Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

Safety Precautions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

-To prevent excessive exothermic heat or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured in these

specifications.

-Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock.

-Use the external devices to function the emergency stop and interlock circuit.

-Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generat ion.

-Do not allow foreign matters such as liquid, flammable materials, metals to go into the inside

of the product. It could cause excessive exothermic heat or smoke generation.

-Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

Copyright / Trademarks

-This manual and its contents are copyrighted.

-You may not copy this manual, in whole or part, without written consent of

Industrial Devices SUNX Co., Ltd.

-Windows is a registered trademark of Microsoft Corporation in th e United States and other

countries.

-All other company names and product names are trademarks or registered trademarks of

their respective owners.

Panasonic

PLC_ORG

Page 3

Introduction

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Thank you for buying a Panasonic product. Before you use the product, please carefully read

the installation instructions and the users manual, and understand their contents in detail to

use the product properly.

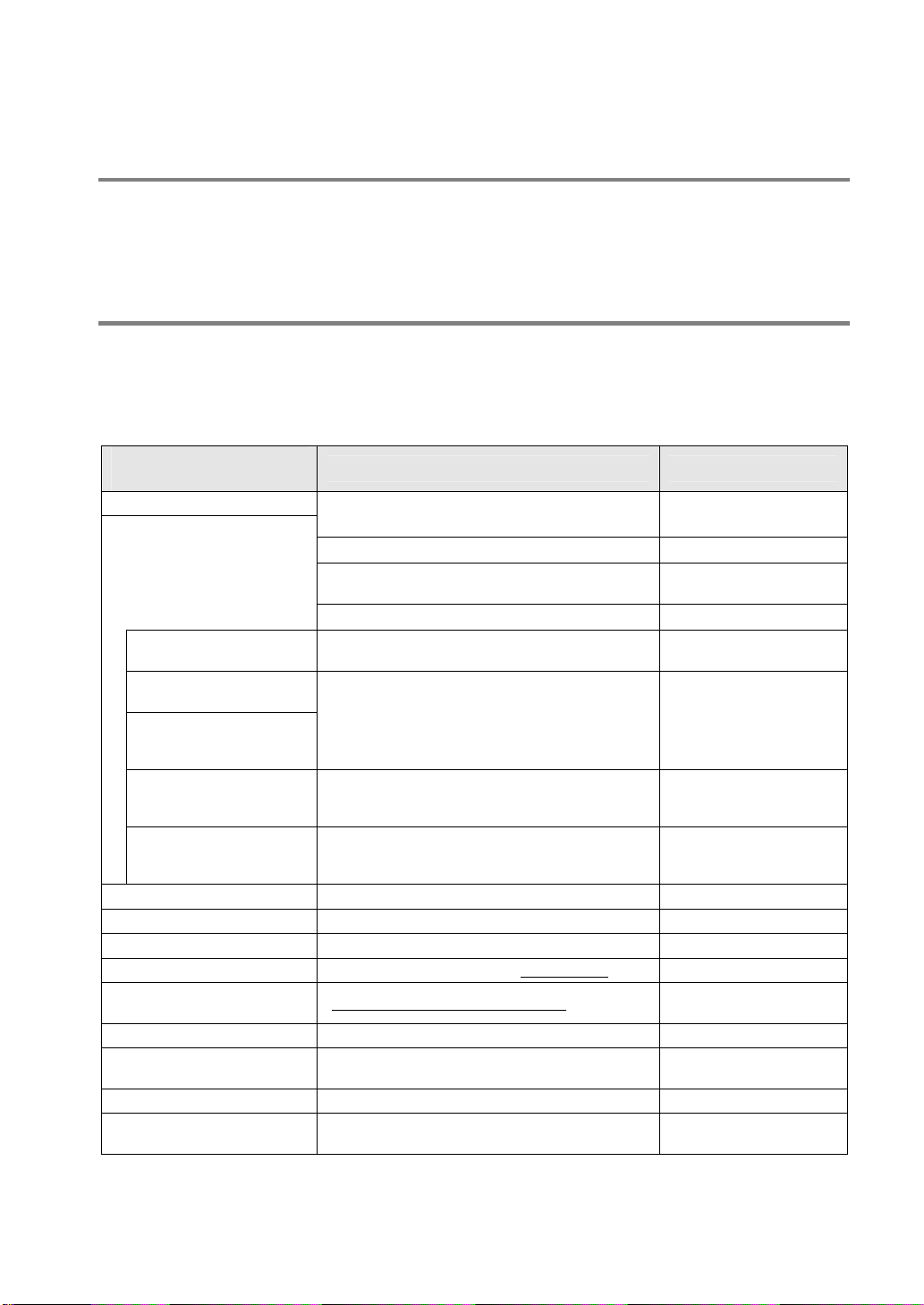

Types of Manual

There are different types of user's manual for the FP7 series, as listed below. Please refer to

a relevant manual for the unit and purpose of your use.

The manuals can be downloaded on our website.

Unit name or purpose of

use

FP7 Power Supply Unit

FP7 CPU Unit

ons for Built-in

Instructi

LAN Port

ons for Built-in

Instructi

COM Port

FP7 Extension Cassette

(Communication)

(RS-232C/RS485 type)

FP7 Extension Cassette

(Communication)

(Ethernet type)

FP7 Extension (Function)

Cassette

Analog Cassette

FP7 Digital Input/Output Unit FP7 Digital Input/Output Unit Users Manual WUME-FP7DIO

FP7 Analog Input Unit FP7 Analog Input Unit Users Manual WUME-FP7AIH

FP7 Analog Output Unit FP7 Analog Output Unit Users Manual WUME-FP7AOH

FP7 High-speed counter Unit FP7 High-speed counter Unit Users Manual WUME-FP7HSC

FP7 Pulse Output Unit FP7 Pulse Output Unit Users Manual

FP7 Positioning Unit FP7 Positioning Unit Users Manual WUME-FP7POSP

FP7 Serial Communication

Unit

PHLS System PHLS System Users Manual WUME-PHLS

Programming Software

FPWIN GR7

Manual name Manual code

FP7 CPU Unit Users Manual (Hardware) WUME-FP7CPUH

FP7 CPU Unit Command Reference Manual WUME-FP7CPUPGR

FP7 CPU Unit Users Manual

(Logging Trace Function)

FP7 CPU Unit Users Manual (Security Function) WUME-FP7CPUSEC

FP7 CPU Unit Users Manual

(LAN Port Communication)

FP7 series Users Manual (SCU communication) WUME-FP7COM

FP7 series Users Manual (Communication

cassette Ethernet type)

FP7 Analog Cassette Users Manual

FP7 series Users Manual (SCU communication) WUME-FP7COM

FPWIN GR7 Introduction Guidance WUME-FPWINGR7

WUME-FP7CPULOG

WUME-FP7LAN

WUME-FP7CCET

WUME-FP7FCA

(Upcoming)

WUME-FP7PG

(Upcoming)

Page 4

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of Contents

1. Functions of Units and Restrictions on Combination.....1-1

1.1 Features and Functions of Units ............................................................ 1-2

1.1.1 Functions of Units....................................................................................1-2

1.1.2 Types of Unit...........................................................................................1-3

1.1.3 Types of Cassette ...................................................................................1-3

1.1.4 Applications that can be Used in Each Port............................................1-3

1.2 Overview of Communication Functions..................................................1-4

1.2.1 PLC Link Functions (MEWNET-W0).......................................................1-4

1.2.2 MEWTOCOL Master/Slave Communication...........................................1-5

1.2.3 MODBUS RTU Master/Slave Communication........................................1-6

1.2.4 General-Purpose Communication...........................................................1-7

1.3 Restrictions on Units Combination.........................................................1-8

1.3.1 Restrictions on the Number of Installed Units.........................................1-8

1.3.2 Restrictions on the Combination of Extension Cassettes (Communication

Cassettes)...............................................................................................1-8

1.3.3 Restrictions on Communication Functions to be Used ...........................1-8

1.3.4 Unit to be Used and Applicable Versions of CPU Unit and FPWIN GR71-8

1.3.5 Restrictions on Consumption Current.....................................................1-9

2. Names and Functions of Parts ..........................................2-1

2.1 Names and Functions of Parts............................................................... 2-2

2.1.1 Communication Port of CPU Unit............................................................2-2

2.1.2 Parts Names and Functions of Serial Communication Unit....................2-3

3. Wiring the COM. Port..........................................................3-1

3.1 Attaching a Communication Cassette....................................................3-2

3.1.1 Attachment Instructions...........................................................................3-2

ii

Page 5

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.2 Wiring of COM Port Terminal Block........................................................3-3

3.2.1 Suitable Wires and Tools........................................................................3-3

3.2.2 Applicable Cable.....................................................................................3-4

3.2.3 Wiring Method.........................................................................................3-5

3.3 Wiring for CPU Unit (GT Power Supply and COM0 Port).......................3-6

3.3.1 Handling of GT Power Supply Terminals................................................3-6

3.3.2 Terminal Layouts and Examples of Wiring .............................................3-6

3.4

Wiring for Communication Cassettes COM.1 to COM.4 Ports...............3-8

3.4.1 Communication Cassette AFP7CCS1 (RS-232C, 1-Channel Insulated

Type).......................................................................................................3-8

3.4.2 Communication Cassette AFP7CCS2 (RS-232C, 2-channel insulated

type) ........................................................................................................3-9

3.4.3 Communication Cassette AFP7CCM1 (RS-422 / RS-485, 1-Channel

Insulated Type) .....................................................................................3-12

3.4.4 Communication Cassette AFP7CCM2 (RS-422 / RS-485, 2-Channel

Insulated Type) .....................................................................................3-15

3.4.5 Communication Cassette AFP7CCS1M1 (RS-232C 1-Channel + RS-485

1-Channel Insulated Type)....................................................................3-19

4. I/O Allocation .......................................................................4-1

4.1 Input/Output Signals Used for Communication.......................................4-2

4.1.1 I/O Allocation of CPU Unit.......................................................................4-2

4.1.2 I/O Allocation of Serial Communication Unit...........................................4-4

4.2 Registration in I/O Map...........................................................................4-6

4.2.1 Settings Using FPWIN GR7 (For CPU with built-in SCU).......................4-6

4.2.2 Settings Using FPWIN GR7 (For Serial Communication Unit) ...............4-6

5. Setting and Confirming Communication Conditions.......5-1

5.1 Setting Applications and Communication Conditions.............................5-2

5.1.1 Applications to be Set for Each Port .......................................................5-2

5.1.2 Conditions to be Set for Each Port..........................................................5-2

iii

Page 6

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.2 Setting Communication Conditions........................................................5-3

5.2.1 Settings Using FPWIN GR7 (For CPU with built-in SCU).......................5-3

5.2.2 Settings Using FPWIN GR7 (For Serial Communication Unit) ...............5-4

6. PLC Link...............................................................................6-1

6.1 Operation of PLC link MEWNET-W0...................................................... 6-2

6.1.1 Overview of PLC Link Operation.............................................................6-2

6.1.2 Operation of Link Relays and Link Registers..........................................6-3

6.2 Configuration Required for PLC Link...................................................... 6-4

6.2.1 Setup Procedure (For CPU with built-in SCU)........................................6-4

6.2.2 Setup Procedure (For Serial Communication Unit).................................6-5

6.2.3 List of Setting Items.................................................................................6-6

6.3 Setting Items for PLC Link...................................................................... 6-7

6.3.1 Station No. Setting ..................................................................................6-7

6.3.2 Max. Station No. Setting..........................................................................6-7

6.3.3 Memory Block Numbers for Link Relays and Link Registers to be Used6-8

6.3.4 Range of Use of Link Relays and Range of Use of Link Registers ........6-8

6.3.5 Starting No. for Link Relay Send Area and Sending Size.......................6-9

6.3.6 Starting No. for Link Register Send Area and Sending Size.................6-10

6.4 PLC Link Response Time..................................................................... 6-12

6.4.1 Response Time of 1 Transmission Cycle..............................................6-12

6.4.2 Response Time When There is a Station Yet to be Added ..................6-14

7. MEWTOCOL Master/Slave Communication...................... 7-1

7.1 Configuration.......................................................................................... 7-2

7.1.1 Setting Communication Conditions.........................................................7-2

7.2 List of MEWTOCOL / MEWTOCOL7 Supporting Commands................ 7-3

7.2.1 List of MEWTOCOL Commands.............................................................7-3

7.2.2 List of MEWTOCOL7 Commands...........................................................7-3

iv

Page 7

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

7.3 MEWTOCOL-COM Master Communication (RECV)..............................7-4

7.3.1 Read Data from an External Device .......................................................7-4

7.3.2 RECV Instruction (When MEWTOCOL-COM is Used)...........................7-7

7.4 MEWTOCOL-COM Master Communication (SEND)..............................7-8

7.4.1 Write Data into an External Device.........................................................7-8

7.4.2 SEND Instruction (When MEWTOCOL-COM is Used).........................7-11

8. MODBUS RTU Master/Slave Communication..................8-1

8.1 Configuration ..........................................................................................8-2

8.1.1 Setting Communication Conditions.........................................................8-2

8.2 List of MODBUS RTU Supported Commands........................................8-3

8.2.1 List of MODBUS Function Codes............................................................8-3

8.3 MODBUS RTU Master Communication (RECV)....................................8-4

8.3.1 Read Data from an External Device .......................................................8-4

8.3.2 RECV Instruction (MODBUS Function Code Specified Type)................8-7

8.3.3 RECV Instruction (MODBUS Function Code Unspecified Type)............8-8

8.4 MODBUS RTU Master Communication (SEND)....................................8-9

8.4.1 Write Data into an External Device.........................................................8-9

8.4.2 SEND Instruction (MODBUS Function Code Specified Type)..............8-12

8.4.3 SEND Instruction (MODBUS Function Code Unspecified Type)..........8-13

9. General-Purpose Communication .....................................9-1

9.1 Operation of General-Purpose Communication......................................9-2

9.1.1 Read Data from an External Device .......................................................9-2

9.1.2 Write Data into an External Device.........................................................9-2

9.2 Configuration ..........................................................................................9-3

9.2.1 Setting Communication Conditions.........................................................9-3

9.3 Sending Operation..................................................................................9-4

9.3.1 Overview of Sending Operation..............................................................9-4

v

Page 8

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

9.3.2 Contents of Sent Data.............................................................................9-6

9.3.3 GPSEND (General-Purpose Communication Sending Instruction)........9-7

9.3.4 Precautions on Sending Data .................................................................9-8

9.4 Receiving Operation...............................................................................9-9

9.4.1 Overview of Receiving Operation............................................................9-9

9.4.2 Contents of Received Data ...................................................................9-12

9.4.3 Precautions on Receiving Data.............................................................9-12

9.4.4 Operations of the "Reception done copy" flag and multiplex reception9-13

9.4.5 GPRECV (General-Purpose Communication Receiving Instruction) ...9-14

9.5 Sending/Receiving Flag Operation....................................................... 9-15

9.5.1 No Header (Start Code), Terminator (End Code) "CR": .......................9-15

9.5.2 Start Code "STX", End Code "ETX":.....................................................9-16

10. Troubleshooting...............................................................10-1

10.1 Self-diagnostic Function....................................................................... 10-2

10.1.1 CPU Unit’s Operation Monitor LED.......................................................10-2

10.1.2 Operation at the Time of Error..............................................................10-2

10.1.3 Serial Communication Unit's Operation Monitor LE D...........................10-3

10.2 What to DO If an Error Occurs (For Each Communication Mode) ...... 10-4

10.2.1 When Using PLC Link Function ............................................................10-4

10.2.2 When Using MEWTOCOL/ MEWTOCOL7/ MODBUS-RTU Function..10-4

10.2.3 When Using General-purpose Communication Function......................10-5

10.3 Checking Status with PMGET Instruction ............................................ 10-6

10.3.1 Specifications of PMGET Instruction.....................................................10-6

10.3.2 List of Communication Parameters.......................................................10-6

10.4 Clearing Errors Using User Programs.................................................. 10-9

10.4.1 Clearing Errors Using User Programs...................................................10-9

vi

Page 9

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

11. Specifications ...................................................................11-1

11.1 Communication Function Specifications...............................................11-2

11.1.1 CPU Unit Communication Specifications..............................................11-2

11.1.2 Extension Cassette Comm unication Specifications..............................11-4

11.2 MEWTOCOL-COM Format...................................................................11-5

11.2.1 MEWTOCOL-COM Command Format .................................................11-5

11.2.2 MEWTOCOL-COM Response Format..................................................11-7

11.3 MEWTOCOL7-COM Format.................................................................11-9

11.3.1 MEWTOCOL7-COM Command Format ...............................................11-9

11.3.2 MEWTOCOL7 Response Format.......................................................11-11

11.4 MODBUS RTU Format .......................................................................11-13

11.4.1 MODBUS RTU Command Format......................................................11-13

11.4.2 MODBUS RTU Response Format ......................................................11-14

vii

Page 10

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

viii

Page 11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1

Functions of Units and

Restrictions on Combination

Page 12

Functions of Units and Restrictions on Combination

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.1 Features and Functions of Units

1.1.1 Functions of Units

CPU Unit

One

communication

cassette can be

attached.

COM.0 port is

equipped as standard.

(For 3-wire RS-232C)

Serial Communication Unit

Two

communication

cassettes can be

Removable serial communication cassettes are used.

Selectable from five communication cassettes in conformity with communication standards

of RS-232C, RS-422 and RS-485. (Sold separately)

One communication cassette can be attached to the CPU unit, and two communication

cassettes to the serial communication unit.

The CPU unit includes a COM.0 port as standard equipment.

The CPU unit includes a RS-232C port (3-wire type) for the connection with a programmable

display and a power supply as standard equipment.

Four communication modes are available.

The PC link, MEWTOCOL, MODBUS RTU and general-purpose communication modes are

provided, and many serial communication devices can be connected by the combination of

communication cassettes.

1-2

Page 13

1.1 Features and Functions of Units

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

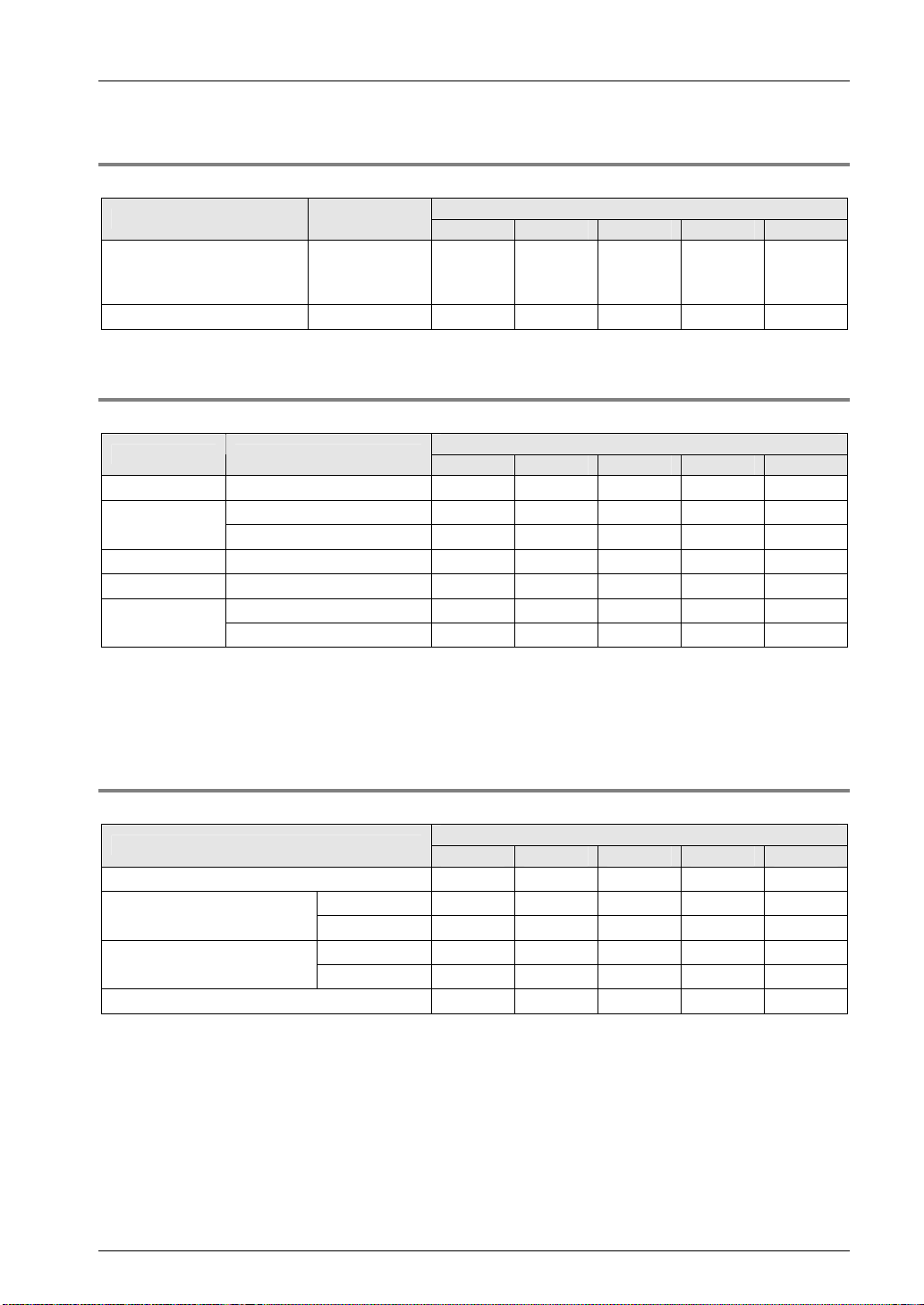

1.1.2 Types of Unit

Types of unit that can perform serial communication

Name Model no.

AFP7CPS4E

CPU Unit

Serial Communication Unit AFP7NSC

(Note 1) The COM.0 port equipped in the CPU unit is a terminal block especially for RS-232C (3-wire type).

AFP7CPS3E

AFP7CPS3

Communication ports that can be allocated

COM.0 COM.1 COM.2 COM.3 COM.4

● ● ●

● ● ● ●

1.1.3 Types of Cassette

Types of communication cassette

Model no. Communication interface

AFP7CCS1 1-channel RS-232C

AFP7CCS2

AFP7CCM1 1-channel RS-422 / RS-485

AFP7CCM2 2-channel RS-422 / RS-485

AFP7CCS1M1

(Note 1) For AFP7CCS2, select and use either 3-wire 2-channel RS-232C or 5-wire 1-channel RS-232C. Switching

should be performed using a switch on the Communication Cassette.

(Note 2) For AFP7CCM1 and AFP7CCM2, select and use either RS-422 or RS-485. Switching should be performed

using a switch on the Communication Cassette.

(Note 3) For AFP7CCS1M1, both 1-channel RS-485 and 3-wire 1-channel RS-232C can be used.

3-wire 2-channel RS-232C

5-wire 1-channel RS-232C

1-channel RS-485

3-wire 1-channel RS-232C

Communication ports that can be allocated

COM.0 COM.1 COM.2 COM.3 COM.4

● ●

● ● ● ●

● ●

● ●

● ● ● ●

● ●

● ●

1.1.4 Applications that can be Used in E ach Port

Available functions for each communication port

Communication function to be used

PLC link

MEWTOCOL7-COM (Note 1)

MEWTOCOL-COM

MODBUS-RTU

General-purpose communication

(Note 1) In MEWTOCOL7-COM, there is no master communication function.

Master

Slave

Master

Slave

Communication ports that can be allocated

COM.0 COM.1 COM.2 COM.3 COM.4

●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ●

1-3

Page 14

Functions of Units and Restrictions on Combination

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.2 Overview of Communication Functions

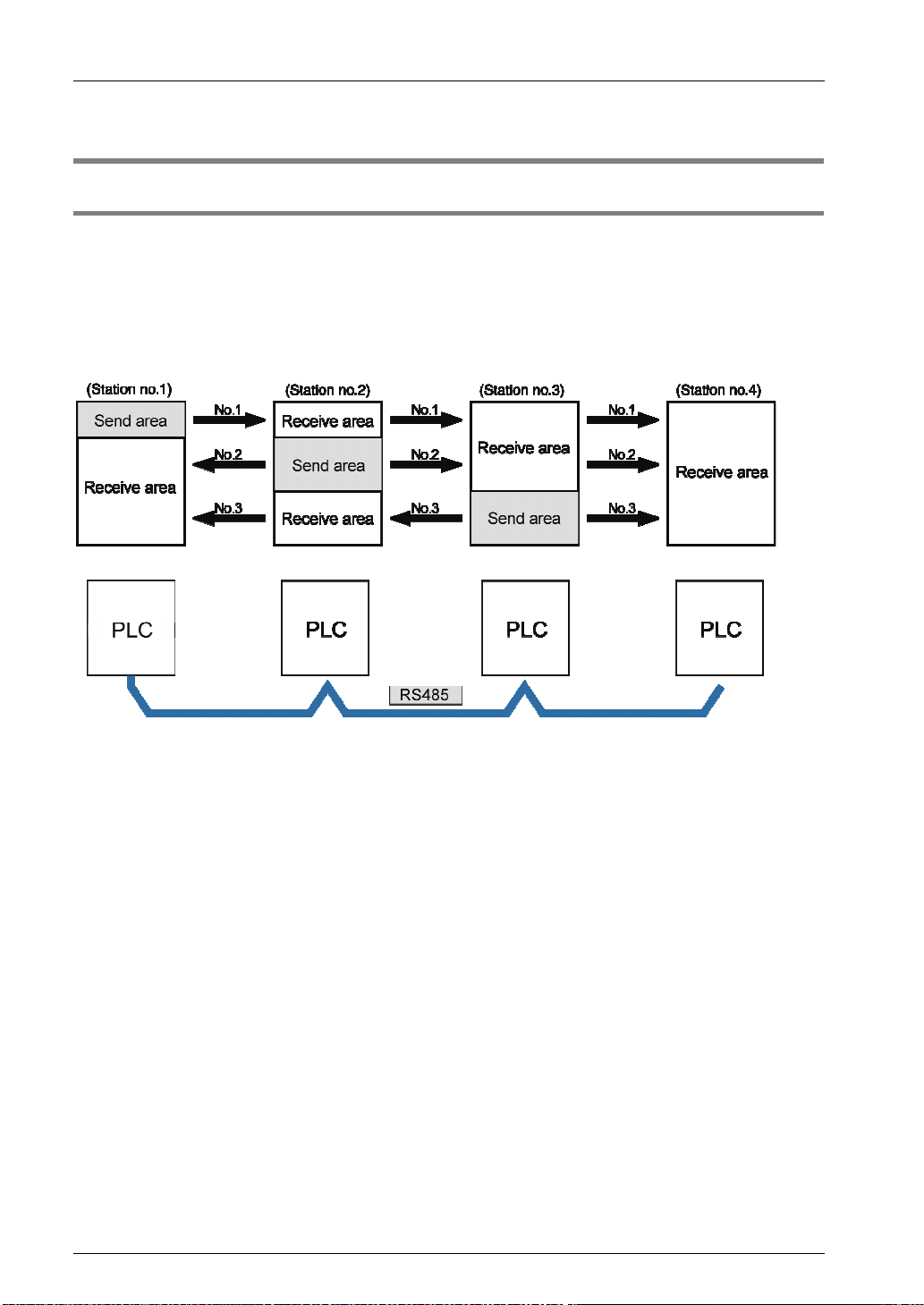

1.2.1 PLC Link Functions (MEWNET-W0)

Overview of function

A system can be configured for the PLC link (MEWNET-W0).

Exclusive internal relays “link relays (L)” and data registers “link registers (LD)” are shared

between the connected PLCs.

Among up to 16 PLCs, data can be exchanged with 1,008 link relay points and 128 link

register words.

Applications of PLC Link Functions (MEWNET-W0)

Among our FP series PLC, it can be used for link functions with the following models. It is also

capable of 1:1 communication via RS-232C port.

FP-X0 (L40MR / L60MR)

FP0R (RS485 type)

FPΣ (Using Communication cassette RS-485 type)

FP-X (Using Communication cassette RS-485 type)

FP2 Multi Communication Unit (Using Communication cassette RS-485 type)

1-4

Page 15

1.2 Overview of Communication Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

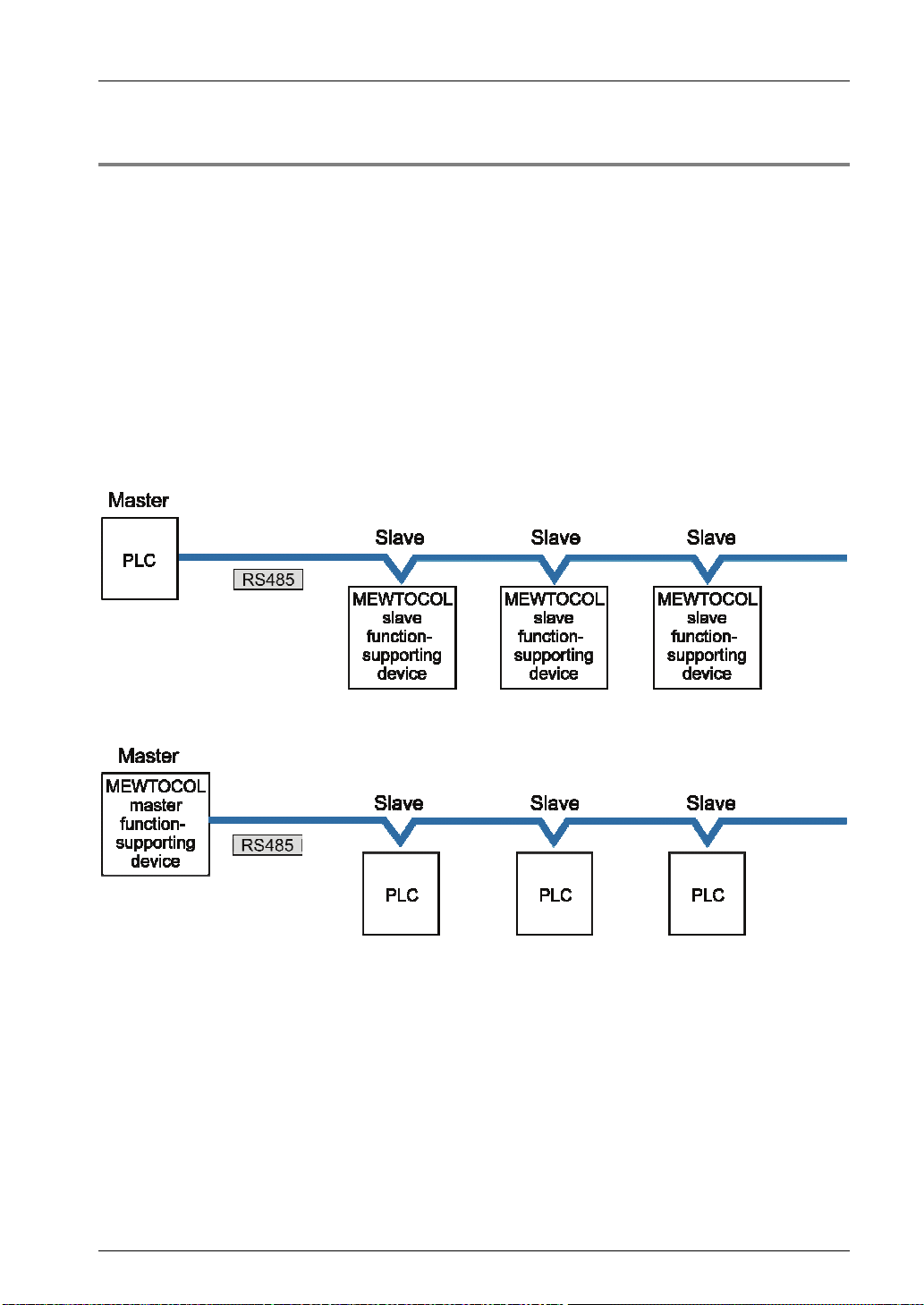

1.2.2 MEWTOCOL Master/Slave Communication

Overview of function

Execute communication using MEWTOCOL-COM, a communication protocol used by our PLC.

In master communication, PLC executes communication by sending commands to devices that

support MEWTOCOL, and receiving responses. Me ssages in accordance wit h the protocol are

automatically generated by PLC. In the user program, read ing and writin g can be done simply by

specifying the station no. an d memory a ddress an d executi ng SE ND/RECV instru ction s.

Slave communication is performed when the computer or display connected to PLC has th e

sending right, and sends commands, and PLC returns responses. In slave communication, PLC

responds automatically, so no program concerning com mu nic ation i s necessary on the P LC side.

The data size that can be sent or received in a single communication is up to 507 words for

register transmission (up to 1,014 words for MEWTOCOL7-COM) and 1 bit for bit transmission.

Master function

Slave function

Examples of applications of MEWTOCOL master communication

This is used for connection with a device that supports our PLC's protocol MEWTOCO L.

Programmable controller FP series

Displacement sensor HL series

Eco power meter KW series

Examples of applications of MEWTOCOL slave communication

This is used for connection with a device that supports our PLC's protocol MEWT OCOL-COM

master communication.

Programmable displays made by various manufacturers

1-5

Page 16

Functions of Units and Restrictions on Combination

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

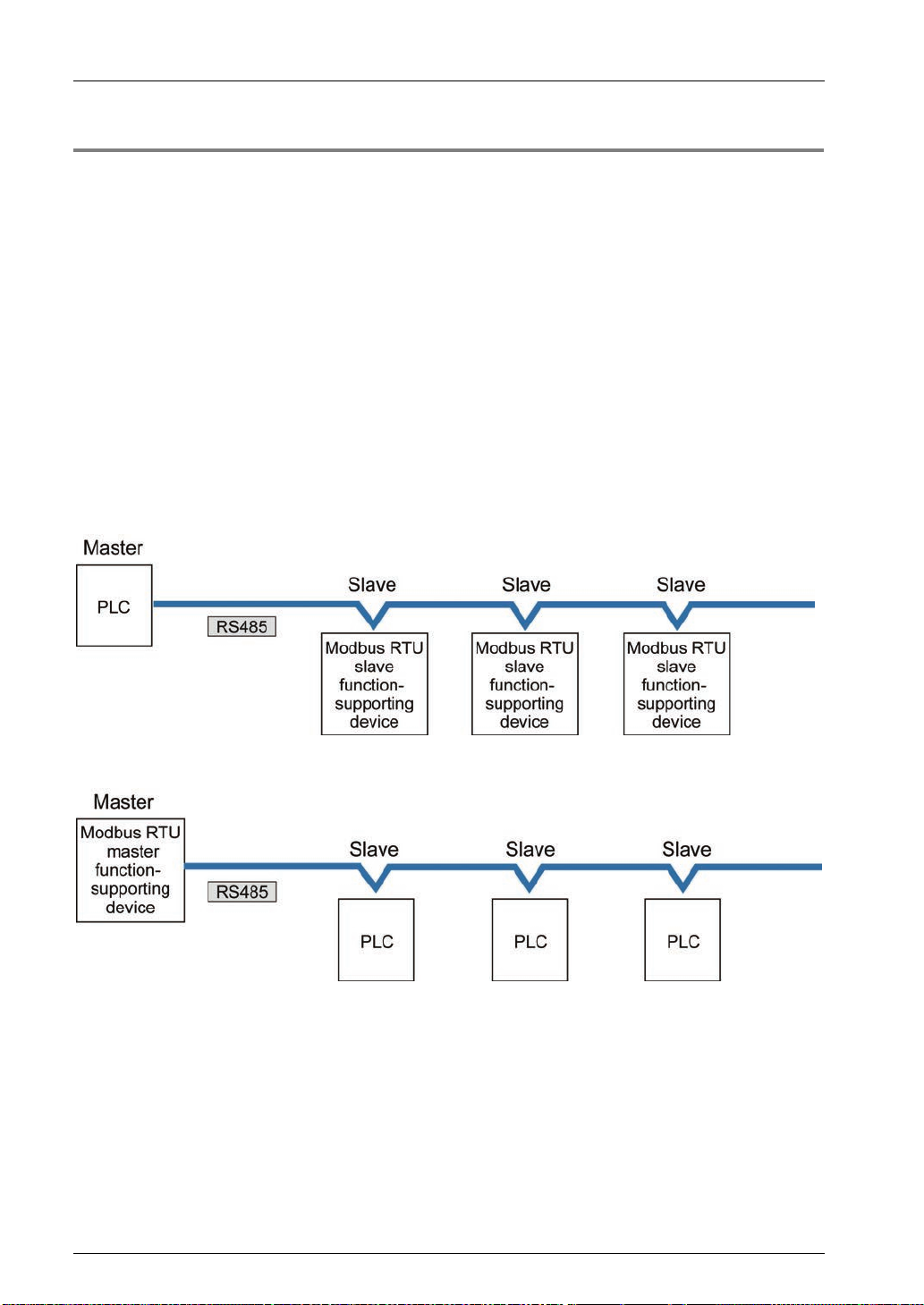

1.2.3 MODBUS RTU Master/Slave Communication

Overview of function

This is used for communicating with other devices that support the MODBUS RTU protocol.

In master communication, communication is performed when the master unit sends

instructions (command messages) to slave units and the slave unit returns responses

(response messages) according to t he instructions. Messages in accordance with the

protocol are automatically generated by PLC. In the user program, reading and writing can

be done simply by specifying the station no. and memory address and executing

SEND/RECV instructions.

Slave communication is performed when the higher device connected to PLC has the

sending right, and sends commands, and PLC returns responses. In slave communication,

PLC responds automatically, so no program concerning comm unication is necessary on the

PLC side.

The data size that can be sent or received in a single communication is up to 127 words for

register transmission and 2,040 bit for bit transmission.

Master function

Slave function

Examples of applications of MODBUS-RTU master communication

This is used for connection with a device that supports the MODBUS-RTU protocol.

Thermoregulator KT series

Devices from other manufacturers that support MODBUS-RTU

Examples of applications of MODBUS-RTU slave communication

This is used when access is made from the higher device using MODBUS-RTU commands.

1-6

Page 17

1.2 Overview of Communication Functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

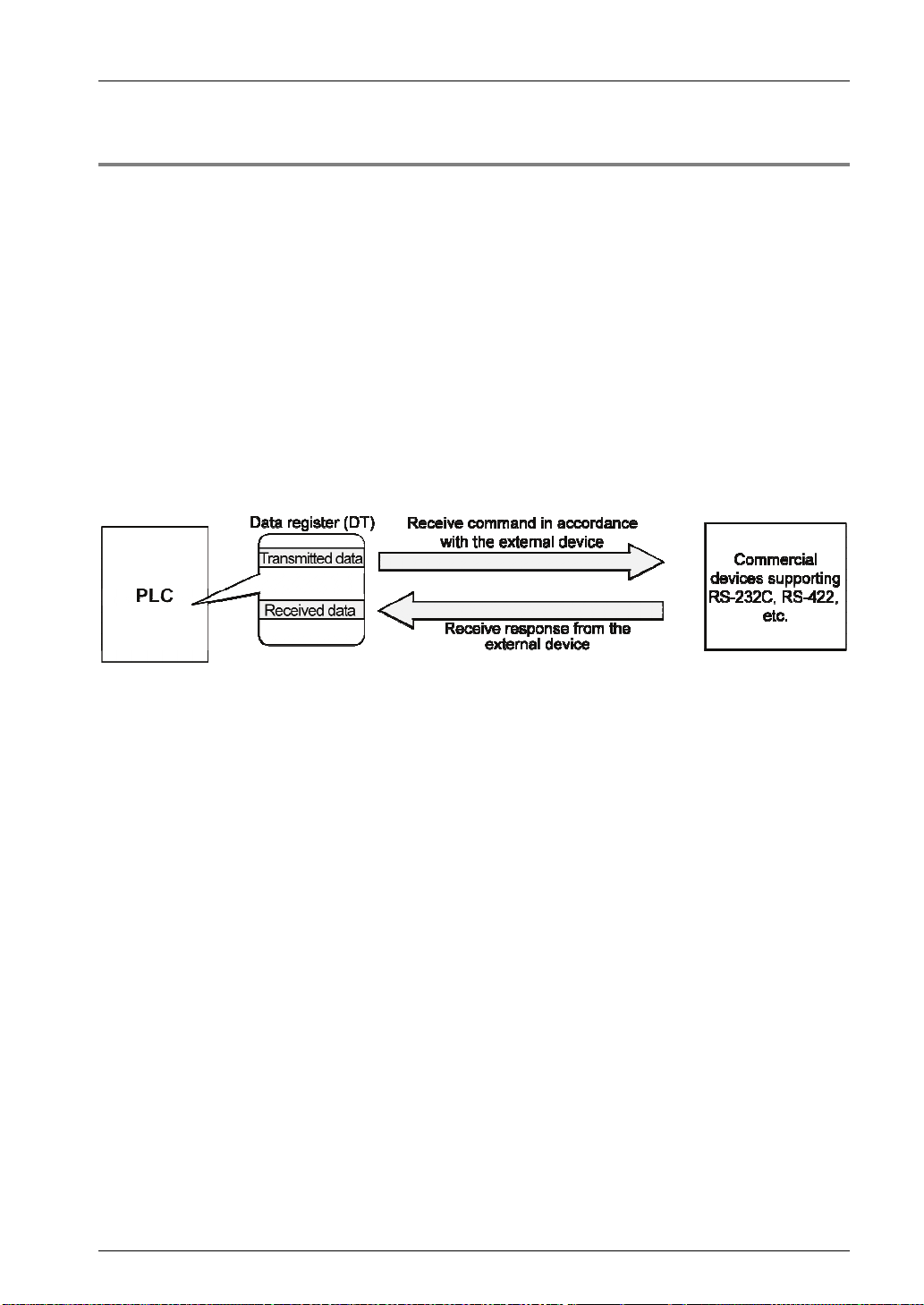

1.2.4 General-Purpose Communication

Overview of function

General-purpose communication is used when PLC executes communication in accordan ce

with the protocol of the partner device.

Formulation and sending of command messages to the partner device, and reception

processing of responses from the partner device, are performed by the user program.

Sending/receiving of data with an external device is executed via given operation memory

(e.g. data register).

Data are sent by converting commands in accordance with the partner device as strings into

ASCII text, setting them into a given data register, and executing GPSEND instruction.

Response received from the partner device is temporarily saved in the buffer. Based on the

reception done flag, GPRECV instruction is executed. The ASCII strings can be converted

into numerical data, etc. as necessary, by the user program.

The data size that can be sent or received in a single communication is up to 4,096 bytes.

(including control codes)

Applications of general-purpose communication

This is used for connection with devices made by differing manufacturers that have dedicated

communication protocols.

1-7

Page 18

Functions of Units and Restrictions on Combination

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.3 Restrictions on Units C ombination

1.3.1 Restrictions on the Number of Installed Units

There are following restrictions depending on units to be used.

Unit type Number of installed units Remarks

Serial Communication Unit Max. 8 units

1.3.2 Restrictions on the Combination of Extension Cassettes

(Communication Cassettes)

One communication cassette can be attached to the CPU unit, and two communication

cassettes to the serial communication unit.

The FP7 communication cassette (Ethernet type) can be attached to the CPU only. It cannot

be attached to the serial communication unit (SCU).

1.3.3 Restrictions on Communication Functions to be Used

There are the following restrictions on functions to be used when using the SCU or ET-LAN

that is built in the CPU unit, or the serial communication unit (SCU).

Function to be used Restrictions

Up to two communication ports can be used. For using two ports, allocate

PLC link function

MEWTOCOL-COM master

MODBUS-RTU master

MEWTOCOL-COM slave

MEWTOCOL7-COM slave

MODBUS-RTU slave

General-purpose

communication

different link areas to them.

CPU with built-in SCU (COM.1 port)

Serial communication unit (COM.1 port)

A maximum of 16 communication ports and the number of connections in

combination can be used simultaneously.

CPU with built-in SCU (COM.1 port to COM. 2 port)

Serial communication unit (COM.1 port to COM.4 port)

CPU with built-in ET-LAN (User connections 1 to 16)

A maximum of 15 communication ports and the number of connections in

combination can be used simultaneously.

CPU with built-in SCU (COM.1 port to COM. 2 port)

Serial communication unit (COM.1 port to COM.4 port)

CPU with built-in ET-LAN

(System connections 1 to 4 / User connections 1 to 16)

There is no restriction.

1.3.4 Unit to be Used and Applicable Versions o f CPU Unit and FPWIN GR 7

For using the unit, the following versions of CPU unit and FPWINGR7 are required.

Unit type

FP7 Serial Communication Unit Ver.1.2 or later Ver.1.3 or later

Applicable versions

CPU unit FPWINGR7

Remarks

1-8

Page 19

1.3 Restrictions on Units Combination

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.3.5 Restrictions on Consumption Current

Including other units, the consumption current should be within the allowable capacity of a

power supply unit.

Unit's consumption current table (24 V)

Product name Model number

196k steps, Built-in Ethernet

function

CPU Unit

When attaching

Extension Cassette

(Communication

Cassette) to CPU

Unit

(Note 1) (Note 2)

Serial Communication Unit AFP7NSC 50 mA or less

When attaching

Extension Cassette

(Communication

Cassette) to Serial

Communication Unit

(Note 1) (Note 2)

(Note 1) The consumption currents listed in the Extension Cassette column indicate the increased amount of the

CPU's consumption current which increases when each extension cassette is added.

(Note 2) The consumption current of extension cassette (communication cassette) varies according to the unit to

which the cassette is attached (CPU or serial communication unit).

120k steps, Built-in Ethernet

function

120k steps, No Ethernet function AFP7CPS3 200 mA or less

RS-232C x 1ch AFP7CCS1 35 mA or less

RS-232C x 2ch AFP7CCS2 60 mA or less

RS-422 / 485 x 1ch AFP7CCM1 60 mA or less

RS-422 / 485 x 2h AFP7CCM2 90 mA or less

RS-232C x 1ch

RS-422 / 485 x 1ch

Ethernet AFP7CCET 35 mA or less

RS-232C x 1ch AFP7CCS1 20 mA or less

RS-232C x 2ch AFP7CCS2 40 mA or less

RS-422 / 485 x 1ch AFP7CCM1 30 mA or less

RS-422 / 485 x 2h AFP7CCM2 60 mA or less

RS-232C x 1ch

RS-422 / 485 x 1ch

AFP7CPS4E 200 mA or less

AFP7CPS3E 200 mA or less

AFP7CCS1M1 70 mA or less

AFP7CCS1M1 50 mA or less

Consumption

current (mA)

REFERENCE

For information on the restrictions on the combination of units, also refer to FP7 CPU

Unit User's Manual (Hardware).

1-9

Page 20

Functions of Units and Restrictions on Combination

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1-10

Page 21

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2

Names and Functions of

Parts

Page 22

Names and Functions of Parts

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

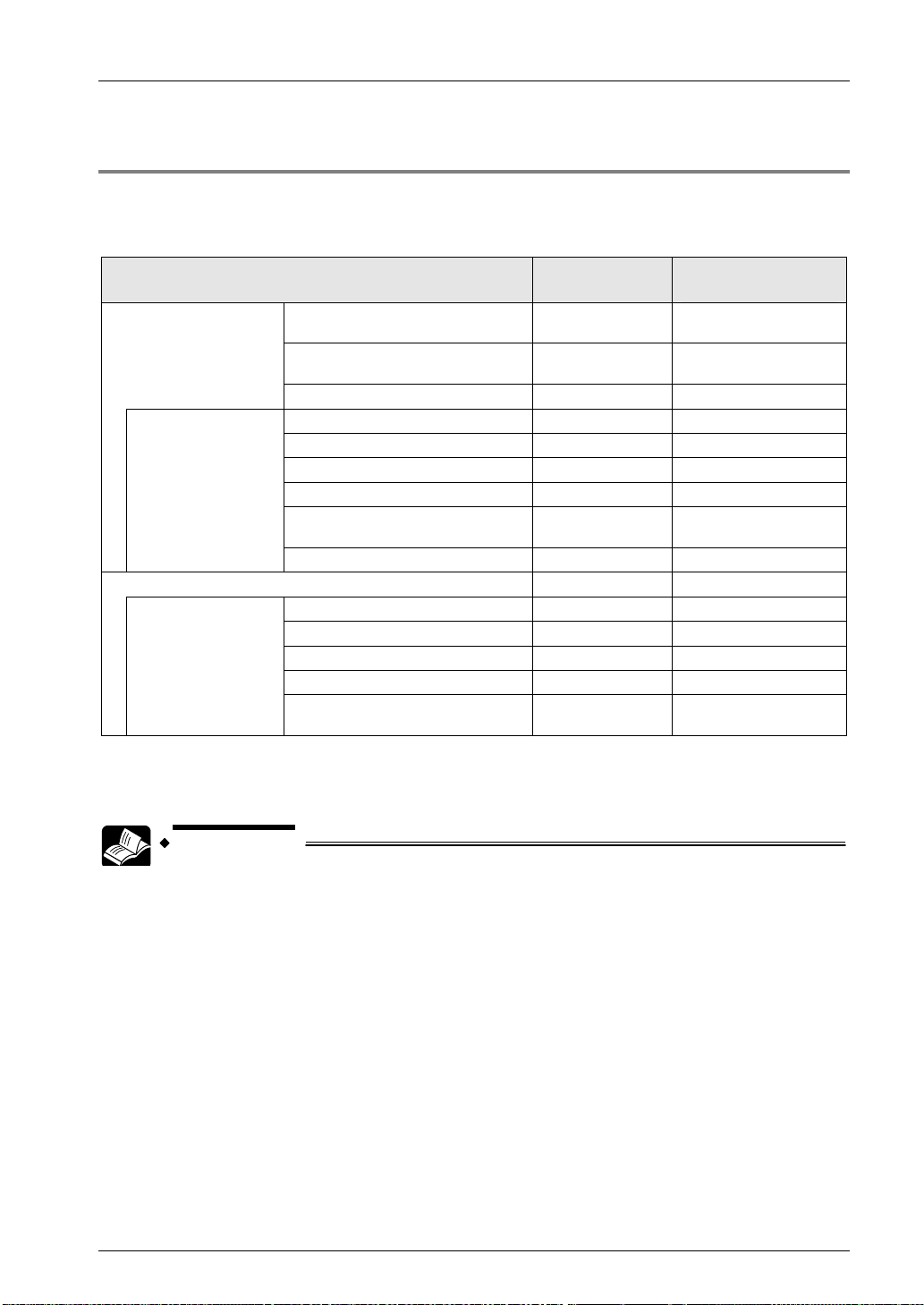

2.1 Names and Functions of Parts

2.1.1 Communication Port of CPU Unit

(In the above figure, a communication cassette is attached to the COM.1 and COM.2 ports.)

Names and Functions of Parts

(1) COM.1 and COM.2 ports

Attach a separately sold communication cassette to use these ports. A blank cover is fitted

when the unit is shipped.

(2) COM.0 port, GT power supply terminals

This is an RS-232C port that is equipped to a standard model of CPU unit. It is equipped with

power supply terminals (5 VDC and 24 VDC) to which a GT series programmable display can

be connected.

(3) LAN port

This is equipped to a standard model of CPU unit. This is used for connection to Ethernet.

(4) USB port

This is equipped to a standard model of CPU unit. This is used for connecting tool software.

REFERENCE

For details of the communication method using LAN port, refer to FP7 CPU

Unit User's Manual (LAN port communication).

For details of the communication using Communication cassette (Ethernet

type) AFP7CCET, refer to FP7 series User's Manual (Communication

cassette Ethernet type).

2-2

Page 23

2.1 Names and Functions of Parts

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

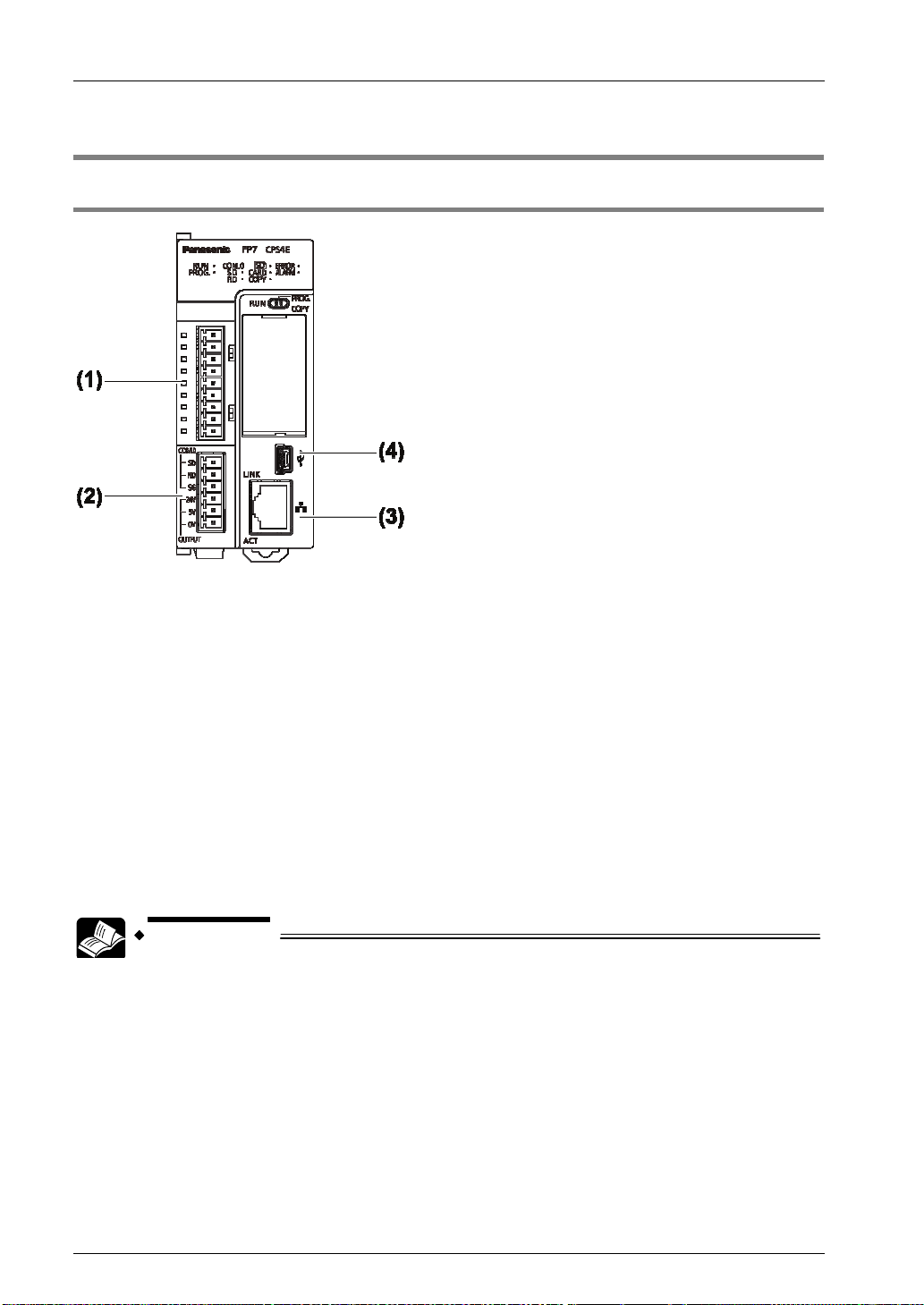

2.1.2 Parts Names and Functions of Serial Communication Unit

(In the above figure, two communication cassettes are attached.)

Names and Functions of Parts

(1) Operation monitor LEDs

Display

- Blue Lights when the power supply of the CPU unit is on.

ERROR Red

ALARM Red Lights when an error occurs in hardware.

LED

color

Description

Lights when the configuration setting is incorrect, or a communication error occurs.

Flashes when the factory acceptance test switch is on. (Flashing cycle: 100 ms)

Flashes when an extension cassette that cannot be used is installed. (Flashing

cycle: 500 ms)

(2) COM.1 and COM.2 ports

Attach a separately sold communication cassette to use these ports. No blank cover is fitted

when the unit is shipped.

(3) COM.3 and COM.4 ports

Attach a separately sold communication cassette to use these ports. A blank cover is fitted

when the unit is shipped.

(4) DIN hook

This is used to fix the unit to a DIN rail.

(5) Unit connector

This is used to connect the internal circuit of an I/O unit or advanced unit.

(6) Factory acceptance test switch

This is used for factory acceptance test. Do not turn it on.

2-3

Page 24

Names and Functions of Parts

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2-4

Page 25

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3

Wiring the COM. Port

Page 26

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.1 Attaching a Communication Cassette

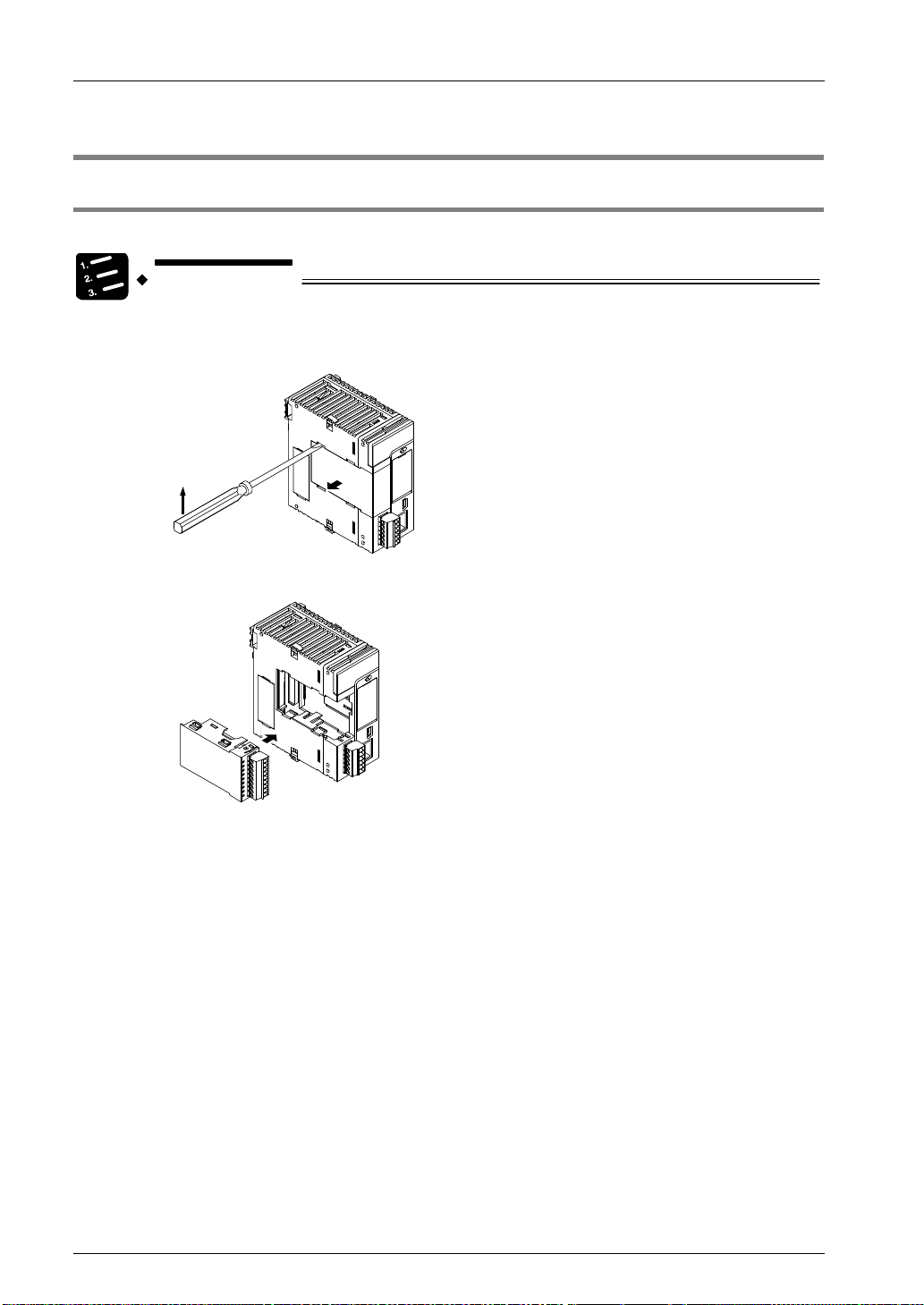

3.1.1 Attachment Instructions

When an optional Communication Cassette is to be used, attach it in the following procedures.

PROCEDURE

1. Using a flathead screwdriver, remove the cover on the side of the CPU unit.

You will find four toggles.

2. Attach a desired Communication Cassette.

The illustration is the CPU unit. As for the Serial Communication Unit, the

attachment procedure is the same.

3-2

Page 27

3.2 Wiring of COM Port Terminal Block

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

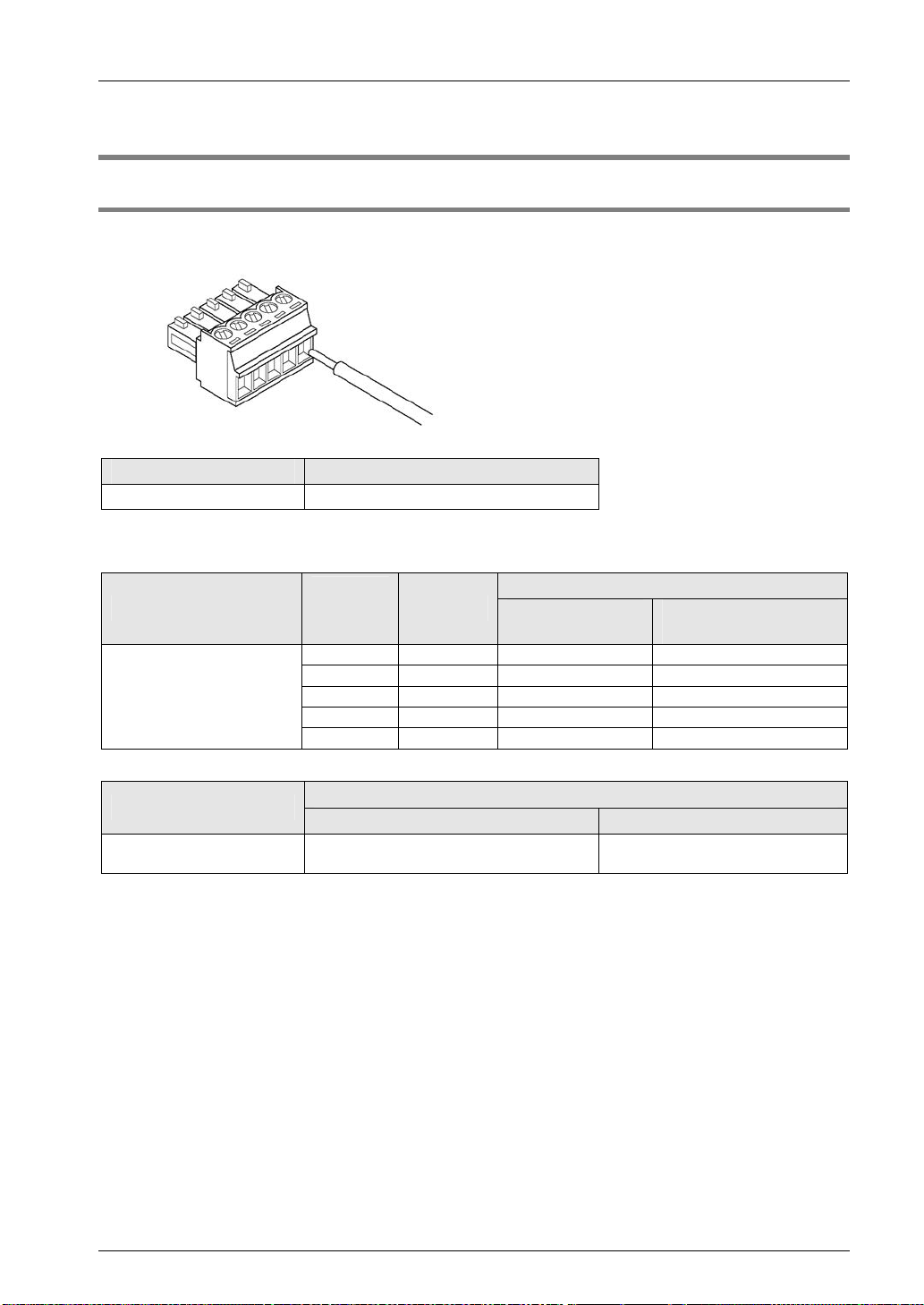

3.2 Wiring of COM Port Terminal Blo ck

3.2.1 Suitable Wires and Tools

A screw-down connection type for terminal block is used for the communication port. Use the

following items for wiring.

Suitable wires (strand wire)

Size Nominal cross-sectional area

AWG #28 to 16 0.08 mm2 to 1.25 mm2

Pole terminal with a compatible insulation sleeve

If a pole terminal is being used, the following models should be used.

Part no.

With insulating

sleeve

Without insulating

sleeve

Manufacturer

Phoenix Contact

Crosssectional

area

0.25 mm2 AWG #24 AI 0.25-6 BU A 0.25-7

0.34 mm2 AWG #22 AI 0.34-6 TQ A 0.34-7

0.50 mm2 AWG #20 AI 0.5-6 WH A 0.5-6

0.75 mm2 AWG #18 AI 0.75-6 GY A 0.75-6

1.00 mm

Size

2

AWG #18 - A 1-6

Pressure welding tool for pole terminals

Manufacturer

Phoenix Contact

Model no.

Part no. Product no.

CRIMPFOX 6 1212034

Screwdriver for terminal block

To tighten the terminals, use a screwdriver by Phoenix Contact (model No. SZS 0.4 x 2.5,

product No. 1205037, blade size 0.4 x 2.5) or our screwdriver (part No. AFP0806). The

tightening torque should be 0.22 to 0.25 N·m.

3-3

Page 28

Wiring the COM. Port

-

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

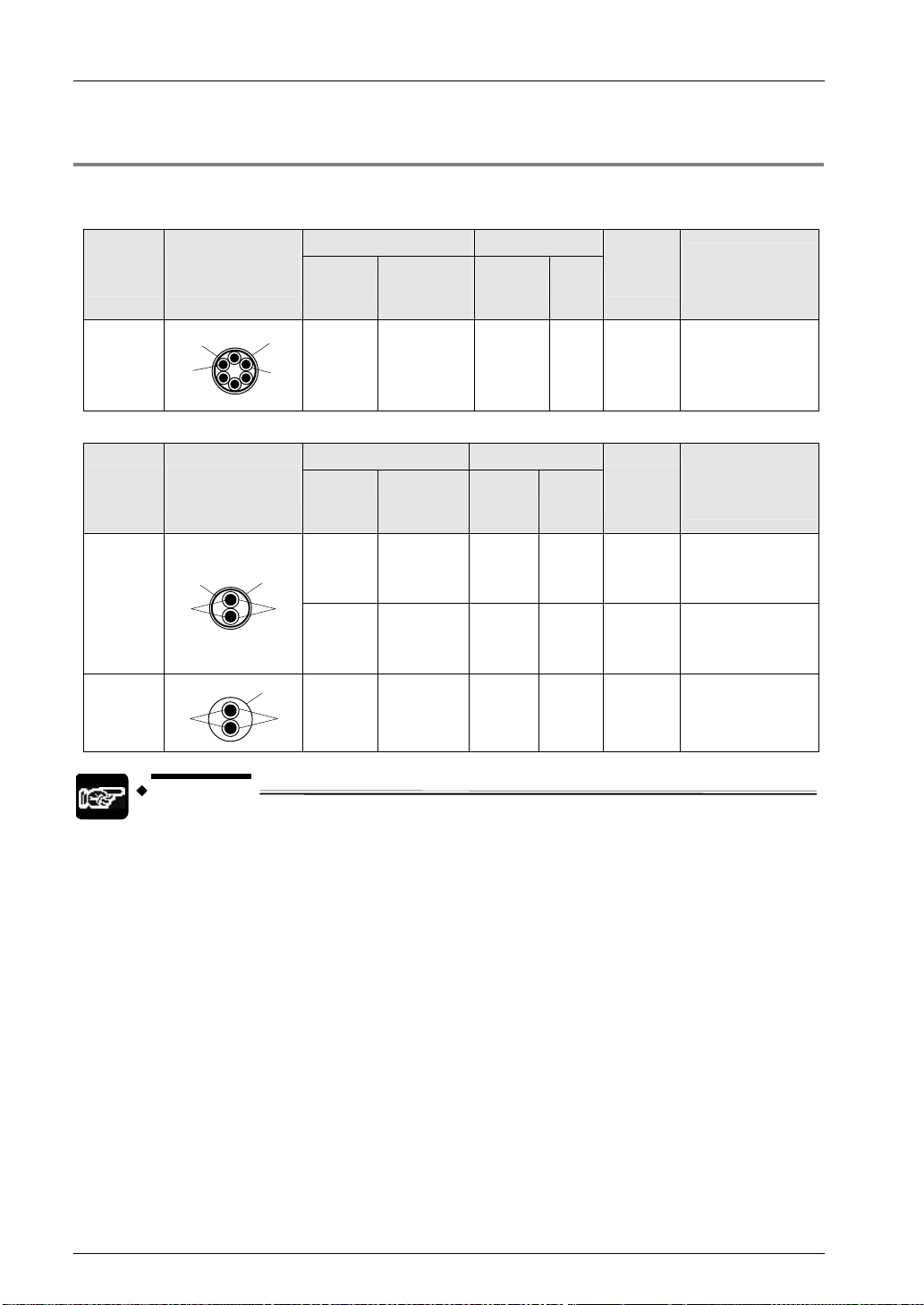

3.2.2 Applicable Cable

Use a cable as prescribed below.

Suitable wires (strand wire): For RS-232C / RS-422 communication

Conductor Insulator

Classifi-

cation

Cross-sectional

view

Size

Resistance

value

(at 20°C)

Material

Thick-

ness

Cable

diam.

Sample

appropriate

cable

Shielded

multi-core

cable

Shield

Conductor

Cover

Insulator

0.3 mm2

(AWG22)

or larger

Max.

58.8 Ω/km

Vinyl

chloride

Max.

0.3 mm

Suitable wires (strand wire): For RS-485 communication

Conductor Insulator

Classifi0c

ation

Cross-sectional

view

Size

Resistance

value

Material

Thick-

ness

(at 20°C)

2

Max.

16.8 Ω/km

Max.

33.4 Ω/km

2

Max.

25.1 Ω/km

Polyethylene

Polyethylene

Polychlorinated

biphenyl

Max.

0.5 mm

Max.

0.5 mm

Max.

0.6 mm

Shielded

twisted

pair

VCTF

Shield

Conductor

Conductor

NOTES

1.25 mm

(AWG16)

Cover

or larger

Insulator

0.5 mm2

(AWG20)

or larger

Cover

0.75 mm

(AWG18)

Insu

lator

or larger

Use shielded twisted pair cables.

Use only one type of transmission cable. Do not mix more than 1 type.

Twisted pair cables are recommended in noisy environments.

When using shielded cable with crossover wiring for the RS-485

transmission line, grounded one end.

Approx.

6.6 mm

Cable

diam.

Approx.

8.5 mm

Approx.

7.8 mm

Approx.

6.6 mm

Onamba Co. Ltd.

ONB-D6 × 0.3 mm

2

Sample

appropriate

cable

Hitachi Cable, Ltd.

KPEV-S1.25 mm

1P

Belden Inc., 9860

Hitachi Cable, Ltd.

KPEV-S0.5 mm

1P

Belden Inc., 9207

VCTF0.75 mm2 × 2C

(JIS)

2

×

2

×

3-4

Page 29

3.2 Wiring of COM Port Terminal Block

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

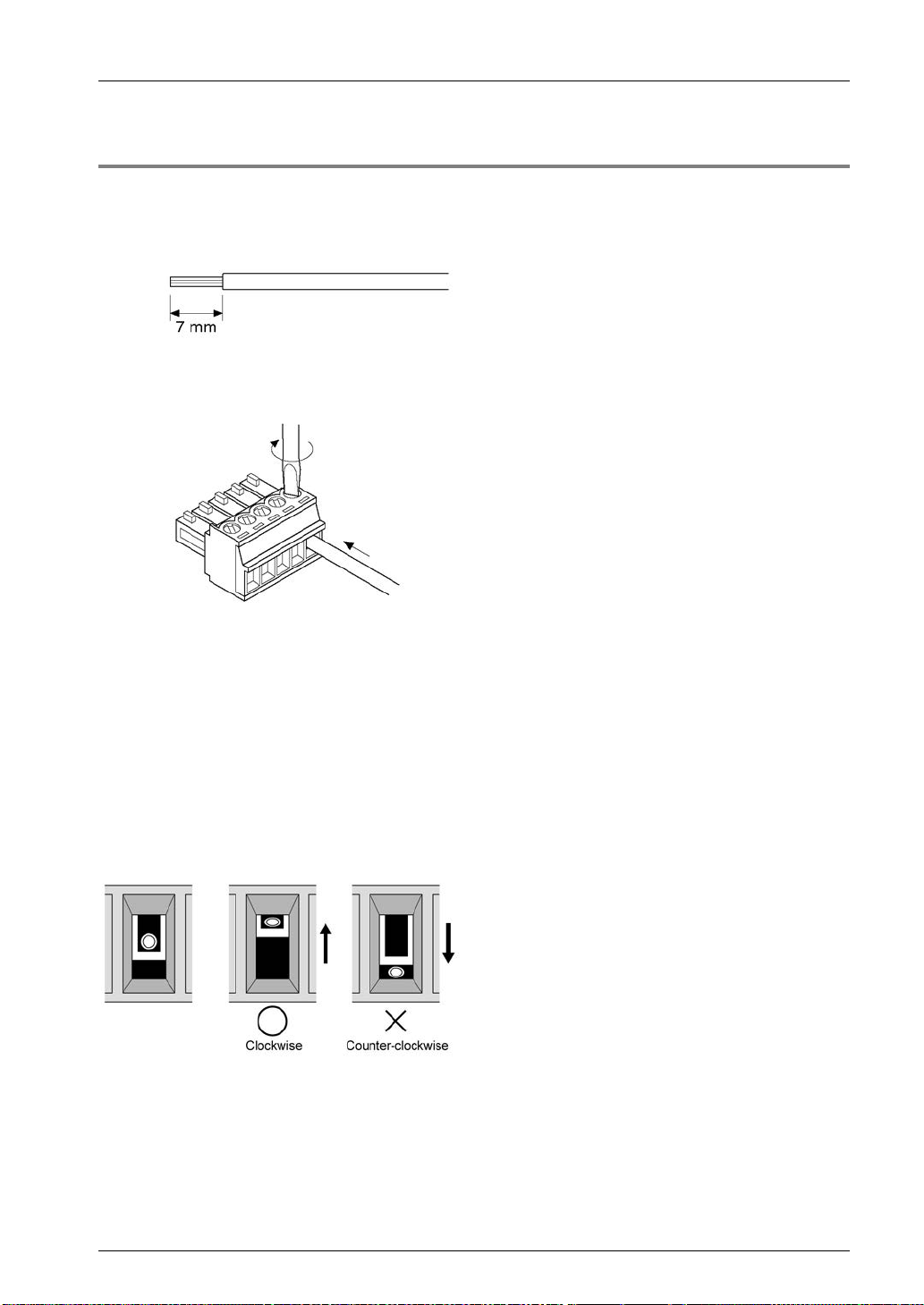

3.2.3 Wiring Method

Wiring method

(1) Remove a portion of the wire’s insulation.

(2) Insert wire into terminal hole until it stops. Tighten screw clockwise to fix wire in place.

(The tightening torque: 0.22 to 0.25 N·m (2.3 to 2.5 kgf·cm))

Precautions on wiring

The following precautions should be observed, to avoid broken or disconnected wire s.

When removing the wire’s insulation, be careful not to scratch the core wire.

Do not twist the wires to connect them.

Do not solder the wires to connect them. The solder may break due to vibration.

After wiring, make sure stress is not applied to the wire.

In the terminal block socket construction, if the wire is fastened upon counter-clockwise

rotation of the screw, the connection is faulty. Disconnect the wire, check the terminal hole,

and then re-connect the wire.

3-5

Page 30

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.3 Wiring for CPU Unit (GT Power Supply and COM0 Port)

3.3.1 Handling of GT Power Supply Terminals

GT power supply terminals can be used as power supply terminals for the GT series of our

programmable displays.

In accordance with the model to be used, use either 5V DC or 24V DC.

NOTES

GT power supply terminals (5V DC / 24V DC) are design exclusively for the

GT series of our programmable displays. Do not use the terminals for other

devices.

GT power supply terminals and COM0 port (RS-232C) are insulated inside.

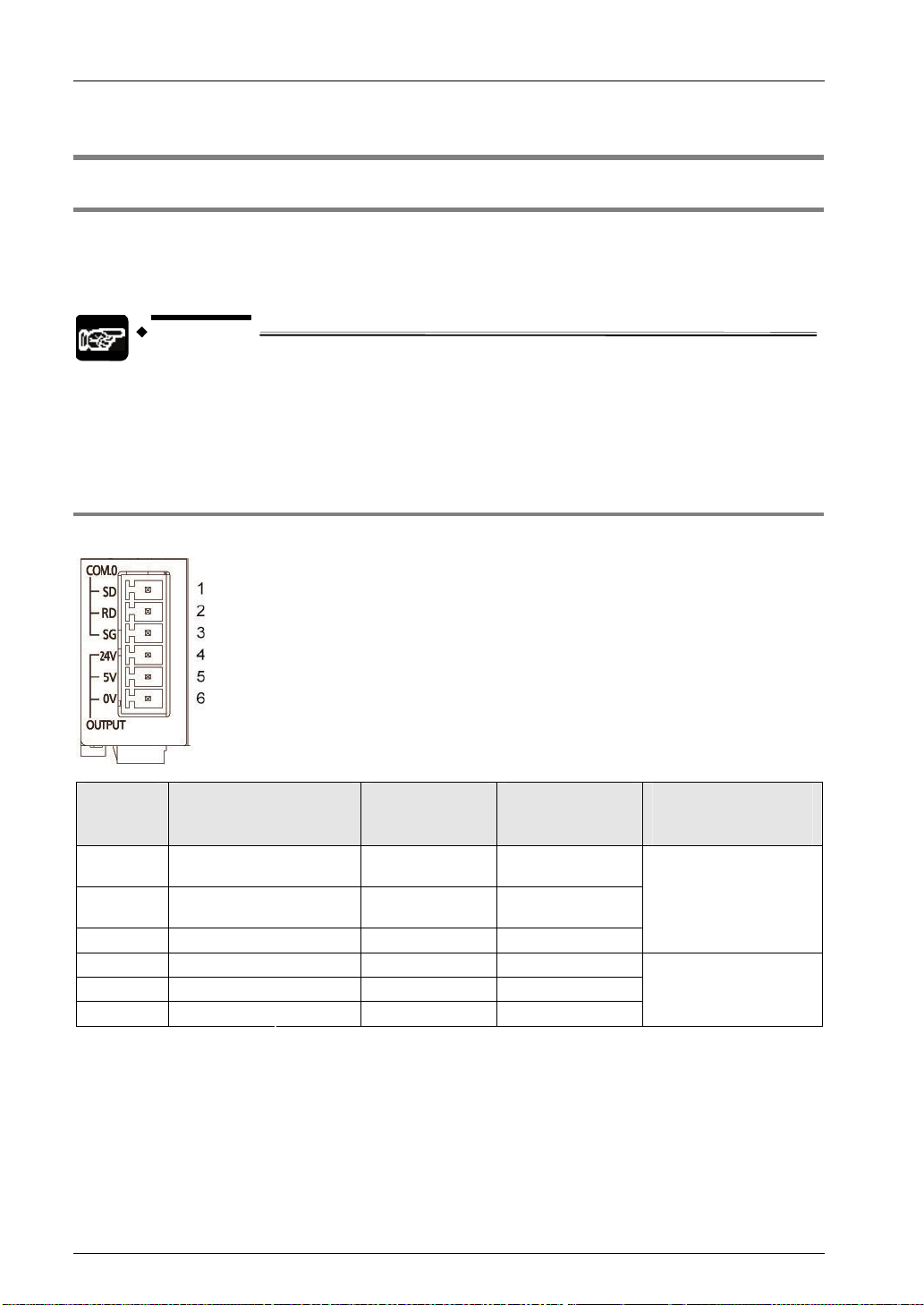

3.3.2 Terminal Layouts and Examples of Wiring

Layout for GT power supply terminals and COM0 port terminals

Terminal

no.

1 COM.0 SD Sent data

2 RD Received data

3 SG Signal Ground -

4 OUTPUT 24V 24V 5 5V 5V 6 0V 0V -

Terminal part

Symbol

Functions

that can be

allocated

Signal direction

PLC →

External device

PLC ←

External device

Ports that can be

allocated

in the software

COM.0

-

3-6

Page 31

3.3 Wiring for CPU Unit (GT Power Supply and COM0 Port)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Example of wiring (in the case of GT02 5V DC type)

COM.0 port terminal / GT power supply terminal

FP7 CPU unit

Terminal

No.

4

GT power

supply

Terminal part symbolSignal name

COM.0

OUTPUT

SDSent Data 1

RDRecei ved Data2

SGSignal Ground3

24V

5V5

0V6

to GT +

terminal

to GT terminal

From 5 V

terminal

From 0 V

terminal

Example of wiring (in the case of GT series 24V DC type)

COM.0 port terminal / GT power supply terminal

Terminal

No.

4

FP7 CPU unit

GT power

supply

Terminal part symbolSignal name

COM.0

OUTPUT

SDSent Data 1

RDRecei ved Data2

SGSignal Ground3

24V

5V5

0V6

From 24V

terminal

From 0V

terminal

to GT +

terminal

to GT terminal

GT02 / GT02L series

5V DC type

Terminal

part symbol

Signal name

Functional Ground

Sent Data SD

Received DataRD

Signal GroundSG

GT series

24V DC type

Terminal

part symbol

Signal name

Functional Ground

Sent Data SD

Received DataRD

Signal GroundSG

5 V+

0 V-

NCRS

NCCS

24V+

0V-

NCRS

NCCS

NOTE

The terminal layout on the display side differs for the existing models GT01

series.

3-7

Page 32

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4

Wiring for Communication Cassettes COM.1 to COM.4 Ports

3.4.1 Communication Cassette AFP7CCS1

(RS-232C, 1-Channel Insulated Type)

Terminal layout

Terminal

no.

1 CH1 SD SD SD: Sent Data

2 RD RD

3 - SG

4 - 9 - - - - -

(Note) Do not connect anything to Terminals No.4 through No.9.

LED part

Symbol

Terminal

part

Symbol

Functions

that can be

allocated

RD: Received

Data

SG: Signal

Ground

Signal

direction

PLC →

External device

PLC ←

External device

-

Ports that can be

allocated

in the software

COM.1

Example of wiring

Terminal

No.

AFP7CCS1

Terminal

part symbol

Signal name

Sent Data 1

Received Data 1

Signal Ground

Functions

SDSD1

RDRD2

SGSG3

Partner

Signal nameSymbol

Received DataRD

Sent DataSD

Signal GroundSG

3-8

Page 33

3.4 Wiring for Communication Cassettes COM.1 to COM.4 Ports

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4.2 Communication Cassette AFP7CCS2

(RS-232C, 2-channel insulated type)

Setting of Application Switch

Applications for use can be switched using a switch on the backplane for Communication

Cassette AFP7CCS2. Settings can be confirmed with LED lamps at the front of the cassette.

3-wire 2-channel RS-232C

5-wire 1-channel RS-232C (RS/CS controlled)

3-9

Page 34

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Terminal layout (in th e setting of 3-wire 2-channel RS-232C)

Terminal

no.

1 CH1 SD SD SD: Sent Data

2 RD RD

3 - SG

4 CH2 SD / R SD SD: Sent Data

5 RD / C RD

6 - SG

7 MODE - - - -

8 3-Wire - - - 9 5-Wire - - - -

(Note 1) Route between CH1 and CH2 are insulated inside.

(Note 2) Do not connect anything to Terminals No.7 through No.9.

LED part

Symbol

Terminal

part

Symbol

Functions

that can be

allocated

RD: Received

Data

SG: Signal

Ground

RD: Received

Data

SG: Signal

Ground

Signal

direction

PLC →

External device

PLC ←

External device

PLC →

External device

PLC ←

External device

-

Ports that can be

allocated

in the software

COM.1

COM.2

Example of wiring (in the setting of 3-wire 2-channel RS-232C)

Terminal

No.

Terminal

part symbol

AFP7CCS2

Signal name

Sent Data 1

Received Data 1

Signal Ground

Sent Data 2

Received Data 2

Signal Ground

Functions

SDSD1

RDRD2

SGSG3

SDSD4

RDRD5

SGSG6

Partner 1

Signal nameSymbol

Received DataRD

Sent DataSD

Signal GroundSG

Partner 2

Signal nameSymbol

Received DataRD

Sent DataSD

Signal GroundSG

3-10

Page 35

3.4 Wiring for Communication Cassettes COM.1 to COM.4 Ports

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Terminal layout (in th e setting of 5-wire 1-channel RS-232C RS/CS controlled)

Terminal

no.

1 CH1 SD SD SD: Sent Data

2 RD RD

3 - SG

4 CH2 SD / R SD

5 RD / C RD

6 - SG - - -

7 MODE - - - 8 3-Wire - - - 9 5-Wire - - - -

(Note) Do not connect anything to Terminals No.6 through No.9.

LED part

Symbol

Terminal

part

Symbol

Functions

that can be

allocated

RD: Received

Data

SG: Signal

Ground

RS: Request to

Send

CS: Clear to

Send

Signal

direction

PLC →

External device

PLC ←

External device

PLC →

External device

PLC ←

External device

Ports that can be

allocated

in the software

COM.1

Example of wiring (in the setting of 5-wire 1-channel RS-232C RS/CS controlled)

Terminal

No.

AFP7CCS2

Terminal

part symbol

Signal name

Sent Data

Received Data

Signal Ground

Request to Send

Clear to Send

Functions

SDSD1

RDRD2

SGSG3

RSSD4

CSRD5

Symbol

RD

SD

SG

RS

CS

Partner

Signal name

Received Data

Sent Data

Signal Ground

Request to Send

Clear to Send

3-11

Page 36

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4.3 Communication Cassette AFP7CCM1

(RS-422 / RS-485, 1-Channel Insulated Type)

Setting of application switch

Applications for use can be switched using a switch on the backplane for Communication

Cassette AFP7CCM1. Settings can be confirmed with LED lamps at the front of the cassette.

Settings for termination resistance selector switch

On the surface of Communication Cassette AFP7CCM2 is located a termination resistance

selector switch.

When RS-422 is used: Turn ON the switch.

When RS-485 is used: Turn ON the switch only when it is the end unit.

3-12

Page 37

3.4 Wiring for Communication Cassettes COM.1 to COM.4 Ports

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Terminal layout (in th e setting of RS-485)

Terminal

no.

1 CH1 SD + / S Transmission line (+) 2 RD - / S Transmission line (-) 3 485 + / R Transmission line (+) 4 422 - / R Transmission line (-) 5 - 9 - - - - -

(Note 1) In the setting of RS-485, Terminal No.1 and Terminal No.3, and Terminal No.2 and Terminal No.4 are

respectively connected inside. They can be used as terminals for crossover wiring for the transmission cable.

(Note 2) Do not connect anything to Terminals No.5 through No.9.

LED part

Symbol

Terminal

part

Symbol

Functions that can

be allocated

Signal

direction

Ports that can be

allocated

in the software

COM.1

Example of wiring (in the setting of RS-485)

AFP7CCM1

No.

Terminal part

symbol

Signal name

Transmission line (+)

Transmission line (-)

Transmission line (+)

Transmission line (-)

Functions

++ / S1

--/ S2

++ / R3

--/ R4

Terminal

Terminal

+

-

Terminal

+

-

Partner 1

Signal name

Transmission line (+)

Transmission line (-)

Partner 2

Signal name

Transmission line (+)

Transmission line (-)

3-13

Page 38

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Terminal layout (in th e setting of RS-422)

Terminal

no.

1 CH1 SD + / S Sent Data (+)

2 RD - / S Sent Data (-)

3 485 + / R Received Data (+)

4 422 - / R Received Data (-)

5 - 9 - - - - -

(Note) Do not connect anything to Terminals No.5 through No.9.

LED part

Symbol

Terminal

part

Symbol

Functions that

can be

allocated

Signal

direction

PLC →

External device

PLC →

External device

PLC ←

External device

PLC ←

External device

Ports that can be

allocated

in the software

COM.1

Example of wiring (in the setting of RS-422)

AFP7CCM1

No.

Terminal part

symbol

Signal name

Sent Data (+)

Sent Data (-)

Received Data (+)

Received Data (-)

Functions

SD (+)+ / S1

SD (-)-/ S2

RD (+)+ / R3

RD (-)-/ R4

Terminal

Terminal

RD (+)

RD (-)

SD (+)

SD (-)

Partner

Signal name

Received Data (+)

Received Data (-)

Sent Data (+)

Sent Data (-)

3-14

Page 39

3.4 Wiring for Communication Cassettes COM.1 to COM.4 Ports

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4.4 Communication Cassette AFP7CCM2

(RS-422 / RS-485, 2-Channel Insulated Type)

Setting of application switch

Applications for use can be switched using a switch on the backplane for Communication

Cassette AFP7CCM2. Settings can be confirmed with LED lamps at the front of the cassette.

Settings for termination resistance selector switch

On the surface of Communication Cassette AFP7CCM2 is located a termination resistance

selector switch.

When RS-422 is used: Turn ON the switch.

When RS-485 is used: Turn ON the switch only when it is the end unit.

3-15

Page 40

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Terminal layout (in th e setting of RS-485)

Terminal

no.

1 CH1 SD + / S Transmission line (+) 2 RD - / S Transmission line (-) 3 485 + / R Transmission line (+) 4 422 - / R Transmission line (-) 5 - - - - 6 CH2 SD + / S Transmission line (+) 7 RD - / S Transmission line (-) 8 485 + / R Transmission line (+) 9 422 - / R Transmission line (-) -

(Note 1) In the setting of RS-485, Terminal No.1 and Terminal No.3, and Terminal No.2 and Terminal No.4 are

respectively connected inside. They can be used as terminals for crossover wiring for the transmission cable.

(Note 2) In the setting of RS-485, Terminal No.6 and Terminal No.8, and Terminal No.7 and Terminal No.9 are

respectively connected inside. They can be used as terminals for crossover wiring for the transmission cable.

(Note 3) Do not connect anything to Terminal No.5.

(Note 4) Route between CH1 and CH2 are insulated inside.

LED part

Symbol

Terminal

part

Symbol

Functions that can

be allocated

Signal

direction

Ports that can

be allocated

in the software

COM.1

COM.2

3-16

Page 41

3.4 Wiring for Communication Cassettes COM.1 to COM.4 Ports

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Example of wiring (in the setting of RS-485)

Terminal

No.

5

AFP7CCM2

Terminal

part symbol

-

Signal name

Transmission line 1 (+)

Transmission line 1 (-)

Transmission line 1 (+)

Transmission line 1 (-)

NC

Transmission line 2 (-)

Functions

++ / S1

--/ S2

++ / R3

--/ R4

NC

+Transmission line 2 (+)+ / S6

-Transmission line 2 (-)-/ S7

+Transmission line 2 (+)+ / R8

--/ R9

Transmission line 1 Partner 1

Terminal

+

-

Signal name

Transmission line (+)

Transmission line (-)

Transmission line 1 Partner 2

Terminal

+

-

Signal name

Transmission line (+)

Transmission line (-)

Transmission line 2 Partner 1

Terminal

+

-

Signal name

Transmission line (+)

Transmission line (-)

Transmission line 2 Partner 2

Terminal

+

-

Signal name

Transmission line (+)

Transmission line (-)

3-17

Page 42

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Terminal layout (in th e setting of RS-422)

Terminal

no.

1 CH1 SD + / S Sent Data (+)

2 RD - / S Sent Data (-)

3 485 + / R Received Data (+) PLC ← External device

4 422 - / R Received Data (-) PLC ← External device

5 - - - - 6 CH2 SD + / S Sent Data (+)

7 RD - / S Sent Data (-)

8 485 + / R Received Data (+) PLC ← External device

9 422 - / R Received Data (-) PLC ← External device

(Note 1) Do not connect anything to Terminal No.5.

(Note 2) Route between CH1 and CH2 are insulated inside.

LED part

Symbol

Terminal

part

Symbol

Functions that

can be allocated

Signal direction

PLC → External device

PLC → External device

PLC → External device

PLC → External device

Ports that can be

allocated

in the software

COM.1

COM.2

Example of wiring (in the setting of RS-422)

AFP7CCM2

No.

5

Terminal

part symbol

-

Signal name

Sent Data 1 (+)

Sent Data 1 (-)

Received Data 1 (+)

Received Data 1 (-)

Received Data 2 (-)

Functions

SD (+)+ / S1

SD (-)-/ S2

RD (+)+ / R3

RD (-)-/ R4

SD (+)Sent Data 2 (+)+ / S6

SD (-)Sent Data 2 (-)-/ S7

RD (+)Received Data 2 (+)+ / R8

RD (-)-/ R9

Terminal

Terminal

RD (+)

RD (-)

SD (+)

SD (-)

Terminal

RD (+)

RD (-)

SD (+)

SD (-)

Partner 1

Signal name

Received Data (+)

Received Data (-)

Sent Data (+)

Sent Data (-)

Partner 2

Signal name

Received Data (+)

Received Data (-)

Sent Data (+)

Sent Data (-)

3-18

Page 43

3.4 Wiring for Communication Cassettes COM.1 to COM.4 Ports

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.4.5 Communication Cassette AFP7CCS1M1 (RS-232C 1-Channel + RS-485

1-Channel Insulated Type)

Settings for termination resistance selector switch

A termination resistance selector switch is locate d on the RS-485 side of the surface of

Communication Cassette AFP7CCS1M1. Turn ON the switch only when it is the end unit.

Terminal

no.

1 CH1 SD + Transmission line (+) 2 RD - Transmission line (-) 3

4

5 - 6

7 CH2 SD SD Sent data 8 RD RD Received data 9 SG SG Signal ground -

(Note 1) Terminal No.1 and Terminal No.3, and Terminal No.2 and Terminal No.4 are respectively connected inside.

(Note 2) Do not connect anything to Terminals No.5 and No.6.

LED part

Symbol

-

Terminal

part

Symbol

+ Transmission line (+) -

- Transmission line (-) -

- - - -

Functions that

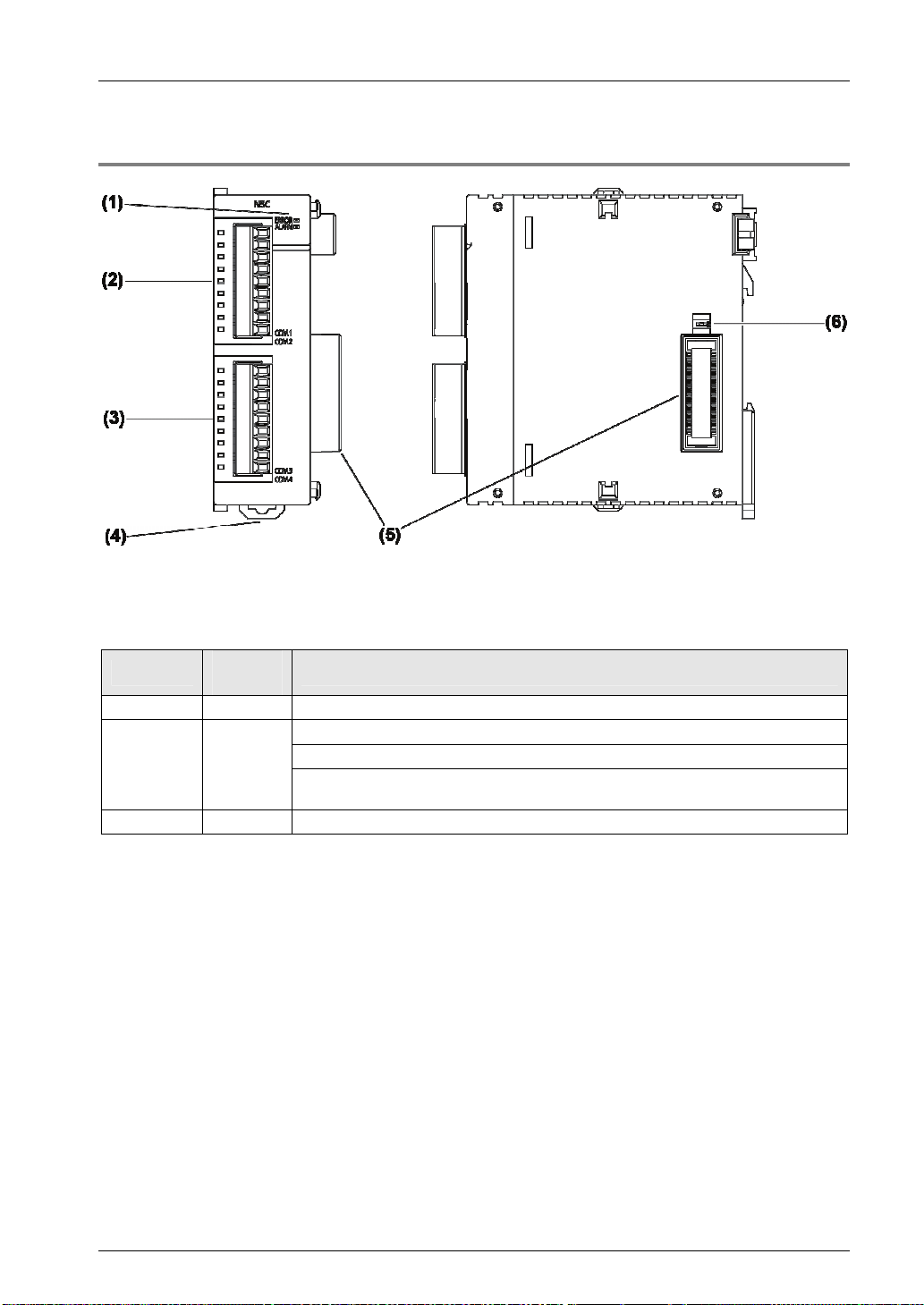

can be allocated

Signal

direction

Ports that can be

allocated

in the software

COM.1

COM.2

3-19

Page 44

Wiring the COM. Port

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Example of wiring

Terminal

No.

5

6

AFP7CCS1M1

Terminal

part symbol

-

-

Signal name

Transmission line (+)

Transmission line (-)

Transmission line (+)

Transmission line (-)

NC

Signal Ground

Functions

++ / S1

--/ S2

++ / R3

--/ R4

NC

NCNC

SDSent DataSD7

RDReceived DataRD8

SGSG9

RS-485 Partner 1

Terminal

+

-

Signal name

Transmission line (+)

Transmission line (-)

RS-485 Partner 2

Terminal

+

-

Signal name

Transmission line (+)

Transmission line (-)

RS-232C partner

Terminal

RD

SG

Signal name

Received Data

Sent DataSD

Signal Ground

3-20

Page 45

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3

I/O Allocation

Page 46

I/O Allocation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.1 Input/Output Signals Used for Communication

4.1.1 I/O Allocation of CPU Unit

Input signal

Input

signal

X0 For COM.1 Port

X1 For COM.2 Port

X2 For COM.0 Port

X3 - Not used Do not use this.

X4 For COM.1 Port

X5 For COM.2 Port

X6 For COM.0 Port

X7 - Not used Do not use this.

X8 For COM.1 Port

X9 For COM.2 Port

XA For COM.0 Port

XB - Not used Do not use this.

XC For COM.1 Port

XD For COM.2 Port

XE For COM.0 Port

XF - Not used Do not use this.

X10 For COM.1 Port

X11 For COM.2 Port

X12 For COM.0 Port

X13

X14 For COM.1 Port

X15

- X1F

(Note 1) The general-purpose communication reception done (copy) flag is effective after the execution of the RECV

Communication

port

- Not used Do not use this.

- Not used Do not use this.

instruction until one of the following instructions is executed. This flag does not remain ON across several scans.

Execute 1: END instruction (scan header), and 2: RECV instruction

Name Description

Generalpurpose

communication

Reception

done flag

Generalpurpose

communication

Reception

done (copy)

flag

Generalpurpose

communication

Clear to send

flag

Master

communication

Clear to send

flag

Reset done

CTS signal

monitor

When the unit completes the data reception,

it turns on (1).

Waiting for data reception: 0, Reception

completed: 1

It turns on (1) if there are copied data when

GPRECV instruction is executed. It turns off

(0) when END instruction is executed.

(Note 1)

Reading completed: 1

No data to be read: 0

It turns on (1) when the unit is set to the

general-purpose communication mode. It

turns off (0) in other modes.

It turns on (1) when the unit is set to modes

other than the PLC link mode or generalpurpose communication mode. It turns off (0)

in other modes.

When the communication channel is reset

under the output Y10 - Y12, the flag is

turned on (1) once the resetting operation is

completed.

Resetting done: 1

Y10 - Y12 is off: 0

Status of the CTS signal sent from the

device communicating with.

Clear to send from COM.1 port = 0

Cannot send from COM.1 port = 1

The RTS signal can be controlled with Y14.

Effective

operation

mode

Generalpurpose

communication

Generalpurpose

communication

Generalpurpose

communication

MEWTOCOL

MODBUS-RTU

Generalpurpose

communication

When RS/CS is

set to valid in

Communication

Block COM.1.

4-2

Page 47

4.1 Input/Output Signals Used for Communication

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Output signal

Output

signal

Y0 For COM.1 Port

Y1 For COM.2 Port

Y2 For COM.0 Port

Y3

- Y7

Y8 For COM.1 Port

Y9 For COM.2 Port

YA For COM.0 Port

YB - Undefined

YC For COM.1 Port

YD For COM.2 Port

YE For COM.0 Port

YF - Undefined

Y10 For COM.1 Port

Y11 For COM.2 Port

Y12 For COM.0 Port

Y13 - Undefined

Y14 For COM.1 Port

Y15 Y1F

(Note 1) When transmission is completed within one scan, it turns off when the GPSEND instruction is executed in

Communication

port

- Undefined

- Undefined

the subsequent scan.

Name Description

Sending done

result

Generalpurpose

communication

Sending active

flag

Master

communication

Sending active

flag

Request to

reset CH

Output RTS

signal

Reports the results of sending in master

communication or general-purpose

communication.

Normal completion: 0, Abnormal completion:

1

Do not turn on "undefined". (Default setting is

0.)

It turns on (1) during sending in the general-

purpose communication mode.

(Note 1)

Sending done: 0, Sending: 1

Do not turn on "undefined". (Default setting is

0.)

It turns on (1) during sending in the master

communication mode.

Sending done: 0, Sending: 1

Do not turn on "undefined". (Default setting is

0.)

By turning on (1) Y10 - Y12, the

communication channel can be reset.

Without a request to reset = 0, With a

request to reset = 1

After ON (1) is output and the completion of

the reset is confirmed by X10 - X12, return to

OFF (0). The reset is performed only once

when this signal rises.

This function can be used to delete

unnecessary received data or to clear errors

before starting normal reception.

1:Sending canceled

2:Reception canceled

3:Re-set communication parameters

4:Clear error information (only for errors that

can be cleared)

Do not turn on "undefined". (Default setting is

0.)

By turning on (1) this output, RTS is

controlled.

Transmission from the device communicating

with is permitted = 0

Transmission from the device communicating

with is prohibited = 1

Monitor the CTS signal from the device

communicating with using X14.

Do not turn on "undefined". (Default setting is

0.)

Effective

operation

mode

MEWTOCOL

MODBUS-RTU

Generalpurpose

communication

Generalpurpose

communication

MEWTOCOL

MODBUS-RTU

Generalpurpose

communication

When RS/CS is

set to valid in

Communication

Cassette

COM.1

-

NOTE

Each contact in the table above is used for reading the operation status. Do

not write over it with a user program. (excluding Y10 - Y12 and Y14)

4-3

Page 48

I/O Allocation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.1.2 I/O Allocation of Serial Commun ication Unit

Input signal

Input

signal

X0 For COM.1 Port

X1 For COM.2 Port

X2 For COM.3 Port

X3 For COM.4 Port

X4 For COM.1 Port

X5 For COM.2 Port

X6 For COM.3 Port

X7 For COM.4 Port

X8 For COM.1 Port

X9 For COM.2 Port

XA For COM.3 Port

XB For COM.4 Port

XC For COM.1 Port

XD For COM.2 Port

XE For COM.3 Port

XF For COM.4 Port

X10 For COM.1 Port

X11 For COM.2 Port

X12 For COM.3 Port

X13

X14 For COM.1 Port

X16 For COM.3 Port

X15,

X17

- X1F

(Note 1) The general-purpose communication reception done (copy) flag is effective after the execution of the RECV

(Note 2): The I/O numbers actually allocated are the numbers based on the starting word number allocated to the unit.

Communication

port

For COM.4 Port

- Not used Do not use this.

instruction until one of the following instructions is executed. This flag does not remain ON across several scans.

Execute 1: END instruction (scan header), and 2: RECV instruction

Example) When the starting word number for the unit is "10", the general-purpose communication reception

done flag for COM.1 port is X100.

Name Description

Generalpurpose

communication

Reception

done flag

Generalpurpose

communication

Reception

done (copy)

flag

Generalpurpose

communication

Clear to send

flag

Master

communication

Clear to send

flag

Reset done

CTS signal

monitor

When the unit completes the data reception,

it turns on (1).

Waiting for data reception: 0, Reception

completed: 1

It turns on (1) if there are copied data when

GPRECV instruction is executed. It turns off

(0) when END instruction is executed.

(Note 1)

Reading completed: 1

No data to be read: 0

It turns on (1) when the unit is set to the

general-purpose communication mode. It

turns off (0) in other modes.

It turns on (1) when the unit is set to modes

other than the PLC link mode or generalpurpose communication mode. It turns off (0)

in other modes.

When the communication channel is reset

under the output Y10 - Y13, the flag is

turned on (1) once the resetting operation is

completed.

Resetting done: 1

Y10 - Y12 is off: 0

Status of the CTS signal sent from the

device communicating with.

Clear to send from COM.1/COM.3 port = 0

Cannot send from COM.1/COM.3 port = 1

The RTS signal can be controlled with

Y14/Y16.

Effective

operation

mode

Generalpurpose

communication

Generalpurpose

communication

Generalpurpose

communication

MEWTOCOL

MODBUS-RTU

Generalpurpose

communication

When RS/CS is

set to valid in

Communication

Cassette

COM.1/COM.3

4-4

Page 49

4.1 Input/Output Signals Used for Communication

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Output signal

Output

signal

Y0 For COM.1 Port

Y1 For COM.2 Port

Y2 For COM.3 Port

Y3 For COM.4 Port

Y4

- Y7

Y8 For COM.1 Port

Y9 For COM.2 Port

YA For COM.3 Port

YB For COM.4 Port

YC For COM.1 Port

YD For COM.2 Port

YE For COM.3 Port

YF For COM.4 Port

Y10 For COM.1 Port

Y11 For COM.2 Port

Y12 For COM.3 Port

Y13 For COM.4 Port

Y14 For COM.1 Port

Y16 For COM.3 Port

Y15

Y17

- Y1F

(Note 1) When transmission is completed within one scan, it turns off when the GPSEND instruction is executed in

(Note 2): The I/O numbers actually allocated are the numbers based on the starting word number allocated to the unit.

Communication

port

- Undefined

- Undefined

the subsequent scan.

Example) When the starting word number for the unit is "10", the sending done result flag for COM.1 port is

Y100.

Name Description

Reports the results of sending in master

Sending done

result

Generalpurpose

communication

Sending active

flag

Master

communication

Sending active

flag

Request to

reset CH

Output RTS

signal

communication or general-purpose

communication.

Normal completion: 0, Abnormal completion:

1

Do not turn on "undefined". (Default setting is

0.)

It turns on (1) during sending in the general-

purpose communication mode.

(Note 1)

Sending done: 0, Sending: 1

It turns on (1) during sending in the master

communication mode.

Sending done: 0, Sending: 1

By turning on (1) Y10 - Y13, the

communication channel can be reset.

Without a request to reset = 0, With a request

to reset = 1

After ON (1) is output and the completion of

the reset is confirmed by X10 - X13, return to

OFF (0). The reset is performed only once

when this signal rises. This function can be

used to delete unnecessary received data or

to clear errors before starting normal

reception.

1:Sending canceled

2:Reception canceled

3:Re-set communication parameters

4:Clear error information (only for errors that

can be cleared)

By turning on (1) this output, RTS is

controlled.

Transmission from the device communicating

with is permitted = 0

Transmission from the device communicating

with is prohibited = 1

Monitors the CTS signal from the device

communicating with using X14/X16.

Do not turn on "undefined". (Default setting is

0.)

Effective

operation

mode

MEWTOCOL

MODBUS-RTU

Generalpurpose

communication

Generalpurpose

communication

MEWTOCOL

MODBUS-RTU

Generalpurpose

communication

When RS/CS is

set to valid in

Communication

Cassette

COM.1/COM.3

-

NOTE

Each contact in the table above is used for reading the operation status. Do

not write over it with a user program. (excluding Y10 - Y14 and Y16)

4-5

Page 50

I/O Allocation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.2 Registration in I/O Map

4.2.1 Settings Using FPWIN GR7 (For CPU with built- in SCU)

For the CPU with built-in SCU, there is no need to set with FPWIN GR7 because the

following fixed areas are allocated.

No. of occupied words

Unit type Model number

CPU Unit CPU with built-in SCU Common

4.2.2 Settings Using FPWIN GR7 (For Serial Communica tion Unit)

The explanation below shows the case that the serial communication unit is registere d in the

slot number 1.

(No. of occupied points)

Input Output

2 words (32 points)

WX0 - WX1 Fixed

2 words (32 points)

WY0 - WY1 Fixed

PROCEDURE

1. Select "Options" > "FP7 Configuration" in the menu bar.

The "FP7 Configuration" dialog box appears.

2. Select "I/O map" in the left pane.

The "I/O map" dialog box is displayed.

3. Double-click Slot No. 0.

The "Unit selection [Slot No. 0]" dialog box is displayed.

4. Select "CPU unit" for Unit type, and select a CPU unit used for Unit name,

and press [OK] button.

The CPU unit is registered. Only CPU unit can be registered in Slot No. 0. Slot

No.1 and subsequent numbers cannot be set unless Slot No. 0 is set.

4-6

Page 51

5. Double-click Slot No. 1 in the "I/O map" dialog box.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The "Unit selection [Slot No. 1]" dialog box is displayed.

4.2 Registration in I/O Map

6. Select "Communications" for Unit type, and select "SCU unit" for Unit name,

and press [OK] button.

"SCU unit" is registered in the I/O map.

The set conditions are reflected in the project being edited.

4-7

Page 52

I/O Allocation

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4-8

Page 53

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5

Setting and Confirming

Communication Conditions

Page 54

Setting and Confirming Communication Conditions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.1 Setting Applications and Communication Conditions

5.1.1 Applications to be Set for Each Port

Available functions for each communication port

Communication function to be used

PLC link

MEWTOCOL7-COM (Note 1)

MEWTOCOL-COM

MODBUS-RTU

General-purpose communication

(Note 1) In MEWTOCOL7-COM, there is no master communication function.

Master

Slave

Master

Slave

COM.0 COM.1 COM.2 COM.3 COM.4

5.1.2 Conditions to be Set for Each Port

Communication condition

Communication port Setting range Default

1 - 99 (MEWTOCOL-COM)

Station no.

Baud rate 300,600,1200,2400,4800,9600,19200,38400,57600,115200,230400 9600

Data length 7 bits, 8 bits 8 bits

Parity None, Odd, Even Odd

Communica

tion format

RS/CS controlled No/Yes Invalid

Send Waiting 0 to 100 ms 0 ms

Modem initialization Invalid, Valid, Re-initialization Invalid