Page 1

MICRO-IMAGECHECKER® A210•A110 MultiChecker V2 Series

11/2004

11/2004

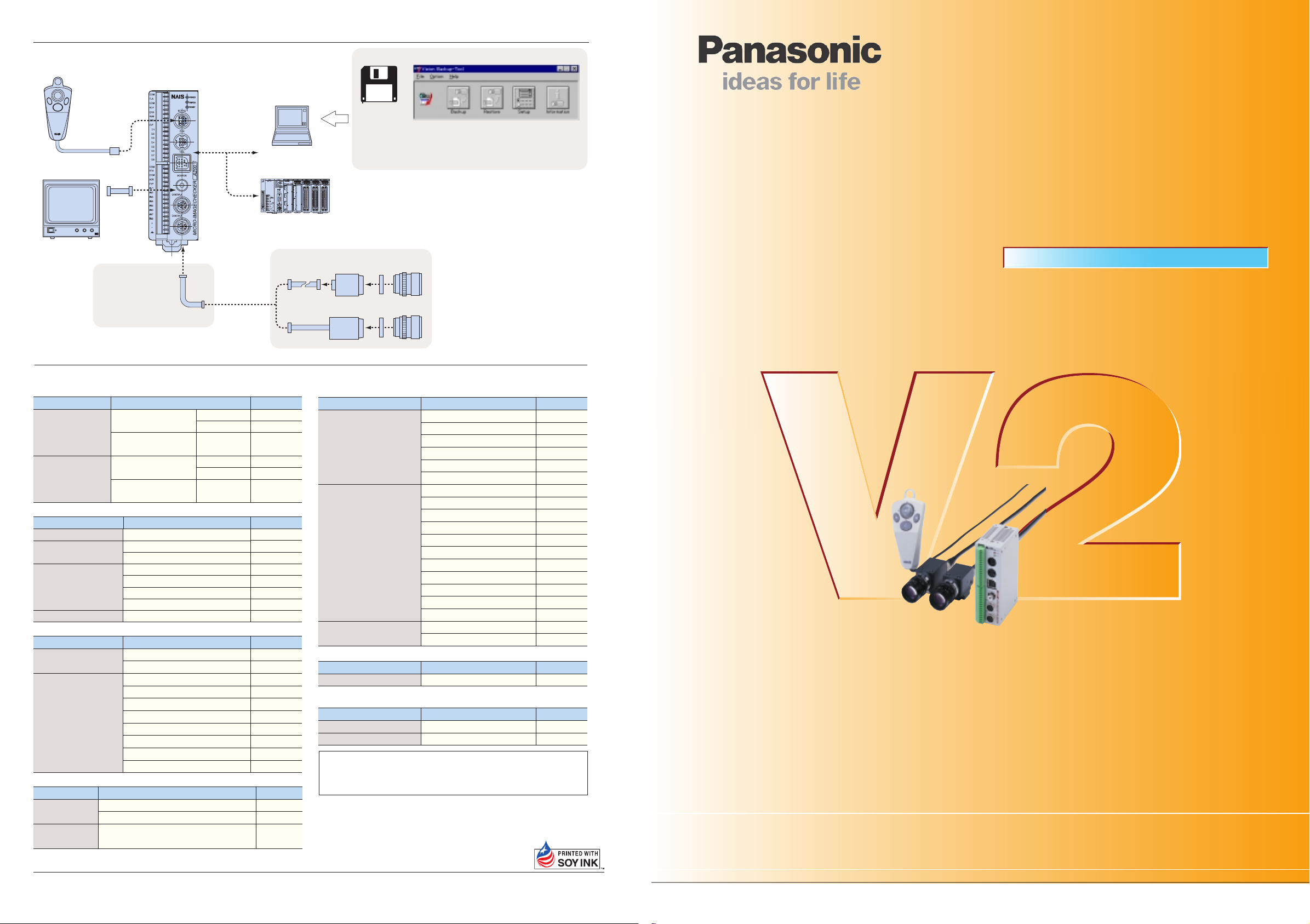

■ System configuration diagram

*1

Serial cable

ENTER

A

B

C

Panasonic

Monitor

Keypad

Monitor cable

(Pin-BNC)

CONTRAST

V-HOLD BLIGHT

Video Monitor GP-BM

Camera extension cable

*2

Controller

PC

PLC (refer to P5)

High-speed

random cable

*3

■ Vision Backup-Tool Ver.2

The product data created with the MICRO-IMAGECHECKER A

series and the image data stored in the controller can be stored

on a PC using Windows.

Stored data can be restored to the A series controller.

However, it is not possible to directly restore type data backed up using

*

Vision Backup-Tool with the previous product (Ver. 1) to V2 (Ver. 2). In

this case, use the dedicated data conversion software (freeware) to

convert the Ver. 1 type data for V2 use, then transfer it to V2 and perform

a backup again. If you require the data conversion software, contact your

Matsushita Automation Controls Co. Ltd. representative.

High-speed

random trigger camera

CS mount camera

Middle ring

Lens

*1 The A100 series connects to one camera.

*2 Use where necessary.

*3 When using 2 cameras with the A200 series,

connect the same type of camera.

Image Processing Device

®

MICRO-IMAGECHECKER

•

A210

MultiChecker Ver.2 Series

A110

■ Table of Product Numbers

● MICRO-IMAGECHECKER A-Series Controller

Item

A210

MICRO-IMAGECHECKER

A200 Series

MICRO-IMAGECHECKER

A100 Series

Multi-Checker V2 : CE

A210

Multi-Checker : CE

A110

Multi-Checker V2 : CE

A110

Multi-Checker : CE

● Camera / Keypad / Monitor

Item

C mount camera

CS mount camera

Keypad

Monitor

● Camera cable

Item Specifications

Double-speed random

camera cable

Camera extension cable

● Serial Cable

COM port

connecting cable

TOOL port

connecting cable

COM port and PC (D-SUB : 9 pin) connection, 3 m

COM port and PLC (discrete-wire cable) connection, 3 m

COM port and PC (D-SUB : 9 pin) connection, 10 cm

Matsushita Electric Works, Ltd.

쮿

Head Office: 1048, Kadoma, Kadoma-shi, Osaka 571-8686, Japan

ARCT1B178E 200111-2YT

Specifications Part No.

NPN Output

PhotoMos Output

NPN Output

NPN Output

PhotoMos Output

NPN Output

Specifications

Progressive Double-speed Random: CE

support electric-shutter with 3 m cable

support electric-shutter with 3 m cable: CE

with 2 m cable

with 3 m cable

with 2 m cable: CE

with 3 m cable: CE

Panasonic GPBM910 (100 V AC/12 V DC)

3 m

3 m: CE

2 m extension: total 5 m

7 m extension : total 10 m

12 m extension: total 15 m

17 m extension: total 20 m

2 m extension : total 5 m: CE

7 m extension: total 10 m: CE

12 m extension: total 15 m: CE

17 m extension: total 20 m: CE

Specifications

Automation Controls Company

ANMA212V2

ANMA218V2

ANMA212

ANMA112V2

ANMA118V2

ANMA112

Part No.

ANM831

ANM832

ANM832CE

ANM85202

ANM85203

ANM85202CE

ANM85203CE

AUGPBM910

Part No.

ANM84303

ANM84303CE

ANM84002

ANM84007

ANM84012

ANM84017

ANM84002CE

ANM84007CE

ANM84012CE

ANM84017CE

Part No.Item

ANM81103

ANM81303

ANM812001

These materials are printed on ECF pulp.

These materials are printed with earth-friendly vegetable-based (soybean oil) ink.

● Lens / middle ring

Item Specifications

CS mount lens

C mount lens

Middle ring

f2.8 CS mount compact lens

f2.8 CS mount compact lens with lock

f4 CS mount compact lens

f4 CS mount compact lens with lock

f8 CS mount compact lens

f8 CS mount compact lens with lock

f6.5 C mount lens

f8.5 C mount lens

f8.5 C mount lens with lock

f16 C mount compact lens

f16 C mount compact lens with lock

f25 C mount compact lens

f25 C mount compact lens with lock

f50 C mount lens

f50 C mount lens with lock

f50 C mount compact lens

f50 C mount compact lens with lock

5 mm middle ring

(0.5/1/5/10/20/40 mm) middle ring

Part No.

ANM8828

ANM88281

ANM8804

ANM88041

ANM8808

ANM88081

ANB842

ANB843

ANB843L

ANB845N

ANB845NL

ANB846N

ANB846NL

ANB847

ANB847L

ANM8850

ANM88501

ANB84805

ANB848

● Data backup software

Item Specifications

Vision Backup-Tool Ver.2 English version

Microsoft windows NT4.0/95/98/Me/2000 compatible. An operating system is not included with this software.

Part No.

ANM70131V2

● Accessories

Item Specifications

I/O terminal block

BNC connector

Unless otherwise specified, estimate and delivery prices do not include technician dispatching

and other related services. Therefore, for the situations given below, additional charges

may be added.

• Installation and trial operation guidance • Inspections, adjustments, and repairs

• Technical support and instruction

To USA Customer

• Products sold by seller are covered by the warranty and patent

indemnification provisions in its Terms and Conditions of Sale only.

For input: 1 piece, for output, 1 piece

Monitor BNC jack to PIN jack adapter

COPYRIGHT © 2001 All Rights Reserved

Specifications are subject to change without notice.

Part No.

ANMA8001

ANM8606

It won’t stop advancing. The monstrously small A Series!

Page 2

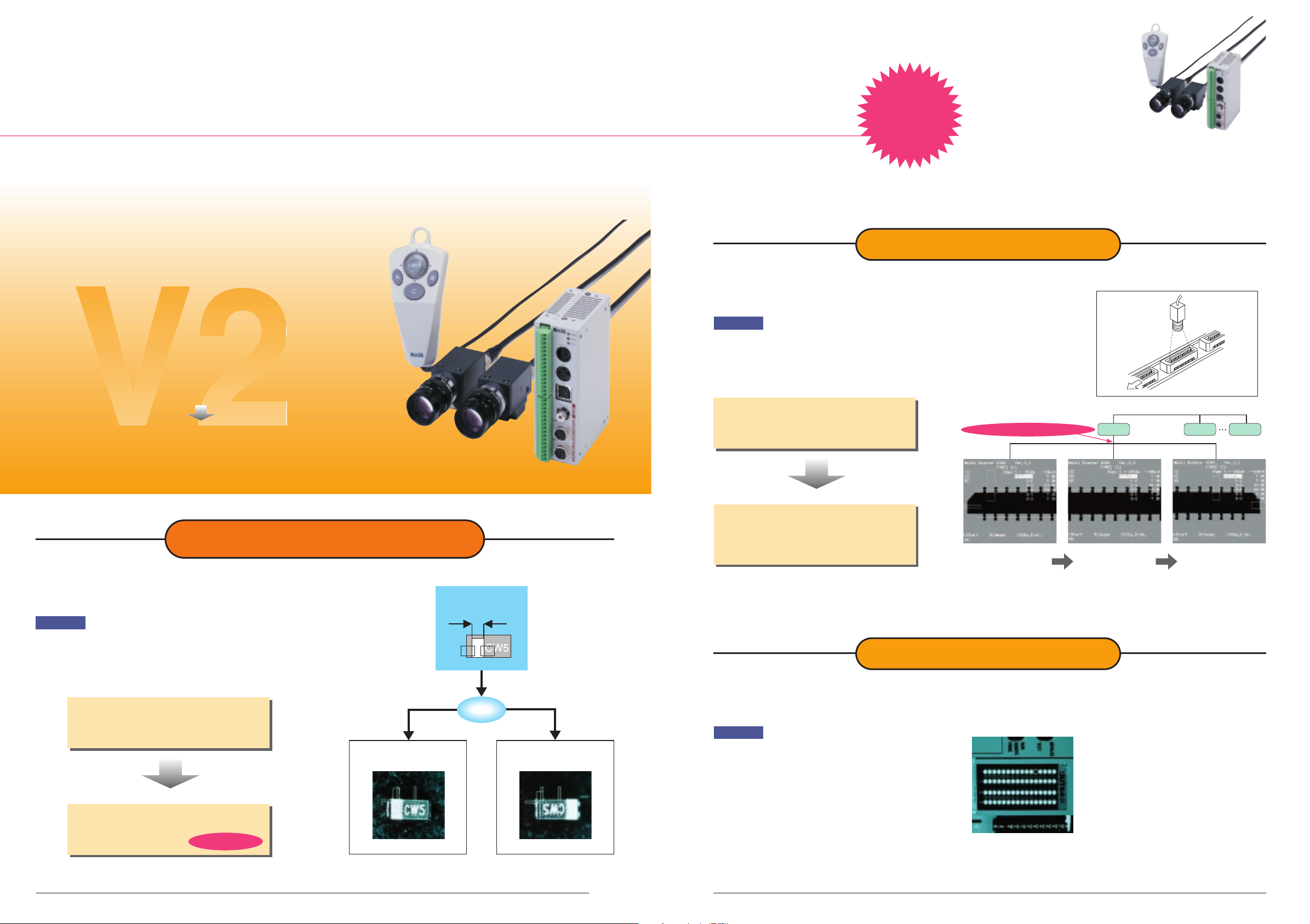

The MultiChecker V2 Series - more powerful

11/2004

11/2004

than ever!

Our highly acclaimed, compact A210 and A110 MultiChecker image processing units are now even more powerful! The V2

(Ver. 2) upgrade includes new functions for even greater convenience. To meet your diverse range of inspection

requirements, we have increased the number of checkers by a factor of three. In addition to making more inspection locations

possible, they now come equipped with a new mode that allows two-level branch inspection using one image checker, and an

extensive range of functions that allow use in a wide range of applications.

New

New

User-Defined Mode

Three times the processing capacity

of their predecessors!

Designed to meet a diverse variety of

inspection needs!

You can now register three times more checkers per type!

●A210 MultiChecker: increased from 32 to 96

●A110 MultiChecker: increased from 16 to 48

Possible to choose from three execution modes to suit your

inspection requirements!

Automatic Switch Mode

Branch inspection without complicated

settings provides great convenience!

MICRO-IMAGECHECKER A210 and A110

Multichecker V2 (Photo shows A210)

Detect the direction

judgment marker

Execute block 1

(5 msec)

Multiple inspections of up to three blocks with no

switching time!

Example

When you wish to perform multiple continuous inspections because the

work will not fit in the field of view of a single image capture.

Conventional method

●Handled by type switching using an external device.

●Type switching requires time and usage restrictions

apply.

User-Defined Mode

●Internally switches to the process block via an

external signal.

●External device is not used, so inspection time is

greatly reduced!

*Can be executed from the keypad as well.

Type switching not required!

First field of vision

(Block 1)

Type 1

Second field of vision

(Block 2)

Type 2 Type 64

Third field of vision

(Block 3)

Example

It is possible to first make a direction judgment, and then perform a

separate inspection (character appearance or mark width measurement)

based on this direction.

Conventional method

●Execute all checkers and output results

●

Perform direction judgment externally and compare results

Execution time: 65msec.

Automatic Switch Mode

●Perform direction judgment and execute the

2

required checker

Execution time:

35msec!

Execution time Execution time

Execution time

reduced by half!reduced by half!

reduced by half!

Normal direction

Execute Block 2

(30msec)

Direction judgment

Reverse direction

Execute Block 3

(30msec)

Execute All Mode

Three times the number of checkers can now be registered per type, so you can

inspect many points at one time!

Example

Multiple simultaneous point inspection possible for applications

such as inspecting LED lighting.

Plenty of external outputs for judgment results (96 points for the

A210 and 48 points for the A110) allow simultaneous output of

judgment results for multiple inspection points.

3

Page 3

As always, the A Series is packed with

11/2004

11/2004

easy-to-use features.

In addition to the ease-of-use and reliability that you expect from the No. 1

manufacturer in the field, we also provide convenient new functions for a diverse range of solutions.

Convenient new display function

■ Data Monitor Function

Titles and results of numerical calculations and judgment outputs can be

displayed on the inspection screen. You can register your own text for

display, and change the maximum and minimum limits for numerical

calculations directly from the menu.

Display text can be registered

Result display reference from

numerical calculation judgment

output possible (10 lines x 2 pages)

Unregistered parts are blank

Judgment conditions can be changed

■ Two-image switch/split function (A210 only)

When using two cameras simultaneously for an

operation such as measuring the distance

between two points, you can use an external

signal to switch the display. It is also possible

to split images captured by two cameras for

display as one image on the screen. You can

select either vertical or horizontal for the image

split direction.

using the ENT key

(numerical calculations only)

Camera A

■ Marker Function

Up to eight graphics (circles, ellipses, rectangles and lines) can be displayed

on the inspection screen. This is very convenient when performing manual

positioning for camera adjustment with production equipment.

Camera B

MICRO-IMAGECHECKER

Switch

Connects to a variety of PLCs

The A Series can connect to a range of PLCs without a communication

program. In addition to the Matsushita Electric Works PLC-FP Series, it can

be used with PLC products from Mitsubishi, Omron, and Allen-Bradley

115.2kbps

(Ver. 2.2 or later).

The A Series can perform type switching data communication and read and

write measurement data and inspection results to and from PLCs without

requiring that you create a communication program.

A Series

Inspection

MICRO-IMAGECHECKER

results

PLC

Inspection conditions can also be modified

■ Compatible PLC products

● Matsushita Electric Works FP Series

● Mitsubishi MELSEC A series/FX Series

● Omron SYSMAC-C Series

● Allen-Bradley SLC500 (Ver. 2.2 or later)

from the PLC!

Speed and precision (Strongest in its class) Reduced size (Smallest in its class)

The A series comes equipped with a 32-bit RISC, 200

MHz CPU with pipeline processing.

It attains 360 MIPS and 1.4 GFLOPS for astronomically

high-speed processing. With the superquick CPU, increased floating point

operation speed, pipeline processing,

32

CPU

bit RISC

specially designed algorithms, and a

large memory capacity, it achieves not

only extremely high-speed inspection,

but also the ultimate in precision as

well.

1.4

time

360

MIPS

Flo

a

o

p

e

r

billio

s

/s

e

tin

g p

o

in

t

a

tio

n

s

n

c

.

With a small 120 × 40mm footprint, installation is simple. Tight installation

with checkers next to each other is also possible. With considerations for

wiring, connectors, and removable terminal blocks, installation with all

units facing one direction is possible for no wasted space.

Installation on DIN rails is also possible.

K!

O

e

id

s

y-

b

-

e

id

S

MICRO-IMAGECHECKER

MICRO-IMAGECHECKER

MICRO-IMAGECHECKER

Removable

terminal block

MICRO-IMAGECHECKER

120

mm

40

mm

MICRO-IMAGECHECKER

Data registers

DT100 1235

DT101 2430

DT102

.....

....

Split display

Two types available to suit your application

■ A210 with two camera connections and

Extensive array of image capture functions

high-end functions

(Fastest images in its class)

■

Double-speed random camera

(progressive rectangular-lattice CCD element)

With the A series, we introduced a progressive double-speed random

camera that provides 3 times the maximum ratio of conventional units with

1/60 second for a high-quality picture and no image degradation. In field

mode, it reaches 4 times for 1/120 second. The result is fast inspection

without having to worry about inspection time or image quality.

■ Internal synchronous signal inspection

Compatible with the internal synchronous signal of NTSC, video scopes and

special cameras can also be used. However, depending on the model, some

may not be able to be connected. Consult your Matsushita Electric Works

representative (there is one connection port).

4 5

Trigger signal

General-type camera

Electric-shutter camera

Random trigger camera*

NEW

ANM831

Double-speed

random camera*

(frame mode)

ANM831NEW

Double-speed

random camera*

(field mode)

*The shutter speed on the random camera, before exposure, needs to be set to 1/120 to 1/20000 seconds.

Time delay

0 to 16.7 ms.

16.7-33.4ms.

ODD

16.7ms.

ODD

EVEN

16.7ms.

ODD

8.3

ms

.

ODD

33.4-50.1ms.

ODD

Twice the picture quality

in one exposure.

EVEN

Progressive

Conventional

method

)

■ A110 with one camera connection and

good cost performance

We offer true cost performance and wipe away the concept that image

processing is expensive.

A110 ControllerA210 (set

A110 (set

)

Page 4

Further refined inspection functions.

11/2004

11/2004

The A Series is loaded with inspection know how that we have distilled over our years in this industry.

With a single unit you can perform fast and accurate detection, dimension measurement and coordinate detection!

Smart matching (A210) / Matching (A110).

1

A

High-speed, high-precision sub-pixel detection (Fastest level in its class).DSmart matching rotational correction (A210)

With a high-speed CPU, vast memory, and original algorithm, even with a

64 × 64-pixel template, 256 × 256-pixel search area, and sub-pixel precision

detection, you still get a processing time of about 10 ms. As you can see, this is

the ultimate in speed and precision for position detection.

Conventional

instruments

A210

Matching search time:

Approx. 10 ms.

Approx. 10 ms.

Approx. 25 ms

With the rotational correction function and the A210, a search is conducted by

tilting the matching and smart matching search areas and templates. Therefore,

even if the work has been tilted, a more precise position inspection is obtained.

Rotation of the search area

Template is tilted

and searched

E Rotation position/tilt detection.

B Smart matching (A210).

Sub-pixel position detection takes place with gray-scale matching and the grayscale differential function gives even more detailed work inspection.

This gives you accurate inspection even in cases where matching processing

alone would fail.

Template Matching detection

-

Correlation = 0.95

Template Matching detection

-

Correlation = 0.85

Differential result

=

Differential result

=

No

difference

=

OK

Difference

detected

=

NG

C Smart template (A210).

Just by showing multiple examples of the correct products, correct product

images can be automatically composed. This allows simple inspection without

setting complex parameters.

OK OK

Smart template

+

OK NG

+

With the rotation search function (±30 degrees), no matter how much the

detection image is tilted, the position and angle of tilt are accurately ascertained.

F Multiple position detection

Supports the multiple

detection function with

matching to allow the

separate detection of

multiple objects of the

same pattern in the

search area. It is an

efficient function when

loading is performed by

robot or the like.

G Teaching function.

Teaching allows changes to be made to the template for matching even from an

external signal. Registering the change can be done simply by showing the object

for detection.

Teaching also supports positional corrections so that even when work is

displaced, teaching can occur.

Teaching with the

touch of a button.

Multiple position

detection.

Rotational* position adjustment function

4

Automatic adjustment and precise inspection takes place even if the work is tilted

or displaced.

Adjustments can be made using the gray-scale data so that differences in

brightness can allow accurate corrections. With multiple and priority functions,

complex adjustments are also greatly simplified.

*A210 = rotational position adjustment function (X/Y/θ)

A110 = position adjustment function (X/Y)

■ Rotational adjustment (A210)

Rotation

correction

Area rotation.

When setting

Affine transform

Rotation

With the affine transform

function, the image will be

rotated so that even if the work

is tilted, setting and changes

can take place.

During adjustment, it is

unnecessary to place work

precisely for reduced time.

■ Accurate position correction (A210/A110)

Detection of

unnecessary portion

▲No filter/width function

Inspection

position offset

Filter/width function reduces chance of erroneous influence

due to dirt or noise.

Erroneous detection

because of dirt

Unnecessary portion

not detected.

▲Filter/width function

Dirt is ignored

Improved binary processing function

5

A A wide range of inspection functions

• Position/size/attitude/size detection with optimum feature extraction labeling.

• Presence/size/orientation inspection with optimum binary window functions.

• High-speed dimension measurements with optimum edge detection functions.

• High-speed length/number/presence inspections with optimum line functions.

mounts

Bearing inspection. Gear tooth inspection. LED lighting inspection.

B Free shape

The shape of the inspection area can be freely

adjusted between rectangular, oval, or polygonal

to match the inspection object. Moreover the

mask area (where no inspection takes place) can

also be adjusted freely as desired.

Reject location

lit up.

Inspection area

Base area

Masking

area

C Image filter function.

Even with binary images containing substantial noise,

stable image processing is possible using filter processing

such as [image erosion] → [image dilation].

The filter functions will differ depending on the inspection

processing.

Original binary image.

Pixel

Original binary image.

3 × 3 image erosion 3 × 3 image dilation

Eroded parts are not processed

3 × 3 image dilation

Dilated parts are processed.

After erosion, dilated parts are processed

3 × 3 image erosion

After dilation, eroded parts are not processed

Not processed

Processing occurs

Noise

Image without filtering

Noise erase

Image with erosion to

dilation filtering

Sub-pixel gray-scale edge

2

Edge positions are measured accurately at the sub-pixel level. Also supports an

edge counting function. Also equipped with the projection scanning formula so

that the required edge position is detected even with products with a poor

surface. With rotational correction, diagonal scanning performs sub-pixel edge

detection with the gray-scale inter-pixel compensating function.

■ Projection scanning edge detection

Averaged

Pitch calculated by

number of pins

Gray-scale window

3

Since the average value for brightness within the area is quickly calculated,

directional distinction can still occur even when binary distinction is difficult due

to the small differences in the gray-scale levels. You can set mask processing

with free shapes (rectangular, oval, polygonal) set to match the inspected object.

GW1 GW2 GW3 GW4

When the direction is correct:

Direction: OK

Direction: Reject

GW1 becomes brighter than GW2, so

GW1 - GW2 > 0 and GW3 - GW4 = 0.

More numerical calculation and judgement output functions.

6

A Supports 96 numerical

calculation formulas (48 on the A110)

Includes sine, cos,

square root, arctan

absolute differential and

projection distance

functions in addition to

addition, subtraction,

multiplication and

division, and you can set

up to 96 formulas (48 for

the A110). You can also

reference up to 16 items

per formula for complex

calculations.

Calculating distances

and angles

New calculation formula New calculation formula

New calculation formula

(also compatible with judgment formulas)(also compatible with judgment formulas)

(also compatible with judgment formulas)

copy functioncopy function

copy function

B Leeway in judgement calculations C Programless data

Even for complex pass/fail judgement

outputs, internal judgment formulae can be

made without using the external PLC.

Depending on the application, Judgement

output can be set for individual and general

judgement for each inspection area freely as

desired.

Internal judgement calculations

A210

A110

96 formulae

48 formulae

External judgement calculations

Judgement output formula

96 formulae

48 formulae

Total

192 formulae

96 formulae

transfer to the PLC

Using the Matsushita Electric Works.

FP-series PLC, the Mitsubishi

MELSEC A/FX series PLC, the Omron

SYSMAC C series PLC, or the AllenBradley SLC 500 PLC (Ver. 2.2 or

later), numerical calculation result

data and judgement output results

can be automatically written to the

data register of the PLC at a

maximum baud rate of 115200 bps.

The image processing data can be

used with the I/O sensitivity of the

PLC.

6 7

Page 5

MICRO-IMAGECHECKER® A210•A110 MultiChecker V2 Series

11/2004

11/2004

Excellent maintenance characteristics and

global compatibility.

Powerful support for startup and maintenance and designed for worldwide use.

Image storage function (A210, A110)

The A Series can store up to 30 defect images, and with the dedicated software

tools you analyze the cause of defects at remote locations using e-mail.

Storing up to 30 pictures* of fault occurrences in its memory, it possible for

analyzing error causes and making adjustments. When setting up the

equipment, inspection images are stored and can be used when making new

adjustments and changes. Moreover, the stored images can be used for testing.

Also, using special software, image data and inspection conditions can be

stored, and then faults can be analyzed and adjustments made at any location

using e-mail. Furthermore, the location of all errors are clearly displayed and

illuminated so that they can be seen at a glance.

OK OKNG NG

NG

Image storage

30

images

Readjustment and

ENTER

B

A

re-testing analysis

C

takes place using

the stored images.

Can be stored

to hard disk or

e-mailed using

special software

*A210 = 30 image, A110 = 8 images

Setup help function

Quantitative support for settings that once relied on intuition.

With the setup help function, focusing, brightness adjustment, exposure

adjustment, binary level settings, and other adjustments that used to be

performed by the operator's professional experience, these adjustments can now

be performed quantitatively. Equipped with an input monitor and test output

functions, connections to external equipment are also greatly simplified. Great

savings can be made in debugging and adjustment by the combination of the trap

function, which halts inspection when an error is found, and the image storage

and spreadsheet functions.

Focus adjustment Aperture adjustment

Global application

English-Japanese interchange and CE certification

Displays for the one controller can be set to either English or Japanese to allow

use in a great number of countries around the globe. The controller and highspeed random trigger camera are standard products and are certified with CE

markings.

8

English

■ Vision Backup-Tool Ver.2

The product data created with the MICRO-IMAGECHECKER A

series and the image data stored in the controller can be stored

on a PC using Windows.

Stored data can be restored to the A series controller.

However, it is not possible to directly restore type data backed up

*

using Vision Backup-Tool with the previous product (Ver. 1) to V2

(Ver. 2). In this case, use the dedicated data conversion software

(freeware) to convert the Ver. 1 type data for V2 use, then transfer it

to V2 and perform a backup again. If you require the data conversion

software, contact your Matsushita Automation Controls Co. Ltd.

representative.

Japanese

Video game

style control

Binarization adjustment

EMC(

89/336/EEC)

EN50081-2:1993

EN50082-2:1995

■ Dimensions (unit: mm)

● A110/A210 Controller

ANMA212V2/ANMA212

ANMA112V2/ANMA112

120

74

● Double-speed random camera: C mount

ANM831

31

29

2-M3(depth 4mm)

Without mounting bracket With mounting bracket

● Operating key pad ● Monitor (Panasonic: GPBM910)

ANM8520

앮

54.5

46.5

8

10

24.5±0.6

19

13

4-M3

(depth 2.5mm)

26±0.6

54.4

(19)

(31.3)

ANM8520앮CE

앮

: Length of cable

ENTER

B

A

C

124.6

*A

ø11.5

● Lens

Mounting screws (locked lens only)

A

B

C Mount lens

ANB842

ANB843(L)

ANB845N(L)

ANB846N(L)

ANB88161

ANB88251

ANB847(L)

ANM8850

ANM88501

CS Mount lens

ANM8808

ANM88081

ANM8804

ANM88041

ANM8828

ANM88281

(10)

40

(

)

5.5

● CS mount camera: CS mount

ANM832/ANM832CE/ANM83203

31

29

1/4-20UNC

31

(depth 9mm)

24.5±0.6

31

(3.25)

2.5

46

18

2-M3(depth 4mm

*A: Approximated length of cable for keypad used

The cable is slightly shorter on keypads with

CE marking.

f=6.5

f=8.5

f=16

f=25

f=16

f=25

f=50

f=50

f=50

f=8

f=8

f=4

f=4

f=2.8

f=2.8

AB

φ

=48

φ

=42

φ

=30

φ

=30

φ

=30.5

φ

=30.5

φ

=48

φ

=27.5

φ

=30.5

AB

φ

=34

φ

=31

φ

=34

φ

=31

φ

=34

φ

=31

42

40

33

37.3

25

25.5

48

38.5

38.5

35

35

41

40

38

37.5

● Camera cable

14

8

26±0.2

)

Without mounting bracket With mounting bracket

AUGPBM910 (100 V AC)

Panasonic

36.5

ANM84303/ANM84303CE

ANM840

148

앮앮

ANM840앮앮ACE

앮

: Length of cable

ø14.7

55

49.5 *1)

24.5±0.2

4-M3(depth 2.5mm)

CONTRAST

V-HOLD BLIGHT

Video Monitor GP-BM

36.5

8

A

(43)

(43)

)

depth 6.7

(

*1) ANM832: 3000

*1) ANM832CE: 2780

*1) ANM83203: 300

220

228

Approx. 80 mm, including

cable connection

Note:

Allow 80 mm behind the monitor for wiring

and heat radiation.

Monitor input/output uses a BNC terminal.

*B: Approximated length of cable used

The cable is slightly shorter on keypads with

CE marking.

4-M3 depth1.5

)

8

(

104

)

9.5

(

)

5.5

(

2-M3(depth 7mm)

+80

–10

+80

–10

+40

–10

29

*B

The A110 does not have a

camera B port

)

depth 14.7

(

38

28±0.218.15

23±0.2

32.15

259

180

1/4-20UNC

depth 10mm

50

10.5±0.2

9

Page 6

MICRO-IMAGECHECKER® A210•A110 MultiChecker V2 Series

11/2004

11/2004

MICRO-IMAGECHECKER® A210•A110 MultiChecker V2 Series

■ A210 • A110 Multi-checker V2 specifications

CPU

Frame memory

Operator interface

Monitor display

Processing Gray-scale

Number of product types

Execution modes

Inspection

External

interface

Inspection start

Other

specifications

Setup tools Image storage

Moving object inspection

Camera support

Number of support cameras

Operating voltage

Setup data backup

Type data saved in the previous controller of the MICRO-IMAGECHECKER A Series (Ver. 1) cannot be directly restored to V2 using the Vision Backup-Tool. In this case, you will

*

need the dedicated data conversion software (freeware) to convert the Ver. 1 type data for V2 use. If you require the data conversion software or information about how to use it,

contact your Matsushita Automatic Controls Co. Ltd. representative. You can also download the data converter software from the follwing Web page.

Binarization

Position/

rotation position

adjustment function

Exposure

adjustment

Smart matching/

matching

(sub-pixel processing)

Gray-scale edge

detection

(sub-pixel processing)

Gray-scale window

Feature extraction

Binary window

Binary edge detection

Line

Conversion data

Numerical

calculations

Judgement output

Serial

Parallel

Display functions

Marker function

function

Debugging

Setup help

External output (D) register = Max. 96 per product type Internal judgement (R) register = Max. 96 per product type External output (D) register = Max. 48 per product type Internal judgement (R) register = Max. 48 per product type

High-speed random trigger camera (progressive) = ANM831 Standard camera = ANM830A, Composite video (NTSC) input used (however the connection requires one port)

32-bit RISC CPU (high-speed processing version) 32-bit RISC CPU

Change between gray-scale memory/gray-scale through/binary memory (A/B/C/D/E/F)/binary through (A/B/C/D/E/F)/gray-scale NG/binary NG (A/B/C/D/E/F)

Max. 96 per product type Rotation position adjustment function Max. 48 per product type X-Y position adjustment function

Shape: rectangular Binarization adjusts according to changes in the gray-scale data Gray-scale mean value detection/judgement

Smart matching = Max. 96 pcs.; Equipped with post-detection ifferential processing function

changes can be imported from external source smart teaching (A210) = judgement learning function by the smart template

Shape: rectangular/polygonal or oval mask Shape: rectangular/polygonal or oval Gray-scale mean value detection/judgement

Image filtering Labeling Output values: counter/center of gravity (to one decimal place)/area/shading/width/principle axis angle

Shape = rectangular/polygonal or oval mas Shape = rectangular/polygonal or oval Image filtering White/black pixel number count/judgement

4 registers, Can quote to numerical conversion, Can convert numerical conversion result to actual distance, Standard distance, No. of pixels, Cooefficient

Sine, cos, absolute differential and projection distance functions four data calculations, arctangent, root, the distance-between-points special substitutions reference to previous data output control

Compatible with Mitsubishi MELSEC A Series/FX Series, Omron C Series PLCs, and Allen-Bradley SLC 500 PLCs (Ver. 2.2 or later)

A210 Multi-checker V2 A110 Multi-checker V2

512 × 480 (pixels) × 256 gradations

Menu selection using the key emulation function (ver. 2.2 or later).

8 bit 256 gradations

6 groups of binary processing from the gray-scale memory (upper and lower threshold settings)

64 32

Execute All mode: Execute all set checkers

Automatic Switch mode: Change the checker to be executed in accordance with the judgment output result

User-Defined mode: Specify the checker for execution when the start signal is input

Priority adjustment multi-stage adjustment sequence setting by

matching/gray-scale edge/binary edge or feature detection.

Max. 96 per product type Max. 48 per product type

Matching = 48 per product type

Sub-pixel accurate multiple detection matching by gray-scale correlation processing

Rotation by raster detection and raster detection position (±30 degrees)

Output = number of detected items/correlation numbers/position/angle teaching registered

Max. 96 per product type Max. 48 per product type

Scanning method = individual/projection gray-scale filter/width function detection by sub-pixel unit

Detection position = forepoint/forepoint and afterpoint/largest differential/multiple edge

Max. 96 per product type Max. 48 per product type

Max. 96 per product type Max. 48 per product type

Shape = rectangular/polygonal or oval mask Shape = rectangular/polygonal or oval

Max. 96 per product type Max. 48 per product type

Max. 96 per product type Max. 48 per product type

Shape = line/mask filter/width functions forepoint edge detection

Max. 96 per product type Max. 48 per product type

Shape = straight line/polygonal line/circle or arc Image filters White/black pixel number count/judgement

Max. 96 per product type Max. 48 per product type

RS232C = 2ch (max.115200bps) Compatible with Matsushita Electric Works PLC FP series

Input = 11points Output = 14 points Removable screw-down terminal block

Image trigger (timing sensor unnecessary) external sensor timing repeat start

Display item suppressing function (menu display hide function)

Image suppress function when setting checkers, Image rotation function when setting checkers (A210)

Clearly display reject location, Rotational adjustment angle display (A210), Data Monitor function

Display of image processed with image filter, simple spreadsheet, checker list display

Maximum of 8 graphics/type (line, rectangle or circle), and registered images are displayed on the main screen

30 screens 8 screens

Save/load function for inspection image (all screens/problem screens)

Store images for reinspection/resetting Windows-PC image save/load function

Trap function Image storage function

Focus setup, aperture setup, lighting adjustment, image profile monitor, recommended

threshold level, I/O monitor, enforce output

Double-speed random camera (progressive)/flash/electronic shutter used

21

24 V DC less than 0.9 A 24 V DC less than 0.7 A

Image data and setup data can be saved to a Windows PC using vision Backup Tool Ver.

http://www.naisvision.com/j

■ A210 • A110 Multi-checker specifications

CPU

Frame memory

Operator interface

Monitor display

Processing Gray-scale

Number of product types

Execution modes

Inspection

External

interface

Inspection start

Other

specifications

Setup tools Image storage

Moving object inspection

Camera support

Number of support cameras

Operating voltage

Setup data backup

Type data saved in the previous controller of the MICRO-IMAGECHECKER A Series (Ver. 1) cannot be directly restored to V2 using the Vision Backup-Tool. In this case, you will

*

need the dedicated data conversion software (freeware) to convert the Ver. 1 type data for V2 use. If you require the data conversion software or information about how to use it,

contact your Matsushita Automatic Controls Co. Ltd. representative.

Binarization

Position/

rotation position

adjustment function

Exposure

adjustment

Smart matching/

matching

(sub-pixel processing)

Gray-scale edge

detection

(sub-pixel processing)

Gray-scale window

Feature extraction

Binary window

Binary edge detection

Line

Conversion data

Numerical

calculations

Judgement output

Serial

Parallel

Display functions

Marker function

function

Debugging

Setup help

External output (D) register = Max. 32 per product type Internal judgement (R) register = Max. 32 per product type External output (D) register = Max. 8 per product type Internal judgement (R) register = Max. 8 per product type

32-bit RISC CPU (high-speed processing version) 32-bit RISC CPU

Change between gray-scale memory/gray-scale through/binary memory (A/B/C/D)/binary through (A/B/C/D)/gray-scale NG/binary NG (A/B/C/D)

Max. 32 per product type Rotation position adjustment function Max. 4 per product type

Shape: rectangular Binarization adjusts according to changes in the gray-scale data Gray-scale mean value detection/judgement

Smart matching = 32 pcs.; Equipped with post-detection ifferential processing function

changes can be imported from external source smart teaching (A210) = judgement learning function by the smart template

Shape: rectangular/polygonal or oval mask Shape: rectangular/polygonal or oval Gray-scale mean value detection/judgement

Image filtering Labeling Output values: counter/center of gravity (to one decimal place)/area/shading/width/principle axis angle

Shape = rectangular/polygonal or oval mas Shape = rectangular/polygonal or oval Image filtering White/black pixel number count/judgement

4 registers, Can quote to numerical conversion, Can convert numerical conversion result to actual distance, Standard distance, No. of pixels, Cooefficient

4 arithmetic calculations, arctangent, root, the distance-between-points special substitutions reference to previous data output control

Numerical calculations results display, Image filtering display function, Accumulated data display, Display list of checkers

Double-speed random camera (progressive) = ANM831 Standard camera = ANM830A, Composite video (NTSC) input used (however the connection requires one port)

A210 Multi-checker A110 Multi-checker

512 × 480 (pixels) × 256 gradations

Menu selection by specialized keypad

8 bit 256 gradations

4 groups of binary processing from the gray-scale memory (upper and lower threshold settings)

64 32

—

Priority adjustment multi-stage adjustment sequence setting by

matching/gray-scale edge/binary edge or feature detection.

Max. 8 per product type Max. 4 per product type

Matching = 4 per product type

Sub-pixel accurate multiple detection matching by gray-scale correlation processing

Rotation by raster detection and raster detection position (±30 degrees)

Output = number of detected items/correlation numbers/position/angle teaching registered

Max. 32 per product type

Scanning method = individual/projection gray-scale filter/width function detection by sub-pixel unit

Detection position = forepoint/forepoint and afterpoint/largest differential/multiple edge

Max. 32 per product type Max. 16 per product type

Max. 32 per product type Max. 16 per product type

Shape = rectangular/polygonal or oval mask Shape = rectangular/polygonal or oval

Max. 32 per product type Max. 16 per product type

Max. 64 per product type Max. 32 per product type

Shape = line/mask filter/width functions forepoint edge detection

Max. 32 per product type Max. 16 per product type

Shape = straight line/polygonal line/circle or arc Image filters White/black pixel number count/judgement

32 per product type

RS232C = 2ch (max.115200bps) Matsushita Electric Works PLC compatible with FP series

Input = 11points Output = 14 points Removable screw-down terminal block

Image trigger (timing sensor unnecessary) external sensor timing repeat start

Display item suppressing function (menu display hide function)

Image suppress function when setting checkers, Image rotation function when setting checkers (A210)

Clearly display reject location, Rotational adjustment angle display (A210)

—

32 screens 8 screens

Save/load function for inspection image (all screens/problem screens)

Store images for reinspection/resetting Windows-PC image save/load function

Trap function Image storage function

Focus setup, aperture setup, lighting adjustment, image profile monitor, recommended

threshold level, I/O monitor, enforce output

High-speed random trigger camera (progressive)/flash/electronic shutter used

21

24 V DC less than 0.9 A 24 V DC less than 0.7 A

Setup data can be saved to a Windows PC using the Vision Backup-Tool Ver. 2

10 11

Loading...

Loading...