Panasonic AFP7MC16EC, FP7, AFP7MC32EC, AFP7MC64EC User Manual

Safety Precautions

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

-To prevent excessive exothermic heat or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured in these

specifications.

-Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock.

-Use the external devices to function the emergency stop and interlock circuit.

-Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generation.

-Do not allow foreign matters such as liquid, flammable materials, metals to go into the inside

of the product. It could cause excessive exothermic heat or smoke generation.

-Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

Copyright / Trademarks

-This manual and its contents are copyrighted.

-You may not copy this manual, in whole or part, without written consent of

Industrial Devices SUNX Co., Ltd.

-Windows is a registered trademark of Microsoft Corporation in the United States and other

countries.

-EtherCAT is registered trademark and patented technology, licensed by Beckhoff

Automation Gmbh, Germany.

-All other company names and product names are trademarks or registered trademarks of

their respective owners.

Panasonic

PLC_EC

Introduction

Unit name or purpose of use

Manual name

Manual code

Thank you for buying a Panasonic product. Before you use the product, please carefully read

the installation instructions and the users manual, and understand their contents in detail to

use the product properly.

Types of Manual

• There are different types of users manual for the FP7 series, as listed below. Please refer to

a relevant manual for the unit and purpose of your use.

• The manuals can be downloaded on our website:

http://industrial.panasonic.com/ac/e/dl_center/manual/

FP7 Power Supply Unit

FP7 CPU Unit

Instructions for Built-in

LAN Port

FP7 Web Server Function Manual See our web site.

Instructions for Built-in

COM Port

FP7 Extension Cassette

(Communication)

(RS-232C/RS485 type)

FP7 Extension Cassette

(Communication)

(Ethernet type)

FP7 Extension (Function)

Cassette

Analog Cassette

FP7 Digital Input/Output Unit FP7 Digital Input/Output Unit Users Manual WUME-FP7DIO

FP7 Analog Input Unit FP7 Analog Input Unit Users Manual WUME-FP7AIH

FP7 Analog Output Unit FP7 Analog Output Unit Users Manual WUME-FP7AOH

Thermocouple Multi-analog

Input Unit

RTD input unit

FP7 Multi Input/Output Unit FP7 Multi Input/Output Unit Users Manual WUME-FP7MXY

FP7 High-speed Counter Unit FP7 High-speed Counter Unit Users Manual WUME-FP7HSC

FP7 CPU Unit Users Manual (Hardware) WUME-FP7CPUH

FP7 CPU Unit Command Reference Manual WUME-FP7CPUPGR

FP7 CPU Unit Users Manual

(Logging Trace Function)

FP7 CPU Unit Users Manual (Security Function) WUME-FP7CPUSEC

FP7 CPU Unit Users Manual

(LAN Port Communication)

FP7 CPU Unit User's Manual (EtherNetIP

Communication)

FP7 CPU Unit Users Manual (EtherNet IP

communication)

FP7 series Users Manual (SCU communication) WUME-FP7COM

FP7 series Users Manual (Communication

cassette Ethernet type)

FP7 Analog Cassette Users Manual WUME-FP7FCA

Thermocouple Multi-analog Input Unit

RTD Input Unit

Users Manual

WUME-FP7CPULOG

WUME-FP7LAN

WUME-FP7CPUETEX

See our web site.

WUME-FP7CCET

WUME-FP7TCRTD

i

Types of Manual

Unit name or purpose of use

Manual name

Manual code

FP7 Pulse Output Unit FP7 Pulse Output Unit Users Manual WUME-FP7PG

FP7 Positioning Unit FP7 Positioning Unit Users Manual WUME-FP7POSP

FP7 Serial Communication

Unit

PHLS System PHLS System Users Manual WUME-PHLS

Programming Software

FPWIN GR7

FP7 series Users Manual (SCU communication) WUME-FP7COM

FPWIN GR7 Introduction Guidance WUME-FPWINGR7

ii

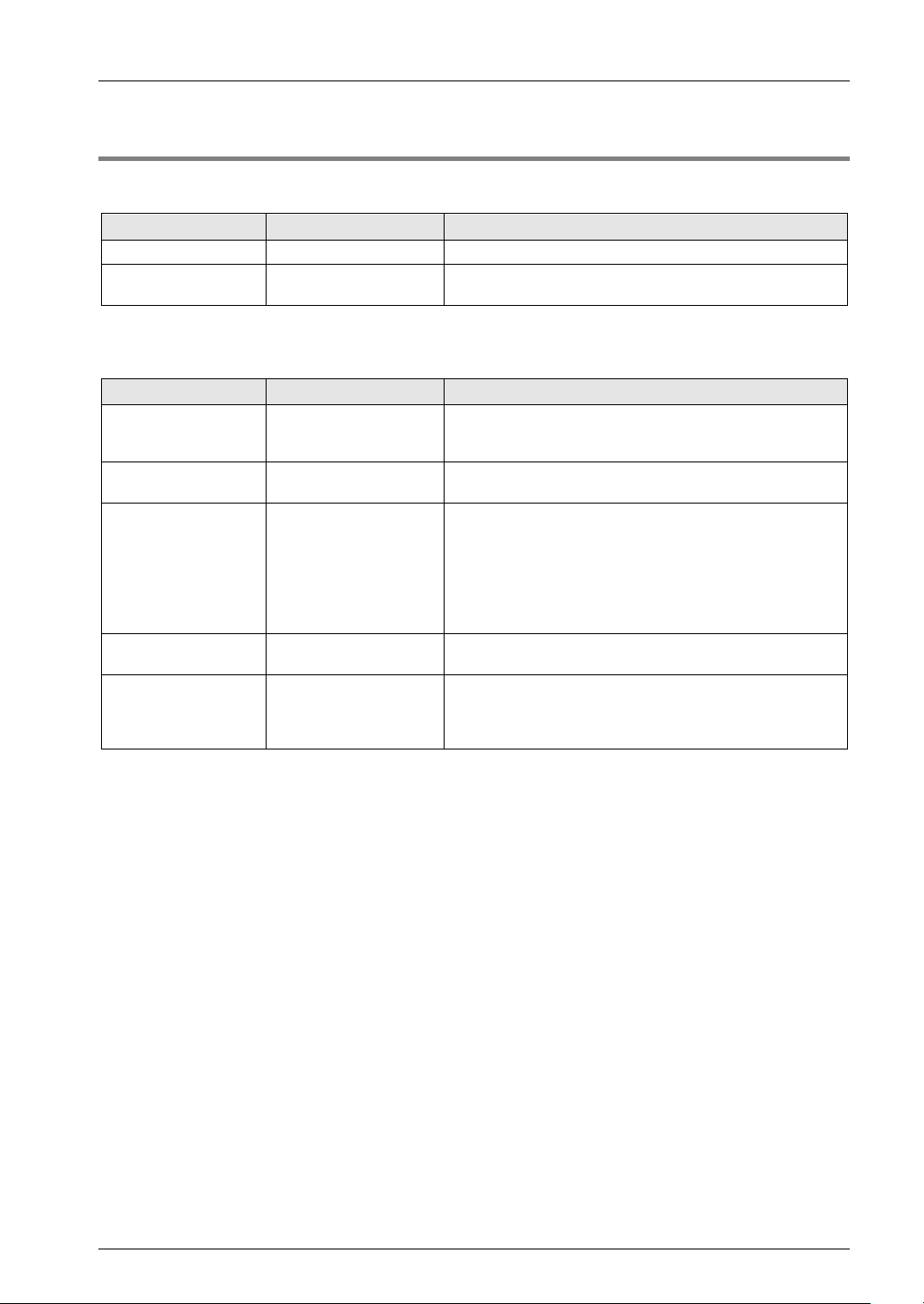

Glossary

To make explanations simple, abbreviations are used for the following terms.

Abbreviation Name Description

FP7 MC Unit FP7 Motion Control Unit The product name of the unit described in this manual.

CMI

As for the following terms, they are expressed differently in software, manuals and

specification concerning FP7 MC Unit and Servo Amplifier A5B.

FP7 MC Unit A5B Description

Station address Station alias

-

General-purpose

input

- General-purpose output

General-purpose

output

Control Motion

Integrator

General-purpose

monitor input

-

-

The software for stting parameters of FP7MC Unit.

This shows the unit numbers allocated to slaves on

EtherCAT network. The left two terms have the same

meaning.

Five inputs of symbols SI-MON1 to SI-MON5 are allocated

on the A5B side.

On the FP7 MC Unit side, eight signals of A5B are treated

as "general-purpose input" and can be monitored through

the unit memory.

NOT, POT, HOmE, SI-MON1 to SI-MON5

For using it in combination with FP7 MC Unit, SI-MON3 and

SI-MON4 are used as limit inputs. NOT and POT are not

used.

On the A5B side, one input of symbol EX-OUT1 is

allocated.

On the FP7 MC Unit side, one signal to A5B are treated as

"general-purpose output" and can be written through the

unit memory.

EX-OUT1

Glossary

iii

Table of Contents

Table of Contents

1. Unit Functions and Restrictions ....................................... 1-1

1.1 Functions of Motion Control ................................................................... 1-2

1.1.1 Functions of Unit ..................................................................................... 1-2

1.1.2 List of Models .......................................................................................... 1-3

1.2 Restrictions............................................................................................ 1-4

1.2.1 Supported Functions ............................................................................... 1-4

1.2.2 Restrictions by Power Consumption in FP7 System ............................... 1-5

1.2.3 Applicable Versions of FPWINGR7 and FP7 Units ................................. 1-5

1.3 System Configuration ............................................................................ 1-6

1.3.1 Example of System Configuration ........................................................... 1-6

1.3.2 Type of Software ..................................................................................... 1-7

1.4 Mechanism of Processing ...................................................................... 1-8

1.4.1 Schematic View ....................................................................................... 1-8

1.4.2 Operation When Powe Supply Turns On ................................................ 1-9

1.4.3 Start/Stop by User Programs .................................................................. 1-9

2. Names and Functions of Parts ......................................... 2-1

2.1 Names and Functions of Parts............................................................... 2-2

2.1.1 Names and Functions of Parts ................................................................ 2-2

2.1.2 Operation monitor LEDs .......................................................................... 2-3

2.1.3 ESM (State Transition Diagram) ............................................................. 2-4

3. Installation and Wiring ...................................................... 3-1

3.1 Settings of Servo Amplifier A5B ............................................................. 3-2

iv

Table of Contents

3.1.1 Checking Rotary Switches ...................................................................... 3-2

3.1.2 Connection of Input Signals .................................................................... 3-3

3.2 Connection of Network .......................................................................... 3-4

3.2.1 Wiring ...................................................................................................... 3-4

3.2.2 Precautions on Wiring ............................................................................. 3-4

4. Basic Procedure ................................................................. 4-1

4.1 Section Details ...................................................................................... 4-2

4.2 Registration in I/O Map ......................................................................... 4-3

4.2.1 Creation of I/O map ................................................................................. 4-3

4.2.2 Download of I/O map .............................................................................. 4-4

4.2.3 Storage of I/O map .................................................................................. 4-4

4.2.4 Confirmation of I/O Allocation ................................................................. 4-4

4.2.5 Confirmation of Slot Numbers ................................................................. 4-5

4.3 Setting of Used Axes............................................................................. 4-6

4.3.1 Registration of Used Axes ....................................................................... 4-6

4.4 Setting of Network Configuration ......................................................... 4-10

4.4.1 Registration of Slaves (Offline) ............................................................. 4-10

4.4.2 Registration of Slaves (Online) ............................................................. 4-12

4.4.3 Setting of Station Addresses and Axis Numbers .................................. 4-14

4.4.4 Download to FP7 MC Unit ..................................................................... 4-16

4.4.5 Restarting Power Supplies and Checking Communication State ......... 4-18

4.5 Connection of Limit and Near Home Switches .................................... 4-20

4.5.1 Connection of Input Signals .................................................................. 4-20

4.5.2 Pin Assignment Setting of Servo Amplifier ........................................... 4-21

4.5.3 Checking Servo Amplifier Input State ................................................... 4-23

4.5.4 Settings of FP7 MC Unit ........................................................................ 4-24

4.5.5 Download to FP7 MC Unit ..................................................................... 4-25

4.5.6 Checking Input State ............................................................................. 4-25

4.6 Saving and Managing Files ................................................................. 4-26

4.6.1 File Type ................................................................................................ 4-26

v

Table of Contents

4.6.2 Saving as CMI Files .............................................................................. 4-26

4.6.3 Export to CSV Files ............................................................................... 4-27

5. Settings of FP7 MC Unit .................................................... 5-1

5.1 MC Common Settings ........................................................................... 5-2

5.1.1 MC Common Settings Dialog Box ........................................................... 5-2

5.1.2 MC Common Settings Parameters ......................................................... 5-3

5.2 Axis Parameter Settings ........................................................................ 5-5

5.2.1 Setting by CMI ......................................................................................... 5-5

5.2.2 Axis Parameters (Basic Setup) ............................................................... 5-6

5.2.3 Axis Parameters (Options) ...................................................................... 5-7

5.2.4 Axis Parameters (Operation) ................................................................... 5-8

5.3 Positioning Table Setting ..................................................................... 5-10

5.3.1 Construction of Positioning Tables ........................................................ 5-10

5.3.2 Operation Patterns and Tables ............................................................. 5-13

5.4 Synchronous Parameter and Cam Pattern Settings ............................. 5-14

5.4.1 Synchronous Parameter Settings ......................................................... 5-14

5.4.2 Cam Pattern Setting .............................................................................. 5-15

5.5 Confirmation of Setting Contents ......................................................... 5-16

5.5.1 Check on Parameter Data ..................................................................... 5-16

5.5.2 Comparison of Parameter Information .................................................. 5-16

5.6 Transfer of Parameters ........................................................................ 5-18

5.6.1 Writing Parameters to Unit .................................................................... 5-18

6. Data Transfer to MC Unit and Test Operation .................. 6-1

6.1 Before Turning On the Power ................................................................ 6-2

6.2 Procedure for Turning On the Power ..................................................... 6-3

vi

6.2.1 Procedure for Turning On the Power ...................................................... 6-3

6.2.2 Procedure for Turning Off the Power ...................................................... 6-3

Table of Contents

6.3 Checking While the Power is ON .......................................................... 6-4

6.3.1 Items to Check When the Power is ON................................................... 6-4

6.3.2 Checking Network Communication State ............................................... 6-5

6.3.3 Checking the safety circuit by the PLC unit ............................................ 6-6

6.3.4 Checking the Operation of Near Home Switch ....................................... 6-7

6.3.5 Checking Rotating and Moving Directions and Moving Distance ........... 6-7

6.4 Monitor Function of CMI ........................................................................ 6-8

6.4.1 Status Monitor ......................................................................................... 6-8

6.4.2 Data Monitor .......................................................................................... 6-10

6.5 Tool Operation Function of CMI .......................................................... 6-12

6.5.1 Tool Operation Function ........................................................................ 6-12

6.5.2 Serve ON/OFF with Tool Operation Function ....................................... 6-14

6.5.3 JOG Operation with Tool Operation Function ....................................... 6-16

6.5.4 Home Return by Tool Operation Function ............................................ 6-18

6.5.5 Positioning by Tool Operation Function ................................................ 6-20

6.5.6 Teaching by Tool Operation Function ................................................... 6-23

7. Creation of User Programs ................................................ 7-1

7.1 How to Create User Programs .............................................................. 7-2

7.1.1 Basic Configuration of Program .............................................................. 7-2

7.2 Overview of Programs ........................................................................... 7-4

7.2.1 Reading Data From Input Control Area .................................................. 7-4

7.2.2 Servo ON/OFF Control Program ............................................................. 7-5

7.2.3 Start Enabled Program ............................................................................ 7-6

7.2.4 Each Control Programs ........................................................................... 7-6

7.2.5 Writing Data to Output Control Area ....................................................... 7-7

7.3 Precautions On Programming ............................................................... 7-8

7.3.1 Turning Off Power Supply Clears Contents in Unit Memories ................ 7-8

7.3.2 Operation Cannot be Switched Once One Operation Has Started ......... 7-8

7.3.3 Operation When PLC Mode Changes From RUN To PROG. ................ 7-8

vii

Table of Contents

8. Automatic Operation (Position Control) .......................... 8-1

8.1 Basic Operation ..................................................................................... 8-2

8.1.1 Patterns of Position Control..................................................................... 8-2

8.1.2 Setting and Operation of E-point Control ................................................ 8-4

8.1.3 Setting and Operation of P-point Control ................................................ 8-6

8.1.4 Setting and Operation of C-point Control ................................................ 8-8

8.1.5 Setting and Operation of J-point Control ............................................... 8-10

8.2 Interpolation Control ............................................................................ 8-12

8.2.1 Type of Interpolation Control (Two-axis Interpolation) .......................... 8-12

8.2.2 Type of Interpolation Control (Three-axis Interpolation) ....................... 8-14

8.2.3 Setting and Operation of Two-Axis Linear Interpolation ....................... 8-17

8.2.4 Setting and Operation of Two-Axis Circular Interpolation ..................... 8-19

8.2.5 Setting and Operation of Three-Axis Linear Interpolation ..................... 8-21

8.2.6 Setting and Operation of Three-Axis Spiral Interpolation ...................... 8-23

8.3 Repeat Function .................................................................................. 8-25

8.3.1 Overview of Repeat Operation .............................................................. 8-25

8.3.2 Stop Operation During Repeat Operation ............................................. 8-26

8.3.3 Setting and Operation of Repeat ........................................................... 8-27

8.4 Sample Programs ................................................................................ 8-29

8.4.1 Sample Programs (E-point, C-point and C-point Controls) ................... 8-29

8.4.2 Precautions on Programming ................................................................ 8-31

8.5 Rewriting Positioning Data by User Programs ..................................... 8-32

8.5.1 Overview of Function ............................................................................. 8-32

8.5.2 Procedure of Rewriting .......................................................................... 8-33

8.5.3 Sample Program (Rewritign Positioning Tables) .................................. 8-34

9. Automatic Operation (Synchronous Control) .................. 9-1

9.1 Synchronous Control ............................................................................. 9-2

9.1.1 Overview of Synchronous Control ........................................................... 9-2

9.2 Settings for Master and Slave Axes ....................................................... 9-4

viii

Table of Contents

9.2.1 Selection of Master Axis and Settings .................................................... 9-4

9.2.2 Selection of Slave Axes and Settings ..................................................... 9-5

9.2.3 Unit Type and Number of Axes ............................................................... 9-5

9.2.4 Setting by CMI ......................................................................................... 9-6

9.3 Start and Cancel of Synchronous Control ............................................. 9-8

9.3.1 Start and Cancel of Synchronous Control ............................................... 9-8

9.3.2 Precautions When Canceling or Starting Synchronous Control ........... 9-10

9.4 Electronic Gear Function ..................................................................... 9-12

9.4.1 Overview of Electronic Gear Function .................................................. 9-12

9.4.2 Types and Contents of Setting Parameters .......................................... 9-13

9.4.3 Gear Ratio Changes while in Operation................................................ 9-14

9.5 Electronic Clutch Function .................................................................. 9-16

9.5.1 What is Electronic Clutch Function? ..................................................... 9-16

9.5.2 Types and Contents of Setting Parameters .......................................... 9-17

9.5.3 Trigger Types for Electronic Clutch ....................................................... 9-18

9.5.4 Engagement Method of Electronic Clutch ............................................. 9-19

9.6 Electronic Cam Function ..................................................................... 9-20

9.6.1 Overview of Electronic Cam Function ................................................... 9-20

9.6.2 Types and Contents of Setting Parameters .......................................... 9-21

9.6.3 Cam Pattern Setting Method ................................................................. 9-22

10. Manual Operation (JOG Operation) ................................ 10-1

10.1 Setting and Operation of Home Return ............................................... 10-2

10.2 Changing Speed During JOG Operation ............................................. 10-4

10.3 Setting and Operation of JOG Inching Operation ................................ 10-6

10.4 Sample Programs ............................................................................... 10-8

10.4.1 Sample Program (JOG Operation)........................................................ 10-8

10.4.2 Precautions on Programming .............................................................. 10-10

ix

Table of Contents

11. Manual Operation (Home Return) .................................. 11-1

11.1 Types of Home Return ........................................................................ 11-2

11.2 Operation of Home Return ................................................................... 11-8

11.3 Sample Programs .............................................................................. 11-10

11.3.1 Sample Program (Home Return) ........................................................ 11-10

11.3.2 Precautions on Programming .............................................................. 11-12

12. Stop Functions ................................................................ 12-1

12.1 Type of Stop Functions ........................................................................ 12-2

12.1.1 Type of Stop Operations ....................................................................... 12-2

12.1.2 Characteristics of Pause Function ........................................................ 12-4

12.1.3 Stop Operation During Interpolation Control ......................................... 12-4

12.1.4 Stop Operation During Synchronous Control ........................................ 12-4

12.2 Settings Related to Stop Function ....................................................... 12-5

12.2.1 MC Common Settings ........................................................................... 12-5

12.2.2 Axis Parameter ...................................................................................... 12-6

12.3 Operation During Stop ......................................................................... 12-7

13. Supplementary Functions .............................................. 13-1

13.1 Dwell Time........................................................................................... 13-2

13.2 Software Limit ...................................................................................... 13-3

13.3 Auxiliary Output Code and Auxiliary Output Contact ............................ 13-4

13.4 Current Value Update .......................................................................... 13-6

13.5 Home Coordinates ............................................................................... 13-8

13.6 Movement Amount Automatic Check ................................................. 13-10

13.7 Monitor Error (Torque / Actual Speed Judgement)............................. 13-11

x

Table of Contents

13.8 EtherCAT Communication Setting..................................................... 13-12

13.8.1 EtherCAT Configurator ........................................................................ 13-12

13.8.2 Device Editor ....................................................................................... 13-13

13.8.3 Overview of PDO Mapping .................................................................. 13-14

13.8.4 Change of PDO Mapping .................................................................... 13-15

13.9 EC Packet Monitor Function .............................................................. 13-18

13.9.1 Overview of Function .......................................................................... 13-18

13.9.2 Stored Files ......................................................................................... 13-18

13.9.3 How to Set ........................................................................................... 13-19

13.9.4 How to Execute ................................................................................... 13-20

13.9.5 Handling of SD Memory Card ............................................................. 13-20

14. Troubleshooting .............................................................. 14-1

14.1 Errors and Warnings ........................................................................... 14-2

14.1.1 Errors and warnings .............................................................................. 14-2

14.1.2 Checking and Clearing by CMI ............................................................. 14-2

14.1.3 Clearing Errors/Warnings Using User Programs .................................. 14-3

14.1.4 Error and Warning Logs ........................................................................ 14-4

14.2 Error Recovery Process ...................................................................... 14-5

14.2.1 Overview ............................................................................................... 14-5

14.3 Error Code Table ................................................................................ 14-6

14.3.1 System Errors (From 00F0 1000H ........................................................ 14-6

14.3.2 AMP Communication Errors (From 00F0 2000H) ................................. 14-6

14.3.3 Axis Operation Errors (From 00F0 3000H) ........................................... 14-7

14.3.4 Setting Value Errors (From 00F0 4000H) ............................................. 14-9

14.3.5 Synchronous Parameter Setting Errors (From 00F0 5000H) ............. 14-12

14.4 Warning Code Table ......................................................................... 14-15

14.4.1 Unit Warnings (From 00B0 0000H) ..................................................... 14-15

xi

Table of Contents

15. Specifications .................................................................. 15-1

15.1 Specifications ...................................................................................... 15-2

15.1.1 General Specifications .......................................................................... 15-2

15.1.2 Communication Specifications .............................................................. 15-3

15.1.3 Performance Specifications................................................................... 15-4

15.2 I/O Allocation ....................................................................................... 15-6

15.3 Whole Configuration of Unit Memories ................................................ 15-8

15.4 Unit Memories (Input and Output Control Areas) ............................... 15-10

15.4.1 Configuration of Input Control Area ..................................................... 15-10

15.4.2 Configuration of Output Control Area .................................................. 15-11

15.4.3 List of Input Control Area Functions .................................................... 15-12

15.4.4 List of Output Control Area Function ................................................... 15-20

15.5 Unit Memories (Common Area) ......................................................... 15-25

15.5.1 Configuration of Common Area ........................................................... 15-25

15.5.2 Setting Parameter Control Area .......................................................... 15-26

15.5.3 Operation Speed Rate Area ................................................................ 15-26

15.5.4 Axis Group Setting Area ...................................................................... 15-27

15.5.5 Current Value Update Data Area ........................................................ 15-28

15.5.6 Positioning Control Starting Table Number Setting Area .................... 15-29

15.5.7 Positioning Control Area...................................................................... 15-29

15.5.8 Error Annunciation and Clear Area ..................................................... 15-30

15.5.9 Warning Annunciation and Clear Area ................................................ 15-32

15.5.10 Synchronous Control Monitor Area ................................................. 15-34

15.6 Unit Memories (Each Axis Information Area) ..................................... 15-36

15.6.1 Configuration of each axis information area........................................ 15-36

15.6.2 Each Axis Information & Monitor Area ................................................ 15-37

15.7 Unit Memories (Each Axis Setting Area) ............................................ 15-40

15.7.1 Configuration of Each Axis Setting Area ............................................. 15-40

xii

15.7.2 Configuration of Parameter Setting Area ............................................ 15-41

15.7.3 Parameter Setting Area ....................................................................... 15-42

15.7.4 Configuration of Positioning Data Setting Area ................................... 15-48

Table of Contents

15.8 Unit Memories (Synchronous Control Setting Area) .......................... 15-55

15.8.1 Configuration of Synchronous Control Setting Area ........................... 15-55

15.8.2 Sychronous Control Setting Area ........................................................ 15-56

15.8.3 Electronic Gear Setting Area ............................................................... 15-57

15.8.4 Clutch Setting Area ............................................................................. 15-57

15.8.5 Electronic Cam Setting Area ............................................................... 15-59

15.9 Dimensions ....................................................................................... 15-60

xiii

Table of Contents

xiv

1

Unit Functions and

Restrictions

Unit Functions and Restrictions

A5B

A5B A5B

FP7MC

EtherCAT

USB

Control FPWIN GR7

Control Motion Integrator

USB

PANATERM

1.1 Functions of Motion Control

1.1.1 Functions of Unit

Controlling Servo Motor MINAS A5B series through EtherCAT

FP7 Motion Control Unit (hereafter FP7 MC Unit) adopts EtherCAT communication and

controls servo motors. It achieves wiring saving by network connection and high-speed control.

(Note): EtherCAT is a registered trademark of Beckhoff Automation Gmbh in Germany and a technology protected

by a patent.

Setting using dedicated software "Control Motion Integrator"

Dedicated software "Control Motion Integrator" (sold separately) is provided for easily

configuring the setting of EtherCAT communication and parameters of position control.

1-2

1.1 Functions of Motion Control

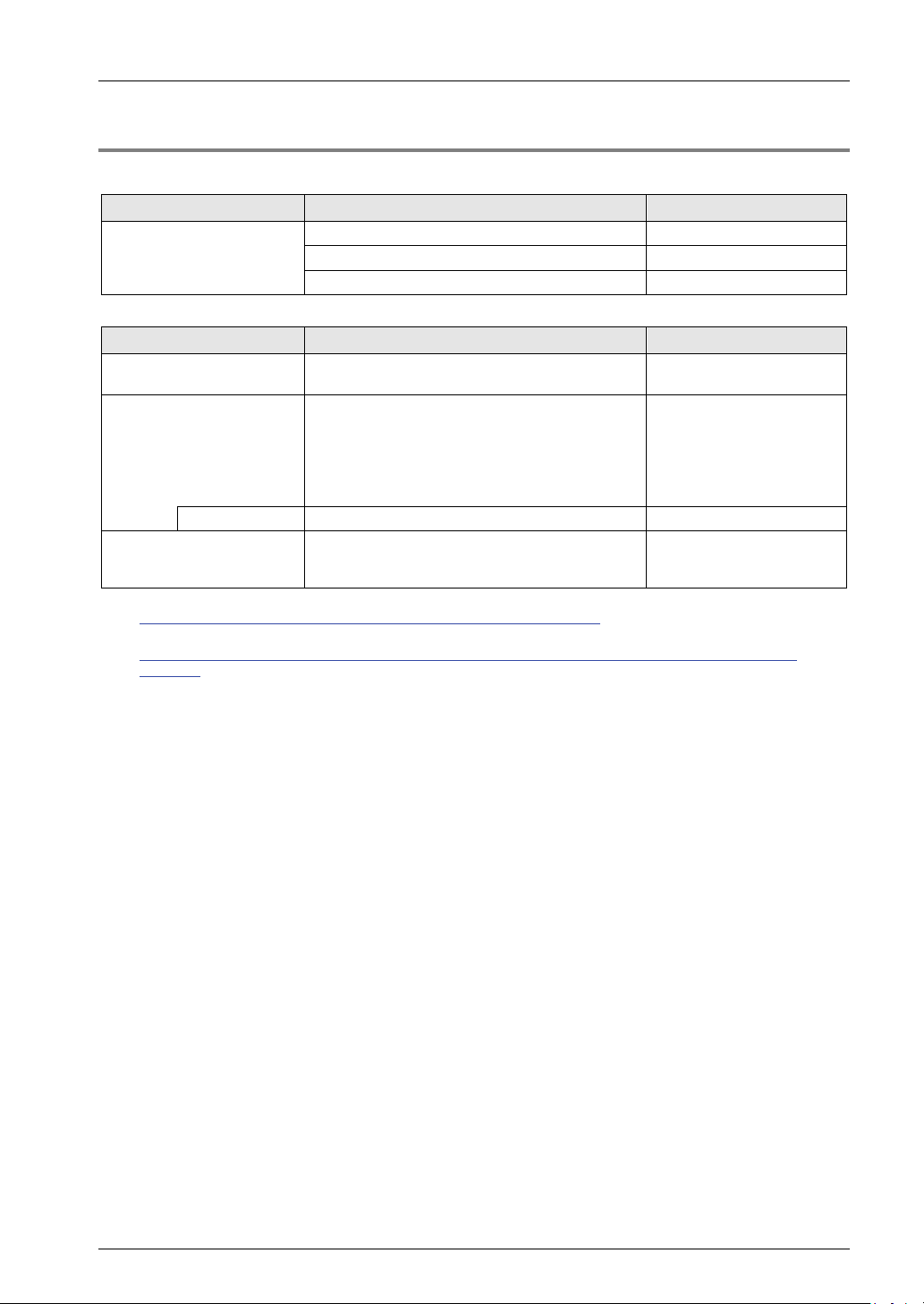

1.1.2 List of Models

Main unit

Product name Max. number of control axes Product no.

FP7 Motion Control Unit

(Abbreviated name: FP7

MC Unit)

Related software

Product name Application Product no.

Programming software

FPWIN GR7

Software

Control Motion Integrator

Key Unit For installing a USB port (Note 3) AFPSMTKEY

Setup support software

PANATERM

(Note 1): For the latest information on FPWIN GR7 and Control Motion integrator, see the following web site.

http://industrial.panasonic.com/ac/e/fasys/plc/software/fpwingr7/index.jsp

(Note 2): For the latest information on PANATERM, see the following web site.

https://industrial.panasonic.com/ww/products/motors-compressors/fa-motors/ac-servo-motors/minas-a5panaterm

(Note 3): All the functions of Control Motion Integrator can be used free of charge for 60 days after the installation. For

using the "EtherCAT communication setting" function continuously after the elapse of 60 days, the key unit

should be installed.

16 axes/unit AFP7MC16EC

32 axes/unit AFP7MC32EC

64 axes/unit AFP7MC64EC

This software is used for configuring the whole

FP7 system and creating user programs.

This software is used for configuring FP7 MC Unit

and monitoring the state..

EtherCAT communication parameters

Setting of positioning parameters

Setting of positioning tables

This software is used for setting parameters and

monitoring the states of Servo Amplifier A5B

series.

For the latest information,

see our web site.

For the latest information,

see our web site.

For the latest information,

see our web site.

Required files for EtherCAT communication

The setup information (ESI files) required for EtherCAT communication is included in the

installation data of software "Control Motion Integrator".

(Note): ESI (EtherCAT Slave Information)

1-3

Unit Functions and Restrictions

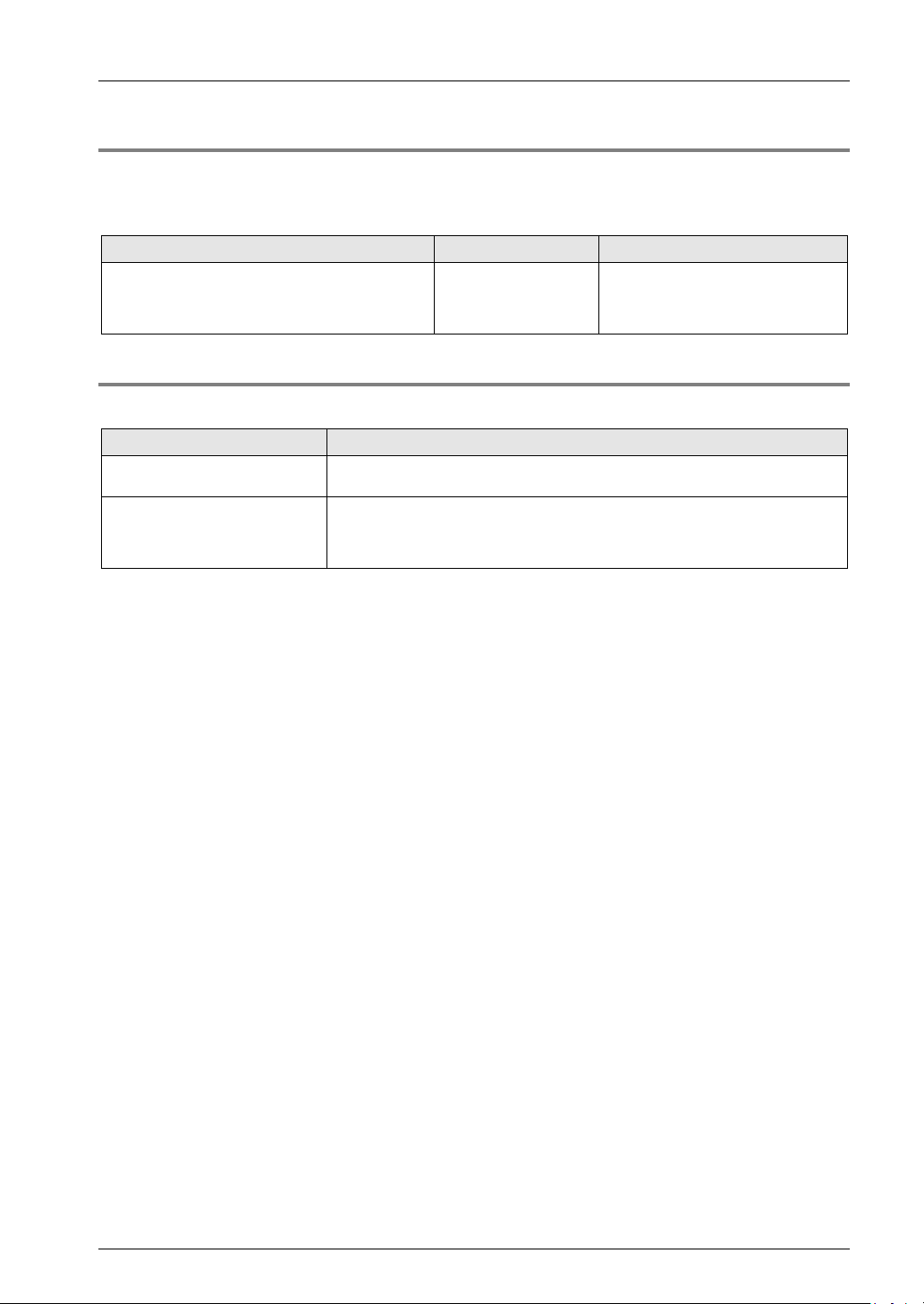

1.2 Restrictions

1.2.1 Supported Functions

FP7 MC Unit is designed in conformity with the specifications and standard of EtherCAT,

however, FP7 MC Unit Ver.1 supports the items listed in the following table only.

Comparison with EtherCAT specifications

Item EtherCAT specifications Supported items by FP7 MC Unit

Transmission

system

Baud rate 100 Mbps Same as on the left.

Trasmission

distance

Transmission

cable

Topology Line, Daisy chain, Star, Tree Daisy chain (without brach)

Max. number of

connected units

Connectable

device

100BASE-TX Same as on the left.

Max. 100 m between nodes Same as on the left.

STP cable, category 5/5e Always use a cable of category 5e or higher.

65535 64

EtherCAT-compatible devices

Panasonic

AC serv motor A5B series

(EtherCAT-compatible type)

Control mode

Control mode of EtherCAT

Cyclic position control mode (csp) Supported

Profile position control mode (pp) Unsupported

Home return position control

mode (hm )

Interpolation position control

mode (ip)

Cyclic speed control mode (csv)

Profile speed control mode (pv)

Cyclic torque control mode (cst)

Profile torque control mode (tq)

Supported function

of A5B

Supported

Unsupported

Supported Unsupported

Supported items by FP7 MC Unit

The cyclic position control mode (csp) is used

when using it in combination with FP7 MC

Unit.

Only the home return position control mode

(Method33/34/37) is supported. The cyclic

position control mode (csp) is used when

using it in combination with FP7 MC Unit.

When using it in combination with FP7 MC

Unit, FP7 MC Unit performs the interpolation

control.

1-4

1.2 Restrictions

1.2.2 Restrictions by Power Consumption in FP7 System

The unit has the following internal current consumption. Make sure that the total current

consumption is within the capacity of the power supply with consideration of all other units

used in combination with this unit.

Name Product no. Consumption current

AFP7MC16EC

FP7 Motion Control Unit

AFP7MC32EC

AFP7MC64EC

180 mA or less

1.2.3 Applicable Versions of FPWINGR7 and FP7 Units

For using FP7 MC Unit, the following versions of FPWIN GR7 and units are required.

Item Applicable versions

Programming tool software

FPWIN GR7

FP7 CPU Unit

Ver.2.12 or later

There is no restriction on the version.

For using the EC packet monitor function of FP7 MC Unit, use FP7 CPU Unit

(Ethernet function- built-in type).

1-5

Unit Functions and Restrictions

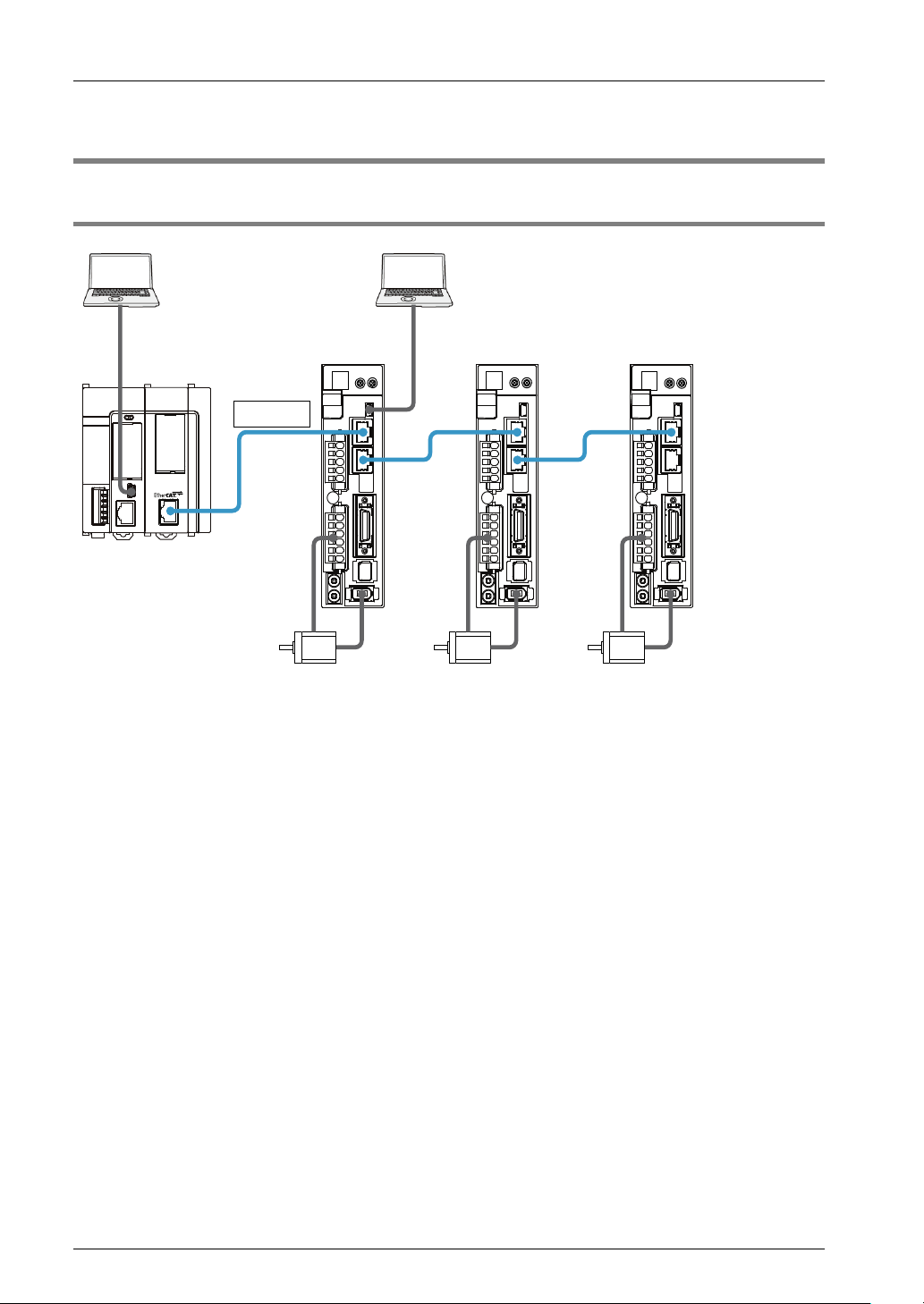

1.3 System Configuration

1.3.1 Example of System Configuration

The following figure shows the example of the configuration of one axis when using over limit

switches and a near home switch.

Configuration of devices

No. Item Explanation

The above figure shows the minimum configuration that FP7 CPU Unit,

FP7 MC Unit and an end unit are combined. For FP7 MC Unit, the units

for 16 axes, 32 axes, and 64 axes are available.

FP7 MC Unit and Servo Amplifier A5B are connected with a shielded

twisted pair (STP) cable.

The over limit switches are connected to the servo amplifier. When

using the servo amplifier in combination with FP7 MC Unit, the over

limit switches are connected to the terminals allocated to the generalpurpose monitor inputs of the servo amplifier (SI-MON3/SI-MON4).

The near home switch is connected to the servo amplifier. It is

connected to the terminal allocated to the near home input (HOME).

①

②

③

④

⑤

FP7

Shielded twisted pair (STP)

cable

Servo Amplifier A5B The units of the number of required axes areconnected.

Over limit switch

Near home switch

1-6

1.3 System Configuration

Application:

Application:

Application:

1.3.2 Type of Software

The following three softwares are used for using the system combining FP7 MC Unit and

Servo Amplifier A5B.

Control Motion Integrator Ver.1.0

This software is used for setting parameters of

FP7 MC Unit, monitoring the state and test

operations.

Setting of EtherCAT communication

parameters

Setting of positioning parameters

Setting of positioning tables, etc.

Download destination:

FP7 MC Unit

Connection with the unit:

Connect to the USB port of FP7 CPU Unit.

FPWIN GR7 Ver.2.12

PANATERM Ver.6.0

This software is used for configuring the whole

FP7 system and creating user programs.

Download destination:

FP7 CPU Unit

Connection with the unit:

Connect to the USB port of FP7 CPU Unit.

This software is used for setting parameters

and monitoring the states of Servo Amplifier

A5B series.

Download destination:

Servo Amplifier A5B

Connection with the unit:

Connect to the USB port of Servo Amplifier

A5B.

1-7

Unit Functions and Restrictions

FP7 CPU FP7 MC A5B

FROM

Slave

processing

MC unit

Operation

processing

part

I/O

Y0: System stop

X0: Link establishment

Input

processing

User program

I/O map

● ● ● ● ●

CPU Config.

Power on

EtherCAT

communication

Positioning

parameters

Positioning tables

● ● ● ● ●

Communication

parameters

UM

FPWIN GR7 CMI PANATERM

Update cycle 500μs

-4000μs

Input control area

Output control area

Busy, Done, Error flag

Start, Stop, Servo on/off

UM

Output

processing

1.4 Mechanism of Processing

1.4.1 Schematic View

1-8

1.4 Mechanism of Processing

1.4.2 Operation When Powe Supply Turns On

• FP7 MC Unit reads the "parameters for FP7 MC Unit" stored in the FROM (FlashROM)

within the unit and sets them in the memory areas within the unit.

• FP7 MC Unit starts the communication with the slaves (servo amplifiers) connected to

EtherCAT. Once the links with the slaves (servo amplifiers) are established, it is notified to

FP7 CPU Unit by the input relay (X0).

• When the mode setting switch is set to RUN mode, FP7 CPU Unit checks that the state of

the FP7 system is correct, switches the mode to RUN mode, and executes user programs.

1.4.3 Start/Stop by User Programs

• In the case of FP7 MC Unit, main I/O signals to execute various controls (such as positioning,

JOG operation, home return, and stop) are allocated to the unit memories (UM).

• In the unit memories (UM) "Output control area", request signals to perform stop control are

allocated. In the unit memories "Input control area", flags such as busy flag and error flag to

check the start conditions are allocated.

• FP7 MC Unit controls operations by reading or writing data to these unit memories.

1-9

Unit Functions and Restrictions

1-10

2

Names and Functions of

Parts

Names and Functions of Parts

①

②

③

④

⑤

⑥

⑦

②-a

②-b

②-c

⑥

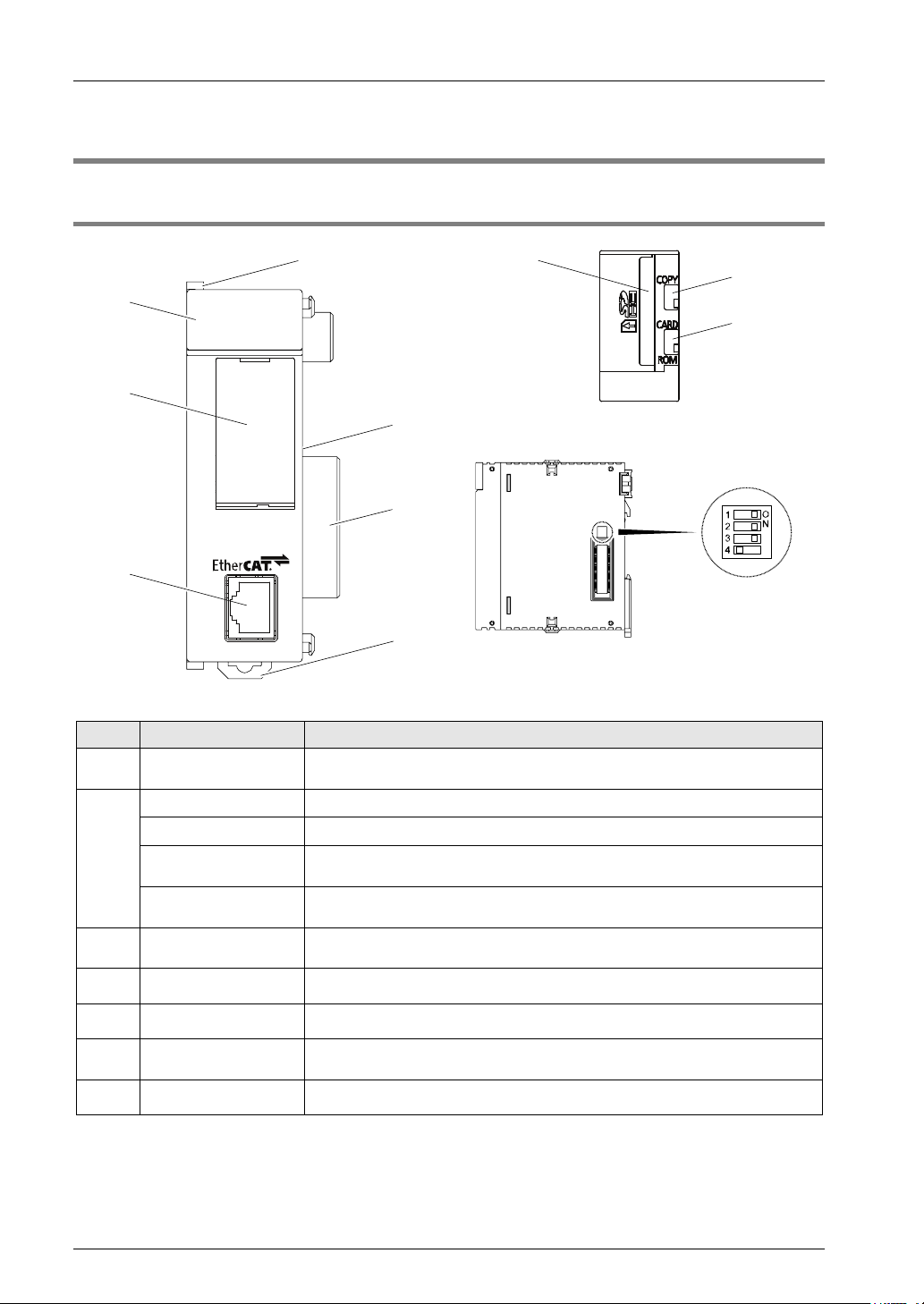

2.1 Names and Functions of Parts

2.1.1 Names and Functions of Parts

Names and functions of parts

No. Name Function

①

②

③

④

⑤

⑥

⑦

Operation monitor

LEDs

Card cover A SD memory card slot is located under the cover.

a: Card slot An SD memory card is inserted.

b: COPY switch

c: Memory selector

switch

Network connector

(RJ45)

DIN hook This hook is used to install the unit on a DIN rail.

Unit connector Connects the internal circuits between units.

Mode setting switch

Fixing hook This hook is used to fix units.

Indicates the state of EtherCAT communication, the occurrence states of

unit's errors and alarms.

This is provided for expansion. Use the switch at the factory default (lower

side) as it is.

This is provided for expansion. Use the switch at the factory default (lower

side) as it is.

This is the connector for connecting to EtherCAT.

This switch is used for the system. Use this at the factory default (no.1-3: ON,

no.4: OFF) as it is.

2-2

2.1.2 Operation monitor LEDs

LED

Color

Status

Description

Blinking

Single flash

Approx.200ms

Approx.1000ms

Approx.200ms

Approx.200ms

2.1 Names and Functions of Parts

- Blue

EC RUN

EC ERR

EC L/A

[SD]

CARD

COPY

ERR

ALM

(Note 1): Blinking and single flash of EC RUN are activated as below.

Green

Red

Green

Green

Green

Green

Red

Red

ON Turns on when the power is supplied to the unit.

OFF INIT state

Blinking Pre-Operational state

Single flash Safe-Operational state

ON Operational state

OFF No error

ON EtherCAT communication error

OFF LINK is not established.

Blinking

ON

ON SD memory card is beng accessed.

OFF Other than the above state.

(Reserved for system)

(Reserved for system)

ON Unit error occurs.

Blinking Unit warnig occurs.

OFF Other than the above states.

ON Unit alarm occurs.

OFF Other than the above state.

LINK is established. Data is

sent/received.

LINK is established. Data is not

sent/received.

Indicates the state of the

ESM (EtherCAT State

Machine) of EtherCAT

communication. Refer to

the next page for details.

Indicates errors in

EtherCAT communication.

Indicates the LINK state of

EtherCAT communication.

2-3

Names and Functions of Parts

Init

Pre-Operational

Safe-Operational

Operational

(IP)

(PI)

(SI)

(SP)

(SO) (OS)

(PS)

(OP)

(OI)

(S→M)

(M→S)

2.1.3 ESM (State Transition Diagram)

Reference: Created by us based on "Operating principle of EtherCAT" issued by ETG

ESM state

(Abbr.)

Init

PreOperational

(PreOP)

SafeOperational

(SafeOP)

Operational

(OP)

(Note): S: Slave, M: Master

communication

Send/Receive

Not available Not available Not available

Available Not available Not available

Available Available Not available

Available Available Available

SDO

PDO

communication

PDO

communication

Description

The state that the

communication part is being

initialized, and data cannot

be sent/received using SDO

(Mailbox) and PDO.

The state that data can be

sent/received using SDO

(Mailbox).

The state that data can be

sent/recevied using SDO

(Mailbox) and data can be

sent (from slaves to master)

using PDO.

The state that data cannot be

sent/received using SDO

(Mailbox) and PDO.

What is ESM (EtherCAT State Machine)?

• ESM shows the state of the communication determined as the specifications of EtherCAT.

• The state transition is performed between FP7 MC Unit and Servo Amplifier A5B, an any

settings or programming by users are not required.

Confirmation method

• The state of ESM can be confirmed by the operation monitor LED "EC RUN" on the front

side of FP7 MC Unit.

• When communication is performed, "Operational (OP)" (EC RUN LED) is ON, and the input

relay (X0 (Link established)" of FP7 MC Unit is ON.

2-4

Loading...

Loading...