Page 1

ORDER NO. DSD1205012CE

Blu-ray Disc Player

Model No. DMP-BBT01EB

DMP-BBT01EG

Colour

(K)...........Black Type

© Panasonic Corporation 2012 Unauthorized copying and distribution is a violation of law.

Page 2

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure 1.) --------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. Caution for AC Cord (For EB)---------------------------5

2.3. Precaution of Laser Diode -------------------------------6

2.4. Service Caution Based On Legal Restrictions ------ 7

2.5. Static Electricity Protection Measures ----------------8

2.6. Ground for electrostatic breakdown

prevention----------------------------------------------------8

3 Service Navigation------------------------------------------------9

3.1. Service Infomation -----------------------------------------9

3.2. Caution for DivX ------------------------------------------ 10

4 Specifications ---------------------------------------------------- 11

4.1. Others (Licenses) ---------------------------------------- 12

5 Location of Controls and Components------------------ 14

6 Operating Instructions ---------------------------------------- 17

6.1. Taking out the Disc from Drive Unit when the

Disc cannot be ejected by [Eject] switch ----------- 17

7 Multiple Pressing Function ---------------------------------- 18

7.1. About the Multiple Pressing of the Unit’s

Remote Control------------------------------------------- 18

7.2. How to enter the Special Modes using the

Multiple Pressing Function of the Unit’s

Remote Control------------------------------------------- 18

8 Service Mode ----------------------------------------------------- 24

8.1. About the Service Mode -------------------------------- 24

8.2. Service Mode List ---------------------------------------- 25

8.3. Self-Diagnostics Functions ---------------------------- 29

9 Service Fixture & Tools --------------------------------------- 32

10 Disassembly and Assembly Instructions --------------- 33

10.1. Unit----------------------------------------------------------- 33

10.2. Drive Unit--------------------------------------------------- 38

11 Measurements and Adjustments -------------------------- 41

11.1. Service Positions ----------------------------------------- 41

11.2. Adjustment of Drive Unit/BD Digital P.C.B. -------- 42

11.3. Caution for Replacing Parts --------------------------- 45

12 Block Diagram --------------------------------------------------- 46

12.1. Overall Block Diagram ---------------------------------- 46

12.2. Input Digi-Net P.C.B. Regulator Circuit Block

Diagram----------------------------------------------------- 47

12.3. BD Digital P.C.B. Regulator Circuit Block

Diagram----------------------------------------------------- 48

12.4. Digital Video/Audio Circuit Block Diagram --------- 49

12.5. Digital (Front End Section) Circuit Block

Diagram----------------------------------------------------- 50

12.6. Digital (Back End Section [1]) Circuit Block

Diagram----------------------------------------------------- 51

12.7. Digital (Back End Section [2]) Circuit Block

Diagram----------------------------------------------------- 52

13 Wiring Connection Diagram --------------------------------- 53

13.1. Interconnection Diagram ------------------------------- 53

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

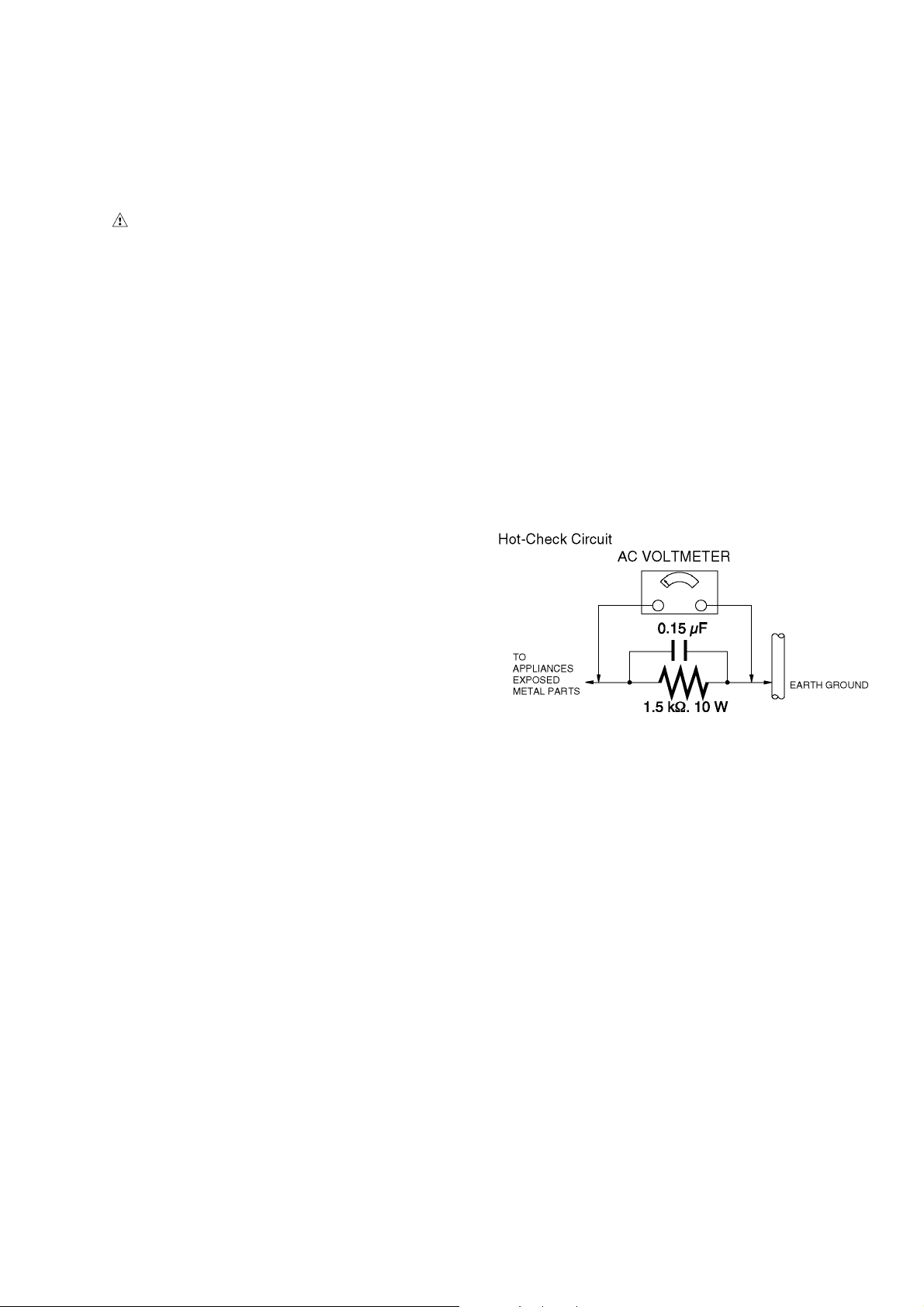

1.3. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

Figure. 1

3

Page 4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

4

Page 5

2.2. Caution for AC Cord (For EB)

2.2.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

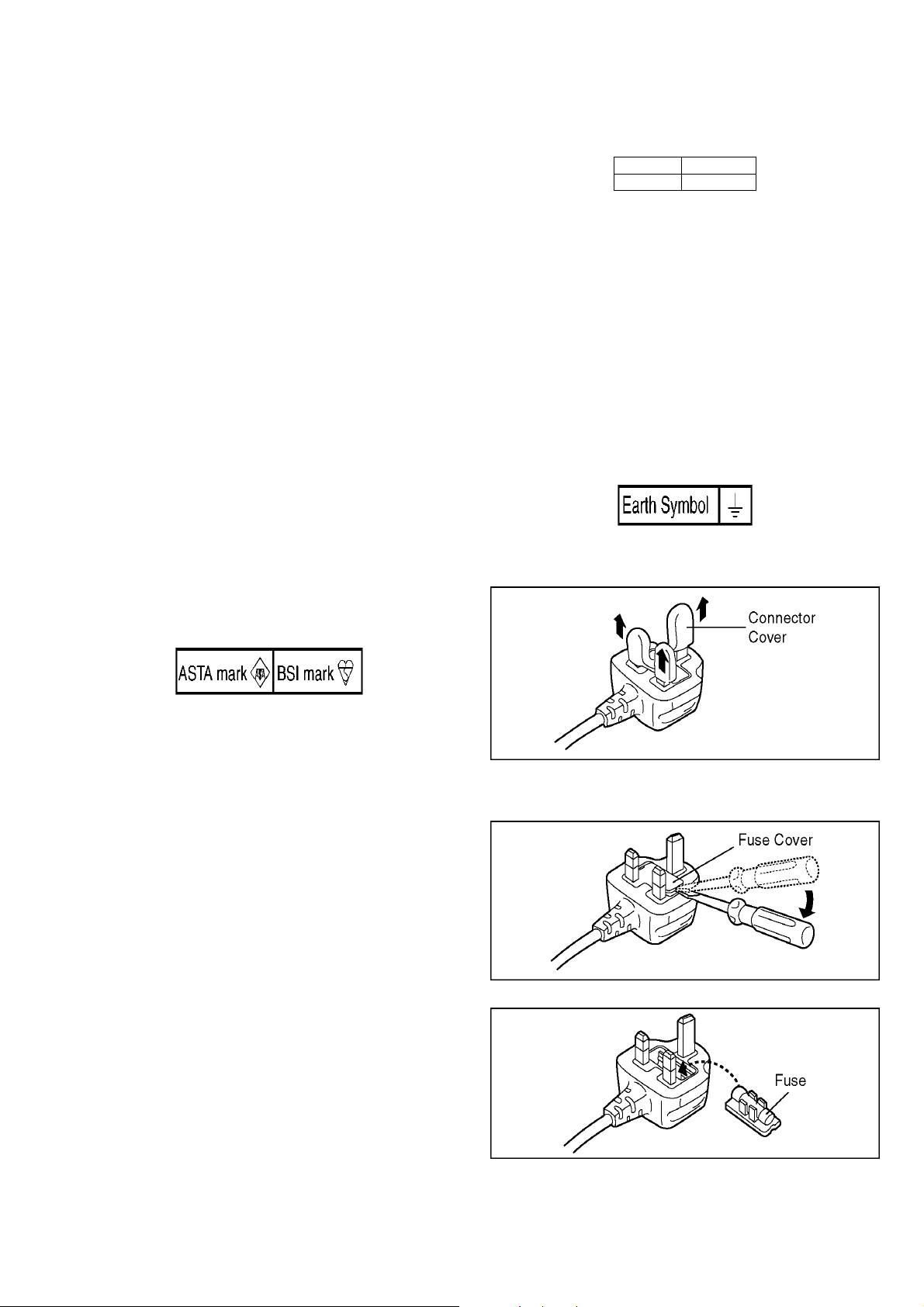

2.2.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

2.2.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

Blue Neutral

Brown Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the terminal in the plug which is marked with the letter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be connected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.2.2.2. Before Use

Remove the Connector Cover as follows.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.2.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

5

Page 6

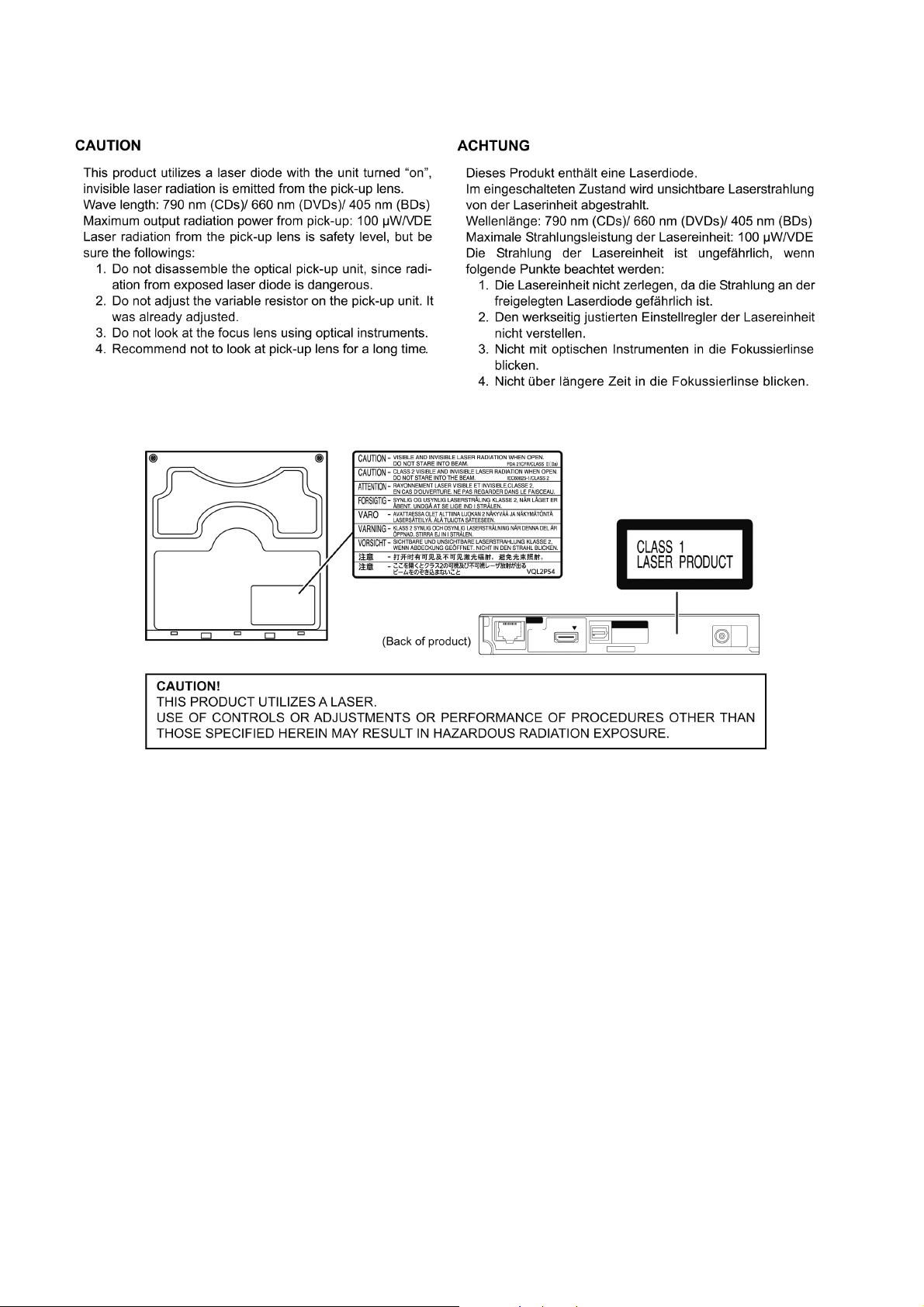

2.3. Precaution of Laser Diode

6

Page 7

2.4. Service Caution Based On Legal Restrictions

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

2.4.1. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

7

Page 8

2.5. Static Electricity Protection Measures

• The laser diode in the traverse unit (optical pick-up) may break down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse unit (optical pick-up).

2.6. Ground for electrostatic breakdown prevention

• As for parts that use optical pick-up (laser diode), the optical pick-up is destroyed by the static electricity of the working environment.

Repair in the working environment that is grounded.

2.6.1. Work table grounding

• Put a conductive material (sheet) or steel sheet on the area where the traverse unit (optical pick-up) is placed, and ground the

sheet.

2.6.2. Human body grounding

• Use the anti-static wrist strap to discharge the static electricity from your body.

2.6.3. When exchange the BDP Drive

• Before remove the ESD prevention bag, make sure to use the anti-static wrist strap to discharge the static electricity when

replace the BDP Drive.

Note:

The ESD prevention bag is used to replace the original short-circuit point.

It can be removed while placing the BDP Drive.

8

Page 9

3 Service Navigation

3.1. Service Infomation

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

1. This service manual does not contain the following information, because of the impossibility of servicing at component level.

• Schematic Diagram, Block Diagram and P.C.B. layout of BD Digital P.C.B..

• Parts List for individual parts of BD Digital P.C.B..

• Exploded View and Parts List for individual parts of Drive Unit.

2. The following category are recycle module part. Please send them to Central Repair Center.

• BD Digital P.C.B. (DMP-BBT01EB: RFKB76275DBT)

• BD Digital P.C.B. (DMP-BBT01EG: RFKB76275CGT)

• Drive Unit: VXY2162

9

Page 10

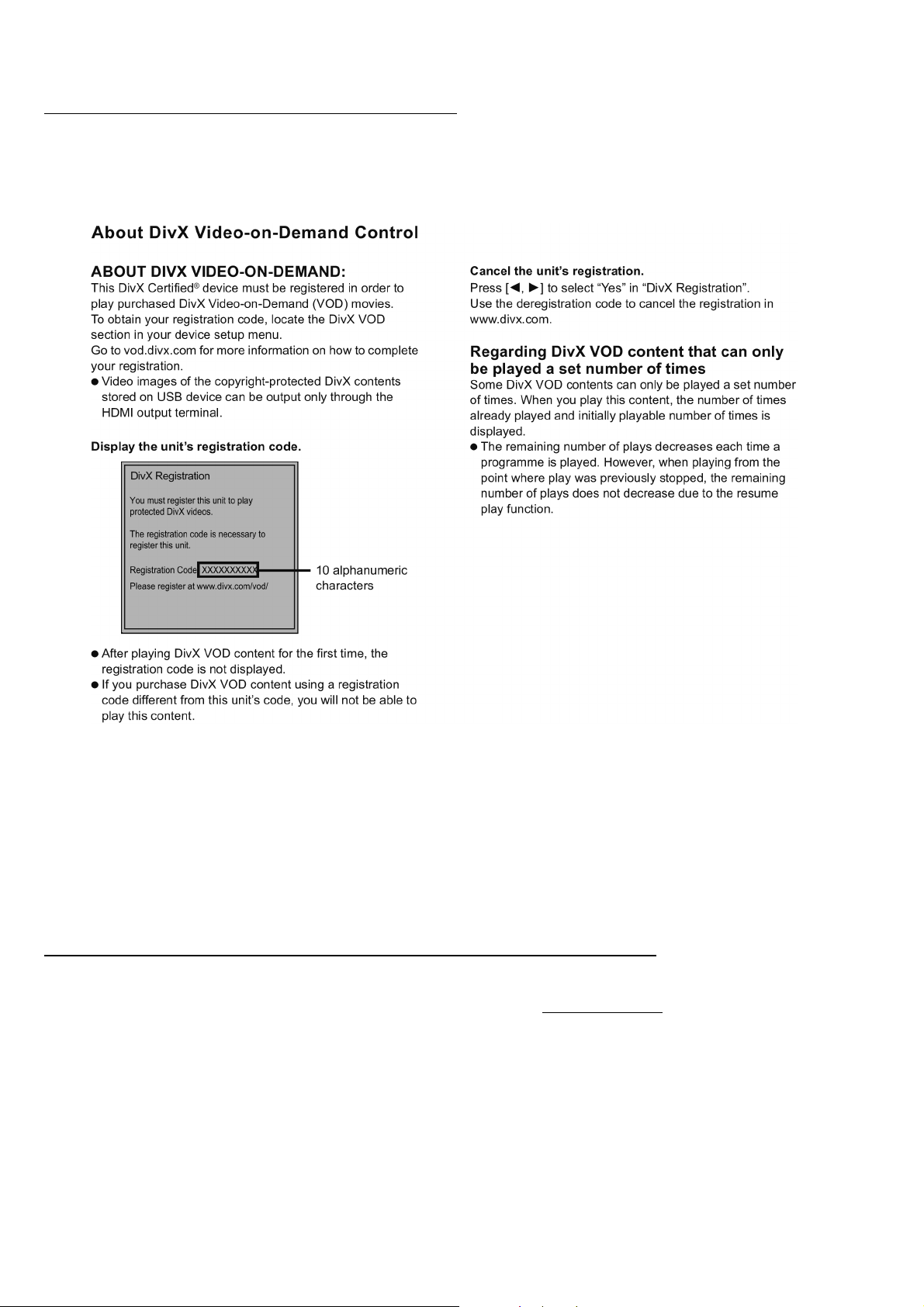

3.2. Caution for DivX

“Warning for Customers Who Use DivX Video-on-Demand content” when replacing the FLASH ROM or EEPROM or P.C.B.

First, copy the Last part of this page for the customers who continue to use DivX Video-on-Demand service.

Appendix:

*Parts that memorize user’s information are only FLASH ROM.

*The registration of Registration Code is possible for half a year up to 6 recorders up to 10 recorders a year.

Registration Code is memorized in FLASH ROM (BD Digital P.C.B.).

If exchange above P.C.B. or FLASH ROM, new registration Code differ from previous Registration Code will be generated.

In this case if your customer uses DivX Video-on-Demand service, he/she will no longer be able to play any content that he/she purchased under that same registration code.

Therefore your customer will need to obtain and register the new registration code.

*Copy this page and cut on the dotted line and give the lower half to your customer.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Warning for Customers Who Use the DivX Video-on-Demand content.

1. The registration code has been changed for the repair of the product or the product exchange.

2. Obtain and register a new registration code, otherwise you will no longer be able to play DivX Video-on-Demand content.

3. Follow the procedure on the DivX Video-on-Demand web site to register at http://vod.divx.com/

*If you do not use the DivX Video-on-Demand content, please ignore this warning.

.

10

Page 11

4 Specifications

Power supply: DC 12V (DC IN terminal)

Power consumption: Approx. 8.9 W

In standby mode: Approx. 0.5 W

In quick start standby mode: Approx. 4 W

Operating temperature range: +5°C to +35°C

Operating humidity range: 10 % to 80 % RH (no condensation)

Signal system: PAL /NTS C

Digital audio output:

Optical digital output: Optical terminal

HDMI AV output:

Output connector: TypeA (19 pin): 1 system

480p (525p) / 576p (625p) /

1080i (1125i) / 720p (750p) /

1080p (1125p)

HDMI (V.1.4a with 3D, Content

Type) This unit supports “HDAVI

Control5” function.

SD card slot:

Connector: 1 system

USB slot:

USB2.0: 1 system

Ethernet:

10BASE-T/100BASE-TX: 1 system

Wireless LAN:

Antenna: Tx 1, Rx 1+diversity

Standard Compliance: IEEE802.11n / IEEE802.11g /

IEEE802.11b

Transmission system: OFDM system, DSSS system

Frequency Range: 2.4GHz band

Transfer rate (standard): IEEE802.11n: Max 150Mbps

* Transfer rates are

theoretial values; however,

actual communication rate

will vary according to

communication

environment or connected

equipment.

Access Mode: Infrastructure mode

Security: WPA™/WPA2™

Optical pick-up: System with 2 lenses

Wave length: 790 nm (CDs)/660 nm (DVDs)/

LASER Specification

Class 1 LASER Product:

Wave length: 790 nm (CDs)/660 nm (DVDs)/

Laser power: No hazardous radiation is emitted

Region management

information:

DVD-Video: region number “2” or “ALL”

BD-Video: region code “B”

Media:

Playable disc:

BD-Video

(Blu-Ray 3D, BD-LIVE):

BD-RE: Version3 (Single Layer / Dual

BD-R: Version2 (Single Layer / Dual

DVD-R/DVD-R DL:

IEEE802.11g: Max 54Mbps

IEEE802.11b: Max 11Mbps

(Encryption type: TKIP/AES,

Authentication type: PSK)

WEP(64bit/128bit)

405 nm (BDs)

405 nm (BDs)

with the safety protection

BD-ROM Version 2.4

Layer), JPEG, MPO

Layer), DivX

DVD-Video format*

®

, MKV

1

,

DVD Video Recording format*

1

AVCHD format*

, DivX®, JPEG,

MPO, FLAC, MP3, MKV, WAV

1

,

DVD-RW:

+R/+RW/+R DL:

DVD-Video format*

DVD Video Recording format*

AVCHD format*

1

, AVCHD format*

Video*

1

,

1

1

,

1

DVD-Video: DVD-Video format

CD-Audio: CD-DA

CD-R/CD-RW: CD-DA, JPEG, MPO, FLAC, MP3,

®

, MKV, WAV

DivX

*1 Finalizing is necessary.

USB device:

USB Standard: USB 2.0 High Speed

®

MP4,MPEG, DivX

, MKV, JPEG,

MPO, FLAC, MP3, WAV

Format: FAT12, FAT16, FAT32, NTFS

SD card:

SD Memory Card*

Format:

2

JPEG, MPO, AVCHD, AVCHD 3D,

MPEG-2

FAT12, FAT16, FAT32

*3

, exFAT

*4

*2 support SDHC, SDXC card

support miniSD

support microSD

(need a microSD

TM

Cards (need a miniSDTM Adaptor.)

TM

/microSDHC/microSDXC Cards

TM

Adaptor.)

*3 Not support long file name

*4 SDXC only

Contents:

JPEG:

(CD-R/CD-RW, DVD-R/DVD-R DL, BD-RE, USB device, SD card)

File format: JPEG

(Motion JPEG and Progressive

JPEG are not supported.)

Pixcels: 34 x 34 to 8192 x 8192

Sub sampling: 4:2:2, 4:2:0

MP3:

(CD-R/CD-RW, DVD-R/DVD-R DL, USB device)

File format: MP3

Compression rate: 32kbps to

320kbps

Sampling rate: 44.1kHz, 48kHz

®

DivX

(CD-R/CD-RW, DVD-R/DVD-R DL, BD-R, USB device)

File format: DivX, DivX HD

(DivX Plus HD is not supported.)

MKV:

(CD-R/CD-RW, DVD-R/DVD-R DL, BD-R, USB device)

File format: MKV

FLAC:

(CD-R/CD-RW, DVD-R/DVD-R DL, USB device)

File format: FLAC

Maximum sampling rate: 192 kHz/24 bit

WAV:

(CD-R/CD-RW, DVD-R/DVD-R DL, USB device)

File format: WAV

Maximum sampling rate: 48 kHz/16 bit

AVCHD (H.264):

(DVD-R/DVD-R DL, DVD-RW, +R/+RW/+R DL, SD card)

File format: AVCHD format V2.0

Dimensions: 179mm(W) x 27mm(H) x 180mm(D)

(including the projecting parts, Horizontal instlation with no pedestal.)

235mm(W) x 95mm(H) x 250mm(D)

(including the projecting parts, Horizontal diagonal instlation with pedestal.)

Mass: Approx. 0.9 kg

Approx. 1.0 kg (induding pedestal)

Solder: This model uses lead free solder

(PbF).

11

Page 12

AC Adaptor Power Source: 100V to 240V,

50/60Hz

Power consumption: 42 W

DC output: DC 12 V, 2500 mA

Note: Specifications are subject to change

without notice.

4.1. Others (Licenses)

12

Page 13

13

Page 14

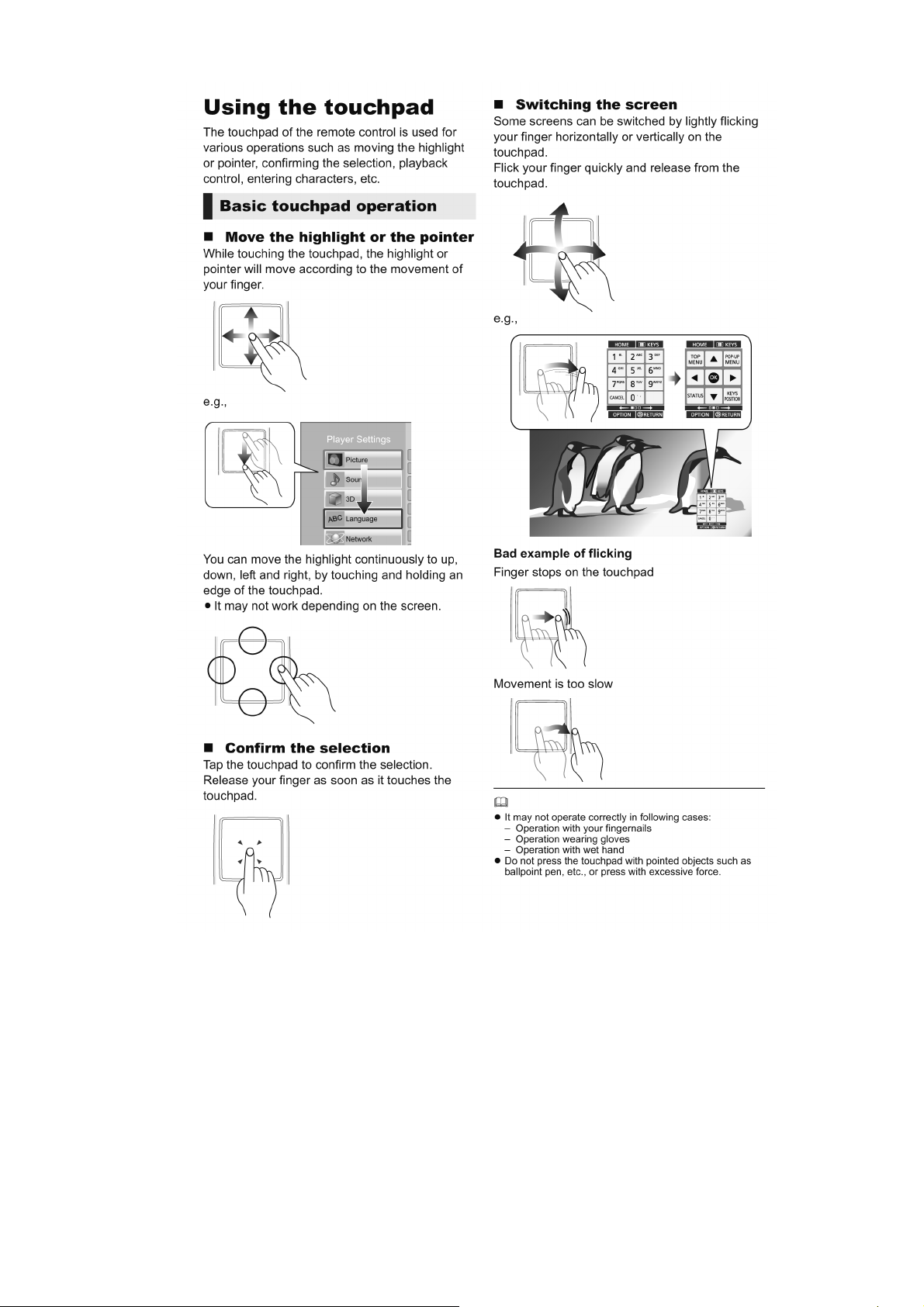

5 Location of Controls and Components

1 Turn the unit on and off

2 Show the Home screen of the VIERA

Connect

3 Show HOME menu

4 Touchpad

Used for various operation

Move the highlight, confirm the selection, etc.

5 Show Option menu

6 Coloured buttons (red, green, yellow, blue)

Used for various purposes depending on the

display

7 Show NETFLIX screen

8 Start up a video communication

9 Show KEYS screen on the screen

10 Return to previous screen

1

Touch to switch the unit from on to standby

mode or vice versa. In standby mode, the unit

is still consuming a small amount of power.

2Discslot

3 Eject the disc*

4 Remote control signal sensor

One of the two sensors will operate

depending on the installation method of the

main unit.

Distance: Within approx. 7 m

Angle (Against front of the sensor):

Approx. 20G up and down, 30G left and right

5 SD card slot

6 USB port

7 Status LED (blue/red)

This will light up in blue when the unit is

turned on.

Blue and red will light up simultaneously

when an error occurs.

This will flash in blue when this unit

receives incoming call etc. of the video

communication.

8 Standby/on LED (red/green)

When the unit is connected to the AC mains

supply, this indicator lights red in standby

mode and lights green when the unit is turned

on. It is also possible to set to turn off when

the unit is in standby mode.

9 CALL LED (blue)

The LED will light up when this unit receives

incoming call etc. of the video

communication.

10 ACCESS LED (amber)

This will flash while accessing the SD card or

USB device.

11 INFO LED (red)

This will light up at the time of error, etc.

* These switches work just by touching the marks. Be

careful not to touch them unintentionally.

The volume of operation sound can be adjusted by “Unit

Operation Volume”.

Standby/on switch* (

/I)

Ɣ

Ɣ

Ɣ

1

INTERNET

2

3

4

HOME

KEYS

5

6

OPTION

RETURN

Indicator LEDs

7891011

7

8

9

10

1

2

3

4

56

14

Pull to flip down

the panel.

Page 15

151617

Page 16

Page 17

6 Operating Instructions

6.1. Taking out the Disc from Drive Unit when the Disc cannot be ejected by [Eject] switch

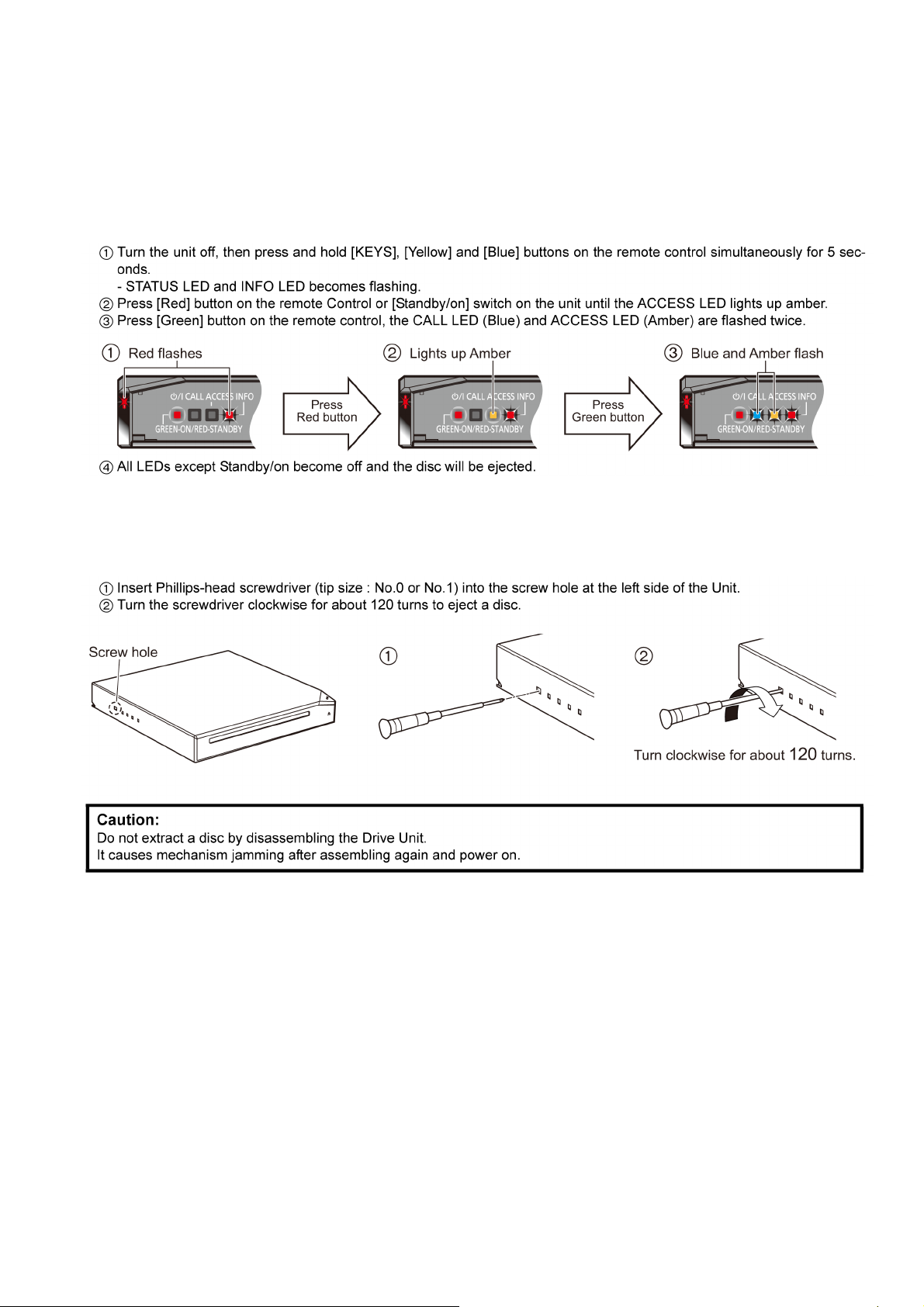

6.1.1. Forcible Disc Eject

6.1.1.1. When the power can be turned off.

6.1.1.2. When the power can not be turned off.

Press [Standby/on] switch on the unit for over 4 seconds to turn off the power forcibly, and step 1 to 3 above.

6.1.1.3. When above methods are not effective.

Page 18

7 Multiple Pressing Function

7.1. About the Multiple Pressing of the Unit’s Remote Control

The remote control which included this unit is possible pressing multiple buttons simultaneously (Multiple Pressing function), and

can operate for the customer’s initial settings and the Service Mode, etc.

The Multiple Pressing function is not available for conventional models’ remote control. Use the remote control included this unit.

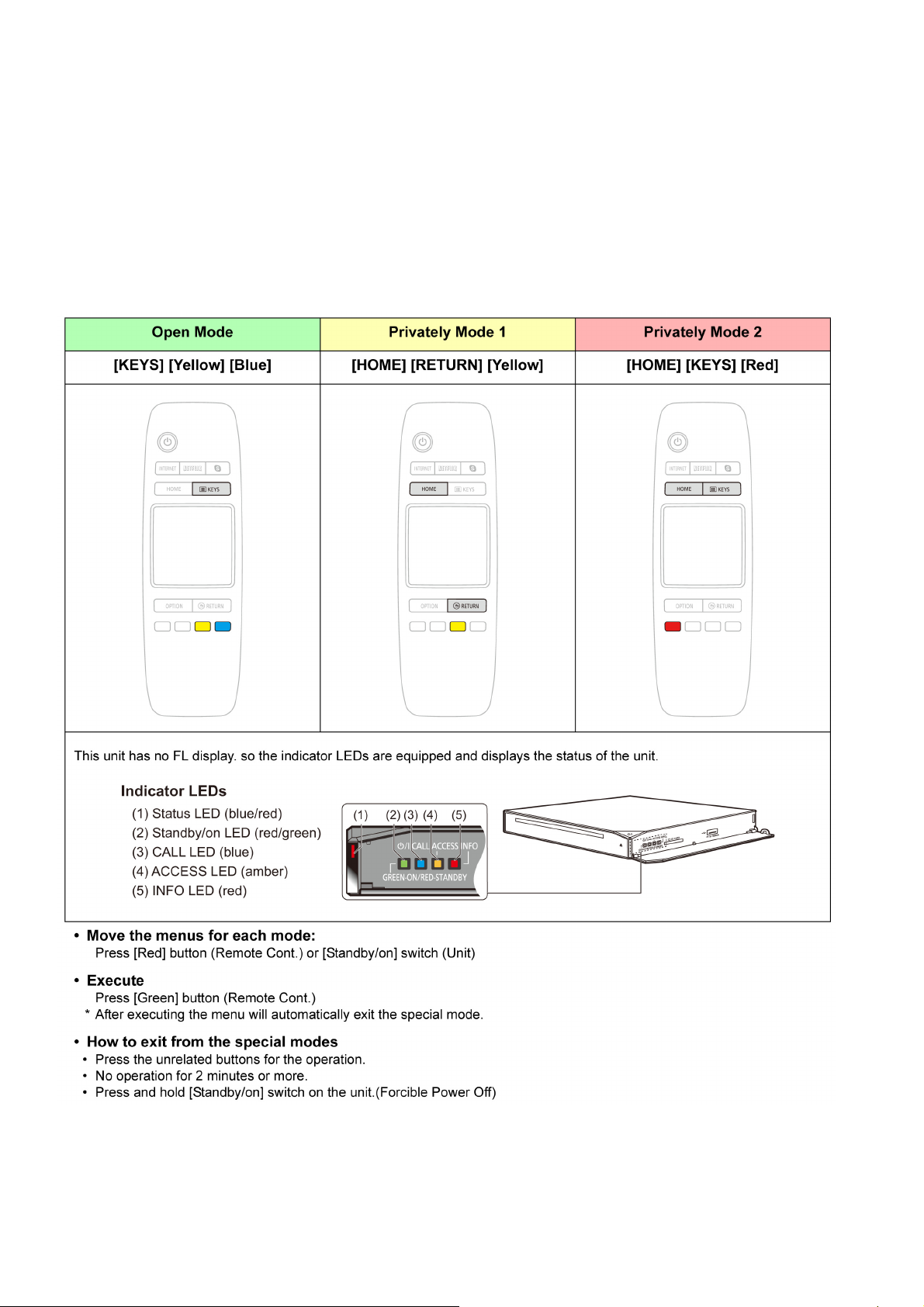

7.2. How to enter the Special Modes using the Multiple Pressing Function of the Unit’s Remote Control

For pressing the multiple buttons of the remote control, this unit can be entering each of the following special modes.

After entering each mode, and then go to the menu you want to run.

18

Page 19

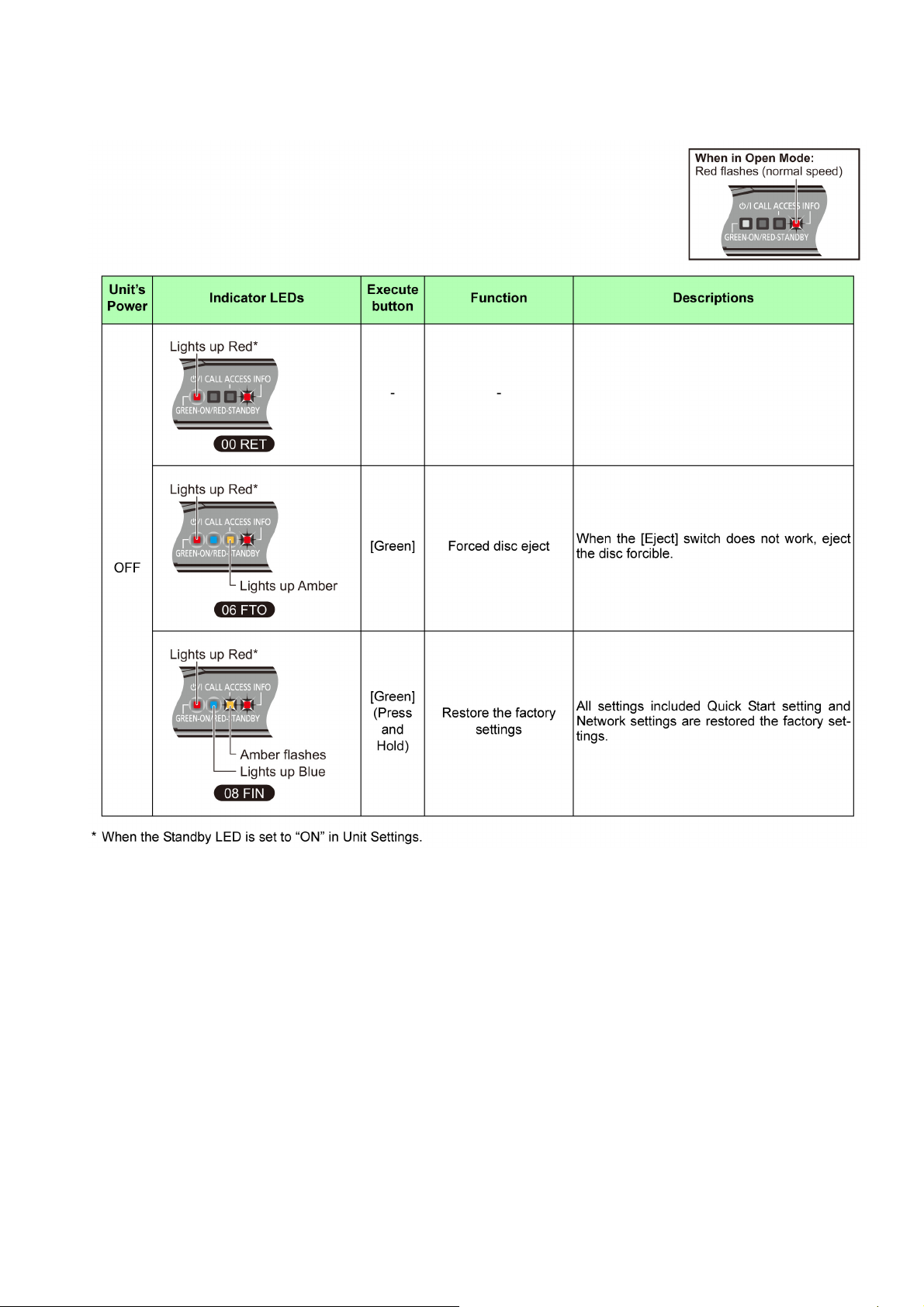

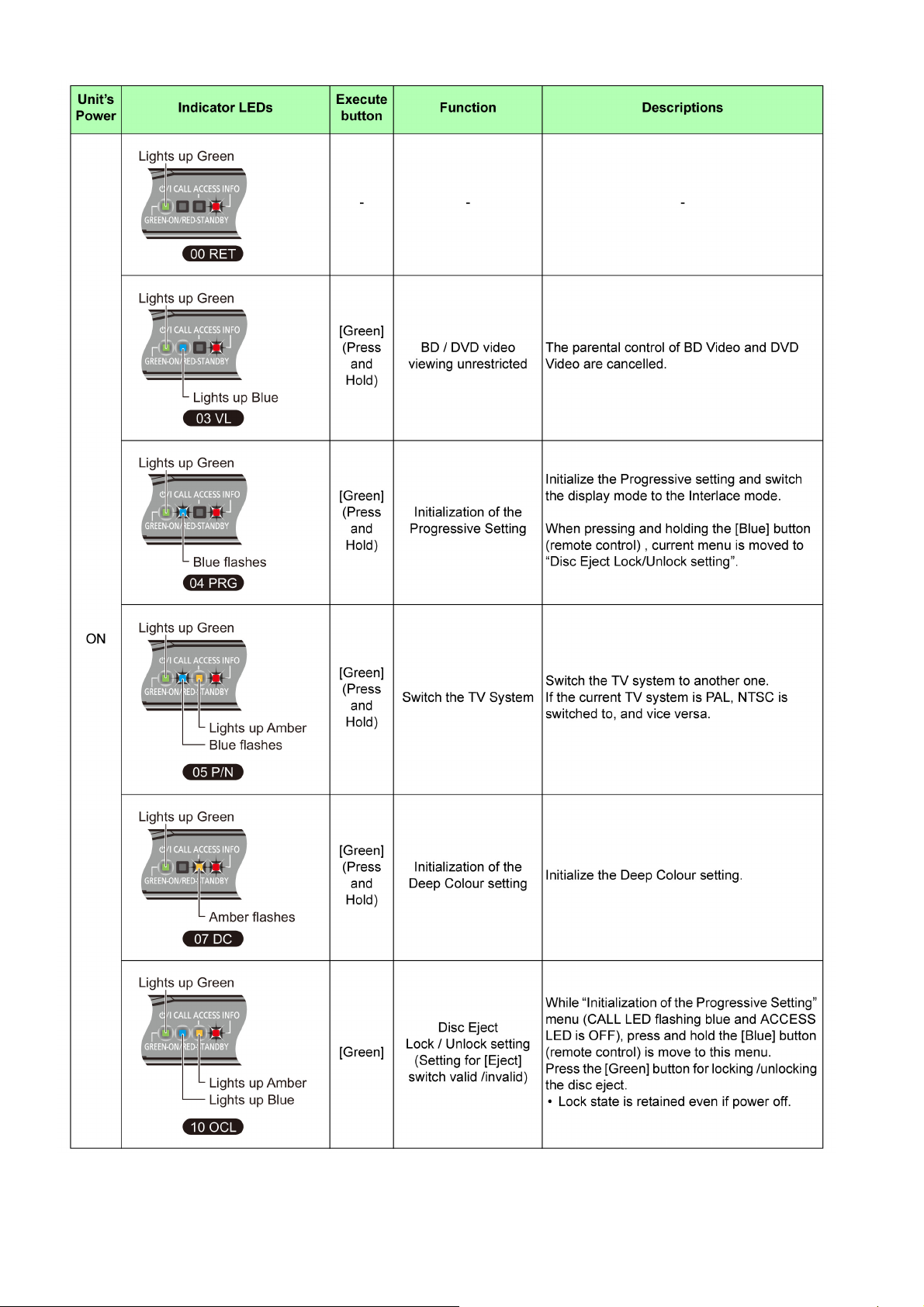

7.2.1. Open Mode (Remote Cont. Buttons: [KEYS] [Yellow] [Blue])

When pressing the 3 buttons, [KEYS], [Yellow] and [Blue] simultaneously for 5 seconds,

INFO LED becomes flashing Red (Normal speed) and Status LED becomes flashing same timing.

19

Page 20

20

Page 21

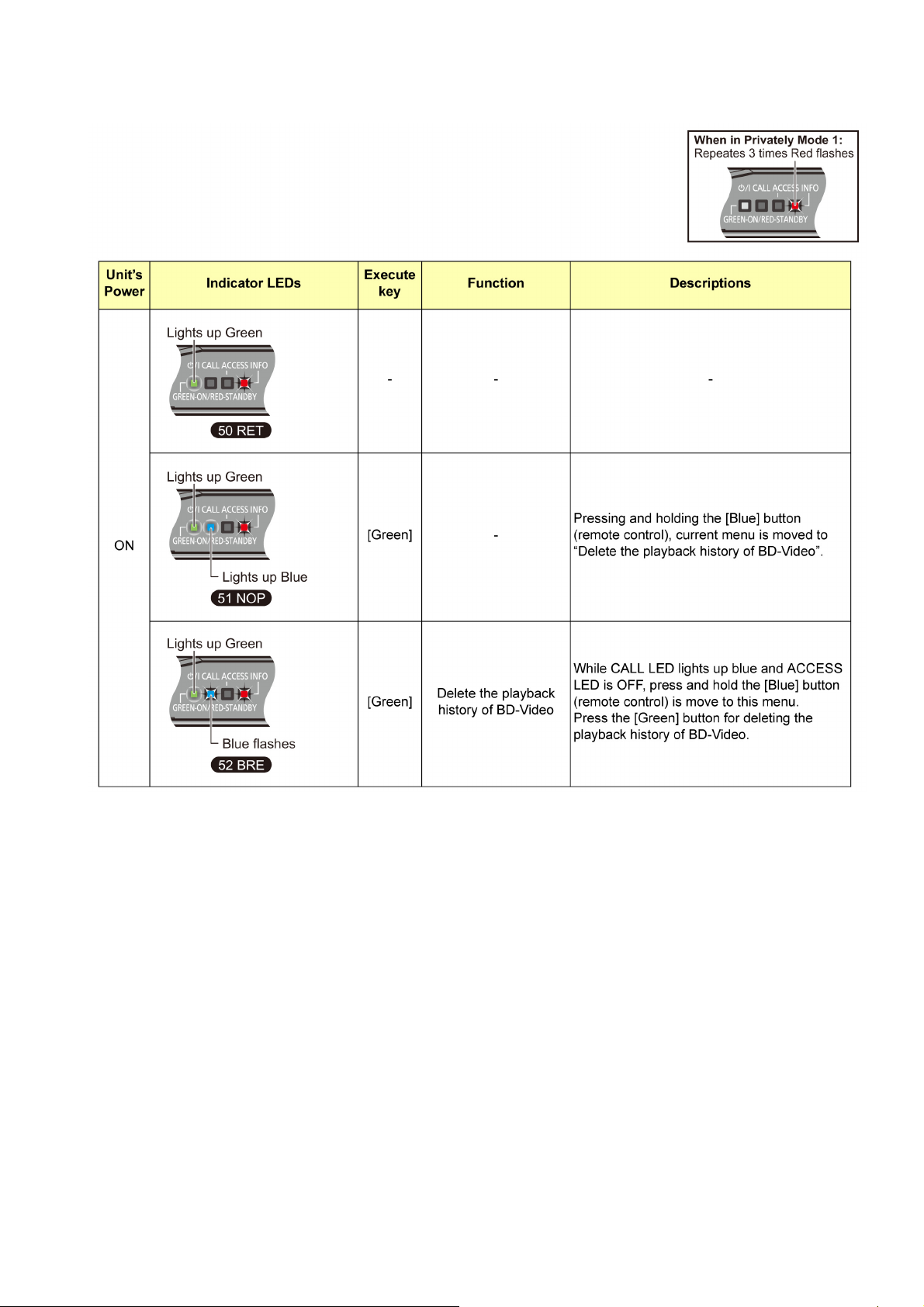

7.2.2. Privately Mode 1 (Remote Cont. Buttons: [HOME] [RETURN] [Yellow])

When pressing the 3 buttons, [HOME], [RETURN] and [Yellow] simultaneously for 5 seconds,repeatedly.

21

Page 22

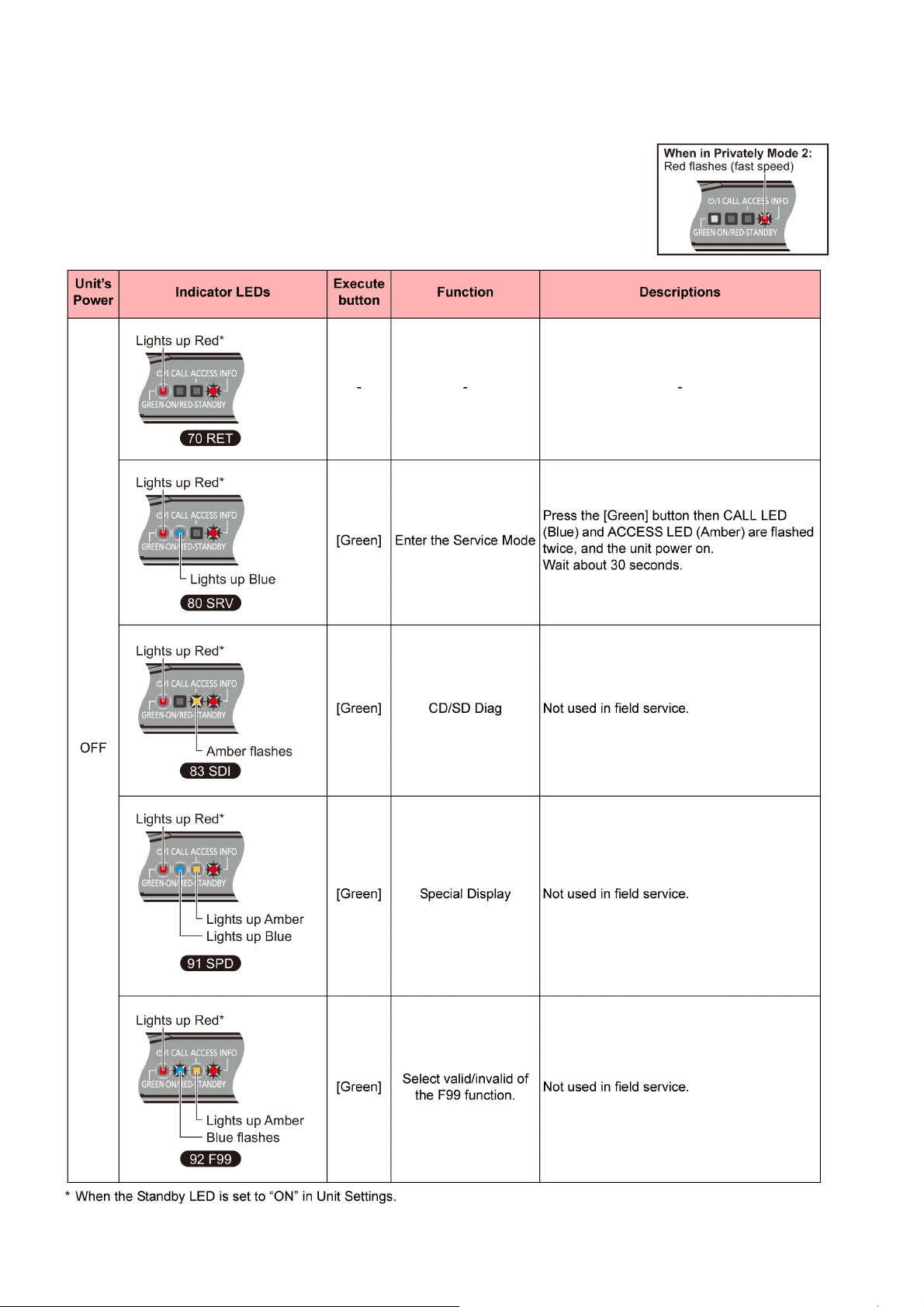

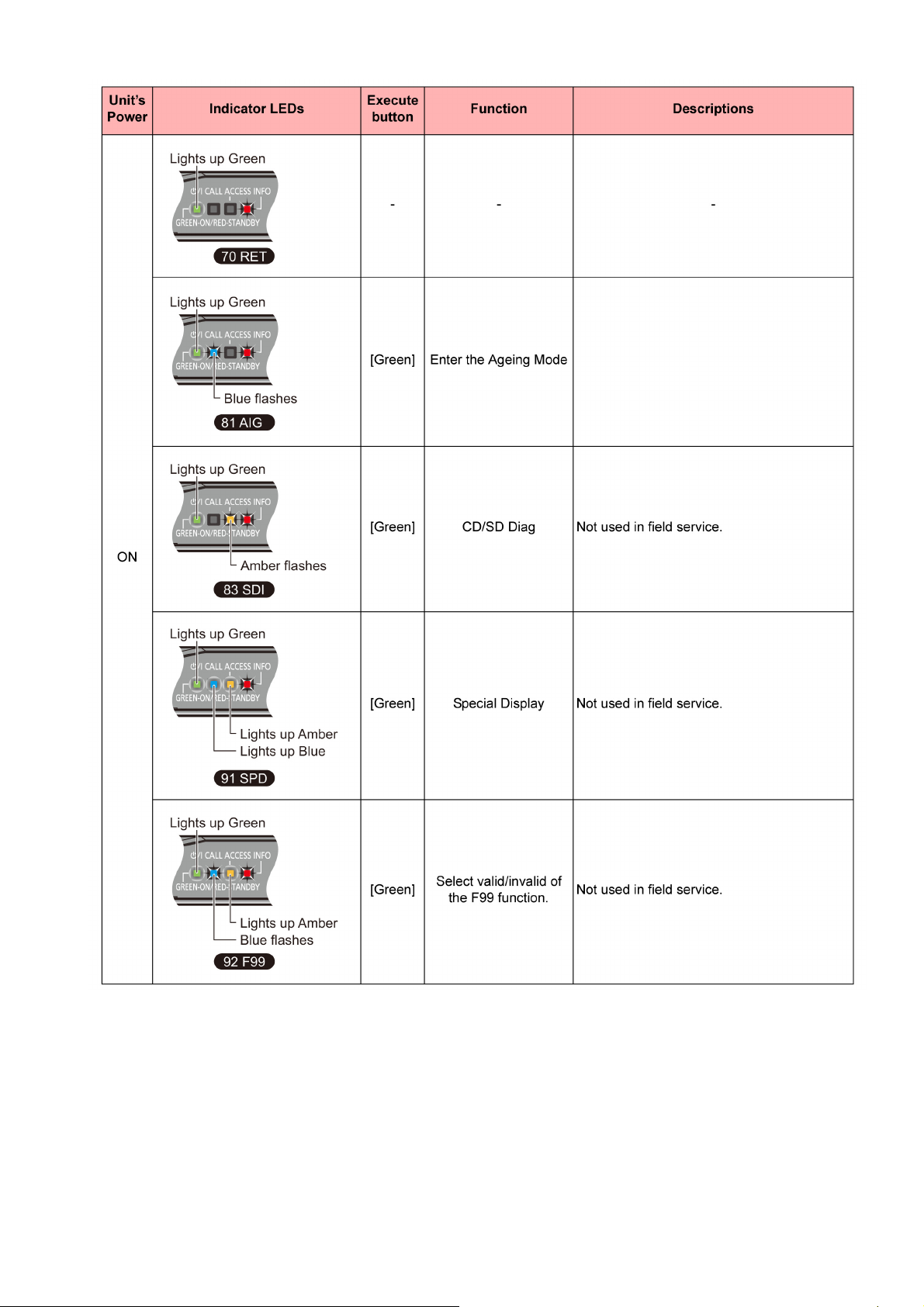

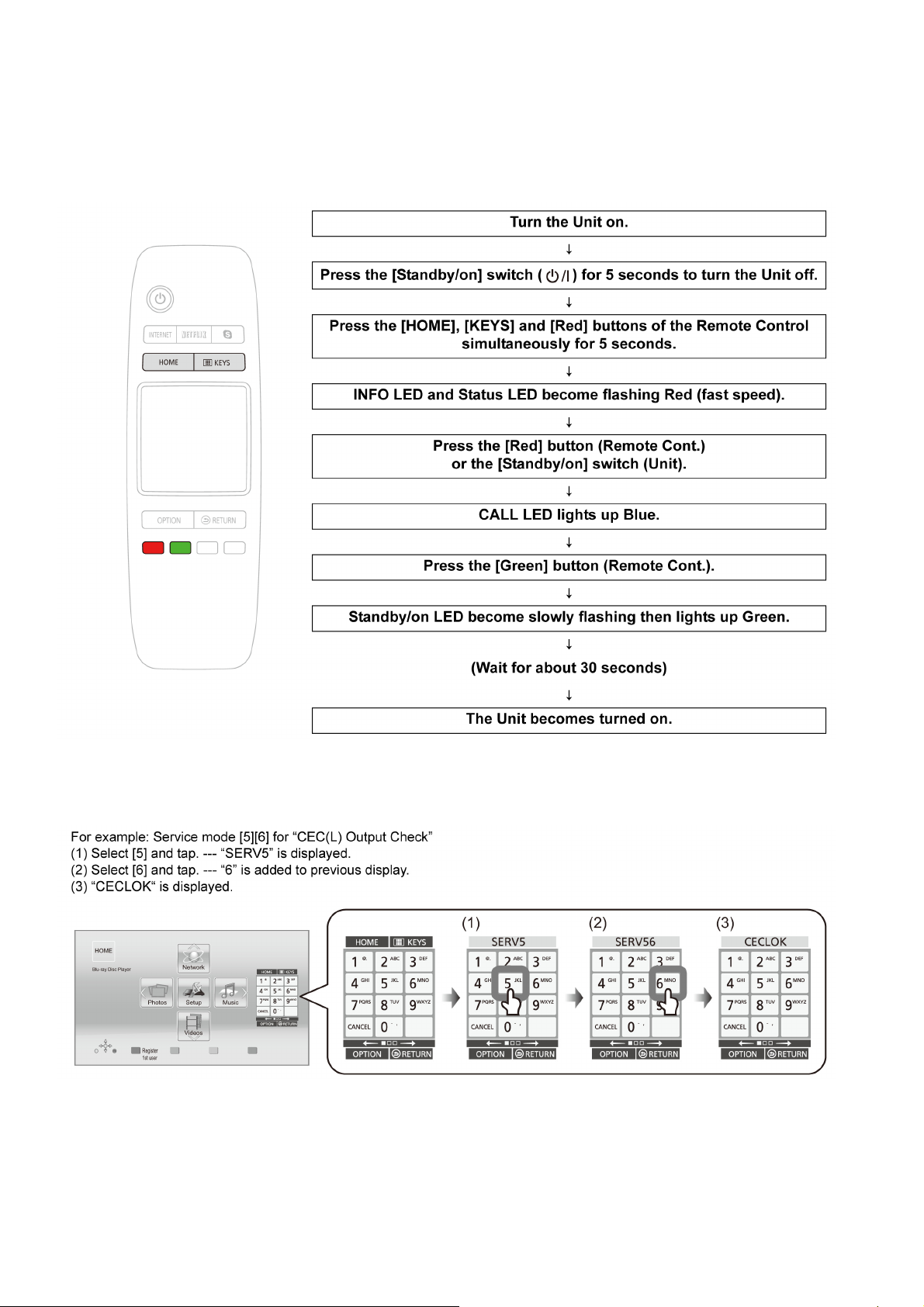

7.2.3. Privately Mode 2 (Remote Cont. Buttons: [HOME] [KEYS] [Red])

When pressing the 3 buttons, [HOME], [KEYS] and [Red] simultaneously for 5 seconds,

INFO LED becomes flashing Red (fast speed) and Status LED becomes flashing same timing.

22

Page 23

23

Page 24

8 Service Mode

8.1. About the Service Mode

Informations necessary for service can be displayed. Connect the display via the HDMI cable before into the service mode.

8.1.1. How to enter the Service Mode

8.1.2. How to operate the Service Mode

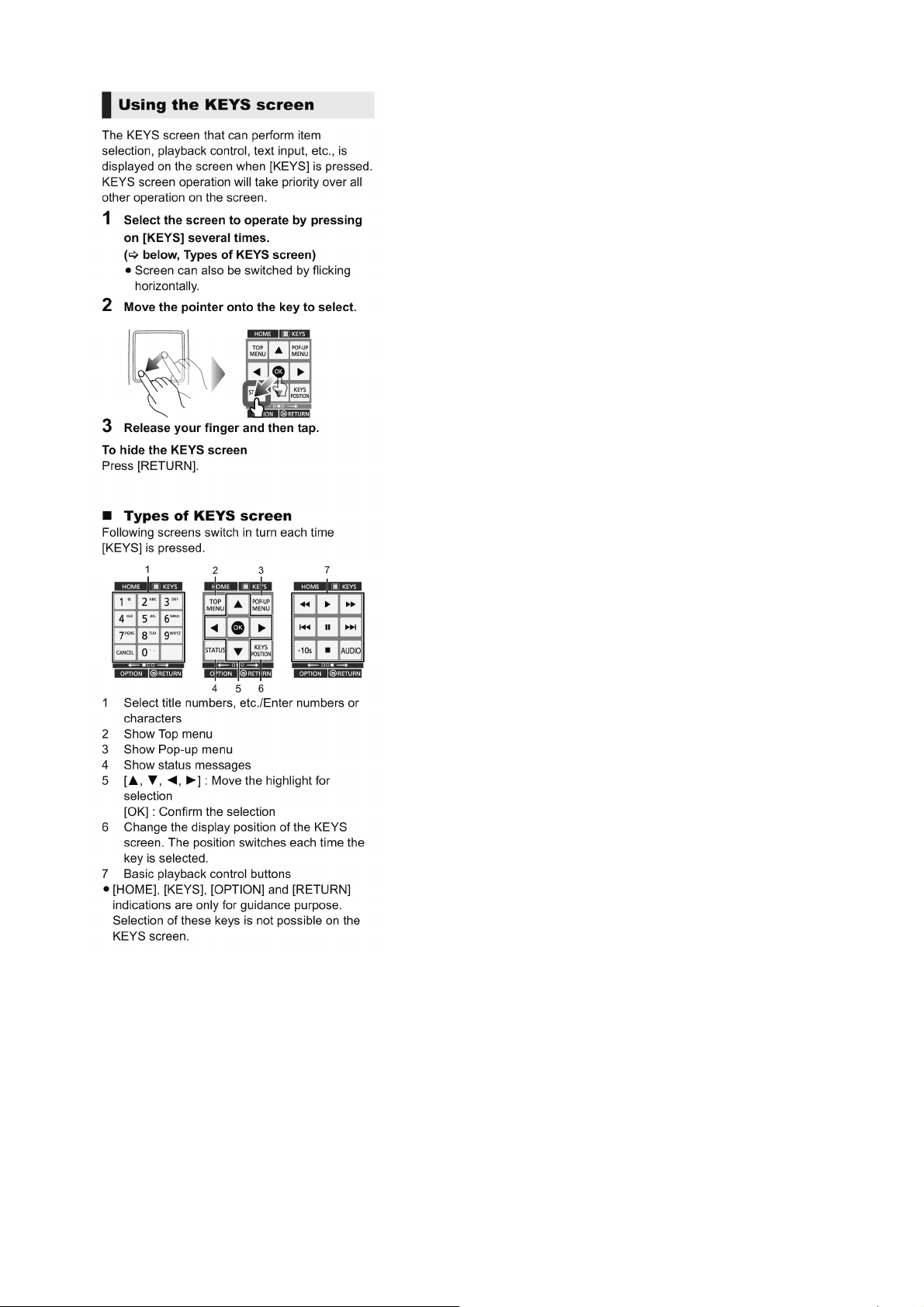

Select the Ten Key pad screen by pressing on [KEYS] several time.

While the Ten Key pad screen is displayed, select numeric key and tap for service mode.

8.1.3. How to exit the Service Mode

Press and hold the [Standby/on] switch (remote control or unit).

>>> The Service Mode is terminated and automatically turns the unit off.

24

Page 25

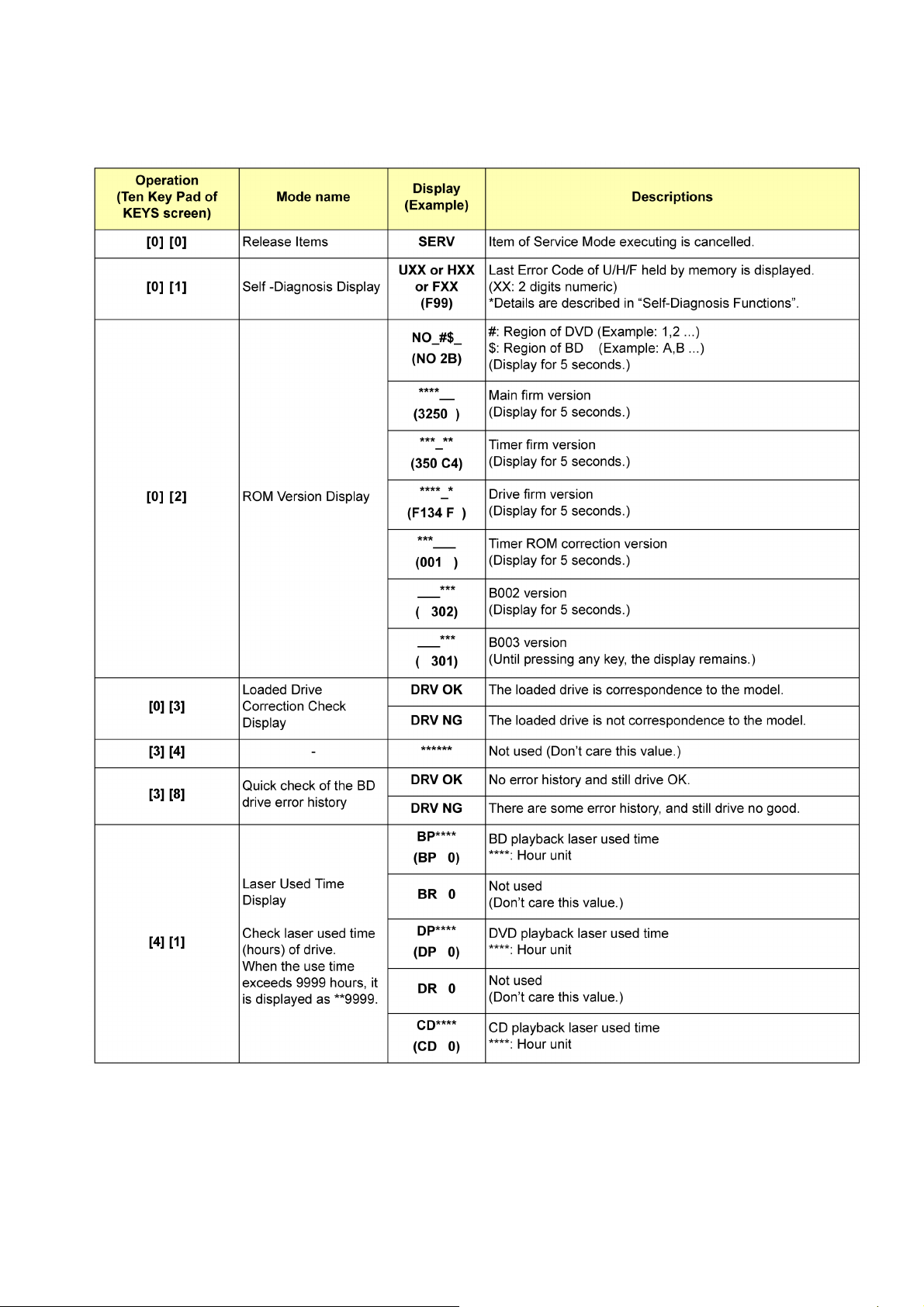

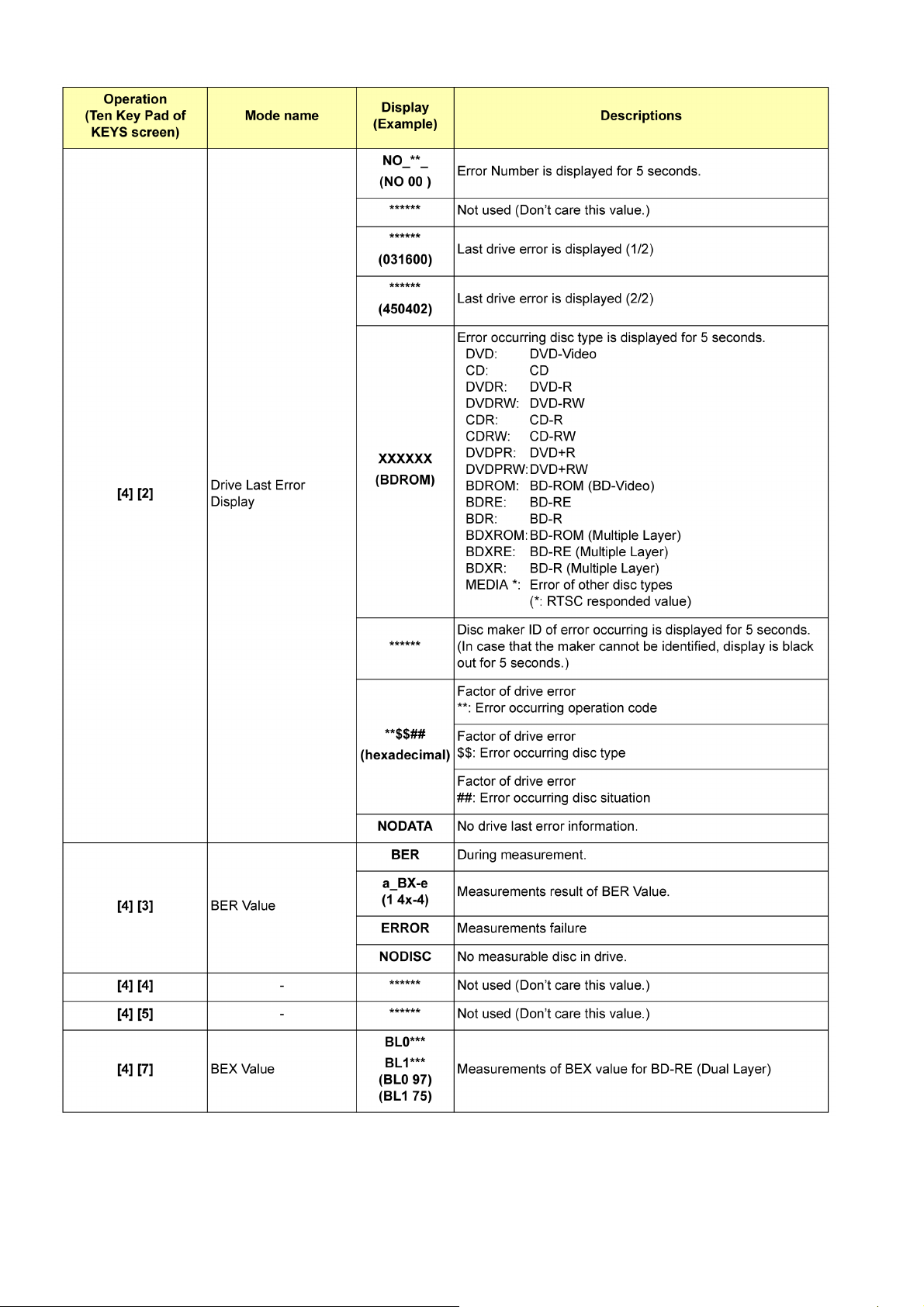

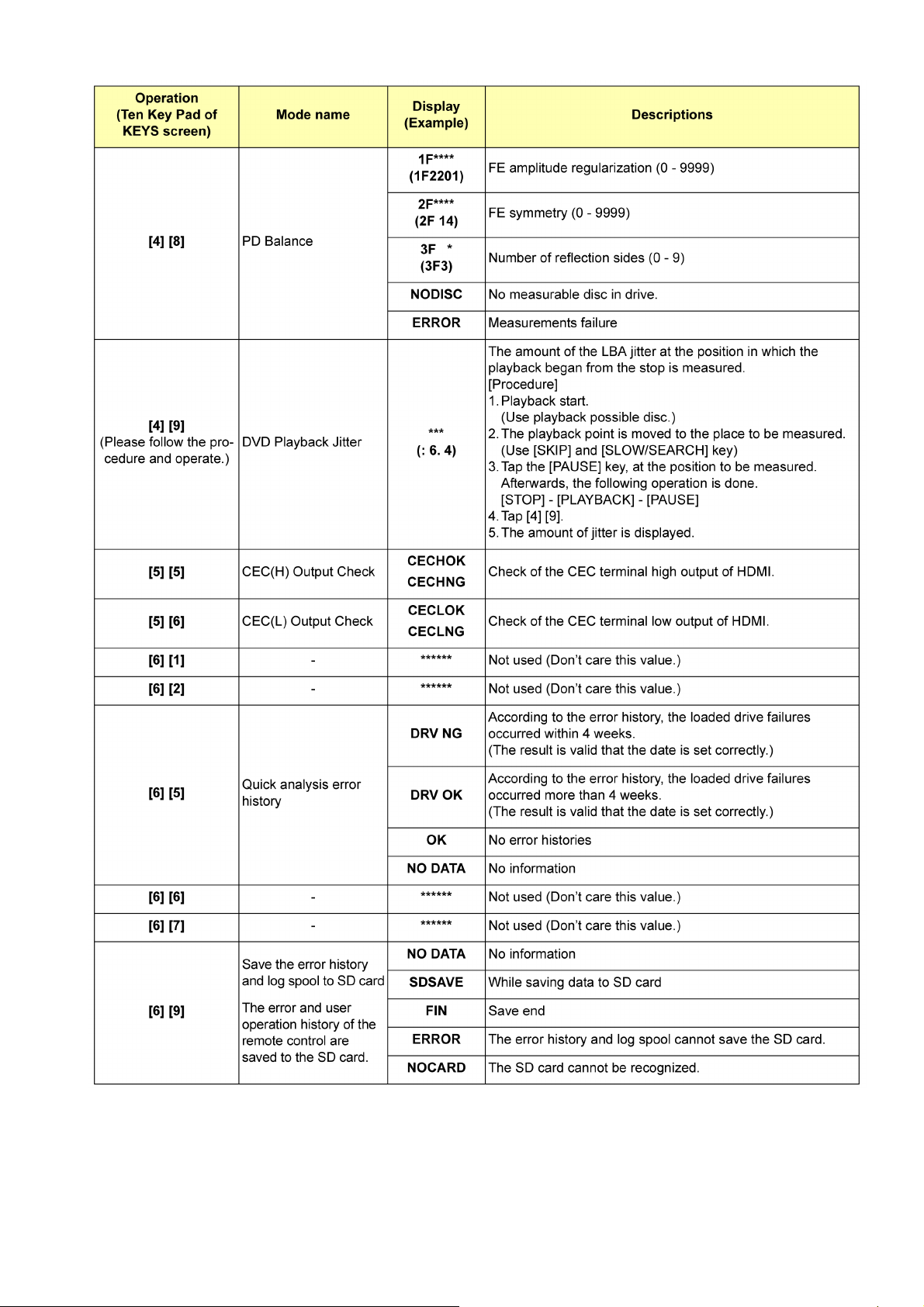

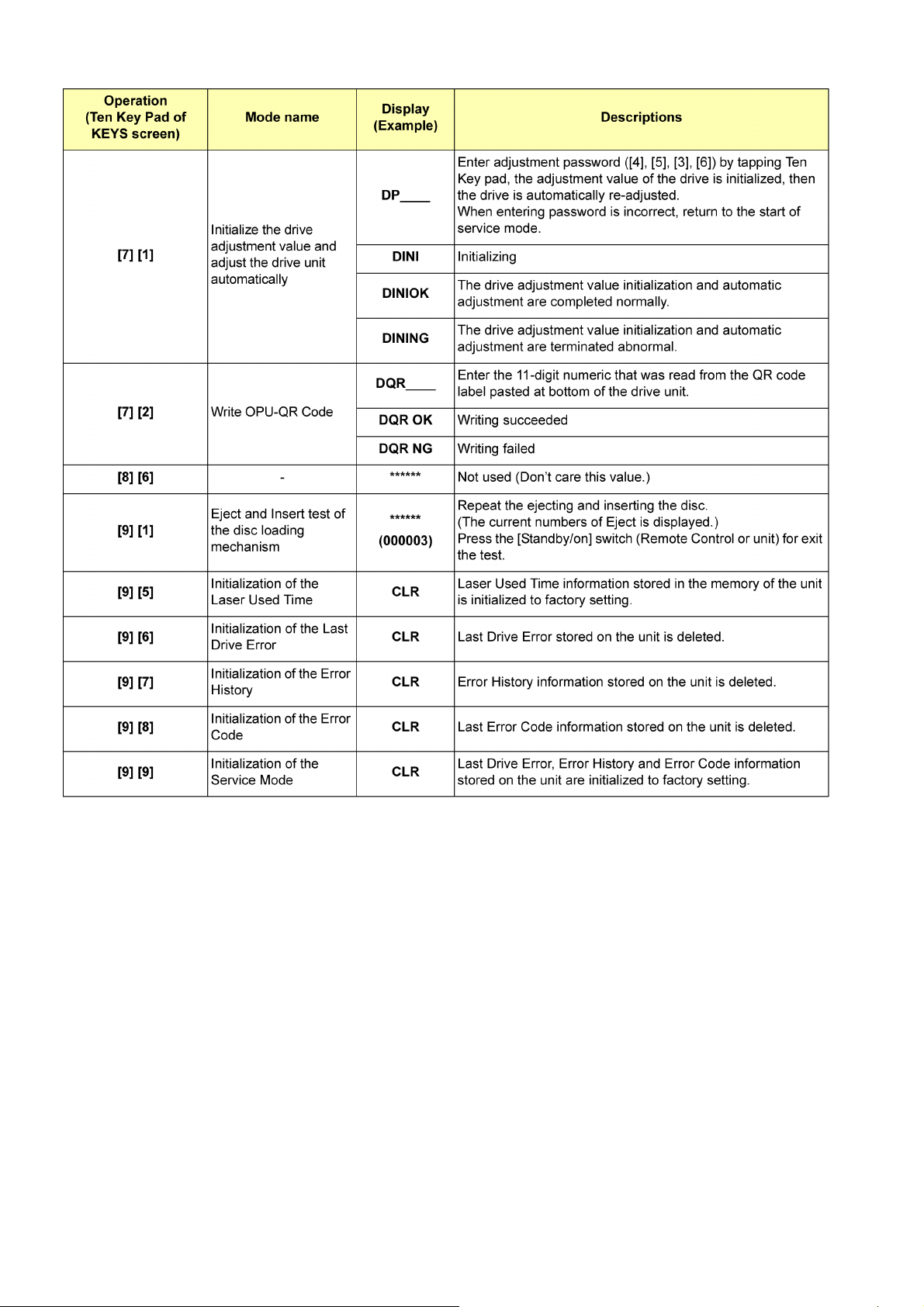

8.2. Service Mode List

The display of information to each command is as follows.

Note:

Do not use it excluding the designated command.

25

Page 26

262728

Page 27

Page 28

Page 29

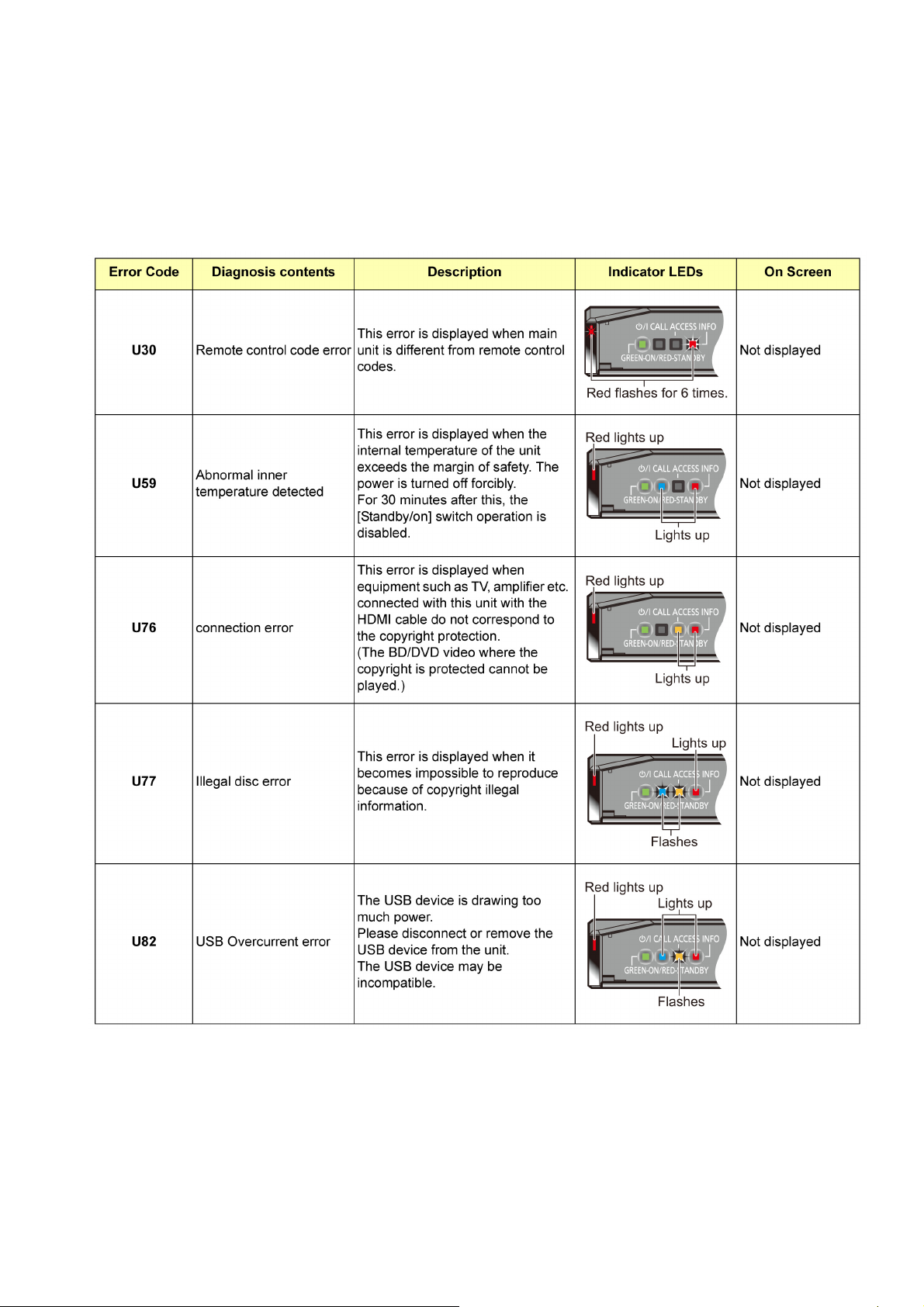

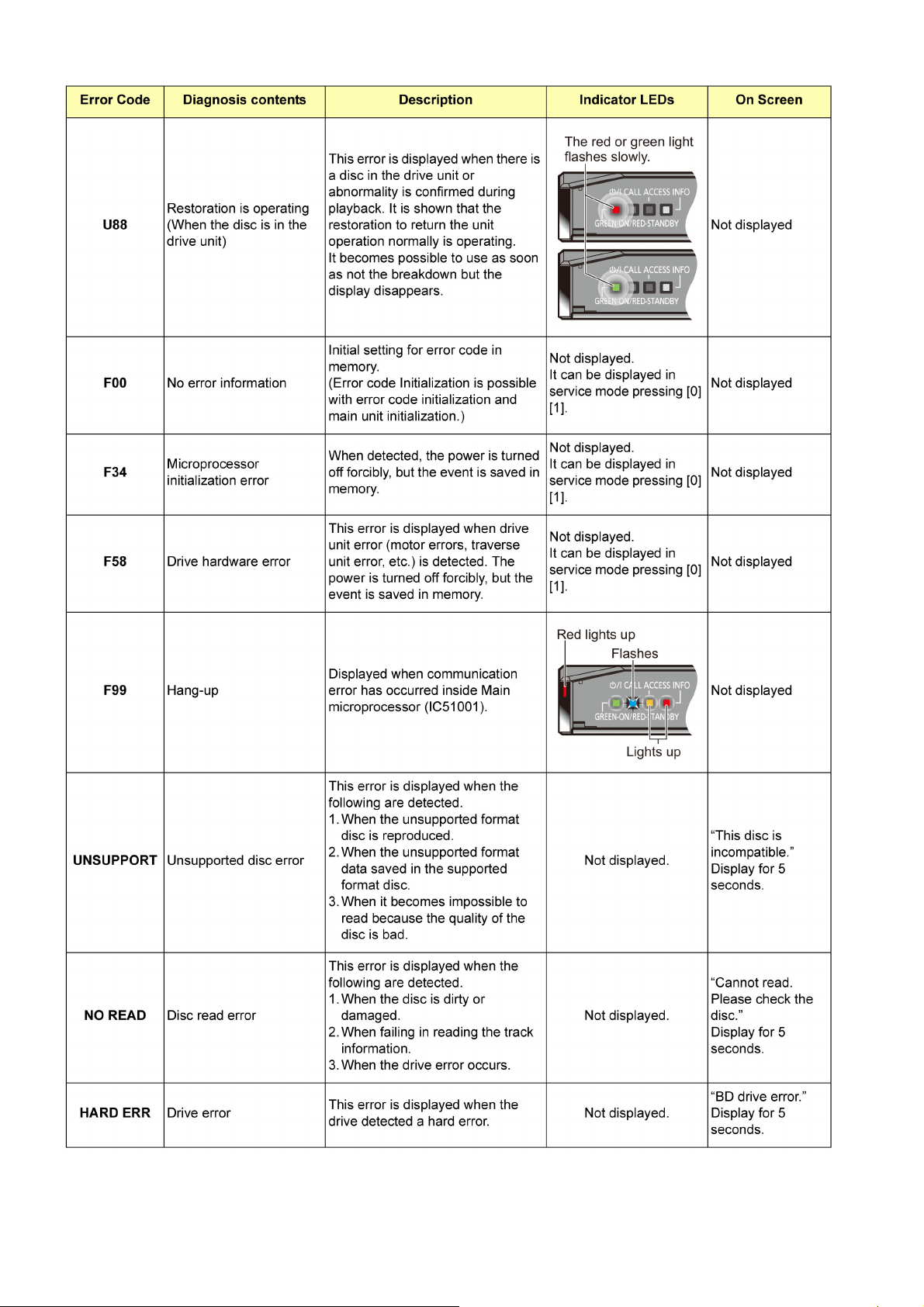

8.3. Self-Diagnostics Functions

8.3.1. Self-Diagnostics Functions

Self-Diagnosis Function provides information for errors to service personnel by Self-Diagnosis Display when any error has

occurred.

U**, H** and F** are stored in memory and held.

You can check last error code by transmitting [0] [1] in Service Mode.

Automatic Display on Indicator LEDs will be cancelled when the power is turned off or AC input is turned off during self-diagnosis

display is ON.

29

Page 30

303132

Page 31

Page 32

9 Service Fixture & Tools

*The above parts are supplied by AVC-CSC-SPC.

Page 33

10 Disassembly and Assembly Instructions

10.1. Unit

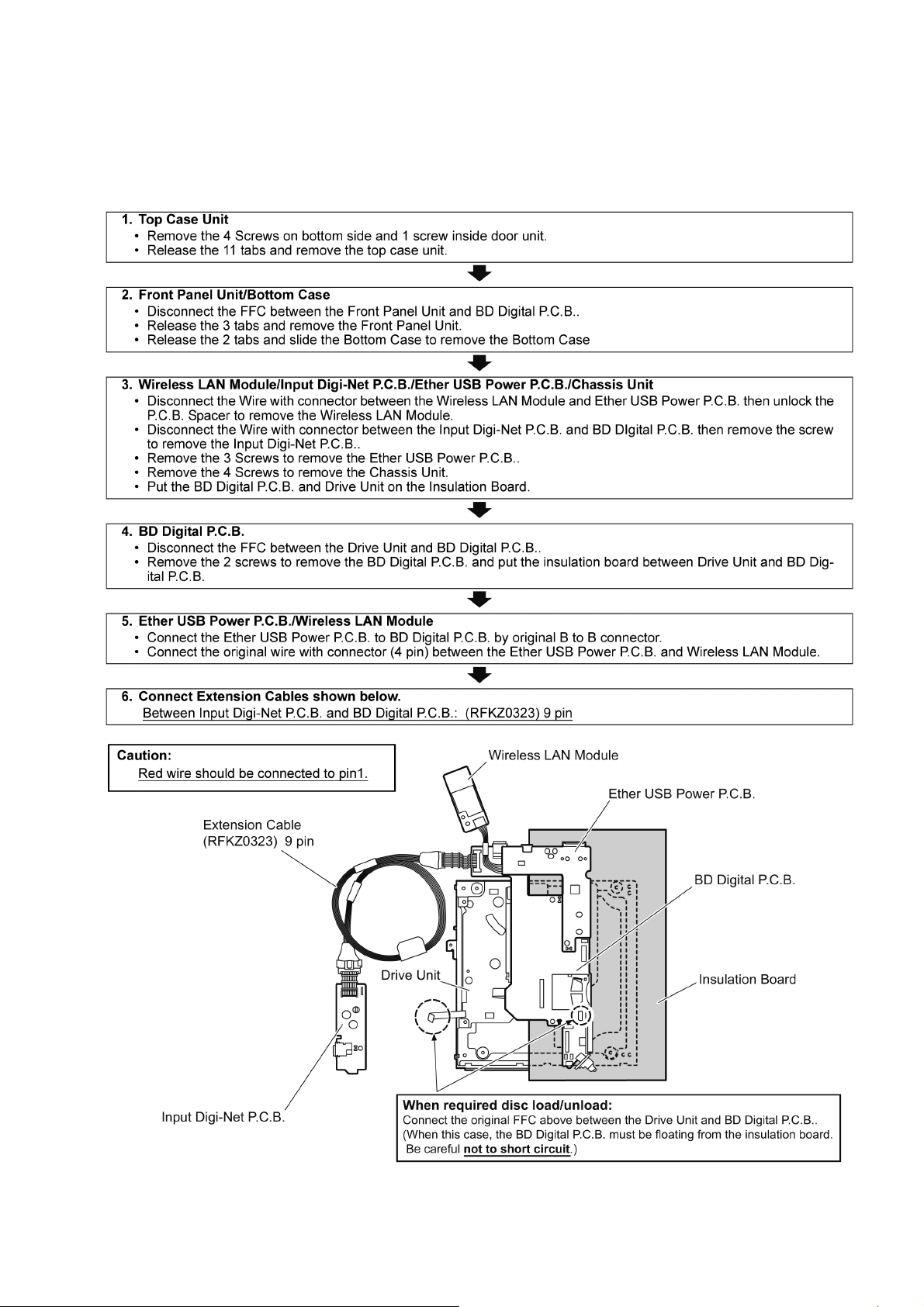

10.1.1. Disassembly Flow Chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

10.1.2. P.C.B. Positions

33

Page 34

10.1.3. Top Case

1. Remove the 4 screws (A).

2. Open the door unit and remove the screw (B).

3. Unlock the 11 tabs and remove the top case unit.

3. Remove the front panel unit.

10.1.5. Door Unit

1. Open the door unit.

2. Pull out the locking tab of the door unit in direction of the

arrow (1).

3. Remove the door unit in direction of the arrow (2).

10.1.4. Front Panel Unit

1. Remove the FFC(A).

2. Unlock the 3 tabs.

34

Page 35

10.1.6. Bottom Case

1. Spread a little chassis unit and bottom case in the

direction of the arrow (1) and unlock the 2 tabs.

then slide the bottom case a little in the direction of the

arrow (2).

(Sliding the bottom case becomes the 5 locking tabs

unlocked.)

2. Remove the bottom case in direction of arrow (3).

10.1.7. Wireless LAN Module

1. Remove the connector (A).

2. Unlock the P.C.B. spacer and remove the wireless LAN

module.

10.1.8. Input Digi-Net P.C.B.

1. Remove the wire with connector (A).

2. Unscrew the screw (A) to remove the input digi-net

P. C . B . .

35

Page 36

10.1.9. Ether USB Power P.C.B.

1. Remove the screw (A) and 2 screws (B).

2. Remove the ether USB power P.C.B. in direction of arrow.

10.1.10. LED Buzzer P.C.B. and IR LED P. C .B .

1. Remove the LED buzzer P.C.B. and IR LED P.C.B. in

direction of arrow.

10.1.11. Chassis Unit

1. Remove the 4 screws (A).

2. Remove the chassis unit in direction of arrow.

36

Page 37

10.1.12. BD Digital P.C.B. and Drive Unit

1. Pull out the Diffused Sheet.

2. Remove the FFC (A), and isolate it with an ESD prevention bag (RPFC0114).

3. Remove the Connector (A), FFC (B) and FFC (C).

4. Remove the 2 screws (A).

5. Remove the FFC (D) then remove the drive unit from the

BD digital P.C.B..

6. Unscrew the 2 screws (B) to remove the drive angle.

37

Page 38

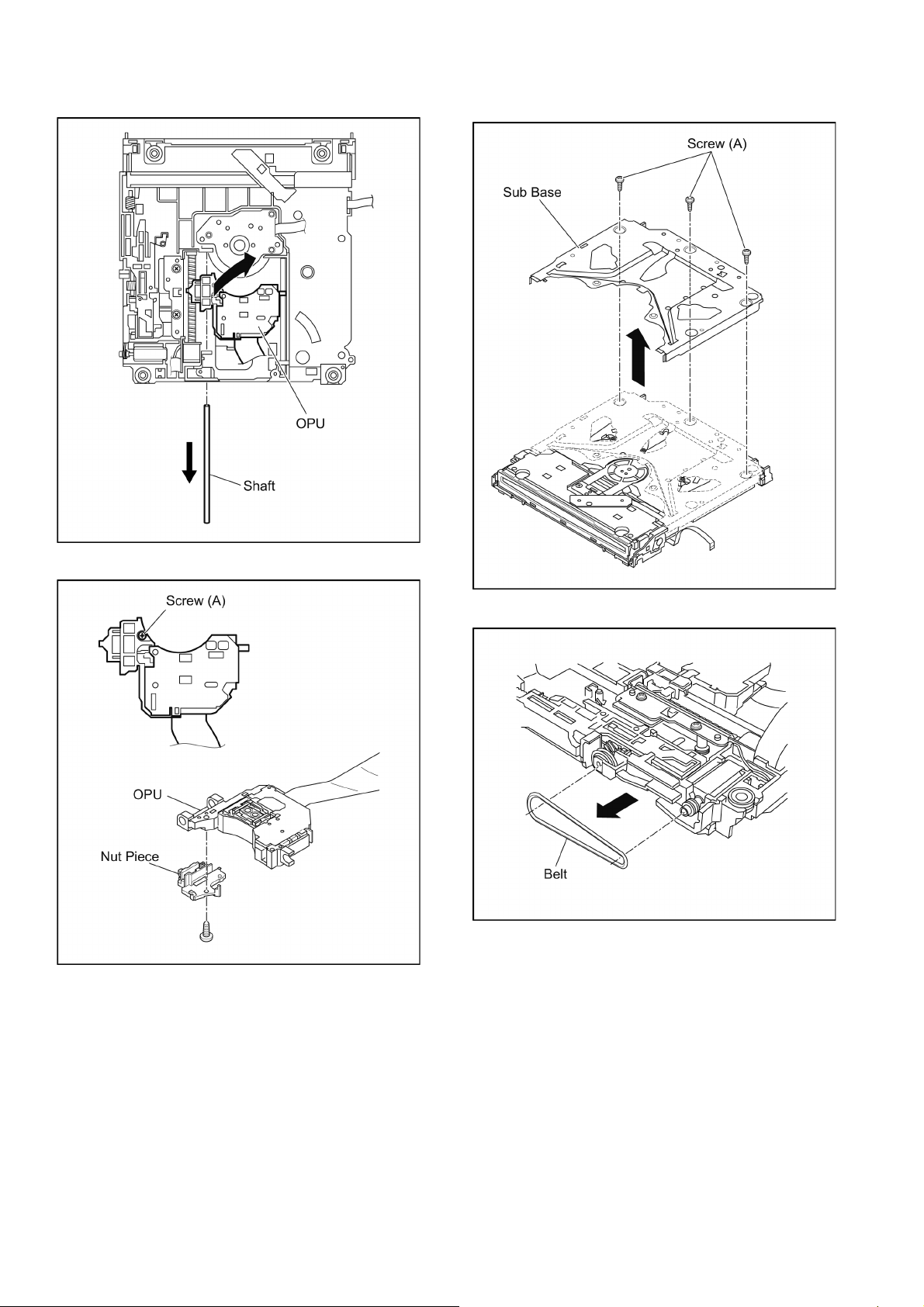

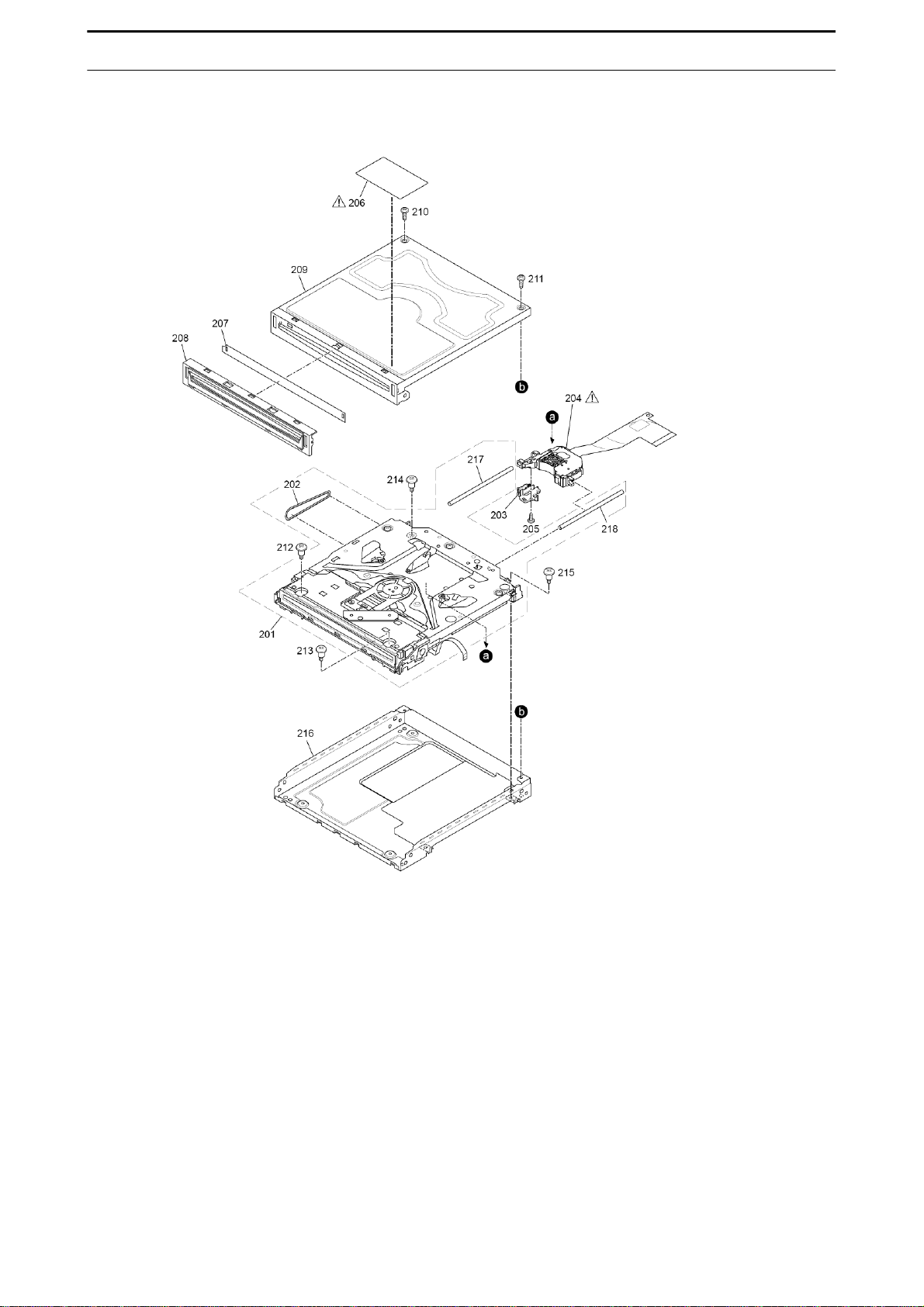

10.2. Drive Unit

10.2.1. Bezel and Tray Door

1. Unlock 7 tabs (A) and 2 tabs (B) to remove the Bezel and

Tray Door.

10.2.2. Top Cover Unit

1. Unscrew the 2 screws (A) and remove the Top Cover

Unit.

38

Page 39

10.2.3. Bottom Cover

1. Unscrew the 4 screws (A) and remove the Bottom Cover.

3. Unscrew the 2 screws (A) and unlock the locking tab (A)

to remove the FPC bracket.

4. Remove the Radiator sheet with FPC sheet.

10.2.4. OPU and Nut Piece Unit

1. Turn over the drive unit.

2. Slide the OPU Sheet and OPU FPC to release from slit of

the FPC bracket.

39

Page 40

5. Remove the shaft then remove the OPU shifted slightly

diagonally.

10.2.5. Belt

1. Unscrew the 3 screws (A) to remove the the Sub Base.

6. Unscrew the screw (A) and remove the Nut Piece.

2. Remove the belt.

40

Page 41

11 Measurements and Adjustments

11.1. Service Positions

For description of the disassembling procedure, see the “10 Disassembly and Assembly Instructions”.

11.1.1. Checking and repairing

41

Page 42

11.2. Adjustment of Drive Unit/BD Digital P.C.B.

11.2.1. Checking out symptoms and repair of Drive Unit/BD Digital P.C.B.

42

Page 43

11.2.1.1. Analysis Procedures

1. Confirmation the pointed symptom - 1

After replacing the BD Digital P.C.B. with normal one, carry out the drive automatic adjustment using the Service Mode [7][2]

and [7][1], confirm the pointed symptom occurs again.

• When the pointed symptom not occurs:

Original BD Digital P.C.B. is defected, go to Step 2.

• When the pointed symptom occurs:

The drive unit is defective, go to Step 3.

2. Replacing BD Digital P.C.B. with the original one, carry out the failure analysis and repair, go to Step 4.

3. Replacing BD Digital P.C.B. with the original one, carry out the drive automatic adjustment using the Service Mode [7][2] and

[7][1].

• When the pick-up unit is defected, replace the pick-up unit with normal one.

• When exterior parts or mechanism are defected, replace the defective parts.

4. Confirmation the pointed symptom - 2

Carry out the drive automatic adjustment using the Service Mode [7][2] and [7][1], recheck the pointed symptom and failure

not occurs.

• When the pointed symptom occurs again, go to Step 1.

11.2.2. In the Case of Necessity the Adjustment

1. When the OPU ass’y is replaced.

2. When the Drive Unit is replaced.

3. When the BD Digital P.C.B. is replaced.

43

Page 44

11.2.3. Adjustment Procedure

44

Page 45

11.3. Caution for Replacing Parts

After replacing the BD Digital P.C.B., [TEST] is displayed, so, once power off again to on.

11.3.1. Caution after replacing parts

After replacing the Drive Unit/BD Digital P.C.B., must be update Firmware.

11.3.2. Standard Inspect Specifications after Repairs

After making repairs, we recommend performing the following inspection, to check normal operation.

45

Page 46

12 Block Diagram

OVERALL BLOCK DIAGRAM

DMP-BBT01EB/EG OVERALL BLOCK DIAGRAM

TRAVERSE MECHANISM UNIT

OPTICAL

PICK-UP

UNIT

IC51001

SERVO CONTROLLER/

OPTICAL DISC CONTROLLER/

AV DECODER/

SYSTEM CONTROLLER

LED

BUZZER

LASER DIODE

FOCUS COIL

BEAM EXPANDER

TRACKING COIL

STEPPING

MOTOR

SPINDLE

MOTOR

LOADING

MOTOR

SD CARD

IC59020

IC51301

NAND FLASH

ROM/2Gbit

PHYSICAL LAYER

TRANSCEIVER

JK59001

ETHERNET

PORT

IC52001

SDRAM/2Gbit

SDRAM/2Gbit

IC52002

MPX/DE-MPX

IC57101

REMOTE

SENSOR

REMOTE

SENSOR

X51001

(27MHz)

IC55004

DISC

MOTOR

DRIVER

P59601

TOP SENSOR

IC57501

USB PORT

(FRONT)

P59301

HIGH SIDE SWITCH

IC59303

HIGH SIDE SWITCH

IC59304

IC59305

USB HUB

CONTROLLER

WIRELESS

LAN

MODULE

IC53002

DIGITAL

AUDIO OUT

(OPTICAL)

(JK56301)

HDMI

JACK

12.1. Overall Block Diagram

46

Page 47

12.2. Input Digi-Net P.C.B. Regulator Circuit Block Diagram

DMP-BBT01EB/EG INPUT DIGI-NET P.C.B. REGULATOR CIRCUIT BLOCK DIAGRAM

P58002

P58001

P58002 P58001

1,2

3,4

P58002 P58001

9

PW X SW5.9V

P58002

P58001

5

PW ST D3.3V

P58002

P58001

8

IR SEL

SW58001

PW X SW12.2V

P STANDBY H

From/To BD DIGITAL P.C.B.

INPUT DIGI-NET P.C.B. REGULATOR CIRCUIT BLOCK DIAGRAM

IC58003

(REGULATOR +3.3V)

13

Vin

14

Vcc

Vfb

1

7

2

Vo

EN

12

Vbst

10

SW1

SW2

11

CKH1

CKH2

CL58003

CKZ1

CKZ3

CKZ5

CKZ9

CKZ8

CL58005

QR58002

123

4

6

5

Q58002

JK58001

1

3

2

DC

JACK

IP58001

IP58002

Q58001

IC58303

(REGULATOR +5.9V)

8

Vin

Vfb

2

EN

7

Vbst

SW

6

1

47

Page 48

12.3. BD Digital P.C.B. Regulator Circuit Block Diagram

DMP-BBT01EB/EG BD DIGITAL P.C.B. REGULATOR CIRCUIT BLOCK DIAGRAM

BD DIGITAL P.C.B. REGULATOR CIRCUIT BLOCK DIAGRAM

LDD VCC

(P55006-20)

TL55004

IC58302

(REGULATOR +5V)

2

VIN

5

4

1

VO

CN

CONT

DR P ON H

(From IC51001-D14)

QR58001

IC57006

(REGULATOR +3.3V)

4

1

5

VOUT

ON

VIN

CL57003

IC56302

(REGULATOR +5V)

5

VIN

4

1

VOUT

ON

CL57119

HDMI P ON H

(From IC51001-A13)

IC55300

(REGULATOR +5V)

1

Vout

PW HDMI5V

( To JK56301-18)

PW ST D3.3V

CKS18

CL57034

IC55006

(REGULATOR +5V)

2

VC

3

1VOVIN

CL55294 CL55295

CL55003

CL55002

CL55296

CL55297

CL55001

CL55030

IP55005

D5V

(To IC55004-29,37,40)

LDD BVCC

(P55006-15)

PDIC VCC

(To P55006-27)

PW DR12V

(To IC55004-45,54.55)

8

Vin

PW X SW3.3V

IC57003

(REGULATOR +1.2V)

5

1

3

VOUT

VDD

CE

CL57011

VDD12STM

( To IC51001-F8)

IC58004

(REGULATOR +1.5V)

13

Vin

14

Vcc

Vfb

1

7

2

Vo

EN

12

Vbst

10

SW1

SW2

11

From/To INPUT DIGI-NET P.C.B.

P58001P58002

1,2

P58001P58002

3,4

PW X SW12.2V

PW X SW5.9V

IC58005

(REGULATOR +1.1V)

13

Vin

14

Vcc

Vfb

1

7

2

Vo

EN

12

Vbst

10

SW1

SW2

11

CL58001

PW PK D1.5V

CL58002

PW PK D1.1V

CL58004

CL58006

PW USB 5.1V

IC58203

(REGULATOR +5.1V)

8

Vin

Vfb

2

EN

7

Vbst

SW

6

1

CL57203

P STANDBY H

(From IC51001-B15)

P58001

P58002

9

P STANDBY H

123

4

6

5

Q58006

CKW1

P58001P58002

5

PW ST D3.3V

CKW5

CKW9

CKW3

IP55004

5 CONT

VDD33STM

( To IC51001-F7)

48

Page 49

12.4. Digital Video/Audio Circuit Block Diagram

DMP-BBT01EB/EG DIGITAL VIDEO/AUDIO CIRCUIT BLOCK DIAGRAM

: VIDEO PB SIGNAL

:

AUDIO PB SIGNAL

DIGITAL VIDEO/AUDIO CIRCUIT BLOCK DIAGRAM

IC53002

(OPTICAL FIBER

TRANSMITTER)

IC51001

(PEAKS-PRO4)

AO2IEC

K4

1

2

G OPTIEC

VIN

VCC

DRIVE

IC

PW ST D3.3V

CK54001

CK54002

CK51010

4 8

73

1

3

19

16

CL56301CL57118

CKS15

CKS16

CKS13

CKS19

CKS18

JK56301

(HDMI JACK)

D2+

D2-

2 6

51

4

6

D1+

D1-

L56301

L56302

4 8

73

7

9

D0+

D0-

2 6

51

10

12

CLK+

CLK-

HDMISDA

HOTPLG

15

HDMISCL

HTTX2P

HTTX2M

HTTX1P

HTTX1M

HTTX0P

HTTX0M

HTTXCP

HTTXCM

HTSCL

HTSDA

HTHPD

A5

B5

A4

B4

A3

B3

A2

B2

E7

E6

D7

SMPIO07

HDMI CEC

B12

13

CEC

18

+5V

PW HDMI5V

(From IC56302-4)

Q56301

PW X SW5.9V

49

Page 50

12.5. Digital (Front End Section) Circuit Block Diagram

DMP-BBT01EB/EG DIGITAL (FRONT END SECTION) CIRCUIT BLOCK DIAGRAM

DIGITAL(FRONT END SECTION) CIRCUIT BLOCK DIAGRAM

IC51001

(PEAKS-PR04)

CL55040

CL55055

CL55053 CL55054

CL55099 CL55098

CL55144 CL55143

CL55146 CL55145

CL55093 CL55092

CL55091

CL55411

CL55410

CL55097

CL55096

CL55095

CL55094

CL55090

CL55052

OPTICAL PICK-UP/TRAVERSE

SPINDLE

MOTOR

STEPPING

MOTOR

FO/TR

ACTUATOR

LASER DIODE

DRIVE(LDD)

LASER

DETECTOR

LASER

DETECTOR

LASER

DETECTOR

DVD

CD

BD

P55006

P55401

P55011

BD/DVD

RF SIGNAL

FOCUS/TRACKING ACTUATOR

SPINDLE MOTOR DRIVE

STEPPING MOTOR DRIVE

DVD FOCUS AND TRACKING SIGNAL

LD CONTROL SIGNAL

BD FOCUS AND TRACKING SIGNAL

CD MAIN AND SUB SIGNAL

BEAM EXPANDER

B19

PWM1A

C18

PWM0B

B17

PWM3B

C19

PWM2A

PWM3A

A17

P12

L23

P13

L22

FG

B20

PWM4

C17

RF SIGNALMOTOR DRIVE SIGNALTRACKING ERROR SIGNALFOCUS ERROR SIGNAL

IN1

Logic

IN47

VREF

STBY

IN58

DAT

CK

EN

FG

INS6

Pre-Drive

V

DD

FO1

G FO2+

G FO2-

G FO1+

G FO1-

G TR+

G TR-

G SA+

G SA-

G SB+

G SB-

G TRVA+

G TRVA-

G TRVB+

G TRVB-

G U

G V

G W

RO1

Logic

Pre-Drive

Pre-Drive

Pre-Drive

Pre-Drive

FO7

RO7

FO8

RO8

FO4

RO4

FO5

RO5

Logic

Upper

Pre-Drive

Upper

Pre-Drive

OSC

Serial

Distribution

Circuit

Stand-by

(ALL)

IC55004

(MOTOR/PWM/DRIVER)

IN2

Logic

Pre-Drive

FO2

RO2

IN3

Logic

Pre-Drive

FO3

RO3

V

DD

V

PUMP

DMOS

3-phase

bridge

Generate

FG

A1

COM

A2

A3

RCS1

ABS

Logic

Pre-Drive

V

DD

DMOS

H/B

FO6

RO6

DMOS

H/B

DMOS

H/B

DMOS

H/B

DMOS

H/B

DMOS

H/B

DMOS

H/B

DMOS

H/B

G LDM-

G LDM+

LOADING

MOTOR

PWM1A

A19

PWM0A

P14

M23

PWM0A

PWM2A

VHALFIN

PWM3A

PWM0B

PWM3B

G SDIO D

G SCLK D

G SEN D

FG

PWM4

P55401

P55401

7

8

39

38

53

52

51

56

47

46

43

41

36

35

34

33

32

31

25

24

22

20

18

7

10

6

9

12

13

11

14

8

27

26

48

RCS2

CS

GND

49

1

16

E23

VHALFOUT

RL55045

RL55152 RL55153

RL55154

RL55039

RL55041

RL55044

RL55043

RL55079

RL55078

B22

PAD0

D22

PAD1

K23

P10

P12

P13

L23

L22

P14

M23

G26

RFA

G25

RFB

F25

AIN

E26

BIN

E25

CIN

D26

DIN

D25

EIN

C26

FIN

B26

GIN

C25

HIN

50

Page 51

12.6. Digital (Back End Section [1]) Circuit Block Diagram

IC51001

(PEAKS-PRO4)

DMP-BBT01EB/EG DIGITAL(BACK END SECTION[1]) CIRCUIT BLOCK DIAGRAM

DIGITAL(BACK END SECTION [1]) CIRCUIT BLOCK DIAGRAM

CK27XO

CK27XI

X51001

(27MHz)

B10

A10

BD DIGITAL P.C.B.

IC59020

(ETHERNET CONTROLLER)

JK59001

(ETHERNET JACK)

11

10

4

5

TX+

TX-

RX+

RX-

CK59631

10M

100M

WOL

5B 4B

Decoder

(LPI Detection)

TXC10

TXD

TXC25M

RXD

RXC25M

TXD10

RXC10

RXD10

10/100

Half /Full

Switch

Logic

10/100M Auto Negotiation

Control Logic

(EEE Capability Exchange)

Manchester Coded

Waveform

Data Recovery

Receive Low Pass Filter

10M Output Waveform

Shaping

(Amplitude Reduction)

TXO+

MDI+[0]

MDI-[0]

MDI+[1]

MDI-[1]

TXO-

RXIN+

RXIN-

CK25O

PLL

MASTER

CKXTAL1

MII RXD3

MII RXD2

MII RXD1

MII RXD0

MII TXD0

MII TXD1

MII TXD2

MII TXD3

RXD3

RXD2

RXD1

RXD0

TXD0

TXD1

TXD2

TXD3

MII RXCLK

RXC

MII RXER

RXER

MII RXDV

RXDV

MDIO INTL

INTB

PHYRSTL

PHYRSTB

MII TXEN

TXEN

MII TXCLK

TXC

MDC

MDC

MDIO

MDIO

31

PMEB

10

1

2

4

5

22

27

23

24

25

26

13

19

39

18

17

16

14

32

29

42

30

Y4

Y2

Y3

W6

Y1

W4

AB1

AA2

AA3

AA4

AC3

AC2

AC1

AE1

AB3

AD2

AD1

AB2

RL59007

RL59004

RL59002

RL59008

MII CRS

CRS

36

W5

RL59011

MII COL

COL

38

Y5

RL59010

RL59003

CL59003

CL59001

IC59305

(USB HUB CONTROLLER)

CKJ59301

CKA59629

CKA59608

CKA59609CK59635

CKA59630

CK59602

CK59601

CK59634

CKJ59302

CKJ59303

X59301

(30MHz)

SD0CMD

SD0CLK

SD0CD

SD0WP

SD0DAT0

SD0DAT1

SD0DAT2

SD0DAT3

7

8

9

1

2

5

10

12

DAT0

DAT1

DAT2

DAT3

CMD

CLK

CD

WP

3.3V

11

P59601

(SD CARD SLOT)

PW USB 5.1V

PW USB 5.1V

P59602P59603

301

P59602P59603

292

P59602P59603

922

P59602P59603

823

P59602P59603

328

P59602P59603

229

P59602P59603

625

P59602P59603

526

2 3

41

T59301

3

1

2

DN

DP

VBUS

IC59303

(HIGH SIDE SWITCH)

VIN

VOUT

/EN

/OC

3

4

1

5

FRONT-SIDE

(H-type)

USBDN1

AF22

USBDP1

AE22

4B

3.3V

4A

PW ST D3.3V

P59303

4

P59303

2

P59303

3

25

26

45

46

DM1

DP2

PPB1

CSB1

CKJ59013

IC59304

(HIGH SIDE SWITCH)

VIN

VOUT

/EN

/OC

3

4

1

5

43

44

PPB2

CSB2

DP1

21

22

1

10

11

DMU

DPU

VDD33

VDD33

VDD33

VBUSM

VDD25OUT

12

VDD25

19

AVDD

24

VDD25

33

VDD25

X1

X2

DM2

CK59011

CK59012

2 3

41

T59302

DP

DN

1 5

62

L59601

3 7

84

29

28

17

AVDD

9

20

30

47

VDD33REG

48

PW ST D3.3V

WIRELESS

LAN MODULE

CKJ59610

CKJ59609

CKJ59606

CKJ59603

CKJ59602

CKJ59601

CKJ59608

CKJ59607

CKJ59605

W25

V23

V25

V24

W24

W26

V22

W23

ETHER USB POWER P.C.B.

PW X SW12.2V

Q57502

Q57501

QR57501

+

BZ51091

BUZZER

SMPIO14

SMPIO16

E13

C12

Data

Alignment

Scrambler

Descrambler

Serial to

Parallel

Parallel to Serial

Supports

EEE Quiet

3 Level

Driver

TD+

Adaptive

Equalizer

ck Slave

3Level

Comparator

MLT-3

to NRZI

PLL

data

4B 5B

Encoder

(LPI Generation)

Variable Current

Link Pulse

RL57002

RL57004

P59301

(USB JACK)

CK59003

CK59004

CKA59602CK59629

CK59628

CK59626

CK59625

CKA59603

CK59005

CKA59605

CK59006

CKA59606

CK59633

CK59605

CK59632

CL59002

51

Page 52

12.7. Digital (Back End Section [2]) Circuit Block Diagram

IC52001

(DDR3 SDRAM/2Gbit)

44

29

IC51301

(NAND FLASH ROM/2Gbit)

DATA

DATA

MMDQ14

MMDQ9

MMA13

MMA0

ED0

ED7

IO0

IO7

MMDQ2

MMDQ3

A3

D7

H7

E3

AC7

AB9

AD4

AC5

AD14

AF10

A13

A0

DQU7

DQU0

DQL7

DQL0

M3

N8

BA2

BA1

M2

BA0

AB13

AE13

MMBA2

MMBA1

AD9

MMBA0

T3

N3

AF25

AC25

ADDRESS

BANK BANK

M3

N8

BA2

BA1

M2

BA0

BANK

ADDRESS

IC51001

(PEAKS-PRO4)

DMP-BBT01EB/EG DIGITAL(BACK END SECTION[2]) CIRCUIT BLOCK DIAGRAM

DIGITAL(BACK END SECTION [2]) CIRCUIT BLOCK DIAGRAM

PW ST D3.3V

12

VCC

37

VCCQ

DATA

DATA

IC52002

(DDR3 SDRAM/2Gbit)

A3

D7

H7

E3

AA16

AB15

AD20

AC18

A13

A0

DQU7

DQU0

DQL7

DQL0

T3

N3

ADDRESS

D

ATA

DATA

MMDQ25

MMDQ31

MMDQ23

MMDQ18

P58001 P58002

1,2

PW X SW3.3V

1

3

REMOCON

IR51921

REMOTE

SENSOR

BD DIGITAL P.C.B.

CK27XO

CK27XI

X51001

(27MHz)

B10

A10

XRST STM

F15

IC57002

(RESET)

1 2

OUT VDD

CL57001

SMPIO05

A14

IC57005

(RESET)

SMPIO22

A11

1 2

OUT VDD

P58001 P58002

3,4

CL57014

CL57031

CL57032

CL57033

CL57103

CL57122

CKD1

INPUT DIGI-NET P.C.B.

TOUCH SW P.C.B.

LED BUZZER P.C.B.

IR LED P.C.B.

P51901P51701

5

REMOCON

PW X SW3.3V

1

3

REMOCON

IR57101

REMOTE

SENSOR

IC57101

(MPX/DE-MPX)

CH0

1

CKJ2

PW X SW12.2V

P58001 P58002

8

IR SEL

PW X SW5.9V

P57501 FT701

1

P57501 FT701

3

D51902

D51901

VDD

1

IC57501

(TOP SENSOR)

ALERT

17

SM CLK

8

SM DATA

6

CS1

CS2

RL701

CS1

CS2

CS1

RL702

CS2

P-ON

D51904

SKYPE

D51903

ACCESS

D51906

INFO

P-OFF

24

CKD3

23

P51701 P51901

8

LED2

CKB8 CKM8

CKM7

CKM5

P51702 P51921

2

CKC2

10

P51701 P51901

7

LED1

CKB7

CKB5

CKB3

CKB2

9

SMPIO17

SMPIO20

D12

E12

PW X SW3.3V

PW X SW5.9V

LED POWER1

INFO LED

P51901P51701

3

CKM3

SKYPE LED

P51901P51701

2

CKM2

USB LED

LED POWER2

D51922

INFO

P51702 P51921

6

CKC6

CKJ6

PW X SW5.9V

INFO LED

QR51902

QR51903

QR51901

QR57502

P51921P51702

5

D51921

SD

CKJ5

CKC5

SD LED

QR51921

SMPIO13

D13

SMPIO21

F12

SMPIO30

C10

D8

SMPIOA2

RL57114

RL57021

RL51107

7

CH1

6

A

VCC

CMMON

5

INH

2

PW X SW3.3V

8

SMPIO23

B11

52

Page 53

13 Wiring Connection Diagram

INTERCONNECTION DIAGRAM

DMP-BBT01EB/EG INTERCONNECTION DIAGRAM

P51701

5R9V 1

USB_LED 2

SKYPE_LED 3

NC 4

INFO_LED 5

LED_PW_CRL 6

LED_POWER1 7

LED_POWER2 8

GND 9

GND 10

P51702

13R3V

2 REMOCON

3GND

45R9V

5SD_LED

6 INFO2_LED

7GND

8GND

9GND

10 GN D

P59603

30 DGND

29 TX+

28 TX27 DGND

26 RX+

25 RX24 DGND

23 BUZZER_P

22 BUZZER_M

21 DGN D

20 DGND

19 PW_ST_ D3R3V

18 PW_ST_ D3 R3V

17 P W_ST_ D3R3 V

16 PW_ ST_D3R3V

15 PW_X_S12R2 V

14 PW_ X_S12 R2 V

13 PW_ X _S12 R2V

12 PW_ X _S12 R2V

11 DGND

10 DGND

9DGND

8DGND

7DGND

6P_STANBY_H

5DGND

4USBEN1

3DGND

2USBDN1

1USBDP1

JK58001

1+12V

2GND

P58002

PW_X_SW12R2V 1

PW_X_SW12R2V 2

PW_X_SW5R9V3

PW_X_SW5R9V 4

PW_ST_D3R3V 5

GND 6

GND 7

IR_SEL 8

P_ STANB Y_H 9

P51921

3R3V 1

REMOCON 2

GND 3

5R9V 4

SD_LED 5

INFO_LED 6

GND 7

GND 8

GND 9

GND 10

INPUT DIGI-NET P.C.B.

IR LED P.C.B.

BD DIGITAL P.C.B.

WIRELESS LAN MODULE

AC ADAPTOR

TOUCH SW P.C.B.

LED BUZZER P.C.B.

ETHER USB POWER P.C.B.

P55006

OL-ACT FOC2+ 1

OL-ACT FOC2- 2

OL-ACT TRK- 3

OL-ACT TRK+ 4

OL-ACT FOC1+ 5

OL-ACT FOC1- 6

CL-ACT SB+ 7

CL-ACT SB- 8

CL-ACT SA- 9

CL-ACT SA+ 10

LDD GND 11

LDD PTG/GND 12

TMP 13

LDD GND 14

LDD BVCC 15

LDD GND 16

LDD MON 17

LDD GND 18

LDMKR 19

LDD VCC 20

LDD GND 21

LDD LDON 22

LDD SDIO 23

LDD SCLK 24

LDD SEN 25

LDD GND 26

PDIC VCC 27

PDIC GND 28

PDIC C/A2 29

PDIC D/A4 30

PDIC SW2 31

PDIC SW1 32

PDIC A/A3 33

PDIC B/A1 34

PDIC GND 35

PDIC RFN 36

PDIC GND 37

PDIC RFP 38

PDIC GND 39

PDIC FJ/B3 40

PDIC GK/B1 41

PDIC EI/B6 42

PDIC HL/B5 43

PDIC GND 44

PDIC VREF 45

DRIVE UNIT

P55401

LO- 8

LO+ 7

ST2- 6

ST1+ 5

ST2+ 4

ST1- 3

GND 2

SW4 1

P55402

GND 2

PD_3R3V 1

P55011

GND 1

COM 2

V3

W4

U5

P55400

D3R3V 4

SW_2E 3

SW_1E 2

FT3.3V 1

P59602

DGND 1

TX+ 2

TX- 3

DGND 4

RX+ 5

RX- 6

DGND 7

BUZZER_P 8

BUZZER_M 9

DGND 10

DGND 11

PW_ST_D3R3V 12

PW_ST_D3R3V 13

PW_ST_D3R3V 14

PW_ST_D3R3V 15

PW_X_S12R2V 16

PW_X_S12R2V 17

PW_X_S12R2V 18

PW_X_S12R2V 19

DGND 20

DGND 21

DGND 22

DGND 23

DGND 24

P_ STANB Y_H 2 5

DGND 26

USBEN1 27

DGND 28

USBDN1 29

USBDP1 30

P58001

1PW_X_SW12R2V

2PW_X_SW12R2V

3PW_X_SW5R9V

4PW_X_SW5R9V

5 PW_ST_D3R3V

6GND

7GND

8IR_SEL

9P_STANBY_H

P59303

1GND

2DP

3DN

4USB5V

P57501

4GND

3CS2

2GND

1CS1

P51901

15R9V

2USB_LED

3SKYPE_LED

4NC

5 INFO_LED

6NC

7 LED_POWER1

8 LED_POWER 2

9GND

10 GN D

13.1. Interconnection Diagram

53

Page 54

Model No. : DMP-BBT01EG/EB Schematic Diagram Note

Page 55

Model No. : DMP-BBT01EG/EB Parts List Note

Page 56

Model No. : DMP-BBT01EG/EB Abbreviation01

Page 57

Model No. : DMP-BBT01EG/EB Abbreviation02

Page 58

Model No. : DMP-BBT01EG/EB Abbreviation03

Page 59

Model No. : DMP-BBT01EG/EB Abbreviation04

Page 60

Model No. : DMP-BBT01EG/EB AUDIO IO (DIGITAL P.C.B.)

Page 61

Model No. : DMP-BBT01EG/EB BP4 (DIGITAL P.C.B.)

Page 62

Model No. : DMP-BBT01EG/EB BP4 ATA (DIGITAL P.C.B.)

Page 63

Model No. : DMP-BBT01EG/EB BP4 FE_SLOT (DIGITAL P.C.B.)

Page 64

Model No. : DMP-BBT01EG/EB DDR BP4 (DIGITAL P.C.B.)

Page 65

Model No. : DMP-BBT01EG/EB DIGI NET (DIGITAL P.C.B.)

Page 66

Model No. : DMP-BBT01EG/EB ETHER USB (DIGITAL P.C.B.)

Page 67

Model No. : DMP-BBT01EG/EB VIDEO (DIGITAL P.C.B.)

Page 68

Model No. : DMP-BBT01EG/EB USB_POWER (ETHER USB POWER P.C.B.)

Page 69

Model No. : DMP-BBT01EG/EB ETHERNET (ETHER USB POWER P.C.B.)

Page 70

Model No. : DMP-BBT01EG/EB LED BUZZER (LED BUZZER P.C.B.)

Page 71

Model No. : DMP-BBT01EG/EB IR LED (IR LED P.C.B.)

Page 72

Model No. : DMP-BBT01EG/EB INPUT DIGI-NET (INPUT DIGI-NET P.C.B.)

Page 73

Model No. : DMP-BBT01EG/EB TOUCH SW (TOUCH SW P.C.B.)

Page 74

Model No. : DMP-BBT01EG/EB DIGITAL P.C.B. (Component Side)

Page 75

Model No. : DMP-BBT01EG/EB DIGITAL P.C.B. (Foil Side)

Page 76

Model No. : DMP-BBT01EG/EB ETHER USB POWER P.C.B. (Component Side)

Page 77

Model No. : DMP-BBT01EG/EB ETHER USB POWER P.C.B. (Foil Side)

Page 78

Model No. : DMP-BBT01EG/EB LED BUZZER P.C.B. (Component Side)

Page 79

Model No. : DMP-BBT01EG/EB LED BUZZER P.C.B. (Foil Side)

Page 80

Model No. : DMP-BBT01EG/EB IR LED P.C.B. (Component Side)

Page 81

Model No. : DMP-BBT01EG/EB IR LED P.C.B. (Foil Side)

Page 82

Model No. : DMP-BBT01EG/EB INPUT DIGI-NET P.C.B. (Component Side)

Page 83

Model No. : DMP-BBT01EG/EB INPUT DIGI-NET P.C.B. (Foil Side)

Page 84

Model No. : DMP-BBT01EG/EB TOUCH SW P.C.B. (Component Side)

Page 85

Model No. : DMP-BBT01EG/EB TOUCH SW P.C.B. (Foil Side)

Page 86

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

BZ51901 L0DCYB000001 BUZZER 1

C51001 F1H0J475A010 6.3V 4.7U 1

C51002 F1H0J475A010 6.3V 4.7U 1

C51003 F1G1A1040006 10V 0.1U 1

C51004 F1G1A1040006 10V 0.1U 1

C51005 F1G1A1040006 10V 0.1U 1

C51006 F1G1A1040006 10V 0.1U 1

C51007 F1G1A1040006 10V 0.1U 1

C51008 F1G1A1040006 10V 0.1U 1

C51015 F1H0J475A010 6.3V 4.7U 1

C51016 F1G1A1040006 10V 0.1U 1

C51017 F1G1A1040006 10V 0.1U 1

C51019 F1G0J4740003 6.3V 0.47U 1

C51022 F1G1A1040006 10V 0.1U 1

C51023 F1G1E1030005 25V 0.01U 1

C51030 F1H0J475A010 6.3V 4.7U 1

C51031 F1G1A1040006 10V 0.1U 1

C51032 F1G1A1040006 10V 0.1U 1

C51033 F1G1A1040006 10V 0.1U 1

C51034 F1G1A1040006 10V 0.1U 1

C51035 F1G1A1040006 10V 0.1U 1

C51036 F1G1A1040006 10V 0.1U 1

C51037 F1G1A1040006 10V 0.1U 1

C51038 F1G1A1040006 10V 0.1U 1

C51039 F1G1E102A086 25V 1000P 1

C51046 F1H0J475A010 6.3V 4.7U 1

C51048 F1G1A1040006 10V 0.1U 1

C51049 F1G1A1040006 10V 0.1U 1

C51050 F1G1A1040006 10V 0.1U 1

C51052 F1G1A1040006 10V 0.1U 1

C51053 F1G1A1040006 10V 0.1U 1

C51054 F1G1A1040006 10V 0.1U 1

C51055 F1G1A1040006 10V 0.1U 1

C51056 F1G1A1040006 10V 0.1U 1

C51057 F1G1A1040006 10V 0.1U 1

C51058 F1G1A1040006 10V 0.1U 1

C51059 F1G1A1040006 10V 0.1U 1

C51060 F1G1A1040006 10V 0.1U 1

C51062 F1G1A1040006 10V 0.1U 1

C51063 F1H0J475A010 6.3V 4.7U 1

C51064 F1G1A1040006 10V 0.1U 1

C51065 F1G1A1040006 10V 0.1U 1

C51067 F1G1A1040006 10V 0.1U 1

C51068 F1H0J225A005 6.3V 2.2U 1

C51069 F1G1E1030005 25V 0.01U 1

C51070 F1G1H180A565 50V 18P 1

C51071 F1G1H120A565 50V 12P 1

C51073 F1G1A1040006 10V 0.1U 1

C51074 F1H0J225A005 6.3V 2.2U 1

C51075 F1H0J225A005 6.3V 2.2U 1

C51076 F1G1E1030005 25V 0.01U 1

C51077 F1G1A1040006 10V 0.1U 1

C51078 F1G1A1040006 10V 0.1U 1

C51079 F1G1A1040006 10V 0.1U 1

C51080 F1G1A1040006 10V 0.1U 1

C51081 F1H0J225A005 6.3V 2.2U 1

C51082 F1G1E1030005 25V 0.01U 1

C51921 F1H1A105A028 10V 1U 1

C52003 F1G1A1040006 10V 0.1U 1

C52004 F1G1A1040006 10V 0.1U 1

C52005 F1J0J106A020 6.3V 10U 1

C52006 F1J0J106A020 6.3V 10U 1

Part No. Part Name & Description Q'ty Remarks

Page 87

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

C52007 F1G1A1040006 10V 0.1U 1

C52008 F1G1A1040006 10V 0.1U 1

C52009 F1G1A1040006 10V 0.1U 1

C52010 F1G1A1040006 10V 0.1U 1

C52011 F1G1E102A086 25V 1000P 1

C52013 F1G1A1040006 10V 0.1U 1

C52014 F1G1A1040006 10V 0.1U 1

C52015 F1G1A1040006 10V 0.1U 1

C52016 F1G1A1040006 10V 0.1U 1

C52017 F1J0J106A020 6.3V 10U 1

C52018 F1H0J475A010 6.3V 4.7U 1

C52019 F1G1A1040006 10V 0.1U 1

C52020 F1G1A1040006 10V 0.1U 1

C52021 F1G1A1040006 10V 0.1U 1

C52022 F1G1A1040006 10V 0.1U 1

C52024 F1G1E102A086 25V 1000P 1

C52025 F1G1A1040006 10V 0.1U 1

C52026 F1G1A1040006 10V 0.1U 1

C52027 F1G1A1040006 10V 0.1U 1

C52028 F1G1A1040006 10V 0.1U 1

C52029 F1G1A1040006 10V 0.1U 1

C52030 F1G1A1040006 10V 0.1U 1

C52037 F1G1A1040006 10V 0.1U 1

C52038 F1G1E102A086 25V 1000P 1

C52040 F1G1E102A086 25V 1000P 1

C52044 F1H0J475A010 6.3V 4.7U 1

C53019 F1G0J1050007 6.3V 1U 1

C55012 F1J1A106A024 10V 10U 1

C55013 F1G1A1040006 10V 0.1U 1

C55015 F1J1C106A059 16V 10U 1

C55017 F1J1E104A137 25V 0.1U 1

C55024 F1J0J2260004 6.3V 22U 1

C55027 F1G1C104A077 16V 0.1U 1

C55028 F1J1A106A024 10V 10U 1

C55029 F1J1C106A059 16V 10U 1

C55033 F1J0J2260004 6.3V 22U 1

C55034 F1J0J2260004 6.3V 22U 1

C55035 F1J0J2260004 6.3V 22U 1

C55036 F1J0J2260004 6.3V 22U 1

C55037 F1J0J2260004 6.3V 22U 1

C55038 F1J0J2260004 6.3V 22U 1

C55039 F1J0J2260004 6.3V 22U 1

C55040 F1J0J2260004 6.3V 22U 1

C55041 F1J0J2260004 6.3V 22U 1

C55042 F1J0J2260004 6.3V 22U 1

C55043 F1J0J2260004 6.3V 22U 1

C55052 F1J0J2260004 6.3V 22U 1

C55053 F1G1E102A086 25V 1000P 1

C55054 F1G1E102A086 25V 1000P 1

C55055 F1G1C104A077 16V 0.1U 1

C55057 F1G1C822A081 16V 8200K 1

C55058 F1G1C822A081 16V 8200K 1

C55059 F1G1C822A081 16V 8200K 1

C55063 F1J1E104A137 25V 0.1U 1

C55065 F1H0J2250008 6.3V 2.2U 1

C55067 F1J1E104A137 25V 0.1U 1

C55068 F1G1A1040006 10V 0.1U 1

C55070 F1G1C104A077 16V 0.1U 1

C55071 F1G1C104A077 16V 0.1U 1

C55079 F1J1C106A059 16V 10U 1

C55081 F1J1C106A059 16V 10U 1

C55083 F1G1C104A077 16V 0.1U 1

Part No. Part Name & Description Q'ty Remarks

Page 88

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

C55084 F1J1C475A059 16V 4.7U 1

C55086 F1H0J4750004 6.3V 4.7U 1

C55087 F1G1E222A086 25V 2200P 1

C55089 F1G0J1050007 6.3V 1U 1

C55095 F1G0J1050007 6.3V 1U 1

C55096 F1G0J1050007 6.3V 1U 1

C55097 F1G0J1050007 6.3V 1U 1

C55099 F1G1A823A032 10V 0.082U 1

C55102 F1G1A104A012 10V 0.1U 1

C55103 F1G1A104A012 10V 0.1U 1

C55104 F1G1C822A081 16V 8200K 1

C55105 F1G1A333A032 10V 0.033U 1

C55113 F1J1A106A024 10V 10U 1

C55115 F1J1C106A059 16V 10U 1

C55117 F1J0J2260004 6.3V 22U 1

C55120 F1G1E102A086 25V 1000P 1

C55121 F1G1E102A086 25V 1000P 1

C55122 F1G1E102A086 25V 1000P 1

C55123 F1G1H1010001 50V 100P 1

C55124 F1G1H1010001 50V 100P 1

C55125 F1G1H1010001 50V 100P 1

C55134 F1G0J105A031 6.3V 1U 1

C55142 F1J0J225A004 6.3V 2.2U 1

C55151 F1G1H1010001 50V 100P 1

C55186 F1J1C475A059 16V 4.7U 1

C55187 F1G1A1040006 10V 0.1U 1

C55190 F1G1E102A086 25V 1000P 1

C55202 F1G1H100A565 50V 10P 1

C55250 F1J1C106A059 16V 10U 1

C55251 F1J1C106A059 16V 10U 1

C55355 F1H1A105A036 10V 1U 1

C55400 F1G1A104A012 10V 0.1U 1

C55403 F1G1H1010001 50V 100P 1

C55404 F1G1H1010001 50V 100P 1

C55406 F1G1E1020001 25V 1000P 1

C55413 F1J0J2260004 6.3V 22U 1

C56342 F1H1A105A028 10V 1U 1

C56343 F1G0J1050007 6.3V 1U 1

C57005 F1G1A1040006 10V 0.1U 1

C57006 F1G0J1050007 6.3V 1U 1

C57007 F1G0J1050007 6.3V 1U 1

C57008 F1G0J1050007 6.3V 1U 1

C57010 F1G1A1040006 10V 0.1U 1

C57011 F1G1A1040006 10V 0.1U 1

C57014 F1G1H1010001 50V 100P 1

C57017 F1H1C104A071 16V 0.1U 1

C57020 F1H1A105A028 10V 1U 1

C57048 F1G1A1040006 10V 0.1U 1

C57101 F1G1A1040006 10V 0.1U 1

C57102 F1G1E102A086 25V 1000P 1

C57103 F1H0J475A010 6.3V 4.7U 1

C57501 F1H1C104A071 16V 0.1U 1

C57502 F1H1C104A071 16V 0.1U 1

C58005 F1H1C104A041 16V 0.1U 1

C58006 F1H1E104A002 25V 0.1U 1

C58008 F1H1A105A028 10V 1U 1

C58015 F1H1A105A028 10V 1U 1

C58016 F1G1E102A086 25V 1000P 1

C58023 F1H1E104A002 25V 0.1U 1

C58024 F1J1C1060001 16V 10U 1

C58025 F1J1C1060001 16V 10U 1

C58031 F1J1A1060011 10V 10U 1

Part No. Part Name & Description Q'ty Remarks

Page 89

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

C58032 F1J1A1060011 10V 10U 1

C58033 F1J1A1060011 10V 10U 1

C58035 F1G1E6820007 25V 6800P 1

C58036 F1G1E222A086 25V 2200P 1

C58043 F1H1E104A002 25V 0.1U 1

C58050 F1H1A105A028 10V 1U 1

C58067 F1H1E104A002 25V 0.1U 1

C58071 F1J1C1060001 16V 10U 1

C58072 F1J1C1060001 16V 10U 1

C58074 F1H1E104A002 25V 0.1U 1

C58075 F1J1C1060001 16V 10U 1

C58076 F1J1C1060001 16V 10U 1

C58077 F1H1E104A002 25V 0.1U 1

C58078 F1H1E104A002 25V 0.1U 1

C58084 F1J0J226A014 6.3V 22U 1

C58085 F1J0J226A014 6.3V 22U 1

C58086 F1H1A105A028 10V 1U 1

C58088 F1J1C1060001 16V 10U 1

C58089 F1J1A1060011 10V 10U 1

C58090 F1J1A1060011 10V 10U 1

C58096 F1J0J226A014 6.3V 22U 1

C58097 F1J0J226A014 6.3V 22U 1

C58100 F1G1E102A086 25V 1000P 1

C58101 F1G1E102A086 25V 1000P 1

C58102 F1G1E102A086 25V 1000P 1

C58143 F1G0J224A001 6.3V 0.22U 1

C58215 F1H1A105A028 10V 1U 1

C58216 F1G1E102A086 25V 1000P 1

C58223 F1H1E104A002 25V 0.1U 1

C58224 F1J1C1060001 16V 10U 1

C58225 F1J1C1060001 16V 10U 1

C58231 F1J1A1060011 10V 10U 1

C58232 F1J1A1060011 10V 10U 1

C58233 F1J1A1060011 10V 10U 1

C58234 F1J1A1060011 10V 10U 1

C58243 F1H1E104A002 25V 0.1U 1

C58315 F1H1A105A028 10V 1U 1

C58316 F1G1E102A086 25V 1000P 1

C58323 F1H1E104A002 25V 0.1U 1

C58324 F1J1C1060001 16V 10U 1

C58325 F1J1C1060001 16V 10U 1

C58331 F1J1A1060011 10V 10U 1

C58332 F1J1A1060011 10V 10U 1

C58333 F1J1A1060011 10V 10U 1

C58343 F1H1E104A002 25V 0.1U 1

C58350 F1G1E102A086 25V 1000P 1

C58351 F1G1E102A086 25V 1000P 1

C58352 F1G1E102A086 25V 1000P 1

C59001 F1J0J226A014 6.3V 22U 1

C59002 F1G1A1040006 10V 0.1U 1

C59003 F1G1H1010001 50V 100P 1

C59010 F1G1A1040006 10V 0.1U 1

C59014 F1G1A1040006 10V 0.1U 1

C59015 F1G1A1040006 10V 0.1U 1

C59301 F1G1H100A565 50V 10P 1

C59302 F1G1H100A565 50V 10P 1

C59303 F1G1A1040006 10V 0.1U 1

C59304 F1J0J106A020 6.3V 10U 1

C59305 F1G1A1040006 10V 0.1U 1

C59306 F1J0J106A020 6.3V 10U 1

C59307 F1J0J106A020 6.3V 10U 1

C59308 F1G1A1040006 10V 0.1U 1

Part No. Part Name & Description Q'ty Remarks

Page 90

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

C59309 F1J0J106A020 6.3V 10U 1

C59310 F1G1A1040006 10V 0.1U 1

C59311 F1G1A1040006 10V 0.1U 1

C59312 F1G1A1040006 10V 0.1U 1

C59313 F1H1A105A028 10V 1U 1

C59314 F1G1A1040006 10V 0.1U 1

C59315 F1J1A1060011 10V 10U 1

C59316 F1J1A1060011 10V 10U 1

C59319 F1G1A1040006 10V 0.1U 1

C59324 F1J1A1060011 10V 10U 1

C59339 F1G1A1040006 10V 0.1U 1

C59343 F1J1A1060011 10V 10U 1

C59344 F1J1A1060011 10V 10U 1

C59346 F1J1A1060011 10V 10U 1

C59347 F1G1A1040006 10V 0.1U 1

C59601 F1G1A1040006 10V 0.1U 1

C59602 F1G1E102A086 25V 1000P 1

C59603 F1G1E102A086 25V 1000P 1

C59605 F1H1H102A013 50V 1000P 1

C59606 F1J0J226A014 6.3V 22U 1

D9000 B3EB00000026 DIODE 1

D9001 B3EB00000026 DIODE 1

D51901 B3AAB0000389 LED 1 E.S.D.

D51902 B3ABB0000386 LED 1 E.S.D.

D51903 B3ACB0000243 LED 1 E.S.D.

D51904 B3AEB0000114 LED 1 E.S.D.

D51906 B3AAB0000389 LED 1 E.S.D.

D51921 B3AEB0000114 LED 1 E.S.D.

D51922 B3AAB0000316 DIODE 1 E.S.D.

D55400 DB2S31100L DIODE 1 E.S.D.

D58001 B0BC013A0007 DIODE 1 E.S.D.

FL59601 J0MAB0000146 FILTER 1

IC51001 RFKB76275CGT IC 1 EG E.S.D. (JIG AND ADJ.)

IC51001 RFKB76275DBT IC 1 EB E.S.D. (JIG AND ADJ.)

IC51301 RFKB76275CGT IC 1 EG E.S.D. (JIG AND ADJ.)

IC51301 RFKB76275DBT IC 1 EB E.S.D. (JIG AND ADJ.)

IC52001 C3ABUY000007 IC 1 E.S.D.

IC52002 C3ABUY000007 IC 1 E.S.D.

IC53002 K7JAAAB00001 IC 1 E.S.D.

IC55004 AN41226A-VFP IC 1 E.S.D.

IC55006 C0CBCYG00004 IC 1 E.S.D.

IC55300 C0CBCDD00025 IC 1 E.S.D.

IC56302 C0CBCDC00074 IC 1 E.S.D.

IC57002 C0EBK0000206 IC 1 E.S.D.

IC57003 C0DBGFC00051 IC 1 E.S.D.

IC57005 C0EBK0000206 IC 1 E.S.D.

IC57006 C0CBCBC00227 IC 1 E.S.D.

IC57101 C0JBAR000432 IC 1 E.S.D.

IC57501 C0ZBZ0001834 IC 1 E.S.D.

IC58003 C0DBAYY00903 IC 1 E.S.D.

IC58004 C0DBAYY00903 IC 1 E.S.D.

IC58005 C0DBAYY00903 IC 1 E.S.D.

IC58203 C0DBAYY01285 IC 1 E.S.D.

IC58302 C0DBGYY01974 IC 1 E.S.D.

IC58303 C0DBAYY01285 IC 1 E.S.D.

IC59020 C1CB00003704 IC 1 E.S.D.

IC59303 C0DBZYY00482 IC 1 E.S.D.

IC59304 C0DBZHE00026 IC 1 E.S.D.

IC59305 C1CB00002807 IC 1 E.S.D.

IP55004 K5H252Z00003 IC PROTEC TO R 1

IP55005 K5H252Z00003 IC PROTEC TO R 1

IP58001 ERBRE2R50V CHIP FUSE 1

Part No. Part Name & Description Q'ty Remarks

Page 91

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

IP58002 ERBRE2R50V CHIP FUSE 1

IR51921 B3RAD0000207 PHOTO DETECTOR 1

IR57101 B3RAD0000206 PHOTO DETECTOR 1

JK56301 K1FY119E0025 CONNECTOR 1

JK58001 K2ED2B000009 CONNECTOR 1

JK59001 K2LZ912B0001 TERMINA L JA CK S 1

L55001 G1C220MA0291 COIL 22UH 1

L55003 G1C100KA0101 COIL 10UH 1

L55006 G1C100KA0101 COIL 10UH 1

L56301 J0MAB0000241 COIL 1

L56302 J0MAB0000241 COIL 1

L58001 G1C4R7Z00014 COIL 4.7UH 1

L58004 G1C3R3Z00005 COIL 3.3UH 1

L58005 G1C3R3Z00005 COIL 3.3UH 1

L58201 G1C4R7MA0535 COIL 1

L58301 G1C4R7Z00014 COIL 4.7UH 1

L59601 J0MAB0000241 COIL 1

LB51001 J0JKC0000021 COIL 1

LB51003 J0JKC0000021 COIL 1

LB51004 J0JCC0000287 COIL 1

LB51006 J0JCC0000287 COIL 1

LB51007 J0JKC0000021 COIL 1

LB51009 J0JCC0000287 COIL 1

LB51010 J0JKC0000021 COIL 1

LB51013 J0JYC0000070 COIL 1

LB51014 J0JCC0000287 COIL 1

LB51016 J0JCC0000287 COIL 1

LB51017 J0JCC0000287 COIL 1

LB51019 J0JCC0000287 COIL 1

LB51020 J0JYC0000070 COIL 1

LB51021 J0JCC0000287 COIL 1

LB51022 J0JCC0000287 COIL 1

LB55001 J0JJC0000005 COIL 1

LB55002 J0JJC0000005 COIL 1

LB55400 J0JJC0000016 COIL 1

LB55401 J0JJC0000016 COIL 1

LB56001 J0JYC0000070 COIL 1

LB59001 J0JGC0000020 COIL 1

LB59303 J0JGC0000020 COIL 1

LB59304 J0JGC0000020 COIL 1

LB59306 J0JGC0000070 COIL 1

LB59602 J0JYC0000070 COIL 1

LB59603 J0JHC0000045 COIL 1

P51601 K1KA06AA0083 CONNECTOR(6P) 1

P51701 K1KB10A00120 CONNECTOR(10P) 1

P51702 K1KB10A00120 CONNECTOR(10P) 1

P51901 K1KA10BA0206 CONNECTOR(10P) 1

P51921 K1KA10BA0206 CONNECTOR(10P) 1

P55006 K1MN45B00027 CONNECTOR(45P) 1

P55011 K1MY05BA0041 CONNECTOR(5P) 1

P55400 K1MN04AA0046 CONNECTOR(4P) 1

P55401 K1MY08BA0041 CONNECTOR(8P) 1

P55402 K1KA02BA0014 CONNECTOR(2P) 1

P57501 K1MN04AA0046 CONNECTOR(4P) 1

P58001 K1KY09AA0607 CONNECTOR(9P) 1

P58002 K1KY09AA0606 CONNECTOR(9P) 1

P59301 K1FY104B0074 CONNECTOR(104P) 1

P59303 K1KA04BA0047 CONNECTOR(4P) 1

P59601 K1NA09E00098 CONNECTOR(9P) 1

P59602 K1YG30000001 CONNECTOR 1

P59603 K1YY30000001 CONNECTOR 1

Q9101 B3HB00000031 TRANSISTOR 1

Part No. Part Name & Description Q'ty Remarks

Page 92

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

Q9102 B3HB00000031 TRANSISTOR 1

Q56301 B1CBGD000001 TRANSISTOR 1 E.S.D.

Q57501 B1ABDF000033 TRANSISTOR 1 E.S.D.

Q57502 B1ABDF000026 TRANSISTOR 1 E.S.D.

Q58001 B1ABDF000026 TRANSISTOR 1 E.S.D.

Q58002 B1DGDC000002 TRANSISTOR 1 E.S.D.

Q58006 B1DGDC000002 TRANSISTOR 1 E.S.D.

QR51901 B1GBCFEN0015 TRANSISTOR 1 E.S.D.

QR51902 B1GBCFEN0015 TRANSISTOR 1 E.S.D.

QR51903 B1GBCFEN0015 TRANSISTOR 1 E.S.D.

QR51921 B1GBCFEN0015 TRANSISTOR 1 E.S.D.

QR55408 DRC5143T0L TRANSISTOR 1 E.S.D.

QR55409 DRC5143T0L TRANSISTOR 1 E.S.D.

QR55410 DRC5143T0L TRANSISTOR 1 E.S.D.

QR55411 DRC5143T0L TRANSISTOR 1 E.S.D.

QR57501 B1GBCFJJ0040 TRANSISTOR 1 E.S.D.

QR57502 B1GBCFEN0015 TRANSISTOR 1 E.S.D.

QR58001 B1GBCFNN0041 TRANSISTOR 1 E.S.D.

QR58002 B1GBCFNN0041 TRANSISTOR 1 E.S.D.

R9000 ERJ2GEJ181X 1/16W 180 1

R9001 ERJ2GEJ181X 1/16W 180 1

R51006 ERJ2GEJ105X 1/16W 1000K 1

R51007 ERJ2GEJ104X 1/16W 100K 1

R51019 ERJ2GEJ561X 1/16W 560 1

R51024 ERJ2RKF5601X 1/10W 5600 1

R51026 ERJ2RKF5601X 1/10W 5600 1

R51028 ERJ2GEJ4R7X 1/16W 4.7 1

R51315 ERJ2GEJ103X 1/16W 10K 1

R51316 ERJ2GEJ473X 1/16W 47K 1

R51317 ERJ2GEJ103X 1/16W 10K 1

R51901 ERJ6GEYJ751V CHIP RESISTOR 1

R51902 ERJ8GEYJ301V CHIP RESISTOR 1

R51903 ERJ6GEYJ391V 1/8W 390 1

R51904 ERJ6GEYJ391V 1/8W 390 1

R51905 ERJ6GEYJ751V CHIP RESISTOR 1

R51922 ERJ6GEYJ391V 1/8W 390 1

R51923 ERJ3GEYJ330V 1/10W 33 1

R52001 ERJ2RKF2700X 1/10W 270 1

R52002 ERJ2RKF2700X 1/10W 270 1

R52003 ERJ2RKF2700X 1/10W 270 1

R52004 ERJ2RKF2700X 1/10W 270 1

R52007 ERJ2RKF2700X 1/10W 270 1

R52008 ERJ2RKF2700X 1/10W 270 1

R52009 ERJ2RKF2400X CHIP RESISTOR 1

R52010 ERJ2GEJ221X 1/16W 220 1

R52011 ERJ2RKF2700X 1/10W 270 1

R52012 ERJ2RKF2700X 1/10W 270 1

R52013 ERJ2RKF2400X CHIP RESISTOR 1

R52014 ERJ2GEJ221X 1/16W 220 1

R52015 ERJ2GEJ103X 1/16W 10K 1

R52018 ERJ2GE0R00X 1/16W 0 1

R52019 ERJ2GE0R00X 1/16W 0 1

R52020 ERJ2RKF1001X CHIP RESISTOR 1

R52021 ERJ2RKF1001X CHIP RESISTOR 1

R52022 ERJ2RHD241X 1/10W 240 1

R52023 ERJ2GEJ103X 1/16W 10K 1

R55003 ERJ2GEJ472X 1/16W 4.7K 1

R55005 ERJ2GEJ333X 1/16W 33K 1

R55021 ERJ3EKF2201V CHIP RESISTOR 1

R55023 ERJ3EKF5101V CHIP RESISTOR 1

R55059 ERJ2GEJ272X 1/16W 2.7K 1

R55060 ERJ2GEJ472X 1/16W 4.7K 1

Part No. Part Name & Description Q'ty Remarks

Page 93

Model No. : DMP-BBT01EG/EB Parts List

Safety

Ref.

No.

R55061 ERJ2GEJ103X 1/16W 10K 1

R55062 ERJ2GEJ223X 1/16W 22K 1

R55063 ERJ2GEJ303X 1/16W 33K 1

R55064 ERJ2GEJ303X 1/16W 33K 1

R55065 ERJ2GEJ303X 1/16W 33K 1

R55066 ERJ2GEJ561X 1/16W 560 1

R55067 ERJ2GEJ561X 1/16W 560 1

R55068 ERJ2GEJ561X 1/16W 560 1

R55069 ERJ2GEJ153X 1/16W 15K 1

R55070 ERJ2GEJ153X 1/16W 15K 1

R55071 ERJ2GEJ153X 1/16W 15K 1

R55079 ERJ2GEJ103X 1/16W 10K 1

R55084 ERJ8RQF1R8V CHIP RESISTOR 1

R55085 ERJ8RQF1R8V CHIP RESISTOR 1