant

on the type of assembly, and in accordance with the

laws governing part and product retention. After the end

of this period, the assembly will no longer be available.

2. Important safety notice

Components identified by the

mark indicates special

characteristics important for safety. When replacing any of

these components, only use specified manufacture’s parts.

3. The S mark means the part is one of some identical parts.

For that reason, it may be different from the installed part.

4. ISO code (Example: ABS-94HB) of the remarks column

shows quality of the material and a flame resisting grade

about plastics.

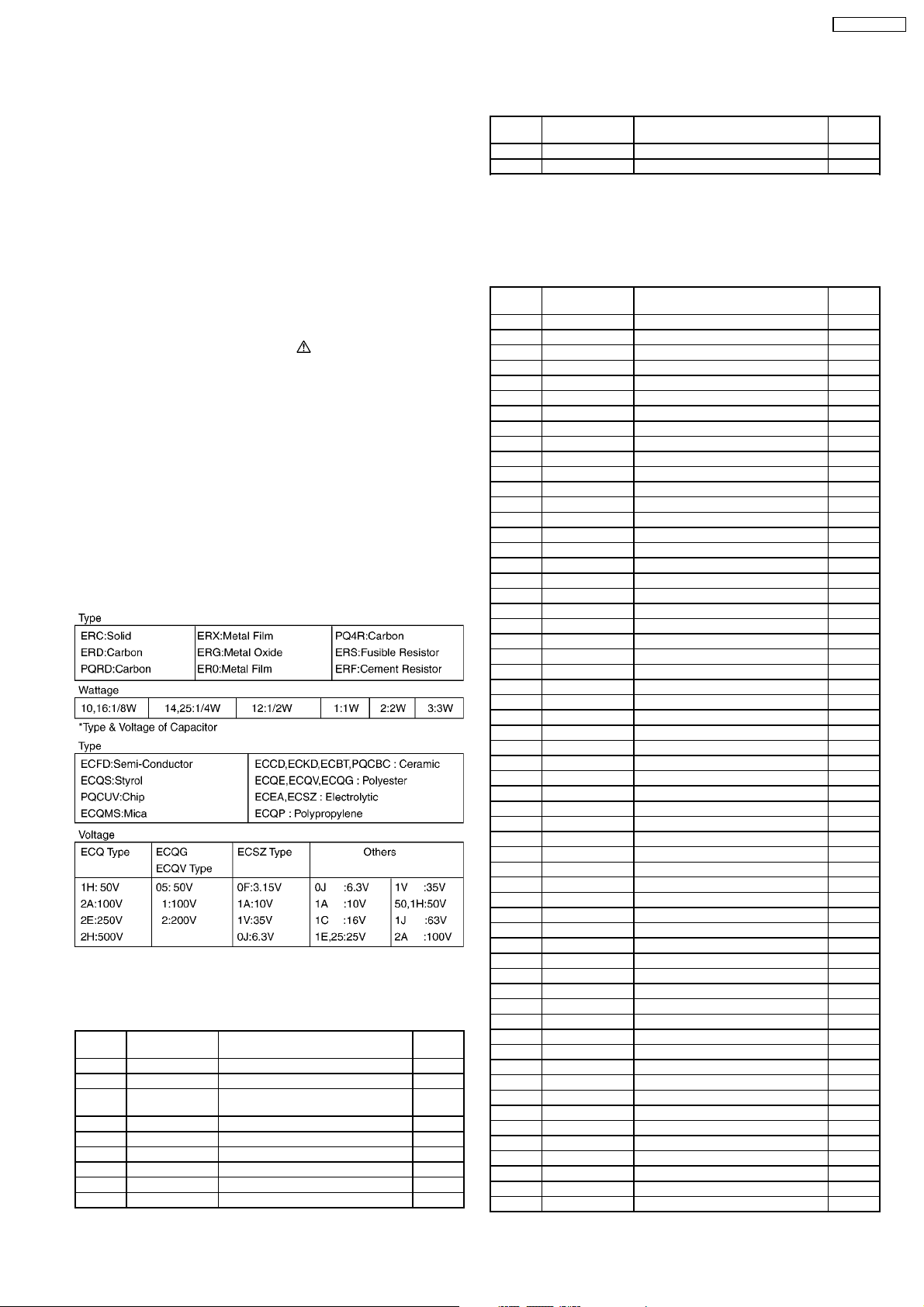

5. RESISTORS & CAPACITORS

Unless otherwise specified;

All resistors are in ohms (Ω) K=1000Ω, M=1000kΩ

All capacitors are in MICRO FARADS (µF)P=µµF

*Type & Wattage of Resistor

26.1. Base Unit

26.1.1. Cabinet and Electrical Parts

Ref.

No.

1 PQQT23004Z LABEL, CHARGE

2 PQKM10675Z1 CABINET BODY PS-HB

3 PQHR11113Z OPTIC CONDUCTIVE PARTS, LED

4 PQBC10428Z1 BUTTON, LOCATOR ABS-HB

5 PQSA10105Y ANTENNA

6 PQJT10229Z CHARGE TERMINAL

7 PQHR11115Z CASE, CHARGE TERMINAL PS-HB

8 PQKF10666Z1 CABINET COVER PS-HB

9 PQHA10030Z RUBBER PARTS, FOOT RUBBER

Part No. Part Name & Description Remarks

LENDS

PS-HB

Ref.

No.

10 PQGT18241Z NAME PLATE

11 PQQT23081Z LABEL, CAUTION

Part No. Part Name & Description Remarks

26.1.2. Main P.C.Board Parts

Note:

(*1) When you have replaced IC401, adjust X401. Refer to

ADJUSTMENTS (BASE UNIT) (P.19).

Ref.

No.

PCB1 PQWPC2105LBH MAIN P.C.BOARD ASS´Y (RTL)

IC201 MN101C94AKA IC

IC401 AN6266FA IC (*1)

Q101 B1AADE000014 TRANSISTOR(SI)

Q102 B1AADE000014 TRANSISTOR(SI)

Q103 B1AADE000014 TRANSISTOR(SI)

Q104 B1ABDE000020 TRANSISTOR(SI)

Q201 B1GBCFGG0028 TRANSISTOR(SI)

Q202 B1ABDE000020 TRANSISTOR(SI)

Q301 B1BCBR000013 TRANSISTOR(SI)

Q302 PQVT2N6517CA TRANSISTOR(SI) S

Q304 B1AAJC000010 TRANSISTOR(SI)

Q305 B1ABDE000020 TRANSISTOR(SI)

Q309 B1ABDE000020 TRANSISTOR(SI)

Q401 B1ABDE000020 TRANSISTOR(SI)

Q402 B1GDCFNN0021 TRANSISTOR(SI)

Q403 B1ABDE000020 TRANSISTOR(SI)

Q405 B1ABDE000020 TRANSISTOR(SI)

D101 MA4300 DIODE(SI) S

D102 B0EAKP000126 DIODE(SI)

D103 MA4100 DIODE(SI) S

D105 MA4300 DIODE(SI) S

D201 B0EAAD000001 DIODE(SI)

D303 B0EAKP000126 DIODE(SI)

D304 B0EAKP000126 DIODE(SI)

D305 B0EAKP000126 DIODE(SI)

D306 B0EAKP000126 DIODE(SI)

D307 MA4180 DIODE(SI) S

D308 B0EAAD000001 DIODE(SI)

D401 B0EAAD000001 DIODE(SI)

DV401 B0CAAB000021 DIODE(SI)

LED201 PQVDSML310MT LED S

L101 G0C100K00039 COIL

L104 PQLQZM100K COIL S

L301 PQLQZK3R3K COIL S

L302 PQLQZK3R3K COIL S

L401 PQLQZK1R5K COIL S

T401 G2BRC0000008 COIL

T402 PQL04B001 COIL

T403 G2BRC0000007 COIL

T404 PQL04B002 COIL

CF401 J0B1075A0127 CERAMIC FILTER

CF402 J0B4553A0065 CERAMIC FILTER

DPX401 J0E4535A0001 IC FILTER

X201 H0D795400007 CRYSTAL OSCILLATOR

X401 H0D102500029 CRYSTAL OSCILLATOR (*1)

JK1 K2LD104A0001 JACK S

SA302 J0LF00000026 VARISTOR (SURGE ABSORBER) S

SA303 J0LF00000048 VARISTOR (SURGE ABSORBER)

Part No. Part Name & Description Remarks

(ICs)

(TRANSISTORS)

(DIODES)

(COILS)

(CERAMIC FILTERS)

(IC FILTERS)

(CRYSTAL OSCILLATORS)

(JACKS)

(VARISTORS)

(RESISTORS)

51

Page 52

KX-TC2105LBB

Ref.

No.

R101 ERDS2TJ221 220

R102 ERJ3GEYJ102 1K

R103 ERJ3GEYJ102 1K

R104 ERDS2TJ151 150

R105 ERJ3GEYJ102 1K

R106 ERJ3GEYJ391 390

R107 PQ4R10XJ101 100 S

R108 PQ4R10XJ270 27 S

R109 ERJ3GEYJ103 10K

R110 ERJ3GEYJ104 100K

R202 ERJ3GEYJ103 10K

R203 ERJ3GEYJ104 100K

R204 ERJ3GEYJ681 680

R205 ERJ3GEYJ104 100K

R206 ERJ3GEYJ104 100K

R207 ERJ3GEYJ102 1K

R208 ERJ3GEYJ103 10K

R209 ERJ3GEYJ104 100K

R210 ERJ3GEYJ823 82K

R211 ERJ3GEY0R00 0

R215 ERJ3GEYJ472 4.7K

R216 ERJ3GEYJ472 4.7K

R217 ERJ3GEYJ472 4.7K

R223 ERJ3GEY0R00 0

R225 ERJ3GEY0R00 0

R230 ERJ3GEY0R00 0

R234 ERJ3GEY0R00 0

R235 ERJ3GEY0R00 0

R302 PQ4R10XJ104 100K S

R303 PQ4R10XJ472 4.7K S

R305 ERJ3GEYJ472 4.7K

R311 PQ4R10XJ821 820 S

R312 PQ4R10XJ103 10K S

R314 ERDS1TJ680 68

R315 ERJ3GEYJ223 22K

R317 ERJ3GEYJ222 2.2K

R318 ERJ3GEYJ222 2.2K

R319 ERJ3GEYJ181 180

R320 ERJ3GEYJ123 12K

R321 ERJ3GEYJ224 220K

R322 ERJ3GEYJ152 1.5K

R323 ERJ3GEYJ221 220

R333 PQ4R10XJ104 100K S

R334 PQ4R10XJ104 100K S

R335 PQ4R10XJ472 4.7K S

R336 ERJ3GEYJ473 47K

R337 PQ4R10XJ222 2.2K S

R401 ERJ3GEYJ561 560

R402 ERJ3GEYJ101 100

R403 ERJ3GEYJ392 3.9K

R404 ERJ3GEYJ470 47

R405 ERJ3GEYJ331 330

R406 ERJ3GEYJ103 10K

R407 ERJ3GEYJ184 180K

R408 ERJ3GEYJ392 3.9K

R409 ERJ3GEYJ223 22K

R410 ERJ3GEYJ333 33K

R412 ERJ3GEYJ823 82K

R413 ERJ3GEYJ153 15K

R415 ERJ3GEYJ274 270K

R416 ERJ3GEYJ334 330K

R417 ERJ3GEYJ393 39K

R418 ECUV1H222KBV 0.0022

R419 ERJ3GEYJ823 82K

R420 ERJ3GEYJ473 47K

R421 ERJ3GEYJ103 10K

R422 ERJ3GEYJ682 6.8K

R423 ERJ3GEYJ222 2.2K

R424 ERJ3GEYJ103 10K

R425 ERJ3GEYJ184 180K

R426 ERJ3GEYJ155 1.5M

R427 ERJ3GEYJ105 1M

R428 ERJ3GEYJ105 1M

Part No. Part Name & Description Remarks

Ref.

No.

R429 ERJ3GEYJ223 22K

R430 ERJ3GEYJ104 100K

R431 ERJ3GEYJ152 1.5K

R432 ERJ3GEYJ153 15K

R433 ERJ3GEYJ103 10K

R434 ERJ3GEYJ332 3.3K

R435 ERJ3GEYJ330 33

R436 ERJ3GEYJ101 100

R441 ERJ3GEYJ154 150K

R442 ERJ3GEYJ222 2.2K

R443 ERJ3GEYJ820 82

R444 ERJ3GEY0R00 0

R445 ERJ3GEYJ472 4.7K

R446 ERJ3GEY0R00 0

C102 ECEA1EKA100 10

C103 ECUV1H103KBV 0.01

C104 ECEA1CK101 100 S

C105 ECUV1H103KBV 0.01

C201 ECUV1H220JCV 22P

C202 ECUV1H220JCV 22P

C203 ECUV1E223KBV 0.022

C204 ECUV1C393KBV 0.039

C205 ECUV1H392KBV 0.0039

C206 ECUV1H391JCV 390P

C207 ECUV1C104KBV 0.1

C208 ECUV1H103KBV 0.01

C209 ECEA0JU471 470

C301 ECKD2H681KB 680P S

C303 ECKD2H681KB 680P S

C304 ECKD2H681KB 680P S

C305 PQCUV1H472KB 0.0047

C308 ECEA1HKS220 22 S

C309 PQCUV1H101JC 100P

C310 PQCUV1H103KB 0.01

C311 ECUV1A105KBV 1

C312 ECEA1HKA3R3 3.3

C313 ECUV1E153KBV 0.015

C314 ECUV1H272KBV 0.0027

C315 ECUV1H103KBV 0.01

C321 PQCUV1H154KR 0.15

C322 PQCUV1H154KR 0.15

C323 PQCUV1A684KB 0.68

C401 ECKERS102MB 0.001 S

C404 ECUV1H100DCV 10P

C407 ECUV1H103KBV 0.01

C408 ECUV1H103KBV 0.01

C409 ECUV1H103KBV 0.01

C410 ECUV1C104KBV 0.1

C411 ECUV1C104KBV 0.1

C412 ECUV1C104KBV 0.1

C413 ECEA1EKA100 10

C414 ECUV1C104KBV 0.1

C415 ECUV1H680JCV 68P

C416 ECUV1C104KBV 0.1

C417 ECUV1H121JCV 120P

C418 ECUV1H121JCV 120P

C419 ECUV1H103KBV 0.01

C420 ECUV1H471JCV 470P S

C421 ECUV1H153KBV 0.015

C422 ECJ1VB1H682K 0.0068

C423 ECUV1C104KBV 0.1

C424 ECUV1E223KBV 0.022

C425 ECUV1C104KBV 0.1

C426 ECUV1C473KBV 0.047

C427 ECUV1H103KBV 0.01

C428 ECJ1VC1H271J 270P

C429 ECUV1H152KBV 0.0015

C430 ECUV1H103KBV 0.01

C431 ECEA1CKA470 47

C432 ECUV1H103KBV 0.01

C433 ECJ1VC1H271J 270P

C434 ECUV1C683KBV 0.068

Part No. Part Name & Description Remarks

(CAPACITORS)

52

Page 53

KX-TC2105LBB

Ref.

No.

C435 ECEA1CKS220 22 S

C436 ECUV1H103KBV 0.01

C437 ECUV1H152KBV 0.0015

C438 ECJ1VC1H151J 150P

C439 ECUV1C104KBV 0.1

C440 ECUV1H430GCV 43P

C441 ECUV1H270GCV 27P

C442 ECUV1H103KBV 0.01

C443 ECEA1EKA100 10

C444 ECEA1HKA4R7 4.7

C445 ECUV1C224KBV 0.22

C446 ECUV1H180JCV 18P

C447 ECUV1H103KBV 0.01

C448 ECUV1H103KBV 0.01

C449 ECUV1H223KBV 0.022

C450 ECUV1H103KBV 0.01

C451 ECUV1H821KBV 820P

C452 ECUV1H102KBV 0.001

C453 ECUV1C104KBV 0.1

C454 ECUV1H470JCV 47P

C455 ECJ1VB1H682K 0.0068

C457 ECUV1H330JCV 33P

C458 ECUV1H390JCV 39P

C459 ECUV1H390JCV 39P

C460 ECEA1CKS220 22 S

C461 ECUV1H102KBV 0.001

C462 ECEA1CKA470 47

C463 ECUV1H100DCV 10P

C466 ECUV1H060DCV 6P S

C468 ECUV1H103KBV 0.01

C469 ECEA1CKA470 47

C470 ECUV1H103KBV 0.01

C471 ECUV1H050CCV 5P

C472 ECUV1H102KBV 0.001

PO301 D4FAR1500003 THERMISTOR (POSISTOR)

SW201 K0H1BB000018 SPECIAL SWITCH

Part No. Part Name & Description Remarks

(OTHERS)

26.2. Handset

26.2.1. Cabinet and Electrical Parts

Ref.

No.

101 PQKM10676Z1 CABINET BODY ABS-HB

102 PQSA10170Z ANTENNA

103 PQSX10296N KEYBOARD SWITCH

104 PQHR11114Z OPTIC CONDUCTIVE PARTS, LED

105 L0AD02A00029 SPEAKER

106 PQJT10230Z CHARGE TERMINAL (L)

107 PQJT10231Z CHARGE TERMINAL (R)

108 PQHS10696Z SPACER, BUZZER SHEET

109 PQKF10667Z1 CABINET COVER ABS-HB

110 PQGT18242Z NAME PLATE

111 PQQT22966Z LABEL, CAUTION

112 PQXA36ASVC BATTERY

113 PQHE10161Z SPACER

114 PQKK10589Z1 LID, BATTERY COVER ABS-HB

26.2.2. Main P.C.Board Parts

Note:

(*1) When you have replaced IC801, adjust X801. Refer to

ADJUSTMENTS (HANDSET) (P.22).

Ref.

No.

PCB100 PQWPC2105LBR MAIN P.C.BOARD ASS´Y (RTL)

IC701 MN101C427AP IC

IC801 AN6265FA IC (*1)

Part No. Part Name & Description Remarks

LENS

Part No. Part Name & Description Remarks

(ICs)

(TRANSISTORS)

PS-HB

Ref.

No.

Q701 B1ADDE000022 TRANSISTOR(SI)

Q702 B1ABDE000020 TRANSISTOR(SI)

Q704 B1ABDE000020 TRANSISTOR(SI)

Q705 B1GBCFGJ0011 TRANSISTOR(SI)

Q801 B1ABDE000020 TRANSISTOR(SI)

Q802 B1ABDE000020 TRANSISTOR(SI)

Q804 B1ABDE000020 TRANSISTOR(SI)

Q805 B1GDCFNN0021 TRANSISTOR(SI)

D601 MA8056H DIODE(SI) S

D602 MA111 DIODE(SI) S

D701 B0ACCL000002 DIODE(SI)

DV1 B0CAAB000021 DIODE(SI)

LED701 PQVDSML310MT LED S

L603 PQLQZK1R0K COIL S

L801 PQLQZMR47K COIL S

T801 G2BRC0000006 COIL

T802 G2AYYYC00058 COIL

T803 PQL04B004 COIL

T804 G2AYYYC00060 COIL

CF1 J0B1075A0127 CERAMIC FILTER

CF2 J0B4553A0065 CERAMIC FILTER

X701 H0D399400013 CRYSTAL OSCILLATOR

X801 H0D102500029 CRYSTAL OSCILLATOR (*1)

DPX1 J0E4935A0001 IC FILTER

CN1 PQJP2D13Z CONNECTOR S

R701 ERJ3GEYJ334 330K

R702 ERJ3GEYJ104 100K

R703 ERJ3GEYJ334 330K

R705 ERJ3GEYJ102 1K

R706 ERJ3GEYJ104 100K

R707 ERJ3GEYJ331 330

R708 ERJ3GEYJ334 330K

R710 ERJ3GEY0R00 0

R712 ERJ3GEYJ102 1K

R713 ERJ3GEYJ222 2.2K

R714 ERJ3GEYJ104 100K

R715 ERJ3GEYJ151 150

R719 ERJ3GEY0R00 0

R729 ERJ3GEYJ222 2.2K

R730 ERJ3GEYJ222 2.2K

R731 ERJ3GEYJ222 2.2K

R801 ERJ3GEYJ823 82K

R802 ERJ3GEYJ820 82

R803 ERJ3GEYJ331 330

R804 ERJ3GEYJ821 820

R805 ERJ3GEYJ332 3.3K

R806 ERJ3GEYJ474 470K

R807 ERJ3GEYJ223 22K

R808 ERJ3GEYJ153 15K

R809 ERJ3GEYJ473 47K

R810 ERJ3GEYJ823 82K

R811 ERJ3GEYJ153 15K

R812 ERJ3GEYJ153 15K

R815 ERJ3GEYJ222 2.2K

R816 ERJ3GEYJ333 33K

R817 ERJ3GEYJ222 2.2K

R818 ERJ3GEYJ393 39K

R819 ERJ3GEYJ103 10K

R820 ERJ3GEYJ102 1K

R821 ERJ3GEY0R00 0

R822 ERJ3GEYJ822 8.2K

R823 ERJ3GEYJ123 12K

R824 ERJ3GEYJ223 22K

R825 ERJ3GEYJ222 2.2K

R826 ERJ3GEYJ184 180K

R827 ERJ3GEYJ223 22K

Part No. Part Name & Description Remarks

(DIODES)

(COILS)

(CERAMIC FILTERS)

(CRYSTAL OSCILLATORS)

(IC FILTERS)

(CONNECTOR AND JACK)

(RESISTORS)

53

Page 54

KX-TC2105LBB

Ref.

No.

R828 ECUV1H392KBV 0.0039

R829 ERJ3GEYJ222 2.2K

R830 ERJ3GEYJ222 2.2K

R831 ERJ3GEYJ104 100K

R832 ERJ3GEYJ221 220

R837 ERJ3GEYJ101 100

R838 ERJ3GEYJ393 39K

R839 ERJ3GEYJ122 1.2K

R841 ERJ3GEYJ473 47K

R842 ERJ3GEYJ473 47K

R843 ERJ3GEYJ102 1K

R844 ERJ3GEY0R00 0

R845 ERJ3GEYJ105 1M

R848 ERJ3GEYJ683 68K

R850 ERJ3GEY0R00 0

R851 ERJ3GEY0R00 0

R852 ERJ3GEYJ104 100K

C869 ERJ3GEY0R00 0

C874 ERJ3GEY0R00 0

C602 ECUV1C104KBV 0.1

C701 ECEA0JKA101 100

C702 ECUV1C104KBV 0.1

C703 ECUV1H220JCV 22P

C704 ECUV1H220JCV 22P

C705 ECUV1C473KBV 0.047

C706 ECUV1C104KBV 0.1

C707 ECUV1C104KBV 0.1

C708 ECUV1C104KBV 0.1

C803 ECUV1H100JCV 10P

C804 ECUV1H391JCV 390P S

C805 ECUV1H050CCV 5P

C807 ECUV1H103KBV 0.01

C808 ECUV1H103KBV 0.01

C809 ECUV1H103KBV 0.01

C810 ECUV1H103KBV 0.01

C811 ECUV1C104KBV 0.1

C812 ECUV1H680JCV 68P

C813 ECUV1C104KBV 0.1

C814 ECEA1CKA100 10

C815 ECUV1H121JCV 120P

C816 ECUV1H121JCV 120P

C817 ECUV1C104KBV 0.1

C818 ECUV1H471JCV 470P S

C820 ECUV1C473KBV 0.047

C821 ECJ1VB1H472K 0.0047

C822 ECUV1C104KBV 0.1

C823 ECUV1H103KBV 0.01

C824 ECUV1C473KBV 0.047

C825 ECUV1C104KBV 0.1

C826 ECUV1C104KBV 0.1

C827 ECUV1H103KBV 0.01

C828 ECUV1H103KBV 0.01

C829 ECUV1H103KBV 0.01

C830 ECUV1H103KBV 0.01

C831 ECUV1H220JCV 22P

C833 ECUV1C224KBV 0.22

C834 ECUV1H103KBV 0.01

C835 ECUV1C474KBV 0.47

C836 ECUV1C104KBV 0.1

C837 ECST0JY106 10 S

C838 ECUV1H270GCV 27P

C839 ECUV1H390GCV 39P

C840 ECUV1C104KBV 0.1

C841 ECUV1H820JCV 82P

C842 ECUV1H152KBV 0.0015

C843 ECUV1H103KBV 0.01

C844 ECUV1H101JCV 100P

C845 ECEA1CKA100 10

C846 ECUV1H103KBV 0.01

C847 ECUV1H123KBV 0.012

C848 ECUV1C104KBV 0.1

C850 ECUV1H103KBV 0.01

Part No. Part Name & Description Remarks

(CAPACITORS)

Ref.

No.

C852 ECUV1H100DCV 10P

C853 ECUV1H103KBV 0.01

C854 ECUV1H103KBV 0.01

C858 ECUV1H100DCV 10P

C859 ECEA1CKA100 10

C860 ECUV1H103KBV 0.01

C861 ECUV1H220JCV 22P

C862 ECUV1H390JCV 39P

C863 ECUV1H390JCV 39P

C864 ECUV1H390JCV 39P

C865 ECUV1H020CCV 2P

C866 ECUV1C333KBV 0.033

C867 ECUV1E223KBV 0.022

C868 ECUV1C104KBV 0.1

C870 ECUV1H150JCV 15P

C872 ECUV1H102KBV 0.001

C876 ECST0JY106 10 S

E101 PQEFBDB111GF BUZZER

E102 PQJM122Z MICROPHONE

Part No. Part Name & Description Remarks

(OTHERS)

26.3. Accessories and Packing

Materials

Note:

(*1) You can download and refer to the Operating

Instructions (Instruction book) on TSN Server.

Ref.

No.

A1 PQLV16LBZ AC ADAPTOR

A2 PQJA10075Z CORD, TELEPHONE

A3 PQQX14815Z INSTRUCTION BOOK (*1)

A4 PQQW14831Z LEAFLET

A5 PQKL10069Z1 STAND, WALL MOUNT ABS-HB

A6 PQQT23066Z LABEL, CORD

P1 PQPP10104Z PROTECTION COVER (for Base

P2 PQPP10105Z PROTECTION COVER (for

P3 PQPK14931Z GIFT BOX

Part No. Part Name & Description Remarks

Unit)

Handset)

54

Page 55

27 FOR SCHEMATIC DIAGRAM

27.1. Base Unit (SCHEMATIC DIAGRAM (BASE UNIT))

1. DC voltage measurements are taken with an oscilloscope or a tester with a ground.

2. The schematic diagrams and circuit board may be modified at any time with the development of new technology.

Important Safety Notice:

Components identified by

any of these components, use only the manufacturer´s specified parts.

27.2. Handset (SCHEMATIC DIAGRAM (HANDSET))

1. DC voltage measurements are taken with an oscilloscope or a tester with a ground.

2. The schematic diagrams and circuit board may be modified at any time with the development of new technology.

mark have special characteristics i mportant for safety. When replacing

KX-TC2105LBB

55

Page 56

KX-TC2105LBB

NC : No Components

KX-TC2105 SCHEMATIC DIAGRAM (Base Unit)

IC201

28 SCHEMATIC DIAGRAM (BASE UNIT)

IC401

56

Page 57

IC701

KX-TC2105LBB

NC : No Components

KX-TC2105 SCHEMATIC DIAGRAM (Handset)

29 SCHEMATIC DIAGRAM (HANDSET)

IC801

57

Page 58

KX-TC2105LBB

Memo

58

Page 59

KX-TC2105LBB

A

ANT1

C401

L401

1

2

3

45

3

4

12 3 4

SW201

C102

J33

C104

DPX401

1

T401

6

5

PQUP11346Z

CF402

D102

D103

D101

T403

64

J31

4

6

J24

C413

PbF

J21

R414

L102

L101

BC

Q101

E

R104

C469

13

3

T402

1

C431

J23

IN GND OUT

J6

R101

B

E

Q102

E

Q103

B

J32

CF401

C443

J19

R418

D104

D105

CH+

CH-

GND

L103

L104

C

C

C304

C462

C460

KA

DV401

C444

T404

64

13

J20

X401

J12

C435

J7

C209

J5

J3

SA301

C303

D308

J30

J13

D201

L201

JK1

J28

J34

J15

D305

J16

PO301

D306

E

C308

J26

J1

2

D304

C

Q301

D307

D401

J22

J36

J11

X201

1

D303

B

R314

J10

J2

B

B

J9

Q302

Q304

J4J27

J25

C301

R301

L301

C

C

J35

D301

C302

E

R306

E

J18

J14

R307

Q303

E

R309

C312

J37

C

J17

SA302

D302

L302

KX-TC2105 CIRCUIT BOARD (Base Unit (Component View))

B

J29

J8

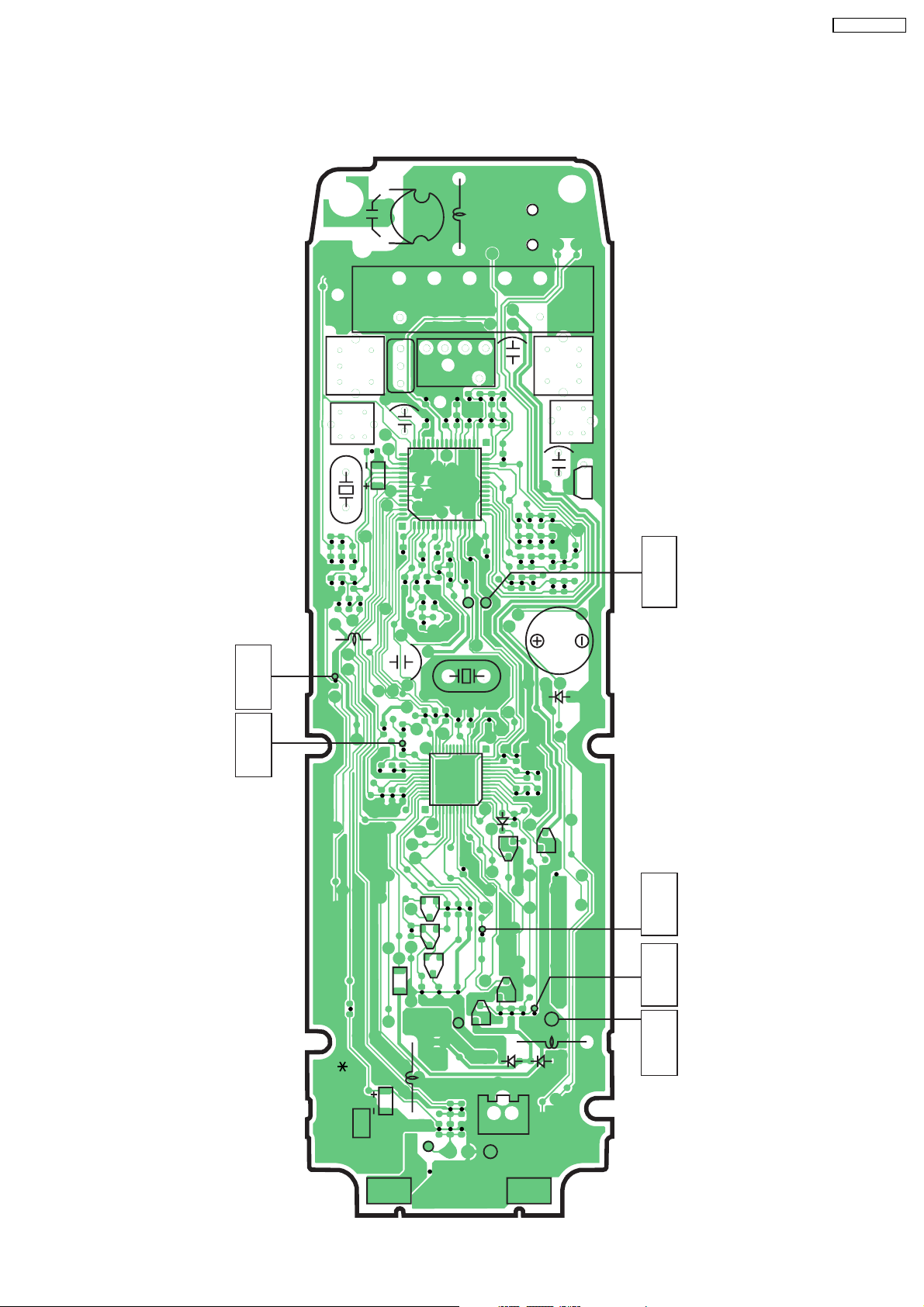

30 CIRCUIT BOARD (BASE UNIT)

30.1. Component View

59

Page 60

KX-TC2105LBB

RING DET

(CPU: 30)

CHG DET

(CPU: 27)

TXDATA

(CPU: 23)

GND2

C306

R221

R222

R224

R320

GND3

R308

R318

R319

C314

Q305

CH_UP

R223

C203

R226

C315

R323

33

34

R305

C313

R321

R236

R225

R227

C321

R317

R322

R228

R304

C310

23

R333

R303

R310

22

44

R229

RING

C309

C205

IC201

1

R230

RING

TIP

R302

C307

R313

R207

R231

C305

R311

R435

C204

C206

TP7

R215

R209

TIP

PbF

R312

Q402

R208

R216

11 12

R205

R232

R210

R337

R427

R217

R206

R233

C452

R428

SQL

C201

C208

R234

C451

C450

R426

R202

R235

PWR_GND

PWR_GND

C101

SA303

Q309

C455

R425

C449

C445

C202

R203

Q202

R334

C323

R336

R431

C463

R422

C439

5VREG

PDown

R335

R421

C441

C437

DC12V

CH+

C322

R102

R103

R110

C461

R433

R429

TXVCO

C448

C475

R420

C436

DC 12V

R105

R106

Q104

R436

R439

C453

R430

3

R424

1

R423

RXVCO

C442

C440

1

C438

R419

C433

R417

C434

Q201

Q403

4

6

RXDT

R109

R441

C457

C447

C446

C430

C432

R418

R108

Q404

C454

C474

R315

C468

C458

R432

435642

IC401

14

R416

CH-

R107 R443

Q405

R442

C456

C408

15

R316

R437

C465

R434

R405

C429

C428

C467

3

1

C409

C311

C103

3

1

C466

C464

C412

C426

C425

C424

C427

R211

C470

R438

C459

C410

29

28

R411

R412

4

C471

6

R440

4

6

9.1VREG

C411

C423

C420

R413

C207

R402

C416

R410

R444

R415

R447

C415

DET

C419

GND1

C105

TP2

C472

RXGND

RXANT

C405

C406

R446

C414

C418

R408

TXGND

C473

R403

Q401

1

R404

6

IFOUT

R407

R409

R406

C421

LOCATOR

C404

C417

C422

R204

TP6

TP1

C402

R401

R445

3

4

C403

C407

LED201

TXANT

IFGND

TXPOWER

KX-TC2105 CIRCUIT BOARD (Base Unit (Flow Solder Side View))

TXGND

RXGND

TXVCO

RXANT

2ND MIX

(RFIC: 37)

RXVCO

IF GND

30.2. Flow Solder Side View

RESET

(CPU: 39)

CDD

(CPU: 13)

CHG LD

(CPU: 4)

XOUT

(CPU: 14)

60

RXDATA

(RFIC: 13)

DET OUT

(RFIC: 27)

IF OUT

(RFIC: 33)

Page 61

ANT2

KX-TC2105LBB

C806

VDD

(CPU: 14)

TXDATA

(CPU: 25)

ANT

T801

31

6

T804

1

C834

X801

R822

R819

C830

C833

C835

C827

C867

R821

L701

C708

5

OG

I

46

CF1

4

3

C845

4356

C837

C842

R820

C840

R823

R842

C701

R708

R845

R723

R725

R726

R727

R728

R715

42

1

R824

C869

C868

R724

Q701

1

C807

C841

C843

R731

36 25

4

C809

R825

R852

R844

R730

24

37

C811

C810

IC801

C844

R849

R729

R712

Q702

DPX1

CF2

R805

R826

C704

IC701

C705

R711

L801

3

4

5

C813

R807

C812

C824

29

28

15

14

C828

C846

R703

RXDT

PDOWN

X701

C703

C702

13

112

48

D702

Q706

R713

R705

C816

R806

2

R808

C815

C817

C826

R722

R718

R816

R809

C825

R701

C814

C820

C818

R815

R720

R717

R707

Q805

BLACK

RED

1

R811

R810

R812

R817

R721

4

6

C859

C821

C875

C822

C829

D701

R719

T802

6

1

C823

BZ1

C602

3

1

T803

R818

4

3

K

DV1

A

C874

KX-TC2105 CIRCUIT BOARD (Component View (Handset))

RXDATA

(RFIC: 13)

RESET

(CPU: 43)

31 CIRCUIT BOARD (HANDSET)

31.1. Component View

Q703

R704

KX-TC2100 series

R832

R710

R709

BAT1

L602

C876

PbF

PQUP11347Z

MIC1

J601 J602

R828

R829

C847

C601

Q705

R714

R706

R827

CN1

C850

21

MIC2

61

Q704

C706

C707

D601D602

VBAT

L603

R702

CHG DET

(CPU: 1)

VBAT

(RFIC: 36)

A

Page 62

KX-TC2105LBB

C873

TXPOWER

3

1

43

DTCOUT

C872

C852

AUTO

6

1

R843

SP+ SP-

C851

4

6

C861

C866

C853

R831

C865

R837

C864

TXPOWER

GND

NDTC

R833

C854

R830

Q802

C870

C857

Q804

R838

R841

R848

C848

C855

R835

C862

C860

IF OUT

C802

IFOUT

C856

R836

C863

R839

C858

(RFIC: 33)

ANT_TP

C801

IFGND

R803

R834

Q803

R804

C808

C836

PSAVE

IF GND

C871

R851

C803

6

C832

R802

C804

C839

R850

R801

C805

311

C831

C838

RXVCO

Q801

3

644

DIRECT

TXVCO

RXVCO

2ND MIX

(RFIC: 37)

TXVCO

KX-TC2105 CIRCUIT BOARD (Flow Solder Side View (HANDSET))

DC Power

Supply

+ -

TALK

FLASH LED701

1

LED702

4

7

LED703

PROGRAM

RINGER

12

GND OUTPUT

LOUD

REDIAL

2

3

LED705

5

8

0

LED704

6

9

PbF

#

PAUSE

CH

31.2. Flow Solder Side View

MIC

62

Page 63

KX-TC2105LBB

63

I.N./N

KXTC2105LBB

Loading...

Loading...