Paasche VL-PL, VLS-PL User Manual

VL & VLS

Internal Mix - Double Action

Airbrushes - PTFE Packings.

VL

INSTRUCTIONS AND PARTS LIST VL/VLS-9/25/2012

Supersedes Instructions & Parts List VL/VLS-8/31/2011

WARNING: Spray materials may be harmful if inhaled or allowed to come into contact with the skin or eyes. Consult the product label and Material Safety Data Sheet supplied for the spray material. Follow all safety precautions. CAUTION: Well Ventilated Area Required to remove fumes, dust or overspray. Secure airhose to Airbrush with V-62 Wrench for safety and to prevent air leaks.

M a x i m u m A i r P r e s s u r e 7 5 P . S . I .

|

S |

L |

|

V |

|

Swivel Nut

INTRODUCTlON:

Paasche® models VL and VLS feature hand crafted construction using quality materials. The bodies are machined brass, polished and chrome plated. Fluid tips are made from nickel silver, needles are stainless steel, the packing washer is PTFE and the handle is nylon. Either airbrush, preferred by professional and hobbyist alike, permits great flexibility in regulation of color and air without work stoppage. Different size aircaps, tips and needles are quickly interchangeable to allow greater diversity in materials and coverage.

Paasche® model VLS, available in three sizes, is equipped with a threaded connection at the color socket so bottle assemblies can be securely fastened for greater mobility. It can also be used with larger gravity feed containers for production work.

Head Sizes - Patterns - Fluid Thickness |

|

Size 1 - Tip size .022 inches or .55mm |

Size 3 -Tip size .029 inches or .73mm |

- Used for fine detail. Pencil Line to 1'' patterns |

-Less detail than the size 1 head. 1/32'' to 1-1/2'' patterns |

- Paint must be thinned further than 3 & 5 heads |

-Can spray slightly thicker paint than size 1 head |

Size 5 -Tip Size .042 inches or 1.06mm

-Less detail than the size 3 head. 1/16'' to 2'' patterns

-Can spray slightly thicker paint than size 3 head

Working Pressures:

•Operating pressures 20-55 PSI; Maximum pressure 75 PSI

•20-30 PSI is best for detail spraying w/ properly thinned paint

•Use the higher pressures for thicker material where fine detail is not critical or thin the paint to allow lower pressures.

Equipment Set-up:

The Airbrush is held in the same manner as a pen, with the index finger comfortably over the Trigger.

1.Attach airhose to air supply and to airbrush. If using a regulator, set pressure between 20 -30 PSI.

2.For VL attach the color cup or bottle assembly to color socket. For VLS tighten lock nut to bottle with wrench

Airbrush Operation:

1.Press down on Trigger to release air and pull back on Trigger to control quantity of color.

2.To spray a fine line without heavy ends, start moving the airbrush without release of color. Then start the color at the beginning of line and stop the color at the end, but continue the motion of the airbrush after the color has stopped.

3.Practice this movement until you can spray a fine line or a broad pattern without heavy build up at the beginning or end of your strokes.

4.Speed of movement controls density of color and fading effects at beginning and end of strokes.

5.For detail, hold the airbrush very close to the surface and then push down for air and pull back very slowly on the Trigger to release a small amount of paint.

6.For background work and broad effects, hold the airbrush away from the work surface and pull back on Trigger to release required amount of color.

7.For stippling remove the aircap, push down on the Trigger and pump the Trigger forward and back. Adjust the air pressure between 15 and 50 PSI for desired stipple effect.

8.For more instruction see the “22 Airbrush Lessons for Beginners” booklet enclosed with your airbrush.

Paasche Airbrush Company |

Phone: 773-867-9191 • Fax: 773-867-9198 |

|

4311 North Normandy Avenue |

Website: paascheairbrush.com |

|

Chicago, IL 60634-1395 |

E-Mail: info@paascheairbrush.com |

Printed in the U.S.A. |

Paasche® VL & VLS Double Action Airbrushes |

Page 2 |

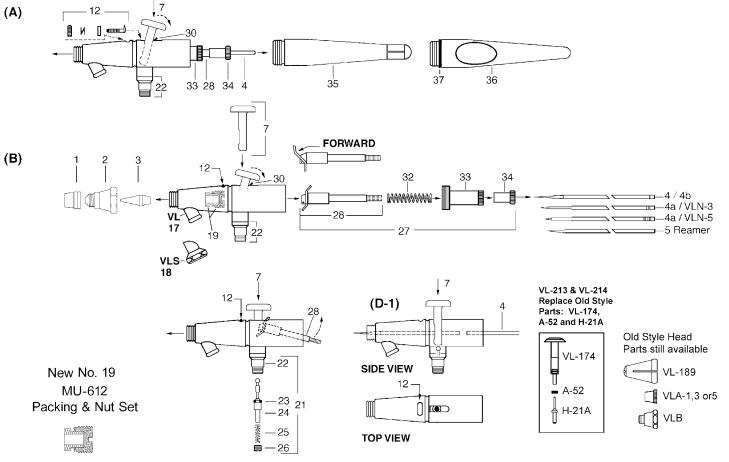

VL and VLS AIRBRUSH PARTS

NO. |

PART |

DESCRIPTION |

NO. |

PART |

DESCRIPTION |

1. |

XI-41 |

Needle Protecting Cap |

27. |

VL-186 |

Needle Valve Assembly L/Needle |

2. |

VLH-1, 3 or 5 |

Head (Specify Size) |

28. |

VL-191A |

Rocker Assembly |

3. |

VLT-1, 3 or 5 |

Tip (Specify Size) |

32. |

VL-140 |

Spring |

4. |

VLN-1 |

Needle (Specify Size) |

33. |

VL-136A |

Needle Adjusting Sleeve |

4a. |

VLN-3, VLN-5 |

Needle (Specify Size) |

34. |

VL-141 |

Locknut |

7. |

VL-213 |

Trigger |

35. |

VL-134N |

Handle |

12. |

VL-175 |

Line Adjustment Assembly |

|

|

|

17. |

VL-163 |

Shell Assembly W/VL-20 |

Optional Items: |

|

|

18. |

VLS-163 |

Shell Assembly W/VL-20 |

4b. |

VLN-1POL |

Polished Needle |

19. |

MU-612 |

PTFE Packing & Packing Nut |

5. |

VL-54 |

Reamer |

|

|

(sold as set) |

23. |

A-53 |

Valve ‘O’ Ring (pack of 6) |

21. |

VL-215 |

Air Valve Assembly |

36. |

HVL-202 |

Standard Length Metal Handle with |

22. |

VL-20 |

Valve Casing |

|

|

Cut-Out and VL-224 ‘O’ Ring |

24. |

VL-214 |

Valve Plunger (with A-53) |

VL-227-1, 3 or 5 |

Multiplehead (Specify Size) |

|

25. |

A-22 |

Valve Spring |

|

VLH-1, 3 or 5 |

Head |

26. |

A-23R |

Air Valve Nut |

|

VLT-1, 3 or 5 |

Tip |

|

|

|

|

VLN-1, 3 or 5 |

Needle |

Loading...

Loading...