Paladin Tools Hydraulic Windrow Sweepers AH, Hydraulic Windrow Sweepers RLH, Hydraulic Windrow Sweepers CH User Manual

51-3849, 5/26/06 1

QC Series

AH, CH, RLH , RLCH & Loader

Hydraulic Windrow Sweepers

Sweepster Serial Number__________________ Manual Number: 51-3849

Release Date: May 26,2006

800-456-7100 www.paladinbrands.com Sweepster 2800 N. Zeeb Rd., Dexter, MI 48130 United States of America

2 51-3849, 5/26/06

51-3849, 5/26/06 3

Table of Contents

Section 1 ... Installation.................................................... 5-19

Section 2 ... Operation and Maintenance...................... 21-30

Section 3 ... Service ........................................................ 31-35

Section 4 ... Parts............................................................ 37-68

Section 5 ... Options ....................................................... 69-7 8

Section 6 ... Appendix .................................................... 79-86

4 51-3849, 5/26/06

51-3849, 5/26/06 5

Installation Manual

QC Series Angle Brooms

Table of Contents

Introduction...............................................................6

Safety Information............................................... 7-12

General Safety Information..................................... 7-8

Safety Signs & Labels ........................................10-11

Product Information Section .................................... 12

AH/CH ................................................................. 13-16

Pump /T ank Mounting............................................. 13

Swing/Brush Head Mounting................................... 14

Swing/Lift Mounting ................................................ 15

Adjusting Scissor Swing ......................................... 16

Loader ..................................................................... 17

Installation/Storage ................................................. 17

RLH/RLCH ......................................................... 18-201

Swing Assembly ..................................................... 18

Brush Head Assembly/Angle Feature ................ 19-20

6 51-3849, 5/26/06

SAFETY SECTION

INTRODUCTION

Introduction

Importance of this Manual

Read this manual before attempting to operate

the equipment.

This operator’s manual should be regarded as part of the

sweeper. Suppliers of both new and secondhand sweepers

are advised to keep documentation indicating that this

manual was provided with the sweeper.

The manual contains information regarding installation,

operation and maintenance required for this sweeper and

optional equipment. It also includes detailed parts lists.

Purpose of Sweeper

This sweeper is designed solely for use in construction

cleanup, road maintenance, grounds maintenance and

similar operations. Use in any other way is considered

contrary to the intended use. Compliance with and strict

adherence to operation, service and repair conditions, as

specified by the manufacturer, are also essential elements of

the intended use.

Contacting SWEEPSTER

If you have any questions about information in this manual or

need to order parts, please call, write, fax or e-mail

SWEEPSTER.

SWEEPSTER

2800 North Zeeb Road

Dexter, Michigan 48130

Phone: (734) 996-91 16 - (800) 456-7100

FAX: (734) 996-9014

e-mail: sweepster@paladinbrands.com

For help with installation, operation or maintenance

procedures, contact our Technical Service Department. Direct

product questions and parts orders to our Sales Department.

When ordering parts or accessories, be prepared to give the

following information:

•Sweeper model, serial number and date of

purchase

•Prime mover, make and model

•Part number, description and quantity

This sweeper should be operated, serviced and repaired

only by persons who are familiar with its characteristics and

acquainted with relevant safety procedures.

Accident prevention regulations, all other generally

recognized safety regulations and all road traffic regulations

must be observed at all times.

Any modifications made to this sweeper may relieve the

manufacturer of liability for any resulting damage or injury.

Safety Alert Symbol

This safety alert symbol indicates important safety

messages in this manual. When you see this

symbol, be alert to the possibility of injury. Carefully read the

message that follows and inform other operators.

Terms Used in Manual

Right-hand, left-hand, front and rear are determined from the

operator’s perspective (either the operator’s seat or standing

behind a walk-behind unit), facing forward in the normal

operating position.

Prime mover refers to the tractor, truck, loader or tow vehicle

that the sweeper is mounted on or towed by.

Optional Equipment

Installation instructions for optional equipment, if applicable,

appear in the Service Manual Section.

Specifications & Features

Due to continuous product improvement, specifications and

features may change without notice.

Warranty

To validate the warranty for this unit, fill out the warranty card

or warranty pages located at the back of this manual. Then,

send this information to SWEEPSTER.

51-3849, 5/26/06 7

SAFETY SECTION

GENERAL SAFETY INFORMATION

•Check prime mover tire pressure before sweeping.

Safety Information

Read this manual

Read all safety information in this manual. All

operators must read and understand the entire

contents of this manual before sweeping. General

safety practices are listed on Safety Information

pages and specific safety

information is located throughout this manual.

Hazard Definitions

•Check tire ratings to be sure they match the prime

mover load. Weigh the sweeper end of the prime

mover, if necessary, to insure proper tire rating.

•Remove from the sweeping area all property that

could be damaged by flying debris.

•Be sure all persons not operating the sweeper are

clear of the sweeper discharge area.

•Always wear proper apparel such as a long-sleeved

shirt buttoned at the cuffs; safety glasses, goggles

or a face shield; ear protection; and a dust mask.

Four hazard classifications are used in this manual. They are

DANGER - Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING -Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION -Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

CAUTION - Used for instructions when machine damage

may be involved.

Operation

CAUTION - A sweeper is a demanding machine.

Only fully trained operators or trainee

operators under the close supervision

of a fully trained person should use

this machine.

Before operating sweeper:

While operating sweeper:

•When operating sweeper, adhere to all govern ment

rules, local laws and other professional guidelines for

your sweeping application.

WARNING - Never raise the sweeper more than a

few feet off the ground. The sweeper

can tip back or the prime mover can

tip over causing death or serious

injury,

•Before leaving the operator’s area for any reason, lower

the sweeper to the ground. Stop the prime mover

engine, set the parking brake and remove the key from

the ignition.

•Minimize flying debris - use the slowest rotating speed

that will do the job. See Operation Section: Operating

Tips

•Keep hands, feet, hair and loose clothing away from all

moving parts.

•Leave the brush hood (shield) and all other shields and

safety equipment in place when operating the sweeper

and prime mover.

•Be aware of the extra weight and width a sweeper adds.

Reduce travel speed accordingly. See Product

Information Section: Operating the Sweeper.

•Learn sweeper and prime mover controls in an off-road

location.

•Be sure that you are in a safe area, away from traffic or

other hazards.

•Check all hardware holding the sweeper to the prime

mover, making sure it is tight.

•Replace any damaged or fatigued hardware with

properly rated fasteners. See Maintenance Section

•Make sure all hydraulic hardware and hydraulic fittings

are tight.

•Replace any damaged or fatigued fittings or hoses.

•When sweeping on rough terrain, reduce speed to avoid

“bouncing” the sweeper. Loss of steering can result.

•Never sweep toward people, buildings, vehicles or other

objects that can be damaged by flying debris.

•Only operate the sweeper while you are in the operating

position. The safety restraint must be fastened while

you operate the prime mover. Only operate the controls

while the engine is running. Protective glasses must be

worn while you operate the prime mover and while you

operate the sweeper.

•While you operate the sweeper slowly in an open area,

check for proper operation of all controls and all

protective devices. Note any needed repairs during

operation of the sweeper. Report any needed repairs.

8 51-3849, 5/26/06

SAFETY SECTION

GENERAL SAFETY INFORMATION

Service & Repair - General

CAUTION - Do not modify the sweeper in any way.

Personal injury could result. If you have

questions, contact your dealer or

SWEEPSTER.

Repair or adjust the sweeper in a safe area, away from

traffic and other hazards.

Before adjusting or servicing - lower the sweeper to the

ground, set parking brake, shut down the prime mover

and remove the key from the ignition.

When working on or around the sweeper, safely secure it

from falling or shifting.

Service & Repair - Hydraulic Safety

Stop the prime mover engine and release hydraulic pressure

before servicing or adjusting sweeper hydraulic systems.

WARNING - Escaping hydraulic fluid can have

enough pressure to penetrate the skin,

causing serious personal injury.

Check lines, tubes and hoses carefully. Do not use your

hand to check for leaks. Use a board or cardboard to check

for leaks. Tighten all connections to the recommended

torque. See Appendix.

Do not bend high pressure lines. Do not strike high pressure

lines, Do not install bent lines, bent tubes, or kinked hoses.

Do not install damaged lines, damaged tubes, or damaged

hoses.

Repair loose lines, loose tubes, and loose hoses. Repair

damaged lines, damaged tubes, and damaged hoses.

Leaks can cause fires. See your SWEEPSTER dealer for

repair or replacement parts.

Replace the parts if any of the following conditions are

present:

•The end fittings are damaged or leaking.

•The outer covering is chafed or cut.

•The reinforcing wire layer is exposed.

•The outer covering is ballooning locally.

•The hose is kinked or crushed.

•The armoring embedded in the outer cover.

•The hoses have been pulled or stretched.

Make sure that all clamps, guards, and shields are installed

correctly.

51-3849, 5/26/06 9

Notes

10 51-3849, 5/26/06

SAFETY SECTION

SAFETY SIGNS & LABELS

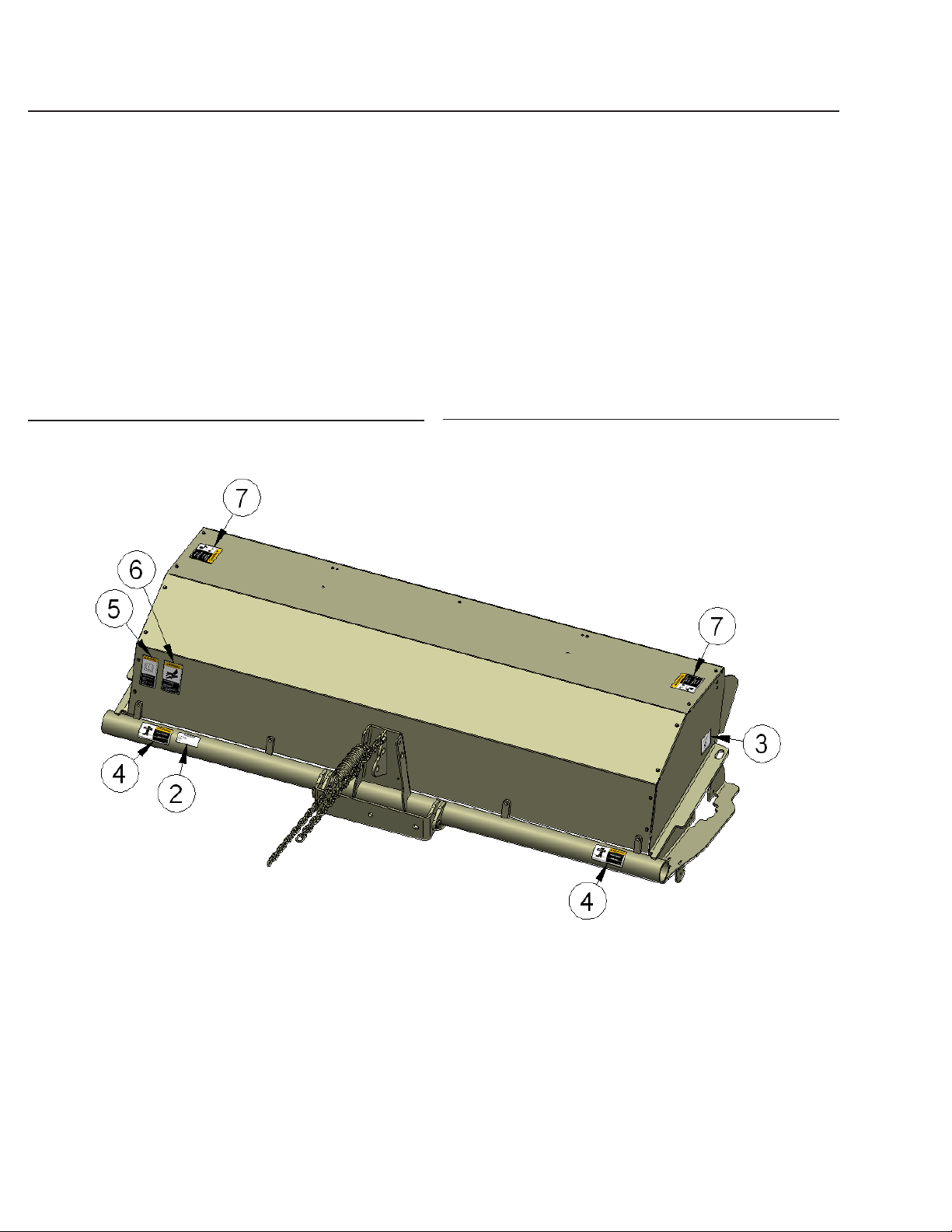

Safety Signs and Labels

There are several specific safety signs on this sweeper. The

exact location of the hazards and the description of the

hazards are reviewed in this section.

Placement or Replacement of Safety Signs

1. Clean the area of application with nonflammable solvent,

and then wash the same area with soap and water.

2. Allow the surface to fully dry.

3. Remove the backing from the safety sign, exposing the

adhesive surface.

4. Apply the safety sign to the position shown in the diagram

above and smooth out any bubbles.

Instructions

• Keep all safety signs clean and legible.

• Replace all missing, illegible, or damaged safety

signs.

• Replacement parts, for parts with safety signs

attached, must also have safety signs attached.

• Safety signs are available, free of charge, from your

dealer or from SWEEPSTER.

Item Part Qty Description

2. 50-0634 1 Label, Serial Number

3. 50-0643 2 Label, Tie Down Point

4. 50-0721 2 Label, Warning, Crush Hazard

5. 50-0722 1 Label, Warning, Misuse Hazard

6. 50-0725 1 Label, Warning, High Pressure Fluid Hazard

7. 50-0726 2 Label, Warning, Flying Objects & Entanglement

51-3849, 5/26/06 11

SAFETY SECTION

SAFETY SIGNS AND LABELS

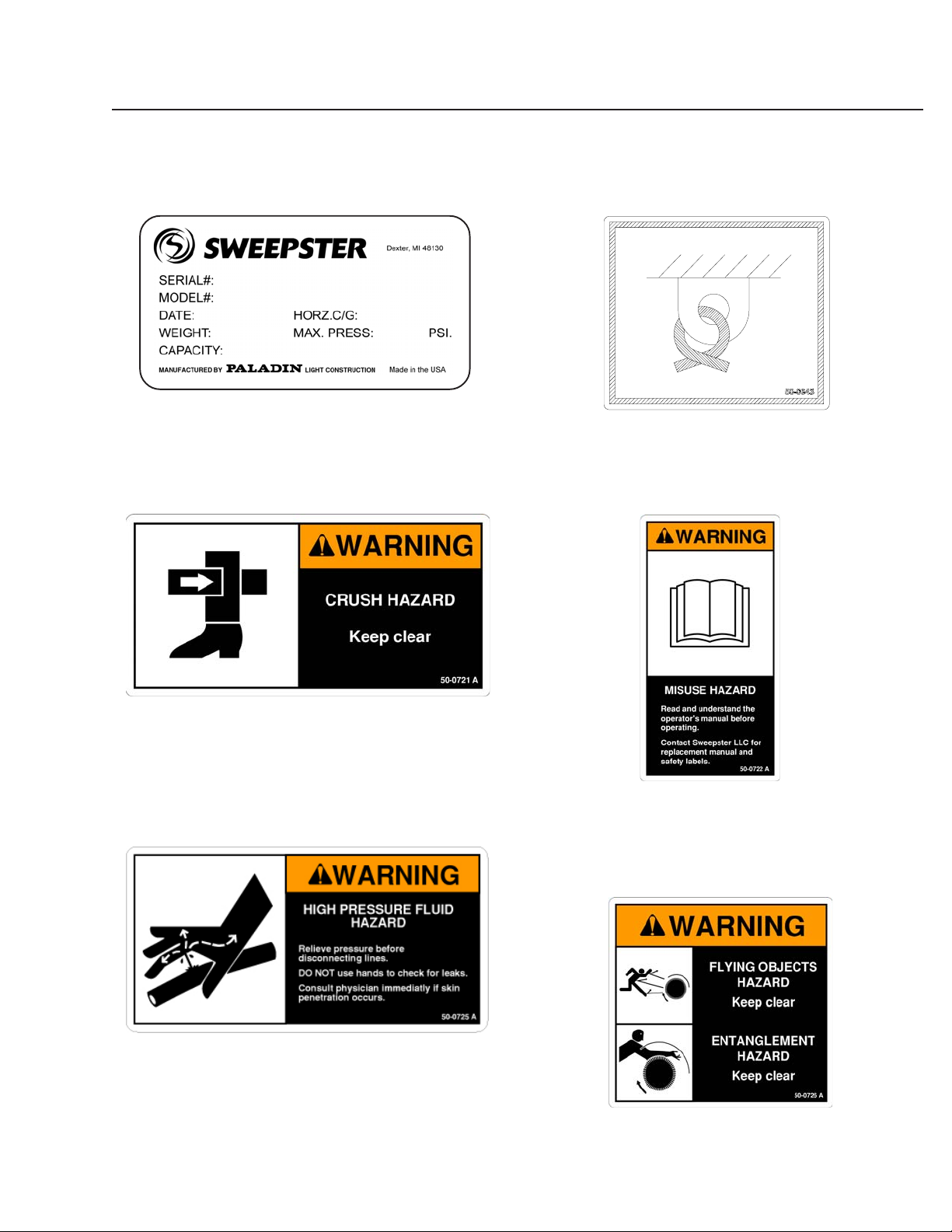

Safety Signs and Labels

2. 50-0634

4. 50-0721

3. 50-0643

5. 50-0722

6. 50-0725

7. 50-0726

12 51-3849, 5/26/06

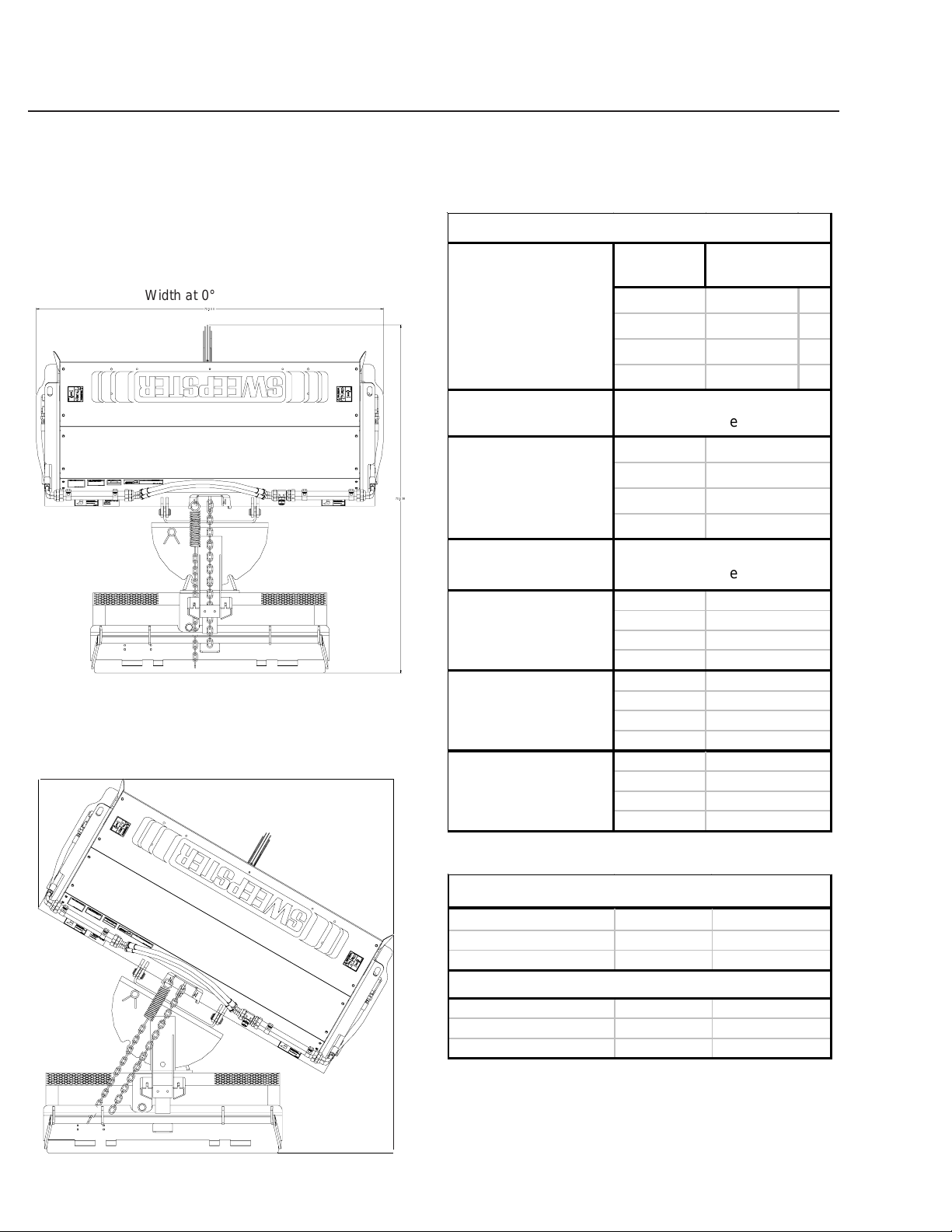

t

t

t

t

5 Ft

Varies

5 Ft

8 Ft

7 Ft

6 Ft

8 Ft

7 Ft

Maximum Width at Full

6 Ft

5 Ft

8 Ft

7 Ft

6 Ft

Varies

OPERATION SECTION

PRODUCT SPECIFICATIONS

Product Information

Section

Specifications and Model

Views

Width at 0° Articulation

Width at Full Articulation

123722

Appro xim at e Weig ht

(Brush Head Onl y)

Max im um Lengt h at 0°

Length at 0° Articulation Length at Full Articulation

Articulation

Maximum Width at 0°

Articulation

123456

Maximum Length at

Full Articulation

Articulation

Sweeping W i dt h at 0°

Articulation

Sweeping W i dt h at F ull

Articulation

QC Brush Head

Single Motor

Dual Motor

383 lbs 419 lbs 5 F

442 lbs 480 lbs 6 F

505 lbs 543 lbs 7 F

572 lbs 612 lbs 8 F

(Mounting Dependent)

70.5 inches

82.5 inches

94.5 inches

106.5 inc hes

5 Ft

6 Ft

7 Ft

8 Ft

(Mounting Dependent)

72 inches

82 inches

93 inches

103 inches

60 inches

72 inches

84 Inches

96 inches

54 inches

64 inches

75 inches

85 inches

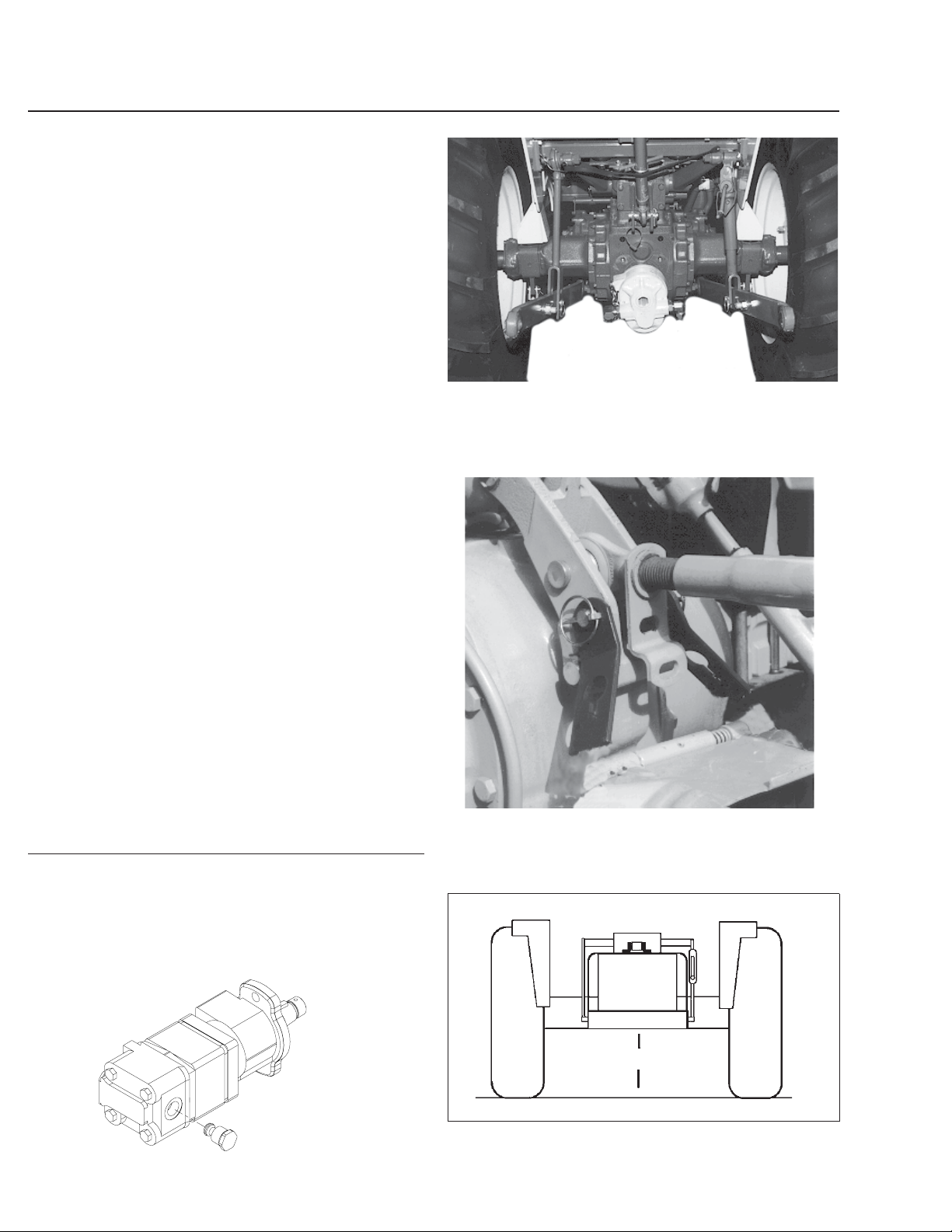

Range of Hydraulic Oil Fl ow

Si ngle Motor 18 cubic inc h 10-18

Si ngle Motor 25 cubic inc h 12-25

Dual M otor 18 c ubi c inch 18-3 6

Maxim um Hydraul ic Oi l P ress ure

Singl e Motor 18 cubic i nch 3500 psi

Singl e Motor 25 cubic i nch 3000 psi

Dual Motor 18 cubi c i nc h 3500 psi

51-3849, 5/26/06 13

Mounting, Pump & T ank Assemblies

NOTE - The following give general instructions. Refer to

instructions included with the mounting assembly for

information specific to a particular prime mover make

and model.

Front Pump Units

1. Remove any parts, such as a knockout, that block access

to the tractor engine’s crankshaft pulley.

2. Attach the mounting assembly to the tractor.

3. Secure the drive hub to the pulley. Some tractors require a

crankshaft adapter.

4. Install the pump mounting bracket on the front of the

tractor. Position the pump so the inlet faces the right-hand

side of the unit. Do not secure with hardware.

5. Assemble the coupling halves and fasten the chain

around them.

6. Apply grease to the pump and drive shafts.

7. Slide the coupling assembly onto the pump shaft.

INSTALLATION SECTION

AH/CH

Rear Pump Units

1. Install the mounting assembly on the tractor.

2. Attach the pump to the rear PTO shaft and secure it

with the chain provided. This prevents the pump from

spinning on the shaft.

CAUTION - Avoid damage to the pump and other

hydraulic components. Do not use rear pump

drive on PTOs faster than 540 RPM.

3. Install the tank and valve assembly.

4. Install hydraulic fittings and hoses.

a. Attach the barb fitting to the pump inlet and the

adapter fitting to the pump outlet.

b. Connect the suction hose to the tank outlet and

to the barb fitting on the pump inlet. Secure

with clamps.

c. Attach the pressure hose to the valve and the

pump’s outlet port. Tighten fittings.

8. Place the keyed end of the drive shaft in the chain coupler.

9. Slide the drive shaft into the drive hub.

10. Fasten the pump to the bracket.

11. Center the chain coupler and tighten set screws.

12. Install the tank and valve assembly.

13. Install hydraulic fittings and hoses.

a. Attach the barb fitting to the pump inlet and the

adapter fitting to the pump outlet.

b. Connect the suction hose to the tank outlet and to the

barb fitting on the pump inlet. Secure with clamps.

c. Attach the 36 inch hose to the valve and the pump’s

outlet port. Tighten the fittings.

14. Go to Swing Assembly.

5. Go to Swing Assembly.

14 51-3849, 5/26/06

INSTALLATION SECTION

AH/CH

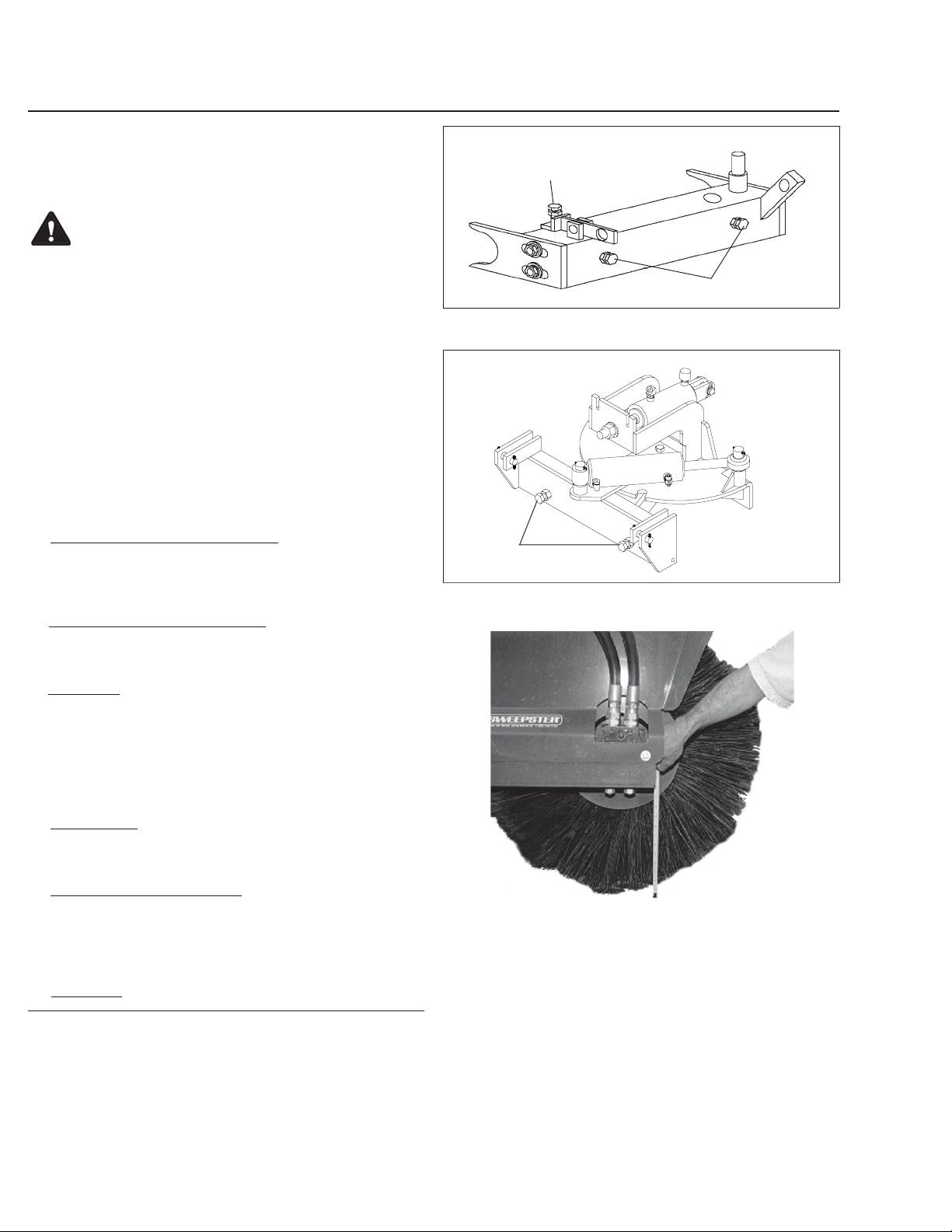

Swing Assembly

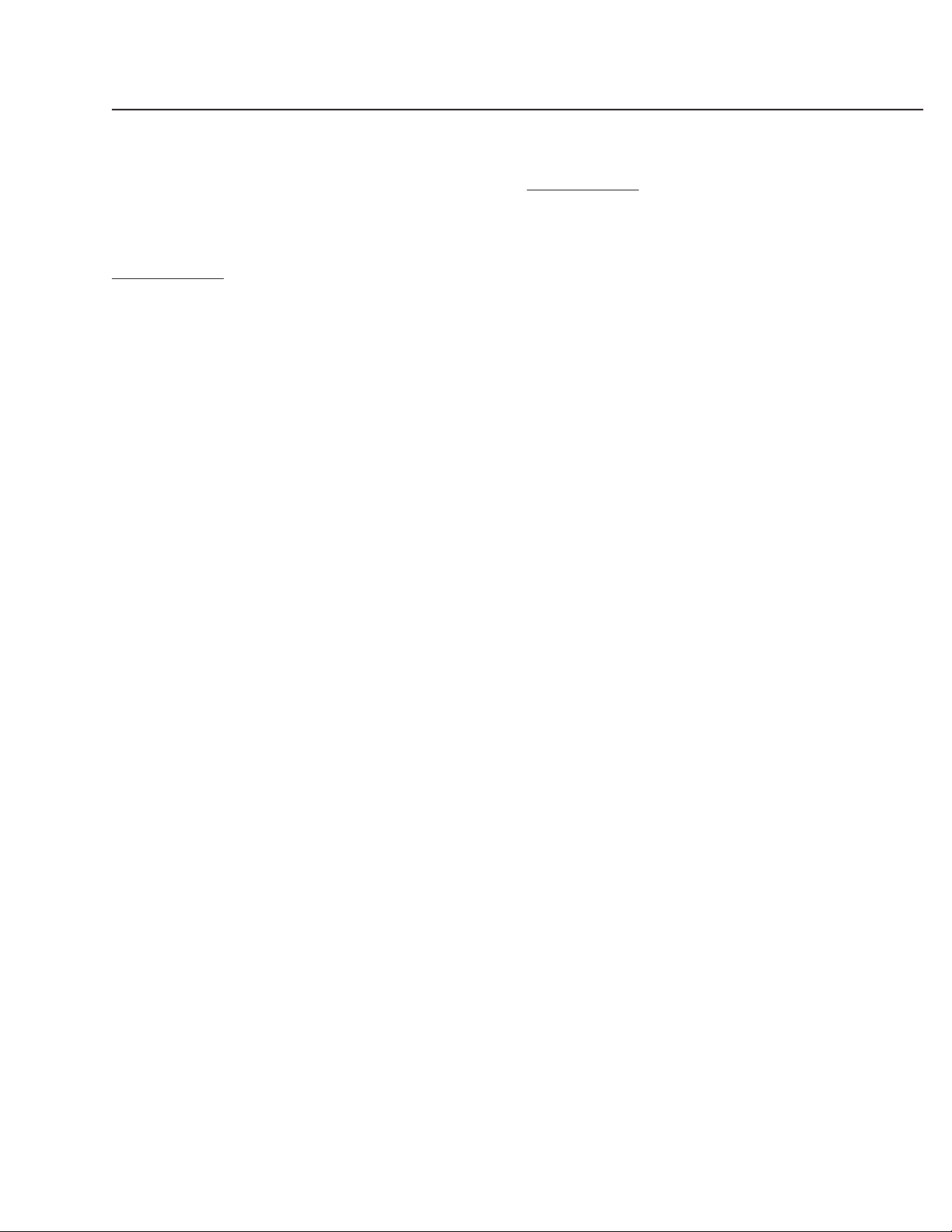

Figure 1 shows the swing assembly attached to the mounting

assembly.

1. Position the swing assembly in front of the mounting

assembly. Remove the pin(s) from the swing assembly.

2. Align holes in the swing assembly with ears on the

mounting assembly. Slide pin(s) through the holes and

secure with cotter pin(s).

3. Go to Brush Head Assembly.

Brush Head Assembly

1. Position the brush head assembly in front of the swing

assembly.

2. Align holes in the brush frame and swing assembly.

Install hardware, using the cap screw in the center hole

and carriage bolts in the remaining holes.

3. Align the brush head plate with the swing assembly plate

and tighten the hardware.

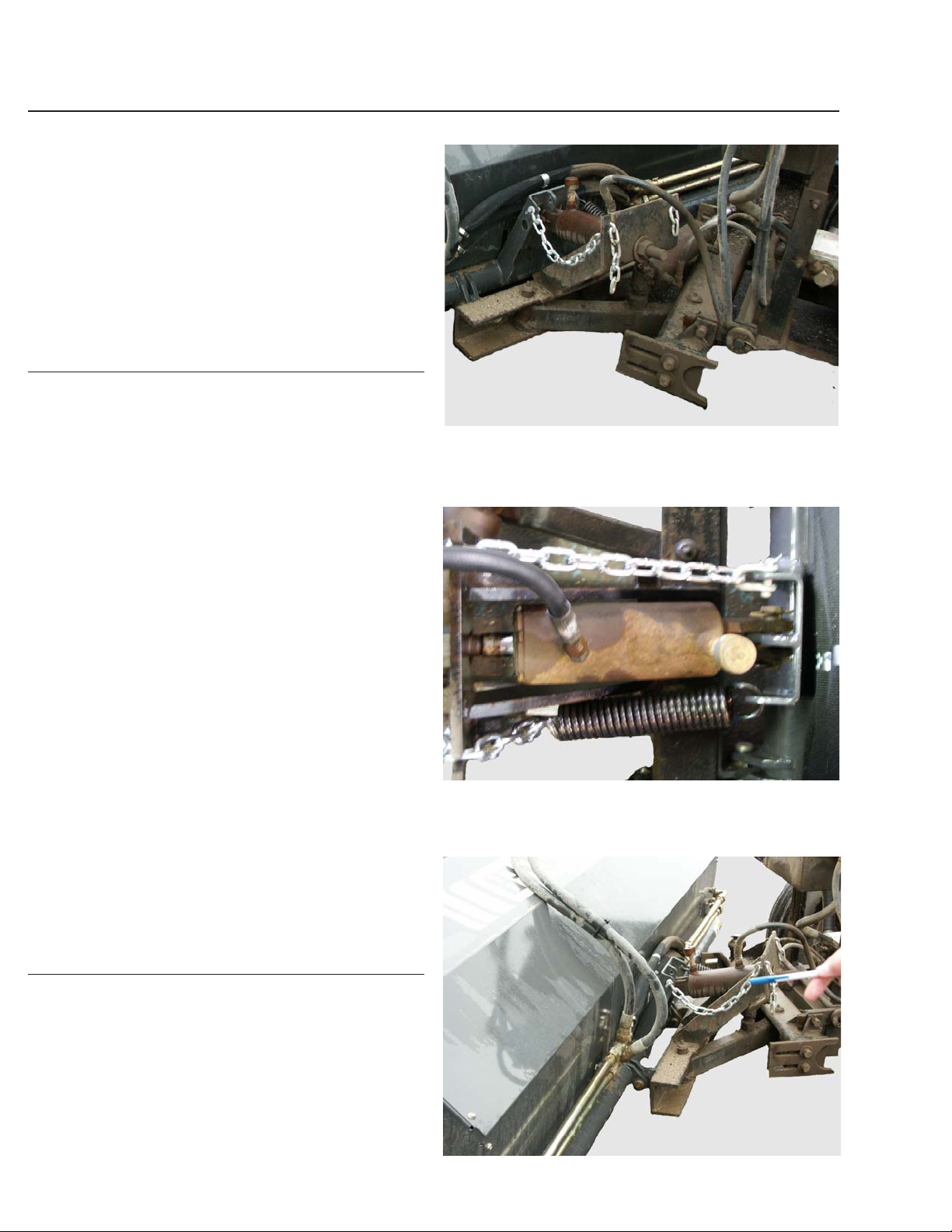

4. Assemble the spring-chain assembly/assemblies. Attach

the spring end(s) to the brush head upright. Then place

the chain in a slot on the swing plate upright. Figure 2

shows a spring-chain assembly installed on the unit.

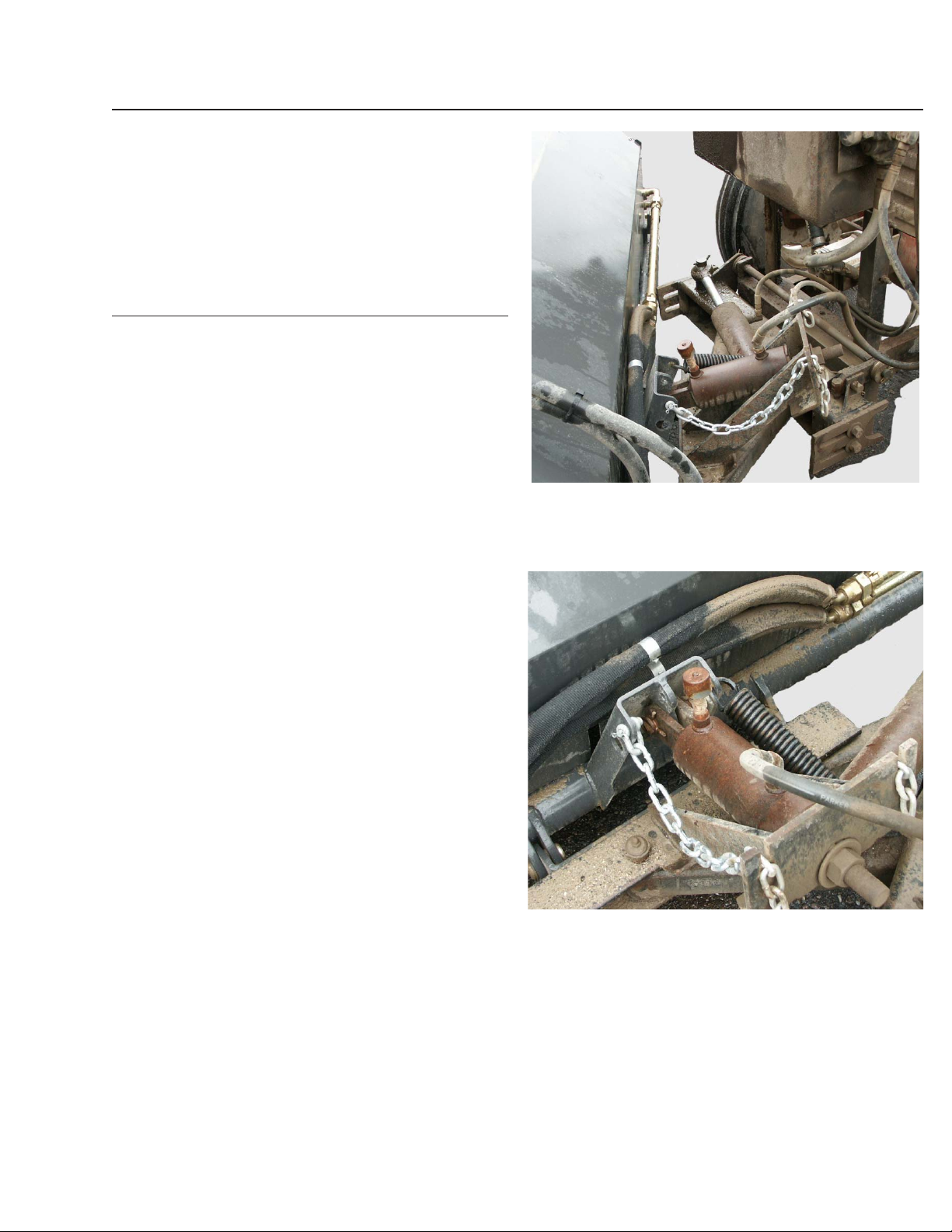

5. Connect the transport chain, which is attached to brush

head upright, to the remaining slot on the swing plate

upright. Figure 3 shows a transport chain installed.

NOTE - Use the transport chain to take weight off the spring-

chain assembly/assemblies while transporting the unit

between job sites.

6. Attach 2, 3/4 inch hoses to brush head tubes. Then,

connect the top hose “T” to the filter base and the bottom

hose ”P” to the run port on the valve.

figure 1

figure 2

NOTE: CH units with manual valves should first move “T”

fitting to left side tubes as shown in figure 3. This

will provide enough hose length to make the proper

connection.

figure 3

51-3849, 5/26/06 15

INSTALLATION SECTION

AH/CH

Swing Cylinder

Figure 4 shows the cylinder fully installed.

1. Connect a hose to each fitting on the cylinder.

2. Attach adapter fittings to hose ends.

3. Connect adapter fittings to remote valves (manual

valves) or the Up port (electric valves).

Lift Cylinder

Figure 5 shows the lift cylinder fully installed.

1. Slide the rod end of the cylinder through the plate on

the swing plate upright. Install flat washer and secure

with a nut.

CAUTION - Avoid cylinder damage. Only place 1 nut on

the rod.

2. Attach the barrel end to the center ear on the brush

head upright. Use the clevis pin and hairpin clip

provided.

3. Connect a hose to the elbow fitting on the cylinder.

4. Connect the hose to the first valve that has a single

port (manual valves) or the L port (electric valves).

figure 4

figure 5

16 51-3849, 5/26/06

INSTALLATION SECTION

AH/CH

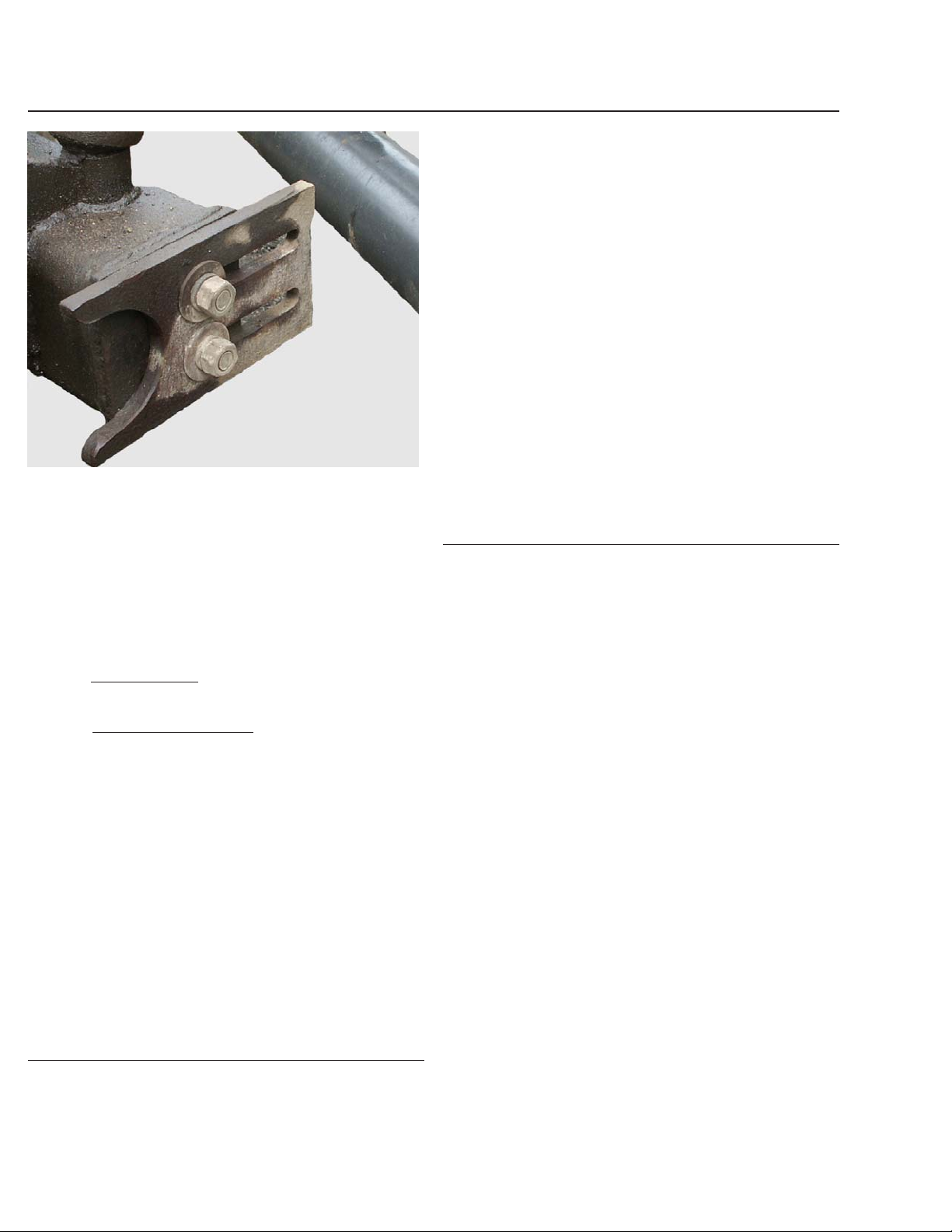

Adjusting Scissor Swing

CAUTION - Support yokes must fit tightly to the brush

frame, or damage to the swing cylinder will

occur.

1. Loosen hardware holding support yokes.

2. Swing the brush head completely to the right.

3. Slide the right-hand support yoke toward the brush head

until it is snug on the brush frame tube, tighten nuts.

4. Swing the brush head completely to the left.

5. Slide the left-hand support yoke until it is snug on the

brush frame tube, tighten nuts.

6. Swing the brush head assembly both directions and

Figure 6

check to make sure that the support yokes fit tightly to the

brush frame. If not, repeat this procedure from step 1.

Before First Use

1. Fill the tank to 2 inches (51mm) from the top. Use ISO

VG-46 hydraulic oil.

2. Make sure that the tractor parking brake is on and the

tractor is in neutral. Then, prime the pump.

Front pump units - Turn the engine on and off in

short bursts without starting.

Rear and mid pump units - Rapidly engage and

disengage the PTO while the engine is running.

3. Check the amount of oil in the tank. Add oil as required to

bring it to the proper level.

4. Run the engine at a slow idle. Stop the engine and then

check for hydraulic leaks. Make corrections before

proceeding.

5. Start the tractor again. Engage the brush and let it run

while watching for excess vibration or other problems.

Test swing and lift functions. Make corrections before

proceeding.

6. Perform procedures described in Adjusting Scissor Swing

(scissor swing only) and Leveling, Setting, Brush Pattern,

Adjusting Spring-Chain Assemblies and Adjusting

Transport Chain in the Maintenance Section.

51-3849, 5/26/06 17

INSTALLATION SECTION

LOADER

Sweeper Installation

(Broom to Prime Mover)

WARNING - Improper attachment of sweeper could

result in injury or death. Do not operate

this machine until you have positive

indication that the attachment is securely

mounted.

1. Position the broom on a level surface.

2. Enter the prime mover.

3. Fasten the safety restraints.

4. Start the engine.

5. Disengage the parking brake.

6. Align the attachment mechanism with the mounting on

the broom, attach to the prime mover. Follow the attaching

procedure in the prime mover owners manual.

7. Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary

hydraulic lines.

8. Unfasten safety restraints and exit the prime mover.

Removing the Sweeper

WARNING - Serious injury or death may result from

disengaging the sweeper when the

sweeper is in an unstable position or

carrying a load. Place the sweeper in a

stable position before disengaging.

CAUTION - Hoses for the sweepers must be removed before

the quick attach is disengaged. Pulling the

sweeper with the hoses could result in damage to

the prime mover or the sweeper.

1. Lower the broom to the ground.

2. Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary

hydraulic lines.

3. Unfasten safety restraints and exit prime mover.

4. Disconnect the broom hydraulic lines from the prime

mover. Connect quick couplers together to keep clean.

5. Disengage attachment mechanism. (mechanical type)

6. Enter prime mover, fasten safety restraints and start the

prime mover.

9. Ensure that the hydraulic quick couplers are clean.

Connect hydraulic lines for the broom to the

prime mover. Twist the collar of the quick couplers

one quarter of a turn in order to secure the hydraulic

connections.

10. While the loader arms are lowered, visually inspect the

attachment mechanism to ensure that it is securely

mounted.

WARNING - Improper attachment of sweeper could

result in injury or death. Do not operate

this machine until you have positive

indication that the attachment is securely

mounted.

7. Disengage attachment mechanism. (hydraulic type)

8. Disengage the parking brake, and back away from the

broom.

Storage

CAUTION - Do not store the sweeper with weight on the

brush. Weight will deform the bristles,

destroying the sweeping effectiveness. To

avoid this problem, place the sweeper on

blocks.

Do not store polypropylene brushes in direct

sunlight. The material can deteriorate and

crumble before the bristles are worn out.

Keep polypropylene brush material away from

intense heat or flame.

18 51-3849, 5/26/06

INSTALLATION SECTION

RLH/RLCH

Swing Assembly

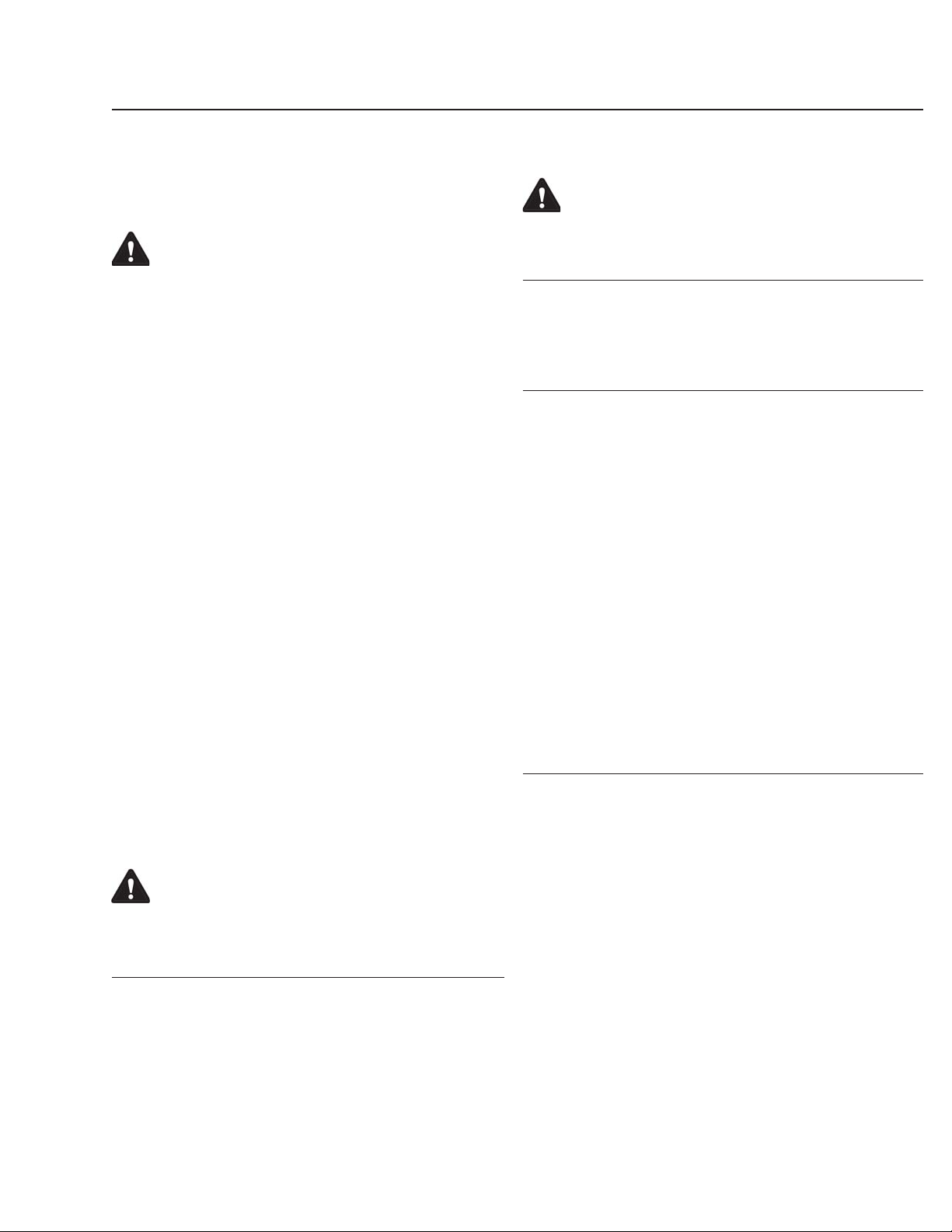

1. Slide the pump onto the rear PTO. Secure with a chain.

Attach the barb to the pump inlet and the elbow and relief

fittings on the pump outlet (figure 7.)

2. Attach bottom plates to the swing assembly using hitch

pins supplied. Plates go inside the frame with bends to

the center.

3. Connect 39-link chains to bottom plates with shackles.

4. Fasten keyhole plates to the tractor toplink using pins

from the tractor (figure 8).

5. Position the swing assembly behind the 3-point hitch with

the half-moon plate to the rear.

6. Lower hitch arms fully.

7. Slide hitch arms onto pins welded to the swing assembly.

Secure with ring pins.

8. Secure the tractor toplink to the top of the swing assembly

using a pin.

9. Raise the hitch until the dimension from the slot in the

center of the swing plate to the ground measures 16

inches (406mm). See figure 9

10. Level the swing assembly from front to back using the

toplink and side to side using the adjustable hitch arm.

11. Attach drop chains to keyhole plates. Adjust so chains

keep the 16 inch (406mm) dimension.

NOTE - For best sweeping results, keep the swing assembly

at least 16 inches (406mm) above the ground and

21 inches (533mm) high to sweep snow. Otherwise,

material tends to carry over the brush and onto the

area swept.

Figure 7

Figure 8

Check Disabler

For rear-mounted brooms the integral check valve cartridge,

located in each motor, must be replaced with a blank

cartridge, part number 03-4891.

16 in. (406 mm)

Figure 9

51-3849, 5/26/06 19

INSTALLATION SECTION

RLH/RLCH

Brush Head Assembly

1. Position the brush head assembly behind the swing

assembly.

2. Align holes in the brush frame and swing assembly.

Install 3 carriage bolts, flat washers, lock washers and

nuts. Do not tighten the hardware; it must remain loose to

level the brush head assembly.

3. Assemble the spring-chain assembly/assemblies. Attach

the spring end(s) to the brush head upright. Then place

the chains in the slots on the swing assembly upright.

4. Connect the transport chain, which is attached to brush

head upright, to the remaining slot on the swing

assembly upright.

NOTE - Use the transport chain to take weight off the spring chain assembly/assemblies while transporting unit

between job sites.

5. Connect pressure and return hoses to prime mover

remotes.

NOTE - If 12 gpm (45.4 lpm) is not available, purchase a

power pack from SWEEPSTER.

6. Attach the pressure hose to the rear tube on the brush

head and the return hose to the front tube. The

Angle Feature

Manual Angle Kit

NOTE - Some sweepers use hydraulic swing instead of

manual angle kit. See Swing Cylinder later in this

section or Option - Hydraulic Swing/Electric Valve at

the back of this manual.

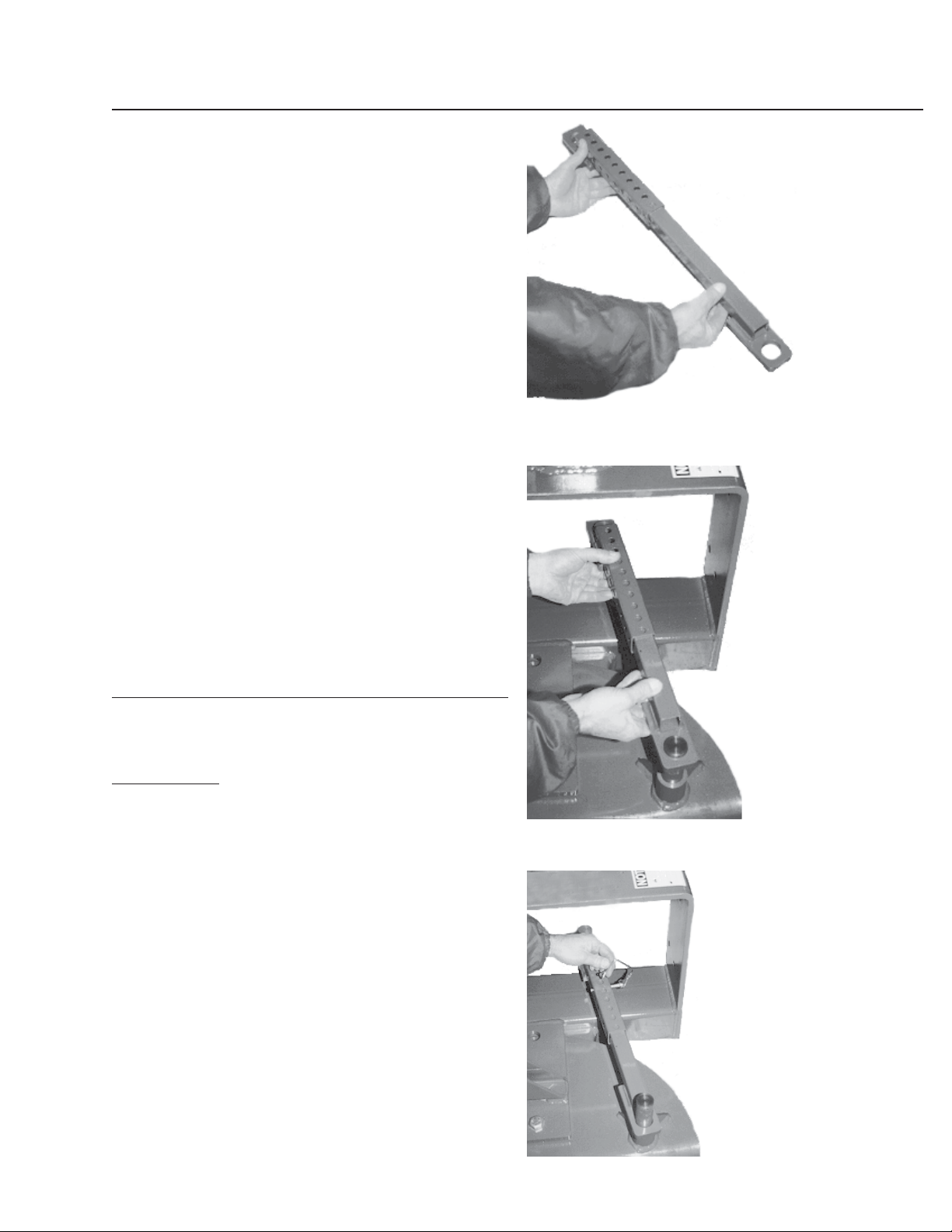

Figure 10

Figure 11

1. Slide the inner link into the outer link (figure 10).

2. Place link ends on swing assembly pins (figure 11).

Secure with cotter pins.

3. Position the brush head assembly at the desired angle.

Align holes in both links and install lock pin to keep the

brush head assembly in position (figure 12).

Figure 12

20 51-3849, 5/26/06

INSTALLATION SECTION

RLH/RLCH

Hydraulic Angle Kit

NOTE - For hydraulic swing with electric valves, refer to

Option - Hydraulic Swing/Electric Valve at the back of

this manual.

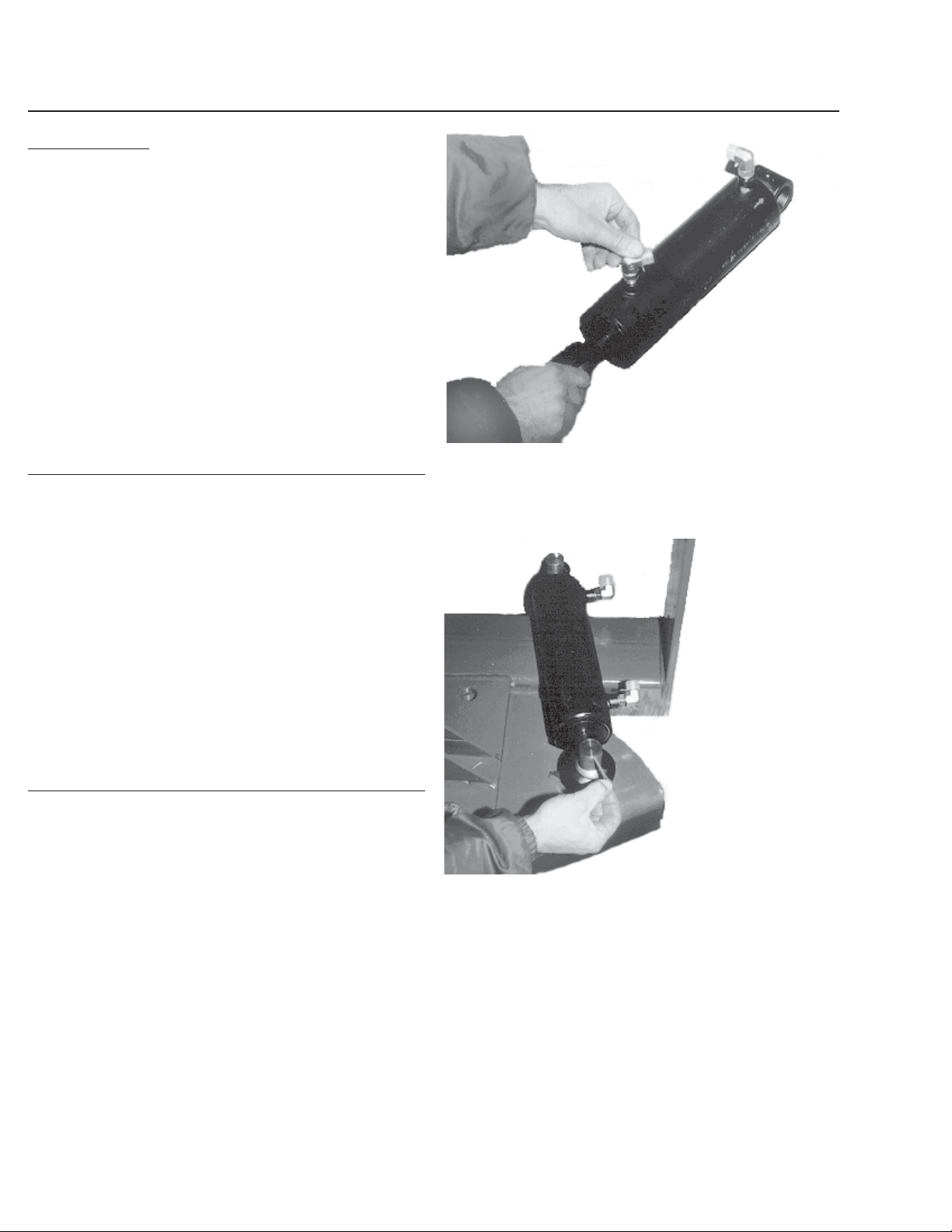

1. Attach fittings to the cylinder with the elbow fitting on the

rod end and the orifice fitting on the barrel end (figure 13).

2. Install the cylinder with the barrel end on the swing

assembly and the rod end on the swing plate. Secure with

cotter pins (figure 14).

3. Connect a hose to each fitting.

4. Attach adapter fittings to hose ends.

5. Connect adapter fittings to remote valves on the prime

mover.

Figure 13

Before First Use

1. Run the prime mover engine at a slow idle. Stop the

engine and then check for hydraulic leaks. Make

corrections before proceeding.

2. Start the prime mover again. Engage the brush and let it

run while watching for excess vibration or other problems.

Test swing and lift functions. Lower the sweeper to the

ground, set the parking brake, shut down the prime mover

and remove the key from the ignition; make corrections

before proceeding.

3. Perform procedures described in Leveling, Setting Brush

Pattern, Adjusting Spring-Chain Assemblies and Adjusting

Transport Chain in the Maintenance section.

Figure 14

51-3849, 5/26/06 21

Operation and

Maintenance Manual

QC Series Angle Brooms

Table of Contents

Operation ........................................................... 22-25

Operation ...................................................................22-23

Storage............................................................................ 23

Leveling Sweeper ...................................................... 24-25

Maintenance. ..................................................... 26-30

Maintenance Schedule ................................................... 26

Maintenance Record ...................................................... 27

Brush Pattern Adjustment ............................................... 28

Replacing Brush Sections ............................................. 29

Lubrication Points ...........................................................

30

22 51-3849, 5/26/06

OPERATION SECTION

SWEEPING/OPERATING TIPS

Before Each Use

Perform daily maintenance as indicated in Maintenance

Schedule.

Run the prime mover and sweeper at a slow idle. Check for

hydraulic leaks or other problems and make corrections, if

necessary, before using the sweeper. See “Hydraulic

inspection guideline”.

WARNING - Avoid serious injury. Check for large

objects that could harm the operator or

others if thrown by the sweeper. Remove

these items before operating.

During Use

Directing Debris

Carry the sweeper low to the ground so that the operator has

good visibility and stability. Avoid any sudden movements.

Avoid excessive downward pressure on the brush sections

to prevent excessive wear. A two to four inch wide pattern is

sufficient for most applications. Ensure that the adjustment

bolts are equally adjusted in order to prevent an uneven

wear pattern. To adjust brush pattern see “Adjusting Brush

Pattern”.

Direct debris by angling the brush head in that direction.

Observe wind direction. Sweeping with the wind makes

sweeping more effective and helps keep debris off the

operator.

Engaging Functions - Tractor Mounts

Methods for engaging run, swing and lift functions differ

according to how the unit is equipped.

Manual Valves with Control Rods

Control rod functions are marked with a label. Pull or push

control rods according to instructions.

Brush Run Swing Lift

Push to stop Push to angle left Push to lower

Pull to run Pull to angle right Pull to raise

Manual Valves without Control Rods

Engage functions with valve control handles.

• With SWEEPSTER hydraulic run, swing and lift:

The first handle (closest to the operator) controls lift. Push

forward to lower and pull back to raise.

The second handle activates the swing function. Push

forward to angle left and pull back to angle right.

The third handle controls brush rotation. Pull back to run

and push forward to stop.

Electric Valves

Activate valves with switches on the control box. Functions are

marked with a label.

Prime Mover Valves

The terms swing and angle are used interchangeably.

Manual Angle Kit

1. Remove the lock pin from links.

2. Position the brush head at the desired angle, aligning

holes in the inner and outer link.

3. Insert and close the lock pin.

Hydraulic Angle Kit

1. Start the prime mover.

2. Rear or mid pump units only - Engage the PTO.

3. Position the brush head at the desired angle by using the

valve control for the swing function.

Activate valves with prime mover controls.

51-3849, 5/26/06 23

OPERATION SECTION

SWEEPING/OPERATING TIPS

Sweeping

To sweep:

1.

Manual angle kit only - Swing the brush head assembly

the direction that you want to direct debris.

2. Start the prime mover at idle and raise the brush.

3. Rear pump units only - Engage the PTO.

4. Hydraulic angle kit only - Swing the brush head assembly

the direction that you want to direct debris.

5. Engage the brush and then lower it to the ground.

6. Increase prime mover engine rpm to sweeping speed.

CAUTION - Avoid hydraulic pump damage on rear pump

units. Do not run the engine at speeds above

standard PTO RPM. This will destroy the pump.

7. Travel forward at 5 mph (8 kph) or less.

CAUTION - Avoid sweeper damage. Reduce travel speed to

avoid hitting immoveable objects.

Operating Tips

CAUTION - Avoid sweeper damage. Do not ram into piles.

Use an appropriate attachment for this type of

job.

Brush, Engine & Travel Speeds

Vary brush, engine and travel speeds to match sweeping

conditions.

Large Areas

When sweeping a large area, such as a parking lot, make a

path down the middle and sweep to both sides. This reduces

the amount of debris that the sweeper must sweep to one

side.

Snow

Fast brush speeds and slow travel speeds are needed to

sweep snow effectively. Start at 3/4 throttle and the lowest

gear of the prime mover. For wet and/or deep snow, increase

to almost full throttle. This helps keep snow from packing up

inside the brush hood.

In deep snow you may need to make multiple passes to get

down to a clean surface.

Brush Head Storage

CAUTION - Do not store sweeper with weight on the brush.

Weight will deform the bristles, destroying the

sweeping effectiveness. To avoid this problem,

place the sweeper on blocks or use optional

stands.

Do not store polypropylene brushes in direct

sunlight. The material can deteriorate and

crumble before the bristles are worn out.

Keep polypropylene brush material away from

intense heat or flame.

To keep snow from blowing back onto a swept area, always

sweep so the wind is at your back.

Dirt & Gravel

To keep dust at a minimum, use the optional dust

suppression kit or plan sweeping for days when it is

overcast and humid or after it has rained. Also, sweep so the

wind blows at your back.

Low brush speeds and moderate travel speeds work best for

cleaning debris from hard surfaces. Brush speeds that are

too fast tend to raise dust because of the aggressive

sweeper action.

To sweep gravel, use just enough brush speed to “roll” the

gravel, not throw it.

Heavy Debris

Travel slowly - 2-3 mph. (3-5 kph)

Sweep a path less than the full width of the sweeper.

Increase engine speed if debris becomes very heavy.

24 51-3849, 5/26/06

MAINTENANCE SECTION

LEVELING THE SWEEPER

Leveling

Level the sweeper for even brush wear and effective use.

CAUTION - Avoid injury. Before adjusting the sweeper ,

always turn off the sweeper and the prime

mover engine and remove the key.

1. Move the sweeper to a flat, paved surface.

2. Lower the brush head assembly so the brush is 2 inches

(51 mm) above the ground.

3. Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary hydraulic

lines.

4.

Unfasten safety restraints and exit prime mover.

5. Check if the swing assembly is level by using a bubble

level. To make corrections:

Scissor swing/plate swing on tractor - Turn leveling

bolts(A) (figure 15 and 16) in or out in equal amounts. If

the front of the swing assembly is high, turn the leveling

bolts in. If it is low, turn the leveling bolts out.

Loader with quick attach mounting - Adjust tilt cylinders. If

the front of the swing assembly is high, extend tilt

cylinders. If low, retract cylinders.

B

A

FIGURE 15

A

FIGURE 16

RLH/RLCH - Adjust the toplink. If the rear of the swing

assembly is high, lengthen the toplink. If low, shorten the

toplink.

6. Position the brush head assembly straight ahead. On

each side, measure from the brush frame to the ground

(figure 17). If measurements are not equal:

Scissor swing - Turn adjustment screw (B) (figure 15) in to

lower the right-hand side of the brush head assembly.

Turn it out to lower the left-hand side.

Plate swing on Tractor/Loader - Loosen hardware that

attaches the swing assembly to the brush head assembly;

lower the high side of the brush head until both sides are

an equal distance above the ground. Tighten the

hardware.

RLH/RLCH - Raise or lower the adjustable hitch arm.

FIGURE 17

51-3849, 5/26/06 25

MAINTENANCE SECTION

LEVELING THE SWEEPER

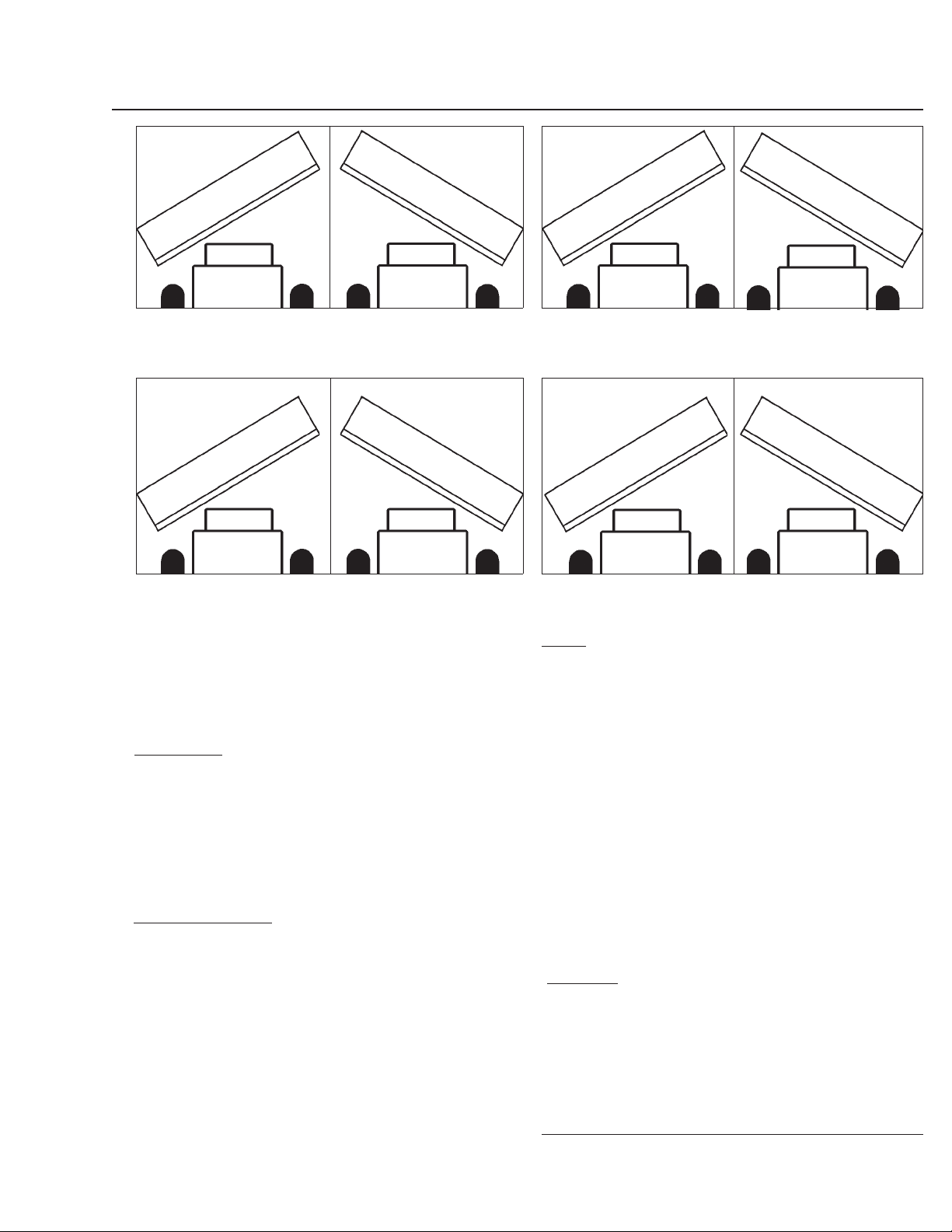

Low

figure 18

High

figure 19

High

Low

High

Low

Low

High

figure 20

Low

figure 21

Low

High

High

Low

Low

HighHigh

7. Measure to see if the brush head assembly is level when

angled. First, angle the brush head to the right. Measure

as in step 4. Then, angle the brush head to the left.

Measure again. If measurements are equal, the sweeper

is level. If not, proceed with this step.

Scissor swing - To correct leveling problems in:

• figure 18, turn leveling screws out. (figure 20, A)

• figure 19, turn leveling screws in. (figure 20, A)

• figure 20, turn the adjustment screw in. (figure 20, B)

• figure 21, turn the adjustment screw out. (figure 20, B)

Plate swing on tractor - To correct leveling problems

shown in:

• figure 18, turn leveling screws out. (figure 21, A)

• figure 19, turn leveling screws in. (figure 21, A)

• figure 20, loosen hardware that attaches the swing

assembly to the brush head assembly; lower the

left-hand side of the brush head until both sides are an

equal distance above the ground. Tighten the hardware.

Loader - To correct leveling problems shown in:

• figure 18, extend tilt cylinders.

• figure 19, retract tilt cylinders.

• figure 20, loosen hardware that attaches the swing

assembly to the brush head assembly; lower the

left-hand side of the brush head until both sides are an

equal distance above the ground. Tighten the

hardware.

• figure 21, loosen hardware that attaches the swing

assembly to the brush head assembly; lower the right hand side of the brush head until both sides are an

equal distance above the ground. Tighten the

hardware.

RLH/RLCH - To correct leveling problems in:

• figure 18, lengthen the hitch toplink.

• figure 19, shorten the hitch toplink.

• figure 20, lower the adjustable 3-Point hitch arm.

• figure 21, loosen hardware that attaches the swing

assembly to the brush head assembly; lower the right hand side of the brush head until both sides are an equal

distance above the ground. Tighten the hardware.

• figure 21, raise the adjustable 3- Point hitch arm.

26 51-3849, 5/26/06

MAINTENANCE SECTION

MAINTENANCE SCHEDULE

Maintenance Schedule

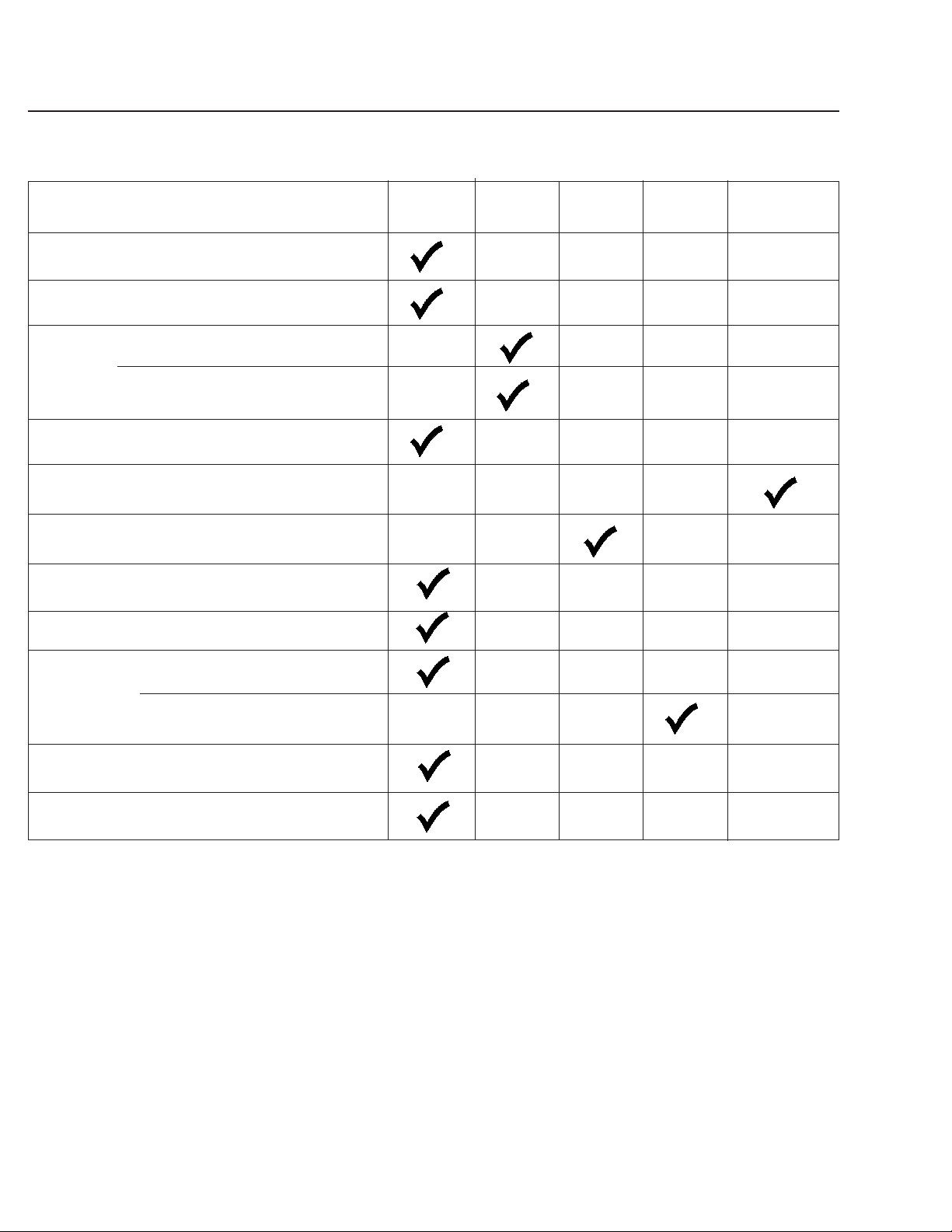

Procedure Before After 100 500 See Prime

Each Use Each Use Hours Hours Mover

Brush head assembly - Level

Brush pattern - Check (See Pattern Adj. Section)

Cylinders - Retract rods

- Grease threaded and ball ends to

prevent rust

Drive shaft, pump - Check (AH/CH; Power Pack)

Manual

Filter, air , prime mover - Clean

Filter, hydraulic - Replace (AH/CH)

Fittings/hoses, hydraulic - Check for leaks/tighten

Check for damage

Fittings, zerk - Grease. (See lubrication points)

Oil, hydraulic - Check Level (AH/CH)

- Replace (AH/CH); use ISO

VG-46 hydraulic oil

Hardware - Check for tightness

Swing plate - Grease (CH/RLH/RLCH/Loader)

Loading...

Loading...