Page 1

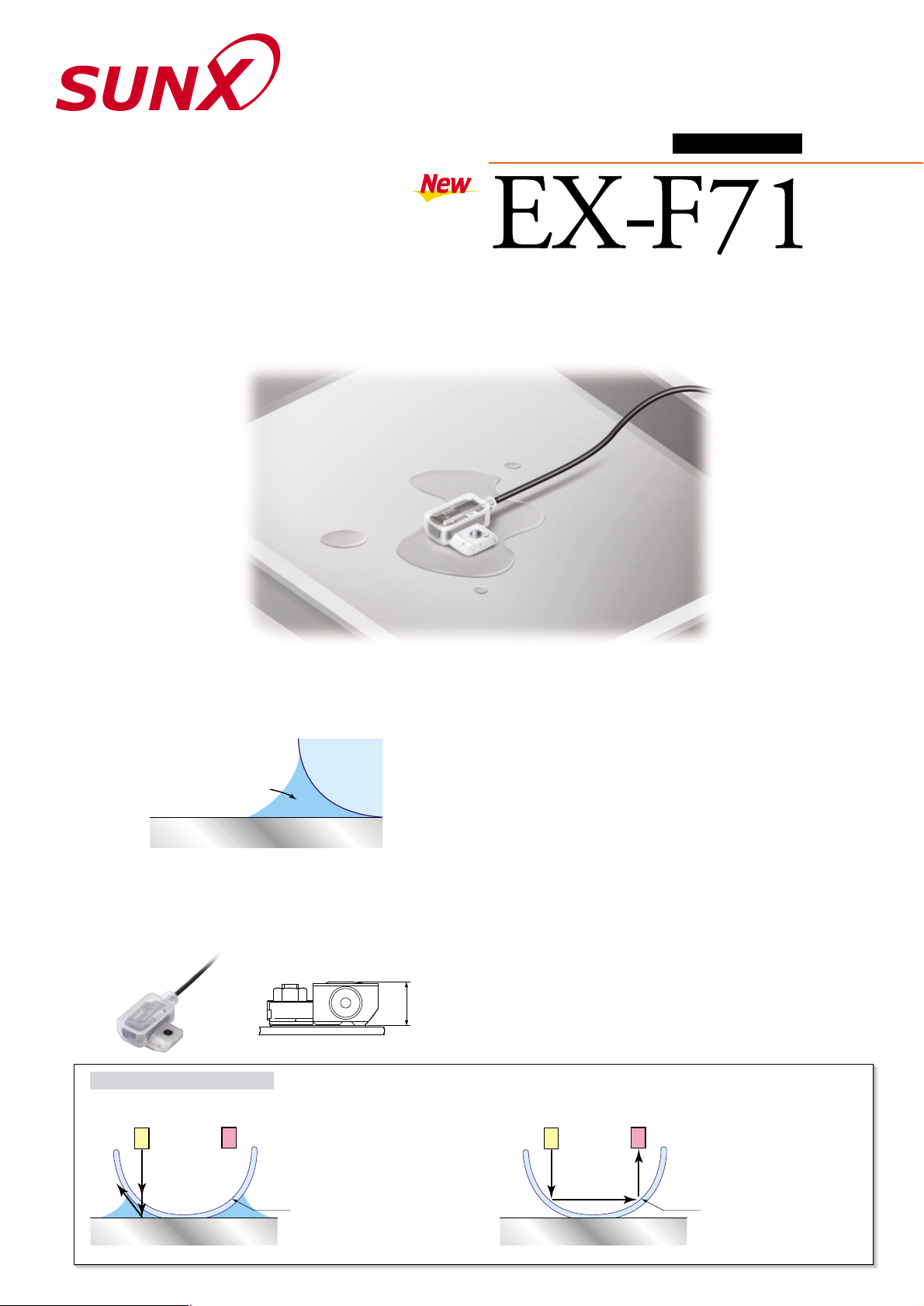

High-speed Detection

Even a Little Chemical Leak

LEAK SENSOR

Amplifier built-in

Reliable Detection

The unique effect of capillarity enables reliable detection of small leaks

and viscous liquids.

Capillarity effect

Liquid

Fiber head

Leakage pan

Compact, Space-saving

This slim (10mm) side-mounting sensor is especially good for use in

confined spaces.

10mm

approx.

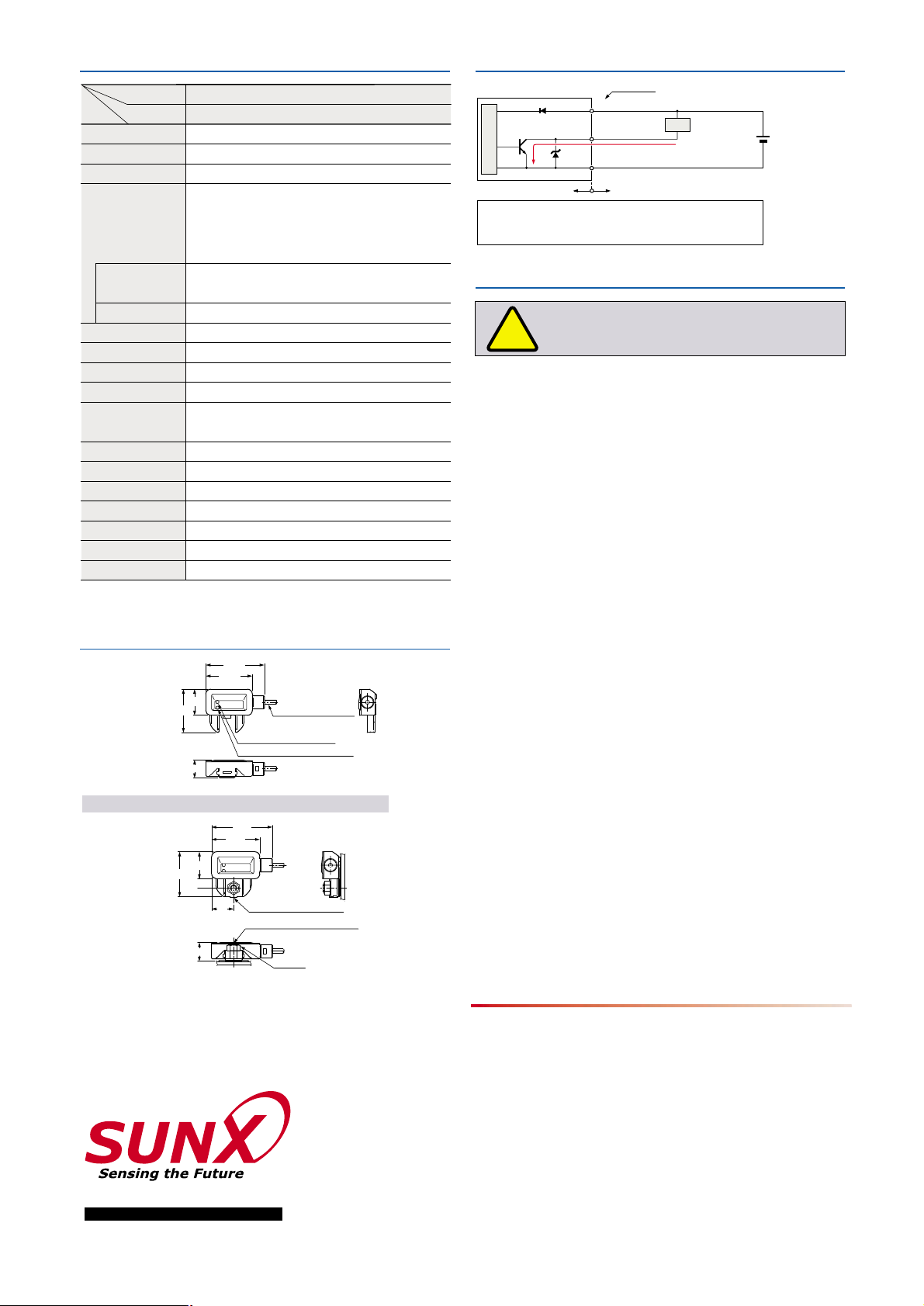

New Type of Detection Method

● When a leak occurs, the beam form the beam-emitting part scatters through the leaked liquid and is not transmitted to the beam-receiving part.

Beam-emitting part

Beam-receiving part

Leaked

liquid

Leakage pan

Sensing

surface

When leakage occurs

The beam from the beamemitting part scatters

through the leaked liquid

and is not transmitted to

the beam-receiving part.

When there is no leakage

The beam from the beamemitting part reflects off of

the surface of the sensor

and is transmitted to the

beam-receiving part.

Beam-emitting part

Beam-receiving part

Sensing

surface

Leakage pan

Safe Design

● If the sensor is not mounted correctly, if the cable is cut or

disconnected, or if the sensor is not operating correctly, the output

is the same as when the beam is not received (LEAK).

● Design deals with human errors such as, forgetting to mount, etc.

Easy Operation Check

This sensor is equipped with a NORMAL indicator (green) which

lights up when mounting correctly, and a FAULT indicator (red) which

lights up when sensing the leaked liquid or when mounted incorrectly

(forgetting to mount exclusive mounting bracket). So, the operation

can be checked easily.

No Need for Sensitivity Adjustment

No need for sensitivity adjustment with adjuster, so initial mounting is

easy.

Easy Installation & Reset

● Bracket mounted with one screw, one-touch sensor mounting.

● No resetting or component replacement required after leak detection.

● The simple shape makes it easy to wipe off the leaked liquid.

Page 2

This product is not a safety sensor. Its use is not intended

or designed to protect life and prevent body injury or

property damage from dangerous parts of machinery. It is

a normal object detection sensor.

SPECIFICATIONS I/O CIRCUIT DIAGRAM

PRECAUTRIONS FOR PROPER USE

DIMENSIONS (Unit: mm)

!

Wiring

Mounting

Others

Assembly dementions with SUS mounting bracket

Designation

Model No.

Item

Sensing object

Supply voltage

Current consumption

Output

Response time

FAULT indicator

NORMAL indicator

Protection

Ambient temperature

Ambient illuminance

Emitting element

Material

Cable

Cable extension

Weight

Accessory

Water, Fluorinert (Note 1)

12 to 24V DC

10% Ripple P-P 10% or less

10mA or less

Incorporated

50ms or less

Red LED (In case liquid leaks or the sensor is mounted erroneously)

Green LED (In case the sensor is mounted normally)

IP67 (IEC)

10 to 60C (No dew condensation or icing allowed)

Storage: 20 to 70C (Note 2)

Incandescent light: 500

?

x at the light-receiving face

Infrared LED (non-modulated)

Enclosure: Polypropylene

0.1mm

2

3-core PVC cabytyre cable, 2m long

Extension up to total 50m is possible with 0.3mm

2

, or more, cable.

25g approx.

SUS mounting bracket

Amplifier built-in leak sensor

EX-F71

Notes: 1) Highly viscous liquid may not be detected stably.

2)

Liquid being detected should also be kept within the rated ambient temperature range.

Symbols ... D

Z

D

Tr

: Reverse supply polarity protection diode

: Surge absorption zener diode

: NPN output transistor

Users’ circuitInternal circuit

50mA max.

Tr

D

ZD

(Blue) 0V

12 to 24V DC

10%

(Brown) V

(Black) Output

Color code

Load

28.5

16

26.5

5.5

13

(Straight type)

SUS mounting bracket

M4 nut

11

35.9

"2.5 cable 2m long

26.5

16

35.9

28.5

FAULT indicator (Red)

NORMAL indicator (Green)

10.7

NPN open-collector transistor

• Maximum sink current: 50mA

•

Applied voltage: 30V DC or less (between output and 0V)

• Residual voltage: 1.0V or less (at 50mA sink current)

0.4V or less (at 16mA sink current)

In normal state: ON

When liquid leaks, or the sensor is mounted erroneously: OFF

Output operation

Short-circuit protection

Sensor circuit

• Make sure to carry out the wiring in the power supply off condition.

• Verify that the supply voltage variation is within the rating.

• Take care that if a voltage exceeding the rated range is applied, or if an AC

power supply is directly connected, the sensor may get burnt or damaged.

• If power is supplied from a commercial switching regulator, ensure

that the frame ground (F.G.) terminal of the power supply is connected to

an actual ground.

•

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

•

Extension up to total 50m is possible with 0.3mm2, or more, cable. However,

in order to reduce noise, make the wiring as short as possible.

•

Do not run the wires together with high-voltage lines or power lines or

put them in the same raceway. This can cause malfunction due to induction.

• Ensure that an isolation transformer is utilized for the DC power supply. If

an autotransformer is utilized, the main amplifier or power supply may be

damaged.

• In case a surge is generated in the used power supply, connect a surge

absorber to the supply and absorb the surge.

•

If air bubbles are trapped within the sensing portion, take care that extra time

may be required to obtain stable sensing, or stable sensing may not be

achieved. Before use, thoroughly check the conditions under which the

sensor is used.

• For proper treatment after a liquid leak, ensure that all liquid is completely

wiped off from both the sensor's sensing surface and from SUS mounting

bracket. A soft cloth must be used to ensure that scratches or other

damage do not occur.

If the sensing surface or SUS mounting bracket is scratched, or if any

traces of liquid remain, then normal functionality will be impaired.

• Do not use during the initial transient time (30 sec. approx.) after the power

supply is switched on.

• Since the sensor is non-modulated type, take sufficient care against

extraneous light. Make sure that extraneous light is not directly incident on

the sensing surface.

• These sensors must not be used at locations containing high levels of

steam or dust, nor used within dangerous atmospheres, such as those

containing corrosive gases.

• Take care that the product does not come in direct contact with organic

solvents, such as, thinner, etc.

• If these sensors are used in an environment where static electricity is

generated, then the pan used to contain liquid leaks must be made of

metal and connected to a proper electrical ground.

No. LCE-EXF71-5 August, 2001

2431-1 Ushiyama-cho, Kasugai-shi, Aichi,

486-0901, Japan

Phone: +81-(0)568-33-7211

FAX: +81-(0)568-33-2631

SUNX Limited

Phone: +81-(0)568-33-7861

FAX: +81-(0)568-33-8591

Overseas Sales Dept.

Printed on 100% recycled paper PRINTED IN JAPAN

http://www.sunx.co.jp/

All information is subject to change without prior notice.

•

Be sure to use SUS mounting bracket when installing the sensor to avoid human

error. Reliable detection cannot be guaranteed when this mounting bracket is not

used.

•

Tightening torque of SUS mounting bracket should be 0.98Nm or

less.

M4 (length 10mm) stud bolt

Loading...

Loading...