Page 1

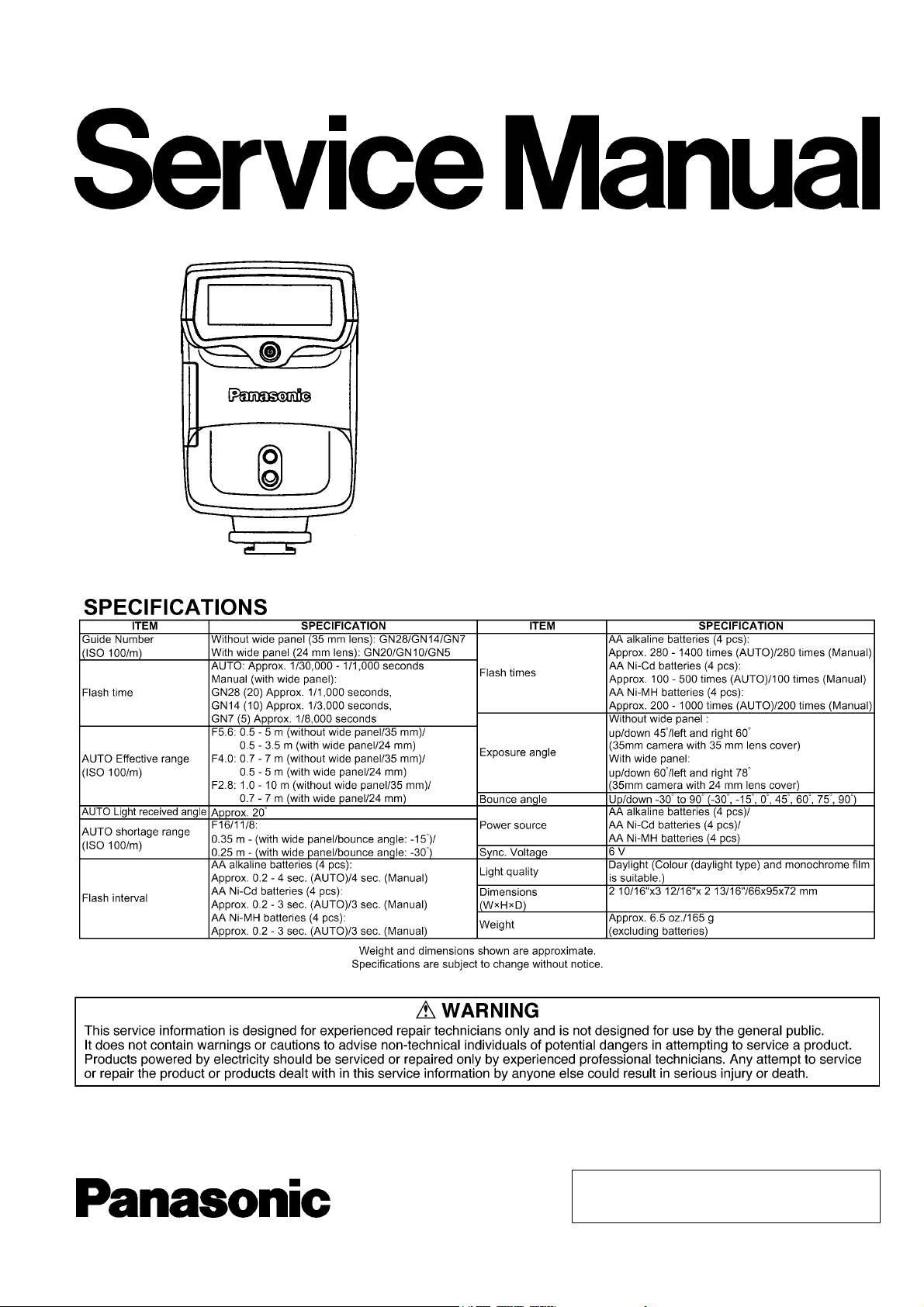

DMW-FL28PP

DMW-FL28E

Colour

(K)...........Black Type

ORDER NO. DSC0411018C0

B26

Flash Unit

© 2004 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copyin g and

distribution is a violation of law.

Page 2

DMW-FL28PP / DMW-FL28E

CONTENTS

Page Page

1 GENERAL DESCRIPTION 3

2 DISASSEMBLY & ASSEMBLY PROCEDURE

2.1. DIASSEMBLY PROCEDURE

2.2. ASSEMBLY PROCEDURE

2.3. DISASSEMBLY DIAGRAM

3 ELECTRICAL ADJUSTMENT

3.1. PREPARATION & SETUP

3.2. ADJUSTMENT PROCEDURES

4 CIRCUIT DESCRIPTION

4.1. Operation for control circuit power supply

4.2. Operation for converter oscillation circuit

4.3. Operation for constant voltage control circuit

4.4. Operation for flash circuit

4.5. Operation for modulated light circuit

4.6. Operation for SLAVE circuit

10

10

10

11

12

12

12

20

20

20

20

20

20

20

4.7. Operation for auto check circuit

4.8. Operation for flash prohibition circuit

5 TROUBLESHOOTING

6 SERVICE HINT

7 SCHEMATIC DIAGRAMS

8 WIRING CONNECTION DIAGRAM

9 CIRCUIT BOARD ASSEMBLIES

10 EXPLODED VIEWS

10.1. FRAME & CASING SECTION

10.2. PACKING PARTS & ACCESSORIES SECTION

11 REPLACEMENT PARTS LIST

11.1. MECHANICAL REPLACEMENT PARTS LIST

11.2. ELECTRICAL REPLACEMENT PARTS LIST

12 SCHEMATIC DIAGRAM FOR PRINTING WITH A4 SIZE

20

20

21

23

25

27

28

29

29

30

31

31

32

34

2

Page 3

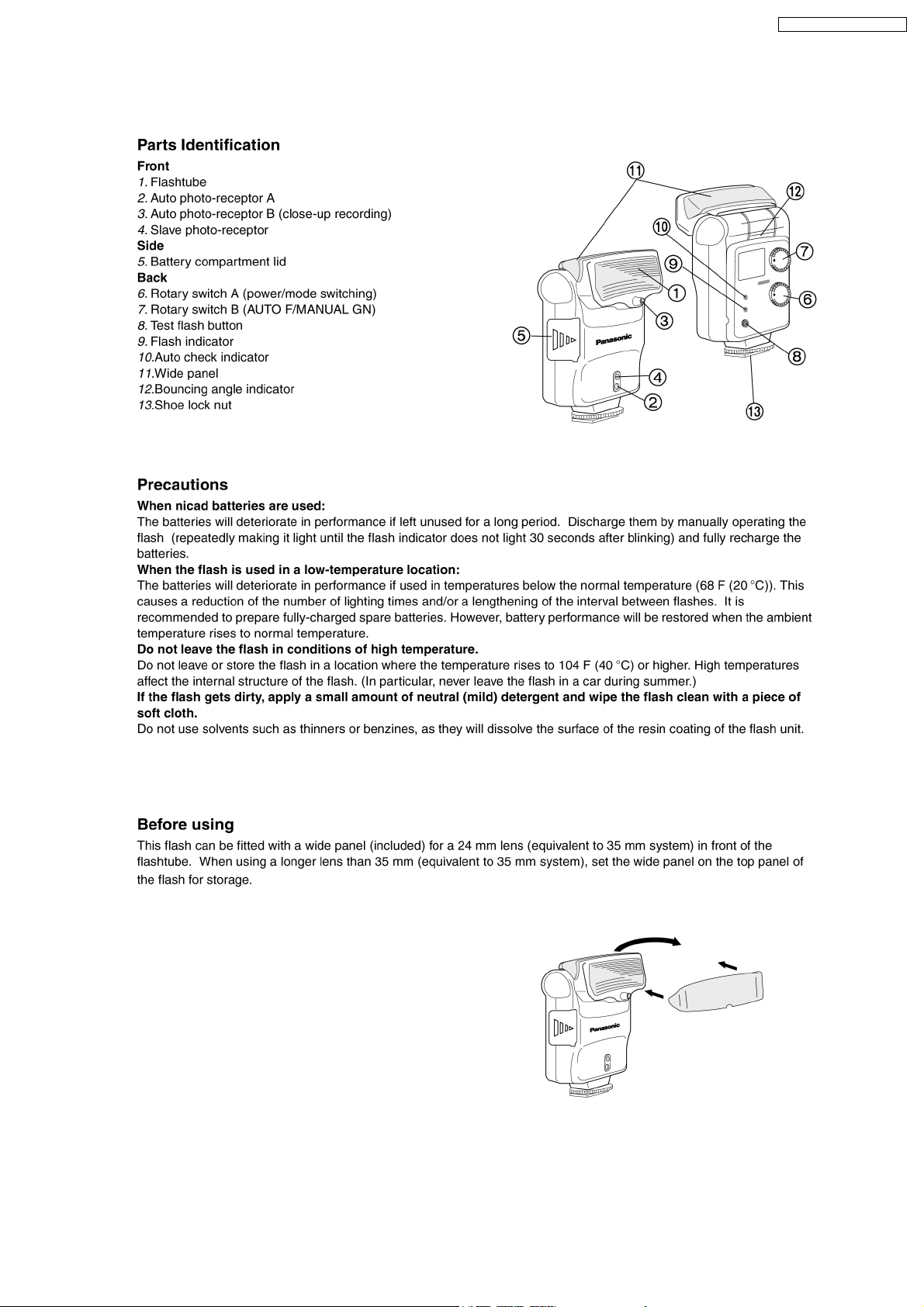

1 GENERAL DESCRIPTION

DMW-FL28PP / DMW-FL28E

3

Page 4

DMW-FL28PP / DMW-FL28E

4

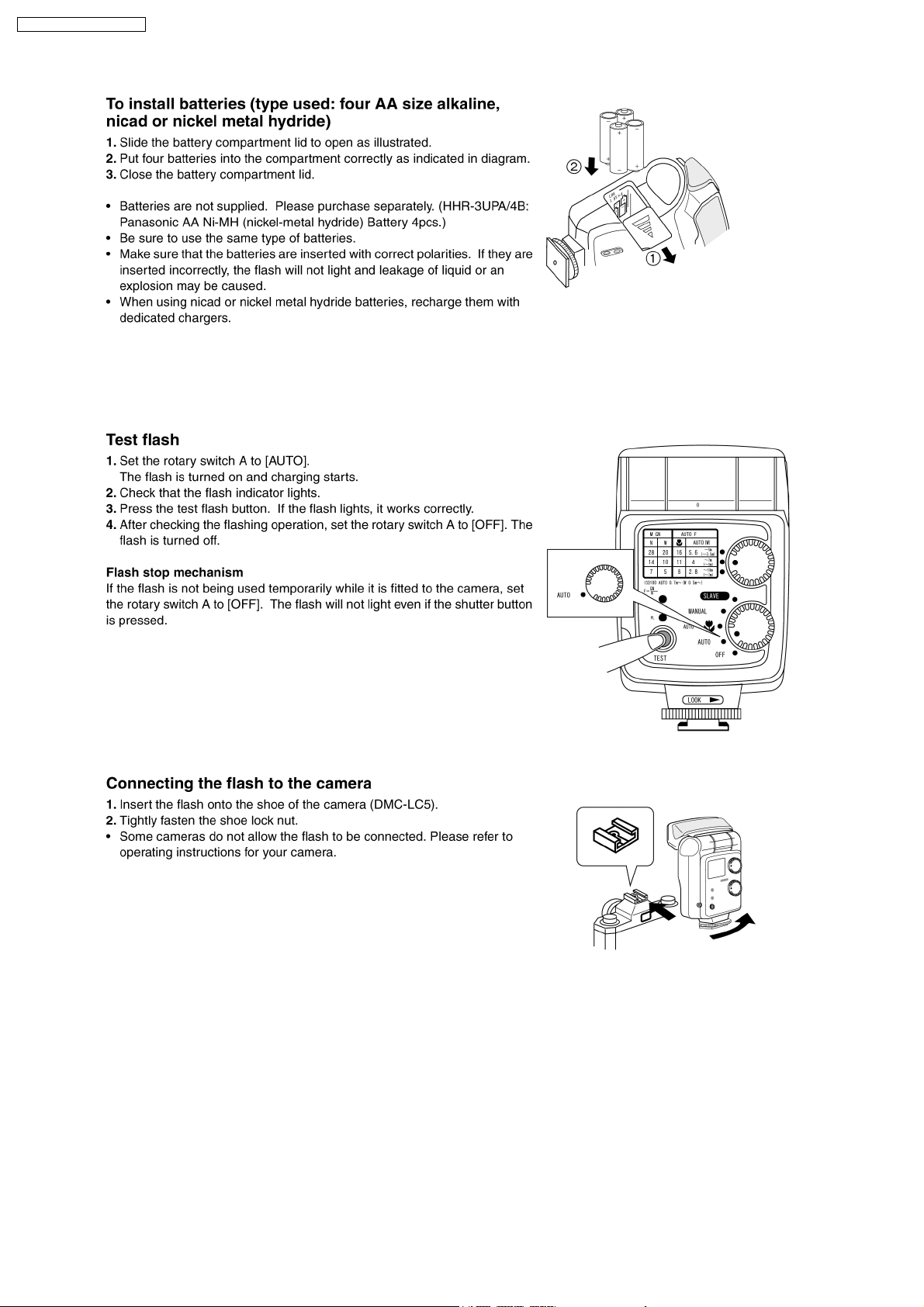

Page 5

DMW-FL28PP / DMW-FL28E

5

Page 6

DMW-FL28PP / DMW-FL28E

6

Page 7

DMW-FL28PP / DMW-FL28E

7

Page 8

DMW-FL28PP / DMW-FL28E

8

Page 9

DMW-FL28PP / DMW-FL28E

9

Page 10

DMW-FL28PP / DMW-FL28E

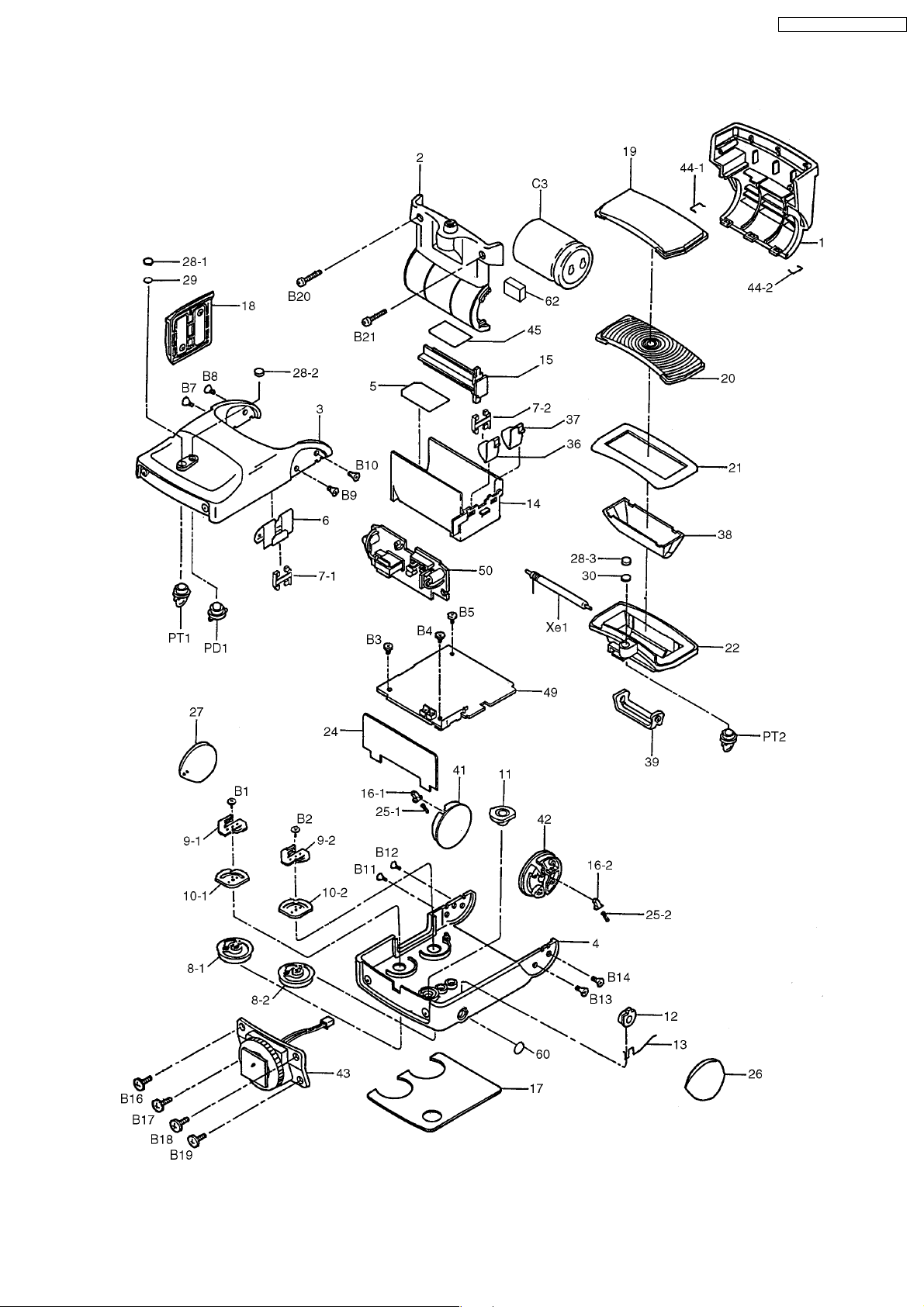

2 DISASSEMBLY & ASSEMBLY PROCEDURE

Refer to the “DISASSEMBLY DIAGRAM”.

2.1. DIASSEMBLY PROCEDURE

1. Remove the battery lid unit (Ref. No. 18).

2. Unscrewed 4 screws (B16 - B19), and then remove the shoe unit (Ref. No. 43).

3. Remove the side rubber 1 (Ref. No. 26) and side rubber 2 (Ref. No. 27).

4. Unscrewed 4 screws (B7 - B10), and then remove the main case (C) (Ref No.3).

Caution

· Be careful of the high voltage capacitor (Ref No. C3) when servicing.

· Be sure to discharge the capacitor (Ref No. C3) to use the resistor for discharging (ERG5SJ102) after connecting

between cathode of Ref No. D2 and battery terminal (-).

5. Remove the insulation sheet (Ref No. 24), and then unscrewed 3 screws (B3 - B5) with the battery case (Ref No. 14) is holding

to up slightly. Remove the C.B.A. (A) and C.B.A. (B)..

6. Remove the 2 locking springs (Ref No. 44-1 and 44-2), and then unscrewed 2 screws (B20 and B21). Remove the main case

(B) (Ref No. 2).

2.2. ASSEMBLY PROCEDURE

2.2.1. Assembly of the Dial Knob (Ref No. 8-1 and 8-2)

Apply the grease to the operation part of main case (D) (Ref No. 4) when assembling the click spring (Ref No. 10-1 and 10-2).

2.2.2. Assembly of the C.B.A.

When assembling the C.B.A., apply the grease to foil side of C.B.A. (A) where is located to jack spring and dial brush terminal after

alcohol cleaning.

2.2.3. Assembly of the Main Case (B)

Apply the grease to the part of click mold (Ref No. 16) is touched to the main case (B) (Ref No. 2), and then install to the main case

(A) (Ref No. 1). Screwed 2 screws (B20 and B21).

2.2.4. Installation of the Photo Transistor

Install the photo transistor (Ref No. PT2) to C.B.A. (A), and then confirm capacitor (Ref No. C11) is installed to the side of reflection

umbrella to the main case (B) (Ref No. 2).

Install the photo diode (Ref No. PD1), and then confirm it to the battery case side of main case (C) (Ref No. 3).

Install the photo transistor (Ref No. PT1), and then confirm it to the side of shoe unit.

2.2.5. Layout of lead wire

The lead wire for SLAVE (black) and lead wire for AUTO (red and black) is located between the insulation sheet and C.B.A. (B).

10

Page 11

2.3. DISASSEMBLY DIAGRAM

DMW-FL28PP / DMW-FL28E

11

Page 12

DMW-FL28PP / DMW-FL28E

3 ELECTRICAL ADJUSTMENT

3.1. PREPARATION & SETUP

3.2. ADJUSTMENT PROCEDURES

12

Page 13

3.2.1. CHARGING VOLTAGE MEASUREMENT & ADJUSTMENT

DMW-FL28PP / DMW-FL28E

13

Page 14

DMW-FL28PP / DMW-FL28E

3.2.2. AUTO OPERATION CONFIRMATION & ADJUSTMENT

14

Page 15

DMW-FL28PP / DMW-FL28E

15

Page 16

DMW-FL28PP / DMW-FL28E

3.2.3. MACRO-AUTO OPERATION CONFIRMATION & ADJUSTMENT

16

Page 17

DMW-FL28PP / DMW-FL28E

17

Page 18

DMW-FL28PP / DMW-FL28E

3.2.4. MANUAL (POWER CONTROL) OPERATION CONFIRMATION & ADJUSTMENT

18

Page 19

DMW-FL28PP / DMW-FL28E

19

Page 20

DMW-FL28PP / DMW-FL28E

4 CIRCUIT DESCRIPTION

Refer to the “SCHEMATIC DIAGRAM”.

4.1. Operation for control circuit power supply

When the position of the rotary switch A is changed from OFF to other position (AUTO/C AUTO/MANUAL/SLAVE), RQ2 turns ON.

Then it starts to supply the control power.

4.2. Operation for converter oscillation circuit

When the position of the rotary switch A is changed from OFF to other position (AUTO/C AUTO/MANUAL/SLAVE), Q3 turns ON,

and then Q1 and Q2 are started to oscillate. That is started to charge C3 through T1 and D2. Then power is supplied to control

circuit through D1 and R53.

4.3. Operation for constant voltage control circuit

When charging voltage becomes 275±5 V after C3 is started to charge, the voltage between R6 and R32 is to be 2 V. That make

1 pin of IC2 be opened, then LD1 is lit up.

When charging voltage is 330±5 V by charging voltage of C3 is increased more, the voltage between R32 and R33 is to be 1.7 V.

The voltage is detected, and then 7 pin of IC2 is L, RQ1 is ON. Between (E) and (B) of Q1 and Q2 is shorted, oscillation is stopped.

When the voltage between R32 and R33 is fallen to 1.65 V after oscillation is stopped, 7 pin of IC2 is opened. Then oscillate again.

The voltage of C3 is maintained between 325 - 330 V because above operation is repeated.

4.4. Operation for flash circuit

Press the test flash button (SW3 is ON) or X terminal is to be L, Q7 is ON and SCR2 is ON through R26. Then electric charge of

C14 is flowed the following.

· (A) of SCR2→ (C) of SCR2→T2 COM→ Primary→C14

After that, trigger pulse is produced at secondary of T2 and XE1 is energized. Thus make a flash. At that time, gate circuit of IT1

is always ON because the voltage of C3 is supplied to it through R18 and R19.

4.5. Operation for modulated light circuit

Q4 is ON by the energy of C4 after XE1 is flashed, the electric charge of C6 is supplied to modulated light circuit. In case of AUTO

mode, (E) of PT1 is connected to GND by the SW 1 and 2. then start to flash. When the received light of PT1 is proper, the base

current of Q5 is flowed through R13.

SCR1 and Q6 is ON at the same time after Q5 is ON, gate voltage of IT1 is to be L and stop to flash. (C AUTO is the same.) In

case of MANUAL mode, operation is almost the same. The base current of Q5 is flowed through TH1, TH2, VR1 and VR2, Q5 is

ON and stop to flash.

SCR1 is also glow light protection circuit. XE current is flowed through R20 and SCR1, Q6 keep being ON until SCR1 is OFF. IT1

keep being OFF is operated glow light protection circuit.

4.6. Operation for SLAVE circuit

When SW1 and 2 to SLAVE mode, RQ3 and 5 is ON commonly. Modulated light circuit is the same for MANUAL mode. RQ6 is

ON at the time RQ3 and 5 is ON, lock when received light is detected by other mode is canceled by Q10 is OFF.

When PD1 is received other flash light, 7 pin of IC3 is to be H and start to flash after SCR2 is ON through R44, D9. Change SW1

and 2 to GND, discharge the electric charge of C17 through D8 and make the flash stop by X contact between test flash button and

shoe.

4.7. Operation for auto check circuit

D3 is connected to GND through SW1 and 2 and RQ3 when the mode is selected except for AUTO and C AUTO. However RQ7

is locked, RQ7 is ON after Q5 is ON when the mode is selected AUTO and C AUTO. Then RQ8 is ON and auto check lamp is

lighted (LD2 is ON) within the time constant between R49 and C22.

4.8. Operation for flash prohibition circuit

When SW1-1 is OFF, between (C) of Q7 and R26 is connected to GND. Thus SCR2 cannot be ON is prohibited to flash when the

power is OFF.

20

Page 21

5 TROUBLESHOOTING

DMW-FL28PP / DMW-FL28E

21

Page 22

DMW-FL28PP / DMW-FL28E

22

Page 23

DMW-FL28PP / DMW-FL28E

6 SERVICE HINT

Malfunction content: Not oscillated.

Symptom: 1. Not oscillated when the power switch is ON.

2. Oscillated when shorting both terminal of CUT1, charging voltage is up to 150 - 250 V and then shorting.

3. Normal charging is performed by shorting CUT1 but flash repeatedly comes to above symptom.

4. Also comes to above symptom after flashed properly.

Cause: T1 is rare shorting and disconnection of CUT1.

Service point: Replace T1 and CUT1.

Remarks: The bond which is fixed to CUT1 is lost color to brown, it may be heated Q1 and Q2. Replace Q1 and Q2 commonly.

Malfunction content: Not oscillated.

Symptom: 1. Not oscillated when the power switch is ON.

Cause: Disconnection of CUT1.

Service point:

Remarks: The bond which is fixed to CUT1 is lost color to brown, it may be heated Q1 and Q2. Replace Q1 and Q2 commonly.

After replacing CUT1, Q1 and Q2, bond these parts and fixed.

2. When shorting both terminal of CUT1, oscillation is performed normally. (Also flash is normal)

Replace CUT1.

Not lost color to brown is only malfunction of CUT1. No replacement of Q1 and Q2 is required. After replacing CUT1,

Q1 and Q2, bond these parts and fixed.

Malfunction content:

Symptom:

Cause: C15 is shorted. (It can be confirmed by tester.)

Service point: Replace C15.

Not flashed.

1. Normal oscillation and charging is performed when the power switch is ON.

2. Not flashed. (test flash button, shoe, sync cord and SLAVE mode)

3. Output voltage of X terminal is normal. (Approx. 5 V is output at (+) terminal of C17.)

4. The voltage of SCR2 anode terminal is less than 280 V. (Almost the voltage is 0 - 230 V.)

When C.B.A. (A) is removed from main case (D), charging is performed by shorting between 2 points shown below.

Malfunction content: Not flashe d.

Symptom: 1. Normal oscillation and charging is performed when the power switch is ON.

2. Not flashed. (test flash button, shoe and sync cord) Lighted. (SLAVE mode) In this case, it cause the sync circuit is

malfunction. Trigger and flash circuit is not malfunction.

3. Output voltage of X terminal is abnormal. (Approx. 5 V is not output at (+) terminal of C17.)

Cause: RQ4 is shorting.

Service point: Replace QR4.

Malfunction content: Oscillated when the power switch is changed to OFF.

Symptom: 1. Oscillation and charging is performed when supply the power at the condition the power switch is OFF. But pilot

Cause: Q3 is shorting.

Service point: Replace Q3.

lamp is not lighted and flashed.

2. When the power switch is ON after above symptom, normal operation for oscillation, charging, lighting and flashin g

is performed.

3. When the power switch is OFF after symptom 2, it occurred symptom 1.

23

Page 24

DMW-FL28PP / DMW-FL28E

24

Page 25

7 SCHEMATIC DIAGRAMS

DMW-FL28PP / DMW- FL28E

H

Q1

T1

Q2

RQ1

R1 10K

D2

W4

C3 800

R4 820

G

(OSC)

F

AUTO

C-AUTO

MANUAL

SLAVE

R2 10K

OFF

R3 1.5K

Q3

SW1-1

D1

(+12V)

(VBATT)

RQ2

CUT1

E

C1 10V 220

CUT2

10K

10K

(OSCS)

R53 330

W8

1.5V x4

W7

D

W1

(GND1)

W10

C4 0.047

R5 1.2M

R9 22KR10 33K

R6 1.2M

8V

R11 68K

R7 1.2MR8 1.2M

Q4

W14

PT1

C6 16V 2.2

OFF

R12 1M

C10 220P

W13

SW1-2

RQ5

C7 0.047

R56 22

W11

W12

MANUAL

C-AUTO

AUTO

C8 0.082

4

5.6

2.8

SW2-1

PT2

SLAVE

C9 0.15

SW2-2

FULL

C11 220P

TH1

VR1

RQ3

22K

1/4

100K

47K

TH2

VR2

C12 0.022

1/16

50K

R57 10K

R13 10K

D3

Q5

(STP)

R14 10K

R15 2.2K

SCR1

R16 3.3K

R17 2.2K

Q6

R18 470K

R19 470K

R20 33K

R21 33

ZD1

W6

XE1

W2

D4

C13 0.01

R22 33

IT1

T2

C14 0.047

C15 0.047

W5

W3

280V

SCR2

R23 1.5M

(TG)

D10

C16 0.047

R25 1K

Q7

R26 560

W15

R27 4.7K

R28 2.2K

D5

RQ4

R29 180K

SW3

5V

C17 16V 1

2.2K

47K

10K

R30 1K

LD1

10K

D8

W16

C

D6

IC1

IC2

1

2

3

4

B

C23 10V 100

C18 16V 2.2

C24 0.01

C19 16V 1

R31 27K

R34 2KR35 10K

R32 11.5K

8

7

6

5

VR3

R33 24.3K

C25 0.01

A

R36 470K

R51 200K

R37 47K

C20 3300P

Q9

Q8

W9

W9

C21 0.039

PD1

R39 15K

D7

R38 1M

R41 680K

R40 10K

R42 22K

R43 22K

IC3

Q10

D9

R46 10K

C26 1000P

RQ7

22K

47K

R48 10K

R55 1K

RQ8

LD2

R50 220

10K

10K

IC4

1

2

3

4

8

7

6

5

R49 680K

Q11

C22 10V 4.7

1

2

3

4

8

7

6

5

RQ6

R44 1K

22K

47K

R45 10K

DMW-FL28PP/E SCHEMATIC DIAGRAM

121110987654321

25

Page 26

DMW-FL28PP / DMW- FL28E

26

Page 27

8 WIRING CONNECTION DIAGRAM

DMW-FL28PP / DMW-FL28E

27

Page 28

DMW-FL28PP / DMW-FL28E

9 CIRCUIT BOARD ASSEMBLIES

G

F

E

E

D

D

< C.B.A. (A) >

C

C

B

B

A

A

< C.B.A. (B) >

DMW-FL28PP/E C.B.A.

654321 64321

28

Page 29

10 EXPLODED VIEWS

10.1. FRAME & CASING SECTION

DMW-FL28PP / DMW-FL28E

29

Page 30

DMW-FL28PP / DMW-FL28E

10.2. PACKING PARTS & ACCESSORIES SECTION

30

Page 31

11 REPLACEMENT PARTS LIST

DMW-FL28PP / DMW-FL28E

11.1. MECHANICAL REPLACEMENT

PARTS LIST

11.1.1. FRAME & CASING SECTION

PARTS LIST

Ref.

No.

1 SS094-98 MAIN CASE (A)

2 SS094-99 MAIN CASE (B)

3 SS095-40 MAIN CASE (C)

4 SS094-97 MAIN CASE (D)

5 SS806-74 BATTERY SEAL

6 SS209-73S BATTERY TERMINAL

7-1 SS040-03 TERMINAL GUARD

7-2 SS040-03 TERMINAL GUARD

8-1 SS058-58 DIAL KNOB

8-2 SS058-58 DIAL KNOB

9-1 SS162-08 DIAL BRUSH TERMINAL

9-2 SS162-08 DIAL BRUSH TERMINAL

10-1 SS162-09 CLICK SPRING

10-2 SS162-09 CLICK SPRING

11 ES011-61 FLASH BUTTON

12 SS203-01 JACK MOLD

13 SS166-15 JACK SPRING

14 SS027-66 BATTERY CASE

15 SS029-09 BATTERY SEPARATOR

16-1 SS038-74 CLICK MOLD

16-2 SS038-74 CLICK MOLD

17 SS222-93 BACK PLATE

18 SS001-69 BATTERY LID UNIT

19 SS056-90 FRONT PANEL

20 SS056-91 FRESNEL PANEL

21 SS228-35 ORNAMENT PLATE

22 SS040-04 REFLECTION UMBRELLA COVER

24 SS800-96 INSULATION SHEET

25-1 SS164-35 SPRING

25-2 SS164-35 SPRING

26 SS024-93 SIDE RUBBER 1

27 SS024-94 SIDE RUBBER 2

28-1 SS022-16 PROTECTION PLATE

28-2 SS022-16 PROTECTION PLATE

28-3 SS022-16 PROTECTION PLATE

29 SS025-13 ND FILTER (0.3)

30 SS025-04 ND FILTER (0.4) (Refer to

36 SS209-71S BATTERY TERMINAL (+)

37 SS209-72 BATTERY TERMINAL (-)

38 SS014-13 REFLECTION UMBRELLA

39 SS011-77 XE BUSHING

41 SS013-57 BOUNCE SHAFT (A)

42 SS013-58 BOUNCE SHAFT (B)

43 SS128-84 SHOE UNIT

44-1 SS166-16 LOCK SPRING

44-2 SS166-16 LOCK SPRING

45 SS804-11 SEAL

Part No. Part Name & Description Remarks

Adjustment

SS025-12 ND FILTER (0.5) (Refer to

SS025-08 ND FILTER (0.6) (Refer to

Procedures)

Adjustment

Procedures)

Adjustment

Procedures)

Ref.

No.

49 SS306-89 C.B.A. (A) (RTL)

50 SS306-90 C.B.A. (B) (RTL)

60 SS228-41 SYNC PLATE

62 SG900-29 CUSHION

B1 SG012-70 SCREW

B2 SG012-70 SCREW

B3 SG022-83 SCREW

B4 SG022-83 SCREW

B5 SG022-83 SCREW

B7 SG052-35 SCREW

B8 SG052-35 SCREW

B9 SG052-35 SCREW

B10 SG052-35 SCREW

B11 SG052-35 SCREW

B12 SG052-35 SCREW

B13 SG052-35 SCREW

B14 SG052-35 SCREW

B16 SG052-34 SCREW

B17 SG052-34 SCREW

B18 SG052-34 SCREW

B19 SG052-34 SCREW

B20 SG022-60 SCREW

B21 SG022-60 SCREW

Part No. Part Name & Description Remarks

11.1.2. PACKING PARTS & ACCESSORIES

SECTION PARTS LIST

Ref.

No.

101 SP500-63 POLY BAG

102 SP500-33 POLY BAG

103 SP500-33 POLY BAG

104 SP603-67 INSTRUCTION BOOK

104 SP603-68 INSTRUCTION BOOK

105 SP012-21 PACKING CASE

106 SP400-35 PAD

107 SS056-92 WIDE PANEL

Part No. Part Name & Description Remarks

DMW-FL28PP

DMW-FL28E

31

Page 32

DMW-FL28PP / DMW-FL28E

11.2. ELECTRICAL REPLACEMENT

PARTS LIST

Ref.

No.

C1 SC100-07 E.CAPACITOR CH 10V 220U

C3 SS505-78 E.CAPACITOR CH 330V 800U

C4 SC201-22 C.CAPACITOR CH 250V0.047U

C6 SC201-27 T.CAPACITOR CH 16V 2.2U

C7 ECJ2XB1H473K C.CAPACITOR CH 50V 0.047U

C8 ECJ2XB1H823K C.CAPACITOR CH 50V 0.082U

C9 SC201-24 C.CAPACITOR CH 50V 0.15U

C10 SC002-22 C.CAPACITOR CH 50V 220P

C11 SC002-22 C.CAPACITOR CH 50V 220P

C12 ECJ2VB1H223K C.CAPACITOR CH 50V 0.022U

C13 ECJ2VB1H103K C.CAPACITOR CH 50V 0.01U

C14 SC102-51 CAPACITOR CH 400V 0.047U

C15 SC102-51 CAPACITOR CH 400V 0.047U

C16 ECJ2XB1H473K C.CAPACITOR CH 50V 0.047U

C17 F3K1C1050001 T.CAPACITOR CH 16V 1U

C18 SC201-27 T.CAPACITOR CH 16V 2.2U

C19 F3K1C1050001 T.CAPACITOR CH 16V 1U

C20 SC201-25 C.CAPACITOR CH 25V 3300P

C21 ECJ2VB1H393K C.CAPACITOR CH 50V 0.039U

C22 F3K1A4750002 T.CAPACITOR CH 10V 4.7U

C23 ECEA1CKS101 E.CAPACITOR 16V 100U

C24 SC201-26 C.CAPACITOR CH 25V 0.01U

C25 SC201-26 C.CAPACITOR CH 25V 0.01U

CUT1 SC014-06 FUSE

CUT2 SC014-12 FUSE

D1 MA2J11100L DIODE

D2 SC105-24 DIODE

D3 MA2J11100L DIODE

D4 SC105-25 DIODE

D5 SC105-20 DIODE

D6 RB501V-40 DIODE

D7 MA2J11100L DIODE

D8 MA2J11100L DIODE

D9 MA2J11100L DIODE

D10 MA2J11100L DIODE

IC1 SS534-23 IC

IC2 NJM2903V IC C0BBBA000032

IC3 NJM2904M IC C0ABBA000021

IC4 TC7W00F IC

IT1 SC013-53 IGBT

LD1 SC125-09 LED

LD2 SC125-10 LED

PD1 SS512-34S PHOTO DIODE

PT1 SS512-18 PHOTO TRANSISTOR

PT2 SS512-08 PHOTO TRANSISTOR

Q1 SC013-01 TRANSISTOR

Q2 SC013-01 TRANSISTOR

Q3 SC013-49 TRANSISTOR

Q4 SC013-51 TRANSISTOR

Q5 SC013-51 TRANSISTOR

Q6 SC013-52 TRANSISTOR

Q7 SC013-51 TRANSISTOR

Q8 SC013-39 TRANSISTOR

Q9 SC013-39 TRANSISTOR

Part No. Part Name & Description Remarks

Ref.

No.

Q10 SC013-39 TRANSISTOR

Q11 SC013-51 TRANSISTOR

R1 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R2 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R3 ERJ3GEYJ152V M.RESISTOR CH 1/10W 1.5K

R4 ERJ3GEYJ821 M.RESISTOR CH 1/10W 820

R5 SC207-85 M.RESISTOR CH 1/4W 1.2M

R6 SC207-85 M.RESISTOR CH 1/4W 1.2M

R7 ERJ6GEYJ125 M.RESISTOR CH 1/10W 1.2M

R8 ERJ6GEYJ125 M.RESISTOR CH 1/10W 1.2M

R9 ERJ6GEYG222 M.RESISTOR CH 1/10W 2.2K

R10 ERJ3GEYJ333 M.RESISTOR CH 1/10W 33K

R11 ERJ3GEYJ683 M.RESISTOR CH 1/10W 68K

R12 ERJ3GEYJ105V M.RESISTOR CH 1/10W 1M

R13 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R14 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R15 ERJ3GEYJ222 M.RESISTOR CH 1/10W 2.2K

R16 ERJ3GEYJ332 M.RESISTOR CH 1/10W 3.3K

R17 ERJ3GEYJ222 M.RESISTOR CH 1/10W 2.2K

R18 ERJ6GEYJ474 M.RESISTOR CH 1/10W 470K

R19 ERJ6GEYJ474 M.RESISTOR CH 1/10W 470K

R20 ERDS2TJ333J C.RESISTOR CH 1/4W 33K

R21 ERJ6GEYG330 M.RESISTOR CH 1/8W 33

R22 ERDS2FJ330 C.RESISTOR 1/4W 33

R23 ERJ8GEYJ155 M.RESISTOR CH 1/4W 1.5M

R25 ERJ3GEYJ102V M.RESISTOR CH 1/10W 1K

R26 ERJ3GEYJ561 M.RESISTOR CH 1/10W 560

R27 ERJ3GEYJ472 M.RESISTOR CH 1/10W 4.7K

R28 ERJ3GEYJ222 M.RESISTOR CH 1/10W 2.2K

R29 ERJ3GEYJ184V M.RESISTOR CH 1/10W 180K

R30 ERJ3GEYJ102V M.RESISTOR CH 1/10W 1K

R31 ERJ3GEYJ273 M.RESISTOR CH 1/10W 27K

R32 SC207-86 M.RESISTOR CH 1/10W 11.5K

R33 SC207-87 M.RESISTOR CH 1/10W 24.3K

R34 ERJ3GEYJ202 M.RESISTOR CH 1/10W 2K

R35 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R36 ERJ6GEYJ474 M.RESISTOR CH 1/10W 470K

R37 ERJ3GEYJ473V M.RESISTOR CH 1/10W 47K D0GB473JA002

R38 ERJ3GEYJ105V M.RESISTOR CH 1/10W 1M

R39 ERJ3GEYD153V M.RESISTOR CH 1/10W 15K D0HB153ZA002

R40 ERJ6GEYG103 M.RESISTOR CH 1/10W 10K

R41 ERJ3GEYJ684 M.RESISTOR CH 1/10W 680K D0GB684JA002

R42 ERJ3GEYJ223 M.RESISTOR CH 1/10W 22K

R43 ERJ3GEYJ223 M.RESISTOR CH 1/10W 22K

R44 ERJ3GEYJ102V M.RESISTOR CH 1/10W 1K

R45 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R46 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R48 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

R49 ERJ3GEYJ684 M.RESISTOR CH 1/10W 680K D0GB684JA002

R50 ERJ6GEYJ220 M.RESISTOR CH 1/10W 22

R51 ERJ3GEYJ204 M.RESISTOR CH 1/10W 200K

R53 ERJ6GEYG331 M.RESISTOR CH 1/10W 330

R55 ERJ3GEYJ102V M.RESISTOR CH 1/10W 1K

R56 ERJ3GEYJ220 M.RESISTOR CH 1/10W 22

R57 ERJ3GEYJ103V M.RESISTOR CH 1/10W 10K D0GB103JA002

RQ1 DTA143XU DIGITAL TRANSISTOR

RQ2 SC032-71 DIGITAL TRANSISTOR

RQ3 DTC124XU DIGITAL TRANSISTOR

RQ4 SC032-79 DIGITAL TRANSISTOR

RQ5 DTA114EUA106 DIGITAL TRANSISTOR

RQ6 DTC124XU DIGITAL TRANSISTOR

RQ7 DTC124XU DIGITAL TRANSISTOR

RQ8 DTC114EU DIGITAL TRANSISTOR

SCR1 SC023-52 THYRISTOR

SCR2 SC023-52 THYRISTOR

T1 SS516-60 TRANSFORMER

T2 SS508-60 TRIGGER COIL

TH1 SC010-15 THERMISTOR

Part No. Part Name & Description Remarks

32

Page 33

DMW-FL28PP / DMW-FL28E

Ref.

No.

TH2 SC010-16 THERMISTOR

VR1 SC065-78 VARIABLE RESISTOR

VR2 SC065-79 VARIABLE RESISTOR

VR3 SC065-80 VARIABLE RESISTOR

XE1 SS501-50 XE TUBE

ZD1 MA3270M DIODE MAZ32700M

Part No. Part Name & Description Remarks

33

Page 34

DMW-FL28PP / DMW-FL28E

12 SCHEMATIC DIAGRAM FOR PRINTING WITH A4 SIZE

34

Page 35

7 SCHEMATIC DIAGRAMS

2

1

DMW-FL28PP / DMW-FL28E

H

Q1

T1

Q2

RQ1

R1 10K

D2

W4

W10

R7 1.2MR8 1.2M

C4 0.047

R4 820

C3 800

G

(OSC)

F

AUTO

C-AUTO

MANUAL

SLAVE

R2 10K

OFF

R3 1.5K

Q3

SW1-1

D1

(+12V)

(VBATT)

RQ2

CUT1

E

C1 10V 220

CUT2

10K

10K

(OSCS)

R53 330

W8

1.5V x4

W7

D

W1

(GND1)

R5 1.2M

R6 1.2M

8V

R9 22KR10 33K

R11 68K

Q4

W14

PT1

C6 16V 2.2

OFF

R12 1M

C10 220P

W13

SW1-2

C7 0.047

R56 22

W11

W12

MANUAL

C-AUTO

AUTO

C8 0.082

4

5.6

2.8

SW2-1

PT2

SLAVE

C9 0.15

SW2-

FULL

C11 220P

TH1

VR1

RQ3

1/4

TH2

VR2

100K

22K

47K

RQ5

10K

R30 1K

LD1

10K

C

D6

IC1

IC2

1

2

3

4

B

C23 10V 100

C18 16V 2.2

C24 0.01

C19 16V 1

R31 27K

R34 2KR35 10K

R32 11.5K

8

7

6

5

VR3

R33 24.3K

C25 0.01

A

R36 470K

R51 200K

R37 47K

C20 3300P

Q9

Q8

W9

W9

C21 0.039

PD1

R39 15K

D7

R38 1M

R4

R40 10K

R42

35

Page 36

C12

0.022

DMW-FL28PP / DMW-FL28E

W6

Q7

SCR2

R23 1.5M

280V

D10

(TG)

R25 1K

C16 0.047

R26 560

SW3

R27 4.7K

R28 2.2K

D5

RQ4

2.2K

47K

W3

T2

W2

XE1

C14 0.047

R18 470K

R57 10K

R13 10K

Q5

R19 470K

R22 33

D4

(STP)

C15 0.047

W5

R20 33K

R14 10K

R15 2.2K

SCR1

IT1

R16 3.3K

Q6

R21 33

D3

R17 2.2K

ZD1

C13 0.01

R29 180K

5V

C17 16V 1

W15

W16

IC3

Q10

D9

R46 10K

C26 1000P

RQ7

22K

47K

R48 10K

R55 1K

RQ8

LD2

R50 220

10K

10K

IC4

1

2

3

4

8

7

6

5

R49 680K

Q11

C22 10V 4.7

1

2

3

4

8

7

6

5

RQ6

R44 1K

22K

47K

R45 10K

36

Loading...

Loading...