ORDER NO. MAC9810034C2

Service Manual

Room Air Conditioners

CS-C73KE / CU-C73KE

CS-C93KE / CU-C93KE

CS-C123KE / CU-C123KE

Contents

● Features ..........................................................1

● Functions ...................................................2 – 4

● Product Specifications .............................5 – 10

● Dimensions ............................................11 – 12

● Refrigeration Cycle Diagram .........................13

● Block Diagram ...............................................14

● Wiring Diagram .............................................. 15

● Operation Details ................................... 16 – 23

● Installation Information ..........................24 – 25

● 2-way, 3-way Valves..............................26 – 32

● Servicing Information ............................. 33 – 36

● Troubleshooting Guide ..........................37 – 38

● Technical Data.......................................39 – 40

● Exploded View ...................................41, 43, 45

● Replacement Parts List .....................42, 44, 46

● Electronic Parts List ....................................... 47

1998 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D)

All rights reserved. Unauthorized copying and distribution is a violation of law.

CS-C73KE

WARNING

!!

!

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain

warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by electricity

should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt with

in this service information by anyone else could result in serious injury or death.

!!

PRECAUTION OF LOW TEMPERATURE

!

!!

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigeration circuit.

!!

Features

• High Efficiency

• Compact Design

• Comfort Enviroment

– 8 hours of sleep mode operation

– Air purifying filter with deodorizing function

to reduce dust, smoke and odours.

• Auto Restart

– Auto restart at random operation after power

failure

• Removable and Washable

Front Panel

• Quality Improvement

– Gas leakage protection

– Prevent compressor reverse cycle

– 2-stage OLP to protect compressor

• Service Improvement

– Easy fan motor replacement procedure

• Operation Improvement

– Economy mode to reduce electrical power

consumption.

– Powerful mode to reaches the desired room

temperature quickly.

• Long Installation Piping

– CS/CU–C73KE, CS/CU–C93KE, long piping up to 10

meter.

– CS/CU–C123KE, long piping up to 15 meter.

– 1 –

Functions

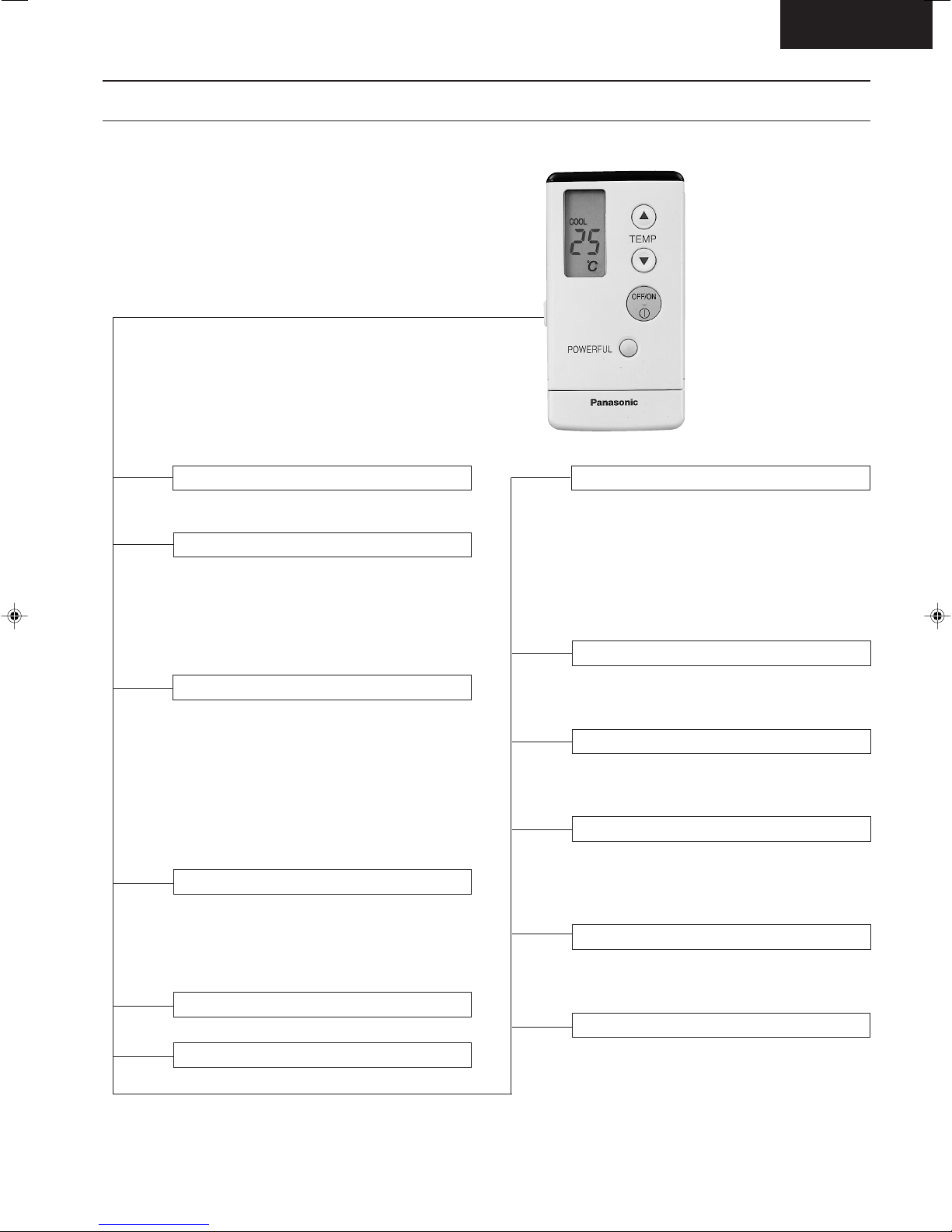

Remote Control

CS-C73KE

OFF / ON I

MODE

FAN SPEED

AIR SWING

Operation OFF / ON

Operation Mode Selection

• AUTO Automatic Operation Mode

• COOL Cooling Operation Mode

• DRY Soft Dry Operation Mode

• FAN Air Circulation Mode

Indoor Fan Speed Selection

• h j k Low Speed

l

• h j k Medium Speed

lll

• h j k High Speed

lllll

• AUTOFAN Automatic Fan Speed

Airflow Direction Control

• AUTO Automatic Airflow Direction

Control

• MANUAL Airflow Direction Manual Control

TEMP.

ON-TIMER

OFF-TIMER

TIMER

SET

CANCEL

CLOCK

Room Temperature Setting

• Temperature Setting (16°C to 30°C)

• Automatic Operation

8 HI

a

a

a

9 Lo

2°C higher than standard

Standard

2°C lower than standard

Timer Operation Selection

• 24-hour, OFF / ON Real Timer Setting.

Time / Timer Setting

• Hours and minutes setting.

Timer Operation Set / Cancel

• ON Timer and OFF Timer setting and

cancellation.

Clock Setting

• Current time setting.

POWERFUL

ECONOMY

Powerful Mode Operation OFF/ON

Economy Mode Operation OFF/ON

– 2 –

SLEEP

Sleep Mode Operation OFF / ON

CS-C73KE

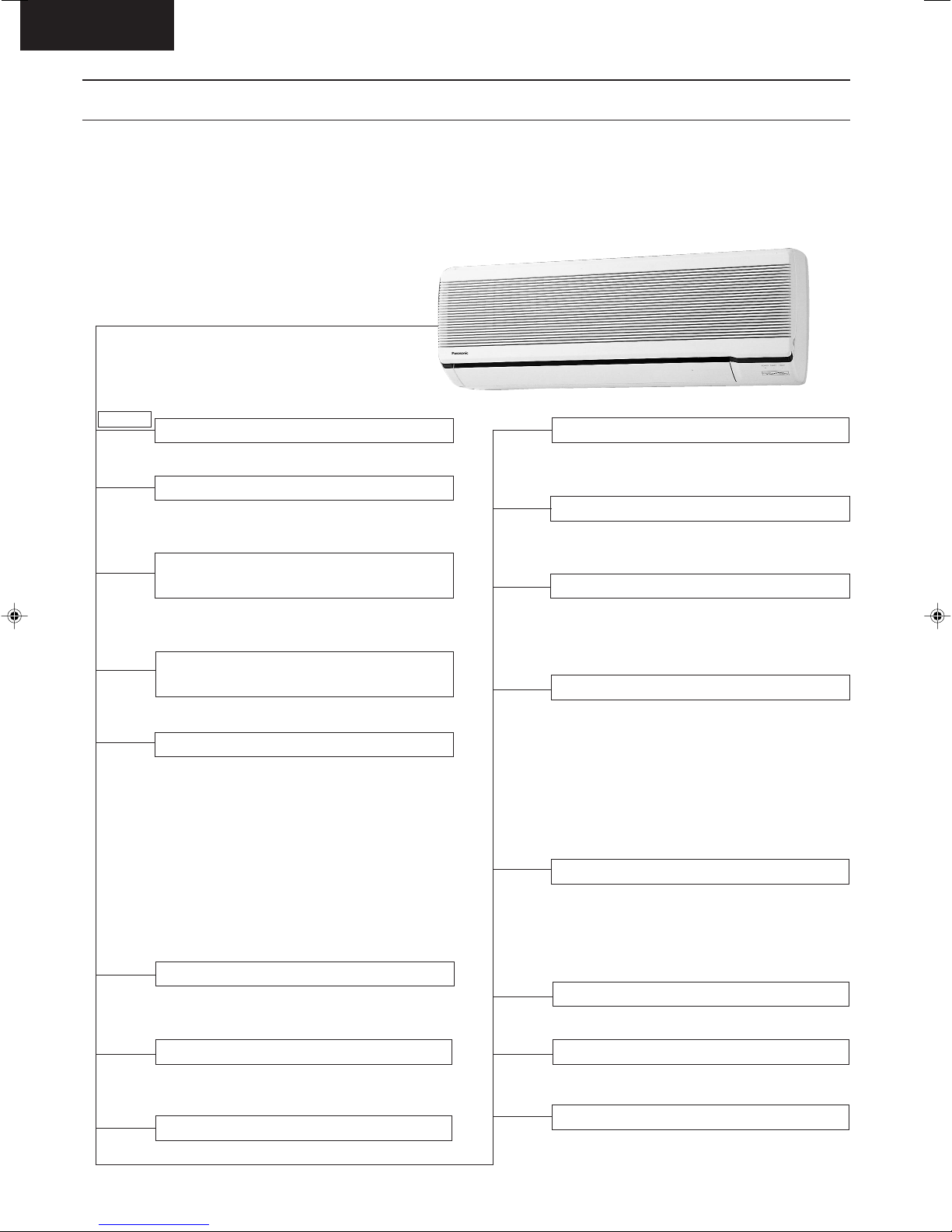

Functions

Indoor Unit

POWER I

AUTO

OFF / ON

TEST RUN

OFF / ON

Power Switch OFF / ON

Auto Operation Button

• Used when the remote control cannot be

used.

Remote Control Signal Receiving

Sound

• It can be controlled by pressing Auto

Operation Button for 10 seconds.

Operation Test Running / Pump

Down Switch

• Used when test running or servicing.

Operation Indication Lamps (LED)

• POWER (Red)...... Lights up in operation,

blinks in Automatic

Operation Mode judging

• SLEEP (Orange)..... Lights up in Sleep

Mode Operation

• TIMER (Orange)..... Lights up in Timer

Setting

• POWERFUL

• ECONOMY

(Orange).....

(Green).....

Lights up in Powerful

Mode Operation

Lights up in Economy

Mode Operation

Operation Mode

• Cooling, Soft Dry, Air Circulation and

Automatic Mode.

Random Auto Restart Control

• Operation is restarted randomly after power

failure at previous setting mode.

Anti-Freezing Control

• Anti-Freezing control for indoor heat

exchanger. (Cooling and Soft Dry)

Sleep Mode Auto Control

• Indoor Fan operates at low speed.

• Operation stops after 8 hours.

Indoor Fan Speed Control

• High, Medium and Low.

• Automatic Fan Speed Mode

– Cooling : Fan rotates at Hi and Me

speed. Deodorizing control is

available.

– Soft Dry : Fan rotates at SLo and Lo

speed. Deodorizing control is

available.

Airflow Direction Control

• Automatic air swing and manual adjusted

by remote control for vertical airflow.

• Manually adjusted by hand for horizontal

airflow.

Starting Current Control

Powerful Operation

• Reaches the desired room temperature

quickly.

Economy Operation

• To reduce electrical power consumption.

Time Delay Safety Control

• Restarting is inhibited for appro. 3 minutes.

7 Minutes Time Save Control

• Cooling Operation only.

– 3 –

Functions

Outdoor Unit

CS-C73KE

CU-C73KE, CU-C93KE

Compressor Reverse Rotation

Protection Control

• To protect compressor from reverse

rotation when there is a instantaneous

power failure.

Overload Protector

• 2-Stage OLP to protect the compressor.

Overload Protector will trip when

– Temperature of compressor increases to

120°C.

– High temperature or high current flows to

compressor.

(Refer circuit diagram for OLP

characteristic)

CU-C123KE

60 Secs. Forced Operation Control

• Once the compressor is activated, it does

not stop within the first 60 secs. However, it

stops immediately with remote control stop

signal.

Outdoor Fan Operation Control

•

Inner protector.

– 4 –

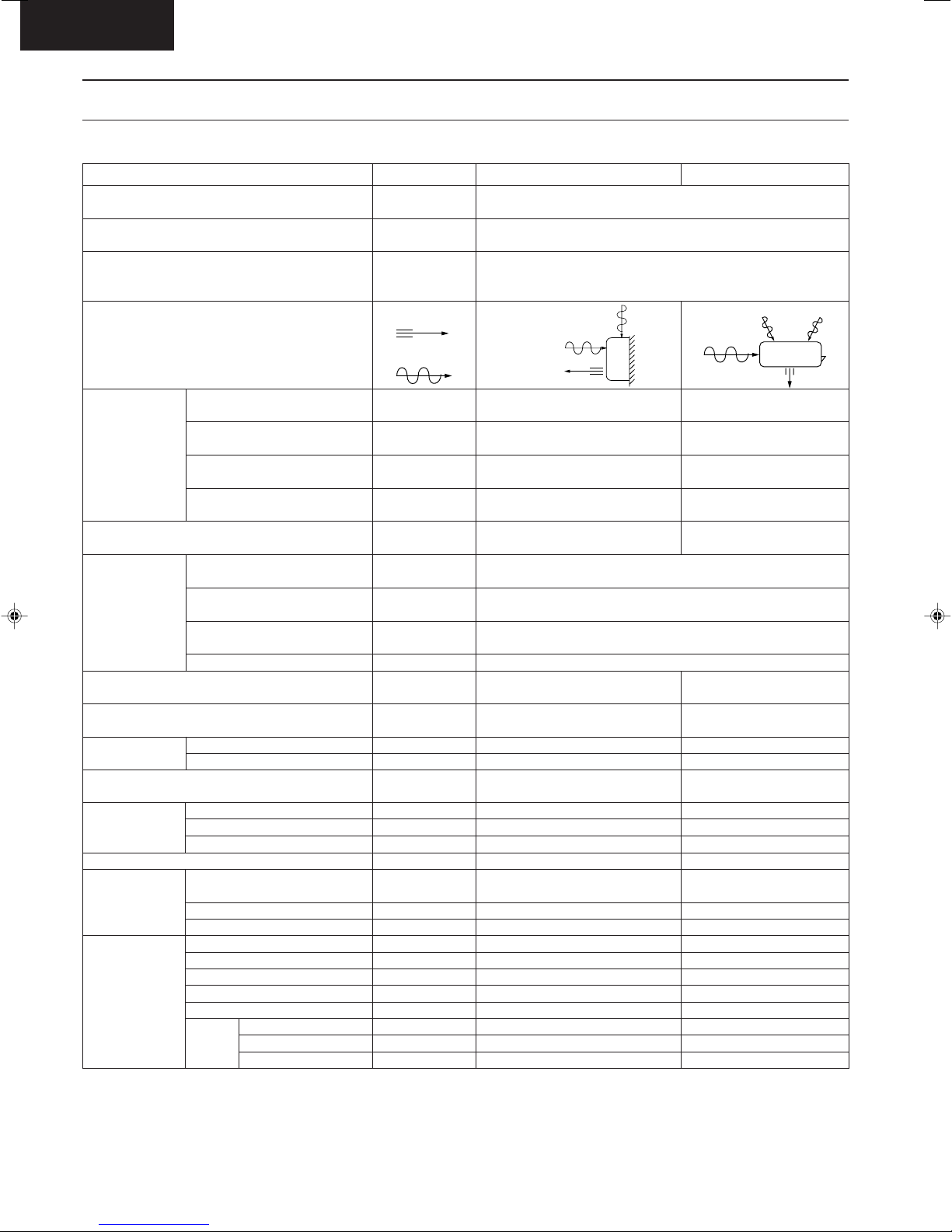

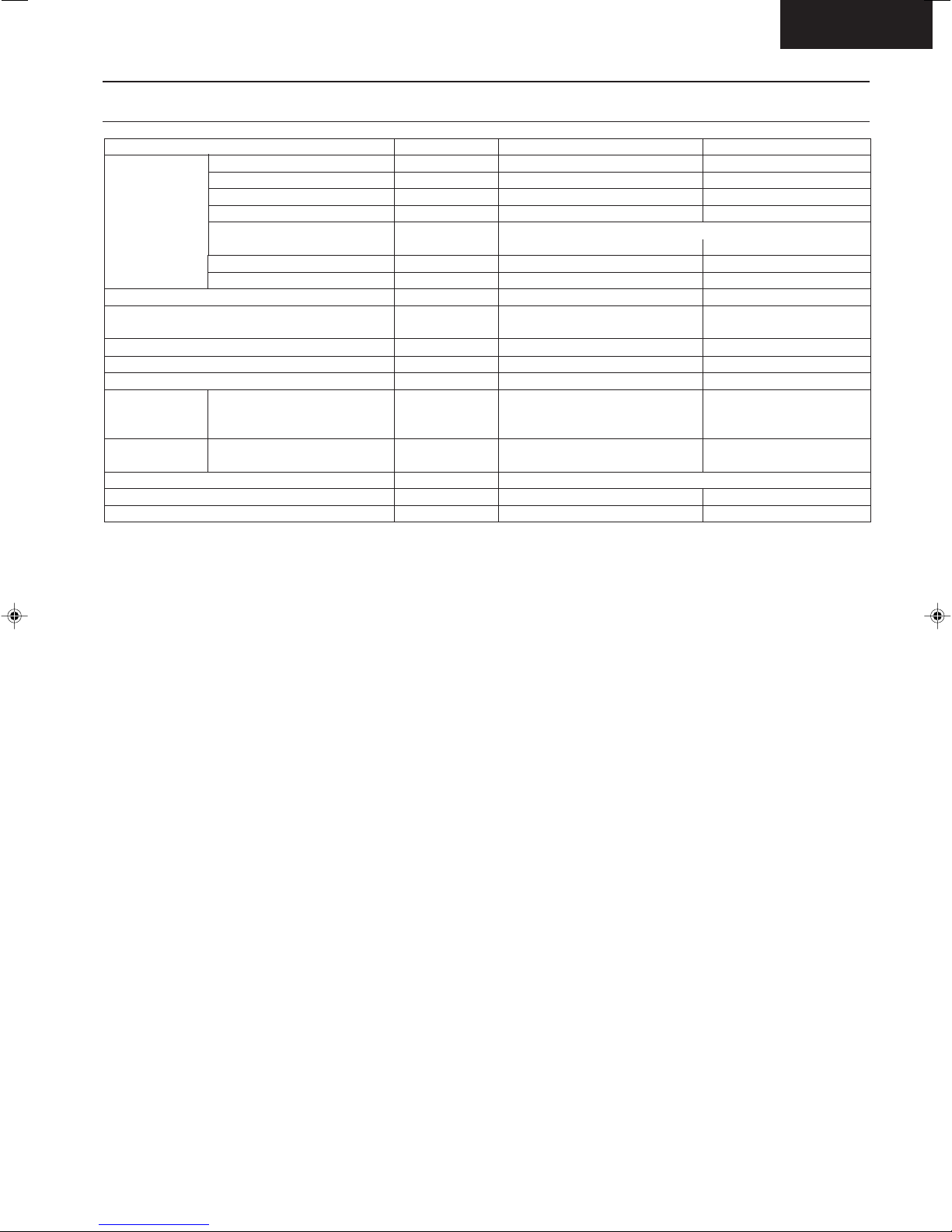

CS-C73KE

Product Specifications

Cooling Capacity

Moisture Removal

Power Source

Airflow Method

Air Volume

Noise Level

Electrical

Data

Indoor Air (Lo)

Indoor Air (Me)

Indoor Air (Hi)

Outdoor Air

Input

Running Current

Unit

kW

Btu/h

s/h

Pint/h

Phase

V

Cycle

OUTLET

INTAKE

3

/min (cfm)

m

3

m

/min (cfm)

3

m

/min (cfm)

m3/min (cfm)

dB (A)

W

A

CS-C73KE

2.05 - 2.00

7,000 - 6,830

230 - 220

SIDE VIEW

5.5 (190)

6.3 (220)

7.0 (250)

–

High 33 - 32, Low 28 - 26

600 - 550

2.8 - 2.7

CU-C73KE

1.3

2.7

Single

50

TOP VIEW

–

–

–

22.2 (780)

High 46 - 45

COP

Starting Current

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord Length

Dimensions

Net Weight

Compressor

Air Circulation

Inner diameter

Length

Number of core-wire

Motor Type

Rated Output

Motor Type

Fan Low

Speed Medium

Height

Width

Depth

Type

Type

Material

Input

Rated Output

High

W/W

A

inch

inch

inch

inch

mm

m

m

inch (mm)

inch (mm)

inch (mm)

lb (kg)

W

W

W

rpm

rpm

rpm

G ; Half Union 3/8"

L ; Half Union 1/4"

G (gas side) ; 3/8"

L (liquid side) ; 1/4"

12

0.7

2.0

2

3 (1.0 mm

10-31/32 (279)

31-15/32 (799)

7-15/32 (190)

20 (9.0)

Cross-flow Fan

AS + Glass Fiber 30%

Induction (4-poles)

29.0 - 27.0

)

–

–

–

10

835

945

1,055

3.42 - 3.64

12

G ; 3-way valve 3/8"

L ; 2-way valve 1/4"

G (gas side) ; 3/8"

L (liquid side) ; 1/4"

–

–

–

–

18-29/32 (480)

30-23/32 (780)

9-21/32 (245)

57 (26)

Rotary (1 cylinder)

rolling piston type

Induction (2-poles)

500

Propeller Fan

AES + Glass Fiber 16%

Induction (6-poles)

54.7 - 47.9

20

–

–

685

– 5 –

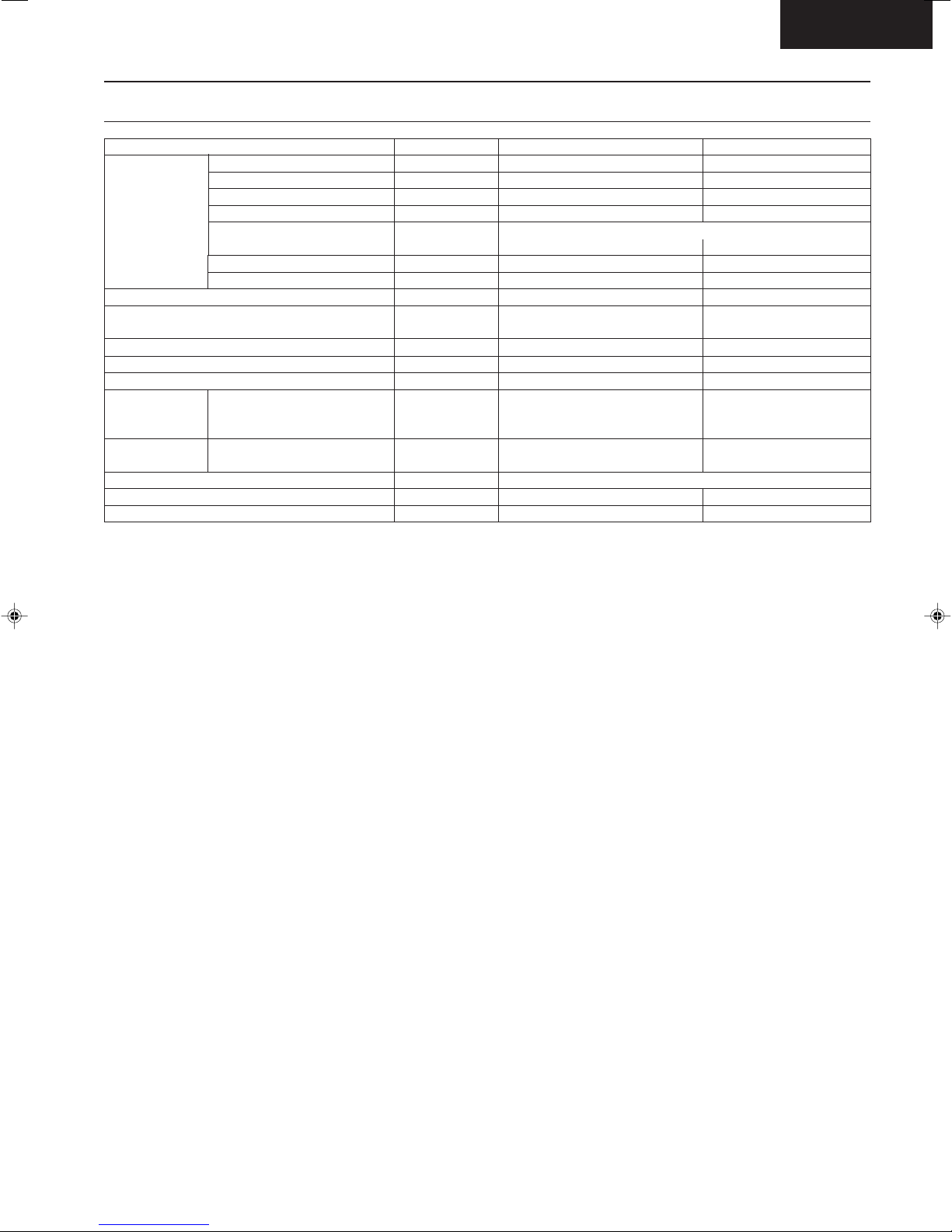

Product Specifications

CS-C73KE

Unit

Heat

Exchanger

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary Tube

Air Filter

Capacity Control

Compressor Capacitor

Fan Motor Capacitor

• Specifications are subject to change without notice for further improvement.

Description

Tube material

Fin material

Fin Type

Row / Stage

FPI

Size (W × H × L)

Length

Flow Rate

Inner Diameter

Material

Style

mm

(c.c)

g (oz)

mm

s/min

mm

µF, VAC

µF, VAC

CS-C73KE

Evaporator

Copper

Aluminium

Slit Fin

(Plate fin configuration, forced draft)

2 × 14

21

614 × 294 × 25.4

–

–

–

Electronic Control

–

–

–

–

P.P.

Honeycomb

Capillary Tube

–

1.5 µF, 400VAC

2 Stage Overload Protector

CU-C73KE

Condenser

Copper

Aluminium

Louver Fin

1 × 18

17

856 × 457.2 × 22

Capillary Tube

SUNISO 4GDID or

ATMOS M60 (260)

645 (22.8)

–

450

7.9

1.2

–

20 µF, 370VAC

1.2 µF, 400VAC

– 6 –

CS-C73KE

Product Specifications

Cooling Capacity

Moisture Removal

Power Source

Airflow Method

Air Volume

Noise Level

Electrical

Data

Indoor Air (Lo)

Indoor Air (Me)

Indoor Air (Hi)

Outdoor Air

Input

Running Current

Unit

kW

Btu/h

s/h

Pint/h

Phase

V

Cycle

OUTLET

INTAKE

3

/min (cfm)

m

3

m

/min (cfm)

3

m

/min (cfm)

m3/min (cfm)

dB (A)

W

A

CS-C93KE

2.75 - 2.65

9,390 - 9,050

230 - 220

SIDE VIEW

6.8 (240)

7.3 (260)

8.7 (310)

–

High 37 - 36, Low 30 - 28

800 - 770

3.5 - 3.6

CU-C93KE

1.6

3.4

Single

50

TOP VIEW

–

–

–

22.2 (780)

High 47 - 46

COP

Starting Current

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord Length

Dimensions

Net Weight

Compressor

Air Circulation

Inner diameter

Length

Number of core-wire

Motor Type

Rated Output

Motor Type

Fan Low

Speed Medium

Height

Width

Depth

Type

Type

Material

Input

Rated Output

High

W/W

A

inch

inch

inch

inch

mm

m

m

inch (mm)

inch (mm)

inch (mm)

lb (kg)

W

W

W

rpm

rpm

rpm

G ; Half Union 3/8"

L ; Half Union 1/4"

G (gas side) ; 3/8"

L (liquid side) ; 1/4"

12

0.7

2.0

2

3 (1.0 mm

10-31/32 (279)

31-15/32 (799)

7-15/32 (190)

20 (9.0)

Cross-flow Fan

AS + Glass Fiber 30%

Induction (4-poles)

35.5 - 33.0

)

–

–

–

15

925

995

1,185

3.44 - 3.44

16.4

G ; 3-way valve 3/8"

L ; 2-way valve 1/4"

G (gas side) ; 3/8"

L (liquid side) ; 1/4"

–

–

–

–

18-29/32 (480)

30-23/32 (780)

9-21/32 (245)

64 (29.0)

Rotary (1 cylinder)

rolling piston type

Induction (2-poles)

700

Propeller Fan

AES + Glass Fiber 16%

Induction (6-poles)

54.7 - 47.9

20

–

–

685

– 7 –

Product Specifications

CS-C73KE

Unit

Heat

Exchanger

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary Tube

Air Filter

Capacity Control

Compressor Capacitor

Fan Motor Capacitor

• Specifications are subject to change without notice for further improvement.

Description

Tube material

Fin material

Fin Type

Row / Stage

FPI

Size (W × H × L)

Length

Flow Rate

Inner Diameter

Material

Style

mm

(c.c)

g (oz)

mm

s/min

mm

µF, VAC

µF, VAC

CS-C93KE

Evaporator

Copper

Aluminium

Slit Fin

(Plate fin configuration, forced draft)

2 × 14

21

614 × 294 × 25.4

–

–

–

Electronic Control

–

–

–

–

P.P.

Honeycomb

Capillary Tube

–

1.5 µF, 400VAC

2-Stage Overload Protector

CU-C93KE

Condenser

Copper

Aluminium

Louver Fin

1 × 18

17

856 × 457.2 × 22

Capillary Tube

SUNISO 4GDID or

ATMOS M60 (320)

760 (26.8)

–

1,040

9.0

1.5

–

30 µF, 370VAC

1.2 µF, 400VAC

– 8 –

CS-C73KE

Product Specifications

Cooling Capacity

Moisture Removal

Power Source

Airflow Method

Air Volume

Noise Level

Electrical

Data

Indoor Air (Lo)

Indoor Air (Me)

Indoor Air (Hi)

Outdoor Air

Input

Running Current

Unit

kW

Btu/h

s/h

Pint/h

Phase

V

Cycle

OUTLET

INTAKE

3

/min (cfm)

m

3

m

/min (cfm)

3

m

/min (cfm)

m3/min (cfm)

dB (A)

W

A

CS-C123KE

3.65 - 3.52

12,500 - 12,000

230 - 220

SIDE VIEW

7.4 (260)

8.0 (280)

9.0 (290)

–

High 39 - 39, Low 34 - 33

1,190 - 1,150

5.3 - 5.4

CU-C123KE

2.1

4.4

Single

50

TOP VIEW

–

–

–

32.2 (1130)

High 49 - 48

COP

Starting Current

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord Length

Dimensions

Net Weight

Compressor

Air Circulation

Inner diameter

Length

Number of core-wire

Motor Type

Rated Output

Motor Type

Fan Low

Speed Medium

Height

Width

Depth

Type

Type

Material

Input

Rated Output

High

W/W

A

inch

inch

inch

inch

mm

m

m

inch (mm)

inch (mm)

inch (mm)

lb (kg)

W

W

W

rpm

rpm

rpm

G ; Half Union 1/2"

L ; Half Union 1/4"

G (gas side) ; 1/2"

L (liquid side) ; 1/4"

12

0.7

2.0

2

3 (1.0 mm

10-31/32 (279)

31-15/32 (799)

7-15/32 (190)

20 (9.0)

Cross-flow Fan

AS + Glass Fiber 30%

Induction (4-poles)

35.5 - 33.0

)

–

–

–

15

1,060

1,145

1,280

3.07 - 3.06

26

G ; 3-way valve 1/2"

L ; 2-way valve 1/4"

G (gas side) ; 1/2"

L (liquid side) ; 1/4"

–

–

–

–

21-1/4 (540)

27-17/32 (699)

11-7/32 (285)

82 (37)

Rotary (1 cylinder)

rolling piston type

Induction (2-poles)

1,100

Propeller Fan

AES + Glass Fiber 16%

Induction (6-poles)

72.0 - 68.0

25

–

–

785

– 9 –

Product Specifications

CS-C73KE

Unit

Heat

Exchanger

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary Tube

Air Filter

Capacity Control

Compressor Capacitor

Fan Motor Capacitor

• Specifications are subject to change without notice for further improvement.

Description

Tube material

Fin material

Fin Type

Row / Stage

FPI

Size (W × H × L)

Length

Flow Rate

Inner Diameter

Material

Style

mm

(c.c)

g (oz)

mm

s/min

mm

µF, VAC

µF, VAC

CS-C123KE

Evaporator

Copper

Aluminium

Slit Fin

(Plate fin configuration, forced draft)

2 × 14

21

614 × 294 × 25.4

–

–

–

Electronic Control

–

–

–

–

P.P.

Honeycomb

Capillary Tube

–

1.5 µF, 400VAC

2-Stage Overload Protector

CU-C123KE

Condenser

Copper

Aluminium

Louver Fin

1 × 20

18

782.9 × 508 × 22

Capillary Tube

SUNISO 4GDID or

ATMOS M60 (410)

815 (28.8)

–

535

17.0

1.7

–

30 µF, 370VAC

1.5 µF, 400VAC

– 10 –

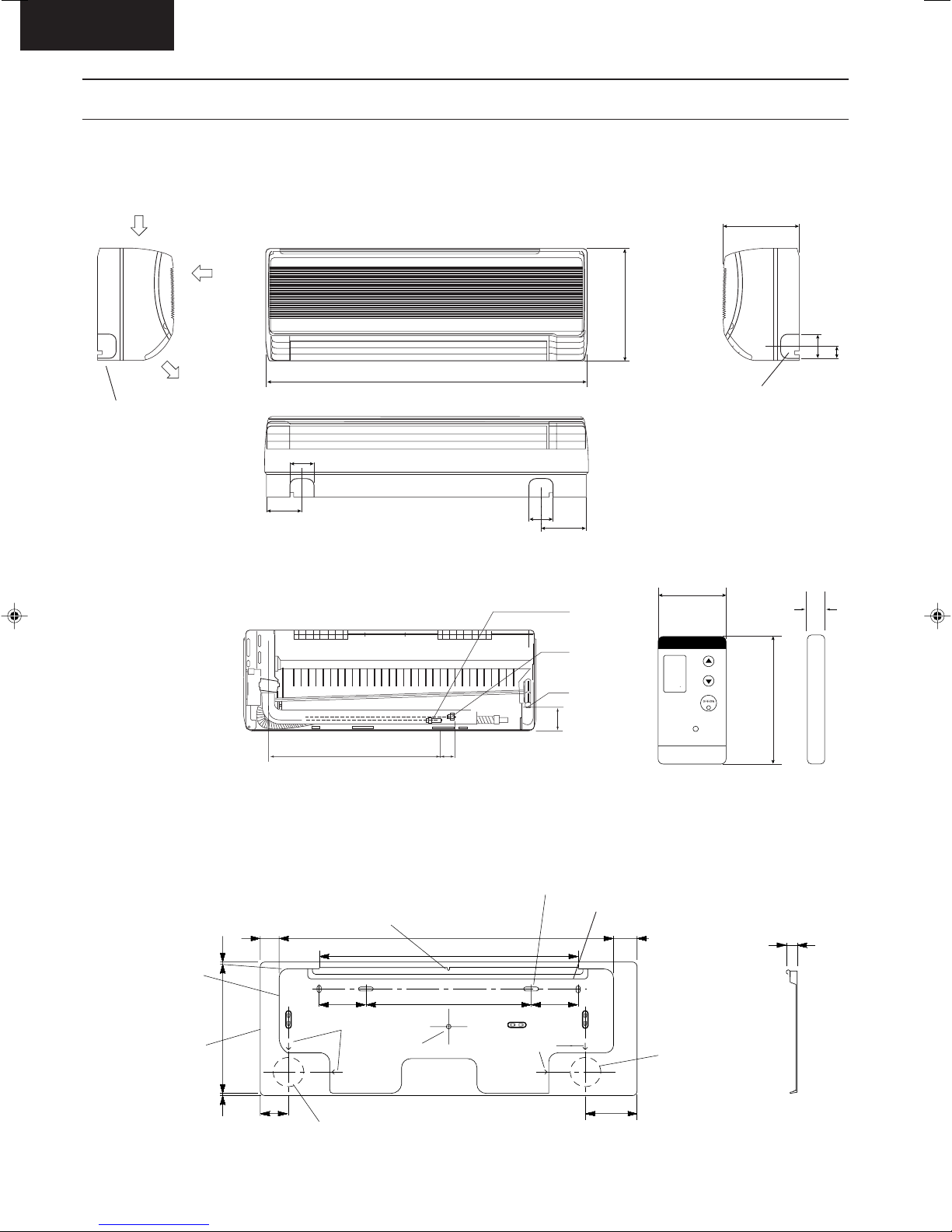

CS-C73KE

Dimensions

CS-C73KE / CS-C93KE / CS-C123KE

Left piping

hole

<Side View>

Air intake

direction

Air outlet

direction

<Front View>

60

58

799

<Back View>

60

83

GAS SIDE

279

Unit : mm

190

60

Right piping hole

<Side View>

Remote control transmitter

65

36

18

Installation

plate

Indoor unit

external

dimensions

line

LIQUID SIDE

TEMP

DRAIN PORT

65

425 48

C

POWERFUL

Relative position between the indoor unit and the installation plate <Front View>

Slot (2 places)

Slot (2 places)

(49)

Right piping hole

(99)

17.8

257.2

4

(40)

(60)

Centre notch

710

550

100 100

350

Arrow

Centre

Arrow

122

16.5

Left piping hole

– 11 –

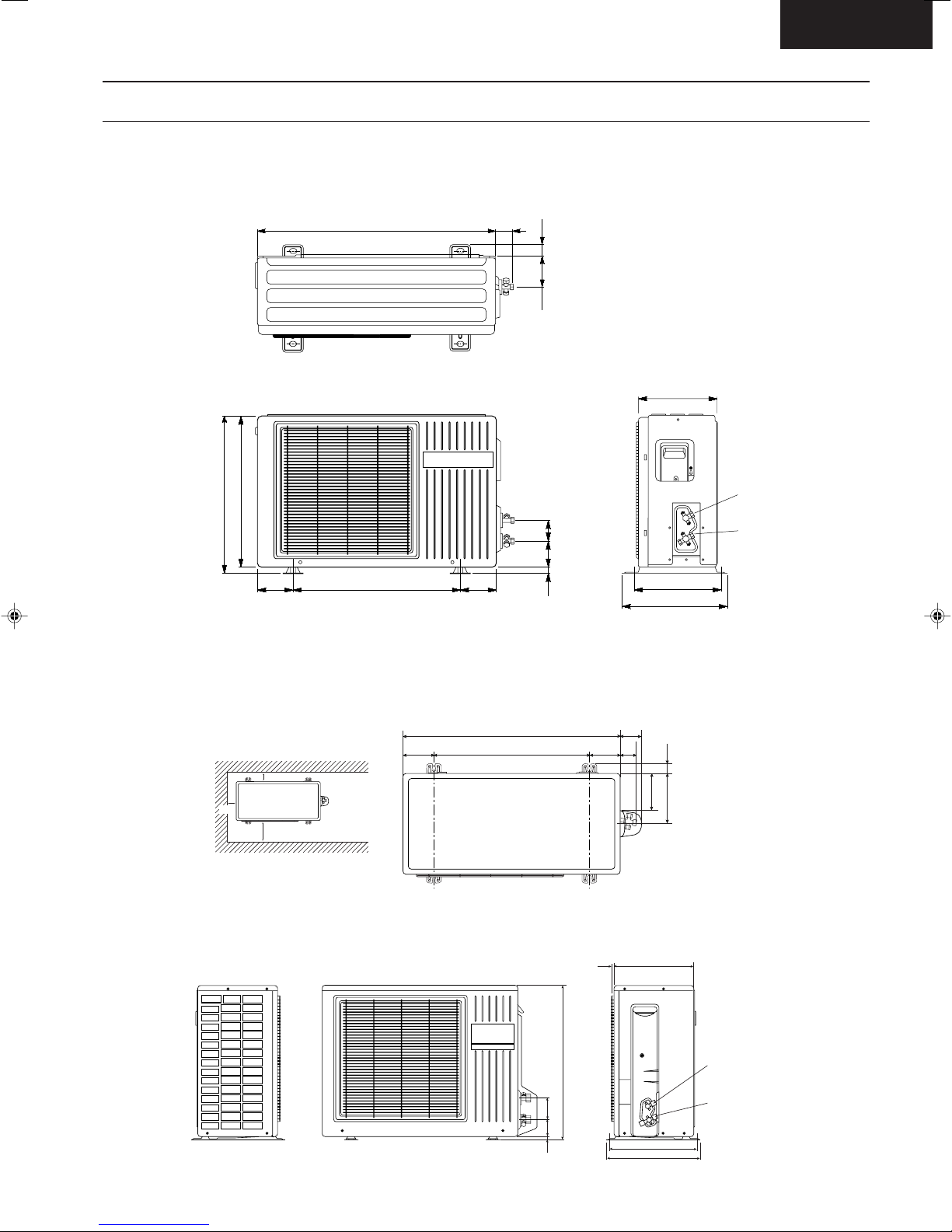

Dimensions

CU-C73KE / CU-C93KE

CS-C73KE

480

467

780 54

105105 570

27.5

93

67

77

13

245

2-way valve at

Liquid side

(High Pressure)

3-way valve at

Gas side

(Low Pressure)

280

312

CU-C123KE

Space necessary for

installation

10 cm

10 cm

100 cm

Anchor Bolt Pitch

323 x 500

699

100 500 99 (52)

7.5

540

11 67 67

69

32162

(120)

285

2-Way Valve at Liquid side

(High Pressure)

3-Way Valve at Gas side

(Low Pressure)

(323)

347

– 12 –

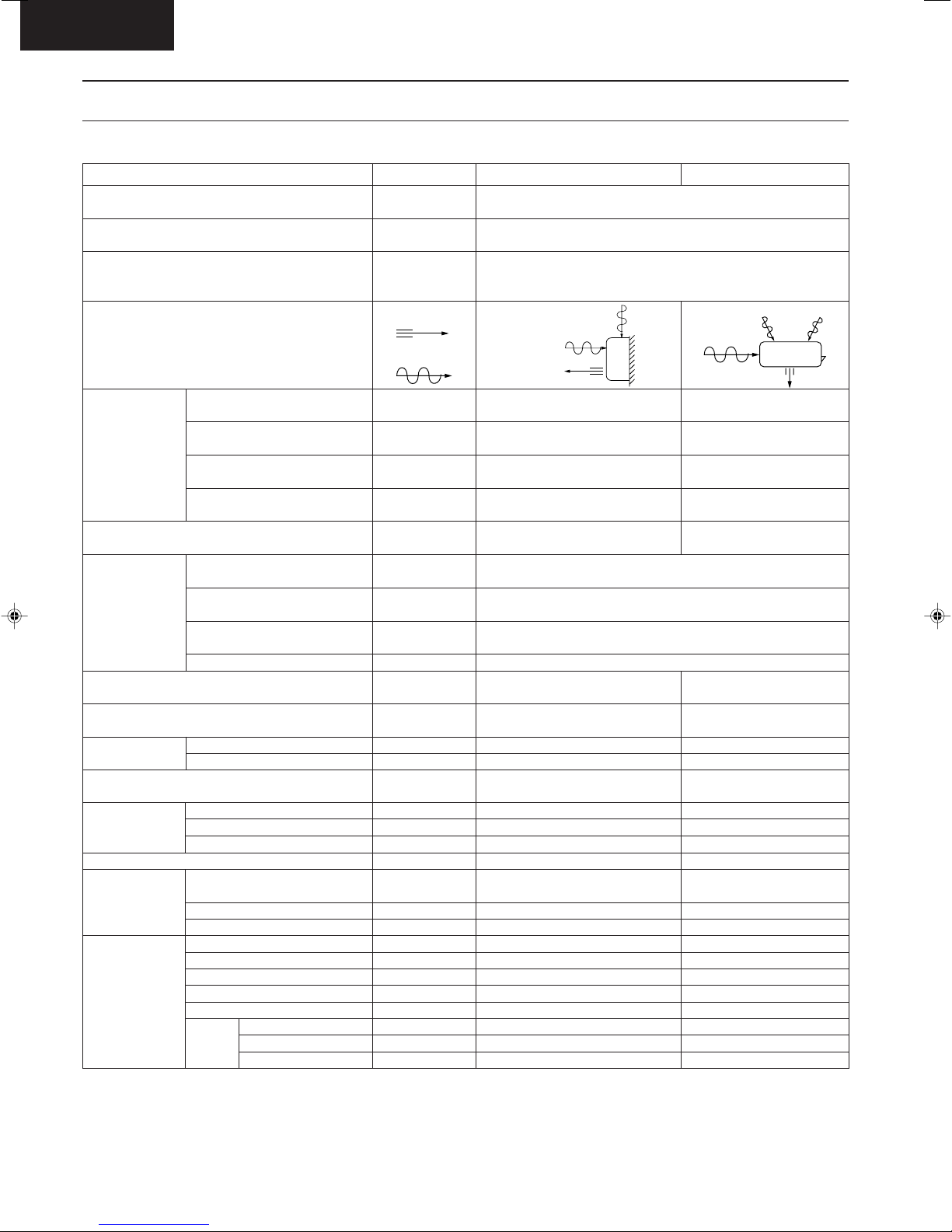

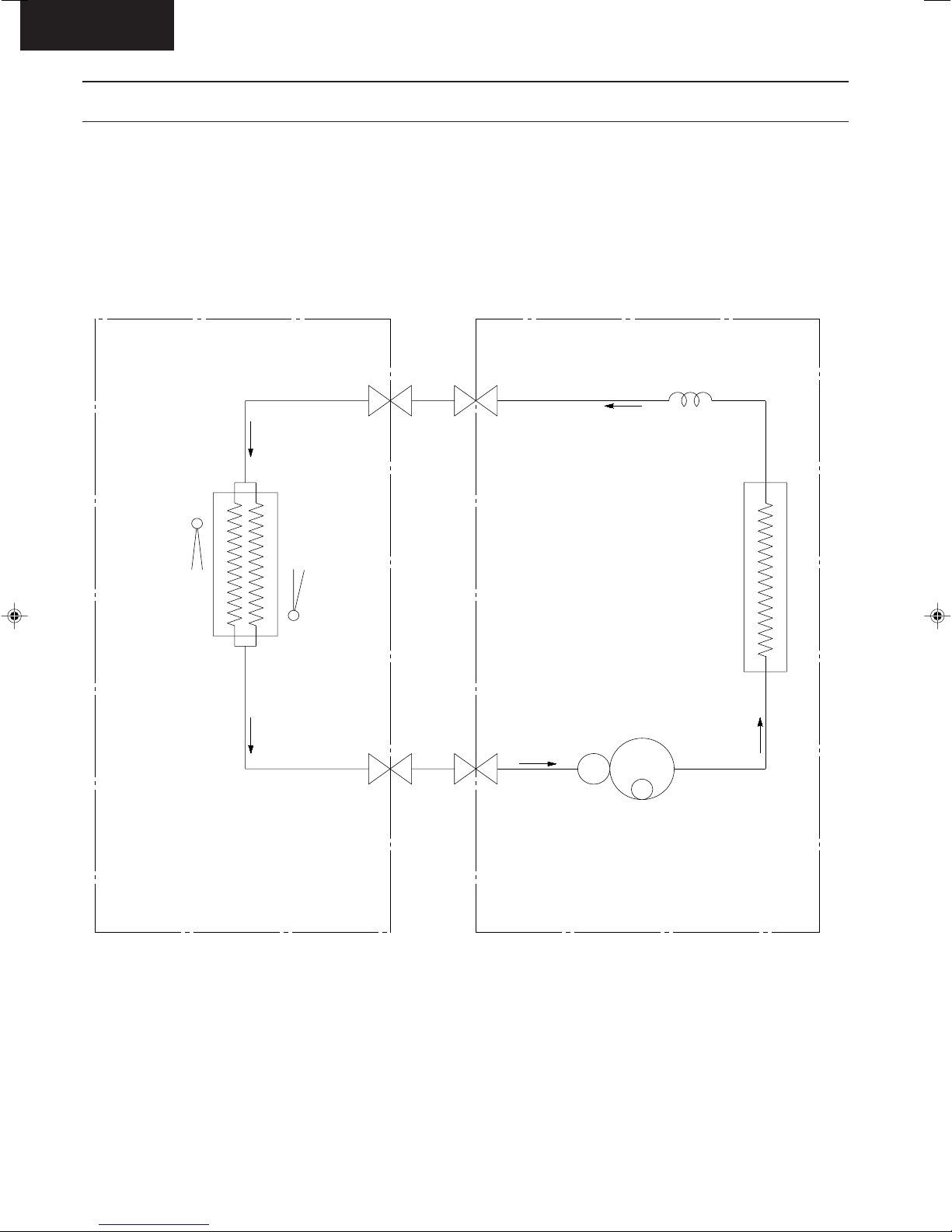

CS-C73KE

Refrigeration Cycle Diagram

CS-C73KE / CU-C73KE

CS-C93KE / CU-C93KE

CS-C123KE / CU-C123KE

INDOOR OUTDOOR

2-WAY

VALVE

CAPILLARY

TUBE

INTAKE

AIR

TEMP.

SENSOR

HEAT EXCHANGER

(EVAPORATOR)

HEAT

EXCHENGER

TEMP.

SENSOR

3-WAY

VALVE

HEAT EXCHANGER

(CONDENSER)

COMPRESSOR

– 13 –

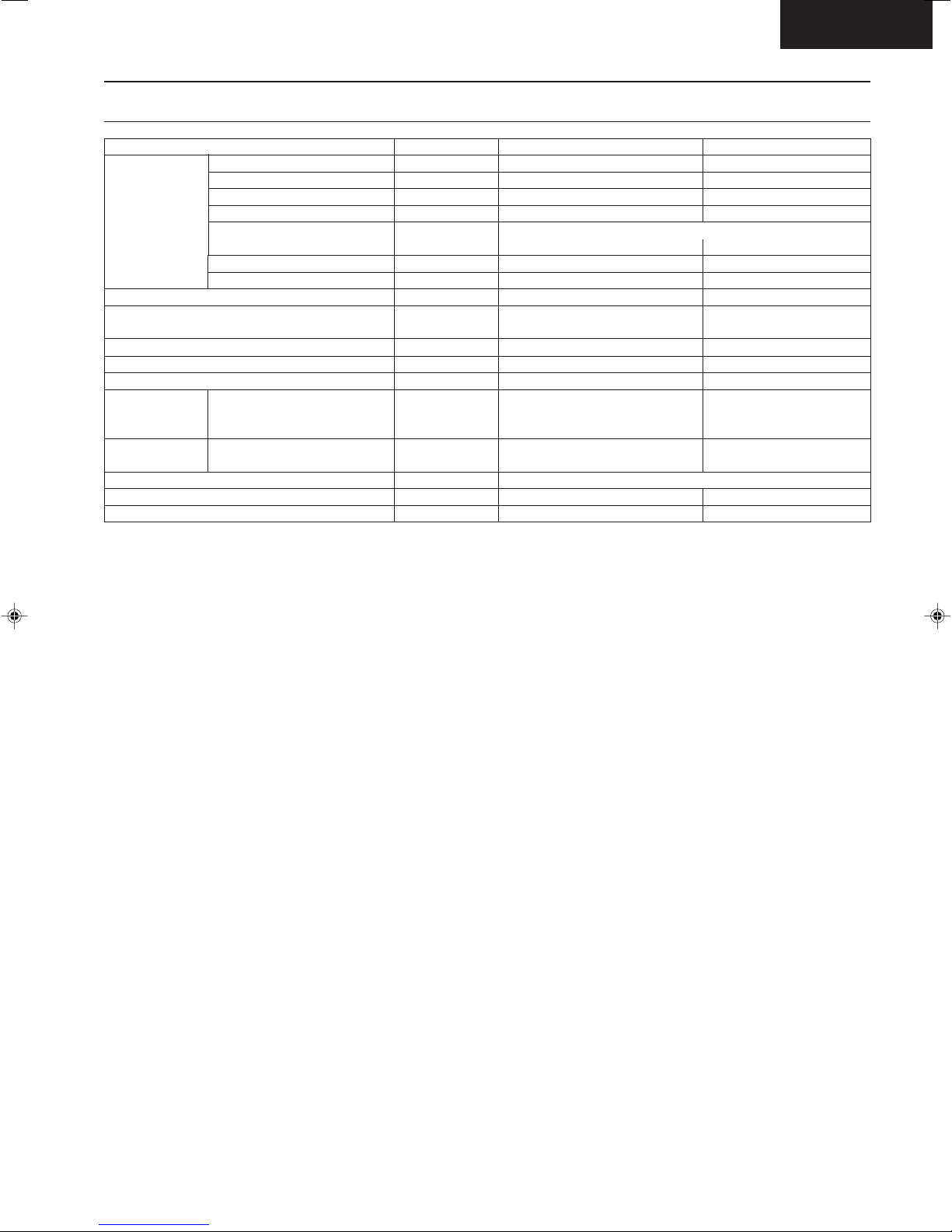

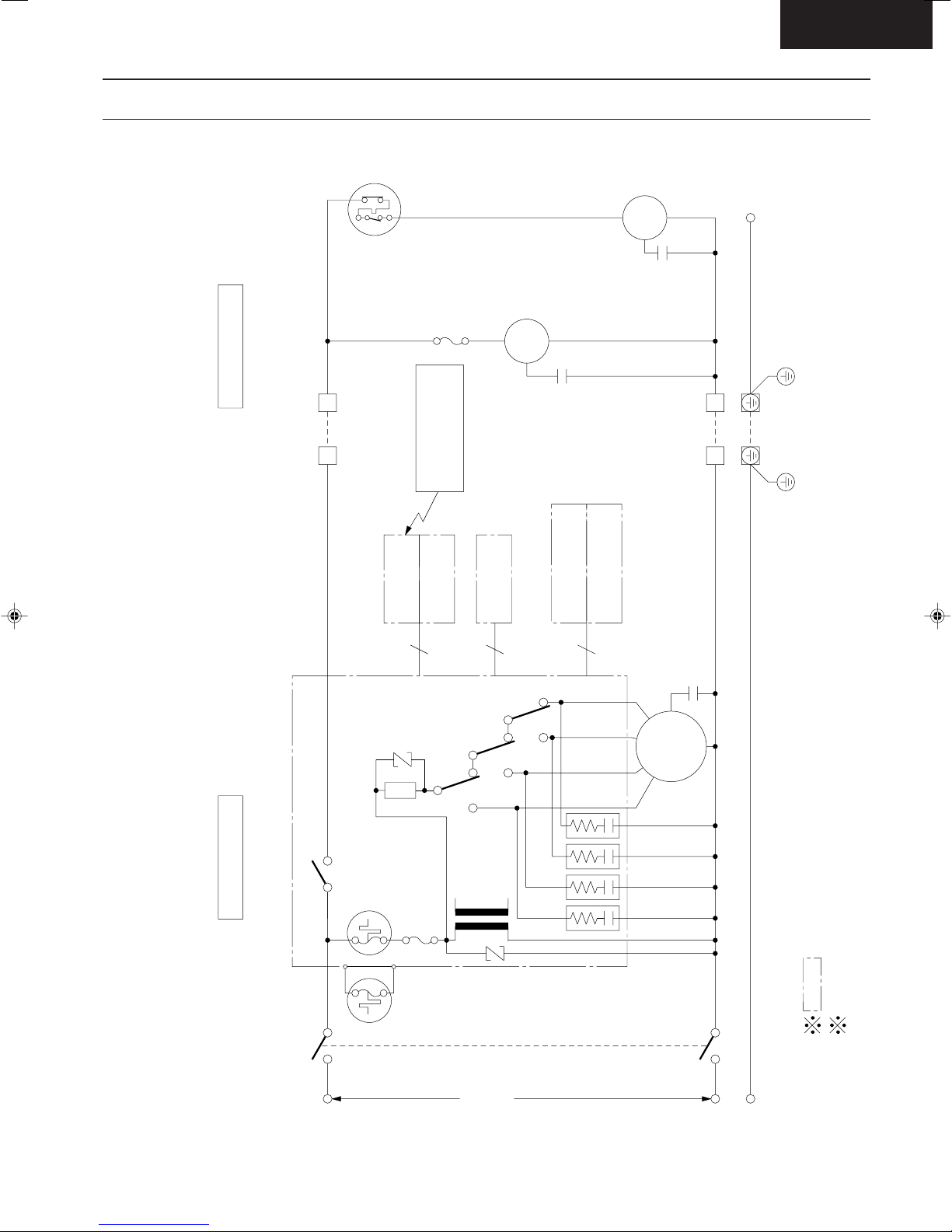

22

11

J9990114

"C"

FUSE

3.15A

RY-PWR

RECEIVER

P.C.B.

Indoor Unit Outdoor Unit

SINGLE PHASE

AC 220-230V

50Hz

C-FM

RY-SHI

RY-HTRANS-

FORMER

(102°C)

FUSE

THERMAL

ZNR1

COMPRESSOR

FAN MOTOR

FAN

MOTOR

OVERLOAD

PROTECTOR

POWER SWITCH

ELECTRONIC CONTROLLER

Indicates the electronic control unit.

Indicates the number of core wires. (Example:6C=6 core wires).

3.15A

FUSE

MAIN

CS/CU-C73KH/C93KH

C73KHBLD.DWG

TRANSMITTER

REMOTE CONTROL

WIRELESS

P.C.B.

INDICATOR

9C

MOTOR

STEPPING5CSENSOR

PIPE TEMP.

TEMP. SENSOR

INTAKE AIR

4C

RY-M

SSR

ZNR2

CONTROL BOX

TEMP. FUSE

(113°C)

CR1

CR2

CR4

CR3

Block Diagram

CS-C73KE

CS-C73KE / CU-C73KE

CS-C93KE / CU-C93KE

CS-C123KE / CU-C123KE

– 14 –

Loading...

Loading...