Panasonic CS-Z25UD3EAW, CS-Z50UD3EAW, CS-Z35UD3EAW, CS-Z60UD3EAW, CS-MZ20UD3EA Operating Instructions Manual

...

Hrvatski Italiano Nederlands Deutsch English

Operating Instructions

Air Conditioner

Model No.

Indoor Unit Outdoor Unit

CS-Z25UD3EAW

CS-Z35UD3EAW

CS-Z50UD3EAW

CS-Z60UD3EAW

CS-MZ20UD3EA

Single Split (R32)

CU-Z25UBEA

CU-Z35UBEA

CU-Z50UBEA

CU-Z60UBEA

* Outdoor Unit

Multi Split (R410A)

CU-3E18PBE

CU-4E23PBE

CU-4E27PBE

CU-5E34PBE

CU-2E12SBE

CU-2E15SBE

CU-2E18SBE

CU-3E23SBE

* Outdoor Unit

Multi Split (R32)

CU-2Z35TBE

CU-2Z41TBE

CU-2Z50TBE

CU-3Z52TBE

CU-3Z68TBE

CU-4Z68TBE

CU-4Z80TBE

CU-5Z90TBE

ACXF55-17690

Operating Instructions

Air Conditioner

2-23

Before operating the unit, please read these operating

instructions thoroughly and keep them for future reference.

The included Installation Instructions should be kept and read

by the installer before installation.

* Kindly consult authorised dealer for connectivity validity.

Bedienungsanleitung

Klimagerät

24-45

Bevor Sie das Gerät in Betrieb nehmen, lesen Sie bitte diese

Bedienungsanleitung aufmerksam durch und bewahren Sie

sie als künftige Referenz auf.

Das mitgelieferte Installationshandbuch sollte aufbewahrt und

vor der Installation vom Installateur gelesen werden.

* Wenden Sie sich bei Fragen zur Gültigkeit der Konnektivität

an Ihren Fachhändler

Handleiding

Airconditioner

46-67

Lees voor u het apparaat gebruikt deze gebruikshandleiding

grondig en bewaar deze voor toekomstig gebruik.

De bijgevoegde installatiehandleiding moet door de

installateur worden bewaard en gelezen vóór de installatie.

* Wij verzoeken u vriendelijk een geautoriseerde dealer

advies te vragen over de aansluitmogelijkheden.

Istruzioni di funzionamento

Condizionatore d’aria

68-89

Prima di utilizzare l’unità, leggere attentamente le istruzioni e

conservare questo opuscolo per potervi fare riferimento in futuro.

Le istruzioni per l’installazione fornite in dotazione

devono essere conservate e lette dall’installatore prima

dell’installazione.

* Si prega di consultare un rivenditore autorizzato per la

validità della connettività.

Upute za rad

Klimatizacijski uređaj

90-111

Prije rada s jedinicom, pažljivo pročitajte ove upute za rad i

čuvajte ih za buduće potrebe.

Instalater prije instaliranja treba čuvati i pročitati priložene

upute za ugradnju.

* Molimo vas da se obratite ovlaštenom zastupniku za

potvrdu povezivosti.

ACXF55-17690_book1.indb 1ACXF55-17690_book1.indb 1 12/7/2017 5:07:00 PM12/7/2017 5:07:00 PM

2

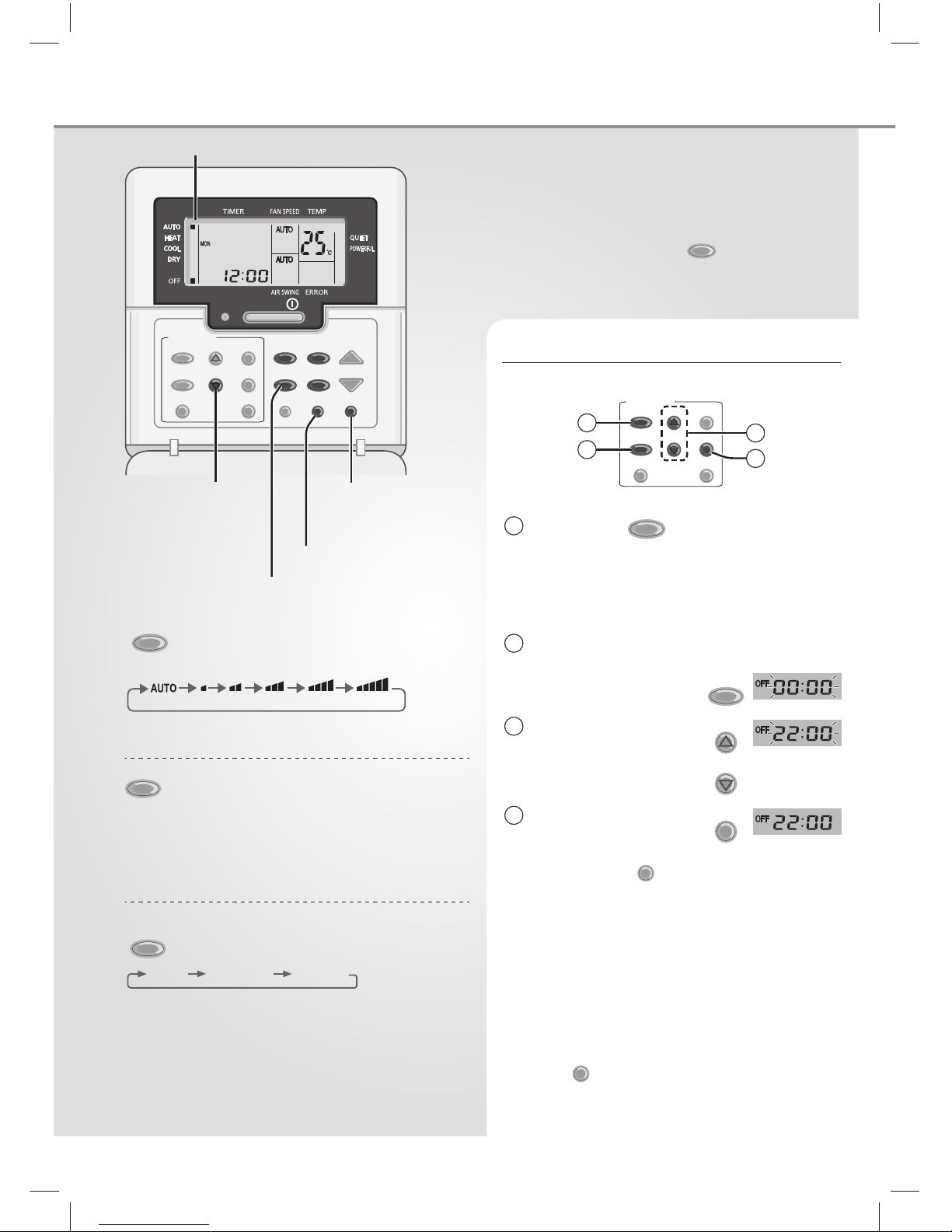

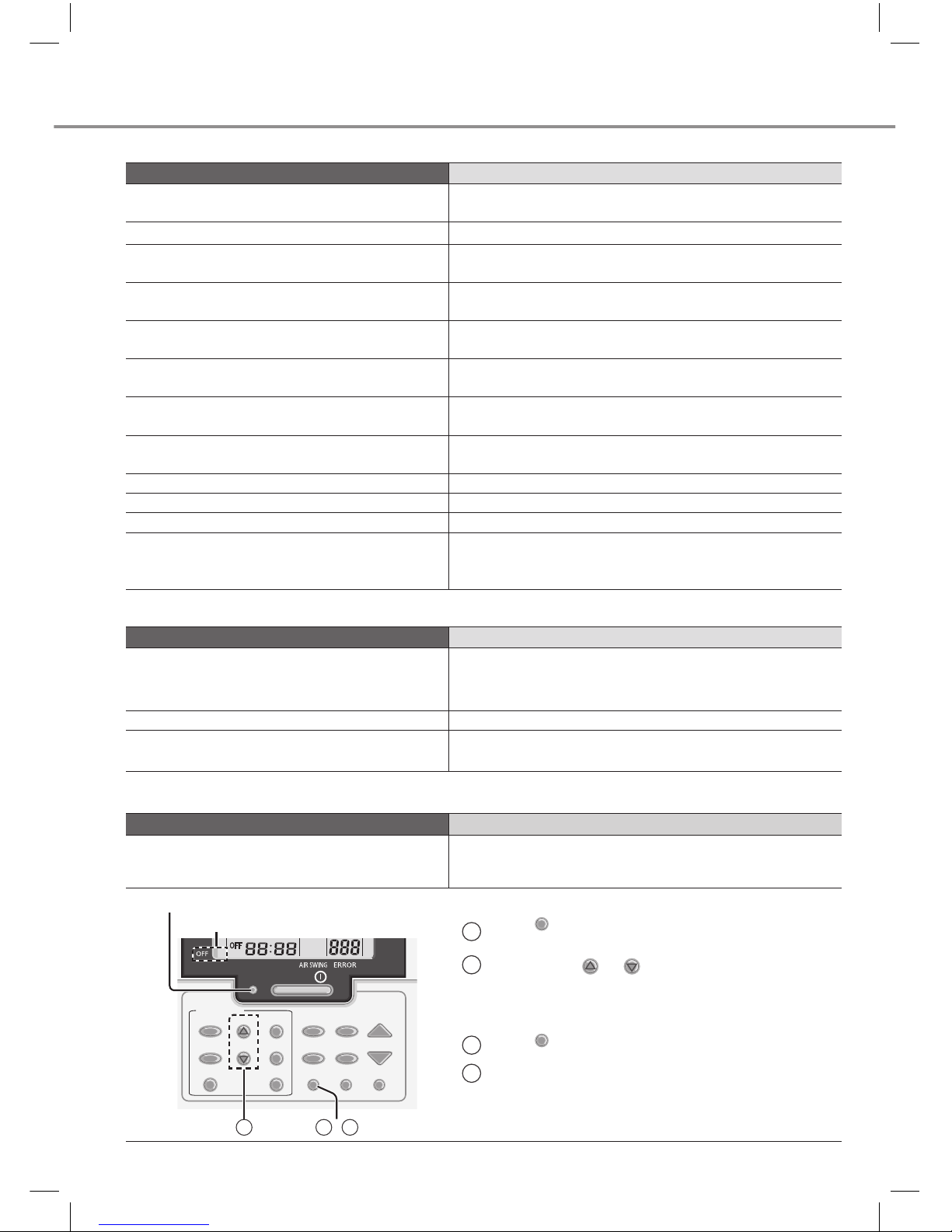

Quick Guide

Remote Control Preparation

a

Press

CLOCK

b

Press to set day

c

Confirm

Repeat steps “b” and “c” to set the

current time.

Flexibility to connect Single

Split System or Multi Split

System Air Conditioner to suit

your needs.

For complete product features,

please refer to catalogue.

OFF

/

ON

TEMP

TIMER/CLOCK

MODE

QUIET/

POWERFUL

FAN SPEED

MODE

CHECK RESET

AIR SWING

OFF/ON

CANCELCLOCK

SET

SELECTUP

DOWN

AC RC

3

1

a

b

c

2

ACXF55-17690_book1.indb 2ACXF55-17690_book1.indb 2 12/7/2017 5:07:00 PM12/7/2017 5:07:00 PM

3

English

Table of contents

Safety precautions

………

4-15

How to use…………… 16-17

To learn more

………………

18

Cleaning instructions

………

19

Troubleshooting

………

20-22

Information………………… 23

The illustrations in this manual are for

explanation purposes only and may differ

from the actual unit. They are subject

to change without notice for future

improvement.

Basic operation

1

Press

OFF

/

ON

to start/stop the operation.

2

Press

MODE

to select the desired mode.

DRY

AUTO HEAT

COOL

3

Select the desired temperature.

UP

DOWN

Selection range: 16 °C ~ 30 °C / 60 °F ~ 86 °F.

Thank you for purchasing

Panasonic Air Conditioner.

ACXF55-17690_book1.indb 3ACXF55-17690_book1.indb 3 12/7/2017 5:07:01 PM12/7/2017 5:07:01 PM

4

Safety precautions

WARNING

Indoor unit and outdoor unit

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance

in a safe way and understand the

hazards involved.

Children shall not play with the

appliance. Cleaning and user

maintenance shall not be made by

children without supervision.

Please consult authorised dealer or

specialist to clean the internal parts,

repair, install, remove and reinstall

the unit. Improper installation and

handling will cause leakage, electric

shock or fire.

Confirm with authorised dealer or

specialist on usage of any specified

refrigerant type. Using refrigerant

type other than the specified may

cause product damage, burst and

injury etc.

Do not use means to accelerate

the defrosting process or to clean,

other than those recommended by

manufacturer.

Any unfit method or using

incompatible material may cause

product damage, burst and serious

injury.

Do not install the unit in a potentially

explosive or flammable atmosphere.

Failure to do so could result in fire.

To prevent personal injury, injury to others

or property damage, please comply with the

following:

Incorrect operation due to failure to follow

instructions below may cause harm or

damage, the seriousness of which is

classified as below:

This appliances is not intended for

accessibility by the general public.

WARNING

This sign

warns of

death or

serious injury.

CAUTION

This sign

warns of

injury or

damage to

property.

The instructions to be followed are classified

by the following symbols:

This symbol denotes an

action that is PROHIBITED.

These symbols denote

actions COMPULSORY.

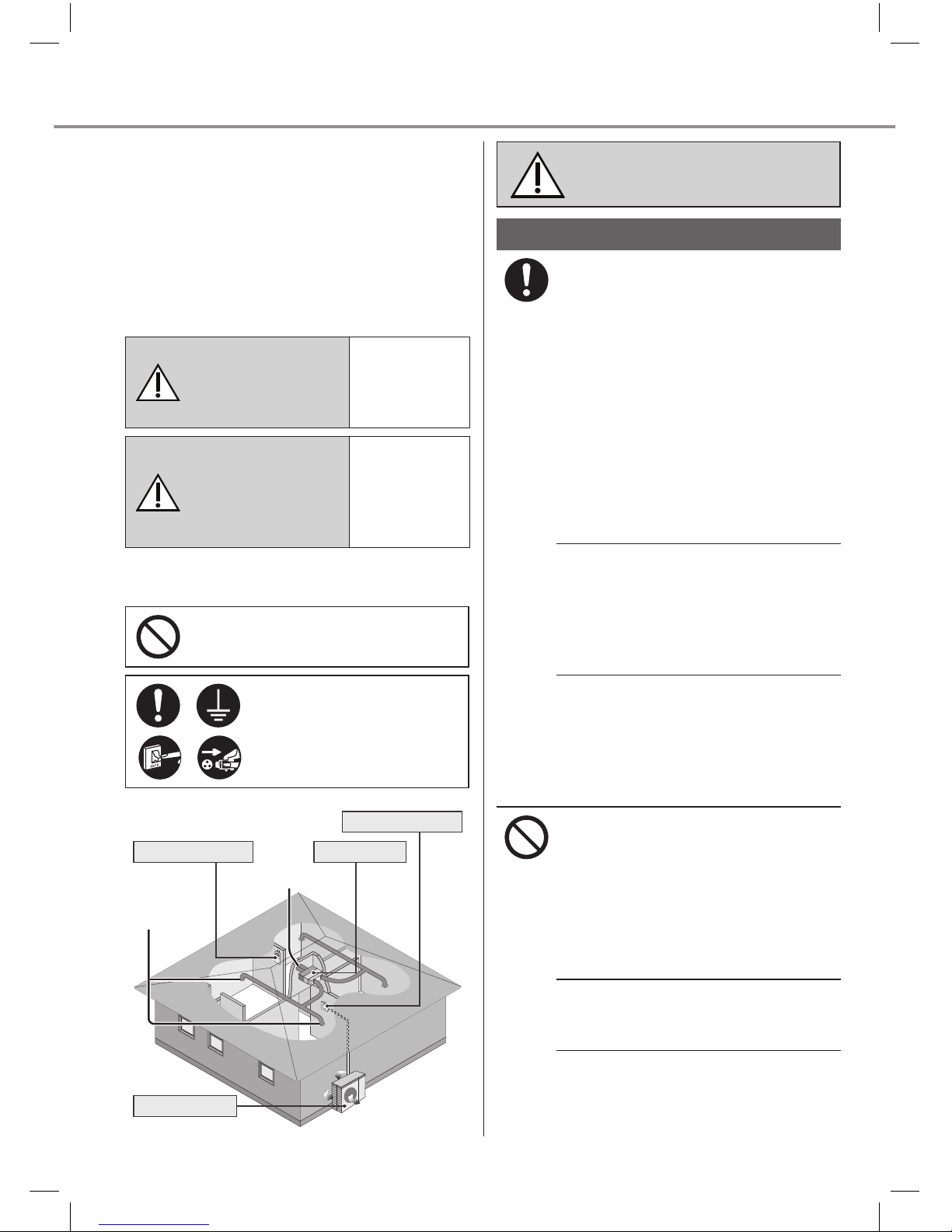

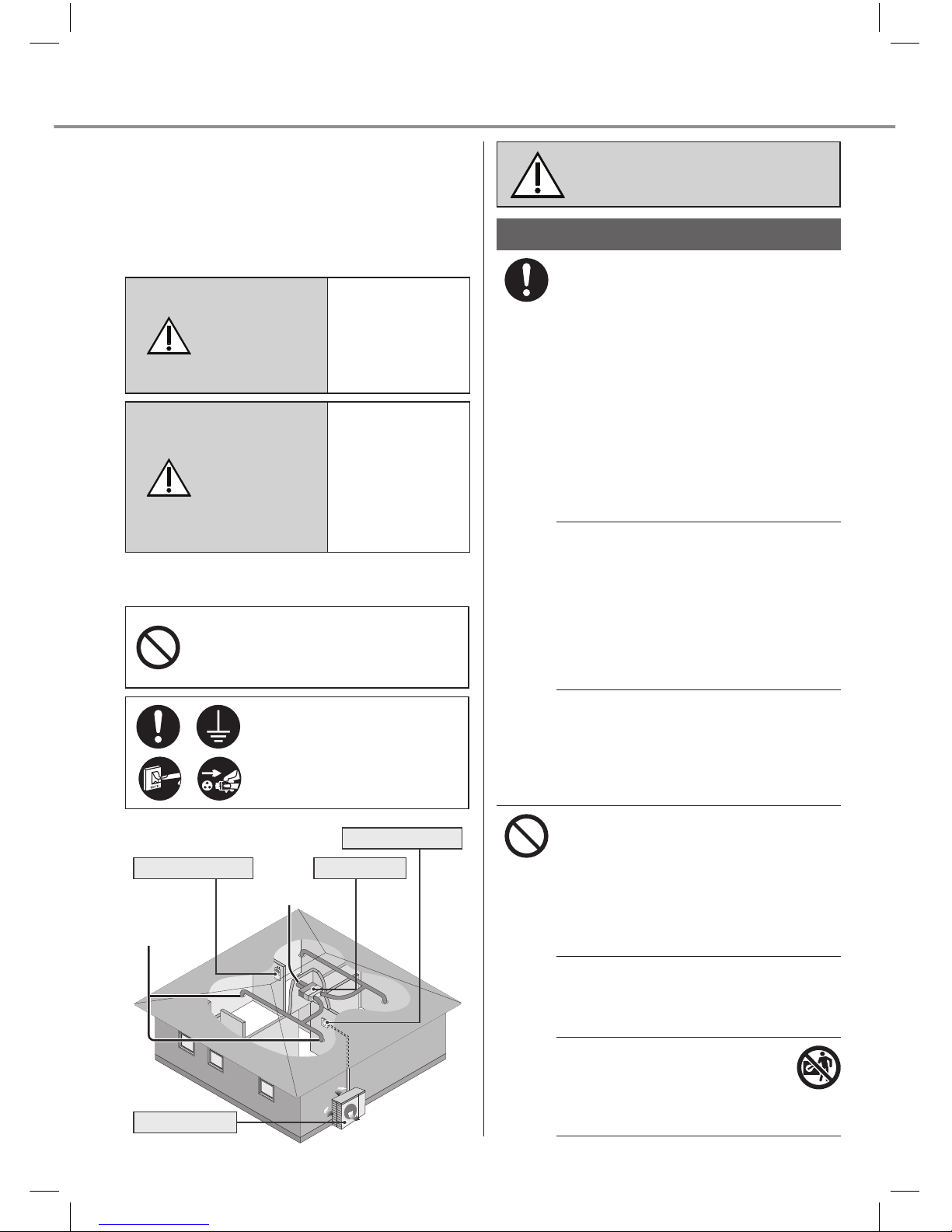

Air inlet

Air inlet

Air outlet

Air outlet

Remote control

Outdoor unit

Power supply

Indoor unit

Air inlet vent

Air outlet

vent

ACXF55-17690_book1.indb 4ACXF55-17690_book1.indb 4 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

5

EnglishSafety precautions

Do not insert your fingers

or other objects into the air

conditioner indoor or outdoor

unit, rotating parts may cause

injury.

Do not touch the outdoor unit during

lightning, it may cause electric

shock.

Do not expose yourself directly to

cold air for a long period to avoid

excess cooling.

Do not sit or step on the unit,

you may fall down accidentally.

Remote control

Do not allow infants and small

children to play with the remote

control to prevent them from

accidentally swallowing the batteries.

Power supply

Do not use a modified

cord, joint cord,

extension cord or

unspecified cord to

prevent overheating

and fire.

To prevent overheating, fire or

electric shock:

•

Do not share the same power outlet

with other equipment.

•

Do not operate with wet hands.

•

Do not over bend the power supply

cord.

•

Do not operate or stop the unit by

inserting or pulling out the power

plug.

If the supply cord is damaged,

it must be replaced by the

manufacturer, service agent or

similarly qualified persons in order to

avoid a hazard.

It is strongly recommended to be

installed with Earth Leakage Circuit

Breaker (ELCB) or Residual Current

Device (RCD) to prevent electric

shock or fire.

To prevent overheating, fire or

electric shock:

•

Insert the power plug properly.

•

Dust on the power plug should be

periodically wiped with a dry cloth.

Stop using the product if any

abnormality/failure occurs and

disconnect the power plug or turn off

the power switch and breaker.

(Risk of smoke/fire/electric shock)

Examples of abnormality/failure

•

The ELCB trips frequently.

•

Burning smell is observed.

•

Abnormal noise or vibration of the

unit is observed.

•

Water leaks from the indoor unit.

•

Power cord or plug becomes

abnormally hot.

•

Fan speed cannot be controlled.

•

The unit stops running immediately

even if it is switched on for

operation.

•

The fan does not stop even if the

operation is stopped.

Contact your local dealer

immediately for maintenance/repair.

This equipment must be earthed to

prevent electrical shock or fire.

Prevent electric shock by switching

off the power supply and unplug:

-Before cleaning or servicing,

-When extended non-use, or

-During abnormally strong lightning

activity.

ACXF55-17690_book1.indb 5ACXF55-17690_book1.indb 5 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

6

Safety precautions

CAUTION

Indoor unit and outdoor unit

Do not wash the indoor unit with

water, benzine, thinner or scouring

powder to avoid damage or

corrosion at the unit.

Do not use for preservation of

precise equipment, food, animals,

plants, artwork or other objects. This

may cause quality deterioration, etc.

Do not use any combustible

equipment in front of the airflow

outlet to avoid fire propagation.

Do not expose plants or pet directly

to airflow to avoid injury, etc.

Do not touch the sharp

aluminium fin, sharp parts may

cause injury.

Do not switch ON the indoor unit

when waxing the floor. After waxing,

aerate the room properly before

operating the unit.

Do not install the unit in oily and

smoky areas to prevent damage to

the unit.

Do not dismantle the unit for

cleaning purpose to avoid injury.

Do not step onto an unstable bench

when cleaning the unit to avoid

injury.

Do not place a vase or water

container on the unit. Water may

enter the unit and degrade the

insulation. This may cause an

electric shock.

Do not open window or door for

long time during operation, it may

lead to inefficient power usage and

uncomfortable temperature changes.

Prevent water leakage by ensuring

drainage pipe is:

-Connected properly,

-Kept clear of gutters and

containers, or

-Not immersed in water

After a long period of use or use with

any combustible equipment, aerate

the room regularly.

After a long period of use, make

sure the installation rack does not

deteriorate to prevent the unit from

falling down.

Remote control

Do not use rechargeable (Ni-Cd)

batteries. It may damage the remote

control.

To prevent malfunction or damage of

the remote control:

•

Remove the batteries if the unit

is not going to be used for a long

period of time.

•

New batteries of the same type

must be inserted following the

polarity stated.

Power supply

Do not disconnect the plug by pulling

the cord to prevent electric shock.

ACXF55-17690_book1.indb 6ACXF55-17690_book1.indb 6 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

7

English Safety precautions

WARNING

This appliance is filled with R32

(mild flammable refrigerant).

If the refrigerant is leaked and

exposed to an external ignition

source, there is a risk of fire.

Indoor unit and outdoor unit

The appliance shall be installed,

and/or operated in a room with floor

area larger than Amin (m²) and

keep away from ignition sources,

such as heat/sparks/open flame

or hazardous areas such as gas

appliances, gas cooking, reticulated

gas supply systems or electric

cooking appliances, etc. (Refer to

Table A of Installation instructions

table for Amin (m²))

Be aware that refrigerant may

not contain an odour, highly

recommended to ensure suitable

flammable refrigerant gas detectors

are present, operating and able to

warn of a leak.

Keep any required ventilation

openings clear of obstruction.

Do not pierce or burn as the

appliance is pressurized. Do not

expose the appliance to heat, flame,

sparks, or other sources of ignition.

Else it may explode and cause injury

or death.

Precaution for using R32

refrigerant

The basic installation work procedures

are the same as conventional refrigerant

(R410A, R22) models.

Since the working pressure is

higher than that of refrigerant R22

models, some of the piping and

installation and service tools are

special. Especially, when replacing

a refrigerant R22 model with a

new refrigerant R32 model, always

replace the conventional piping and

flare nuts with the R32 and R410A

piping and flare nuts on the outdoor

unit side.

For R32 and R410A, the same flare

nut on the outdoor unit side and pipe

can be used.

The mixing of different refrigerants

within a system is prohibited. Models

that use refrigerant R32 and R410A

have a different charging port thread

diameter to prevent erroneous

charging with refrigerant R22 and for

safety.

Therefore, check beforehand. [The

charging port thread diameter for

R32 and R410A is 1/2 inch.]

Must always ensure that foreign

matter (oil, water, etc.) does not

enter the piping. Also, when storing

the piping, securely seal the opening

by pinching, taping, etc. (Handling of

R32 is similar to R410A.)

•

Operation, maintenance, repairing

and refrigerant recovery should be

carried out by trained and certified

personnel in the use of flammable

refrigerants and as recommended

by the manufacturer. Any personnel

conducting an operation, servicing

or maintenance on a system or

associated parts of the equipment

should be trained and certified.

ACXF55-17690_book1.indb 7ACXF55-17690_book1.indb 7 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

8

•

Any part of refrigerating circuit

(evaporators, air coolers, AHU,

condensers or liquid receivers) or

piping should not be located in the

proximity of heat sources, open

flames, operating gas appliance or

an operating electric heater.

•

The user/owner or their authorised

representative shall regularly check

the alarms, mechanical ventilation

and detectors, at least once a

year, where as required by national

regulations, to ensure their correct

functioning.

•

A logbook shall be maintained. The

results of these checks shall be

recorded in the logbook.

•

In case of ventilations in occupied

spaces shall be checked to confirm

no obstruction.

•

Before a new refrigerating system

is put into service, the person

responsible for placing the system

in operation should ensure that

trained and certified operating

personnel are instructed on the

basis of the instruction manual

about the construction, supervision,

operation and maintenance of the

refrigerating system, as well as the

safety measures to be observed,

and the properties and handling of

the refrigerant used.

•

The general requirement of

trained and certified personnel are

indicated as below:

a) Knowledge of legislation,

regulations and standards

relating to fl ammable

refrigerants; and,

b) Detailed knowledge of and

skills in handling fl ammable

refrigerants, personal protective

equipment, refrigerant

leakage prevention, handling

of cylinders, charging, leak

detection, recovery and

disposal; and,

c) Able to understand and to apply

in practice the requirements

in the national legislation,

regulations and Standards; and,

d) Continuously undergo regular

and further training to maintain

this expertise.

1. Installation (Space)

•

Product with flammable

refrigerants, shall not be installed in

an unventilated space, if that space

is smaller than Amin (m²).

•

In case of field charge, the effect

on refrigerant charge caused by

the different pipe length has to be

quantified, measured and labelled.

•

Must ensure the installation of pipework shall be kept to a minimum.

Avoid use dented pipe and do not

allow acute bending.

•

Must ensure that pipe-work shall be

protected from physical damage.

•

Must comply with national gas

regulations, state municipal rules

and legislation. Notify relevant

authorities in accordance with all

applicable regulations.

•

Must ensure mechanical

connections be accessible for

maintenance purposes.

•

In cases that require mechanical

ventilation, ventilation openings

shall be kept clear of obstruction.

•

When disposal of the product, do

follow to the precautions in #12 and

comply with national regulations.

Always contact to local municipal

offices for proper handling.

Safety precautions

ACXF55-17690_book1.indb 8ACXF55-17690_book1.indb 8 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

9

English

2. Servicing

2-1. Service personnel

•

The system is inspected, regularly

supervised and maintained by

a trained and certified service

personnel who is employed by the

person user or party responsible.

•

Ensure the actual refrigerant

charge size is in accordance with

the room size within which the

refrigerant containing parts are

installed.

•

Ensure refrigerant charge not to

leak.

•

Any qualified person who is

involved with working on or

breaking into a refrigerant circuit

should hold a current valid

certificate from an industryaccredited assessment authority,

which authorizes their competence

to handle refrigerants safely in

accordance with an industry

recognised assessment

specification.

•

Servicing shall only be performed

as recommended by the equipment

manufacturer. Maintenance and

repair requiring the assistance of

other skilled personnel shall be

carried out under the supervision of

the person competent in the use of

flammable refrigerants.

•

Servicing shall be performed

only as recommended by the

manufacturer.

2-2. Work

•

Prior to beginning work on

systems containing flammable

refrigerants, safety checks are

necessary to ensure that the risk

of ignition is minimised. For repair

to the refrigerating system, the

precautions in #2-2 to #2-8 must

be followed before conducting

work on the system.

•

Work shall be undertaken under

a controlled procedure so as to

minimize the risk of a flammable

gas or vapour being present while

the work is being performed.

•

All maintenance staff and others

working in the local area shall be

instructed and supervised on the

nature of work being carried out.

•

Avoid working in confined spaces.

Always ensure away from source,

at least 2 meter of safety distance,

or zoning of free space area of at

least 2 meter in radius.

•

Wear appropriate protective

equipment, including respiratory

protection, as conditions warrant.

•

Ensure that the conditions within

the area have been made safe

by limit of use of any flammable

material. Keep all sources of

ignition and hot metal surfaces

away.

Safety precautions

ACXF55-17690_book1.indb 9ACXF55-17690_book1.indb 9 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

10

Safety precautions

2-3. Checking for presence of

refrigerant

•

The area shall be checked with an

appropriate refrigerant detector

prior to and during work, to

ensure the technician is aware of

potentially flammable atmospheres.

•

Ensure that the leak detection

equipment being used is suitable

for use with flammable refrigerants,

i.e. non sparking, adequately

sealed or intrinsically safe.

•

In case of leakage/spillage

happened, immediately ventilate

area and stay upwind and away

from spill/release.

•

In case of leakage/spillage

happened, do notify persons down

wind of the leaking/spill, isolate

immediate hazard area and keep

unauthorized personnel out.

2-4. Presence of fire extinguisher

•

If any hot work is to be conducted

on the refrigeration equipment or

any associated parts, appropriate

fire extinguishing equipment shall

be available at hand.

•

Have a dry powder or CO2 fire

extinguisher adjacent to the

charging area.

2-5. No ignition sources

•

No person carrying out work in

relation to a refrigeration system

which involves exposing any pipe

work that contains or has contained

flammable refrigerant shall use

any sources of ignition in such a

manner that it may lead to the risk

of fire or explosion. He/She must

not be smoking when carrying out

such work.

•

All possible ignition sources,

including cigarette smoking, should

be kept sufficiently far away from

the site of installation, repairing,

removing and disposal, during

which flammable refrigerant

can possibly be released to the

surrounding space.

•

Prior to work taking place, the

area around the equipment is to

be surveyed to make sure that

there are no flammable hazards or

ignition risks.

•

“No Smoking” signs shall be

displayed.

2-6. Ventilated area

•

Ensure that the area is in the open

or that it is adequately ventilated

before breaking into the system or

conducting any hot work.

•

A degree of ventilation shall

continue during the period that the

work is carried out.

•

The ventilation should safely

disperse any released refrigerant

and preferably expel it externally

into the atmosphere.

ACXF55-17690_book1.indb 10ACXF55-17690_book1.indb 10 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

11

English

2-7. Checks to the refrigeration

equipment

•

Where electrical components are

being changed, they shall be fit

for the purpose and to the correct

specification.

•

At all times the manufacturer’s

maintenance and service

guidelines shall be followed.

•

If in doubt consult the

manufacturer’s technical

department for assistance.

•

The following checks shall be

applied to installations using

flammable refrigerants.

-

The charge size is in accordance

with the room size within which

the refrigerant containing parts

are installed.

-

The ventilation machinery and

outlets are operating adequately

and are not obstructed.

-

If an indirect refrigerating circuit is

being used, the secondary circuit

shall be checked for the presence

of refrigerant.

-

Marking to the equipment

continues to be visible and

legible. Markings and signs that

are illegible shall be corrected.

-

Refrigeration pipe or components

are installed in a position where

they are unlikely to be exposed

to any substance which may

corrode refrigerant containing

components, unless the

components are constructed of

materials which are inherently

resistant to being corroded or are

properly protected against being

so corroded.

2-8. Checks to electrical devices

•

Repair and maintenance to

electrical components shall include

initial safety checks and component

inspection procedures.

•

Initial safety checks shall include

but not limit to:-

-

That capacitors are discharged:

this shall be done in a safe

manner to avoid possibility of

sparking.

-

That there no live electrical

components and wiring are

exposed while charging,

recovering or purging the system.

-

That there is continuity of earth

bonding.

•

At all times the manufacturer’s

maintenance and service guidelines

shall be followed.

•

If in doubt consult the

manufacturer’s technical

department for assistance.

•

If a fault exists that could

compromise safety, then no

electrical supply shall be connected

to the circuit until it is satisfactorily

dealt with.

•

If the fault cannot be corrected

immediately but it is necessary to

continue operation, an adequate

temporary solution shall be used.

•

The owner of the equipment must

be informed or reported so all

parties are advised thereinafter.

Safety precautions

ACXF55-17690_book1.indb 11ACXF55-17690_book1.indb 11 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

12

Safety precautions

3. Repairs to sealed components

•

During repairs to sealed

components, all electrical supplies

shall be disconnected from the

equipment being worked upon prior

to any removal of sealed covers,

etc.

•

If it is absolutely necessary to

have an electrical supply to

equipment during servicing, then

a permanently operating form of

leak detection shall be located at

the most critical point to warn of a

potentially hazardous situation.

•

Particular attention shall be paid

to the following to ensure that by

working on electrical components,

the casing is not altered in such a

way that the level of protection is

affected. This shall include damage

to cables, excessive number of

connections, terminals not made

to original specification, damage to

seals, incorrect fitting of glands, etc.

•

Ensure that apparatus is mounted

securely.

•

Ensure that seals or sealing

materials have not degraded such

that they no longer serve the

purpose of preventing the ingress

of flammable atmospheres.

•

Replacement parts shall be in

accordance with the manufacturer’s

specifications.

NOTE: The use of silicon sealant

may inhibit the effectiveness of some

types of leak detection equipment.

Intrinsically safe components do not

have to be isolated prior to working

on them.

4. Repair to intrinsically safe

components

•

Do not apply any permanent

inductive or capacitance loads to

the circuit without ensuring that

this will not exceed the permissible

voltage and current permitted for

the equipment in use.

•

Intrinsically safe components are

the only types that can be worked

on while live in the presence of a

flammable atmosphere.

•

The test apparatus shall be at the

correct rating.

•

Replace components only with

parts specified by the manufacturer.

Unspecified parts by manufacturer

may result ignition of refrigerant in

the atmosphere from a leak.

5. Cabling

•

Check that cabling will not be

subject to wear, corrosion,

excessive pressure, vibration,

sharp edges or any other adverse

environmental effects.

•

The check shall also take into

account the effects of aging or

continual vibration from sources

such as compressors or fans.

6. Detection of flammable

refrigerants

•

Under no circumstances shall

potential sources of ignition be

used in the searching or detection

of refrigerant leaks.

•

A halide torch (or any other detector

using a naked flame) shall not be

used.

ACXF55-17690_book1.indb 12ACXF55-17690_book1.indb 12 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

13

English

7. Leak detection methods

The following leak detection

methods are deemed acceptable for

all refrigerant systems.

•

No leaks shall be detected when

using detection equipment with a

capability of 10

−6

Pa·m3/s or better,

for example, a helium sniffer.

•

Electronic leak detectors may

be used to detect flammable

refrigerants, but the sensitivity may

not be adequate, or may need recalibration.

(Detection equipment shall be

calibrated in a refrigerant-free

area.)

•

Ensure that the detector is not a

potential source of ignition and is

suitable for the refrigerant used.

•

Leak detection equipment shall

be set at a percentage of the

LFL of the refrigerant and shall

be calibrated to the refrigerant

employed and the appropriate

percentage of gas (25 % maximum)

is confirmed.

•

Leak detection fluids are suitable

for use with most refrigerants but

the use of detergents containing

chlorine shall be avoided as

the chlorine may react with the

refrigerant and corrode the copper

pipe-work.

•

If a leak is suspected, all naked

flames shall be removed/

extinguished.

•

If a leakage of refrigerant is found

which requires brazing, all of the

refrigerant shall be recovered from

the system, or isolated (by means

of shut off valves) in a part of the

system remote from the leak.

Oxygen free nitrogen (OFN) shall

then be purged through the system

both before and during the brazing

process.

OFN = oxygen free nitrogen,

type of inert gas.

8. Removal and evacuation

•

When breaking into the refrigerant

circuit to make repairs – or for

any other purpose – conventional

procedures shall be used. However,

it is important that best practice

is followed since flammability is

a consideration. The following

procedure shall be adhered to:

remove refrigerant -> purge the

circuit with inert gas -> evacuate ->

purge again with inert gas -> open

the circuit by cutting or brazing

•

The refrigerant charge shall be

recovered into the correct recovery

cylinders.

•

The system shall be “flushed” with

OFN to render the unit safe.

•

This process may need to be

repeated several times.

•

Compressed air or oxygen shall not

be used for this task.

•

Flushing shall be achieved by

breaking the vacuum in the system

with OFN and continuing to fill until

the working pressure is achieved,

then venting to atmosphere, and

finally pulling down to a vacuum.

•

This process shall be repeated until

no refrigerant is within the system.

•

When the final OFN charge is used,

the system shall be vented down

to atmospheric pressure to enable

work to take place.

•

This operation is absolutely vital if

brazing operations on the pipe work

are to take place.

•

Ensure that the outlet for the

vacuum pump is not close to

any ignition sources and there is

ventilation available.

Safety precautions

ACXF55-17690_book1.indb 13ACXF55-17690_book1.indb 13 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

14

Safety precautions

9. Charging procedures

•

In addition to conventional

charging procedures, the following

requirements shall be followed.

-

Ensure that contamination of

different refrigerants does not

occur when using charging

equipment.

-

Hoses or lines shall be as short

as possible to minimize the

amount of refrigerant contained

in them.

-

Cylinders shall be kept upright.

-

Ensure that the refrigeration

system is earthed prior to

charging the system with

refrigerant.

-

Label the system when charging

is complete (if not already).

-

Extreme care shall be taken

not to over fi ll the refrigeration

system.

•

Prior to recharging the system it

shall be pressure tested with OFN

(refer to #7).

•

The system shall be leak tested on

completion of charging but prior to

commissioning.

•

A follow up leak test shall be carried

out prior to leaving the site.

•

Electrostatic charge may

accumulate and create a hazardous

condition when charging and

discharging the refrigerant. To

avoid fire or explosion, dissipate

static electricity during transfer by

grounding and bonding containers

and equipment before charging/

discharging.

10. Decommissioning

•

Before carrying out this procedure,

it is essential that the technician

is completely familiar with the

equipment and all its details.

•

It is recommended good practice

that all refrigerants are recovered

safely.

•

Prior to the task being carried

out, an oil and refrigerant sample

shall be taken in case analysis is

required prior to re-use of reclaimed

refrigerant.

•

It is essential that electrical power

is available before the task is

commenced.

a) Become familiar with the

equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure

ensure that:

•

mechanical handling equipment

is available, if required, for

handling refrigerant cylinders;

•

all personal protective equipment

is available and being used

correctly;

•

the recovery process is

supervised at all times by a

competent person;

•

recovery equipment and

cylinders conform to the

appropriate standards.

d) Pump down refrigerant system,

if possible.

e) If a vacuum is not possible,

make a manifold so that

refrigerant can be removed from

various parts of the system.

f) Make sure that cylinder is

situated on the scales before

recovery takes place.

g) Start the recovery machine and

operate in accordance with

manufacturer’s instructions.

h) Do not over fi ll cylinders. (No

more than 80 % volume liquid

charge).

ACXF55-17690_book1.indb 14ACXF55-17690_book1.indb 14 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

15

English

i) Do not exceed the maximum

working pressure of the cylinder,

even temporarily.

j) When the cylinders have been

fi lled correctly and the process

completed, make sure that the

cylinders and the equipment

are removed from site promptly

and all isolation valves on the

equipment are closed off.

k) Recovered refrigerant shall

not be charged into another

refrigeration system unless it has

been cleaned and checked.

•

Electrostatic charge may accumulate

and create a hazardous condition

when charging or discharging the

refrigerant.

To avoid fire or explosion,

dissipate static electricity during

transfer by grounding and bonding

containers and equipment before

charging/discharging.

11. Labelling

•

Equipment shall be labelled stating

that it has been de-commissioned

and emptied of refrigerant.

•

The label shall be dated and signed.

•

Ensure that there are labels on the

equipment stating the equipment

contains flammable refrigerant.

12. Recovery

•

When removing refrigerant from

a system, either for servicing

or decommissioning, it is

recommended good practice that all

refrigerants are removed safely.

•

When transferring refrigerant

into cylinders, ensure that only

appropriate refrigerant recovery

cylinders are employed.

•

Ensure that the correct number

of cylinders for holding the total

system charge are available.

•

All cylinders to be used are

designated for the recovered

refrigerant and labelled for that

refrigerant (i.e. special cylinders for

the recovery of refrigerant).

•

Cylinders shall be complete

with pressure relief valve and

associated shut-off valves in good

working order.

•

Recovery cylinders are evacuated

and, if possible, cooled before

recovery occurs.

•

The recovery equipment shall

be in good working order with a

set of instructions concerning the

equipment that is at hand and

shall be suitable for the recovery of

flammable refrigerants.

•

In addition, a set of calibrated

weighing scales shall be available

and in good working order.

•

Hoses shall be complete with leakfree disconnect couplings and in

good condition.

•

Before using the recovery machine,

check that it is in satisfactory

working order, has been properly

maintained and that any associated

electrical components are sealed

to prevent ignition in the event

of a refrigerant release. Consult

manufacturer if in doubt.

•

The recovered refrigerant shall be

returned to the refrigerant supplier

in the correct recovery cylinder, and

the relevant Waste Transfer Note

arranged.

•

Do not mix refrigerants in recovery

units and especially not in cylinders.

•

If compressors or compressor oils

are to be removed, ensure that

they have been evacuated to an

acceptable level to make certain

that flammable refrigerant does not

remain within the lubricant.

•

The evacuation process shall be

carried out prior to returning the

compressor to the suppliers.

•

Only electric heating to the

compressor body shall be

employed to accelerate this

process.

•

When oil is drained from a system,

it shall be carried out safely.

Safety precautions

ACXF55-17690_book1.indb 15ACXF55-17690_book1.indb 15 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

16

How to use

FAN SPEED

To select fan speed

(Remote control display)

• For AUTO, the indoor fan speed is automatically

adjusted according to the operation mode.

MODE

To select operation mode

AUTO - For your convenience

HEAT - To enjoy warm air

COOL - To enjoy cool air

DRY - To dehumidify the environment

QUIET/

POWERFU

L

To switch between quiet &

powerful

QUIET POWERFUL NORMAL

QUIET: To enjoy quiet operation

• This operation reduces airflow noise.

OFF

/

ON

TEMP

TIMER/CLOCK

MODE

QUIET/

POWERFUL

FAN SPEED

MODE

CHECK RESET

AIR SWING

OFF/ON

CANCELCLOCK

SET

SELECTUP

DOWN

AC R C

Remote control display

Press and hold

for approximately

10 seconds to show

temperature setting

in °C or °F.

Press to restore the

remote control to

previous setting.

Not used in normal

operations.

Not applicable

POWERFUL: To reach temperature quickly

• This operation stops automatically after 20

minutes.

• To eliminates the POWERFUL indicator after 20

minutes operation, press

QUIET/

POWERFU

L

button again.

Can be activated in all modes and can be

cancelled by pressing the respective button again.

Daily timer setting

To turn ON or OFF the unit at a preset time.

TIMER/CLOCK

CANCELCLOCK

SELECT

MODE

OFF/ONSET

U

P

DOW

N

3

4

1

2

1

Press TIMER

MODE

to enter timer mode

• Press once to change the display from clock

to timer or vice-versa.

• Press for 4 seconds to change the display

from daily timer to weekly timer or viceversa.

2

Select ON or OFF timer Example:

OFF at 22:00

OFF/ON

3

Set the time

UP

DOWN

4

Confirm

SET

• To cancel, press

CANCE

L

.

• When ON timer is set, the unit may start early

before the actual set time in order to achieve

the desired temperature on time.

• Timer operation is based on the clock set in the

remote control and repeats daily once set.

• The timer closest to the current time will be

activated first.

• If timer is cancelled manually or due to power

failure, you can restore the previous setting by

pressing

SET

.

ACXF55-17690_book1.indb 16ACXF55-17690_book1.indb 16 12/7/2017 5:07:02 PM12/7/2017 5:07:02 PM

17

EnglishHow to use

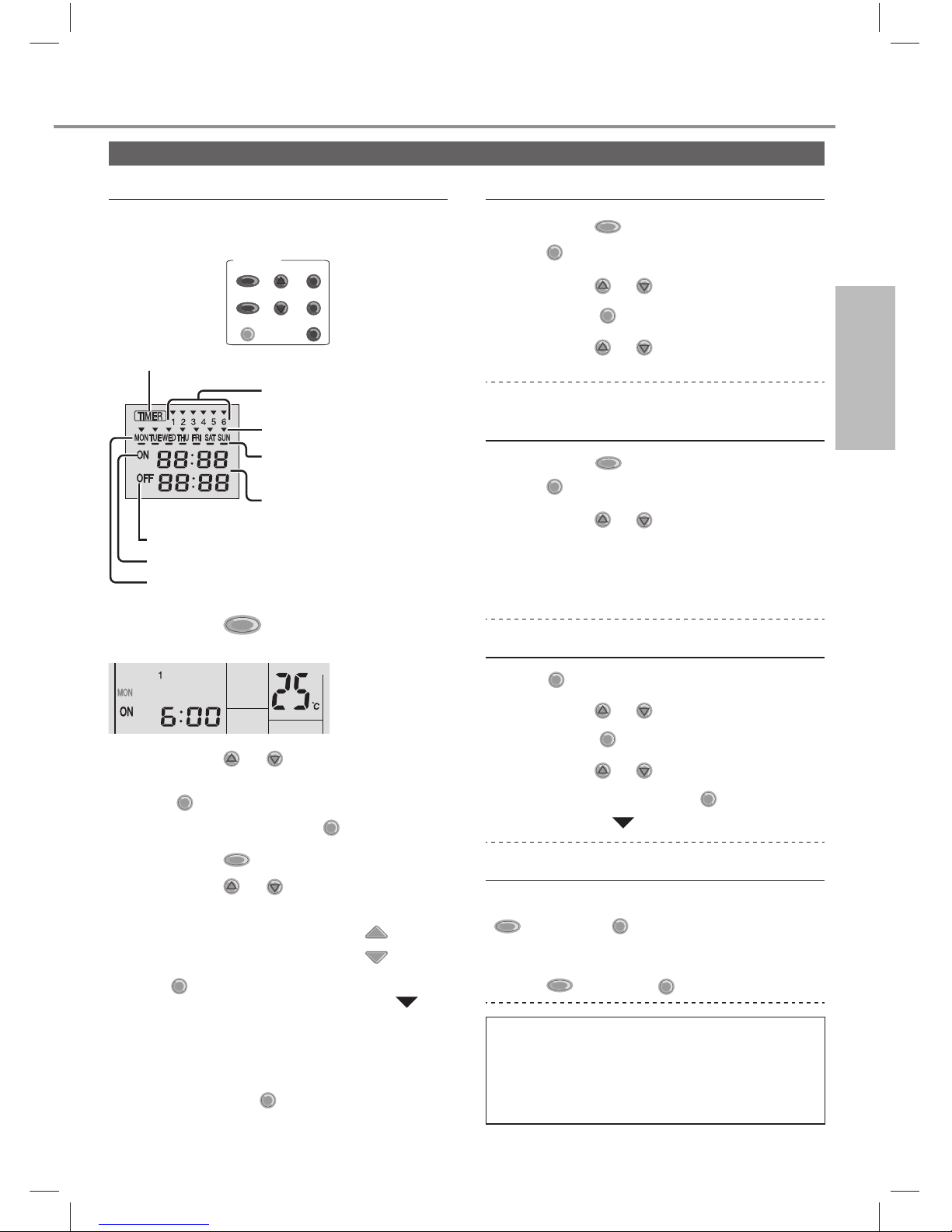

Weekly timer setting

Promotes energy saving by allowing you to set

up to 6 programmes in any given day.

TIMER/CLOCK

CANCELCLOCK

SELECT

MODE

OFF/ON

SET

U

P

D

OWN

Lights up if Timer operation is selected

Programme number in a

day (1 ~ 6)

Time to be selected

(10 minutes step)

ON Timer

OFF Timer

Day to be selected

Indicates the selected day

Indicates the next timer

operation day

1. Press TIMER

MODE

for 4 seconds to change

display to weekly timer.

2. Press TIMER UP or

DOWN

to select your

desired day.

3. Press

SELECT

to confirm your selection.

4. “1” will be blinking, press

SELECT

to set

programme 1.

5. Press TIMER

OFF/ON

to select ON or OFF timer.

6. Press TIMER

UP

or

DOWN

to select your

desired time.

If you want to set the timer together with

your desired temperature, press

TEMP

to

select the temperature.

7. Press

SET

to confirm programme 1. The

selected day will be highlighted with .

• After 2 seconds, the display will move to the

next programme. Repeat steps 4 to 7 to set

programmes 2 to 6.

• During timer setup, if no button is pressed within

30 seconds, or if the

SET

button is pressed, the

setting at that moment is confirmed and timer

setup is ended.

To check current timer programme

1. Press TIMER

MODE

to enter timer mode and

press

SELECT

to enter day setting.

2. Press TIMER

UP

or

DOWN

until your desired day is

shown, press

SELECT

to confi rm your selection.

3. Press TIMER

UP

or

DOWN

to check the set

programmes.

To modify current timer programme or

add new timer programme

1. Press TIMER

MODE

to enter timer mode and

press

SELECT

to enter day setting.

2. Press TIMER

UP

or

DOWN

until your desired day is

shown.

3. Perform steps 4 to 7 of “Weekly timer setting”

to modify existing timer programme, or add any

timer programme.

To cancel current timer programme

1. Press

SELECT

to enter day.

2. Press TIMER

UP

or

DOWN

until your desired day is

shown, press

SELECT

to enter programme setting.

3. Press TIMER

UP

or

DOWN

until your desired

programme is shown. Press

CANCE

L

to cancel the

programme and will disappear.

To disable/enable Weekly Timer

• To disable weekly timer setting, press TIMER

MODE

, then press

CANCE

L

.

• To enable previous weekly timer setting, press

TIMER

MODE

, then press

SET

.

Note

• Daily timer and weekly timer could not be set

at the same time.

• Same timer programme cannot be set in the

same day.

To set the timer

ACXF55-17690_book1.indb 17ACXF55-17690_book1.indb 17 12/7/2017 5:07:03 PM12/7/2017 5:07:03 PM

18

Operation mode

• It is possible to operate the indoor units individually or simultaneously. The priority of

operation is placed on the first unit that turned on.

• During operation, HEAT and COOL modes cannot activate at the same time for different

indoor units.

• The power indicator blinks to indicate the indoor unit is standing by for different operation

mode.

AUTO : For your convenience.

Single

• Unit selects operation mode every 10 minutes according to the setting and room

temperatures.

Multi

• Unit selects operation mode every 3 hours according to setting temperature,

outdoor temperature and room temperature.

HEAT : Unit takes a while to warm up.

COOL : Provides efficient comfort cooling to suit your needs.

DRY : Unit operates at low fan speed to give a gentle cooling operation.

Energy saving temperature setting

Operating the unit within the recommended temperature range may save energy.

HEAT : 20 °C ~ 24 °C /

68 °F ~ 75 °F.

COOL: 26 °C ~ 28 °C /

79 °F ~ 82 °F.

Operating conditions

Use this air conditioner under the following temperature range.

Temperature °C (°F)

Indoor Single split outdoor unit *

1

Multi split outdoor unit *

2

DBT WBT DBT WBT DBT WBT

COOL

Max. 32 (89.6) 23 (73.4) 43 (109.4) 26 (78.8) 46 (114.8) 26 (78.8)

Min. 16 (60.8) 11 (51.8) -10 (14.0) - -10 (14.0) -

HEAT

Max. 30 (86.0) - 24 (75.2) 18 (64.4) 24 (75.2) 18 (64.4)

Min. 16 (60.8) - -15 (5.0) -16 (3.2) -15 (5.0) -16 (3.2)

DBT: Dry bulb temperature, WBT: Wet bulb temperature

*1 CU-Z25UBEA, CU-Z35UBEA, CU-Z50UBEA, CU-Z60UBEA

*

2

CU-3E18PBE, CU-4E23PBE, CU-4E27PBE, CU-5E34PBE, CU-2E12SBE, CU-2E15SBE, CU-2E18SBE,

CU-3E23SBE, CU-2Z35TBE, CU-2Z41TBE, CU-2Z50TBE, CU-3Z52TBE, CU-3Z68TBE, CU-4Z68TBE,

CU-4Z80TBE, CU-5Z90TBE

To learn more...

Single

Single split system

Multi

Multi split system

ACXF55-17690_book1.indb 18ACXF55-17690_book1.indb 18 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

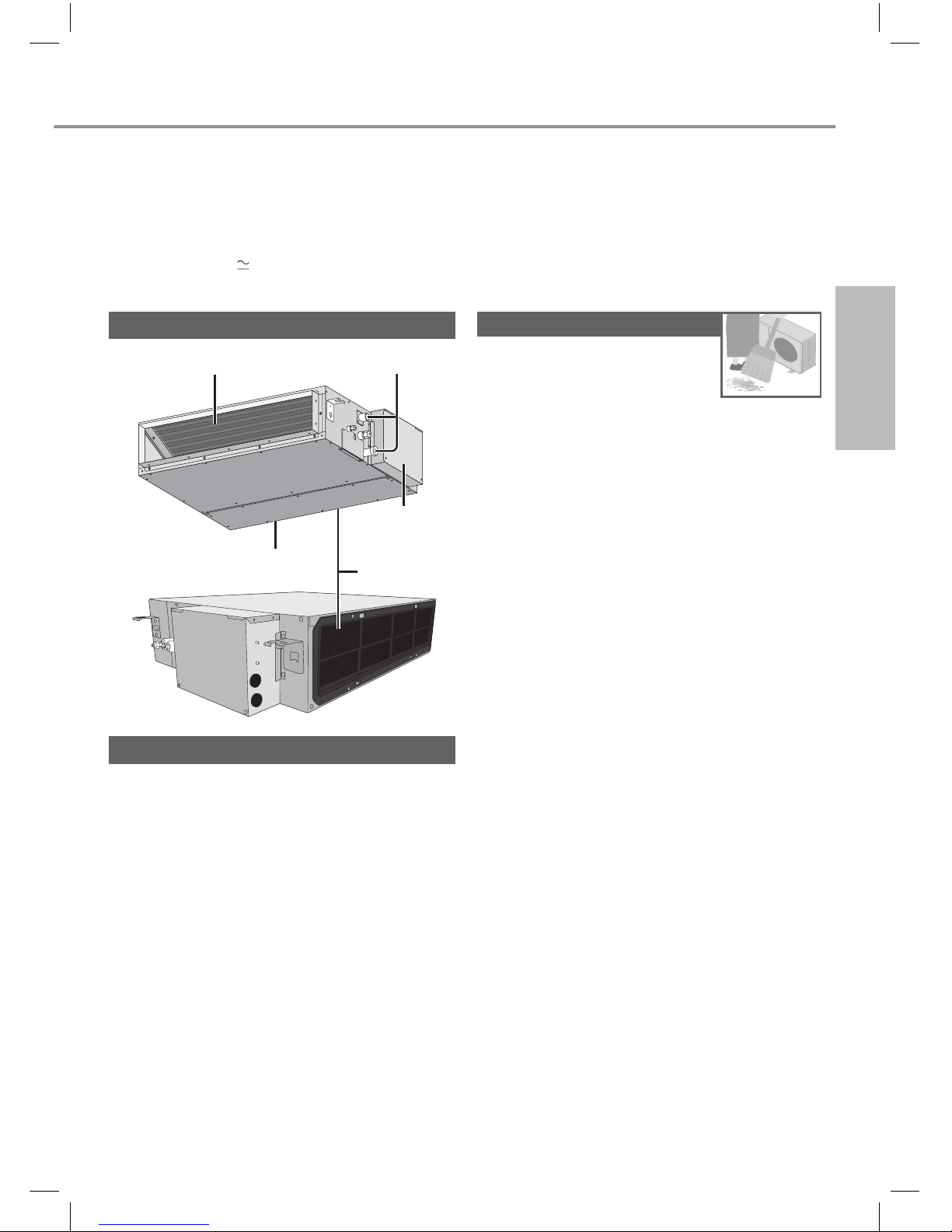

19

English

To ensure optimal performance of the unit, cleaning has to be carried out at regular

intervals. Dirty unit may cause malfunction. Please consult authorised dealer.

• Switch off the power supply and unplug before cleaning.

• Do not touch the aluminium fin, sharp parts may cause injury.

• Do not use benzine, thinner or scouring powder.

• Use only soap (

pH 7) or neutral household detergent.

• Do not use water hotter than 40 °C / 104 °F.

Indoor unit

Air outlet side duct flange (rear)

Electrical

box

Water drain

Air filter

Air intake side duct flange

Air Filter

• The air filter is located in the air intake side

of the unit.

• For cleaning the air filter, please consult

your dealer. Do not attempt to clean inside

the unit by yourself.

• If the air filter gets blocked, the efficiency of

the air conditioner drops significantly.

Outdoor unit

Clear debris that surround the

unit.

Clear any blockage from the

drain pipe.

Cleaning instructions

To learn more... / Cleaning instructions

ACXF55-17690_book1.indb 19ACXF55-17690_book1.indb 19 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

20

Troubleshooting

The following symptoms do not indicate malfunction.

Symptom Cause

Operation LED blinks during operation and

the indoor fan is stopped.

• The unit is in defrost mode, and the melted frost is

drained from the outdoor unit.

TIMER indicator is always on. • The timer setting repeats daily once set.

Operation is delayed a few minutes after

restarting.

• The delay is a protection to the unit’s compressor.

Indoor fan stops occasionally during heating

operation.

• To avoid unintended cooling effect.

Indoor fan stops occasionally during automatic

fan speed setting.

• This helps to remove the surrounding odour.

Airflow continues even after operation has

stopped.

• Extraction of remaining heat from the indoor unit

(maximum 30 seconds).

The room has a peculiar odour. • This may be due to damp smell emitted by the wall,

carpet, furniture or clothing.

Cracking sound during operation. • Changes of temperature caused the expansion/

contraction of the unit.

Water flowing sound during operation. • Refrigerant flow inside the unit.

Mist emerges from indoor unit. • Condensation effect due to cooling process.

Outdoor unit emits water/steam. • Condensation or evaporation occurs on pipes.

Discoloration of some plastic parts. • Discoloration is subject to material types used in plastic

parts, accelerated when exposed to heat, sun light, UV

light or environmental factor.

Check the following before calling for servicing.

Symptom Check

Operation in HEAT/COOL mode is not working

efficiently.

• Set the temperature correctly.

• Close all doors and windows.

•

Clear any obstruction at the air inlet and air outlet vents.

Noisy during operation. • Check if the unit has been installed at an incline.

The unit does not work. • Check if the circuit breaker is tripped.

• Check if timers have been set.

The following symptoms indicate malfunction.

Symptom Check

At remote control, OFF indicator does not

shown on remote control display but operation

LED OFF.

• Use remote control to retrieve error code as follows.

OFF

/

ON

TEMP

TIMER/CLOCK

MODE

QUIET/

POWERFUL

FAN SPEED

MODE

CHECK RESET

AIR SWING

OFF/ON

CANCELCLOCK

SET

SELECTUP

DOWN

AC R C

OFF Indicator

Operation LED

3

/

12

Ensure the operation LED is in OFF condition.

1

Press

CHECK

for 5 seconds

2

Press TIMER

UP

or

DOWN

• If error code and abnormality can be identified, the

operation LED will be ON continuously, then jot

down the error code.

3

Press

CHECK

again for 5 seconds to quit checking

4

Reveal the error code to authorised dealer

ACXF55-17690_book1.indb 20ACXF55-17690_book1.indb 20 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

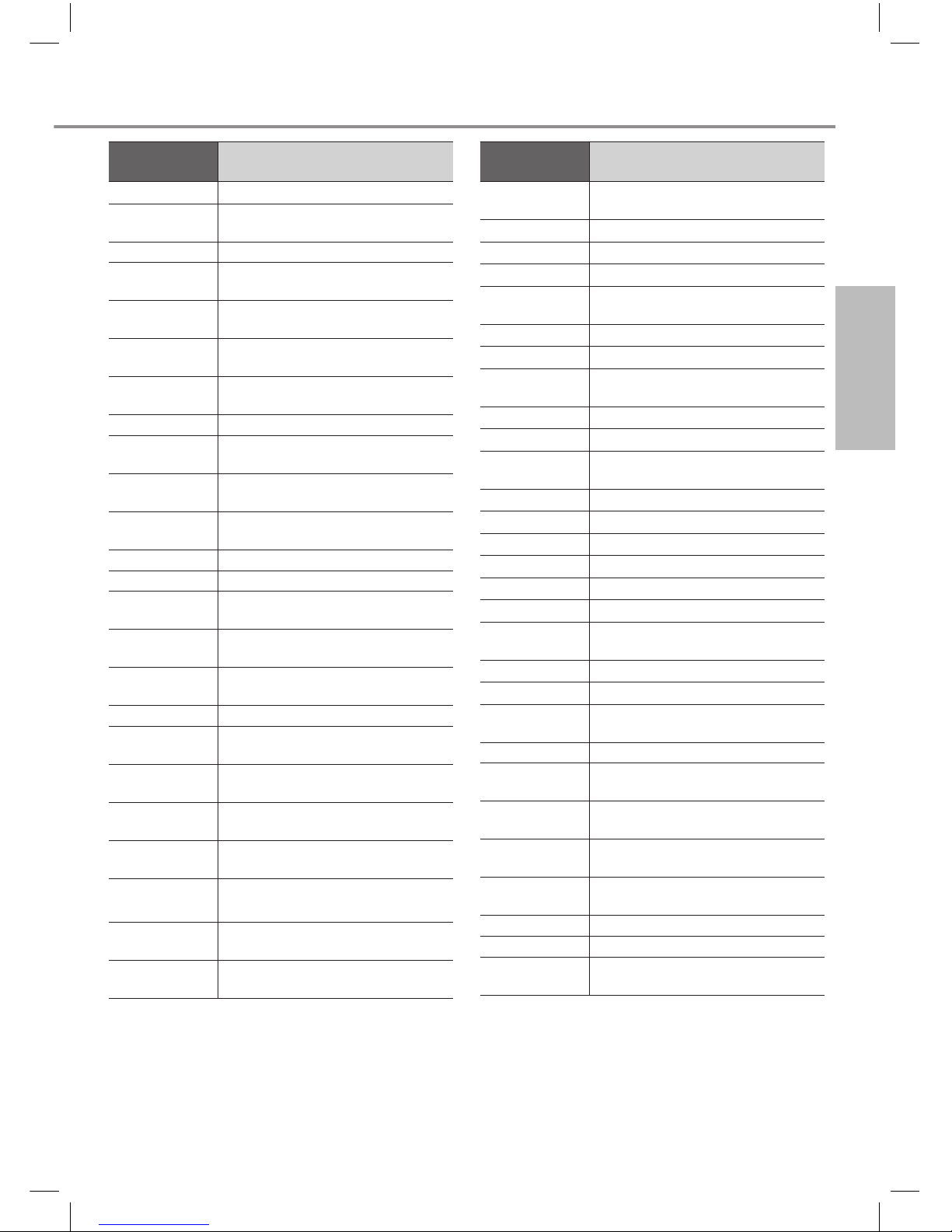

21

EnglishTroubleshooting

Diagnostic

display

Abnormality/Protection

control

H 00 No memory of failure

H 11

Indoor/outdoor abnormal

communication

H 12 Indoor unit capacity unmatched

H 14

Indoor intake air temperature sensor

abnormality

H 15

Outdoor compressor temperature

sensor abnormality

H 16

Outdoor current transformer (CT)

abnormality

H 17

Outdoor suction temperature sensor

abnormality

H 19 Indoor fan motor mechanism lock

H 21

Indoor float switch operation

abnormality

H 23

Indoor heat exchanger temperature

sensor 1 abnormality

H 24

Indoor heat exchanger temperature

sensor 2 abnormality

H 25

Indoor ion device abnormality

H 26

Minus ION abnormality

H 27

Outdoor air temperature sensor

abnormality

H 28

Outdoor heat exchanger temperature

sensor 1 abnormality

H 30

Outdoor discharge pipe temperature

sensor abnormality

H 31 Abnormal swimming pool sensor

H 32

Outdoor heat exchanger temperature

sensor 2 abnormality

H 33

Indoor/outdoor misconnection

abnormality

H 34

Outdoor heat sink temperature sensor

abnormality

H 35

Indoor/outdoor water adverse current

abnormality

H 36

Outdoor gas pipe temperature sensor

abnormality

H 37

Outdoor liquid pipe temperature

sensor abnormality

H 38

Indoor/outdoor mismatch (brand

code)

Diagnostic

display

Abnormality/Protection

control

H 39

Abnormal indoor operating unit or

standby units

H 41 Abnormal wiring or piping connection

H 50 Ventilation fan motor locked

H 51 Ventilation fan motor locked

H 52

Left-right limit switch fixing

abnormality

H 58 Indoor gas sensor abnormality

H 59 Eco sensor

abnormality

H 64

Outdoor high pressure sensor

abnormality

H 67 nanoe

abnormality

H 70 Light sensor

abnormality

H 71

DC cooling fan inside control board

abnormality

H 72

Abnormality tank temperature sensor

H 97 Outdoor fan motor mechanism lock

H 98 Indoor high pressure protection

H 99 Indoor operating unit freeze protection

F 11 4-way valve switching abnormality

F 16 Total running current protection

F 17

Indoor standby units freezing

abnormality

F 18 Dry circuit blocked abnormality

F 87 Control box overheat protection

F 90

Power factor correction (PFC) circuit

protection

F 91 Refrigeration cycle abnormality

F 93

Outdoor compressor abnormal

revolution

F 94

Compressor discharge pressure

overshoot protection

F 95

Outdoor cooling high pressure

protection

F 96

Power transistor module overheating

protection

F 97 Compressor overheating protection

F 98 Total running current protection

F 99

Outdoor direct current (DC) peak

detection

* Some error code may not be applicable to your model. Consult authorised dealer for clarification.

ACXF55-17690_book1.indb 21ACXF55-17690_book1.indb 21 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

22

Troubleshooting

When...

■ Conducting a seasonal inspection after extended non-use

• Check that there is no obstruction around the air inlet and outlet vents.

• These units are mounted inside the ceiling. It uses external air intake vent and air outlet vent

to operate. Please consult your nearest dealer for seasonal inspection.

• After 15 minutes of operation, it is normal to have the following temperature difference

between the air inlet and outlet vents:

COOL: ≥ 8°C / 14.4°F HEAT: ≥ 14°C / 25.2°F

■ The units are not going to be used for a long period of time

•

Activate HEAT mode for 2~3 hours to remove moisture left in the internal parts thoroughly to

prevent mould growth.

• Turn off the power supply and unplug.

NON SERVICEABLE CRITERIA

TURN OFF THE POWER SUPPLY AND UNPLUG then please consult an authorised

dealer when in following conditions:

• Abnormal noise during operation.

• Water/foreign particles have entered the remote control.

• Water leaks from Indoor unit.

• Circuit breaker switches off frequently.

• Power cord becomes unnaturally warm.

• Switches or buttons are not functioning properly.

ACXF55-17690_book1.indb 22ACXF55-17690_book1.indb 22 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

23

English

English

Information for Users on Collection and Disposal of Old Equipment

These symbols on the products, packaging, and/or accompanying documents mean that used electrical

and electronic products should not be mixed with general household waste.

For proper treatment, recovery and recycling of old products, please take them to applicable collection

points, in accordance with your national legislation.

By disposing of these products correctly, you will help to save valuable resources and prevent any

potential negative effects on human health and the environment which could otherwise arise from

inappropriate waste handling.

For more information about collection and recycling of old products, please contact your local

municipality, your waste disposal service or the point of sale where you purchased the items.

Penalties may be applicable for incorrect disposal of this waste, in accordance with national legislation.

For business users in the European Union

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for

further information.

[Information on Disposal in other Countries outside the European Union]

These symbols are only valid in the European Union. If you wish to discard these items, please contact

your local authorities or dealer and ask for the correct method of disposal.

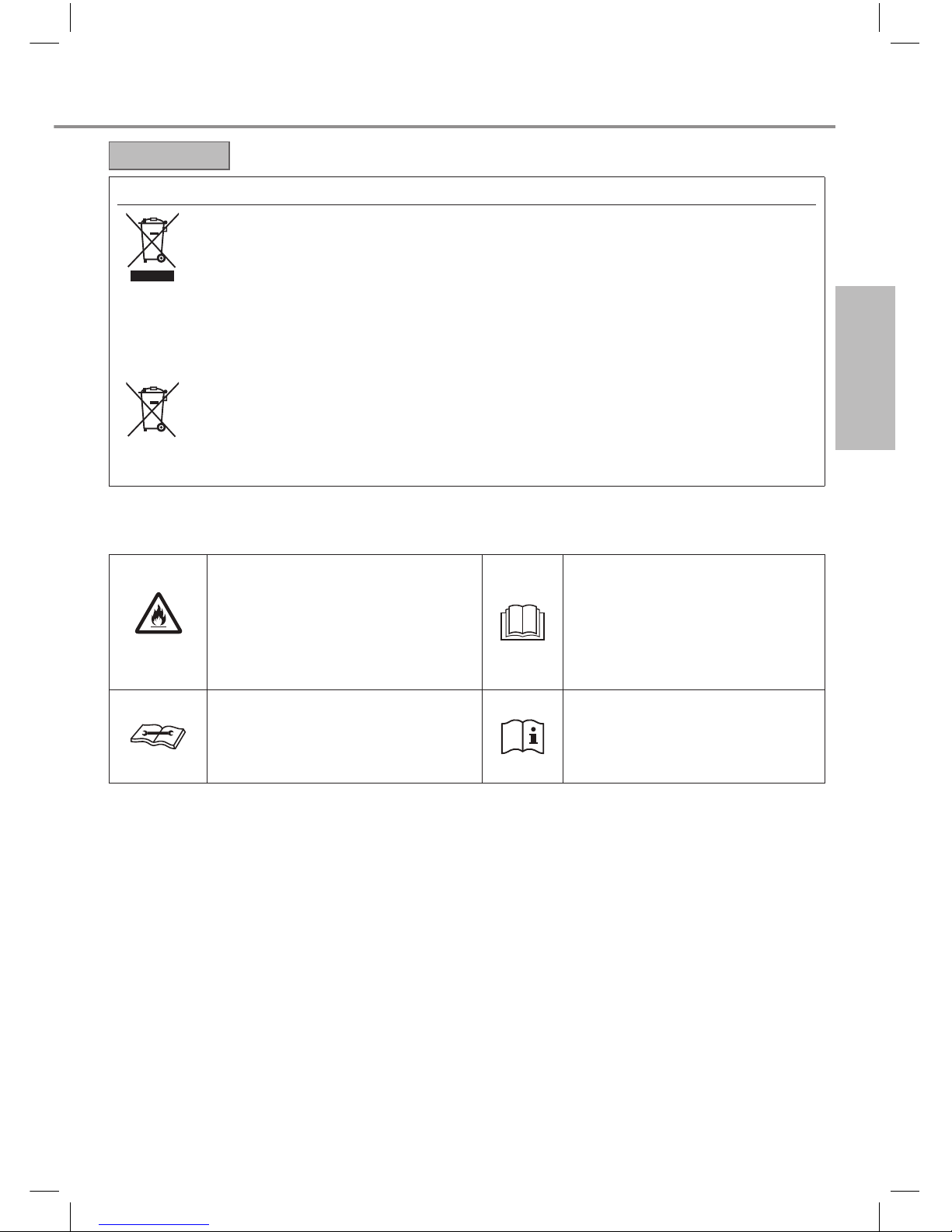

Information

Troubleshooting / Information

WARNING

This symbol shows that this

equipment uses a flammable

refrigerant. If the refrigerant is

leaked, together with an external

ignition source, there is a

possibility of ignition.

This symbol shows that the

Operation Instructions should

be read carefully.

This symbol shows that a service

personnel should be handling this

equipment with reference to the

Installation Instructions.

This symbol shows that there

is information included in the

Operation Instructions and/or

Installation Instructions.

ACXF55-17690_book1.indb 23ACXF55-17690_book1.indb 23 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

24

Kurzanleitung

Vorbereitung Der Fernbedienung

a

Drücken Sie die Taste

CLOCK

b

Drücken, um Tag einzustellen

c

Bestätigen

Wiederholen Sie die Schritte “b” und “c”,

um die aktuelle Uhrzeit einzugeben.

Flexibilität zum Anschließen

von Single-Split- oder MultiSplit-Klimaanlagen nach

Ihren Bedürfnissen.

Näheres zu den Features dieses

Produkts siehe im Produktkatalog.

OFF

/

ON

TEMP

TIMER/CLOCK

MODE

QUIET/

POWERFUL

FAN SPEED

MODE

CHECK RESET

AIR SWING

OFF/ON

CANCELCLOCK

SET

SELECTUP

DOWN

AC RC

3

1

a

b

c

2

ACXF55-17690_book1.indb 24ACXF55-17690_book1.indb 24 12/7/2017 5:07:04 PM12/7/2017 5:07:04 PM

25

Deutsch

Inhalt

Sicherheitshinweise … 26-37

Bedienung …………… 38-39

Funktionsdetails... ……… 40

Reinigungsanweisungen … 41

Störungssuche ……… 42-44

Informationen …………… 45

Die Abbildungen in diesem Handbuch

dienen nur Erläuterungszwecken und

können sich von dem tatsächlichen

Gerät unterscheiden. Sie können durch

künftige Verbesserungen am Gerät

ohne vorherige Ankündigung geändert

werden.

Grundlegender Betrieb

1

Drücken Sie

OFF

/

ON

, um das Gerät ein- bzw. auszuschalten.

2

Drücken Sie

MODE

, um den gewünschten Modus auszuwählen.

DRY

AUTO HEAT

COOL

3

Gewünschte Temperatur einstellen.

UP

DOWN

Einstellbereich: 16 °C ~ 30 °C / 60 °F ~ 86 °F.

Wir danken Ihnen für den Kauf

Ihres Panasonic-Klimageräts.

ACXF55-17690_book1.indb 25ACXF55-17690_book1.indb 25 12/7/2017 5:07:05 PM12/7/2017 5:07:05 PM

26

Sicherheitshinweise

VORSICHT

Innen- und Außengerät

Dieses Gerät kann von Kindern ab 8

Jahren sowie Personen verwendet werden,

welche eingeschränkte körperliche,

sensorische oder geistige Fähigkeiten

aufweisen bzw. fehlende Erfahrung und

Kenntnis im Umgang mit diesem Gerät

haben, wenn sie zuerst auf sichere Weise

instruiert wurden oder während der

Gerätebedienung beaufsichtigt werden

und die damit verbundenen Gefahren

verstanden haben.

Kinder sollten nicht mit dem Gerät spielen.

Reinigung und Benutzerwartung sollten nur

von Kindern durchgeführt werden, wenn

diese dabei beaufsichtigt werden.

Bitten wenden Sie sich an einen

Fachhändler oder Kundendienst, um

die Einbauteile reinigen zu lassen, und

wenn das Gerät repariert, montiert,

ausgebaut oder neu installiert werden

soll. Eine unsachgemäße Installation und

Handhabung kann elektrische Schläge

oder Brände verursachen oder dazu

führen, dass Wasser aus dem Gerät tropft.

Zur Verwendung des korrekten Kältemittels

wenden Sie sich an Ihren Fachhändler

bzw. Kundendienst. Durch den Einsatz

eines anderen als des angegebenen

Kältemittels kann das Produkt beschädigt

werden oder gar Verletzungen hervorrufen.

Verwenden Sie nur die vom Hersteller

empfohlenen Mittel zum Beschleunigen der

Entfrostung und für die Reinigung.

Durch den Einsatz ungeeigneter Verfahren

oder die Verwendung inkompatibler

Materialien können Beschädigungen des

Produkts, Explosionen und ernsthafte

Verletzungen hervorgerufen werden.

Stellen Sie das Gerät nicht in einer

potenziell explosiven oder entflammbaren

Atmosphäre auf. Bei Nichtbeachtung kann

es zu Bränden kommen.

Fassen Sie nicht in das Innenoder Außengerät und stecken Sie

auch keine Gegenstände hinein,

drehende Teile könnten sonst zu

Verletzungen führen.

Um Personen- oder Geräteschäden zu

vermeiden, sind die nachfolgend aufgeführten

Sicherheitshinweise zu beachten:

Die verwendeten Warnhinweise untergliedern sich

entsprechend ihrer Wichtigkeit wie folgt:

Dieses Gerät ist nicht für die Verwendung durch die

allgemeine Öffentlichkeit gedacht.

VORSICHT

Die Nichtbeachtung

dieses Hinweises

kann zu schweren

Verletzungen

oder gar zum Tod

führen.

ACHTUNG

Die

Nichtbeachtung

dieses Hinweises

kann zu

Verletzungen

oder zu

Beschädigungen

führen.

Bei den folgenden Symbolen handelt es sich um

Verbote bzw. Gebote:

Dieses Symbol weist darauf hin,

dass eine bestimmte Tätigkeit

NICHT durchgeführt werden

darf.

Diese Symbole weisen darauf

hin, dass bestimmte Tätigkeiten

durchgeführt werden MÜSSEN.

Lufteintritt

Lufteintritt

Luftaustritt

Luftaustritt

Fernbedienung

Außengerät

Stromversorgung

Innengerät

Lufteintrittsöffnung

Luftaustrittsöffnung

Luftaustrittsöffnung

ACXF55-17690_book1.indb 26ACXF55-17690_book1.indb 26 12/7/2017 5:07:06 PM12/7/2017 5:07:06 PM

27

DeutschSicherheitshinweise

Fassen Sie bei Gewittern nicht das

Außengerät an, da die Gefahr von

Stromschlägen besteht.

Halten Sie sich nicht zu lange im kalten

Luftstrom auf.

Stellen oder setzen Sie sich nicht

auf das Außengerät, Sie könnten

herunterfallen und sich verletzen.

Fernbedienung

Kinder sollten Sie nicht mit der

Fernbedienung spielen lassen, da sonst

die Gefahr besteht, dass sie Batterien

verschlucken könnten.

Stromversorgung

Verwenden Sie keine

modifizierten oder

miteinander verbundenen

oder nicht spezifizierten

Netzkabel und auch keine

Verlängerungskabel,

um Überhitzung und

Brandgefahr zu vermeiden.

Beachten Sie Folgendes, um eine

Überhitzung, Feuer oder Stromschläge zu

vermeiden:

•

Schließen Sie keine anderen elektrischen

Geräte zusammen mit dem Klimagerät

an.

•

Das Klimagerät darf nicht mit nassen oder

feuchten Händen bedient werden.

•

Das Netzkabel darf nicht geknickt werden.

•

Das Klimagerät darf nicht durch

Einstecken oder Herausziehen des

eventuell vorhandenen Steckers ein- bzw.

ausgeschaltet werden.

Bei Beschädigung des Netzkabels muss

das Kabel durch den Hersteller, seinen

Kundendienst oder eine entsprechend

autorisierte Person ausgewechselt werden,

um eine Gefährdung für Personen zu

vermeiden.

Es wird dringend empfohlen, das

Klimagerät zusätzlich mit einem FISchutzschalter zu versehen, um

Stromschläge oder Brände zu vermeiden.

Beachten Sie Folgendes, um eine

Überhitzung, Feuer oder Stromschläge zu

vermeiden:

•

Stecken Sie den eventuell vorhandenen

Netzstecker richtig in die Steckdose.

•

Staub auf dem eventuell vorhandenen

Stecker sollte regelmäßig mit einem

trockenen Tuch weggewischt werden.

Im Fall einer Funktionsstörung oder einer

Fehlfunktion ist das Produkt auszuschalten

und der Netzstecker zu ziehen bzw. der

Sicherungsautomat zu öffnen

(Gefahr von Rauchbildung, Feuer oder

elektrischen Schlägen)

Beispiele für Funktionsstörungen bzw.

Fehlfunktionen

•

Der Fehlerstrom-Schutzschalter löst

häufig aus.

•

Es riecht verbrannt.

•

Ungewöhnliche Geräusche oder

Vibrationen.

•

Wasser tropft aus dem Innengerät.

•

Das Netzkabel bzw. der Netzstecker wird

ungewöhnlich warm.

•

Die Ventilatordrehzahl wird nicht geregelt.

•

Das Gerät bleibt sofort stehen, wenn es

eingeschaltet wird.

•

Der Ventilator bleibt nicht stehen, wenn

das Gerät abgeschaltet wird.

Wenden Sie sich für Wartungs- und

Reparaturarbeiten umgehend an Ihren

Fachhändler.

Dieses Gerät muss geerdet sein, um

Stromschläge oder Brände zu vermeiden.

Um Stromschläge zu vermeiden, schalten

Sie das Gerät aus und unterbrechen Sie

die Stromversorgung,

- bevor das Gerät gereinigt oder gewartet

wird,

- wenn das Gerät längere Zeit außer

Betrieb genommen werden soll, oder

- wenn starke Gewitter herrschen.

ACXF55-17690_book1.indb 27ACXF55-17690_book1.indb 27 12/7/2017 5:07:06 PM12/7/2017 5:07:06 PM

28

Sicherheitshinweise

ACHTUNG

Innen- und Außengerät

Um Beschädigungen oder eine Korrosion

des Geräts zu vermeiden, reinigen Sie

das Innengerät nicht mit Wasser, Benzin,

Verdünner oder Scheuerpulver.

Verwenden Sie das Gerät nicht zum

Kühlen von Präzisionsgeräten, Nahrung,

Tieren, Pflanzen, Kunstwerken oder

ähnlichen Objekten, da diese sonst in

Mitleidenschaft gezogen werden könnten.

Um eine Ausbreitung von Feuer

zu vermeiden, dürfen keine

Verbrennungsgeräte in den Luftstrom des

Geräts gestellt werden.

Um Unterkühlungen zu vermeiden, sollten

Haustiere oder Pflanzen nicht direkt dem

Luftstrom ausgesetzt werden.

Fassen Sie nicht die scharfkantigen

Aluminiumlamellen an, Sie könnten

sich sonst verletzen.

Das Klimagerät darf nicht eingeschaltet

sein, wenn der Fußboden gewachst

wird. Belüften Sie den Raum nach dem

Wachsen sorgfältig, bevor Sie das Gerät

einschalten.

Um Beschädigungen des Geräts zu

vermeiden, sollte es nicht in fett- und

rauchhaltigen Bereichen montiert werden.

Um Verletzungen zu vermeiden, darf

das Gerät nicht zu Reinigungszwecken

auseinandergebaut werden.

Steigen Sie nicht auf eine instabile

Unterlage, wenn Sie das Gerät reinigen,

sonst besteht Verletzungsgefahr.

Stellen Sie keine Vase oder andere

Wassergefäße auf das Gerät. Ansonsten

könnte Wasser in das Gerät gelangen

und die Isolierung beeinträchtigen, was zu

Stromschlägen führen könnte.

Während des Betriebs sollte vermieden

werden, Fenster bzw. Türen längere Zeit

offen zu halten, da es anderenfalls zu

einem ineffizienten Energieverbrauch und

unangenehmen Temperaturschwankungen

kommen kann.

Um ein Austreten von Wasser zu

verhindern, ist darauf zu achten, dass die

Kondensatleitung

- fachgerecht angeschlossen wird,

- nicht direkt in einen Abfluss geführt wird,

bei dem Rückstaugefahr besteht,

- nicht in einen mit Wasser gefüllten

Behälter geführt wird.

Nach einer längeren Nutzung von

Kaminen oder ähnlichem sollte der Raum

regelmäßig gelüftet werden.

Nach einer langen Nutzungsdauer ist zu

kontrollieren, ob die Montagehalterung

noch einwandfrei ist, damit das Gerät nicht

herunterfällt.

Fernbedienung

Es sollten keine wiederaufladbaren Ni-CdAkkus verwendet werden. Diese könnten

die Fernbedienung beschädigen.

Beachten Sie Folgendes, um

Fehlfunktionen oder eine Beschädigung

der Fernbedienung zu vermeiden:

•

Nehmen Sie die Batterien aus dem

Batteriefach, wenn die Fernbedienung

längere Zeit nicht benutzt wird.

•

Es sind stets neue Batterien gleichen

Typs einzulegen, wobei die Polarität zu

beachten ist.

Stromversorgung

Um Stromschläge zu vermeiden, ziehen

Sie den eventuell vorhandenen Stecker

nicht am Netzkabel heraus.

ACXF55-17690_book1.indb 28ACXF55-17690_book1.indb 28 12/7/2017 5:07:06 PM12/7/2017 5:07:06 PM

29

Deutsch Sicherheitshinweise

VORSICHT

Dieses Gerät ist mit R32

(schwaches brennbares Kältemittel)

gefüllt. Falls das Kältemittel ausläuft

und einer externen Zündquelle

ausgesetzt wird, besteht Brandgefahr.

Innen- und Außengerät

Das Gerät sollte in einem Raum mit einer

Wohnfläche größer als Amin (m²) installiert

und/oder betrieben werden. Es sollte von

Zündquellen wie Hitze/Funken/offenen

Flammen oder explosionsgefährdeten

Bereichen wie Gasgeräten, Gaskochern,

netzförmigen Gasversorgungssystemen

oder Elektroküchengeräten usw.

ferngehalten werden. (Bitte beachten Sie

hierzu Tabelle A Montageanleitung Tabelle

für Amin (m²))

Beachten Sie, dass das Kältemittel

evtl. geruchlos ist. Daher wird dringend

empfohlen, dass geeignete Gasmelder

für brennbare Kältemittel vorhanden,

betriebsbereit und in der Lage sind, vor

Lecks zu warnen.

Halten Sie eventuell erforderliche

Lüftungsöffnungen von Hindernissen frei.

Unterlassen Sie es, das Gerät gewaltsam

zu öffnen oder zu verbrennen, da es unter

Druck steht. Setzen Sie das Gerät auch

keinen heißen Temperaturen, Flammen,

Funken oder anderen Zündquellen aus.

Anderenfalls kann es explodieren und

Verletzungen verursachen.

Vorsichtsmaßnahmen für die

Verwendung des Kältemittels

vom Typ R32

Die grundlegenden Installationsverfahren sind mit

denen bei Modellen mit konventionellen Kältemitteln

(R410A, R22) identisch.

Da der Arbeitsdruck höher als bei Modellen

mit dem Kältemittel R22 ist, gibt es einige

gesonderte Rohrleitungen, Montageschritte

und Wartungswerkzeuge. Insbesondere,

wenn Sie ein Kältemittel-R22-Modell

durch ein neues Kältemittel-R32-Modell

ersetzen, tauschen Sie immer an der

Außeneinheit die herkömmlichen Rohre

und Überwurfmuttern durch die speziellen

R32- und R410A-Rohrleitungen und

-Überwurfmuttern aus.

Für R32 und R410A kann an der

Außeneinheit und für das Rohr die gleiche

Überwurfmutter verwendet werden.

Die Vermischung verschiedener Kältemittel

in einem System ist untersagt. Modelle,

die die Kältemittel R32 und R410A

verwenden, haben einen unterschiedlichen

Ladeanschluss-Gewindedurchmesser,

um eine fehlerhafte Befüllung mit dem

Kältemittel R22 zu verhindern und die

Sicherheit zu erhöhen.

Überprüfen Sie dies deshalb im Voraus.

[Der Ladeanschluss-Gewindedurchmesser

für R32 und R410A beträgt 1/2 Zoll.]

Es ist immer sicherzustellen, dass keine

Fremdstoffe (Öl, Wasser usw.) in die

Rohrleitungen eindringen. Versiegeln

Sie darüber hinaus ordnungsgemäß die

Öffnungen, wenn Sie die Rohrleitungen

lagern, indem Sie sie zuklemmen, zukleben

usw. (Die Handhabung von R32 ist mit der

von R410A vergleichbar.)

•

Betrieb, Wartung, Reparatur und

Rückgewinnung des Kältemittels

sollten von im Umgang mit brennbaren

Kältemitteln geschultem und zertifiziertem

Personal und entsprechend den

Empfehlungen des Herstellers

durchgeführt werden. Alle Personen,

die ein System oder damit verbundene

Systemteile bedienen, warten oder

instand halten, müssen dafür geschult

und zertifiziert sein.

ACXF55-17690_book1.indb 29ACXF55-17690_book1.indb 29 12/7/2017 5:07:06 PM12/7/2017 5:07:06 PM

30

•

Sämtliche Teile des Kühlkreislaufs

(Verdampfer, Luftkühler, AHU,

Kondensatoren oder Flüssigkeitssammler)

sowie die Rohrleitungen dürfen sich

nicht in der Nähe von Wärmequellen,

offenen Flammen, Betriebsgasgeräten

oder laufenden elektrischen Heizgeräten

befinden.

•

Der Benutzer/Eigentümer oder

sein Bevollmächtigter muss die

Alarme, die Gerätebeatmung und die

Melder mindestens einmal jährlich,

soweit nach nationalen Vorschriften

erforderlich, regelmäßig überprüfen,

um ihre ordnungsgemäße Funktion zu

gewährleisten.

•

Ein Betriebsbuch ist zu führen. Die

Ergebnisse dieser Prüfungen sind im

Betriebsbuch zu vermerken.

•

Bei Lüftungen in besetzten Räumen ist zu

prüfen, ob keine Behinderung vorliegt.

•

Vor der Inbetriebnahme eines

neuen Kältesystems sollte die für

die Inbetriebnahme des Systems

verantwortliche Person sicherstellen,

dass geschultes und zertifiziertes

Bedienpersonal anhand der

Betriebsanleitung über den Aufbau,

die Überwachung, den Betrieb und die

Wartung des Kältesystems sowie die zu

beachtenden Sicherheitsvorkehrungen

und die Eigenschaften und Handhabung

des verwendeten Kältemittels

eingewiesen wird.

•

Die allgemeinen Anforderungen an

geschultes und zertifiziertes Personal sind

nachfolgend angegeben:

a) Kenntnisse in puncto Gesetzgebung,

Vorschriften und Normen im

Zusammenhang mit brennbaren

Kältemitteln,

b) Detaillierte Kenntnisse und

Fähigkeiten zu folgenden Themen:

Umgang mit brennbaren Kältemitteln,

persönliche Schutzausrüstung,

Verhinderung von Kältemittelaustritt,

Umgang mit Flaschen, Befüllung,

Lecksuche, Rückgewinnung und

Entsorgung,

c) Fähigkeit, die Anforderungen der

nationalen Gesetzgebung sowie der

Vorschriften und Normen zu verstehen

und in der Praxis anzuwenden und

d) Absolvieren einer kontinuierlichen

Fort- und Weiterbildung zur

Aufrechterhaltung dieses Know-hows.

1. Installation (Ort)

•

Produkte mit brennbaren Kältemitteln

dürfen nicht in einem unbelüfteten Raum

installiert werden, wenn dieser kleiner als

Amin (m²) ist.

•

Bei einer Feldladung muss der

sich durch die unterschiedliche

Rohrlänge ergebende Einfluss auf die

Kältemittelfüllung quantifiziert, gemessen

und gekennzeichnet werden.

•