Page 1

AM1

49.2

24.1

17.5

Compliance with RoHS Directive

ORDERING INFORMATION

HIGH CONTACT CAPACITY,

PRECISE OPERATION

FEATURES

• 10 A High current switching capacity

and high precision

• Wide allowance of operating speed

• Versatile variety of actuators

• UL/C-UL approved

Ex. AM 1 5 0 1 K F

AM1 (NZ BASIC)

SWITCHES

TYPICAL APPLICATION

• General industrial machinery

• Medical equipment

• Measuring instruments

• Transportation equipment

• Home electric appliances

Type of

switch

NZ basic

(AM1)

switch

Remarks: Not every combination is available. Please refer to the following table, “PRODUCT TYPES”.

1: Flat, solder terminal

3: Flat, screw terminal

5: Grooved, solder terminal

7: Grooved, screw terminal

Upper body cover shape & terminal Actuators

Upper body cover shape 0: Pin plunger

Flat Grooved

Basic

specifications

0: Standard type

1: Oil tight type

3: Reversed

action type

4: One way type

1: Hinge lever (leaf spring)

3: Hinge roller lever (roller, leaf, spring)

4: Hinge short roller lever

5: Overtravel plunger

6: Compact overtravel plunger

7: Panel mount plunger

811: Panel mount roller plunger

812: Panel mount cross roller plunger

Contact

F: Cadmium

free

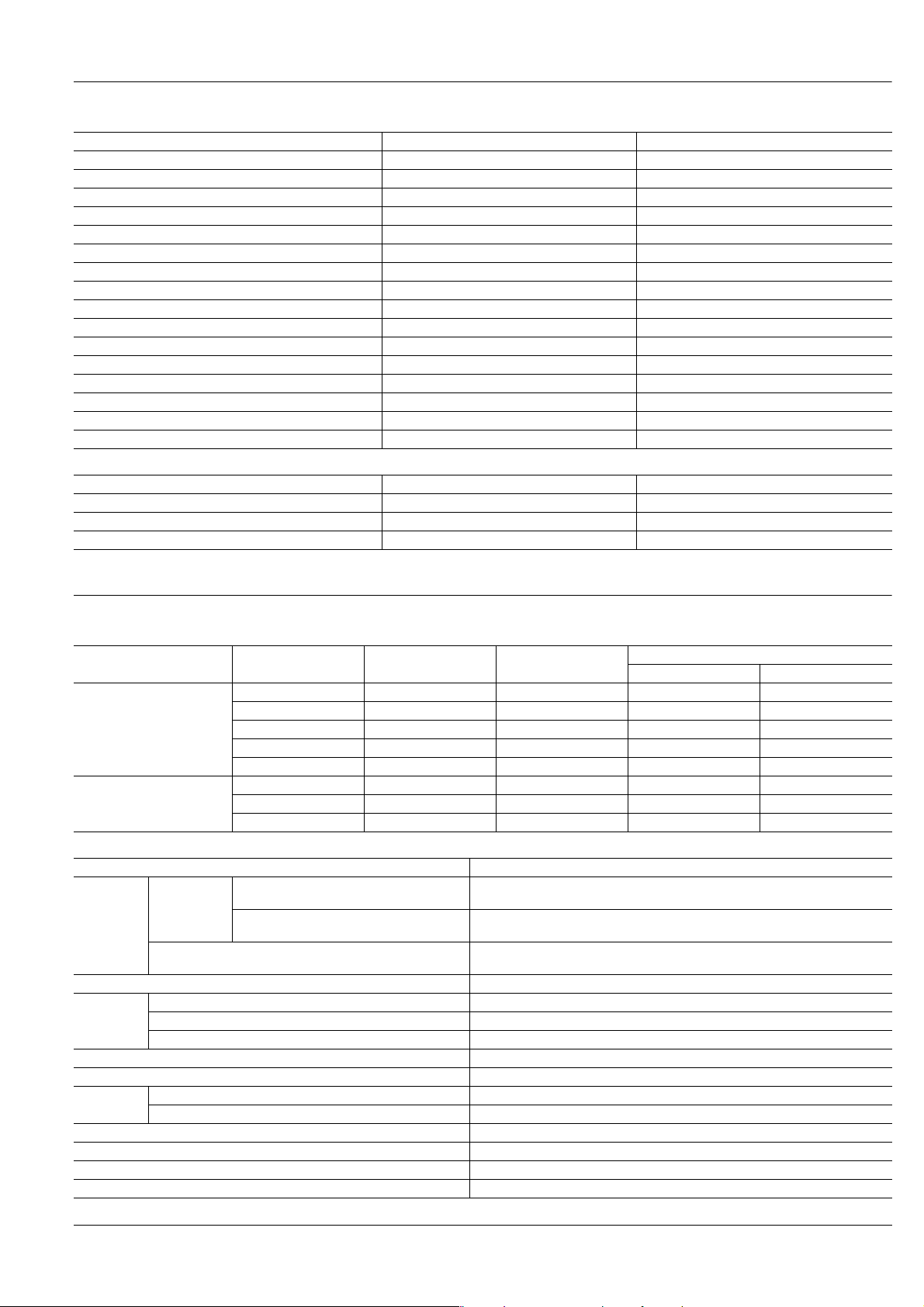

TERMINAL VARIATION

Standard types, reversed action types and oil tight types are available in two terminal designs, solder and screw terminals, as shown

in the above columns:

Differences in dimension between solder and screw terminals are as follows;

mm

Solder terminal

49.2

N.O.

CIRCUT

N.C.

CIRCUT

Terminal plate

6.3

17.5

Screw terminal

9.1

49.2

CNONC

17.5

20.219.8

M4 screw P0.7

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 2

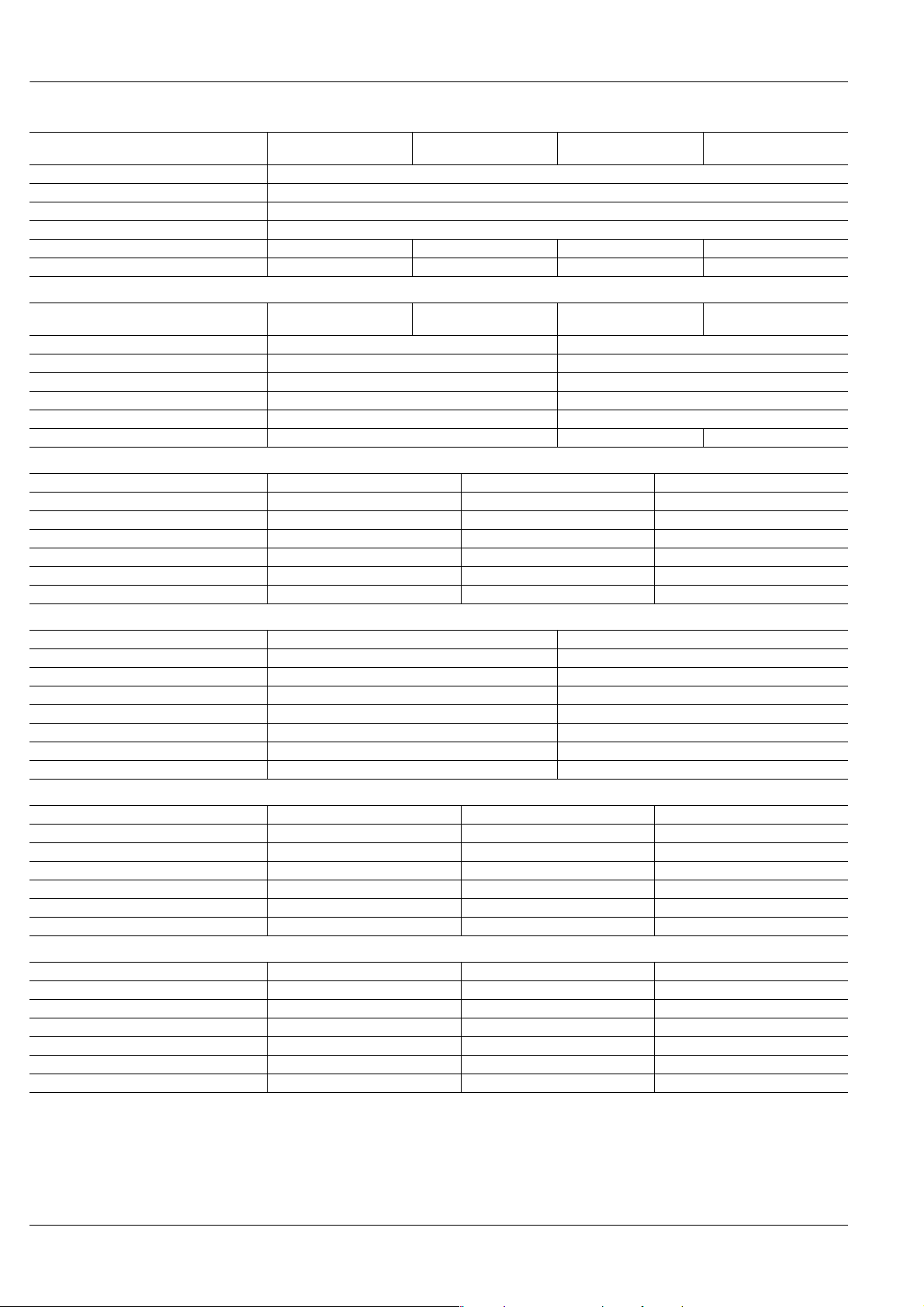

PRODUCT TYPES

1. Standard type

Actuator Solder terminal Screw terminal

Pin plunger AM1100KF AM1300KF

Over travel plunger AM1105KF AM1305KF

Compact over travel plunger AM1106KF AM1306KF

Panel mount plunger AM1107KF AM1307KF

Panel mount roller plunger AM110811KF AM130811KF

Panel mount cross roller plunger AM110812KF AM130812KF

Flexible leaf lever AM1101KF AM1301KF

Flexible roller leaf lever AM1103KF AM1303KF

Rigid lever AM1501KF AM1701KF

Rigid short roller lever AM1504KF AM1704KF

Rigid roller lever AM1503KF AM1703KF

One way type•Rigid short roller lever AM1544KF AM1744KF

One way type•Rigid roller lever AM1543KF AM1743KF

Reversed action type•Rigid lever AM1531KF AM1731KF

Reversed action type •Rigid short roller lever AM1534KF AM1734KF

Reversed action type•Rigid roller lever AM1533KF AM1733KF

2. Oil tight types

Actuator Solder terminal Screw terminal

Rigid lever AM1511KF AM1711KF

Rigid short roller lever AM1514KF AM1714KF

Rigid roller lever AM1513KF AM1713KF

Remarks: 1. Standard part number indicates UL/C-UL mark.

2. Standard packing for inner carton: 20cps.

AM1

SPECIFICATIONS

1. Contact Rating

Type Voltage

Standard types

One way types

Reversed action types

Oil tight types

Resistive load

φ

= 1)

(cos

125 V AC 10 A 6 A 3 A 1.5 A

250 V AC 10 A 6 A 2 A 1 A

480 V AC 1 A 0.5 A — —

125 V DC 0.5 A 0.05 A — —

250 V DC 0.25 A 0.03 A — —

125 V AC 10 A 6 A 3 A 1.5 A

250 V AC 10 A 6 A 2 A 1.0 A

125 V DC 0.5 A 0.05 A — —

Inductive load

(cos φ = 0.6 to 0.7)

2. Characteristics

Item Specifications

Pin plunger types (O.T.: specified value)

Expected

life

Insulation resistance Min. 100 MΩ(at 500 V DC)

Dielectric

strength

Contact resistance (initial) (by voltage drop, 1 A, 6–8 V DC) Max. 50 mΩ

Vibration resistance (Pin plunger type) Single amplitude: 0.75 mm, 10 to 55 Hz (contact opening: max. 1 msec.)

Shock

resistance

Allowable operating speed (at no load) 0.1 to 1,000 mm/sec. (at pin plunger position)

Max. operating cycle rate (at no load) 240 cpm

Ambient temperature –25°C to +80°C (no freezing at low temperature)

Weight Approx. 20 to 55 g

Mechanical

Other types (O.T.: specified value)

Electrical (O.T.: Max.)

Between open terminals 1,000 Vrms for 1 min.

Between each terminal and other exposed metal parts 2,000 Vrms for 1 min.

Between each terminal and ground 2,000 Vrms for 1 min.

Pin plunger types Min. 300 m/s2 (contact opening: max. 1 msec.)

Other types Min. 50 m/s2 (contact opening: max. 1 msec.)

Min. 2 ×107 (60 cpm) (at rated overtravel)

(Oil tight: Min. 1.5 ×106)

Min. 5 ×106 (60 cpm) (at rated overtravel)

(Oil tight: Min. 1.5 ×106)

Min. 5 ×105 (20 cpm) (at rated load)

(Oil tight: Min. 1.5 ×105)

Motor or lamp load

N.C. N.O.

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 3

AM1

OPERATING CHARACTERISTICS

Standard types

Types of actuator Pin plunger Overtravel plunger

Operating force, max. 3.63 N

Release force, min. 1.12 N

Pretravel, max. mm 0.4

Movement differential, max. mm 0.05

Overtravel, min. mm 0.13 1.5 1.5 5.6

Operating position, mm 15.9±0.4 28.2±0.5 21.2±0.5 21.8±0.8

Compact overtravel

plunger

Panel mount plunger

Types of actuator

Operating force, max. 3.63 N 1.47 N

Release force, min. 1.12 N 0.14 N

Pretravel, max. mm 0.4 4

Movement differential, max. mm 0.05 1.3

Overtravel, min. mm 3.6 1.6

Operating position, mm 33.3±1.2 17.5±0.8 28.6±0.8

Panel mount roller

plunger

Panel mount cross roller

plunger

Flexible leaf lever Flexible roller leaf lever

Standard types (cont' d)

Types of actuator Rigid lever Rigid short roller lever Rigid roller lever

Operating force, max. 0.69 N 1.57 N 0.98 N

Release force, min. 0.14 N 0.42 N 0.2 N

Pretravel, max. mm 10 4.5 7.5

Movement differential, max. mm 1.3 0.7 1.3

Overtravel, min. mm 5.6 2.4 3.6

Operating position, mm 19.1±0.7 30.2±0.4 30.2±0.7

One way types

Types of actuator Rigid short roller lever Rigid roller lever

Operating force, max. 2.23 N 1.67 N

Release force, min. 0.42 N 0.42 N

Pretravel, max. mm 3.5 4.5

Movement differential, max. mm 0.4 0.5

Overtravel, min. mm 1.5 2.4

Free position, max. mm 31.8 43.3

Operating position, mm 30.2±0.4 41.3±0.4

Reversed action types

Types of actuator Rigid lever Rigid short roller lever Rigid roller lever

Operating force, max. 1.67 N 5.30 N 2.35 N

Release force, min. 0.27 N 1.67 N 0.56 N

Pretravel, max. mm 5.0 2.5 3.6

Movement differential, max. mm 0.9 0.4 0.7

Overtravel, min. mm 5.6 2.0 4.0

Operating position, mm 19.1±0.8 30.2±0.5 30.2±0.8

Oil tight types

Types of actuator Rigid lever Rigid short roller lever Rigid roller lever

Operating force, max. 0.69 N 1.67 N 0.98 N

Release force, min. 0.14 N 0.42 N 0.20 N

Pretravel, max. mm 10 4.5 7.5

Movement differential, max. mm 1.5 0.7 1.3

Overtravel, min. mm 5.6 2.4 3.6

Operating position, mm 19.1±0.7 30.2±0.4 30.2±0.7

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 4

DIMENSIONS

1. Standard types

Pin plunger

AM1100KF (Solder terminal)

AM1300KF (Screw terminal)

Overtravel plunger

P. T .

O.P.

4.2

+0.1

−0.05

4.5±0.1

2.4

23.3±0.3

25.4±0.1

49.2

4.2 dia. hole

11.9

14.6 15

5.4

+0.1

−0.05

9.1

17.5

mm General tolerance: ±0.4

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

AM1

3.63 N

1.12 N

0.4

0.05

0.13

15.9±0.4

AM1105KF (Solder terminal)

AM1305KF (Screw terminal)

Compact over plunger

AM1106KF (Solder terminal)

AM1306KF (Screw terminal)

P. T .

O.P.

Plunger: Plastic

P.T.

0.4 max.

O.P.

±0.5

21.2

4.2

+0.10

–0.05

23.3±0.3

Plunger: Hardening steel

8.4

15

±0.3

23.3

14.3

Operating force,

max.

4 dia.

6.35 dia.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

Operating force,

max.

4.2

7.1 dia.

14.5

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

+0.10

4.2

dia.

–0.05

Overtravel,

min. mm

Operating position,

mm

3.63 N

1.12 N

0.4

0.05

1.5

28.2±0.5

3.63 N

1.12 N

0.4

0.05

1.5

21.2±0.5

Panel mount plunger

AM1107KF (Solder terminal)

AM1307KF (Screw terminal)

Plunger: Plastic

P.T.

0.4 max.

O.P.

±0.8

21.8

±0.5

16

13.1

+0.10

4.2

–0.05

23.3

All Rights Reserved © C

R8

±0.3

8.25 dia.

14.3

+0.10

4.2

dia.

–0.05

M12 × P1

Lock nut

(2 thick)

Nut (2 thick)

OPYRIGHT Panasonic Electric Works Co., Ltd.

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

3.63 N

1.12 N

0.4

0.05

5.6

21.8±0.8

Page 5

AM1

Panel mount roller plunger

mm General tolerance: ±0.4

AM110811KF (Solder terminal)

AM130811KF (Screw terminal)

Panel mount cross roller plunger

AM110812KF (Solder terminal)

AM130812KF (Screw terminal)

P.T.

0.4 max.

O.P.

33.3

±0.5

16

P.T.

0.4 max.

O.P.

33.3

±0.5

16

90°

±0.3

23.3

±1.2

15.5

+0.10

4.2

–0.05

90°

±0.3

23.3

±1.2

15.5

+0.10

4.2

–0.05

14.3

+0.10

4.2

dia.

–0.05

14.3

+0.10

4.2

dia.

–0.05

Roller 12.7 dia. × 4.6

: Plastic

M12 × P1

Nut (2 thick)

Roller 12.7 dia. × 4.6

: Plastic

M12 × P1

Nut (2 thick)

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

3.63 N

1.12 N

0.4

0.05

3.6

33.3±1.2

3.63 N

1.12 N

0.4

0.05

3.6

33.3±1.2

Dimensions and Operating characteristics are the same as those of Panel mount roller plunger type. However, the roller joins the switch body at an angle of 90°.

Flexible leaf lever

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

AM1101KF (Solder terminal)

AM1301KF (Screw terminal)

F. P.

O.P.

49.6±0.8

Leaf: Stainless steel

4.8

14.6

mm

Flexible roller leaf lever

Operating force,

max.

AM1103KF (Solder terminal)

AM1303KF (Screw terminal)

F. P. O.P.

46±0.8

Leaf: Stainless steel

14.6

Roller 9.5 dia.×4:

Plastic

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

1.47 N

0.14 N

4

1.3

1.6

17.5±0.8

1.47 N

0.14 N

4

1.3

1.6

28.6±0.8

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 6

Rigid lever

AM1

mm General tolerance: ±0.4

AM1501KF (Solder terminal)

AM1701KF (Screw terminal)

Rigid short roller lever

AM1504KF (Solder terminal)

AM1704KF (Screw terminal)

20.1±0.5

20.1±0.5

26.1

R26.7

26.1

R63.5

O.P.

Lever: Stainless steel

F. P.

O.P.

Roller 9.5 dia.×4:

Plastic

F. P.

4.8

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

0.69 N

0.14 N

10

1.3

5.6

19.1±0.7

1.57 N

0.42 N

4.5

0.7

2.4

30.2±0.4

Rigid roller lever

AM1503KF (Solder terminal)

AM1703KF (Screw terminal)

20.1±0.5

26.1

R48.3

O.P.

Roller 9.5 dia.×4:

Plastic

F. P.

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

0.98 N

0.2 N

7.5

1.3

3.6

30.2±0.7

2. One way types

This type is operated only to one direction, not to the reversed direction by the construction of the roller lever, pivoting away from the

cam on the return stroke.

Rigid short roller lever

AM1544KF (Solder terminal)

AM1744KF (Screw terminal)

27.8 max.

20.1±0.5

R21.1

26.1

O.P.

Roller 4.75 dia.×4.75:

Plastic

F. P.

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

2.23 N

0.42 N

3.5

0.4

1.5

30.2±0.4

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 7

AM1

Rigid roller lever

mm General tolerance: ±0.4

AM1543KF (Solder terminal)

AM1743KF (Screw terminal)

34.1 max.

20.1±0.5

R31

26.1

O.P.

Roller 9.5 dia.×4:

Plastic

F. P.

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

1.67 N

0.42 N

4.5

0.5

2.4

41.3±0.4

3. Reversed action types

When the actuator is operated, the switching mechanism returns to the free position. Extraordinary force by pushing the plunger too

much is not put on the switching mechanism, which means stability in life.

Rigid lever

Lever: Stainless steel

F. P.

O.P.

4.8

17.5

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

1.67 N

0.27 N

5.0

0.9

5.6

19.1±0.8

AM1531KF (Solder terminal)

AM1731KF (Screw terminal)

20.1±0.5

9.1

16.9±0.8

+0.1

4.2

−0.05

18.7

4.5±0.1

25.4±0.1

11.9 11.9

49.2

R56

+0.1

4.2 dia. hole

−0.05

Rigid short roller lever

AM1534KF (Solder terminal)

AM1734KF (Screw terminal)

Rigid roller lever

AM1533KF (Solder terminal)

AM1733KF (Screw terminal)

20.1±0.5

20.1±0.5

R19

18.7

18.7

R41

Roller 9.5 dia.×4:

Plastic

F. P.

O.P.

Roller 9.5 dia.×4:

Plastic

O.P.

F. P.

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

5.30 N

1.67 N

2.5

0.4

2.0

30.2±0.5

2.35 N

0.56 N

3.6

0.7

4.0

30.2±0.8

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 8

AM1

4. Oil tight types

The pushbutton part is sealed with the rubber cap and the connected part between the cap and body is also coated with resin so that

these parts are kept away from foreign matters. This type has resistance to oil.

Rigid lever

Operating force,

Plunger seal

26.1

R63.5

Lever: Stainless steel

4.8

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

20.1±0.5

O.P.

F. P.

max. mm

Overtravel,

min. mm

Operating position,

AM1511KF (Solder terminal)

mm

AM1711KF (Screw terminal)

Rigid short roller lever

mm General tolerance: ±0.4

0.69 N

0.14 N

10

1.5

5.6

19.1±0.7

AM1514KF (Solder terminal)

AM1714KF (Screw terminal)

Rigid roller lever

AM1513KF (Solder terminal)

AM1713KF (Screw terminal)

20.1±0.5

20.1±0.5

16.9±0.8

16.9±0.8

Plunger seal

Plunger seal

R26.7

26.1

26.1

O.P.

R48.3

F. P.

Roller 9.5 dia.×4:

Plastic

F. P.

O.P.

Roller 9.5 dia.×4:

Plastic

Operating force,

max.

Release force,

min.

Pretravel, max.

mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

Operating force,

max.

Release force,

min.

Pretravel,

max. mm

Movement differential,

max. mm

Overtravel,

min. mm

Operating position,

mm

1.67 N

0.42 N

4.5

0.7

2.4

30.2±0.4

0.98 N

0.20 N

7.5

1.3

3.6

30.2±0.7

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Page 9

AM1

NOTES

1. Regarding fastening of switch body

1) In fastening the switch body, use M4

mounting screws to attach switches with

the torque 1.5 N·m or less.

2) After mounting and wiring, the

insulation distance between ground and

each terminal should be confirmed as

sufficient.

2. Adjustment of the operating device

The operating device should be

positioned so that it applies no stress to

the pushbutton or actuator when the

switch is in the open position. If this

condition is exceeded, the mechanical

and electrical performance will be

impaired. In addition, the force applied by

the operating device should be in a

perpendicular direction. Even if the

pushbutton is used in the full total travel

position, there will be no influence on the

life of the switch.

3. Soldering operations

Soldering should be done in less than 5

seconds, with a 60 watt iron (tip

temperature = 350°C max.). Care should

be taken not to apply force to the terminal

during soldering.

4. Avoid using switches in the

following conditions:

• In corrosive gases such as hydrogen

sulfide.

• In flammable or explosive gases such

as gasoline or thinner etc.

• In a dusty environment.

• In an ambient humidity over 85%.

• In conditions where the perpendicular

operating speed is less than 0.1 mm/sec.

or more than 1,000 mm/sec.

• In a silicon atmosphere.

5. Others

Caution should be taken not to drop

switches.

All Rights Reserved © C

OPYRIGHT Panasonic Electric Works Co., Ltd.

Loading...

Loading...