Panasonic AFPX-C14R, AFPX-C14P, AFPX-C14T, AFPX-C14TD, AFPX-C14PD User Manual

...

User's Manual

PROGRAMMABLE CONTROLLER

FP-X

ARCT1F409E-9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety Precautions

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

-Battery may explode if mistreated. Do not recharge, disassemble or dispose of fire.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

-To prevent excessive exothermic heat or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured in these

specifications.

-Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock.

-Use the external devices to function the emergency stop and interlock circuit.

-Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generation.

-Ground the protective earth (PE) terminal (Class D grounding). Failure to do so could lead to

an electric shock.

-Do not allow foreign matters such as liquid, flammable materials, metals to go into the inside

of the product. It could cause excessive exothermic heat or smoke generation.

-Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

Copyright / Trademarks

-This manual and its contents are copyrighted.

-You may not copy this manual, in whole or part, without written consent of

Panasonic Electric

Works SUNX Co., Ltd.

-Windows is a registered trademark of Microsoft Corporation in the United States and other

countries.

-Ethernet is a registered trademark of Fuji Xerox Co., Ltd. and Xerox Corp.

-All other company names and product names are trademarks or registered trademarks of

their respective owners.

PLC_FPX

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of Contents

Before You Start

Differences in Functions Between Versions of Controller

Restriction on using the Add-on cassette

Programming Tool Restrictions

1. Features, Functions and Restrictions ................................................... 1-1

1.1 Features and Functions of the Unit ............................................................................ 1-2

1.2 Unit Types ................................................................................................................... 1-6

1.3 Restricti on s on Unit Combinations .......................................................................... 1-10

1.4 Programming Tools .................................................................................................. 1-14

2. Specifications and Functions of Control Unit ...................................... 2-1

2.1 Parts and Functions .................................................................................................... 2-2

2.2 Power Supply Specifications ...................................................................................... 2-5

2.3 Input Specifications .................................................................................................... 2-6

2.4 Output Spec ifications ................................................................................................. 2-8

2.5 Limitations on Number of Simultaneous Input/Output On Points .......................... 2-11

2.6 Terminal Layout ........................................................................................................ 2-20

3. Expansion Cassette and Expansion F P0 Adapter Specifications ...... 3-1

3.1 Expansion Method ...................................................................................................... 3-2

3.2 FP-X Expansion Unit ................................................................................................... 3-3

3.3 FP-X Expansion FP0 Adapter ................................................................................... 3-11

4. I/O Allocation ........................................................................................... 4-1

4.1 I/O Allocation ............................................................................................................... 4-2

4.2 Allocation of FP-X Control Unit .................................................................................. 4-3

4.3 FP0 Expansion Unit Allocation ................................................................................... 4-3

4.4 Allocation of FP0 Expansion Unit .............................................................................. 4-4

4.5 I/O All oc a t io n of FP-X Add-on Cassette ..................................................................... 4-6

5. Installation and Wiring ........................................................................... 5-1

5.1 Installation ................................................................................................................... 5-2

5.2 Installation Using Expansion Cable ........................................................................... 5-5

5.3 Expansion Method of FP0 Expansion Unit ................................................................ 5-8

5.4 How to Install Add-on Cassette .................................................................................. 5-9

5.5 Power Supply ............................................................................................................ 5-11

5.6 Wirin g of In put and Output ....................................................................................... 5-17

5.7 Wirin g of Te r m i na l B loc k .......................................................................................... 5-20

5.8 Wiring of Add-on Casset t e Terminal Block .............................................................. 5-22

5.9 Handling of Backup Batt ery...................................................................................... 5-25

5.10 Safety Measu res ...................................................................................................... 5-29

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6. Tool Port and USB Port .......................................................................... 6-1

6.1 Tool Port and USB Port .............................................................................................. 6-2

6.2 Functions of Tool Port ................................................................................................ 6-3

6.3 USB Port ...................................................................................................................... 6-6

7. Communication Cassette ....................................................................... 7-1

7.1 Functions and Types .................................................................................................. 7-2

7.2 Communication Specifications ................................................................................ 7-16

7.3 Communication Funct io n 1: Comput er Link ............................................................ 7-20

7.4 Communication Function 2: General-purpose Serial Communication ................... 7-36

7.5 Communication Function 3: PC(PLC) Link .............................................................. 7-56

7.6 Communication Funct io n 4: MODBUS RTU Communication ................................. 7-75

7.7 Ethernet Co mmunicat io n (AFPX -COM5) .................................................................. 7-81

8. Application Cassette ............................................................................... 8-1

8.1 Expansion of Application Cassette ............................................................................ 8-2

8.2 Application Casset t es ................................................................................................. 8-3

8.3 Specificat io ns ............................................................................................................. 8-5

9. High-speed Counter, Pulse Output and PWM Output Functions (For Tr

Type) ............................................................................................................ 9-1

9.1 Overview of Each Fun ction s....................................................................................... 9-2

9.3 High-speed Counter Function .................................................................................. 9-11

9.4 Pulse Output Function .............................................................................................. 9-19

9.5 PWM Output Function (Pul se I/ O Cassett e) ............................................................. 9-51

10. High-speed counter, Pulse Output and PWM Output functions (For Ry

Type) .......................................................................................................... 10-1

10.1 Overview of Each Funct ions................................................................................... 10-2

10.3 High-speed Counter Fu nction ................................................................................ 10-9

10.4 Pulse Output Function (Pulse I/O Cassette) ........................................................ 10-20

10.5 PWM Output Function (Pulse I/ O Cassett e) ......................................................... 10-51

11. Security Functions .............................................................................. 11-1

11.1 Type of Security Functions..................................................................................... 11-2

11.2 Password Protect Funct ion .................................................................................... 11-3

11.3 Upload Prot ect ion ................................................................................................... 11-7

11.4 Setting Fun ction for FP M emory Loader ................................................................ 11-9

11.5 Table of Security Settings/Cancel ........................................................................ 11-13

12. Other Functions .................................................................................. 12-1

12.1 Transfer Function between Memories.................................................................... 12-2

12.2 Function of Mast er M emory Cassett e .................................................................... 12-3

12.3 P13 (ICWT) Instruction ............................................................................................ 12-8

12.4 Analog Pot entio met er ............................................................................................. 12-9

12.5 Sampling Trace Function ...................................................................................... 12-10

12.6 Time Constant Processing ................................................................................... 12-13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

13. Self-Diagnostic and Troubleshooting ............................................... 13-1

13.1 Self-Diagnostic function ......................................................................................... 13-2

13.2 Troubleshooting ...................................................................................................... 13-4

14. Precautions During Programming ..................................................... 14-1

14.1 Use of Duplicat ed Output ....................................................................................... 14-2

14.2 Handling BCD Data ................................................................................................. 14-4

14.3 Handling Ind ex Regi st ers ....................................................................................... 14-5

14.4 Operation E rrors ..................................................................................................... 14-7

14.5 Instruction of Leading Edge Detection Method ..................................................... 14-9

14.6 Precautions for Programming .............................................................................. 14-13

14.7 Rewrite Funct io n Du ring RUN .............................................................................. 14-14

14.8 Processing During Forced Input and Output ....................................................... 14-19

15. Specifications...................................................................................... 15-1

15.1 Table of Specifications ........................................................................................... 15-2

15.2 Table of I/O Number Allocation ............................................................................ 15-13

15.3 Relays, Memory Areas and Con st ants ................................................................. 15-16

16. Dimensions ......................................................................................... 16-1

16.1 Dimensions ............................................................................................................. 16-2

16.2 Cable/Adapter Specifications ................................................................................. 16-4

17. Appendix ............................................................................................. 17-1

17.1 System Regist ers / Speci al Int ernal Relays / Special Data Regist ers ................... 17-2

17.2 Table of Basic Instructions ................................................................................... 17-48

17.3 Table of High-level Instr uc tions ........................................................................... 17-56

17.4 Tabl e of E rror codes ............................................................................................. 17-76

17.5 MEWTOCOL-COM Communicat io n Co mmand s .................................................. 17-89

17.6 Hexadecimal /Binary/BCD ...................................................................................... 17-90

17.7 ASCII Codes .......................................................................................................... 17-91

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Before You Start

Operating environment (Use the unit within the range of the general specifications when installing)

*Ambient temperatures:0 ~ +55 ℃

*Ambient humidity: 10% to 95% RH (at 25°C, non-condensing)

*Keep the height below 2000m.

*For use in pollution Degree 2 environment.

*Do not use it in the following environments.

- Direct sunlight

- Sudden temperature changes causing condensation.

- Inflammable or corrosive gas.

- Excessive airborne dust, metal particles or saline matter.

- Benzine, paint thinner, alcohol or other organic solvents or strong alkaline solutions such as ammonia

or caustic soda.

- Direct vibration, shock or direct drop of water.

- Influence from power transmission lines, high voltage equipment, power cables, power equipment,

radio transmitters, or any other equipment that would generate high switching surges.

(Min.100mm or less)

Static electricity

-Before touching the unit, always touch a grounded piece of metal in order to discharge static electricity.

-In dry locations, excessive static electricity can cause problems.

Wiring the Power Supply to the Control Unit

- Use a power supply wire that is thicker than 2 mm2 (AWG14), and twist it.

- The unit has sufficient noise immunity against the noise generated on the power line.

However, it is recommended to take measures for reducing noise such as using a isolating transformer

before supplying the power.

- Allocate an independent wiring for each power supplying line, input/output device and operating device.

- If using a power supply without a protective circuit, power should be supplied through a protective

element such as a fuse.

- Be sure to supply power to a control and an expansion units from a single power supply.

Turning on/off of the power of all the units must be conducted simultaneously.

Power supply sequence

In order to protect the power supply sequence, make sure to turn off the control unit before the

input/output power supply. If the input/output power supply is turned off before the control unit, or if the

control unit is not shut off momentarily, the controller detects change of input level, and might conduct an

unexpected operation.

Before turning on the power

When turning on the power for the first time, be sure to take the precautions given below.

• When performing installation, check to make sure that there are no scraps of wiring, particularly

conductive fragments, adhering to the unit.

• Verify that the power supply wiring, I/O wiring, and power supply voltage are all correct.

• Sufficiently tighten the installation screws and terminal screws.

• Set the mode selector to PROG. Mode.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Before entering a program

Be sure to perform a program clear operation before entering a program.

Operation procedure when using FPWIN GR Ver.2

Select “Online Edit Mode” on the FPWIN GR “On line” menu.

Select “Clear Program” on the “Edit” menu.

When the confirmation dialog box is displayed, click on “Yes” to clear the program.

Request concerning program stor a ge

To prevent the accidental loss of programs, the user should consider the following measures.

• Drafting of documents

To avoid accidentally losing programs, destroying files, or overwriting the contents of a file, documents

should be printed out and then saved.

• Specifying the password carefully

The password setting is designed to avoid programs being accidentally overwritten. If the password is

forgotten, however, it will be impossible to overwrite the program even if you want to. Also, if a

password is forcibly bypassed, the program is deleted. When specifying the password, note it in the

specifications m anual or in another safe location in case it is forgotten at some point.

• Upload protection

When the upload protection setting is specified, programs will be disabled to be read out. If the setting

is cancelled forcibly, all programs and system registers will be deleted. Therefore, note that programs

and system registers should be managed on your own responsibility.

Backup battery

Do not install the battery when it is not used.

There is a possibility of leak if the battery remains discharged.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

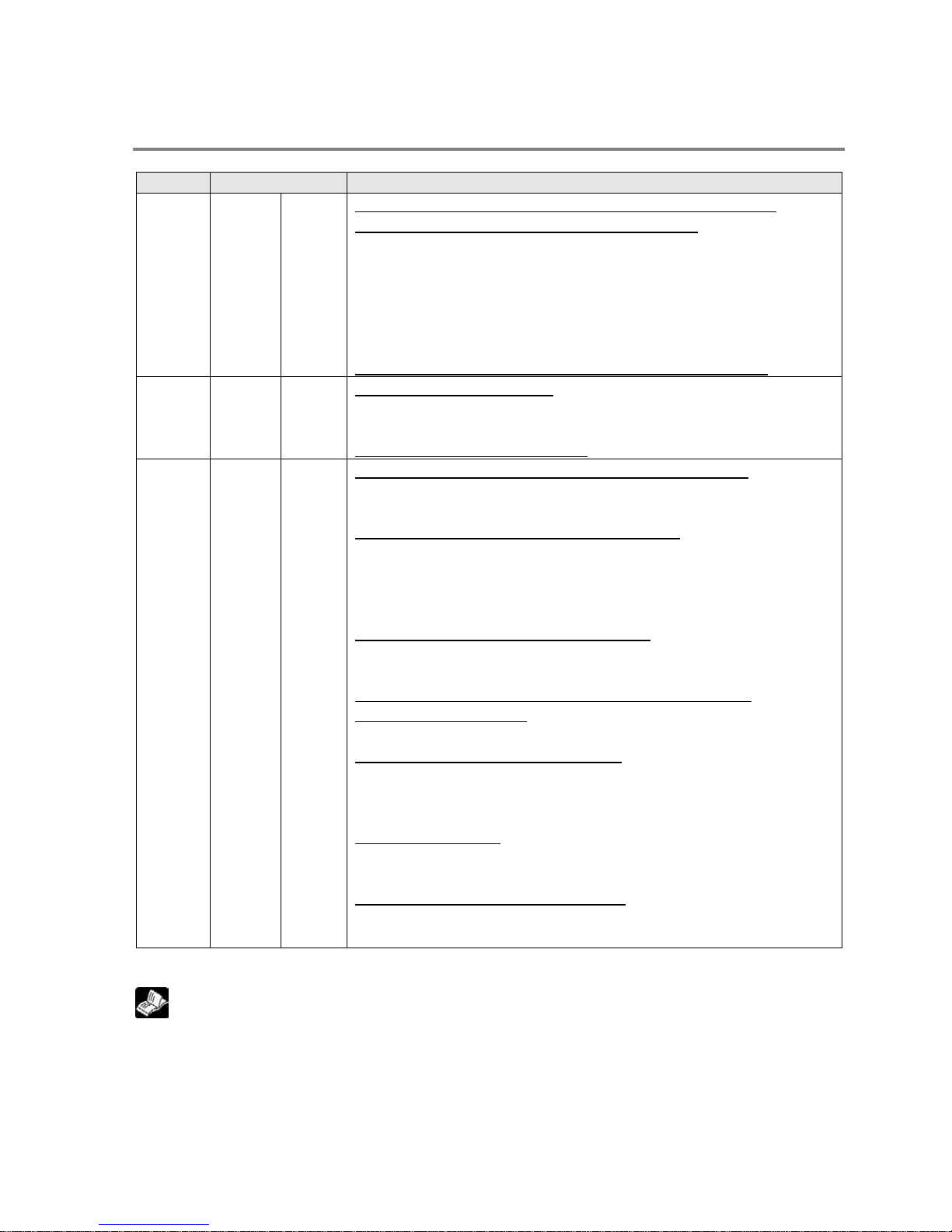

Differences in Functions Between Versions of Controller

Version

Usable model

Usable functions

V1.10 Ry type -

UP/DOWN switching of high-speed counter by SYS instruction

Real number basic compare instructions 18 types

STF=S1, S2 ANF=S1, S2 ORF=S1, S2

STF<>S1, S2 ANF<>S1, S2 ORF<>S1, S2

STF>S1, S2 ANF>S1, S2 ORF>S1, S2

STF>=S1, S2 ANF>=S1, S2 ORF>=S1, S2

STF<S1, S2 ANF<S1, S2 ORF<S1, S2

STF<=S1, S2 ANF<=S1, S2 ORF<=S1, S2

V1.20

System register 36 for setting expansion unit recognition time

Ry type -

MEWTOCOL master function

F145(SEND) Data send

F146(RECV) Data receive

V2.00

E356(EZPID) Easy PID instruction

Ry type Tr type

Time constant processing of input (Refer to Chapter 12.6.)

CPU input: System register setting

Other input: F182(FILTR) Time constant processing

Sampling trace function (Refer to Chapter 12.5.)

Sampling by instructions

F155(SMPL) Sampling

F156(STRG) Sampling trigger

Sampling by specifying time

Leading contact, trailing contact instructions

ST↑ AN↑ OR↑

ST↓ AN↓ OR↓

An arbitrary device can be specified for the setting value of

Timer/counter instruction.

e.g.) TML 0, DT0

Other additional convenient instructions

F252(ACHK) ASCII data check

F284(RAMP) Inclination output

Baud rate setting (300, 600, 1200 bps) by SYS instruction

High-speed operation

F0(MV) and F1(DMV) instructions Execution time: Approx. 1us

Only when every operands are without index modifier.

Note) The Ry and Tr types with the same specifications have the same version name

Function addition to existing instructions

F70(BCC) Block check code calculation

F356(EZPID) Easy PID instruction

Reference: <Programming Manual ARCT1F313E>

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

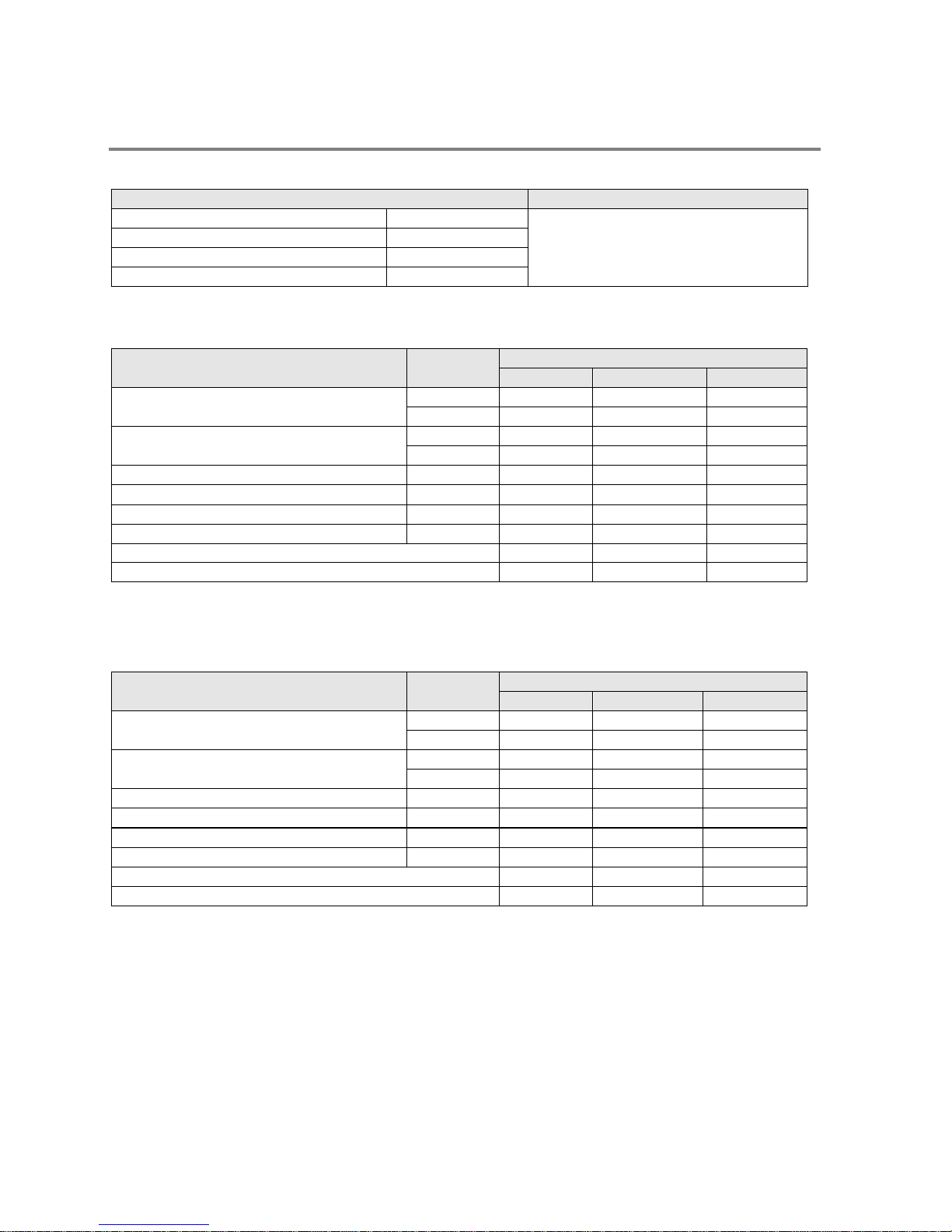

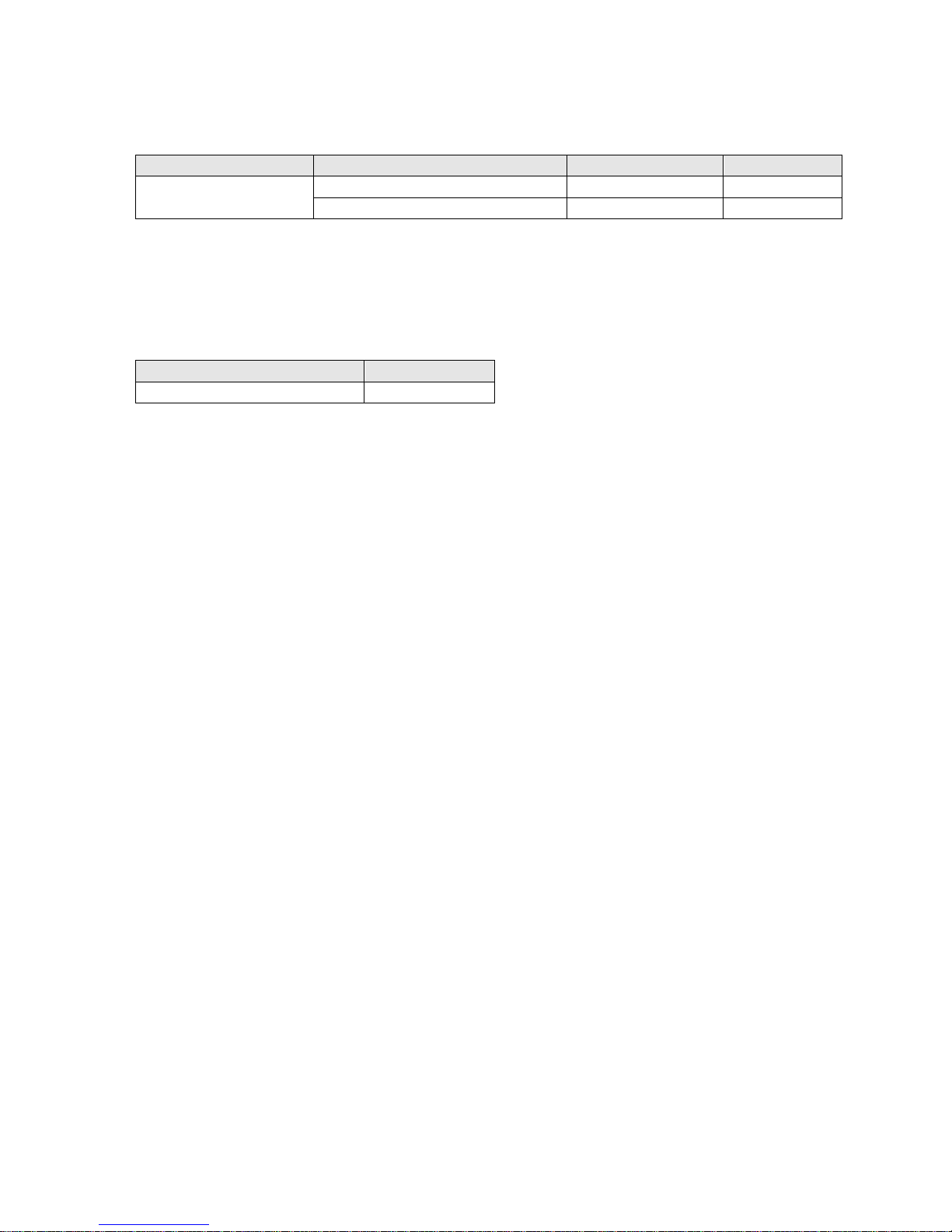

Restriction on usin g the Add-on cassette

Application cassettes that the version of the FP-X control unit is specified

FP-X Application cassette

Version of contro l unit

FP-X Analog output cassette

AFPX-DA2

Ver. 2.40 or later

FP-X Analog I/O cassette

AFPX-A21

FP-X Thermocouple cassette

AFPX-TC2

FP-X RTD cassette

AFPX-RTD2

Application cassettes that have restric tions wh en mor e t han one units are used simultaneously

Current output range

FP-X Application cassette

Quantity

used

Control unit

C14

C30

C60

AFPX-DA2

1 ○ ○ ○

2 - △

Note1)

△

Note1)

AFPX-A21

1 ○ ○ ○

2 - ○ ○

AFPX-DA2 + AFPX-A21

Each 1 - △

Note1)

△

Note1)

AFPX-DA2 + AFPX-COM5

Each 1 ×

Note2)

×

Note2)

×

Note2)

AFPX-A21 + AFPX-COM5

Each 1 ×

Note2)

×

Note2)

×

Note2)

AFPX-A21 + AFPX-DA2 + AFPX-COM5

Each 1 - ×

Note2)

×

Note2)

AFPX-DA2 1unit + AFPX-COM5 1unit

- ×

Note2)

×

Note2)

AFPX-A21 2units + AFPX-COM5 1unit

- ×

Note2)

×

Note2)

Note1) Up to 2 channels can be used for the current output range.

(When using two units, it is possible to use the 2-ch current output range and 2-ch voltage output range.)

Note2) The AFPX-DA2 and AFPX-A21 both cannot be used with the AFP-COM5 (Ethernet).

Voltage output range ( W hen u sing with the output current of 1 mA or below)

FP-X Application cassette

Quantity

used

Control unit

C14

C30

C60

AFPX-DA2

1 ○ ○ ○

2 - ○ ○

AFPX-A21

1 ○ ○ ○

2 - ○ ○

AFPX-DA2 + AFPX-A21

Each 1 - ○ ○

AFPX-DA2 + AFPX-COM5

Each 1 ○ ○ ○

AFPX-A21 + AFPX-COM5

Each 1 ○ ○ ○

AFPX-A21 + AFPX-DA2 + AFPX-COM5

Each 1 - ○ ○

AFPX-DA2 1unit + AFPX-COM5 1unit

-

○ ○

AFPX-A21 2units + AFPX-COM5 1unit

-

○ ○

Note) In the voltage output range, when using them with the output current at 1 mA to 10 mA, the

condition is the same as the current output range.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

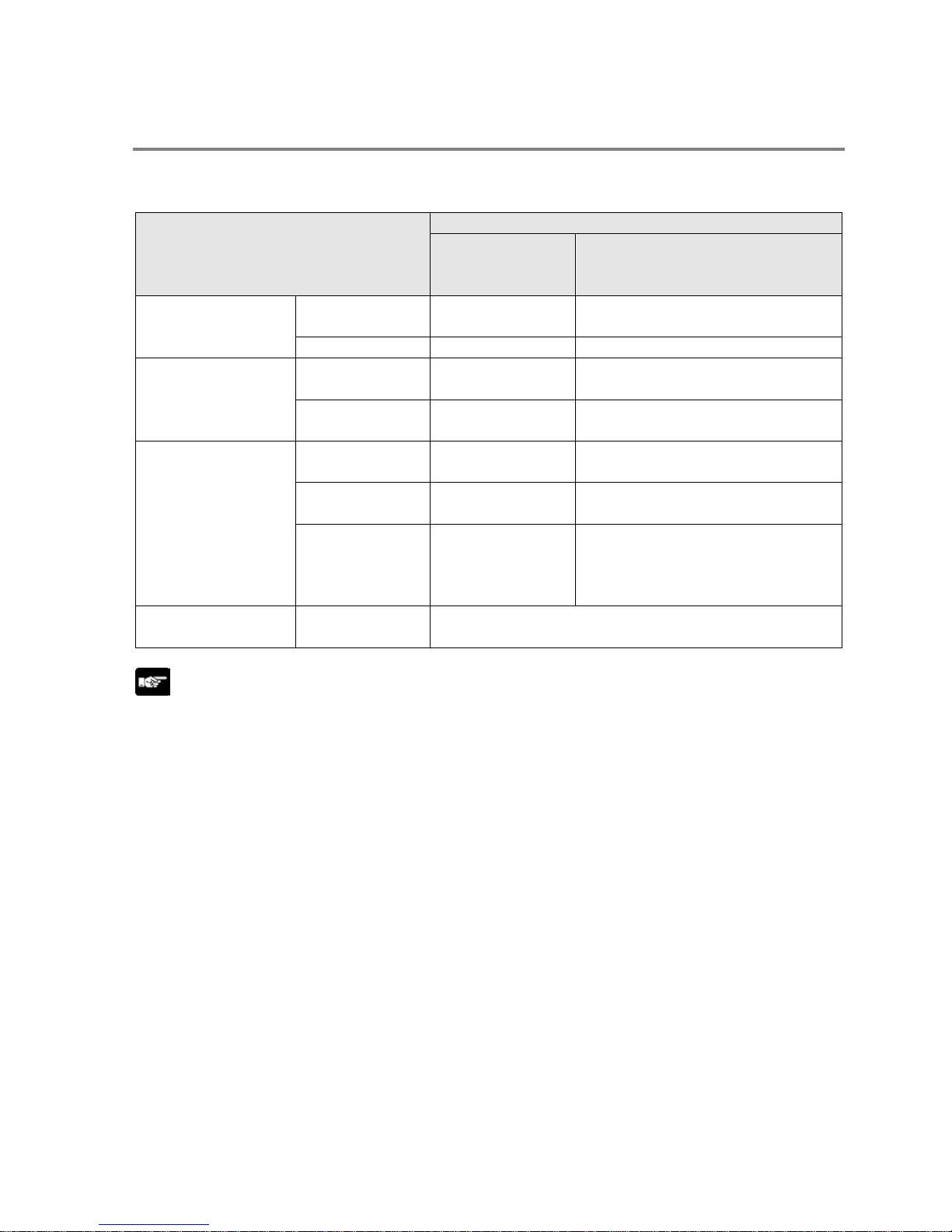

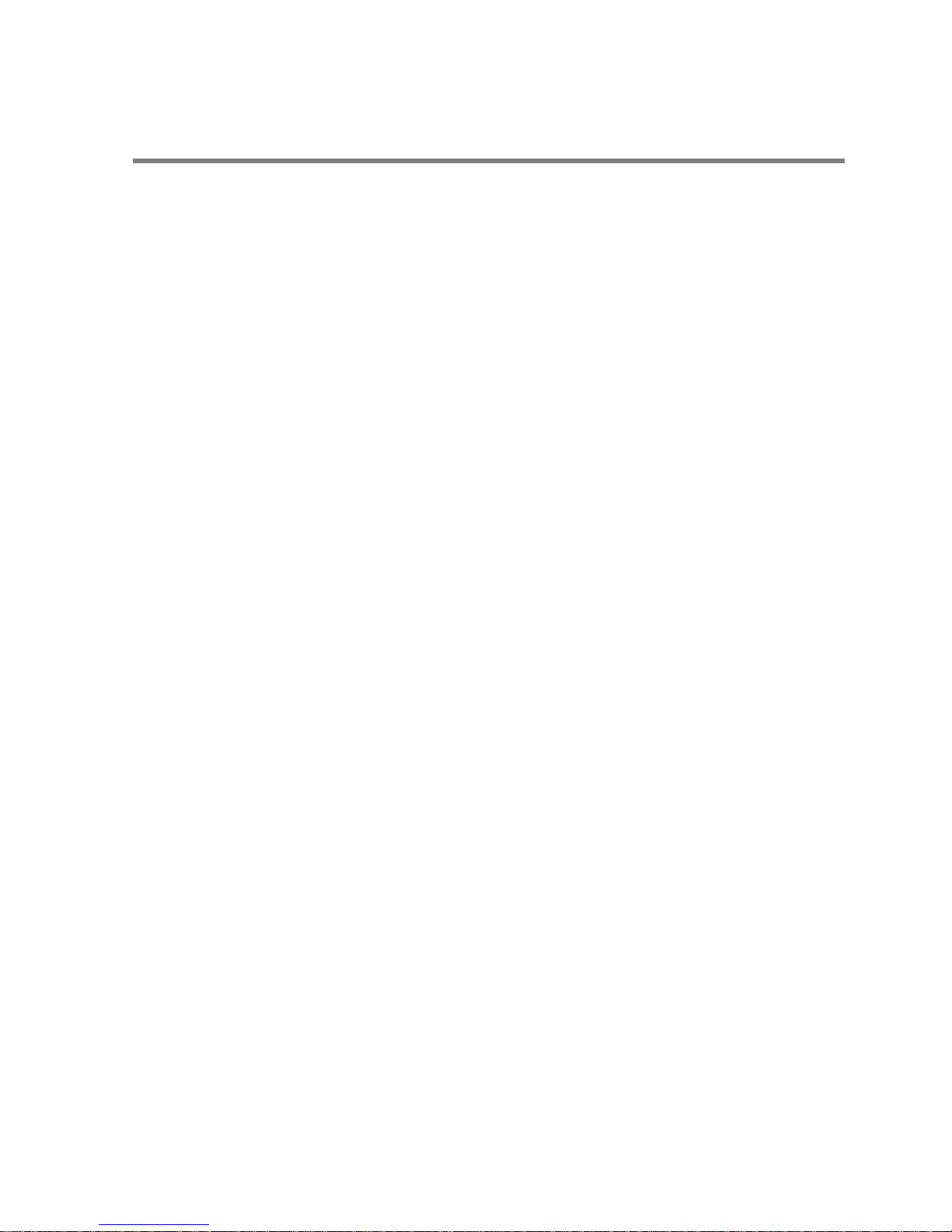

Programming Tool Restrictions

Restrictions on usable programming tools depending on the units (as of Feb. 2009)

Type of programming tool

Type of unit

AFPX-C14R

AFPX-C30R

AFPX-C60R

AFPX-C14T, C14TD, C14P, C14PD

AFPX-C30T, C30TD, C30P, C30PD

AFPX-C60T, C60TD, C60P, C60PD

Windows software

FPWIN GR Ver.2

Used

(Ver. 2.5 or later)

Used

(Ver. 2.70 or later)

FPWIN GR Ver.1

Not used

Not used

Windows software

Conforms to

IEC61131-3

FPWIN Pro

Ver.6

Used Used

FPWIN Pro

Ver.5

Used

(Ver. 5.1 or later)

Used

(Ver. 5.22 or later)

Handy programming

unit

AFP1113V2

AFP1114V2

Not used Not used

AFP1113

AFP1114

Not used Not used

AFP1111A

AFP1112A

AFP1111

AFP1112

Not used Not used

FP memory loader

AFP8670

AFP8671

Used

(Only programs and system registers can be transmitted.)

Note: Precautions concerning ver sion upgrade

• In case of using FPWIN GR Ver.1, please purchase upgrade model FPWIN GR Ver.2.

• FPWIN GR Ver. 2.0 can be upgraded to Ver. 2.5 or later free of charge at our web site.

• FPWIN Pro Ver. 6.0 can be upgraded free of charge at our web site.

• The handy programming unit cannot be used.

Do not download any programs for other units such as FP1 to the FP-X using the handy programming

unit.

Website address:

http://panasonic-denko.co.jp/ac/e/dl/software-list/patch/plc.jsp

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Chapter 1

Features, Functions and Restrictions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.1 Features and Functi ons of the Unit

Features

• Com pact size general-purpose PLC that is suitable for the small-scale facility control.

• Can be directly connected to a personal computer using USB communication port.

• High dimensional security functions to deal with copying programs.

• Supports analog control.

• Following items are provided as options,

- Application cassettes, such as the positioning control function by the high-speed counter and

pulse output.

- Fulfilling communication cassettes.

- Realtime clock function.

Basic functions as compact size general-purpose PLC suitable for the small-scale facility control

Basic functions including the followings are equipped even though it is a general-purpose style such as

AC power supply, screw terminal block and relay output.

1. 32k-step program capacity

2. 0.32 µs command processing speed

3. Max. 382-points I/O control

Single-phase 8-channel and 2-phase 4 channel high-speed count er functions are equipped for

the control unit.

Fulfilling function enhancement

Various add-on cassettes are avai lable as options (such as 10 types of application cassettes and

6 types of communication cassette).

• Application cassettes

DC 8-point input type, transistor 8-point NPN output type, transistor 6-point PNP output type, DC 4-point

input + transistor 3-point NPN output type, analog 2-ch output type, analog 2-ch input + analog 1-ch

output type, thermocouple 2-ch type, RTD 2-ch type, analog 2-ch input type, high-speed counter input +

pulse output type, master memory type with realtime clock (32k-step program can be copied and stored.)

• Communication cassettes

1-ch RS232C type, 2-ch RS232C type, 1-ch RS485/RS422 changeover type, 1-ch RS232C + 1-ch

RS485 type, Ethernet + 1-ch RS232C type, 2-ch RS485 type

FP0 expansion unit s can be connected as well as the excl usive expansion unit.

A maximum of 3 FP0 expansion units can be connected using the expansion FP0 adapter.

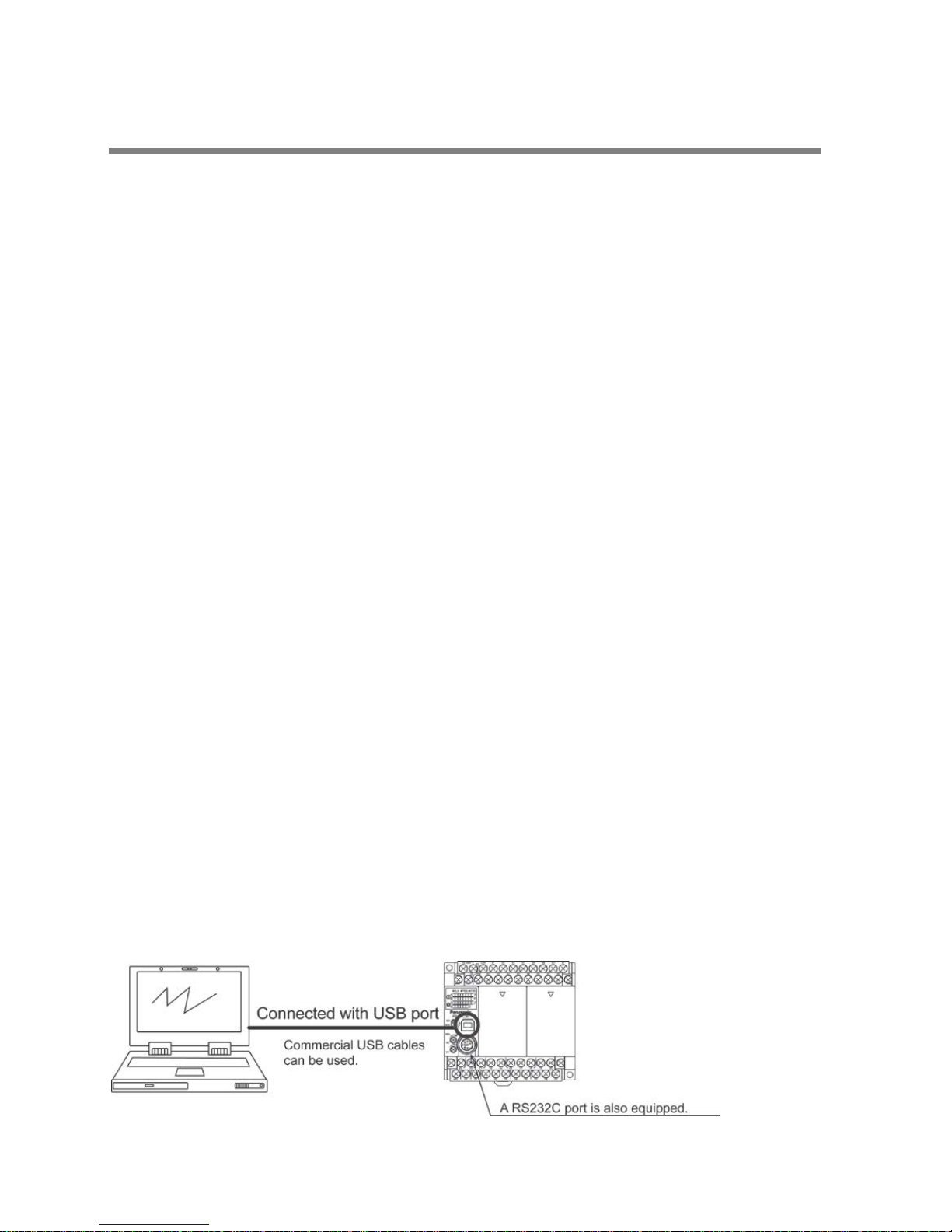

A personal com puter can be directly connected with the USB c ommunicat ion port.

A personal computer can be directly connected with the USB cable (excluding C14).

The USB⇔RS232C conversion adapter/cable is not necessary.

(A tool port (RS232C) is also equipped.)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

High dimensional security functions to deal with copying programs.

The uploading disabling function prohibits uploading (reading) programs in the PLC main unit and

prevent illegal copying.

(It also enables to transfer the programs to the FP-X master memory cassette, when the uploading

disabling function is specified).

The protection for programs can be selected from

3 security methods.

• 4-digit password

• 8-digit password

•

Uploading disabling

A full rang e of communication functions

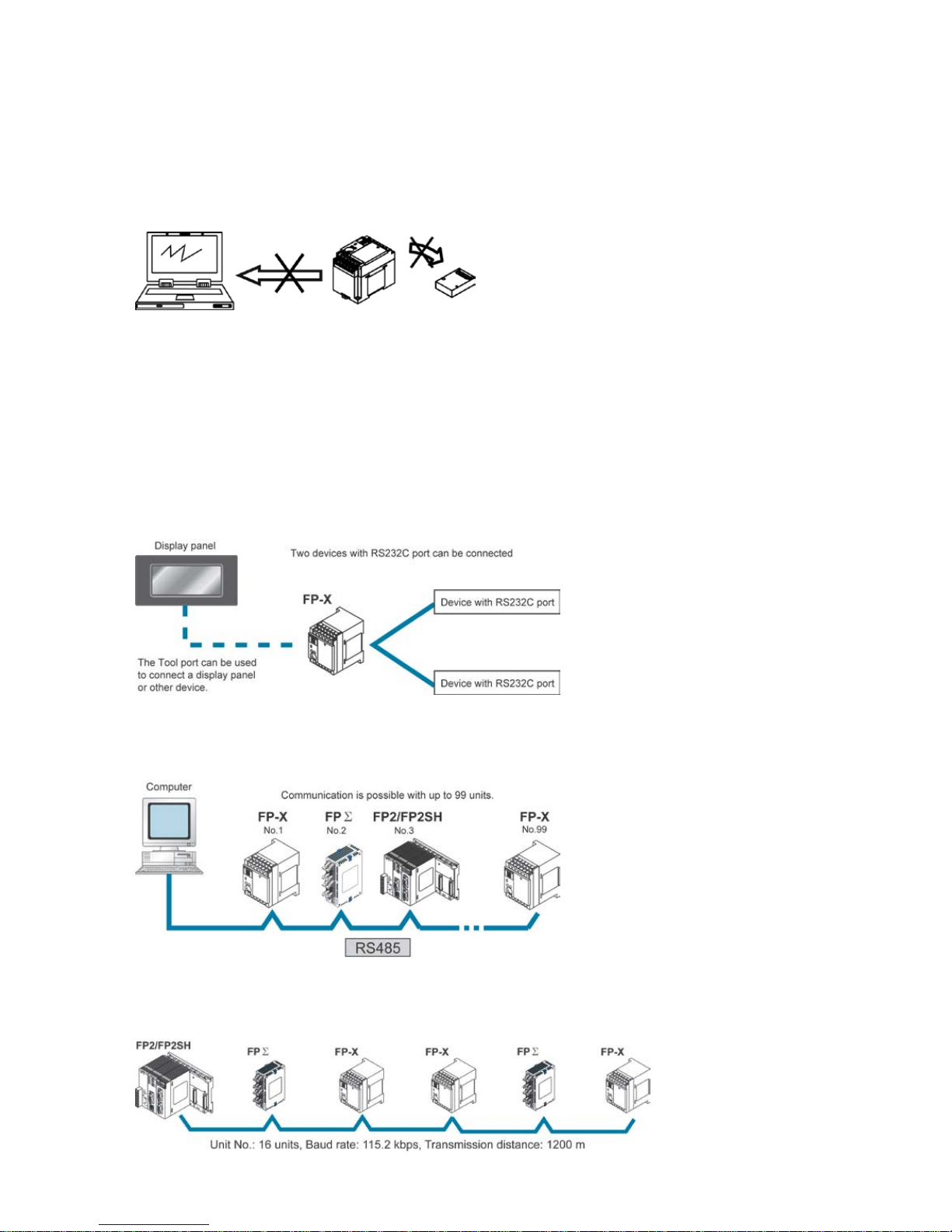

Using the Tool port (RS232C) provided as a standard feature on the main unit, communication can be

carried out with a display panel or computer. Additionally, communication cassettes with RS232C,

RS485 and Ethernet interfaces are available as an option. Installing a 2-channel RS232C type

communication cassette in the FP-X makes it possible to connect two devices with RS232C port. A full

lineup of communication functions means you can also work with 1:N communication (up to 99 units)

and PC(PLC) link function (up to 16 units).

Controlling two devices with RS232C port with one FP-X

When using the 2-channel RS232C type communication cassette

1:N communication possible wi t h up to 99 stations (units)

When using the 1-channel RS485/RS422 type communication cassette

When using the 1-channel RS485 and 1-channel RS232C in combination

Link with FP2 and FP

Σ is possible

Data sharing between small size and medium size PLCs is easily achievable in one network.

The FP-X supports MEWNET-W0, and the programless PLC link with the FP2 or FPΣ is possible.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

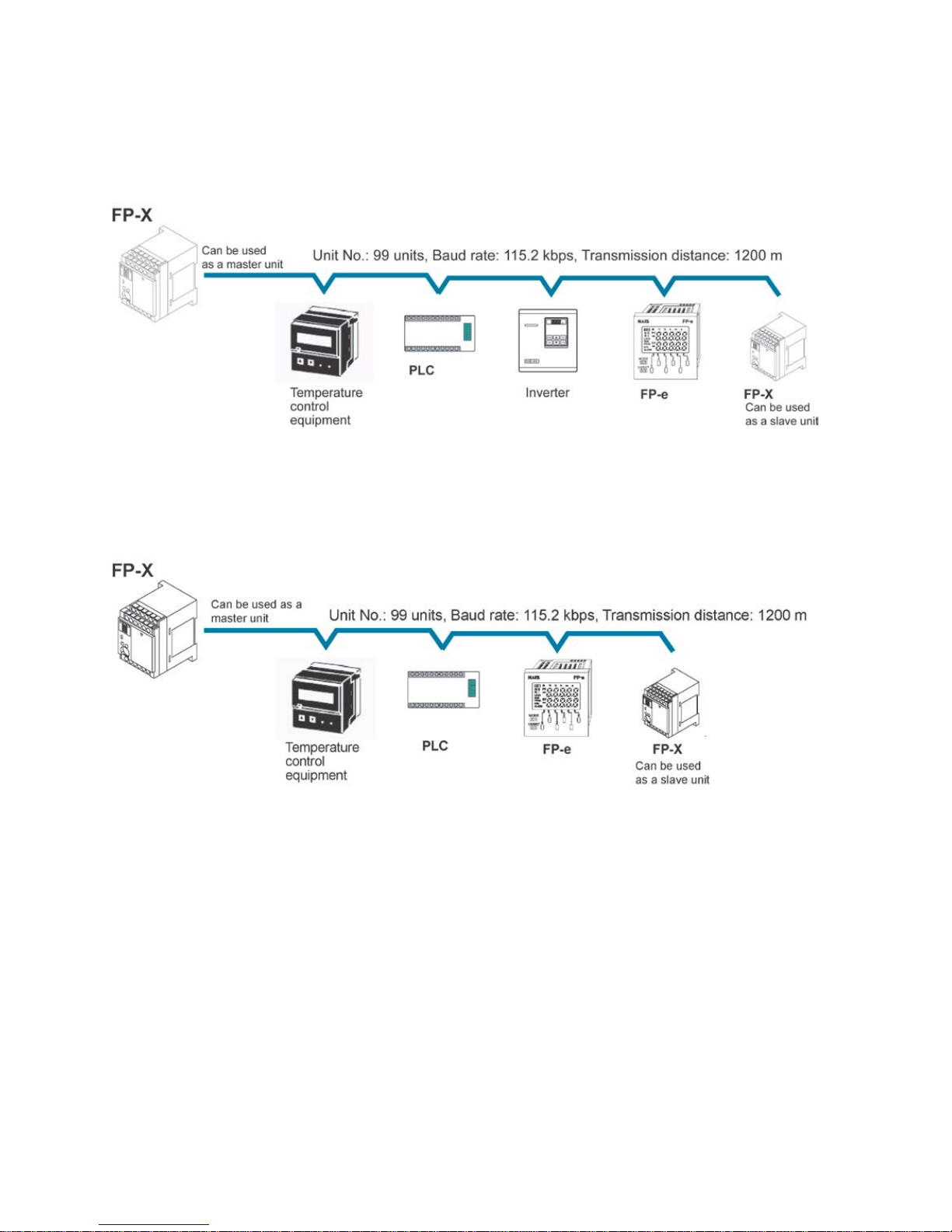

Supports Modbus RTU

It can be used as a master unit/slave units (F145 and F146 instructions).

It can be easily communicated with a temperature control device, inverter, FP-e or overseas PLCs.

It is possible to communicate with up to 99 units

MEW TOCOL communication

It can be used as a master unit/slave units (F145 and F146 instructions).

It can be easily communicated with a PLC, image processor, temperature control device, message

runner or eco-power meter.

It is possible to communicate with up to 99 units

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

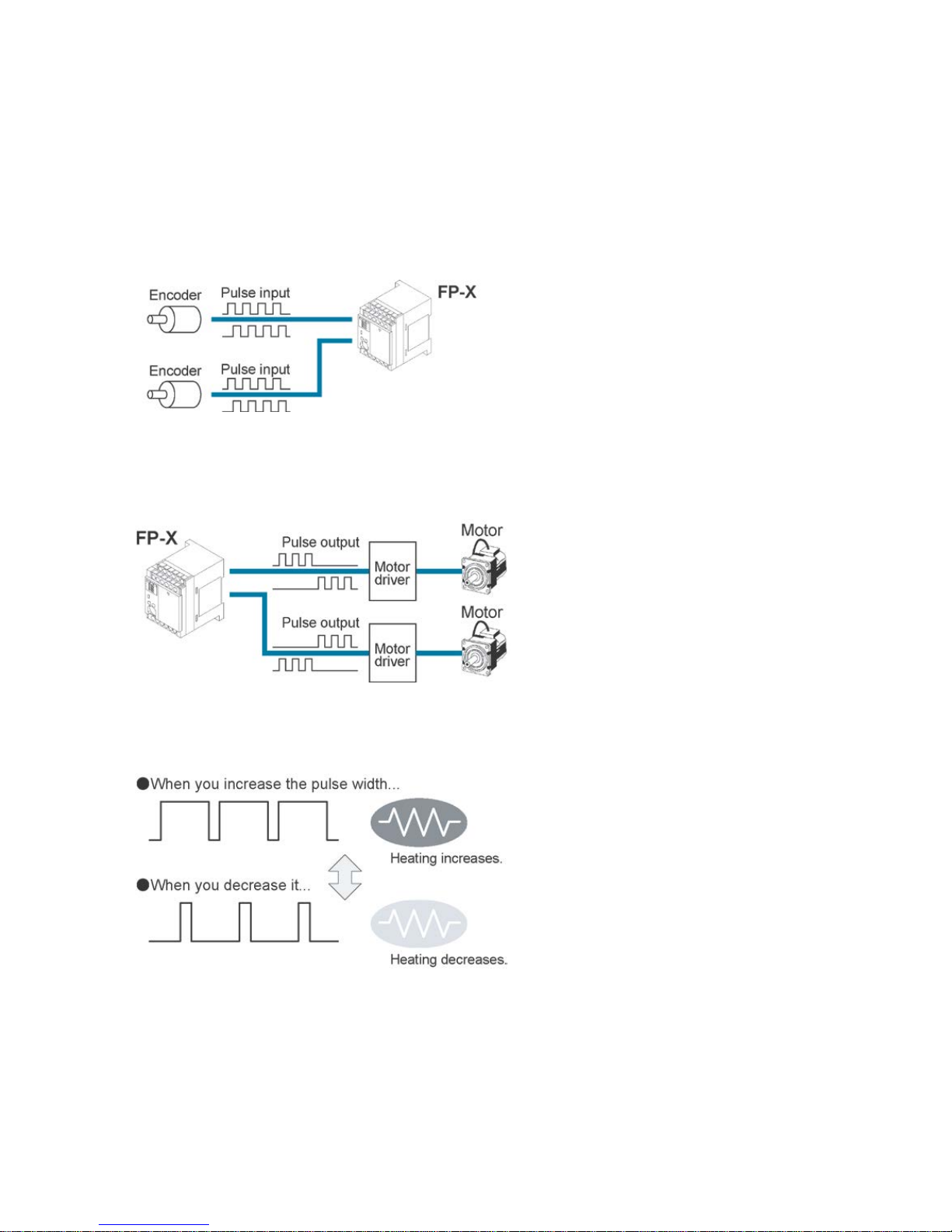

Positioning control supported through high-speed counter and pulse output

With the FP-X Tr type, a high-speed counter function can be used by using the CPU I/O.

With the FP-X Ry type, a high-speed counter and pulse output functions can be used by using the pulse

I/O cassette. The pulse output function supports frequencies of up to 100kHz, enabling positioning

control using a stepping motor or servo motor.

Note) The pulse I/O cassette cannot be used for the FP-X Tr type.

Measurement using high-speed counter supported

Increment input mode, decrement input mode, 2-phase input mode, individual input mode, and direction

discrimination mode are supported.

Note) Differs depending on combinations.

Positioning control based on puls e output supported

Pulse/direction and clockwise/counter –clockwise output are supported.

Heater control based on PWM output function supported

The pulse output at any duty ratio can be picked up with special instruction.

Analog potentiometer ( volume dial)

An analog potentiometer (volume dial) is provided as a standard feature. This can be used in

applications such as analog timers, without using the programming tools.

Realtime clock function can be added

Optional FP-X master memory cassette (AFPX-MRTC) and backup battery enables the realtime clock

function.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

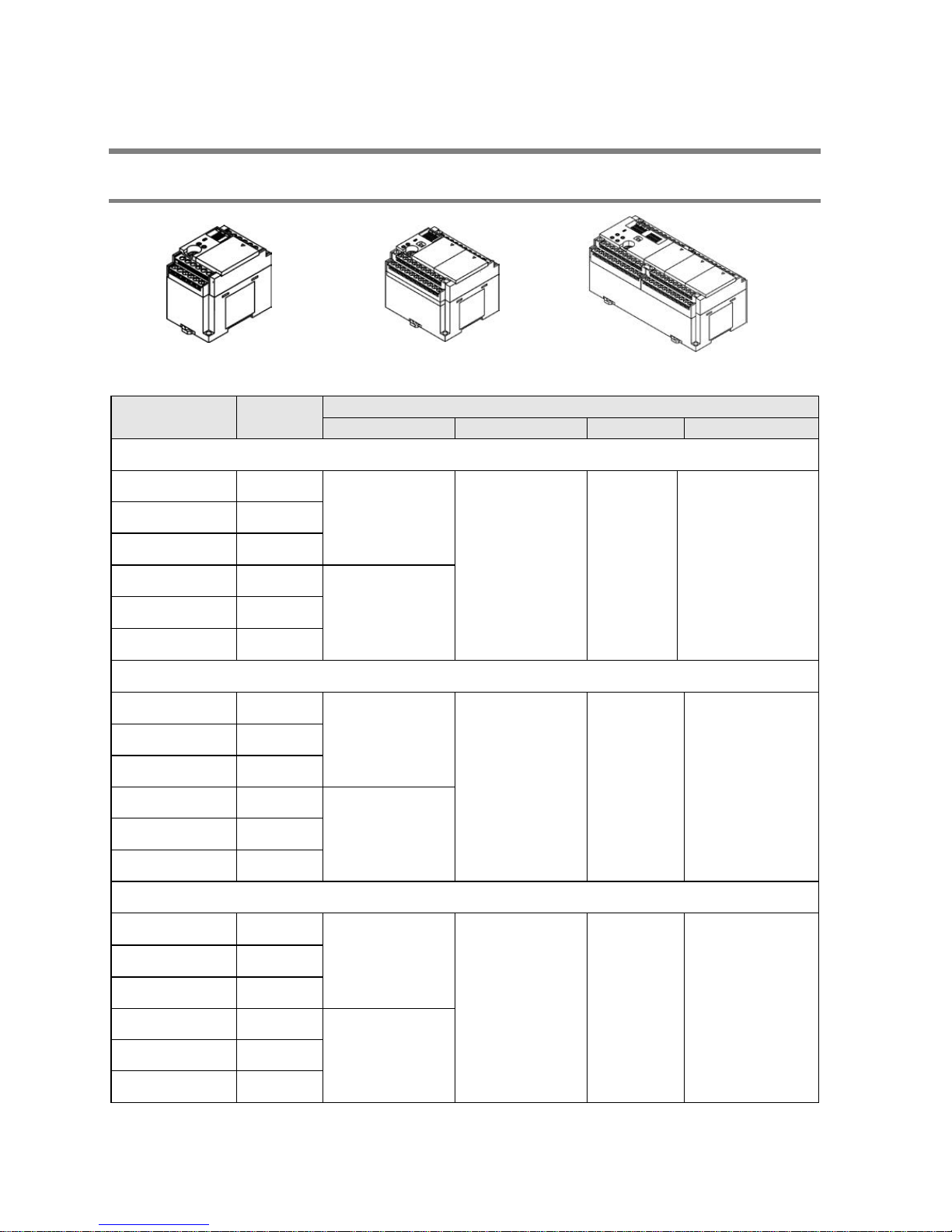

1.2 Unit Types

1.2.1 FP-X Control Units

C14

C30

C60

Product No.

No. of I/O

points

Specifications

Power supply

Input

Output

Connection

Relay type ( Ry typ e)

AFPX-C14R 8/6

100 to 240 V AC

24 V DC

(Common

polarities

+ & - common)

Relay Terminal block

AFPX-C30R 16/14

AFPX-C60R 32/28

AFPX-C14RD 8/6

24 V DC

AFPX-C30RD 16/14

AFPX-C60RD 32/28

Transi s tor type (NPN) (Tr type)

AFPX-C14T 8/6

100 to 240 V AC

24 V DC

(Common

polarities

+ & - common)

Transistor

(NPN)

Terminal block

AFPX-C30T 16/14

AFPX-C60T 32/28

AFPX-C14TD 8/6

24V DC

AFPX-C30TD 16/14

AFPX-C60TD 32/28

Transi s tor type (PNP) (Tr type)

AFPX-C14P 8/6

100 to 240 V AC

24 V DC

(Common

polarities

+ & - common)

Transistor

(PNP)

Terminal block

AFPX-C30P 16/14

AFPX-C60P 32/28

AFPX-C14PD 8/6

24V DC

AFPX-C30PD 16/14

AFPX-C60PD 32/28

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

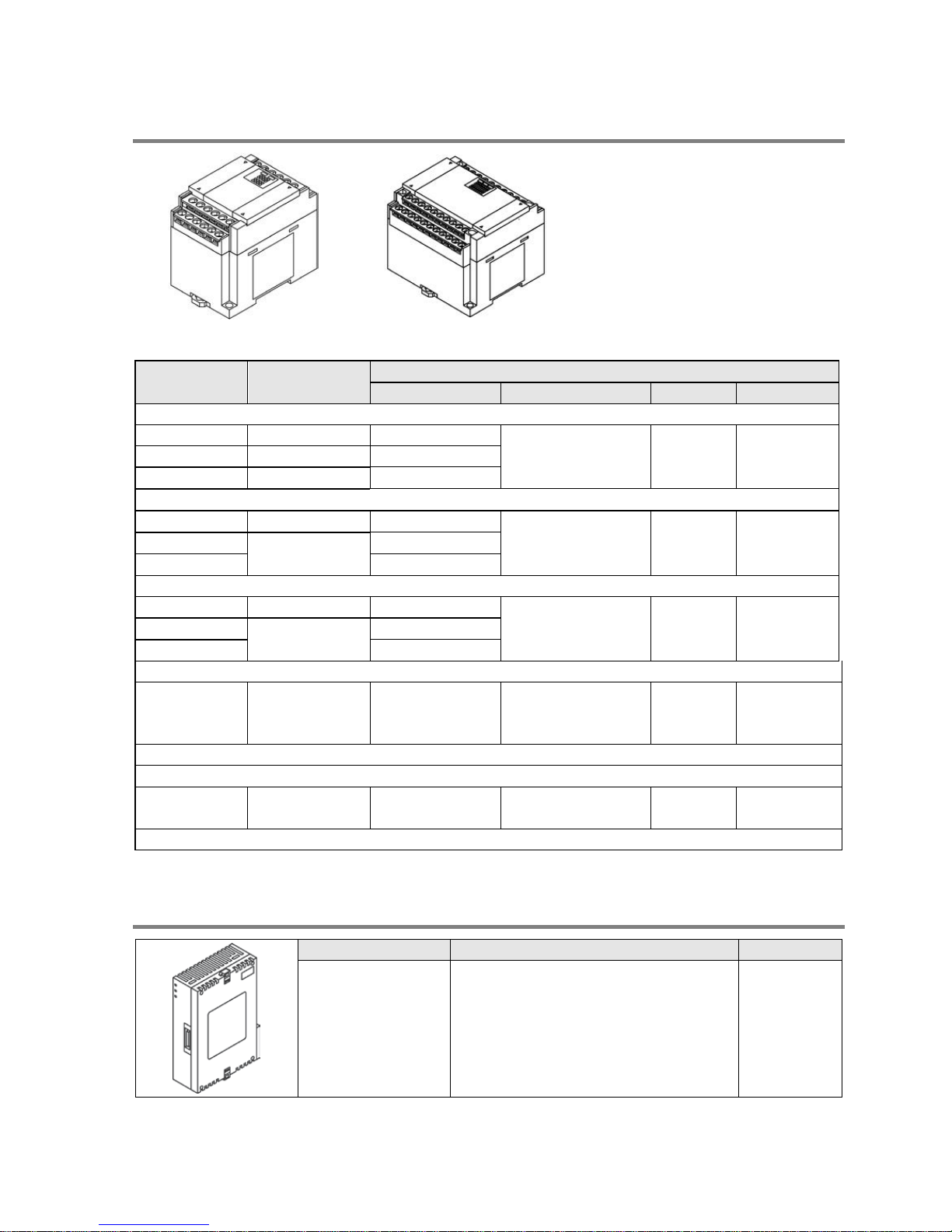

1.2.2 FP-X Expansion Unit

E14/E16 E30

Product No.

No. of I/O

points

Specifications

Power supply

Input

Output

Connection

Relay type ( Ry typ e)

AFPX-E16R 8/8 -

24 V DC

(Common polarities

+ & - common)

Relay

Terminal

block

AFPX-E30R

16/14

100 to 240 V AC

AFPX-E30RD

16/14

24 V DC

Transi s tor type (NPN) (Tr type)

AFPX-E16T 8/8 -

24 V DC

(Common polarities

+ & - common)

Transistor

(NPN)

Terminal

block

AFPX-E30T

16/14

100 to 240 V AC

AFPX-E30TD

24V DC

Transi s tor type (PNP) (Tr type)

AFPX-E16P

8/8

-

24 V DC

(Common polarities

+ & - common)

Transistor

(PNP)

Terminal

block

AFPX-E30P

16/14

100 to 240 V AC

AFPX-E30PD 24V DC

Input-only typ e

AFPX-E16X

16/0

(X300 to X30F)

-

24 V DC

(Common polarities

+ & - common)

-

Terminal

block

- The input specifications are the same as AFPX-E16R.

Output-only type (R elay type)

AFPX-E14YR

0/14

(Y300 to Y30D)

- - Relay

Terminal

block

- The output specifications are the same as AFPX-E16R.

An 8-cm expansion cable is provided with expansion unit

1.2.3 FP-X Expa ns ion FP 0 Adapt er

Name

Specifications

Product No.

FP-X Expansion

FP0 adapter (with 8

cm expansion

cable, power supply

cable)

For connecting FP0 expansion unit AFPX-EFP0

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

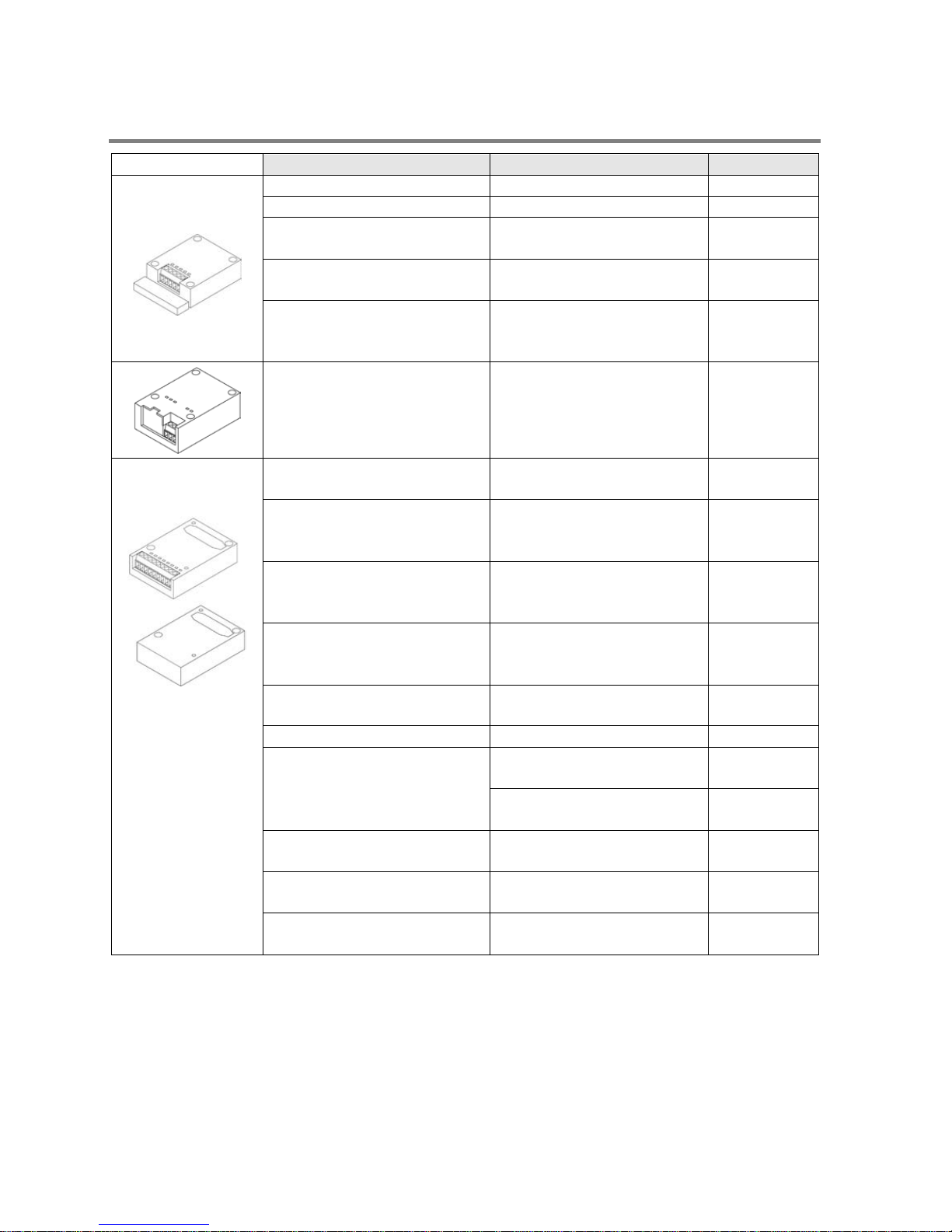

1.2.4 Add-on Cas settes (Comm un ication casset tes/ A pplication ca ssette s)

Name

Specifications

Product No.

Communication

cassette

FP-X Communication cassette

5-wire 1-channel RS232C

AFPX-COM1

FP-X Communication cassette

3-wire 2-channel RS232C

AFPX-COM2

FP-X Communication cassette

1-channel RS485/RS422

(insulated)

AFPX-COM3

FP-X Communication cassette

1-channel RS485 (insulated)

3-wire 1-channel RS232C

AFPX-COM4

FP-X Communication cassette

2-channel RS485 (insulated)

(non-insulated between

channels)

AFPX-COM6

FP-X Communication cassette

Ethernet,

3-wire 1-channel RS232C

AFPX-COM5

Application

cassette

FP-X Analog input cassette

2-channel analog input

(non-insulated)

AFPX-AD2

FP-X Analog output cassette

2-channel analog output

(insulated) (insulated

between channels)

AFPX-DA2

FP-X Analog I/O cassette

2-channel analog input

(insulated) + 1-channel

analog output (insulated)

AFPX-A21

FP-X Thermocouple cassette

2-channel thermocouple input

(insulated) (insulated

between channels)

AFPX-TC2

FP-X RTD cassette

2-ch RTD input (insulated)

(insulated between channels)

AFPX-RTD2

FP-X Input cassette 8-point DC input AFPX-IN8

FP-X Output cassette

8-point transistor output

(NPN)

AFPX-TR8

6-point transistor output

(PNP)

AFPX-TR6P

FP-X I/O cassette

4-point DC input + 3-point

transistor output (NPN)

AFPX-IN4T3

FP-X Pulse I/O cassette

2-ch high-speed counter +

1-ch pulse output

AFPX-PLS

FP-X Master memory cassette

Master memory + realtime

clock

AFPX-MRTC

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

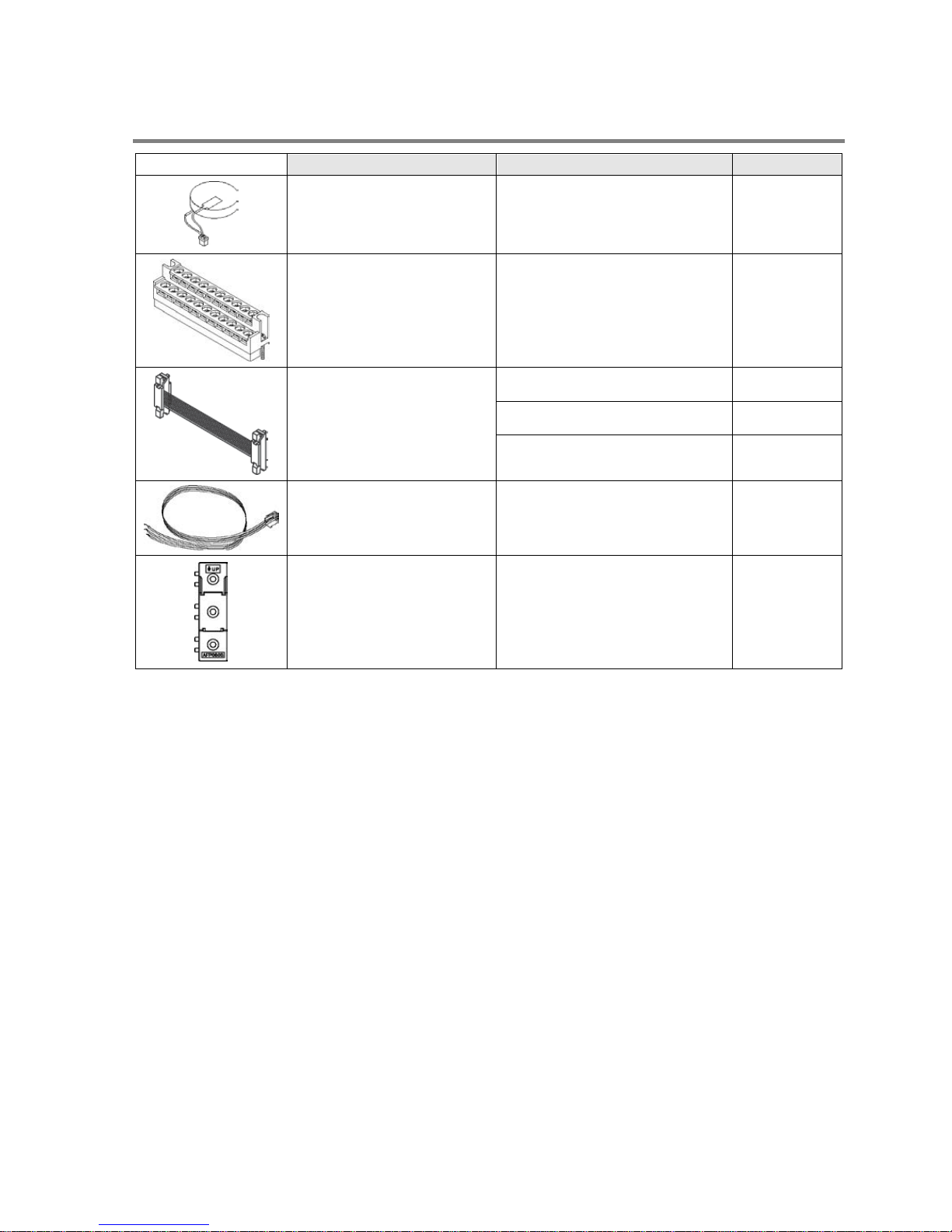

1.2.5 Related Part s

Name

Description

Product No.

FP-X Backup battery

Necessary for the backup of

data registers, etc. or for using

the realtime clock function.

AFPX-BATT

FP-X terminal block

(C30/C60)

For C30/C60 control unit

for E30 expansion I/O unit

with 21-pin cover (no printing)

4 pcs/pack

AFPX-TAN1

FP-X expansion cable

Note)

8 cm AFPX-EC08

30 cm AFPX-EC30

80 cm AFPX-EC80

FP0 power supply cable

For Expansion FP0 adapter,

Length: 1 m

AFP0581

FP0 mounting plate

(slim type)

Used for expansion FP0

adapter and FP0 Expansion

unit, 10 pcs/pack

AFP0803

Note) The total length of the expansion cable should be within 160 cm.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

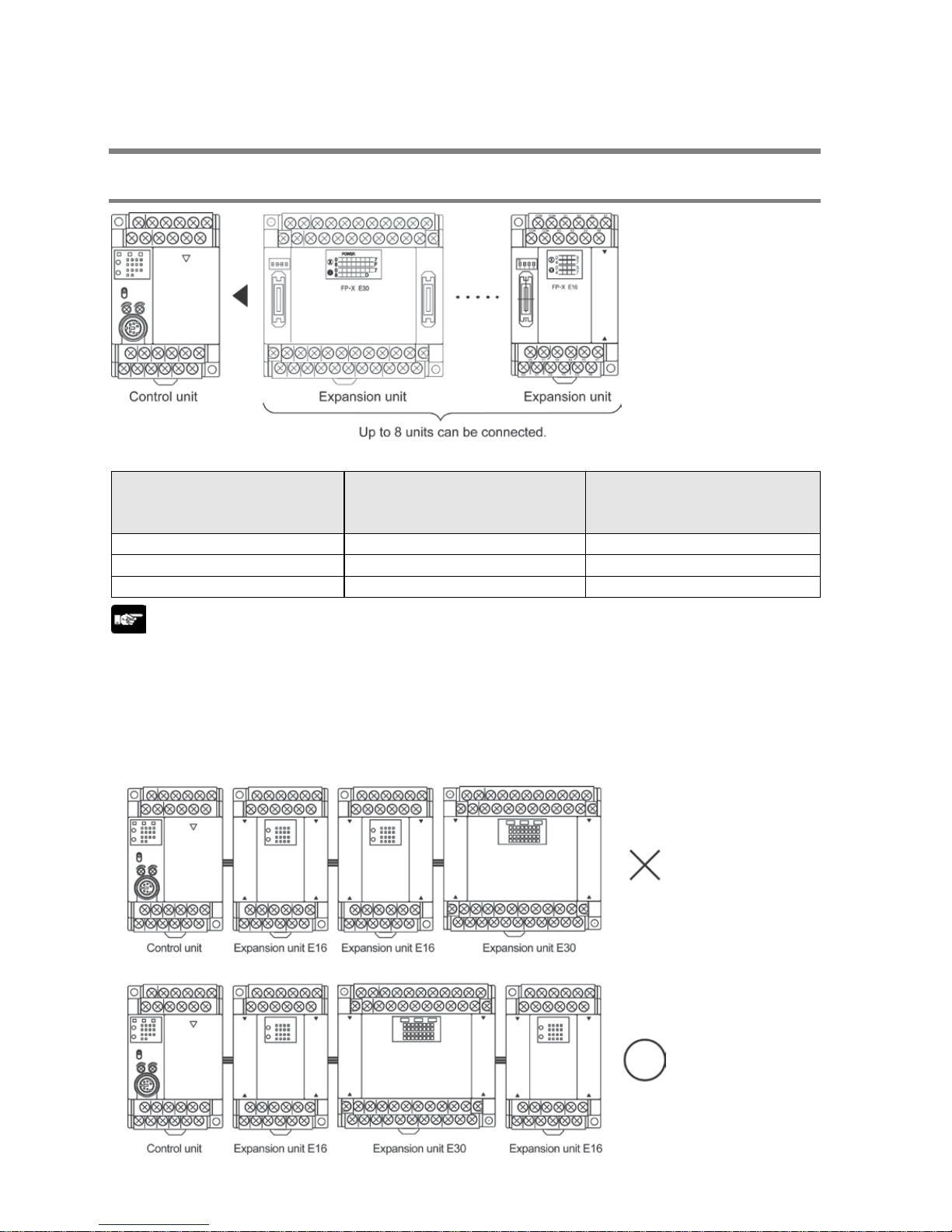

1.3 Restrictions on Uni t Combina t ions

1.3.1 Restr ictions on FP-X Expansion Unit

Controllable I/O points

Type of control unit

Number of I/O points whe n

using control unit

Number of I/O points whe n

using 8 units of E30

expansion I/O unit

FP-X C14 Control unit 14 points Max. 254 points

FP-X C30 Control unit 30 points Max. 270 points

FP-X C60 Control unit

60 points

Max. 300 points

Note:

- Up to eight units of FP-X can be connected, however, the restrictions on each expansion unit vary.

- For AFPX-E16/E14: Two units cannot be connected consecutively since the power should be supplied

from the unit with the power supply (as no power supply is built in AFPX-E16).

E16 expansion I/O unit cannot be connected on the right side of the control unit or AFPX-E30.

- For AFPX-E30: There is no restriction on AFPX-E30 so that up to 8 units can be connected

consecutively.

- The total length of the expansion cable should be within 160 cm.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

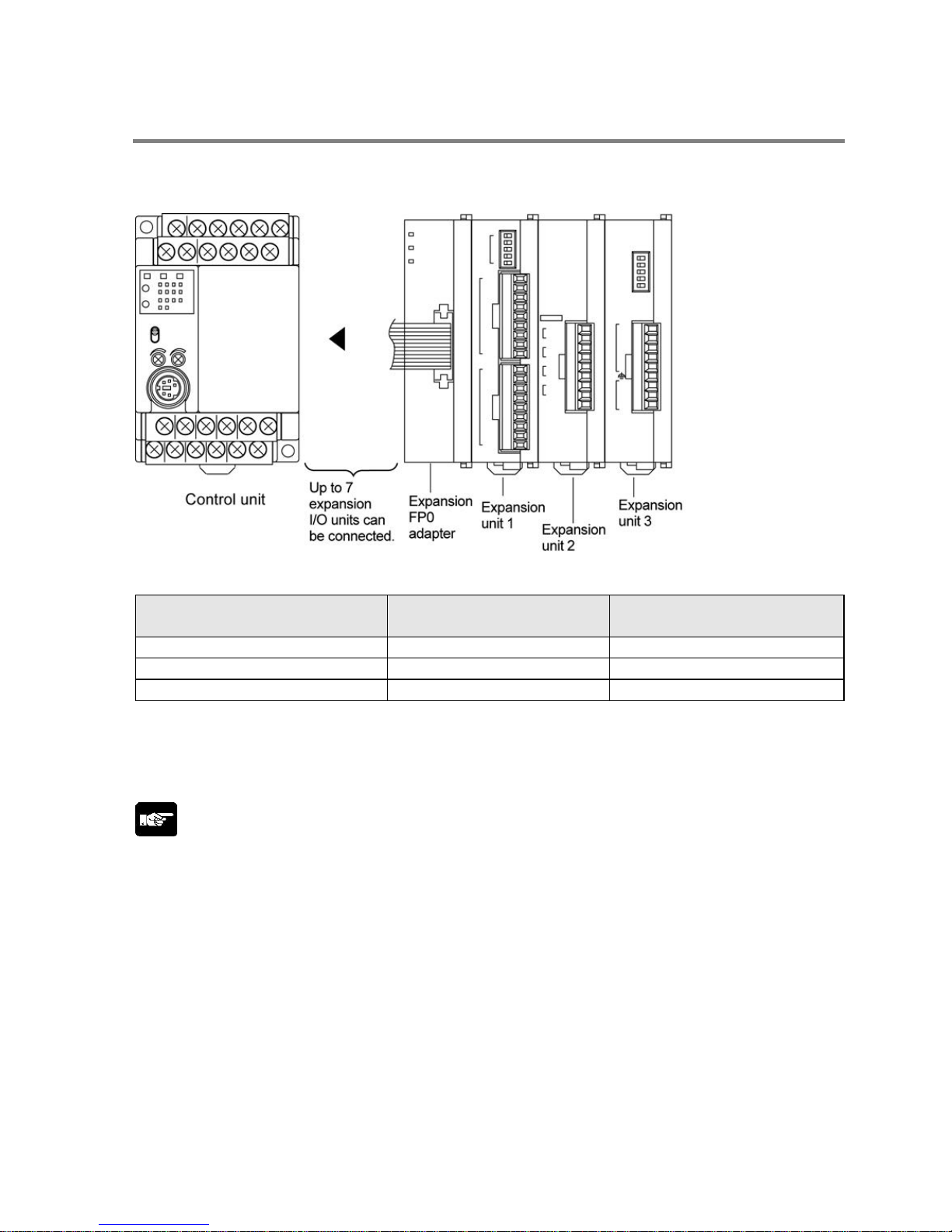

1.3.2 Restrictions on FP0 Expansion U nit

Up to three dedicated FP0 expansion units can be added using the FP-X and the expansion FP0 adapter.

The relay output type and the transistor output type can be used in combination.

Controllable I/O points

Type of control unit

Number of I/O points whe n

using control unit

Number of I/O points whe n

using FP0 expansion unit

FP-X C14 Control unit

14 points

Max. 110 points

FP-X C30 Control unit 30 points Max. 126 points

FP-X C60 Control unit

60 points

Max. 156 points

Note1) Up to seven FP-X expansion I/O units can be also installed between the control unit and the

expansion FP0 adapter.

Note2) Only one expansion FP0 adapter can be installed at the last position of the FP-X expansion bus.

(It should be installed at the right hand side of the AFPX-E16 and E30.)

Note:

• Install the FP0 thermocouple unit on the right side of other expansion units. If it is installed on the left

side, the total precision will deteriorate.

• Install the FP0 CC-Link slave unit on the right side of the other expansion units. There is no expansion

connector on the right side.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

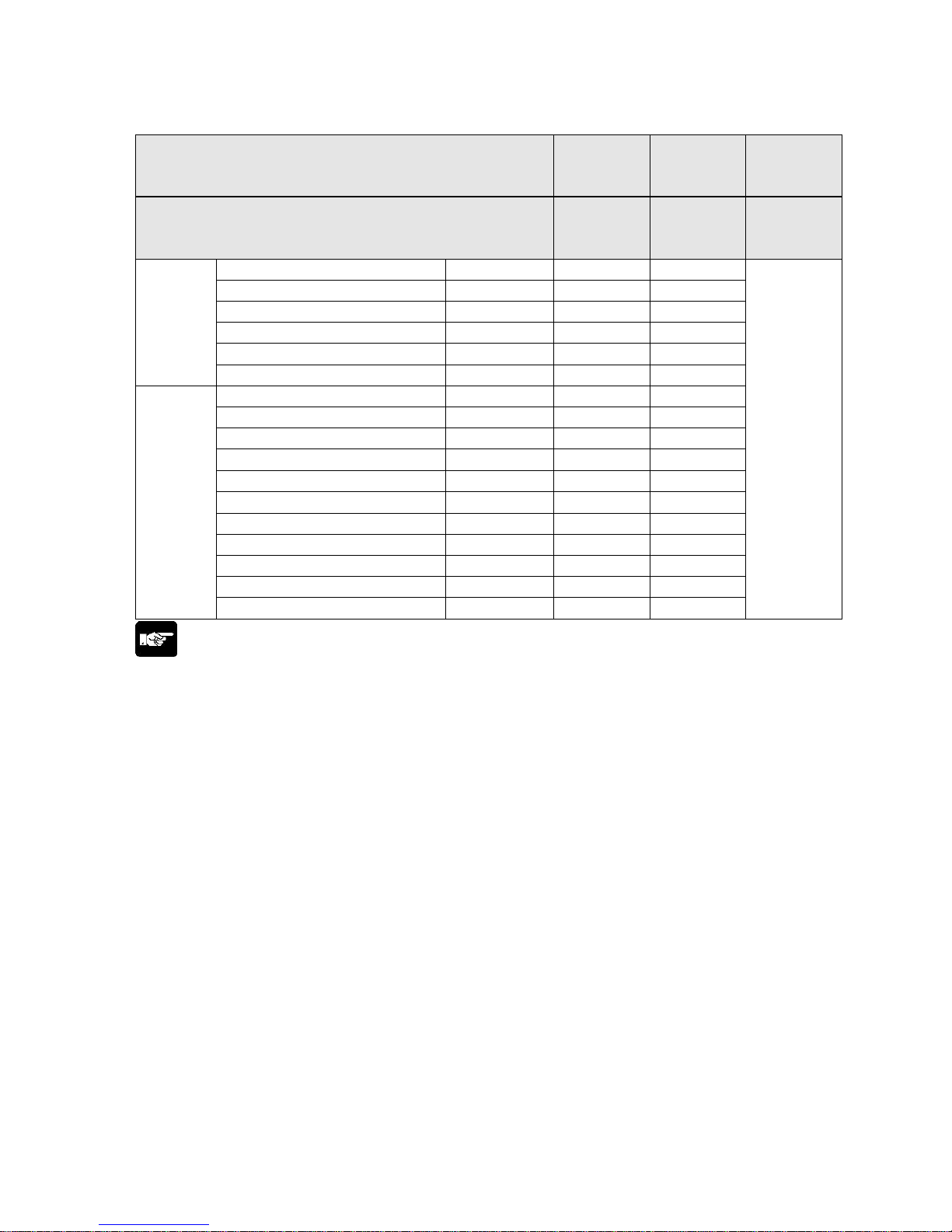

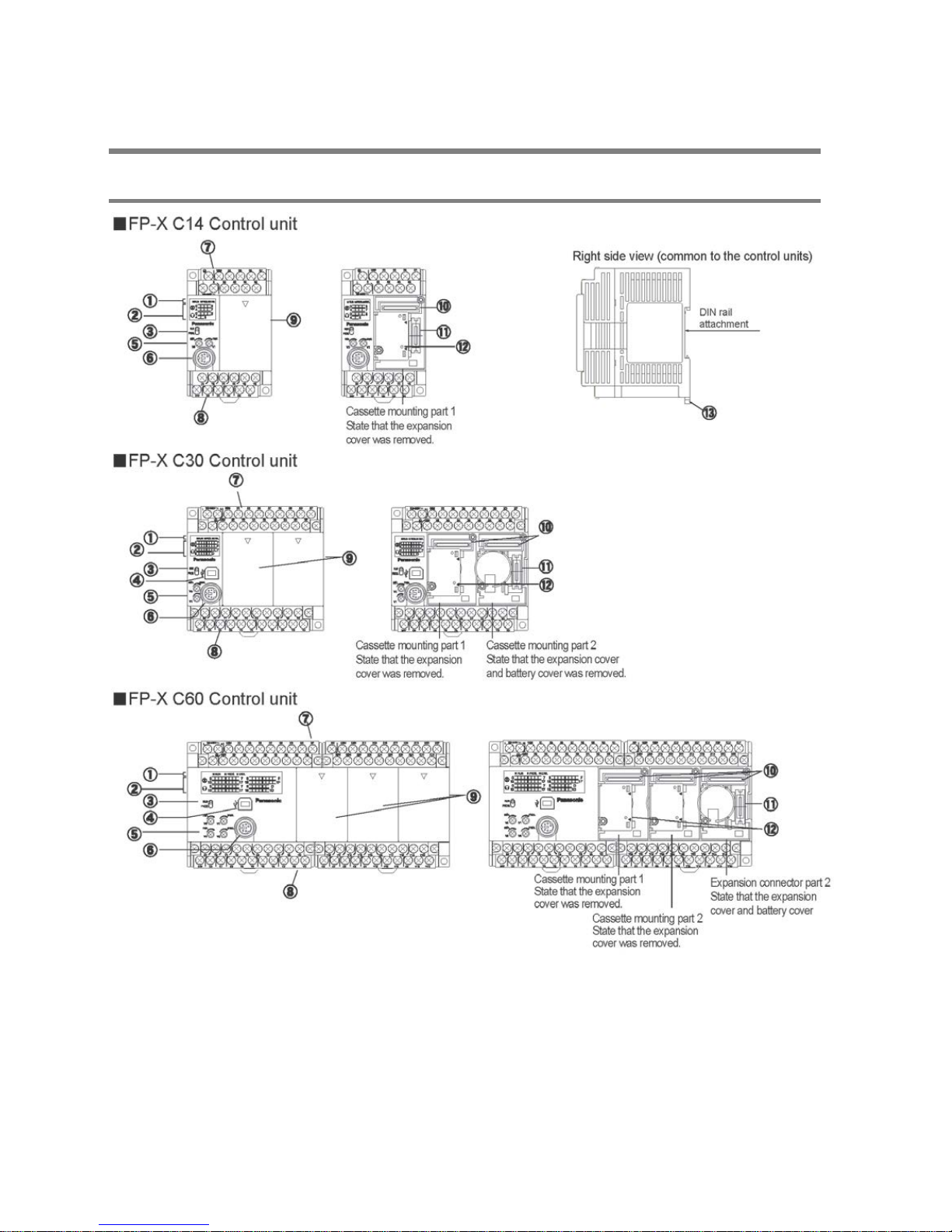

1.3.3 Restrictions on FP-X Add-on Cassette

The add-on cassette is installed in the cassette mounting part 1 and 2 (only the cassette mounting part 1

is available for C14) of the control unit.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

A: Available, N/A: Not available

Restrictions on control unit

FP-X C14

FP-X C30

FP-X C60

FP-X C30

FP-X C60

FP-X C60

Type of add-on cassette

Cassette

mounting

part 1

Cassette

mounting

part 2

Expansion

connector

part

Communication

cassette

FP-X Communication cassette AFPX-COM1 A N/A

The add-on

cassette

cannot be

installed.

FP-X Communication cassette

AFPX-COM2

A

N/A

FP-X Communication cassette AFPX-COM3 A N/A

FP-X Communication cassette

AFPX-COM4

A

N/A

FP-X Communication cassette AFPX-COM5 A N/A

FP-X Communication cassette

AFPX-COM6

A

N/A

Application

cassette

FP-X Analog input cassette AFPX-AD2 A A

FP-X Input cassette

AFPX-IN8

A

A

FP-X Analog output cassette AFPX-DA2 A A

FP-X Analog I/O cassette

AFPX-A21

A

A

FP-X Thermocouple cassette AFPX-TC2 A A

FP-X RTD cassette

AFPX-RTD2

A

A

FP-X Output cassette AFPX-TR8 A A

FP-X Output cassette

AFPX-TR6P

A

A

FP-X I/O cassette AFPX-IN4T3 A A

FP-X Pulse I/O cassette

AFPX-PLS

A

Note5)

A

Note5)

FP-X Master memory cassette AFPX-MTRC A

Note1)

A

Note1)

Note:

1. Only one FP-X master memory cassette AFPX-MRTC can be installed. If 2 units are installed, E26

(user ROM error) will occur.

2. One application cassette can be installed in either cassette mounting part 1 or 2 of C30/C60.

3. As only one communication cassette can be installed in the cassette mounting part 1, it should be

installed on the application cassette if the application cassette is installed. (It cannot be installed in the

cassette mounting part 2.)

4. The add-on cassette cannot be installed in the expansion connector part of C60 (it does not work).

5. The pulse I/O cassette cannot be installed on the FP-X Tr type.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.4 Programming Tools

1.4.1 Tools Needed for Programming

1. Programming tool software

- The tool software can also be used with the FP

series.

- “FPWIN Pro Ver.6” or “FPW IN GR Ver.2” Windows

software is used with FP-X.

FPWIN GR Ver.1x, NPST-GR and FP

Programmer cannot be used.

2. PC connection c able

- The dedicated cable is available.

- A commercial USB cable can be used for the

connection for C30/C60 control unit.

1.4.2 Soft ware En vir onmen t and Su itable Cabl e

Standard ladder diagram tool software FPWIN-GR Ver.2

Type of software OS (Operating system)

Hard disk

capacity

Product No.

FPWIN GR Ver.2

Englishlanguage menu

Full type

Windows98

WindowsMe

Windows2000

WindowsXP

Windows Vista

Windows7

40MB or more

AFPS10520

Upgrade

version

AFPS10520R

Note1) Ver.1.1 must be installed to install the upgrade version.

Note2) Ver.2.0 can be upgraded to the latest version after Ver. 2.1 free of charge at our web site

(http://panasonic-denko.co.jp/ac/e/dl/software-list/patch/plc.jsp). Use the latest version.

Conforms to IEC61131-3 programming tool software FPWIN-Pro Ver.6

Type of software OS (Operat ing sy ste m)

Hard disk

capacity

Product No.

FPWIN Pro Ver.6

English-language menu

Windows2000

WindowsXP

Windows Vista

Windows7

100MB or more FPWINPROFEN6

Note1) The small type and upgrade version is not available for Ver.6.

Note2) Ver.6.0 can be upgraded to the latest version after Ver. 6.1 free of charge at our web site

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Type of comput er and suitable cable

For the connection between a personal computer (RS232C) and the control unit (RS232C)

PC side connector

PLC side connector

Specifications

Product No.

D-sub 9-pin

female-Mini DIN round 5-pin

L type (3 m)

AFC8503

female-Mini DIN round 5-pin Straight type (3 m) AFC8503S

Note) Note) A USB/RS232C conversion cable is necessary to connect the unit to the USB port of a

personal computer using a PC connection cable.

For the connection between a personal computer (USB) and the cont r ol unit (USB)

USB cable (For C30 and C60 only)

Use a commercial cable.

Cable type

Length

USB 2.0 (or 1.1) AB type

Max. 5 m

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Chapter 2

Specifica tions and Functions of Control

Unit

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.1 Parts and Functions

2.1.1 Parts and Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...