Panasonic AFPE224300, AFPE224305, AFPE224322, AFPE224302, AFPE214325 User Manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of Contents

Precautions before using FP-e unit

Programming tools

1.Features and Configurations.................................................................. 1-1

1.1 Features and Functions..................................................................................................1-2

1.1.1 Features......................................................................................................................1-2

1.1.2 Functions....................................................................................................................1-2

1.2 Unit Name and Product Number....................................................................................1-3

1.2.1 FP-e control unit .........................................................................................................1-3

1.2.2 Related parts ..............................................................................................................1-3

1.3 Programming Tool...........................................................................................................1-4

1.3.1 When using a tool software........................................................................................1-4

2.Functions and I/O specifications............................................................ 2-1

2.1 Section Names and Functions.......................................................................................2-2

2.2 Display Modes and Functions........................................................................................2-4

2.2.1 Display modes and functions......................................................................................2-4

2.2.2 Mode Displays............................................................................................................2-5

2.3 Input and Output Specifications....................................................................................2-6

2.3.1 Input specifications.....................................................................................................2-6

2.3.2 Output specifications ..................................................................................................2-8

2.4 Display/Front Operation Switch Specifications ...........................................................2-9

2.5 Calendar timer................................................................................................................2-10

2.5.1 Area for calendar timer.............................................................................................2-10

2.5.2 Setting of calendar timer function.............................................................................2-10

2.5.3 Accuracy of calendar timer.......................................................................................2-11

2.6 Limitations in data hold/non-hold function ................................................................2-12

3.Installation and Wiring ............................................................................ 3-1

3.1 Installation........................................................................................................................3-2

3.1.1 Operating environment...............................................................................................3-2

3.1.2 Mounting and Removing the Unit...............................................................................3-5

3.2 Terminal Layout Diagram and Terminal Block Wiring.................................................3-6

3.2.1 Terminal layout diagram.............................................................................................3-6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.2.2 Terminal block wiring..................................................................................................3-6

3.3 Power Supply Wiring.......................................................................................................3-8

3.3.1 Power supply wiring....................................................................................................3-8

3.3.2 Grounding...................................................................................................................3-9

3.4 Wiring of Input and Output...........................................................................................3-10

3.4.1 Input wiring................................................................................................................3-10

3.4.2 Output wiring.............................................................................................................3-12

3.4.3 Common precautions for input and output wiring.....................................................3-12

3.5 Wiring COM. Port...........................................................................................................3-13

3.6 Safety Measures ............................................................................................................3-16

3.6.1 Safety measures.......................................................................................................3-16

3.6.2 Momentary power failures ........................................................................................3-17

3.6.3 Protection of power supply and output sections.......................................................3-17

3.7 Memory backup battery ................................................................................................3-18

3.7.1 Installation of memory backup battery.....................................................................3-18

(For FP-e unit with a calendar timer function) ...................................................................3-18

3.7.2 System register setting.............................................................................................3-18

(For FP-e unit with a calendar timer function) ...................................................................3-18

4.Display and Settings in N (Normal) Mode..............................................4-1

4.1 Display and operation in N (Normal) mode...................................................................4-2

4.2 Instructions to control the display.................................................................................4-3

4.2.1 F180 (SCR): Screen display instruction, Number of steps: 9.....................................4-3

4.2.2 F180 (SCR) instruction: FPWIN GR Wizard............................................................. 4-8

4.2.3 F181 (DSP) : Screen change instruction Number of steps: 3 ................................ 4-9

4.3 N mode sample program...............................................................................................4-10

4.4 Display screen and lock with the program .................................................................4-11

5.Data Display and Settings in S (Switch) Mode......................................5-1

5.1 Display and operation in S (Switch) mode....................................................................5-2

5.2 S mode sample program.................................................................................................5-3

6.Data Display and Settings in R (Register) Mode ................................... 6-1

6.1 Display and operation in R (Register) mode.................................................................6-2

6.2 Operation in R (Register) mode......................................................................................6-3

6.2.1 Specifying the device type..........................................................................................6-3

6.2.2 Changing the data ......................................................................................................6-4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6.2.3 Changing the unit No. of COM. port...........................................................................6-5

7.I (I/O Monitor) Mode................................................................................. 7-5

7.1 I/O monitor........................................................................................................................7-5

8.PID Control............................................................................................... 8-5

8.1 PID Control.......................................................................................................................8-5

8.1.1 Operation of PID control.............................................................................................8-5

8.2 PID control instruction....................................................................................................8-5

8.2.1 F355 (PID)..................................................................................................................8-5

8.3 PID control sample program ..........................................................................................8-5

8.4 Example of temperature control ....................................................................................8-5

9.Specifications .......................................................................................... 9-5

9.1 Specifications ..................................................................................................................9-5 9

9.1.1 General specifications ................................................................................................9-5

99

9.1.2 Performance specifications ........................................................................................9-5

99

9

.1.3 Specifications (High-Speed Counter/Pulse Output/PWM Output) .............................9-5 9

9.1.4 Functions and Restrictions (High-Speed Counter/Pulse Output/PWM Output).........9-5

9.2 I/O Allocation....................................................................................................................9-5

9.3 Relays,memory Areas and Constants...........................................................................9-5

9.4 ASCII characters displayed in the FP-e unit.................................................................9-5

9

.4.1 Available ASCII characters.........................................................................................9-5

9

.4.2 ASCII code and display..............................................................................................9-5

10.Dimensions .......................................................................................... 10-5

10.1 Dimensions ..................................................................................................................10-5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

11. Appendix ......................................................................................11-1

11.1 System Registers / Special Internal Relays / Special Data Registers... 11-3

11.1.1 Table of System Registers for FP-e.......................................................11-5

11.1.2 Table of Special Internal Relays for FP-e..............................................11-9

11.1.3 Table of Special Data Registers for FP-e ............................................11-13

11.2 Table of Basic Instructions.................................................................. 11-20

11.3 Table of High-level Instructions........................................................... 11-54

11.4 Table of Error codes.......................................................................... 11-114

11.5 MEWTOCOL-COM Communication Commands.............................. 11-128

11.6 Hexadecimal/Binary/BCD.................................................................. 11-129

11.7 ASCII Codes...................................................................................... 11-130

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Precautions before using FP-e unit

Installation environment

Do not use the FP-e Control Unit in the places where it will be exposed to the followings:

- Direct sunlight and ambient temperature outside the range of 0ºC to 55ºC (32°F to 131°F).

- Ambient humidity outside the range of 30% to 85% RH(at 25ºC) and sudden temperature changes

causing condensation.

- Inflammable or corrosive gas.

- Excessive vibration or shock.

- Excessive airborne dust, metal particles or salts.

- Water or oil in any from including spray or mist.

- Benzine, paint thinner, alcohol or other organic solvents or strong alkaline solutions such as ammonia

or caustic soda.

- Influence from power transmission lines, high voltage equipment, power cables, power equipment,

radio transmitters, or any other equipment that would generate high switching surges.

Static electricity

- Before touching the unit, always touch a grounded piece of metal in order to discharge static electricity.

- In dry locations, excessive static electricity can cause problems.

Cleaning

- Do not use thinner based cleaners because they deform the unit case and fade the colors.

Power supply

- An insulated power supply with an internal protective circuit should be used. The power supply for the

control unit operation is a non-insulated circuit.

- If using a power supply without a protective circuit, power should be supplied through a protective

element such as a fuse.

- If an incorrect voltage is directly applied, the internal circuit may be damaged or destroyed.

Power supply sequence

- Have the power supply sequence such that the power supply of the control unit turns off before the

power supply for input and output turns off.

- If the power supply for input and output is turned off before the power supply of the

control unit turns off, the control unit will detect the input fluctuations and may begin an unscheduled

operation.

Before turning on the power

When turning on the power for the first time, be sure to take the precautions as shown below.

- When performing installation, confirm that there are no scraps of wiring, particularly conductive

fragments, adhering to the unit.

- Confirm that the power supply wiring, I/O wiring, and power supply voltage are all correct.

- Sufficiently tighten the installation screws and terminal screws.

- Set the RUN/PROG. switch to PROG. mode.

Before entering a program

Be sure to perform a program clear operation before entering a program.

Operation procedure when using Windows software FPWIN GR Ver. 2

1. Press “CTRL” and “F2” keys at the same time to switch the display to “Online Monitor.”

2. Select [Edit (E)] → [Program Clear (L)] on the menu.

3. When the confirmation dialog box appears, click [Yes (Y)] to clear the program.

Storing a program

To prevent the accidental loss of programs, users are requested to take the following measures.

Drafting documents

To avoid accidentally losing programs, destroying files, or overwriting the contents of a file,

documents should be printed out and then saved.

Specifying the password carefully

The passward setting is designed to avoid programs being accidental ly overwritten. If the password is

forgotten, however, it will be impossible to overwrite the program even if you want to. Also, if a

passward is forcibly cleared, the program is deleted. When spesifying the passward, note it in the

spcifications or in another safe locaton in case it is forgotten at some point.

Battery

Do not install the battery when it is not used.

There is a possibility of leak if the battery remains discharged.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

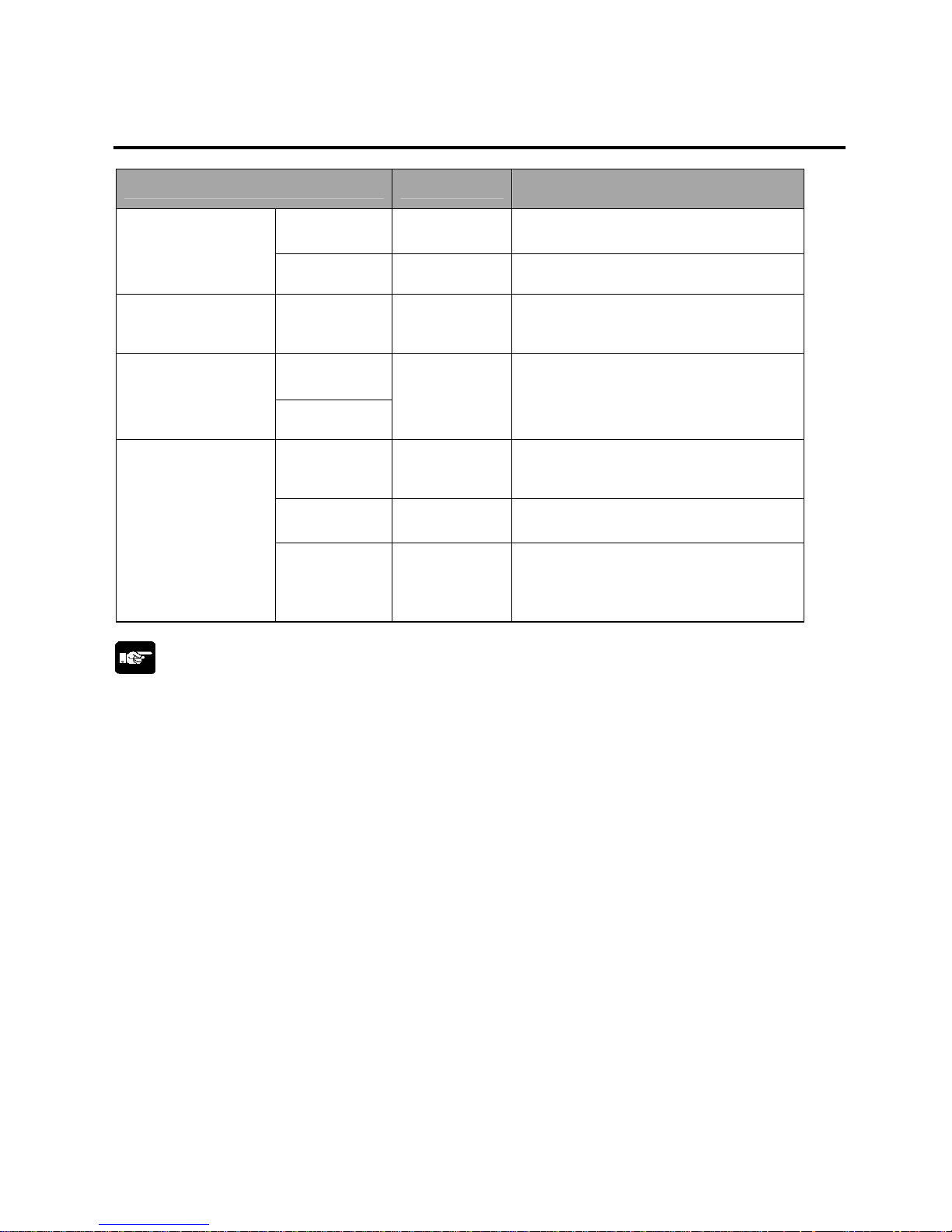

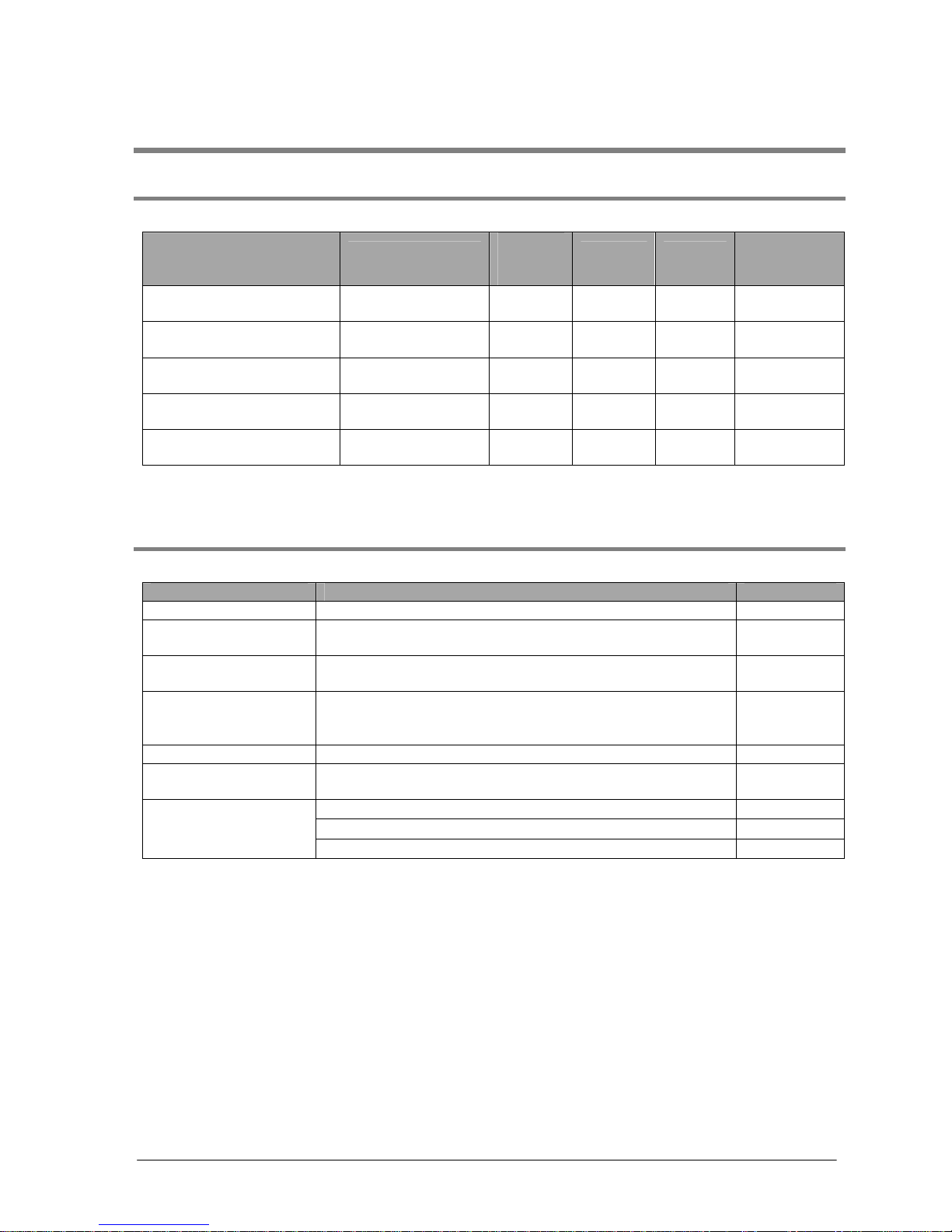

Programming tools

(As of Apr., 2004)

Type Restrictions

Instruction used/Function

restrictions

FPWIN GR

Ver. 2

Available. Available from Ver. 2.2 or higher.

*1)

Windows software

FPWIN GR

Ver. 1

Not available. Not available.

Windows software

conforms to IEC

61131-3

FPWIN Pro

Ver. 4

Available Available from Ver. 4.1 or higher.

*2)

NPST-GR

Ver. 4

MS-DOS software

NPST-GR

Ver. 3

Not available. Not available.

AFP1113V2

AFP1114V2

Not available.

Instructions and functions described

in *3 can not be used.

Use FPWIN GR or FPWIN Pro.

AFP1113

AFP1114

Not available. Not available.

Handy

programming unit

AFP1111A

AFP1112A

AFP1111

AFP1112

Not available. Not available.

Notes: Precautions concerning programming tools

*1) Customers who use FPWIN GR Ver. 2 can upgrade the version from

our HP free of charge.

Use Ver. 2.3 or higher to set the COM. port to MODBUS S RTU.

(MODBUS S RTU is available from FP-e main unit Ver.1.2 or higher.)

*2) Customers who use FPWIN Pro Ver.4 can upgrade the version from our

HP free of charge.

The COM. port cannot be set to MODBUS S RTU.

It will be available from FPWIN Pro Ver. 5.

*3) Functions that can not be used using a handy programming unit

(AFP1113V2 and AFP1114V2):

- Screen display registry instruction <F180 (SCR)>

- Screen display switch instruction <F181 (DSP)>

- Leading edge differential instruction (Initial execution type) <DFI>

- On-delay timer instruction <TML>

- Clear multiple steps instruction <SCLR>

- Floating-point type data instruction <F309> to <F338>

- PID processing instruction <F355>

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Chapter 1

Features and Configurations

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-2

1.1 Features and Functions

1.1.1 Features

1. IP 66-compliant panel mounting type

Mounting panel front is waterproof and compliant with IP66, IEC standard.

Compact controller: 48 mm (H), 48 mm (W), 70 mm (D)

2. Indicator function

Simple characters and numerical values (with a minus sign) can be displayed up to 5 digits. *

4 modes (N, S, R, and I modes) can be selected.

Those 4 modes each have 2 selectable displays.

Data indication section can be displayed in red, green, or orange.

3. Operation switches

Set data can be changed.

This switch can be used as an input switch.

4. Control function

In addition to the functions of the programmable controller FP0 series, pulse output and high-speed

counter functions are installed.

General-purpose communication COM. port is included as standard unit.

FP-e units with the calendar timer or thermocouple input function are also provided.

*Numerical values are displayed only in 16-bit. The data can be disp layed in a bit, decimal, or

hexadecimal system.

1.1.2 Functions

Item Description

Power supply 24V DC

Input 8 points

*1)

(24V DC)

Output 6 points (5 points : Tr. NPN 0.5A, 1 point : Ry 2A)

Program capacity 2.7 k step

Operation speed 0.9 µ/step (Basic instruction)

I/O update and Base time 2 ms

*2)

Pulse catch/Interrupt input 6 points in total (High-speed counter included)

High-speed counter

Single phase: 4 points (10 kHz in total)

Dual phase: 2 points (2 kHz in total)

*3)

Pulse output 2 points (10 kHz in total)

*4)

COM. port

RS232C/RS485 (according to models)

* Must be provided aside from tool ports

*1) Thermocouple input type: 6 points

*2) Thermocouple input type: 2 to 3 ms (Typical), Max: 15 ms. (The time takes longer every 250 ms.)

*3) Thermocouple input type: 5 kHz (Single phase), 1 kHz (Dual phase)

*4) Thermocouple input type: 5 kHz

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-3

1.2 Unit Name and Product Number

1.2.1 FP-e control unit

Name

Number of I/O

points

Thermo-

couple

input

Calendar

timer

COM

port

Product No.

FP-e control unit

(Standard type)

Input: 8/Output: 6

(Tr. NPN: 5, Ry: 1)

Not

available

Not

available

RS232C AFPE224300

FP-e control unit

(Calendar timer type)

Input: 8/Output: 6

(Tr. NPN: 5, Ry: 1)

Not

available

Available RS232C AFPE224305

FP-e control unit

(Thermocouple input type)

Input: 6/Output: 6

(Tr. NPN: 5, Ry: 1)

2 points Available RS232C AF PE214325

FP-e control unit

(Standard type)

Input: 8/Output: 6

(Tr. NPN: 5, Ry: 1)

Not

available

Not

available

RS485 AFPE224302

FP-e control unit

(Thermocouple input type)

Input: 6/Output: 6

(Tr. NPN: 5, Ry: 1)

2 points

Not

available

RS485 AFPE214322

1.2.2 Related parts

Name Description Product No.

Terminal driver Used for connecting a terminal AFP0806

Rubber gasket

Used for a waterproof unit

(included in a unit package)

ATC18002

Mounting frame

Used for mounting a unit.

(included in a unit package)

ATA4811

Battery for FPΣ

Used for calendar timer and operation memory backup.

(Included in calendar timer function-provided type and

themocouple input type)

AFPG804

Protective cover Oil resistant soft cover AQM4803

Terminal socket set

Set of four types of terminal socket for FP-e

(Maintenance parts)

AFPE804

Color: Black, with NAiS·FP-e mark

AFPE803

Color: Ash gray, without NAiS·FP-e mark

AFPE805

Panel cover

(20-pack)

Color: Black, without NAiS·FP-e mark

AFPE806

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-4

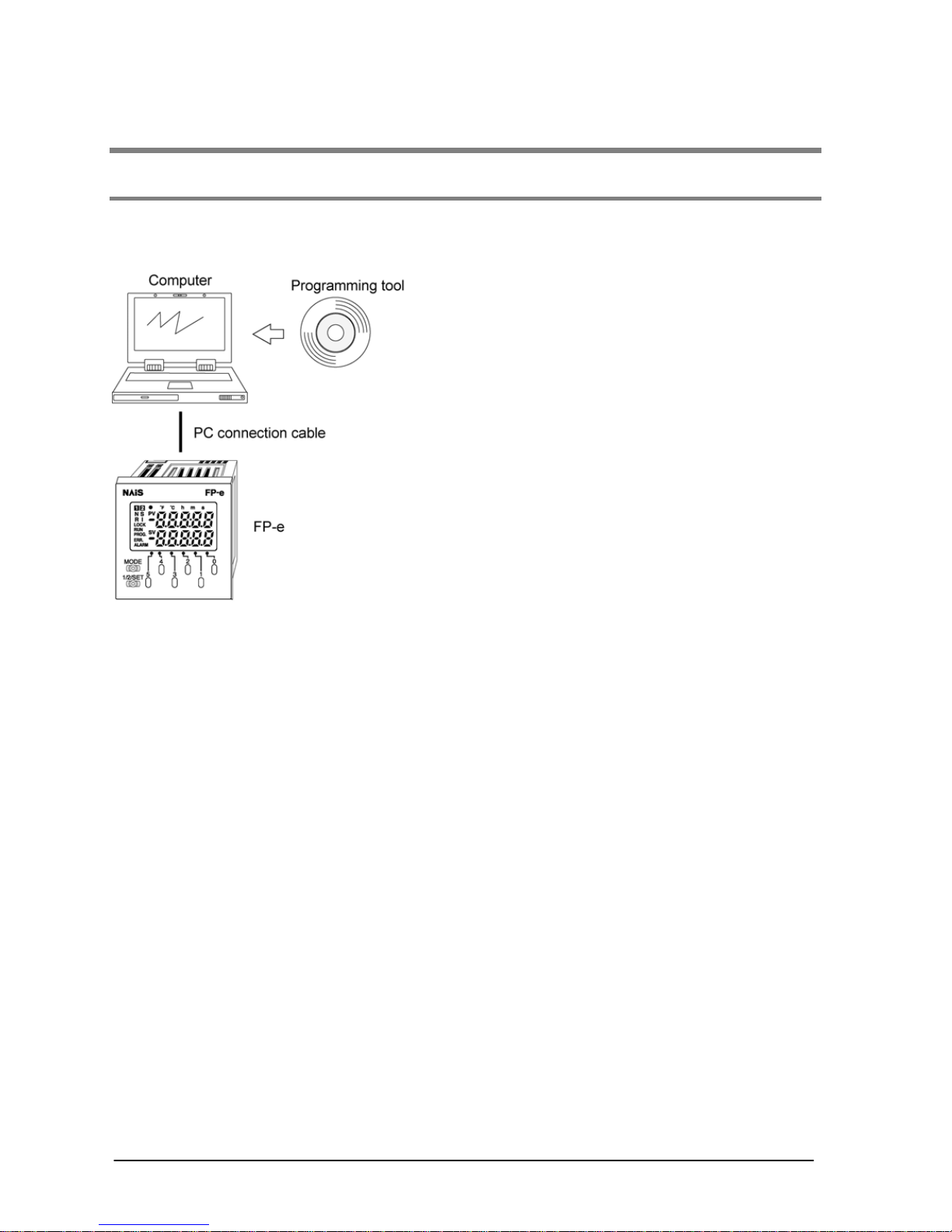

1.3 Programming Tool

1.3.1 When using a tool softwar e

- Tools needed for programming

1. Programming tool software

· The tool software can also be used with the FP series.

· The "FPWIN GR Ver. 2” or “FPWIN Pro Ver. 4” (for Windows) is used with FP-e controllers.

· Note that the earlier “FPWIN GR Ver. 1,” “NPST-GR (DOS version), or “FP programmer” cannot

be used.

2. PC connection cables

This cable is needed for connection between the FP-e unit and the computer.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-5

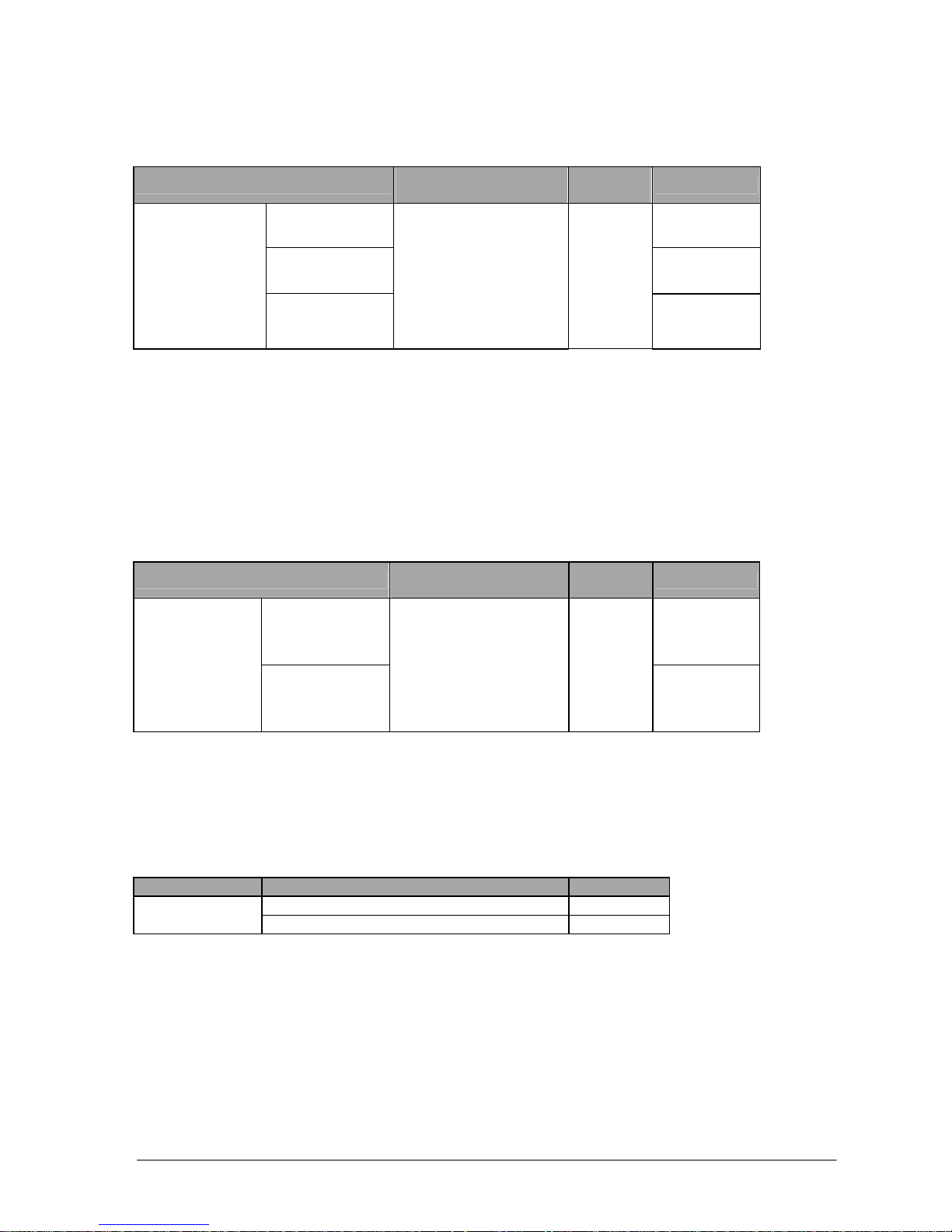

Software environment and suitable cables

- Standard ladder diagram tool software “FPWIN GR Ver. 2”

Type of software

OS

(Operating system)

Hard disc

capacity

Product No.

Full type AFPS10520

Upgraded version AFPS10520R

FPWIN GR Ver. 2

English-language

menu

Small type

WINDOWS

95 (OSR2 or higher)/

98/Me/

NT (Ver. 4.0 or higher)/

2000/XP

40 MB

or more

AFPS11520

Note 1) To use the “FP-e,” software Ver. 2.2 or higher is required.

The software Ver. 2.3 or higher is required to set the COM. port to MODBUS S RTU.

Customers who use the Ver.2 software can upgrade it through our HP free of charge.

Note 2) Customers who use the “FPWIN GR Ver.1” can use the “FPWIN GR Ver. 2” after purchasing

the upgraded version software.

(The upgraded version software can be installed only when the “Ver.1.1” has been previo usly

installed.

Note 3) Small type version can be used for the “FP-e,” “FPΣ,” “FP0,” “FP1,” and “FP-M” series.

- IEC61131-3-compliant programming tool software FPWIN Pro Ver.4

Type of software

OS

(Operating system)

Hard disc

capacity

Product No.

Full type AFPS50540

FPWIN Pro Ver.4

English-language

menu

Small type

WINDOWS

95 (OSR2 or higher)/

98/Me/

NT (Ver. 4.0 or higher)/

2000/XP

100 MB

or more

AFPS51540

Note 1)To use the “FP-e software Ver. 4.1 or higher is required.

Customers who use the Ver. 4 software can upgrade it through our HP free of charge.

The COM. port cannot be set to MODBUS S RTU. It will be available from FPWIN Pro Ver. 5

Note 2) Small type version can be used for the “FP-e,” “FPΣ,” “FP0,” “FP1,” and “FP-M” series.

- Type of computer and suitable cables

Connecter Connecter on PLC side Product No.

Mini DIN round 5-pin AFC8503

D-Sub 9-pin

Mini DIN round 5-pin streight type AFC8503S

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-1

Chapter 2

Functions and I/O specifications

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-2

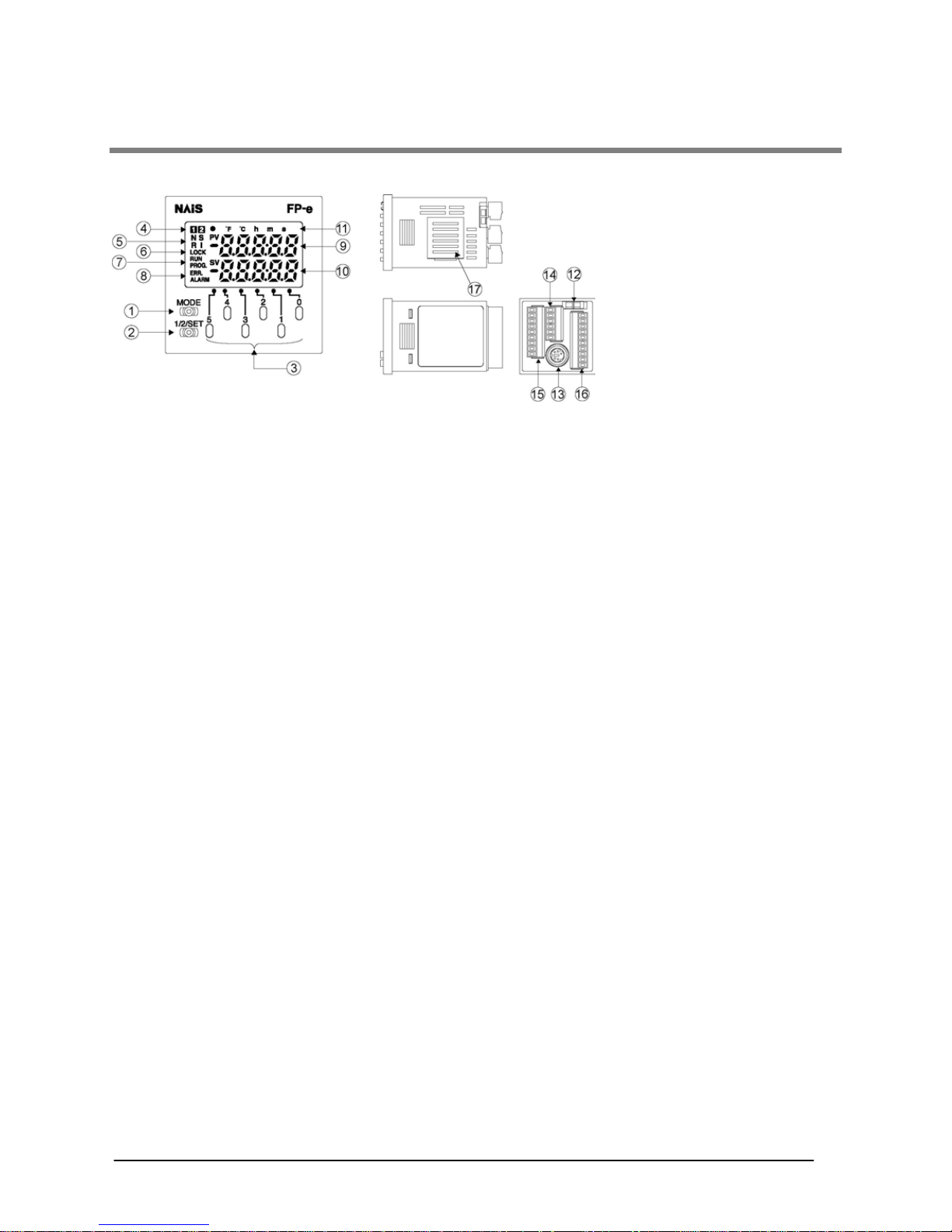

2.1 Section Names and Functions

①Display mode switch

Changes the display mode to N, S, R, or I.

When the switch is pressed for 2 seconds or longer, the front switch key is locked. Pressing the switch

once more for 2 seconds or longer unlocks the key.

②Screen changeover switch

Changes the display to 1

st

Screen or 2nd Screen.

When the numerical data is changed, pressing the switch for one second or longer determines the data.

③Front operation switch

Changes the data. This switch is also used as the input switch.

Pressing a switch of the digit for which you would like to change the numerical value during the data

change adds one to the numerical value displayed.

(Data display blinks during the data change.)

④Display screen No.

Indicates the screen number used currently. “1

st

” or “2nd” is displayed.

⑤Display mode

Indicates “N,” “S,” “R,” or “I.”

⑥LOCK display

Shows that the switch is locked.

(This display is lit when “LOCK” using the front switch or “ALL LOCK” using the program is selected.)

⑦RUN/PROG. display

Displays the operation mode (RUN or PROG.).

⑧ERR./ALARM display

Indicates when an error or an alarm occurs.

ERR. : Lights up if an error is detected during the self-diagnostic function.

ALARM: Lights up if a hardware error occurs, or if operation slows because of the program,

and the watchdog timer is activated.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-3

⑨Data display (Upper section)

N and S modes

- Display the data registered using the F180 (SCR) command.

- Display the data in red, green, or orange.

R mode

- Displays the address in the memory area in green.

I mode

- Displays the external input monitor in green.

⑩Data display (Lower section)

N and S modes

- Display the data registered using the F180 (SCR) command.

- Blink when the numerical value is changed.

- Display the data in red, green, or orange.

R mode

- Displays the data in the memory area in green.

I mode

- Displays the external output monitor in green.

⑪Setting display

Indications (e.g.●, ºF, ºC, h, m, s, SV, and PV) and dot between the digits can be displayed individually

by the ladder program.

⑫Mode switch (RUN/PROG.)

Changes the mode of the FP-e unit to RUN or PROG. Modes can also be changed from the

programming tool.

When performing remote switching from the programming tool, the position of the mode s witch and the

actual mode of operation may differ.

Verify the mode with the RUN/PROG. display on the front.

When power is supplied, the mode displayed is activated.

⑬Tool port (RS232C)

Used to connect a programming tool.

A commercial mini-DIN 5-pin connector is used for the tool port on the control unit.

*The followings are default settings. Use the system register to change the settings.

Baud rate---------------------------9600bps

Character bit length--------------8 bit

Parity check------------------------Odd parity

Stop bit------------------------------1 bit

⑭Power supply/COM. port connector

⑮Input connector

⑯Output connector

⑰Battery cover

Note: Colors in the display section

④ to ⑦ and ⑪: green ⑧: red

⑨ and ⑩: red, green, or orange (N and S modes), green (R and I modes)

Pin No. Name Abbr. Signal direction

1 Signal ground SG 2 Send data SD Unit → External device

3 Receive data RD Unit ← External device

4 (Not used) - 5 +5V +5V Unit → External device

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-4

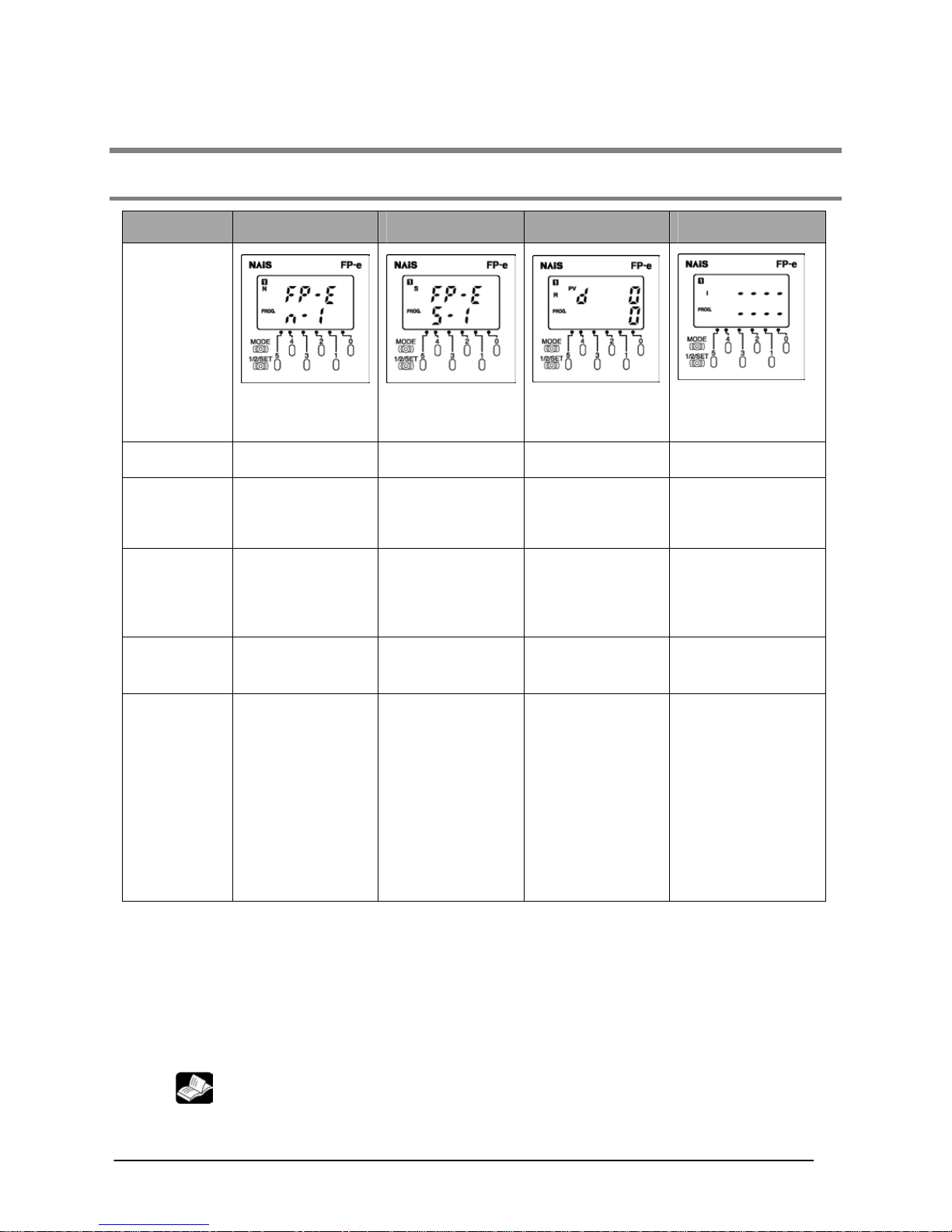

2.2 Display Modes and Functions

2.2.1 Display modes and functi ons

Mode

N mode

(Normal mode)

S mode

(Switch mode)

R mode

(Register mode)

I mode

(I/O monitor mode)

Screen

Registered by F180

(SCR) command

Registered by F180

(SCR) command

Data monitor of the

internal memory

· External I/O monitor

· Thermocouple input

monitor

Number of

screens

2 2 2 2

Display in

the upper

section

Arbitrary data

display

(Characters/Nume

rical values)

Arbitrary data

display

(Characters/Nume

rical values)

Address in the

memory area

· Input status

monitor

·Thermocouple input

CH.0 monitor

Display in

the lower

section

Arbitrary data

display

(Characters/

Numerical values)

Arbitrary data

display

(Characters/

Numerical values)

Data in the

memory area

(Displayed in a

decimal number

system.)

· Output status

monitor

·Thermocouple input

CH.1 monitor

Operation

switch

Used for changing

numerical values

Used as the input

switch

Used for changing

numerical values

Used as the input

switch

Example

Using the F180

(SCR) command, the

elapsed value on the

counter is displayed

in the upper section,

and the set value is

displayed in the

lower section. The

set value can be

changed with the

front operation

switch.

Using the F180

(SCR) command, the

message is

displayed in the

upper section, and

the data is displayed

in the lower section.

The display

description can be

changed with the

input switch.

When program

operation is checked,

the data description

can be checked by

specifying the

arbitrary memory

area with the front

operation switch. The

data can also be

changed with the

front operation

switch.

When program

operation is checked,

external I/O status is

monitored. The front

operation switch can

be used as the input

switch.(However, the

input status of the

front operation switch

cannot be monitored.)

Note 1) Whenever the display mode switch is pressed, the mode displayed changes as follows:

N→S→R→I→N. The display can also be switched from the program using the F180 (DSP)

command.

Note 2) When the display mode switch is pressed for 2 seconds or longer, the front switch is locked.

Pressing the switch once more for 2 seconds or longer unlocks the switch.

Note 3) Screen changeover switch changes the display to 1

st

Screen or 2nd Screen.

Note 4) When the numerical values are changed, pressing the screen changeover switch for one second

or longer determines the data.

Note 5) The operation switches can also be used as input switches in all modes.

Reference: A.2 I/O Allocation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-5

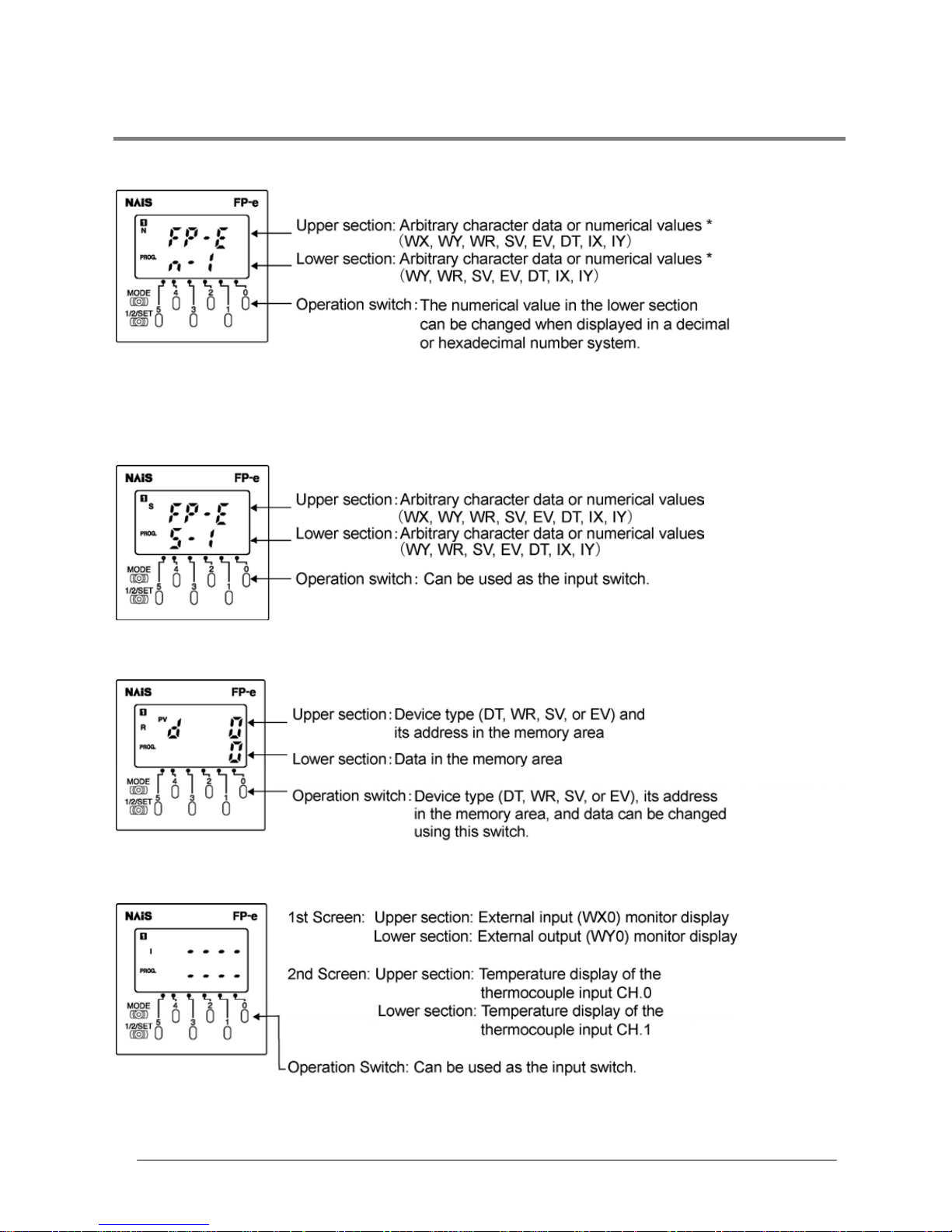

2.2.2 Mode Displays

N (Normal) mode Screen is registered using the F180 (SCR) command.

*Numerical values are displayed only in 16-b it. T he data can be displayed in

a bit, decimal, or hexadecimal system.

S (Switch) mode Screen is registered using the F180 (SCR) command.

R (Register) mode Screen cannot be defined using the F180 (SCR) command.

I (I/O monitor) mode Screen cannot be defined using the F180 (SCR) command.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-6

2.3 Input and Output Specifications

2.3.1 Input specifications

- DC input specifications (X0 toX7)

Item Description

Number of input

8 points

6 points (thermocouple input type)

Insulation method

Optical coupler

Rated input voltage

24 V DC

Operating voltage range

21.6 to 26.4 V DC

Rated input current

Approx. 4.3 mA

Input points per common

8 points/common,

6 points/common (thermocouple input type)

(Either the positive or negative of the input

power supply can be connected to

common terminal.)

ON voltage/ON current

19.2 V or less / 4 mA or less

OFF voltage/OFF current

2.4 V or more / 1 mA or more

Input impedance

Approx. 5.1 kΩ (X0, X1)

Approx. 5.6 kΩ (X2 to X7)

Response time OFF to ON

50 µs or less (X0, X1)

Note)

100 µs or less (X2 to X5)

Note)

2 ms or less (X6, X7)

ON to OFF

50 µs or less (X0, X1)

Note)

100 µs or less (X2 to X5)

Note)

2 ms or less (X6, X7)

Operation indicator

LCD display (I/O monitor mode)

Note) X0 through X5 are inputs for the high-speed counter and have a fast response time. If used as

normal inputs, you are recommend to insert a timer in the ladder program as chattering and

noise may be interpreted as an input signal.

Also, the above specifications apply when the rated input voltage is 24V DC and the temperature

is 25 ºC.

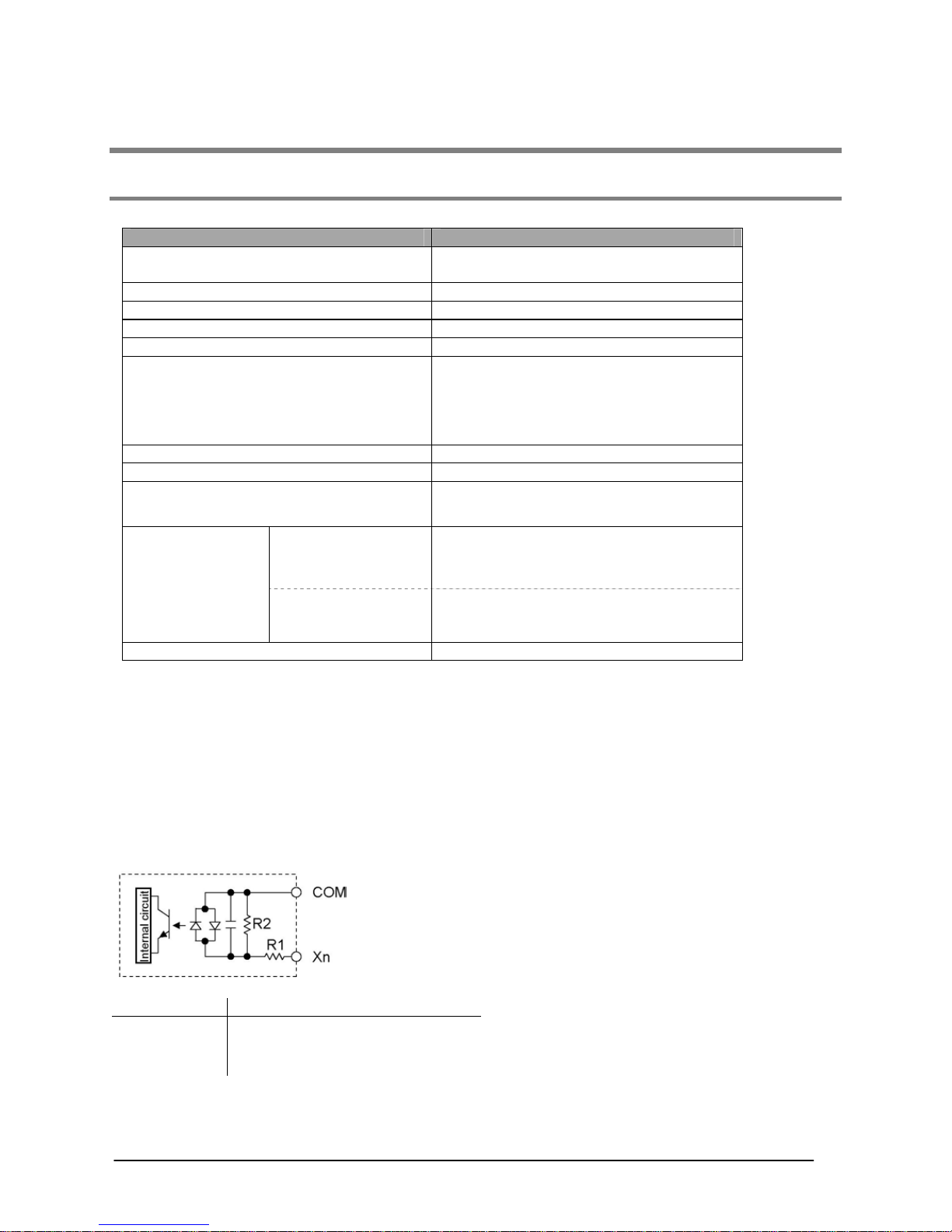

Internal circuit diagram

R

1

R

2

X0 and X1

5.1 kΩ 3 kΩ

X2 to X5

5.6 kΩ 2 kΩ

X6 and X7

5.6 kΩ 1 kΩ

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-7

- Thermocouple input specifications

Item Specifications

Number of input

2 points (CH0: WX1, CH1: WX2)

Temperature sensor type

Thermocouple type K

Input range

- 30.0 to 300.0 ºC

*1)

(- 22 to 572 ºF)

Accuracy

±0.5%FS±1.5 ºC (FS = -30 to 300 ºC)

Resolution

0.1 ºC

Conversion time

250 ms/2CH

*2)

Insulation method

Between internal circuit and thermocouple input

circuit: noninsulated

*3)

Between CH0 and CH1 of thermocouple input:

PhotoMos insulation

Detection function of wire

disconnection

Available

*1)Temperature can be measured up to 330 ºC (626 ºF). When the measured temper ature exceeds 330

ºC (626 ºF) or the thermocouple wiring is disconnected, “K20000” is written to the register.

*2)Temperature conversion for thermocouple input is performed every 250 ms. The conversion data is

updated on the internal data register after the scan is completed.

*3)The internal circuit and thermocouple input circuit are not insulated. Therefore, use the nongroundi ng

type thermocouples and sheath tubes.

Note:

- To prevent the influence of noise, use the shielded thermocouples and compensating lead wires

after grounding them. When the shielding types are not used, thermocouples and compensating

lead wires should be used less than 10 m.

- When the wire of the thermocouple is extended, be sure to use compensating lead wires

according to the thermocouple type.

- It takes about 2 seconds until the input processing is completed after the power is supplied.

Therefore, the input data is necessary to be valid after the temperature input completion flags X4E

(CH0) and X4F (CH1) turn ON.

After that, the temperature input completion flags turn on for only one scan at every time that the

temperature conversion process has been completed (every 250ms approx).

- 1 to 50 times (Average) can be set using the system register 409. The initial setting is “0.” (Average:

20 times)

Set the value to 20 or more to prevent the fluctuation of the thermocouple input value.

- For accurate temperature measurement, we recommend to warm up the unit for 30 minutes after the

power is supplied.

- Connecting/disconnecting the thermocouple input terminal block while the thermocouple unit is ON

will lower accuracy temporarily. In that case, it is recommended to warm up the unit for at least 15

minutes.

- A rapid temperature change in the thermocouple unit might change the temperature data temporarily.

- Prevent a direct air (wind) from the cooling fan built in the control panel etc. The direct air (wind) to the

thermocouple unit will lower accuracy.

Example of Input temperature and internal data processing

Input temperature Internal data (WX1 and WX2)

- 30.0 ºC (- 22.0 ºF) K-300 (K-220)

25.0 ºC ( 77.0 ºF) K 250 (K 770)

200.0 ºC (392.0 ºF) K2000 (K3920)

To display the temperature in the Fahrenheit scale (ºF), turn Y37 contact ON.

F = C x 9/5 + 32

F: Fahrenheit, C: Celsius, 0 ºC = 32 ºF, 100 ºC = 212 ºF

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-8

2.3.2 Output specifications

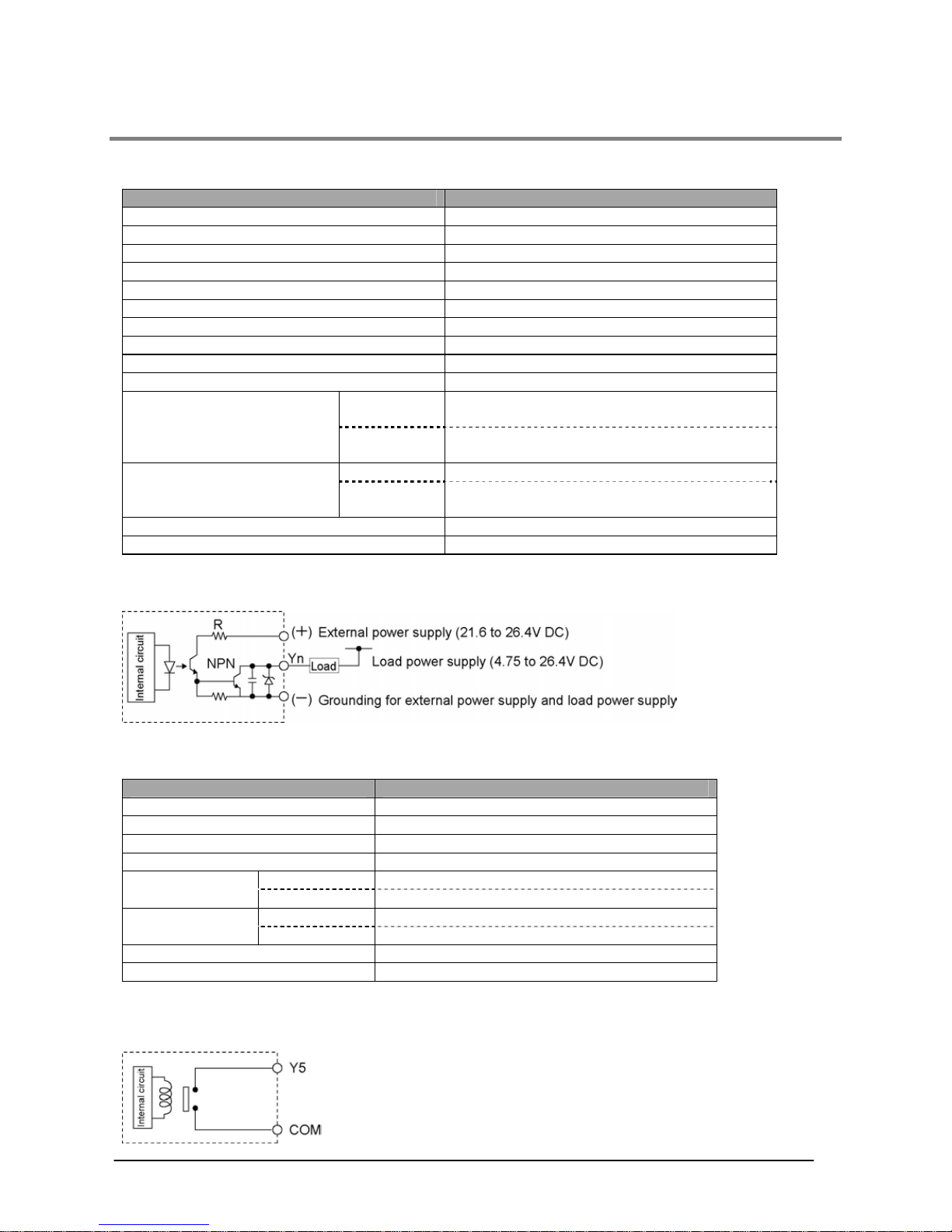

-Transistor output specifications (For Y0 to Y4)

Item Description (NPN)

Number of output

5 points

Insulation method

Optical coupler

Output type

Open collector

Rated load voltage

5 to 24 V DC

Operating load voltage range

4.75 to 26.4 V DC

Max. load current

0.5 A

Max. surge current

1 A

Output points per common

5 points/common

OFF state leakage current

100 µA or less

ON state voltage drop

1.5 V or less

OFF to ON

50 µs or less (For Y0 and Y1)

1 ms or less (For Y2,Y3 and Y4)

Response time

ON to OFF

50 µs or less (For Y0 and Y1)

1 ms or less (For Y2,Y3 and Y4)

Voltage

21.6 to 26.4 V DC

External power supply

(For driving internal circuit)

Current

6 mA/point (For Y0 and Y1)

3 mA/point (For Y2, Y3, and Y4)

Surge absorber

Zener diode

Operation indicator

LCD display (I/O monitor mode)

Internal circuit diagram

- Relay output specifications (Y5)

Item Description

Number of output

1 point

Output type

Normally open (1 Form A)

Rated control capacity

2 A 250 V AC, 2 A 30 V DC

Note1)

Output points per common

1point/common

OFF to ON

Approx. 10 ms

Response time

ON to OFF

Approx. 8 ms

Mechanical

Min. 20,000,000 operations

Life time

Electrical

Min. 100,000 operations (resistive load)

Note2)

Surge absorber

None

Operation indicator

LCD display (I/O monitor mode)

Note1) Resistance load

Note2) Open/Close frequency: 20 times/min (at the rated control capacity)

Internal circuit diagram

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-9

2.4 Display/Front Operation Switch Specifications

- Display section specifications

Item Description

Data display

5 digits with a decimal point. (Minus sign can also be used.)

Note)

7-segment, color selectable display (Green, red, or orange)

Mark display

PV SV (Green, red, or orange)

● ºF ºC h m s (Green)

Display mode

4 modes (Green)

N : Normal mode---Simple characters, data display,

data setting/data input switch

S : Switch mode----Simple characters, data setting/PLC external

input switch

R : Register mode---Internal data, timer/counter value reading

and writing modes

I : I/O monitor mode---I/O status display/PLC external input switch

Screen No.

(Green)

Status display

LOCK, RUN and PROG. (Green) ERR ALARM (Red)

Switch input

8 points For mode switching 1 point

For screen switching 1 point

For data setting or external input 6 points

*Refer to the input address (below) for external input.

Display

Negative backlight LCD

(Colors in the numerical section can be changed: green, red, or orange

Size of the

characters

7-segment 6.7 mm LOCK

PV SV 1.6 mm ERR 1.4 mm

N S R I 1.7 mm ALARM

● ºF ºC h m s 1.6 mm

Note: Numerical values are displayed only in 16-bit. T he data can be disp layed in a bit, decimal, or

hexadecimal system.

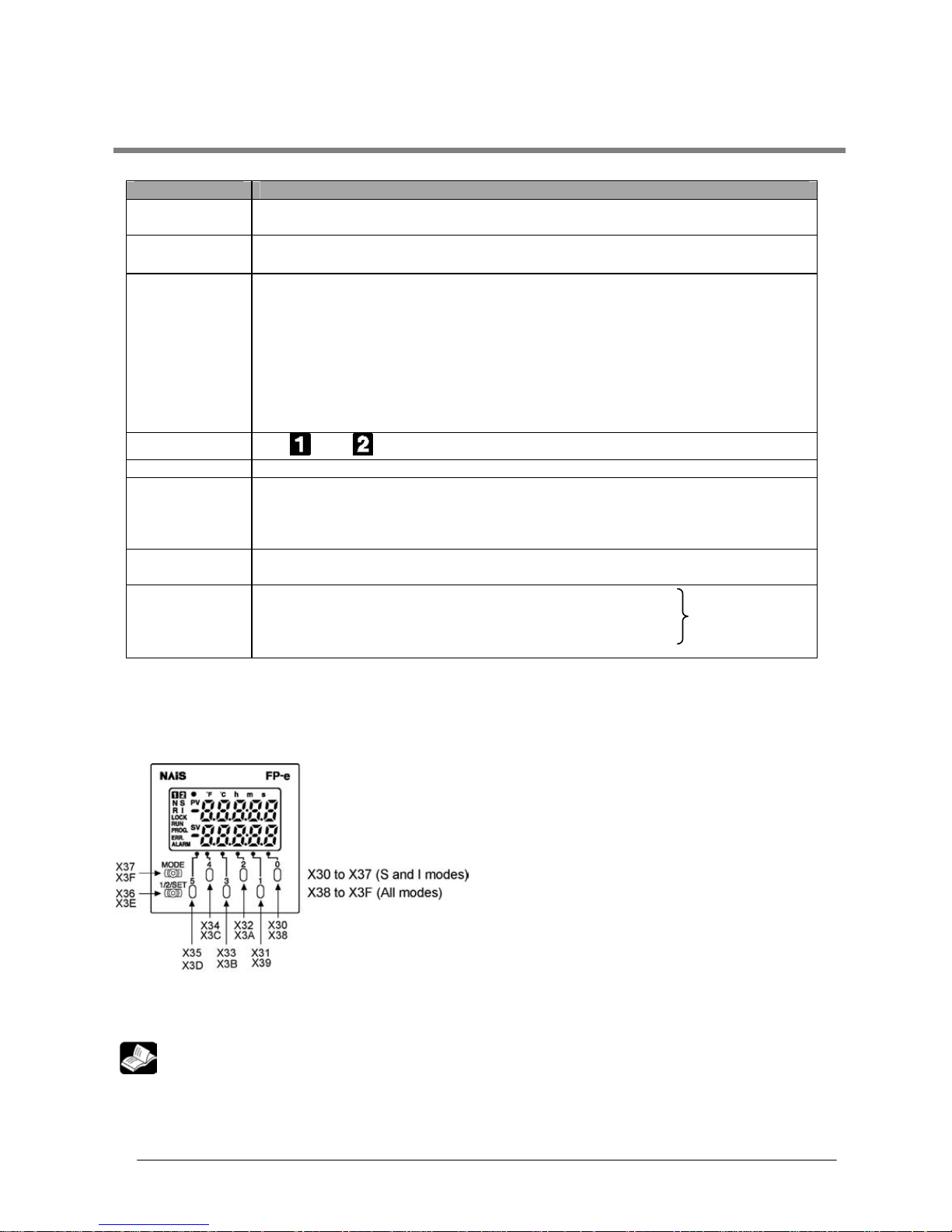

- Front operation switch (External input address)

When the front operation switch is used for external input, use the allocated addresses as shown below.

Example: When “0” is pressed during the S mode, “X30” and “X38” turn ON at the same time.

Reference: A.2 I/O allocation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-10

2.5 Calendar timer

2.5.1 Area for calendar timer

With the clock/calendar function, data indicating the hour, minute, second, day, year

and other information stored in the special data registers DT9053 to DT9057 can be

read using the transmission instruction and used in sequence programs.

Special data

Register No.

Upper byte Lower byte Reading Writing

DT9053 Hour data

H00 to H23

Minute data

H00 to H59

Available Not available

DT9054 Minute data

H00 to H59

Second data

H00 to H59

Available Available

DT9055 Day data

H01 to H31

Hour data

H00 to H23

Available Available

DT9056 Year data

H00 to H99

Month data

H01 to H12

Available Available

DT9057

—

Day- of - theweek data

H00 to H06

Available Available

Note:

1. The area above is available for the FP-e unit with a calendar timer function.

2. The value is not fixed initially when the battery is connected. Set the appropriat e valu e to the calendar

timer.

Lithium battery is included in the FP-e unit, but it is not connected to the unit. Connect the battery to the

unit before using the FP-e controller.

3. Put in a new battery within a minute after removing the old battery.

4. A calendar timer is available only when a battery is installed.

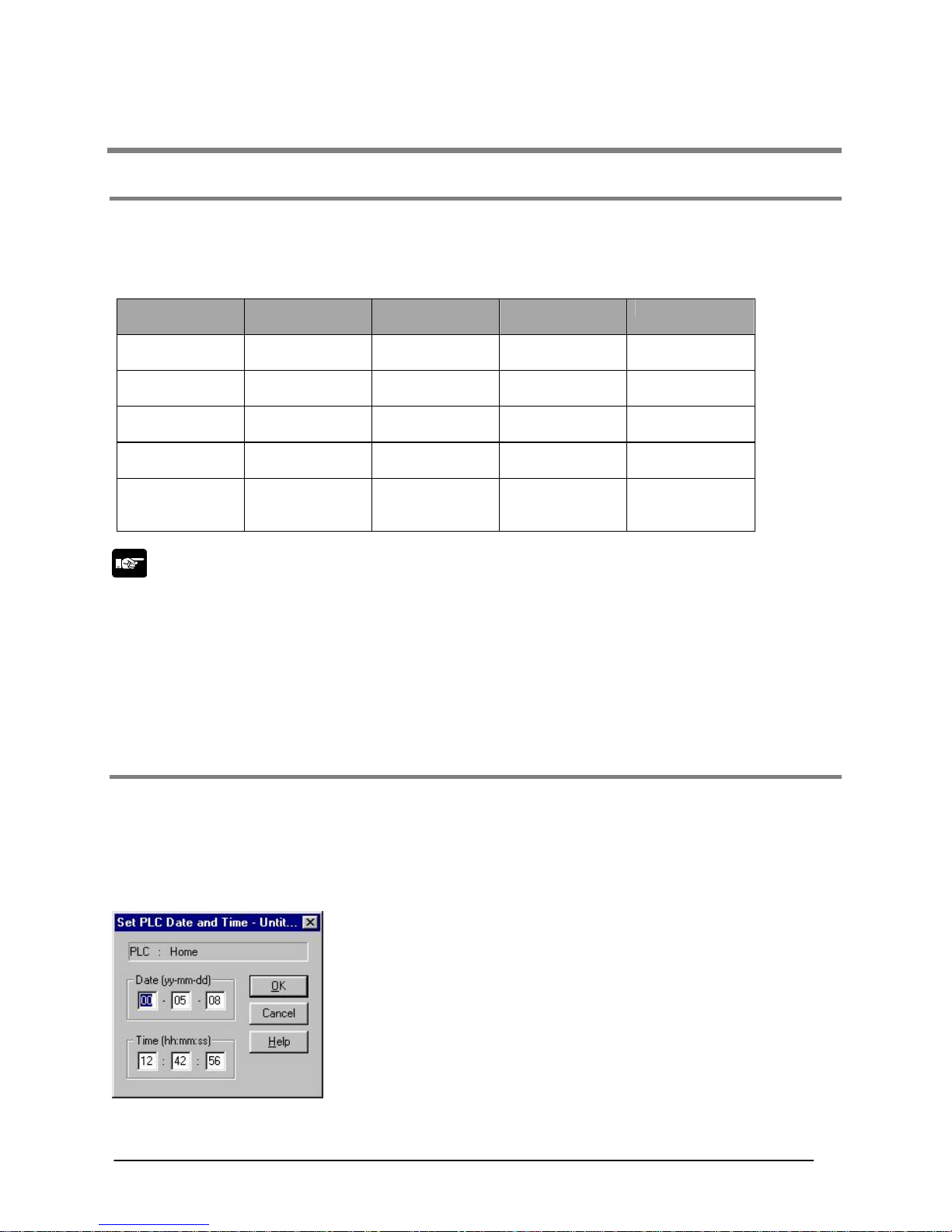

2.5.2 Setting of calendar timer function

There are two ways to set the calendar timer function as described below.

- Setting using FPWIN GR

1. Press the [CTRL] and [F2] keys at the same time, to switch the screen to [Online].

2. Select “Set PLC Date and Time” under “Tool” on the menu bar.

PLC Date and Time setting dialog box

The above steps display the “Set PLC Date and

Time dialog box” shown on the left. Input the date and time, and

click on the “OK” button.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-11

- Setting and changing using program

1. The values written to the special data registers DT9054 to DT9057, which are allocated as the calendar

timer setting area, are transferred.

2. A value of H8000 is written to DT9058.

Example: showing the date and time being written

Set the time to 12:30:00 on the 5

th

day of October, 2002 when the X0 turns ON.

2.5.3 Accuracy of calendar timer

Accuracy

200 s / month (0 ºC)

70 s / month (25 ºC)

240 s /month (55 ºC)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-12

2.6 Limitations in data hold/non-hold function

Setting a system register can expand the data hold area. In this case, however, a back-up battery must be

previously installed.

Product No. Settings

Note 1

Data

AFPE224300

AFPE224302

AFPE224322

Note 2

System register setting Non-hold

System register setting with a back-up battery Hold AFPE224305

AFPE214325

System register setting without a back-up battery Non-hold

Note 1: System register settings are effective only when a back-up battery is installed in

the FP-e control unit.(A set value will be returned to the default value.)

Note 2: A back-up battery cannot be installed in this type of product.

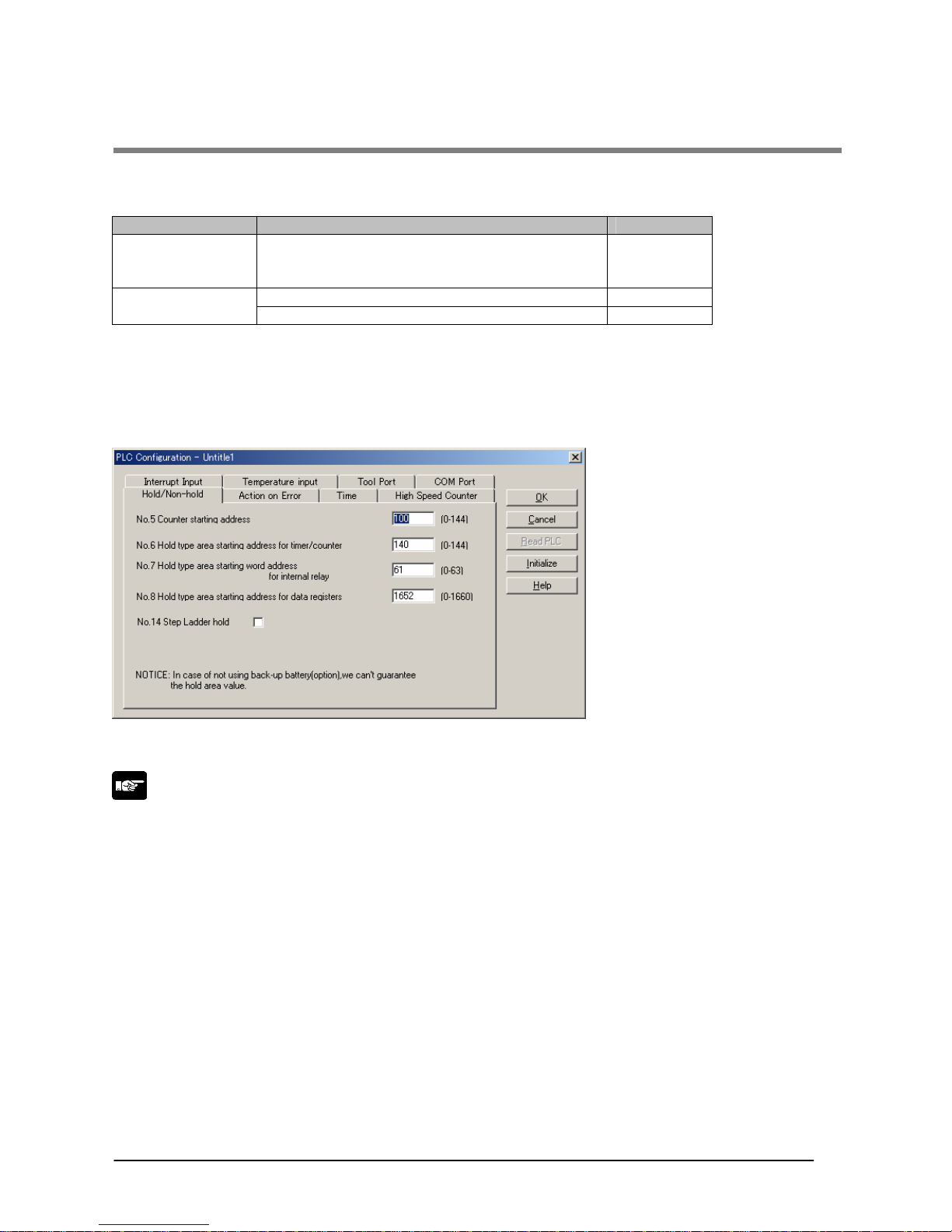

System register setting screen – (Hold/Non-hold)

Areas for Nos. 6, 7, 8 and 14 can be expanded.

Note: “NOTICE” in the screen above is described for the FPWIN GR Ver. 2.24 or higher.

Note: System register initial values on Hold/Non-hold tab are within the ones that can be backed up

with a ROM.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3-1

Chapter 3

Installation and Wiring

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3-2

3.1 Installation

3.1.1 Operating environment

Avoid mounting the unit in the following locations:

-Ambient temperatures outside the range of 0 ºC to 55 ºC.

-Ambient humidity outside the range of 30 % to 85 %RH (at 25 ºC, non-condensing).

-Sudden temperature changes causing condensation

-Corrosive and inflammable gases

-Excessive airborne dust, metal particle, or salts

-Benzine, thinner, alcohol or other organic solvents, or strong alkaline solutions such as ammonia or

caustic soda

-Excessive vibration or shock

-Direct sunlight

-Water, oil, or chemicals in any form including spray or mist

Measures regarding noise:

-The unit should be installed apart from the high voltage cables, high voltag e equipment, power cables,

power equipment, or any other equipment that would generate high switching surges.

-The unit should also be installed apart from the devices which have radio transmitters.

-If noise occurs in the power supply line even after the above countermeasures are taken, you are

recommended to supply power through an insulation transformer, noise filter, or like.

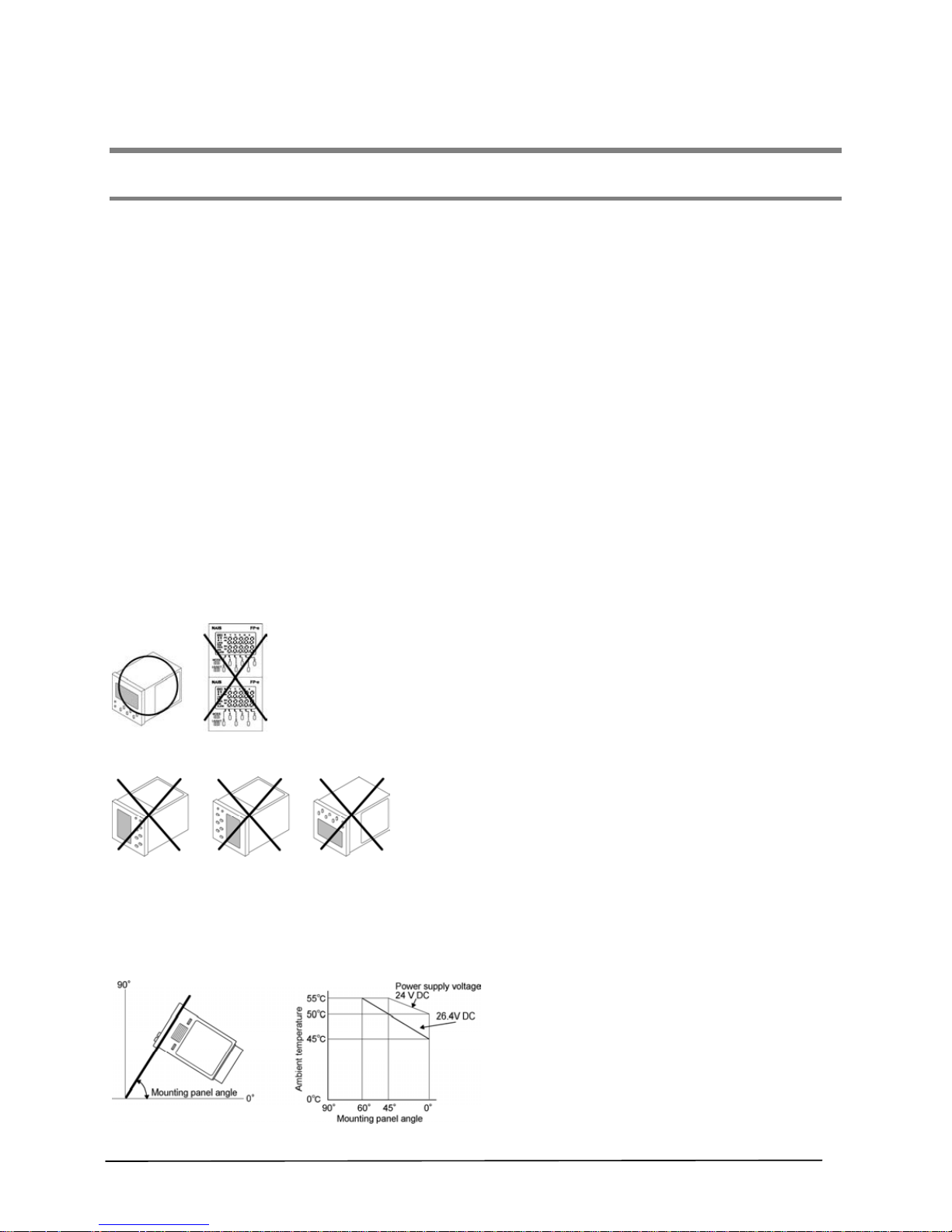

Measures regarding heat discharge:

-Always amount the unit oriented with the LCD facing upward in order to prevent the generation of heat.

Do not amount the units vertically as shown below.

-Do not install the unit as shown below.

-Do not amount the unit above which generate large heat such as heaters, transformers, or large scale

resisters.

Note that the ambient temperature and electrical voltage are restricted when the mounting panel is

installed at the angle of 0 (horizontal) to 60.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3-3

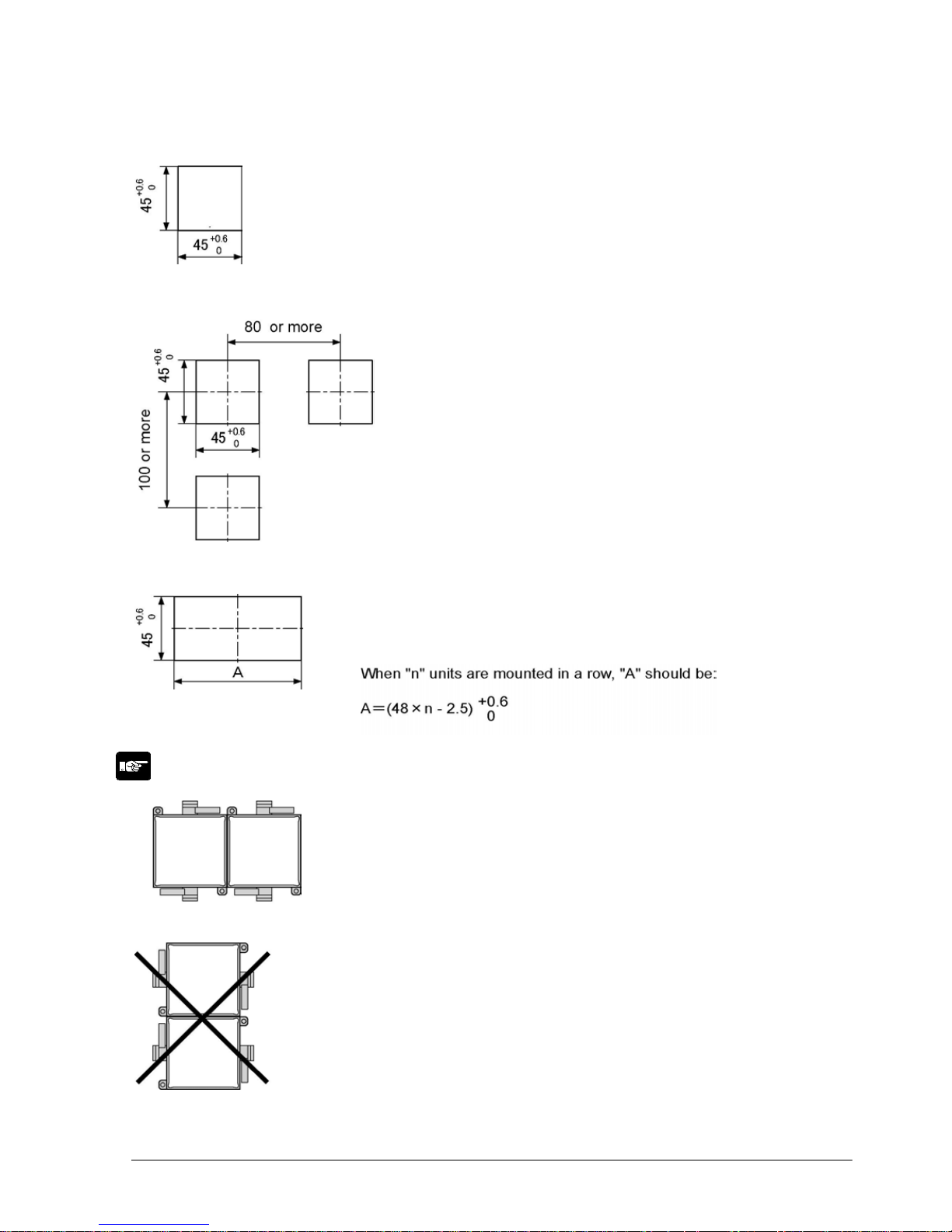

Mounting panel cut size (Unit: mm)

- Standard mounting panel cut size

Mounting panel cut size is shown in the diagram on

the left.

(Panel thickness: 1 to 5 mm)

-When using two or more units:

Make holes in the specified size as shown in

the diagram on the left.

-When mounting units in a row

Units can be mounted horizontally in a row. In that

case, however, waterproofing property on the unit will

be lost.

Note: When mounting the units horizontally in a row:

Mount the units oriented with the molded spring

sections of the mounting flame facing upward

and downward.

Do not mount the units vertically in a row in

order to prevent the generation of heat.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3-4

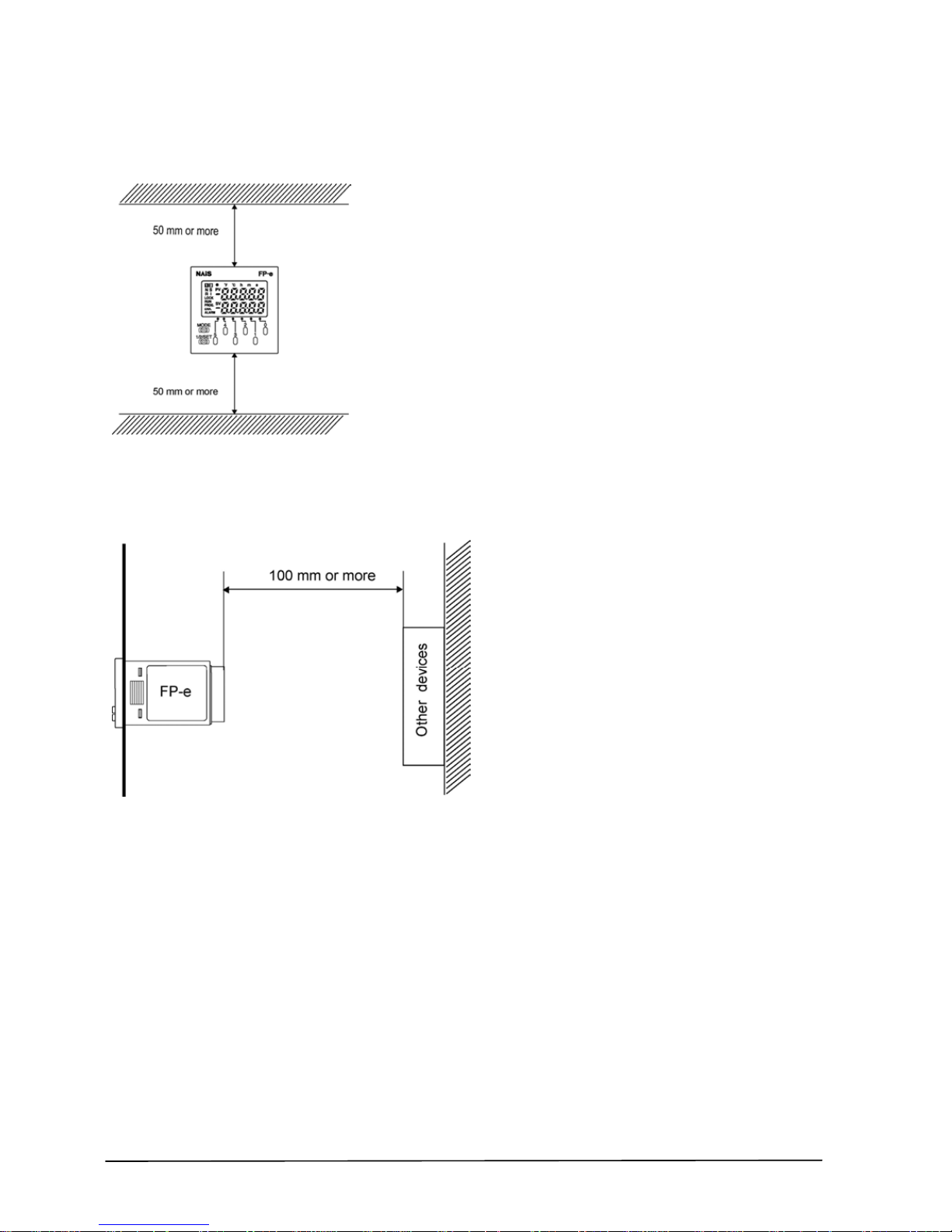

Installation space

- Leave at least 50 mm of space between the wiring ducts of the unit and other devices to allow heat

radiation and unit replacement.

- Maintain 100 mm or more space between the unit and other devices in order to allow room for

programming tool connections and wiring, or to avoid radiated noise and heat from other devices.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...