Page 1

Guide to Using

@RISK for Six

Sigma

Version 5.5

May, 2009

Palisade Corporation

798 Cascadilla St.

Ithaca, NY USA 14850

(607) 277-8000

(607) 277-8001 (fax)

http://www.palisade.com (website)

sales@palisade.com (e-mail)

Page 2

Copyright Notice

Copyright © 2009, Palisade Corporation.

Trademark Acknowledgments

Microsoft, Excel and Windows are registered trademarks of Microsoft, Inc.

IBM is a registered trademark of International Business Machines, Inc.

Palisade, TopRank, BestFit and RISKview are registered trademarks of Palisade

Corporation.

RISK is a trademark of Parker Brothers, Division of Tonka Corporation and is used under

license.

Page 3

Welcome

Welcome to @RISK, the world’s most powerful risk analysis tool!

@RISK has long been used to analyze risk and uncertainty in any

industry. With applications in finance, oil and gas, insurance,

manufacturing, healthcare, pharmaceuticals, science and other fields,

@RISK is as flexible as Excel itself. Every day tens of thousands of

professionals use @RISK to estimate costs, analyze NPV and IRR,

study real options, determine pricing, explore for oil and resources,

and much more.

A key application of @RISK is Six Sigma and quality analysis.

Whether it’s in DMAIC, Design for Six Sigma (DFSS), Lean projects,

Design of Experiments (DOE), or other areas, uncertainty and variable

lies at the core of any Six Sigma analysis. @RISK uses Monte Carlo

simulation to identify, measure, and root out the causes of variability

in your production and service processes. A full suite of capability

metrics gives you the calculations you need to step through any Six

Sigma method quickly and accurately. Charts and tables clearly show

Six Sigma statistics, making it easy and effective to illustrate this

powerful technique to management. The Industrial edition of @RISK

adds RISKOptimizer to your Six Sigma analyses for optimization of

project selection, resource allocation, and more.

Industries ranging from engine manufacturing to precious metals to

airlines and consumer goods are using @RISK every day to improve

their processes, enhance the quality of their products and services,

and save millions. This guide will walk you through the @RISK Six

Sigma functions, statistics, charts and reports to show you how

@RISK can be put to work at any stage of a Six Sigma project.

Example case studies round out the guide, giving you pre-built

models you can adapt to your own analyses.

The standard features of @RISK, such as entering distribution

functions, fitting distributions to data, running simulations and

performing sensitivity analyses, are also applicable to Six Sigma

models. When using @RISK for Six Sigma modeling you should also

familiarize yourself with these features by reviewing the @RISK for

Excel Users Guide and on-line training materials.

Page 4

Page 5

Table of Contents

Chapter 1: Overview of @RISK and Six Sigma Methodologies 1

Introduction.........................................................................................3

Six Sigma Methodologies..................................................................7

@RISK and Six Sigma........................................................................9

Chapter 2: Using @RISK for Six Sigma 13

Introduction.......................................................................................15

RiskSixSigma Property Function....................................................17

Six Sigma Statistics Functions .......................................................21

Six Sigma and the Results Summary Window ..............................35

Six Sigma Markers on Graphs.........................................................37

Case Studies 39

Example 1 – Design of Experiments: Catapult..............................41

Example 2 – Design of Experiments: Welding...............................47

Example 3 – Design of Experiments with Optimization................53

Example 4 – DFSS: Electrical Design.............................................61

Example 5 – Lean Six Sigma: Analysis of Current State – Quotation

Process...........................................................................................63

Example 6 – DMAIC: Roll Through Yield Analysis........................73

Example 7 – Vendor Selection ........................................................77

Table of Contents v

Page 6

Example 8 – Six Sigma DMAIC Failure Rate..................................81

Example 9 – Six Sigma DMAIC Failure Rate using RiskTheo......85

vi Introduction

Page 7

Chapter 1: Overview of @RISK and Six Sigma Methodologies

Introduction.........................................................................................3

What is Six Sigma?...................................................................................3

The Importance of Variation..................................................................5

Six Sigma Methodologies..................................................................7

Six Sigma / DMAIC .................................................................................7

Design for Six Sigma (DFSS).................................................................7

Lean or Lean Six Sigma...........................................................................8

@RISK and Six Sigma........................................................................9

@RISK and DMAIC.................................................................................9

@RISK and Design for Six Sigma (DFSS) .........................................10

@RISK and Lean Six Sigma..................................................................11

@RISK 5.0 Help System © Palisade Corporation, 1999

Chapter 1: Overview of @RISK and Six Sigma Methodologies 1

Page 8

2 Introduction

Page 9

Introduction

In today’s competitive business environment, quality is more

important than ever. Enter @RISK, the perfect companion for any Six

Sigma or quality professional. This powerful solution allows you to

quickly analyze the effect of variation within processes and designs.

In addition to Six Sigma and quality analysis, @RISK can be used to

analyze any situation in which there is uncertainty. Applications

include analysis of NPV, IRR, and real options, cost estimation,

portfolio analysis, oil and gas exploration, insurance reserves, pricing,

and much more. To learn more about @RISK in other applications,

and the use of @RISK in general, refer to the @RISK User’s Guide

included with your software.

What is Six Sigma?

Six Sigma is a set of practices to systematically improve processes by

reducing process variation and thereby eliminating defects. A defect

is defined as nonconformity of a product or service to its

specifications. While the particulars of the methodology were

originally formulated by Motorola in the mid-1980s, Six Sigma was

heavily inspired by six preceding decades of quality improvement

methodologies such as quality control, TQM, and Zero Defects. Like

its predecessors, Six Sigma asserts the following:

• Continuous efforts to reduce variation in process outputs is key

to business success

• Manufacturing and business processes can be measured,

analyzed, improved and controlled

• Succeeding at achieving sustained quality improvement

requires commitment from the entire organization, particularly

from top-level management

Six Sigma is driven by data, and frequently refers to “X” and “Y”

variables. X variables are simply independent input variables that

affect the dependent output variables, Y. Six Sigma focuses on

identifying and controlling variation in X variables to maximize

quality and minimize variation in Y variables.

Chapter 1: Overview of @RISK and Six Sigma Methodologies 3

Page 10

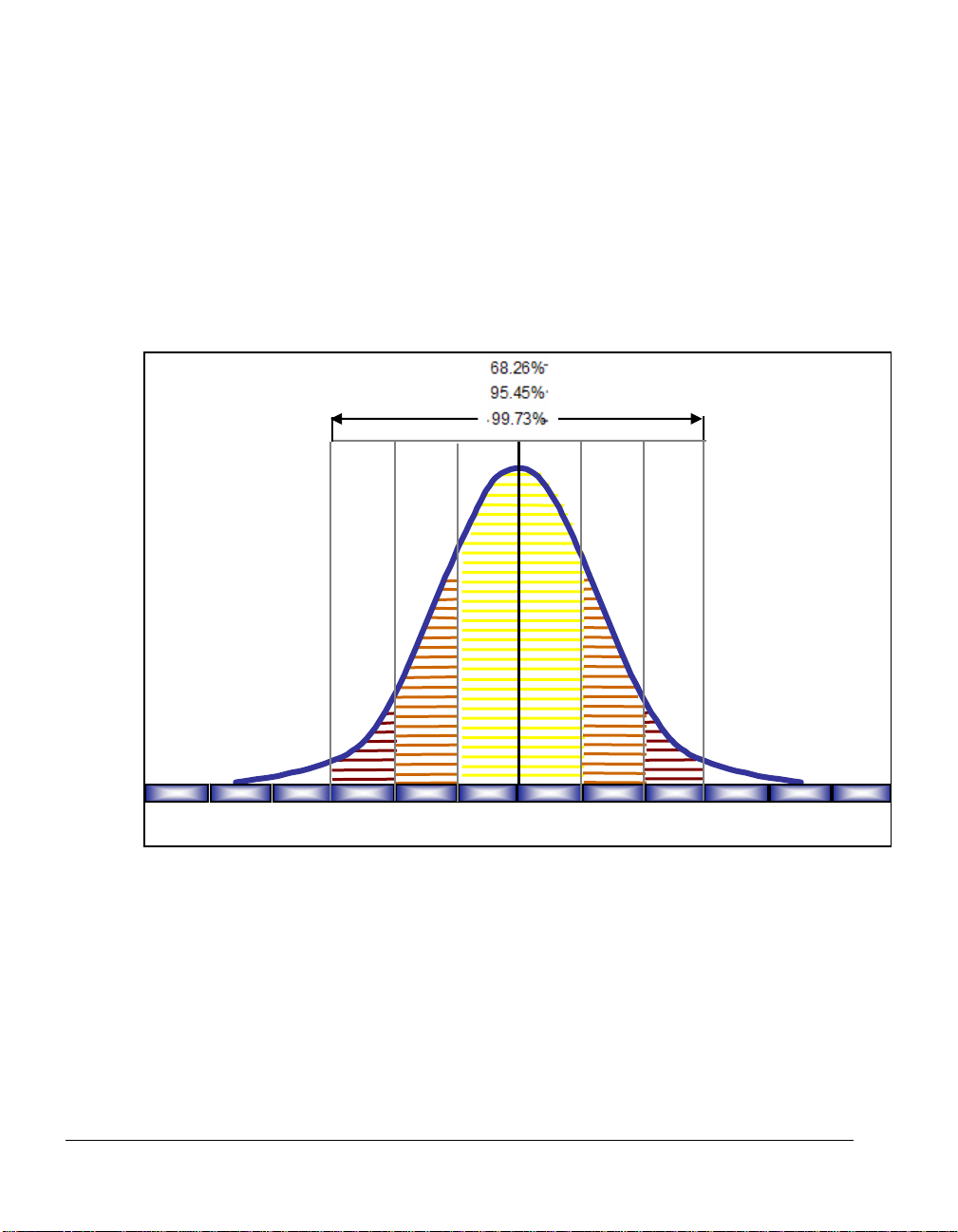

The term Six Sigma or 6σ is very descriptive. The Greek letter sigma

(σ) signifies standard deviation, an important measure of variation.

The variation of a process refers to how tightly all outcomes are

clustered around the mean. The probability of creating a defect can

be estimated and translated into a “Sigma level.” The higher the

Sigma level, the better the performance. Six Sigma refers to having

six standard deviations between the average of the process center

and the closest specification limit or service level. That translates to

fewer than 3.4 defects per one million opportunities (DPMO). The

chart below illustrates Six Sigma graphically.

-6

-3 -4 -5

-2

-1

+1

+4 +3 +2

+5

Six sigmas – or standard deviations – from the mean.

The cost savings and quality improvements that have resulted from

Six Sigma corporate implementations are significant. Motorola has

reported $17 billion in savings since implementation in the mid 1980s.

Lockheed Martin, GE, Honeywell, and many others have experienced

tremendous benefits from Six Sigma.

4 Introduction

+6

Page 11

The Importance of Variation

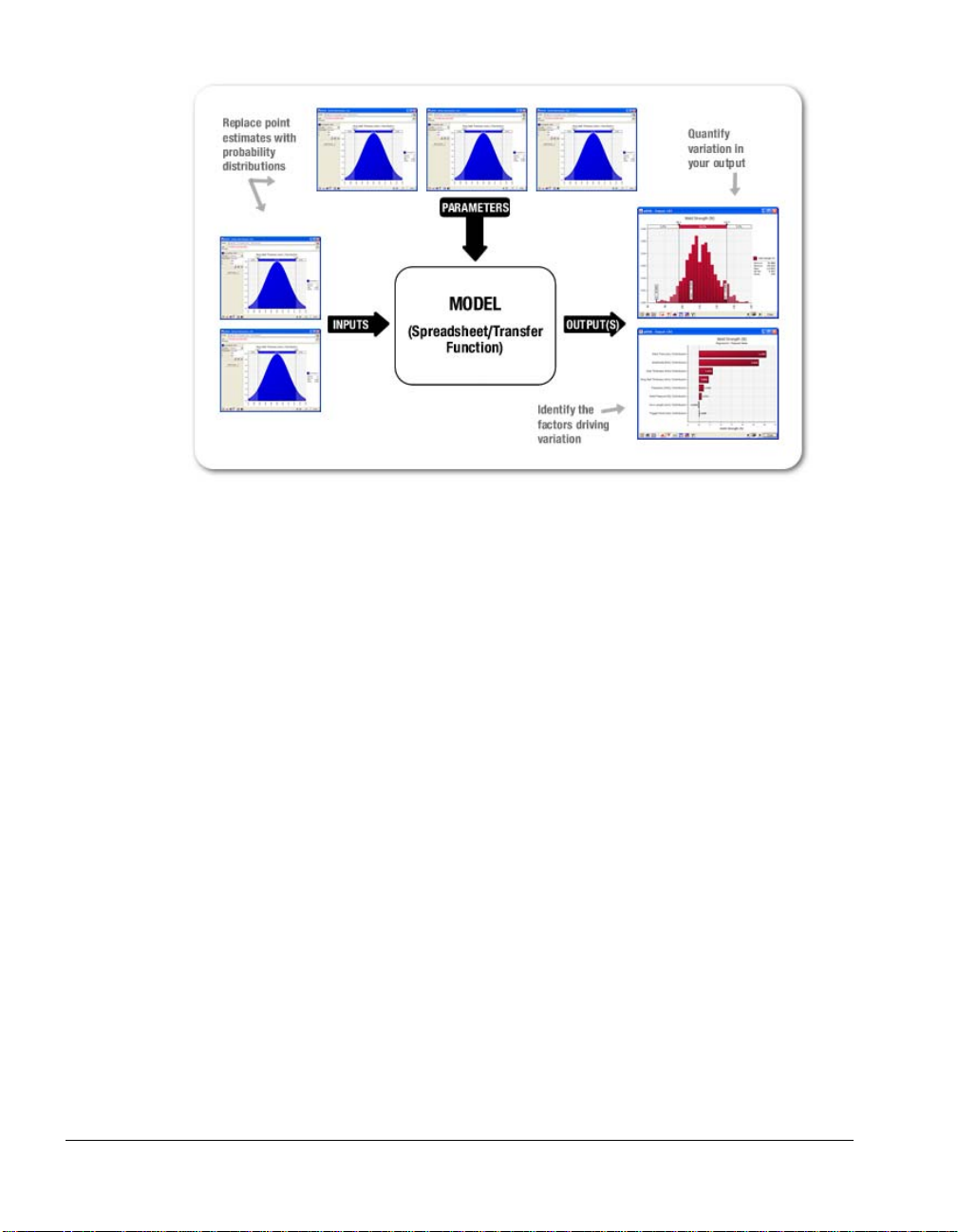

Too many Six Sigma practitioners rely on static models that don’t

account for inherent uncertainty and variability in their processes or

designs. In the quest to maximize quality, it’s vital to consider as

many scenarios as possible.

That’s where @RISK comes in. @RISK uses Monte Carlo simulation to

analyze thousands of different possible outcomes, showing you the

likelihood of each occurring. Uncertain factors are defined using over

35 probability distribution functions, which accurately describe the

possible range of values your inputs could take. What’s more, @RISK

allows you to define Upper and Lower Specification Limits and

Target values for each output, and comes complete with a wide range

of Six Sigma statistics and capability metrics on those outputs.

@RISK Industrial edition also includes RISKOptimizer, which

combine the power of Monte Carlo simulation with genetic algorithmbased optimization. This gives you the ability to tackle optimization

problems like that have inherent uncertainty, such as:

• resource allocation to minimize cost

• project selection to maximize profit

• optimize process settings to maximize yield or minimize cost

• optimize tolerance allocation to maximize quality

• optimize staffing schedules to maximize service

The figure here illustrates how @RISK helps to identify, quantify, and

hone in on variation in your processes.

Chapter 1: Overview of @RISK and Six Sigma Methodologies 5

Page 12

6 Introduction

Page 13

Six Sigma Methodologies

@RISK can be used in a variety of Six Sigma and related analyses. The

three principal areas of analysis are:

• Six Sigma / DMAIC / DOE

• Design for Six Sigma (DFSS)

• Lean or Lean Six Sigma

Six Sigma / DMAIC

When most people refer to Six Sigma, they are in fact referring to the

DMAIC methodology. The DMAIC methodology should be used

when a product or process is in existence but is not meeting customer

specification or is not performing adequately.

DMAIC focuses on evolutionary and continuous improvement in

manufacturing and services processes, and is almost universally

defined as comprising of the following five phases: Define, Measure,

Analyze, Improve and Control:

1) Define the project goals and customer (internal and external

Voice of Customer or VOC) requirements

2) Measure the process to determine current performance

3) Analyze and determine the root cause(s) of the defects

4) Improve the process by eliminating defect root causes

5) Control future process performance

Design for Six Sigma (DFSS)

DFSS is used to design or re-design a product or service from the

ground up. The expected process Sigma level for a DFSS product or

service is at least 4.5 (no more than approximately 1 defect per

thousand opportunities), but can be 6 Sigma or higher depending on

the product. Producing such a low defect level from product or

service launch means that customer expectations and needs (CriticalTo-Qualities or CTQs) must be completely understood before a design

can be completed and implemented. Successful DFSS programs can

reduce unnecessary waste at the planning stage and bring products to

market more quickly.

Chapter 1: Overview of @RISK and Six Sigma Methodologies 7

Page 14

Unlike the DMAIC methodology, the phases or steps of DFSS are not

universally recognized or defined -- almost every company or

training organization will define DFSS differently. One popular

Design for Six Sigma methodology is called DMADV, and retains the

same number of letters, number of phases, and general feel as the

DMAIC acronym. The five phases of DMADV are defined as: Define,

Measure, Analyze, Design and Verify:

1) Define the project goals and customer (internal and external

VOC) requirements

2) Measure and determine customer needs and specifications;

benchmark competitors and industry

3) Analyze the process options to meet the customer needs

4) Design (detailed) the process to meet the customer needs

5) Verify the design performance and ability to meet customer

needs

Lean or Lean Six Sigma

“Lean Six Sigma” is the combination of Lean manufacturing

(originally developed by Toyota) and Six Sigma statistical

methodologies in a synergistic tool. Lean deals with improving the

speed of a process by reducing waste and eliminating non-value

added steps. Lean focuses on a customer “pull” strategy, producing

only those products demanded with “just in time” delivery. Six

Sigma improves performance by focusing on those aspects of a

process that are critical to quality from the customer perspective and

eliminating variation in that process. Many service organizations, for

example, have already begun to blend the higher quality of Six Sigma

with the efficiency of Lean into Lean Six Sigma.

Lean utilizes “Kaizen events” -- intensive, typically week-long

improvement sessions -- to quickly identify improvement

opportunities and goes one step further than a tradition process map

in its use of value stream mapping. Six Sigma uses the formal DMAIC

methodology to bring measurable and repeatable results.

Both Lean and Six Sigma are built around the view that businesses are

composed of processes that start with customer needs and should end

with satisfied customers using your product or service.

8 Six Sigma Methodologies

Page 15

@RISK and Six Sigma

Whether it’s in DMIAC, Design of Experiments or Lean Six Sigma,

uncertainty and variability lie at the core of any Six Sigma analysis.

@RISK uses Monte Carlo simulation to identify, measure, and root out

the causes of variability in your production and service processes.

Each of the Six Sigma methodologies can benefit from @RISK

throughout the stages of analysis.

@RISK and DMAIC

@RISK is useful at each stage of the DMAIC process to account for

variation and hone in on problem areas in existing products.

1) Define. Define your process improvement goals,

incorporating customer demand and business strategy.

Value-stream mapping, cost estimation, and identification of

CTQs (Critical-To-Qualities) are all areas where @RISK can

help narrow the focus and set goals. Sensitivity analysis in

@RISK zooms in on CTQs that affect your bottom-line

profitability.

2) Measure. Measure current performance levels and their

variations. Distribution fitting and over 35 probability

distributions make defining performance variation accurate.

Statistics from @RISK simulations can provide data for

comparison against requirements in the Analyze phase.

3) Analyze. Analyze to verify relationship and cause of

defects, and attempt to ensure that all factors have been

considered. Through @RISK simulation, you can be sure all

input factors have been considered and all outcomes

presented. You can pinpoint the causes of variability and risk

with sensitivity and scenario analysis, and analyze tolerance.

Use @RISK’s Six Sigma statistics functions to calculate

capability metrics which identify gaps between

measurements and requirements. Here we see how often

products or processes fail and get a sense of reliability.

Chapter 1: Overview of @RISK and Six Sigma Methodologies 9

Page 16

4) Improve. Improve or optimize the process based upon the

analysis using techniques like Design of Experiments.

Design of Experiments includes the design of all informationgathering exercises where variation is present, whether under

the full control of the experimenter or not. Using @RISK

simulation, you can test different alternative designs and

process changes. @RISK is also used for reliability analysis

and – using RISKOptimizer - resource optimization at this

stage.

5) Control. Control to ensure that any variances are corrected

before they result in defects. In the Control stage, you can

set up pilot runs to establish process capability, transition to

production and thereafter continuously measure the process

and institute control mechanisms. @RISK automatically

calculates process capability and validates models to make

sure that quality standards and customer demands are met.

@RISK and Design for Six Sigma (DFSS)

One of @RISK’s main uses in Six Sigma is with DFSS at the planning

stage of a new project. Testing different processes on physical

manufacturing or service models or prototypes can be cost

prohibitive. @RISK allows engineers to simulate thousands of

different outcomes on models without the cost and time associated

with physical simulation. @RISK is helpful at each stage of a DFSS

implementation in the same way as the DMAIC steps. Using @RISK

for DFSS gives engineers the following benefits:

• Experiment with different designs / Design of Experiments

• Identify CTQs

• Predict process capability

• Reveal product design constraints

• Cost estimation

• Project selection – using RISKOptimizer to find the optimal

portfolio

• Statistical tolerance analysis

• Resource allocation – using RISKOptimizer to maximize

efficiency

10 @RISK and Six Sigma

Page 17

@RISK and Lean Six Sigma

@RISK is the perfect companion for the synergy of Lean

manufacturing and Six Sigma. “Quality only” Six Sigma models may

fail when applied to reducing variation in a single process step, or to

processes which do not add value to the customer. For example, an

extra inspection during the manufacturing process to catch defective

units may be recommended by a Six Sigma analysis. The waste of

processing defective units is eliminated, but at the expense of adding

inspection which is in itself waste. In a Lean Six Sigma analysis,

@RISK identifies the causes of these failures. Furthermore, @RISK can

account for uncertainty in both quality (ppm) and speed (cycle time)

metrics.

@RISK provides the following benefits in Lean Six Sigma analysis:

• Project selection – using RISKOptimizer to find the optimal

portfolio

• Value stream mapping

• Identification of CTQs that drive variation

• Process optimization

• Uncover and reduce wasteful process steps

• Inventory optimization – using RISKOptimizer to minimize

costs

• Resource allocation – using RISKOptimizer to maximize

efficiency

Chapter 1: Overview of @RISK and Six Sigma Methodologies 11

Page 18

12 @RISK and Six Sigma

Page 19

Chapter 2: Using @RISK for Six Sigma

Introduction.......................................................................................15

RiskSixSigma Property Function....................................................17

Entering a RiskSixSigma Property Function ....................................18

Six Sigma Statistics Functions .......................................................21

RiskCp......................................................................................................23

RiskCpm ..................................................................................................23

RiskCpk ...................................................................................................24

RiskCpkLower........................................................................................25

RiskCpkUpper........................................................................................25

RiskDPM .................................................................................................26

RiskK........................................................................................................26

RiskLowerXBound.................................................................................27

RiskPNC ..................................................................................................27

RiskPNCLower.......................................................................................28

RiskPNCUpper.......................................................................................28

RiskPPMLower.......................................................................................29

RiskPPMUpper.......................................................................................29

RiskSigmalLevel ....................................................................................30

RiskUpperXBound.................................................................................31

RiskYV .....................................................................................................31

RiskZlower..............................................................................................32

RiskZMin.................................................................................................33

RiskZUpper.............................................................................................33

Six Sigma and the Results Summary Window ..............................35

Six Sigma Markers on Graphs.........................................................37

Chapter 2: Using @RISK for Six Sigma 13

Page 20

14

Page 21

Introduction

@RISK’s standard simulation capabilities have been enhanced for use

in Six Sigma modeling through the addition of four key features.

These are:

The standard features of @RISK, such as entering distribution

functions, fitting distributions to data, running simulations and

performing sensitivity analyses, are also applicable to Six Sigma

models. When using @RISK for Six Sigma modeling you should also

familiarize yourself with these features by reviewing the @RISK for

Excel Users Guide and on-line training materials.

1) The RiskSixSigma property function for entering

specification limits and target values for simulation outputs

2) Six Sigma statistics functions, including process capability

indices such as RiskCpk, RiskCpm and others which return

Six Sigma statistics on simulation results directly in

spreadsheet cells

3) New columns in the Results Summary window which give

Six Sigma statistics on simulation results in table form

4) Markers on graphs of simulation results which display

specification limits and the target value

Chapter 2: Using @RISK for Six Sigma 15

Page 22

16 Introduction

Page 23

RiskSixSigma Property Function

In an @RISK simulation the RiskOutput function identifies a cell in a

spreadsheet as a simulation output. A distribution of possible

outcomes is generated for every output cell selected. These

probability distributions are created by collecting the values

calculated for a cell for each iteration of a simulation.

When Six Sigma statistics are to be calculated for an output, the

RiskSixSigma property function is entered as an argument to the

RiskOutput function. This property function specifies the lower

specification limit, upper specification limit, target value, long term

shift, and the number of standard deviations for the six sigma

calculations for an output. These values are used in calculating six

sigma statistics displayed in the Results window and on graphs for

the output. For example:

RiskOutput(“Part Height”,,RiskSixSigma(.88,.95,.915,1.5,6))

specifies an LSL of .88, a USL of .95, target value of .915, long term

shift of 1.5, and a number of standard deviations of 6 for the output

Part Height. You can also use cell referencing in the RiskSixSigma

property function.

These values are used in calculating Six Sigma statistics displayed in

the Results window and as markers on graphs for the output.

When @RISK detects a RiskSixSigma property function in an output,

it automatically displays the available Six Sigma statistics on the

simulation results for the output in the Results Summary window and

adds markers for the entered LSL, USL and Target values to graphs of

simulation results for the output.

Chapter 2: Using @RISK for Six Sigma 17

Page 24

Entering a RiskSixSigma Property Function

The RiskSixSigma property function can be typed directly into a cell’s

formula as an argument to a RiskOutput function. Alternatively the

Excel Function Wizard can be used to assist in entering the function

directly in a cell formula.

@RISK’s Insert Function command allows you to quickly insert a

RiskOutput function with an added RiskSixSigma property function.

Simply select the Output menu RiskOutput (Six Sigma Format)

command from @RISK’s Insert Function menu and the appropriate

function will be added to the formula in the active cell.

18 RiskSixSigma Property Function

Page 25

Output Properties – Six Sigma Tab

@RISK also provides a Function Properties window which can be

used to enter a RiskSixSigma property function into a RiskOutput

function. This window has a tab titled Six Sigma that has entries for

the arguments to the RiskSixSigma function. Access the RiskOutput

Function Properties window by clicking on the properties button in

the @RISK Add Output window.

Chapter 2: Using @RISK for Six Sigma 19

Page 26

The default settings for an output to be used in Six Sigma calculations

are set on the Six Sigma tab. These properties include:

• Calculate Capability Metrics for This Output. Specifies that

capability metrics will be displayed in reports and graphs for

the output. These metrics will use the entered LSL, USL and

Target values.

• LSL, USL and Target. Sets the LSL (Lower Specification

Limit), USL (Upper Specification Limit) and Target values for

the output.

• Use Long Term Shift and Shift. Specifies an optional shift

for calculation of long-term capability metrics.

• Upper/Lower X Bound. The number of standard deviations

to the right or the left of the mean for calculating the upper or

lower X-axis values.

Entered Six Sigma settings result in a RiskSixSigma property

function being added to the RiskOutput function. Only outputs

which contain a RiskSixSigma property function will display Six

Sigma markers and statistics in graphs and reports. @RISK Six Sigma

statistics functions in Excel worksheets can reference any output cell

that contains a RiskSixSigma property function.

Note: All graphs and reports in @RISK use the LSL, USL, Target,

Long Term Shift and the Number of Standard Deviations values from

RiskSixSigma property functions that existed at the start of a

simulation. If you change the specification limits for an output (and

its associated RiskSixSigma property function), you need to re-run

the simulation to view changed graphs and reports.

20 RiskSixSigma Property Function

Page 27

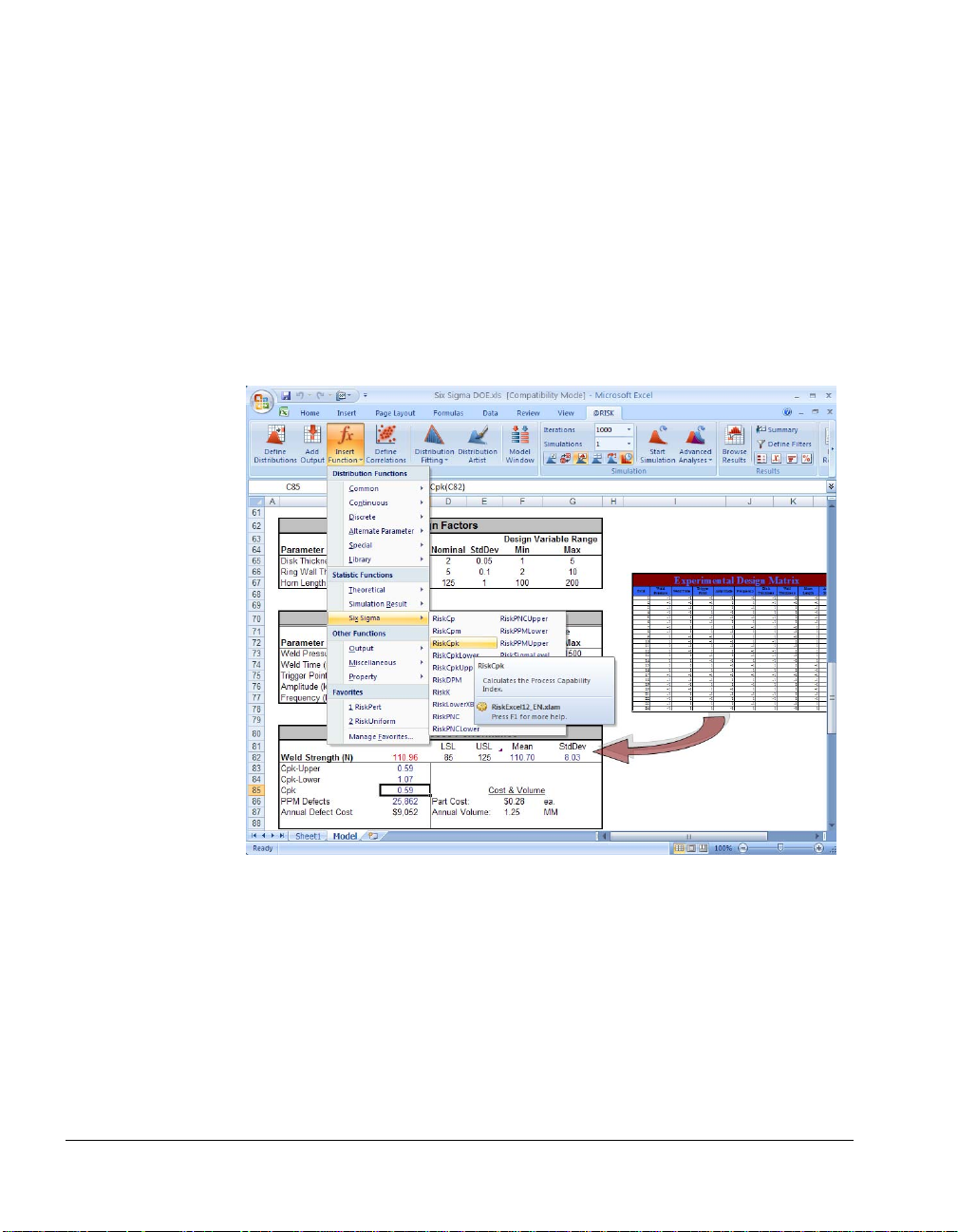

Six Sigma Statistics Functions

A set of @RISK statistics functions return a desired Six Sigma statistic

on a simulation output. For example, the function RiskCPK(A10)

returns the CPK value for the simulation output in Cell A10. These

functions are updated real-time as a simulation is running. These

functions are similar to the standard @RISK statistics functions (such

as RiskMean) in that they calculate statistics on simulation results;

however, these functions calculate statistics commonly required in Six

Sigma models. These functions can be used anywhere in spreadsheet

cells and formulas in your model.

Some important items to note about @RISK’s Six Sigma statistics

functions are as follows:

• If a cell reference is entered as the first argument to the statistics

function and that cell has a RiskOutput function with a

RiskSixSigma property function, @RISK will use the LSL, USL,

Target, Long Term Shift and Number of Standard Deviation

values from that output when calculating the desired statistic.

• If a cell reference is entered as the first argument, the cell does not

have to be a simulation output identified with a RiskOutput

function. However, if it is not an output, an optional

RiskSixSigma property function needs to be added to the

statistic function itself so @RISK will have the necessary settings

for calculating the desired statistic.

• Entering an optional RiskSixSigma property function directly in a

statistics function causes @RISK to override any Six Sigma

settings specified in the RiskSixSigma property function in a

referenced simulation output. This allows you to calculate Six

Sigma statistics at differing LSL, USL, Target, Long Term Shift

and Number of Standard Deviation values for the same output.

• If a name is entered instead of cellref, @RISK first checks for an

output with the entered name, and the reads its RiskSixSigma

property function settings. It is up to the user to ensure that

unique names are given to outputs referenced in statistics

functions.

• The Sim# argument entered selects the simulation for which a

statistic will be returned when multiple simulations are run. This

argument is optional and can be omitted for single simulation

runs.

Chapter 2: Using @RISK for Six Sigma 21

Page 28

• When an optional RiskSixSigma property function is entered

directly in a Six Sigma statistics function, different arguments

from the property function are used depending on the calculation

being performed.

• Statistics functions located in template sheets used for creating

custom reports on simulation results are only updated when a

simulation is completed.

Entering Six Sigma Statistics Functions

@RISK’s Insert Function command allows you to quickly insert a Six

Sigma Statistics Function. Simply select the Six Sigma command in

the Statistics function category on the @RISK’s Insert Function menu,

then select the desired function. The selected function will be added

to the formula in the active cell.

22 Six Sigma Statistics Functions

Page 29

RiskCp

RiskCpm

Description

Examples

Guidelines

Description

Examples

Guidelines

RiskCp(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) calculates

the Process Capability for cellref or output name in Sim#, optionally

using the LSL and USL in the included RiskSixSigma property

function. This function will calculate the quality level of the

specified output and what it is potentially capable of producing.

RiskCP(A10) returns the Process Capability for the output cell

A10. A RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskCP(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns the

Process Capability for the output cell A10, using an LSL of 100 and

a USL of 120.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskCpm(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) returns

the Taguchi capability index for cellref or output name in Sim #,

optionally using the USL, LSL, and the Target in the RiskSixSigma

property function. This function is essentially the same as the Cpk

but incorporates the target value which in some cases may or may

not be within the specification limits.

RiskCpm(A10) returns the Taguchi capability index for cell A10 .

RiskCpm(A10,, RiskSixSigma(100, 120, 110, 0, 6)) returns the

Taguchi capability index for cell A10, using an USL of 120, LSL of

100, and a Target of 110.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

Chapter 2: Using @RISK for Six Sigma 23

Page 30

RiskCpk

Description

Examples

Guidelines

RiskCpk(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) calculates

the Process Capability Index for cellref or output name in Sim#

optionally using the LSL and USL in the included RiskSixSigma

property function. This function is similar to the Cp but takes into

account an adjustment of the Cp for the effect of an off-centered

distribution. As a formula, Cpk = either (USL-Mean) / (3 x sigma) or

(Mean-LSL) / (3 x sigma) whichever is the smaller.

RiskCpk(A10) returns the Process Capability Index for the output

cell A10. A RiskSixSigma property function needs to be entered in

the RiskOutput function in Cell A10.

RiskCpk(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns the

Process Capability Index for the output cell A10, using an LSL of

100 and a USL of 120.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

24 Six Sigma Statistics Functions

Page 31

RiskCpkLower

Description

Examples

Guidelines

RiskCpkUpper

Description

Examples

Guidelines

RiskCpkLower(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the one-sided capability index

based on the Lower Specification limit for cellref or output name in

Sim# optionally using the LSL in the RiskSixSigma property

function.

RiskCpkLower(A10) returns the one-sided capability index based

on the Lower Specification limit for the output cell A10. A

RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskCpkLower(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the one-sided capability index for the output cell A10, using an LSL

of 100.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskCpkUpper(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the one-sided capability index

based on the Upper Specification limit for cellref or output name in

Sim# optionally using the USL in the included RiskSixSigma

property function.

RiskCpkUpper(A10) returns the one-sided capability index based

on the Upper Specification limit for the output cell A10. A

RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskCpkUpper(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the Process Capability Index for the output cell A10, using an LSL

of 100.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

Chapter 2: Using @RISK for Six Sigma 25

Page 32

RiskDPM

RiskK

Description

Examples

Guidelines

Description

Examples

Guidelines

RiskDPM(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) calculates

the defective parts per million for cellref or output name in Sim#

optionally using the LSL and USL in the included RiskSixSigma

property function.

RiskDPM(A10) returns the defective parts per million for the output

cell A10. A RiskSixSigma property function needs to be entered in

the RiskOutput function in Cell A10.

RiskDPM(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns the

defective parts per million for the output cell A10, using an LSL of

100 and USL of 120.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskK(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) calculates

a measure of process center for cellref or output name in Sim#

optionally using the LSL and USL in the included RiskSixSigma

property function.

RiskK(A10) returns a measure of process center for the output cell

A10. A RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskK(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns a

measure of process center for the output cell A10, using an LSL of

100 and USL of 120.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

26 Six Sigma Statistics Functions

Page 33

RiskLowerXBound

RiskPNC

Description

Examples

Guidelines

Description

Examples

Guidelines

RiskLowerXBound(cellref or output name, Sim#,

RiskSixSigma(LSL, USL, Target, Long Term Shift, Number of

Standard Deviations)) returns the lower X-value for a specified

number of standard deviations from the mean for cellref or output

name in Sim #, optionally using the Number of Standard Deviations

in the RiskSixSigma property function.

RiskLowerXBound(A10) returns the lower X-value for a specified

number of standard deviations from the mean for cell A10.

RiskLowerXBound(A10,, RiskSixSigma(100, 120, 110, 1.5, 6))

returns the lower X-value for -6 standard deviations from the mean

for cell A10, using a Number of Standard Deviations of 6.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskPNC(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target, Long Term Shift, Number of Standard Deviations))

calculates the total probability of defect outside the lower and

upper specification limits for cellref or output name in Sim#

optionally using the LSL, USL and Long Term Shift in the included

RiskSixSigma property function.

RiskPNC(A10) returns the probability of defect outside the lower

and upper specification limits for the output cell A10. A

RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskPNC(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns the

probability of defect outside the lower and upper specification limits

for the output cell A10, using an LSL of 100, USL of 120 and

LongTerm shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

Chapter 2: Using @RISK for Six Sigma 27

Page 34

RiskPNCLower

Description

Examples

Guidelines

RiskPNCUpper

Description

Examples

Guidelines

RiskPNCLower(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the probability of defect outside

the lower specification limits for cellref or output name in Sim#

optionally using the LSL, USL and LongTerm Shift in the included

RiskSixSigma property function.

RiskPNCLower (A10) returns the probability of defect outside the

lower specification limits for the output cell A10. A RiskSixSigma

property function needs to be entered in the RiskOutput function in

Cell A10.

RiskPNCLower(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the probability of defect outside the lower specification limits for the

output cell A10, using an LSL of 100, USL of 120 and LongTerm

shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskPNCUpper(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the probability of defect outside

the upper specification limits for cellref or output name in Sim#

optionally using the LSL, USL and LongTerm Shift in the included

RiskSixSigma property function.

RiskPNCUpper(A10) returns the probability of defect outside the

upper specification limits for the output cell A10. A RiskSixSigma

property function needs to be entered in the RiskOutput function in

Cell A10.

RiskPNCUpper(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the probability of defect outside the upper specification limits for

the output cell A10, using an LSL of 100, USL of 120 and

LongTerm shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

28 Six Sigma Statistics Functions

Page 35

RiskPPMLower

Description

Examples

Guidelines

RiskPPMUpper

Description

Examples

Guidelines

RiskPPMLower(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the number of defects below the

lower specification limit for cellref or output name in Sim# optionally

using the LSL and LongTerm Shift in the included RiskSixSigma

property function.

RiskPPMLower(A10) returns the number of defects below the

lower specification limit for the output cell A10. A RiskSixSigma

property function needs to be entered in the RiskOutput function in

Cell A10.

RiskPPMLower(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the number of defects below the lower specification limit for the

output cell A10, using an LSL of 100 and LongTerm shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskPPMUpper(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the number of defects above the

upper specification limit for cellref or output name in Sim#

optionally using the USL and LongTerm Shift in the included

RiskSixSigma property function.

RiskPPMUpper(A10) returns the number of defects above the

upper specification limit for the output cell A10. A RiskSixSigma

property function needs to be entered in the RiskOutput function in

Cell A10.

RiskPPMUpper(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the number of defects above the upper specification limit for the

output cell A10, using an USL of 120 and LongTerm shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

Chapter 2: Using @RISK for Six Sigma 29

Page 36

RiskSigmalLevel

Description

Examples

Guidelines

RiskSigmaLevel(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates the Process Sigma level for

cellref or output name in Sim# optionally using the USL and LSL

and Long Term Shift in the included RiskSixSigma property

function. (Note: This function assumes that the output is normally

distributed and centered within the specification limits.)

RiskSigmaLevel(A10) returns the Process Sigma level for the

output cell A10. A RiskSixSigma property function needs to be

entered in the RiskOutput function in Cell A10.

RiskSigmaLevel(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

the Process Sigma level for the output cell A10, using an USL of

120, LSL of 100, and a Long Term Shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

30 Six Sigma Statistics Functions

Page 37

RiskUpperXBound

RiskYV

Description

Examples

Guidelines

Description

Examples

Guidelines

RiskUpperXBound(cellref or output name, Sim#,

RiskSixSigma(LSL, USL, Target, Long Term Shift, Number of

Standard Deviations)) returns the upper X-value for a specified

number of standard deviations from the mean for cellref or output

name in Sim #, optionally using the Number of Standard Deviations

in the RiskSixSigma property function.

RiskUpperXBound(A10) returns the upper X-value for a specified

number of standard deviations from the mean for cell A10.

RiskUpperXBound(A10,, RiskSixSigma(100, 120, 110, 1.5, 6))

returns the upper X-value for -6 standard deviations from the mean

for cell A10, using a Number of Standard Deviations of 6.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskYV(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) calculates

the yield or the percentage of percentage of the process that is free

of defects for cellref or output name in Sim# optionally using the

LSL, USL and LongTerm Shift in the included RiskSixSigma

property function.

RiskYV(A10) returns the yield or the percentage of the process

that is free of defects for the output cell A10. A RiskSixSigma

property function needs to be entered in the RiskOutput function in

Cell A10.

RiskYV(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns the yield

or the percentage of the process that is free of defects for the

output cell A10, using an LSL of 100, USL of 120 and LongTerm

shift of 1.5.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

Chapter 2: Using @RISK for Six Sigma 31

Page 38

RiskZlower

Description

Examples

Guidelines

RiskZlower(cellref or output name, Sim#, RiskSixSigma(LSL,USL,

Target,LongTerm Shift,Number of Standard Deviations)) calculates

how many standard deviations the Lower Specification Limit is

from the mean for cellref or output name in Sim# optionally using

the LSL in the included RiskSixSigma property function.

RiskZlower(A10) returns how many standard deviations the Lower

Specification Limit is from the mean for the output cell A10. A

RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskZlower(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns how

many standard deviations the Lower Specification Limit is from the

mean for the output cell A10, using an LSL of 100.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

32 Six Sigma Statistics Functions

Page 39

RiskZMin

Description

Examples

Guidelines

RiskZUpper

Description

Examples

Guidelines

RiskZMin(cellref or output name, Sim#, RiskSixSigma(LSL, USL,

Target, LongTerm Shift, Number of Standard Deviations)

calculates the minimum of Z-Lower and Z-Upper for cellref or

output name in Sim# optionally using the USL and LSL in the

included RiskSixSigma property function.

RiskZMin(A10) returns the minimum of Z-Lower and Z-Upper for

the output cell A10. A RiskSixSigma property function needs to be

entered in the RiskOutput function in Cell A10.

RiskZMin(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns the

minimum of Z-Lower and Z-Upper for the output cell A10, using a

USL of 120 and LSL of 100.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

RiskZUpper(cellref or output name, Sim#,

RiskSixSigma(LSL,USL, Target,LongTerm Shift,Number of

Standard Deviations)) calculates how many standard deviations

the Upper Specification Limit is from the mean for cellref or output

name in Sim# optionally using the USL in the included

RiskSixSigma property function.

RiskZUpper(A10) returns how many standard deviations the

Upper Specification Limit is from the mean for the output cell A10.

A RiskSixSigma property function needs to be entered in the

RiskOutput function in Cell A10.

RiskZUpper(A10, ,RiskSixSigma(100,120,110,1.5,6)) returns

how many standard deviations the Upper Specification Limit is

from the mean for the output cell A10, using a USL of 120.

A RiskSixSigma property function needs to be entered for cellref

or output name, or a RiskSixSigma property function needs to be

included

Chapter 2: Using @RISK for Six Sigma 33

Page 40

34

Page 41

Six Sigma and the Results Summary Window

The @RISK Results Summary window summarizes the results of

your model and displays thumbnail graphs and summary statistics

for your simulated output cells and input distributions.

When @RISK detects a RiskSixSigma property function in an output,

it automatically displays the available Six Sigma statistics on the

simulation results for the output in the table. These columns may be

hidden or displayed as desired.

Customizing the Displayed Statistics

The Results Summary window columns can be customized to select

which statistics you want to display on your results. The Columns

icon, at the bottom of the window, displays the Columns for Table

dialog.

Chapter 2: Using @RISK for Six Sigma 35

Page 42

Generating a Report in Excel

If you select to show Percentile values in the table, the actual

percentile is entered in the rows Value at Entered Percentile.

The Results Summary window can be exported to Excel to get a

report containing the displayed statistics and graphs. To do this, click

the Copy and Export icon at the bottom of the window and select

Report in Excel.

36 Six Sigma and the Results Summary Window

Page 43

Six Sigma Markers on Graphs

When @RISK detects a RiskSixSigma property function in an output,

it automatically adds markers for the entered LSL, USL and Target

values to graphs of simulation results for the output.

These markers can be removed if desired using the Markers tab of the

Graph Options dialog. Additional markers may also be added. The

Graph Options dialog is displayed by right-clicking on the graph or

by clicking the Graph Options icon (the second icon from the left on

the bottom of the graph window).

Chapter 2: Using @RISK for Six Sigma 37

Page 44

38 Six Sigma Markers on Graphs

Page 45

Case Studies

Example 1 – Design of Experiments: Catapult..............................41

Example 2 – Design of Experiments: Welding...............................47

Example 3 – Design of Experiments with Optimization................53

Example 4 – DFSS: Electrical Design.............................................61

Example 5 – Lean Six Sigma: Analysis of Current State –

Quotation Process.........................................................................63

Example 6 – DMAIC: Roll Through Yield Analysis........................73

Example 7 – Vendor Selection ........................................................77

Example 8 – Six Sigma DMAIC Failure Rate..................................81

Example 9 – Six Sigma DMAIC Failure Rate using RiskTheo......85

Case Studies 39

Page 46

40

Page 47

Example 1 – Design of Experiments: Catapult

Example Model: Six Sigma DOE Catapult.xls

The catapult or trebuchet model is a classic example used to teach

Design of Experiments. It illustrates Monte Carlo simulation and

tolerance analysis.

Suppose you are manufacturing catapults and customers demand the

distance the catapult throws a standard ball is 25 meters, plus or

minus 1 meter. There are many design specifications involved in

producing your catapults, such as:

• Angle of Launch

• Mass of the Ball

• Distance Pulled

• Spring Constant

Case Studies 41

Page 48

Entering a Distribution

Each of the design factors contains an @RISK probability distribution

to represent different possible values each factor could take. @RISK

probability distributions can be entered directly as formulas, using

@RISK’s Insert Function command or by using the Define

Distribution icon on the @RISK toolbar. For example, a Uniform

distribution represents the possible values for Distance Pulled.

42 Example 1 – Design of Experiments: Catapult

Page 49

Entering RiskSixSigma Properties

The output is Distance Thrown, and contains a RiskSixSigma

property function defining Lower Specification Limit, Upper

Specification Limit, and Target for Distance Thrown. Like inputs, an

@RISK output can be typed into the formula bar or defined via dialog

box using the Add Output button on the @RISK toolbar.

Capability metrics Cpk, Cpk Upper, Cpk Lower, Sigma Level, and

DPM are calculated for the catapult, enabling you to determine

whether it is ready for production.

Case Studies 43

Page 50

Graphing the Results

The resulting distribution of Distance Thrown shows that about 60%

of the time the distance is outside of specification limits.

Sensitivity analysis identifies the most important design factors

affecting Distance Thrown as the Distance Pulled, followed by the

Mass of the Ball.

This model can help explore the theory of Taguchi or Robust

Parameter Design. Taguchi theory states that there are two types of

variables which define a system – those whose levels affect the

process variation, and those whose levels do not. The idea behind

Taguchi Design is to set variables of the first type at a level which

44 Example 1 – Design of Experiments: Catapult

Page 51

minimizes total process variation. Variables which don’t affect

process variation are used to control and/or adjust the process.

In the catapult model, you can adjust various design parameters –

such as Pull Distance and Mass of Ball – to try to minimize the

variation in the output Distance Thrown. Considering that 60% of

the time the Distance Thrown is outside the specification limits of 24

to 26 meters, there is room for improvement.

Case Studies 45

Page 52

46 Example 1 – Design of Experiments: Catapult

Page 53

Example 2 – Design of Experiments: Welding

Example Model: Six Sigma DOE.xls

Suppose you are analyzing a metallic burst cup manufactured by

welding a disk onto a ring (see below). The product functions as a

seal and a safety device, so it must hold pressure in normal use, and it

must separate if the internal pressure exceeds the safety limit.

Disk

Ring

Welding

Horn

Disk

Ring

Fixture Base

The model relates the weld strength to process and design factors,

models the variation for each factor, and forecasts the product

performance in relation to the engineering specifications. Modeling a

response based on multiple factors can often be accomplished by

generating a statistically significant function through experimental

design or multiple regression analysis.

Case Studies 47

Page 54

Design Factors

Weld Pressure

Weld Time

Trigger Point

Amplitude

Frequency

Process Factors

Disk

Thickness

Ring Wall

Thickness

Horn

Length

Experimental

Design Matrix

Transfer Function

Response(s)

In this example, @RISK simulates the variation using Normal

distributions for each factor. @RISK distributions support cell

referencing so that you can easily set-up a tabular model that can

be updated throughout a product and process development

lifecycle.

The uncertain factors are:

Design Variables

• Disk thickness

• Horn wall thickness

• Horn length

Process Variables

• Weld pressure

• Weld time

• Trigger point

• Amplitude

• Frequency

48 Example 2 – Design of Experiments: Welding

Page 55

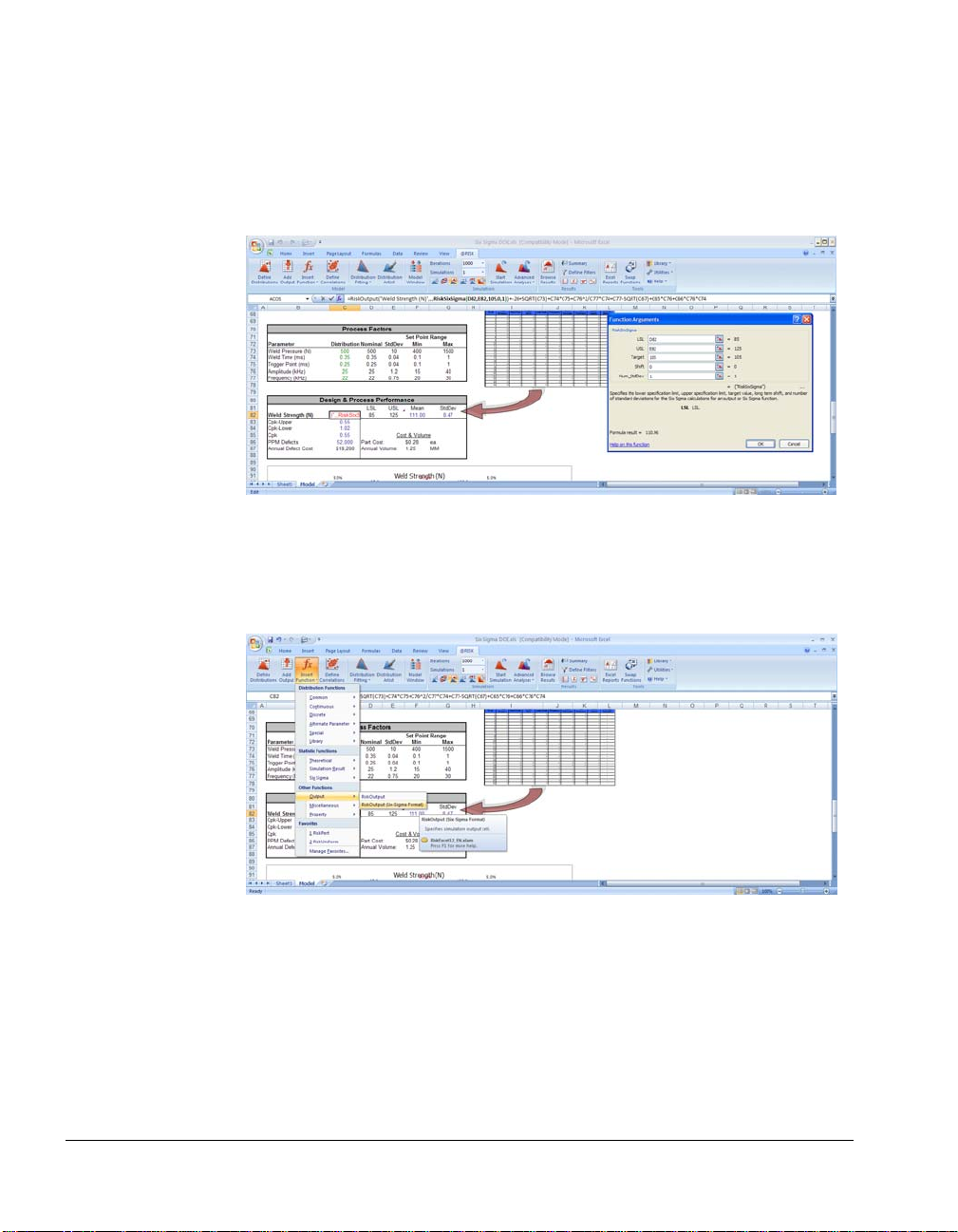

Adding Distributions

Adding a distribution to each factor is as easy as clicking on the

Define Distribution icon on the @RISK toolbar. From there you

can select a Normal distribution and input its parameters or cell

references, as shown below. You could also type the formula

directly into Excel’s formula bar for each input. For example, the

cell for Well Pressure contains the formula

=RiskNormal(D73,E73)

The Six Sigma Output

The output is Weld Strength (N) in the Design & Process

Performance section, and contains a RiskSixSigma property

function that includes the Lower Specification Limit (LSL), Upper

Specification Limit (USL), and Target value specified. As with

defining input distributions, you can type the output formula

directly in the output cell or use the Add Output dialog. The

formula would be:

=RiskOutput("Weld Strength (N)",,,RiskSixSigma(D82,E82,105,0,1))+

[the mathematical calculation]

Case Studies 49

Page 56

The Add Output dialog appears below:

Clicking on the properties button (fx) brings up the Output

Properties dialog with the Six Sigma tab. Here you can enter

LSL, USL, Target value, and other Six Sigma properties for

your output. These are used to calculate Six Sigma statistics.

50 Example 2 – Design of Experiments: Welding

Page 57

Simulation Results

After you run the simulation, Six Sigma statistics were generated

using @RISK Six Sigma functions for Cpk-Upper, Cpk-Lower,

Cpk, and PPM Defects (or DPM). Standard @RISK statistics

functions (like RiskMean) were also used.

The @RISK output distribution displays the expected

performance based on the design and process input variation and

shows LSL, USL, and Target value with markers. You can easily

access the output statistics using the reporting features or through

@RISK functions.

Case Studies 51

Page 58

The @RISK Sensitivity Analysis clearly shows that the Weld Time

and Amplitude parameters are driving the Weld Strength

variation.

The next steps for this problem could include two options: The

engineer can attempt to reduce or better control the variation

within the Weld Time and Amplitude, or use RISKOptimizer to

find the optimal process and design targets to maximize yield or

reduce scrap cost.

52 Example 2 – Design of Experiments: Welding

Page 59

Example 3 – Design of Experiments with Optimization

Example Model: Six Sigma DOE Opt.xls

This model demonstrates the use of RISKOptimizer in experimental

design. RISKOptimizer combines Monte Carlo simulation with

genetic algorithm-based optimization. Using these two techniques,

RISKOptimizer is uniquely capable of solving complex optimization

problems that involve uncertainty.

With RISKOptimizer, you can choose to maximize, minimize, or

approach a target value for any given output in your model.

RISKOptimizer tries many different combinations of controllable

inputs that you specify in an effort to reach its goal. Each

combination is called a “solution,” and the total group of solutions

tried is called the “population.” “Mutation” refers to the process of

randomly trying new solutions unrelated to previous trials. You can

also set constraints that RISKOptimizer must abide by during the

optimization.

For uncertain, uncontrollable factors in your model, you define

@RISK probability distribution functions. For each trial combination

of inputs, RISKOptimizer also runs a Monte Carlo simulation,

sampling from those @RISK functions and recording the output for

that particular trial. RISKOptimizer can run thousands of trials to get

you the best possible answer. By accounting for uncertainty,

RISKOptimizer is far more accurate than standard optimization

programs.

In this example, as above, the part under investigation is a metallic

burst cup manufactured by welding a disk onto a ring. The product

functions as a seal and a safety device, so it must hold pressure in

normal use, and it must separate if the internal pressure exceeds the

safety limit.

The model relates the weld strength to process and design factors,

models the variation for each factor, and forecasts the product

performance. RISKOptimizer was used to search for the optimal

combination of process settings and nominal design values to

minimize scrap cost, called Annual Defect Cost in the model. This is

the same as maximizing yield.

Case Studies 53

Page 60

The process and design variables RISKOptimizer will adjust are:

Design Variables

• Disk thickness

• Horn wall thickness

• Horn length

Process Variables

• Weld pressure

• Weld time

• Trigger point

• Amplitude

• Frequency

All in an effort to minimize the output Annual Defect Cost.

54 Example 3 – Design of Experiments with Optimization

Page 61

RISKOptimizer Toolbar

The RISKOptimizer toolbar added to Excel 2000-2003 appears below:

Model RISKOptimizer Start Reports Utilities

Settings Optimization

The RISKOptimizer toolbar in Excel 2007 appears as follows:

Case Studies 55

Page 62

The Optimization Model

Clicking on the Model Definition icon brings up the following

dialog where you define which cells to adjust, what your output

is, and what constraints to use. In addition to the inputs and

outputs described above, we will also define a constraint where

the Trigger Point must always be less than or equal to Weld Time.

56 Example 3 – Design of Experiments with Optimization

Page 63

Optimization Settings

Clicking on Optimization Settings icon brings up the following

dialog where you can set a variety of conditions for how the

optimization and simulations will run.

Case Studies 57

Page 64

Running the Optimization

When you click Start Optimization, the RISKOptimizer Progress

window appears, showing you a summary status of the analysis.

The magnifying glass button opens the RISKOptimizer Watcher

dialog, which displays more detailed information about the

optimization and simulations being run. Below you can see a

chart of simulations run and best values obtained.

58 Example 3 – Design of Experiments with Optimization

Page 65

The Summary tab displays Best, Original, and Last values calculated,

as well as parameters for the optimization like Crossover and

Mutation Rates.

The Diversity tab visually shows the different cells being calculated

and the various possible solutions.

After simulation and optimization, RISKOptimizer efficiently

found a solution that reduced the Annual Defect Cost to under

$8,000.

Using RISKOptimizer can save time and resources in a quality

improvement and cost reduction effort. The next steps for this

problem would be to validate the model and optimized solution

through experimentation.

Case Studies 59

Page 66

60 Example 3 – Design of Experiments with Optimization

Page 67

Example 4 – DFSS: Electrical Design

Example Model: Six Sigma Electrical Design.xls

This simple DC circuit consists of two voltage sources - one independent

and one dependent - and two resistors. The independent source specified

by the design engineer has an operational power range of 5,550 W + 300

W. If the power draw on the independent voltage source is outside of the

specification, the circuit will be defective. The design performance results

clearly indicate that the design is not capable of performance with a

percentage of the circuits failing on both the high and low end of the

limits. The PNC values identify the Percent of Nonconforming units

expected on the upper and lower ends of the specification.

The basic model logic follows:

Inputs

VI

VD

R1

R2

Power Supply

(Independent)

Outputs

Transfer Function

(V=IR, P=VI)

PI

Resistors

Power Supply

(Dependent)

Vs

+

R1

R2

XiVs = i

Case Studies 61

Page 68

The model calculates the standard deviation for each component

based on known information and the following assumptions within

this model:

1) The mean of the component values are centered within the

tolerance limits.

2) The component values are normally distributed. Note that

@RISK can be used to fit a probability distribution to a data

set or to model other types of probability distributions, if

needed.

A RiskSixSigma property function in the Output cell PowerDEP

defines Upper Limit, Lower Limit, and Target that are used for Six

Sigma results calculations. @RISK Six Sigma functions are used to

calculate Cpk Lower, Cpk Upper, Cpk, Cp, DPM, PNC Upper and

PNC Lower.

Sensitivity Analysis

The @RISK Sensitivity Analysis identifies the input variables driving

variation in the output. The sensitivity shows that the two voltage

sources are the main contributors to the variation in power

consumption. Armed this information, the engineering team can

focus their improvement efforts on the voltage sources instead of the

resistors.

The model can be used to test different components and tolerances,

performances and yields can be compared, and the optimal solution

can be selected to maximize yield and reduce cost.

62 Example 4 – DFSS: Electrical Design

Page 69

Example 5 – Lean Six Sigma:

Analysis of Current State –

Quotation Process

Example Model: Six Sigma Quotation Process.xls

In both Lean and Six Sigma approaches to continuous improvement,

one of the key requirements is to understand the current state of the

process under review. This is initially done in the Value Stream

Mapping phase of a Lean Implementation or in the Define and

Measure phases of the DMAIC Six Sigma process. Most practitioners

put the process together in one or more sessions and, after a cursory

review, the team moves on to generating solutions. There is

significant benefit, however to taking the time to model the process

and prove that the data and assumptions that were made are accurate.

This becomes vitally important when one or more of the following are

true:

• The process is critical to the success of the enterprise (Mission

Critical)

• There is significant denial that the process needs improvement

• Improvement costs will be significant

• The results of the continuous improvement effort may come

under significant scrutiny at a later date

• The process is subject to the Hawthorne Effect – the more we

study it, the better it gets

Simulation has the ability to prove the initial analysis of the current

state and show the true situation that the analysis team encountered.

There are three often very different processes at work in every area:

the process that we think exists; the process we have documented;

and the process that really is being carried out on a daily basis. A

carefully constructed @RISK simulation can document the actual

process and model the impact of improvements later in the

Continuous Improvement cycle. And the model is straightforward to

construct.

Case Studies 63

Page 70

Developing the Model and Collecting Data

This example focuses on the process flow of an organization’s

internal sales quotation process, and was taken from an actual

company. There are many tools used to graphically show the

process. The one we will use here is a Swimlane Chart.

The entire quotation process had over 36 individual steps and

was impacted by ten individuals or departments. Cursory data

indicated that it took up to four weeks to get the quote through

the system, yet for critical issues, quotes could be expedited

through the system in less than one week. Long quote cycletimes

prevented the company from effective bidding in often lucrative

emergency orders for their products and services. Because of the

fact that expedited quotes could be done in one quarter of the

time, management thought that the issue resided in the personnel,

not the process. The analysis team needed a tool to prove the

process was at fault.

After developing the chart, the team had a question: How long

does it take to process a quotation from the receipt of the request

to the release of the quote package to the Engineering

department? This is the first part of the process and had data that

was relatively easy to acquire, and findings here could be applied

throughout the process.

64 Example 5 – Lean Six Sigma: Analysis of Current State – Quotation Process

Page 71

This portion of the quotation process has four steps. First, the data is

collected and entered (Step A). Next, it goes into a queue for

Customer Service review (Step B). Here, corrections and additional

data are entered onto the form and tracking number assigned (Step

C). Finally the packet is put into a queue for the Engineering

department to perform the quotation activity (Step D).

The team developed a simple time sheet that captured the times that

the paperwork went from area to area, and how long it was worked

on in each step of the process. From this data, the team performed

some initial analysis of the four steps in this portion of the process.

Case Studies 65

Page 72

Building the Distributions and Defining the Output

A simple distribution of the data, for our purposes, means that

the data follows a single curve. Complex distributions are made

up of several separate distributions and are typically more

difficult to define. The data that the team gathered has both

types.

@RISK can find the distribution behind the data through the Fit

Distributions button on the toolbar. A fitted distribution can

then be entered as a distribution function in the spreadsheet.

With your data in Excel, select the Fit Distributions button and

follow the prompts. @RISK will analyze the data and check its fit

to a series of distribution functions.

For the team’s data on Step C (Review), the result from @RISK’s

distribution fitting is shown below. The resulting distribution

was then placed directly into the spreadsheet cell below the “CReview” heading using the Write to Cell button. (The team

selected the Normal distribution over the slightly better fitting

Weibull because, with a small dataset, the difference between the

two curves was acceptable.)

66 Example 5 – Lean Six Sigma: Analysis of Current State – Quotation Process

Page 73

The team continued to do this for all the distributions for each of the

four steps. Finally they set the Total Time for the four Steps A-D as

the @RISK output and ran the simulation.

The results of the simulation were revealing. The mean Total Time to

process a quote was about 1700 minutes, which is over one calendar

day. It could take anywhere from 350 minutes (almost 6 hours) to

well over 2 calendar days.

The only value-added portion of the time is the Review step. This

step took an average of 35 minutes to complete, with a range of from 6

to 64 minutes. This was reviewed with the area affected and

management, though surprised, agreed with the findings.

Statistics on Simulation Results

@RISK also allowed the team to generate basic statistics that interact

with the output cell. As an example, the team wanted to add the

mean, maximum, minimum and standard deviation of the Total Time

output cell to a table in the spreadsheet. From @RISK’s Insert

Function menu, the team selected Simulation Result in the Statistics

section. From this set, the RiskMean function was chosen. Finally the

output cell “Total Time” was selected as the argument. Now every

time the simulation is run, this cell is updated with the mean of the

Total Time.

The team repeated this for the maximum, minimum, and standard

deviation selections.

Case Studies 67

Page 74

Entering Six Sigma Functions

Next the team wanted to add the Cpk analysis of the output cell

using the @RISK Six Sigma functions. In the output cell Total

Time, they entered a RiskSixSigma function, where:

• a cell reference identified the the header cell where the name

of the output was taken

• a cell reference identified the Lower Specification Limit for

the expected result

• a cell reference identified the Upper Specification Limit for

the expected result

• a cell reference identified the Target value for the expected

result

The RiskSixSigma function was easily set up using the Output

Properties dialog (accessed by clicking the Function Properties fx

icon in @RISK’s Add/Edit Output dialog).

68 Example 5 – Lean Six Sigma: Analysis of Current State – Quotation Process

Page 75

With the output now configured, the team wanted the simulation to

calculate the @RISK Six Sigma functions of Cp, CpkUpper,

CpkLower and Cpk. This is done by inserting the correct function

(such as RiskCp, RiskCpkUpper, etc) from Six Sigma in the Statistics

section of @RISK’s Insert Function menu or by typing them into the

formula bar. These will be recalculated for every simulation.

Case Studies 69

Page 76

Graphing the Simulation Output

Through @RISK’s results graphs and Six Sigma markers showing

LSL, USL, and Target values directly on the graph, management

was surprised to see that it took, on average, over a full day to

complete 35 minutes of work. The simulation results for the Total

Time output, and for the values sampled from the input

distribution fo Step C – Review are shown below.

70 Example 5 – Lean Six Sigma: Analysis of Current State – Quotation Process

Page 77

The team could, based on the simulation, document the actual

flows and detail what happens when the quotes are not

expedited. Management saw the potential improvement if the

entire process were tracked and improved. This management

buy-in at the project onset proved to be key to the long term

success of the project.

From this initial model, the team constructed the full model for