Page 1

ORDER NO.CHM0602003CE

Portable DVD/CD PLAYER

DVD-LS91PP

RAE1905Z-3C Mechanism Series

Colour

(S).................Silver Type

B12

Specifications

Operating temperature

range: +5 to +35°C (+41 to +95°F)

Operating humidity range: 5-85% RH (no condensation)

Region number: Region No.1

Discs played

[8cm (3”) or 12cm (5”)]:

Signal system: NTSC

DVD (DVD-Video)

DVD-RAM [DVD-VR, JPEG(*4,6,7),

MP3(*2,6)]

DVD-R [DVD-Video, DVD-VR,

JPEG(*4,6,7), MP3(*2,6)]

DVD-R DL (DVD-Video, DVD-VR)

DVD-RW [DVD-Video, DVD-

VR,JPEG(*4,6,7), MP3(*2,6)]

+R/RW (Video)

+R DL (Video)

CD, CD-R/RW [CD-DA, Video-CD,

SVCD(*1), MP3(*2, 6), WMA(*3, 6),

JPEG (*4,6,7), HighMAT Level 2

(Audio and Image)]

*1: Conforming to IEC62107

*2: MPEG-1 Layer3, MPEG-2 Layer3

*3: Windows Media Audio Ver9.0 L3.

Not compatible with Multiple Bit Rate

(MBR)

*4: Exif Ver 2.1 JPEG Baseline files

Picture resolution: between 160×120

and 6144×4096 pixels (sub sampling

is 4:2:2, 4:2:0 or 4:4:4)

*6: The total combined maximum

number of recognizalbe audio and

picture contents and groups: 4000

audio and picture contents and 400

groups.

*7: Extremely long and slender

pictures may not be displayed.

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

A

A

DVD-LS91PP

LCD screen: 9” -Si, TFT wide-screen LCD

Composite-video output/

input:

Output/input level: 1Vp-p (75W)

Output/input terminal: Mini-jack

Number of terminals: 1system (output/input selectable)

Audio output/input:

Output/input level: 1.5Vrms (1kHz, 0dB, 10kW)

Output/input terminal: Stereo mini-jack

Number of terminals: 1system (output/input selectable)

Audio performance:

(1) Frequency response:

lDVD (linear audio): 4Hz-22kHz (48kHz sampling)

4Hz-44kHz (96kHz sampling)

lCD audio: 4Hz-20kHz

(2) S/N ratio:

lCD audio: 115dB

(3) Dynamic range:

lDVD (linear audio): 98dB

lCD audio: 97dB

(4) Total harmonic distortion:

lCD audio: 0.008%

Digital audio output:

Optical digital output: Mini optical terminal

Number of terminals: 1system

(also used for audio output/input)

Headphone output:

Output: Stereo mini-jack

Number of terminals: 2systems

Battery duration:

*CGR-H713: Option

*Room temperature

*using headphone

When brightness is set to “-5” while

playing DVD: 6 hours (CGR-H712)

/10 hours (CGR-H713)

When brightness is set to “0” while

playing DVD: 4 hours (CGR-H712)

/7 hours (CGR-H713)

When brightness is set to “+5” while

playing DVD: 3 hours (CGR-H712)

/5 hours (CGR-H713)

When LCD panel is off while DVD

playing: 10 hours (CGR-H712)

/15 hours (CGR-H713)

Battery recharge time (at

20°C)

8 hours (CGR-H712)

/10 hours (CGR-H713)

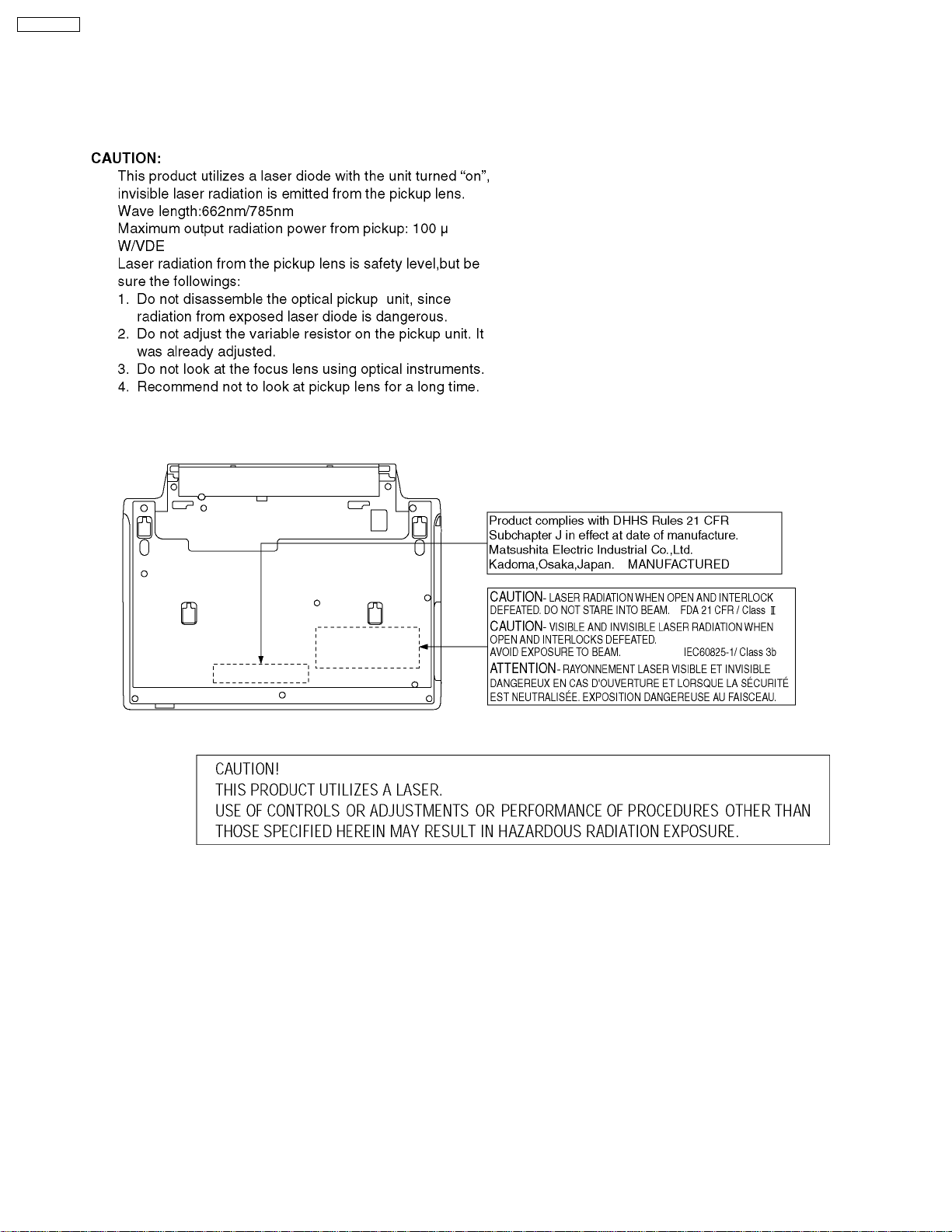

Pickup:

Wave length: 662nm/ 785nm (DVD/CD)

Laser power: CLASS 2/ CLASS 1 (DVD/CD)

Power supply: DC 12V (DC IN terminal) /

DC 7.2V (Exclusive battery terminal)

Power consumption

13W (Unit only: 10W)

(Using included AC adaptor):

Power consumption in

0.3W

Standby mode

(Using included AC adaptor):

Power consumption in

13W

Recharge mode

(Using included AC adaptor):

AC adaptor:

Power source:

C 100-240V, 50/60Hz

Power consumption: 28W

DC output: 12V, 1.5A

Car DC adaptor:

DC output: 12V 2A (Vehicle with 12V battery

only)

Battery pack CGR-H712

(lithium ion):

Voltage: 7.2V

Capacity: 4500mAh

Dimensions (excluding

protrusions and battery):

235.4(W) x 179.2(D) x 46.0*(H) mm

9

/32”(W)x71/16”(D)x113/16”(H)]

[9

61

*24.3mm (

[D=185.0mm (7

[H=51.5mm (2

/64”) at lowest point

9

/32”) including battery]

1

/32”) including battery]

Mass (including battery): approximately 1094g (38.59 oz)

solder:

This model uses lead free solder (PbF).

Note

Specifications are subject to change without notice.

Mass and dimensions are approximate.

Manufactured under license from Dolby Laboratories.

“Dolby“ and the double-D symbol are trademarks of Dolby

Laboratories.

“DTS“ and “DTS 2.0+ Digital Out” are trademarks of Digital Theater

Systems, Inc.

pparatus Claims of U.S. Patent Nos. 4,631,603, 4,577,216, and

4,819,098, licensed for limited viewing uses only.

This product incorporates copyright protection technology that is

protected by method claims of certain U.S. patents and other

intellectual property rights owned by Macrovision Corporation and

other rights owners. Use of this copyright protection technology

must be authorized by Macrovision Corporation, and is intended for

home and other limited viewing uses only unless otherwise

authorized by Macrovision Corporation. Reverse engineering or

disassembly is prohibited.

Windows Media, and the Windows logo are trademarks, or

registered trademarks of Microsoft Corporation in the United States

and/or other countries.

WMA is a compression format developed by Microsoft Corporation.

It achieves the same sound quality as MP3 with a file size that is

smaller than that of MP3.

MPEG Layer-3 audio decoding technology licensed from

Fraunhofer llS and Thomson multimedia.

HighMAT™ and the HighMAT logo are either trademarks or

registered trademarks of Microsoft Corporation in the United States

and/or other countries.

2

Page 3

DVD-LS91PP

CONTENTS

Page Page

1 SAFETY PRECAUTIONS 5

1.1. GENERAL GUIDELINES

2 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

3 PRECAUTION OF LASER DIODE

4 HOW TO REPLACE THE LITHIUM BATTERY

5 LITHIUM ION BATTERY

6 Service caution based on legal restrictions

6.1. General description about Lead Free Solder (PbF)

7 HANDLING PRECAUTIONS FOR TRAVERSE DECK

7.1. Handling of optical pickup

7.2. Grounding for electrostatic breakdown prevention

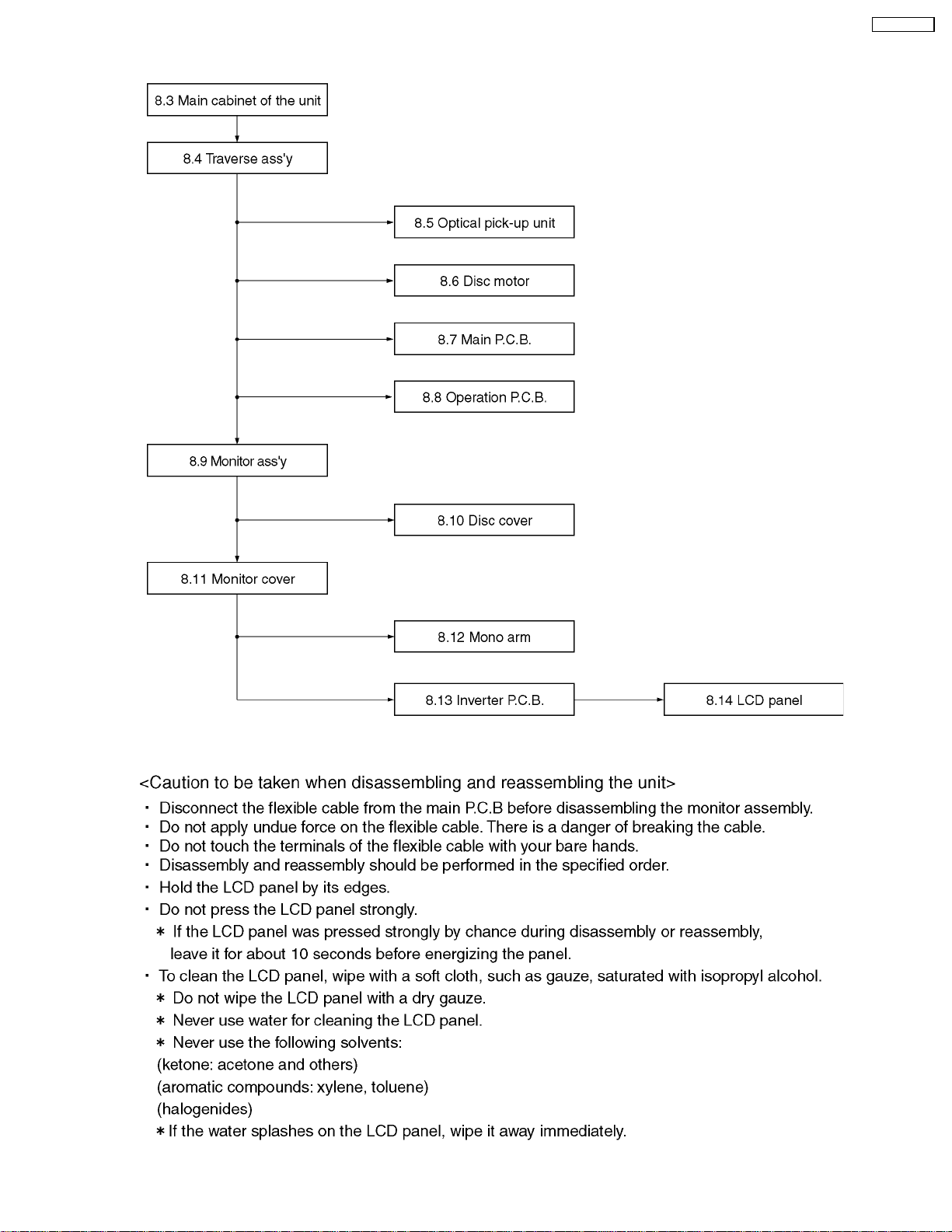

8 DISASSEMBLY, REASSEMBLY AND SERVICE POSITION

8.1. Disassembly

8.2. P.C.B. location

8.3. Main cabinet of the unit

8.4. Traverse assembly

8.5. Optical pick-up unit

8.6. Disc motor

8.7. Main P.C.B.

8.8. Operation P.C.B.

8.9. Monitor assembly

8.10. Disc cover

8.11. Monitor cover

8.12. Mono arm

8.13. Inverter P.C.B.

8.14. LCD panel

8.15. Replacing the fuse in the car dc adaptor

8.16. Service position

9 SELF-DIAGNOSIS FUNCTION AND SERVICE MODE

9.1. Optical Pickup Breakdown Diagnosis

9.2. UHF displays

9.3. Service Mode Table 1

9.4. DVD Self Diagnostic Function-Error Code

9.5. Last Error Code saved during NO PLAY

9.6. Service mode table

9.7. Lens cleaning

10 SERV ICE PREC AUTIONS

10.1. Recovery after the dvd player is repaired

10.2. Firmware version-up of the DVD player

11 ADJUSTMENT PROCEDUR ES

11.1. Service Tools and Equipment

11.2. Important points in adjustment

11.3. Storing and Handling Test Discs

11.4. Optical adjustment

11.5. Electrical adjustment (LCD)

10

11

12

12

13

14

14

15

15

15

16

16

17

18

18

18

19

20

20

21

22

22

26

26

29

30

30

30

31

31

31

31

32

34

11.6. Electrical check (Video output check)

5

12 Abbreviation s

13 VOL TAGE CHART

5

6

7

7

8

8

9

9

9

13.1. MAIN P.C.B.

13.2. INVERTER P.C.B.

14 BLOCK DIAGRAM

14.1. OVERALL BLOCK DIAGRAM

14.2. POWER SUPPLY BLOCK DIAGRAM

14.3. SERVO BLOCK DIAGRAM

14.4. AUDIO BLOCK DIAGRAM

14.5. VIDEO BLOCK DIAGRAM

15 INTERCONN ECTIO N SCHEMATIC DIAGRAM & SCHEMATIC

DIAGRAM NOTES

15.1. INTERCONNECTION SCHEMATIC DIAGRAM

15.2. SCHEMATIC DIAGRAM NOTES

16 SCHE MATIC DIAGRAM

16.1. CHARGE BATTERY SECTION (MAIN P.C.B. (1/10))

SCHEMATIC DIAGRAM

16.2. POWER SUPPLY SECTION (MAIN P.C.B. (2/10))

SCHEMATIC DIAGRAM

16.3. SERVO SECTION (MAIN P.C.B. (3/10)) SCHEMATIC

DIAGRAM

16.4. OPTICAL PICK UP SECTION (MAIN P.C.B. (4/10))

SCHEMATIC DIAGRAM

16.5. DV3 SECTION (MAIN P.C.B. (5/10)) SCHEMATIC

DIAGRAM

16.6. VIDEO OUT SECTION (MAIN P.C.B. (6/10)) SCHEMATIC

DIAGRAM

16.7. AUDIO OUT SECTION (MAIN P.C.B. (7/10)) SCHEMATIC

DIAGRAM

16.8. OPERATION SECTION (MAIN P.C.B. (8/10))

SCHEMATIC DIAGRAM

16.9. LCD IF SECTION (MAIN P.C.B. (9/10)) SCHEMATIC

DIAGRAM

16.10. XBS SECTION (MAIN P.C.B. (10/10)) SCHEMATIC

DIAGRAM

16.11. OPERATION SECTION (OPERATION P.C.B.)

SCHEMATIC DIAGRAM

16.12. INVERTER SECTION SCHEMATIC DIAGARAM

17 CIRC UIT BOARD ASSEMBLY

17.1. MAIN P.C.B. (1/2) (COMPONENT SIDE)

17.2. MAIN P.C.B. (2/2) (FOIL SIDE)

17.3. OPERATION & INVERTER P.C.B.

18 EXPL ODED VIEW S

18.1. Casing Parts & Mechanism Section Exploded View

18.2. Mechanism Section Exploded View

35

36

38

38

41

43

43

44

45

46

47

49

49

50

51

51

52

53

54

55

56

57

58

59

60

61

62

63

63

64

65

67

67

68

3

Page 4

DVD-LS91PP

18.3. Packing & Accessories Exploded View 69 19 REPLACEMENT PARTS LIST 70

4

Page 5

DVD-LS91PP

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1MW and 5.2MW .

When the exposed metal does not have a return path to

the chassis, the reading must be

.

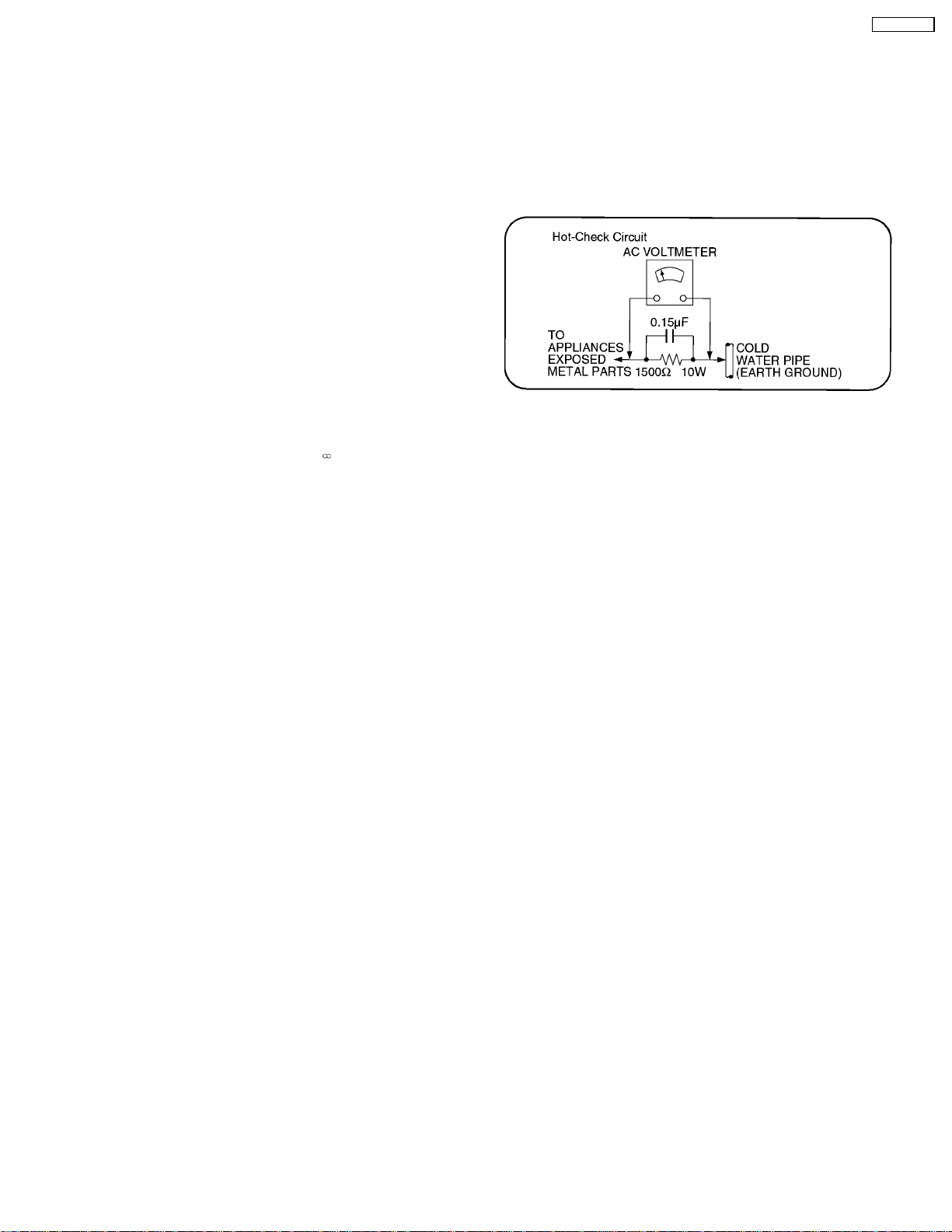

1.1.2. LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kW, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the ACplug in theAC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

2 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

5

Page 6

DVD-LS91PP

8. Minimize bodily motions when handling unpackaged replacement ES devices.(Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

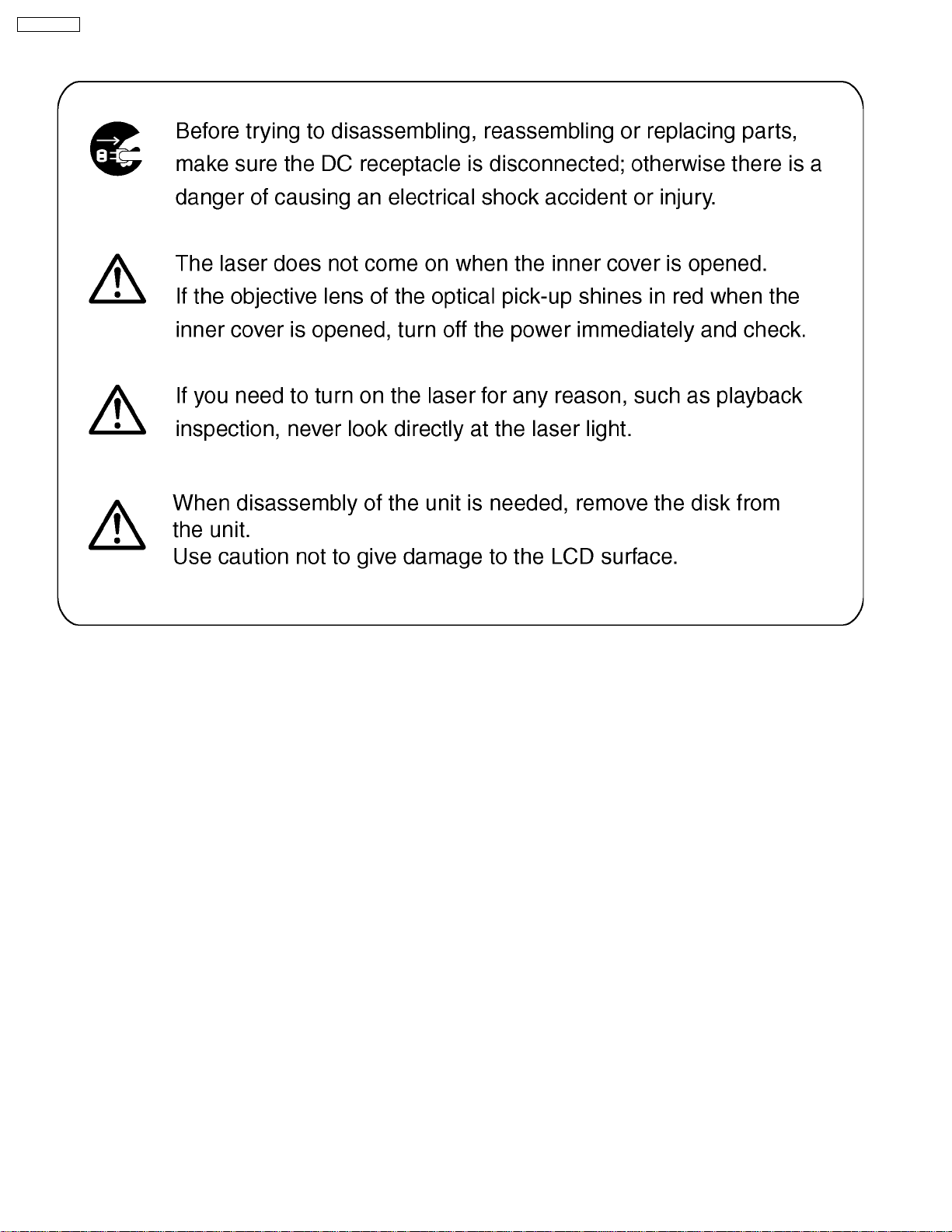

3 PRECAUTION OF LASER DIODE

6

Page 7

4 HOW TO REPLACE THE LITHIUM BATTERY

This model is using a lithium battery for the remote control ass’y.

NOTE:

The lithium battery is a critical component. ( Type No.: CR2025 Manufactured by Panasonic. )

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

DVD-LS91PP

5 LITHIUM ION BATTERY

7

Page 8

DVD-LS91PP

6 Service caution based on legal restrictions

6.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86 F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB

using the lead free solder. (See right figure)

Service caution for repair work using Lead Free Solder (PbF)

- The lead free solder has to be used when repairing the equipment for which the lead free solder is used.(Definition: The letter

of "PbF" is printed on the PCB using the lead free solder.)

- To put lead free solder, it should be well molten and mixed with the original lead free solder.

- Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

- Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

- Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350+-30

degrees C (662+-86 F).

Recommended Lead Free Solder (Service Parts Route.)

- The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

Page 9

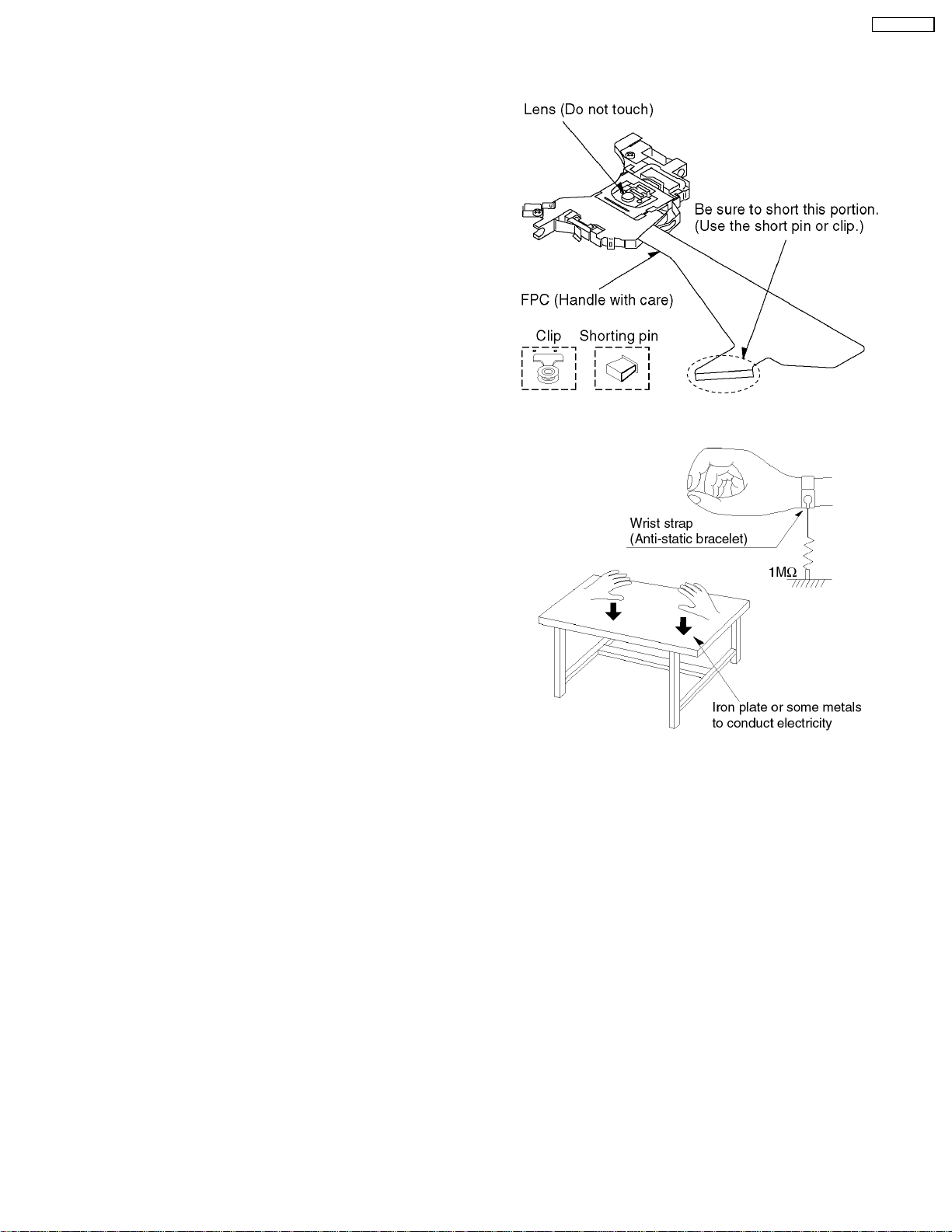

7 HANDLING PRECAUTIONS FOR TRAVERSE DECK

DVD-LS91PP

The laser diode in the optical pickup may break down due to

potential difference caused by static electricity of clothes or

human body.

So be careful of electrostatic break down during repair of the

optical pickup.

It has already been adjusted.

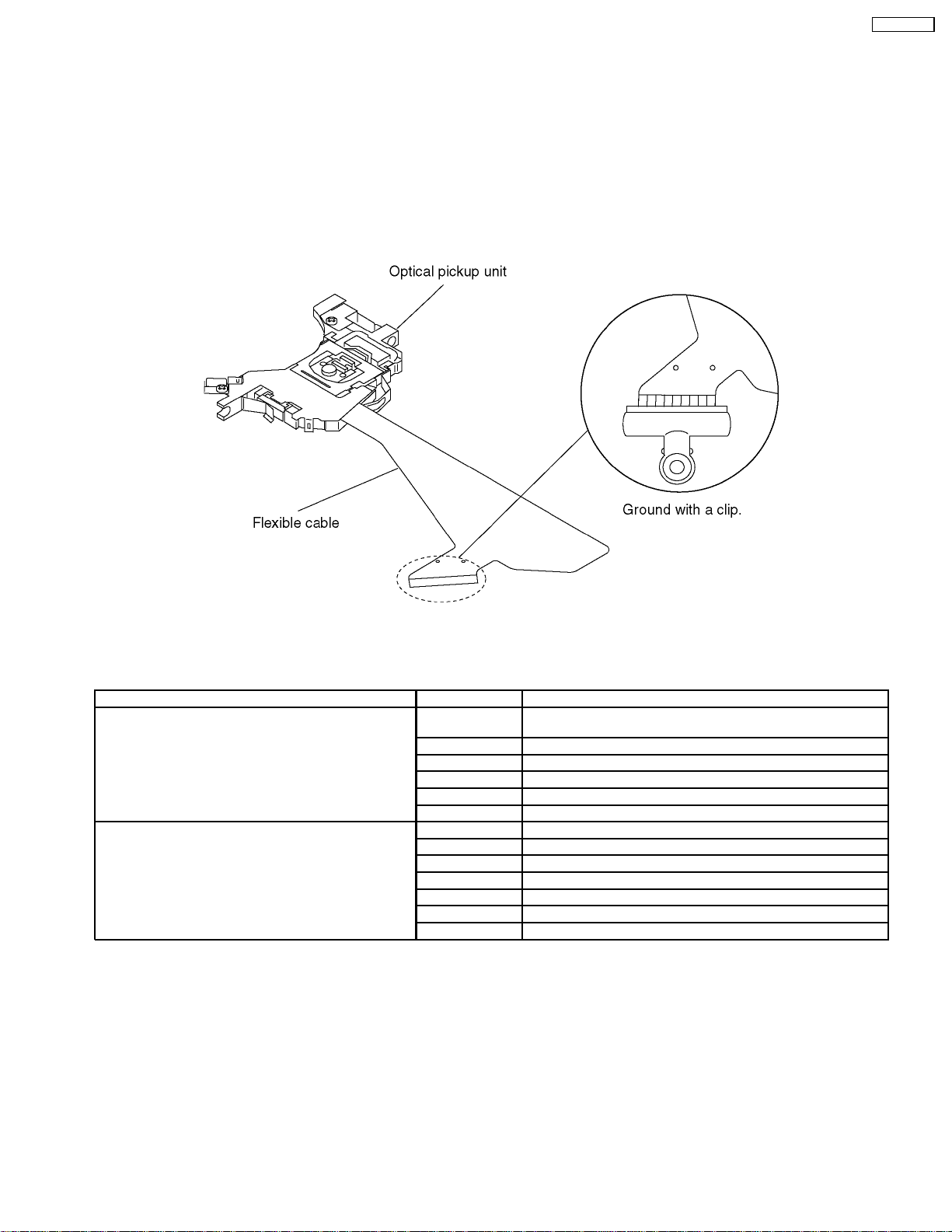

7.1. Handling of optical pickup

1. Do not subject the optical pickup to static electricity as it is

extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic

shorting pin is inserted into the flexible board (FPC Board).

When removing or connecting the short pin, finish the job in

as short times as possible.

3. Be careful not toapply excessive stressto the flexible board

(FPC Board).

4. Do not turn the variable resistor (Laser power adjustment).

7.2. Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the antistatic wrist strap to discharge the static

electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area

where the optical pickup is placed and ground the sheet.

Caution

The static electricity of your clothes will not be grounded

through the wrist strap. So take care not to let your

clothes touch the optical pickup.

9

Page 10

DVD-LS91PP

8 DISASSEMBLY, REASSEMBLY AND SERVICE POSITION

10

Page 11

8.1. Disassembly

DVD-LS91PP

11

Page 12

DVD-LS91PP

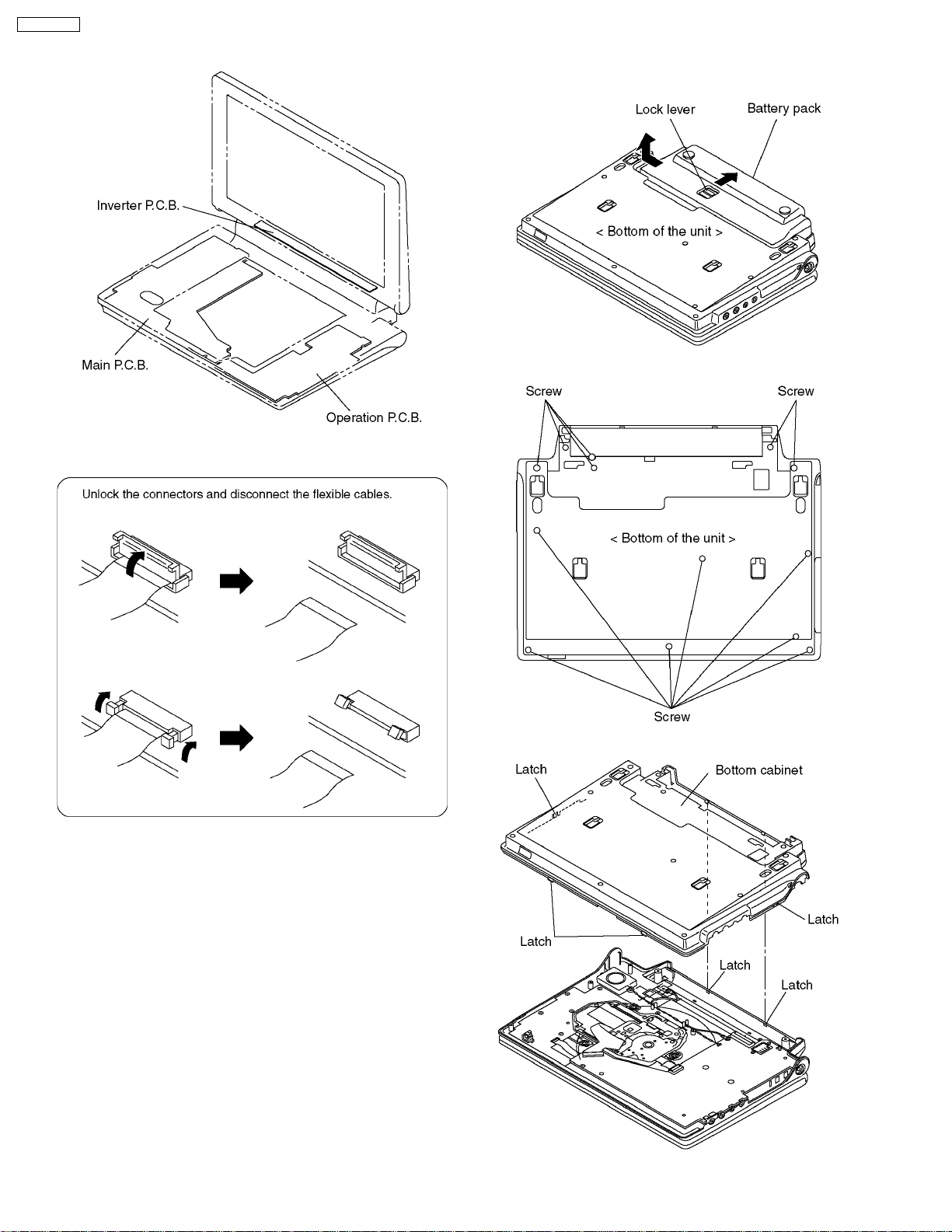

8.2. P.C.B. location

8.3. Main cabinet of the unit

<Removing battery pack>

Release the lock lever and remove the battery pack in the

direction of the arrow.

1. Remove the 13 screws from the bottom of the unit.

2. Release the latches and remove the bottom cabinet.

12

Page 13

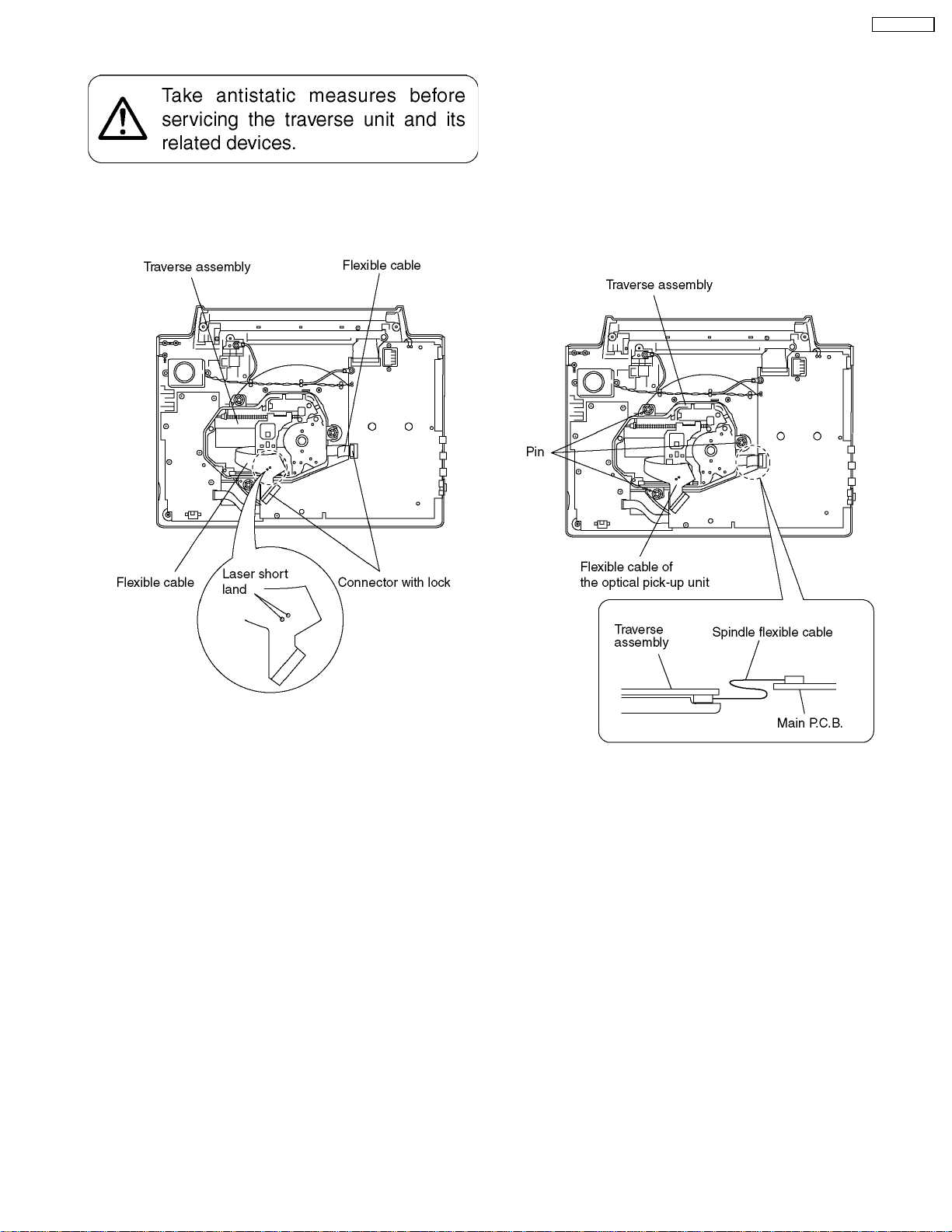

8.4. Traverse assembly

8.4.1. Removing traverse assembly

1. Solder the 2 laser short lands on the flexible cable.

2. Unlock the connectors and remove the flexible cables.

DVD-LS91PP

8.4.2. Reinstalling traverse assembly

1. Reinstall the traverse assembly to the specified pin of the

unit.

2. Reinstall the flexible cable of the optical pickpup unit and

lock it securely.

3. Remove the solder of each laser short land of the flexible

cable.

Caution:

Remove the solders completely: otherwise the laser

diode won’t emit light.

4. Reinstall the spindle flexible cable as shown figure.

13

Page 14

DVD-LS91PP

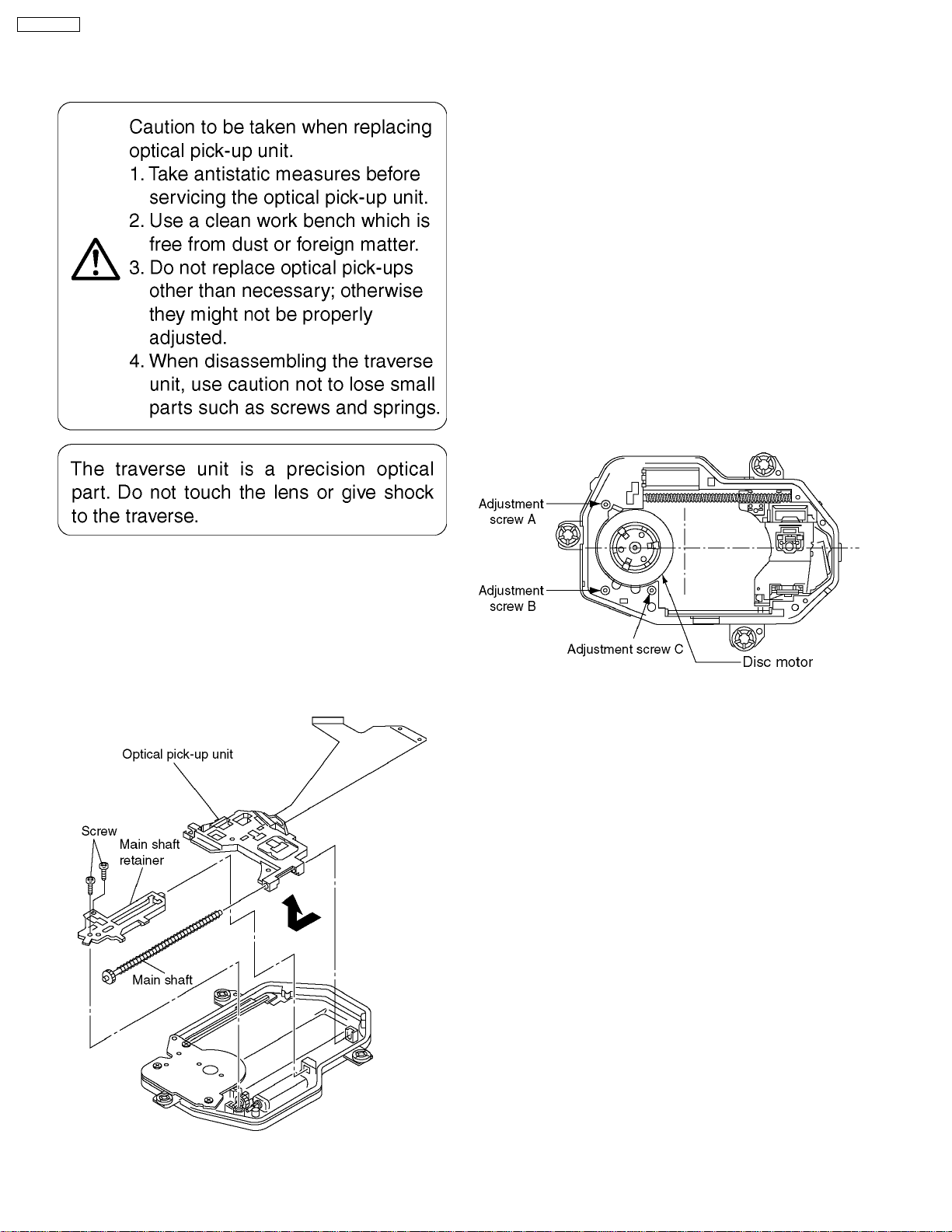

8.5. Optical pick-up unit

8.5.1. Removing optical pick-up unit

8.5.2. Reinstalling optical pick-up unit

The optical pick-up unit is factory adjusted. Do not touch the

adjustment screw.

1. Reassemble the disassembled parts in the reverse order of

disassembly.

2. When reinstalling the traverse assembly on the main unit

after installing the optical pick-up unit, make sure to remove

the solder from each of the two laser short lands on the

flexible cable.

Caution:

· Remove the solders completely; otherwise the laser

diode won´t emit light.

· After replacing the optical pick-up unit, check the quality

of images played back and make optical adjustment.

8.6. Disc motor

8.6.1. Removing disc motor

1. Remove the adjustment screws A, B, and C.

2. Remove the disc motor.

Make sure that the traverse assembly removed before trying to

remove the optical pick-up unit.

When removing the traverse assembly, solder the two laser

short lands on the flexible cable of the optical pick-up unit.

1. Remove the two screws securing the main shaft retainer.

2. Remove the main shaft retainer.

3. Slide the main shaft in the direction indicated by the arrow

to remove the optical pick-up unit.

8.6.2. Caution to be taken when

replacing the disc motor

1. The mounting screws of the disc motor also serve as

adjustment screws. When reinstalling the disc motor, first

turn the screws A, B, and C as far as they go by usual force

to secure them (do not overtighten).

2. Back off the adjustment screws Aand C two complete turns

and secure them.

3. Back off the adjustment screw B one and a half turns and

secure them.

· This makes it nearly possible to play back disks and

adjust the jitter.

Thereafter, adjust the adjustment screws C and A as

indicated.

14

Page 15

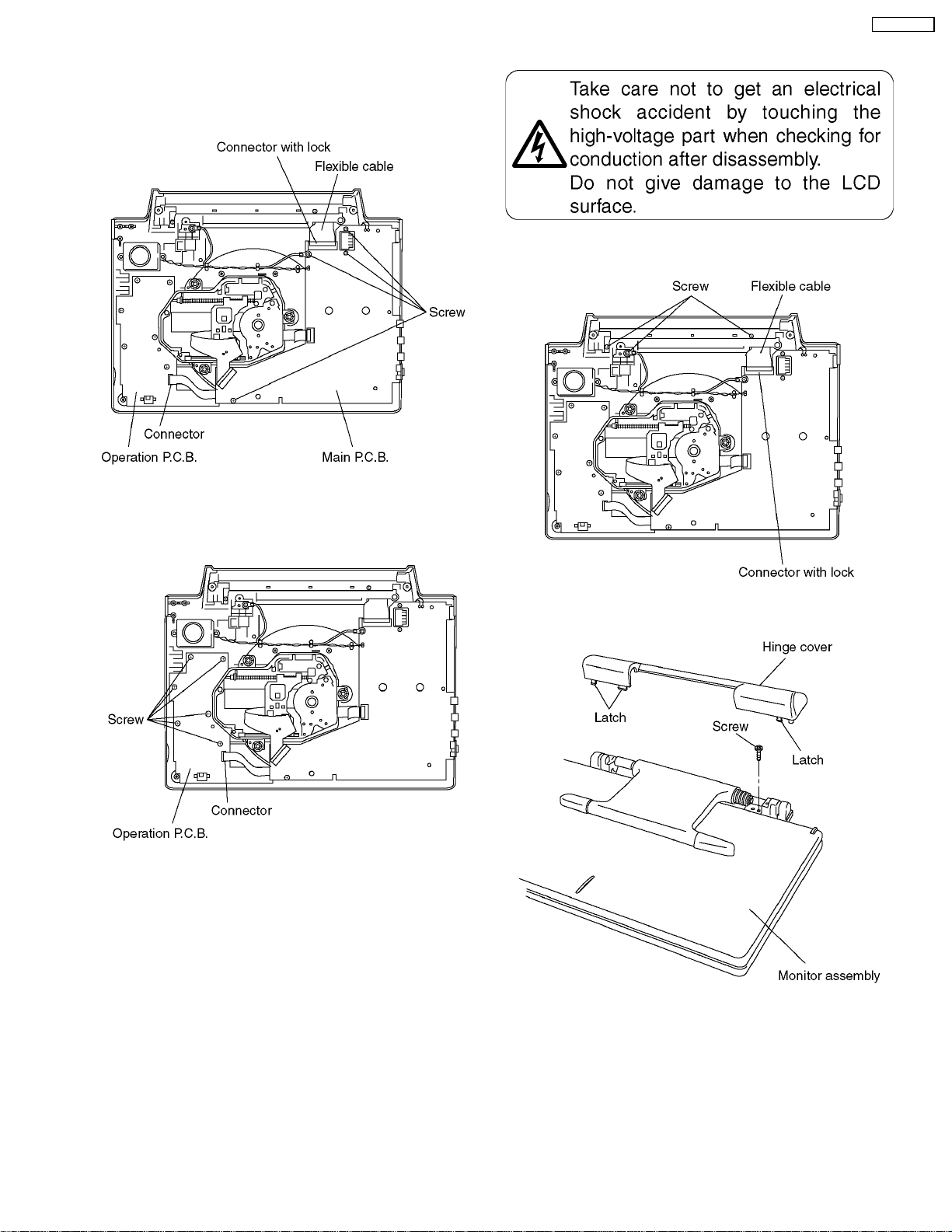

8.7. Main P.C.B.

1. Unlock the connector and remove the flexible cable.

2. Remove the connector.

3. Remove the 4 screws and remove the main P.C.B..

DVD-LS91PP

8.9. Monitor assembly

1. Unlock the connector and remove the flexible cable.

2. Remove the 3 screws.

8.8. Operation P.C.B.

1. Remove the connector.

2. Remove the 6 screws and remove the operation P.C.B.

3. Release the latches and remove the hinge cover.

4. Remove the screw and remove the monitor assembly.

15

Page 16

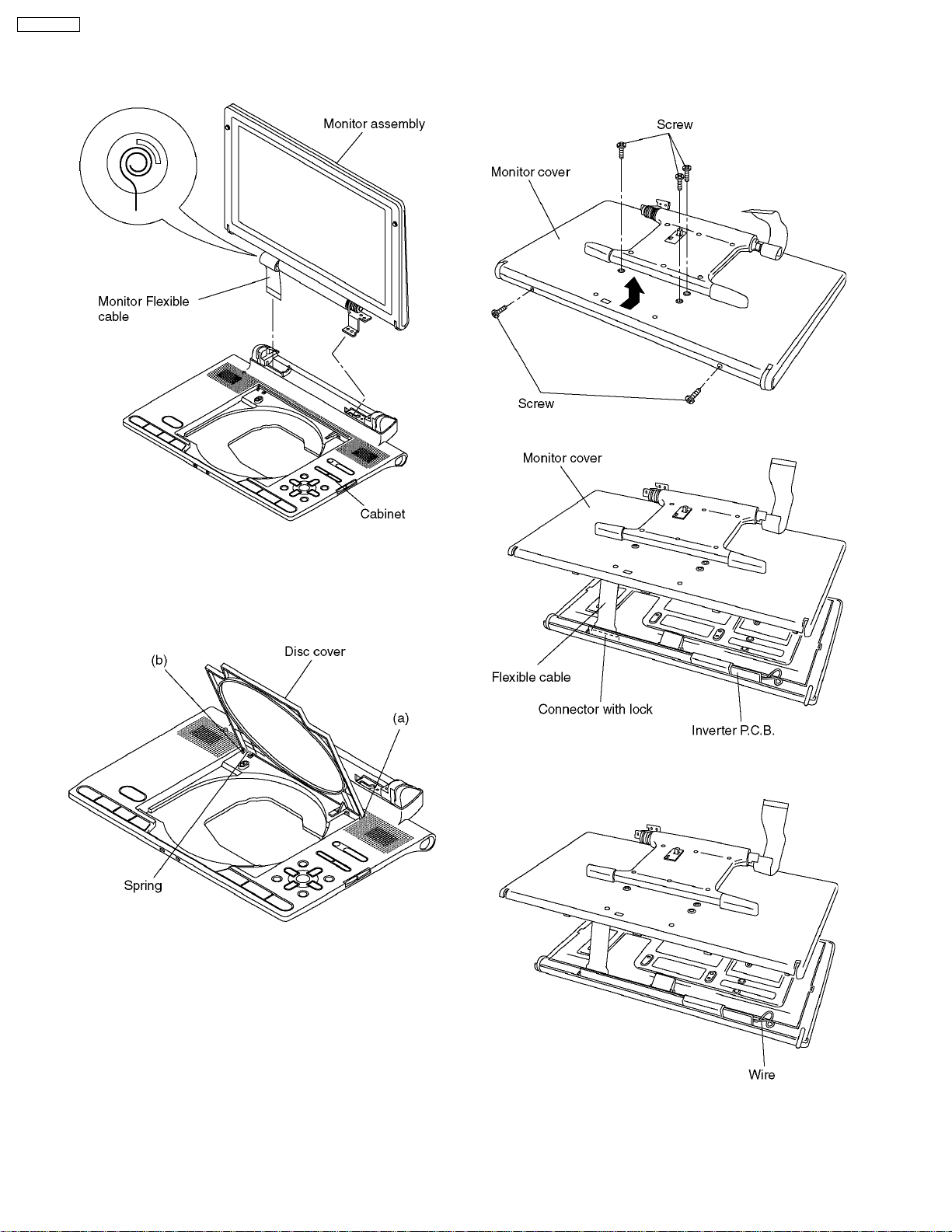

DVD-LS91PP

<Caution to be taken when installing monitor assembly>

1. Roll the flexible cable as shown figure.

2. Install the monitor assembly on the cabinet.

8.11. Monitor cover

1. Remove the 5 screws

2. Remove the monitor cover into the direction of the arrow.

3. Unlock the connector and remove the flexible cable.

8.10. Disc cover

1. Remove the disc cover in order of (a) and (b).

Caution:

Please don’t lose the spring

<Caution to be taken when installing monitor cover>

Please do not nip the wire.

16

Page 17

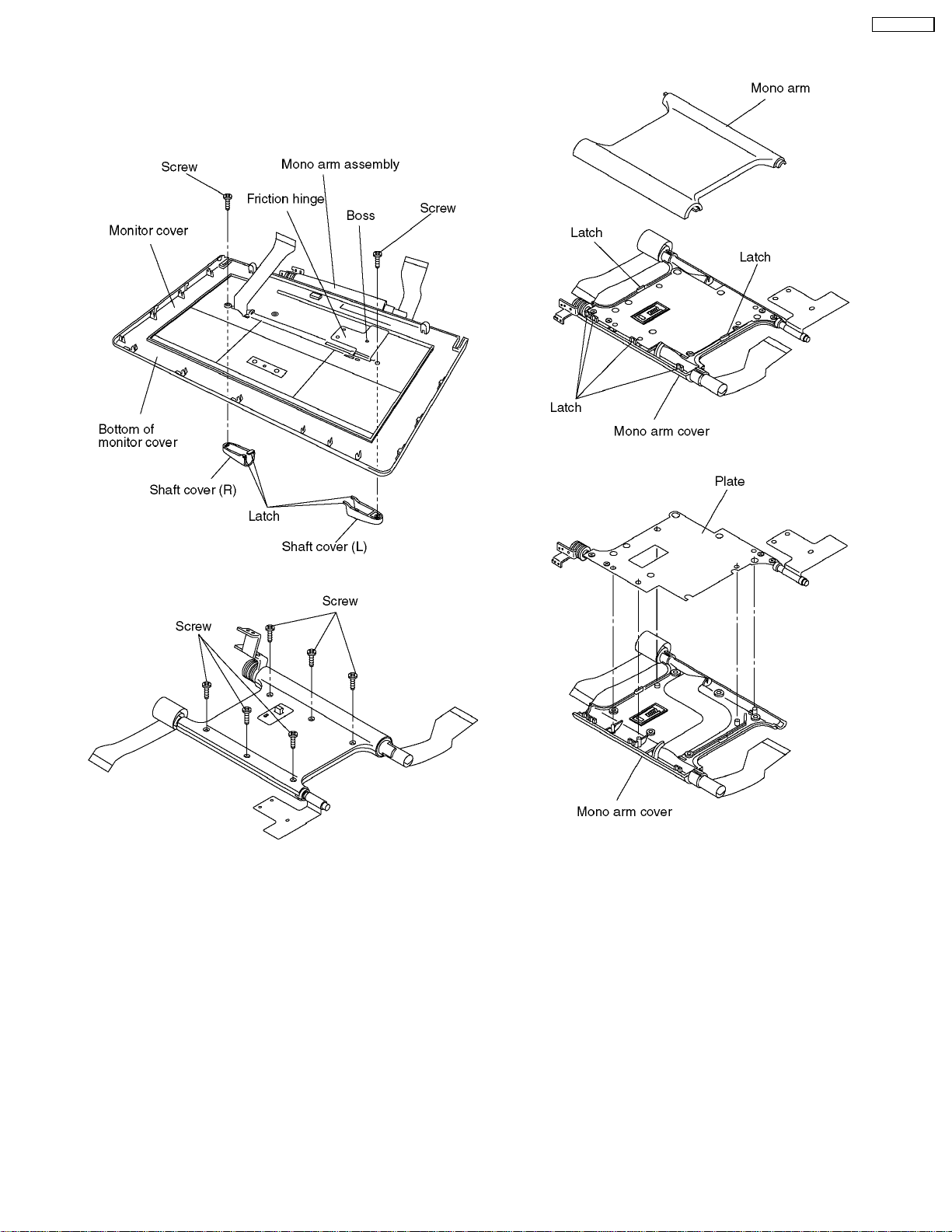

8.12. Mono arm

1. Remove the 2 screws.

2. Release the latches and remove the shaft covers.

3. Release the friction hinge from boss and remove the mono

arm assembly.

DVD-LS91PP

5. Release the latches and remove the mono arm

6. Remove the plate.

4. Remove the 6 screws.

17

Page 18

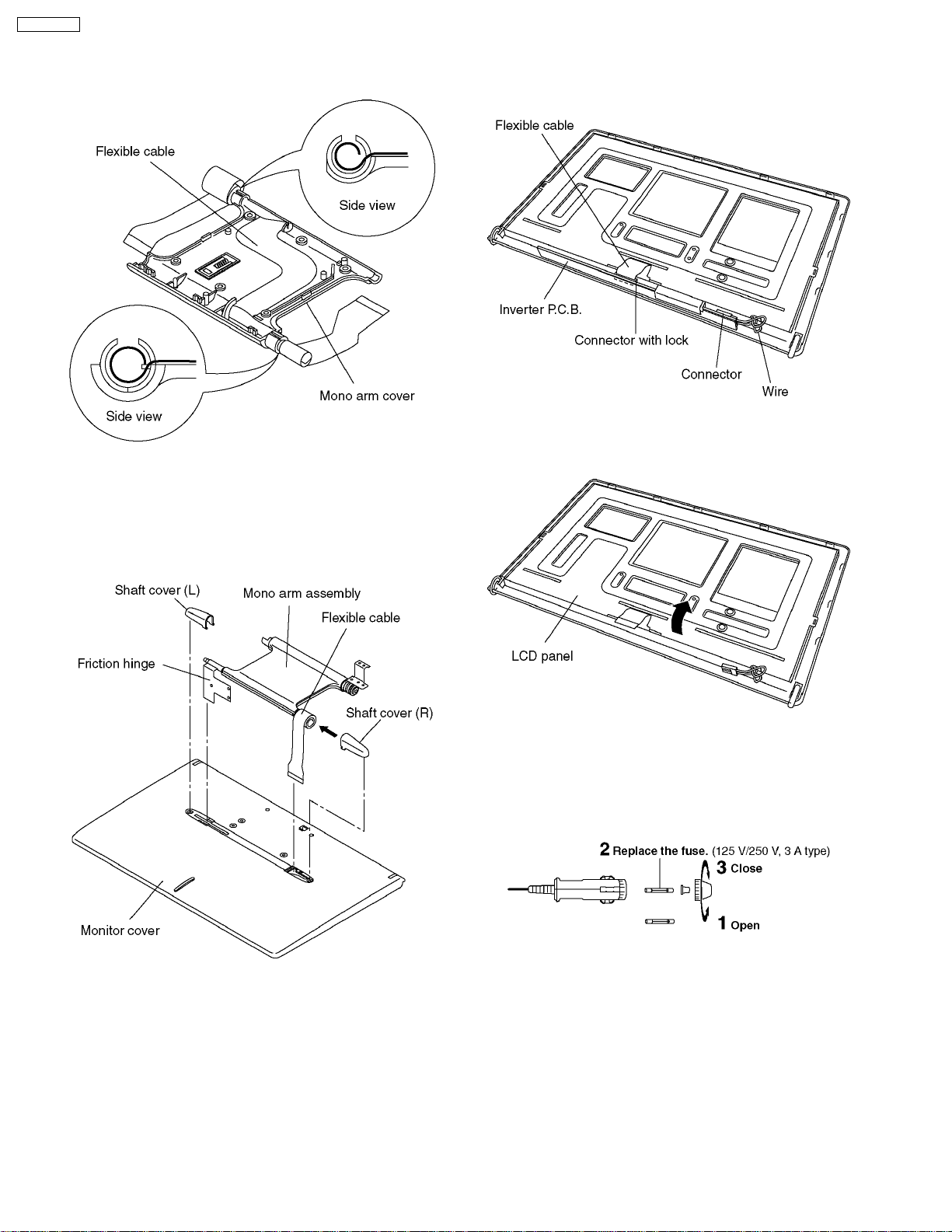

DVD-LS91PP

<Caution to be taken when installing mono arm>

1. Roll the flexible cables as shown figure and install it to

mono arm cover.

8.13. Inverter P.C.B.

1. Unlock the connector and remove the flexible cable.

2. Remove the connector and remove the inverter P.C.B.

8.14. LCD panel

2. Install mono arm.

3. Roll 3 turns of the flexible cable and Install the shaft

cover (R) to flexible cable.

4. Pass the flexible cable and the friction hinge into the

holes in the monitor cover.

5. Install the shaft covers to monitor cover.

1. Remove the LCD panel into the direction of the arrow.

8.15. Replacing the fuse in the car

dc adaptor

· Replace only with the specified 125V/250V, 3A fuse. Use of

any other type can cause fire.

18

Page 19

DVD-LS91PP

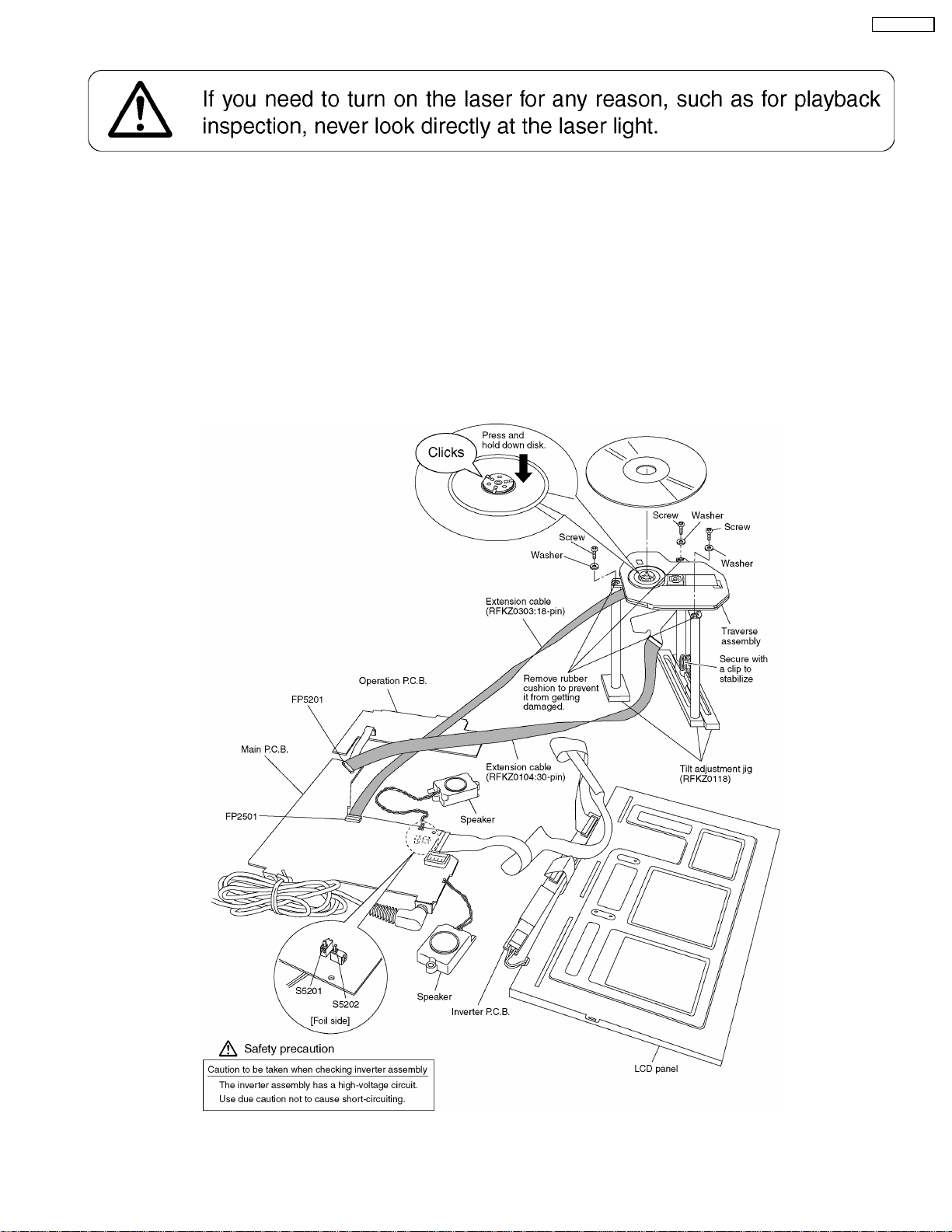

8.16. Service position

8.16.1. Board checks

1. Connect the main P.C.B and the traverse assembly with an extension cable.

2. Install the traverse assembly to the tilt adjustment jig using three screws and three washers.

Caution:

· Remove the rubber cushion from the traverse assembly to prevent it from getting damaged.

3. Install a dick on the traverse assembly.

Caution:

· Make sure the disk is securely installed on the disk motor.

4. Remove the main P.C.B., operation P.C.B., inverter P.C.B., and LCD panel as shown below.

5. The disk cannot be played back with the disk cover removed. Press and hold down the S5201 and S5202. (Secure with

cellulose tape.)

19

Page 20

DVD-LS91PP

9 SELF-DIAGNOSIS FUNCTION AND SERVICE MODE

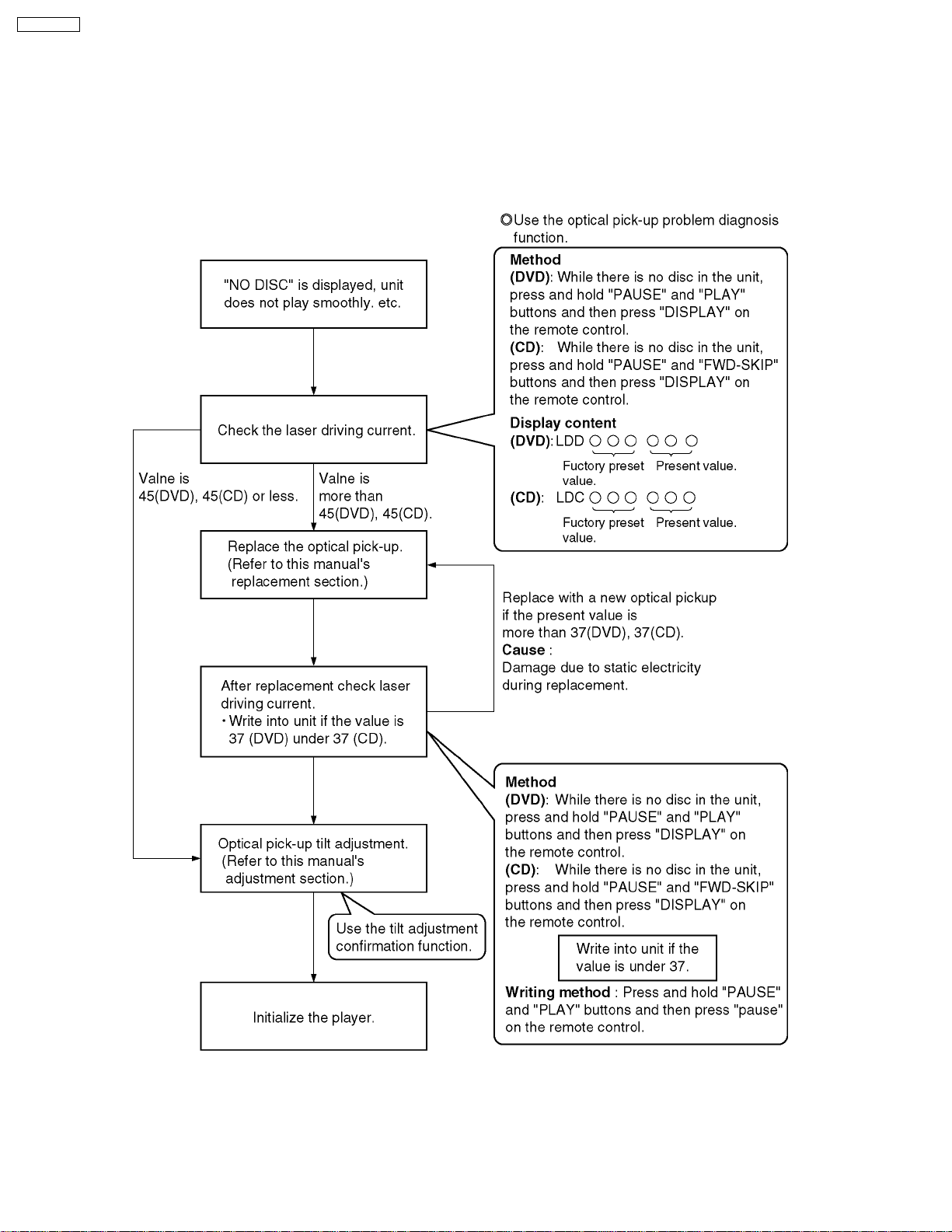

9.1. Optical Pickup Breakdown Diagnosis

As a new feature, this unit has an “optical pick-up problem diagnosis function” and “a tilt adjustment confirmation function” built

in. Use the following procedure to efficiently determine the problem and adjust tilt.If "NO DISC" is displayed, before exchanging

the optical pick-up, carry out problem diagnosis first. If the present laser driving current is over 55, the optical pick-up may need

to be exchanged.

Note:

Carry out diagnosis within 3 minutes of turning the unit on. (The player’s current can increase as it warms up, so turn the unit

off and allow it to cool down before diagnosis.)

20

Page 21

Cautions to be taken when replacing the optical pickup

The optical pickup may break down due to the static

electricity of human body. Take proper protection measures

against static electricity before repairing the parts around

the optical pickup. (See the page describing the

PREVENTION OF STATIC ELECTRICITY DISCHARGE.)

1. Do not touch the areas around the laser diode and

actuator.

2. Do not judge the laser diode with a tester. (The tester

will be damaged easily.)

3. It is recommended to use a destaticized soldering iron

DVD-LS91PP

for short-circuiting or removing the laser diode.

(Recommended soldering iron) HAKKO ESD Product

4. Solder the land of the flexible cablein theoptical pickup.

Note:

· When using a soldering iron which is not

destaticized, short-circuit the terminal face of the

flexible case with a clip. After that, short-circuit

the land.

· After the repairing work is completed, remove the

solder according to the correct procedure shown

in this Technical Guide.

9.2. UHF displays

Use the internal service mode for evaluation of malfunctions.

Display Method Display Diagnosis

Items displayed when in use CHECK THE

Press the "0" button on the remote control while holding

down the PAUSE and PLAY buttons on the player.

The last error code generated is saved in the EEPROM

DISC

H01 Inner cover trouble

H02 Spindle servo error

H03 Traverse error

H04 Tracking servo error

H05 Seek error

F0** Disc format error

F1** Disc code error

F2** Decoder LSI error

F5** DSC

F6** ECC error

F7** Microcomputer error

F8** Microcomputer error

Focus error

21

Page 22

DVD-LS91PP

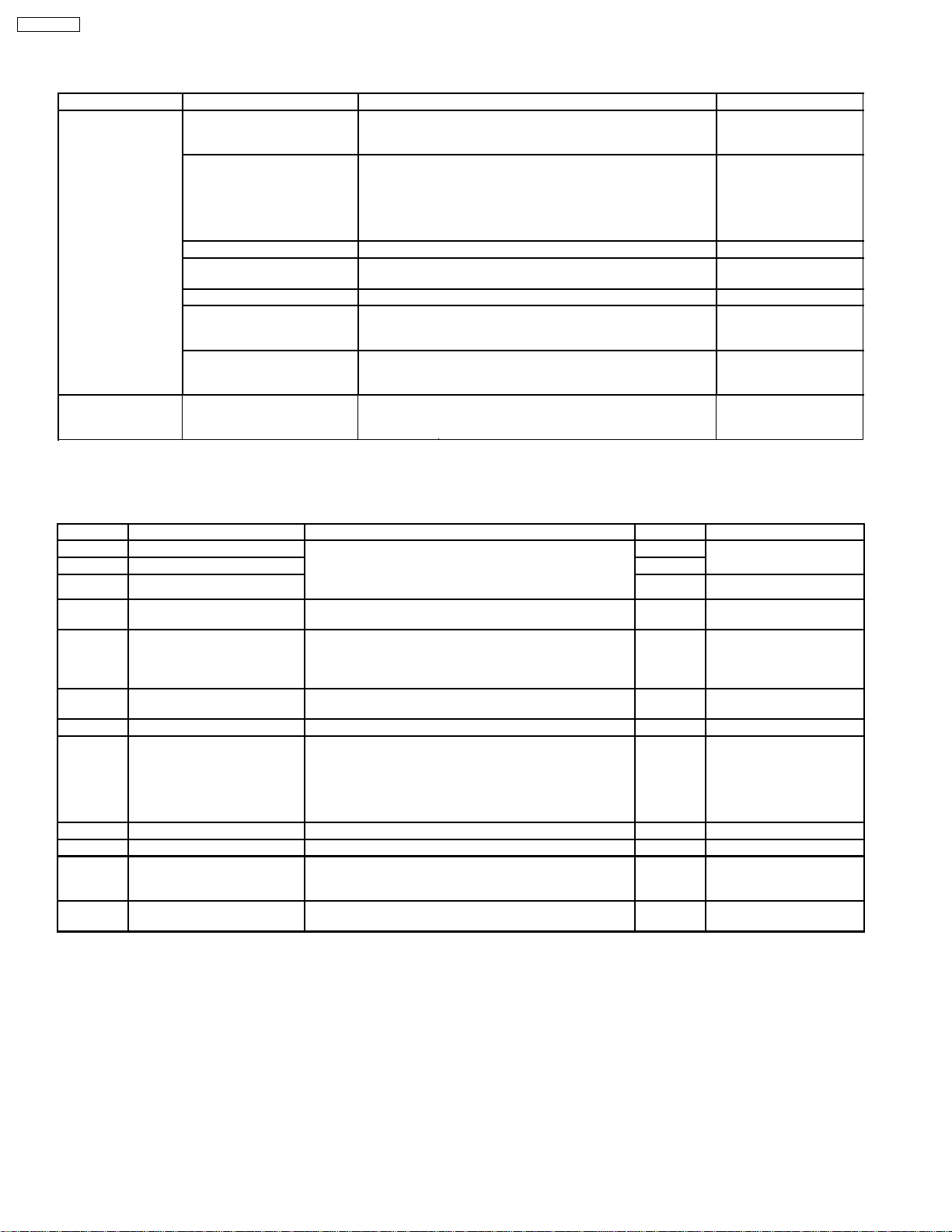

9.3. Service Mode Table 1

The service modes can be activated by pressing various button combination on the player and remote control unit.

Player buttons Remote control unit buttons Application Note

PAUSE

+

PLAY

PAUSE

BWD-SKIP

PLAY

0 Displaying the UHF display F_ _ _ Refer to section 9.4. Self-

5 Jitter check, tilt adjustment

*Display shows xx_yyyzz

"xx" and "zz" shown to the right have nothing to do with the jitter

value. "xx" is the error counter, while "zz" is the focus drive value.

Refer to section 11.4. for Optical Pickup Tilt Adjustment

Procedure.

6 Checking the region numbers and broadcast system

7 Checking the program version Check the IC3001 FLASH

9 Lighting Confirmation Function of Display Tube

DISPLAY Checking the laser drive current Refer to section 8.5.

PAUSE Writing the laser drive current value after replacing the optical

pickup (do not use for anything other than optical pickup

replacement)

The user setting is returned to the state of the factory shipment. Refer to section 9.6.

—

Diagnosis Function (UHF

Display).

Refer to section 11.4.

Optical Pickup Tilt

Adjustment

ROM program.

Optical Pickup

Replacement Procedure.

Initializing the DVD

player.

9.4. DVD Self Diagnostic Function-Error Code

<Displayed during normal operations>

Error code Contents Case of Occurrence Task Remarks

U11 Focus Servo error Dirty disc

CHECK DISK Servo

U15 DVD-R not finalized Servo

U70-1 HDMI/DVI EDID reading error Occurs when connection is HDMI/DVI and EDID data for

U70-2 HDMI/DVI non-HDCP

compliance

U70-3 HDMI/DVI authentication error Occurs when connection is HDMI/DVI and authentication of

H01 Tray loading error Tray movement error. Unable to open. Unable to close. Panel When OPEN:

H02 Spindle error Spindle motor errorFG pulse abnormal. Cable cut, etc. Servo

H03 Traverse motor error Traverse abnormal Servo

H05 Seek time out error Unable to access. TOC reading error, etc.

H07 Driver IC thermal shutdown Spindle motor error (short circuit in between brushes)

Incompatible media

DVD-R and RW not finalized.

Output may result when a pickup error occurs.

the picture receiver cannot be read.

Occurs when connection is HDMI/DVI and the picture

receiver is not compliant with HDCP.

HDCP:Copyright protection technology

Digital video signal encryption method

the picture receiver (using HDCP) failed.

Pickup error, disc error, etc.

Output results when a dirty disc is used.

(Applicable to brush-type spindle motors only)

Servo U11 may also result when

DVD-R is not finalized.

AV

AV

AV

FOPEN->CLOSE->OPEN>H01

When CLOSE:

FCLOSE->OPEN->CLOSE>H01

Servo Changed to U11 from D80

series onward.

Servo

22

Page 23

<Recorded but not displayed during normal>

Error code Contents Case of Occurrence Task Remarks

F010 Set value exceeded parental

value in the designated country

F020 TT_SRPT does not

existÅiRLBN is 0

F021 TT_SRP number is 0 DVD-Video/Audio

F022 Set value exceeds TT_SRP

number

F023 SRP in conformity with VTSN

or VTS_TTN does not exist

F024 Set value exceeds

TT_SRP.PTT_Ns

F030 TTU_SRP number is 0 DVD-Video/Audio

F031 Set value exceeds TTU_SRP

number

F041 PGCI_SRP number is 0 DVD-Video/Audio

F042 Set value exceeds PGCI_SRP

number

F051 Set value exceeds TMAP_SRP

number

F052 Set TMAP_SA is 0 DVD-Video/Audio

F053 MAP_EN number is 0 DVD-Video/Audio

F060 C_POSIT exists, but PGMAP

does not exist in PGC

F061 C_POSIT exists, but PG

number in PGC is 0

F062 Set value exceeds PG number

in PGC

F063 C_POSIT exists, but C_PBIT

does not exist in PGC

F064 C_POSIT exists, but Cell

number in PGC is 0

F065 Set Cell number is 0 DVD-Video/Audio

DVD-Video

Disc management data error

(Error in management data related to viewing restrictions)

DVD-Video/Audio

Disc management data error

(Error in title-related management data)

Disc management data error

(Error in title-related management data)

DVD-Video/Audio

Disc management data error

(Error in title-related management data)

DVD-Video/Audio

Disc management data error

(Error in title-related management data)

DVD-Video/Audio

Disc management data error

(Error in chapter-related management data)

Disc management data error

(Error in title-related management data)

DVD-Video/Audio

Disc management data error

(Error in title-related management data)

Disc management data error

(Error in title-related or menu-related management data)

DVD-Video/Audio

Disc management data error

(Error is title-related management data)

DVD-Video/Audio

Disc management data error

(Error in management data for time-search)

Disc management data error

(Error in management data for time-search)

Disc management data error

(Error in management data for time-search)

DVD-Video/Audio

Disc management data error

(Error in title-related management data)

DVD-Video/AudioDisc management data error(Number of

chapter is 0 or management data is arranged in violation of

specifications.)

DVD-Video/Audio

When one of the following conditions applies

· Disc management data error

(Error in title-related or chapter-related management

data)

· Management data is arranged in violation of

specifications.

DVD-Video/Audio

Disc management data error

(Error in title-related or chapter-related management data)

DVD-Video/Audio

Disc management data error

(Chapter number is 0)

Disc management data error

(Chapter number is 0)

Disc

Disc

Disc

Disc May occur when a wrong

number is set

(when the set number

exceeds the maximum

number of titles in the disc).

Disc

Disc May occur when a wrong

chapter number is set

(when the set number

exceeds the maximum

number of chapters in the

disc).

Disc

Disc May occur when a wrong

title number is set

(when the set number

exceeds the maximum

number of titles in the disc).

Disc

Disc May occur when a wrong

title number is set

(when the set number

exceeds the maximum

number of titles in the disc).

Disc

Disc

Disc

Disc

Disc

Disc May occur when a wrong

chapter number is set

(when the set number

exceeds the maximum

number of chapters in the

title).

Disc

Disc

Disc

DVD-LS91PP

23

Page 24

DVD-LS91PP

Error code Contents Case of Occurrence Task Remarks

F066 Set value exceeds cell number

in PGC

DVD-Video/Audio

Disc management data error

(Chapter number is 0)

Disc May occur when a wrong

chapter number is set

(when the set number

exceeds the maximum

number of chapters in the

title).

F067 Must be a block cell DVD-Video/Audio

Disc

Disc management data error

(Data error related to angles in the title)

F070 Not NV_PCK data DVD-Video/Audio

Disc

Disc management data error

(Management data or its arrangement is in violation of

specifications)

F080 Searched Cell number is not

found

DVD-Video/Audio

Disc management data error

(Chapter number is 0)

Disc May occur when a wrong

chapter number is set

(when the set number

exceeds the maximum

number of chapters in the

title).

0xF0C0 Management data error, no

playback file

<No contents (management data and playback files do not

exist)>

Disc Defined in DEFMAIN.H

Set under the following conditions

· When a DVD-Video/VR/Audio management data

contains an error

· When playback contents do not exist

(Search continues to the end and no contents error

results when SD and PCF file management data error

exists)

0xF0C1 Disallowed region code DVD-Video

Disc Defined in DEFMAIN.H

Disallowed through region code

DVD-Video disc region code different from the player region

code was set at the time of playback.

0xF0C2 PAL playback disallowed DVD-Video/VR

Disc Defined in DEFMAIN.H

May be displayed when

EEPROM was falsified.

Set when a DVD-Video/VR disc containing a PAL program

is set on a model that plays no PAL contents.

0xF0C3 All titles not playable under the

parental lock

0xD0C5 VCD/CDÅFCD-ROM other

than CD-DA disallowed

DVD-VideoSet when viewing restrictions disallows

playback.

Playback disallowed for a CD not compliant with the player

May be set when disc is not CD-DA, and it contains no file

such as an MP3/WMA file compliant with the player.

Disc Defined in DEFMAIN.H

Disc Defined in DEFMAIN.H

This error is rarely recorded

even when a disc described

left is set. The error exists

for a reason unknown.

F0C6 SD card: FAT error SD card format not readable

The card might have been formatted on a Windows PC.

F0C7 SD card: physical error <Physical card error>

Disc Mounted on D86-generation

and newer models

Drive

The SD card may be destroyed physically.

Possible insertion of a card other than SD card/MMC

Only mini SD card adapter may be inserted

F0C8 SD card : master boot record

error

F0E5 Firm file reading error at the

time of downloading

F103 Illegal Highlight Position Occurs mainly in cases where the disc violates

SD card is not destroyed physically, but reading not normal.

SD card formatting may correct the error.

DFD disc reading error

(Firm rewrite data was not read correctly)

Drive Mounted on D86-generation

and newer models

Disc

AV ILL_HLPOS

specifications.

Occurs when a location set for highlighting does not exist

on a DVD-V disc.

F4FF Compulsory initialization failure

(time-out)

Compulsory initialization failed despite a wrong EEPROM

value

UI Defined in DEFMAIN.H

F500 DSC error Servo LSI error Servo

F501 DSC not ready Error Servo

F502 DSC time-out error Servo LSI error, servo adjustment error Servo

F505 DSC attention error Servo error Servo

F506 Invalid media Unsupported media, data is unreadable Servo

0x9010 DSC command escape OPEN request Servo Not an error

0x9020 Unrecorded field Entered an unrecorded field on a multi-session CD-R, RW Servo Not an error

F0BB No DVD-R playback Copyright protection (CSS) exists for DVD-R.

Drive Registration

DVD-R does not play back because it is an illegal copy.

F0BC No DVD-RAM playback Copyright protection (CSS) exists for DVD-RAM.

Drive Registration

DVD-RAM does not play back because it is an illegal copy.

24

Page 25

Error code Contents Case of Occurrence Task Remarks

F0BF No playback because physical

layer cannot be detected

F600 Management data is

inaccessible because of a

demodulation error.

F601 Unstable sector ID was

requested

F603 KEYDET acquisition

impossible due to

demodulation error.

F700 MBX Overflow Incorrect processing error within microcomputer

F701 Message command not

complete error

F702 Message command changed Incorrect processing error within microcomputer

F740 When HDMI device key writing

failed

F750 When the HDMI Device Key

was wrong

F890 Tried to send message during

transmission to AV task

F891 Message transmission to AV

task failed (Mailbox overflow,

etc.)

F893 Flash data falsification error When an error is found in Flash ROM data Sys

F894 EEPROM error When accessing EEPROM failed Sys Subsite value eutered with

F895 Firm type disagreement

(destination mismatch)

F896 Firm type disagreement (non-

existent jumper)

F897 Incomplete initialization When initialization is not performed after firm writing Sys Defined in DEFMAIN.H

F898 Disagreement between the AV

Dec hardware version and the

system controller firm type

F899 Disagreement between system

controller and panel controller

communication specifications

F8A0 Message command is

improper

0xB000 Target file was not found DVD-RAM disc management data error

0xB001 Disc is not DVD-RAM or RW DVD disc management data error Disc Set when UDF

0xA002 For hang-up prevention, no

error.

Media identification impossible

(examples)

1. Detection impossible due to inferior disc non-compliant

with specifications

2. CDV or other unsupported media

3. Disc was inserted upside down.

Data necessary for NaviPack and other navigation transfers

became impossible to acquire due to a damaged disc and

other causes, and playback transfer became impossible.

Attempt was made to access a non-existent disc location

due to authoring record and other errors.

Data for decrypting copyright protection (CSS) became

impossible to acquire due to a damaged disc or other

causes, playback is not possible.

Occurs mainly in cases where microcomputer software has

a problem.

Incorrect processing error within microcomputer

Occurs mainly in cases where microcomputer software has

a problem.

Occurs mainly in cases where microcomputer software has

a problem.

I2C error occurred while writing to Device Key in Tx. AV

Occurs when the wrong Device Key is written into Tx. AV

Player system error Disc Player control software

Player system error Disc Player control software

When the destination and type of used firm differ Sys Defined in DEFMAIN.H

When a jumper falling under no type is set Sys Defined in DEFMAIN.H

When the destination and type of used firm differ Sys

Mismatch in firm/product numbers for the system controller

and panel controller used

Player system error Disc Player control software

(recorded in the DVD-VR format)

CD mediaDisc management data error Disc Set for hang-up prevention

Drive Registration

ECC Registration

ECC Registration

ECC Registration

AV MSG_QOVR

AV MSG_NOTCOMP

AV MSG_CMDCHG

operation is abnormal

operation is abnormal

INITIALI.C immediately

Sys Panel Mounted on D9-generation

and newer models

operation is abnormal

Disc

management data error

occurs

when the ISO9660 pass

table for CD-ROM is

abnormal.

DVD-LS91PP

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disc for protection of copyrights.

25

Page 26

DVD-LS91PP

9.5. Last Error Code saved during NO PLAY

Error code Error Content

F0BF 6) Cannot playback because physical layer is not recoginizable

F0C0 8) DVD: Cannot playback because it is not DVD Video/Adio/VR

F0C1 9) DVD: Prohibited by the restricted region code

F0C2 A) DVD: PAL restricted playback

F0C3 B) DVD: Parental lock setting prohibits the playback of the entire title

F0C4 C) VCD: Prohibited because it is in PHOTO CD fromat

F0C5 VCD/CD: Prohibited because it is CDROM without CD-DA

9.6. Service mode table

Pressing various button combinations on the player and remote control unit can activate the service modes.

26

Page 27

DVD-LS91PP

27

Page 28

DVD-LS91PP

28

Page 29

DVD-LS91PP

9.7. Lens cleaning

When cleaning the lens, use the lens cleaner which product part N o. SZZP1038C.

29

Page 30

DVD-LS91PP

10 SERVICE PREC AUTIONS

10.1. Recovery after the dvd player is repaired

· When FROM or main P.C.B. is replaced, carry out the recovery processing to optimize the drive.

Playback the recovery disk to process the recovery automatically.

· Recovery disc (Product number: RFKZD03R 005)

· Performing recovery

1. Load the recovery disc RFKZD03R005 on to the player and run it.

2. Recovery is performed automatically. When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

Note:

This unit requires no initialization process carried out after the traditional DVD players were repaired.

When the recovery measures are taken, the customer setting will return to the factory setting as same as the procedure

described in item of "Initialization" in 9.6. is carried out. Write down the contents of the setting before recovery processing, and

reset the player.

10.2. Firmware version-up of the DVD player

· The firmware of the DVD player may be renewed to improve the quality including operationability and playerbility to the

substandard discs.processing to optimize the drive.

The recovery disc has also firmware version-up.

· After version-up, recovery processing is executed automatically.

· Part number of the recovery disc for version-up will be noticed when it is supplied.

· Updating firmware

1. Load the recovery disc that is supplied to the player and run it.

2. Firmware version of the player is automatically checked. Appropriate message appears whenever necessary.

3. Using remote controller´s cursor key, select whether version updating is to be done or not. (Selection of Yes/No)

4. a. If Yes is selected, version updating is performed.

b. If No is selected, only recovery is performed.

5. a. When updating is finished, remove the disc according to the message appearing on the screen.

b. Remove the disc according to the message appearing on the screen.

6. Turn off the power.

Note:

If the AC power supply is shut out during version-up due to a power failure, the version-up is improperly carried out.

In such a case, replace the FROM and carry out the version-up again.

30

Page 31

11 ADJUSTMENT PROCEDURES

<Caution>

Be sure to take static electricity countermeasures before adjusting the optical system. Adjust the optical systems according to

the prescribed procedure.

11.1. Service Tools and Equipment

Application Name Number

Tilt adjustment DVD test disc DVDT-S15AS or DVDT-S01

Inspection Extension cable

(Traverse ass’y to main P.C.B.)

Extension cable

(Traverse ass’y to main P.C.B.)

Tilt adj. jig RFKZ0118

Others Screw lock RZZ0L01

Grease JGS0101

Lubricating oil RFKXGUD24

Confirmation CD test disc PVCD-K06

VCD test disc PVCD-K06

Recovery disc RFKZD03R005

11.2. Important points in adjustment

RFKZ0104 (30Pin)

RFKZ0303 (18Pin)

or any other commercially available disc

or any other commercially available disc

DVD-LS91PP

11.2.1. Important points in optical adjustment

· Optical pickup tilt adjustment is needed after replacement of the following components.

1. Optical pickup unit

2. Disc motor

3. Traverse motor

4. Optical pickup peripheral parts (such as rail)

Notes

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However, make adjustment if there is

a noticeable degradation in picture quality.

Optical adjustments cannot be made inside the optical pickup.

11.2.2. Important points in electrical adjustment

· Follow the adjustment procedures described in this Manual.

11.3. Storing and Handling Test Discs

· Surface precision is vital for DVD test discs. Be sure to store and handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness. Place them into their case after use and store them vertically. Store discs

in a cool place where they are not exposed to direct sunlight or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped when placed on a surface made of glass, etc. If this happens, use a

new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be incorrect and some discs will not be playable.

31

Page 32

DVD-LS91PP

11.4. Optical adjustment

11.4.1. Optical pick gate adjustment

Measurement point Adjustment point Mode Disc

-----

Measuring apparatus Adjustment value

None (Use the service indication on the main unit) Adjust the jitter value to the minimum level.

Tangential adjustment screw

(Adjustment screw A)

Radial tilt adjustment screw

(Adjustment screw B)

Remove the solder shorts before trying to make the adjustment.

11.4.1.1. Preparations

1. Connect the main P.C.B. to the traverse ass’y with the extension cable.

2. Install the traverse ass’y to the tilt adjustment jig with three screws and three washers.

Caution

Remove the rubber cushion of the traverse ass’y.

3. Install the traverse ass’y to the disc.

Caution

Make sure the disc is installed on the disc motor securely.

4. Disassemble the Main P.C.B., Operation P.C.B., Inverter P.C.B. and LCD panel as shown in figure below.

5. The disc cannot be played back with the Disccoverattached. Pressand hold downthe S5201and S5202(Secure with cellulose

tape)

Tracking servo "ON"

Tracking servo "ON"

DVDT-S01/S15AS

32

Page 33

11.4.1.2. Adjustment

1. Play back the disc (DVDT-S01/S15AS) and make sure the RF signal is outputted.

2. Play back the areas within a radius of 40 ± 1 mm of the disc (middle circumference).

3. Turn the adjustment screw C to minimize the jitter value in the radial direction.

(*Once turn the screw to the full position and then back off. You should finish tightening in the tightening direction.)

4. Turn the adjustment screw A to minimize the jitter value in the tangential direction.

(*Once turn the screw to the full position and then back off. You should finish tightening in the tightening direction.)

5. DISC height measurement (Measure the middle of the deflection of the disc and motor surface.)

DVD-LS91PP

*If the measured height is out of range, adjust to the specified value using the adjustment screws A, B, and C (by the same

angle).

11.4.1.3. Checking after adjustment

Play back the test disc and ordinary discs to make sure that there is not any deterioration of image quality or missing of sound at

the inner, middle, and outer circumferences.

33

Page 34

DVD-LS91PP

11.5. Electrical adjustment (LCD)

[How to enter into the LCD panel adjustment mode]

Play back the specified video signal (10 steps, color bas

signal).

Press and hold down "Back skip" and "Pause" of the main unit

at the same time while pressing "Menu" on the remote control

unit.

[The DVD player is now in the FT02 mode]

Press the "Forward skip button twice to enter into the FT04

mode (LCD panel adjustment mode).

Press the "Playback" button to play back the signal which has

been played back before stopping and then, press the "Pause

(still) button.

[How to exit to normal mode]

(Exit the F4 mode)

1. Turn off the primary power supply (Remove the DC power

supply).

Turn on the power supply. Press the "Stop" to stop the system.

Press "Cancel" on the remote control unit (The Cancel key is

enabled only when the system is stopped.)

lWhenever the LCD panel is replaced, make the following

checks and adjustments.

lPress the "Enter" key and fix the settings.

lWhen the EEPROM" (IC3002) of the Main P.C.B. is replaced,

call up the LCD Panel adjustment mode (FT04) and execute

the AUDIO on the remove control unit and then check the

condition of the screen. Make adjustments as necessary.

11.5.1. Adjusting VCO oscillation

frequency

Adjustment is required when Check point

The synchronization of the LCD

screen is irregular after any VCO-

related circuit part is replaced

Adjustment procedure Adjustment UP Adjustment

Use “1” on remote control unit. DVD

player/remote

control unit

Details of adjustment Input video signal

Press “ “ and ” ”buttons on

remote controller, set the right

side number to “71”.

TP8201

player/remote

-----

DOWN

DVD

control

11.5.2. Adjusting DC offset of impressed

voltage

Adjustment is required when Check point

Noise such as horizontal stripes

is found on the screen.

Adjustment procedure Adjustment UP Adjustment

Use “3” on remote control unit. DVD

player/remote

control unit

Details of adjustment Input video signal

Press “ “and” ”buttons on

remote controller, set the right

side number to “AI”.

TL8401

DOWN

DVD

player/remote

control

10step monochrome

11.5.3. Adjusting white balance

red/subcontrast red

Adjustment is required when Check point

Remarkable deviation in white

balance is found

Adjustment procedure Adjustment UP Adjustment

Use “6” on remote control unit. DVD

Details of adjustment Input video signal

(White balance)

Press “

remote controller, set the number

Press “

remote controller, set the right

“and “ “ buttons on

of center to “80”.

(Sub contrast)

“ and “ “ buttons on

side number to “7E”.

player/remote

control unit

TL8602

DOWN

DVD

player/remote

control

10step monochrome

11.5.4. Adjusting whitebalance

blue/subcontrast blue

Adjustment is required when Check point

Remarkable deviation in white

balance is found

Adjustment procedure Adjustment UP Adjustment

Use “7” on remote control unit. DVD

Details of adjustment Input video signal

(White balance)

Press “

remote controller, set the number

Press “

remote controller, set the right

“and “ “ buttons on

of center to “71”.

(Sub contrast)

“and “ “ buttons on

side number to “84”.

player/remote

control unit

TL8604

DOWN

DVD

player/remote

control

10step monochrome

34

Page 35

11.5.5. Adjusting amplitude of impressed

voltage

Adjustment is required when Check point

----- TL8401

Adjustment procedure Adjustment UP Adjustment

Use “2” on remote control unit. DVD

Details of adjustment Input video signal

Press “ “ and “ “ buttons on

remote controller, set the right

side number to “15”.

player/remote

control unit

10step monochrome

DOWN

DVD

player/remote

control

11.5.6. Adjusting pedestal

Adjustment is required when Check point

----- TL8603

Adjustment procedure Adjustment UP Adjustment

Use “4” on remote control unit. DVD

Details of adjustment Input video signal

Press “ “ and “ “ buttons on

remote controller, set the number

of center to “91”.

player/remote

control unit

10step monochrome

DOWN

DVD

player/remote

control

11.5.7. Adjusting contrast

Adjustment is required when Check point

----- TL8603

Adjustment procedure Adjustment UP Adjustment

Use “4” on remote control unit. DVD

player/remote

control unit

DOWN

DVD

player/remote

control

DVD-LS91PP

11.5.9. Adjusting color

Adjustment is required when Check point

----- TL8604

Adjustment procedure Adjustment UP Adjustment

Use “5” on remote control unit. DVD

Details of adjustment Input video signal

Press “ “ and “ “ buttons on

remote controller, set the right

number to “81”.

player/remote

control unit

75% color bar

DOWN

DVD

player/remote

control

11.6. Electrical check (Video output

check)

11.6.1. Checking video output (composite

signal)

Check point Mode Disc

Video output terminal Color bar

playback (75%)

Measuring apparatus Check value

Oscilloscope Y: 1000 mV ± 100 mV

Cyan: 650 mV ± 100 mV

Purpose: Keep the interchangeability of video signal

output

1. Terminate the composite signal of the video output

terminal with 75 W and input into the oscilloscope.

2. Select color bar 75% from the titles of the DVD test disc

and play back.

3. Check that the composite signal output is the following

value:

DVDT-S15AS

Details of adjustment Input video signal

Press “ “ and “ “ buttons on

remote controller, set the right

side number to “71”.

10step monochrome

11.5.8. Adjusting TINT

Adjustment is required when Check point

----- TL8604

Adjustment procedure Adjustment UP Adjustment

Use “5” on remote control unit. DVD

Details of adjustment Input video signal

Press “ “ and “ “ buttons on

remote controller, set the number

of center to “75”.

player/remote

control unit

75% color bar

DOWN

DVD

player/remote

control

35

Page 36

DVD-LS91PP

12 Abbreviations

INITIAL/LOGO ABBREVIATIONS

A A0~UP

ACLK

AD0~UP

ADATA

ALE

AMUTE

AREQ

ARF

ASI

ASO

ASYNC

B BCK

BCKIN

BDO

BLKCK

BOTTOM

BYP

BYTCK

C CAV

CBDO

CD

CDSCK

CDSRDATA

CDRF

CDV

CHNDATA

CKSL

CLV

COFTR

CPA

CPCS

CPDT

CPH1~3

CPUADR

CPUADT

CPUIRQ

CPRD

CPV

CPWR

CS

CSYNCIN

CSYNCOUT

D DACCK

DEEMP

DEMPH

DIG0~UP

DIN

DMSRCK

DMUTE

DO

DOUT0~UP

DRF

DRPOUT

DREQ

DRESP

DSC

DSLF

DVD

ADDRESS

AUDIO CLOCK

ADDRESS BUS

AUDIO PES PACKET DATA

ADDRESS LATCH ENABLE

AUDIO MUTE

AUDIO PES PACKET REQUEST

AUDIO RF

SERVO AMP INVERTED INPUT

SERVO AMP OUTPUT

AUDIO WORD DISTINCTION SYNC

BIT CLOCK (PCM)

BIT CLOCK INPUT

BLACK DROP OUT

SUBCODEBLOCKCLOCK

CAP. FOR BOTTOM HOLD

BYPATH

BYTE CLOCK

CONSTANT ANGULAR VELOCITY

CAP. BLACK DROP OUT

COMPACT DISC

CD SERIAL DATA CLOCK

CD SERIAL DATA

CD RF (EFM) SIGNAL

COMPACT DISC-VIDEO

CHANNEL DATA

SYSTEM CLOCK SELECT

CONSTANT LINEAR VELOCITY

CAP. OFF TRACK

CPU ADDRESS

CPU CHIP SELECT

CPU DATA

CLOCK PULSE SOURCE DRIVE

CPU ADDRESS LATCH

CPU ADDRESS DATA BUS

CPU INTERRUPT REQUEST

CPU READ ENABLE

GATE DRIVER CLOCK PULSE

CPU WRITE ENABLE

CHIP SELECT

COMPOSITE SYNC IN

COMPOSITE SYNC OUT

D/A CONVERTER CLOCK

DEEMPHASIS BIT ON/OFF

DEEMPHASIS SWITCHING

FL DIGIT OUTPUT

DATA INPUT

DM SERIAL DATA READ CLOCK

DIGITAL MUTE CONTROL

DROP OUT

DATA OUTPUT

DATA SLICE RF (BIAS)

DROP OUT SIGNAL

DATA REQUEST

DATA RESPONSE

DIGITAL SERVO CONTROLLER

DATA SLICE LOOP FILTER

DIGITAL VIDEO DISC

INITIAL/LOGO ABBREVIATIONS

E EC

ECR

ENCSEL

ETMCLK

ETSCLK

F FBAL

FCLK

FE

FFI

FEO

FG

FSC

FSCK

G GND COMMON GROUNDING (EARTH)

H HA0~UP

HD0~UP

HINT

HRXW

I IECOUT

IPFRAG

IREF

ISEL

L LDON

LPC

LRCK

M MA0~UP

MCK

MCKI

MCLK

MDATA

MDQ0~UP

MDQM

MLD

MPEG

O ODC

OEH

OEV 1, 2

OFTR

OSCI

OSCO

OSD

P P1~UP

PCD

PCK

PDVD

PEAK

PLLCLK

PLLOK

PWMCTL

PWMDA

PWMOA, B

ERROR TORQUE CONTROL

ERROR TORQUE CONTROL

REFERENCE

ENCODER SELECT

EXTERNAL M CLOCK (81MHz/40.5MHz)

EXTERNAL S CLOCK (54MHz)

FOCUS BALANCE

FRAME CLOCK

FOCUS ERROR

FOCUS ERROR AMP INVERTED INPUT

FOCUS ERROR AMP OUTPUT

FREQUENCY GENERATOR

FREQUENCY SUB CARRIER

FS (384 OVER SAMPLING) CLOCK

HOST ADDRESS

HOST DATA

HOST INTERRUPT

HOST READ/WRITE

IEC958 FORMAT DATA OUTPUT

INTERPOLATION FLAG

I (CURRENT) REFERENCE

INTERFACE MODE SELECT

LASER DIODE CONTROL

LASER POWER CONTROL

L CH/R CH DISTINCTION CLOCK

MEMORY ADDRESS

MEMORY CLOCK

MEMORY CLOCK INPUT

MEMORY SERIAL COMMAND CLOCK

MEMORY SERIAL COMMAND DATA

MEMORY DATA INPUT/OUTPUT

MEMORY DATA I/O MASK

MEMORY SERIAL COMMAND LOAD

MOVING PICTURE EXPERTS GROUP

OPTICAL DISC CONTROLLER

SOURCE DRIVER OUTPUT ENABLE

GATE DRIVER OUTPUT ENABLE

OFF TRACKING

OSCILLATOR INPUT

OSCILLATOR OUTPUT

ON SCREEN DISPLAY

PORT

CD TRACKING PHASE DIFFERENCE

PLL CLOCK

DVD TRACKING PHASE DIFFERENCE

CAP. FOR PEAK HOLD

CHANNEL PLL CLOCK

PLL LOCK

PWM OUTPUT CONTROL

PULSE WAVE MOTOR DRIVE A

PULSE WAVE MOTOR OUT A, B

36

Page 37

INITIAL/LOGO ABBREVIATIONS

R RE

RFENV

RFO

RS

RSEL

RST

RSV

S SBI0, 1

SBO0

SBT0, 1

SCK

SCKR

SCL

SCLK

SDA

SEG0~UP

SELCLK

SEN

SIN1, 2

SOUT1, 2

SPDI

SPDO

SPEN

SPRCLK

SPWCLK

SQCK

SQCX

SRDATA

SRMADR

SRMDT0~7

SS

STAT

STCLK

STD0~UP

STENABLE

STH

STSEL

STV

STVALID

SUBC

SBCK

SUBQ

SYSCLK

T TE

TIBAL

TID

TIN

TIP

TIS

TPSN

TPSO

TPSP

TRCRS

TRON

TRSON

READ ENABLE

RF ENVELOPE

RF PHASE DIFFERENCE OUTPUT

(CD-ROM) REGISTER SELECT

RF POLARITY SELECT

RESET

RESERVE

SERIAL DATA INPUT

SERIAL DATA OUTPUT

SERIAL CLOCK

SERIAL DATA CLOCK

AUDIO SERIAL CLOCK RECEIVER

SERIAL CLOCK

SERIAL CLOCK

SERIAL DATA

FL SEGMENT OUTPUT

SELECT CLOCK

SERIAL PORT ENABLE

SERIAL DATA IN

SERIAL DATA OUT

SERIAL PORT DATA INPUT

SERIAL PORT DATA OUTPUT

SERIAL PORT R/W ENABLE

SERIAL PORT READ CLOCK

SERIAL PORT WRITE CLOCK

SUBCODEQCLOCK

SUB CODE Q DATA READ CLOCK

SERIAL DATA

SRAM ADDRESS BUS

SRAM DATA BUS 0~7

START/STOP

STATUS

STREAM DATA CLOCK

STREAM DATA

STREAM DATA INPUT ENABLE

SOURCE START PULSE

STREAM DATA POLARITY SELECT

GATE DRIVER SCAN START PULSE

STREAM DATA VALIDITY

SUB CODE SERIAL

SUBCODECLOCK

SUBCODEQDATA

SYSTEM CLOCK

TRACKING ERROR

BALANCE CONTROL

BALANCE OUTPUT 1

BALANCE INPUT

BALANCE INPUT

BALANCE OUTPUT 2

OP AMP INPUT

OP AMP OUTPUT

OP AMP INVERTED INPUT

TRACK CROSS SIGNAL

TRACKING ON

TRAVERSE SERVO ON

INITIAL/LOGO ABBREVIATIONS

V VBLANK

VCC

VBLANKING

COLLECTOR POWER SUPPLY

VOLTAGE

VCDCONT

VIDEO CD CONTROL (TRACKING

BALANCE)

VDD

VFB

VREF

VSS

W WAIT

WDCK

WEH

WSR

X X

XALE

XAREQ

XCDROM

XCS

XCSYNC

XDS

XHSYNCO

XHINT

XI

XINT

XMW

XO

XRE

XSRMCE

XSRMOE

XSRMWE

XVCS

XVDS

XVSYNCO

DRAIN POWER SUPPLY VOLTAGE

VIDEO FEED BACK

VOLTAGE REFERENCE

SOURCE POWER SUPPLY VOLTAGE

BUS CYCLE WAIT

WORD CLOCK

WRITE ENABLE HIGH

WORD SELECT RECEIVER

X´ TAL

X ADDRESS LATCH ENABLE

X AUDIO DATA REQUEST

X CD ROM CHIP SELECT

X CHIP SELECT

X COMPOSITE SYNC

XDATASTROBE

X HORIZONTAL SYNC OUTPUT

XH INTERRUPT REQUEST

X´ TAL OSCILLATOR INPUT

X INTERRUPT

X MEMORY WRITE ENABLE

X´ TAL OSCILLATOR OUTPUT

X READ ENABLE

X SRAM CHIP ENABLE

X SRAM OUTPUT ENABLE

X SRAM WRITE ENABLE

X V-DEC CHIP SELECT

X V-DEC CONTROL BUS STROBE

X VERTICAL SYNC OUTPUT

DVD-LS91PP

37

Page 38

DVD-LS91PP

13 VOLTAGE CHART

Note:

· Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance)

with the chassis taken as standard. Therefore, there may exist some errors in the voltage values, depending on the internal

impedance of the DC circuit tester.

· Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point,

because it may differ from an actual measuring value due to difference of Measuring instrument and its measuring condition

and product itself.

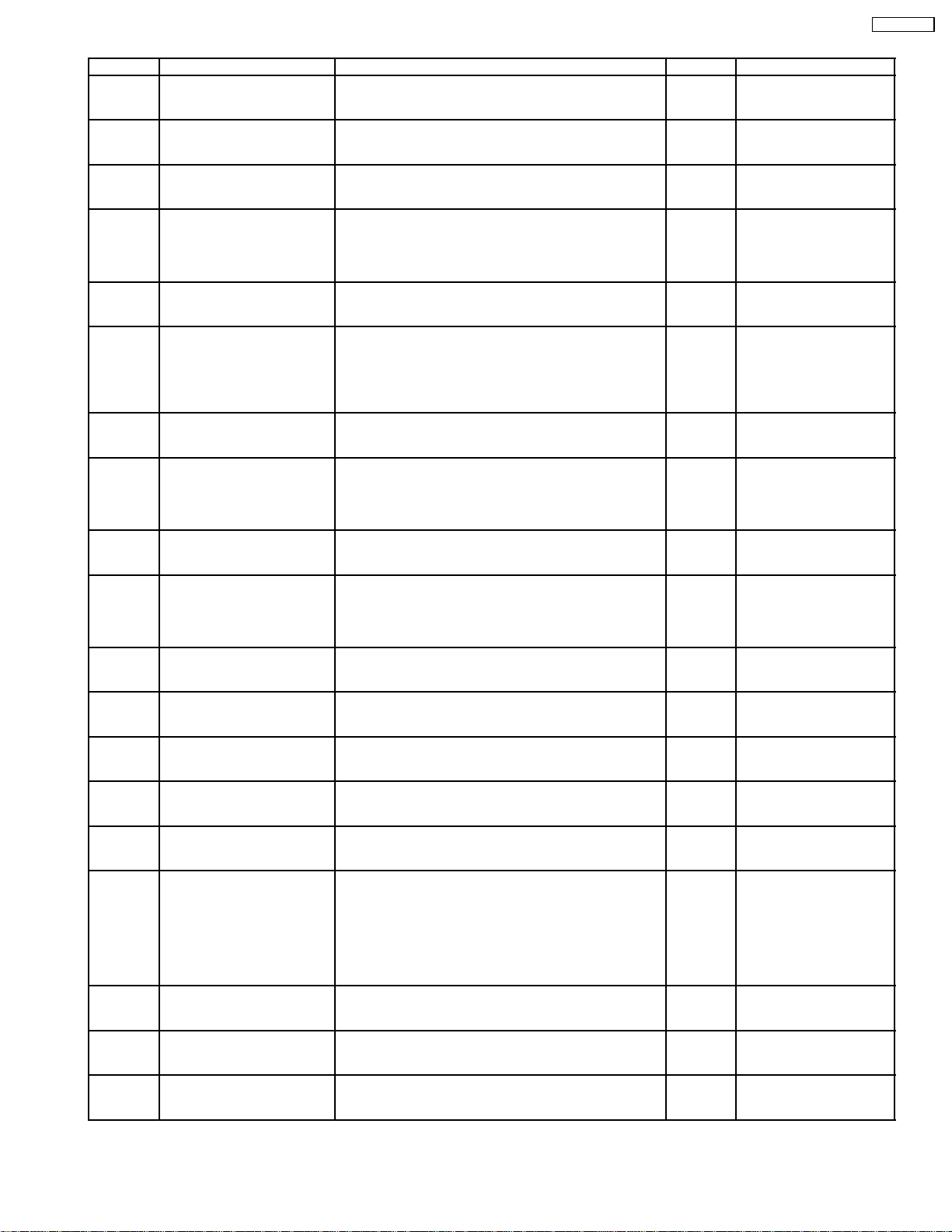

13.1. MAIN P.C.B.

Ref No.

MODE 1 2 34567891011121314151617181920

PLAY 0.3 9.0 9 .0 8.2 0 0 6.1 9.0 3 .3 0 0 0.1 2.3 1. 8 1.1 1.3 1.0 1.0 2.1 1.1

STOP 0.8 9.0 9.0 8.2 0 0 6.2 9.0 3.4 0 0 0.1 2.3 1.8 1.1 1.3 1.0 1.0 2.1 1.1

Ref No.

MODE 21 22 23 24 25 26 27 28 29 3 0 31 32 33 34 35 36 37 38 39 40

PLAY 1.5 1.0 1 .0 1.4 1.1 1.9 1.0 1.7 0 0 0 9.0 2.5 1 .0 1.0 1.3 1.1 1.8 0.5 0

STOP 1.5 1.0 1.0 1.4 1.1 1.9 1.0 1.7 0 0 0 9.0 2.5 1.0 1.0 1.3 1.1 1.8 0.2 0

Ref No.

MODE 41 42 43 44 45 46 47 48

PLAY 0.5 1.0 0 0 3.3 3.3 3.3 0

STOP 0.2 1.0 0 0 3.3 3.3 3.3 0

Ref No.

MODE 123456 12345 12345

PLAY 3.3 0 1.3 5.0 0 5.4 5.4 0 5.4 0 5.0 5.4 0 3.3 0 5.0

STOP 3.3 0 1.3 5.0 0 5.4 5.4 0 5.4 0 5.0 5.4 0 3.3 0.6 5.0

Ref No.

MODE 1 2 345678 12345 1234

PLAY 8.9 0 0 1.2 11.7 0 8.0 11.8 11.3 0 3.3 9.9 11.0 3.3 8.9 -0.1 0

STOP 8.7 0 0 1.2 11.7 0 8.0 11.8 11.1 0 3.3 8.9 10.8 3.3 9.0 0 0

Ref No.

MODE 12345678910111213141516

PLAY 1.3 0.9 5 .0 9.3 4.5 0.3 1.0 1.0 0.5 0.9 4. 5 0.3 5.6 5.6 0 8.9

STOP 1.3 0.9 5.0 9.3 4.5 0.2 1.0 1.0 0.7 0.7 4.5 0.2 5.4 5.3 0 8.9

Ref No.

MODE 1234567891011121314151617181920

PLAY 1.6 1.6 1 .5 1.6 1.6 1.6 0 5.4 3.2 0 3.1 2.4 2.7 2.8 2.4 2.4 2 .4 2.4

STOP 1.6 1.6 1.6 1.6 1.6 1.6 0 5.4 0 0 2.7 2.7 2.7 2.7 2.4 2.4 2.4 2.4

Ref No.

MODE 21 22 23 24 25 26 27 28

PLAY 5.4 5.4 1 .6 1.6 1.6 1.6 3.2 2.8

STOP 5.4 5.4 1.6 1.6 1.6 1.6 0 2.8

Ref No.

MODE 1234567891011121314151617181920

PLAY 0 0 0 0 0 0 3.5 0 0 2.9 2.9 0 0 2.9 0.8 0 0.6 0 2. 4 0

STOP 0 0.1 0.1 0.1 0 0.1 0.1 0 5.0 5.0 5.0 5.0 5.0 5.0 5.0 0 0 0 5.0 5.0

Ref No.

MODE 21 22 23 24 25 26 27 28

PLAY 1.6 1.4 3.2 2.5 5.0 0 5.4 5.4

STOP 1.6 1.6 0 5.0 5.0 0 5.4 5.4

Ref No.

MODE 1234567891011121314151617181920

PLAY 1.2 0 3.2 0 3.2 0 0 0 0 0 3.2 3.1 3.2 3.2 0. 3 0.9 0.9 1.2 1.7 1.3

STOP 0.5 1.1 0.3 1.5 1.8 0.9 1.3 1.2 0.8 0 3.2 3.1 3.2 3.2 0.3 1.4 1.3 1.1 1.7 1.2

Ref No.

MODE 21 22 23 24 25 26 27 2 8 29 30 31 32 33 34 35 36 37 38 39 40

PLAY 1.9 1.3 1 .4 1.7 1.9 1.6 0 1.5 1.0 0 .9 0.8 0.9 1.1 1.4 1.4 1.3 3.2 1. 3 1.1 1.1

STOP 2.1 1.3 1.5 2.1 0.5 1.4 0 2.5 1.1 0.5 0.5 -1.2 0.9 -0.5 1.5 0.8 3.2 -0.1 0.9 1.3

Ref No.

MODE 41 42 43 44 45 46 47 4 8 1 2345678

PLAY 1.1 1.1 1 .2 1.3 1.3 0 3.2 1.4 00003.23.203.2

STOP 1.1 0.8 1.1 1.1 0.9 0 3.2 0.9 00003.23.203.2

Ref No.

MODE 1234567891011121314151617181920

PLAY 0 0 3.2 00003.2000000003.21.91.60

STOP 0 0 3.2 00003.2000000003.23.23.20.5

IC1001

IC1003 IC1004 IC1101

IC1401 IC1411

IC1601

IC2601

IC2651

IC3001

IC1001

IC1001

IC1412

IC2601

00

00

IC2651

IC3001

IC3001

IC3002

IC3004

38

Page 39

Ref No.

MODE 21 22 23 24 25 26 27 28 2 9 30 31 32 33 34 35 36 37 38 39 40

PLAY 0 1.1 1.1 0.9 0.8 0.8 1.1 1.4 1.4 1.2 1.3 1.2 1.2 0 3.2 1 .1 1.1 1.2 1.3 1.3

STOP 0 1.1 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0 3.2 1.1 0.8 1.1 1.0 0.8

Ref No.

MODE 41 42 43 44 45 46 47 48 4 9 50 51 52 53 54 55 56 57 58 59 60

PLAY 1.3 1.2 0.9 0 1.1 0.8 1.2 1.7 1.6 1.1 1.1 0 3 .2 0.5 3.2 0.8 0.9 1.3 1.7 1.3

STOP 0.9 0.5 1.0 0 1.1 0.3 1.5 1.8 0.8 1.3 1.3 0 3.2 0.8 3.2 1.4 1.3 1.1 1.7 1.2

Ref No.

MODE 61 62 63 64 65 66 67 68 6 9 70 71 72 73 74 75 76 77 78 79 80

PLAY 1.9 1.4 1.4 1.8 0 3.2 3.2 0 3 .2 0 0 3.0 3.0 2.6 2.9 3.2 3.2 2.8 0 0

STOP 2.0 1.3 1.5 2.1 0 3.2 3.2 0 3.2 0 0 3.0 3.0 3.2 3.2 3.2 3.2 2.8 0 3.2

Ref No.

MODE 81 82 83 84 85 86 87 88 8 9 90 91 92 93 94 95 96 97 98 99 100

PLAY 0.1 0 1.1 3.1 1.9 3.2 3.2 3.2 3.2 1.4 1.6 0 3.2 3.2 3. 2 3.2 3.2 0 3.2 3.2

STOP 3.2 0 1.1 3.2 3.2 0 0 0 3.2 1.6 1.6 0 3.2 3.2 3.2 3.2 3.2 0 3.2 3.2

Ref No.

MODE 101 1 02 103 104 105 106 107 108 109 110 111 112 113 114 1 15 116 117 118 119 120

PLAY 3.2 3.2 0.9 0 2.2 1.7 0 0 1.7 3.2 0.3 0.3 1.8 1.8 1.6 1.6 1.6 1.6 3.2 1.8

STOP 3.2 3.2 0.9 0 2.2 1.7 0 0 1.7 3.2 0.2 0.2 0 1.8 1.6 1.6 1.6 1.6 3.2 3.2

Ref No.

MODE 121 1 22 123 124 125 126 127 128 129 130 131 132 133 134 1 35 136 137 138 139 140

PLAY 1.3 0 0.2 1.0 0.2 0 2. 2 1.6 2.6 2.7 2 .7 2.6 2.7 2.6 2 .4 2.5 2.4 2.5 1.8 1.6

STOP 1.3 000000.31.62.22.22.22.22.22.22.22.22.22.21.91.6

Ref No.

MODE 141 1 42 143 144 145 146 147 148 149 150 151 152 153 154 1 55 156 157 158 159 160

PLAY 1.5 1.6 0 1.6 1.4 3.2 0.8 0.8 0.5 3.2 2.1 1.0 1.0 2.1 0 0.5 0.6 3 .2 0 3. 2

STOP 1.6 1.6 0 1.6 1.6 3.2 0.8 0.8 0.4 3.2 2.1 1.0 1.0 2.1 0 0.4 0.8 3.2 0 3.2

Ref No.

MODE 161 1 62 163 164 165 166 167 168 169 170 171 172 173 174 1 75 176 177 178 179 180

PLAY 0.5 1.5 1.5 0 1.1 1.6 1.6 1.6 0.8 0 0 0.8 1.3 0 3 .2 0 0 0 0 0

STOP 0 1.5 0 0 1.1 1.4 1.6 1.6 0 0 0 0.5 1.3 0 3.2 0 0 0 0 0

Ref No.

MODE 181 1 82 183 184 185 186 187 188 189 190 191 192 193 194 1 95 196 197 198 199 200

PLAY 0 0 0 3.2 0 0 3.2 3.2 000000003.22.02.42.7

STOP 0 0 0 3.2 0 0 3.2 3.2 000000003.22.92.72.8

Ref No.

MODE 201 2 02 203 204 205 206 207 208 209 210 211 212 213 214 2 15 216 217 218 219 220

PLAY 2.5 2.6 2.5 3.2 0 2.6 2.3 2.4 2.3 2.4 2.3 2.4 2.6 3.2 0 2.4 2.4 1 .0

1.9 1.9

STOP 3.0 2.9 3.2 3.2 0 3.0 2.9 2.9 3.1 2.9 3.0 3.2 2.9 3.2 0 2.7 2.8 1.1

2.6 2.6

Ref No.

MODE 221 2 22 223 224 225 226 227 228 229 230 231 232 233 234 2 35 236 237 238 239 240

PLAY 3.1 0 1.5 3.2 1.5 0 3. 0 3.0 2.8 0 1.5 0 0 1.1 1.6 0 0 0

3.2 1.5

STOP 3.1 0 1.5 3.2 1.5 0 3.1 3.1 3.0 0 2.0 0 0 1.1 1.5 0 0 0

3.2 1.4

Ref No.

MODE 241 2 42 243 244 245 246 247 248 249 250 251 252 253 254 2 55 256 1 2 3

PLAY 0.2 1.7 0.3 1.7 0.4 1.3 1.7 0 3.2 0000000 0

3.1 3.2

STOP 0 1.5 0 1.5 0 1.2 1.3 0 3.2 0000000 0

3.1 3.1

Ref No.

MODE 1234567891011121314151617181920

PLAY 3.2 2.5 3.2 2.4 2.4 0 2.4 2.3 3.2 2.3 2.5 0 2.4 3.2 2. 0 3.1 3.0 3.0 2 .8 1.6

STOP 3.2 2.7 3.2 3.0 3.0 0 2.9 3.1 3.2 3.0 2.9 0 2.8 3.2 2.6 3.1 3.1 3.1 3.0 1.9

Ref No.

MODE 21 22 23 24 25 26 27 28 2 9 30 31 32 33 34 35 36 37 38 39 40

PLAY 1.6 0 0.3 0.4 0.4 1.8 3.2 0 1.3 1.7 1. 7 1.5 0 0 0 0 3.2 1.5 1 .9 0

STOP 1.5 0 0 0.1 0.1 1.3 3.2 0 1.5 1.5 1.5 1.4 0 0 0 0 3.2 1.5 2.6 0

Ref No.

MODE 41 42 43 44 45 46 47 48 4 9 50 51 52 53 54

PLAY 0 2.4 3.2 2.4 2.5 0 2 .5 2.7 3.2 2.7 2.8 0 2. 3 0

STOP 0 2.8 3.2 3.0 2.9 0 2.9 3.0 3.2 2.9 2.8 0 2.9 0

Ref No.

MODE 1234567891011121314151617181920

PLAY 4.9 00000.200.52.201.602.13.32.14.92.22.202.2

STOP 4.9 0 0 0 0 0.1 0 0.5 2.1 0 1.5 0 2.1 3.3 2.1 4.9 2.2 2.2 0 2.2

Ref No.

MODE 21 22 23 24 25 26 27 28 2 9 30 31 32

PLAY 2.2 0 1.6 1.6 0 4. 5 0 0 4.4 0 0 -0.2

STOP 2.2 0 1.3 1.3 0 4.4 0 0 4.4 4.4 0 -0.3

Ref No.

MODE 1 2 3 4567891011121314151617181920

PLAY 0 1.6 1.6 0 0 3.3 00000000000000

STOP 0 1.6 1.6 0 0 3.3 0000002.30000000

Ref No.

MODE 21 22 23 24

PLAY 3.3 2.9 3.3 3.3

STOP 3.3 2.9 3.2 3.3

Ref No.

MODE 1 2 3 45678910111213141516

PLAY -0.2 0.2 -0.2 -0.2 0.2 0 0 0 0.1 0 1.6 0.5 0.5 0 1.6 4.9

STOP -0.2 0.1 -0.2 0.1 0.1 0 0 0 0.1 0 1.6 0.4 0.4 0 1.6 4.9

Ref No.

MODE 12345678

PLAY 1.4 2.7 0 1.6 1.7 3.3 3.3 0

STOP 1.4 2.8 0 1.6 1.7 3.3 3.3 0

IC3007

IC3202

IC3202

IC3009

IC3201

IC3009

IC3009

IC3201

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3004

IC3203

IC3204

39

DVD-LS91PP

Page 40

DVD-LS91PP

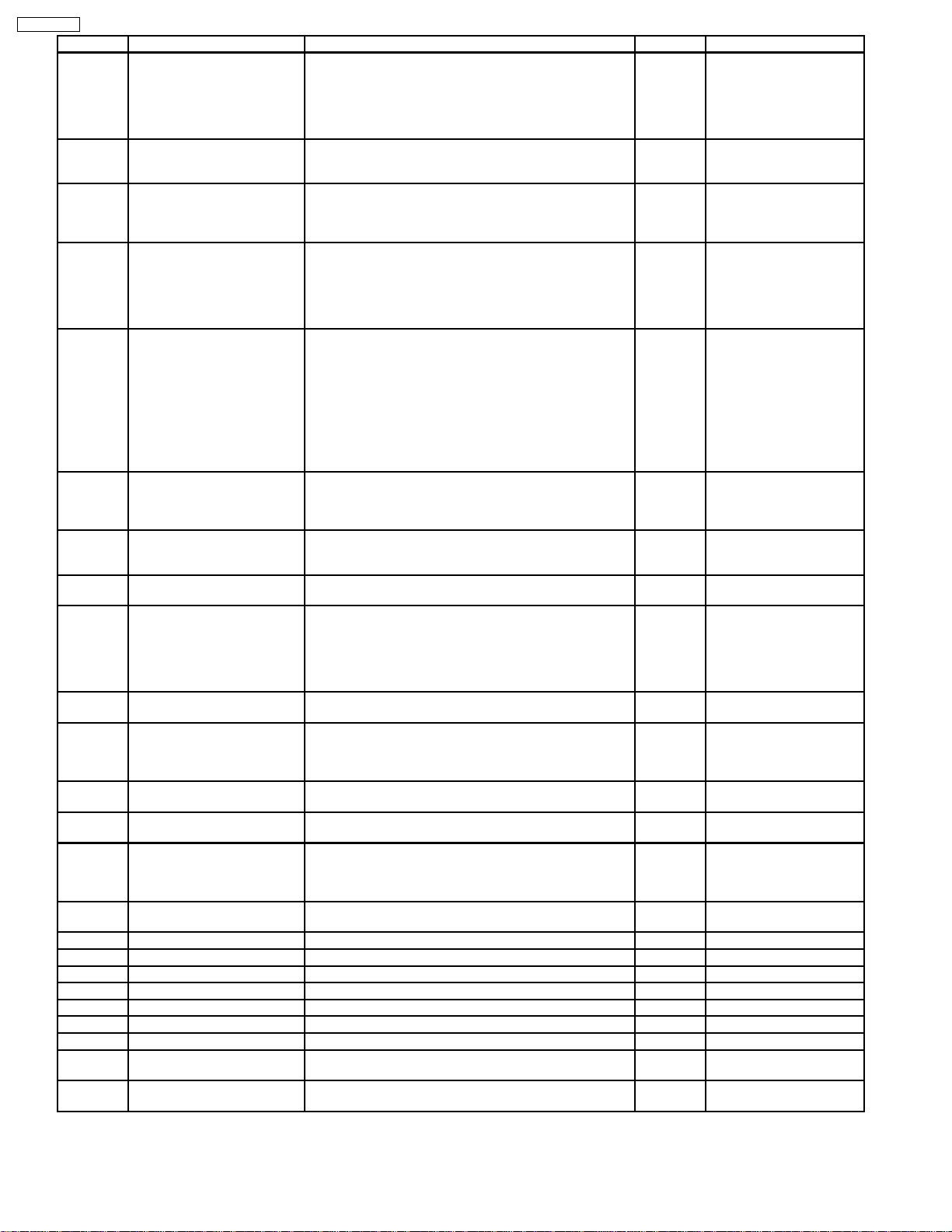

Ref No.

MODE 1234567891011121314

PLAY 0 0 0 3.3 3.3 3.3 0 0 0 3.3 0 0 3.3 3.3

STOP 0 0 0 3.3 3.3 3.3 0 0 0 3.3 0 0 3.3 3.3

Ref No.

MODE 12345 12345

PLAY 5. 4 0 5.4 0 5.0 5 .4 0 3 .3 0 5. 0

STOP 5.4 0 5.4 0 5.0 5.4 0 3.3 0 5.0

Ref No.

MODE 12345678910111213141516

PLAY 0 3.2 2.8 3.2 1.6 0. 8 1.6 1.6 0 0 5.0 0 2.5 2.4 2.5 0

STOP 0 3.2 2.8 3.2 1.6 0 1.6 1.6 0 0 5.0 0 2.5 2.4 2.5 5.0

Ref No.

MODE 12345678910111213141516

PLAY 2. 5 2.5 2.5 2.5 0 0 0 0 0.1 0 2.5 2.4 2.4 0 2 .5 5.0

STOP 2.5 2.5 2.5 2.5 00000.102.52.42.402.55.0

Ref No.

MODE 12345678 12345678

PLAY 4. 2 4.2 4.2 0 4.2 4.2 4.2 8 .3 2.2 4.2 4.2 2.2 4.0 0 8 .3 4.1

STOP 4.2 4.2 4.2 0 4.2 4.2 4.2 8.3 1.9 4.2 4.2 1.9 4.0 0 8.3 3.9

Ref No.

MODE 1 2 3 4567891011121314151617181920

PLAY 0 0 3.2 3.2 0 3.2 0.5 0 1.6 1.6 0 1.6 1.6 0 1.6 3.2 1. 6 1.6 1.6 0

STOP 0 0 3.2 3.2 0 3.2 0.1 0 1.6 1.6 0 1.6 1.6 0 1.6 3.2 1.6 1.6 1.6 0

Ref No.

MODE 21 22 23 24 25 26 27 28 1 2 345678

PLAY 0 1.4 0 1.6 1.6 1.6 3.2 1.6 2.5 2.5 2.5 0 4.2 4.2 4.2 8.3

STOP 0 1.4 0 1.6 1.6 1.6 3.2 1.6 2.5 2.5 2.5 0 4.2 4.2 4.2 8.3

Ref No.

MODE 12345678 1234

PLAY 00003.200.23.2 3.31.800

STOP 0 0 0 0 0 0 0 3.2 3.3 1.9 0 0

Ref No.

MODE 1234567891011121314151617181920

PLAY 0 3.3 0.3 2.9 3.3 3. 3 3.3 0 3. 3 3.3 3.3 1.7 1.5 0 0 3.3 0 3.3 0 0

STOP 0 3.3 0.2 2.9 3.3 3.3 3.3 0 3.3 3.3 3.3 1.7 1.5 0 0 3.3 0 3.3 0 0

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 3 1 32 33 34 35 36 37 38 39 40

PLAY 0 0.1 0.1 0 0.3 0.7 3.3 3.3 0 0 3.2 3.3 3.3 2.9 0 0 0 0 3.0 2.6

STOP 00000.20.73.33.3003.23.33.32.900003.02.7

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 5 1 52 53 54 55 56 57 58 59 60

PLAY 2. 9 3.3 3.3 3.3 0.1 3.3 2.7 3.3 3.3 0 0 3.3 3.3 0 3.3 3.3 0.4 0 0 0

STOP 2.9 3.3 3.3 3.3 0.1 3.3 2.7 3.3 3.3 0 0 3.3 3.3 0 3.3 3.3 0.3 0 0 0

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 7 1 72 73 74 75 76 77 78 79 80

PLAY 3. 3 0 0 0 3. 3 3.3 3.3 3.3 3.3 0 3 .3 3.3 3.3 0 3.3 0 0 0 3 .3 3.3

STOP 3.3 0 0 0 3.3 3.3 3.3 3.3 3.3 0 3.3 3.3 3.3 0 3.3 0 0 0 3.3 3.3

Ref No.

MODE 12345 1234

PLAY 0. 7 0.7 0 0.6 3.2 3.3 3.3 0.2 0

STOP 0.7 0.7 0 0.6 3.2 3.3 3.3 0 0

Ref No.

MODE 1 2 3 4567891011121314151617181920

PLAY 0 0 0 2.0 5.0 3.4 3.4 3 .4 0 0 0 0 3.8 2.5 2.5 2. 5 2.5 7.5 2.5 2.5

STOP 0 0 0 2.0 5.0 3.4 3.4 3.4 00003.82.52.52.52.57.52.52.5

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 3 1 32 33 34 35 36 37 38 39 40

PLAY 2. 5 0 1.4 1.5 1.5 0 0.3 0 0.3 0.3 0.1 0 3.3 3.3 0 1.8 2.6 5.0 0 3.3

STOP 2.5 0 1.5 1.6 1.6 0 0.2 0 0.5 0.2 0.4 0 3.3 3.3 0 1.8 2.6 5.0 0 3.3

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 5 1 52 53 54 55 56 57 58 59 60

PLAY 2. 9 0.3 0 3.3 1.6 3.3 0.3 3 .7 3.3 3.2 3.2 3.0 2.3 2.7 0.1 5.0 3 .6 2.5 0.2 2.9

STOP 2.9 0.2 0 3.3 1.6 3.3 0.3 3.4 3.3 3.2 3.2 2.8 2.2 2.7 0 5.0 3.6 2.5 0.2 2.9

Ref No.

MODE 61 62 63 64 1 2345678

PLAY 0 2.5 2.0 2.0 2.9 0 0 0 3 .3 3.2 0.4 3.3

STOP 0 2.5 2.0 2.0 2.9 0 0 0 3.3 3.2 0.4 3.3

Ref No.

MODE 1 2 3 4 5 6 7 8 12345678

PLAY 0 0 0 0 3.3 3.3 0 3.3 -2.5 -2.5 -2.5 -12.4 1.6 1.6 1.4 7.5

STOP 00003.33.303.3 -2.5 -2.5 -2.5 -12.4 1.6 1.6 1.4 7.5

Ref No.

MODE 1234567891011121314

PLAY 1. 5 1.5 1.2 1.5 1.5 1.3 0 1 .2 1.5 1.5 3.3 3.3 3.3 3.3

STOP 1.6 1.6 1.4 1.6 1.6 1.3 0 1.3 1.5 1.5 3.3 3.3 3.3 3.3

Ref No.

MODE 12345 123

PLAY 5. 4 0 3.3 0 5.0 3 .3 5.0 0

STOP 5.4 0 3.3 0 5.0 3.3 5.0 0

IC4001 IC4002

IC4005

IC4008

IC5201 IC6001

IC6003 IC6007

IC8001

IC8401 IC8403

IC8801

IC3205

IC4003