Page 1

INSTRUCTION MANUAL

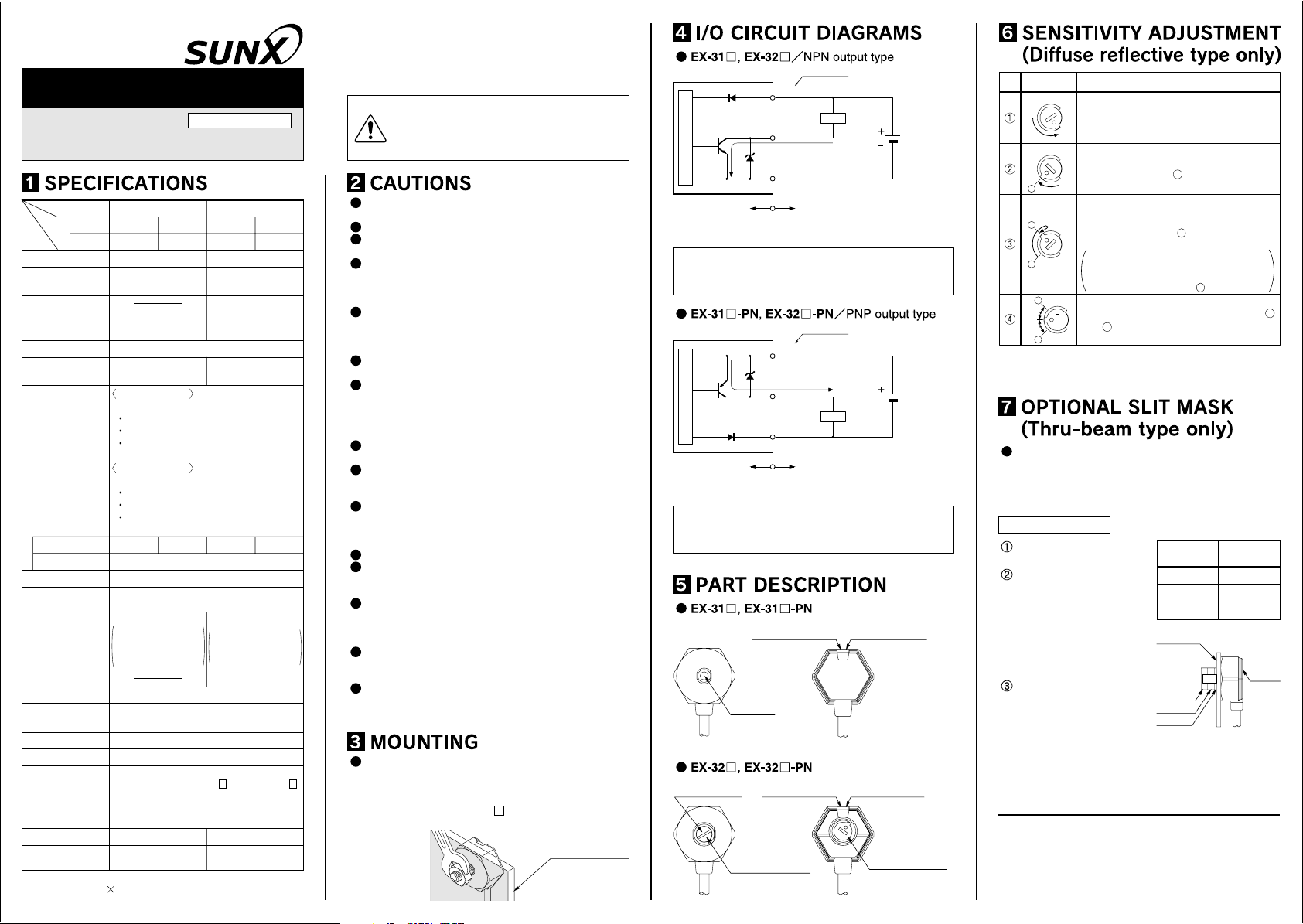

New-form Beam Sensor

Amplifier Built-in

EX-30 Series

Type

Thru-beam type

NPN output

Item

PNP output

Model No.

Sensing range

Sensing object

EX-31A

EX-31A-PN

EX-31B

EX-31B-PN

500mm

ø2mm or more

opaque object

Hysteresis

Repeatability

(perpendicular to sensing axis)

Supply voltage

Current consumption

0.05mm or less 0.5mm or less

12 to 24V DC±10% Ripple P-P 10% or less

Emitter: 10mA or less

Receiver: 15mA or less

NPN output type

NPN open-collector transistor

Maximum sink current: 50mA

Applied voltage: 30V DC or less

Residual voltage: 1V or less

Output

PNP output type

PNP open-collector transistor

Maximum source current: 50mA

Applied voltage: 30V DC or less

Residual voltage: 1V or less

Output operation

Short-circuit protection

Light ON Dark ON Light ON Dark ON

Incorporated (restored automatically

Response time

Operation indicator

Stability indicator

Orange LED (lights up when the output is ON

(

incorporated on the receiver for thru-beam type

Green LED

lights up under stable light

received condition or stable

dark condition, incorporated

on the receiver

Sensitivity adjuster

Protection

–

Ambient temperature

Ambient humidity

Emitting element

Material

Cable

Weight

Accessories

Note:

The sensing range is specified for white non-glossy

paper (100 100mm) as the object.

25 to +55˚C (No dew condensation or icing allowed

Storage: –30 to +70˚C

35 to 85% RH, Storage: 35 to 85% RH

Red LED (modulated

Enclosure: Die-cast zinc

Lens: Polycarbonate (EX-31 ), Acrylic (EX-32 )

Enclosure cover: Polycarbonate

0.1mm2 3-core (thru-beam type sensor

emitter: 2-core) cabtyre cable, 2m long

Emitter/Receiver: 20g approx.

Nut: 2 Nos.

Toothed washer: 2 Nos.

Diffuse reflective type

EX-32A

EX-32A-PN

50mm (Note

Opaque, translucent

or transparent object

15% or less of operation distance

20mA or less

(

between output and 0V

(

at 50mA sink current

0.4V or less (at 16mA sink current

(

between output and +V

(

at 50mA source current

0.4V or less (at 16mA source current

0.5ms or less

Green LED

lights up under stable light

received condition or stable

dark condition

Continuously variable adjuster

)

IP67 (IEC

20g approx.

Nut: 1 No.

Toothed washer: 1 No.

EX-32B

EX-32B-PN

)

)

)

)

)

)

)

)

)

)

)

,

)

Thank you very much for using SUNX sensors.

Please read this Instruction Manual carefully and

thoroughly for the correct and optimum use of this

sensor. Kindly keep this manual in a convenient

place for quick reference.

This product is not a safety sensor. Its use is

not intended or designed to protect life and

prevent body injury or property damage from

dangerous parts of machinery. It is a normal

object detection sensor.

Make sure to carry out the wiring in the power

supply off condition.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the

rating.

If power is supplied from a commercial switching

regulator, ensure that the frame ground (F.G.)

terminal of the power supply is connected to an

actual ground.

In case noise generating equipment (switching

regulator, inverter motor, etc.) is used in the vicinity

of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

Do not use during the initial transient time (50ms

after the power supply is switched on.

Extension up to total 50m (thru-beam type: both

emitter and receiver) is possible with 0.3mm

more, cable.

However, in order to reduce noise, make the wiring

as short as possible.

Make sure that stress is not applied directly to the

sensor cable joint.

Do not run the wires together with high-voltage lines

or power lines or put them in the same raceway.

This can cause malfunction due to induction.

Take care that the sensor is not directly exposed to

fluorescent light from a rapid-starter lamp or a high

frequency lighting device, as it may affect the

sensing performance.

Avoid dust, dirt, and steam.

Take care that the sensor does not come in direct

contact with water, oil, grease, or organic solvents,

such as, thinner, etc.

Make sure to use an isolation transformer for the

DC power supply. If an auto-transformer (single

winding transformer) is used, this product or the

power supply may get damaged.

In case a surge is generated in the used power

supply, connect a surge absorber to the supply and

absorb the surge.

In case of using the sensor at a place where static

electricity is generated, use a metal mounting plate.

Also, ensure to ground the mounting plate.

Mount the sensor on a mounting plate 3mm or less

thick, using the enclosed nut and toothed washer.

When tightening the nut, hold the sensor with hand

or a spanner and make sure that the tightening

torque is 0.6N

Do not tighten the sensor itself with a spanner, etc.

•

m (EX-32 : 1.0N • m) or less.

Mounting plate

(3mm or less thick)

2

, or

Color code

(Brown) +V

D

Tr

Sensor circuitSensor circuit

Internal circuit

The emitter of the thru-beam type sensor does not

Note:

incorporate the output.

Symbols...D

)

Tr

ZD

(Blue) 0V

:

Reverse supply polarity protection diode

ZD

: Surge absorption zener diode

Tr

: NPN output transistor

(Brown) +V

ZD

D

(Blue) 0V

Load

(Black) Output (Note)

50mA max.

Users’ circuit

Color code

50mA max.

(Black) Output (Note)

Load

12 to 24V DC

±10%

12 to 24V DC

±10%

Sensitivity adjuster

Step

MAX

Turn the sensitivity adjuster fully

Description

counterclockwise to the minimum

sensitivity position.

In the light received condition, turn the

MAX

sensitivity adjuster slowly clockwise and

confirm the point where the sensor

A

B

A

enters the ‘Light’ state operation.

In the dark condition, turn the sensitivity

adjuster further clockwise until the sensor

enters the ‘Light’ state operation and then bring

MAX

it back to confirm point where the sensor just

returns to the ‘Dark’ state operation.

B

The position at the middle of points

and is the optimum sensing position.

A

Optimum position

If the sensor does not enter the ‘Light’

state operation even when the sensitivity

adjuster is turned fully clockwise, this

extreme position is point .

B

A

B

B

A

Note: Turn the sensitivity adjuster slowly. Turning with

excessive strength will damage the adjuster.

Apply the optional slit mask (OS-EX30-10) when

Internal circuit

The emitter of the thru-beam type sensor does not

Note:

incorporate the output.

Symbols...D

:

Reverse supply polarity protection diode

ZD

: Surge absorption zener diode

Tr

: PNP output transistor

Users’ circuit

Operation indicator

(

Orange)(Note

)

Stability indicator

(

Green)(Note

)

detecting small objects or for increasing the

accuracy of sensing position.

However, the sensing range is reduced when

the slit mask is mounted.

Mounting method

Insert the sensor into the

mounting plate.

Fit the washer and

spacers enclosed with the

slit mask. Note that the

number of spacers to be

fitted differs with the

mounting plate thickness,

Mounting plate

thickness

3mm 0 No.

2mm 1 No.

1mm 2 Nos.

Mounting

plate

No. of spacers

as given in the table on

Beam axis

the right.

Mount the slit mask. Make

sure that the tightening

torque is 0.6N.m or less.

Slit mask

Spacer

Washer

Sensor

Note: Not incorporated on the emitter.

Beam-receiving

part

Operation indicator

(

)

Orange

Stability indicator

(

)

Green

http://www.sunx.co.jp/ SUNX Limited

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Beam-emitting part

Sensitivity adjuster

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN

Loading...

Loading...