Page 1

EY6535.book

MULTI Drill & Driver

Operating Instructions

Model No. : EY6535

IMPORTANT

This manual contains safety information. Read manual completely before first using

this product and save this manual for future use.

SAVE THESE INSTRUCTIONS

Page 2

EY6535.book 2

GENERAL SAFETY RULESFOR ALL BATTERY

OPERATED TOOLS

WARNING!

Read and understand all instructions.

• Failure to follow all instructions listed

below, may result in electric shock, fire

and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

1) Keep your work area clean and well

lit.

Cluttered benches and dark areas invite

accidents.

2) Do not operate power tools in explo-

sive atmospheres, such as in the

presence of flammable liquids,

gases, or dust.

Power tools create sparks which may

ignite the dust or fumes.

3) Keep bystanders, children, and visi-

tors away while operating a power

tool.

Distractions can cause you to lose control. Make sure that no one is beneath,

or on the other side of the area when

you are working.

Electrical Safety

4) A battery operated tool with integral

batteries or a separate battery pack

must be recharged only with the

specified charger for the battery.

A charger that may be suitable for one

type of battery may create a risk of fire

when used with another battery.

5) Use battery operated tool only with

specifically designated battery pack.

Use of any other batteries may create a

risk of fire.

Personal Safety

6) Stay alert, watch what you are doing,

and use common sense when operating a power tool. Do not use tool

while tired or under the influence of

drugs, alcohol, or medication.

A moment of inattention while operating

power tools may result in serious personal injury.

7) Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves

away from moving parts.

Loose clothes, jewelry, or long hair can

be caught in moving parts.

8) Avoid accidental starting. Be sure

switch is in the locked or off position

before inserting battery pack.

Carrying tools with your finger on the

switch or inserting the battery pack into

a tool with the switch on invites accidents.

9) Remove adjusting keys or wrenches

before turning the tool on.

A wrench or a key that is left attached to

a rotating part of the tool may result in

personal injury.

10)Do not overreach. Keep proper foot-

ing and balance at all times.

Proper footing and balance enable better control of the tool in unexpected situations.

11) Use safety equipment. Always wear

eye protection.

Dust mask, non-skid safety shoes, hard

hat, or hearing protection must be used

for appropriate conditions.

Tool use and care

12)Use clamps or other practical way to

secure and support the workpiece to

a stable platform.

Holding the work by hand or against

your body is unstable and may lead to

loss of control.

13)Do not force tool. Use the correct tool

for your application.

The correct tool will do the job better

and safer at the rate for which it is

designed.

14)Do not use tool if switch does not

turn it on or off.

—

2

—

Page 3

EY6535.book 3

A tool that cannot be controlled with the

switch is dangerous and must be

repaired.

15)Disconnect battery pack from tool or

place the switch in the locked or off

position before making any adjustments, changing accessories, or

storing the tool.

Such preventive safety measures

reduce the risk of starting the tool accidentally.

16)Store idle tools out of reach of chil-

dren and other untrained persons.

Tools are dangerous in the hands of

untrained users.

17)When battery pack is not in use, keep

it away from other metal objects like:

paper clips, coins, keys, nails,

screws, or other small metal objects

that can make a connection from one

terminal to another.

Shorting the battery terminals together

may cause sparks, burns or a fire.

18)Maintain tools with care. Keep cutting

tools sharp and clean.

Properly maintained tools with sharp

cutting edge are less likely to bind and

are easier to control.

19)Check for misalignment or binding of

moving parts, breakage of parts, and

any other condition that may affect

the tool’s operations. If damaged,

have the tool serviced before using.

Many accidents are caused by poorly

maintained tools.

20)Use only accessories that are recom-

mended by the manufacturer for your

model.

Accessories that may be suitable for

one tool may create a risk of injury when

used on another tool.

Service

21)Tool service must be performed only

by qualified repair personnel.

Service or maintenance performed by

unqualified personnel may result in a

risk of injury.

22)When servicing a tool, use only iden-

tical replacement parts. Follow

instructions in the Maintenance section of this manual.

Use of unauthorized parts or failure to

follow Maintenance Instructions may

create a risk of shock or injury.

SPECIFIC SAFETY RULES

1) Hold tool by insulated gripping sur-

faces when performing an operation

where the cutting tool may contact

hidden wiring.

Contact with a “live” wire will make

exposed metal parts of the tool “live”

and shock the operator.

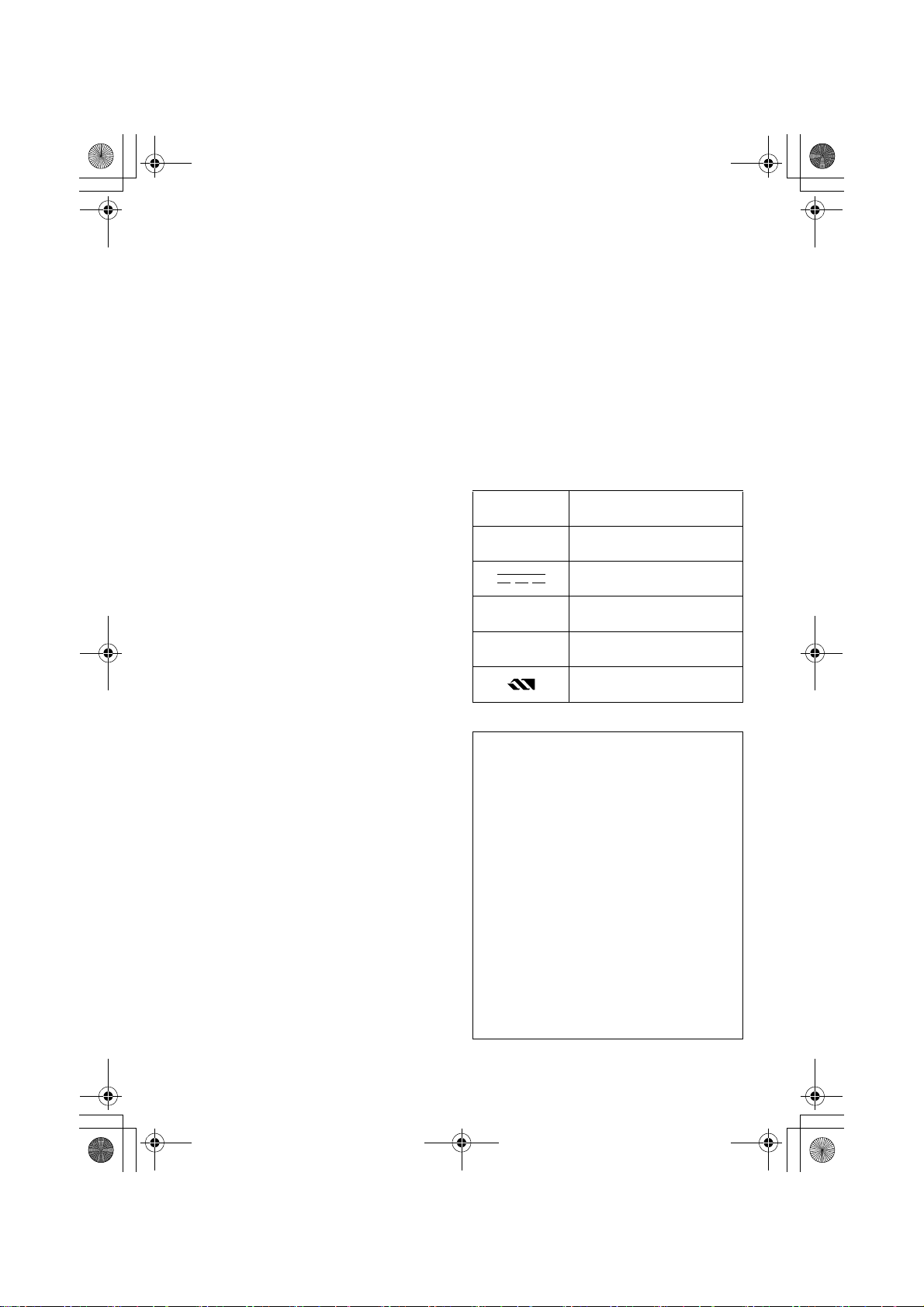

Symbol Meaning

VVolts

Direct Current

0

n

.../min

no load speed

revolutions or

reciprocation per minutes

Rotation only

WARNING!

Some dust created by power sanding,

sawing, grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause

cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and

cement and other masonry products

• Arsenic and chromium from chemicallytreated lumber.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work

with approved safety equipment, such as

dust masks that are specially designed

to filter our microscopic particles.

—

3

—

Page 4

EY6535.book 4

FOR BATTERY CHARGER

& BATTERY PACK

1) SAVE THESE IN-

STRUCTIONS

manual contains important safety and

operating instructions for battery

charger EY0230.

2) Before using battery charger, read all

instructions and cautionary markings on

(1) battery charger, (2) battery pack.

3)

CAUTION

injury, charge only Battery Pack as

shown below.

EY9103, EY9101, EY9001, EY9006,

EY9180, EY9080, EY9182, EY9086,

EY9065, EY9066, EY9106, EY9107,

EY9136, EY9230, EY9200, EY9108,

EY9168

Other types of batteries may burst causing personal injury and damage.

4) Do not expose charger to rain or snow.

5) To reduce risk of damaging the electric

plug and cord, pull by plug rather than

cord when disconnecting charger.

6) Make sure cord is located so that it will

not be stepped on, tripped over, or otherwise subjected to damage or stress.

7) An extension cord should not be used

unless absolutely necessary.

Use of improper extension cord could

result in a risk of fire and electric shock.

If extension cord must be used, make

sure:

a. that pins on plug of extension cord

are the same number, size and

shape as those of plug on charger.

b. that extension cord is properly wired

and in good electrical condition.

c. that wire size is large enough for

ampere rating of charger as specified

below.

-To reduce the risk of

-This

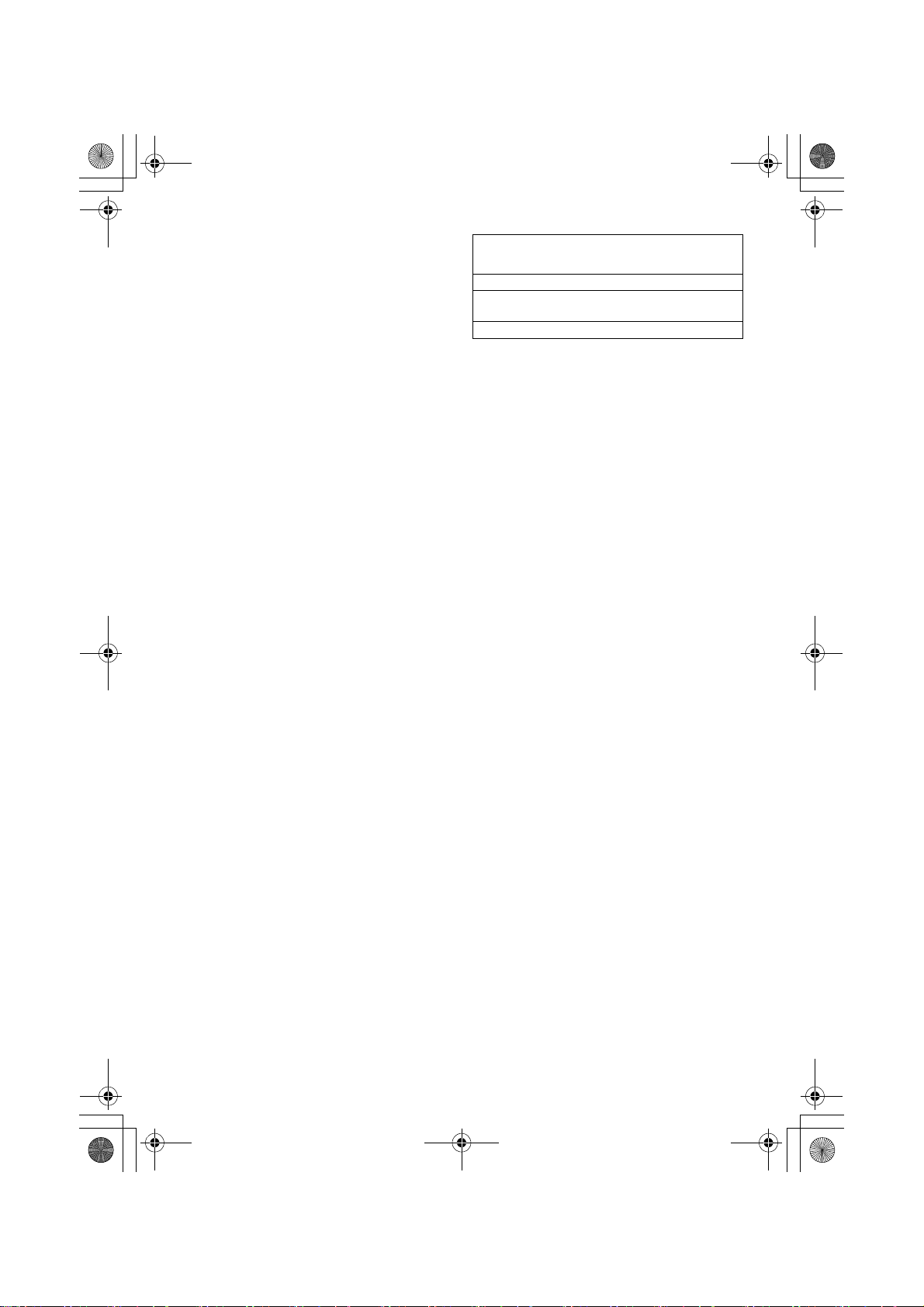

RECOMMENDED MINIMUM AWG SIZE OF

EXTENSION CORDS FOR

BATTERY CHARGERS

AC Input Rating. Amperes AWG Size of Cord

Equal to or

greater than

0 2 18 18 18 16

8) Do not operate charger with damaged

cord or plug—replace them immediately.

9) Do not operate charger if it has received

a sharp blow, been dropped, or otherwise damaged in any way; take it to a

qualified serviceman.

10)Do not disassemble charger; take it to a

qualified serviceman when service or

repair is required. Incorrect reassembly

may result in a risk of electric shock or

fire.

11) To reduce the risk of electric shock,

unplug charger from outlet before

attempting any maintenance or cleaning.

12) The charger and battery pack are specifically designed to work together. Do

not attempt to charge any other cordless

tool or battery pack with this charger.

13) Do not attempt to charge the battery

pack with any other charger.

14) Do not attempt to disassemble the battery pack housing.

15) Do not store the tool and battery pack in

locations where the temperature may

reach or exceed 122°F (50°C) (such as

in a metal tool shed, or a car in the summer), which can lead to deterioration of

the storage battery.

16)Do not charge battery pack when the

temperature is BELOW 32°F (0°C) or

ABOVE 104°F (40°C). This is very

important in order to maintain optimal

condition of the battery pack.

17) Do not incinerate the battery pack. It can

explode in a fire.

18)Avoid dangerous environment. Do not

use charger in damp or wet locations.

But less

than

Length of Cord, Feet

25 50 100 150

—

4

—

Page 5

EY6535.book 5

19)The charger is designed to operate on

standard household electrical power

only. Do not attempt to use it on any

other voltage!

20)Do not abuse cord. Never carry charger

by cord or yank it to disconnect from

outlet. Keep cord away from heat, oil

and sharp edges.

21)Charge the battery pack in a well ventilated place, do not cover the charger

and battery pack with a cloth, etc., while

charging.

22) Use of an attachment not recommended

may result in a risk of fire, electric shock,

or injury to persons.

23) Do not short the battery pack. A battery

short can cause a large current flow,

over heating and create the risk of fire or

personal injury.

24) NOTE: If the supply cord of this appliance is damaged, it must only be

replaced by a repair shop authorized by

the manufacturer, because special purpose tools are required.

25) TO REDUCE THE RISK OF ELECTRIC

SHOCK, THIS APPLIANCE HAS A

POLARIZED PLUG (ONE BLADE IS

WIDER THAN THE OTHER).

This plug will fit in a polarized outlet only

one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does

not fit, contact a qualified electrician to

install the proper outlet. Do not change

the plug in any way.

—

5

—

Page 6

EY6535.book 6

FUNCTIONAL DESCRIPTION

(E)

(A)

(B)

(D)

(F)

(G)

(I)

(C)

(J)

(K)

(H)

(A)

Square drive (Ball detent)

(C)

Reversing lever / Switch lock

Mode Selector switch (Drill driver with

(E)

clutch function / Impact)

(G)

Battery pack (EY9230)

(I)

Battery charger (EY0230)

(K)

Quick change chuck

—

(B)

Clutch handle

(

D)

Variable speed control trigger

(F)

Bit holder

(H)

Battery pack release button

(J)

Keyless drill chuck

—

6

Page 7

EY6535.book 7

ASSEMBLY

Selecting Mode

Select Mode Applications & work material Original Options Accessories in the market

Drill Driver

Impact

Drilling

Driving

Fastening

Wood

Metal

Wood screw

Metal screw

Wood screw

Metal screw

Tech screw

Plastic anchor

Coach screw (Lag bolt)

Bolt nut

Concrete anchor

13mm(1/2") keyless

EY9X003E

Quick change chuck for

6.35mm (1/4")

Hexagonal shank bits

(Quick release type)

EY9HX110E

Select appropriate mode (Drill driver mode or

Impact mode) sliding the Mode selector switch.

Note: When selecting the mode, disconnect battery pack from tool or place Reversing lever in the

center position.(switch lock)

Do not operate Mode selector switch until the

rotation of the spindle comes to a complete

stop.

Wood/metal

Hole saw

(+)(-) head

Torx head

(+)(-) head

Torx head

Hexagonal socket

Drill driver mode

with clutch function

Impact mode

Attaching or Detaching Original Options and Accessories

Keep the body above freezing point (0°C 32°F) when attach or detach original options and accessories

to the square drive on the body. The cushion rubber in the square drive to push up the ball may get

hard under freezing point. This requires extra force in detaching and attaching accessories.

—

—

7

Page 8

EY6535.book 8

Using Keyless drill chuck

(EY9X003E)

CAUTION: • Use keyless drill chuck ONLY in

Drill Driver Mode of EY6535.

This chuck is not designed to be

used in IMPACT MODE.

It can be damaged and its life will

be reduced. Moreover, the chuck

and its metal parts, such as the

push button, front parts, and bit

may become very hot. To prevent

skin burns, use work gloves and/or

allow heated parts to cool down

before handling.

• Make sure the work environment is

safe. When retracting drill from

work material, Keyless drill chuck

may detach if subjected to 100kg

or more of pull force. Detachment

will be sudden. Use care and avoid

excessive force when retracting

drill from work material.

1. Attaching Keyless drill chuck

Attach the chuck by sliding the female detent

on the bottom of the chuck to the square drive

on the body.

Make sure the chuck is firmly connected to the body

3. Removing the bit

Turn the lock collar counterclockwise (looking

from the front).

Then remove the bit.

1

2

CAUTION: If the drill bit becomes too tight to

remove, hold two lock collars with

pipe wrenches and turn them in

opposite directions.

2. Inserting the bit

Insert the bit, and turn the lock collar clockwise(looking from the front) holding the sleeve

until jaws close firmly.

2

1

4. Detaching Keyless drill chuck

To detach the chuck, PUSH the button to

release the chuck from the square drive.

PUSH

CAUTION: Drill bit blade is sharp. Make sure to

8

—

—

remove the drill bit before you set

and detach the keyless drill chuck.

Page 9

EY6535.book 9

Using Quick change chuck

(EY9HX110)

This Quick change chuck is

designed to be used with Panasonic EY6535.

Top collar : To insert or to

Top collar

Bottom collar

Use 6.35mm (1/4") hexagonal bits.

To ensure proper securement of the bit, use only

hexagonal bits with 9.25mm (3/8") detent.

6.35mm (1/4")

CAUTION: Make sure the work environment is

1. Attaching Quick change chuck

Attach the Quick change chuck by pulling the

bottom collar forward and sliding the female

detent on the bottom of the chuck to the

square drive on the body.

Release the bottom collar to make sure the

Quick change chuck is firmly connected to the

body.

2. Inserting the bit

Pull the top collar of the Quick change chuck

forward, then insert the bit.

Release the bottom collar to make sure the bit

is firmly connected to the chuck.

Bottom collar: To attach or to

safe. When retracting bit from work

material, Quick change chuck may

detach if subjected to 50kg or more

of pull force. Detachment will be sudden. Use care and avoid excessive

force when retracting bit from work

material.

remove bit.

detach Quick

change chuck.

9.25mm (3/8")

1

3. Removing the bit

Pull the top collar of the Quick change chuck

forward, then pull the bit.

1

2

CAUTION: lmpact mechanism creates heat.

Square drive and accessory may

become very hot and may cause skin

burns. To prevent skin burns, use

work gloves and/or allow heated

parts to cool down before handling.

4. Detaching Quick change chuck

Pull the bottom collar of the Quick change

chuck forward to detach it.

Attaching or removing battery

pack

1. To connect the battery pack:

Insert the battery pack. It snaps into place to

indicate proper connection.

2. To remove the battery pack:

Press the two buttons on the sides of the battery pack. Slide the battery pack out of the tool

body.

OPERATION

Switch Operation

1. The speed increases with the amount of

depression of the trigger. When beginning

work, depress the trigger slightly to start the

rotation slowly.

2. A feedback electronic controller is used to

give a strong torque even in low speed.

3. The brake operates when the trigger is

released and the motor stops immediately.

2

Top Collar

Reversing Lever Operation

(Forward ( ), Switch lock, Reverse ( ))

CAUTION: Do not operate reversing lever until

1. For reverse rotation, set the lever to reverse.

Check the direction of rotation before use.

9

—

—

rotation of the spindle comes to a

complete stop. Shifting during rotation of the chuck may damage the

tool.

Page 10

EY6535.book 10

2. After use, set the lever to its center position

(switch lock).

Clutch Torque Setting

Adjust the torque to one of the 18 possible set-

tings or " " position required to do the job.

CAUTION: Test the setting before actual opera-

tion. Set the scale at this mark ( ).

CAUTION: To eliminate excessive temperature

increase of the tool surface, do not

operate the tool continuously, that is

consecutively replacing the battery

packs.

• Do not close up vent holes on the

sides of the body during operation.

Otherwise, the machine function is

adversely affected to cause a failure

• Impact mechanism creates heat.

Square drive and accessory

become very hot. They may cause

burns.

• Do not strain the tool(motor).

This may cause damage to the

unit.

• Keep body or skin away from

exhaust vent to avoid risk of being

burned by hot air.

• When operating with a Ni-MH battery pack, make sure the work

place is well-ventilated.

For Appropriate use of Battery pack

Ni-MH Battery pack EY9230

• Charge the Ni-MH battery fully before storage

in order to ensure a longer service life.

• The ambient temperature range is between

0°C (32°F) and 40°C (104°F).

If the battery pack is used when the battery

temperature is below 0°C (32°F), the tool may

fail to function properly. In that case, charge

the battery until charging is completed for

appropriate functioning of the battery.

Battery Pack Life

The rechargeable batteries have a limited life. If

operation time becomes extremely short after

recharging, replace the battery pack with a new

one.

Note: Use under extremely hot or cold conditions

will reduce operating capacity per charge.

Charging

Note: When you charge the battery pack for the

first time, or after prolonged storage,

charge it for about 24 hours to bring the

batteries up to full capacity.

Battery charger (EY0230)

1. Plug the charger into the AC outlet.

2. Insert the battery pack firmly into the charger.

Battery pack

3. During charging, the charging lamp will be lit.

When charging is completed, an internal electronic switch will automatically be triggered to

prevent overcharging.

• Charging will not start if the battery pack is

warm (for example, immediately after

heavy-duty operation).

The orange standby lamp will be lit until the

battery cools down. Charging will then

begin automatically.

4. When charging is completed, the charging

lamp will start flashing rapidly.

2

Battery charger

To AC outlet

1

—

10

—

Page 11

EY6535.book 11

5. If the battery pack is too cold, or if the battery

pack has not been used for a long time, the

charging lamp starts flashing slowly to indicate protective charging. Protective charging

takes longer to fully charge the battery pack,

than the standard charging time. (Max. charging time is approx. 90 minutes).

• If a fully charged battery pack is inserted

into the charger again, the charging lamp

may light up and then flash slowly. After

several minutes, the charging lamp may

flash quickly to indicate the charging is

completed.

6. If the charging lamp does not light immediately after the charger is plugged in, or if after

the standard charging time the lamp does not

go off, consult an authorized servicer.

Note: • Before charging a cold battery pack

(below 5°C (41°F)) in a warm place,

leave the battery pack at the place and

wait for more than one hour to warm up

the battery to the level of the ambient

temperature. (Battery pack may not be

fully charged.)

• Cool down the charger when charging

more than two battery packs consecutively.

• Do not insert your fingers or any metallic

objects into charger contact opening.

CAUTION: • Do not use power source from an

• Do not cover vent holes on the

LAMP INDICATIONS OF THE EY0230

Charger is plugged into a wall outlet.

Flashing

Lit

Flashing quickly

Flashing slowly

Lit

Flashing

Ready to charge.

Now charging

Charging is completed

Protective charging

Battery pack is warm. Charging will begin

when temperature of battery pack drops.

Charging is not possible. Clogged with

dust or malfunction of the battery pack.

engine generator.

charger and the battery pack.

MAINTENANCE

Use only dry, soft cloth for wiping the unit. Do not use a damp cloth, thinner, benzine, or other volatile

solvents for cleaning.

BATTERY RECYCLING

ATTENTION:

A nickel metal hydride battery that is recyclable powers the product you have purchased.

Please call 1-800-8-BATTERY for information on how to recycle this battery.

11

—

—

Page 12

EY6535.book 12

TIGHTENING TORQUE

• The power required for tightening a bolt will vary, according to bolt material and size, as well as the

material being bolted. Choose the length of tightening time accordingly.

Reference values are provided below.

(They may vary according to tightening conditions.)

FACTORS AFFECTING TIGHTENING TORQUE

The tightening torque is affected by a wide variety of factors including the followings. After tightening,

always check the torque with a torque wrench.

1) Voltage

When the battery pack becomes nearly discharged, the voltage decreases and the tightening

torque drops.

Bolt Tightening Conditions

M6, M8, M10, M12, M14 x 25 mm (1") Standard bolt

kgf-cm

(in-lbs)

1300

(1100)

1200

(1000)

1000

(850)

800

(700)

600

(500)

400

Tightening torque

(350)

200

(170)

M6

0.1 0.25 0.5

Tightening time (Sec.)

(Bolt size : Millimeters)

M14

M12

M10

M8

123

Bolt

Nut

Tightening conditions

*The following bolts are used.

Standard bolt: Strength type 4.8

High tensile type 12.9

Explanation of the strength type

4.8

Washer

Steel plate

thickness 10 mm (3/8")

Washer

Spring washer

Bolt yield point

(80% of tensile strength)

48 kgf/mm

Bolt tensile strength 60 kgf/mm

(85,000psi)

2

(68,000psi)

2

—

12

—

Page 13

EY6535.book 13

2) Tightening time

Longer tightening time results in increased

tightening torque. Excessive tightening, however, adds no value and reduces the life of

the tool.

3) Different bolt diameters

The size of the bolt diameter affects the tightening torque.

Generally, as the bolt diameter increases,

tightening torque rises

4) Tightening conditions

• Tightening torque will vary, even with the

same bolt, according to grade, length, and

torque coefficient (the fixed coefficient indicated by the manufacturer upon production).

• Tightening torque will vary , even with the

same bolting material (e.g. steel), according to the surface finish.

• Torque is greatly reduced when the bolt

and nut start turning together.

5) Socket play

• Torque is lowered as the six-sided configu-

ration of the socket of the wrong size is

used to tighten a bolt.

6) Switch (Variable speed control trigger)

Torque is lowered if the unit is used with the

switch not fully pulled out.

7) Effect of Connecting Adaptor

The tightening torque will be lowered through

the use of a universal joint or a connecting

adaptor.

—

13

—

Page 14

EY6535.book 14

ACCESSORIES

Use only bits suitable for size of drill’s chuck.

Use Panasonic original Optional Keyless drill chuck (EY9X003E) and Quick change chuck (EY9HX110E)

for maximum performance.

SPECIFICATIONS

MAIN UNIT

Model EY6535

Drill driver Mode

Drilling

Maximun

recommen

ded

capacities

No load speed 0 - 650 /min (rpm) 0 - 2200 /min (rpm)

Clutch Torque

Impact per minute

Motor DC Motor 15.6V

Square drive 12.7 mm (1/2") square drive with ball detent

Weight (with battery pack) 2.2 kg ( 4.8 lbs.)

Overall length 216 mm ( 8 - 1/2")

Screw

driving

Bolt Fastening Not feasible

Wood drilling ø 27 mm (1 - 1/16")

Metal drilling ø 13 mm (1/2")

Machine screw M5 Not feasible

Wood screw ø 6.8 mm (17/64")

Tech screw ø

Coach screw (Lag bolt)

1.0 Nm (10 kgf-cm, 8.7 in-lbs.) -

5.4 Nm (55 kgf-cm, 47.7 in-lbs.)

Approx.

-

(Caution: Do not use Keyl ess drill chuck for impact mode)

6 mm (15/64")

ø10 mm (3/8")

Impact mode

Not feasible

Standard Bolt: M12

High Tensile Bolt: M10

-

0 - 3300 /min (ipm)

KEYLESS DRILL CHUCK

Model EY9X003E

Chuck Capacity 1.6 mm - 13 mm (1/16" - 1/2")

BATTERY PACK

Model EY9230

Storage battery Ni-MH Battery

Battery voltage 15.6V DC (1.2V x 13 cells)

BATTERY CHARGER

Model EY0230

Electrical Rating See the name plate on the bottom of the charger.

Weight 0.78 kg (1.72 lbs)

Charging time

Note: This chart may include models that are not available in your area.

Please refer to the catalogue.

CAUTION: This Panasonic Multi Drill & Driver is designed to use only battery pack type EY9230,

EY9136. Use with other battery pack type may damage the tool and the battery, and may

result in the risk of fire and personal injury.

15.6 V 12 V 9.6 V 7.2 V Standard charging time

EY9136

EY9230 EY9200

EY9001

EY9006

EY9101

EY9103

EY9106

EY9107

EY9108

EY9080

EY9086

EY9180

EY9182

-

--

EY9065

EY9066

-

EY9168 Approx. 30 min.

Approx. 20 min.

Approx. 25 min.

Approx. 45 min.

—

14

—

Page 15

EY6535.book

— MEMO —

—

15

—

Page 16

EY6535.book 16

30-DAY QUALITY

SATISFACTION GUARANTEE:

If you are dissatisfied with any Panasonic

Cordless Power Tool for any reason, simply return it to the place of purchase with

a dated proof of purchase, in the original

packaging, with all accessories, parts

and instructions, within 30 days of the

date of purchase, for a full refund, or call

Panasonic at 201-392-6655. Abuse or

misapplication of any power tool voids the

guarantee.

PANASONIC CONSUMER ELECTRONICS COMPANY

EY981065351 H1306

One Panasonic Way, Secaucus, New Jersey 07094

Printed in Japan

Loading...

Loading...