Page 1

Service Manual

Colour Television EURO 2 Chassis

TX-25AD1E TX-29AD1E

Safety

Specifications

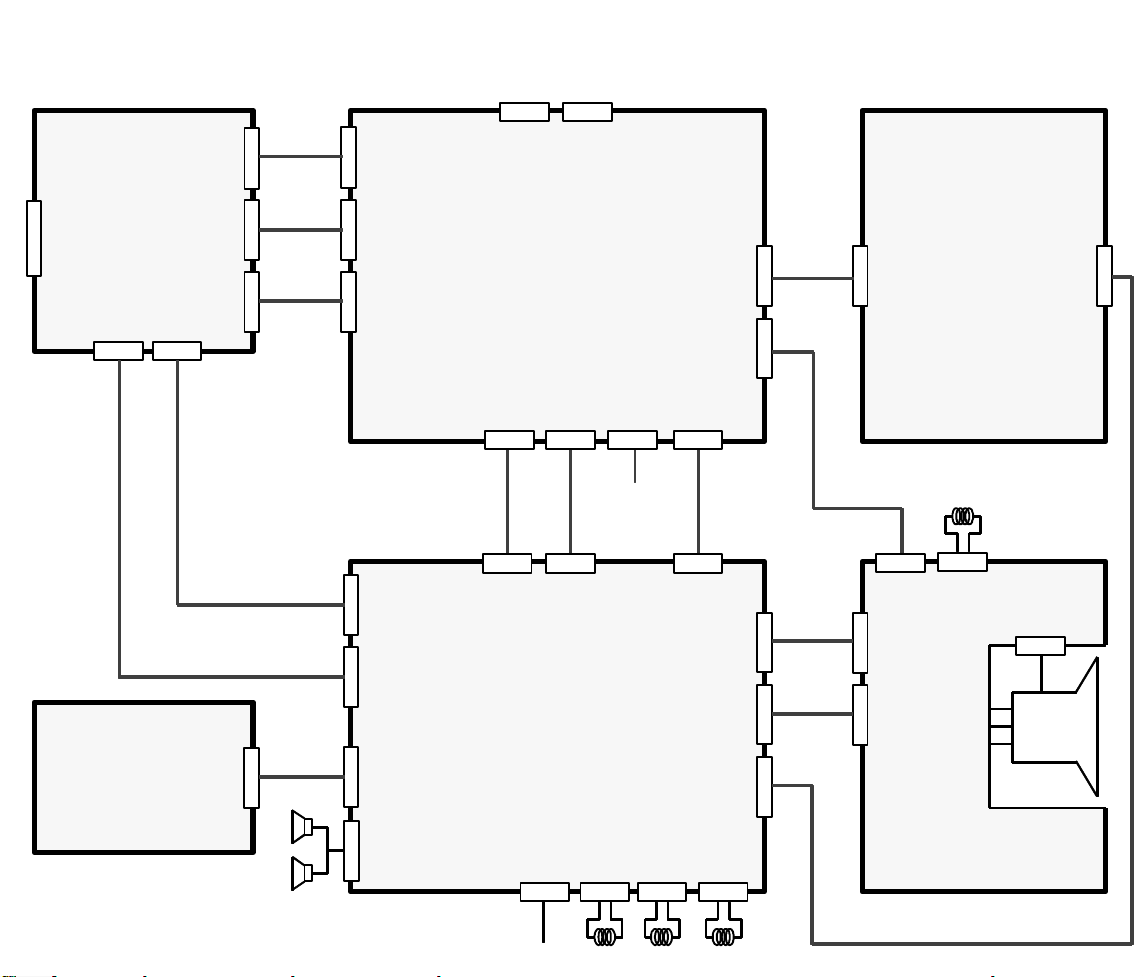

Block Diagram(Video)

Block Diagram(Audio)

Block Diagram(Control)

Parts List

Service Information

PCB view(E)

PCB view(Y)

PCB view(F)

PCB view(A)

PCB view(B)

Adjustments

Self Check

Service Hints

Mechanical View

Disassembly

Location of Controls

Waveforms

E Schematic (25)

E Schematic (29)

Y Schematic

F Schematic

A Schematic

B Schematic

GO

BACK

Notes

Service Support

About....

EXIT

PCB view(M)

M Schematic

Page 2

Service Manual

Specifications

( Information in brackets {} refer to TX-25AD1E)

Power Source : 220-240V AC 50Hz

Power Consumption : 110W { 100W }

Aerial Impedance : 75W unbalanced, Coaxial Type

Receiving System : PAL B/G, PAL 60,

SECAM B/G

Receiving Channels : VHF E2 - E12

VHF H1 - H2 (ITALY)

VHF A - H (ITALY)

VHF R1 - R2

VHF R3 - R5

VHF R6 - R12

UHF E21 - E69

CATV (S01 - S05)

CATV S1 - S10 (M1 - M10)

CATV S11 - S20 (U1 - U10)

CATV S21 - S41 (HYPERBAND)

Intermediate Frequency :

Video 38.9 MHz

Sound 33.4 MHz/33.16 MHz/33.05MHz

Colour 34.47 MHz

34.5 MHz/34.65 MHz - (SECAM)

Video / Audio

Terminals :

AUDIO MONITOR OUT Audio(RCA x 2) 500mV rms,1kW

AV1 IN Video (21 pin ) 1 Vp-p 75W

Audio (21 pin ) 500mV rms,10kW

RGB (21 pin )

AV1 OUT Video (21 pin ) 1 Vp-p 75W

Audio (21 pin ) 500mV rms, 1kW

SM - 95015

Colour Television

TX-29AD1E

TX-25AD1E

EURO-2 Chassis

AV2 IN Video (21 pin ) 1 Vp-p 75W

Audio (21 pin ) 500mV rms,10 kW

S-Video IN Y : 1 Vp-p 75W

(21 pin ) C : 0.3 Vp-p 75W

AV2 OUT Video (21 pin ) 1 Vp-p 75W

Audio (21 pin ) 500mV rms, 1kW

Selectable output (21 pin )

AV3 IN S-Video IN Y : 1 Vp-p 75W

(4-pin ) C : 0.3 Vp-p 75W

Audio (RCA x 2) 500mV rms,10kW

Video (RCA x 1) 1 Vp-p 75W

High Voltage : 31kV _1kV at zero beam current

Picture Tube : 72cmV{63 cmV}

Super Flat FST 110°

measured diagonally.

Audio Output :

Internal Speaker 2 x 20 W (Music Power)

8W Impedance

Headphones 1 x 8 W Impedance

Accessories supplied : Remote Control

UM3 Battery

Dimensions : Height : 551mm {504mm}

Width : 668mm {606mm}

Depth : 467mm {448mm}

Net Weight 41kg {30kg}

Specifications are subject to change without notice.

Weight and dimensions shown are approximate.

Page 3

Contents

Safety Precautions 2

Location of Controls 3

Chassis Service Position 4

Service Mode 7

Self Check 8

Adjustment Procedure 8

Alignment Settings 9

Waveform Pattern Table 10

P.C.B. Views 11

Block Diagrams 16

Schematic Diagrams 20

Parts Location 26

Replacement Parts List 27

Safety Precautions

General Guide Lines

1. It is advisable to insert an isolation transformer in the AC

supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the high

voltage circuits. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

3. After servicing, see that all the protective devices such as

insulation barriers, insulation papers, shields and isolation RC combinations are correctly installed.

4. When the receiver is not being used for a long period of time,

unplug the power cord from the AC outlet.

5. Potentials as high as 32 kV are present when this receiver is

in operation. Operation of the receiver without the rear cover

involves the danger of a shock hazard from the receiver

power supply. Servicing should not be attempted by anyone

who is not familiar with the precautions necessary when

working on high voltage equipment. Always discharge the

anode of the picture to the chassis before handling the tube.

6. After servicing make the following leakage current checks to

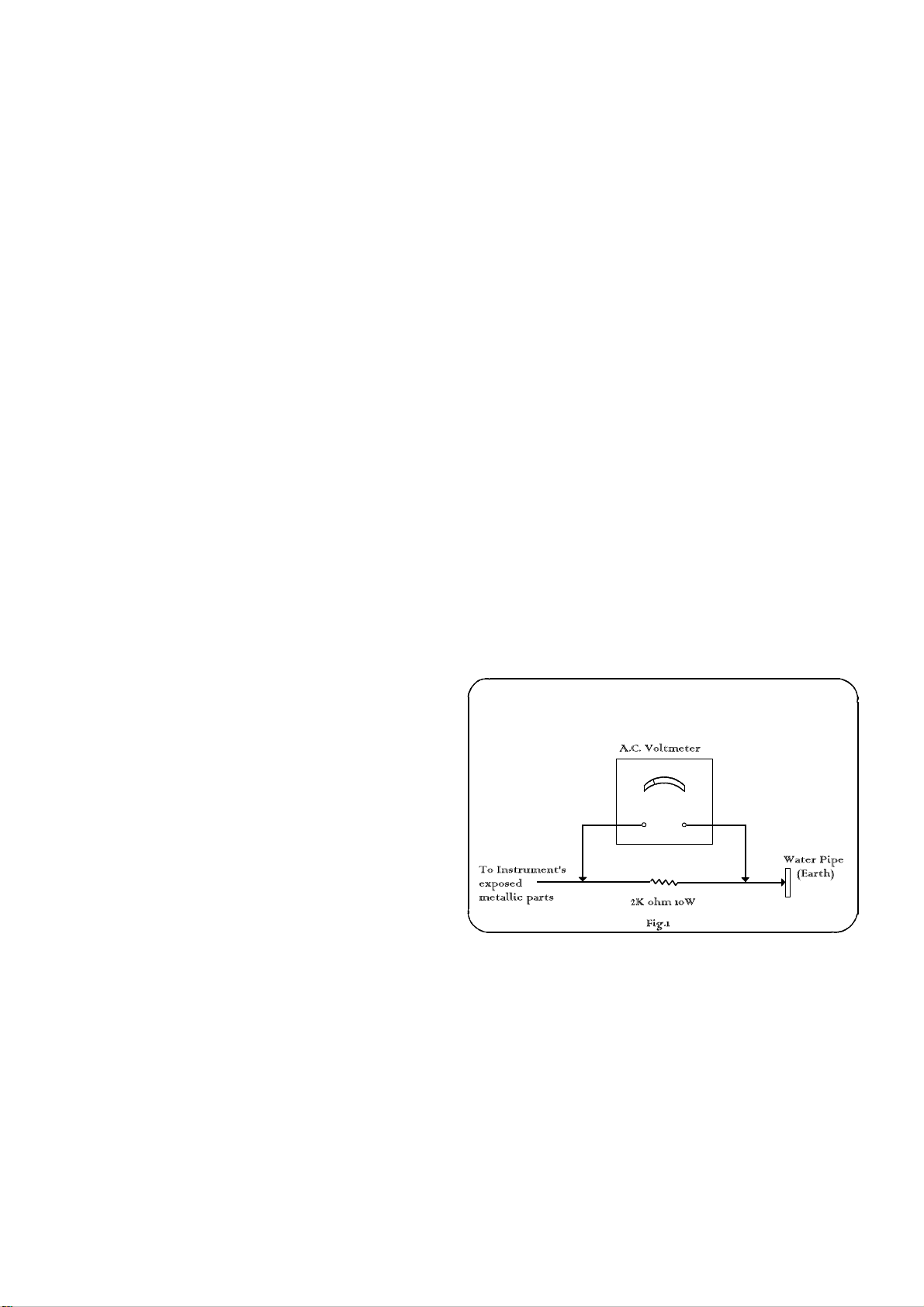

prevent the customer from being exposed to shock hazards.

3. Use an AC voltmeter with high impedance to measure the

potential across the resistor.

4. Check each exposed Metallic part and check the voltage at

each point.

5. Reverse the AC plug at the outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 1.4 Vrms. In

case a measurement is outside the limits specified, there is a

possibility of a shock hazard, and the receiver should be

repaired and rechecked before it is returned to the customer.

HOT CHECK CIRCUIT

Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs of the plug.

2. Turn on the receiver's power switch.

3. Measure the resistance value with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screw heads, aerials ,

connectors, control shafts etc. When the exposed metallic

part has a return path to the chassis the reading should be

between 4M ohm and 20M ohm. When the exposed metal

does not have a return path to the chassis the reading must

be infinite.

Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 2k ohm 10W resistor in series with an exposed

metallic part on the receiver and an earth such as a water

pipe.

X-Radiation Warning

1. The potential sources of X-Radiation in TV sets are the high

voltage section and the picture tube.

2. When using a picture tube test jig for service ensure that the

jig is capable of handling 32kV without causing X-Radiation.

NOTE : It is important to use an accurate periodically calibrated high

voltage meter

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should indicate 31kV

_1kV at zero beam current if the meter indication is out of

tolerance, immediate service and correction is required to

prevent the possibility of premature component failure.

3. To prevent an X-Radiation possibility, it is essential to use

the specified tube.

Page 4

Location Of Controls

Service Hints

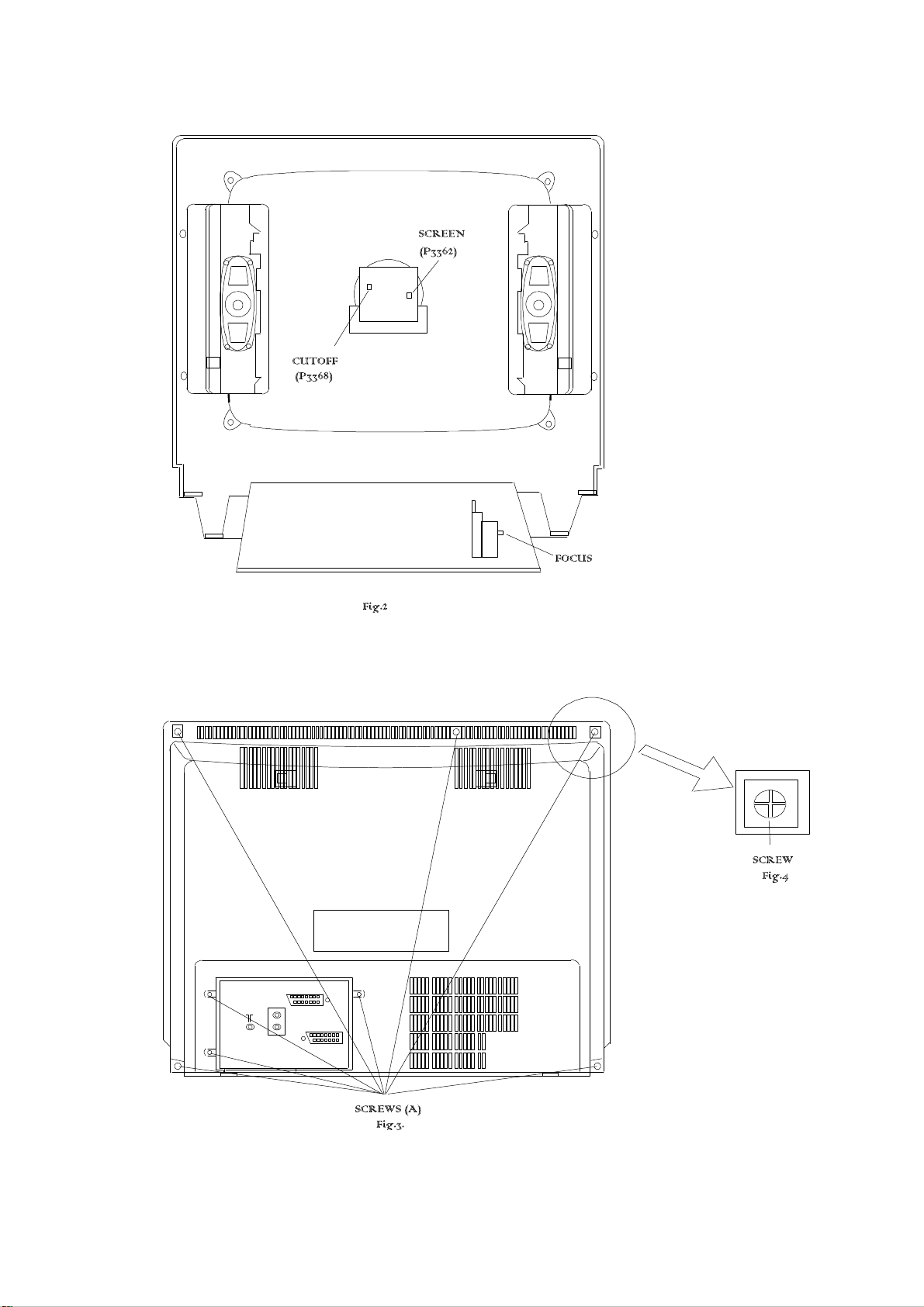

How to remove the rear cover

1. Remove the 8 fixing screws (A) as shown in Fig.3/Fig.4.

Page 5

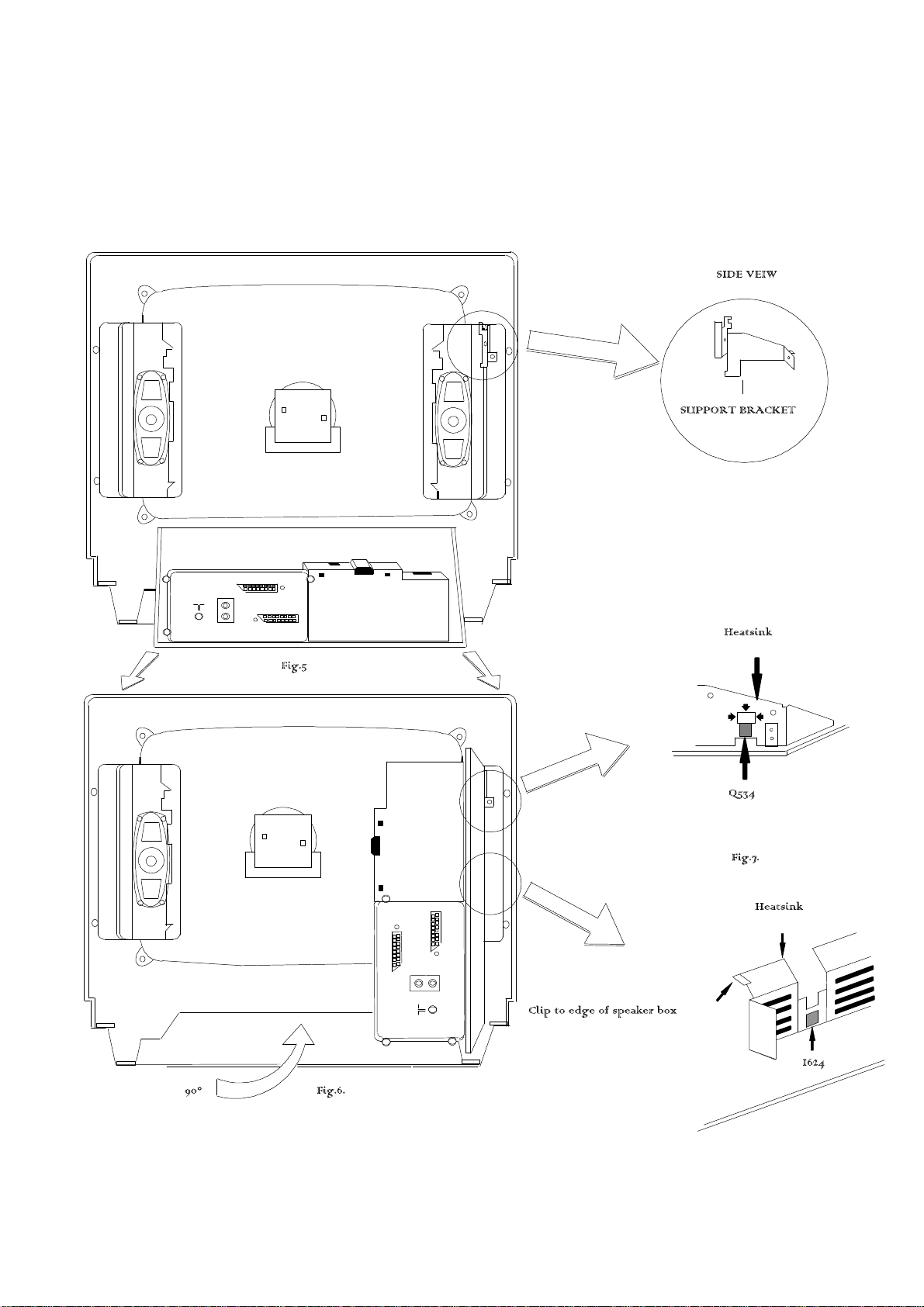

How to move the chassis into the Service position

1. Hold and lift the rear of the E- PCB chassis and M - PCB as shown in fig.5. and gently pull the chassis toward you. Realese the M PCB as explained on page 6

2. Turn the chassis through 90_, anti-clockwise, as shown in fig.6.

3. Clip the chassis onto the support bracket as shown in fig.6 and fig.7.

4. After servicing ensure all wiring is returned to its original position before returning the receiver to the customer.

Page 6

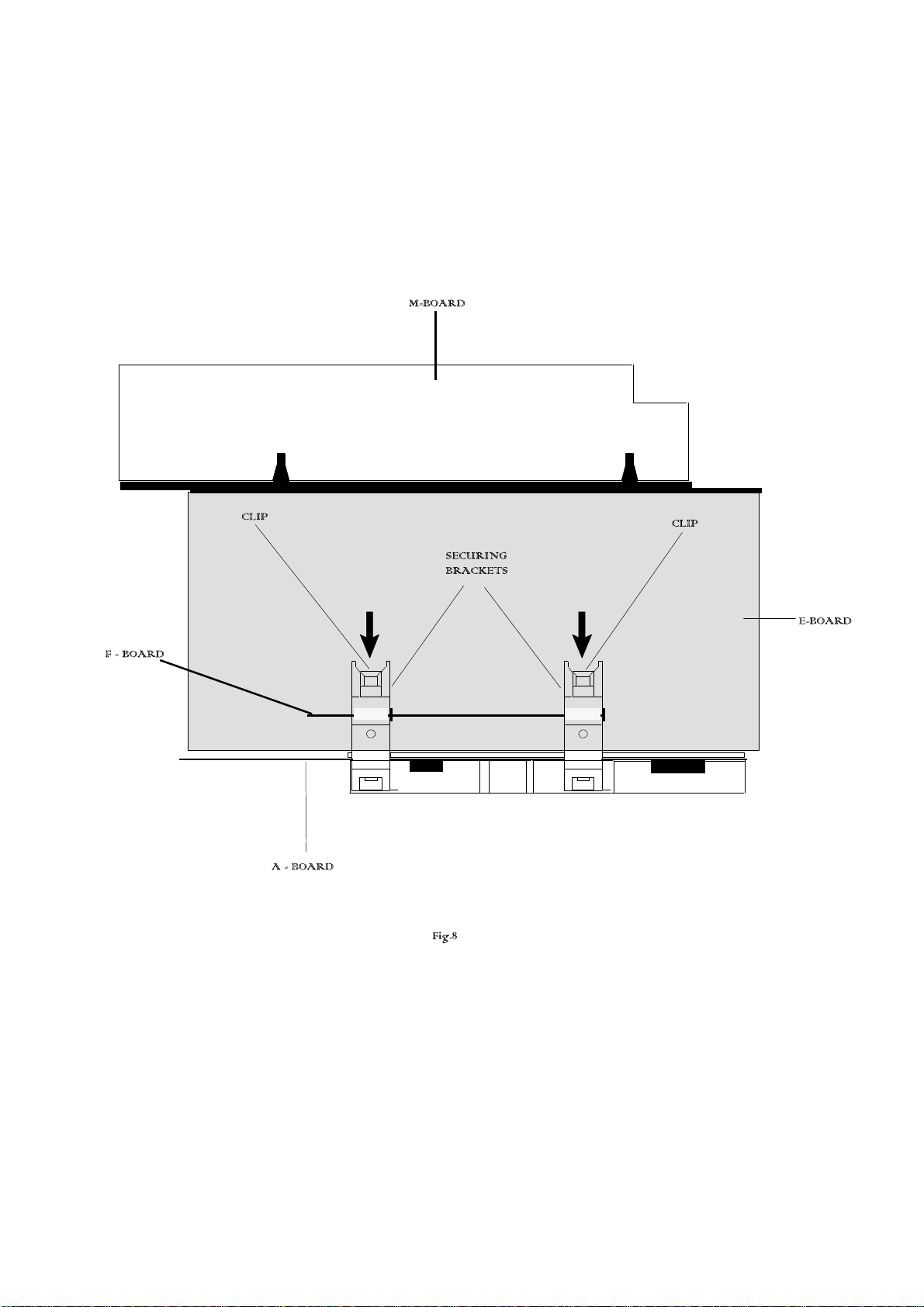

HOW TO REMOVE THE CONTROL PANEL (M-BOARD)

1. Remove the E-board from the cabinet with the M-board attached.

2. Unclip by lifting the front of the M-board vertically.

3. After servicing ensure all wiring is returned to its original position before returning the receiver to the customer.

HOW TO REMOVE THE A - BOARD

1. Disconnect the 5 leads from the A - board.

2. Release the A and F boards securing brackets by pushing the clips in the direction shown in Fig.8, and remove the A - board by

gently lifting vertically.

3. After servicing ensure all wiring is returned to its original position before returning the receiver to the customer.

Page 7

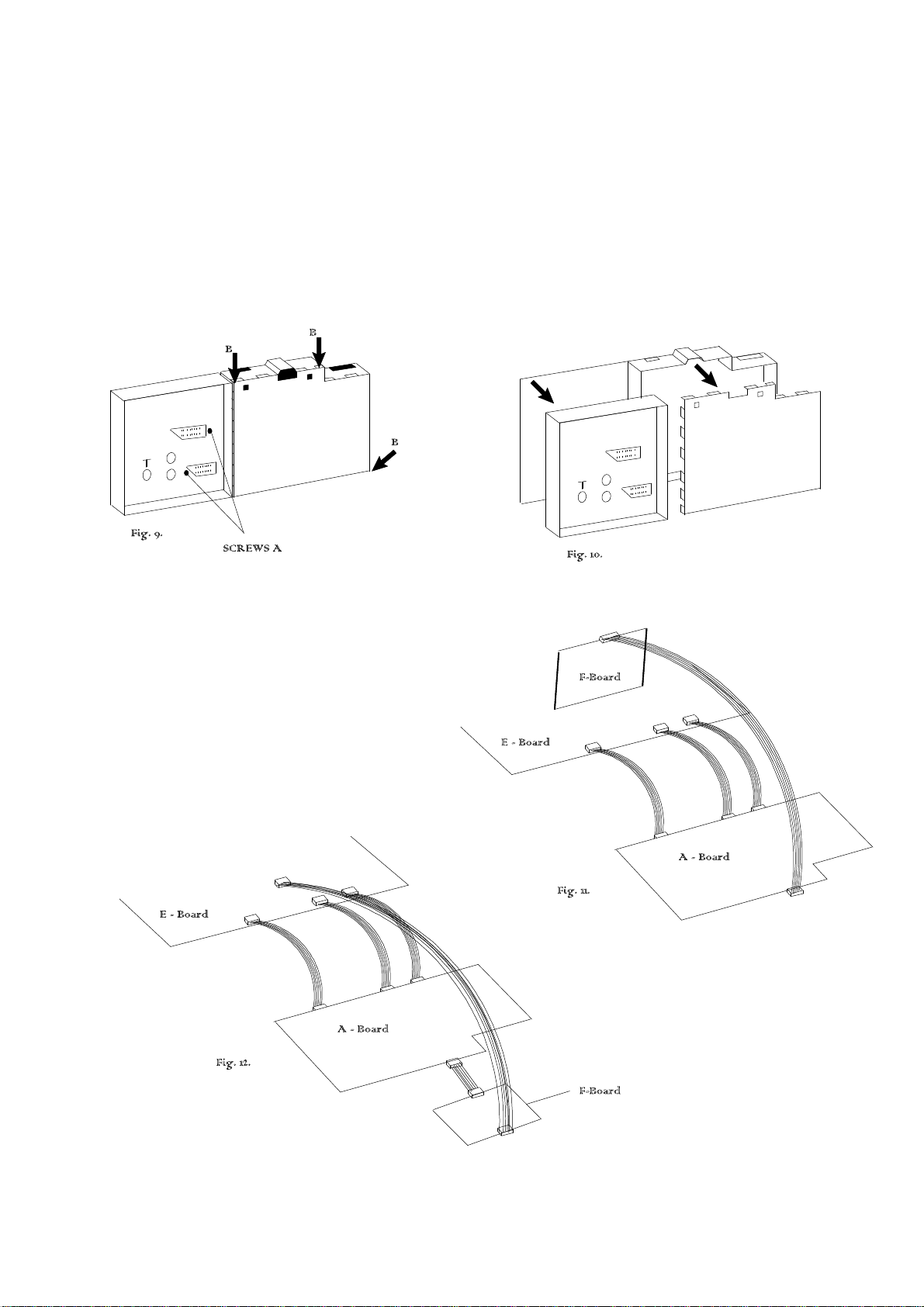

Service position for the A-Board

1. Remove the A-board from the main chassis (E-board) as shown in Fig.8.

2. Remove the two screws (A) (fig.9) from the plastic AV cover and unclip the AV cover from the A-board.

3. Carefully unclip the three metal clips marked B in fig.9.

4. Unclip the front metal cover (Fig10) and remove from the A-board.

5. Fit the extension leads to the A-board making sure that the A-board does not touch the E-board (fig.11).

6. After servicing ensure all wiring is returned to its original position before returning the receiver to the customer.

Note : The extension lead wire kit is supplied as a service kit. (Part number TZS4EP001).

Page 8

Service Mode

The remote control is used for entering and storing adjustments, with the exception of cut-off adjustments which must always be done prior to

service adjustment. Perform adjustments in accordance with screen display. The display on the screen also specifies the CCU variants as

well as the approx. setting values.The adjustment sequence for the service mode is indicated below.

1. Set the Bass to maximum position, set the Treble to minimum

position, press the F button followed by the Volume down on

the customer controls at the front of the TV and at the same

time press the Reveal button on the remote control, this will

place the TV into the Service Mode.

2. Press the RED / GREEN buttons to step down / up through

the functions.

NOTE: This TV also has the option of using a Memory Pack which enables you to copy the preset TV channels and analogue levels into the

Memory Pack and then upload them onto another EURO-2 TV set.

3. Press the YELLOW / BLUE buttons to alter the function

values.

4. Press the STORE button on the preset panel after each

adjustment has been made to store the required values.

5. To exit the Service Mode press the Normalisation button.

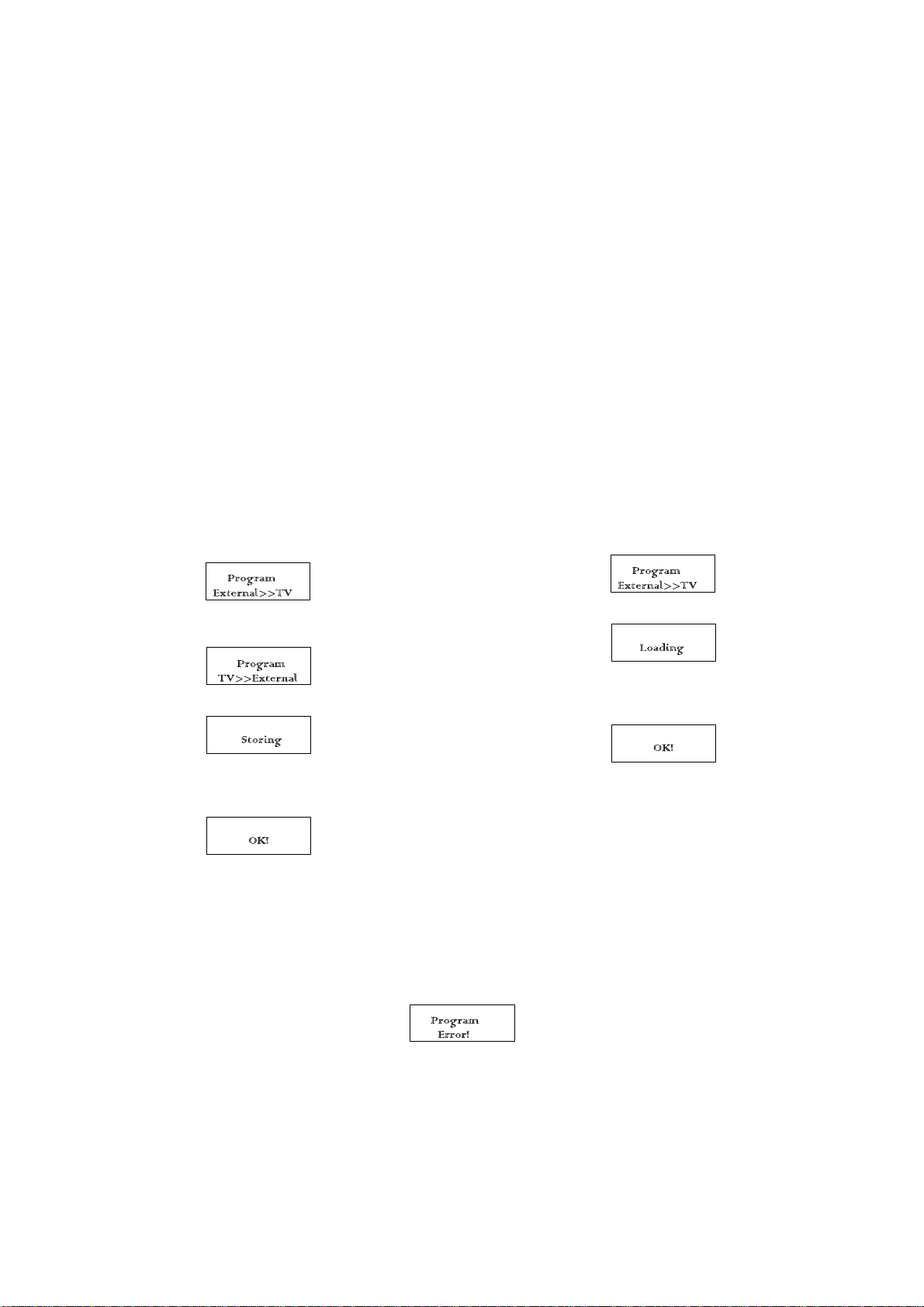

Using the Memory Pack

TV to Memory Pack process

1. Plug the memory pack into the lower of the two 21 pin

terminals at the back of the TV and switch the TV on. If the

TV has only one 21 pin connector then this will be able to

accept the memory pack.

2. Go into the Service Mode as explained above. The screen

will show:-

3. Press the blue button on the remote control. The screen will

show:-

Memory Pack to TV Process

1. Plug the memory pack into the lower of the two 21 pin

terminals at the back of the TV and switch the TV on. If the

TV has only one 21 pin connector then this will be able to

accept the memory pack.

2. Go into the Service Mode as explained above. The screen

will show:-

3. Press the STORE button on the TV. The screen will show:-

4. All the tuning information stored inside the Memory Pack will

4. Press the STORE button on the TV. The screen will show:-

5. All the tuning information stored inside the TV will now be

transferred to the Memory Pack. This process will take 2-3

minutes to complete and when finished the screen will show:-

now be transferred to the TV. This process will take 2-3

minutes to complete and when finished the screen will show:-

5. The tuning information from the Memory Pack has now been

copied into the TV

6. To exit from the Service Mode switch off the TV.

7. The process has now been completed and the Memory Pack

can now be removed.

Errors

If an error occurs while using the Memory Pack the TV will detect this and the screen will show:-

If this happens then switch off the TV and repeat the process that was being used. If the errors continue to occur then check the connectors

between the TV and the memory pack and check the 9V battery inside the memory pack.

Page 9

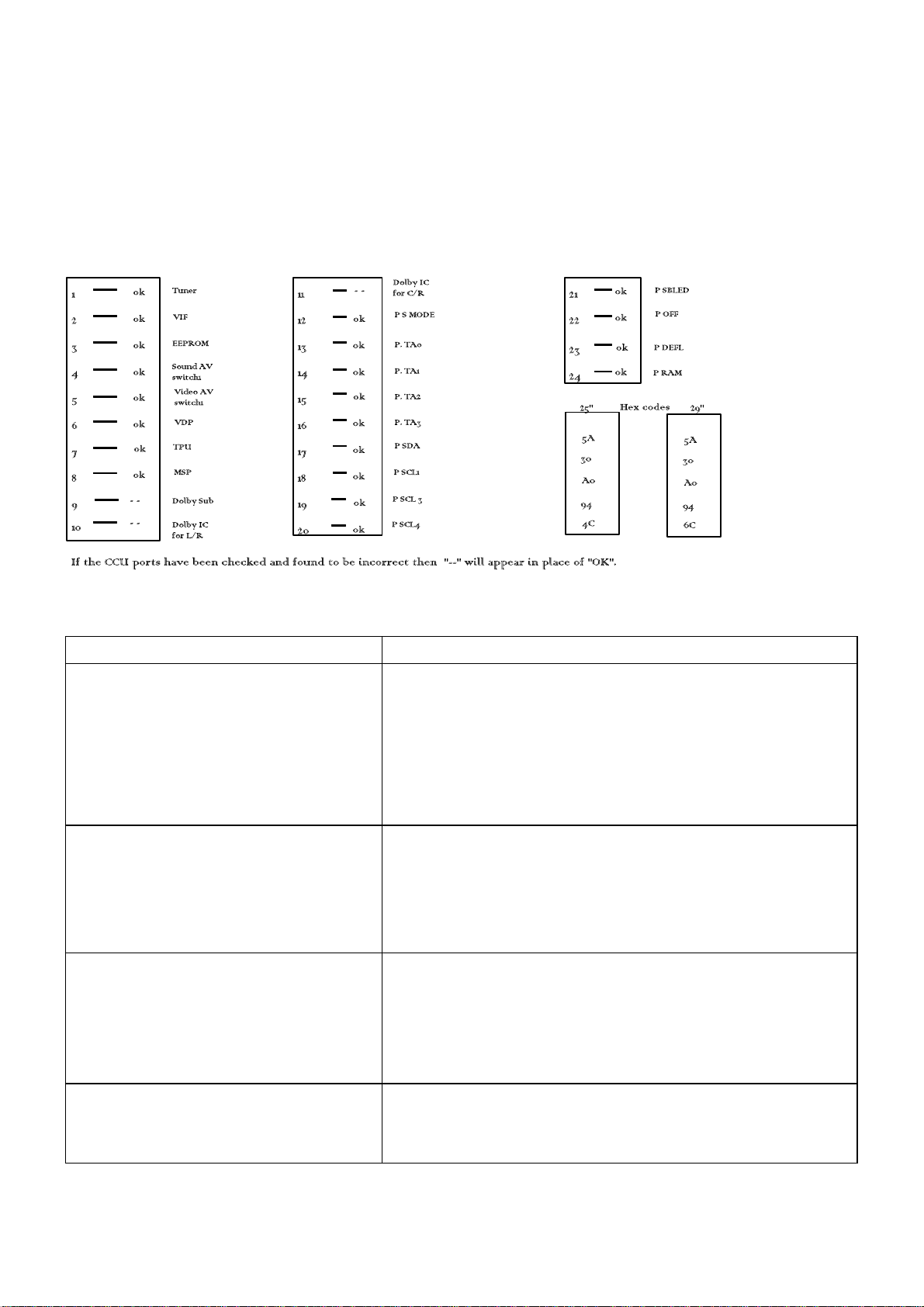

SELF CHECK

Self check is used to automatically check the Bus lines and Hexadecimal code of the TV set.

To enter the Self Check mode press Function down button, on the Preset Panel, at the same time pressing the Status button, on the Remote

Control, and the screen will show:-

Adjustment Procedure

Item/Preparation Adjustments

+B SET-UP

1. Operate the TV set

2. Set the controls:

Brightness minimum

Contrast minimum

RF AGC

1. Receive a test pattern.

2. Connect an oscilloscope between the

tuner RF AGC and ground.

3. Set the oscilloscope gain range to

1V/div.

CUT OFF

1. Receive a black and white signal.

2. Degauss the tube externally.

3. Set the TV into Service Mode 1.

4. Select Ug2 Test.

1. Set the +B voltage up as follows:

Adjust P633 so that U147 shows 147V +/- 0.5V

2. Confirm the following voltages.

U5 5 +/- 0.25V U28 28 +/- 1.0V

U8 8 +/- 0.5V U40 38.5+1.5/-1.0V

U12 12 +/- 0.5V U210 209 +/- 10V

U16 16.0 +/- 0.5/-1V U5SB 5.0 +/- 0.25V

U25 24.8 +/- 1.0V UM 8 +/- 0.5

1. Check that the noise becomes large when the RF AGC VR

P4701 is turned counterclockwise. After the check turn it

clockwise.

2. Gradually turn the RF AGC VR anti-clockwise, and set the

RF AGC VR to the point where the RF AGC voltage is just falling to a

point where this voltage drops by 0.2V from the maximum value.

1. Confirm which colour has the biggest value

2. Turn the screen VR P3368 to minimum.

3. Connect an oscilloscope to the cathode with the biggest value colour.

4. Adjust P3368 to get a low light pulse voltage of 180V +/- 5V.

5. Adjust P3362 to whichever colour reaches 50 +/- 10 first.

COMB FILTER

1. Receive A PAL colour bar signal. 1. Confirm input video signal (pin 4 W2601 is 1Vp-p).

2. Adjust P2601 to obtain 2Vp-p at TPF1.

Page 10

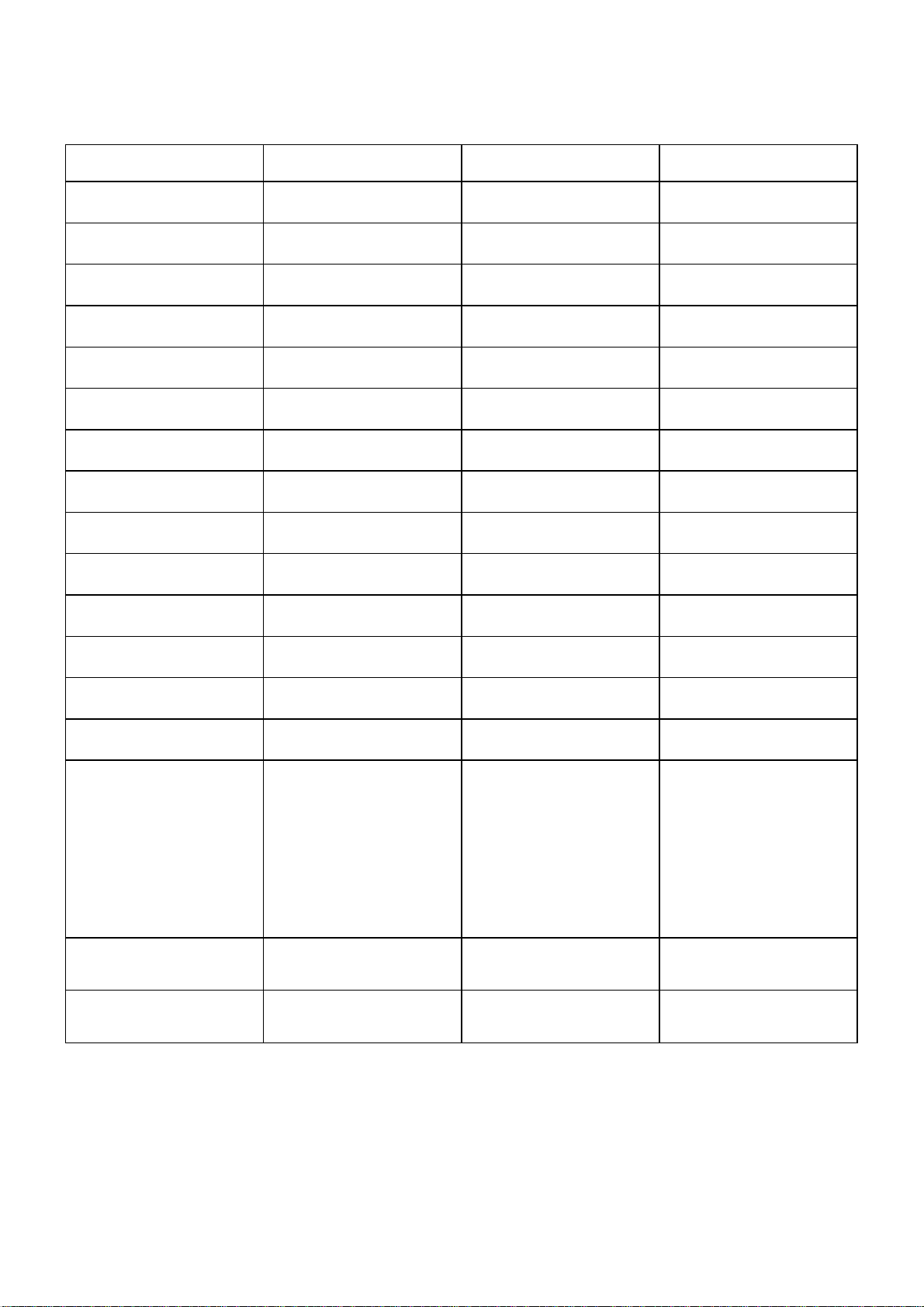

Alignment Settings

Alignment Function TX-29AD1E TX-25AD1E Settings / Special features

1. Vertical amplitude V-AMP

051

2. Vertical symmetry V-SYM

013

3. Vertical linearity V-LIN

012

4. Vert. D.C. Vert. D.C.

000

5. V-Pos. V. Pos

003

6. Horizontal amplitude H-AMP

-033

7. Horizontal position H-POS

049

8. Text Position TEXT POSITION

045

9. EW-amplitude E-W AMP1

-058

10. EW-amplitude E-W AMP2

023

11. Trapezium-comp TRAPEZ-1

-014

12. Trapezium- comp TRAPEZ-2

012

13. Colour VCO COLOUR VCO

015

14. Cut-off DC CUT-OFF DC

050

15. Ug2 Test Ug2 Test

107 021 023

16. Cutoff Cutoff

045 055 050

17. White White

224 255 237

V-AMP

063

V-SYM

002

V-LIN

-020

Vert. D.C.

000

V. Pos

005

H-AMP

-044

H-POS

069

TEXT POSITION

049

E-W AMP1

-058

E-W AMP2

044

TRAPEZ-1

-000

TRAPEZ-2

-009

COLOUR VCO

006

CUT-OFF DC

050

Ug2 Test

94 044 020

Cutoff

057 064 056

White

200 255 248

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Optimum setting

Not to be adjusted.

To adjust the screen settings.

Turn P3362 until a colour

reaches 25"5, place an

oscilloscope probe on the

cathode with the highest output

and adjust P3368 so the

oscilloscope trace reads

150V 0-peak (160V 0-peak TX 25AD1E), then turn P3362 up so

the highest numbered box on the

TV screen reads 050 " 010.

Press the GREEN button to step

through the settings.

Adjust for optimum.

Press the GREEN button to step

through the settings.

Adjust for optimum.

Page 11

PCB

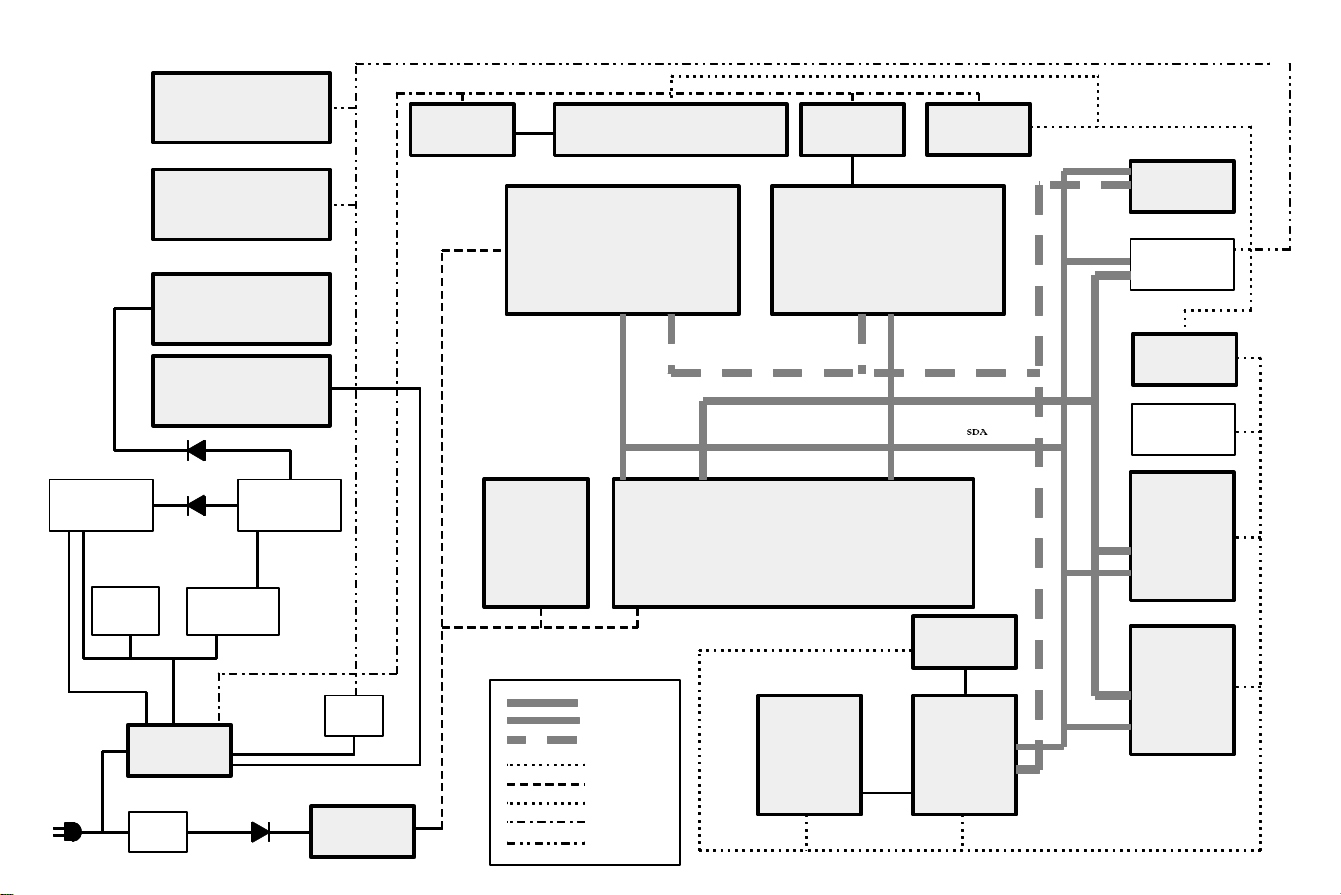

POWER SUPPLY AND CONTROL BLOCK DIAGRAM

I2651

COMB FILTER

CONTROL

I2601

COMB FILTER

I561

VERTICAL OUTPUT

I466

AUDIO OUTPUT

27V

D557

Y

200V

FBT

D547

I4071

12V REG

I1871

EPROM

PROGRAMME

MEMORY

SOUND PROCESSOR

IF PROCESSOR

I1301

I4700

MICROPROCESSOR

CONTROL

I1801

I1351

8V REG

I1601

VIDEO PROCESSOR

I661

12V REG

12V

I1941

EEPROM

MEMORY

TUNER

I646

9V REG

HEADPHONE

AMP

I1011

AV

SWITCHING

9V

Q526

DRIVER

150V

PSU

CONTROL

T6101

I611

Q543

LINE

OUTPUT

2

4

V

15V

D6101

20V

5V

Q674

I1601

5V REG

5VSB

CLOCK 4

DATA

CLOCK 1

12V

5VSB

9V

15V

5V

15V

9V

I1751

TEXT

MEMORY

I1981

RESET

I1701

TELETEXT

I1111

AV

SWITCHING

Page 12

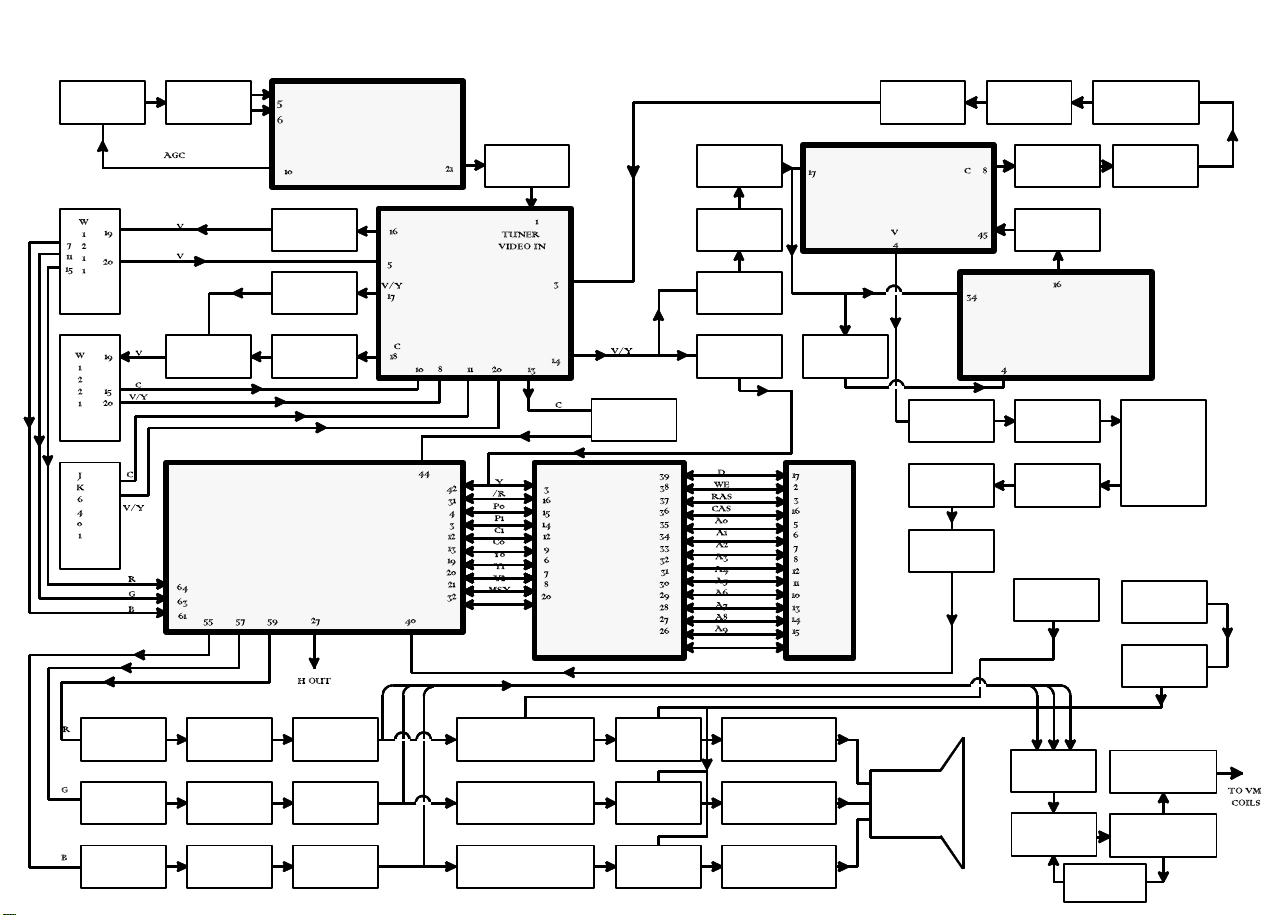

VIDEO BLOCK DIAGRAM

AV1

AV2

AV3

TUNER

X4704

FILTER

Q1172

MIXER

VIDEO DEMODULATOR

Q1123

BUFFER

Q1167

BUFFER

Q1163

BUFFER

I1601

VIDEO PROCESSOR

I4700

I1111

AV SWITCH

Q4701

BUFFER

Q1182

BUFFER

I1701

TELETEXT

Q2613

BUFFER

Q2614

AMP

Q1267

BUFFER

Q1192

BUFFER

Q2651

BUFFER

I

1

7

5

1

M

E

M

O

R

Y

Q2602

BUFFER

I2601

COMB FILTER

Q2611

BUFFER

FILTER

Q2601

BUFFER

Q2604

BUFFER

SPOT SU

Q2612

BUFFER

Q2653

BUFFER

I2651

Q2609

BUFFER

Q2603

DRIVER

Q3368

PRESS

Q2608 Q2606

AMP

Q2610

BUFFER

Q2607

Q2605

AMP

Q3359

CUTOFF

Q3368

SPOT SU

PRESS

Q1651

AMP

Q1641

AMP

Q1631

AMP

Q1653

BUFFER

Q1643

BUFFER

Q1633

BUFFER

Q1656

AMP

Q1646

AMP

Q1636

AMP

Q3162 Q3164 Q3166

Q3169 Q3391

Q3172 Q3174 Q3176

Q3179 Q3381

Q3182 Q3184 Q3186

Q3189 Q3371

Q3393

DRIVE

Q3383

DRIVE

Q3373

DRIVE

Q3394 Q3397

OUTPUT AMP

Q3384 Q3387

OUTPUT AMP

Q3374 Q3377

OUTPUT AMP

RESISTOR

MATRIX

Q3109 Q3108

Q3111 Q3122

Q3143

AMP

Q3131 Q3136

OUTPUT AMP

Q3126 Q3127

DRIVER

Page 13

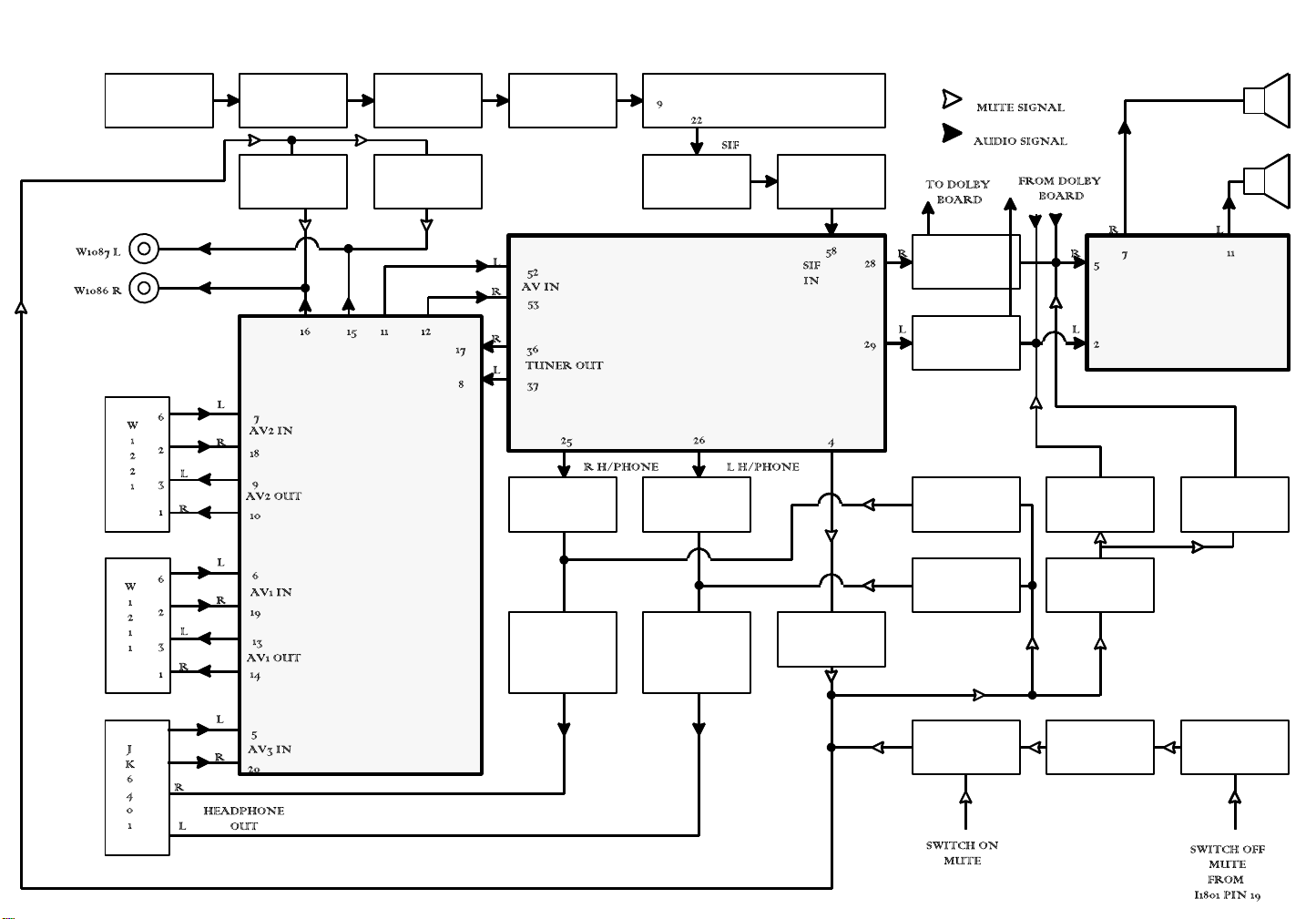

AUDIO BLOCK DIAGRAM

TUNER

AV2

X4704

FILTER

Q1091

MUTE

AV SWITCHING

I1011

Q4704

BUFFER

Q1071

MUTE

Q4704

AMP

Q1466

BUFFER

SIF FILTER

Q4702

AMP

I1301

AUDIO

MIXER

DEMODULATOR

VOLUME

BASS

TREBLE

CONTROL

Q1476

BUFFER

I4700

Q4703

BUFFER

Q1486

BUFFER

Q1496

BUFFER

Q6403

MUTE

Q6433

MUTE

AUDIO OUTPUT

Q498

MUTE

Q497

MUTE

I466

AMP

Q496

MUTE

AV1

AV3

Q6413

Q6417

AMP

Q6443

Q6447

AMP

Q1382

MUTE

Q463

MUTE

Q494

MUTE

Q1812

BUFFER

Page 14

WIRING BLOCK DIAGRAM

MAFEB

Y

W

1

2

41W

127

1

W

1

933

W

6

301W640

2

W

6

4

01J

K

6

4

01W

1

2

5

1W2

6

0

1W1

6

5

1W612

W

214

W

252

W4001

W63

0

W

6

60W54

8

W

3

317

W

3

1

52W

260

2

W3316

W6102

W6010

W1370

W610

W1951

W1511

W511

W1201

W211

AV3

W1221

W1211

AV1

AV2W7

4

0

W534

W569

W619

DEGAUSS

V DY

H DY

W534VMCOIL

W3316

W554

TO CRT

SCREEN

FACTORY

ADJUSTMENT

Page 15

WAVEFORM PATTERN TABLE

Page 16

SCHEMATIC DIAGRAM FOR MODELS

TX-29/25AD1E

(EURO-2S CHASSIS)

Notes

1. RESISTOR

All resistors are carbon ¼W resistor, unless marked.

Unit of resistance is OHM (W) (K=1,000, M=1,000,000).

2. CAPACITOR

All capacitors are ceramic 50V capacitors, unless marked, the unit of capacitance is mF unless otherwise stated.

3. COIL

Unit of inductance is mH, unless otherwise stated.

4. TEST POINT

:Test Point Position

3

:Waveform Test Point Position

5. EARTH SYMBOL

Chassis Earth (Cold)

Line Earth (Hot)

6. VOLTAGE MEASUREMENT

Voltage is measured by a DC voltmeter.

Measurement conditions are as follows:

Power source AC 220-240V, 50Hz

Receiving Signal Colour Bar signal (RF)

All customer controls Maximum position

7.

: Indicates the Video signal path

: Indicates the Audio signal path

: Indicates the Vertical/Horizontal signal path

8. This schematic diagram is the latest at the time of printing and is subject to change without notice.

Precautions

a. Do not touch the hot part, or the hot and cold parts at the same time, as you are liable to a shock hazard.

b. Do not short-circuit the hot and cold circuits as electrical components may be damaged.

c. Do not connect an instrument, such as an oscilloscope, to the hot and cold circuits simultaneously, as this may cause fuse failure.

Connect the earth of the instruments to the earth connection of the circuit being measured.

d. Make sure to disconnect the power plug before removing the chassis.

Remarks

1. The Power Circuit contains a circuit area which uses a separate power supply to isolate the earth connection. The circuit is defined by

HOT and COLD indications in the schematic diagram. All circuits, except the Power Circuit, are COLD.

Page 17

PARTS LOCATION

NOTE :

2

1

4

3

5

7

6

13

17

18

15

10

22

9

11

20

21

12

8

16

14

19

Page 18

REPLACEMENT PARTS LIST

Important Safety Notice

PARTS COMMON TO TX-29AD1E AND TX-25AD1E

MISCELLANEOUS COMPONENTS

1) EUR51920 REMOTE CONTROL

2) ********** SEE DIFFERENCE LIST

3) ********** SEE DIFFERENCE LIST

4) ********** SEE DIFFERENCE LIST

5) THT1009R CRT FIXING SCREW

6) ********** SEE DIFFERENCE LIST

7) ********** SEE DIFFERENCE LIST

8) TNP117038AA M P.C.B.

9) ********** SEE DIFFERENCE LIST

10) ********** SEE DIFFERENCE LIST

11) ENV578F5G3 TUNER

12) TNP117039AC B P.C.B.

13) TMX8E005 CHASSIS FRAME

14) TMW8E016 CONTROL BRACKET

15) TKP8E1109 A.V. DOOR

16) ********** SEE DIFFERENCE LIST

17) ********** SEE DIFFERENCE LIST

18) TSX8E0011 MAINS LEAD

19) TKP8E1109 A.V. DOOR

20) TBX8E021 POWER BUTTON

21) TBM153022 PANASONIC BADGE

22) TNP117035 F P.C.B.

TQB8E0917A INST BOOK GERMAN

TQB8E0917B INST BOOK DUTCH

TQB8E0917D INST BOOK FRENCH

TQB8E0917E INST BOOK SPANISH

TQB8E0917F INST BOOK SWEDISH

TQB8E0917G INST BOOK NORWEGIAN

TQB8E0917H INST BOOK SUOMI

TQB8E0917J INST BOOK PORTUGUESE

TQB8E0917K INST BOOK DANISH

TBM8E1182 ANTENNA BLIND SHEET

TBX8E022 OPERATE KEY

TEK6343 LID DAMPER

TBM8E1359 INDICATION SHEET

TBM8E1360 INDICATION SHEET

TBM8E1475 BLIND SHEET

TEK6940 LID CATCHER

TES2249 SPRING FOR POWER BUTTON

TES2298 CRT EARTH SPRING

TMW8E017 L.E.D. HOLDER

TNA10804 VIF PACK

TPD8E562 CUSHION

UM-3DEP-2P BATTERY

CAPACITORS

C202 ECQB1H103J FILM 50V 10nF

C203 ECEA1CU221 ELECT 16V 220mF

C204 ECQB1H104J FILM 50V 100nF

C206 222236516334 FILM 160V 330nF

C209 ECQB1H104J FILM 50V 100nF

C212 ECEA1HUR22 ELECT 50V 0.22mF

C226 ECQB1H104J FILM 50V 100nF

C228 ECKC1H102J CERAMIC 50V 1000pF

C229 ECKC1H102J CERAMIC 50V 1000pF

C462 ECEA1EU101 ELECT 25V 100mF

C463 ECEA1EU471 ELECT 25V 470mF

C465 ECEA1CU470 ELECT 16V 47mF

C466 ECEA1HU222 ELECT 50V 2200mF

C467 ECQB1H103J FILM 50V 10nF

C471 ECEA1HU010 ELECT 50V 1mF

C472 ECEA1CU101 ELECT 16V 100mF

C473 ECEA1EGE222 ELECT 25V 2200mF

C476 ECEA1HU4R7 ELECT 50V 4.7mF

C479 222236576104 FILM 760V 100nF

C481 ECEA1HU010 ELECT 50V 1mF

C482 ECEA1CU101 ELECT 16V 100mF

C483 ECEA1EGE222 ELECT 25V 2200mF

C486 ECEA1HU4R7 ELECT 50V 4.7mF

C489 222236576104 FILM 760V 100nF

C492 ECEA1VU4R7 ELECT 35V 4.7mF

C495 ECEA1EU101 ELECT 25V 100mF

C496 ECEA1CU100 ELECT 16V 10mF

C521 ECEA1HU101 ELECT 50V 100mF

C524 222236516105 FILM 160V 1mF

C527 ECQM2683JZ FILM 250V 68nF

C531 ECQM2564KZ FILM 250V 560nF

C536 ECWH12H103J FILM 1250V 10nF

C538 ECWF2H514J FILM 500V 510nF

C543 ECEA2VU2R2 ELECT 350V 2.2mF

C544 ECKC3D152J CERAMIC 2KV 1.5nF

C547 ECKC2H101J CERAMIC 500V 100pF

C548 ECEA2EU220 ELECT 250V 22mF

C549 ECEA2AU2R2 ELECT 100V 2.2mF

C557 ECKC2H101J CERAMIC 500V 100pF

C558 ECEA1VU102 ELECT 35V 1000mF

C561 ECEA1VU222 ELECT 35V 2200mF

C562 222236576104 FILM 760V 100nF

C564 ECQB1H473K FILM 50V 47nF

C568 222236516224 FILM 160V 220nF

C574 ECEA1VU332 ELECT 35V 3300mF

C577 222236516105 FILM 160V 1mF

C579 ECKC1H472J CERAMIC 50V 4.7nF

C592 ECEA1CU330 ELECT 16V 33mF

C594 ECKC1H103JB CERAMIC 50V 10nF

C595 ECQB1H102J FILM 50V 1nF

C618 ECOS2GG181NG ELECT 400V 180mF

C619 ECQE6104K FILM 600V 100nF

C622 ECEA1HFS470 ELECT 50V 47mF

C623 222236516224 FILM 160V 220nF

C626 ECKC3D471JB CERAMIC 2KV 470pF

C628 ECKC1H221J CERAMIC 50V 220pF

C629 ECQB1H153K FILM 50V 15nF

C631 ECQB1H472J FILM 50V 4.7nF

C632 ECQB1H103J FILM 50V 10nF

C634 ECEA1HGE010 ELECT 50V 1mF

C635 ECKC3D331J CERAMIC 2KV 330pF

C636 ECKC2H472J CERAMIC 500V 4.7nF

C637 ECQB1H222J FILM 50V 2200pF

C638 ECQF6333JZH FILM 600V 33nF

C639 ECKCWS222MEJ CERAMIC 2200pF

Page 19

C647 222236516334 FILM 160V 330nF

C650 ECKC3A102J CERAMIC 1KV 1nF

C651 ECOS2EA221AB ELECT 400V 220mF

C656 ECKC2H681J CERAMIC 500V 680pF

C657 ECEA1HU471 ELECT 50V 470mF

C661 ECKC2H821J CERAMIC 500V 820pF

C662 ECEA1EU222 ELECT 25V 2200mF

C666 222236516224 FILM 160V 220nF

C667 ECEA1CU471 ELECT 16V 470mF

C671 ECKC2H681J CERAMIC 500V 680pF

C672 ECEA1EU222 ELECT 25V 2200mF

C677 ECEA1CU471 ELECT 16V 470mF

C681 ECEA1EGE101 ELECT 25V 100 mF

C682 ECKC2H331J CERAMIC 500V 330pF

C687 ECEA1HGE102 ELECT 50V 1000mF

C1001 ECEA1CU470 ELECT 16V 47mF

C1002 ECUV1H104ZFX S.M. CAP 50V 100nF

C1011 ECEA1CU470 ELECT 16V 47mF

C1012 ECUV1H473ZFX S.M. CAP 50V 47nF

C1013 ECEA1CU470 ELECT 16V 47mF

C1019 ECEA1CU470 ELECT 16V 47mF

C1020 ECEA1CU470 ELECT 16V 47mF

C1021 ECEA1HUR47 ELECT 50V 0.47mF

C1022 ECEA1HUR47 ELECT 50V 0.47mF

C1023 ECUV1H221JCX S.M. CAP 50V 220pF

C1024 ECUV1H221JCX S.M. CAP 50V 220pF

C1031 ECEA1HNR47 ELECT 50V 0.47mF

C1032 ECEA1HUR47 ELECT 50V 0.47mF

C1033 ECUV1H221JCX S.M. CAP 50V 220pF

C1034 ECUV1H221JCX S.M. CAP 50V 220pF

C1036 ECEA1CU470 ELECT 16V 47mF

C1038 ECEA1CU470 ELECT 16V 47mF

C1041 ECUV1H103KBX S.M. CAP 50V 10nF

C1042 ECUV1H103KBX S.M. CAP 50V 10nF

C1043 ECEA1HUR47 ELECT 50V 0.47mF

C1044 ECEA1HUR47 ELECT 50V 0.47mF

C1051 ECEA1HNR33 ELECT 50V 0.33mF

C1052 ECEA1HNR33 ELECT 50V 0.33mF

C1071 ECEA1CN470 ELECT 16V 47mF

C1091 ECEA1CU470 ELECT 16V 47mF

C1101 ECEA1HUR47 ELECT 50V 0.47mF

C1111 ECEA1HU470 ELECT 50V 47mF

C1112 ECUV1H473ZFX S.M. CAP 50V 47nF

C1116 ECUV1H473ZFX S.M. CAP 50V 47nF

C1121 ECEA1HUR47 ELECT 50V 0.47mF

C1124 ECUV1H473ZFX S.M. CAP 50V 47nF

C1126 ECEA1CU470 ELECT 16V 47mF

C1151 ECUV1H102KBX S.M. CAP 50V 1nF

C1158 ECEA1HUR47 ELECT 50V 0.47mF

C1161 ECUV1H102KBX S.M. CAP 50V 1nF

C1178 ECUV1H473ZFX S.M. CAP 50V 47nF

C1179 ECEA1CU470 ELECT 16V 47mF

C1183 ECUV1H104ZFX S.M. CAP 50V 100nF

C1193 ECUV1H104ZFX S.M. CAP 50V 100nF

C1226 ECUV1H560JCX S.M. CAP 50V 56pF

C1231 ECUV1H104ZFX S.M. CAP 50V 100nF

C1241 ECUV1H472KBX S.M. CAP 50V 4.7nF

C1242 ECUV1H472KBX S.M. CAP 50V 4.7nF

C1263 ECUV1H102KBX S.M. CAP 50V 1nF

C1266 ECUV1H104ZFX S.M. CAP 50V 100nF

C1271 ECUV1H102KBX S.M. CAP 50V 1nF

C1273 ECEA1HUR47 ELECT 50V 0.47mF

C1282 ECEA1HUR47 ELECT 50V 0.47mF

C1284 ECEA1HUR47 ELECT 50V 0.47mF

C1301 ECEA1CU100 ELECT 16V 10mF

C1302 ECUV1H104ZFX S.M. CAP 50V 100nF

C1303 ECEA1CU100 ELECT 16V 10mF

C1304 ECUV1H104ZFX S.M. CAP 50V 100nF

C1306 ECEA1CU101 ELECT 16V 100mF

C1307 ECUV1H104ZFX S.M. CAP 50V 100nF

C1309 ECEA1CU100 ELECT 16V 10mF

C1310 ECEA1CU100 ELECT 16V 10mF

C1311 ECUV1H104ZFX S.M. CAP 50V 100nF

C1312 ECEA50Y3R3 ELECT 50V 3.3mF

C1313 ECUV1H471JCX S.M. CAP 50V 470pF

C1314 ECUV1H471JCX S.M. CAP 50V 470pF

C1315 ECEA1CU100 ELECT 16V 10mF

C1316 ECUV1H104ZFX S.M. CAP 50V 100nF

C1321 ECUV1H030CCX S.M. CAP 50V 30pF

C1322 ECUV1H030CCX S.M. CAP 50V 30pF

C1326 ECQM1H334J FILM 50V 330nF

C1327 ECUV1H221JCX S.M. CAP 50V 220pF

C1331 ECUV1H391JCX S.M. CAP 50V 390pF

C1332 ECUV1H391JCX S.M. CAP 50V 390pF

C1346 ECUV1H221JCX S.M. CAP 50V 220pF

C1347 ECUV1H221JCX S.M. CAP 50V 220pF

C1351 ECEA1CU470 ELECT 16V 47mF

C1352 ECUV1H104ZFX S.M. CAP 50V 100nF

C1353 ECUV1H104ZFX S.M. CAP 50V 100nF

C1377 ECUV1H104ZFX S.M. CAP 50V 100nF

C1382 ECUV1H104ZFX S.M. CAP 50V 100nF

C1409 ECUV1H470JCX S.M. CAP 50V 47pF

C1411 ECUV1H070DCX S.M. CAP 50V 7pF

C1412 ECUV1H100DCX S.M. CAP 50V 10pF

C1413 ECUV1H220JCX S.M. CAP 50V 22pF

C1416 ECUV1H070DCX S.M. CAP 50V 7pF

C1417 ECUV1H560JCX S.M. CAP 50V 56pF

C1444 ECUV1H102KBX S.M. CAP 50V 1nF

C1454 ECUV1H102KBX S.M. CAP 50V 1nF

C1463 ECUV1H102KBX S.M. CAP 50V 1nF

C1465 ECUV1H560JCX S.M. CAP 50V 56pF

C1467 ECUV1H102KBX S.M. CAP 50V 1nF

C1468 ECUV1H102KBX S.M. CAP 50V 1nF

C1473 ECUV1H102KBX S.M. CAP 50V 1nF

C1475 ECUV1H560JCX S.M. CAP 50V 56pF

C1483 ECUV1H102KBX S.M. CAP 50V 1nF

C1487 ECUV1H103KBX S.M. CAP 50V 10nF

C1493 ECUV1H102KBX S.M. CAP 50V 1nF

C1497 ECUV1H103KBX S.M. CAP 50V 10nF

C1601 ECEA1CU470 ELECT 16V 47mF

C1602 ECUV1H103KBX S.M. CAP 50V 10nF

C1606 ECEA0JU102 ELECT 6.3V 1000 mF

C1607 ECUV1H103KBX S.M. CAP 50V 10nF

C1611 ECEA1CU470 ELECT 16V 47mF

C1612 ECUV1H103KBX S.M. CAP 50V 10nF

C1613 ECEA1CU100 ELECT 16V 10mF

C1614 ECUV1H473ZFX S.M. CAP 50V 47nF

C1615 ECUV1H103KBX S.M. CAP 50V 10nF

C1616 ECUV1H101JCX S.M. CAP 50V 100pF

C1617 ECUV1H470JCX S.M. CAP 50V 47pF

C1618 ECUV1H470JCX S.M. CAP 50V 47pF

C1619 ECUV1H103KBX S.M. CAP 50V 10nF

C1620 ECUV1H102KBX S.M. CAP 50V 1nF

C1621 ECUV1H103KBX S.M. CAP 50V 10nF

C1622 ECEA1CU100 ELECT 16V 10mF

C1624 ECEA1HNR22 ELECT 50V 0.22mF

C1625 ECUV1H101JCX S.M. CAP 50V 100pF

C1626 ECUV1H104ZFX S.M. CAP 50V 100nF

C1627 ECEA1HNR22 ELECT 50V 0.22mF

C1641 ECUV1H104ZFX S.M. CAP 50V 100nF

C1651 ECUV1H104ZFX S.M. CAP 50V 100nF

C1652 ECUV1H104ZFX S.M. CAP 50V 100nF

C1653 ECUV1H104ZFX S.M. CAP 50V 100nF

C1655 ECEA1CU470 ELECT 16V 47mF

C1661 ECUV1H102KBX S.M. CAP 50V 1nF

C1662 ECUV1H683ZFX S.M. CAP 50V 68nF

C1663 ECUV1H102KBX S.M. CAP 50V 1nF

C1666 ECUV1H102KBX S.M. CAP 50V 1nF

C1667 ECUV1H683ZFX S.M. CAP 50V 68nF

C1668 ECUV1H104ZFX S.M. CAP 50V 100nF

C1672 ECEA1CU100 ELECT 16V 10mF

C1673 ECUV1H104ZFX S.M. CAP 50V 100nF

Page 20

C1680 ECUV1H471JCX S.M. CAP 50V 470pF

C1681 ECUV1H102KBX S.M. CAP 50V 1nF

C1682 ECUV1H102KBX S.M. CAP 50V 1nF

C1683 ECUV1H271JCX S.M. CAP 50V 270pF

C1684 ECUV1H121JCX S.M. CAP 50V 120pF

C1685 ECUV1H102KBX S.M. CAP 50V 1nF

C1686 ECUV1H271JCX S.M. CAP 50V 270pF

C1687 ECUV1H121JCX S.M. CAP 50V 120pF

C1688 ECUV1H471JCX S.M. CAP 50V 470pF

C1691 ECUV1H104ZFX S.M. CAP 50V 100nF

C1692 ECUV1H104ZFX S.M. CAP 50V 100nF

C1693 ECUV1H104ZFX S.M. CAP 50V 100nF

C1696 ECUV1H102KBX S.M. CAP 50V 1nF

C1697 ECUV1H100DCX S.M. CAP 50V 10pF

C1698 ECUV1H102KBX S.M. CAP 50V 1nF

C1699 ECUV1H100DCX S.M. CAP 50V 10pF

C1701 ECEA1CU470 ELECT 16V 47mF

C1702 ECUV1H103KBX S.M. CAP 50V 10nF

C1704 ECEA1CU470 ELECT 16V 47mF

C1706 ECUV1H104ZFX S.M. CAP 50V 100nF

C1714 ECUV1H103KBX S.M. CAP 50V 10nF

C1717 ECUV1H102KBX S.M. CAP 50V 1nF

C1721 ECUV1H473ZFX S.M. CAP 50V 47nF

C1722 ECUV1H102KBX S.M. CAP 50V 1nF

C1752 ECUV1H103KBX S.M. CAP 50V 10nF

C1753 ECEA1CU100 ELECT 16V 10mF

C1801 ECUV1H103KBX S.M. CAP 50V 10nF

C1802 ECEA1CU470 ELECT 16V 47mF

C1804 ECUV1H103KBX S.M. CAP 50V 10nF

C1811 ECUV1H332KBX S.M. CAP 50V 3.3nF

C1816 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

C1826 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

C1836 ECUV1H104ZFX S.M. CAP 50V 100nF

C1838 ECUV1H101JCX S.M. CAP 50V 100pF

C1843 ECUV1H472KBX S.M. CAP 50V 4.7nF

C1845 ECUV1H560JCX S.M. CAP 50V 56pF

C1849 ECEA1HU4R7 ELECT 50V 4.7mF

C1851 ECUV1H470JCX S.M. CAP 50V 47pF

C1852 ECUV1H390JCX S.M. CAP 50V 39pF

C1853 ECUV1H390JCX S.M. CAP 50V 39pF

C1857 ECUV1H560JCX S.M. CAP 50V 56pF

C1859 ECUV1H560JCX S.M. CAP 50V 56pF

C1871 ECUV1H103KBX S.M. CAP 50V 10nF

C1879 ECUV1H560JCX S.M. CAP 50V 56pF

C1888 ECUV1H103KBX S.M. CAP 50V 10nF

C1891 ECUV1H102KBX S.M. CAP 50V 1nF

C1893 ECUV1H102KBX S.M. CAP 50V 1nF

C1894 ECUV1H102KBX S.M. CAP 50V 1nF

C1922 ECUV1H103KBX S.M. CAP 50V 10nF

C1925 ECUV1H103KBX S.M. CAP 50V 10nF

C1931 ECUV1H103KBX S.M. CAP 50V 10nF

C1941 ECUV1H103KBX S.M. CAP 50V 10nF

C1942 ECEA1CU470 ELECT 16V 47mF

C1961 ECUV1H332KBX S.M. CAP 50V 3.3nF

C1962 ECUV1H332KBX S.M. CAP 50V 3.3nF

C1963 ECUV1H332KBX S.M. CAP 50V 3.3nF

C1964 ECUV1H332KBX S.M. CAP 50V 3.3nF

C1971 ECUV1H104ZFX S.M. CAP 50V 100nF

C1972 ECEA1CU470 ELECT 16V 47mF

C1973 ECUV1H104ZFX S.M. CAP 50V 100nF

C1974 ECUV1H104ZFX S.M. CAP 50V 100nF

C1976 ECUV1H104ZFX S.M. CAP 50V 100nF

C1977 ECEA1CU470 ELECT 16V 47mF

C1981 ECUV1H104ZFX S.M. CAP 50V 100nF

C1982 ECUV1H101JCX S.M. CAP 50V 100pF

C2603 ECUV1H100DCX S.M. CAP 50V 10pF

C2604 ECUV1H104ZFX S.M. CAP 50V 100nF

C2605 ECEA1CKA470 ELECT 16V 47mF

C2606 ECUV1H104ZFX S.M. CAP 50V 100nF

C2607 ECUV1H104ZFX S.M. CAP 50V 100nF

C2609 ECEA1CKA470 ELECT 16V 47mF

C2611 ECUV1H104ZFX S.M. CAP 50V 100nF

C2612 ECEA1CKA470 ELECT 16V 47mF

C2613 ECUV1H104ZFX S.M. CAP 50V 100nF

C2614 ECUV1H103ZFX S.M. CAP 50V 10nF

C2615 ECUV1H103ZFX S.M. CAP 50V 10nF

C2616 ECEA1CKA470 ELECT 16V 47mF

C2617 ECEA1HKNR47 ELECT 50V 0.47mF

C2618 ECEA1CKA470 ELECT 16V 47mF

C2619 ECUV1H104ZFX S.M. CAP 50V 100nF

C2620 ECEA1CKA100 ELECT 16V 10mF

C2621 ECQM1H474J FILM 50V 470nF

C2623 ECUV1H103ZFX S.M. CAP 50V 10nF

C2625 ECUV1H103ZFX S.M. CAP 50V 10nF

C2627 ECEA1CKA470 ELECT 16V 47mF

C2628 ERJ6GEY0R00 WIRE LINK

C2630 ECEA1CKA470 ELECT 16V 47mF

C2631 ECEA1CKA470 ELECT 16V 47mF

C2632 ECUV1H103ZFX S.M. CAP 50V 10nF

C2633 ECUV1H103ZFX S.M. CAP 50V 10nF

C2634 ECUV1H103ZFX S.M. CAP 50V 10nF

C2635 ECUV1H103ZFX S.M. CAP 50V 10nF

C2636 ECEA1CKA100 ELECT 16V 10mF

C2645 ECUV1H331JCX S.M. CAP 50V 330pF

C2651 ECUV1H103ZFX S.M. CAP 50V 10nF

C2652 ECUV1H470JCX S.M. CAP 50V 47pF

C2653 ECUV1H103ZFX S.M. CAP 50V 10nF

C2654 ECUV1H680JCX S.M. CAP 50V 68pF

C2655 ECUV1H103ZFX S.M. CAP 50V 10nF

C2656 ECUV1H102KBX S.M. CAP 50V 1nF

C2657 ECUV1H103ZFX S.M. CAP 50V 10nF

C2658 ECEA1HKA4R7 ELECT 50V 4.7mF

C2660 ECEA1HKA4R7 ELECT 50V 4.7mF

C2661 ECUV1H103ZFX S.M. CAP 50V 10nF

C2662 ECUV1H103ZFX S.M. CAP 50V 10nF

C2664 ECEA1HKA4R7 ELECT 50V 4.7mF

C2665 ECEA1HKA4R7 ELECT 50V 4.7mF

C2666 ECUV1H103ZFX S.M. CAP 50V 10nF

C2667 ECUV1H103ZFX S.M. CAP 50V 10nF

C2668 ECEA1HKA0R1 ELECT 50V 0.1mF

C2669 ECUV1H181JCX S.M. CAP 50V 180pF

C2670 ECEA1HKA2R2 ELECT 50V 2.2mF

C2671 ECUV1H152KBX S.M. CAP 50V 1.5pF

C2672 ECUV1H223KBX S.M. CAP 50V 22nF

C2673 ECUV1H220JCX S.M. CAP 50V 22pF

C2674 ECEA1HKA4R7 ELECT 50V 4.7mF

C2675 ECUV1H181JCX S.M. CAP 50V 180pF

C2676 ECEA1CKA100 ELECT 16V 10mF

C2677 ECUV1H103ZFX S.M. CAP 50V 10nF

C2678 ECUV1H180JCX S.M. CAP 50V 18pF

C2679 ECUV1H103ZFX S.M. CAP 50V 10nF

C2680 ECEA1CKA470 ELECT 16V 47mF

C2681 ECUV1H103ZFX S.M. CAP 50V 10nF

C2682 ECEA1CKA100 ELECT 16V 10mF

C2683 ECUV1H103 ZFX S.M. CAP 50V 10nF

C2684 ECEA1CKA470 ELECT 16V 47mF

C2685 ECUV1H103ZFX S.M. CAP 50V 10nF

C2686 ECUV1H104ZFX S.M. CAP 50V 100nF

C3101 ECUV1H030CCX S.M. CAP 50V 30pF

C3102 ECUV1H103ZFX S.M. CAP 50V 10nF

C3103 ECEA1HU100 ELECT 50V 10mF

C3122 ECUV1H102KBX S.M. CAP 50V 1nF

C3124 ECUV1H471JCX S.M. CAP 50V 470pF

C3131 ECKC2H471J CERAMIC 500V 470pF

C3134 ECEA1CU101 ELECT 16V 100mF

C3136 ECKC2H471J CERAMIC 500V 470pF

C3139 ECEA1CU101 ELECT 16V 100mF

C3141 ECEA1CU471 ELECT 16V 470mF

Page 21

C3143 ECEA1CU100 ELECT 16V 10mF

C3144 ECEA1CU470 ELECT 16V 47mF

C3146 ECEA2EU220 ELECT 250V 22mF

C3152 ECEA2EU220 ELECT 250V 22mF

C3153 ECEA1VU101 ELECT 35V 100 mF

C3168 ECUV1H103ZFX S.M. CAP 50V 10nF

C3169 ECEA1CU100 ELECT 16V 10mF

C3177 ECUV1H150JCX S.M. CAP 50V 15pF

C3178 ECUV1H103ZFX S.M. CAP 50V 10nF

C3179 ECEA1CU100 ELECT 16V 10mF

C3187 ECUV1H121JCX S.M. CAP 50V 120pF

C3188 ECUV1H103ZFX S.M. CAP 50V 10nF

C3189 ECEA1CU100 ELECT 16V 10mF

C3356 ECEA1CU220 ELECT 16V 22mF

C3357 ECUV1H104ZFX S.M. CAP 50V 100nF

C3364 ECKC3A331J CERAMIC 1000V 330pF

C3366 ECEA2EU220 ELECT 250V 22mF

C3367 ECQM2104KZ FILM 250V 100nF

C3369 ECEA1CU100 ELECT 16V 10mF

C3373 ECUV1H104ZFX S.M. CAP 50V 100nF

C3377 ECUV1H681JCX S.M. CAP 50V 680pF

C3383 ECUV1H104ZFX S.M. CAP 50V 100nF

C3387 ECUV1H681JCX S.M. CAP 50V 680pF

C3392 ECEA1CU471 ELECT 16V 470mF

C3393 ECUV1H104ZFX S.M. CAP 50V 100nF

C3397 ECUV1H681JCX S.M. CAP 50V 680pF

C4701 ECUV1H151JCX S.M. CAP 50V 150pF

C4702 ECUV1H331JCX S.M. CAP 50V 330pF

C4703 ECEA1HKAR47 ELECT 50V 0.47mF

C4704 ECUV1H104ZFX S.M. CAP 50V 100nF

C4705 ECUV1H104ZFX S.M. CAP 50V 100nF

C4706 ECUV1H104ZFX S.M. CAP 50V 100nF

C4707 ECUV1H104ZFX S.M. CAP 50V 100nF

C4708 ECEA1CKA100 ELECT 16V 10mF

C4709 ECUV1H104ZFX S.M. CAP 50V 100nF

C4710 ECEA1CKA100 ELECT 16V 10mF

C4711 ECUV1H390JPX S.M. CAP 50V 39pF

C4712 ECUV1H150JCX S.M. CAP 50V 15pF

C4713 ECUV1H104ZFX S.M. CAP 50V 100nF

C4714 ECEA1EKA100 ELECT 25V 10mF

C4715 ECUV1H104ZFX S.M. CAP 50V 100nF

C4716 ECEA1CKA100 ELECT 16V 10mF

C4717 ECUV1H683ZFX S.M. CAP 50V 68nF

C4718 ECUV1H102KBX S.M. CAP 50V 1nF

C4719 ECEA1HKAR47 ELECT 50V 0.47mF

C4720 ECUV1H104ZFX S.M. CAP 50V 100nF

C4721 ECEA1HKA2R2 ELECT 50V 2.2mF

C4722 ECUV1H104ZFX S.M. CAP 50V 100nF

C4723 ECUV1H104ZFX S.M. CAP 50V 100nF

C4724 ECUV1H104ZFX S.M. CAP 50V 100nF

C4725 ECUV1H104ZFX S.M. CAP 50V 100nF

C4726 ECEA1CKA470 ELECT 16V 47mF

C4729 ECUV1H102KBX S.M. CAP 50V 1nF

C4730 ECUV1H102KBX S.M. CAP 50V 1nF

C4733 ECUV1H270JPX S.M. CAP 50V 27pF

C4742 ECUV1H100DCX S.M. CAP 50V 10pF

C4744 ECUV1H100DCX S.M. CAP 50V 10pF

C4745 ECUV1H102KBX S.M. CAP 50V 1nF

C4746 ECUV1H104ZFX S.M. CAP 50V 100nF

C4747 ECUV1H102KBX S.M. CAP 50V 1nF

C4748 ECUV1H102KBX S.M. CAP 50V 1nF

C4749 ECUV1H102KBX S.M. CAP 50V 1nF

C4790 ECEA1HKA010 ELECT 50V 1mF

C6101 ECEA1HU471 ELECT 50V 470mF

C6102 ECQM1H334J FILM 50V 330nF

C6103 ECQM1H104J FILM 50V 100nF

C6104 ECEA1HU101 ELECT 50V 100mF

C6106 ECEA1HU101 ELECT 50V 100mF

C6301 ECEA1CU470 ELECT 16V 47mF

C6303 ECUV1H103ZFX S.M. CAP 50V 10nF

C6401 ECEA1CU101 ELECT 16V 100mF

C6402 ECEA1CU101 ELECT 16V 100mF

C6403 ECUV1H103ZFX S.M. CAP 50V 10nF

C6406 ECEA1HU4R7 ELECT 50V 4.7mF

C6407 ECUV1H102KBX S.M. CAP 50V 1nF

C6408 ECEA1HU4R7 ELECT 50V 4.7mF

C6409 ECUV1H561JCX S.M. CAP 50V 560pF

C6410 ECUV1H561JCX S.M. CAP 50V 560pF

C6417 ECEA1CU471 ELECT 16V 470mF

C6418 ECUV1H103ZFX S.M. CAP 50V 10nF

C6436 ECEA1HU4R7 ELECT 50V 4.7mF

C6437 ECUV1H102KBX S.M. CAP 50V 1nF

C6438 ECEA1HU4R7 ELECT 50V 4.7mF

C6447 ECEA1CU471 ELECT 16V 470mF

C6448 ECUV1H103ZFX S.M. CAP 50V 10nF

C6491 ECUV1H271JCX S.M. CAP 50V 270pF

C6591 ECUV1H271JCX S.M. CAP 50V 270pF

C6812 ECQU2A154MN FILM 250V 150nF

C6815 ECQU2A224MN FILM 250V 220nF

DIODES

D206 MA4300 DIODE

D465 MA165TA5 DIODE

D466 MA165TA5 DIODE

D467 MA165TA5 DIODE

D468 MA165TA5 DIODE

D471 MA700TA5 DIODE

D481 MA700TA5 DIODE

D491 MA167TA5 DIODE

D526 MA165TA5 DIODE

D527 EU02 DIODE

D536 ERB0615 DIODE TYPD0753VAG

D537 TVSRU2AM DIODE

D544 TVSES1FV1 DIODE

D547 AU02V0 DIODE

D548 MA165TA5 DIODE

D549 MA167TA5 DIODE

D557 EU02 DIODE

D561 ERA15-02V3 DIODE

D562 MA165TA5 DIODE

D563 MA165TA5 DIODE

D567 MA4062 DIODE

D613 RBV4-08 DIODE

D622 MA167TA5 DIODE

D624 BYT56K15/10 DIODE

D630 MA165TA5 DIODE

D636 MA167TA5 DIODE

D651 RG4CLFL1 DIODE

D656 EU02 DIODE

D661 ERD32-02L7 DIODE

D671 ERD32-02L7 DIODE

D674 MA4120 DIODE

D678 MA4027 DIODE

D681 EU02 DIODE

D686 RU4AMLF-M1 DIODE

D1019 PMLL5242B DIODE

D1020 PMLL5242B DIODE

D1023 PMLL5242B DIODE

D1024 PMLL5242B DIODE

D1033 PMLL5242B DIODE

D1034 PMLL5242B DIODE

D1036 PMLL5242B DIODE

D1038 PMLL5242B DIODE

D1070 PMLL5242B DIODE

D1080 PMLL4148L DIODE

D1081 PMLL4148L DIODE

D1082 PMLL4148L DIODE

D1090 PMLL5242B DIODE

D1121 PMLL5242B DIODE

D1123 PMLL5242B DIODE

D1156 PMLL5242B DIODE

Page 22

D1158 PMLL5242B DIODE

D1172 PMLL5242B DIODE

D1221 PMLL5232B DIODE

D1222 PMLL5232B DIODE

D1270 PMLL5242B DIODE

D1273 PMLL5242B DIODE

D1282 PMLL5242B DIODE

D1284 PMLL5242B DIODE

D1381 PMLL5239B DIODE

D1382 PMLL4148L DIODE

D1617 PMLL4148L DIODE

D1623 PMLL4148L DIODE

D1624 PMLL4148L DIODE

D1681 PMLL4148L DIODE

D1682 PMLL4148L DIODE

D1941 PMLL5232B DIODE

D3126 PMLL4148L DIODE

D3127 PMLL4148L DIODE

D3133 PMLL4148L DIODE

D3138 PMLL4148L DIODE

D3368 PMLL4148L DIODE

D3372 MA165TA5 DIODE

D3373 PMLL4148L DIODE

D3374 PMLL4148L DIODE

D3377 PMLL4148L DIODE

D3382 MA165TA5 DIODE

D3383 PMLL4148L DIODE

D3384 PMLL4148L DIODE

D3387 PMLL4148L DIODE

D3391 MA165TA5 DIODE

D3392 MA165TA5 DIODE

D3393 PMLL4148L DIODE

D3394 PMLL4148L DIODE

D3397 PMLL4148L DIODE

D6101 TVSS1WBS10 DIODE

D6103 PMLL4148L DIODE

D6106 PMLL4148L DIODE

D6301 LN81RPHL DIODE

D6381 PMLL4148L DIODE

D6382 PMLL4148L DIODE

D6391 PMLL4148L DIODE

D6392 PMLL4148L DIODE

D6491 PMLL4148L DIODE

D6492 PMLL4148L DIODE

D6591 PMLL4148L DIODE

D6592 PMLL4148L DIODE

FUSES

F547 TR5-T2000 FUSE

F656 TR5-T1250 FUSE

F661 TR5-T2000 FUSE

F671 TR5-T2000 FUSE

F6811 2153.15H FUSE

F68111 EYF52BC FUSE HOLDER

F68112 EYF52BC FUSE HOLDER

INTEGRATED CIRCUITS

I466 LA4282 AUDIO OUTPUT

I561 TDA8175-3 VERTICAL OUTPUT

I611 TDA4605-3 SWITCHABLE POWER SUPPLY

I646 L78M09MRB 9V REGULATOR

I661 LM317T 12V REGULATOR

I676 TL431ACLPM COIL

I1011 TEA6420 AUDIO SWITCH

I1111 TEA6415B VIDEO SWITCH

I1301 MSP3410-15 AUDIO PROCESSOR

I1351 AN78L08TA 8V REGULATOR

I1601 VDP3108-25 VIDEO PROCESSOR

I1701 TPU3040-18 TEXT PROCESSOR

I1751 81C1000A-70P DRAM

I1801 CCU3000I-05 CENTRAL CONTROL UNIT

I1871 27C010-07A1E EPROM

I1981 MN1280R RESET

I2601 MC141625A FILTER

I2651 UPC1860GS-E1 DELAY

I4700 LA7577N V.I.F.

I4701 AN78N12 12V REGULATOR

I6101 AN78L05TA 5V REGULATOR

I6301 RPM-637CBRS1 LED RECEIVER

SOCKETS/TERMINALS/LINK WIRES

BC1 ERJ6GEY0R00 WIRE LINK

BC2 ERJ6GEY0R00 WIRE LINK

BC4 ERJ6GEY0R00 WIRE LINK

BC5 ERJ6GEY0R00 WIRE LINK

B11 ERJ6GEY0R00 WIRE LINK

B12 ERJ6GEY0R00 WIRE LINK

B15 ERJ6GEY0R00 WIRE LINK

B16 ERJ6GEY0R00 WIRE LINK

B17 ERJ6GEY0R00 WIRE LINK

B18 ERJ6GEY0R00 WIRE LINK

B19 ERJ6GEY0R00 WIRE LINK

H1871 832AG11D-ESL I.C. SOCKET

JC1001 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1002 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1003 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1004 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1005 ERJ6GEY0R00 WIRE LINK

JC1006 ERJ6GEY0R00 WIRE LINK

JC1007 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1008 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1009 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1010 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1011 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1012 ERJ6GEY0R00 WIRE LINK

JC1013 ERJ6GEY0R00 WIRE LINK

JC1014 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1015 ERJ6GEY0R00 WIRE LINK

JC1016 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1017 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1018 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1019 ERJ6GEY0R00 WIRE LINK

JC1020 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1021 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1022 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1023 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1024 ERJ6GEY0R00 WIRE LINK

JC1025 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1026 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1027 ERJ6GEY0R00 WIRE LINK

JC1029 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1030 ERJ6GEY0R00 WIRE LINK

JC1031 ERJ6GEY0R00 WIRE LINK

JC1032 ERJ6GEY0R00 WIRE LINK

JC1033 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1034 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1035 ERJ6GEY0R00 WIRE LINK

JC1036 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1037 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1040 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1041 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1042 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1043 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1044 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1045 ERJ6GEY0R00 WIRE LINK

Page 23

JC1047 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1048 ERJ6GEY0R00 WIRE LINK

JC1049 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1050 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1051 ERJ6GEY0R00 WIRE LINK

JC1052 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1053 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1054 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1055 ERJ6GEY0R00 WIRE LINK

JC1056 ERJ6GEY0R00 WIRE LINK

JC1057 ERJ6GEY0R00 WIRE LINK

JC1058 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1059 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1060 ERJ6GEY0R00 WIRE LINK

JC1061 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1062 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1064 ERJ6GEY0R00 WIRE LINK

JC1065 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1066 ERJ6GEY0R00 WIRE LINK

JC1067 ERJ6GEY0R00 WIRE LINK

JC1068 ERJ6GEY0R00 WIRE LINK

JC1069 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1070 ERJ6GEY0R00 WIRE LINK

JC1071 ERJ6GEY0R00 WIRE LINK

JC1072 ERJ6GEY0R00 WIRE LINK

JC1073 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1074 ERJ6GEY0R00 WIRE LINK

JC1075 ERJ6GEY0R00 WIRE LINK

JC1076 ERJ6GEY0R00 WIRE LINK

JC1077 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1078 ERJ6GEY0R00 WIRE LINK

JC1079 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1080 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1081 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1082 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1083 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1084 ERJ6GEY0R00 WIRE LINK

JC1085 ERJ6GEY0R00 WIRE LINK

JC1086 ERJ6GEY0R00 WIRE LINK

JC1087 ERJ6GEY0R00 WIRE LINK

JC1088 ERJ6GEY0R00 WIRE LINK

JC1089 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1090 ERJ6GEY0R00 WIRE LINK

JC1091 ERJ6GEY0R00 WIRE LINK

JC1093 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1094 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1095 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1096 ERJ6GEY0R00 WIRE LINK

JC1097 ERJ6GEY0R00 WIRE LINK

JC1098 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1099 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1100 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1101 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1102 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1103 ERJ6GEY0R00 WIRE LINK

JC1104 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1105 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1106 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1107 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1108 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1109 ERJ6GEY0R00 WIRE LINK

JC1111 ERJ6GEY0R00 WIRE LINK

JC1112 ERJ6GEY0R00 WIRE LINK

JC1113 ERJ6GEY0R00 WIRE LINK

JC1114 ERJ8GEY0R00 METAL 0.125W 1% 0W

JC1115 ERJ6GEY0R00 WIRE LINK

JC1116 ERJ6GEY0R00 WIRE LINK

JC1117 ERJ6GEY0R00 WIRE LINK

JC1118 ERJ6GEY0R00 WIRE LINK

JK6401 TJB16656 A.V. TERMINAL

J2 ERJ6GEY0R00 WIRE LINK

W1951 MKS165810808 CONNECTOR

COILS

L204 ELER220KA COIL

L206 EXCELSA35T COIL

L230 EXCELSA24T COIL

L538 297-23293 COIL

L542 ELC08D055 COIL

L554 ELER220KA COIL

L626 EXCELDR35C COIL

L650 EXCELDR35C COIL

L686 EXCELSA35T COIL

L1037 TSC925-4 CHOKE

L1301 EXCELDR35V COIL

L1303 EXCELDR35V COIL

L1351 ELEV4R7KA COIL

L1413 ELEV6R8KA COIL

L1601 ELEV4R7KA COIL

L1606 EXCELDR35V COIL

L1611 ELEV4R7KA COIL

L1619 EXCELDR35V COIL

L1622 ELEV4R7KA COIL

L1634 EXCEMT101BT COIL

L1644 EXCEMT101BT COIL

L1652 ELEV4R7KA COIL

L1654 EXCEMT101BT COIL

L1684 ELEMV1R5MA COIL

L1687 ELEMV1R5MA COIL

L1691 EXCEMT101BT COIL

L1692 EXCEMT101BT COIL

L1693 EXCEMT101BT COIL

L1694 EXCEMT101BT COIL

L1701 ELEV4R7KA COIL

L1714 EXCELDR35V COIL

L1751 EXCELDR35V COIL

L1801 ELEV4R7KA COIL

L1837 EXCELDR35V COIL

L1845 ELEV3R3KA COIL

L1857 ELEV3R3KA COIL

L1859 ELEV3R3KA COIL

L1871 EXCELDR35V COIL

L1878 ELEV3R3KA COIL

L1888 ELEV4R7KA COIL

L1931 ELEV4R7KA COIL

L1941 EXCELDR35V COIL

L1972 EXCELDR35V COIL

L1974 EXCELDR35V COIL

L1977 EXCELDR35V COIL

L2602 TLT221K991R COIL

L2603 TLT221K991R COIL

L2604 TLT221K991R COIL

L2605 TLT220K991R COIL

L2607 TLT220K991R COIL

L2608 EXCELDR35V COIL

L2609 EXCELDR35V COIL

L2651 TLT150K991R COIL

L2653 TLT101K991R COIL

L2654 TLT101K991R COIL

L2655 TLT101K991R COIL

L2656 TLT100K991R COIL

L3161 SDL-4101 COIL

L3171 SDL-4101 COIL

L3181 SDL-4101 COIL

L4701 ELESNR47KA COIL

L4704 ELESN2R2KA COIL

L4705 EIV7EN200B COIL

L4706 EIV7EN201B COIL

L4707 ELESN100KA COIL

L6403 ELEBT6R8KA COIL

L6404 ELEBT6R8KA COIL

Page 24

L6417 ELEBT6R8KA COIL

L6447 ELEBT6R8KA COIL

L6811 ELF18D415F FILTER

L6812 ELF18D415F FILTER

CONTROLS

P633 EVMEASA00B52 CONTROL 500W

P2601 EVND4AA00B13 CONTROL 1K W

P3362 RH092GDJ6J VARIABLE RESISTOR

P3368 EVN65UA00B24 CONTROL 20KW

P4701 EVNDXAA03B53 CONTROL 5KW

TRANSISTORS

Q463 BC557B TRANSISTOR

Q465 BC547B TRANSISTOR

Q494 BC547B TRANSISTOR

Q496 BC547B TRANSISTOR

Q497 BC557B TRANSISTOR

Q498 BC547B TRANSISTOR

Q526 2SD836-AL TRANSISTOR

Q534 BU2508AXRL TRANSISTOR

Q591 BC557B TRANSISTOR

Q592 BC557B TRANSISTOR

Q593 BC547B TRANSISTOR

Q594 2SD1265A TRANSISTOR

Q624 2SK1118LB TRANSISTOR

Q667 BC547B TRANSISTOR

Q674 BUZ71AF1 TRANSISTOR

Q681 BC557B TRANSISTOR

Q682 2SA1535LB TRANSISTOR

Q1071 BC817-25 TRANSISTOR

Q1091 BC817-25 TRANSISTOR

Q1123 BC847B TRANSISTOR

Q1163 BC847B TRANSISTOR

Q1167 BC857B TRANSISTOR

Q1172 BC847B TRANSISTOR

Q1182 BC847B TRANSISTOR

Q1192 BC847B TRANSISTOR

Q1221 BC847B TRANSISTOR

Q1222 BC847B TRANSISTOR

Q1267 BC847B TRANSISTOR

Q1382 BC857B TRANSISTOR

Q1466 BC860B TRANSISTOR

Q1476 BC860B TRANSISTOR

Q1486 BC860B TRANSISTOR

Q1496 BC860B TRANSISTOR

Q1609 BC847B TRANSISTOR

Q1612 BC847B TRANSISTOR

Q1631 BC847B TRANSISTOR

Q1633 BC847B TRANSISTOR

Q1636 BC857B TRANSISTOR

Q1641 BC847B TRANSISTOR

Q1643 BC847B TRANSISTOR

Q1646 BC857B TRANSISTOR

Q1651 BC847B TRANSISTOR

Q1653 BC847B TRANSISTOR

Q1656 BC857B TRANSISTOR

Q1663 BC847B TRANSISTOR

Q1664 BC847B TRANSISTOR

Q1667 BC847B TRANSISTOR

Q1673 BC847B TRANSISTOR

Q1812 BC847B TRANSISTOR

Q1816 BC847B TRANSISTOR

Q1822 BC847B TRANSISTOR

Q1824 BC847B TRANSISTOR

Q1827 BC857B TRANSISTOR

Q1831 BC847B TRANSISTOR

Q2601 BC847B TRANSISTOR

Q2602 BC847B TRANSISTOR

Q2603 BC847B TRANSISTOR

Q2604 BC847B TRANSISTOR

Q2605 BC857B TRANSISTOR

Q2606 BC857B TRANSISTOR

Q2607 BC847B TRANSISTOR

Q2608 BC847B TRANSISTOR

Q2609 BC857B TRANSISTOR

Q2610 BC857B TRANSISTOR

Q2611 BC857B TRANSISTOR

Q2612 BC857B TRANSISTOR

Q2613 BC847B TRANSISTOR

Q2614 BC847B TRANSISTOR

Q2616 BC847B TRANSISTOR

Q2651 BC847B TRANSISTOR

Q2653 BC847B TRANSISTOR

Q3108 BC847B TRANSISTOR

Q3109 BC847B TRANSISTOR

Q3111 BC857B TRANSISTOR

Q3122 BC847B TRANSISTOR

Q3126 BC847B TRANSISTOR

Q3127 BC857B TRANSISTOR

Q3131 2SB940APLB TRANSISTOR

Q3136 2SD1264APLB TRANSISTOR

Q3143 BC847B TRANSISTOR

Q3162 BC857B TRANSISTOR

Q3164 BC847B TRANSISTOR

Q3166 BC857B TRANSISTOR

Q3169 BC857B TRANSISTOR

Q3172 BC857B TRANSISTOR

Q3174 BC847B TRANSISTOR

Q3176 BC857B TRANSISTOR

Q3179 BC857B TRANSISTOR

Q3182 BC857B TRANSISTOR

Q3184 BC847B TRANSISTOR

Q3186 BC857B TRANSISTOR

Q3189 BC857B TRANSISTOR

Q3359 BC847B TRANSISTOR

Q3368 2SB710A-XR TRANSISTOR

Q3371 BC857B TRANSISTOR

Q3373 2SC4714RL2 TRANSISTOR

Q3374 2SC3063RL TRANSISTOR

Q3377 2SA1698RL TRANSISTOR

Q3381 BC857B TRANSISTOR

Q3383 2SC4714RL2 TRANSISTOR

Q3384 2SC3063RL TRANSISTOR

Q3387 2SA1698RL TRANSISTOR

Q3391 BC857B TRANSISTOR

Q3392 2SA1309ATA TRANSISTOR

Q3393 2SC4714RL2 TRANSISTOR

Q3394 2SC3063RL TRANSISTOR

Q3397 2SA1698RL TRANSISTOR

Q4701 BC847B TRANSISTOR

Q4702 BC847B TRANSISTOR

Q4703 BC847B TRANSISTOR

Q4704 BF370-126 TRANSISTOR

Q4705 BF370-126 TRANSISTOR

Q6111 BC847B TRANSISTOR

Q6114 BC847B TRANSISTOR

Q6403 BC847B TRANSISTOR

Q6413 BC847B TRANSISTOR

Q6417 BC857B TRANSISTOR

Q6433 BC847B TRANSISTOR

Q6443 BC847B TRANSISTOR

Q6447 BC857B TRANSISTOR

Page 25

RESISTORS

RL6101 TSE10818 RELAY

R201 ERD25TJ223 CARBON 0.25W 5% 22KW

R206 ERG2ANJ223 METAL 2W 5% 22KW

R259 ERD25TJ473 CARBON 0.25W 5% 47KW

R462 ERD25TJ101 CARBON 0.25W 5% 100W

R463 ERD25TJ103 CARBON 0.25W 5% 10KW

R466 ERD25TJ153 CARBON 0.25W 5% 15KW

R471 ERD25TJ102 CARBON 0.25W 5% 1KW

R472 ERD25TJ333 CARBON 0.25W 5% 33KW

R477 ERD25TJ684 CARBON 0.25W 5% 680KW

R478 ERD25TJ332 CARBON 0.25W 5% 3K3W

R479 ERDS1TJ2R2 CARBON 0.5W 5% 2.2W

R481 ERD25TJ102 CARBON 0.25W 5% 1KW

R482 ERD25TJ333 CARBON 0.25W 5% 33KW

R484 ERD25TJ273 CARBON 0.25W 5% 27KW

R485 ERD25TJ561 CARBON 0.25W 5% 560W

R486 ERD25TJ333 CARBON 0.25W 5% 33KW

R487 ERD25TJ684 CARBON 0.25W 5% 680KW

R488 ERD25TJ332 CARBON 0.25W 5% 3K3W

R489 ERDS1TJ2R2 CARBON 0.5W 5% 2.2W

R490 ERD25TJ563 CARBON 0.25W 5% 56KW

R491 ERQ14AJ100 METAL 0.25W 5% 10W

R492 ERD25TJ102 CARBON 0.25W 5% 1KW

R493 ERD25TJ473 CARBON 0.25W 5% 47KW

R494 ERD25TJ684 CARBON 0.25W 5% 680KW

R496 ERD25TJ103 CARBON 0.25W 5% 10KW

R497 ERD25TJ103 CARBON 0.25W 5% 10KW

R498 ERD25TJ103 CARBON 0.25W 5% 10KW

R499 ERD25TJ473 CARBON 0.25W 5% 47KW

R521 ERQ14AJ3R3 METAL 0.25W 5% 3R3W

R526 ERD25TJ560 CARBON 0.25W 5% 56W

R527 ERDS1TJ152 CARBON 0.5W 5% 1K5W

R528 ERDS1TJ152 CARBON 0.5W 5% 1K5W

R531 ERF10ZK6R8 WIRE 10W 5% 6R8W

R541 ERG1ANJ152 METAL 1W5% 1K5W

R543 ERD25TJ103 CARBON 0.25W 5% 10KW

R546 ERDS1TJ184 CARBON 0.5W 5% 180KW

R548 ERD25TJ223 CARBON 0.25W 5% 22KW

R549 ERDS1TJ224 CARBON 0.5W 5% 220KW

R557 ERQ12HKR22 FUSIBLE 0.5W 5% 0R22W

R561 ERQ12HJ1R5 FUSIBLE 0.5W 5% 1R5W

R563 ERD25TJ104 CARBON 0.25W 5% 100KW

R564 ERD25TJ223 CARBON 0.25W 5% 22KW

R566 ERD25TJ472 CARBON 0.25W 5% 4K7W

R567 ERD25TJ472 CARBON 0.25W 5% 4K7W

R568 ERD25TJ1R5 CARBON 0.25W 5% 1R5W

R569 ERDS1TJ821 CARBON 0.5W 5% 820W

R572 ERO25CKF1801 METAL 0.25W 1% 1K8W

R573 ERO25CKF1801 METAL 0.25W 1% 1K8W

R579 ERD25TJ332 CARBON 0.25W 5% 3K3W

R592 ERD25TJ103 CARBON 0.25W 5% 10KW

R593 ERD25TJ103 CARBON 0.25W 5% 10KW

R598 ERD25TJ102 CARBON 0.25W 5% 1KW

R613 ERF10ZK5R6 WIRE 10W 5% 5R6W

R614 ERDS1TJ394 CARBON 0.5W 5% 390KW

R616 ERC12GK154D SOLID 0.5W 5% 150KW

R619 232266296706 THERMISTOR

R621 ERG2FJ183 METAL 0.5W 5% 18KW

R622 ERDS1TJ394 CARBON 0.5W 5% 390KW

R623 ERD25TJ472 CARBON 0.25W 5% 4K7W

R624 ERD25TJ121 CARBON 0.25W 5% 120W

R625 ERC12GK154D SOLID 0.5W 5% 150KW

R626 ERG2FJ183 METAL 0.5W 5% 18KW

R627 ERD25TJ103 CARBON 0.25W 5% 10KW

R628 ERG3FJ393 METAL 0.5W 5% 18KW

R629 ERG1ANJ470 METAL 1W5% 47W

R630 ERD25TJ270 CARBON 0.25W 5% 27W

R631 ERD25TJ101 CARBON 0.25W 5% 100W

R632 ERO25CKF1400 METAL 0.25W 1% 140W

R633 ERO25CKF3921 METAL 0.25W 1%3R92KW

R634 ERDS1TJ1R5 CARBON 0.5W 5% 1R5W

R636 ERD25TJ473 CARBON 0.25W 5% 47KW

R639 ERD75TAJ825 CARBON 0.75W 5% 8M2 W

R651 ERDS1TJ474 CARBON 0.5W 5% 470KW

R666 ERO25CKF3301 METAL 0.25W 1% 3K3W

R667 ERO25CKF3900 METAL 0.25W 1%3R9KW

R668 ERD25TJ103 CARBON 0.25W 5% 10KW

R674 ERD25TJ223 CARBON 0.25W 5% 22KW

R676 ERO25CKF1002 METAL 0.25W 1% 10KW

R677 ERO25CKF1002 METAL 0.25W 1% 10KW

R678 ERD25TJ121 CARBON 0.25W 5% 120W

R680 ERQ12HJ1R5 FUSIBLE 0.5W 5% 1R5W

R681 ERDS1TJ4R7 CARBON 0.5W 5% 4R7W

R682 ERD25TJ222 CARBON 0.25W 5% 2K2W

R683 ERG3FJ101 METAL 3W5% 100W

R684 ERD25TJ682 CARBON 0.25W 5% 6K8W

R686 NKS2 FUSABLE 0.25W 5% 0.1W

R688 NKS2 FUSABLE 0.25W 5% 0.1W

R1001 ERQ14AJ3R3 METAL 0.25W 5% 3R3W

R1011 ERQ14AJ100 METAL 0.25W 5% 10W

R1019 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1020 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1021 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R1022 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R1023 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1024 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1031 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R1032 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R1033 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1034 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1036 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1038 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1041 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1042 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1071 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1072 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1073 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R1074 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1091 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1092 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1093 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R1094 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1095 ERJ6GEYJ474 S.M.CARB 0.1W 5% 470KW

R1116 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1117 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1120 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1121 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1122 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1123 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1124 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1125 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1126 ERQ14AJ100 METAL 0.25W 5% 10W

R1127 ERJ6GEY0R00 WIRE LINK

R1131 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1132 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1133 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1151 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1152 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1153 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1156 ERJ6GEYJ470 S.M.CARB 0.1W 5% 47W

R1158 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1159 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1161 ERJ6GEYJ682 S.M.CARB 0.1W 5% 6K8W

R1162 ERJ6GEYJ333 S.M.CARB 0.1W 5% 33KW

R1163 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1166 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1167 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1168 ERJ6GEYJ680 S.M.CARB 0.1W 5% 68W

R1169 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1171 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

Page 26

R1172 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1173 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1174 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1177 ERJ6GEYJ561 S.M.CARB 0.1W 5% 560W

R1178 ERQ14AJ100 METAL 0.25W 5% 10W

R1181 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1182 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1183 ERJ6GEYJ680 S.M.CARB 0.1W 5% 68W

R1184 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1185 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1191 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1192 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1193 ERJ6GEYJ680 S.M.CARB 0.1W 5% 68W

R1194 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1195 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1221 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1222 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1225 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1237 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1241 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1242 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1251 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1261 ERJ6GEY0R00 WIRE LINK

R1263 ERJ8GEYJ104 S.M.CAR 0.125W 5% 100KW

R1264 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1266 ERJ6GEYJ680 S.M.CARB 0.1W 5% 68W

R1267 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1268 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1269 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1270 ERJ6GEYJ470 S.M.CARB 0.1W 5% 47W

R1271 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1272 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1273 ERJ6GEYJ470 S.M.CARB 0.1W 5% 47W

R1276 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1277 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1281 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R1282 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1283 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R1284 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1349 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1381 ERJ6GEYJ223 S.M.CARB 0.1W 5% 22KW

R1382 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1386 ERJ6GEY0R00 WIRE LINK

R1412 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1464 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1465 ERJ6GEYJ183 S.M.CARB 0.1W 5% 18KW

R1466 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1467 ERJ6GEY0R00 WIRE LINK

R1474 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1476 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1477 ERJ6GEY0R00 WIRE LINK

R1484 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1486 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1487 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1494 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1496 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1497 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R1608 ERJ6GEY0R00 WIRE LINK

R1609 ERJ8GEYJ273 S.M.CARB 0.125W 5% 27KW

R1612 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1613 ERJ6GEYJ560 S.M.CARB 0.1W 5% 56W

R1614 ERJ6GEYJ331 S.M.CARB 0.1W 5% 330W

R1615 ERJ6GEYJ221 S.M.CARB 0.1W 5% 220W

R1616 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1617 ERJ6GEYJ333 S.M.CARB 0.1W 5% 33KW

R1618 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1619 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1621 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1622 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1623 ERJ6GEYJ123 S.M.CARB 0.1W 5% 12KW

R1624 ERJ6GEYJ333 S.M.CARB 0.1W 5% 33KW

R1626 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R1627 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1630 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1631 ERJ6GEYJ470 S.M.CARB 0.1W 5% 47W

R1632 ERJ6GEYJ391 S.M.CARB 0.1W 5% 390W

R1633 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1634 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R1636 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1637 ERJ8GEYJ471 S.M.CAR 0.125W 5% 470W

R1641 ERJ6GEYJ821 S.M.CARB 0.1W 5% 820W

R1642 ERJ6GEYJ391 S.M.CARB 0.1W 5% 390W

R1643 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1644 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R1646 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1647 ERJ8GEYJ471 S.M.CAR 0.125W 5% 470W

R1652 ERJ6GEYJ391 S.M.CARB 0.1W 5% 390W

R1653 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1654 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R1656 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1657 ERJ8GEYJ471 S.M.CAR 0.125W 5% 470W

R1661 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1664 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1666 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1667 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R1669 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1671 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1672 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1673 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1674 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1680 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1681 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1682 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1683 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1684 ERJ6GEY0R00 WIRE LINK

R1691 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1692 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1693 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1694 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R1696 ERJ8GEYJ103 S.M.CAR 0.125W 5% 10KW

R1698 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1717 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1718 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1753 ERJ6GEY0R00 WIRE LINK

R1807 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1808 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1809 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1811 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1812 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1815 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1816 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1819 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1821 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1822 ERJ6GEYJ392 S.M.CARB 0.1W 5% 3K9W

R1823 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1824 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R1825 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1826 ERJ6GEYJ563 S.M.CARB 0.1W 5% 56KW

R1827 ERJ6GEYJ393 S.M.CARB 0.1W 5% 39KW

R1828 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1829 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R1831 ERJ6GEYJ392 S.M.CARB 0.1W 5% 3K9W

R1832 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1837 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1838 ERJ6GEYJ331 S.M.CARB 0.1W 5% 330W

R1840 ERJ6GEY0R00 WIRE LINK

R1842 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1843 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

Page 27

R1844 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1845 ERJ6GEYJ470 S.M.CARB 0.1W 5% 47W

R1847 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1849 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1851 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1856 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1857 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1858 ERJ8GEYJ103 S.M.CAR 0.125W 5% 10KW

R1859 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1863 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1872 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1873 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1878 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1879 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1882 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1884 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1885 ERJ8GEY0R00 METAL 0.125W 1% 0W

R1886 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R1887 ERJ6GEY0R00 WIRE LINK

R1888 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1889 ERJ8GEY0R00 METAL 0.125W 1% 0W

R1891 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1893 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1897 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1920 ERJ8GEYJ472 S.M.CAR 0.125W 5% 4K7W

R1921 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R1922 ERJ6GEYJ821 S.M.CARB 0.1W 5% 820W

R1925 ERJ6GEYJ331 S.M.CARB 0.1W 5% 330W

R1933 ERJ6GEY0R00 WIRE LINK

R1941 ERJ6GEY0R00 WIRE LINK

R1953 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1957 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1958 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1959 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1961 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1962 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1963 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1964 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R1983 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R1993 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R2601 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R2602 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2603 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R2607 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2609 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2610 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2612 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2613 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2615 ERJ6GEY0R00 WIRE LINK

R2616 ERJ6GEY0R00 WIRE LINK

R2617 ERJ6GEY0R00 WIRE LINK

R2620 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2621 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2622 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2623 ERJ6GEYJ561 S.M.CARB 0.1W 5% 560W

R2624 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2625 ERJ6GEYJ561 S.M.CARB 0.1W 5% 560W

R2626 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R2627 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R2628 ERJ6GEY0R00 WIRE LINK

R2631 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R2632 ERJ6GEY0R00 WIRE LINK

R2633 ERJ6GEY0R00 WIRE LINK

R2634 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R2636 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R2637 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R2638 ERJ6GEYJ750 S.M.CARB 0.1W 5% 75W

R2639 ERJ6GEYJ754 S.M.CARB 0.1W 5% 750KW

R2640 ERJ6GEY0R00 WIRE LINK

R2640 ERJ6GEYJ121 S.M.CARB 0.1W 5% 120W

R2641 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2642 ERJ6GEYJ473 S.M.CARB 0.1W 5% 47KW

R2643 ERJ6GEYJ333 S.M.CARB 0.1W 5% 33KW

R2644 ERJ6GEY0R00 WIRE LINK

R2645 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R2646 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R2649 ERJ6GEY0R00 WIRE LINK

R2651 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R2652 ERJ6GEYJ681 S.M.CARB 0.1W 5% 680W

R2653 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R2654 ERJ6GEYJ681 S.M.CARB 0.1W 5% 680W

R2655 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R2656 ERJ6GEYJ221 S.M.CARB 0.1W 5% 220W

R2658 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R2659 ERJ6GEYJ221 S.M.CARB 0.1W 5% 220W

R2660 ERJ6GEYJ104 S.M.CARB 0.1W 5% 100KW

R2662 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R2664 ERJ6GEYJ335 S.M.CARB 0.1W 5% 3M3W

R2665 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R2666 ERJ6GEY0R00 WIRE LINK

R2667 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R2668 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R2669 ERJ6GEYJ271 S.M.CARB 0.1W 5% 270W

R2670 ERJ6GEYJ511 S.M.CARB 0.1W 5% 510W

R2671 ERJ6GEYJ272 S.M.CARB 0.1W 5% 2K7W

R2672 ERJ6GEYJ822 S.M.CARB 0.1W 5% 8K2W

R2673 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R2675 ERJ6GEYJ562 S.M.CARB 0.1W 5% 5K6W

R2676 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R2677 ERJ6GEYJ681 S.M.CARB 0.1W 5% 680W

R2680 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R2681 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3101 ERJ6GEYJ562 S.M.CARB 0.1W 5% 5K6W

R3102 ERJ6GEYJ562 S.M.CARB 0.1W 5% 5K6W

R3103 ERJ6GEYJ562 S.M.CARB 0.1W 5% 5K6W

R3106 ERJ6GEYJ563 S.M.CARB 0.1W 5% 56KW

R3107 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R3108 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3109 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R3111 ERDS1FYJ222 CARBON 0.5W 5% 2K2W

R3112 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R3113 ERD25TJ681 CARBON 0.25W 5% 680W

R3121 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R3122 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R3123 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3124 ERJ6GEYJ681 S.M.CARB 0.1W 5% 680W

R3126 ERJ6GEYJ122 S.M.CARB 0.1W 5% 1K2W

R3127 ERQ14AJ100 METAL 0.25W 5% 10W

R3128 ERQ14AJ820 METAL 0.25W 5% 82W

R3129 ERQ14AJ820 METAL 0.25W 5% 82W

R3130 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3131 ERD25TJ563 CARBON 0.25W 5% 56KW

R3132 ERD25TJ122 CARBON 0.25W 5% 1K2W

R3133 ERD25TJ2R7 CARBON 0.25W 5% 2R7W

R3134 ERDS1FVJ390 CARBON 0.5W 5% 39W

R3135 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3136 ERD25TJ563 CARBON 0.25W 5% 56KW

R3137 ERD25TJ122 CARBON 0.25W 5% 1K2W

R3138 ERD25TJ2R7 CARBON 0.25W 5% 2R7W

R3139 ERDS1FVJ390 CARBON 0.5W 5% 39W

R3141 ERDS1FYJ101 CARBON 0.5W 5% 100W

R3142 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R3143 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R3144 ERJ6GEYJ681 S.M.CARB 0.1W 5% 680W

R3146 ERDS1FYJ181 CARBON 0.5W 5% 180W

R3152 ERQ12HJ102 METAL 0.5W 5% 1KW

R3153 ERQ14AJ3R9 FUSIBLE 0.25W 5% 3R9W

R3160 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3161 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3162 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3163 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R3164 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

Page 28

R3166 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3167 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3168 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3169 ERJ6GEYJ122 S.M.CARB 0.1W 5% 1K2W

R3170 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3171 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3172 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3173 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R3174 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3176 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3177 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3178 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3179 ERJ6GEYJ122 S.M.CARB 0.1W 5% 1K2W

R3180 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3181 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3182 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3183 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R3184 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3186 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3187 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W

R3188 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3189 ERJ6GEYJ122 S.M.CARB 0.1W 5% 1K2W

R3307 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R3308 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R3309 ERJ6GEYJ101 S.M.CARB 0.1W 5% 100W

R3354 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3358 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3359 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R3361 ERQ12HJR39 FUSABLE 0.5W 5% 0R39W

R3365 ERD25TJ220 CARBON 0.25W 5% 22W

R3366 ERQ12AJ101 FUSABLE 0.5W 5% 100W

R3367 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R3368 ERJ6GEYJ103 S.M.CARB 0.1W 5% 10KW

R3369 ERJ6GEYJ682 S.M.CARB 0.1W 5% 6K8W

R3370 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3371 ERJ6GEYJ272 S.M.CARB 0.1W 5% 2K7W

R3372 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R3373 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R3374 ERDS1TJ913 CARBON 0.5W 5% 91KW

R3375 ERG2ANJ183 METAL 2W5% 18KW

R3376 ERD25TJ561 CARBON 0.25W 5% 560W

R3379 ERD25TJ103 CARBON 0.25W 5% 10KW

R3380 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3381 ERJ6GEYJ272 S.M.CARB 0.1W 5% 2K7W

R3382 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R3383 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R3384 ERDS1TJ913 CARBON 0.5W 5% 91KW

R3385 ERG2ANJ183 METAL 2W5% 18KW

R3386 ERD25TJ561 CARBON 0.25W 5% 560W

R3389 ERD25TJ103 CARBON 0.25W 5% 10KW

R3390 ERJ6GEYJ100 S.M.CARB 0.1W 5% 10W

R3391 ERJ6GEYJ272 S.M.CARB 0.1W 5% 2K7W

R3392 ERJ6GEYJ332 S.M.CARB 0.1W 5% 3K3W

R3393 ERJ6GEYJ152 S.M.CARB 0.1W 5% 1K5W

R3394 ERDS1TJ913 CARBON 0.5W 5% 91KW

R3395 ERG2ANJ183 METAL 2W5% 18KW

R3396 ERD25TJ561 CARBON 0.25W 5% 560W

R3397 ERJ6GEYJ562 S.M.CARB 0.1W 5% 5K6W

R3399 ERD25TJ103 CARBON 0.25W 5% 10KW

R4701 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R4702 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R4703 ERJ6GEYJ472 S.M.CARB 0.1W 5% 4K7W

R4705 ERJ6GEY0R00 WIRE LINK

R4707 ERJ6GEYJ683 S.M.CARB 0.1W 5% 68KW

R4708 ERJ6GEYJ153 S.M.CARB 0.1W 5% 15KW

R4709 ERJ6GEYJ102 S.M.CARB 0.1W 5% 1KW

R4710 ERJ6GEYJ181 S.M.CARB 0.1W 5% 180W

R4711 ERJ6GEYJ151 S.M.CARB 0.1W 5% 150W

R4713 ERJ6GEYJ222 S.M.CARB 0.1W 5% 2K2W

R4714 ERJ6GEYJ471 S.M.CARB 0.1W 5% 470W