Page 1

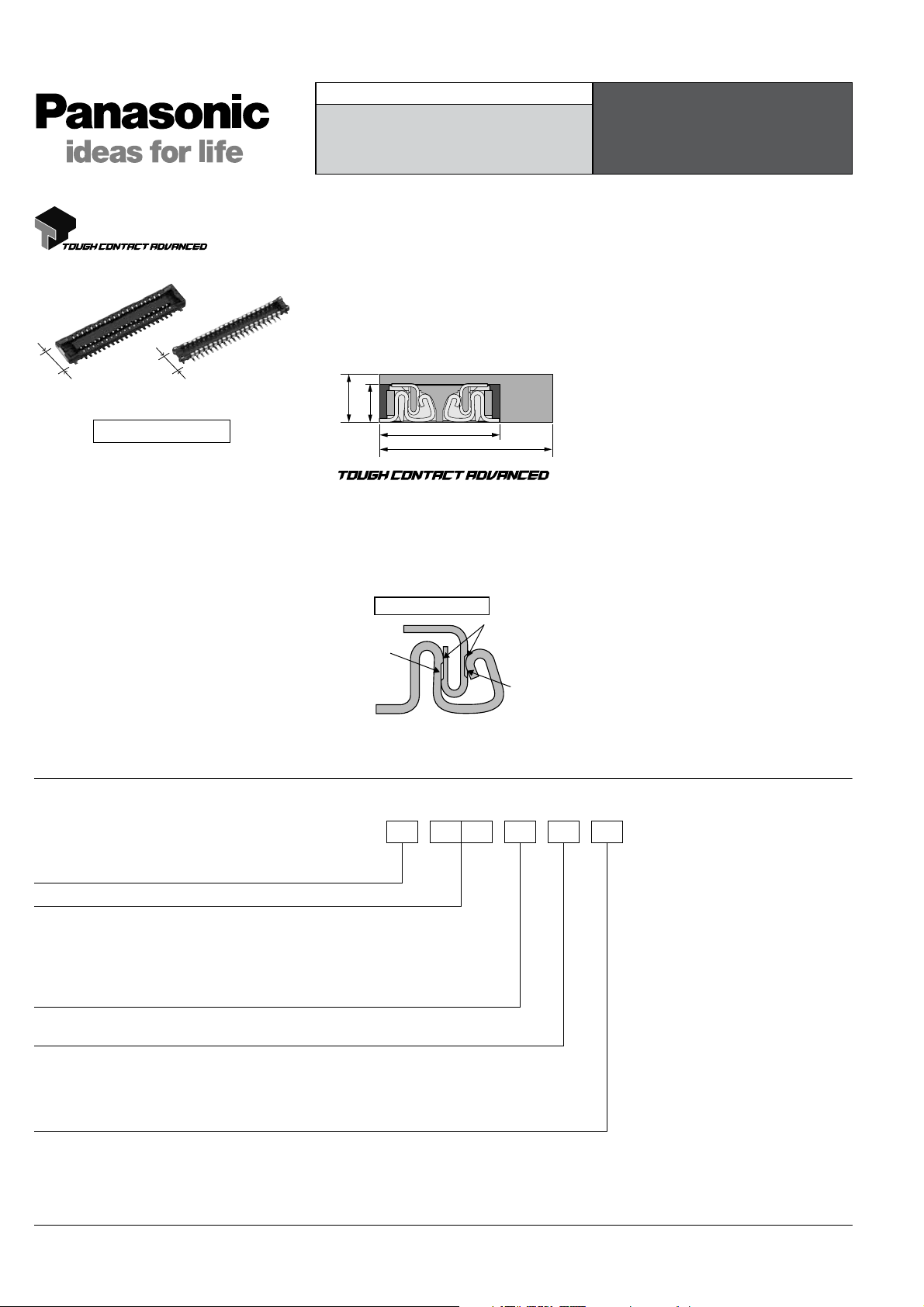

AXE5, 6

For board-to-FPC

2.5mm

Socket Header

2.0mm

RoHS compliant

Narrow pitch connectors

(0.4mm pitch)

FEATURES

1. 2.5 mm wide slim two-piece style

connectors

Compact and slim structure contributes

overall miniaturization of product design.

<Compared to F4S series (40 pin

contacts, when mated)>

• Width: 30% down

• Footprint: 30% down

F4S

1.0

0.8

2. “ ”

ensures high resistance to various

environments in lieu of slim and low

profile body

3. Simple lock structure provides

tactile feedback to ensure excellent

mating/unmating operation feel.

A4S

2.5

3.6

A4S Series

4. Mated heights of 0.8 and 1.0 mm are

available for the same foot pattern.

5. Connectors for inspection available

APPLICATIONS

Recommended for board-to-FPC

connections of mobile equipment,

such as cellular phones, smart

phones, laptops, and portable music

players

Simple lock structure

Simple lock

The connector gives the tactile feedback

when inserted, allowing reliable mating.

ORDERING INFORMATION

AXE 2 4

5: Narrow Pitch Connector A4S (0.4 mm pitch) Socket

6: Narrow Pitch Connector A4S (0.4 mm pitch) Header

Number of pins (2 digits)

Mated height

<Socket>

1: For mated height 0.8/1.0 mm

<Header>

1: For mated height 0.8 mm

2: For mated height 1.0 mm

Functions

2: Without positioning bosses

Surface treatment (Contact portion / Terminal portion)

<Socket>

4: Ni plating on base, Au plating on surface (for Ni barrier available)

<Header>

4: Ni plating on base, Au plating on surface

Double contact

V-notch

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

ACCTB7E 201201-T

Page 2

AXE5, 6

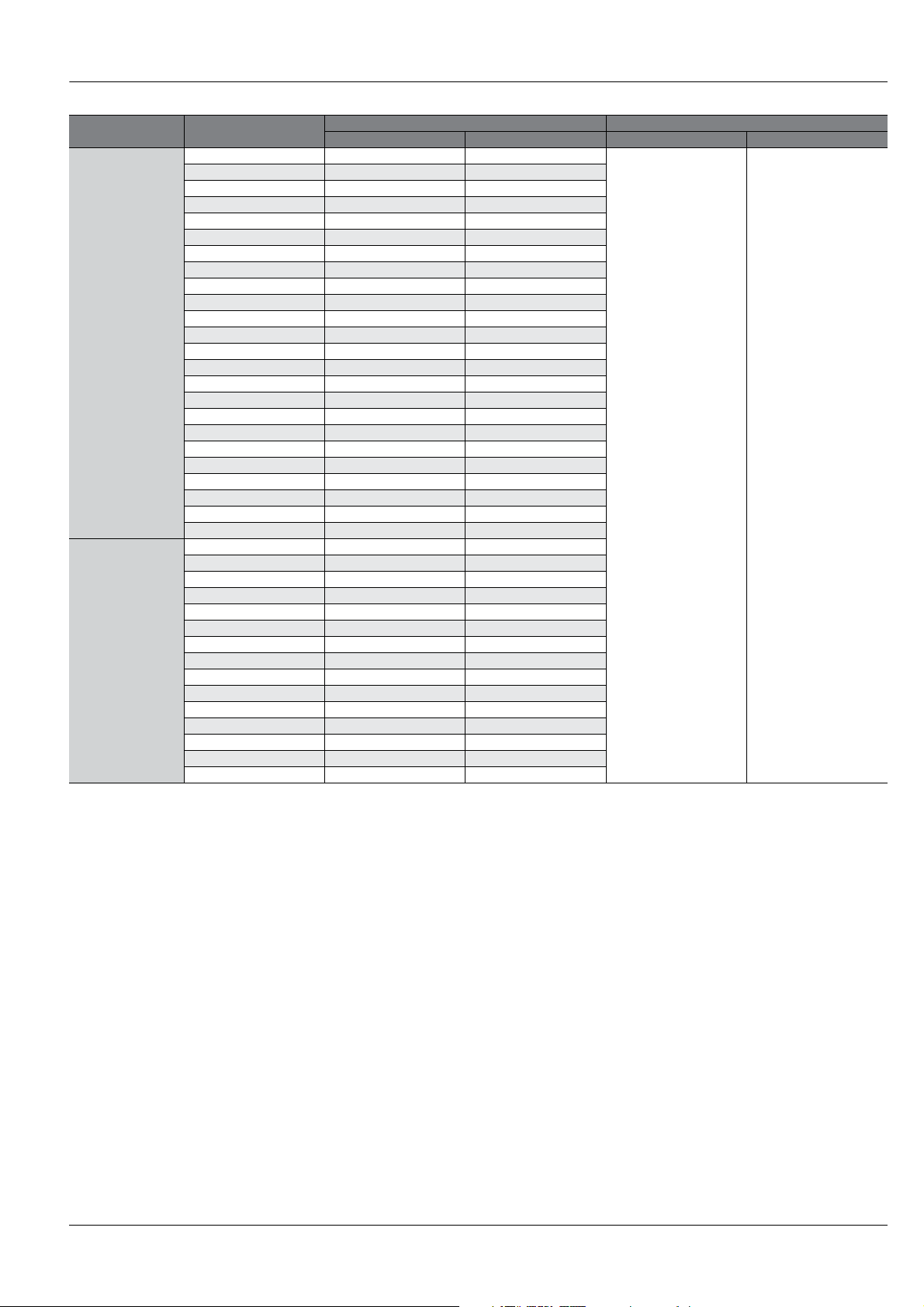

PRODUCT TYPES

Mated height Number of pins

10 AXE510124 AXE610124

12 AXE512124 AXE612124

14 AXE514124 AXE614124

16 AXE516124 AXE616124

18 AXE518124 AXE618124

20 AXE520124 AXE620124

22 AXE522124 AXE622124

24 AXE524124 AXE624124

26 AXE526124 AXE626124

28 AXE528124 AXE628124

30 AXE530124 AXE630124

0.8mm

1.0mm

Notes: 1. Order unit:

For volume production: 1-inner carton (1-reel) units

Samples for mounting check: 50-connector units. Please contact our sales office.

Samples: Small lot orders are possible. Please contact our sales office.

2. The above part numbers are for connectors without positioning bosses, which are standard. When ordering connectors with positioning bosses, please contact our

sales office.

3. Please contact us for connectors having a number of pins other than those listed above.

32 AXE532124 AXE632124

34 AXE534124 AXE634124

36 AXE536124 AXE636124

38 AXE538124 AXE638124

40 AXE540124 AXE640124

44 AXE544124 AXE644124

50 AXE550124 AXE650124

54 AXE554124 AXE654124

56 AXE556124 AXE656124

60 AXE560124 AXE660124

64 AXE564124 AXE664124

70 AXE570124 AXE670124

80 AXE580124 AXE680124

10 AXE510124 AXE610224

12 AXE512124 AXE612224

14 AXE514124 AXE614224

20 AXE520124 AXE620224

24 AXE524124 AXE624224

26 AXE526124 AXE626224

30 AXE530124 AXE630224

32 AXE532124 AXE632224

40 AXE540124 AXE640224

44 AXE544124 AXE644224

50 AXE550124 AXE650224

54 AXE554124 AXE654224

60 AXE560124 AXE660224

70 AXE570124 AXE670224

80 AXE580124 AXE680224

Socket Header Inner carton (1-reel) Outer carton

Part number Packing

5,000 pieces 10,000 pieces

ACCTB7E 201201-T

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

Page 3

AXE5, 6

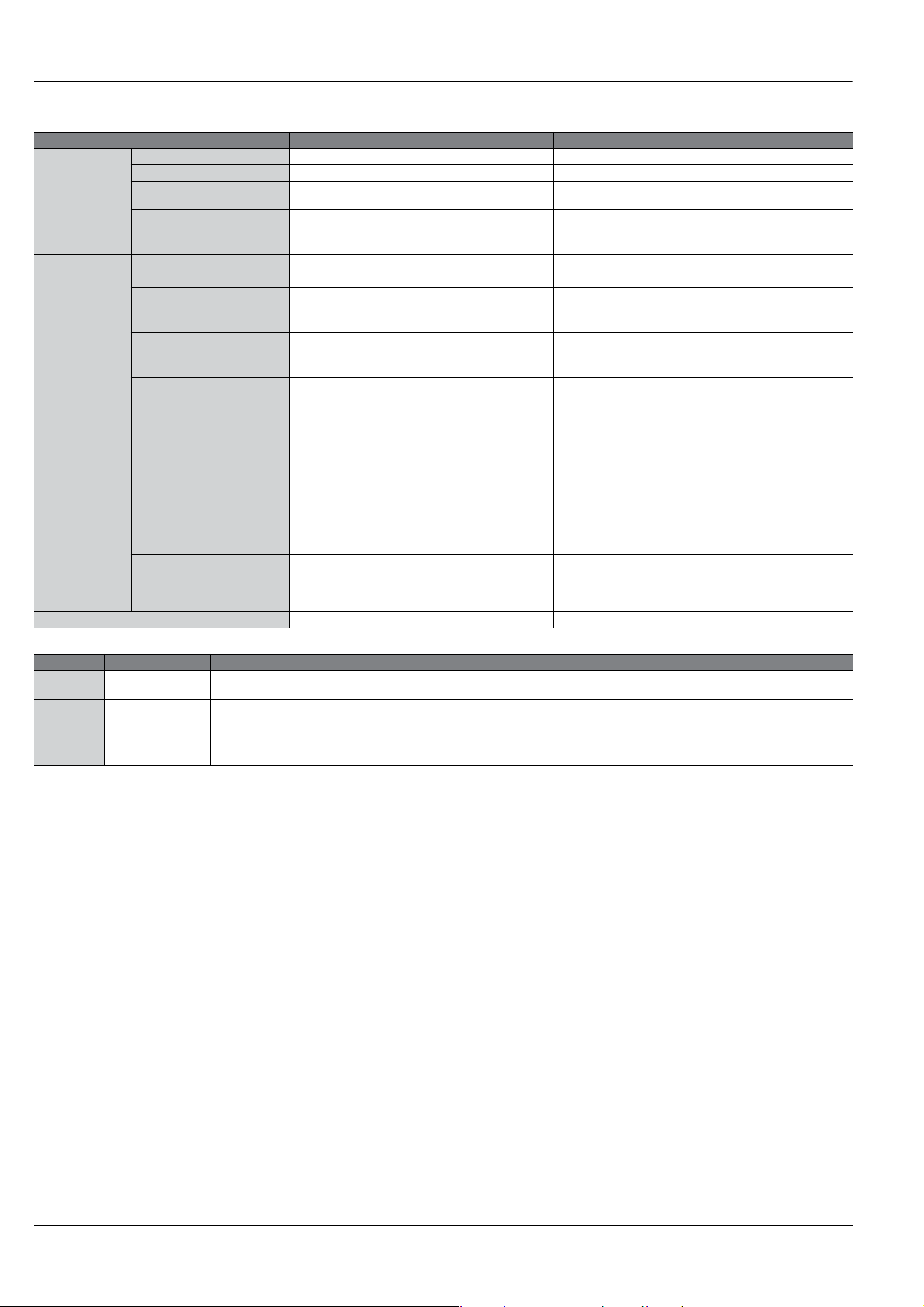

SPECIFICATIONS

Characteristics

Item Specifications Conditions

Rated current 0.3A/pin contact (Max. 5 A at total pin contacts)

Rated voltage 60V AC/DC

Electrical

characteristics

Mechanical

characteristics

Environmental

characteristics

Lifetime

characteristics

Unit weight 20 pin contact type: Socket: 0.02 g Header: 0.01 g

Material and surface treatment

Part name Material Surface treatment

Molded

portion

Contact and

Post

Breakdown voltage 150V AC for 1 min.

Insulation resistance Min. 1,000MΩ (initial) Using 250V DC megger (applied for 1 min.)

Contact resistance Max. 90mΩ

Composite insertion force Max. 1.200N/pin contacts × pin contacts (initial)

Composite removal force Min. 0.165N/pin contacts × pin contacts

Contact holding force

(Socket contact)

Ambient temperature –55°C to +85°C No freezing at low temperatures. No dew condensation.

Soldering heat resistance

Storage temperature

Thermal shock resistance

(header and socket mated)

Humidity resistance

(header and socket mated)

Saltwater spray resistance

(header and socket mated)

H2S resistance

(header and socket mated)

Insertion and removal life 30 times

LCP resin

(UL94V-0)

Copper alloy

—

Contact portion:

Te r minal portion: Base: Ni plating Surface: Au plating (except the terminal tips)

The socket terminals close to the portion to be soldered have nickel barriers (exposed nickel portions).

Soldering terminals: Sockets: Base: Ni plating Surface: Pd+Au flash plating (except the terminal tips)

Min. 0.20N/pin contacts

Peak temperature: 260°C or less (on the surface of

the PC board around the connector terminals)

300°C within 5 sec. 350°C within 3 sec. Soldering iron

–55°C to +85°C (product only)

–40°C to +50°C (emboss packing)

5 cycles,

insulation resistance min. 100MΩ,

contact resistance max. 90mΩ

120 hours,

insulation resistance min. 100MΩ,

contact resistance max. 90mΩ

24 hours,

insulation resistance min. 100MΩ,

contact resistance max. 90mΩ

48 hours,

contact resistance max. 90mΩ

Base: Ni plating Surface: Au plating

Headers: Base: Ni plating Surface: Au plating (except the terminal tips)

No short-circuiting or damage at a detection current of 1 mA

when the specified voltage is applied for one minute.

Based on the contact resistance measurement method

specified by JIS C 5402.

Measuring the maximum force.

As the contact is axially pull out.

Infrared reflow soldering

No freezing at low temperatures. No dew condensation.

Sequence

0

1. –55 °C, 30 minutes

−3

2. ~ , Max. 5 minutes

+3

3. 85 °C, 30 minutes

0

4. ~ , Max. 5 minutes

Bath temperature 40±2°C,

humidity 90 to 95% R.H.

Bath temperature 35±2°C,

saltwater concentration 5±1%

Bath temperature 40±2°C, gas concentration 3±1 ppm,

humidity 75 to 80% R.H.

Repeated insertion and removal speed of max. 200 times/

hours

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

ACCTB7E 201201-T

Page 4

AXE5, 6

DIMENSIONS (Unit: mm)

The CAD data of the products with a CAD Data mark can be downloaded from: http://industrial.panasonic.com/ac/e

Socket (Mated height: 0.8 mm/1.0 mm)

CAD Data

A

B±0.1

0.40±0.05

0.15±0.03

0.70 (Suction face)

Y note

Z note

Note: Since the soldering terminals has a single-piece construction,

sections Y and Z are electrically connected.

0.30±0.03

C±0.1

(0.90)

0.77

2.20

2.50

1.06

General tolerance: ±0.2

Te rminal coplanarity

0.08

(Contact and

soldering terminals)

2.50

1.72

(0.39)

Dimension table (mm)

Number of pins/

dimension

10 4.5 1.6 3.4

12 4.9 2.0 3.8

14 5.3 2.4 4.2

16 5.7 2.8 4.6

18 6.1 3.2 5.0

20 6.5 3.6 5.4

22 6.9 4.0 5.8

24 7.3 4.4 6.2

26 7.7 4.8 6.6

28 8.1 5.2 7.0

30 8.5 5.6 7.4

32 8.9 6.0 7.8

34 9.3 6.4 8.2

36 9.7 6.8 8.6

38 10.1 7.2 9.0

40 10.5 7.6 9.4

44 11.3 8.4 10.2

50 12.5 9.6 11.4

54 13.3 10.4 12.2

56 13.7 10.8 12.6

60 14.5 11.6 13.4

64 15.3 12.4 14.2

70 16.5 13.6 15.4

80 18.5 15.6 17.4

A B C

Header (Mated height: 0.8 mm)

CAD Data

Soldering terminals

0.70 (Suction face)

0.40±0.05

0.15±0.03

0.15±0.03

A

B±0.1

C±0.1

0.65

1.42

0.84

1.46

Soldering terminals

(0.31)

General tolerance: ±0.2

Te rminal coplanarity

0.08

(Post and

soldering terminals)

2.00

1.28

(0.36)

Dimension table (mm)

Number of pins/

dimension

10 3.8 1.6 3.2

12 4.2 2.0 3.6

14 4.6 2.4 4.0

16 5.0 2.8 4.4

18 5.4 3.2 4.8

20 5.8 3.6 5.2

22 6.2 4.0 5.6

24 6.6 4.4 6.0

26 7.0 4.8 6.4

28 7.4 5.2 6.8

30 7.8 5.6 7.2

32 8.2 6.0 7.6

34 8.6 6.4 8.0

36 9.0 6.8 8.4

38 9.4 7.2 8.8

40 9.8 7.6 9.2

44 10.6 8.4 10.0

50 11.8 9.6 11.2

54 12.6 10.4 12.0

56 13.0 10.8 12.4

60 13.8 11.6 13.2

64 14.6 12.4 14.0

70 15.8 13.6 15.2

80 17.8 15.6 17.2

A B C

ACCTB7E 201201-T

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

Page 5

AXE5, 6

Header (Mated height: 1.0 mm)

Soldering terminals

Socket and Header are mated

Header

0.80±0.1

Socket

0.70 (Suction face)

Header

Socket

0.40±0.05

0.15±0.03

0.15±0.03

1.00±0.1

A

B±0.1

C±0.1

0.85

1.42

0.84

1.46

(0.31)

Soldering terminals

General tolerance: ±0.2

Te rminal coplanarity

0.08

(Post and

soldering terminals)

2.00

1.28

(0.36)

Dimension table (mm)

Number of pins/

dimension

10 3.8 1.6 3.2

12 4.2 2.0 3.6

14 4.6 2.4 4.0

20 5.8 3.6 5.2

24 6.6 4.4 6.0

26 7.0 4.8 6.4

30 7.8 5.6 7.2

32 8.2 6.0 7.6

40 9.8 7.6 9.2

44 10.6 8.4 10.0

50 11.8 9.6 11.2

54 12.6 10.4 12.0

60 13.8 11.6 13.2

70 15.8 13.6 15.2

80 17.8 15.6 17.2

A B C

EMBOSSED TAPE DIMENSIONS (Unit: mm) (Common for respective contact types, sockets and headers)

Specifications for taping

(In accordance with JIS C 0806-1990. However, not applied to

the mounting-hole pitch of some connectors.)

Tape I Tape II

(A±0.3)

(B)

(C)

(1.75)

8.0 (2.0) (4.0)

1.5 dia.

+0.1

0

Leading direction after packaging

(A±0.3)

(C)

(1.75)

8.0 (2.0) (4.0)

1.5 dia.

+0.1

0

Dimension table (Unit: mm)

Type/Mated height Number of pins Type of taping A B C D Quantity per reel

Common for sockets

and headers

0.8 mm/1.0 mm

24 or less Tape I 16.0 — 7.5 17.4 5,000

26 to 70 Tape I 24.0 — 11.5 25.4 5,000

80 Tape II 32.0 28.4 14.2 33.4 5,000

Connector orientation with respect to embossed tape feeding direction

Direction

of tape progress

Type

Socket Header

Specifications for the plastic reel

(In accordance with EIAJ ET-7200B.)

(D±1)

Top cover tape

Embossed carrier tape

380 dia.

Embossed mounting-hole

Taping reel

Common for A4S

Note: There is no indication on this product regarding top-bottom or left-right orientation.

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

ACCTB7E 201201-T

Page 6

For board-to-FPC

Connectors for

inspection usage

(0.4mm pitch)

AXE5, 6

A4S Series

FEATURES

1. 3,000 mating and unmating cycles

2. Same external dimensions and foot

APPLICATIONS

Ideal for module unit inspection and

equipment assembly inspection

pattern as standard type.

3. Improved mating

2.5mm

Socket Header

2.0mm

Insertion and removal easy due to a

reduction in mating retention force. This

is made possible by a simple locking

structure design.

RoHS compliant

Note: Mating retention force cannot be

warranted.

TABLE OF PRODUCT TYPES

✩: Available for sale

Product name Number of pins

12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 44 50 54 56 60 64 70 80

A4S

for inspection

Notes: 1. Please inquire about number of pins other than those shown above.

2. Please inquire with us regarding availability.

3. Please keep the minimum order quantities no less than 50 pieces per lot.

4. Please inquire if further information is needed.

10

✩ ✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩✩

PRODUCT TYPES

Specifications Par t No. Specifications Part No.

Socket Without positioning bosses AXE5E∗∗26 Header Without positioning bosses AXE6E∗∗26

Note: When placing an order, substitute the “∗” (asterisk) in the above part number with the number of pins for the specific connector.

NOTES

Recommended PC board and metal

mask patterns

Connectors are mounted with high pitch

density, intervals of 0.35 mm, 0.4 mm or

0.5 mm.

In order to reduce solder bridges and

other issues make sure the proper levels

of solder is used.

The figures to the right are recommended

metal mask patterns. Please use them as

a reference.

• Socket (Mated height: 0.8mm/1.0mm)

Recommended PC board pattern (TOP VIEW)

0.40±0.03

1.06±0.03

2.90±0.03

Recommended metal mask opening pattern

1.06±0.01

2.90±0.01

0.23±0.03

(0.92)

C 0.30

0.90±0.03

1.45±0.03

Metal mask thickness: When 120µm

(Terminal opening ratio: 70%)

(Metal-part opening ratio: 100%)

0.40±0.01

0.20±0.01

(0.92)

0.90±0.01

1.45±0.01

: Insulation area

(0.50)

(0.40)

C 0.30

0.20±0.03

2.00±0.01

1.90±0.03

2.80±0.01

• Header (Mated height: 0.8mm/1.0mm)

Recommended PC board pattern (TOP VIEW)

0.40±0.03

0.23±0.03

(0.65)

1.10±0.03

1.66±0.03

0.60±0.03

(0.53)

0.45±0.03

0.80±0.03

2.40±0.03

Recommended metal mask opening pattern

Metal mask thickness: When 120µm

(Terminal opening ratio: 70%)

(Metal-part opening ratio: 100%)

0.40±0.01

0.20±0.01

1.26±0.01

2.30±0.01

1.66±0.01

0.60±0.01

(0.53)

0.45±0.01

0.80±0.01

(0.52)

Please refer to the latest product

specifications when designing your

product.

ACCTB7E 201201-T

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

Page 7

NO TES FOR USING ADVANCED SERIES

NARROW -PITCH CONNECT ORS

Connector mounting

Excessive mounter chucking force may

deform the molded or metal part of the

connector. Consult us in advance if

chucking is to be applied.

Soldering

1) Manual soldering.

• Due to the connector’s low profile, if an

excessive amount of solder is applied

during manual soldering, the solder may

creep up near the contact points, or

solder interference may cause imperfect

contact.

• Make sure that the soldering iron tip is

heated within the temperature and time

limits indicated in the specifications.

• Flux from the solder wire may adhere to

the contact surfaces during soldering

operations. After soldering, carefully

check the contact surfaces and clean off

any flux before use.

• Be aware that a load applied to the

connector terminals while soldering may

displace the contact.

• Thoroughly clean the iron tip.

2) Reflow soldering

• Screen-printing is recommended for

printing paste solder.

• To determine the relationship between

the screen opening area and the PCboard foot pattern area, refer to the

diagrams in the recommended patterns

for PC boards and metal masks. Make

sure to use the terminal tip as a reference

position when setting. A v oid an excessiv e

amount of solder from being applied,

otherwise, interference by the solder will

cause an imperfect contact.

Terminal

Paste

solder

PC board

foot pattern

• Consult us when using a screen-printing

thickness other than that recommended.

• Depending on the size of the connector

being used, self alignment may not be

possible. Accordingly, carefully position

the terminal with the PC board pattern.

• The recommended reflow temperature

profile is given in the figure below

Recommended reflow temperature profile

Upper limit (Soldering heat resistance)

Temperature

Lower limit (Solder wettability)

260°C

230°C

180°C

150°C

Preheating

60 to 120 sec.

Peak temperature

220°C

200°C

25 sec.

70 sec.

Time

• The temperature is measured on the

surface of the PC board near the

connector terminal.

• Some solder and flux types may cause

serious solder creeping. Solder and flux

characteristics should be taken into

consideration when setting the reflow

soldering conditions.

• When performing reflow soldering on

the back of the PC board after reflow

soldering the connector, secure the

connector using, for example, an

adhesive (Double reflow soldering on the

same side is possible)

3) Reworking on a soldered portion

• Finish reworking in one operation.

• For reworking of the solder bridge, use

a soldering iron with a flat tip. Do not add

flux, otherwise, the flux may creep to the

contact parts.

• Use a soldering iron whose tip

temperature is within the temperature

range specified in the specifications.

Do not drop or handle the

connector carelessly. Otherwise, the

terminals may become deformed due

to excessive force or applied

solderability may be degraded during

reflow.

Do not insert or remove the

connector when it is not soldered.

Forcibly applied external pressure on

the terminals can weaken the

adherence of the terminals to the

molded part or cause the terminals to

lose their evenness.

Excessive prying-force applied to

one end may cause product breakage

and separation of the solder joints at

the terminal.

When removing the connector, be

sure not to tilt the connector

exceeding 15 degrees widthwise.

Excessive force applied for insertion

in a pivot action as shown may also

cause product breakage.

Align the header and socket positions

before connecting them.

or less

15 degrees

When cutting or bending the PC

board after mounting the connector,

be careful that the soldered sections

are subjected to excessive forces.

The soldered areas should not be subjected to forces.

Notes when using a FPC.

• When the connector is soldered to an

FPC board, during insertion and removal

forces may be applied to the terminals

and cause the soldering to come off. It is

recommended to use a reinforcement

board on the backside of the FPC board

to which the connector is being

connected. Mak e sure that the reinforcing

plate is larger than the outline of the

recommended PC board pattern (Outline

+ approx. 1 mm). The reinforcing plate is

made of SUS, glass epoxy or polyimide

that is 0.2 to 0.3 mm thick.

This connector employs a simple locking

structure. However, the connector may

come off depending on the size and

weight of the FPC, layout and reaction

force of FPC, or by drop impact. Make

sure to fully check the equipment’s

condition. To prevent any problem with

loose connectors, adopt measures to

prevent the connector from coming off

inside the equipment.

Other Notes

When coating the PC board after

soldering the connector (to prevent the

deterioration of insulation), perform the

coating in such a way so that the coating

does not get on the connector.

The connectors are not meant to be used

for switching.

Please refer to the latest product

specifications when designing your

product.

(Common)

ACCTB11E 201201-T

Panasonic Corporation Automation Controls Business Unit industrial.panasonic.com/ac/e

Loading...

Loading...