Panasonic eneloop 2017-2018 Catalog

Catalogue 2017-2018

Index

Panasonic Energy Europe 5

• Panasonic group worldwide 5

• Creating new life with energy 6

• Innovating on the world stage 8

• An advanced global approach to battery production 10

• Panasonic Energy Europe, your professional battery partner 11

Shopper insights rechargeable batteries 12

What is eneloop? 14

eneloop 2017-2018 20

eneloop range 21

• eneloop pro 22

• eneloop 24

• eneloop lite 26

• eneloop for DECT 28

• Rechargeable battery information chart 30

• Cross reference 32

• Spacers 33

• Chargers 34

• Charger information chart 38

Panasonic is committed to creating a better life and a better world, continuously contributing to

the evolution of society and to the happiness of people around the globe.

Panasonic

Worldwide

Group

Worldwide leading enterprise

Panasonic Corporation Inc. is one of the largest electronic

product manufacturers in the world. It manufactures and

markets a wide range of products under the Panasonic brand

to enhance and enrich lifestyles all around the globe.

Displays 40

Technical specications 42

POS materials 43

Company name: Panasonic Corporation

Head Oce Location: Osaka – Japan

President: Kazuhiro Tsuga

Foundation: March, 1918 (incorporated in December, 1935)

Net sales

Number of employees

Number of consolidated Companies

(1)

: 7,553.7 billion yen

(1)

: 249,520

(1)

: 475 (including parent company)

Panasonic - A powerful Global Brand

Best Global

Green Brand 2014

N°1

* www.interbrand.com (1) as of March 31, 2016

in Electronics Sector*

68th

Best Global

Brand 2016*

4

5

Leading Energy Solutions for the Future

Panasonic’s vision for the future centers on the need to develop products that offer greater

convenience, a higher level of performance, and improved environmental sustainability.

And we’re already delivering on that promise. Some recent examples include the supply of

next-generation lithium-ion batteries for Tesla Motors’ electric vehicles, the development

ralos ni tnemevlovni gnisaercni-reve ruo dna ,sresu elibom rof secived gnigrahc sseleriw fo

energy—and how we can use it to help people in remote areas. It’s the dawn of a new and

exciting era for Panasonic and the global community.

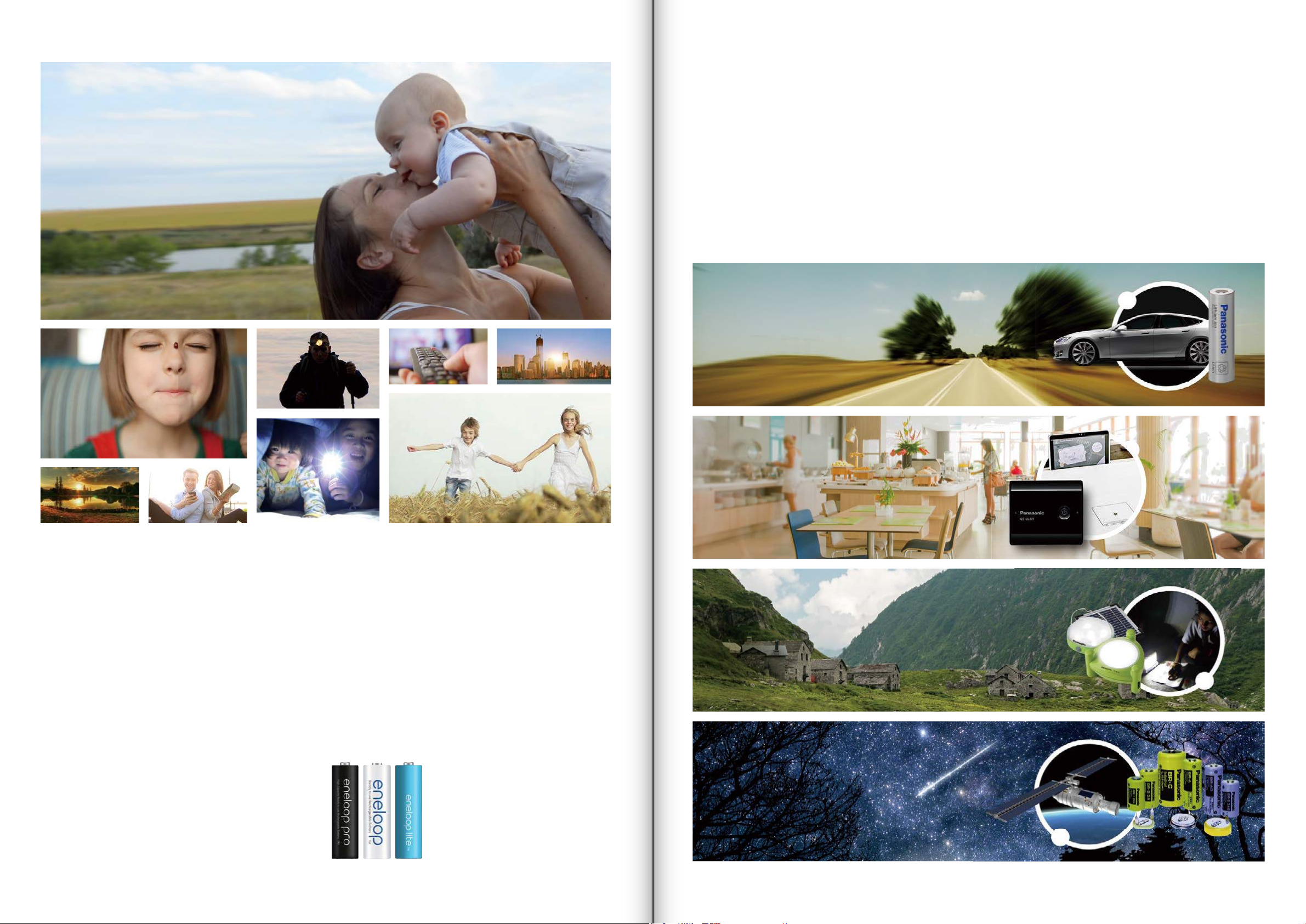

Leading Energy Solutions for the Future

Panasonic’s vision for the future centers on the need to develop products that oer greater

convenience, a higher level of performance, and improved environmental sustainability.

And we’re already delivering on that promise. Some recent examples include the supply of

next-generation lithium-ion batteries for Tesla Motors’ electric vehicles, the development

of wireless charging devices for mobile users, and our ever-increasing involvement in solar

energy—and how we can use it to help people in remote areas. It’s the dawn of a new and

exciting era for Panasonic and the global community.

Next-Generation lithium-ion

batteries for Tesla Motors

Creating

New Life

with Energy

Batteries are essential to daily life. All around us, in the

devices we need to work and play, Panasonic energy is

helping us not to live, but to ourish. For more than

90 years, we’ve been creating products most trusted for

performance, safety, and reliability. Our technology is driven

by continuous research and development as we nd new

ways to extend endurance. Passion for quality has led to

the supply of over 200 billion dry-cell batteries* to more than

120 countries, establishing Panasonic as the premier brand

for convenience and value. With superior technology and

a rm commitment to sustainability, we’re leading the world

to new life and new possibilities.

*As of March 2016

Revolutionary wireless

mobile charging

technology for cafés

Ecient solar lanterns

for people without power

access

Ultra-reliable battery

power for space

exploration

6 7

1923

Developed and released cannonball-shaped

battery-powered shell lamp

Relea sed the Excel D ry Batter y for shell lamp

1931

Star ted in-hous e dry-cell pr oduction in O saka,

takin g over the Komori dr y-batter y factory

1935

National Storage Battery Co., Ltd. established

Matsushita Dry Battery Co., Ltd. established

1937

Automotive lead-acid batteries released

1954

Relea sed Nationa l Hyper, Japan’s fi rs t fully

metal-jacketed dry battery

196 3

National Hi-Top manganese dry batteries released

1964

Commen ced produc tion of Cadnic a Ni-Cd batte ries

1967

Alkaline batteries released

Developed compact sealed lead-acid batteries

1969

Released National Neo Hi-Top manganese

dry batteries

1970

Released Pananica Ni-Cd batteries

1971

Develo ped lithium p rimary bat teries (Gra phite Fluori de BR line)

197 9

Matsushita Battery Industrial Co., Ltd. established

1980

Started production of the world’s fi rst amorphous

silicon solar cells

1987

Released Ultra Alkaline and

Panasonic Alkaline batteries

1989

Developed nickel-metal hydride batteries

1991

Released mercury-free manganese batteries

1992

Released mercury-free alkaline batteries

2005

Rechargeable eneloop released

to the market

2008

Released EVOLTA alkaline d ry batteries

Panasonic Corporation Energy

Company established

Relea sed Recharg eable EVOLTA

nickel-metal hydride batteries

2009

Developed multi-purpose lithium-ion battery modules

2013

Released Solar LED Lantern

2014

Panasonic eneloop goes global

2015

Solar storage device launched

Historical Highlights

Take a look at the events that shaped Panasonic’s remarkable

90

-year

evolution.

12

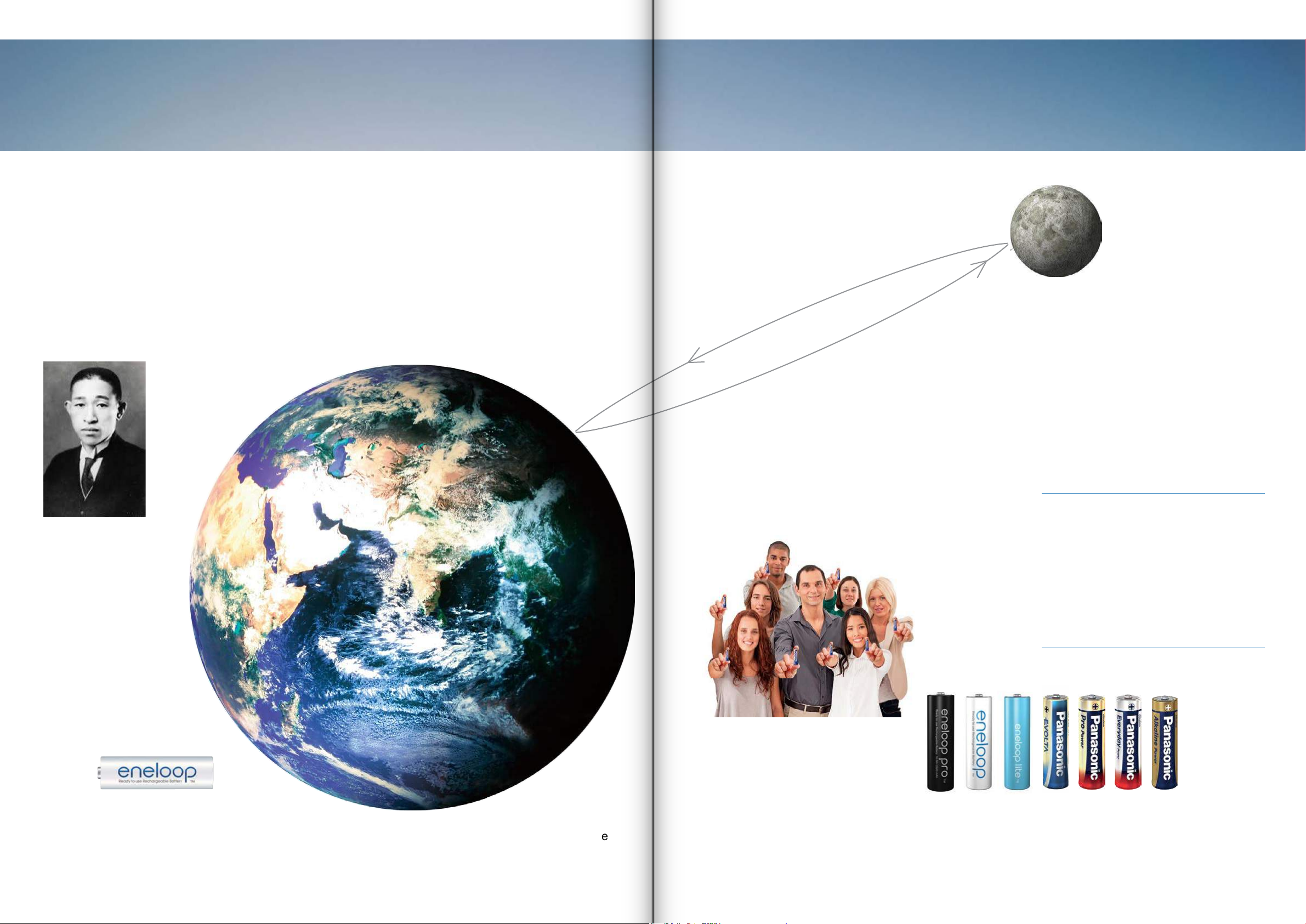

180 billion

9,000,000 km

That’s about twelve

return trips to the

moon.

… would extend for

a distance of

Panasonic batteries are sold in more

Assuming a 5 cm average

length and laid end-to-end,

an accumulated total of 180

billion dry batteries…

Every day, Panasonic energy helps us to get more out of life. For more than

90 years, we’ve been creating products trusted worldwide for performance,

safety, and reliability. Our technology is driven by continuous research and

development as we fi nd new ways to extend endurance and improve safety.

Our passion for quality has led to the supply of over 180 billion dry batteries* in

more than 120 countries. With superior technology and an ongoing commitment

to sustainability, we’re leading the way to new life and new possibilities.

* As of September 2015

Innovating on the World Stage

1923

Developed and released cannonball-shaped

battery-powered shell lamp

Relea sed the Excel D ry Batter y for shell lamp

Historical Highlights

Take a look at the events that shaped Panasonic’s remarkable

90

-year

evolution.

Every day, Panasonic energy helps us to get more out of life. For more than

90 years, we’ve been creating products trusted worldwide for performance,

safety, and reliability. Our technology is driven by continuous research and

development as we fi nd new ways to extend endurance and improve safety.

Our passion for quality has led to the supply of over 180 billion dry batteries* in

more than 120 countries. With superior technology and an ongoing commitment

to sustainability, we’re leading the way to new life and new possibilities.

* As of September 2015

Panasonic batteries

are sold in more than

120 countries

170 billion

Over the last century, Panasonic energy has become synonymous

with performance, safety, and reliability. Driven forward by constant

scientic research, we aim to develop products that open doors to

new life and new possibilities today and in the future.

More than 200 billion dry batteries sold in 120 countries.

since 1931

Higher Quality, Better

Performance, and

Enhanced Protection

From our rst bicycle battery

lamp developed in 1923 by

company founder Konosuke

Matsushita to the latest

Ni-MH cells powering

next-generation EVs,

Panasonic has always

been guided by

innovation.

200 billion

13

That’s about

13 return trips

to the moon.

Assuming a 5 cm average

length and laid end-to-end,

an accumulated total of 200

billion dry batteries …

... would extend for

a distance of

10,000,000 km

Panasonic

batteries

by numbers

*

Information is accurate

as of November 2016.

8 9

400 million

Over 400 million eneloop rechargeable

batteries shipped

*

120

Panasonic batteries are sold in more

than 120 countries

An Advanced Global Approach

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Continual research and development in all areas, from

materials, production processes, and system technology at

our dedicated lab facilities has kept Panasonic at the very

forefront of battery design. A focus on improving battery

safety and endurance has led to high-value products that

exceed expectations in every area.

Pursuing Better Quality Batteries

Developing High-Quality, High-Capacity Batteries

Quality ControlResearch & Development

An Advanced Global Approach to Batt ery Production

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Japan

Energy Device

Business Division

China

Panasonic Energy (Shanghai) Co., Ltd.

Panasonic Energy (Wuxi) Co., Ltd.

India

Poland

Panasonic Energy

Poland S.A.

Belgium

Panasonic Energy

Belgium N.V.

United States

of America

Panasonic Energy

Corporation of America

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Eco-friendly Processes and Design

Environmental Efforts

Japan

Energy Device

Business Division

China

Panasonic Energy (Shanghai) Co., Ltd.

Panasonic Energy (Wuxi) Co., Ltd.

India

Poland

Panasonic Energy

Poland S.A.

Belgium

Panasonic Energy

Belgium N.V.

United States

of America

Panasonic Energy

Corporation of America

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Eco-friendly Processes and Design

Environmental Efforts

Japan

Energy Device

Business Division

China

Panasonic Energy (Shanghai) Co., Ltd.

Panasonic Energy (Wuxi) Co., Ltd.

Thailand

Panasonic Energy (Thailand) Co., Ltd.

Indonesia

PT. Panasonic Global Energy

Indonesia

India

Panasonic Carbon

India Co., Ltd.

Panasonic Energy

India Co., Ltd.

Poland

Panasonic Energy

Poland S.A.

Belgium

Panasonic Energy

Belgium N.V.

United States

of America

Panasonic Energy

Corporation of America

Costa Rica

Panasonic Centroamericana S.A.

Tanzania

Panasonic Energy

Tanzania Co., Ltd.

Peru

Panasonic

Peruana S.A.

Brazil

Panasonic do

Brasil Limitada

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Eco-friendly Processes and Design

• Recycling resources

(Wuxi Factory)

Environmental Efforts

We limit our impact on the environment in a variety of ways:

• Reducing CO2 during production processes (Kasai Factory)

Japan

Energy Device

Business Division

China

Panasonic Energy (Shanghai) Co., Ltd.

Panasonic Energy (Wuxi) Co., Ltd.

Thailand

Panasonic Energy (Thailand) Co., Ltd.

Indonesia

PT. Panasonic Global Energy

Indonesia

India

Panasonic Carbon

India Co., Ltd.

Panasonic Energy

India Co., Ltd.

Poland

Panasonic Energy

Poland S.A.

Belgium

Panasonic Energy

Belgium N.V.

United States

of America

Panasonic Energy

Corporation of America

Costa Rica

Panasonic Centroamericana S.A.

Tanzania

Panasonic Energy

Tanzania Co., Ltd.

Peru

Panasonic

Peruana S.A.

Brazil

Panasonic do

Brasil Limitada

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Eco-friendly Processes and Design

• Recycling resources

(Wuxi Factory)

Environmental Efforts

We limit our impact on the environment in a variety of ways:

• Reducing CO2 during production processes (Kasai Factory)

• ISO14001* and ISO9001*

certication

for all factories

* Tanzanian factories excepted

Japan

Energy Device

Business Division

China

Panasonic Energy (Shanghai) Co., Ltd.

Panasonic Energy (Wuxi) Co., Ltd.

Thailand

Panasonic Energy (Thailand) Co., Ltd.

Indonesia

PT. Panasonic Global Energy

Indonesia

India

Panasonic Carbon

India Co., Ltd.

Panasonic Energy

India Co., Ltd.

Poland

Panasonic Energy

Poland S.A.

Belgium

Panasonic Energy

Belgium N.V.

United States

of America

Panasonic Energy

Corporation of America

Costa Rica

Panasonic Centroamericana S.A.

Tanzania

Panasonic Energy

Tanzania Co., Ltd.

Peru

Panasonic

Peruana S.A.

Brazil

Panasonic do

Brasil Limitada

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

An Advanced Global Approach to Batt ery Production

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Eco-friendly Processes and Design

• Recycling resources

(Wuxi Factory)

Environmental Efforts

We limit our impact on the environment in a variety of ways:

• Reducing CO2 during production processes (Kasai Factory)

• ISO14001* and ISO9001*

certication

for all factories

* Tanzanian factories excepted

Japan

Energy Device

Business Division

China

Panasonic Energy (Shanghai) Co., Ltd.

Panasonic Energy (Wuxi) Co., Ltd.

Thailand

Panasonic Energy (Thailand) Co., Ltd.

Indonesia

PT. Panasonic Global Energy

Indonesia

India

Panasonic Carbon

India Co., Ltd.

Panasonic Energy

India Co., Ltd.

Poland

Panasonic Energy

Poland S.A.

Belgium

Panasonic Energy

Belgium N.V.

United States

of America

Panasonic Energy

Corporation of America

Costa Rica

Panasonic Centroamericana S.A.

Tanzania

Panasonic Energy

Tanzania Co., Ltd.

Peru

Panasonic

Peruana S.A.

Brazil

Panasonic do

Brasil Limitada

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Continual research and development in all areas, from

materials, production processes, and system technology at

our dedicated lab facilities has kept Panasonic at the very

forefront of battery design. A focus on improving battery

safety and endurance has led to high-value products that

exceed expectations in every area.

Panasonic Manganese

batteries contain no lead,

mercury, or cadmium,

while our Coin batteries

contain zero mercury.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

Almost all batteries in the Panasonic family are made on

fully automated and computer-controlled production lines

for superior consistency of quality and greater efficiency.

Integral Computer-Controlled Production Lines

An Advanced Global Approach to Batt ery Production

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Eco-friendly Processes and Design

• Recycling resources

(Wuxi Factory)

Environmental Efforts

We limit our impact on the environment in a variety of ways:

• Reducing CO2 during production processes (Kasai Factory)

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe five-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Pursuing Better Quality Batteries

Quality ControlResearch & Development

Panasonic’s holistic approach to manufacturing encompasses four key

areas—research and development, production, quality control, and

environmental effort—at a number of state-of-the-art facilities around

the world. Guiding principles of continual product improvement

and the strictest quality control are governed by our desire to

deliver premium products to customers with minimal impact on the

environment.

Poland

Belgium

China

Panasonic Energy (Shanghai) Co., Ltd.

Poland

Belgium

China

Panasonic Energy (Shanghai) Co., Ltd.

China

Panasonic Energy (Shanghai) Co., Ltd.

China

Panasonic Energy (Shanghai) Co., Ltd.

Poland

Belgium

China

Panasonic Energy (Shanghai) Co., Ltd.

China

Panasonic Energy (Shanghai) Co., Ltd.

An Advanced Global Approach

An Advanced Global Approach

Panasonic Energy Europe,

to Battery Production

to Battery Production

to Battery Production

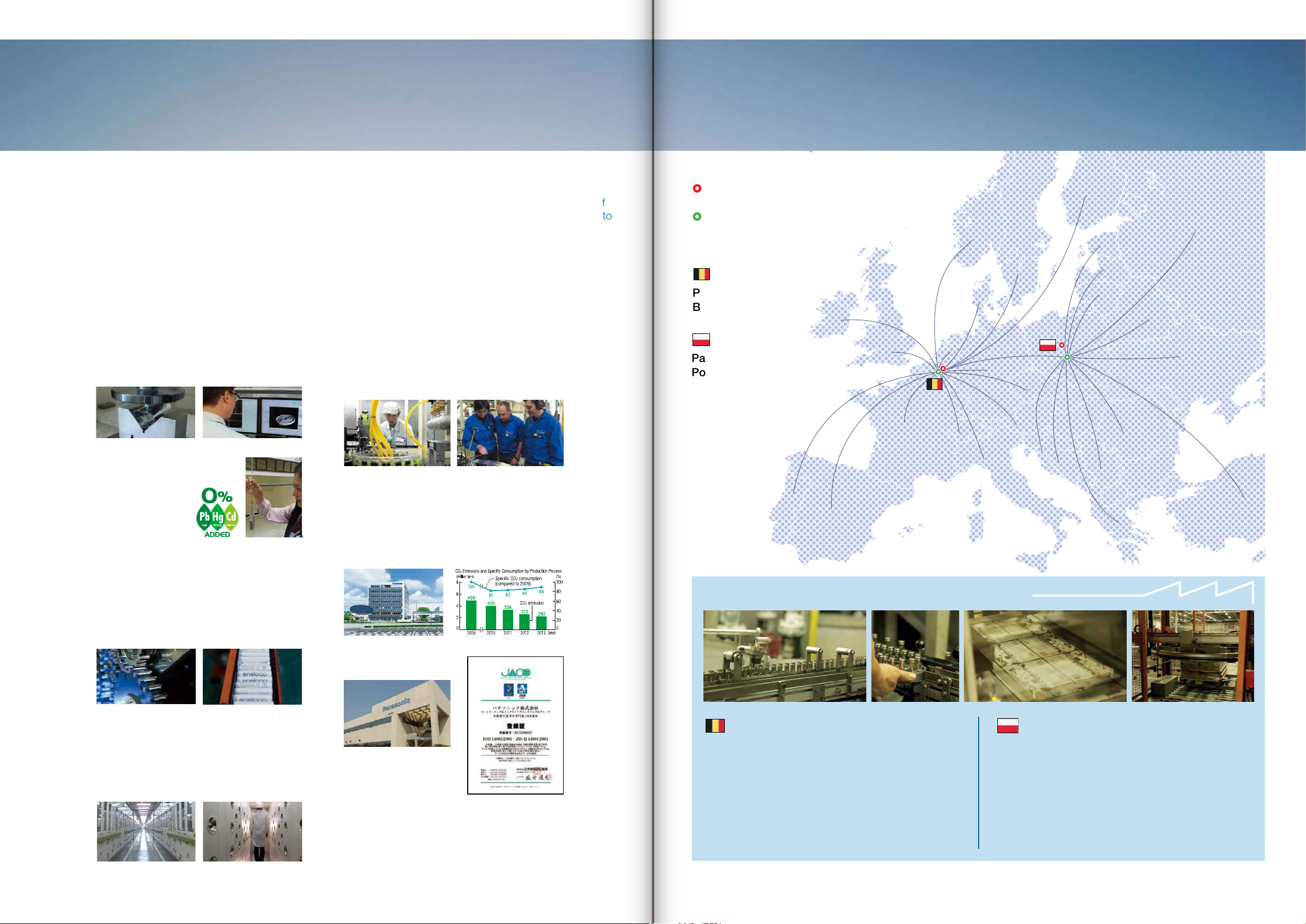

Panasonic’s holistic approach to manufacturing encompasses four key areas—research and development, production,

quality control, and environmental eort—at a number of state-of-the-art facilities around the world. Guiding principles of

continual product improvement and the strictest quality control are governed by our desire to deliver premium products to

customers with minimal impact on the environment.

Panasonic Battery Factory

Panasonic European Distribution Centre

Research & Development

Developing High-Quality, High-Capacity Batteries

Continual research and development in all areas, from

materials, production processes, and system technology at

our dedicated lab facilities has kept Panasonic at the very

forefront of battery design. A focus on improving battery

safety and endurance has led to high-value products that

exceed expectations in every area.

Quality Control

Pursuing Better Quality Batteries

More than two million batteries are produced and tested

worldwide each year. We lead the industry in product

quality with larger-scale testing facilities than other

companies. Furthermore, all batteries are subjected

to severe ve-category testing covering discharge

performance, leakage resistance, shelf life, performance

in extreme environments, and product stability over time.

Belgium

Panasonic Energy

Belgium N.V.

Poland

Panasonic Energy

Poland S.A.

Producing Products Without

Specied Harmful Substances

Panasonic zinc carbon

batteries contain no lead,

mercury or cadmium,

while our Coin batteries

contain zero mercury.

Integral Computer-Controlled Production Lines

Almost all batteries in the Panasonic family are made on

fully automated and computer-controlled production lines

for superior consistency of quality and greater eciency.

Manufacturing

contaminant-free clean rooms that exceed all industry

environmental standards. Advanced manufacturing

techniques ensure the same highly consistent quality no

Contaminant-free Clean Facilities

The vast majority of production takes place in

matter where our products are purchased.

10

Environmental Eorts

Eco-friendly Processes and Design

We limit our impact on the environment in a variety of ways:

• Reducing CO2 during production processes (Kasai Factory)

• Recycling recources

(Wuxi Factory)

• ISO14001* and ISO9001*

certication for all factories

* Except Tanzanian factories

A CLOSER LOOK AT OUR FACTORIES

Located in: Tessenderlo, Belgium

Established in: September 29th 1970

Number of employees: 360 employees

In-house production of batteries, starting from the

creation of the battery can, to labeling of nished

products, packing, and automatic palletization.

your professional battery partner

BELGIUM FACTORY POLAND FACTORY

Located in: Gniezno, Poland

Established in: December 15th 1993

Number of employees: 344 employees

In-house production of zinc-carbon batteries (sizes

R03, R6, R14, R20) and LR6 alkaline batteries,

packing of eneloop and other batteries.

11

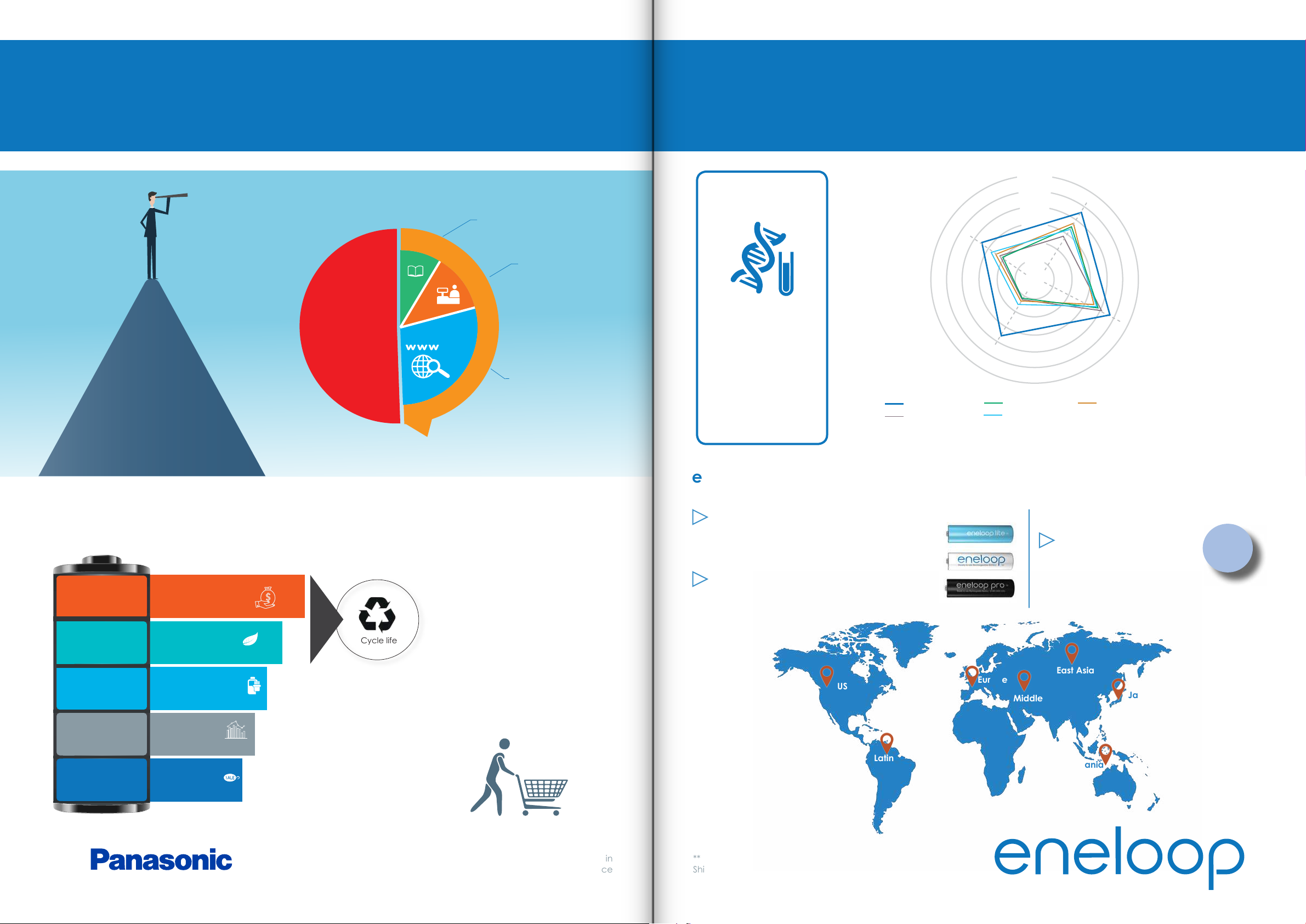

rechargeable batteries

22%

47%

Where

do people

search for

information

about

rechargeable

*

batteries

?

Shopper insights

P

E

O

P

L

E

53%

PEOPLE NOT

SEARCHING FOR

INFO

G

eneloop brand image

100%

80%

DNA

searches in magazines

W

H

O

S

E

A

R

C

H

F

O

R

I

N

F

O

B

E

F

O

R

E

B

U

Y

I

N

30%

asks store sta

70%

searches online

eneloop is clearly

perceived as the

most eco-friendly,

young, fun &

joyful brand. This is

opposed to other

rechargeable

batteries, which have

the same DNA as

alkaline batteries.

eneloop worldwide

eneloop worldwide

Source: Haystack rechargeable online survey July 2016. n:2007 in GE, PL, UK, IT, FR

**

**

Passionate

Young / Fun / Joyful

eneloop (n=55)

Brand C (n=81)

60%

40%

20%

0%

Brand A (n=33)

Brand D (n=175)

Ecofriendly

Advanced

Brand B (n=151)

Main reasons to buy rechargeable batteries

56%

42%

40%

27%

13%

Combined promotion

Money saving

vs non-rechargeable

Environment

Always batteries available

when needed

Performance vs

non-rechargeable

Cycle life

Cycle life is one of the most important key

drivers for buying rechargeable batteries.

*

Sold in over

80

million batteries

400

shipped worldwide

countries

USA

Latin

America

Europe

Middle East

Asia/Oceania

Registered trademark

in over

60

countries

East Asia

Japan

TM

*Source: Haystack rechargeable online survey July 2016 n:2007 in

Germany, Poland, UK, Italy & France

** Total period: from November 2005 to October 2016

Shipment over 80 countries

12 13

Loading...

Loading...