Panasonic CM602-L Reference Manual

CM602-L

Reference Manual

Page 1-1

1.

1. GENERAL DESCRIPTION

This chapter describes the following items.

Names and mechanisms of units

This describes the names and functions of each unit using the illustrations.

Production process

This describes the placement process step by step.

Specifications

This describes the specifications of the machine and applicable boards.

∗

This machine can use the high-speed head (12 nozzles / 8 nozzles) and the multi-functional

head.

EJM4A-E-RMA01-A00-01

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-2

1.

1.1 Names and Mechanisms of Units

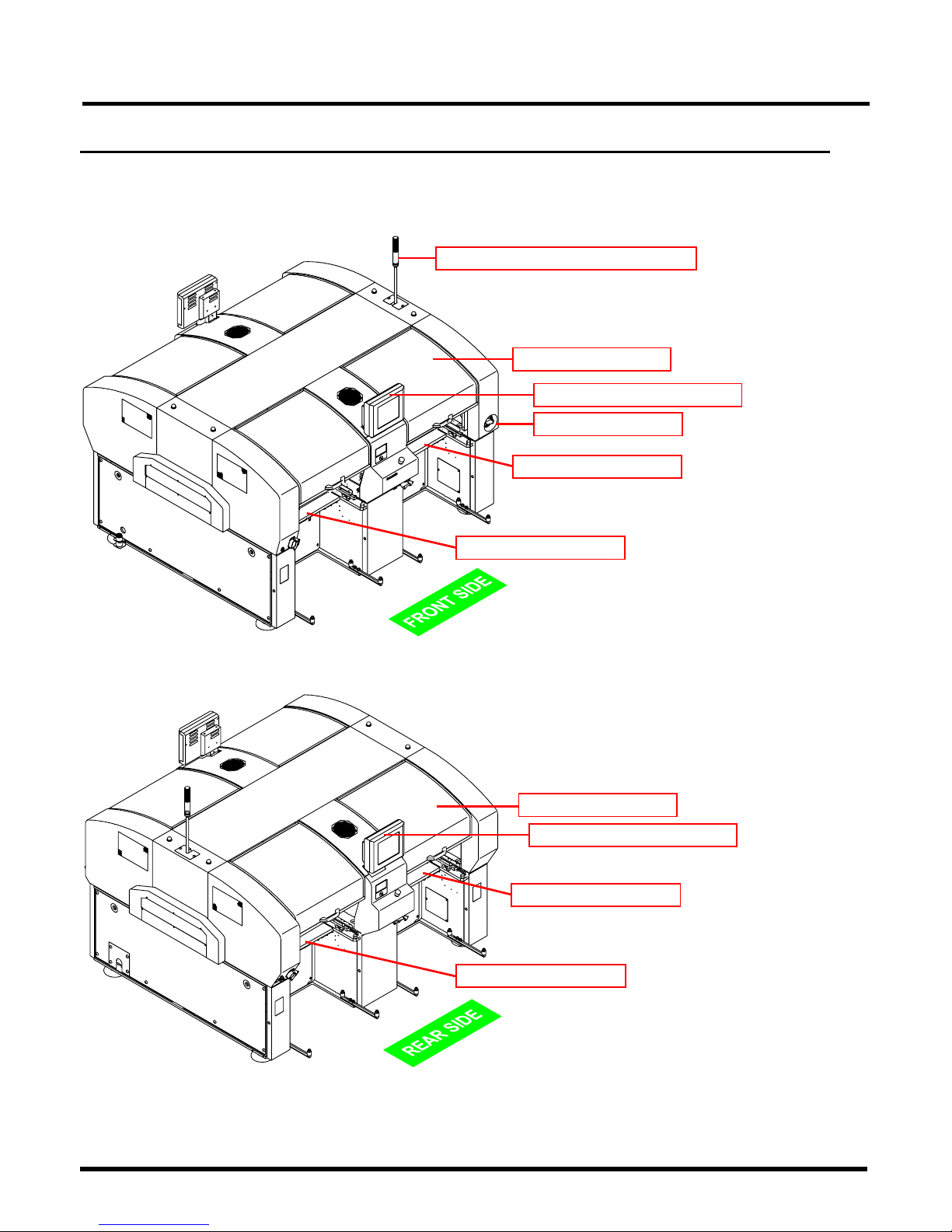

1.1.1 External Views

1. Front view

2. Rear view

EJM4A-E-RMA01-A01-00

EJM4A-AB01

Rear cover

Feeder table 2

Feeder table 4

Rear color touch panel

EJM4A-AA01

Status indicator (Three-color signal tower)

Front cover

Power supply switch

Feeder table 3

Feeder table 1

Front color touch panel

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-3

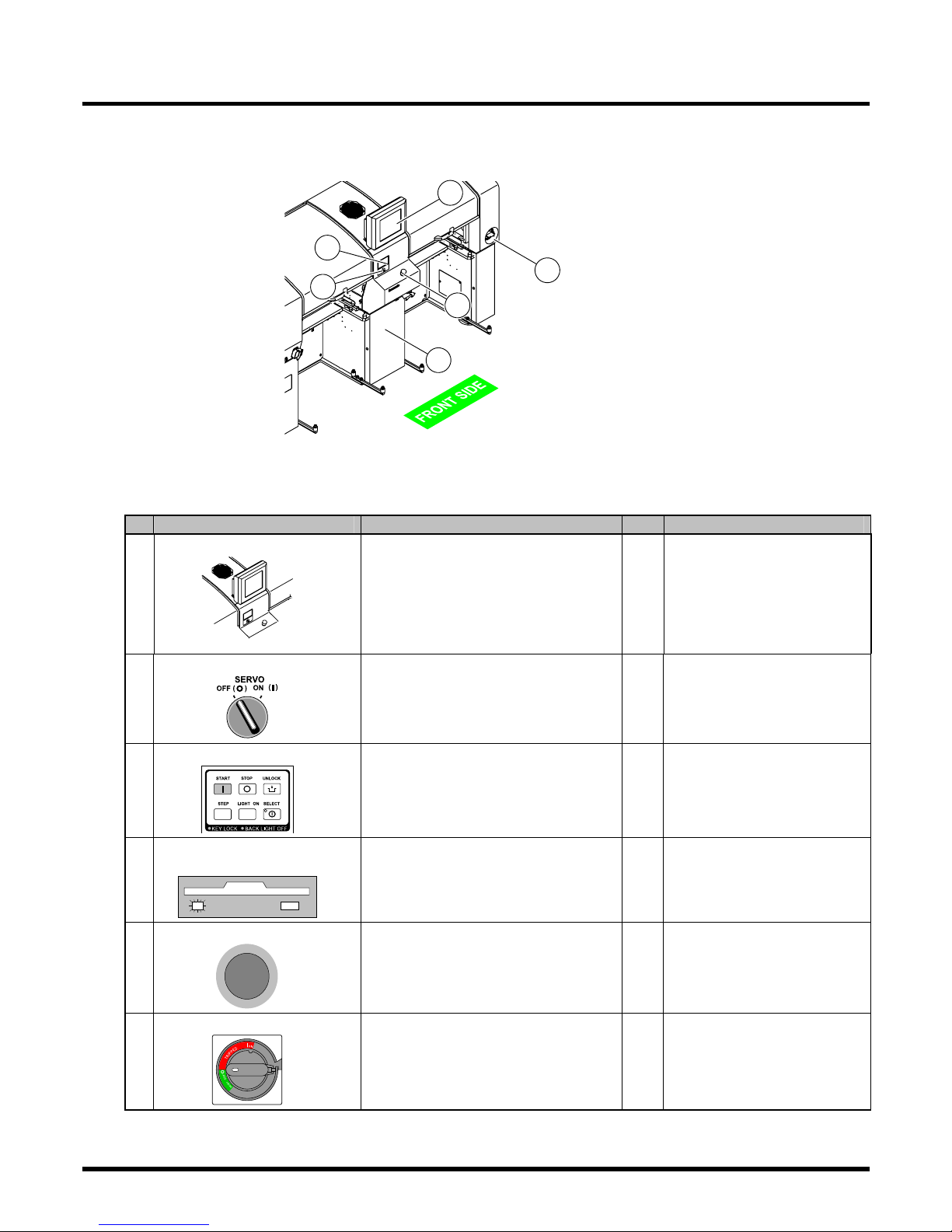

1.1.2 Operating Units

1. Front view

∗

The emergency stop button, color touch panel, operating panel, and servo switch of the same

number exist on the rear side.

No.

Unit name

Function Qty. Reference item

Color touch panel

EJM4A-412E

Used to operate the machine. 2 Operation Manual

Servo switch

Used to turn ON/OFF the servo-system

power.

2 Operation Manual

Operating panel

Used to put the machine into operation,

bring it to a stop, and for the other

operations.

2 Operation Manual

Floppy disk drive

(Inside the cover)

Used to read and write programming

data.

1 • Programming Manual

• Handling of floppy disk

Emergency stop button

If this button is pressed, the machine

comes to an emergency stop.

2 Safety precautions

Power supply switch

Used to turn ON/OFF the power and air

sources of the machine. (When the

power supply switch is turned OFF, air

becomes OFF in synchronization with

that.)

1 Safety precautions

EJM4A-E-RMA01-A01-00

EJM4A-AA01

1

2

3

4

5

6

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-4

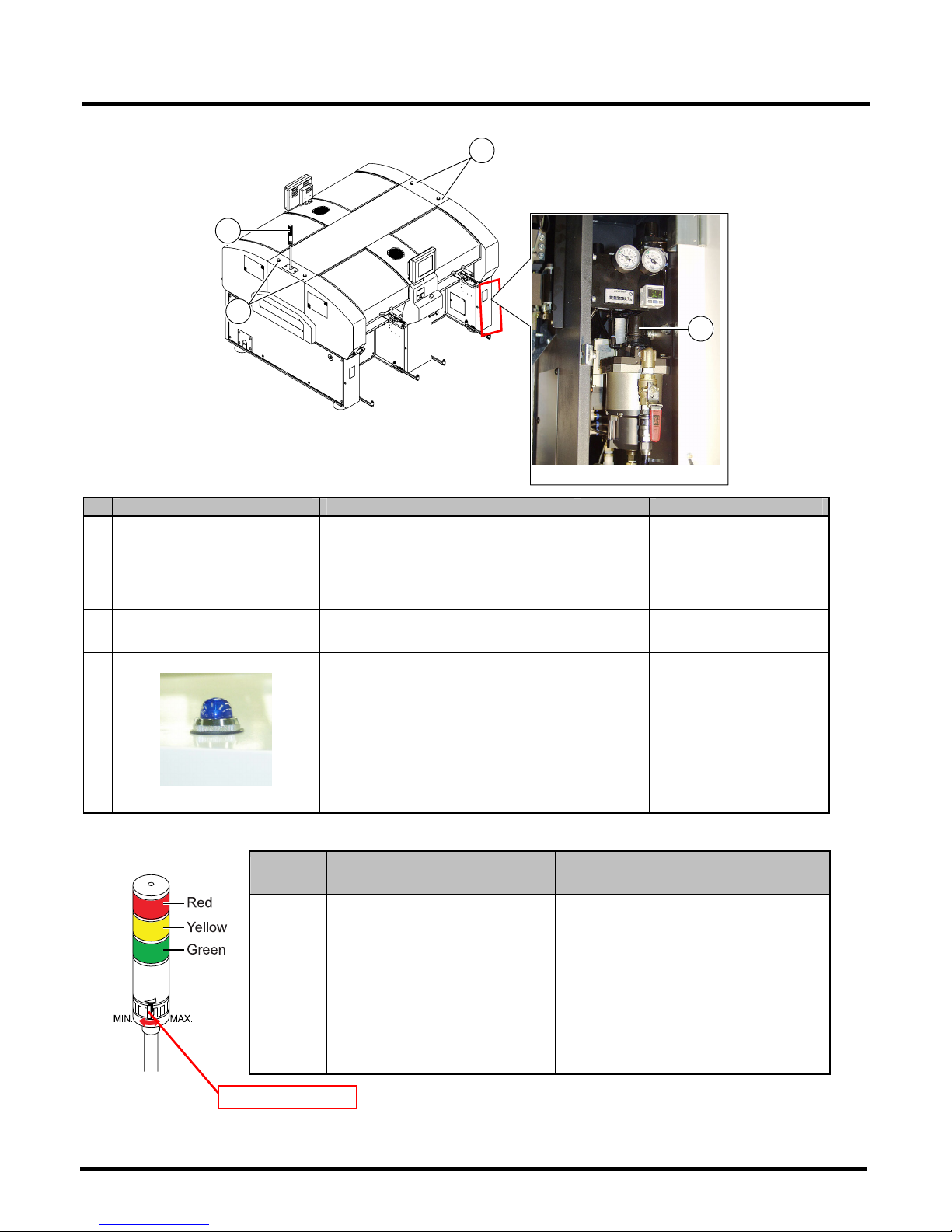

2. Rear view

No. Unit name Function Qty. Reference item

Status indicator

(Three-color signal tower)

Indicates the machine’s operational

status, and warns you of any trouble

occurred during operation by sounding

a buzzer. You can adjust the volume of

buzzer using the knob.

1 See below.

Regulator knob

(Inside the cover)

Used to adjust the supply air pressure. 1 Operation Manual

Stage indicator lamp

EJM4A-019P

If components run out or trouble occurs,

the corresponding stage lamp blinks.

During automatic operation

• Not lit: Normally running

• Lit: Components have run out.

• Blinking: Warning of the shortage of

component

During teaching

• Lit: Running

4

Explanation of status indicator lamp (three-color signal tower)

Color,

Status

Description Trouble description

Red,

Blinking

Trouble; operation cannot be

continued. (Emergency stop)

• Emergency stop

• Trouble in shafts of motors, etc.

• Drop in air pressure

• Board transport trouble

Yellow,

Blinking

Trouble or warning; operation can

be continued.

Immediate/Cycle stop, Out of materials

Green, Lit

During automatic operation, or

during machine adjustment

running

Normally running

EJM4A-E-RMA01-A01-00

EJM4A-122E

Knob

4Z4C-AB01

EJM4A-062P

3

1

3

2

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-5

1.1.3 Main Units

No.

Unit name Function Qty.

Board conveyor L/R

4Z4C-030TC0AA

4Z4C-030UC0AA

This unit loads and unloads boards.

In placement, it secures a board by

sandwiching it in between the Y and

the Z direction, and keeps it at the

placement position.

1 on the

L/R side

each

Line camera

4Z4C-161DC1AA

This camera is used to recognize

components.

It supports the recognition of all the

components, from minute ones to

large-sized irregular-shaped ones.

4

Nozzle changer

Standard for multi-functional head

4ZTC-050NC1AA

Option

High-speed head (12 nozzles) High-speed head (8 nozzles)

EJM4A-153E00. 4ZTC-050MC1AA

In changing boards, this unit

changes nozzles automatically.

4

EJM4A-E-RMA01-A01-01

EJM4A-112E

2

2

3

3

1

1

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-6

No.

Unit name

Function

Qty.

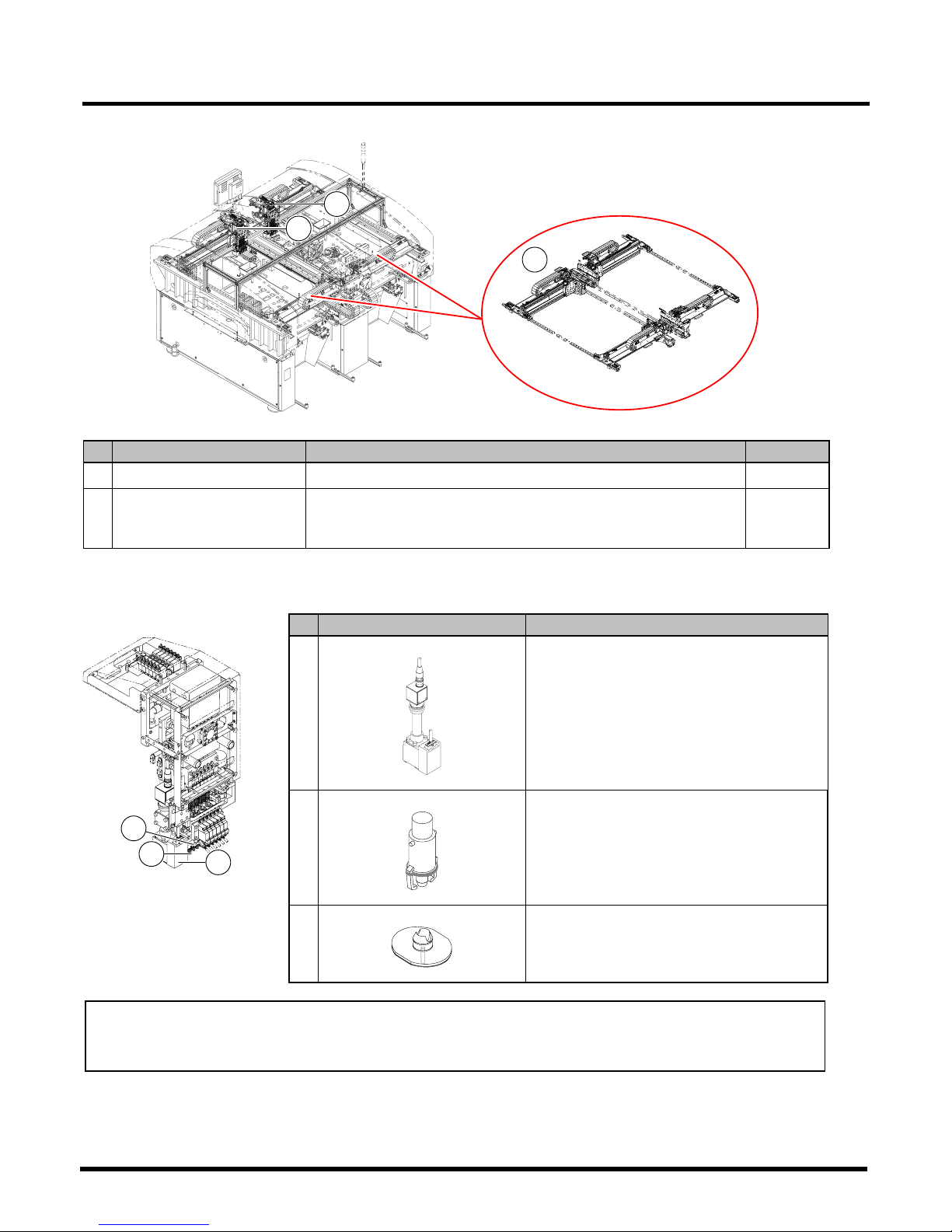

XY unit

These units move the head unit in place fast and precisely.

4

Transfer head

This unit transfers chips from feeders to a board.

The high-speed head is equipped with 12 or 8 nozzle holders, and

the multi-functional head is equipped with 3 nozzle holders.

4

Detailed explanation of transfer head

∗

Description uses the illustrations for the high-speed head (12 nozzles).

No.

Unit name Function

Head camera

EJM4A-142E

This camera is used for the board recognition,

heat compensation, and calibration.

Nozzle holder

444C-402E

Nozzles are fit in this holder. The high-speed

head is equipped with 12 or 8 nozzle holders,

and the multi-functional head is equipped with

3 nozzle holders.

Nozzle

444C-407E

This picks up components with a vacuum

pressure.

There are various kinds of sizes and shapes

of nozzles in response to components.

NOTICE

The conventional transfer head of CM402 cannot be installed.

(However, the lightweight head can be installed.)

EJM4A-143E

5

5

EJM4A-144E

4

EJM4A-E-RMA01-A01-01

EJM4A-152E

7

8

6

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-7

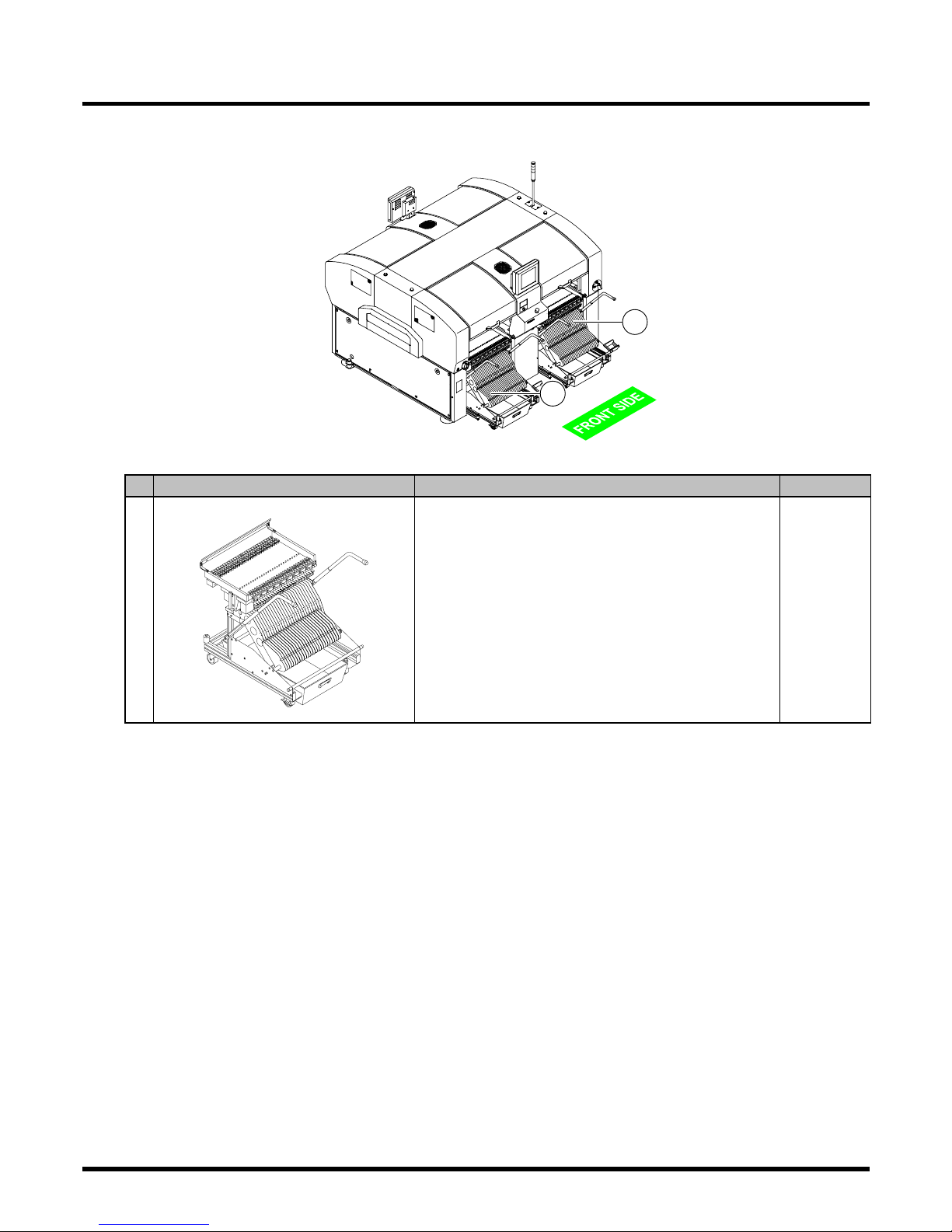

1.1.4 Component Feeding Unit

No. Unit name Function Qty.

Collectively changing truck

4Z4C-15XYC1AA

This is a truck where intelligent feeders are placed.

∗

When the collectively changing truck preparation unit

(option) is available, the preparation work is available

while this machine is running.

4

EJM4A-E-RMA01-A01-00

EJM4A-AC01

1

1

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-8

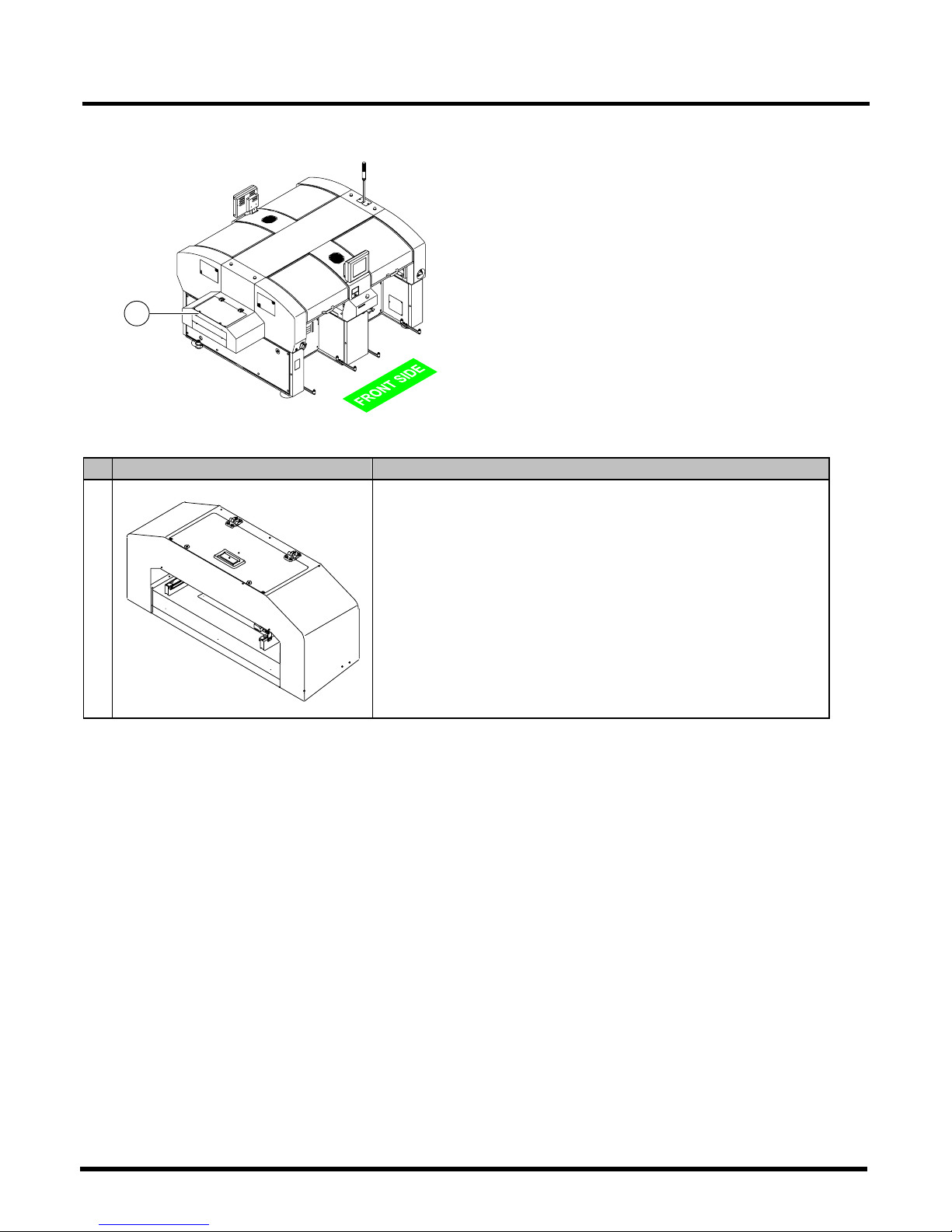

1.1.5 Extension Conveyor (Option)

No. Unit name Function

Extension conveyor

E64C-010E

This unit extends the conveyor.

It can be installed on both the upstream and the downstream process

side.

Since its cover is equipped with a safety switch, the machine cannot

be operated with that cover open. If the cover is opened during

operation, the safety cover error occurs.

For the standard specifications (with no extension conveyor), the

safety sensor is included because an opening for transport is close to

movable parts. When, however, the extension conveyor is included,

the safety sensor is not included because a safe distance between an

opening for transport and movable parts is secured.

∗

For the extension conveyor, there is no safety sensor of transport

section.

EJM4A-E-RMA01-A01-00

EJM4A-AG01

1

CM602-L

Reference Manual

1.1 Names and Mechanisms of Units

Page 1-9

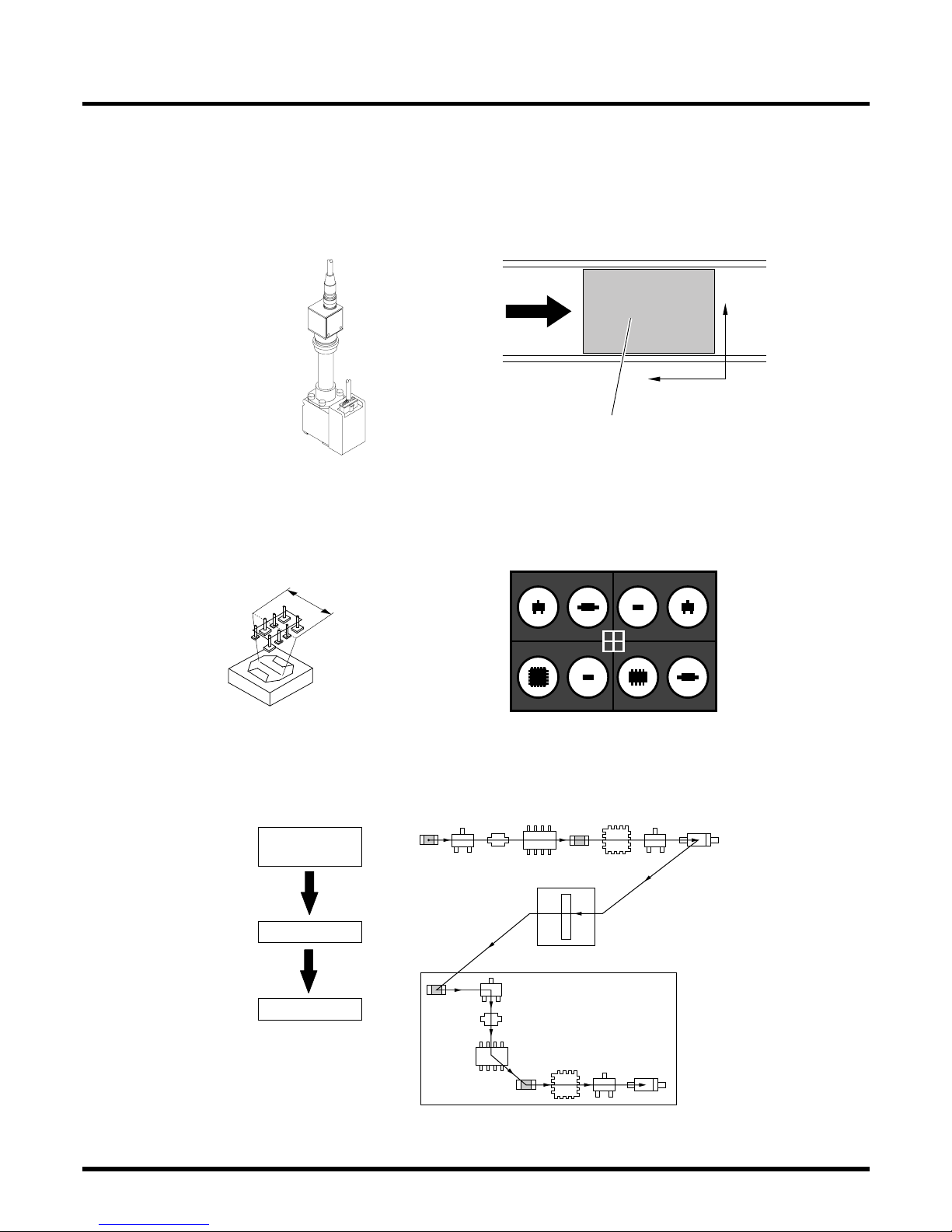

1.1.6 Recognition Camera

This machine has the two recognition cameras: head camera and line camera.

A) Head camera

The head camera is installed on the head unit, and recognizes the precise position of board.

∗

Description uses the illustrations for the high-speed head (8 nozzles).

EJM4A-142E

Y

X

4Z4C-009E

Positioning reference

Board

B) Line camera

The line camera is installed on the main-body frame, and recognizes components (displacement,

inclination, chipping, etc.).

Line camera

Line width: 55 mm

4Z4C-001E

Conceptual illustration

Recognition image

4Z4C-002E

Conceptual illustration

Process

Eight components are scanned and recognized all together, while the head is moved so that it

will cross over the line.

Component

pickup

Recognition

Placement

EJM4A-E-RMA01-A01-01

Start

Batch recognition

Board

4Z4C-006E

Loading...

Loading...