Palfinger ILF 33, ILF 55, ILF 44 Installation Manual

ILF 33 – 3300 lbs. Capacity

ILF 44 – 4400 lbs. Capacity

ILF 55 – 5500 lbs. Capacity

INSTALLATION MANUAL

& CHECK-OFF SHEET

09/16

ILF 33/44/55 Installation Manual

Palfinger Liftgates ILF 33/44/55 Installation Manual

Document Part Number: 90-0815-000 / 15-696_90-00_00-00

ECN-M0819, Rev. 1.1, 09-14-16

Copyright © 2016 Palfinger Liftgates LLC.

All rights reserved.

Information in this document is subject to change without notice.

Visit www.palfinger.com for up to date information and notifications.

If you received this product with damaged or missing parts,

contact Palfinger Liftgates at (888)-774-5844

Parts Order

liftgateparts@palfinger.com

Technical Support

technicalapplications@palfinger.com

PALFINGER Liftgates, LLC.

15939 Piuma Ave.

Cerritos, CA 90703

Tel (888)-774-5844

Fax (562)-924-8318

PALFINGER Liftgates, LLC.

572 Whitehead Road.

Trenton, NJ 08619

Tel (609)-587-4200

Fax (609)-587-4201

Rev 1.1 2

ILF 33/44/55 Installation Manual

Table of Contents

1 Manual Updates for v1.1 .......................................................................................................... 5

2 Safety Information ................................ ................................................................ .................... 6

3 Important Information .............................................................................................................. 7

Important Dimensions ................................................................................................... 9 3.1

Recommended Tools .................................................................................................... 9 3.2

4 Dimension Sheet ...................................................................................................................... 10

5 General Overview of ILF Liftgate ............................................................................................. 12

6 Chassis and Body Preparation ................................................................................................ 14

Installation Dimensions ................................................................................................. 14 6.1

Chassis Cut Out ILF 33 ................................................................................................. 15 6.2

6.2.1 Installation Dimensions ILF 44 and ILF 55 ....................................................... 16

Chassis Cut Out ILF 44/55 ................................ ............................................................ 17 6.3

Frame Cap ................................................................ .................................................... 18 6.4

Bed Extension Installation ............................................................................................. 20 6.5

Dock Bumper Installation – Weld On (Optional) ............................................................ 22 6.6

7 Liftgate Installation (Truck) ...................................................................................................... 24

Installation ..................................................................................................................... 24 7.1

8 Liftgate Installation (Trailer) ..................................................................................................... 30

Installation ..................................................................................................................... 30 8.1

Operation of B-15 Sensor ............................................................................................. 34 8.2

Operation of B-13 Sensor ............................................................................................. 35 8.3

9 Electrical Installation ................................................................................................................ 36

Wire Crimping ............................................................................................................... 37 9.1

Circuit Breaker Installation ............................................................................................ 38 9.2

Cable Routing ............................................................................................................... 39 9.3

Main Power Connections .............................................................................................. 40 9.4

On-Off Switch Installation (Truck Application) ............................................................... 41 9.5

On-Off Switch Installation (Trailer Application) .............................................................. 42 9.6

Remote Hand Control Installation ................................................................................. 44 9.7

Foot Control Installation (Optional) ................................................................................ 46 9.8

Electrical Schematic ...................................................................................................... 48 9.9

Control Board Codes .................................................................................................... 49 9.10

Rev 1.1 3

ILF 33/44/55 Installation Manual

10 Lubrication ................................................................................................................................ 50

11 Hydraulic Schematic ................................................................................................................ 51

12 Decal Placement and Inspection ................................ ............................................................. 52

13 Final Inspection Check List ................................ ..................................................................... 54

Company Information:

Company Name:

Advisor Name:

Trailer Year Make & Model:

Liftgate Information:

Liftgate Serial Number:

Liftgate Model Number:

Date of Purchase:

Date of Installation:

Rev 1.1 4

ILF 33/44/55 Installation Manual

1 Manual Updates for v1.1

Updated Section 7.8: Foot control installation

Updated Section 8.2: Decal placement

Rev 1.1 5

ILF 33/44/55 Installation Manual

2 Safety Information

This manual follows the guidelines set forth in “ANSI Z535.4-2007” for alerting you to possible

hazards and their potential severity.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

! DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

! WARNING indicates potentially hazardous situation which, if not avoided, could result in death or

serious injury.

! CAUTION indicates a potentially hazardous situation which, if not avoided, may result minor or

moderate injury.

CAUTION without the safety alert symbol is used to address practices not related to personal

injury. (In this manual we use it to alert you to potentially hazardous situation which, if not avoided,

may result in property damage.)

NOTICE without the safety alert symbol is used to address practices not related to personal injury.

(In this manual we use it to alert you to special instructions, steps, or procedures.)

Rev 1.1 6

ILF 33/44/55 Installation Manual

3 Important Information

Before Getting Started

“READ FIRST”

The ILF liftgate is a heavy duty industrial hydraulic lifting device. Performance and reliability

are closely related to proper installation, battery cable connections, and grounding. All

grounding surfaces MUST be cleaned, prepped, and sealed per this manual. “Cut to size”

cables MUST be properly crimped and sealed as factory supplied. All connections MUST be

dressed with dielectric grease or equivalent sealer.

Review lift gate invoice, packing slip, and installation drawing to assure delivery of correct gate

and complete delivery of accessories and optional equipment.

Read and understand the “Installation Manual” and “Owner’s Manual” in their entirety before

starting your Installation.

Refer to your truck manufacturer’s instructions before adding any auxiliary equipment. Installer is

responsible for compliance with this manual, OEM and FMVSS requirements.

All welding should be performed by qualified personnel per AWS standards.

Always Ground closest to your welding point to prevent arcing through moving parts or electrical

parts.

Contact PALFINGER Liftgates for Special Installations not covered in this Installation Manual.

Do not paint cylinder shafts or nylon bearings (Use non-chlorinated brake cleaner to remove over

spray)

Final Check-Off-Sheet at rear of this manual MUST be filled out and kept in your records for

future reference.

Refer to owner’s manual for Operation and Maintenance information.

Check the battery voltage before installation. Flooded lead acid batteries should measure 12.6V

and AGM batteries should measure 12.8V. If batteries are not at these voltages, fully charge

before installation

Rev 1.1 7

ILF 33/44/55 Installation Manual

Improper operation of this liftgate may result in severe personal injury or death. DO NOT

operate unless you have been properly instructed, have read and are familiar with the

procedures in this manual. This manual has been designed to illustrate the steps needed for

the basic installation of the ILF liftgate. It also provides safety information and simple

preventive maintenance tips.

This manual is not intended for use as a repair or troubleshooting guide. Repairs should be

performed by a Palfinger Liftgates Authorized Service Center.

This manual has been designed for use in conjunction with the ILF series liftgates only which is

designed for different capacities. There are four options to determine the model and serial number of

the installed liftgate:

1) Refer to the serial number tag on the liftgate (Top of Mount Frame).

2) Ask your employer or lessor;

3) Call your PALFINGER Liftgates Authorized Service Center for assistance.

4) Call PALFINGER Liftgates for assistance in the USA at 888-774-5844. You can also contact

PALFINGER Liftgates by fax (562) 924-8318 or on the internet at www.palfinger.com

For technical support, contact PALFINGER Liftgates or an authorized PALFINGER service center.

www.palfinger.com

Rev 1.1 8

ILF 33/44/55 Installation Manual

Metric Wrench Set

Basic Screwdrivers

Pliers

Wire Crimp Pliers

Digital Multimeter

Snap Ring Pliers

Hammer

Metric Allen Set 1.5mm-10mm

½” Impact & Sockets

Sm. Metric Socket Set

Assorted Drill Bits

Floor Jack or Equiv.

Sm. To Med. Bottle Jack

Forklift or O/H Crane

Hand Held Grinder

Paint Gun

Cutting Torch or Equiv.

3/8 Drill Motor

Pry Bar

Heat Gun or Equiv.

Min. 250 Amp Welder

Important Dimensions 3.1

Minimum Bed Height dimensions are ALWAYS MAXIMUM LOADED TRUCK.

Maximum Bed Height dimensions are ALWAYS DRY UNLOADED TRUCK.

Installing a gate at or close to minimum bed height normally results in a gate that will NOT open

and close from stored position if the minimum floor height is exceeded when truck is loaded.

Ensure trailer body does not interfere with installation or operation of the ILF liftgate series.

It is not recommended to cut, torch, or remove support materials from trailer. Removing gussets,

stiffeners, light rings, or other such support structures may VOID your trailer warranty.

Call technical support before starting the installation if any questions or concerns arise on

mounting dimensions or procedures.

Mounting Notes:

Read and clearly understand manual BEFORE beginning ANY work.

The basic rule of PALFINGER Liftgates‟s ILF installation is to lift mount frame

to achieve MAXIMUM ground clearance WITHOUT exceeding Min “F” dimension.

Recommended Tools 3.2

Rev 1.1 9

ILF 33-44-55 Installation Manual

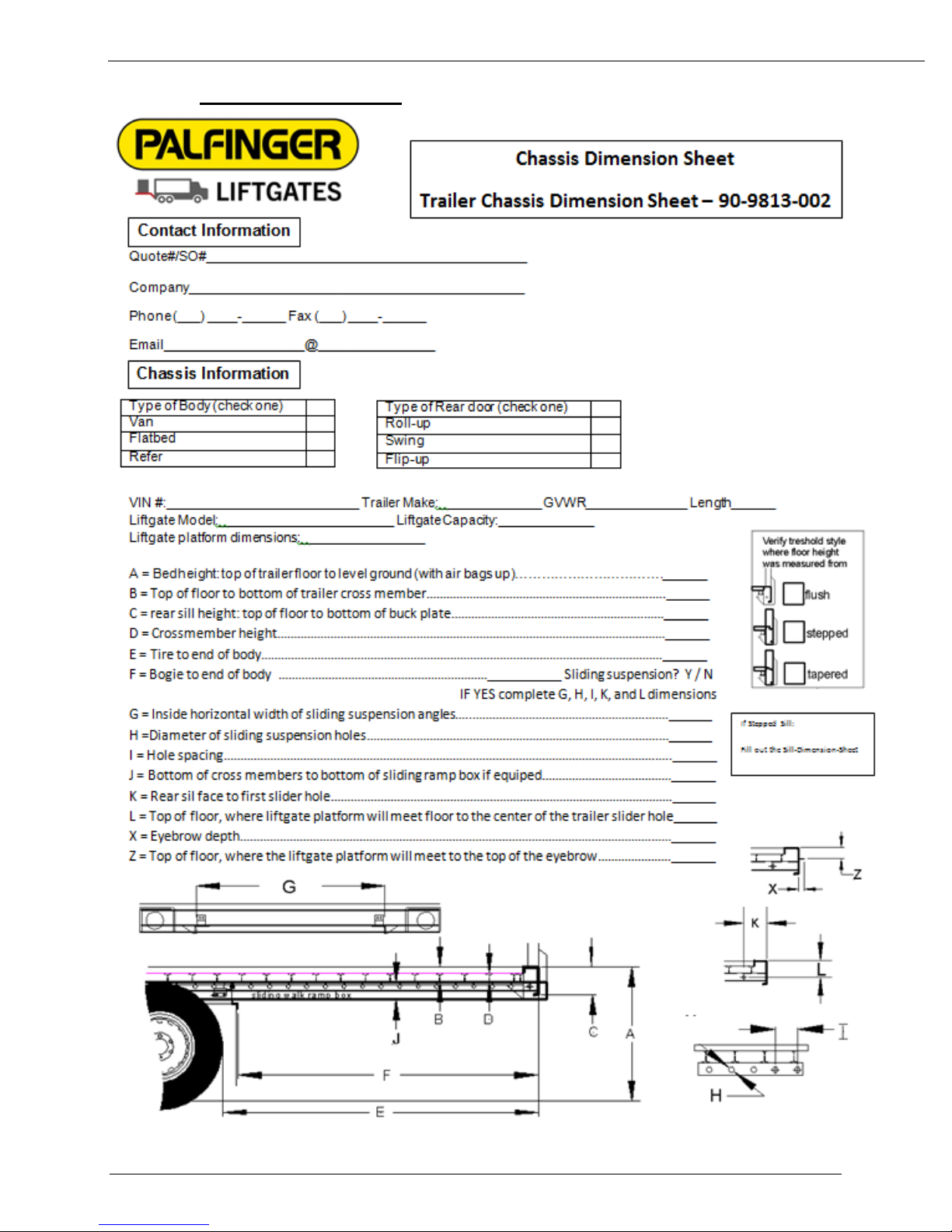

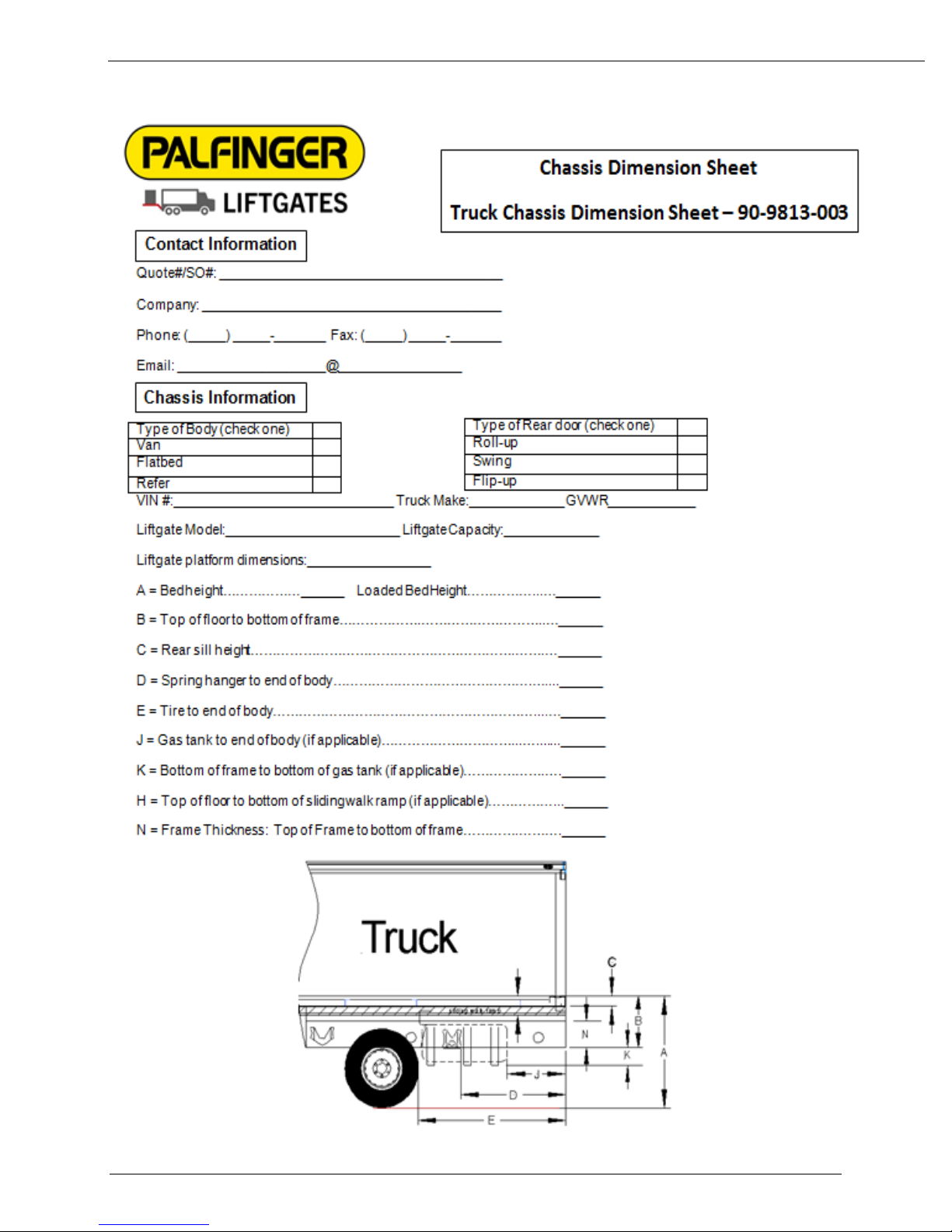

4 Dimension Sheet

Rev 1.1 10

ILF 33-44-55 Installation Manual

Rev 1.1 11

ILF 33/44/55 Installation Manual

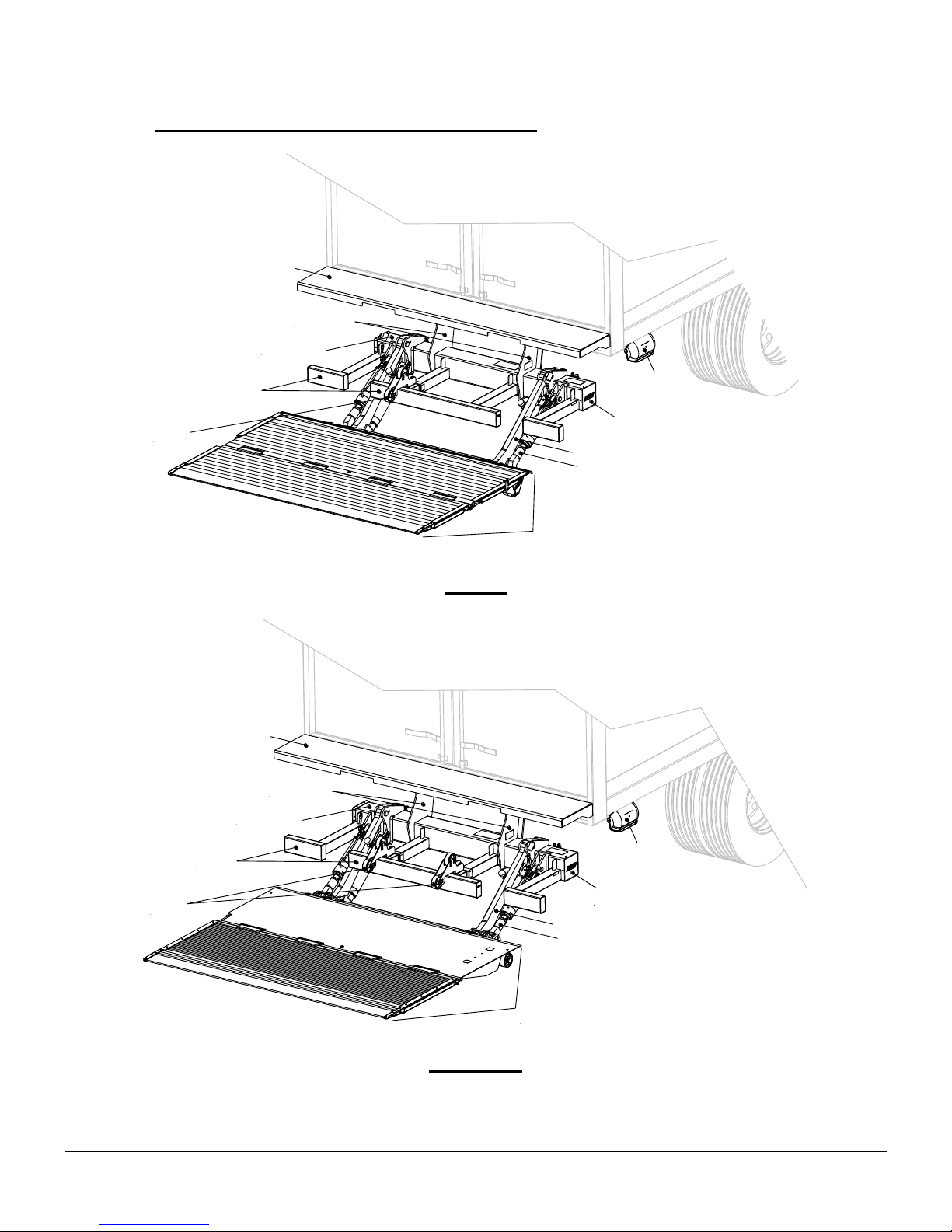

Bumper

Bed

Extension

Mount Frame

Tilt Arm

Lift Arm

Control

Box

Hydraulic

Power Unit

Aluminum

Platform

Mount Plates

Parting

Wheel

Bumper

Bed

Extension

Mount Frame

Tilt Arm

Lift Arm

Control

Box

Hydraulic

Power Unit

Steel/Aluminum

Platform

Mount Plates

Parting

Wheels

5 General Overview of ILF Liftgate

ILF 33

ILF 44/55

Rev 1.1 12

ILF 33/44/55 Installation Manual

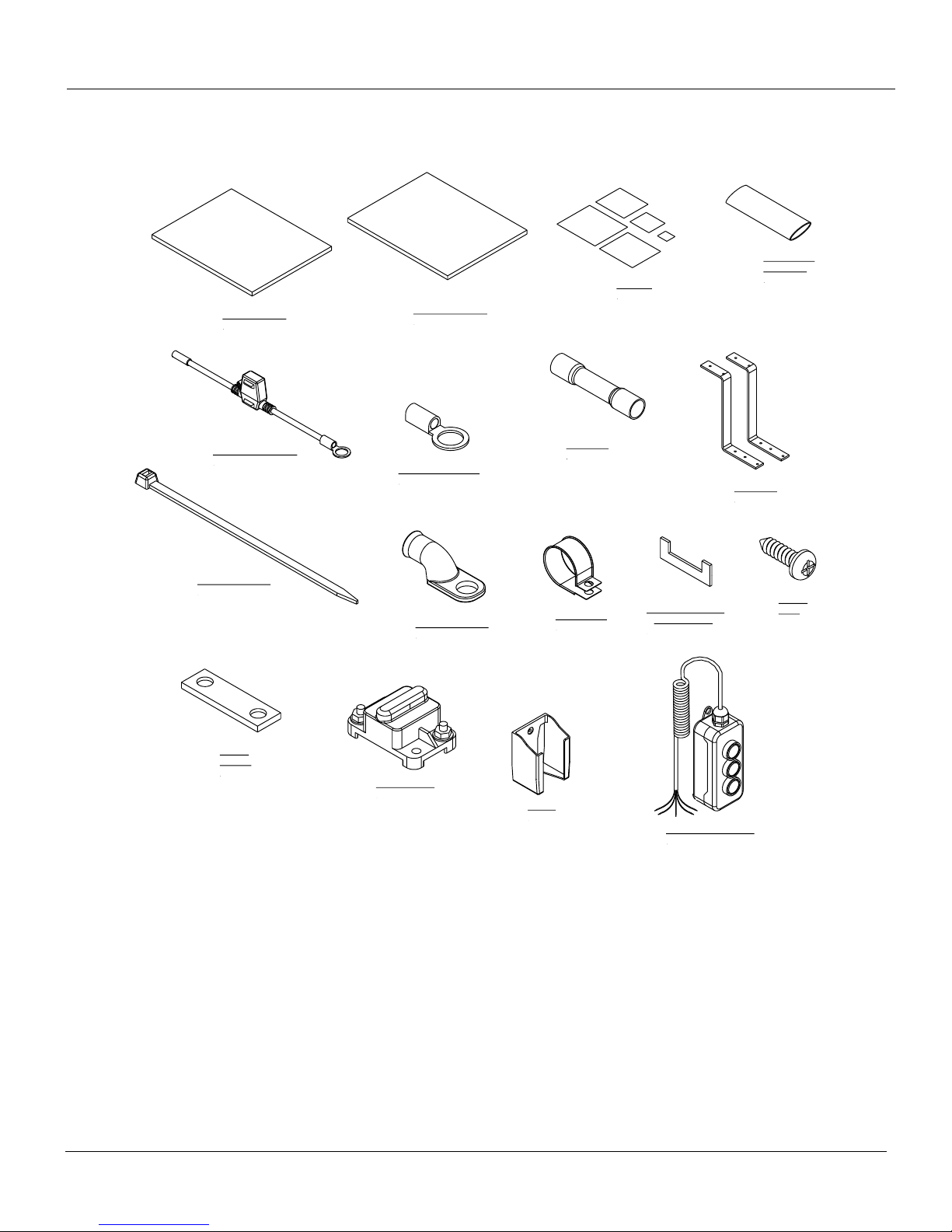

In-Line Fuse, 20 Amp

1 pcs

Heat Shrink,

ø1/2" x 3"L

1 pc

Copper

Bus Bar

1 pc

Circuit Breaker

1 pc

Owner's Manual

1 pc

Installation Manual

1 pc

Battery Lug, 5/16"

1 pc

Decal Kit

15 pcs

8" Nylon Cable Tie

12 pcs

Ring Connector, 3/8"

1 pc

Butt Splice

1 pcs

Holster

1 pc

3-Button Hand Control

1 pc

Cable Clamp

5 pcs

Screws

2 pcs

Mount Plate Gusset

Only for ILF 55

2 pcs

Z-Brackets

2 pcs

Boxed Items Included with Liftgate for Installation

Rev 1.1 13

ILF 33/44/55 Installation Manual

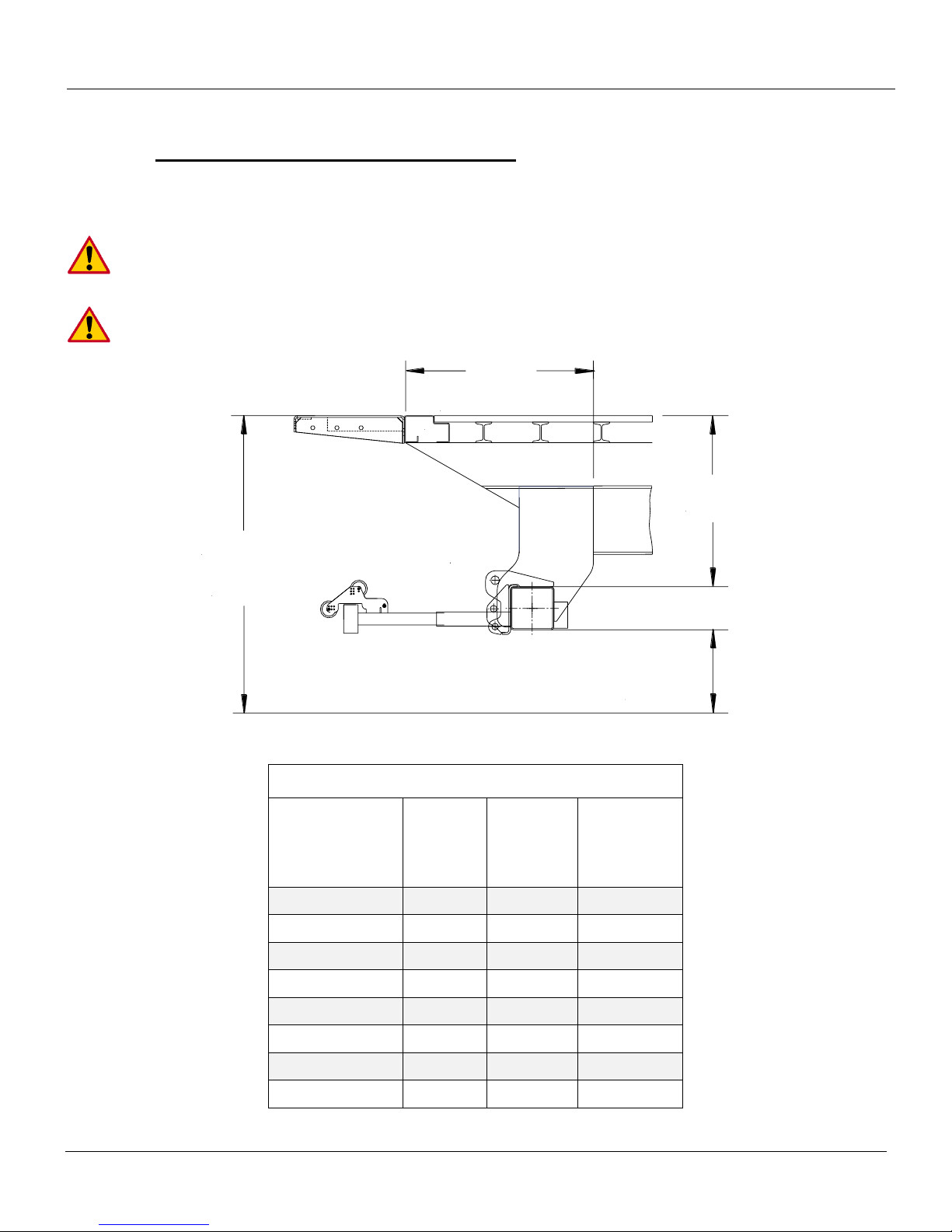

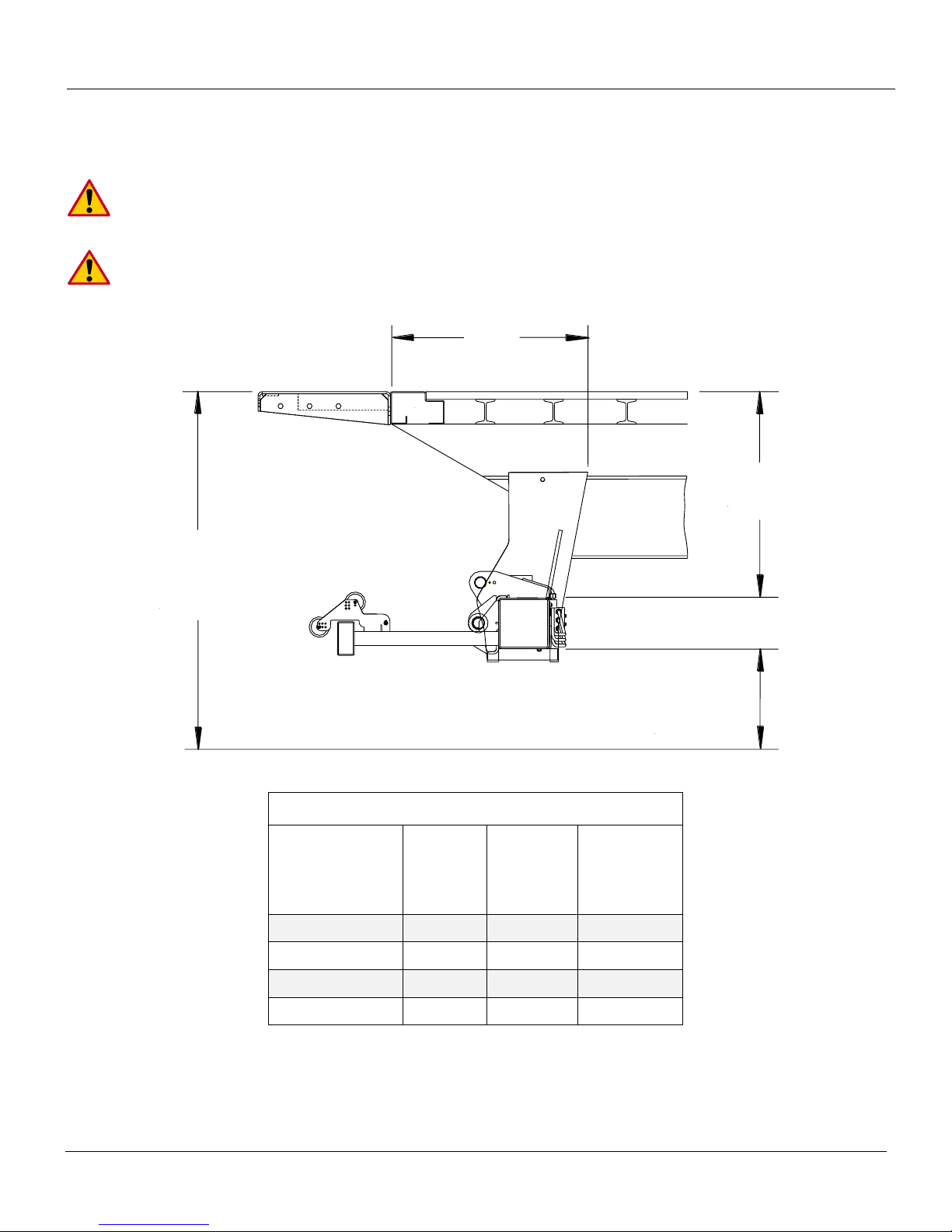

"K"

Mount Clearance

(Reference)

"F" Dim.

Bed Height

Max. 62"

Min. 46"

"G"

Ground

Clearance

Sill

ILF 33 Mounting Dimension Table

Bed Height

(Loaded)

F

Dim.

G

Dim.

K

Dim.

(Ref.)

62“

33“

20“

29“

58“

32“

19“

30“

56“

31“

18“

31“

54“

30“

17“

31.5“

52“

29“

16“

32.5“

50“

28“

15“

33“

48“

27“

14“

34“

46“

26“

13“

35“

6 Chassis and Body Preparation

Installation Dimensions 6.1

IMPORTANT:

Always use the smallest F-dim possible for best ground clearance

(Don‟t exceed max. ground clearance)

Minimum bed height is when truck/trailer is loaded to MAX GVW

Rev 1.1 14

ILF 33/44/55 Installation Manual

22"

12"

18"

13"

21"

12"

17"

13"

Assuming 26" F-Dimension

Assuming 27" F-Dimension

Assuming 28" F-Dimension

Cut

Assuming 29" F-Dimension

Assuming 30" F-Dimension

Assuming 31" F-Dimension

Assuming 32" F-Dimension

Assuming 33" F-Dimension

Cut

Cut

Cut

Spacer

Bed Extension

Sill

(Over 4"

in Height)

Chassis

Cut

Fig. 1

Fig. 2

Chassis Cut Out ILF 33 6.2

These dimensions are starting points due to variation of installations. The final dimensions

may vary depending on actual installation F-Dim.

1. Determine the correct frame cut out according to your specific bed height. With long overhangs it is

even more important to maintain min F = Max ground clearance, Fig. 1.

2. If the vehicles sill measures more than 4” in height, add a spacer to the rear of the vehicle, Fig. 2.

The spacer will shift the bed extension back allowing the platform to clear the bottom of the sill when

it is in stored position. Reference cutout dimensions from Step 1 to determine the chassis cutout.

Rev 1.1 15

ILF 33/44/55 Installation Manual

"K"

Mount Clearance

(Reference)

"F" Dim.

Bed Height

Max. 55"

Min. 50"

"G"

Ground

Clearance

Sill

ILF 44/55 Mounting Dimension Table

Bed Height

(Loaded)

F

Dim.

G

Dim.

K

Dim.

(Ref.)

55“

28“

19.5“

26“

54“-53“

27“

19“

27“

52“-51“

26“

18“

28“

50“

25“

17“

29“

6.2.1 Installation Dimensions ILF 44 and ILF 55

IMPORTANT:

Always use the smallest F-dim possible for best ground clearance

(Don‟t exceed max. ground clearance)

Minimum bed height is when truck/trailer is loaded to MAX GVW

Rev 1.1 16

ILF 33/44/55 Installation Manual

22"

12"

18"

13"

21"

12"

17"

13"

Assuming 26" F-Dimension

Assuming 27" F-Dimension

Assuming 28" F-Dimension

Cut

Assuming 29" F-Dimension

Assuming 30" F-Dimension

Assuming 31" F-Dimension

Assuming 32" F-Dimension

Assuming 33" F-Dimension

Cut

Cut

Cut

Spacer

Bed Extension

Sill

(Over 4"

in Height)

Chassis

Cut

Fig. 3

Fig. 4

Chassis Cut Out ILF 44/55 6.3

These dimensions are starting points due to variation in installations. The final dimensions

may vary depending on actual installation F-Dim.

3. Determine the correct frame cut out according to your specific bed height. With long overhangs it is

even more important to maintain min F = Max ground clearance, Fig. 3.

4. If the vehicles sill measures more than 4” in height, add a spacer to the rear of the vehicle, Fig. 4.

The spacer will shift the bed extension back allowing the platform to clear the bottom of the sill when

it is in stored position. Reference cutout dimensions from Step 1 to determine the chassis cutout.

Rev 1.1 17

Loading...

Loading...