Page 1

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Replaceable Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearing a Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Media Tray Empty or Misfeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Jam at A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Jam at B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Jam at C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Jam at D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Jam at E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the Photosensitive Drum . . . . . . . . . . . . . . . . . . . . . . . . . 31

Error Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Repacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Bi-directional Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

USB (Universal Serial Bus) Interface . . . . . . . . . . . . . . . . . . . . . . . 51

1

Page 2

Settings and Printing

• Microsoft, Windows and Windows NT are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

• Avery and all other related brands and product names are trademarks of Avery Dennison

Corporation.

• 3M and 3M logo are trademarks or registered trademarks of 3M.

• All other acknowledgements are trademarks or registered trademarks of their respective

holders.

Maintenance and Specifications

Maintenance and Specifications

2

Page 3

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

3

Replaceable Components

Replaceable Components

■

Supplies

When print is faded or indicators show the following status, the replacement of a supply is

needed.

Indicators

Printer

components

Toner cartridge

For U.S.A :

KX-PDP7

For other countries:

KX-PDP8

Drum unit

For all countries:

KX-PDM7

ERROR

TONER/

DRUM UNIT

Low Toner

Change the toner cartridge soon.

Toner Empty

Replace the toner cartridge now.

Change Drum Unit

Change the drum unit soon.

Drum Unit Worn out

Replace the drum unit now.

Drum Unit Worn out

and Toner Empty

Replace the drum unit and toner

cartridge now.

Message of printer

status display

Average life

—

4,000 pages

20,000 pages

✱1, ✱2

—

n

: Indicator is turned off.

: Indicator is lit.

, : Indicator is blinking (with an interval of 1 second).

*1 Refer to the next page.

*2 The toner cartridge provided with the printer is a starter kit toner car tridge, which

has less toner. (The page life expectancy is 2,000 pages.)

Page 4

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Replaceable Components

*1Average life is based on an average of 5% coverage of the printable area and standard

density when the recommended media is used (refer to Example: 5% coverage). The life of

a toner cartridge is varied depending on the coverage, temperature, humidity or media etc.

So the average life cannot be assured. Continuously printing 10% coverage of the printable

area will reduce the life of the toner to about half as compared to printing 5% coverage.

Example (5% coverage)

Personal Image Editing System

Feature:

Congratulations on your purchase of the XX-XXXX, the three-in-one solution to today's office

needs. This amasing little desktop unit can be used as a : Printer, Scanner, Copier.

Printer Specification

Printing Method:

Print Speed:

Resolution:

Paper Feed:

Paper Outout:

Software Emulation:

Paper Size/Weight:

Memory Capacity:

Dimensions:

Mass {Weight}:

Consumables:

Noise Level:

CPU:

Other Specification

Operating Environment:

Storing Environment:

Feature:

Congratulations on your purchase of the XX-XXXX, the three-in-one solution to today's office

needs. This amasing little desktop unit can be used as a : Printer, Scanner, Copier.

❈ Application Soft : Text Bridge, Card Scan

Model No. XX-XXXX

Semiconductor Laser Electro-Photography

X ppm maximum (A4 size paper, text mode, 5 % image area)

600 dpi X 600 dpi

1 Multi-purpose manual feed up to 250 sheets of paper [75 g/m

Face-down paper ejection (up to 150 sheets) [75 g/m2 (20 lbs.)]

GDI + Soft XXXX

Letter, Legal, A4, Envelope, Executive, OHP, Label

2 MB

399 (W) X 390 (D) X 254 (H) mm (15.7" X 15.4" X 10")

Approx. 10 Kg {22 lbs.}

Starter toner cartridge : 20,000 pages average

Toner cartridge: 4,000 pages average

Drum unit: 20,000 pages average

Printing: 48 dBA

Stadby: 27 dBA

Intel 80C51 compatible

10 to 32.5˚C [50 to 90.5˚F] 20 to 80% RH

0 to 35˚C [32 to 95˚F] 20 to 80% RH

2

(20 lbs.)]

4

Page 5

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Cleaning the Printer

Cleaning the Printer

Periodic cleaning of the printer is recommended. The frequency of cleaning is dependent

upon the environment in which the printer is used.

You should clean the printer:

•at least once a month.

•when you replace the toner cartridge.

•when print quality has deteriorated.

CAUTION

•Do not use benzene, thinner, aerosol cleaners, or any abrasive powder.

External

5

1

2

Turn the power OFF.

Clean all the covers with a soft cloth. Use any mild commercial cleaner.

Internal

1

2

Turn the power off and remove the power cord for your safety.

Remove the media tray out of the printer.

Page 6

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

6

Cleaning the Printer

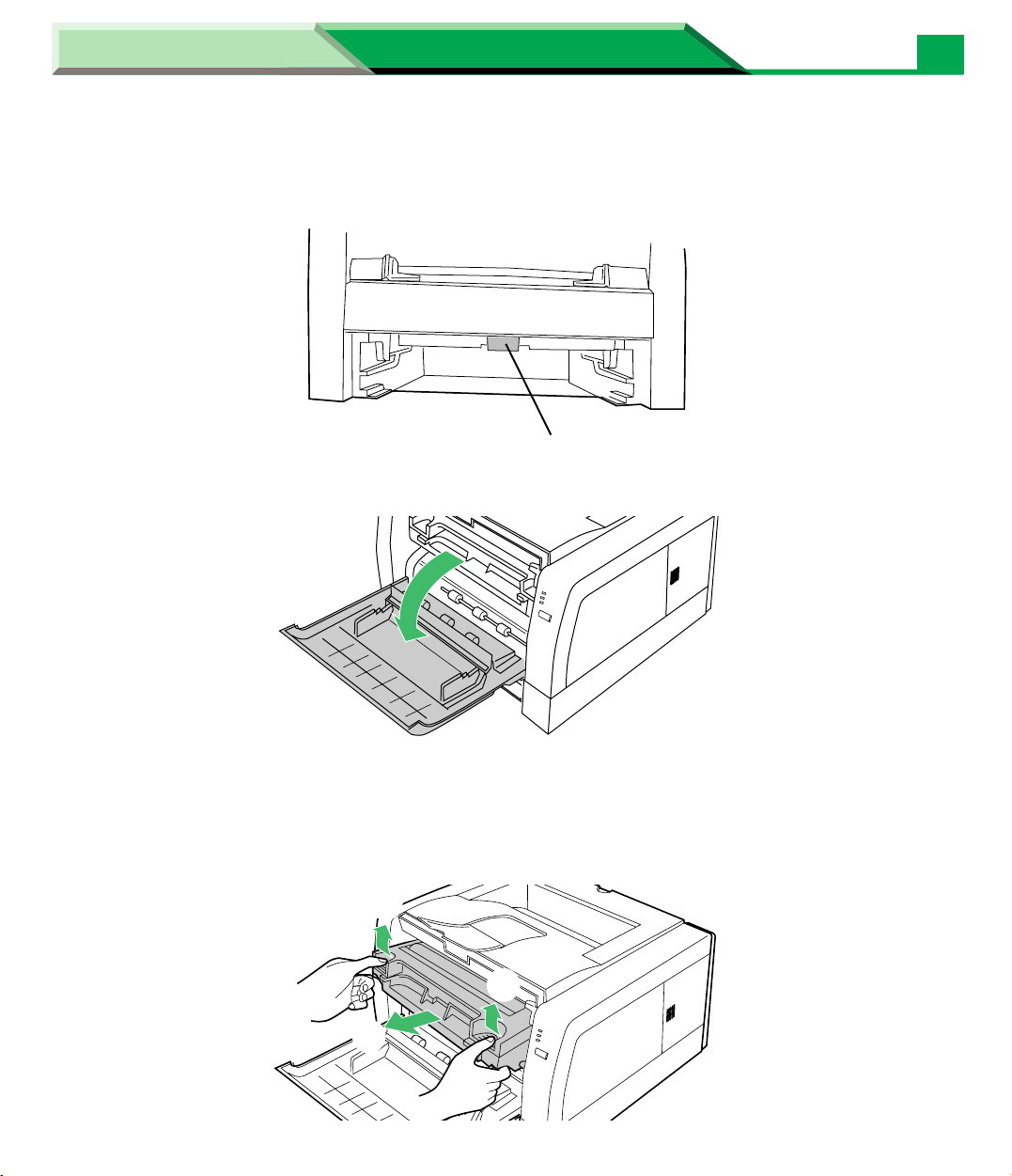

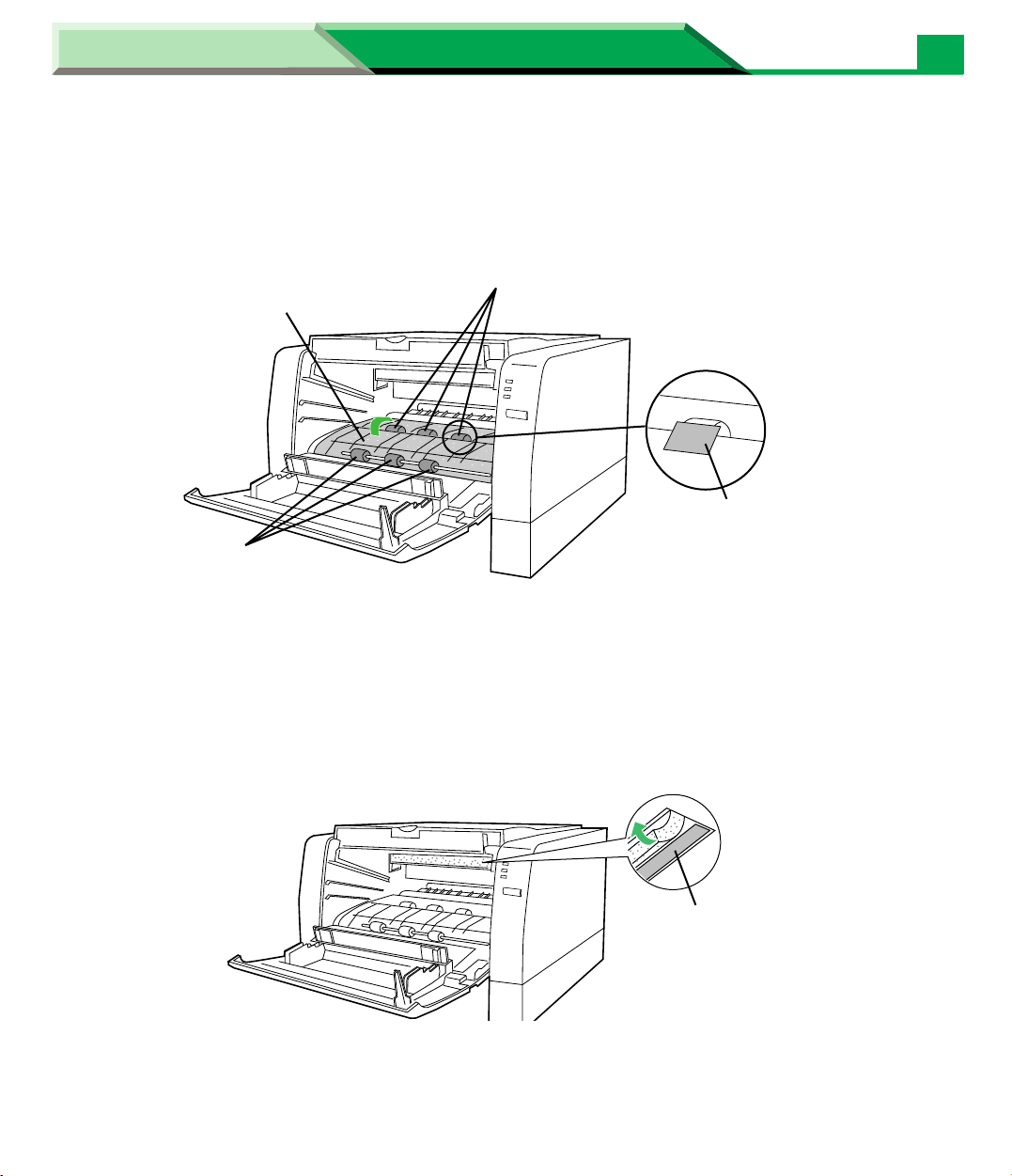

3

4

While rotating the pick up roller, wipe it with a soft cloth that has been

moistened with a mild commercial cleaner.

Pick up roller

Open the front cover.

5

Lift the drum unit up ( # ) and slide it out of the printer ( $ ).

• To avoid possible toner spillage, it is recommended to place the drum unit on a

newspaper or drop cloth.

#

#

$

Page 7

Settings and Printing

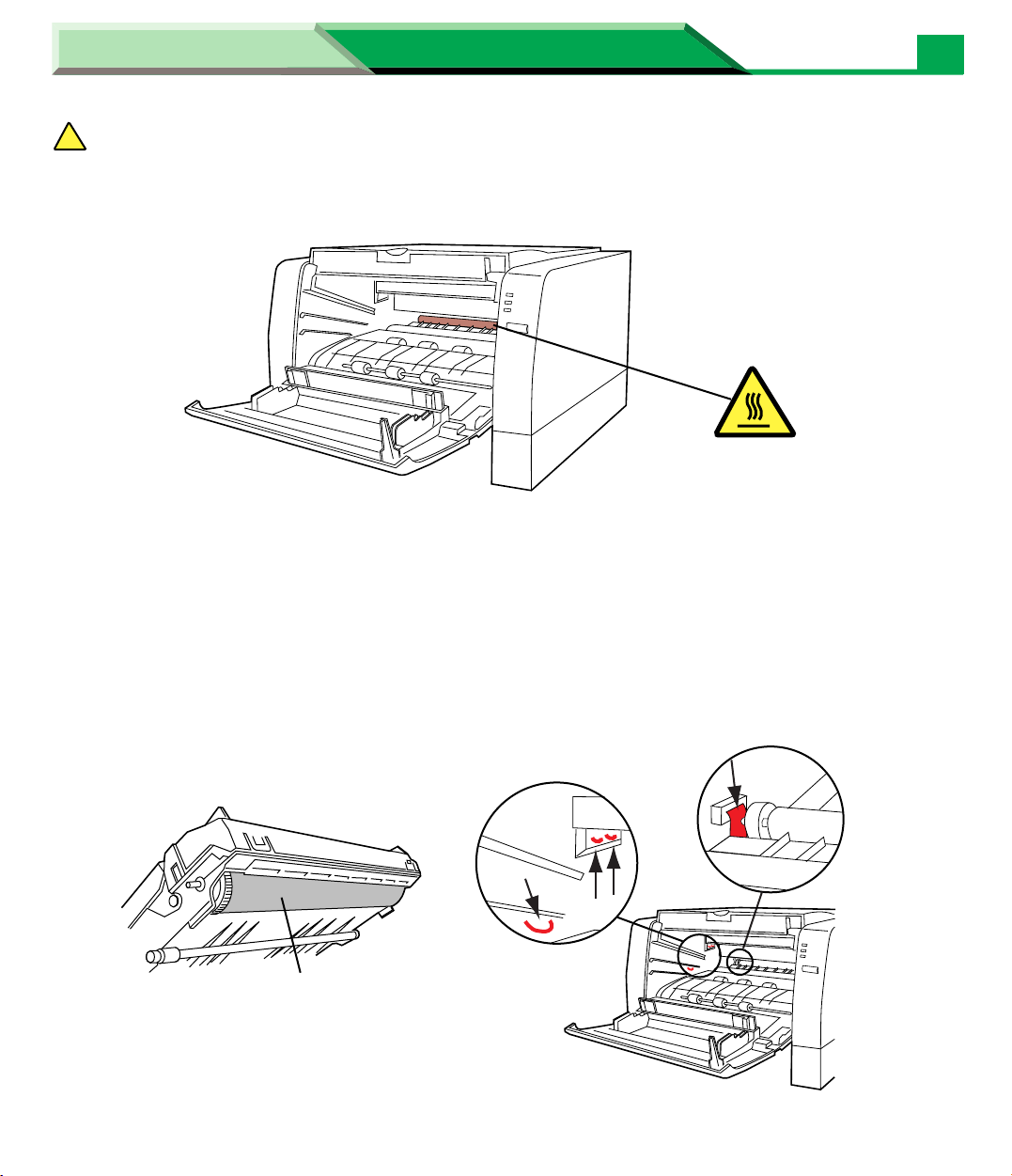

SAFETY CAUTION

!

•It is very hot inside the printer; to avoid personal injury, do not touch the components

illustrated below.

Maintenance and Specifications

Maintenance and Specifications

Cleaning the Printer

CAUTION:

HOT SURFACE

CAUTION

•To prevent any damage to the drum unit, observe the following precautions.

— Do not touch the black drum surface illustrated below.

— Do not expose the drum unit to light for more than 5 minutes.

— Do not expose the drum unit to direct sunlight.

— Do not keep the drum unit near dust or dirt.

— Do not place the drum unit in a high humid area.

•Do not touch electrodes illustrated below to prevent static electricity damage to the printer.

7

Black drum

Electrodes (shown in red)

Page 8

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

8

Cleaning the Printer

6

Wipe rollers (A) and (B), and paper chute with a soft cloth that has been

moistened with a mild commercial cleaner.

•Be sure to remove the paper dust.

(B)

Paper chute

Sheet: Not to damage

(A)

NOTE

•Front rollers (A) can be rotated half. Inner rollers (B) can be rotated to the direction of the

arrow. Be sure not to damage the sheets in front of the inner rollers (B).

7

Turn the sponge up and carefully wipe the laser unit cover glass with a

dry lint-free cloth.

Laser unit cover glass:

Not to touch with hand

CAUTION

To avoid a damage to the printer,

•Do not use rubbing alcohol to wipe the laser unit cover glass.

•Do not touch the laser unit cover glass by hand.

Page 9

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

9

Cleaning the Printer

8

9

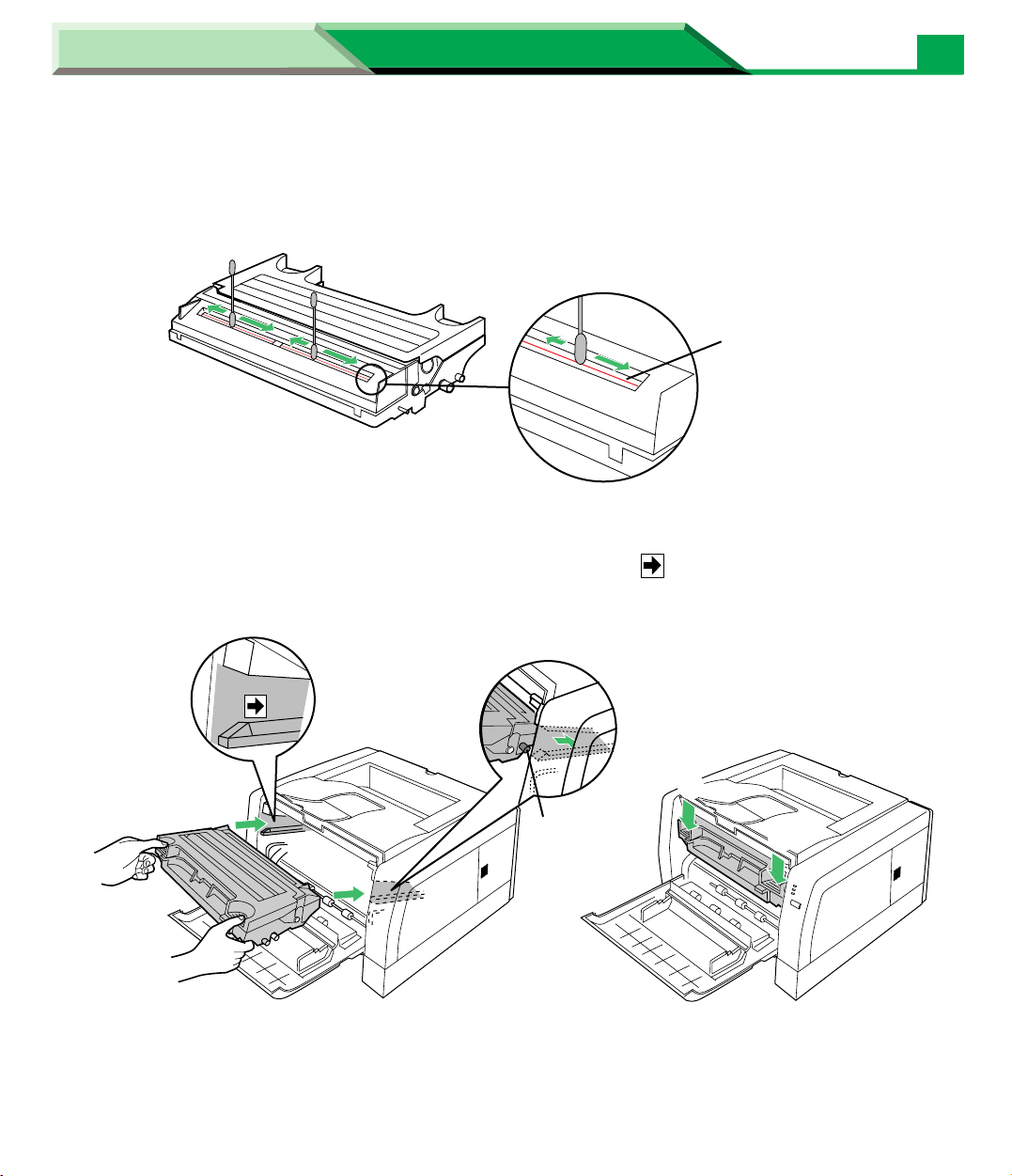

Carefully wipe the corona wire of the drum unit by sliding a dry cotton

swab from end to end a few times.

corona wire

Firmly inser t the drum unit in the slot of the printer ( # ) [insert the side

pins of the drum unit into the groove (label )]. Push down ( $ ).

10

$

#

Side pin

Close the front cover and replace the media tray into the printer.

$

Page 10

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

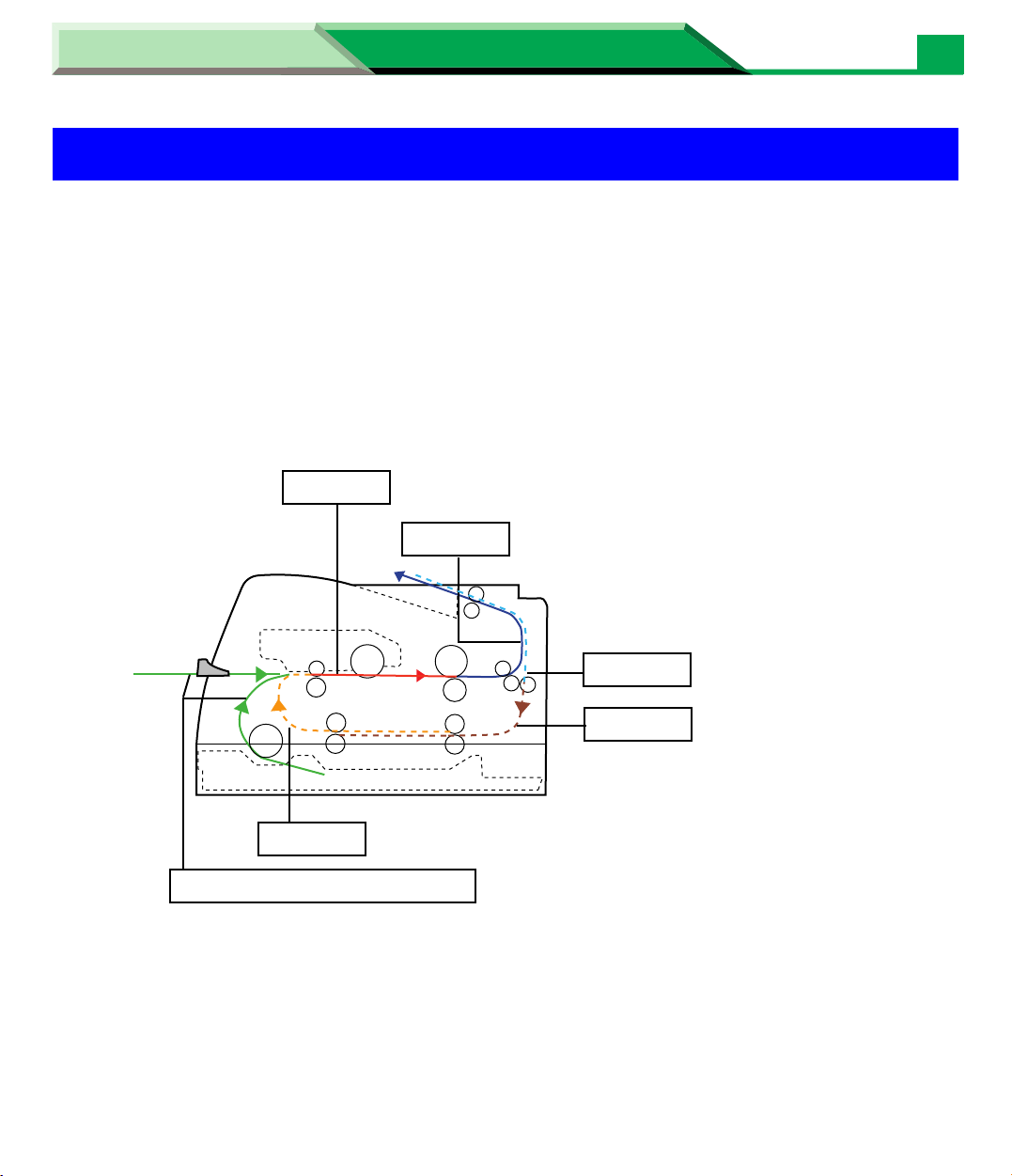

Clearing a Jam

Clearing a Jam

If the printer has frequent media jams, make sure that you follow these guidelines:

•Always use high-quality paper and transparencies. see “Media” on page 43.

2

• Make sure that you load thick paper [106 – 165 g/m

manual feed.

If a media jam occurs, the printer status display reports “Media Tray Empty or Misfeed” or “J am

at <Location>”. The <Locations> are the various sensors throughout the paper path, listed as

A through E.

Jam at A (see page 13)

Jam at B (see page 15)

(29 – 44 lbs.)] or labels only in the

10

Jam at D (see page 20)

Jam at E (see page 21)

Jam at C (see page 18)

Media Tray Empty or Misfeed (see page 11)

Page 11

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Clearing a Jam

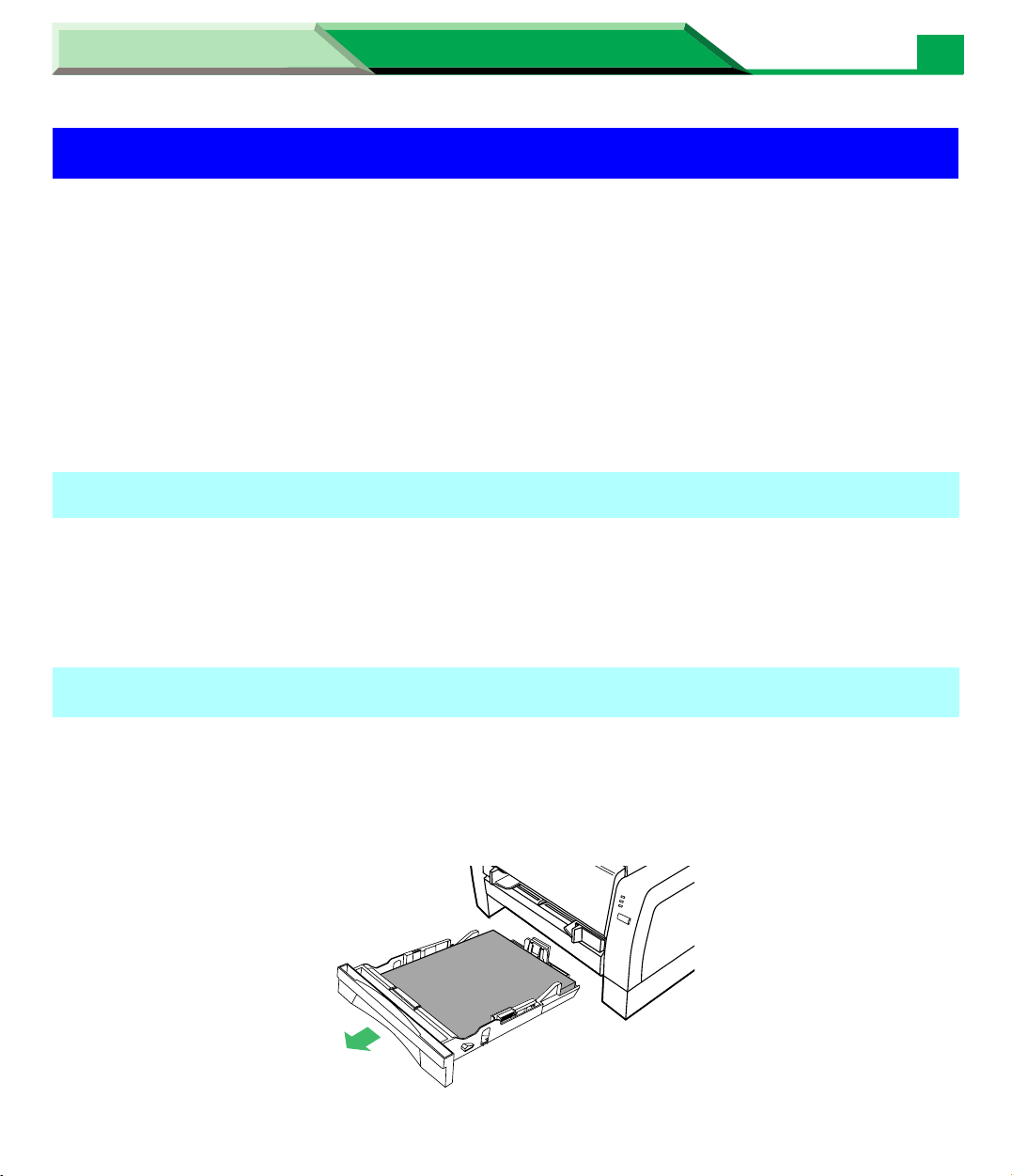

Media Tray Empty or Misfeed

When media is not in the media tray or media feed error has occurred, load the media in the

media tray or clear the media feed error as follows:

11

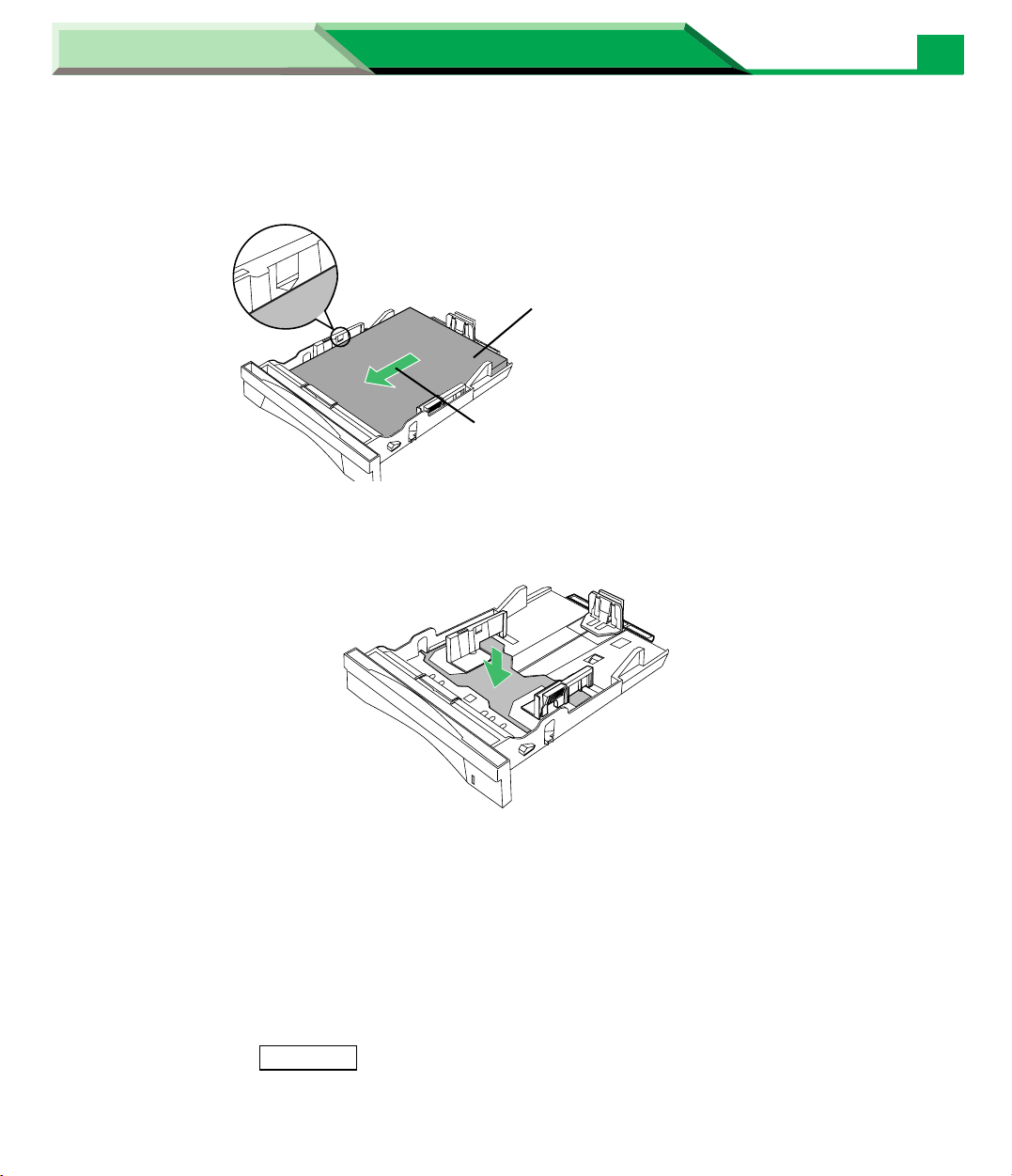

1

2

Pull the media tray out of the printer.

Tap the media stack on a level surface to avoid media jams or skewed

printing.

•If a media feed error has occurred, remove the media stack from the media tray and

tap it.

Page 12

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

12

Clearing a Jam

3

NOTE

•If the metal plate is in the up position by accident, the media tray cannot be inserted into the

Place the media with the print side down.

•Be sure that the media does not exceed the limit mark.

Print side down

Paper feeds in direction

of arrow.

printer. Before loading the media, push down the metal plate until it clicks, locking it in place.

4

CAUTION

Be sure to hold the media tray with both hands so you do not drop it especially when it is fully

loaded.

5

Replace the media tray into the printer.

Press the

or click

CONTINUE

Resume

button for less than 5 seconds on the printer panel

on the printer status display to clear the error status,

and continue/start printing.

Page 13

Settings and Printing

Jam at A

Maintenance and Specifications

Maintenance and Specifications

13

Clearing a Jam

1

2

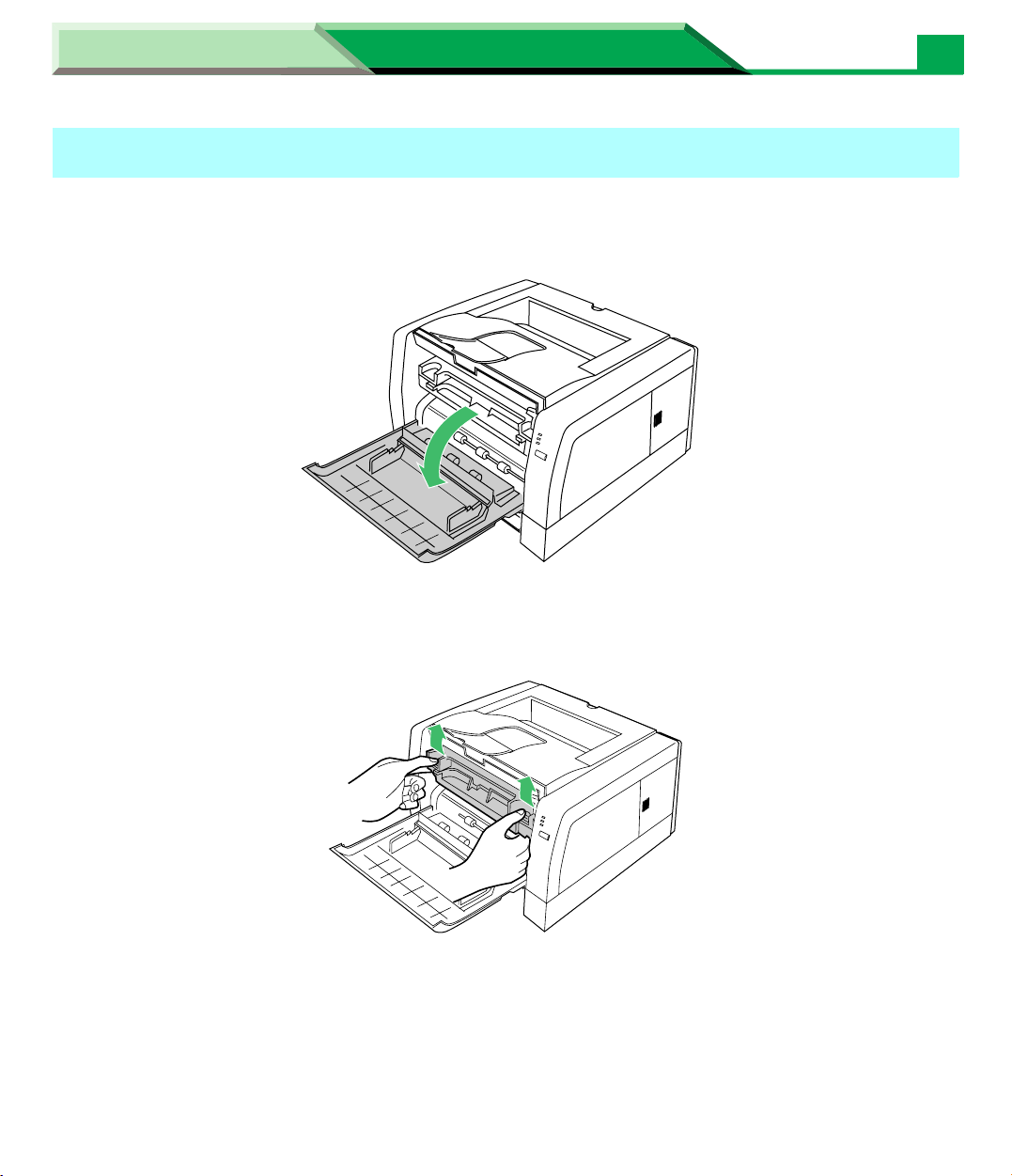

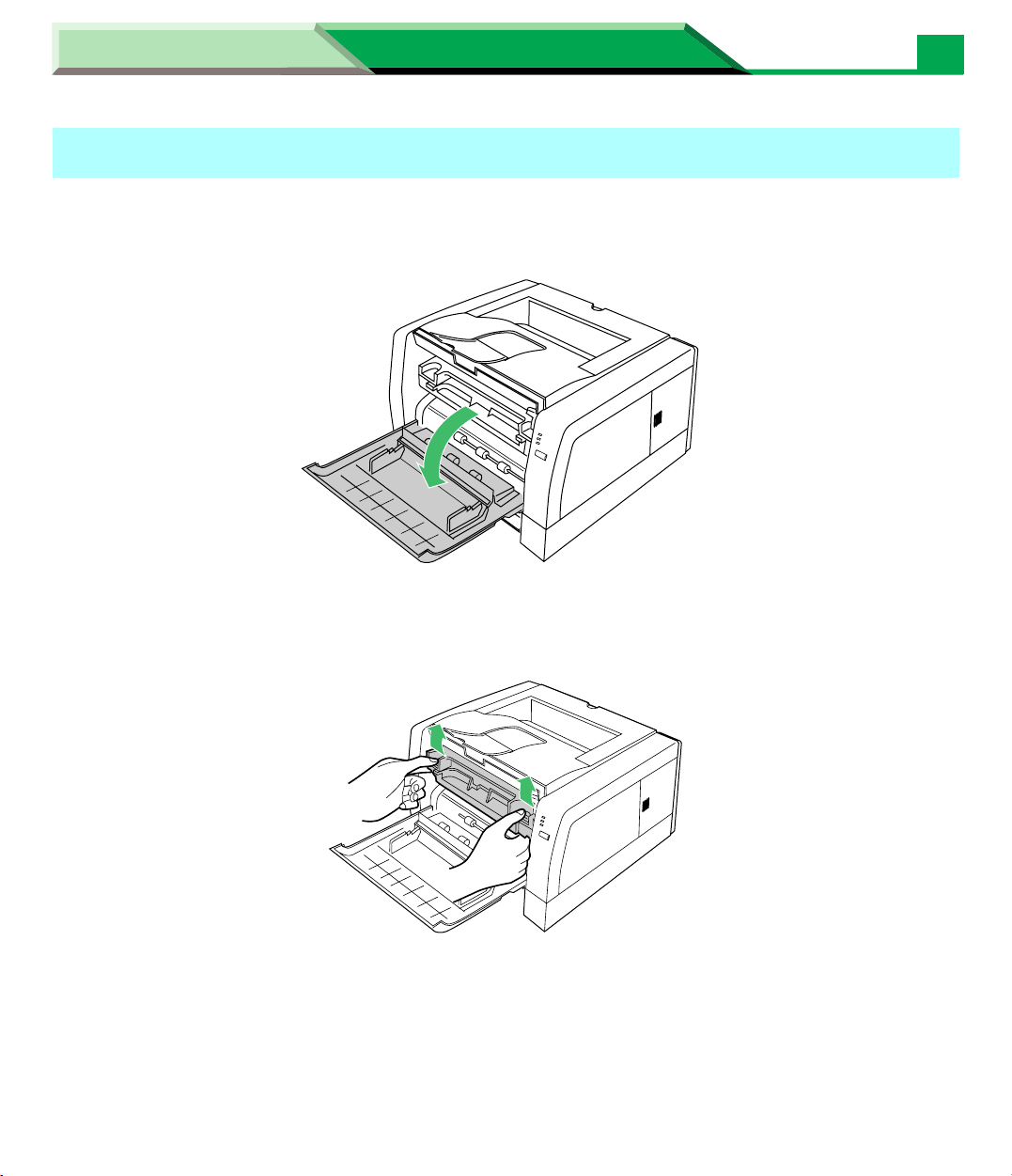

Open the front cover.

Lift the drum unit up.

Page 14

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

14

Clearing a Jam

3

4

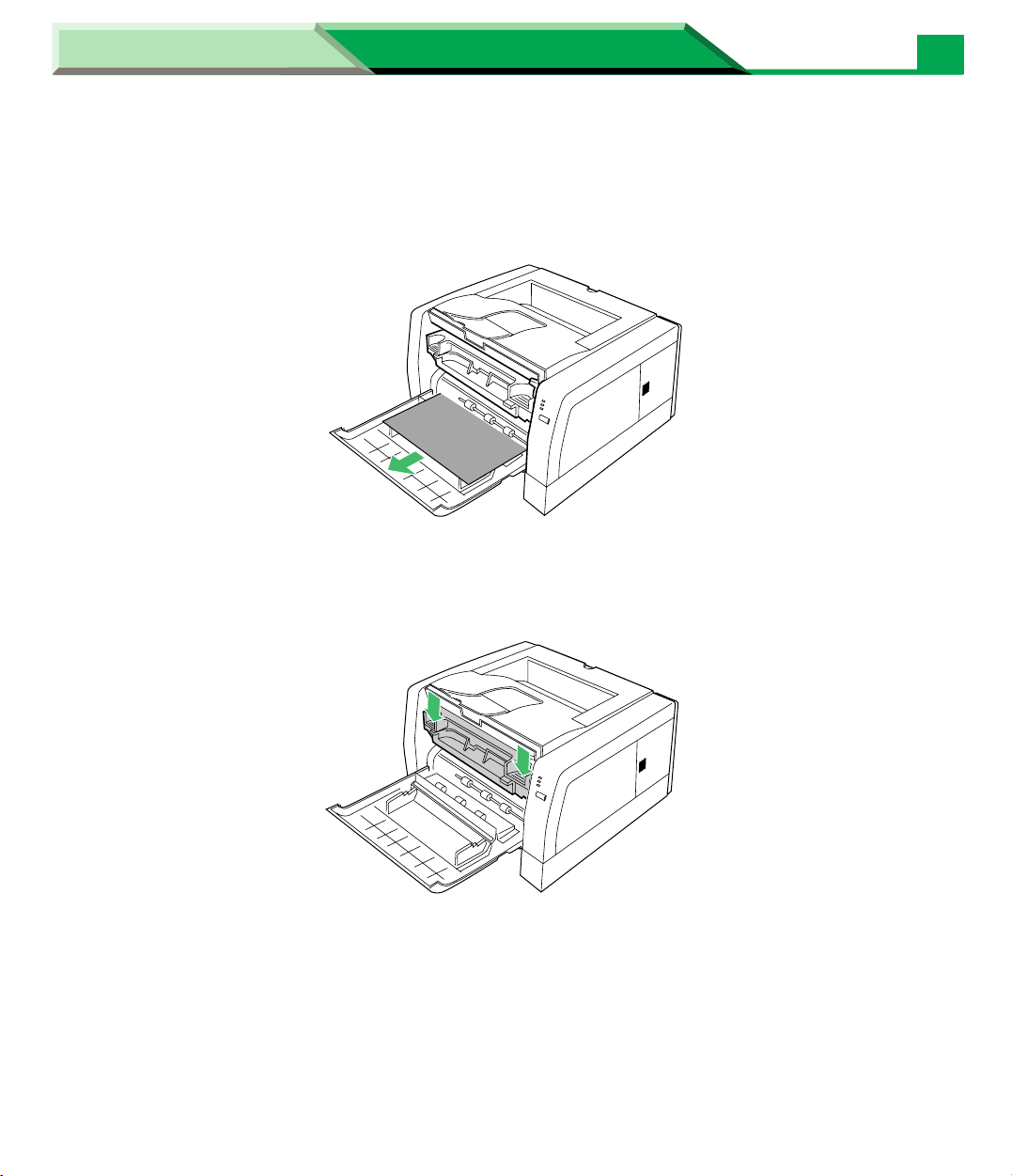

Grasp both sides of the jammed media and

printer.

Push the drum unit down.

slowly

pull it out of the

5

Close the front cover.

Page 15

Settings and Printing

Jam at B

Maintenance and Specifications

Maintenance and Specifications

15

Clearing a Jam

1

2

Open the front cover.

Lift the drum unit up.

Page 16

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

16

Clearing a Jam

3

Remove the jammed media from the output tray.

- Or -

Open the rear cover of the printer ( #) and remove the jammed media

( $).

#

$

CAUTION HOT SURFACE

Page 17

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

17

Clearing a Jam

4

5

Push the drum unit down.

Close the front cover.

Page 18

Settings and Printing

Jam at C

Maintenance and Specifications

Maintenance and Specifications

18

Clearing a Jam

1

1

2

Perform the jam recovery steps for Jam at A (see page 13).

- Or -

Pull the media tray out of the printer.

Slowly pull the jammed media ($) out of the printer while pushing the

center tab (#) of the jam release pan down.

#

Rear side of

Printer

$

Page 19

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

19

Clearing a Jam

3

4

Replace the media tray into the printer.

Open and close the front cover to clear the error indication.

$

#

Page 20

Settings and Printing

Jam at D

Maintenance and Specifications

Maintenance and Specifications

20

Clearing a Jam

1

2

Open the rear cover of the printer ( # ) and grasp both sides of the

jammed media and slowly pull it out of the printer ( $ ).

$

#

CAUTION HOT SURFACE

Open and close the front cover to clear the error indication.

#

$

Page 21

Settings and Printing

Jam at E

Maintenance and Specifications

Maintenance and Specifications

21

Clearing a Jam

1

1

2

Perform the jam recovery steps for Jam at D (see page 20).

- Or -

Pull the media tray out of the printer.

Slowly pull the jammed media ($) out of the printer while pushing the

center tab (#) of the jam release pan down.

#

Rear side of

Printer

$

Page 22

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

22

Clearing a Jam

3

4

Replace the media tray into the printer.

Open and close the front cover to clear the error indication.

$

#

Page 23

Settings and Printing

Troubleshooting

Trouble Possible Cause Corrective Action

Maintenance and Specifications

Maintenance and Specifications

23

Troubleshooting

The background of the

images is printed in

gray.

ABCD--------

-----------------

--------

Faded image is printed

at the different position

from the original.

ABCD--------

-----------------

--------

ABCD--------

-----------------

--------

The toner cartridge has

reached the end of useful life.

The drum unit has reached the

end of useful life.

Incorrect type of media is used. Check the media usable or not

Your printer is in extremely high

humidity .

Printer driver is not set

correctly for paper.

The toner cartridge has

reached the end of useful life.

Your printer is in extremely high

or low humidity.

Print density is high. Display the Printer Console

Replace the toner cartridge.

Replace the drum unit.

(see “Media” on page 43).

Check the environment (see

“Specifications” on page 41).

Set the media type setting of

the printer driver correctly (see

page 22 in “Settings and

Printing”).

Replace the toner cartridge.

Check the environment (see

“Specifications” on page 41)

window and set the density

( ) to the lighter level (see

“Using the Printer Console

Window” on page 41 in

“Settings and Printing”).

Page 24

Settings and Printing

Trouble Possible Cause Corrective Action

Maintenance and Specifications

Maintenance and Specifications

24

Troubleshooting

Toner spots appear on

the page.

ABCD--------

-----------------

--------

The entire page prints

in black.

A white or black spots

appear in intervals of

94 mm.

Toner spots put on the

photosensitive drum.

Clean the toner spots with soft

cloth (refer to “Cleaning the

Photosensitive Drum” on page

31).

The drum unit is damaged. Replace the drum unit.

The corona wire in the drum

unit is dirty.

Clean the corona wire in the

drum unit (see “Cleaning the

Printer” on page 5).

The drum unit is damaged. Replace the drum unit.

Paste/Glue of a label or dust is

attached to the photosensitive

drum of the drum unit.

Wipe the photosensitive drum

of the drum unit (see “Cleaning

the Photosensitive Drum” on

page 31).

94 mm

94 mm

The photosensitive drum of the

drum unit is dirty or scratched.

Replace the drum unit.

Page 25

Settings and Printing

Trouble Possible Cause Corrective Action

Maintenance and Specifications

Maintenance and Specifications

25

Troubleshooting

Horizontal lines appear

in intervals of 94 mm.

94 mm

94 mm

White and horizontal

lines appear on the

page.

ABCD--------

-----------------

--------

A small dust is bitten in the

gear of the photosensitive

drum.

Remove the dust from the gear

(see “Cleaning the

Photosensitive Drum” on page

31).

Dust

The drum unit is damaged. Replace the drum unit.

The toner cartridge is

Replace the toner cartridge.

damaged.

The toner cartridge is stored for

a long period.

Print several blank pages until

the lines disappear.

(Try shaking to loosen toner.)

Try shaking to loosen toner.

Page 26

Settings and Printing

Trouble Possible Cause Corrective Action

Maintenance and Specifications

Maintenance and Specifications

26

Troubleshooting

A black and vertical

line appears on the

page.

ABCD--------

-----------------

--------

A white vertical line

appears on the page.

ABCD--------

-----------------

--------

Corona wire of the drum unit is

dirty.

The toner cartridge is

damaged.

The drum unit is damaged. Replace the drum unit.

The fuser unit is damaged. Display the Printer Console

The laser unit cover is dirty. Clean the laser unit cover (see

A small matter is mixed with the

roller of the toner cartridge.

Clean the corona wire in the

drum unit (see “Cleaning the

Printer” on page 5).

Replace the toner cartridge.

window and click icon ( )

to print a cleaning data (see

“Using the Printer Console

Window” on page 41 in

“Settings and Printing”).

If it is not recovered, call for

service to replace the fuser

unit.

“Cleaning the Printer” on page

5).

Replace the toner cartridge.

Page 27

Settings and Printing

Trouble Possible Cause Corrective Action

Maintenance and Specifications

Maintenance and Specifications

27

Troubleshooting

The printer prints

aslant.

ABCD--------

-----------------

--------

The print out media is

wrinkled.

The media is not installed

correctly.

Too much media is loaded in

the media tray.

Incorrect type of media is used. Check the media usable or not

The media is not installed

correctly.

The media is moist. Use fresh paper.

Incorrect type of media is used. Check the media usable or not

Install media correctly in the

media tray.

Adjust media guides correctly.

Decrease the media stack so

that the height of media does

not exceed the limit mark.

(see “About Media” on page 8

in “Settings and Printing”),

(see “Media” on page 43).

Install media correctly in the

media tray.

Adjust media guides correctly.

(see “About Media” on page 8

in “Settings and Printing”),

(see “Media” on page 43).

The back of the printed

page appears dirty.

The transfer roller or fuser unit

is contaminated after clearing a

jam.

The toner cartridge has

reached the end of useful life.

Incorrect type of media is used. Use a correct media (see

Display the Printer Console

window and click icon ( )

to print a cleaning data (see

“Using the Printer Console

Window” on page 41 in

“Settings and Printing”).

Replace the toner cartridge.

“About Media” on page 8 in

“Settings and Printing”),

(see “Media” on page 43).

Page 28

Settings and Printing

Trouble Possible Cause Corrective Action

Maintenance and Specifications

Maintenance and Specifications

28

Troubleshooting

Frequent mediapicking errors occur.

Image is cut. Image size is bigger than print

The length media guide of the

media tray is not set correctly.

The media is not set correctly

in the media tray.

Pick up roller is dirty. Clean the pick up roller (see

area.

Check the length media guide

is set to the groove indicating

the media size.

Check the loaded media is not

curled.

Check the media is not set on

the media height stopper (A) of

the length media guide.

A

“Cleaning the Printer” on page

5).

Adjust the image within the

print area. 4.2 mm (0.17″) is

required for the top, bottom

and sides margins.

Page 29

Settings and Printing

■ If you can’t make a print

Trouble Possible Corrective Action

Maintenance and Specifications

Maintenance and Specifications

29

Troubleshooting

Printer not

operating.

The printer does not

print correctly.

The printer may not be

plugged into an AC outlet or

turned on.

The interface cable(s) may

not be connected properly.

The printer driver is not set

correctly.

Appropriate driver may not

be installed or correct printer

may not be selected.

Make sure that you plugged in the

printer and turned it on.

Make sure that you connected the

interface cable(s) properly (see “Bi-

directional Parallel Interface” on

page 49), [see “USB (Universal

Serial Bus) Interface” on page 51].

Ensure the correct printer port is

selected in the printer driver for

cable used (see “Setting the Printer

Driver” on page 22 in “Settings and

Printing”).

If the communication link between

your computer and the printer is

working but the printer ejects a

blank page when printing from your

application or through Windows,

make sure that the appropriate

driver is installed and that you have

selected the printer correctly.

The setting for

printing is not

effective.

Some applications may not

allow you to change the

settings through the printer

driver’s setting window.

Change the application’s settings.

Page 30

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Troubleshooting

■ If the print out is ragged

If the print out is ragged because of the curl of paper as illustrated below, slide the media tray

out of the printer and turn over the paper stack, then insert the media tray.

30

■ If you cannot install the printer driver in Microsoft® Windows NT®

operating system Version 4.0

The printer driver cannot be installed with Add Printer Wizard in Windows NT 4.0. Install the

printer driver with Setup.exe (see “Installing the Printer Software” in the Setup Guide).

■ Number of lines are changed in 2up or 4up printing using

Microsoft® Excell spreadsheet

Adjust the height of the cell size of the spreadsheet.

■ Printer Status Display alerts when printing many files

When printing many files, “Power Off or Cable Problem or Printer Busy” may be displayed on

the Printer Status Display. Wait for a while. The printing will be automatically resumed.

Page 31

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Troubleshooting

Cleaning the Photosensitive Drum

If the paste or glue of a label is attached to the photosensitive drum of the drum unit, clean it

following the steps below.

31

1

2

3

Open the front cover of the printer.

Lift the drum unit up ( # ) and slide it out of the printer ( $ ).

#

#

$

While pushing the drum unit as illustrated below ( # ), lift the toner

cartridge up ( $ ).

#

$

Page 32

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

32

Troubleshooting

4

5

Remove the toner cartridge from the drum unit.

If a paste/glue of a label is attached, find the portion that it is attached

while rotating the gear of the photosensitive drum in the direction of the

arrow.

•The paste will be attached the portion that white or black spots of the print appear.

Paste

Gear

CAUTION

To prevent any damage to the drum unit, observe the following precautions.

•Do not rotate the photosensitive drum in the opposite direction of the above illustration,

otherwise the drum unit may be damaged.

•Do not touch the black drum surface.

•Do not expose the drum unit to light for more than 5 minutes.

•Do not expose the drum unit to direct sunlight.

•Do not keep the drum unit near dust or dirt.

•Do not place the drum unit in a high humidity area.

Page 33

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

33

Troubleshooting

6

Wipe the photosensitive drum with a dry cotton swab or remove the small

dust in the gears of the photosensitive drum.

Dust

CAUTION

• Do not use a shar p-pointed something like a ball-point pen to prevent the damage to the

drum unit when removing the paste.

7

Insert the side pins of the toner car tridge into the slots of the drum unit

(#). Push the toner cartridge in the drum unit ($).

$

#

Side pin

$

Page 34

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

34

Troubleshooting

8

Firmly inser t the drum unit in the slot of the printer ( # ) [inser t the side

pins of the drum unit into the groove (label )]. Push down ( $ ).

$

#

Side pin

$

9

Close the front cover.

Page 35

Settings and Printing

Error Indication

Maintenance and Specifications

Maintenance and Specifications

35

Error Indication

Indicators

1

*

READY

ERROR

TONER/

DRUM UNIT

READY

ERROR

TONER/

DRUM UNIT

READY

ERROR

TONER/

DRUM UNIT

Possible Cause

Front cover is open.

Media tray is empty.

Printer failed to feed a media

from media tray.

Media jam has occurred.

RAM overflow or overrun has

occurred.

Internal error has occurred.

Toner is low.

Drum unit is wearing out.

Recovery

Close the front cover.

Load media in the media tray

and press the CONTINUE

button (less than 5 seconds).

Remove the jammed media, then

open the front cover and close it.

Press the CONTINUE button

(less than 5 seconds).

Turn the power off for a few

secondes then on again. If the

error continues, call for service.

Replace the toner cartridge soon.

Replace the drum unit soon.

READY

ERROR

TONER/

DRUM UNIT

Drum unit is not installed.

Toner is empty.

Drum unit is worn out.

Drum unit is worn out and toner

is empty.

Install the drum unit.

Replace the toner cartridge now.

Replace the drum unit now.

Replace the toner cartridge and

drum unit now.

, : Indicator is lit. , : Indicator is blinking fast (with an interval of 1 second).

: Indicator is turned off.

1

*

The indication varies depending on the printer status.

Page 36

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Repacking Instructions

Repacking Instructions

Repacking

It is highly recommended that you keep the original carton and ALL packing materials.

Should you need to transport or ship your printer, please follow these instructions.

SAFETY CAUTION

The printer weighs about 10 kg {22 lbs.}.

NOTE

•Should you need to send your printer for service, consult your reseller first or Panasonic.

•Please use the original carton and all of the original packing materials.

•Do not ship printer with drum unit installed.

•Improper repacking of the printer may result in a service charge to remove spilled toner.

• Since the printer uses dry toner, extreme care must be taken when handling. The printer

should be handled in the upright (vertical) position.

36

Material required:

•Original cartons and packing materials

•Newspaper or drop cloth

•Shipping tape and scissors

1

2

Turn off the printer; remove the power cord and all interface cables.

Open the front cover.

Page 37

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

37

Repacking Instructions

3

Lift the drum unit up ( # ) and slide it out of the printer ( $ ).

•To avoid possible toner spillage, it is recommended to place the drum unit on a newspaper, drop cloth or best to place back in original (Black) shipping bag.

#

#

$

CAUTION

•To prevent any damage to the drum unit, observe the following precautions.

— Do not touch the black drum surface illustrated below.

— Do not expose the drum unit to light for more than 5 minutes.

— Do not expose the drum unit to direct sunlight.

— Do not keep the drum unit near dust or dirt.

— Do not place the drum unit in a high humid area.

Black drum

Page 38

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

38

Repacking Instructions

4

5

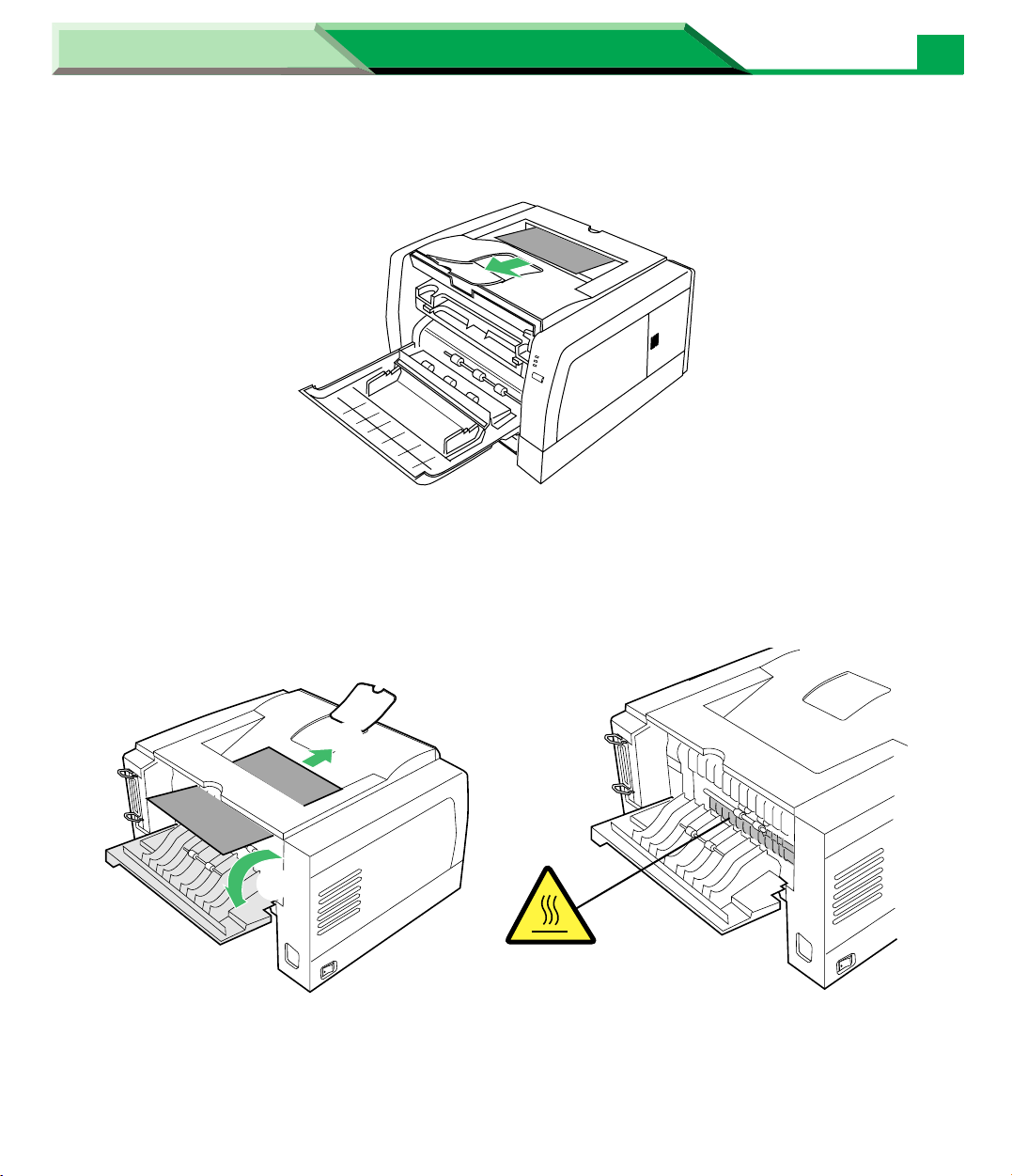

While pushing the drum unit as illustrated below ( # ), lift the toner

cartridge up ( $ ).

$

#

Replace the shipping cover on the toner cartridge.

Page 39

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

39

Repacking Instructions

6

7

Insert the toner car tridge into a plastic bag and cer tainly seal the end of

the bag tightly.

#

%

Wrap the drum unit with the protective sheet to protect the drum surface.

$

8

9

Insert the drum unit into a plastic bag and seal the end of the bag tightly.

Close the front cover.

Page 40

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

40

Repacking Instructions

10

NOTE

• If a toner vacuum is available, it is the best tool for cleaning spilled toner. Do not use a

11

Wipe off any loose toner in and around the printer.

standard office vacuum; the toner will not be retained by typical vacuum dust collectors.

Repack the printer.

Drum unit

Toner cartridge

AC cord

Page 41

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

Specifications

Printer

Printing Method:

Semiconductor Laser

Print Speed:

14 ppm (pages per minute) maximum (A4 size plain paper, simplex printing, 5% image area)

1

ppm maximum (Letter size plain paper, simplex printing, 5% image area)

15*

1

Maximum print speed is 14.6 ppm.

*

First Print:

15 seconds

Resolution:

600 x 600 dpi (dots per inch)

41

Paper Feed:

Media tray (universal cassette): up to 250 sheets of paper [75 g/m

Manual feed: 1 sheet

Paper Output:

2

Up to 150 sheets of paper [75 g/m

Power Source:

Refer to the nameplate on the rear of the unit

Memory:

2 MB

Interface:

Bi-directional parallel, USB

Warm Up Time

Less than 25 seconds [at 22°C (71.6°F), 50% RH]

Operating Environment:

10 to 32.5°C (50 to 90.5°F), 20 to 80% RH

Storage Environment:

0 to 35°C (32 to 95°F), 10 to 80% RH

(20 lbs.)]

2

(20 lbs.)]

Page 42

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

Dimensions:

399 (W) X 390.5 (D) X 254 (H) mm (15.7″ X 15.4″ X 10″)

Mass {Weight}:

Approx. 10 kg {22 lbs.}

Consumables / Life:

Starter toner cartridge (provided with printer); 2,000 pages average*

Toner cartridge; 4,000 pages average*

Drum unit; 20,000 pages average*

1

1

1

*1 Average life at 5 % image area with repetitive printing of 10 pages (Letter / A4 size, single-

sided printing, default density).

5% image area means that the black area within the printing area is 5%. Printing 10%

image area continuously will reduce the life of the toner to about half as compared to

printing 5% image area. The Toner Saving mode allows you to save toner (see “Quality Tab”

on page 31 in “Settings and Printing”).

42

Power Consumption:

Printing*

2

(average): 310 W or less

Standby (average): 70 W or less

Power saving (When the fan stops.): 5.5 W or less

Meets E

NERGY STAR

® power conservation requirements.

*2Maximum print speed, duplex printing

Noise Level:

Printing: 49 dBA

Standby: 37dBA

CPU:

Intel 80C51 compatible

Page 43

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

Media

■ Paper Specifications

This printer is designed to work well with most types of paper. However, differences in paper

may have significant effects on the quality of the print or the reliability of paper handling. It is

strongly recommended that you always test paper before purchasing it to make sure it

provides desirable performance. The following guidelines will be helpful.

Basic Weight:

60 to 105 g/m

Thickness:

3.7 to 7.5 mils (1 mil=1/1000″ )

Moisture Content:

4% to 6%

Smoothness:

100 to 300 Sheffield

2

(16 to 28 lbs.)

43

Acid Content:

5.5 PH minimum

Fusing Compatibility:

Must not scorch, melt, offset material, or release hazardous emissions when heated to 200°C

(392°F) for 0.1 second

Cutting Dimensions:

±0.0313 inch of nominal, corners 90°±4°

Grain:

Long grain

Cut Edge Conditions:

Cut with sharp blades, no paper dust

Ash Content:

Not to exceed 10%

Curl:

No allowable curl toward the side to be printed

Packing:

Polylaminated moisture proof ream wrap

Page 44

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

NOTE

•Please store your paper according to the recommendations of the manufacturer.

■ Paper and Envelope Sizes

The following paper and envelope sizes are supported by the printer.

Medium Name Dimension

Paper Letter 216 x 279 mm (8.5″ x 11″)

A4 210 x 297 mm (8.27″ x 11.7″)

Legal 216 x 356 mm (8.5″ x 14″)

B5 176 x 250 mm (6.92″ x 9.84″)

Executive 184 x 267 mm (7.25″ X 10.5″)

44

Specifications

1

A5*

1

A6*

Envelope*

1

Duplex printing cannot be performed with A5, A6 size paper or envelope.

*

1

Envelope #9 98 x 225 mm (3.87″ x 8.87″)

Envelope #10 105 x 241 mm (4.12″ x 9.5″)

International DL 110 x 220 mm (4.33″ x 8.66″)

International C5 162 x 229 mm (6.38″ x 9.01″)

Monarch 98 x 191 mm (3.87″ x 7.5″)

148.5 x 210 mm (5.85″ x 8.27″)

105 x 148.5 mm (4.13″ x 5.85″)

Page 45

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

■ Types of Paper to Avoid

•Extremely smooth or shiny paper or paper that is highly textured

•Coated papers

•Acid paper

• Letterhead imprinted with low temperature or thermography. These materials may transfer

onto the fusing roller and cause damage. Any pre-printed paper should use inks compatible

with 200°C (392°F) for 0.1 second.

•Damaged or wrinkled paper, or paper with irregularities such as tabs, staples, etc.

•Multipart forms or carbonless paper

•Paper with a cotton and/or fiber content over 25%

•Ink jet media (paper, transparency, etc.) (It may transfer onto the fuser unit’s roller and

cause damage.)

■ Transparencies and Labels

You may also print on labels and transparencies that are made for the printer. Panasonic has

tested and found that the following work satisfactorily.

45

OHP transparencies 3M CG3300

Labels AVERY 5160, AVERY 5161, AVERY 5162, AVERY 5163,

AVERY 5660, AVERY 5661, AVERY 5662, AVERY 5663

Avery L7159, Avery L7160, Avery L7161, Avery L7162,

Avery L7163, Avery L7164

•To avoid damaging the printer, do not use ink jet transparency.

• Transparencies and adhesive material of labels should be stable at 205°C (400°F), the

printer’s maximum temperature.

•Re-using transparencies that have been fed through the printer once (for example, after jams

or if the transparency is ejected without being printed) can reduce the life of the consumables

and paper path components.

•When using transparencies, if the print quality is poor, print on the other side.

Page 46

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

NOTE

• With any label stock, the labels must completely cover the backing material (see figure

below).

NOYES

46

Labels cover the entire

backing material

The backing material is exposed.

■ Envelope Specifications

It is recommended that you purchase only high quality envelopes with diagonal seams, as

shown in the diagram below:

High quality envelopes have the following characteristics:

•A thin, sharply creased leading edge

•Paper weight of 90 g/m

•Flat, free of curls, wrinkles, nicks, etc.

NOTE

•Wrinkle may occur in some case, even if high quality envelopes are used.

2

(24 lbs.)

Page 47

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

It is not recommended that you use envelopes with any of the following characteristics (using

these may result in paper jams):

•Irregularly shaped envelopes

•Envelopes with curls, wrinkles, nicks, twists, dog-ears or other damage

•Envelopes with side seam construction

•Highly textured envelopes, or with extremely shiny surfaces

•Envelopes that seal by removing a peel-off strip

•Envelopes with more than one flap to be sealed

•Self-adhesive envelopes

•Envelopes that are baggy or not sharply creased

•Embossed envelopes

•Envelopes that have previously been printed with a laser printer

•Envelopes that have been previously printed inside

47

Curl

Side seam

construction

Twist

Peel-off strip

Multiple flaps

WaveDog-ears

Self adhesive

Bent-edge

Page 48

Settings and Printing

Do not attempt to print on any of the following types of envelopes. These may cause damage

to your printer.

•Envelopes with clasps, snaps or tie strings (see Figure 1)

•Envelopes with transparent windows (see Figure 2)

• Envelopes that will melt, discolour, scorch, offset or release hazardous emissions when

exposed to 200°C (392°F) for 0.1 second

•Envelopes that use encapsulated types of adhesive that do not require moistening but rely

on pressure to seal them

Maintenance and Specifications

Maintenance and Specifications

Specifications

48

Figure 1

Always test a sample of the envelopes you are thinking of buying. Confirm that the envelope

performs acceptably.

For best printing results

•Avoid printing in high humidity i.e., above 70%.

High humidity may cause the envelope to curl and pick up excess toner.

High humidity may also cause the envelope to seal.

• Envelope storage is very important. Store them away from moisture and humid air, where

they can lay flat and their edges won’t be bent or damaged. The humidity should not exceed

70% RH.

Figure 2

Page 49

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Bi-directional Parallel Interface

Connector type:36PIN Anphenole connector

Cable: use a shielded cable 2 meters (6.6 feet) or less in length

Pin configuration

Pin Signal

1 nStrobe

2 Data 1

3 Data 2

4 Data 3

5 Data 4

6 Data 5

7 Data 6

8 Data 7

9 Data 8

10 nAck

11 Busy

12 PError

13 Select

14 nAutoFd

15 NC

16 GND

17 FG

18 Vcc

Pin Signal

19 GND

20 GND

21 GND

22 GND

23 GND

24 GND

25 GND

26 GND

27 GND

28 GND

29 GND

30 GND

31 ninit

32 nFault

33 GND

34 NC

35 NC

36 nSelectIn

49

Specifications

Parallel Interface connector (printer side)

18

36

1

19

Page 50

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

Specifications

CAUTION

•If the cable is connected to PC via printer buffer or selector, the printer may not print.

•A print server cannot be used for printing.

NOTE

•Be sure to use only a shielded cable. The printer will not operate properly if any of the pins

are not connected.

50

Page 51

Settings and Printing

Maintenance and Specifications

Maintenance and Specifications

USB (Universal Serial Bus) Interface

Cable: use a shielded cable 5 m (16.4 feet) or less in length.

Pin configuration

Signal pin Signal

51

Specifications

1V

2 -Data

3 + Data

4 Ground

USB Interface connector (printer side)

BUS

12

3

4

NOTE

• Be sure to use a full-speed shielded cable which the Data + and Data – cables are the

twisted pair.

•When using KX-P7100 printer and other USB devices simultaneously, we cannot guarantee

normal printing.

Loading...

Loading...