Panasonic DMREZ-47-VP, DMREZ-475-VP Service manual

ORDER NO.CHM0704017CE

DVD Recorder

Model No.DMR-EZ47VP

DMR-EZ475VP

Vol. 1

Colour

(K).......................Black Type

B24

© 2007 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

DMR-EZ47VP / DMR-EZ475VP

CONTENTS

Page Page

1 Safety Precaution 4

1.1. General guidelines

1.2. Caution for fuse replacement

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to

Electrostatic Sensitive (ES) Devices

2.2. Precaution of Laser Diode

2.3. Service caution based on legal restrictions

3 Service Navigation

3.1. Service Information

3.2. Caution for DivX

4 Specifications

5 Location of Controls and Components

5.1. Each Buttons

6 Operation Instructions

6.1. (DVD) Taking out the Disc from RAM-Drive Unit when the

Disc cannot be ejected by OPEN/CLOSE button

6.2. (VHS) Removing Cassette Tape manually

7 Service Mode

7.1. (DVD) Self-Diagnosis and Special Mode Setting

7.2. (VHS) Self-Diagnosis and Special Mode Setting

8 Service Fixture & Tools

9 Assembling and Disassembling Instructions

9.1. Disassembly Flow Chart

9.2. P.C.B. Positions

9.3. Caution with inserting cassette tape when disassembling

the unit

9.4. Top cover

9.5. Front Panel

9.6. Front (L) P.C.B. & Front (R) P.C.B.

9.7. DVD drive

9.8. SD/DV Jack P.C.B.

9.9. Rear Panel, Fan Motor

9.10. Digital P.C.B.

9.11. VHS Mechanism Unit

9.12. Main P.C.B.

9.13. Digital I/F P.C.B.

10 Measu remen ts and Adjustments

10.1. Service Positions

10.2. Caution for Replacing Parts

10.3. Standard Inspection Specifications after Making Repairs

11 Block Diagram

11.1. Power Supply Block Diagram

11.2. Main P.C.B. Regulator Block Diagram

11.3. Analog Video Block Diagram

11.4. Analog Audio Block Diagram

10

10

12

12

14

16

16

26

32

33

33

34

35

36

36

37

39

39

40

40

41

42

42

43

43

47

50

53

53

54

55

57

4

4

5

5

6

7

8

8

8

9

11.5. Analog Timer Block Diagram

11.6. System Control & Servo Block Diagram

12 Schem atic Diagram

12.1. Interconnection Schematic Diagram

12.2. Power Supply Section (Power & Digital I/F P.C.B.(1/3))

Schematic Diagram (P)

12.3. Digital I/F (1/4) Section (Power & Digital I/F P.C.B.(2/3))

Schematic Diagram (IF)

12.4. Digital I/F (2/4) Section (Power & Digital I/F P.C.B.(2/3))

Schematic Diagram (IF)

12.5. Digital I/F (3/4) Section (Power & Digital I/F P.C.B.(2/3))

Schematic Diagram (IF)

12.6. Digital I/F (4/4) Section (Power & Digital I/F P.C.B.(2/3))

Schematic Diagram (IF)

12.7. Tuner Section (Power & Digital I/F P.C.B.(3/3)) Schematic

Diagram (IF)

12.8. Video Section (Main P.C.B.(1/4)) Schematic Diagram (V)

12.9. VHS Audio Section (Main P.C.B.(2/4)) Schematic Diagram

(A)

12.10. Syscon/Servo/Timer (1/4) Section (Main P.C.B.(3/4))

Schematic Diagram (S)

12.11. Syscon/Servo/Timer (2/4) Section (Main P.C.B.(3/4))

Schematic Diagram (S)

12.12. Syscon/Servo/Timer (3/4) Section (Main P.C.B.(3/4))

Schematic Diagram (S)

12.13. Syscon/Servo/Timer (4/4) Section (Main P.C.B.(3/4))

Schematic Diagram (S)

12.14. I/O Section (1/4) (Main P.C.B.(4/4)) Schematic Diagram (I)

12.15. I/O Section (2/4) (Main P.C.B.(4/4)) Schematic Diagram (I)

12.16. I/O Section (3/4) (Main P.C.B.(4/4)) Schematic Diagram (I)

12.17. I/O Section (4/4) (Main P.C.B.(4/4)) Schematic Diagram (I)

12.18. DV Jack/SD Card Schematic Diagram

12.19. Front (L) Schematic Diagram

12.20. Front (R) Schematic Diagram

13 Printe d Circuit Board

13.1. Power & Digital I/F P.C.B.

13.2. Main P.C.B.

13.3. DV Jack/SD Card P.C.B.

13.4. Front (L) P.C.B., Front (R) P.C.B.

14 Appendix for Schematic Diagra m

14.1. Voltage and Waveform Chart

58

59

61

61

63

65

66

67

68

69

70

71

72

73

74

75

77

78

79

80

82

83

83

85

85

90

95

96

97

97

2

14.2. Abbreviations 104

15 Parts and Exploded Views

110

15.1. Exploded Views

15.2. Replacement Parts List

DMR-EZ47VP / DMR-EZ475VP

110

114

3

DMR-EZ47VP / DMR-EZ475VP

1 Safety Precaution

1.1. General guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

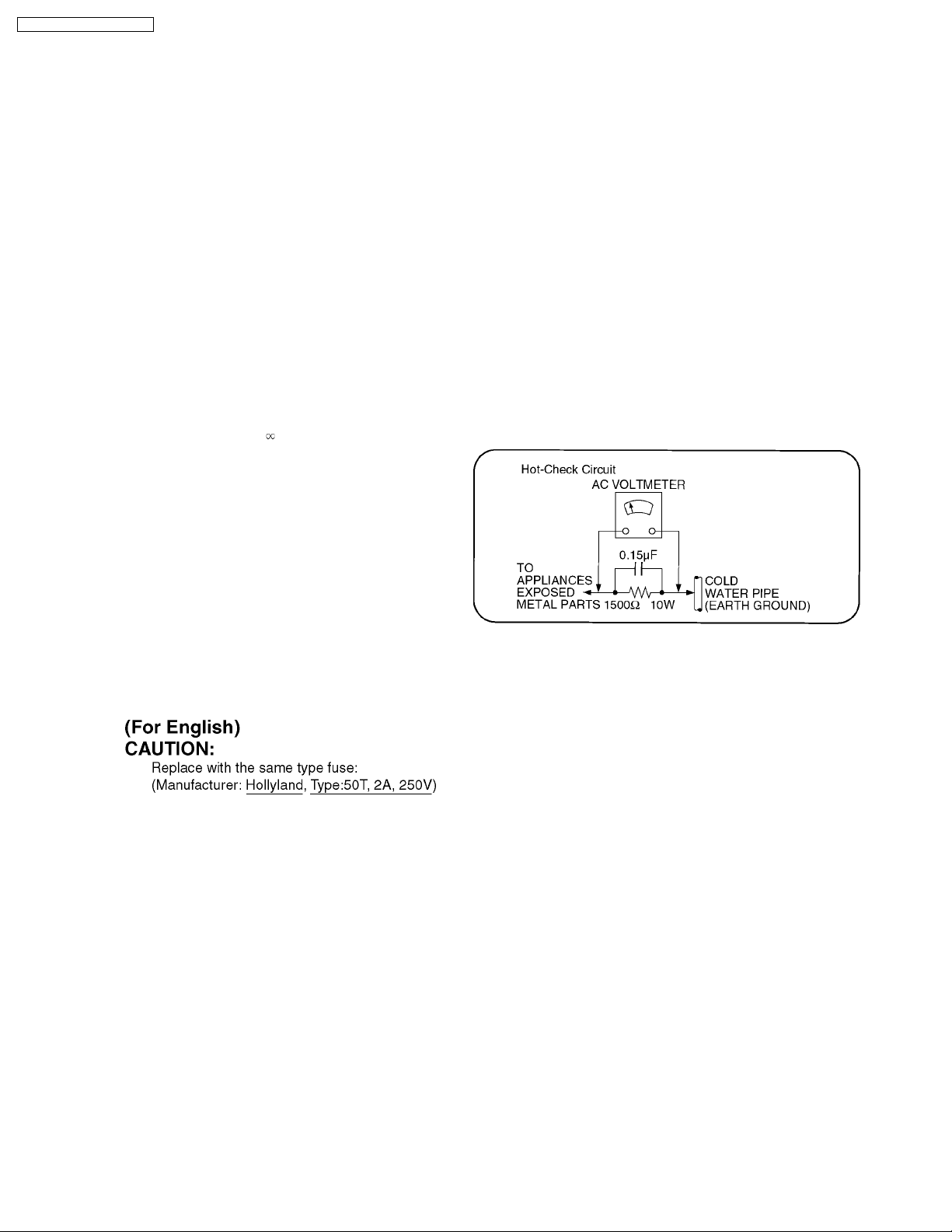

1.1.1. Leakage current cold check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the

chassis, the reading must be

.

1.1.2. Leakage current hot check

(See Figure 1 .)

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the ACplugintheACoutlet and repeateach of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliampere. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

1.2. Caution for fuse replacement

Figure 1

4

DMR-EZ47VP / DMR-EZ475VP

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatic Sensitive

(ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatic Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistor-sand

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient

to damage an ES device).

5

DMR-EZ47VP / DMR-EZ475VP

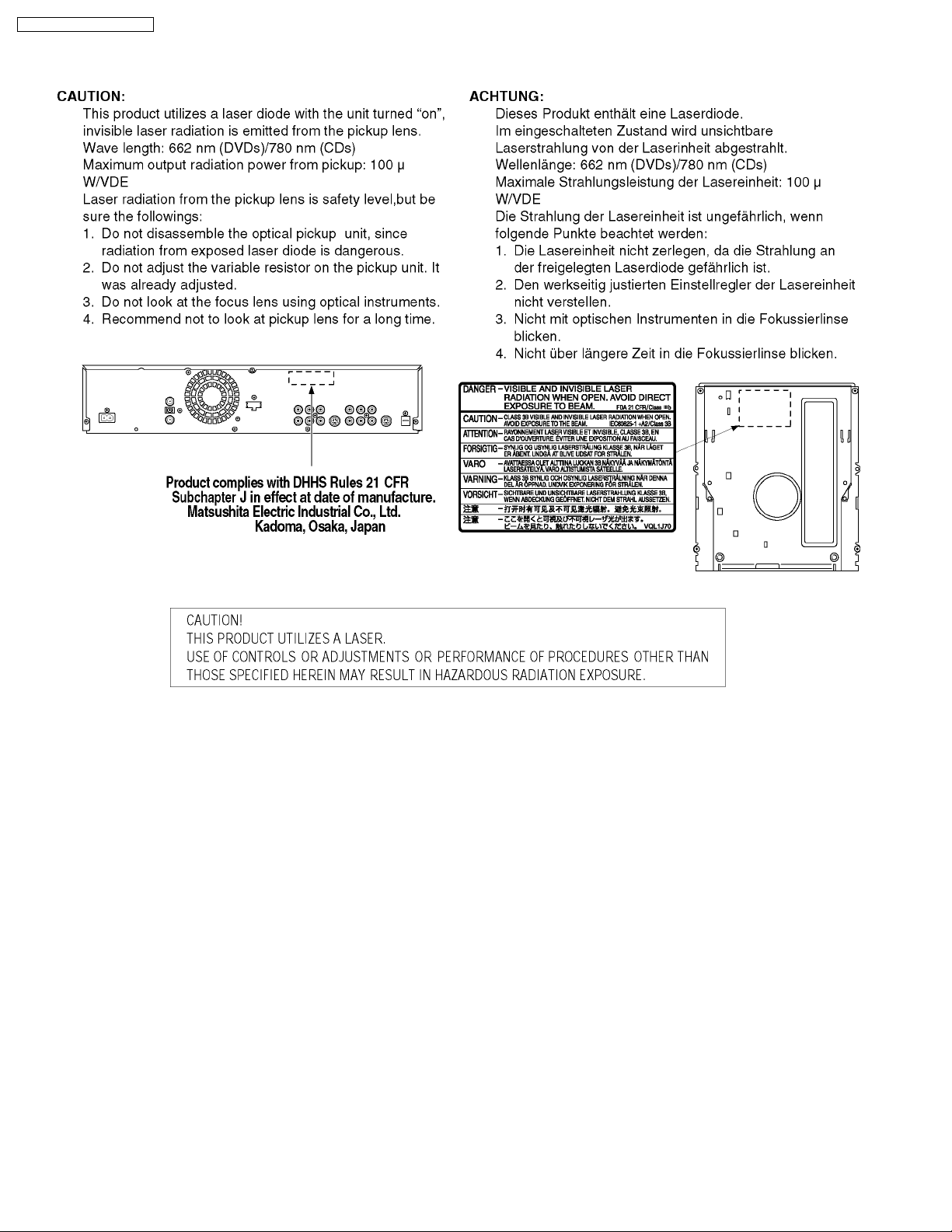

2.2. Precaution of Laser Diode

6

DMR-EZ47VP / DMR-EZ475VP

2.3. Service caution based on legal restrictions

2.3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

7

DMR-EZ47VP / DMR-EZ475VP

3 Service Navigation

3.1. Service Information

3.2. Caution for DivX

8

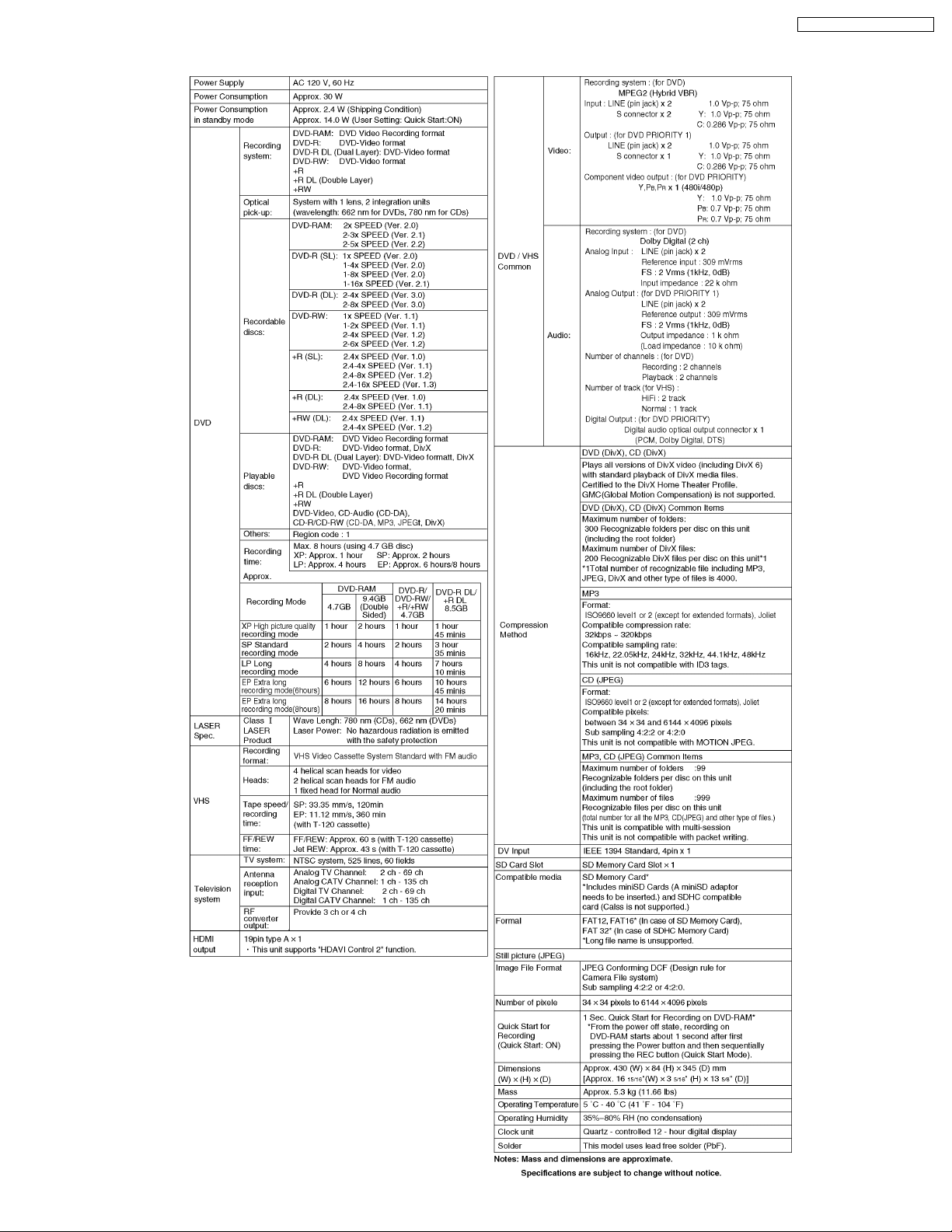

4 Specifications

DMR-EZ47VP / DMR-EZ475VP

9

DMR-EZ47VP / DMR-EZ475VP

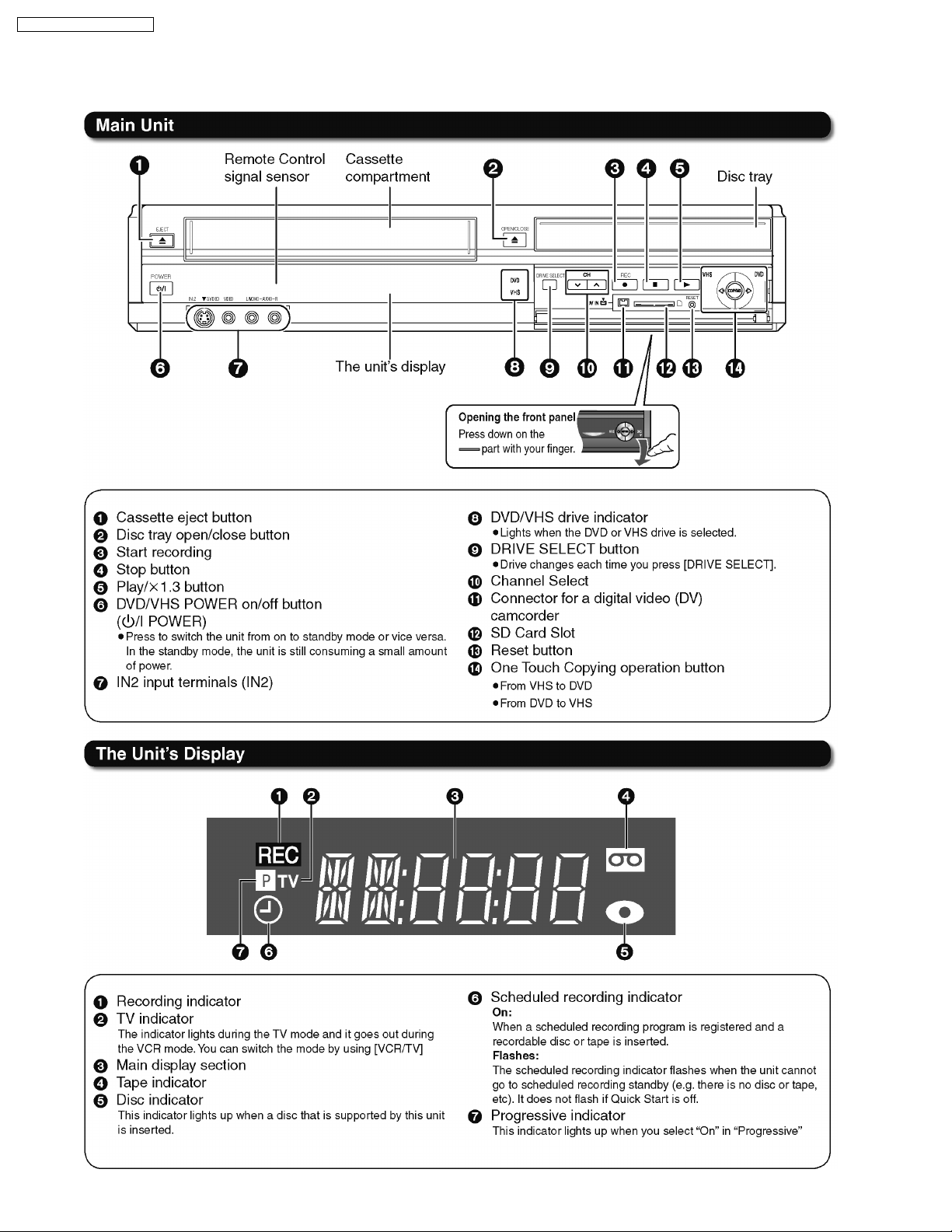

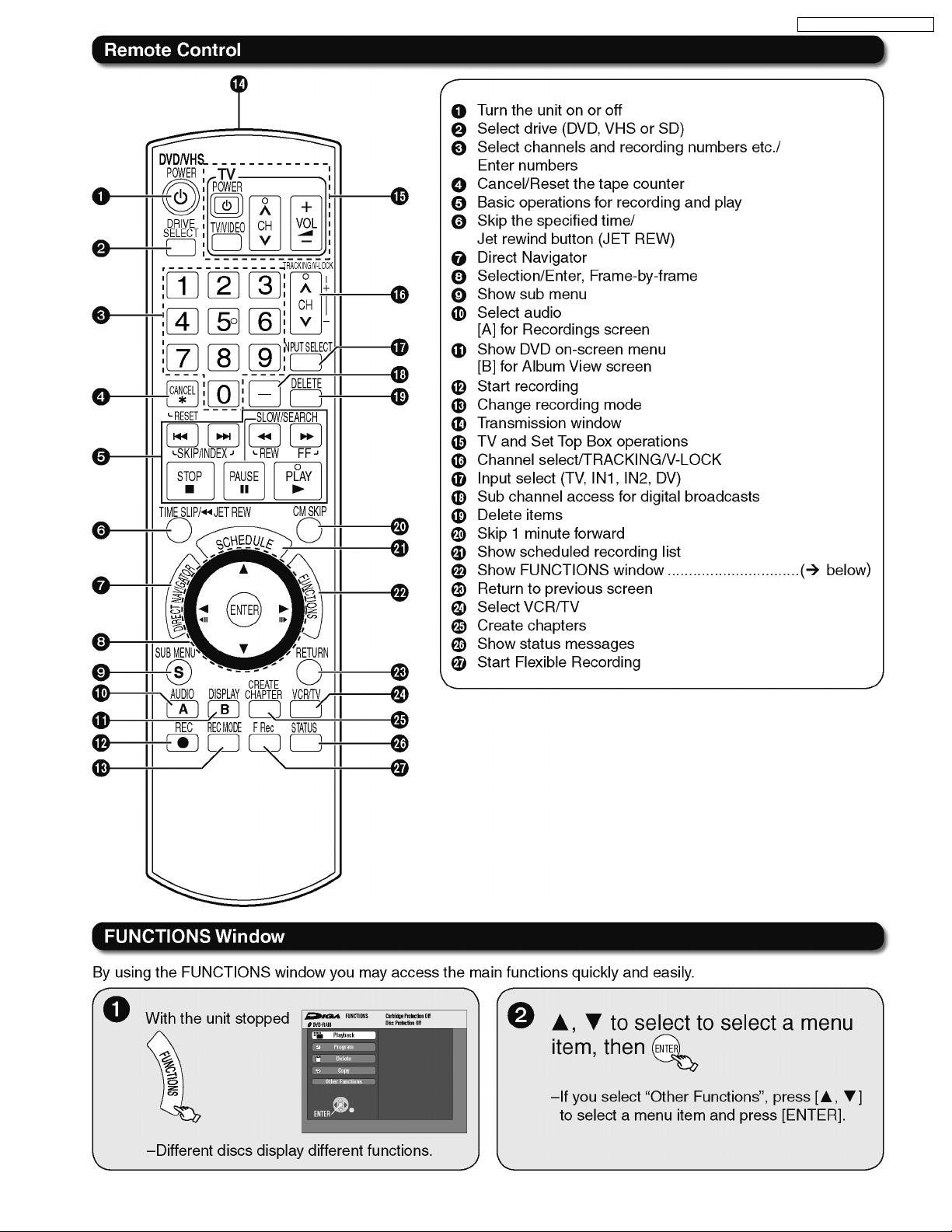

5 Location of Controls and Components

5.1. Each Buttons

10

DMR-EZ47VP / DMR-EZ475VP

11

DMR-EZ47VP / DMR-EZ475VP

6 Operation Instructions

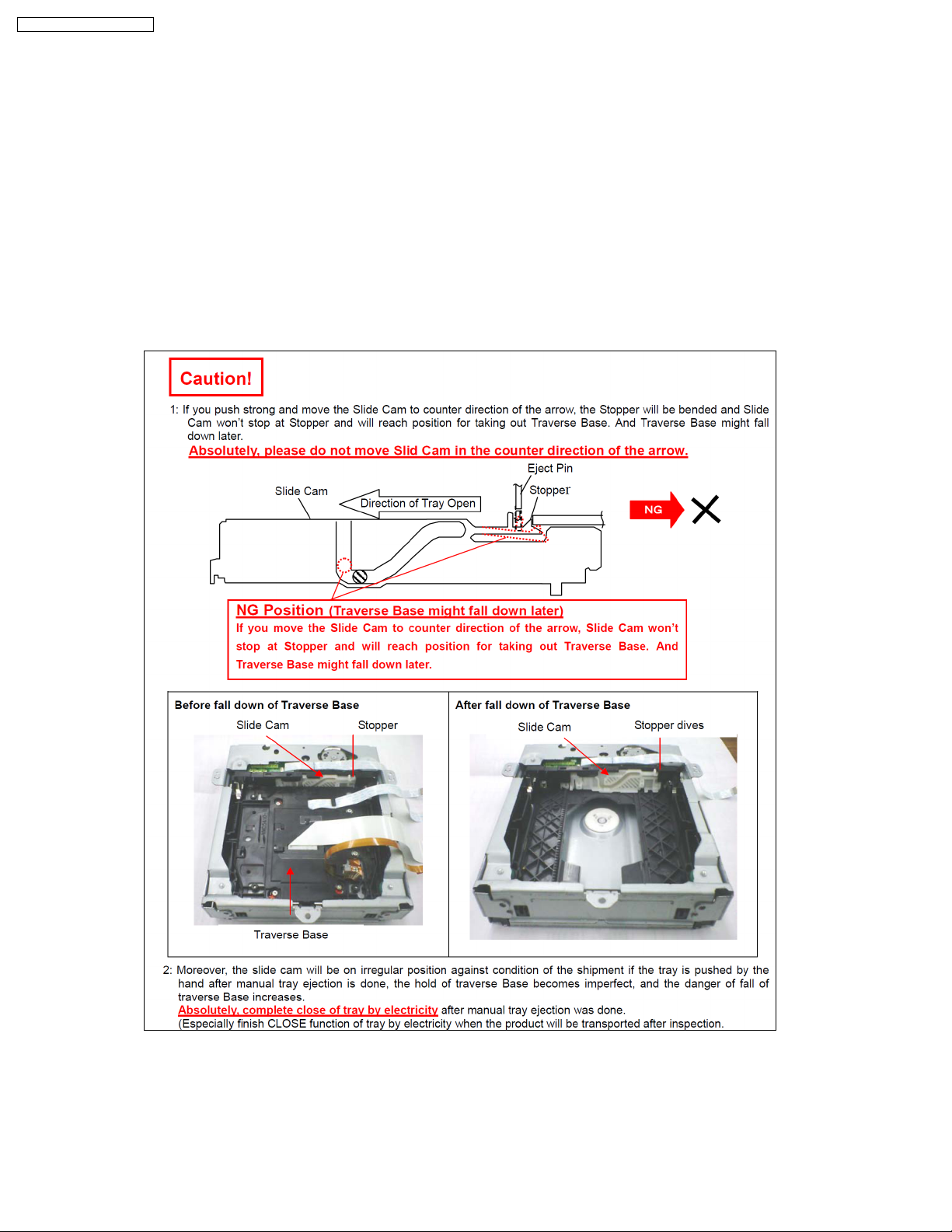

6.1. (DVD) Taking out the Disc from RAM-Drive Unit when the Disc cannot

be ejected by OPEN/CLOSE button

6.1.1. (DVD) Forcible Disc Eject

6.1.1.1. (DVD) When the power can be turned off.

1. Turn off the power and press [STOP], [CH UP] keys on the front panel simultaneously for 5 seconds.

6.1.1.2. (DVD) When the power can not be turned off.

1. Press [POWER] key on the front panel for over 10 seconds to turn off the power forcibly, and press [STOP] [CH UP] keys on

the front panel simultaneously for 5 seconds.

6.1.2. (DVD) When the Forcible Disc Eject can not be done.

12

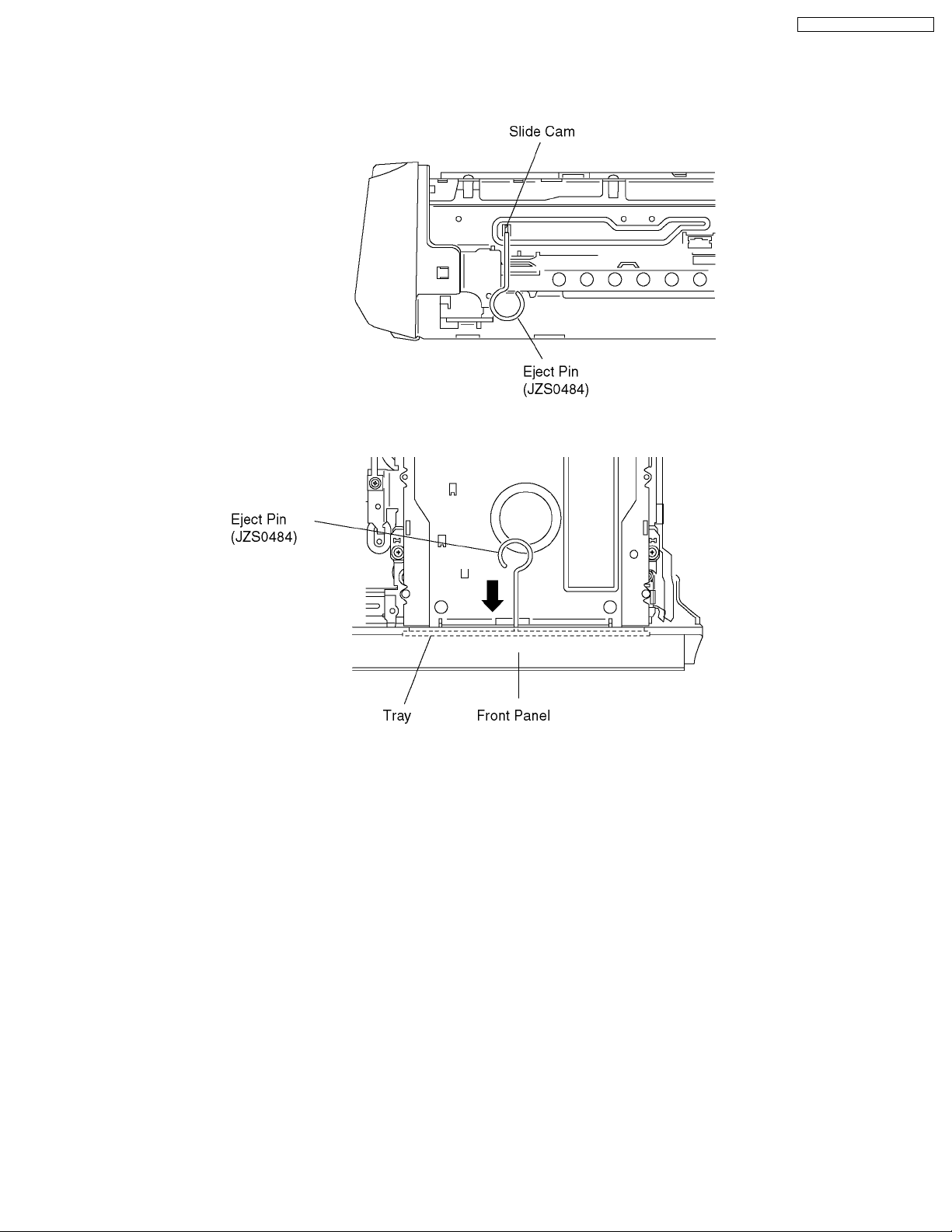

1. Turn off the power and pull out AC cord.

2. Remove the Top Case.

3. Push in SLIDE CAM by Eject Pin(JSJ0484) or minus screw driver (small) to eject tray slightly.

4. Push out Tray by Eject Pin (JZS0484) or minus screw driver (small).

DMR-EZ47VP / DMR-EZ475VP

13

DMR-EZ47VP / DMR-EZ475VP

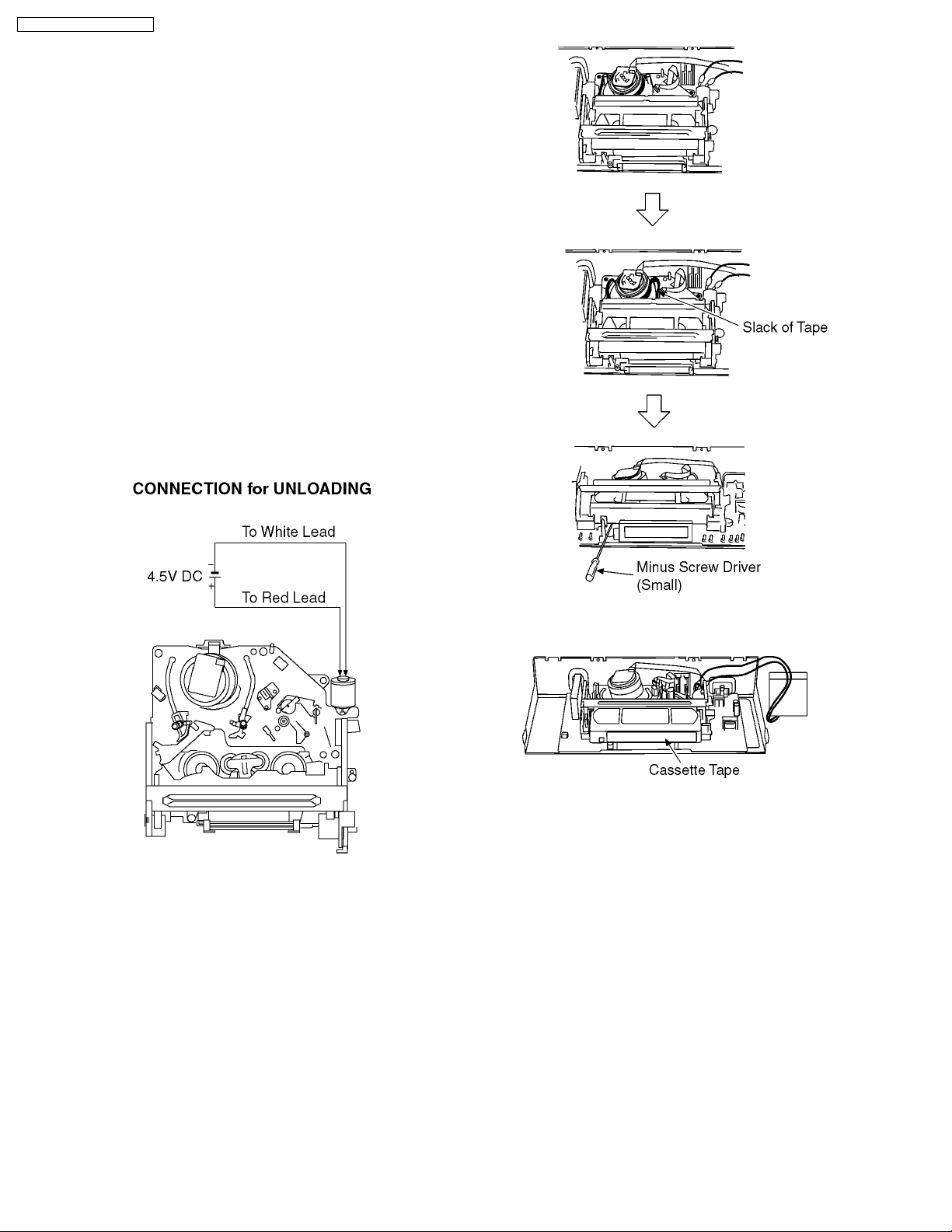

6.2. (VHS) Removing Cassette

Tape manually

When the cassette tape could not be uninstalled from an

electrical malfunction, there are 2 ways to remove a cassette

tape.

6.2.1. (VHS) Removal by compulsory

unloading.

If Service Mode can be activated when the power can not be

turned on, this operation is able.

1. Press [STOP] and [CH UP] button simultaneously for more

than 5 seconds.

6.2.2. (VHS) Removal by manual

operation by rotating the Loading

Motor with the batteries.

1. Disconnect the AC plug, and remove the Top Panel and the

Front Panel by referring to the Disassembly Procedures.

2. Connect three batteries (1.5V spec.) to the Loading Motor

in series for supplying 4.5V to rotate the Loading Motor as

shown below.

3. Stop unloading just before unloading will be completed as

shown below, and then the tape becomes slack as shown

below.

4. Rotate the S-Reel by a small minus screwdriver to remove

the slack tape as shown below.

5. Then unload again to remove the cassette tape as shown

below.

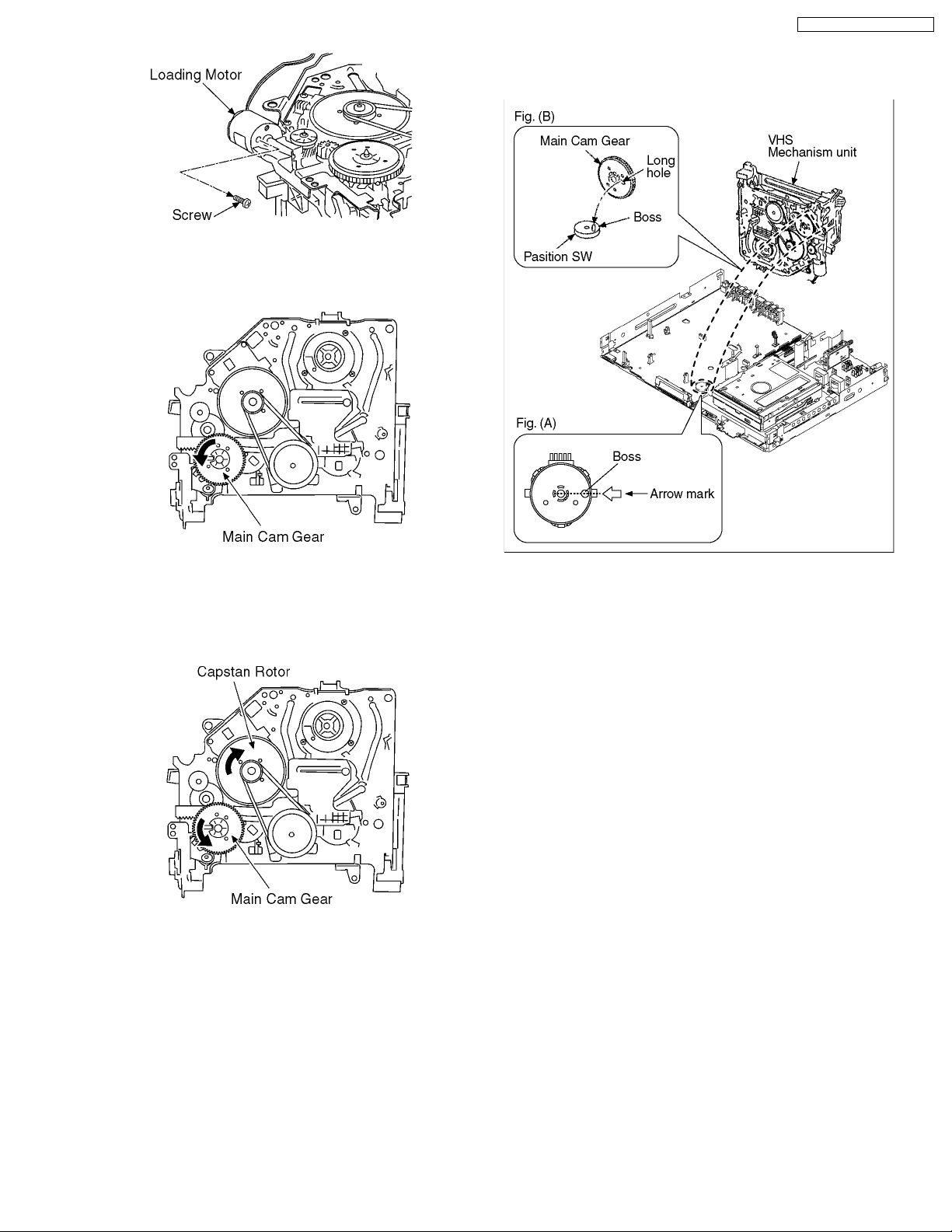

6.2.3. (VHS) Take out Cassette

Tapemanually after removing the

mechanism

1. Disconnect the AC plug, and remove the Top Case, Front

Panel and the Mechanism by referring to "9 Assembling

and Disassembling Instructions"

2. Remove the Screw and remove the Loading Motor as

shown below.

14

3. Rotate the Main Cam Gear counter-clockwise until just

before the unloading will be completed as shown below. .

DMR-EZ47VP / DMR-EZ475VP

7. Set the Position Switch to EJECT POSITION certainly and

attach the mechanism to chassis as shown below.

4. Rotate the Capstan Motor clockwise to remove the slack

tape as shown below.

5. Rotate the Main Cam Gear counter-clockwise again to

remove the cassette-tape as shown below.

6. Attach Loading Motor and tighten the screw.

15

DMR-EZ47VP / DMR-EZ475VP

7 Service Mode

7.1. (DVD) Self-Diagnosis and Special Mode Setting

7.1.1. (DVD) Self-Diagnosis Functions

Self-Diagnosis Function provides information for errors to service personnel by “Self-Diagnosis Display” when any error has

occurred.

U**, H** and F** are stored in memory and held.

You can check latest error code by transmitting [0] [1] of Remote Controller in Service Mode.

Automatic Display on FL will be cancelled when the power is turned off or AC input is turned off during self-diagnosis display is ON.

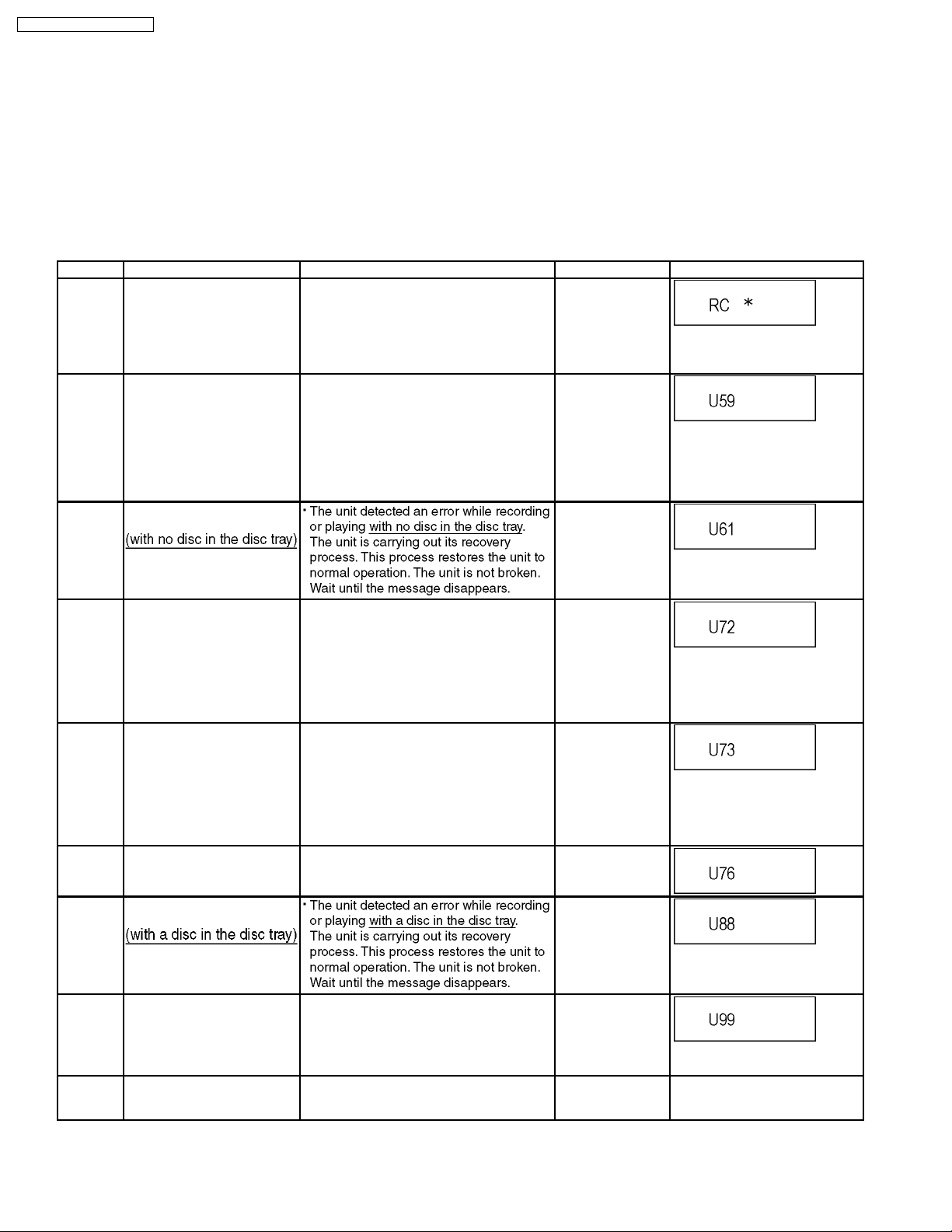

Error Code Diagnosis contents Description Monitor Display Automatic FL display

U30 Remote control code error Display appears when main unit and remote

U59 Abnormal inner temperature

detected

U61 The unit is carrying out its

recovery process.

controller codes are not matched.

Display appears when the drive has abnormal

temperature.

The power is turned off forcibly.

For 30 minutes after this, all key entries are

disabled. (Fan motor operates at the highest

speed for the first 5 minutes. For the

remaining 25 minutes, fan motor is also

stopped.) The event is saved in memory as

well.

No display

“*” is remote controller code of the

main unit.

Display for 5 seconds.

No display

“U59 is displayed for 30 minutes.

No display

U72 HDMI connection error

(communication error)

U73 HDMI connection error

(authentication error)

U76 Injustice disc error HDMI cannot output because you are

U88 The unit is carrying out its

recovery process.

U99 Hang-up Displayed when communication error has

F00 No error information Initial setting for error code in memory

This error is displayed when there are any

communication problems with the unitand the

equipments (TV, amplifier etc.) connected to

the unit by HDMI. (or when there is a problem

with the HDMI cable)

When authentication error occurs while the

equipments (TV, amplifier etc.) are connected

by HDMI. (or when there is a problem with the

HDMI cable)

connected to a model that does not support

copyright protection.

occurred between Main microprocessor and

Timer microprocessor.

(Error code Initialization is possible with error

code initialization and main unit initialization.)

U72 display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

No display

U73 display disappears when

error has been solved by Power

OFF/ON of connecting equipment

or by inserting/removing of HDMI

cable.

No display

No display

No display

Displayed is left until the

[POWER] key is pressed.

No display No display

16

DMR-EZ47VP / DMR-EZ475VP

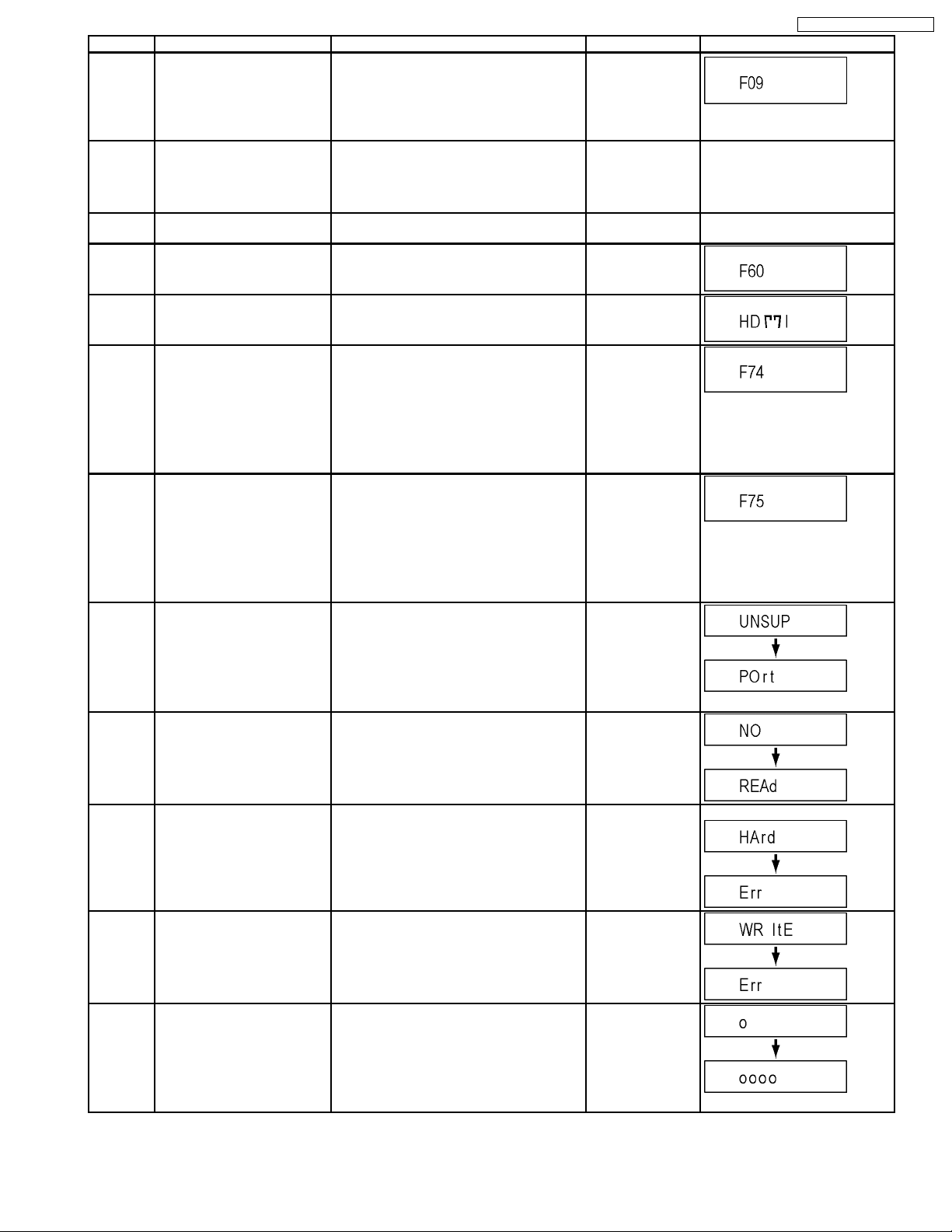

Error Code Diagnosis contents Description Monitor Display Automatic FL display

F09 Serial Communication Error

between VHS Microprocessor

and Timer Microprocessor.

F34 Initialization error when main

microprocessor is started up

for program recording

F58 Drive hardware error When drive unit error is detected, the event is

F60 DVD module has not been

started.

Please confirm Serial Communication

terminal of Microprocessor.

NOTE:

If F09 appears just after updating Firmware,

pull off and insert AC plug, then it will

disappear.

When initialization error is detected after

starting up main microprocessor for program

recording, the power is turned off

automatically.

The event is saved in memory.

saved in memory.

Defect of Digital P.C.B.

Mode: No change

No display

No display No display

No display No display

No display

HDMI HDMI connection check This unit is confirming that ut is connected

F74 HDIM Device Key

Communication error.

F75 HDIM Device Key Information

error

UNSUPPORTUnsupported disc error *An unsupported format disc was played,

NO READ Disc read error *A disc is flawed or dirty.

with equipment compatible with HDAVI

control.

HDMI connection could not be authenticated

due to a transfer malfunction.

Factor of HDMI Device key-road failure

· When HDMI LSI is damaged.

· When the bus line of I2C doesn´t operate

normally.

· When device key information recorded is

damaged.

HDMI connection could not be authenticated

due to an internal data malfunction.

Factor of HDMI Device key-road failure

· When HDMI LSI is damaged.

· When the bus line of I2C doesn´t operate

normally.

· When device key information recorded is

damaged.

although the drive starts normally.

*The data format is not supported, although

the media type is supported.

*Exceptionally in case of the disc is dirty.

*A poor quality failed to start.

*The track information could not be read.

No display

No display

No display

“This disc is

incompatible.”

Display for 5 seconds.

“Cannot read.

Please check the

disc.”

HARD

ERR

No REC Recording is impossible [No REC] is displayed when recording is

SELF

CHECK

Drive error The drive detected a hard error. “DVD drive error.” Display for 5 seconds.

impossible due to the defect, dirt or wound of

media.

Restoration operation Since the power cord fell out during a power

failure or operation, it is under restoration

operation.

*It will OK, if a display disappears

automatically. If a display does not disappear,

there is the possibility that defective Digital

P.C.B.

17

No display

No display

“0” is displayed one by one.

DMR-EZ47VP / DMR-EZ475VP

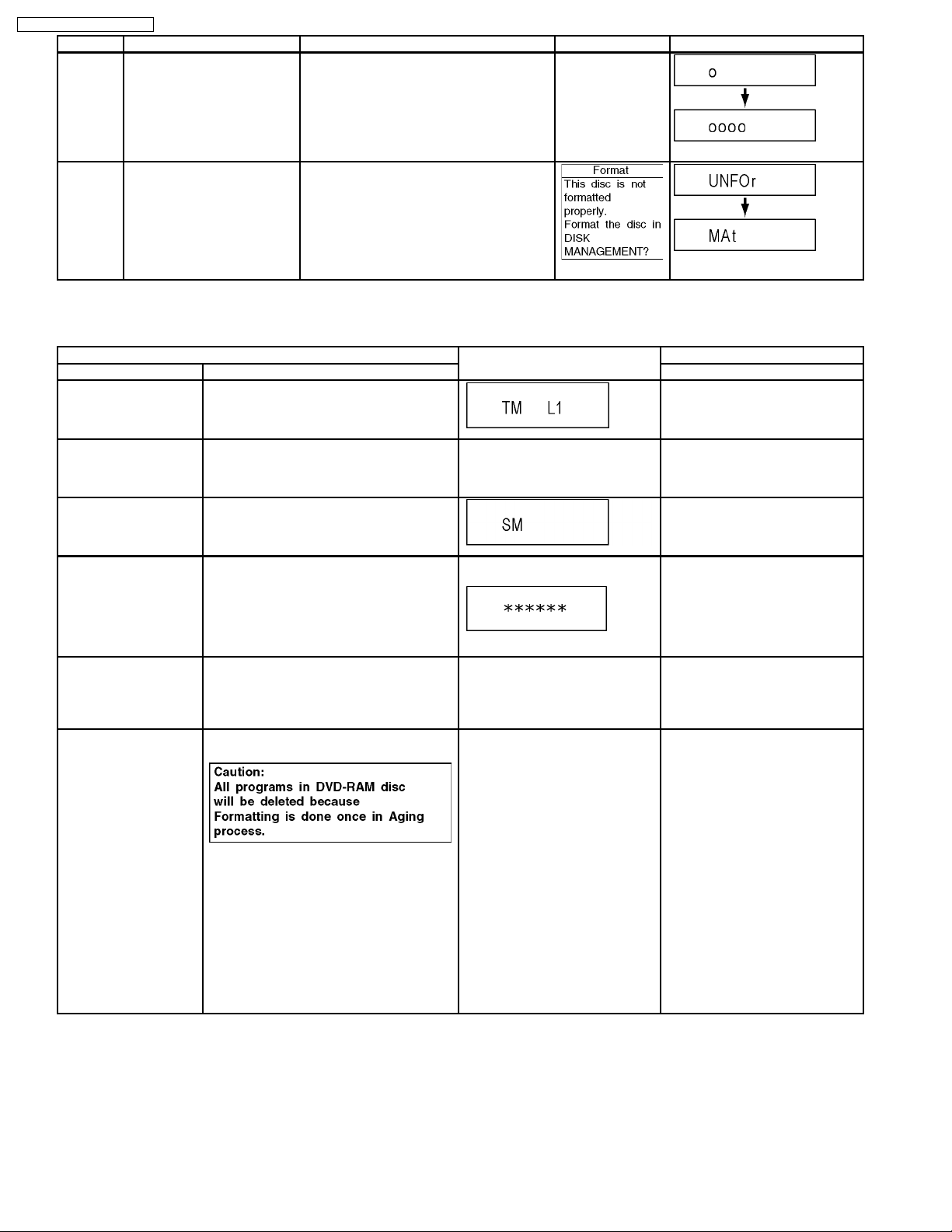

Error Code Diagnosis contents Description Monitor Display Automatic FL display

PLEASE

WAIT

UNFORMATUnformatted disc error You have inserted an unformatted DVD-RAM

Unit is in termination process Unit is in termination process now.

“BYE” is displayed and power will be turned

off.

In case “Quick Start” of setup menu is ON, it

is displayed in restoration operation for AC

off.

or DVD-RW that is unformatted or recorded

on other equipment.

No display

“0” is displayed one by one.

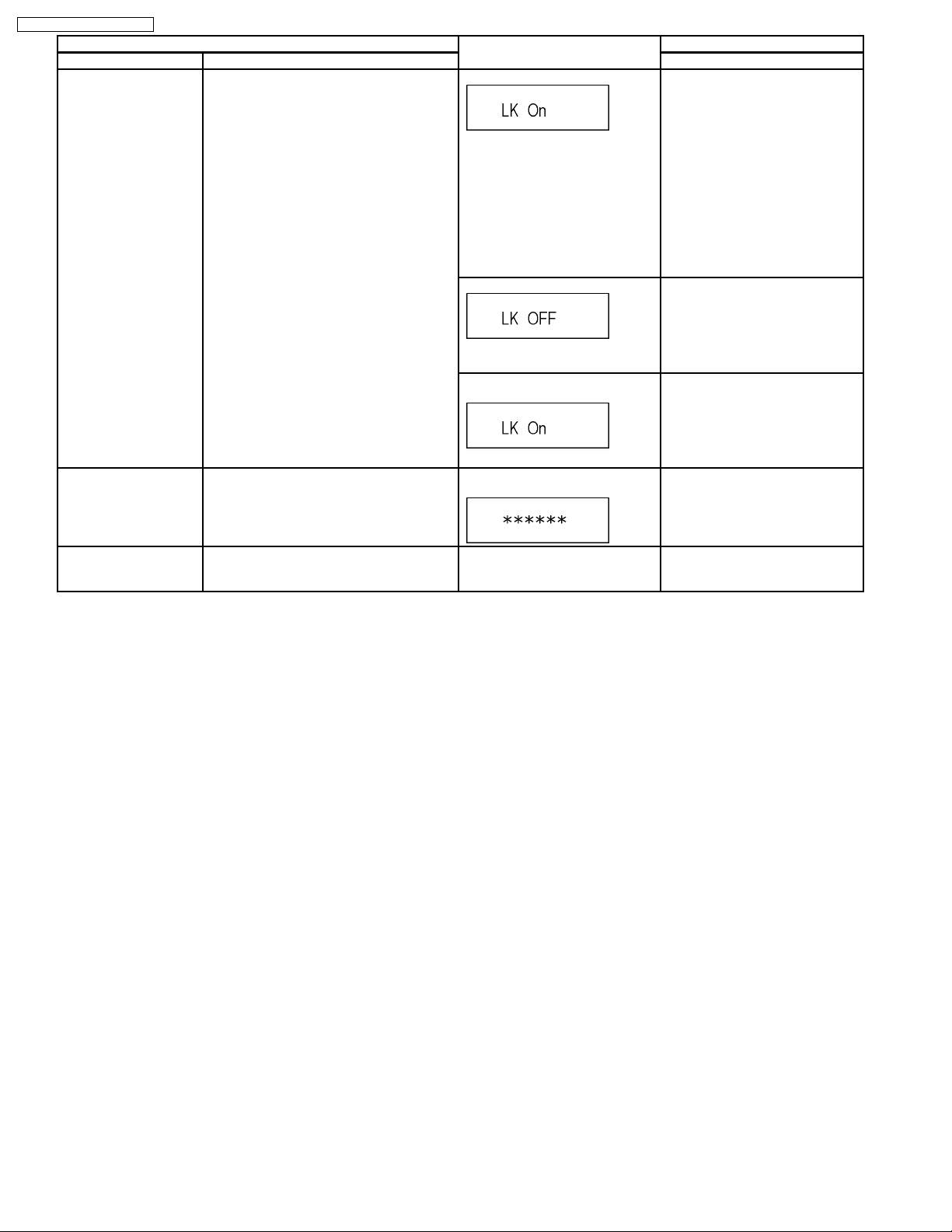

7.1.2. (DVD) Special Modes Setting

Item FL display Key operation

Mode name Description Front Key

TEST Mode *All the main unit´s parameters are initialized. Press [VHS to DVD COPYING],

Rating password The audiovisual level setting password is

initialized to “Level 8”.

Service Mode Setting every kind of modes for servicing.

*Details are described in “7.1.3. (DVD)

Service Modes at a glance”.

Forced disc eject Removing a disc that cannot be ejected.

The tray will open and unit will shift to P-off

mode.

*During Schedule Recording, Forced disc

eject is invalid.

While Demonstration Lock is being set, this

Forced disc eject function is not accepted.

Forced power-off When the power button is not effective while

power is ON, turn off the power forcibly.

*When Schedule Recording is ON, execute

“Forced Power-off” after releasing Schedule

Recording.

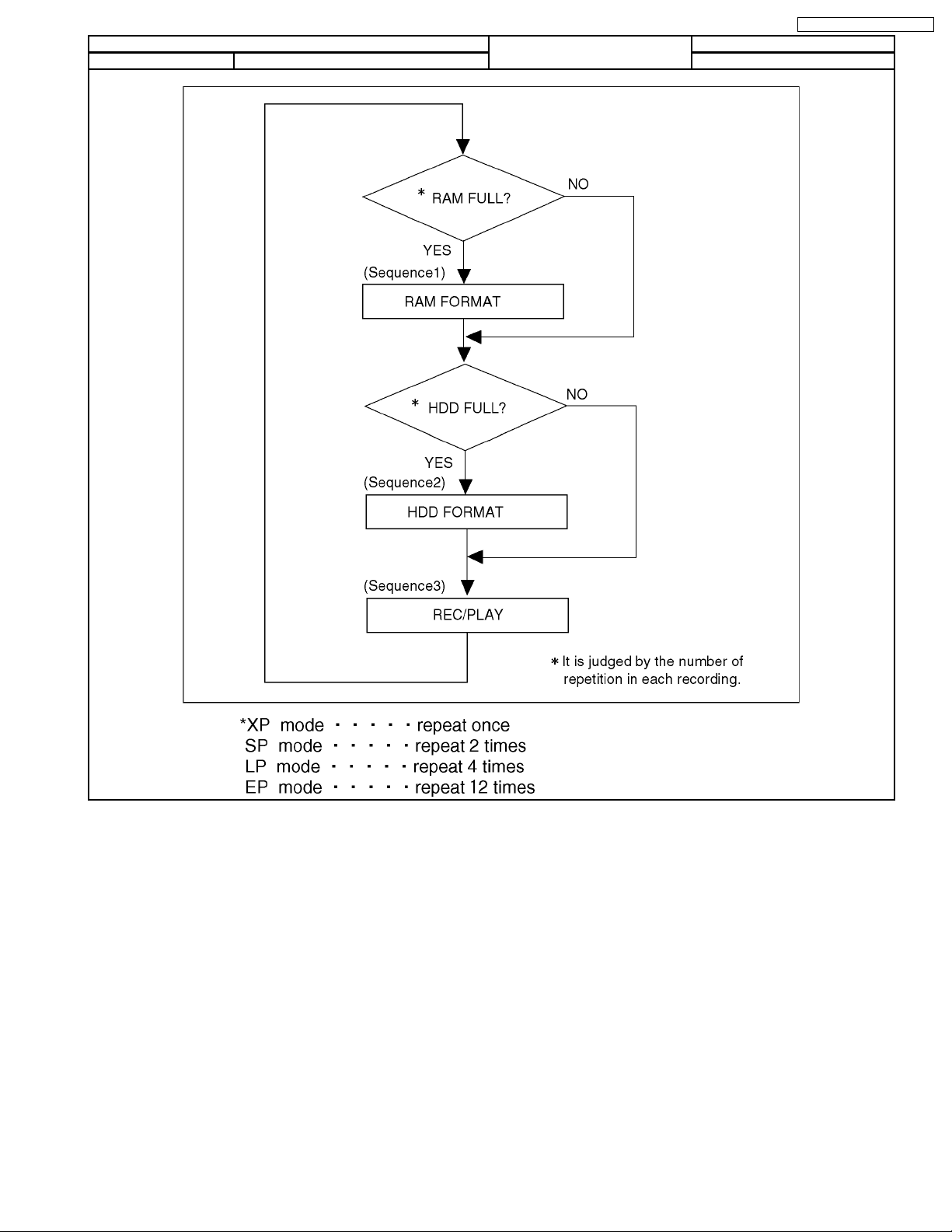

Aging Perform sequence of modes as * Aging

Description shown below continually.

No display When the power is on (E-E mode).

The display before execution

leaves.

Display in P-off mode. Press [POWER] key over than 10

Display following the then mode. Set DRIVE SELECT to DVD.

[REC] and [OPEN/CLOSE] keys

simultaneously for five seconds

when power is off.

While the tray is open, press [REC]

and [PLAY] simultaneously for 5

seconds.

When the power is off, press [VHS

to DVD COPYING], [OPEN/CLOSE]

and [STOP] keys simultaneously for

5 seconds.

When the power is off, press

[STOP] and [CH UP] keys

simultaneously for 5 seconds.

seconds.

When the power is ON, press [CH

DOWN], [VHS to DVD COPYING]

and [OPEN/CLOSE]

simultaneously for over 5 seconds

and less than 10 seconds.

NOTE1:

If Unit has not turned into Aging

mode by operations shown above,

execute TEST MODE once and reexecute operation shown above.

(*All the main unit’s parameters are

initialized by TEST mode.)

NOTE2:

If the unit has hung-up because of

pressing keys for over 10 seconds,

once turn off the power, and reexecute this command.

*When releasing Aging mode,

press [POWER] key, AC-OFF.

18

DMR-EZ47VP / DMR-EZ475VP

Item FL display Key operation

Mode name Description Front Key

Aging Contents (Example):

19

DMR-EZ47VP / DMR-EZ475VP

Item FL display Key operation

Mode name Description Front Key

Demonstration

lock/unlock

Progressive initialization The progressive setting is initialized to

Ejection of the disc is prohibited.

The lock setting is effective until unlocking the

tray and not released by “Main unit

initialization” of service mode.

Interlace.

*When lock the tray.

“LOCK” is displayed for 3 seconds.

*When unlock the tray.

“UNLOCK” is displayed for 3

seconds.

*When press OPEN/CLOSE key

while the tray being locked.

Display “LOCK” for 3 seconds.

The display before execution

leaves.

When the power is on, press

[STOP] and [POWER] keys

simultaneously for 5 seconds.

*The time difference of

simultaneous key pressings should

be within 0.5 sec.

Note1:

When a disc in not in tray, this

setting is not effective.

Note2:

Time difference between

pressing of [STOP] and

[POWER] should be within 0.5

seconds.

When the power is on and tray

being locked, press [STOP] and

[POWER] keys simultaneously for 5

seconds.

Press [OPEN/CLOSE] key while the

tray being locked.

When the power is on (E-E mode),

press [STOP] and [VHS to DVD

COPYING] simultaneously for 5

seconds.

ATP Initialization ATP setting and all parameters (including

clock) are intialized, and the unit turns off

automatically.

It is same with display in stop mode. When the power is on (E-E mode),

press [CH UP] and [CH DOWN]

simultaneously for 5 seconds.

20

DMR-EZ47VP / DMR-EZ475VP

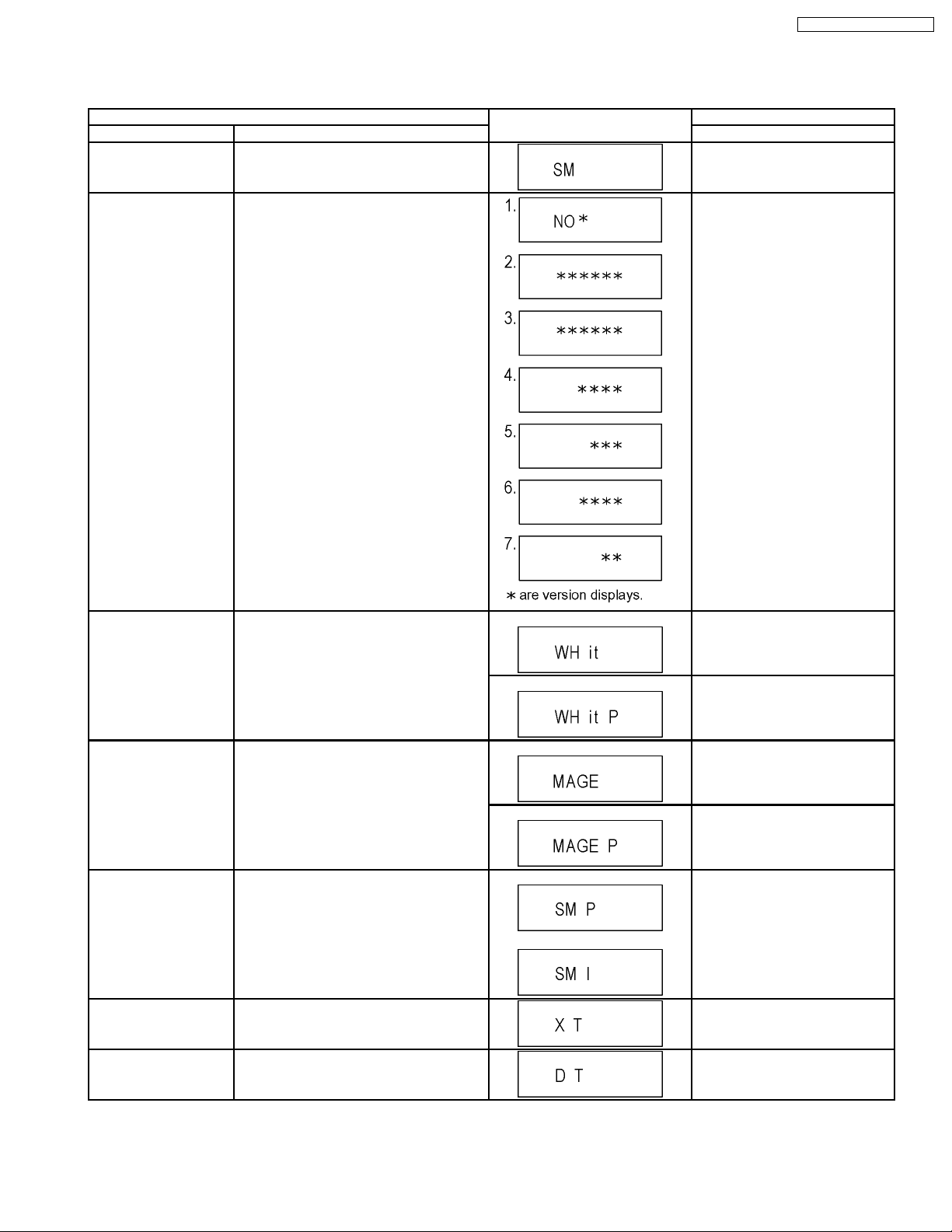

7.1.3. (DVD) Service Modes at a glance

Service mode setting: While the power is off, press [STOP], [VHS to DVD COPYING] and [OPEN / CLOSE] simultaneously for

five seconds.

Item FL display Key operation

Mode name Description (Remote controller key)

Release Items Item of Service Mode executing is cancelled. Press [0] [0] or [Return] in service

mode.

ROM Version Display 1. Region code (displayed for 5 sec.)

2. Main firm version (displayed for 5 sec.)

3. Timer firm version (displayed for 5 sec.)

4. Drive firm version (displayed for 5 sec.)

5. ROM correction version

(displayed for 5 sec.)

6. VHS Microprocessor version

(displayed for 5 sec.)

7. VHS ROM correction version

(left displated)

White Picture Outpu t White picture is output as component Output

from AV Decoder.

*White picture

(Saturation rate : 100%)

*It is enable to switch Interlace/Progressive by

“I/P switch: [1] [4]”

Press [0] [2] in service mode

*Initial mode is “Interlace”. Press [1] [1] in service mode.

Switch Interlace/Progressive Press [1] [4] in White Picture Output

mode.

*I/P are switched alternately.

Magenta Picture Output Magenta picture is output with Component

Output from AV Decoder.

*Magenta picture

(Saturation rate: 100%)

*It is enable to switch Interlace/Progressive by

“I/P switch: [1] [4]”

I/P Switch Switch Interlace and Progressive in EE mode.

*Initial setting is “Interlace”.

*This command is effective during executing

“White Picture Output”, “Magenta Picture

Output” and mode.

Audio Mute (XTMUTE) Check whether mute is applied normally by

the timer microprocessor.

Audio Mute (XDMUTE) Check whether mute is applied normally by

the Digital P.C.B..

*Initial mode is “Interlace”. Press [1] [2] in service mode.

Switch Interlace/Progressive Press [1] [4] in Magenta Picture

Initial mode is Interlace

Switch Interlace/Progressive

Output mode.

*I/P are switched alternately.

Press [1] [4] in I/P Switch mode.

*I/P are switched alternately.

Press [2] [1] in service mode.

Press [2] [2] in service mode.

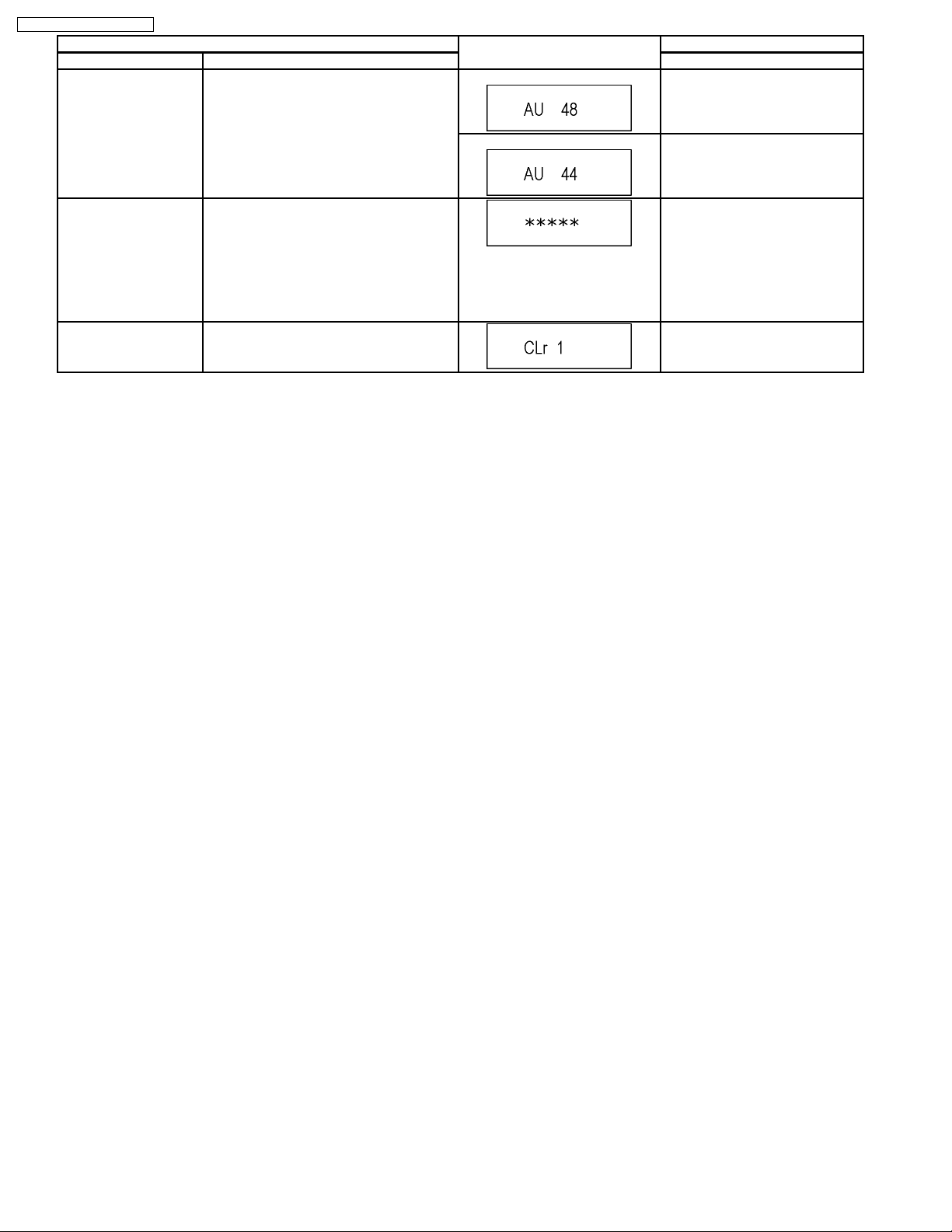

21

DMR-EZ47VP / DMR-EZ475VP

Item FL display Key operation

Mode name Description (Remote controller key)

Audio Pattern Output The audio pattern stored in the internal

memory is output

(Lch: 1kHz/-18dB)

(Rch: 400Hz/-18dB)

*Audio sound clock switching operation of

DAC can be confirmed by sub command [2]

[4].

Laser Used Time

Check laser used time (hours) of drive.

Indiction

Delete the Laser Used

Time

Laser used time stored in the memory of the

unit is deleted.

Initial mode (Audio 48kHz) Press [2] [3] in service mode.

Audio 44.1kHz/48kHz switching Press [2] [4] in Audio Pattern Output

mode.

*48 kHz / 44.1 kHz are switched

alternately.

Press [4] [1] in service mode.

●(*****) is the used time display in

hour.

●Laser used time of DVD/ CD in

Playback/Recording mode is

counted.

Press [9] [5] in service mode.

22

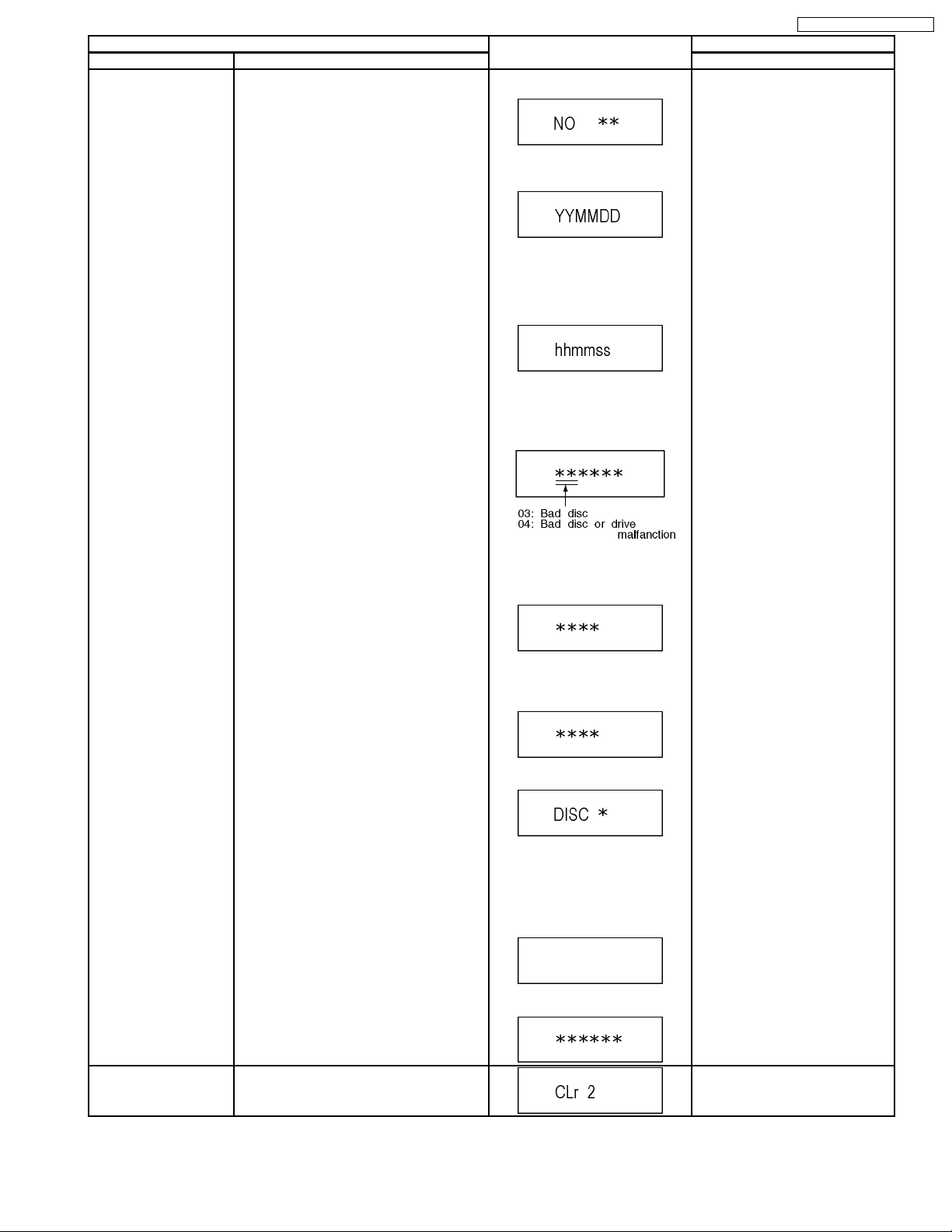

Item FL display Key operation

Mode name Description (Remote controller key)

RAM Drive Last Error RAM Drive error code display.

*For details about the drive error code, refer

to the Service Manual for the specific RAM

Drive.

1. Error Number is displayed for 5

seconds.

Press [4] [2] in service mode.

When “INFO******” is being

displayed, past 99 error histories

can be displayed by pressing [0] [1]

- [9] [9]

2. Time when the error has

occurred (1/2) is displayed for 5

seconds.

YY: Year

MM: Month

DD: Day

3. Time when the error has

occurred (2/2) is displayed for 5

seconds.

hh: Hour

mm: Minute

ss: Second

4. Last Drive Error code No.1 is

displayed for 5 seconds.

DMR-EZ47VP / DMR-EZ475VP

5. Last Drive Error code No.2 (1/2)

is displayed for 5 seconds.

(This Error Code is unnecessory

for service.)

6. Last Drive Error code No.2 (2/2)

is displayed for 5 seconds.

(This Error Code is unnecessory

for service.)

7. Error occurring Disc type is

displayed for 5 seconds.

DISC 1: DVD

DISC 2: CD

DISC 3: DVD-RAM 2.6GB

DISC 4: DVD-RAM 4.7GB

DISC 5: DVD-R

DISC : Unknown Disc

8. Unused (No display)

9. Factor of Drive Error occurring is

left displayed

Delete the Last Drive

Error

Delete the Last Drive Error information stored

on the DVD RAM-Drive.

Press [9] [6] in service mode.

23

DMR-EZ47VP / DMR-EZ475VP

Item FL display Key operation

Mode name Description (Remote controller key)

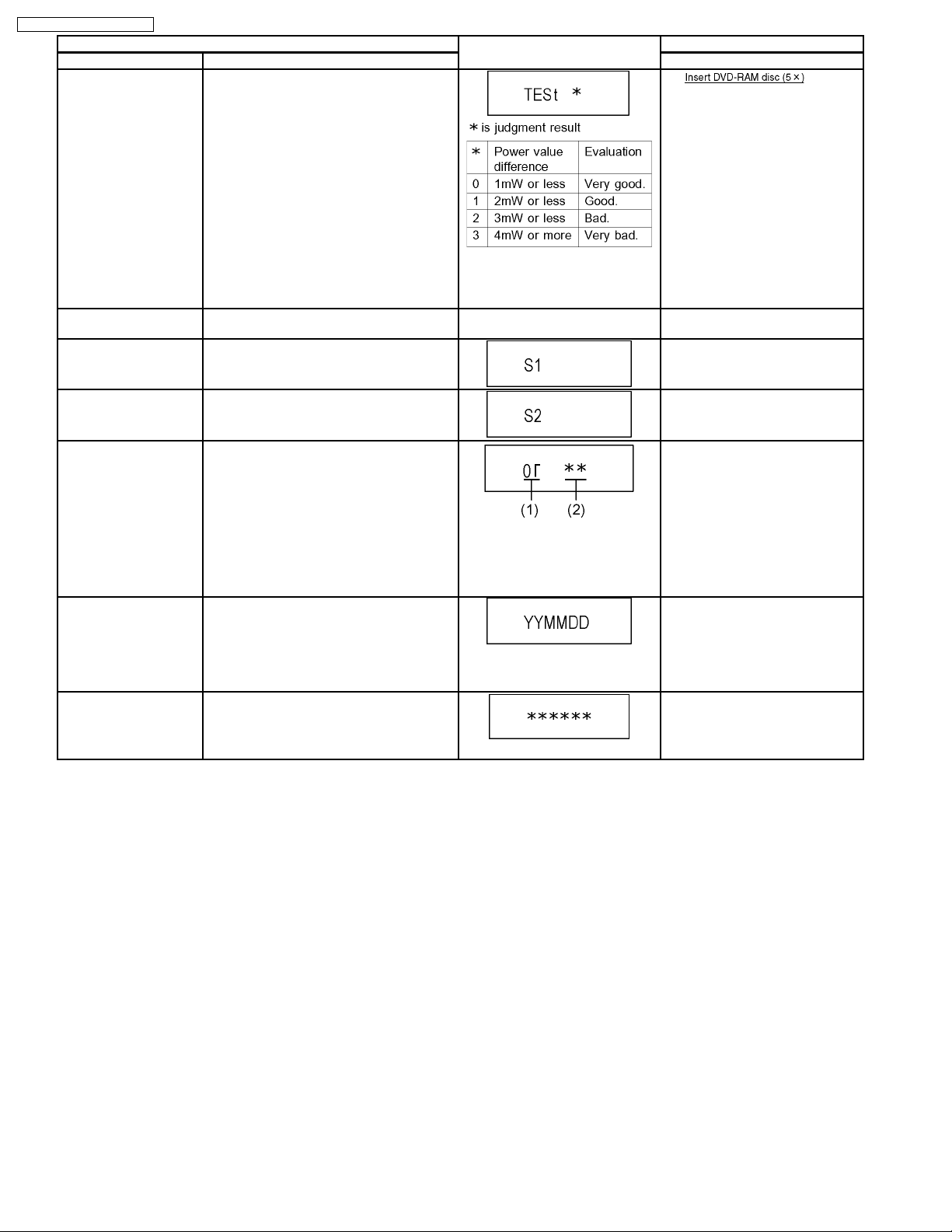

Laser power confirmation Drive state is judged based on difference

between laser power value at shipping and

present laser power value.

Turn on all FL/LEDs All segments of FL and all LEDs are turned

on.

S1 signal output Forcibly superimpose the S1 signal (approx.

4.5V DC) on the EE chroma signal, and check

the output on the S terminal.

S2 signal output Forcibly superimpose the S2 signal (approx.

2V DC) on the EE chroma signal, and check

the output on the S terminal.

Front connection

inspection

Press all front keys and check the connection

between Main P.C.B. and Front key Switches.

1. into RAM

Drive in service mode. (Other

media are assumed to be noncorrespondence.)

2. Press [4] [4].

If DVD-RAM disc in not inserted,

[NO DISC] is displayed.

If power value study was filed,

[ERROR] is displayed.

All segments are turned on. Press [5] [1] in service mode.

Press [5] [2] in service mode.

Press [5] [3] in service mode.

Press [5] [4] in service mode.

*When finish this mode, press

[POWER] for 10 seconds.

Production Date Display Display the date when the unit was produced.

Display the accumlated

Display the accumulated unit´s working time.

working time

(1) Each time a key is pressed,

segment turned on increases one

by one.

(2) Total number of keys that have

been pressed.

Press [6] [1] in service mode.

YY: Year

MM: Month

DD: Day

Press [6] [4] in service mode.

(Indicating unit: Second)

24

Item FL display Key operation

Mode name Description (Remote controller key)

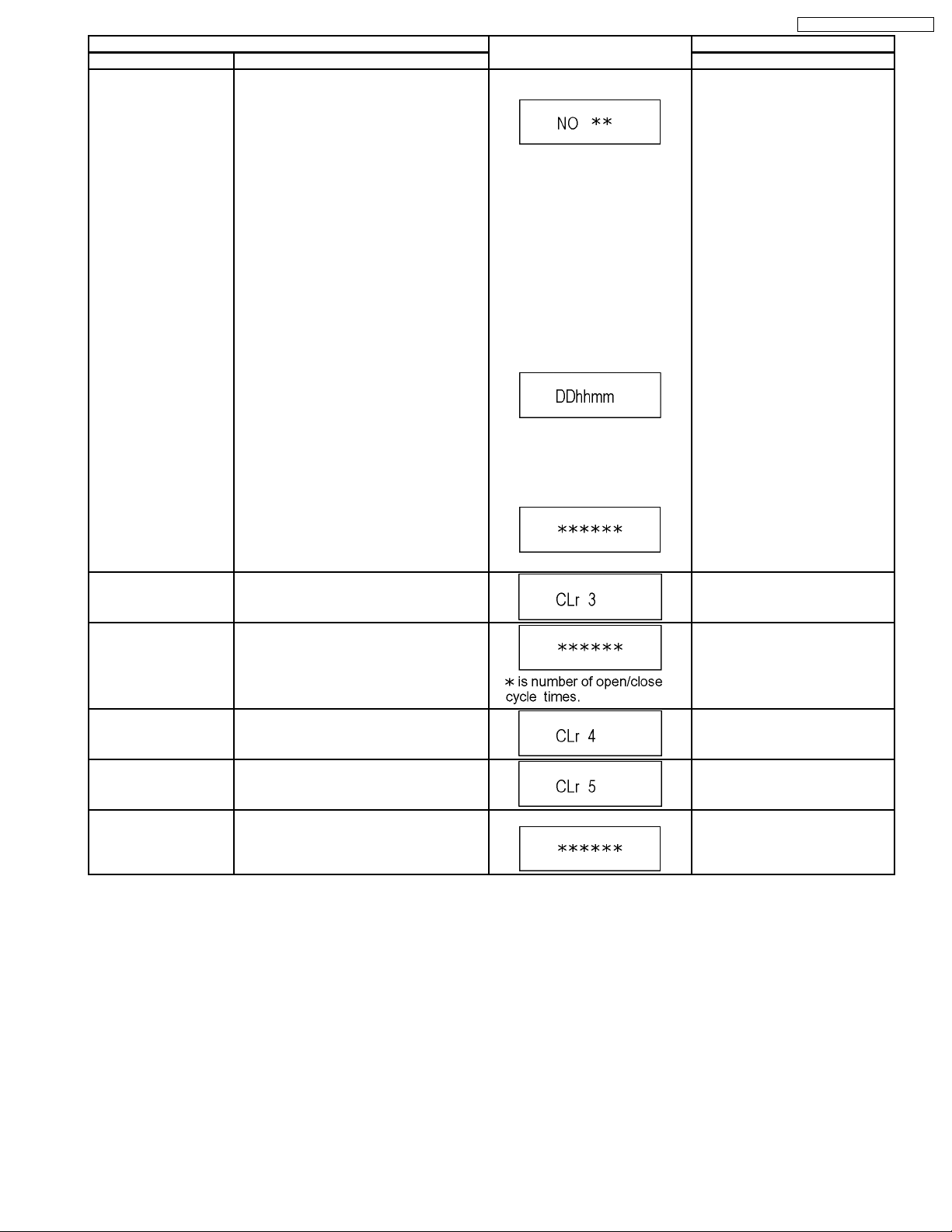

Display the Error History Display the Error History stored on the unit. Display reason of error for 5

seconds.

Press [6] [5] in service mode.

Then press [0] [1] ~ [1] [9], the past

19 error histories are displayed.

01:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

02:

Defect of RAM Drive.

03:

Defect of Disc.

04:

Defect of Digital P.C.B. or

Communication Error.

05:

Defect of Digital P.C.B.

(AV DEC / MAIN CPU)

Display the time when the error has

occurred for 5 seconds.

DD: Day

hh: Hour

mm: Minute

Accumulated working time till

occuring of the error is left

displayed.

DMR-EZ47VP / DMR-EZ475VP

(Indicating unit: Second)

Delete the Error History Delete Error History information stored on the

Press [9] [7] in service mode.

unit.

Tray OPEN/CLOSE Test The RAM drive tray is opened and closed

repeatedly.

Press [9] [1] in service mode

*When releasing this mode, press

the [POWER] button of Remote

Controller more than 10 seconds.

Error code initialization Initialization of the last error code held by

Press [9] [8] in service mode.

timer (Write in F00)

Initialize Service Last Drive Error, Error history and Error

Press [9] [9] in service mode.

Codes stored on the unit are initialized to

factory setting.

Finishing service mode Release Service Mode. Display in STOP (E-E) mode. Press power button on the front

panel or Remote controller in

service mode.

25

DMR-EZ47VP / DMR-EZ475VP

7.2. (VHS) Self-Diagnosis and Special Mode Setting

7.2.1. (VHS) Self-Diagnosis Functions

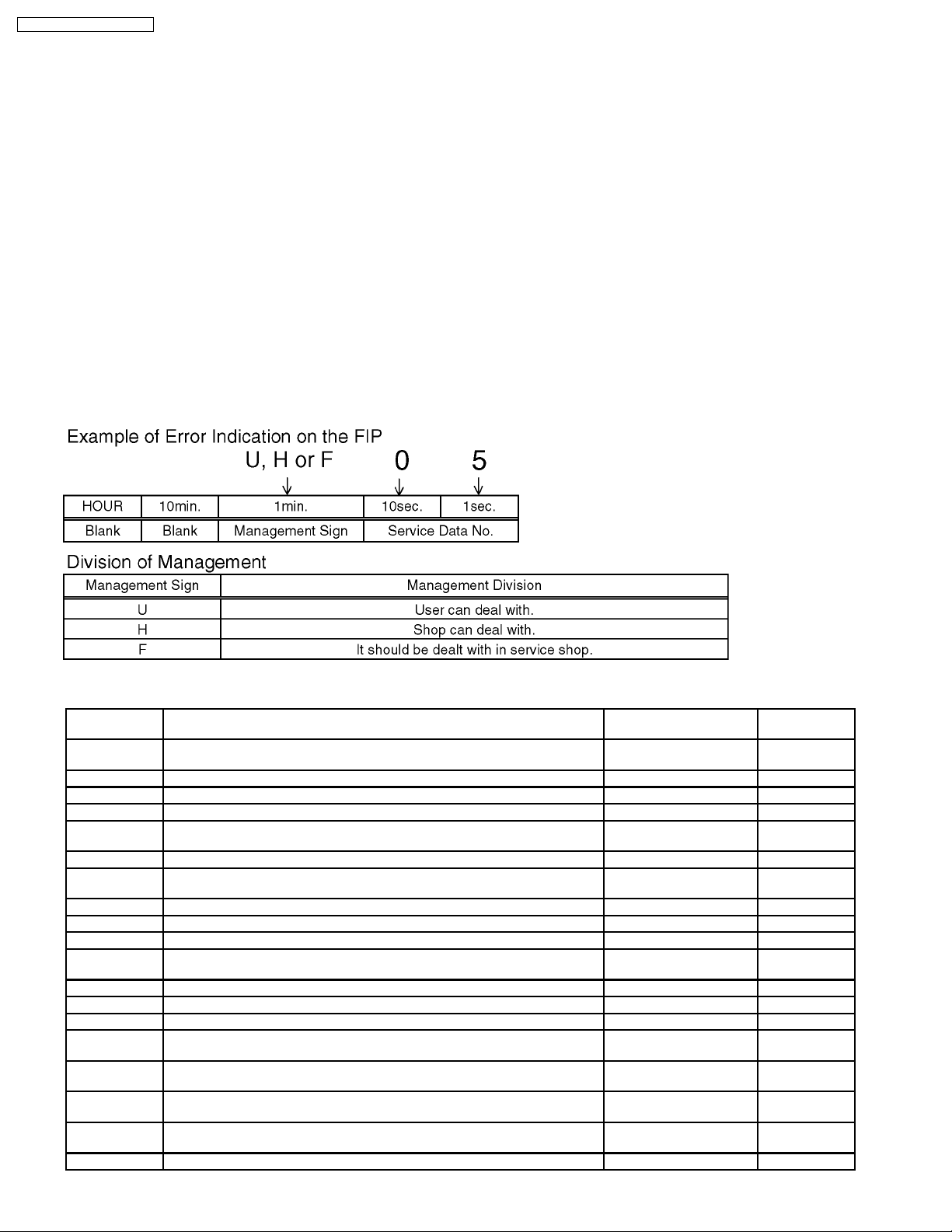

This model has a self-diagnosis and display function. If the VHS section detects trouble during installation or during use, one of the

following Error Codes will automatically appear in the display on VHS side. Error Codes are displayed in the form of a single English

letter followed by two numbers, as for example "H01".

Note:

1. The indication "U" is displayed on the FIP while power remains on.

2. The indication "H" or "F" is displayed on the FIP, and the power is automatically turned off. When the power is turned on

again, the Error indication code will disappear and the unit will return to normal display mode (either clock or counter is

displayed).

3. This Error indication code will be stored in the microprocessor even after the AC plug being disconnected.

The two-digit number portion of the stored Error indication code can be re-displayed in "second" display portion (the last 2

digits of the FIP) by placing the unit is Service Mode Number 3 When turning on Service Data Display as for example "01"

or "02" etc. If a second error occurs, the most recent error will be displayed and stored until 3 self-diagnosis histories in

maximum.

4. To erase the stored Error Code data, Press STOP and EJECT buttons on VHS simultaneously for over 5 seconds in Service

Mode 3.

Error Number at a glance

Memory No.

(Error No.)

H01 The cylinder could not be started.

(Error of the cylinder or the cylinder driver.)

H02 The CAP FG could not be detected. Yes Yes

F03 Mechanism lock during without the unloading and the cassette-up. Yes Yes

F04 Mechanism lock during unloading Yes Yes

F05 S-reel pulse cannot be detected when a cassette tape is inserted.

(Error of the S-reel system or the Capstan system.)

F06 Mechanism lock during the Cassette-up. Yes Yes

F09 Communication Error between VHS Microprocessor (IC6001) and Timer

Microprocessor (IC7501)

H07 The recording circuit can not be operated in REC mode. Yes Yes

H08 The recording circuit is operated in except for REC mode. Yes Yes

U11 Cylinder clogs during the PLAY mode. Yes Yes

F15 S-reel pulse cannot be detected when a cassette tape is inserted.

(Error of the S-reel system or the Capstan system.)

H16 Detection of the Cylinder lock during the constant rotation No Yes

H17 Detection of S-reel lock during the constant tape running Yes Yes

H18 Detection of T-reel lock during the constant tape running Yes Yes

F20 NG1 in the PG Shifter Automatic Adjustment

(The cylinder rotation is unstable during the automatic adjustment.)

F21 NG2 in the PG Shifter Automatic Adjustment

(The vertical sync signal is lacked while over 5 seconds on the alignment tape.)

F22 NG3 in the PG Shifter Automatic Adjustment

(The installing position of Heads to the cylinder is our of specification.)

F23 NG4 in the PG Shifter Automatic Adjustment

(The servo is not locked to the cylinder for more than 10 sec.)

H80 An exceptional ejection depends on a Error No Yes

Reason Automatic display Memory

Yes Yes

No Yes

Yes Yes

No Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

26

7.2.2. (VHS) Special Modes Setting

Item FL display Key operation

Mode name Description Front Key

Tracking Center Tape Tracking is adjusted to center

FIX position.

VHS Service Mode In order to make service easy, a part

of inside information of a

microprocessor is displayed on FIP.

*Details are described in "7.2.3.

(VHS) Service Modes ".

DMR-EZ47VP / DMR-EZ475VP

No display. During PLAYBACK, press [CH UP]

and [CH DOWN] keys

simultaneously.

Press [STOP], and [EJECT] keys

simultaneously for 3 seconds when

power is off.

Eject Ejecting Cassette Tape No display. While in other than Timer REC mode,

press [STOP] key for 3 seconds or

press [STOP] key of the Remote

Controller for 3 seconds in VHS

mode.

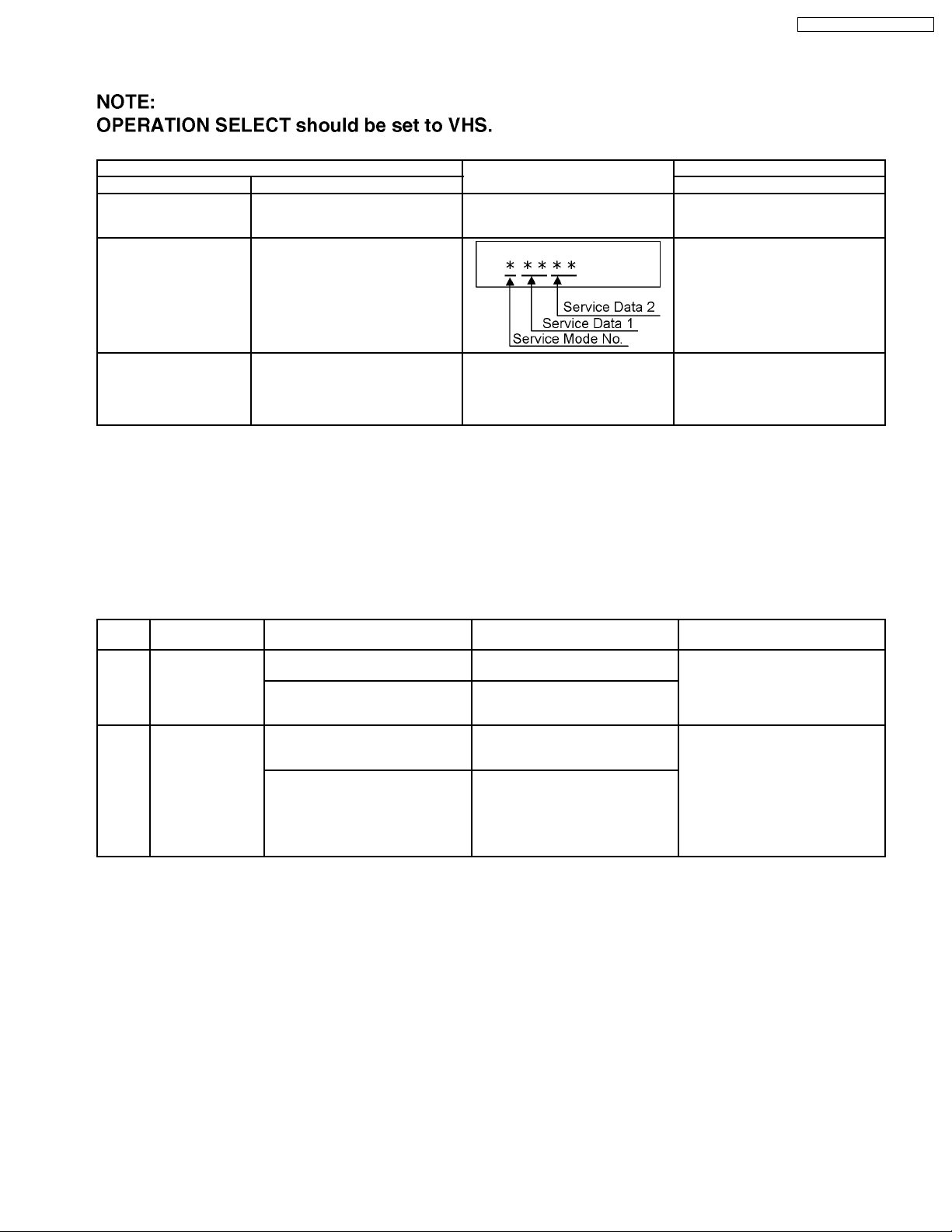

7.2.3. (VHS) Service Modes

<Service Mode Setting>

Set OPERATION SELECT to VHS.

When power is OFF, press [STOP] and [EJECT] keys simultaneously for 3 seconds to into Service Mode.

In Service Mode, press [STOP] and [EJECT] keys simultaneously to add Service Number.

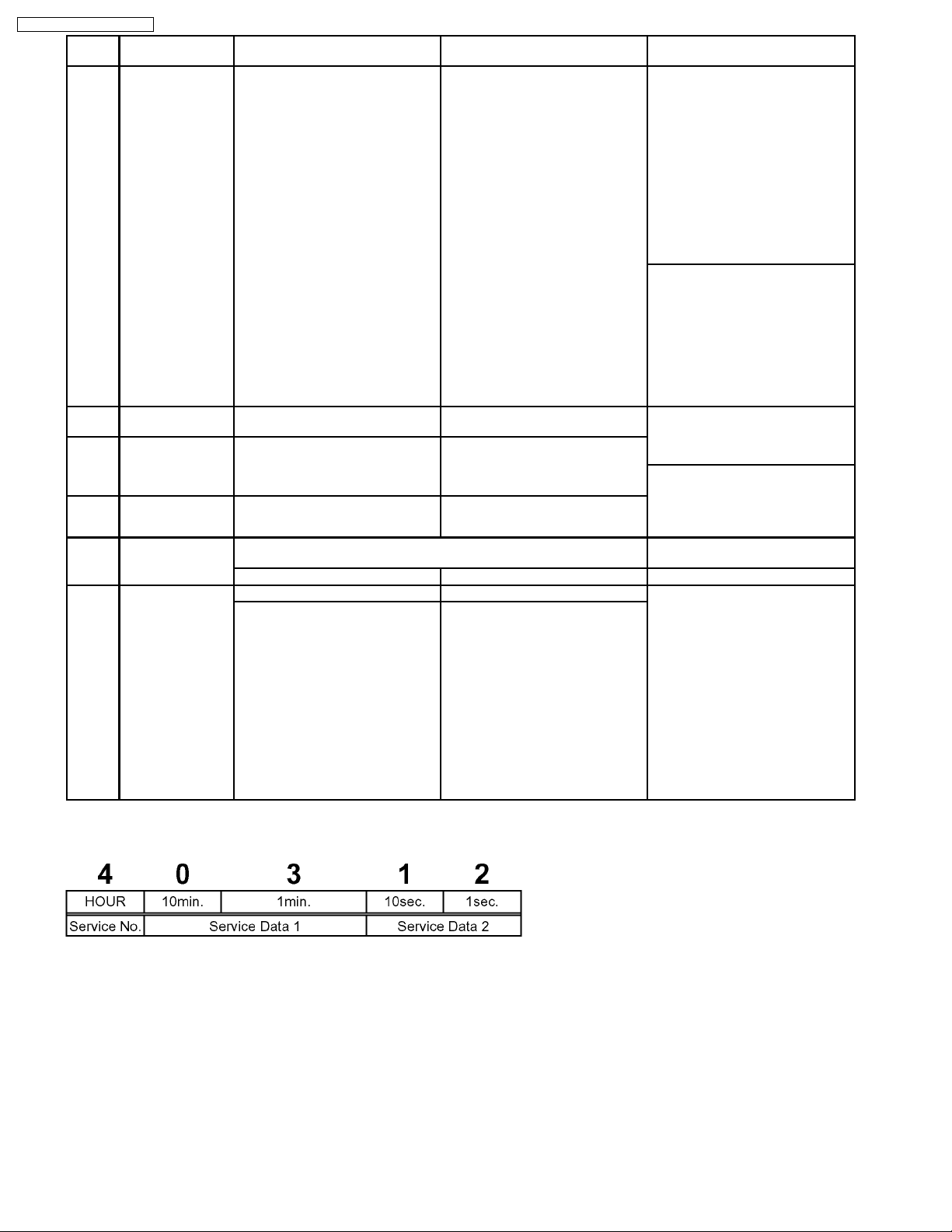

7.2.3.1. (VHS) Service Mode and Service Data at a glance

Service

Number

0 Indication for the

1 Indication for the

Contents Contents of Indication on minute Contents of Indication on second Remarks

inner data of

IC6001

inner data of

IC6001

VHS mode

(Real time)

VHS mode Management number of the

Starting / finishing edges detecting

data

(Real time)

00: Both starting / finishing edges

have not been

01: Starting edge is detecting now

02: Finishing edge is detecting now

03: Both starting / finishing edges

are detecting now

Process number

(Real time)

processing during mechanism

shifting

Data of receiving key (Real time)

Indicate the receiving code when the

key of VHS or remote controller

being operated.

27

DMR-EZ47VP / DMR-EZ475VP

Service

Number

2 Indication for the

inner data of

IC6001

3 Self-diagnosis

history (1st)

4 Self-diagnosis

history (2nd)

5 Self-diagnosis

history (3rd)

6 Indication for the

inner data of

IC6001

7 Manual mechanism

operation

Contents Contents of Indication on minute Contents of Indication on second Remarks

Mechanism position

(Real time)

0L: EJECT position

02: DOWN position

03: RREW position

04: LOAD position

05: REV position

06: PLAY position

07: POFF position

08: STOP_R position

09: STOP_F position

- : FF/REW position

- : Intermediate between

each positions

Error number of history 1 Supplementary data 1 and 2 of

Error number of history 2 Supplementary data 1 and 2 of

Error number of history 3 Supplementary data 1 and 2 of

Real time servo data (4 digits)

(Real time)

Higher rank 1 BYTE of SERVO data Lower rank 1 BYTE of SERVO data

Real time mechanism position Real time ordering for the Motors Press the STOP key, and then the

0L: EJECT position

02: DOWN position

03: RREW position

04: LOAD position

05: REV position

06: PLAY position

07: POFF position

08: STOP_R position

09: STOP_F position

- : FF/REW position

- : Intermediate between

each positions

Ordering for the Motors

(Real time)

0*, 2*: CYL off,

CAP off

1*: CYL off,

CAP on (fwd)

3*: CYL off,

CAP on (rev)

8*, A*: CYL on,

CAP off

9*: CYL on,

CAP on (fwd)

B*: CYL on,

CAP on (rev)

*0: Motor off

*1: Loading

*2: Unloading

*3: Break (Load + Unload)

history 1.

history 2.

history 3.

0*, 2*: CYL off,

CAP off

1*: CYL off,

CAP on (fwd)

8*, A*: CYL on,

CAP off

9*: CYL on,

CAP on (fwd)

B*: CYL on,

CAP on (rev)

*0: Motor off

*1: Loading

*2: Unloading

*3: Break (Load + Unload)

There are next conditions in this

mode for enable the mechanism

operations without a cassette tape.

● The starting / finishing edges are

not detected.

● The reel lock is not detected

● The tape and the positions are not

detected.

, And so on.

Press the EJET key for over 3

seconds in this mode, and then the

VHS is shifted into the special

modes, such as PG Adjustment,

Model Code Setting, and so on.

The orders for the motors are as

follows.

Bit 7: CYL ON/OFF

Bit 6: -----------------Bit 5: CAP FWD/REV

Bit 4: CAP ON/OFF

Bit 3: -----------------Bit 2: -----------------Bit 1: UNLOADING(H)

Bit 0: LOADING(H)

In the Self-Diagnosis Memory, next 3

BYTE is memorized for an Error.

1 BYTE: Its Error number

2 BYTE: Its supplementary data

In these modes, the supplementary

data 3 and 4 instead of the Error

number and supplementary data 1

and 2 are indicated only while

pressing STOP key.

cassette tape is unloaded.

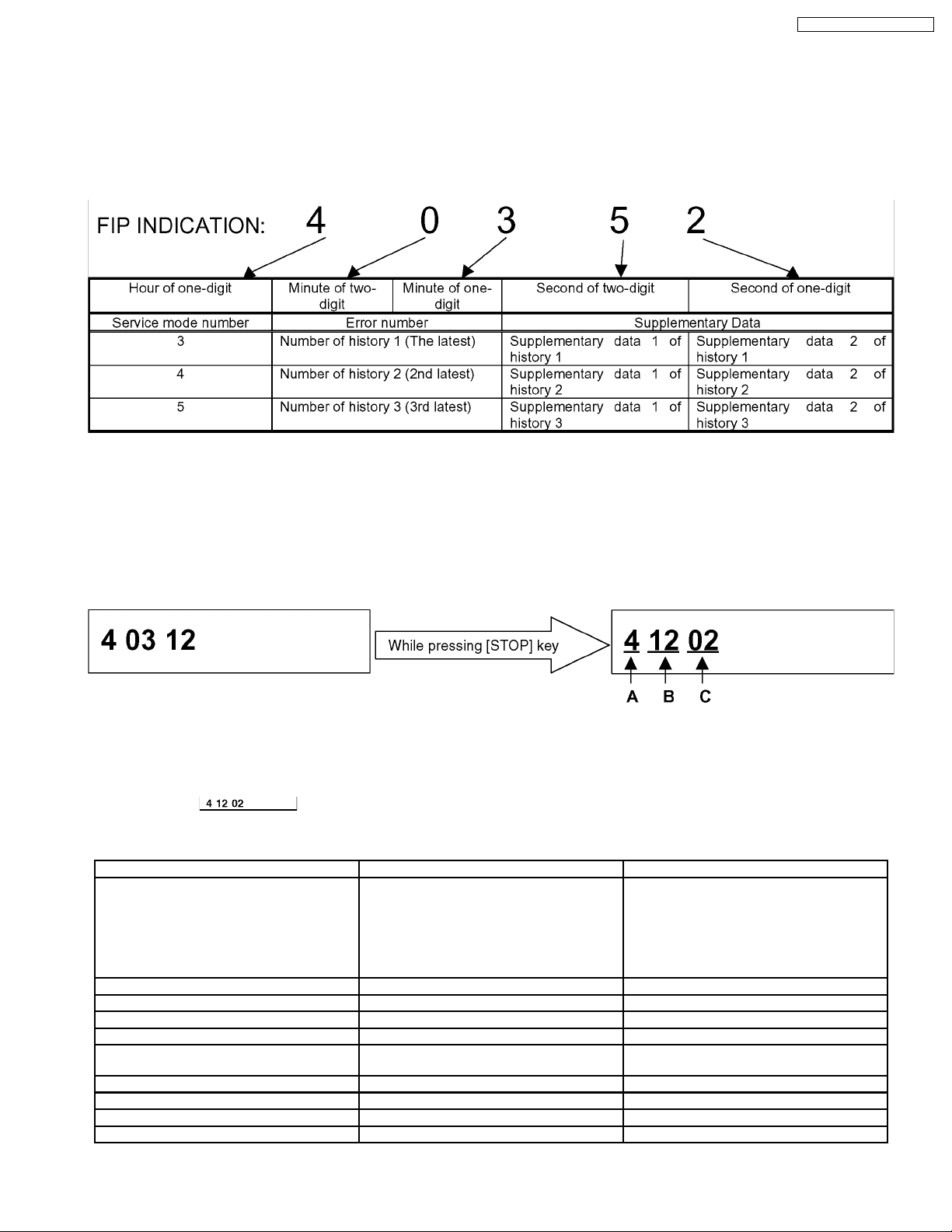

7.2.3.2. Example of FIP

7.2.4. (VHS) Self-Diagnosis History Memory Function

7.2.4.1. (VHS) Condition for memorizing of the self-diagnosis history

1. The self-diagnosis result and the supplementary data are the condition memorized just as an Error is detected.

2. There are the histories from number 1 to number 3.

3. The latest Error is memorized on history number 1,and then the old histories are shifted to the history number 2, 3.

4. Put out data from the memory number 3 by the shift is deleted.

5. If the latest Error is same with the history number 1 (2nd-latest), it is not memorized.

(The same Error number is not memorized in succession)

28

DMR-EZ47VP / DMR-EZ475VP

7.2.4.2. (VHS) Condition for clearing the self-diagnosis history

1. A case of that press the STOP key and the EJECT key simultaneously over 5 seconds.

7.2.4.3. (VHS) Indication of the self-diagnosis history.

1. The self-diagnosis histories and its supplementary data could be indicated on the FIP with Service mode of number from 3 to

5.

2. The procedure of setting the service mode and the format if the indication are same as usual.

Both the Error numbers and its supplementary data of history 1, 2and 3 are indicated by selecting the Service mode 3, 4 and 5 as

shown above.

In case of that any Error has not been memorized, the Error number and its supplementary data is indicated as " - ".

7.2.4.4. (VHS) Display of Supplementary Data 3 and 4

During displaying the Self-Diagnosis History, press [STOP] key on front panel to change the display.

*Example of Display

A: Service Mode Number.

B: Supplementary Data 3...Mechanism process shifting Number.

C: Supplementary Data 4...LM(Loading Motor information)

*Display of

occurred while mechanism was between REV position and LOAD position.

<Supplementary Data 3>

[EJECT] [FF] [REW]

10: PLAY → passing REV

11: passing REV

12: passing REV → LOAD

(Capstan STOP)

13: LOAD → DOWN

14: DOWN → EJECT

15: EJECT completion

[PLAY] [REC] [STILL]

20: Cylinder starting up, Phase drawing 30: Cylinder starting up, Phase drawing 40:Turning forward

21: Audio muting, VV selection 31: REC signal output 41:Speed is 0, Capstan is OFF

[P.ON] [STILL → PLAY] [CUE]

-- Process of turning on power 48: Tape sending 49: x2 speed sending, Turning point of

[P.OFF] [CUE → PLAY] [REV]

70: PLAY → P.OFF 4A: Finishing edge Checking, Tape sending 80: PLAY → P.OFF

means that " Loading Motor turns ON when [EJECT] button was pressed, but an error has

U0: PLAY → STOP F

U1: STOP F → FF

U2: FF starting up

4-: PLAY Checking, Tape sending 81: Rewinding

A0: PLAY → STOP F

A1: STOP → REW

A2: REW starting up

Calculating remains

P.OFF → REV

29

DMR-EZ47VP / DMR-EZ475VP

<Supplementary Data 4> (LM Information)

Result of request of driving Loading Motor.

Display Description

1 There was no change of mechanism position. (Loading Motor was OFF)

2 There was some change of mechanism position. (Loading Motor was ON)

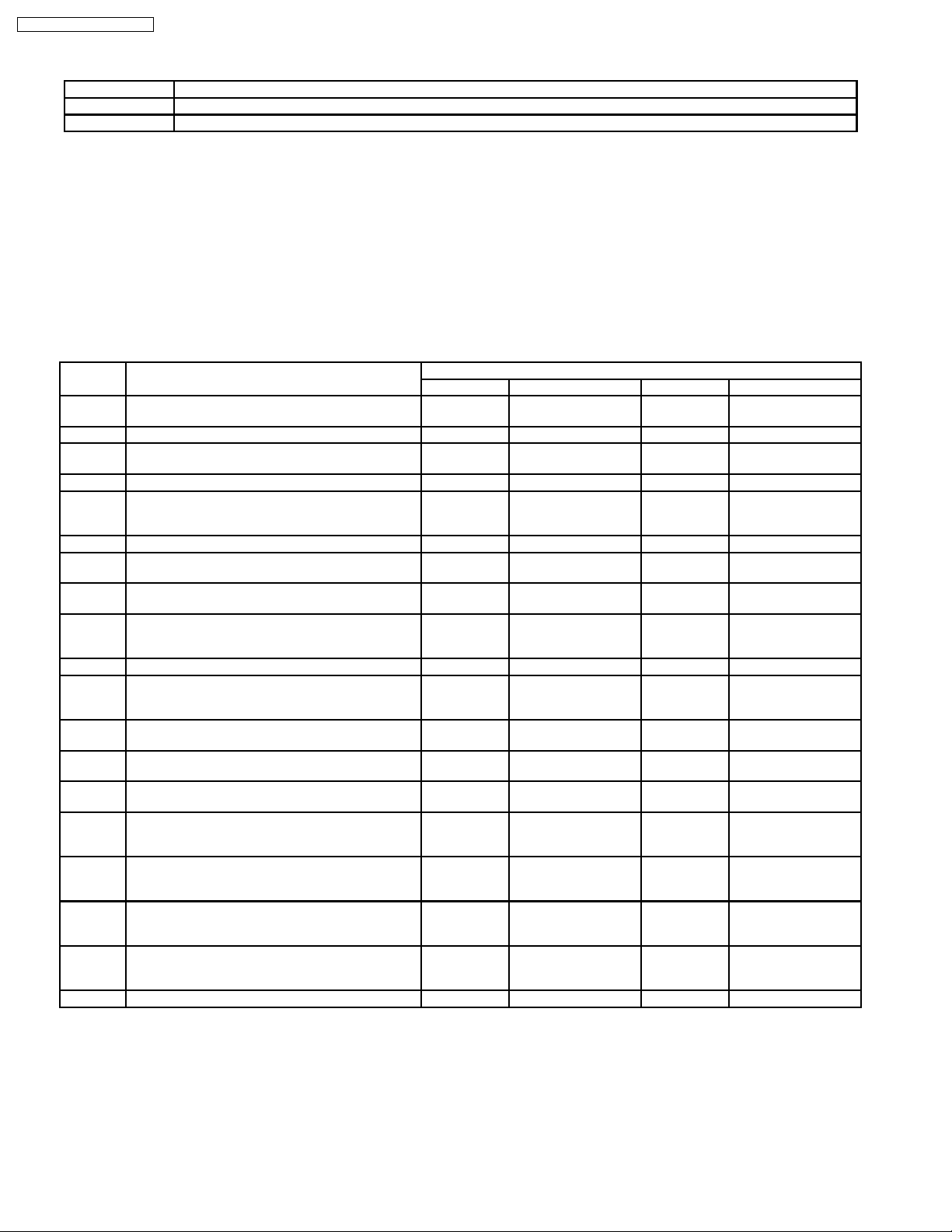

7.2.5. (VHS) Description of Self Diagnosis Memory

In this Self-Diagnosis Function, in case error has occurred continuously, maximum of the newest 3 error data are

memorized.

And in order to analyze cause of error, the error number and the supplementary data of mode, mechanism position and

so on are memorized.

7.2.5.1. (VHS) Error Number and Supplementary Data

The Supplementary Data as shown below are memorized to each error number.

Error No. Reason Supplementary Data

Data 1 Data 2 Data 3 Data 4

01 The cylinder could not be started.

(Error of the cylinder or the cylinder driver.)

02 The CAP FG could not be detected. VHS mode - Process No. Number of FG

03 Mechanism lock during without the unloading and the

cassette-up.

04 Mechanism lock during unloading VHS mode - Process No. LM information

05 S-reel pulse cannot be detected when a cassette

tape is inserted.

(Error of the S-reel system or the Capstan system.)

06 Mechanism lock during the Cassette-up. VHS mode Standby position Process No. LM information

07 The recording circuit can not be operated in REC

mode.

08 The recording circuit is operated in except for REC

mode.

09 Serial communication Error between VHS

Microprocessor (IC6001) and Timer Microprocessor

(IC7501).

11 Cylinder clogs during the PLAY mode. VHS mode - Process No. 15 S-reel pulse cannot be detected when a cassette

tape is inserted.

(Error of the S-reel system or the Capstan system.)

16 Detection of the Cylinder lock during the constant

rotation

17 Detection of S-reel lock during the constant tape

running

18 Detection of T-reel lock during the constant tape

running

20 NG1 in the PG Shifter Automatic Adjustment

(The cylinder rotation is unstable during the

automatic adjustment.)

21 NG2 in the PG Shifter Automatic Adjustment

(The vertical sync signal is lacked while over 5

seconds on the alignment tape.)

22 NG3 in the PG Shifter Automatic Adjustment

(The installing position of Heads to the cylinder is our

of specification.)

23 NG4 in the PG Shifter Automatic Adjustment

(The servo is not locked to the cylinder for more than

10 sec.)

80 An exceptional ejection depends on a Error VHS mode Refer to *Note 3 Process No. -

VHS mode - - -

VHS mode Standby position Process No. LM information

VHS mode Tape position Process No. LM information

VHS mode - Process No. -

VHS mode - Process No. -

- - - -

VHS mode Value of S-Reel Pulse

counted

VHS mode Tape position Process No. -

VHS mode Tape position Process No. Number of FG

VHS mode Tape position Process No. Number of FG

VHS mode - Process No. -

VHS mode - Process No. -

VHS mode - Process No. -

VHS mode - Process No. -

Process No. -

Note 1: Details of "VHS mode" of the Supplementary Data 1 (These values are hexadecimal indication)

0: STOP, 1: EJECT, 2: REW, 3: FF, 4:REV, 5: CUE, 6: SLOW, 7: POWEROFF, 8: PLAY, 9: STIL,

A: REC, B: REC PAUSE, C: ADUB, D: ADUB PAUSE, E: INSERT, F: INSERT PAUSE

Note 2: Explanation of "Tape position" of the Supplementary Data

The Tape position Data is the area data of S-reel that is used for judgment of reducing speed in the Main microprocessor

IC6001, and as the tape position is moved from the starting edge to the finishing edge, the value becomes smaller.

The Tape Data does not become "0" even if the tape reaches the finishing edge as the hub remains, and the tape position

values are different between the large hub and the small hub as the each diameters are different from each other.

30

Loading...

Loading...