Panasonic AQUAREA User Manual

2014

Order-Nr. A2W-SPX-140519-016

Aquarea Air / Water-heatpump – heating and cooling systems

DESIGN HANDBOOK

for Bi-Bloc and Monobloc systems

Aquarea air / water heat pump – design handbook 07 / 2014

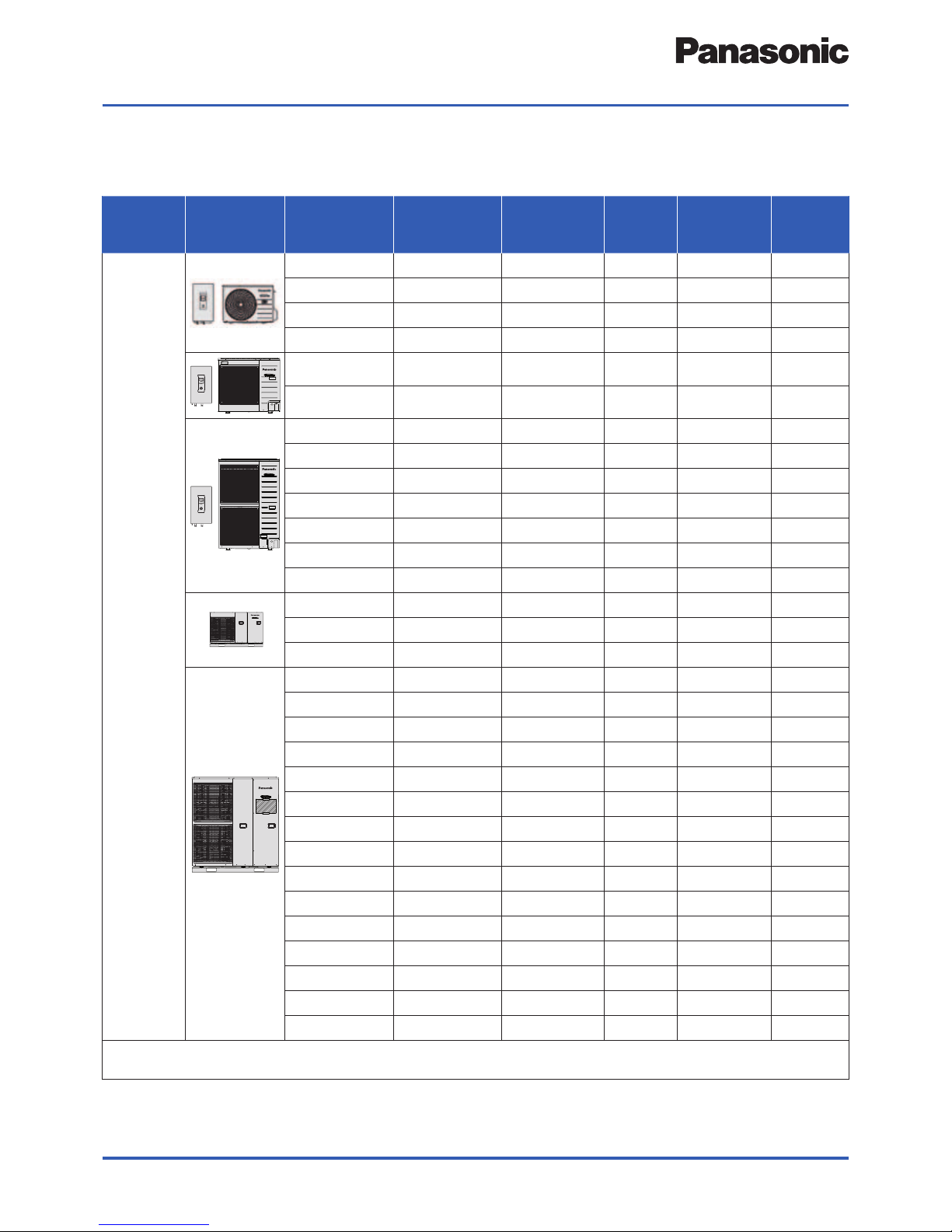

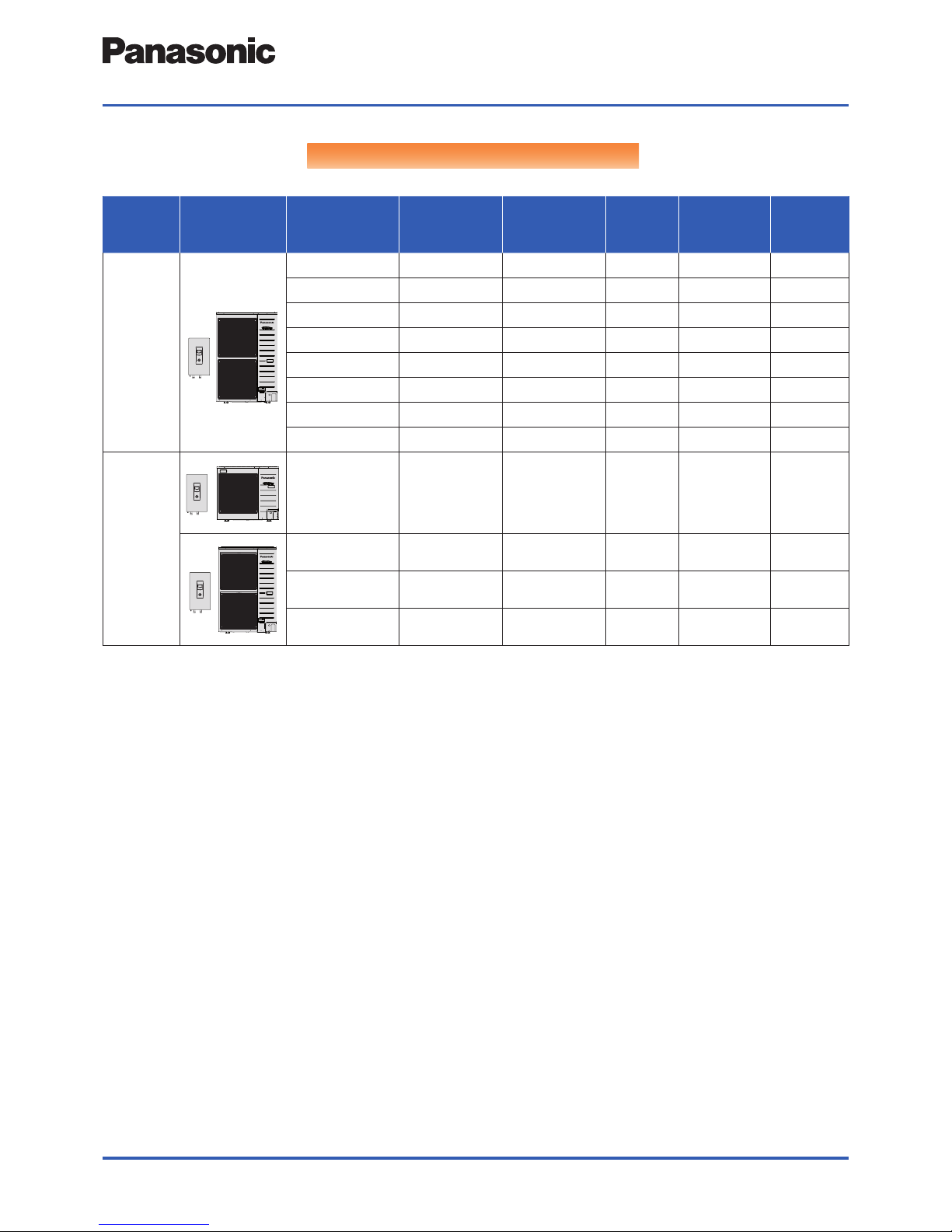

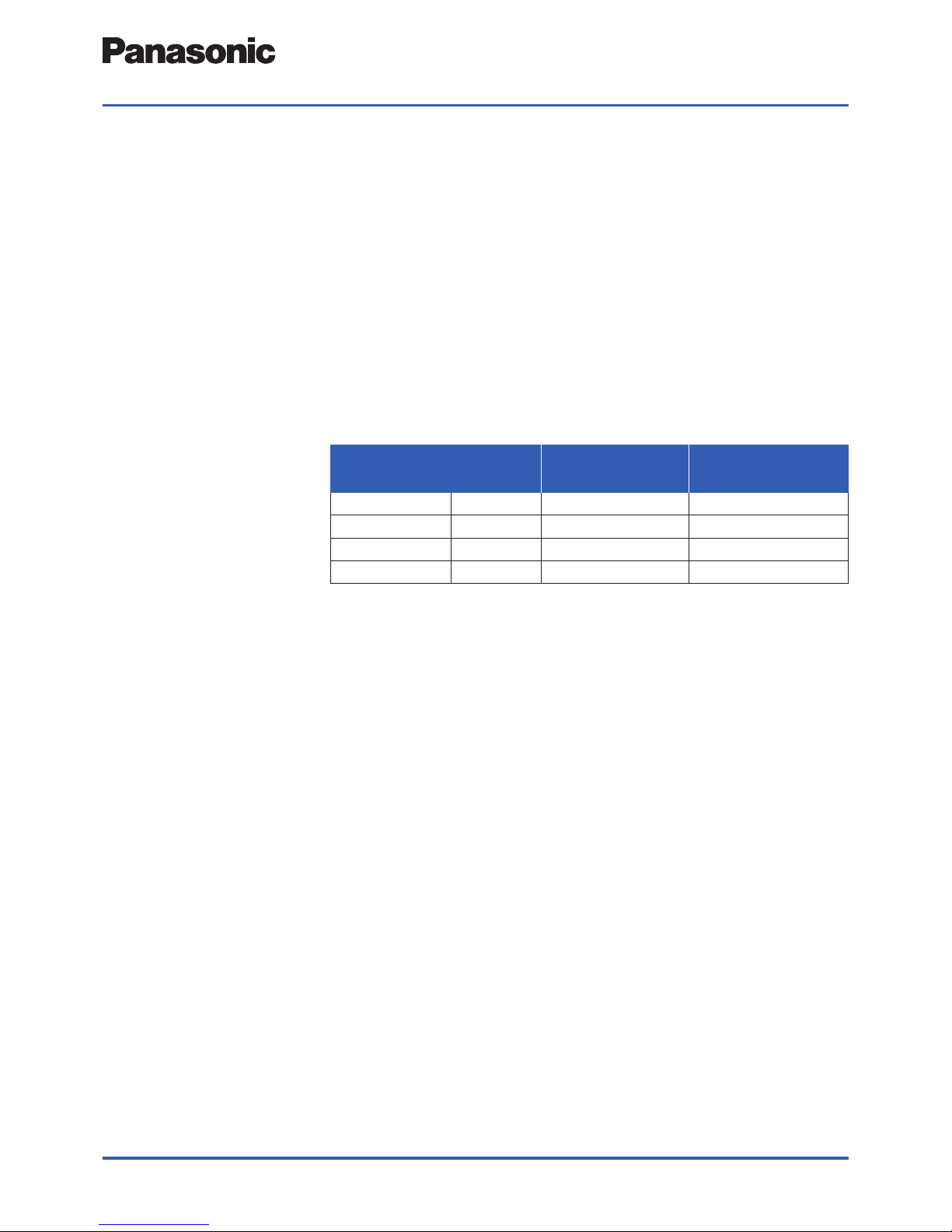

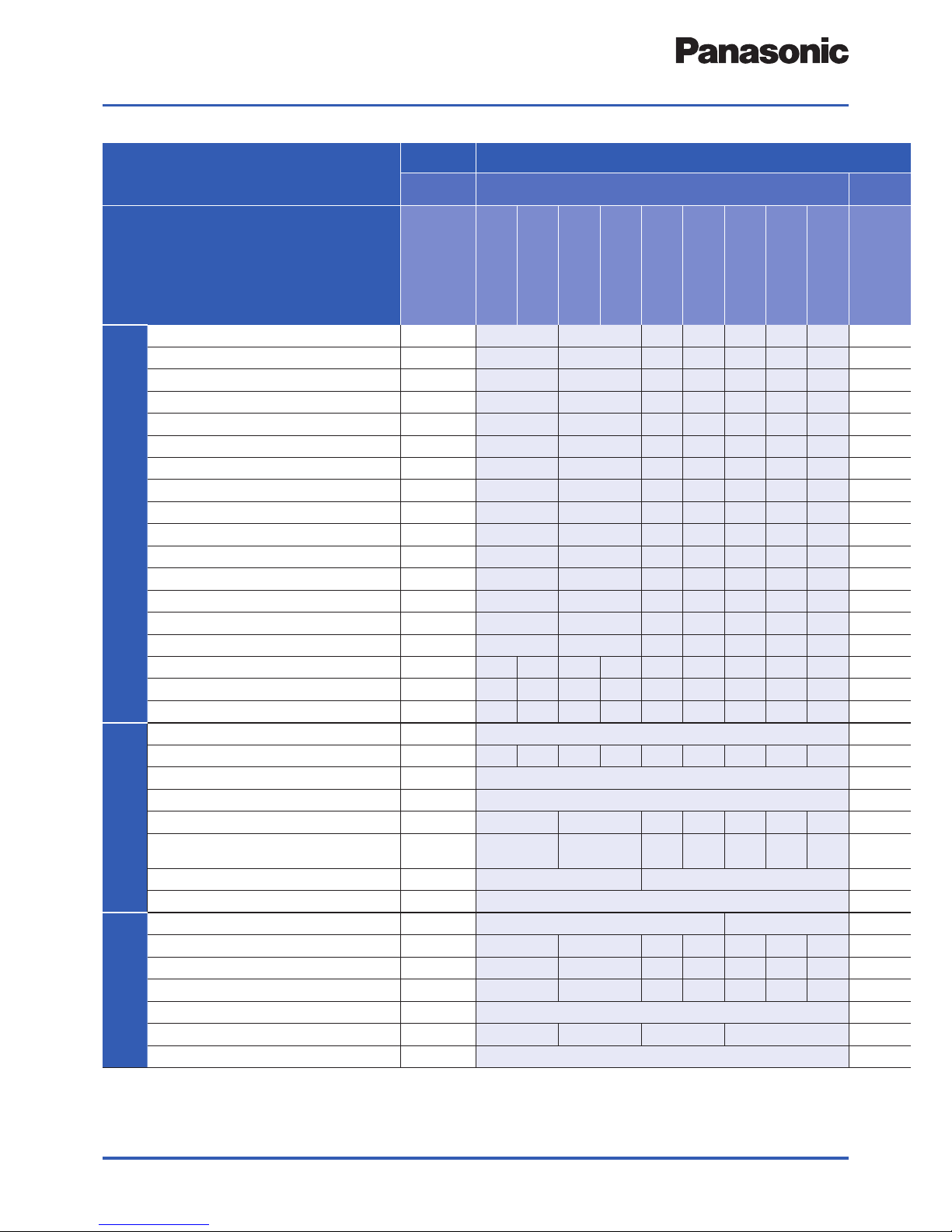

Series Units Hydromodule

(Indoor unit

Bi-Bloc)

Outdoor unit

(Bi-Bloc or

Monobloc)

Operating mode Nominal

heating

capacity kW

Capacity of

additional elec-

tric heater kW

Single or

Three phase

Aquarea LT

WH-SDF03E3E5* WH-UD03EE5 Heating 3 3 single phase

WH-SDC03E3E5* WH-UD03EE5 Heating + cooling 3 3 single phase

WH-SDF05E3E5* WH-UD05EE5 Heating 5 3 single phase

WH-SDC05E3E5* WH-UD05EE5 Heating + cooling 5 3 single phase

WH-SDC07F3E5* WH-UD07FE5 Heating + cooling 7 3 single phase

WH-SDC09F3E5* WH-UD09FE5 Heating + cooling 9 3 single phase

WH-SDC09F3E8* WH-UD09FE8 Heating + cooling 9 3 three phase

WH-SDC12F6E5* WH-UD12FE5 Heating + cooling 12 6 single phase

WH-SDC12F9E8* WH-UD12FE8 Heating + cooling 12 9 three phase

WH-SDC14F6E5* WH-UD14FE5 Heating + cooling 14 6 single phase

WH-SDC14F9E8* WH-UD14FE8 Heating + cooling 14 9 three phase

WH-SDC16F6E5* WH-UD16FE5 Heating + cooling 16 6 single phase

WH-SDC16F9E8* WH-UD16FE8 Heating + cooling 16 9 three phase

WH-MDC05F3E5* Heating + cooling 5 3 single phase

WH-MDF06E3E5* Heating 6 3 single phase

WH-MDF09E3E5* Heating 9 3 single phase

WH-MDC09E3E5* Heating + cooling 9 3 single phase

WH-MDF09C3E8 Heating 9 3 three phase

WH-MDC09C3E8 Heating + cooling 9 3 three phase

WH-MDF12C6E5 Heating 12 6 single phase

WH-MDC12C6E5 Heating + cooling 12 6 single phase

WH-MDF12C9E8 Heating 12 9 three phase

WH-MDC12C9E8 Heating + cooling 12 9 three phase

WH-MDF14C6E5 Heating 14 6 single phase

WH-MDC14C6E5 Heating + cooling 14 6 single phase

WH-MDF14C9E8 Heating 14 9 three phase

WH-MDC14C9E8 Heating + cooling 14 9 three phase

WH-MDF16C6E5 Heating 16 6 single phase

WH-MDC16C6E5 Heating + cooling 16 6 single phase

WH-MDF16C9E8 Heating 16 9 three phase

WH-MDC16C9E8 Heating + cooling 16 9 three phase

* Devices have a high efciency pump and full the criteria of the Ecodesign Directive valid from 2015 for energy-related products (ErP)

Overview of units

3

Aquarea air / water heat pump – design handbook 07 / 2014

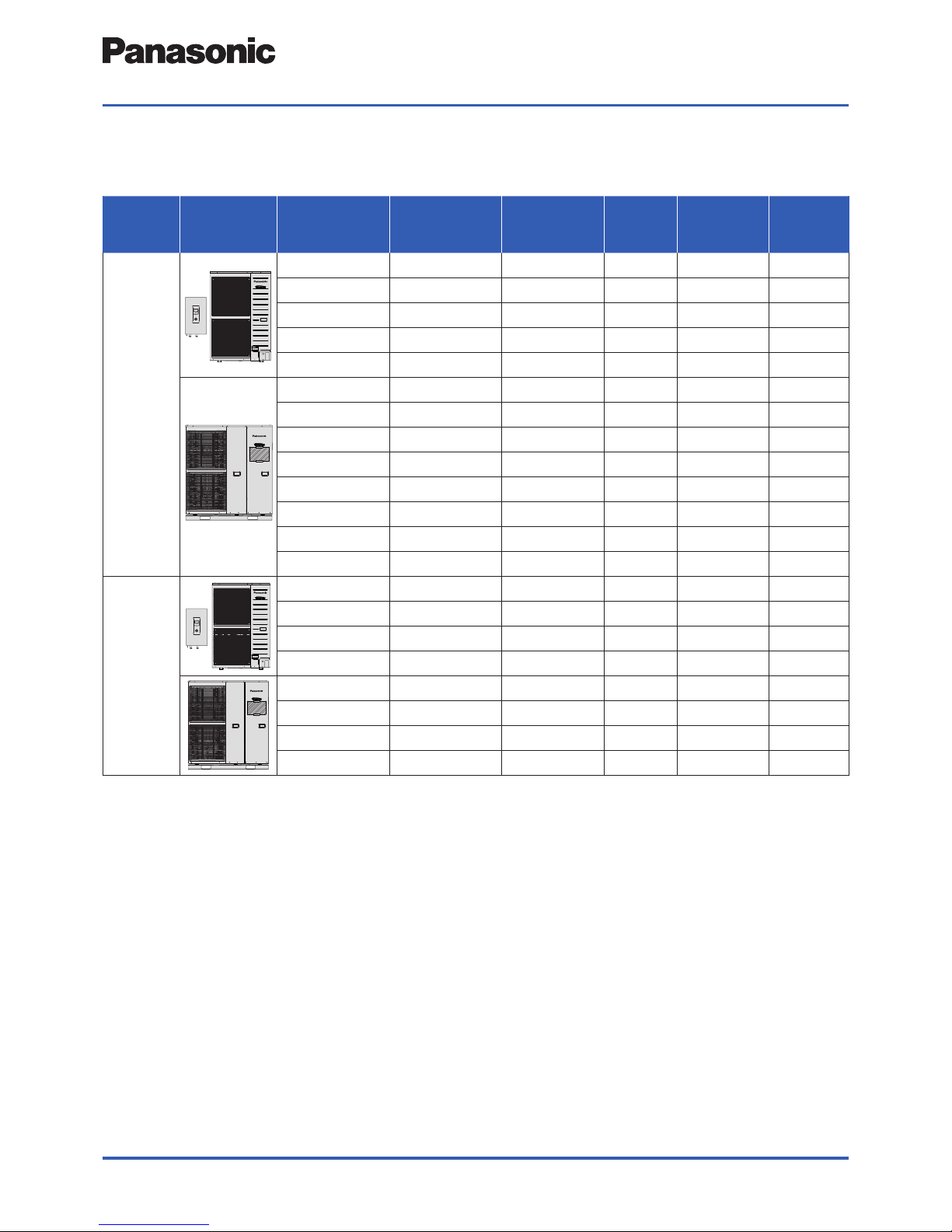

Series Units Hydromodule

(Indoor unit

Bi-Bloc)

Outdoor unit

(Bi-Bloc or

Monobloc)

Operating mode Nominal

heating

capacity kW

Capacity of

additional elec-

tric heater kW

Single or

Three phase

Aquarea

T-CAP

WH-SXC09F3E5* WH-UX09FE5 Heating + cooling 9 3 single phase

WH-SXC09F3E8* WH-UX09FE8 Heating + cooling 9 3 three phase

WH-SXC12F6E5* WH-UX12FE5 Heating + cooling 12 6 single phase

WH-SXC12F9E8* WH-UX12FE8 Heating + cooling 12 9 three phase

WH-SXC16F9E8* WH-UX16FE8 Heating + cooling 16 9 three phase

WH-MXF09D3E5 Heating 9 3 single phase

WH-MXC09D3E5 Heating + cooling 9 3 single phase

WH-MXF09D3E8 Heating 9 3 three phase

WH-MXC09D3E8 Heating + cooling 9 3 three phase

WH-MXF12D6E5 Heating 12 6 single phase

WH-MXC12D6E5 Heating + cooling 12 6 single phase

WH-MXF12D9E8 Heating 12 9 three phase

WH-MXC12D9E8 Heating + cooling 12 9 three phase

Aquarea

HT

WH-SHF09F3E5* WH-UH09FE5 Heating 9 3 single phase

WH-SHF09F3E8* WH-UH09FE8 Heating 9 3 three phase

WH-SHF12F6E5* WH-UH12FE5 Heating 12 6 single phase

WH-SHF12F9E8* WH-UH12FE8 Heating 12 9 three phase

WH-MHF09D3E5 Heating 9 3 single phase

WH-MHF09D3E8 Heating 9 3 three phase

WH-MHF12D6E5 Heating 12 6 single phase

WH-MHF12D9E8 Heating 12 9 three phase

Overview of all available models and their properties (for explanation of unit names, refer to the “Systematics” section)

4

Aquarea air / water heat pump – design handbook 07 / 2014

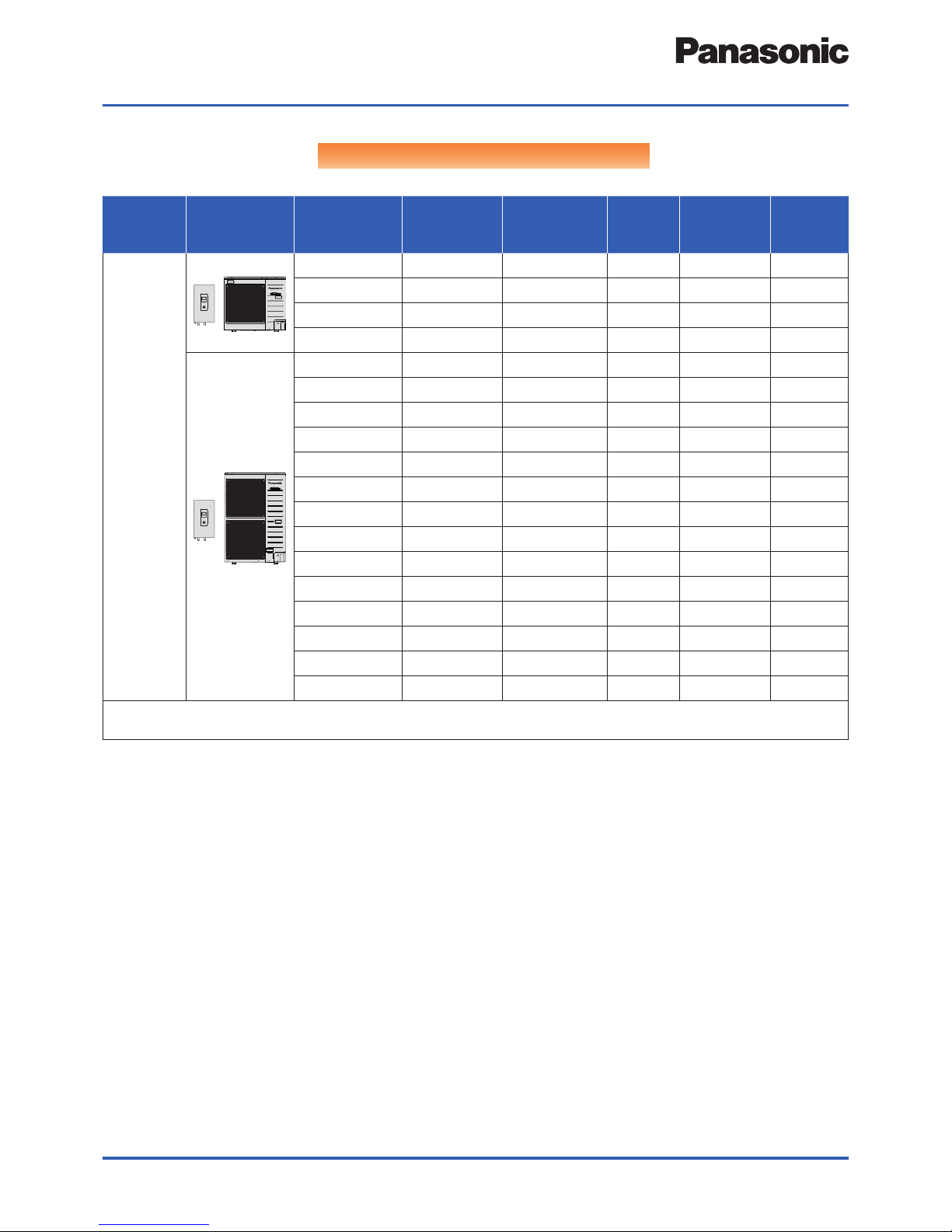

Series Units Hydromodule

(Indoor unit

Bi-Bloc)

Outdoor unit

(Bi-Bloc or

Monobloc)

Operating mode Nominal

heating

capacity kW

Capacity of

additional elec-

tric heater kW

Single or

Three phase

Aquarea LT

WH-SDF07C3E5 WH-UD07CE5 Heating 7 3 single phase

WH-SDC07C3E5 WH-UD07CE5 Heating + cooling 7 3 single phase

WH-SDF09C3E5 WH-UD09CE5 Heating 9 3 single phase

WH-SDC09C3E5 WH-UD09CE5 Heating + cooling 9 3 single phase

WH-SDF09C3E8 WH-UD09CE8 Heating 9 3 three phase

WH-SDC09C3E8 WH-UD09CE8 Heating + cooling 9 3 three phase

WH-SDF12C6E5 WH-UD12CE5 Heating 12 6 single phase

WH-SDC12C6E5 WH-UD12CE5 Heating + cooling 12 6 single phase

WH-SDF12C9E8 WH-UD12CE8 Heating 12 9 three phase

WH-SDC12C9E8 WH-UD12CE8 Heating + cooling 12 9 three phase

WH-SDF14C6E5 WH-UD14CE5 Heating 14 6 single phase

WH-SDC14C6E5 WH-UD14CE5 Heating + cooling 14 6 single phase

WH-SDF14C9E8 WH-UD14CE8 Heating 14 9 three phase

WH-SDC14C9E8 WH-UD14CE8 Heating + cooling 14 9 three phase

WH-SDF16C6E5 WH-UD16CE5 Heating 16 6 single phase

WH-SDC16C6E5 WH-UD16CE5 Heating + cooling 16 6 single phase

WH-SDF16C9E8 WH-UD16CE8 Heating 16 9 three phase

WH-SDC16C9E8 WH-UD16CE8 Heating + cooling 16 9 three phase

* Devices have a high efciency circulating pump and full the criteria of the Ecodesign Directive valid from 2015 for energy-related products (ErP)

Overview of units

Phase-out models C,D & E series

5

Aquarea air / water heat pump – design handbook 07 / 2014

Series Units Hydromodule

(Indoor unit

Bi-Bloc)

Outdoor unit

(Bi-Bloc or

Monobloc)

Operating mode Nominal

heating

capacity kW

Capacity of

additional elec-

tric heater kW

Single or

Three phase

Aquarea

T-CAP

WH-SXF09D3E5 WH-UX09DE5 Heating 9 3 single phase

WH-SXC09D3E5 WH-UX09DE5 Heating + cooling 9 3 single phase

WH-SXF09D3E8* WH-UX09DE8 Heating 9 3 three phase

WH-SXC09D3E8 WH-UX09DE8 Heating + cooling 9 3 three phase

WH-SXF12D6E5 WH-UX12DE5 Heating 12 6 single phase

WH-SXC12D6E5 WH-UX12DE5 Heating + cooling 12 6 single phase

WH-SXF12D9E8* WH-UX12DE8 Heating 12 9 three phase

WH-SXC12D9E8 WH-UX12DE8 Heating + cooling 12 9 three phase

Aquarea

HT

WH-SHF09D3E5 WH-UH09DE5 Heating 9 3 single phase

WH-SHF09D3E8 WH-UH09DE8 Heating 9 3 three phase

WH-SHF12D6E5 WH-UH12DE5 Heating 12 6 single phase

WH-SHF12D9E8 WH-UH12DE8 Heating 12 9 three phase

Overview of all available models and their properties (for explanation of unit names, refer to the “Systematics” section)

Phase-out models C,D & E series

6

Aquarea air / water heat pump – design handbook 07 / 2014

Table of contents

1 Introduction ......................................................................................................... 8

1.1 Operating principles of the air / water heat pump

...................................................... 8

1.2 Coefcient of Performance and performance factor

................................................... 9

1.3 Economical and environmentally friendly

............................................................... 10

2 Heat pump system

............................................................................................... 12

2.1 Heat source

.................................................................................................. 12

2.2 Heat pump

.................................................................................................... 13

2.2.1 Function and properties

.......................................................................... 13

2.2.2 Operating mode

................................................................................... 13

2.3 Heat utilisation

............................................................................................... 14

2.3.1 Heating

.............................................................................................. 14

2.3.2 Water heating

...................................................................................... 15

2.3.3 Cooling

.............................................................................................. 16

2.4 Systematics and overview

................................................................................. 17

2.4.1 Systematics

........................................................................................ 17

Hydromodule

....................................................................................... 17

Outdoor unit

........................................................................................ 18

Monobloc unit

...................................................................................... 18

2.4.2 Overview

............................................................................................ 19

Series

................................................................................................ 20

Bi-Bloc and Monobloc system

.................................................................. 21

3 Products, functions and technical data

..................................................................... 22

3.1 Bi-Bloc system

............................................................................................... 22

3.1.1 Product features

................................................................................... 22

Hydromodule

....................................................................................... 24

Outdoor unit

........................................................................................ 27

Technical data

...................................................................................... 30

3.2 Monobloc system

........................................................................................... 38

3.2.1 Monobloc unit

...................................................................................... 40

Technical data

...................................................................................... 42

3.3 Accessories

.................................................................................................. 44

3.3.1 Hot water tank

..................................................................................... 44

3.3.2 Extras

................................................................................................ 53

4 Closed-loop control

.............................................................................................. 54

4.1 Design

........................................................................................................ 54

4.2 Functions

..................................................................................................... 54

4.2.1 Basic functions

..................................................................................... 54

4.2.2 Further functions

.................................................................................. 57

4.2.3 Safety functions

.................................................................................... 58

4.3 Extensions and external interfaces

...................................................................... 58

4.3.1 External room thermostat

........................................................................ 58

4.3.2 Deactivation of heating circuits in cooling mode

............................................. 59

4.3.3 External control of the Aquarea heat pump

................................................... 59

4.3.4 External solar thermal installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.3.5 Aquarea Heat Pump Manager

.................................................................. 61

4.3.6 “Smart Grid” function via the Heat Pump Manager

......................................... 63

7

Aquarea air / water heat pump – design handbook 07 / 2014

5 Project Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.1 Design steps

................................................................................................. 66

5.2 Panasonic Aquarea Designer

............................................................................. 66

5.3 Establishing the heating load and outside design temperature

..................................... 67

5.4 Sizing the Hot Water Cylinder

............................................................................ 69

5.5 Establishing the heat emitter temperatures

............................................................ 71

5.6 Operating mode and bivalence point

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.7 Heat pump selection

........................................................................................ 73

5.7.1 General criteria

.................................................................................... 73

5.7.2 What capacity is needed?

....................................................................... 73

5.8 Planning of installation room

.............................................................................. 76

5.8.1 Room volume for bi-bloc system

............................................................... 77

5.8.2 Assembly conditions and minimum distances from hydromodule

........................ 77

5.9 Planning heat source – air

................................................................................. 79

5.9.1 Bi-Bloc system

..................................................................................... 79

Capacity decrease in long refrigerant pipe runs

............................................. 80

Assembly conditions and minimum distances around outdoor unit

...................... 80

Fastening of the outdoor unit

.................................................................... 81

5.9.2 Monobloc system

.................................................................................. 82

Assembly conditions and minimum distances from monobloc unit

....................... 83

Fastening of the monobloc unit

................................................................. 84

5.10 Acoustics

..................................................................................................... 85

5.10.1 Sound pressure level

............................................................................. 85

5.10.2 Sound power levels for estimation of sound pressure level

............................... 86

5.11 Cooling

........................................................................................................ 89

5.11.1 Cooling with underoor heating

................................................................. 89

5.11.2 Cooling with fan convectors

..................................................................... 89

5.12 Electrical connection

........................................................................................ 90

5.12.1 Power supply

....................................................................................... 90

5.12.2 Connections to the inputs and outputs

........................................................ 93

5.12.3 DNO and tariffs

.................................................................................... 94

5.13 Hydraulics

.................................................................................................... 94

5.13.1 Hydraulic integration

.............................................................................. 94

Hydraulic decoupling for standard pumps and high-efciency pumps

without differential pressure control

............................................................ 95

Hydraulic decoupling for high-efciency pumps with differential pressure control

...... 95

Inline/Strainer lter

................................................................................ 96

Magnetic Particle Filter

........................................................................... 96

System volume

.................................................................................... 96

5.13.2 Pumping height and pipe network resistance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.13.3 Pumping height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.13.4 Hydraulic balancing

............................................................................. 101

5.13.5 Special behaviour when cooling

.............................................................. 101

5.13.6 Expansion vessel

................................................................................ 102

5.13.7 Heating water quality

........................................................................... 103

5.13.8 Use of buffer tanks

.............................................................................. 103

6 Examples

......................................................................................................... 104

6.1 Legend

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Examples 1 to 10

.......................................................................................... 105 – 114

7 Appendix

.......................................................................................................... 115

8

Aquarea air / water heat pump – design handbook 07 / 2014

Introduction

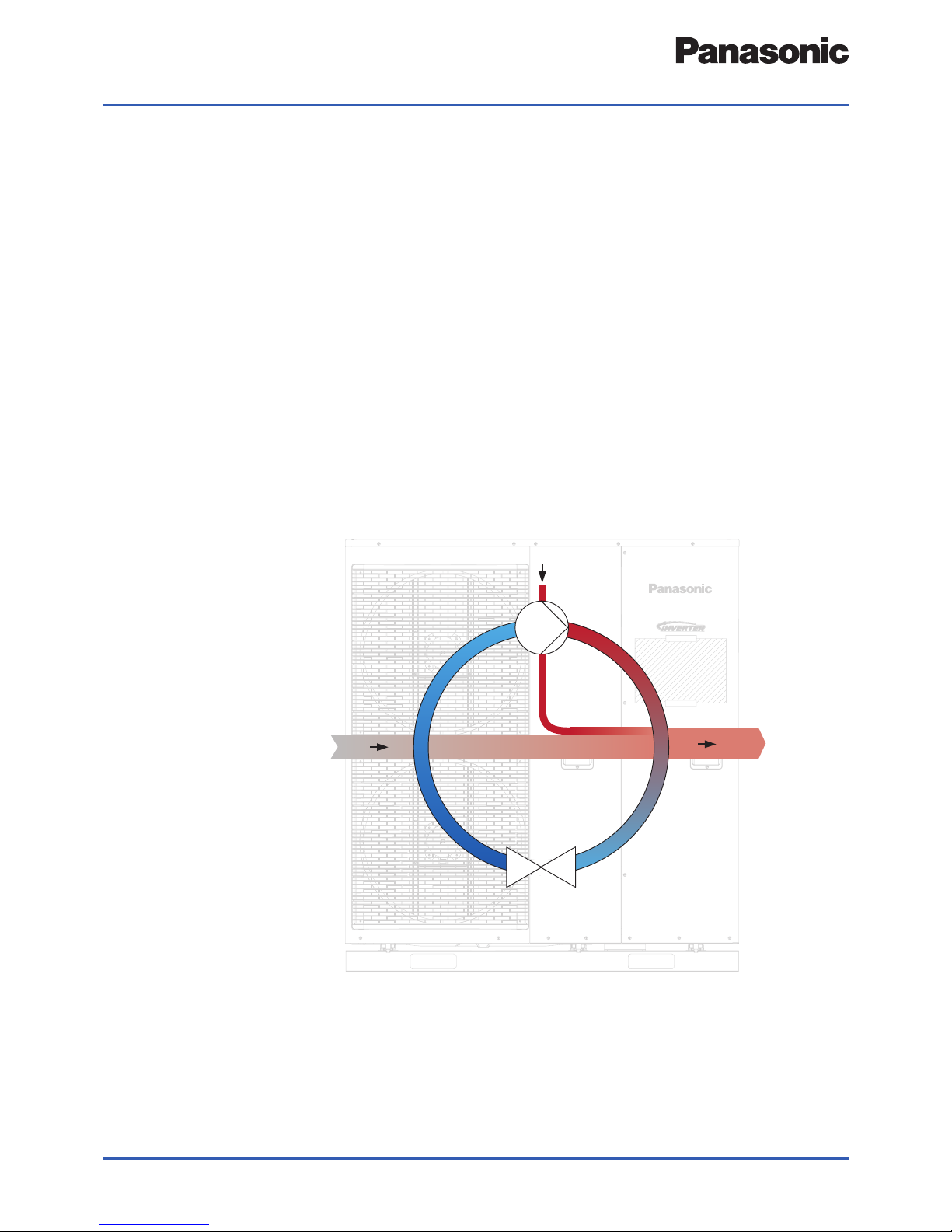

Operating principles of the air / water heat pump

1 Heat energy content

in ambient air (Evaporator)

2 Electrical input

3 Available heat energy

(Condenser)

4 Compressor

5 Expansion valve

For comfortable living to be achieved, room temperatures should be

slightly above 20 °C. This temperature deviates only slightly from the

outside temperature during most of the year.

In contrast to heating systems that utilise a boiler, which generates temperatures of several hundred degrees during the combustion process, a

heat pump generates only the temperature that is needed. In doing so, the

Aquarea air / water heat pump utilises the heat energy in the surrounding

air to heat buildings and provide hot water. In other words, the system

utilises the freely available environmental air. Electricity is needed only to

operate the compressor, electronics, pumps and to operate the

additional

electric heater in the event of extremely low outside temperatures.

Operating principles of an air / water heat pump

1 Introduction

1.1 Operating principles of the air / water heat pump

3

5

4

2

1

9

Aquarea air / water heat pump – design handbook 07 / 2014

Introduction

Coefcient of Performance and performance factor

Ambient heat is brought up to a higher temperature level in a cyclical

process. To do this, an environmentally compatible refrigerant undergoes

four steps:

• The refrigerant boils inside the evaporator where it is transformed

from a liquid into the gas state. During this step, heat is extracted

from the surrounding air (gure 1 on the previous page).

• Inside the compressor the pressure of the gaseous refrigerant is

greatly increased. The temperature increases accordingly. This step

occurs with the supply of electric energy (gure 2 on the previous

page).

• In the condenser, the gaseous refrigerant condenses and dissipates

the latent heat of condensation to the heating water, whereby it cools

down at the same time (gure 3 on the previous page).

• The pressure of the liquid coolant drops suddenly when it passes

through the expansion valve, causing its temperature to drop heavily

and thus allowing it to once more absorb heat from the ambient environment (gure 5 on the previous page).

This process is a continuous cycle and can be controlled by the

inverter-plus technology of the Aquarea heat pump so that the current

heat re quirement is catered for.

Reversing the cycle process causes the unit to act like a refrigerator.

This allows Aquarea heat pumps to be used also for air conditioning.

The Coefcient of Performance (COP) of a heat pump is dened as the

ratio of heat power output to the electrical power input and says something about the efciency of the heat pump at a certain moment.

Depending upon the outside temperature and the temperature of the

generated heat, the COP of heat pumps will differ. It is generally the

case that the coefcient of performance decreases in proportion with

an increasing temperature difference between the outside temperature

and the temperature of the heat generated. A comparison of the efciency

of different heat pumps is only possible at the same temperatures.

COPs for air / water heat pumps are normally measured at the following

temperatures:

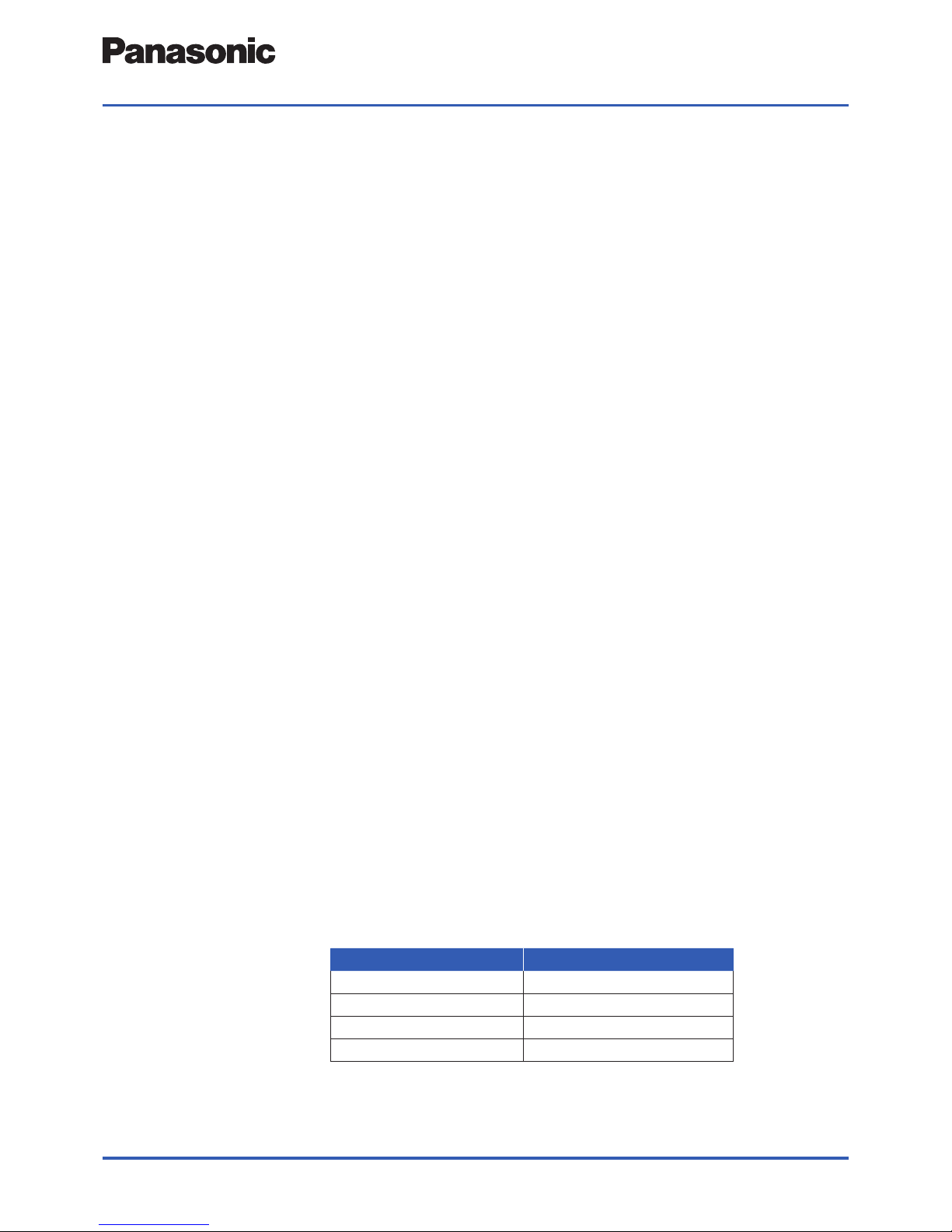

Outside temperature Output ow temperature

A-15 W35

A-7 W35

A7 W35

A2 W55

(A stands for Air, W stands for Water)

1.2 Coefcient of Performance and performance factor

10

Aquarea air / water heat pump – design handbook 07 / 2014

Introduction

Economical and environmentally friendly

Example Coefcient of performance = 5.08 (A7 / W35)

For an outside temperature of 7 °C the air / water heat pump produces

hot water at 35 °C at a COP of 5.08. Thus, 5.08 kilowatt-hours of heat

energy can be generated from one kilowatt-hour of electrical energy.

Performance factor is more meaningful than the COP, which represents

the ratio of heat energy output to the electrical energy input over a certain period. The seasonal performance factor (SPF) is the ratio of heat

energy output to the electrical enegy input over a one year period. It is

obtained from heat and electricity meters and includes all aspects of the

heat pump system.

Similar to the coefcient of performance for the heating operation, the

coefcient of performance for the cooling operation is dened as the

ratio of heat power removed to the electrical power input. In contrast to

COP, it is abbreviated with EER = energy efciency ratio.

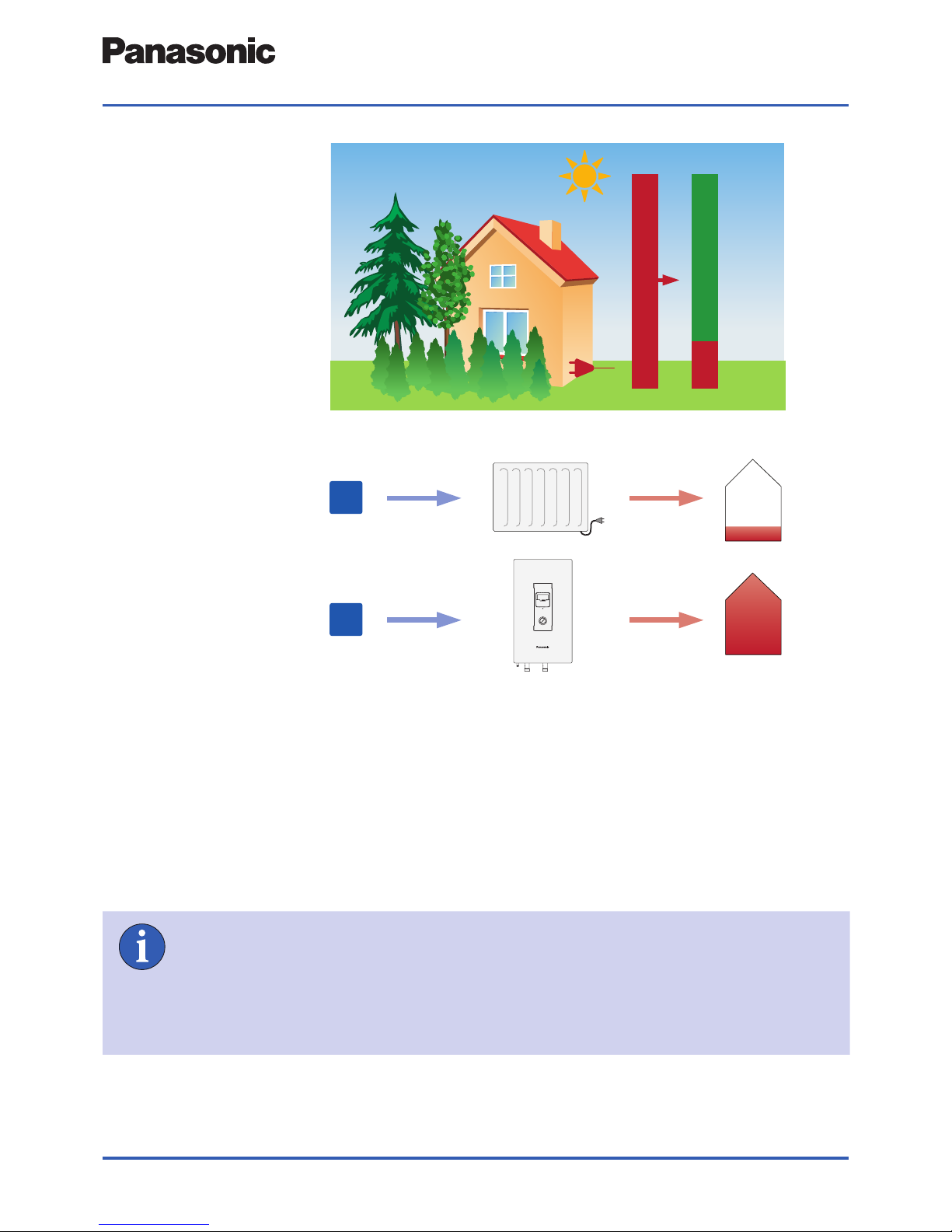

More than 75 % of energy use in the household is used for heating and

hot water. At the same time fuel prices (oil, gas, wood pellets) are subject to strong price uctuations and are becoming increasingly more

expensive.

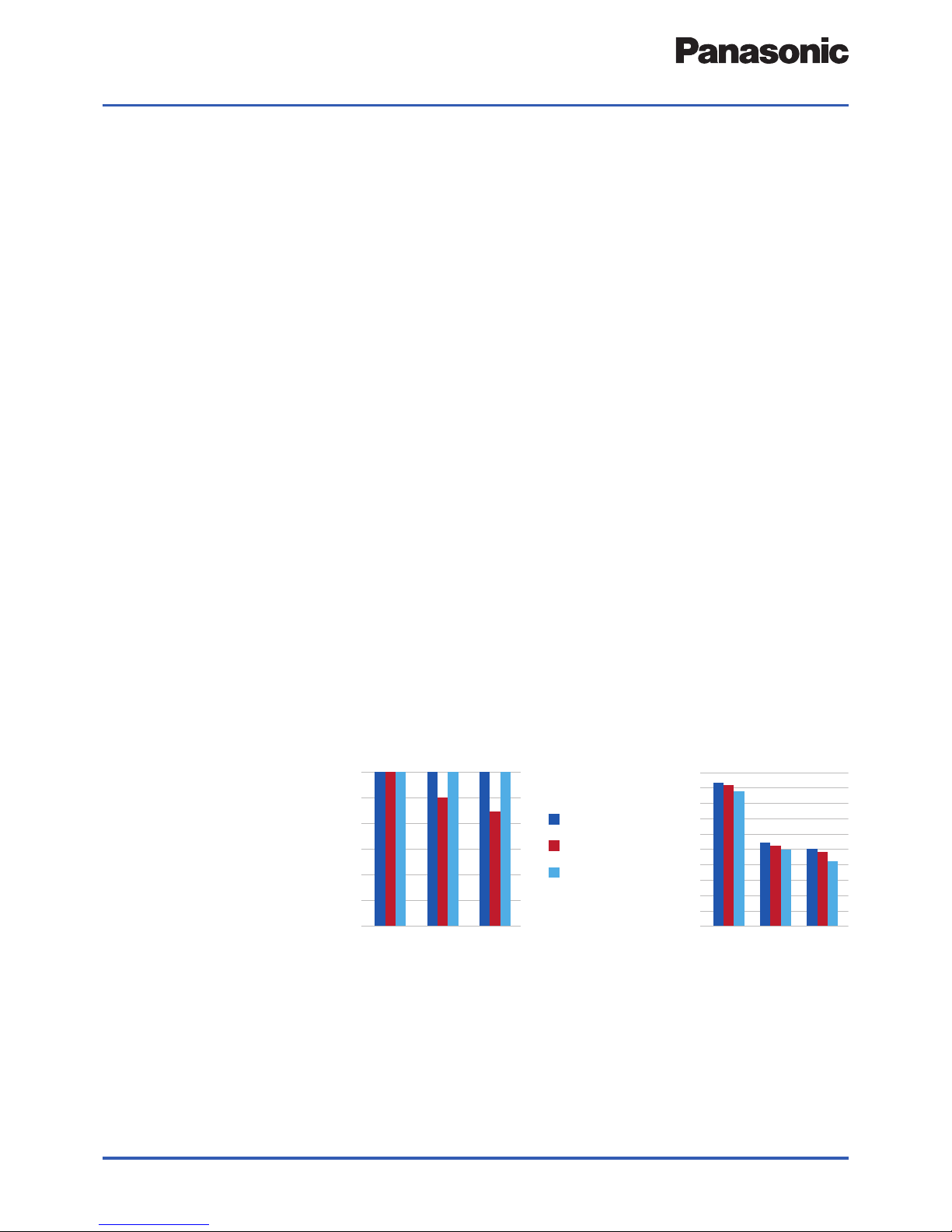

In contrast, an Aquarea heat pump utilises up to 80 % free ambient heat

can be used. Electrical energy must be used only for the remaining 20 %

of the heat pump operation. In comparison with a direct electric heater,

the amount of electrical energy used for the same heat production is

reduced down to a quarter.

In comparison with fossil fuel based heating systems, the dependence

on oil price and risky energy imports is therefore reduced. In addition,

the share of renewable energy in electricity production today is already

about 25 % in the UK and expected to rise. Besides the ambient heat,

the electric energy used for heat pumps is increasingly derived from

renewable energy sources.

Besides low electricity use, a yearly oil or gas service is no longer required. Additionally, the investment costs for an Aquarea air / water heat

pump are proportionally lower in comparison to other heating systems

with natural gas connection, chimney, oil tank or boreholes.

Aquarea heat pumps can optionally be operated also with cooling

function and supplemented with a solar system. This allows comfort

and efciency to be increased further.

1.3 Economical and environmentally friendly

11

Aquarea air / water heat pump – design handbook 07 / 2014

Introduction

Economical and environmentally friendly

Air to water heat pump heating installations can receive nancial support

via the UK Domestic Renewable Heat Incentive (dRHI) and the non-domestic RHI. Current tariff rates can be found at www.ofgem.gov.uk. For

equipment of less than 45 kW, it is also a requirement of these schemes

that both equipment and installer be accredited with the Microgeneration

Certication Scheme (MCS) – www.microgenerationcertication.org

Comparison of power consumption of an Aquarea heat pump to a direct electric heater

for the same electricity input

80 %

20

%

12

1 Aquarea heat pump 2 Conventional electric heating

Note Panasonic offers a free program for sizing heat pumps with which the

seasonal performance factor can be calculated according to VDI 4650,

the Aquarea Designer (see the “Panasonic Aquarea Designer” section

in the planning chapter).

Please see www.microgenerationcertication.org for details of how to

apply for MCS accreditation.

1 kW

5.08 kW

1 kW

1 kW

outputinput

12

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Heat source

Smooth and efcient operation of the heat pump system requires careful design and

consideration of all aspects of the system from the heat source up to the heat utilisation.

Air as a heat source is available everywhere and can be utilised without

limit by means of an air-heat exchanger in combination with fans at very

low expense. However, the outside temperature uctuates signicantly in

the course of the year and is inversely proportional to the heat requirement.

This means that the most heat must be generated when the heat source

is at its coldest state. This must be accounted for during the planning

phase so that the required internal temperatures are always achieved.

Likewise the noise of the fans and air ow must be considered by ensuring minimum distances from neighbouring plots as well as by selecting a

suitable installation location.

2 Heat pump system

1 2 3

1 Heat source

ambient air

2 Heat pump

Bi-Bloc or Monobloc unit

3 Heat utilisation

Water heating

Heating

Cooling

2.1 Heat source

13

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Heat pump

Function and properties, operating mode

The heat pump as the core piece of the heat pump system was developed

by Panasonic in three different series. In this manner, individual requirements for the heat supply of buildings should be considered with each

series’ properties in mind:

Ideal for low-temperature heat emitters or underoor heating systems;

also for radiators.

For high temperature radiators (e.g. radiators in the refurbishment context), Aquarea HT can supply a water temperature of 65 °C without assistance even at outside temperatures of -15 °C.

For applications at which the kW output capacity should be kept constant

even at outside temperatures of -7 or -15 °C. It is ensured that even

under extremely low outside temperatures sufcient capacity is always

at disposal for heating the house without assistance from other heat

generators.

With the exception of the HT series, all models are available with cooling

mode. Furthermore, Aquarea heat pumps are available in 2 version:

Monobloc (the whole unit outdoors) or Bi-Bloc (indoor and outdoor unit)

(for details see the chapter 3).

It is generally true that the larger the difference between outside temperature and the temperature of the generated heat, the lower the performance factor of the heat pump. Since high temperature differences occur extremely rarely with correctly designed heat pump systems in the

course of the year, temporary heating with an additional electric heater is

often accepted. Alternatively to an additional electric heater, it is possible

to work with an alternative heat generator like a condensing boiler or a

stove with a back boiler. The four different operating modes are:

1. Monovalent operating mode

Heat pump serves as the sole heat generator.

2. Mono-energetic operating mode

Electricity is used to operate a heat pump and additional electrical

heater (electric heat pump + additional electric heater for peak load).

3. Bivalent alternative operating mode

A second heat generator supplies the property using a further energy

source, under certain conditions (e.g. stove with back boiler instead of

heat pump for outside temperatures < -5 °C).

2.2 Heat pump

2.2.1 Function

and properties

Aquarea LT

Aquarea HT

Aquarea T-CAP

2.2.2 Operating mode

Supply

temperature

65ºC

AQUAREA HT

HIGH TEMPERATURE HEAT PUMP

High COP

5,08

AQUAREA LT

LOW TEMPERATURE HEAT PUMP

100 %

Output

up to -15°C

AQUAREA T-CAP

TOTAL CAPACITY HEAT PUMP

14

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Heat utilisation

Heating

2.3 Heat utilisation

2.3.1 Heating

4. Bivalent parallel operating mode

Besides the heat pump, a second heat generator is used using a further

energy source. Both heat generators are operated simultaneously

(e.g. heat pump + condensing boiler for outside temperatures < 0 °C).

In contrast to heat generators such as boilers that produce water supply

temperatures of over 80 °C, the maximum water supply temperature of

the Aquarea heat pump is limited at 55 °C or 65 °C for Aquarea HT. This

must be accounted for during the designing of heat emitter circuits.

Underoor heating is ideal with a heat pump as the oor is a large emitter area and therefore you can use a low temperature to heat the room.

Fan convectors have the advantage of good heat dissipation to the indoor

air and are easily controllable, with the advantage of using a lower temperature than standard radiators to heat the room. At the same time they

can be used for either heating or cooling operation.

When radiators are used, they should be planned likewise with a low

design temperature of e.g. 45 °C in order to ensure a high efciency of

the heat pump system. An additional electric heater of 3 to 9 kW caters

for sustained heating comfort even under very low outside temperatures,

due to the mono-energetic mode. A bivalent operation in combination

with an external heater is a possible alternative.

The Aquarea heat pump is provided with an outside temperature

dependent control of the supply water temperature and can activate

a heating circuit in connection with a room thermostat. The control

of further heating circuits can occur via an additional heating circuit

controller or an overriding system controller on site.

Note When the heat pump is operated in connection with an additional

electric heater in mono-energetic mode, the additional electric heater

should cover a maximum of 15 % of the heat requirement.

If your system must comply with the UK Microgeneration Certication

Scheme’s MIS 3005 document, an additional electric heater should be

only designed to operate for space heating for the coldest 1 % of the year.

Note To comply with UK subsidy requirments for sub-45 kW appliances,

the document “Heat Emitter Guide” should also be consulted:

www.microgenerationcertication.org

15

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Heat utilisation

Water heating

2.3.2 Water heating The Aquarea heat pump has a water heating operation integrated within

the control system. Upon demand, the water heating operation is

switched on and heats the hot water tank via a 3-way directional valve.

Since the required temperature for water heating in general lies above

the temperature of the heating operation over the year, the coefcient of

performance (COP) is low in the water heating mode in comparison to

the heating mode. For efciency reasons, the hot water storage temperature is therefore set below 60 °C. A hot water temperature of 45 to 50 °C

is sufcient for normal applications and is not at all connected with

reduced comfort. However with lower stored temperatures, attention

must be paid to the danger of legionella which especially thrive within

the range 30 to 45 °C.

The Panasonic hot water cyinders are equipped with an electric immersion

heater which can be activated for legionella control, on a periodic timer

basis.

Aquarea heat pumps can be combined easily with solar thermal installations, which can largely take over water heating in the summer months.

Note The requirments for the control of legionella propagation in the work-

place are described in HSE guide L8

Attention When using the Panasonic hot water tank, the quality of water must

comply with the potable water directive 98/83/EC. When the chloride

and sulphate content exceeds 250 mg / l, water treatment is required.

For values above 250 mg / l the guarantee expires.

Water regulations must be considered at all times when installing an

Aquarea heat pump.

16

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Heat utilisation

Cooling

2.3.3 Cooling Depending on the product series, the cooling mode can be manually

switched via the control panel/remote control or is automatically

switched at dened temperature points. Depending on the product

series, switching over to heating mode occurs manually at the end of

the cooling period or automatically at the dened temperature thresholds.

Room cooling is possible by means of radiant panels such as underoor,

wall or ceiling cooling systems or particularly via fan convectors. Individual

heating circuits that are not suitable for the cooling operation can be

deactivated by a control system via a 2-way directional valve. For all

transfer systems, it is possible for the temperature to fall below the dew

point, which can result in condensation in the cooling mode, with high

relative humidity. This must be ruled out particularly with radiant panels,

via a dew-point sensor, the supply water temperature must be raised

through mixing with the return ow, or the cooling mode must be switched

off in an emergency. Fan convectors can be operated with much lower

supply water temperatures in comparison to radiant panels in the cooling

mode and therefore have greater cooling capacities. However, fan convectors for the cooling mode must always be provided with a condensate

drain and piping with closed-cell insulation.

Attention In the cooling mode, condensation of moisture in the air can occur on

the surface of the heat transfer systems when the temperature falls

below the dew point. This can lead to damage to the building or to the

danger of slipping on oor surfaces.

The temperature falling below the dew point must therefore be avoided

by means of suitably placed dew point sensors or the condensate

occurring must be drained safely. The affected piping must be insulated

fully against this condensation risk.

17

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Systematics and overview

Systematics

2.4 Systematics and overview

Example

For easy and clear categorisation of different Aquarea models, a key is

used, from which the models with their respective specic properties and

functions can be read.

The WH-MDC05F3E5 is a compact heat pump unit (M), in the LT series

(D), with a cooling function (C), a rated power of 5 kW (05), of the

generation F (F), for the European market (E), with a single-phase

voltage supply (5).

2.4.1 Systematics

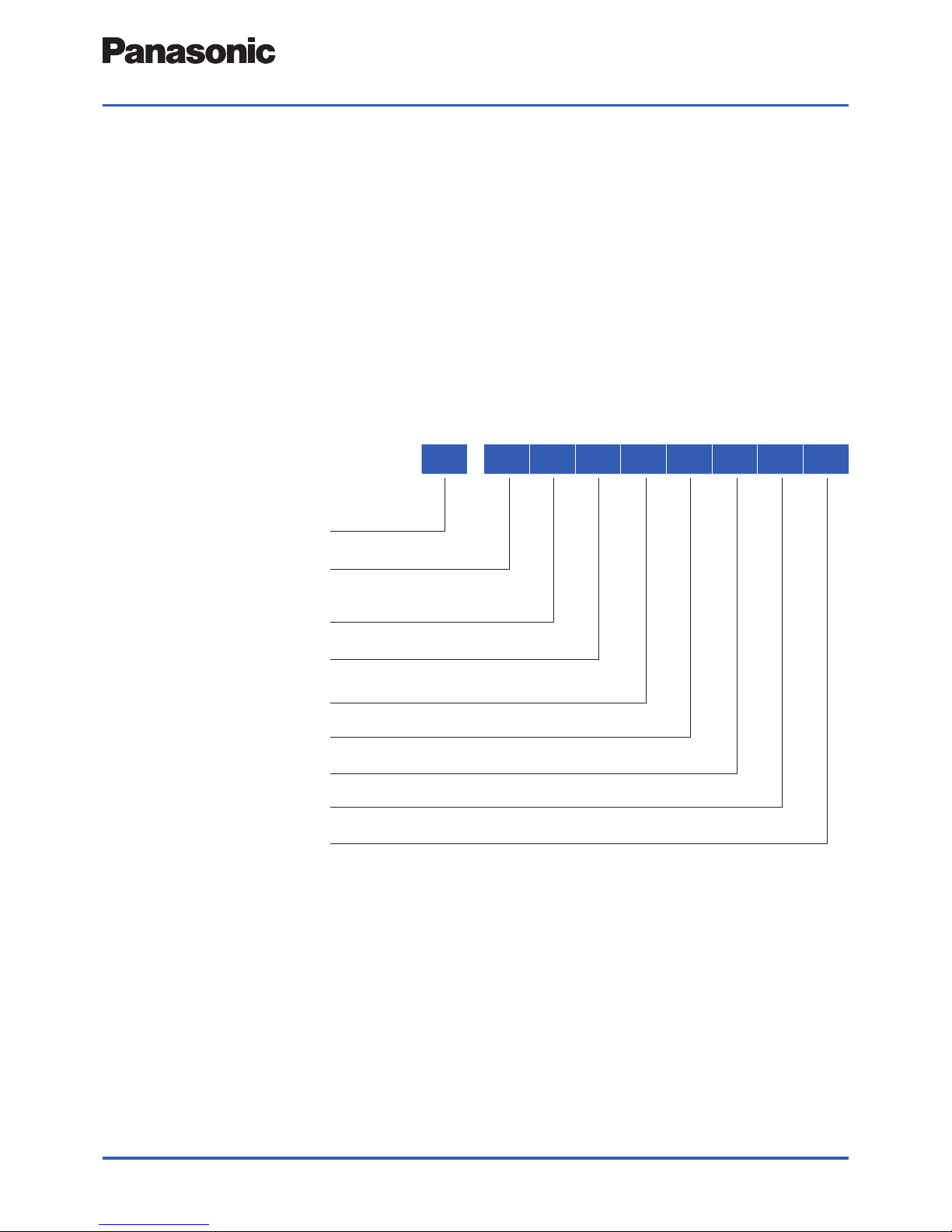

WH - S D C 07 F 3 E 5

Systematics

of hyrdomodule

(Indoore unit Bi-Bloc)

WH: air / water

heat pump

S: Split unit

D: Aquarea LT,

X: Aquarea T-CAP, H: Aquarea HT

F: Only heating, C: Heating and cooling

2

Nominal heating capacity (03 to 16: 3 to 16 kW 1)

C, D, E, F: Generation

Capacity of the additional electric heater (3: 3 kW, 6: 6 kW, 9: 9 kW)

Market (E: Europe)

Electricity supply (5: single phase, 8: three phase)

1

The available power classes differ depending on the respective series.

The table at the start of the document provides an overview of the power classes

for each individual series.

2

The units of the Aquarea HT series can only be used for heating mode and do not have

a cooling mode.

18

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Systematics and overview

Systematics

WH - M D C 09 F 3 E 5

WH - U D 07 F E 5

WH: Air / water

heat pump

M: Monobloc unit

D: Aquarea LT,

X: Aquarea T-CAP, H: Aquarea HT

F: Only heating, C: Heating and cooling

2

Nominal heating capacity (05 bis 16: 3 bis 16 kW 1)

C, D, E, F: Generation

Capacity of the additional electric heater (3: 3 kW, 6: 6 kW, 9: 9 kW)

Market (E: Europe)

Electricity supply (5: single phase, 8: three phase)

WH: Air / water heat pump

U: Split unit

D: Aquarea LT,

X: Aquarea T-CAP

1

, H: Aquarea HT

Nominal heating capacity (03 to 16: 3 to 16 kW

1

)

C, D, E, F: Generation

Market (E: Europe)

Voltage supply (5: single phase, 8: three phase)

Systematics

of outdoor unit (Bi-Bloc)

Systematics

of monobloc unit

1

The available power classes differ depending on the respective series.

The table at the start of the document provides an overview of the power classes

for each individual series.

2

The units of the Aquarea HT series can only be used for heating mode and do not have

a cooling mode.

19

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Systematics and overview

Overview

2.4.2 Overview The Aquarea heat pump system has three different series which are

again available in several model variants. This allows the best possible

consideration of the individual heating requirements and climate control

requirements of buildings with Aquarea heat pumps.

Monobloc system

• Heating and cooling or heating

• Nominal heating capacity (3, 5, 6, 7, 9, 12, 14 or 16 kW)

• Capacity of additional electric heater (3, 6 or 9 kW)

• Electric connection (single phase or three phase)

Overview of series and model variants

Aquarea LT Aquarea T-CAP

Aquarea HT

Bi-Bloc system

The variety of properties and functions of the Aquarea heat pumps

leads

to a large number of different model variants, which often only differ from

one another through small differences like the capacity of the additional

electric heater. Externally viewed, the units are nearly similar apart from

distinctive differences like the monobloc or bi-bloc system and they can

therefore be described together with regard to many properties. Relevant

differences are pinpointed at an appropriate point.

Supply

temperature

65ºC

AQUAREA HT

HIGH TEMPERATURE HEAT PUMP

High COP

5,08

AQUAREA LT

LOW TEMPERATURE HEAT PUMP

100 %

Output

up to -15°C

AQUAREA T-CAP

TOTAL CAPACITY HEAT PUMP

20

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Systematics and overview

Overview

The Aquarea heat pump models are congured so that a suitable model

is available for all typical applications. All models are listed with their

properties and functions in the table at the beginning of the Design

Handbook.

As shown in the overview tables the available systems differ externally,

especially between the monobloc systems and bi-bloc systems, and the

units are equipped with one or two fans depending on the rated power.

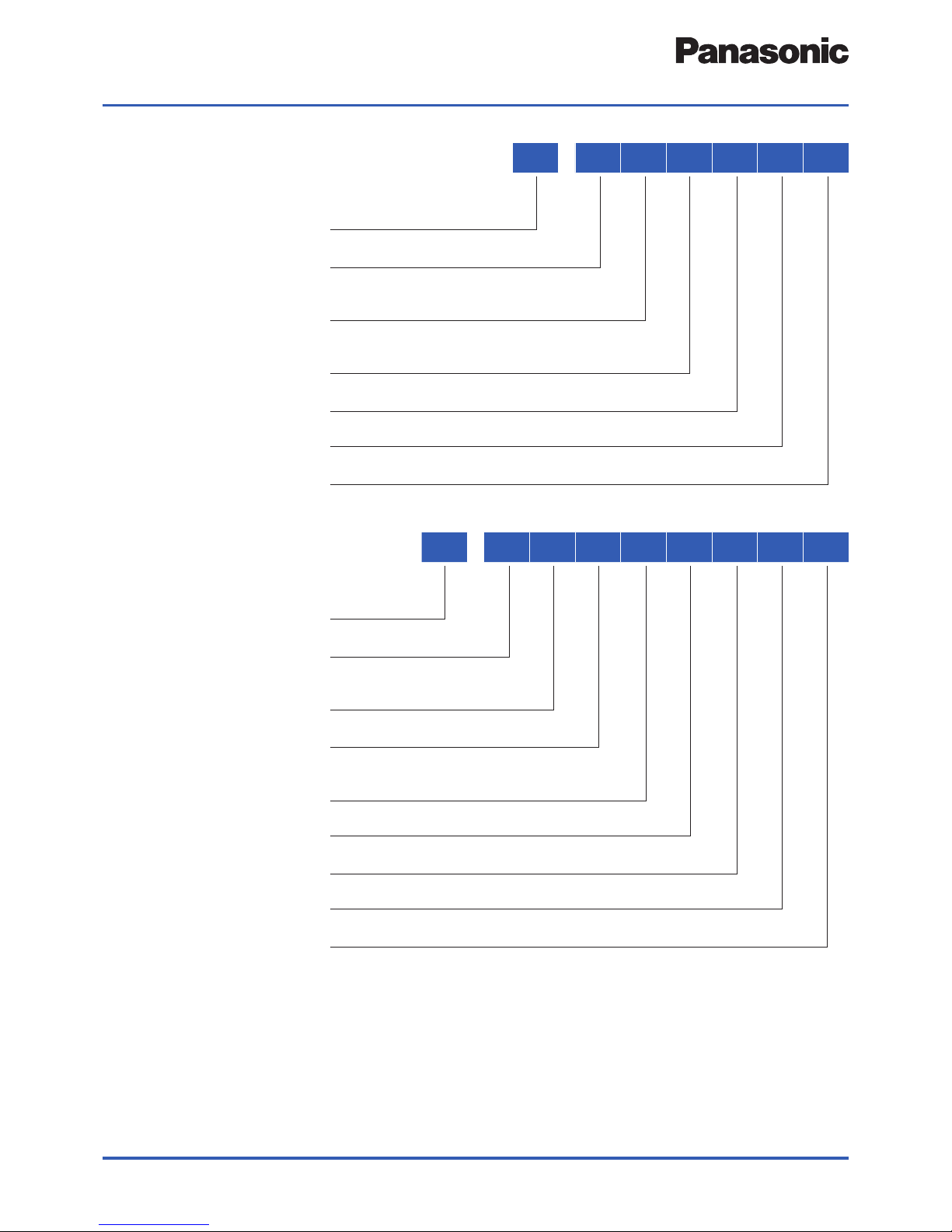

Series

Aquarea LT

Aquarea T-CAP

Aquarea HT

The Aquarea series differ through their maximum supply water

temperature and capacity stability at very low outside temperatures

as follows:

Maximum supply water temperature: 55 °C

Capacity at very low outside temperatures: kW heating capacity varies

Maximum supply water temperature: 55 °C

Capacity at very low outside temperatures: Heating capacity is

constant up to -15 °C

at 35 °C output water

temperature

Maximum supply water temperature: 65 °C

Capacity at very low outside temperatures: Heating capacity is

constant up to -15 °C

at 35 °C output water

temperature

Heating capacity and coefcient of performance (COP) of the Aquarea LT Aquarea T-CAP

and Aquarea HT series with 12 kW at different outside temperatures and a supply water

temperature of 35 ˚C and a return water temperature of 30 ˚C.

12

10

8

6

4

2

0

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

+7

°C -7 °C

-15 °C

COP

kW

+7 °C -7 °C -15 °C

Aquarea T-CAP

Aquarea LT

Aquarea HT

21

Aquarea air / water heat pump – design handbook 07 / 2014

Heat pump system

Systematics and overview

Overview

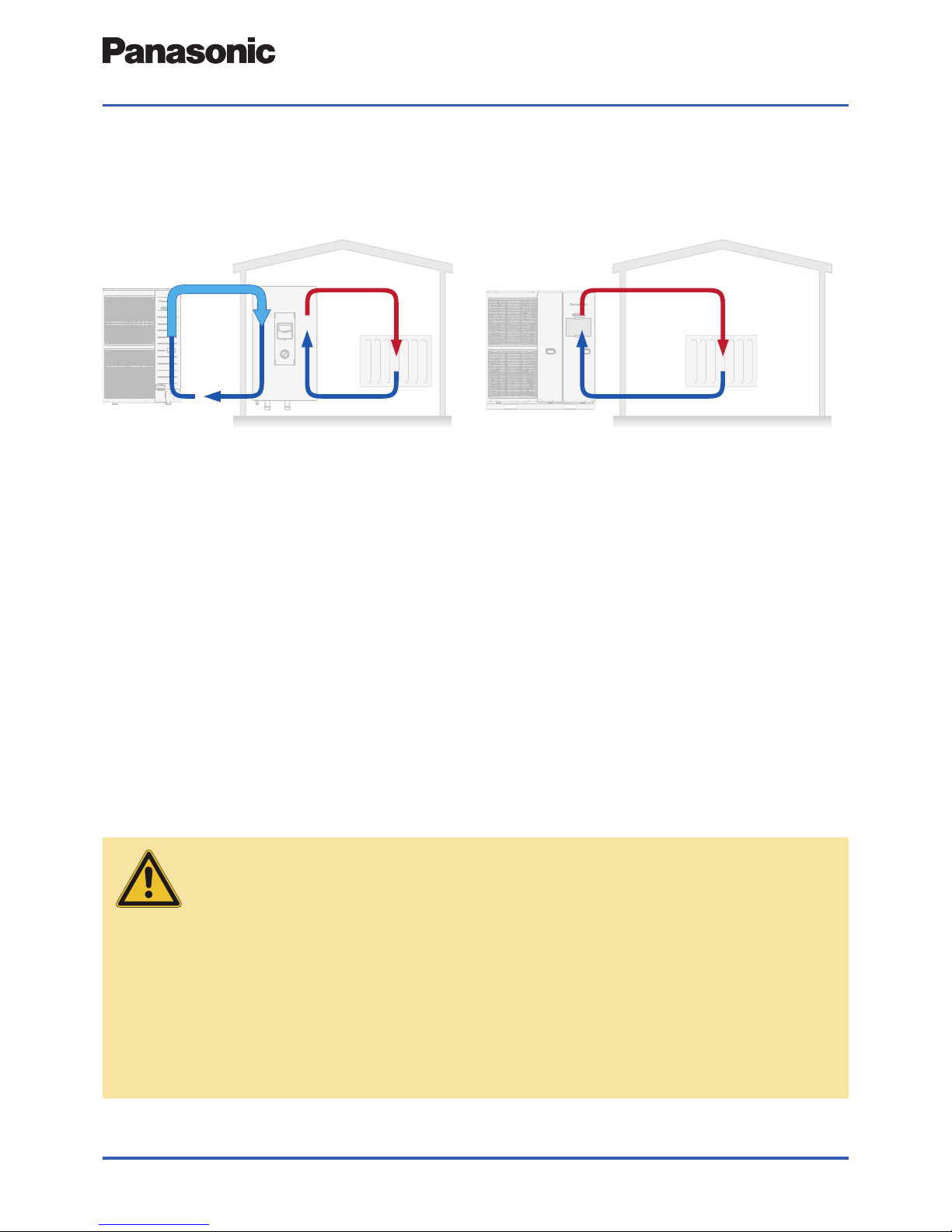

Difference between Bi-Bloc system (left) and monobloc system (right)

The bi-bloc system consists of a freely installed outdoor unit and a

hydromodule that is normally installed in the installation room or in a

different frost-free room. In the case of this design, the two units are

connected by means of refrigerant piping, in which there is no danger of

freezing. The heat pump is controlled by means of the controller on the

hydromodule.

The Monobloc system consists of only one unit that is installed outdoors.

Refrigerant piping is not required for the installation, it is connected

directly to the heating system. Monobloc systems are easy to install, but

need more space. Moreover, the water within the heating system is in

danger of freezing due to power failure or when the power supplier cuts

off the supply.

The heat pump is operated via a wired remote control that is mounted

inside the building and is connected to the Monobloc unit by means

of a 15-metre long cable.

Bi-Bloc system

Monobloc system

Bi-Bloc and Monobloc system

1

4

35

2 2

1 Refrigerant circuit

2 Heating circuit (water)

3 Outdoor unit

4 Hydromodule

5 Monobloc unit

Attention The Monobloc system is in danger of freezing when the heating circuit

is lled with water and the outside temperature decreases below +4 °C!

This can lead to substantial damage to the unit.

Freedom from frost must be ensured within the heating system through

one of the following options:

1. The heating circuit is operated with a foodgrade frost protection

mixture (propylene glycol).

2. An auxiliary electric heater inside the Monobloc unit prevents the

heating circuit from freezing.

3. The heating circuit is emptied via an owner-provided device

(manually or automatically).

22

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Product features

Specic hydromodules and outdoor units are supplied together as a set,

as each set is ne tuned to work together. Different hydromodules and

outdoor units can not thus be combined arbitrarily. The Aquarea Bi-Bloc

system consists of the hydromodule (indoor) and an outdoor unit. For all

typical applications a suitable Aquarea Bi-Bloc system model consisting

of hydro-module and outdoor unit is available.

• up to 80 % energy extraction from ambient air for a greater

energy efciency

• maximum COP of 5.00 for single phase 3 kW model for A7 / W35

• inverter technology allows controllable output of the unit and

contributes to energy saving

• environmentally compatible refrigerant (R410A with Aquarea LT and

T-CAP and R407C with Aquarea HT), does no damage to the ozone

layer

• All units from generation E onwards are equipped with high-efciency

pumps

• optimum control by means of room thermostats

(room thermostats not supplied)

• models for heating mode as well as heating and cooling mode

are available

• optimised capacity depending on the return water temperature

• integrated control of the hot water tank and heating system

• 24-hour timer with operating mode control

• operation and control on the hydromodule

• simple programming via the controller

• Aquarea hydromodule is equipped for safety reasons with:

- 2

FI RCD circuit breakers

with 3, 5, 7, 9, 12, 14 and 16 kW units

- 3 FI RCD circuit breakers with 12, 14 and 16 kW units

(Phase-out models)

3.1.1 Product features

Energy efciency

and environmental

friendliness

3 Products, functions and technical data

3.1 Bi-Bloc system

High level of comfort

Easy operation

23

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Product features

Easy maintenance

and assembly

• compact design

• easy control of the water pressure through a gauge in the front casing

• easy to open - hydromodule and outdoor unit

• exible assembly due to long piping

• piping up to 30 metres with a height difference up to 20 metres

(for models up to 9 kW)

• piping up to 40 metres with a height difference of up to 30 metres

(for models with 12 to 16 kW)

• the piping connection to the outdoor units can occur in four directions

(front, rear, side, bottom)

Supply water

temperature (°C)

Outside

temperature (°C)

Cooling mode

1

Maximum 20 43

Minimum 5 16

Heating mode Maximum 55 / 65

2

35

Minimum 25 -20

3

1

valid for models with cooling mode

2

valid for Aquarea HT

3

If the outside temperatures drop below the specied value, the heating capacity decreases

signicantly. This can lead to the shutdown of the unit due to internal safety functions.

24

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Hydromodule

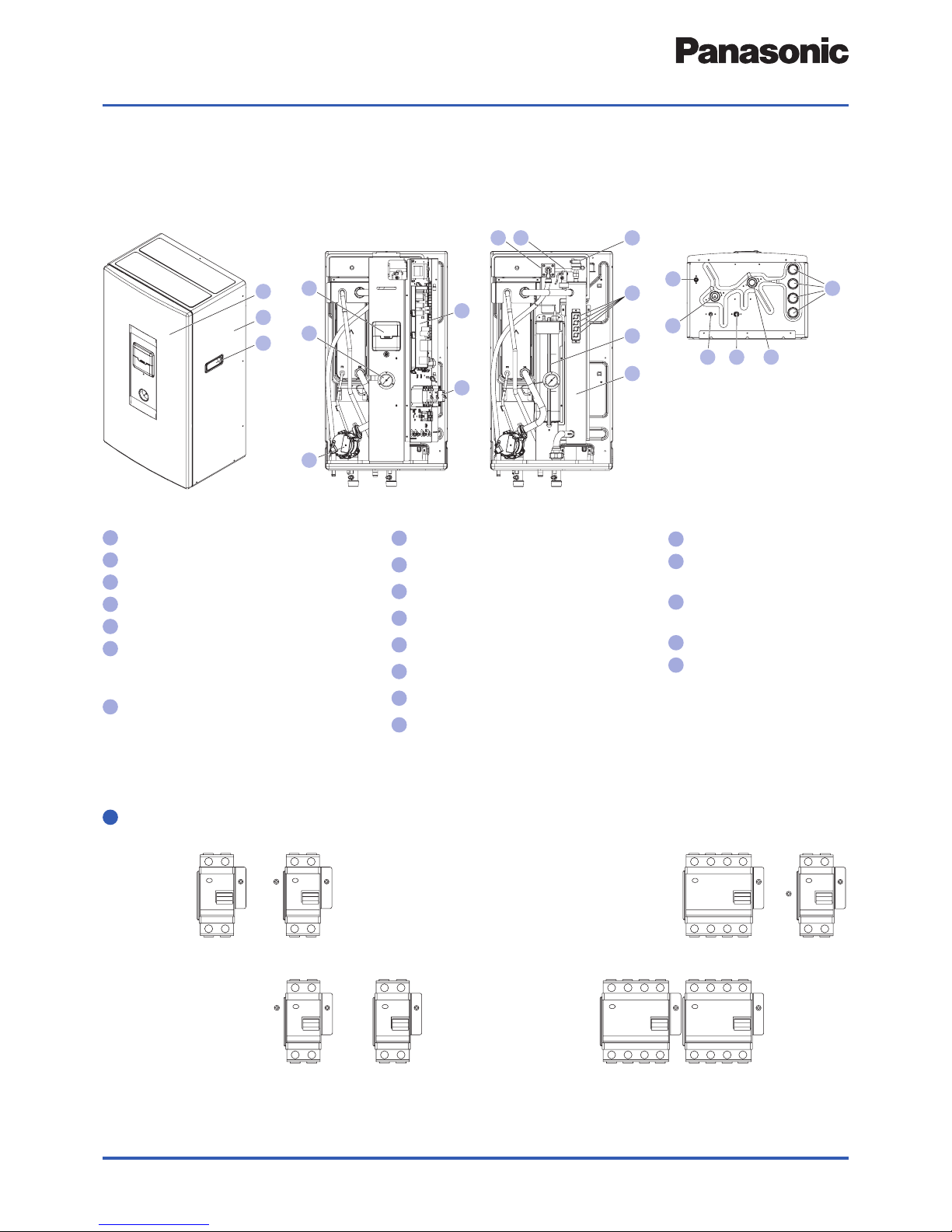

Hydromodule

Components

single phase

3 to 5 kW

three phase

9 kW

single phase

7 to 16 kW

three phase

12 to 16 kW

Component name

1

Electronic printed circuit board

2

Controller

3

Safety valve

4

Flow rate cut-out

5

Manometer (water pressure gauge)

6

Water circulation pump

(Illustration shows a high-efciency pump

without differential pressure control)

7

FI RCD circuit breakers (differs from

model to model, see Detail A)

8

Cabinet front plate

9

Cabinet

10

Handle

11

Overload protection

12

Additional electric heater

13

10 L Expansion vessel

14

Cable passage

15

Deaeration

POWER SUPPLY 1

NL

POWER SUPPLY 2

NL

POWER SUPPLY 1

NL

POWER SUPPLY 2

NL

POWER SUPPLY 2

POWER SUPPLY 1

L

A1 LA2 LA3

N

NL

POWER SUPPLY 3

L

C1LC2 LC3

N

POWER SUPPLY 1

L

A1 LA2 LA3

N

14

d

a

e

c

b

6

5

2

3

9

8

10

1

7

12

11

13

154

Connection name

a

Supply water Ø R 1¼

b

Gas side refrigerant

connection (19.1 mm)

c

Liquid side refrigerant

connection (6.4 to 9.5 mm)

d

Water drain

e

Supply water Ø R 1¼

A

Different FI RCD circuit breakers

25

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Hydromodule

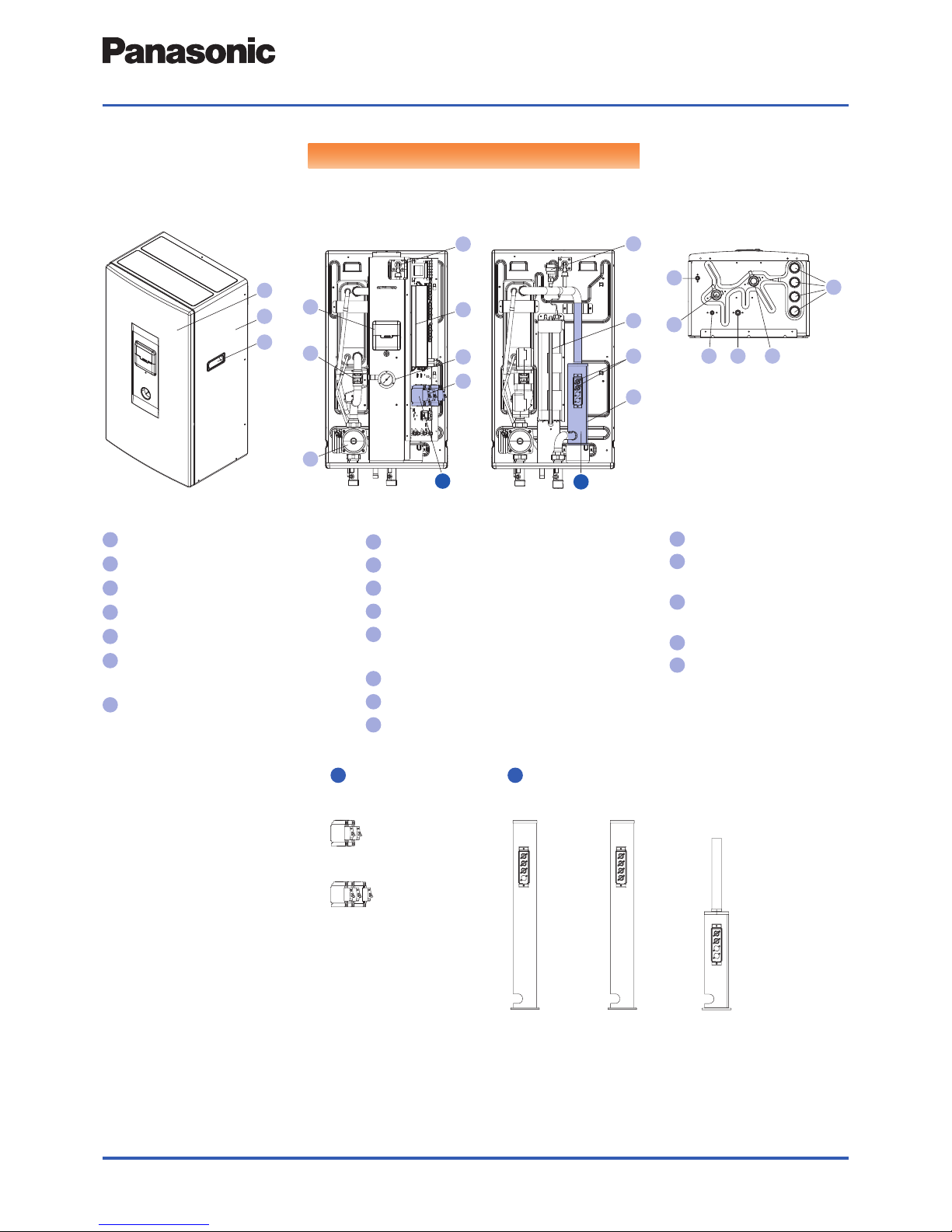

Hydromodule

Components

8

d

a

e

c

b

6

4

2

10

9

11

3

1

5

7

A

B

13

12

14

15

Phase-out models C & D series

single and three phase, 3 to 9 kW

single and three phase, 12 to 16 kW

single phase,

7

to

9 kW

Detail A (left) and B (right) of the components of hydromodule

single phase,

12

to

16 kW

three phase, 12

to

16 kW

and single phase 3

to

5 kW

Component name

1

Electronic printed circuit board

2

Controller

3

Safety valve

4

Flow rate cut-out

5

Manometer (water pressure gauge)

6

3-stage water circulation pump

(Figure shows standard pump)

7

FI RCD circuit breakers (differs from

model to model, see Detail A)

8

Cable passage

9

Cabinet front plate

10

Cabinet

11

Handle

12

Overload protection (differs from

one model to the other, see Detail B)

13

Additional electric heater (3, 6 and / or 9 kW)

14

10 l Expansion vessel

15

Deaeration

Connection name

a

Supply water Ø R 1¼

b

Gas side refrigerant

connection (19.1 mm)

c

Liquid side refrigerant

connection (6.4 to 9.5 mm)

d

Water drain

e

Supply water Ø R 1¼

A

Different FI RCD

circuit breakers

B

Different electric heating and

overload protection elements

26

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Hydromodule

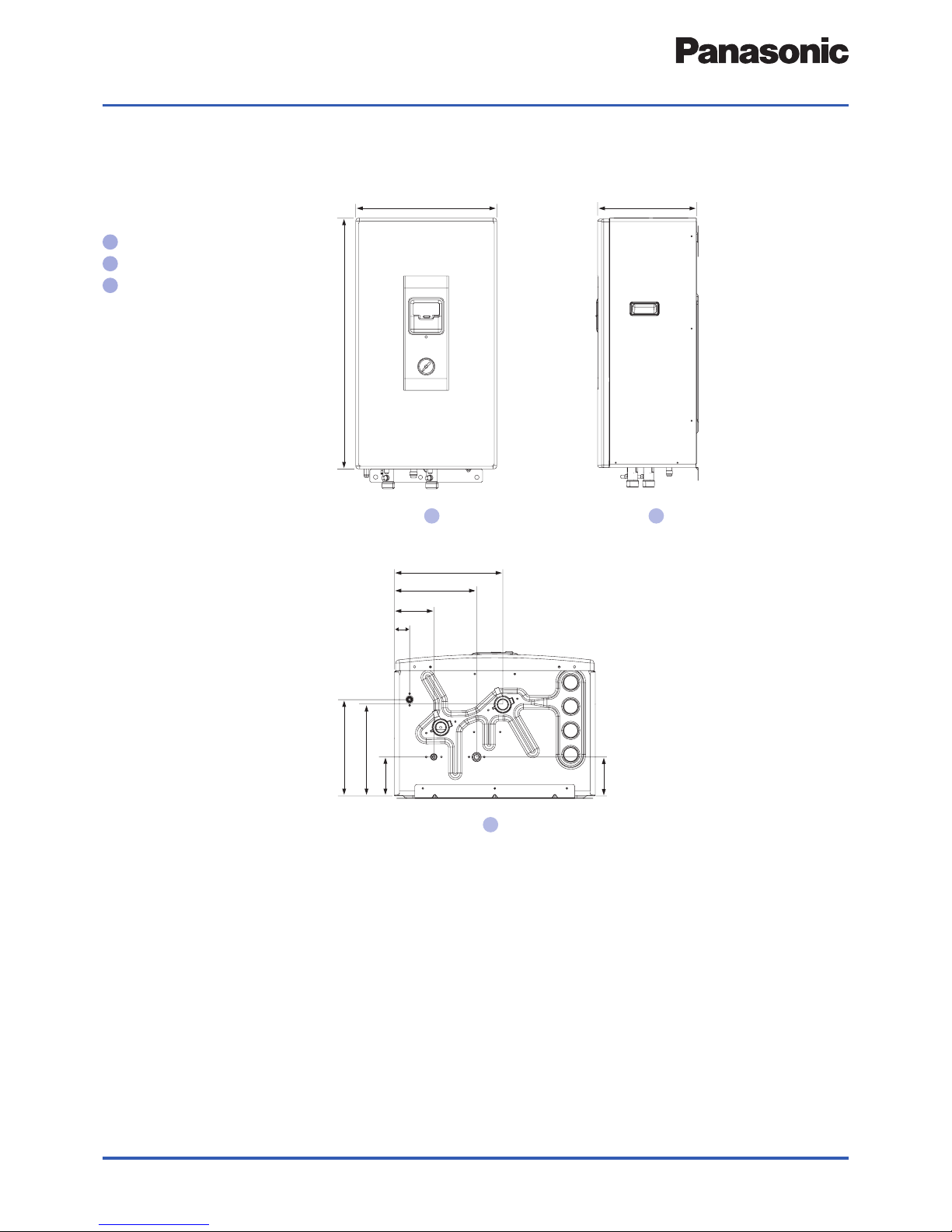

Dimensional drawing

for hydromodule

1

Front view

2

Side view

3

Bottom view

Dimensions of hydromodule in mm

98.5

97.5

38

502

892

353

271

241

228.5

97.5

205.5

1 2

3

27

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Outdoor unit

540

622

330

298

23

124

846 69

160

29837

2

3

1

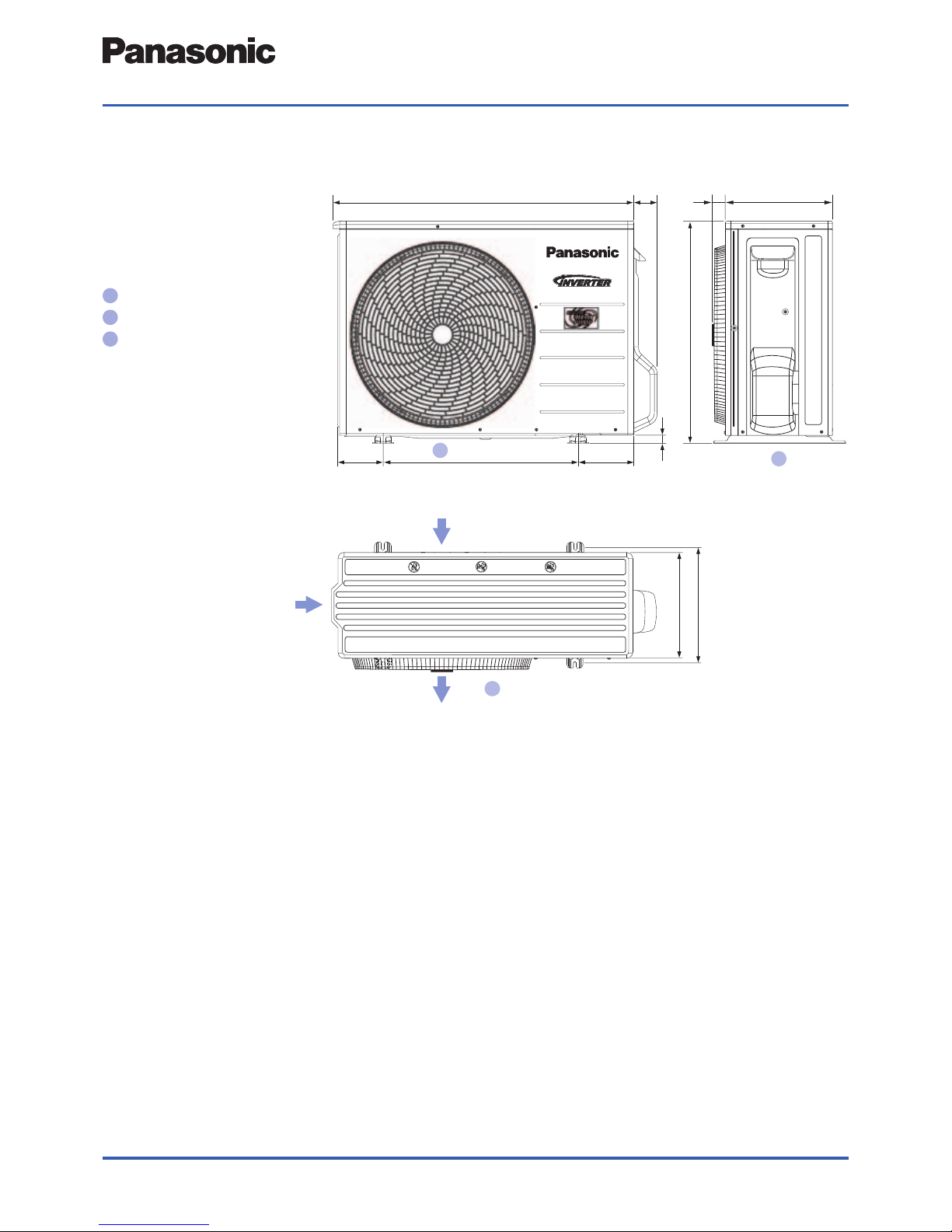

Outdoor unit

Dimensional drawing

for outdoor unit with

one fan (3 and 5 kW)

1

Front view

2

Side view

3

Bottom view

Dimensions of outdoor unit with one fan (3 and 5 kW) in mm.

The air ow is depicted by arrows.

28

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Outdoor unit

620

795

400

355

320

24

140

900

140

320

2

3

1

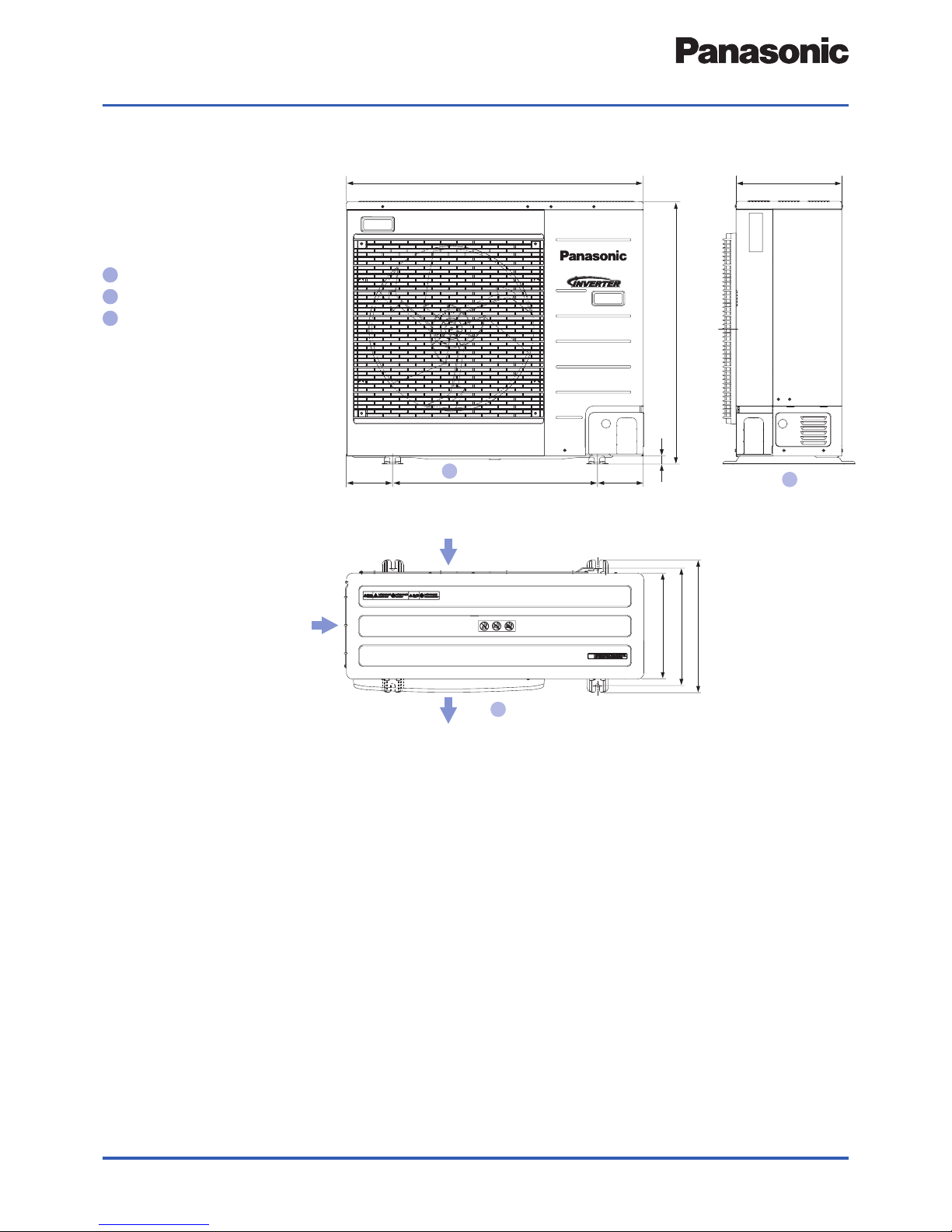

Outdoor unit

Dimensional drawing

for outdoor unit with

one fan (7 and 9 kW)

1

Front view

2

Side view

3

Top view

Dimensions of outdoor unit with one fan (7 and 9 kW) in mm.

The air ow is depicted by arrows.

29

Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Outdoor unit

1,340

400

355

320

900

320

2

3

620

140 140

1

24

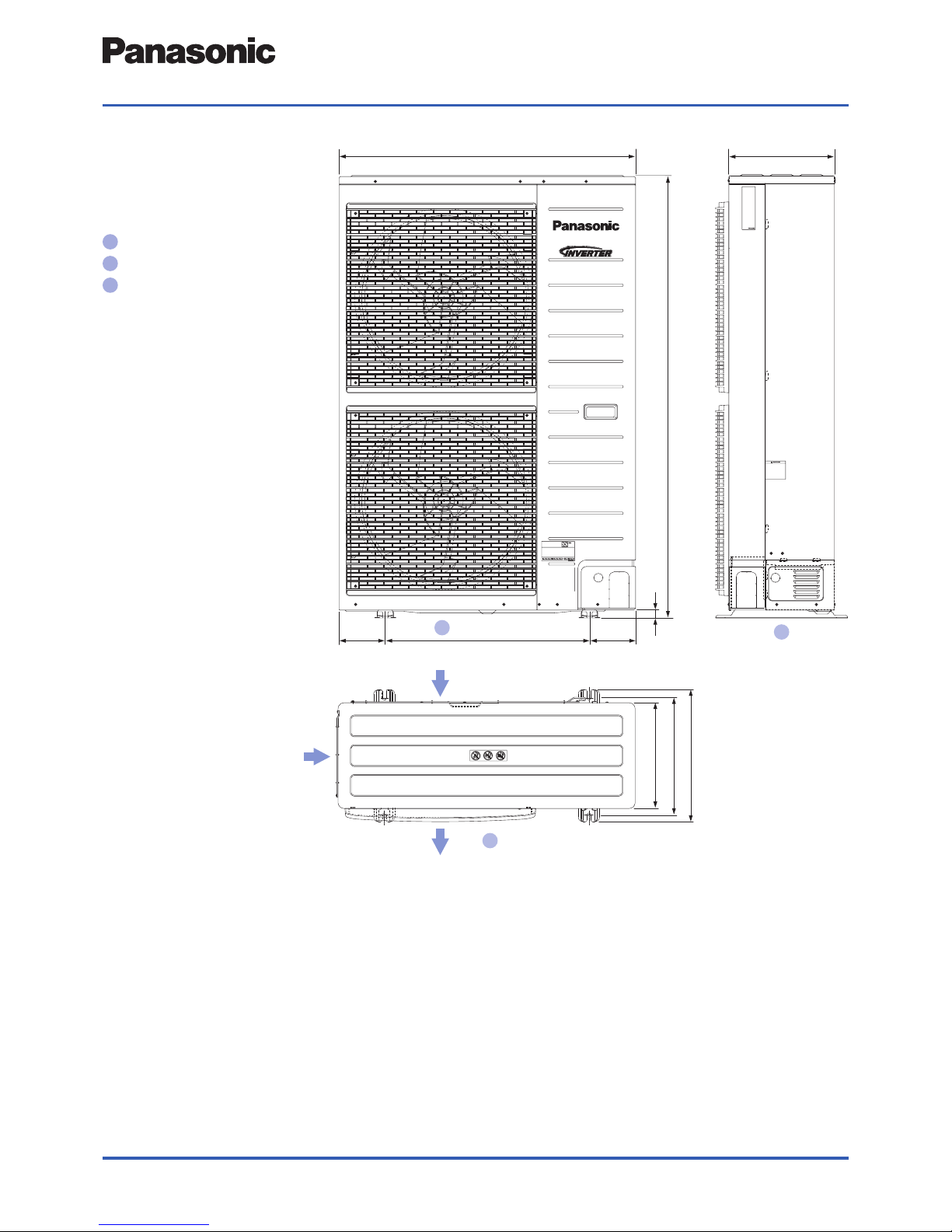

Dimensional drawing

for outdoor unit with

two fans

1

Front view

2

Side view

3

Top view

Dimensions of outdoor unit with two fans in mm. The air ow is depicted by arrows.

30 Aquarea air / water heat pump – design handbook 07 / 2014

Products, functions and technical data

Bi-Bloc system

Technical data

Bi-Bloc system

Series

Aquarea LT Aquarea LT

Phases single phase

Hydromodule

Model

WH-SDF03E3E5*

WH-SDC03E3E5*

WH-SDF05E3E5*

WH-SDC05E3E5*

WH-SDC07F3E5*

1

WH-SDC09F3E5*

1

WH-SDC12F6E5*

1

WH-SDC14F6E5*

1

WH-SDC16F6E5*

1

Output capacity

Heating capacity A-15 / W35

kW 3.2 4.2 4.29 5.9 9 9.73 10.24

Power consumption A-15 / W35

kW 1.39 1.94 1.88 2.5 3.55 3.9 4.24

3.13 3.44 3.8 4.6 3.64 4.99 3.35 5.20 6.70 3.82 5.21 3.75 5.58

Coefcient of performance A-15 / W35

– 2.3 2.16 2.28 2.36 2.54 2.49 2.42

2.55 2.52 2.47 2.29 2.48 2.42 2.60 2.37 2.37 2.41 2.18 2.4 2.15

Heating capacity A-7 / W35

kW 3.2 4.2 5.75 6.55 10.74 11.55 12.28

9.49 10.07 10.86 12.01 9.31 12.63 8.88 11.77 15.75 9.31 11.91 9 12

Power consumption A-7 / W35

kW 1.19 1.62 1.99 2.38 3.58 3.96 4.32

Coefcient of performance A-7 / W35

– 2.69 2.59 2.89 2.75 3 2.91 2.84

3.16 2.85 2.76 2.66 2.84 2.73 2.93 2.67 2.61 2.84 2.61 2.7 2.5

Heating capacity A2 / W35

kW 3.2 4.52 6.55 6.7 11.4 12.4 13

Power consumption A2 / W35

kW 0.9 1.35 1.96 2.14 3.31 3.69 3.96

2.53 3.31 3.7 4.09 2.5 3.42 2.31 3.25 5.00 / 2.58² 2.61 3.68 2.61 3.68

Coefcient of performance A2 / W35

– 3.56 3.35 3.34 3.13 3.44 3.36 3.28

3.59 3.44 3.26 3.24 3.67 3.43 3.82 3.47 3.18 / 3.68² 3.45 3.26 3.45 3.26

Heating capacity A7 / W35

kW 3.2 5 7 9 12 14 16

Power consumption A7 / W35

kW 0.64 1.08 1.57 2.18 2.53 3.07 3.74

1.86 2.51 2.94 3.82 1.89 2.53 1.77 2.49 3.74 1.94 2.69 1.94 2.69

Coefcient of performance A7 / W35

– 5 4.63 4.46 4.13 4.74 4.56 4.28

4.84 7.74 4.42 4.14 4.89 4.79 5.06 4.71 4.28 4.64 4.46 4.64 4.46

Heating capacity A2 / W55

kW 3.2 4.1 6 9.1 9.5 9.8 9.8

Power consumption A2 / W55

kW 1.49 2.07 3.16 4.18 4.4 4.55 4.55

3.98 4.18 4.4 4.55 4.11 5.51 4.07 5.47 7.5 3.92 4.9 3.91 4.7

Coefcient of performance A2 / W55

– 2.15 1.98 1.9 2.18 2.16 2.15 2.15

2.21 2.18 2.16 2.15 2.19 2.18 2.21 2.19 2.13 2.3 2.2 2.3 2.3

Cooling capacity A35 / W7

kW – 3.2 – 4.5 6 7 10 11.5 12.2

Power consumption A35 / W7

kW – 1.04 – 1.67 2.28 2.88 3.65 4.36 4.76

2.21 3.51 4.4 4.8 2.25 3.6 2.21 3.56 4.76 – – – –

Coefcient of performance (EER) A35 / W7

– – 3.08 – 2.69 2.63 2.43 2.81 2.64 2.56

3.17 2.85 2.61 2.54 3.11 2.78 3.17 2.81 2.56 – – – –

Unit data

Dimensions (H × W × D)

mm 892 × 502 × 353

Weight

kg 43 44 43 44 43 43 45 45 46

Water-side connection

inch AG R 1¼

Pump – speed stepping

3

Pump – power consumption (max.)

W 25 29 63 96 60 76 105

Volumetric ow rate of heating circuit for

A7 / W35 / 30

l / min 9.2 14.3 20.1 25.8 34.4 40.1 45.9

25.8 34.4 40.1 45.9 25.8 34.4 25.8 34.4 45.9 25.8 34.4 25.8 34.4

Minimum circulation

l / min 5 10

Safety valve (open / closed)

bar 3 / ≤ 2.65

Electric

Capacity of the additional electric heater kW 3 6

Power consumption (heating / cooling) kW 2.35 2.59 4.59 5.01 5.3 5.52 5.74

Operation and starting current (heating / cooling) A 3 5 7.2 10 16 19.5 21.3

Power supply 1 (current consumption) A 11 12 21 22.9 24 25 26

11.8 8.8 9.4 9.9 25 29 14.7 11.9 15.5 28.5 29 14.5 10.8

Power supply 1 (frequency / voltage) Hz / V 50 / 230

Power supply 2 (current consumption) A 26 26 13 26

Power supply 2 (frequency / voltage) Hz / V 50 / 230

50 / 230 50 / 400 50 / 230 50 / 400 50 / 230 50 / 230 50 / 400

Panasonic measurement data in accordance with EN 14511-2. The data is to be considered as guidance values and not as a performance guarantee

* Devices have a high efciency pump and full the criteria of the Ecodesign Directive valid from 2015 for energy-related products (ErP)

1

Preliminary data

Panasonic measurement data in accordance with EN 14511-2. The data is to be considered as guidance values and not as a performance guarantee

* Devices have a high efciency pump and full the criteria of the Ecodesign Directive valid from 2015 for energy-related products (ErP)

1

Preliminary data

Loading...

Loading...