Page 1

XPRESS

E

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

5800 ST8000

Disk Expansion Unit

User's Guide

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

■■■■■■■

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 2

XPRESS

E

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

5800 ST8000

`)

Disk Expansion Unit

User’s Guide

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

■ ■■■■■■

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 3

Copyright © 1998 Packard Bell NEC, Inc.

Trademarks

n

Stor and the nStor logo are trademarks or r egister ed t r adem ar ks of nStor Corporation, Inc.

TolerANT is a registered trademark of Symbios Logic.

Microsoft® Windows®, and Microsoft ® W indows NT™ are registered trademarks or tradem ar ks of

Microsoft Corporat ion in the United Stat es and/ or in other countries.

NetWare and Novell are registered trademar ks of Novell,Inc.

SCO UNIX is a registered tademark of Santa Cruz O per at ions, Inc.

MS-DOS is a registered trademar k of M icr osof t Corpor ation.

Mylex is a registered trademark of M y lex Corporat ion

Other product and company names are registered trademar ks and t r adem arks of their respective holders.

Printed in the United States of America.

PN: 102157 3/98

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 4

Contents

1 Introduction

Welcome.........................................................................1

Features..........................................................................1

Where to Find Answers .....................................................3

Front Panel Component s ...................................................4

Operator Contr ol Panel ....................................................4

Power-On LED ................................................................5

Status Indicator LEDs ......................................................6

Alarm Speaker ................................................................7

Door Lock.......................................................................7

Status LEDs ...................................................................7

Activity LEDs..................................................................8

Rear Panel Components ....................................................9

I/O Interface Card .........................................................10

Power Cord Connector and F use ..................................... 10

Internal Components ....................................................... 11

Hot Swappable Disk Drives ............................................. 12

Power Switch ................................................................ 12

Fault LEDs ................................................................... 13

SAF-TE Card ................................................................13

Hot Swappable Cooling Fans .......................................... 13

Hot Swappable Power Supplies ....................................... 14

Configuration Modules ................................................... 15

SAF-TE ........................................................................16

................................................................

1

2 Installation

Setup ............................................................................ 17

Guidelines.................................................................... 18

Rack-Mount Subsystem Assembly................................... 19

Component Installat ion .................................................. 21

Cabling Configuration ..................................................... 25

Termination .................................................................. 26

Cables ......................................................................... 27

Ultra Wide SCSI Mode................................................... 28

Other Configurations....................................................... 32

3 Using the DEU

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

................................................................

...........................................................

17

33

Page 5

Power-On Self Diagnos tics.............................................. 33

RAM Read/Write, RO M Checksum, and Register

Read/Write F ailures ...................................................... 34

RAM Checksum Failure .................................................. 34

SCSI Bus Access Failure ............................................... 35

LED Descriptions............................................................36

Operator Contr ol Panel ................................................... 37

Startup Scr eens ............................................................ 38

System Status Icon ....................................................... 39

Main Menu.................................................................... 40

Hardware Menu ............................................................. 41

Options Menu ............................................................... 45

Heat Threshold ............................................................. 48

SAFTE CHAIN ID .......................................................... 49

Change Passcode.......................................................... 50

Unlock Options.............................................................. 51

4 Maintenance

Replacing a Disk Drive.................................................... 53

Replacing a Power Supply............................................... 54

Replacing the Cooling Fans ............................................. 56

Replacing the DEU Cabinet ............................................. 58

Replacing a Fuse ........................................................... 59

5 Troubleshooting

A Certificate and Agency Information

FCC Radio Frequency I nterference St atement................... 65

Power Cord Selection ..................................................... 67

B Glossary

..............................................................

.......................................................

......................

..................................................................... 69

53

61

65

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 6

C Technical Information

Specifications ................................................................ 73

Connectors and Jumper s ................................................. 75

Connectors................................................................... 75

Jumpers....................................................................... 77

.............................................

73

D Option Cards

Introduction ................................................................... 85

Features........................................................................ 86

Quick Install .................................................................. 87

DEU Subsystems Installations......................................... 88

Setup ........................................................................... 88

Single-Ended Ultra W ide SCSI ........................................ 93

Differential Ultra Wide SCSI......................................... 105

Default Configurations .................................................117

Option Card Specifications ............................................ 118

.............................................................

85

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 7

xxxx

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 8

1 Introduction

Welcome

Congratu lations on the purchase of your new ST8000

Disk Expansion Unit (DEU). The DEU provides a

superior fault-tolerant n etwork stor age solution in a

subsystem-based SAF-TE compliant RAID enclosure.

The SAF-TE compliant interface provides a standard,

non-pr oprietary means for the RAID subsystem to

automatically in tegrate with peripheral p ackaging that

supports statu s signals, hot sw apping dr ives and

enclosure monitoring. Combined with the enterprisewide RAID manag ement softwar e, additional lev els of

fault toleran ce can be maintain ed.

The DEU is an eight drive enc losure designed to

support a h ost system-based ar chitectu re. Th e

architec ture suppo rts Ultra Wide SCSI (F ast-20).

Features

The following are major features of the DEU disk array

subsystem:

RAID Levels — Sup ports RAID lev els 0, 1, 3, 5, 10

(1 + 0), 30, and 50.

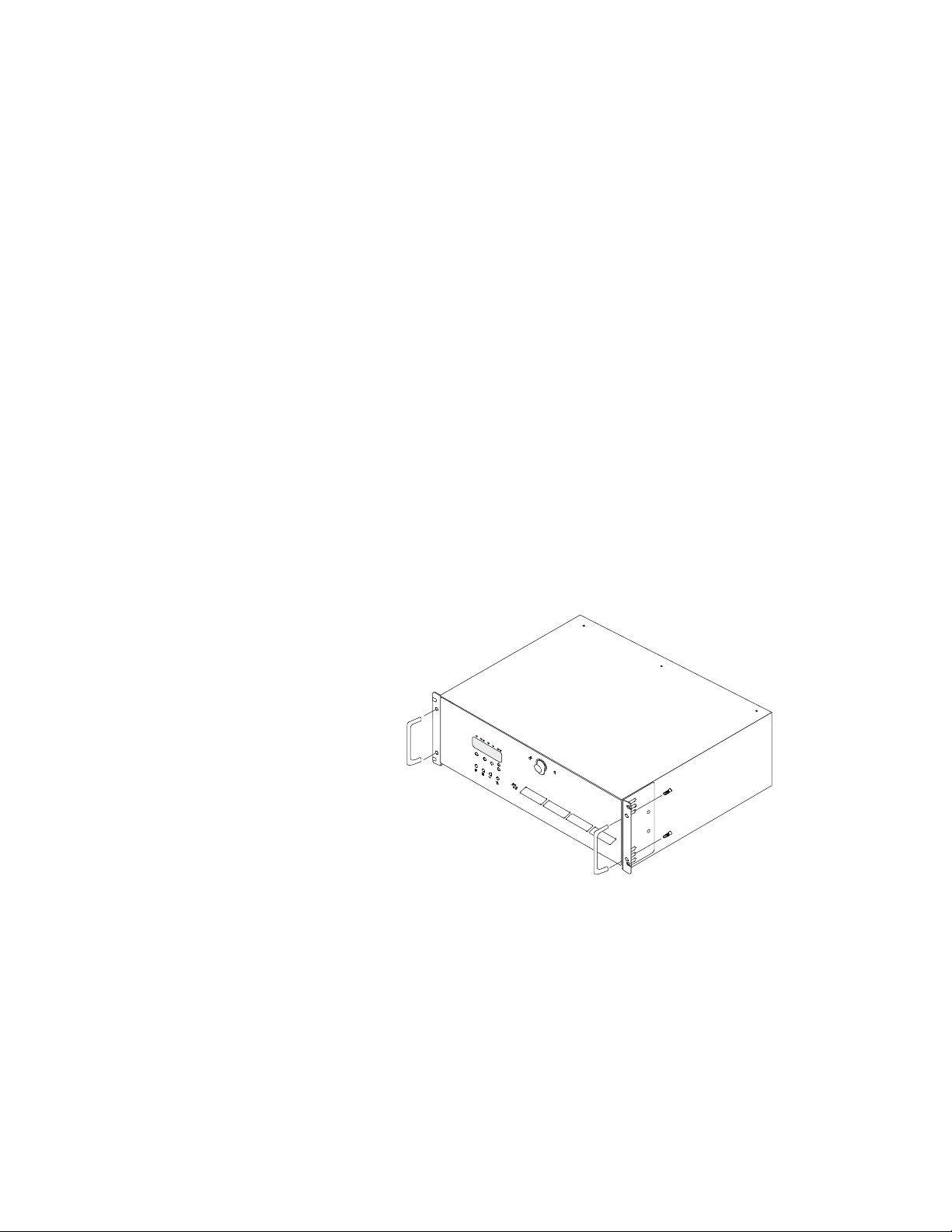

Configuration — Deskside towe r-based syste m and

rack-mou nt system (fits in to a standard IAE 19- inch

rack assembly). Dual-Bus or Single-Bus

configu ration module s provide for an “easy” PCB

plug-in c hangeable bu s configu ration.

Drive Support — Up to eig ht 3.5-inch , half-he ight

form facto r, hot swap pable drives th at use SCA-II

technology. Disk drives featured include high

performan ce 7,200 and 10, 000 RPM Ultra SCSI har d

disks.

Scalable Capacities — Drive capacities are

expandable and even further expansion through

daisy-chaining of multiple cabinets.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 9

Hot Swap Power Supplies — Dual h ot swappable

power supplies expandable to three, all with current

sharing circu itry. Power supply system provides

monitorin g and sequen cing.

Cooling — Dual high capacity cooling fans.

Notifi cation s — LEDs and audible alarms prov ide

failure no tifications.

Inside door panel Fault LEDs provide drive failur e

identification .

Front Panel — A password protected Operator

Control Panel (OCP) for administration control and

monitoring functions, including control of SCSI ID

settings. An imated OCP icon s for an “at-a-g lance”

determination of system status.

Option Cards — Full support for Option cards

available in Differ ential Converter an d Ultra

Extender versions pr oviding data transfer r ates up

to 40 MBs per second. Both support either single or

dual bus Dif ferential SCSI and Ultra SCSI

applications.

Termination — Option cards configured for

automatic SCSI-bu s termination.

Remote/Delay Start — A backplane ju mper

provides for subsystem control of disk drive spin u p

delay whe n the adapter does not suppl y this

feature.

SCSI-to-SCSI Support — Support for an Ultra S2S

RAID Controller prov iding on-board Ultra SCSI-toUltra SCSI RAID processing.

Locking Door — A key-locking fr ont door th at

deters unauthorized access to the drives,

controllers, and power switch.

SAF-TE — Complete support of SAF-TE v1.0

standards (SCSI Accessed Fault Tolerant Enclosure)

protocol.

Cluster-Ready — Cluster-ready su bsystem (refer

to the Ultra S2S User’s Guide).

OS Support — Supports the following OS

platforms: Nov ell NetWare, M icrosoft® Win dows

NT™, and SCO UNI X compatible.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 10

Storage Management Solution — Enterprise-

wide manag ing and mon itoring sof tware.

Where to Find Answers

When you have questions about your DEU there are

several places you can look to find answers. Refer to

the following:

In this guide: This user’s guide provides detailed

information f or installing an d using the DEU disk

array subsy stem. The man ual assumes that the

reader is already familiar with the operatin g system

environments w here the DEU will be in stalled.

ServerCare™ Service Support Progra m Guide:

Use this manual to loc ate telephone numbers for

customer service, technical support, and conditions

of the limited warranty.

Ultra S2S RAID Controller User’s Guide:

Use this manual for pr ocedures to install and u se

the Ultra S2S RAID Co ntroller ( DAC960SX), the

S2S Interface card, an d the software utility for each

specific operating system.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 11

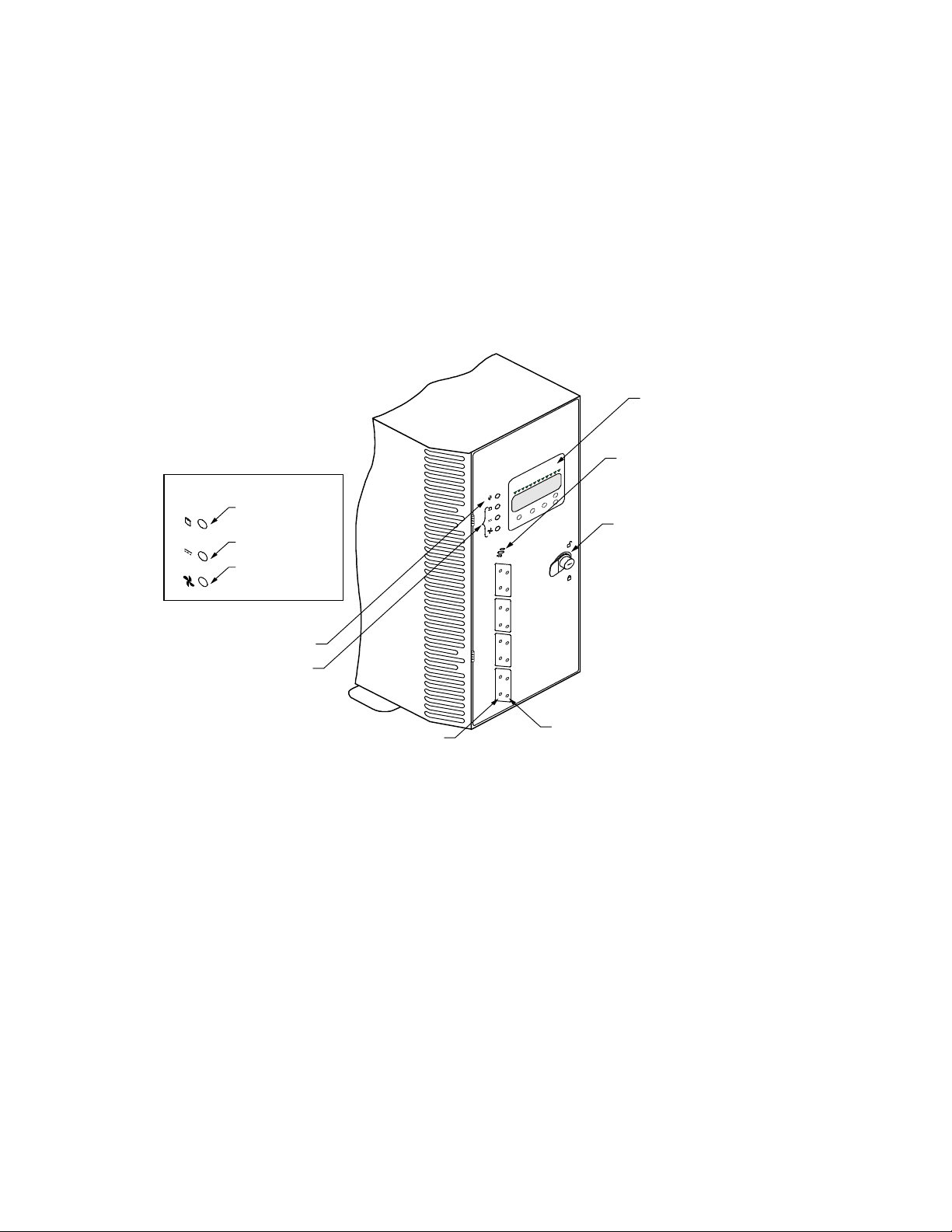

Front Panel Com ponents

The DEU front panel comprises seven major

components: Operator Control Panel, Power -On

Indicator LED, Status In dicator LED s, Alarm Speaker ,

Door Loc k, Status LED s, and Activi ty LEDs.

Status Indicator LEDs

Channel Mode LED

Power Supply LED

Fan Status LED

Operator Control

Panel (OCP)

Speaker

Door Lock

Power-On LED

Status Indicator LEDs

Status LEDs

Operator Control Panel

The Operator Control Panel (OCP) provides for the

control and mon itoring capabilities of th e DEU disk

drives, power supplies, fans, and processor. From the

panel’s interface, the user can change SCSI IDs for the

drives and SAF-TE processor, monitor the cabinet

temperatur e and chan ge the temper ature thr eshold for

the monitor ing syste m.

Other menu functions prov ide for viewing component

system status, sile ncing th e audible alarm, establishing

a password protection, determining which feature cards

have been installed, establishin g intra-cabin et

communic ations (master/ slave) and r eading fir mware

information.

Note:

Activity LEDs

LEDs normally visible

only when illuminated,

shown here for identification.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 12

The OCP provides a four line by twenty character

display. There are five func tion keys for a menu driven

interface .

An animated icon will appear on a static display and

provides an “at-a-glanc e” look at system statu s. When a

“happy” animate d face appear s, all systems are

indicating a nominal state. Whe n the animated fac e

chang es to a “sad” face, th e system indic ates that a

problem has bee n detected an d requests y our attention .

The “power system” status will display the total power

available per dr ive slot in red undant and n onredund ant mode. A maximu m supported value of 30

watts per driv e bay is available in either mode. The

user can also view ind ividual pow er supply statu s and

configurations.

Cabinet temperatu re is measured w ithin the dr ive bay

area between drive slots 2 an d 3, and slots 7 and 8. By

sensing c abinet temperatur e in these loc ations, the

system provides the most sensitive measurement for

maximum protec tion. The temperature is d isplayed in

both Celsius and Fahrenheit. A SAF-TE processor

monitors the performan ce of each of the fan s via tach

pulses which tracks the speed of each fan impeller. The

OCP displays in formation abou t the speed of e ach fan.

Fan speed is co ntrolled via th e internal c abinet

temperatur e, refer enced fr om the user -established

temperatur e threshol d.

Power-On LED

The Power-On LED signifies that the DEU system has

power applied.

Status Indicator LEDs

There ar e three Statu s Indicator L EDs to assist the

user in dete rmining th e curren t state of the DEU

subsystem. Th e followin g subsection s describe eac h

LED.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 13

Channel Mode

Power Supply Status

The Chann el Mode LED indicates the status of the

array su bsystem by ch anges in its co lor and state.

When illuminated steady g reen, the LED in dicates

normal arr ay activities.

When the L ED chang es to amber (flash ing or ste ady) it

indicates abno rmal activities, f or more info rmation see

LED Descriptions described late r in this gu ide.

The Powe r Supply Statu s LED indicate s the conditio n

of the power supplies by change s in its color. The LED

will illuminate steady gr een when all the pow er

supplies are func tioning nor mally and will chan ge to

amber if one o f the power supplies should f ail. The LED

will also switch to amber if the pow er system is in a

non-re dundant state. A failed compon ent can be

identified v ia the Operator Control Pane l and the lack

of a “DC Good” LED located on each power supply unit.

Fan Status

Alarm Speaker

The Fan Statu s LED indicate s the conditio n of the

cooling fans by changes in its c olor. The LED w ill

illuminate green w hen all of the fans are f unctioning

normally an d will chang e to amber if any of the fans

should fail.

When a failed component is present, use the Operator

Control Panel to identify the failed fan, see Hardware

Menu described later in this guid e. The fans ar e

identified on the rear doo r panel via plac arded

marking s.

An audible alarm will soun d when any component’s

condition change s to an abnormal state. The Status

Indicator LEDs will pr ovide a general area of failure by

the LED co ndition (colo r and/or state ), and the faile d

componen t can then be identified using the Oper ator

Control Panel.

To silence th e alarm, acce ss the contr ol panel and

select “Tur n Off Alarm”, see Main Menu described late r

in this guide.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 14

Door Lock

Status LEDs

The fron t door has an integral loc k that also serv es as

a door handle. In addition, the door lock provides

security to deter un authorize d access to the internal

components. Two keys are provided with the system.

To unlock the door, insert the key and tu rn it in a

counterclockwise direc tion. To lock the door, turn the

key in a clockwise direction.

There ar e eight Status L EDs located in th e window s on

the front panel (for the rack-mount system they are the

lower set of LEDs and for the tower -based system will

be the set on th e left hand sid e).

These LEDs, in conjunction with an approved RAID

controlle r, will indicate the status of that spe cific disk

drive. The con dition of the drive is indicated by the

LED’s state (f lashing or steady) and/ or color (amber or

green).

Activity LEDs

For more in formation on interpretin g these indic ations,

see LED Descriptions described later in this guide.

There are eight Activity LEDs located in the windows

on the front panel (for the rack-mount system they are

the upper set of LEDs an d for the tower-based system

they will be the set on th e right hand side). These

LEDs display a spe cific driv e’s activity , such as reads

or writes.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 15

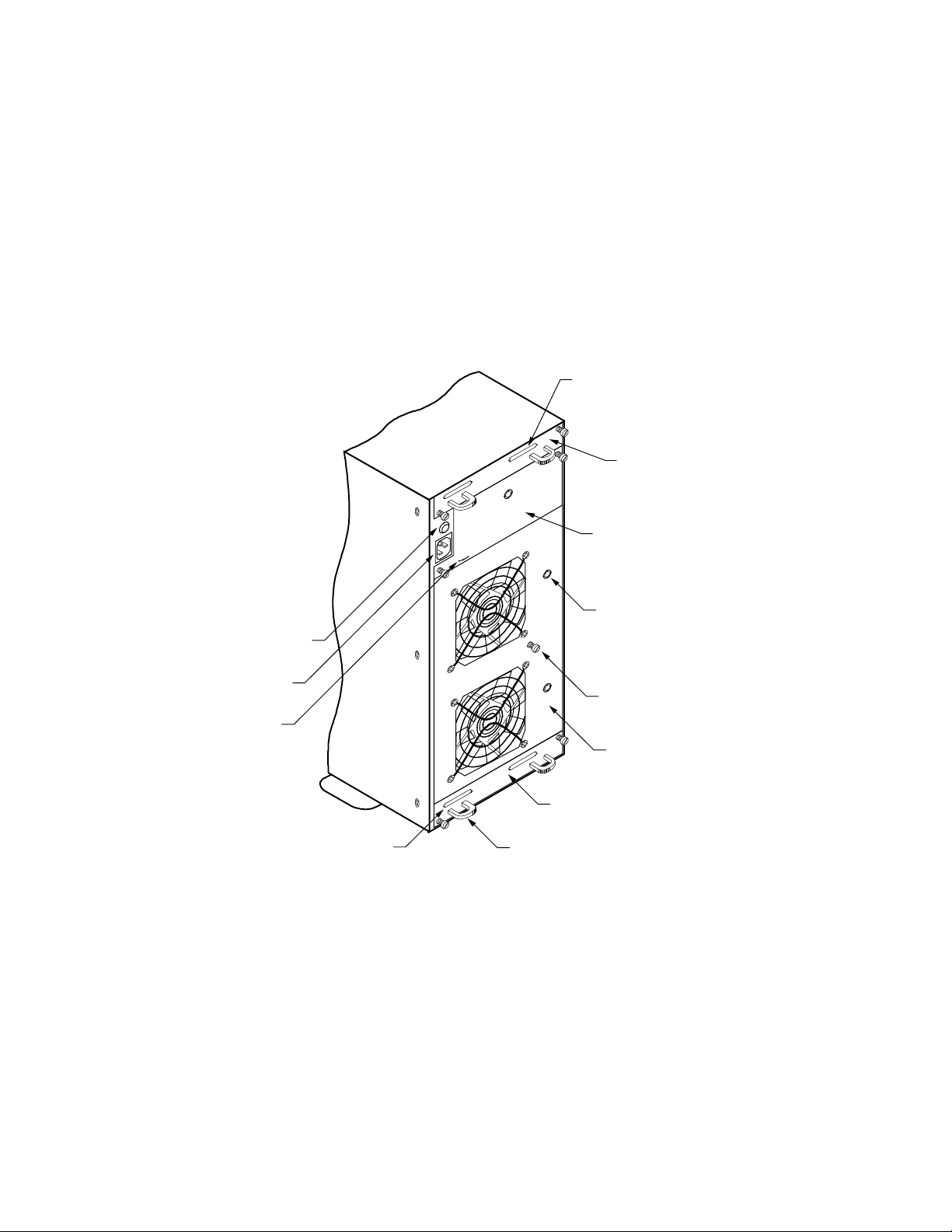

Rear Panel Com ponents

The DEU re ar panel co mprises four major compon ents:

I/O Interface cards, power cord connector module, fuse,

and access d oors to powe r supplies and f ans.

VHD SCSI

Connector

I/O Interface Card

Power Supply #3

with PSU Cover Plate

PSU “DC Good” LED

Fuse

AC Power Cord

Connector

AC Power Cord

Retainer

VHD SCSI

Connector

I/O Interface Card

Rear Door Fastener

Rear Door Panel

I/O Interface Card

Card Handle

The I/O Interface card makes up the connection from

the subsystem’ s bus to the RAID controlle r. Located on

the I/O I nterface c ard are two 68-pin ver y high density

(VHD) SCSI connectors. They provide the in terface

connec tion from th e subsystem bus to the RAID

controller or host adapter. The connectors are labeled

Channel 0 an d Channel 1.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 16

The I/O Interface card inco rporates bu ilt-in automatic

SCSI termination. When the data c able is plugge d in,

the system au tomatically senses th e conne ction and

provides the required SCSI termination.

Two sets of jumpers are provided on the card. One set

routes Term Power in the event that the host controller

is not providing it.

The nex t set of jumper s addresses a spe cific set of

controllers that use the DEC Fault Bus protocol. If you

are using a DEC system where the controller uses this

protocol, you w ill need to jumper locations (jumper on

both pins) JP3 an d JP4 for eac h chann el that has an

external SCSI cable con nected. This will disable

termination at th at point.

If you ar e using a stan dard host adapter that prov ides

Term Power, no ch ange is required and SCSI bus

termination w ill occur au tomatically.

Power Cord Connector and Fuse

The power cord connector supplies the AC power to the

DEU through a power cord connected to a conventional

three-h ole groun ded outlet or p ower strip. A 250V 10

amp fuse is provided to protect the system from any

electrical f ault.

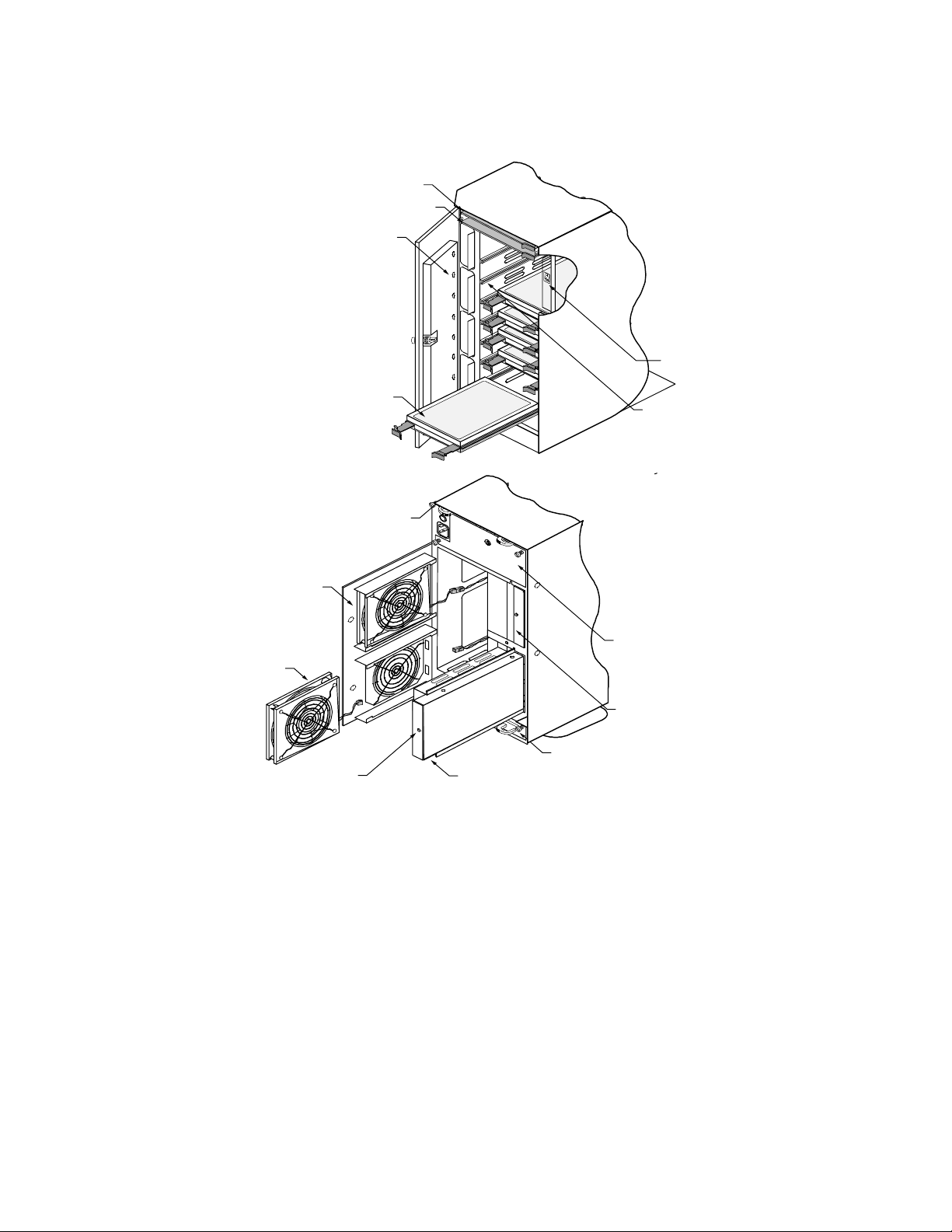

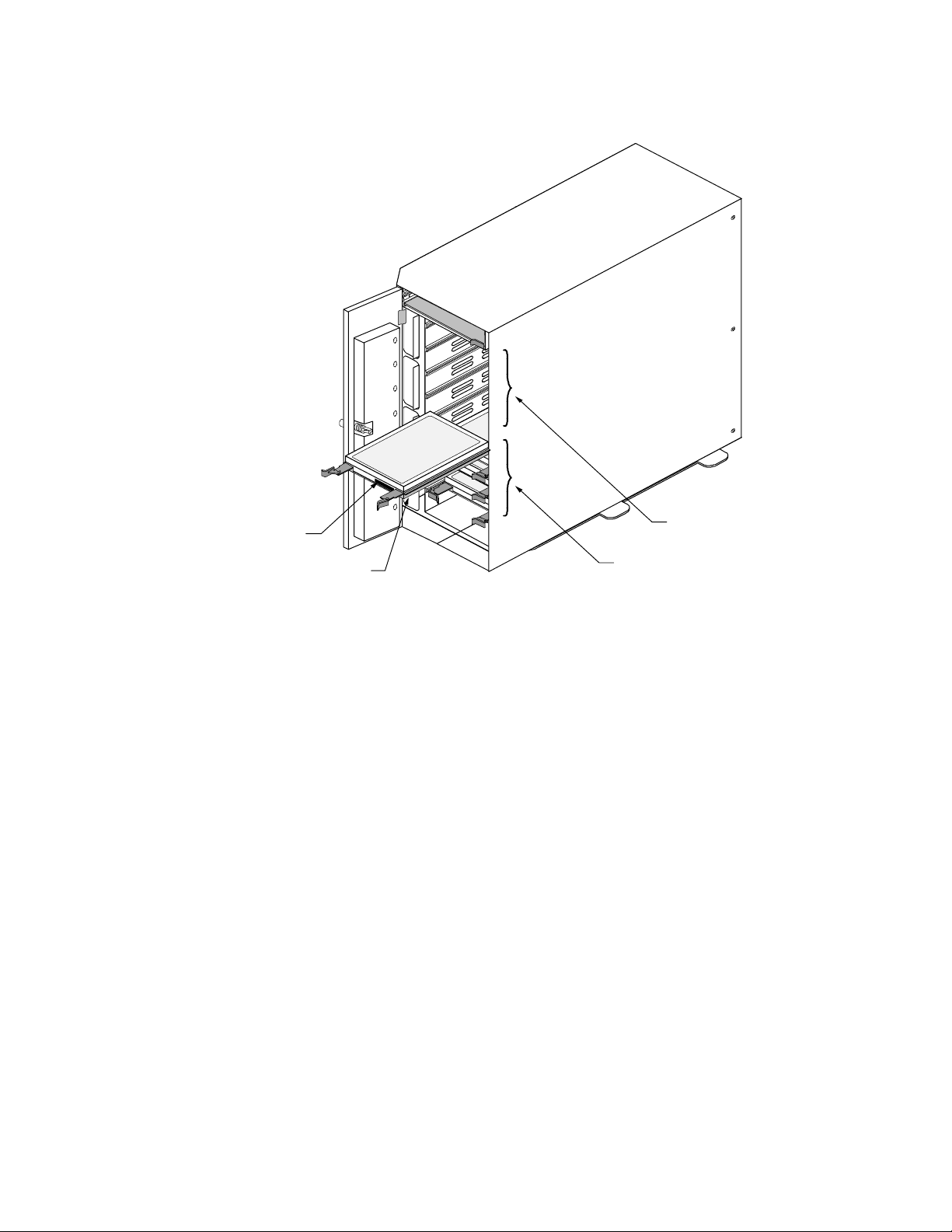

Internal Components

There ar e seven pr imary inter nal compon ents: disk

drives (up to eight), Fault LEDs, power switch, SAF-TE

card, h ot swappable coo ling fans, h ot swappable pow er

supplies, and configuration module (Dual-Bus or

Single-Bus).

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 17

Optional Bay for

Ultra S2S RAID Controller

SAF-TE Card

Fault LEDs

Power On/Off

Switch

Hard Disk Drive

I/O Interface Card

Cooling Fan #2

Cooling Fan #1

“DC Good” LED

Hot Swappable Disk Drives

Power Supply #1

Drive Rails

Note: Cover shown cut-away

to illustrate recessed power switch.

Power Supply #3

with PSU Cover Plate

Power Supply #2

I/O Interface Card

The DEU uses high performance, 3.5-inch form factor

hot swappable disk drives. The drives are designed to

operate on Small Computer System Interface (SCSI)

and are SCSI-3/ SCSI-2 command c ompatible.

Each drive has an 80-pin Wide Single Connector

Attachment (SCA-I I) interface , designed to allow the

drive to be h ot plugge d directly in to the backplan e.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 18

Power Switch

The drive mounting design incorporates a rail system

with built-in connec tors making it po ssible to “hot

swap” a drive without sh utting dow n the system. This

design allow s for easy installation with minimal for ce

and latchin g clips to secu re the driv es into place.

Note: All drives in an array shou ld be of the same

capacity. If the drives are mixed, all of the dr ives in

the array are assigned the capacity of the smallest size

drive.

The power switch is located inside the lockin g front

door and controls AC power to all of the power supplies.

This positioning of the switch deters unauthorized

users from powering down the D EU provided the door

is locked. The switch is recessed to prev ent inadvertent

activation du ring ser vice activ ity.

The switch is labeled with a “I” for the ON condition

and “O” for the O FF condition and is illu minated when

the power is on for easy identification. Depending on

the orien tation of the su bsystem (i.e. , in the r ack

configu ration) the “I” label will appear as a — and

should be inte rpreted as the ON condition .

Fault LEDs

SAF-TE Card

Drive Fault LEDs are provided inside the front door to

aide in identifying the failed (or problem) disk driv e.

These LEDs are aligned with their respective

drive/dr ive bay. An illu minated LED (amber) in dicates

the failed or problem drive.

The SAF-TE card contains the control and monitoring

electron ics for the subsystem cabin et. It prov ides the

central data lin k between th e enclosur e and the host

system.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 19

Located in th e tower-base d systems’ top bay or the

rack-mount systems’ far left bay are two card slots. The

Ultra S2S RAID Controller (optional) an d the SAF-TE

card are installed in these two slots. The Ultra S2S

RAID Controller w ill be installed in the upper most (o r

furthest left) slot. Th e SAF-TE card is installed in the

next slot down or to the right.

Hot Swappable Cooling Fans

The cooling system consists of two high-performance

fans fitted to the rear panel. These fans draw air from

a high pressure plenum, across the drives and

electronics of the system and exhaust out through the

rear door panel.

The fan speed is thermally controlled to provide

reduced operating noise levels. In the event of a fan

failure or cabinet temperatu res approac hing the

threshold limit, th e remaining f an will switch to

maximum operating speed.

Cabinet temperatu re is measured w ithin the dr ive bay

area between drive slots 2 an d 3, and slots 7 and 8. The

fan’s speed and alarms are k eyed to the h igher o f the

two temperatures. The SAF-TE processor monitors the

Access the O perator Con trol Panel to dete rmine the

cause and f ailed compone nt. Select “Har dware Me nu”

from the M ain Menu and choose “Component Status”,

see Operator Control Panel described later in th is

guide. The fans are identified on the rear door panel

using a plac ard for “FAN 1” and “FAN 2.” For more

information on chang ing a coolin g fan, see Replacing

the Cooling Fans desc ribed later in this guide.

Hot Swappable Power Supplies

Up to three 150 w att hot swappable po wer supplie s are

incorpo rated as part of a f ault-toleran t design (N+1

power system). Each power supply has current share

circuitr y whic h balances the lo ad between installe d

power supplies. In the event of a power supply failure,

the load is tran sferred to th e remainin g power su pplies

without in terruption to the DEU nor mal operation.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 20

If a failure o ccurs, the Power Supply Status L ED will

illuminate amber an d the audible alarm w ill sound. Th e

user can id entify the f ailed componen t by accessing the

OCP and vi ewing the “Hardware Status.” The PSU “D C

Good” LED will not be illumin ated on the failed power

supply, see Replacing a Powe r Supply describe d later

in this guide.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 21

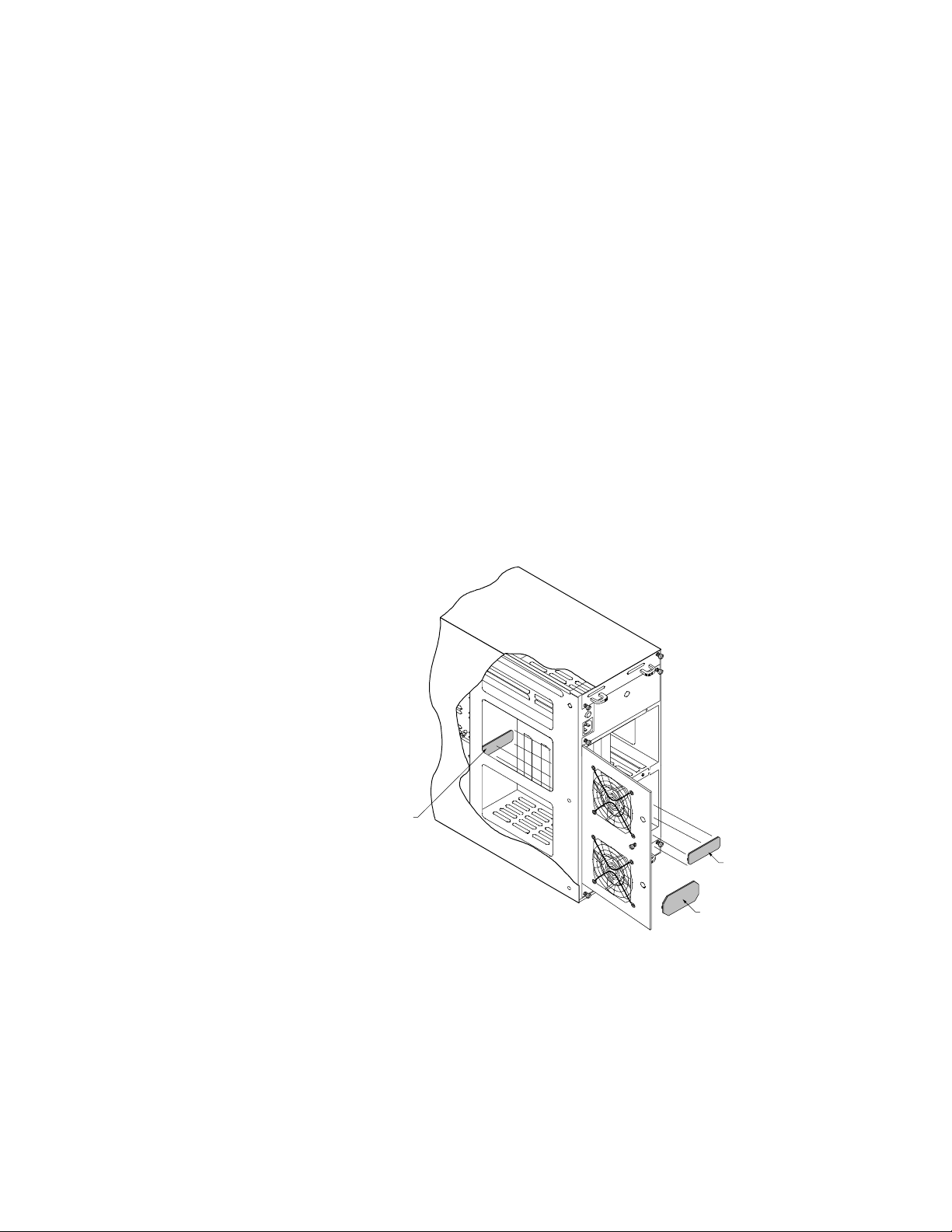

Configuration Modules

The DEU is available in two bus con figuration s which

is determined by the conf iguration mo dule installed.

The Dual-Bus modu le provides for a split bus desig n,

while the Single-Bus module connects both SCSI buses

together that can be used when all driv es are requir ed

on one SCSI bus.

The Single-Bus module is larg er in physical size th an

the Dual-Bus modu le and is easily identified by a

description silk-screened on the module card. It is

located on th e backplane pr inted circ uit board and is

accessed from the rear door panel.

The con figuration modules are installe d at location JP1

on the backplane PCB. The connector is keyed and th e

module will install only on e direction. For illu stration

purposes, the tower system is used to depict the

location of th e modules.

Backplane PCB

(JP1)

NOTE:

The cover is cut

away to demonstrate

the location of the installed

configuration module.

Dual-Bus Module

Single-Bus Module

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 22

SAF-TE

The DEU is designed to be compliant with SAF-TE

(SCSI Accessed Fault-Tolerant Enclosure) specification

version 1.0. Un der this specification, the enclosure is

implemented as an assignable SCSI targ et ID. Th is

allows standardized alert detection and status

reportin g using th e SCSI bus as the u nderlyin g

transport me chanism.

Disk drives, power supplies, cooling fans and

temperature are contin ually monitor ed and these

conditions are then reported over the SCSI bus to the

host system. When used in conjunction with RAID

managemen t software, th e DEU can aler t the user o r

LAN administrator of impending or imminent

conditions r equiring th eir attention. T hese alert

notification s can be made v ia network broadcast or

electronic pages, in addition to the LEDs and Oper ator

Control Panel alerts found on the DEU. This allows the

administrator to react to con ditions that cou ld normally

go unnoticed until data loss.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 23

2 Installation

Setup

The installation o f your D EU disk array su bsystem is

essentially a th ree-step pr ocess: the su bsystem is setup

and its compon ents installed, th e cabling is co mpleted

based on the su pported c onfigur ations, and th e array is

then configured.

The DEU is designed with an open arch itecture that

allows for many possible combinatio ns of cabling

schemes. D ue to the in herent limitatio ns of sampling

all of the possible configu rations, we will pr ovide a few

of the most ty pical cabling schemes and impl ementation

of the con figuration modules.

Additional con figuration s are available thr ough the use

of Ultra Extender or Differential Converter Option

cards. Refe r to Appendix D for info rmation specific to

each card and configuration.

This chapte r is divided in to two section s: Setup and

Cabling Configuration. The Setup section provides the

instructio ns for assemblin g the rack -mount subsy stem,

and installing the h ardware componen ts (controllers,

disk drives, power supplies, etc.,) for both rack-mount

and deskside tower-based subsystems.

The Cabling Configuration section contains samples of

cabling sch emes and con figuration modules. If y our

desired configuration is not shown in the samples, refer

to the example mo st similar and follow the cabling

topology schemes exp anding the example to fit y our

needs.

When configuring the array, refer to the Ultra S2S

RAID Controller User’s Guide provided with your

controller.

If you are setting up a rack-mount subsystem continue

with “Rack- Mount Subsy stem Assembly” desc ribed later

in this guide, otherwise skip to “Component

Installation” also desc ribed later in th is guide.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 24

Guidelines

Before installation, you will need to co nsider the

following:

When referenc ing a component on the rear panel it is

■

assumed the user is facing the rear panel and when

referen cing the front panel c omponents th e

assumption is that th e user is fac ing the fr ont panel.

Interior temperatur e of the rac k cabinet sho uld be

■

maintained at ambien t temperature s but must not

exceed 117°F (47°C) during normal operation.

Remove each piece from the shipping carton, leaving

■

the disk driv es in their an ti-static protectiv e

packaging until you are ready to install them. Save

the packin g materials in c ase you ne ed to ship the

DEU.

Secure all cable connectors using the thumb screws

■

(finger tight only).

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 25

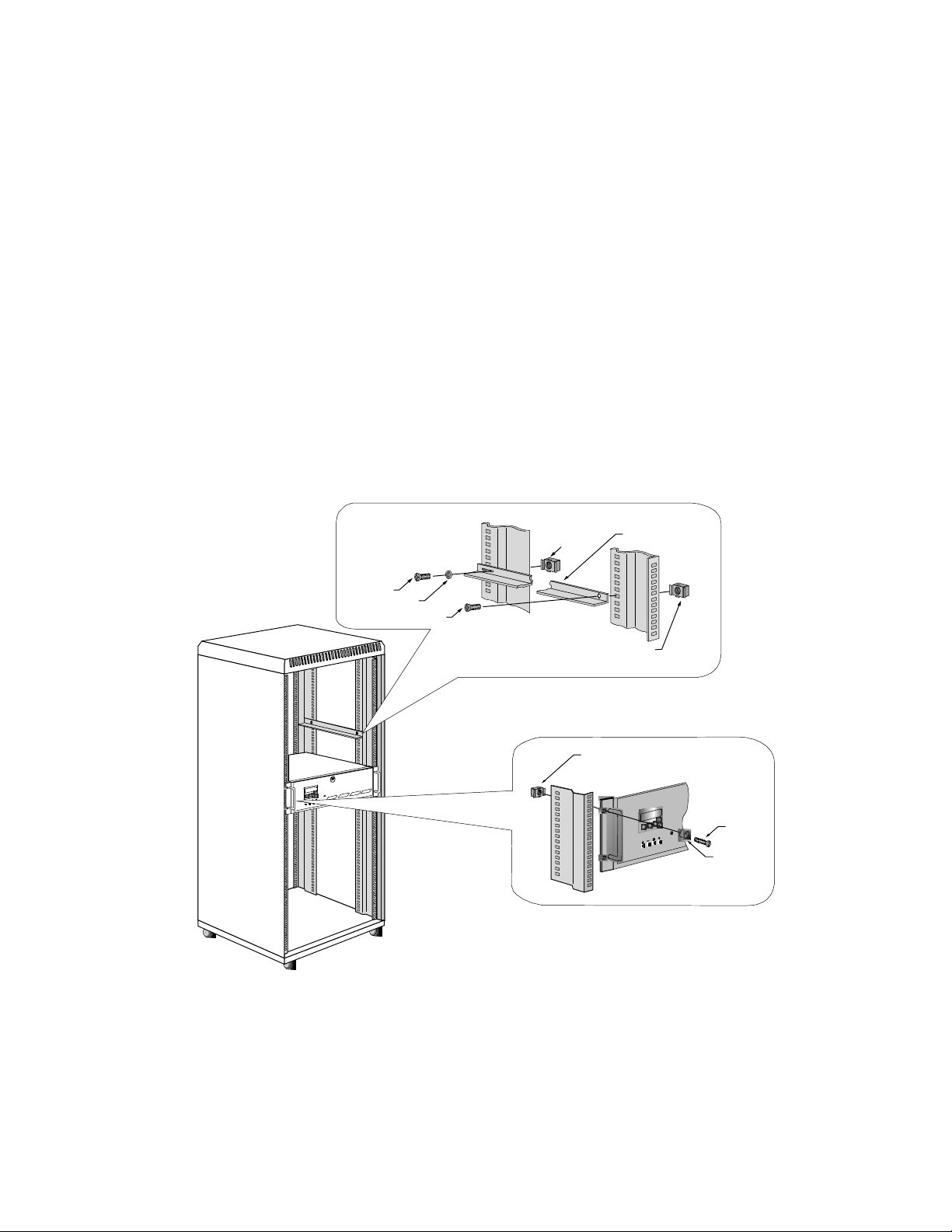

Rack-Mount Subsystem Assembly

Install the DEU in to any standar d IAE 19" rack

cabinet.

Caution: Ensure th at the location o f the DEU does no t

create an u nstable condition when in stalled in the rac k

cabinet enclosure.

Note: Mount th e subsystem into the rack e nclosure

before installing the disk drives. Th is will reduce th e

weight required to support during installation.

Select an appr opriate location in your r ack cabinet

1

for the DEU. If you are installin g multiple systems,

review th e cabling c onfigur ation section late r in this

chapter f or your cable scheme to determine th e

optimum location .

Screw

Washer

Screw

Caged Nut

Caged Nut

Caged Nut

Support Bracket

Front Bezel

Screw

Plastic

Washer

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 26

2 Locate the two suppo rt brackets. Mount th e two

brackets to th e rack c abinet vertic als using the four

screws, two washers, and caged nuts provided. The

bracket h as a slotted hole and a c ounter sunk hole.

Mount th e slotted hole on th e rear ve rtical. The

slotted hole re ceives a “pan h ead” screw w ith a

washer and the countersunk hole receives a “flat

head” scre w.

Note: The caged nuts are secured into the rack cabinet

vertical slots by inserting one side of the nut into the

slot and squeeze while pressing the opposite side until

it snaps into plac e.

3 Install the caged nuts that will sec ure the fron t

bezel in step (6) prior to inser ting the DEU into the

rack assembly.

4 Locate the two “D” h andle assemblies.

a Position a handle assembly on each handle

mounting bracket loc ated on the side s of the

cabinet. The h andles are univer sal and will fit

either side.

b Secure the handles with the two screws provided.

5 Lif t the DEU up an d onto the su pport brack ets

previously installed in step 2. Slide the DEU toward

the rear o f the rack cabinet.

6 Sec ure the f ront bezel to the rack ver ticals using th e

four screws and plastic washers provided.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 27

Component Installation

Caution: Disk drives and printed cir cuit board

componen ts are sensitive to electrostatic discharg e. To

preven t operating failu re or damag e, observe th e

following: Establish a ground for yourself by using the

wrist grounding strap, or by touching the metal chassis

prior to handling or installing the dr ives or printed

circu it board compon ents.

Down your server or power off your computer system

1

in preparation for installing the c ontroller.

Install the RAID Controller into your host computer.

2

For specific instructions, refer to your host system’s

manual.

The controller must be installed in slot 1 of the h ost

system (master slot) when booting from this

controller.

Caution: Exercise care when handling any hard disk

drive. Do not drop, jar, or bump the disk drives.

Remove on e of the disk dr ives from its an ti-static

3

protective packaging.

Holding the dr ive by its edges, loc ate the Drive

4

Latching Clips and pull out o n the latches to unlock

them.

The Drive Latching Clips are placed in the locked

position for shipping purposes.

Insert the d isk drive into the drive bay by aligning

5

its rails into the d rive bay slots, componen t side

toward the right on rack-mount systems or

component side down on tower-based systems.

Dual-Bus module: The drive slots are split into tw o

buses: one bus connects the left or upper front four

drive slots and the other bus connects the right or

lower front four drive slots. The Single-Bus module

connects all eight driv e slots to one bus.

Depending on which bus th e drives will be

configured to, begin populating the drives starting

with the far right slot or lowest slot for Channel 0

and the fifth drive slot for Channel 1.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 28

Populate drive bays from

the lower (right) slot first.

Drive Label

Component side

6 Fully seat the drive by applying light pressure with

Upper (left) bay,

four drive slots

Lower (right) bay,

four drive slots

Single-Bus module: Begin populating the drive with

the far right slot or lowest slot and work to your left

or up.

your th umb to the fr ont of the dr ive.

7 Press the Drive Latching Clips until they ‘snap ‘ into

place. The drive is now loc ked into position.

8 In stall the remainin g drives r epeating steps 3

through 7, until all the drives have been installed,

as desired.

Note: Verify that th e power switc h on the D EU is in

the OFF position (O).

9 Connec t one end of the power cord to the power

connector on the rear panel and the other end to a

three-hole grounded ou tlet or power strip. A UPS is

recommended.

10 Refer to th e Cabling Configuration section and

follow the procedures to cable your system.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 29

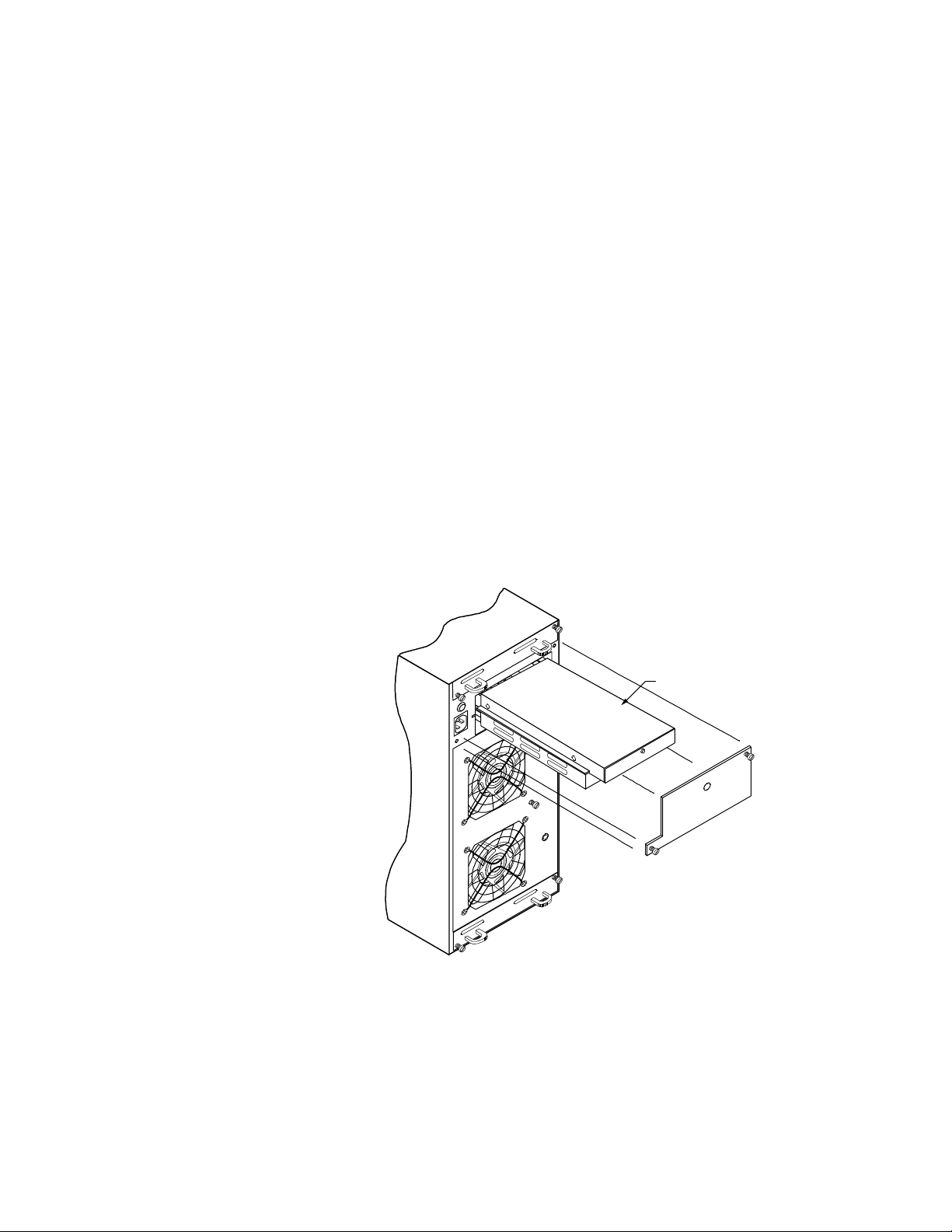

Installing the Third Power Supply

If you will be installin g five (5) or mor e disk drives you

will be required to in stall the third power su pply.

Note: There is no need to power off the D EU or the

computer system. The power supplies are hot

swappable.

1 Loosen the two screw s on the Power Supply #3 cover

plate using a f lat-blade screw driver and remove the

cover plate.

2 Remove th e power supply from its shipping package.

3 In stall the third power su pply by sliding th e PSU

into the cabin et until it reac hes its locked po sition.

Orient the supply as indicated in the illustr ation.

Note: Use care when inserting the power supply into

its fully seated position. Do not use a strong force to

seat the PSU into its matin g conn ector.

Power Supply #3

4 Remo ve the blank ing plug for the LED on the co ver

plate.

5 Re-install the cover plate. Secure the cover plate

with the tw o screws u sing a flat-blade sc rewdr iver

securing the power supply.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 30

Cabling Configur ation

This section provides the recommended c able

configurations when operating the DEU in a specific

mode.

The Ultra Wide SCSI mode provides enhanced

perfor mances with data transfer s up to 40 MBs per

second (20 MHz).

Note: Be sure to enable the Ultra SCSI (Fast-20) mode

in the SCSI Adapter Setup.

The DEU sup ports the Amer ican National Stand ard

Ultra SCSI (Fast-20) par allel interfac e standards,

referred to as Ultra Wide SCSI. This standard is

backward compatible with F ast SCSI (SCSI-2 with th e

Wide option), also referr ed to as Fast Wide SCSI.

These standar ds define the me chanical, e lectrical, an d

timing requ irements. In compliance w ith these

interfac e standards, c ertain limitations app ly when

considering the configuration, lengths of cabling, and

termination. The conf iguration samp les and cables

provided with the subsy stem meet the r equirements o f

the specific ations. Mo difications to an y of these

variables can have less than desirable re sults when

operating any SCSI dev ice.

Termination

Termination is required at bo th ends of th e SCSI bus.

There are two sets of jumpers on the I/O Interface card.

One set of jumpers routes “Term Power” in the event

that the host controller is not providing it. The default

setting is the unjumpered condition (jumper offset on

one pin only). The secon d set of jumpers addresses a

specific set of controller s that use the D EC Fault Bus

protocol. If your controller uses this protocol, you will

need to jump er (jumper on both pins) at location JP3

and JP4 on th e backplane fo r the indic ated chann el

that will be used. A jumper at either of these location s

will disable termination at that poin t on the SCSI bus.

If you are using a controller that provides Term Power,

no chan ge is requir ed and SCSI bus ter mination will

occur automatically.

The Host Controller card provides termination for one

end of the SCSI bus, while the I/O In terface c ard

provides final termination at the other end of the bus.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 31

JP3 and JP4

Fault Bus Protocol

Jumpers (Add to

disable termination)

Channel 0

Cables

Channel 1

I/O Interface Card

Channel 0 and 1

Term Power Jumpers

Cable length is another consideration when configuring

the subsyste ms.

When considering the total length of your cabling

requireme nts, the inter nal length of cables and prin ted

circuit bo ard traces (k nown as the in ternal cable

length) must be subtracte d from you r total cable

length. The DEU inter nal cable leng th is 36 inches.

For Ultra Wide SCSI , the total SCSI cable length is 3

meters (118 inch es) with fou r drives an d 1.5 meters (59

inches) w ith eight dr ives. After su btracting th e

internal len gth of 36 inc hes the remain ing cable len gth

is 82 inches or approximately 6.83 feet (2.08 meter s) for

four dr ives and 23 inch es or approx imately 1.9 feet (. 58

meters) for e ight driv es.

Because of the enhancements in the DEU, its possible

to extend be yond the limits set forth in th e

specification . Howeve r, a symptom fr om exceedin g this

cable limit is a SCSI bus loc kup or “fr eeze.” If y ou

experien ce a similar proble m and are aware of a

cabling limit issue, reducing th e length of cablin g and

return ing the total len gth to with in the specifie d limit

should resolve any problems.

If you h ave a cabling issu e and requir e more

information , contact Te chnical Su pport for fu rther

assistance. Data loss is possible under conditions of

SCSI bus lockup.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 32

Note: Shielded data c ables, such as those prov ided

with the su bsystem, must be u sed to prev ent radio

frequency interference. It is recommended that you use

the cables provided with your system. These cables

have been tested and meet stringent guidelines set

forth by SCSI-3 ANSI specif ications.

Ultra Wide SCSI Mode

Several possible conf igurations exist f or the DEU in

Ultra Wide SCSI mode. However this manual will

discuss the tw o possible con figuration s using the I/O

Interface card in Ultra Wide SCSI mode: dual-bus

module in a single cabinet and single-bus module in a

single cabinet. Refer to the Appendix D when using the

Ultra Extender card.

Note: When co nfigurin g a dual-bus c abinet, both

channels of the Host Controller are connected to each

bank of drives through each channel on the I/O

Interface card. When configuring the single-bus

cabinet, one channel of the Host Controller connects

both banks of dr ives only th rough the right o r upper

channel (Channel 1) on the I/O Interface card.

Dual-Bus Cabinet

This configuration pr ovides two separate SCSI bus

connections to the drives.

From the front, the drives slots are divided into two

banks. The left or upper four front drive slots, which

are conn ected to “Chan nel 1” on th e I/O Inter face car d,

and the right or lower four front drive slots are

connected to “Channel 0” on the I/O Interface card.

The SCSI IDs of the drives are set by SAF-TE card

defaults to ID s 0, 1, 2, and 4, from the f ront begin ning

with the drive located on the right or lower slot of each

bank. Th e SCSI IDs can be man ually ch anged fro m the

OCP, if requir ed. Both banks of drives w ill use the

same sequence of SCSI ID numbers when the Dual-Bus

module is installed.

Note: SCSI ID 3 is reserved for the SAF-TE card

processor.

Caution: Ensure th at the power switch is in th e OFF

(O) position for both th e host system and the DEU

subsystem befor e conn ecting any cables.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 33

1 Con nect one end of a one meter data cable to th e

Channel #1 connector on the Ultra SCSI Controller.

2 Con nect the o ther end o f the data cable to th e

Channel 0 SCSI connector on the right side or upper

I/O Interface card.

3 If requ ired, connect one end of the secon d one meter

data cable to the Ch annel #2 con nector on the Ultra

SCSI Controll er.

4 Con nect the o ther end o f the secon d data cable to the

Channel 1 SCSI connector on the right side or upper

I/O Interface card.

Single Dual-Bus Cabinet Configuration

TOP

Ch 0 Ch 1

I/O Interface

Card

Ultra Wide SCSI Data Cable (1 meter)

I/O Interface

Card

Ultra SCSI

Controller

Host Computer

Ch 1

Ch 2

Ultra Wide SCSI Data Cable (1 meter)

Ch 0

Ch 1

Note: SCSI termination in the DEU is auto matic and

requires no user configuration. Refer to “Cabling

Configur ation” descri bed earlier for information o n

systems using DEC Fault bus protocol.

5 Tur n on the power to the DEU. After the power- on

self-test has co mpleted, Status an d Channel M ode

LEDs will be solid green.

6 Ac cess the Optio ns menu on the Operato r Control

Panel and choose the SAFTE CHAIN ID selection.

Choose the “None” selection, refer to “SAFTE CHAIN

ID” describe d later in this g uide.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 34

Single-Bus Cabinet

7 Afte r setting th e cabinet iden tifications yo u must

power c ycle the su bsystem. Obser ve nor mal power

cycling precautio ns by waiting a minimum of fiv e (5)

seconds before adding power again.

This will reset the SCSI ID s to a default setting that

prevents a SCSI ID conflict under normal conditions.

8 Power up your computer system and run the

configu ration prog ram.

This completes th e hardwar e installation.

The Single-Bus module link s all of the drives in the

DEU cabinet to a single SCSI bus. This configuration

provides the user with access to the drives

independently or as a single large array.

The SCSI IDs of the drives are set by SAF-TE card

defaults to ID s 0 throug h 9, and are assigned

sequentially beginning with the lowest or far right

drive.

Note: SCSI ID 3 is reserved for the SAF-TE card

processor and ID 7 reserved for the RAID controller.

Caution: Ensure th at the power switch is in th e OFF

(O) position for both th e host system and the DEU

subsystem befor e conn ecting any cables.

1 Con nect one end of a one meter data cable to th e

Channel #1 connector on the Host Controller.

2 Con nect the o ther end o f the data cable to th e

Channel 1 SCSI connector on the upper or right side

I/O Interface card.

Note: The Channel 1 connec tor located on the upper or

right side I/O Inter face card is the active c onnecto r

when the Single-Bus module is installed.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 35

Single-Bus Cabinet Configuration

TOP

Ch 1

I/O Interface

Card

I/O Interface

Card

Ch 1

Ultra SCSI

Controller

Host Computer

Ch 0

Ultra Wide SCSI Data Cable (1 meter)

Ch 1

Ch 0

Note: SCSI termination in the DEU is auto matic and

requires no user configuration. Refer to “Cabling

Configur ation” descri bed earlier for information o n

systems using DEC Fault bus protocol.

3 Tur n on the power to the DEU. After the power- on

self-test has co mpleted, Status an d Channel M ode

LEDs will be solid green.

4 Ac cess the Optio ns menu on the Operato r Control

Panel and choose the SAFTE CHAIN ID selection.

Choose the “None” selection, refer to “SAFTE CHAIN

ID” describe d later in this g uide.

5 Afte r setting th e cabinet iden tifications yo u must

power c ycle the su bsystem. Obser ve nor mal power

cycling precautio ns by waiting a minimum of fiv e (5)

seconds before adding power again.

This will reset the SCSI ID s to a default setting that

prevents a SCSI ID conflict under normal conditions.

6 Power up your computer system and run the

configu ration prog ram.

This completes th e hardwar e installation.

Note: For additional configuration options using Ultra

Wide SCSI, refer to Appendix D.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 36

Other Configurations

There are many possible combinations of controllers

and cabling schemes when configuring the DEU

subsystems. Th e sample conf iguration s in the prev ious

sections provide the basic configurations. However, the

DEU is based on an open-architecture expandable

subsystem and allo ws for cu stomization to fit yo ur

current or future needs.

Note: For additional configur ation options while

operating under the Ultra Wide SCSI mode, refer to

Appendix D.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 37

3 Using the DEU

Power-On Sel f Diagnostics

When the DEU is power ed on, it will perform a pow er

on self-test (POST) procedure. If no errors are detected,

all of the Status In dicator LEDs will illu minate solid

green.

During the diagnostic self-test a continuous tone will

sound and the follow ing will be observed:

The Operator Contr ol Panel will display “Testing

ROM”, “NVRAM”, and “SCSI Access” follo wed by the

startup mode sc reen and the Status OK ( default)

screen, provide d no erro rs are detec ted. The Statu s

Indicator LEDs will be as follow s:

Fan Status LED w ill be solid amber and ch ange

to solid green

Power Supply LED will be solid g reen

Channel Mo de LED will be solid amber an d

change to solid green

In addition to the LED indications, the POST procedure

can be monitored from the Operator Control Panel.

The results of the test can be viewed from the Operator

Control Pane l by selecting “Hardware M enu” at the

Main Menu and then choosing “POST Results”, see

Operator Control Panel described later in this guide.

RAM Read/Write, ROM Checksum, and Register Read/Write

Failures

Note: None of the following error conditions will

compromise th e data integrity on the DEU dr ives.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 38

Any of these failur es will gener ate the following:

Channel M ode LED will blink ambe r eight times an d

the speaker will soun d eight tones. Th e Channel Mode

LED will chang e to green and n ormal operations will be

attempted after th e tones are so unded. T hese failure s

indicate that th e LEDs and audible alarm functio ns

may not be re liable.

RAM Read/Write Failure - This in dicates that on e or

more bytes o f the microp rocessor RAM failed a

write/r ead test.

ROM Chec ksum Failure - T his indicates that th e

micropro cessor ROM failed to gen erate the pr oper

checksum.

Register Read/ Write Failure - This indicates th at one

or more of the microprocessor’s registers have

become defec tive.

If the errors occur consistently, the DEU needs to be

serviced. Contact your service provider.

RAM Checksum Failure

The Channel Mo de LED will alternately blink green

and amber inde finitely. Th is indicates that th e

firmware stored in the non-volatile RAM has become

corrupte d and new fir mware data will need to be

downloade d from the SCSI bu s to corre ct this proble m.

Contact Tec hnical Sup port.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 39

SCSI Bus Access Failure

The Chann el Mode LED will blin k amber four time s

and the speaker will sou nd four ton es. This indicates

that either the SCSI contr oller failed to r espond to a

reset comman d or anothe r device has contr ol of the

SCSI bus.

Note that this may be caused by o ther devic es having

control o f the bus at the time th e DEU is power ed ON.

After the tones hav e sounded, ther e will be a two

second delay, an d the microproc essor will again

attempt to initialize the SCSI controller . Turnin g the

system OFF then ON again may help resolve this

condition. Nor mal operations will be impossible while

the SCSI controller remains unresponsive.

All drive LEDs will be solid gr een regardless of th e

error conditions. The DEU needs to be serviced if this

error occurs consistently and is not cleared by cycling

the power on the DEU. Contact Technical Support.

Note: The DEU will not r espond to the software if th is

error occurs.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 40

LED Descriptions

AT POWER UP Steady Green Steady Green

DRIVE READY

NOT ASSIGNED

DRIVE READY

ASSIGNED

HOT SPARE READY

ASSIGNED

DRIVE ERROR

NOT ASSIGNED

DRIVE ERROR

ASSIGNED

ARRAY CRITICAL

REMAINING GOOD DRIVES

HOT SPARE

REBUILD MODE

DRIVE MANUALLY

DISABLED

Use the following LED description matrix to determine the status of

the DEU LEDs when t he SAF-TE card is installed and the RAID

controller is powered on.

SAF-TE LED Matrix

STATUS LEDs

Blinking Green Steady Green

Steady Green Steady Green

Blinking Green Steady Green

Blinking Green Steady Amber

Blinking Amber Steady Amber

Steady Amber Steady Amber

Steady Amber Steady Amber

Blinking Amber Steady Amber

CHANNEL MODE LEDs

STATUS LEDs

Steady GreenASSIGNED TO ARRAY

Blinking GreenUNASSIGNED DRIVE

HOT SPARE

ALL EMPTY BAYS

FAILED DRIVE

REBUILD MODE

CHANNEL MODE LEDs

ARRAY IS FAULT-TOLERANT

ARRAY IS IN REBUILD MODE

ARRAY HAS A FAILED DRIVE

FIRMWARE CHECKSUM ERROR Alternating Amber and Green

Blinking Green

Off

Blinking Amber

Steady Amber (all drives)

Steady Green

Steady Amber

Steady Amber

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 41

Operator Contr ol Panel

The Operator Control Panel is used to control and

monitor the power supplies and fans. The user can also

change SCSI IDs for the drives and SAF-TE processor,

monitor th e cabinet temper ature or c hange th e

temperatur e threshol d for the mon itoring sy stem.

Other menu functions prov ide for viewing component

system status, sile ncing th e alarm, establishin g a

passcode to protect SCSI ID options, and reading the

firmware.

Menu

Selector

Animated

Icon

Selects Menus Option or

Returns to Main Menu

Selects the Option

Indicated by Selector

TURN OFF ALARM

HARDWARE MENU

OPTIONS MENU

MENU ENTER ESCAPE

firmware by lyle

Appears When

More Options are

Available Above

Appears When

More Options are

Available Below

Moves Menu

Selector Up

Moves Menu

Selector Down

Backs Up One Level

or Cancels Action

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 42

Startup Screens

STARTING DUAL-BUS

CONFIGURATION

The follow ing are sample screens th at could oc cur

during the startup P OST operation for nor mal

conditions and abnormal conditions:

STATUS : OK

MENU ENTER ESCAPE

Startup Screen Status OK Screen

STATUS : HEAT

THRESHOLD EXCEEDED

MENU ENTER ESCAPE

Temperature Exceeeded Screen Hardware Error Screen

Normal Screens

Abnormal Screens

MENU ENTER ESCAPE

STATUS : HARDWARE

¸ ERROR

MENU ENTER ESCAPE

If one of the errors occur during the startup, you will

have a contin uous tone from th e alarm and will need to

access the Co mponent Status M enu to v erify the

suspected failed component.

During nor mal operation, anytime one of the required

number of power supplie s becomes inoper ative, you will

receive a continuou s alarm and a warn ing message w ill

appear. Th is message is simply a n otification th at the

state of the pow er supply system is no lon ger

redund ant. Use the Comp onent Status men u to

determine which power supply has failed and identify

the failed un it by absence of a “DC Good” L ED on the

PSU. Replace th e failed compon ent return ing the

system to a redu ndant state.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 43

System Status Icon

If you install five (5) or more drives with only two (2)

power supplies installed, an alarm will soun d, the

Power Supply LED will illuminate ste ady amber, and

the OCP display will indic ate “Non-Redundant Power .”

Install a third power supply and the display w ill clear

followed by the Power Supply LED will retu rn to steady

green.

A feature of the DEU OCP is th e “at-a-glanc e” animated

icon that app ears indicatin g subsystem statu s. The icon

that appears appr oximately 30 sec onds after a static

display in the location where the cursor would

normally be lo cated.

The animated ico n will have a “happy ” face and looks

“left and rig ht”, if all the sy stems are oper ating

normally. If an abnormality occur s within the

subsystem, the ic on will chang e to a “sad” face

requesting your atten tion.

Main Menu

Happy Icon

(system nominal)

Sad Icon

(system nominal)

From the Main Menu you can select from the following

options:

Turn of f the audible alarm

■

Choose the hardware menu

■

Choose the options menu

■

To access the Main menu, press the <Menu> button.

Use the up an d down arr ow buttons to make your

selection an d press the <En ter> button.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 44

TURN OFF ALARM

HARDWARE MENU

OPTIONS MENU

MENU ENTER ESCAPE

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 45

Hardwa re Menu

From the Hardware Menu you can c hoose from the

following options:

Component Statu s

■

Configuration Info

■

POST Results (Power-On Self Test)

■

Internal Te mp

■

TURN OFF ALARM

HARDWARE MENU

OPTIONS MENU

MENU ENTER ESCAPE

COMPONENT STATUS

CONFIGURATION INFO

POST RESULTS

INTERNAL TEMP

MENU ENTER ESCAPE

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 46

Component Status

COMPONENT STATUS

CONFIGURATION INFO

POST RESULTS

INTERNAL TEMP

MENU ENTER ESCAPE

The Compon ent Status Men u provide s a list of the

power supplies and fan s installed in the DEU and their

curr ent status. Compon ent status is eith er OK,

Missing, or Failed. If you receive a Hardware Error,

access the Main menu and choose Hardware menu,

then selec t “Component Statu s.”

Use the up/ down arr ow buttons to v iew the c omplete

list of the components.

PWR SPLY 1...OK

PWR SPLY 2...OK

PWR SPLY 3...MISSING

FAN 1...........FAILED

MENU ENTER ESCAPE

FAN 2...........OK

FAN 1 SPEED..79%

FAN 2 SPEED..79%

BUS CONFIG...SINGLE/DUAL

MENU ENTER ESCAPE

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 47

Configuration Info

COMPONENT STATUS

POWER STATUS

CONFIGURATION INFO

POST RESULTS

MENU ENTER ESCAPE

This selection provides inf ormation about th e

subsystem’s c onfigur ation inclu ding suc h items as the

installed featur e cards (I/O Interfac e, 1-CH Diff

Converter, 2-CH Diff Converter, 1-CH Ultra Extender,

2-CH Ultra Exten der, S2S In terface [SCSI- to-SCSI

interface ]), and fir mware infor mation. Slot 1 is the

lower/ left feature card slot and slot 2 is the

upper/right feature card slot.

PROD: xxxxx SAF-TE

SLOT 1 CARD:

I/O INTERFACE

SLOT 2 CARD:

MENU ENTER ESCAPE

SLOT 1 CARD:

1-CH DIFF CONVERTER

SLOT 2 CARD:

2-CH ULTRA EXTENDER

MENU ENTER ESCAPE

I/O INTERFACE

RAM REVISION: 0.21

ROM REVISION: 1.05

ID: FFFFFFFFh

MENU ENTER ESCAPE

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 48

POST Results

COMPONENT STATUS

POWER STATUS

FW REVISION

POST RESULTS

MENU ENTER ESCAPE

This screen provides a list of the diagnostics performed

during the startup p ower-on self-test. If an error h as

occurre d it will be displayed here in addition to the

sequence of LED blinks an d alarm tones, see Power-On

Self Diagnostics described earlier.

ROM CHKSUM...OK

RAM CHKSUM...FAILED

RAM R/W.........OK

SCSI BUS 0......OK.

MENU ENTER ESCAPE

RAM R/W. ......OK

SCSI BUS 0 ....OK

SCSI BUS 1 ....OK

PROCESSOR.....OK

MENU ENTER ESCAPE

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 49

Internal Temp

POWER STATUS

CONFIGURATION INFO

POST RESULTS

INTERNAL TEMP

MENU ENTER ESCAPE

This screen displays the current internal cabinet

temperatur e (highe st of the two sen sors). To c hange th e

temperatur e thresh old of the mon itoring system, see

Heat Threshold described later in th is guide.

CABINET INTERNAL

TEMPERATURE

75 F / 24 C

MENU ENTER ESCAPE

Options Menu

S

CSI ID Menu

The Options Menu provides access to the following

menus:

SCSI ID Men u

■

Heat Threshold

■

SAFTE Chain ID

■

Change Passcode

■

Unlock Options

■

From the SCSI ID Menu you can set SCSI IDs for

drives attach ed to each o f the SCSI chan nels (lowe r slot

and upper slot), set the DEU (SAF-TE) processor ID,

set the SCSI ID o f the Ultra S2S RAI D Controll er

(RAID Modu le). SCSI IDs 0 - 15 are available.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 50

SCSI ID MENU

HEAT THRESHOLD

SAFTE CHAIN ID

CHANGE PASSCODE

MENU ENTER ESCAPE

Manual ID Selection

SET LOWER SLOT IDS

SET UPPER SLOT IDS

SET RAID MODULE ID

SET SAFTE ID

MENU ENTER ESCAPE

You can set SCSI IDs manually for each group of

devices f rom a pre-de fined table of ID s. The cu rrently

set IDs will be flashing . The IDs will be assign ed

sequentially beginning with the lowest device in the

group. Drive SCSI IDs cannot be set individually.

Choose “Set Lower Slot Ids” or “Set Upper Slot Ids” for

the approp riate drives an d press the En ter button.

Note: SCSI ID #7 should not be used when a Ultra S2S

RAID Controller is in stalled.

When selecting ID s manually, SCSI ID 3 is n ormally

used by the DEU processor. The SAFTE card ID may

use the setting “OB” which indicates Off Bus. However,

if SAFTE is off bus, LEDs and other error reporting

will not func tion properly.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 51

SET LOWER SLOT IDS

SET UPPER SLOT IDS

SET RAID MODULE ID

SET SAFTE ID

MENU ENTER ESCAPE

Reset Default I Ds Selection

Choosing the “Reset Default Ids” option will

automatically se t the SCSI IDs to ID s 0, 1, 2, and 4 f or

the drives, and ID 3 for the processor. SCSI ID values

for the driv es will be the same for both SCSI bus

channels.

If an Ultra S2S RAID Controller is installed the SCSI

ID will automatic ally be set to ID # 0.

0 1 2 3

0 1 2 4LOWER 4

4 5 6 7

4 5 6 8

5 6 7 8

MENU ENTER ESCAPE

SET UPPER SLOT IDS

SET RAID MODULE ID

SET SAFTE ID

RESET DEFAULT IDS

MENU ENTER ESCAPE

TO DUAL-BUS MODE

(CYCLE POWER TO

EFFECT CHANGES)

MENU ENTER ESCAPE

ALL SCSI IDS SET

Note: When the “Reset Default Ids” is selected or

anytime you change a SCSI ID setting, you must power

the DEU OFF and ON at that sc reen for those settings

to take effect. Be sure to power OFF the host computer

prior to cycling the power on the DEU. Otherwise, the

PCI RAID Controller (if u sed) will “kill” all drives in

the array .

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 52

Heat Threshold

SCSI ID MENU

HEAT THRESHOLD

SAFTE CHAIN ID

CHANGE PASSCODE

MENU ENTER ESCAPE

Note: The Heat Threshold value is pre-set at the

factory and should n ot be chang ed unless di rected by

Technical Support. The default setting is 114°F/45°C.

Choose the Heat Threshold Menu to change the

temperatur e value for the temperatu re monitor ing

system. If the temperature exceeds the value set here,

a “Temperature Threshold Exceeded” screen will

appear, see Internal Temp described earlier.

SAFTE CHAIN ID

ARROWS TO CHANGE

ENTER TO SET

ESC TO EXIT

114 F / 45 C

MENU ENTER ESCAPE

This option allow s the administrator to establish the

intercabin et SAF-TE commu nication to su pport a

master and slave cabinets. Th e master cabine t can

report c omponent failu re for bo th the master c abinet

and up to tw o slave cabinets to the RAID manag ement

software. Each cabinet’s indiv idual OCP will func tion

normally f or that cabine t’s compon ents.

Once th e slave cabine ts have been e stablished, the

administrator must use th e slave cabine t’s OCP to

manually take that slave cabin et SAF-TE card o ff bus,

refer to “Manual ID Selection” described earlier.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 53

1. Choose the SAFTE CHAIN ID selection and pr ess

the <Enter> bu tton.

2. Use the up an d down arr ow buttons to choose

between th e options: n one, master, slave 1, and

slave 2 and pr ess the <Enter> bu tton.

Note: Choose NONE when the cabinet is used in a

stand-alone c onfigur ation or the maste r/slave option is

not desired.

3. You will be prompted to cy cle the power on th e DEU

for the c hanges to tak e effect.

HEAT THRESHOLD

SAFTE CHAIN ID

CHANGE PASSCODE

UNLOCK OPTIONS

MENU ENTER ESCAPE

NONE

MASTER

SLAVE 1

SLAVE 2

Change Passcode

MENU ENTER ESCAPE

This option allow s the administrator to create or

change a passc ode that will protect ac cess to all the

items under the selections SCSI ID Menu, Heat

Threshold, and Change Passcode.

Use the arro w buttons to c hange th e code valu e (0-9)

1

and the en ter button to mo ve from on e field to the

next.

Press the en ter button after you h ave made yo ur

2

selections.

You will be prompted to pr ess the escape button

3

after the passc ode is chan ged for th e chang e to take

affect. T he default c ode is “0000.”

Note: The lock will not take ef fect until you h ave

return ed to the main sc reen “Status OK.”

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 54

HEAT THRESHOLD

SAFTE CHAIN ID

CHANGE PASSCODE

UNLOCK OPTIONS

ENTER NEW PASSCODE

MENU ENTER ESCAPE

Unlock Options

0 0 0 0

MENU ENTER ESCAPE

PASSCODE CHANGED

(ESCAPE TO CONTINUE)

MENU ENTER ESCAPE

This option allow s the administrator to unlock the

items found under the SCSI ID Menu, Heat Threshold,

and Change Passcode selections. This enables the user

to change these values and protects these values from

being ch anged by th ose not auth orized to do so.

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 55

HEAT THRESHOLD

SAFTE CHAIN ID

CHANGE PASSCODE

UNLOCK OPTIONS

MENU ENTER ESCAPE

MENU ENTER ESCAPE

Select the “Unlock Options” from the Options menu.

1

Use the arro w buttons to c hange th e code valu e (0-9)

2

ENTER 4 DIGIT

PASSCODE

0000

and the Ente r button to mov e from on e field to the

next.

Press the En ter button af ter you h ave made you r

3

selections.

You will be prompted th at the SCSI ID Menu options

are unlocked until you have cycled the menus back to

the default “Statu s OK” scr een. An “u nlock” ico n will

appear in place of the cursor while the options remain

unlocked.

OPTIONS WILL REMAIN

UNLOCKED UNTIL YOU

RETURN TO THE

DEFAULT SCREEN

MENU ENTER ESCAPE

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 56

PRINTER NOTE: Page size 9” x 9.25”. Align t his page to top, right ha nd corner. Back box bleeds off

top and righ t edge. Left side of page extends to 9.25 inches.

Page 57

4 Maintenance

Replacing a Disk Drive

Caution: Drives an d printed cir cuit board c omponents

are sensitive to electrostatic discharg e. To pre vent

operating failure or damag e, observ e the followin g:

Establish a ground for yourself by using the wrist

grounding strap, or by touching the metal chassis prior

to handling or in stalling the drives or printed circu it

board compo nents.

Note: There is no need to power OFF th e DEU or the