PALFINGER PC 1500, PC 2700, PC 3800 User Manual

PALFINGER CRANE TECHNOLOGY - OUR LEADING MODELS

North America

OVERVIEW

CONTENTS

AFTERAFTERSALESSALESSUPPORTSU PORT |

4 |

|

|

FEATURESFEATURES| |BENEFITSBENEFITS |

5 |

|

|

PALFINGERPALFINGERCOMPACTCOMPACTSERIESSERIES |

|

|

|

|

PC 1500 |

8 |

|

|

PC 2700 |

9 |

|

|

PC 3800 |

10 |

|

PALFINGERPALFINGERKNUCKLEKNUCKLEBOOMBOOMCRANESCRANES

PK 3400 |

11 |

PK 4200 |

12 |

PK 5.001 SLD 1 |

13 |

PK 5.001 SLD 3 |

13 |

PK 7.001 SLD 1 |

14 |

PK 7.001 SLD 3 |

14 |

PK 8.501 SLD 1 |

15 |

PK 8.501 SLD 3 |

15 |

PK 8501 CM |

16 |

PK 9.501 SLD 5 |

17 |

PK 11.001 SLD 1 |

18 |

PK 11.001 SLD 3 |

18 |

PK 11001 CM |

19 |

PK 12.501 SLD 5 |

20 |

PK 13002 |

21 |

PK 13.501 SLD 1 |

22 |

PK 13.501 SLD 3 |

22 |

PK 14002-EH |

23 |

PK 14.501 SLD 5 |

24 |

PK 16002 |

25 |

PK 17.001 SLD 1 |

26 |

PK 17.001 SLD 3 |

26 |

PK 18002-EH |

27 |

PK 18500 |

28 |

PK 19.001 SLD 5 |

29 |

PK 19502 |

30 |

PK 22002-EH |

31 |

PK 23500 |

32 |

PK 23502 |

33 |

PK 26002-EH |

34 |

PK 30002 |

35 |

PK 32080 |

36 |

PK 33002-EH |

37 |

PK 34002-SH |

38 |

PK 37002 |

39 |

PK 40002-EH |

40 |

PK 46002 |

41 |

PK 50002-EH |

42 |

PK 63002-EH |

43 |

PK 65002-SH |

44 |

PK 76002-EH |

45 |

PK 78002-SH |

46 |

PK 88002-EH |

47 |

PK 92002-SH |

48 |

PK 100002 HPLS |

49 |

PK 110002-SH |

50 |

PK 165.002 TEC 7 |

51 |

PK 200002L-SH |

52 |

PALFINGERPALFINGERMATERIALMATERIALHANDLINGHANDLINGCRANESCRANES

PW 310 |

53 |

PW 32001 |

54 |

PW 35001-SH |

55 |

PW 38001 |

56 |

PW 38001EL |

57 |

PW 42001-SH |

58 |

PW 50001-SH |

59 |

1

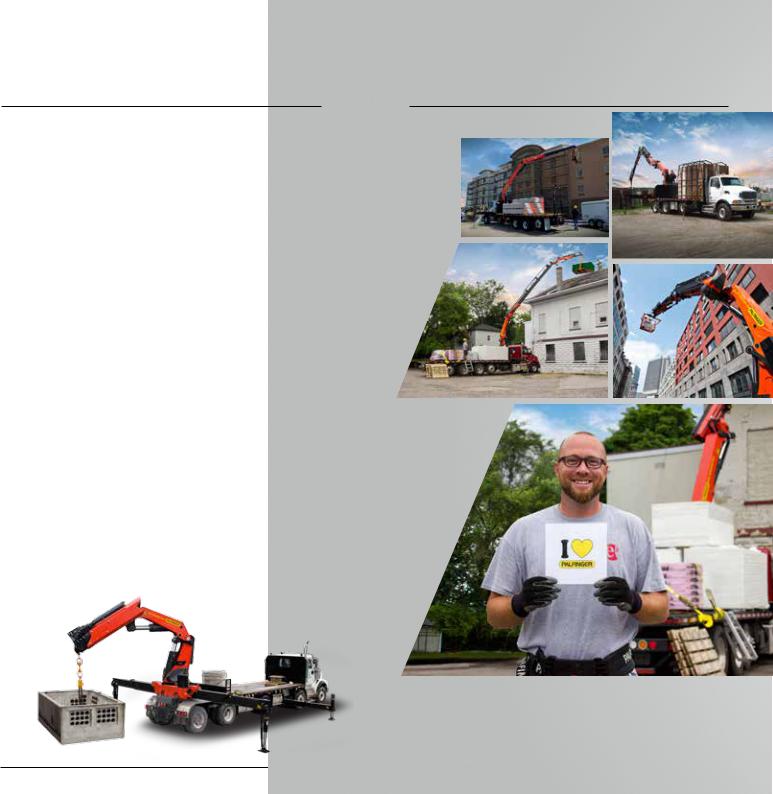

PASSION

IS OUR STRENGTH

EACH DAY BRINGS NEW CHALLENGES.

HOWEVER VARIED AND DIVERSE YOUR DAILY APPLICATIONS MAY BE - WHETHER WOOD, CONCRETE OR STEEL - THEY ALL HAVE ONE THING IN COMMON:

A STRONG PARTNER.

Your obstacles out in the field matter and that’s why we put so much passion into our equipment - to make you more successful. Our machines are more than just technology… they are the result of your experiences and our innovations – worldwide. Our products are solutions that we develop with you.

From a young age, we have instilled values that shape the relationships we trust today. From friendships, teammates, spouses and business associates, we’ve learned to carefully select who we can rely on – because without trust, what do we really have?

With PALFINGER, you’re in safe hands because we understand that trust is an earned reward. Our relationship doesn’t end with a closed sale – PALFINGER goes beyond. You can count on us, the people behind the product, because at the end of the day the most important thing that we build is your business.

We are proud to stand for the best quality on the market and we are even prouder to stand by you.

PALFINGER offers some of the lightest-weight knuckle boom cranes in the industry. With models that cover the entire range of working capacities, you can count on smoother, safer and more efficient crane operations with our Radio Remote Control, KTL protection, superior hydraulics and other features that are unique to PALFINGER. You can depend on us to add a competitive advantage to your business because we are experts in construction, building supplies, roofing, precast concrete, forming, utilities, municipalities and a variety of other industries. Plus, expert installations and service from our nation-wide dealer network gives you dependable after sales support.

PALFINGER

ON THE JOB

PALFINGER equipment is designed with your operator in mind, because when you spend most of your time with a machine, it becomes part of you. It’s about more than technology – it’s about pride and motivation.

Invest in equipment that your operator will love too.

2 |

3 |

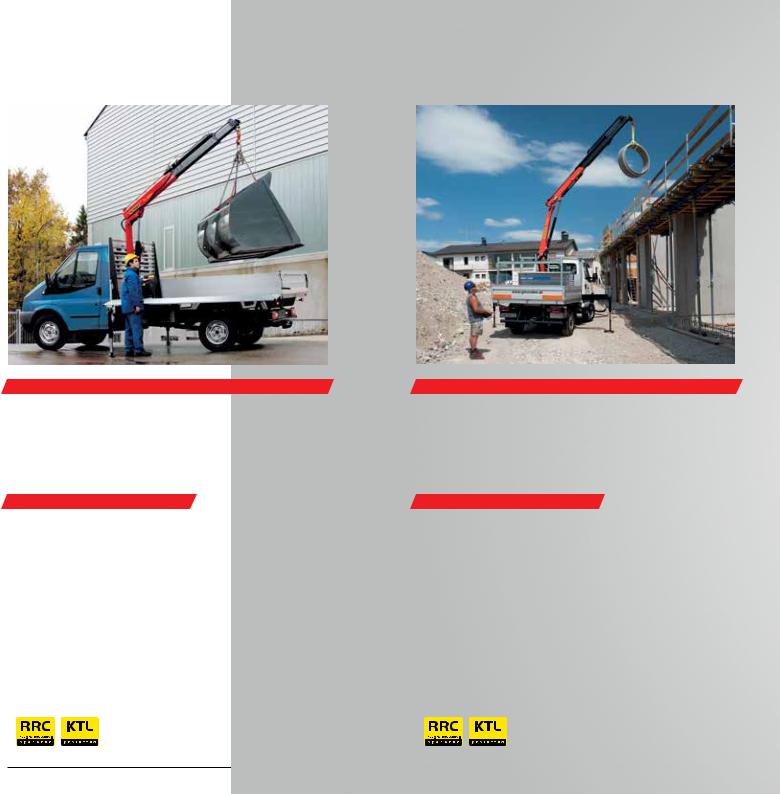

AFTER SALES

SUPPORT

PALSOFT | PALDESK

COMPLETE INFORMATION

With our customer-oriented PALSOFT software products, PALFINGER dealers and clients have access to complete information on technical product data, spare parts catalogs, user manuals, assmebly guidelines for mounting the crane on trucks, diagrams of hydrualic systems and wiring, data files on machine calibration for each and every product (PALIPEDIA), and tools for calculating axle load and stability as well as for ascertaining dimensions of auxilary frames (PacWin.NET and PAF - only applicable in certain markets). In addition, our partners also have the diagnostics software PALDIAG at their disposal.

A quick and smooth exchange of data between dealers and PALFINGER is necessary for successful teamwork. PALFINGER Paldesk offers ON- LINE-Availability of essential data. In addition to being able to order spare parts directly online, the wealth of information provided by the software PALIPEDIA is another advantage of the system.

SPARE PARTS DELIVERY

GENUINE COMPONENTS

Spare parts centers guarantee the smooth delivery of spare parts at reasonable prices, in impeccable quality and in excellent packaging - and all within 24 hours throughout North and Latin America. The North American Spare Parts Centre is located at the PALFINGER plant in Niagara Falls, Canada.

PALFINGER UNIVERSITY

QUALIFIED EXPERTS

Our service is provided exclusively by qualified and expert customer service staff, who are kept up-to-date with the current standards, latest technologies and

regulations by PALFINGER University. These state-of-the-art training centers lend themselves perfectly for contemporary and practical work sessions.

WARRANTY

A COMPREHENSIVE PLAN

è12 months full warranty on all cranes including labor at a service workshop

è36 months warranty on all structural parts on crane used for hook operation

FEATURES | BENEFITS

PALTRONIC

IN CONTROL

The PALTRONIC Overload Protection Systems are state of the art monitoring and control systems designed for PALFINGER cranes. They serve as an electronic overload protection system and control all aspects of crane operation. PALTRONIC can be optionally fitted with the following advanced systems: HPLS, AOS and SHB.

ACTIVE-OSCILLATION SUPPRESSION (AOS)

MAXIMUM PRECISION

The PALFINGER AOS system dampens the boom system of the crane, so that the crane remains nearly still even after a sudden stop of the lifting function. The system is especially useful for longer boom versions.

DUAL POWER SYSTEM (DPS)

UTILIZES FULL CAPACITY

The DPS make it possible to use the full lifting capacity of the fly-jib by using two pressure ranges on the fly-jib. Therefore, cranes with a jib combination can use the full lifting capacity of the fly-jib even at a great outreach, when the extension boom is not completely extended.

SYNCRONIZED ROPE

CONTROL (SRC)

EASE OF USE

The SRC system maintains a constant distance between the pulley head and the hook block, resulting in ease of use for the operator and improved efficiency of any operation.

RADIO REMOTE CONTROL

INFORMS THE OPERATOR

The radio control transmitter (handset) is equipped with an LED display showing how much the crane is loaded from 60% to 100% capacity. In an overload situation, it also indicates the function that has caused the overload.

KTL CATAPHORETIC DIP PAINTING

RETAINING HIGH VALUE

Innovative surface coating technology for increased quality and environmental compatibility.

Excellent corrosion protection for all components because the coating is elastic, abrasion proof and UV resistant.

HIGH PERFORMANCE

STABILITY CONTROL

OFFERS GREATER STABILITY

HPSC is an optional comprehensive stability system that uses fully proportional sensors along with our PALFINGER real data algorithm. This industry leading technology offers crane stability with fully variable stabilizer positioning.

ROPE TENSION CONTROL (RTC)

REDUCING SET-UP TIME

The new RTC system is an automatic rope tensioning device that helps to fold and unfold the crane. This innovation from PALFINGER significantly shortens the set-up time.

4 |

5 |

AFTER SALES

SUPPORT

LOW MAINTENANCE |

FLY-JIBS |

BOOM EXTENSION SYSTEM |

INCREASING APPLICATION RANGE |

EXCEPTIONAL SERVICABILITY |

|

With the low maintenance boom extensions system, PALFINGER HP cranes lead the way in ser- vice-friendliness. The use of sliding elements made from special synthetic material, together with the highly dependable KTL painting, means that the operator no longer needs to grease the boom system.

Efficient and environmentally friendly!

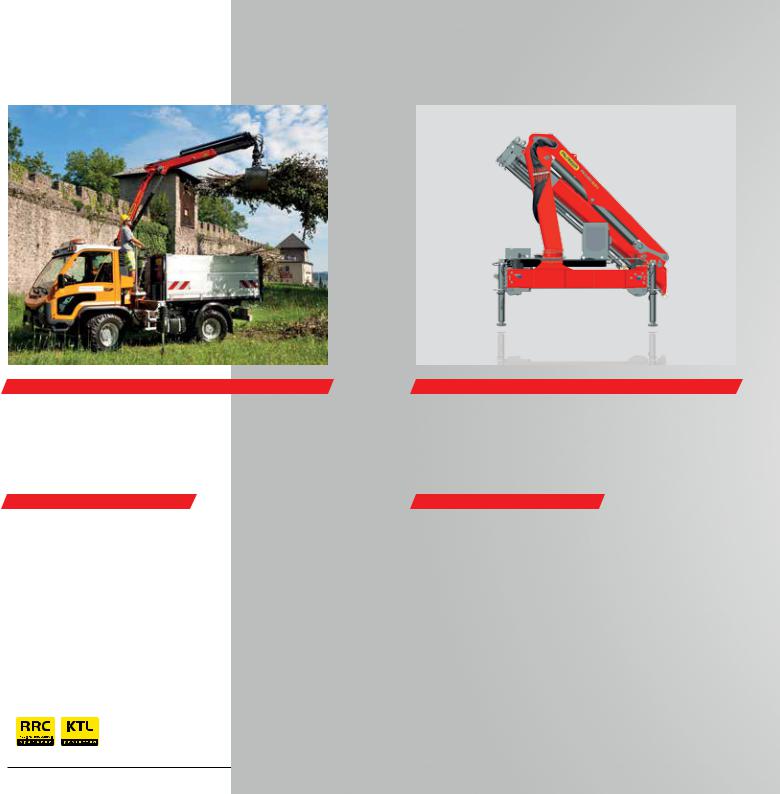

TILTABLE STABILIZER PLATES

REDUCING GROUND PRESSURE

All stabilizers come equipped with a stabilizer plate tiltable to 14° on a ball joint. Allowing the stabilizer plate to adjust for optimal ground contact, the larger plate reduces ground pressure. (For High Performance models)

POWER LINK

INCREASED LIFTING POWER

The linkage system is a special connection between the outer boom and the main boom and is used to increase lifting power at awkward angles. The PALFINGER POWER LINK system has not only the linkage on the outer boom, but also between the main boom and the crane column.

POWER LINK PLUS

BACKWARDS FOLDING BOOM

POWER LINK PLUS is a backwards folding outer boom first developed by PALFINGER.

The outer boom unfolds “backwards” up to 15° above horizontal, with full lifting power.

An additional fly-jib extends the field of activity of a crane, opening up a wider range of new applications. The same crane can be used with or without the fly-jib and is therefore is adaptable for various job applications. The fly-jib can be used with various attachments (grab, rotator) and/or a rope winch. We offer a full fly-jib range for cranes 11 meter-tons and above.

WARNING LIGHTS ON STABILIZERS

OPTIMAL VISABILITY

LED warning lights on the stabilizer rams provide better visibility of the stabilizer ram position. This increases safety for both crane operator and pedestrians. (For High Performance models)

SPIRAL HOSE

OPTIMAL PROTECTION

The highly dependable spiral hose, which protects the hydraulic hoses, is now utilized on all cranes 4 metertons and above.

Expect optimal protection of the hydraulic hoses against damage or dirt. (For HP models).

SHB

FOR GREATER SAFETY

The SHB Slewing Limitation system limits the capacity of the crane in unstable areas, like over the vehicle’s cab. It still allows the crane to work at full capacity in stable areas.

FEATURES |

BENEFITS

CONTINUOUS SLEWING |

INTERLOCK SYSTEM |

MECHANISM |

MAXIMUM SAFETY |

AN UNRESTRICTED RADIUS |

|

The PALFINGER Continuous Slewing Mechanism permits an unrestricted radius of action. The crane is rotated or “slewed” using a gear box and hydraulic motor rather than a rack and pinion system. All continuous slewing mechanisms come as standard with a high quality roller ball bearing.

OIL COOLER

LIGHT WEIGHT & COMPACT

PALFINGER oill coolers are offered from 8.5kW to 20.0kW depending on the size of the crane. They are lightweight, compact, and can be mounted directly to the crane base under a protective guard.

INTEGRAL SUBFRAME BASE

WEIGHT | HEIGHT SAVINGS

PALFINGER heavy duty cranes have, depending on their performance class as standard or optional feature, a special base that doubles as a section of subframe for the truck. Since the crane can be mounted directly to the truck chassis, the result is huge weight and height savings.

HIGH POWER LIFTING SYSTEM (HPLS)

INCREASED CAPACITY

The PALFINGER HPLS increases the capacity of a crane up to 15% with reduced operating speed.

This electronic system is controlled by the PALTRONIC safety system.

PALFINGER has developed an innovative locking mechanism for manually extended outriggers which meets the latest EN 12999 crane safety standard. The new outrigger lock has a redundancy built in, so that even if the primary locking mechanism fails, the outrigger is still prevented from sliding out during transport.

RETURN OIL UTILIZATION

EFFICIENT EXTENSIONS

RETURN OIL UTILIZATION is a regenerative hydraulic circuit for the extension booms.

It speeds up the boom extend and retract functions by up to 30%.

CABLE WINCH

INCREASED MANEUVERABILITY

The performance of the winch itself influences the efficiency of the crane to a great extent.

Our full range of winches offer an ideal possible combination in its corresponding crane class.

HYDRAULIC FLIP-UP

STABILIZER LEGS

OPTIMIZED INSTALLATIONS

The crane’s stabilizer legs can be fully tilted up 180° hydraulically. Stabilizer support of the crane is possible despite obstacles. Guard rails, walls or fences can be overcome.

6 |

7 |

PC 1500 |

PC 2700 |

|

CLASS: COMPACT |

CLASS: COMPACT |

|

|

|

|

|

|

|

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

|

TECHNICAL SPECIFICATIONS |

|

LIFTING CAPACITIES |

|||

Max. Lifting Moment |

10,020 ft. lbs |

|

Max |

2,200 lbs |

|

Max. Lifting Moment |

19, 010 ft. lbs |

|

Max |

4,400 lbs |

Max. Hydraulic Reach |

10‘ 2“ |

|

3‘ 11“ |

2,200 lbs |

|

Max. Hydraulic Reach |

16‘ 5“ |

|

4‘ 7“ |

3,950 lbs |

Max. Manual Reach |

13‘ 9“ |

|

6‘ 11“ |

1,400 lbs |

|

Max. Manual Reach |

19‘ 8“ |

|

8‘ 6“ |

2,150 lbs |

Max. Hydraulic Reach w/ Jib |

N/A |

|

10‘ 2“ |

970 lbs |

|

Max. Hydraulic Reach w/ Jib |

N/A |

|

12‘ 2“ |

1,520 lbs |

Rotation Angle |

325o |

|

13‘ 9“ |

710 lbs |

|

Rotation Angle |

325o |

|

16‘ 5“ |

1,100 lbs |

Stabilizer Spread Standard |

N/A |

|

|

|

|

Stabilizer Spread Standard |

N/A |

|

19‘ 8“ |

890 lbs |

Basic Model Weight |

360 lbs |

|

|

|

|

Basic Model Weight |

460 lbs |

|

|

|

LIFTING MOMENT (MT**) |

|

LIFTING MOMENT (MT**) |

|

A |

|

A |

B |

1.4 |

|

2.6 |

2.5 |

8 |

9 |

PC 3800 |

PK 3400 |

|

CLASS: COMPACT |

CLASS: COMPACT |

|

|

|

|

|

|

|

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

|

TECHNICAL SPECIFICATIONS |

|

LIFTING CAPACITIES |

|||

Max. Lifting Moment |

26,930 ft. lbs |

|

Max |

4,400 lbs |

|

Max. Lifting Moment |

22,430 ft. lbs. |

|

10‘ |

1,995 lbs |

Max. Hydraulic Reach |

16‘ 5“ |

|

4‘ 7“ |

4,400 lbs |

|

Max. Hydraulic Reach |

32‘ 2“ |

|

20‘ |

1,000 lbs |

Max. Manual Reach |

23‘ 4“ |

|

8‘ 6“ |

3,100 lbs |

|

Max. Manual Reach |

32‘ 2“ |

|

30‘ |

425 lbs |

Max. Hydraulic Reach w/ Jib |

N/A |

|

12‘ 2“ |

2,150 lbs |

|

Max. Hydraulic Reach w/ Jib |

N/A |

|

|

|

Rotation Angle |

325 o |

|

16‘ 5“ |

1,600 lbs |

|

Rotation Angle |

370o |

|

|

|

Stabilizer Spread Standard |

N/A |

|

19‘ 8“ |

1,280 lbs |

|

Stabilizer Spread Standard |

9‘ 6“ |

|

|

|

Basic Model Weight |

520 lbs |

|

23‘ 4“ |

620 lbs |

|

Basic Model Weight |

990 lbs. |

|

|

|

LIFTING MOMENT (MT**) |

|

LIFTING MOMENT (MT**) |

||||

A |

B |

|

STD |

A |

B |

C |

3.7 |

3.6 |

|

3.1 |

3.0 |

2.8 |

2.9 |

10 |

11 |

|

PK 5.001 SLD 1 |

PK 4200 |

PK 5.001 SLD 3 |

CLASS: PERFORMANCE |

CLASS: SOLID |

|

|

|

|

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

TECHNICAL SPECIFICATIONS |

|

||

Max. Lifting Moment |

28,220 ft. lbs |

|

10‘ |

1,995 lbs |

|

Max. Lifting Moment |

33,190 ft. lbs |

Max. Hydraulic Reach |

32‘ 2“ |

|

20‘ |

1,325 lbs |

|

Max. Hydraulic Reach |

36' 5" |

Max. Manual Reach |

32‘ 2“ |

|

30‘ |

725 lbs |

Max. Manual Reach |

42‘ 0“ |

|

Max. Hydraulic Reach w/ Jib |

N/A |

|

|

|

|

Max. Hydraulic Reach w/ Jib |

N/A |

Rotation Angle |

370o |

|

|

|

|

Rotation Angle |

400o |

Stabilizer Spread Standard |

9‘ 6“ |

|

|

|

|

Stabilizer Spread Standard |

14‘ 3" |

Basic Model Weight |

1,080 lbs |

|

|

|

|

Basic Model Weight |

1,530 lbs |

LIFTING MOMENT (MT**) |

|

LIFTING MOMENT (MT**) |

||||||

STD |

A |

B |

C |

|

STD |

A |

B |

C |

3.9 |

3.7 |

3.6 |

3.5 |

|

4.6 |

4.4 |

4.3 |

4.1 |

LIFTING CAPACITIES

10‘ |

3,230 lbs |

20‘ |

1,565 lbs |

30‘ |

860 lbs |

40' |

505 lbs |

12 |

13 |

PK 7.001 SLD 1 PK 7.001 SLD 3 CLASS: SOLID

PK 8.501 SLD 1 PK 8.501 SLD 3 CLASS: SOLID

|

|

|

|

|

|

|

|

|

|

|

|

|

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

|

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

||

|

Max. Lifting Moment |

44,500 ft. lbs |

|

10‘ |

4,430 lbs |

|

Max. Lifting Moment |

58,710 ft. lbs |

|

10‘ |

5,730 lbs |

|

Max. Hydraulic Reach |

36‘ 9“ |

|

20‘ |

2,140 lbs |

|

Max. Hydraulic Reach |

38‘ 9“ |

|

20‘ |

2,815 lbs |

|

Max. Manual Reach |

42‘ 0“ |

|

30‘ |

1,275 lbs |

|

Max. Manual Reach |

52‘ 6“ |

|

30‘ |

1,675 lbs |

|

Max. Hydraulic Reach w/ Jib |

N/A |

|

40' |

510 lbs |

|

Max. Hydraulic Reach w/ Jib |

N/A |

|

40' |

910 lbs |

|

Rotation Angle |

400o |

|

|

|

|

Rotation Angle |

400o |

50' |

700 lbs |

|

|

Stabilizer Spread Standard |

14‘ 3" |

|

|

|

|

Stabilizer Spread Standard |

16‘ 0" |

|

|

|

|

Basic Model Weight |

1,650 lbs |

|

|

|

|

Basic Model Weight |

2,320 lbs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LIFTING MOMENT (MT**) |

|

LIFTING MOMENT (MT**) |

||||||

STD |

A |

B |

C |

|

STD |

A |

B |

C |

6.2 |

6.0 |

5.8 |

5.6 |

|

8.1 |

7.9 |

7.6 |

7.4 |

14 |

15 |

PK 8501 CM |

PK 9.501 SLD 5 |

|

CLASS: HIGH PERFORMANCE |

CLASS: SOLID |

|

|

|

|

|

|

|

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

TECHNICAL SPECIFICATIONS |

|

|

LIFTING CAPACITIES |

|||

Max. Lifting Moment |

60,180 ft. lbs |

|

10‘ |

5,100 lbs |

|

Max. Lifting Moment |

65,050 ft. lbs |

|

10‘ |

6,470 lbs |

Max. Hydraulic Reach |

32‘ 6“ |

|

20‘ |

3,075 lbs |

|

Max. Hydraulic Reach |

38‘ 9“ |

|

20‘ |

3,080 lbs |

Max. Manual Reach |

N/A |

|

30‘ |

1,395 lbs |

|

Max. Manual Reach |

52‘ 6“ |

|

30‘ |

1,875 lbs |

Rotation Angle |

390o |

|

40‘ |

N/A |

|

Max. Hydraulic Reach w/ Jib |

N/A |

|

40‘ |

1,060 lbs |

Stabilizer Spread Standard |

13' 0“ |

|

50‘ |

N/A |

Rotation Angle |

400o |

|

50‘ |

680 lbs |

|

Basic Model Weight |

2,425 lbs |

|

|

|

|

Stabilizer Spread Standard |

16‘ 0“ |

|

|

|

|

|

|

|

|

|

Basic Model Weight |

2,380 lbs |

|

|

|

LIFTING MOMENT (MT**) |

|

LIFTING MOMENT (MT**) |

|||||

STD |

A |

B |

|

STD |

A |

B |

C |

8.3 |

8.1 |

7.8 |

|

9.0 |

8.7 |

8.5 |

8.2 |

16 |

17 |

Loading...

Loading...