Page 1

Programmable Controller

FP0H Control Unit

User's Manual

EtherNet/IP Edition

[Applicable model]

AFP0HC32ET/AFP0HC32EP

WUME-FP0HEIP-05

2021.2 panasonic.net/id/pidsx/global

Page 2

(MEMO)

2 WUME-FP0HEIP-05

Page 3

Introduction

Thank you for purchasing a Panasonic product. Before you use the product, please carefully

read through the user’s manual, and understand it in detail to use the product properly.

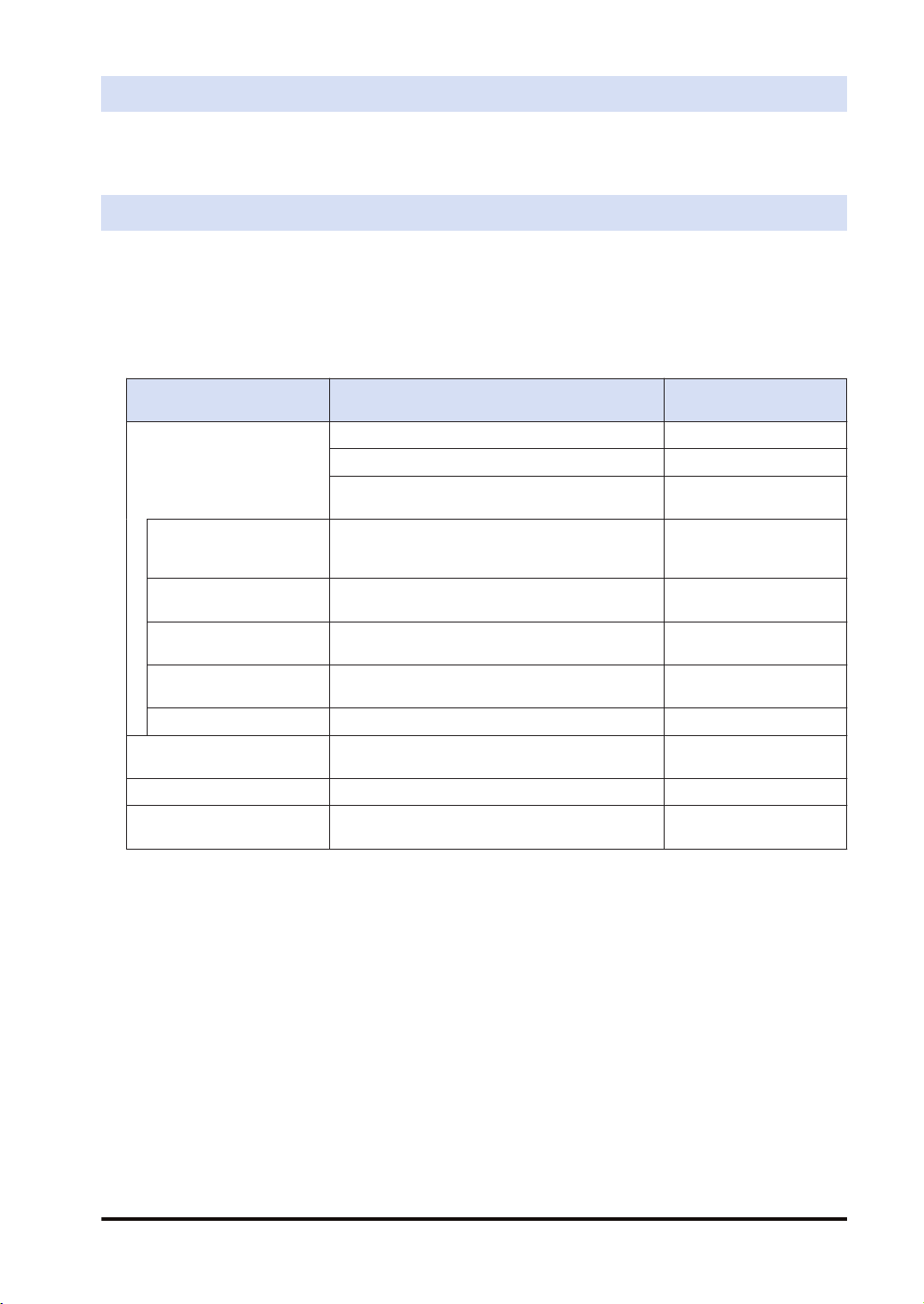

Types of Manual

● This manual describes the "EtherNet/IP communication function" implemented in FP0H

Control Unit.

● There are different types of user’s manual for the FP0H series. Please refer to a relevant

manual for the unit and purpose of your use.

● The manuals can be downloaded on our download center: https://

industrial.panasonic.com/ac/e/dl_center/.

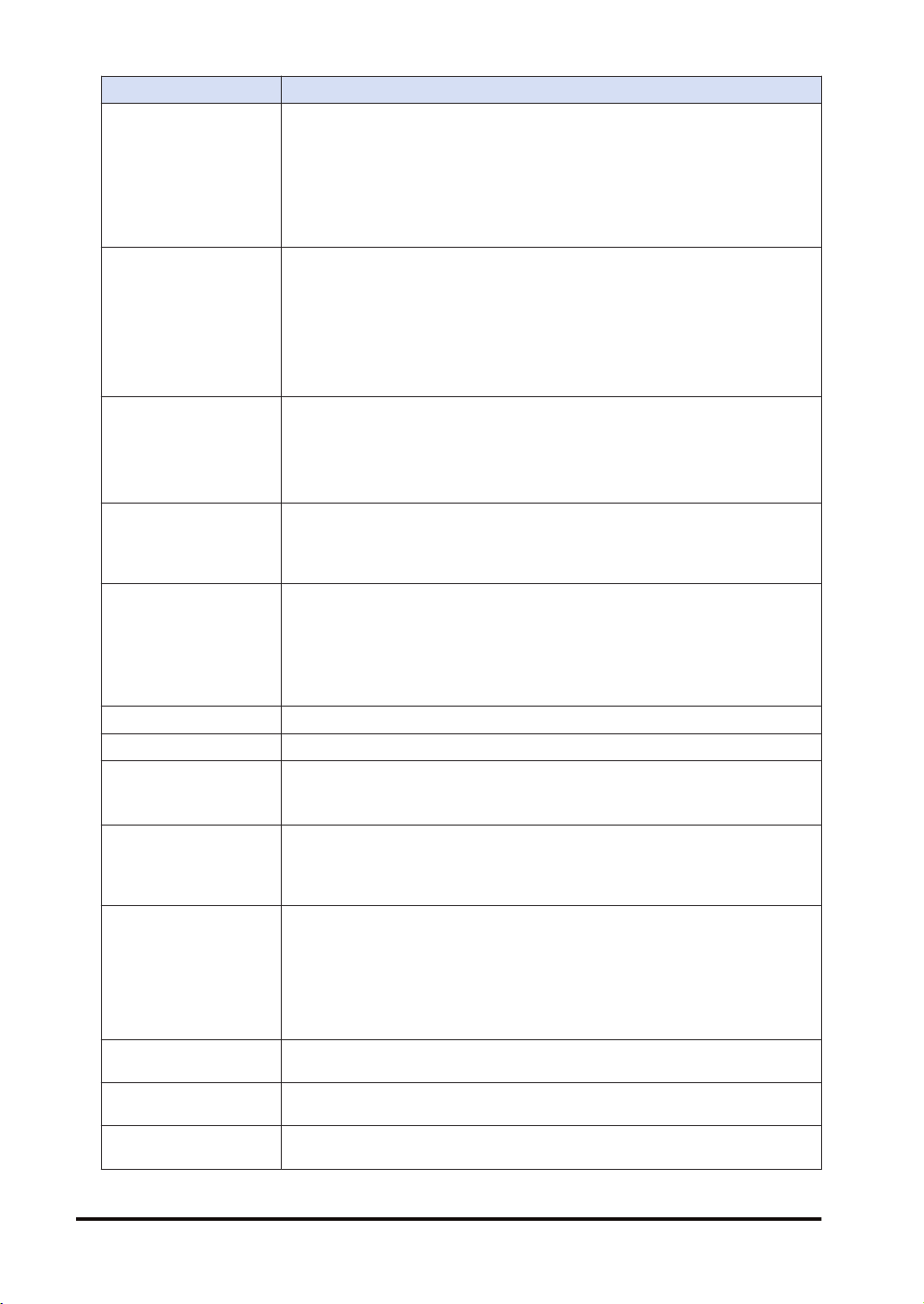

Unit name or purpose of

use

FP0H Control Unit

Positioning Function/PWM

Output/High-speed

Counter Function

Serial Communication

Function

Ethernet Communication

Function

EtherNet/IP

Communication Function

Logging trace function FP0H User‘s Manual (Logging/Trace Function) WUME-FP0HLOG

FP0H Extension

(Communication) Cassette

FP0H Positioning Unit FPsigma Positioning Unit User’s Manual ARCT1F365E

FP0H Positioning Unit RTEX

Manual name Manual code

FP0H User‘s Manual (Basic) WUME-FP0HBAS

FP0H Programming Manual WUME-FP0HPGR

FP0H Programming Manual (SD Card Access

Instructions)

FP0H User‘s Manual

(Positioning/PWM Output/High-speed Counter)

FP0H User‘s Manual (COM Communication) WUME-FP0HCOM

FP0H User‘s Manual (Ethernet Communication) WUME-FP0HET

FP0H User‘s Manual (EtherNet/IP) WUME-FP0HEIP

FP0H User‘s Manual (COM Communication) WUME-FP0HCOM

FP0H Positioning Unit RTEX User’s Manual

(FPWIN GR7)

WUME-FP0HSD

WUME-FP0HPOS

WUME-FP0HRTEXGR7

WUME-FP0HEIP-05 iii

Page 4

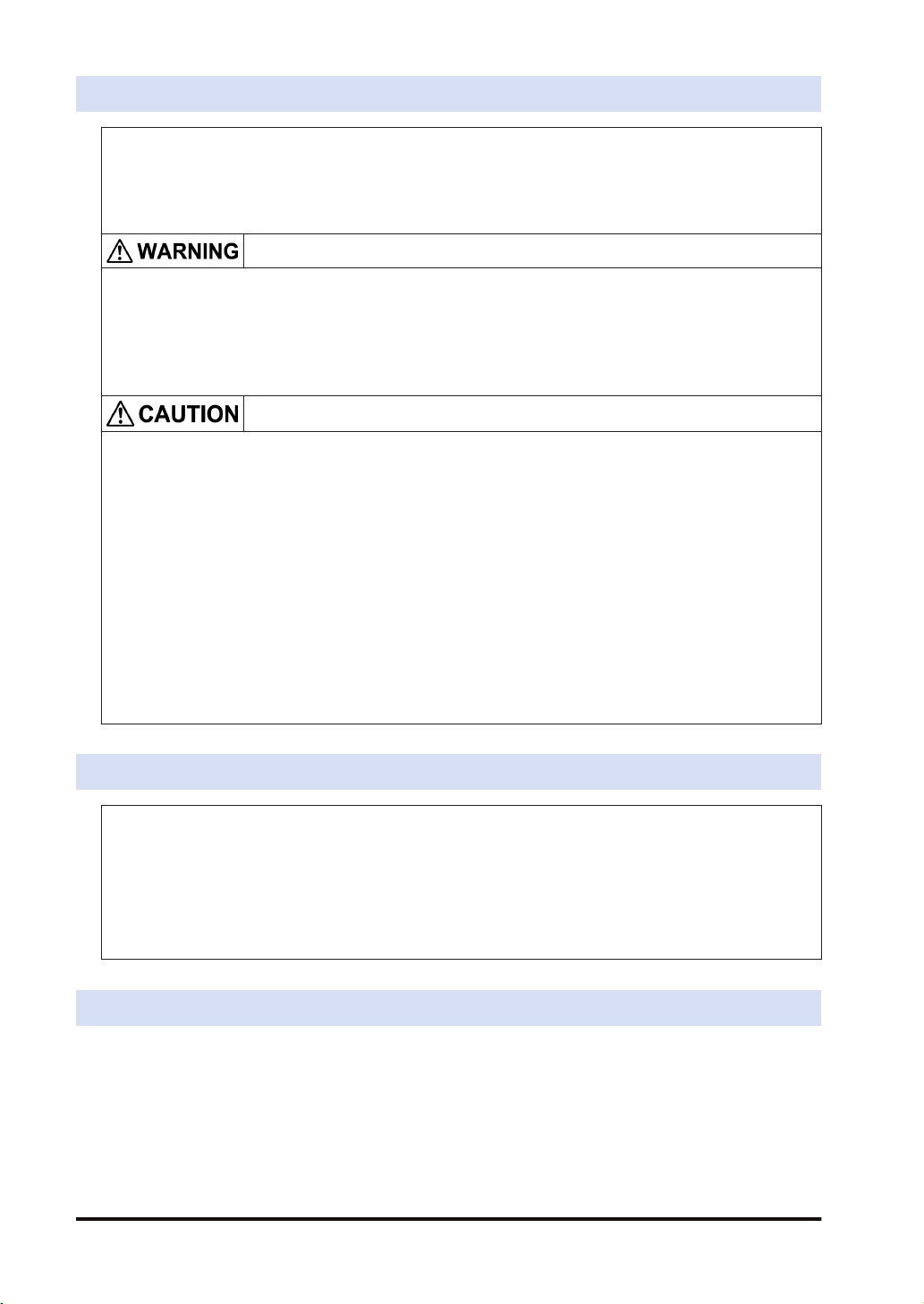

SAFETY PRECAUTIONS

● To prevent accidents or personal injuries, please be sure to comply with the following items.

● Prior to installation, operation, maintenance and check, please read this manual carefully for proper use.

● Before using, please fully understand the knowledge related to the equipment, safety precautions and all

other precautions.

● Safety precautions are divided into two levels in this manual: Warning and Caution.

Incorrect operation may lead to death or serious injury.

● Take appropriate safety measures to the external circuit of the product to ensure the security of the whole

system in case of abnormalities caused by product failure or external.

● Do not use this product in areas with inflammable gases.

Otherwise it may lead to an explosion.

● Do not put this product into a fire.

Otherwise it could cause damage to the battery or other electronic parts.

Incorrect operation may lead to injury or material loss.

● To prevent the excessive exothermic heat or smoke generation of the product, a certain margin is required

for guaranteed characteristics and performance ratings of relative products.

● Do not decompose or transform it.

Otherwise it will lead to the excessive exothermic heat or smoke generation of the product.

● Do not touch terminal blocks during power-on.

Otherwise it may result in an electric shock.

● Set an emergency stop and interlock circuit in the external devices.

● Connect wires and connectors reliably.

Otherwise it may lead to the excessive exothermic heat or smoke generation of the product.

● Do not undertake construction (such as connection and disconnection) while the power supply is on.

It could lead to an electric shock.

● If the equipment is used in a manner not specified by the Panasonic, the protection provided by the

equipment may be impaired.

● This product has been developed/produced for industrial use only.

Description on Copyright and Trademarks

● The copyright of this manual is owned by Panasonic Industrial Devices SUNX Co., Ltd

● Unauthorized reproduction of this manual is strictly prohibited.

● Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

● Ethernet is a registered trademark of Fuji Xerox Co., Ltd. and Xerox Corporation.

● EtherNet/IP is a registered trademark of ODVA (Open DeviceNet Vendor Association).

● SDHC and SD logos are trademarks of LLC.

● Other company and product names are trademarks or registered trademarks of their respective companies.

Network Security

When this product is connected to a network, you might receive damage as listed below.

(1) Information leakage or outflow through this product

(2) Fraudulent operation of this product by a malicious third party

(3) Obstructing or stopping this product by a malicious third party

Sufficient network security measures, including the following measures, should be taken at your

own risk to prevent such damages.

● Use this product on a network where safety is secured by using a firewall.

iv

WUME-FP0HEIP-05

Page 5

● When using this product on a system where a PC is connected, make sure that checking and

cleaning of infection by computer virus or malicious program is performed periodically.

● In order to prevent malicious attacks, set user name and password to limit users who can log

in.

● Take measures such as limiting an access through a user authentication method so as not to

leak information to the network such as image data, authentication information (user name

and password), alarm email information, FTP server information, DDNS server information,

etc.

● Be sure to close all browsers immediately after accessing this product as an administrator.

● Periodically change the administrator's password.

● Do not install this product in a location where the product or cables can be easily damaged.

● Furthermore, it is recommended that the product be used in an environment that has VPN

(Virtual Private Network) or leased line network.

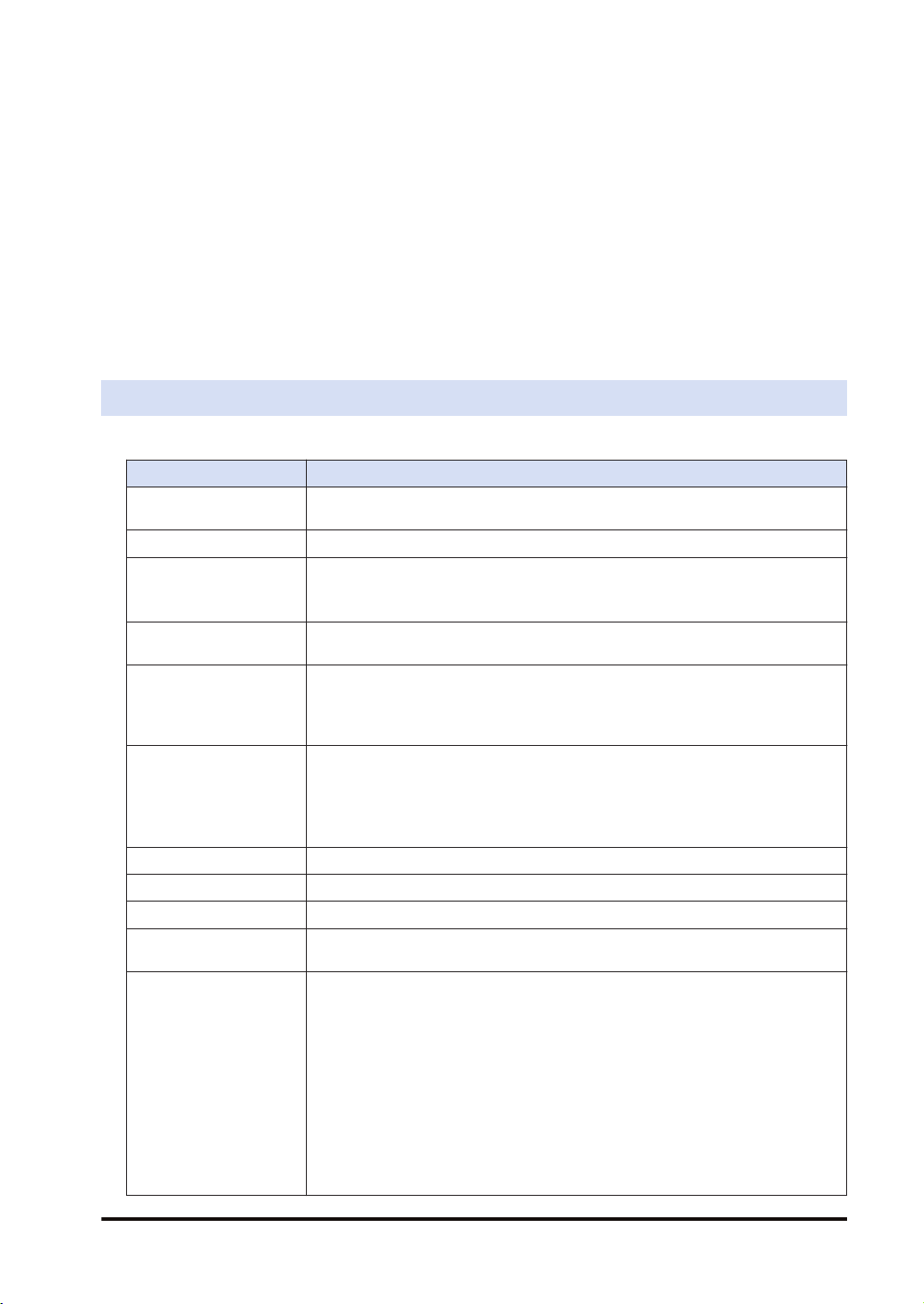

Glossary

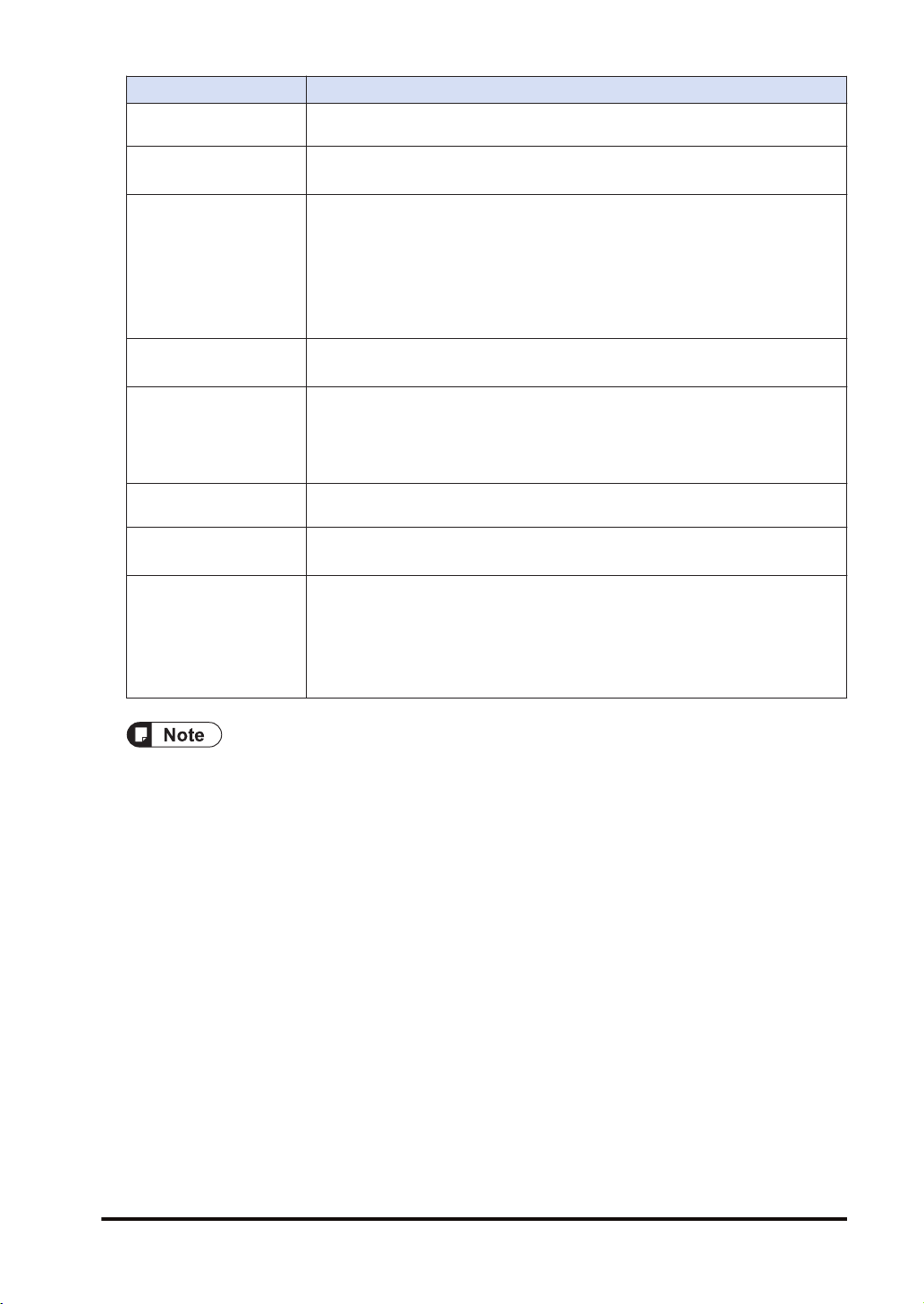

The following terms are used in this manual and the EtherNet/IP setting tool.

Term Description

Originator

Target he side which the connection is opened is called target, such as PLC, I/O devices.

Scan List

I/O map

EDS file

(Electric data sheet)

Node no.

Connection setting The details of the connections with targets registered in the scan list are set.

Node name Arbitrary node names can be given.

Device name Device names of targets. The device name is registered in the EDS file.

Connection Name

Application Type

The side which opens the connection of the cyclic communication is called

originator, i.e. controllers such as PLC.

Connection setting with targets registered in FP0H. Information required for the

communication with the targets and the device allocation of own unit are registered.

For FP0H, the connection with targets are established according to the scan list.

Information required for the transmission from the own unit (FP0H) to other PLCs

and the device allocation of the own unit are registered.

EDS files are provided for each product by each vendor. This file contains the

information on the communication for registering targets in the scan list.

The EDS files of each target should be registered for constructing the scan list with

the setting tool.

A node number is set when a target is registered in the scan list.

Numbers that do not overlap are allocated in the scan list as node numbers.

Node numbers are not used in the cyclic communication, however, as each target

is recognized by these numbers, they are used for monitoring the communication

state of each node or controlling the start/stop of the communication.

The type of the connection manager registered in the EDS file is selected by the

name. By selecting this, the application type (communication method) is changed.

The communication method can be selected by the application type.

Three communication methods are available;

1: Exclusive Owner (Two-way communication)

2: Input Only

3: Listen Only

Although "Exclusive Owner" and "Input Only" are independent connections, "Listen

Only" can be connected only when either of the above connections is established,

and it will be automatically cut if the independent connection is disconnected.

Also, it will be reconnected automatically when the above independent connection

is reconnected.

When FP0H is used as a target, "Input Only" can be selected.

WUME-FP0HEIP-05 v

Page 6

Term Description

Set the operation method of "Compatibility Check" , which checks the information of

the connected target device against the revision of the EDS file.

Three verification methods are available. The default is "Follow Adapter(Target)

Compatibility Check

Communication Method

(Tag/Instance)

Input Send Trigger

COS Transmission

Disable Time

Timeout Period

Input Information (T>O) This is the setting for the transmission from a target to the FP0H (originator).

Output Information (O>T) This is the setting for the transmission from the FP0H (originator) to a target.

RPI

(Requested Packet

Interval)

Point to Point

(1:1 communication)

Multicast

(Multicast communication)

TTL

Instance ID/Tag name

Data Size

Rule".

1: Check

2: Not check

3: Follow Adapter(Target) Rule

For connecting from an originator to target, there are two methods to specify the

device area of the target.

by specifying numbers (Instance)

by specifying symbols (Tag).

When setting connections, the methods available for each target are displayed.

For using the FP0H as a target, either method can be selected.

However, the selectable instance numbers for the instance method are 100 to 199.

The transmission timing is selected from Cyclic or COS (Change of state).

However, COS depends on devices.

COS is basically a cyclic communication, however, it also performs transmission

when sent data changes.

The FP0H does not support COS.

Transmission disable time (RPI of input information x 1/4) is displayed when "Input

Send Trigger" is set to "Change of State (COS)".

Even if the unit detects the change in data, it is not sent within the transmission

disable time.

In the cyclic communication, transmission data is sent as UDP packet. The timeout

is judged on a receiver side.

The timeout period is selected from 4, 8, 16, 32, 64, 128, 256 and 512 times of RPI.

The timeout period should be 10 msec or more.

RPI can be specified for T>O direction and O>T direction separately, so each

timeout period may be different values.

Set the transmission interval for the cyclic communication. Set a value within the

communication capacity of a target. The usable RPI range depends on devices.

For the FP0H, it is 1 ms to 10 s (by 0.5 ms).

One to one communication is performed between an originator and a target.

Transmitted packets are received only by each other.

Other devices connected to the same HUB do not receive those transmission

packets.

Transmission data is sent as a multicast packet. By connecting multiple originators

to one target, one multicast packet can be received by multiple originators.

(Note) Multicast packets are basically received by all devices connected to the

same HUB which includes the devices unrelated to the communication, and it leads

to an unnecessary communication load.

When using the multicast communication, set not to exceed 100% by the load

factor calculation of the setting tool.

TTL (Time To Live) is used to set the hierarchies of the network in which

transmission packets can exist when sending multicast packets to other PLCs.

Set an instance ID or tag name according to the communication method of the

selected connection.

The data sizes of the originator and target for the cyclic communication must be the

same. When they do not match, the communication cannot be performed.

vi WUME-FP0HEIP-05

Page 7

Term Description

Parameter setting

PPS performance index

(Packet per sec)

Normal packet and

large packet

Protocol used for

cyclic communication

Heartbeat

Forward open

Large forward

open

RUN/IDLE bit

Data size, instance ID and other parameters that can be changed in the EDS file

can be changed.

This is an index of sent/received packets processed in one second.

The packet whose size is within 510 bytes is called normal packet. The packet

whose size is 511 bytes to 1444 bytes is called large packet.

The maximum communication performance varies according to the data size used

for communication.

Performance index of FP0H

For 510 bytes or less: Max. 5000 pps

For 511 bytes or more: Max. 2500 pps

The cyclic communication is performed using UDP. The used port number is 2222.

For "Input Only" or "Listen Only", a packet called heartbeat whose data size is zero

is sent from the originator (FP0H). For the RPI of the heartbeat, the value 16 times

of the RPI of transmitted data from a target is automatically applied.

The heartbeat is used for confirming the continuation of the connection on the

target side. It is used for detect the timeout.

This is a command for opening the connection of EtherNet/IP and sent using TCP.

The used port number is 44818.

This is a command for opening the connection when sending/receiving data whose

size is larger than 511 bytes.

Operation state flag (RUN/IDLE) sent by connected devices in cyclic

communication.

RUN : 1

IDLE : 0

When the RUN/IDLE bit of the originator does not change to RUN, the target may

not operate properly. For details, refer to "5.2.3 RUN/IDLE Bit".

● Do not use "2222" and "44818" for the port numbers set to the connections of Ethernet

communication.

WUME-FP0HEIP-05

vii

Page 8

(MEMO)

viii WUME-FP0HEIP-05

Page 9

Table of Contents

1 FP0H EtherNet/IP Function ..................................................................1-1

1.1 What is EtherNet/IP? ..........................................................................1-2

1.1.1 Overview of EtherNet/IP .................................................................. 1-2

1.1.2 FP0H EtherNet/IP Function ............................................................. 1-2

1.2 Names and Functions of Parts............................................................1-4

1.2.1 Control Unit ...................................................................................... 1-4

1.2.2 LED Displays When PLC Operates ................................................. 1-4

1.3 Restrictions .........................................................................................1-6

2 Cyclic Communication .........................................................................2-1

2.1 Cyclic Communication Function..........................................................2-2

2.1.1 Overview of Cyclic Communication ................................................. 2-2

2.1.2 Operation of Cyclic Communication................................................. 2-3

2.1.3 Data Refresh of Cyclic Communication ........................................... 2-3

2.1.4 Data Area Specifications Using Tag/Instance .................................. 2-4

2.2 Cyclic Communication of FP0H ..........................................................2-6

2.2.1 Connection using FP0H as originator .............................................. 2-6

2.2.2 Connection Using FP0H as Target................................................... 2-7

2.2.3 Example of Configuration When FP0H is Originator and Target...... 2-7

3 Setting Procedure .................................................................................3-1

3.1 Overview of Settings...........................................................................3-2

3.1.1 System Example .............................................................................. 3-2

3.1.2 Setting Procedure ............................................................................ 3-2

3.2 Initial Setting of Ethernet /IP ...............................................................3-4

3.2.1 Ethernet Settings ............................................................................. 3-4

3.2.2 Starting EtherNet/IP Setting Screen ................................................ 3-5

3.2.3 EtherNet/IP Basic Configuration ...................................................... 3-5

3.2.4 Items of Ethernet /IP Basic Configuration ........................................ 3-6

3.3 Settings of Connection Using FP0H as Originator..............................3-8

3.3.1 Settings ............................................................................................ 3-8

3.3.2 Registering EDS File of Target Device............................................. 3-8

3.3.3 Adding Target in Scan List ............................................................... 3-9

3.3.4 Setting IP Address of Target ............................................................ 3-10

3.3.5 Setting Tag/Instance ........................................................................ 3-11

3.3.6 Specifying Data Area Corresponding to Tag/Instance ..................... 3-13

3.3.7 Reference: Setting of Target "FP0H(B)"........................................... 3-15

3.4 Settings of Connection Using FP0H as Target ...................................3-16

3.4.1 Settings ............................................................................................ 3-16

3.4.2 Adding I/O Map to Scan List ............................................................ 3-16

3.4.3 Registering Tag Name/Instance ID .................................................. 3-17

3.4.4 Registering Data Area Corresponding to Tag/Instance.................... 3-18

3.4.5 Reference: Setting of Originator "FP7" ............................................ 3-19

3.5 Confirmation of Load Factor Calculation.............................................3-21

3.5.1 Load Factor Calculation ................................................................... 3-21

WUME-FP0HEIP-05

ix

Page 10

3.5.2 Displaying Load Factor Calculation ................................................. 3-21

3.6 Saving EtherNet/IP Settings ...............................................................3-22

3.6.1 Saving EtherNet/IP Settings in Project ............................................ 3-22

3.6.2 Saving/Reading EtherNet/IP Settings in File ................................... 3-22

3.6.3 Writing EtherNet/IP Settings to FP0H .............................................. 3-23

4 Tool Operation.......................................................................................4-1

4.1 Scan List Window ...............................................................................4-2

4.1.1 Display Contents of Scan List Window ............................................ 4-2

4.1.2 Operations in Scan List Window ...................................................... 4-3

4.2 Device List Window.............................................................................4-7

4.2.1 Display Contents of Device List Window ......................................... 4-7

4.2.2 Operations from EDS File Menu...................................................... 4-7

4.3 Various Setting Screens......................................................................4-9

4.3.1 Operations in Device Setting Screen ............................................... 4-9

4.3.2 Operations in Connection Setting Screen........................................ 4-9

4.3.3 Operations in I/O Map Setting Screen ............................................. 4-12

4.3.4 Display Contents of Calculate Load Factor Screen ......................... 4-13

4.3.5 Display Contents of Device Property Screen................................... 4-15

4.3.6 Switching Tabs in Each Setting Screen ........................................... 4-16

5 Startup and Operation ..........................................................................5-1

5.1 Startup Operation of Cyclic Communication.......................................5-2

5.1.1 When FP0H is Originator ................................................................. 5-2

5.1.2 When FP0H is Target....................................................................... 5-3

5.2 Checking EtherNet/IP Communication State......................................5-4

5.2.1 Unit Annunciation Relays................................................................. 5-4

5.2.2 Cyclic Communication State Tables of EtherNet/IP ......................... 5-4

5.2.3 RUN/IDLE Bit ................................................................................... 5-4

5.3 Judgement and Operation of Abnormality ..........................................5-6

5.4 Delay Time of Communication Data ...................................................5-7

5.4.1 Delay time of sent data .................................................................... 5-7

5.4.2 Delay Time of Reception Data ......................................................... 5-7

6 Instruction References .........................................................................6-1

6.1 High-level Instructions Used for EtherNet/IP Control..........................6-2

6.1.1 Information Acquisition of EtherNet/IP (F465 ETSTAT) ................... 6-2

7 Reference Information..........................................................................7-1

7.1 Calculation Method of Load Factor.....................................................7-2

7.2 Cyclic Communication: List of Abnormal Statuses .............................7-5

7.3 PLC Link and Ethernet Switch ............................................................7-8

8 Appendix................................................................................................8-1

8.1 Supported Data Types........................................................................8-2

x

WUME-FP0HEIP-05

Page 11

1 FP0H EtherNet/IP Function

1.1 What is EtherNet/IP? ..........................................................................1-2

1.1.1 Overview of EtherNet/IP .................................................................. 1-2

1.1.2 FP0H EtherNet/IP Function ............................................................. 1-2

1.2 Names and Functions of Parts............................................................1-4

1.2.1 Control Unit ...................................................................................... 1-4

1.2.2 LED Displays When PLC Operates ................................................. 1-4

1.3 Restrictions .........................................................................................1-6

WUME-FP0HEIP-05 1-1

Page 12

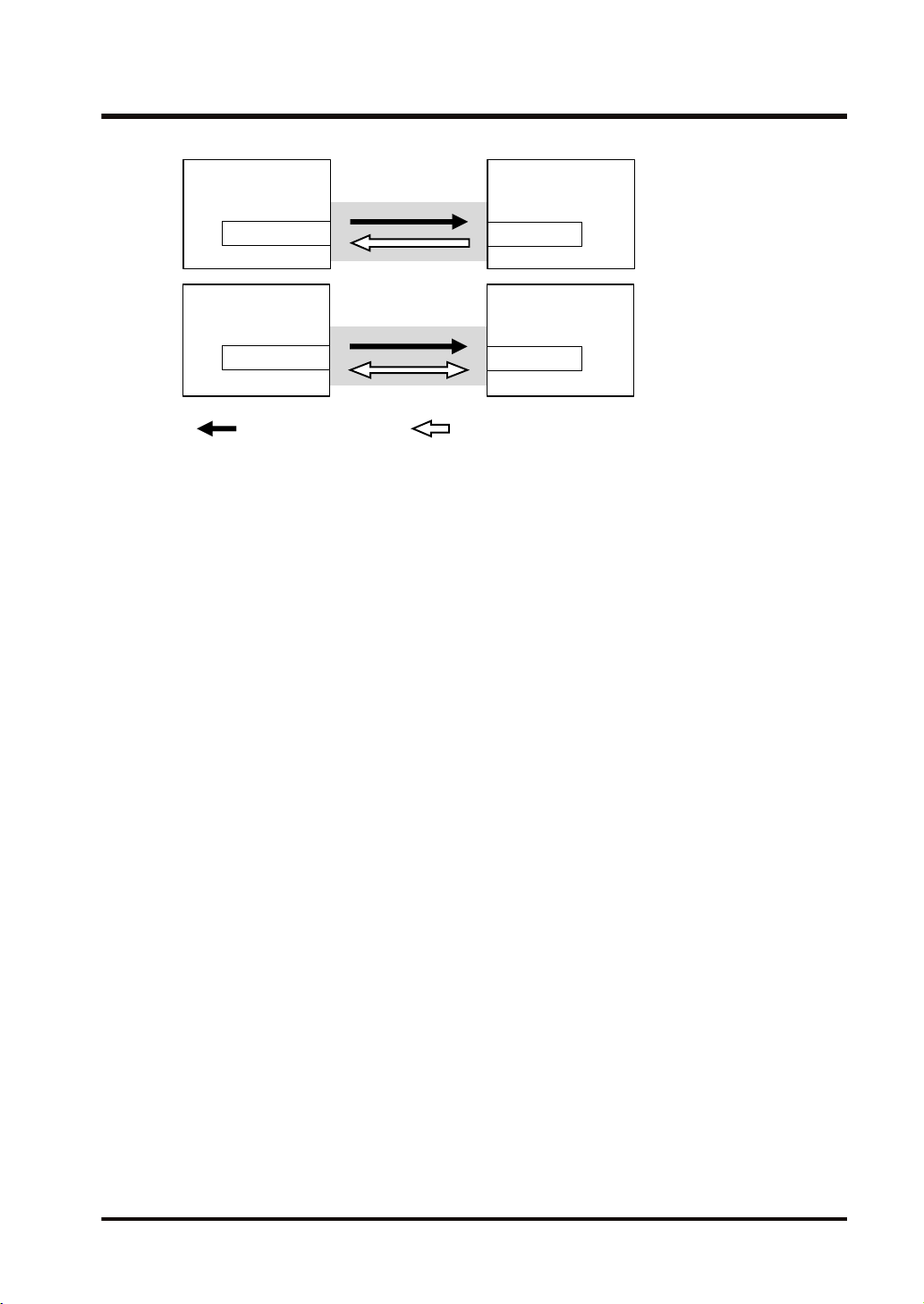

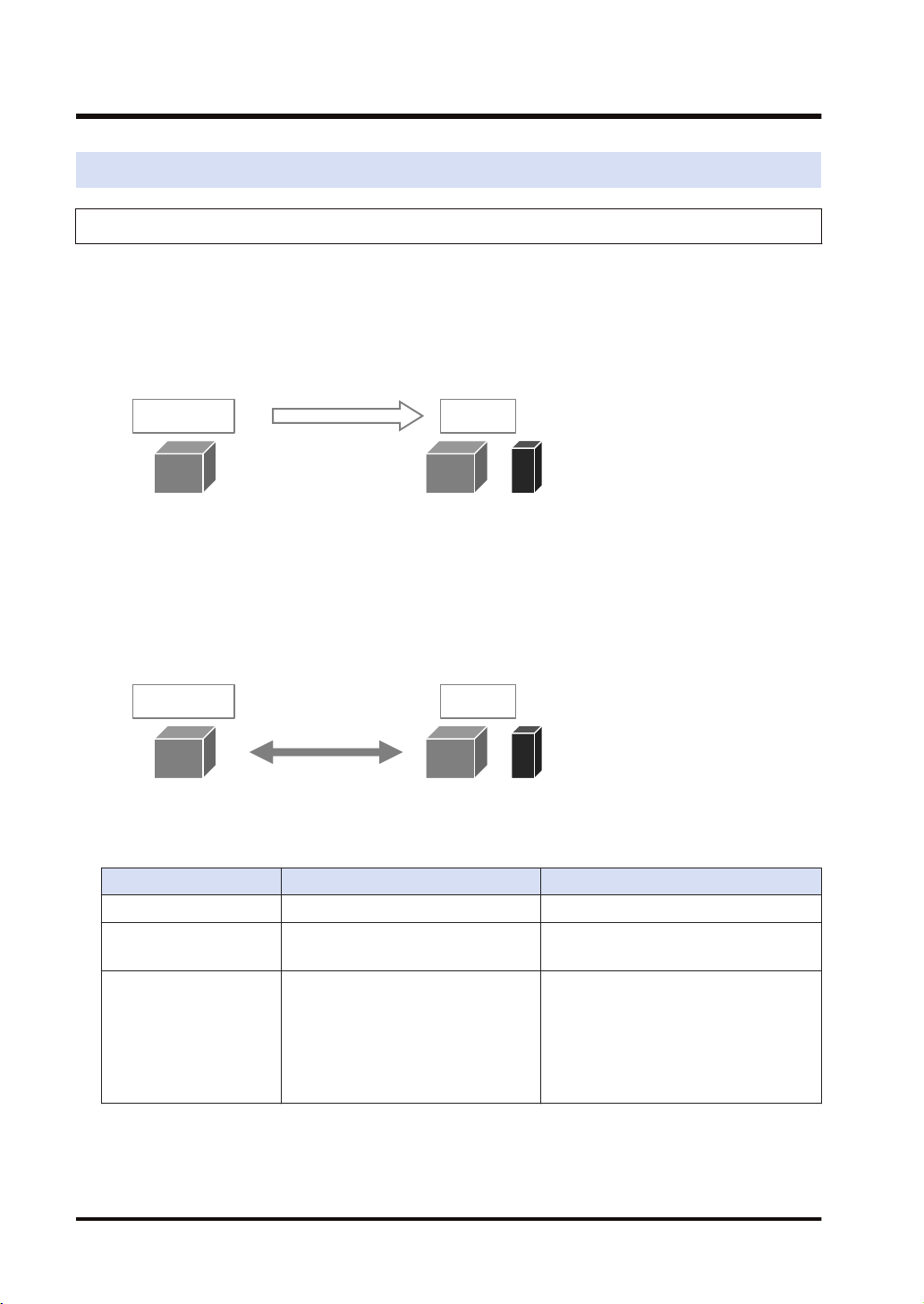

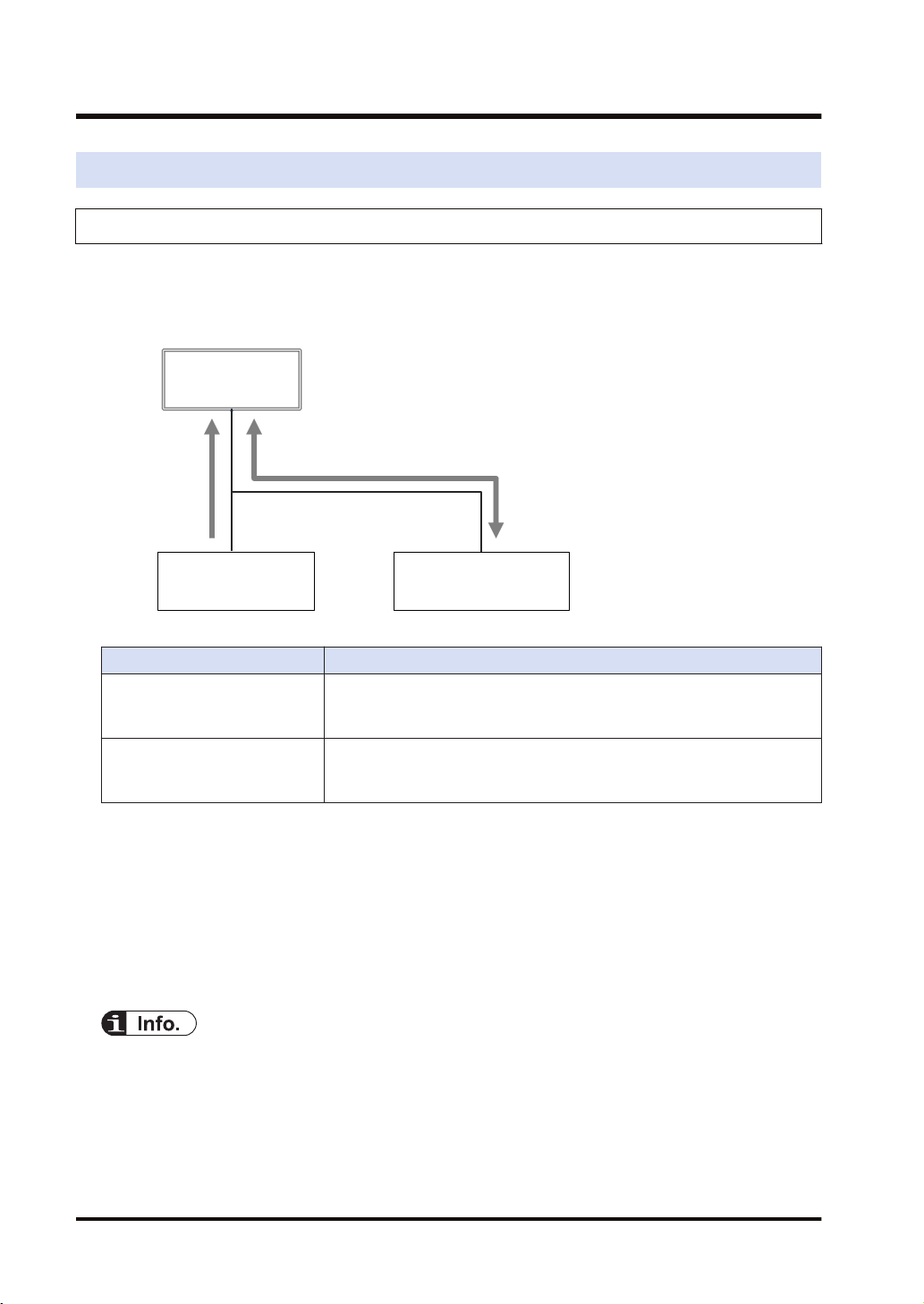

FP0H

Connection 1

Connection 2

: Opens connection. : Sends cyclic data.

PLC

Originator

Target Originator

Target

1.1 What is EtherNet/IP?

1.1 What is EtherNet/IP?

1.1.1 Overview of EtherNet/IP

EtherNet/IP (Ethernet Industrial Protocol) is an industrial multi-vendor realtime Ethernet system

for executing the communication protocol for CIP (Common Industrial Protocol) control in an

application layer on standard Ethernet.

Cyclic communication can be performed among devices compatible with EtherNet/IP. In cyclic

communication, devices compatible with EtherNet/IP send or receive data between "specified

data areas" in a "specified cycle". Even when the number of nodes increases, the cycle does

not increase.

For information on CIP, refer to the documents of ODVA.

1.1.2 FP0H EtherNet/IP Function

The FP0H can perform the cyclic communication with PLCs and I/O devices compatible with

EtherNet/IP on the EtherNet/IP network.

The send and receive areas are allocated from the device area of the FP0H for the cyclic

communication. Data is sent/received from the allocated area with specified intervals (RPI).

The EtherNet/IP function of FP0H is set from the "EtherNet/IP settings" menu of programming

software FPWIN GR7.

■

Originator and Target

In each connection (communication line) of cyclic communication, there are "originator" which

opens each connection and "target" which a connection is opened.

The PLC (FP0H) can be set as the both originator and target.

For the communication between the FP0H and a PLC, the settable connection is "Input Only"

(i.e. data can be sent in one direction, from target to originator). By using two connections, data

can be sent and received.

For the communication between the FP0H and other I/O devices, the FP0H is the originator.

According to devices, the data transmissions by "Input Only" (from target to originator) and

"Exclusive Owner" (two-way) may be available.

1-2 WUME-FP0HEIP-05

Page 13

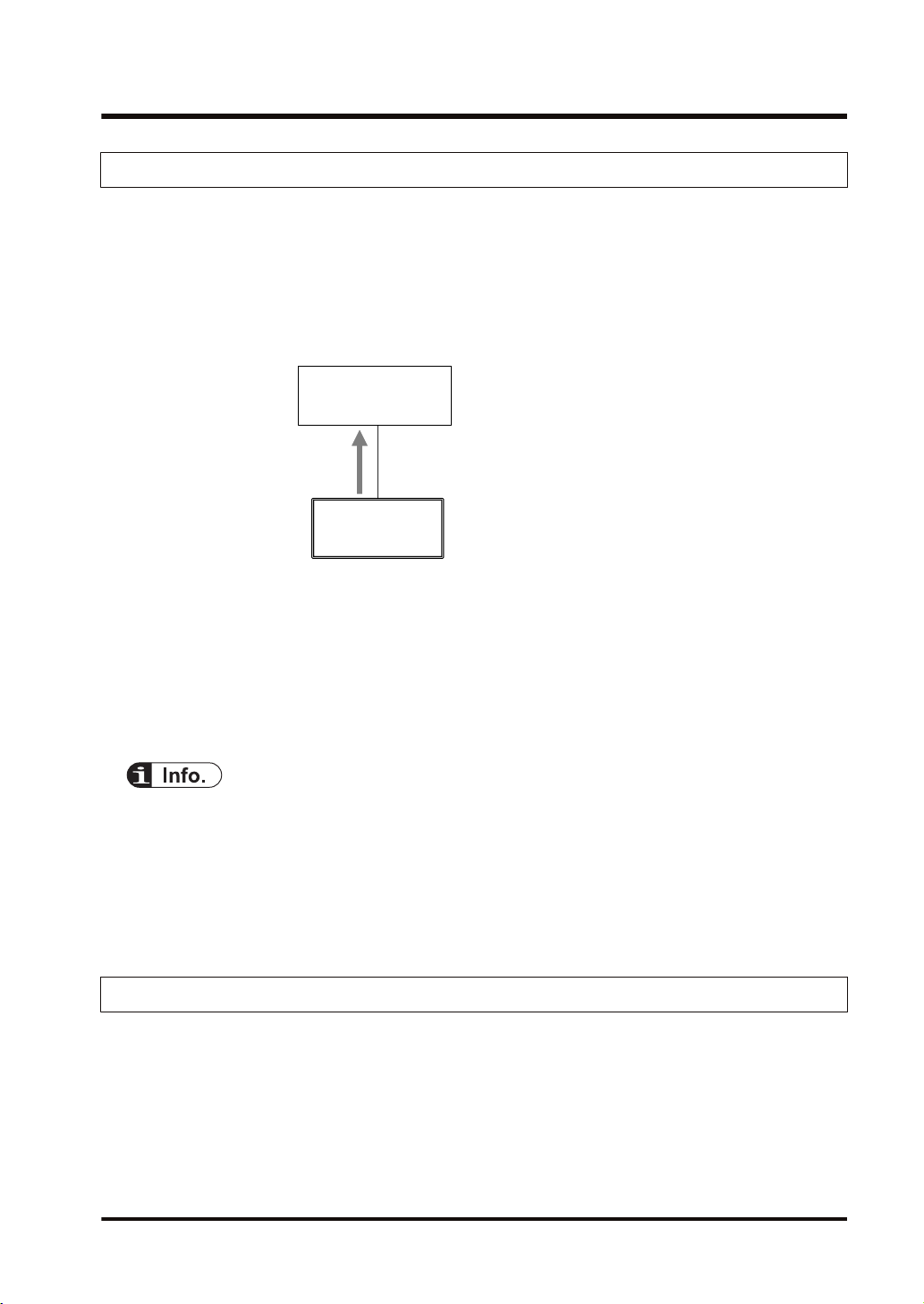

FP0H

Connection

Input Only

: Opens connection. : Sends cyclic data.

I/O device

Originator

Target

FP0H

Connection

Exclusive Owner

I/O device

Originator

Target

1.1 What is EtherNet/IP?

WUME-FP0HEIP-05 1-3

Page 14

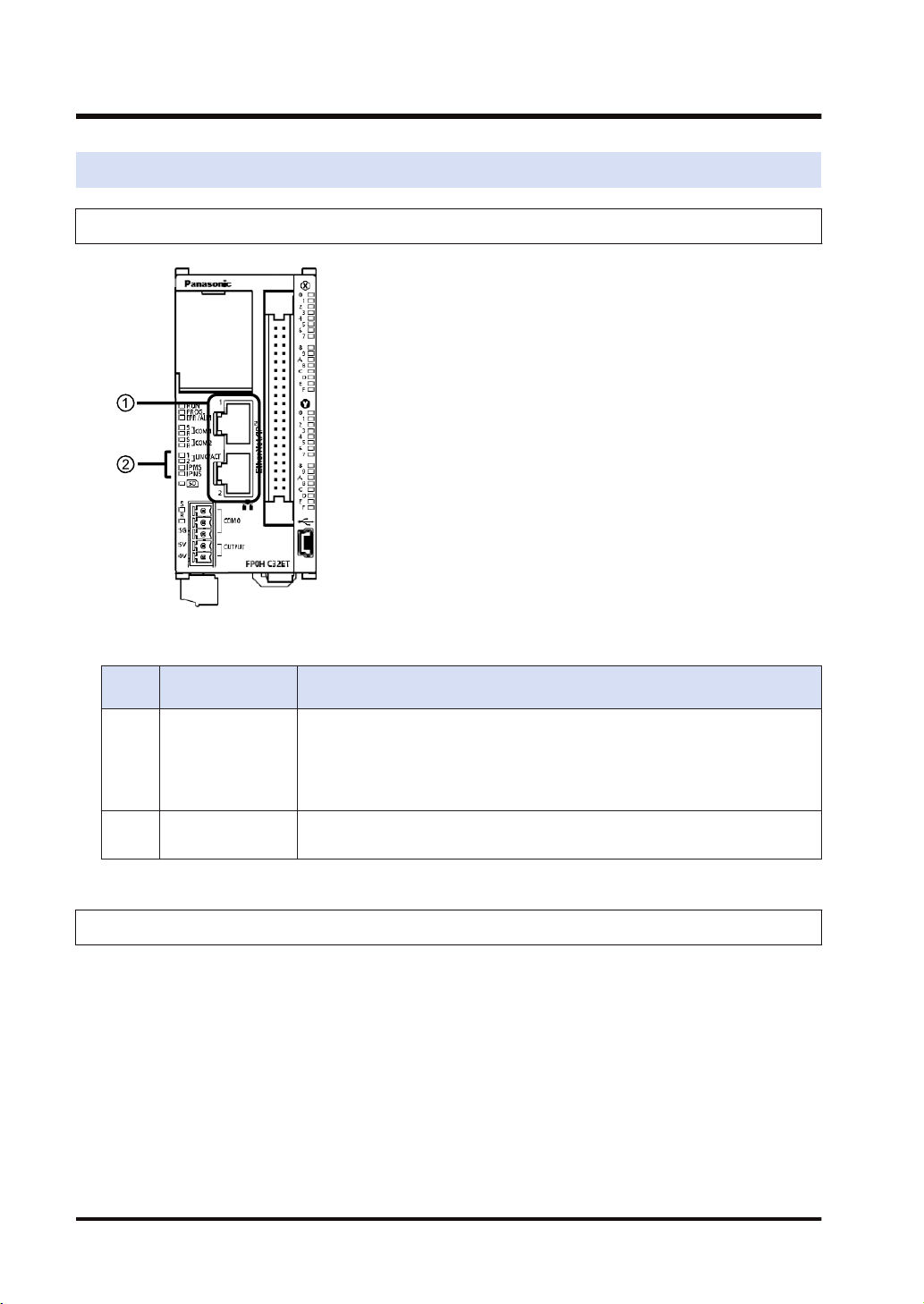

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

1.2.1 Control Unit

■

Names and Functions of Parts

Numb

er

Name Description

(1) LAN port

Operation monitor

(2)

LED

It is mounted to the FP0H Control Unit (Ethernet type). It is used for connecting

to Ethernet and EtherNet/IP.

The IP address and MAC address are common to the LAN ports 1 and 2. The

wiring can be simplified by using the two ports.

The MAC address is printed on the side face of the unit.

IP MS: Displays the operating condition of the unit.

IP NS: Displays the communication status of network.

1.2.2 LED Displays When PLC Operates

The state of the PLC can be confirmed from the lighting state of the LEDs when the PLC is

operating. The PLC states indicated by the LEDs are as follows.

1-4 WUME-FP0HEIP-05

Page 15

1.2 Names and Functions of Parts

MS (Module status indicator) <Green/Red>

LED display PLC state

LED OFF The EtherNet/IP function is disabled.

Green ON The EtherNet/IP function is normally activated.

Green

Flashing

Red ON Unrecoverable fault occurs.

Red Flashing Recoverable fault occurs. (such as a setting that load factor exceeds)

This state does not exist.

NS (Network status indicator) <Green/Red>

LED display PLC state

LED OFF The EtherNet/IP function is disabled or IP address is not established.

Green ON More than one connection is established.

Green

Flashing

Red ON IP address duplication is detected.

Red Flashing This state does not exist.

■

LED displays when PLC is started

Connection is not established, but IP address is acquired.

The MS and NS LEDs turn on in the following order when the FP0H is started.

Each lighting time of the lighting order 1 to 4 is 0.25 seconds.

Lighting

order

1 Green ON OFF

2 Red ON OFF

3 Green ON Green ON

4 Green ON Red ON

5 Green ON OFF

Lighting state

MS NS

WUME-FP0HEIP-05 1-5

Page 16

1.3 Restrictions

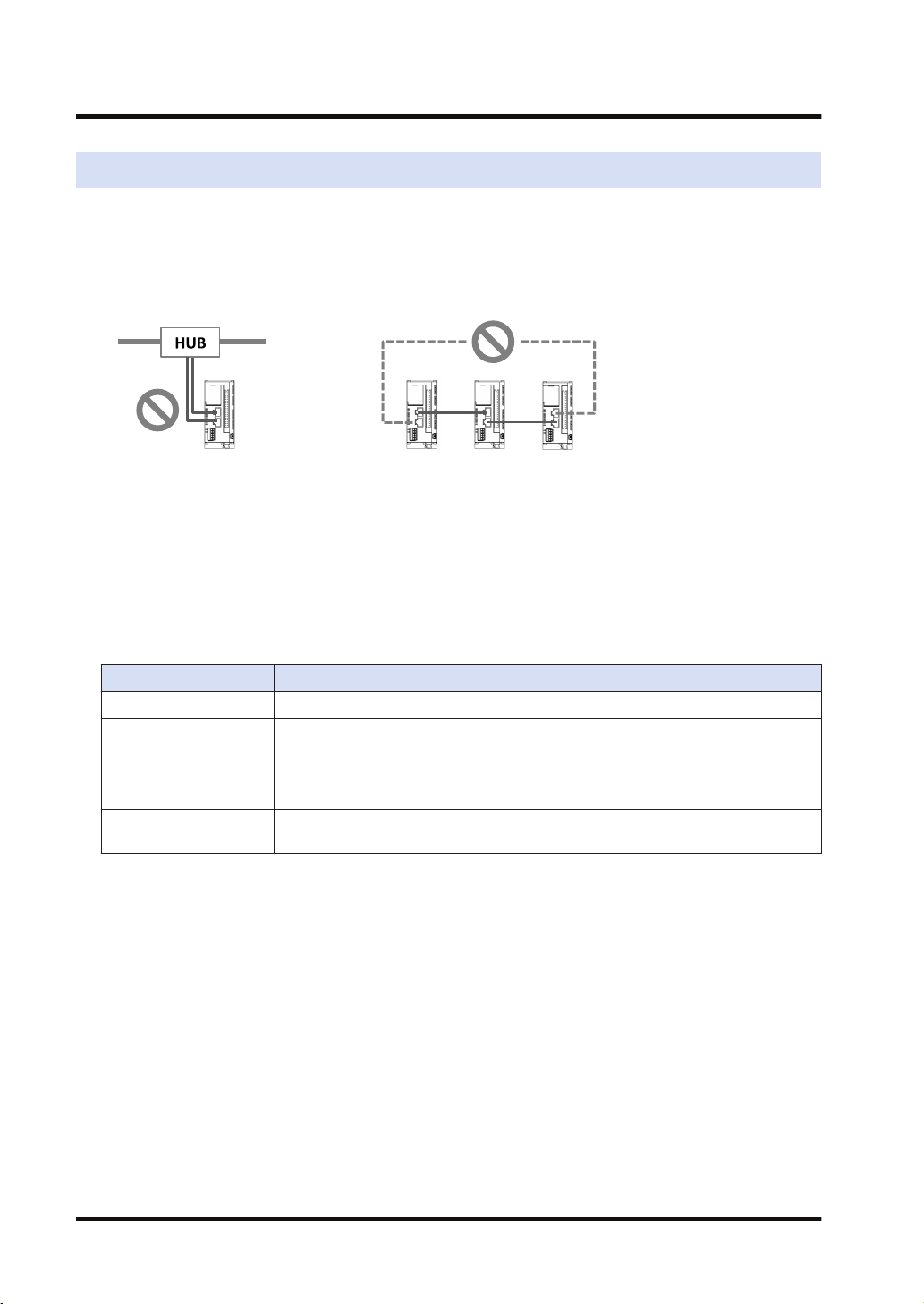

1.3 Restrictions

■

Connecting to External Devices

LAN ports 1 and 2 have the same IP address and MAC address.

● Do not connect the cables from the two LAN ports to the same switching HUB.

● When performing daisy chain connection, do not connect devices in a ring shape.

■

Number of connections

For the FP0H, the total number of connections of Ethernet communication and EtherNet/IP

communication should be 9 or less. For the details of the setting of the number of connection,

refer to "3.2.1 Ethernet Settings".

(The no. of user connections of Ethernet communication) + (EtherNet/IP communication) 9

connections

■

Restrictions by FP0H specifications

Item Specifications

RPI 1 to 10000 ms (In 0.5 ms unit)

Cyclic communication

allowable

communication band

Usable devices WX, WY, WR, WL, DT, LD

Device specification of

each tag/instance

5000 pps (Packet size: 2 to 510 bytes)

2500 pps (Packet size: 511 to 1450 bytes)

Max. 8 devices

1-6 WUME-FP0HEIP-05

Page 17

2 Cyclic Communication

2.1 Cyclic Communication Function..........................................................2-2

2.1.1 Overview of Cyclic Communication ................................................. 2-2

2.1.2 Operation of Cyclic Communication................................................. 2-3

2.1.3 Data Refresh of Cyclic Communication ........................................... 2-3

2.1.4 Data Area Specifications Using Tag/Instance .................................. 2-4

2.2 Cyclic Communication of FP0H ..........................................................2-6

2.2.1 Connection using FP0H as originator .............................................. 2-6

2.2.2 Connection Using FP0H as Target................................................... 2-7

2.2.3 Example of Configuration When FP0H is Originator and Target...... 2-7

WUME-FP0HEIP-05 2-1

Page 18

Opens connections.

PLC PLC

I/O device

Originator

Target

Cyclic communication

PLC PLC

I/O device

Originator

Target

2.1 Cyclic Communication Function

2.1 Cyclic Communication Function

2.1.1 Overview of Cyclic Communication

The cyclic communication is a function to perform data transmission with constant intervals

(RPI) between PLC and PLC or PLC and I/O device on the EtherNet/IP network.

In the cyclic communication, one device opens a communication line which is called connection

for a destination device. The side which opens the connection (communication line) is called

"originator", and the side which the connection is opened is called "target".

Connection information on the cyclic communication is set in the originator. The originator

connects to the target according to the connection information. The tag/instance required for the

connection from the originator is registered in the target.

Once the connection is open, the cyclic communication begins according to the settings of the

connection information.

Comparison of originator and target

Item Originator Target

Applicable model PLC PLC, I/O device

When starting

communication

Connection information

2-2 WUME-FP0HEIP-05

Opens connections.

(Connects to targets.)

Target connection information

● IP Address

● Tag/Instance

Cyclic communication information

● RPI

● Communication method, etc.

Connection is opened.

(Connected from originator.)

Connected from originator

● Tag/Instance

Page 19

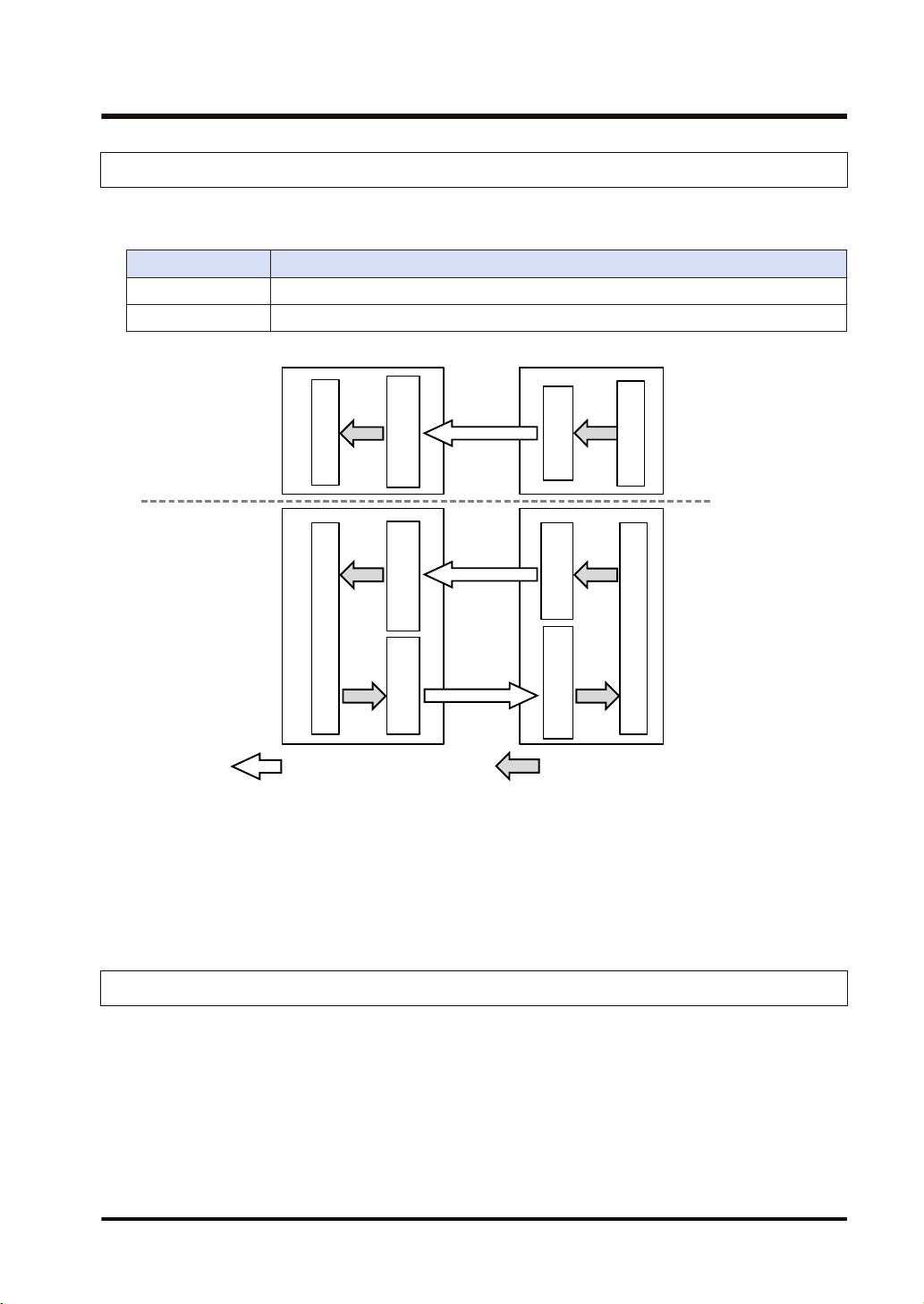

Send buffer

Receive buffer

Data area

Receive buffer

Send buffer

Data area

Input Only

Exclusive Owner

: Sends cyclic data. : Refreshes data.

Receive buffer

Send buffer

Data area

Data area

Originator

Target

2.1 Cyclic Communication Function

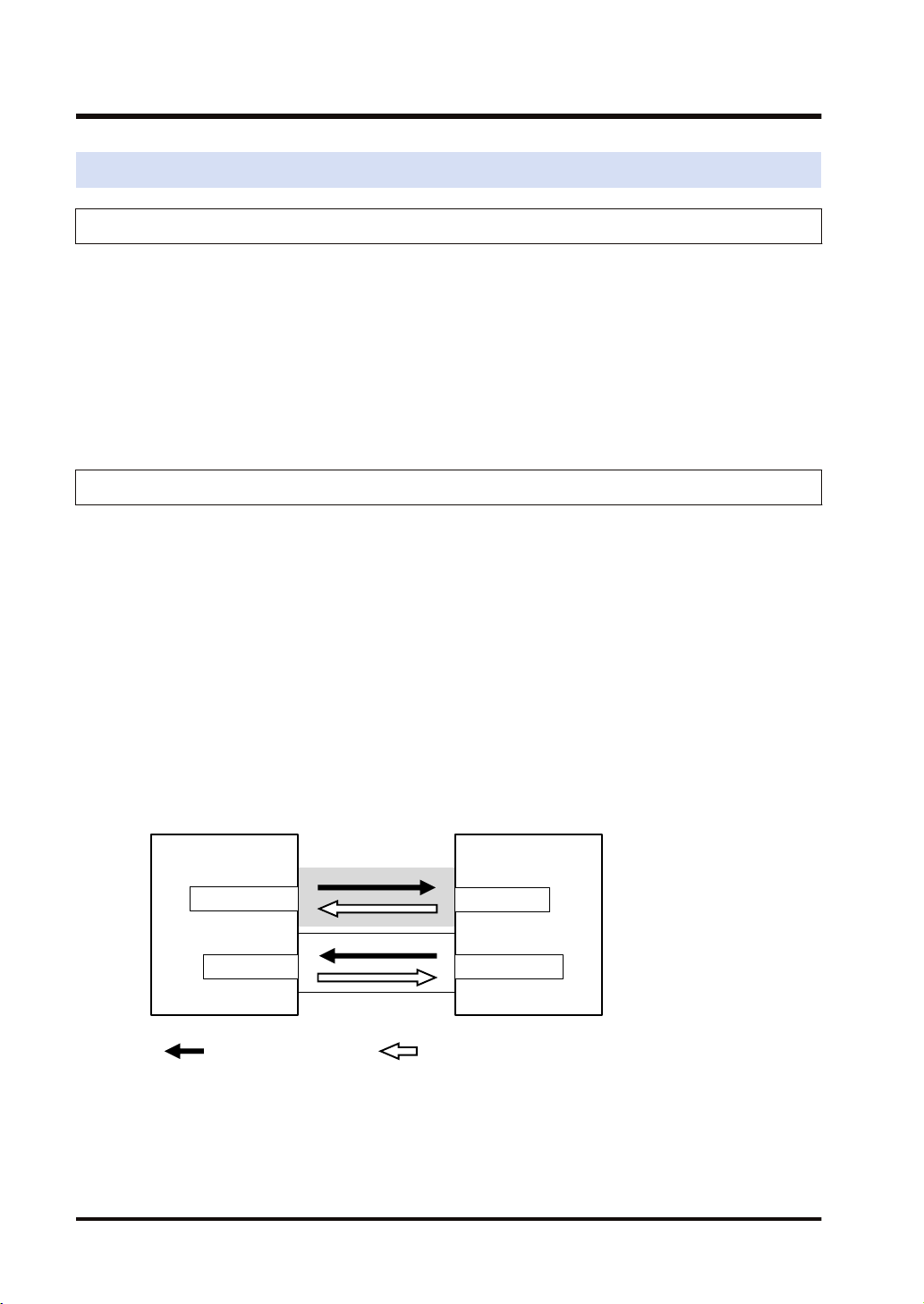

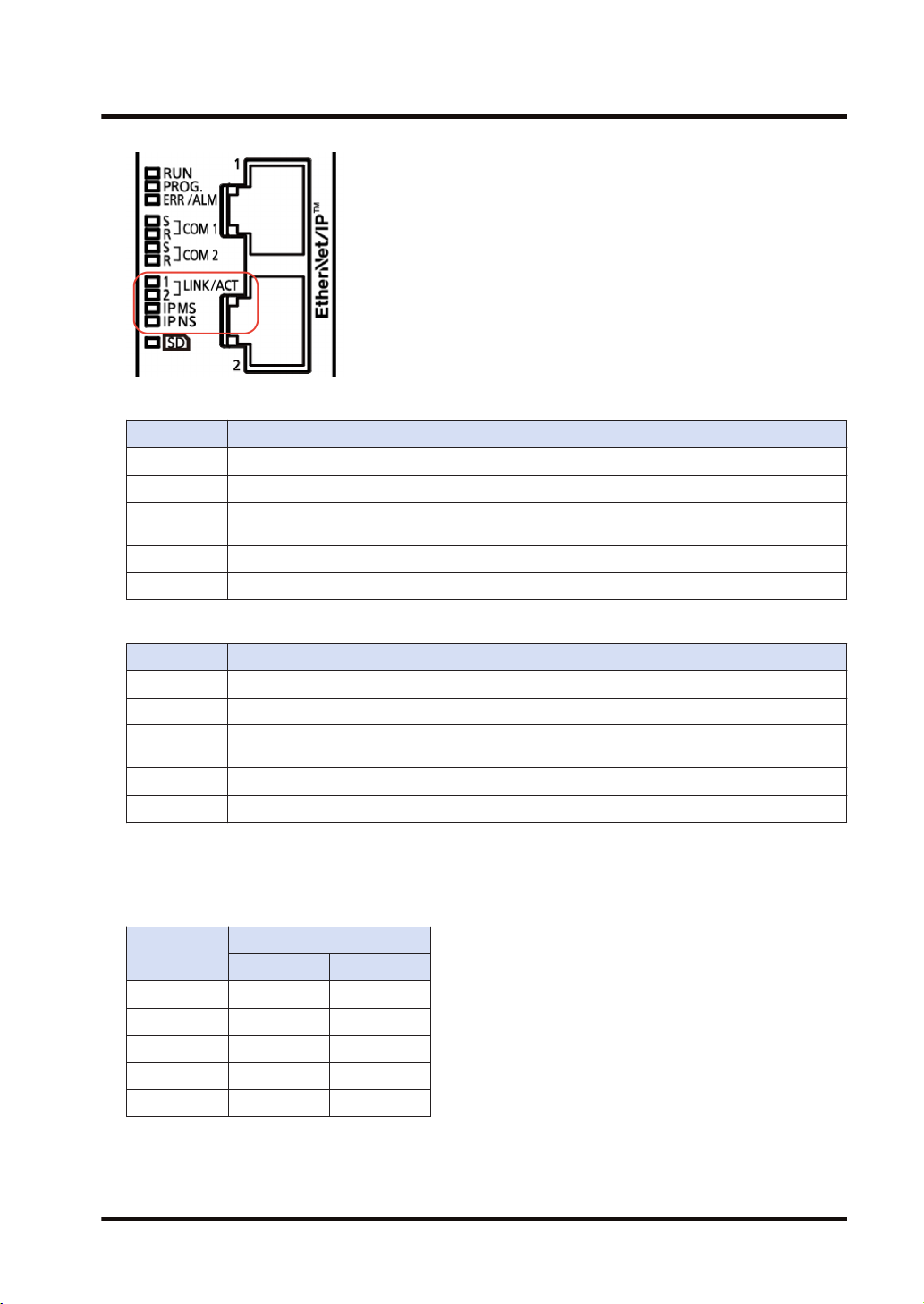

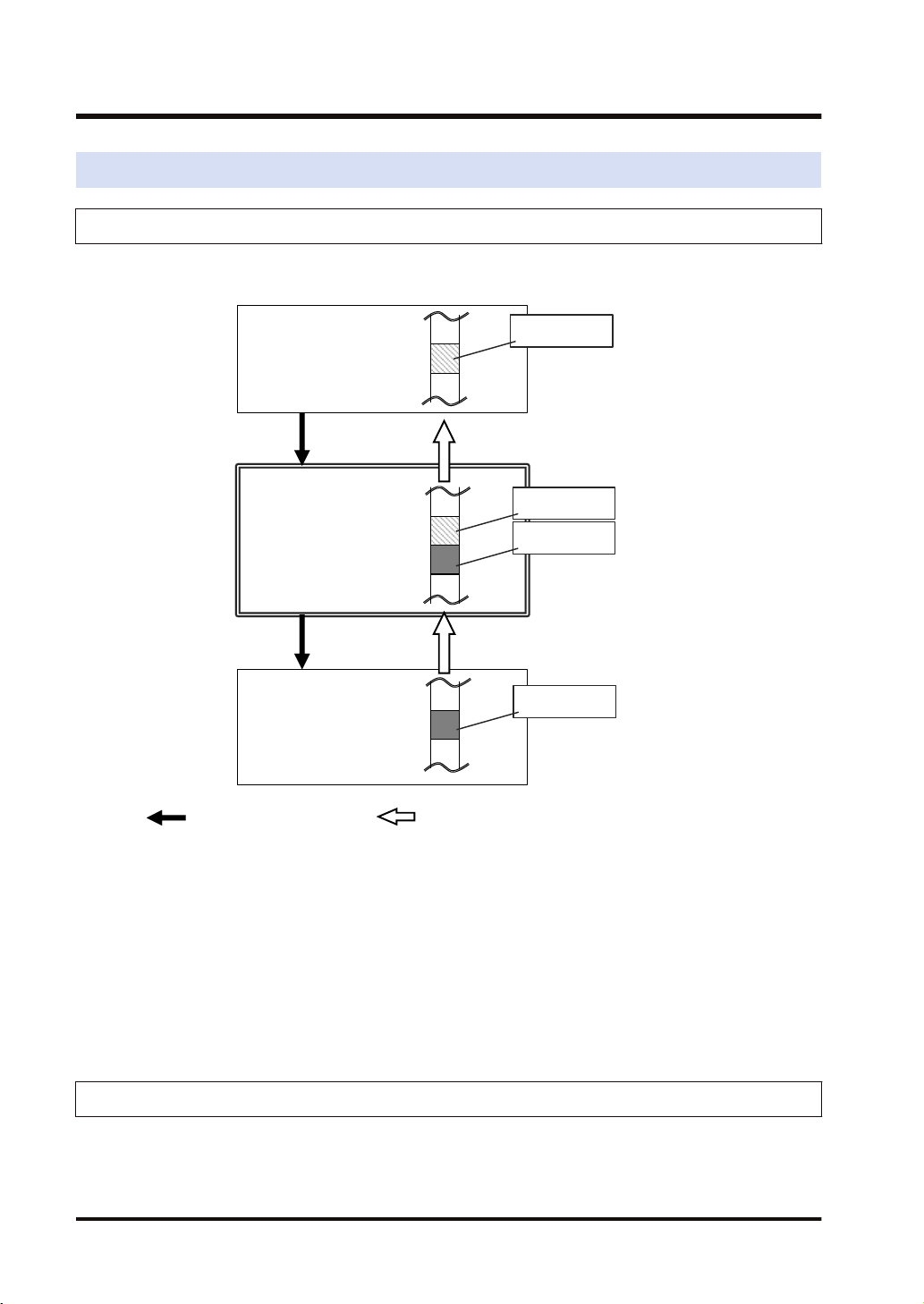

2.1.2 Operation of Cyclic Communication

The communication behavior in the cyclic communication varies according to the settings of

connections.

Description

Input Only Data is sent in the input direction only (From target to originator)

Exclusive Owner Data is sent bi-directionally.

(Note 1) The transfer operations Data area>Send buffer and Receive buffer>Data area in each device are

● For some target devices, "Exclusive Owner" setting is not available.

● When PLCs including FP0H are set as targets, "Input Only" setting is only available.

● For sending/receiving data between PLC and PLC, it is necessary to use two connections

2.1.3 Data Refresh of Cyclic Communication

In the cyclic communication, data is refreshed in synchronization with operation cycle and RPI.

The refresh of sent data and received data is controlled for each RPI.

WUME-FP0HEIP-05 2-3

called "Refresh".

and open them each other.

Page 20

Send buffer

Receive buffer

Data area

: Sends cyclic data. : Refreshes data.

Data area

Input

refresh

Output

refresh

<Receiver side>

<Sender side>

2.1 Cyclic Communication Function

Refresh direction Refresh operation

In refresh processing at the beginning of scan, if there is incoming data in the receive

Input refresh

Output refresh

■ Refresh operation when starting communication

● After confirming that the connection is open with the connection open flag, refreshes sent

data.

● After detecting received data with the received data existence flag, refreshes received data.

● After refreshing received data, the normal reception active flag turns ON.

buffer for the cyclic communication, it is copied to the operation memory. After the

completion of the refresh operation, the latest received data will be an object to be

refreshed in the next time.

In refresh processing at the beginning of scan, if there is space in the send buffer for the

cyclic communication, it is copied from the data area. If the refreshing has not been

completed at the time of data transmission, the previous refreshed data is sent.

2.1.4 Data Area Specifications Using Tag/Instance

In the cyclic communication, the data send and received areas are specified using "Tag" or

"Instance".

● For "Tag", the areas are specified by symbols. For "Instance", they are specified by numbers.

● For some target devices, only either of "Tag" and "Instance" may be available.

● In the connection of "Exclusive Owner", the receive area of each target is specified by

another tag or instance.

(Note) Even when specifying by tag, numbers are assigned to packets during the actual cyclic

communication.

2-4 WUME-FP0HEIP-05

Page 21

Exclusive Owner only

TargetOriginator

: Opens connection. : Sends cyclic data.

Data area

Data area

Instance (100)

When specifying "Instance"

Tag (Tag_1)When

specifying "Tag"

Tag (Tag_1)

When specifying "Tag"

Instance (100)

When specifying "Instance"

Settings of target and originator

Settings

Originator

Target

Tag/Instance of connected target

Data area/size of originator corresponds to Tag/Instance

Tag/Instance connected from originator

Data area/size of target corresponds to Tag/Instance

2.1 Cyclic Communication Function

● In each connection, the sizes of the data areas which correspond to the originator and target

should be the same.

● For the FP0H, the data areas of each connection can be allocated to the operation memories in

a maximum of 8 areas. Device names that can be allocated are WX, WY, WR, WL, LD, and DT.

For the automatic allocation, the WL and LD areas are used.

WUME-FP0HEIP-05 2-5

Page 22

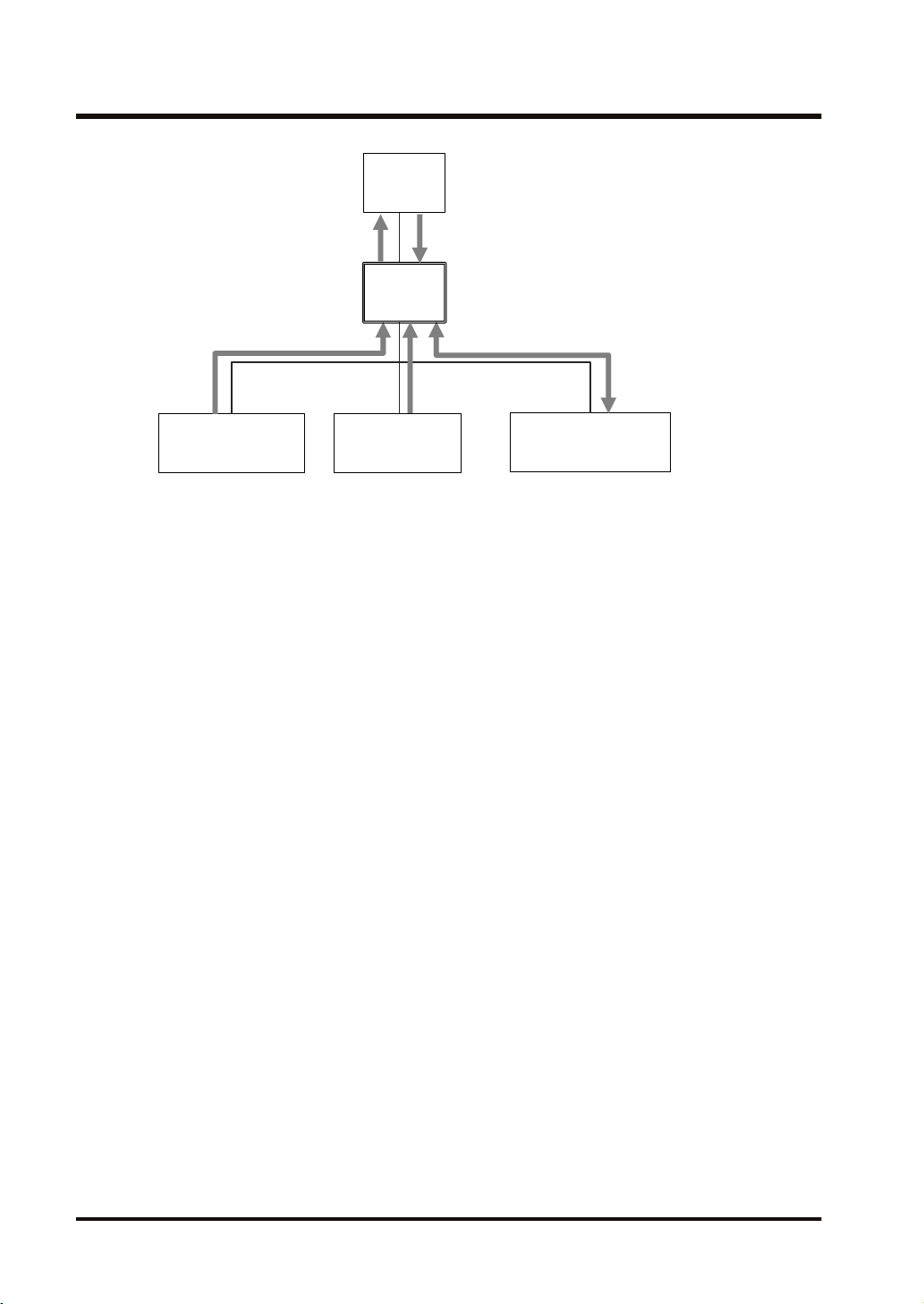

Low-order PLC

Input Only

I/O device

Exclusive Owner

Target 1 Target 2

Connection 1

Receiving data

FP0H

Connection 2

Sending/Receiving data

Originator

2.2 Cyclic Communication of FP0H

2.2 Cyclic Communication of FP0H

2.2.1 Connection using FP0H as originator

■

Illustration of operation

The FP0H establishes connections with targets registered in Scan List and performs the cyclic

communication.

Description

Input direction

(Direction from Target to

Originator)

Output direction

(Direction from Originator to

Target)

■

Settings

Data is sent from targets to the FP0H periodically.

Data is sent from the FP0H to targets periodically.

Register target low-order PLCs and I/O devices in "Scan List" of FP0H and register connection

information. The registration is made for each target.

Register the following information in the connection information.

● Connected target information (IP address, Tag/Instance)

● Data area and size that corresponds to Tag/Instance

● Cyclic communication information (RPI, Communication method)

● Scan List is a list for setting the connection information with "Target". Use Programming

software FPWIN GR7 for the registration.

● For registering other companies' EtherNet/IP devices in Scan List, the EDS files of those

devices are required. Communication parameters that can be set in each device are defined in

the EDS files.

2-6 WUME-FP0HEIP-05

Page 23

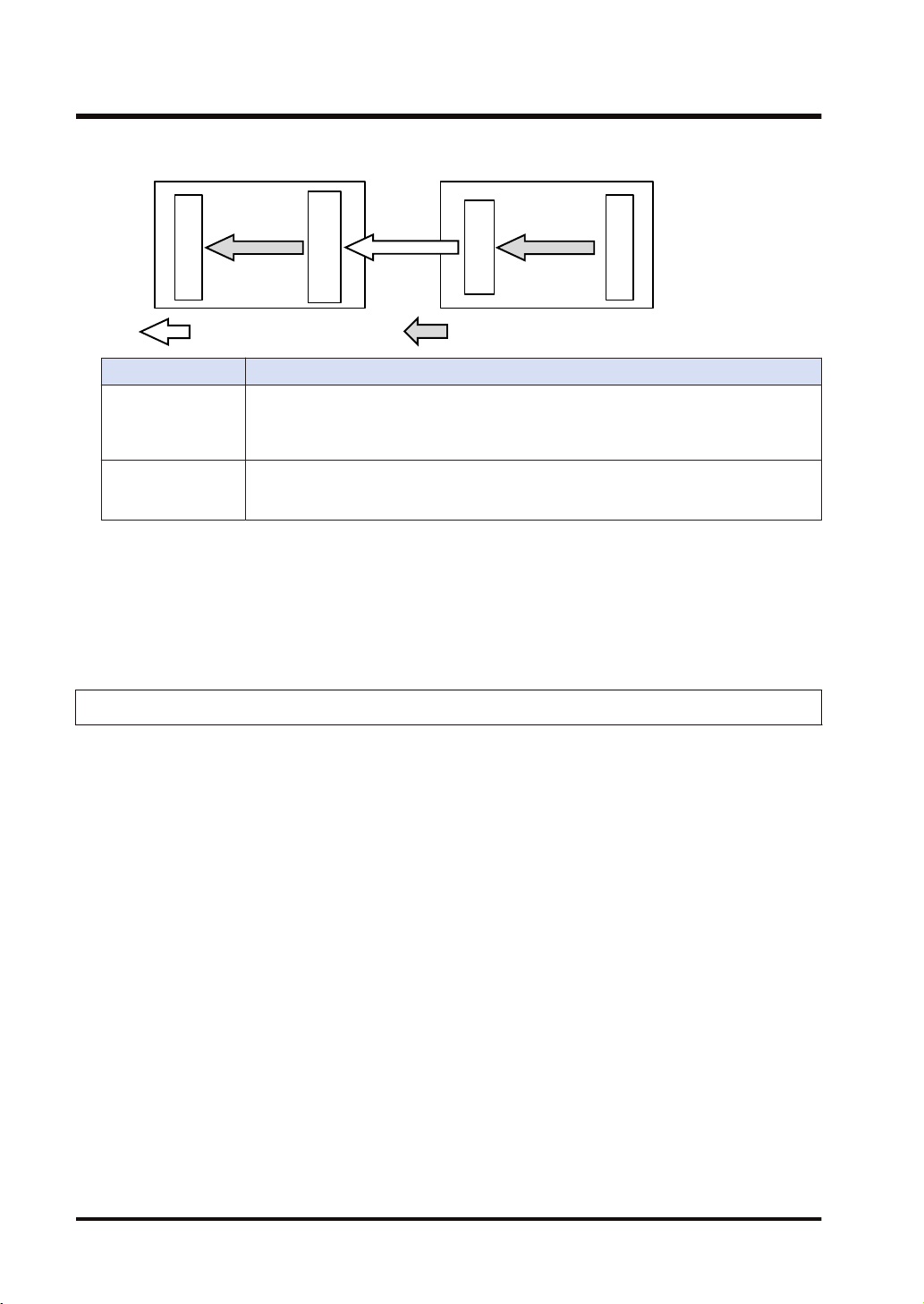

High-order PLC

(FP7)

Originator

Connection 1

Sends data to High-order PLC.

FP0H

Input Only

Target

2.2 Cyclic Communication of FP0H

2.2.2 Connection Using FP0H as Target

■

Illustration of operation

● The high-order PLC (FP7) (originator) makes a connection for the registered tag/instance.

● When the FP0H is used as target, only the transmission to originator (Input Only) is

available.

● Once the connection from an originator is established, the FP0H sends data to the originator

from the buffer for the cyclic communication periodically.

■

Settings

Register the tag/instance information in the "I/O map" of the FP0H.

● The tag/instance information is registered for each originator.

● The tag/instance information includes the following information.

• Connected tag/instance

• Data area and size that corresponds to Tag/Instance

● I/O map is a list for setting the connection information with "Originator". Use Programming

software FPWIN GR7 for the registration.

● The EDS file of FP0H can be downloaded from our download center.

https://industrial.panasonic.com/ac/j/dl_center/

● For using the FP0H as a target, the both methods, tag and instance, are available. However,

the selectable instance IDs for the instance method are 100 to 199.

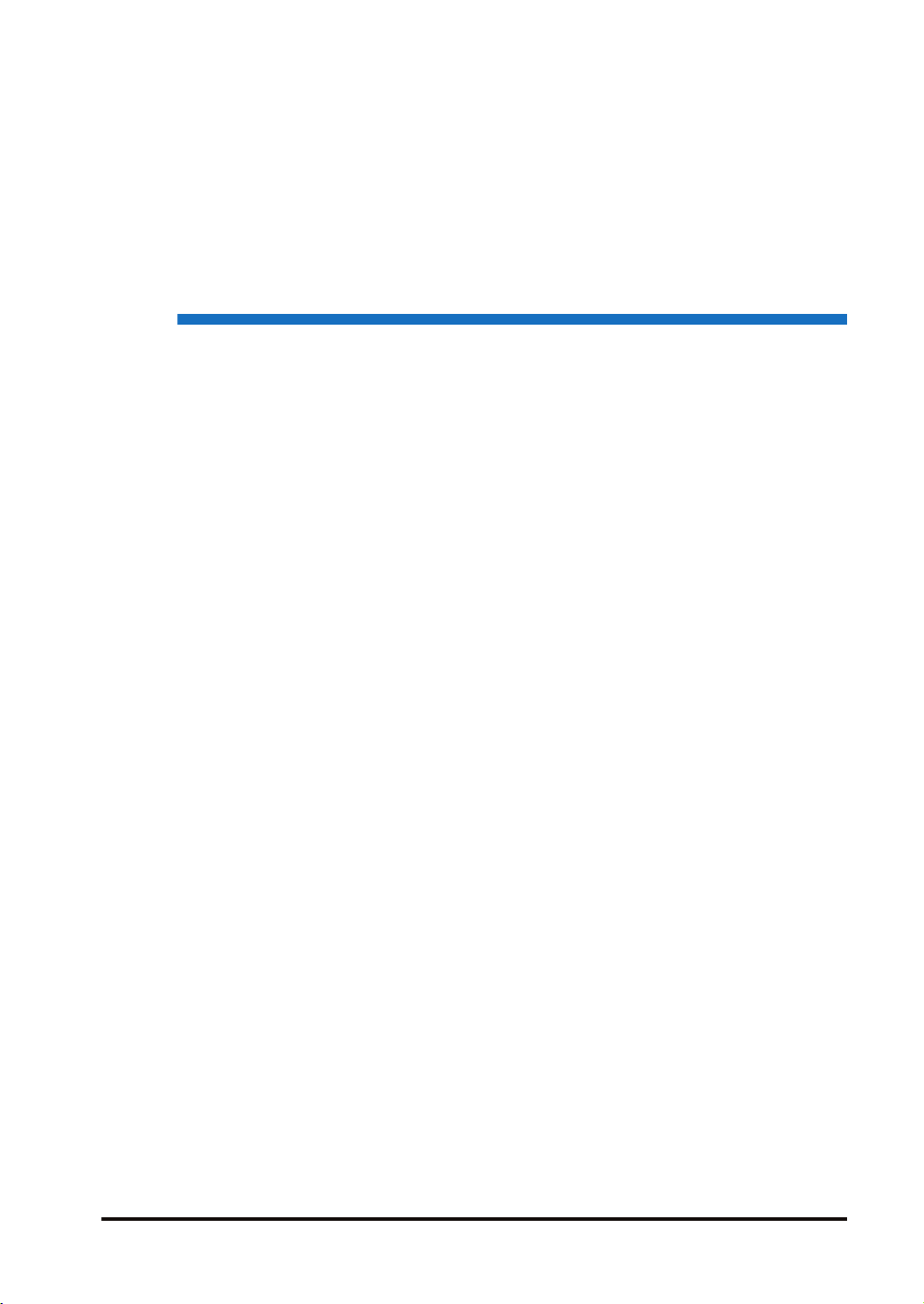

2.2.3 Example of Configuration When FP0H is Originator and Target

■

Illustration of operation

Example of Configuration When FP0H is Originator and Target In the example, the FP0H uses

five connections.

WUME-FP0HEIP-05 2-7

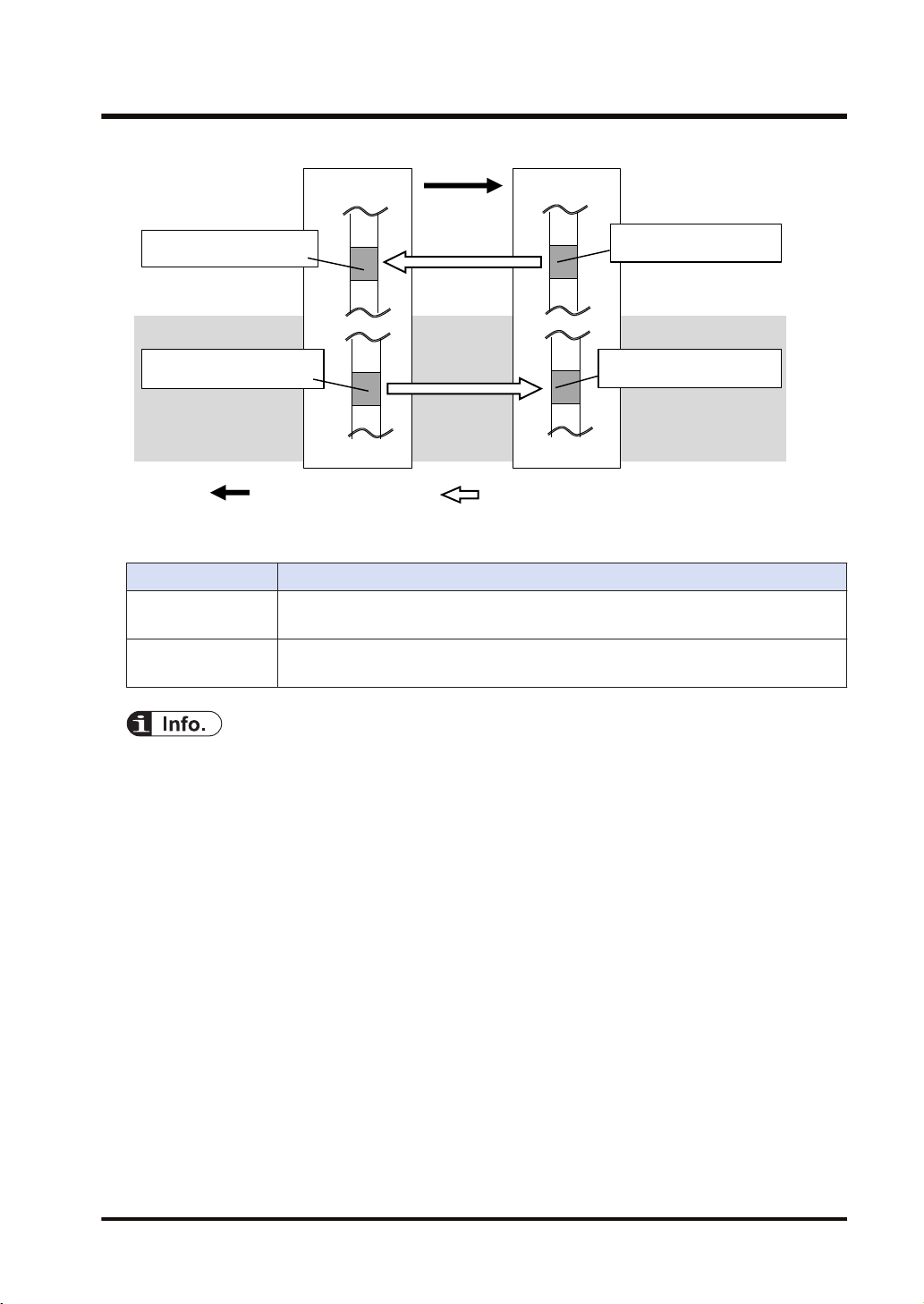

Page 24

FP7

Target 1

Low-order PLC

Input Only

I/O device B

Exclusive Owner

Target 2 Target 3

Target 4

Connection 1

Sends data to FP7.

Connection 2

Sends data from FP7.

Connection 3

Receives data.

Connection 4

Receives data.

Connection 5

Sends and Receives data.

FP0H

FP0H

I/O device A

Input Only

Originator 1

2.2 Cyclic Communication of FP0H

■

Target settings

Set the FP0H as below to send/receive data with the high-order FP7.

● Register the FP7 in the scan list and set the connection information.

● Register the I/O map for connecting the FP7 and set the tag/instance information.

■

Originator settings

Set the FP0H as below to receive data from low-order devices (low-order PLC, I/O devices A

and B). When the connection with a target is "Exclusive Owner", data can be sent and received.

● Register the low-order PLC, I/O devices A and B in the scan list and set the connection

information.

2-8 WUME-FP0HEIP-05

Page 25

3 Setting Procedure

3.1 Overview of Settings...........................................................................3-2

3.1.1 System Example .............................................................................. 3-2

3.1.2 Setting Procedure ............................................................................ 3-2

3.2 Initial Setting of Ethernet /IP ...............................................................3-4

3.2.1 Ethernet Settings ............................................................................. 3-4

3.2.2 Starting EtherNet/IP Setting Screen ................................................ 3-5

3.2.3 EtherNet/IP Basic Configuration ...................................................... 3-5

3.2.4 Items of Ethernet /IP Basic Configuration ........................................ 3-6

3.3 Settings of Connection Using FP0H as Originator..............................3-8

3.3.1 Settings ............................................................................................ 3-8

3.3.2 Registering EDS File of Target Device............................................. 3-8

3.3.3 Adding Target in Scan List ............................................................... 3-9

3.3.4 Setting IP Address of Target ............................................................ 3-10

3.3.5 Setting Tag/Instance ........................................................................ 3-11

3.3.6 Specifying Data Area Corresponding to Tag/Instance ..................... 3-13

3.3.7 Reference: Setting of Target "FP0H(B)"........................................... 3-15

3.4 Settings of Connection Using FP0H as Target ...................................3-16

3.4.1 Settings ............................................................................................ 3-16

3.4.2 Adding I/O Map to Scan List ............................................................ 3-16

3.4.3 Registering Tag Name/Instance ID .................................................. 3-17

3.4.4 Registering Data Area Corresponding to Tag/Instance.................... 3-18

3.4.5 Reference: Setting of Originator "FP7" ............................................ 3-19

3.5 Confirmation of Load Factor Calculation.............................................3-21

3.5.1 Load Factor Calculation ................................................................... 3-21

3.5.2 Displaying Load Factor Calculation ................................................. 3-21

3.6 Saving EtherNet/IP Settings ...............................................................3-22

3.6.1 Saving EtherNet/IP Settings in Project ............................................ 3-22

3.6.2 Saving/Reading EtherNet/IP Settings in File ................................... 3-22

3.6.3 Writing EtherNet/IP Settings to FP0H .............................................. 3-23

WUME-FP0HEIP-05

3-1

Page 26

: Opens connection. : Sends cyclic data.

FP0H(A)

IP:192.168.1.5

LD40

LD49

LD40

LD49

LD30

LD39

FP0H(B)

FP7

LD30

LD39

IP:192.168.1.6

IP:192.168.1.7

Originator

Originator

Target

Target

Tag_Test2

Tag_Test1

Tag_Test2

Tag_Test1

3.1 Overview of Settings

3.1 Overview of Settings

3.1.1 System Example

This chapter describes the case of setting FP0H(A) in the following system example.

Operation of FP0H(A)

● The data received from the Tag (Tag_Test2) of the FP0H(B) is stored in the data area (LD40

to 49) of the FP0H(A). The FP0H(A) is the originator for the FP0H(B).

Add the FP0H(B) in the scan list and make the connection setting.

● The data stored in the data area (LD30 to 39) of the FP0H(A) is sent to the FP7. The

FP0H(A) is the target for the FP7.

Add the tag (Tag_Test1) in the I/O map and register the data area.

● The number of used connections totals two.

3.1.2 Setting Procedure

The setting procedure is as follows.

Use Programming software Control FPWIN GR7 (hereinafter referred to FPWIN GR7) for the

settings.

3-2 WUME-FP0HEIP-05

Page 27

3.1 Overview of Settings

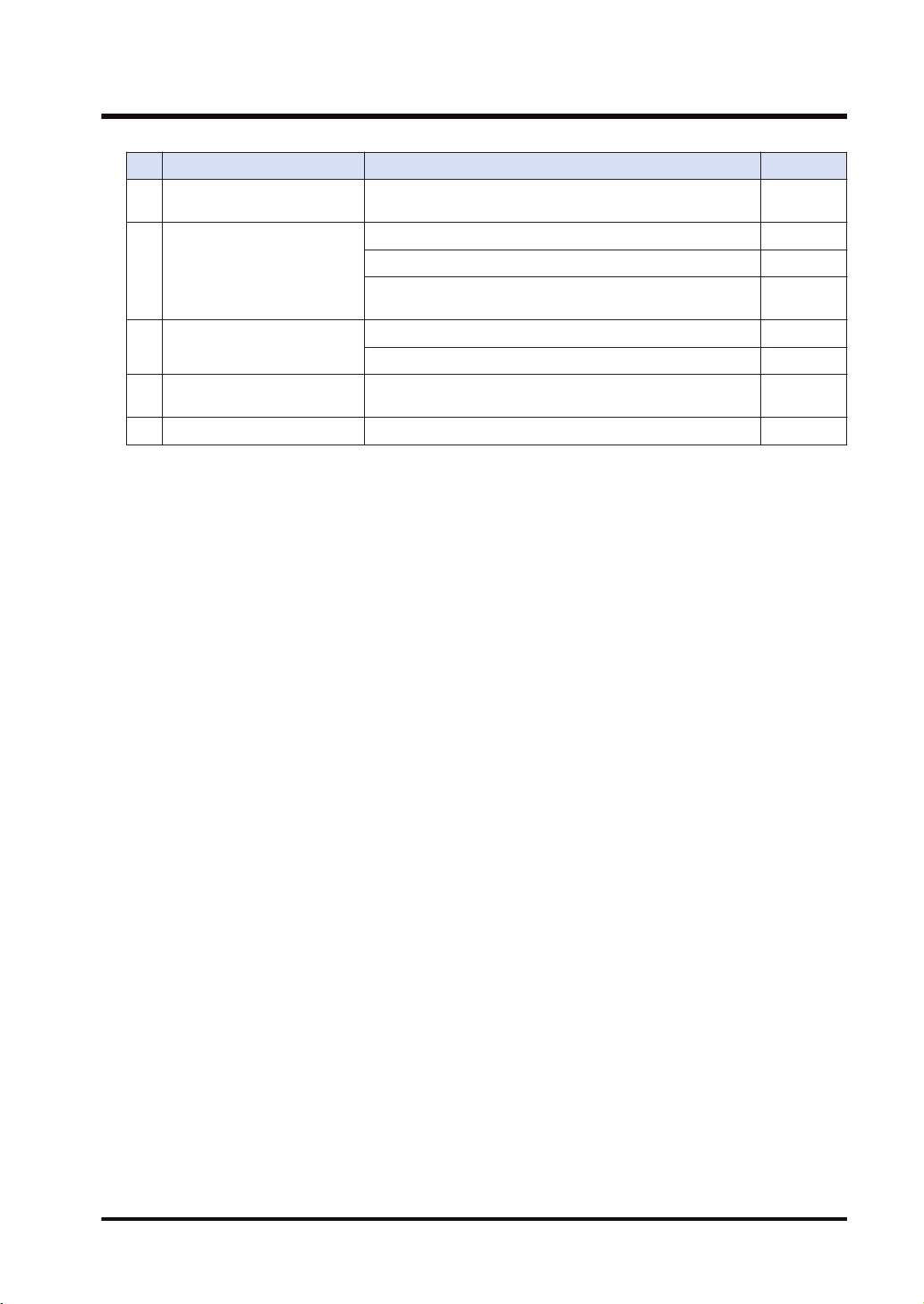

Item Outline of operation Reference

1 Initial setting of Ethernet /IP

Settings of connection using

2

FP0H as originator

Settings of connection using

3

FP0H as target

Confirmation of load factor

4

calculation

5 Saving of Ethernet/IP settings Save the settings of EtherNet/IP. "P.3-22"

Enable EtherNet/IP communication in the "Ethernet settings"

and make the initial setting of EtherNet/IP.

Register EDS Files of target devices. "P.3-8"

Add targets in the scan list. "P.3-9"

Register connection information (such as connected targets,

cyclic communication, corresponding data areas and sizes).

Add I/O map in the scan list. "P.3-16"

Register the tag/instance information connected. "P.3-17"

Confirm the load factor calculation is 100% or less. "P.3-21"

"P.3-4"

"P.3-10"

WUME-FP0HEIP-05 3-3

Page 28

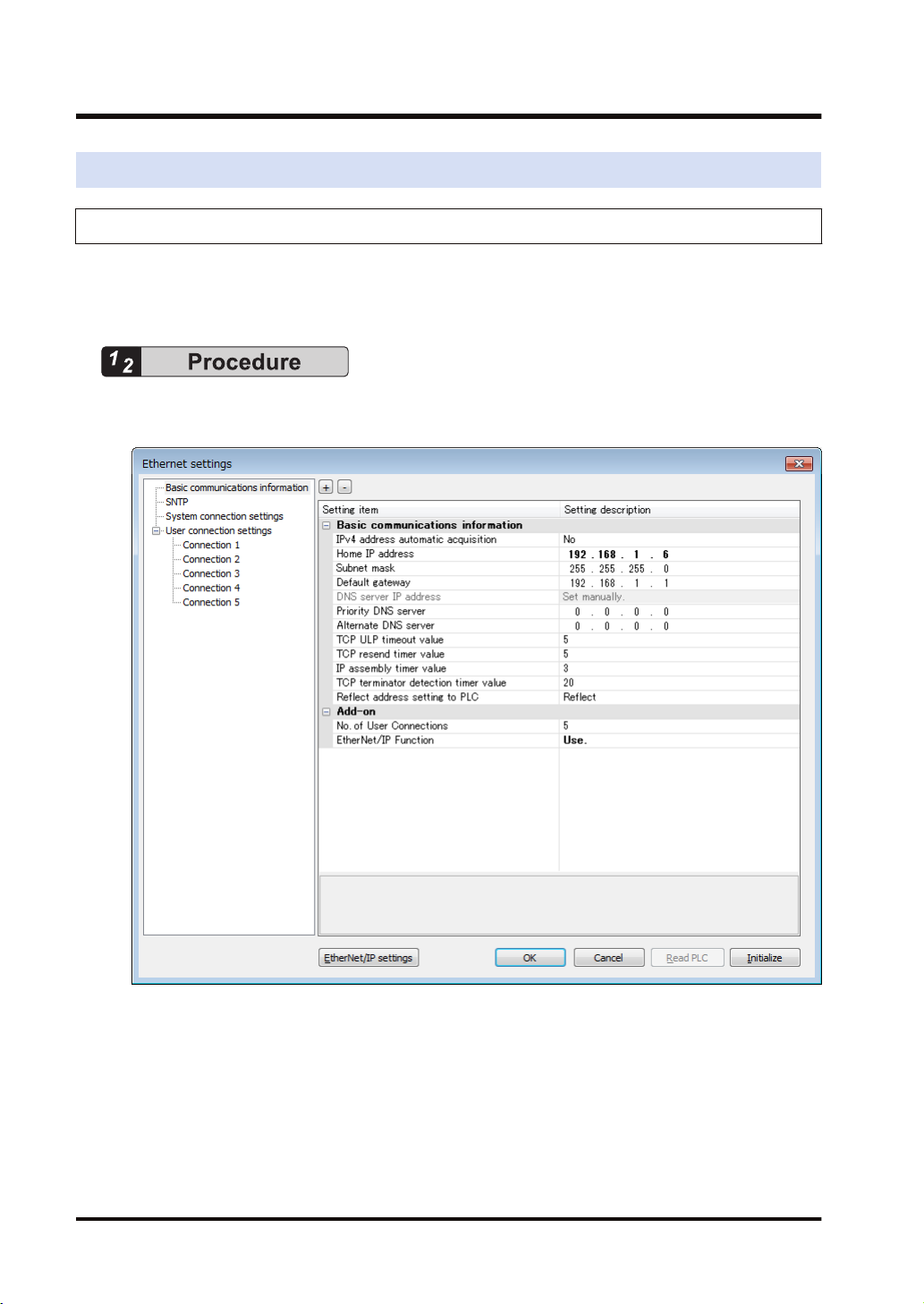

3.2 Initial Setting of Ethernet /IP

3.2 Initial Setting of Ethernet /IP

3.2.1 Ethernet Settings

This is the setting for the communication function via LAN ports including EtherNet/IP. Use

FPWIN GR7 for the setting. The following procedure is explained on the condition that FPWIN

GR7 has already started.

1. Select Option>Ethernet settings from the menu bar.

The "Ethernet settings" dialog box appears.

2. As necessary, change "Home IP address" and "No. of User Connections".

In this example, "IP address = 192.168.1.6", and "No. of User Connections = 5".

3. Change the setting of "EtherNet/IP Function" to "Use".

4. Press the [OK] button.

3-4 WUME-FP0HEIP-05

Page 29

3.2 Initial Setting of Ethernet /IP

● The number of connections available for EtherNet/IP is (9-"No. of user connection"). When the

value is "5" which is initial value, the number of connections available for EtherNet/IP is "4".

● If the setting of “EtherNet/IP Function” is changed to"" "Not use", the EtherNet/IP setting

information will be cleared.

3.2.2 Starting EtherNet/IP Setting Screen

The following procedure is explained on the condition that FPWIN GR7 has already started.

1. Select Option>EtherNet/IP Settings from the menu bar.

The EtherNet/IP setting screen appears.

The following description assumes that the EtherNet/IP setting screen has been activated.

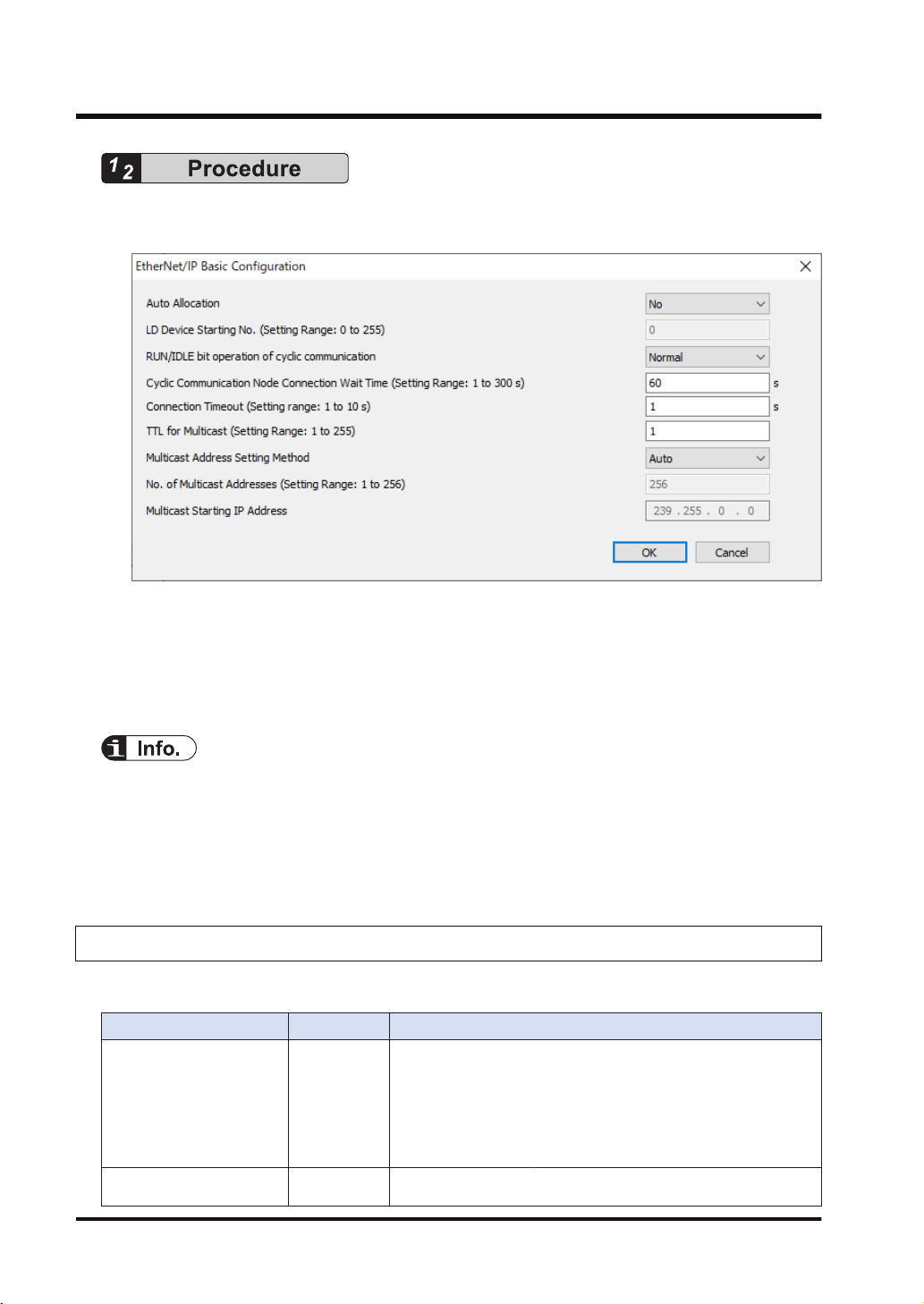

3.2.3 EtherNet/IP Basic Configuration

Make the EtherNet/IP basic configuration. The following procedure is explained on the

assumption that the EtherNet/IP setting screen has been activated.

WUME-FP0HEIP-05 3-5

Page 30

3.2 Initial Setting of Ethernet /IP

1. Select Setting>EtherNet/IP Basic Configuration from the menu bar.

The EtherNet/IP Basic Configuration dialog box appears.

2. Change "Auto Allocation", "RUN / IDLE bit operation of cyclic communication", "Connection

Timeout" as necessary.

In this example, they are set as follows: "Auto Allocation = No", "RUN/IDLE bit operation of

cyclic communication = Normal", and "Connection Timeout = 1 s".

3. Press the [OK] button.

● When allocating devices manually, set "Auto Allocation" to "No".

● For performing operation check, set "RUN/IDLE bit operation of cyclic communication" to

"Limited". When selecting "Normal", the RUN/IDLE bit of the FP0H does not turn "ON" unless

the communications with all the targets registered in the scan list are established.

● The "Connection Timeout" can be set with the unit firmware Ver.1.7 or later.

3.2.4 Items of Ethernet /IP Basic Configuration

■

Settings relating to cyclic communication operation

Item Default Description

Set whether to use the automatic allocation of devices or not (Yes/

No).

Auto Allocation Yes

LD Device Starting No. 0

Auto Allocation

"Yes":

Auto Allocation "No": Devices are allocated manually.

Set the starting device number to be allocated at the time of the

device automatic allocation.

Devices for the I/O map setting and

connection setting are automatically

allocated.

3-6 WUME-FP0HEIP-05

Page 31

3.2 Initial Setting of Ethernet /IP

Item Default Description

Default: 0 (Allocated from LD0 in sequence.)

Set the operating condition of the RUN/IDLE bit (Normal/Limited).

RUN/IDLE bit operation of

cyclic communication

■

Settings relating to abnormality judgement

Item Default Description

Cyclic Communication

Node

Connection Wait Time

Connection Timeout

(Note 1) The "Connection Timeout" can be set with the unit firmware Ver.1.7 or later.

■

Settings relating to Multicast

Item Default Description

TTL for Multicast 1

Multicast Address Setting

Method

No. of Multicast Addresses (256)

Multicast Starting IP Address (239.255.0.0)

(Note 1)

Normal

60 s

1 s Set the connection timeout period.

Auto Set "Auto" or "Specify".

"Normal": Turns on when the FP0H is in RUN mode and normally

communicating with all the targets (except FP0H)

registered in the scan list.

"Limited": Turns on when the FP0H is in RUN mode.

Set the period of time during which retry is repeated without error

determination.

Specify the number of routers that multicast transmission

packets can pass.

Set the number of multicast addresses.

This item is valid when Multicast Address Setting Method

is specified.

Set the starting IP address of multicast.

This item is valid when Multicast Address Setting Method

is specified.

■

Operation of Auto Allocation

Devices are allocated using the value specified for "LD Device Starting No." in "EtherNet/IP

Basic Configuration" as the starting device.

● Allocating order

I/O map no. 1

I/O map no. 2

:

Node 1 of scan list (Input to Output)

Node 2 of scan list (Input to Output)

:

Devices are automatically reallocated when either the scan list or I/O map is added (deleted)

and the allocated data size is changed.

WUME-FP0HEIP-05 3-7

Page 32

: Opens connection. : Sends cyclic data.

FP0H(A)

LD40

LD49

LD40

LD49

FP0H(B)

LD30

LD39

IP:192.168.1.6

IP:192.168.1.7

Originator

Target

Tag_Test2

Tag_Test2

Add in Scan List.

3.3 Settings of Connection Using FP0H as Originator

3.3 Settings of Connection Using FP0H as Originator

3.3.1 Settings

This section describes the setting method of the connection using the FP0H as originator. The

FP0H(A) in the figure below is an object for the setting.

■

Illustration of operation

Ten word data is sent from the data area (LD40 to 49) of the FP0H(B) to the data area (LD40 to

49) of the FP0H(A).

■

Settings

● Add the FP0H(B) to the scan list of the FP0H(A).

● Set the data area of FP0H(B) by specifying the tag (Tag_Test2).

● Set the data area of the own unit for the tag (Tag_Test2).

3.3.2 Registering EDS File of Target Device

When using other companies' devices as targets, their EDS files should be registered in the

EtherNet/IP setting tool. Please acquire EDS files from each vendor's website.

3-8 WUME-FP0HEIP-05

Page 33

3.3 Settings of Connection Using FP0H as Originator

Register EDS Files of target devices in "Device List".

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

1. Select EDS File>Register from the menu bar.

2. Select an EDS file to be registered from the explorer screen and press "Open".

The used target device will be added to "Device List". Once the EDS file is registered, the

registration is not required from the next time.

3.3.3 Adding Target in Scan List

Add connected targets in the scan list. The following procedure is explained on the assumption

that the EtherNet/IP setting screen has been activated.

1. Select and right-click a registered target device (in this example, FP0H CONTROL UNIT...)

from Device List.

WUME-FP0HEIP-05 3-9

Page 34

3.3 Settings of Connection Using FP0H as Originator

2. Select "Add to Scan List" from the displayed menu.

The target will be added.

● The display content of the target added to Scan List

Node no. 1

Node Name FP0H CONTROL UNIT AFP0HC32E

Connection Name Input Only (Tag type)

3.3.4 Setting IP Address of Target

Set the IP address of the target added to Scan List. The following procedure is explained on the

assumption that the EtherNet/IP setting screen has been activated.

1.

Select the node name of the target from Scan List.

3-10 WUME-FP0HEIP-05

Page 35

3.3 Settings of Connection Using FP0H as Originator

The "Device Setting" screen appears.

2. Set the "IP Address" of the target.

In this example, "IP address = 192.168.1.7".

3. Specify a node name as necessary.

In this example, "Node Name = FP0H(B)".

● Unchanging the node name does not affect the cyclic communication. The change is reflected

in Scan List. It helps to distinguish the targets of the same device.

● When setting "Valid/Invalid Flag" to "Invalid", the reservation node setting is enabled.

3.3.5 Setting Tag/Instance

Set the communication method (Tag/Instance) corresponding to the target added to Scan List.

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

1. Select the connection name from Scan List.

WUME-FP0HEIP-05 3-11

Page 36

3.3 Settings of Connection Using FP0H as Originator

The "Connection Setting" screen appears.

2. Select a communication method (Tag or Instance) in "Connection Name".

Once "Connection Name" is selected, "Communication Method" (Tag/Instance) will change.

In this example, "Connection Name = Input Only (Tag type)".

3. According to the target, change "Tag Name/Instance Name" and "Data Size".

3-12 WUME-FP0HEIP-05

Page 37

3.3 Settings of Connection Using FP0H as Originator

(Note) The Instance ID and data size are changed from "Parameter Setting".

In this example, "Tag Name = Tag_Test2", and "Data Size = 20 bytes (10 words)".

● For some targets, "Application Type" (Input Only/Exclusive Owner) can be selected from

"Connection Name".

● When "Exclusive Owner" is selected for "Application Type", specify "Output Information (O>T)"

for sending data from the originator to the target.

● Items such as "RPI" and "Input Send Trigger" can be changed in the "Connection Setting"

screen. Refer to "4.3.2 Operations in Connection Setting Screen".

3.3.6 Specifying Data Area Corresponding to Tag/Instance

For setting the data area manually, change the auto allocation to "No" in the "EtherNet/IP Basic

Configuration". When it is set to "Yes", this procedure is not required.

WUME-FP0HEIP-05 3-13

Page 38

3.3 Settings of Connection Using FP0H as Originator

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

1. Select the connection name whose setting is made from Scan List.

The "Connection Setting" screen appears.

2. Press "Add" in the Device Allocation area.

3.

Specify "Device Type", "Device No." and "Data Size", and press "Register".

3-14 WUME-FP0HEIP-05

Page 39

3.3 Settings of Connection Using FP0H as Originator

In this example, "Device Type = LD", "Device No. = 40" and "Data Size = 10".

● When "Exclusive Owner" is selected for "Application Type", specify "Output Information

(O>T)" for sending data from the originator to the target.

3.3.7 Reference: Setting of Target "FP0H(B)"

For the target FP0H(B), add the I/O map and set as follows.

Item Settings

IP Address 192.168.1.7

Communication

method

Tag Name Tag_Test2

Data Size 10 words

Tag

WUME-FP0HEIP-05 3-15

Page 40

FP0H(A)

IP:192.168.1.5

LD40

LD49

LD30

LD39

FP7

LD30

LD39

IP:192.168.1.6

Originator

Target

Tag_Test1

Tag_Test1

Set in I/O map.

3.4 Settings of Connection Using FP0H as Target

3.4 Settings of Connection Using FP0H as Target

3.4.1 Settings

This section describes the setting method of the connection using the FP0H as target, The

FP0H(A) in the figure below is an object for the setting.

■

Illustration of operation

Ten word data is sent from the data area (LD30 to 39) of the FP0H(A) to the data area (LD30 to

39) of FP7.

When the FP0H is used as target, only the data transmission to originator is available.

■

Settings

● Register a tag (Tag_Test1) specified from the FP7 (Originator) in the "I/O map".

● Set the data area (LD30 to 39) corresponding to the tag.

3.4.2 Adding I/O Map to Scan List

Add the I/O map in Scan List. The following procedure is explained on the assumption that the

EtherNet/IP setting screen has been activated.

1.

Select and right-click "I/O Map - Scheduled Connections: 0" from Scan List.

3-16 WUME-FP0HEIP-05

Page 41

3.4 Settings of Connection Using FP0H as Target

2. Select "Add I/O Map" from the displayed menu.

The I/O map will be added to Scan List.

● The display content of the I/O map added to Scan List

I/O map No. 1

Communication method Tag

Tag Name/Instance ID Tag_1

3.4.3 Registering Tag Name/Instance ID

Register the Tag Name/Instance ID specified from originator. The following procedure is

explained on the assumption that the EtherNet/IP setting screen has been activated.

1.

Select the target I/O map from Scan List.

WUME-FP0HEIP-05 3-17

Page 42

3.4 Settings of Connection Using FP0H as Target

"I/O Map Setting" screen appears.

2. Select Communication Method (Tag or Instance).

In this example, "Communication Method = Tag".

3. Input Tag Name/Instance ID.

In this example, "Tag Name = Tag_Test1".

4. Input "Data Size" of transmission data.

In this example, "Data Size = 10 words".

● Register Tag/Instance for each connected originator.

● When connected from more the one originators, the connections are distinguished by each

instance ID/tag name.

3.4.4 Registering Data Area Corresponding to Tag/Instance

For setting the data area manually, change the auto allocation to "No" in the "EtherNet/IP Basic

Configuration". When it is set to "Yes", this procedure is not required.

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

1.

Select the target I/O map from Scan List.

3-18 WUME-FP0HEIP-05

Page 43

3.4 Settings of Connection Using FP0H as Target

"I/O Map Setting" screen appears.

2. Press "Add" in the Device Allocation area.

3. Specify "Device Type", "Device No." and "Data Size", and press "Register".

In this example, "Device Type = LD", "Device No. = 30" and "Data Size = 10".

● Register Tag/Instance for each connected originator.

● When connected from more the one originators, the connections are distinguished by each

instance ID/tag name.

3.4.5 Reference: Setting of Originator "FP7"

For the originator FP7, add the FP0H in Scan List and set as follows.

Item Settings

Target IP Address 192.168.1.6

Connection Name Input Only (Tag type)

WUME-FP0HEIP-05 3-19

Page 44

3.4 Settings of Connection Using FP0H as Target

Item Settings

Tag Name Tag_Test1

Data Size 10 words

3-20 WUME-FP0HEIP-05

Page 45

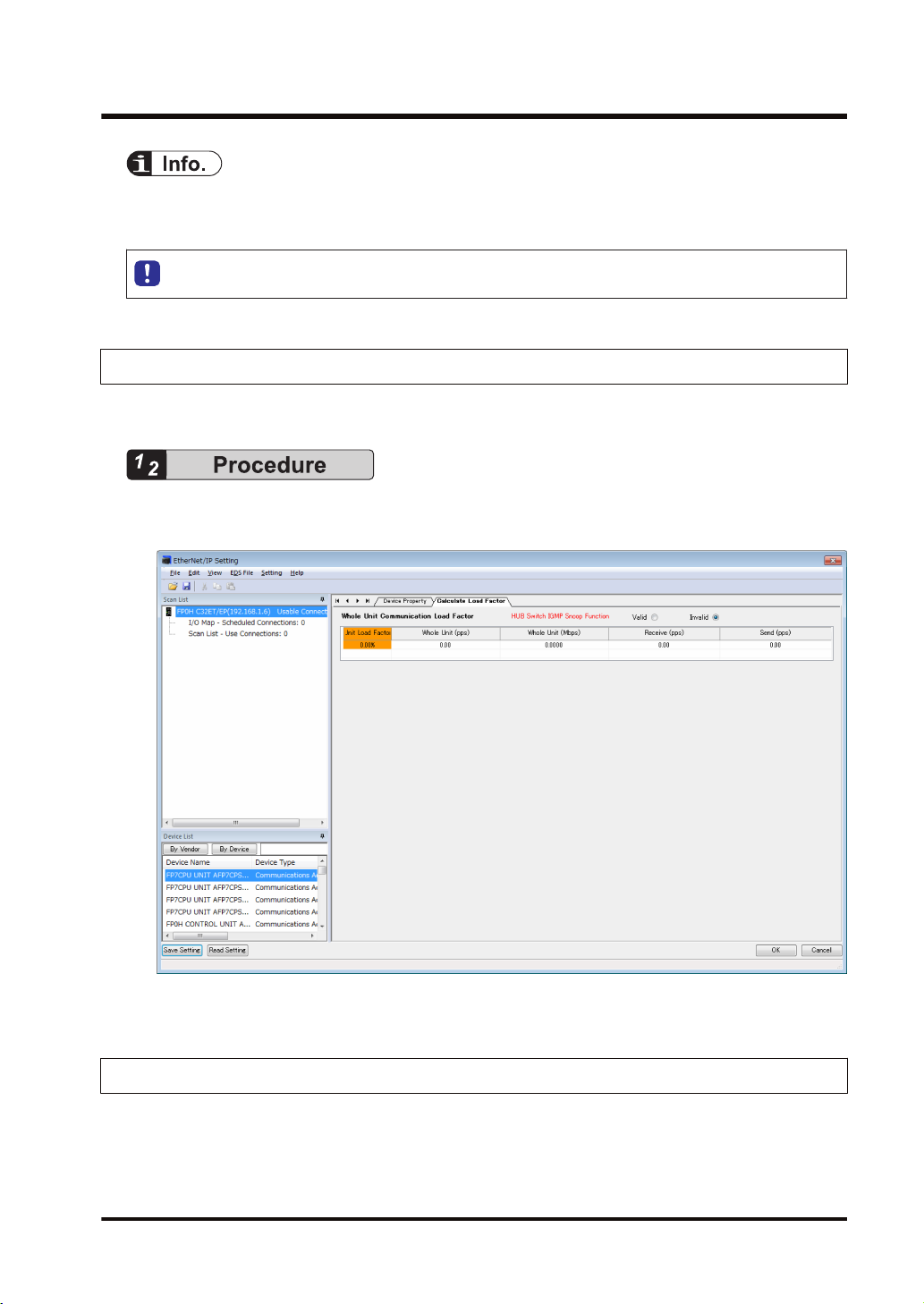

3.5 Confirmation of Load Factor Calculation

3.5 Confirmation of Load Factor Calculation

3.5.1 Load Factor Calculation

The load factor is the calculated ratio of the number of actually used packets to the maximum

number of packets which the FP0H can send/receive in one second by cyclic communication.

● Packets other than by cyclic communication or unnecessary received packets are not

considered for calculating the load factor.

● Reserved nodes are not included in the calculation of load factor.

3.5.2 Displaying Load Factor Calculation

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

1. Select the uppermost "FP0H C32ET/EP(192.168.1.6) Usable Connect..." from Scan List.

The "Calculate Load Factor" window appears.

2. Confirm each load factor of the whole unit, I/O map and scan list.

Load factors for each setting of I/O map and scan list are calculated separately.

● The load factors of FP0H and each target should be 100% or less.

WUME-FP0HEIP-05 3-21

Page 46

3.6 Saving EtherNet/IP Settings

3.6 Saving EtherNet/IP Settings

3.6.1 Saving EtherNet/IP Settings in Project

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

Press the [OK] button on the lower right of the screen.

1.

3.6.2 Saving/Reading EtherNet/IP Settings in File

Save and read the settings specified in the EtheNet/IP Setting screen into a separate file from

the project file. The saved EtherNet/IP settings can be reused in multiple units and projects.

The following procedure is explained on the assumption that the EtherNet/IP setting screen has

been activated.

3-22 WUME-FP0HEIP-05

Page 47

3.6 Saving EtherNet/IP Settings

1. Press "Save Settings" on the lower left of the EtherNet/IP Setting screen.

The saving destination and file names appear.

(The same operation is performed when selecting "File" from the menu bar.)

2. Enter a saving destination and file name, and press [Save] button.

The settings specified in the EtherNet/IP Setting screen will be saved as a file whose

extension is ".fp0heip".

● Closing the window with the "X" mark or "Cancel" on the lower right of the window

cancels and stops the operation.

3.6.3 Writing EtherNet/IP Settings to FP0H

Transfer the settings specified in the EtherNet/IP Setting screen to the FP0H.

The following procedure is explained on the condition that FPWIN GR7 has already started.

1. Select Online>Download To PLC from the FPWIN GR7 menu bar.

The EtherNet/IP settings will also be downloaded to the control unit along with information

on programs, comments and system registers.

WUME-FP0HEIP-05 3-23

Page 48

(MEMO)

3-24 WUME-FP0HEIP-05

Page 49

4 Tool Operation

4.1 Scan List Window ...............................................................................4-2

4.1.1 Display Contents of Scan List Window ............................................ 4-2

4.1.2 Operations in Scan List Window ...................................................... 4-3

4.2 Device List Window.............................................................................4-7

4.2.1 Display Contents of Device List Window ......................................... 4-7

4.2.2 Operations from EDS File Menu...................................................... 4-7

4.3 Various Setting Screens......................................................................4-9

4.3.1 Operations in Device Setting Screen ............................................... 4-9

4.3.2 Operations in Connection Setting Screen........................................ 4-9

4.3.3 Operations in I/O Map Setting Screen ............................................. 4-12

4.3.4 Display Contents of Calculate Load Factor Screen ......................... 4-13

4.3.5 Display Contents of Device Property Screen................................... 4-15

4.3.6 Switching Tabs in Each Setting Screen ........................................... 4-16

WUME-FP0HEIP-05

4-1

Page 50

4.1 Scan List Window

4.1 Scan List Window

4.1.1 Display Contents of Scan List Window

The information displayed in Scan List is as follows.

Item Description

(1) Own unit

(2) No. of I/O maps

(3) Each I/O map

(4) No. of nodes

Each

(5)

connection

Shows the product name, (IP address) and the number

of usable connections.

No. of usable connection = "No. of connections

allocated to Ethernet/IP" - "No. of set connection".

No. of tags/instances registered in I/O map

This number should be same as the number of

originators to be connected to the FP0H.

Tags/instances registered in I/O map

For Tag

Shows the registered number and Tag (tag name).

For Instance

Shows the registered number and Instance (instance

ID).

No. of connections registered in Scan List

Shows the number of targets to be connected to the

FP0H.

Targets and connections registered in Scan List

The display contents are as follows.

Upper line

Shows a node number and node name.

Lower line

Shows a connection name.

Window display when

selected

The "Calculate Load

Factor" window appears.

(Refer to "P.4-13".)

-

"I/O Map Setting" screen

appears. (Refer to

"P.4-12".)

-

Upper line

The "Device Setting"

screen appears. (Refer to

"P.4-9".)

Lower line

The "Connection Setting"

screen appears. (Refer to

"P.4-9".)

4-2 WUME-FP0HEIP-05

Page 51

4.1 Scan List Window

4.1.2 Operations in Scan List Window

Scan List can be edited by selecting and right-clicking an item in Scan List.

Available operations vary according to the selected item.

■

When selecting the home unit

Display item Description

Device Property Shows the device property of the home unit.

■

When selecting the number of I/O maps

Display item Description

Add I/O Map Add an I/O map.

WUME-FP0HEIP-05 4-3

Page 52

4.1 Scan List Window

■

When selecting each I/O map

Display item Description

Delete I/O Map The selected I/O map is deleted from Scan List.

Reallocate Device Devices are reallocated from the selected I/O map downward. (The

target is I/O map only.)

By specifying the LD device starting number, devices are automatically

reallocated.

■

When selecting the number of nodes

Display item Description

Delete All All nodes added to Scan List are deleted.

Paste The copied node is pasted at the end of Scan List.

4-4 WUME-FP0HEIP-05

Page 53

4.1 Scan List Window

■

When selecting each node

Display item Description

Add Connection Connections are added to the selected node.

Depending on target devices, more than one connection can be established for one

node.

Delete The selected node is deleted from Scan List.

Delete All All nodes added to Scan List are deleted.

Rearrange Scan List Scan list is rearranged from the selected node downward.

By specifying the starting number of node number and IP address, it is rearranged.

Reallocate Device For only Scan List, devices are reallocated from the selected node downward

By specifying the LD device starting number, devices are automatically reallocated.

Copy The selected node is copied.

Cut The selected node is cut.

Paste The copied node is pasted after the selected node.

Device Property The device property of the selected node is displayed.

Device Setting The device setting of the selected node is displayed.

WUME-FP0HEIP-05 4-5

Page 54

4.1 Scan List Window

■

When selecting each connection

Display item Description

Edit Connection The connection setting of the selected connection is displayed.

Delete Connection When there are more than two connection for one node, the selected

Device Property The device property of the selected connection is displayed.

Device Setting The device setting of the selected connection is displayed.

connection is deleted.

4-6 WUME-FP0HEIP-05

Page 55

4.2 Device List Window

4.2 Device List Window

4.2.1 Display Contents of Device List Window

The display contents of the Device List window are as follows.

Display item Description

By Vendor Sorts registered EDS files by vendor.

By Device Sorts registered EDS files by device type.

Find Displays only the EDS files found by pressing the button after entering a retrieval word.

Display All Clears retrieval results and displays all registered EDS files.

List of registered

devices

All devices whose EDS files have been registered are displayed in the EtherNet/IP

Setting screen.

4.2.2 Operations from EDS File Menu

Select and right-click the device name to be operated from Device List.

(Or select "EDS File" from the menu bar.)

Display item Description

Register EDS File A new EDS file is registered in Device List.

Delete EDS File The EDS file of the selected device is deleted.

Edit EDS File

Comment...

WUME-FP0HEIP-05 4-7

A comment can be added to the EDS file of the selected device.

Page 56

4.2 Device List Window

Display item Description

Add to Scan List The selected device is added to Scan List.

Device Property The "Device Property Information" defined in the EDS file of the selected device can

Import Device Data

Base...

Export Device Data

Base...

be confirmed.

The device database (EDS file list information registered in Device List) can be

imported.

(Note)

Always save the EtherNet/IP setting before the import operation. Because the

EtherNet/IP setting is terminated after the import operation, the information in the

middle of change operation will be cleared.

Specify the folder in which the device database to be imported is stored. After the

completion of the import, the EtherNet/IP Setting screen is automatically terminated.

Restart the EtherNet/IP Setting.

The device database (EDS file list information registered in Device List) can be

exported (stored).

Select an storage folder for the device data base from the explorer.

As registered EDS files, icon files, device database files are output to the selected

folder, specify an empty folder for the storage destination.

4-8 WUME-FP0HEIP-05

Page 57

4.3 Various Setting Screens

4.3.1 Operations in Device Setting Screen

The operations of "Device Setting" are as follows.

Item Default Description

Set whether to make the communication with nodes valid or

Valid/Invalid Flag Valid

Node Name

IP Address

Product name registered in

the EDS file

Automatically acquired

when adding the target in

Scan List

invalid.

When set to Invalid, the device is set as a reserved device and

exempt from the communication.

Specify the node name of the device.

The specified node name is displayed in Scan List.

Set the IP address of the target. It can be set arbitrarily.

4.3 Various Setting Screens

4.3.2 Operations in Connection Setting Screen

The operations of "Connection Setting" are as follows.

WUME-FP0HEIP-05 4-9

Page 58

4.3 Various Setting Screens

(1) Common information

Item Description

Node Name Shows the node name of the target. The node name can be changed in "Device Setting".

Device Name Shows the device name of the target.

Select from the connection settings registered in EDS files.

Connection Name

Application Type

Compatibility Check

Communication

method

Timeout Period

Input Send Trigger

COS Transmission

Disable Time

Parameter setting

When the target is FP0H, the communication method (Tag or Instance) can be selected.

Tag: Input Only (Tag type) / Instance: Input Only (ID type)

Depending on target devices, select the application type.

The application type of a selected connection setting is displayed.

Example) Exclusive Owner, Input Only

Set the operation method of "Compatibility Check" which check the information of the

connected target device against the revision of the EDS file.

Select from Check, Not Check and Follow Adapter (Target) Rule.

Shows the set communication method (Tag/Instance).

Set the communication timeout period of cyclic communication. In the cyclic

communication, transmission data is sent as UDP packet. The timeout is judged on a

receiver side. The timeout period should be 10 msec or more.

RPI can be specified for T>O direction and O>T direction separately, so each timeout

period may be different values.

The timeout period is selected from the range of 4 (RPI x 4), 8 (RPI x 8), 16 (RPI x

16), .... 256 (RPI x 256) and 512 (RPI x 512) times of RPI.

The timing that the target sends data is selected from Cyclic or COS (Change of state).

COS is basically a cyclic communication, however, it also performs transmission when

sent data changes.

Some devices do not support COS. The FP0H does not support COS.

Transmission disable time (RPI of input information x 1/4) is displayed when "Input Send

Trigger" is set to "Change of State (COS)".

Even if the unit detects the change in data, it is not sent within the transmission disable

time.

Parameter setting window appears by pressing the [Parameter Setting] button.

Following screen is example of FP0H.

4-10 WUME-FP0HEIP-05

Page 59

Item Description

4.3 Various Setting Screens

Parameters defined in the EDS file can be set.

● The data size of Input Information (T>O) or Output Information (O<T) can be

changed.

● The instance ID can be changed (Only for target devices that can be changed).

● Others (Defined in the EDS file)

(2) Input Information (T>O): Target to Originator

(Output Information (O>T): Originator to Target *Available for Exclusive Owner only)

Item Description

RPI

Connection Type

Tag Name/Instance

ID

Data Size Shows the data size entered in "Parameter Setting"" in word unit.

Device Allocation

Set the transmission interval for the cyclic communication.

The usable RPI range depends on target devices.

Select a communication method that is selectable for the selected connection.

Point to Point / Multicast

The items vary according to the communication method of each connection.

● For "Tag": Set a tag name.

● - For "Instance": The instance ID is displayed. (It cannot be changed.)

* For allocating devices manually, set "Auto Allocation" in "EtherNet/IP Basic

Configuration" to "No".

It is possible to "Add", "Edit" or "Delete" devices allocated in the send area or receive

area.

The data size is changed in "Parameter Setting".

(The details are as follows.)

WUME-FP0HEIP-05 4-11

Page 60

4.3 Various Setting Screens

(3) Device Allocation

Up to eight device allocations can be registered for send or receive of each connection. The

maximum number of words that is available for device allocation is 16k words in total.

(Allocation cannot be performed beyond 16,384 words.)

When selecting "Add" or "Edit"), the following settings are available.

Item Description

No. Shows the device registration number.

Device Type Select Device Type from WX, WY, WR, WL, DT and LD.

Device No. Set the starting number of the device.

Data Size: Set the data size secured from the device number.

(Example) When Device Type is "WL", Device No. is "20" and Data Size is "20",

WL20 to 39 are secured as the device allocation area.

Offset Set "Offset" when allocating devices after no.2.

(Example) When the data size of device no.1 is "20 words", the data size of device no.2

is "10 words" and the data size of device no.3 is "10 words",

Set the offset of device no.2 to "20 words" and the offset of device no.3 to "30 words".

4.3.3 Operations in I/O Map Setting Screen

The operations in "I/O Map Setting" are as follows.