Page 1

Order No: PHAAM1111084C1

Installation Manual

Indoor Unit Outdoor Unit

CS-S9NKUW-1

CS-S12NKUW-1

CS-S18NKU-1

CS-S22NKU-1

CU-S9NKU-1

CU-S12NKU-1

CU-S18NKU-1

CU-S22NKU-1

Please file and use this manual together with the service manual for Model No. CU-2S18NBU, Order No. PHAAM1111121C1.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic HA Air-Conditioning (M) Sdn. Bhd. 2011.

Unauthorized copying and distribution is a violation of law.

Page 2

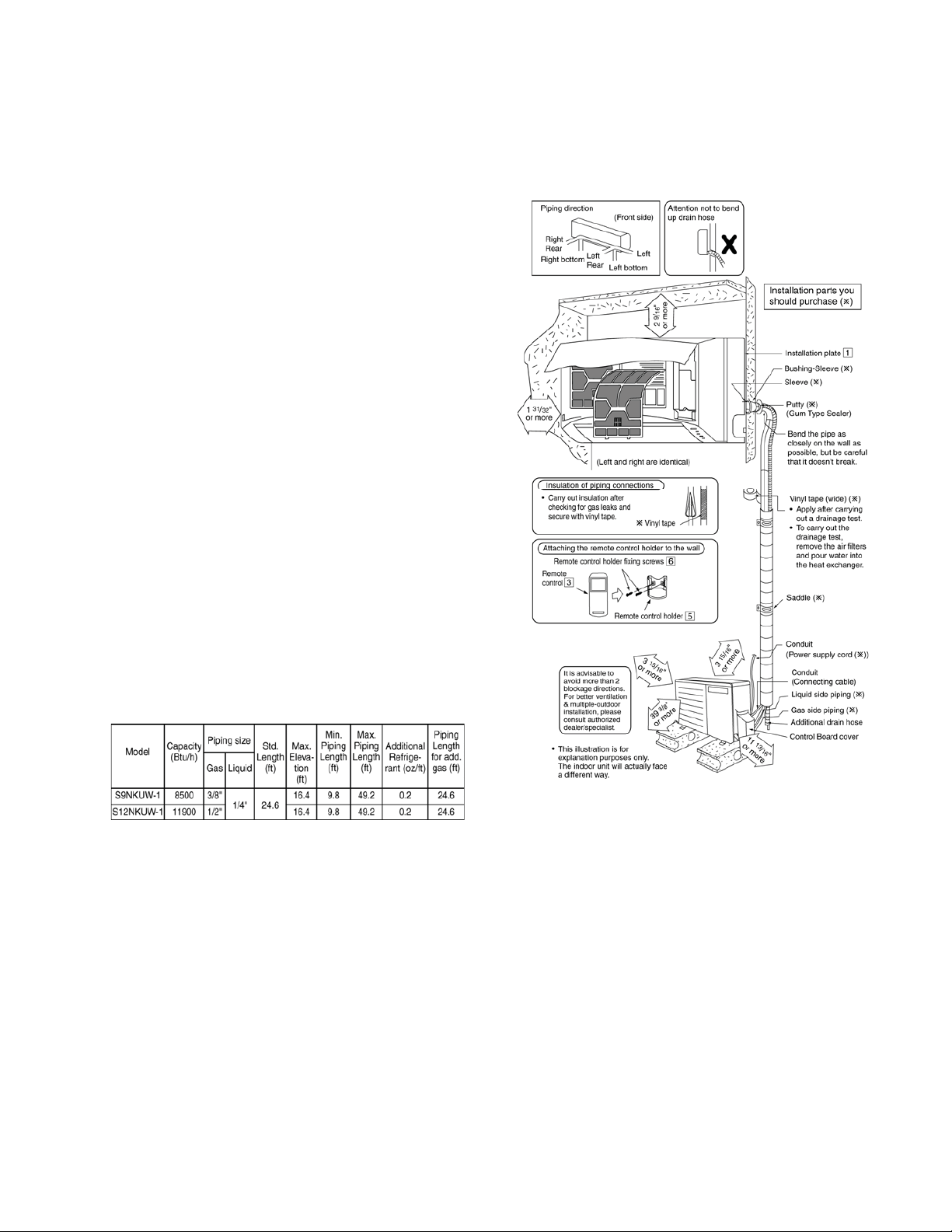

10. Installation Instruction

10.1 S9NKUW-1 S12NKUW-1

10.1.1 Select the Best Location

10.1.1.1 Indoor Unit

x Do not install the unit in excessive oil fume area

such as kitchen, workshop

There should not be any heat source or

x

near the unit.

x

There should not be any obstacles blocki

circulation.

x

A place where air circulation in the room

x

A place where drainage can be ea

A place where noise prevention is taken

x

c

onsiderat

Do not install the unit near a door

x

x Ensure the spaces indicated by arrows from the

wall, ceili

Recommended installation height for ind

x

shall be at least 8.2 ft.

ion.

ng, fence or other obstacles

and etc.

steam

ng the air

is good.

sily done.

into

way.

.

oor unit

10.1.1.2 Outdoor Unit

x If an awning is built over the unit to prevent direct

sunli

ght or rain, be careful that heat radiat

the con

x There should not be any animal or plant which

coul

Keep the spaces indicated by arrows from

x

ceiling, fence or other obstacles.

x

Do not place any obstacles

sho

x

If piping length is over the [piping length

addition

adde

denser is not obstru

d be affected by hot air discharg

rt circuit of the discharg

al gas], additional refrigerant sh

d as shown in the tabl

cted.

which may cause a

ed air.

e.

ion from

ed.

wall,

for

ould be

10.1.2 Indoor/Outdoor Unit Installation

Diagram

Example: For S9NKUW-1

If the unit is installe

additional refrigerant should be 1.64 oz .... (32.8 - 24.6)

ft x 0.2 oz/ft = 1.64 oz.

d at 32.8 ft distance, the quantity of

31

Page 3

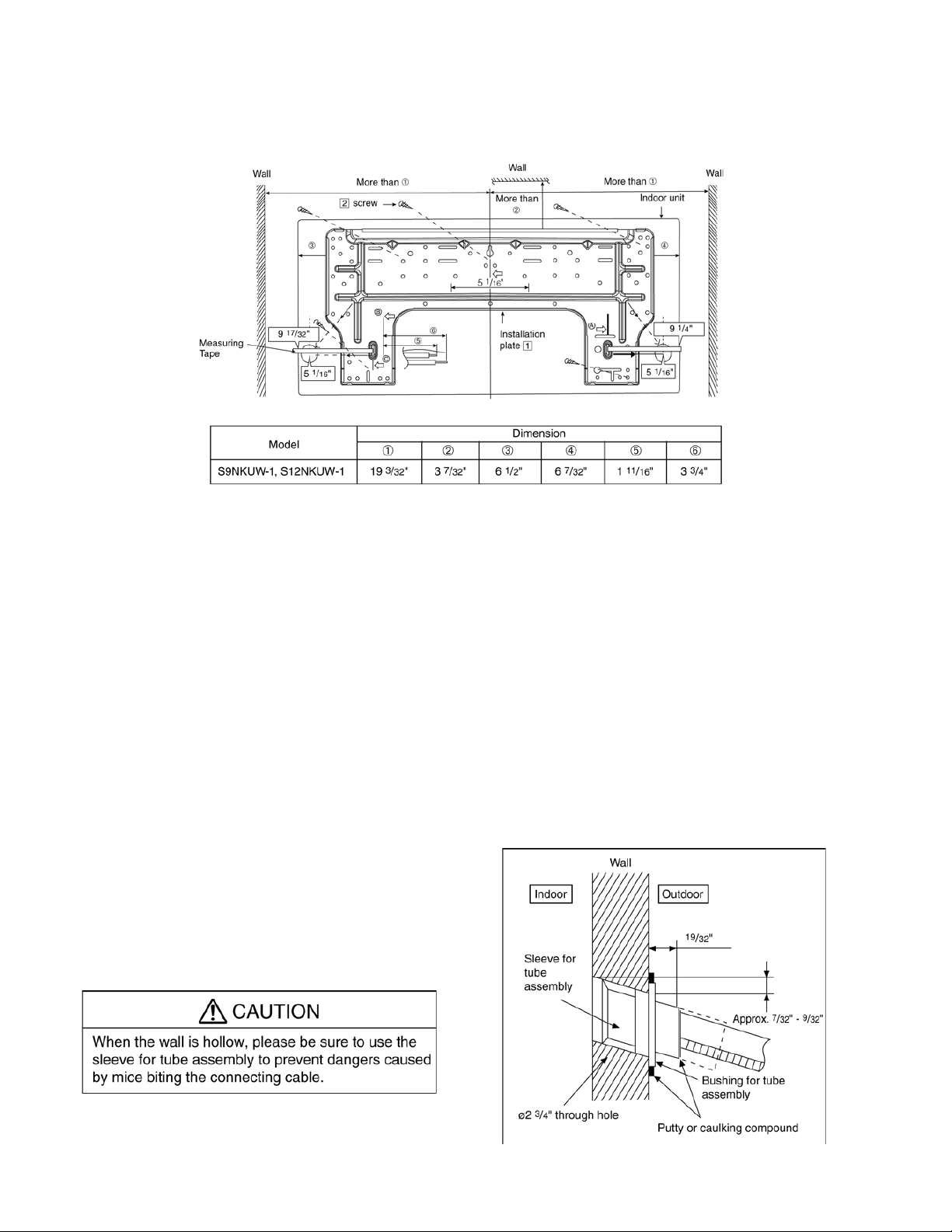

10.1.3 Indoor Unit

10.1.3.1 How to Fix Installation Plate

The mounting wall shall be strong and solid enough to prevent if from the vibration.

The ce

ntre of installation plate should be at more than c at right and left of the wall.

The distance from installation plate edge to ceiling should more than d.

From installation plate left edge to unit’s left side is e.

From installation plate right edge to unit’s right side is f.

B : For left side piping, piping connection for liquid should be about g from this line.

ƻ

: For left side piping, piping connection for gas should be about h from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

o Always mount the installation plate horizontally by aligning the marking-off line with the thread and us

a level gaug

2 Drill the piping plate hole with ø2 ¾” hole-core drill.

o Line according to the left and right side of the installation plate. The meeting point of the extended lin

the cente

above. The h

r

espec

o

Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoo

side.

e.

r of the hole. Another method is by putting measuring tape at position as sh

ole center is obtained by measuring the distance namely 5 1/16” for left and righ

tively.

10.1.3.2 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 19/32”

from the wall.

ing

e is

own in the diagram

t hole

r

4

Finish by sealing the sleeve with putty or

caulking compound at the final stage.

32

Page 4

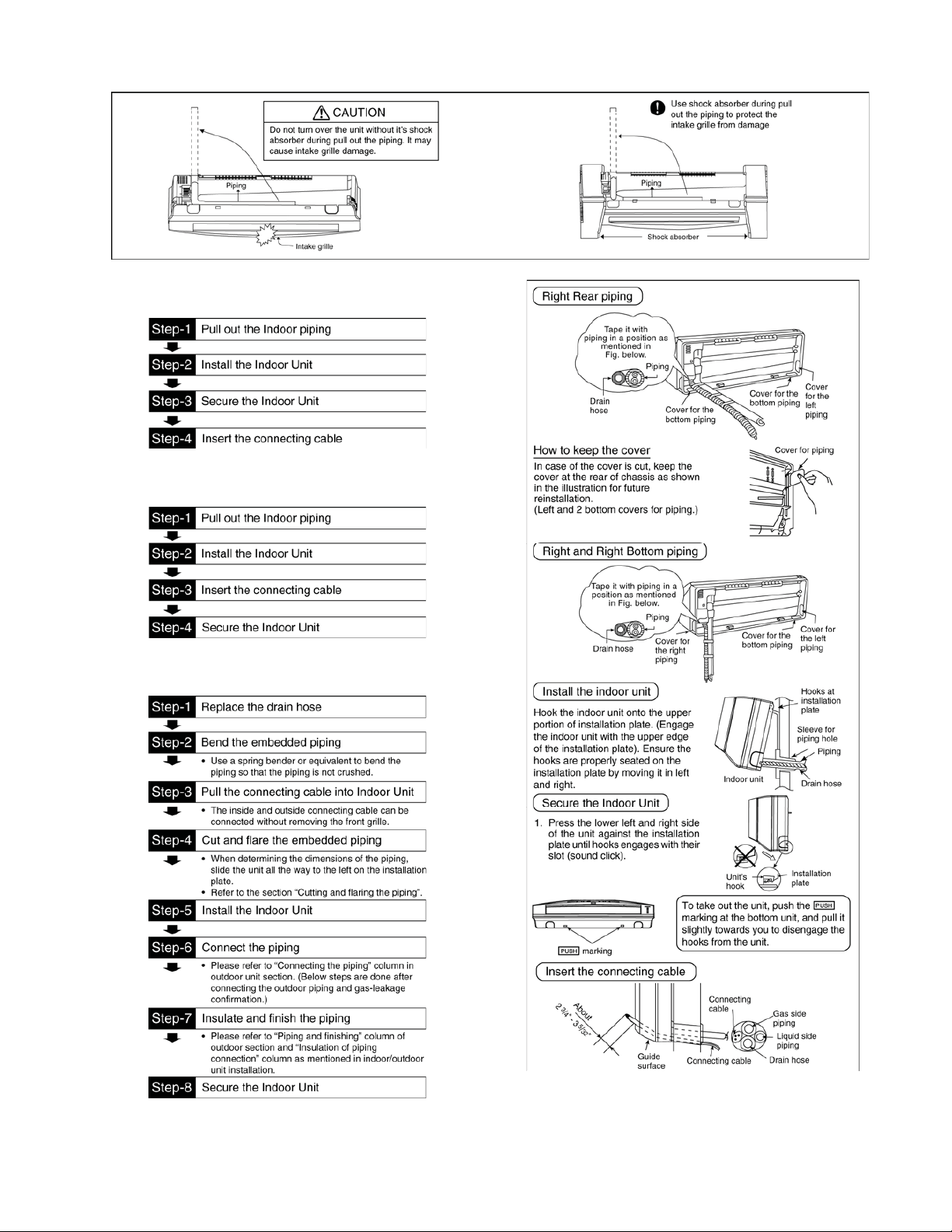

10.1.3.3 Indoor Unit Installation

10.1.3.4 For the right rear piping

10.1.3.5 For the right bottom piping

10.1.3.6 For the embedded piping

(Thi

s can be used for left rear piping and bottom

piping also.)

33

Page 5

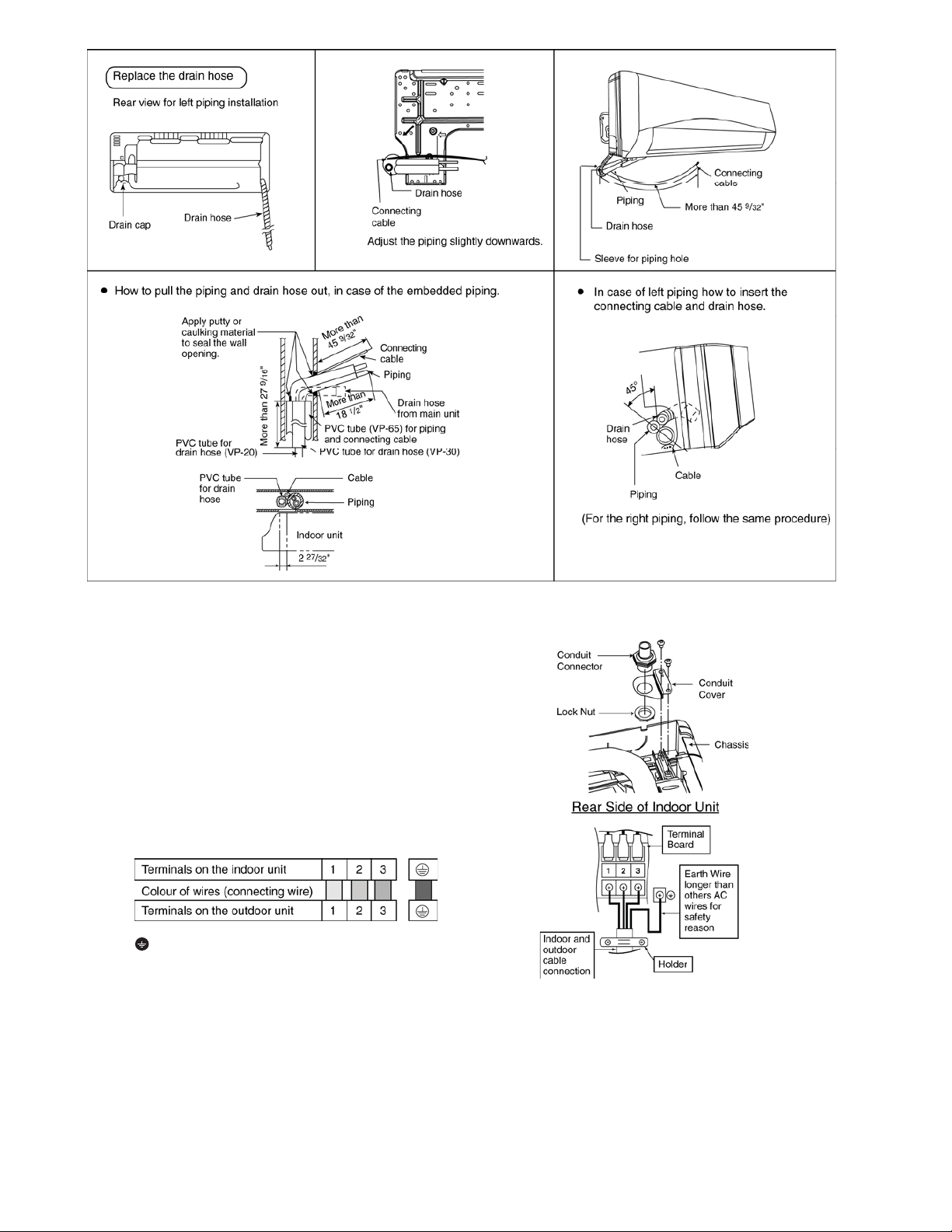

10.1.3.7 Connect the Cable to the Indoor Unit

1. The inside and outside connecting cable can

be co

nnected without remo

Unscrew the conduit cove

2.

nector to conduit cove

con

se

cure it against chassi

3.

Connecting wire between indoor unit an

r unit should be UL listed or

outdoo

approved 4 condu

in accordan

Ensure the colour of wires of outdoor un

o

and terminal number are the same as the

indoo

r's resp

This equipment must be properly earthed.

o Earth lead wire shall be

(Y/G) in colou

other lead wires as shown in the figure fo

electri

cal safety in case of the slip

ctor wires minimum AWG1

ce with local electric code

ectively.

r and shall be longer than

ving the front grille.

r and fix the conduit

r with lock nut, then

s.

d

CSA

6

s.

it

Yellow/Green

r

ping.

34

Page 6

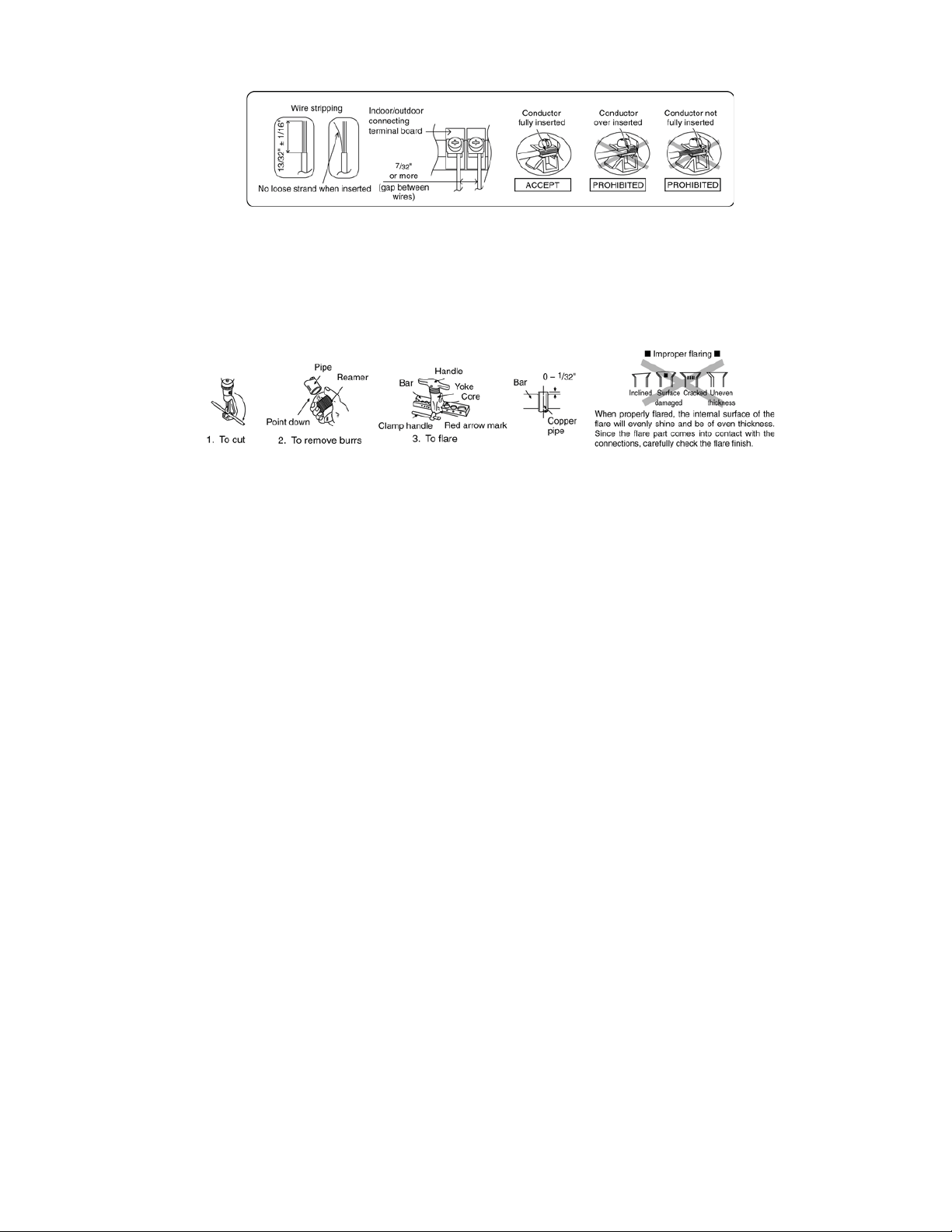

10.1.3.8 Wire Stripping and connecting requirement

10.1.3.9 Cutting and flaring the piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end

down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

35

Page 7

10.1.4 Outdoor Unit

10.1.4.1 Install the Outdoor Unit

x After selecting the best location, start installation to Indoor/Outdoor Unit Installation Diagram.

1

Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø13/32

When installing at roof, please consider strong wind and earthqua

2

ke.

”).

Please fasten the installation stand firmly with bolt or nails.

Model A B C D

S9NKUW-1,

S12NKUW-1

22 7/16” 4 1/8” 23/32” 12 19/32”

10.1.4.2 Connect the Piping

Do not over tighten, over tightening may cause gas leakage.

10.1.4.2.1 Connecting the piping to

indoor

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

x Align the center of piping and suffici

the flare nut with fingers.

x

Further tighten the flare nut with torque wren

cified torque as stated in

spe

the table.

ently tighten

ch in

Piping size Torque

1/4” 13.3 lbf.ft

3/8” 31.0 lbf.ft

1/2” 40.6 lbf.ft

5/8” 47.9 lbf.ft

3/4” 73.8 lbf.ft

10.1.4.2.2 Connecting the piping to

outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

10.1.4.2.3 Connecting the piping to outdoor multi

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve) onto the copper pipe.

Align center of piping to valve and then tighten with torque wrench to the specified torque as stated in the table.

36

Page 8

10.1.4.2.4 Gas leak checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 10.1.4.3.

10.1.4.3 Evacuation of the equipment

When installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following

procedures.

1.

Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-wa

valve.

Connect the micron gauge between vacuum pump and service port of outdoor un

2.

Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge

3.

down to a value of 500 microns.

To make sure micron gauge a value 500 microns and close the low side valve of the charging set and turn of

4.

the vacuum pump.

Disconnect the vacuum pump hose from the service po

5.

6.

Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf.ft

7. Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Op

g a hexagonal wrench

usin

Mount valve caps onto the 2-way valve and the 3-wa

8.

o

Be sure to check for gas leaka

(5/32”).

ge.

rt of the 3-way valve.

with a torque wrench.

y valve.

its.

10.1.4.4 Connect the Cable to the Outdoor Unit

1. Remove Top panel.

2. Remove Control Board Cover (Resin and

emove Plugs

3.R

Fix the conduit connectors to the knockout holes

4.

lock-n

uts, then secure them against the side pa

5.

All wires pass through condu

Connecting wire between indoor unit and outdoor unit

6.

should be UL listed or CSA approved 4 condu

wire

s minimum AWG16 in accordance

c code

electri

Wire connection to the power supply (208/230V 60Hz)

7.

throug

h circui

Connect the UL listed or CSA approved wire

o

minimum AWG14 to the terminal boa

con

GFCI.

Connect the power supply cord and connecting

8.

betwe

en indoor unit and outdoor unit according to the diagram below

.

its.

s.

t breaker.

nect the other end of the wires to EL

Metal).

ctor

with local

rd,

and

CB /

with

nel.

s

wire

.

y

and to pull

f

en”

37

Page 9

Secure the wire onto the control board wi

9.

(clamper).

10.

After completing wiring connections, re

board cove

original position with the screws.

11. For wire stripping and connection requirement, refe

ruction g of indoor un

inst

This equipment must be properly earthed.

o Earth lead wire shall be Yellow/Green (Y/G) in colour

r (Metal and Resin) and the top pan

it.

and shall be longer than other lead wires as shown in

the figure for electrical safety in case of the slip

th the holder

attach the control

el to the

r to

ping.

10.1.4.5 Piping Insulation

1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diag

ram. Please wrap the insulated piping end to prevent water from going inside

If drain hose or connecting piping is in the room (where dew may form), please increase the insulation

2.

g POLY-E FOAM with thickn

usin

ess ¼” or above.

the piping.

by

38

Page 10

10.2 S18NKU-1 S22NKU-1

10.2.1 Select the Best Location

10.2.1.1 Indoor Unit

x Do not install the unit in excessive oil fume areas

su

ch as kitchens, workshops etc.

x There should not be any heat source or

near the unit.

x

There should not be any obstacles blocki

circulation.

x

A place where air circulation in the room

x

A place where drainage can be ea

A place where noise prevention is taken

x

c

onsiderat

Do not install the unit near

x

x Ensure the spaces indicated by arrows from the

wall, ceili

Recommended installation height for ind

x

shall be at least 8.2 ft.

ion.

a doorway.

ng, fence or other obstacles

steam

ng the air

is good.

sily done.

into

.

oor unit

10.2.1.2 Outdoor Unit

x If an awning is built over the unit to prevent direct

sunli

ght or rain, be careful that heat radiat

the con

x There should not be any animal or plant which

coul

Keep the spaces indicated by arrows from

x

ceiling, fence or other obstacles.

x

Do not place any obstacles

sho

x

If piping length is over the [piping length

addition

adde

x

Recommended installation height for outdoor un

sho

denser is not obstru

d be affected by hot air discharg

rt circuit of the discharg

al gas], additional refrigerant sh

d as shown in the tabl

uld be above the seasonal snow

cted.

which may cause a

ed air.

e.

ion from

ed.

wall,

for

ould be

level.

10.2.2 Indoor/Outdoor Unit Installation

Diagram

it

Example: For S18NKU-1

If the unit is installe

additional refrigerant should be 1.64 oz .... (41 - 32.8)

ft x 0.2 oz/ft = 1.64 oz.

d at 41 ft distance, the quantity of

39

Page 11

10.2.3 Indoor Unit

10.2.3.1 How to Fix Installation Plate

The mounting wall must be strong and solid enough to prevent if from the vibration.

The ce

ntre of installation plate should be at more than c at right and left of the wall.

The distance from installation plate edge to ceiling should more than d.

From installation plate left edge to unit’s left side is e.

From installation plate right edge to unit’s right side is f.

B : For left side piping, piping connection for liquid should be about g from this line.

ƻ

: For left side piping, piping connection for gas should be about h from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

o Always mount the installation plate horizontally by aligning the marking-off line with the thread and us

a level gaug

2 Drill the piping plate hole with ø2 ¾” hole-core drill.

o Line according to the left and right side of the installation plate. The meeting point of the extended lin

the cente

above. The h

r

espec

o

Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoo

side.

e.

r of the hole. Another method is by putting measuring tape at position as sh

ole center is obtained by measuring the distance namely 5 1/16” for left and righ

tively.

10.2.3.2 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 19/32”

from the wall.

ing

e is

own in the diagram

t hole

r

4

Finish by sealing the sleeve with putty or

caulking compound at the final stage.

40

Page 12

10.2.3.3 Indoor Unit Installation

10.2.3.4 For the right rear piping

10.2.3.5 For the right bottom piping

10.2.3.6 For the embedded piping

(Thi

s can be used for left rear piping and bottom

piping also.)

41

Page 13

10.2.3.7 Connect the Cable to the Indoor Unit

1. The inside and outside connecting cable can

be co

nnected without remo

Unscrew the conduit cove

2.

nector to conduit cove

con

se

cure it against chassi

3.

Connecting wire between indoor unit an

r unit should be UL listed or

outdoo

approved 4 condu

in accordan

Ensure the colour of wires of outdoor un

o

and terminal number are the same as the

indoo

r's resp

This equipment must be properly earthed.

o Earth lead wire shall be

(Y/G) in colou

other lead wires as shown in the figure fo

electri

cal safety in case of the slip

ctor wires minimum AWG1

ce with local electric code

ectively.

r and shall be longer than

ving the front grille.

r and fix the conduit

r with lock nut, then

s.

d

CSA

6

s.

it

Yellow/Green

r

ping.

42

Page 14

10.2.3.8 Wire Stripping and connecting requirement

10.2.3.9 Cutting and flaring the piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end

down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

43

Page 15

10.2.4 Outdoor Unit

10.2.4.1 Install the Outdoor Unit

x After selecting the best location, start installation to Indoor/Outdoor Unit Installation Diagram.

1

Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut (ø13/32

When installing at roof, please consider strong wind and earthqua

2

ke.

Please fasten the installation stand firmly with bolt or nails.

Model A B C D

S18NKU-1,

S22NKU-1

”).

24 1/8” 5 5/32” 5/8” 14 3/32”

10.2.4.2 Connect the Piping

10.2.4.2.1 Connecting the piping to

indoor

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Do not over tighten, over tightening may cause gas leakage.

Piping size Torque

1/4” 13.3 lbf.ft

3/8” 31.0 lbf.ft

1/2” 40.6 lbf.ft

5/8” 47.9 lbf.ft

3/4” 73.8 lbf.ft

Connect the piping

x Align the center of piping and suffici

ently tighten

the flare nut with fingers.

x

Further tighten the flare nut with torque wren

cified torque as stated in

spe

the table.

ch in

10.2.4.2.2 Connecting the piping to

outdoor

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge.

Make flare after inserting the flare nut (locate at valve)

onto the copper pipe.

Align center of piping to valve and then tighten with

torque wrench to the specified torque as stated in the

table.

10.2.4.2.3 Gas leak checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 10.2.4.3.

44

Page 16

10.2.4.3 Evacuation of the equipment

When installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following

procedures.

1.

Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-wa

valve.

Connect the micron gauge between vacuum pump and service port of outdoor un

2.

Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge and to pull

3.

its.

down to a value of 500 microns.

To make sure micron gauge a value 500 microns and close the low side valve of the charging set and turn of

4.

the vacuum pump.

Disconnect the vacuum pump hose from the service po

5.

6.

Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf.ft

rt of the 3-way valve.

with a torque wrench.

7. Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Op

g a hexagonal wrench

usin

Mount valve caps onto the 2-way valve and the 3-wa

8.

o

Be sure to check for gas leaka

(5/32”).

y valve.

ge.

10.2.4.4 Connect the Cable to the Outdoor Unit

1. Remove control board cover (Resin and Metal).

2. Remove particular

3. Remove

Fix the conduit connectors to the knockout holes with lock-nuts, then secure them against the side pa

4.

All wires pass through conduits & particular plate’s opening hol

5.

Connecting wire between indoor unit and outdoor unit should be UL listed or CSA approved 4 conducto

6.

wire

Wire connection to the power supply (208/230V 60Hz) through circuit breaker.

7.

o

plug

s minimum AWG16 in accordance with local electric co

Connect the UL listed or CSA approved wires minimum AWG12 to the terminal board, and con

other en

Connect the power supply cord and connecting wire between indoor unit and outdoor unit according to the

8.

diagram below.

plate.

s.

d of the wires to EL

e.

des.

CB / GFCI.

y

f

en”

nel.

r

nect the

45

Page 17

9. Secure the wire onto the control board with the holder (clamper).

10. After completing wiring connections, reattach the particular plate and control board cover (metal and resin) to

the original position with the screws.

11. For wire stripping and connection requirement, refer to instruction g of indoor unit.

This equipment must be properly earthed.

o Earth lead wire shall be Yellow/Green (Y/G) in colour and longer than other lead wires for electrical

safety in case of the slipping.

10.2.4.5 Piping Insulation

1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness ¼” or above.

46

Loading...

Loading...