Paladin Tools 1112 AM Operation And Use Manual

Support: 1.800.272.8665

Int’l Phone: 001.804.550.1121

E-Mail: paladin@paladin-tools.com

Web: www.paladin-tools.com

Tool Operation and Use Guide

Paladin Tools

®

1

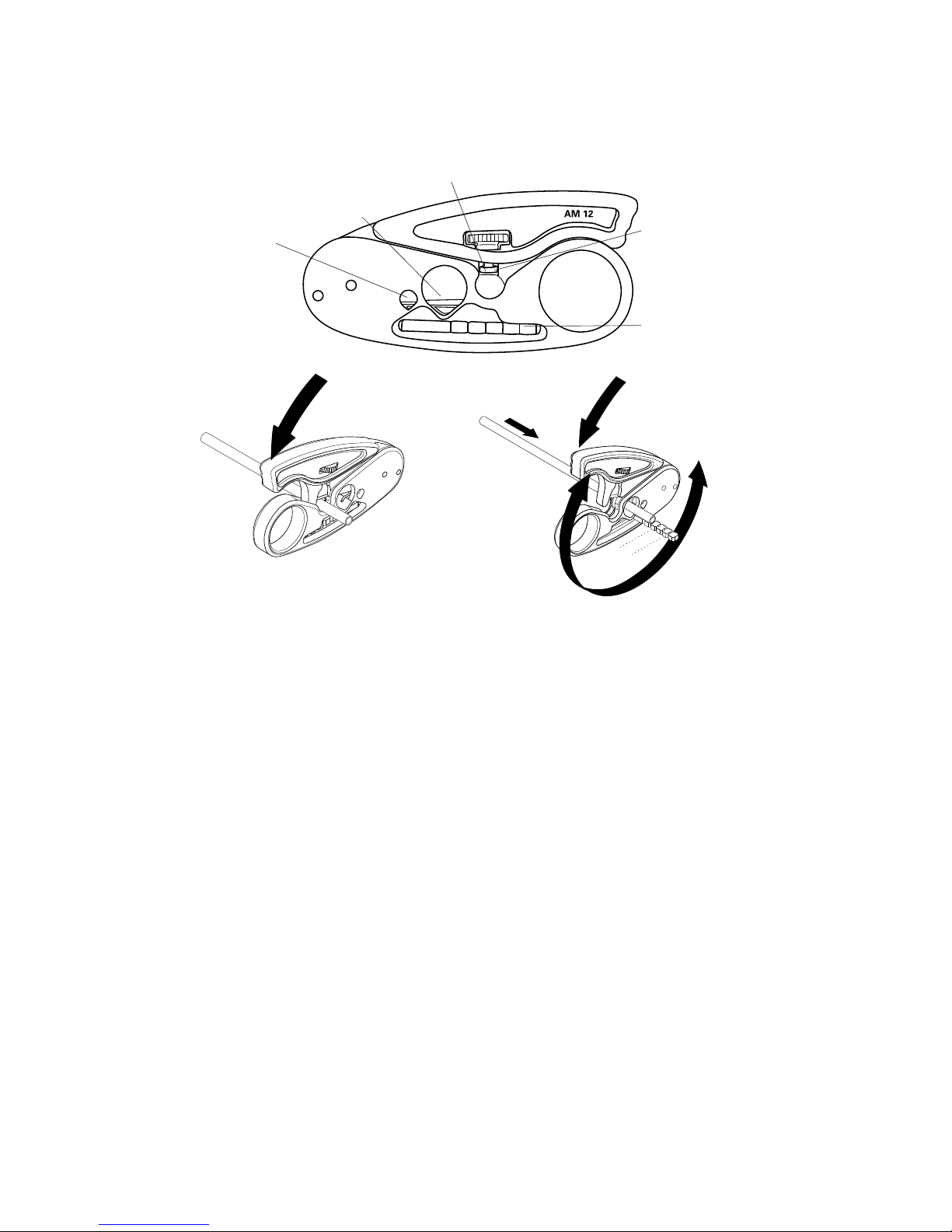

1112 AM 12 Twisted Pair Cable

Stripper

To cut cable:

1. Install the wire or cable into the circular hole

closest to the finger loop.

2. Grip the tool & squeeze the top handle down until

the cable is cut.

To strip wire & cable:

1. Adjust the blade depth screw to the desired cutting

depth.

2. Place wire/cable into the smallest hole it can fit

into.

3. Put your finger into the finger loop & spin the tool

clockwise around the cable 3 to 6 times. Do not

squeeze the top handle down when spinning.

4. Open the handle & remove the cable. Pull the

stripped insulation off the cable.

Note: The AM 12 is especially useful for 4-pair UTP

& STP cables.

Cutting cable

Stripping cable

Blade depth

adjustment screw

Stripping length

gauge

Strip/cut up to 12 AWG (0.1” diameter)

Strip/cut up to

0.5” diameter

Strip/cut up to

0.2” diameter

Tool Operation and Use Guide

2

Blade Depth Adjustment Screw

Round Cable

Stripper

Cable

Cutter

1116 Data SureStrip™ Twisted Pair

Cable Stripper

To cut wire & cable:

1. Install the wire or cable into the cable cutter section.

2. Grip the tool & squeeze the top handle down until

the article is cut.

To strip round wire & cable:

1. Adjust the blade depth screw to set the blade cut

depth to desired level to ensure a non-scoring strip.

This may take several test settings before achieving

optimum depth.

2. Place wire/cable into the center round hole of the

tool.

3. Place your finger into the finger loop & spin the

tool clockwise around the cable 3 to 6 times. Do

not press down on the top lever. The tool has a

self-regulating spring to control stripping.

4. Open the tool & remove the cable. Pull the stripped

insulation off the cable.

To strip flat satin telephone cable:

1. Place cable into the flat cable stripper area located

at the front of the tool.

2. Close the tool & hold tool in palm or one hand, &

hold the cable steady in other hand.

3. Using a straight, no-angled motion, pull the tool

away & off from the end of the cable. This will strip

off the outer jacket exposing the inner conductors.

Perfect for 25-Pair!

Flat Cable

Stripper

Paladin Tools

®

3

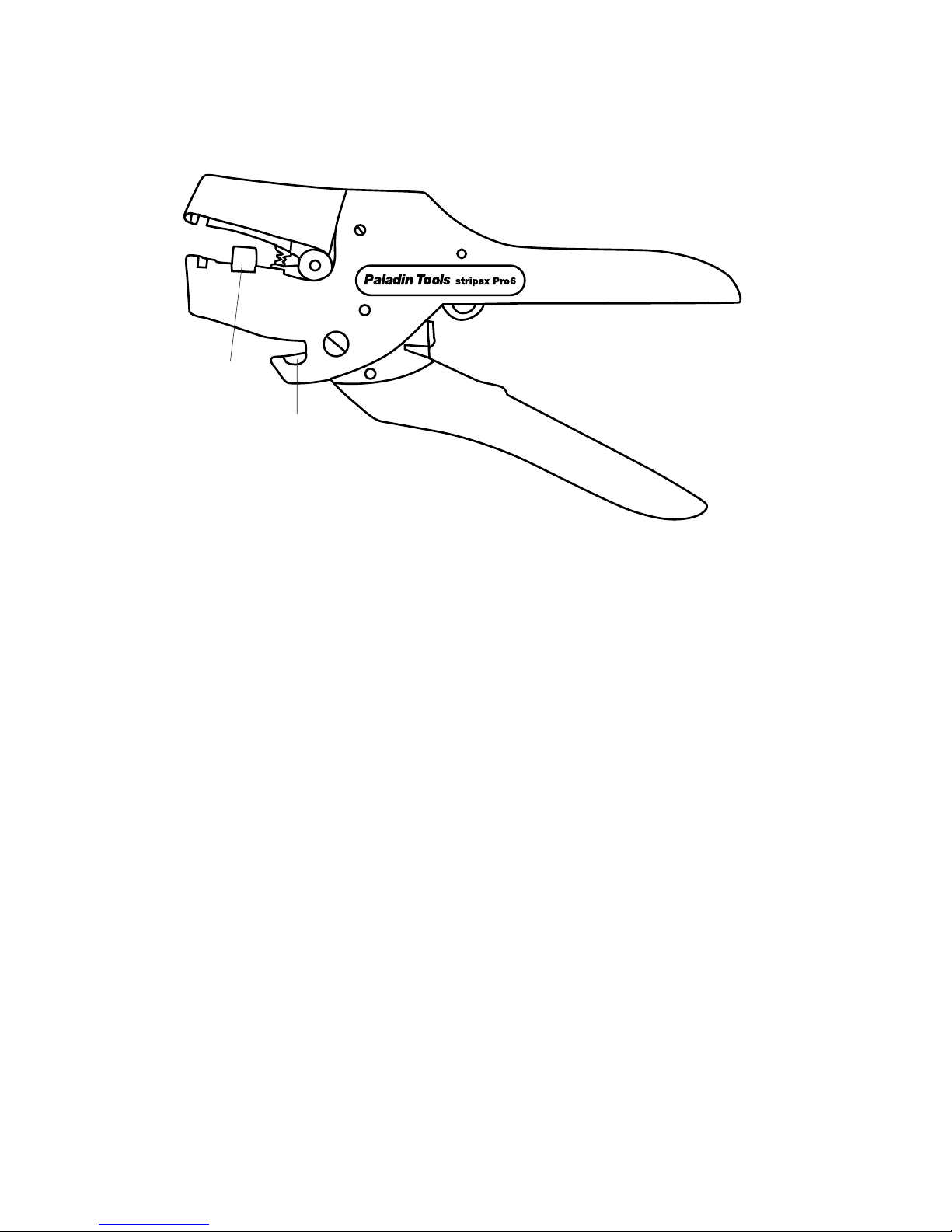

1113 pictured

To cut wire:

1. Place the wire in the cutting slot located in the

bottom handle.

2. Squeeze the handles to close the cutting blade.

To strip wire:

1. Adjust the orange wire stop located in the jaws of

the tool to the desired strip length. Squeeze the

sides of the stop & slide to the proper length. Use

the metric ruler on the side of the tool as a guide

for the length.

2. Adjust the top slider for the proper insulation thick-

ness of the wire. Position the button fully forward

for thicker insulation & fully backward for thinner

insulation.

3. Insert the wire into the front of the jaws. Make

sure the end of the wire is flush against the front

edge of the wire stop.

4. Squeeze the handles to close the jaws & engage

the stripping blades.

Note: Not for use on Teflon or Kapton insulated wire

1113 & 1114 stripax® Pro Wire

Strippers

Wire stop

Cutting slot

Tool Operation and Use Guide

4

Paladin Tools

®

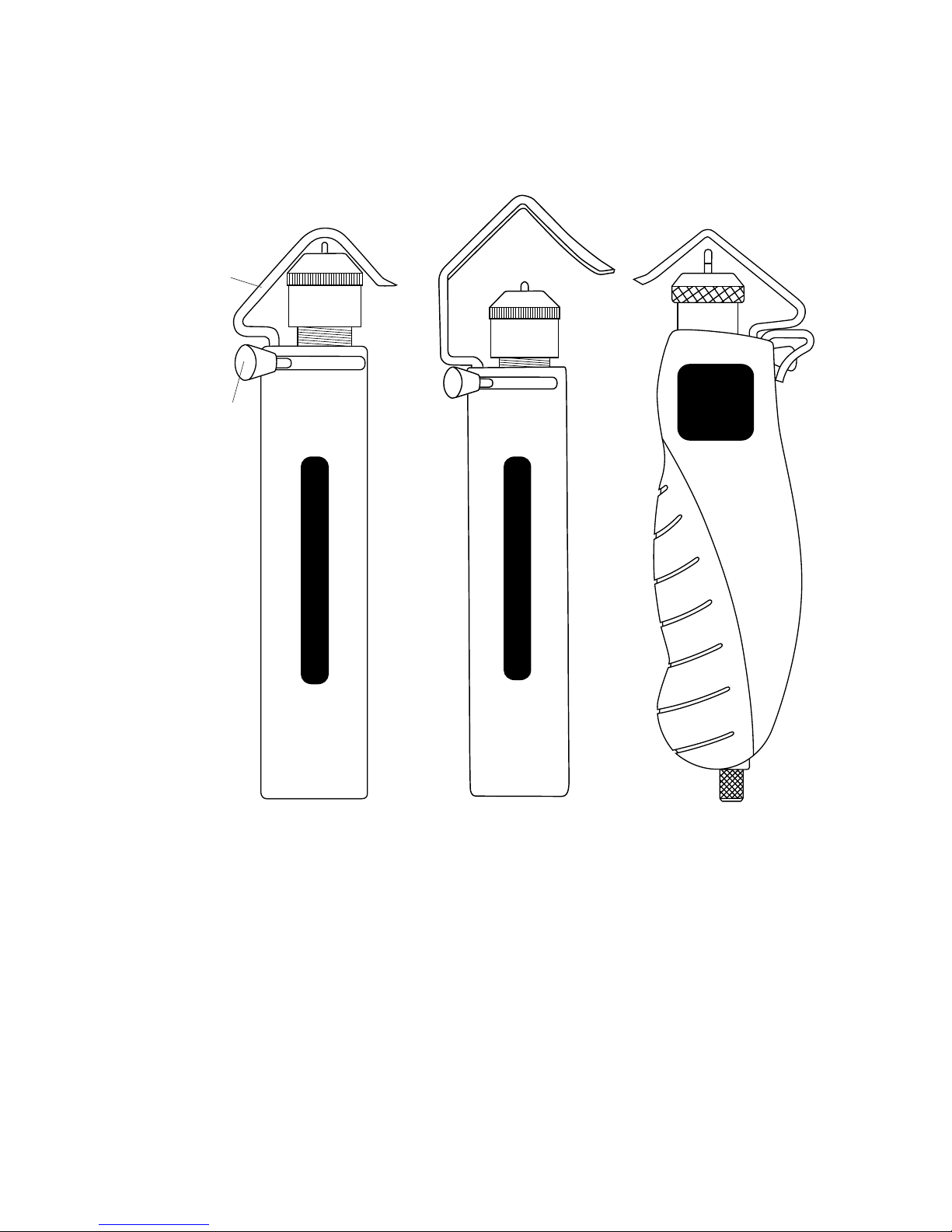

AM 25

1820

Paladin

Tools

®

1822

1820 Series Cable Strippers/Slitters

Operating instructions:

1. Rotate the silver blade head in clockwise or counterclockwise directions to decrease or increase the

blade cutting depth respectively. (For 1822, rotate

bottom knob to set cable diameter)

2. Lift the spring-loaded retaining clamp & install the

cable. Release the clamp to allow the clamp to hold

the cable in place.

(cont’d on page 5)

Retaining

clamp

system

Springloaded

blade

direction

trigger

Paladin Tools

®

AM 35

1821

Paladin Tools

®

5

3. For circular slitting, rotate the tool clockwise about

the cable until adequate penetration of the insulation is achieved.

4. For longitudinal slitting, push & hold the trigger to

the right & slide the tool down the length of the

cable.

5. For spiral slitting, push & hold the trigger in the

center & rotate the tool down the length of the

cable. This creates a “corkscrew”-type slit. Remove

the tool from the cable.

6. After cable is slit, remove the insulation by pressing

the pointed end of the cable clamp into the groove

& pulling the insulation away. Peel off the remaining

loose insulation.

To replace blades:

1. Lift the cable clamp up.

2. Unscrew the silver head.

3. Remove spring, blade & washer.

4. Remove washer from “old” blade.

5. Spare blade is in handle. Remove cap from bottom

corner to access. (For 1822, spare blades on side

of handle)

6. Replace cap.

7. Slip washer over blade.

8. Install new blade/washer & then replace spring.

9. Screw silver head back on.

Tool Operation and Use Guide

6

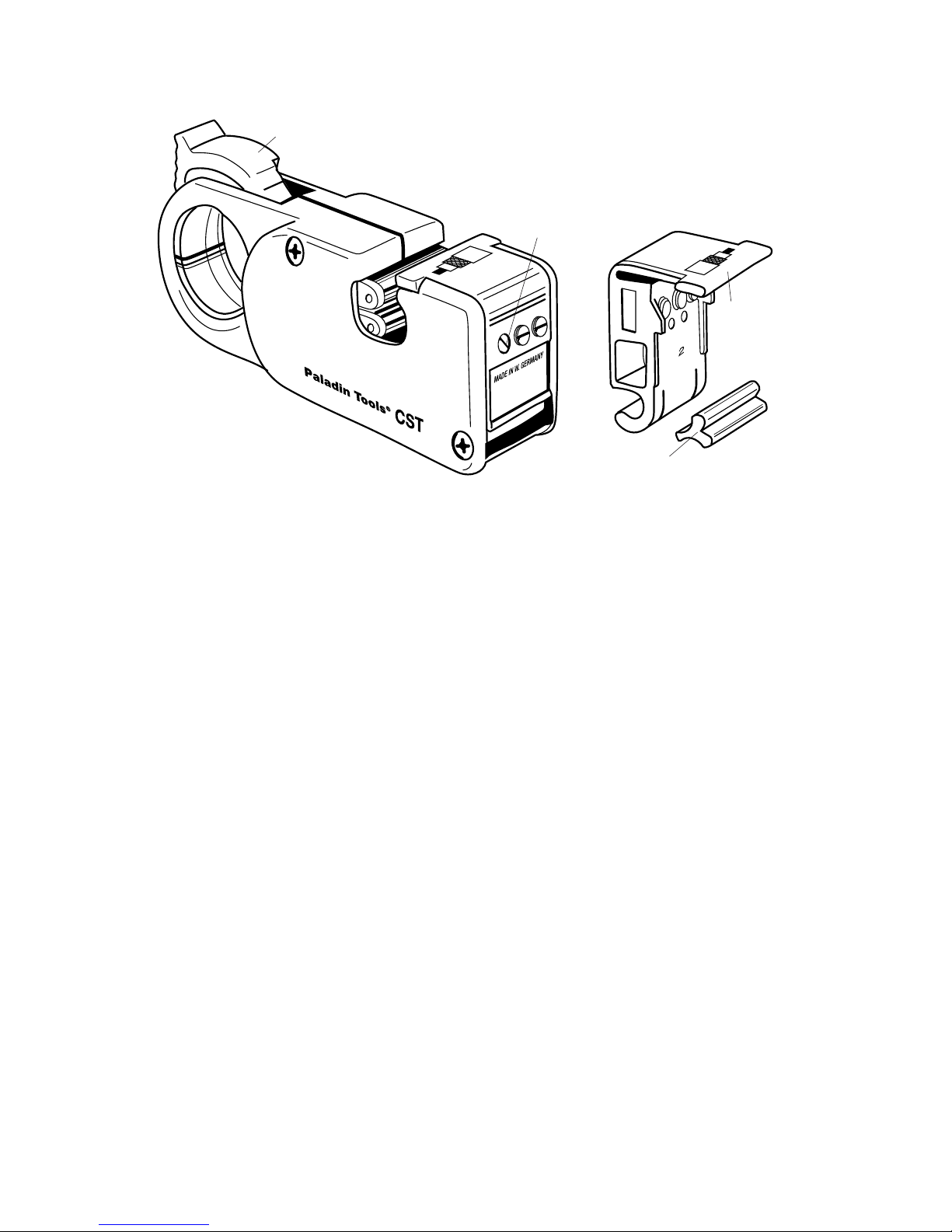

1240 Series CST (Coax) Strippers

To strip coaxial cable:

1. Make sure the blade cassette is installed in the

back section of the tool.

2. Fully retract the rollers by moving the cam switch

lever to the full, back position.

3. Push the locking slide on the bottom to the fully

advanced position.

4. Insert the cable into the side of the tool where the

arrow indicates.

5. Push the cam switch lever to the fully forward

position to lock the cable in place. Pull the locking

slide on bottom of tool back to set the cam.

6. Adjust the screws located on the back side of the

tool to position the blade cutting depths for each

stripping level (jacket, shield, inner dielectric

insulation).

7. Place your finger in the round hole & rotate the

tool around the cable clockwise in the direction of

the arrow.

8. Hold the cable with one hand & pull the tool out

away from the cable to strip.

9. Repeat the above steps until the proper cutting

depth is achieved.

Cam

Y-block

Adjustment

screws

Memory

cassette

Paladin Tools

®

7

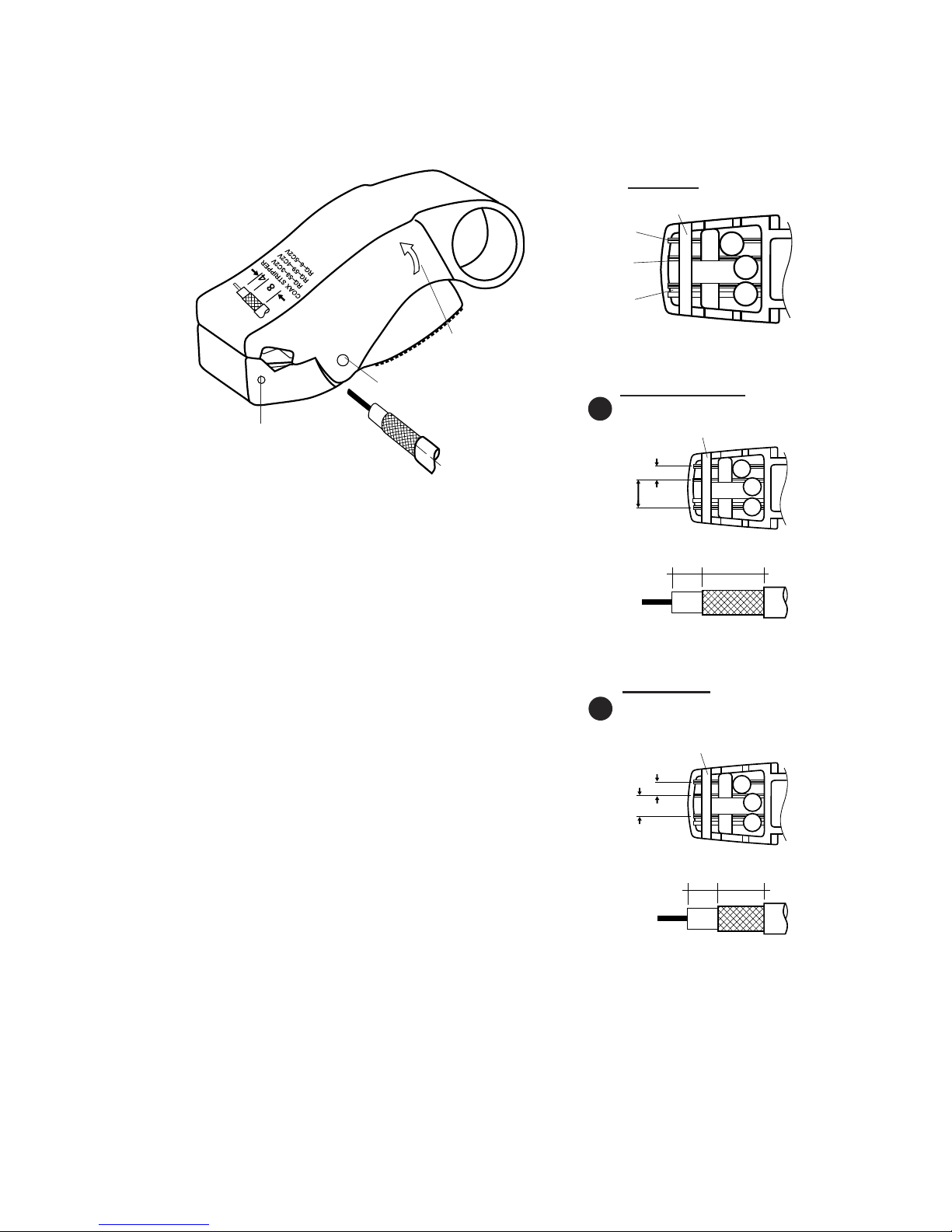

To strip coaxial cable:

1. Set up blade strip lengths to

Option “A” or “B” by removing the

retaining pin from the bottom jaw.

Move the blades to the desired strip

length channels. For 2-level strip,

remove center blade. Re-insert the

retaining pin.

2. Adjust blade depth using the hex

key to turn the hex screws in

bottom jaw for each blade.

3. Test strip. Install cable in front of

tool in direction of graphic. Rotate

tool clockwise 6 times around cable.

Remove tool from cable and remove

stripped layers with fingers.

4. Repeat set-up of strip length &/or

depth until desired strip is achieved.

Notes:

1. The 1257 is preset for standard RG6 CATV “F” cable.

See step 2 above to adjust blades for RG59 cable.

2. Do not hold jaws down during stripping; jaws adjust

automatically.

1255 LC CST-58/59

Pin

A Pre-set blade positions

a b d

.157 .315

.157” (4mm)

.315”

(8mm)

1255, 1256, 1257 & 1258 LC CST Coax

Strippers

Blade detail

1255 Example

Direction to rotate

around cable

Conductor blade

Conductor blade

Shaft pin

Retaining pin

for fixed blades

Shield/

braid blade

Retaining pin

B Optional user-set

blade positions

a b c

Pin

.157 .236

.157” (4mm)

.236”

(6mm)

Tool Operation and Use Guide

8

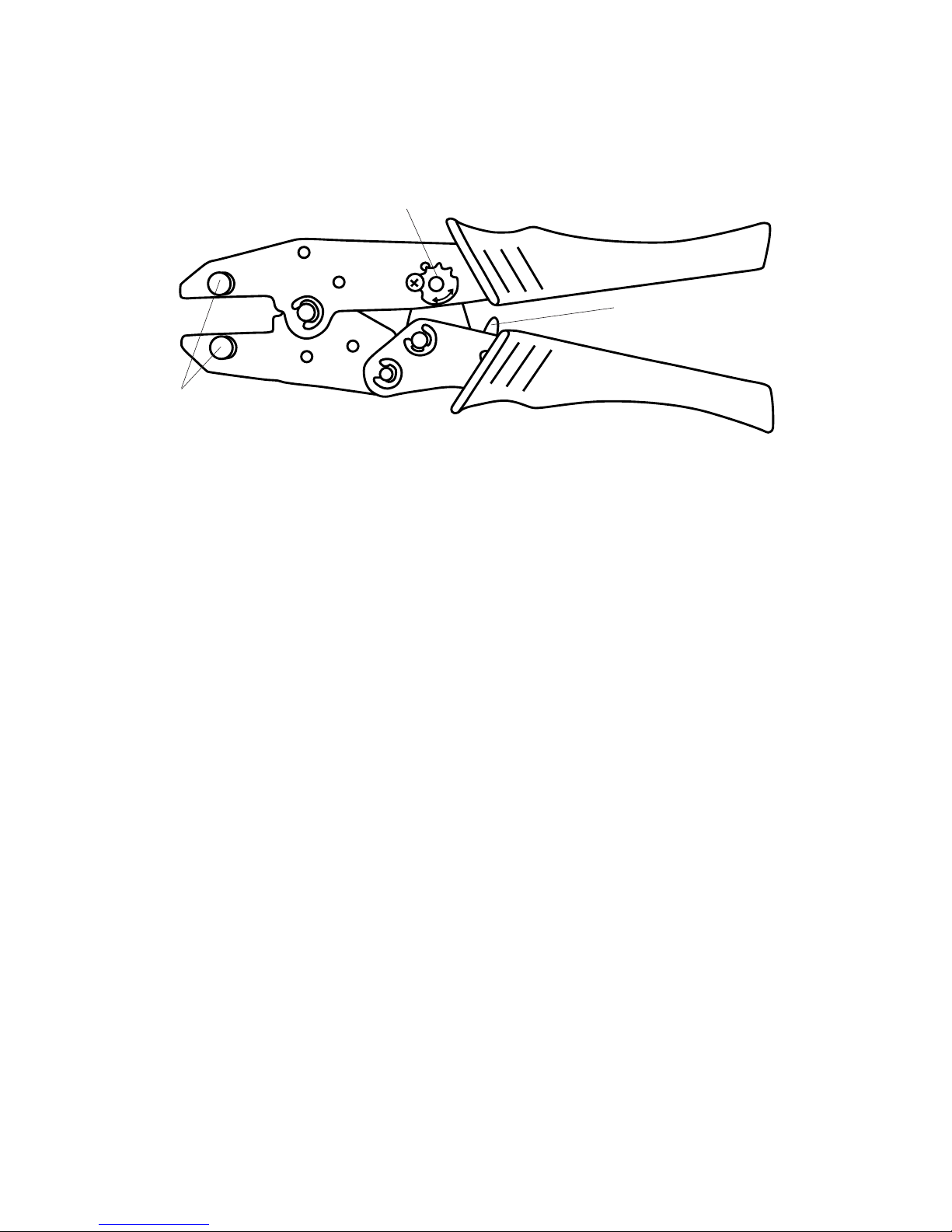

1300 Series Crimpers

Operating Instructions:

1. Install the required die set in the crimp tool by

removing the thumb screws located in the jaws.

Install the die set with the text facing outward

when crimper is in position shown above.

2. Install the thumb screws & tighten to maximum

thumb tightness. Note: Do not use pliers or tools

to tighten the thumb screws—only hand tightening is necessary.

3. Assemble cable & connector as specified by the

connector & cable manufacturers’ instructions.

4. Insert connector/cable assembly into the die set &

squeeze the handles through a complete ratchet

cycle. Crimp is complete.

Emergency release:

In the case of an emergency where a crimp cycle is

stopped & the tool needs to be reopened, flip the

safety release forward in the direction of the jaws to

engage the release mechanism.

Ratchet strength adjustment:

See page 11 for optimum ratchet gear settings &

adjustments.

Ratchet strength

adjustment

Safety release

Thumb screws

Paladin Tools

®

9

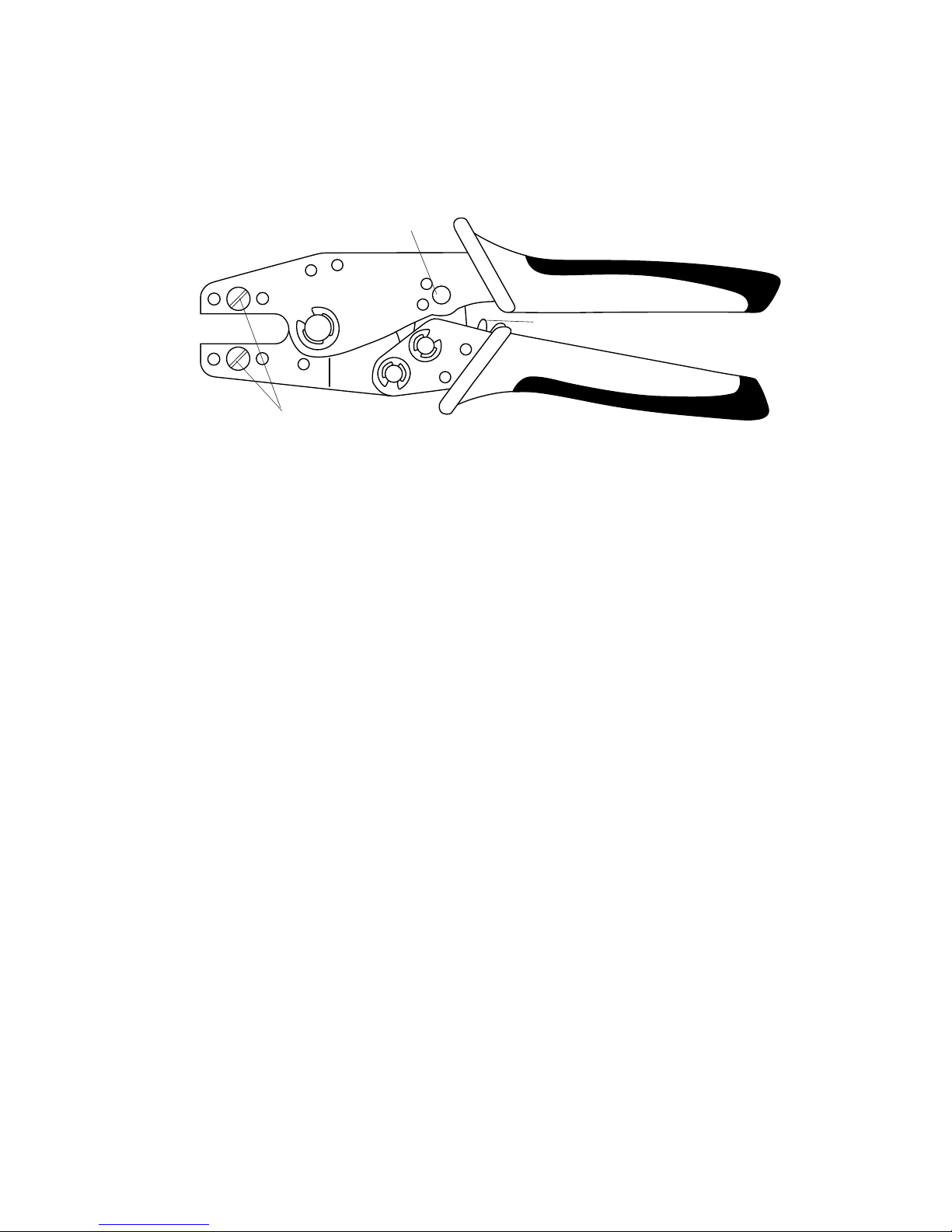

8000/CrimpALL® Series Crimpers

Safety release

Operating Instructions:

1. Install the required die set in the crimp tool by

removing the thumb screws located in the jaws.

Install the die set with the text facing outward

when crimper is in position shown above.

2. Install the thumb screws & tighten to maximum

thumb tightness. Note: Do not use pliers or tools

to tighten the thumb screws—only hand tightening is necessary.

3. Assemble cable & connector as specified by the

connector & cable manufacturers’ instructions.

4. Insert connector/cable assembly into the die set &

squeeze the handles through a complete ratchet

cycle. Crimp is complete.

Emergency release:

In the case of an emergency where a crimp cycle is

stopped & the tool needs to be reopened, flip the

safety release forward in the direction of the jaws to

engage the release mechanism.

Ratchet strength adjustment:

See page 11 for optimum ratchet gear settings &

adjustments.

Thumb screws

Ratchet strength

adjustment

Tool Operation and Use Guide

10

1600 Series Crimpers

To crimp a cable assembly:

1. For interchangeable-die crimp tools, install the

required die set in the crimp tool by removing the

screws located in the jaws. Install the die set in

the jaws & tighten the screws to securely hold the

die set.

2. Assemble cable & connector as specified by the

connector & cable manufacturers’ instructions.

3. Insert connector/cable assembly into the die set &

squeeze the handles through a complete ratchet

cycle. Crimp is complete.

Emergency release:

In the case of an emergency where a crimp cycle is

stopped & the tool needs to be reopened, flip the

safety release forward in the direction of the jaws to

engage the release mechanism. The release is located

between the handles.

Ratchet strength adjustment:

See page 11 for optimum ratchet gear settings &

adjustments.

Ratchet strength

adjustment

Safety release

Die screws

Loading...

Loading...