Panasonic AR User Manual

ORDER NO. DCS-JUL2002-002-MS

Service Manual

Microwave Oven

NN-G61 AR

Specifications

Power Source:

Power requirement:

Output:

Microwave Frequency:

Timer:

Outside Dimensions:

Oven Cavity Dimensions:

Weight:

220 V AC, 50 Hz

Microwave:

Heater:

Microwave:

Heater:

Specifications subject to change without notice

1.450 W

860 W

900 W: Full Power (IEC 705-88)

800 W

2.450 MHz

99 min. 99 sec.

306 (W) x 555 (D) x 428 (H) mm

31 liters

Approx. 18 Kg

Panasonic do Brasil Ltda.

CS / DST - 2002

! WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It

does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

! WARNING

1. This product should be serviced only by trained, qualified personnel.

2. Check for radiation leakage before and after every servicing according to the procedure for measuring radiation leakage.

3. If the unit cannot be repaired on site, advise the customer not to use until unit is repaired.

4. There are special components used in the microwave oven which are important for safety. These parts are marked with a on the

replacement parts list. It is essential that these critical parts should be replaced only with the manufactures specified parts to

prevent microwave leakage, shock, fire, or other hazards. Do not modify the orginal design.

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(A) Do not operate or allow the oven to be operated with the door open.

(B) Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave source, and

make repairs as necessary:

(1) Interlock operation

(2) Proper door closing

(3) Seal and sealing surfaces (arcing, wear, and other damage)

(4) Damage to or loosening of hinges and latches.

(5) Evidence of dropping or abuse

(C) Before turning on microwave power for any service test or inspection within the microwave generating compartments, check

the magnetron, waveguide or transmission line, and cavity for proper alignment, integrity and connections.

(D) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and trans-mission

systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the

owner.

(E) A microwave leakage check to verify compliance with the Federal Performance Standard should be performed on each oven

prior to release to the owner.

CONTENTS

Safety Precautions ...................................................................................................................... 03

Procedure for Measuring Microwave Energy Leakage ................................................................ 04

Component Test Procedure ........................................................................................................ 05

Measurements and Adjustments ................................................................................................. 06

Electric Diagram .......................................................................................................................... 07

Schematic Diagram ..................................................................................................................... 08

Connections ................................................................................................................................. 10

Oven exploded view .................................................................................................................... 11

Cabinet exploded view ................................................................................................................ 12

Wiring Material ............................................................................................................................ 13

Cabinet Parts List ........................................................................................................................ 14

Door Assembly and Parts List .................................................................................................... 15

Escutcheon Assembly and Parts List .......................................................................................... 16

Electrical Parts List ..................................................................................................................... 17

Packing Parts List ....................................................................................................................... 18

Troubleshooting Guide ................................................................................................................. 19

SAFETY PRECAUTIONS

NN-G61 AR

CAUTIONS TO BE OBSERVED WHEN

TROUBLESHOOTING

Unlike many other appliances, the microwave oven is highvoltage, high-current equipment. Though it is

free from danger in ordinary use, extreme care should be

taken during repair.

CAUTION

Servicemen should remove their watches whenever

working close to or replacing magnetron.

Check the grounding

Do not operate on a 2-wire extension cord. The microwave

oven is designed to be used when grounded.

It is imperative, therefore, to make sure it is grounded properly before beginning repair work.

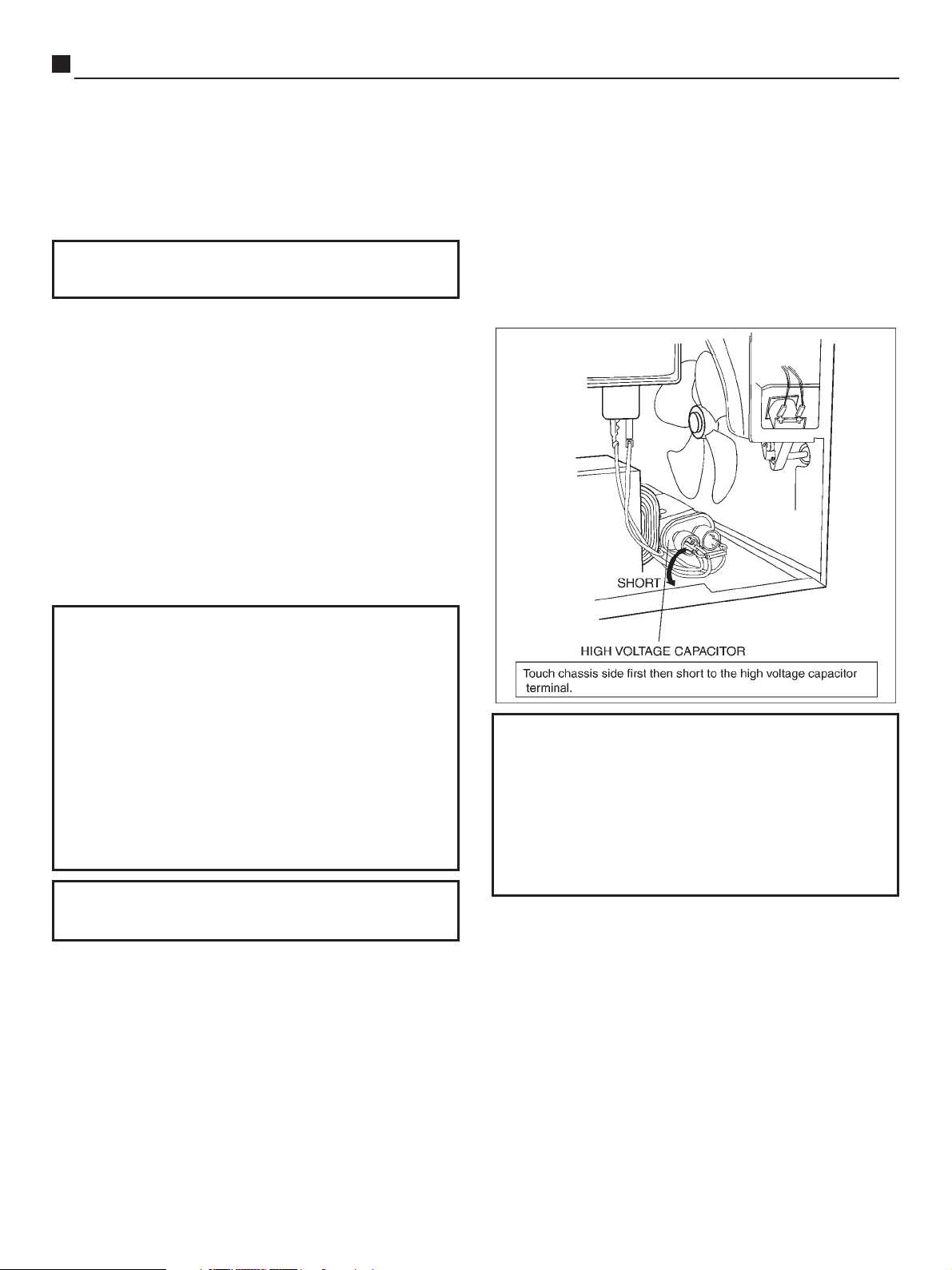

Warning about the electric charge in the high voltage

capacitor

For about 30 seconds after the oven is turned off, an electric charge remains in the high voltage capacitor.

When replacing or checking parts, turn the oven off, wait

30 seconds and short the terminal of the high voltage capacitor (terminal of lead wire from diode) to chassis ground

with an insulated handle screwdriver or an insulated jumper

lead wire to discharge.

CONFIRM AFTER REPAIR

After repair or replacement of parts, make sure that the

screws of the oven, etc. are neither loose nor missing. Microwaves might leak if screws are not properly tightened.

1. Make sure that all electrical connections are tight before

inserting the plug into the wall outlet.

2. The special connection cable used for connection of this

apparate may be replaced only by qualified service-personnel using a special cable, which can be obtained only

from the Panasonic -Service. (Refer to Parts List).

Important Note

1. High voltage above 250V are existing on following parts

during operation.

Magnetron

High voltage transformer

High voltage Diode

High voltage Capacitor

Unusual attention should be paid during repair or

troubleshooting of product.

2. If the microwave oven is operated with incorrect installed

door hinge or magnetron, it can cause microwave leakage of over 5mW/cm2.

Hence it is absolutely necessary to check if magnetron

and door hinge are correctly and safely intalled after

repair or replacement.

WARNING

Never touch any circuit wiring your hand nor even with an

insulated tool during operation

When parts must be replaced, remove the power plug

from the outlet.

Avoid inserting nails, wire, etc. through any holes in

the unit during operation.

CAUTION

MICROWAVE RADIATION

Personnel should not be exposed to the microwave energy

which may radiate from the magnetron or other microwave

generating device it is improperly used or connected all

input and output microwave connection waveguides,

flanges, and gasket must be secure. Never operate the

device without a microwave energy absorbing load

attached. Never look into an open waveguide or antena

while the device is energized.

Never insert a wire, nail or any other metal objects through

the lamp holes on the cavity or any other holes or gaps,

because such objects may work as an antenna and cause

microwave leakage.

- 3 -

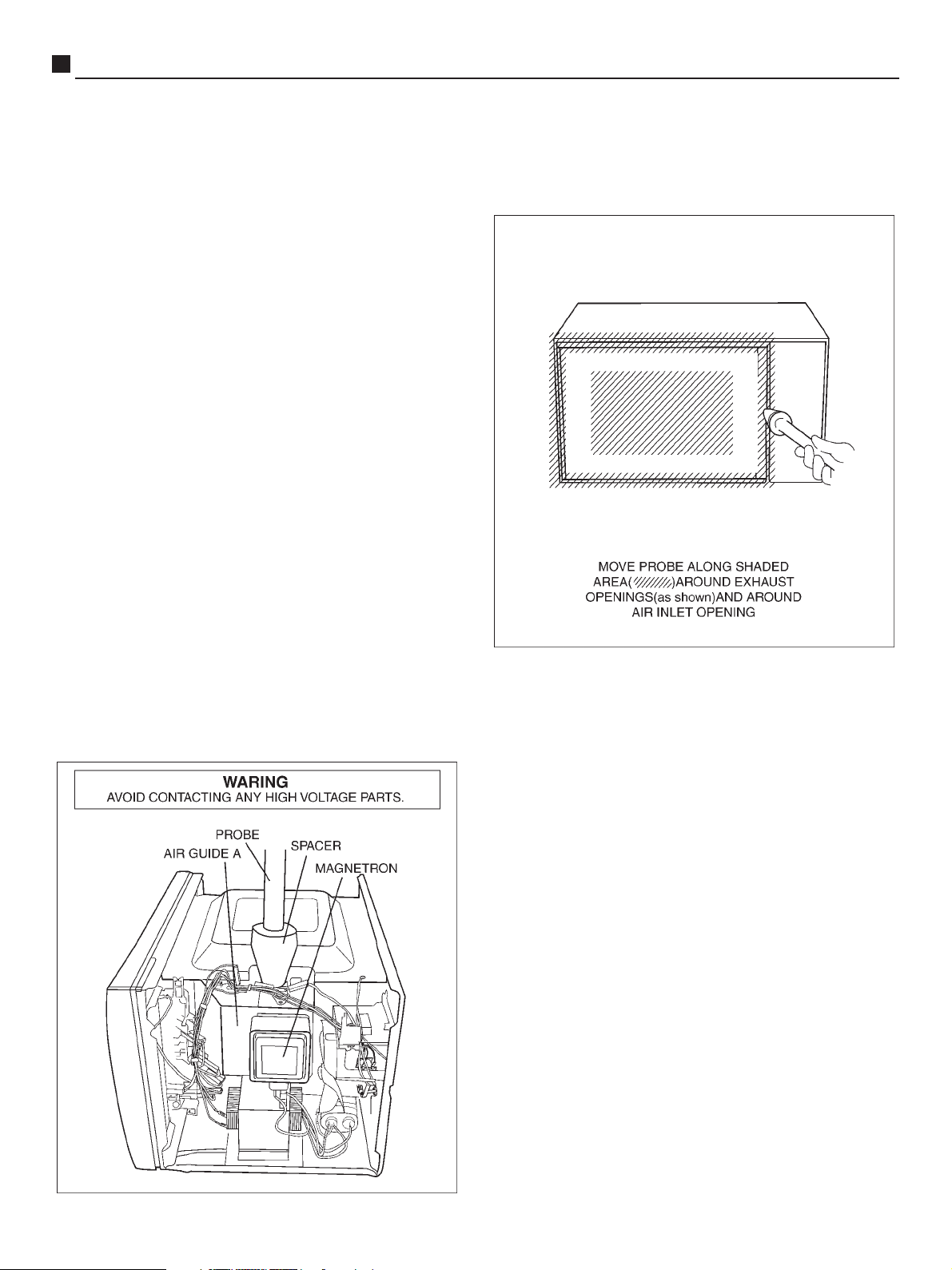

PROCEDURE FOR MEASURING MICROWAVE ENERGY LEAKAGE

Equipment

*Electromagnetic radiation monitor

*Glass thermometer 212°F or 100°F

*600cc glass beaker

Procedure for measuring radiation leakage

Note before measuring:

(1) Do not exceed meter full scale deflection. Leakage monitor

should initially be set to the highest scale.

(2) To prevent false readings the test probe should be held by

the grip portion of the handle only and moved along the shaded

area shown in Figure no faster than 1 inch/sec (2.5 cm/sec)

(3) Leakage with the outer panel removed less than 5mW/cm2

(4) Leakage for a fully assembled oven with door normally closed

less than 2mW/cm2.

(5 ) Leakage for a fully assembled oven [Before the latch switch (primary)

is interrupted] while pulling the door less than 2mW/cm2

1. Pour 275±15cc (9ozs± 1/2oz) of 20± 5°C(68± 9°F) water

in a beaker which is graduated to 600cc, and place the

beaker in the center of the oven.

2. Set the radiation monitor to 2450MHz and use it following

the manufactuers recommended test procedure to assure

correct results.

3. When measuring the leakage, always use the 2 inch (5cm)

spacer supplied with the probe.3.

4. Tap the start pad or set the timer and with the magnetron

oscillating, measure the leakage by holding the probe

perpendicular to the surface being measured.

(2) Measurements with a fully assembled oven.

After all components, including the outer panel are fully

assembled, measure for radiation leakage around the door

periphery, the door viewing window, the exhaust opening and air

inlet openings.

(1) Measurement with the outer panel removed.

Whenever you replace the magnetron, measure for radiation

leakage before the outer panel is installed and after all necessary

components are replaced or adjusted. Special care should be

taken in measuring around the magnetron.

- 4 -

COMPONENT TEST PROCEDURE

NN-G61 AR

CAUTION

1. High voltage is present at the high voltage terminal of

the high voltage transformer during any cook cycle.

2. It is neither necessary nor advisable to attempt

measurement of the high voltage.

3. Before touching any oven components or wiring, always

unplug the oven from its power source and discharge

the high voltage capacitor.

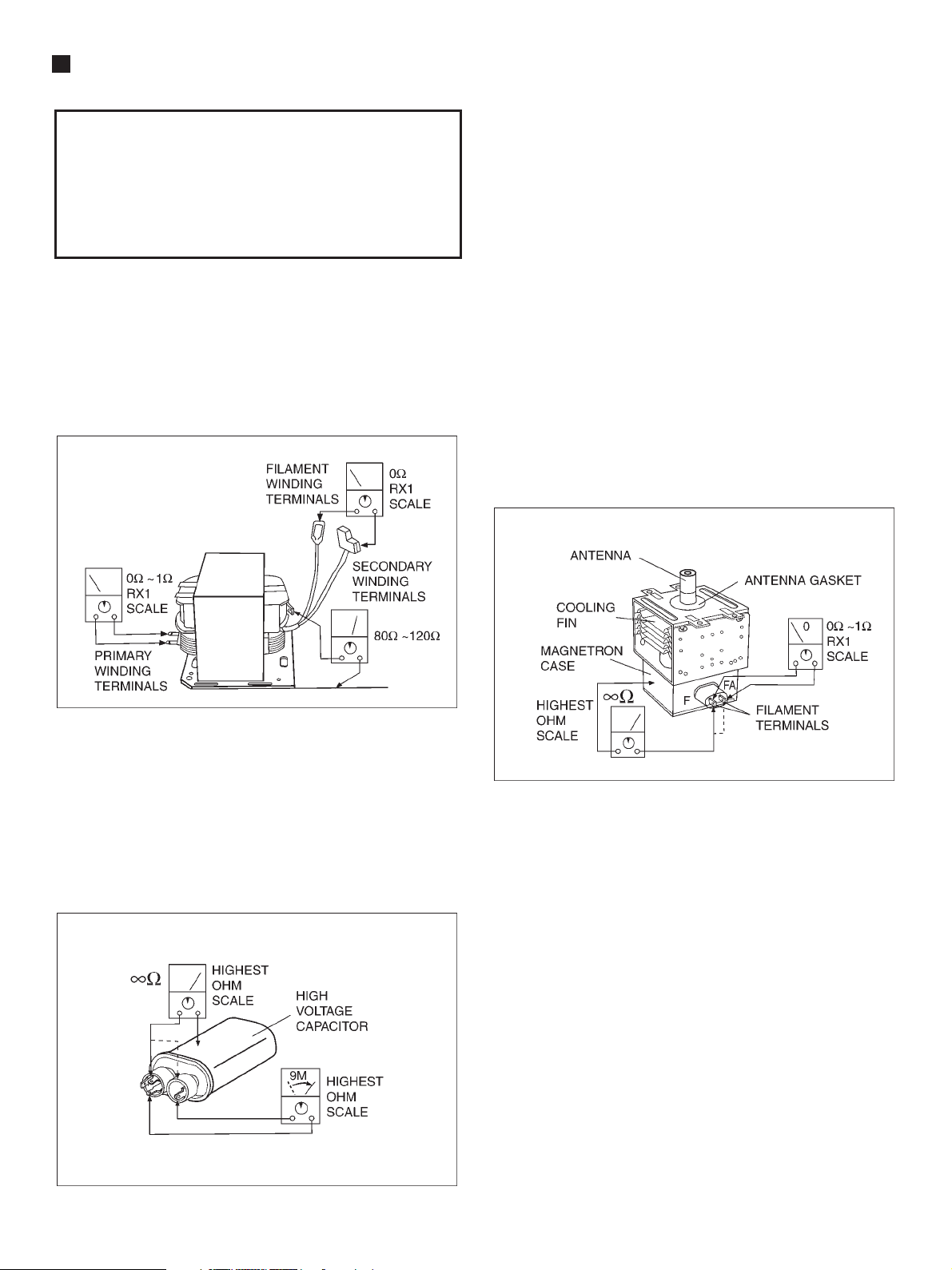

High voltage transformer

1. Remove connections from the transformer terminals and check

continuity.

2. Normal (cold) resistance readings should be as follows:

Secondary winding Approx. 80Ω; ~ 120Ω;

Filament winding Approx. 0Ω;

Primary winding (0v ~ 230/240V) Approx. 0Ω; ~ 3Ω;

Diode

1. Isolate the diode assembly from the circuit by disconnecting

the leads.

2. With the ohmmeter set on the highest resistance scale,

measure the resistance across the diode terminals. Reverse

the meter leads and again observe the resistance reading.

Meter with 6V, 9V or higher voltage batteries should be used

to check the front-to-back resistance of the diode, otherwise

an infinite resistance may be read in both directions. A normal

diodes resistance will be infinite in one direction and several

hundred KΩ; in the order direction.

Magnetron

Continuity checks can only indicate an open filament or a shorted

magnetron. To diagnose for an open filament or shorted

magnetron.

1. Isolate magnetron from the circuit by disconnecting the leads.

2. A continuity check across magnetron filament terminals should

indicate one ohm or less.

3. A continuity check between each filament terminal and

magnetron case should read open.

High voltage capacitor

2. Check continuity of capacitor with ohmmeter on highest ohm scale.

2. A normal capacitor will show continuity for a short time, and

then indicate 9MΩ; once the capacitor is charged.

3. A shorted capacitor will show continuous continuity.

4. An open capacitor will show constant 9MΩ;.

(Due to internal 9MΩ; resistor)

5. Resistance between each terminal and chassis should be infinite.

Membrane key board (Membrane switch assembly)

Check continuity between switch terminals, by pressing an

appropriate pad on the key board.

The contacts assignment of the respective pads on the key board

is as shown in the schematic diagram.

Protector diode

1. Isolate the protector diode assembly from the circuit by

disconnecting its leads.

2. With the ohmmeter set on the highest resistance scale,

measure the resistance across the protector diode terminals.

Reverse the meter leads and again observe the resistance

reading. A normal protector diodes resistance will be infinite in

both directions. It is faulty if it shows continuity in one or both

directions.

- 5 -

MEASUREMENTS AND ADJUSTMENTS

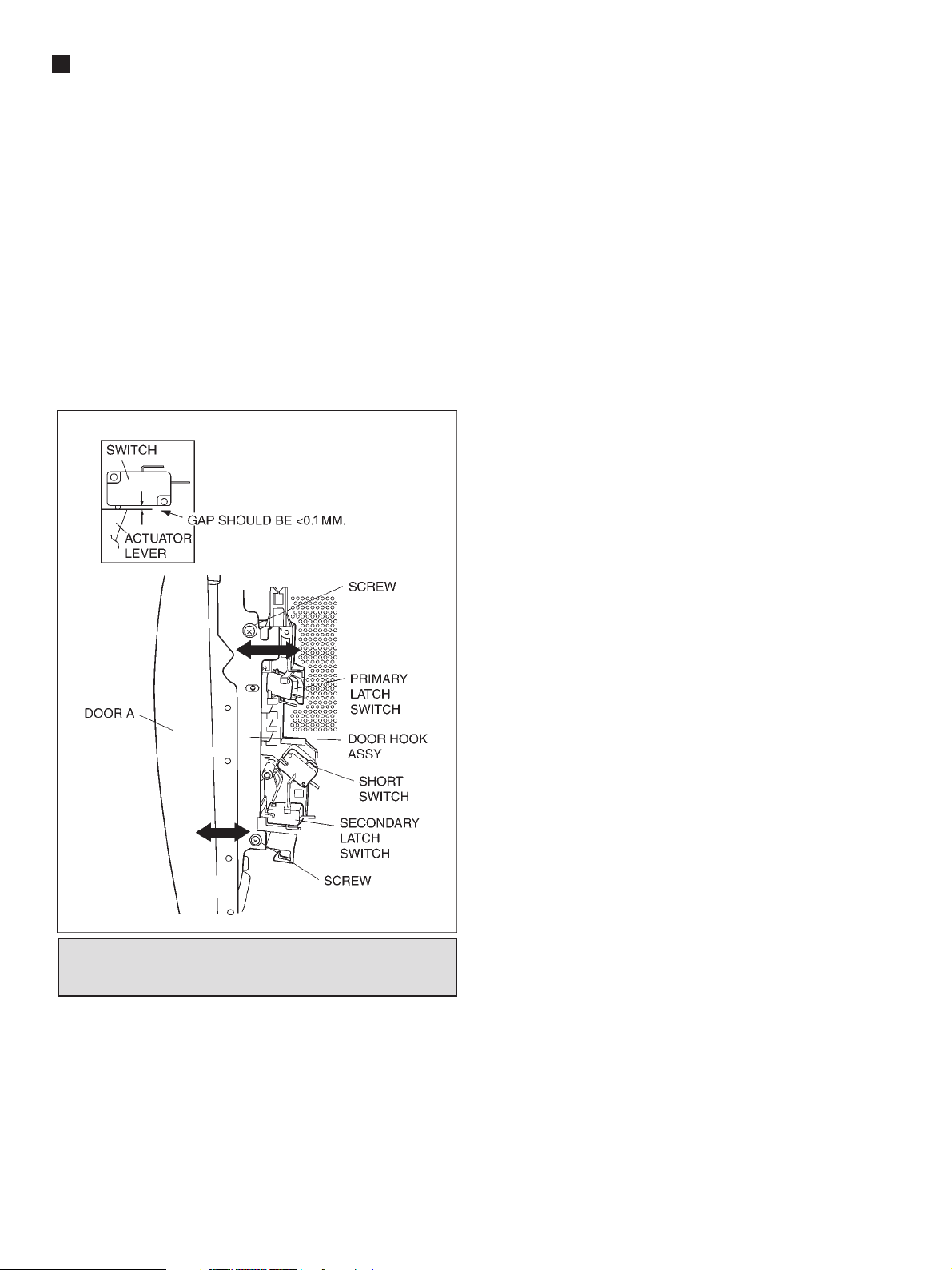

Adjustment of Primary latch switch, Secondary latch switch

and short switch

1. When mounting Primary latch switch, Secondary latch switch

and short switch to door hook assembly, mount the Primary

latch switch, the Secondary latch switch and the short switch

to the door hook assembly as shown in Figure.

NOTE: No specific adjustment during installation of Primary

latch switch, Secondary latch switch and short switch

to the door hook is necessary.

2. When mounting the door hook assembly to the oven assembly,

adjust the door hook assembly by moving it in the direction of

arrow in Figure so that the oven door will not have any play in

it. Check for play in the door by pulling the door assembly.

Make sure that the latch keys move smoothly after adjustment

is completed. Completely tighten the screws holding the door

hook assembly to the oven assembly.

Measurement of microwave output

The output power of the magnetron can be determined by

performing IEC standard test procedures.

However, it is possible to test the magnetron by following

procedure outlined below.

Necessary equipment:

*1 liter beaker *Glass thermometer

*Wrist watch or stopwatch

NOTE: Check the line voltage under load to ensure it meets

specifications. Low voltage condition will cause a reduction

in magnetron output. Temperature readings and heating

time, should be as accurate as possible.

Output power performance test procedure.

1. Fill the beaker with exactly one litre of tap water. Stir the water

using the thermometer and note the temperature. (Record as T1)

2. Place the beaker in the center of cook plate. Set the oven for

High power and heat for exactly one minute.

3. After completion of the heating cycle, stir the water again with

the thermometer and note the temperature. (Record as T2)

The normal temperature rise (T2-T1), for these models should

be more than 7.0°C using the High power

selection with the oven operating at the specified line voltage.

Please confirm that the gap between the switch housing and

switch actuator lever is no more than 1.0mm when the door

is closed.

- 6 -

Loading...

Loading...