Page 1

Colour Television

CT-F2156WLP

GP41 Chassis

Order No. MTV0601454CE

Specification

Power Source AC SINGLE 220 V, 50/60 Hz

Power Consumption 67 W

Standby condition : 2 W

Aerial Terminal Impedance : 75Ω, Coaxial type

Tuning System

Receiving System MTS STEREO

Receiving Channels Regular TV

VHF BAND 2-13 (NTSC M U.S.A)

UHF BAND 14-69 (NTSC M U.S.A.)

CATV 1-125 (U.S.A. CATV)

Intermediate Frequency 38.0 MHz

Video 31.5 MHz (D, K) / 32.5 MHz (B, G)

Sound 33.57 MHz (PAL) /

Colour 33.6 MHz (SECAM)

Video/Audio/Terminals

DVD

Frequency Synthesizer

Auto Search Tuning

Pos : 100 Positions

32.0 MHz (I) / 32.5 MHz (M)

34.42 MHz (NTSC) /

33.75 MHz (SECAM)

Y 1.0 Vp-p, 75Ω

P

B

P

R

AV 1, 2, 3

Video in 1.0 Vp-p, 75Ω

Audio in Approx. 0.5V , 47KΩ

Audio Amp AUDIO L-R 0.5V RMS

(PHONE JACK TYPE x 2)

High Voltage 27.5 ±1.5 at zero

Picture Tube A51LYZ295X Type 21 (500 mm)

Audio Output 16 W speaker

Dimensions (W x D x H) 648 mm x 472 mm x 488 mm

Weight (Mass) 24.5 kg (Net)

Note:

Specifications are subject to change without notice. Mass and

dimensions shown are approximate.

0.7 Vp-p, 75Ω

0.7 Vp-p, 75Ω

beam current

Measured diagonally,

104° defl ect ion

© 2006 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

CT-F2156WLP

CONTENTS

Page Page

1 Safety Precautions 3

1.1. General Guide

1.2. Leakage Current Cold Check

1.3. Leakage Current Hot Check (See Fig. 1)

1.4. X-Radiation

1.5. GP41 Block Diagram

2 Service Hints

2.1. HOW TO MOVE CHASSIS INTO SERVICE POSITION.

3 Market Mode Function

3.1. Service Mode Access

3.2. Service Mode 1 Controls

3.3. Service Mode 1 Function

3.4. Service Mode 2 Controls (OPTION data 1 ~ 3)

4 Adjustment Procedure

4.1. Adjustment Procedure

3

3

3

3

4

5

5

6

6

6

6

6

7

7

4.2. COLOUR PURITY

4.3. CONVERGENCE

4.4. WHITE BALANCE (MARKET MODE CHK 4)

4.5. ADJUSTMENT OF CRT VRS

5 Conductor Views

6 Schematic Diagrams

6.1. SCHEMATIC DIAGRAM FOR GP41 CHASSIS

6.2. A Board

6.3. L Board

6.4. G Board

7 Parts Locations

8 Replacement Parts List

8.1. Replacement Parts List Notes

8.2. Replacement Parts List

7

8

9

10

11

12

12

14

19

22

25

26

26

27

2

Page 3

CT-F2156WLP

1 Safety Precautions

1.1. General Guide

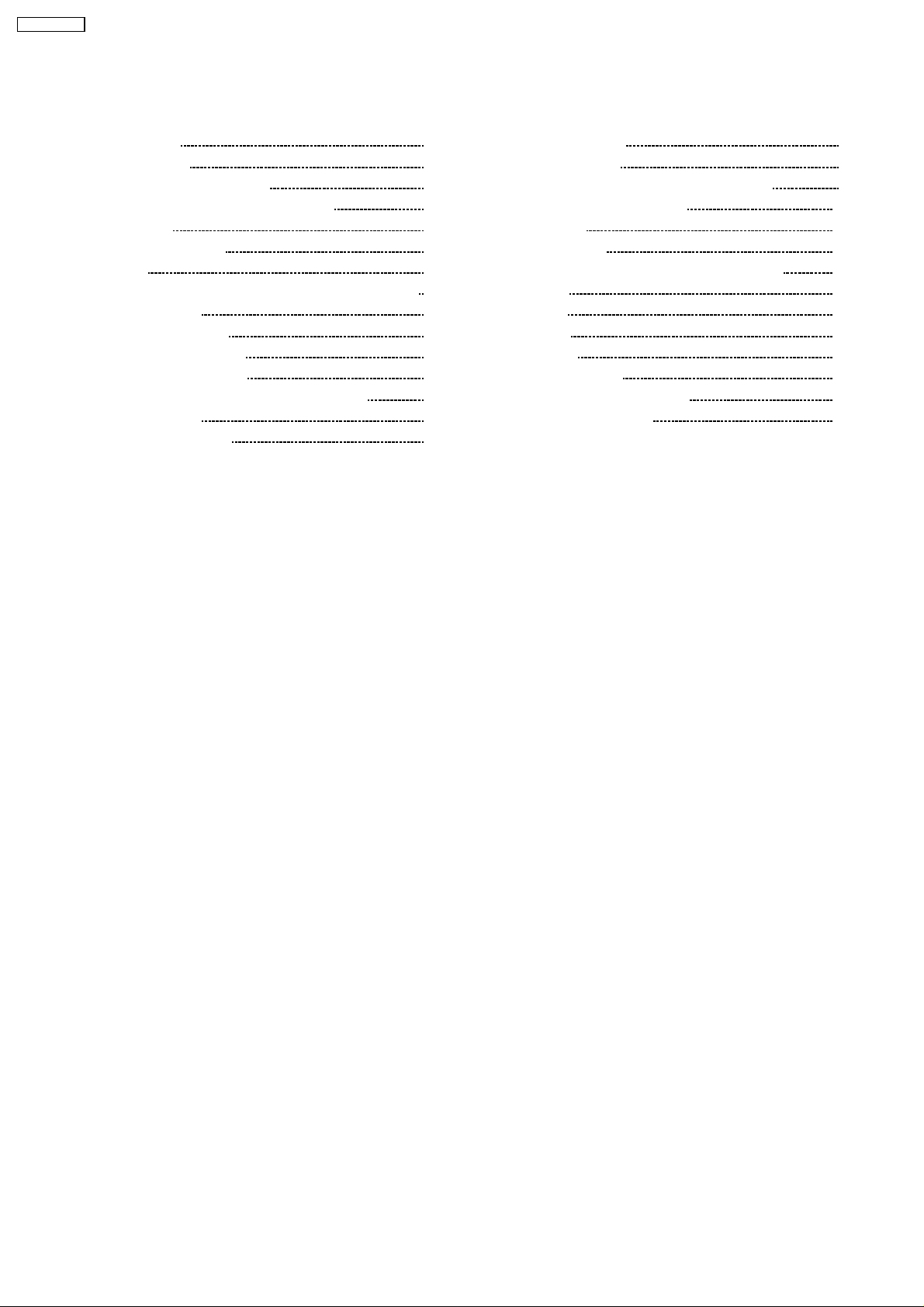

1. It is advisable to insert an isolation transformer in the AC

supply before servicing a hot chassis. Fig. 1.

Fig. 1

2. When servicing, observe the original lead dress, especially

the lead dress in the high voltage circuits. If a short circuit is

found, replace all parts which have been overheated or

damaged by the short circuit.

3. After servicing, observe that all the protective devices such

as insulation barriers, insulation papers, shields, and

isolation R-C combinations, are properly installed.

4. When the receiver is not to be used for a long period of

time, unplug the power cord from the AC outlet.

5. Potential, as high as

is in operation. Operation of the receiver without the

receiver power supply. Servicing should not be attempted

by anyone who is not thoroughly familiar with the

precautions necessary when working on high voltage

equipment. Always discharge the anode of the picture tube

to the receiver chassis before handling the tube.

After servicing make the following leakage current checks to

prevent the customer from being exposed to shock

hazards.

29kV

kV is present when this receiver

1.3. Leakage Current Hot Check

(See Fig. 1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 2 kΩ, 10 W resistor in series with an exposed

metallic part on the receiver and an earth such as a water

pipe.

3. Use an AC voltmeter, with high impedance type, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point. Fig. 3.

Fig. 3

5. Reverse the ACplug in the AC outlet and repeat each of the

above measurements.

6. The potential any point should not exceed

case of a measurement being outside of the limits specified,

there is a possibility of a shock hazard, and the receiver

should be repaired and re-checked before it is returned to

the customer. Fig. 4.

1.0 V rms

. In the

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug. Fig. 2.

Fig. 2

2. Turn on the receiver’s power switch.

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screw heads, aerials,

connectors, control shafts, etc. When the exposed metallic

part has a return path to the chassis, the reading should be

ΩΩΩΩ

4M

between

not have a return path to the chassis, the reading must be

zero.

and 20 M

ΩΩΩΩ

. When the exposed metal does

Fig. 4

1.4. X-Radiation

Warning :

1. The potential sources of X-Radiation in TV sets are the EHT

section and the picture tube.

2. When using a picture tube test rig for service, ensure that

the rig is capable of handling

Radiation.

Note:

It is important to use an accurate periodically calibrated

high voltage meter.

1. Set the brightness to minimum.

2. Measure the High Voltage. The meter reading should

indicate

tolerance, immediate service and correction is required to

prevent the possibility of premature component failure.

3. To prevent the possibility of X-Radiation, it is essential to

use the specified picture tube.

27.5 ± 1.5V

. If the meter indication is out of

29 kV

without causing X-

3

Page 4

_

_

CT-F2156WLP

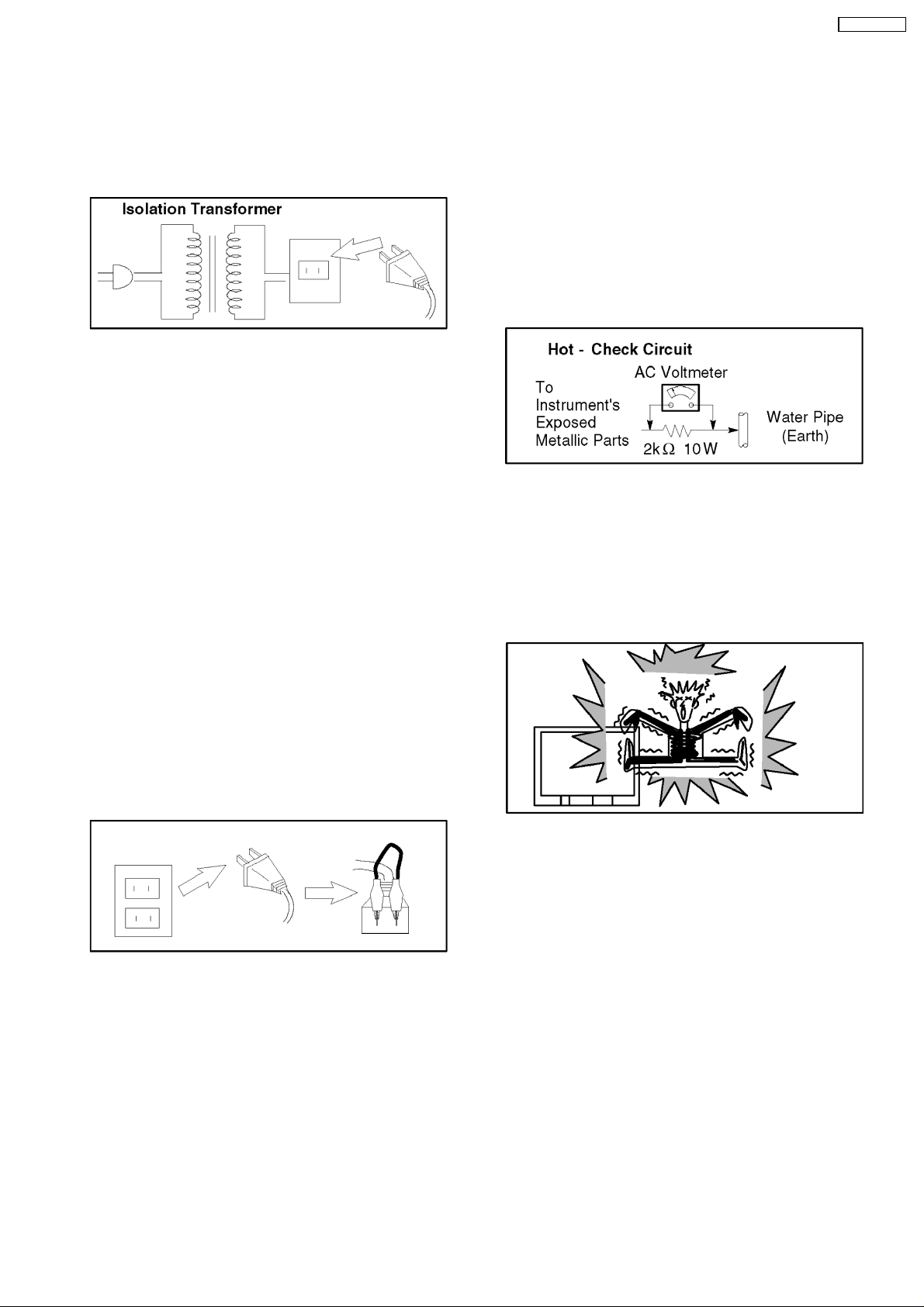

1.5. GP41 Block Diagram

CRT

coil

defl.

29" models

CRT

DRIVE

L

VM DRIVE

PIP models

IC1101

EEPROM

RGB

SCL SDA

SCL

SDA

R/G/B

PVP

IN

IC1801

CVBS

GP41 CHASSIS BLOCK DIAGRAM

PP

SPEAKER

R/G/B

CVBS OUT

AMP

AUDIO

A

VCT-IF

OUT

AUDIO

IC2301

REAR INPUTS

VM

V

H

IC601

IF

IN

IN

V

A

MON_OUT

AV1 : V/L/R

AV3 : YUV/V/L/R

V OUT

TUNER

AV2 : V/L/R

FRONT INPUTS

MON_OUT

H OUT

V/L/R

MAIN

POWER

SWITCH

G

AV2 : V/L/R

FRONT INPUTS

GEOMAGNETIC

AMP

IC2401

WOOFER

4

Page 5

2 Service Hints

2.1. HOW TO MOVE CHASSIS INTO SERVICE POSITION.

1. Remove 9 screws.

CT-F2156WLP

2. Draw out Main Chassis.

3. Stand the Main Chassis.

5

Page 6

CT-F2156WLP

3 Market Mode Function

3.1. Service Mode Access

1. Set timer ON.

2. Press remote’s RECALL (

3. Set to normal mode : Press the volume down button on front, together press the off timer button on remote control.

3.2. Service Mode 1 Controls

) and panel’s volume down key simultaneously to enter SERVICE 1.

1. Key 3 / 4

previous / next service 1 item

2. Key 8 / 9

adjust user brightness (-/+)

3. Program up / down

program position up / down

4. Volume +

increment of selected item

3.3. Service Mode 1 Function

1. H-POS

-128~127

2. V-POS

-128~127

3. H-AMP

-128~127

4. V-AMP

-128~127

5. EW-AMP1

-128~127

6. LOW_Corner

-128~127

7. TRAPEZ 1

-128~127

8. UPPER_Corner

-128~127

9. V-LIN

-128~127

10. V-SYM

-128~127

5. Volume decrement of selected item

6. OK (remote)

store / save selected item

7. Normal (remote)

exit service mode

11. ANGEL

-128~127

12. BOW

-128~127

13. DVCO

-128~127

14. H-POS

-128~127

15. G-CUT OFF

N/A

16. B-CUT OFF

0~511

17. R-DRIVE

0~511

18. G-DRIVE

0~511

19. B-DRIVE

0~511

20. SUB-Bright

-128~127

3.4. Service Mode 2 Controls (OPTION data 1 ~ 3)

1. Key 3 / 4

previous / next service 2 item

2. Key 8 / 9

toggle for options bit 0 - 7

3. Program up / down

program position up / down

4. Volume +

increment of selected item

5. Volume decrement of selected item

6. OK (remote)

store / save selected item

7. Normal (remote)

exit service mode

NOTE: Service mode 2 options bit refer to each model spec.

6

Page 7

4 Adjustment Procedure

4.1. Adjustment Procedure

4.1.1. +B Voltage

CT-F2156WLP

Item / preparation

1. Operate the TV set.

2. Set control as follows :

Brightness ........... minimum

Contrast ............... minimum

Adjustment procedure

1. Confirm the DC voltage at the indicated test points, as

follows :

TPD 15 : 3.35 ± 0.2V

TPD 16 : 141 ± 2V

TPD 17 : 8.2 ± 0.5V

TPD 18 : 1.9 ± 0.2V

TPD 19 : 5.2 ± 0.2V

TPD 20 : 175 ± 15V

4.1.2. High Voltage

Item / preparation

1. Receive the crosshatch pattern.

2. Set to 0 Beam.

Screen VR .......... minimum

Contrast .............. minimum

Adjustment procedure

1. Connect a DC voltage meter to D866 and confirm the +B

voltage is 141.0 ± 2V.

2. Connect a high frequency voltmeter to heater and confirm

that voltage reads 6.30 ± 0.24 (VRMS).

3. Normalize the brightness and contrast.

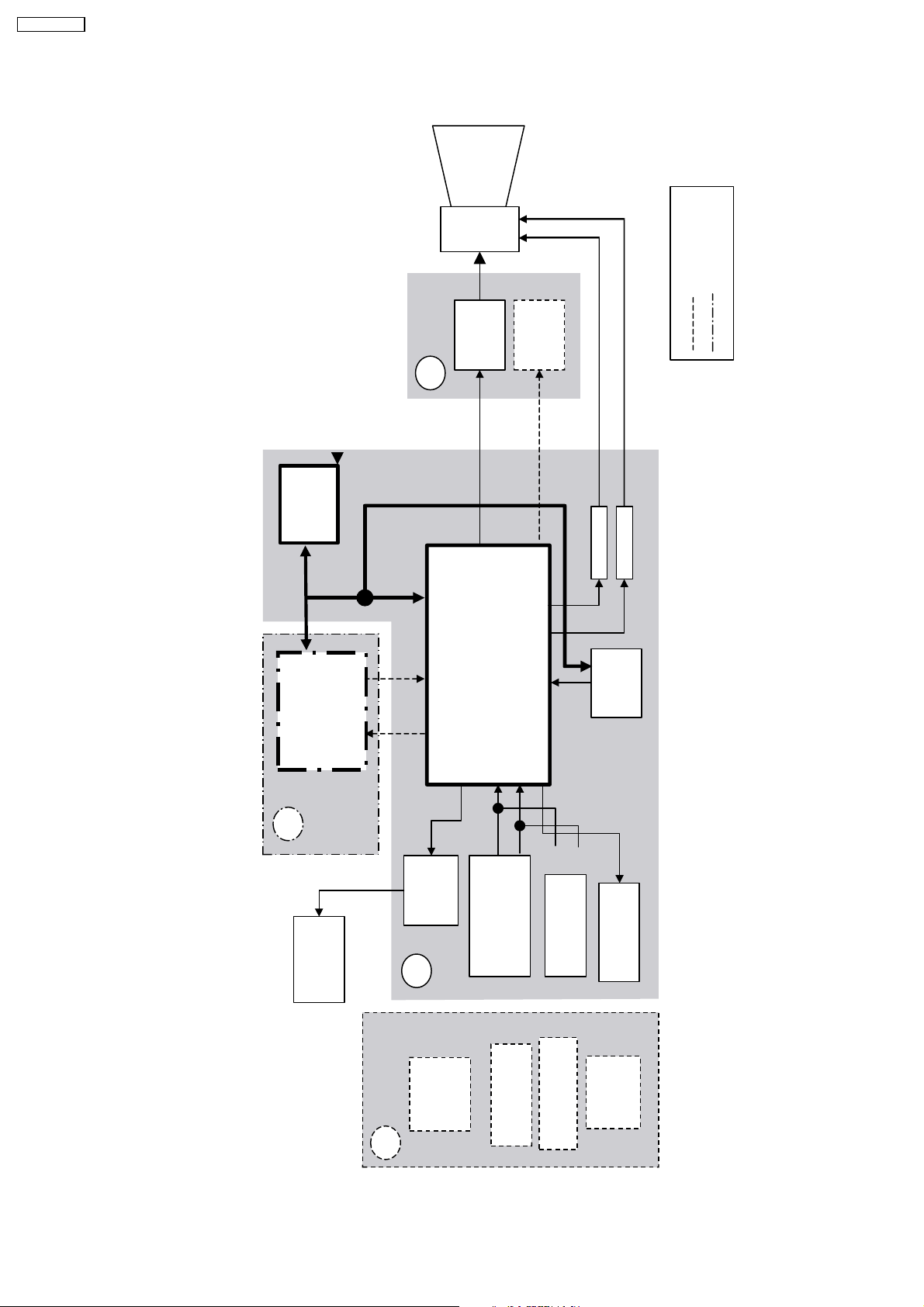

4.1.3. NTSC TINT COLOUR

Item / preparation

1. Connect oscilloscope probe to TPL1 (R OUT) with 10k

series resistor.

2. Press Main Menu and set system to use AV-NTSC (3.58

MHz).

DYNAMIC ................... Normal

Channel CLR Set ..... STD

Adjustment procedure

1. Adjust Sub-Tint so that No. 2, 3 and 4 becomes level

waveform is similar to Fig. 3.

2. Confirm phase at Tint is changes more than ± 15 by Tint

control.

3. Confirm that colour level is maximum when colour DAC is

adjusted to maximum position.

Note:

Use remote control only when adjusting user mode to

Sub-Tint.

Ω

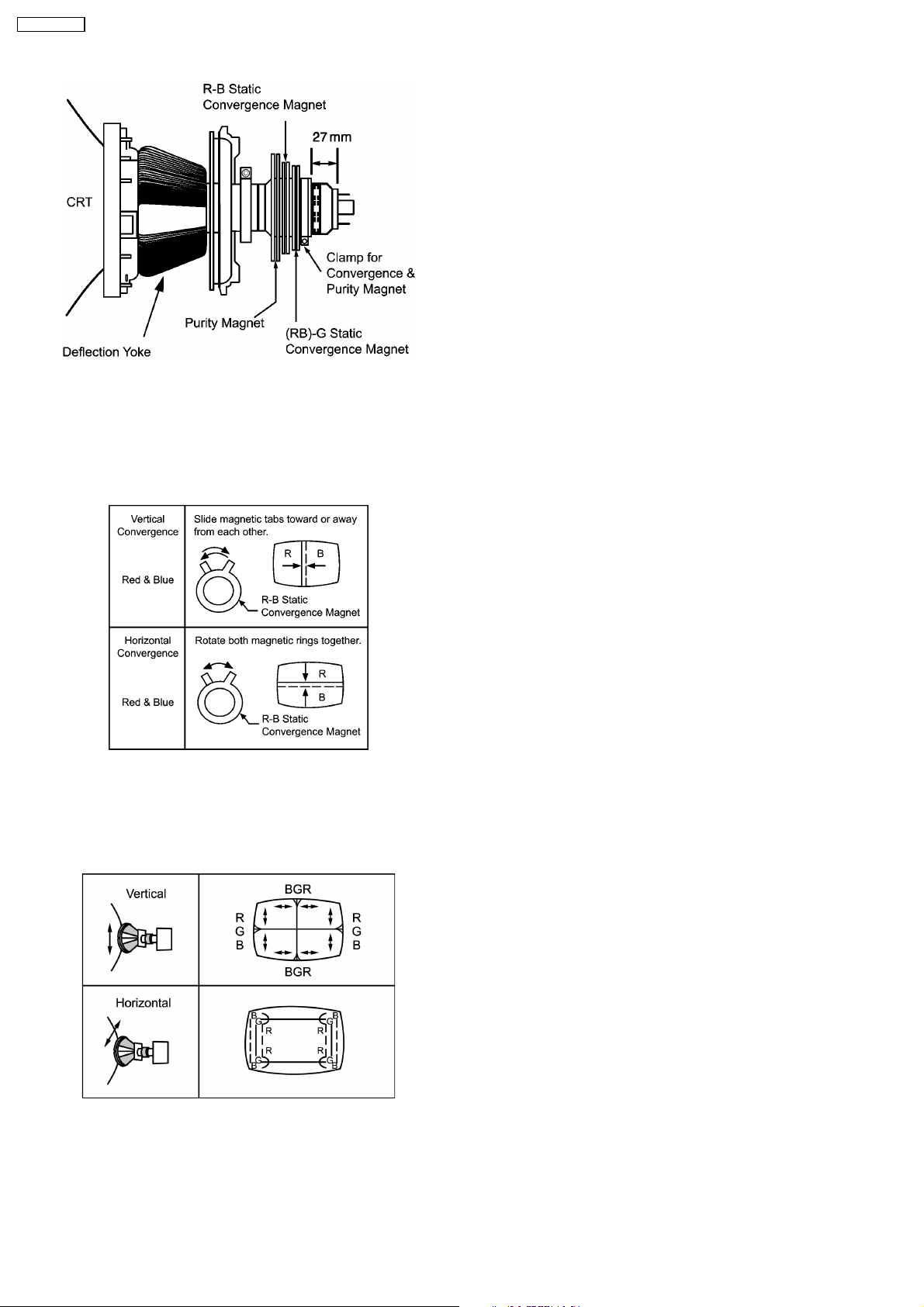

4.2. COLOUR PURITY

1. Set Bright and Contrast controls to their maximum

positions.

2. Operate the TV set over 60 minutes.

3. Full degauss the picture tube by using an external

degaussing coil. By rotating R-B static convergence

magnet.

4. Apply a crosshatch pattern signal and adjust roughly the

static convergence magnets.

5. Apply a green pattern signal.

6. Loosen a clamp screw for the Deflection Yoke and move

the Deflection Yoke as close to the purity magnet as

possible.

7. Adjust the purity magnet so that a vertical green field is

obtained at the center of the screen.

8. Slowly press the Deflection Yoke and set it where a uniform

green field is obtained.

9. Adjust roughly the Low Light controls and make sure that a

uniform white field is obtained.

10. Tighten the clamp screw.

7

Page 8

CT-F2156WLP

4.3. CONVERGENCE

1. Apply a crosshatch pattern signal and set Contrast control

to the maximum position.

2. Adjust Bright control to obtain a clear pattern.

3. Adjust Red and Blue line at center of the screen.

4. Adjust Red and Blue with Green line at center of the screen

by rotating (RB)-G static convergence magnet.

5. Lock convergence magnets with silicone sealer.

6. Remove the DY wedges and slightly tilt the Deflection Yoke

vertically.

7. Fix the Deflection Yoke by re-inserting the DY wedges.

8. If purity error is found, repeat “Colour Purity” adjustment.

8

Page 9

4.4. WHITE BALANCE (MARKET MODE CHK 4)

Preparation

1. Receive a colour bar signal with colour “OFF”, and operate

the TV set for more than 30 minutes.

2. Set the picture menu to “DYNAMIC NORMAL” and the AI to

off.

3. Connect an oscilloscope to KG on L BOARD.

4. Set the TV set to Market Mode : white balance adjustment

(CHK 4).

5. Screen VR : Min.

6. Set the data level of RGB CUT OFF / DRIVE and SUB

BRIGHT.

Adjustment

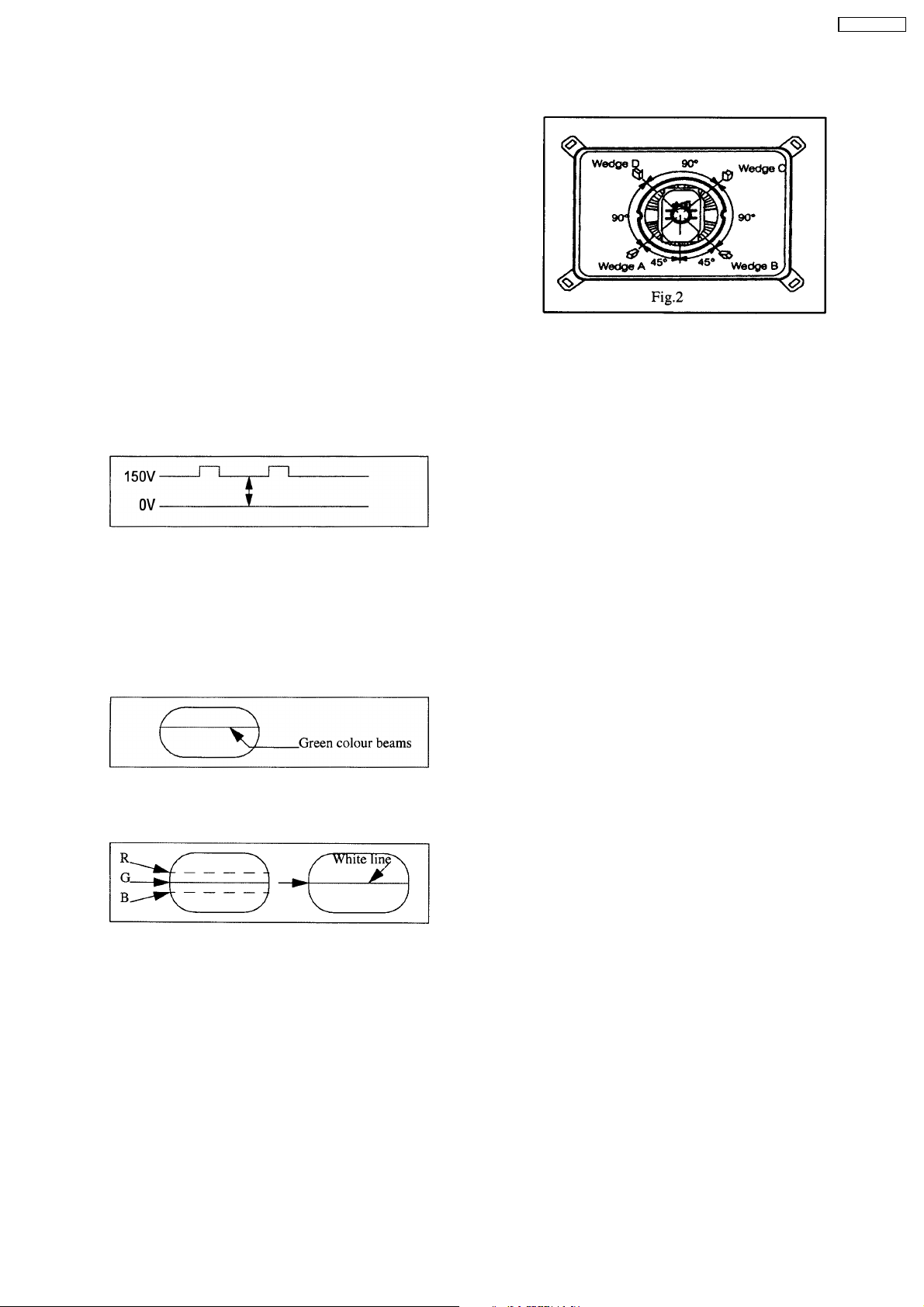

1. Select G-CUTOFF adjustment mode and collapse vertical

scan.

2. Adjust G-CUTOFF control to become the DC=0 V to video

level at 150 V as shown in Fig. 1.

8. Wedge A shown in Fig. 2 should be fixed within a range of

45° to the left of the vertical line as shown.

9. After inserting wedge A, insert wedges B, C and D.

The wedges should be set 90° apart from each other.

10. Be certain that the four wedges are firmly fixed and the

Deflection Yoke is tightly clamped in place otherwise the

Deflection Yoke may shift its position and cause a loss of

convergence and purity.

CT-F2156WLP

Fig. 1

3. Slowly turn the screen control clockwise until a green colour

horizontal line appears on the picture tube. This is the

setting point for the screen control.

Note:

Do not adjust the G-CUTOFF setting in the following

procedure.

4. Adjust the remaining R and B-CUTOFF controls so as to

get a white horizontal line on the screen.

5. Return to full field SCAN by pushing the position 5 key on

the remote control.

6. Adjust the R-Drive and B-Drive controls as to obtain a

uniform white on the white bar of the greyscale pattern.

7. Confirm correct B/W rendition and greyscale tracking or

repeat CUTOFF and drive control setup.

Note:

Write down the original value for each address adjustment

before adjusting anything.

9

Page 10

CT-F2156WLP

4.5. ADJUSTMENT OF CRT VRS

PREPARATION

1. Set DY to CRT not to tilt up and down left and right deflection. (fig 1)

2. Set CY to CRT and set CY magnet primarily.

Pur Mg : Set Pur Mg that 2magnets are top position.

VRS Mag : Set VRS Mg that 2magnets are horizontal position.

ADJUSTMENT

1. Receive the white balance pattern.

2. Adjust V-CENTER.

3. Set R,B CUT OFF to minimum, and set G CUT OFF to center.

4. Receive the aging pattern.

5. Set 2 magnet of vertical position to up and down equally so that center part of CRT (Fig. 2)

10

Page 11

5 Conductor Views

CT-F2156WLP

11

Page 12

CT-F2156WLP

6 Schematic Diagrams

6.1. SCHEMATIC DIAGRAM FOR GP41 CHASSIS

12

Page 13

CT-F2156WLP

13

Page 14

CT-F2156WLP

6.2. A Board

6.2.1. A Board (1/5)

<1A>

<2A>

<3A>

<4A>

<5A>

<6A>

<7A>

<8A>

14

<9A>

Page 15

6.2.2. A Board (2/5)

CT-F2156WLP

<1A>

<2A>

<3A>

<4A>

<5A>

<6A>

<1B>

<2B>

<3B>

<4B>

<7A>

<8A>

<5B>

<6B>

<7B>

<8B>

<9A>

<9B>

15

Page 16

CT-F2156WLP

6.2.3. A Board (3/5)

<1B>

<2B>

<3B>

<4B>

<1C>

<2C>

<3C>

<5B>

<6B>

<7B>

<8B>

<4C>

<5C>

<6C>

<7C>

<8C>

<9B>

<9C>

16

Page 17

6.2.4. A Board (4/5)

CT-F2156WLP

<1C>

<2C>

<3C>

<4C>

<1D>

<2D>

<5C>

<6C>

<7C>

<8C>

<3D>

<4D>

<5D>

<6D>

<7D>

<8D>

<9C>

<9D>

17

Page 18

CT-F2156WLP

6.2.5. A Board (5/5)

<1D>

<2D>

<3D>

<4D>

<5D>

<6D>

<7D>

<8D>

<9D>

18

Page 19

6.3. L Board

6.3.1. L Board (1/3)

CT-F2156WLP

<1A>

<2A>

<3A>

<4A>

<5A>

<6A>

<7A>

<8A>

19

<9A>

Page 20

CT-F2156WLP

6.3.2. L Board (2/3)

<1A>

<2A>

<3A>

<4A>

<5A>

<1B>

<2B>

<3B>

<6A>

<7A>

<8A>

<4B>

<9A>

<9B>

20

Page 21

6.3.3. L Board (3/3)

<1B>

<2B>

<3B>

CT-F2156WLP

<4B>

<9B>

21

Page 22

CT-F2156WLP

6.4. G Board

6.4.1. G Board (1/3)

<1A>

<2A>

<3A>

<4A>

<5A>

<6A>

22

<7A>

Page 23

6.4.2. G Board (2/3)

CT-F2156WLP

<1A>

<2A>

<3A>

<4A>

<1B>

<2B>

<3B>

<5A>

<6A>

<7A>

<4B>

<5B>

23

Page 24

CT-F2156WLP

6.4.3. G Board (3/3)

<1B>

<2B>

<3B>

<4B>

<5B>

24

Page 25

7 Parts Locations

CT-F2156WLP

25

Page 26

CT-F2156WLP

8 Replacement Parts List

8.1. Replacement Parts List Notes

26

Page 27

8.2. Replacement Parts List

CT-F2156WLP

Ref.

No.

1 A51LYZ295X PICTURE TUBE

2 EASG15S02H2 SPEAKER

3 TBM4G1396 MODEL NAME PLATE

4 TBM4G3017 PANASONIC BADGE

5 TBX4G90411 POWER BUTTON

6 TKP4G13080-1 AC CORD BRACKET

7 TKP4G13291 DOOR

8 TKU4GA2610 BACK COVER

9 TLK4G9097X DEGAUSSING COIL

10 TLY4G348T DEFLECTION YOKE

11 TMM4G503 RUBBER WEDGE

NLA TNP4G366AE G BOARD

NLA TNP4G389AT A BOARD

NLA TNP4G390AF L BOARD

12 TP-5400PW CONVERGENCE YOKE

13 TXFKY01EW03 CABINET ASSY

C002 ECJ1VF1H103Z C 0.01UF, Z, 50V

C003 ECJ1VC1H220J C 22PF, J, 50V

C004 ECJ1VC1H220J C 22PF, J, 50V

C006 F2A1C101A310 E 100UF, 16V

C1064 ECJ2FB0J225K C 2.2UF, K, 6.3V

C1103 F1J1H103A590 C 0.01UF, J, 50V

C1118 ECJ1VF1H104Z C 0.1UF, Z, 50V

C1131 F1J1H103A590 C 0.01UF, J, 50V

C1142 ECJ1VF1H104Z C 0.1UF, Z, 50V

C2113 F2A1H3R3A317 E 3.3UF, 50V

C2117 ECJ1VF1H104Z C 0.1UF, Z, 50V

C2129 F2A1C102A159 E 1000UF, 16V

C2303 F2A1H4R7A317 E 4.7UF, 50V

C2314 F2A1E470A270 E 47UF, 25V

C2315 ECA1EM471B E 470UF, 25V

C2321 F1J1H102A018 C 0.1UF, Z, 50V

C2322 F1J1H102A018 C 0.1UF, Z, 50V

C2325 F2A1C470A310 E 47UF, 16V

C2326 F2A1C470A310 E 47UF, 16V

C2328 F1J1E474A101 C 0.47UF, 25V

C2329 F1J1E474A101 C 0.47UF, 25V

C2401 ECA1EM101B E 100UF, 25V

C2402 ECEA1HN2R2U E 2.2UF, 50V

C2407 ECA1EM222E E 2200UF, 25V

C2408 ECJ1VC1H102J C 1000PF, J, 50V

C2409 ECA1CM100B E 10UF, 16V

C253 ECEA1HN2R2U E 2.2UF, 50V

C254 F1J1H102A018 C 0.1UF, Z, 50V

C257 ECEA1HN2R2U E 2.2UF, 50V

C258 F1J1H102A018 C 0.1UF, Z, 50V

C301 ECJ2VB1C104K C 0.1UF, K, 16V

C302 ECJ2VB1C104K C 0.1UF, K, 16V

C3023 ECJ1VF1C105Z C 10UF, Z, 16V

C3024 ECJ1VF1C105Z C 10UF, Z, 16V

C3025 ECJ1VF1C105Z C 10UF, Z, 16V

Part No. Part Name & Description Remarks

EUR7717050 REMOTE CONTROL

K4BC02H00007 2P PUSH TERMINAL

L0EYAA000001 SUB WOOFER

TES4G206 COIL SPRING

TES4G214 SPRING (POWER BUTTON)

TES4G409-1 SPRING (DOOR)

THT4G10139 SCREW

THT4G1014J SCREW

TKK4G8603 SPEAKER BRACKET

TMM4G904 RUBBER WASHER

TPD4G1182 CUSHION (TOP)

TPD4G2161 CUSHION (BOTTOM)

TPE4G14003 LAMI BAG

TPE4G14025 SET COVER

TQB4G5090 FAN BAG

TSMA011 MAGNET

TSN63115-4 PURITY MAGNET

TSX4G203V-1 AC POWER CORD

TXFPC01EW04 CARTON

CAPACITORS

Ref.

No.

C3027 ECJ1VF1C105Z C 10UF, Z, 16V

C303 ECJ2VB1C104K C 0.1UF, K, 16V

C305 F2A1C4710045 E 470UF, 16V

C306 D0GB240JA008 F 24,J, 1/16V

C307 D0GB240JA008 F 24,J, 1/16V

C308 D0GB240JA008 F 24,J, 1/16V

C3150 F2A1H2R2A118 E 2.2UF, 50V

C3151 F2A1H2R2A118 E 2.2UF, 50V

C3184 ERJ3GEY0R00 M 0OHM,J,1/16W

C3185 ERJ3GEY0R00 M 0OHM,J,1/16W

C3186 ECJ1VB1H222K C 2200PF, K, 50V

C3187 ECJ1VB1H222K C 2200PF, K, 50V

C350 ECA1CM101B E 100UF, 16V

C360 ECKW3D102KBP C 1000PF, K, 2KV

C363 F2A1C4710045 E 470UF, 16V

C366 F2A1C101A310 E 100UF, 16V

C368 ECA2EM100B E 10UF, 250V

C370 F1J1H272A021 C 2700PF, 50V

C371 F1J1H272A021 C 2700PF, 50V

C372 F1J1H272A021 C 2700PF, 50V

C373 ECJ1VC1H471J C 470PF, J, 50V

C374 ECJ1VC1H471J C 470PF, J, 50V

C376 ECJ1VC1H471J C 470PF, J, 50V

C401 ECJ1VC1H560J C 56PF, J, 50V

C404 ECQB1333JF P 0.033UF, J, 100V

C406 F2A1H221A247 E 220UF, 50V

C407 ECJ1VC1H560J C 56PF, J, 50V

C408 ECQB1154JF P 0.15UF, J, 100V

C454 ECQV1H154JM P 0.15UF, J, 50V

C502 ECKR3A821KBP C 820PF, K, 1KV

C504 F1J1H681A590 C 680PF, 50V

C507 ECJ1VF1C105Z C 1UF, K, 16V

C511 ECA1VM101B E 100UF, 35V

C514 F2A1E102A225 E 1000UF, 25V

C516 F2A1E102A225 E 1000UF, 25V

C519 F2A2C2210013 E 220UF, 160V

C520 F2A0J221A317 E 220UF, 6.3V

C550 ECQM4223JZ P 0.022UF, J,400V

C552 ECA2EM100B E 10UF, 250V

C554 F0C2E184A039 P 0.18UF, 250V

C559 F0C3C752A002 P 7500PF, 1.6kV

C560 ECQM4393JZ P 0.039UF, J,400V

C561 ECKW3D271JBR C 270PF, J, 2kV

C565 F0A1H273A039 C 0.027UF, 50V

C567 ECQM4473JZ P 0.047UF, J,400V

C568 F0C3D102A003 C 0.027UF, 50V

C601 F1J1H183A021 C 0.018UF, 50V

C602 ECJ1VB1H222K C 2200PF, K, 50V

C604 F2A1C101A310 E 100UF, 16V

C606 ECJ1VF1H104Z C 0.1UF, Z, 50V

C607 ECJ1VF1H103Z C 0.01UF, Z, 50V

C611 ECJ1VF1H104Z C 0.1UF, Z, 50V

C613 ECJ1VF1H104Z C 0.1UF, Z, 50V

C614 ECJ1VC1H100C C 10PF, C, 50V

C615 ECJ1VC1H100C C 10PF, C, 50V

C618 F2A1C101A310 E 100UF, 16V

C619 F2A1C101A310 E 100UF, 16V

C620 ECJ1VB1H333K C 0.033UF, K, 50V

C622 F2A1C101A310 E 100UF, 16V

C623 F2A1C101A310 E 100UF, 16V

C626 F2A1C101A310 E 100UF, 16V

C627 F2A1C101A310 E 100UF, 16V

C628 F2A1A471A274 E 470UF, 10V

C630 ECJ1VF1H103Z C 0.01UF, Z, 50V

C631 ECJ1VB1H333K C 0.033UF, K, 50V

C632 F2A1H4R7A317 E 4.7UF, 50V

C633 ECJ1VC1H471J C 470PF, J, 50V

C634 ECJ1VC1H471J C 470PF, J, 50V

C635 F2A1C101A310 E 100UF, 16V

C639 ECJ1VF1H104Z C 0.1UF, Z, 50V

C640 ECJ1VF1H104Z C 0.1UF, Z, 50V

Part No. Part Name & Description Remarks

27

Page 28

CT-F2156WLP

Ref.

No.

C642 ECJ1VF1H104Z C 0.1UF, Z, 50V

C645 ECJ1VF1H104Z C 0.1UF, Z, 50V

C646 ECJ1VF1H104Z C 0.1UF, Z, 50V

C652 ECJ1VF1H104Z C 0.1UF, Z, 50V

C654 ECJ1VF1H104Z C 0.1UF, Z, 50V

C655 ECJ1VF1H104Z C 0.1UF, Z, 50V

C656 ECJ1VC1H270J C 27PF, J, 50V

C657 ECJ1VC1H560J C 56PF, J, 50V

C662 F2A0J101A317 E 100UF, 6.3V

C665 ECJ1VC1H150J C 15PF, J, 50V

C666 ECJ1VC1H150J C 15PF, J, 50V

C667 ECJ1VC1H180J C 18PF, J, 50V

C668 ECJ1VC1H180J C 18PF, J, 50V

C813 ECKCNA472ME7 C 4700PF, M,

C815 F1A2E152A001 C 1500PF, 250V

C818 ECQB1H104JF P 0.1UF, 50V

C821 ECKW3D561KBP C 560PF, K, 2KV

C826 F0A1H103A039 C 2200PF, 50V

C827 ECQB1H333JF P 0.033UF, J, 50V

C838 F0CAF2240003 CAP 250VAC 0.22UF

C840 F1A2E471A002 C 470pF, 250V

C841 ECKW3D151KBR C 150PF, 2kV

C842 F2A1H2200033 E 22UF, 50V

C843 F2A1E102A223 E 1000UF, 25V

C846 F1B2H471A025 P 470PF, J, 50V

C847 F2A1E222A224 E 2200UF, 25V

C848 ECQB1H222JF P 2200PF, J, 50V

C849 F1B2H471A025 C 470PF, 500V

C851 F0A1H103A039 C 2200PF, 50V

C854 ECKWAE472ZED C 4700PF, Z,500V

C855 ECKWAE472ZED C 4700PF, Z,500V

C856 F2B2G2710010 E 220UF, 400V

C857 ECQM4473JZ P 0.047UF, J,400V

C859 ECKW3D821KBP C 820PF, K, 2KV

C863 ECA1CM221B E 220UF, 16V

C865 ECKW3D331JBP C 330PF, J, 2KV

C867 F2A2C2210013 E 220UF, 160V

C869 F1J1E563A003 C 0.056UF, 25V

C870 F2A1C332A260 E 3300UF, 16V

C871 F1B2H471A025 C 470PF, 500V

C872 F2A1C102A252 E 1200UF, 16V

C873 L6Y5P4B122K C 1200PF, K,500V

C875 F1J1H332A021 C 3300PF, 50V

C877 F2A1C1000079 C 10UF, 16V

C879 F2A0J331A260 E 10UF, 16V

C882 F2A1C101A310 E 330UF, 6.3V

C884 F2A1C102A159 E 33UF, 50V

C886 F2A1H330A342 E 1000UF, 16V

C887 F2A1C102A159 E 33UF, 50V

C890 ECJ1VB1C104K C 0.1UF, K, 16V

C891 F2A1C101A310 E 100UF, 16V

C893 ECA1CM221B E 220UF, 16V

C897 F1J1H332A021 C 3300PF, 50V

C898 ECJ1VF1C105Z C 1UF, Z, 16V

D1061 B3AGA0000089 DIODE

D1132 B0BA3R800012 DIODE

D2103 B0AACK000004 DIODE

D2107 B0AACK000004 DIODE

D2108 B0AACK000004 DIODE

D361 B0AACK000004 DIODE

D362 B0AACK000004 DIODE

D363 B0AACK000004 DIODE

D364 B0AACK000004 DIODE

D365 B0AACK000004 DIODE

D366 B0AACK000004 DIODE

D367 B0AACK000004 DIODE

D402 B0HAJL000003 DIODE

D503 B0AACK000004 DIODE

D504 B0AACK000004 DIODE

D507 B0ACCK000005 DIODE

D511 MA4108J DIODE

D512 B0HAJL000003 DIODE

Part No. Part Name & Description Remarks

DIODES

Ref.

No.

D513 B0HAMP000090 DIODE

D515 B0HAMP000090 DIODE

D520 B0ACDJ000009 DIODE

D552 B0HAMP000090 DIODE

D556 ERB06-15 DIODE

D557 B0HAMR000095 DIODE

D558 MA185 DIODE

D601 B0ADDJ000025 DIODE

D610 MAZ80560HL DIODE

D670 MA2S72800L DIODE

D671 MA2S72800L DIODE

D683 MA2S72800L DIODE

D684 MA2S72800L DIODE

D830 B0HAJL000001 DIODE

D831 B0BA01700055 DIODE

D836 D4EAC6210002 VARISTOR

D837 B0ACCK000012 DIODE

D845 FMLG12S DIODE

D846 B0BA01800037 ZENER DIODE

D847 B0BA8R000010 DIODE

D848 FMLG12S DIODE

D851 B0EAKT000018 DIODE

D852 B0HAJL000003 DIODE

D853 B0AACK000004 DIODE

D854 B0AACK000004 DIODE

D860 B0EBNT000022 DIODE

D861 MAZ20820A0LS DIODE

D862 B0BA4R400007 ZENER DIODE

D863 B0HAJL000003 DIODE

D865 B0BA3R500008 DIODE

D866 B0HAPV000009 DIODE

D867 B0JAME000058 DIODE

D872 B0JAPK000011 DIODE

D873 B0AACK000004 DIODE

D876 B0AACK000004 DIODE

D881 B0BA01500052 DIODE

D882 B0BA01500052 DIODE

D883 B0JAPK000013 DIODE

D884 B0AACK000004 DIODE

D887 B0AACK000004 DIODE

IC1101 TVR4GAS577 EEPROM IC

IC2301 C0ZAZ0000164 IC

IC2401 C0ZAZ0000177 IC

IC451 AN15525A IC

IC601 TVR4G20-7 IC

IC605 C0ZAZ0000162 IC

IC801 C5HABZZ00168 IC, HYBRID

IC802 C0EAS0000026 IC

IC851 C0DAEJG00001 IC, POWER SUPPLY

IC857 C0DBEHE00005 IC, POWER SUPPLY

IC860 B3PAA0000363 PHOTO COUPLER

IC871 C0DAEJG00001 IC, POWER SUPPLY

IC875 C0DBEHE00005 IC, POWER SUPPLY

L002 G0C100K00008 COIL

L003 G0C4R7JA0055 PEAKING COIL

L2302 J0JKA0000038 BEAD CORE

L2304 J0JKA0000038 BEAD CORE

L2306 J0JKA0000024 EMI FILTER

L2323 J0JKA0000038 BEAD CORE

L2324 J0JKA0000038 BEAD CORE

L2401 J0JKA0000038 BEAD CORE

L376 J0JKA0000024 EMI FILTER

L412 J0JKA0000024 EMI FILTER

L505 J0JKA0000024 EMI FILTER

L514 J0JKA0000038 BEAD CORE

L515 J0JKA0000038 BEAD CORE

L550 J0JKB0000034 EMI FILTER

L557 G0D820000005 LINEARITY COIL

L601 G0C100K00008 COIL

L602 G0C100K00008 COIL

Part No. Part Name & Description Remarks

INTEDGRATED

CIRCUITS

COILS

28

Page 29

CT-F2156WLP

Ref.

No.

L603 G0C100K00008 COIL

L604 G0C100K00008 COIL

L605 TALV35VB8R2K PEAKING COIL

L606 G0C100K00008 COIL

L607 TALV35VB8R2K PEAKING COIL

L608 G0C3R9KA0030 PEAKING COIL

L609 J0JKB0000034 EMI FILTER

L611 G0C100K00008 COIL

L625 J0JKA0000038 BEAD CORE

L630 TSK1032 BEAD CORE

L635 TSK1032 BEAD CORE

L657 J0JCC0000411 BEAD CORE

L841 J0JKA0000038 BEAD CORE

L842 J0JKA0000025 BEAD CORE

L843 J0JKA0000038 BEAD CORE

L845 J0JKA0000023 BEAD CORE

L865 J0JKA0000025 BEAD CORE

L866 J0JKA0000023 BEAD CORE

L867 J0JKB0000039 EMI FILTER

L869 J0JKA0000038 BEAD CORE

L894 G0A220GA0002 CHOKE COIL

Q1060 B1ADDF000005 TRANSISTOR

Q1061 B1ADDF000005 TRANSISTOR

Q1062 B1ABCE000015 TRANSISTOR

Q2101 B1ADDF000005 TRANSISTOR

Q2401 B1ABCE000015 TRANSISTOR

Q301 B1GFCFAA0004 TRANSISTOR

Q302 B1GFCFAA0004 TRANSISTOR

Q303 B1GFCFAA0004 TRANSISTOR

Q304 B1ADDF000005 TRANSISTOR

Q305 B1ADDF000005 TRANSISTOR

Q306 B1ADDF000005 TRANSISTOR

Q354 B1ADDF000005 TRANSISTOR

Q360 B1ACAA000019 TRANSISTOR

Q361 B1ACAA000019 TRANSISTOR

Q362 B1ACAA000019 TRANSISTOR

Q370 B1BAAL000016 TRANSISTOR

Q371 B1BAAL000016 TRANSISTOR

Q372 B1BAAL000016 TRANSISTOR

Q501 2SC4212H TRANSISTOR

Q520 B1ADBM000004 TRANSISTOR

Q551 2SC6073000LK TRANSISTOR

Q603 B1ABCE000015 TRANSISTOR

Q604 B1ABCE000015 TRANSISTOR

Q608 B1ABCE000015 TRANSISTOR

Q846 B1ABCF000176 TRANSISTOR

Q850 B1BCCM000002 TRANSISTOR

Q857 B1BAAN000037 TRANSISTOR

Q870 B1ADDF000005 TRANSISTOR

R005 D0GB512JA008 F 5.1KOHM,J,1/16W

R006 ERJ3GEYJ473 M 47KOHM,J,1/16W

R007 ERJ3GEYJ682 M 6.8KOHM,J,1/16W

R008 ERJ3GEYJ101 M 100OHM,J,1/16W

R009 ERJ3GEYJ101 M 100OHM,J,1/16W

R1026 ERJ3EKF2211 M2.21KOHM,F,1/16W

R1027 ERJ3EKF3241 M3.24KOHM,F,1/16W

R1028 ERJ3EKF5111 M5.11KOHM,F,1/16W

R1029 ERJ3EKF9091 M9.09KOHM,F,1/16W

R1030 ERJ3EKF2152 M21.5KOHM,F,1/16W

R1031 ERJ3EKF2321 M2.32KOHM,F,1/16W

R1061 ERJ3GEYJ121 M 120OHM,J,1/16W

R1062 ERDS2TJ102 C 1KOHM,J, 1/4W

R1063 ERJ3GEYJ152 M 1.5KOHM,J,1/16W

R1065 ERJ3GEYJ121 M 120OHM,J,1/16W

R1066 ERJ3GEYJ152 M 1.5KOHM,J,1/16W

R1067 ERJ3GEYJ470 M 47OHM,J,1/16W

R1105 ERJ3GEYJ103 M 10KOHM,J,1/16W

R1106 ERJ3GEYJ102 M 1KOHM,J,1/16W

R1108 ERJ3GEYJ101 M 100OHM,J,1/16W

R1109 ERJ3GEYJ103 M 10KOHM,J,1/16W

R1112 ERJ3GEYJ102 M 1KOHM,J,1/16W

Part No. Part Name & Description Remarks

TRANSISTORS

RESISTORS

Ref.

No.

R1114 ERJ3GEYJ151 M 150OHM,J,1/16W

R1115 ERJ3GEYJ101 M 100OHM,J,1/16W

R1131 ERJ3GEYJ220 M 22OHM,J,1/16W

R1132 ERJ3GEYJ220 M 22OHM,J,1/16W

R1140 ER0S2CKF1002 M 10KOHM,F, 1/4W

R1142 ERJ3EKF1001 M 1KOHM,F,1/16W

R1150 ERJ3GEYJ101 M 100OHM,J,1/16W

R1201 ERJ3GEYJ102 M 1KOHM,J,1/16W

R1202 ERJ3GEYJ102 M 1KOHM,J,1/16W

R1228 ERJ3GEYJ101 M 100OHM,J,1/16W

R1229 ERJ3GEYJ101 M 100OHM,J,1/16W

R2112 ERJ3GEYJ102 M 1KOHM,J,1/16W

R2114 ERJ3GEYJ104 M 100KOHM,J,1/16W

R2302 ERX2FJSR33E M 0.33OHM,J, 2W

R2317 D0GB622JA008 F 6.2KOHM,J,1/16W

R2318 D0AE1R0JA046 C 1OHM,J,1/16W

R2319 D0AE1R0JA046 C 1OHM,J,1/16W

R2401 ERJ3GEYJ222 M 2.2KOHM,J,1/16W

R2405 ERJ3GEYJ103 M 10KOHM,J,1/16W

R2406 ERJ3GEYJ102 M 1KOHM,J,1/16W

R253 D0GB751JA008 F 750OHM,J,1/16W

R255 D0GB751JA008 F 750OHM,J,1/16W

R256 ERDS2TJ472 C 4.7KOHM,J, 1/4W

R257 ERDS2TJ472 C 4.7KOHM,J, 1/4W

R3004 ERJ3GEYJ104 M 100KOHM,J,1/16W

R3005 ERJ3GEYJ750 M 75OHM,J,1/16W

R3006 ERJ3GEYJ750 M 75OHM,J,1/16W

R3008 ERJ3GEYJ104 M 100KOHM,J,1/16W

R3009 ERJ3GEYJ750 M 75OHM,J,1/16W

R301 ERJ3GEYJ103 M 10KOHM,J,1/16W

R3010 ERJ3GEYJ750 M 75OHM,J,1/16W

R3011 ERJ3GEYJ750 M 75OHM,J,1/16W

R302 ERJ3GEYJ103 M 10KOHM,J,1/16W

R3022 ERJ3GEYJ104 M 100KOHM,J,1/16W

R3024 ERJ3GEYJ104 M 100KOHM,J,1/16W

R303 ERJ3GEYJ103 M 10KOHM,J,1/16W

R304 ECJ1VB1H222K C 2200PF, K, 50V

R305 ECJ1VB1H222K C 2200PF, K, 50V

R306 ECJ1VB1H222K C 2200PF, K, 50V

R310 D0AE181JA046 C 180OHM,J, 1/4W

R3101 ERDS2TJ470 C 47OHM,J, 1/4W

R3102 ERDS2TJ470 C 47OHM,J, 1/4W

R3104 ERJ3GEY0R00 M 0OHM,J,1/16W

R3105 ERJ3GEY0R00 M 0OHM,J,1/16W

R311 D0AE181JA046 C 180OHM,J, 1/4W

R312 D0AE181JA046 C 180OHM,J, 1/4W

R3140 ERJ3GEY0R00 M 0OHM,J,1/16W

R3152 ERJ3GEYJ104 M 100KOHM,J,1/16W

R3153 ERJ3GEYJ104 M 100KOHM,J,1/16W

R317 ERJ3GEYJ151 M 150OHM,J,1/16W

R318 ERJ3GEYJ151 M 150OHM,J,1/16W

R319 ERJ3GEYJ151 M 150OHM,J,1/16W

R3247 ERJ3GEY0R00 M 0OHM,J,1/16W

R3250 ERJ3GEY0R00 M 0OHM,J,1/16W

R363 ERJ3GEYJ102 M 1KOHM,J,1/16W

R364 ERJ3GEYJ102 M 1KOHM,J,1/16W

R365 ERJ3GEYJ102 M 1KOHM,J,1/16W

R366 ERC14GK152 S 1.5KOHM, 1/4W

R367 ERC14GK152 S 1.5KOHM, 1/4W

R368 ERC14GK152 S 1.5KOHM, 1/4W

R369 ERJ3GEY0R00 M 0OHM,J,1/16W

R373 ERJ3EKF1431 F 1.43KOHM, 1/8W

R374 ER0S2CHF1431 M 1.43KOHM, 1/4W

R375 ERJ3EKF1431 F 1.43KOHM, 1/8W

R381 ERJ3GEYJ121 M 120OHM,J,1/16W

R382 ER0S2CHF1000 M 100OHM,1/10W

R383 ER0S2CHF1000 M 100OHM,1/10W

R384 ER0S2CHF1000 M 100OHM,1/10W

R385 ERJ3GEY0R00 M 0OHM,J,1/16W

R391 ERG2FJ103H M 10KOHM,J, 2W

R392 ERJ3GEYJ101 M 100OHM,J,1/16W

R393 D0AE301JA046 C 300OHM,J, 1/4W

R394 ERG2FJ103H M 10KOHM,J, 2W

Part No. Part Name & Description Remarks

29

Page 30

CT-F2156WLP

Ref.

No.

R395 ERDS2TJ101 C 100OHM,J, 1/4W

R396 D0AE301JA046 C 300OHM,J, 1/4W

R397 ERG2FJ103H M 10KOHM,J, 2W

R398 ERJ3GEYJ101 M 100OHM,J,1/16W

R399 D0AE301JA046 M 10KOHM,J, 2W

R401 ERDS2TJ104 C 100KOHM,J, 1/4W

R403 ERJ3GEYJ563 M 56KOHM,J,1/16W

R404 ERJ3GEYJ153 M 15KOHM,J,1/16W

R405 ERDS2TJ563 C 56KOHM,J, 1/4W

R406 D0AE1R5JA046 C 1.5OHM,J, 1/4W

R407 ERG1SJ221E M 220OHM,J, 1W

R413 ERJ3GEYJ183 M 18KOHM,J,1/16W

R416 ERX1SJ1R2E M 1.2OHM,J, 1W

R451 ERJ3GEYJ223 M 22KOHM,J,1/16W

R453 ERJ3GEYJ101 M 100OHM,J,1/16W

R501 ERJ3GEYJ273 M 27KOHM,J,1/16W

R502 ERJ3GEYJ103 M 10KOHM,J,1/16W

R504 ERG2SJS332H M 10KOHM,J,1/10W

R507 ERDS2TJ561 C 560OHM,J, 1/4W

R508 ERG3FJ152H M 1.5KOHM,J, 3W

R509 ERG3FJ182H M 1.8KOHM,J, 3W

R511 ERJ3EKF1002 M 10KOHM,F,1/16W

R512 ERJ3EKF1152 F 11.5KOHM,J, 1/10W

R513 ERQ14AJ100E F 10OHM,J, 1/4W

R518 D0DK5R6JA019 W 5.6KOHM,J,10W

R522 D0AE623JA046 C 62KOHM,J, 1/4W

R523 ERJ3GEYJ103 M 10KOHM,J,1/16W

R524 ERDS2TJ104 C 100KOHM,J, 1/4W

R525 ERJ3GEYJ392 M 3.9KOHM,J,1/16W

R552 ERG1SJ102P M 1KOHM,J, 1W

R553 ERJ3GEYJ183 M 18KOHM,J,1/16W

R559 D0C12R7JA042 M 2.7OHM,J, 1W

R580 ERJ3GEYJ392 M 3.9KOHM,J,1/16W

R601 ERJ3GEYJ470 M 47OHM,J,1/16W

R602 ERDS2TJ103 C 10KOHM,J, 1/4W

R604 ERJ3GEYJ470 M 47OHM,J,1/16W

R605 ERJ3GEYJ470 M 47OHM,J,1/16W

R606 ERJ3GEYJ752 M 7.5KOHM,J,1/16W

R607 ERJ3GEYJ752 M 7.5KOHM,J,1/16W

R608 ERJ3GEYJ470 M 47OHM,J,1/16W

R609 ERJ3GEYJ822 M 8.2KOHM,J,1/16W

R611 ERJ3GEYJ101 M 100OHM,J,1/16W

R614 ERJ3GEYJ221 M 220OHM,J,1/16W

R615 ERJ3GEYJ122 M 1.2KOHM,J,1/16W

R616 ERJ3GEYJ563 M 56KOHM,J,1/16W

R618 ERJ3GEY0R00 M 0OHM,J,1/16W

R619 ERJ3GEYJ332 M 3.3KOHM,J,1/16W

R620 ERJ3EKF1002 M 10KOHM,F,1/16W

R621 ERJ3EKF2002 M 20KOHM,F,1/10W

R624 ERJ3GEYJ102 M 1KOHM,J,1/16W

R625 ERJ3GEYJ102 M 1KOHM,J,1/16W

R626 ERJ3GEYJ103 M 10KOHM,J,1/16W

R627 ERJ3GEYJ103 M 10KOHM,J,1/16W

R628 ERJ3GEYJ823 M 82KOHM,J,1/16W

R629 ERJ3GEY0R00 M 0OHM,J,1/16W

R632 ERJ3GEYJ682 M 6.8KOHM,J,1/16W

R636 ERJ3GEYJ101 M 100OHM,J,1/16W

R638 ERJ3GEY0R00 M 0OHM,J,1/16W

R641 ERJ3GEY0R00 M 0OHM,J,1/16W

R643 ERJ3GEY0R00 M 0OHM,J,1/16W

R645 ERJ3GEYJ101 M 100OHM,J,1/16W

R647 ERJ3GEYJ750 M 75OHM,J,1/16W

R656 ERJ3GEYJ823 M 82KOHM,J,1/16W

R658 ERDS2TJ470 C 47OHM,J, 1/4W

R659 ERJ3GEYJ470 M 47OHM,J,1/16W

R660 ERJ3GEYJ470 M 47OHM,J,1/16W

R662 ERJ3GEYJ221 M 220OHM,J,1/16W

R664 ERDS2T0T C 0OHM, 1/4W

R665 ERDS2T0T C 0OHM, 1/4W

R669 ERDS2T0T C 0OHM, 1/4W

R681 ERJ3GEYJ472 M 4.7KOHM,J,1/16W

R682 ERJ3GEYJ472 M 4.7KOHM,J,1/16W

R685 ERJ3GEYJ104 M 100KOHM,J,1/16W

Part No. Part Name & Description Remarks

Ref.

No.

R686 ERJ3GEYJ104 M 100KOHM,J,1/16W

R701 ERJ3GEYJ103 M 10KOHM,J,1/16W

R825 ERJ3GEYJ471 M 470OHM,J,1/16W

R827 ERJ3GEYJ153 M 15KOHM,J,1/16W

R829 ERJ3EKF3092 F 30.9KOHM, 1/8W

R830 D0AE201JA046 C 200OHM,J, 1W

R831 D0AE752JA046 C 7.5KOHM,J, 1W

R832 ERJ3EKF4022 M 40.2KOHM,J,1/10W

R833 D0AE362JA046 C 3.6KOHM,J, 1W

R834 ERG2FJ823H M 82KOHM,J, 2W

R836 ERG1SJ330P M 33OHM,J, 1W

R837 ERDS2TJ222 C 2.2KOHM,J, 1/4W

R839 ERJ3GEYJ472 M 4.7KOHM,J,1/16W

R840 RCR100TAJ825 C 8.2MOHM,J, 1W

R847 ER0S2CHF3652 M 36.5KOHM,J,1/16W

R850 ERG3SJS470H M 47OHM,J, 1/2W

R852 D0AE162JA046 C 1.6KOHM,J, 152V

R853 D0D72R2KA002 W 2.2OHM,K, 7W

R854 ERG2FJ470H M 47OHM,J, 2W

R856 ERG2SJS104H M 100KOHM,J, 2W

R861 ERX1SJ4R7P M 4.7OHM,J, 1W

R863 ERDS2TJ101 C 100OHM,J, 1/4W

R864 ERJ3GEYJ103 M 10KOHM,J,1/16W

R866 ERJ3GEYJ392 M 3.9KOHM,J,1/16W

R867 ERDS2TJ222 C 2.2KOHM,J, 1/4W

R868 ERDS2TJ101 C 100OHM,J, 1/4W

R871 ERJ3GEYJ103 M 10KOHM,J,1/16W

R872 ERJ3EKF1052 F 10.5KOHM, 1/10W

R873 ERJ3EKF1802 M 18KOHM,F,1/16W

R875 ERJ3GEYJ103 M 10KOHM,J,1/16W

R876 ERJ3EKF1002 M 10KOHM,F,1/16W

R877 ERJ3EKF5101 F 5.1KOHM, 1/10W

R882 ERJ3GEYJ332 M 3.3KOHM,J,1/16W

R884 ERJ3GEYJ562 M 5.6KOHM,J,1/16W

R885 ERJ3GEYJ752 M 7.5KOHM,J,1/16W

R886 D0GB433JA008 F 43KOHM, 1/10W

R887 ERG1SJ273P M 27KOHM,J, 1W

R888 ERJ3GEYJ103 M 10KOHM,J,1/16W

R889 ERX3FJ3R3H M 3.3OHM,J, 3W

R893 ERJ3EKF5102 M 51KOHM, 1/10W

R894 ERJ3EKF1303 M 130KOHM, 1/10W

T551 ZTFP12507A FLYBACK TRANS

T553 ETH19Y210BZ H DRIVE TRANS

T801 ETS39AG4F6NC SWITCHING TRANS

A1 K1KA13A00140 CONNECTOR

A13 K1KA13A00140 CONNECTOR

A17 K1KA13A00138 CONNECTOR

A18 K1KA13A00140 CONNECTOR

A2 K1KA13A00140 CONNECTOR

A32 K1KA13A00138 CONNECTOR

A4 K1KA04AA0190 CONNECTOR

A5 K1KA04AA0190 CONNECTOR

A8 K1KA04AA0093 CONNECTOR

CF835 TAP4GA0005 POSISTOR

F840 K5D502BLA016 FUSE

G30 K1KA02AA0180 CONNECTOR

JA1 ERJ3GEY0R00 M 0OHM,J,1/16W

JA10 ERJ3GEY0R00 M 0OHM,J,1/16W

JA11 ERJ3GEY0R00 M 0OHM,J,1/16W

JA12 ERJ3GEY0R00 M 0OHM,J,1/16W

JA13 ERJ3GEY0R00 M 0OHM,J,1/16W

JA14 ERJ3GEY0R00 M 0OHM,J,1/16W

JA15 ERJ3GEY0R00 M 0OHM,J,1/16W

JA16 ERJ3GEY0R00 M 0OHM,J,1/16W

JA17 ERJ3GEY0R00 M 0OHM,J,1/16W

JA19 ERJ3GEY0R00 M 0OHM,J,1/16W

JA2 ERJ3GEY0R00 M 0OHM,J,1/16W

JA20 ERJ3GEY0R00 M 0OHM,J,1/16W

JA21 ERJ3GEY0R00 M 0OHM,J,1/16W

JA3 ERJ3GEY0R00 M 0OHM,J,1/16W

JA4 ERJ3GEY0R00 M 0OHM,J,1/16W

Part No. Part Name & Description Remarks

TRANSFORMERS

OTHERS

30

Page 31

CT-F2156WLP

Ref.

No.

JA5 ERJ3GEY0R00 M 0OHM,J,1/16W

JA6 ERJ3GEY0R00 M 0OHM,J,1/16W

JA7 ERJ3GEY0R00 M 0OHM,J,1/16W

JA8 ERJ3GEY0R00 M 0OHM,J,1/16W

JA9 ERJ3GEY0R00 M 0OHM,J,1/16W

JK3002 K4BK10B00003 REAR AV TERMINAL

JK3003 K4BK08B00008 AV TERMINAL

JK3201 K4BZ07B00002 AV TERMINAL

JS103 ERJ3GEY0R00 M 0OHM,J,1/16W

JS104 ERJ3GEY0R00 M 0OHM,J,1/16W

JS105 ERJ3GEY0R00 M 0OHM,J,1/16W

JS110 ERJ3GEY0R00 M 0OHM,J,1/16W

JS2315 ERJ3GEY0R00 M 0OHM,J,1/16W

JS2341 ERJ3GEY0R00 M 0OHM,J,1/16W

JS2342 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3043 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3044 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3045 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3046 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3131 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3132 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3145 ERJ3GEY0R00 M 0OHM,J,1/16W

JS3146 ERJ3GEY0R00 M 0OHM,J,1/16W

JS631 ERJ3GEY0R00 M 0OHM,J,1/16W

JS632 ERJ3GEY0R00 M 0OHM,J,1/16W

JS633 ERJ3GEY0R00 M 0OHM,J,1/16W

JS634 ERJ3GEY0R00 M 0OHM,J,1/16W

JS670 ERJ3GEY0R00 M 0OHM,J,1/16W

JS850 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG3142 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG3147 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG3148 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG3165 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG3167 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG835 ERJ3GEY0R00 M 0OHM,J,1/16W

JSG894 ERJ3GEY0R00 M 0OHM,J,1/16W

L2 K1KA13A00140 CONNECTOR

L3 K1KA04AA0190 CONNECTOR

LF830 ELF15N022A LINE FILTER

RL831 K6B1CDA00029 RELAY

RM1062 B3RAD0000120 REMOCON RECEIVER

SC351 K3B09CA00013 CRT SOCKET

SW1011 EVQ11G05R SWITCH

SW1012 EVQ11G05R SWITCH

SW1013 EVQ11G05R SWITCH

SW1014 EVQ11G05R SWITCH

SW1015 EVQ11G05R SWITCH

SW1016 EVQ11G05R SWITCH

SW840 K0F122A00172 SWITCH

TU001 ENV56K19G3F TUNER

X601 H0Z202500001 CRYSTAL OSC

XF101 J0C4400A0002 DELAY LINE

Part No. Part Name & Description Remarks

31

Loading...

Loading...